Patents

Literature

367results about How to "Improve performance parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrodes and methods for microbial fuel cells

InactiveUS20080292912A1Raise the potentialImprove performanceTreatment by combined electrochemical biological processesCell electrodesMicrobial fuel cellFuel cells

Methods of improving a performance parameter of a microbial fuel cell are provided according to embodiments of the present invention which include heating an electrode and exposing the heated electrode to ammonia gas to produce a treated electrode characterized by an increased positive surface charge on the electrode surface. Improved performance parameters include increased maximum power density, increased coulombic efficiency, increased volumetric power density and decreased microbial fuel cell operation time to achieve maximum power density

Owner:PENN STATE RES FOUND

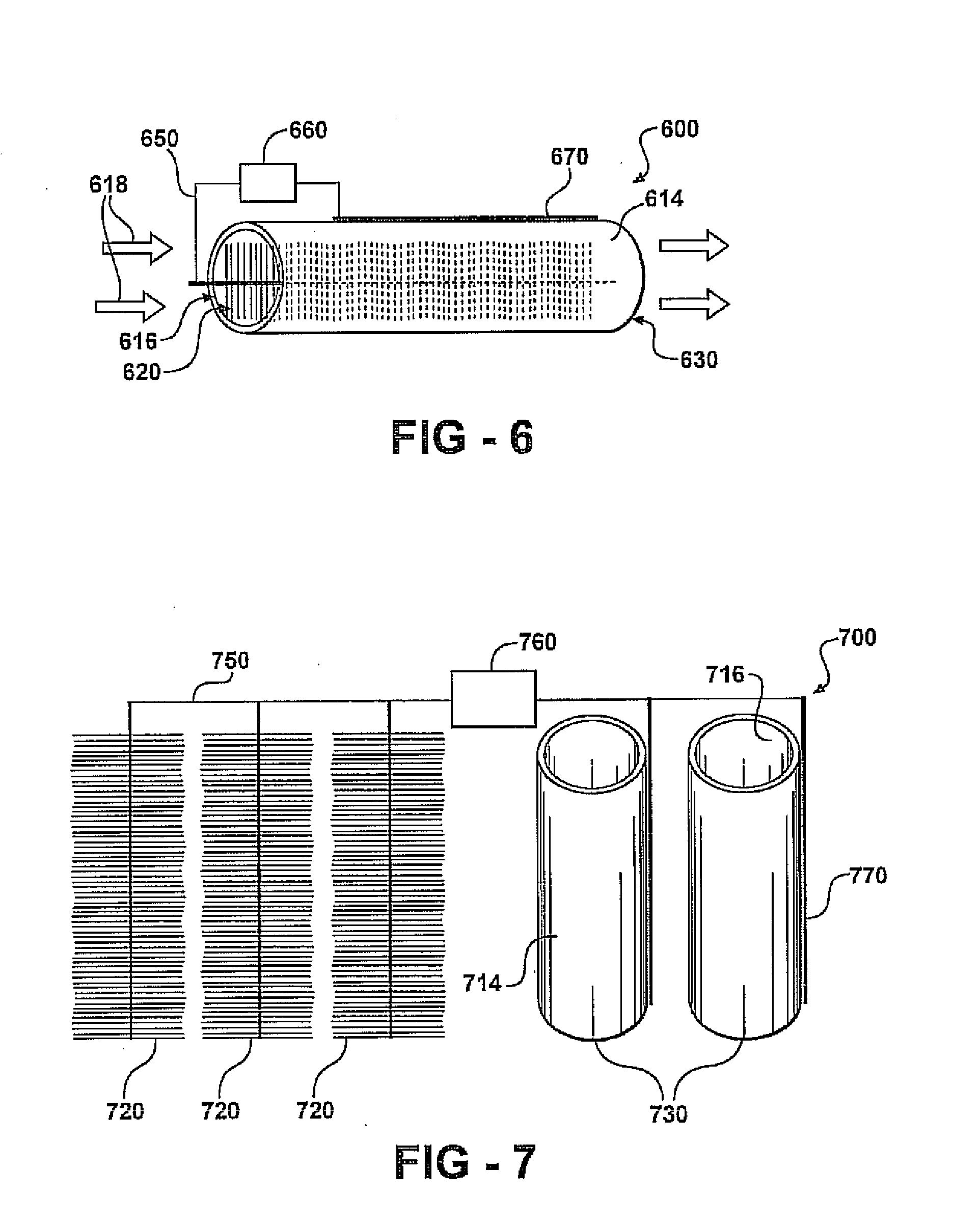

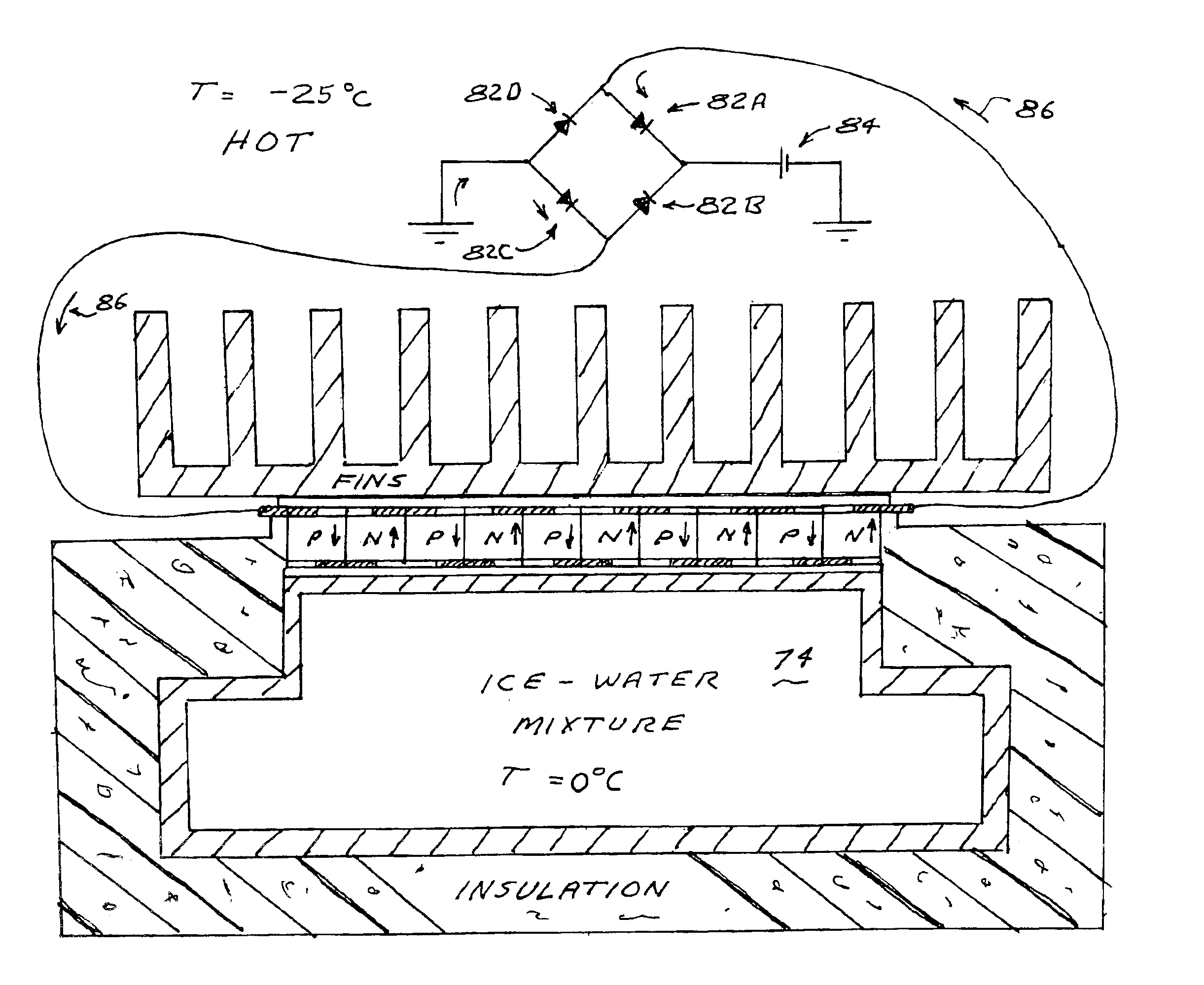

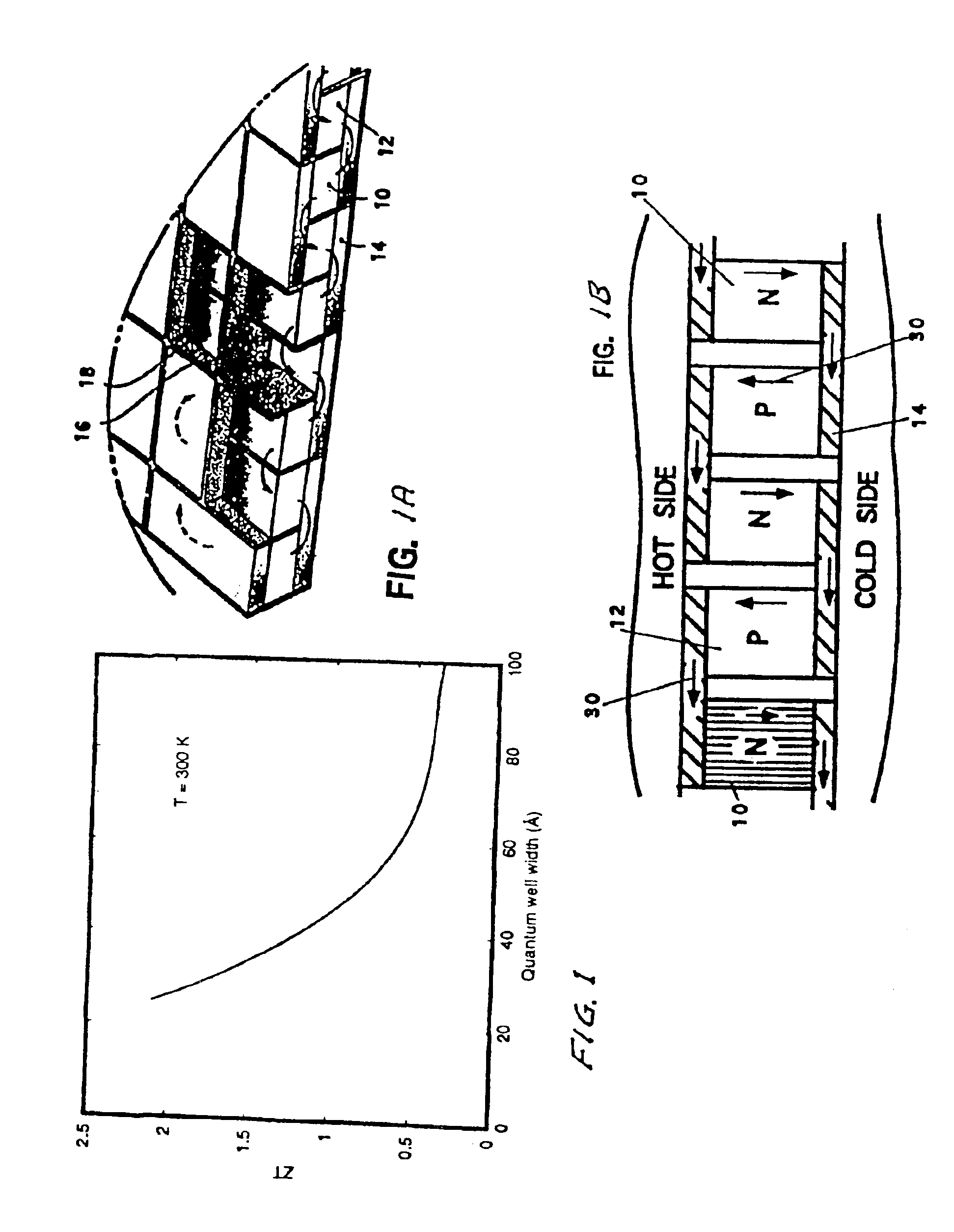

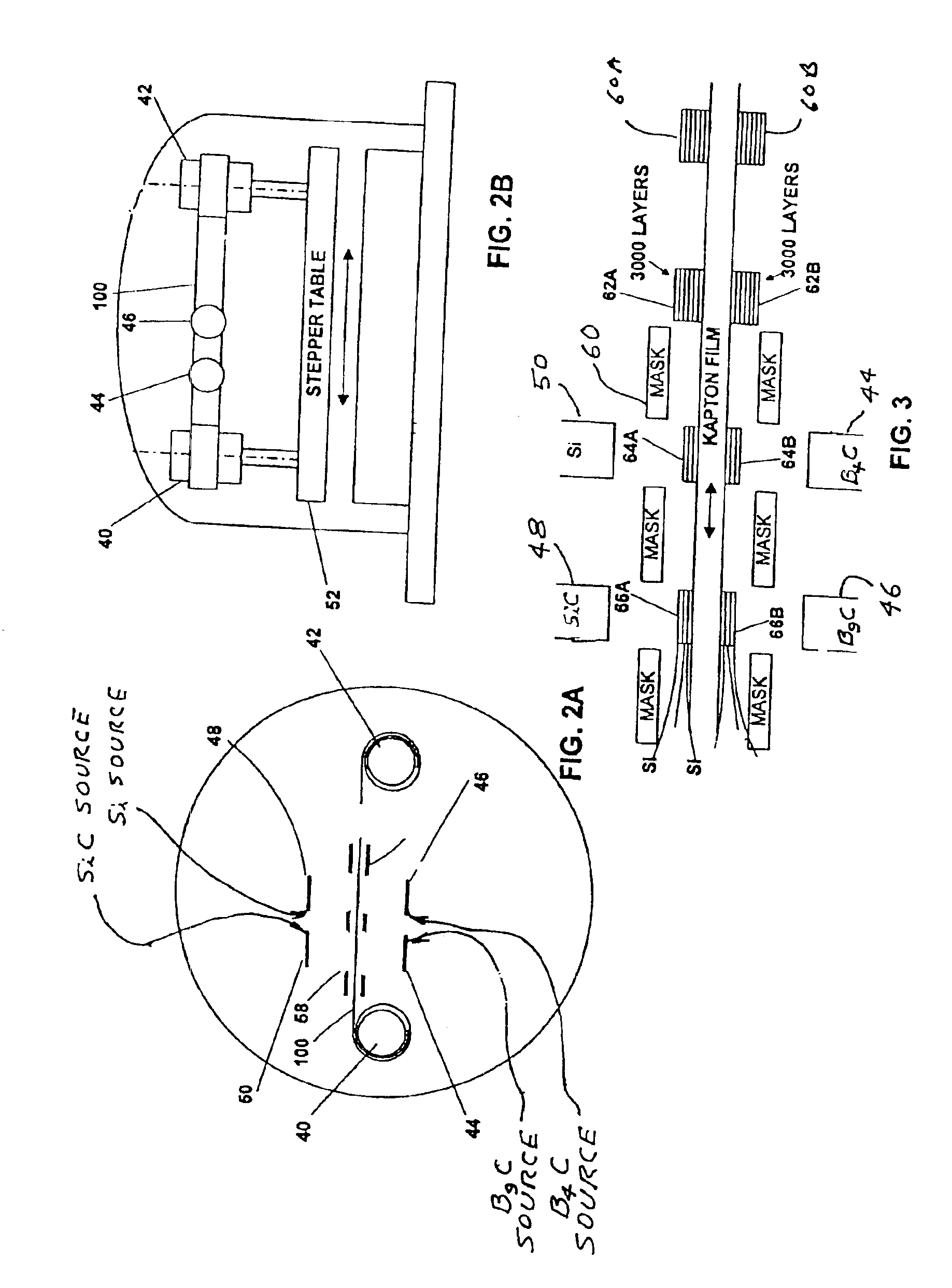

Thermoelectric power from environmental temperature cycles

InactiveUS6914343B2Constant temperatureGood performance parameterElectric signal transmission systemsThermoelectric device with peltier/seeback effectTemperature cyclingElectric generator

An electric generator system for producing electric power from the environmental temperature changes such as occur during a normal summer day on Earth or Mars. In a preferred embodiment a phase-change mass is provided which partially or completely freezes during the relatively cold part of a cycle and partially or completely melts during the relatively hot part of the cycle. A thermoelectric module is positioned between the phase-change mass and the environment. The temperature of the phase-change mass remains relatively constant throughout the cycle. During the hot part of the cycle heat flows from the environment through the thermoelectric module into the phase change mass generating electric power which is stored in an electric power storage device such as a capacitor or battery. During the cold part of the cycle heat flows from the phase change mass back through the module and out to the environment also generating electric power that also is similarly stored. An electric circuit is provided with appropriate diodes to switch the direction of the current between the hot and cold parts of the cycle. A preferred phase change mass is a solution of water and ammonia that has freeze points between about 270 K to about 145 K depending on the water ammonia ratio. Preferably, a finned unit is provided to efficiently transfer heat from a module surface to the environment.

Owner:HI Z TECH

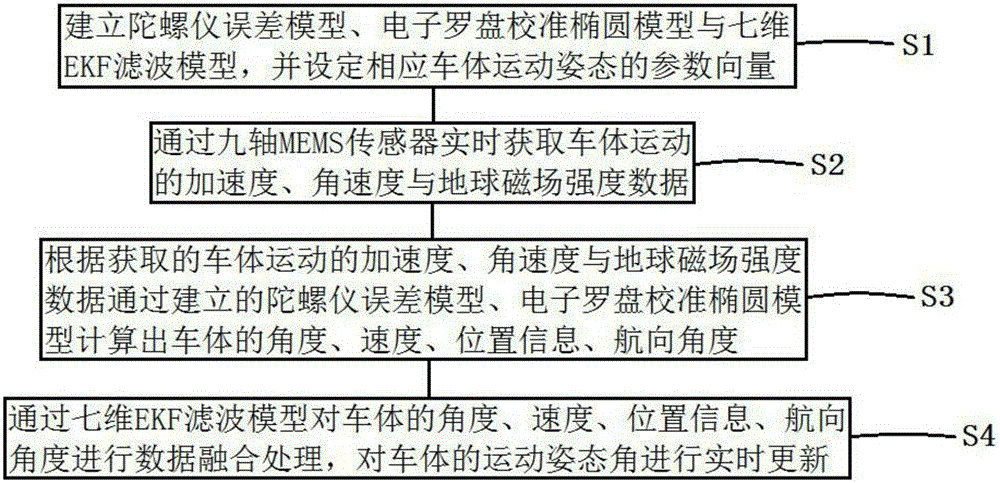

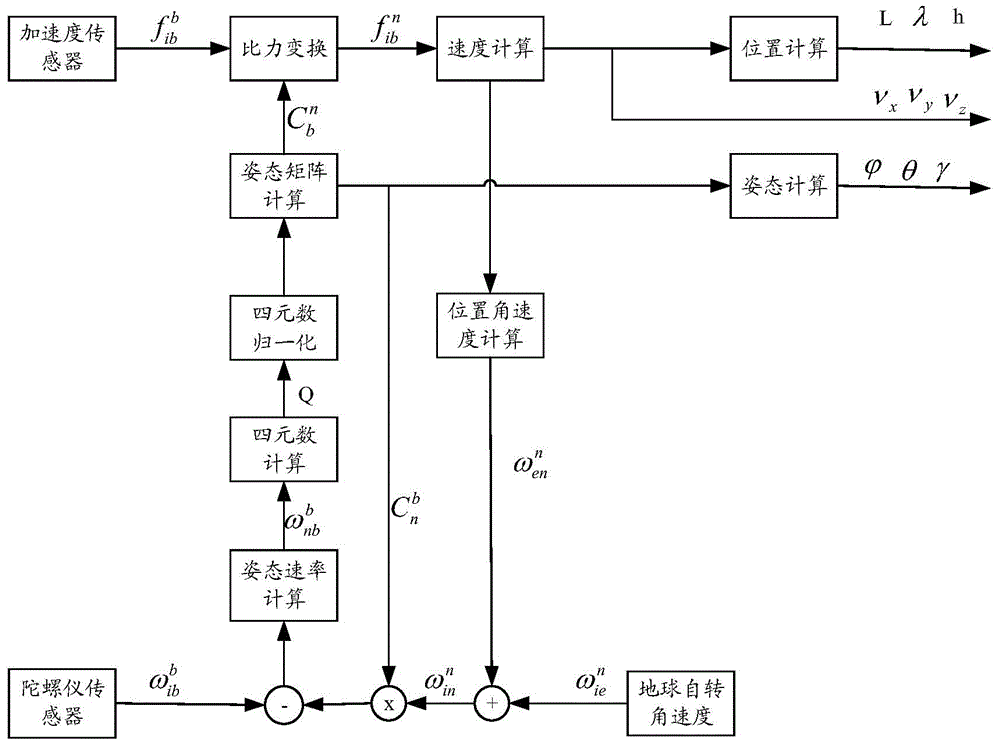

Whole attitude angle updating method applied to agricultural machinery and based on nine-axis MEMS (micro-electromechanical system) sensor

ActiveCN105203098AReduce precisionHigh precisionNavigational calculation instrumentsNavigation by terrestrial meansGyroscopeEllipse

The invention discloses a whole attitude angle updating method applied to agricultural machinery and based on a nine-axis MEMS (micro-electromechanical system) sensor. The whole attitude angle updating method applied to agricultural machinery and based on the nine-axis MEMS sensor comprises the following steps: a gyroscope error model, an electronic compass calibration ellipse model and a seven-dimensional EKF (extended Kalman filter) model are established, and parameter vectors of corresponding motion attitudes of a vehicle body are set; data including the acceleration, the angular velocity and the geomagnetic field intensity of vehicle body motion are acquired in real time; the angle, the speed, the location information and the heading angle of the vehicle body are calculated through the established gyroscope error model and electronic compass calibration ellipse model; data fusion processing is performed on the angle, the speed, the location information and the heading angle of the vehicle body through the seven-dimensional EKF model, and the motion attitude angle of the vehicle body is updated in real time. The method comprising the steps has small errors and high precision and is stable and reliable.

