Patents

Literature

392results about How to "Slow down the spread" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

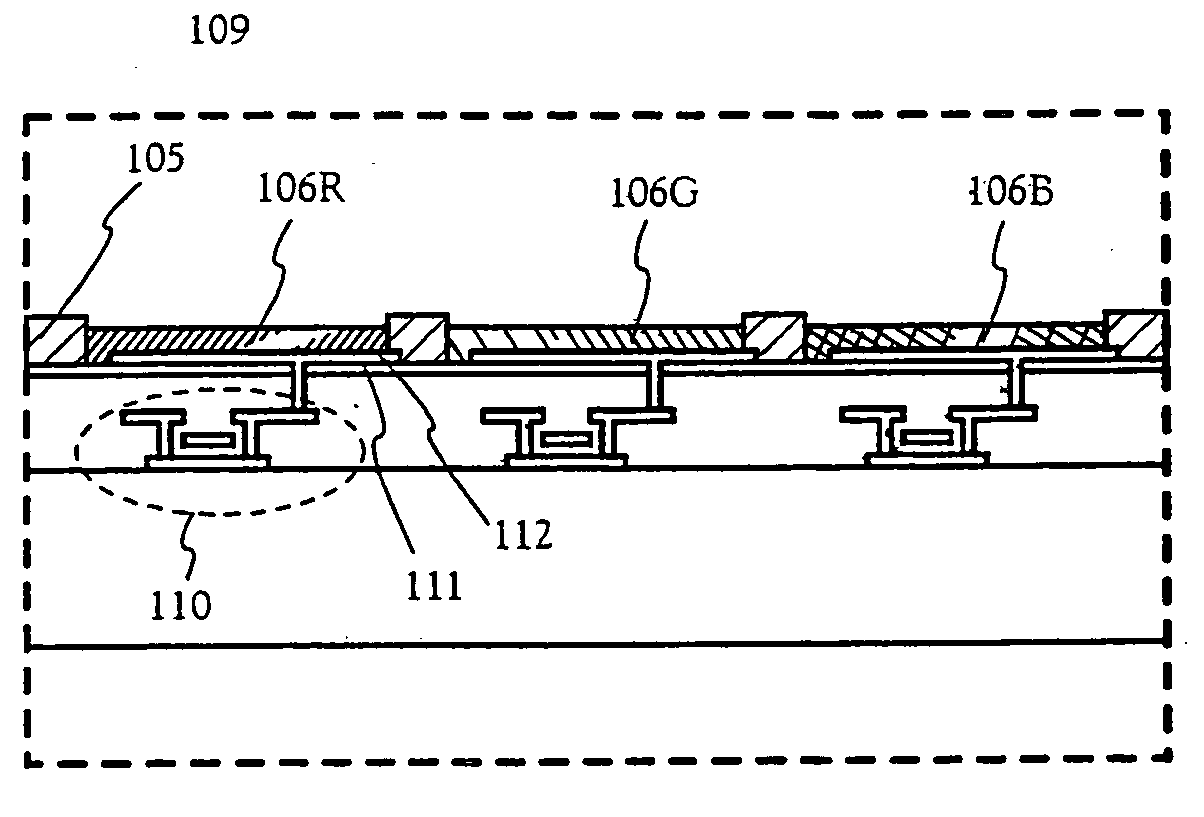

