Thermal interface material, and its preparing method

A technology of thermal interface materials and polymer materials, applied in heat exchange materials, chemical instruments and methods, thin material processing, etc., can solve the problems of increased thermal resistance of thermal interface materials, small carbon nanotube content, and insufficient heat conduction. , to achieve uniform and uniform heat conduction, reduce contact thermal resistance, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

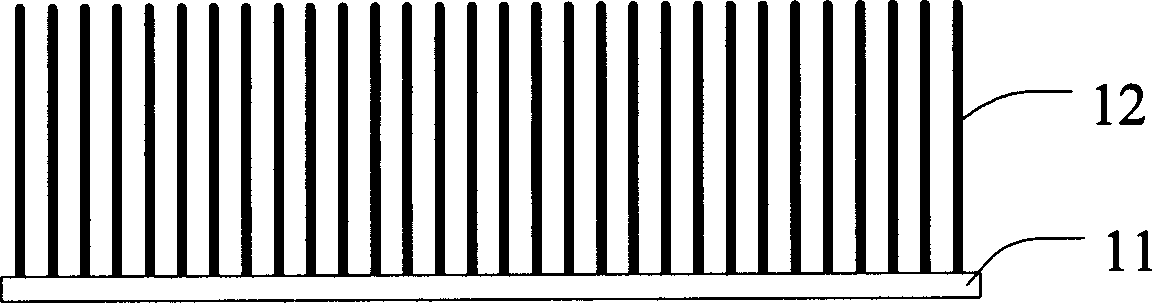

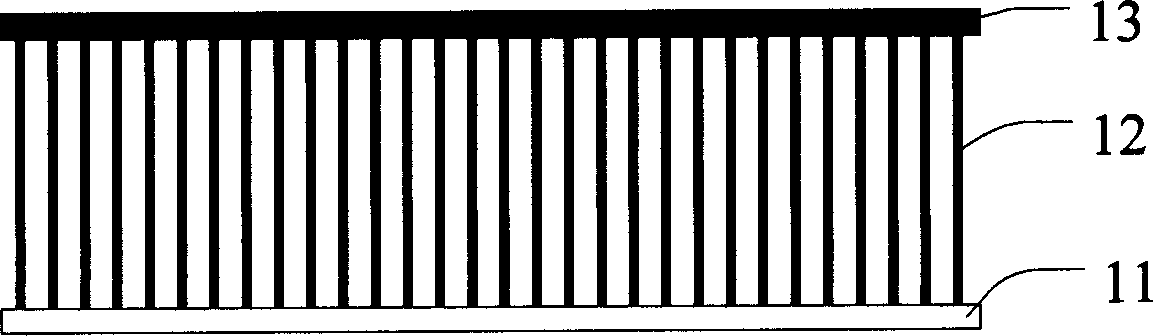

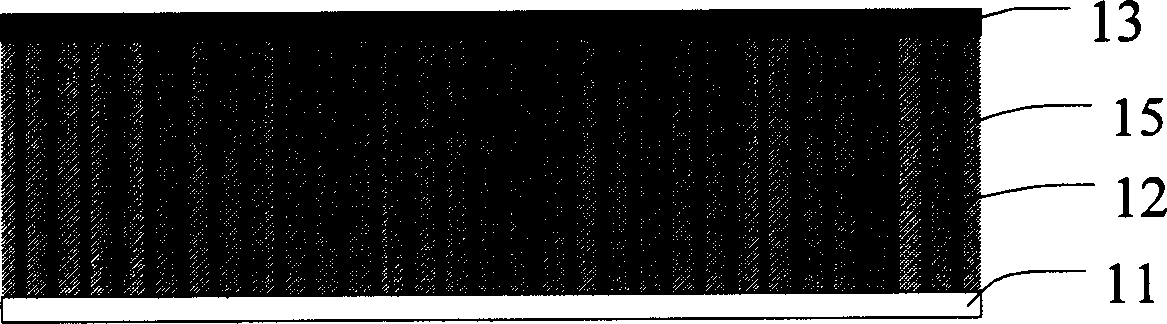

[0037] The technical solution will be further described in detail below in conjunction with the accompanying drawings.

[0038] see Figure 4 , the present embodiment provides a thermal interface material 10, which includes a carbon nanotube array 12, a polymer material 15 filled between the carbon nanotube arrays 12; The heat flow collector 13. see Figure 5 , in another embodiment, the thermal interface material 10 ′ includes two heat flow collectors 13 respectively connected to the two ends of the carbon nanotube array 12 .

[0039] Preferably, the carbon nanotube array 12 is perpendicular to the heat flow collector 13 .

[0040] The material of the heat collector 13 includes metals with good thermal conductivity such as aluminum, copper, gold or silver.

[0041] The heat collector 13 is a metal film, and the metal film 13 in this embodiment is an aluminum film.

[0042] The thickness of the metal film ranges from 1 micron to 10 microns.

[0043] The polymer material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com