Owner:SHANGHAI HUACE NAVIGATION TECH

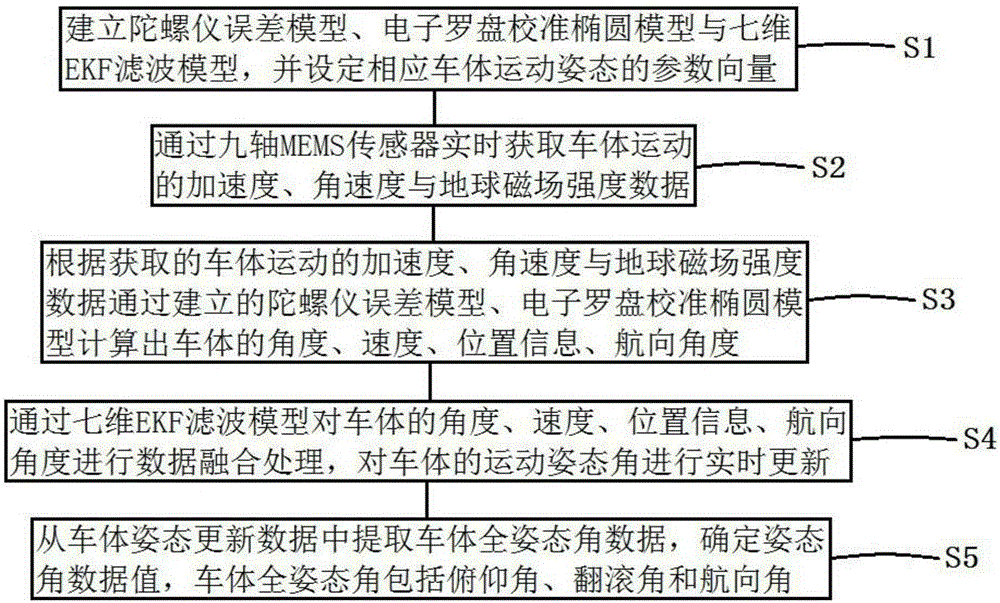

Method of Updating All-Attitude Angle of Agricultural Machine Based on Nine-Axis MEMS Sensor

InactiveUS20170350721A1Small amount of calculationReduce error interferenceNavigational calculation instrumentsNavigation by terrestrial meansGyroscopeEllipse

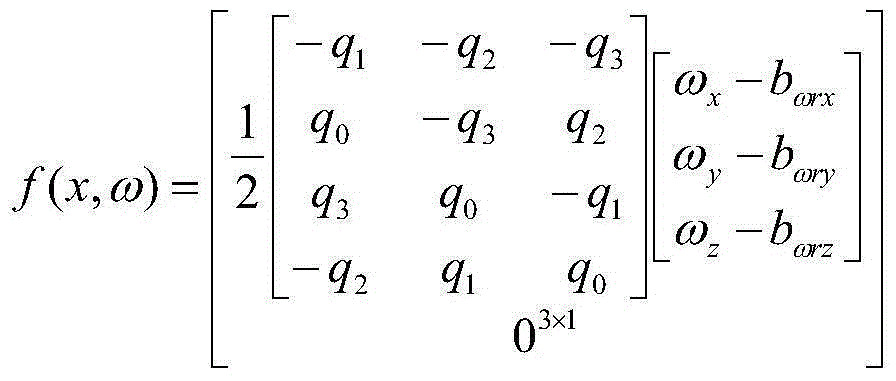

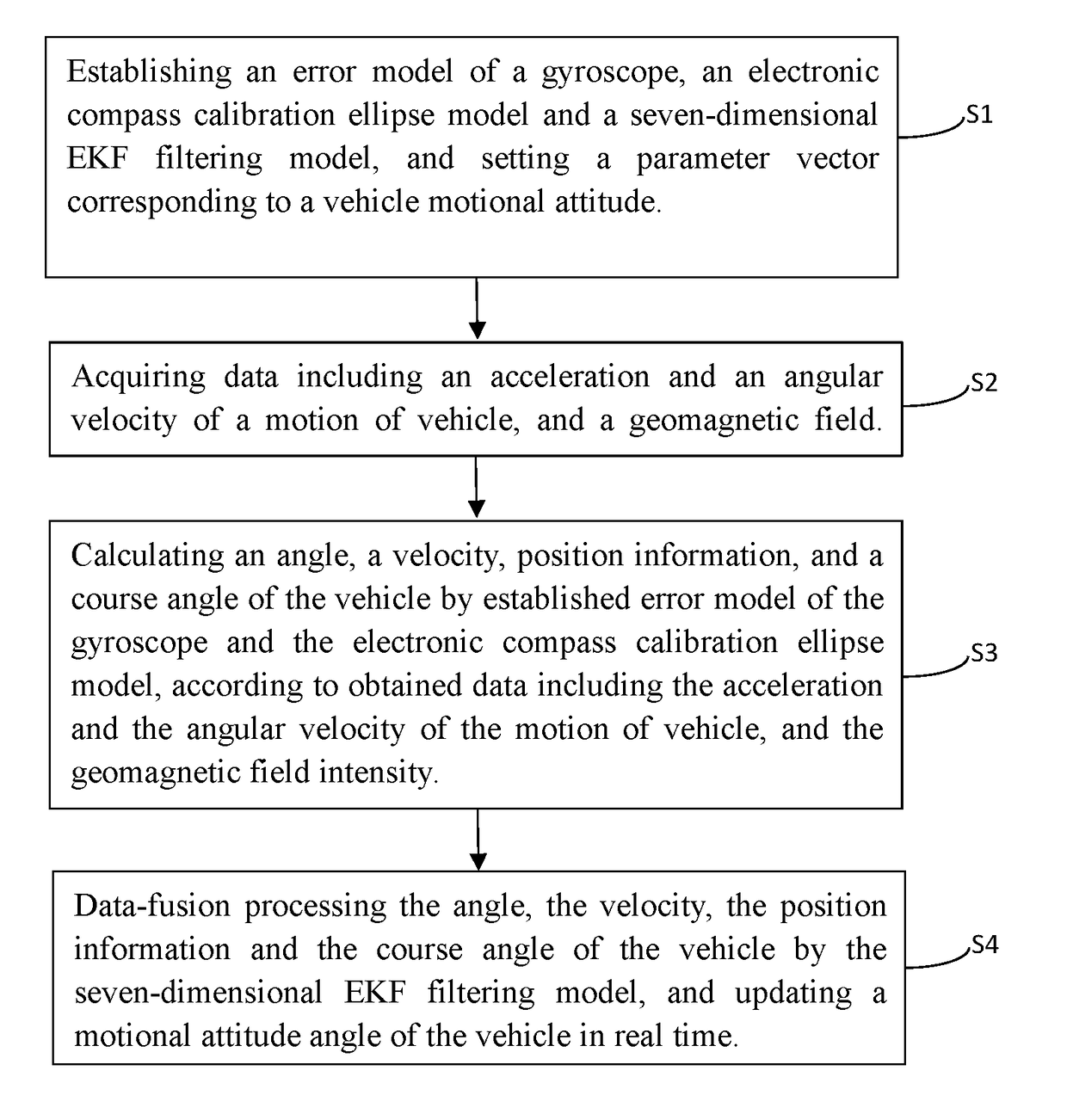

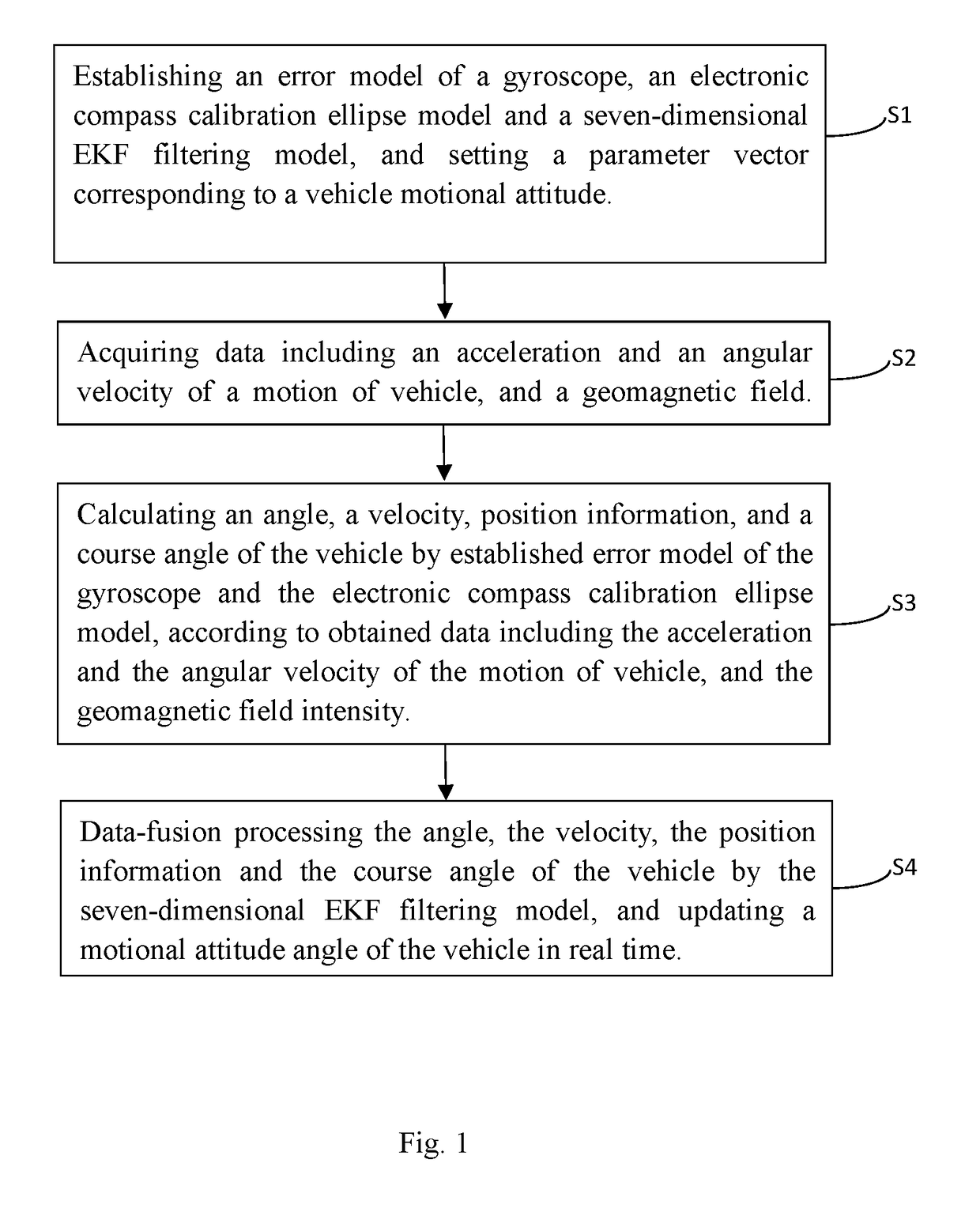

A method of updating an all-attitude angle of an agricultural machine based on a nine-axis MEMS sensor includes the following steps: establishing an error model of a gyroscope, an electronic compass calibration ellipse model and a seven-dimensional EKF filtering model, and setting a parameter vector corresponding to a vehicle motional attitude (S1); acquiring data including an acceleration and an angular velocity of a motion of vehicle, and an geomagnetic field intensity in real time (S2); calculating an angle, a velocity, position information, and a course angle of the vehicle by established error model of the gyroscope and the electronic compass calibration ellipse model(S3); data-fusion processing the angle, the velocity, the position information and the course angle of the vehicle by the seven-dimensional EKF filtering model, and updating a motional attitude angle of the vehicle in real time. The steps of the method have a small error, high precision, and reliability.

Owner:SHANGHAI HUACE NAVIGATION TECH

Electrodes and methods for microbial fuel cells

InactiveUS20100151279A1Raise the potentialImprove performanceTreatment by combined electrochemical biological processesCell electrodesMicrobial fuel cellFuel cells

Methods of improving a performance parameter of a microbial fuel cell are provided according to embodiments of the present invention which include heating an electrode and exposing the heated electrode to ammonia gas to produce a treated electrode characterized by an increased positive surface charge on the electrode surface. Improved performance parameters include increased maximum power density, increased coulombic efficiency, increased volumetric power density and decreased microbial fuel cell operation time to achieve maximum power density

Owner:PENN STATE RES FOUND

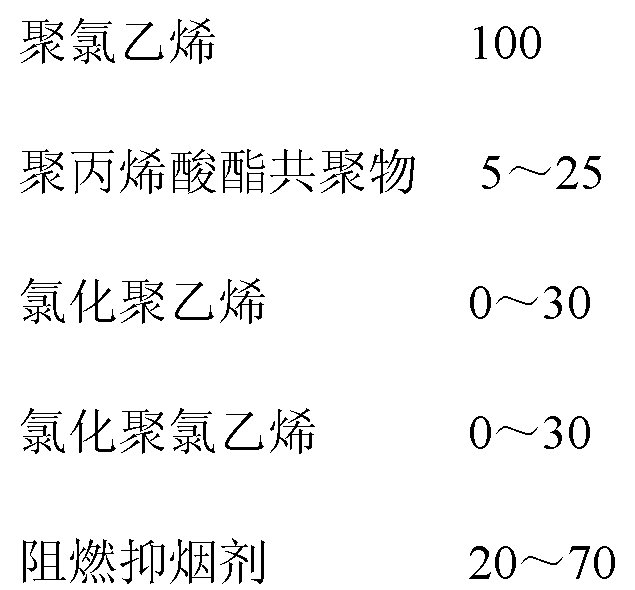

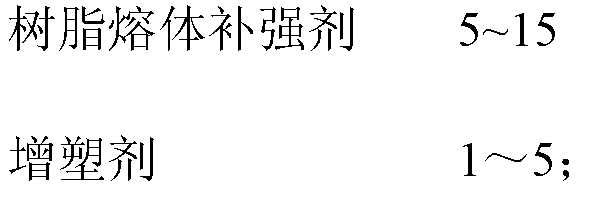

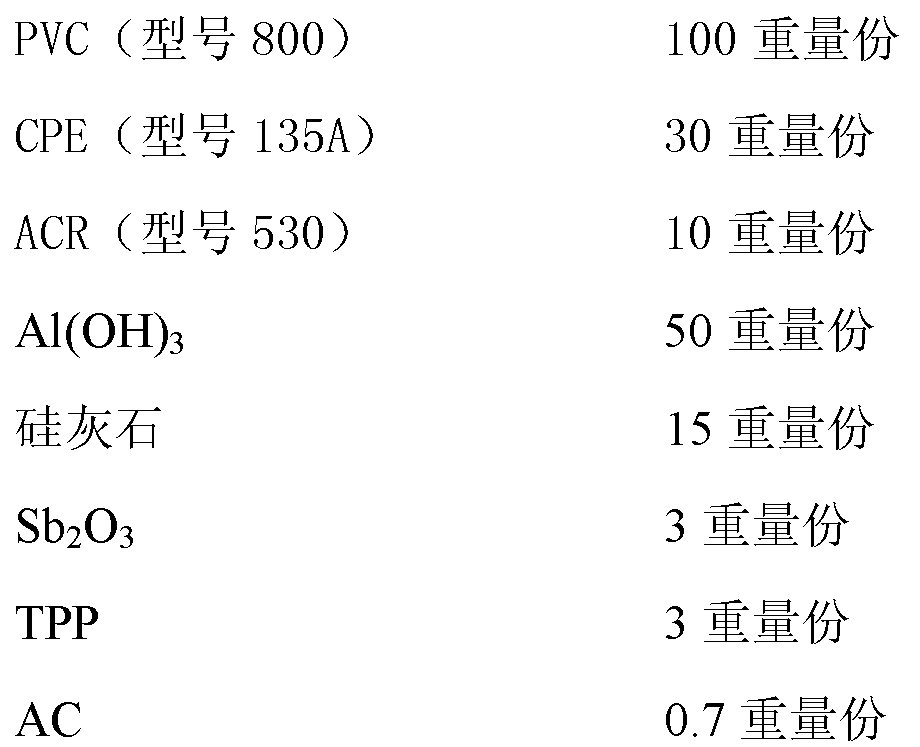

Composition for flame-retardant polyvinyl chloride (PVC) plastic foam board, product prepared from same, and preparation method thereof

The invention relates to a composition for a flame-retardant polyvinyl chloride (PVC) plastic foam board, and the flame-retardant PVC plastic foam board produced by a double screw extrusion method. The composition comprises the following components in part by weight: 100 parts of polyvinyl chloride, 5 to 25 parts of polyacrylate copolymer, 0 to 30 parts of chlorinated polyethylene, 0 to 30 parts of chlorinated polyvinyl chloride, 20 to 70 parts of flame retardant and smoke suppression agent, and 0 to 5 part of plasticizer, and also comprises a resin melt reinforcing agent and additives such as a foaming agent, a lubricating agent and a stabilizing agent and the like. After the produced flame-retardant PVC plastic foam board is detected by Shanghai Building Material and Component Quality Surveillance Office and State Laboratory of Fire Science (University of Science and Technology of China, Hefei), the oxygen index is more than or equal to 32, the smoke density grade is less than or equal to 75, the average combustion time is less than or equal to 30 seconds, the heat release rate is less than 250W / g, the heat conductivity is 0.047W / m.K, and the flame-retardant PVC plastic foam board meets the B1 requirement of GB / T8624-1997, and meets the V-0 standard of UL-94.

