Patents

Literature

409 results about "Polyvinyl fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinyl fluoride (PVF) or –(CH₂CHF)ₙ– is a polymer material mainly used in the flammability-lowering coatings of airplane interiors and photovoltaic module backsheets. It is also used in raincoats and metal sheeting.

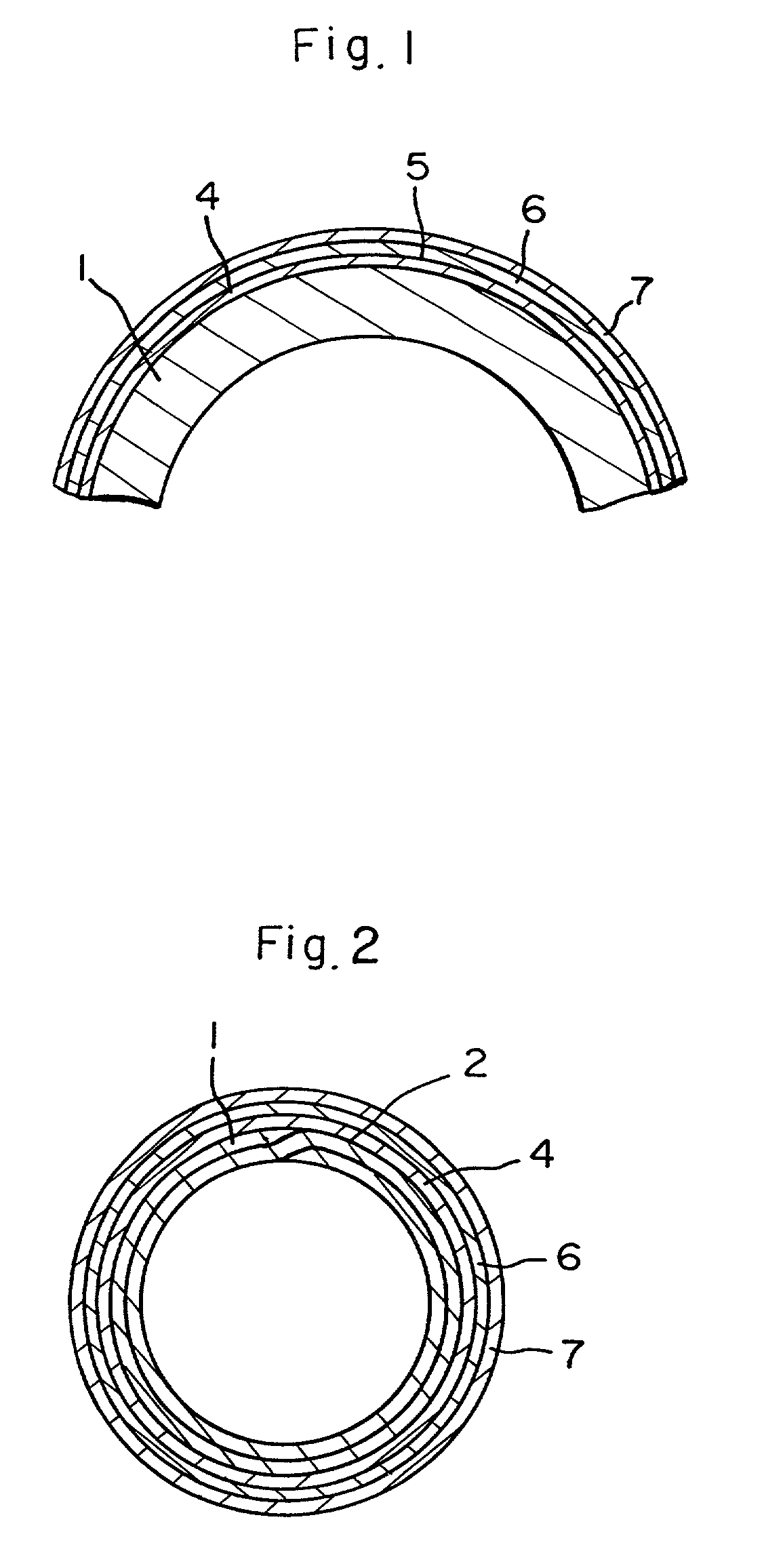

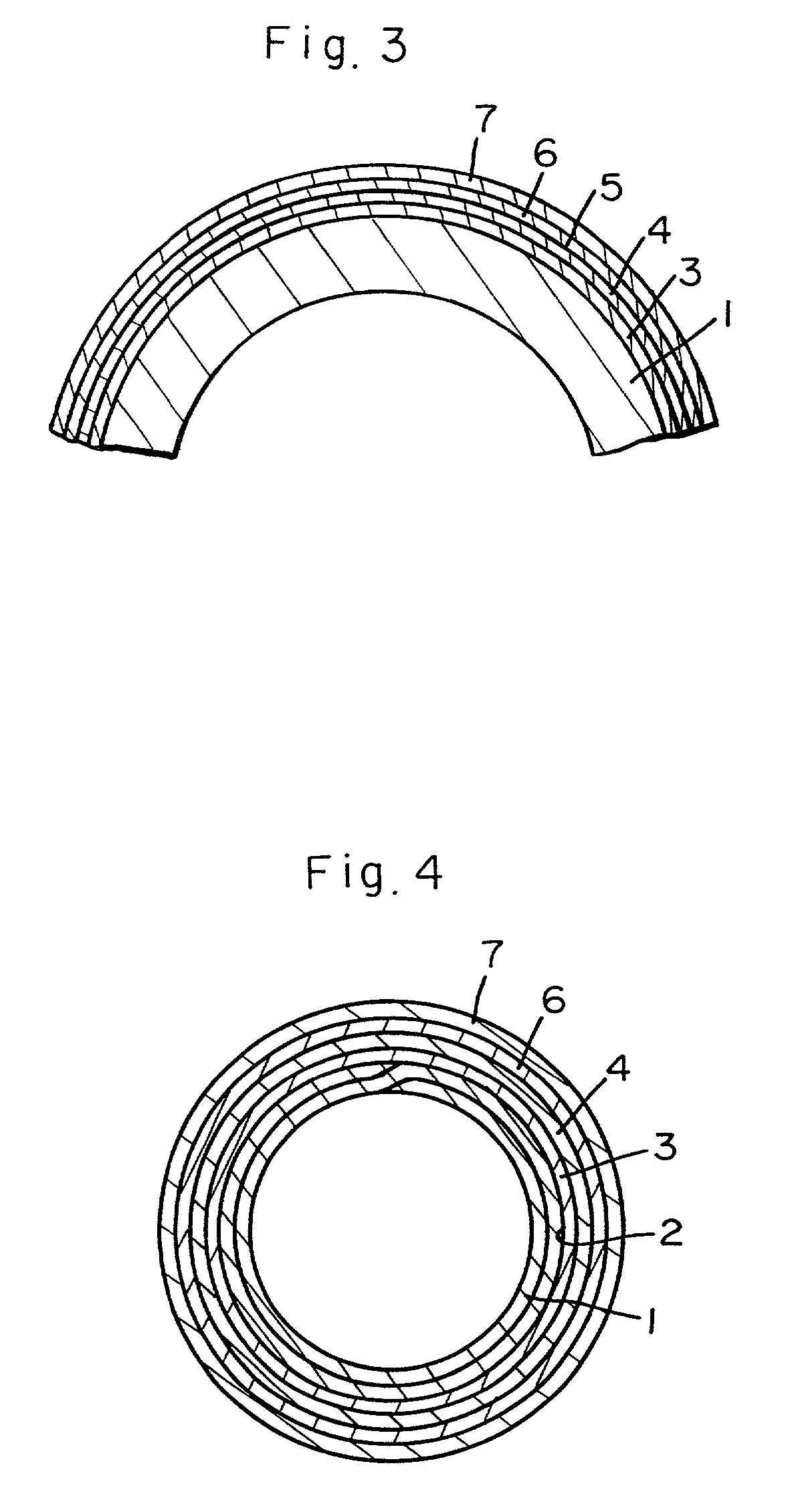

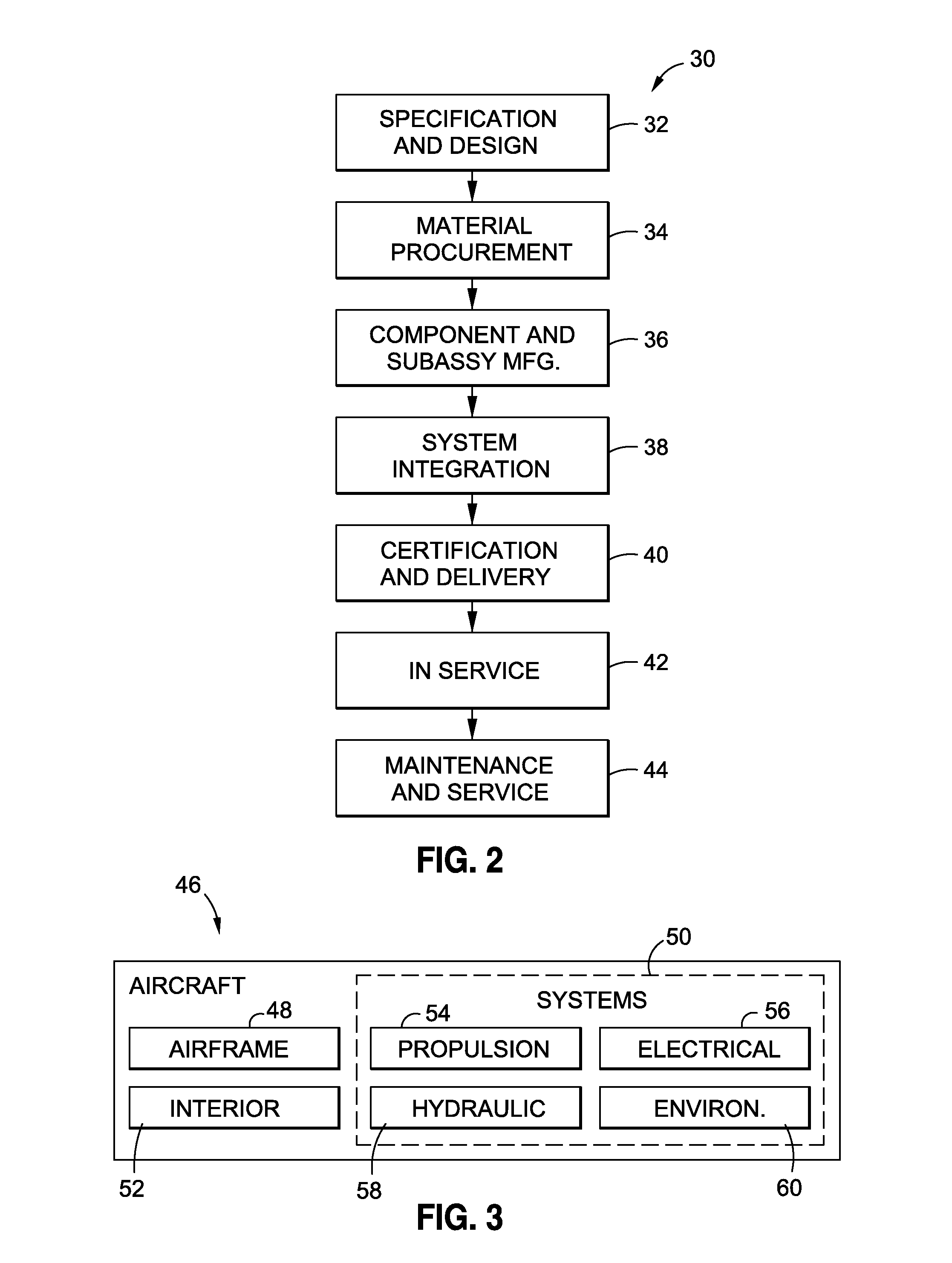

Multi-layer sheet having a weatherable surface layer

InactiveUS20060057392A1Synthetic resin layered productsElectrical equipmentPolymer scienceWeather resistance

A multi-layer sheet and a process for producing the sheet are disclosed. The sheet can comprise a first polymer layer comprising a film of polyvinyl fluoride (PVF) or polyvinylidene fluoride (PVDF) having an adhesive coating on one side; second optionally pigmented polymer layer extruded onto the adhesive coating of the first polymer layer; and optionally a third polymer layer. Also a photovoltaic module comprising a prebonded backskin that comprises the multi-layer sheet.

Owner:PERFORMANCE MATERIALS NA INC

Multilayer coated corrosion resistant article and method of production thereof

InactiveUS20050031894A1Increase heightImprove heat resistanceSynthetic resin layered productsCoatingsPhosphateZinc

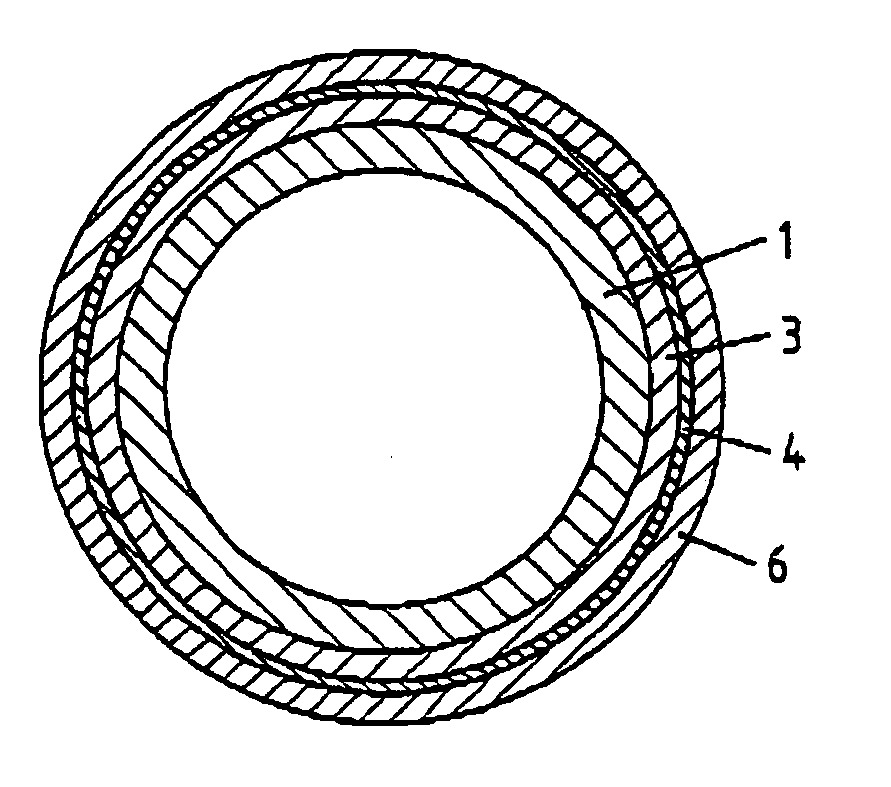

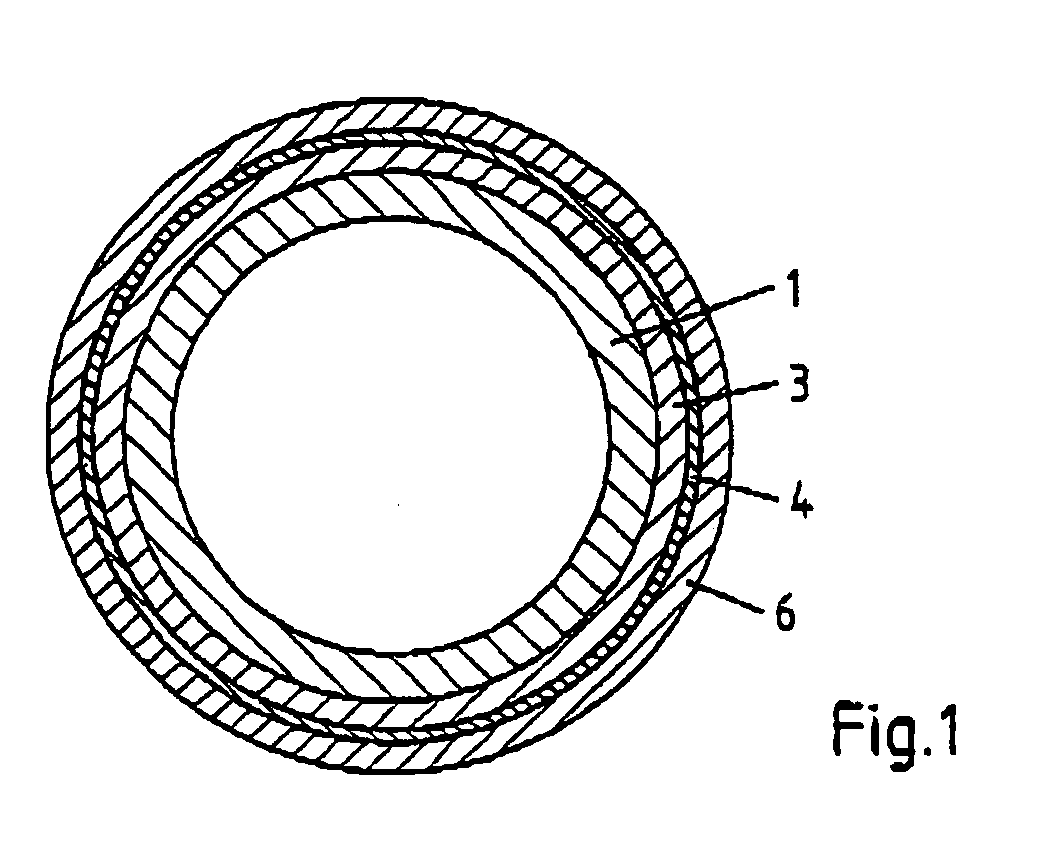

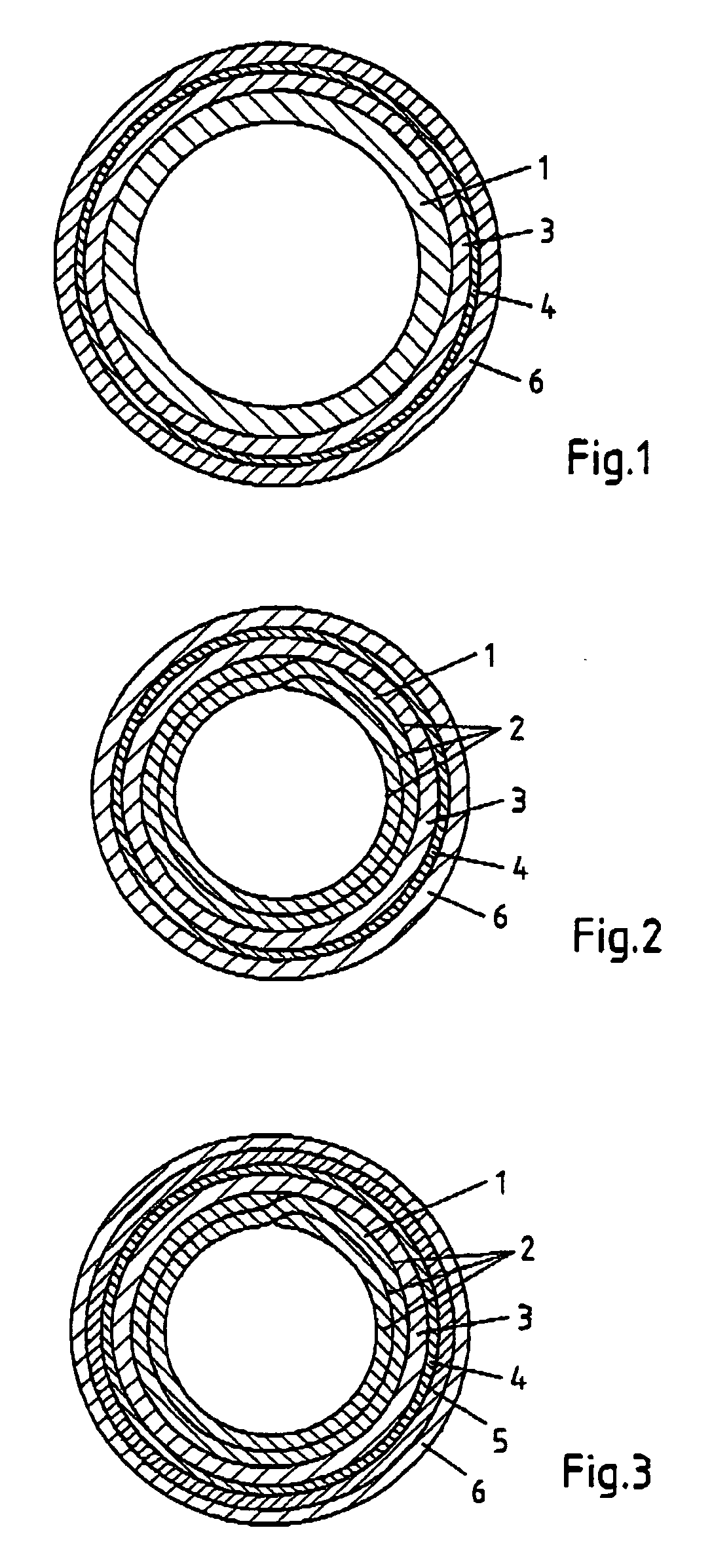

The disclosure relates to a corrosion resistant article comprising a metal body 1 and a protective coating applied on at least one surface of said metal body 1, said protective coating comprising: (a) a zinc layer 3 comprising metallic zinc; (b) a silicate layer 4 comprising at least one silicate; and (c) a synthetic resin layer 6 comprising at least one fluoroplastic material such as, for example, polyvinylfluoride. In particular, the disclosure relates to a corrosion resistant brake pipe or fuel pipe having a protective coating for use in motor vehicles. The protective coating is substantially free of chromates and phosphates and, hence, environmentally acceptable.

