Patents

Literature

33 results about "Scratch hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scratch hardness tests are used to determine the hardness of a material to scratches and abrasion. The earliest test was developed by mineralogist Friedrich Mohs in 1820 (see Mohs scale). It is based on relative scratch hardness, with talc assigned a value of 1 and diamond assigned a value of 10. Mohs' scale had two limitations; it was not linear, and most modern abrasives fall between 9 and 10.

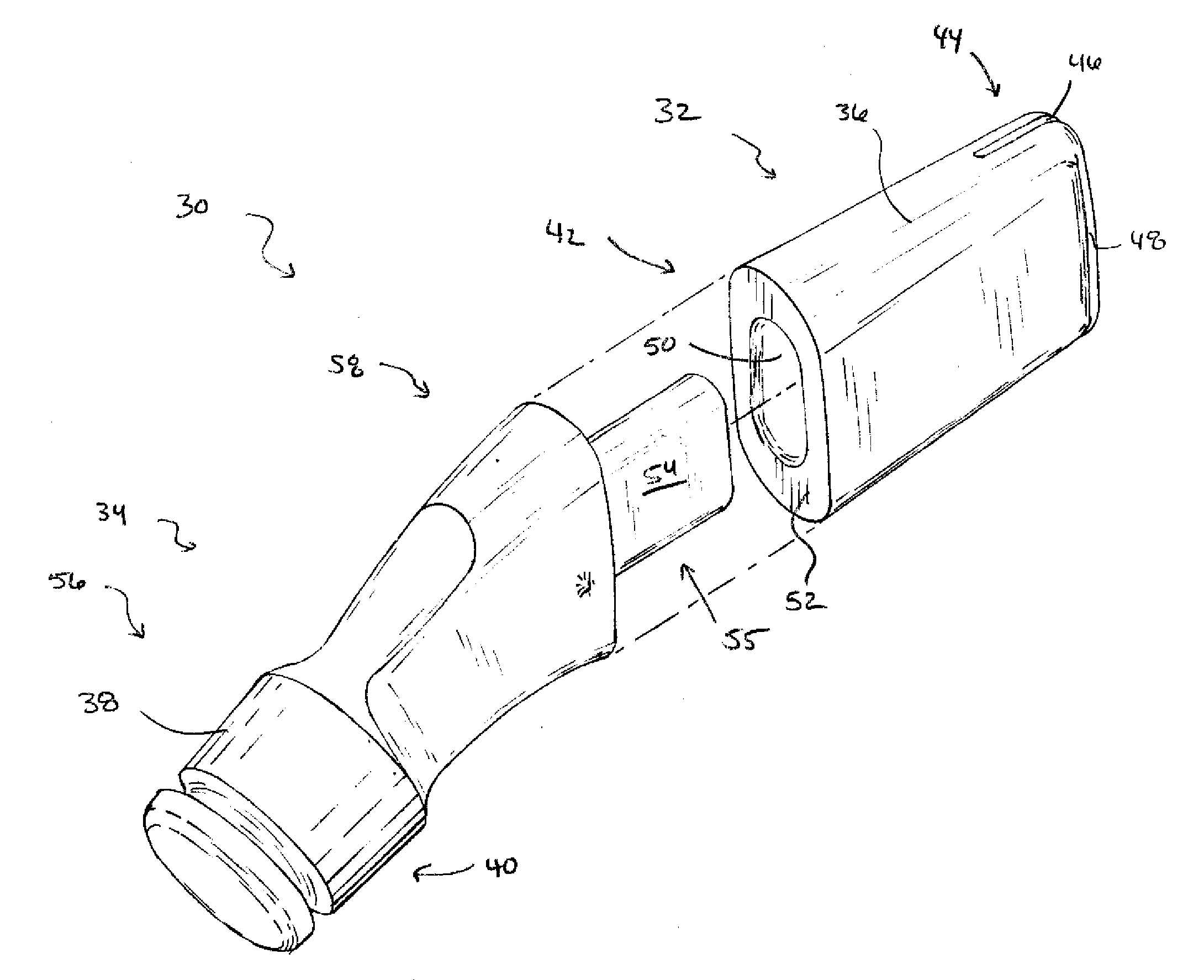

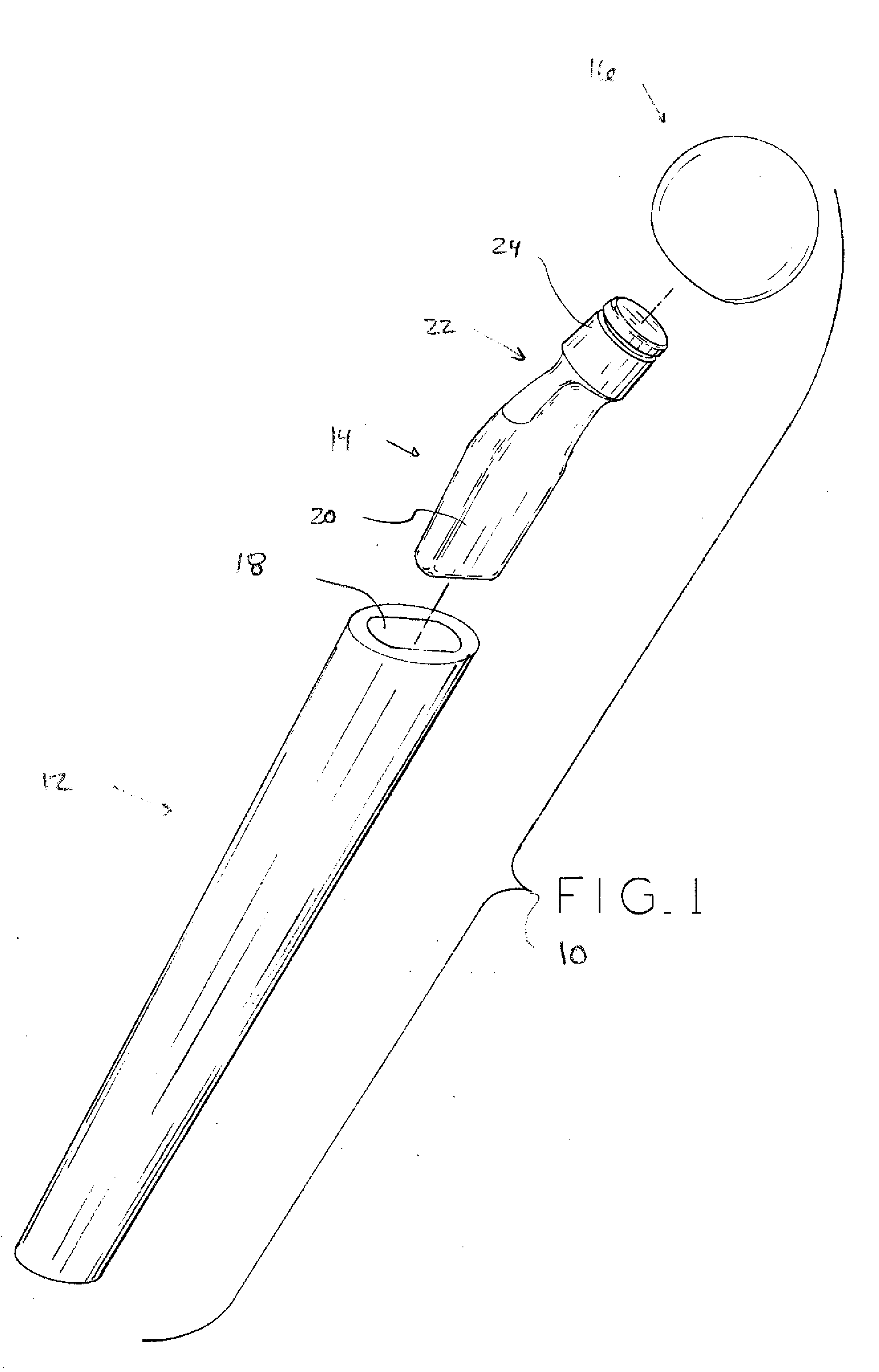

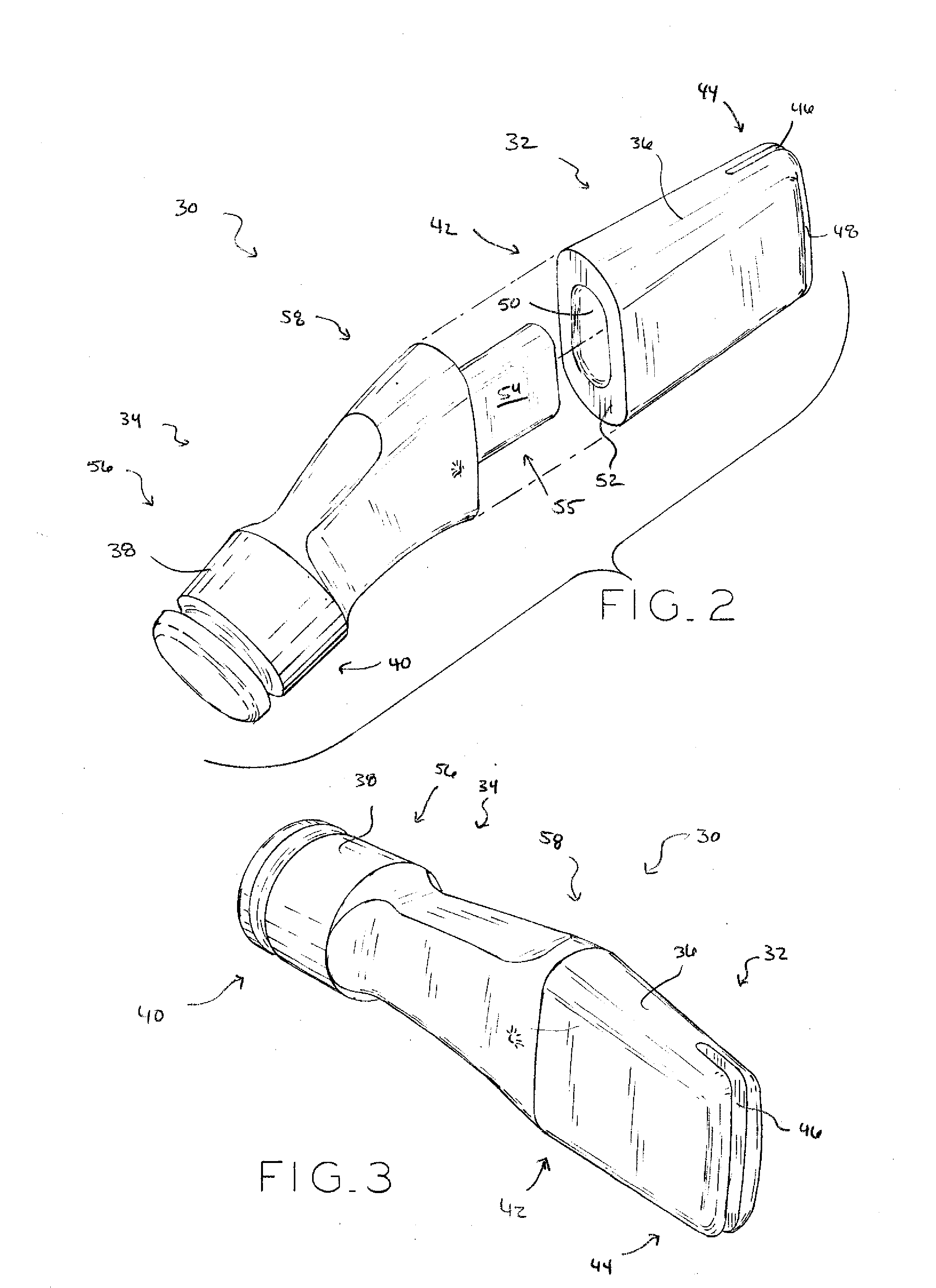

Provisional prosthetic component formed of multiple materials

InactiveUS20080133023A1Minimize deflectionControl deflectionJoint implantsFemoral headsMulti materialScratch hardness

The present invention relates to provisional prosthetic components for a medical device and the surgical methods for utilizing the same. In one embodiment, the provisional prosthetic component includes a first portion and a core. The first portion is capable of mating with another prosthetic component. The first portion of the provisional prosthetic component may have a scratch hardness which is less than the scratch hardness of the prosthetic component. This allows for the first portion to be placed in mating engagement with the prosthetic component without scratching or damaging the junction of the prosthetic component. Additionally, the core of the provisional prosthetic component may have a scratch hardness greater than the scratch hardness of the first portion of the provisional prosthetic component and / or a stiffness sufficient to minimize deflection of the provisional prosthetic component during trial reduction and range of motion testing.

Owner:ZIMMER TECH INC

Window for display device and display device including the same

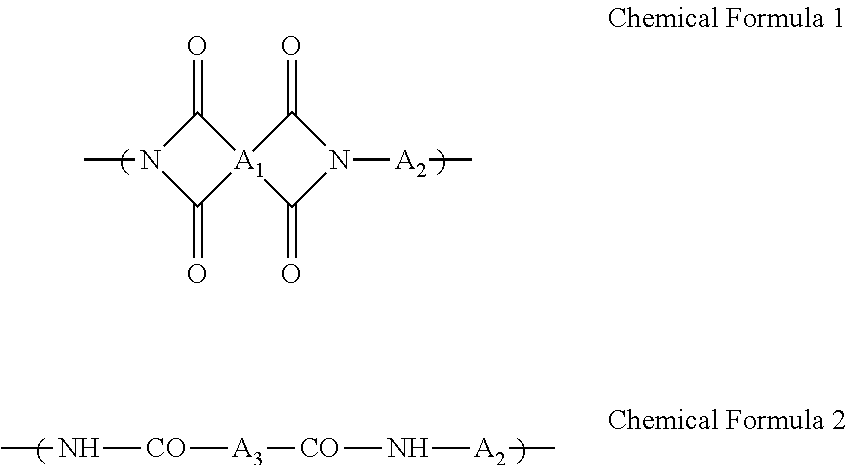

InactiveUS20160194448A1High hardnessGood optical performanceDigital data processing detailsFilm/foil adhesivesScratch hardnessImide

A window for a display device including a plastic substrate including a poly(imide-amide) copolymer and a hard-coating layer disposed on at least one side of the plastic substrate, wherein the plastic substrate has pencil scratch hardness of greater than or equal to about 3H under a vertical load of about 1 kilogram according to ASTM D3363 and a yellow index (YI) of less than or equal to 3 according to ASTM E313.

Owner:SAMSUNG ELECTRONICS CO LTD +1

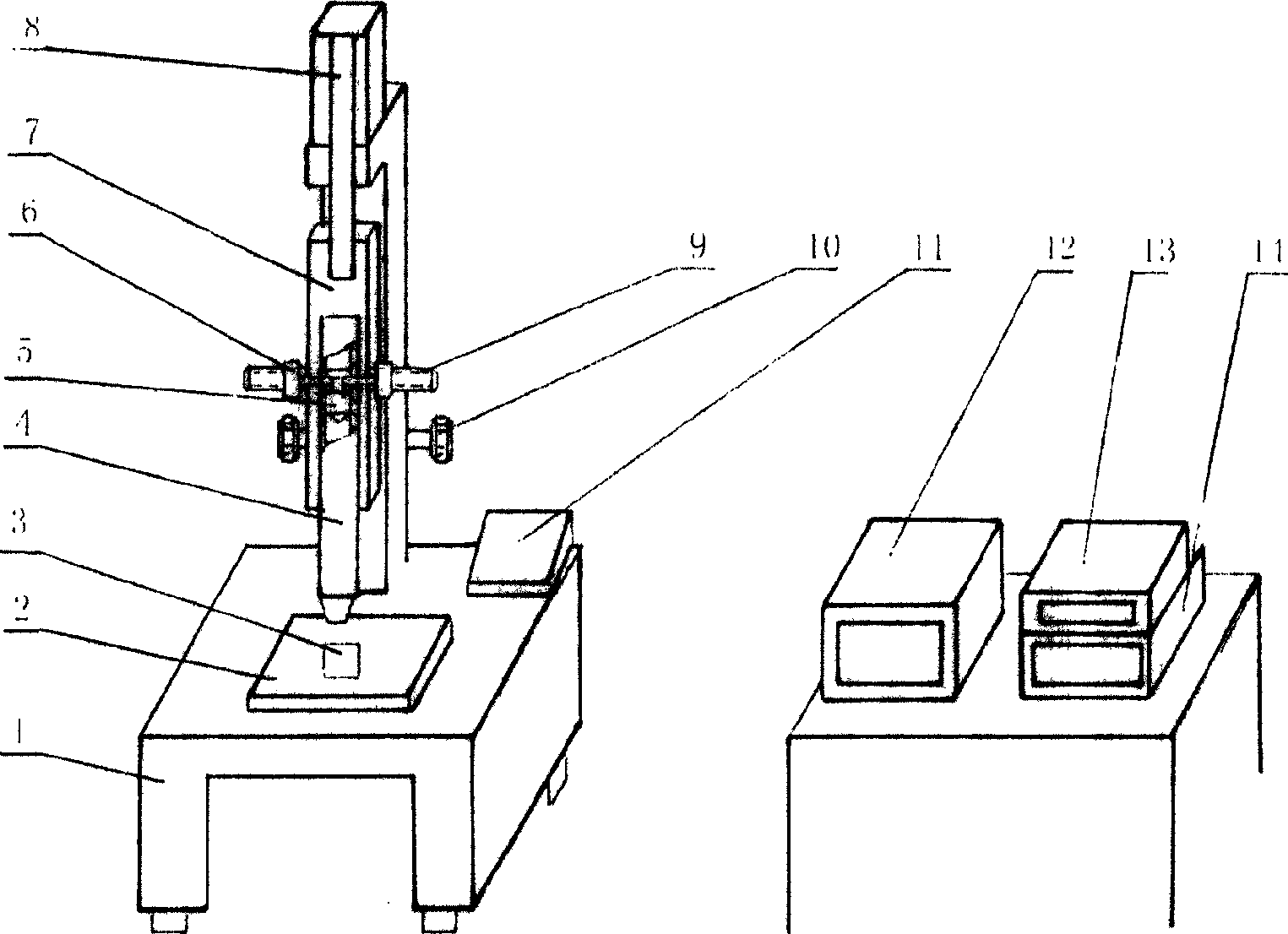

Scratch hardness reference device

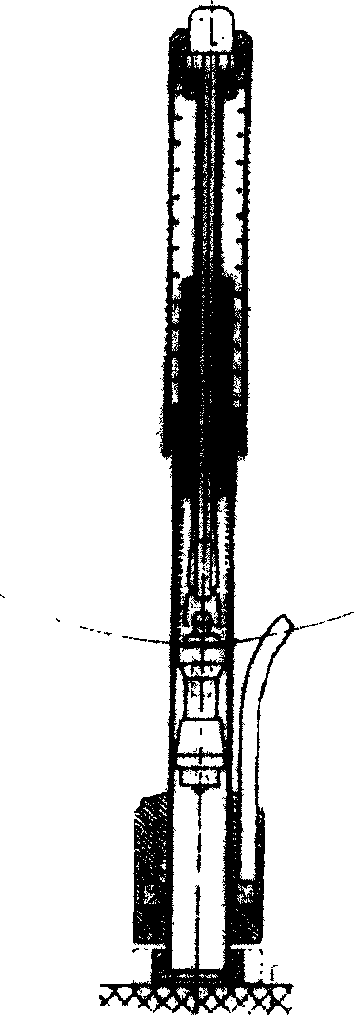

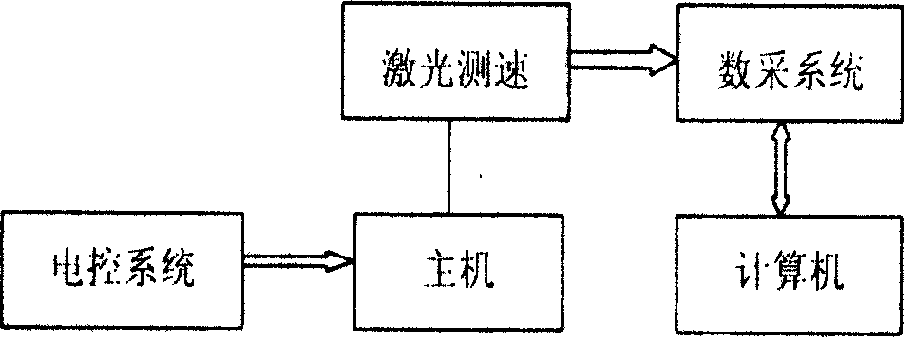

InactiveCN1635357AImplement direct value transferAvoid Conversion ErrorsInvestigating material hardnessScratch hardnessRadial position

This invention relates to Richter hardness basic device, which comprises the following: base socket on the workbench; impact part with tungsten carbide ball head; guiding cylinder to control the impact part radium direction; impact part lift clamper structure; control device; speed test device and data collection device, wherein the impact part gets energy form the gravity and the speed test device adopts the laser Doppler speed test system.