Owner:SHANGHAI YUANQI ENERGY TECH DEV

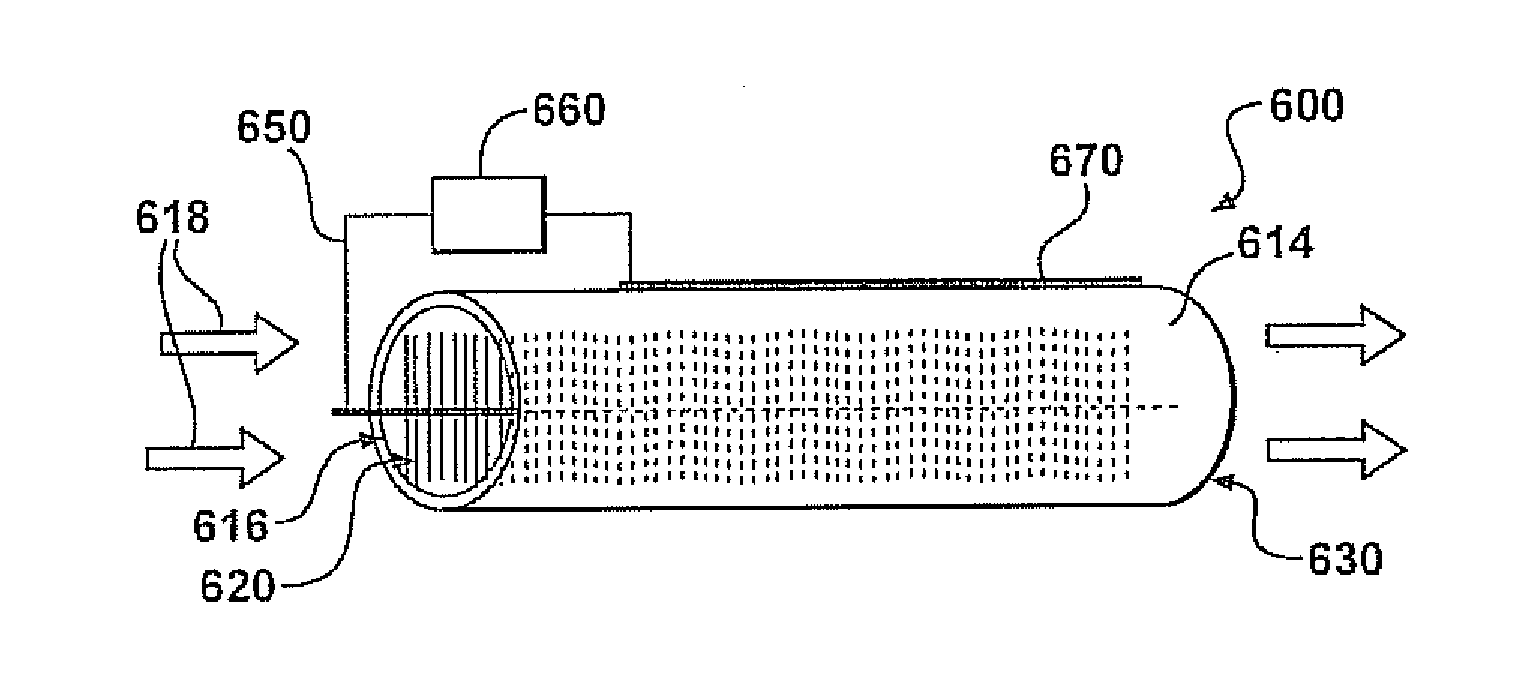

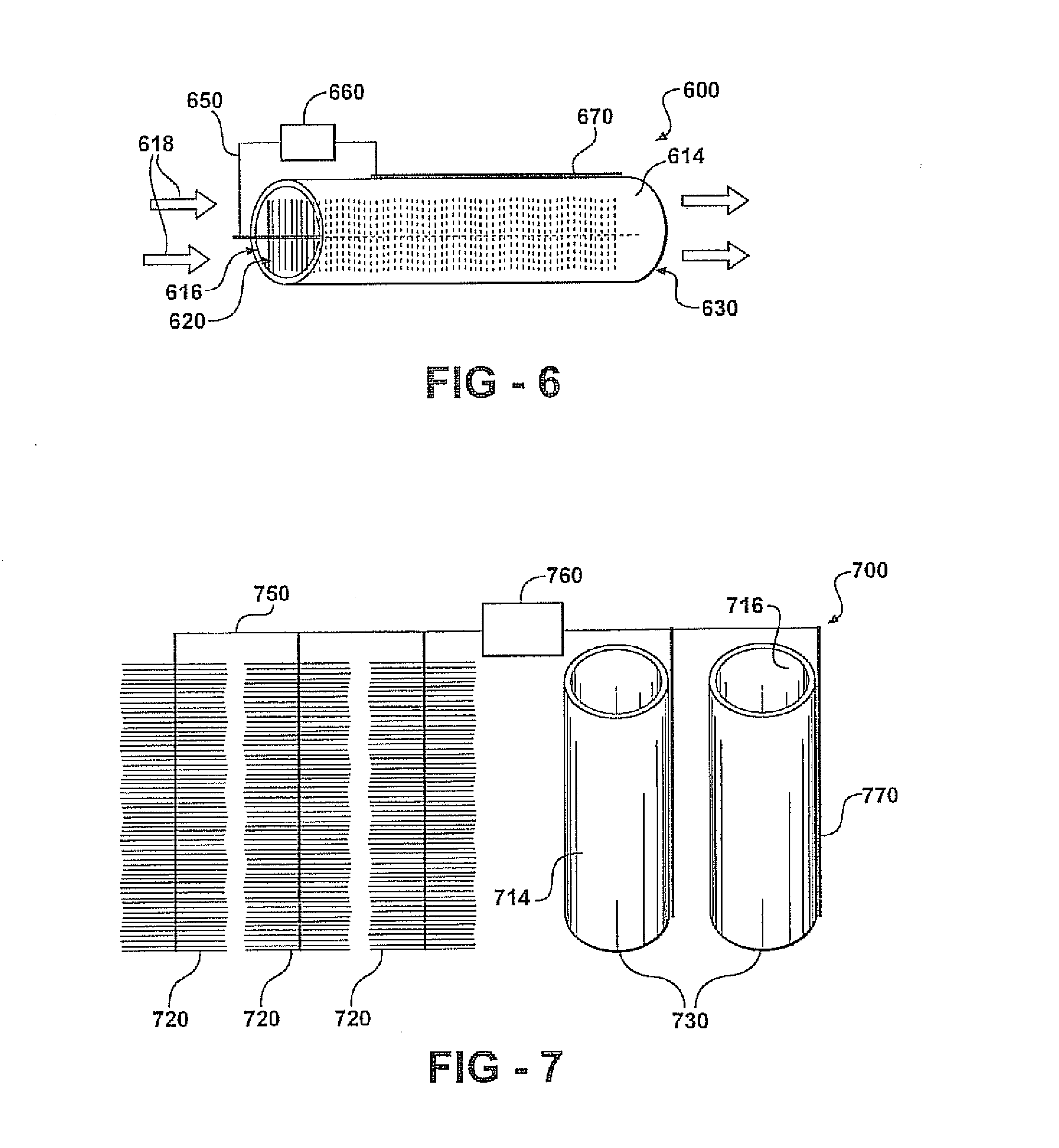

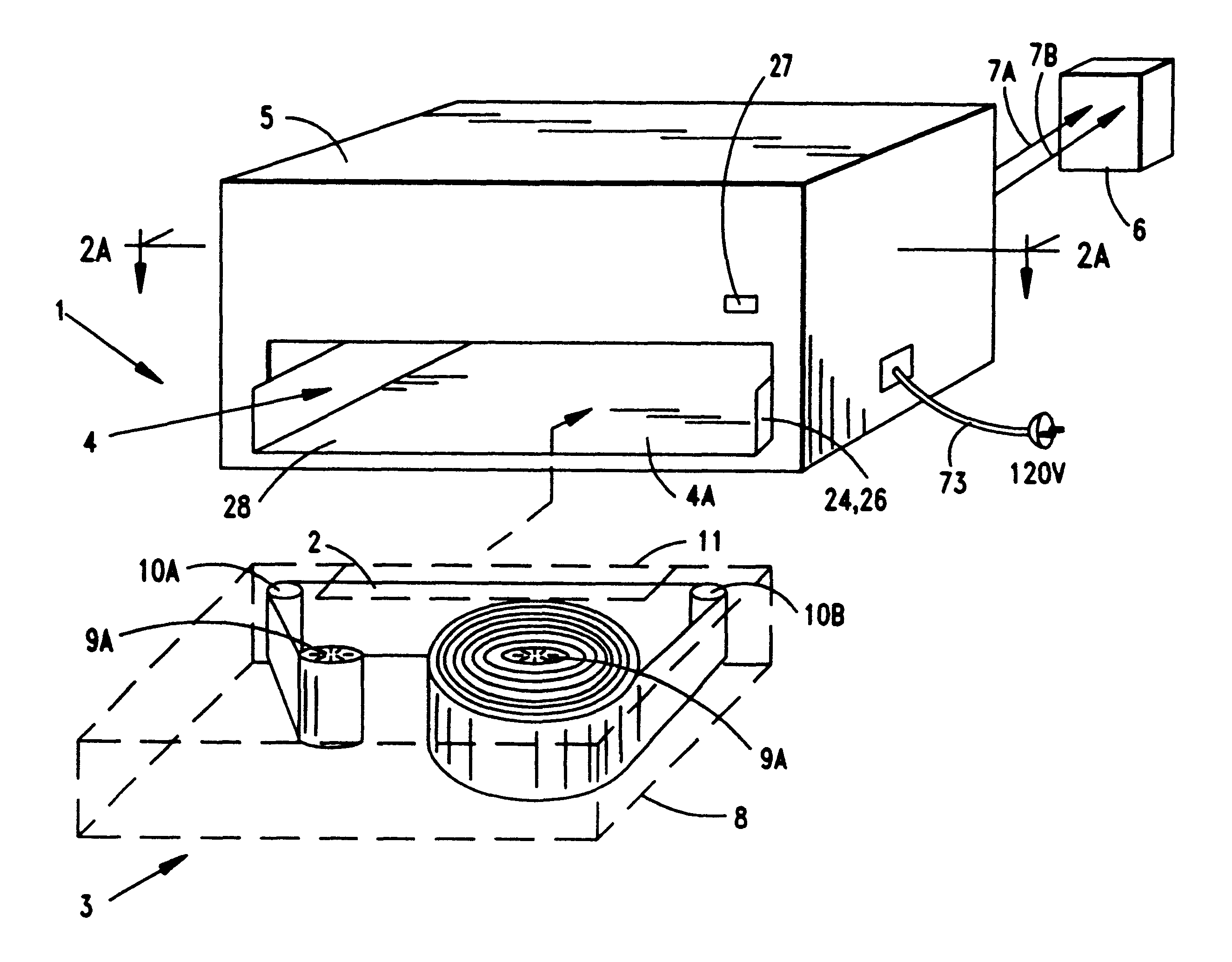

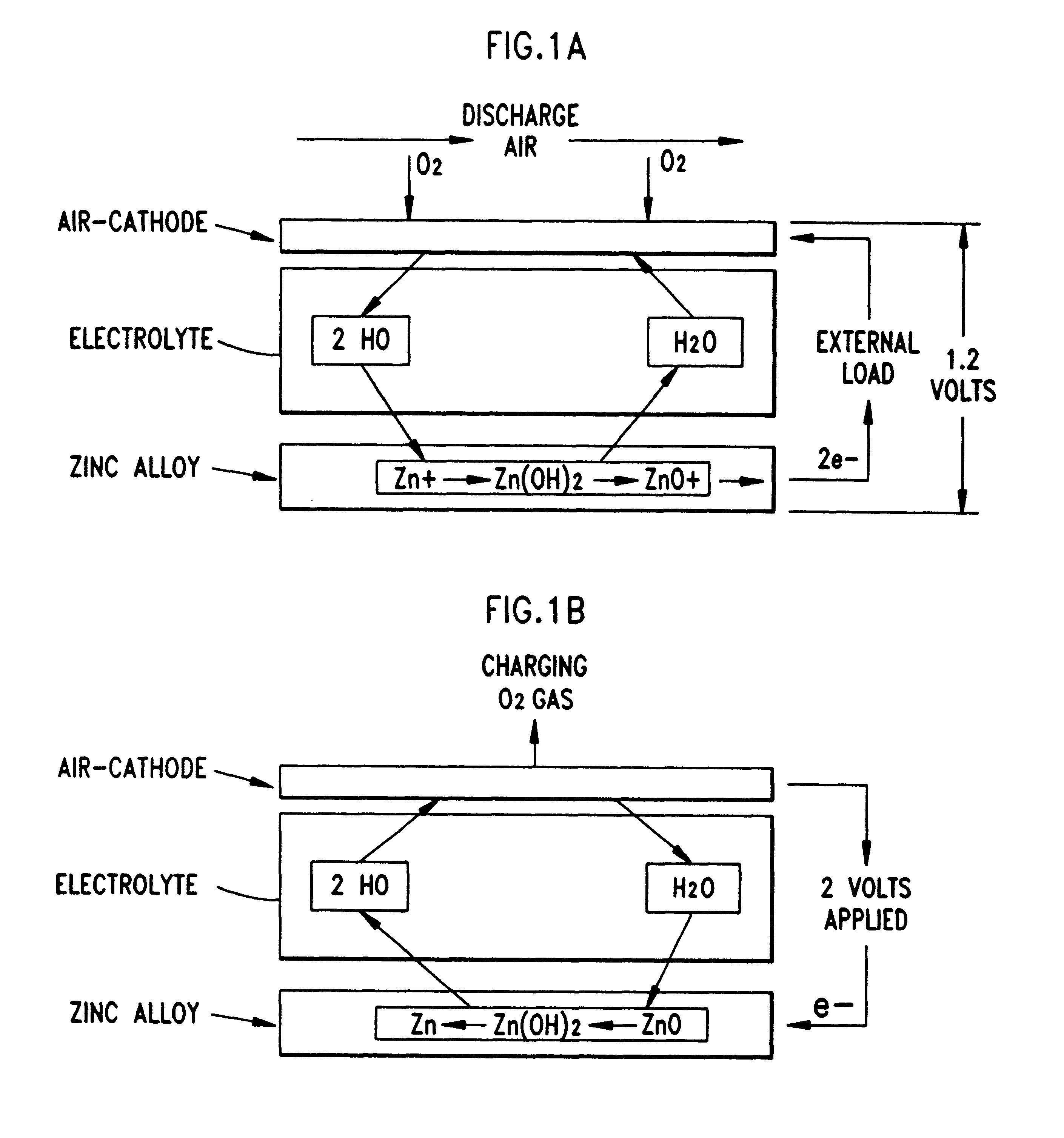

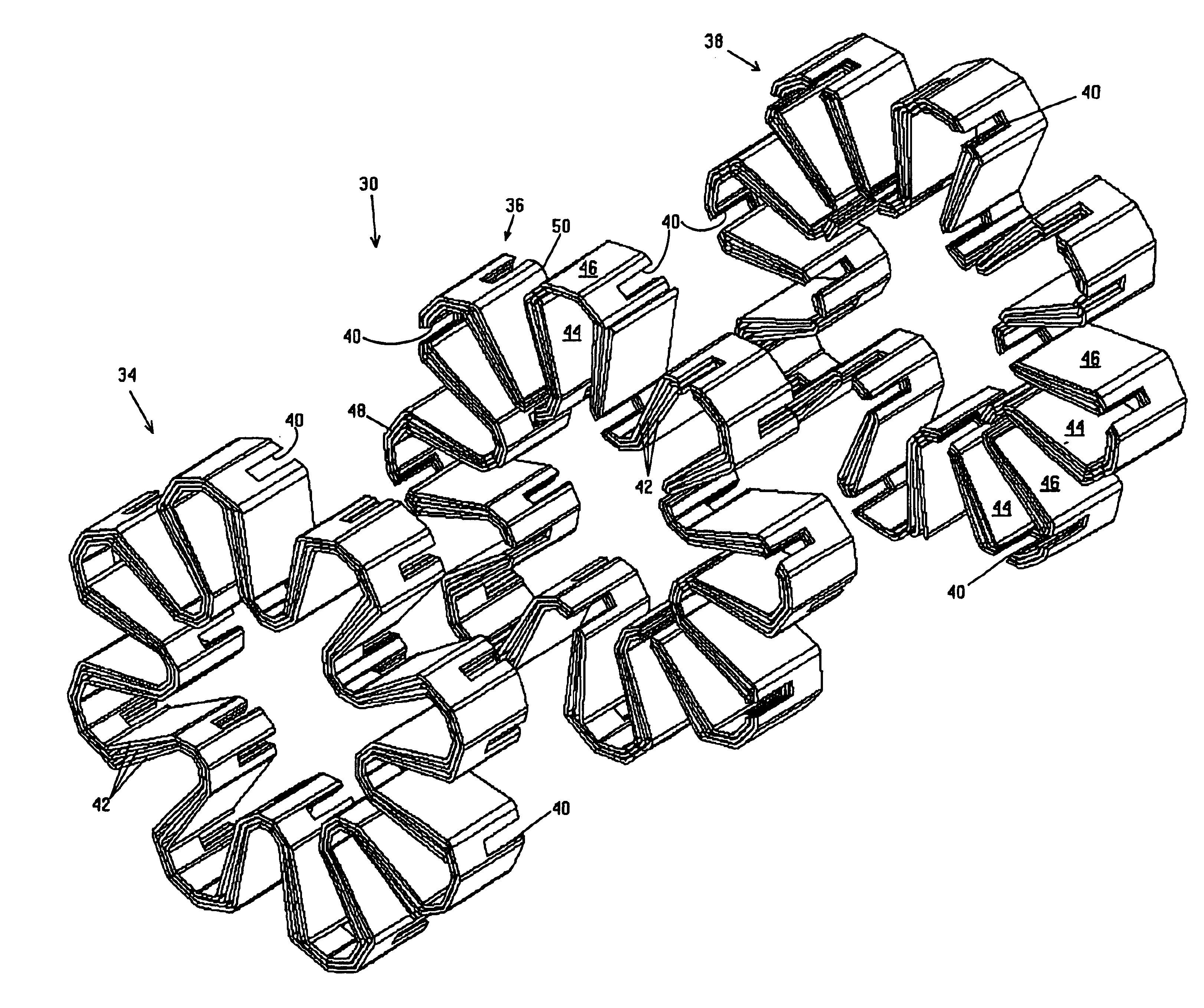

System and method for producing electrical power using metal-air fuel cell battery technology

InactiveUS6296960B1Improve performance parametersIncrease energy densityFuel and primary cellsBatteries circuit arrangementsElectricityFuel cells

Improved metal-air fuel cell battery systems having metal-fuel realized in the form of metal-fuel tape cartridges and metal-fuel cards, which can be either manually or automatically inserted within the power generation bay of the system. In order to produce a range of output voltages, the metal-fuel tape has a plurality of electrically-isolated metal-fuel tracks and the metal-fuel cards have a plurality of electrically-isolated metal-fuel strips. An output voltage configuration subsystem is provided for configuring the voltages produced by the individual cells to produce a desired output. A subsystem is provided for detecting oxide formation on the metal-fuel tracks and strips so that only metal-fuel that has been oxidized is reduced during recharging operations. A subsystem is also provided for controlling the flow of oxygen into the power generation head in order to control the power output from the system.

Owner:REVEO

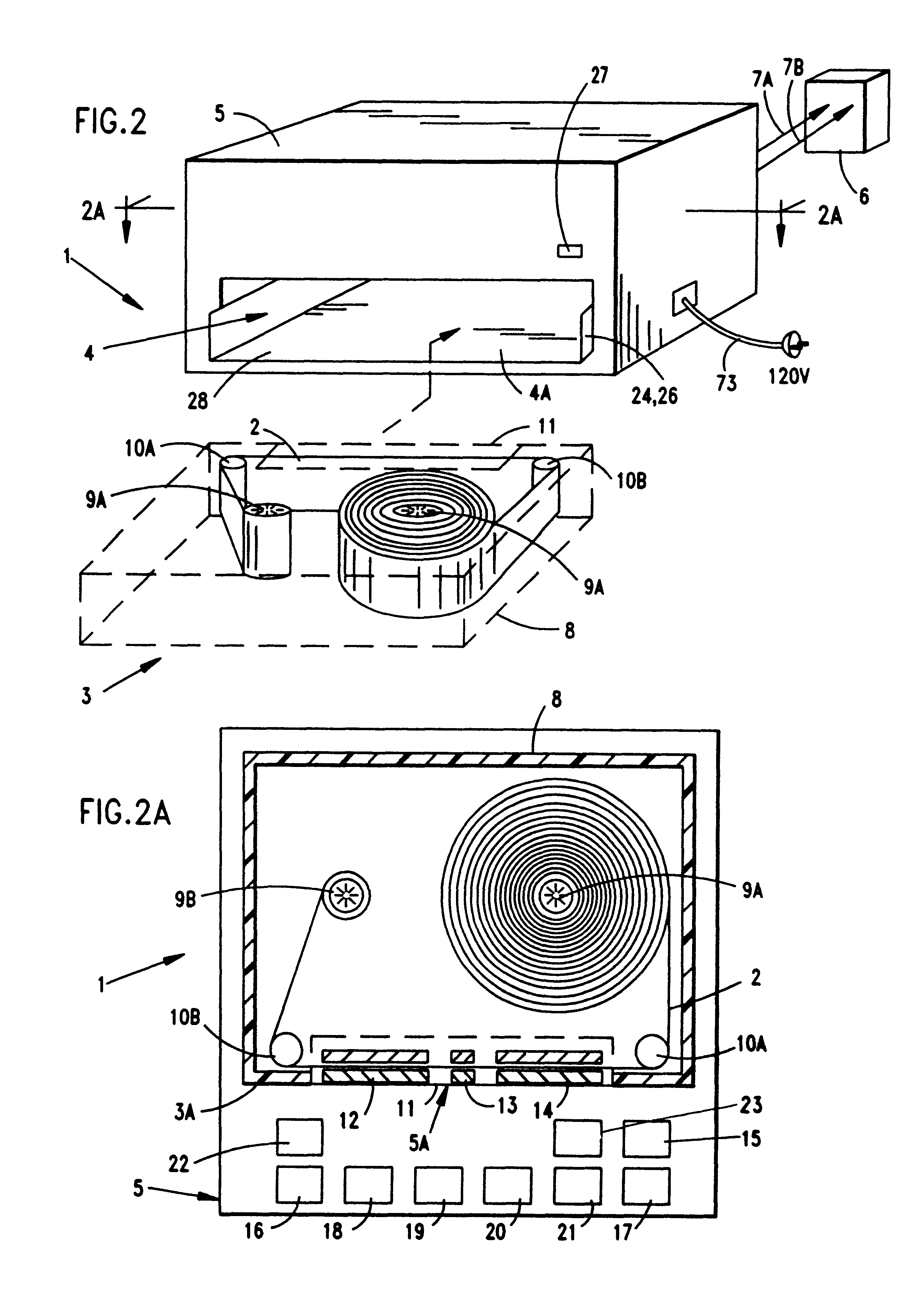

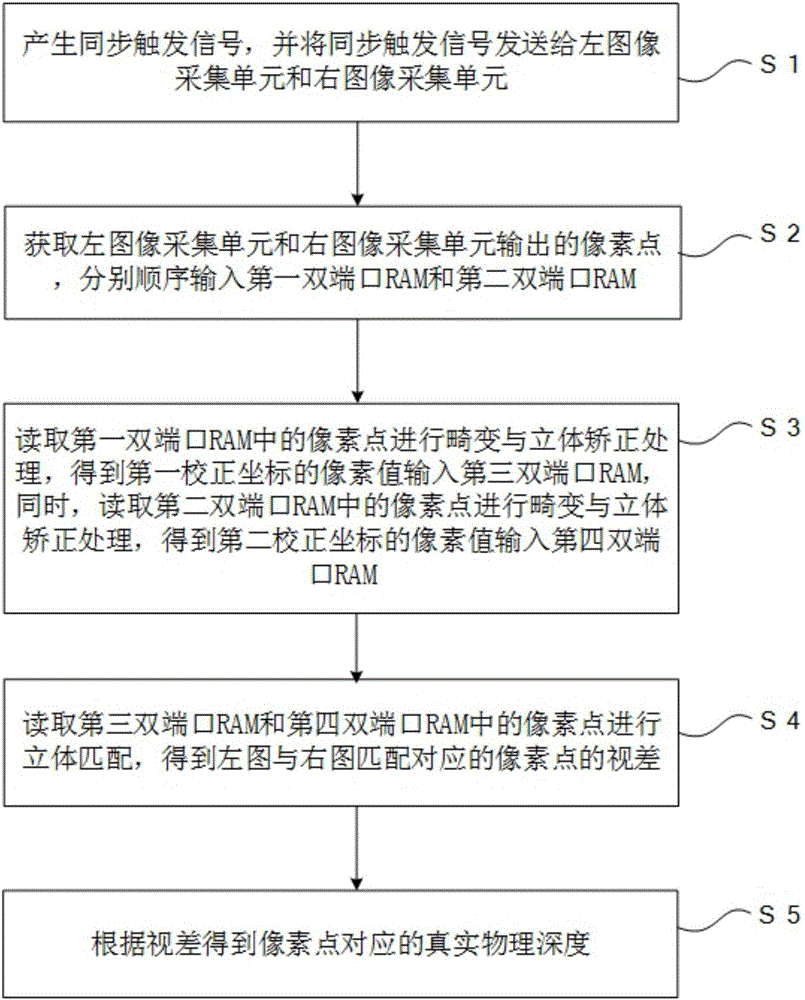

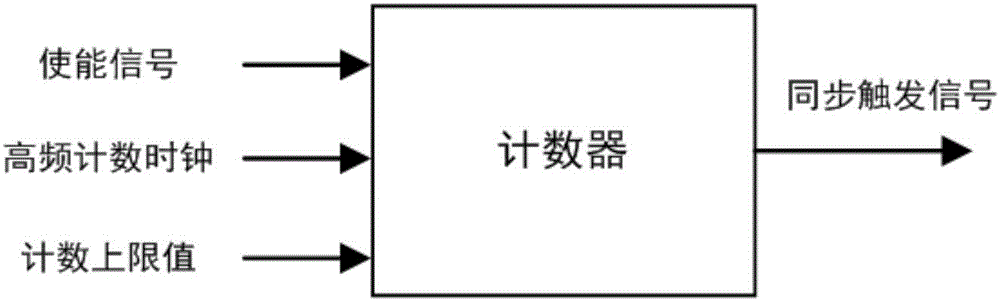

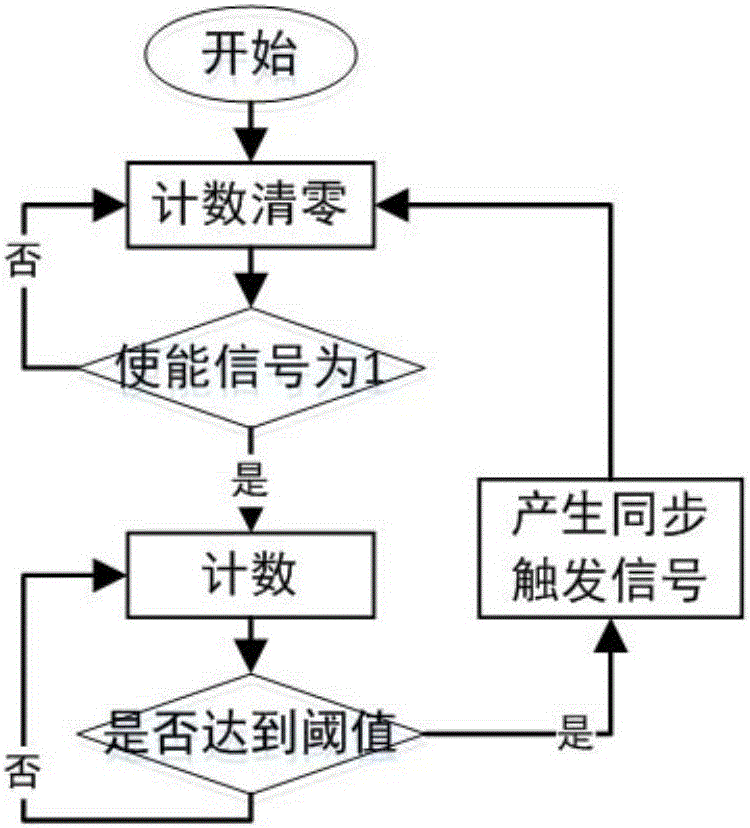

Binocular stereo vision system and depth measuring method

InactiveCN106525004AIncrease speedImprove performance parametersPicture interpretationParallaxStereo matching

The invention belongs to the technical field of 3D sensing measurement, and provides a binocular stereo vision system and a depth measuring method. The depth measuring method used for the binocular stereo vision system comprises the steps that a synchronous trigger signal is generated and sent to a left image collection unit and a right image collection unit; FPGA running water and concurrent design is adopted, pixel points output by the left image collection unit and the right image collection unit are subjected to distortion and stereo correction processing, the optical parallax of pixel points which correspond to and are matched with a left image and a right image are obtained after stereo matching, and finally the real physical depth corresponding to the pixel points is obtained according to the optical parallax. According to the binocular stereo vision system and the depth measuring method, an FPGA platform is selected, the integration level is high, the processing speed is high, the real-time requirement is met, and the binocular stereo vision technology is brought to the commercial level.

Owner:HUMANPLUS INTELLIGENT ROBOTICS CO LTD

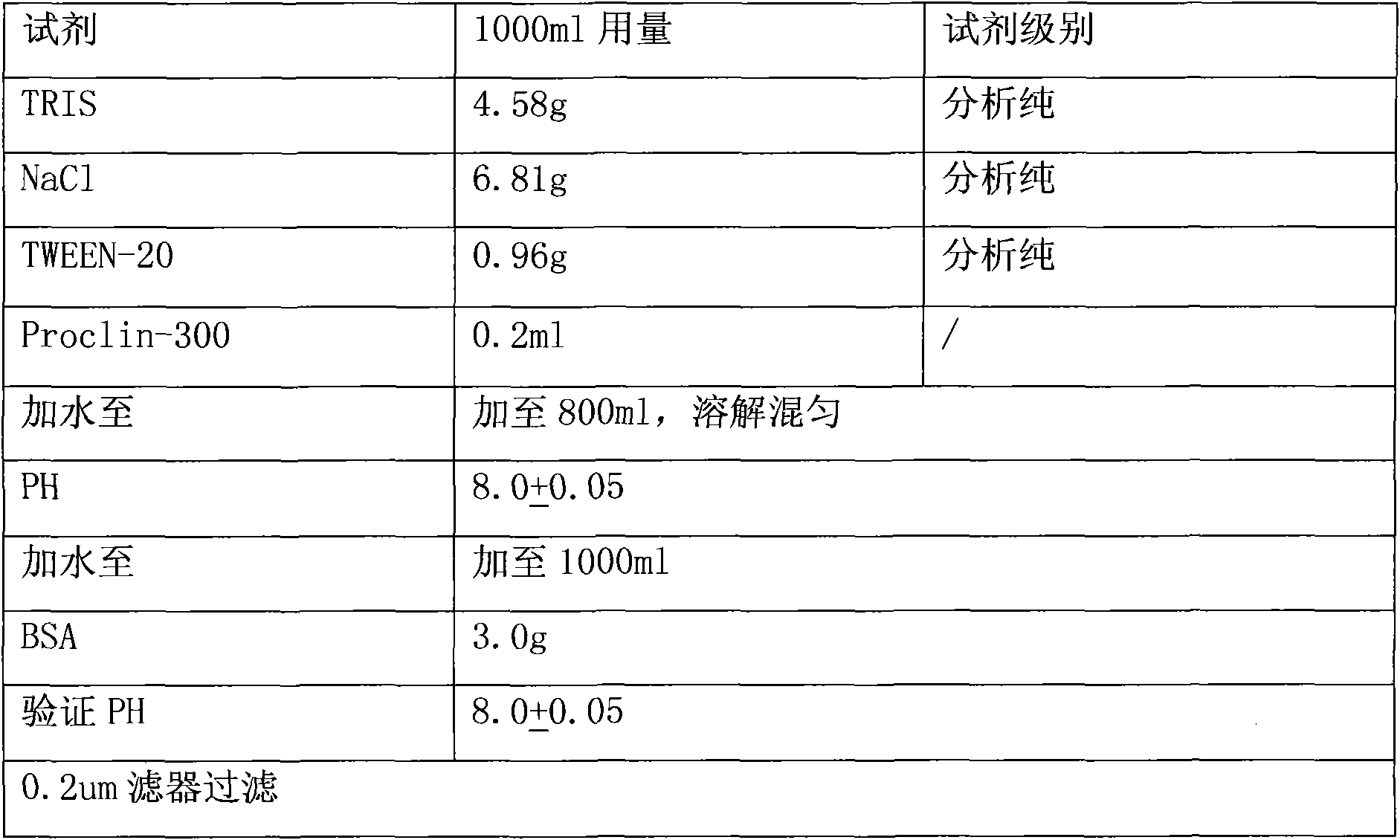

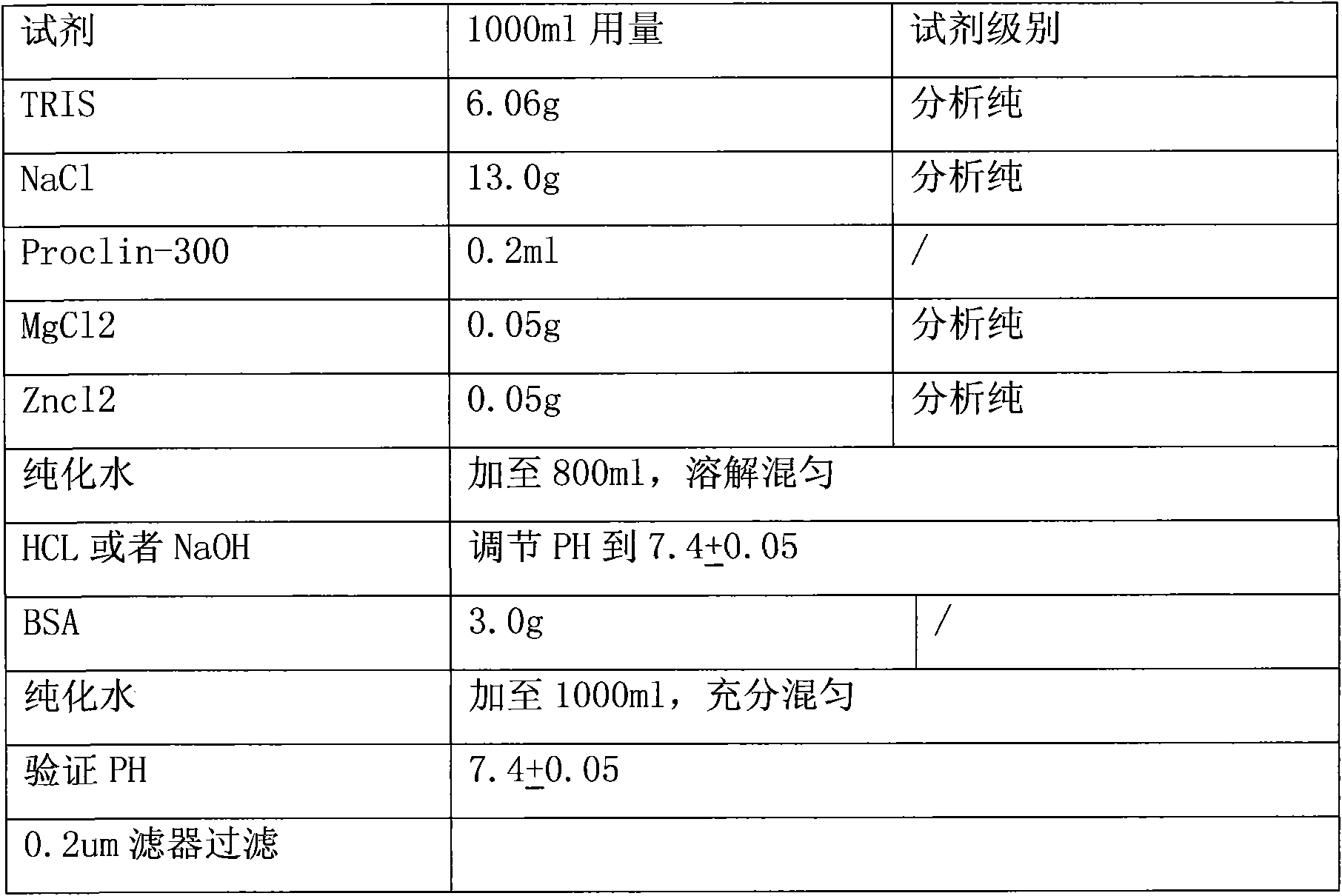

Quantitative creatine kinase-myoglobin (CK-MB) determination kit and assay method thereof

InactiveCN102435738AHigh detection sensitivityImprove featuresChemiluminescene/bioluminescenceCreatine kinaseQuality control

The invention discloses a quantitative creatine kinase-myoglobin (CK-MB) determination kit. The kit is characterized in that the kit contains CK-MB magnetic separation reagent, enzymatic reactant, reaction enhancer, diluent, CK-MB calibrator, CK-MB quality control material, cleaner concentrate and substrate solution. The invention also discloses a preparation method for the kit. The kit integrates the chemiluminescence technology with immunomagnetic beads to provide a homogeneous phase-approximating reaction system. Compared with the prior art, the kit has higher assay sensitivity and specificity, and achieves better performance parameters, and mover, the product cost is greatly reduced.