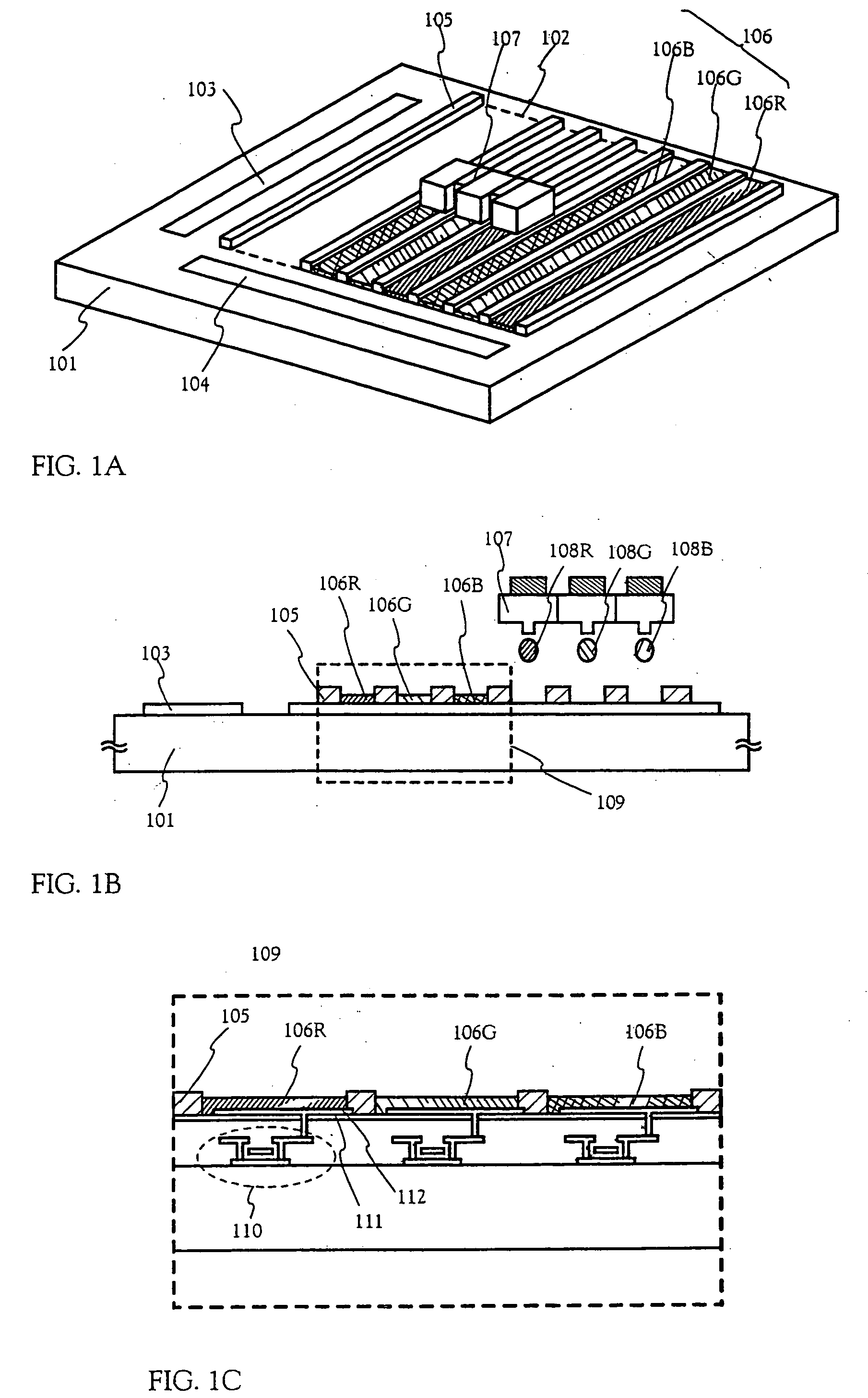

