Patents

Literature

382results about How to "Uniform heat conduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

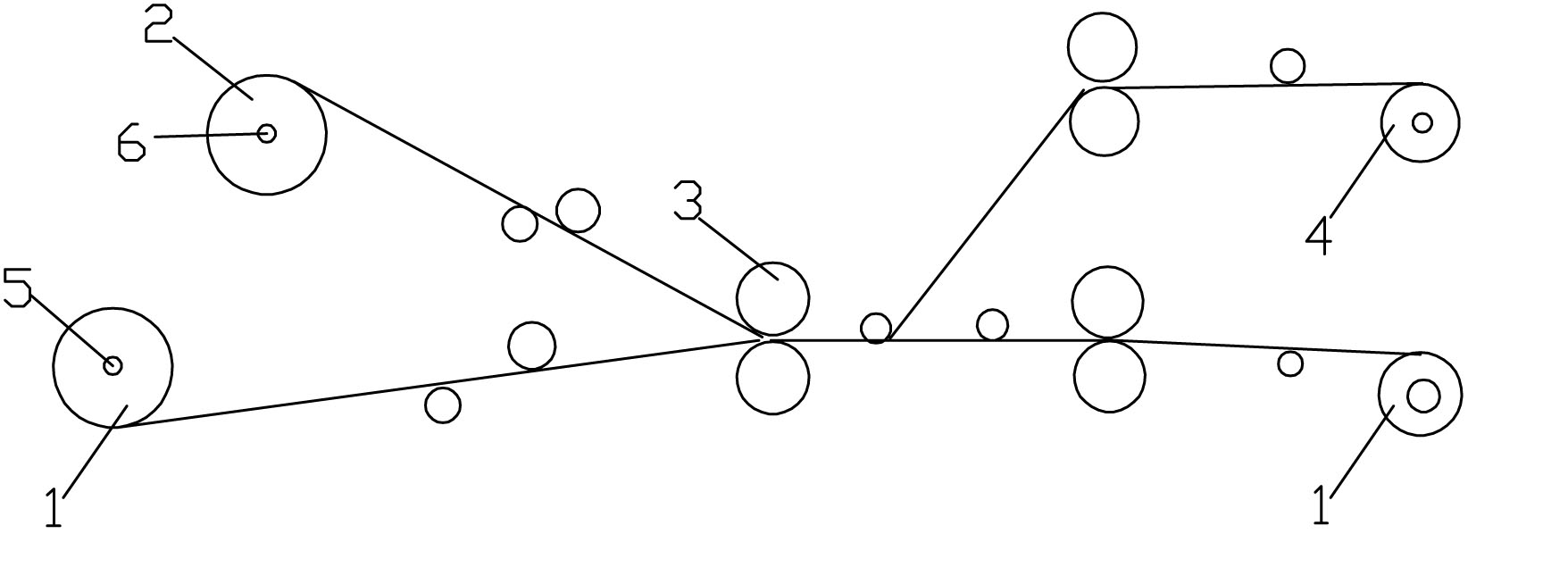

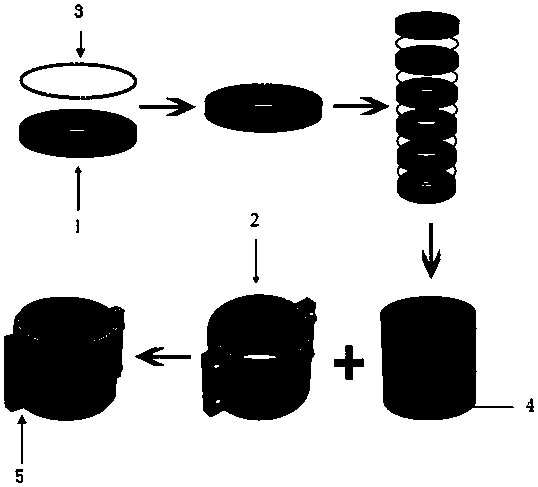

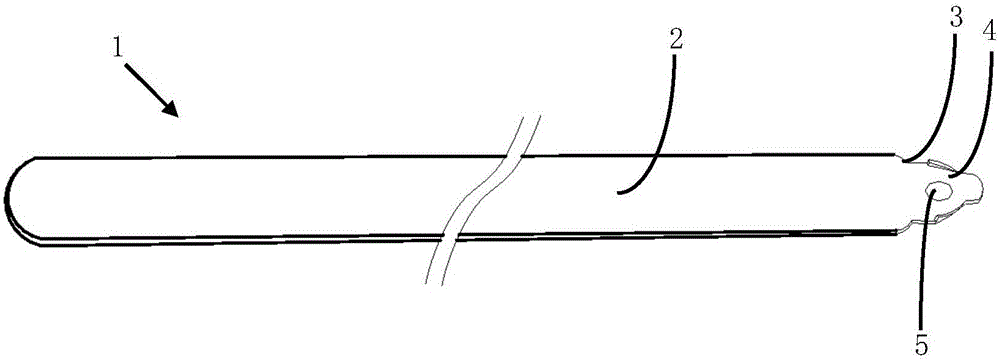

Device and method for high-speed rapid growth of diamond single-crystal

InactiveCN101037793AEasy to adjust temperatureSimple and applicable structurePolycrystalline material growthFrom chemically reactive gasesHydrogenGas phase

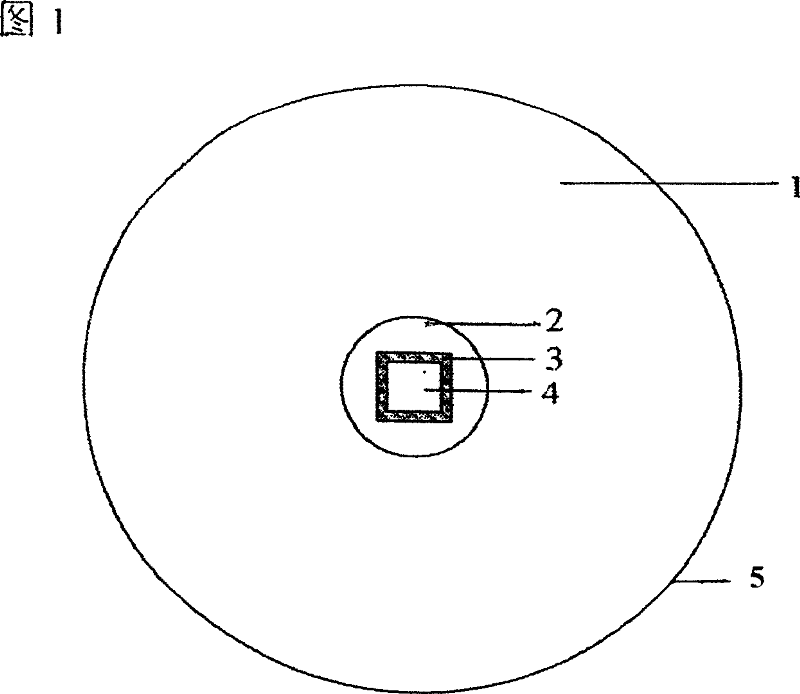

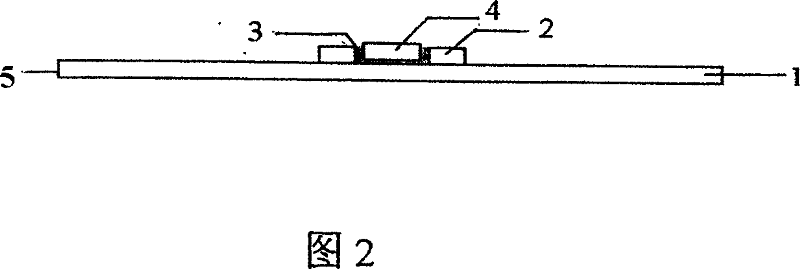

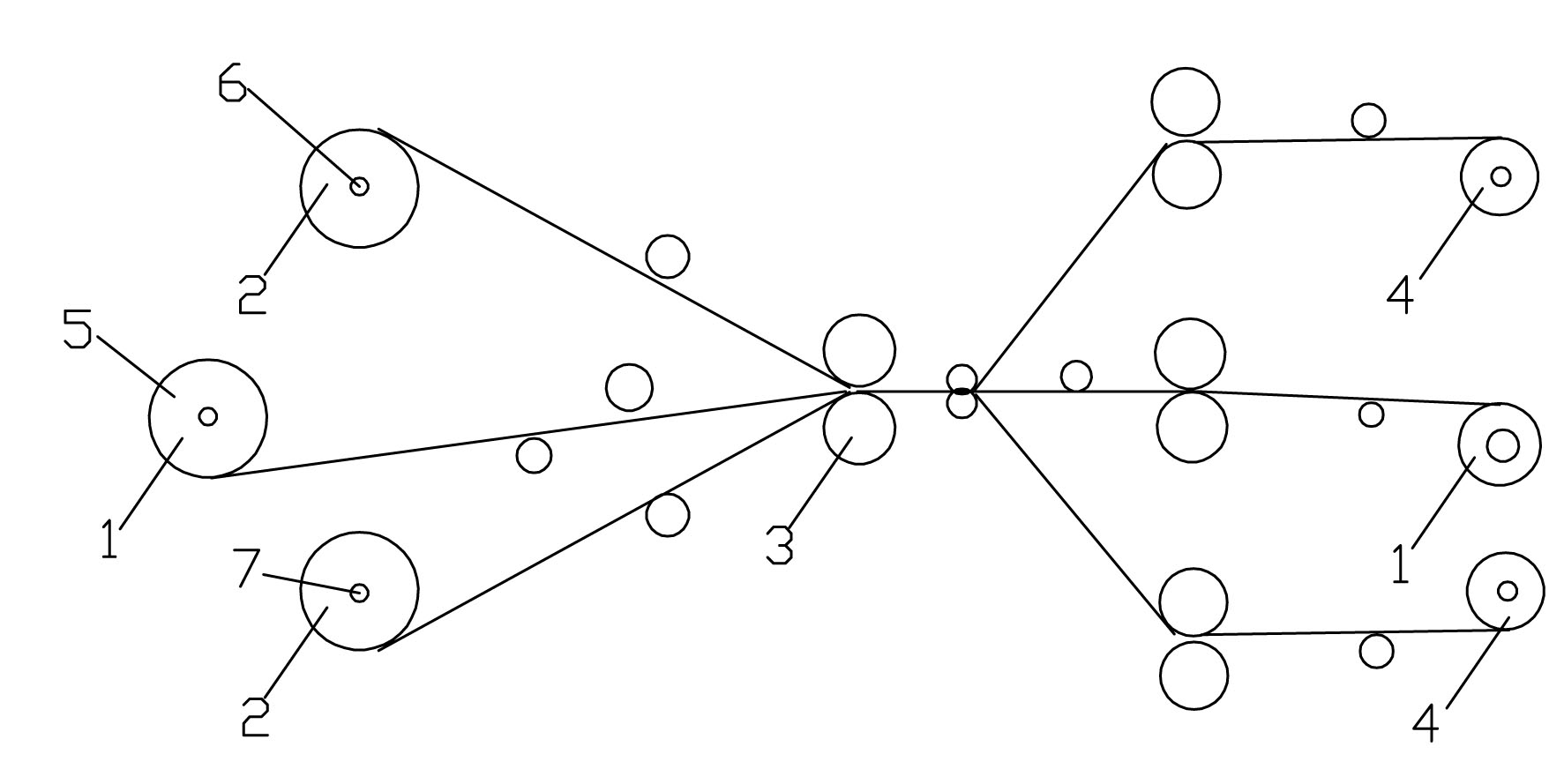

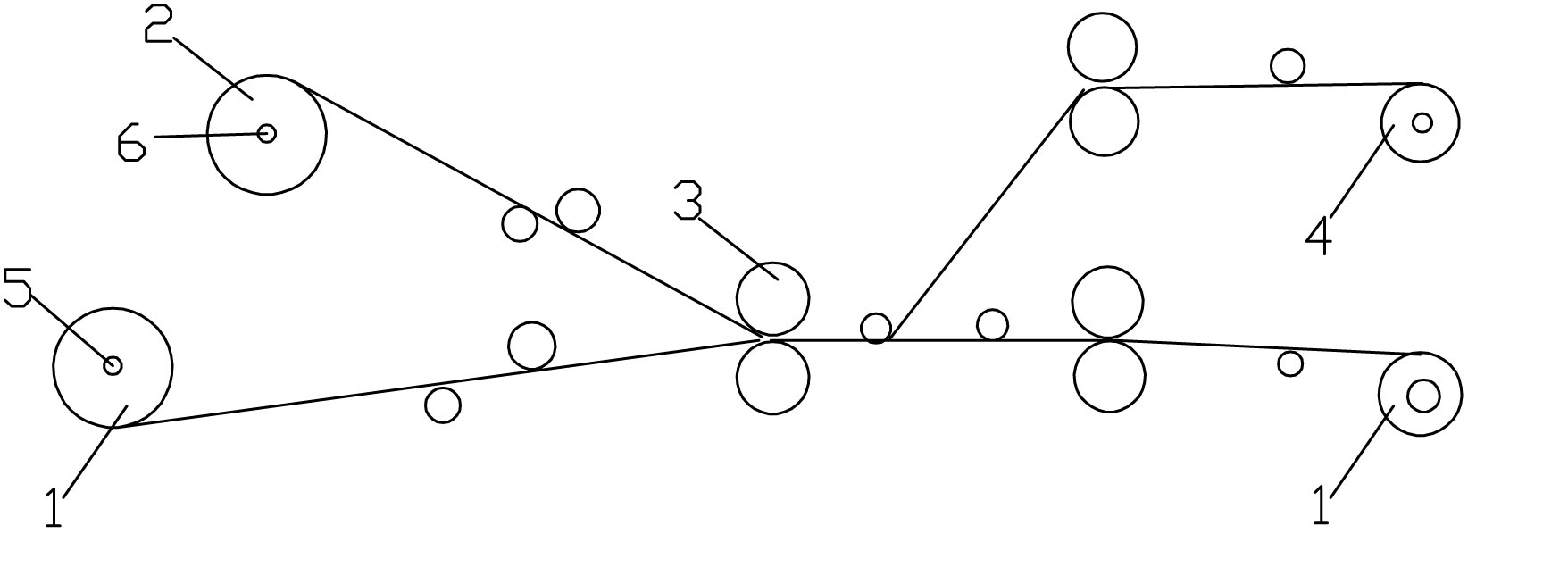

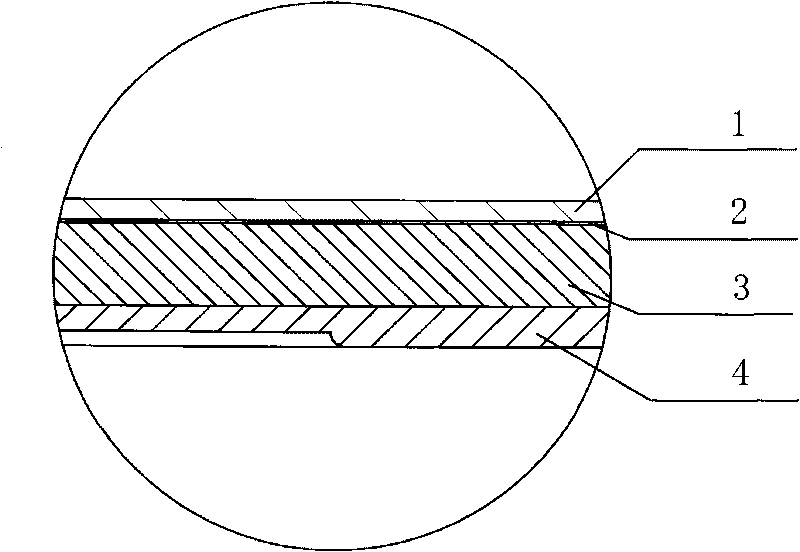

The inventive apparutus and method for growing diamond monocrystal at high-speed belongas to the technical field of diamond materials. The said apparatus is provided with sample tray 5 on the substrate holder in the settling chamber of chemical vaporous depositon system; sample tray 5 being provided with close annular frame 2 on the multi-crystal diamond film. It can also be provided with diamond powder 3 in the cavern in the close annular frame 2. The inventive method is that, monocrystal diamond crystallon 4 is placed into the settling chamber through the cavern in the close annular frame 2 and is etched in advance by plasma in situ; then diamond monocrystal is grown in the atmosphere of methane, hydrogen and nitrogen. The method includes that possible non-diamond phase and structural cavern are determined to be treated by observing brightness variation of growth face. The inventive apparatus is simple and easy to machine; and it does not bring any pollution for growing monocrystal diamond and has good thermal conduction. Transparent diamond monocrystal can be produced by the inventive method, and the growing speed can be more than 100 mm / hour.

Owner:JILIN UNIV

Special masonry mortar for self-insulating wall

InactiveCN101182178AImprove water retentionReduce the impactSolid waste managementCrack resistanceEmulsion

The invention relates to masonry mortar special for self-insulation walls, which is a powdery mixture and consists of the components with the following weight portions of 52-68 portions of cementing materials, 20-36 portions of gradation aggregates, 12-25 portions of vitrified hollow micro-pearl, 0.2-0.26 portions of redispersibility emulsion, 3-12 portions of thickener rheology agent, 0.05-0.3 portions of water retaining agent, 0.05-0.3 portions of anti-fissure strengthening agent and 0.012-0.035 portions of anti-entraining agent. The invention has the advantages of good water retention, lowheat conductivity, high mechanical strength, good flexible crack resistance, good waterproof performance, good dry shrinkage resistance, good fireproof performance, easy construction, high performance-price ratio, energy saving performance, etc.

Owner:WUHAN LAIKELIAN SCI & TECH

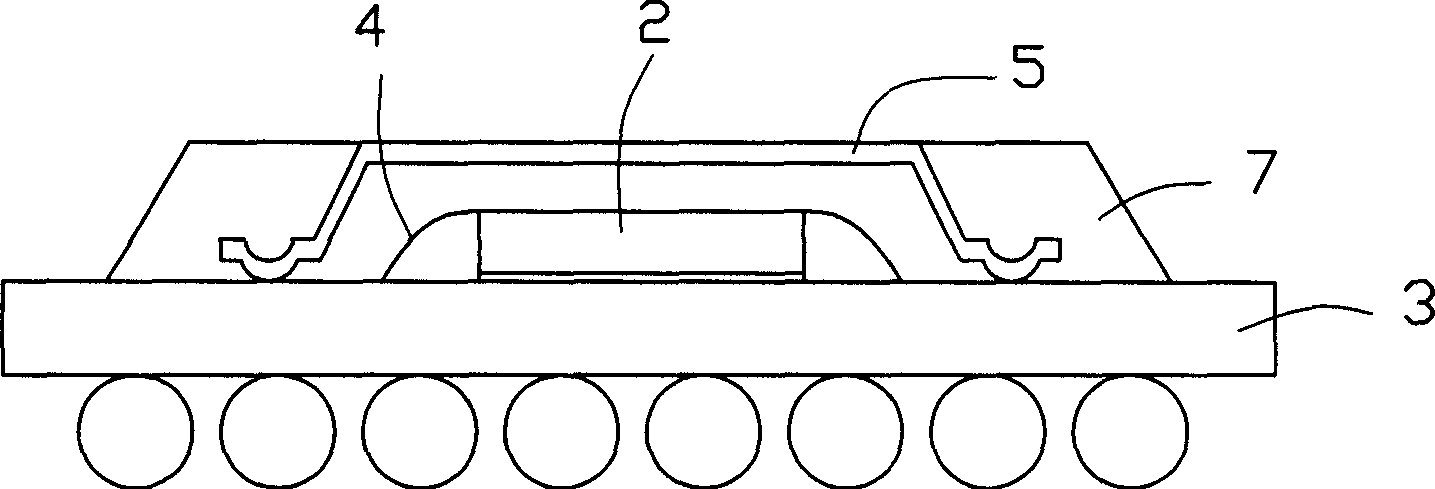

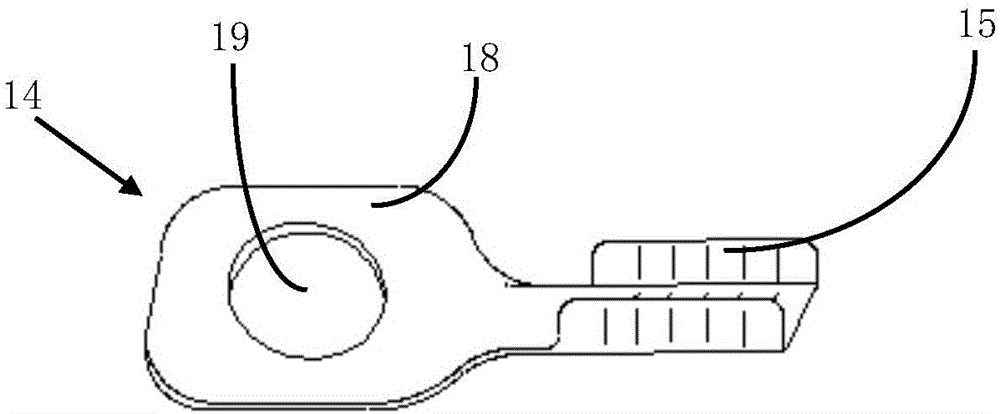

Thermal sensitive ceramic heater and heating body and heating core applied to thermal sensitive ceramic heater

ActiveCN104797015AImprove insulation performanceIncrease productivityOhmic-resistance electrodesHeater elementsHeat conductingHeat sensitive

The invention discloses a thermal sensitive camera heater. The thermal sensitive camera heater comprises a heating portion, a connection wire harness and a mounting frame, the heating portion is formed by a heating body and a radiator, the heating body comprises a heat conducting tube and a heating core, the heating core comprises a heating slice, an electrode slice and insulation paper, and the connection wire harness comprises a connection slice. Not fewer than two semi-circular grooves are formed in the outer lateral side of the heat conducting tube. A heat conducting face of the heat conducting tube is 0-15mm wider than the radiator. The thermal sensitive camera heater has the advantages that by the aid of the connection slice added on the electrode slice, reliable connection point contact and stable connection between the heater and the wire harness and convenience in manufacturing are achieved; by the aid of the heat conducting tube and the radiator which are different in width, the radiator can be combined with the heat conducting tube more stably and more uniform in radiation; by the aid of the semi-circular grooves in the lateral side of the heat conducting tube, the inner wall of the heat conducting tube causes less damage to a heating core insulation film, combination of the heating core in the heat conducting tube is tighter, and safety and heat efficiency are improved greatly.