Owner:中国航空工业第一集团公司三〇四所

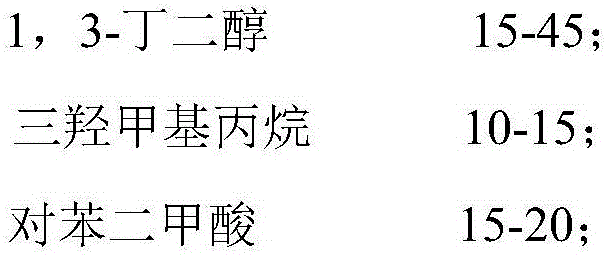

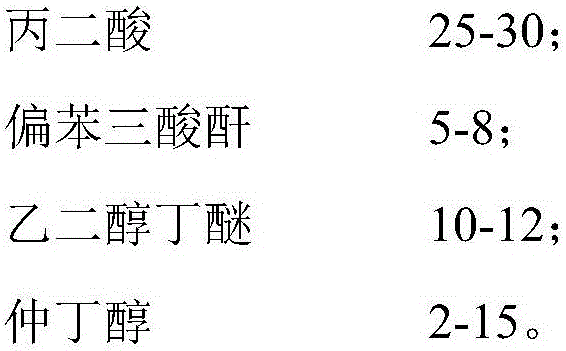

Automotive waterborne floating-coat coating and preparation method thereof

InactiveCN105754463AFlat shapeNo peeling phenomenon observedPolyurea/polyurethane coatingsEpoxyFumed silica

The invention discloses an automotive waterborne floating-coat coating and a preparation method thereof. The automotive waterborne floating-coat coating is characterized by comprising a component A and a component B, wherein the component A comprises the following components in percentage by weight: 15%-35% of polyester resin, 25%-35% of epoxy resin, 15%-25% of a pigment, 3%-5% of talcum powder, 15%-25% of calcium carbonate, 0.1%-0.5% of a polyurethane defoaming agent, 0.3%-0.8% of etherified amino resin, 0.1%-0.5% of a fumed silica anti-settling agent, 0.1%-0.5% of a flatting agent, 0.5%-1.5% of a wetting agent, 1%-2% of a flash-rust inhibitor and the balance of deionized water; and the component B is a closed waterborne isocyanate curing agent. After an electro-deposition coating plate is coated with the automotive waterborne floating-coat coating and dried, a paint film presents an excellent smooth form, a paint film stripping phenomenon is not observed during adhesiveness testing of the paint film, and the hardness, tested by virtue of a pencil scratch hardness method, of the paint film is an level F or above.

Owner:SHANGHAI DAZHONG ALLIED AUTO REFITTING

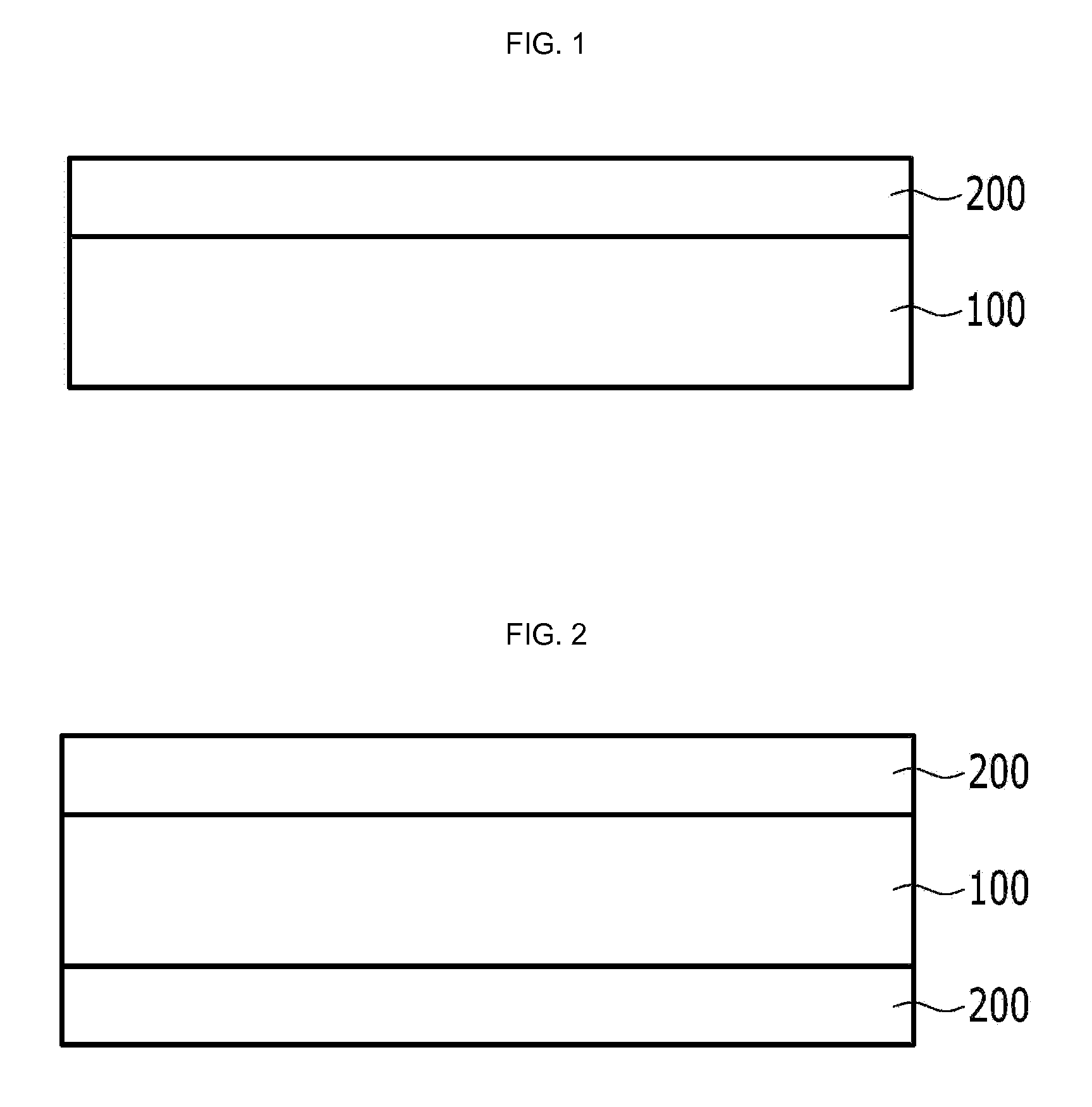

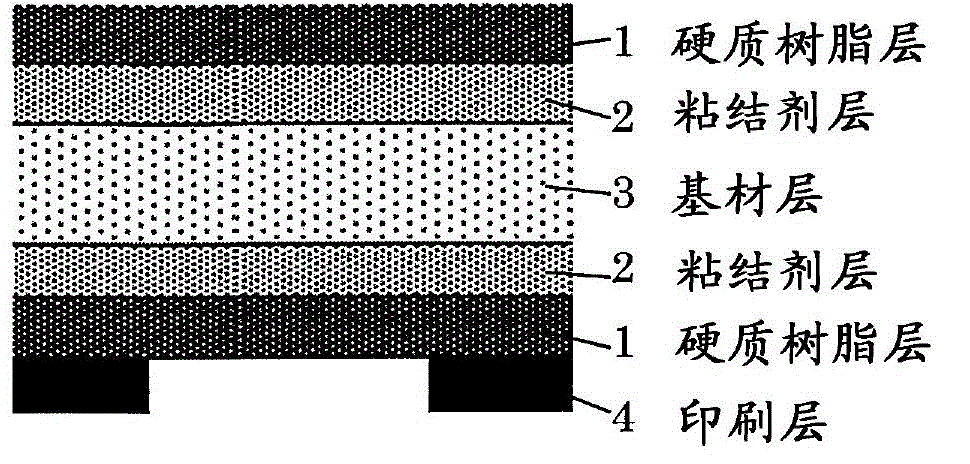

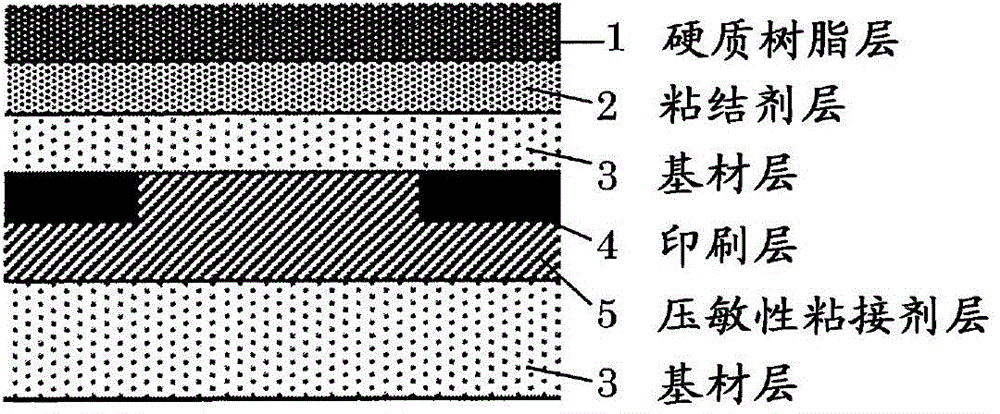

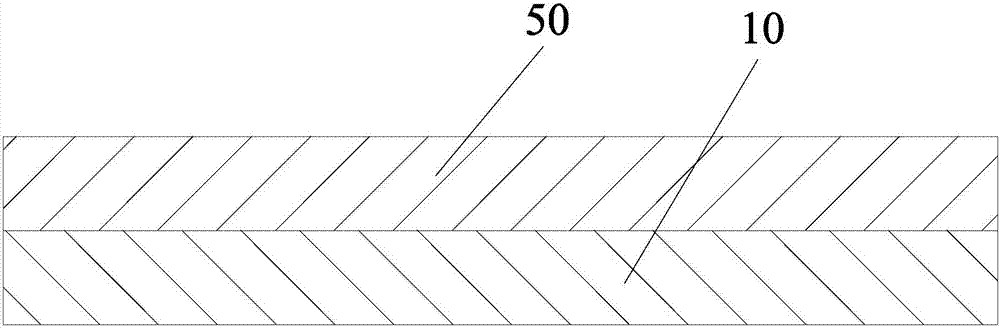

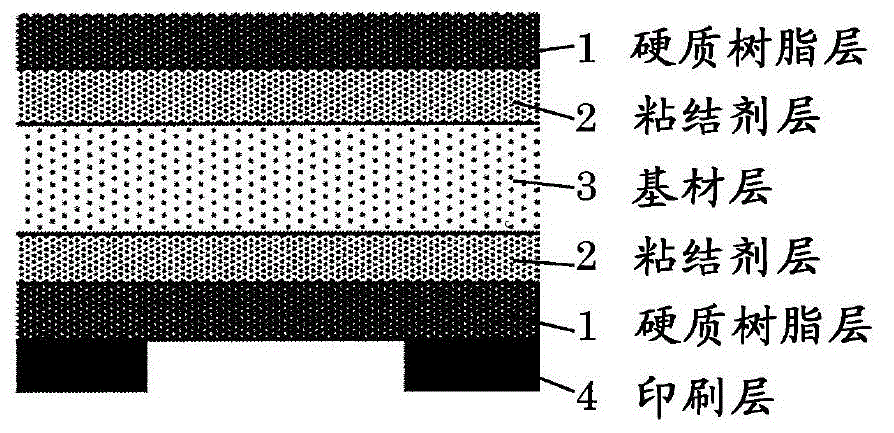

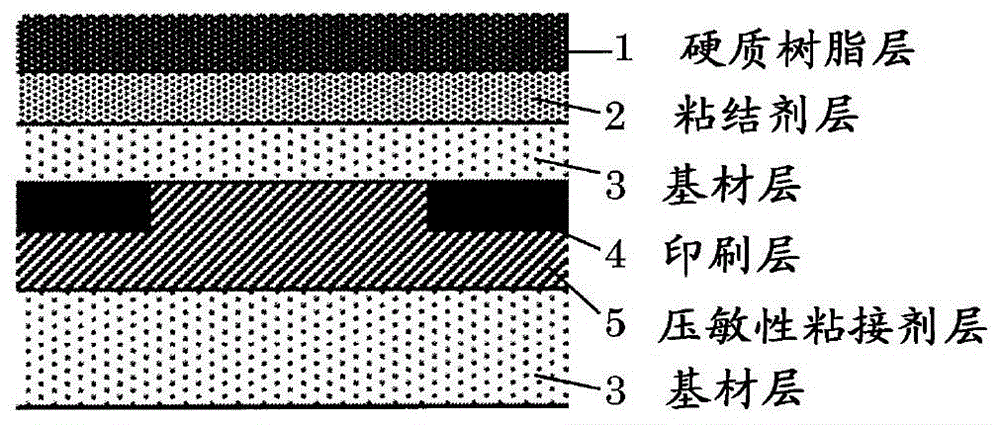

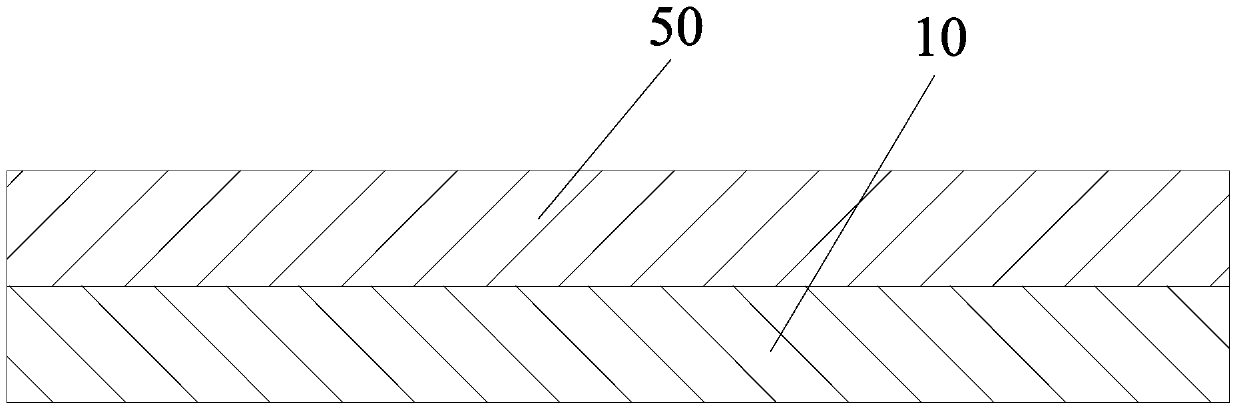

Resin laminate

InactiveCN104129129AHigh surface hardnessStrong designSynthetic resin layered productsScratch hardnessTransmittance

The invention provides a resin laminate having relatively high surface hardness and high transparency. The resin laminate has a hard resin layer and a substrate layer. The hard resin layer is formed by a curing resin composition with multi-functional (methyl)acryloyl monomers as an essential ingredient, has a three-dimensional cross-linking structure and a thickness of 25 [mu]m-250[mu]m. The substrate layer is formed by a monolayer thermoplastic resin or two or more layers of a multi-layer thermoplastic resin. An independent tensile elasticity modulus of the hard resin layer is 2.000-4,000 MPa; and a total light transmittance is over 90%. Besides, a ratio (t1 / t2) of a total thickness (t1) of the substrate layer to the thickness (t2) of the hard resin layer is 0.25-10; and a scratch hardness of the resin laminate is over 40 g.

Owner:NIPPON STEEL CHEMICAL CO LTD

Windows for display device and display device including the same

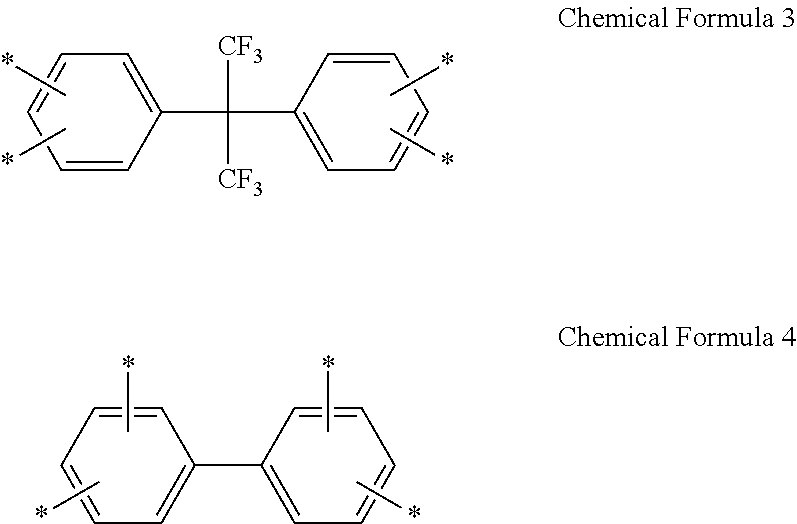

InactiveUS20170106636A1High hardnessGood optical performanceSynthetic resin layered productsElectrical equipmentX-rayDisplay device

A window for a display device including: a plastic substrate including a poly(imide-amide) copolymer, which is a reaction product of a reagent combination of 4,4′-hexafluoroisopropylidene diphthalic anhydride, 3,3′,4,4′-biphenyltetracarboxylic dianhydride, 2,2′-bis-trifluoromethyl-4,4′-biphenyldiamine, and terephthaloyl chloride, and a hard coating layer disposed on at least one side of the plastic substrate, wherein the plastic substrate has pencil scratch hardness of greater than or equal to 3H when measured according to an ASTM D3363 standard at a vertical load of about 0.5 kilograms, and a peak intensity ratio A2 / A1 of a peak intensity A2 at a position of about 23.5° in 2θ to a peak intensity A1 at a position of about 15.5° in 2θ of an X-ray diffraction spectrum is greater than or equal to about 0.8.