Owner:ELISHA HLDG LLC

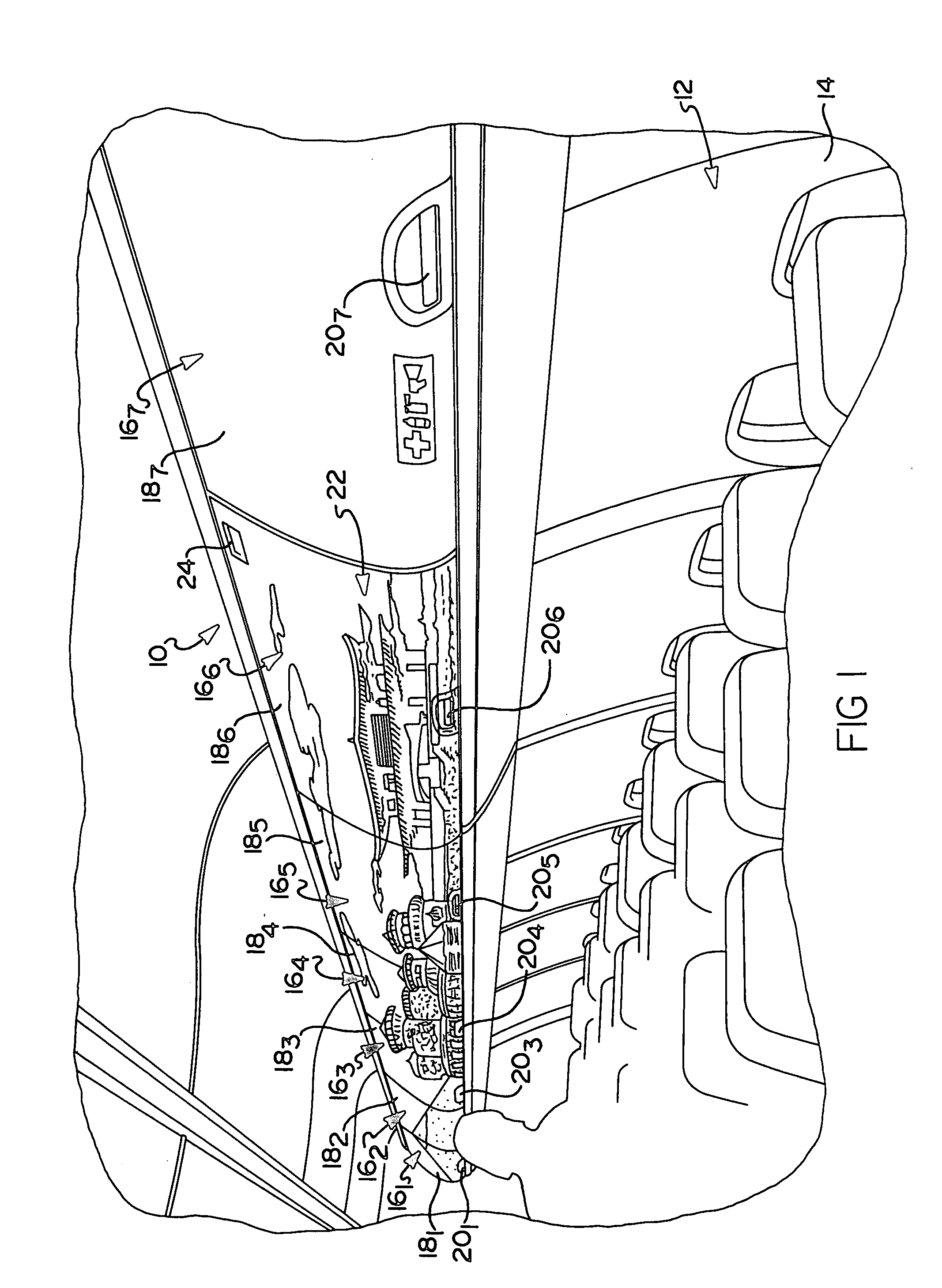

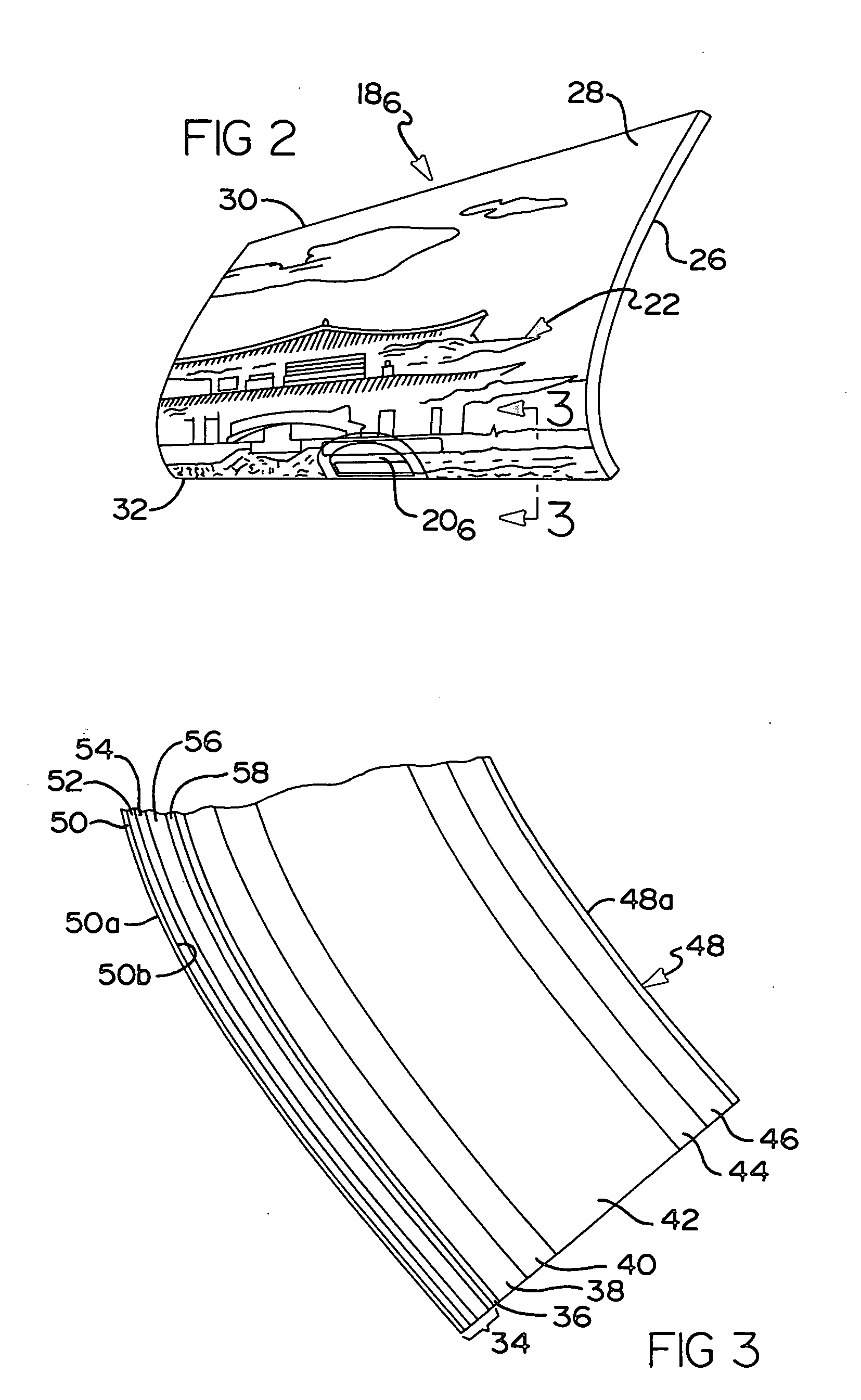

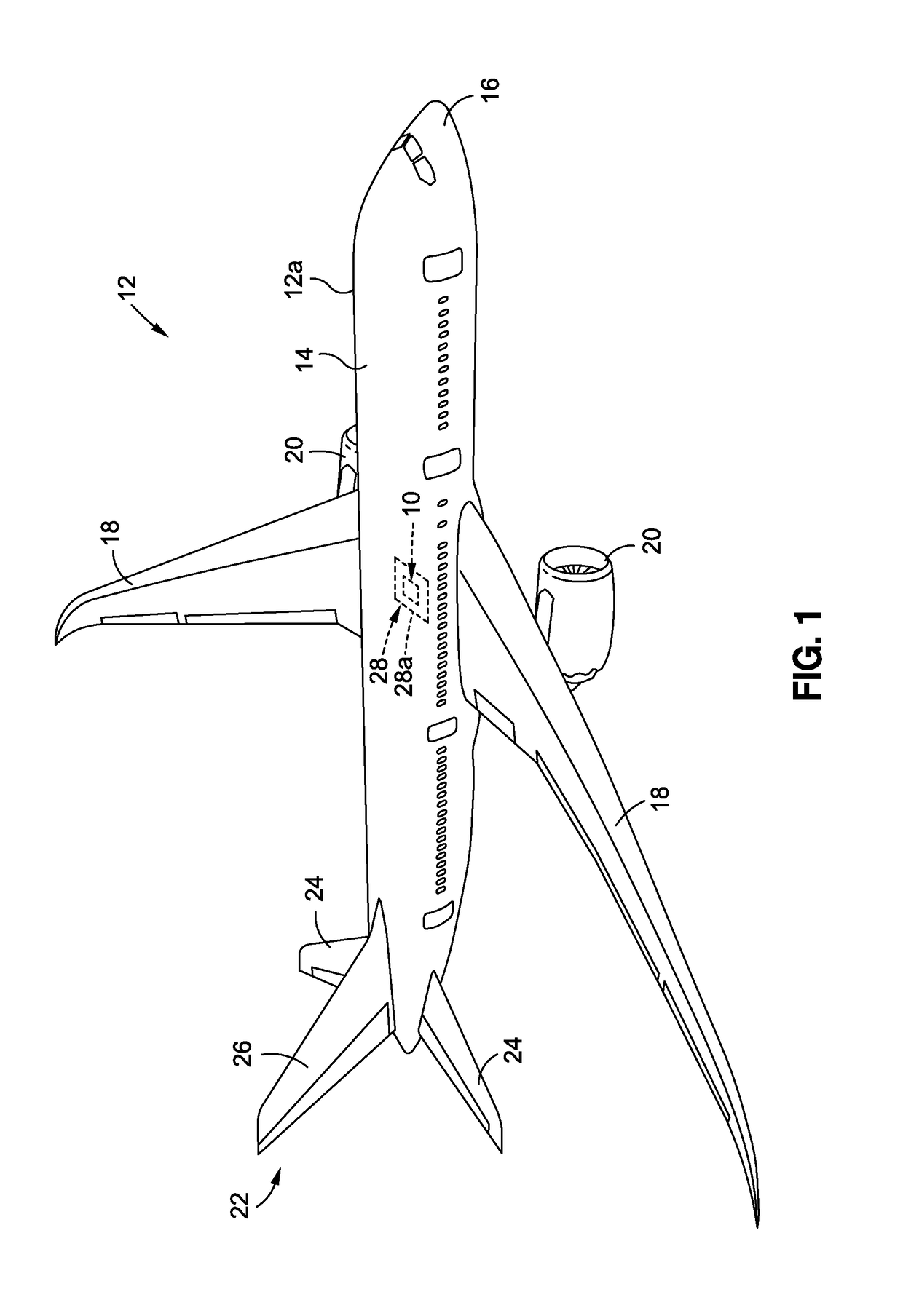

Laminate panel for use in structrual components

InactiveUS20050052516A1Quick and easy changeHigh ink loadingSynthetic resin layered productsGlass/slag layered productsGlass fiberAdhesive

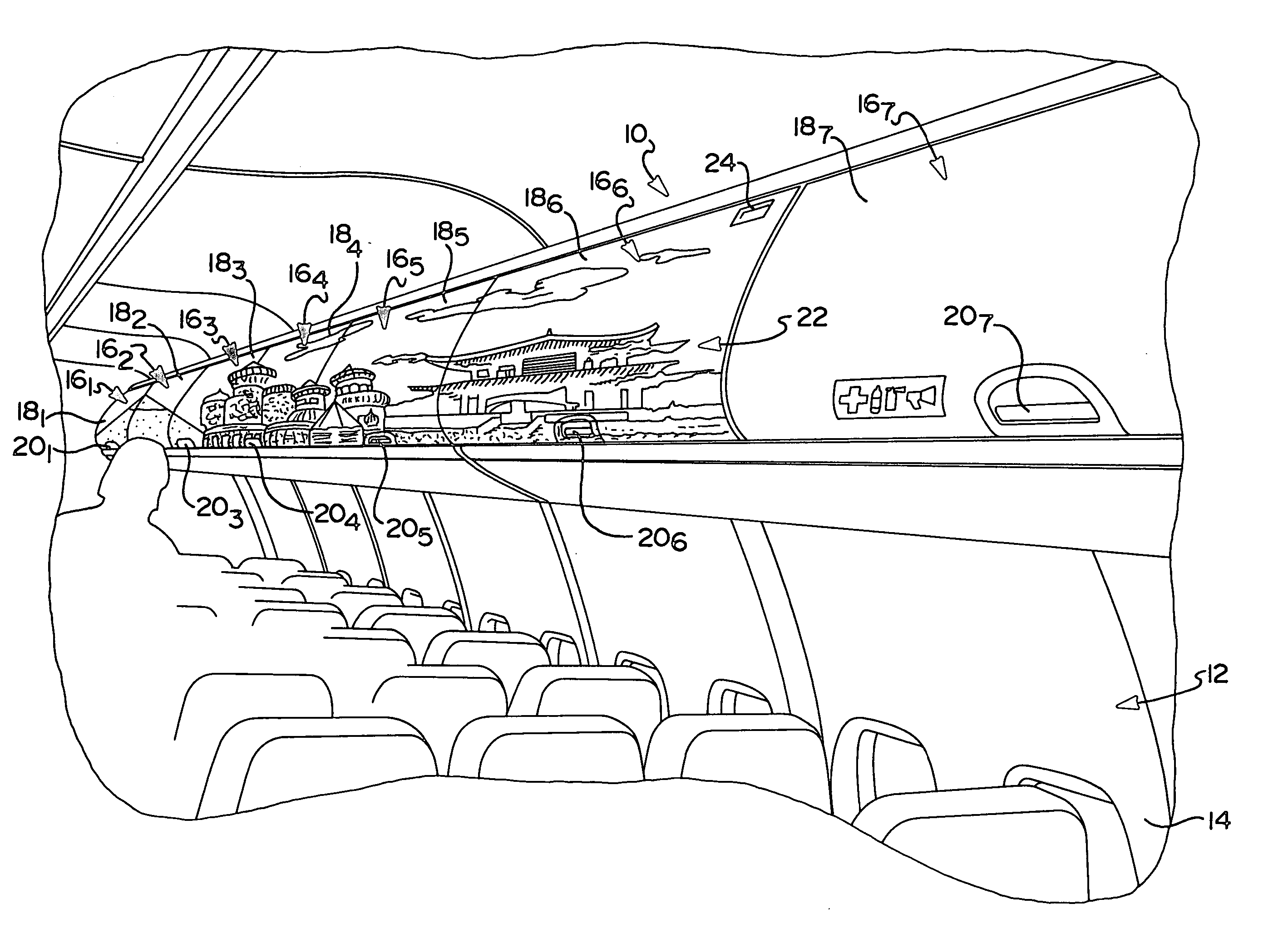

A laminate panel especially well suited to help form an overhead stowage bin door on an aircraft, wherein the door includes a portion of a high contrast color advertising mural or message integrally formed therewith. The door includes a honeycomb support layer on which at least one fiberglass pre-preg layer is formed. A polyvinyl fluoride (PVF) film is used as a substrate for the color mural or message. A ultraviolet (UV) curable ink is deposited directly on the PVF film via an ink jet printing process that produces a high color density, high color contrast image. The PVF film in one form is a Tedlar® PVF film. The ink is cured virtually immediately after it is deposited on the PVF film. An additional layer of PVF film is then secured to a side of the printed-on PVF film opposite to that on which the ink is deposited via a layer of embossing resin to form the laminate panel. The laminate panel is then secured via a suitable adhesive to the fiberglass pre-preg and honeycomb support layer in a subsequent manufacturing step. The stowage bin door and process of making same enable a portion of a high color density, high contrast image, advertising mural or message to be integrally formed with the door.