Owner:SUZHOU GUOWEI CERAMIC ELECTRICAL APPLIANCE CO LTD

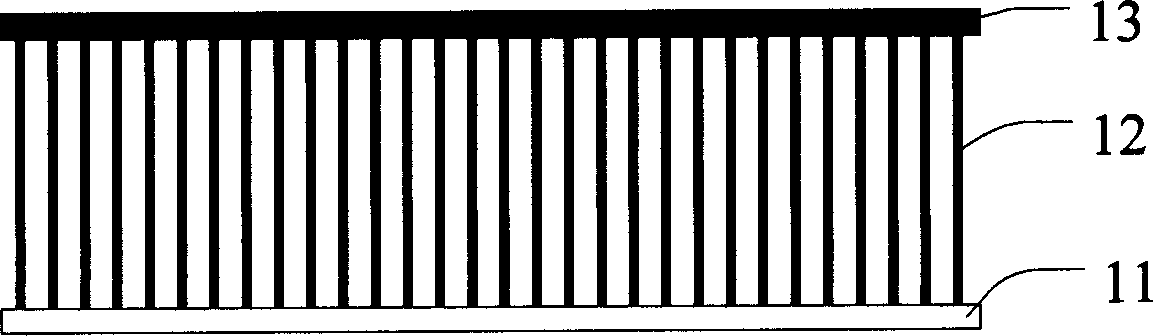

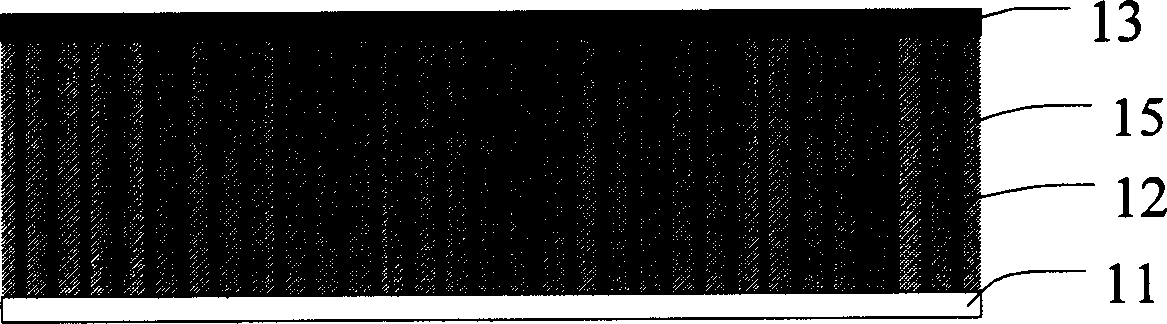

Silica gel based carbon material oriented heat conduction interface material and production method thereof

The invention relates to a silica gel based carbon material oriented heat conduction interface material. The material comprises components in percentage by weight as follows: 9.5%-20% of siloxane-based resin with the viscosity being 200 cp-2,000 cp, 19.5%-35% of heat conductive filler, 35%-70% of an anisotropic carbon material and 1%-10% of an auxiliary agent and is prepared with a stirring and curing production method. The silica gel based carbon material oriented heat conduction interface material has the advantages as follows: according to the heat conductive interface material prepared by mixing the siloxane-based resin with the viscosity being 200 cp-2,000 cp, the heat conductive filler, the anisotropic carbon material and the auxiliary agent, the anisotropic carbon material mixed in gel is orientated through electric fields on upper and lower surfaces, longitudinal orientation of the carbon material is realized, the conduction path of the heat conductive material is in the direction where the large heat conduction coefficient is large, and the heat conduction performance is realized to the maximum; with the addition of the heat conductive filler, the defect that the heat conduction performance of the carbon material in direction, perpendicular to the orientation direction, of the carbon material, namely, in the horizontal direction of mixed gel, is poor after the anisotropic carbon material is orientated is overcome, balanced conduction of heat is guaranteed, and a production method is simple.

Owner:PINGHU ALLIED IND

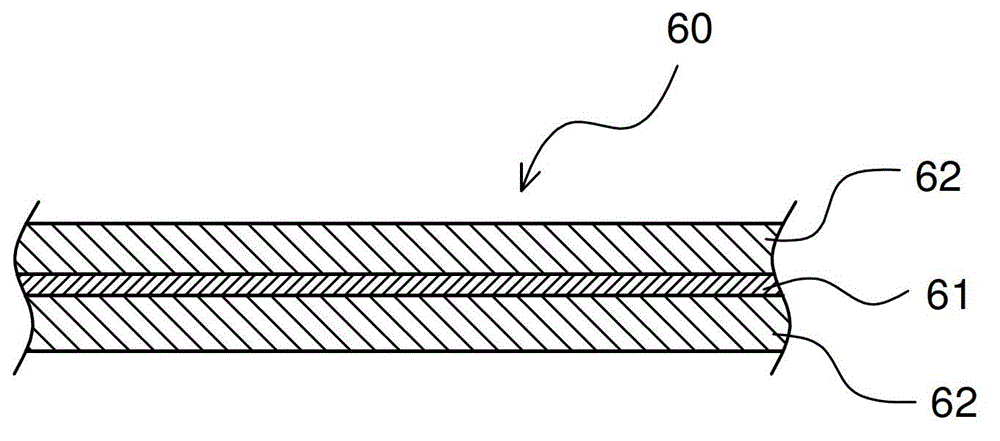

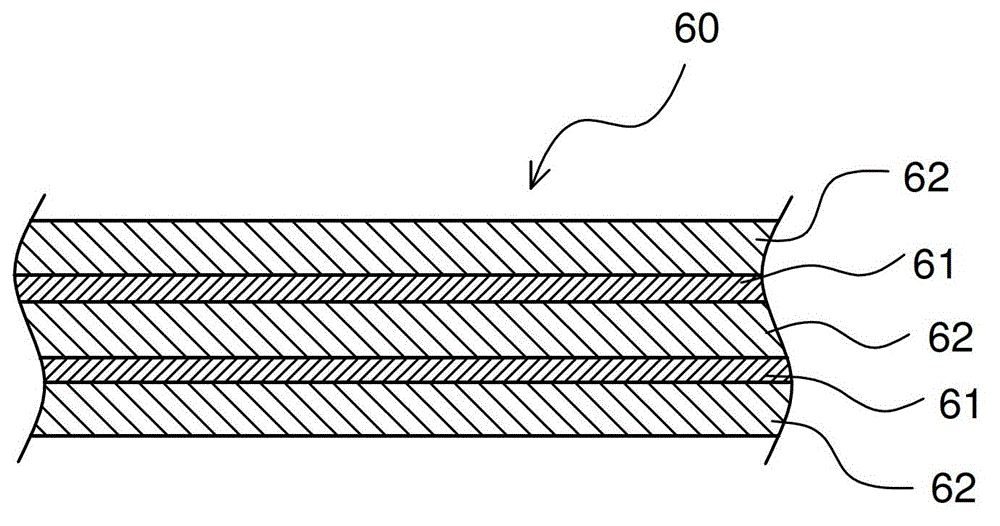

Thermal interface material and semiconductor packaging structure

InactiveCN102867793AHigh planar thermal conductivityUniform heat conductionSemiconductor/solid-state device detailsSolid-state devicesIndiumSemiconductor package

The invention discloses a thermal interface material and a semiconductor packaging structure. The semiconductor packaging structure comprises a substrate, a chip and a heat dissipation plate. The chip is arranged on the substrate, and the heat dissipation plate is arranged on the chip. The thermal interface material is contained between the chip and the heat dissipation plate; the thermal interface material comprises a grapheme layer and two low-melting-point metal layers; the two low-melting-point metal layers are covered on the grapheme layer from top to bottom. According to the thermal interface material and the semiconductor packaging structure, the flat heat-transfer efficiency between the chip and the heat dissipation plate can be improved through the grapheme material with high thermal conductivity; and the cost is lower than that of the thermal interface material using pure indium.

Owner:ADVANCED SEMICON ENG INC

Thermo-curable 3D printing photosensitive resin and preparation method thereof

ActiveCN106947034AIncrease activation energyHigh tensile strengthAdditive manufacturing apparatus3D object support structuresDecompositionHalf-life

The invention discloses a thermo-curable 3D printing photosensitive resin and a preparation method and an application thereof. The photosensitive resin includes, by weight, 50-70 parts of a prepolymer, 30-50 parts of a diluent, 1-5 parts of a photo-initiator and 0.5-5 parts of a thermal-initiator, wherein the decomposition temperature of the thermal-initiator is higher than or equal to 100 DEG C when the half-life period thereof is 1 h. After photo-curing 3D printing shaping, the 3D printing photosensitive resin can be subjected to curing by heating as a post-curing method with a stable constant temperature heating device, such as a drying box and the like, so that the 3D printing photosensitive resin develops application in a non-transparent sample, a sample having complex shape, an ultra-thick sample, a colored sample and the like, and enables the samples to have better mechanical performances.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

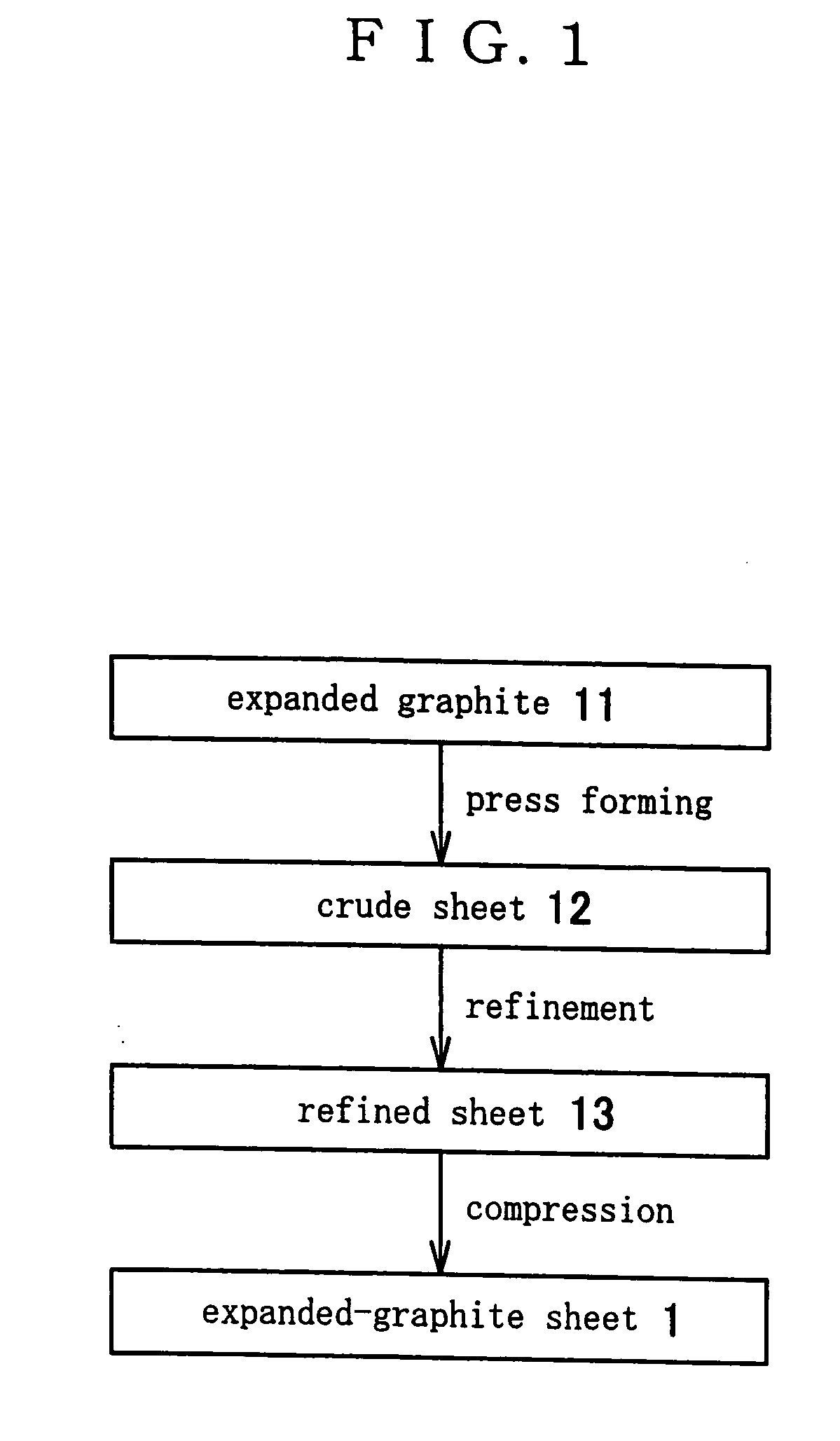

Thermal interface material producing method

ActiveCN1848414AThermal conductivity performanceUniform heat conductionNanotechSemiconductor/solid-state device detailsCarbon nanotubeMaterials science

The present invention provides a preparation method of thermal interface material. Said method includes the following steps: providing a carbon nano tube array, using phase change material to fill the gap of the described carbon nano tube array so as to form composite phase change material; along the direction crossed with the described carbon nano tube array cutting the described phase change material into slab with predefined thickness; heating the described composite phase change material slab to the temperature above the phase change temperature of said phase change material, making two ends of the described carbon nano tube array be exposed from said phase change material, then cooling the described composite phase change material slab so as to form thermal interface material.

