Solar cell backboard with excellent weathering resistance and preparation method thereof

A solar cell and battery backplane technology, which is applied in the direction of climate sustainability, chemical instruments and methods, circuits, etc., can solve problems affecting the performance of the backplane, achieve excellent bonding strength, excellent weather resistance, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

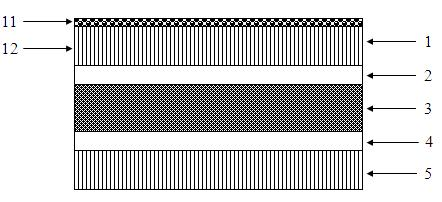

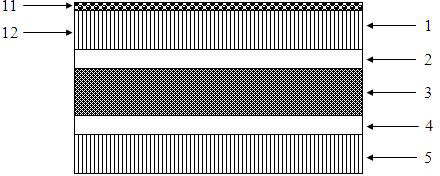

[0026] The preparation method of the solar cell backboard of the present invention comprises the following steps:

[0027] a. Using double-layer co-extrusion method, PVDF resin and polyacrylic acid resin are extruded at a working temperature of 180-230°C to prepare the F-containing composite film;

[0028] B, carry out pretreatment with described F-containing composite film, PET film, transition layer;

[0029] c. Coating glue on one side of the PET film, drying it at 60-120°C, and then pressing it with the F-containing composite film;

[0030] d. Coating glue on the surface of the other side of the PET film, drying it at 60-120° C., and then pressing it with the transition layer, thereby preparing a solar battery back sheet with excellent weather resistance.

[0031] Wherein, the pressing in step c is at a temperature of 80-100°C and a temperature of 5-25Kg / cm 2 Pressing under a certain pressure, and then baking at a temperature of 50-100°C for 6-48 hours; the pressing in s...

Embodiment 1

[0034] 1. Preparation of materials:

[0035] Prepare PVDF resin and polyacrylic resin, PET film with a thickness of 0.125mm, polyurethane glue, and EVA film with a thickness of 0.05mm.

[0036] 2. Preparation of the backplate:

[0037](1) Using a double-layer co-extrusion method, PVDF resin and polyacrylic acid resin were extruded at a working temperature of 230 ° C to prepare a F-containing composite film with a thickness of 0.03 mm. The PVDF layer thickness is 0.015mm.

[0038] (2) Pretreat the PET film; the surface energy of the film after treatment is 48 dynes.

[0039] (3) Coat the glue on the surface of the PET film with a coating thickness of 40 microns, then dry it at 60°C, and then press it with the F-containing composite film at a certain temperature and pressure; the pressure temperature is 80°C, and the pressure is 25Kg / cm 2 , and then baked at 50°C for 48 hours.

[0040] (4) Coat glue on the other surface of the PET film with a coating thickness of 40 micr...

Embodiment 2

[0045] 1. Preparation of materials:

[0046] Prepare PVDF resin and polyacrylic resin, PET film with a thickness of 0.3mm, polyurethane glue, and EVA film with a thickness of 0.02mm.

[0047] 2. Preparation of the backplate:

[0048] (1) Extrude PVDF resin and polyacrylic acid resin at a working temperature of 200°C by double-layer co-extrusion to prepare a F-containing composite film with a thickness of 0.05mm, in which the thickness of the PVDF layer is 0.008mm;

[0049] (2) Pretreat the PET film; the surface energy of the film after treatment is 52 dynes;

[0050] (3) Coat glue on one side of the PET film with a coating thickness of 50 microns, then dry it at 120°C, and then press it with the F-containing composite film at a certain temperature and pressure, and the pressure temperature is 100°C. Pressure 15Kg / cm 2 , and then baked at 100°C for 6 hours;

[0051] (4) Coat the surface of the other side of the PET film with glue, the coating thickness is 50 microns, dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com