Patents

Literature

593results about How to "Reduce thermal contact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat conductive silicone grease composition

ActiveCN102634212AImprove thermal conductivityExtended service lifeHeat-exchange elementsCarbon nanotubeGraphite

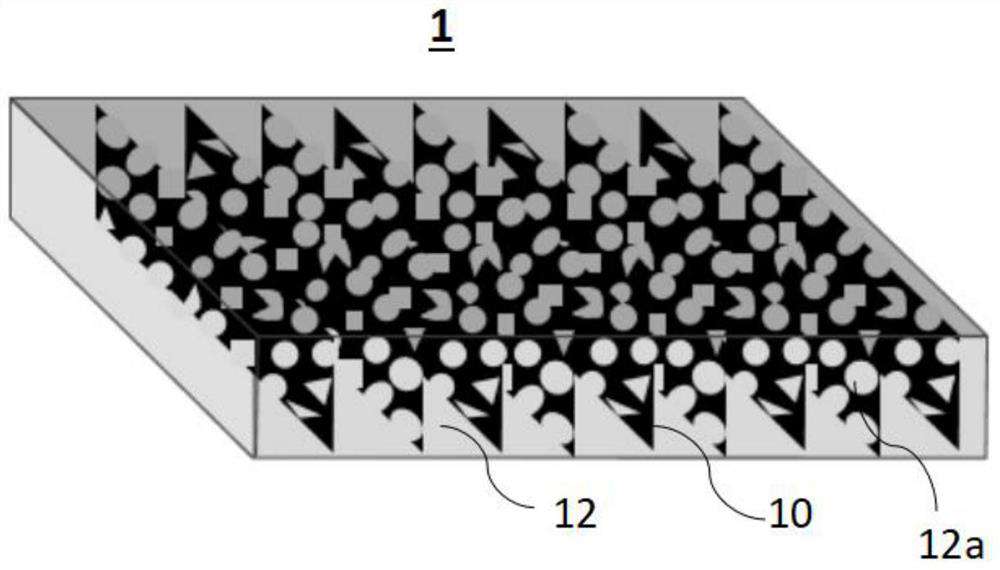

The invention discloses a heat conductive silicone grease composition which mainly contains a carbon nano tube, graphite, phase-change capsule particles and silicone oil, wherein the carbon nano tube can speed up the conduction of heat further; the phase-change capsule particles are used for improving the initial temperature absorption velocity of a heat end; the phase-change capsule particles, the carbon nano tube and graphite in a fluid form full-three-dimensional network distribution of particles (phase-change capsule), a line ( the carbon nano tube) and a plane (graphite) in the fluid finally. The heat conductive silicone grease composition provided by the invention has high heat conduction rate and low heat resistivity, the heat radiation efficiency of the heat conductive silicone grease is improved greatly, the service life of the heat conductive silicone grease is prolonged greatly, and the heat conductive silicone grease composition has high practical value.

Owner:HUZHOU MINGSHUO OPTOELECTRONICS TECH CO LTD

Thermoelectric conversion module

InactiveUS20060005873A1Improve conductivityImprove substantial filling densityThermoelectric device with peltier/seeback effectCouplingTemperature difference

A thermoelectric conversion module for generating power by using a temperature difference and realizing a large-size module with soundness to improve substantial filling density of a thermoelectric semiconductor, including a sliding member having high heat conductivity intervening at least between a heating plate of a high-temperature heat source side and a heat source side electrode portion of a thermoelectric semiconductor and a coupling plate for coupling the heating plate to the cooling plate, wherein the thermoelectric semiconductors and the electrode portions are integrated by being sandwiched between the cooling plate and the heating plate via the sliding member, and the sliding member in the pressurized state accepts relative sliding between the sliding member and the heat source side electrode portion or the heating plate.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY +1

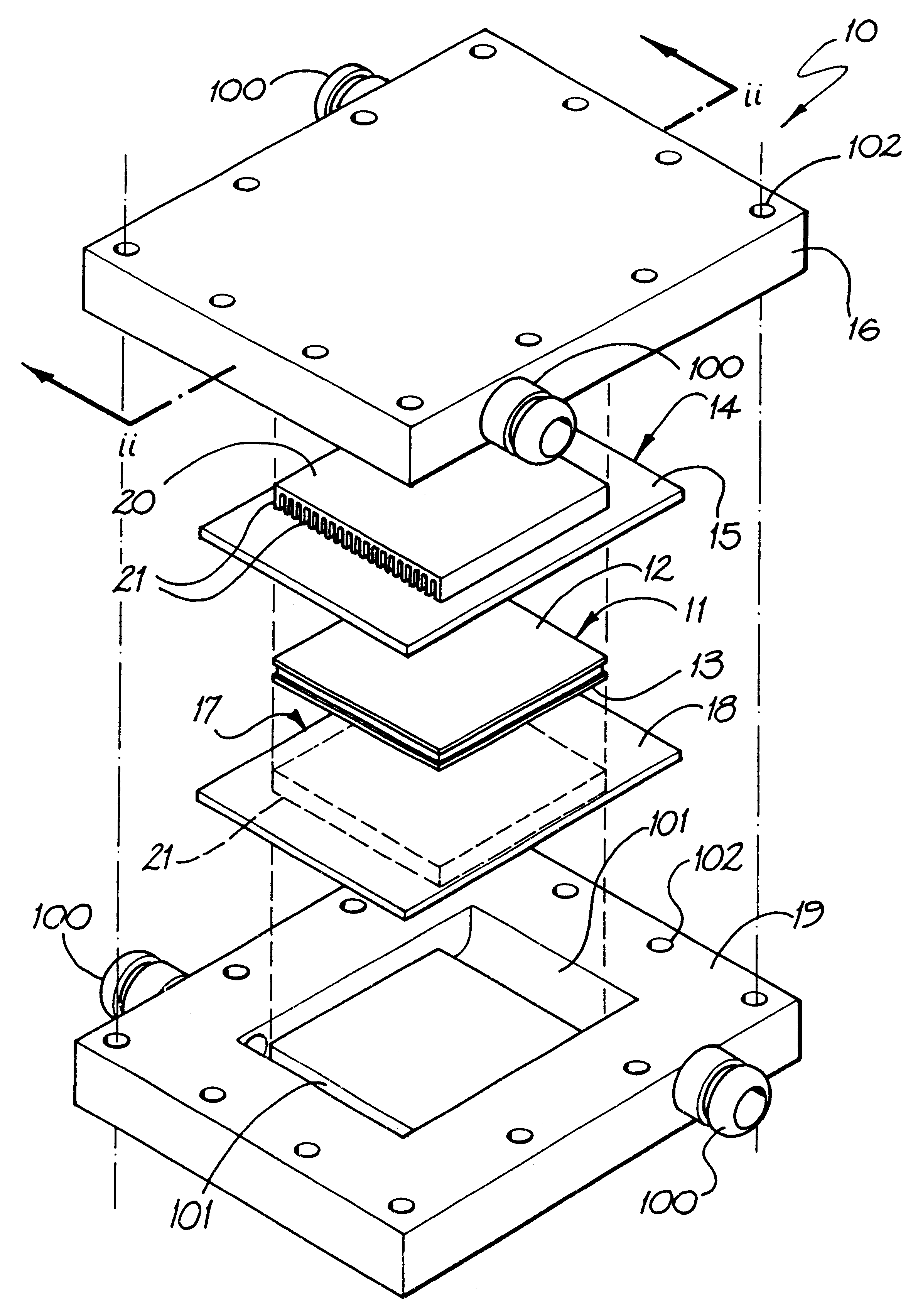

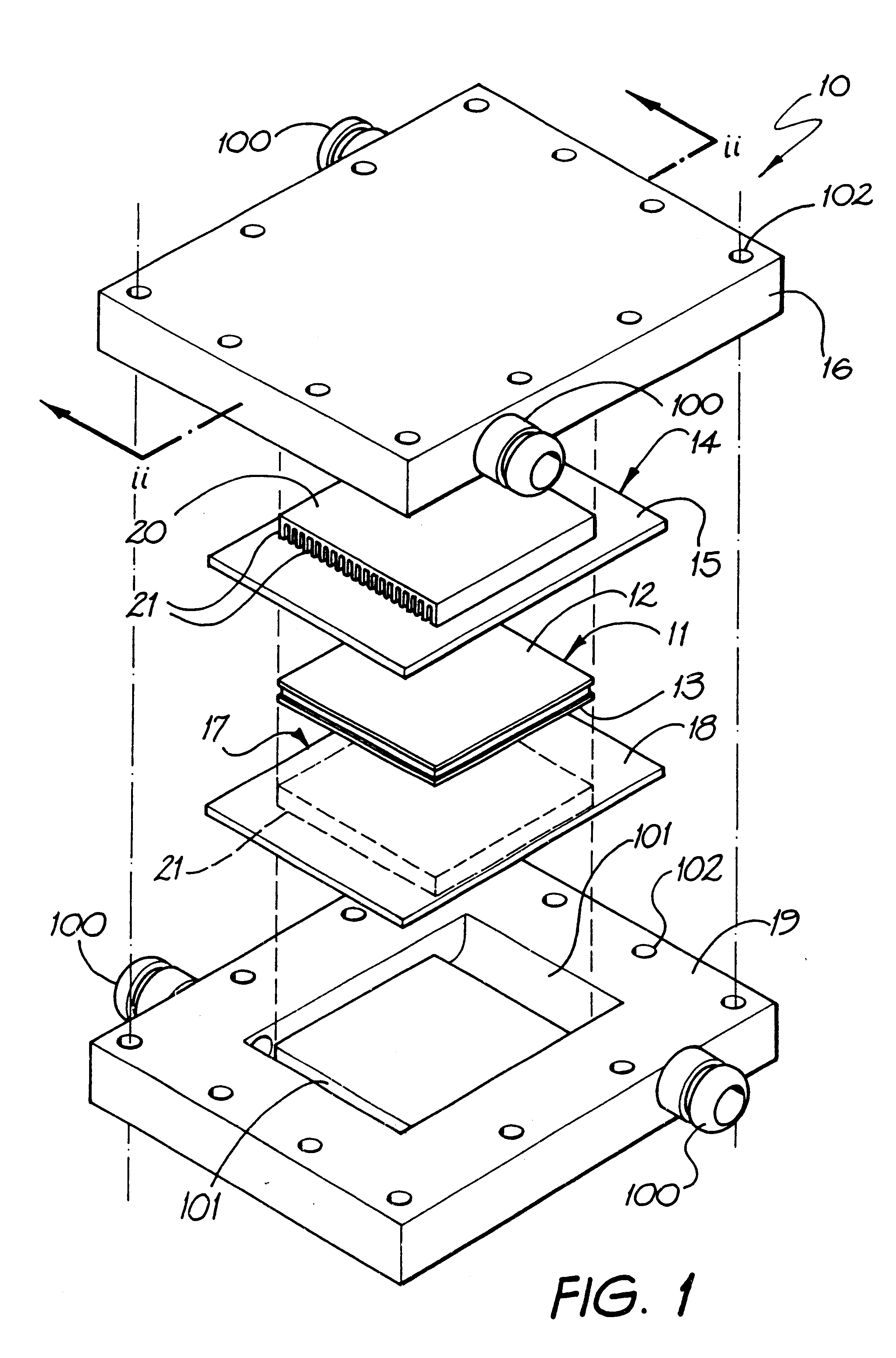

Heat exchanger for an electronic heat pump

InactiveUS6619044B2Low melting pointImprove thermal conductivityDomestic cooling apparatusMachines using electric/magnetic effectsPlate heat exchangerElectron

A heat exchanger 17 for an electronic heat pump 11 includes a thermally conductive base plate 18 having first and second surfaces, the first surface being flat and adapted to make intimate surface contact with a surface of the electronic heat pump and the second surface being obverse to the first surface and supporting an array of thermally conductive fins 21. The adjacent fins 21 define there between a plurality of micro channels.

Owner:HYDROCOOL

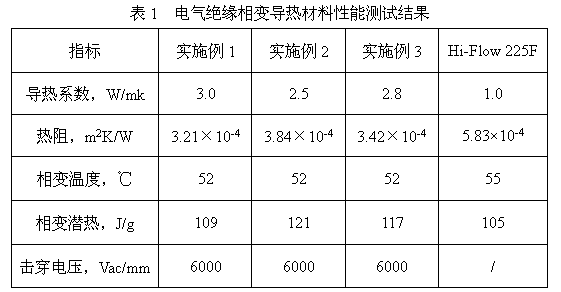

Electrical insulating phase-change heat conducting material and preparation method thereof

InactiveCN103849356AImprove thermal conductivityReduce thermal resistanceHeat-exchange elementsHeat conductingWorking temperature

The invention discloses an electrical insulating phase-change heat conducting material and a preparation method thereof. The electrical insulating phase-change heat conducting material is prepared from 4-12% of two-component molding liquid silicone rubber, 10-30% of paraffin-acrylic phase change microcapsules, 50-70% of heat-conducting powder, 1-2% of silane coupling agent, and 10-25% of ethenyl terminated silicon oil. The electrical insulating phase-change heat conducting material disclosed by the invention is high in heat conductivity coefficient, low in heat resistance, and good in electrical insulating property, is in a solid state at room temperature, can be conveniently attached to the surface of a cooling fin or an electronic component; the electrical insulating phase-change heat conducting material is subjected to phase change to become soft (but not become liquid) when the working temperature of the component is achieved, the electrical insulating phase-change heat conducting material plays an electric insulating effect when the contact thermal resistance is reduced and the heat-conducting property is improved, a short circuit of the electric component is not caused, and the safety and the reliability of the electronic component are improved.

Owner:NO 33 RES INST OF CHINA ELECTRONICS TECHNOOGY GRP

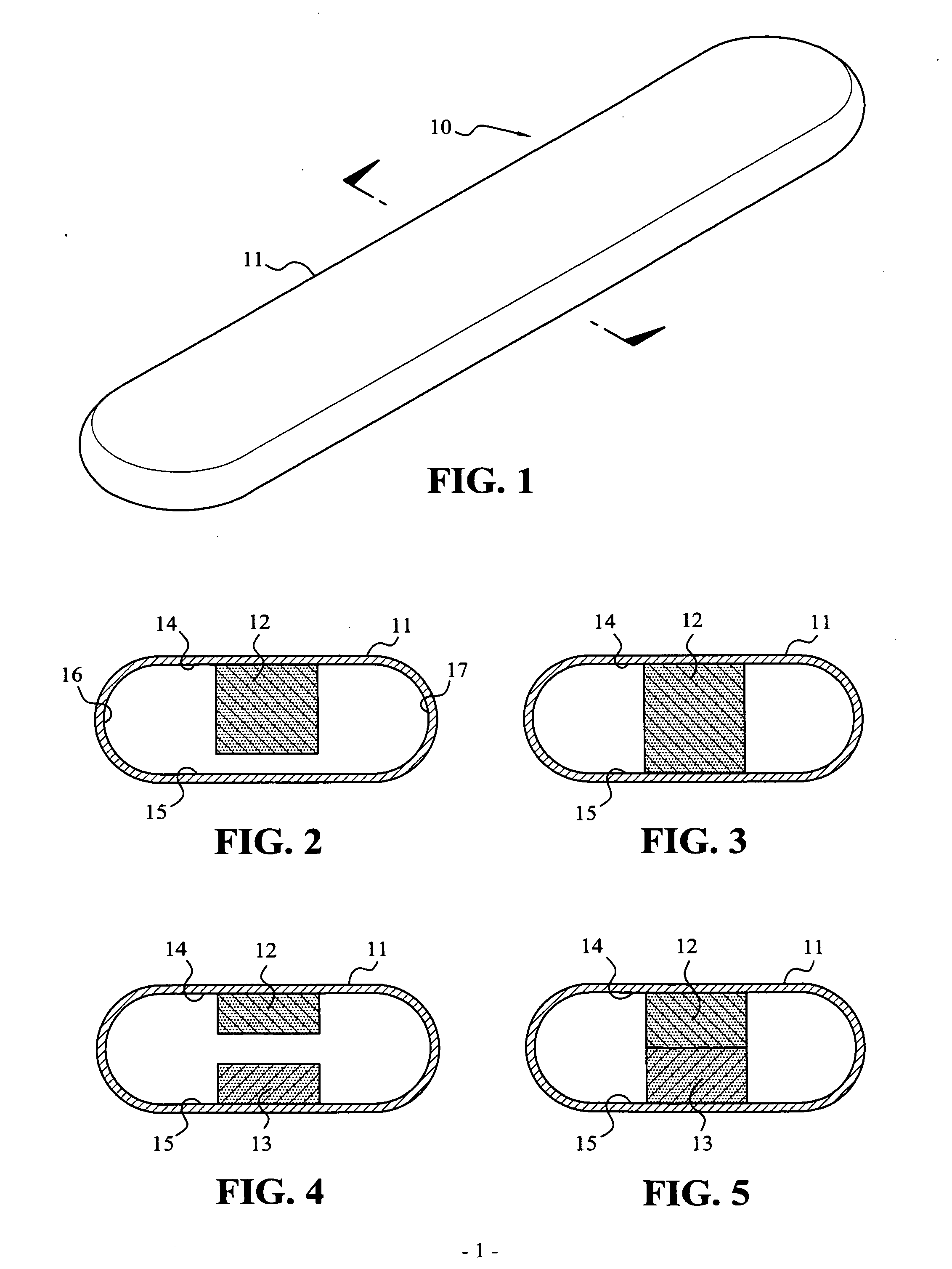

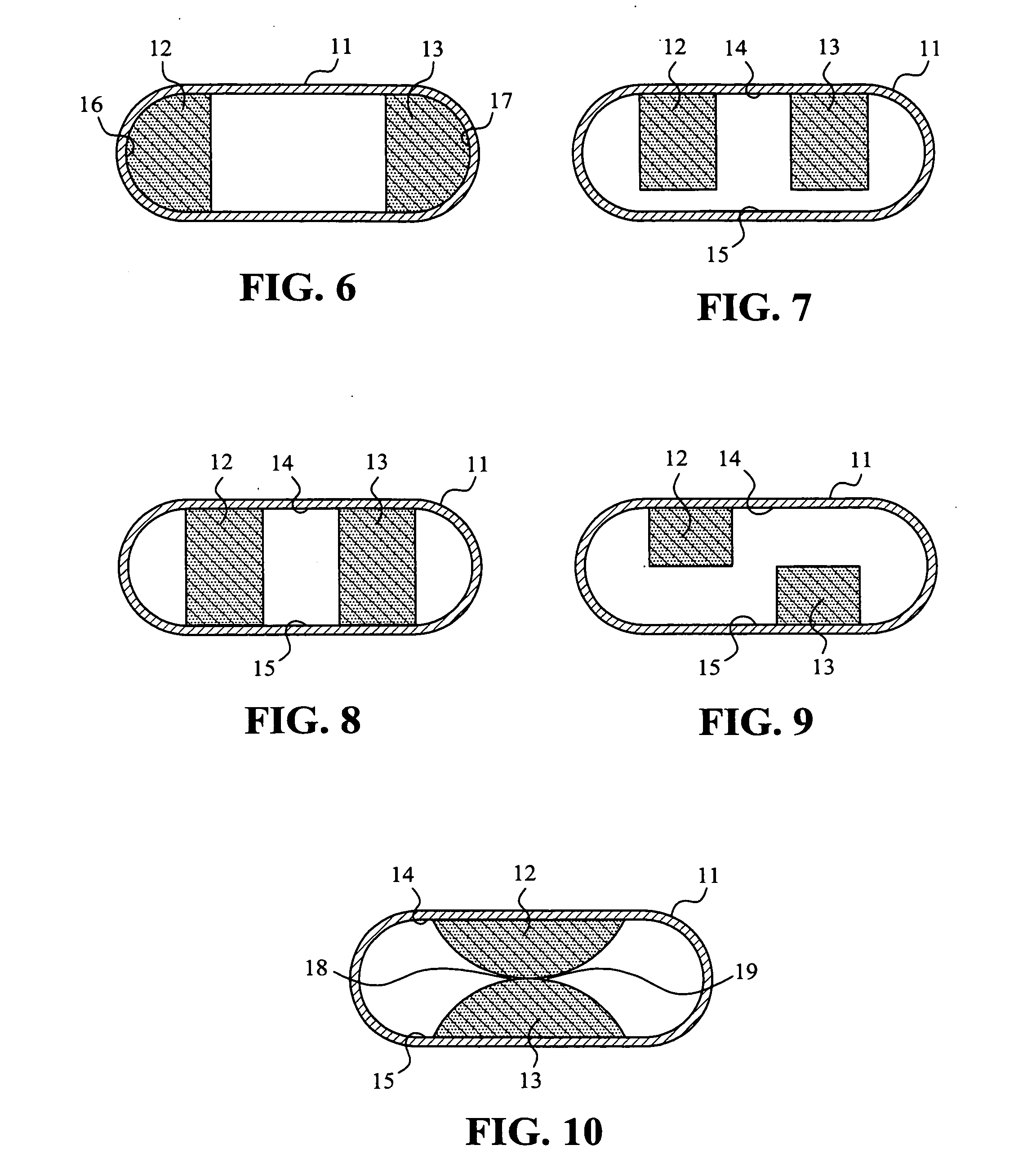

Ultra-thin heat pipe

InactiveUS20100266864A1Fully compressedReduce thermal contact resistanceIndirect heat exchangersHeat exchange apparatusMetalHeat pipe

An ultra-thin heat pipe comprises a flat metal tube and one or more sintered powder portions. The flat metal tube has an upper tube wall, a lower tube wall and two lateral walls connecting with the upper tube wall and the lower tube wall. The sintered powder portions extends axially and are formed on an inner face of at least one of the upper tube wall, the lower tube wall and the lateral walls such that vapor passage space is formed at one or more sides of the sintered powder portions.