Owner:TSINGHUA UNIV +1

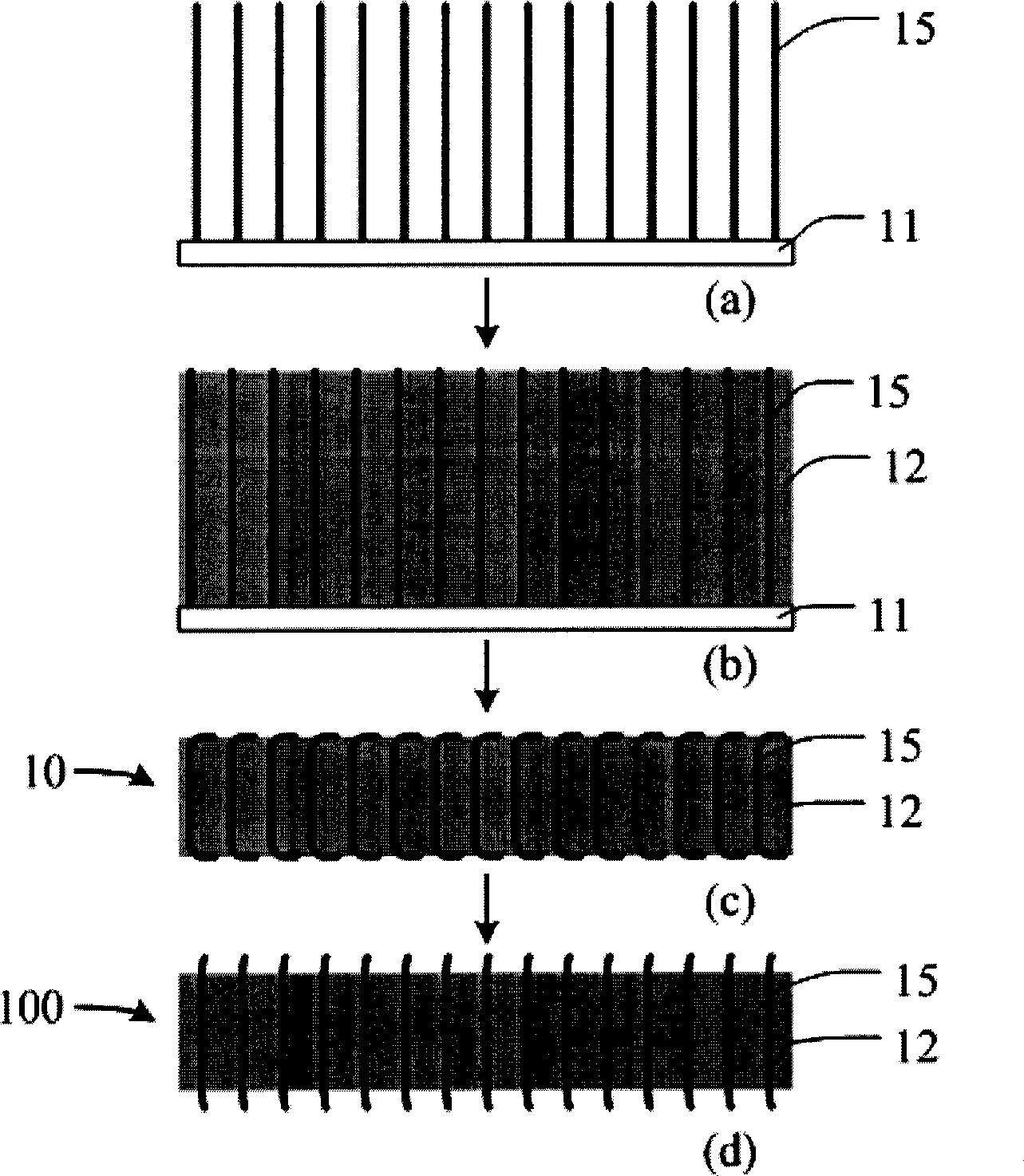

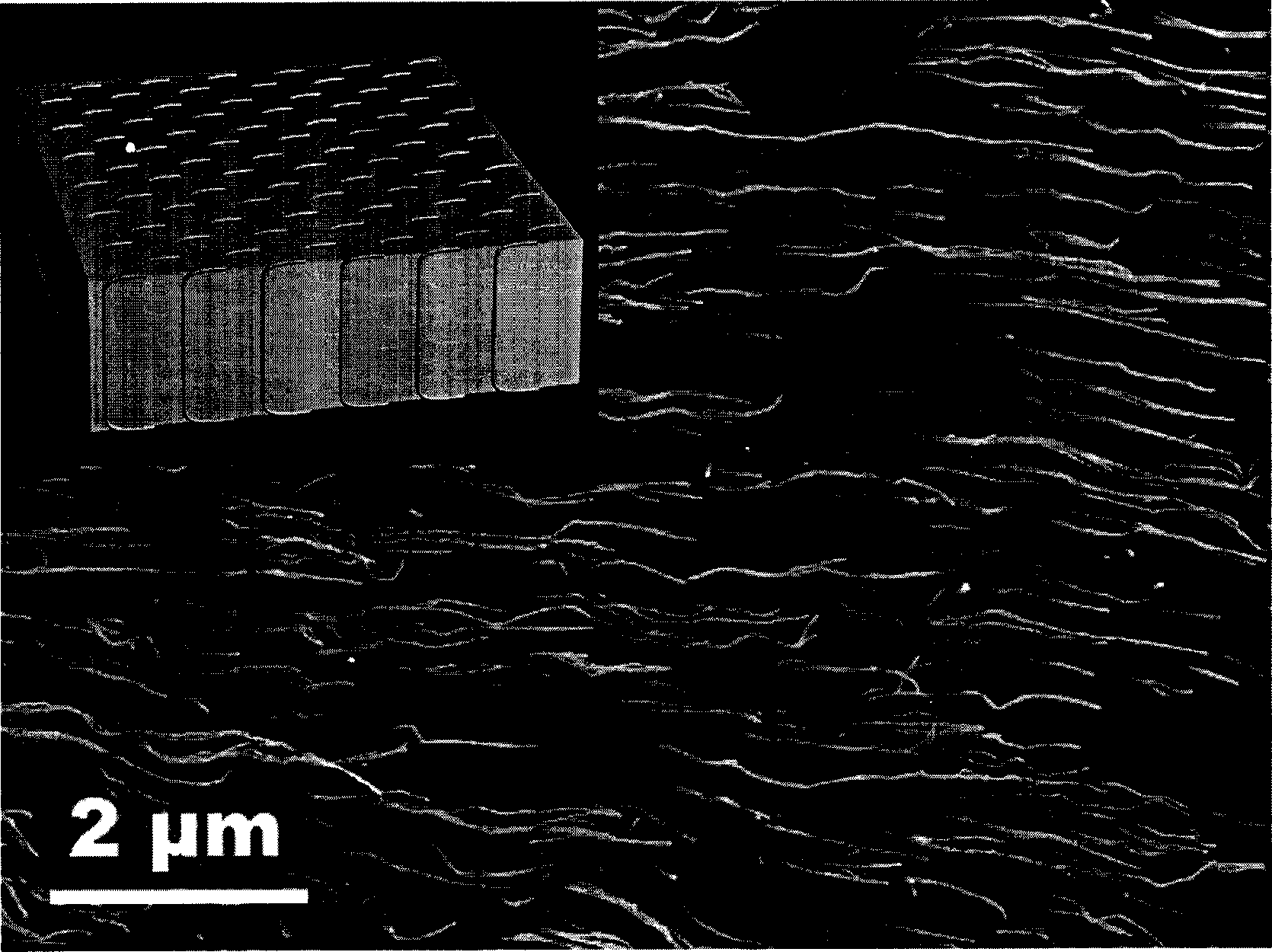

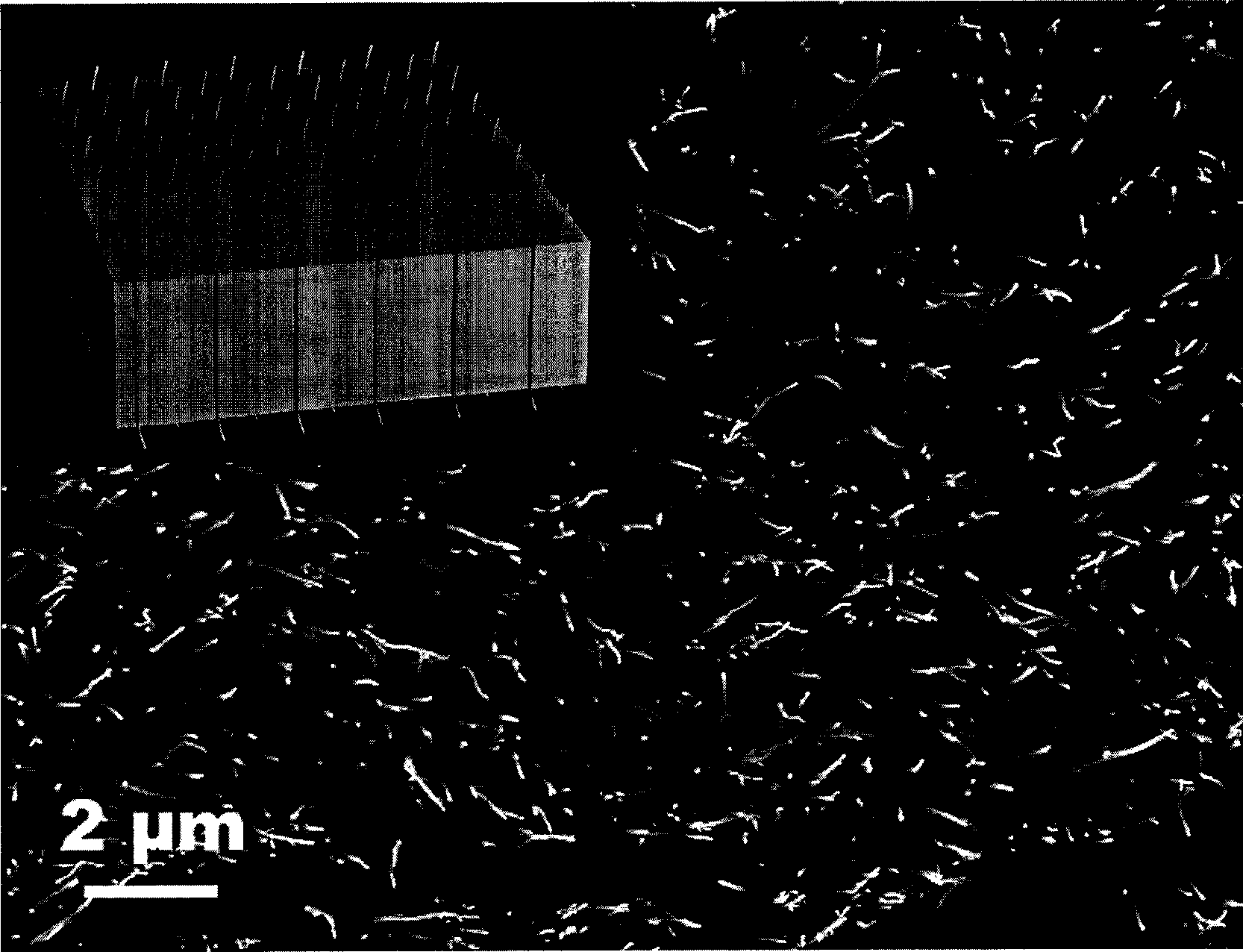

Expanded-graphite sheet

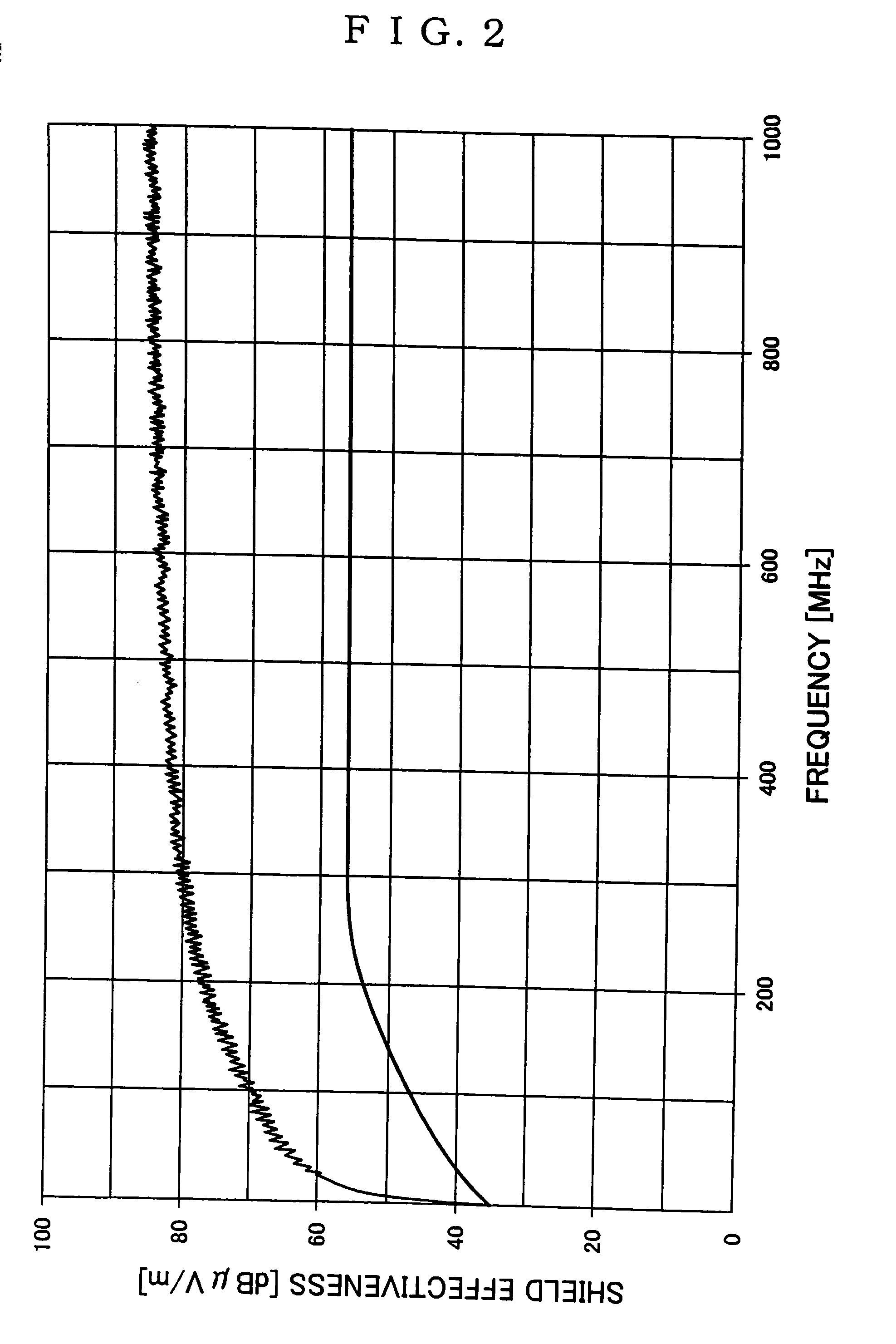

InactiveUS20070110661A1Easy to produceImprove thermal conductivityGraphiteMagnetic/electric field screeningGraphitePerpendicular direction

This invention provides an expanded-graphite sheet whose thermal conductivity in their surfacewise directions is relatively uniform and higher than its thermal conductivity in perpendicular direction and which can be produced efficiently at relatively low cost. Because the expanded-graphite sheet is made of expanded graphite alone and has the thermal conductivities in parallel direction of 350 W / (m·K) or more, its thermal conductivities in parallel direction is much higher than its thermal conductivity in perpendicular direction; therefore, it is suitable for the conduction and diffusion of heat. Besides, the expanded-graphite sheet can be produced easily, in a short time, efficiently, at relatively low cost.

Owner:TOYO TANSO KK

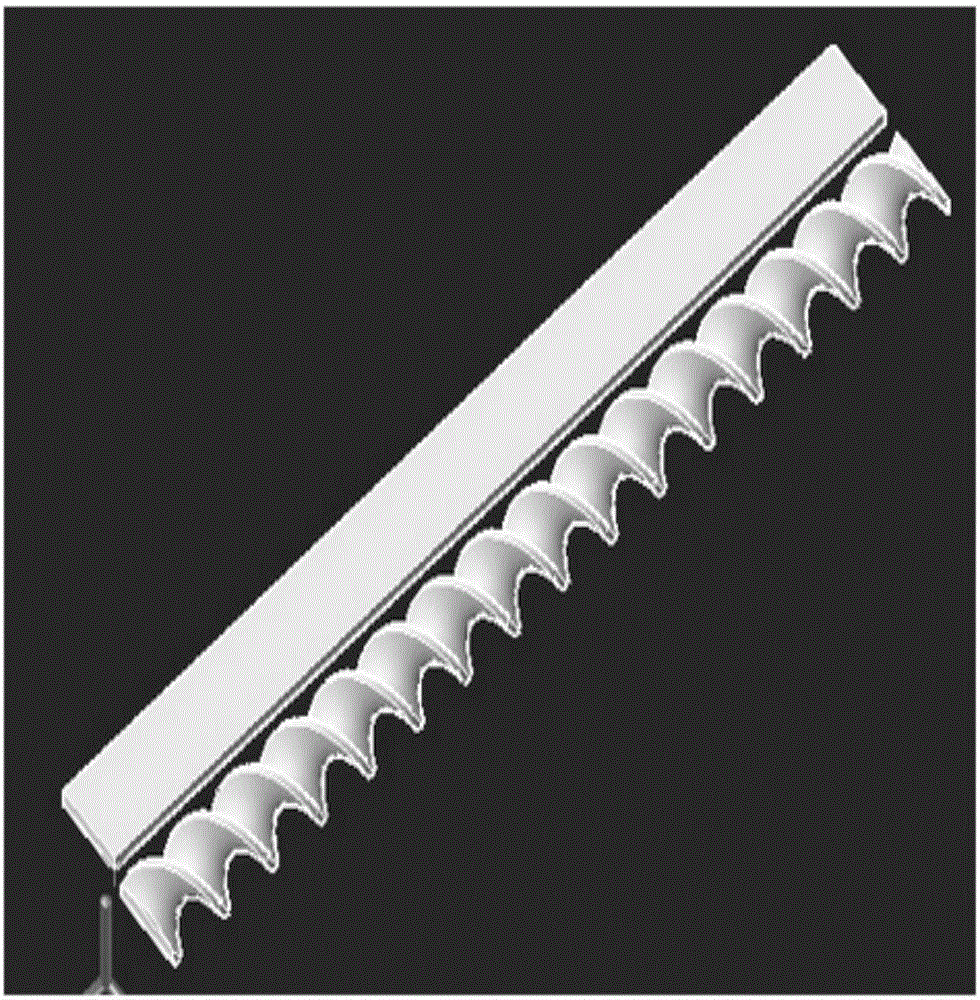

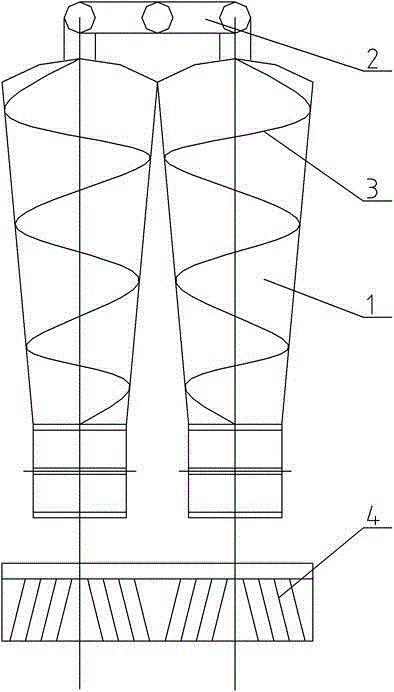

Spiral-body-enhanced metal-based or polymer-based composite and preparation method

ActiveCN105803241AIncrease binding areaAvoid breakingVacuum evaporation coatingSputtering coatingGas phaseCarbon nanotube

The invention provides a spiral-body-enhanced metal-based or polymer-based composite and a preparation method. The composite is formed by distributing an array formed by a plurality of spiral enhancing bodies in a metal matrix and combining the surface-modified spiral enhancing bodies with the metal matrix in a metallurgical manner. The metal matrix is made of frequently-used electronic packaging metal materials such as Al, Cu and Ag. The spiral enhancing bodies are formed by depositing diamond on a spiral-body-shaped substrate through a chemical vapor deposition method to obtain lining supporting diamond spiral bodies, and graphene or carbon nanotubes grow in the direction perpendicular to the surface to obtain a spiral diamond heat conductor structure with a vertical-array graphene wall or a carbon nanotube forest on the surface. The high-heat-conductivity composite is obtained by distributing the spiral enhancing bodies in the metal matrix to form an array and adding enhancing particles to further improve the heat conductivity. The composite can be used as electronic packaging, heat sink materials and the like, and the packaging problems of high-temperature, high-frequency and high-power electronic devices are solved.

Owner:CENT SOUTH UNIV

Thermal interface material, and its preparing method

ActiveCN1891780AThermal conductivity performanceImprove thermal conductivityNanotechSolid-state devicesHeat flowCarbon nanotube

The invention offers heat interface material. It includes many carbon nanometer tubes, polymeric material which is set between the carbon nanometer tubes, at least one heat flow collectors which are connected to the carbon nanometer tube. The heat flow collector can reduce thermal contact resistance and be good for the heat conduction of the carbon nanometer tube. And the invention also offers the manufacturing method of the heat interface material.

