Patents

Literature

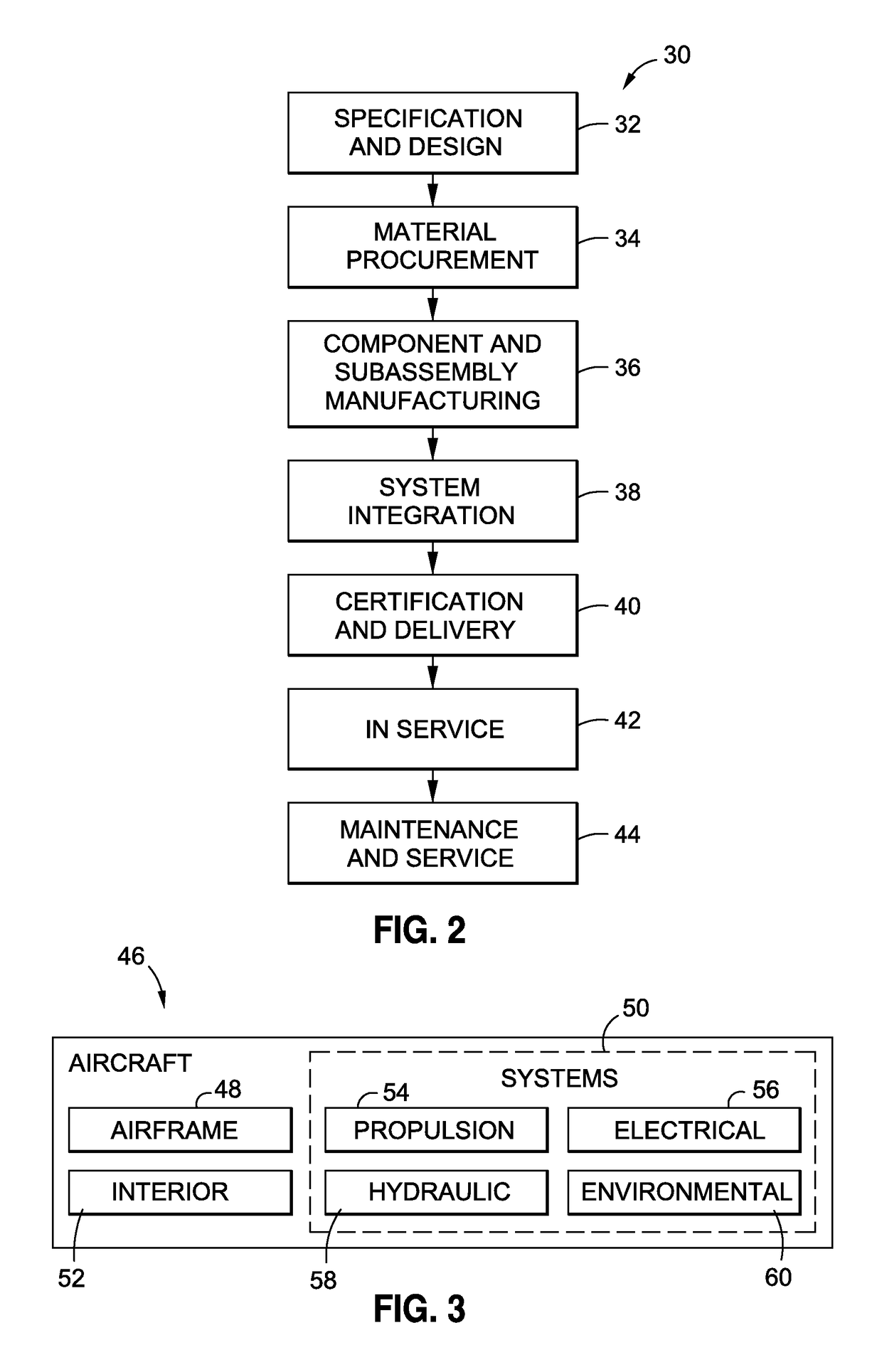

286 results about "Decorative laminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Decorative laminates are laminated products primarily used as furniture surface materials or wall paneling. It can be manufactured as either high- or low-pressure laminate, with the two processes not much different from each other except for the pressure applied in the pressing process.