Owner:SAMSUNG ELECTRONICS CO LTD +1

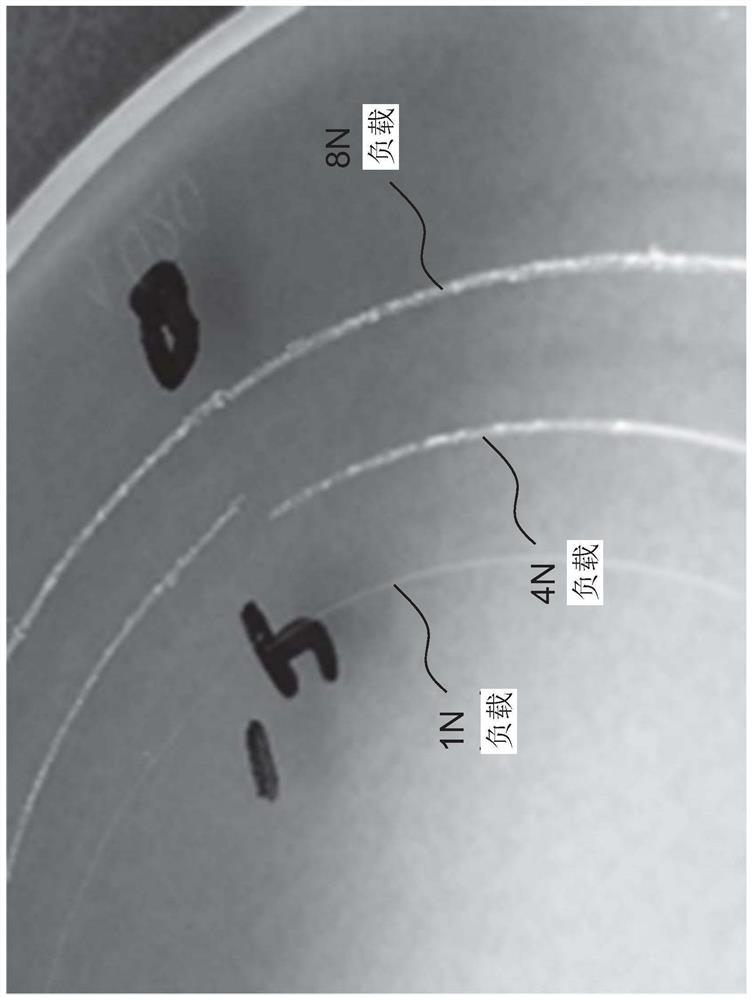

Scratch resistant pmma and polycarbonate-siloxane copolymer compositions

The present invention relates to a scratch resistant pmma and polycarbonate-siloxane copolymer compositions. The thermoplastic compositions include: from about 62 wt% to about 99 wt% poly(methyl methacrylate) (PMMA) or copolymers thereof; and from about 1 wt% to about 38 wt% of a poly(carbonate-siloxane) copolymer having a siloxane content of from about 25 wt% to about 45 wt%. The compositions arescratch resistant. Scratch resistance may be determined as comprising a scratch depth of less than 20 micron ([mu]m) as measured in accordance with the Erichsen scratch hardness test at a force of 4Newton (N). Articles including the thermoplastic composition are also described.

Owner:SHPP GLOBAL TECH BV

Coating compositions and articles coated therewith

InactiveUS20060106159A1Reduce reflectionLight transmittancyPolyurea/polyurethane coatingsScratch hardnessOptical transmittance

A coating composition is taught which 1) is essentially free of matting agents, 2) includes a two-package curing type acrylic urethane base resin that can form a coating film, which has a surface scratch hardness of 2H and a predetermined light transmittancy, and 3) includes 0.1% to 1.5% by weight of transparent particles having an average particle size of 5 μm to 30 μm. The coating film formed by the coating composition has a surface scratch resistance by means of the two-package curing type acrylic urethane, and is prevented from regular reflections generating images therearound by means of the transparent particles having an average particle size of 5 μm to 30 μm.

Owner:KYOWA SANGYO

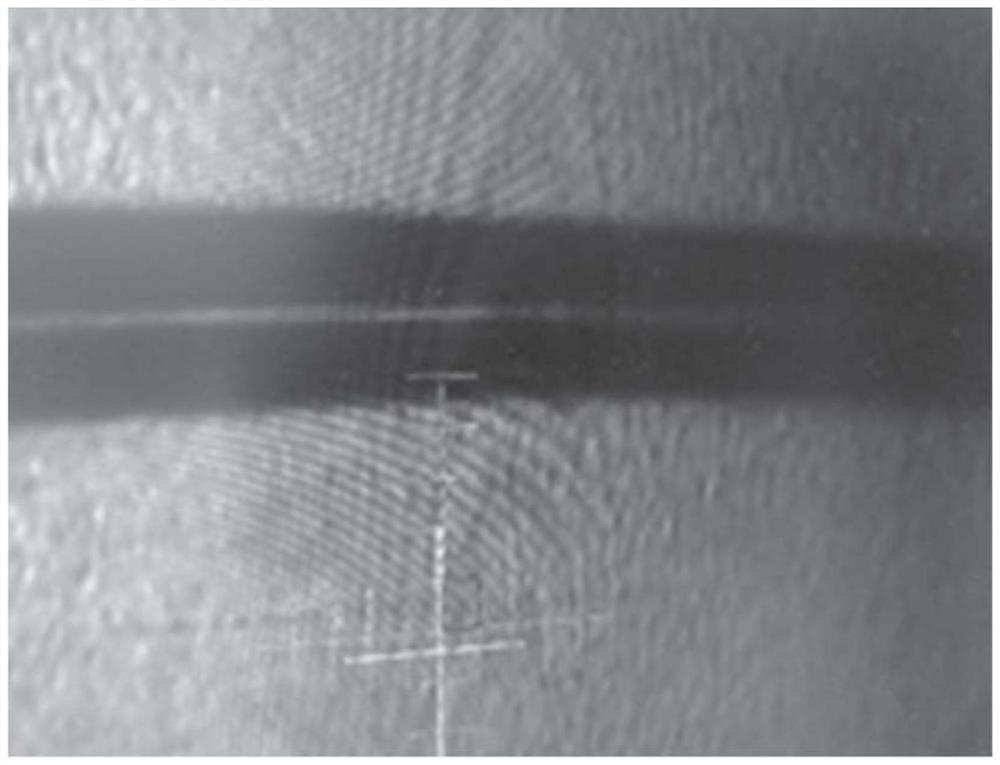

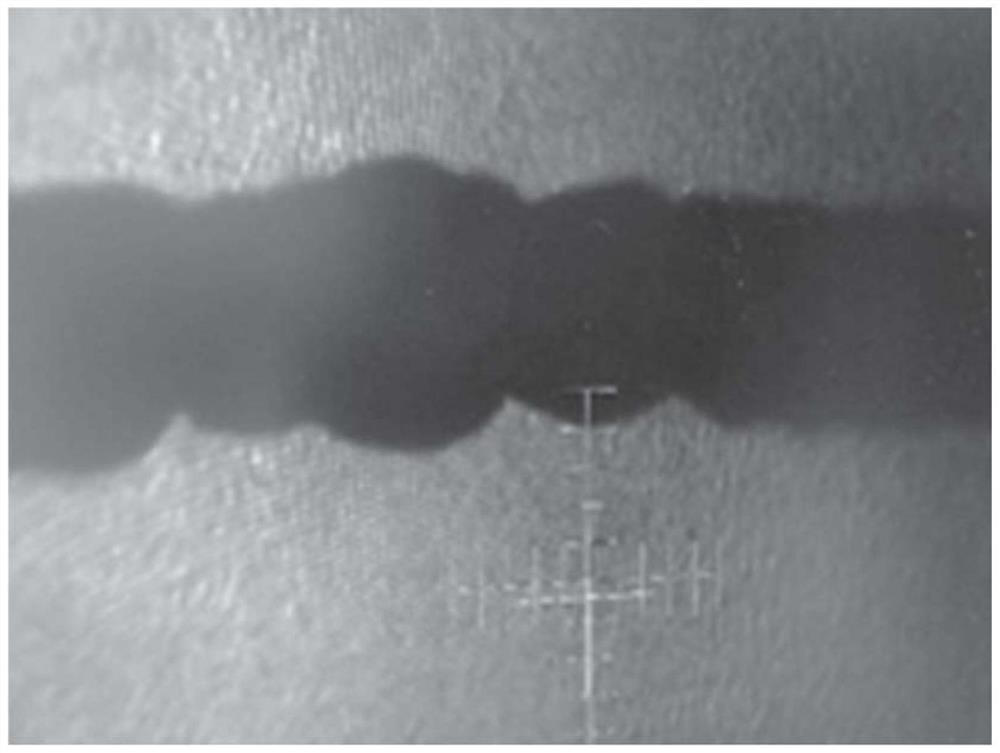

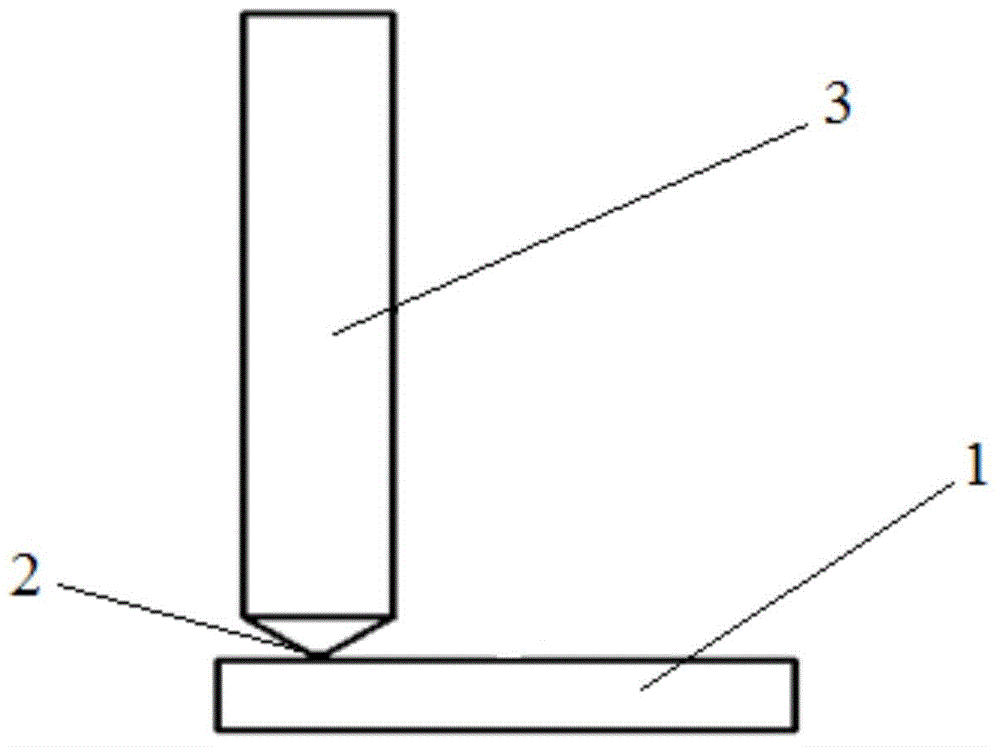

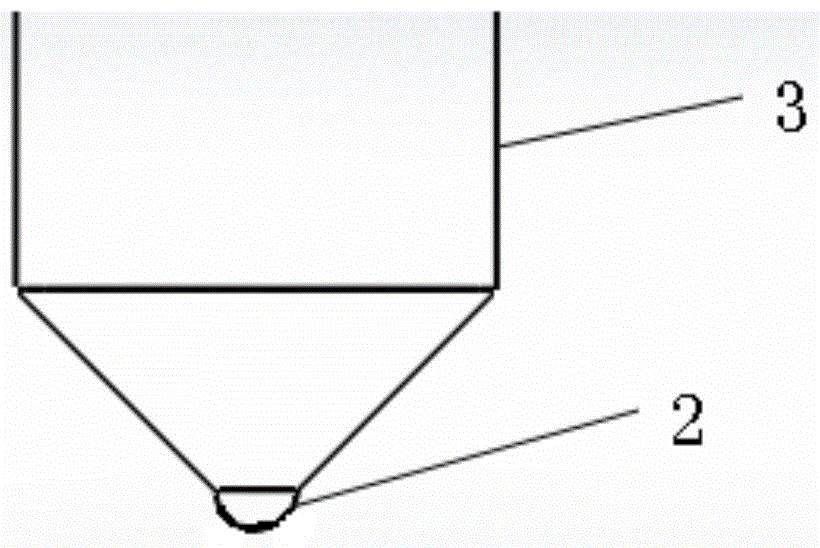

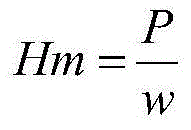

Scratch hardness test method

InactiveCN104897495AIncrease useLess destructiveInvestigating material hardnessScratch hardnessTest sample

The invention relates to a scratch hardness test method. The test method comprises specific steps as follows: (1), a to-be-tested sample is cleaned and dried; (2), the to-be-tested sample is fixed on a base of a tester, a contact probe provided with a pressure head is fixed on a fixture of the tester, the direction of the contact probe is adjusted, and accordingly, the pressure head is perpendicular to the surface of the to-be-tested sample; (3), pressure P and a scratch speed of the pressure head on the surface of the to-be-tested sample are set through the tester; (4), a power supply is switched on, and a scratch test is performed; (5), after the scratch test ends, widths of 3-5 scratches on the surface of the to-be-tested sample are measured, and the average value W of the widths of the scratches is taken; (6), a scratch hardness value is calculated according to the average value W of the scratch widths and the pressure P. Compared with the prior art, the test method is simple and convenient to operate; the spherical pressure head is adopted for the test, difficulty for scratch measurement and errors of calculation of scratch hardness values can be reduced, the test accuracy is high, and the scratch hardness test method is economical and practical and has good universality.