Owner:TSINGHUA UNIV +1

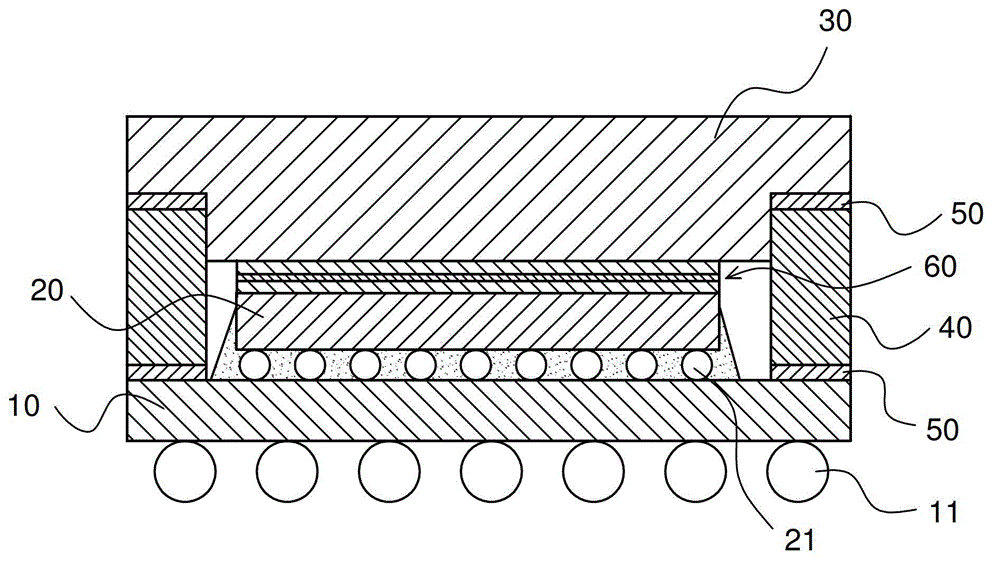

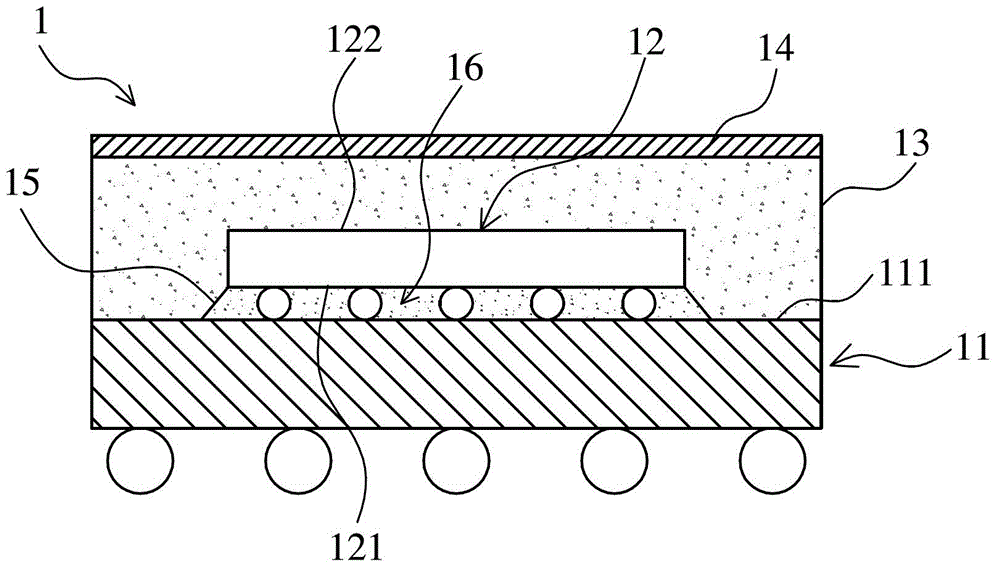

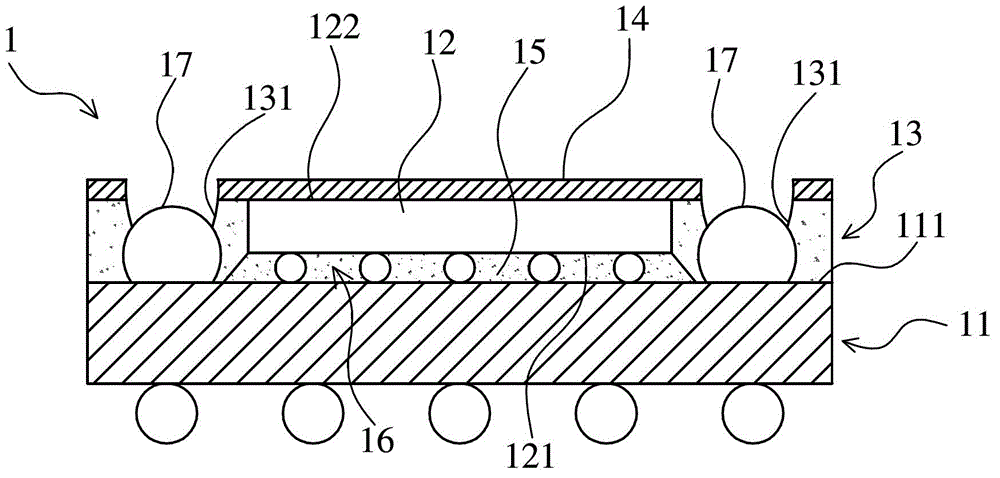

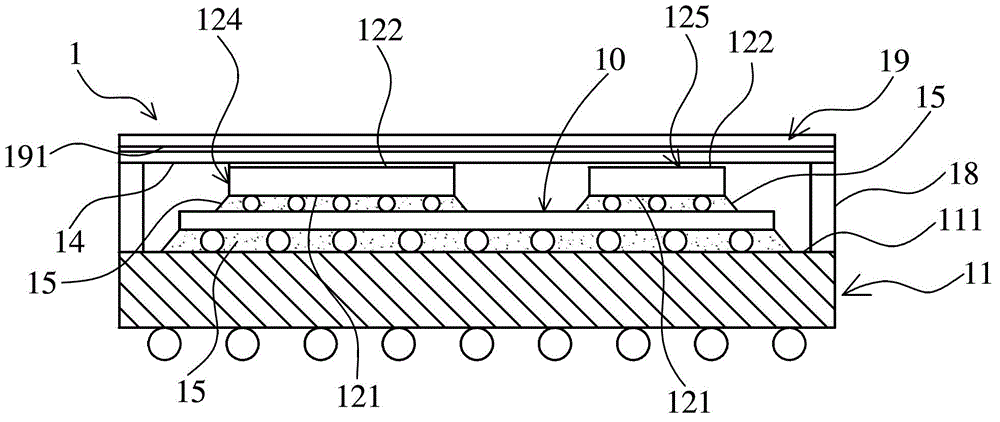

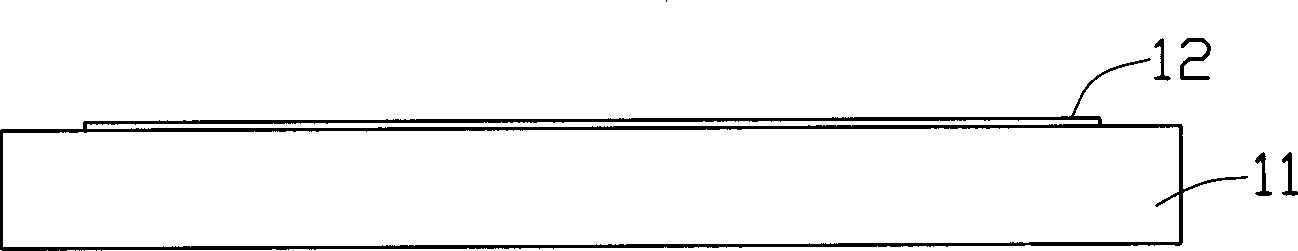

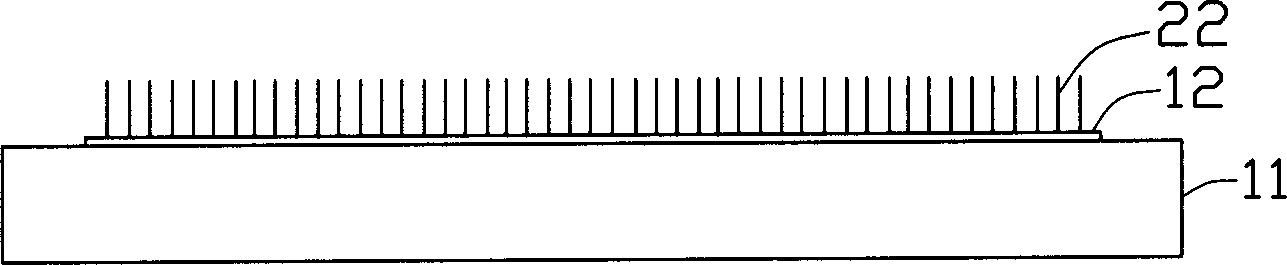

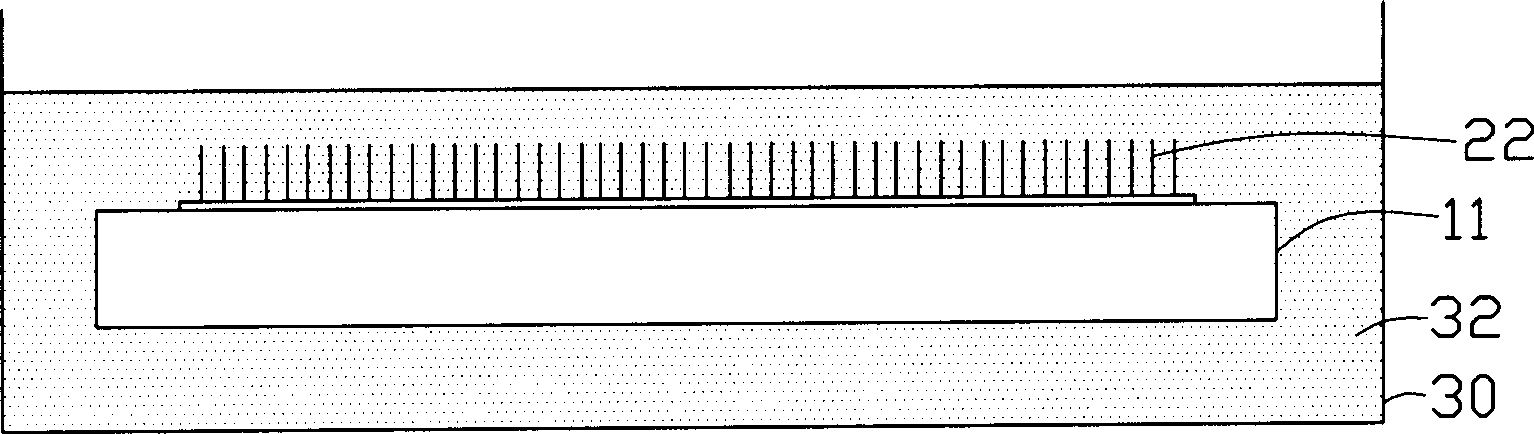

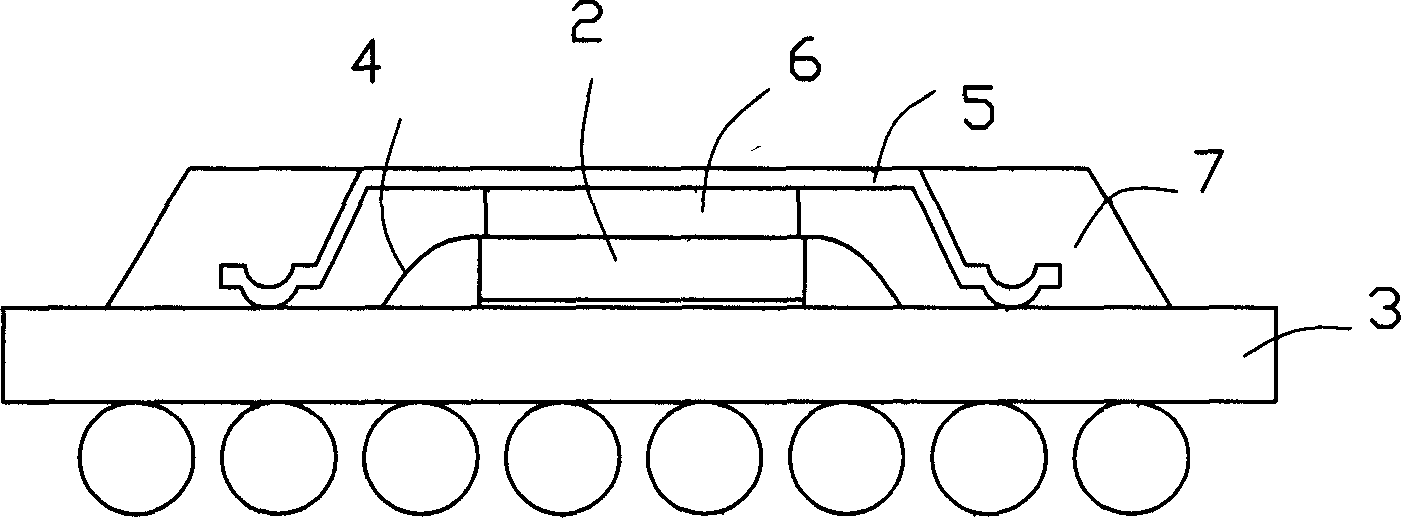

Semiconductor packaging structure

InactiveCN102881667ASolve for uniformitySolve the costSemiconductor/solid-state device detailsSolid-state devicesHeat conductingSemiconductor package

The invention discloses a semiconductor packaging structure which comprises a substrate, at least one chip, a packaging colloid and a grapheme layer. The grapheme layer is arranged on the packaging colloid or arranged on the surface e of the chip. By means of the grapheme layer, the semiconductor packaging structure has high planarity heat-conductivity coefficient, facilities lateral heat conductivity, increases even conduction of heat and heat exchange area, and further improves the heat conducting-out efficiency of the chip.

Owner:ADVANCED SEMICON ENG INC

Method for preparing nanometer glass fiber thermal insulation material by flame method

ActiveCN101694079ALow thermal conductivityLarge specific surface areaGlass making apparatusPulp beating methodsGlass fiberAlkali free

The invention discloses a method for preparing a nanometer glass fiber thermal insulation material by a flame method. The method for preparing the nanometer glass fiber thermal insulation material comprises the following steps: (1) taking high-alkali glass beads or alkali-free glass beads as materials and adopting a flame injection-blowing technology to prepare glass fiber; (2) conducting pulping-dispersing on 25-30% by weight of high-alkali glass fiber with average diameter of 2-3mum, 30-40% by weight of high-alkali glass fiber with average diameter of 1-2mum, 20-30% by weight of high-alkali glass fiber with average diameter of 0.3-0.5mum and 15-20% by weight of alkali-free glass fiber with average diameter of 0.1-0.3mum; (3) conducting wet forming on pulp and then conducting suction dehydration; and (4) drying the obtained wet paper at the temperature of 200-300 DEG C, thus obtaining the product. The thermal insulation material has large specific surface area, low heat conduction coefficient and good thermal insulation effect; in addition, the thermal insulation material is natural raw mineral material and does not contain any hazardous substance.

Owner:宣汉正原微玻纤有限公司

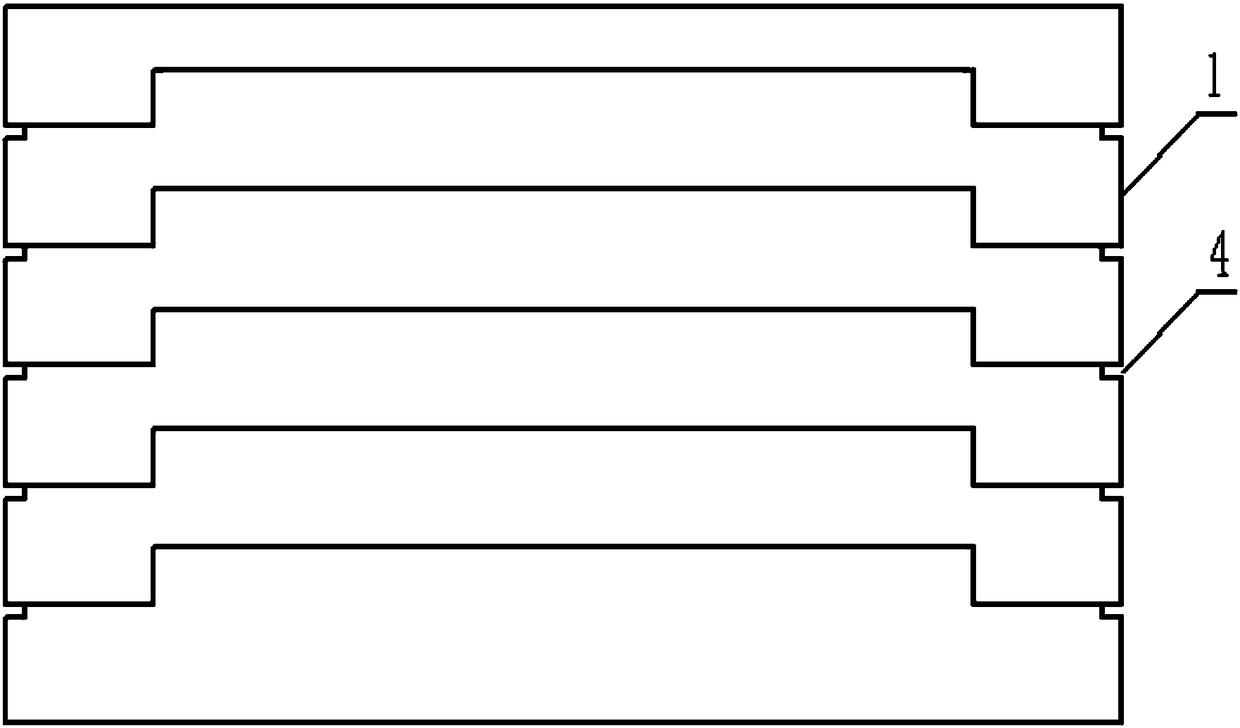

Thermal-interface material and production thereof

ActiveCN1681381AThermal conductivity performanceUniform heat conductionMaterial nanotechnologySemiconductor/solid-state device detailsCarbon nanotubePolymer composite materials

Owner:TSINGHUA UNIV +1

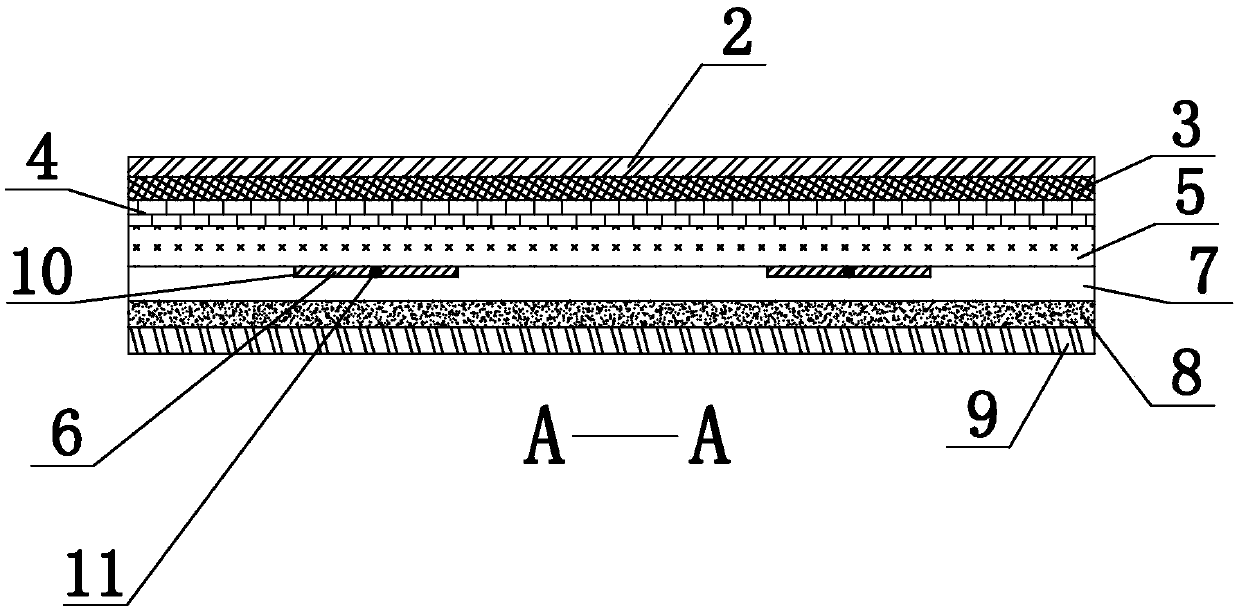

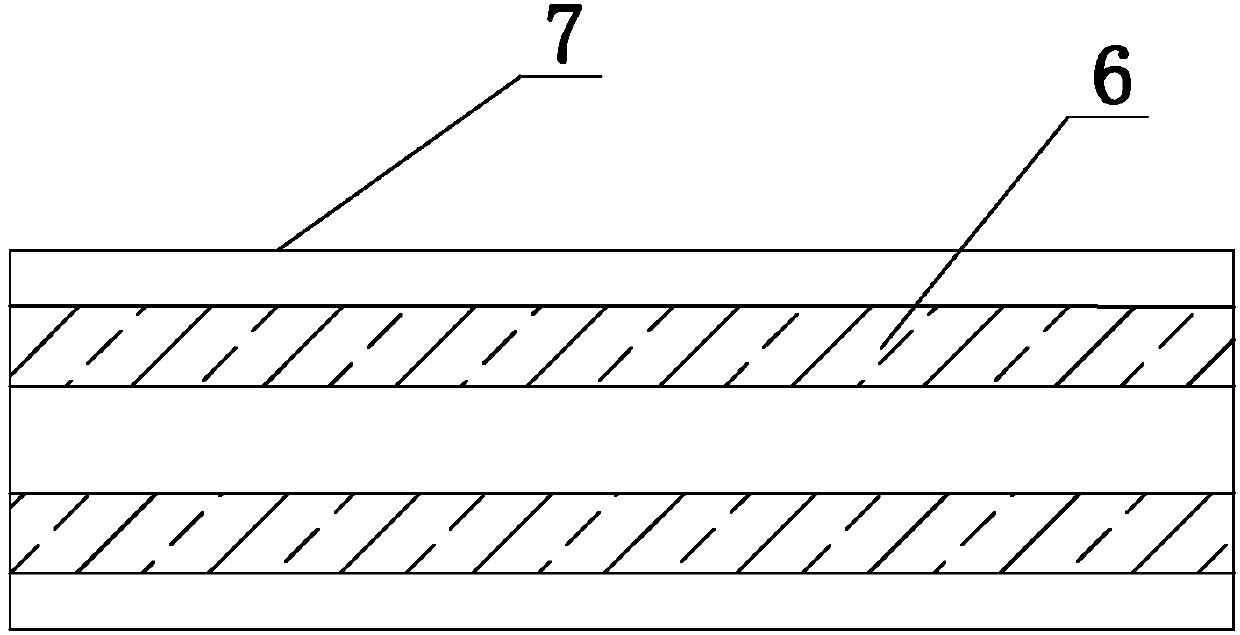

Graphene spontaneous heating floor, manufacturing method and low-voltage spontaneous heating floor system

ActiveCN107631344AHeating up fastUniform heat conductionLighting and heating apparatusElectric heating systemEngineeringFar infrared

The invention provides a graphene spontaneous heating floor, a manufacturing method and a low-voltage spontaneous heating floor system. The graphene spontaneous heating floor sequentially comprises anabrasion resisting layer, a surface decoration layer, an upper insulation inflaming retarding and temperature resisting waterproof layer, an upper base material floor layer, a lower base material floor layer, a lower insulation inflaming retarding and temperature resisting waterproof layer and a heat insulation layer from top to bottom. The upper surface of the lower base material floor layer isprovided with at least one groove. The grooves are internally paved with graphene heating elements and conducting circuits. The two ends of each conducting circuit are connected with connector clips.The connector clips of each conducting circuit are both connected with an independent control unit. The upper surface of the upper base material floor layer is provided with a plurality of blind holes, and magnet columns are embedded into the blind holes. The graphene spontaneous heating floor has the beneficial effects that a graphene material is adopted for conducting heat, the temperature is raised quickly, and heat conduction is uniform; and each floor is an intelligently-integrated independent unit, zone control of the indoor temperature is achieved, the energy consumption is reduced, andthe service life of the floor is prolonged; and graphene releases far infrared rays, by cooperating with the magnet therapy characteristics of magnets, the graphene spontaneous heating floor strengthens the physical body, protects health and is beneficial to family health.

Owner:戴明

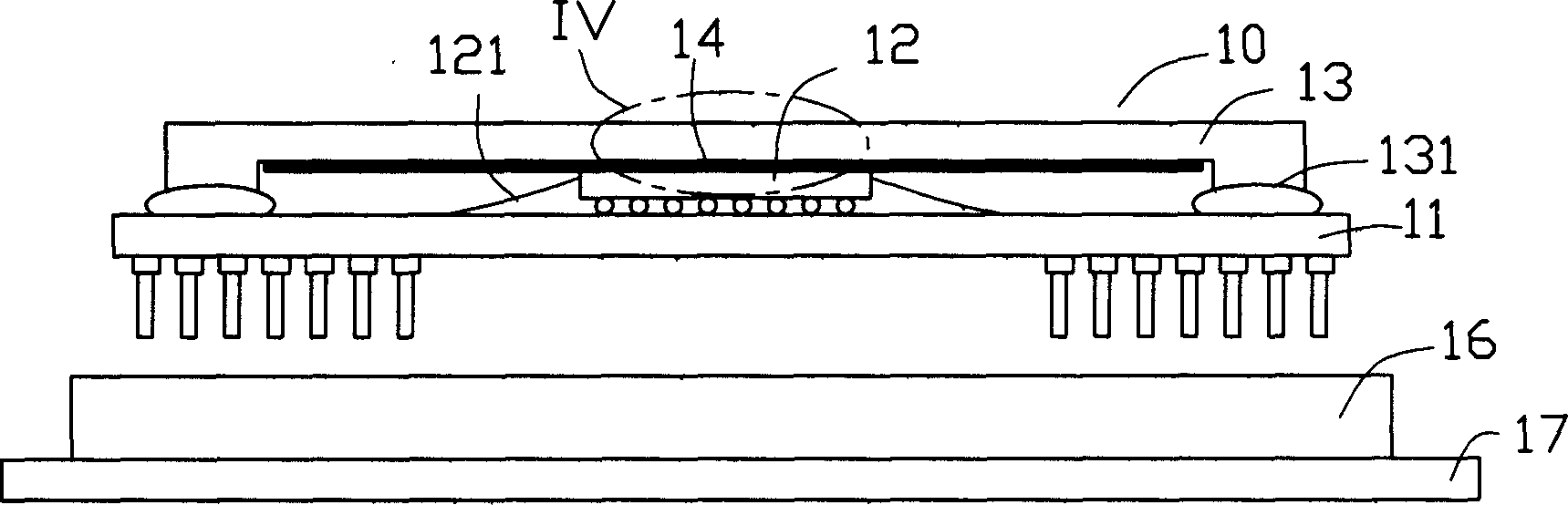

Integrated circuit packaging structure and manufacturing method thereof

InactiveCN1734754AImprove thermal conductivityImprove efficiencySemiconductor/solid-state device detailsSolid-state devicesCarbon nanotubeEngineering

The IC package structure comprises a base plate, an IC on base plate, an integrated heat sink plate composed of inner and outer surfaces that is arranged on top of IC chip with edge lower end fixed on base, and a carbon nano pipe array formed on the said inner surface with two ends vertical contact to integrated heat sink plate and IC chip; wherein, there is nano metal material of high thermal conductivity filled in the said pipe.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