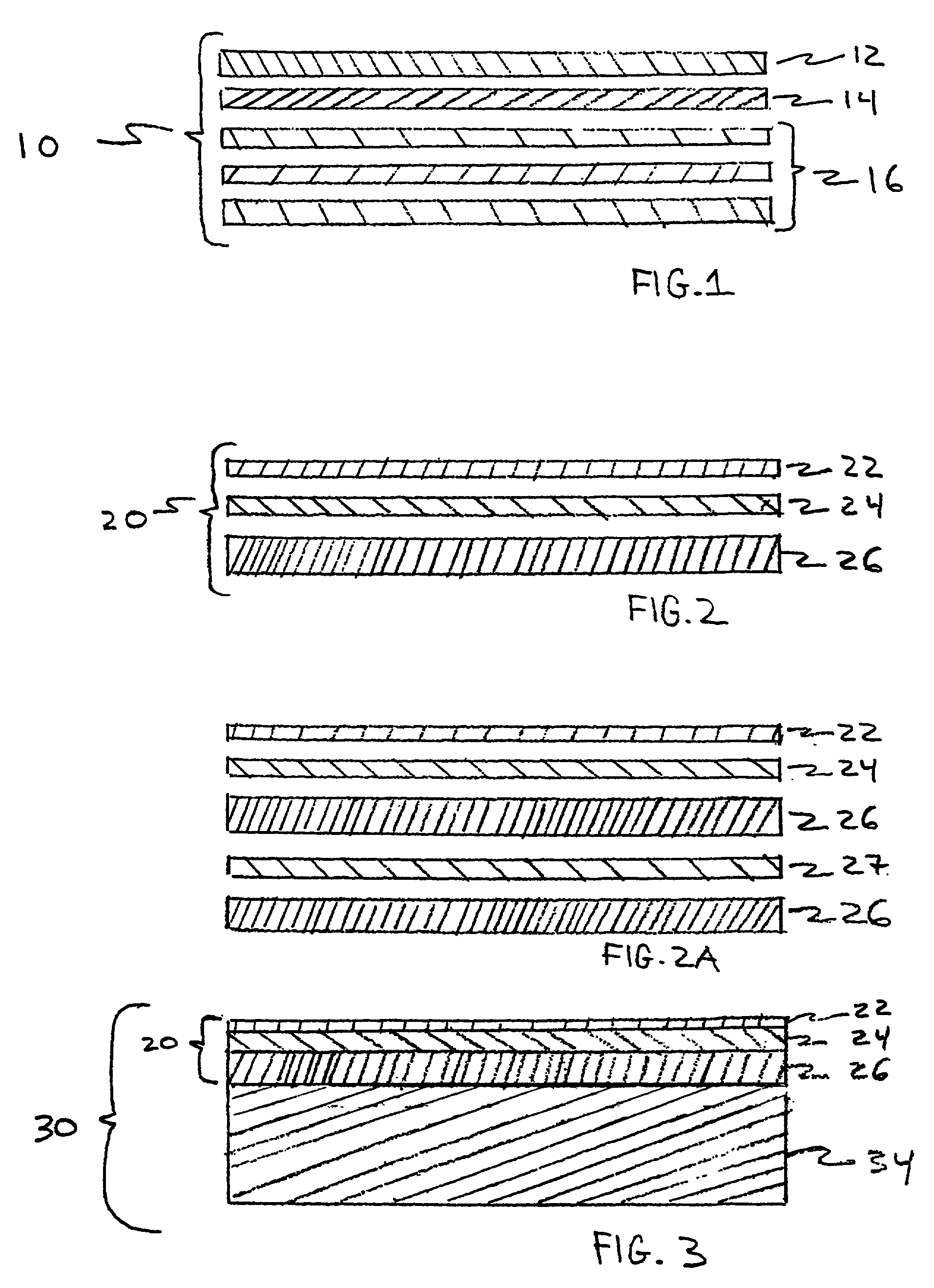

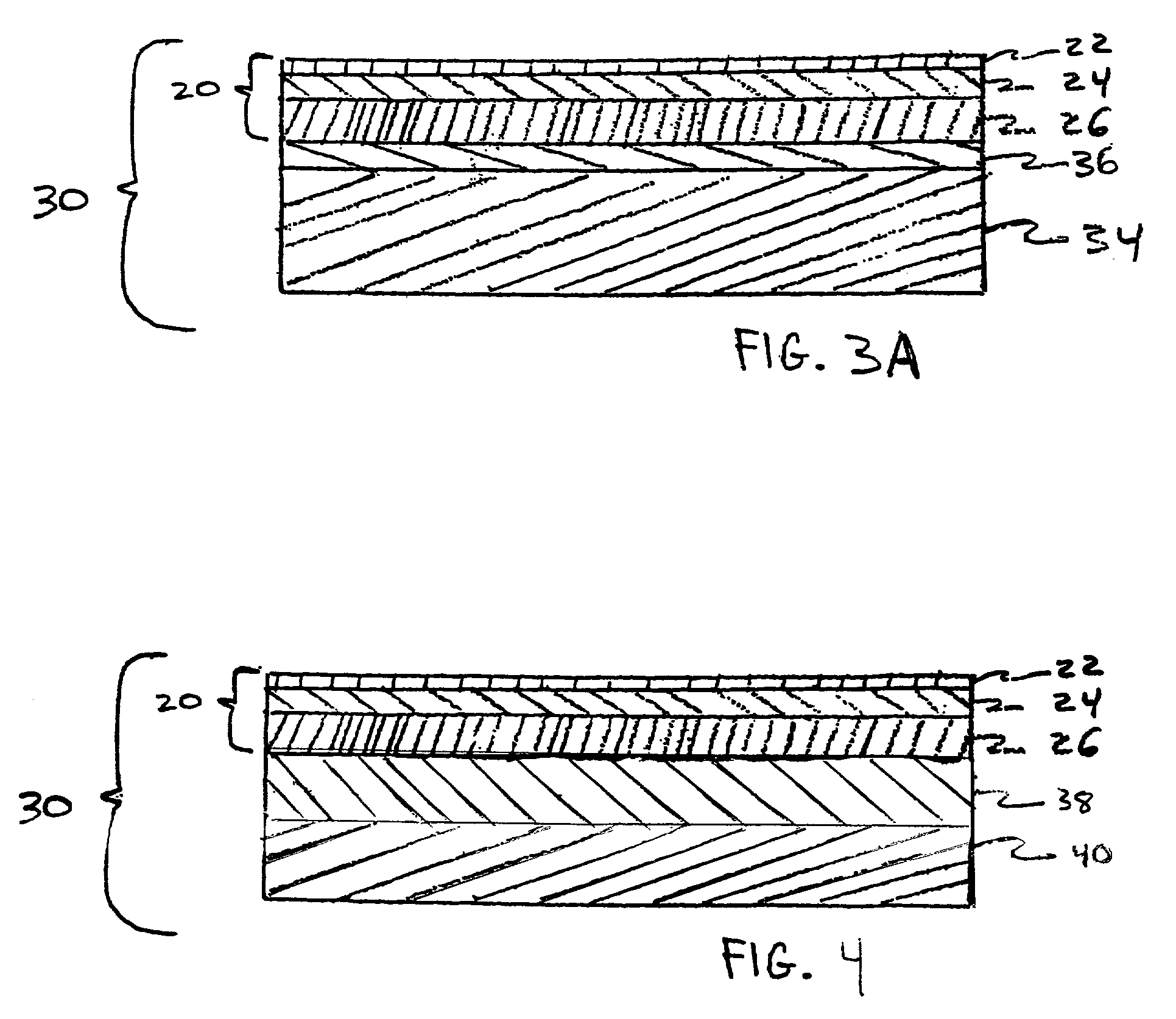

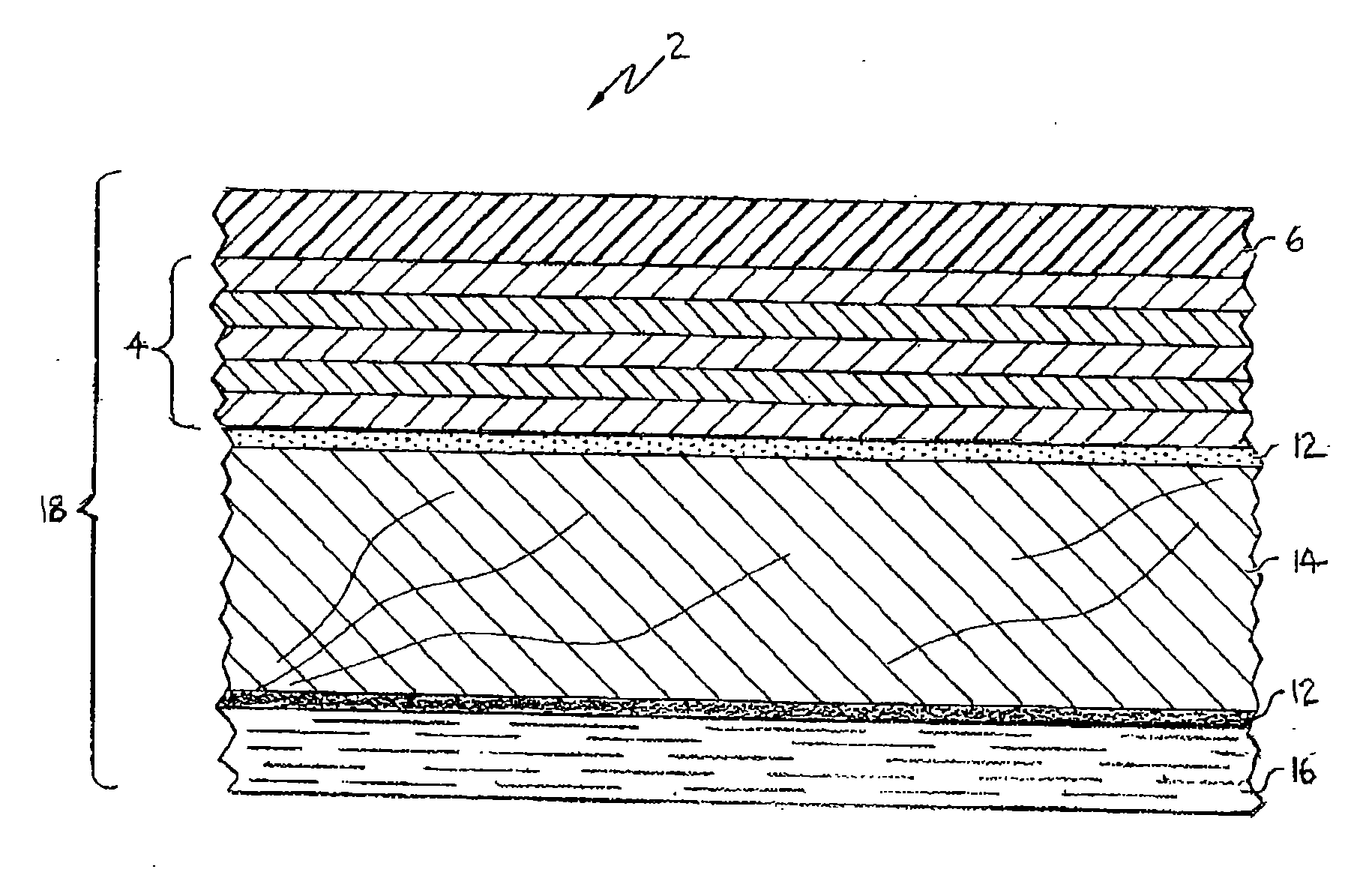

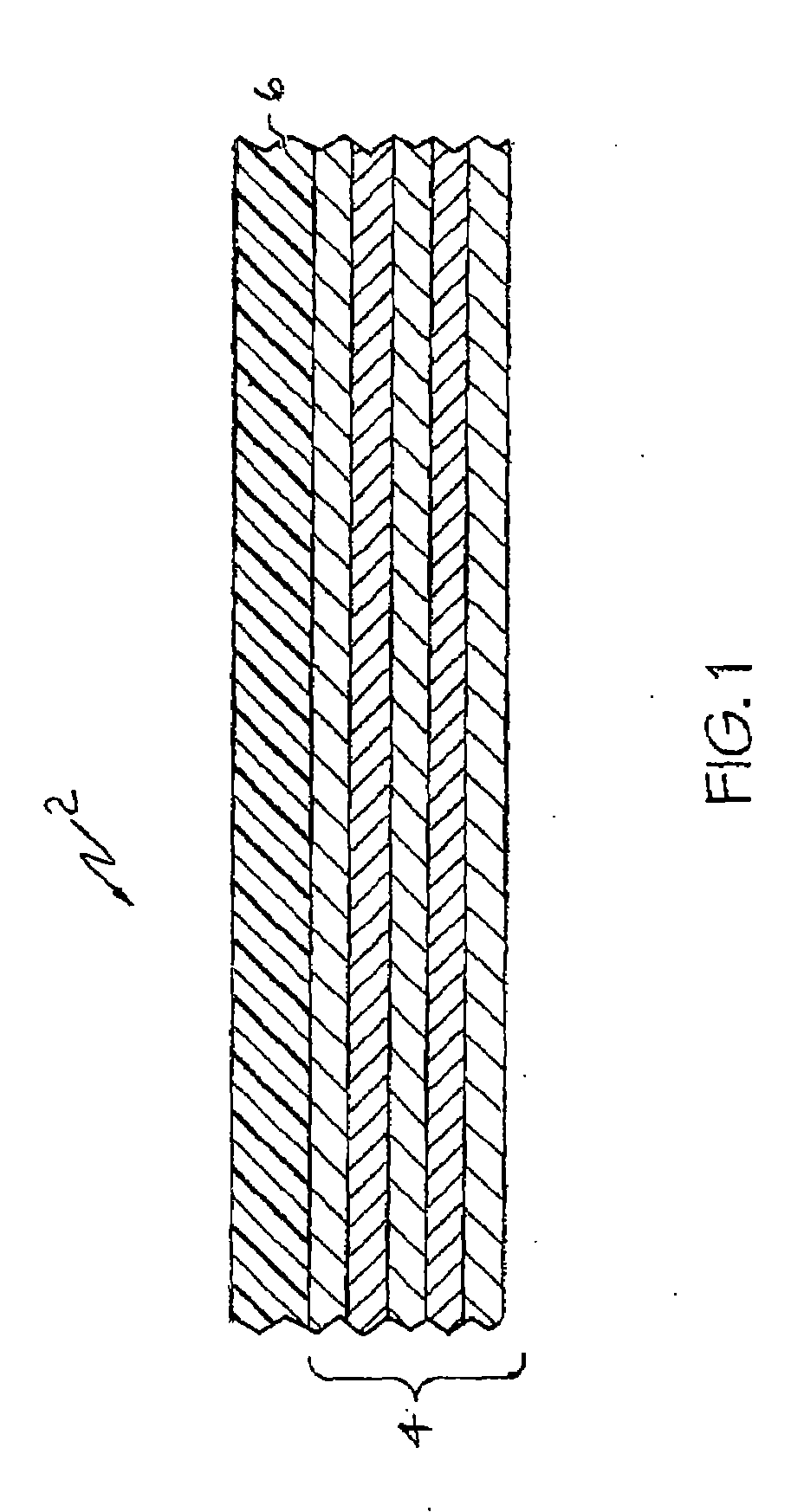

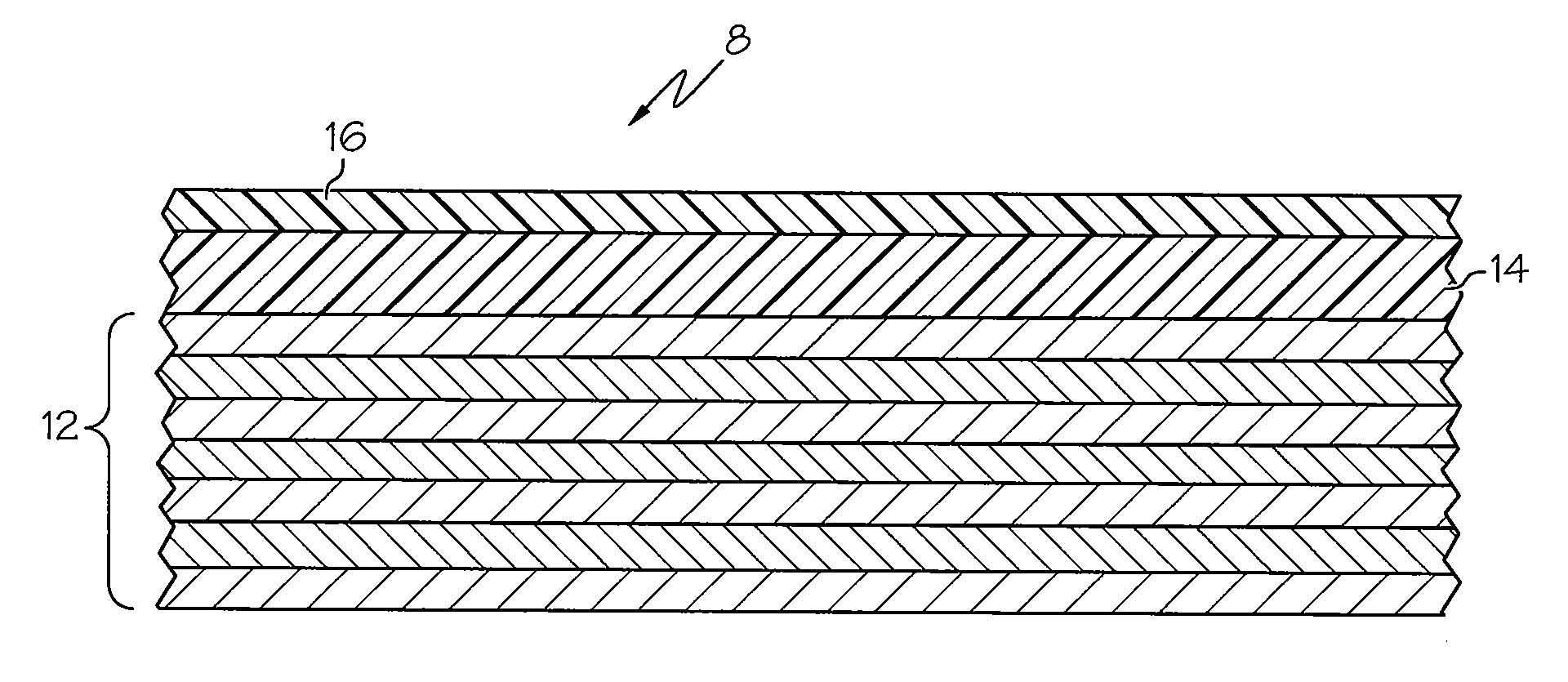

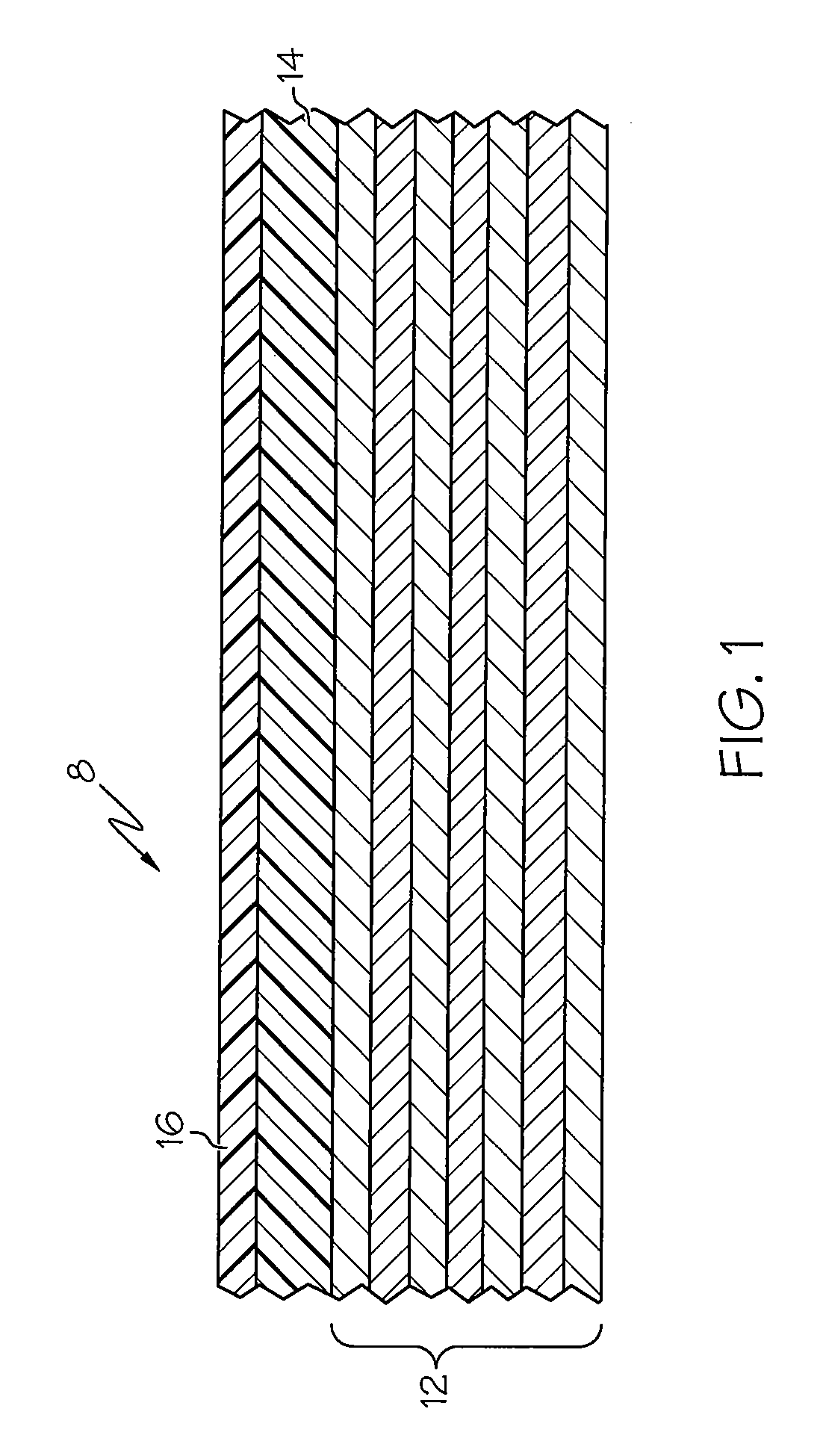

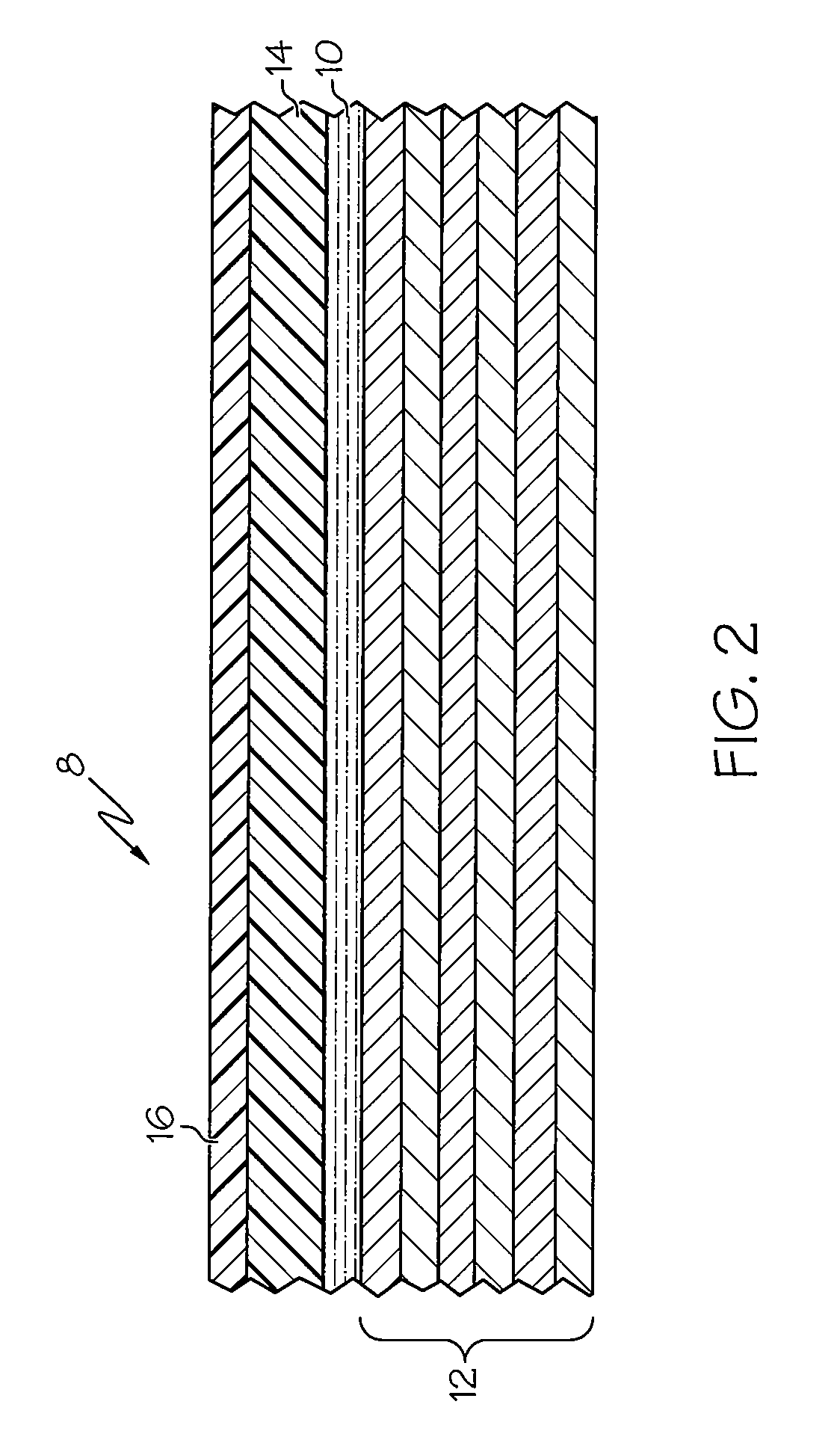

Fiber-reinforced decorative laminate

InactiveUS20050266221A1Desirable flexural strengthNot adversely affect flammabilityCovering/liningsLayered product treatmentCelluloseEngineering

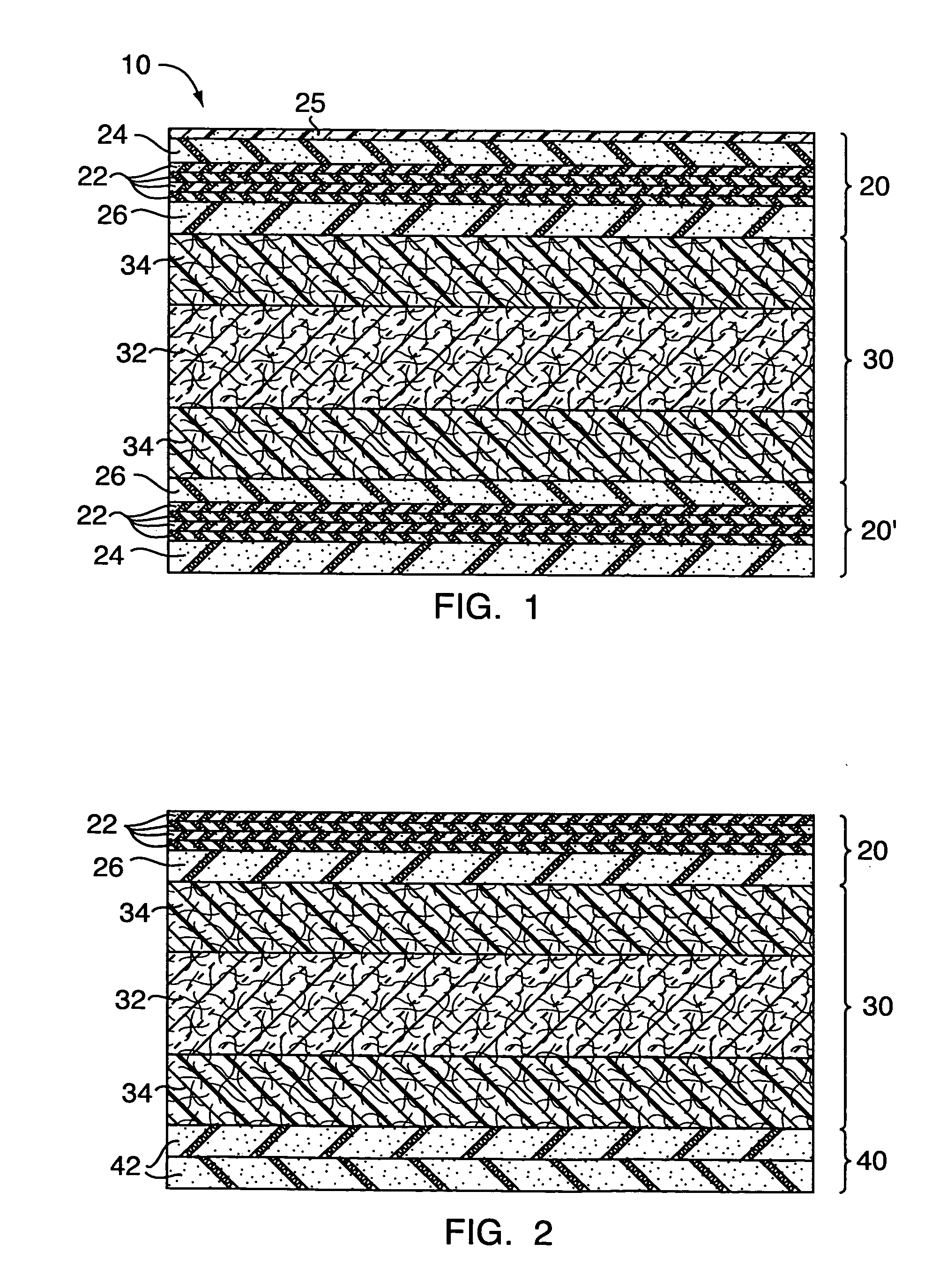

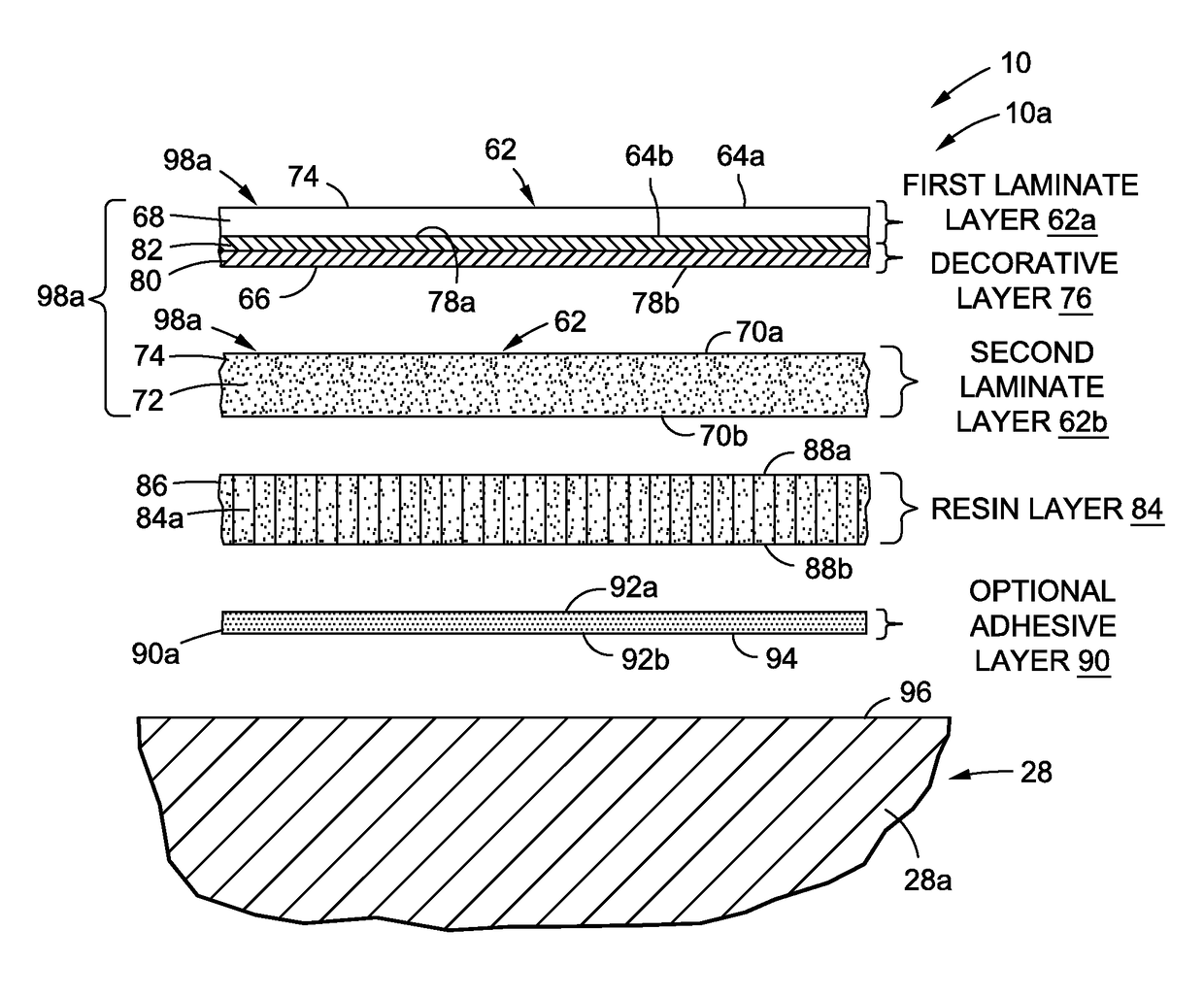

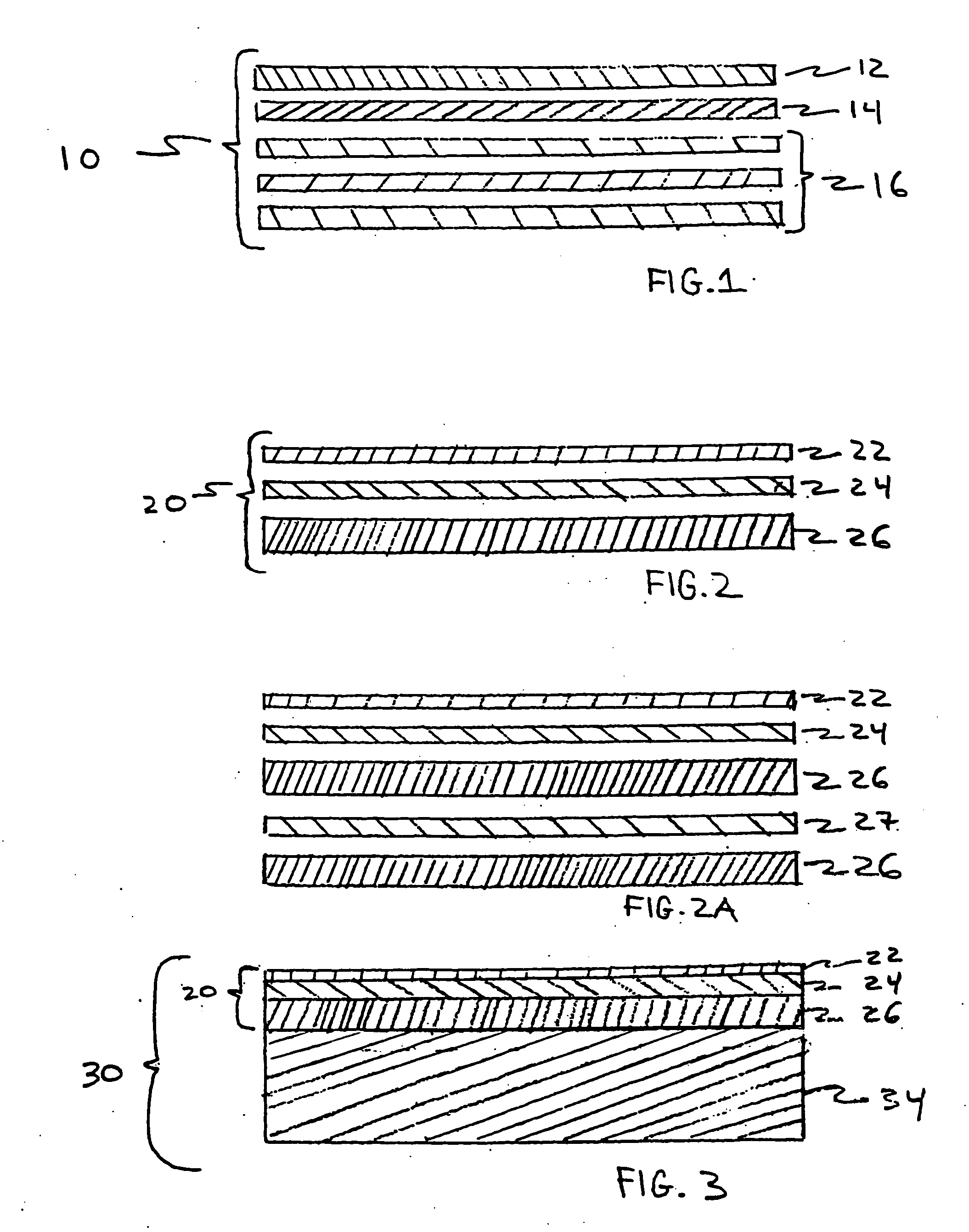

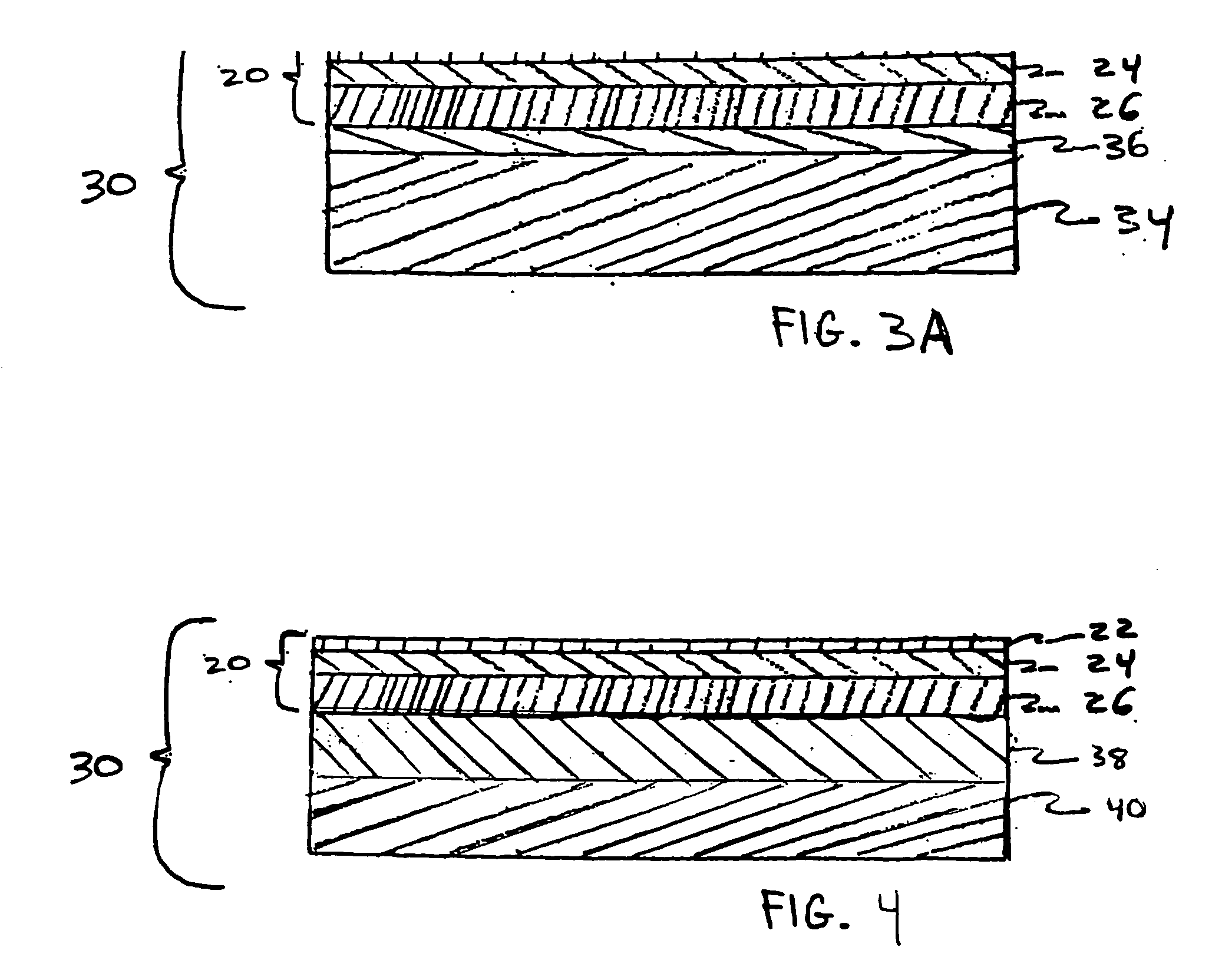

A method for the production of a fiber-reinforced decorative laminate is provided. The method includes stacking, in a superimposed relationship, a decorative layer and a fiber-reinforced core layer. The decorative layer, which includes one or more decorative sheets, is at least partially resin-impregnated, and at least partially cured. The fiber-reinforced core layer includes at least one fiber-reinforced sheet, which is substantially devoid of cellulose, and at least partially resin-impregnated, and at least partially cured. The decorative and core layers are simultaneously cured, under heat and pressure, to create the fiber-reinforced decorative laminate. A fiber-reinforced decorative laminate produced according to the above method is also provided.