Owner:INNER MONGOLIA KEHUI BIOLOGICAL TECH

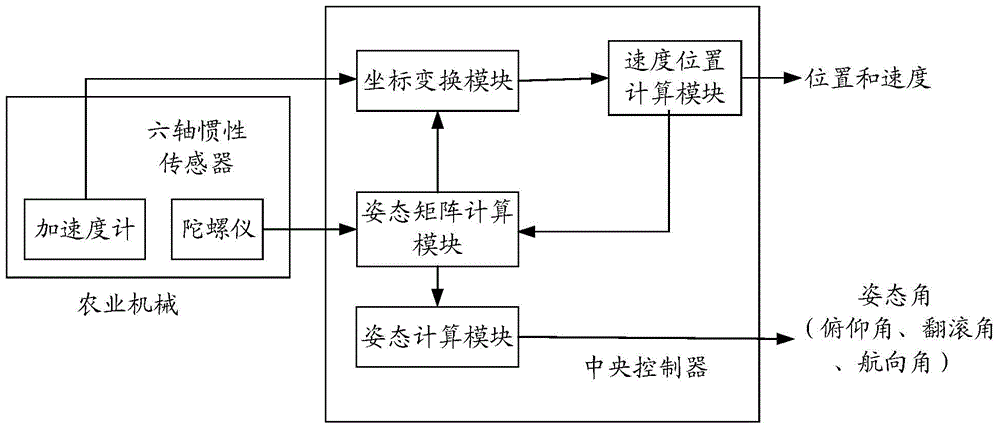

Strapdown inertial navitation system and control method for agricultural machines

InactiveCN104697526AReduce mistakesReduce distractionsNavigation by speed/acceleration measurementsGyroscopeModularity

The invention relates to a strapdown inertial navitation system for agricultural machines. The system comprises a six-axis inertial sensor and a central control unit. The six-axis inertial sensor comprises acceleration sensors in three directions and a three-axis gyroscope sensor. The central control unit comprises a coordinate conversion module, a speed position calculating module, an attitude matrix calculating module and an attitude calculating module. The invention further relates to a control method for the agricultural machines based on the strapdown inertial navitation system. According to the strapdown inertial navitation system and control method for the agricultural machines of the structure, the six-axis inertial sensor is adopted, the size is small, weight is low, the structure is simple, the cost performance is high, the system can be integrated into a control center of the agricultural machines conveniently through the modular design, meanwhile, the advantages of being stable in running, rich in output motion information and the like are achieved, control precision is high, especially the requirement of the agricultural machines and other ground vehicles for aided driving control is met, and the application range is wide.

Owner:SHANGHAI HUACE NAVIGATION TECH

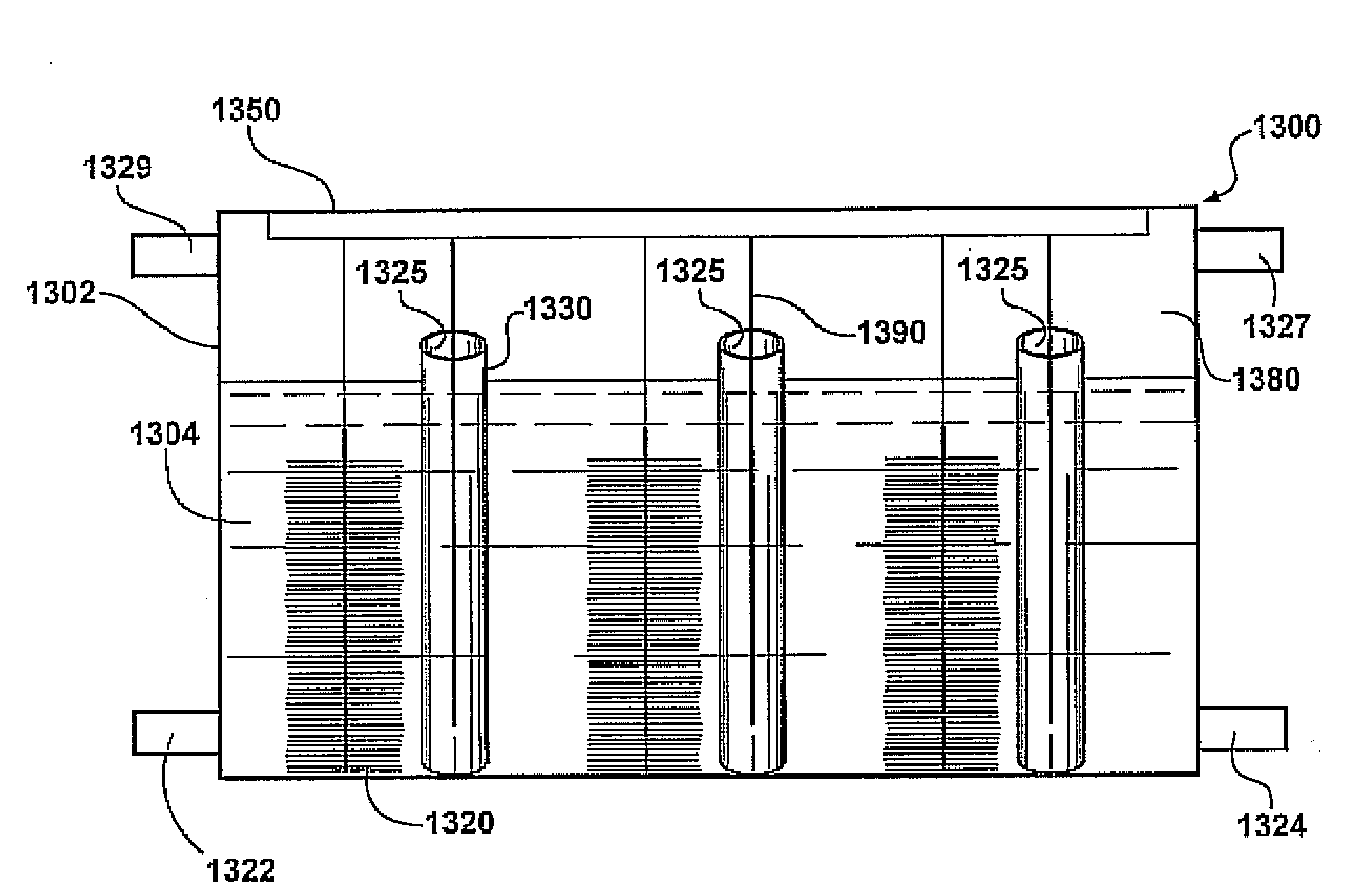

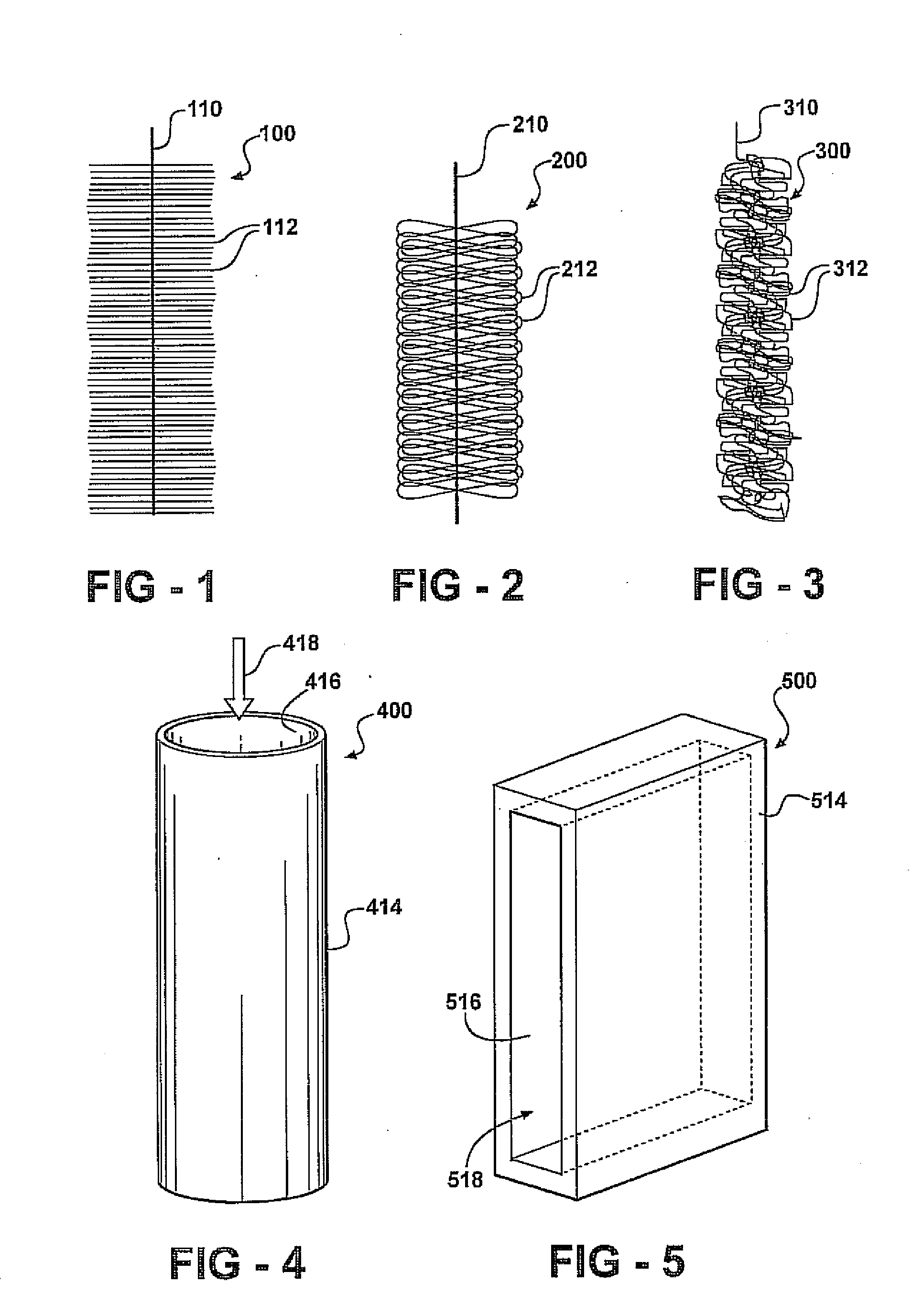

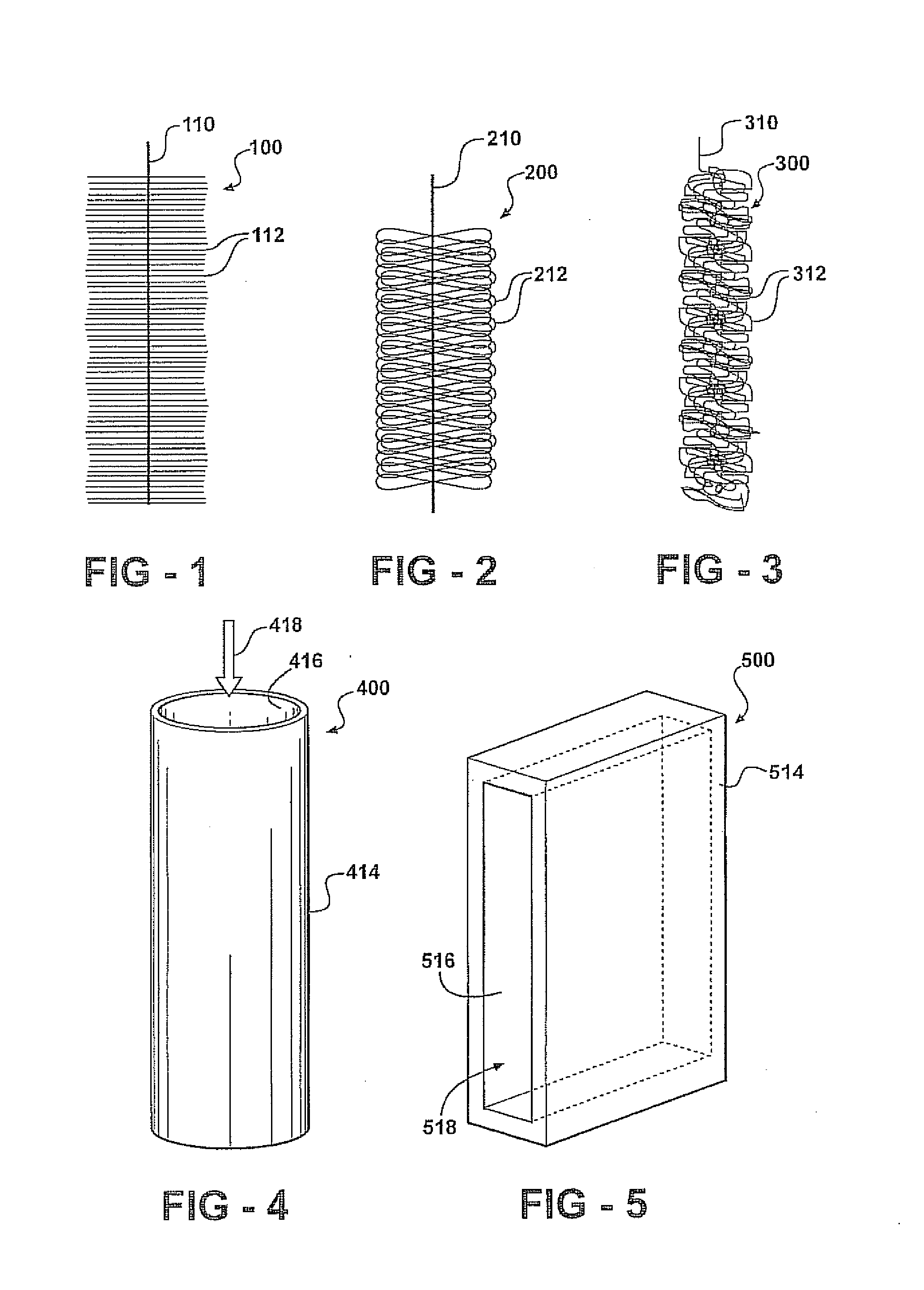

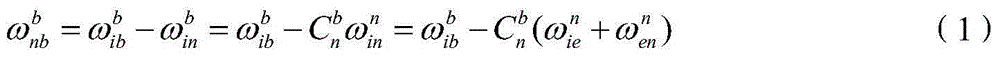

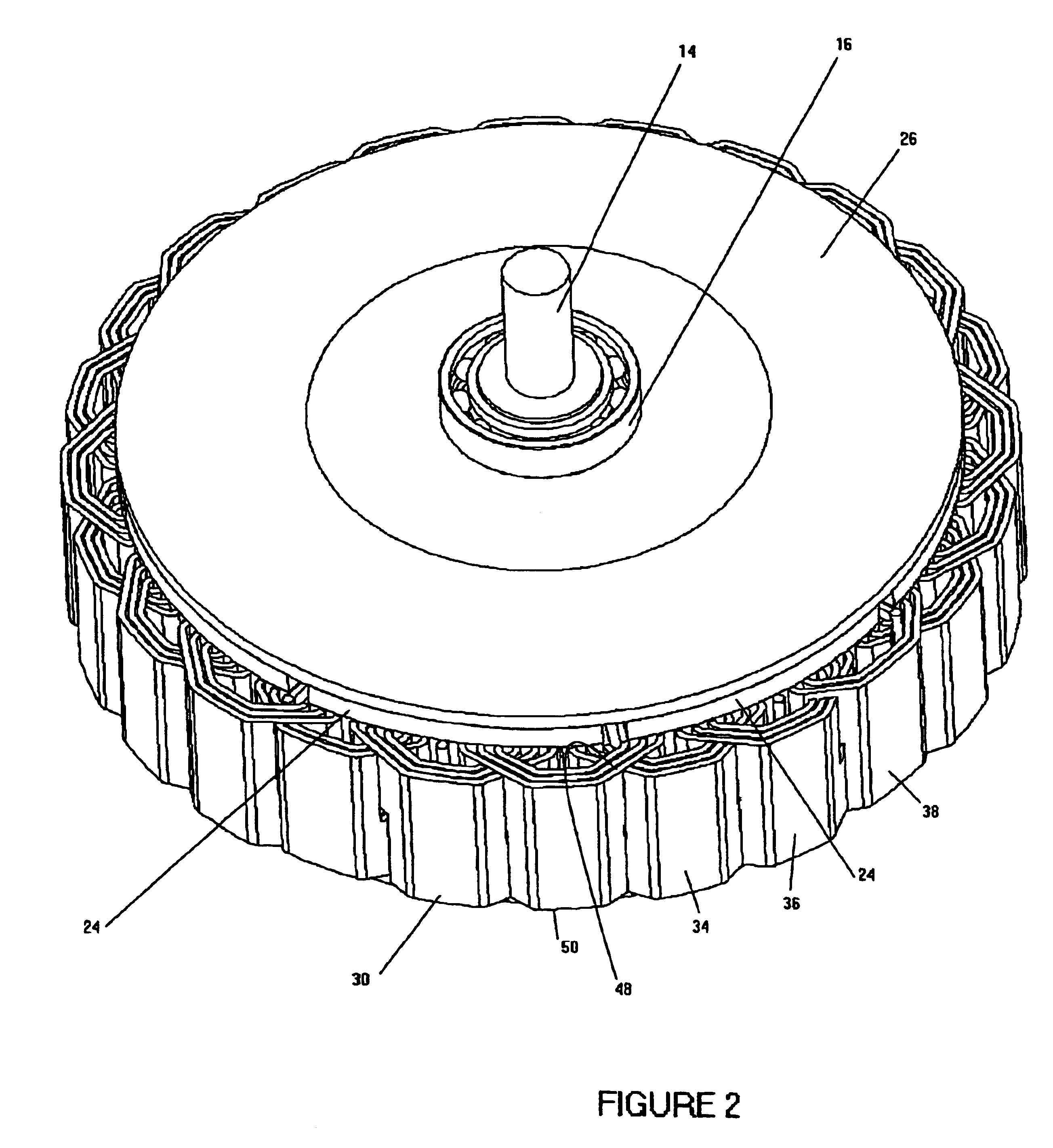

Electromotive devices using notched ribbon windings

InactiveUS6856063B1Improve power densityImprove performance parametersSynchronous generatorsMagnetic circuitElectrical resistance and conductanceElectrical conductor

A multiple phase winding for an electromotive device comprised of individual phase windings. Each phase winding includes multiple layers of conductors and defines working length portions and interior and exterior end-turn portions, wherein at least one set of end-turn portions defines notches which cut across the height dimension of all the layers of conductors. The notches of different phases intermesh. This geometry promotes low electrical resistance within the phase windings and good conductive heat transfer between the multiple phase winding and the housing of the electromotive device, allowing higher power density from the device.

Owner:MAGNETIC POWER MOTION

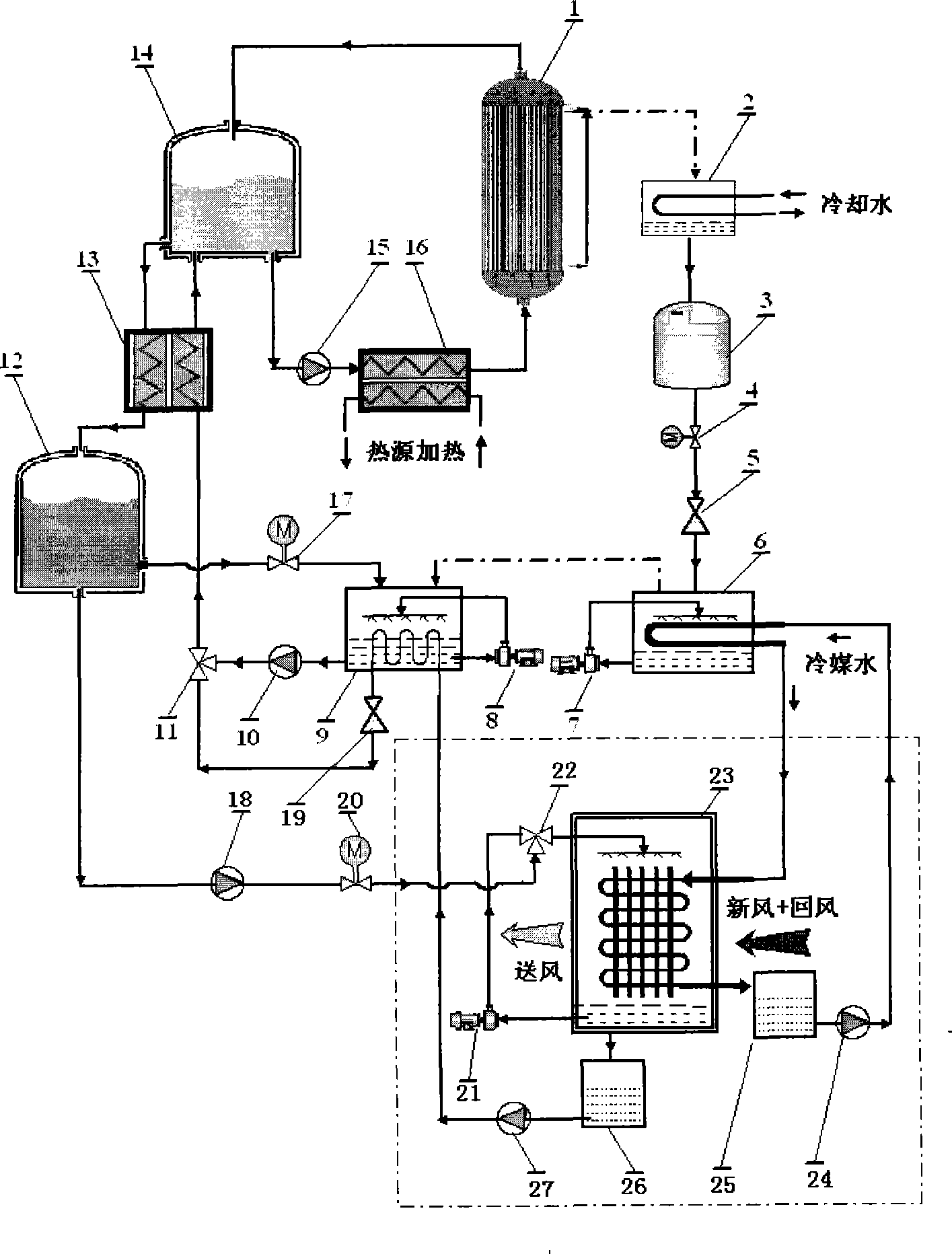

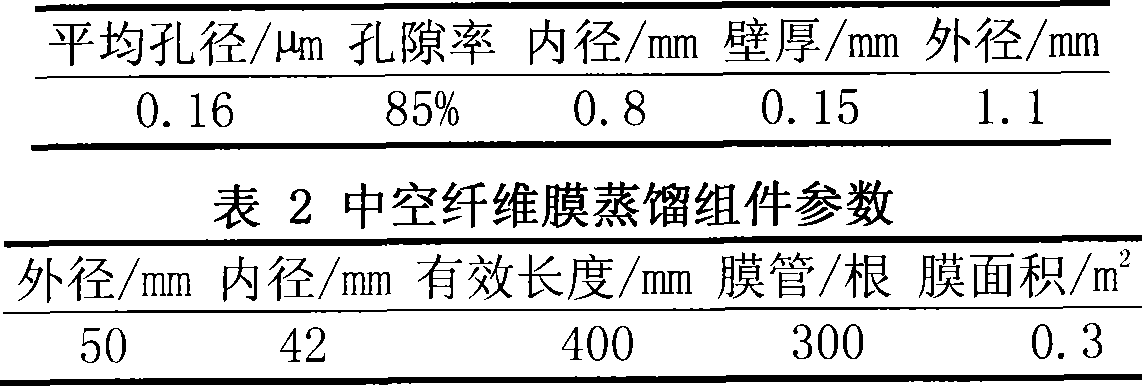

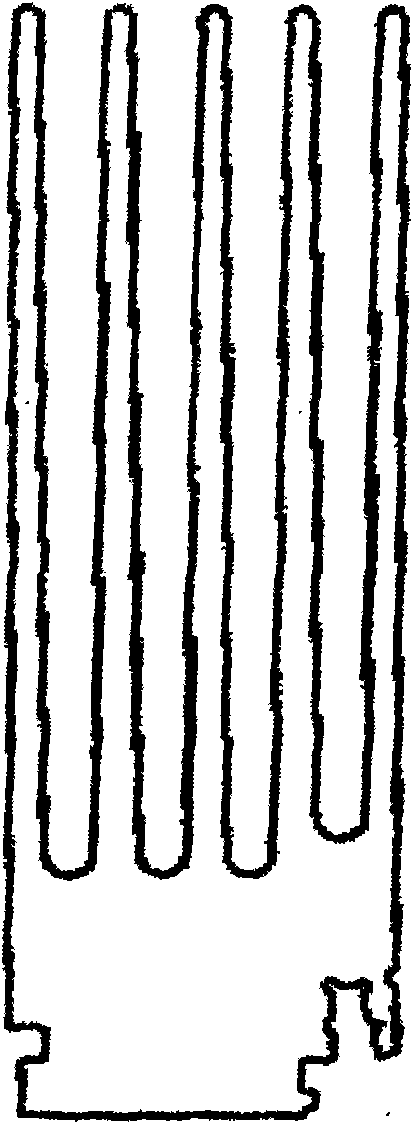

Temperature and humidity independent control air conditioner system based on film distillation technology

InactiveCN101435615AImprove efficiencyImprove qualitySpace heating and ventilation safety systemsSpace heating and ventilation control systemsAfter treatmentDistillation

The invention relates to a temperature and humidity independent control air-conditioning system based on the membrane distillation technology, which comprises a lithium bromide absorption refrigerating system, a lithium bromide solution dehumidifying system and an auxiliary connecting part, wherein the lithium bromide absorption refrigerating system is utilized to control the supply air temperature, and the lithium bromide solution dehumidifying system is utilized to control the supply air humidity; the solution analysis process in the lithium bromide absorption refrigerating system and the solution regeneration process in the lithium bromide solution dehumidifying system are subjected to centralized treatment in a membrane distillation component; a concentrated lithium bromide solution after treatment is divided into two parts, wherein one part is taken as an absorbent solution of an absorber in the absorption refrigerating system, and the other part is taken as a spraying solution in the solution dehumidifying system to perform dehumidification treatment on the air; simultaneously a low-temperature diluted lithium bromide solution treated by the dehumidifying system is taken as a cooling solution of the absorber in the absorption refrigerating system to recover energy, so that the efficiency of the system is improved and the energy of the system is saved.