Owner:YEH CHIANG TECH CORP

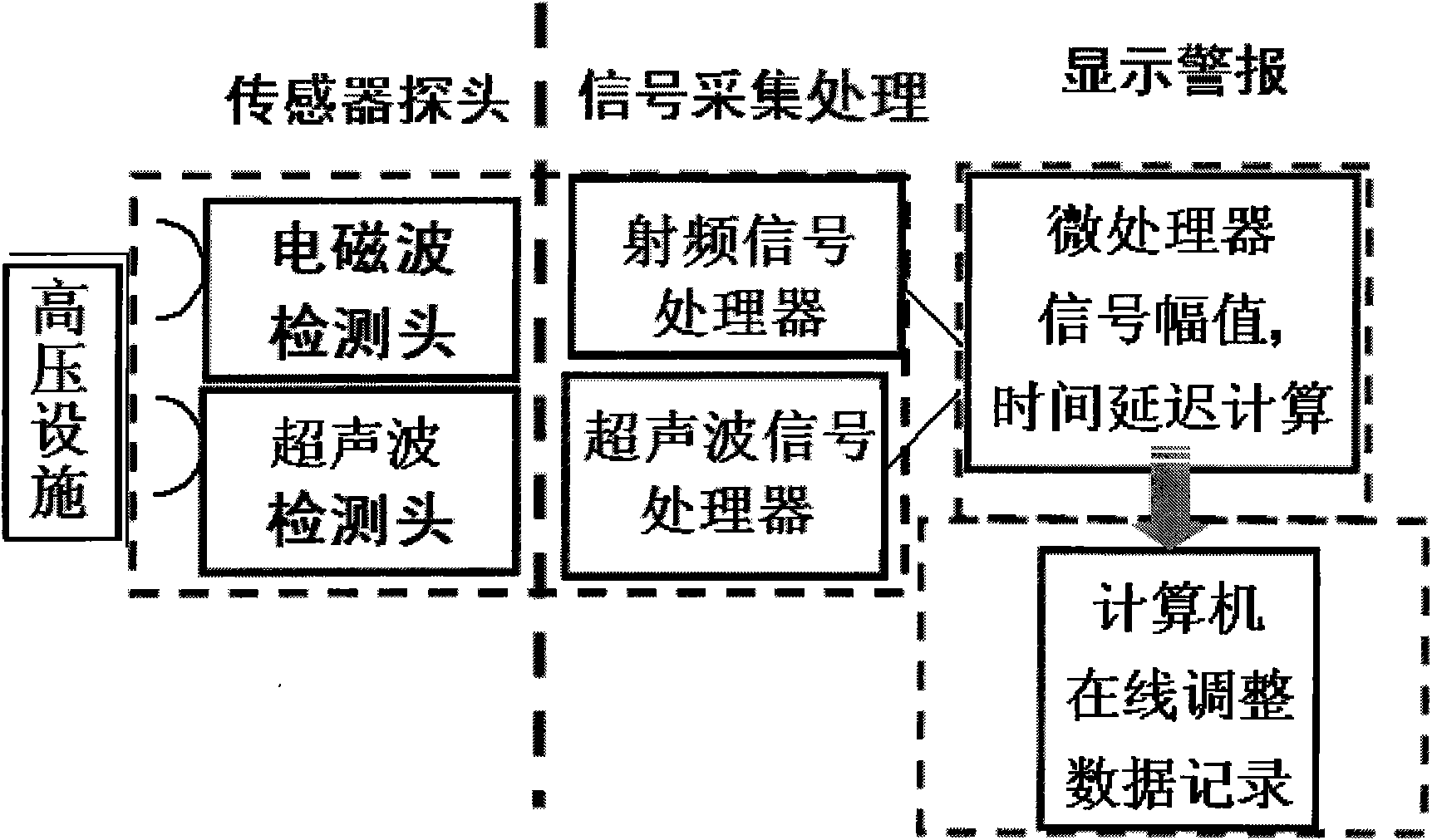

Acoustic-electric detection device for insulation defects of power cable

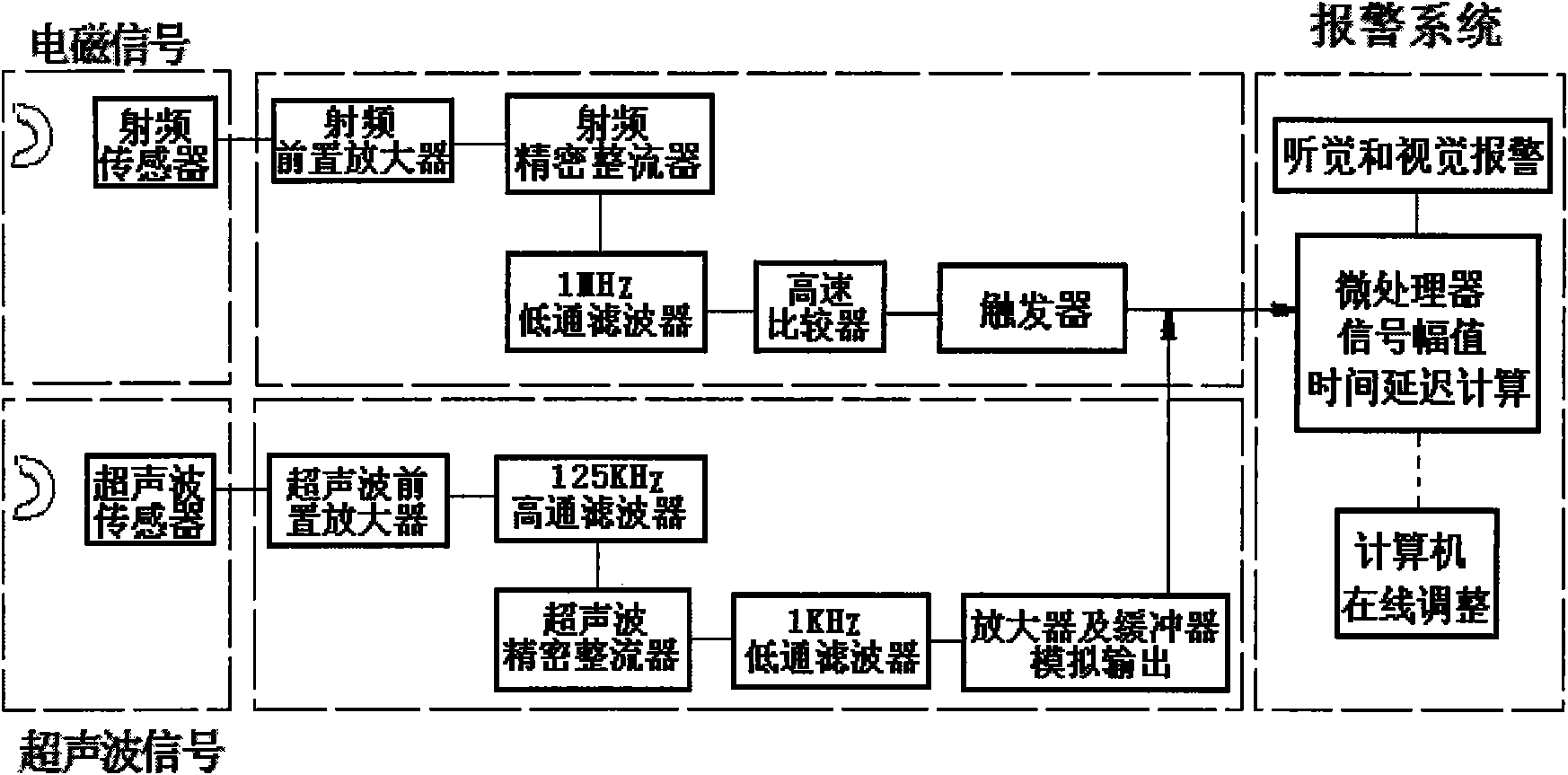

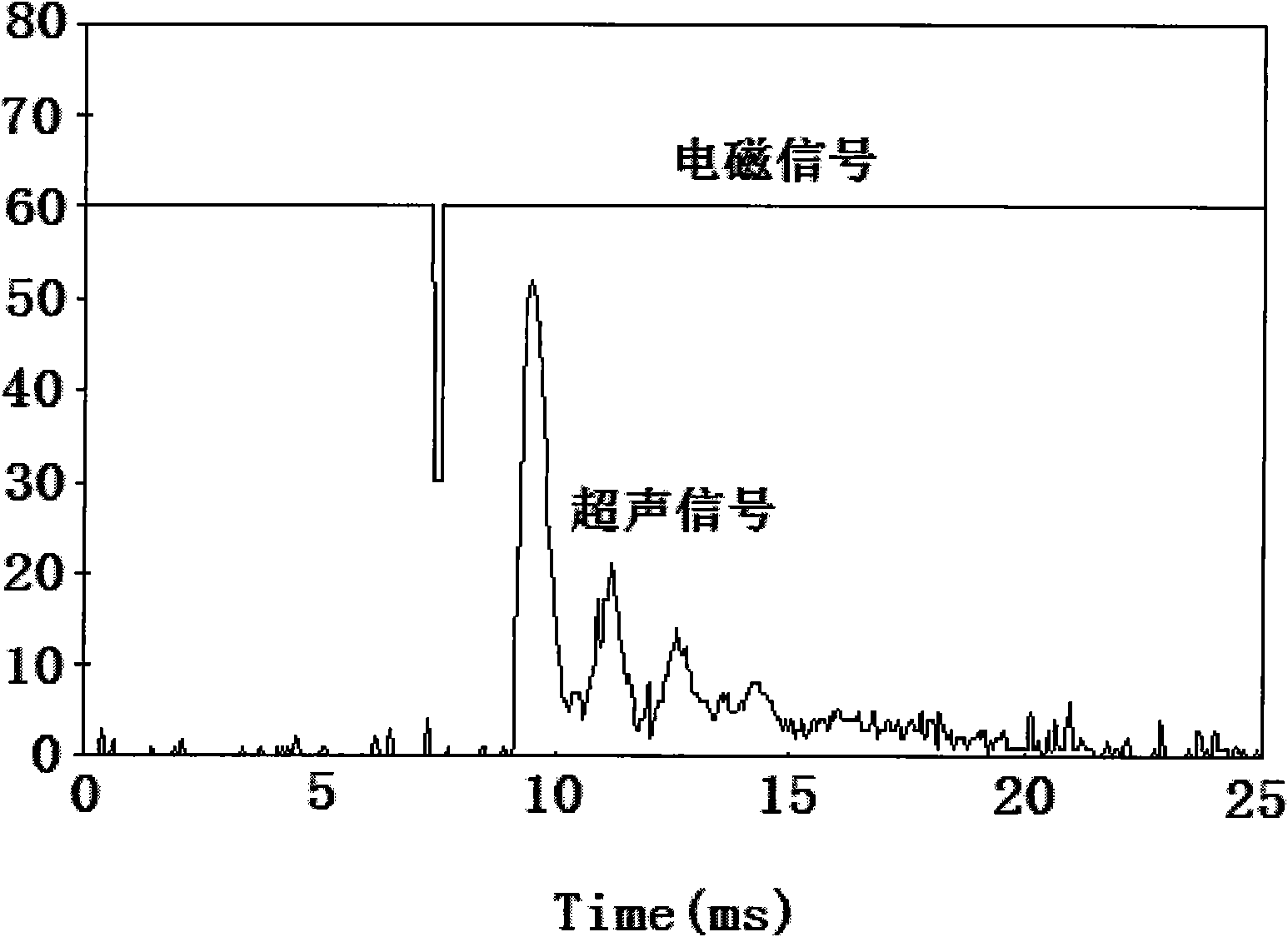

InactiveCN101666850ARealize detection and alarmHigh sensitivityTesting dielectric strengthElectricityPower cable

The invention relates to an acoustic-electric detection device for the insulation defects of a power cable, characterized by comprising a cable to be detected and a two-channel detection mechanism connected with the cable to be detected. The output end of the two-channel detection mechanism is connected with a receiving device and comprises an electromagnetic wave detecting head and an ultrasonicwave detecting head; the electromagnetic wave detecting head is connected with the cable to be detected; the surface of the ultrasonic wave detecting head is coated by silicone grease; the electromagnetic wave detecting head and the ultrasonic wave detecting head are electrically connected with respective signal acquisition processors and transfer cable insulation defect signals detected by the two-channel detection mechanism to the signal acquisition processors; and the signals processed by the signal acquisition processors are sent to a signal displaying and alarming system to detect and alarm the insulation defects of the cable. Partial defects in the cable are found and positioned as early as possible by the online monitoring or the routing inspection of the partial discharge of the cable. The invention finds the partial defects in the cable as early as possible, grasps the operation conditions of the cable in time and prevents major accidents from occurring.

Owner:YANAN POWER SUPPLY BUREAU

Heat conductive phase-change material and production method thereof

The invention relates to a heat conductive phase-change material which consists of the following components in percentage by weight: 75-90% of heat conductive filler, 2-8% of low-melting-point solid resin, 5-15% of liquid resin, 0.01-1% of an antioxidant and 0.02-2% of a coupling agent, and the phase-change material is prepared through a production method of mixing raw materials, mixing the heat conductive filler, pressing and forming, and cooling. The heat conductive phase-change material, which is prepared by mixing the heat conductive filler, the low-melting-point solid resin, the liquid resin, the antioxidant and the coupling agent, disclosed by the invention has the advantages that the phase-change material is in a shape of flaky solid at room temperature, so that the material is convenient in using and operation and can be directly attached on the surface of a heat-radiating component; when the component runs to the working temperature of the heat conductive phase-change material, phase change occurs and the material becomes soft, so as to wet the surface of the component to a great extent, and contact thermal resistance is reduced to the lowest so as to guarantee a heat conductive interstitial property better than that of heat conductive grease or a graphite flake; in addition, with excellent thixotropy, the material, when being used in a vertical direction, is protected away from circumstance of overflow or flowing.