Owner:DEUT BANK TRUST COMPANY AMERICAS

Decorative laminate with non-visible light activated material and system and method for using the same

ActiveUS9718302B2Synthetic resin layered productsSpecial ornamental structuresUltravioletLight activated

Owner:THE BOEING CO

Decorative laminate board

InactiveUS20060099386A1Quickly blunting the toolsSimple processDecorative surface effectsSynthetic resin layered productsEngineeringLaser beams

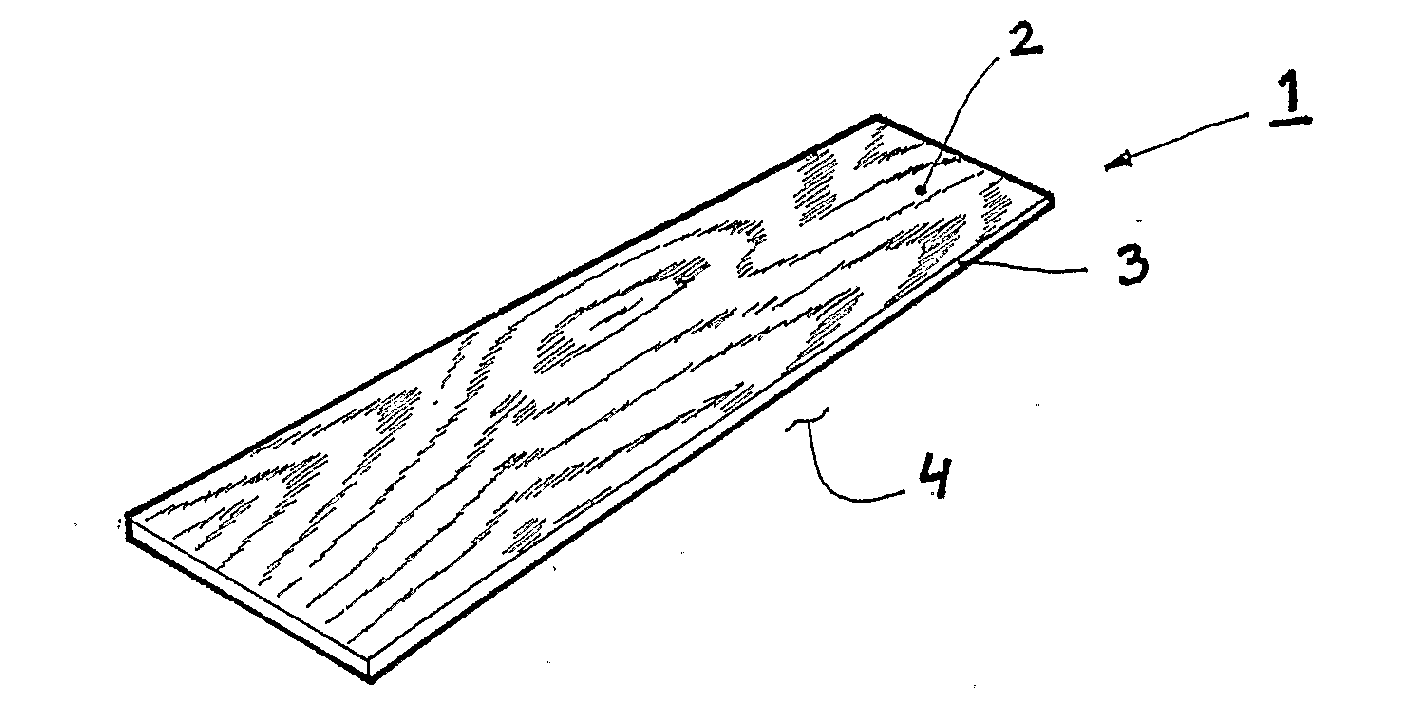

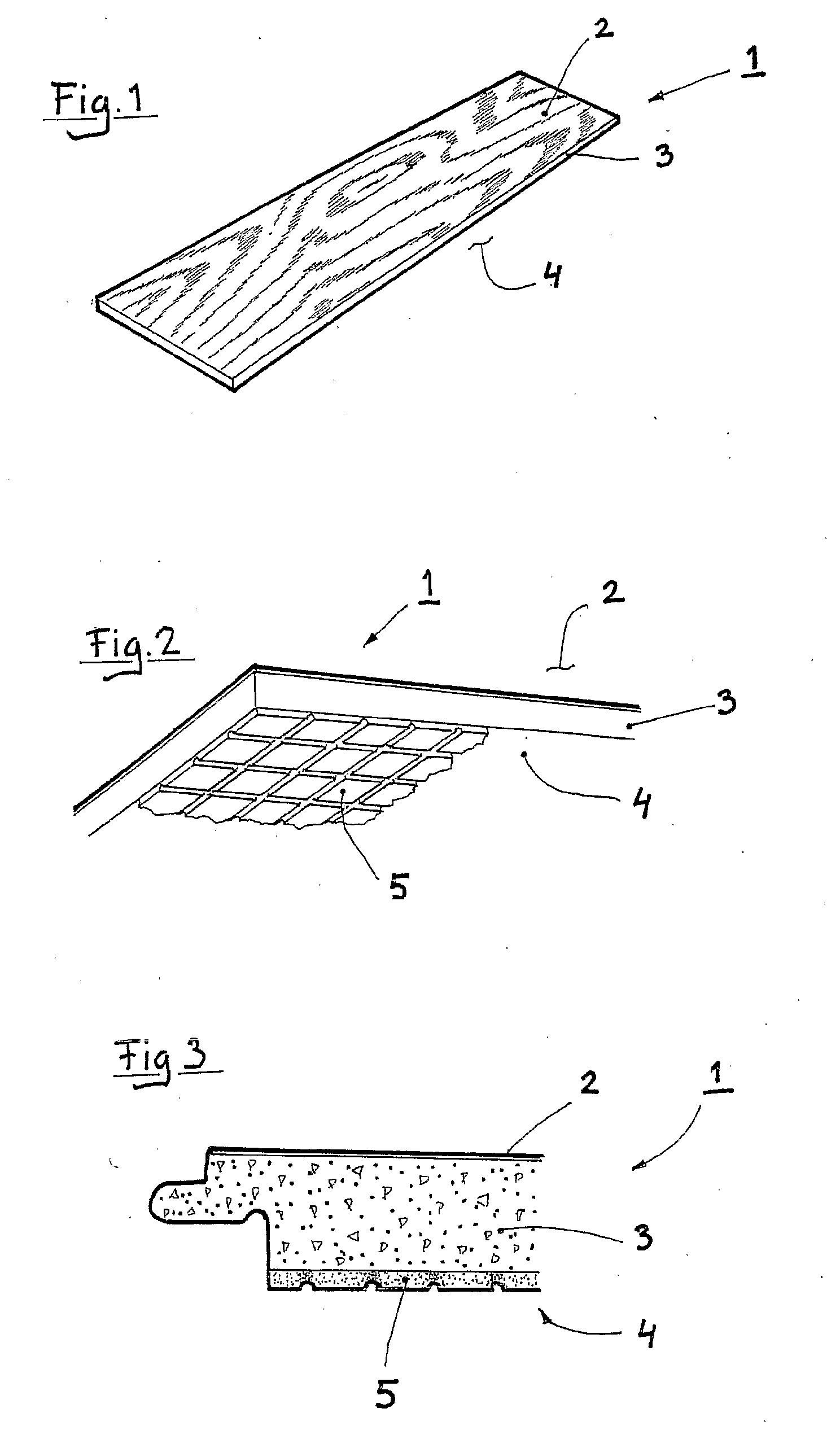

A decorative laminate board having edges, a decorative upper layer and a rear layer. The decorative laminate board includes at least a base layer, an intermediate decor layer and a wear layer where at least one of said layers comprises polymers. Predetermined portions of the decorative upper layer is provided with an embossed surface through means of a laser beam.

Owner:PERGO

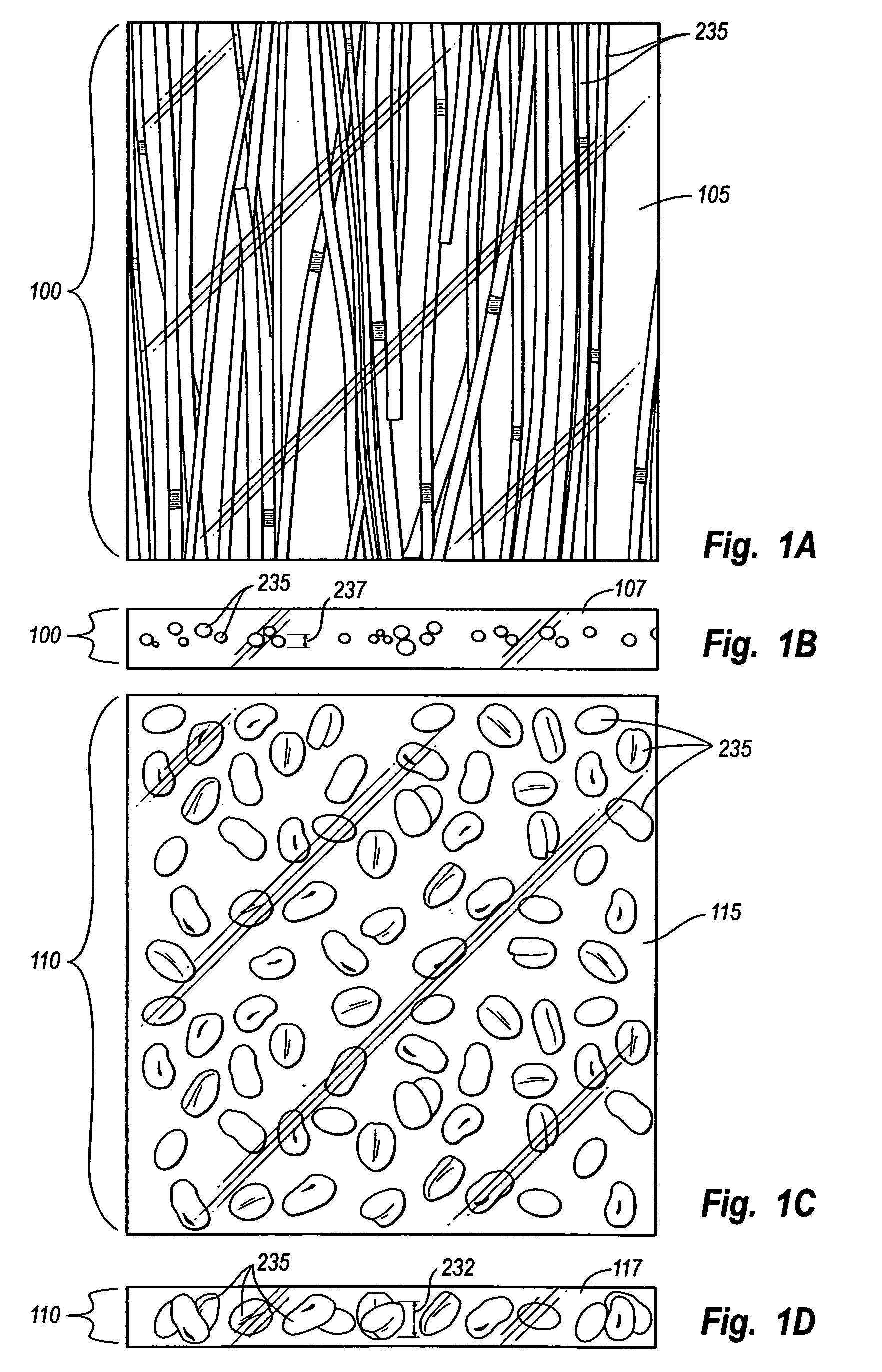

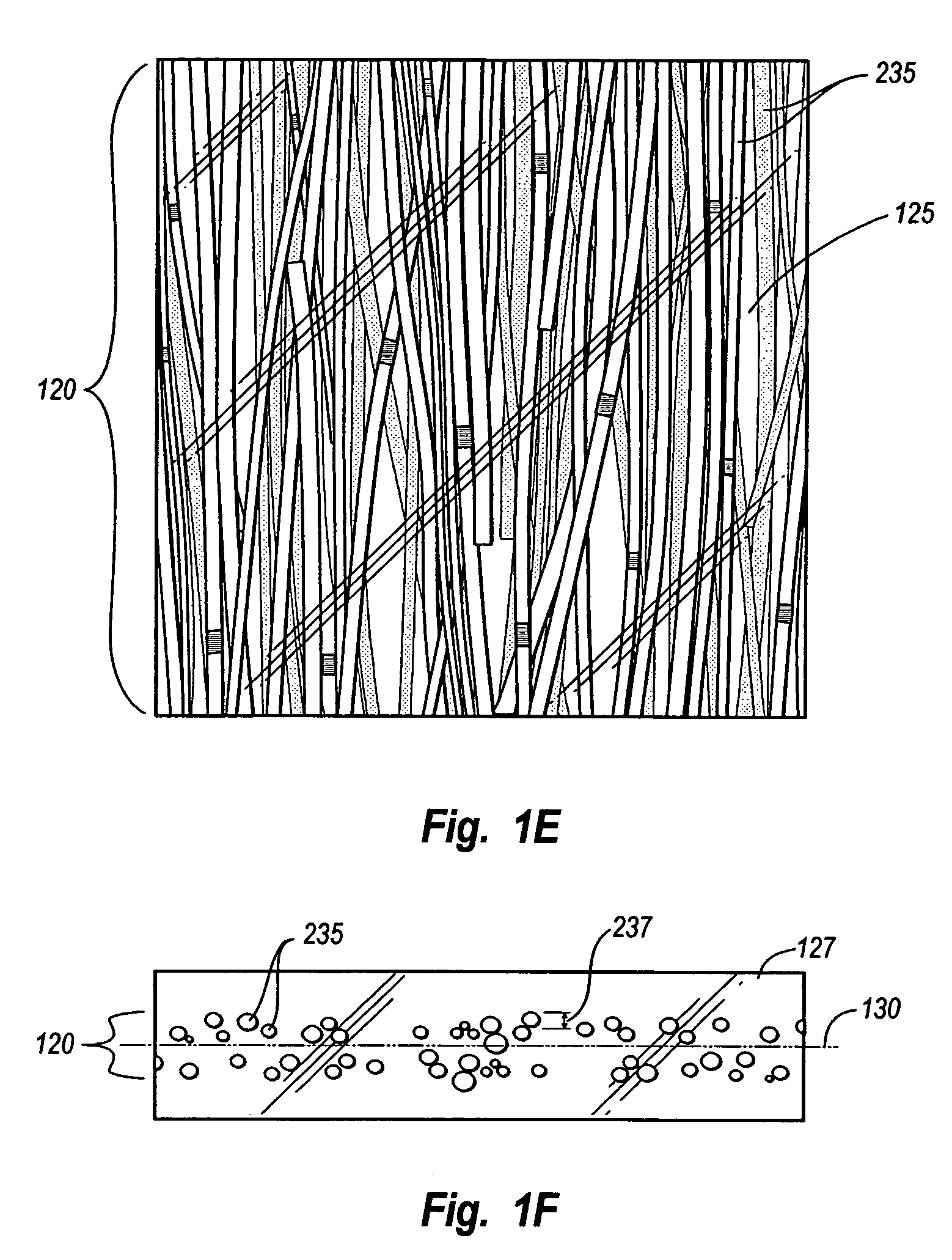

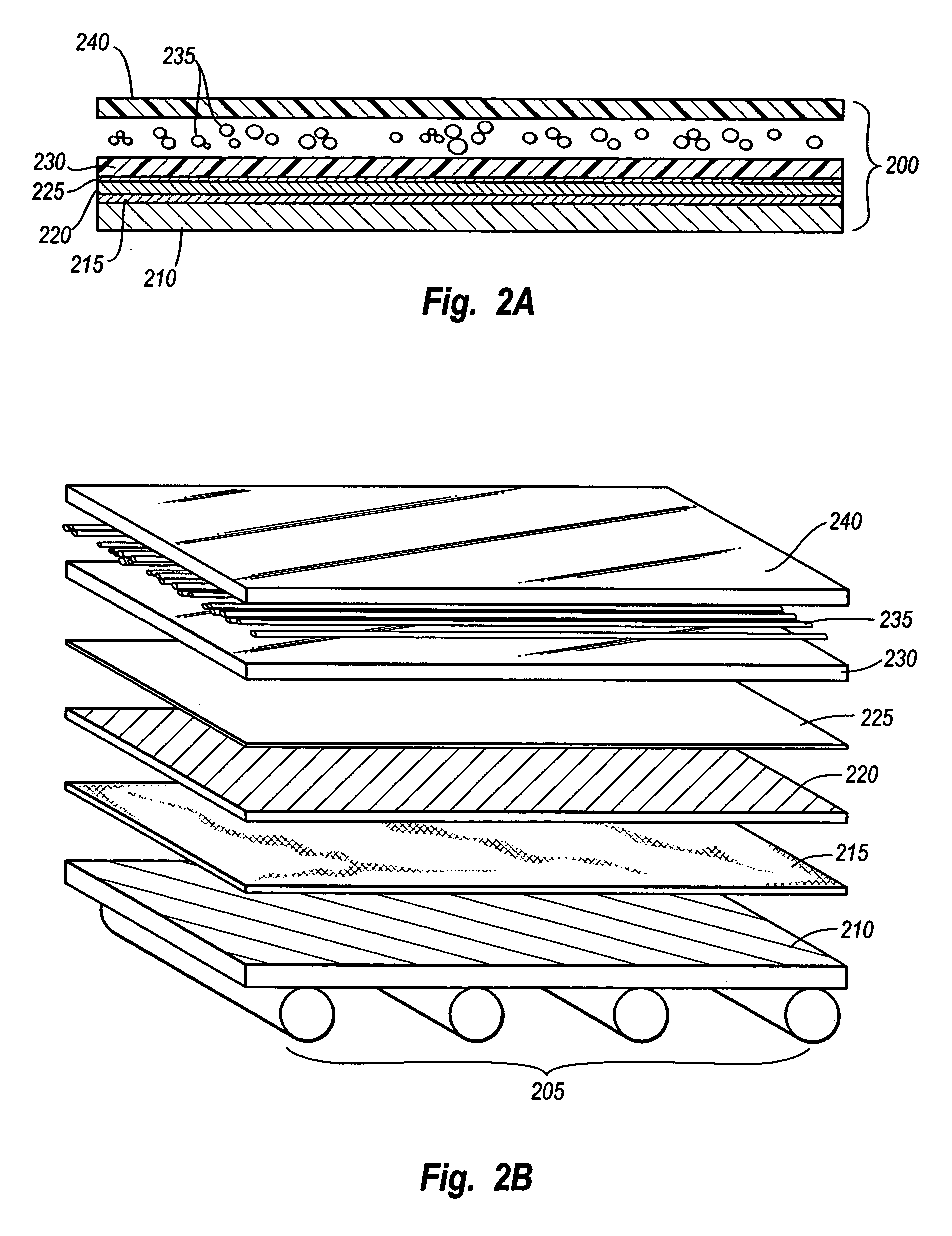

Architectural laminate panel with embedded compressible objects and methods for making the same

InactiveUS7008700B1Significantly trapping airPicture framesDecorative surface effectsCompressible materialEngineering

A decorative laminate panel comprises compressible objects embedded inside, wherein the compressible objects would be flattened in unnatural shapes under conventional processes. For example, an exemplary decorative laminate product comprises thatch reed, willow reed, bamboo, weeds, grasses, twigs and branches of a tree or bush, beans, and so forth. In at least one exemplary implementation of the present invention, an extruded sheet, such as PETG or polycarbonate, is softened and melted around the compressible materials such that the compressible materials do not deform. Imperfections in the decorative laminate panel can be easily removed, thereby allowing for producing a high quality decorative laminate panel with high efficiency and relatively low cost compared with conventional methods and materials.

Owner:3FORM

Process for the manufacturing of an improved core for decorative laminates and a decorative laminate obtained by the process

InactiveUS6841023B2Improve brittlenessImprove the overall coefficientOrganic chemistryLamination ancillary operationsPolyesterFiber

A process for the manufacturing of a core forming a carrying structure for decorative laminates. The core comprises particles of cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin. The particles are bonded to each other in a pressing procedure with a bonding agent comprising an adhesive such as a polymerizing monomer.i) The particles are achieved by grinding cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin so that it passes through a 2 mm screen, preferably a 1 mm screen,ii) 100 parts per weight of particles is mixed with 1-100 parts per weight of fiber, the fiber additive having an average length in the range 1-15 mm.iii) The particle-fiber mixture is allowed to absorb a selected amount of water, the amount of water being in the range 1-15% by weight, The water is either added at any stage before the adding of bonding agent, and / or being used as a solvent in the bonding agent, and that,iv) 85 parts per weight of the particle mixture is mixed with 2-15 parts per weight of a bonding agent, the bonding agent selected from the group consisting of,a) A mixture of polyols, such as polyester or polyether, crude methylene diphenyl diisocyanate and possibly a small amount of blowing agent in a ratio forming a polymeric resin with a density in the range 600-1400 kg / m3.b) A formaldehyde based resin such as phenol-formaldehyde resin, urea-formaldehyde resin, melamine-urea-formaldehyde resin, melamine-urea-phenol-formaldehyde resin or phenol-resorcinol-formaldehyde resin, orc) Polyvinyl acetate resin.v)The mixture is applied between the belts of the continuos belt press or the press plates of a static press, optionally with at least one intermediate carrier web, the belts or press plates allowing a mainly uniform and specified material thickness to form. A slightly porous and preconditioned core with a selected water content in the range 0.8-12% is hereby achieved. The invention also relates to a decorative laminate achieved through the process.

