Thermal-interface material and production thereof

一种热界面材料、制造方法的技术,应用在冷却/通风/加热改造、用于材料和表面科学的纳米技术、薄料处理等方向,能够解决热界面材料导热系数降低、均匀性难得到保证、不利器件等问题,达到增大直接接触面积、降低体积及重量、导热一致均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

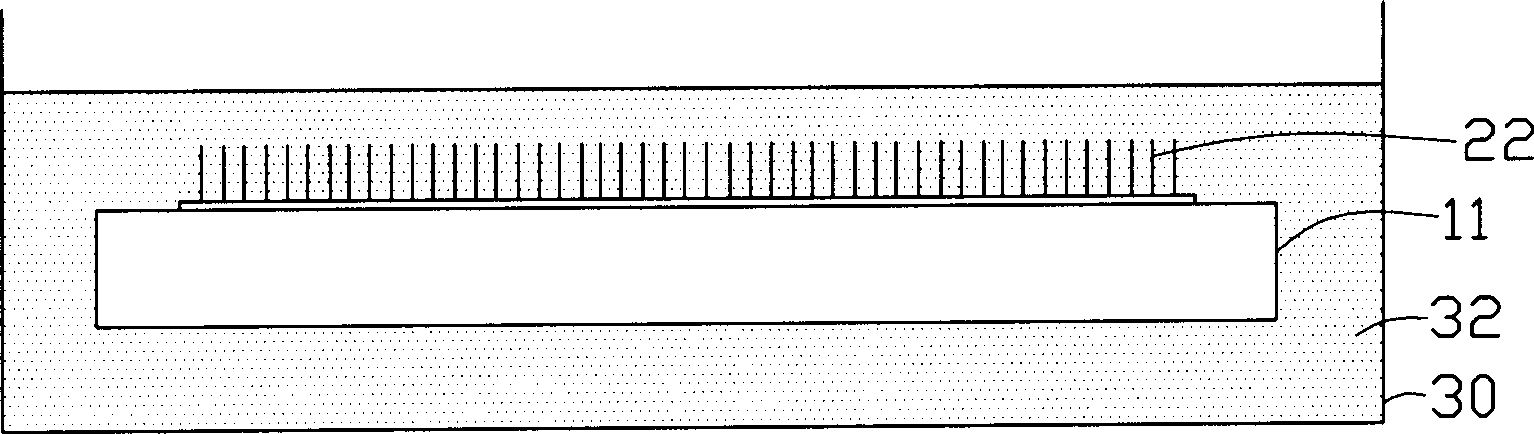

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

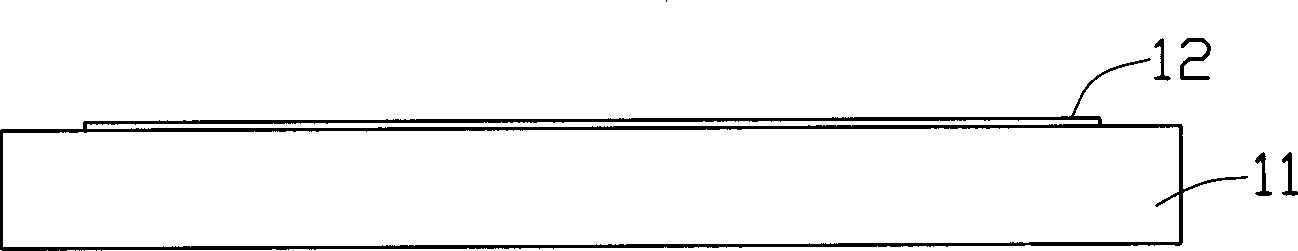

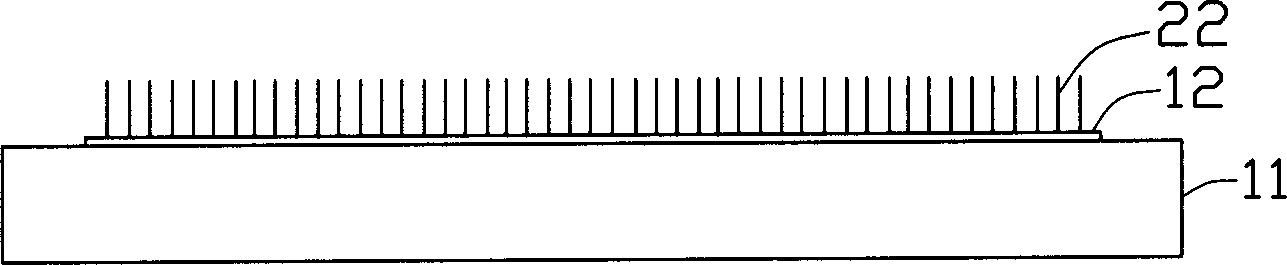

[0026] see figure 1 with figure 2 Firstly, a catalyst thin film 12 is uniformly formed on a substrate 11, and the formation of the catalyst thin film 12 can be accomplished by thermal deposition, electron beam deposition or sputtering. The material of the substrate 11 can be glass, quartz, silicon or alumina. In this embodiment, porous silicon is used, and there is a porous layer on its surface, and the diameter of the pores is extremely small, generally less than 3 nanometers. The catalyst film 12 is made of iron, or other materials, such as gallium nitride, cobalt, nickel and alloys thereof.

[0027] Then, the catalyst film 12 is oxidized to form catalyst particles (not shown), and then the substrate 11 distributed with catalyst particles is put into a reaction furnace (not shown), and carbon source gas is introduced at 700-1000 degrees...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com