Owner:PINGHU ALLIED IND

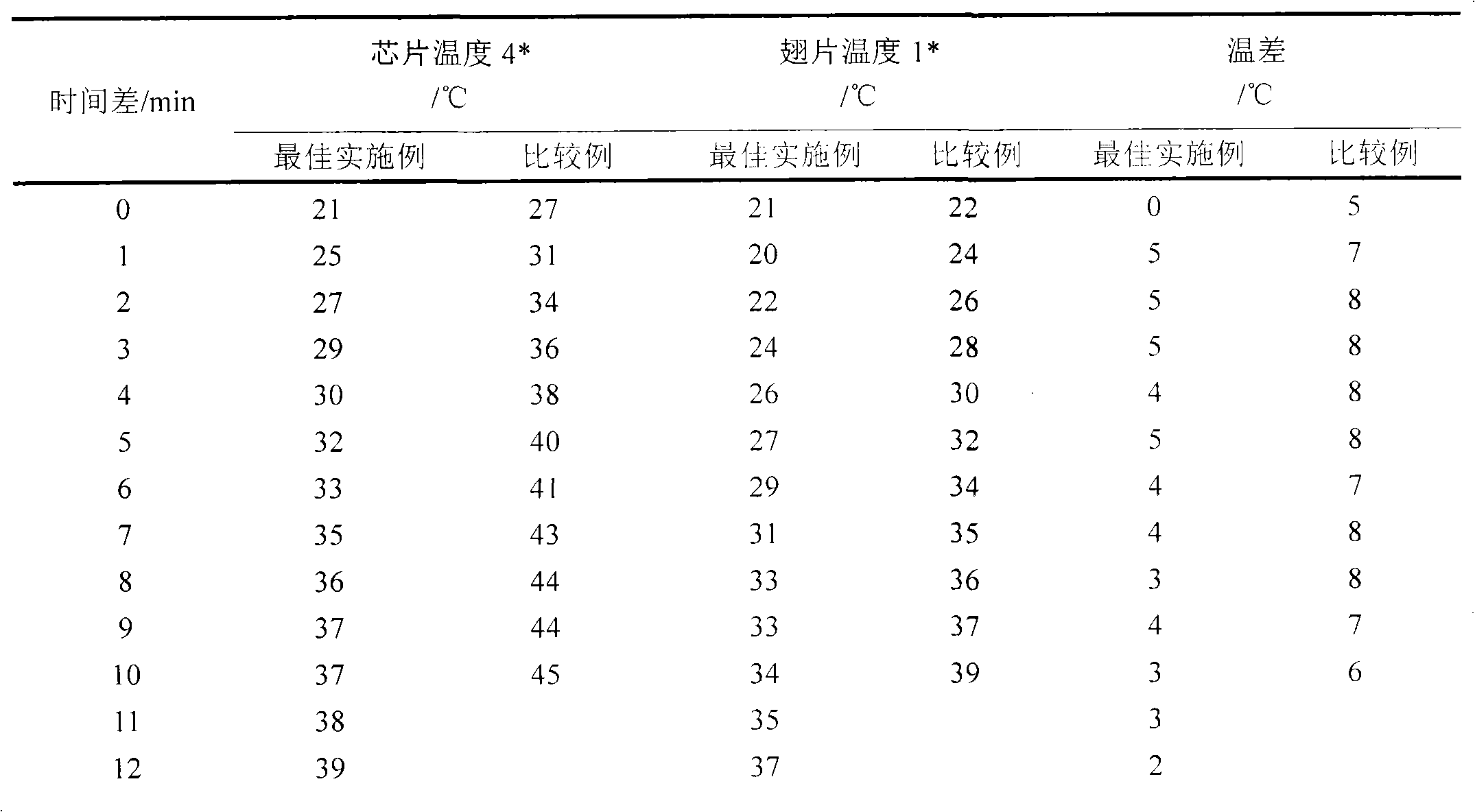

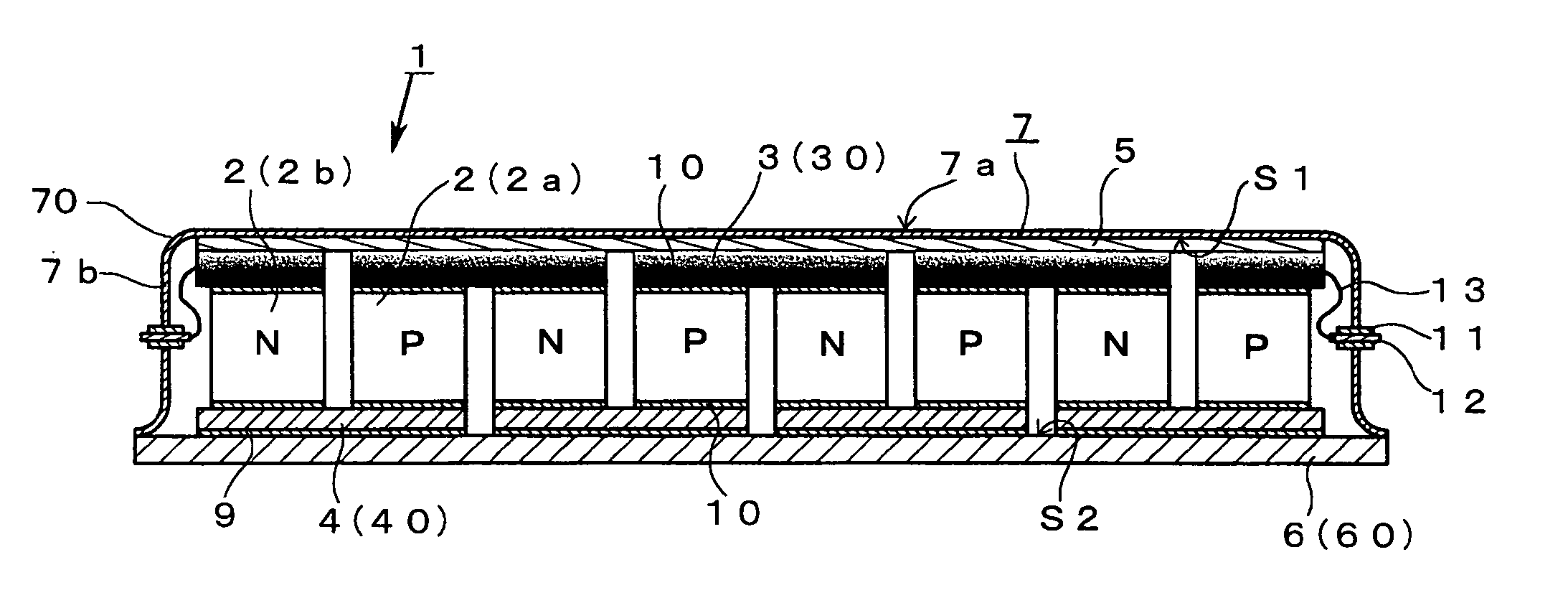

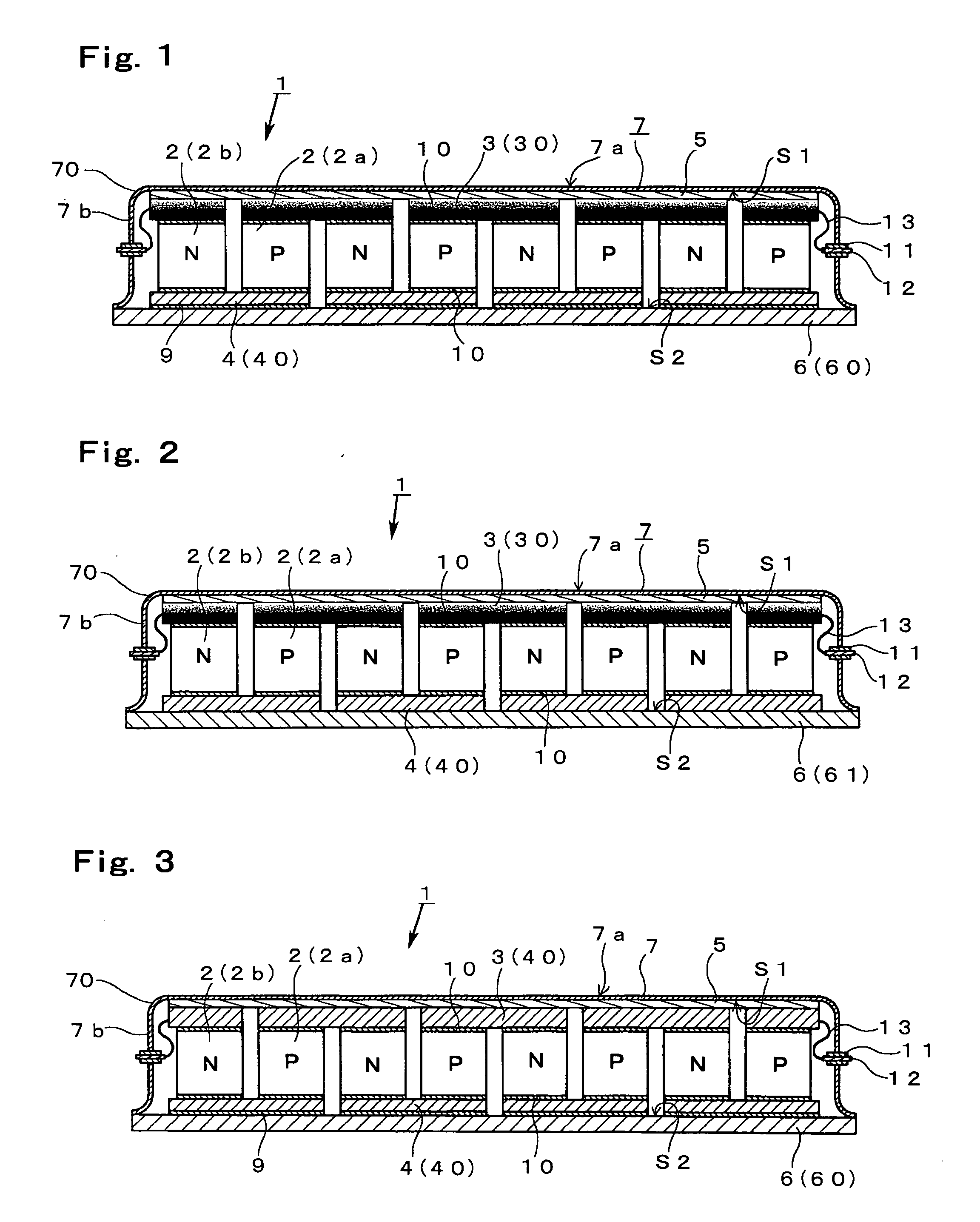

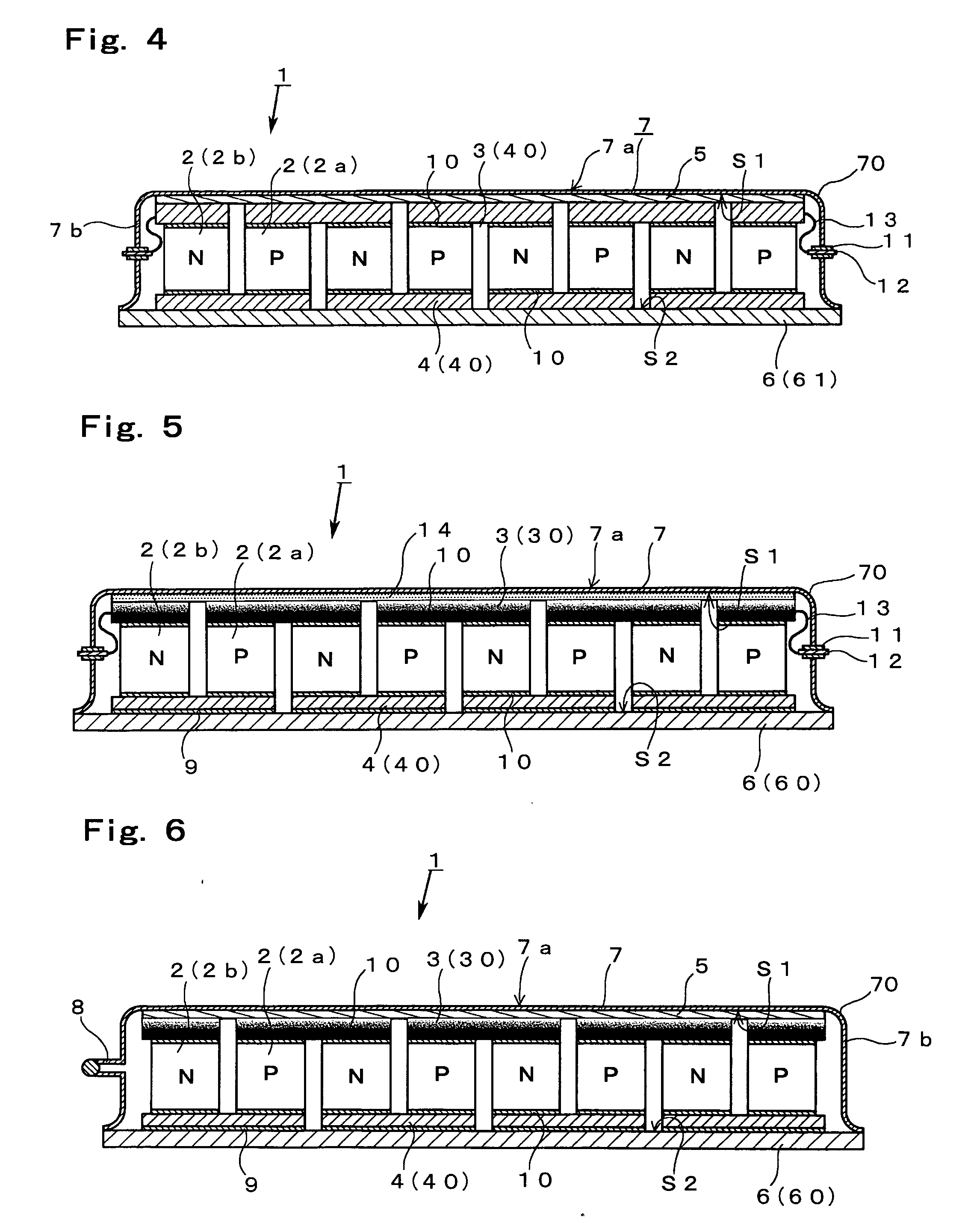

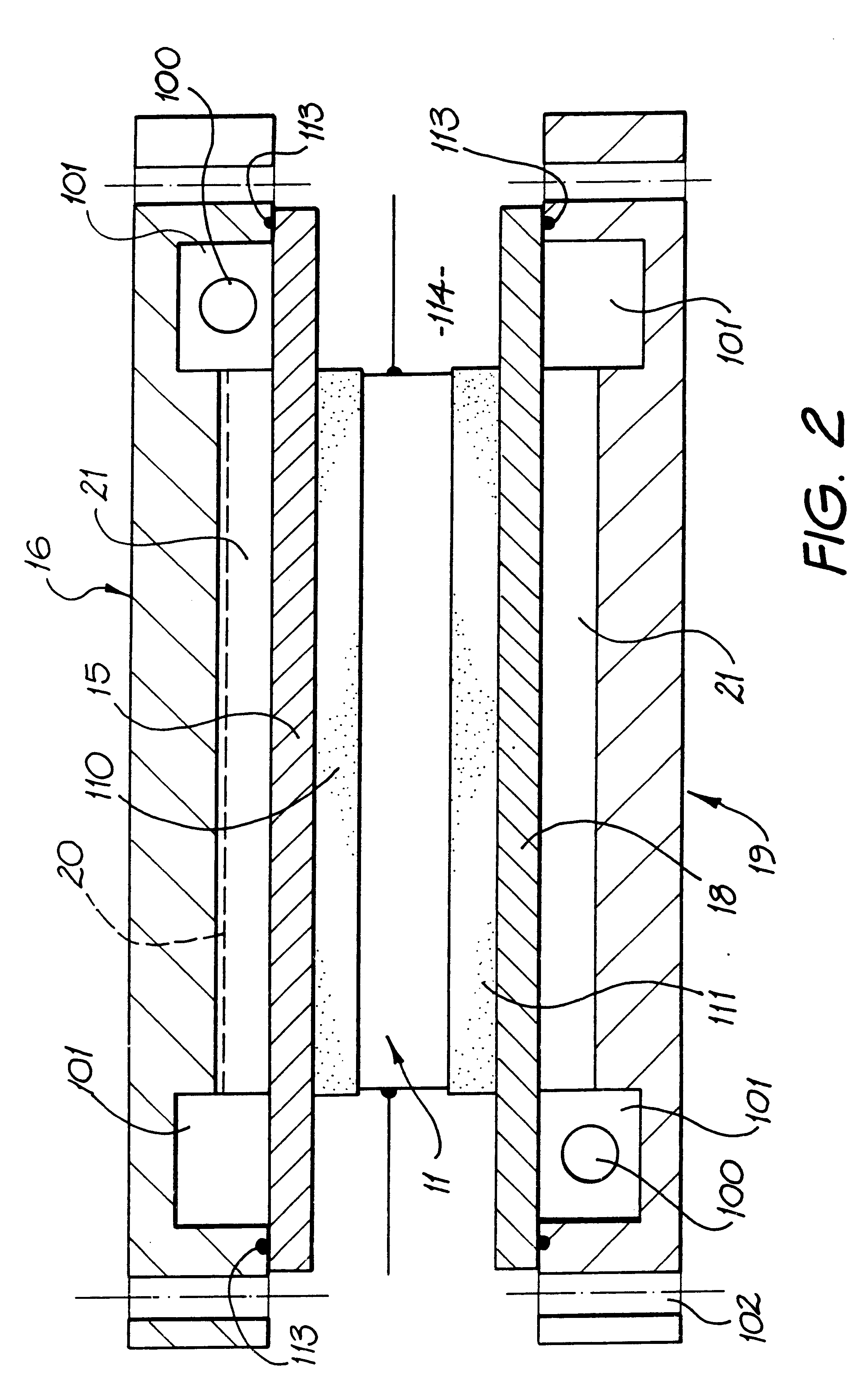

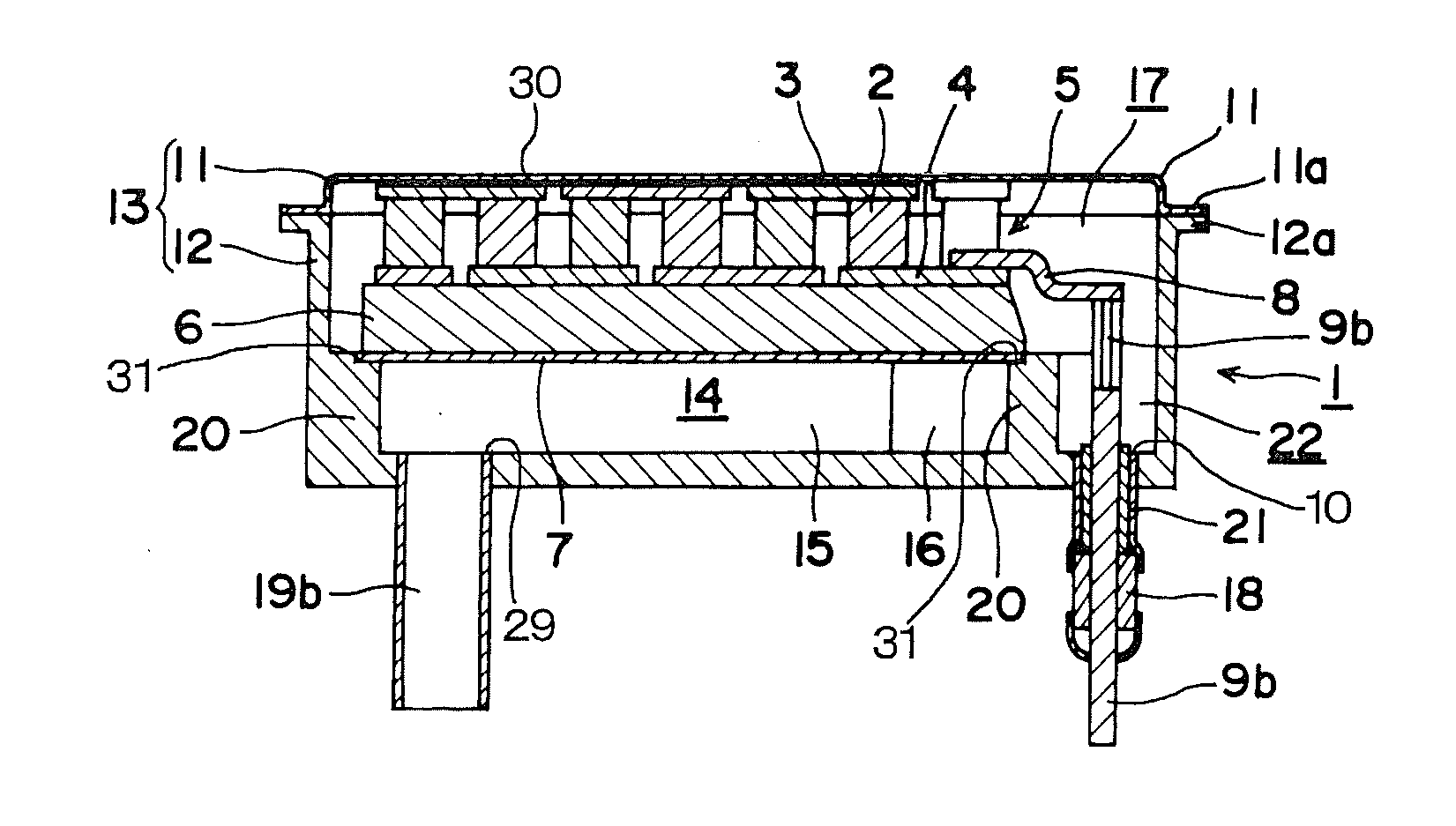

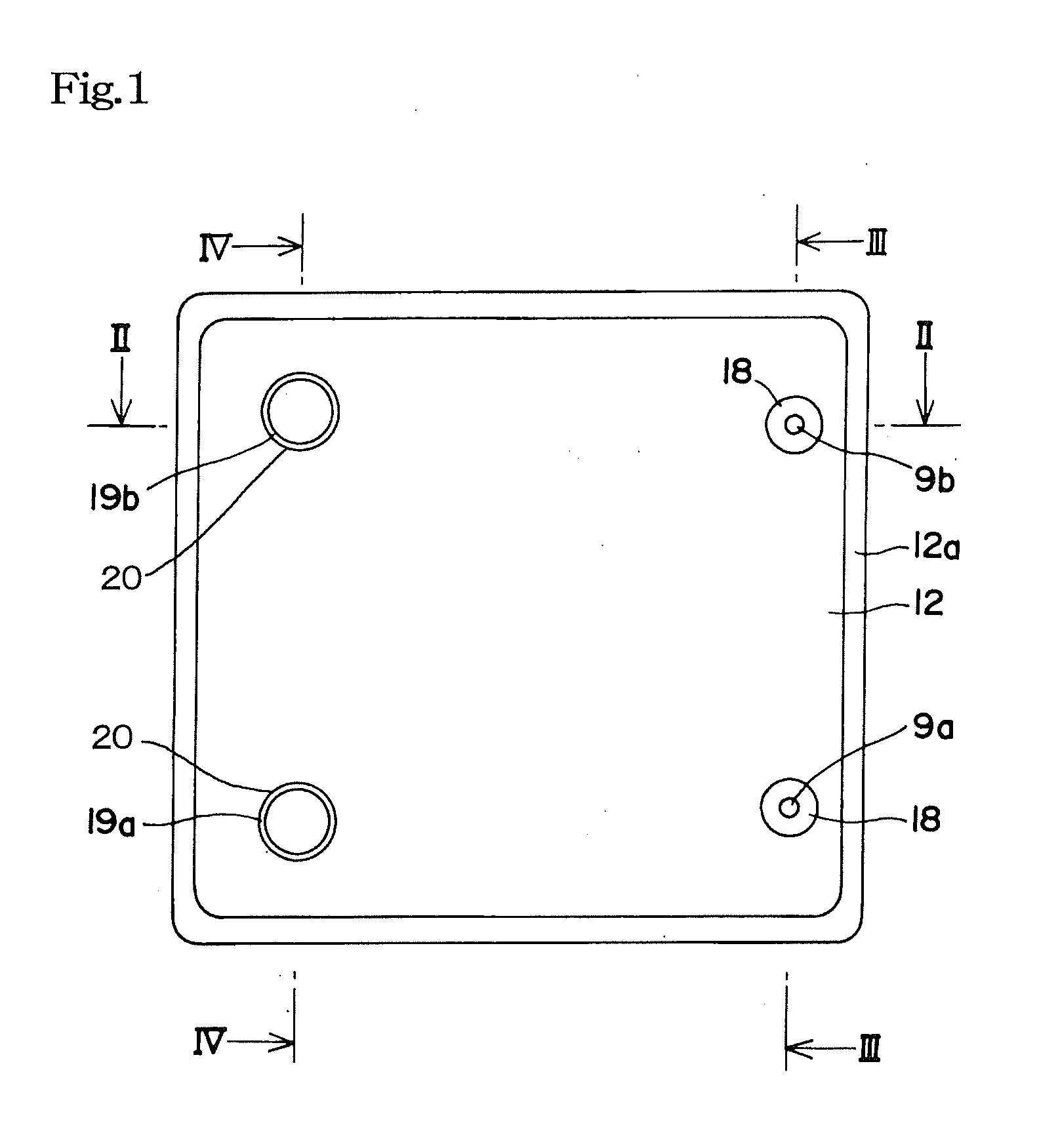

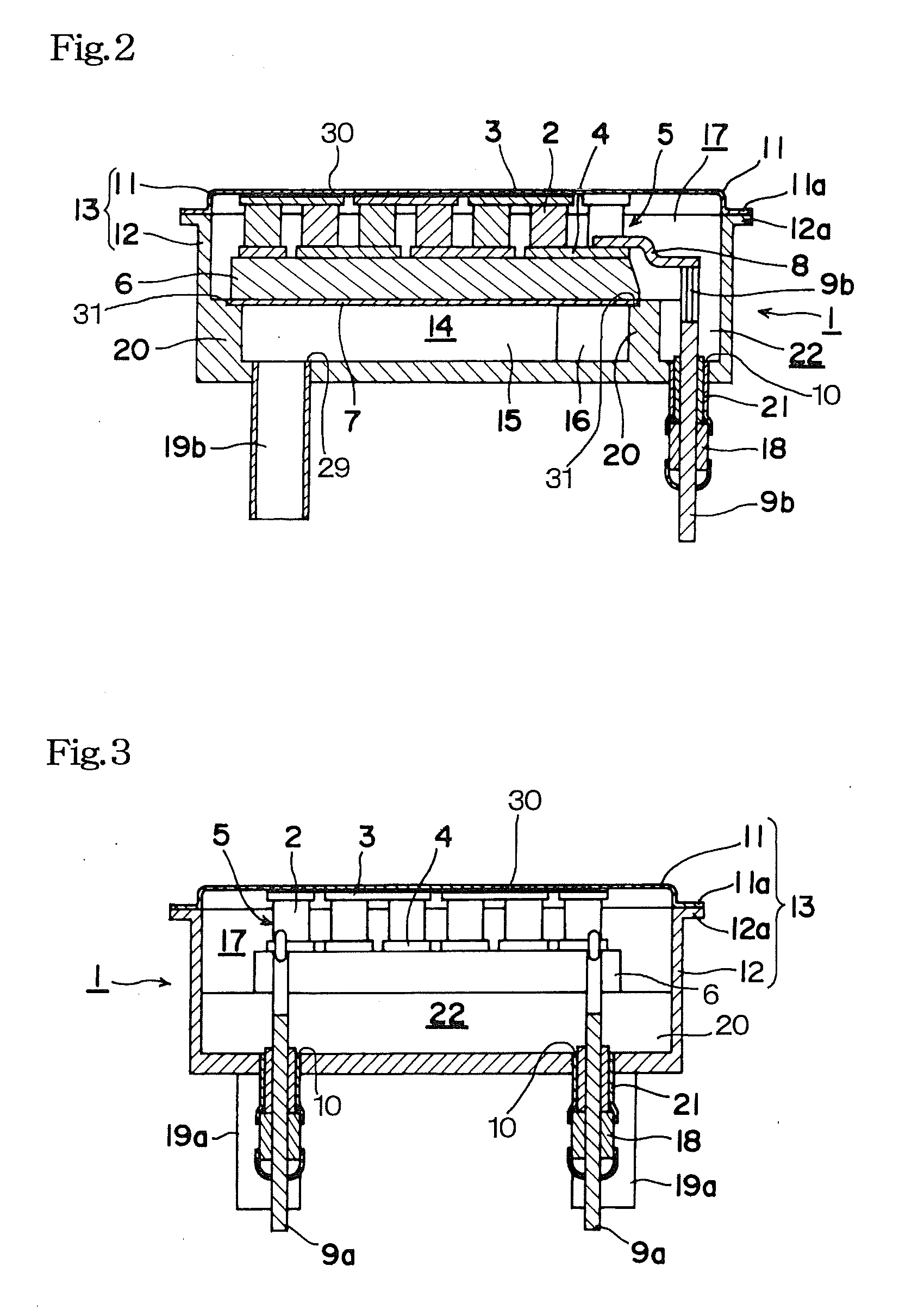

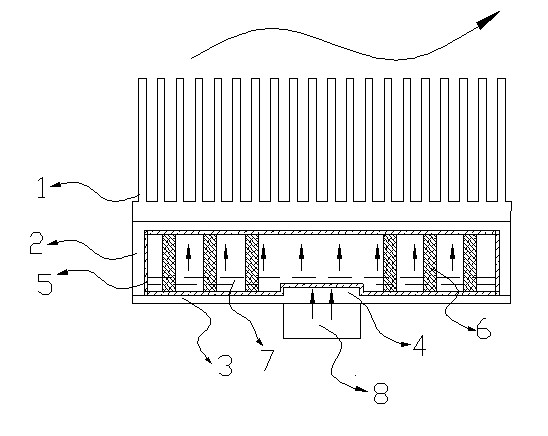

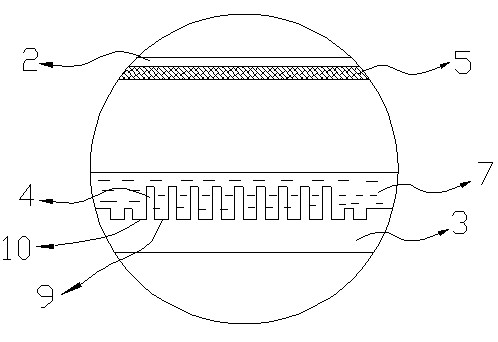

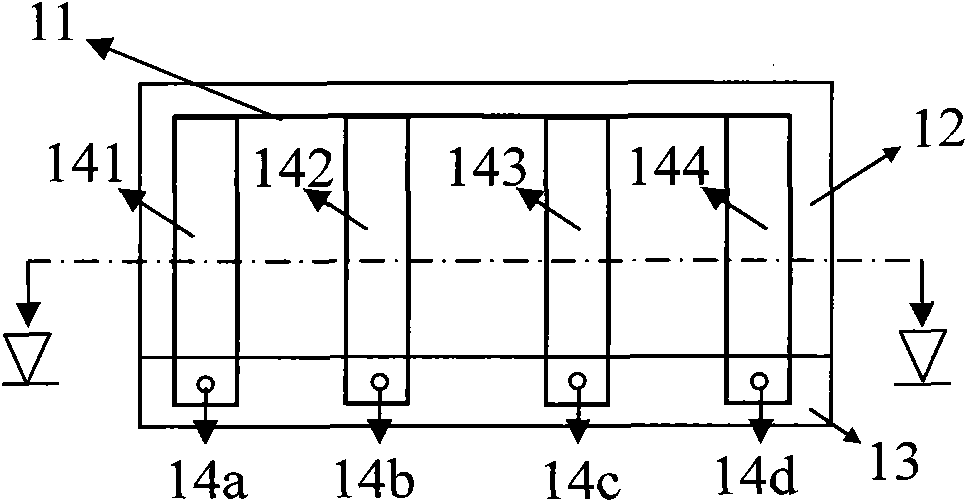

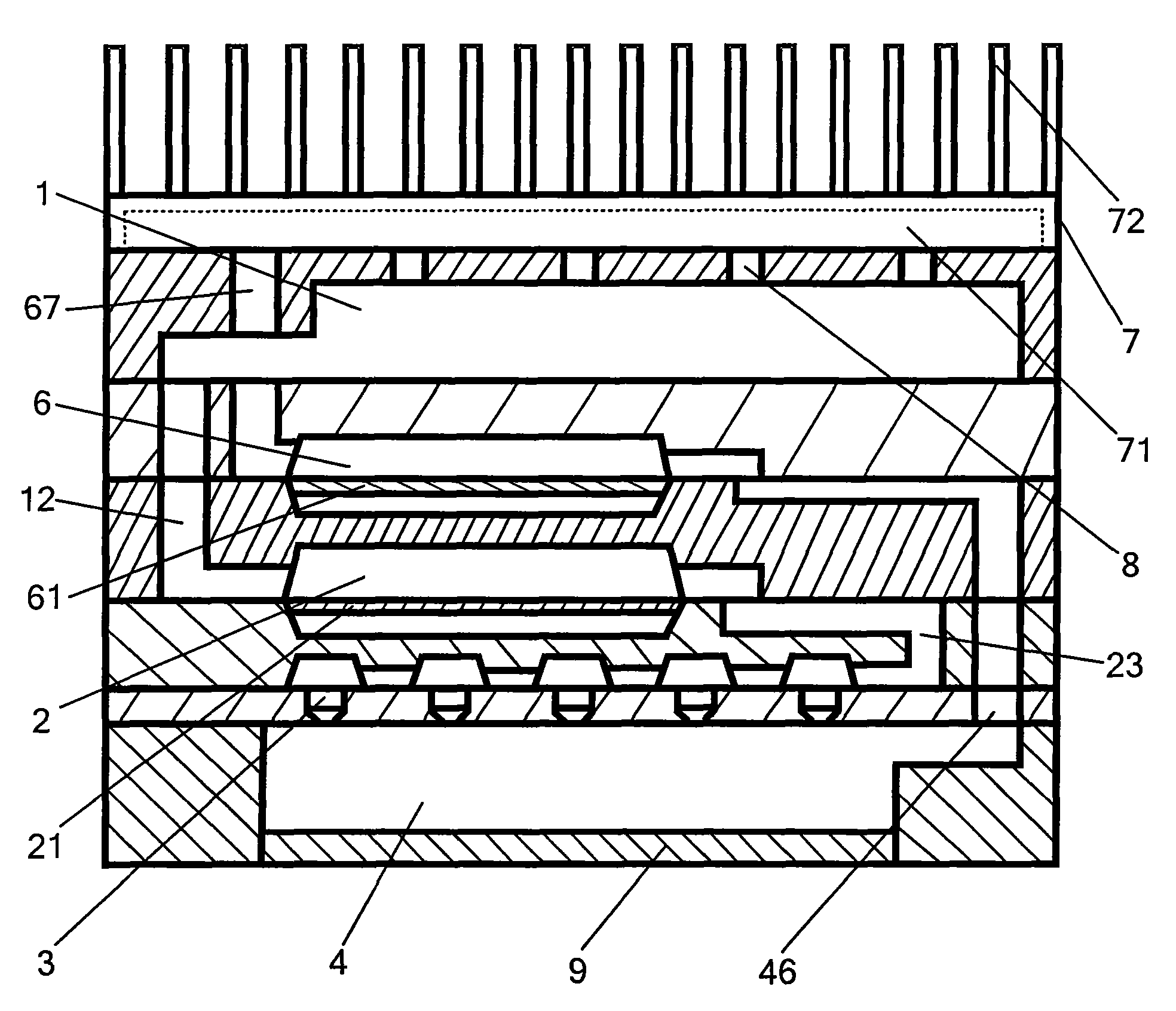

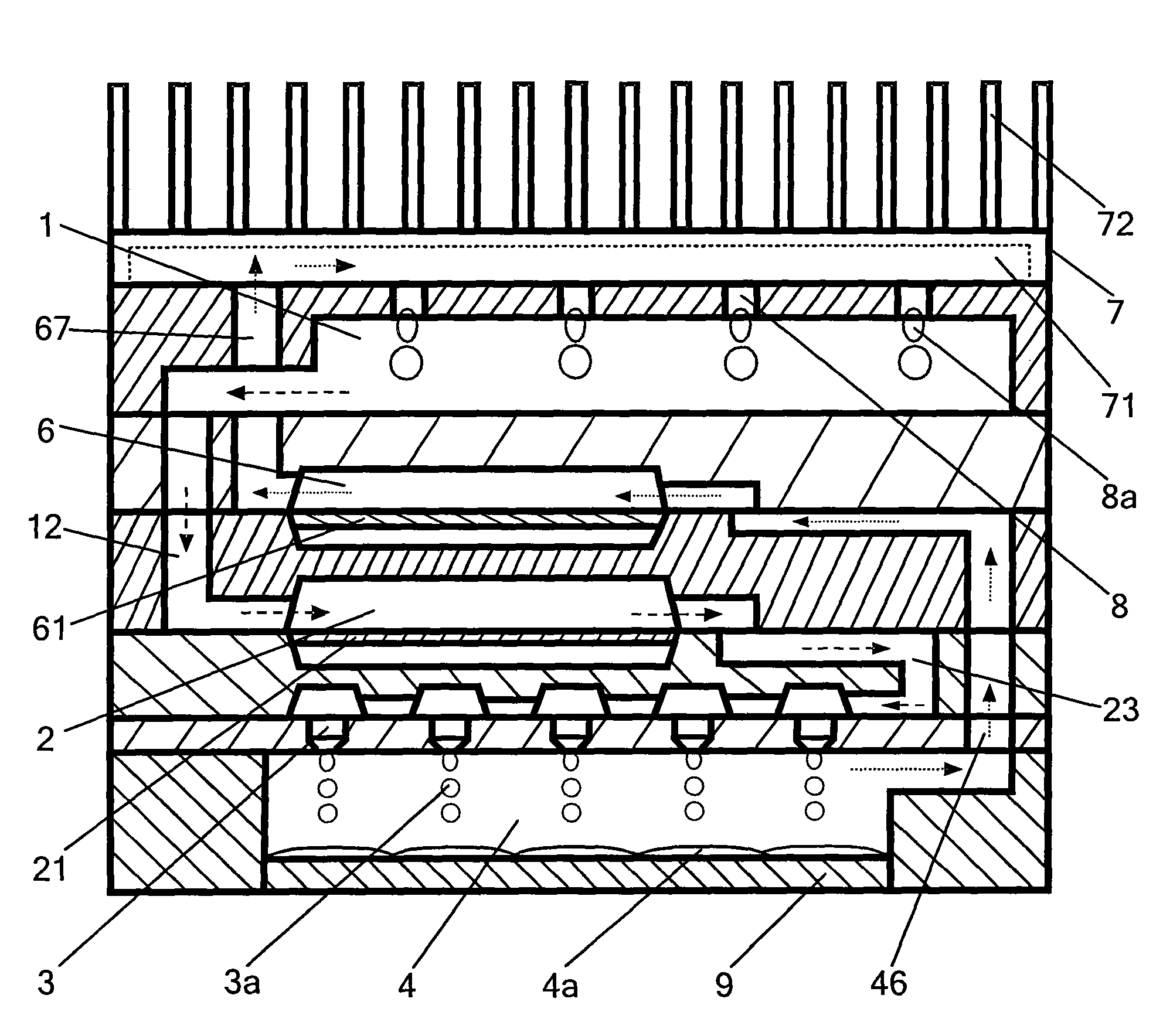

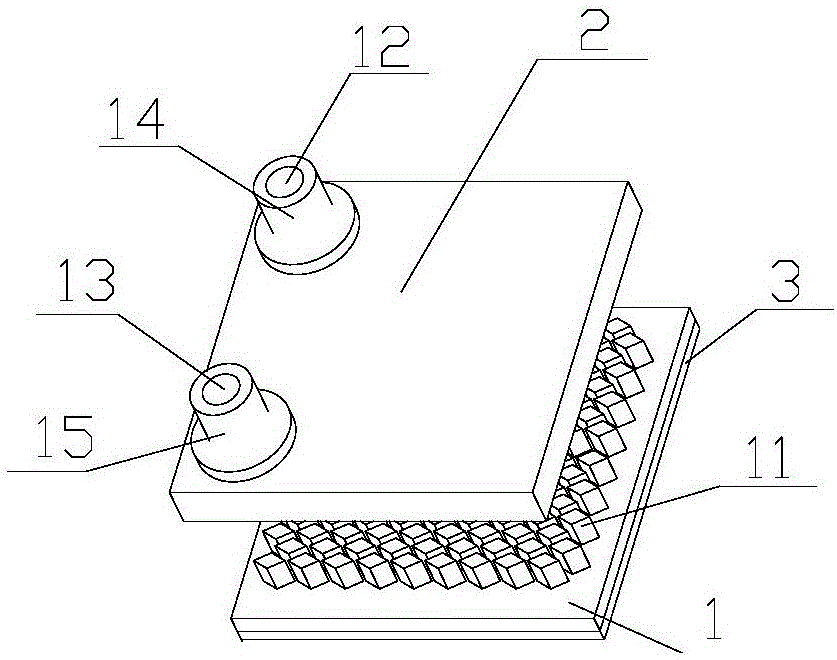

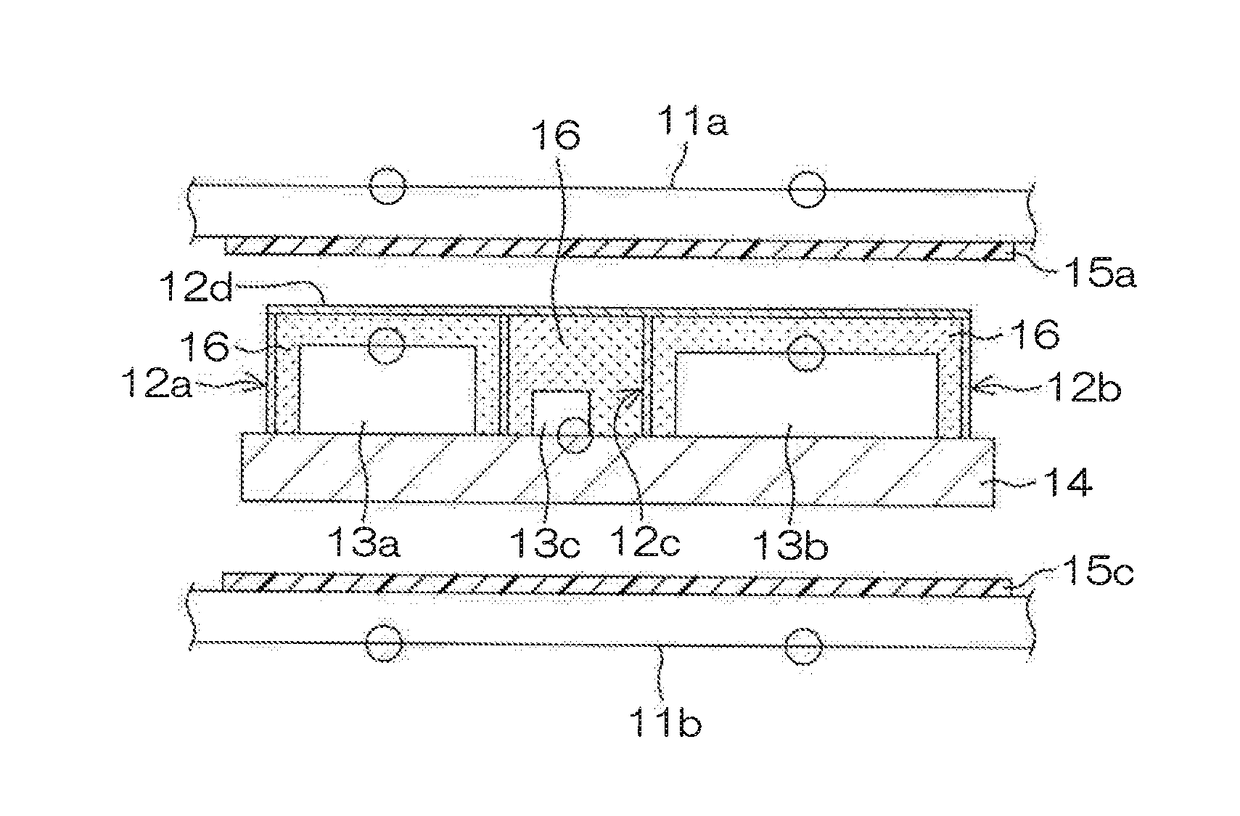

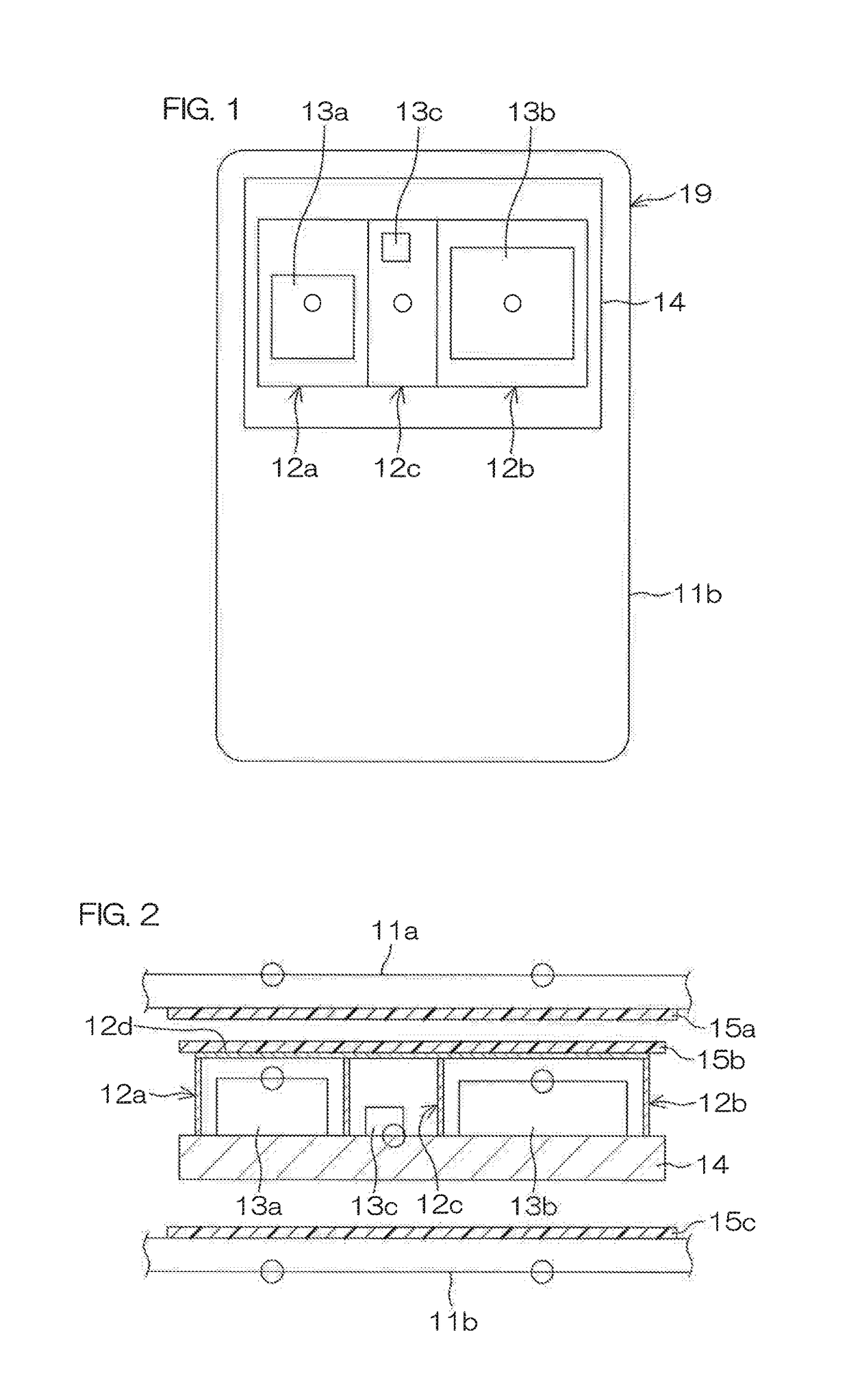

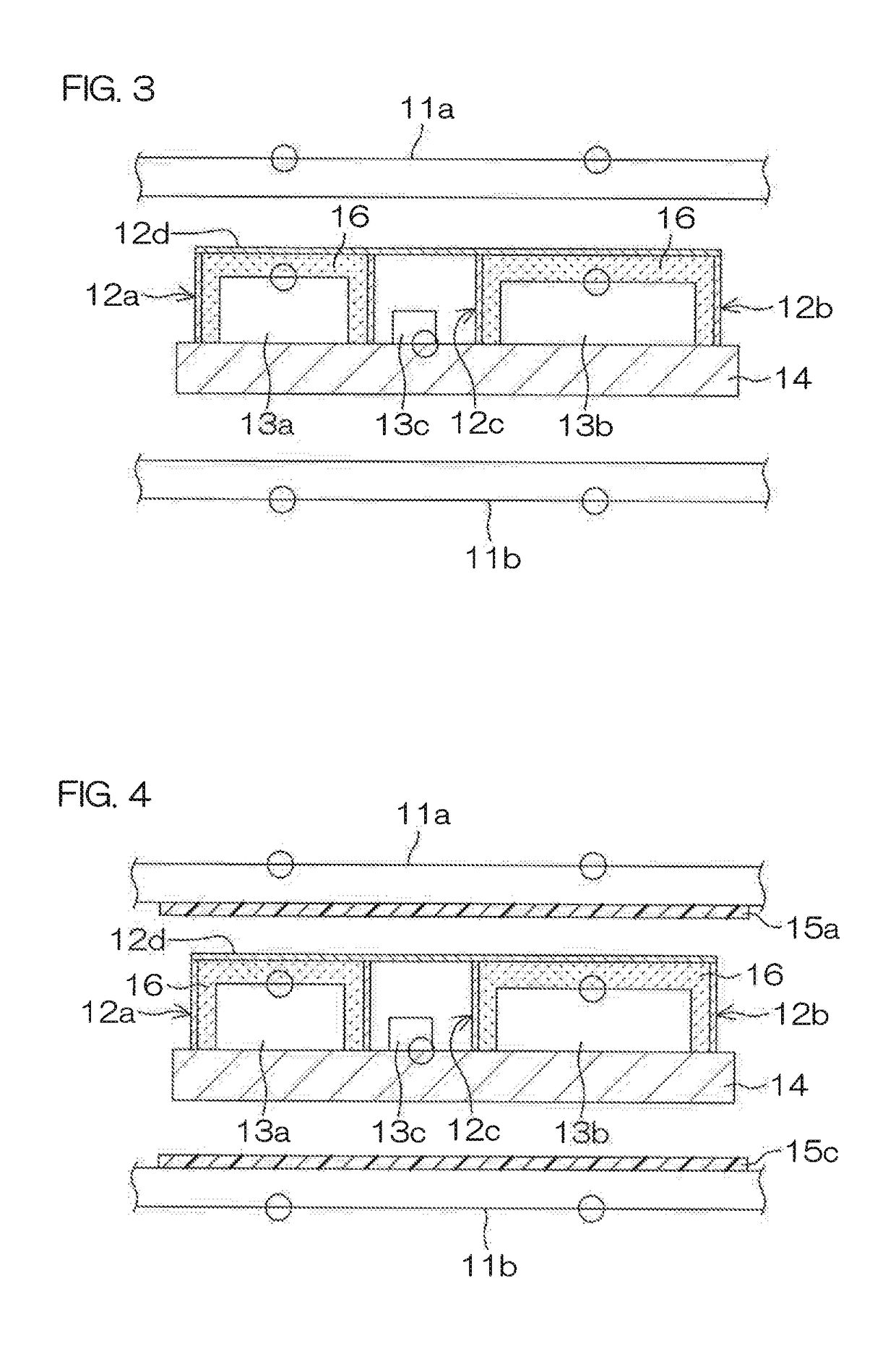

Packaged thermoelectric conversion module

InactiveUS20110265838A1Thermal contact resistance at the contact interface can be reducedReduce thermal contact resistanceThermoelectric device with peltier/seeback effectEngineeringThermal contact

A packaged thermoelectric conversion module that does not need a pressing mechanism for reducing a thermal contact resistance or an application of a thermal-conductive grease between a heat source of a thermoelectric conversion module sealed in an airtight container, wherein an interior of an airtight container 13 containing a thermoelectric conversion module 5 is decompressed or evacuated, wherein the interior of the airtight container 13 is partitioned into two chambers 14 and 17 by a partition plate 7, wherein one chamber 17 is provided with the thermoelectric conversion module 5 and electrodes 9a and 9b led out to the outside of the airtight container 13, while the other chamber 14 is provided with a flow path 16 for introducing a thermal medium 26 or 25 from an external thermal medium supplying source and circulating the thermal medium 26 or 25 between the chamber 14 and the external thermal medium supply source, and heat is transferred to or received from one surface of the thermoelectric semiconductor 2 by the thermal medium 26 or 25 via the partition plate 7, while heat is transferred or received between the other surface of the thermoelectric semiconductor 2 and an external heat source via the airtight container 13.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