Owner:PERGO

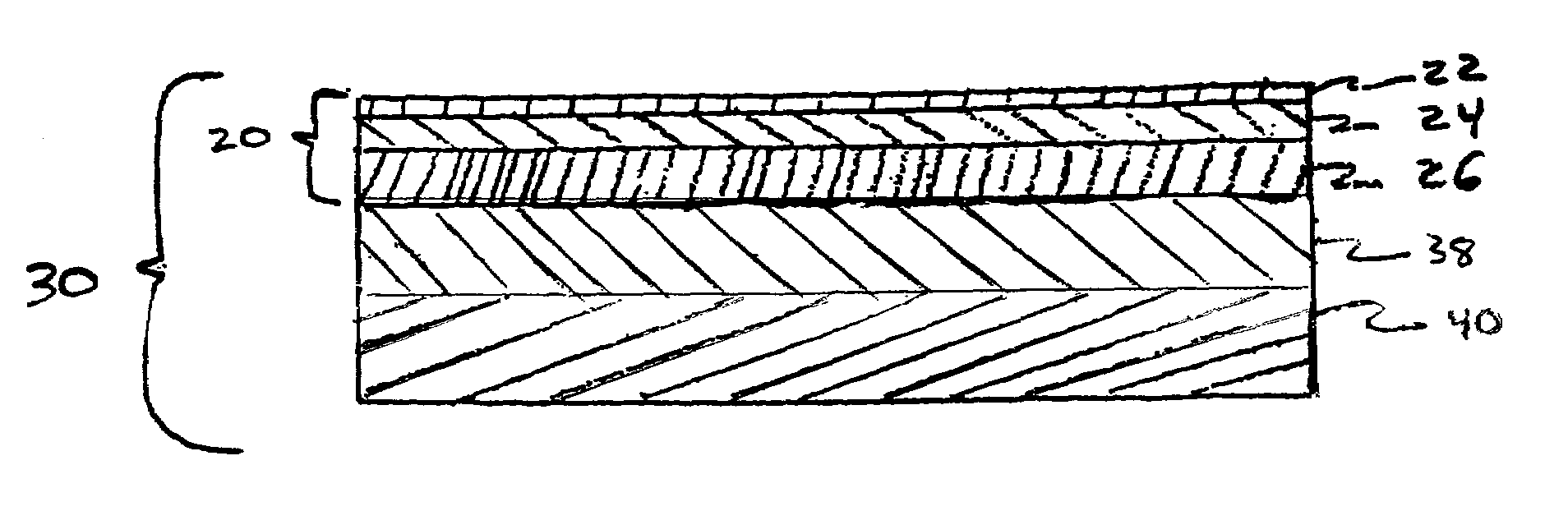

Decorative laminate assembly and method of producing same

InactiveUS7081300B2Improve wear qualityAvoid laborCovering/liningsOrnamental structuresWear resistantEngineering

A decorative laminate assembly having a decorative laminate top layer assembly. This top layer assembly includes, in descending superimposed relationship, a decorative layer and a core layer that includes PETG, or other polymeric material. Preferably, the top layer assembly also includes a wear resistant overlay layer on top of the decorative layer, and the core layer's PETG is in a sheet form. The top layer assembly may be directly bonded to a water resistant substrate. The decorative laminate assembly of the present invention can be used for a variety of purposes, including flooring applications. When the present invention is used for flooring applications, it is preferred that the overlay layer has enhanced wear resistant qualities and that the water resistant substrate comprise PVC or cement fiberboard.

Owner:THE DILLER +1

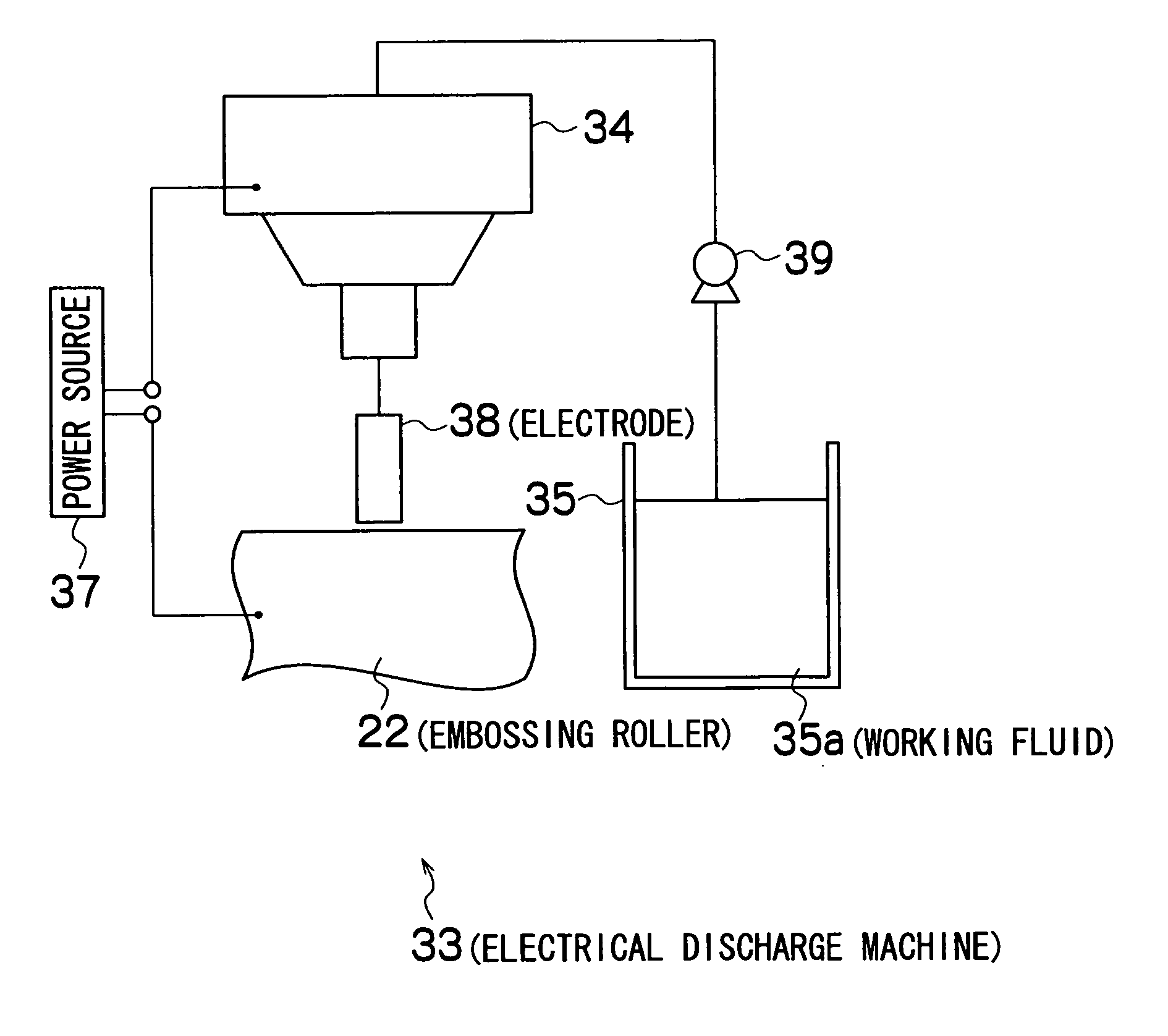

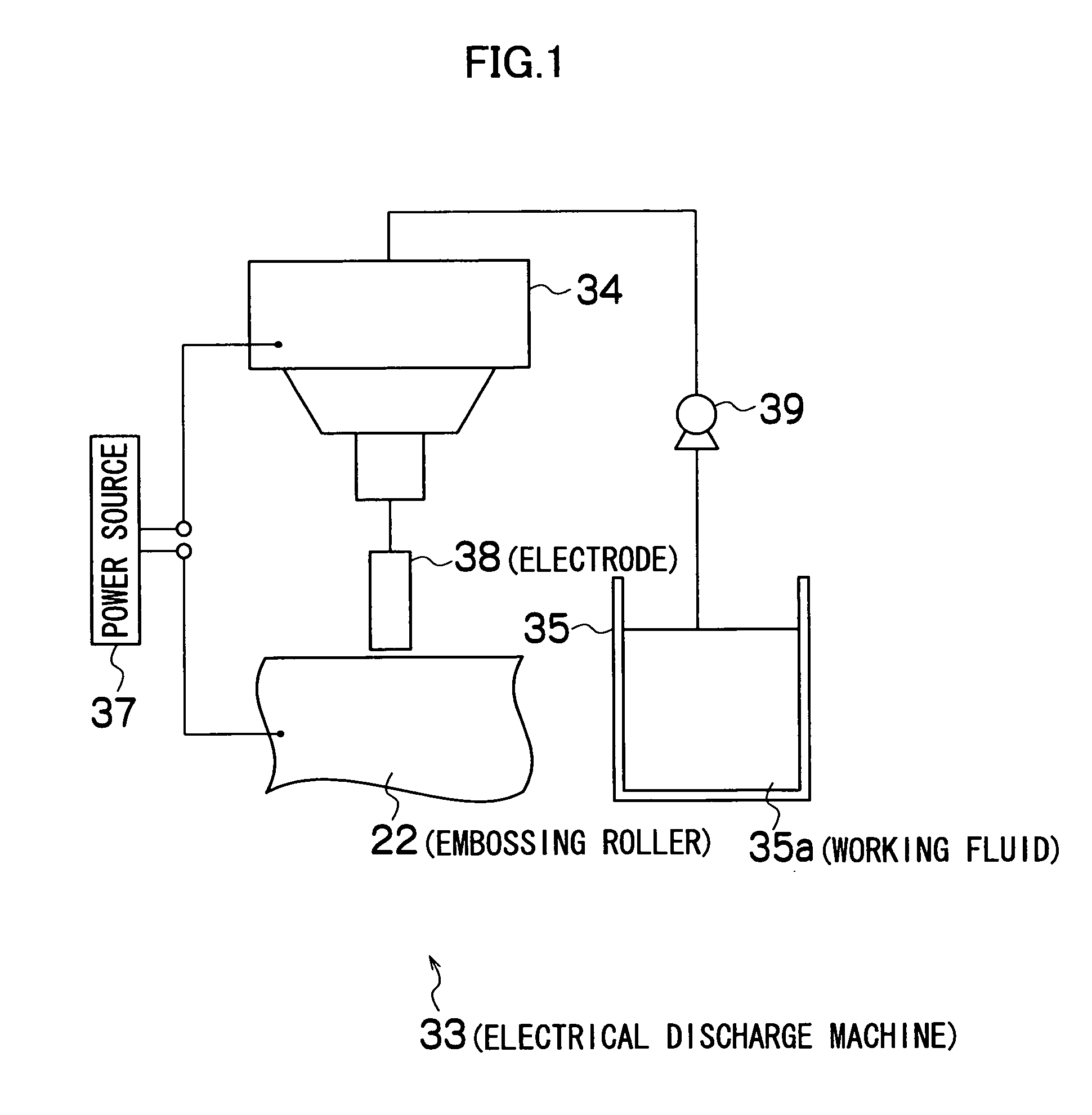

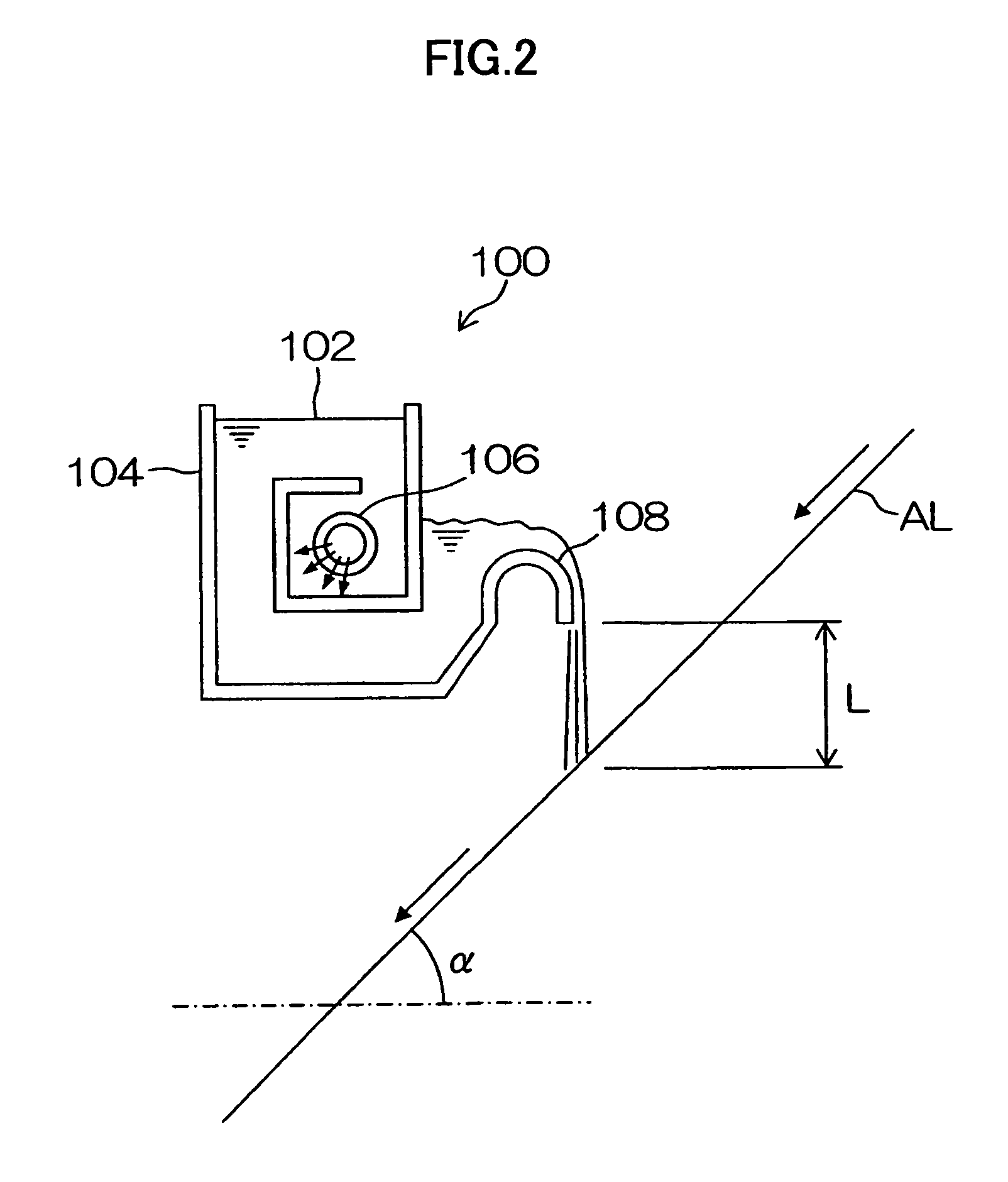

Method for providing surface texturing of aluminum sheet, substrate for lithographic plate and lithographic plate

InactiveUS20050258136A1Layered productsSurface reaction electrolytic coatingEngineeringAluminum substrate

According to the present invention, since the concavo-convex pattern of the embossing form is formed by electrical discharge machining, the peaks on the surface of the resultant embossing form are all of the same level or height, which enables the enhancement of the service life of the embossing form. Further, since the concavo-convex pattern of the embossing form is formed by electrical discharge machining, even a complicated and minute concavo-convex pattern can be formed. Accordingly, when applying the method of the present invention to, for example, the production of a substrate for a lithographic plate, an aluminum substrate for a lithographic plate which excels in plate wear, sensitivity and resistance to stains can be produced. And when applying the same to the production of an aluminum decorative laminate, an aluminum decorative laminate which excel in glossiness and paint adhesion can be produced.

Owner:FUJIFILM HLDG CORP +1

Coated pressing surfaces for abrasion resistant laminate and making laminates therefrom

A press plate for producing decorative laminate from resin impregnated paper, with alumina particles on its pressing surface, is coated with diborides selected from the group consisting of hafnium diboride, molybdenum diboride, tantalum diboride, titanium diboride, tungsten diboride, vanadium diboride, or zirconium diboride or mixtures thereof for making the press plate resistant to scratching. The preferred diborides are titanium and zirconium. The most preferred diboride is titanium. The color, gloss and surface appearance of laminate pressed with a titanium diboride coated press plate is substantially the same as laminate pressed with the press plate before coating.

Owner:WILSONART

Decorative solar control laminates

InactiveUS20070196630A1Decorative surface effectsDuplicating/marking methodsPolymer sciencePolymer chemistry

The present invention provides decorative laminates having the benefits of solar control laminates and processes for producing same. Laminates of the present invention comprise a polymer sheet having upper and lower surfaces, said sheet having a thickness of at least about 0.25 mm, said polymer having a modulus of between about 20,000 psi (138 MPa) and about 100,000 psi (690 MPa), as determined according to ASTM D 638-03, at least one of said surfaces of said sheet having disposed thereon an image, a film layer and, optionally, an adhesive composition, at least a portion of said adhesive composition being in contact with said image.

Owner:EI DU PONT DE NEMOURS & CO

Self-adhesive laminate and method of making it

InactiveUS20060062955A1High strengthSave materialLamination ancillary operationsDecorative surface effectsSolvent freeRoom temperature

A decorative laminate includes a laminate substrate coated with an adhesive layer. The adhesive layer is a layer of a physically setting, solvent-free adhesive material including an acrylic polymer. The adhesive layer is self-adhesive at room temperature. The adhesive-coated laminate substrate has a peeling-off force of at least 0.2 N / mm2, after application on a carrier. A method for the production of the adhesive-coated laminate substrate, its use as a coating material, and a composite of the adhesive-coated laminate substrate and a carrier material are also provided.

Owner:WILSONART

Decorative laminated safety glass utilizing a rigid interlayer and a process for preparing same

Owner:EI DU PONT DE NEMOURS & CO

Decorative laminate assembly and method of producing same

InactiveUS20060157195A1Improve wear qualityAvoid laborCovering/liningsLayered product treatmentWear resistantEngineering

A decorative laminate assembly having a decorative laminate top layer assembly. This top layer assembly includes, in descending superimposed relationship, a decorative layer and a core layer that includes PETG, or other polymeric material. Preferably, the top layer assembly also includes a wear resistant overlay layer on top of the decorative layer, and the core layer's PETG is in a sheet form. The top layer assembly may be directly bonded to a water resistant substrate. The decorative laminate assembly of the present invention can be used for a variety of purposes, including flooring applications. When the present invention is used for flooring applications, it is preferred that the overlay layer has enhanced wear resistant qualities and that the water resistant substrate comprise PVC or cement fiberboard.

Owner:LAURENCE KENNETH JOHN +3

Decorative laminated safety glass

InactiveUS20050271865A1Low viscosityLamination ancillary operationsDuplicating/marking methodsEngineeringDecorative laminate

The present invention is a decorative laminated article comprising an image bearing thermoplastic interlayer wherein the image has been printed on the interlayer using an ink jet printing process, wherein the pigment comprises at least one pigment selected from the group consisting of: PY 120; PY 155; PY 128; PY 180; PY 95; PY 93; PV19 / PR 202; PR 122; PB 15:4; PB 15:3; and PBI 7. The interlayer material of the present invention can be, for example, PVB, PET, or polyurethane.