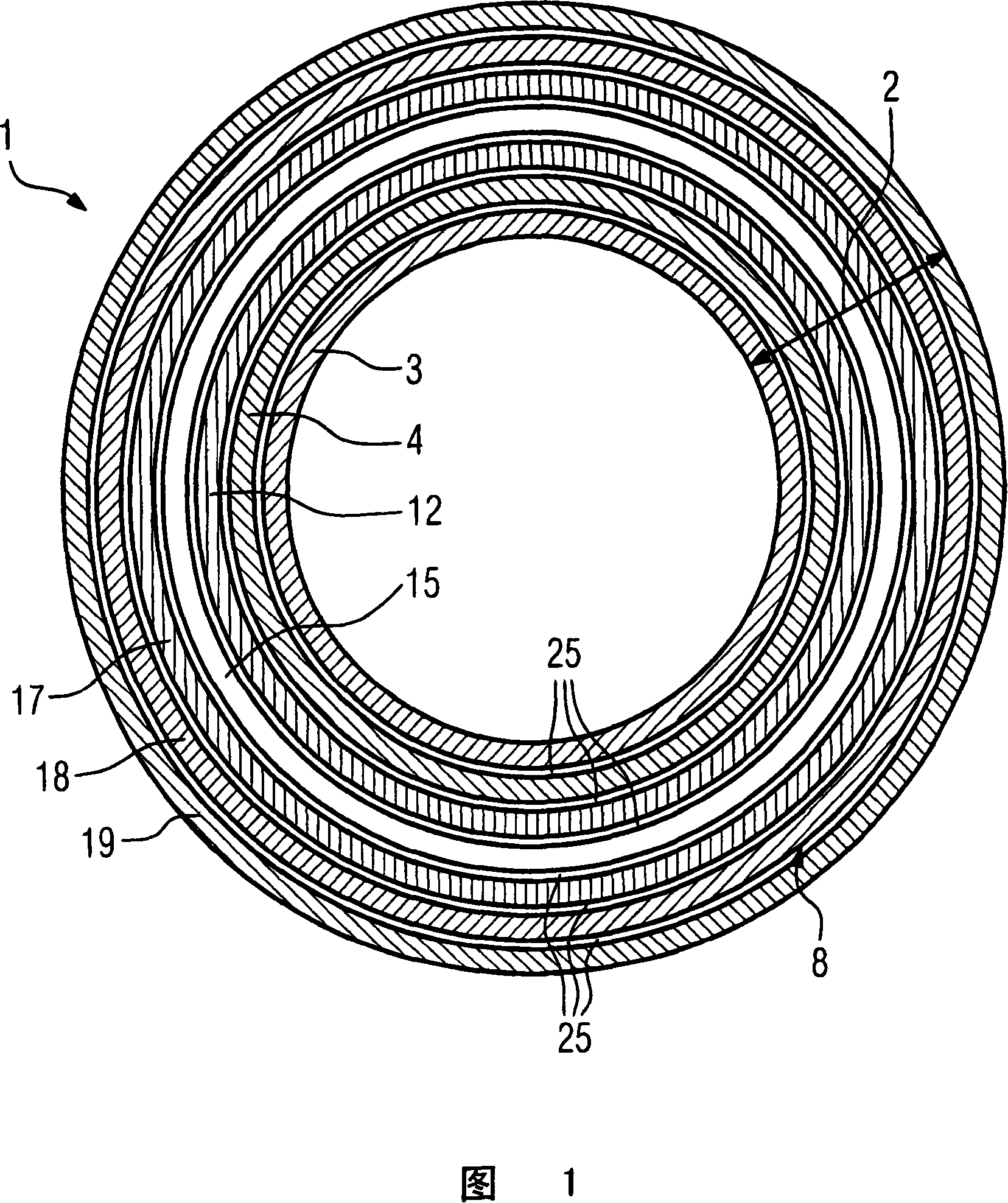

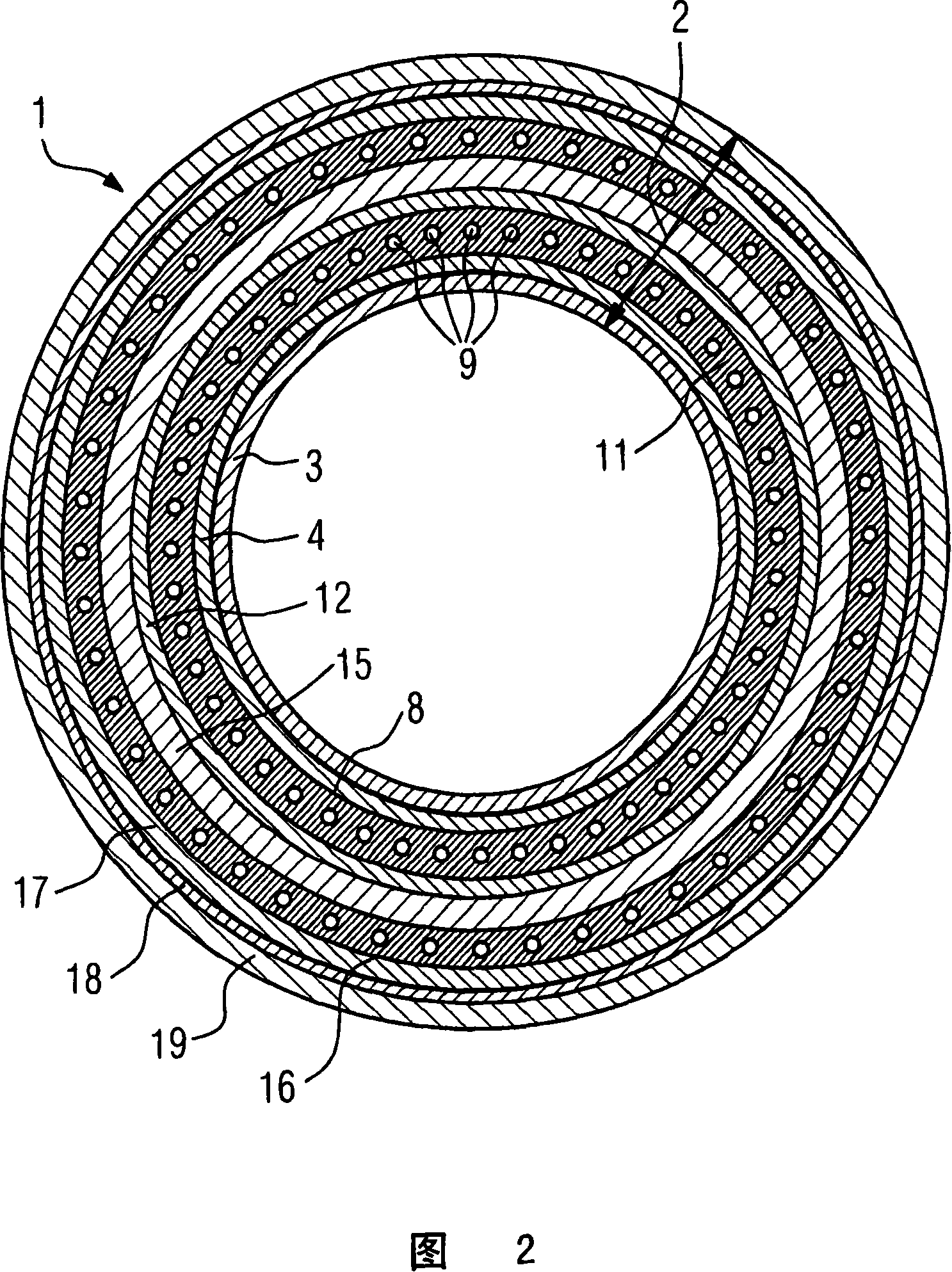

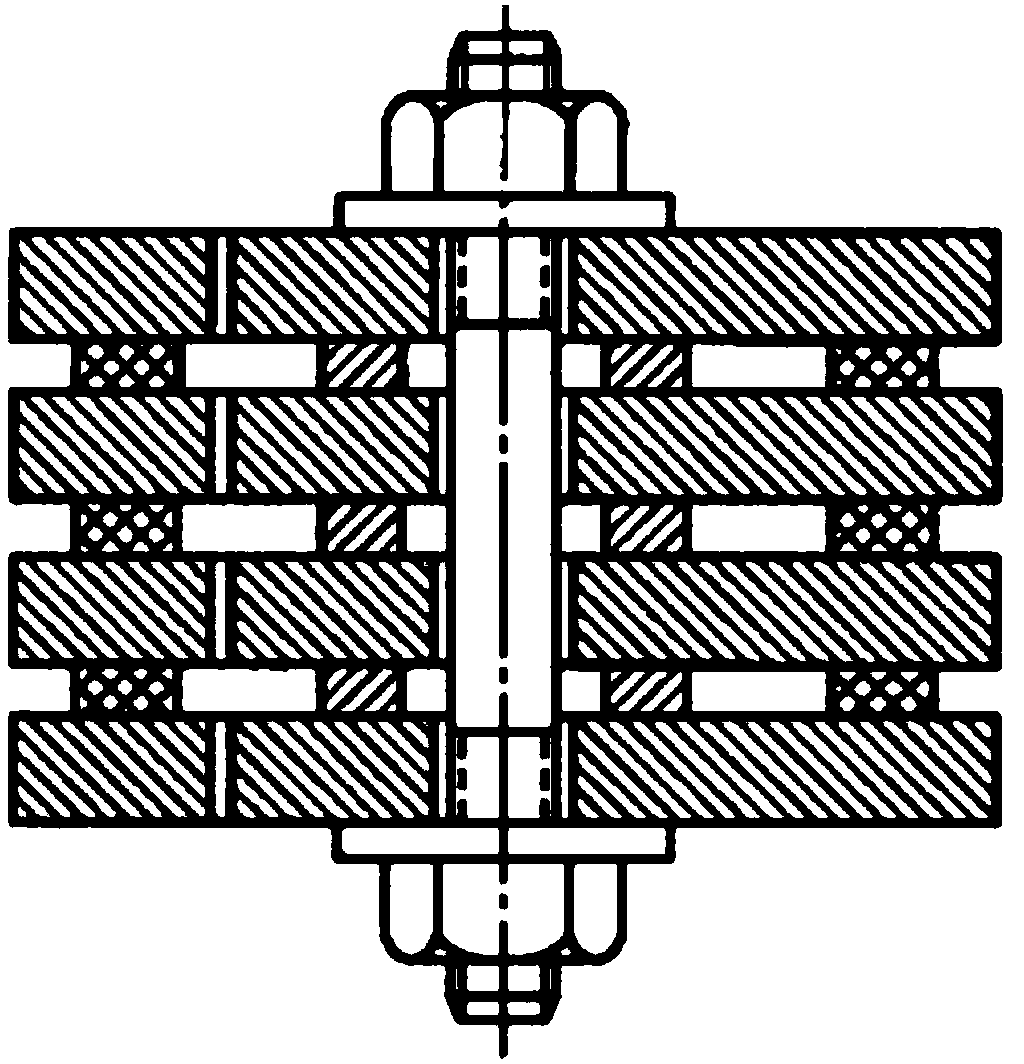

Gradient coil system and magnetic resonance chromatography X-ray camera

ActiveCN101122632AFast heat conductionEasy to installTransformers/inductances coolingMagnetic measurementsPlate heat exchangerResonance

A gradient coil system for a magnetic resonance tomography apparatus has a layer structure including a gradient coil layer and a cooling layer. The cooling layer is fashioned as a plate heat exchanger, composed of plates, for cooling the gradient coil layer. In this way, a highly efficient cooling of the gradient coil layer is achieved with a lower structural height compared to conventional tubular configurations.

Owner:SIEMENS HEALTHCARE GMBH

Composite graphene microchip heat dissipation master batch and preparation method and application thereof

ActiveCN105694102ASolving Dispersion ProblemsImprove mechanical propertiesMasterbatchContinuous reactor

The invention relates to the field of graphene materials, in particular to a composite graphene microchip heat dissipation master batch. According to the defects that due to the fact that graphene powder which is directly added to and applied in plastics is difficult to disperse, heat dispersion is affected, and agglomeration is prone to occur in graphene preparation and storage, a screw extruder is utilized to serve as a continuous reactor, the graphene powder is subjected to stripping at the same time of being subjected to dispersion and fixation through three-dimensional porous inorganic matter, and a heat conduction network is formed through continuous polymerization. The defects that agglomeration is prone to occur in graphene preparation and storage, and dispersion is difficult to achieve in the application process are overcome. Therefore, application of graphene serving as an efficient heat dispersing material in the field of the plastics is promoted. The composite graphene microchip heat dissipation master batch can be directly added for use just like ordinary master batches in the field of the plastics, is widely applied to high-load rubber tire heat dissipation, rubber pad heat dissipation, electronic component joint heat dissipation, LED heat dissipation and the like and has a wide market prospect.

Owner:陕西千弘同高信息科技有限公司

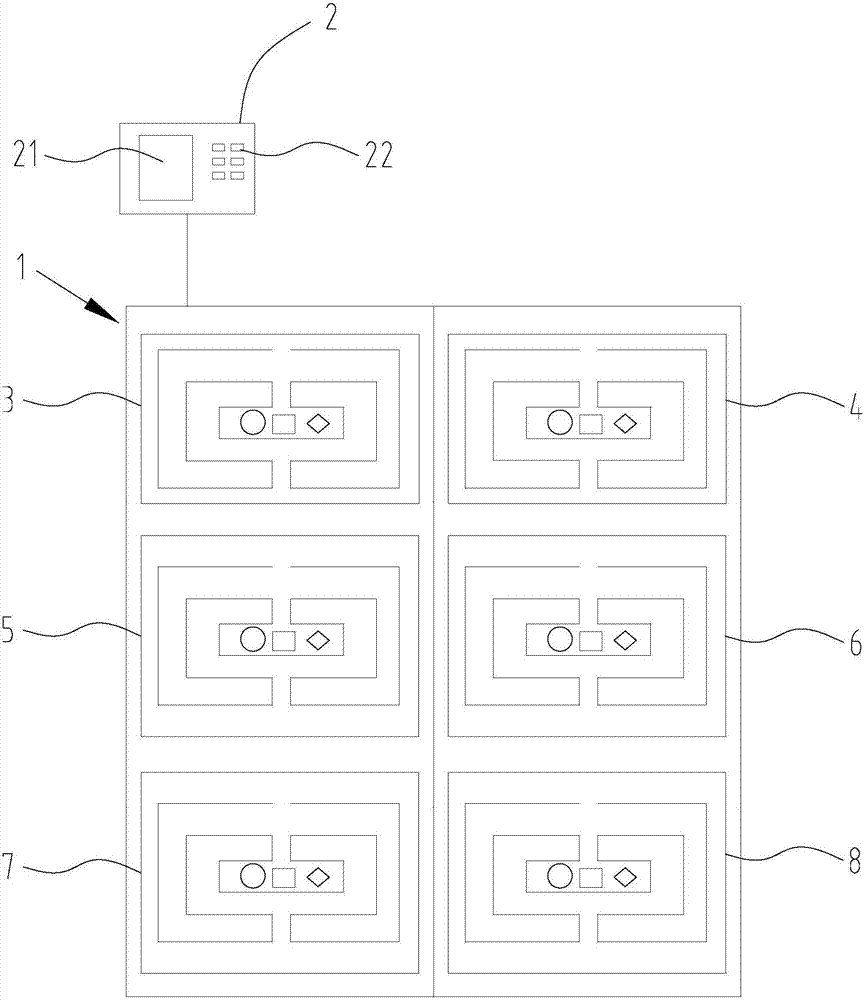

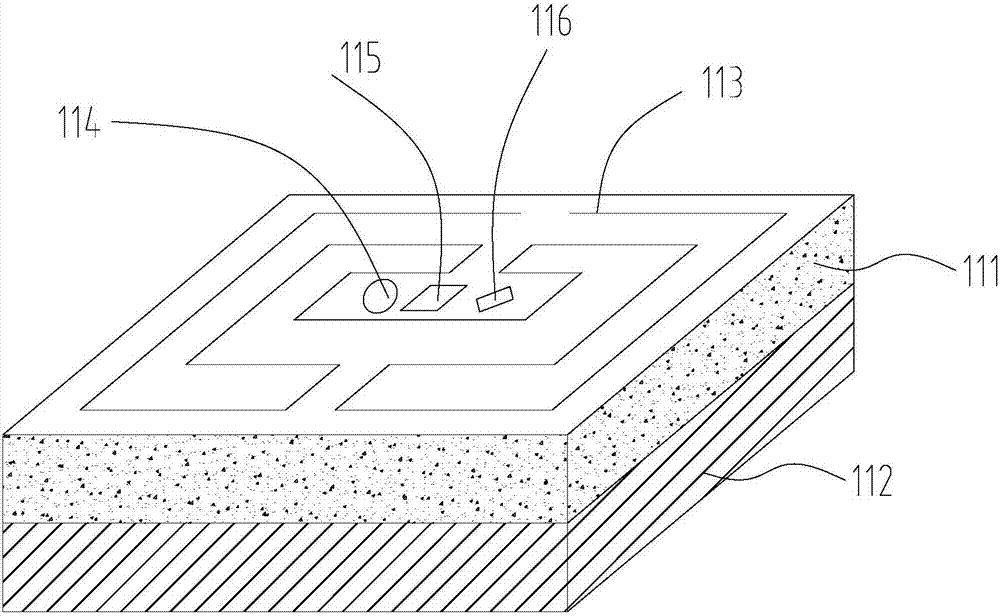

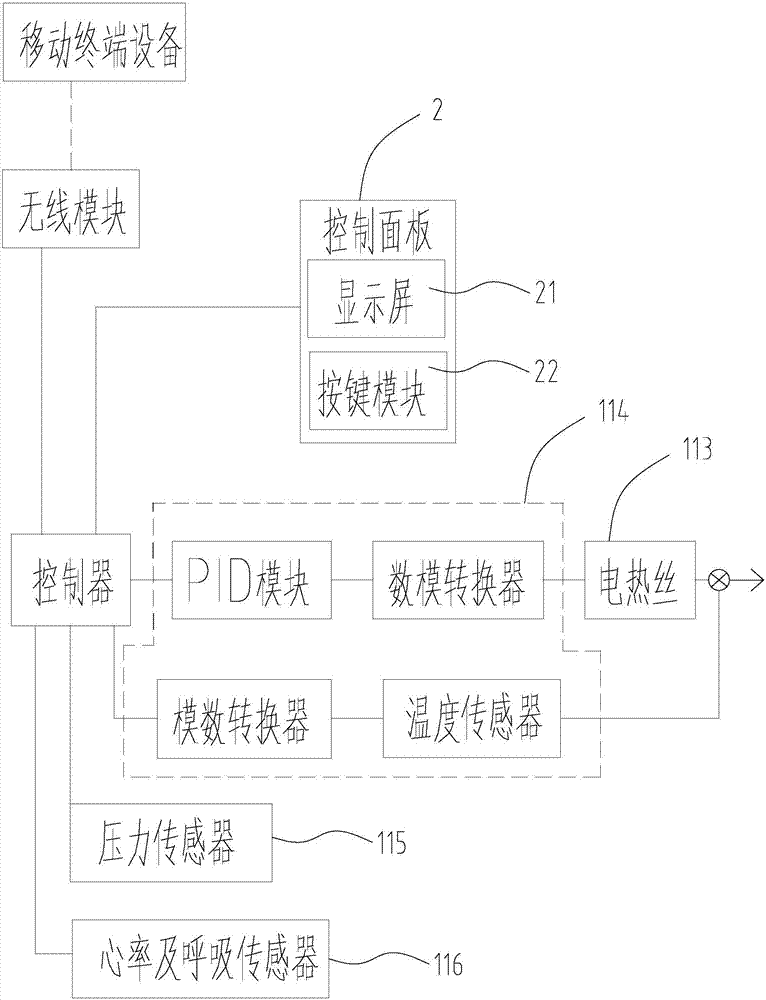

Intelligent graphene electric blanket and controlling system thereof

InactiveCN106937412AImprove thermal conductivityUniform heat conductionOhmic-resistance heating detailsHeating element materialsElectricityTemperature control

The invention relates to an intelligent graphene electric blanket comprising an insulated heat-conduction outer sleeve, a controller, a power supply, a control panel, and a plurality of electric blanket core bodies coated inside the insulated heat-conduction outer sleeve. The electric blanket core bodies consist of cloth bottom layers, graphene coating layers coating the cloth bottom layers, and heating wires seamed at the graphene coating layers; and temperature control modules, pressure sensors and heart rate and respiratory sensors are arranged at the graphene coating layers of the electric blanket core bodies. The controller and the power supply are arranged inside the control panel; and the power supply provides power for the controller and the power supply is connected with commercial power. The temperature control modules, the pressure sensors, the heart rate and respiratory sensors, and the heating wires that are arranged at the graphene coating layers are connected with the controller respectively. Therefore, problems that heat conduction of the existing electric blanket is not realized uniformly, the specific part of the electric blanket can not heated, and electric blanket controlling can not be carried out intelligently can be solved.