Owner:SHANGHAI UNIV OF ENG SCI

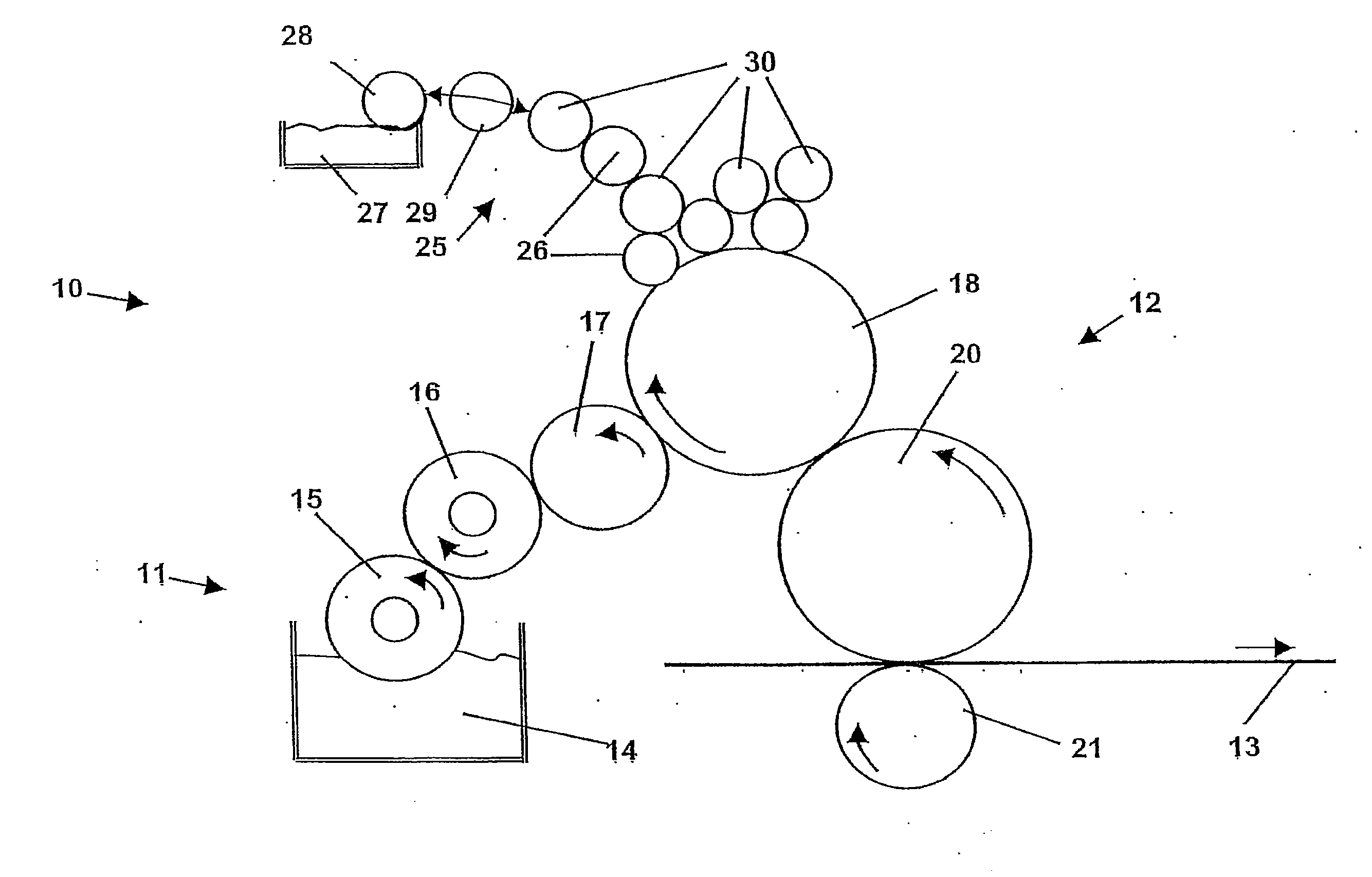

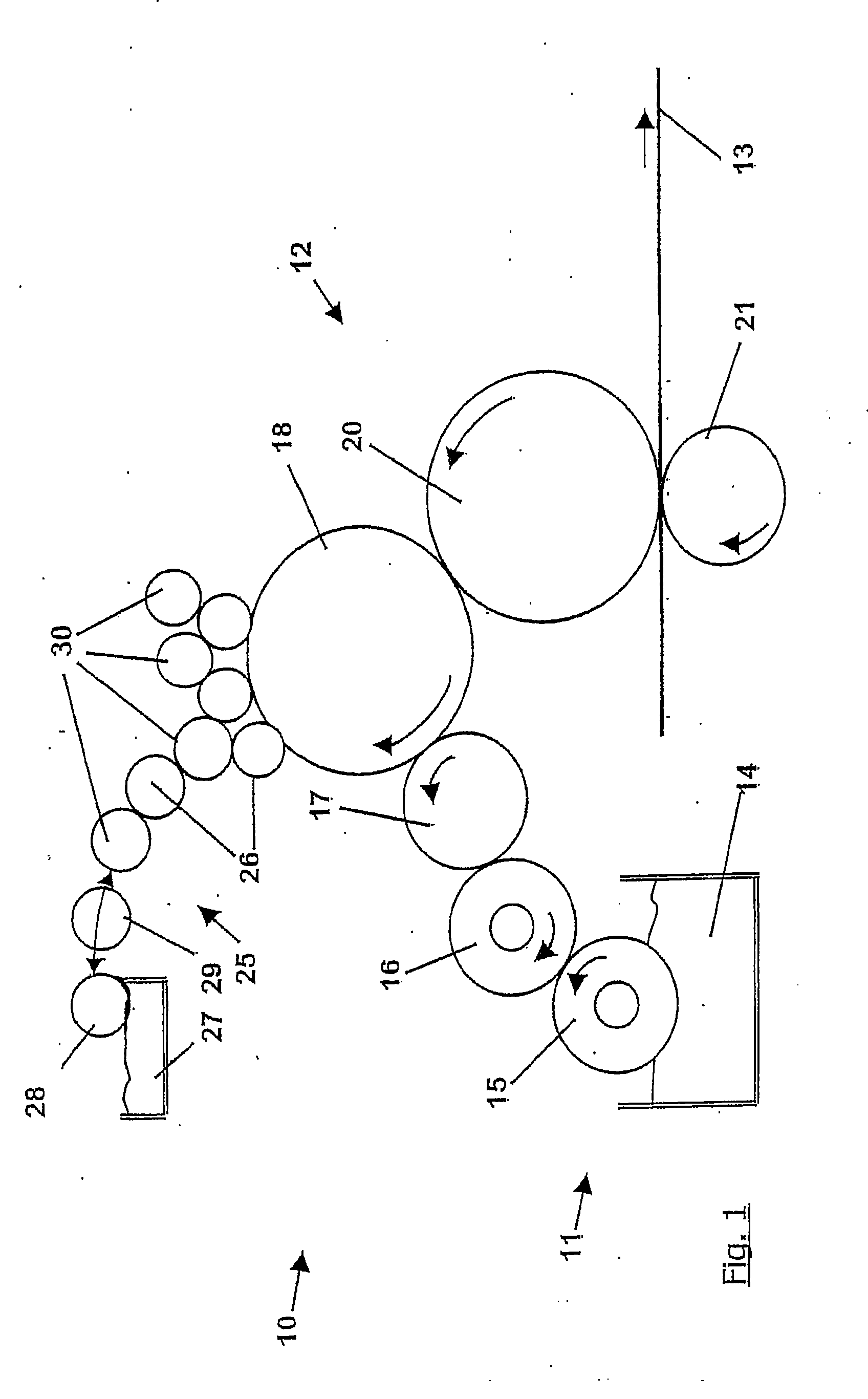

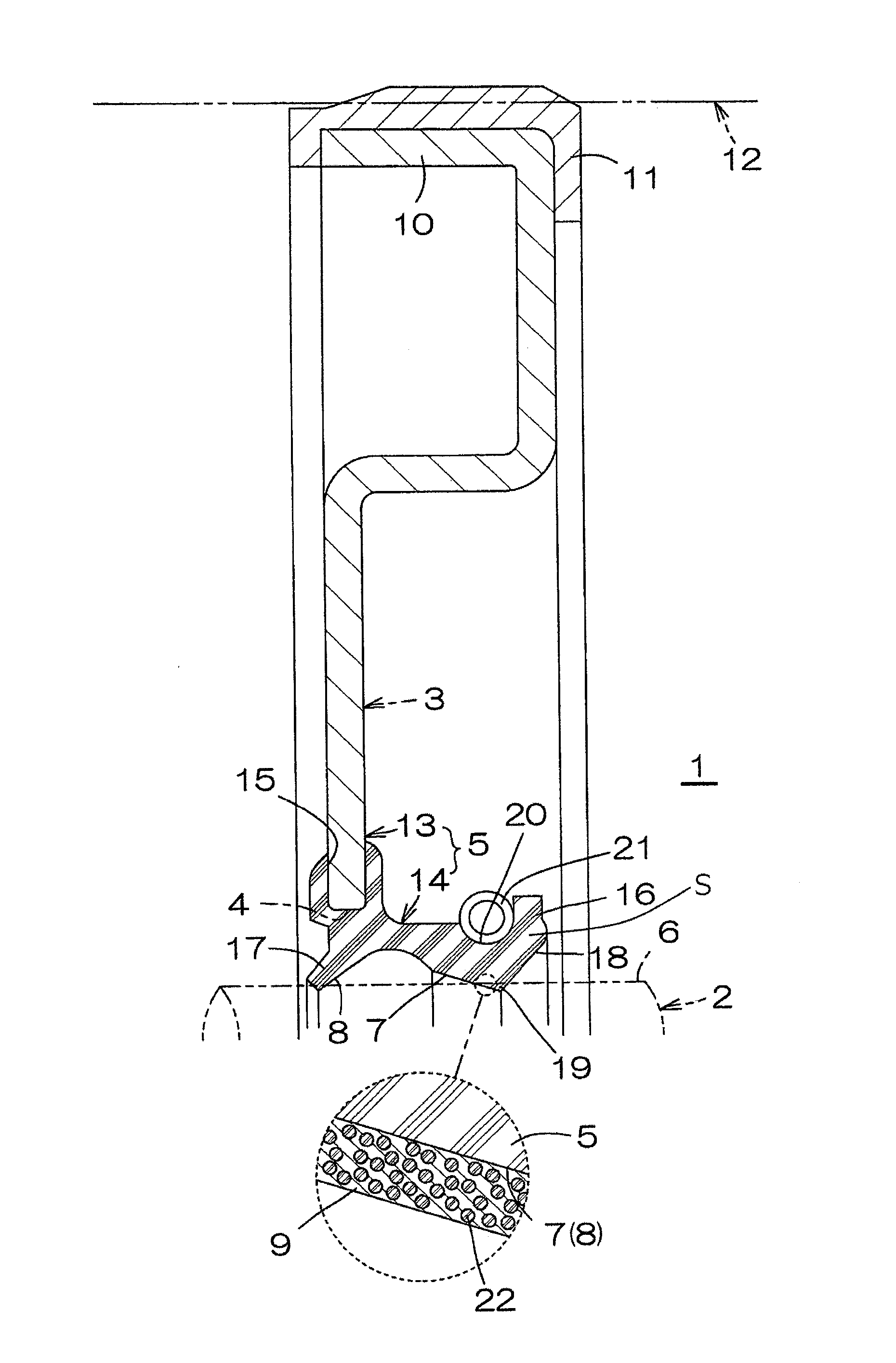

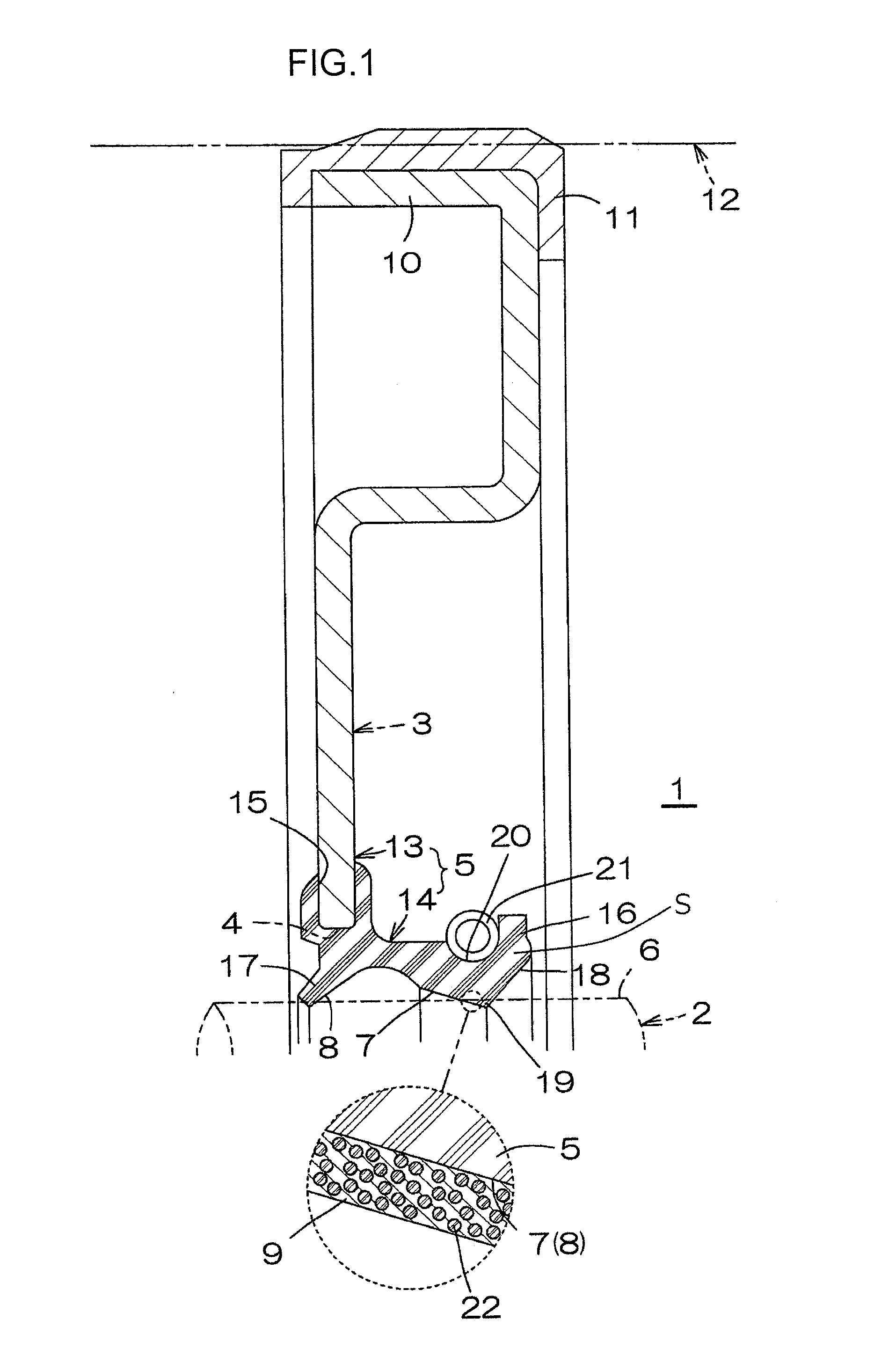

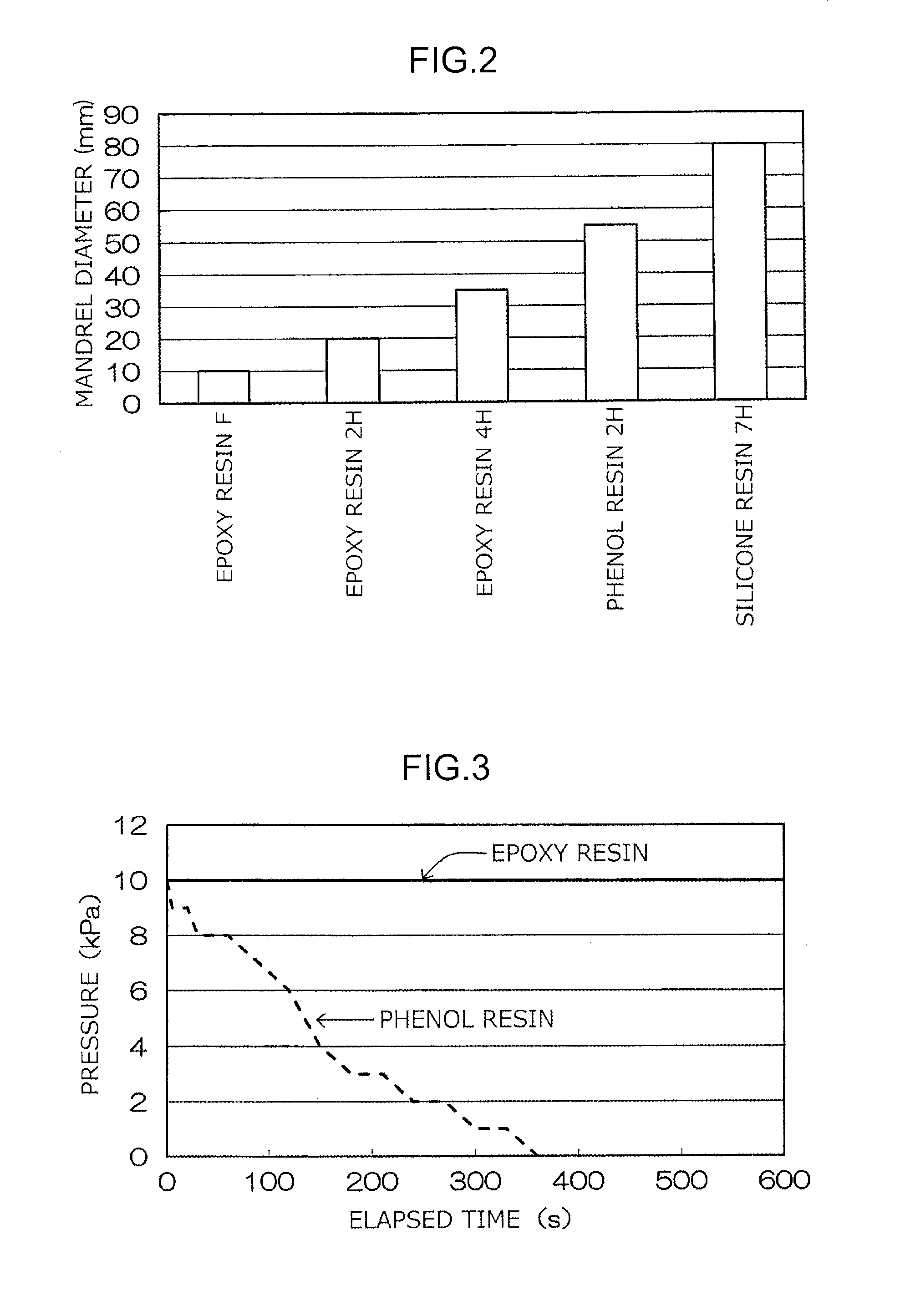

Contact or transfer roller

InactiveUS20110041713A1Reduce surface tensionIncrease surface tensionPrinting roller shellsPrinting blanketsEpoxyLacquer

A distributor or transfer roller is provided for printing machines, in particular for offset printing machines. The roller has at least a substantially rigid core and a cover made of a polymeric material applied on and permanently fixed to the core. The cover is applied directly on the core or on a hard-elastic intermediate layer having a hardness of ≧10 Shore D, optionally by an adhesion promoting layer. The cover is at least substantially made of a fluorinated polymer and has a hardness of ≧15 Shore D and / or a scratch hardness according to ISO 15184 of 6B or harder. The polymeric material can be a duroplastic material, a fluorinated polyurethane resin, polyester resin, epoxy resin, acrylate resin and / or polyether resin, a highly cross-linked non-elastic fluoropolymer, a fluorothermoplastic, a polymeric non-elastic fluorosilicone, or a fluoropolymer lacquer.

Owner:WEROS TECH

Bright sinking ink

The invention discloses bright sinking ink which comprises the following raw materials in percentage by mass: 25-45% of a sinking agent, 15-20% of a brightening agent, 1-3% of a dispersing agent and 30-70% of a solvent. Tests show that the bright sinking ink meets technical index requirements of a national standard GB / T 4100-2006 Ceramic Tile and national standards GB6566-2010 Radioactive Nuclide Limit for Building Material, HJ / T 297-2006 Technical Requirement for Environmental Labeling Products Ceramics Tiles and EN 101: 1992 Vitreous and Porcelain Enamels-Determination of Surface Scratch Hardness According to the Mohs Scale, and meanwhile has excellent sinking effects and good surface gloss.