Owner:EI DU PONT DE NEMOURS & CO

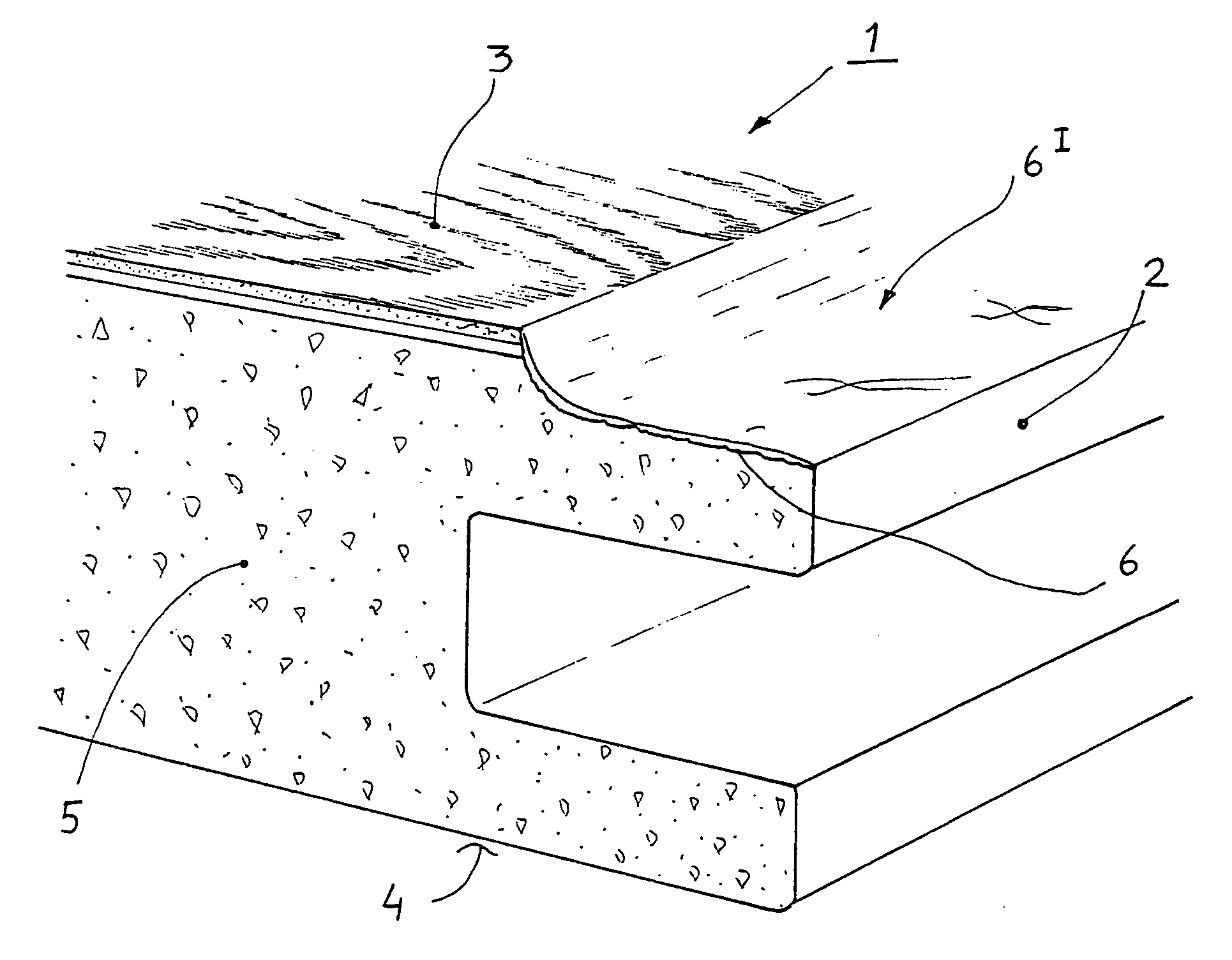

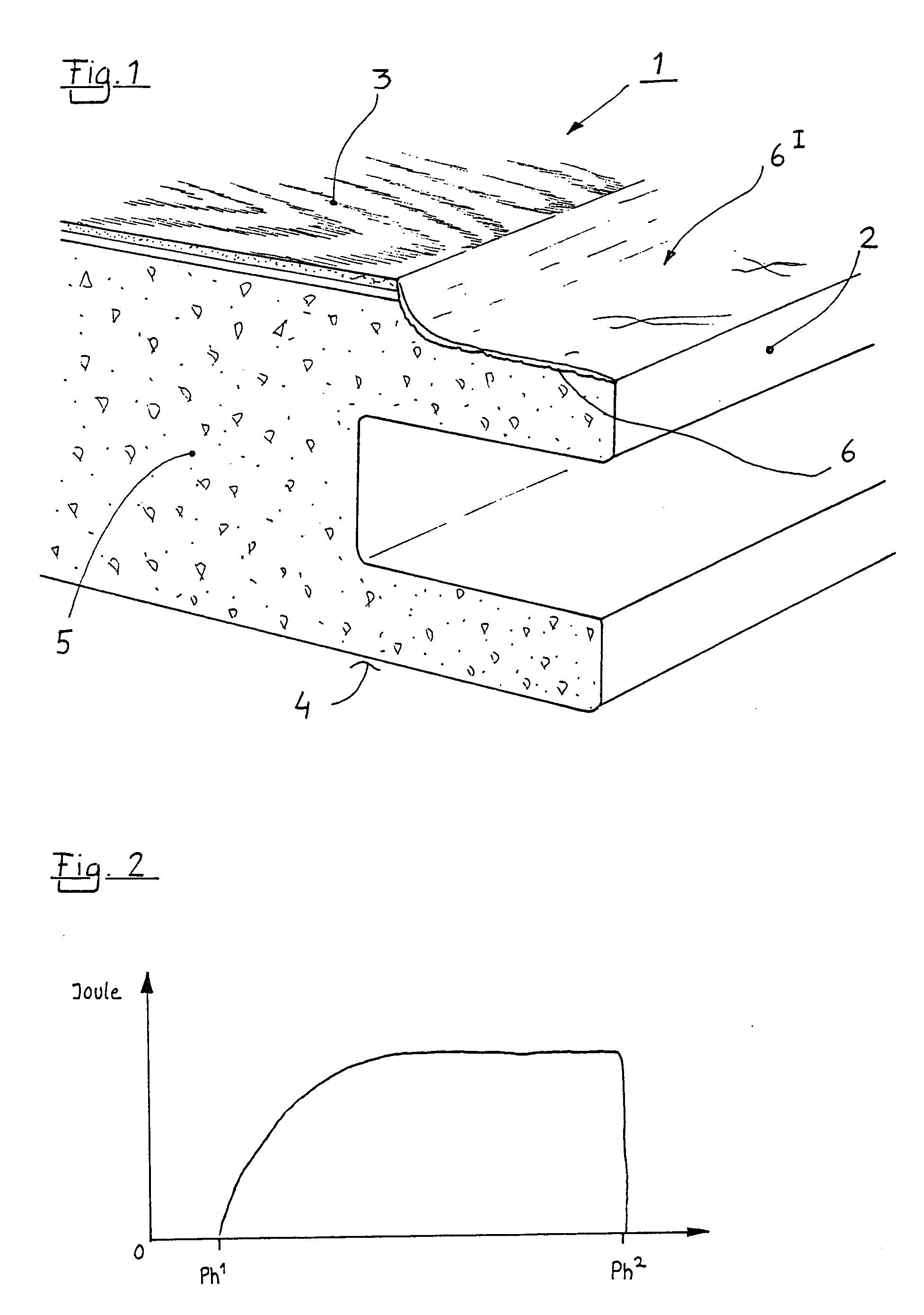

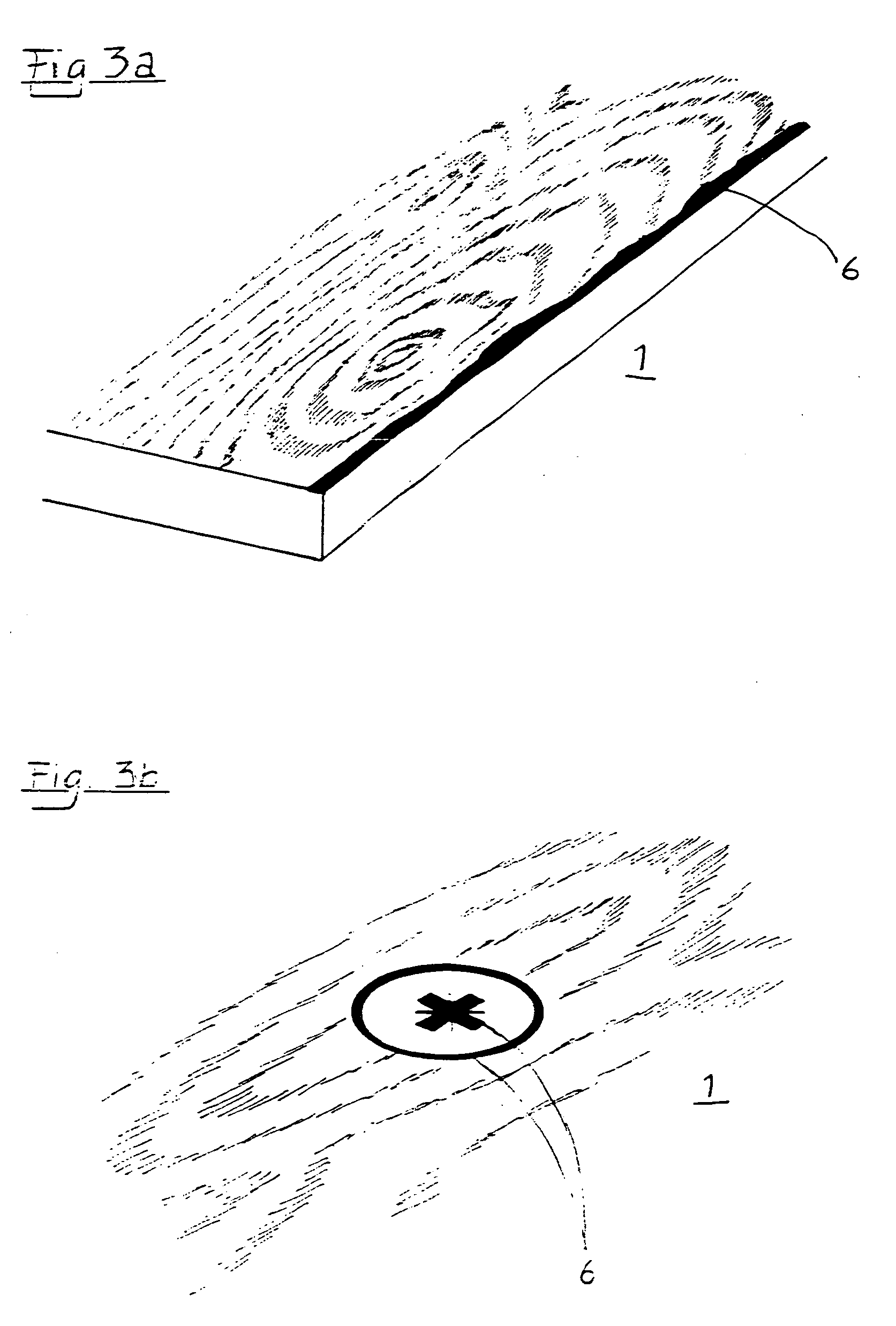

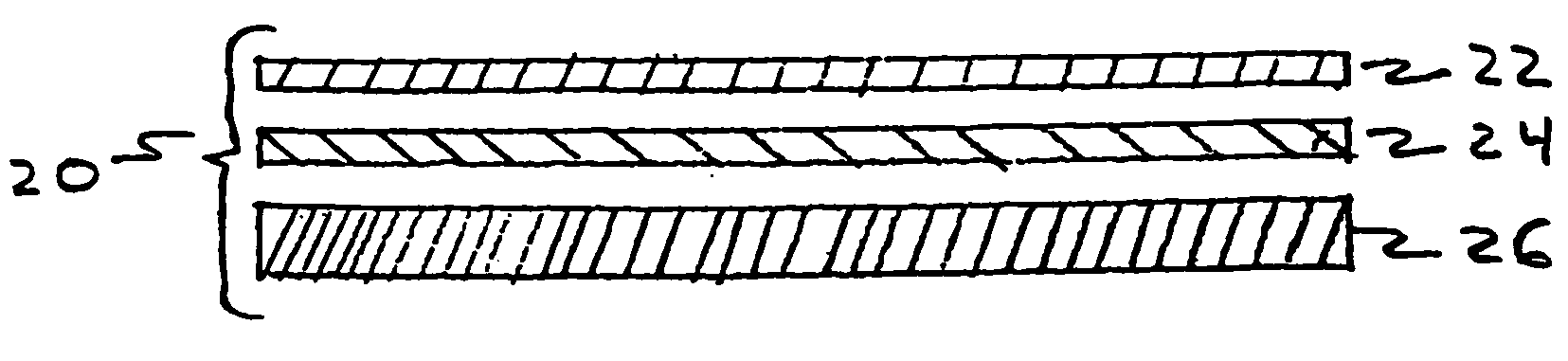

Decorative, low noise laminate equipped with a patterned balance layer formed by compression

InactiveUS20100021699A1Muffle sound levelReduce noise levelCovering/liningsDecorative surface effectsCelluloseLow noise

A decorative laminate, comprising an upper decorative layer and a carrying core. The upper side of the core is provided with the decorative layer and the lower side of the core is provided with a balance layer. The balance layer has the purpose of preventing warping of said decorative laminate and at the same time has the purpose of acoustic dampening. The balance layer comprises a polymer and cellulose said balance layer having a density in the range 30-300 kg / m3. A predetermined area portion of the balance layer is compressed so that the density is increased by a factor of 1.3 or more. Said increased density does not exceed the density 1100 kg / m3. The balance layer thereby forms at least one low density area and at least one high density area.

Owner:PERGO

Antimicrobial melamine resin and products

An antimicrobial melamine resin includes an antimicrobial agent incorporated therein. The melamine resin is useful for making melamine-based decorative laminate articles having a tough, mar-resistant antimicrobial surface and for molded melamine articles exhibiting antimicrobial properties.

