Velcro combination sealing device for all-round sealing of cabinet panel cable holes

A sealing device and an all-round technology, applied in the sealing of engines, electrical components, mechanical equipment, etc., can solve problems such as poor sealing effect, fireproof mud affecting the quality and effect of sealing, complex disassembly and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

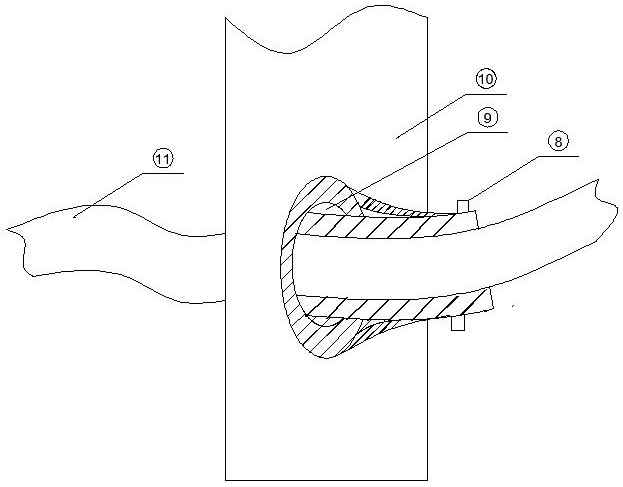

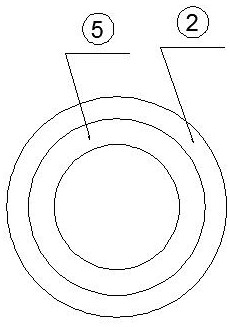

[0037] Such as Figure 1-5 As shown, the present embodiment provides a Velcro combined sealing device for sealing the cable hole of the cabinet panel in all directions, including a first fixing mechanism, a second fixing mechanism, and the first fixing mechanism and the second fixing mechanism. A sealing mechanism connected to the fixing mechanism; the first fixing mechanism includes a nylon tower buckle A wrapped on the hole wall and a positioning module for fixing the nylon tower buckle A; the second fixing mechanism includes a nylon tower buckle A wrapped on the outside of the cable The nylon tower buckle B on the surface and the safety buckle 8 arranged on the nylon tower buckle B, the sealing mechanism includes a nylon tower buckle C adhered to the nylon tower buckle A and the nylon tower buckle B.

[0038] The positioning module includes an organic silicon concave groove 1 embedded in the hollow wall 10, a card slot 4 arranged in the organic silicon concave groove 1, and...

Embodiment 2

[0057] Such as Figure 1-6 As shown, the Velcro combination sealing device provided in this embodiment to block the cable hole of the cabinet panel in all directions is an improvement on the basis of Embodiment 1: the nylon tower buckle B is in contact with the cable One side is a suede surface, and the other side is designed to be a suede surface 13 in the middle of which is in contact with the nylon tower button A, and both sides are hook surfaces 12. The suede surface 13 in the middle of the nylon tower button B is bonded to the hook surface 5 of the nylon tower button A, and the two parts of the hook surface 13 of the nylon tower button B are bonded to the suede surface of the nylon tower button C . Realize double sealing, and the sealing effect is better.

[0058] The suede and hook surfaces of Velcro A, Velcro B, and Velcro C are extruded and compounded to play the role of a buckle. With a slight pressure, it can produce greater pulling force and tearing force. After ...

Embodiment 3

[0060] Such as Figure 1-6 As shown, the method of using a Velcro combined sealing device for all-round sealing of the cabinet screen cable hole provided by this embodiment includes the following steps:

[0061] S1: Inlay the positioning module into the wall of the hole such as the box, cabinet, screen, etc. for a full circle;

[0062] S2: Wrap the nylon tower buckle A on the wall of the hole and fix it in the positioning module;

[0063] S3: Wrap the cable with a nylon tower buckle B and fix it with a safety buckle;

[0064] S4: Bond nylon tower buckle A and nylon tower buckle B with nylon tower buckle C.

[0065] The present invention is applicable to the technical field of plugging holes with different sizes of cables and wires in various types of boxes, cabinets, screens, etc. For all incoming and outgoing single or multiple cables, the central control room of the wires, the main engine room, the power distribution device room, and the holes of different sizes and vario...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com