Owner:泉州信和石墨烯研究院有限公司

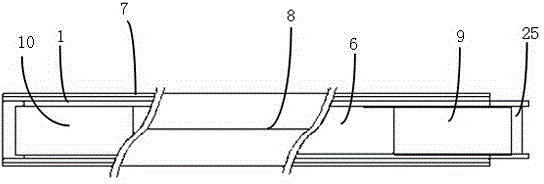

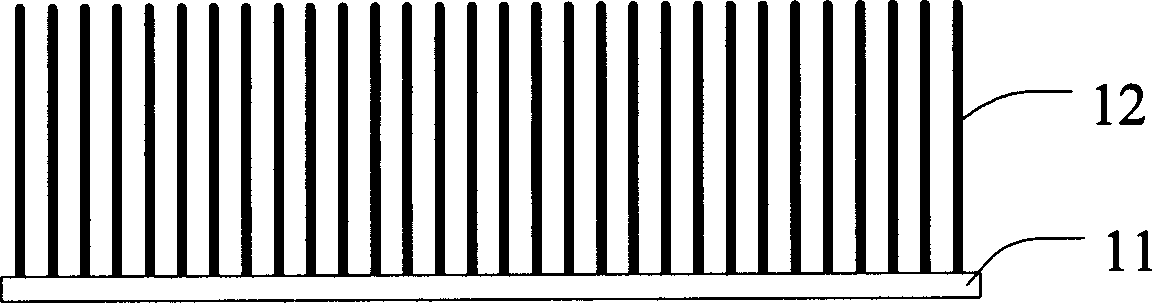

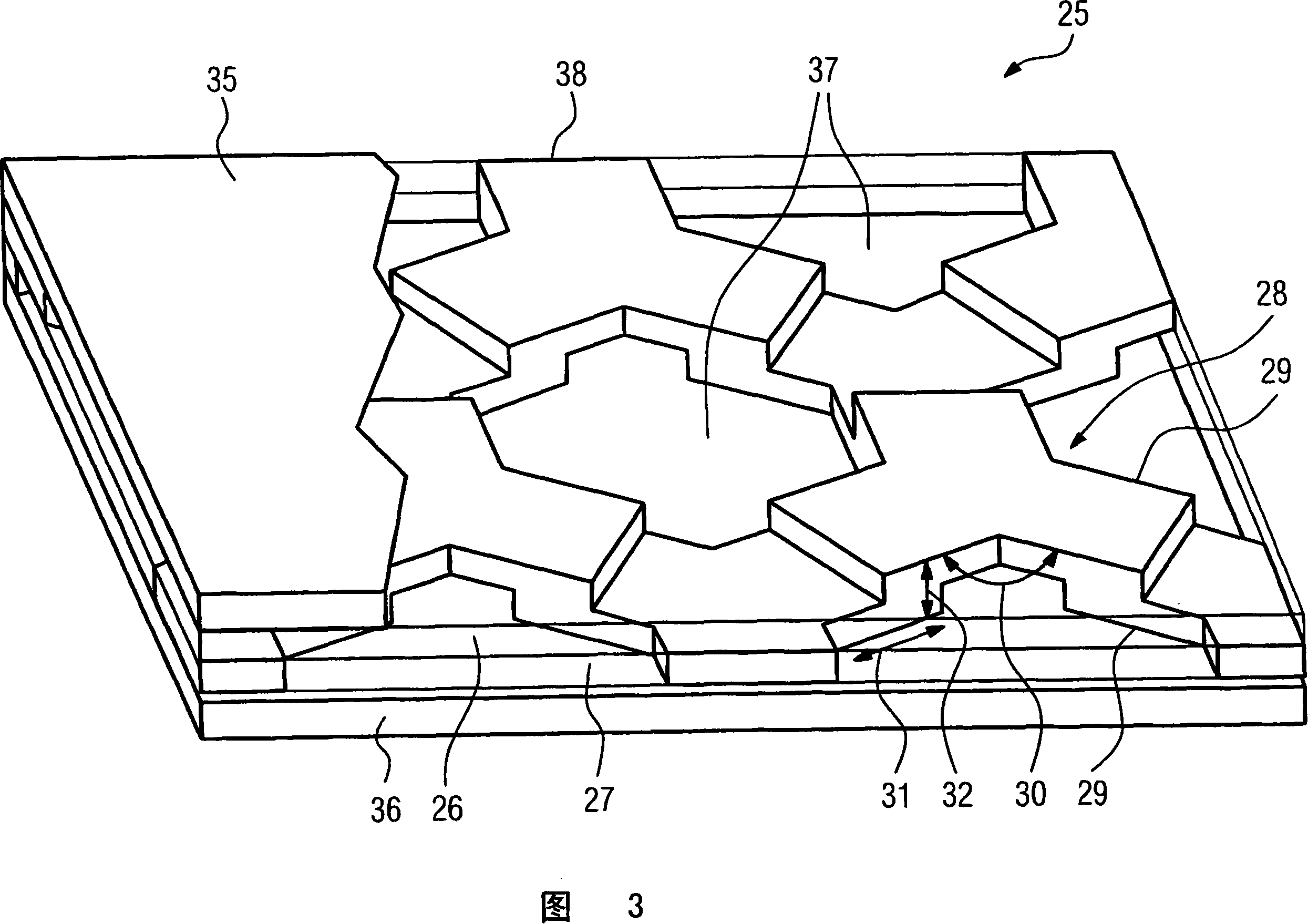

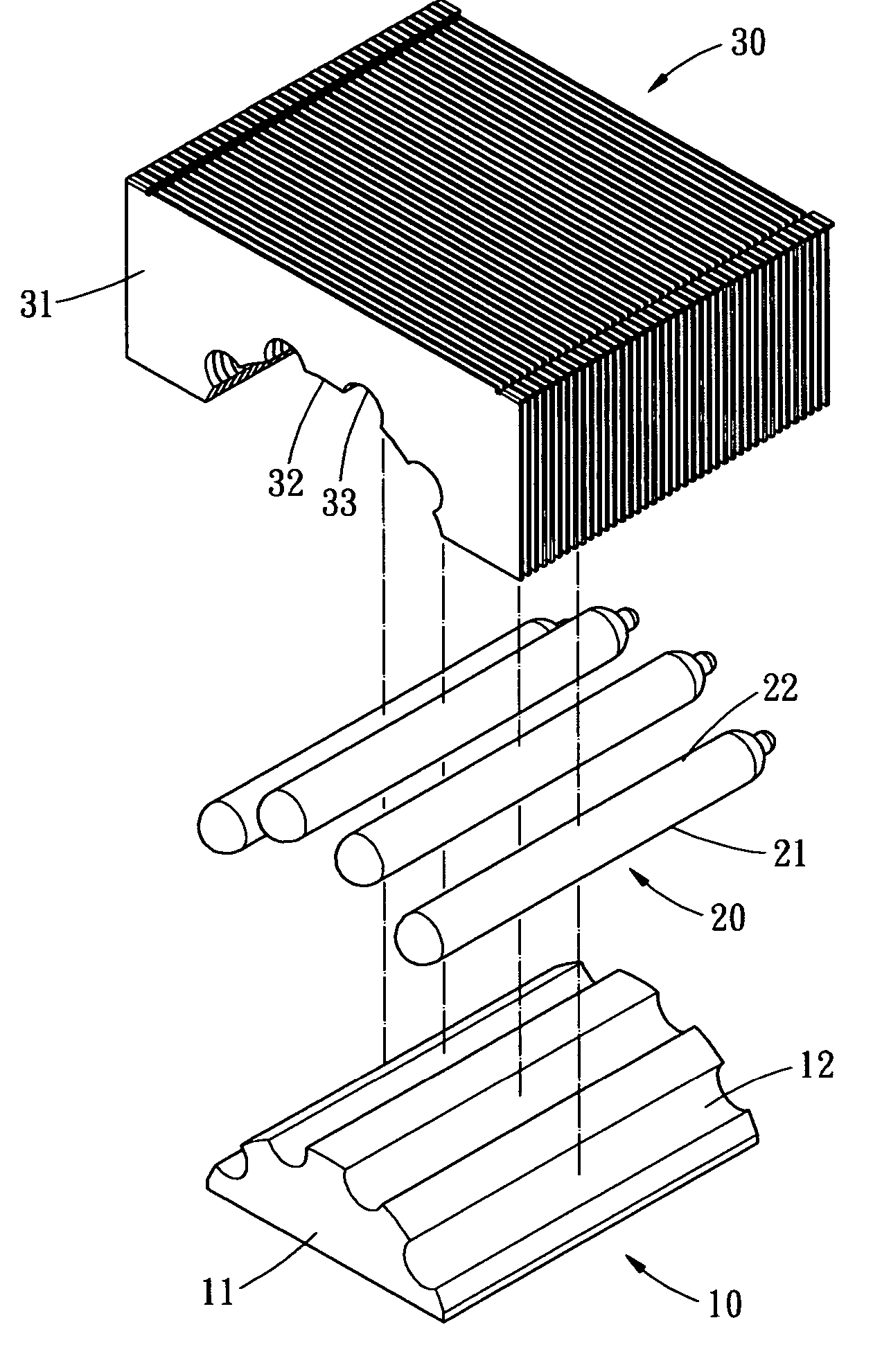

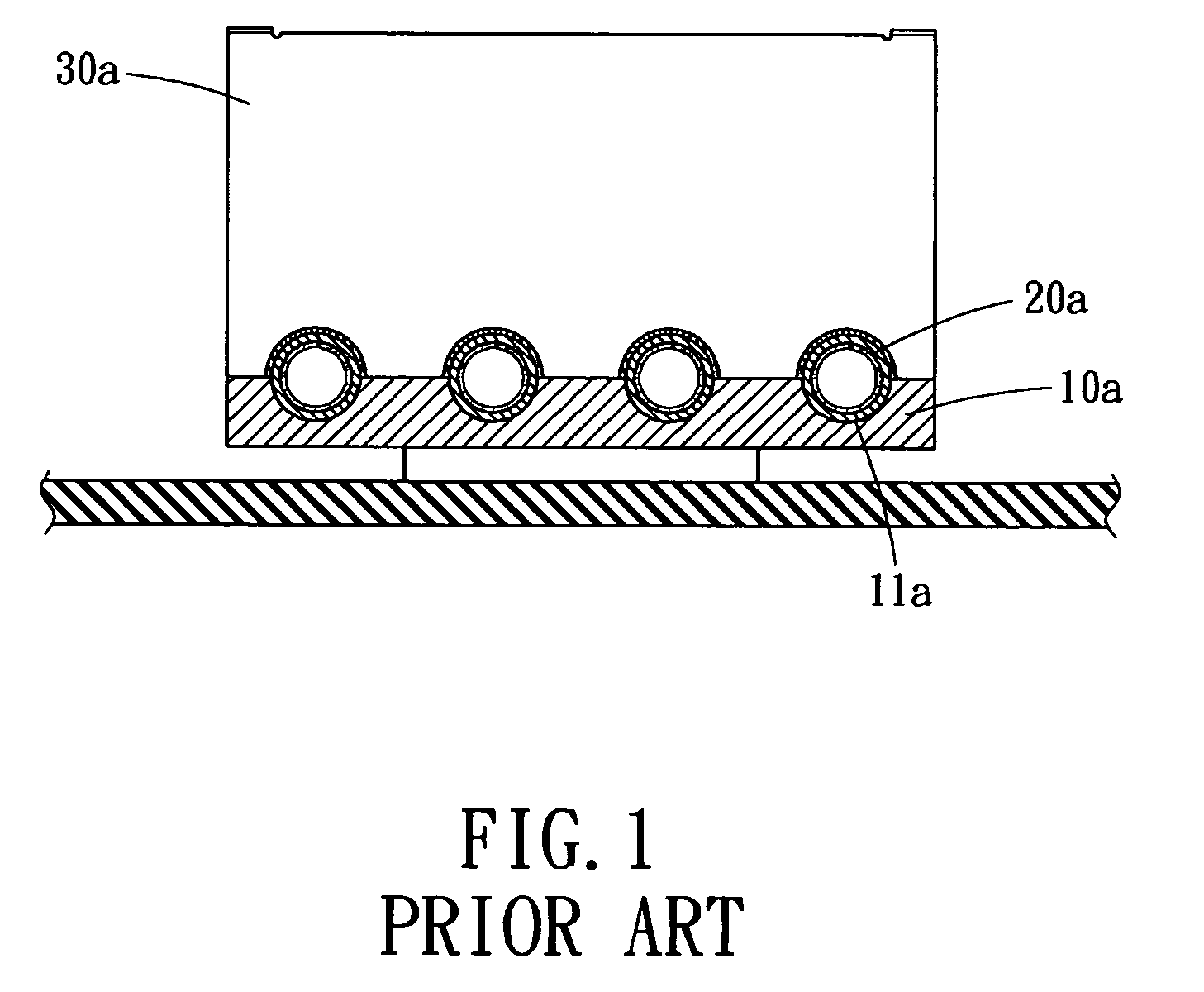

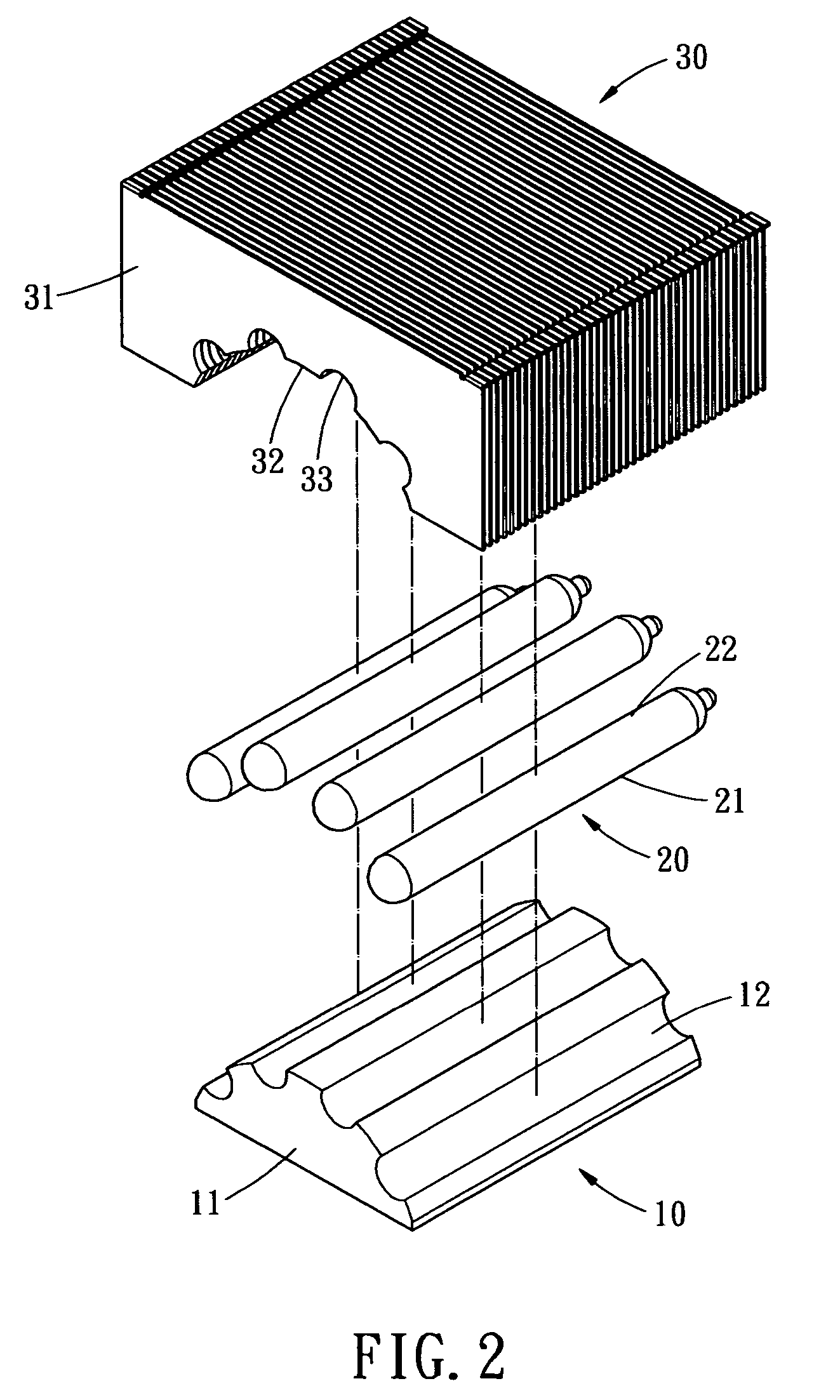

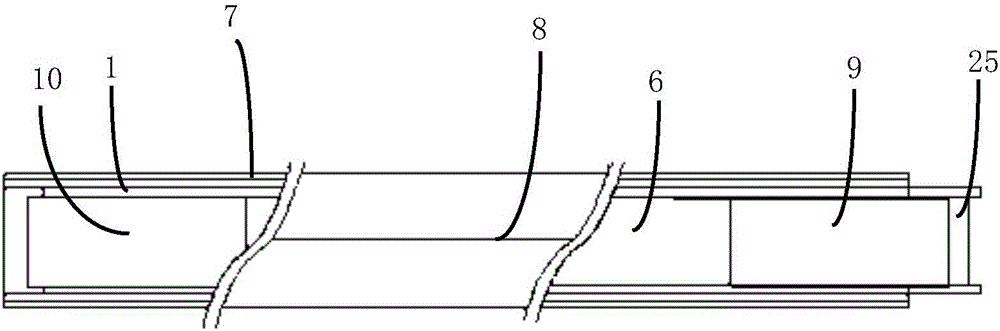

Structure of a uniform thermal conductive heat dissipation device

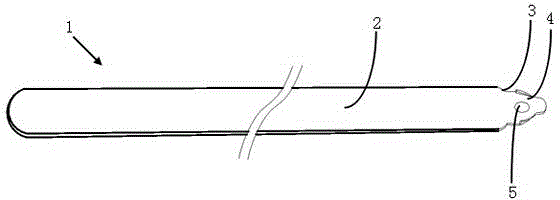

InactiveUS20050145369A1Even heat dissipationUniform heat conductionSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorWorking fluid

An improved structure of a uniform thermal conductive heat dissipation device, having a thermal conductor and a plurality of heat pipes. The thermal conductor includes a convex body member, on which a plurality of parallel connecting parts is formed to allow the heat pipes embedded therein. Each of the heat pipes has a wick structure and a working fluid therein. Each heat pipe has a heat absorbing portion and a heat dissipation portion. The heat absorption portion is closely in contact with the thermal conductor. Thereby, each of the heat is subject to the same amount of heat to result in a uniform thermal conduction and dissipation effect.

Owner:CHAUN CHOUNG TECH

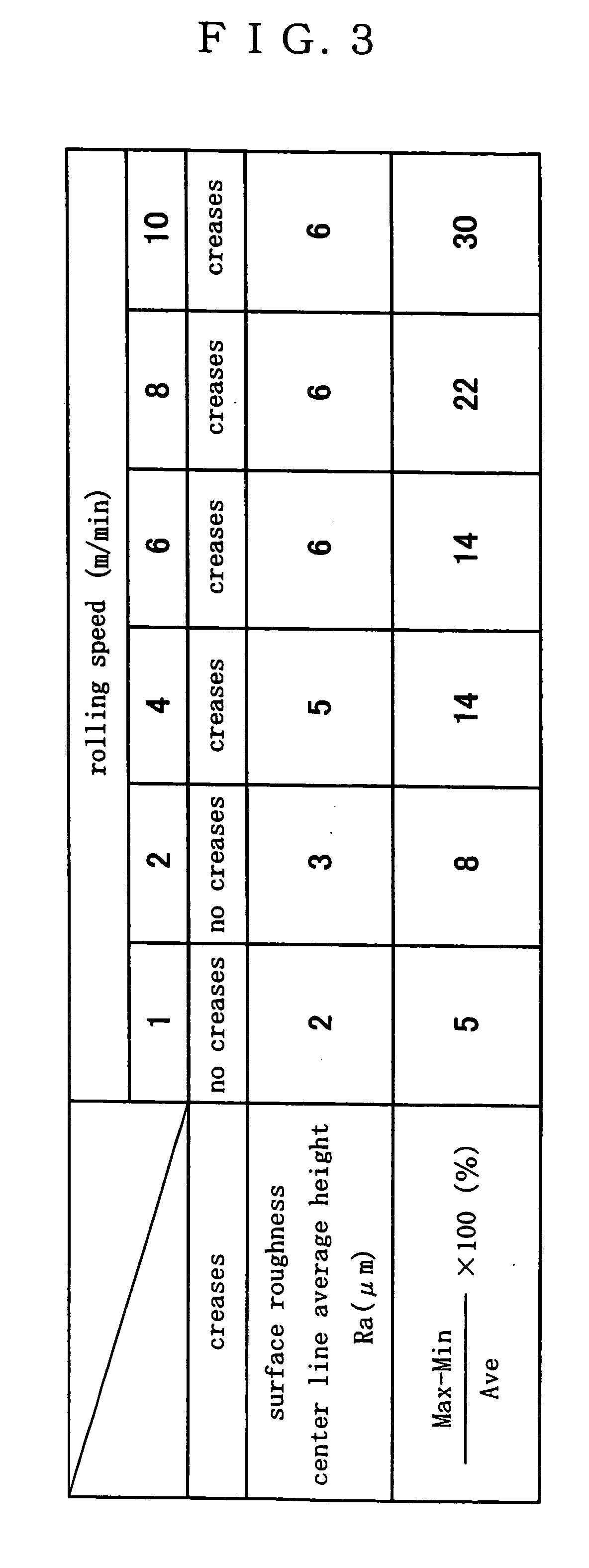

Method for manufacturing graphite foil capable of heat conduction and electricity conduction

ActiveCN102039712AThickness is easy to controlEasy to control uniformityLamination ancillary operationsSynthetic resin layered productsElectricityGraphite

The invention provides a method for manufacturing a graphite foil capable of heat conduction and electricity conduction. The method comprises the following steps: 1) spraying graphite powder onto a glue film with a basement membrane through a powder blower; and 2) rolling and flattening the graphite powder and the glue film to obtain a graphite belt capable of heat conduction and electricity conduction. In the method for manufacturing a graphite foil capable of heat conduction and electricity conduction, the graphite powder is sprayed onto the glue film, and the rolling and flattening method is adopted to overcome the defect that a flexible graphite plate is easily fractured; heating, baking and other processes are not required in the manufacturing process, so the energy consumption is low, and the obtained finished product can be used in heat conduction of a curve surface, such as a pipeline surface, and the heat conductive coefficient reaches 400W / mK, and is higher than the heat conductive coefficient of an aluminum foil; and the graphite material is difficult to oxidize, so the finished product is more durable, and is suitable in the fields of surface heat conduction and heating films.