Owner:MICROBAN PROD CO INC

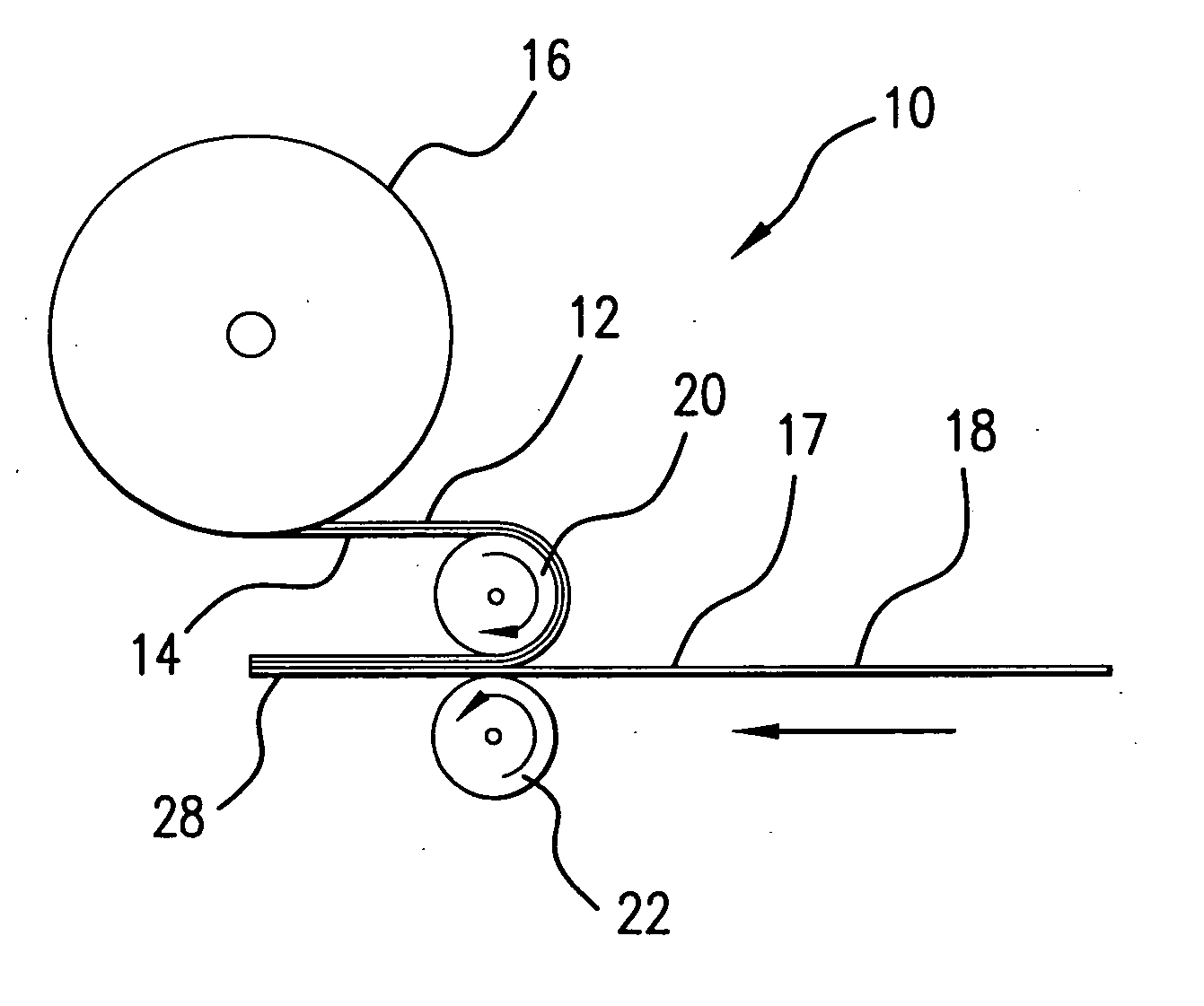

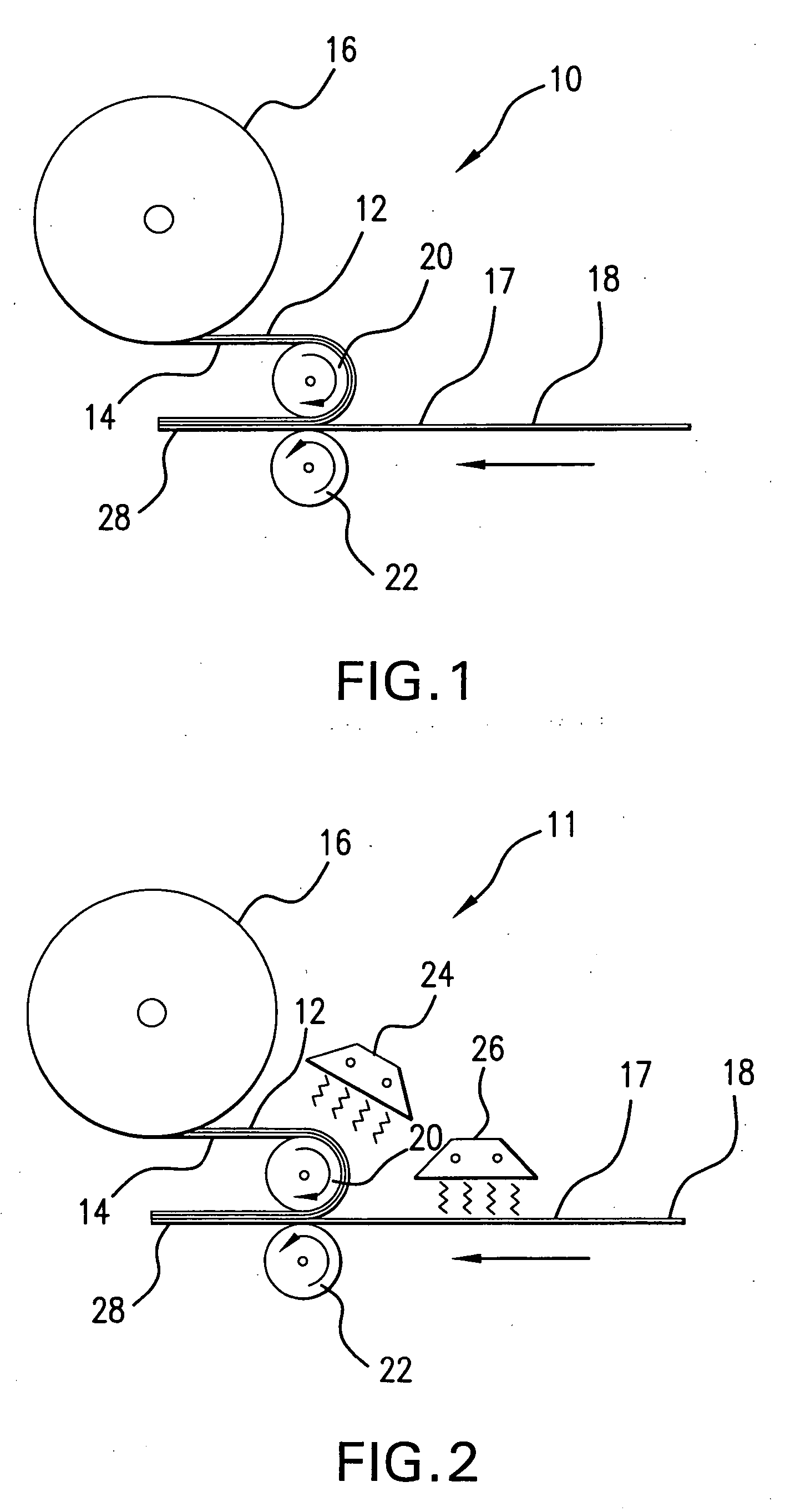

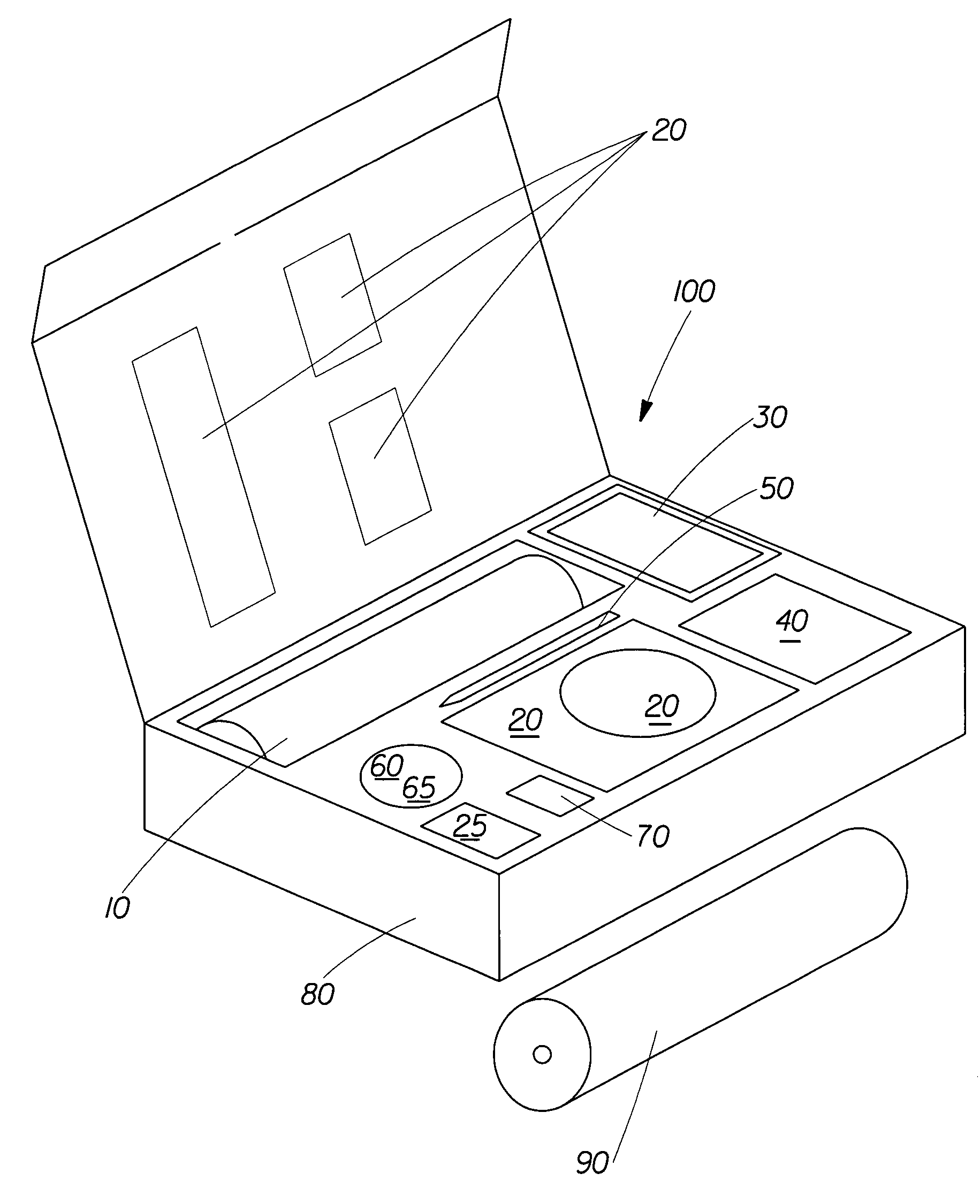

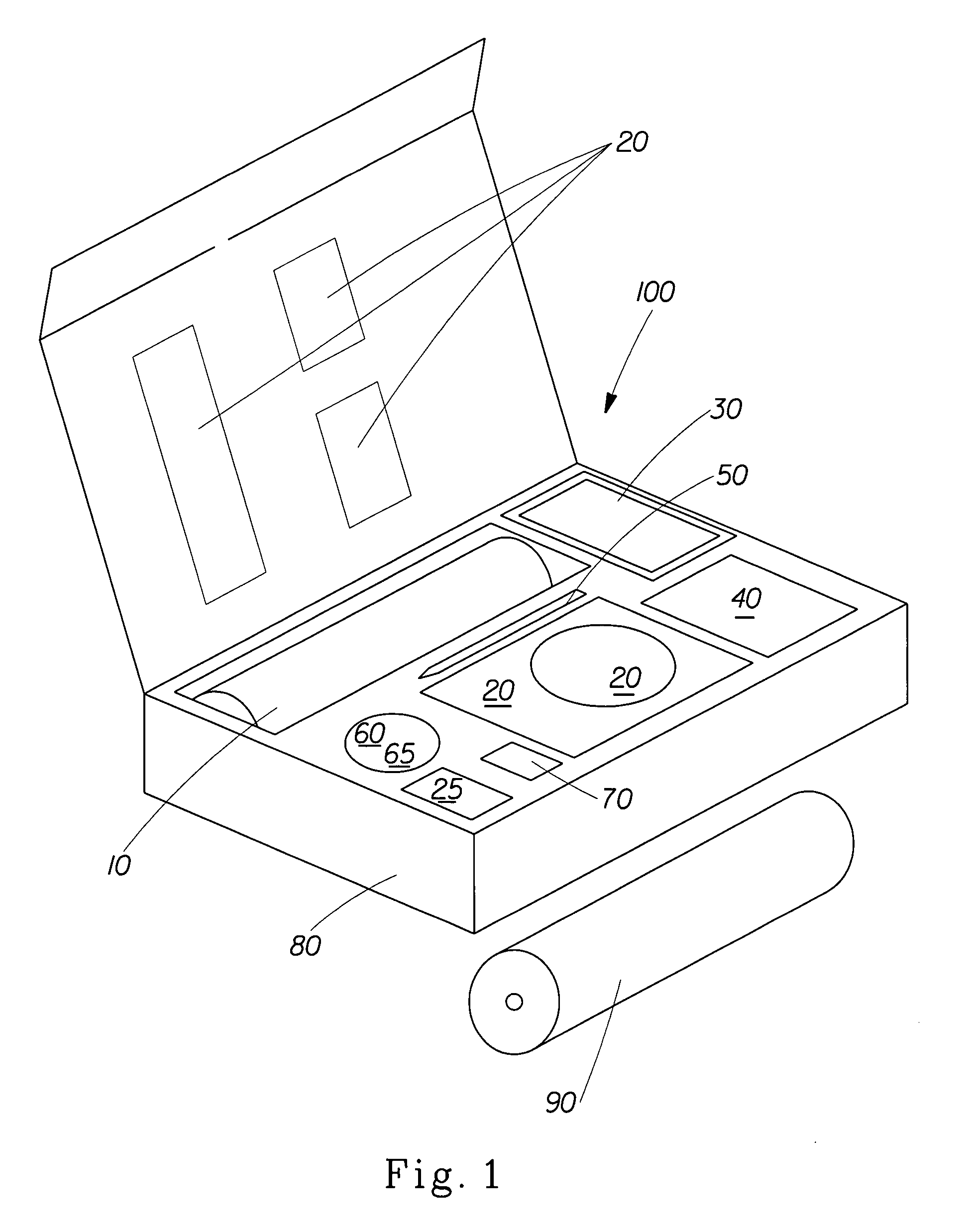

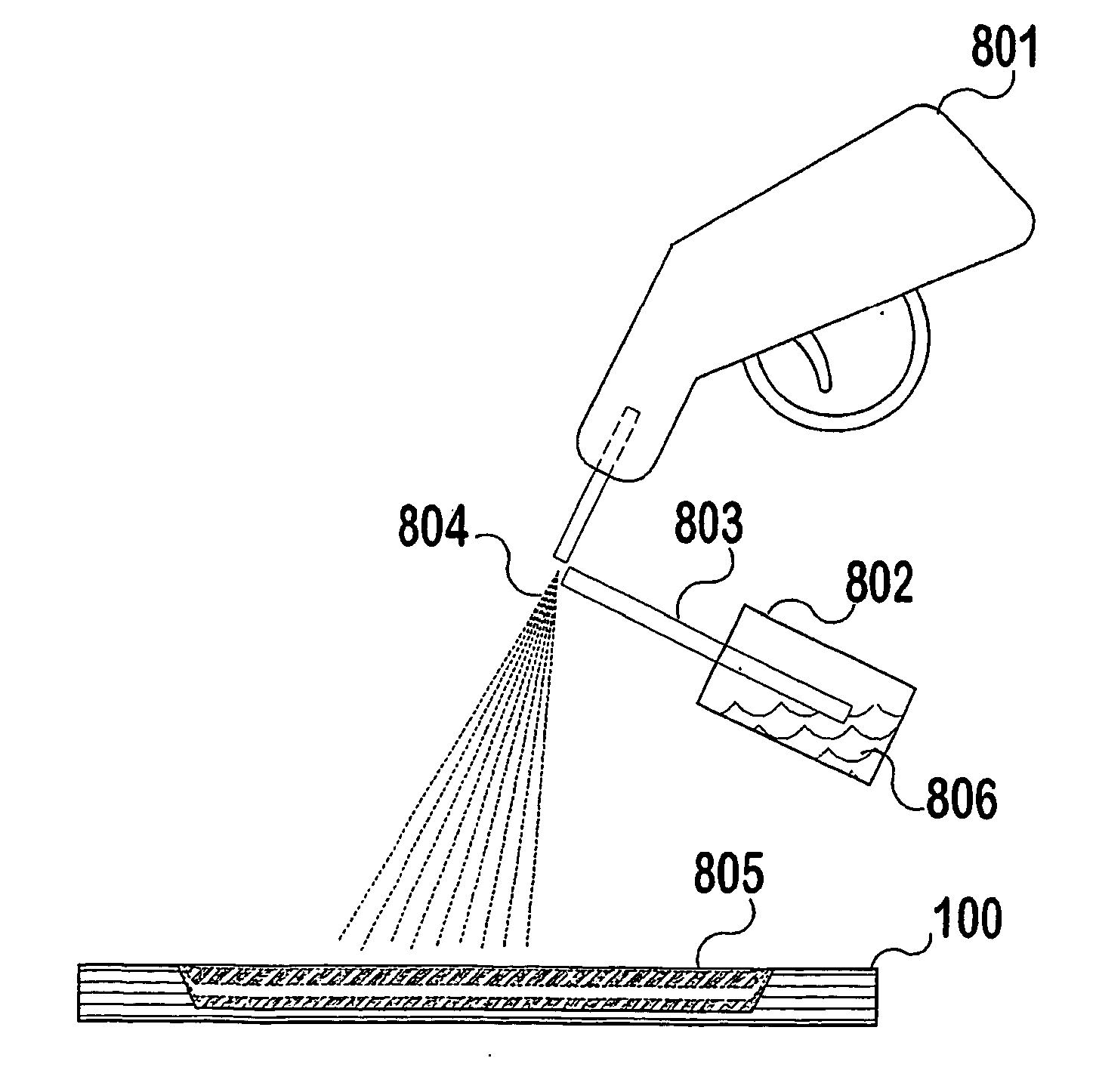

Kit for applying a decorative laminate to a target surface

InactiveUS20070205118A1Broaden applicationDecorative surface effectsPaperhangingTarget surfaceBiomedical engineering

A kit provides implements for applying a decorative laminate to a target surface. The kit comprises an applicator adapted to hold a roll of surface covering material and to apply the surface covering material to a target surface. The kit also comprises instructions for the application of a surface covering material to the target surface.

Owner:THE PROCTER & GAMBLE COMPANY

Through color high pressure decorative laminate and method of making same

InactiveUS20090155593A1Increase pressureAesthetically objectionableNon-fibrous pulp additionSpecial paperPolymer scienceFunctional monomer

A decorative laminate is provided and includes a core having a plurality of stacked paper sheets which are impregnated therein a melamine-formaldehyde resin and an internal plasticizer for the melamine-formaldehyde resin, the plasticizer comprising an amino-functional monomer; a decorative sheet overlying the core, the decorative sheet having impregnated therein a melamine-formaldehyde resin and an internal plasticizer for the melamine-formaldehyde resin; and, optionally, an overlay sheet on the decorative sheet. A combustion accelerant is also included in the resin.

Owner:THE DILLER

Multi-colored decorative laminate

InactiveUS20080044677A1More balanced constructionKeep it flatCovering/liningsSynthetic resin layered productsCardboardPhotoluminescence

A decorative laminate includes a core layer, a decorative layer and an optional overlay layer. The core layer includes one or more resin impregnated paper sheets. The decorative layer includes a dry paper sheet (i.e., one without any resin impregnation). A plurality of geometric patterns is printed on the decorative paper sheet with photoluminescent material of different colors, where the resulting patterns of different colors are simultaneously visible when exposed to ultraviolet light. The optional overlay layer includes one or more resin impregnated paper sheets. The decorative layer paper sheet is stacked with the core layer and the optional overlay layer, when utilized, and laminated under heat and pressure to form the decorative laminate.

Owner:PANOLAM INDS INT

Decorative laminated safety glass

InactiveUS20050048229A1Duplicating/marking methodsLight effect designsEngineeringDecorative laminate

The present invention is a decorative laminated article comprising an image bearing thermoplastic interlayer wherein the image has been printed on the interlayer using an ink jet printing process, wherein the pigment comprises at least one pigment selected from the group consisting of: PY 120; PY 155; PY 128; PY 180; PY 95; PY 93; PV19 / PR 202; PR 122; PB 15:4; PB 15:3; and PBI 7. The interlayer material of the present invention can be, for example, PVB, PET, or polyurethane.

Owner:EI DU PONT DE NEMOURS & CO

Process for manufacturing decorative laminated wired tempered glass shower rooms

The invention discloses a tempered glass shower room, and particularly relates to a process for manufacturing decorative laminated wired tempered glass shower rooms. The process includes steps of determining the thickness of glass; cutting the glass; severing the edges of the glass; polishing the edges of the glass; forming mounting holes in the glass; cleaning and drying the glass; tempering the glass; tempering heat-bent glass; performing semi-tempering on the glass; processing the glass by the aid of a homogenizing technology; clamping wires and adhesive in the glass; softening the glass by means of rolling; forming the shower rooms by the aid of high-pressure vessels. The process for manufacturing the decorative laminated wired tempered glass shower rooms has the advantage that the quality of products and service effects can be improved.

Owner:HANGZHOU HUIQUAN DECORATIVE MATERIAL PROD CO LTD

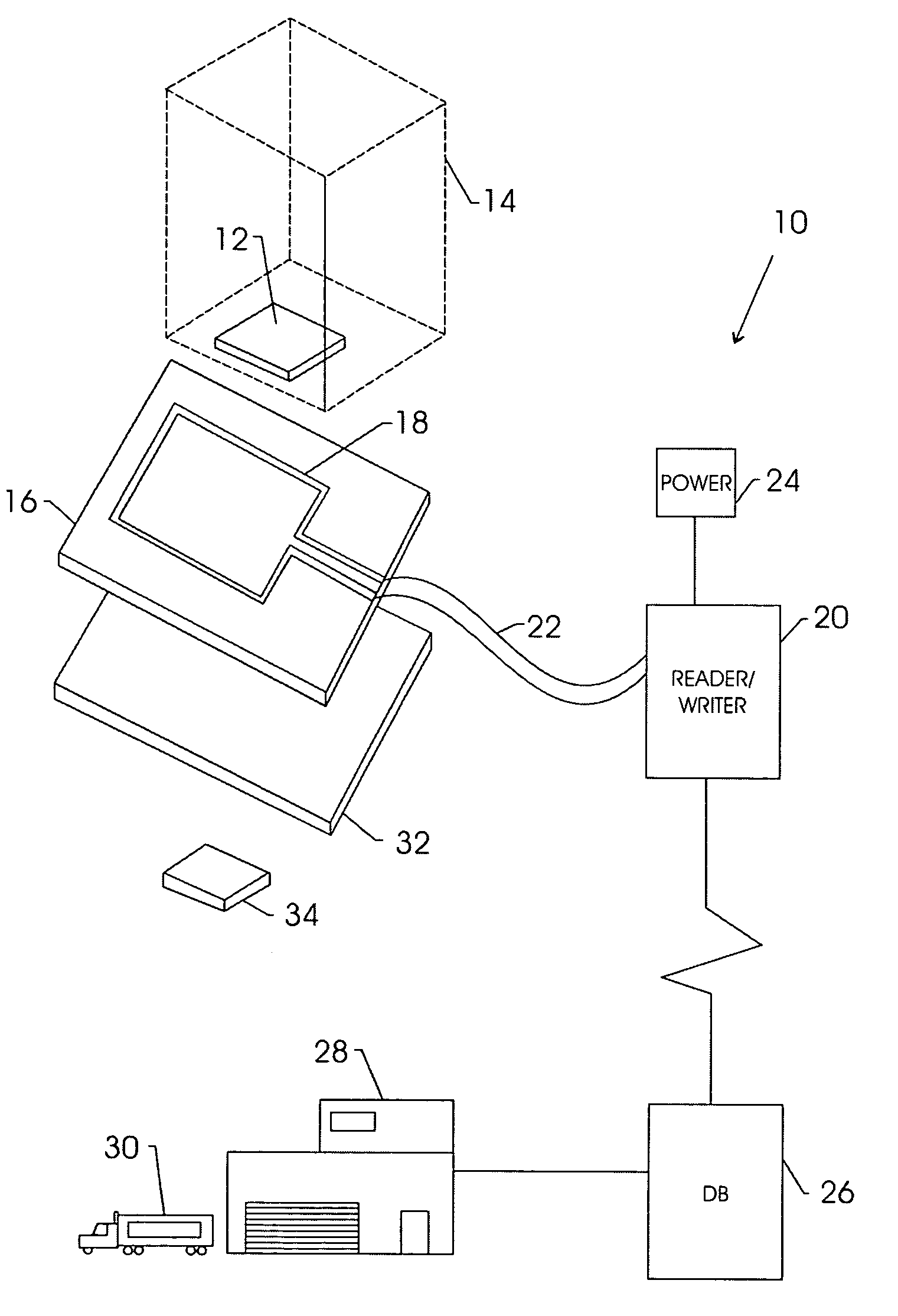

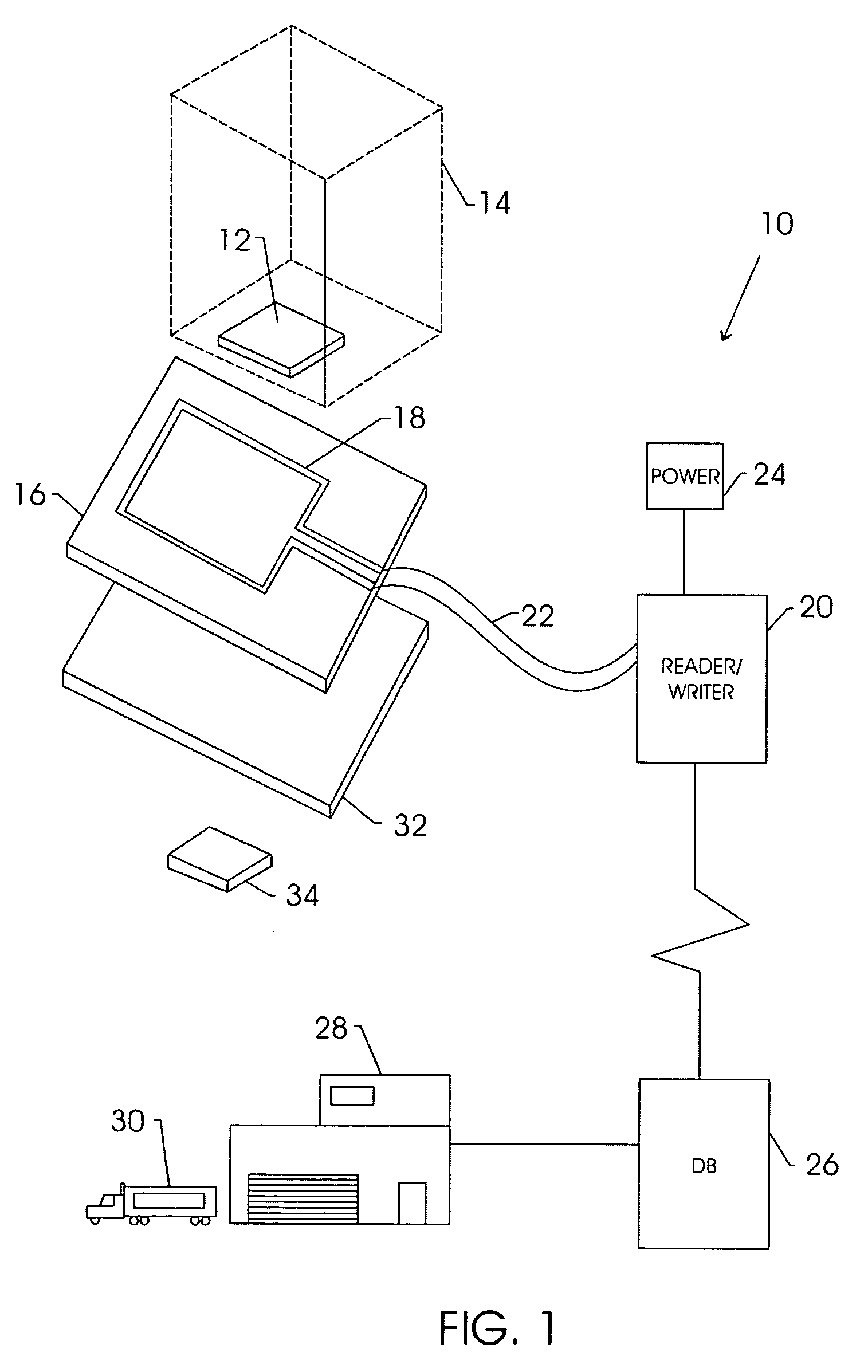

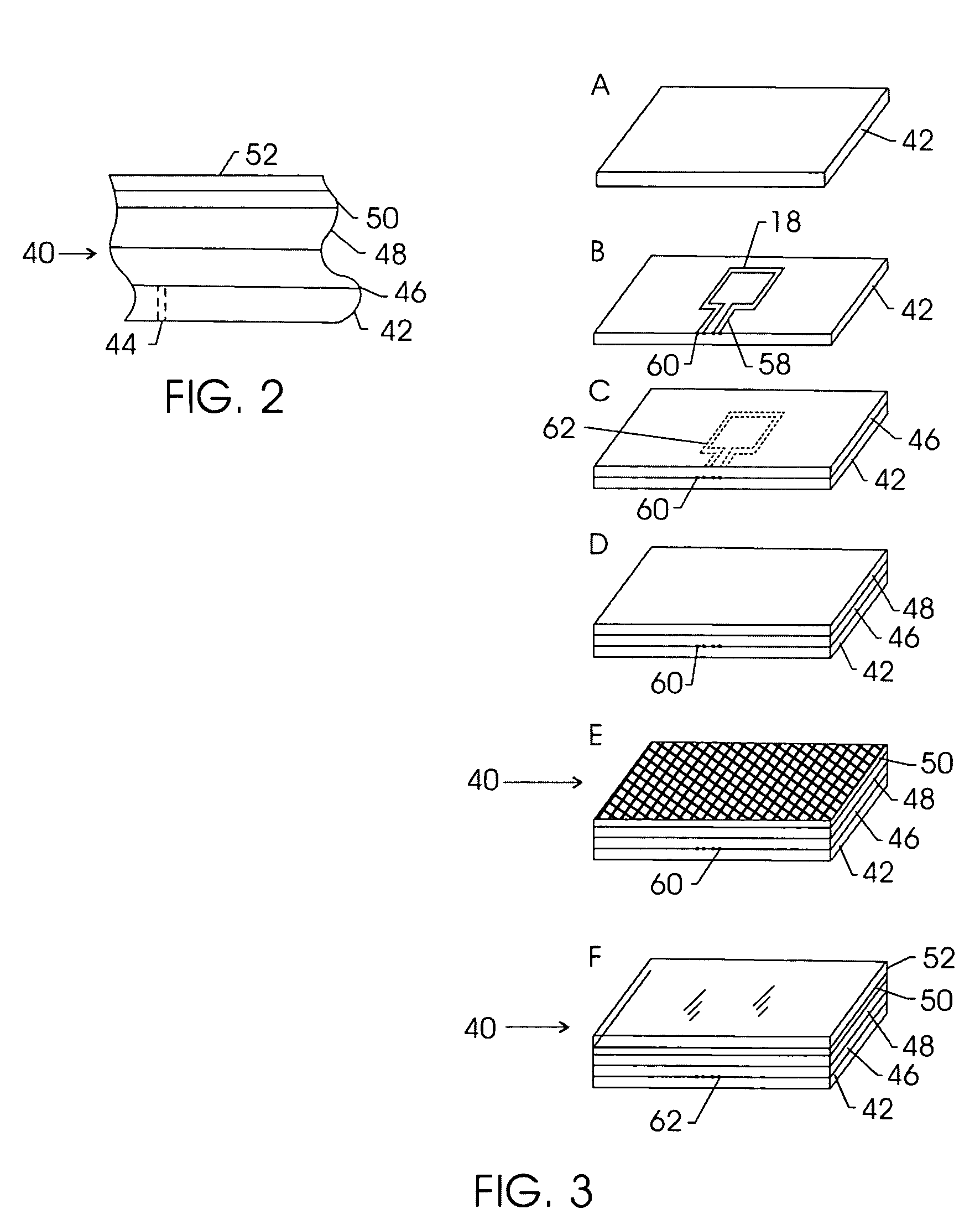

Decorative surface covering with embedded RF antenna and RF shield and method for making the same

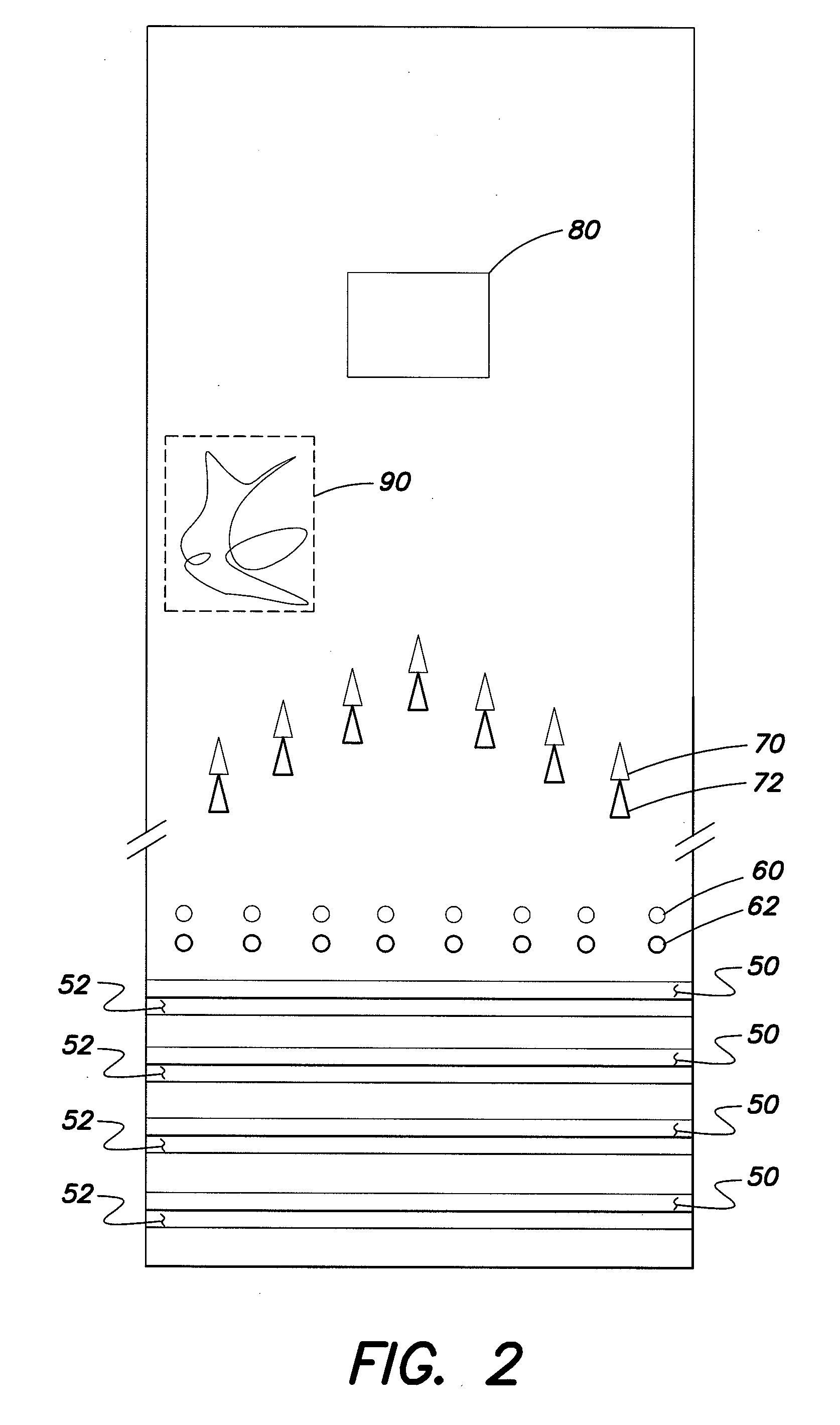

ActiveUS7209039B2Decorative surface effectsRadiating elements structural formsHigh pressureSurface cover

A technique is provided for printing an RFID antenna using conductive ink on a substrate and incorporating that substrate as a layer in a decorative surface such as a high pressure decorative laminate. In addition, a technique is provided for incorporating a conductive mesh into a surface, such as a high pressure decorative laminate, to form an RFID shield which prevents stray signals from reaching an RFID antenna. A technique is also provided for integrating both a printed antenna and conductive mesh shield into a single surface, such as a decorative surface, to allow the reading of desired RFID tags while preventing the reading of undesired RFID tags.