Owner:XI AN JIAOTONG UNIV

Manufacturing method of vehicle aluminum alloy radiating fin

ActiveCN101660883ATake advantage ofImprove performance parametersDomestic articlesLaminated elementsManganeseImpurity

The invention relates to the technical field of manufacturing radiating fins, in particular to a manufacturing method of a vehicle aluminum alloy radiating fin. The vehicle aluminum alloy radiating fin is manufactured in the mode of heating extrusion; aluminum alloy is obtained by aluminum liquid regeneration smelting, wherein, smelted aluminum liquid contains 85% of aluminum ingot A00 and residual leftover material in percentage by weight; generated aluminum alloy comprises the following components in percentage by weight: 0.325-0.355% of silicon, 0.50-0.54% of magnesium, 0.10-0.30% of iron,less than 0.02% of copper, less than 0.02% of manganese, less than 0.02% of chromium, less than 0.02% of zinc, less than or equal to 0.03% of titanium, less than or equal to 0.05% of other single impurity by control, less than 0.15% of total trace element, and the balance aluminum. The invention has the beneficial effect of simple technology and low cost; in addition, the invention fully utilizesleftover and accelerates industry development, each performance parameter of the manufactured radiating fin is relatively improved, so that the radiating fin has favorable performance.

Owner:东莞市奥达铝业有限公司

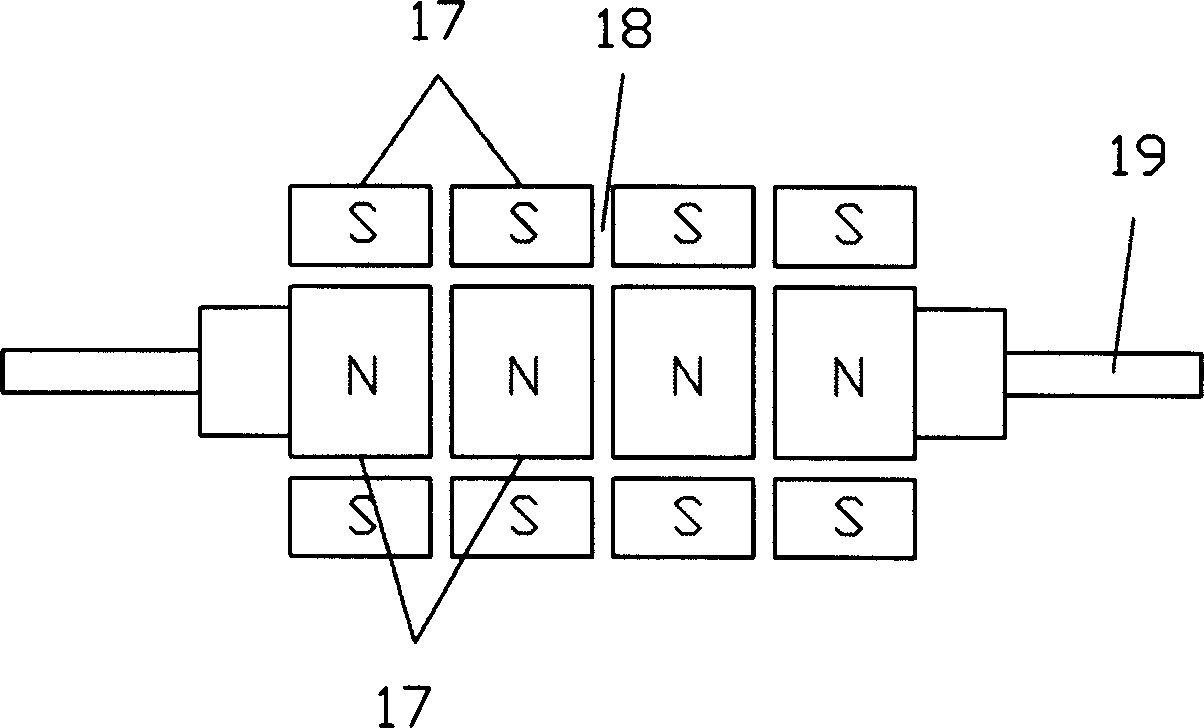

Hollow anode for plasma thruster of cusped magnetic field

InactiveCN104675650AImprove anode lifeImprove efficiencyMachines/enginesUsing plasmaIonizationNuclear magnetic resonance

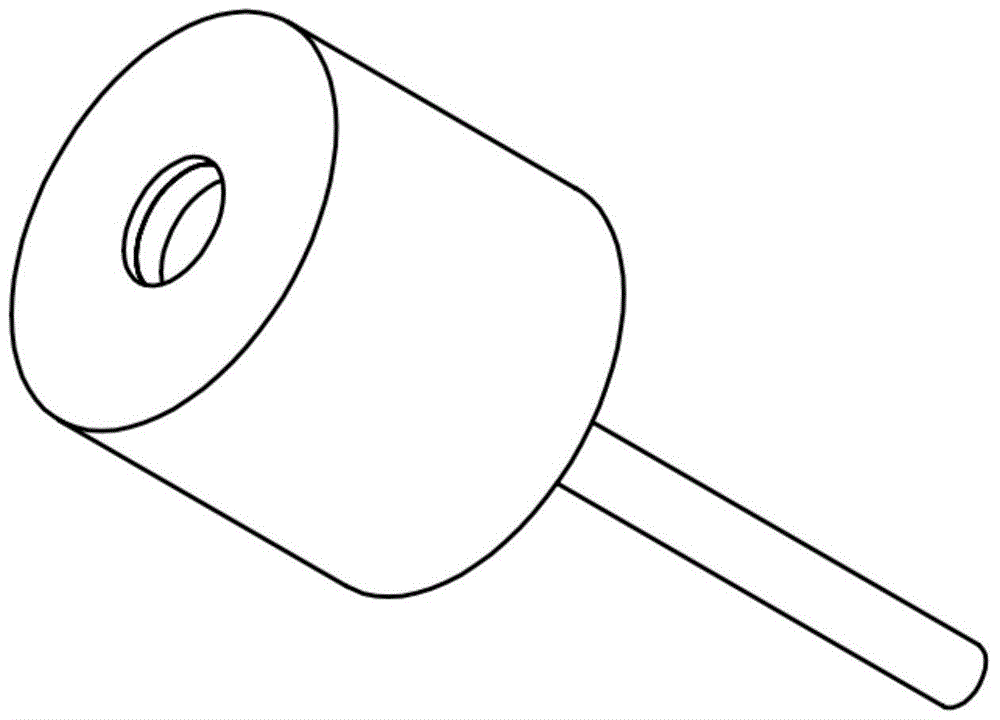

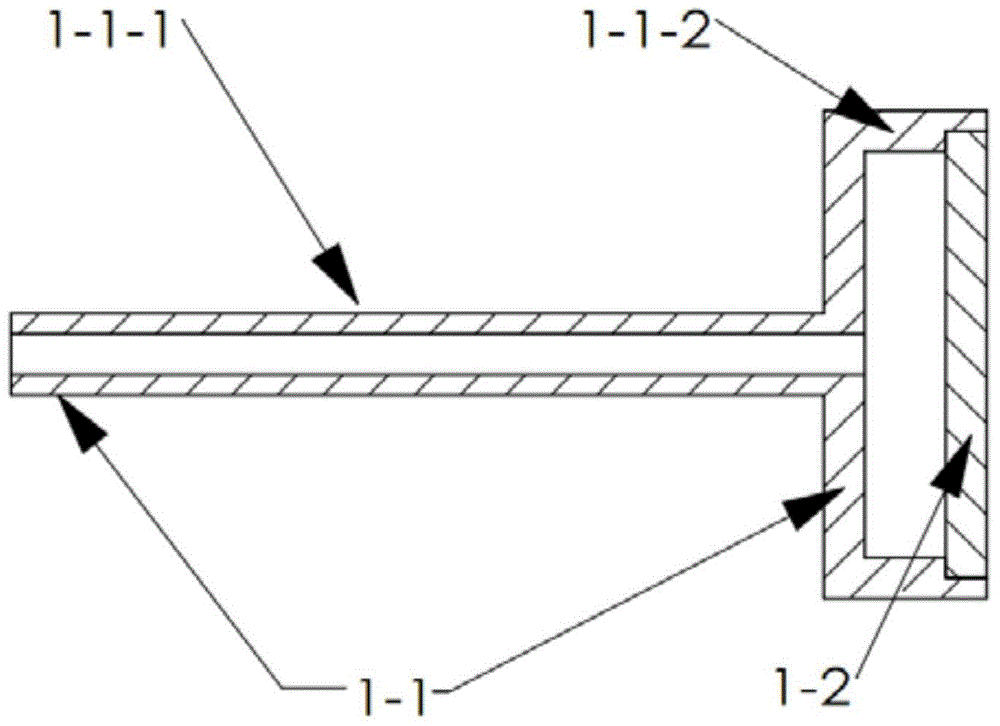

The invention provides a hollow anode for a plasma thruster of a cusped magnetic field, and relates to a plasma thruster of a cusped magnetic field. By the hollow anode for the plasma thruster of the cusped magnetic field, the problems that a permanent magnet is demagnetized and the service life of a thrust is shortened due to the fact that an anode of the existing thruster of a cusped magnetic field is over hot are solved. The ionization rate of the thruster is increased, and the performance of the thruster is further improved. The hollow anode for the plasma thruster of the cusped magnetic field comprises a gas distributor, a buffering cavity and a ceramic sleeve, wherein a gas supply piece comprises a guide tube and a cavity; and the gas distributor comprises the gas supply piece and a distributor bottom plate. The hollow anode for the plasma thruster of the cusped magnetic field is used in the field of plasma thrusters of the cusped magnetic field.

Owner:HARBIN INST OF TECH

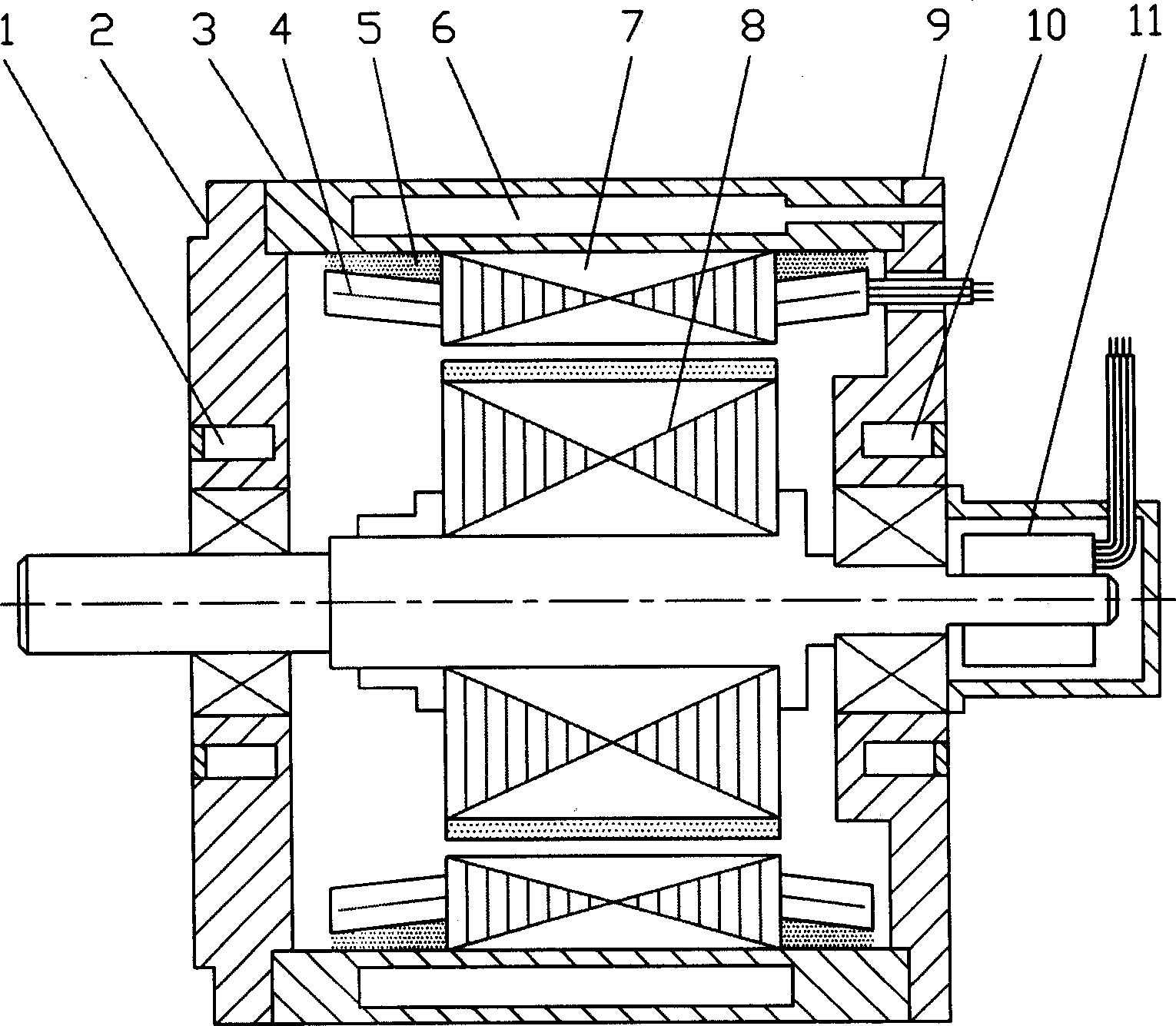

Direct cooling permanent magneta A.C. servo electric machine and brushless D.C. electric machine and application in fuel cell

InactiveCN1560982AImprove cooling effectReduce volumeMagnetic circuit rotating partsCooling/ventillation arrangementBrushless motorsFuel cells

This invention relates to a direct cold permanent magnet AC server motor and brushless motor including a shell, stators and rotators characterizing in designing an axial labyrinth channel in the shell with inlet and an outlet at the end. Cold medium of water or air is plug into the channel to flow from one end to the other, so the axial temperature of the motor is very uniform, at the same time, structure of the labyrinth channel can increase paths for medium passing to further improve cold effect.

Owner:ZHEJIANG UNIV +1

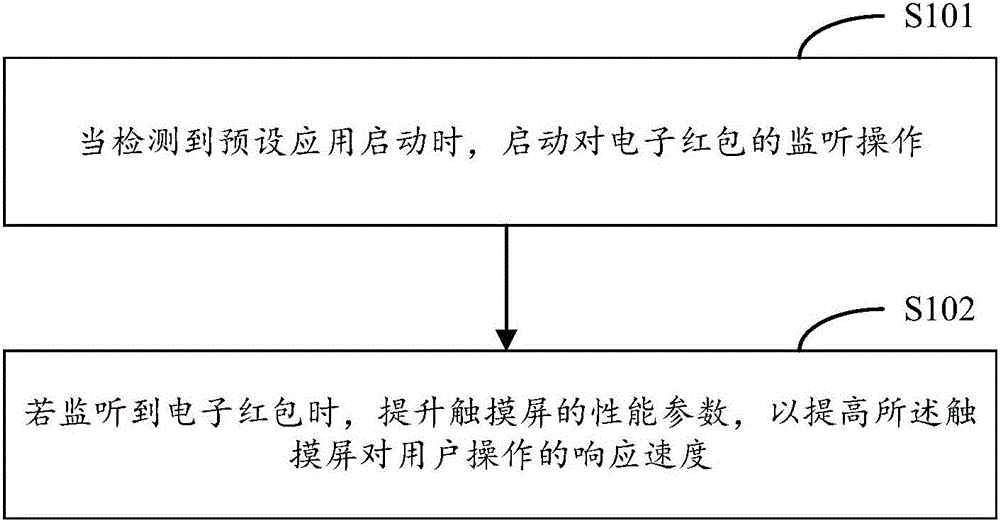

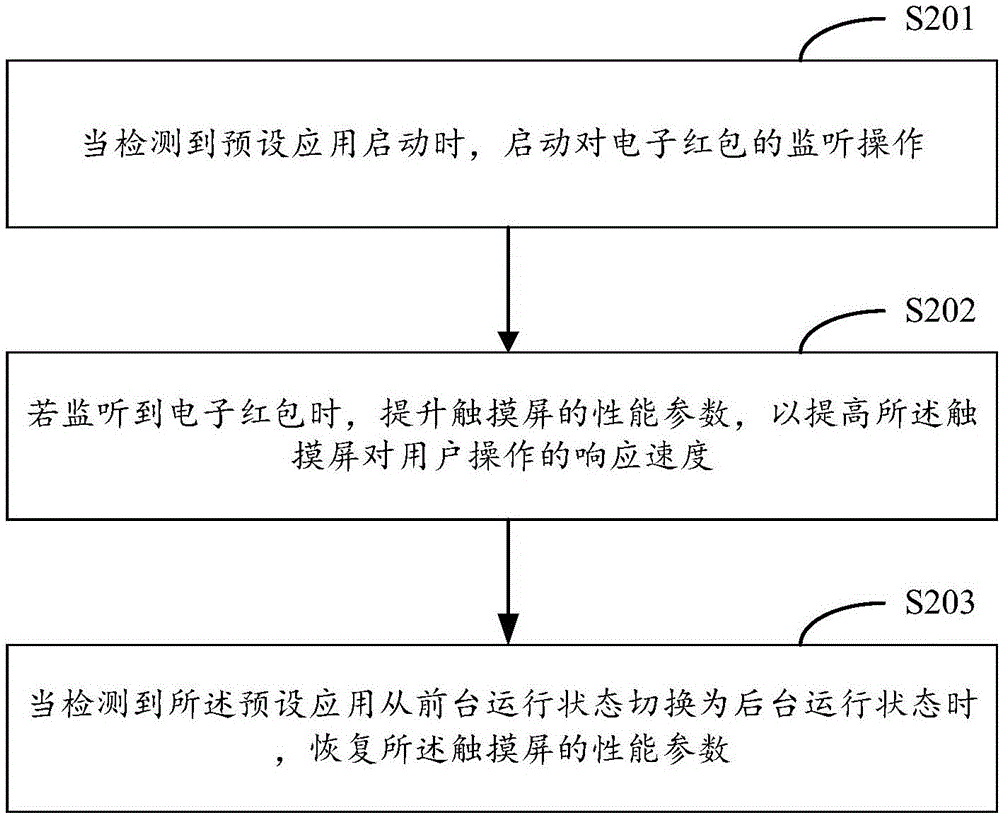

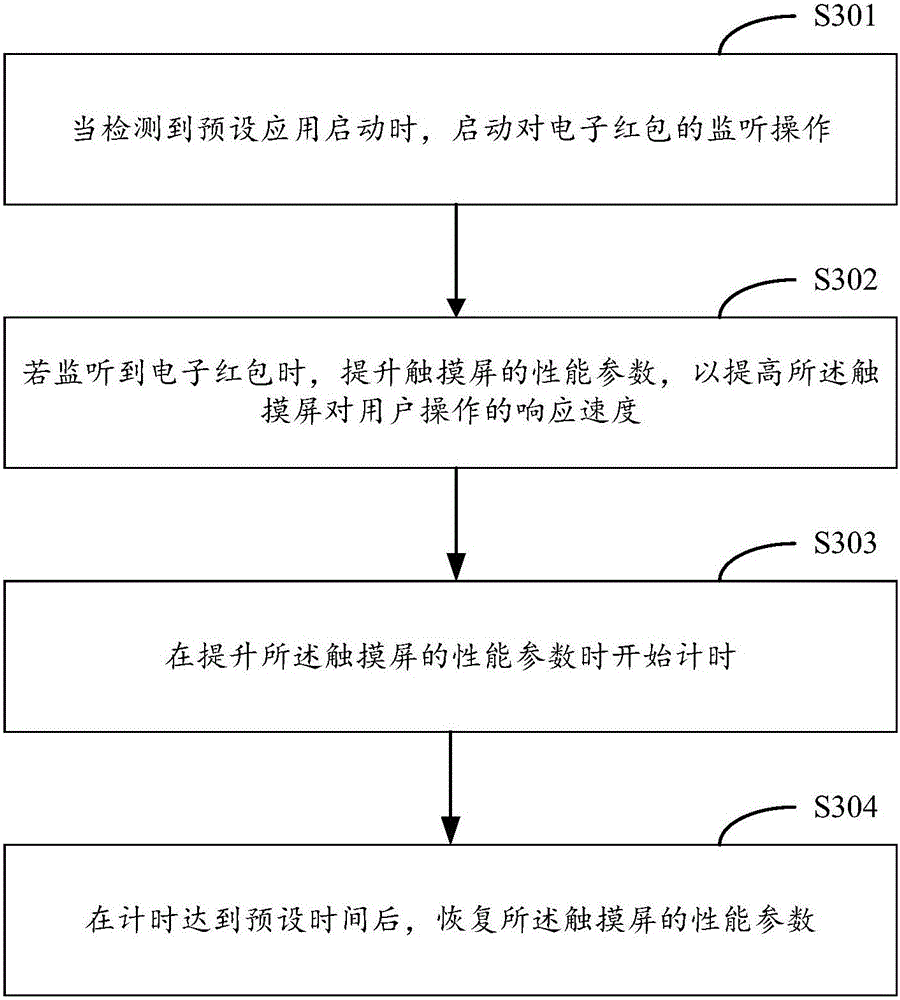

Touch screen parameter adjustment method and mobile terminal

InactiveCN106383654AProcessing speedImprove performance parametersSubstation equipmentInput/output processes for data processingComputer terminalTouchscreen

The invention is applied to the technical field of communication and provides a touch screen parameter adjustment method and a mobile terminal. The adjustment method includes the following steps: initiating monitor operation of a digital red envelope when the startup of a preset application is detected; and increasing performance parameters of a touch screen when the digital red envelope is monitored to enhance the responsive rate of the touch screen to the user operation. The present invention, by monitoring the digital red envelop, has the advantages of increasing the responsive rate of the touch screen to the user operation during the distribution of the digital red envelope, thus shortening the user operation time when a user snatches the red envelope, accelerating the digital red envelope processing speed of the mobile terminal, and improving the probability of the user getting the red envelope.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Heat treatment method for diesel engine cam

InactiveCN101476029AReduce distortionReach hardnessSolid state diffusion coatingFurnace typesMechanical equipmentCam

The invention discloses a diesel engine cam thermal treatment method comprising a carburizing step, a quenching step and a tempering step.After the carburizing step, a pit cooling method is adopted for reducing the deformation of the cam because of the heat treatment process, two times of alkaline bath quenching are adopted for not only reducing thermal stress and deformation, but also having functions of thinning heart crystal grains and eliminating network carbide for satisfying metallography requirement in the first quenching process of the cam, and having a function of assuring to obtain cryptocrystal martensite, residual austenite and partial of granule carbide on the surface for satisfying performance requirements of rigidity, wearing resistance property, contact fatigue degree and the like of the cam surface in the second quenching process of the cam;simultaneously, the cam heart can obtain lath martensite and fine homogeneous ferrite, and the mechanical property of the cam heart can be improved; according to the invention, design requirements of heat rigidity, wearing resistance property, fatigue strength, mechanical property of the cam heart and deflection can all be satisfied, therefore, the manufactured cams can be extensively used in large-scale heavy-duty mechanical equipment.