Owner:THE BOEING CO

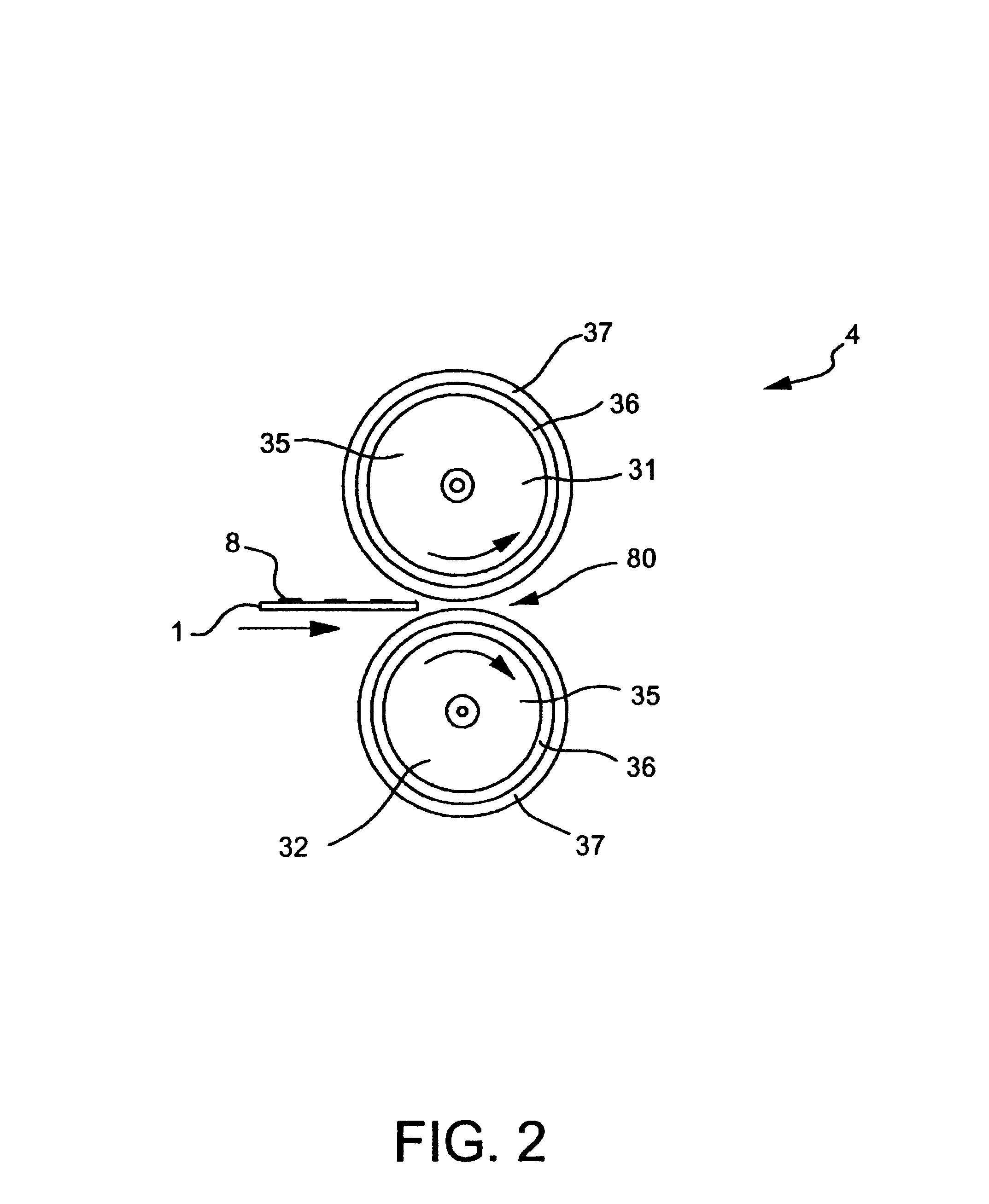

Fuser apparatus for adjusting gloss of a fused toner image and method for fusing a toner image to a receiver

Disclosed are apparatus and methods to adjust gloss of a fused toner image, and in particular to reduce differential gloss within the fused toner image so as to provide prints which more closely resemble lithographic prints in image quality. In embodiments, the apparatus and methods employ a finishing member having an outer contact surface thereon which contacts a previously fused toner image under conditions of elevated temperature and pressure. The contact surface is comprised of a fluorocarbon thermoplastic random copolymer co-cured with a fluorinated resin, such as polyfluoroethylenepropylene (FEP). In embodiments, the contact surface comprises a fluorocarbon thermoplastic random copolymer co-cured with a fluorinated resin including subunits of:wherein:x is from 1 to 50 or 60 to 80 mole percent,y is from 10 to 90 mole percent,z is from 10 to 90 mole percent, andx +y+z equals 100 mole percent.

Owner:EASTMAN KODAK CO

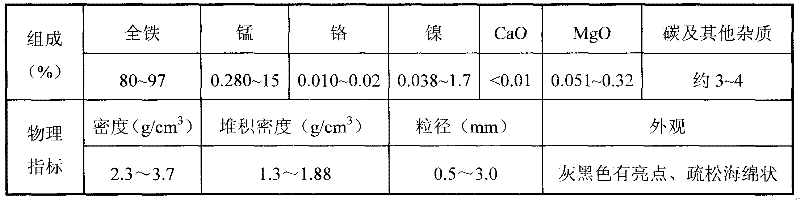

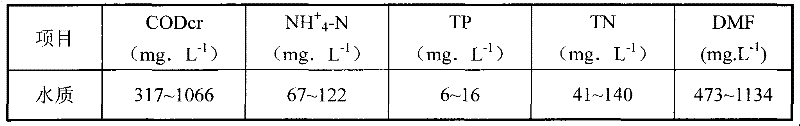

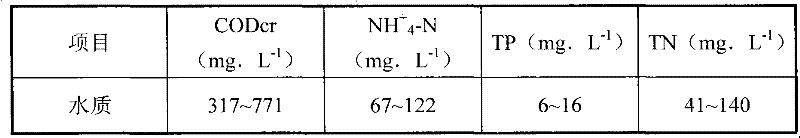

Sponge iron-AT (Attapulgite)-PVF (Polyvinyl Fluoride) composite filler and application thereof on water treatment

InactiveCN102161527AEasy to fixLarge biomassSustainable biological treatmentBiological water/sewage treatmentPolyvinyl chlorideTotal nitrogen

The invention relates to a sponge iron-AT (Aluminium Titanate)-PVF (Polyvinyl Fluoride) composite filler and application thereof on water treatment. The composite filler is formed by filling attapulgite composite hydrophilic polyurethane foam of the size of 1.5*1.5*1.5cm and sponge with the grain diameter of 2-5cm at the weight ratio of 1: (4-50). The sponge iron-AT-PVF composite filler has the characteristics of low cost, good water treatment effect, high degrading speed and high removal rate on elements N and P as well as organic matters which are difficult to be degraded in the wastewater. The TN (Total Nitrogen) and TP (Total Phosphorus) indexes in the effluent can be drastically lowered under the aerobic or anaerobic conditions when the composite filler is put into a common biochemical treating pond.

Owner:LANZHOU JIAOTONG UNIV

Heat and corrosion resistant steel pipe having multi-layered coating

A heat and corrosion resistant steel pipe having multi-layered coating comprising a steel pipe, a Zn-Ni alloy plating layer deposited to the outer surface of the steel pipe and a polyvinyl fluoride layer formed on the Zn-Ni alloy plating layer with an epoxy resin being intervened therebetween as an intermediate layer. A metal plating layer comprising Zn-Ni plating layer and Ni-plating layer may be used instead of the Zn-Ni plating layer. A chromate layer may be formed on the metal plating layer.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Photovoltaic backplane adhesive and preparation method thereof

ActiveCN102887988AImprove hydrolysis resistanceImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterHexafluoropropylene

The invention discloses a photovoltaic backplane adhesive which comprises a component A and a component B, wherein the component A contains hydrolysis resistant polyester polyol, and component B comprises an isocyanate curing agent; and the molar ratio of the isocyanate group in the isocyanate curing agent and the hydroxyl in the hydrolysis resistant polyester polyol is (0.9-1.3):1. The photovoltaic backplane adhesive adopts the hydrolysis resistant polyester polyol and the isocyanate curing agent, and the molar ratio of the isocyanate group and the hydroxyl in the hydrolysis resistant polyester polyol is (0.9-1.3):1, so that the hydrolysis resistance, the adhesive property and the weather fastness of the prepared photovoltaic backplane adhesive are improved. The photovoltaic backplane adhesive can be used for interlamination compounding of a film, and is especially suitable for the interlamination compounding of a photovoltaic backplane, thus being suitable for splicing and compounding the photovoltaic backplanes made of polyethylene terephthalate (PET), polyvinylidene fluoride (PDVF), tetrafluoroethylene-hexafluoropropylene-vinylidene fluoride (THV), polyvinyl fluoride (PVF), polyethylene (PE) and other films.

Owner:CSI SOLAR POWER GROUP CO LTD +1

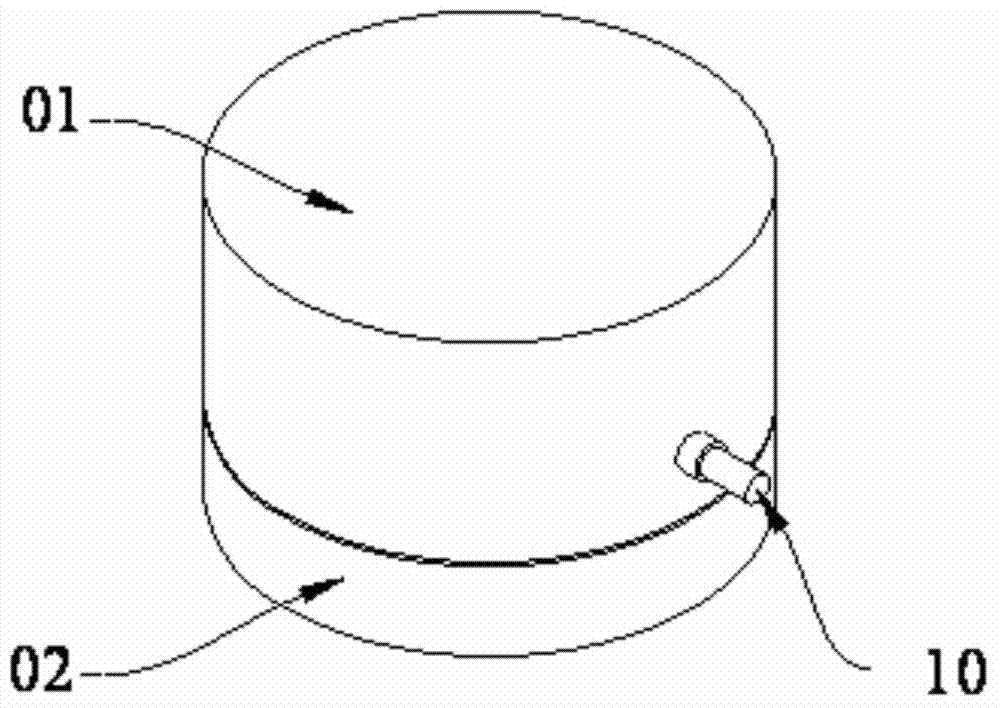

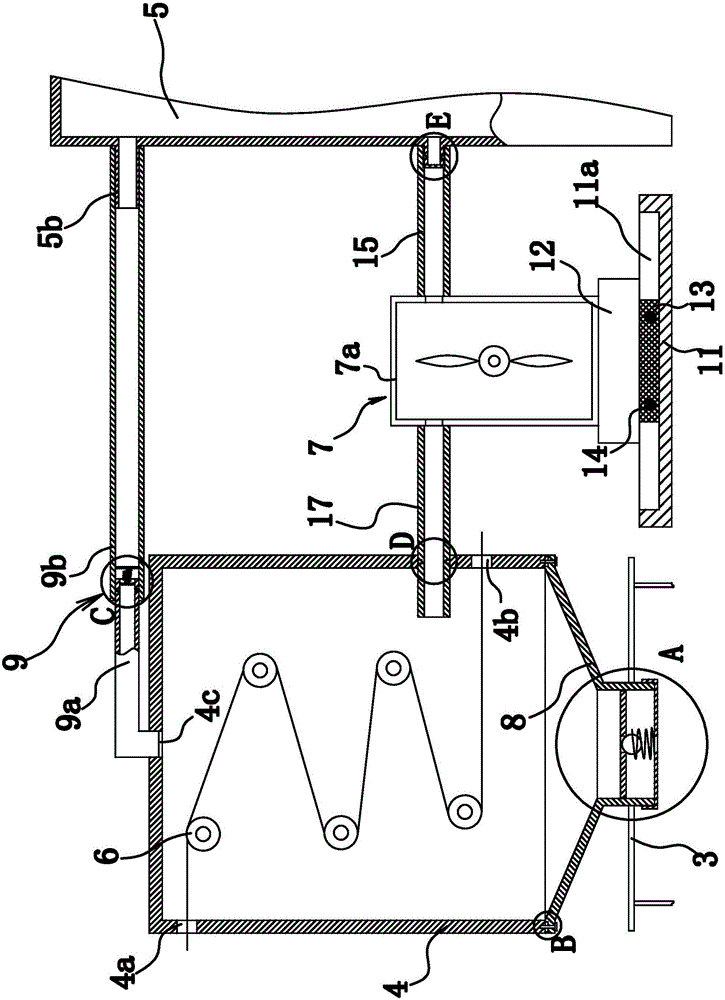

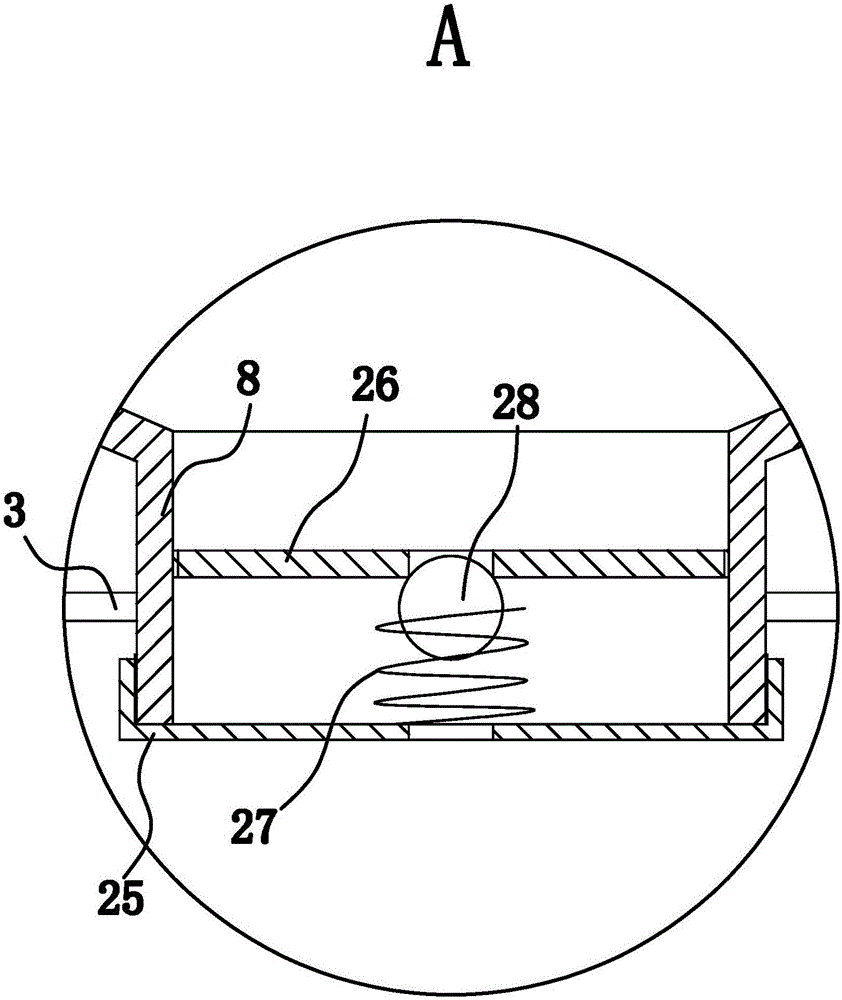

Concrete stress sensor by piezoelectric properties of PVDF (polyvinylidene fluoride) film

InactiveCN103674353AGood flexibilityHigh mechanical strengthForce measurement using piezo-electric devicesStrength propertiesPolyvinylidene difluorideEngineering

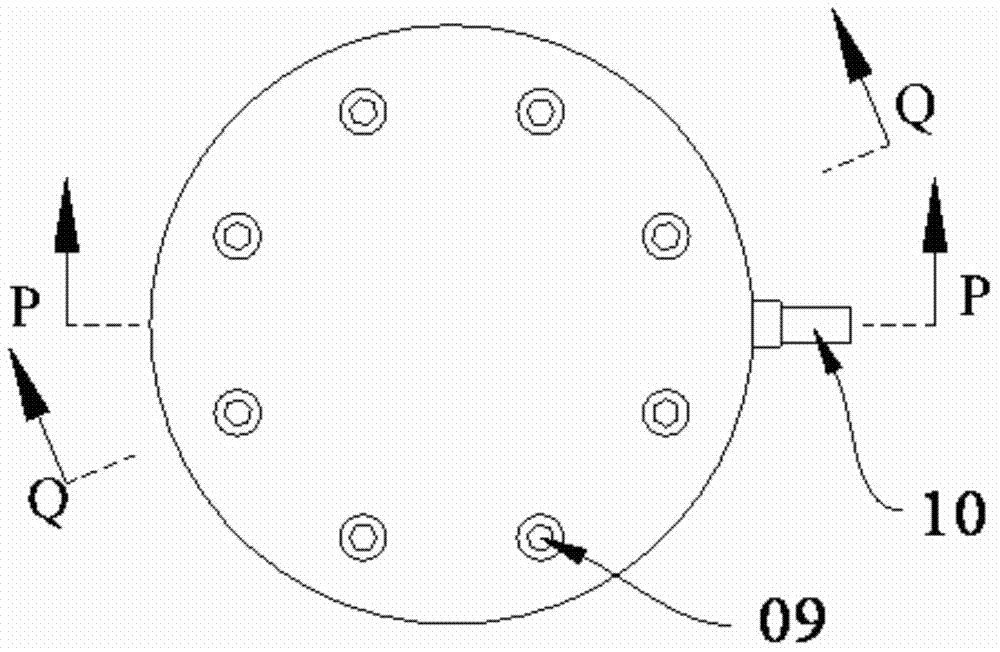

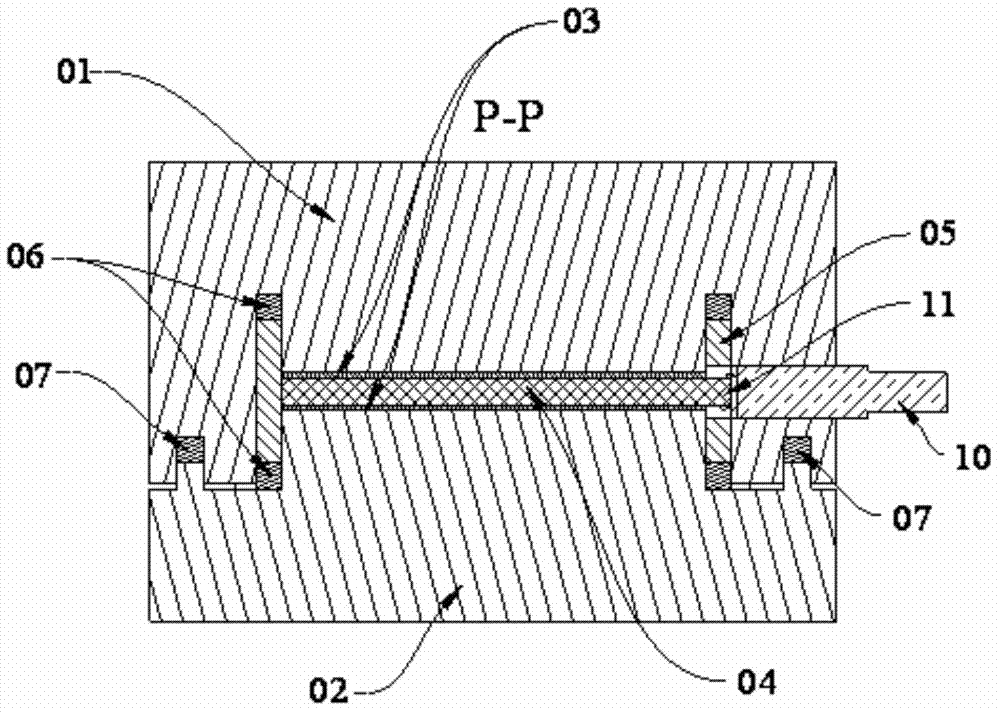

The invention discloses a concrete stress sensor by piezoelectric properties of a PVDF (polyvinylidene fluoride) film. The concrete stress sensor comprises an upper sensor shell, a lower sensor shell and the PVDF piezoelectric film, the upper sensor shell and the lower sensor shell are buckled together, the PVDF piezoelectric film is arranged between the upper sensor shell and the lower sensor shell, a nylon sleeve is sleeved on the periphery of the PVDF piezoelectric film, so that the PVDF piezoelectric film is positioned on a boss, insulating layers are respectively arranged on the upper end face and the lower end face of the PVDF piezoelectric film and closely contact with the upper sensor shell and the lower sensor shell, the nylon sleeve and the insulating layers form a sealed insulating space, so that a PVDF piezoelectric film and the sensor shells are separated in an insulating manner, and connection electrodes are respectively arranged on the upper surface and the lower surface of the PVDF piezoelectric film, so that piezoelectric signals are led to the outside of the sensor. The PVDF piezoelectric film is clamped between the two metal shells, a load is transmitted to the PVDF film by the aid of the sensor metal shells, the concrete stress sensor is sensitive in sensing, simple in structure, convenient to package and small in size, and can be embedded into concrete materials to finish an impact stress test.