Owner:WILSONART

Method of producing decorative paper and decorative laminate comprising such decorative paper

The invention relates to a method of producing decorative paper which is coated with at least one ink-fixing layer, which is printable and which can be impregnated with a thermosetting resin, in order to produce a high- or low-pressure decorative laminate. The inventive method comprises the following steps consisting in: (a) producing a base sheet of decorative paper using paper-making means; and (b) coating at least one of the faces of the base paper sheet with said at least one ink-fixing layer, by means of curtain coating. The invention also relates to high- or low-pressure decorative laminates comprising such decorative paper.

Owner:MUNKSJOE ARCHES

Building external wall furring brick decorative plate

ActiveCN103408268AEasy to operateImprove efficiencyCovering/liningsCeramic shaping apparatusBrickCrack resistance

The invention discloses a building external wall furring brick decorative plate. Currently, external wall decorative plate researches are focused on functional respective of thermal insulation, crack resistance, flame prevention, and the like. However, the decorative function, except change in color, is not shown. According to the invention, glass fiber mesh cloth or synthetic fiber non-woven fabric cloth is adopted as an enhancing mesh cloth; cement mortar, re-dispersible powder or alkali-resistant elastic latex, synthetic staple fiber, and cellulose ether are prepared into a composite slurry; the slurry is pressed into a base blank; and furring tiles are adhered to the base blank, such that the furring brick decorative plate is prepared. According to the invention, the adhesion work for adhering small tiles on the external wall is changed into the adhesion work of large plates, such that operation is simplified. The decorative plate has the advantages of a decorative plate. Also, tiles of different patterns, colors, and sizes can be adhered, such that appearance and practicality are both taken into consideration. The base blank is prepared by using the composite slurry and the enhancing mesh cloth, such that the decorative plate has excellent crack resistance, tensile resistance, and light weight in the physical respect.

Owner:黑龙江华新保温材料有限公司

Preparation method of high-light-resistant titanium dioxide pigment for laminated paper

ActiveCN109705630AImprove retentionGood dispersant effectInorganic compound additionPigment treatment with non-polymer organic compoundsALUMINUM PHOSPHATESlurry

The invention provides a preparation method of a high-light-resistant titanium dioxide pigment for laminated paper. The method comprises the following steps: preparing titanium dioxide slurry from a rutile-type titanium dioxide initial product prepared by adopting a chlorination process method, and adjusting the pH value to 8.5-10.5; adding a citric acid radical-containing organic substance as a dispersing agent, and performing grinding treatment; performing heating to 55-65 DEG C for coating treatment, performing coating by using a dense aluminum phosphate coating layer, performing coating byusing a loose silicon aluminum compound coating layer, and performing coating by using a loose boehmite-type hydrated aluminum oxide coating layer; performing washing by using deionized water until conductivity of a filter cake is greater than 15000 omega*cm, and performing drying; and adding amino-containing organic matter in the steaming powder process, and performing organic coating treatmentto obtain the titanium dioxide pigment for the decorative laminated paper. The method provided by the invention has the advantages that the titanium dioxide pigment prepared by the method has the characteristics of high light performance, good whiteness and a high retention rate in the laminated decorative paper, and the prepared titanium dioxide pigment has a medium color bottom phase and the advantage of easy color matching, and can be widely used in the field of the high-end laminated decorative paper.

Owner:中信钛业股份有限公司

Wood veneer surfaced decorative laminate product and method of making same

InactiveUS20080268273A1Readily wetLow viscositySynthetic resin layered productsPretreated surfacesEngineeringMoisture resistance

A wood veneer surfaced laminate and method of making it are provided which produces a product having the appearance of a natural wood product, but with the toughness, moisture resistance, stain resistance, impact resistance, and abrasion resistance of melamine resin surfaced laminate products. The wood veneer surfaced laminate is made by providing a sheet of a natural or engineered wood veneer; impregnating the sheet with a first liquid curable resin such that said liquid resin substantially completely impregnates the sheet; coating a second liquid curable resin onto a surface of the sheet; laminating the sheet to a core while curing the resins to form a natural or engineered wood veneer surfaced laminate.

Owner:THE DILLER

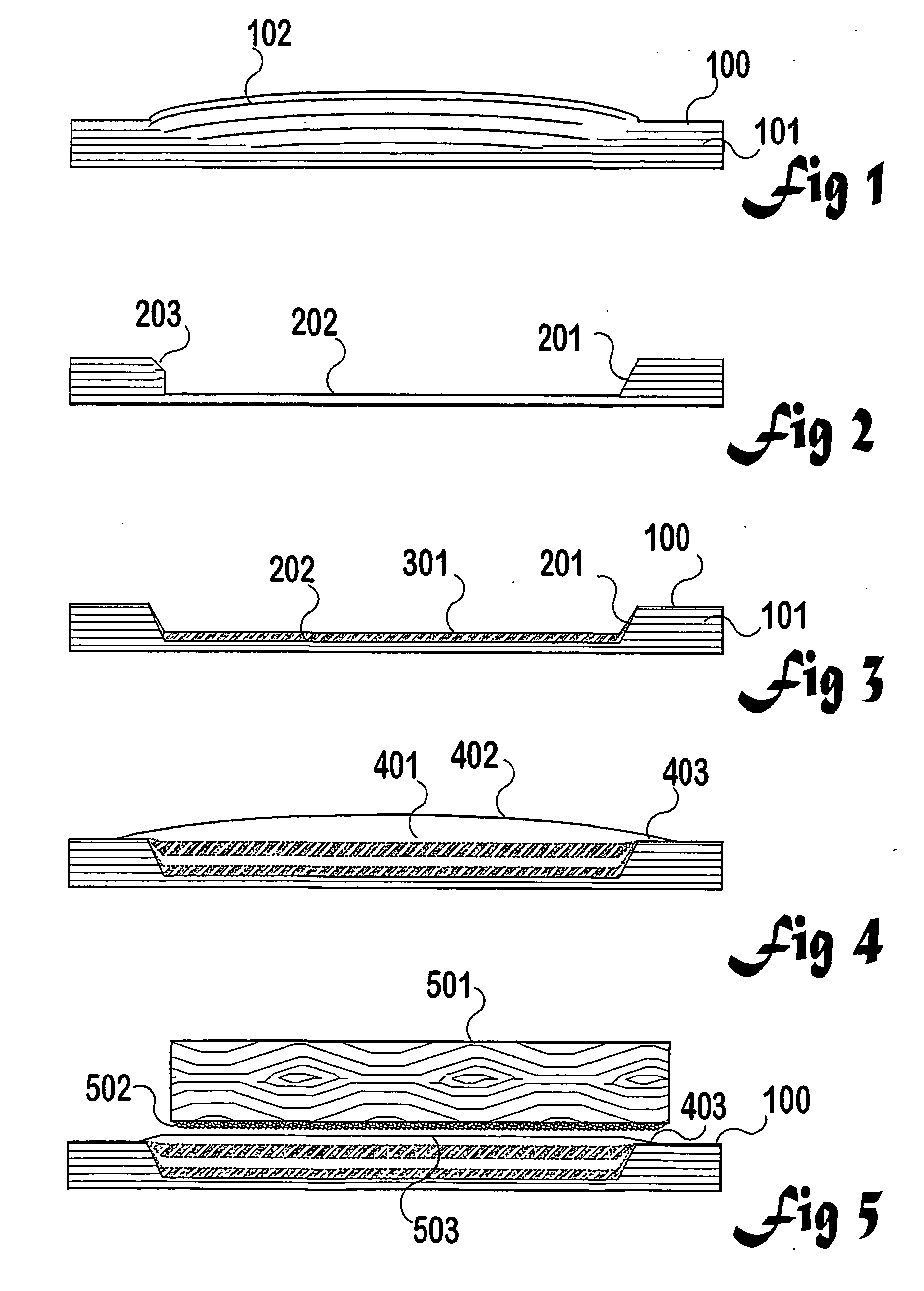

Method for restoring a plastics surface

InactiveUS20040131769A1Reducing height of surfaceReduce the overall heightLayered productsPretreated surfacesCyanoacrylateEngineering

A method for repair of a defect in a thermoset decorative laminate comprises (a) debridement of damaged material to below the level of the adjacent surface, (b) replacement of the lost mass with layers of cyanoacrylate, or a two-part filler for deep defects, (c) surface flattening, (d) colouring and patterning of the surface, and (e) coating the surface of the defect with a material giving a similar texture, so that the adjacent surface appearance is matched. Applications include kitchen bench repairs where the surface has been damaged by heat, and defects in other non-metallic surfaces.

Owner:SAXON GEORGE BERNARD

Decorative laminates incorporating flame retardant engineering thermoplastic films

ActiveUS20100272976A1Synthetic resin layered productsConstructions elementsSurface layerDecorative laminate

A decorative laminate that contains at least three layers that include a surface layer, a backing layer and a color layer positioned between the surface and backing layers. The surface layer or backing layer or both are made of flame retardant engineering thermoplastic materials.

Owner:SCHNELLER

Nonwoven decorative laminates and methods of making the same

ActiveUS20160089851A1Big advantageLamination ancillary operationsDecorative surface effectsEngineeringNonwoven fabric