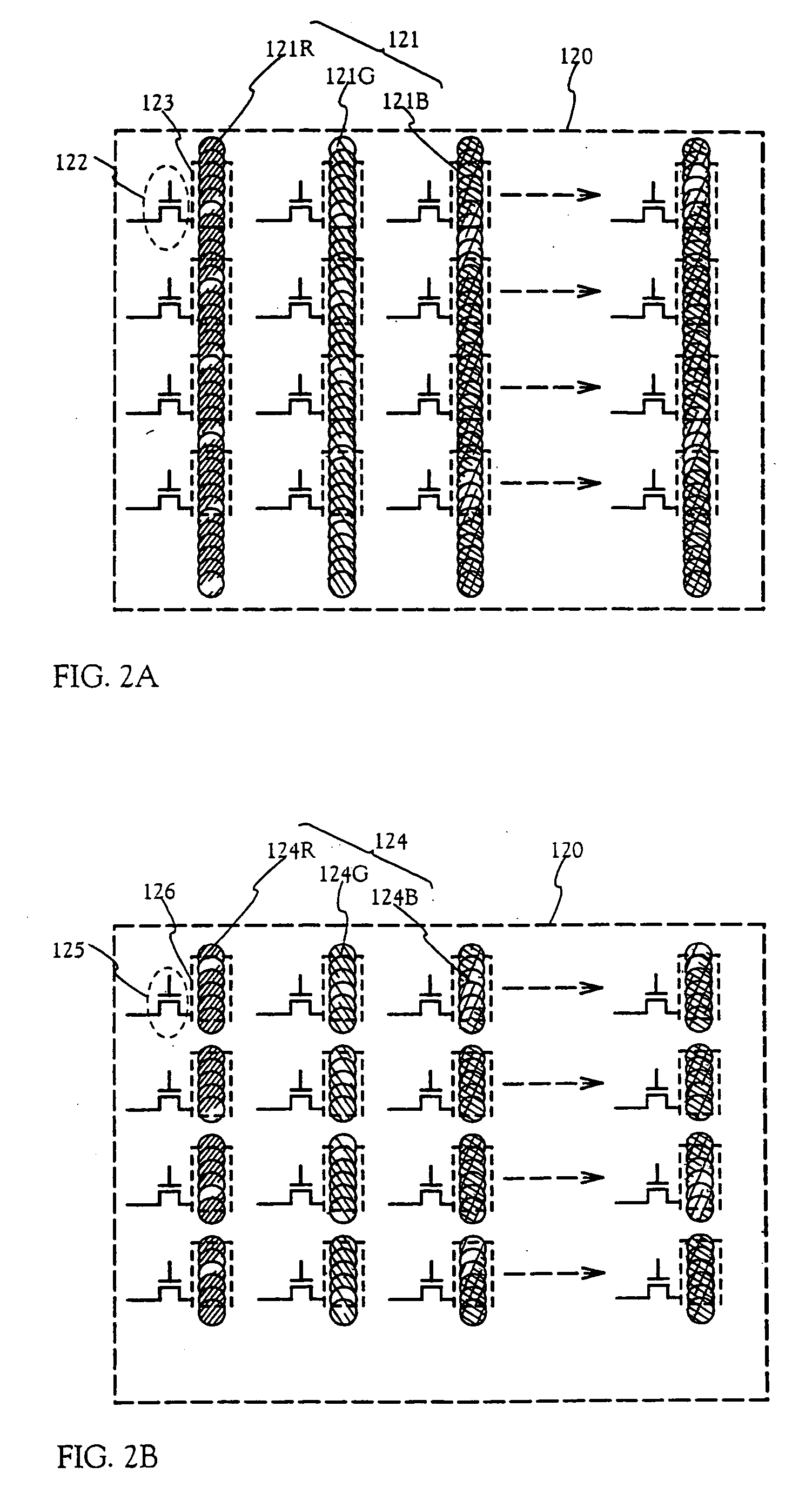

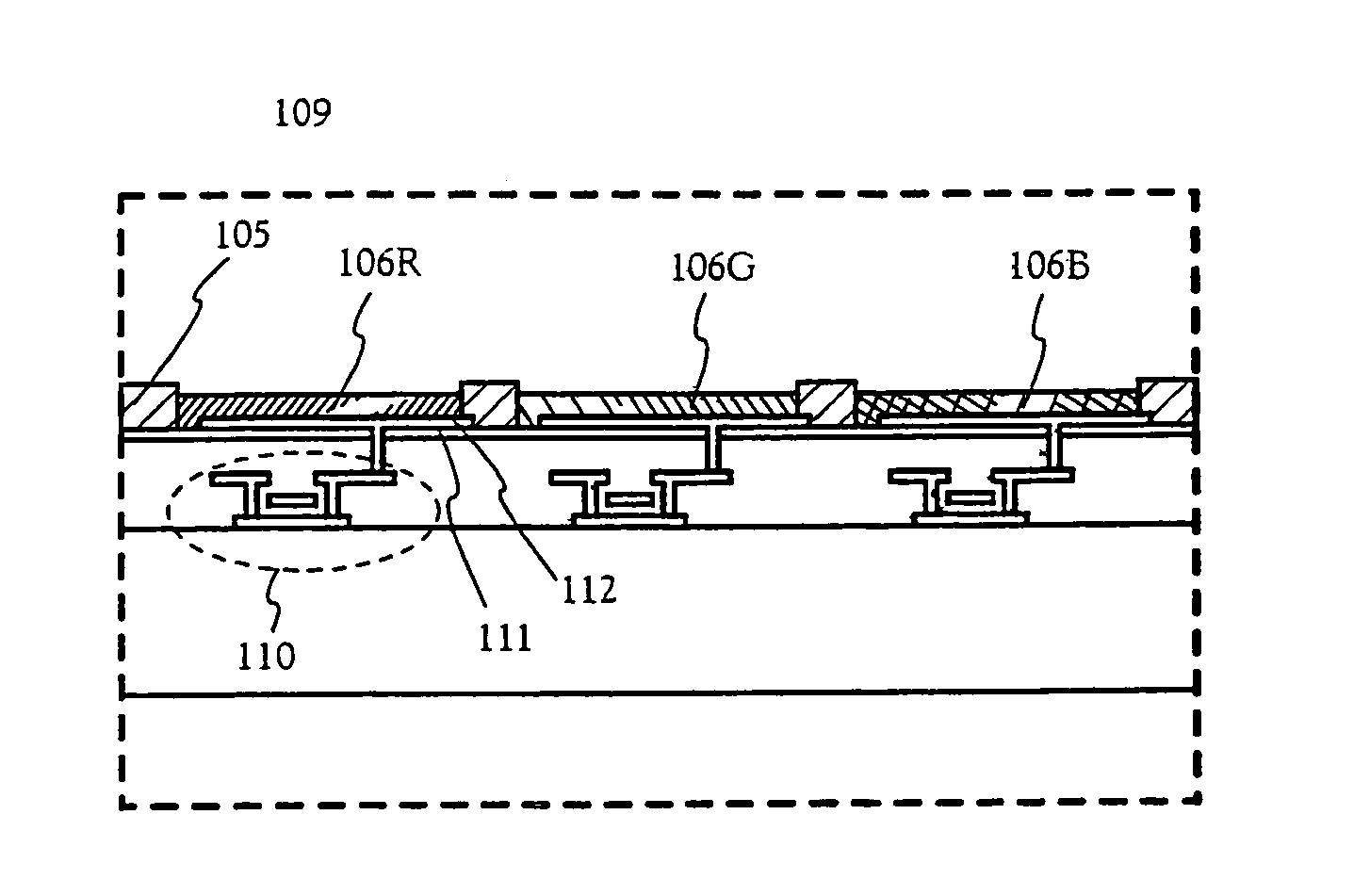