Owner:CENT SOUTH UNIV

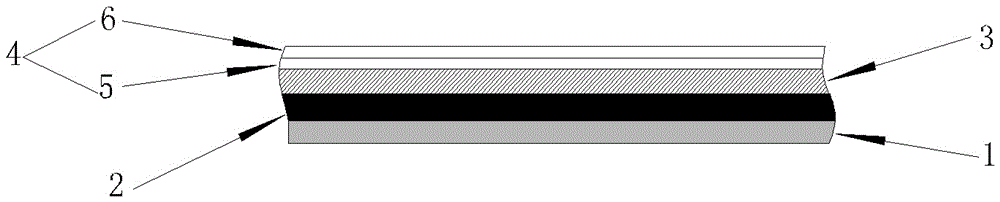

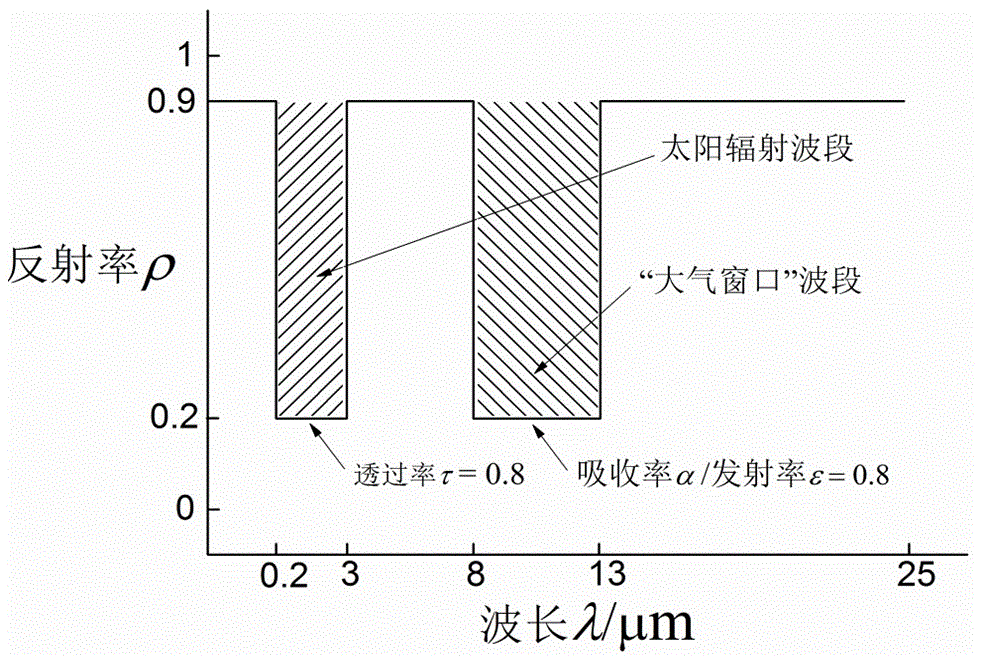

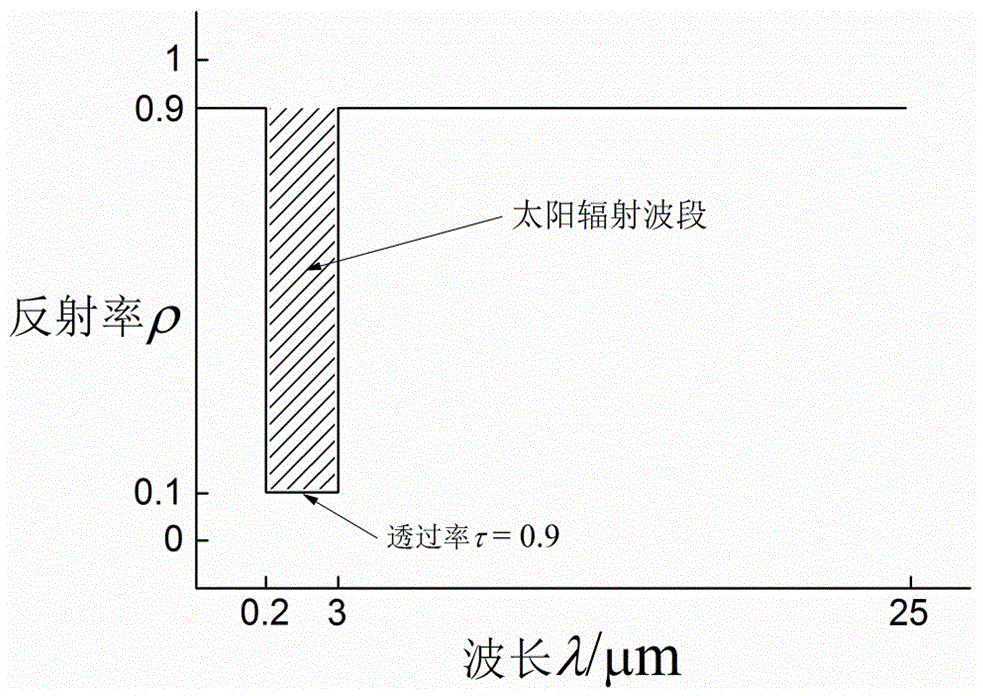

Multifunctional spectrum selective encapsulation material

ActiveCN105957912AImprove transmittanceHigh absorptivity/emissivityPhotovoltaic energy generationSemiconductor devicesPolyesterEmissivity

The invention relates to a multifunctional spectrum selective encapsulation material. The material comprises a substrate, and a black polyvinyl fluoride-polyester-polyvinyl fluoride (TPT) material layer, a photovoltaic cell and a spectrum selective composite material layer are sequentially arranged on one side of the substrate; and the spectrum selective composite material layer is compounded by a selective reflective film and a selective emission film. The transmittance of the spectrum selective composite material layer at the solar radiation band of 0.2-3mu m is more than 0.8, the emissivity at the ''atmospheric window'' band of 8-13mu m is more than 0.8, and the reflectivity at the band of more than 13mu m is more than 0.9. By adopting the material, electric energy and heat can be obtained by day via solar photovoltaic heating, and cold can also be obtained at night via radiation refrigeration, so that the limitations of traditional solar PV / T systems and radiation refrigeration devices are effectively solved.

Owner:UNIV OF SCI & TECH OF CHINA

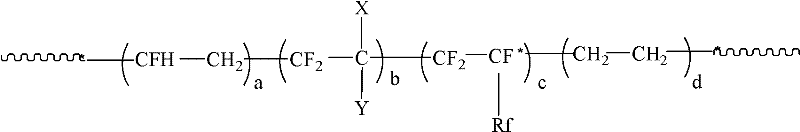

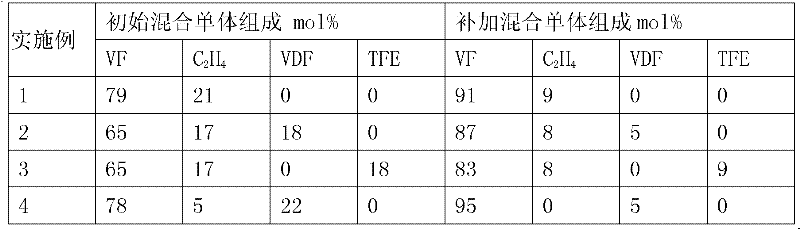

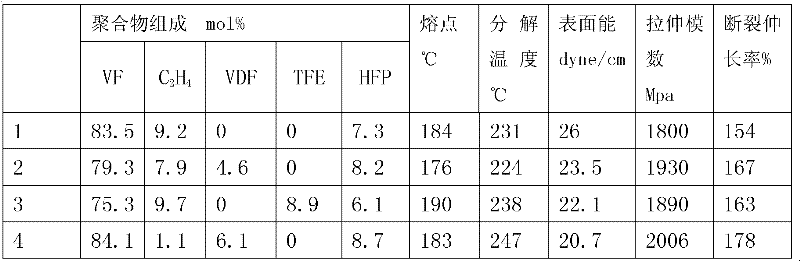

Melt-processable modified polyvinyl fluoride resin and preparation method thereof

The invention relates to a melt-processable modified polyvinyl fluoride (PVF) resin which is polymerized by vinyl fluoride, ethylene, one or more of CF2=CXY and one or more of CF2=CFRf. Reaction monomers are subjected to a copolymerization reaction under the action of an initiating agent in an aqueous phase or an emulsion, reaction temperature ranges from 40 DEG C to 100 DEG C, and reaction pressure ranges from 1 MPa to 10 MPa. According to the melt-processable modified polyvinyl fluoride resin, high-temperature performance of the PVF resin is kept, treatment temperature of the resin is reduced simultaneously, conventional melt processing can be used for processing the resin, and obtained thin-film materials have good combination properties.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

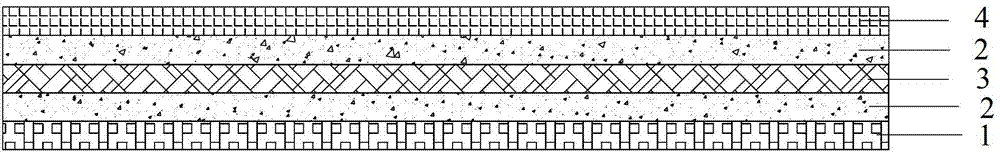

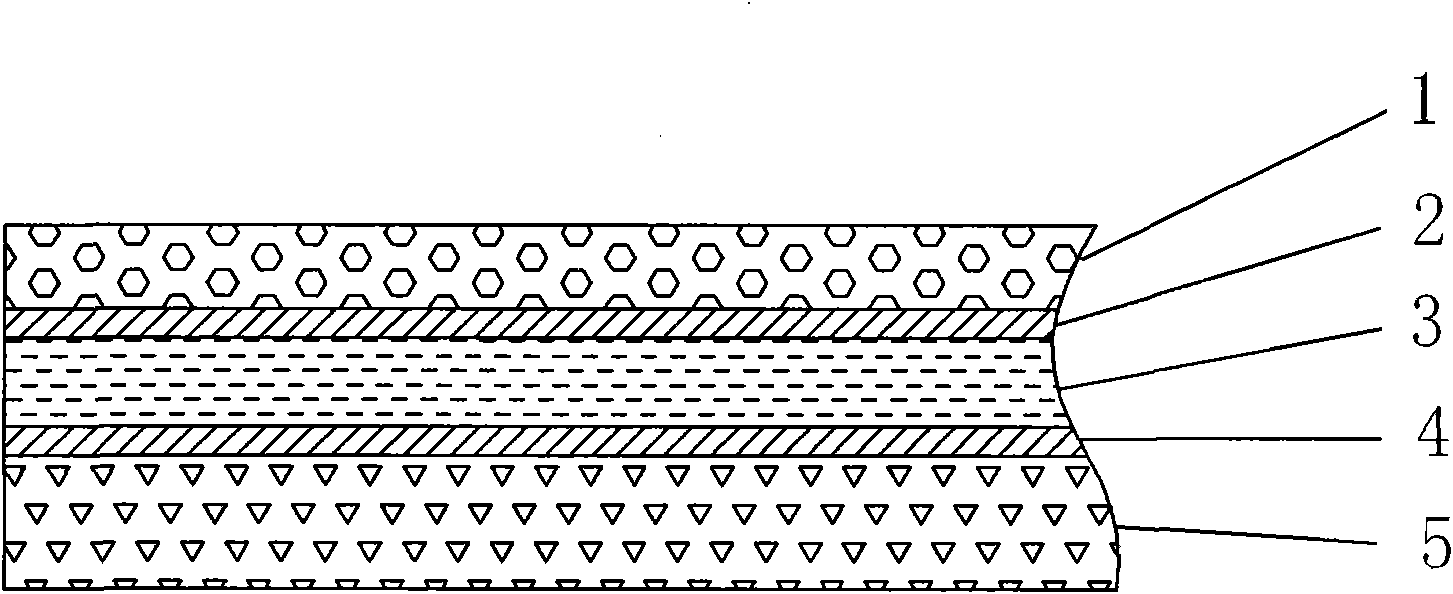

Solar cell backboard with excellent weathering resistance and preparation method thereof

InactiveCN102637763AGood weather resistanceHigh bonding strengthFinal product manufactureSynthetic resin layered productsComposite filmPolyethylene glycol

The invention discloses a solar cell backboard with excellent weathering resistance and a preparation method for the solar cell backboard. The cell backboard has a five-layer structure which from outside to in side successively comprises an F (fluorine)-containing composite film, a first glue layer, a PET (polyethylene glycol terephthalate) thin film, a second glue layer and a transition layer. According to the solar cell backboard, the F-containing composite film and the transition layer are used for replacing an imported PVDF (polyvinylidene fluoride) film or a PVF (polyvinyl fluoride) film, so that the cost is greatly lowered. Meanwhile, the F-containing composite film can resist such damages as ultraviolet irradiation and the like, the backboard is guaranteed to have excellent weathering resistance, and the backboard and a solar cell assembly are guaranteed to have excellent bonding strength by adoption of the transition layer.

