Preparation method of high-heat conductivity flexible graphite film

A flexible graphite, high thermal conductivity technology, applied in the field of preparation of high thermal conductivity flexible graphite film, can solve the problems of inability to guarantee the consistency of the thickness and strength index of flexible graphite film, and the inability to separate harmful gases from raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

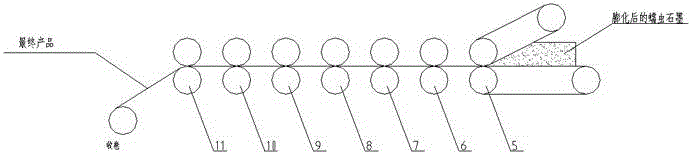

[0023] Embodiment: the preparation method of a kind of high thermal conductivity flexible graphite film of this example is characterized in that described method comprises:

[0024] a. Use high-quality natural high-purity large-grain flake graphite with complete lattice structure and carbon content > 99%. The particle size of flake graphite is ≥ 250um. Start the feeding fan to send the expandable flake graphite raw material in the hopper into the high-temperature furnace for expansion , the expansion temperature is 800℃~1200℃, and the worm graphite is obtained by treatment;

[0025] b. Carry out steam desulfurization during the expansion process of worm graphite;

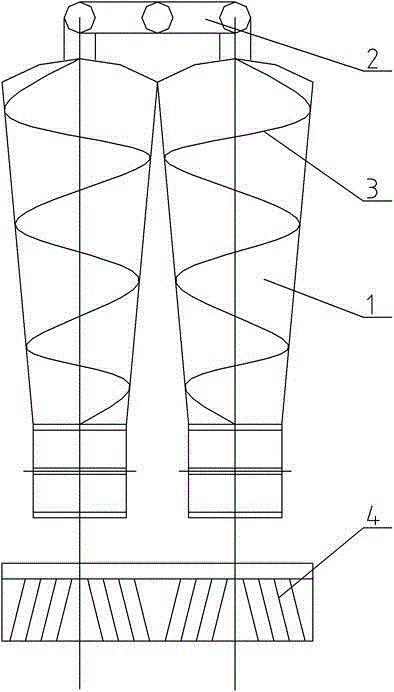

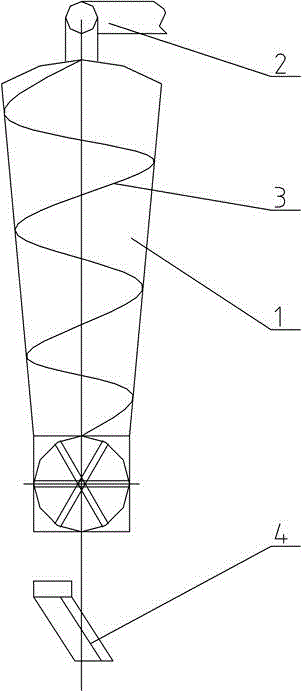

[0026] c. Graphite after steaming and desulfurization is fed by double cyclones at the blanking port of the extruder. figure 1 , figure 2 , the blanking port of the puffing furnace includes two cylinders 1 with a large top and a small bottom. The upper parts of the two cylinders are connected with a blanking pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com