Owner:CHONGQING YUEJIN MACHINERY

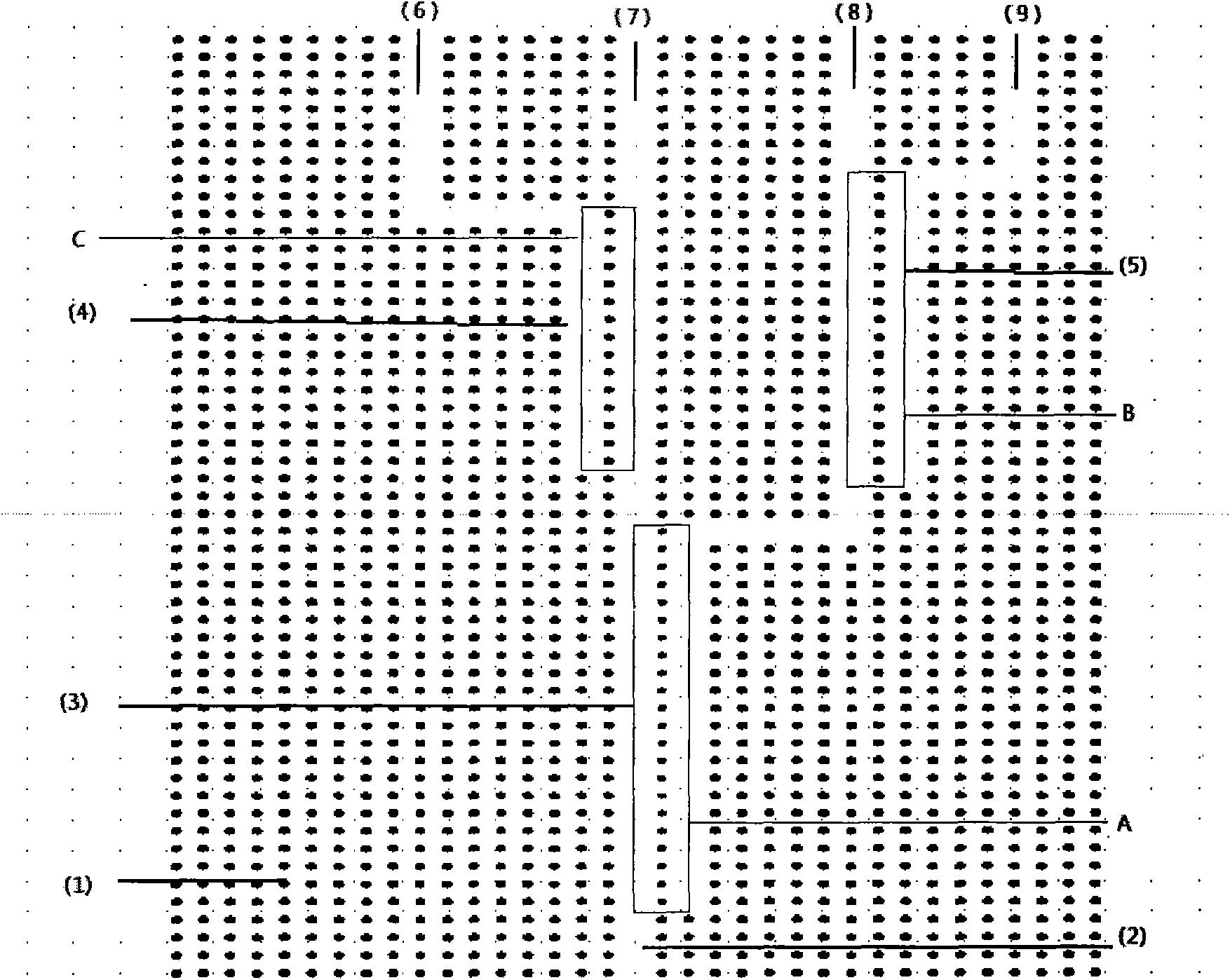

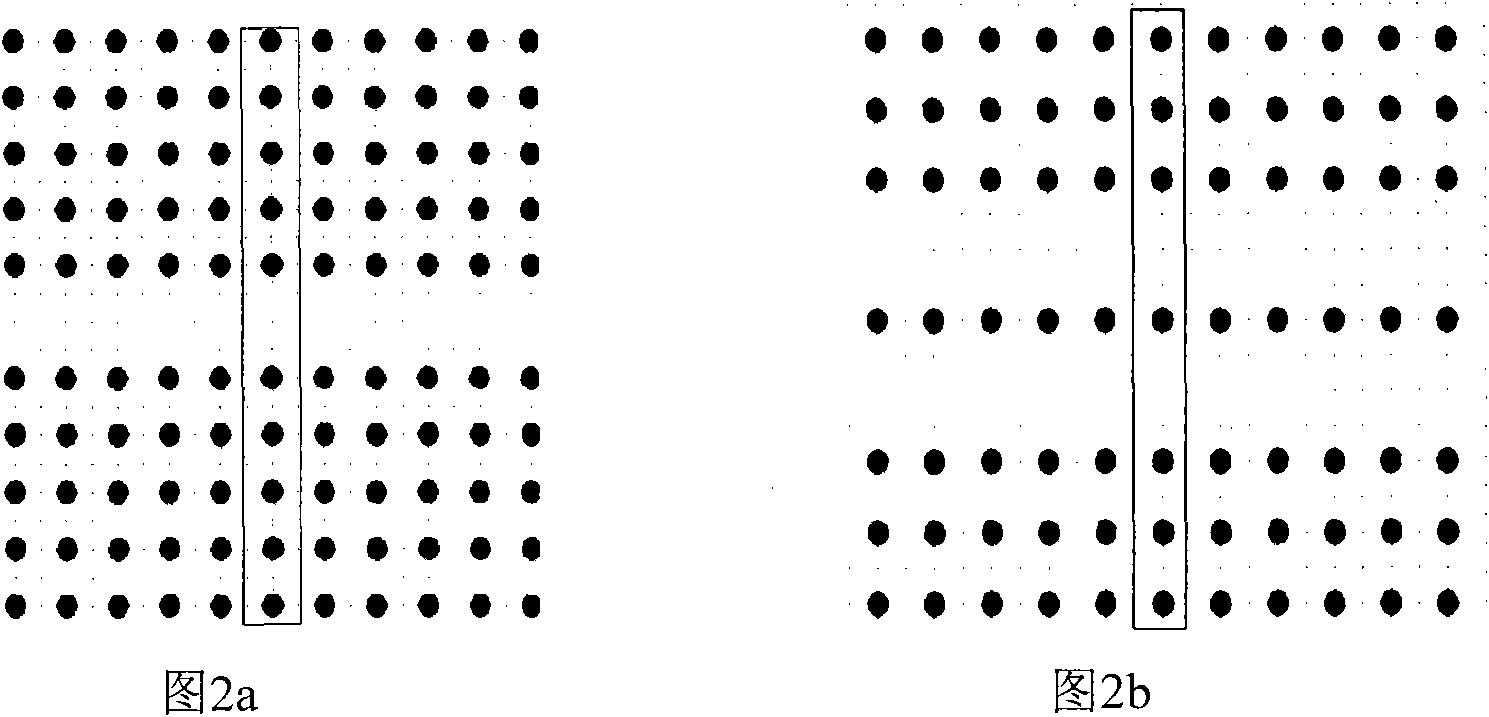

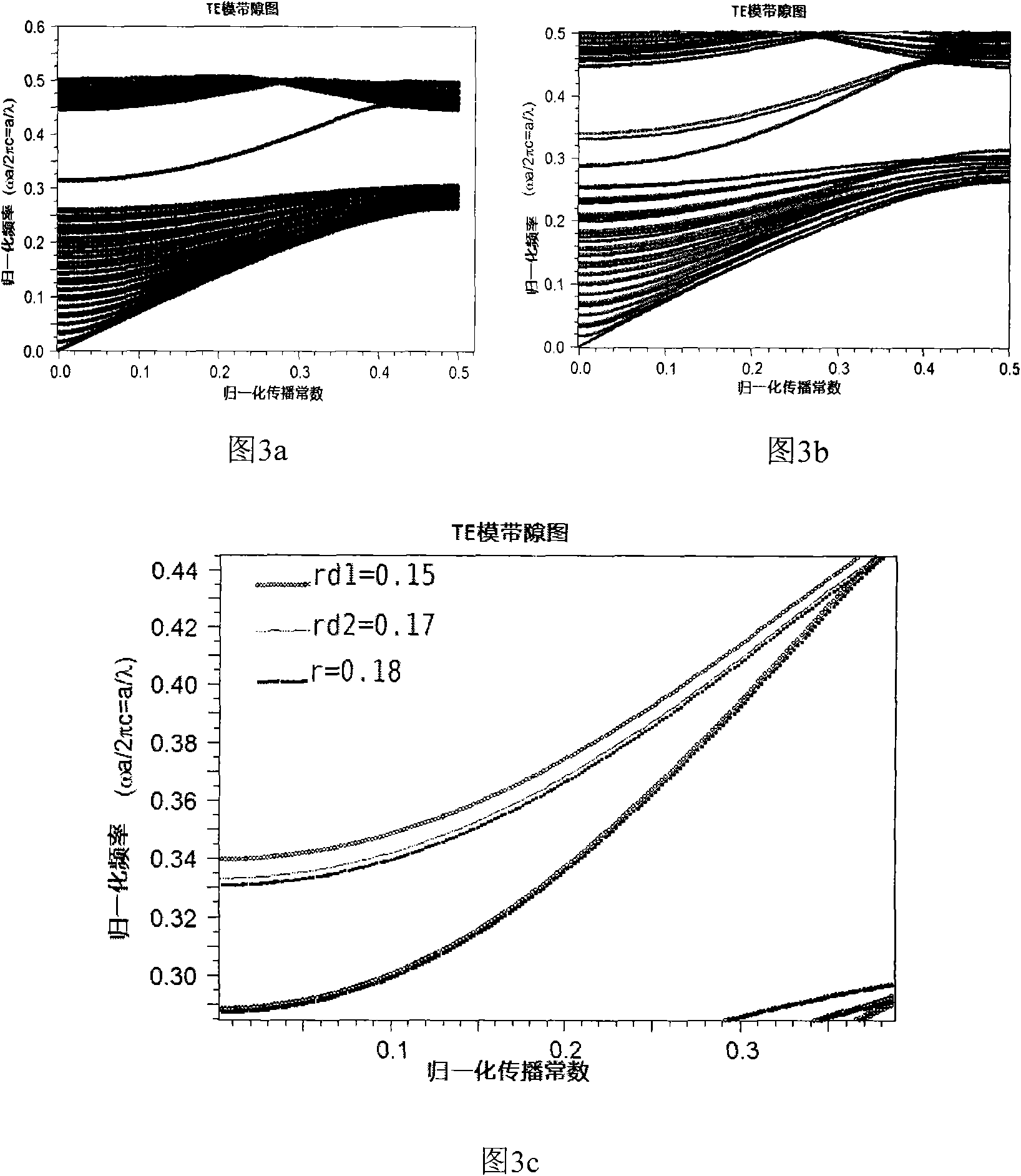

Two-dimensional photonic crystal four-wavelength division multiplexer based on multiple-mode interference

InactiveCN102116905AImprove isolationImprove performance parametersOptical light guidesPhotonic crystalMultiplexer

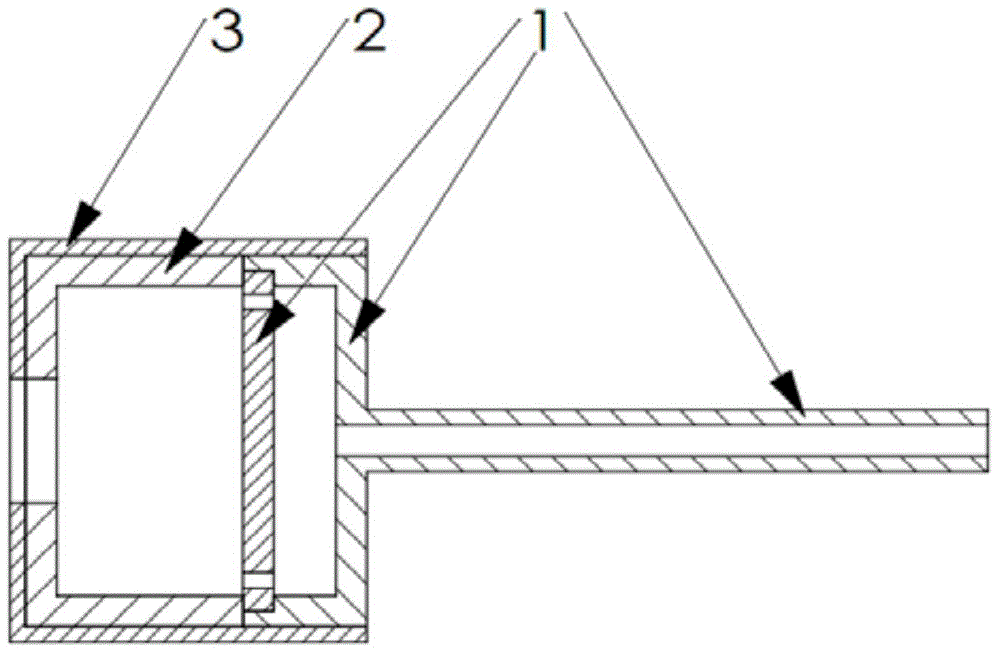

The invention relates to a two-dimensional photonic crystal four-wavelength division multiplexer based on multiple-mode interference, which comprises two-dimensional periodically arrayed medium column photonic crystals (1), wherein the multiplexer also comprises a single mode input waveguide (2), a first multi-mode interference coupling area (3), a second multi-mode interference coupling area (4), a third multi-mode interference coupling area (5), a first single mode output waveguide (6), a second single mode output waveguide (7), a third single mode output waveguide (8) and a fourth single mode output waveguide (9), which are arranged between the medium column photonic crystals (1). By finely tuning the size of the radius of the medium column in the coupling area, the structure of component is more compact and the property parameter is more optimized.

Owner:NANJING UNIV OF POSTS & TELECOMM

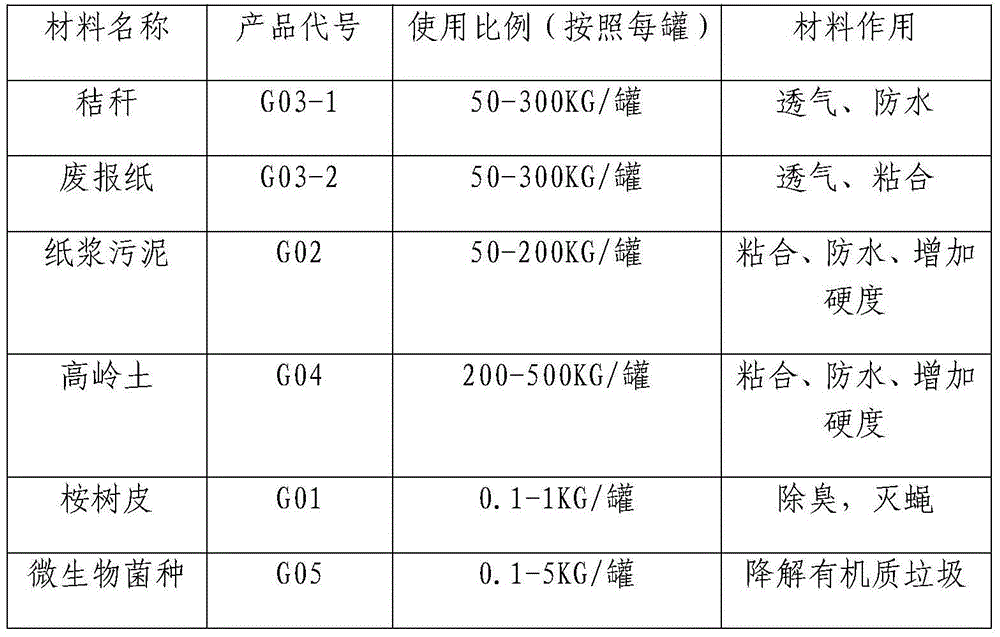

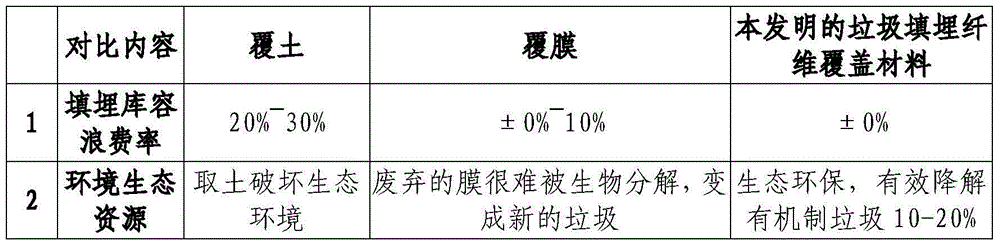

Garage embedding fiber covering material

The invention provides a garbage embedding fiber covering material which comprises the following components in parts by weight: 5-30 parts of straws, 5-30 parts of paper, 5-20 parts of pulp sludge, 20-50 parts of kaolin, 0.01-0.1 part of eucalyptus bark and 0.01-0.5 part of a microbial strain solution, wherein microbial strains are spore strains. After being used and dried, a coating of the garbage embedding fiber covering material provided by the invention has main dual effects of gas permeability and water guide; a core microbial technology for quickly degrading household garbage organic pollutants is uniquely added to quickly and effectively deodorize and kill flies for a long time; meanwhile, the garbage embedding fiber covering material has the necessary physical strength and flame resistance; moreover, by adding functional additives and grass seeds, operations such as deodorizing, fly killing and greening can be completed by one step in a spraying and covering process.

Owner:GUIZHOU OURUIXIN ENVIRONMENTAL PROTECTION TECH

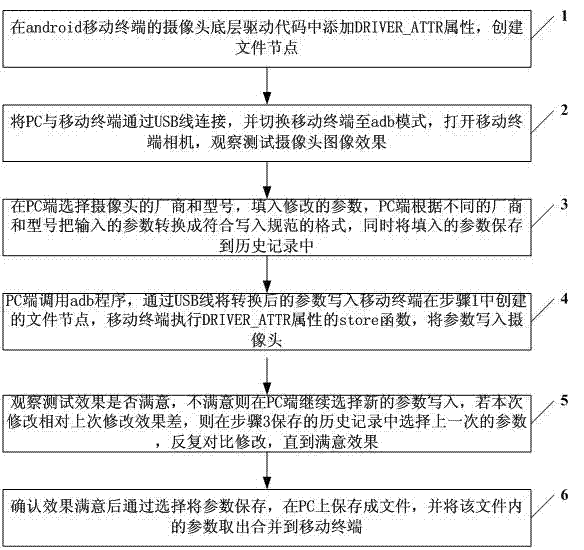

Camera online debugging method

ActiveCN103049375AEfficient debuggingImprove debugging efficiencySoftware testing/debuggingCamera imageComputer terminal

The invention discloses a camera online debugging method. A camera is arranged on a mobile terminal. The camera online debugging method includes the following steps: adding DRIVER_ATTR attributes in a camera bottom driving code at an android mobile terminal, and building document nodes; connecting a person computer (PC) with the mobile terminal through a universal serial bus (USB), switching the mobile terminal to an adb mode, opening the mobile terminal camera, and observing and testing camera image effect; selecting manufacturers and models of the camera at the PC end, and filling modified parameters; calling an adb program through the PC end, writing the switched parameters in the document nodes built in the mobile terminal through the USB, executing a store function of the DRIVER_ATTR attributes through the mobile terminal, and writing the parameters in the camera; contrasting and modifying repeatedly till results are satisfied; and storing the parameters. The camera online debugging method performs online real-time humanized and efficient debugging on the camera, can effectively improve camera debugging efficiency of the android system, and picks up best effect parameters conveniently.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

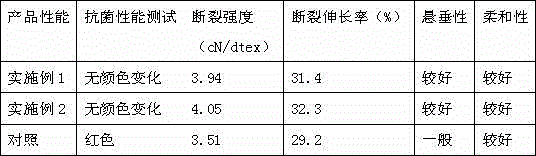

Radiation-proof yarn and production method thereof

The invention belongs to the technical field of textile material production, and discloses a radiation-proof yarn. The radiation-proof yarn is formed by blending of metal wires, polyacrylonitrile fibers and viscose according to a weight ratio of 1: 5: 4. The invention further discloses a production method of the radiation-preventive yarn. The radiation-proof yarn is good in radiation proofing performance and flexibility, not easy to fracture and good in antibacterial effect and market prospect.

Owner:SHANDONG WENDAO TRADING

Automobile reduction gearbox casing and preparation process of casing

ActiveCN102865354AImprove corrosion resistanceHigh strengthGearing detailsBreaking strengthManganese

The invention discloses an automobile reduction gearbox casing. The casing comprises 0.2% of yttrium, 0.06% of titanium, 0.05% of cerium, 0.05% of lanthanum, 0.02% of samarium, 0.5% of zinc, 2% of manganese, and the balance being magnesium. The invention also discloses a preparation method of the automobile reduction gearbox casing. The automobile reduction gearbox casing is excellent in breaking strength, hardness, creep resistance and corrosion resistance and has good market application value.

Owner:山东银光钰源轻金属精密成型有限公司

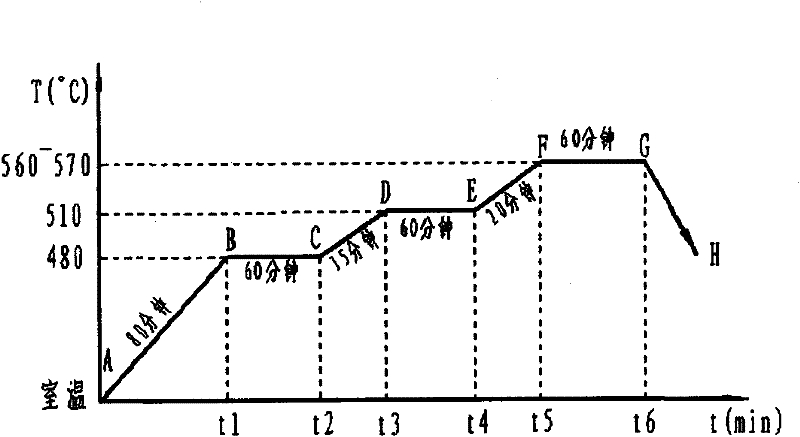

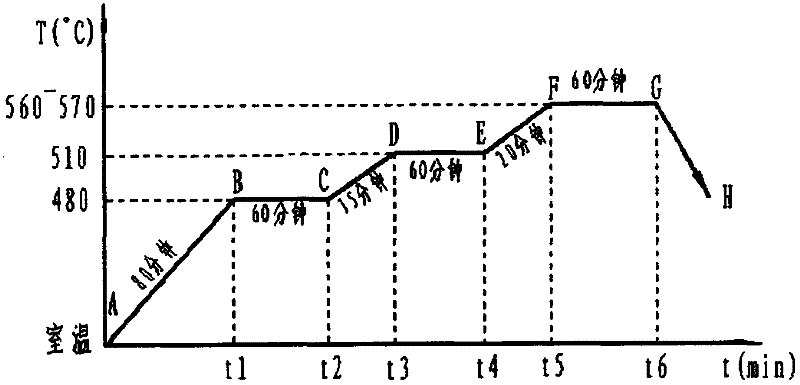

Heat treatment method for ultracrystalline magnetic core

ActiveCN102363830AImprove performanceImprove performance parametersFurnace typesInductances/transformers/magnets manufactureNon magneticHeat treated

The invention discloses a heat treatment method for an ultracrystalline magnetic core. The method comprises the following steps of: annealing in a non-magnetic field mode during the heat treatment of the ultracrystalline magnetic core, and protecting by using argon, namely setting different annealing temperatures under the condition of a certain annealing heat-preserving time t, testing at the nine temperatures of 520 DEG C, 530 DEG C, 540 DEG C, 550 DEG C, 560 DEG C, 570 DEG C, 580 DEG C, 590 DEG C and 600 DEG C, comparing test results, and finding the optimum annealing temperature T; setting the heat-preserving time under the condition of a certain optimum annealing temperature T, testing within 15 minutes, 30 minutes, 45 minutes and 60 minutes, comparing test results under different kinds of heat-preserving time, and finding the optimum heat-preserving time t; and drawing a conclusion, wherein the optimum annealing temperature is between 560 and 570 DEG C, and the optimum heat-preserving time is 60 minutes. The heat treatment method is simple, the performance of the magnetic core subjected to the heat treatment is high, and property parameters of the ultracrystalline magnetic core are far higher than standard parameters, so the properties of products with the magnetic core can be improved greatly, and the cost of the products can be reduced.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