Owner:JIANGSU UNIV OF SCI & TECH

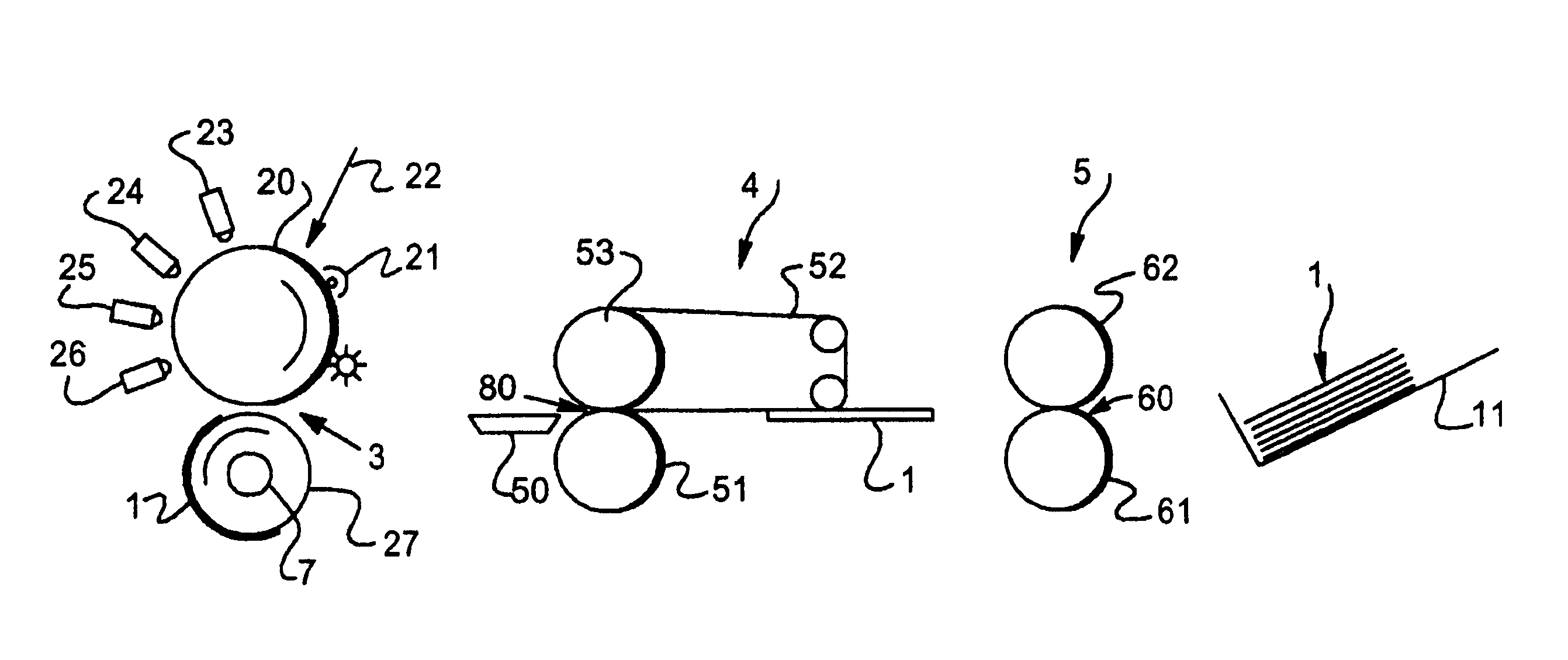

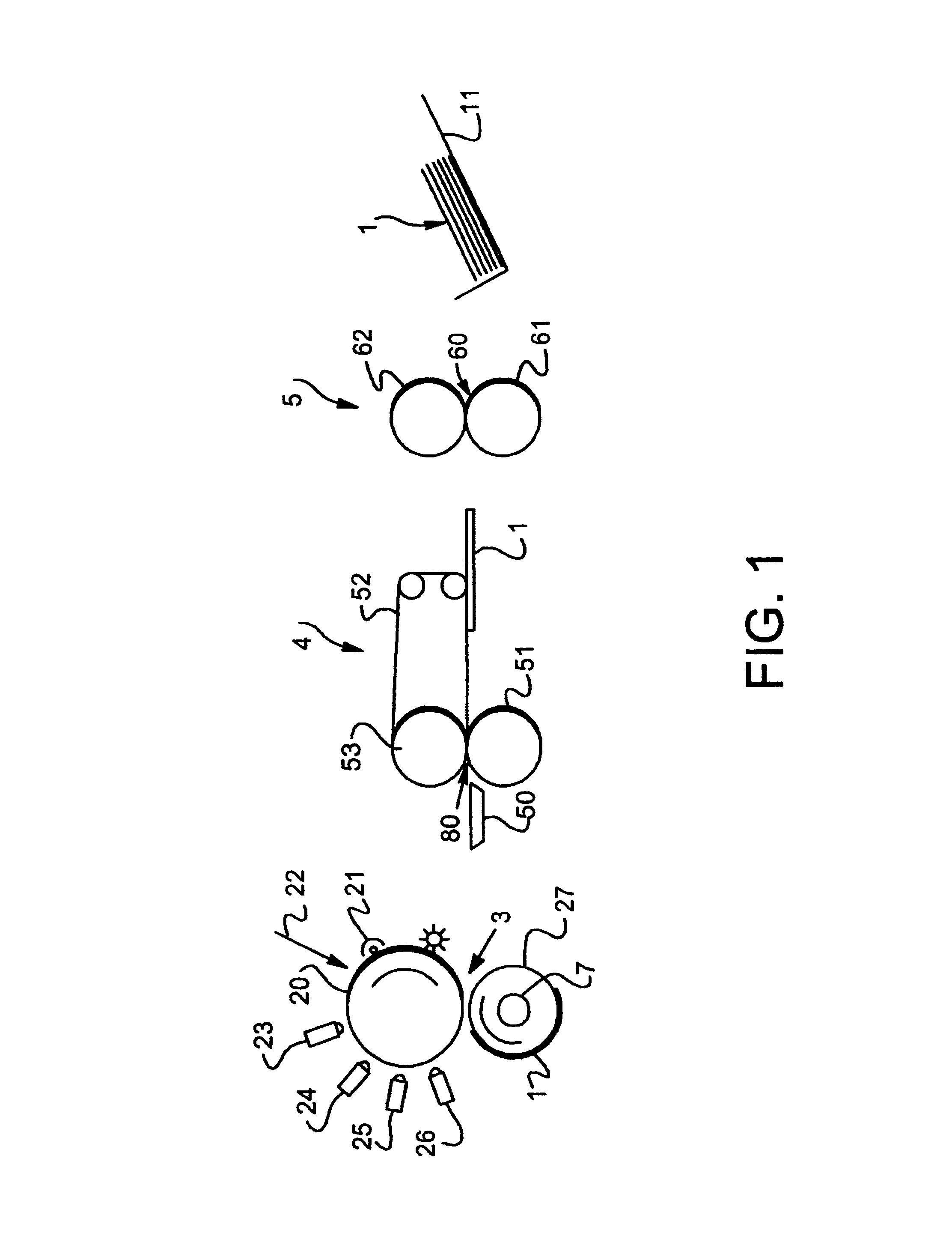

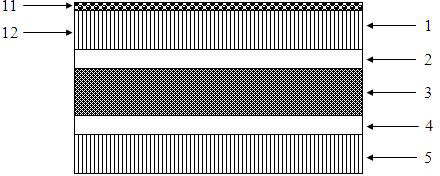

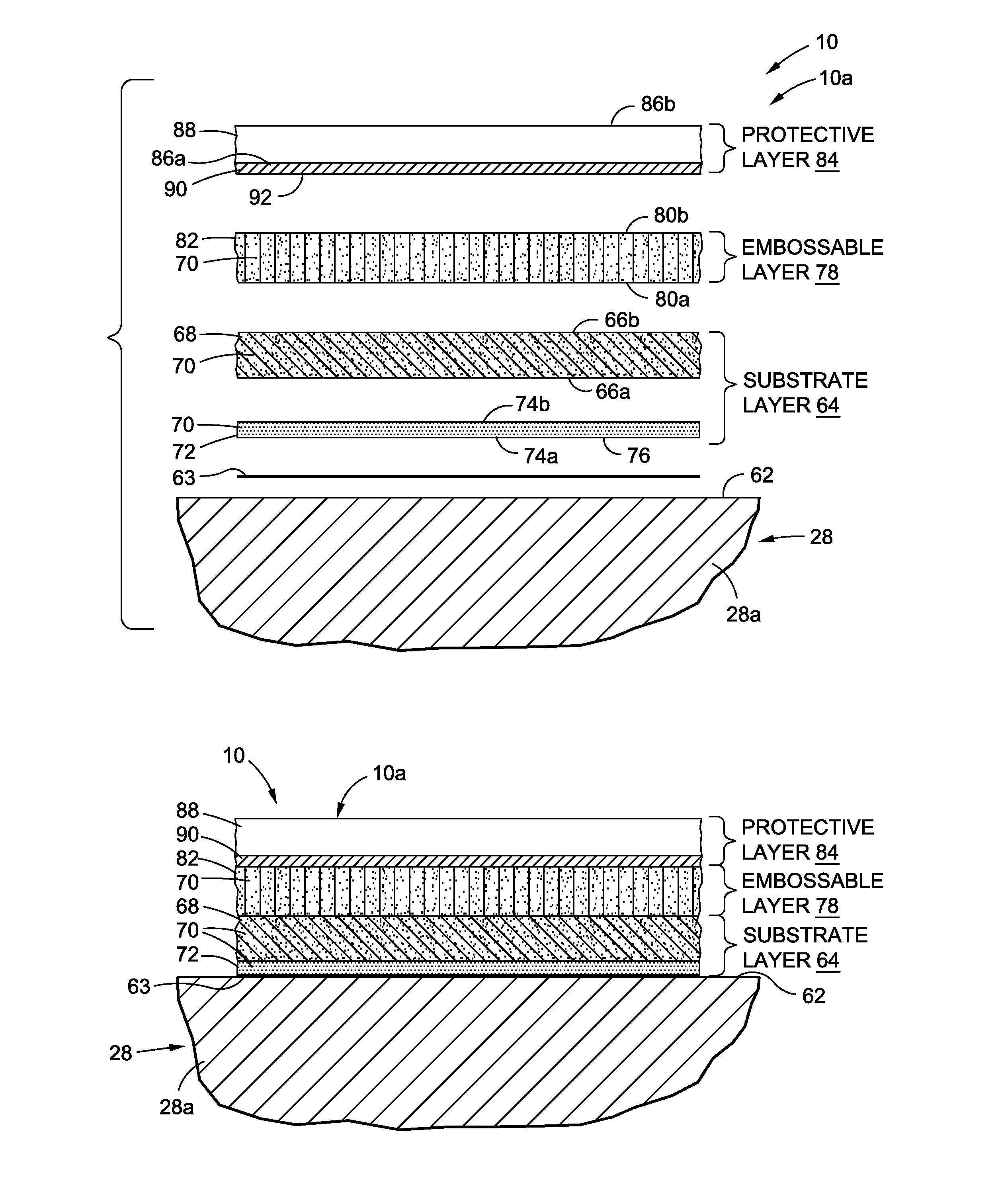

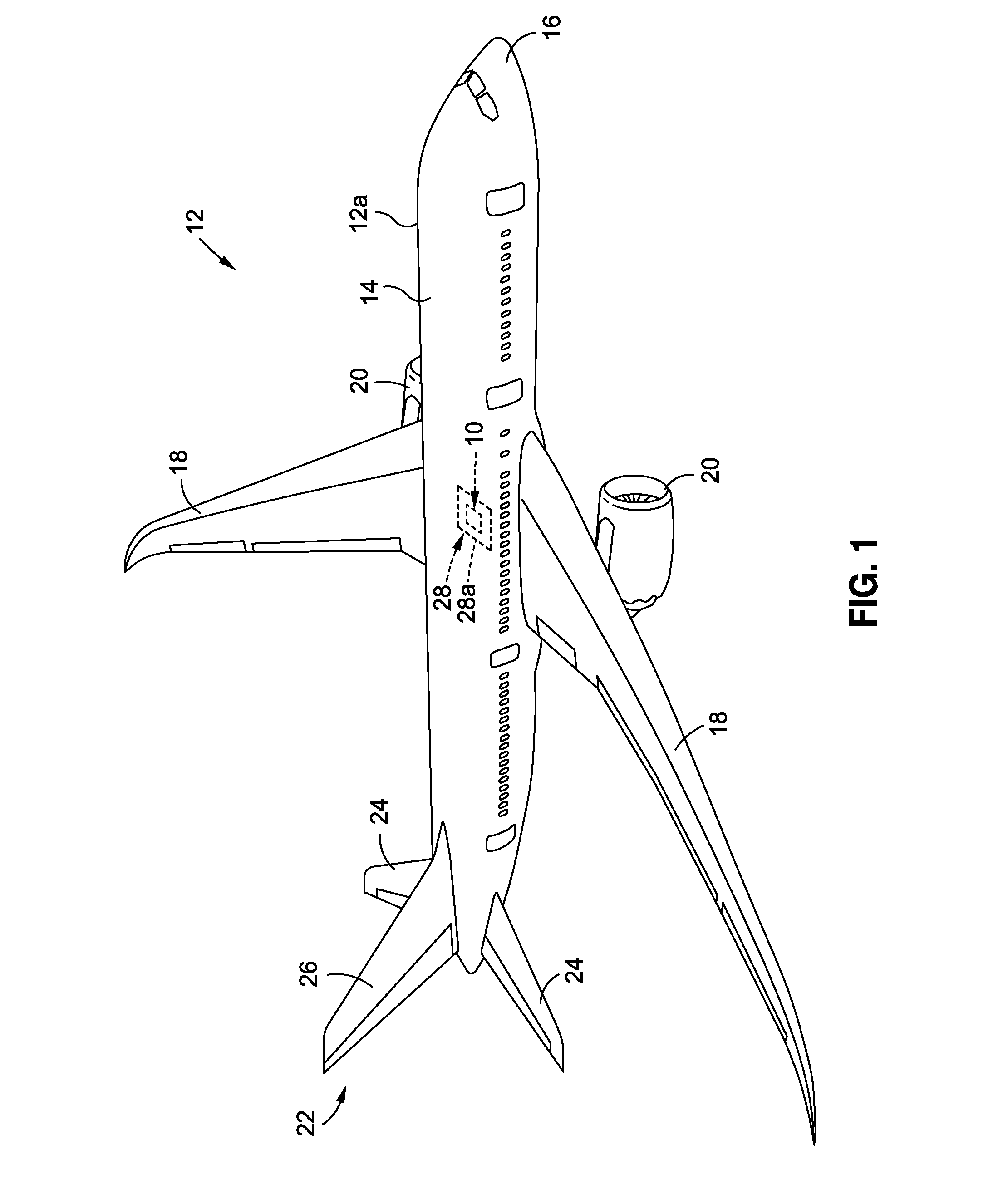

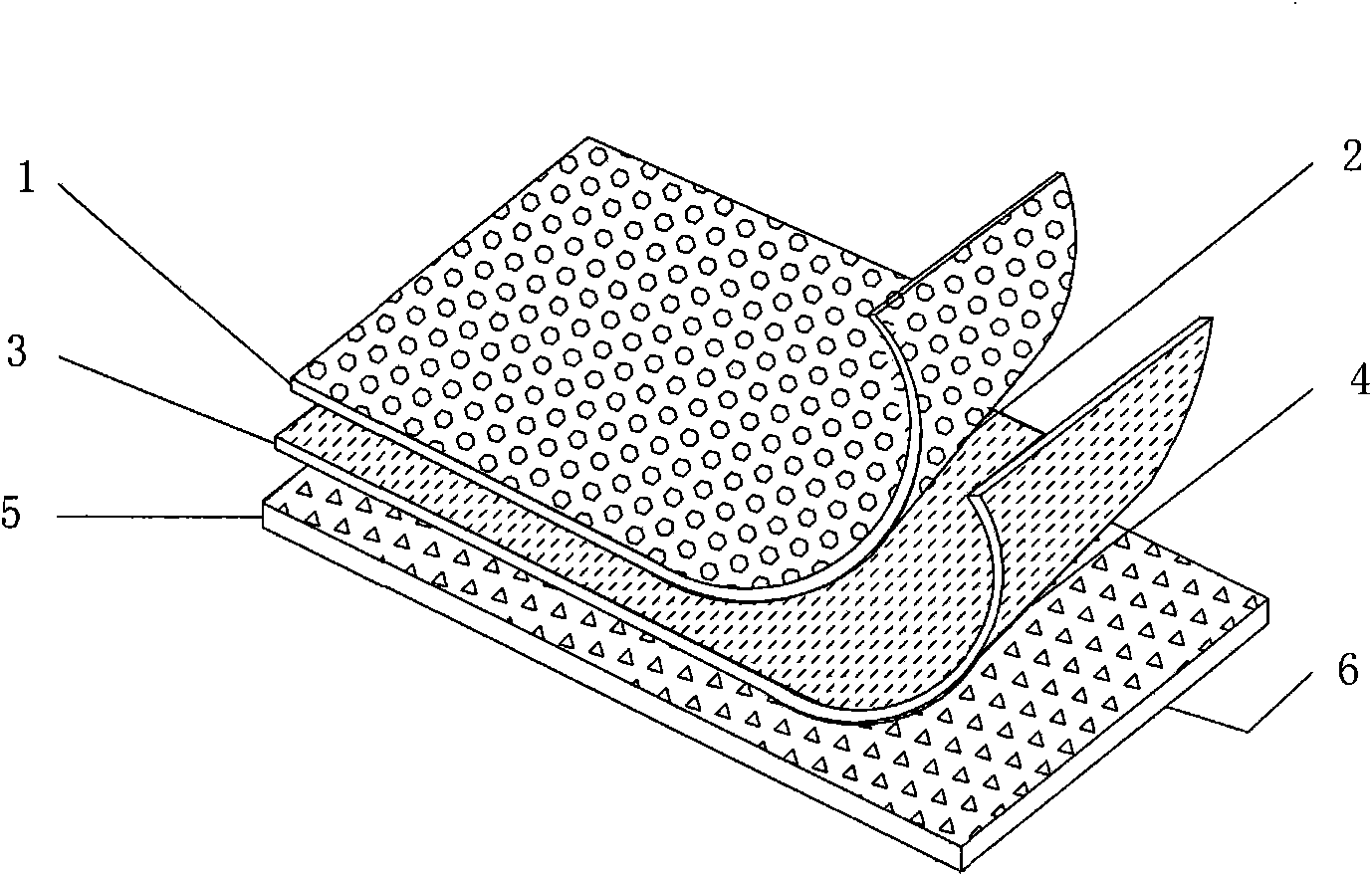

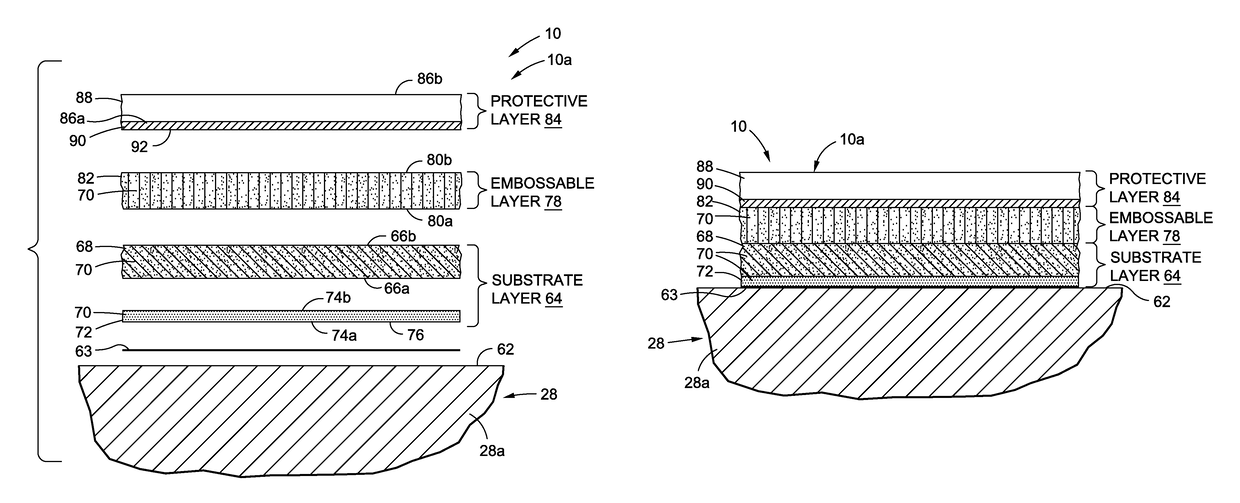

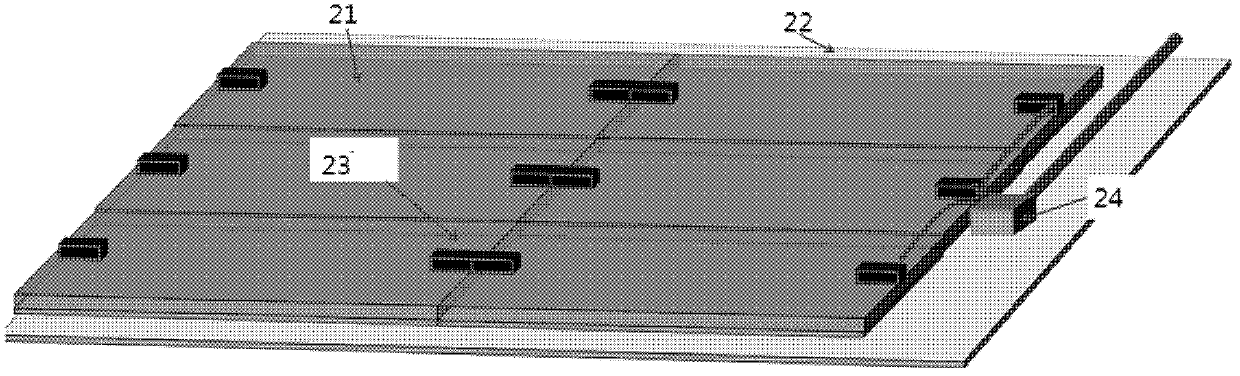

Nonwoven decorative laminates and methods of making the same

ActiveUS20160089851A1Big advantageLamination ancillary operationsDecorative surface effectsEngineeringNonwoven fabric

A decorative laminate for application to a structural component is provided. The decorative laminate has a substrate layer of a nonwoven fabric material with or without a flame retardant material. The decorative laminate further has an embossable layer disposed upon the substrate layer. The embossable layer includes an embossing resin material and the flame retardant material. The decorative laminate further has a protective layer disposed upon the embossable layer. The protective layer includes a polyvinyl fluoride-based material and has a decorative material printed on a first side of the protective layer facing the embossable layer. An adhesive layer is applied to the substrate layer of the decorative laminate. The decorative laminate is applied to the structural component with the substrate layer facing a bonding surface of the structural component and with an adhesive layer applied between the decorative laminate and the bonding surface of the structural component.

Owner:THE BOEING CO

Preparation of polyvinyl fluoride thin film by solution casting method

InactiveCN101168296AImproving the method of cast film productionHigh film forming rateFlat articlesCoatingsEvaporationPolyvinyl chloride

The invention relates to a formula and technique for preparing polyvinyl fluoride thin film by using liquor flowing and extending method, wherein the technique comprises dissolving the polyvinyl fluoride in a strong polar solvent to be a dilute solution which is used as primary liquid for preparing films, then flowing and extending the primary liquid for preparing films from the machine gap after filtering and de-aerating, or coating the primary liquid on a dry roller which is continuously heated and rotates in uniform speed or on a steel belt via a roll-type coater, to form film, or using the roller which is continuously heated and rotates in uniform speed, to dip in the liquor for forming film, finally releasing film rapidly after evaporation of the solvent. The forming, drying and shaping are simultaneously carried through in the process of film preparation, the rate of filming is high, and the efficiency is high, the filming apparatuses which are fit for filming are many, the filming technique is simple and flexible, the thin film has good setting-out level and flat degree, homogeneous thickness and high extending degree.

Owner:BEIJING UNIV OF CHEM TECH

Composite material with high obstruction and high performance and preparation method thereof

InactiveCN101554789AGood weather resistanceImproves resistance to gas permeationLamination ancillary operationsSynthetic resin layered productsPolyurethane adhesiveSolvent free

The invention relates to a composite material with high obstruction and high performance and a preparation method thereof. The composite material with high obstruction and high performance is a laminated body sequentially compounded by a polyfluoroethylene thin film layer, a polyurethane adhesive layer, an AL / PET film layer, a polyurethane adhesive layer, a Kevlar fabric layer and a polyurethane coating. The composite material can ensure lower gas permeability and good mechanical properties and fatigue resistivity under the condition of lighter quality and can be really adapted to the application requirement on the material with high obstruction in the aerospace field. The preparation method is a dry method solvent-free composite technology, the solid content of adhesive used for the method is 100 percent, and no solvent is contained. The method has the great characteristics of environment protection, high product hygiene index and product quality guarantee.

Owner:CHINESE TEXTILE ACAD +1

High-hardness wear-resistant rubber sealing piece and preparation method thereof

The invention discloses a high-hardness wear-resistant rubber sealing piece. The high-hardness wear-resistant rubber sealing piece comprises the following raw materials in parts by weight: 60 to 120 parts of modified silicone rubber 15 to 35 parts of ethylene-propylene- diene-terpolymer rubber, 5 to 15 parts of hydrogenated butyronitrile rubber, 4 to 8 parts of chlorosulfonated polyethylene, 2 to 5 parts of polyvinyl fluoride resin, 2 to 8 parts of polyethylene, 1 to 6 parts of nano-silicon dioxide, 2 to 8 parts of silicon carbide, 1 to 4 parts of zinc oxide, 2 to 5 parts of magnesium oxide, 1 to 5 parts of nylon, 2 to 6 parts of glycol, 3 to 6 parts of graphite powder, 2 to 5 parts of a silane coupling agent KH-560, 1 to 5 parts of polycarbonate, 2 to 5 parts of n-butyl acetate, 3 to 8 parts of zinc stearate, 1 to 5 parts of chlorinated paraffin, 2 to 5 parts of polyethylene glycol, 2 to 7 parts of aids, 1 to 3 parts of a dispersing agent and 2 to 5 parts of a plasticizer. The invention also provides a preparation method of the high-hardness wear-resistant rubber sealing piece. The high-hardness wear-resistant rubber sealing piece provided by the invention has excellent toughness, hardness and wear resistance.