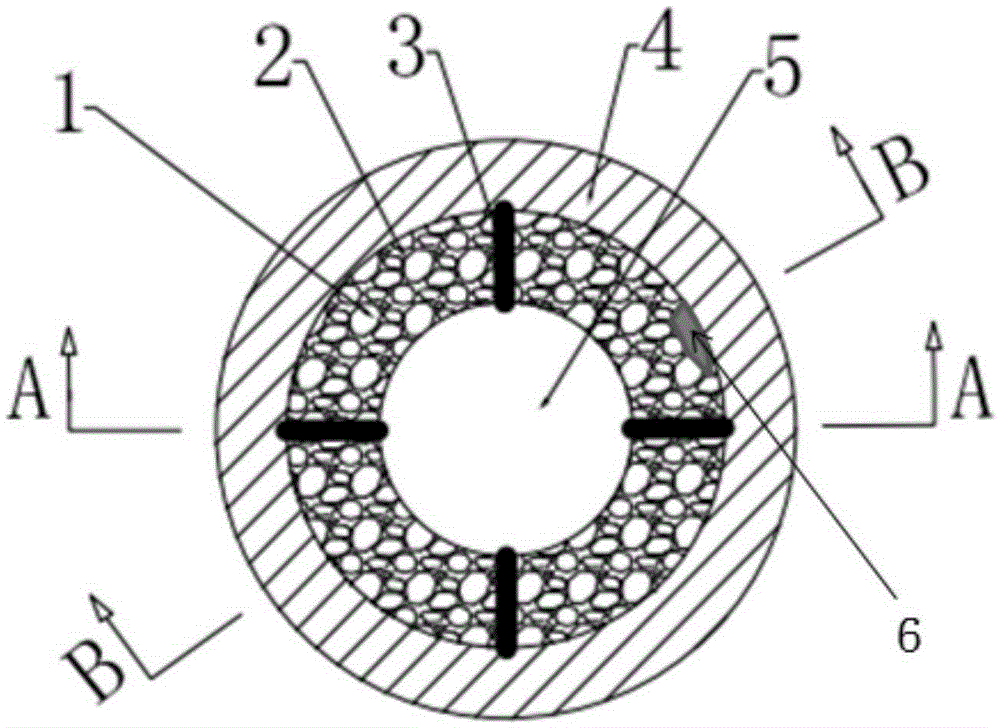

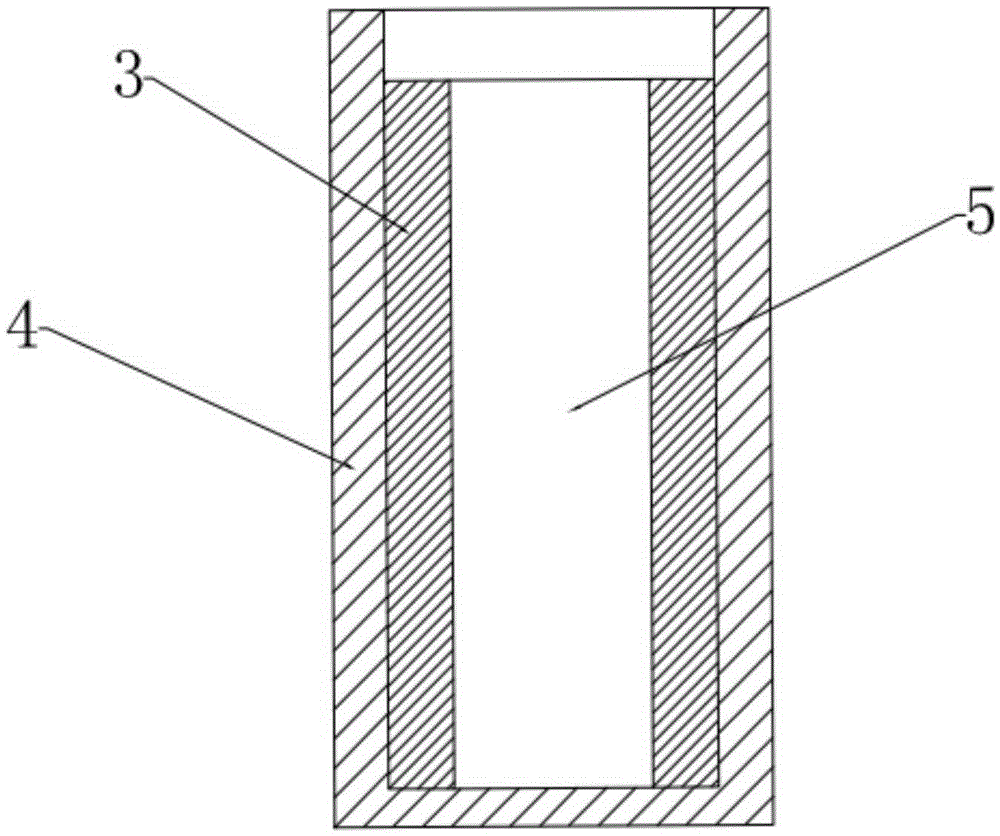

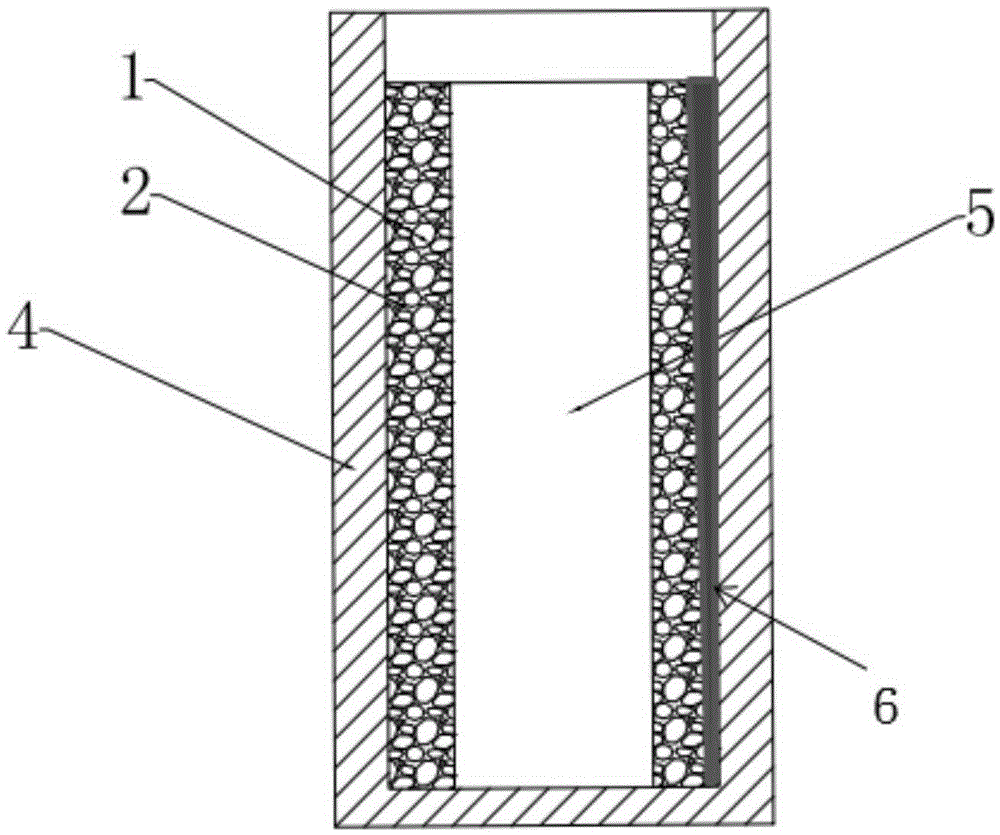

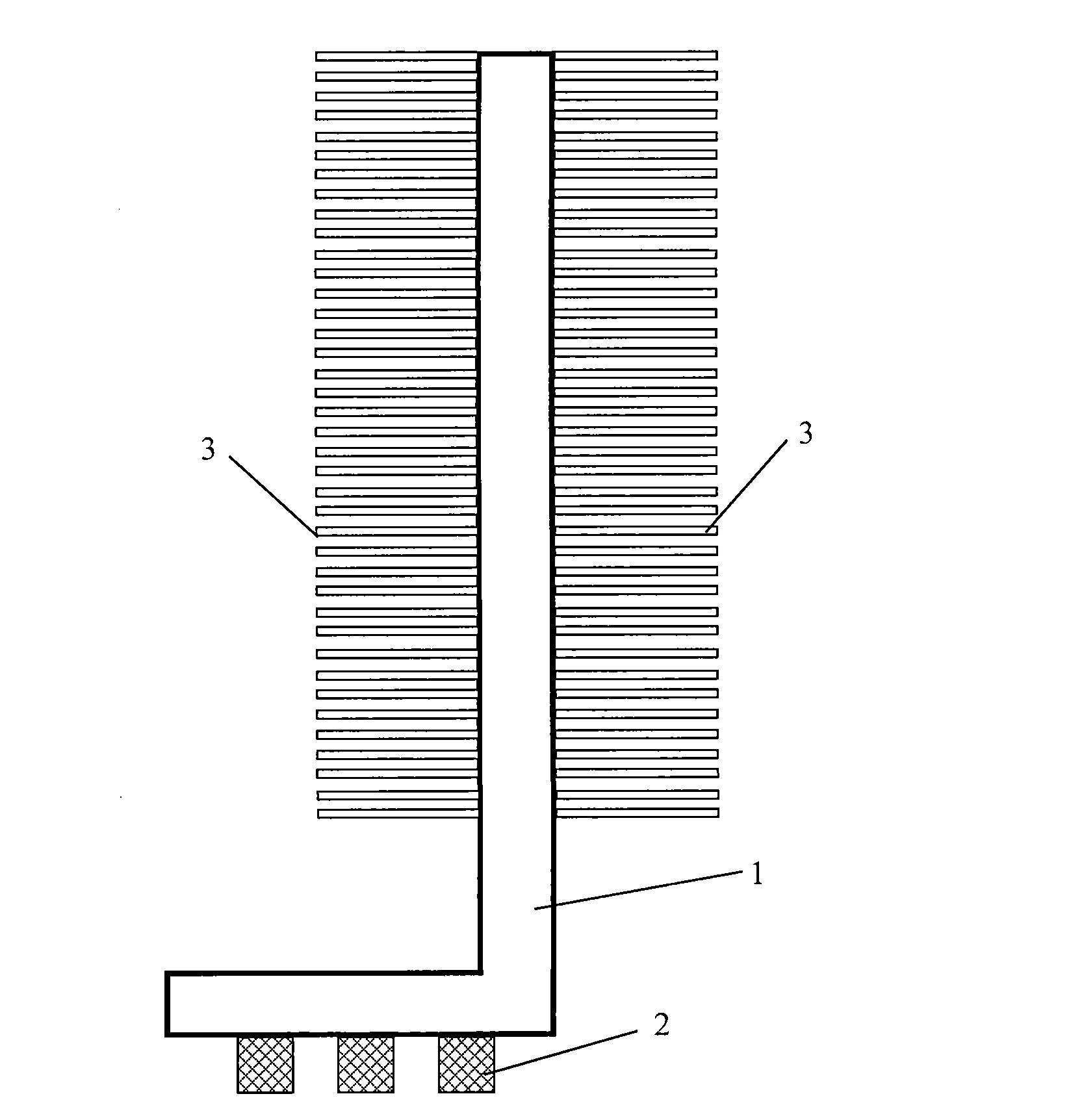

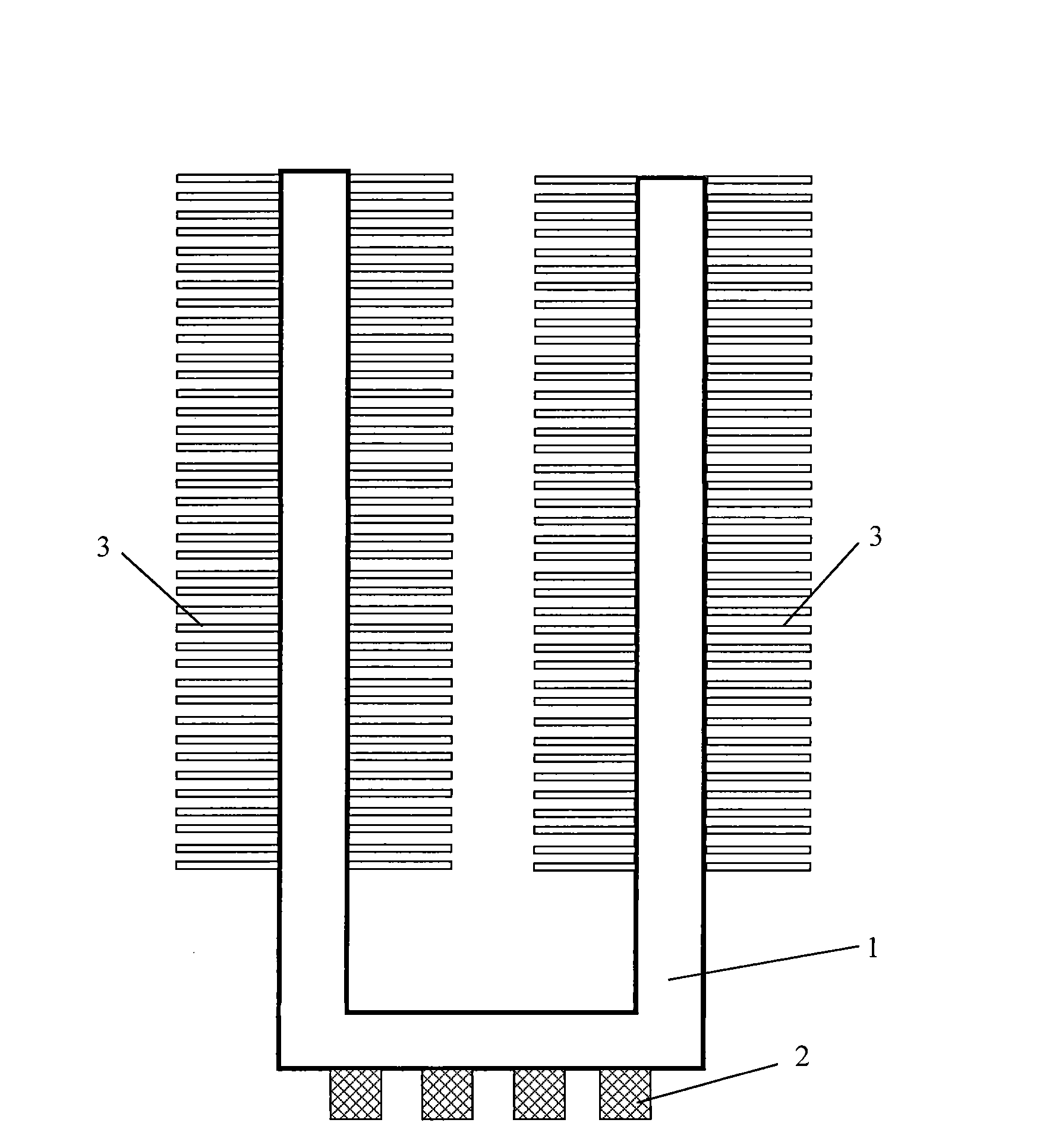

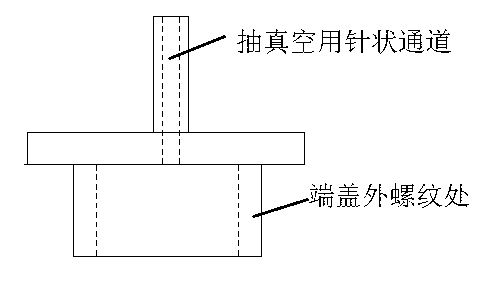

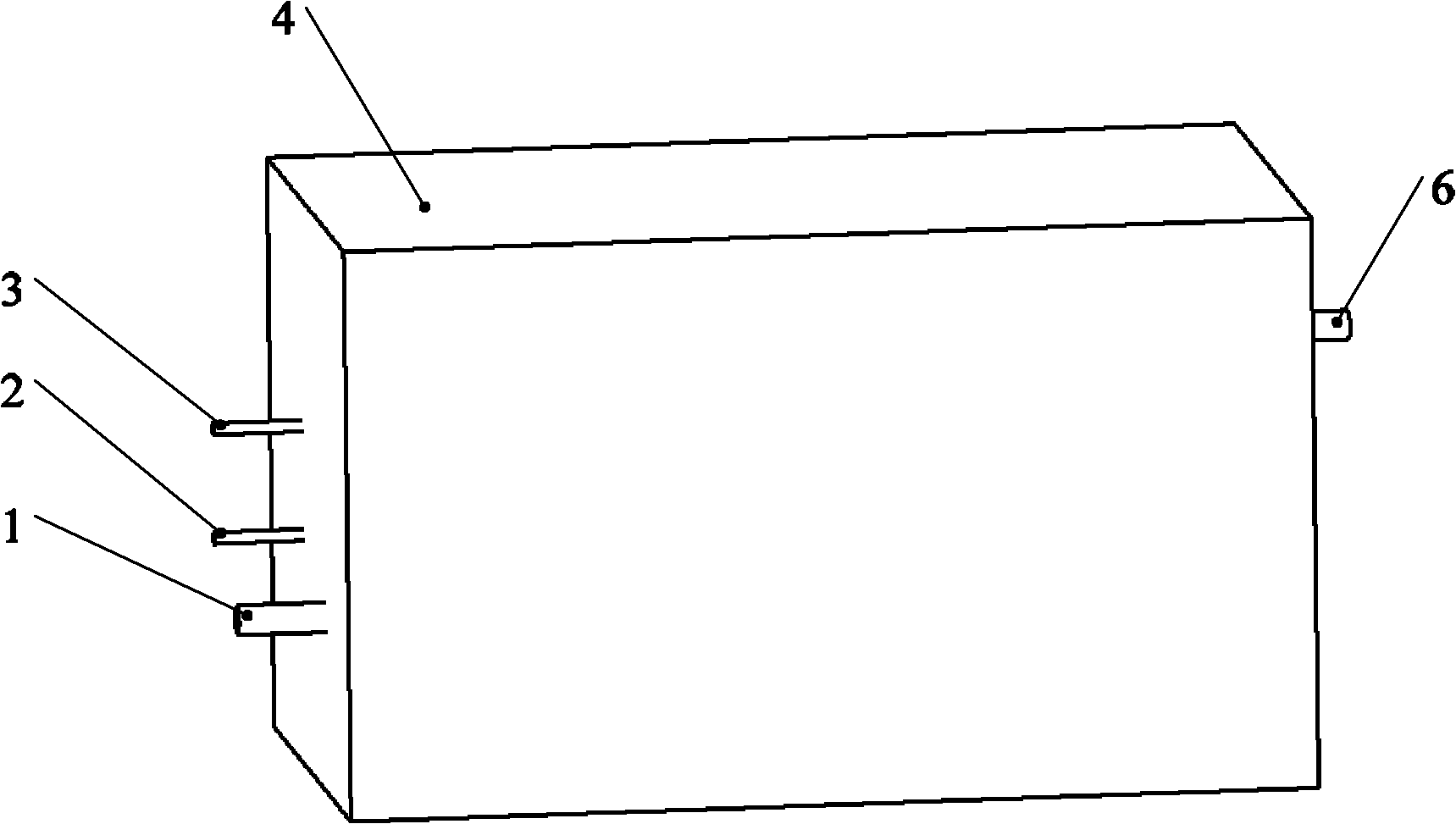

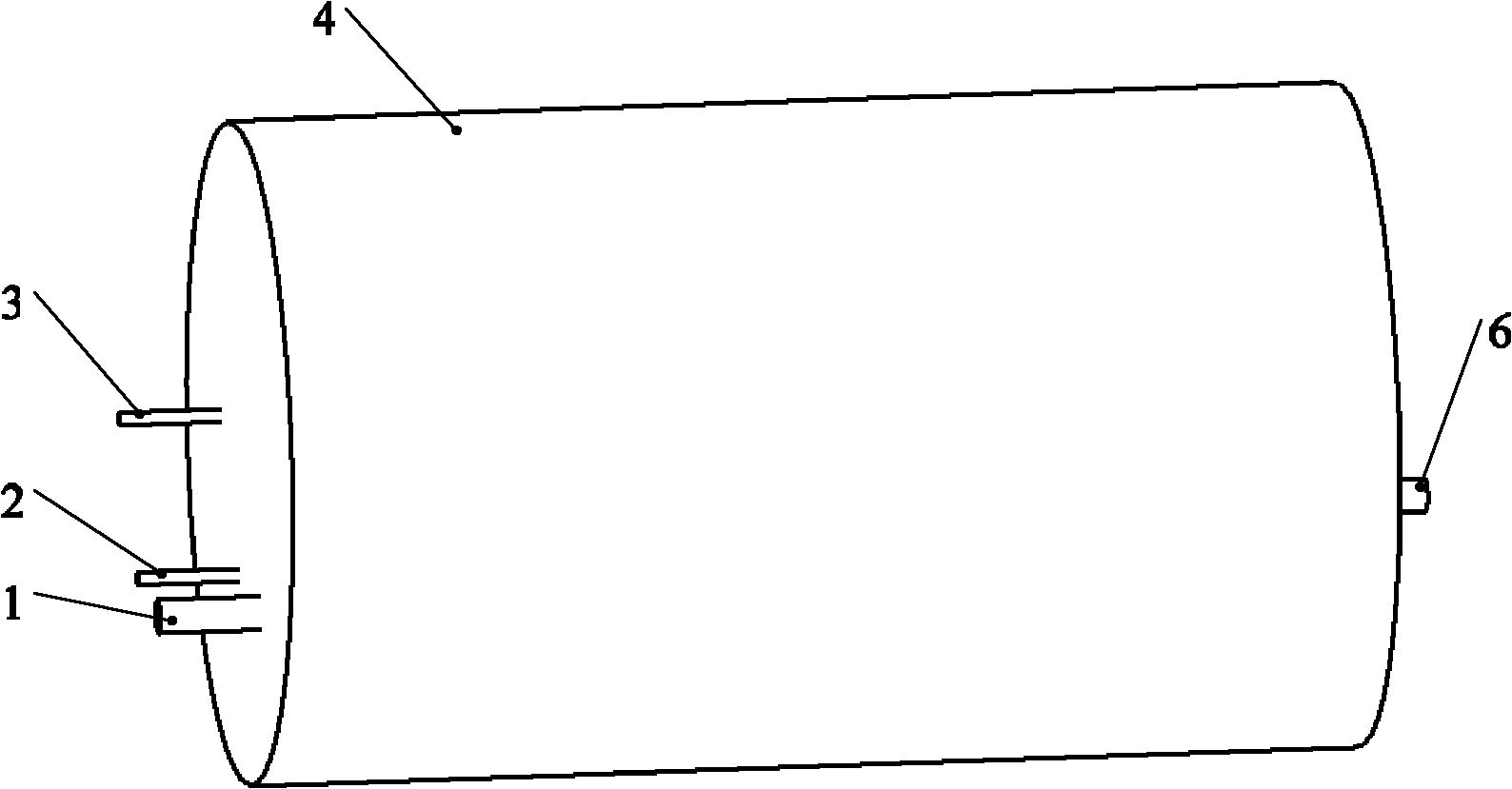

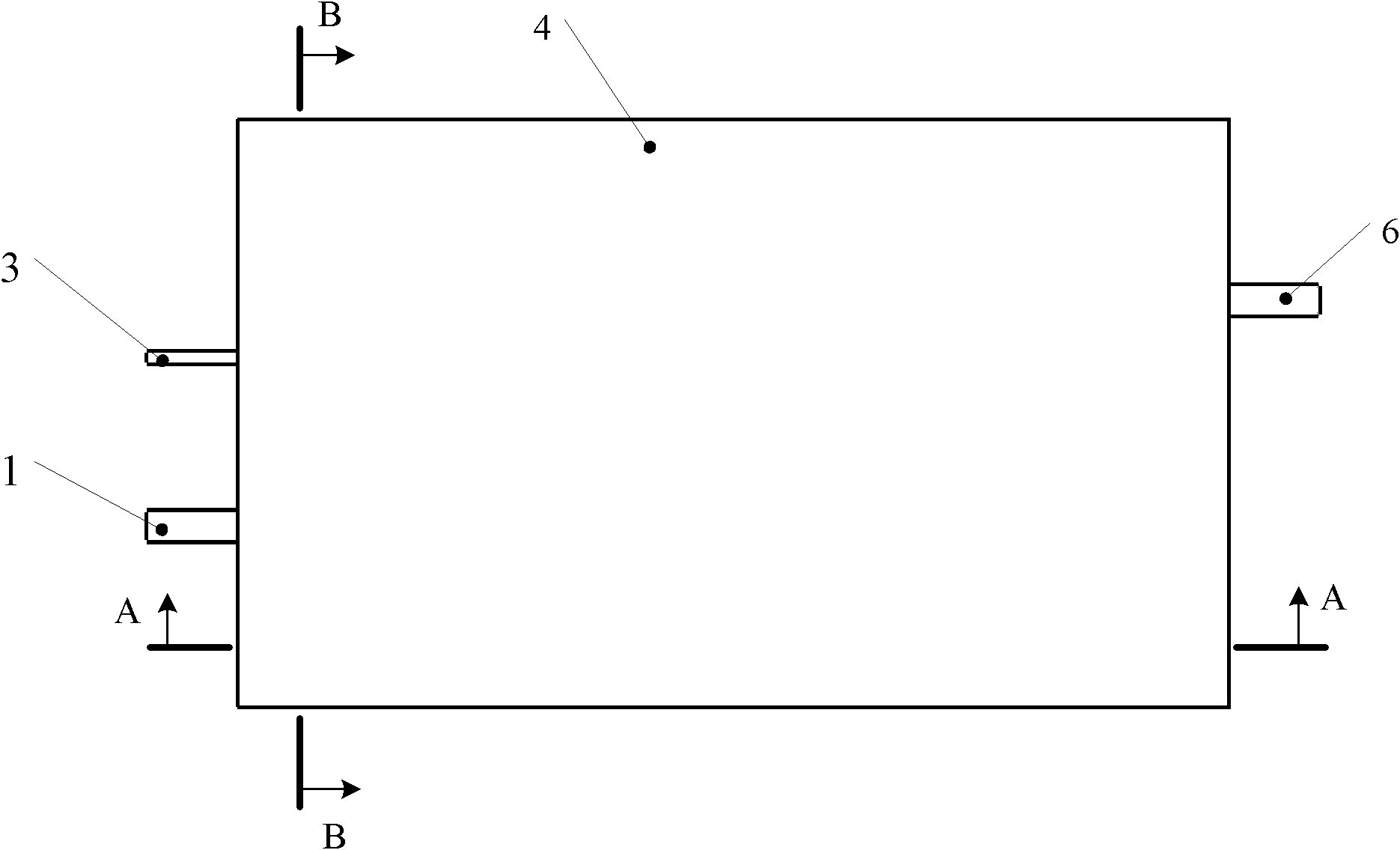

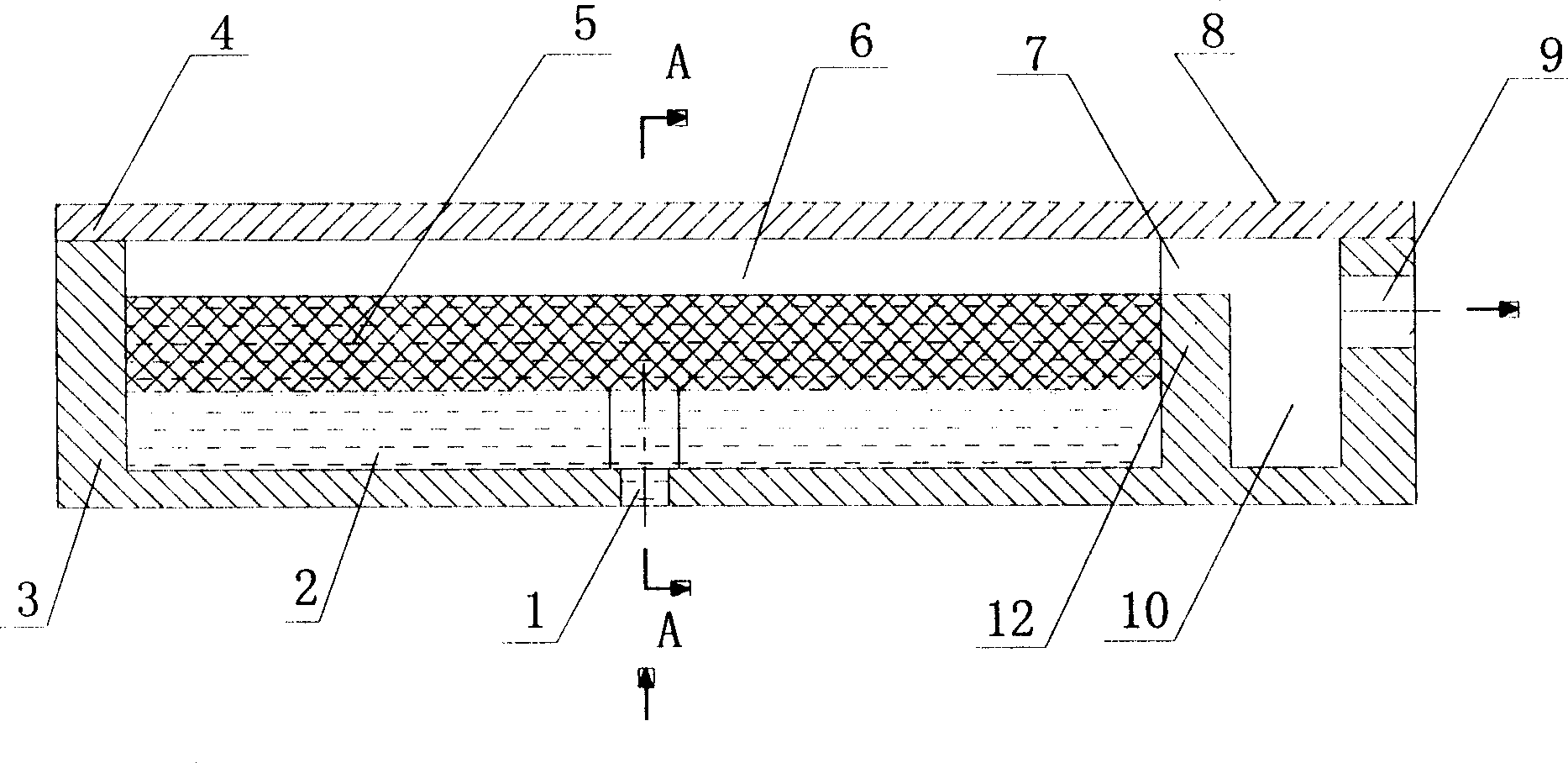

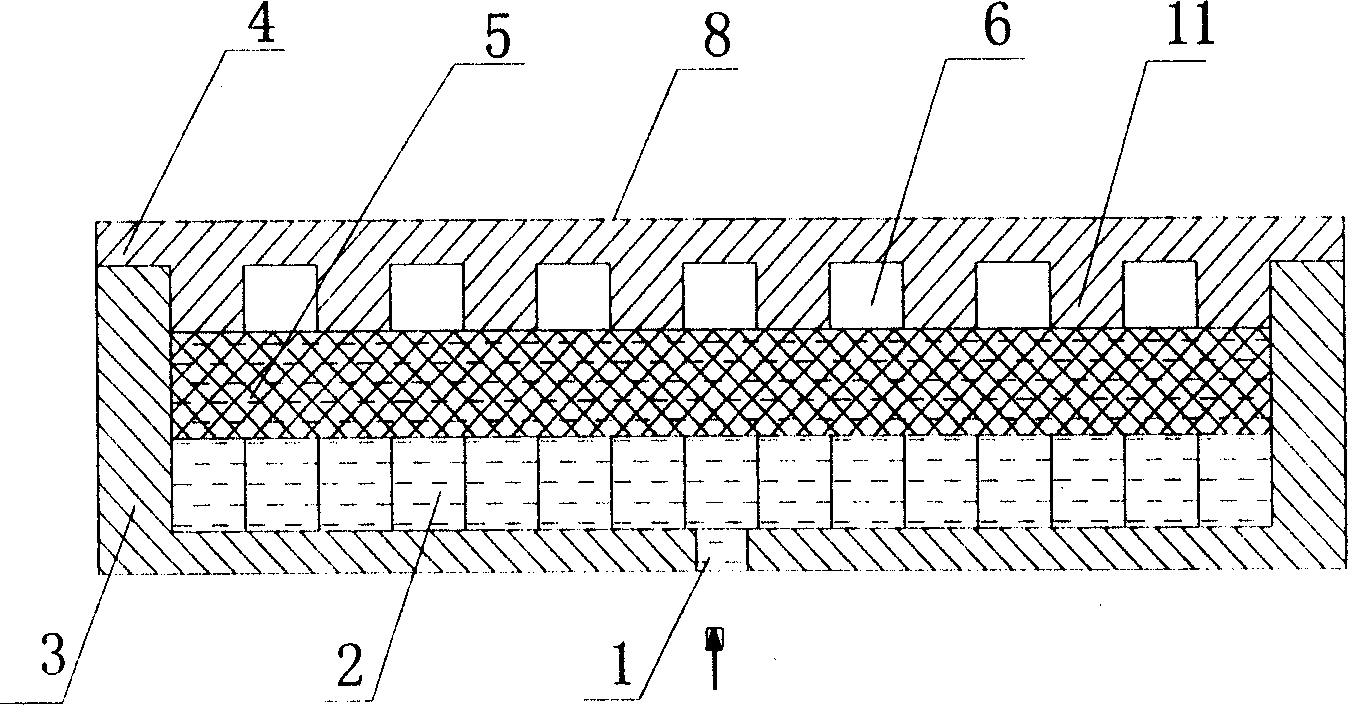

Combined heat dissipating device provided with fins and foam heat conduction structure

ActiveCN105356004AReduce temperature riseIncrease the heat exchange areaSecondary cellsPhase-change materialLithium-ion battery

The invention relates to a combined heat dissipating device provided with fins and a foam heat conduction structure and used for assisting heat dissipation of an individual battery (5). The combined heat dissipating device comprises a shell sleeve (4) sleeving the individual battery (5), wherein a foam structure fills the space between the shell sleeve (4) and the individual battery (5), the foam structure (2) is full filled with a phase-change material (1), multiple fins (3) separating the foam structure (2) are further arranged between the shell sleeve (4) and the individual battery (5), and the two sides of each fin (3) are respectively in tight fit with the shell sleeve (4) and the individual battery (5). Compared with the prior art, the combined heat dissipating device has the advantages of effectively reducing the temperature of a lithium ion battery and preventing thermal runaway.

Owner:SHANGHAI MAKESENS ENERGY STORAGE TECH CO LTD

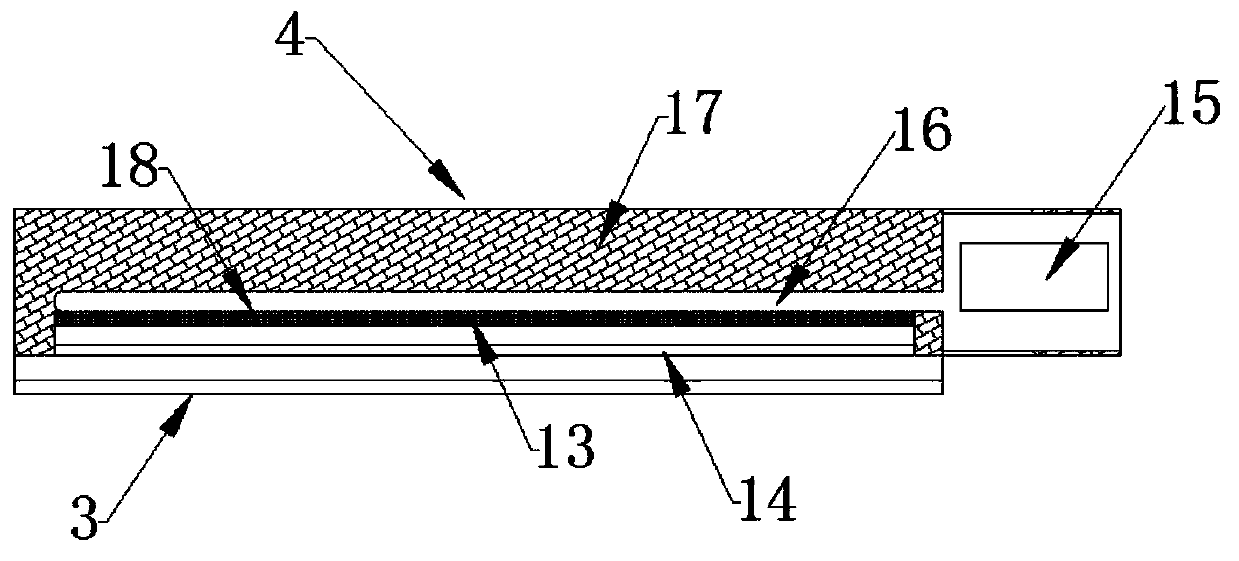

Flat-panel vapor chamber

InactiveCN102095323AHigh mechanical strengthReduce the return pathSemiconductor/solid-state device detailsSolid-state devicesComputer moduleElectron

The invention relates to a flat-panel vapor chamber which belongs to a heat radiating device of a micro electronic device and is used for heat diffusion of a power module and solving the surface deformation problem of the traditional flat-panel vapor chamber and a heat source contact surface so as to further reduce the deformation with the contact surface of a heat source part. The flat-panel vapor chamber comprises heat radiating fins and a metal cavity, wherein the metal cavity consists of a box body and a cover plate; the metal cavity is internally pumped with vacuum and filled with liquid working medium; the box body and the heat radiating fins are tightly contacted or connected into a whole; the inner wall surface of the box body is provided with capillary cores, and supporting bodies are arranged between the box body and the cover plate; the central part of the inner wall surface of the cover plate is provided with a boss, and the thickness of the boss is 0.2-2.0mm; the cross section area of the boss is larger than or equal to the contact area of the heat source; and the inner wall surface of the cover plate including the boss is provided with capillary cores. The flat-panel vapor chamber has the advantages of simple structure and convenience for manufacturing and processing, can be used for effectively reducing the surface deformation and the contact heat resistance, and has high working medium refluxing efficiency and higher working efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

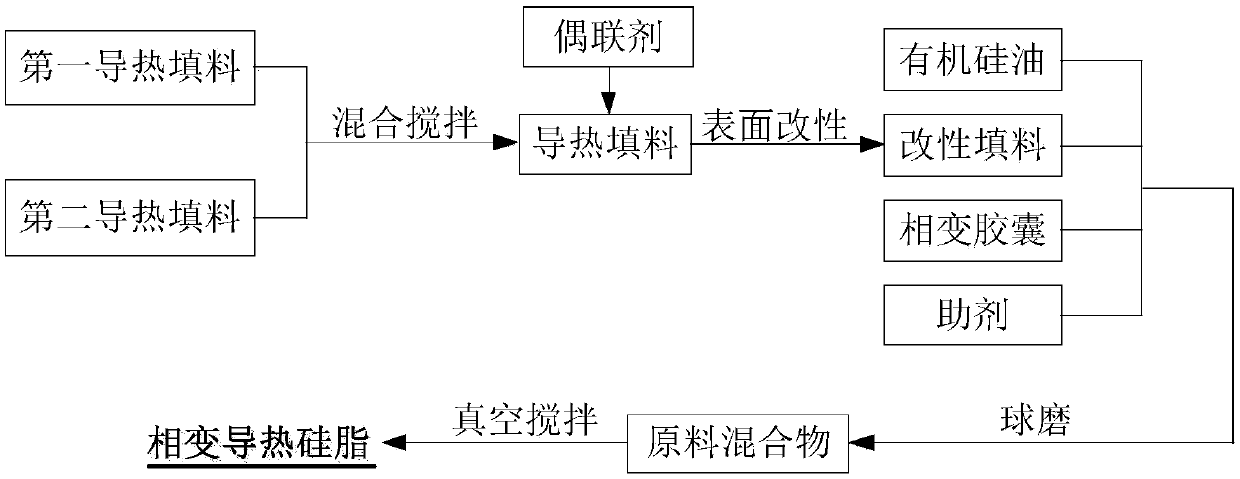

Phase-change heat-conducting silicone grease and preparation method thereof

PendingCN108047722AHigh thermal conductivityLarge specific surface areaHeat-exchange elementsHeat conductingPhase change

The invention provides phase-change heat-conducting silicone grease and a preparation method thereof. The phase-change heat-conducting silicone grease is prepared from organic silicone oil, phase-change capsules, heat-conducting filler and an assistant. The invention also provides the preparation method of the phase-change heat-conducting silicone grease. The preparation method comprises the following steps: preparation of modified heat-conducting filler, preparation of a raw-material mixture, vacuum stirring treatment and the like. The phase-change heat-conducting silicone grease prepared bythe method has the beneficial effects that the fluidity and the wettability are good, the service life is long, the compatibility between the heat-conducting filler and the silicone oil is good, the heat-storage function is achieved, the interfacial thermal contact resistance of nodes and a radiating device of a high-power electrical appliance can be effectively reduced, and the heat transfer canbe accelerated; the preparation process is simple, the cost performance is high, and the application is wide.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

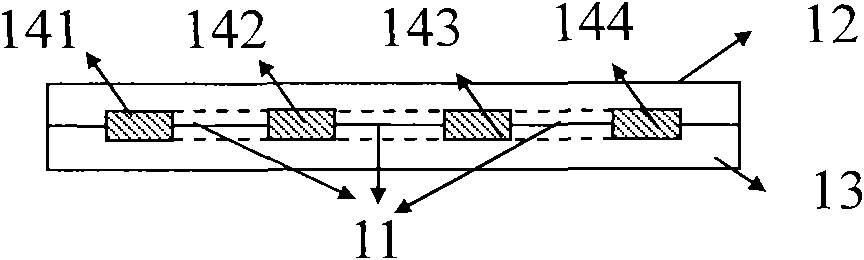

Method and device for testing thermal physical property of solid material with independent probe by using harmonic method

ActiveCN101782541AGuaranteed NDTReal-time display of torque valueMaterial thermal conductivityMaterial heat developmentElectricityThermal diffusivity

The invention relates to a method and a device for testing the thermal physical property of a solid material with an independent probe by using a harmonic method. The device comprises the independent probe, a pressure adjusting part, a torque measuring part and a harmonic measuring unit, wherein the independent probe is positioned between two identical samples to be tested to form a sandwich structure and is arranged parallel to a sample fixing table; the pressure adjusting part is positioned and pressed on the upper end face of the first sample to be tested; the sandwich structure is arranged on the sample fixing table; the torque measuring part is sleeved on one end of the pressure adjusting part; the harmonic measuring unit is electrically connected with the independent probe; and a torsion value and contact thermal resistance between the independent probe and the two samples to be tested are fitted and calculated according to a harmonic measurement principle. In the test, the sandwich structure is arranged on a lug boss of the sample fixing table, the pressure adjusting part is adjusted until the torsion value is displayed to be the optimal torsion value, and then the thermal conductivity coefficient and the thermal diffusivity of the sample to be tested are tested by the harmonic method. Differences among thermal conductivity values of the samples to be tested under the condition of a plurality of torsion values smaller than the optimal torsion value are measured and calculated for obtaining the contact thermal resistances between the samples to be tested and the independent probe under the condition of the plurality of torsion values.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