Owner:广东金牌陶瓷有限公司

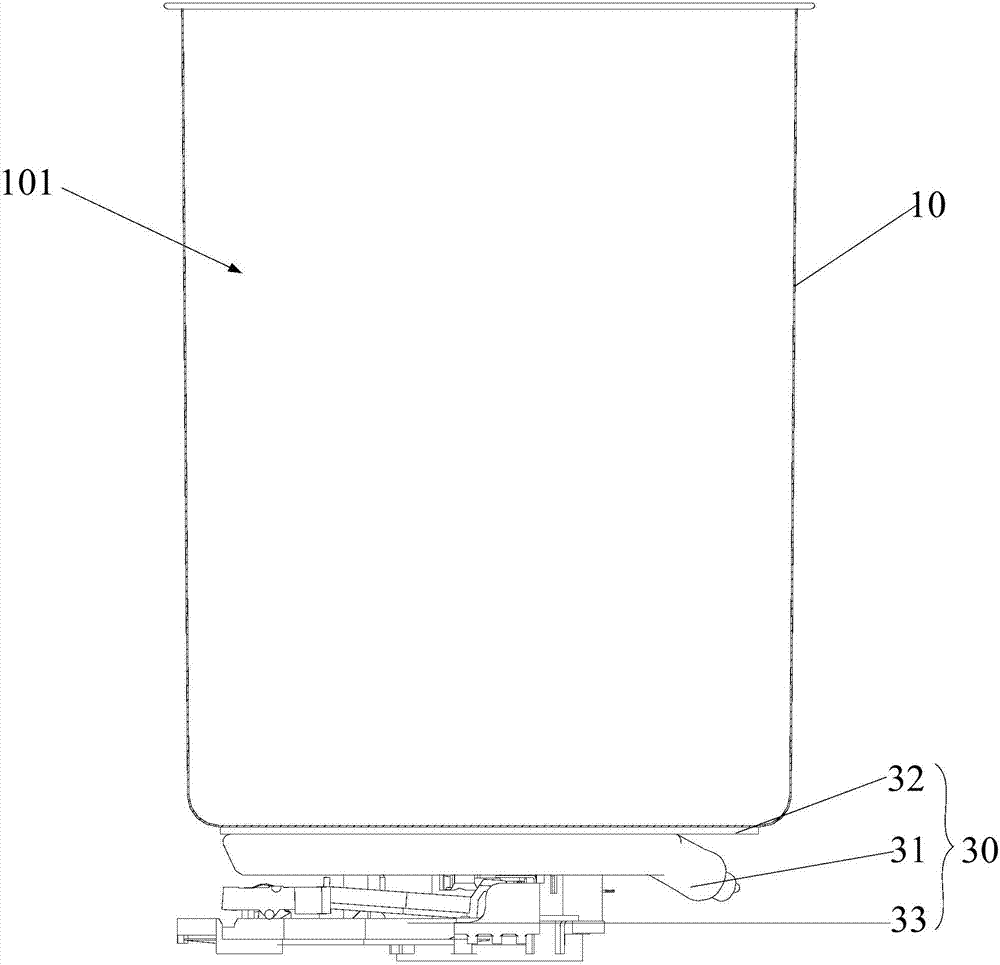

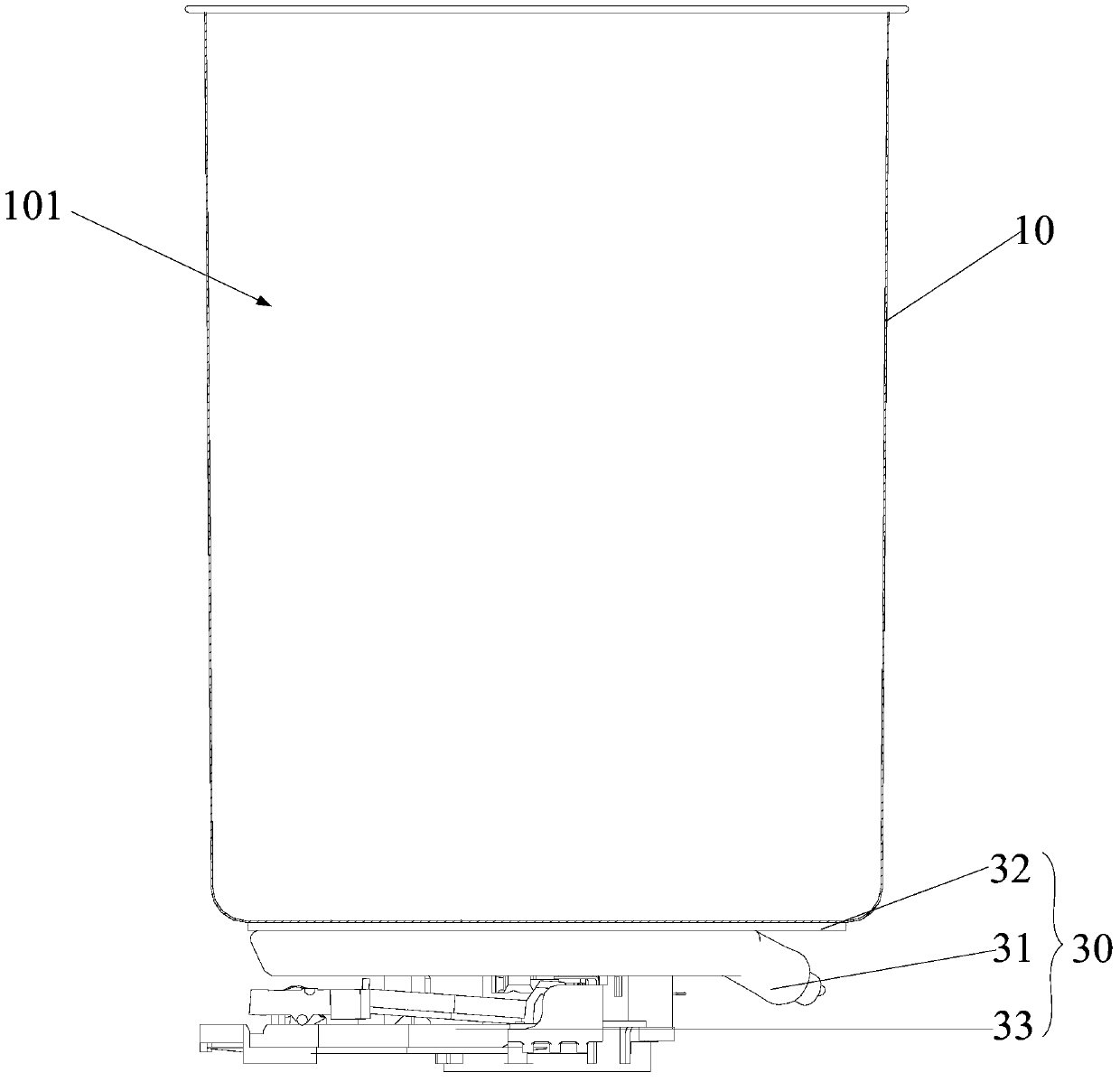

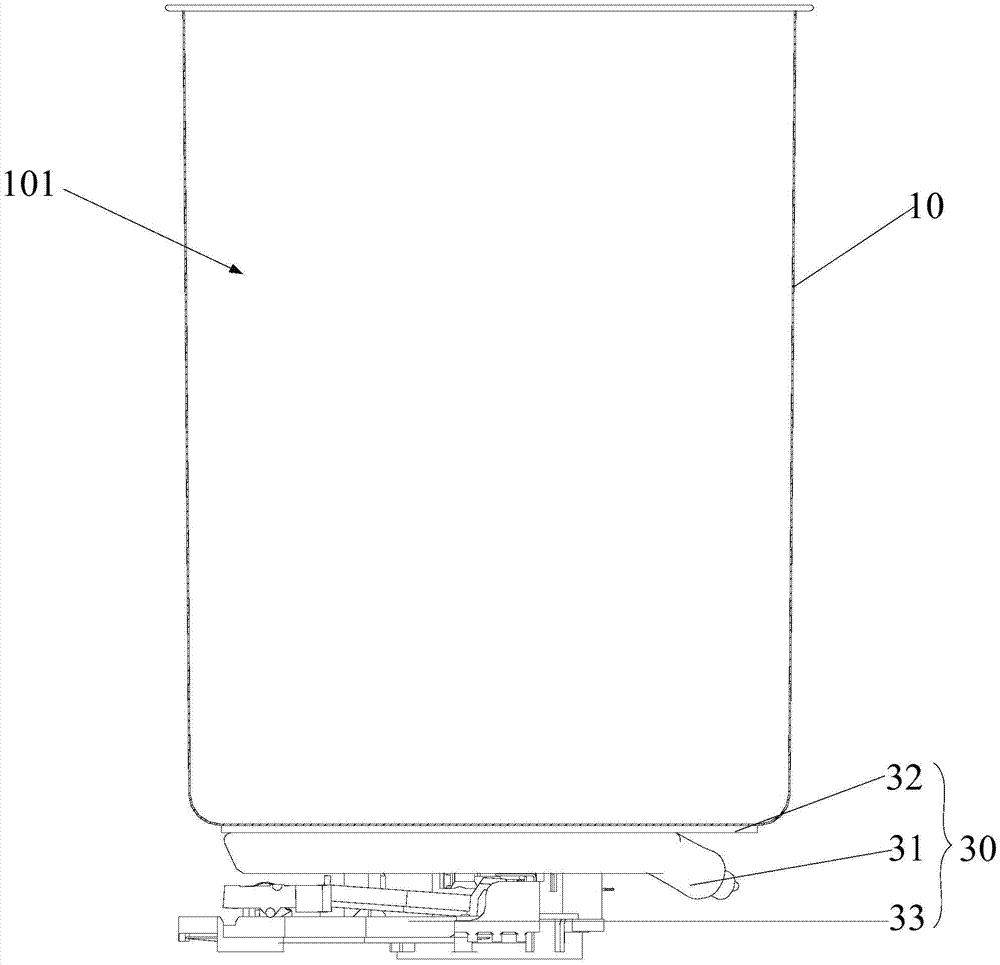

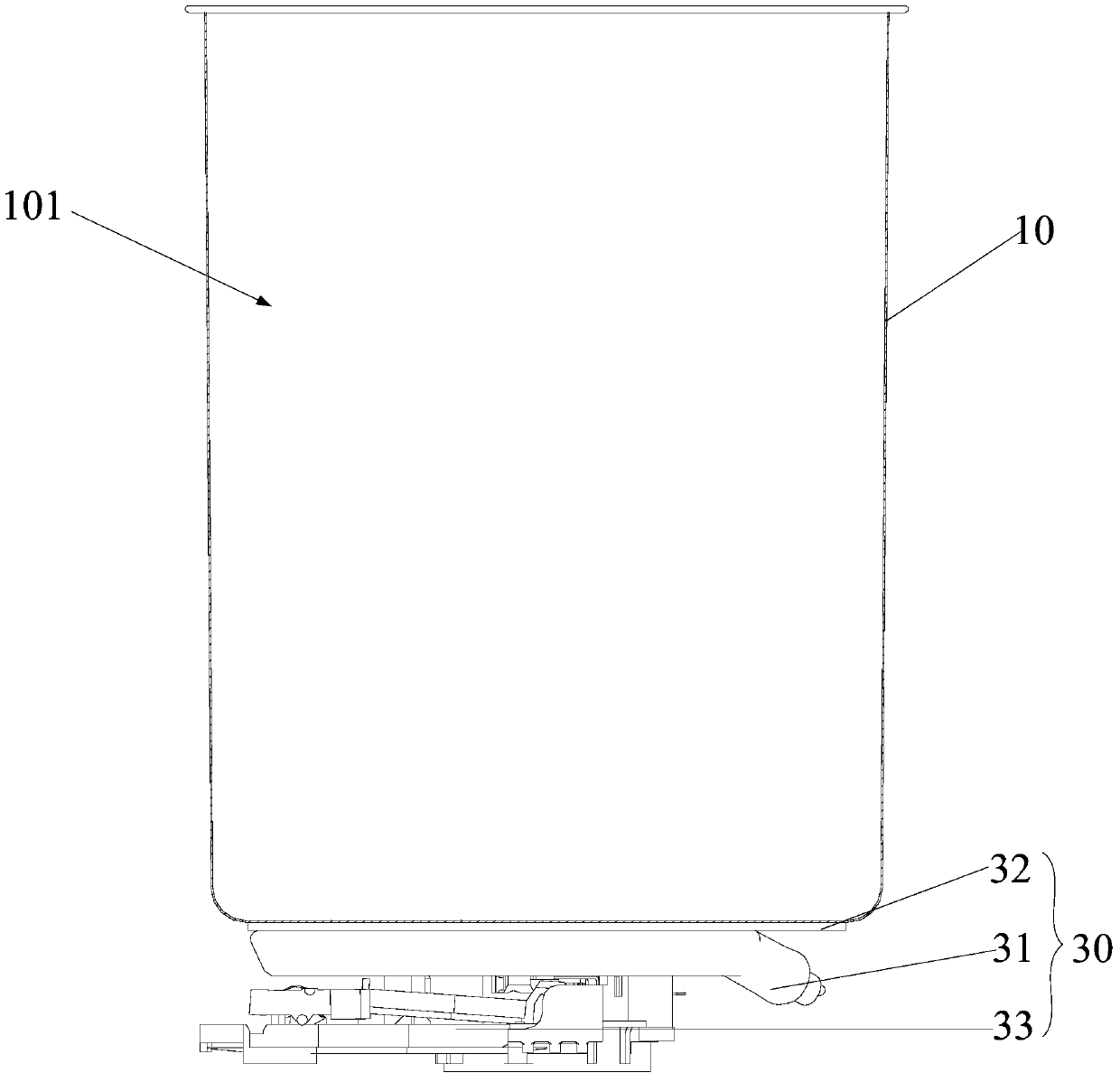

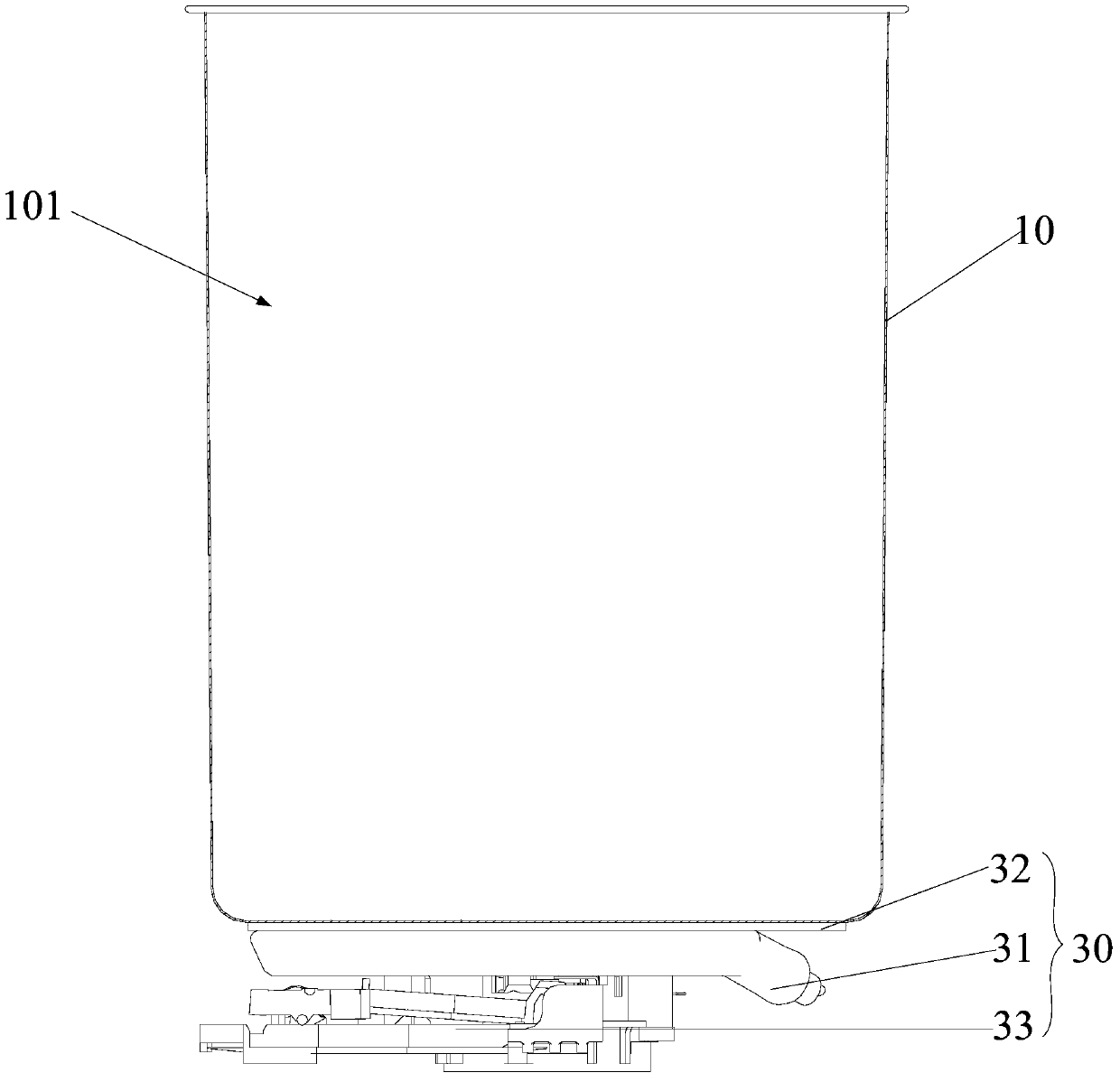

Liquid heating container

The invention provides a liquid heating container comprising a container body, a heating assembly and a coating; the container body has a contain cavity used for containing liquid; the heating assembly is used for heating up the liquid in the contain cavity; the coating is formed on the inner wall of the container body, the coating thickness is d, and the surface scratch hardness is h. The ratio between coating thickness d and the surface scratch hardness h is between 0.56micro / H and 50micro / H, thus providing wear resistant, strong clunging force and durable performances of the coating, prolonging the product service life, and improving the product market competitiveness.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

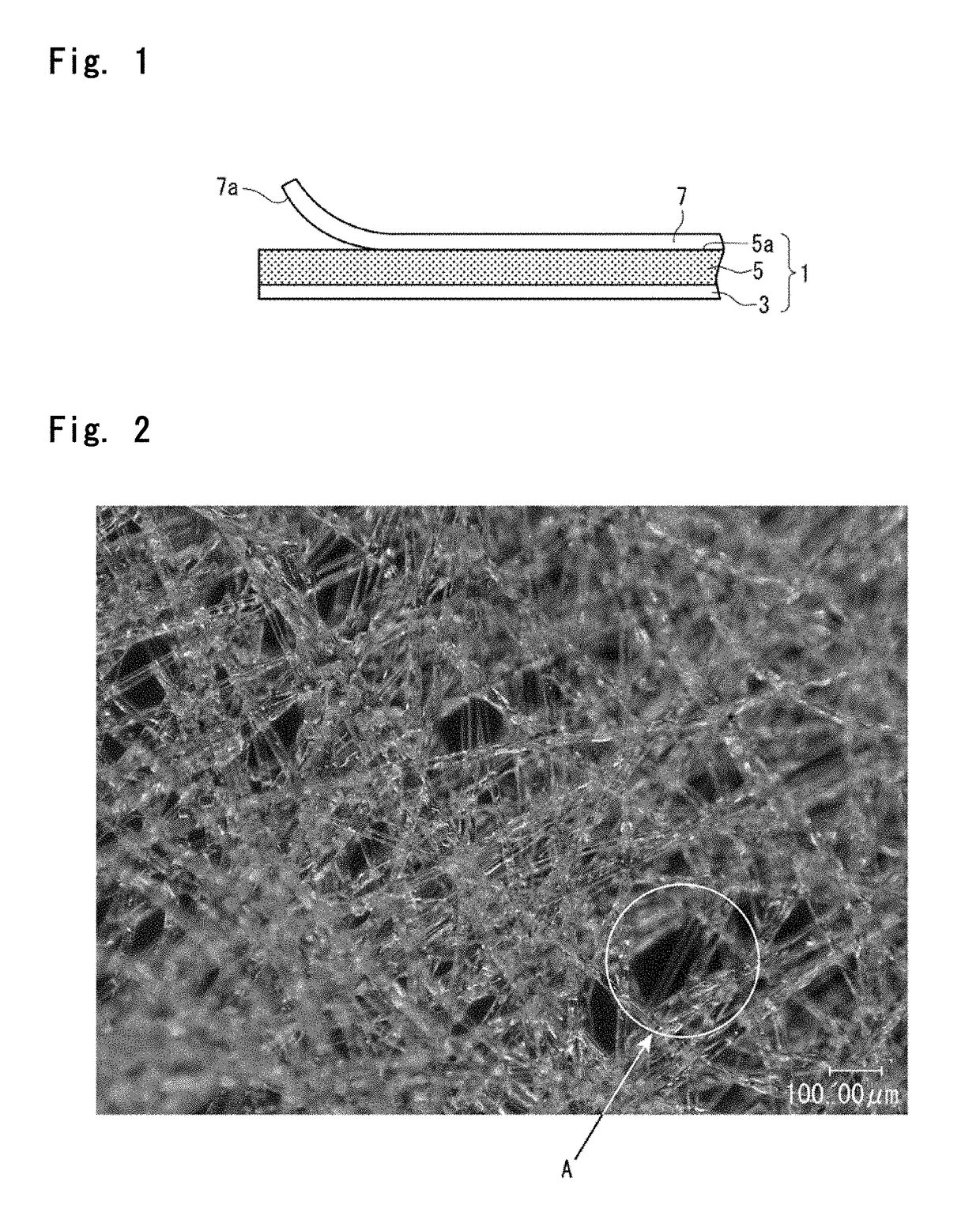

Flexible wiring board and use thereof

InactiveUS20160295686A1Increased durabilityImprove conductivityFlexible printed circuitsCircuit conductive materialsScratch hardnessCross cut

Provided is a flexible wiring board having high durability. The present invention provides a flexible wiring board including a flexible substrate and a conductive film formed on the flexible substrate. The conductive film contains a conductive powder and a curd product of a heat curable resin. The conductive film has pencil hardness of at least 2H, based on a pencil scratch hardness test in accordance with JIS K5600 5-4 (1999). The conductive film has adhesiveness of at least 95 / 100 by a 100 squares cross-cut test in accordance with JIS K5400 (1990).