Owner:安徽亚兰密封件股份有限公司

Apparatus for removing halogen hydracids from biomass hydrolysates

ActiveUS20110070131A1Inexpensive materialsSilicon halogen compoundsMaterial heat developmentHydrogen halidePolymer science

An apparatus for removing hydrogen halide and water from hydrolysates that were obtained by way of halogen-acid hydrolysis from vegetable biomasses, characterized in that: —said apparatus comprises two containers, which are connected to each other by a tube, —at the inlet of the first container two flows are fed, one representing the hydrolysates and the other a heat transfer medium, which dissolves in the hydrolysate only to an economically justifiable extent (no additional process steps due to potential contamination during mixing), or enriches matter therefrom, —both flows are sprayed together in the first container, thereby producing a homogeneous mixing of the two flows, including heat transfer, which subsequently results in complete evaporation of water and the hydrogen halide dissolved in the hydrolysates, —the evaporation produces a mixture of granular solid bodies and heat transfer medium droplets, which is pulled from the first container into the second container via the connecting tube by way of a pressure gradient, —the second container is configured as a cyclone or centrifugal force precipitator, and a separation of liquid (heat transfer medium droplets) and solid constituents (granular solid bodies) from the gas flow takes place. An apparatus, characterized in that the second container (here: cyclone) on the inside wall may be lined with polyvinylchloride [PVC] (hard), PVC (chlorinated), polyethylene (PE), polypropylene (PP), polybutylene (PB), polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF), polyvinyl fluoride (PVF), ethylene-propylene-diene rubber (EPDM), ethylene-propylene copolymer, ethylene-tetrafluoroethylene (ETFE), perfluoro-ethylene-propylene plastic (FEP), fluoropolymer plastics (FPM and FKM=group designation), perfluoro trifluoroethylene (PCTFE), perfluorinated rubber (FFPM and FFKM), butyl robber (HR), isoprene rubber (IR), chlorinated polyethylene (PE-C) and rubber (collective term for rubbers containing sulfur) and copolymers and mixtures thereof from said polymers, or comprises them.

Owner:GREEN SUGAR AG

Nonwoven decorative laminates and methods of making the same

ActiveUS9855721B2Big advantageLamination ancillary operationsDecorative surface effectsEngineeringNonwoven fabric

A decorative laminate for application to a structural component is provided. The decorative laminate has a substrate layer of a nonwoven fabric material with or without a flame retardant material. The decorative laminate further has an embossable layer disposed upon the substrate layer. The embossable layer includes an embossing resin material and the flame retardant material. The decorative laminate further has a protective layer disposed upon the embossable layer. The protective layer includes a polyvinyl fluoride-based material and has a decorative material printed on a first side of the protective layer facing the embossable layer. An adhesive layer is applied to the substrate layer of the decorative laminate. The decorative laminate is applied to the structural component with the substrate layer facing a bonding surface of the structural component and with an adhesive layer applied between the decorative laminate and the bonding surface of the structural component.

Owner:THE BOEING CO

Flame-retardant PVC (polyvinyl chloride) artificial leather and preparation process thereof

InactiveCN103951913AGood component compatibilityGood mechanical propertiesSynthetic resin layered productsTextiles and paperMelamine phosphatePolyvinyl chloride

The invention provides flame-retardant PVC (polyvinyl chloride) artificial leather and a preparation process thereof. The flame-retardant PVC artificial leather comprises the following components in parts by weight: 70-120 parts of PVC resin powder, 30-50 parts of DOP (dioctyl-phthalate) plasticizer, 15-25 parts of halogen-free phosphate plasticizer, 3-6 parts of heat stabilizer, 8-12 parts of wollastonite, 30-50 parts of isopropyl phenyl diphenyl phosphate, 8-12 parts of melamine phosphate, 15-25 parts of melamine cyanurate, 20-30 parts of antimonous oxide, 15-25 parts of zinc borate, 15-30 parts of activity aluminum hydroxide, 3-8 parts of calcium carbonate, 3-8 parts of AC (activated carbon) foaming agent. The preparation process of the flame-retardant PVC artificial leather is as follows: weighing materials, high-speed stirring, banburying, refining (initial plasticizing), extruding and forming, refining (strengthened plasticizing), four-roll rolling, adhering with fireproof cloth, PVC foaming, surface-treating and obtaining products. The flame-retardant PVC artificial leather disclosed by the invention is good in flame retardant performance.

Owner:FOSHAN GAOMING JUNTENG PLASTICS

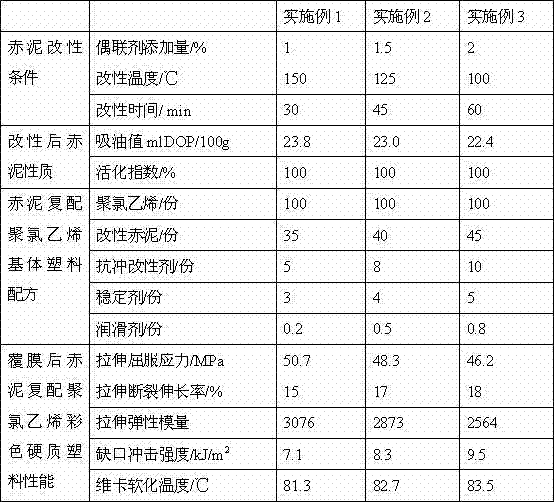

Production method of red mud complexed polyvinyl chloride colorized rigid plastic

ActiveCN102492234ALow alkali contentRealize comprehensive utilizationSynthetic resin layered productsLaminationRed mudPolyvinyl chloride

The invention relates to a production method of modified red mud complexed polyvinyl chloride colorized rigid plastic. The method is characterized in that: graded red mud with a specification of -800 meshes is modified by using a titanate coupling agent; 35-45 parts of the modified red mud, 100 parts of polyvinyl chloride, 5-10 parts of an impact modifier, 3-5 parts of a stabilizing agent, and 0.2-0.8 parts of a lubricating agent are subject to high-speed mixing, melt extrusion and filming, such that the colorized rigid plastic is obtained. According to the invention, red mud is subject to a modification treatment, such that the compatibility of the red mud and polyvinyl chloride is substantially improved. When the plastic is subject to the filming treatment, a monotonic brownish red color of the red mud complexed polyvinyl chloride substrate plastic is changed, a woody pattern is provided, the color is diversified, and the plastic is provided with a good appearance.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

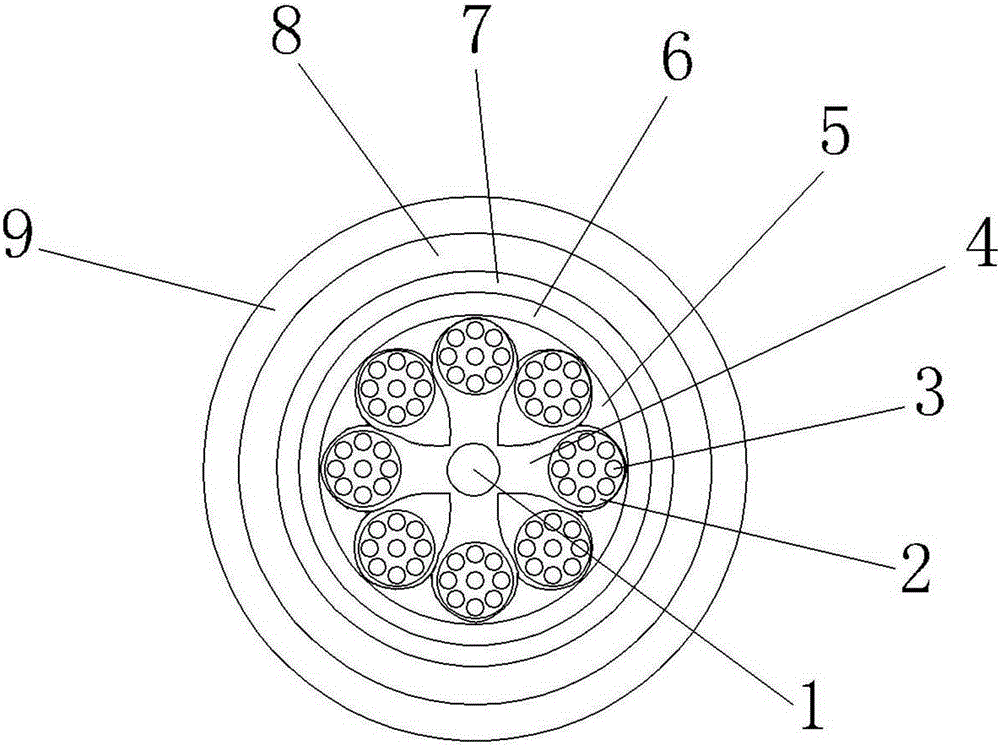

High-intensity wear resistant cable used for construction

InactiveCN105244109AImprove stabilityImprove extrusion resistancePower cables with screens/conductive layersInsulated cablesCalcium silicateWear resistant

The invention discloses a high-intensity wear resistant cable used for construction. A raw material of a sheath layer comprises, by weight, 60-90 parts of terpolymer EP rubber, 30-60 parts of W type chloroprene rubber, 40-80 parts of nitrile rubber, 30-60 parts of polyvinyl fluoride resin, 20-50 parts of EVA resin, 30-60 parts of modified epoxy resin, 12-22 parts of fluorinated polyethylene, 5-12 parts of zinc oxide, 3-8 parts of magnesium oxide, 2-9 parts of calcium stearate, 3-9 parts of nylon, 2-12 parts of active white carbon black, 2-8 parts of nanometer white carbon black, 2-6 parts of active calcium silicate, 3-8 parts of nanometer silica, 1-5 parts of a vulcanizing agent DCP, 2-8 parts of chloranil, 3-9 parts of a promoter DM, 3-9 parts of polyethylene glycol, 2-8 parts of a dispersant CNF, 1-5 parts of an antiager RD, 2-6 parts of an antiager AW, and 1-6 parts of N-cyclohexylthiophthalimide. The cable is high in intensity and highly resistant to wear.

Owner:安徽华峰电缆集团有限公司

Preparation method of ultra oil-resistant coated fabric, obtained product and application thereof

ActiveCN101660278AGood oil resistanceGood weather resistanceSynthetic resin layered productsLarge containersPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses a method for preparing ultra oil-resistant coated fabric and ultra oil-resistant coated fabric prepared by using the method. The preparation method mainly includes the steps offorming an oil-resistant diffusion layer on an internal coating of the oil-resistant coated fabric. A fluororesin film, preferably a polyvinyl fluoride film or a polyvinylidene fluoride film, can beused as the oil-resistant diffusion layer. The obtained ultra oil-resistant coated fabric has excellent oil resistance and weather fastness, and a membraneous oil tank made from the coated fabric hasextremely slight pollution to stored oils.

Owner:PETRO OIL & LUBRICANT RES INST OF THE GENERAL LOGISITIC DEPT OF PLA

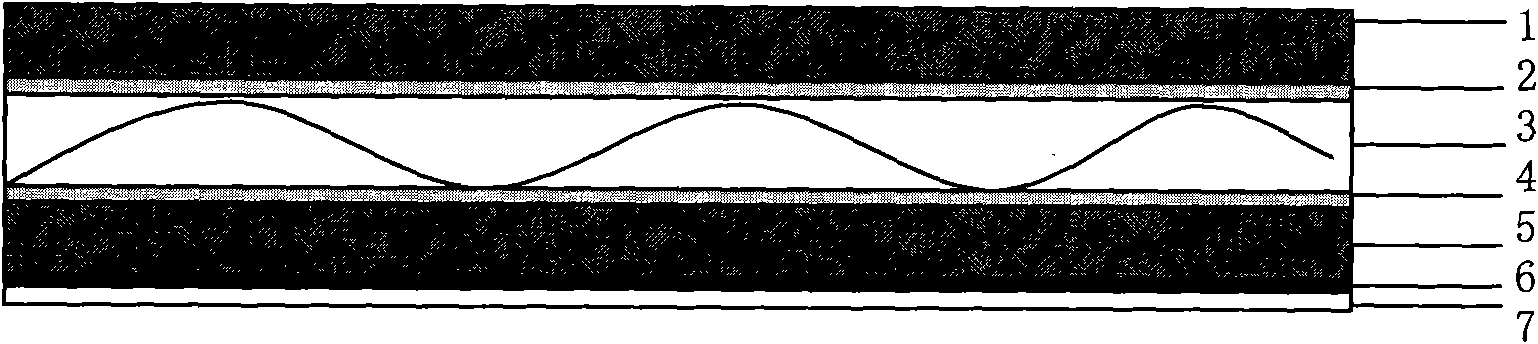

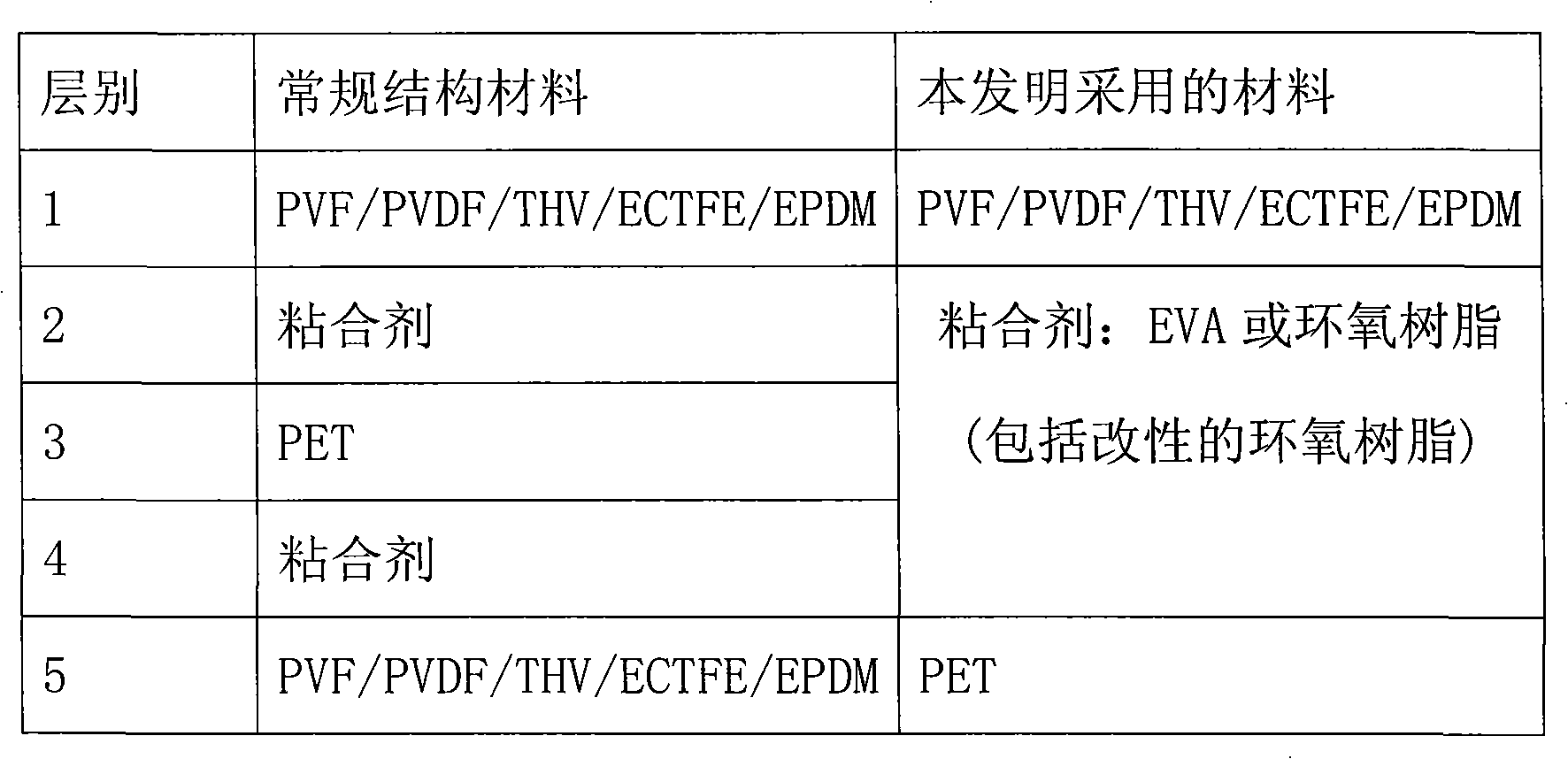

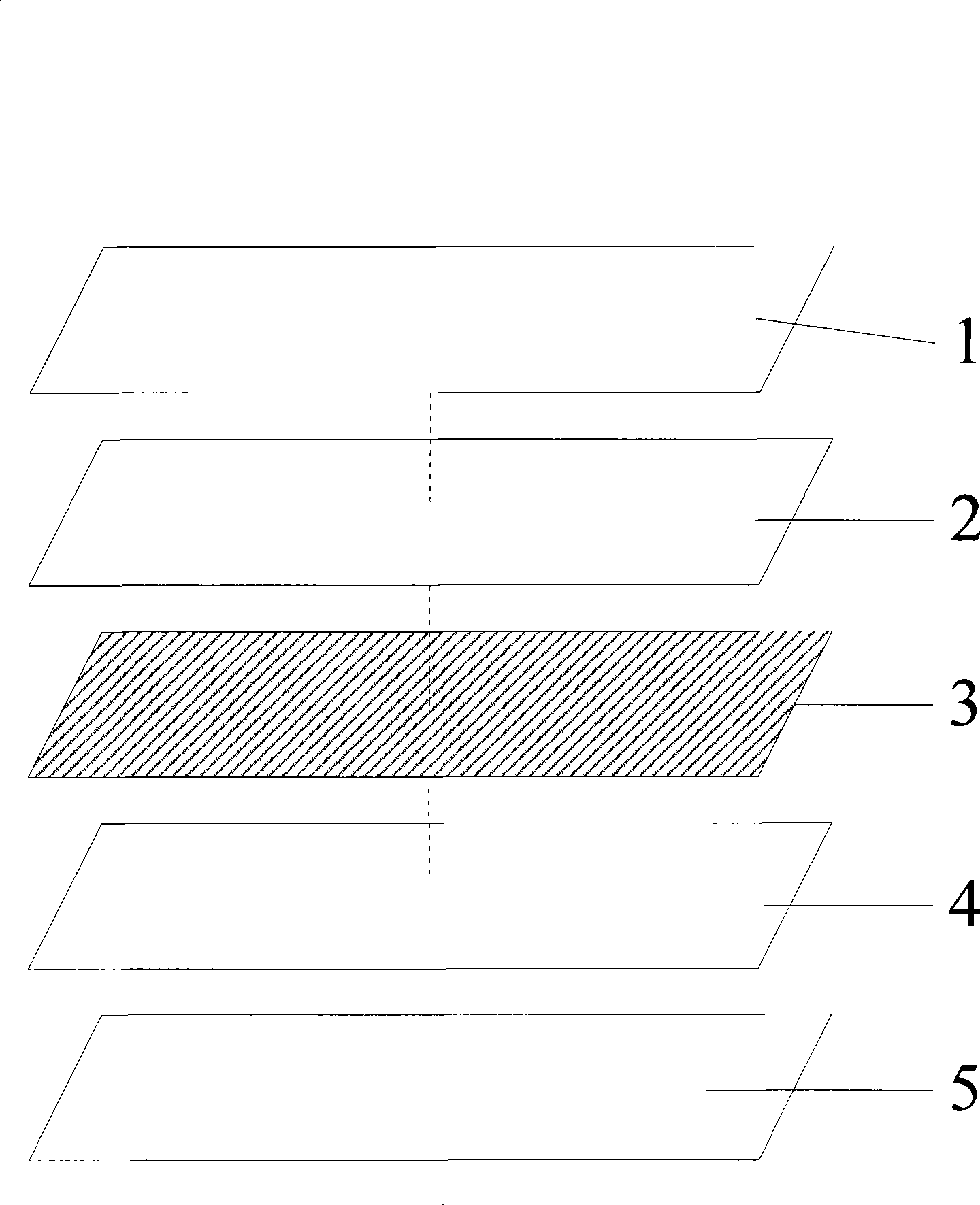

Special back seal film for solar cell

InactiveCN101847667AImprove bindingLow costSynthetic resin layered productsPhotovoltaic energy generationEpoxyComposite film

The invention relates to a backboard material of a back protective layer of a solar cell assembly. The special back seal film for a solar cell is a composite film formed by carrying out vacuum hot pressing and laminating on the following three layered film materials: the outer layer is made of one of the following materials: polyvinyl fluoride, polyvinylidene fluoride, fluoroplastics, ethylene-trifluorochloroethylene copolymer or ethylene-propylene-diene monomer; the middle layer is one of the following materials: ethylene-vinyl acetate or epoxy resin; and the inner layer is polyethylene terephthalate. The backboard material of the invention has the advantages of strong binding force, low cost, good dimensional stability and the like, has good air isolating performance, good oxidation protection and moisture resistance, good electrical insulation performance and performance of preventing an adhesive substance from hydrolyzing for a long time, and is the excellent back seal film for the solar cell.

