Method for preparing grapheme by means of aqueous phase cutting and stripping

A technology of graphene and graphite, which is applied in the field of graphene prepared by shear exfoliation in water phase, can solve the problems of low packing density of graphene powder, difficulty in application and transportation, limited dispersion ability, etc., and achieves convenience for further use and complete lattice structure , Ease of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

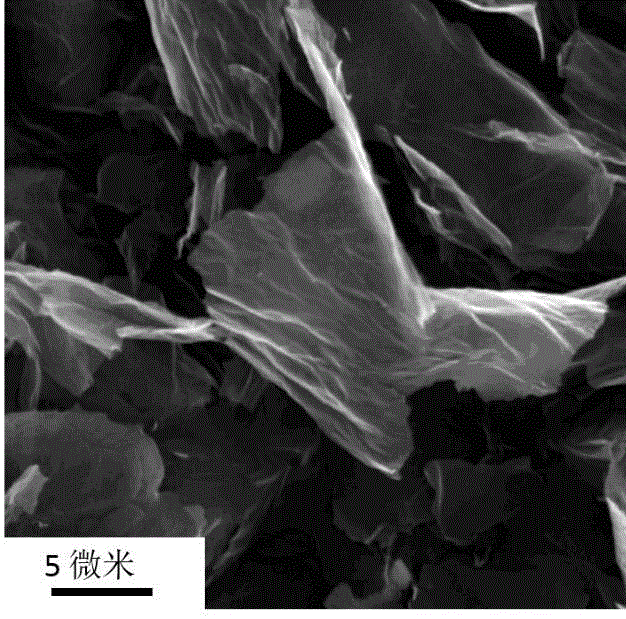

[0026] Mix 200 ml of concentrated sulfuric acid (98%) with 10 grams of potassium permanganate (purity>95%), 10 grams of flake graphite powder (particle diameter is 500 microns or 35 mesh, carbon content>95%), control the temperature of the system below 35 o C. After stirring continuously for 2 hours, slowly add it into 1000 ml of ice water, and remove the heat of reaction in time to avoid excessive temperature of the system. Then 20 milliliters of hydrogen peroxide was added and stirred for 5 minutes, and the graphite intercalation compound was obtained after filtration.

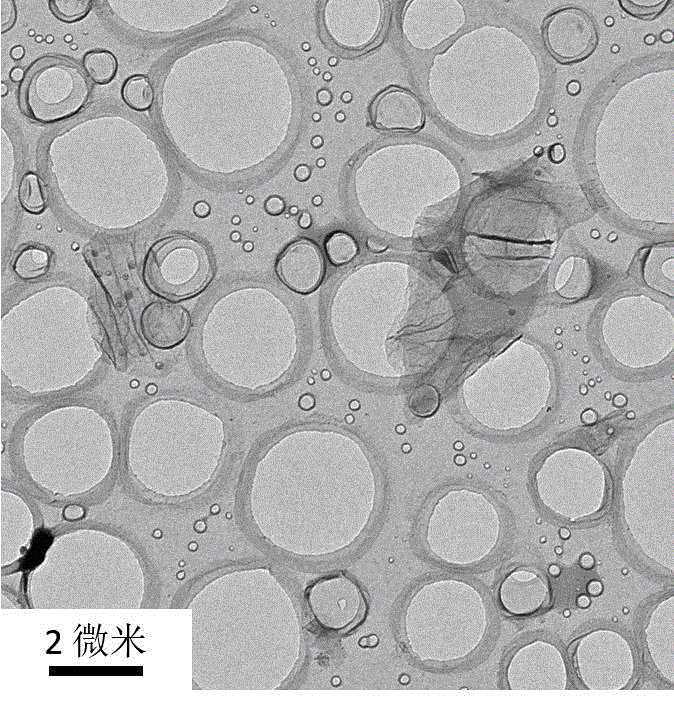

[0027] The graphite intercalation compound obtained after filtration (wet) was mixed with 10 g of sodium hydroxide and 250 ml of water. A black graphene suspension was obtained after treatment with a shear stirrer (power 500 W) at 18,000 rpm for 50 min. After the obtained black solution was centrifuged at 10,000 rpm for 10 minutes, the supernatant was poured off to obtain an aqueous phase paste with high s...

Embodiment 2

[0029] Evenly mix 100 ml of fuming sulfuric acid (containing 20% sulfur trioxide), 5 ml of hydrogen peroxide and 10 grams of flake graphite powder (particle diameter is 500 microns), and control the system temperature below 35 o C. After continuous stirring for 2 hours, slowly add it into 1000 ml of ice water, pay attention to remove the heat of mixing in time to avoid excessive temperature of the system. Then 20 milliliters of hydrogen peroxide was added and stirred for 5 minutes, and the graphite intercalation compound was obtained after filtration.

[0030] The graphite intercalation compound obtained after filtration (wet) was mixed with 10 g of sodium hydroxide and 250 ml of water. A black graphene suspension was obtained after treatment with a shear stirrer (power 500 W) at 18,000 rpm for 50 min. After the obtained black solution was centrifuged at 10,000 rpm for 10 minutes, the supernatant was poured off to obtain an aqueous phase paste with high single-layer graphen...

Embodiment 3

[0032] Mix 30 grams of ammonium persulfate, 200 milliliters of concentrated sulfuric acid (98%) and 10 grams of flake graphite powder (500 microns in particle diameter), stir at room temperature for 6 hours, then slowly add it to 1000 milliliters of ice water, pay attention to remove the heat of mixing in time, Avoid excessive system temperature. Then 20 milliliters of hydrogen peroxide was added and stirred for 5 minutes, and the graphite intercalation compound was obtained after filtration.

[0033] The graphite intercalation compound obtained after filtration (wet) was mixed with 10 g of sodium hydroxide and 250 ml of water. A black graphene suspension was obtained after treatment with a shear stirrer (power 500 W) at 18,000 rpm for 50 min. After the obtained black solution was centrifuged at 10,000 rpm for 10 minutes, the supernatant was poured off to obtain an aqueous phase paste with high single-layer graphene content. Compared with graphite raw materials, the yield of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com