Owner:NORITAKE CO LTD

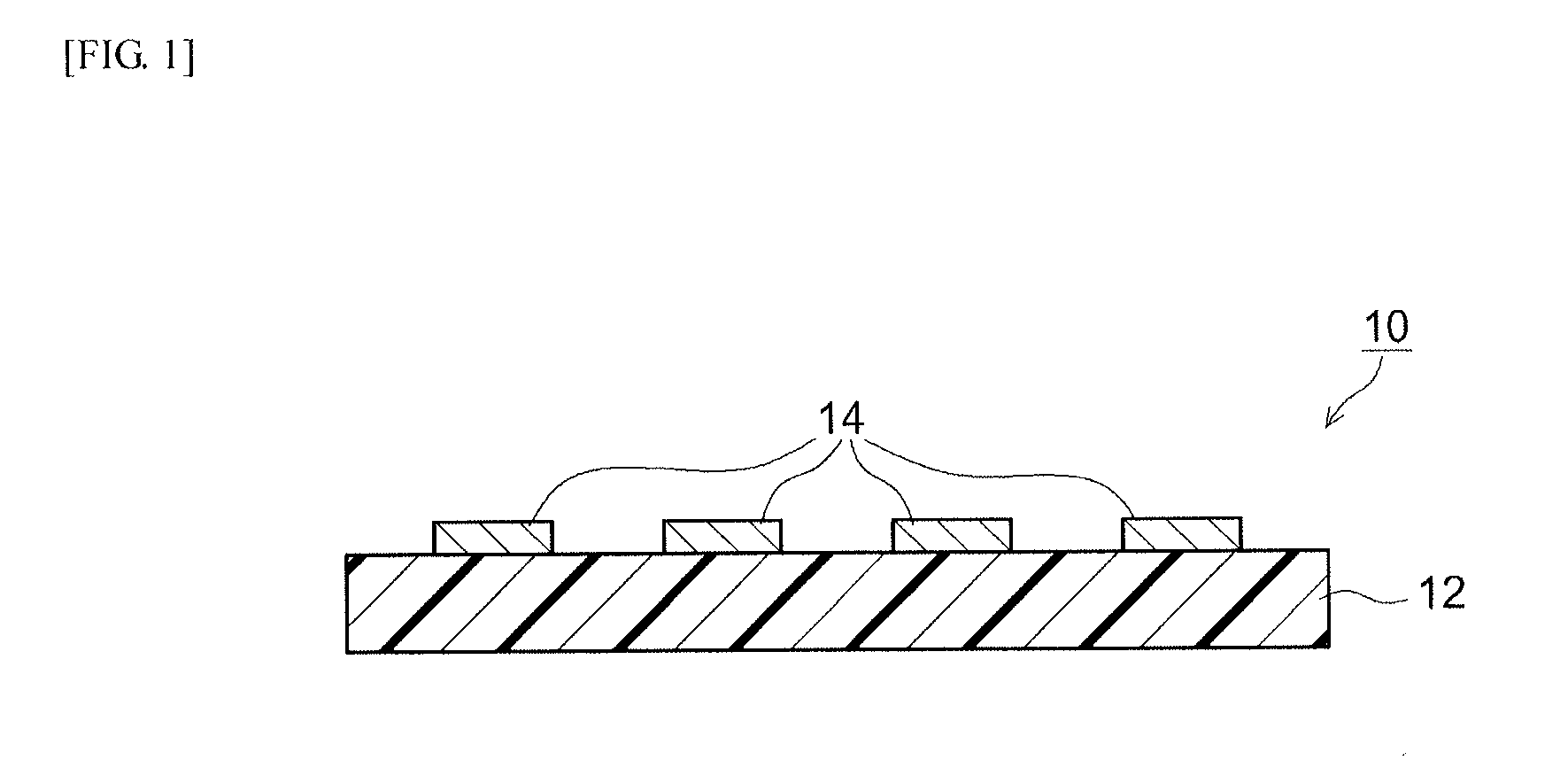

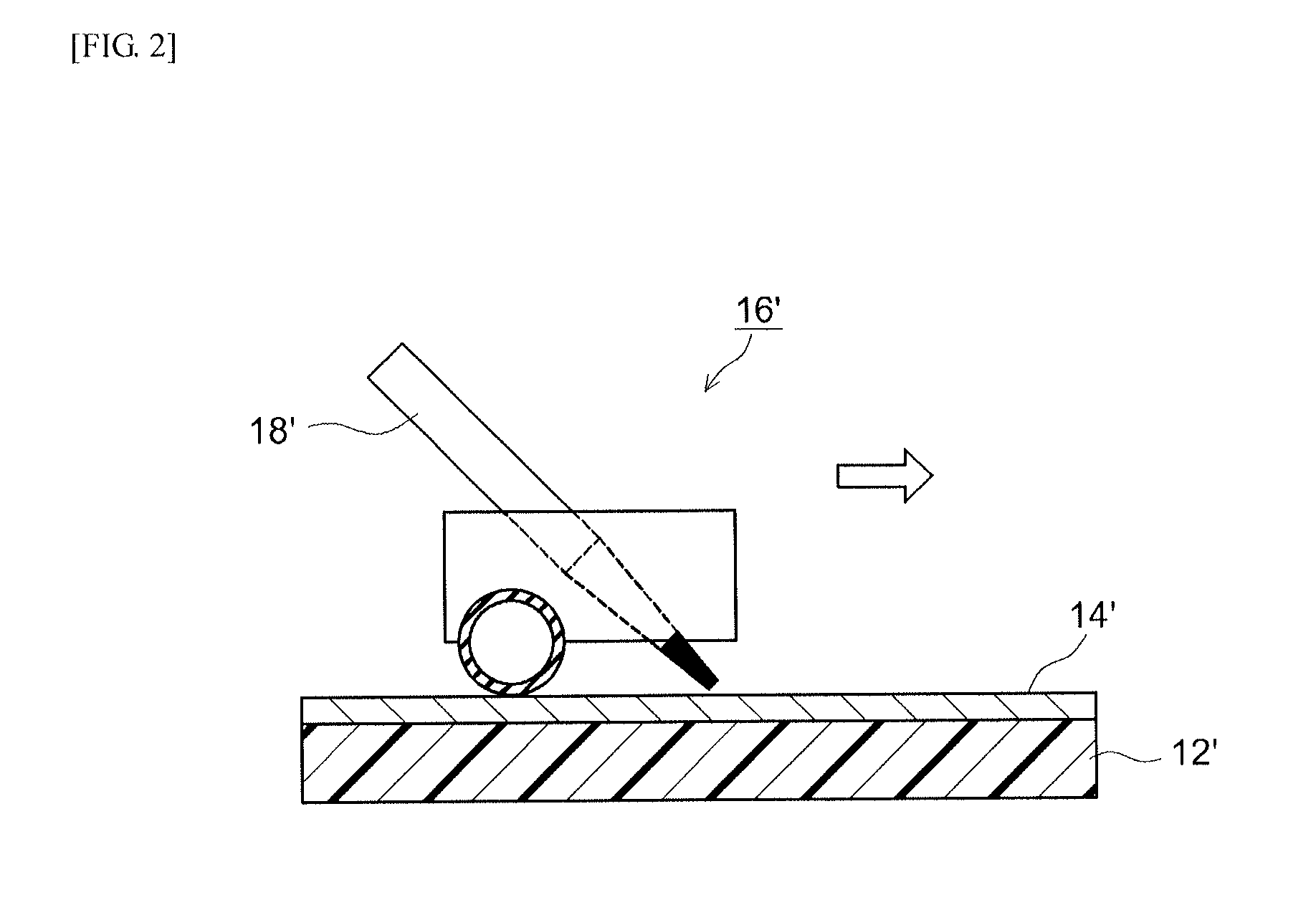

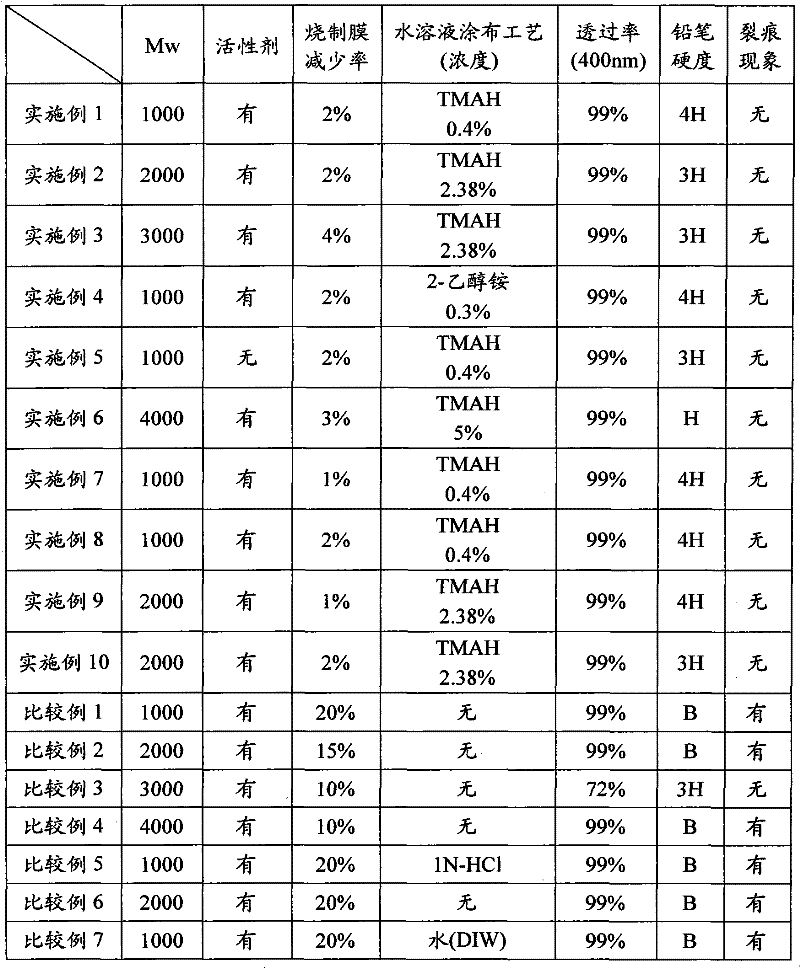

Method for forming curing laminated film of siloxane resin compound

The invention relates to a method for forming curing laminated films of a siloxane resin compound. By using the siloxane resin compound, the curing laminated films which have the characteristics of excellent transparency, high scratch hardness, high insulation, low dielectric constant, excellent smoothness, no film loss during a sintering process, no crack even in case of thick films, no film peeling on a substrate interface and excellent sealing performances. The method comprises the steps of coating the siloxane resin compound containing a silanol group or an alkoxy silyl group on a substrate, pre-baking the siloxane resin compound, flushing and sintering the compound after the compound is processed in an alkaline aqueous solution. Then Sintered curing laminated films of the siloxane resin compound having the silanol group or the alkoxy silyl group are formed.

Owner:MERCK PATENT GMBH

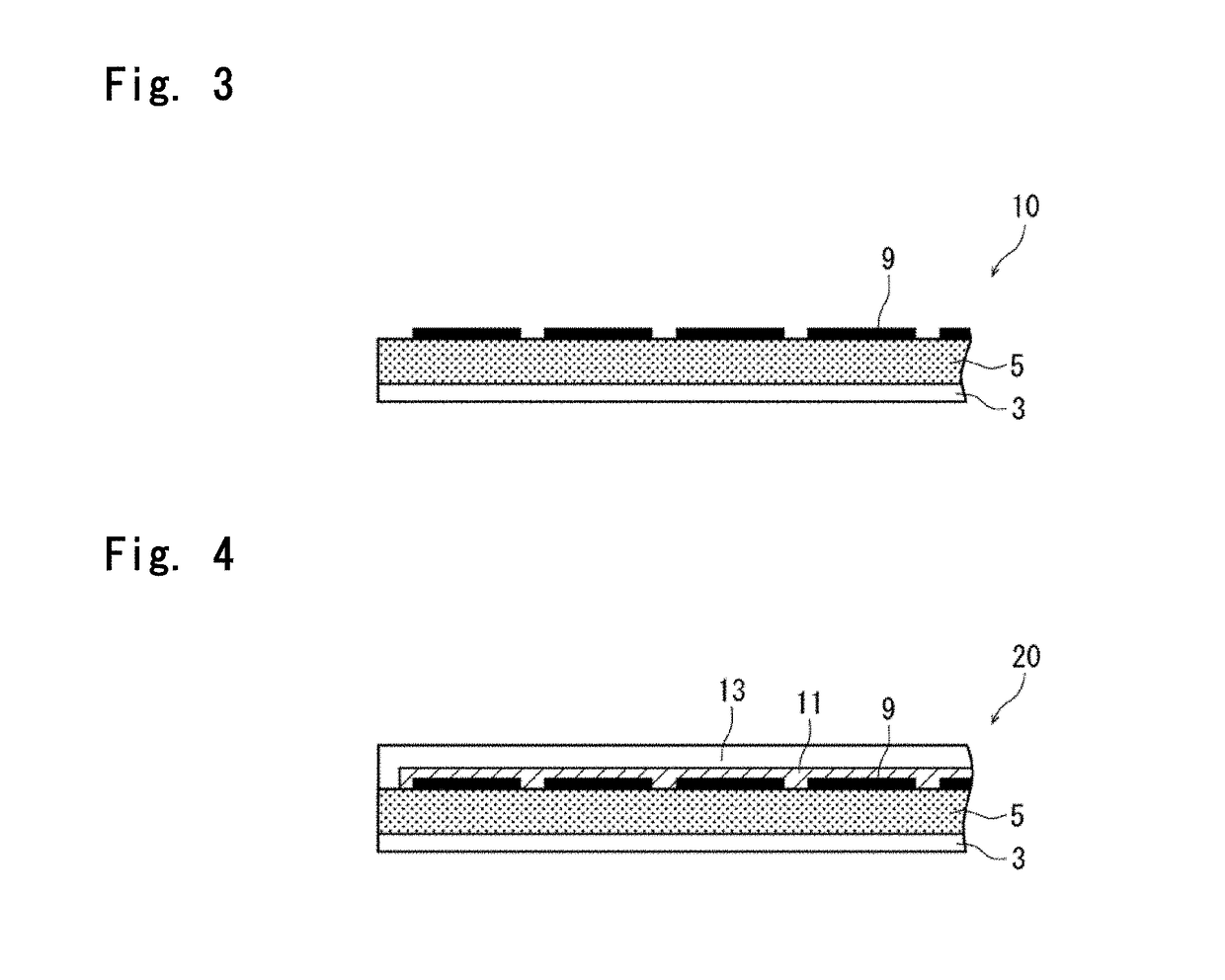

Resin laminate

InactiveCN104129130AHigh surface hardnessBe patient enoughSynthetic resin layered productsScratch hardnessTransmittance

The invention provides a resin laminate having relatively high surface hardness and high transparency. The resin laminate has a hard resin layer and a substrate layer. The hard resin layer is formed by a curing resin composition with multi-functional(methyl)acryloyl monomers as an essential ingredient, has a three-dimensional cross-linking structure and a thickness of 25 [mu]m-250[mu]m. The substrate layer is formed by a monolayer thermoplastic resin or two or more layers of a multi-layer thermoplastic resin. An independent tensile elasticity modulus of the hard resin layer is 2.000-4,000 MPa; and a total light transmittance is over 90%. Besides, a ratio (t1 / t2) of a total thickness (t1) of the substrate layer to the thickness (t2) of the hard resin layer is 0.25-10; and a Bierbaum scratch hardness of the resin laminate is 20 kg / mm<2>-700 kg / mm<2>.