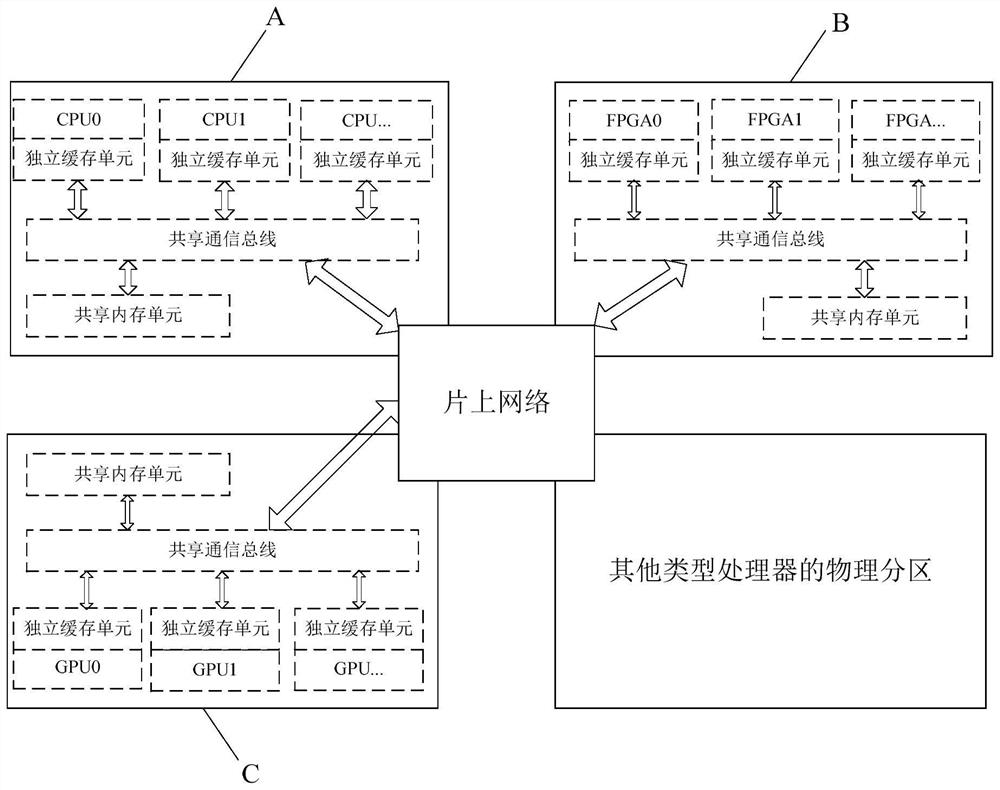

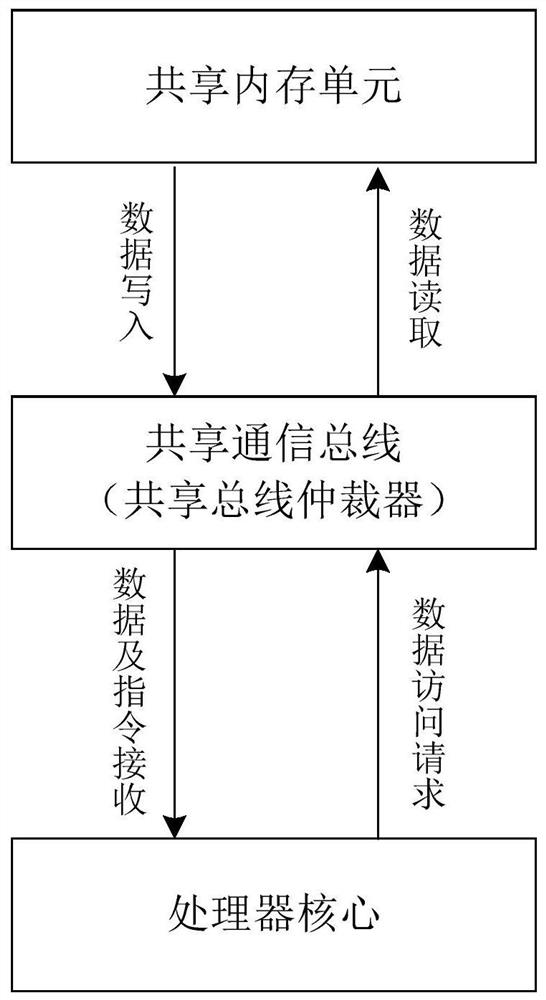

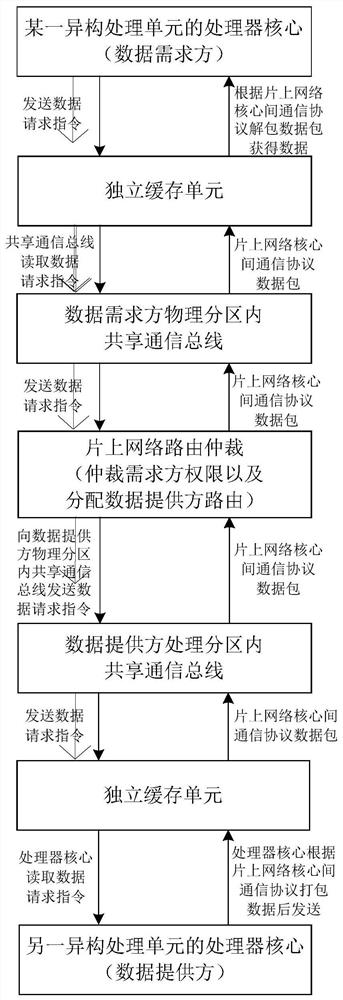

Inter-core secure communication system of multi-core heterogeneous domain controller

ActiveCN113312299AReduce occupancyHigh bandwidthResource allocationMultiple digital computer combinationsComputer networkComputer architecture

The invention relates to an inter-core secure communication system for a multi-core heterogeneous domain controller, which comprises a plurality of physical partitions divided according to the type of processors in the multi-core heterogeneous domain controller and a network-on-chip connected with each physical partition; processors of the same type are located in the same physical partition; each processor comprises a processor core and an independent cache unit which are connected with each other; each physical partition further comprises a shared communication bus and a shared memory unit, and the isomorphic processor cores of the processors of the same type in the same physical partition are connected with the shared communication bus through the independent cache units of the processors; the shared communication bus is connected with the shared memory unit, and the shared communication buses in different physical partitions are connected with the network-on-chip. According to the invention, an inter-core communication mechanism between a plurality of isomorphic processor cores and heterogeneous processor cores is established, the transmission quantity of data between the cores and the safety of the data are optimized, and the comprehensive performance of the multi-core heterogeneous domain controller is improved.

Owner:BEIHANG UNIV

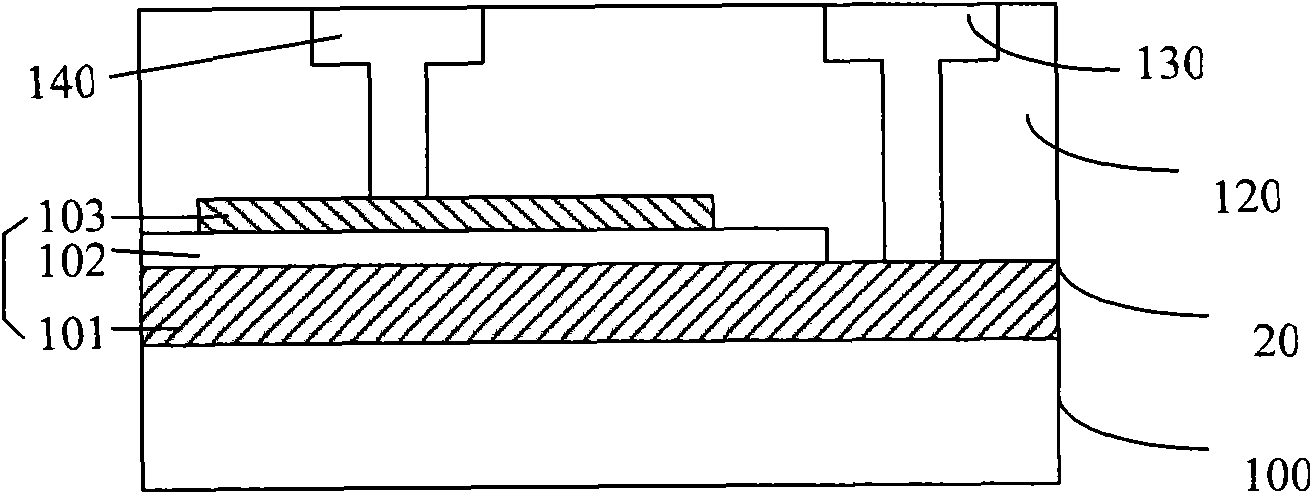

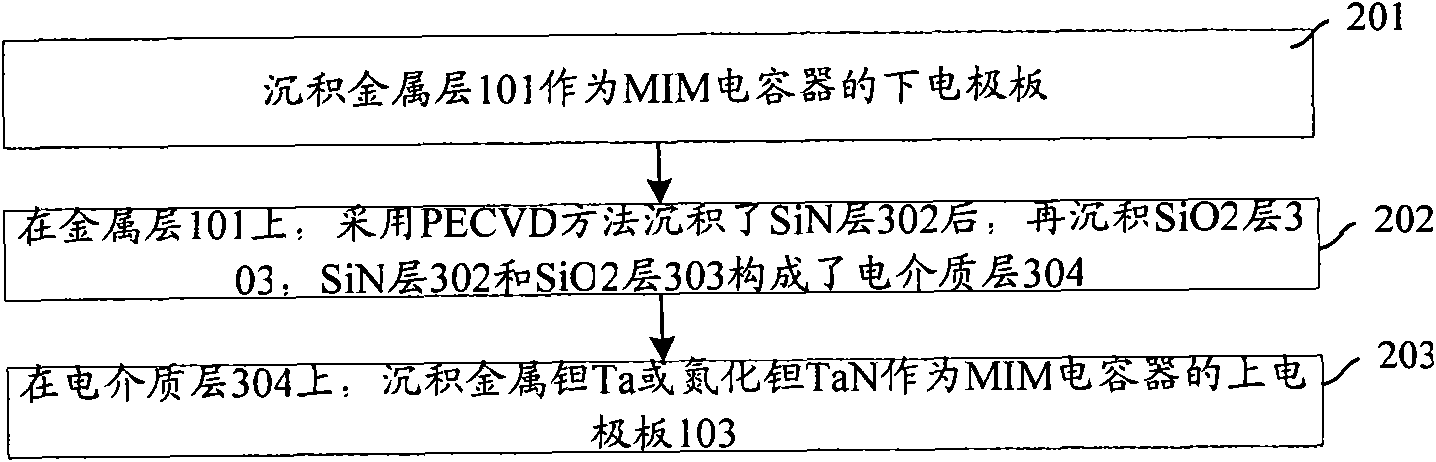

Method for manufacturing capacitor of metal-insulator-metal structure

ActiveCN101783286AImprove performance parametersBond stabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetal-insulator-metalEngineering

The invention discloses a method for manufacturing a capacitor of a metal-insulator-metal (MIM) structure. The manufacturing method comprises the following steps: firstly, depositing a lower electrode plate; secondly, manufacturing a dielectric layer; and finally, depositing an upper electrode plate. The method for manufacturing the dielectric layer comprises the steps of: depositing a SiO2 layer after depositing a SiN layer. The method provided by the invention has the advantage of improving performance parameters of the MIM capacitor.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

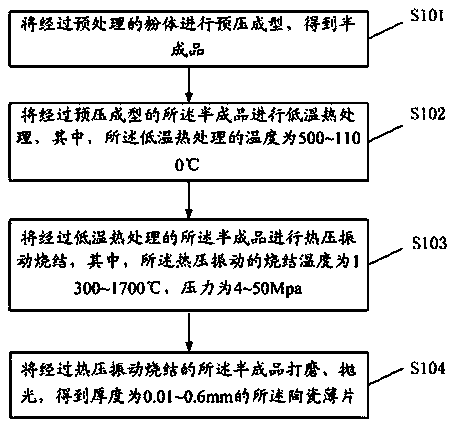

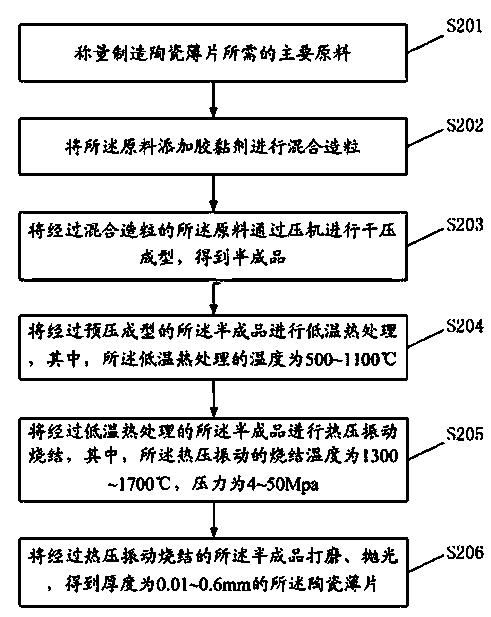

Ceramic slice and preparation method thereof

The invention discloses a ceramic slice and a preparation method thereof. The ceramic slice is mainly made of zirconia and rare earth oxides, is prepared through a hot-press vibration sintering technology, and has a thickness of 0.01 to 0.6 mm. Correspondingly, the invention also discloses a preparation method of the ceramic slice. The preparation method comprises the following steps: carrying out pre-pressing and forming on powder, which has been subjected to a pretreatment, so as to obtain a half-finished product; subjecting the half-finished product to a low temperature thermal treatment; subjecting the half-finished product to hot-press vibration sintering; and finally polishing and burnishing the half-finished product so as to obtain the ceramic slice with a thickness of 0.01 to 0.6 mm. The strength of the provided ceramic slice can reach 1400 MPa or more, the toughness can reach 10 MPa.m<1 / 2>, and the performance parameters of the ceramic slice are prominently higher than that of common ZrO2 products. The ceramic slice can satisfy the requirements on slice and ultrathin slice with a thickness of 0.01 to 0.6 mm and has the advantages of difficultness in breakage, little loss, long service life, and durability.

Owner:JIN GANG NEW MATERIALS +1

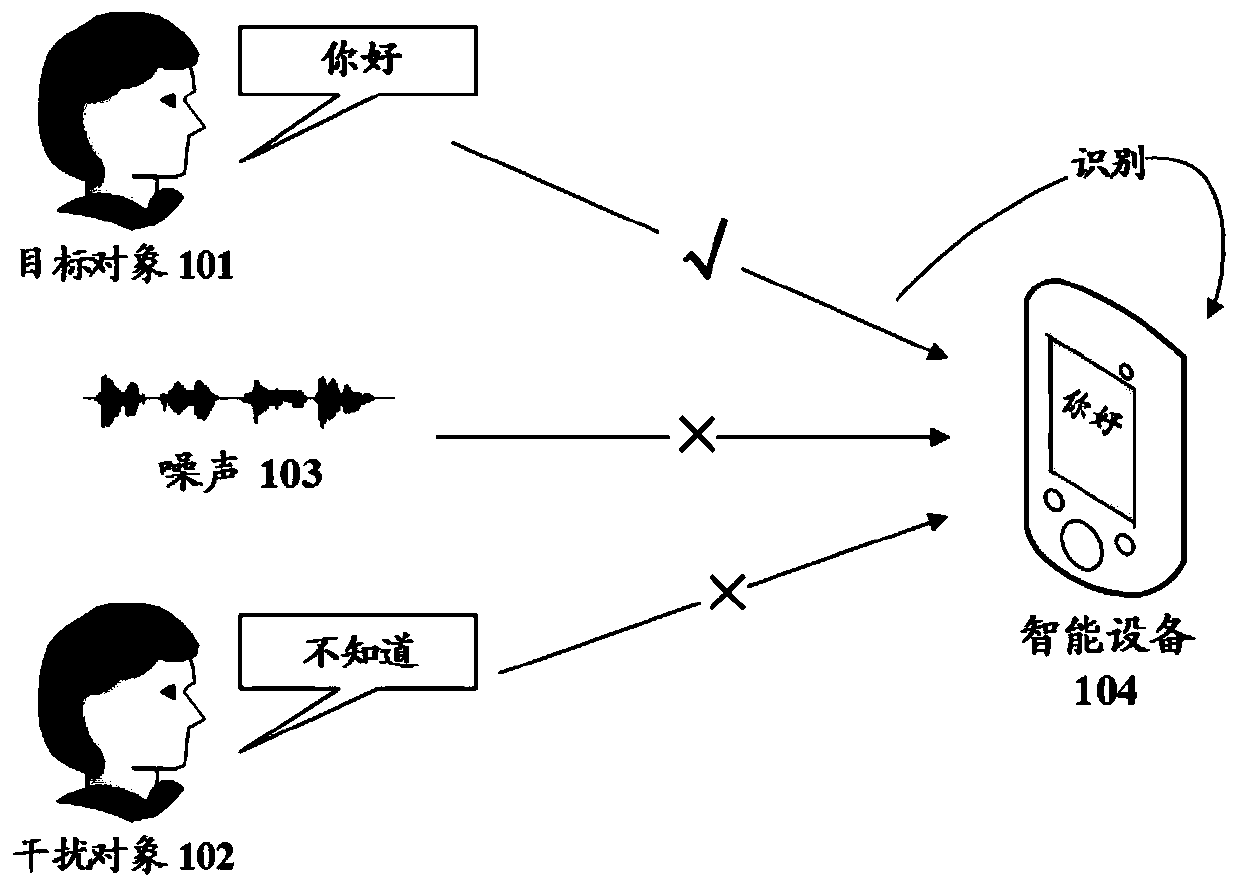

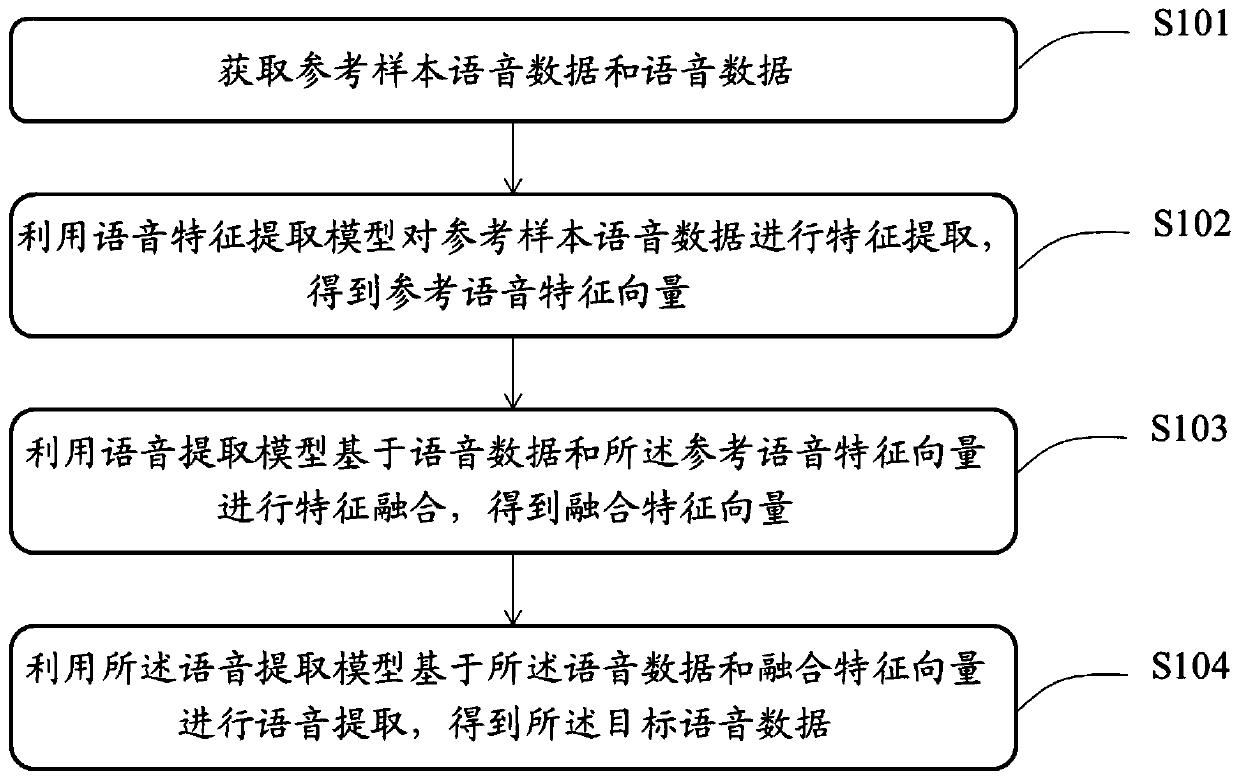

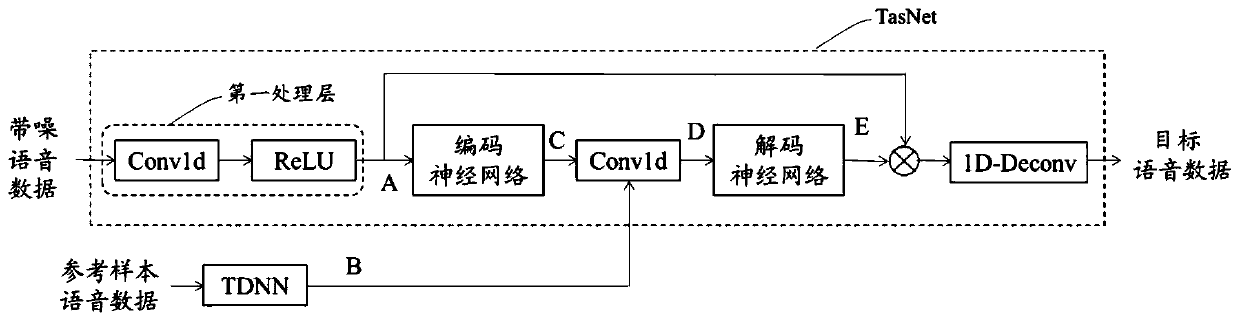

Target voice extraction method, device and equipment, medium and joint training method

ActiveCN111179911AImprove accuracyImprove signal-to-noise ratioSpeech recognitionVoice dataSpeech sound

The disclosure provides a target voice extraction method, device and equipment, a medium and a joint training method. The target voice extraction system comprises a voice feature extraction model anda voice extraction model. The joint training method of the target voice extraction system comprises the following steps: performing feature extraction on training reference sample voice data by usingthe voice feature extraction model to obtain a reference voice feature vector, setting the training reference sample voice data to be pure voice data corresponding to the target object; performing feature fusion based on training voice data and the reference voice feature vector by using the voice extraction model to obtain a fusion feature vector, setting the training voice data to be noisy voicedata from which target voice data corresponding to a target object is to be extracted; utilizing the voice extraction model to perform voice extraction based on the training voice data and the fusionfeature vector to obtain the target voice data; and performing joint training on the voice feature extraction model and the voice extraction model based on the reference voice feature vector and thetarget voice data.