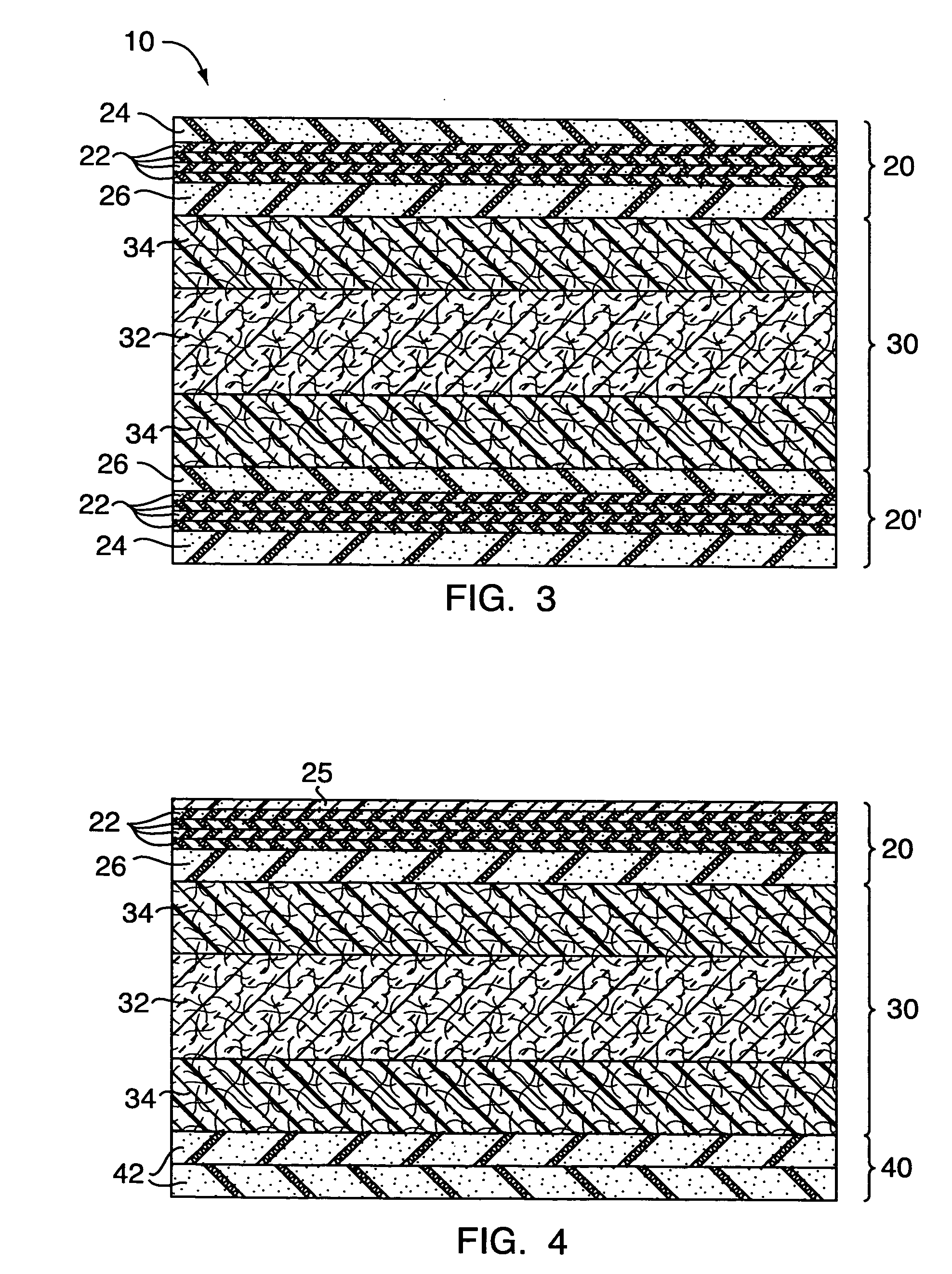

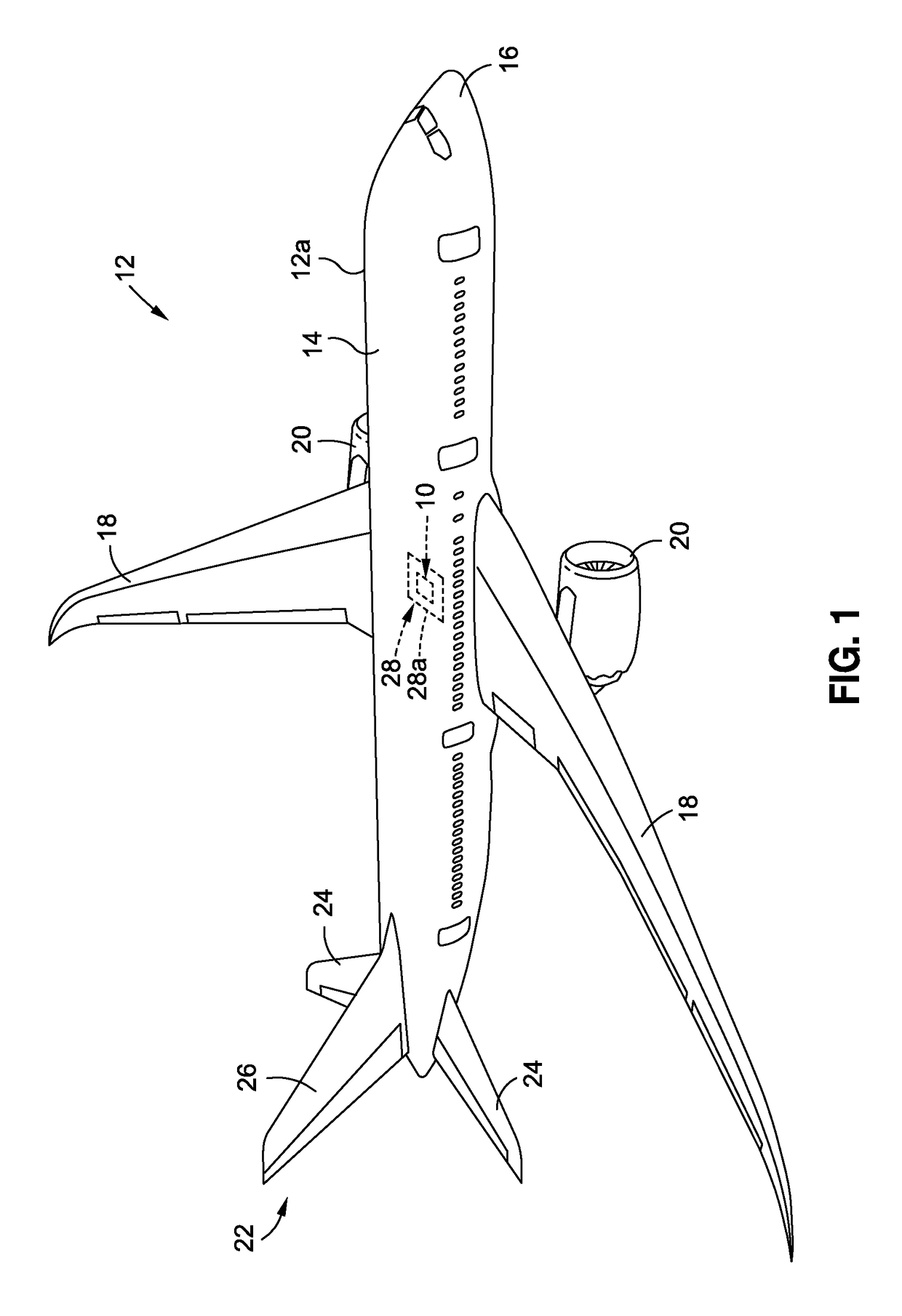

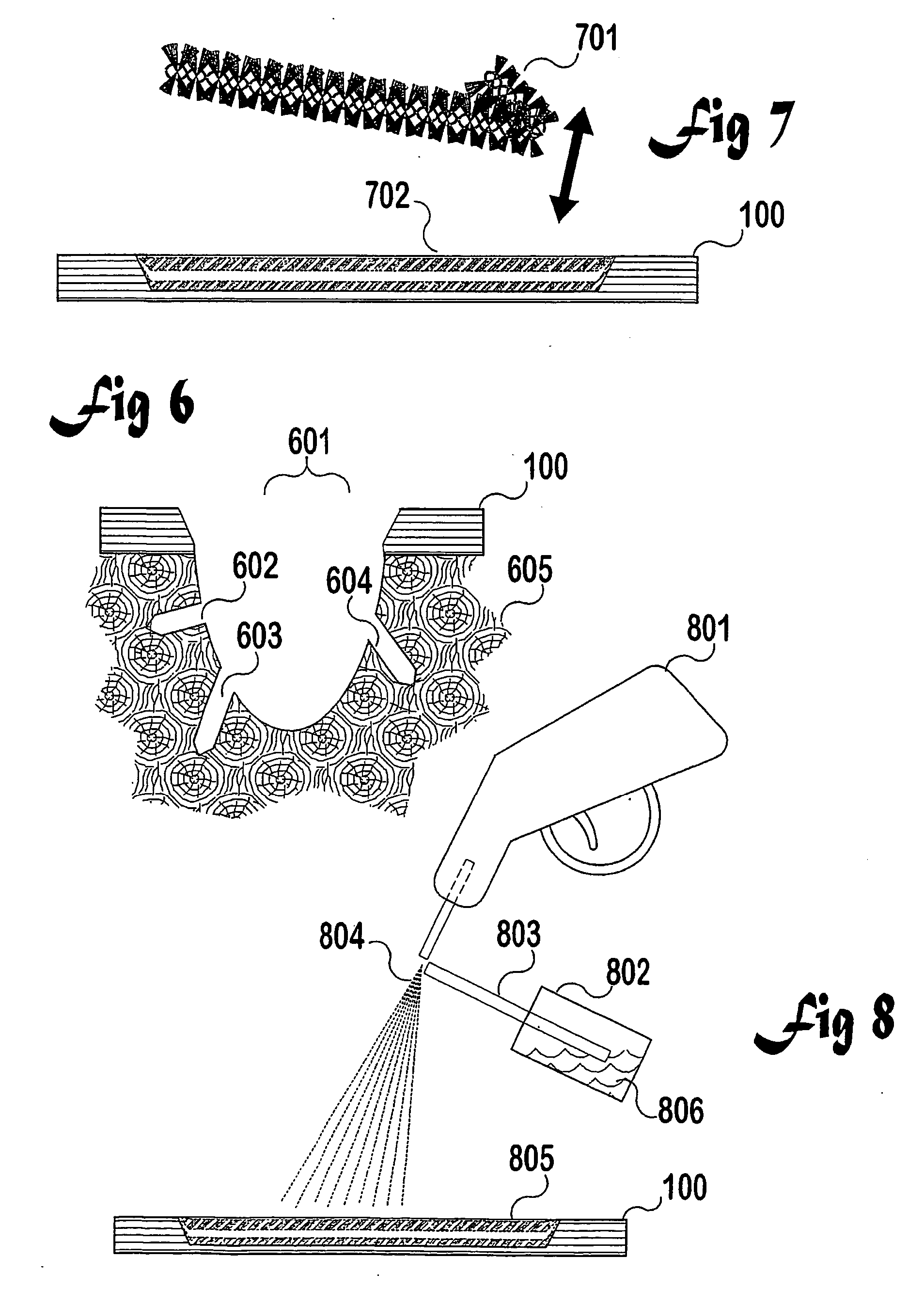

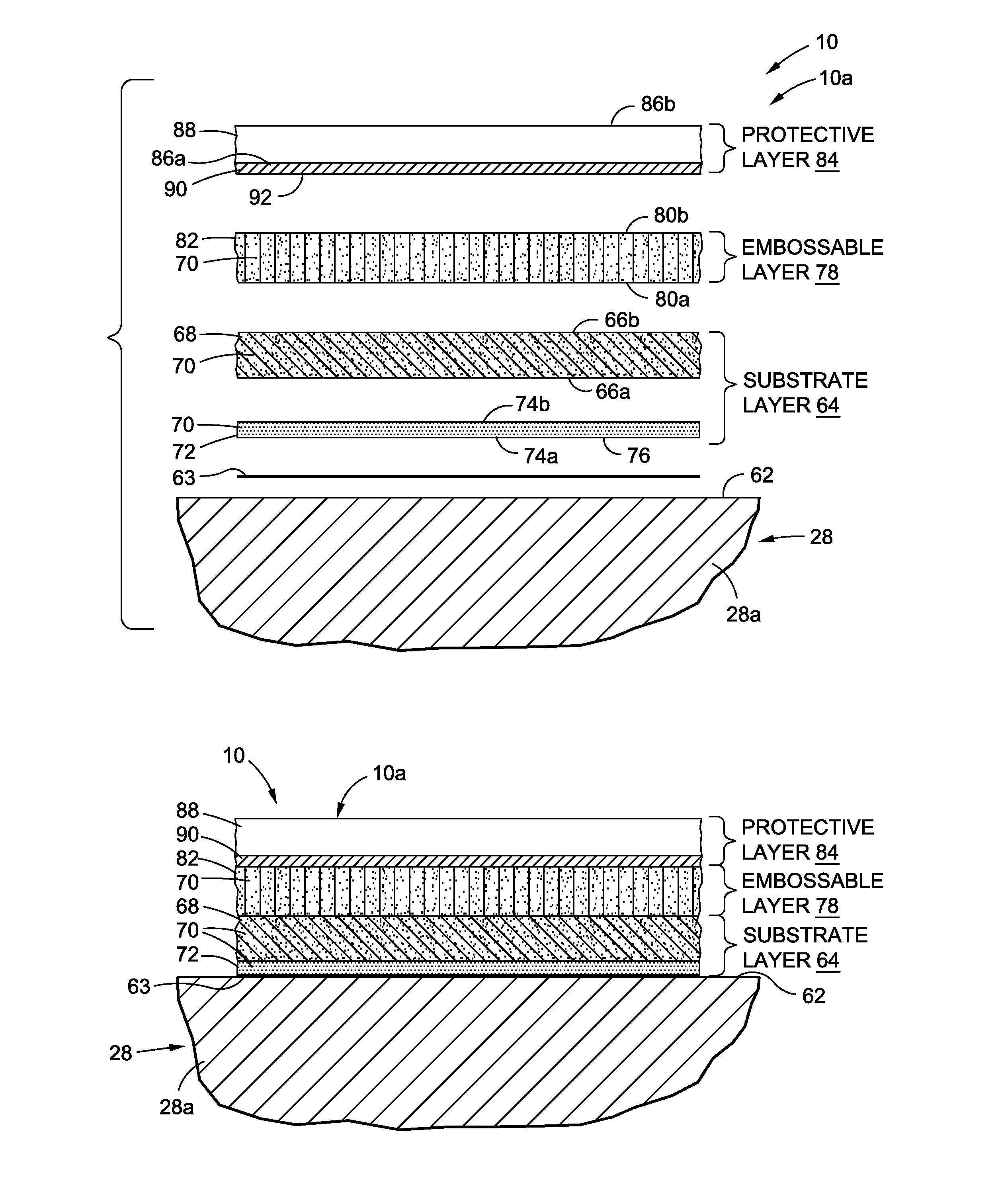

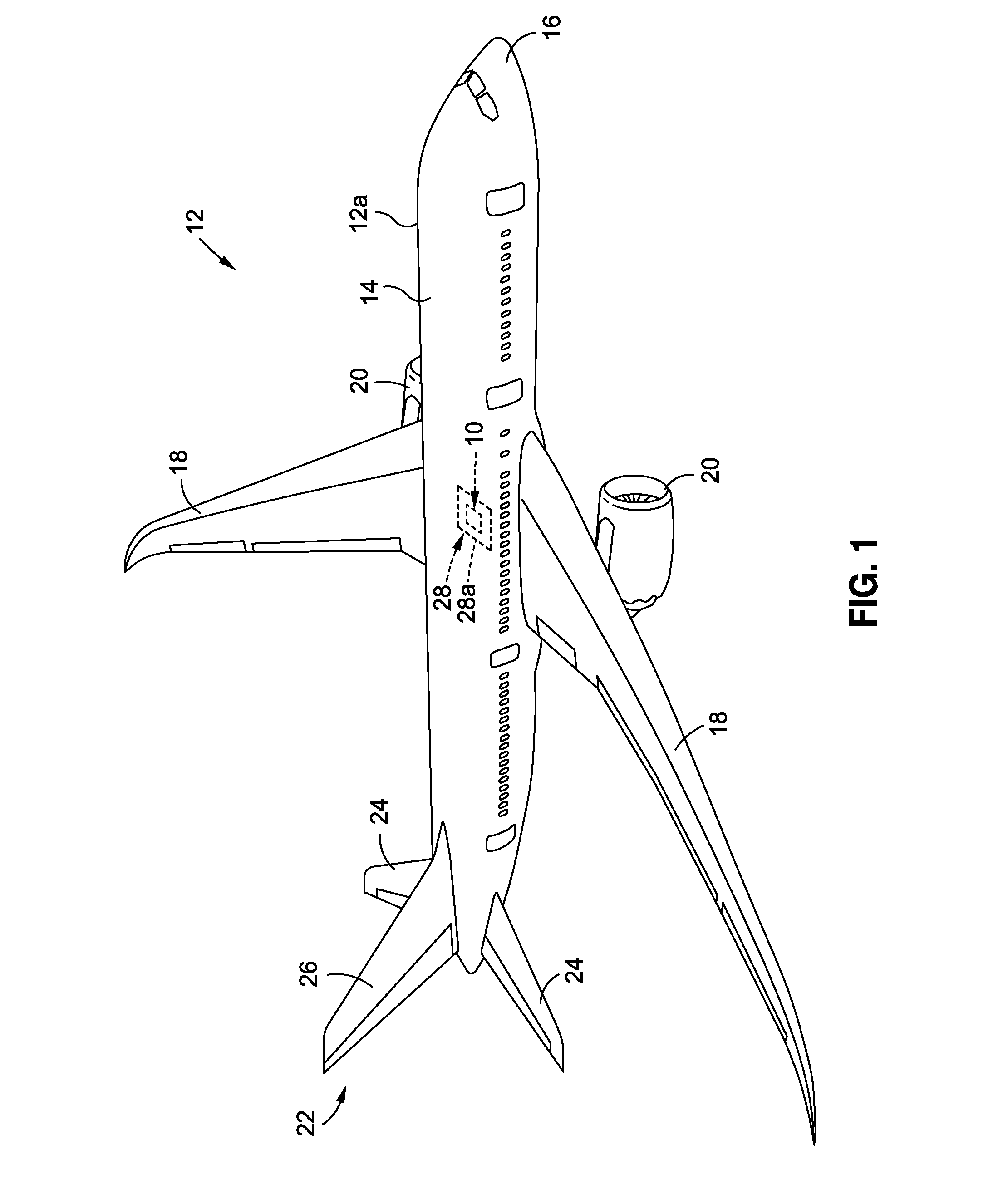

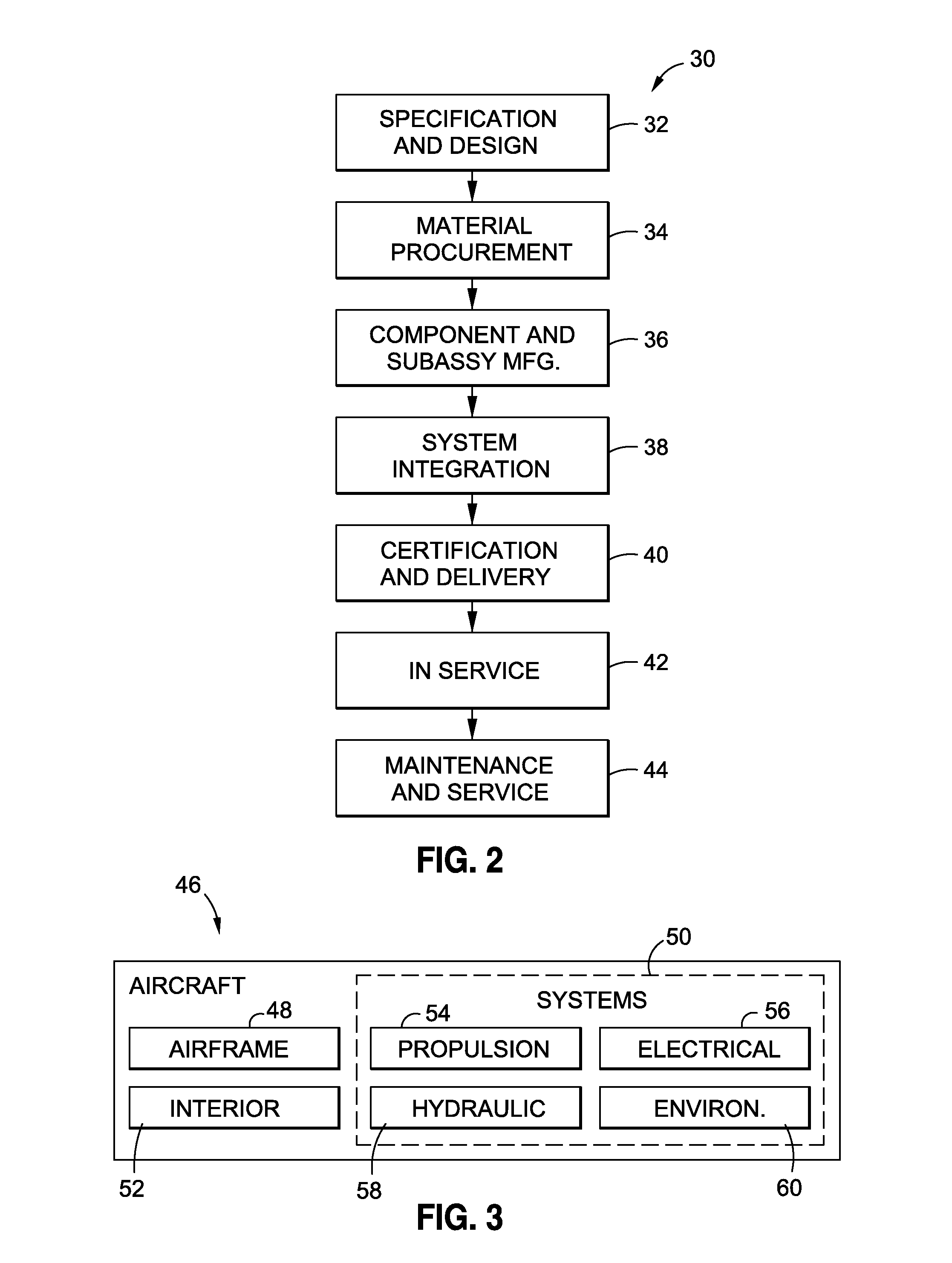

A decorative laminate for application to a structural component is provided. The decorative laminate has a substrate layer of a nonwoven fabric material with or without a flame retardant material. The decorative laminate further has an embossable layer disposed upon the substrate layer. The embossable layer includes an embossing resin material and the flame retardant material. The decorative laminate further has a protective layer disposed upon the embossable layer. The protective layer includes a polyvinyl fluoride-based material and has a decorative material printed on a first side of the protective layer facing the embossable layer. An adhesive layer is applied to the substrate layer of the decorative laminate. The decorative laminate is applied to the structural component with the substrate layer facing a bonding surface of the structural component and with an adhesive layer applied between the decorative laminate and the bonding surface of the structural component.

Owner:THE BOEING CO

Fireproof plate and manufacturing process thereof

InactiveCN101736873AWith fire resistanceNon-spontaneous combustionCovering/liningsLaminationSpontaneous combustionEngineering

The invention discloses a fireproof plate and a manufacturing process thereof. The fireproof plate comprises a substrate; the surface of the substrate is compounded with a decorative layer; and the substrate is a door plate main body which is made of a fireproof base material plate. The manufacturing process for the fireproof plate comprises the following steps: a, manufacturing the fireproof base material plate in a required dimension, making the surface flat and smooth, and manufacturing the fireproof base material plate into the door plate main body; b, after coating a bonding agent on the surface of the door plate main body which is obtained in the step a, attaching the decorative layer and pressing the decorative layer by a compression roller; and c, molding through a heat pressure machine or a vacuum forming machine to manufacture a finish product. The fireproof plate has the characteristics of wide application, low cost, good decorative effect, capacity of preventing and stopping fire and non spontaneous combustion.

Owner:杨建文

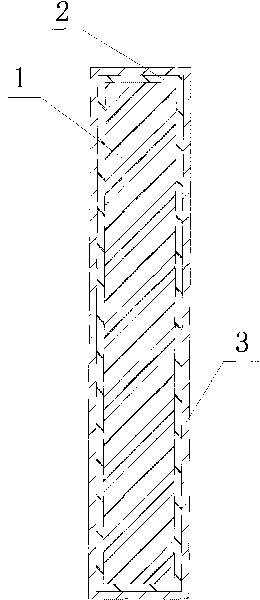

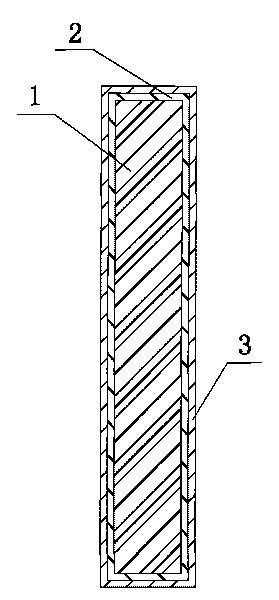

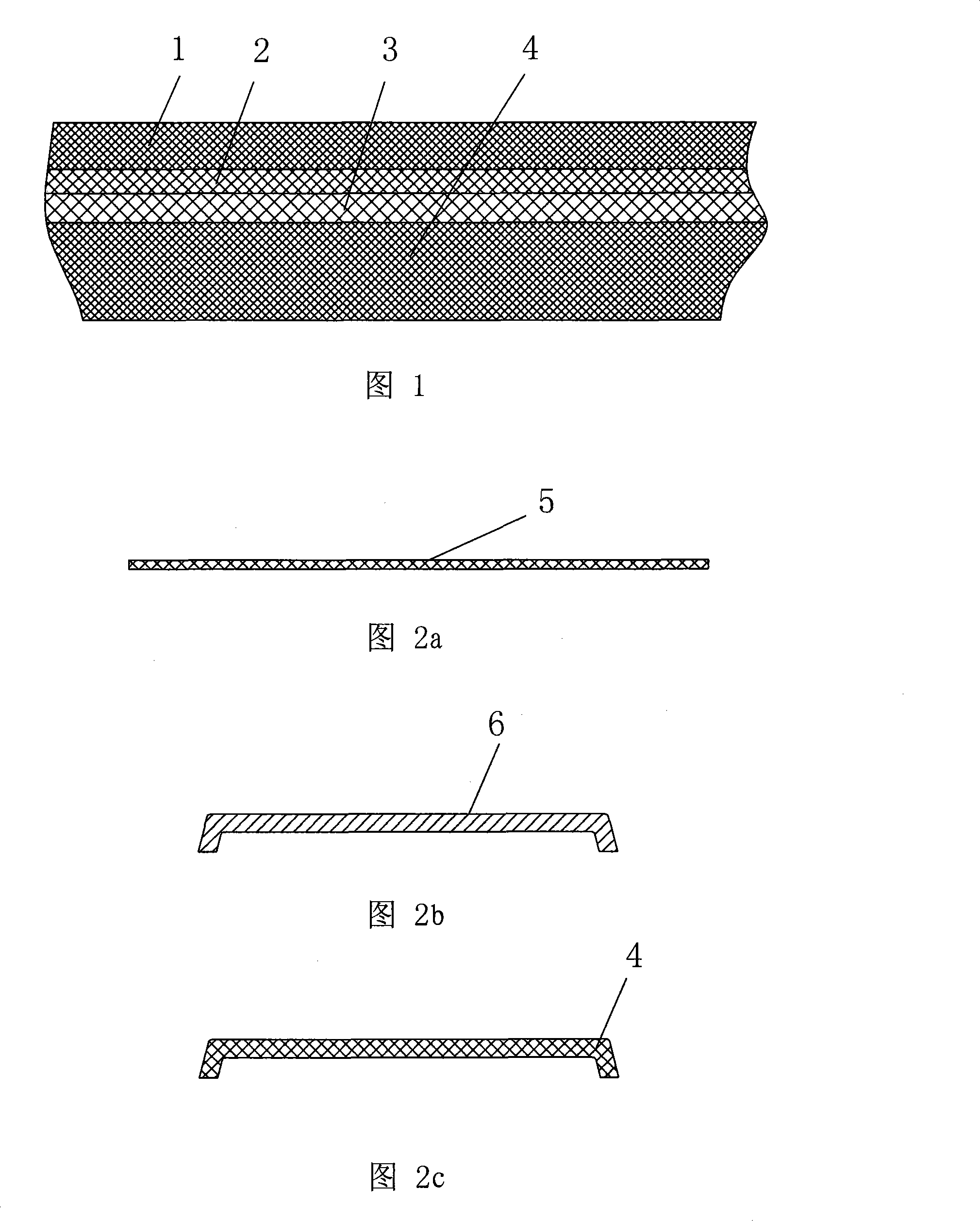

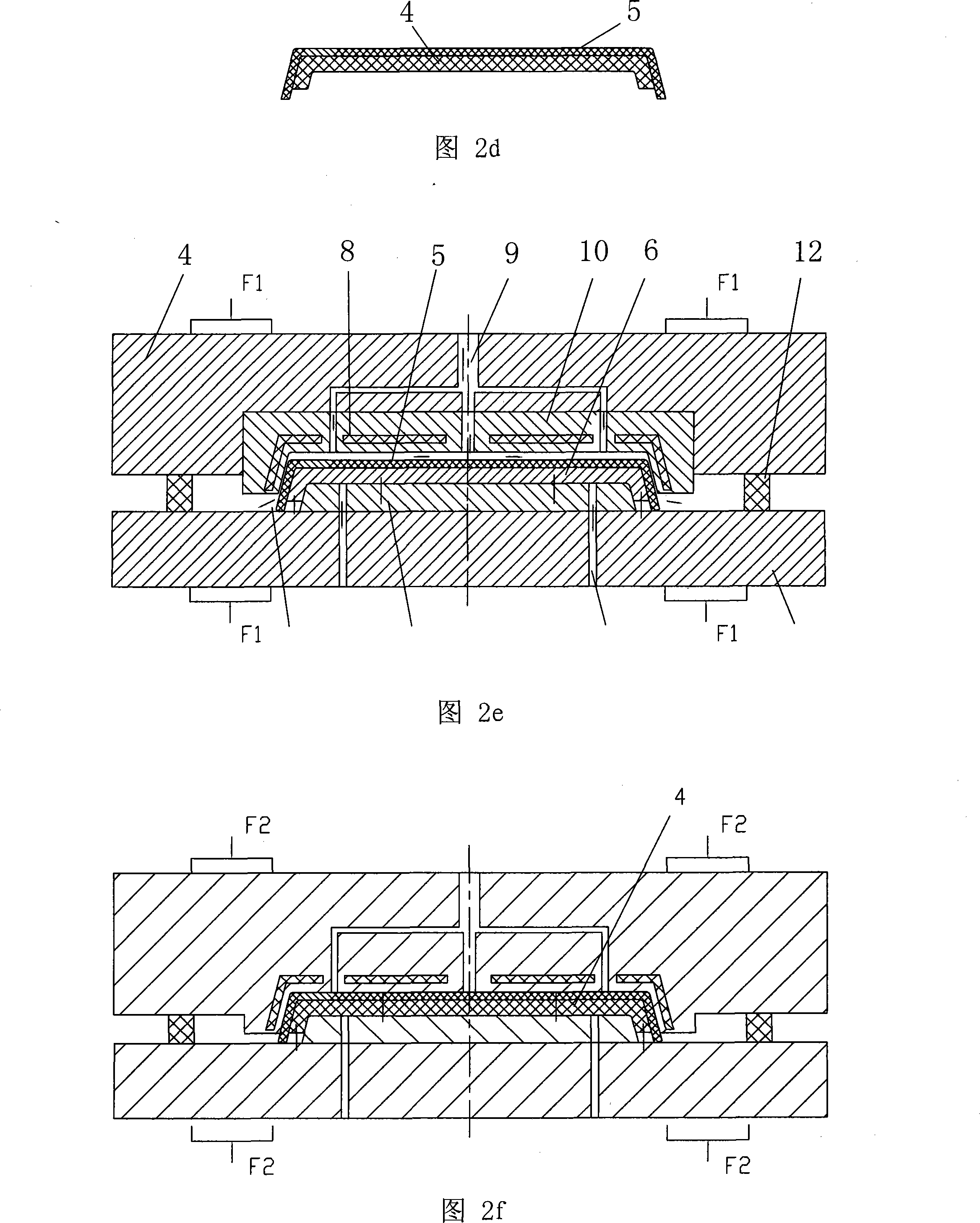

Case clipped with decorative layer and machining apparatus and method

InactiveCN101252818AHigh surface hardnessNot easy to fadeSpecial ornamental structuresLaminationScreen printingHardness

The invention discloses an outer casing sandwiched with a decorative layer and used for electronic products. The outer casing comprises a film (1), a printing layer (2) with patterns and / or characters, a bonding layer (3), a film (5) composed of the bonding layer (3), and plastic base material (4) fitted with the bonding layer (3) of the film (5) which are overlapped in sequence. The invention also discloses a processing device for fabricating the outer casing sandwiched with the decorative layer, and the method thereof. The product fabricated by the invention enables the printing layer to be covered on the interior of the outer casing, and the color of the printing image can keep bright and is uneasy to fade away. The front surface of the outer casing has higher hardness, and is uneasy to generate scratches and lose the color. The outer casing also omits subsequent processing after injection molding, such as paint spraying, electroplating and silk screen printing, etc., the qualified rate is promoted, the cost is reduced, and the environmental pollution in the production field is greatly improved.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com