Device for forming ink coating layer on single coating layer or three coating layers and its method

A technology of coating layer and ceramic coating layer, which is applied in the direction of coating, device for coating liquid on the surface, special surface, etc., can solve the problem of not cooking food normally, uneven heat conduction, and not being able to fully exert scratch resistance, etc. problems, achieving the effects of reduced defective rate, uniform heat conduction, and advanced patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings. In addition, in this specification and drawings, the same code|symbol is attached|subjected to the component which has substantially the same functional structure, and repeated description is abbreviate|omitted.

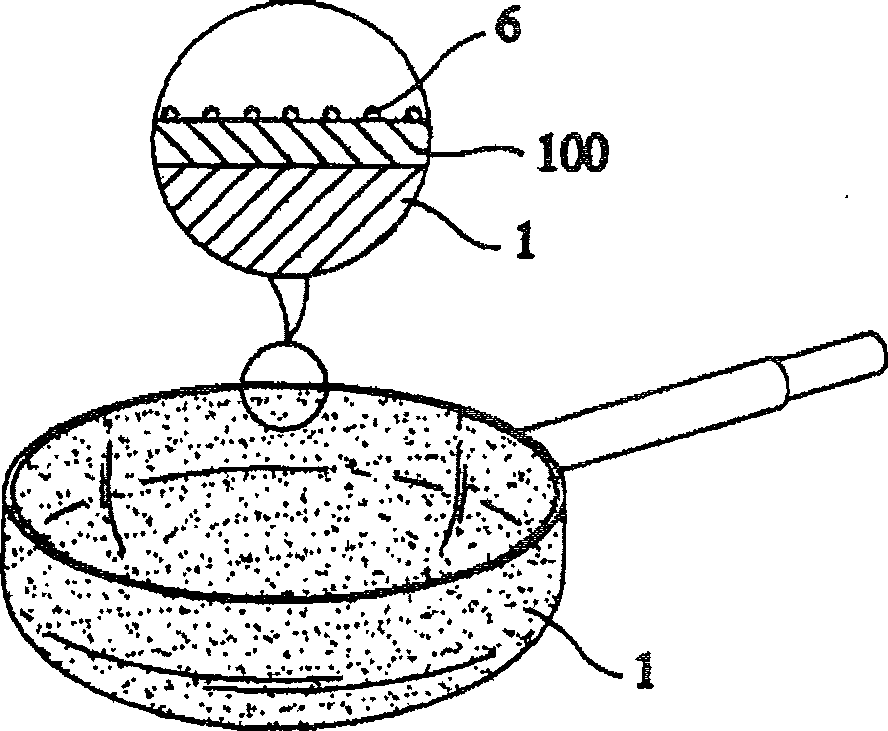