Owner:湖北联投恒达石墨有限公司

Three-dimension porous tissue engineering carrier material and preparation and application

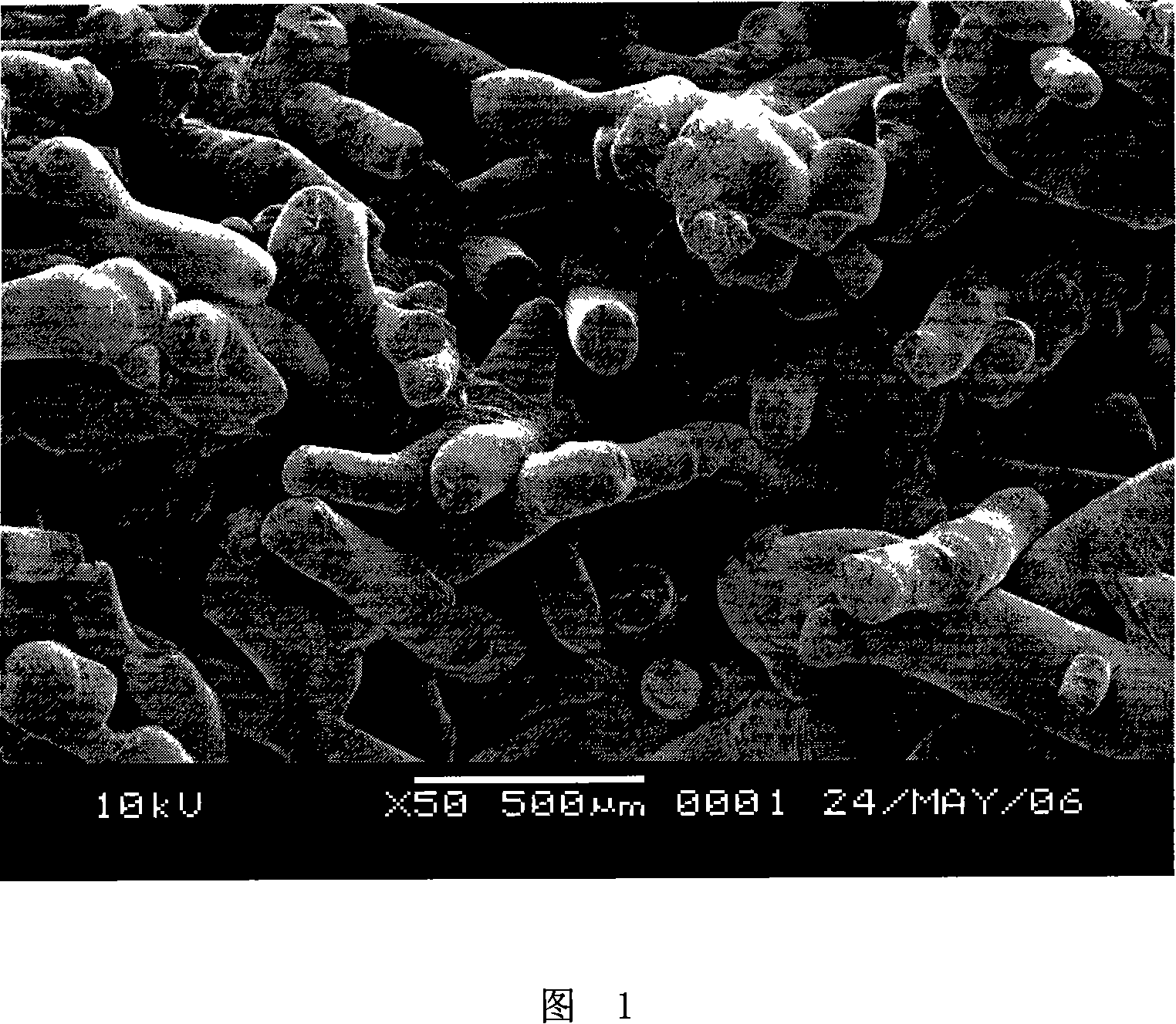

InactiveCN101147812AGood 3D through-hole structureUniform heat conductionProsthesisPorosityMicrometer

The present invention relates to a three-dimensional porous tissue engineering carrier material, its preparation and application. Said three-dimensional porous tissue engineering carrier material includes three-dimensional porous structure, its internal porous structure is uniform, three-dimensional through degree is above 90%, pore size is 50-500 micrometer and porosity is 65-90%. Its preparation method includes the following steps: using polyhydroxybutyrate valerate (PHBV) and polycaprolactone (PCL) as raw material, mixing them, melting and spinning to obtain fibre whose diameter is 10-500 micrometer, cutting said fibre to make said fibres have identical length, making said fibres be uniformly arranged and filled into a mould, sealing said mould for 5min-1n at 50-80deg.C, demoulding, sterilizing and packaging so as to obtain the invented product. Said product can be used for repairing or reconstructing some tissue organs.

Owner:DONGHUA UNIV

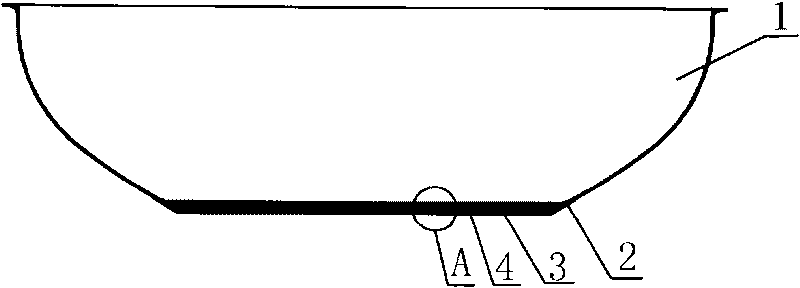

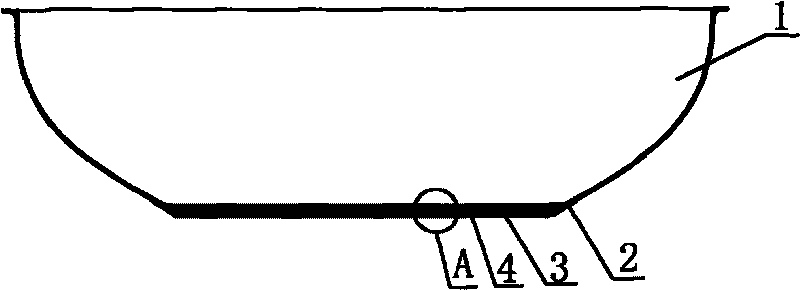

Composite bottom aluminum pot and production process thereof

ActiveCN101711649AImprove bindingSolve the technical problem that the compound bottom is not firmCooking-vessel materialsMolten spray coatingMetal sheetMaterials science

The invention belongs to the technical field of kitchenware, and relates to a composite bottom aluminum pot and a production process thereof. The pot bottom of the composite bottom aluminum pot has a structure that the bottom external surface of the pot bottom is downwards provided with a combination layer, an aluminum sheet and a composite metal bottom sheet in turn. The production process comprises the following steps: surface-roughening and coating a composite metal sheet and a composite pot body or surface-roughening and coating a composite pot body to prepare the composite bottom aluminum pot. The composite bottom aluminum pot has the advantages of firm composite pot body bottom, little cooking fume, long service life, reasonable production process, excellent performance of the product, suitability for popularization and application on composite pots of the same type.

Owner:ZHEJIANG AISHIDA ELECTRIC CO LTD

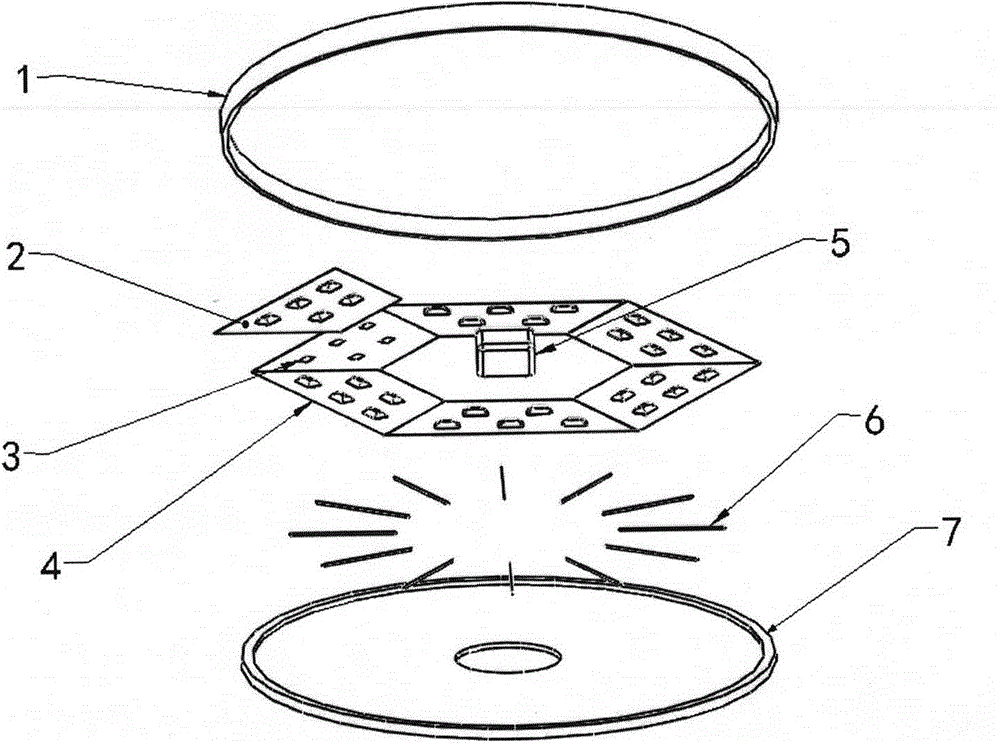

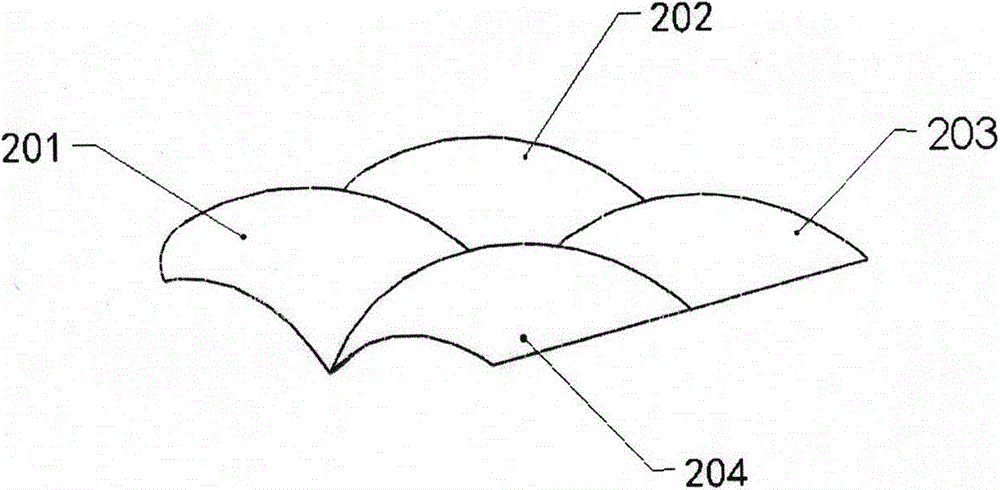

Microlens array based large-power ceiling lamp

InactiveCN104421775ASimple structureReduce engineering difficultyPlanar light sourcesPoint-like light sourceAdhesiveLed array

The invention discloses a microlens array based large-power ceiling lamp. The microlens array based large-power ceiling lamp comprises a housing, a light source module, a driving power supply and a radiating system; the housing comprises a base plate and a lampshade; the light source module comprises a microlens array, an LED array light source and a bottom plate; the radiating system comprises a heat transfer adhesive and a ceramic radiating sheet; the lampshade is positioned on the top of the lamp and is closely combined with the base plate through a clamp; the LED array light source and the driving power supply are both positioned on the bottom plate and are combined with the bottom plate through fixing parts; the driving power supply is positioned in the center of a ring belt which is composed of the bottom plate; the microlens array cover the LED array light source, and each microlens is corresponding to single LED lamp bead; the radiating system is positioned on the rear surface of the bottom plate; the ceramic radiating sheet is in filling connection with the bottom plate through the heat transfer adhesive, wherein the bottom plate is combined with the base plate through the fixing part. According to the microlens array based large-power ceiling lamp, the secondary optical design is performed, thus the light collecting efficiency is improved, the light diffusion angle is expanded, the radiating effect is obvious, and the appearance is nice.

Owner:CHINA JILIANG UNIV

Pressure loading device for rubber sealing ring and pressure loading test method

ActiveCN108279162ARealize ring forceThe actual use state is the sameMaterial strength using tensile/compressive forcesFree stateEngineering

The invention provides a pressure loading device for a rubber sealing ring and a pressure loading test method. The pressure loading device comprises a metal ring and a segmented type sleeve sleeved onthe metal ring, wherein the segmented type sleeve and the metal ring are matched by adopting a mode that the smallest gap is equal to zero; a ring groove is arranged in the side wall of the metal ring; the depth of the ring groove is equal to the height of the rubber sealing ring pressed in the storage process with ammunition, and circumferential-stress loading for the rubber sealing ring can berealized by matching of the metal ring, the ring groove and the sleeve; the loading method comprises the following sequential steps of: adopting the pressure loading device to carry out pressure loading on the rubber sealing ring, carrying out ageing test, eliminating pressure loading, measuring the height of the rubber sealing ring restoring to a free state, and calculating permanent compressiondeformation rate. By adoption of the pressure loading device for pressure loading, the actual deformation condition of the rubber sealing ring in the cartridge body can be accurately simulated and acquired.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

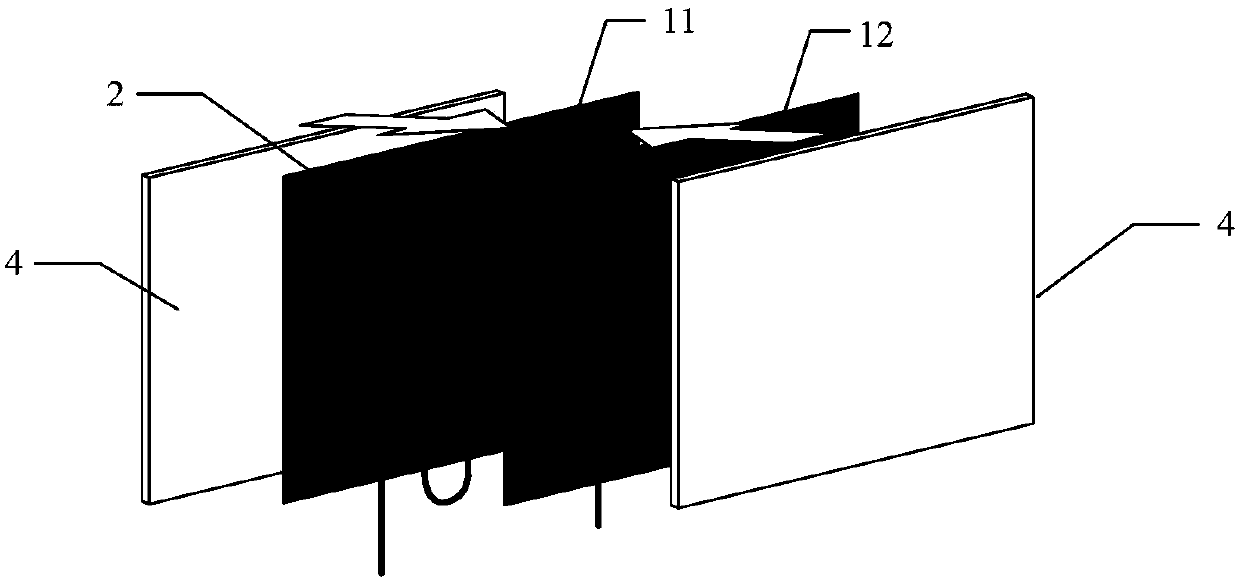

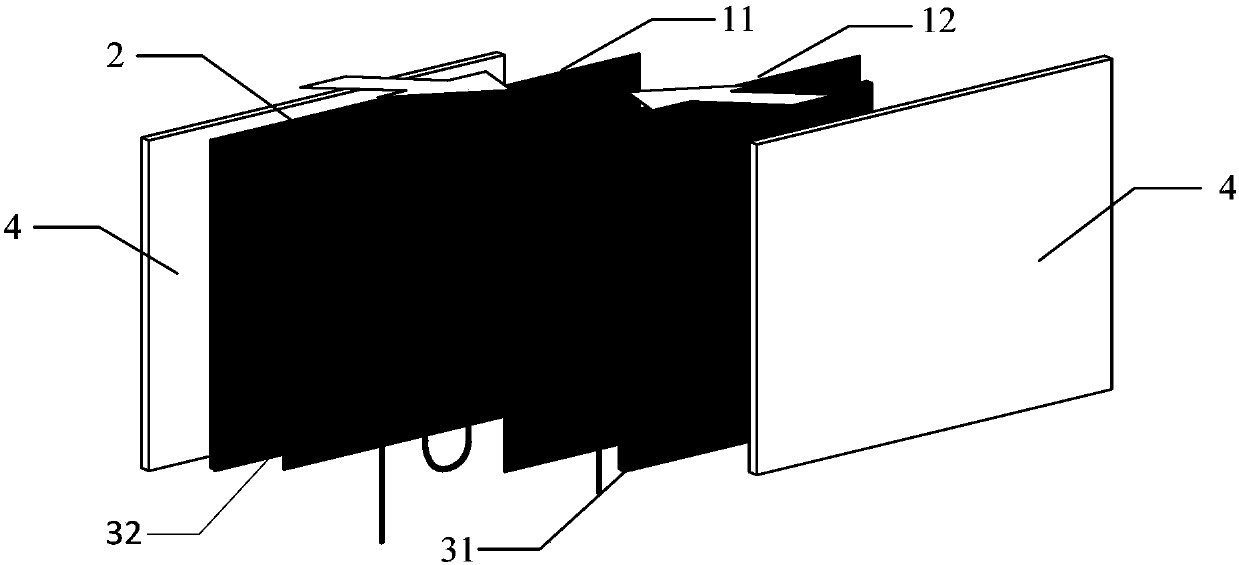

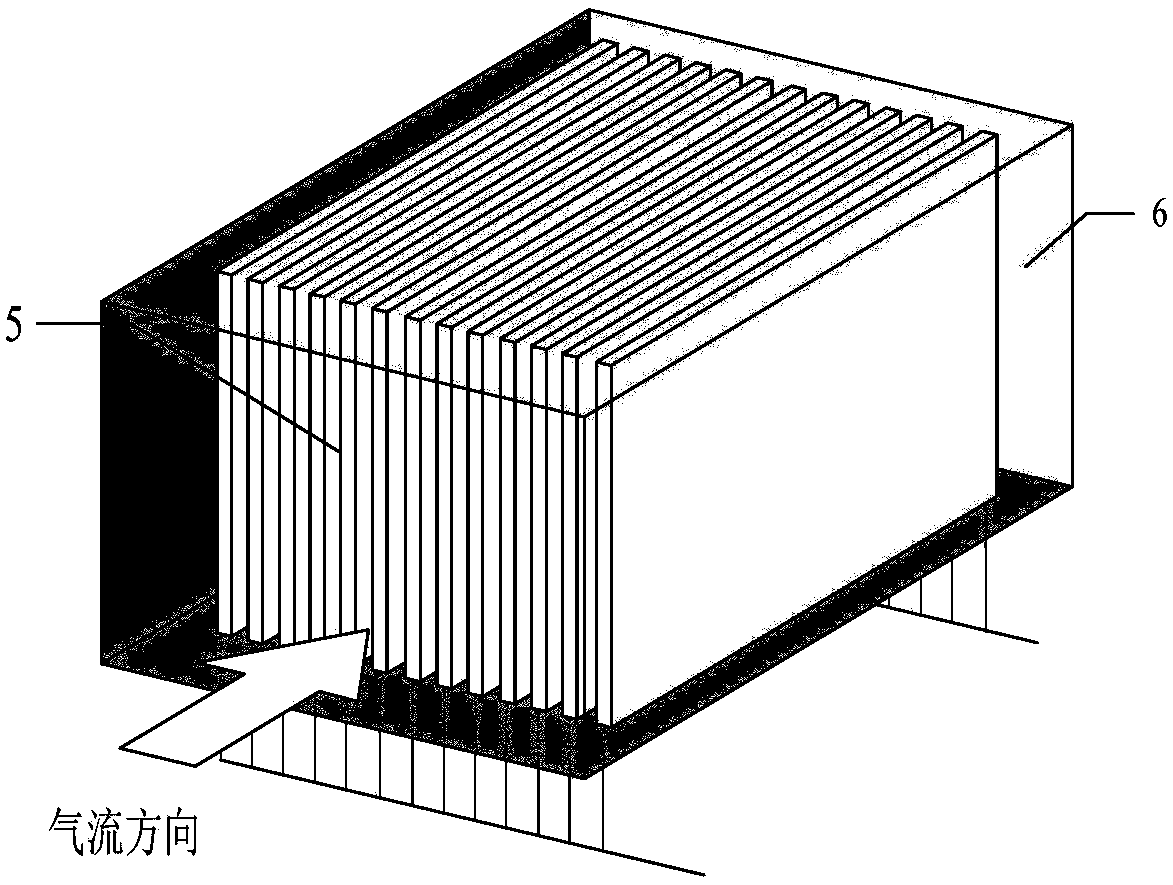

Air purification sheet and air purification module

ActiveCN107687677AStable supportImprove thermal conductivityMechanical apparatusLighting and heating apparatusBiochemical engineeringAir purification

The invention provides an air purification sheet and an air purification module. The air purification sheet comprises a base material sheet, a purification coating and a heating assembly, wherein thepurification coating is arranged on the outer surface of the base material sheet; the base material sheet comprises a first supporting sheet and a supporting sheet; the heating assembly is arranged between the first supporting sheet and the second supporting sheet. Thus, the air purification sheet is simple in structure, convenient to manufacture and low in wind drag. The heating assembly is arranged in the air purification sheet and can make the purification coating rapidly regenerate in situ. The service life of a purifying material is prolonged. The air purification sheet can be used for effectively purifying indoor gaseous pollutants for a long term.

