Spectroscopic photovoltaic and photo-thermal joint hydrogen production system and use method thereof

A hydrogen production system and photovoltaic technology, applied in cells, electrolytic components, energy input, etc., can solve the problems of high cost and low hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

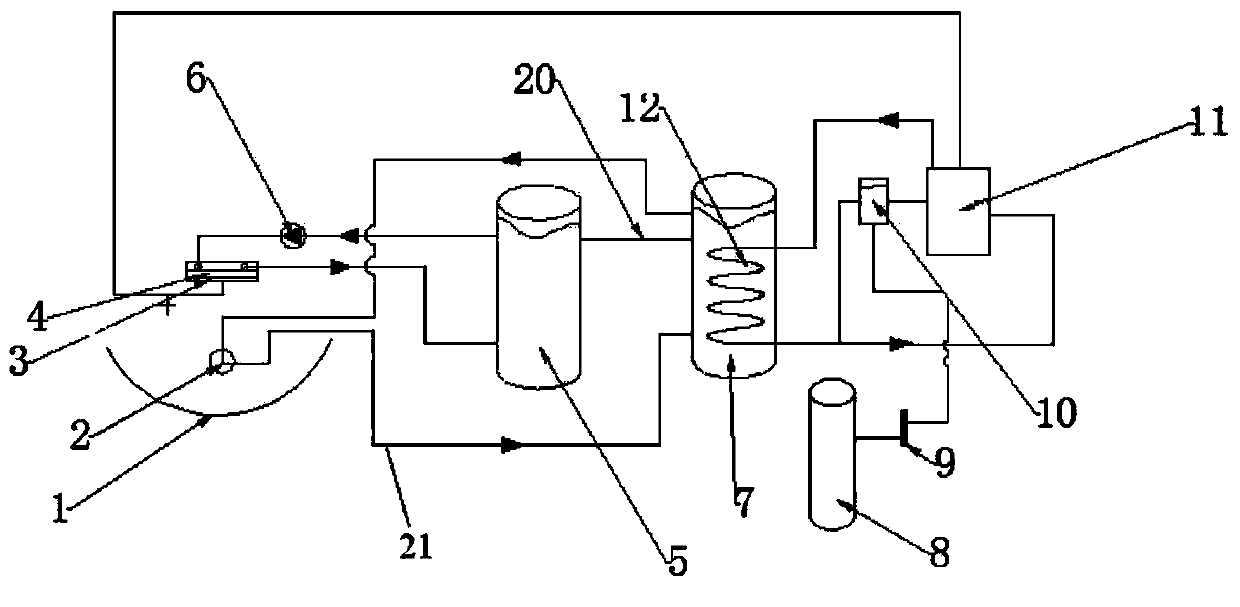

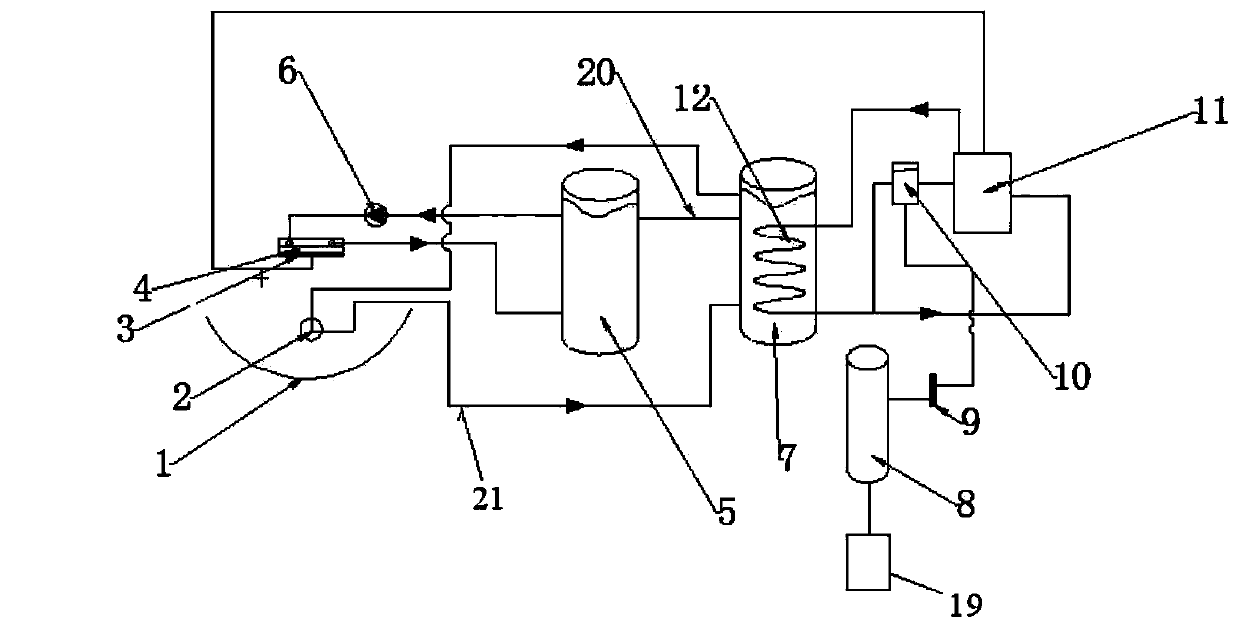

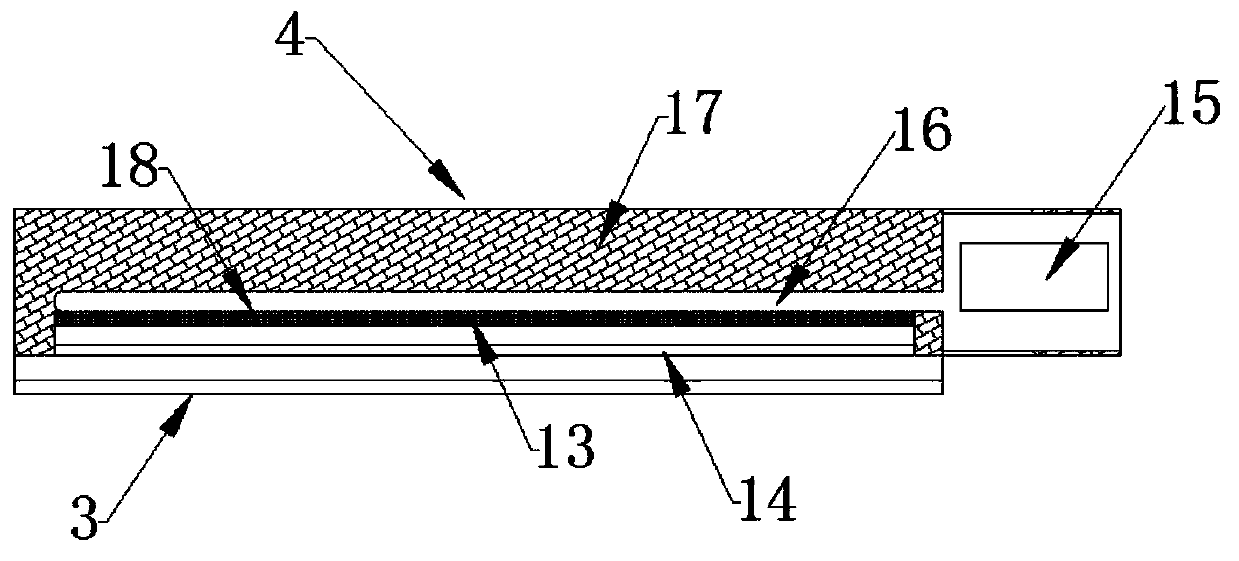

[0071] Photovoltaic photothermal combined hydrogen production system of the present invention such as figure 1 , 2 and 3. The photovoltaic photothermal combined hydrogen production system mainly includes a photovoltaic photothermal integrated device 4, a light concentrating device 1, a light splitting device 3, a heat collecting tube 2, an electrolytic cell 11, a heat exchange pipe 15, a hydrogen storage device 8, and a first water tank 5 and the system that the second water tank 7 and water pump 6 form. Among them, the structure composed of photovoltaic photothermal integrated device 4 is glass 14, photovoltaic module 18, heat collecting plate 13 and heat pipe 16, wherein photovoltaic module 18, heat collecting plate 13 and heat pipe 16 are made of ethylene-vinyl acetate copolymer (EVA ) and polyvinyl fluoride composite film (TPT) are closely combined by lamination technology. The back of the photovoltaic module is filled with heat insulating material 17 . Moreover, the s...

Embodiment 2

[0100] On the basis of Embodiment 1, the photovoltaic hydrogen production system further includes a fuel cell 19 connected to the hydrogen storage system 8 . It is used to generate electricity by receiving hydrogen from the hydrogen storage system 8 as fuel. This enables the conversion of discontinuous, high-energy-density solar energy into high-density, continuous, and storable hydrogen-converted electrical energy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com