Owner:HUNAN HUANQIU SOLAR TECH DEV

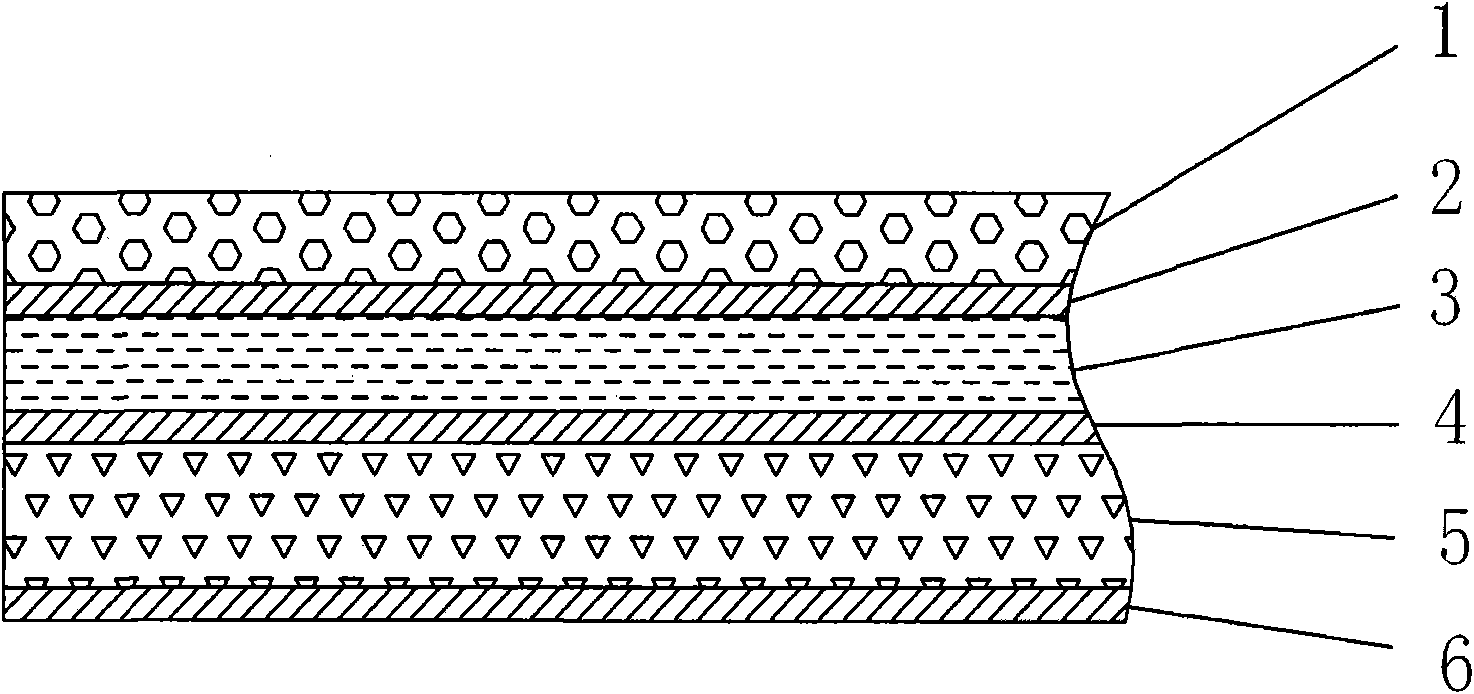

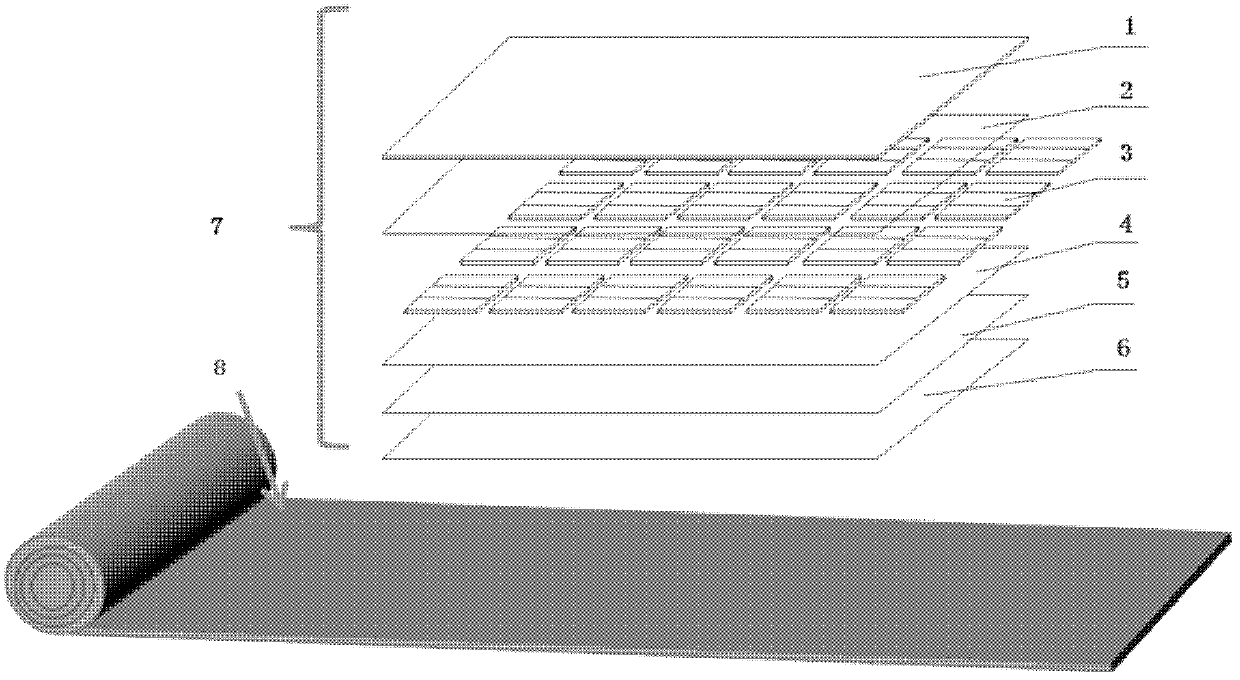

Solar battery rear panel compound film and method for making same

InactiveCN101097967ASimple preparation processImprove performanceFinal product manufacturePhotovoltaic energy generationEngineeringPolyvinyl fluoride

The invention relates to a solar-energy battery back board composite membrane, and a relative production. The composite film is composed of following three layers as one polyvinyl fluoride film at 0.035-0.045mm thick, a PET film at 0.18-0.30mm thick, and an EVA coat at 0.025-0.035mm thick. The production comprises that respectively coating solidifiers on the surfaces of polyvinyl fluoride film and PET film, to be thermally adhered to obtain a base film, then coating an EVA coat on another surface of the PET film to obtain the solar-energy battery back board composite film. The invention has simple production and better property.

Owner:周均华

Compound film for solar battery rear board and its making method

InactiveCN101123278ASimple preparation processImprove performancePhotovoltaic energy generationSemiconductor devicesComposite filmFirming agent

The invention relates to a solar battery backplane composite film and the manufacturing method. The solar battery backplane composite film consists of the following three materials: poly fluoride film with a thickness of 0.035mm to 0.045mm; PET film with a thickness of 0.18mm to 0.30mm; poly fluoride film with a thickness of 0.035mm to 0.045mm. The manufacturing method comprises the following steps: the surfaces of the poly fluoride film and the PET film are covered by a firming agent; the PET film is positioned between the two poly fluoride films; and the solar battery backplane composite film is obtained by heat pressing and adhesion and solidifying. The manufacturing technique of the solar battery backplane composite film of the invention is simple and has a good property. The solar battery panel encapsulated after the products prevents effectively the erosion of vapor, oxygen and corrosive gas-liquid, and has the advantages of high and low temperature resistance, anti-aging, and anti-cracking, thus effectively protecting the battery functions and making the solar battery panel output electricity energy for a long time.

Owner:PERLIGHT SOLAR

Laminated solar battery pack and manufacture method thereof

InactiveCN101447519AHigh degree of aging resistanceExtended service lifePhotovoltaic energy generationSemiconductor devicesEpoxyComposite film

A laminated solar battery pack comprises a surface layer, an upper ethylene-vinyl acetate copolymer layer, a solar battery layer, a lower ethylene-vinyl acetate copolymer layer and a back plate layer, which are sequentially laminated and arranged from top to bottom and are packaged together, wherein the surface layer is a polyvinyl fluoride composite film; and the back plate layer is an epoxy resin plate. The small solar battery pack can be widely used in the field of solar products, such as solar table lamp, solar flashlight, solar mobile phone charger and the like, to improve the aging resistance and prolong the service life of the products.

Owner:中电电气(南京)太阳能研究院有限公司

Anti-aging PVC (Polyvinyl Chloride) coating canopy plus material and manufacturing process thereof

ActiveCN106739354ASimple structureImprove job stabilityLamination ancillary operationsSynthetic resin layered productsPolyesterPolyvinyl chloride

The invention provides an anti-aging PVC (Polyvinyl Chloride) coating canopy plus material and a manufacturing process thereof. By using the anti-aging PVC coating canopy plus material and the manufacturing process thereof, the problem that a peculiar smell cannot be removed from an existing canopy plus material is solved. In the anti-aging PVC coating canopy plus material and the manufacturing process thereof, the plus material comprises a basic fabric and two PVC films, wherein the two PVC films are located on the upper side and the lower side of the basic fabric respectively; the PVC films and the basic fabric are laminated together at a high temperature of 190 to 200 DEG C; two side surfaces which are back to back on the two PVC films are subjected to matting treatment; the basic fabric is a 20*20 biaxial basic fabric which is formed by adopting 1,000D*1,000D polyester filaments through warping and weaving; each PVC film is prepared from the following raw materials in parts by weight: 100 parts of PCV resin powder, 3 to 4 parts of antimonous oxide, 50 to 60 parts of dioctyl phthalate, 3 to 4 parts of dimethyl adipate, 3 to 5 parts of titanium pigment, 3 to 6 parts of stabilizer, 2 to 4 parts of soybean oil, 20 parts of calcium carbonate and 3 to 5 parts of activated carbon powder. The manufacturing process comprises the production procedure of the basic fabric, the calendering process of the PVC films and the processing process of a product. The anti-aging PVC coating canopy plus material has the advantage that the peculiar smell can be absorbed.

Owner:ZHEJIANG FEIHU NEW MATERIAL CO LTD

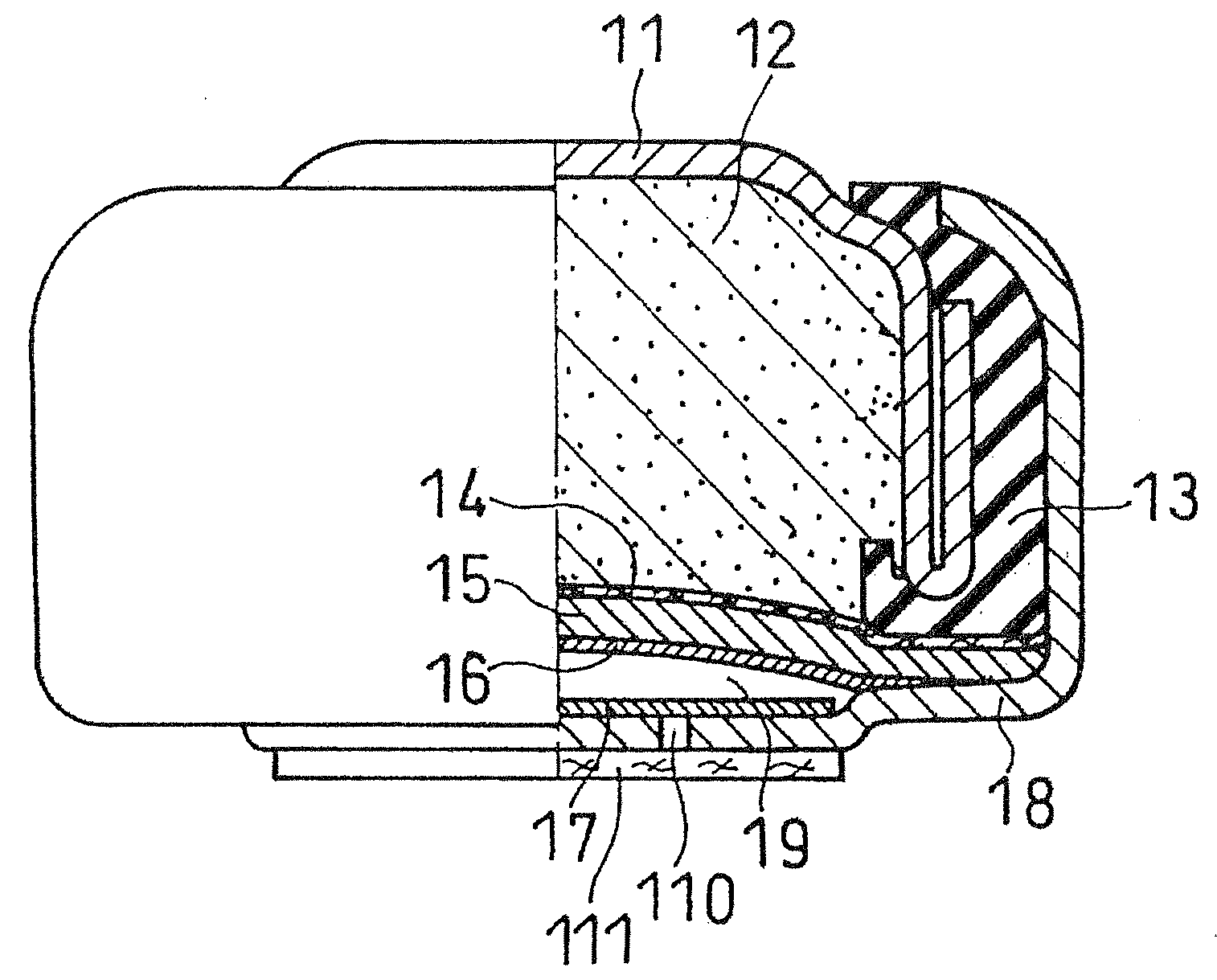

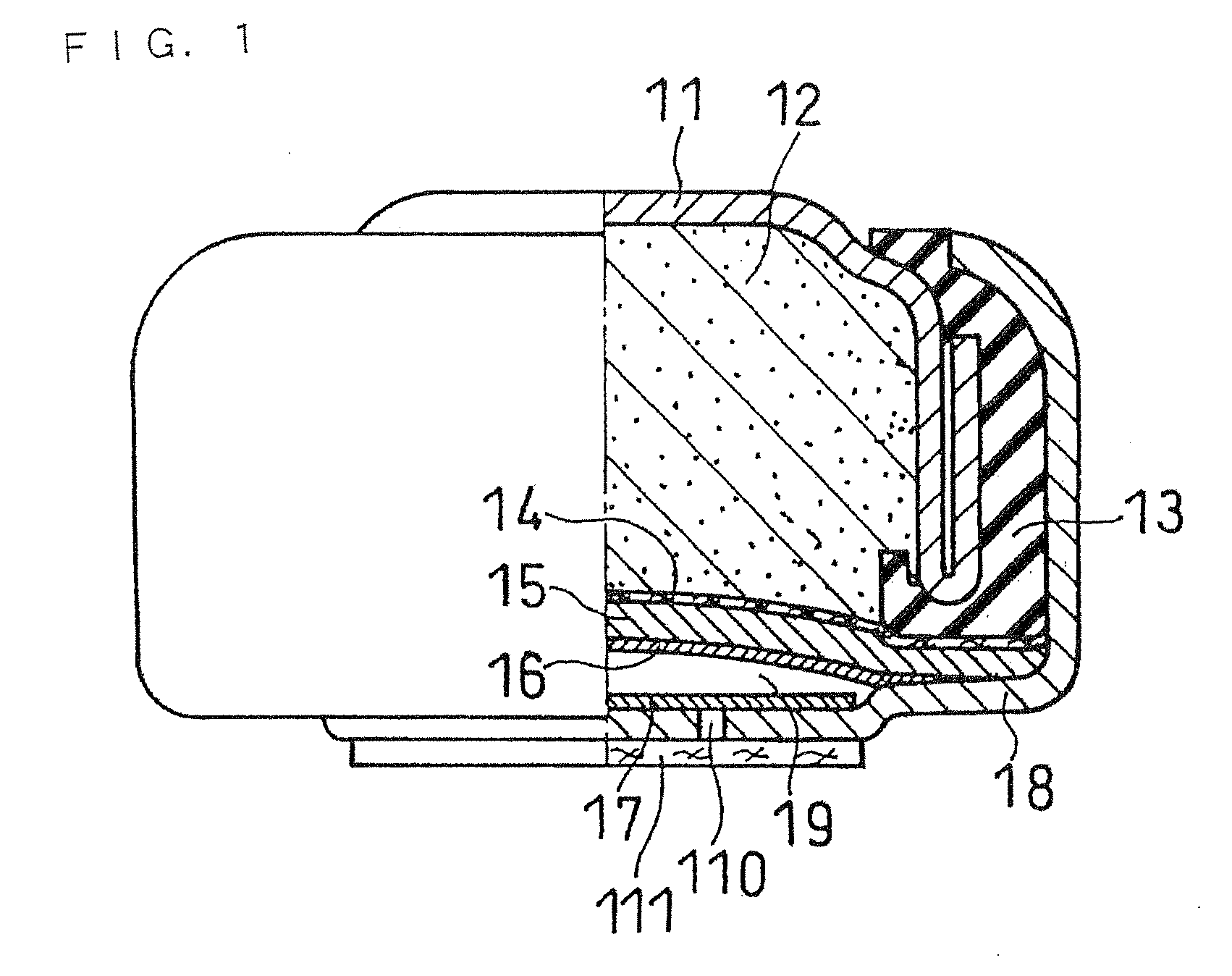

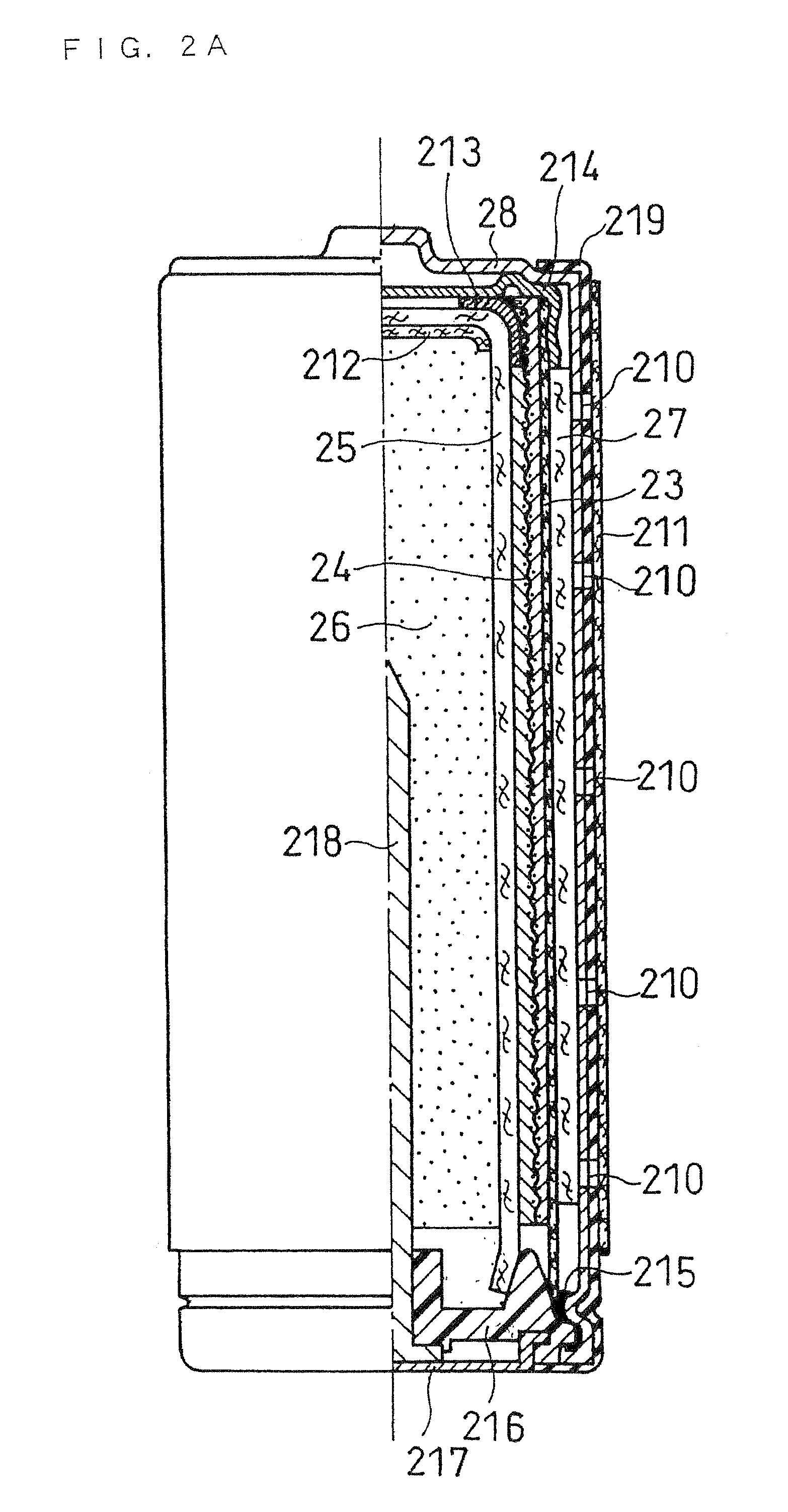

Oxygen permeable film, oxygen permeable sheet, and cell including these

InactiveUS20090202876A1Favorable high rate discharge characteristicExpanding allowable operation rangeFuel and primary cellsCell electrodesWater vaporPolyvinylidene difluoride