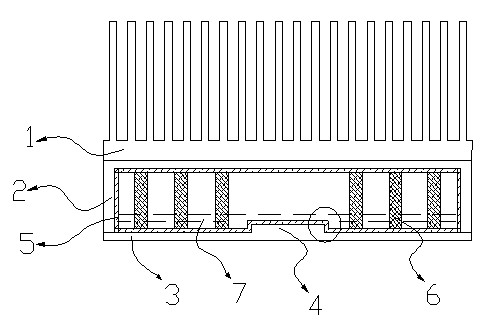

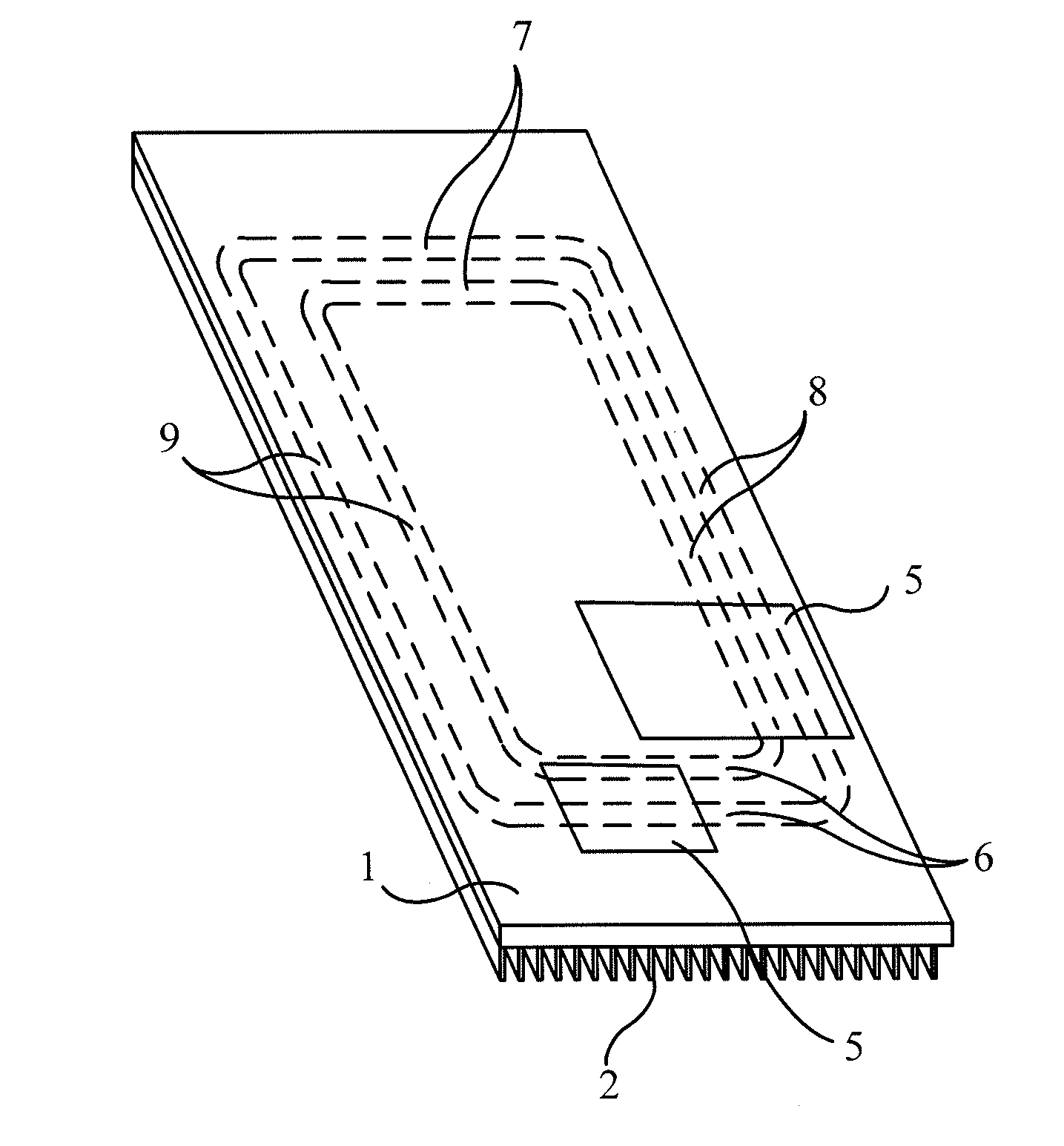

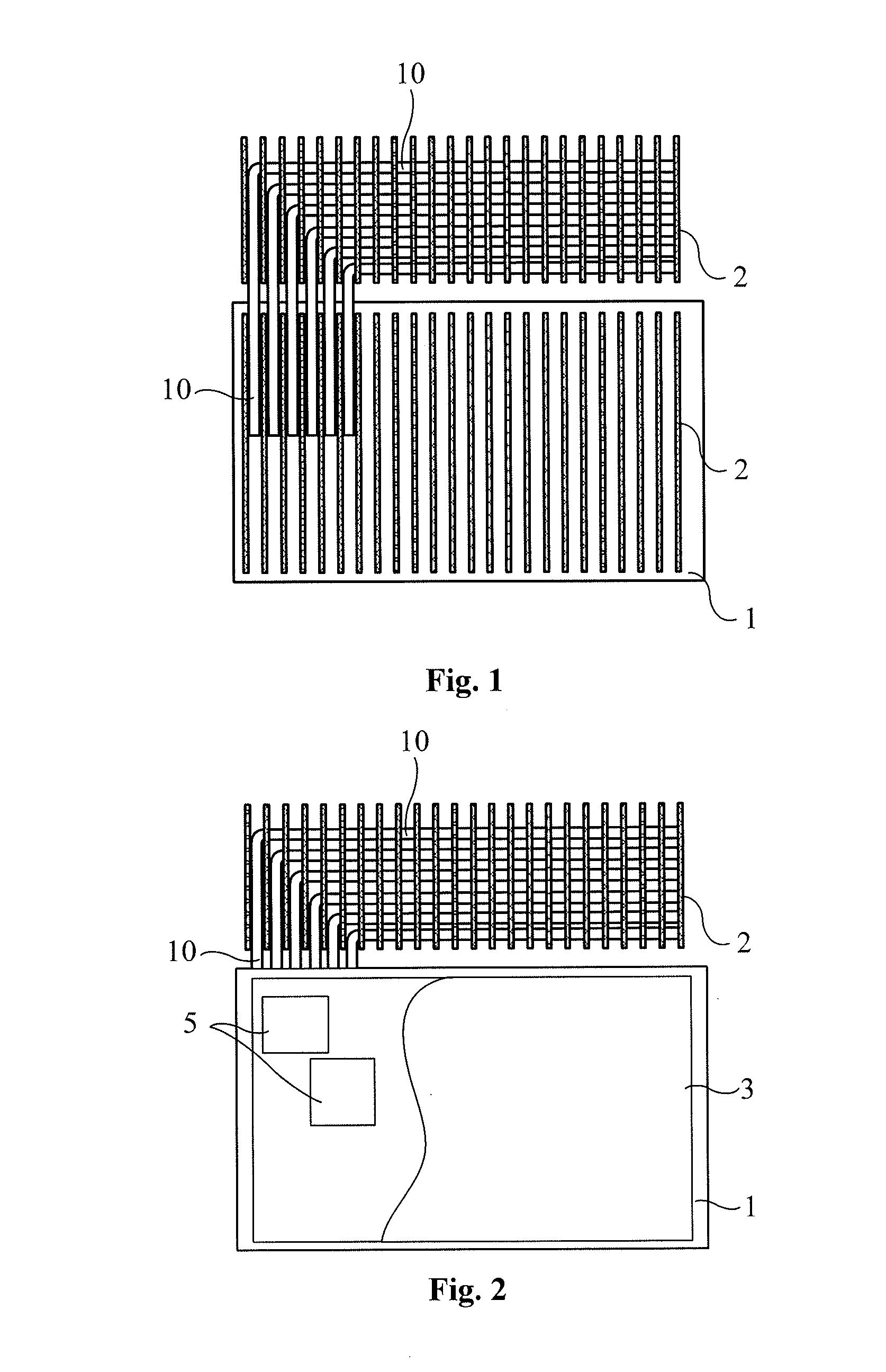

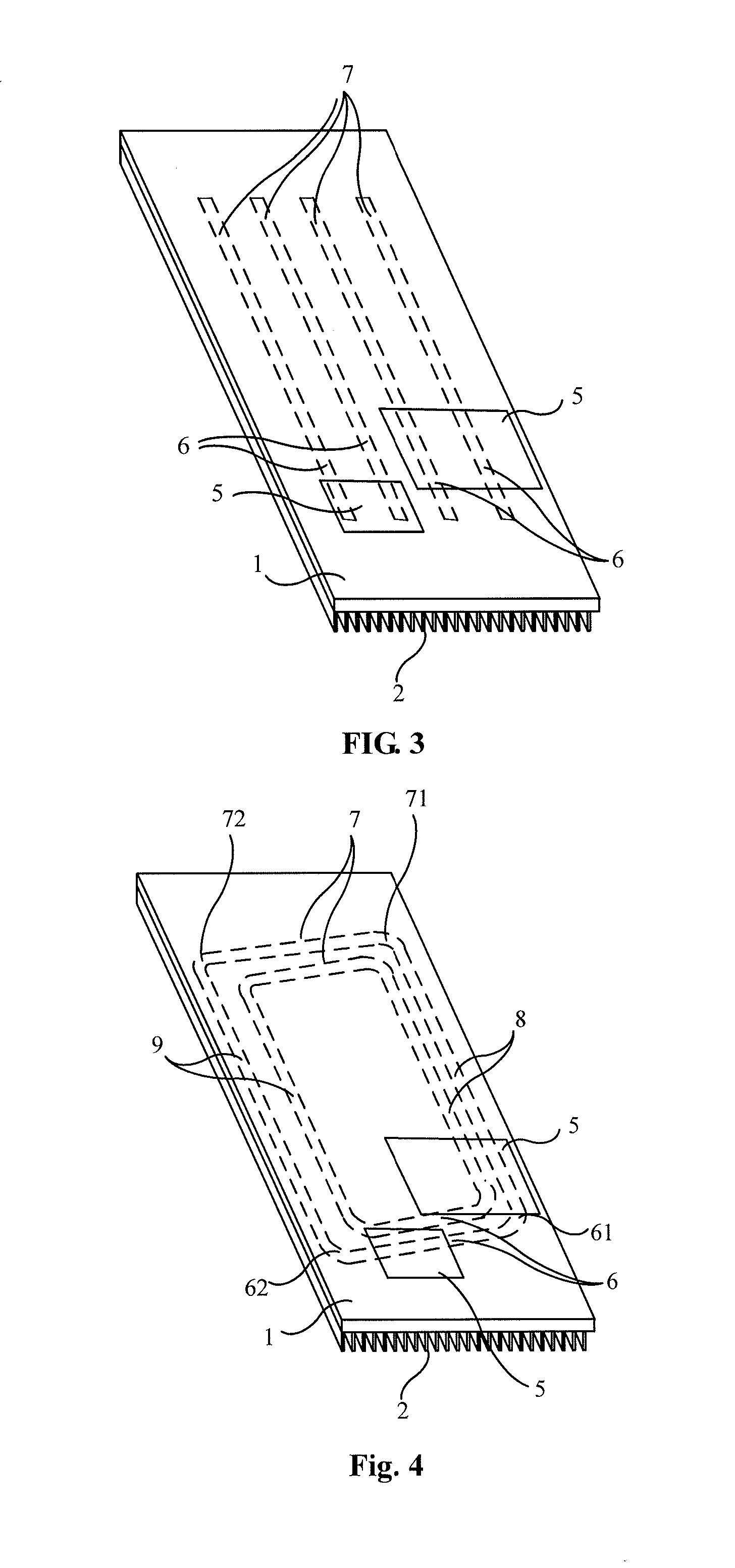

Heat dissipation device and radio frequency module with the same

ActiveUS20120087090A1Reduce thermal contact resistanceImprove effectIndirect heat exchangersCooling/ventilation/heating modificationsRadio frequencyEngineering

A heat dissipation device and a radio frequency module with the same are provided. The heat dissipation device includes a substrate (1). The substrate (1) having a surface where a heat absorbing surface (5) is formed. There are multiple hollow conduits inside the substrate (1) to act as evaporating conduits (6). The heat dissipation device further comprises condensing conduits (7) intercommunicated with the evaporating conduits (6). The evaporating conduits (6) and the condensing conduits (7) form sealed conduits. The sealed conduits are filled with liquid which vaporizes upon heating. At least the evaporating conduits (6) are set in the substrate (1).

Owner:HUAWEI TECH CO LTD

Novel LED and a high-power radiator of a radiating element

ActiveCN101515572AIncrease contact areaImprove heat transfer effectSemiconductor/solid-state device detailsSolid-state devicesMetallic materialsEvaporation

The invention relates to a novel LED and a high-power radiator of a radiating element, comprising flat plate heat pipes which are of two or more via-hole array flat plate structures arranged side by side; the via-hole array flat plate structures are formed by carrying out extrusion or punch forming on metal materials; the equivalent diameter of the via hole is 0.5-3mm; the via hole is filled with liquid propellant and both ends of the flat plate heat pipes are packaged by sealing; an evaporation section of the flat plate heat pipe contacts heating surfaces of the LED and the high-power radiating element and a condensation section thereof radiates through the radiating element. The novel LED and the high-power radiator of a radiating element overcome the disadvantages that the contact area of the existing circular heat pipes and the heating surfaces of the LED and the high-power radiating element is small, the equivalent resistance of heat conduction is large and the manufacturing process is complex, which have the advantages of high radiating efficiency and simple process.

Owner:GUANGWEI HETONG ENERGY TECH BEIJING CO LTD

Heat-conducting gasket and preparation method thereof

PendingCN113183544AImprove bindingImprove thermal conductivityNon-macromolecular adhesive additivesLamination ancillary operationsPolymer sciencePolymer chemistry

The invention provides a heat-conducting gasket, which comprises a heat-conducting film and a binder layer, and optionally comprises other heat-conducting fillers, wherein the heat-conducting is provided with a plurality of holes penetrating through the upper surface and the lower surface of the heat-conducting film, and the holes are filled with a binding agent. Therefore, the binding agents in different layers can be connected through the plurality of holes to form a continuous structure, the heat-conducting film is wrapped on the microscale, the binding agent and the heat-conducting film can be strongly combined together without a surface coating, and meanwhile, the problem of layering of the heat-conducting film is avoided.

Owner:CHANGZHOU FUXI TECH CO LTD

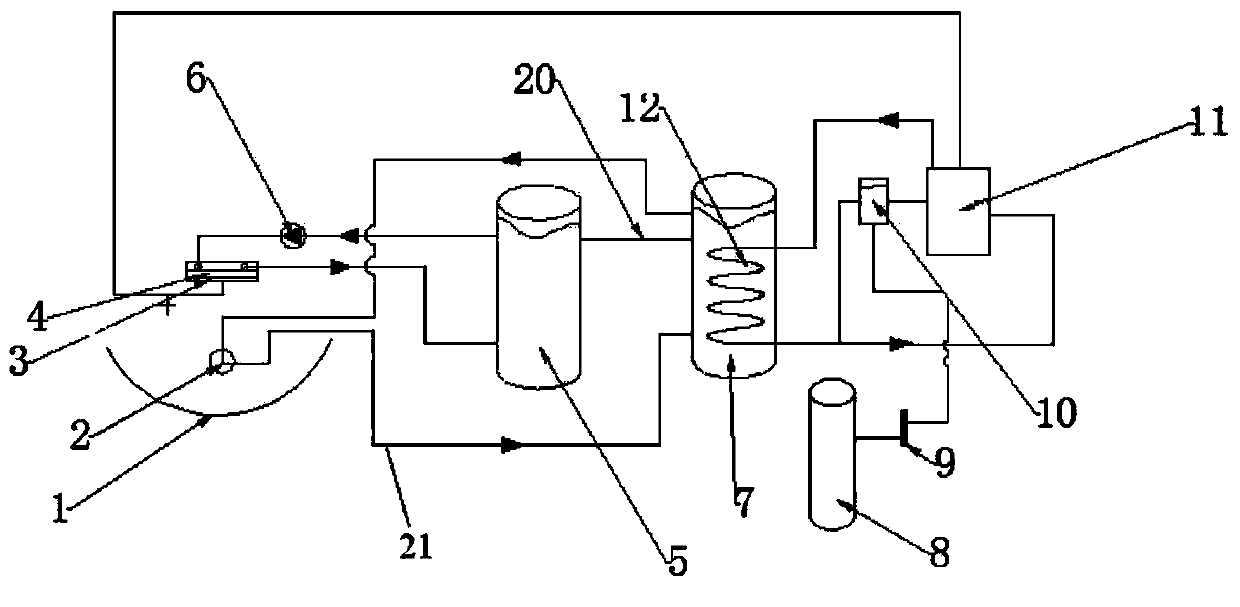

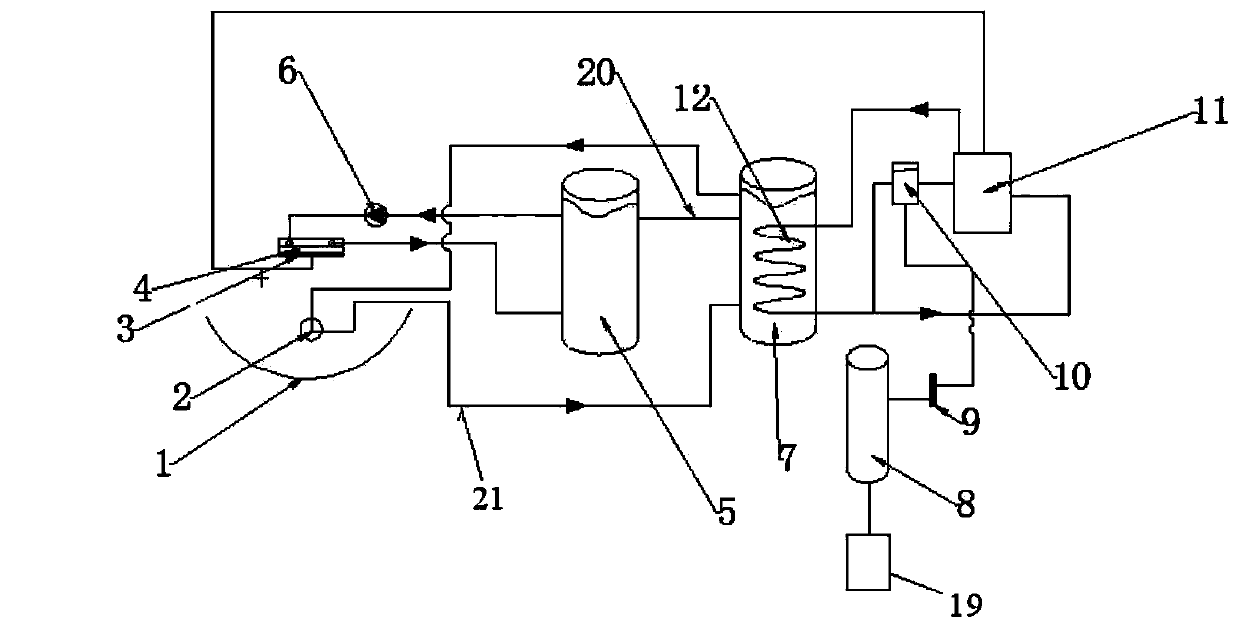

Working medium contact cooling system of power batteries and working method of working medium contact cooling system

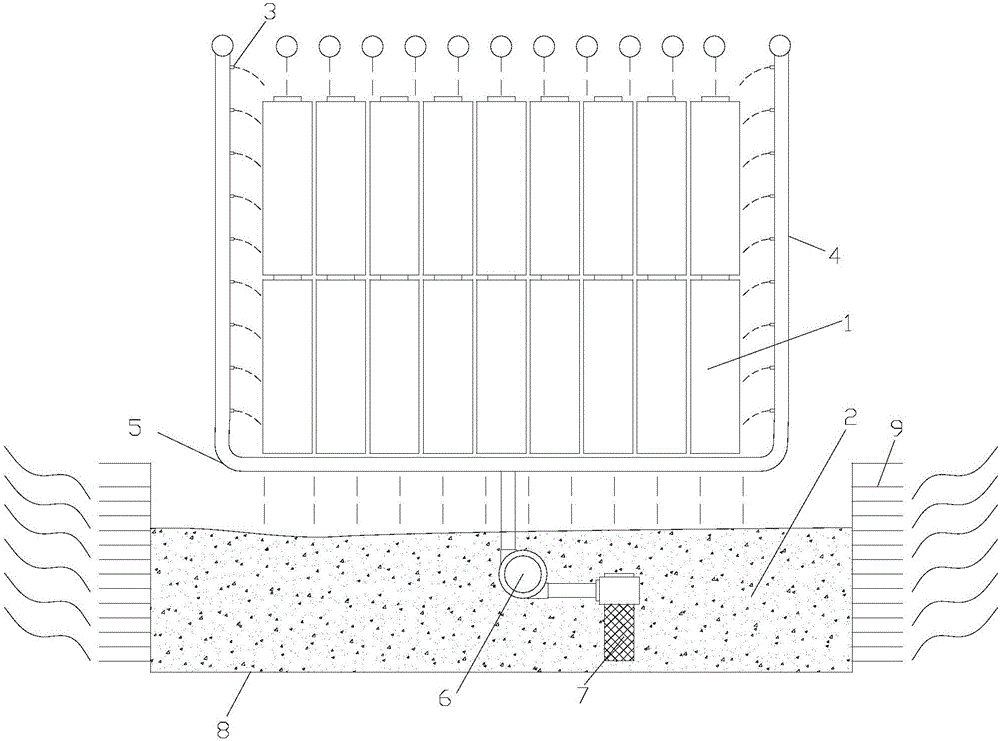

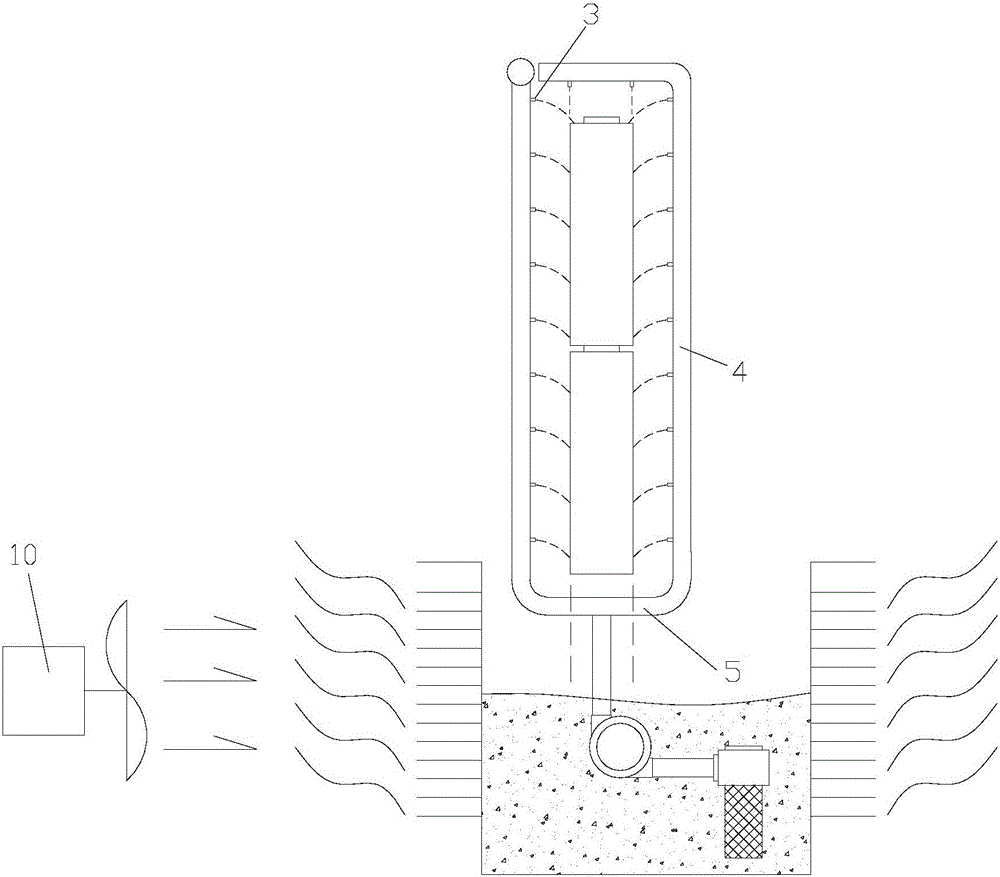

ActiveCN105977572AReduce thermal contact resistanceImprove heat transfer efficiencySecondary cellsBatteriesPower batteryHeat conducting

The invention discloses a working medium contact cooling system of power batteries. An insulating liquid heat-conducting working medium is contained in a working medium box; a working medium pump sinks into the insulating liquid heat-conducting working medium; a filter is arranged at an inlet of the working medium pump; the working medium pump is connected with a spray main pipe; a plurality of spray branch pipes are connected with the spray main pipe in parallel; each spray branch pipe is provided with a plurality of nozzles; the nozzles are opposite to a high-power battery pack; the spray branch pipes and the spray main pipe form a cage frame; the high-power battery pack is placed in the cage frame; the spray branch pipes are distributed on the side surfaces and the upper part of the high-power battery pack to form a relatively open spray structure; and the insulating liquid heat-conducting working medium is a nonpolar substance and is free of a phase change in the spray process. The invention further provides a working method of the working medium contact cooling system of the power batteries. According to the working medium contact cooling system, the cooling structure is reasonable and the cooling efficiency is high.

Owner:佛山久安储能科技有限公司

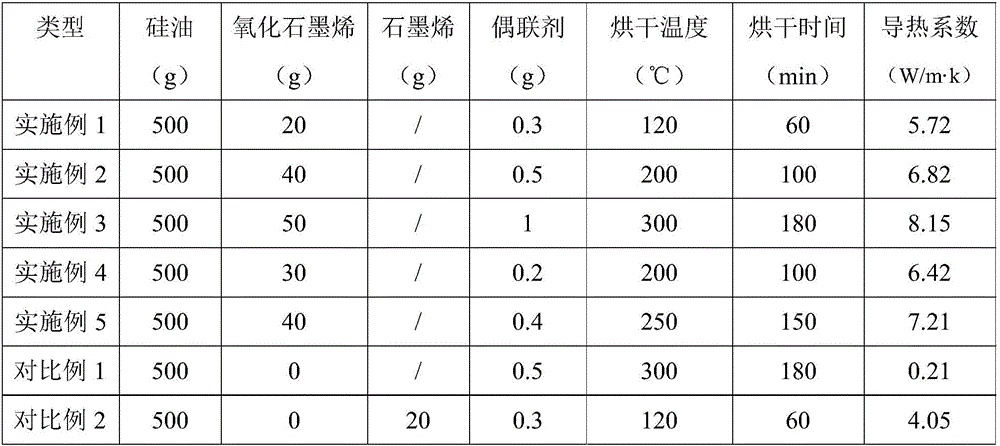

Preparation method of heat-conducting silicone grease

ActiveCN105733265AGood dispersionEnhanced interface bindingHeat-exchange elementsDispersityHeat conducting

The invention relates to the field of heat interface materials, and in particular relates to a preparation method of heat-conducting silicone grease. The preparation method comprises the following steps: (1) adding graphene oxide into an ethanol solution of a silane coupling agent, ultrasonically mixing for one hour, filtering by suction, and drying; (2) uniformly mixing silane coupling agent-modified graphene oxide and silicone oil to obtain a mixture, and grinding the mixture on a grinding machine; (3) placing the mixture into a drying oven, and processing the mixture at a high temperature; and (4) stirring in vacuum to obtain the heat-conducting silicone grease. Rich oxygen-containing groups in the graphene oxide are first combined with the coupling agent by virtue of chemical bonds, so that the processed graphene and the silicone oil have a good combined interface, the dispersity of the graphene in the silicone oil is facilitated, the compatibility and the affinity between the graphene and the silicone oil are improved, and the contact heat resistance between the graphene and the silicone oil is effectively reduced; and meanwhile, the graphene oxide is reduced by adopting a thermal reduction method, so that the heat conduction coefficient of the heat-conducting silicone grease is increased by utilizing the high heat-conduction capacity of the graphene.

Owner:JIANGNAN GRAPHENE RES INST

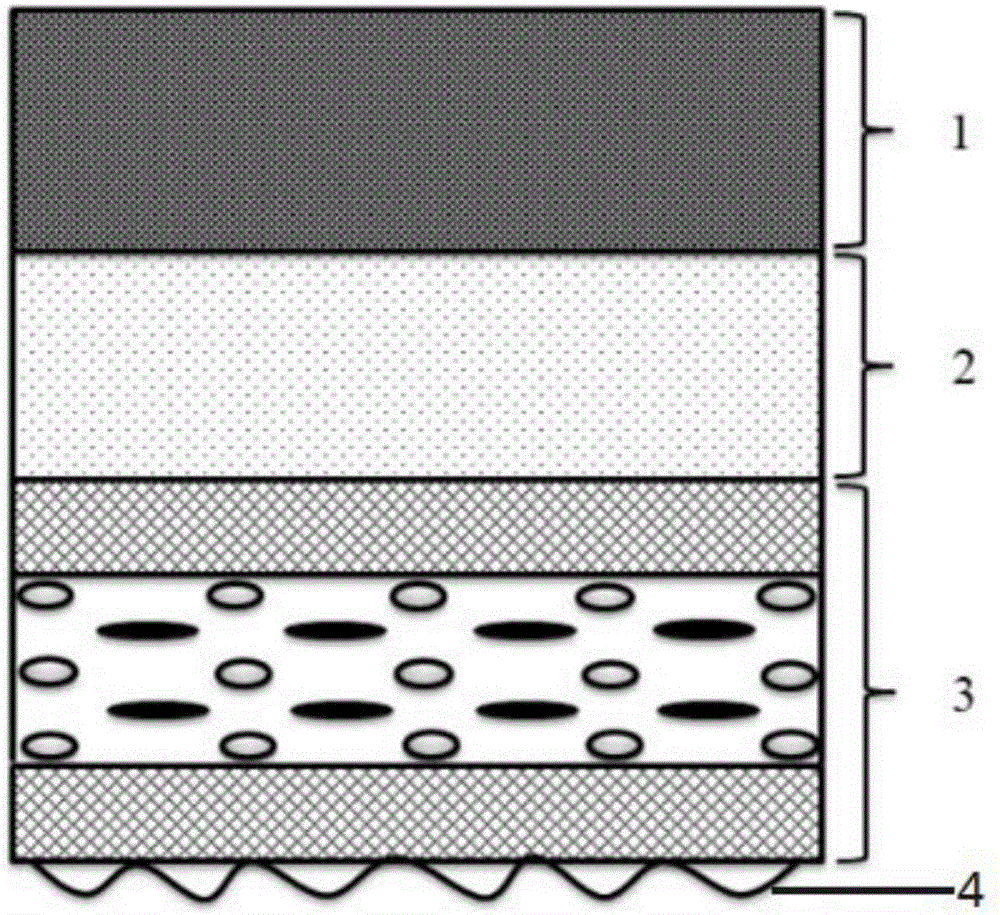

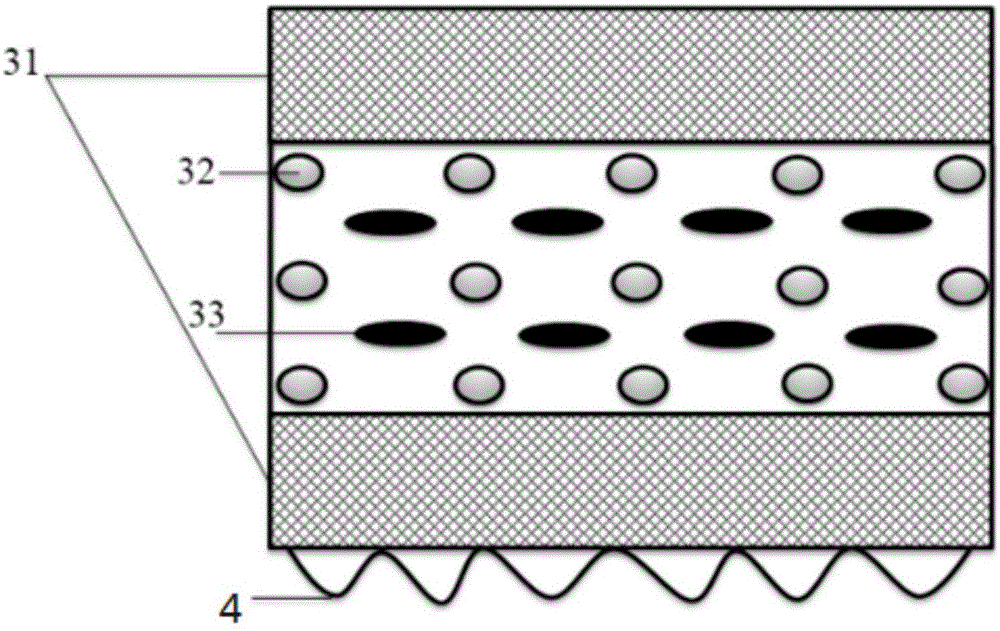

Light-weight high-performance heat-insulating protective clothing fabric and preparation method thereof

InactiveCN106515097AReduce thicknessReduce weightLamination ancillary operationsSynthetic resin layered productsHuman bodyEngineering

The invention provides a light-weight high-performance heat-insulating protective clothing fabric and a preparation method thereof. The light-weight high-performance heat-insulating protective clothing fabric is prepared by successively compounding the following functional structure layers from a direction close to a fire source to a direction close to human body: a flame-retardant outer layer with flame-retardant effect, a waterproof moisture-permeable layer with waterproof and moisture-permeable effects, and a heat-insulating layer with heat-insulating effect. The heat-insulating layer has a three-layer composite structure, wherein the inner and outer layers are non-woven fabric layers; the middle layer is a mixed layer of aerogel and a microencapsulated phase change material; and the structure has high heat insulation performance, effectively reduces natural thickness and weight of clothing, thereby providing excellent protective properties and wear comfortableness for firefighters. The light-weight high-performance heat-insulating protective clothing fabric has the advantages of light weight, convenience in combination and shaping, good reusability and wide range of application, can be used for clothing in emergency lifesaving environments like fire ground and battle ground, and can be also used as an aerospace protective material.