Owner:TENCENT TECH (SHENZHEN) CO LTD

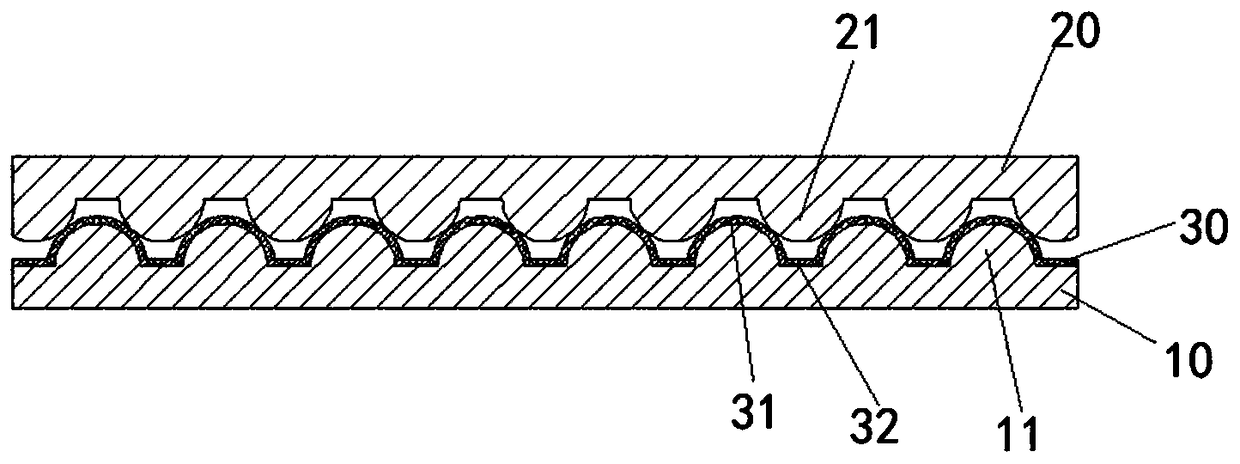

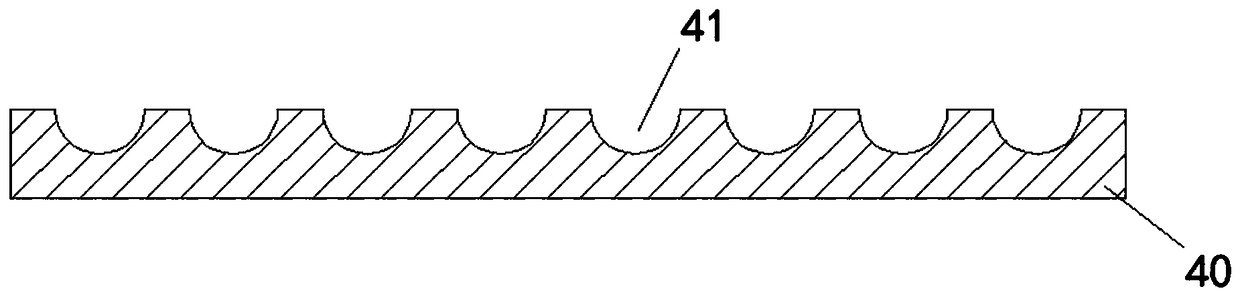

Flexible pressure sensor with interlaced microstructure and manufacturing method thereof

InactiveCN109489875AReliable manufacturingReliable productionForce measurementCarbon nanotubeEngineering

The invention is applicable to the technical field of sensor fabrication and packaging, and discloses a flexible pressure sensor with an interlaced microstructure and a manufacturing method thereof. The flexible pressure sensor consists of first and second flexible substrates, and a carbon nanotube film is arranged between the first and second flexible substrates. One sides of the first and secondflexible substrates are provided with several spherical-crown-shaped staggered first and second protrusions respectively, and the carbon nanotube film is attached to the surface, with the first protrusions, of the first flexible substrate. The manufacturing method is used for manufacturing the flexible pressure sensor. According to the flexible pressure sensor with the interlaced microstructure and the manufacturing method thereof, a staggered hemispherical internal structure is adopted, through the combination of the high conductivity of carbon nanotubes, the linear measurement range and sensitivity of the sensor are improved, the stability, the precision, the accuracy and the reliability are high, and the response time is short.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Capacitor and inductor scheme with e-fuse application

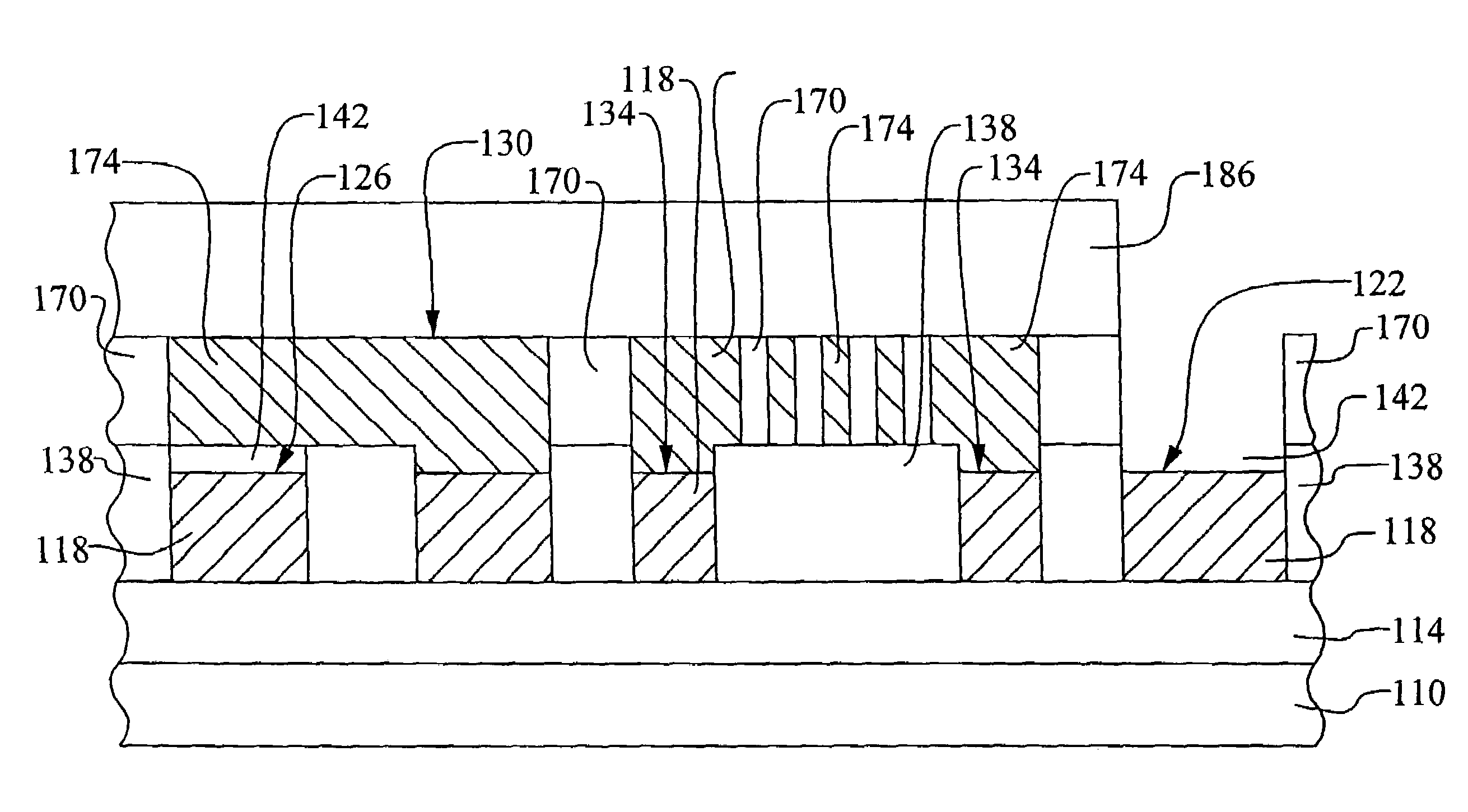

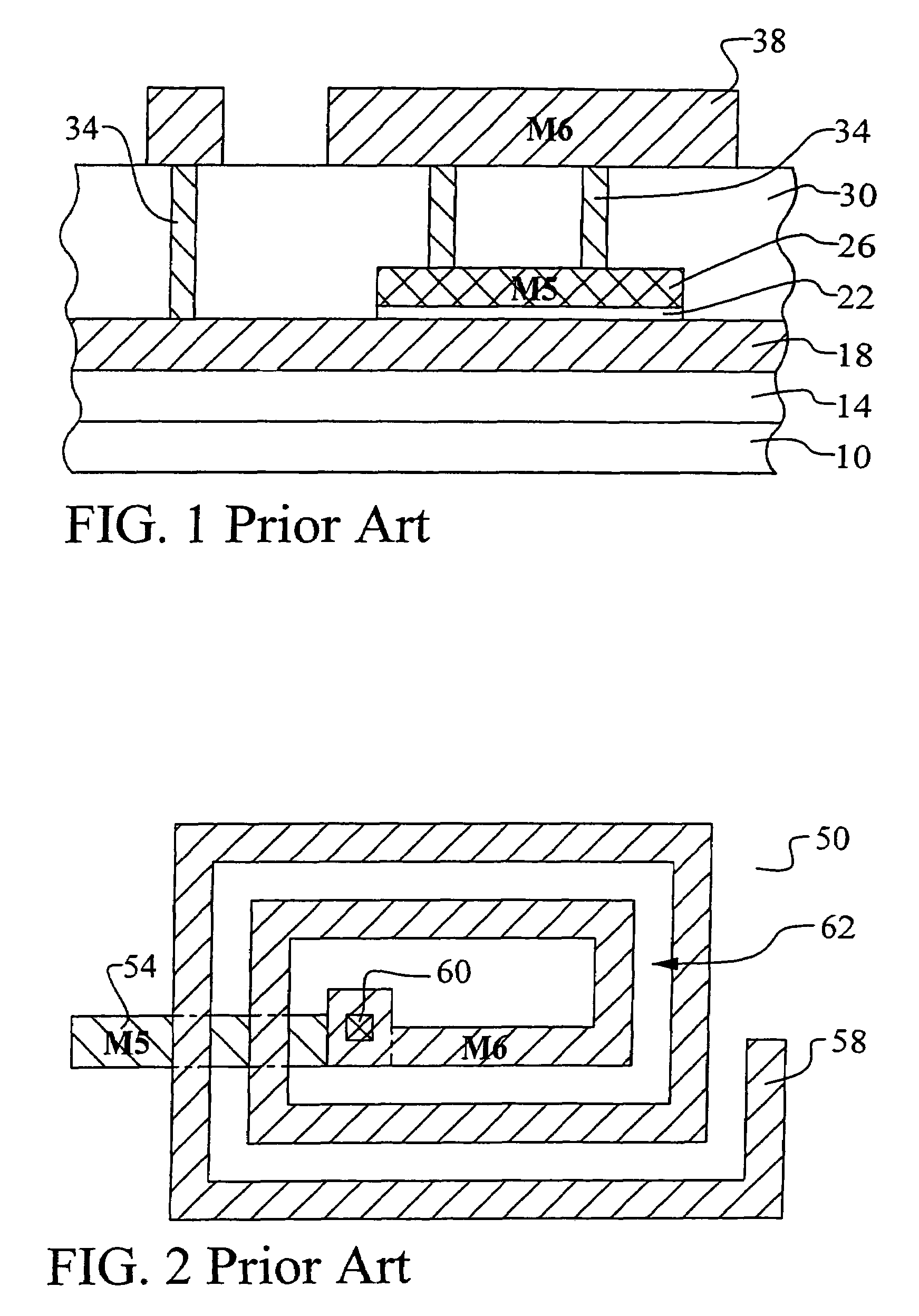

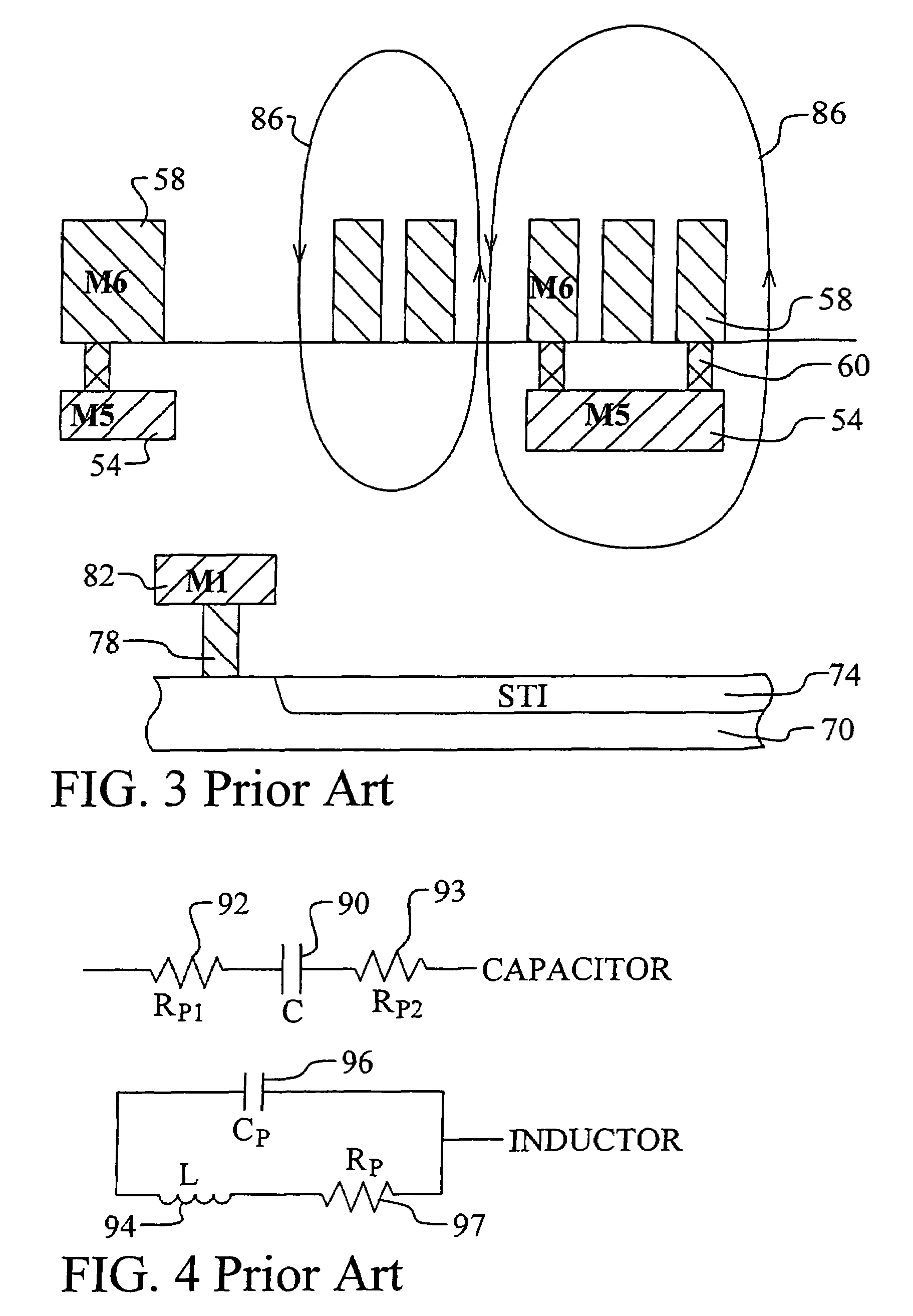

InactiveUS7348654B2Improve performance parametersLess interferenceSemiconductor/solid-state device detailsSolid-state devicesDevice formDirect coupling

RF devices formed in integrated circuit devices include a top metal level overlying a substrate. The top metal level comprises pads and portions of planned RF devices and an RF metal level overlying the top metal level completes the RF devices which may be an interconnected RF network that may include capacitors, inductors or both. Openings are formed in a passivation layer overlying the RF metal level to provide direct access to the RF devices. The interconnected RF network may include fuses enabling the network to be selectively altered by cutting relatively thin interconnect lines using a laser directed through the openings. The RF devices or portions of the RF network may be directly coupled to external devices and utilized in SOC (System On a Chip) and SIT (System In Package) technologies.

Owner:TAIWAN SEMICON MFG CO LTD

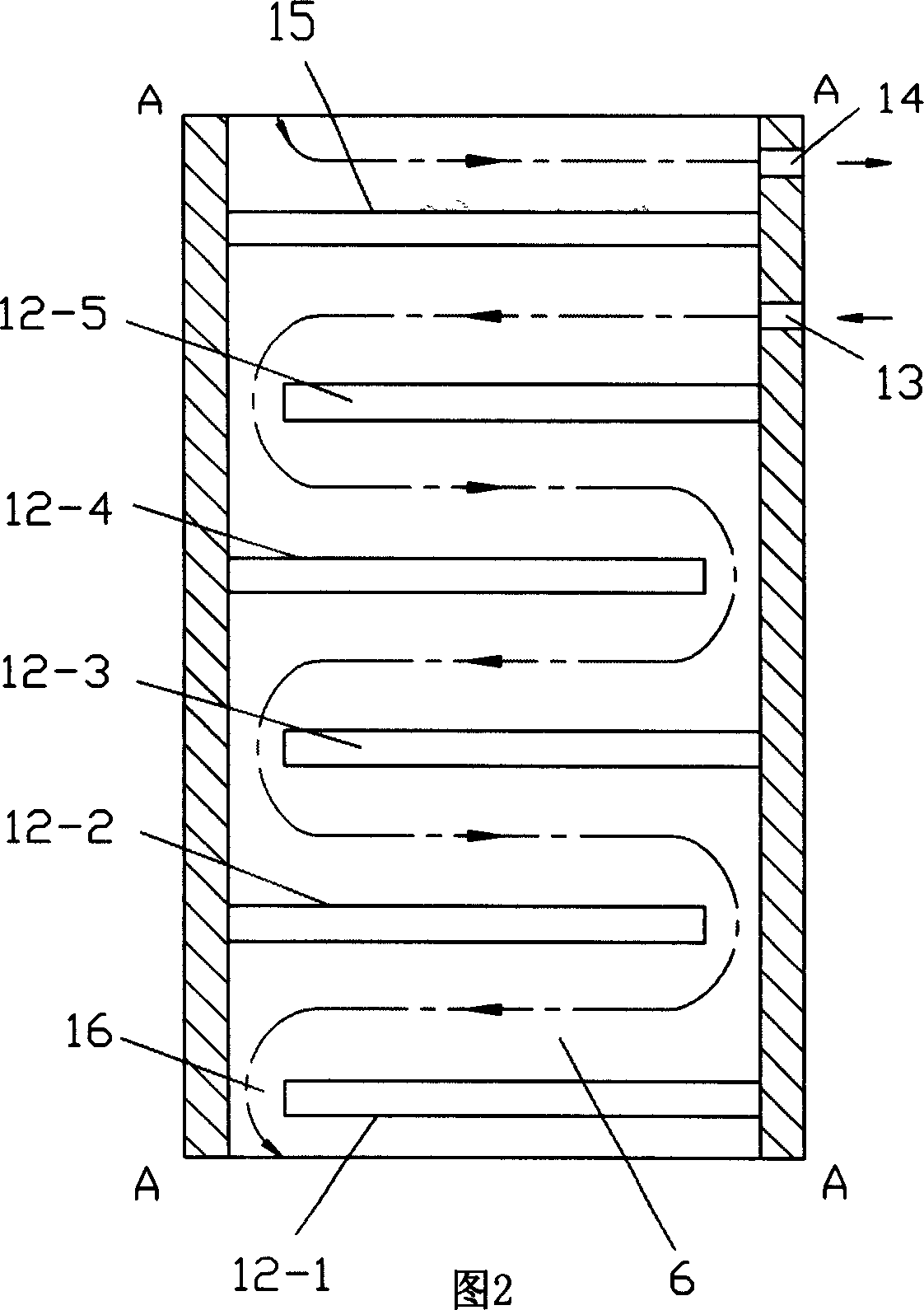

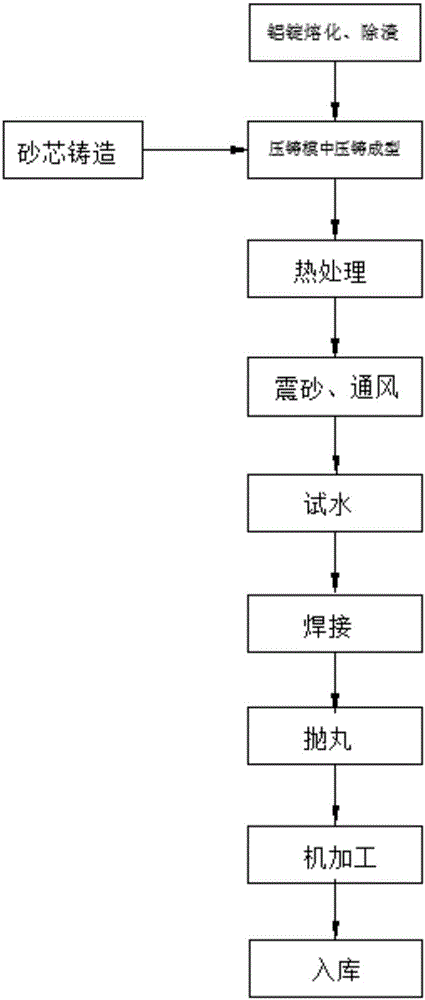

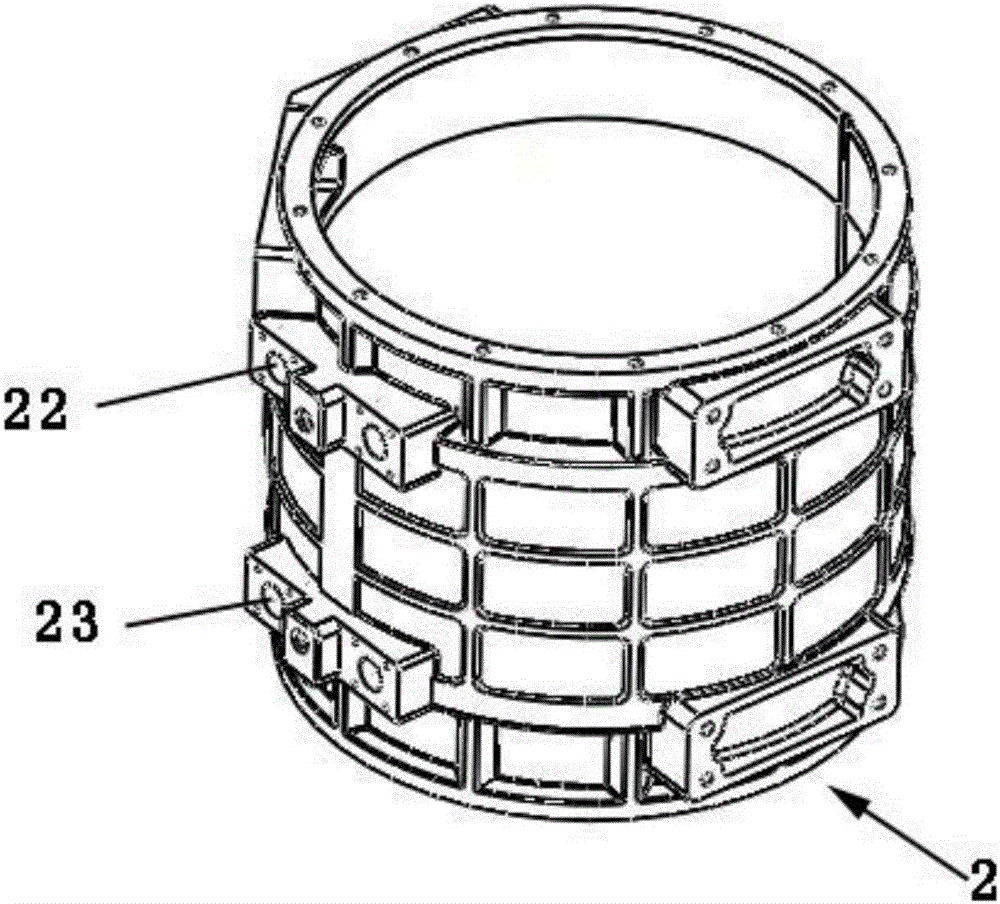

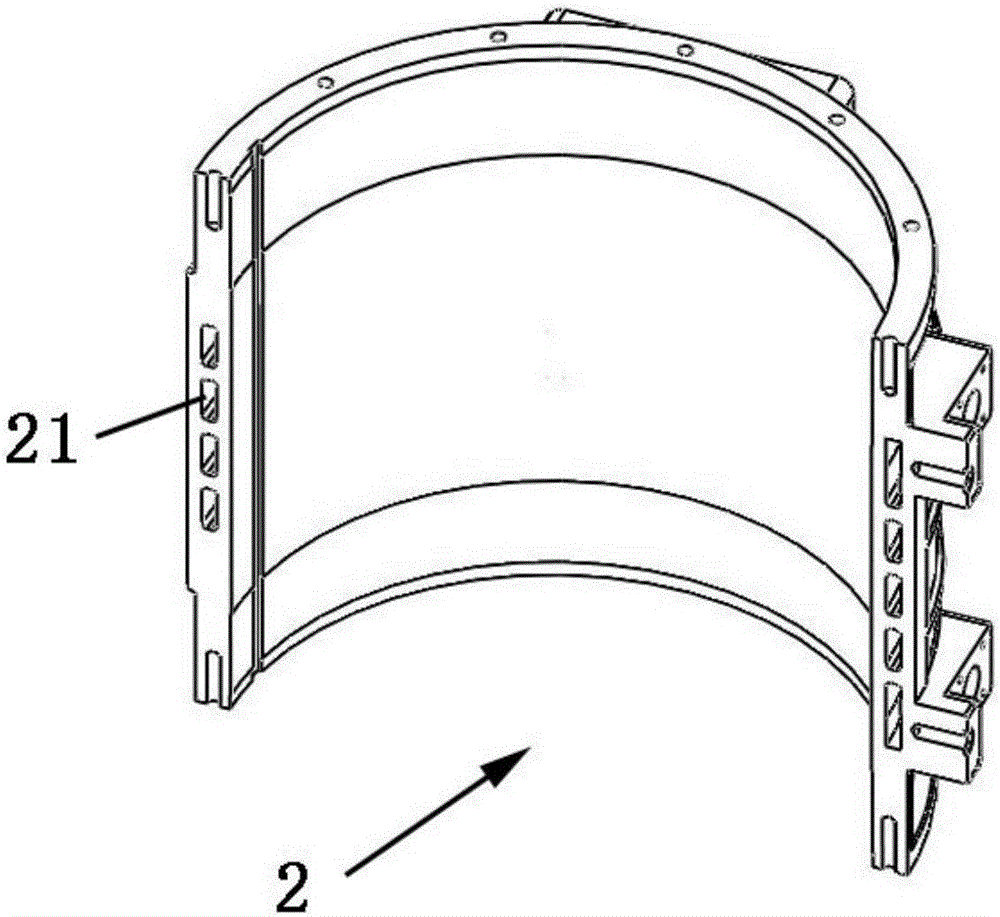

New energy vehicle water-cooling motor shell manufacturing process and its structure

ActiveCN106329858AReasonable manufacturing process designImprove performance parametersManufacturing dynamo-electric machinesSupports/enclosures/casingsAutomotive engineeringCasting defect

The invention relates to a new energy vehicle water-cooling motor shell manufacturing process and its structure. The water-cooling motor shell manufacturing process is reasonably designed and is capable of increasing the various performance parameters of the water-cooling motor shell. According to the invention, after eleven steps of processing and manufacturing referred to as from (a) to (k), the water-cooling motor shell is characterized by its stable and reliable structure, absence of casting defects and residual sand cores in spiral waterway and up-to-scratch hardness. Therefore, the service life time of the water-cooling motor shell is increased and the actual utilization need can be met.

Owner:惠州古川科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com