Owner:TSINGHUA UNIV

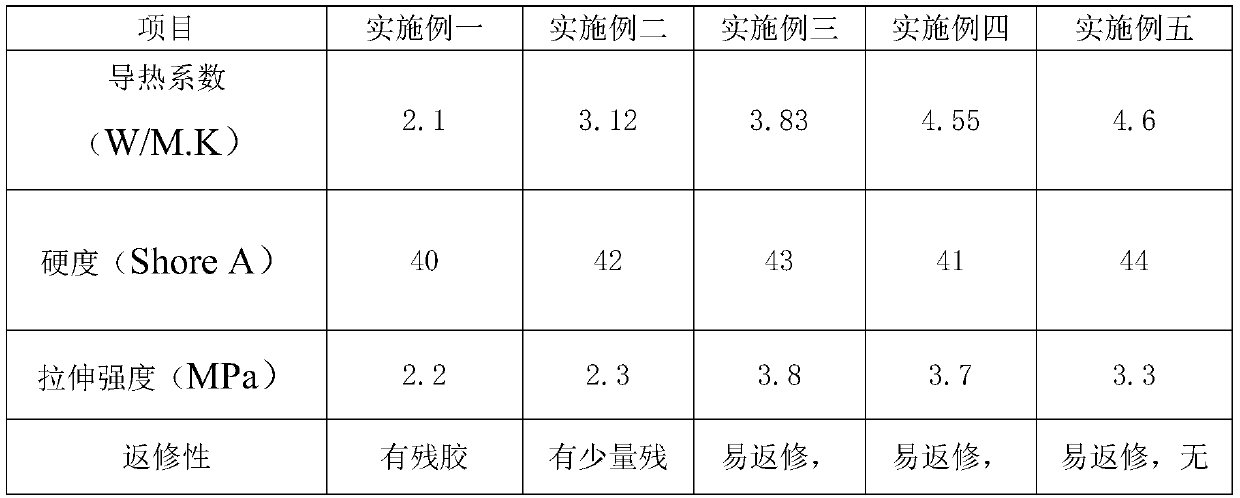

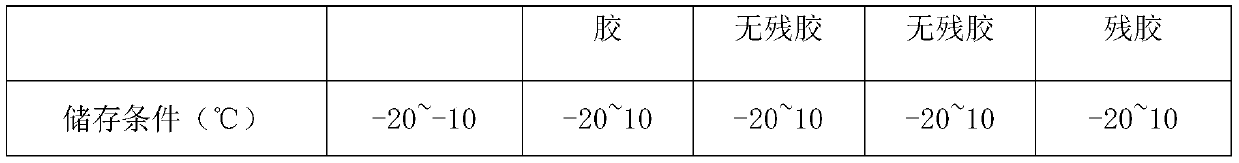

Easy-to-repair thermal-conducting gel and preparation method thereof

InactiveCN111073300ARaise storage temperatureEvenly dispersedHeat-exchange elementsPolymer scienceElectronic component

The invention discloses an easy-to-repair high-thermal-conducting gel and a preparation method thereof. The easy-to-repair thermal-conducting gel is based on vinyl silicone oil and vinyl MQ resin; a thermal-conducting agent is added, the heat-conducting gel is enabled to have good heat conductivity and certain fluidity as the existing thermal-conducting gel and can be used for filling gaps and irregular parts between electronic components and radiators and has excellent processability and is very suitable for automatic production operation. White carbon black and a release agent are also addedinto the thermal-conducting gel accordingly, the thermal-conducting gel can be cured into a block similar to the thermal-conducting gasket after being heated and has integrity and can be integrally stripped from the PCB and avoids the situation that the thermal-conducting gel remains on the PCB and is difficult to remove and even pollutes other components during repair and improves the repairability of the thermal-conducting gel.

Owner:SHENZHEN FENGSHENGYUAN TECH CO LTD

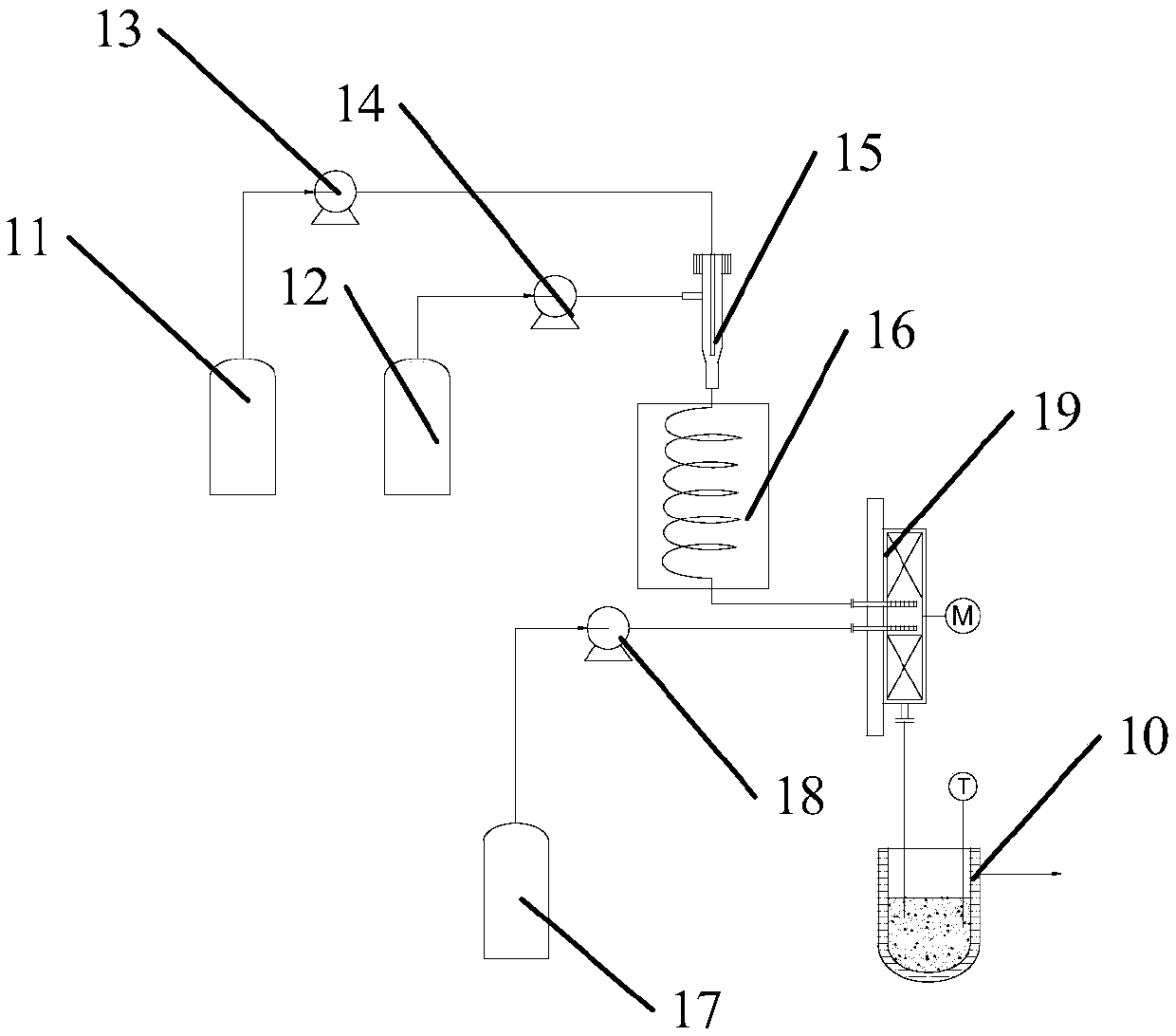

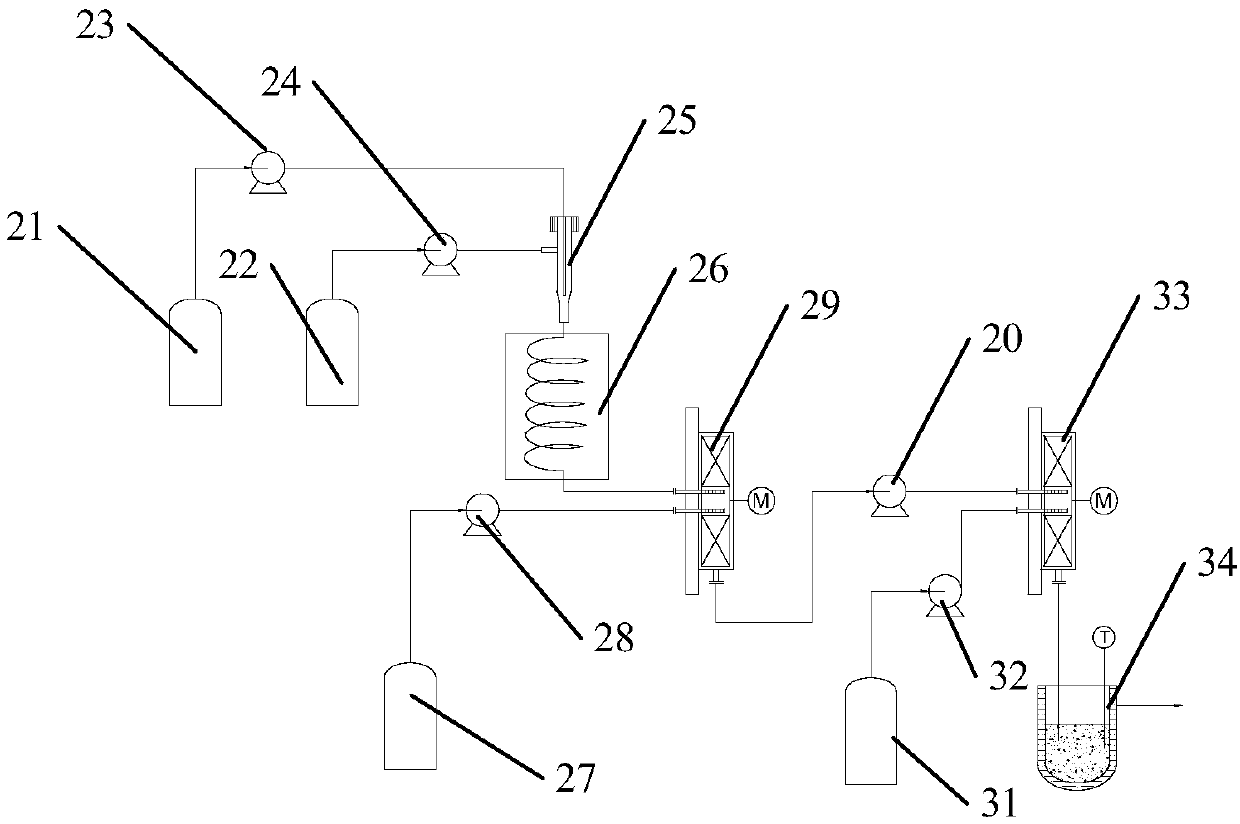

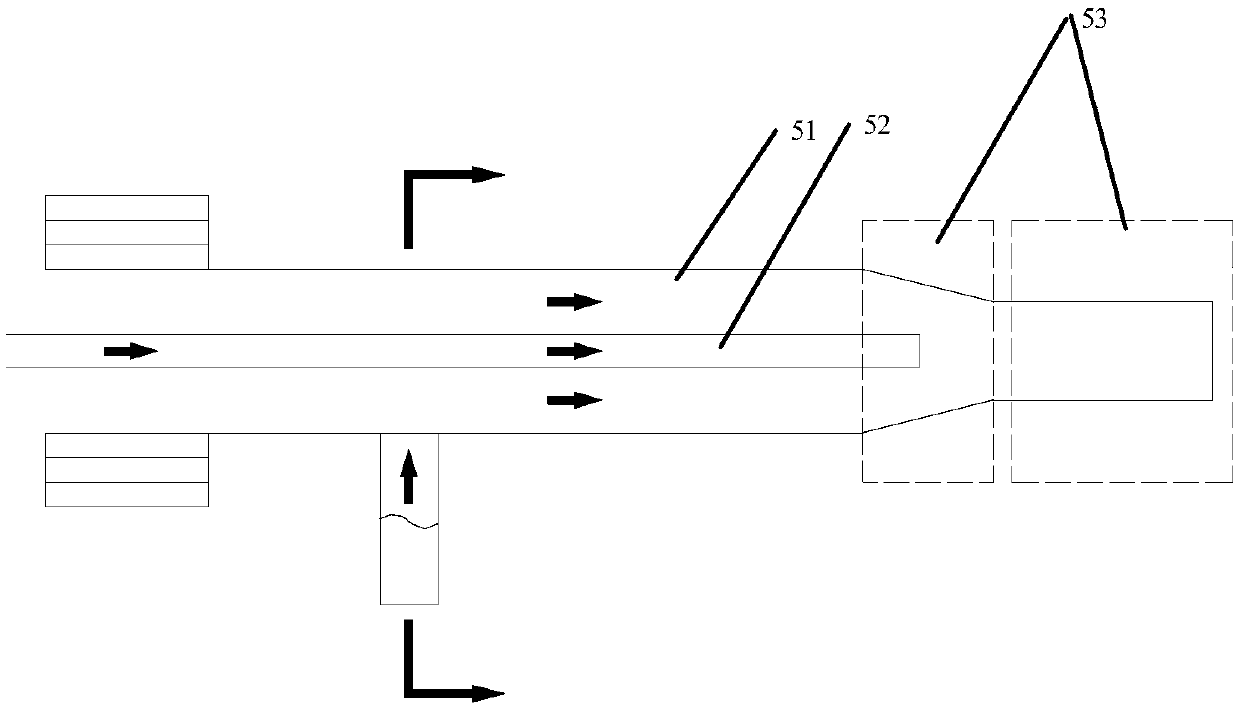

Continuous production system of azo reactive dye using supergravity

ActiveCN109651843APerformance close to or the same asUniform heat conductionReactive dyesDecompositionCoupling reaction

The invention provides a continuous production system of azo reactive dye using supergravity. Firstly, a supergravity reactor is applied to a coupling reaction, which can greatly increase the reactionconversion rate and improve the quality of the product, and a spiral coil reactor is adopted for performing a diazotization reaction during the production. Compared with a current method that the diazotization reaction is performed by adopting a stirred tank reactor, the temperature rise of the system temperature can be accurately controlled, the diazotization reaction time is significantly shortened, the decomposition of diazonium salt is reduced to a large extent, and the industrial continuous production can be achieved.

Owner:BEIJING UNIV OF CHEM TECH

Thermo-sensitive ceramic heater

ActiveCN106793193AImprove insulation performanceIncrease productivityOhmic-resistance electrodesHeater elementsHeat sensitiveMaterials science

The invention discloses a thermo-sensitive ceramic heater. The thermo-sensitive ceramic heater comprises a heating part, a connecting wire harness and a mounting bracket, wherein the heating part consists of a heating element and a radiator; the heating element comprises a heat conduction tube and a heating core; the heating core comprises a heating sheet, an electrode sheet and insulating paper; the connection wire harness comprises a connecting sheet; at least two semi-circular grooves are formed in the outer side surface of the heat conduction tube; the width of the heat conduction face of the heat conduction tube is 0-15 mm larger than that of the radiator. Through the design that the connecting sheet is added to the electrode sheet, the effects of reliable contact between the heater and a connecting point of the connection wire harness, stable connection and convenient manufacture are achieved. The structure that the width of the heat conduction tube is not equal to that of the radiator is adopted, so that combination between the radiator and the heat conduction tube is more stable, and heat dissipation is more uniform. Meanwhile, as the semi-circular grooves are formed in the side surface of the heat conduction tube, damage of the inner wall of the heat conduction tube to the insulating paper of the heating core is less, the heating core in the heat conduction tube is combined more tightly, and the security and the heat efficiency are greatly improved.

Owner:WUXI GUOWEI CERAMIC ELECTRICAL APPLIANCES CO LTD

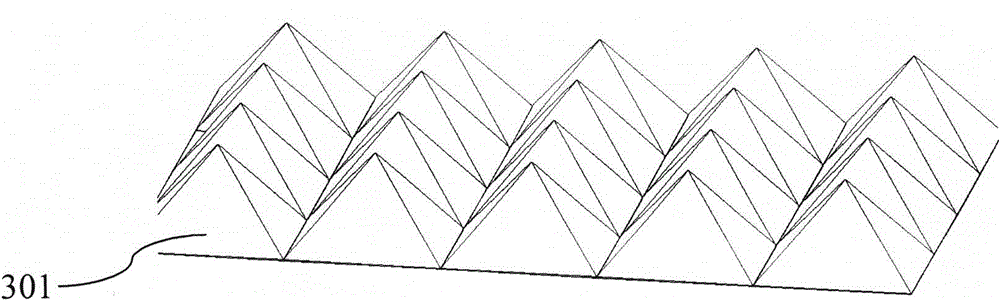

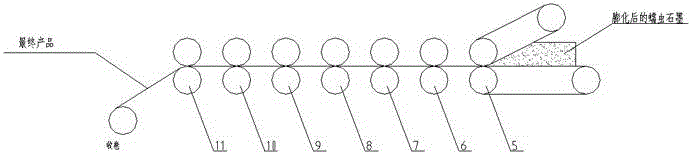

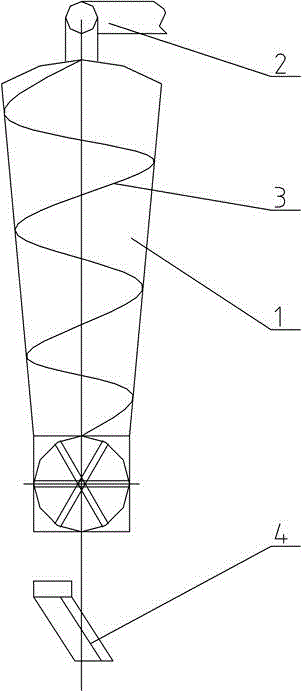

Preparation method of high-heat conductivity flexible graphite film

The invention relates to a preparation method of a graphite film, in particular to a preparation method of a high-heat conductivity flexible graphite film, and mainly solves the technical problems that in the prior art, harmful gas and raw materials in graphite cannot be efficiently separated, and the consistency of the thickness index, the density index and the strength index of the flexible graphite film cannot be guaranteed. The preparation method comprises the following steps: performing high-temperature bulking on high-quality natural high-purity large-particle flake graphite with a complete lattice structure and the carbon content greater than 99%, performing steam discharge desulfurization on vermicular graphite, and performing dual-cyclone discharging on the vermicular graphite after the steam discharge desulfurization at a discharging port of a bulking furnace, so that the vermicular graphite is flatly piled and densely distributed on a press roll table; calendaring the vermicular graphite through the press roll table, and rolling to obtain the final high-heat conductivity flexible graphite film.

Owner:浙江国泰萧星密封材料股份有限公司

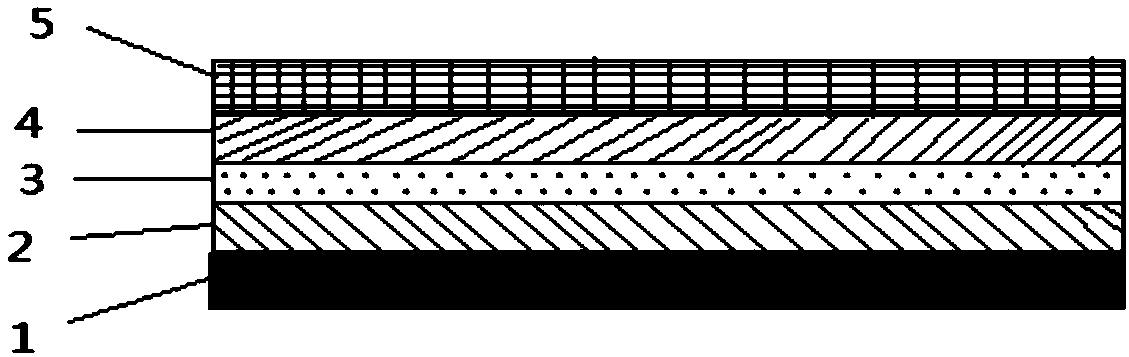

Graphene heating carpet

InactiveCN108552913AImprove thermal conductivityUniform heat conductionSynthetic resin layered productsHeating element materialsTemperature controlElectrical conductor

The invention discloses a graphene heating carpet comprises a carpet bottom layer, a first insulating layer, a heating layer, a second insulating layer and a carpet surface layer which are sequentially connected from bottom to top; the heating layer comprises a graphene heating slurry, a metal current carrying strip and a heating wire, wherein the two ends of the graphene heating slurry are respectively connected with two metal carrier flow strips, the electric heating wires are uniformly arranged in the graphene heating slurry, and the two ends of the electric heating wires are perpendicularly connected to the two metal carrying strips, which are connected with the temperature sensor, the temperature controller and the plug through a electrical conductor; the temperature sensor is positioned between the second insulating layer and the carpet surface layer; the temperature controller is characterized with heat preservation, heating and timing. As the graphene is adopted for heating, the conversion rate of the heat energy is almost up to 100 percent, thereby the effect of high efficiency and energy conservation is accomplished; meanwhile, the graphene releases far infrared rays withthe wavelength of 8-14 microns, therefore the graphene can be used for resisting bacteria and inhibiting bacteria.

Owner:芜湖智为有道信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com