Owner:TIANJIN POLYTECHNIC UNIV

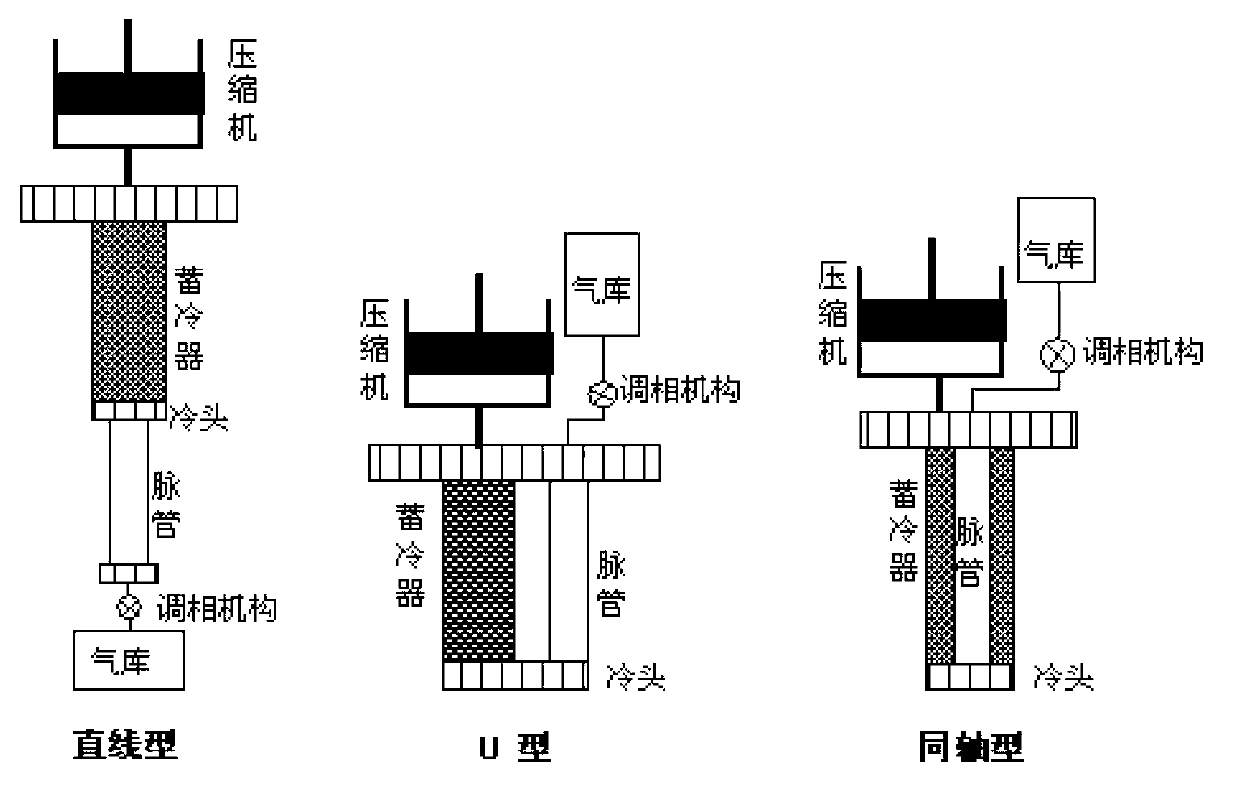

Conical slit-type hot end heat exchanger of coaxial pulse tube refrigerator and manufacturing method

ActiveCN102735088AImprove thermodynamic performanceImprove machine performanceCompression machinesSoldering apparatusPulse tube refrigeratorEngineering

The invention discloses a conical slit-type hot end heat exchanger of a coaxial pulse tube refrigerator and a manufacturing method. The heat exchanger structurally consists of a hot end flange, a conical slit and a hot end plug, wherein the conical slit is inserted into the hot end flange in a tight fit way, the radius of a circle of contact on the top of a cone frustum is equal to the radius of a cold accumulator and the radius of the bottom of the cone frustum is equal to the radius of the hot end plug. The hot end plug and the hot end flange not only can be connected through bolts to form a detachable split-type hot end heat exchanger, but also can be hermetically welded to form an integrated hot end radiator. The conical slit-type hot end heat exchanger has the advantages that the structure is simple, compact and high-efficiency, the hot end radiating capacity of the refrigerator can be exerted to the utmost extent and the hot end pressure ratio of the pulse tube refrigerator is increased at the same time. The structure can intensively realize the major functions of a high-efficiency hot end heat exchanger, a hot end gas flow guide device of the pulse tube refrigerator and a hot end gas even distributor of the cold accumulator, and can improve the performance of the entire pulse tube refrigerator to a great extent.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Chip cooling device

InactiveCN101645430AUniform temperature distributionImprove sealingSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

The invention discloses a chip cooling device which comprises a cooling room positioned at the bottom of the device and matched with the chip, a cooling liquid pond stored with cooling liquid, a firstmicro channel, a first micro pump, a second micro channel, a micro nozzle, a third micro channel, a second micro pump, a fourth micro channel, a condenser and a micropore, wherein one end of the first micro pump is communicated with the cooling liquid pond by the first micro channel and the other end is communicated with the micro nozzle by the second micro channel; the micro nozzle is arranged above the cooling room and communicated with the cooling room; one end of the second micro pump is communicated with the cooling room by the third micro channel and the other end is communicated with the condenser by the fourth micro channel; the condenser is positioned above the cooling liquid pond and a condensing channel is arranged in the interior of the condenser; and a radiating fin is arranged on the top of the condensing channel which is communicated with the cooling liquid pond by the micropore. The chip cooling device has small volume, high heat dissipation efficiency, very high controllability and working flexibility and can meet the cooling requirements of the chip in different working conditions.

Owner:ZHEJIANG UNIV

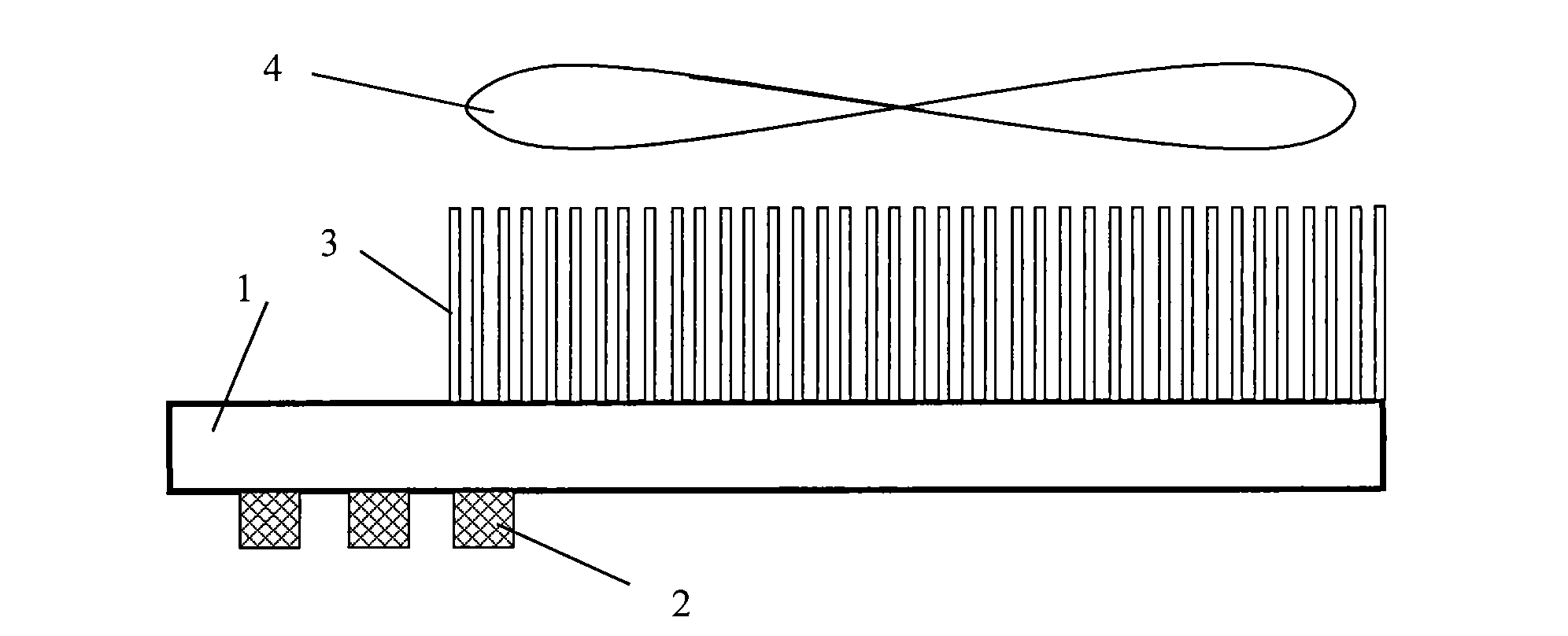

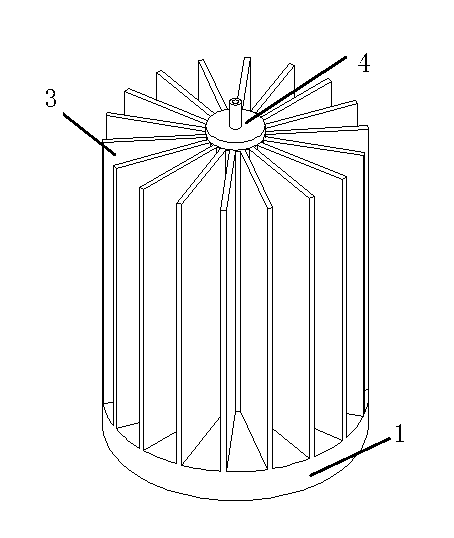

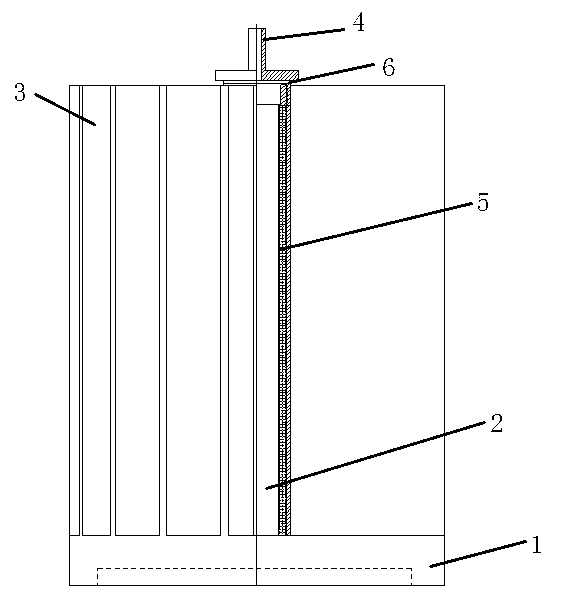

Method for improving heat radiating efficiency of LED lighting source and integrated radiator

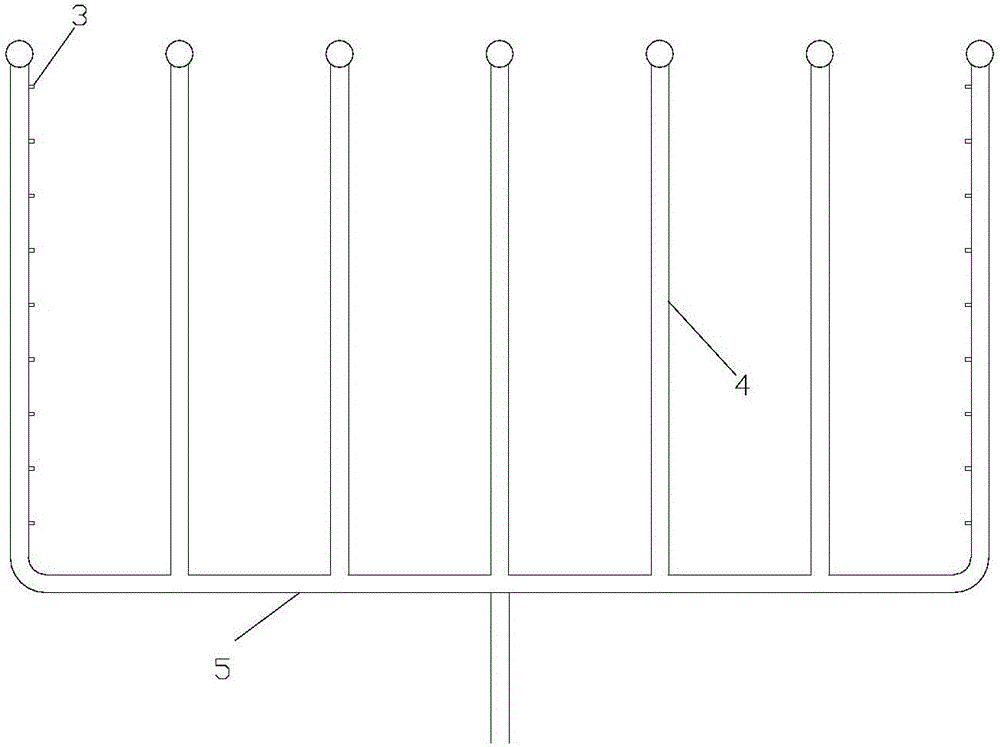

ActiveCN103307579AImprove cooling effectExtend working lifePoint-like light sourceLighting heating/cooling arrangementsDifferential pressureEvaporation

The invention discloses a method for improving the heat radiating efficiency of an LED lighting source and an integrated radiator. The method comprises the steps as follows: an LED chip substrate is mounted in a substrate groove of a heat pipe radiator, so that heat produced by the LED lighting source is conducted to an evaporation end of a cylindrical straight heat pipe in the radiator, a working medium in the heat pipe absorbs the heat and produces liquid-vapor phase transition, produced vapor is spread to a whole heat pipe body under the action of differential pressure inside the heat pipe, and further the vapor exchanges heat with a surrounding environment through the heat pipe wall and radiating fins on the pipe wall; and the vapor is attached to the inside of a liquid suction core of the pipe wall after condensed into droplets and flows back to the evaporation end of the heat pipe under the action of the differential pressure inside the wick, so that circulatory heat radiation is realized. The radiator comprises a heat pipe radiator substrate (1), the cylindrical straight heat pipe (2), the radiating fins (3), a heat pipe end cover (4), the webby wick (5) and a rubber gasket. The radiator is simple in structure and good in radiating effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Microchannel liquid cooling heat radiator and conduction cool plug for high heat flux chip

ActiveCN106252309AImprove cooling effectReduce thermal contact resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringCooling fluid

The invention relates to a microchannel liquid cooling heat radiator and a conduction cool plug for a high heat flux chip. The microchannel liquid cooling heat radiator is fixedly arranged on one side of the chip, and comprises a chip package plate, a cover plate and a cooling liquid circulation device. The chip package plate is packaged and fixed on one side of the chip. The edge of the other side of the chip package plate and the edge of the cover plate are sealed and fixedly connected. A circulation cavity is formed between the chip package plate and the cover plate. A number of heat radiating teeth are arranged on one side of the chip package plate in the circulation cavity. The cover plate is provided with a liquid inlet hole and a liquid outlet hole. The liquid inlet hole and the liquid outlet hole are respectively communicated with a cooling liquid circulation device through liquid cooling pipes. According to the heat radiator provided by the invention, a microchannel heat radiating structure with a number of heat radiating teeth is arranged on one side of the chip package plate in the circulation cavity; the contact heat resistance is reduced; the heat exchange efficiency is improved; and the heat radiator is favorable for heat radiating of the high heat flux density heating chip and other concentrated heat sources.

Owner:BEIJING INST OF RADIO MEASUREMENT

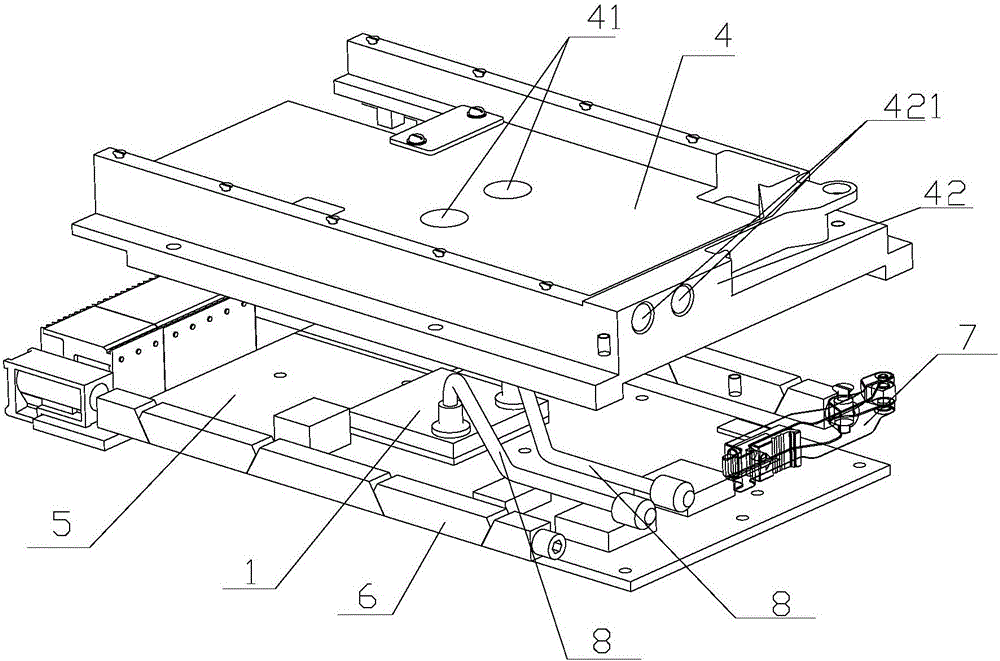

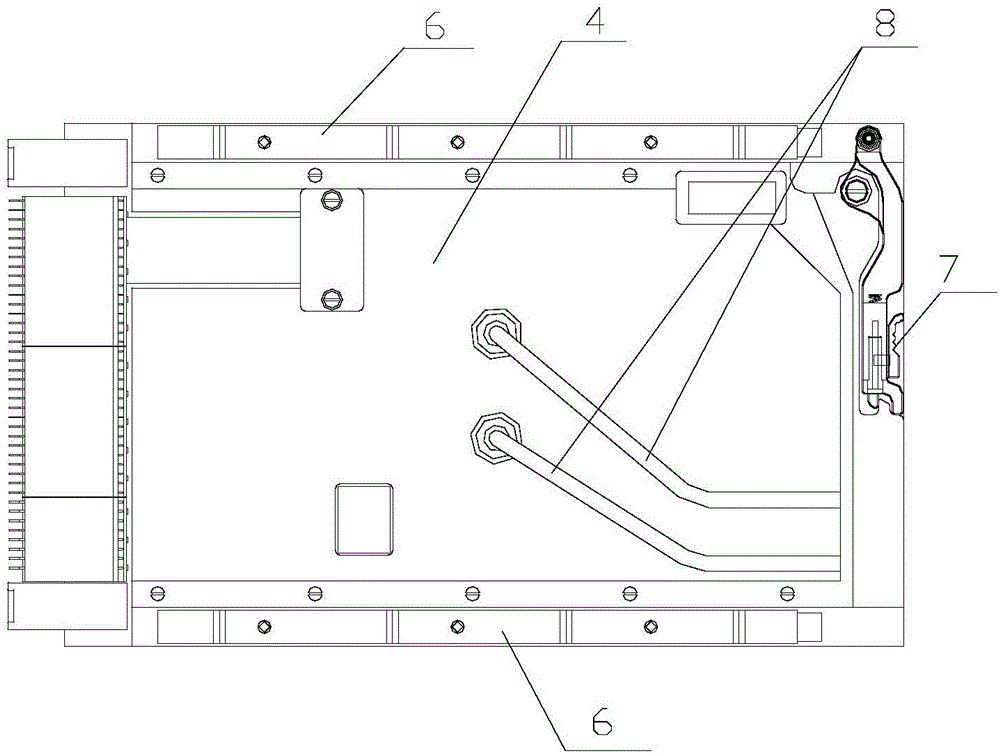

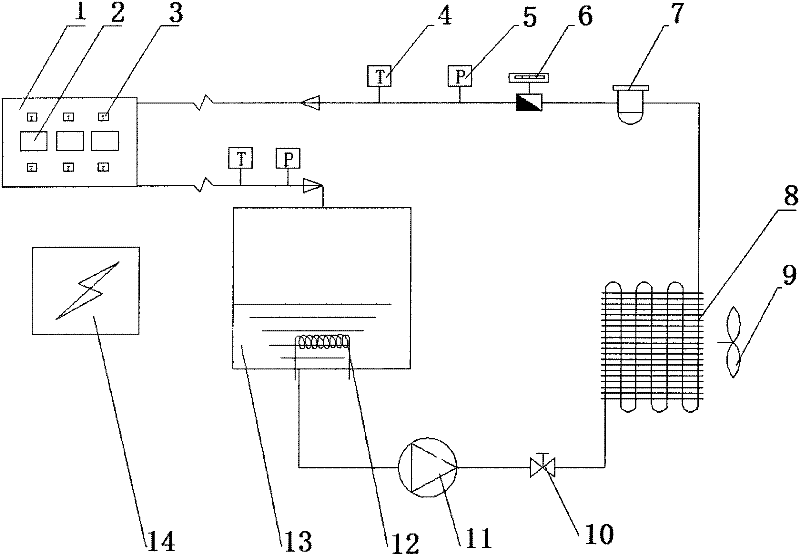

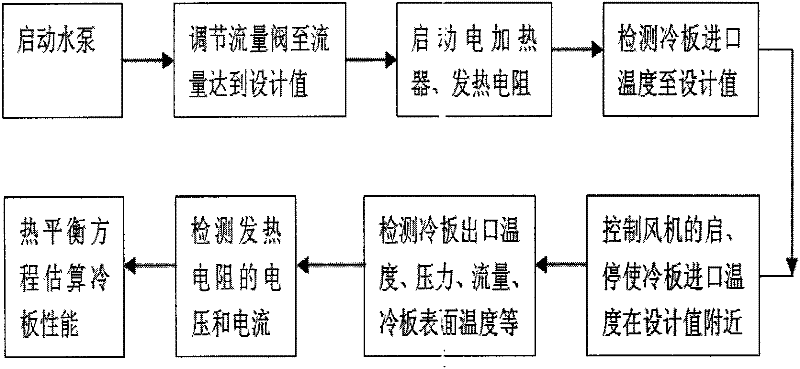

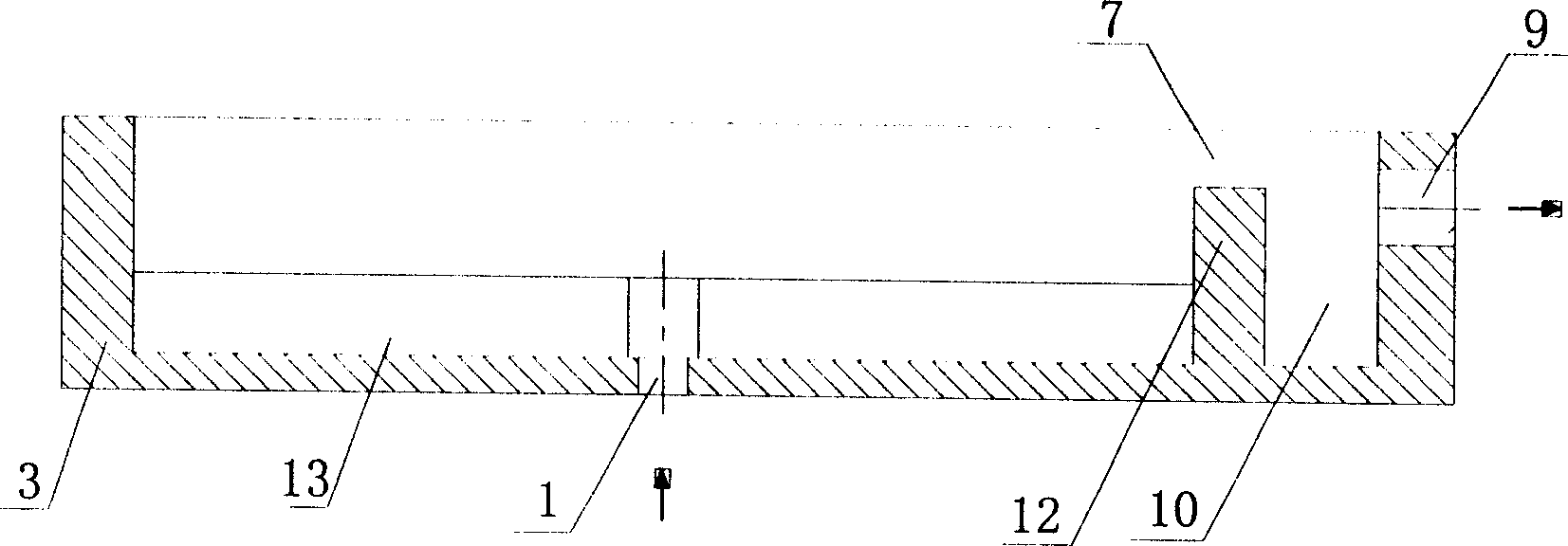

Cold plate performance test device

InactiveCN102374878AWide flow rangeMeet the test requirementsMeasurement devicesElectrical resistance and conductanceHeat resistance

The invention provides a cold plate performance test device which is characterized by comprising a thermometer (4), a pressure meter (5), a flowmeter (6), a filter (7), a heat radiator (8), a flow valve (10), a water pump (11), a water tank (13) and a cold plate (1) which are sequentially connected together in series through a pipeline, wherein a fan (9) is fixed together with the heat radiator (8) through a bracket; an electric heater (12) is arranged on the side wall of the water tank (13) in a threaded connection manner; a heating resistance module (2) and a wall temperature sensor (3) are fixed on the surface of the cold plate (1) through bolts; and a control unit (14) is connected with the heating resistance module (2), the wall temperature sensor (3), the thermometer (4), the pressure meter (5), the flowmeter (6), the fan (9), the water pump (11) and the electric heater (12) through a conductive wire, so that a control part of the device is formed. The cold plate performance test device disclosed by the invention has the advantages of wide measurement range, small measurement error and high measurement precision.

