Fireproof plate and manufacturing process thereof

A manufacturing process and technology of fireproof panels, which are applied in fire prevention, building construction, lamination devices, etc., can solve problems such as low added value of products, confusion at the construction site, and influence on construction progress, and achieve good decorative effects, low cost, and easy construction. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

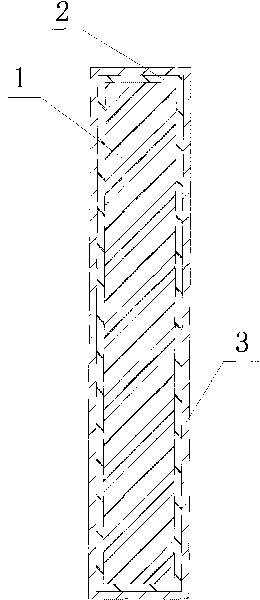

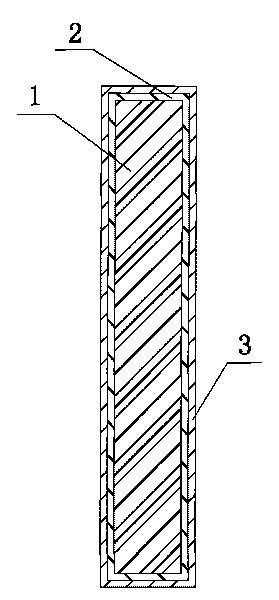

[0024] Such as figure 1 As shown, a fireproof board includes a substrate 1, a decorative layer 2 is compounded on the surface of the substrate, and the substrate is a board body made of a fireproof base material board.

[0025] The fireproof substrate is a plate made of suitable fireproof materials such as glass magnesium, cement fiber, calcium silicate or perlite, and the decorative layer is decorative paper, wood grain paper, PVC film, thermal transfer paper, water Transfer paper (film), melamine laminated board or wood-plastic composite paper is used as the decorative layer.

[0026] The surface of the decoration layer is coated with an unsaturated resin layer 3 . It can be used as a protective layer to protect the entire board from damage and improve product quality.

[0027] A manufacturing process of a fireproof board, comprising the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com