Owner:NIPPON STEEL CHEMICAL CO LTD

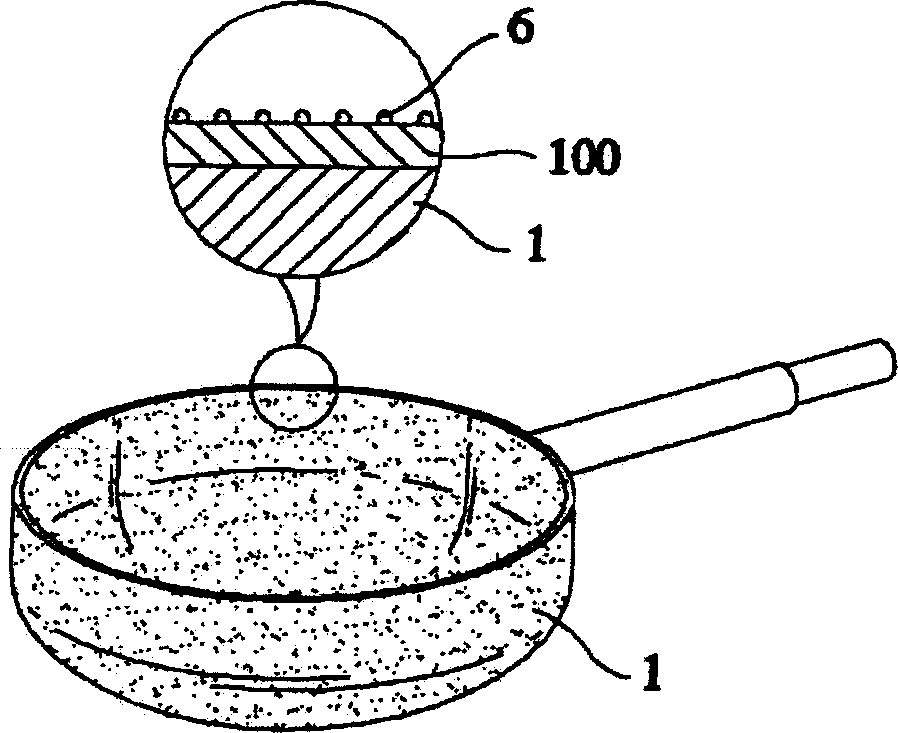

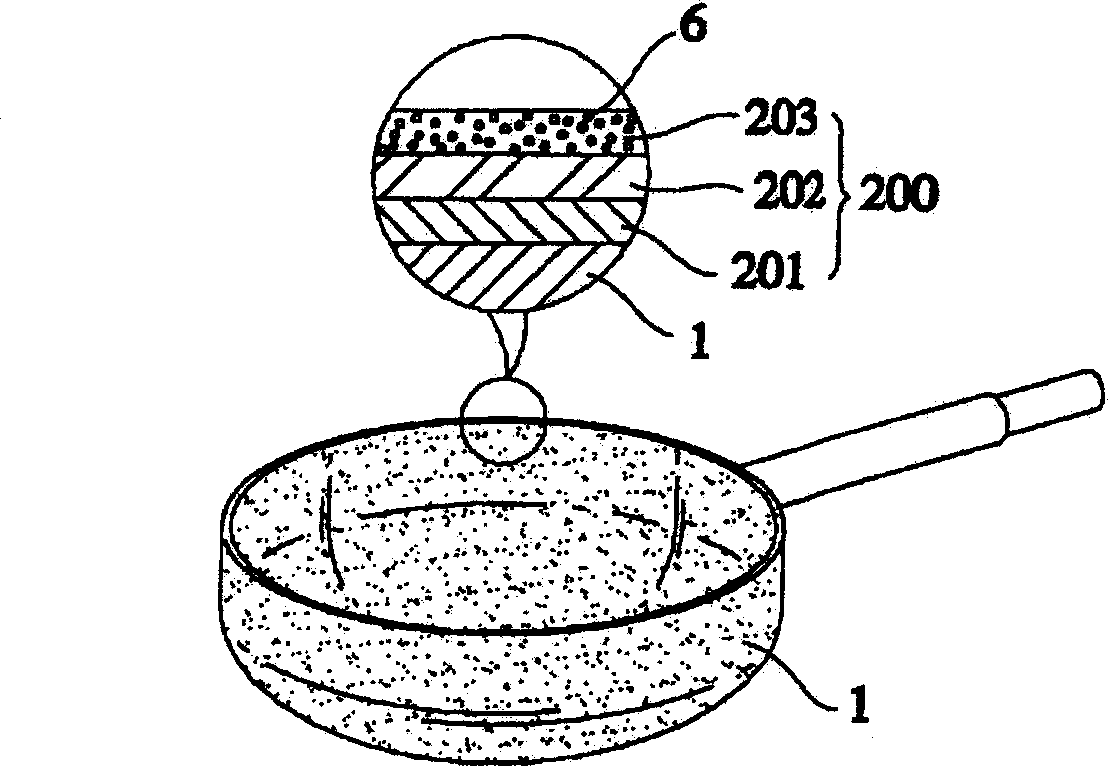

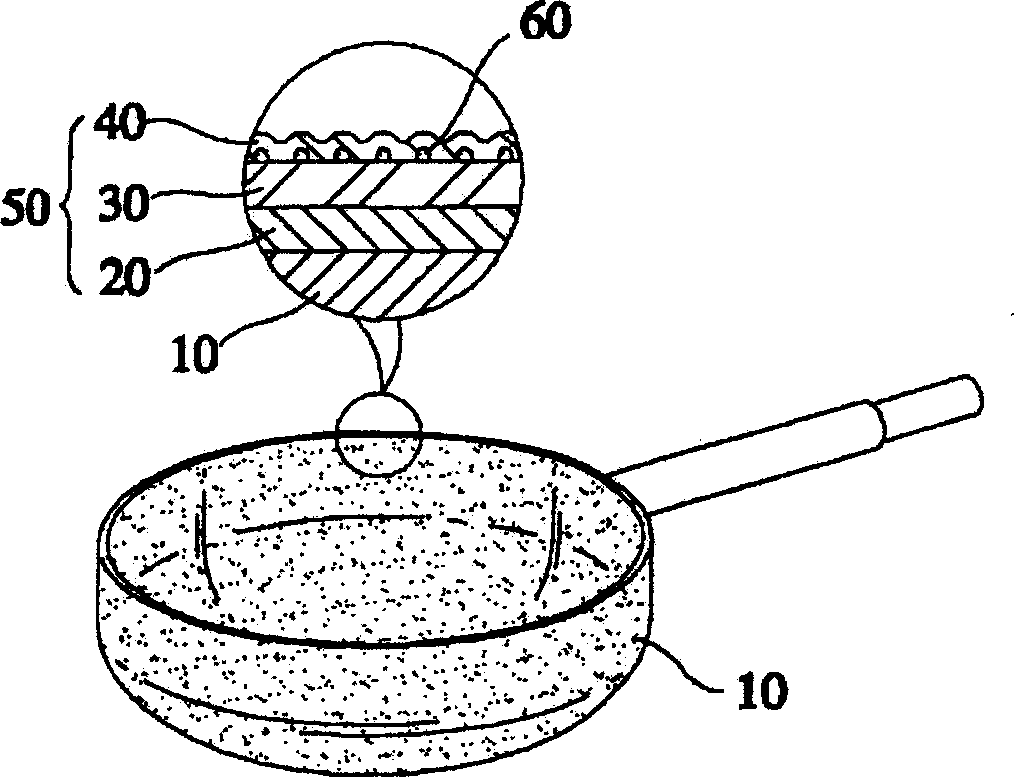

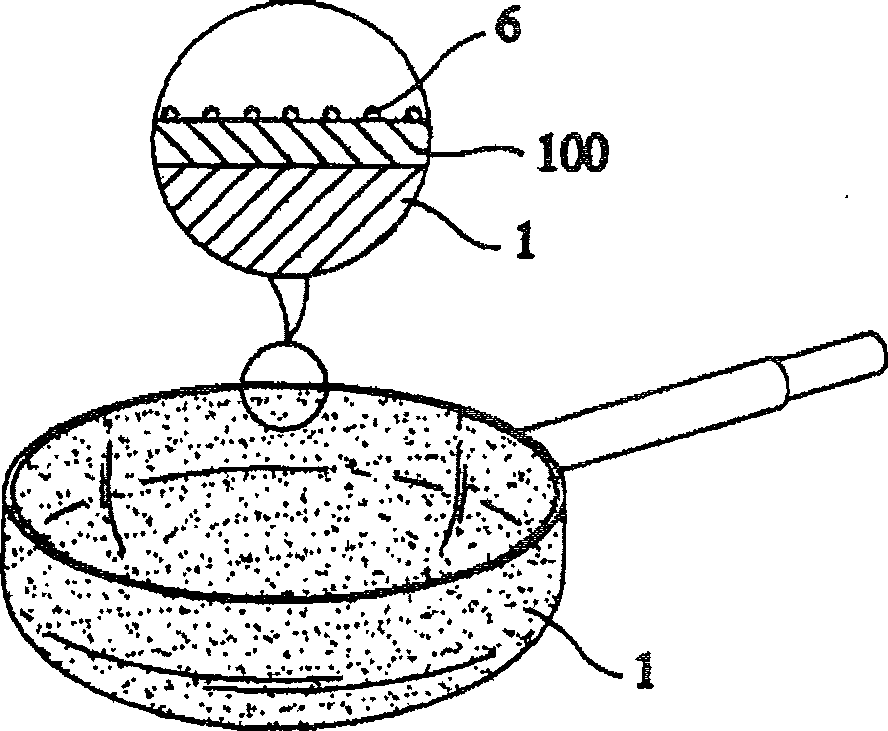

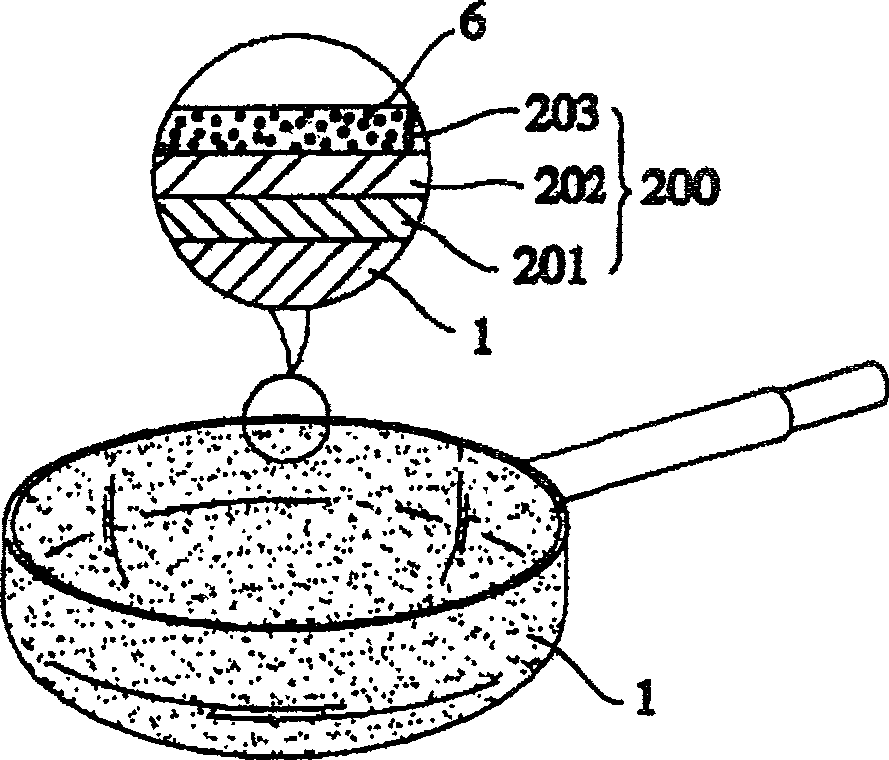

Device for forming ink coating layer on single coating layer or three coating layers and its method

InactiveCN1899702AIncreased durabilityImprove productivitySpraying apparatusPretreated surfacesScratch hardnessProduction rate

The present invention is a kind of utensil with ink pigment layer painted onto one single or three coatings and its coating forming process. The utensil has raised scratch hardness, raised wear resistance, raised production efficiency, raised cooking performance and improved appearance. Onto the single ceramic coating or the three coatings, ink pigment is sprayed to form discontinuous spots and irregular uneven patterns.

Owner:金玲

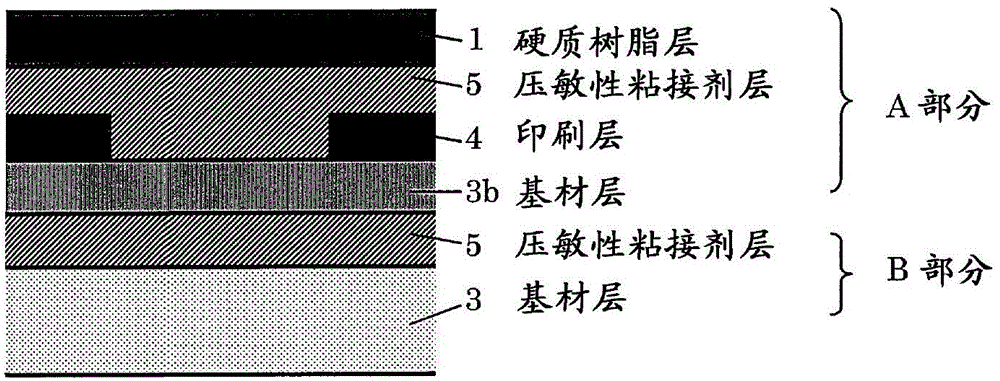

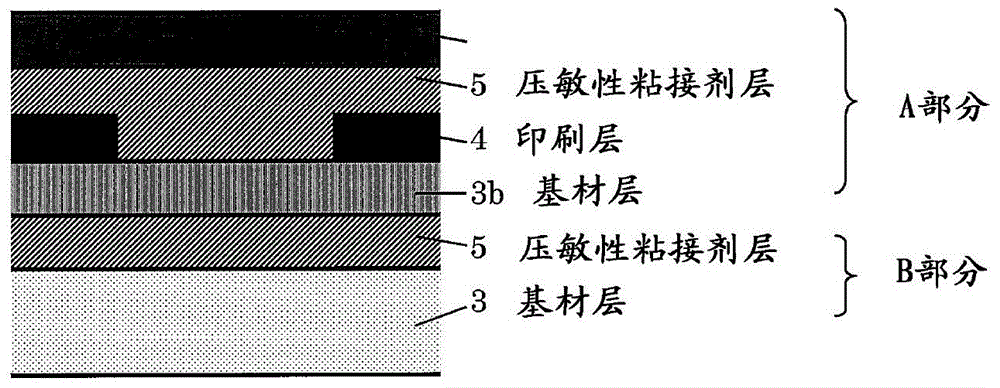

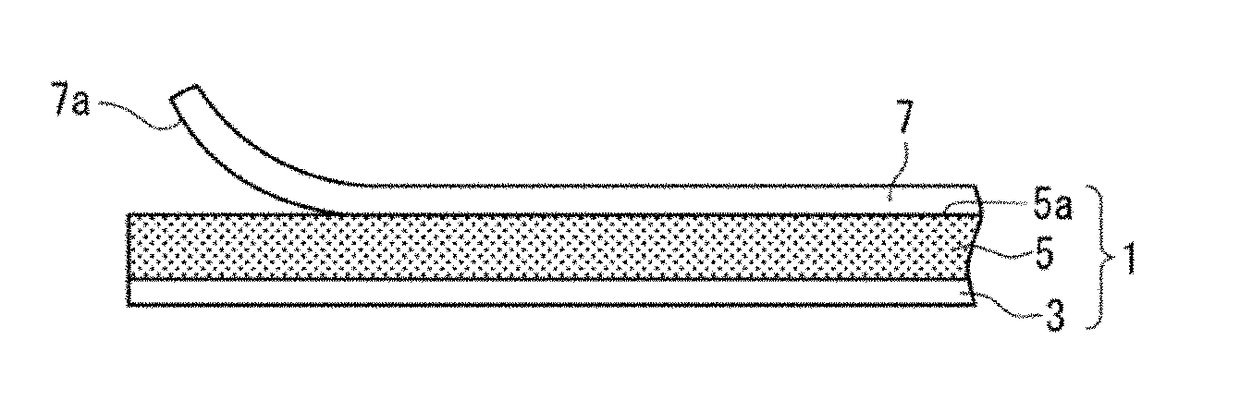

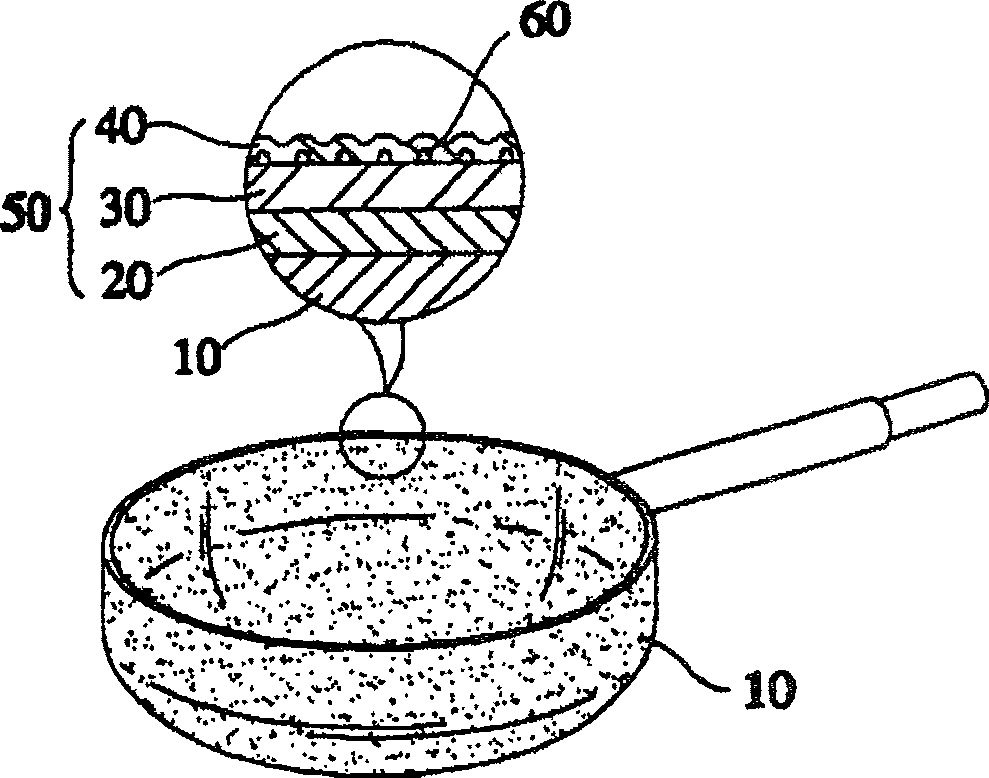

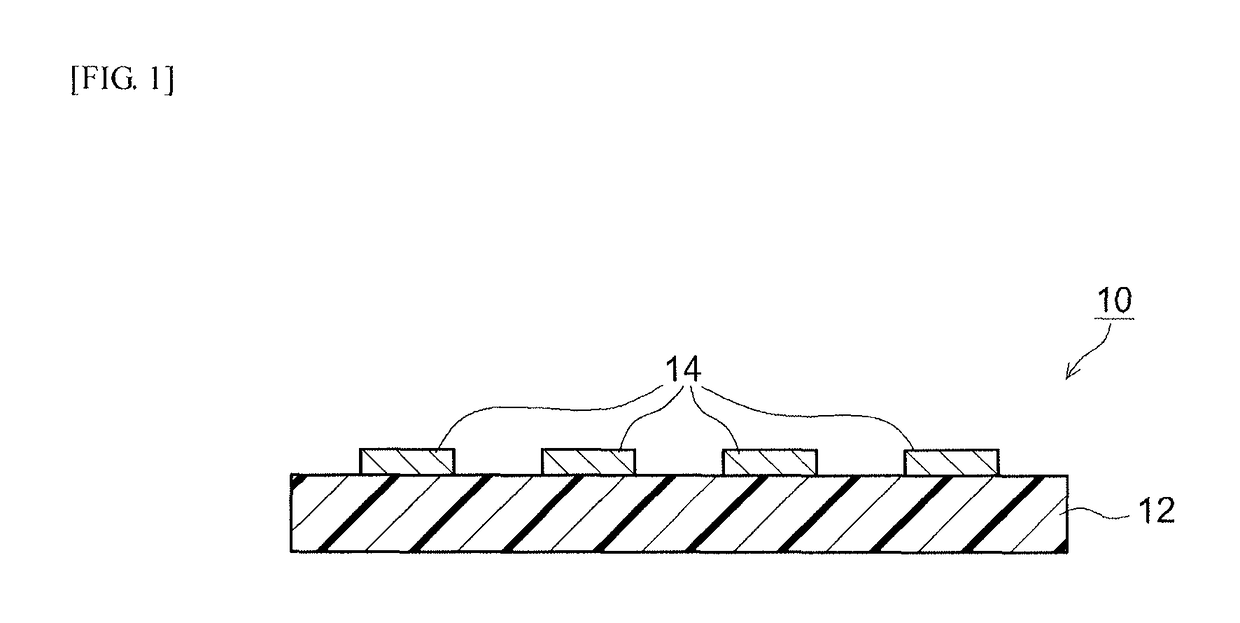

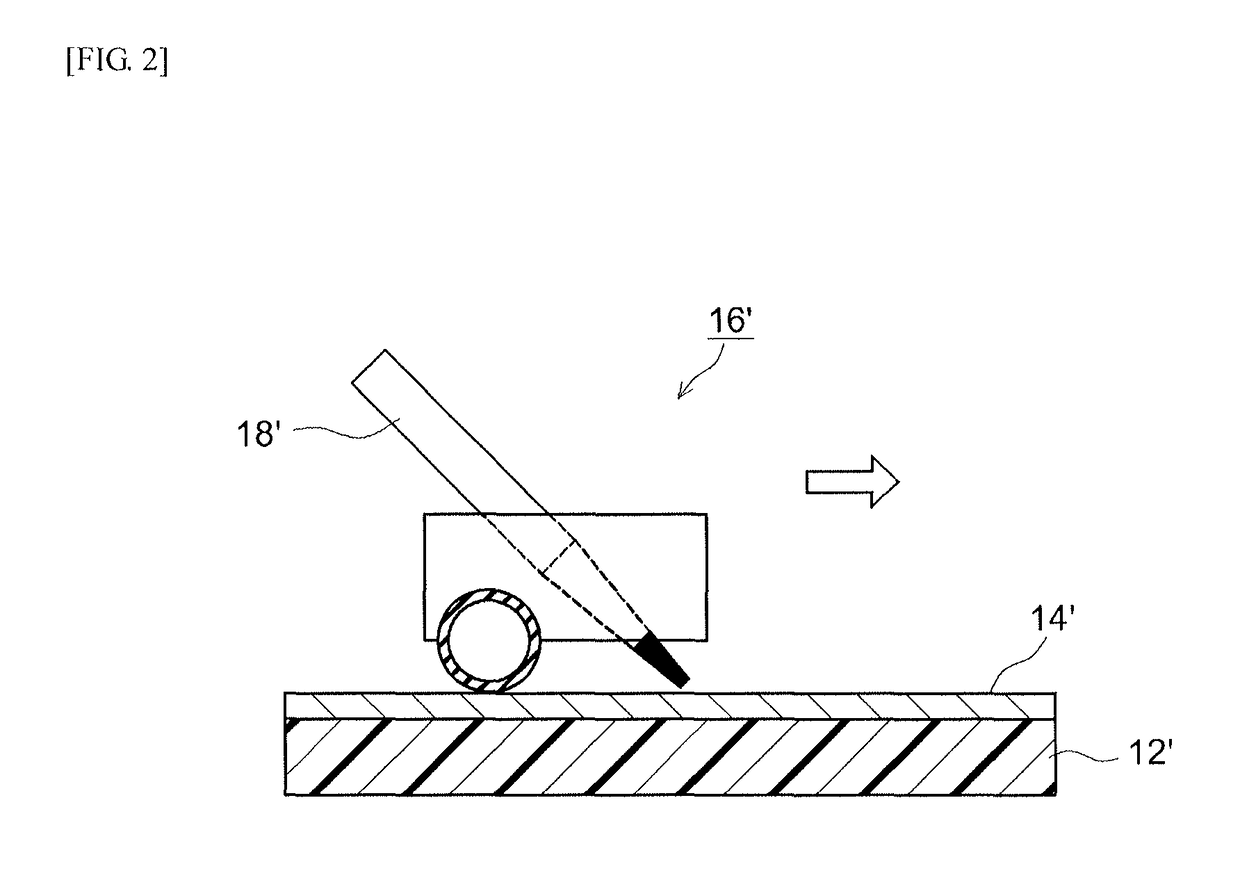

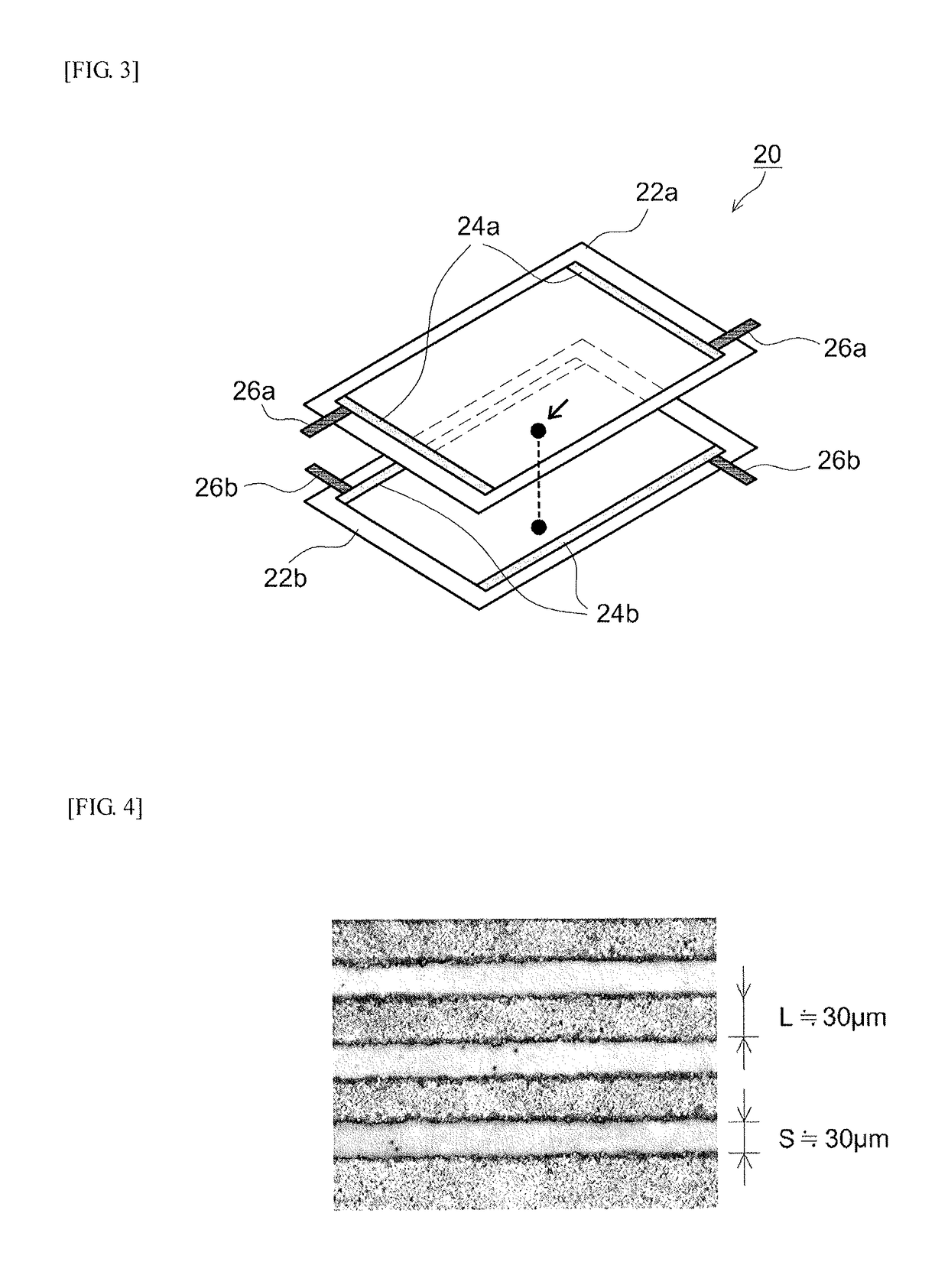

Printing sheet, printed article, makeup-applied printed article and method of producing makeup-applied printed article