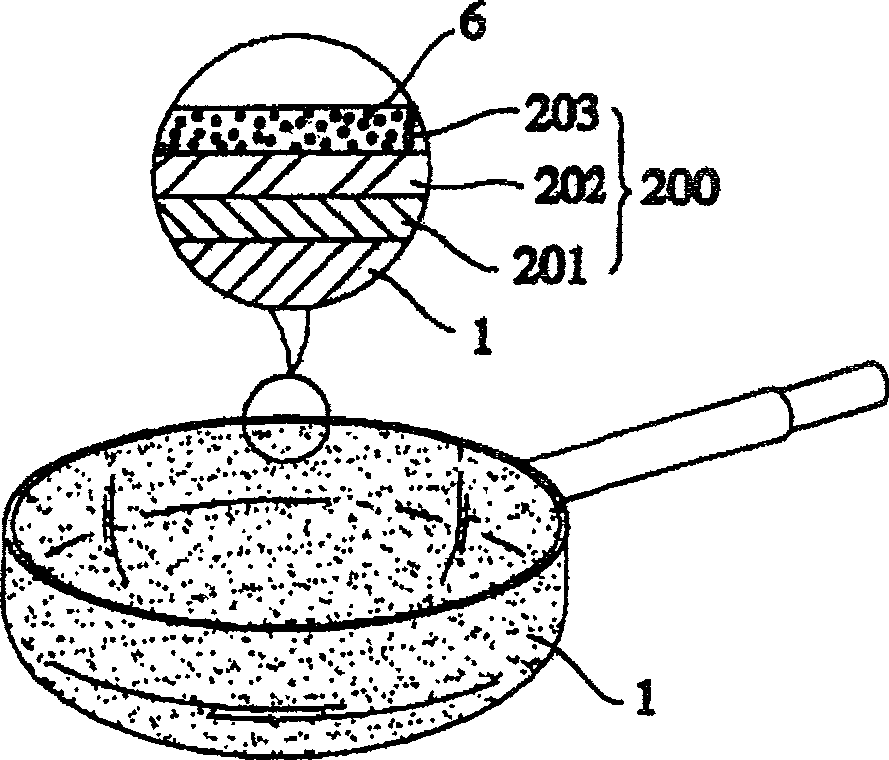

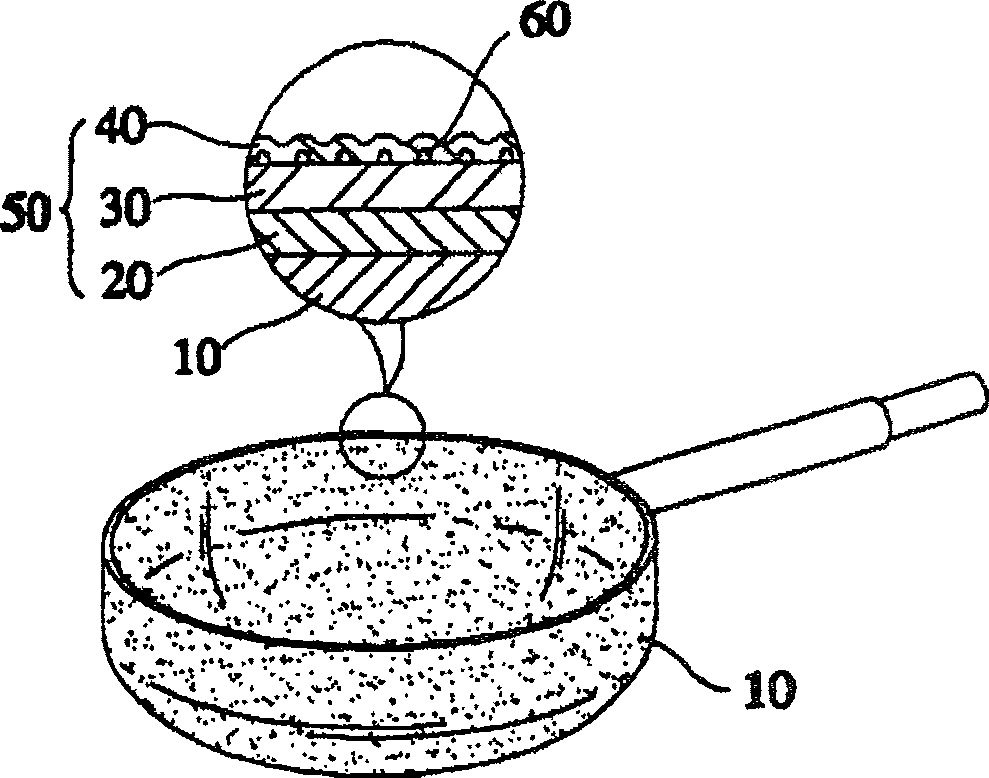

[0043] figure 1 and figure 2 It is a perspective view showing the device of the present invention and an enlarged cross-sectional view of the surface coating layer.

[0044] Such as figure 1As shown, the single coating layer 100 of the ceramic coating layer is formed by coating the ceramic paint on the surface of the utensil 1, and the single coating layer 100 of the above-mentioned ceramic coating layer is coated with ceramics in spots with a sprayer. Ink pigments of the same or different types as the above-mentioned single coating layer, such as paint, form an irregular concave-convex discontinuous coating layer 6 together with the single coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com