Owner:CHINA NORTH VEHICLE RES INST

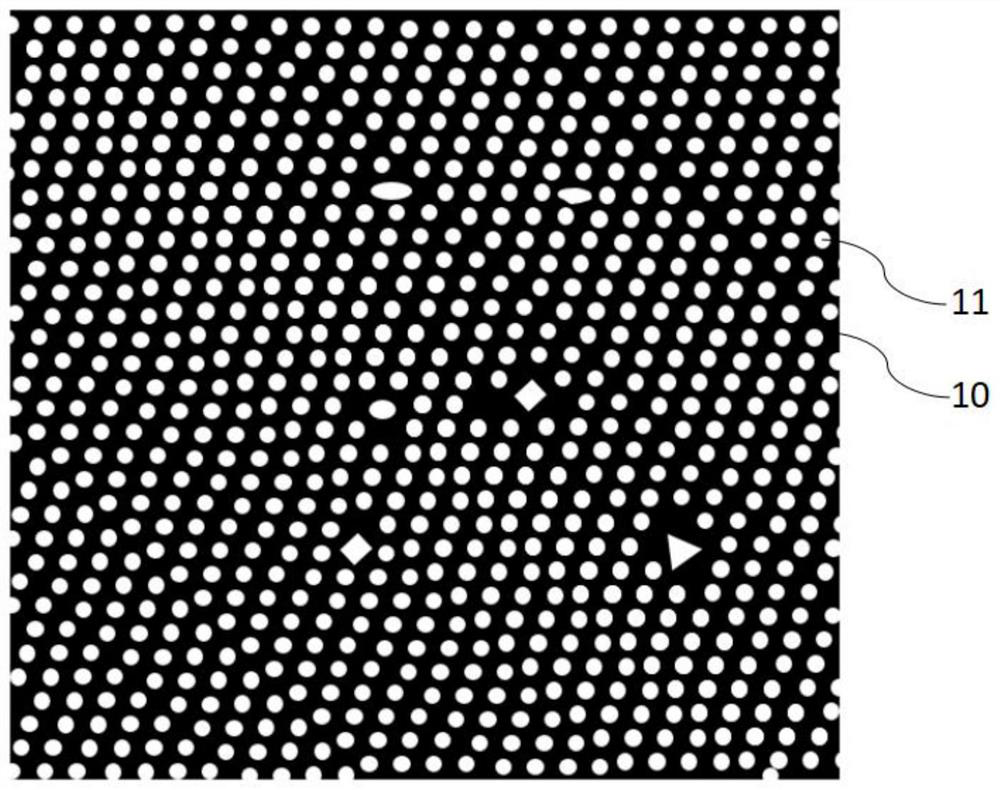

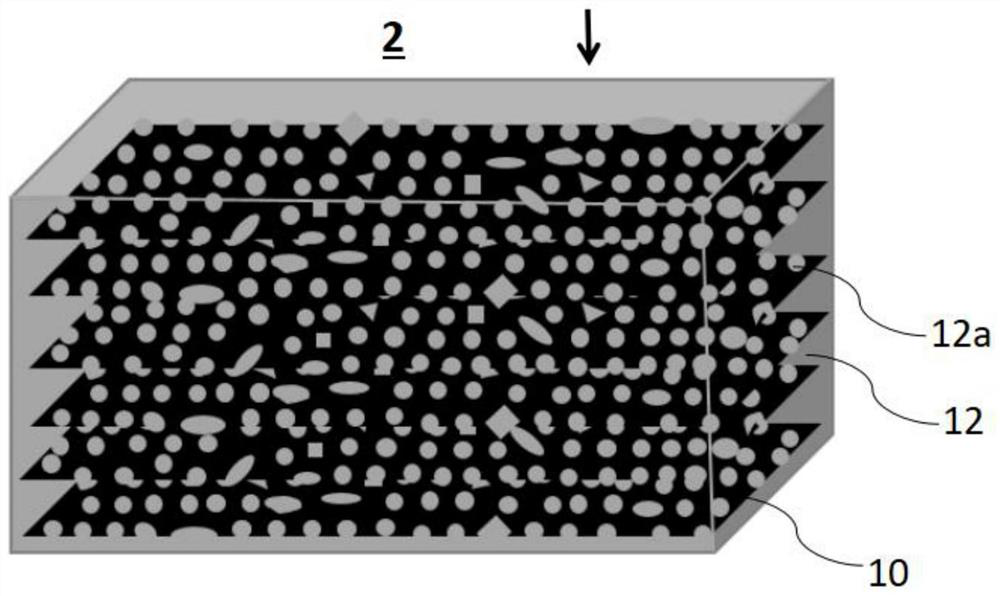

Composite material and preparation method thereof

ActiveCN108079934ALarge specific surface areaIncrease loadOther chemical processesAluminium silicatesCarbon filmMicrosphere

The invention relates to a composite material and a preparation method thereof, and can be widely applied to the fields of batteries, environmental protection, adsorptive dehumidification, air conditioning, refrigeration, heat pumps, pressure-variable separation purification, hydrogen storage production and the like. The composite material comprises a supporting framework material, carbon microspheres and / or a carbon film and a loading material, the loading material comprises salt, an electrode material and a physical adsorbent, the carbon microspheres and / or the carbon film are / is firmly attached to the wall surfaces of pores in the supporting framework material, and the loading material is uniformly distributed inside the carbon microspheres and / or the carbon film, so that direct embedment of the loading material between carbon atoms is achieved, the anti-agglomeration inactivation capacity is obviously enhanced, and the service life is effectively prolonged; the composite material breaks through a limitation of the specific surface area of the original skeleton material, so that the specific surface area of the composite material can be effectively increased under the premise ofincreasing the loading capacity, and the adsorption, reaction or electron migration rate can be increased; the composite material conveniently achieves close contact between the adsorbent and a heat-exchanging wall surface by an extruding, bonding or brazing method, so that the contact heat resistance between the two is effectively reduced.

Owner:SHANDONG UNIV

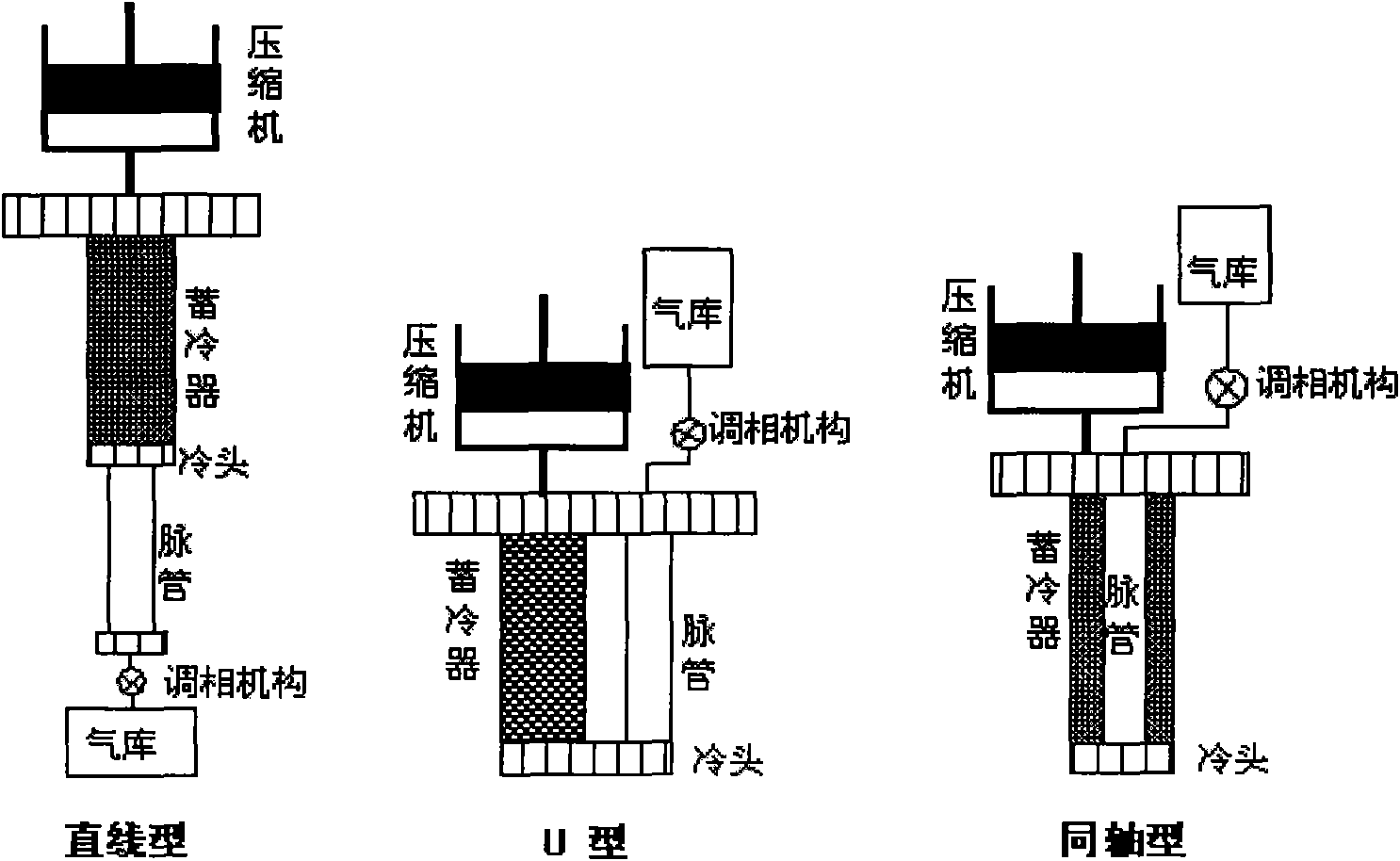

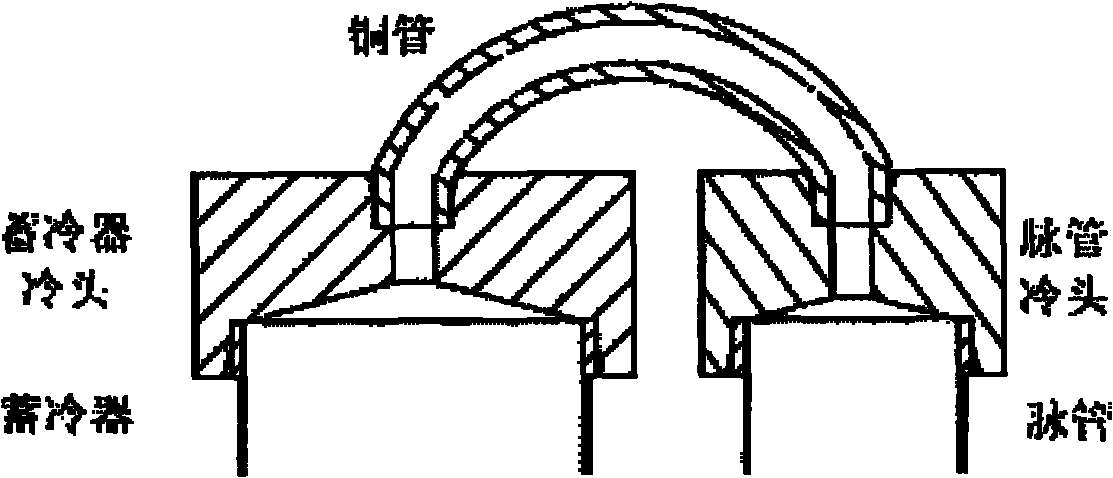

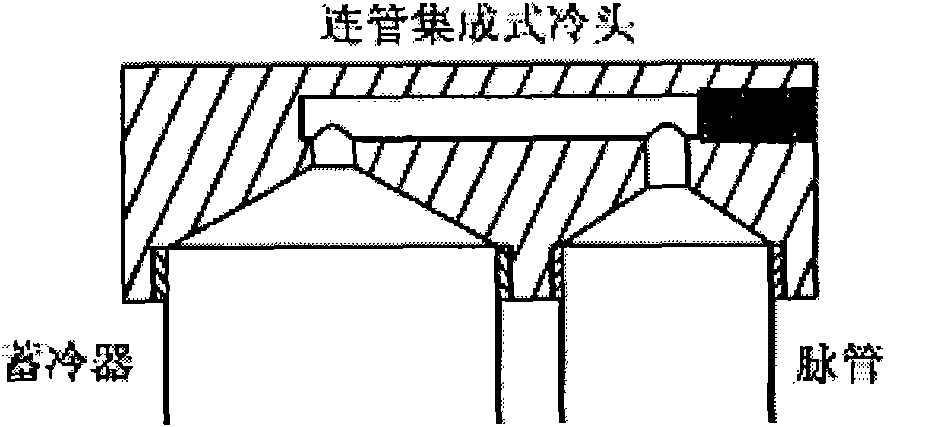

Integrated slit cold head of U-shaped pulse tube refrigerating machine and manufacturing method

InactiveCN102042711AMaintain laminar effectImprove thermodynamic performanceCompression machinesGas cycle refrigeration machinesEngineeringTop cap

The invention discloses an integrated slit cold head of a U-shaped pulse tube refrigerating machine and a manufacturing method. The cold head comprises two parts of a top cover and a lower flange, wherein two cylindrical lug bosses protrude below a big lug boss of the top cover, outer diameters of the two cylindrical lug bosses are respectively equal to inner diameters of a cold regenerator and a pulse tube; the two lug bosses integrally cut and penetrate through a slit in parallel horizontally and uniformly; through insertion holes matched with the cylindrical lug bosses of the top cover are arranged on the lower flange, a sealing groove and a location groove matched with the big lug boss of the top cover are cut on the upper surface of the lower flange, the lower flange, the cold regenerator and the pulse tube are hermetically welded to form an assembly; the top cover and the lower flange not only can be connected by bolts to form a detachable split cold head, but also can be hermetically welded to form an integrated cold head. In the invention, the main functions of three parts of an efficient cold end heat exchanger, a pulse tube cold end gas director and a cold regenerator cold end gas distributor can be intensively realized in an integrated slit cold head structure, the overall performance of the U-shaped pulse tube refrigerating machine is enhanced.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

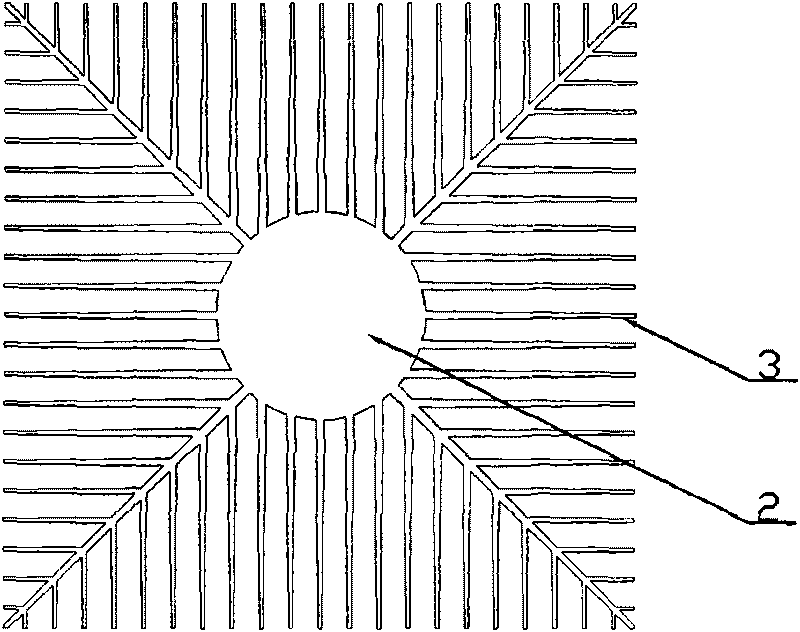

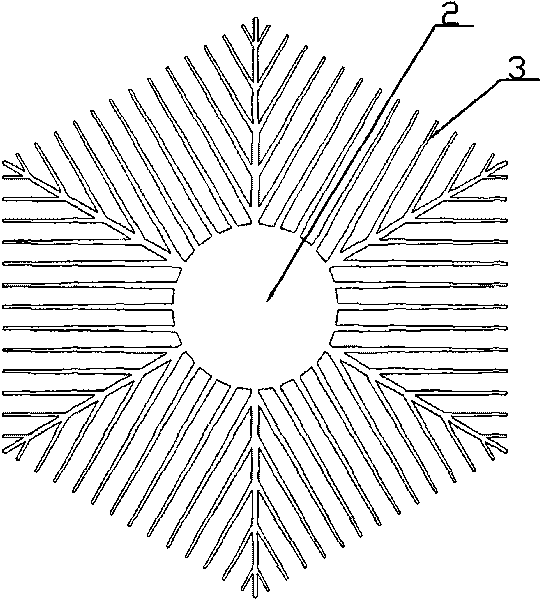

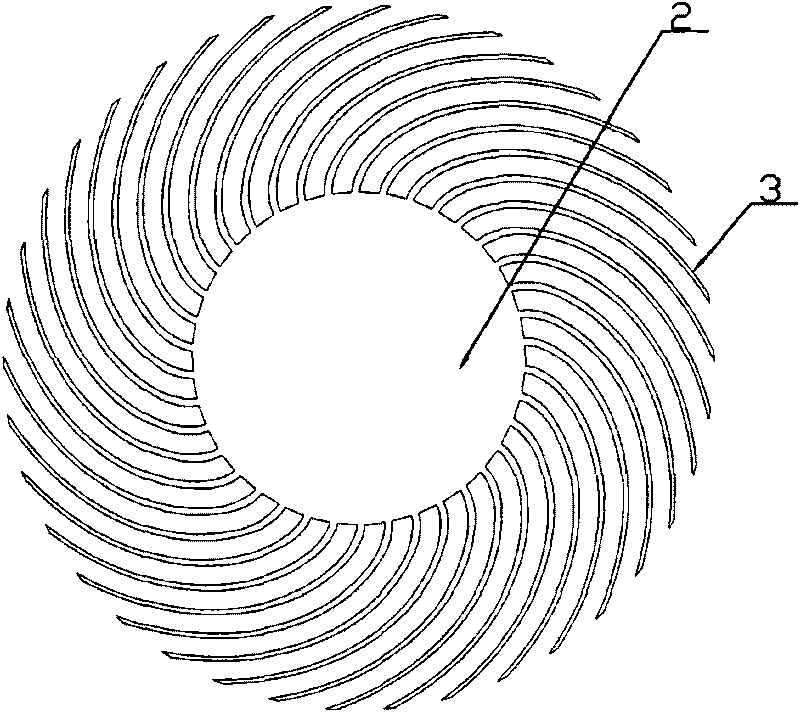

LED lampwick and LED illuminating lamp thereof

InactiveCN101713529AEasy to processEnlarge the contact heat transfer areaPlanar light sourcesMechanical apparatusHeat conductingEngineering

The invention provides an LED lampwick and an LED illuminating lamp thereof, aiming to solve the problem of heat radiation of an LED. A sunflower type heat radiating fin is adopted, and a heat conducting wick (4) and the LED (1) are designed into an independent part, LED lampwick, which is convenient for the inner encapsulation of the lampwick and the assembly of the whole lamp and is convenient to realize the standard generalization of an LED illuminating lamp part. The cone and thread embedded heat radiating fin structure solves the problem of contact heat resistance between the heat conducting wick (4) and the heat radiating fin and is convenient for the maintenance of the LED lamp. The heat radiating capability is improved by additionally mounting a convection shield (8) through a chimney sucking principle, and the cost is effectively reduced.

Owner:秦彪

Spectroscopic photovoltaic and photo-thermal joint hydrogen production system and use method thereof

The invention relates to a photovoltaic photo-thermal joint hydrogen production system. The photovoltaic photo-thermal joint hydrogen production system comprises a light condensing device, a spectroscopic device, a photovoltaic and photo-thermal integrated device, a heat transfer pipeline, a water tank, an electrolyzing device and a hydrogen-water separating device, wherein the photovoltaic and photo-thermal integrated device comprises a photovoltaic assembly, a heat collecting plate and a heat pipe; and the electrolyzing device comprises an electrolytic cell and an electrolytic water pipeline which forms a circulating loop with the electrolytic cell. The invention also provides a use method of the photovoltaic photo-thermal joint hydrogen production system. Compared with the prior art, the photovoltaic photo-thermal joint hydrogen production system has an advantage that the total utilization efficiency of solar energy is effectively improved. The heat pipe aims at effectively lowering the temperature of the photovoltaic assembly with the heat transfer effect in order to increase the electrolytic hydrogen production efficiency by 10-15 %; the electrolytic water exchanges heat with a hot water system so as to raise the temperature of the electrolytic water, and thus the electrolytic hydrogen production efficiency of the system can be increased by 5 to 7%. The total hydrogen production efficiency of the system can be increased by about 20%, and the thermal efficiency can be increased by above 60%.

Owner:BEIHANG UNIV

Electronic terminal equipment and method for assembling same

InactiveUS20170090532A1Reduce temperatureReduce generationMagnetic/electric field screeningDigital data processing detailsEngineeringLiquid resin

The electronic terminal equipment comprising an electronic substrate on which a heat-generating electronic component is mounted and an electromagnetic shield member attached in proximity to the heat-generating electronic component, the electronic substrate being filled with a cured product of a thermally-conductive curable liquid resin between the electromagnetic shield member and the electronic substrate, and a thermally-conductive film being disposed in contact with an upper surface of the electromagnetic shield member or facing the upper surface thereof so as to diffuse heat that came up through the cured thermally-conductive curable liquid resin.

Owner:KANEKA CORP

High-temperature heat storage and evaporation integrated device

InactiveCN102162636AImprove heat transfer efficiencyImprove featuresThermal insulationHeat storage plantsInsulation layerLight pipe

The invention discloses a high-temperature heat storage and evaporation integrated device, which comprises a heat storage block (5), a liquid storage tank (7), a heat insulation layer (4), a heating pipe (8) and an evaporation pipe (9). The heat insulation layer (4) is tightly attached to the outer wall of the liquid storage tank (7); the heat storage block (5) is placed in the liquid storage tank (7); a plurality of through holes are regularly distributed on the heat storage block (5) at equal intervals; and the heating pipe (8) and the evaporation pipe (9) alternately pass through the through holes on the heat storage block (5). The heating pipe (8) and the evaporation pipe (9) are light pipes or reinforced heat exchange pipes; and a high-temperature heat transfer working medium is filled in the container of the liquid storage tank (7).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Plane capillary core evaporimeter for CPL

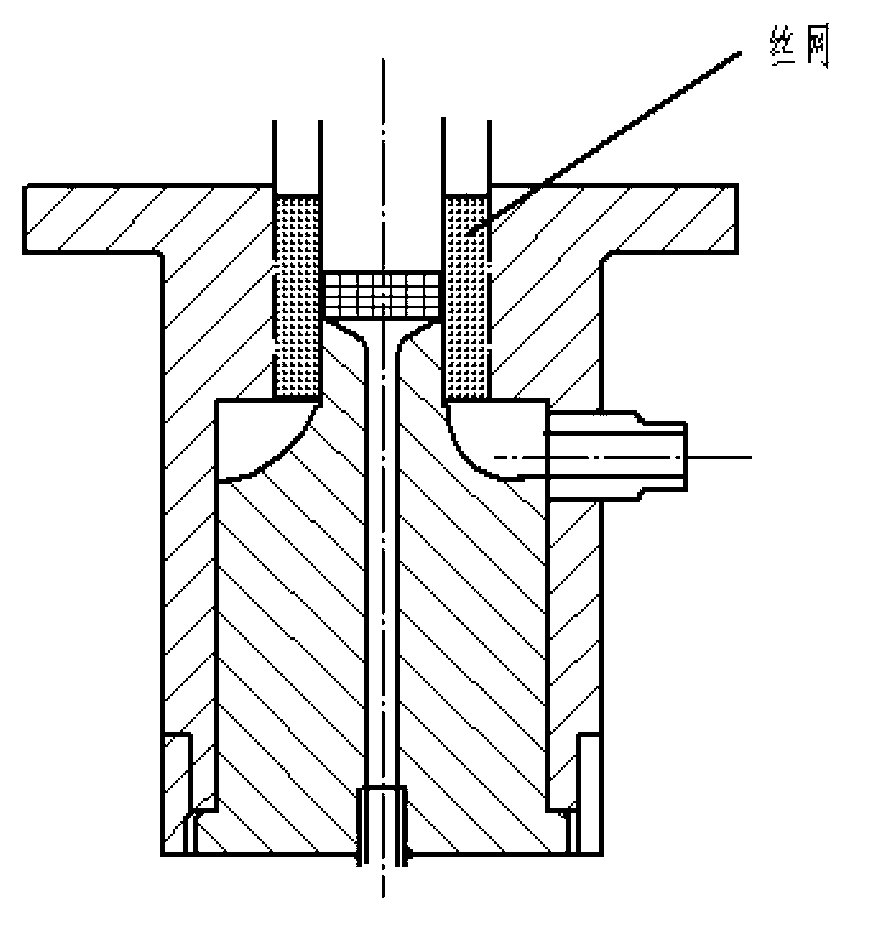

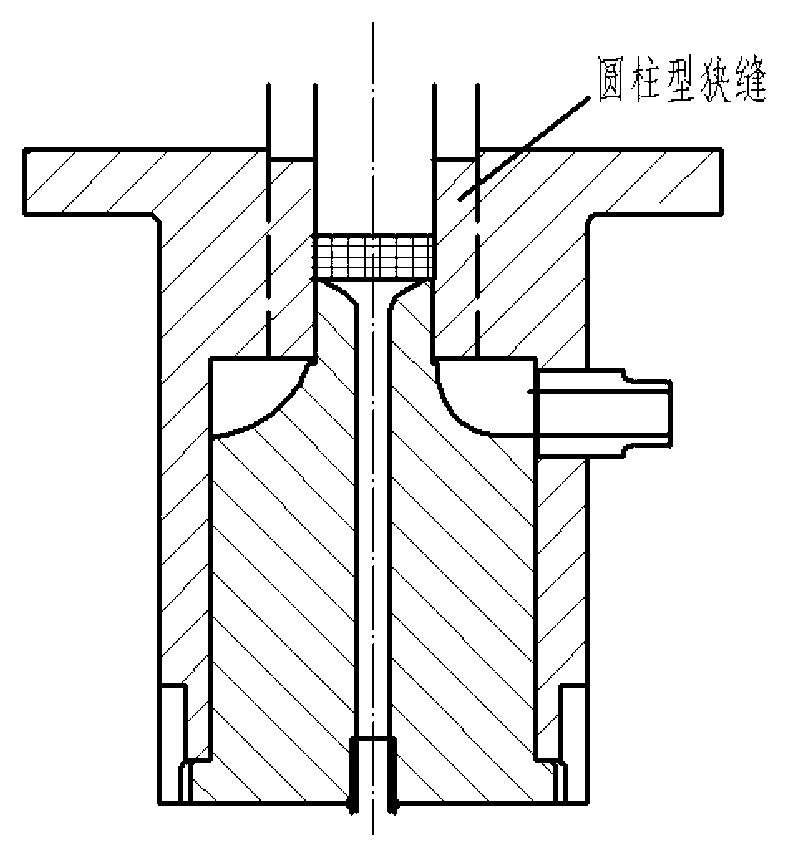

InactiveCN1725946AReduce thermal contact resistanceImprove heat transfer efficiencyInstrumental cooling apparatusCooling/ventilation/heating modificationsWire gauzeEngineering

A planar capillary core evaporator for CPL consists of base, top cover being fixed and sealed with base, an isolation plate for isolating top cover to liquid and steam collection cavity, the liquid collection cavity formed by horizontal and longitudinal channels and cross arranged and opened with return liquid inlet on it, steam collection cavity opened with vapor outlet, top cover longitudinal steam channel being connected to steam cavity and capillary core set between two cavities.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com