InactiveUS20180304618A1Appropriate hardnessComplex surface shapeOther printing matterLayered productsScratch hardnessRough surface

A printing sheet that is capable of imparting a feeling of depth and a three-dimensional feeling to a printed image, and is capable of withstanding a strong stress at the time of applying a makeup onto the printed image. The printing sheet comprises a base sheet and an inorganic solid layer provided on the base sheet, a surface of the inorganic solid layer having a scratch hardness of not less than H as measured by the pencil hardness test specified under the JIS K 5600-5-4 and, further, the surface of the inorganic solid layer being a rough surface having an arithmetic mean roughness (Ra) specified under the JIS B 0601-2001 of 4 to 10 μm and a mean length (RSm) of elements specified under the JIS B 0601-2001 of 50 to 150 μm.

Owner:TOKUYAMA CORP

Device for forming ink coating layer on single coating layer or three coating layers and its method

InactiveCN100486717CImprove scratch resistanceImprove wear resistanceSpraying apparatusPretreated surfacesScratch hardnessCeramic coating

Owner:金玲

A kind of automobile water-based intermediate coating and preparation method thereof

InactiveCN105754463BFlat shapeNo peeling phenomenon observedPolyurea/polyurethane coatingsEpoxyScratch hardness

The invention discloses an automotive waterborne floating-coat coating and a preparation method thereof. The automotive waterborne floating-coat coating is characterized by comprising a component A and a component B, wherein the component A comprises the following components in percentage by weight: 15%-35% of polyester resin, 25%-35% of epoxy resin, 15%-25% of a pigment, 3%-5% of talcum powder, 15%-25% of calcium carbonate, 0.1%-0.5% of a polyurethane defoaming agent, 0.3%-0.8% of etherified amino resin, 0.1%-0.5% of a fumed silica anti-settling agent, 0.1%-0.5% of a flatting agent, 0.5%-1.5% of a wetting agent, 1%-2% of a flash-rust inhibitor and the balance of deionized water; and the component B is a closed waterborne isocyanate curing agent. After an electro-deposition coating plate is coated with the automotive waterborne floating-coat coating and dried, a paint film presents an excellent smooth form, a paint film stripping phenomenon is not observed during adhesiveness testing of the paint film, and the hardness, tested by virtue of a pencil scratch hardness method, of the paint film is an level F or above.

Owner:SHANGHAI DAZHONG ALLIED AUTO REFITTING

liquid heating vessel

The invention provides a liquid heating container comprising a container body, a heating assembly and a coating; the container body has a contain cavity used for containing liquid; the heating assembly is used for heating up the liquid in the contain cavity; the coating is formed on the inner wall of the container body, the coating thickness is d, and the surface scratch hardness is h. The ratio between coating thickness d and the surface scratch hardness h is between 0.56micro / H and 50micro / H, thus providing wear resistant, strong clunging force and durable performances of the coating, prolonging the product service life, and improving the product market competitiveness.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Composition for making a drilling fluid a non-invasive drilling fluid

The invention relates to a composition for making a drilling fluid a non-invasive drilling fluid, the composition comprising: a first component comprising particles having a scratch hardness above 2 Mohs; and a second component comprising particles selected from the group of frag-mented seeds of Tamarindus indica, comminuted bark from Litsea glutinosa, or comminuted Ocimum tenuiflorum. The invention further relates to a non-invasive drilling fluid comprising the composition, and a method for drilling a wellbore.

Owner:欧洲穆德股份有限公司

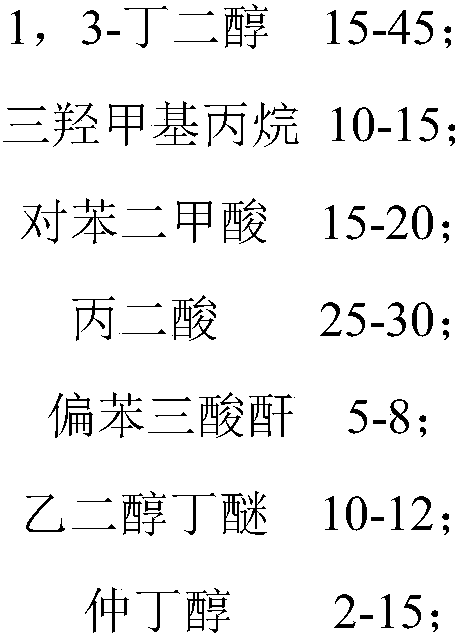

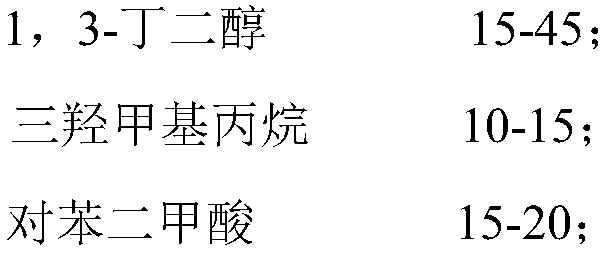

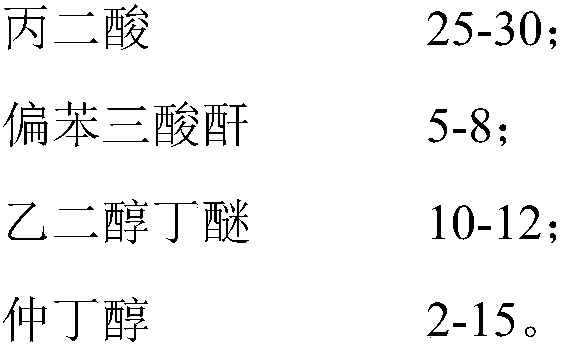

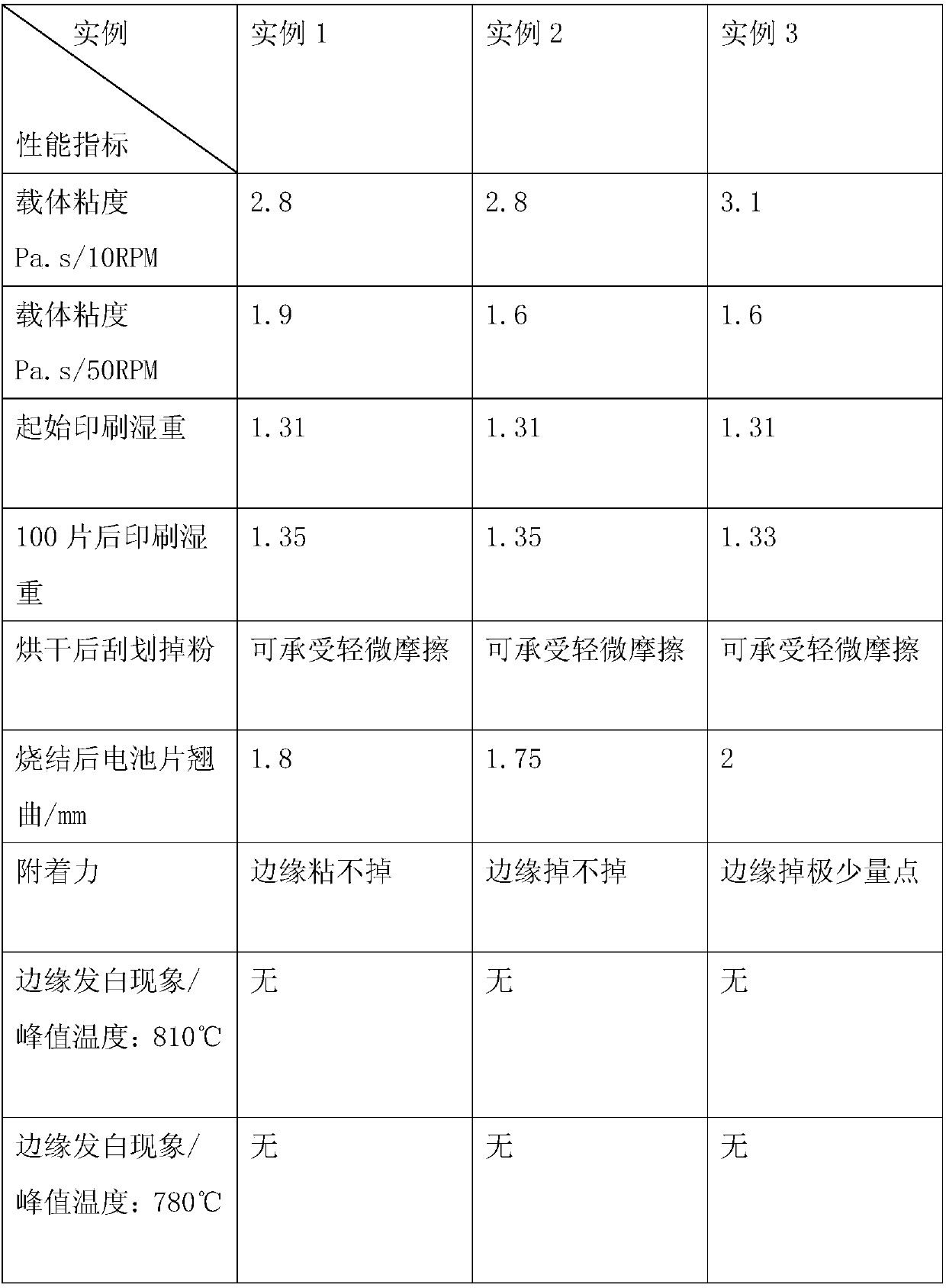

Organic carrier for solar cell slurry and preparation method of organic carrier

InactiveCN107778764AGood dispersion and wettabilityImprove carrying capacityInksPhotovoltaic energy generationSlurryBond strength

The invention discloses an organic carrier for aluminum paste on back of a solar crystalline silicon cell and a preparation method of the organic carrier. The organic carrier comprises the following components in percentage by mass: 86-90.4% of an organic solvent, 3.2-5% of a surfactant, 2-4.5% of ethyecellulose, 1-7% of cellulose acetate butyrate and 3.4-5% of phenolic aldehyde or aldehyde resin,totaling 100%. The aluminum paste prepared by using the organic carrier disclosed by the invention has excellent thixotropy, the aluminum paste standing for a long time is not layered or settled, hasexcellent bearing capacity on powder, has a uniform coating property during printing, is stable in continuous printing, and has excellent bonding strength and scratch hardness after drying. The sintered crystalline silicon cell has small deformation, the adhesive force at the overlap joint of the back aluminum paste and back silver paste is excellent, the adhesive force between the back aluminumpaste and the crystalline silicon cell is excellent, and whitening and cracking phenomena do not occur on the edge.

Owner:湖南利德电子浆料股份有限公司

Flexible wiring board and use thereof

InactiveUS10208159B2Adhesiveness of the conductive film and the flexible substrate is further improvedDisconnections lackFlexible printed circuitsCircuit conductive materialsScratch hardnessCross cut

Provided is a flexible wiring board having high durability. The present invention provides a flexible wiring board including a flexible substrate and a conductive film formed on the flexible substrate. The conductive film contains a conductive powder and a curd product of a heat curable resin. The conductive film has pencil hardness of at least 2H, based on a pencil scratch hardness test in accordance with JIS K5600 5-4 (1999). The conductive film has adhesiveness of at least 95 / 100 by a 100 squares cross-cut test in accordance with JIS K5400 (1990).

Owner:NORITAKE CO LTD

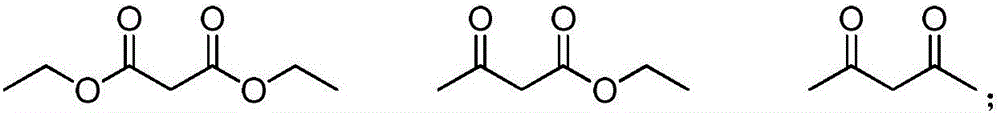

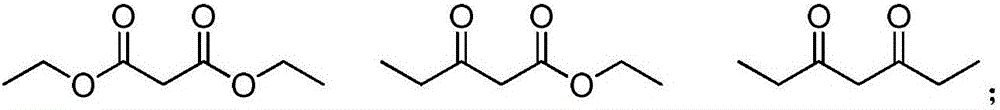

High-solid automobile finish varnish and preparation method thereof

The present invention provides a high-solid automotive finish varnish composition, which contains a polymer with the following special structure: a) a thermosetting hydroxyl acrylic resin; One or more polymers of ester and acetylacetone groups; c) polymers containing unsaturated acrylate groups; d) crosslinking agent. In the varnish composition of the present invention, the two types of polymers of components b) and c) appear in pairs, and their function is to cross-link to form a Michael addition reaction during the baking of the car body after the varnish is sprayed. membrane. The finish varnish composition of the present invention has the characteristics of high solid content in construction, low VOC emission, easy film thickness, good anti-sagging; high hardness of the paint film, scratch resistance, full and bright appearance, good aging resistance and medium corrosion resistance, etc. It is especially suitable for automobile body coating, and can also be used in outdoor protective coating occasions such as motorcycles, construction machinery, railway locomotives and light industrial products.

Owner:中山大桥化工集团有限公司 +1

Modified raw lacquer and preparation thereof

InactiveCN101348692BSimple processEasy to operateNatural resin coatingsNatural resin chemical modificationScratch hardnessLacquer

Owner:BEIJING FORESTRY UNIVERSITY

Liquid heating container

ActiveCN106993932AReduce noiseImprove thermal conductivityCooking-vessel materialsWater-boiling vesselsScratch hardnessWear resistant

The invention provides a liquid heating container comprising a container body, a heating assembly and a coating; the container body has a contain cavity used for containing liquid; the heating assembly is used for heating up the liquid in the contain cavity; the coating is formed on the inner wall of the container body, the coating surface scratch hardness is h, and the heat conduction coefficient is [lambda]. The ratio between coating surface scratch hardness h and the heat conduction coefficient [lambda] is between 0.1(m.k).H / W and 45(m.k).H / W, thus ensuring the coating to be wear resistant and durable; the coating is good in heat conduction effect, thus improving the product heating efficiency.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

liquid heating vessel

The invention provides a liquid heating container comprising a container body, a heating assembly and a coating; the container body has a contain cavity used for containing liquid; the heating assembly is used for heating up the liquid in the contain cavity; the coating is formed on the inner wall of the container body, the coating surface scratch hardness is h, and the heat conduction coefficient is [lambda]. The ratio between coating surface scratch hardness h and the heat conduction coefficient [lambda] is between 0.1(m.k).H / W and 45(m.k).H / W, thus ensuring the coating to be wear resistant and durable; the coating is good in heat conduction effect, thus improving the product heating efficiency.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

A kind of ceramic filter purification material and preparation method thereof

ActiveCN107126765BImprove purification efficiencyHigh hardnessOther chemical processesFiltration separationRare earthTitanium oxide

The invention discloses a ceramic filter purifying material which comprises main materials and auxiliary materials. The main materials are kaolin, the mixing amount of the kaolin is 20%-80% in weight percentage, the auxiliary materials comprise tourmaline, radium stones, rare earth, crystal quartz, clay, powdered borax, foaming agents, catalysts, cocoanut active charcoal, titanium oxide and zirconium oxide, and total mixing amount of the auxiliary materials is 20%-80% in weight percentage, filtering holes with irregular hole diameters are uniformly formed in the inside and the outer surface of the ceramic filter purifying material, the diameter of each filtering hole ranges from 0.01 micrometer (10 nanometers) to 500 micrometers (0.5 millimeter), the volume of each filtering hole is 0.02-1.5cm<3> / g, surface scratch hardness reaches grade 6, compression-resistant hardness is 100-170kg / cm<2>, the weight is 0.09-0.21g / cm<3>, the hole diameter of one side is large, and the hole diameter of the opposite side is small, so that a conical structure is formed. The preparation method of the materials includes the steps: grinding the main materials and the auxiliary materials, screening the grinded mixture by the aid of a 100-150-mesh sieve, and grinding parts of materials to form particles with the diameter ranging from 1 to 3 micrometers; firing and simultaneously mixing the mixture at the temperature ranging from 60 DEG C to 80 DEG C; performing pressing formation; firing clay at the temperature ranging from 800 DEG C to 1300 DEG C to form ceramic products. The ceramic filter purifying material is high in hardness, environmentally friendly, healthy and reusable.

Owner:JIANGSU RAMON ENERGY TECH

liquid heating vessel

The invention provides a liquid heating container comprising a container body, a heating assembly and a coating; the container body has a contain cavity used for containing liquid; the heating assembly is used for heating the liquid in the contain cavity; the coating is formed on the inner wall of the container body, the coating surface scratch hardness is h, wherein 1H<h<=9H. The liquid heating container arranges the coating on the inner wall of the container body; the coating is flat when directly observed, yet has accidented structures in a microscopic scope, thus easily forming gasification cores on the coating; the gasification core grows to form a bubble, and the bubble grows in a proper size and breaks away from the coating, thus greatly reducing heater noises in a water boiling process, bringing conveniences for people daily life and works, improving consumer usage comfort level, and greatly increasing product market competitiveness.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com