An oxygen permeable film including an aggregate of water-repellent particles and having an average particle size of the particles of 0.01 to 50 μm has a contact angle with water of not less than 120° and super water repellency, and therefore has an excellent water vapor permeation inhibiting capability. As the particles, fluorocarbon resins such as polytetrafluoroethylene, polyvinyl fluoride and polyvinylidene fluoride are suitable. The specific surface area of the oxygen permeable film is preferably not less than 0.1 m2 / g and not more than 500 m2 / g.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Waterproof integrated pressure-sensitive-adhesive modularized crystalline silicon solar power generation board system and preparation method thereof

ActiveCN102709358AFlexibleHigh degree of freedom in constructionRoof covering using slabs/sheetsRoof covering using tiles/slatesComputer moduleEngineering

The invention discloses a waterproof integrated pressure-sensitive-adhesive modularized crystalline silicon solar power generation board system which consists of a pressure-sensitive-adhesive crystalline silicon solar panel component module and a waterproof coil layer assorted with the pressure-sensitive-adhesive crystalline silicon solar panel component module. An adhesive layer composed of creepage adhesive is arranged at the bottom of the pressure-sensitive-adhesive crystalline silicon solar panel component module, TPT (tedlar / PET / tedlar) is covered on the adhesive layer, and a crystalline silicon battery cell and toughened glass are sequentially arranged on the TPT and are adhered with the same by hot-melt adhesive. Products of the waterproof integrated pressure-sensitive-adhesive modularized crystalline silicon power generation board system are material-saving, energy-saving and environment-friendly during production and construction, and be applicable to flat roofs and curved roofs simultaneously. The waterproof integrated pressure-sensitive-adhesive modularized crystalline silicon power generation board system has flexibility of flexible film solar cells and low cost which fails to be qualified by the flexible film solar cells. Mounting process can be simplified and economy and convenience are achieved. Further, the waterproof integrated pressure-sensitive-adhesive modularized crystalline silicon power generation board system can be processed and completed directly in a factor, can be paved by adhesives during construction, and photovoltaic utilization can be effectively popularized.

Owner:南通金丝楠膜材料有限公司

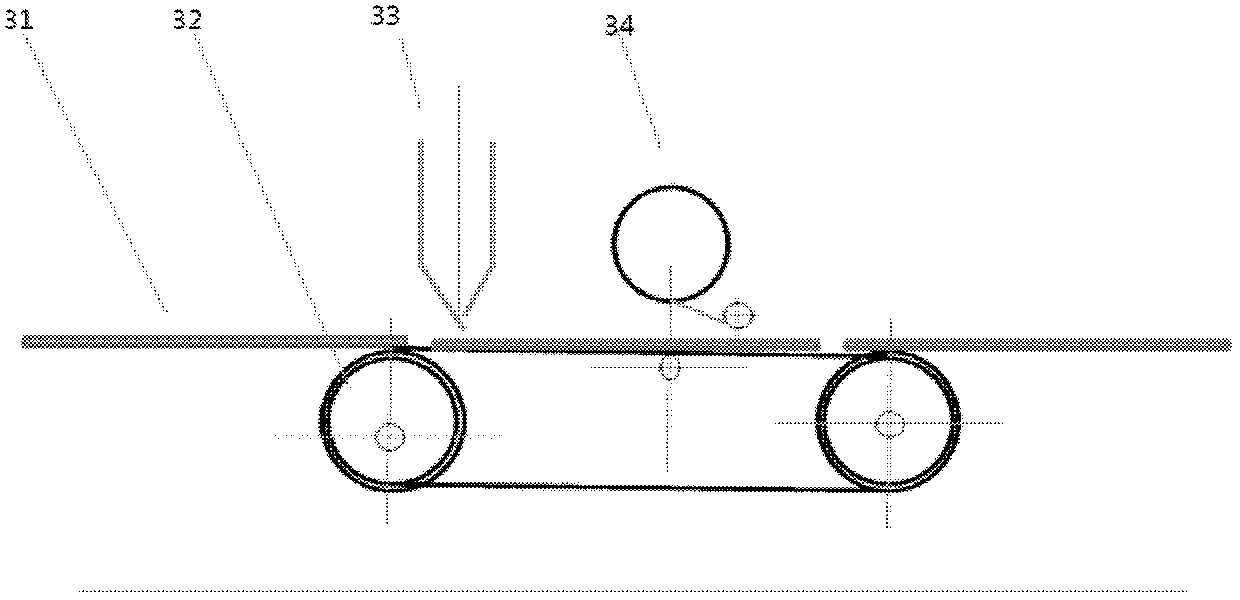

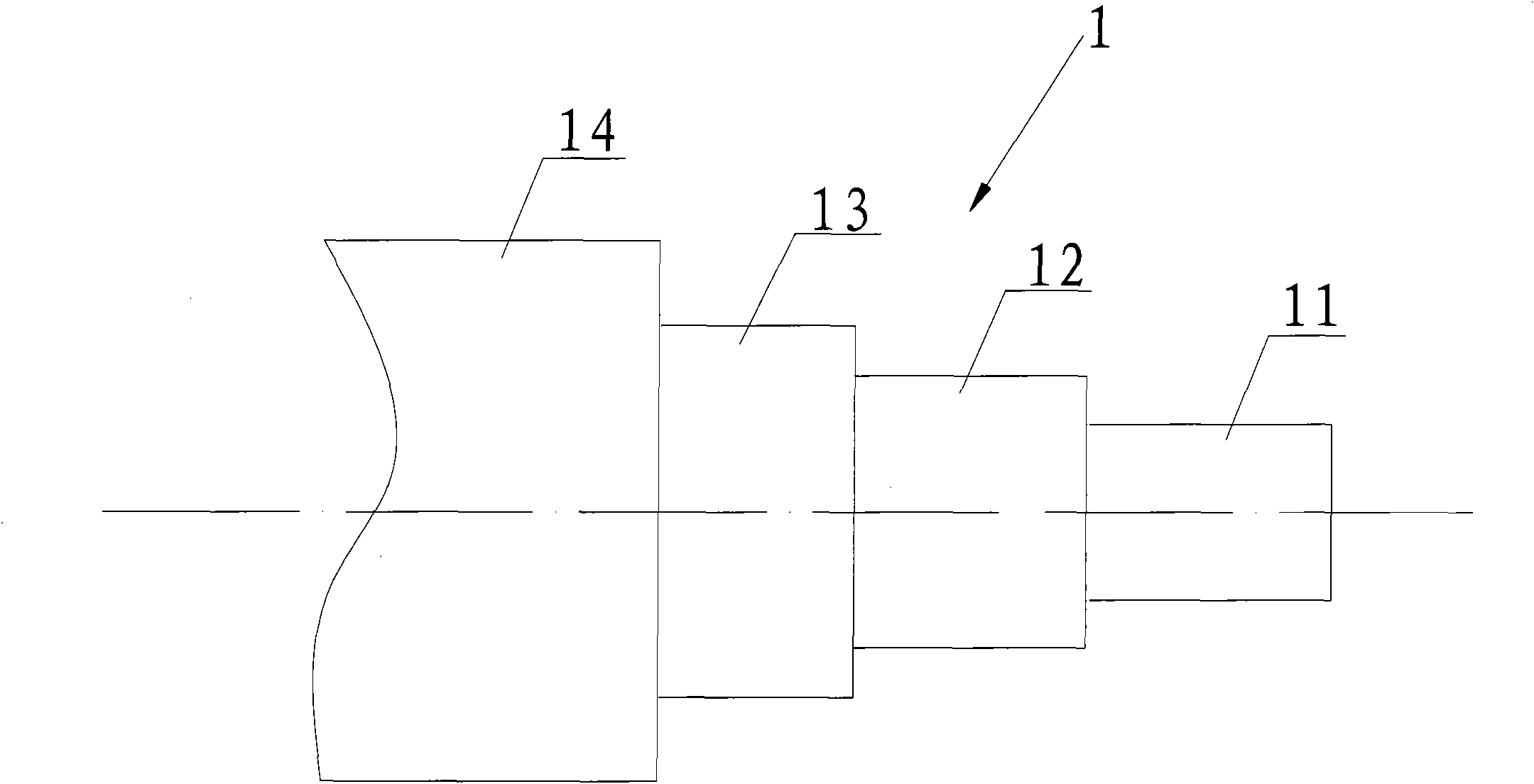

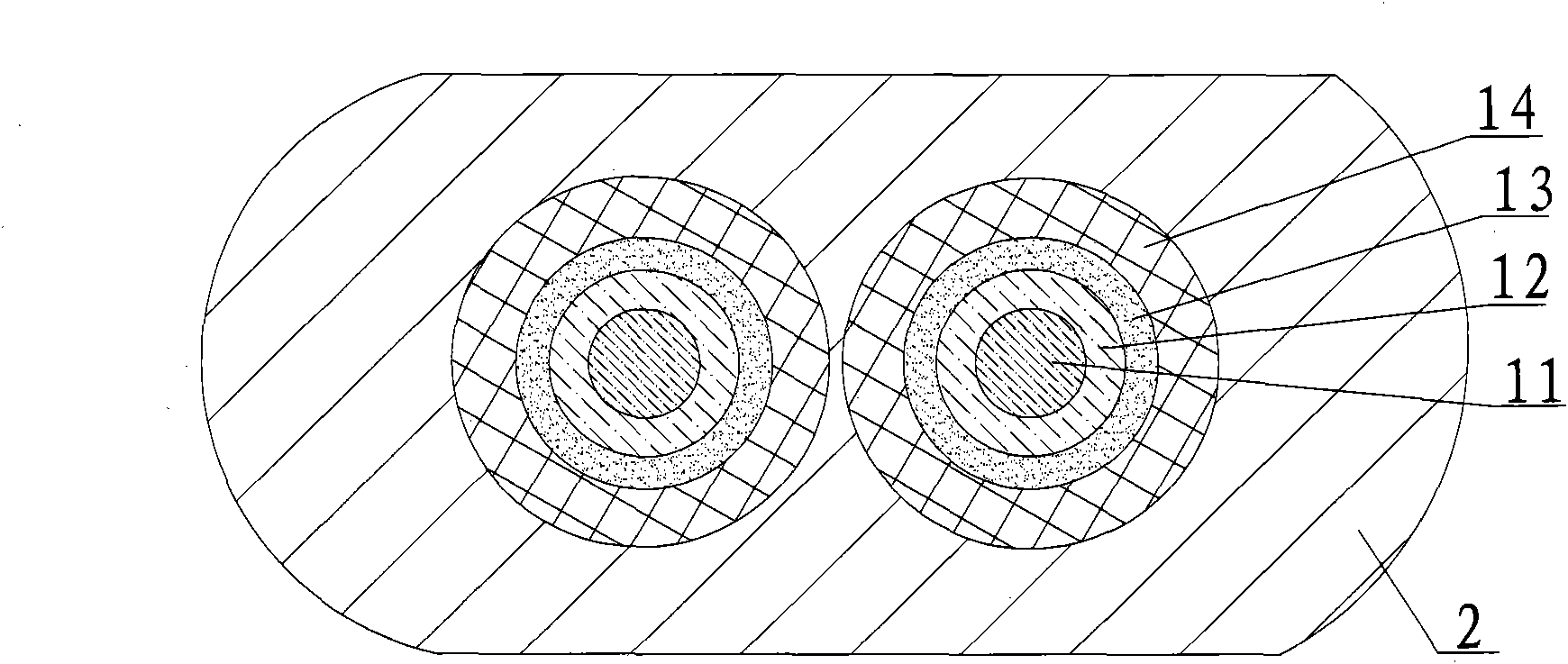

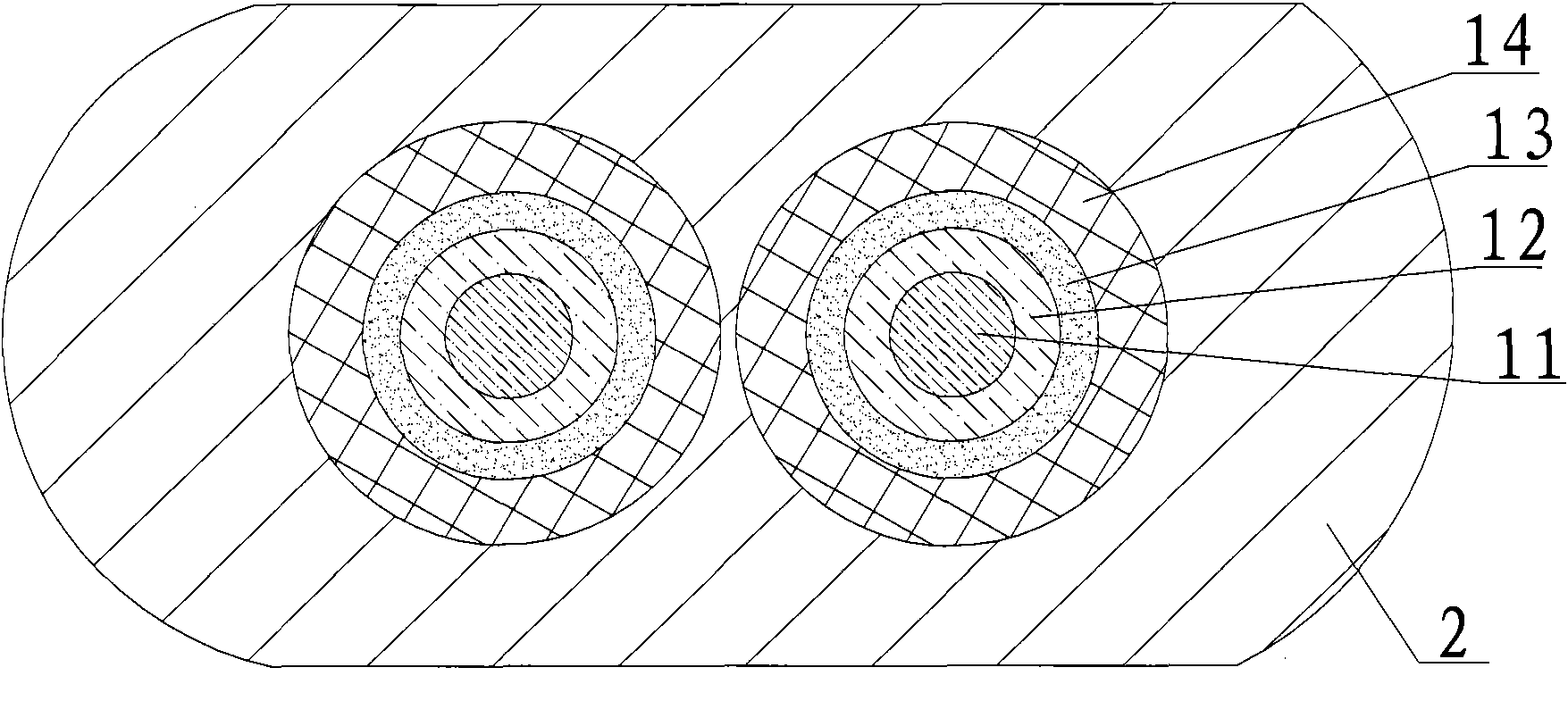

Tightly packaged fiber, and dual-core indoor cable and processing method thereof

InactiveCN101957484AStrong chemical resistanceStrong creep resistanceFibre mechanical structuresDistribution frameFiber

The invention relates to a tightly packaged fiber, and a dual-core cable using the tightly packaged fiber and a processing method thereof. The tightly packaged fiber consists of a single-mode or multi-mode fiber core, a cladding layer clad on the circumference of the fiber core, a primary coating layer coated on the circumference of the cladding layer and a secondary coated layer tightly sleeved on the circumference of the primary coating layer, wherein the secondary coated layer is a polyvinyl fluoride protection layer. By taking polyvinyl fluoride which has relatively high chemical corrosion resistance, creep resistance and compressive strength and relatively wide bearable temperature range as the secondary coated layer of the tightly packaged fiber, the tightly packaged fiber can have enough mechanical and environmental protection capability and can be independently used. The dual-core cable using the tightly packaged fiber, which is processed by the method has the advantages of small volume, light weight, stable performance and low cost, is suitable for indoor comprehensive wiring and can be used as internal connection wires of various optical devices, optical modules and optical distribution frames.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

Preparation of polyvinyl fluoride thin film by fusion extrusion casting method

InactiveCN101168294ASolve pyrolysis problemsShorten the production cycleFlat articlesCoatingsPolyvinyl chlorideSolvent

The invention relates to a formula and technique for preparing polyvinyl fluoride thin films by using a melt-out extrusion blowing method, wherein the technique uses polyvinyl fluoride and solvent to prepare gelatins with high weight solid content at certain temperature, wherein the gelatin is melted, extruded, and flows and extends at low temperature via a screw type air-out extrusion machine, a flowing and extending melting film films via rapid cooling in the bosh, which is dried and shaped through hot-air or infra-red hot passage. The flowing and extending melting film before drying is also capable of being as a film planticle, which is dried and shaped after extending in lengthways and transverse directions. The preparing technique has the advantages that the technique employs gelatins with high weight solid content to melt and extrude out, thereby substantially reducing the processing temperature of the polyvinyl fluoride, avoiding disassembling at high temperature, besides, compared with a liquor flowing and extending filming technique, the invention has the advantages of short period of production, simple technique, energy saving, low investment for the apparatus, the thickness of the prepared flowing and extending film is capable of being adjusted randomly, and the tensile property is great, and the prepared film can be further extended in two-way to acquire a thin film product with high intensity and high modulus.

Owner:BEIJING UNIV OF CHEM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com