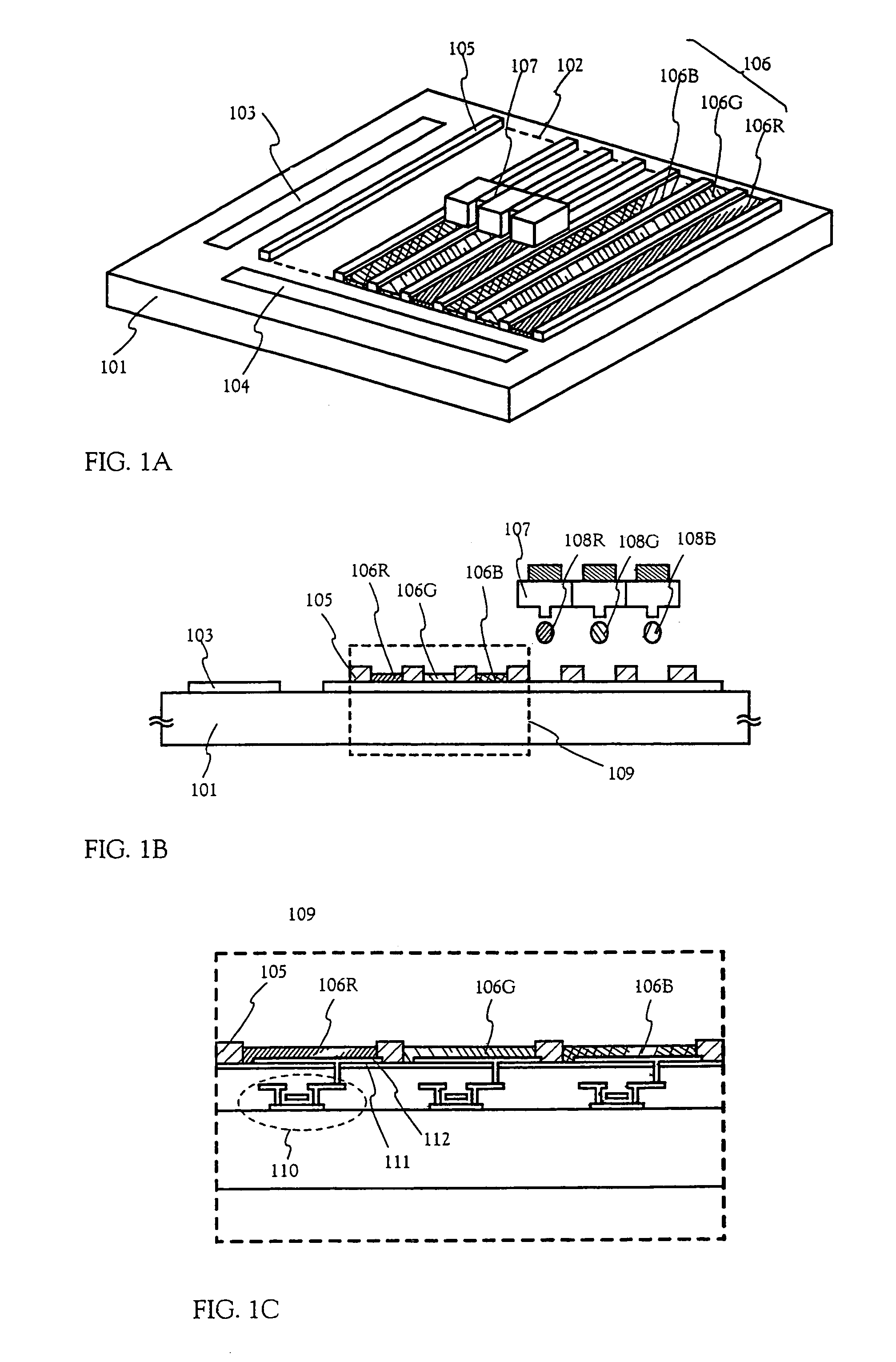

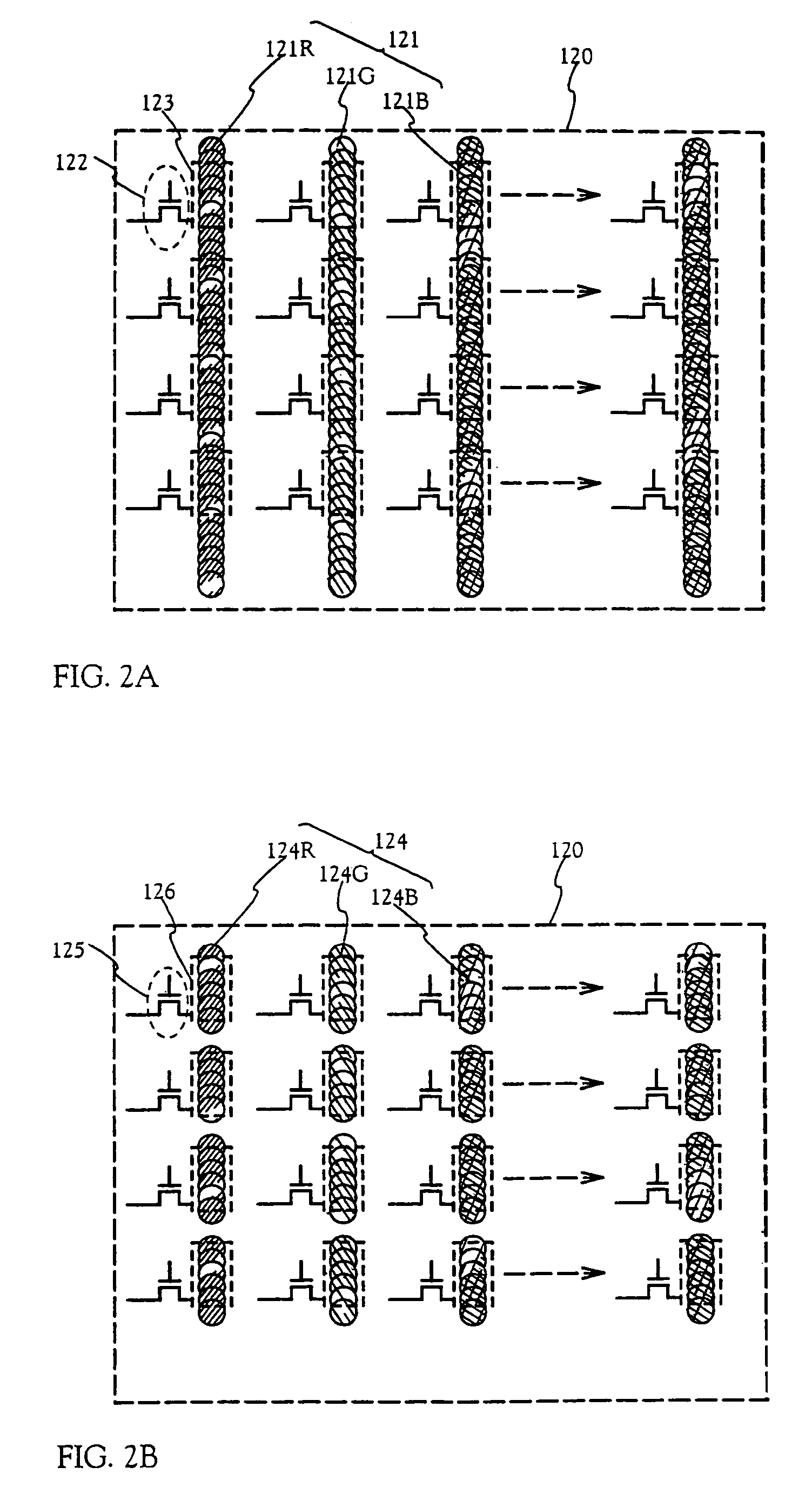

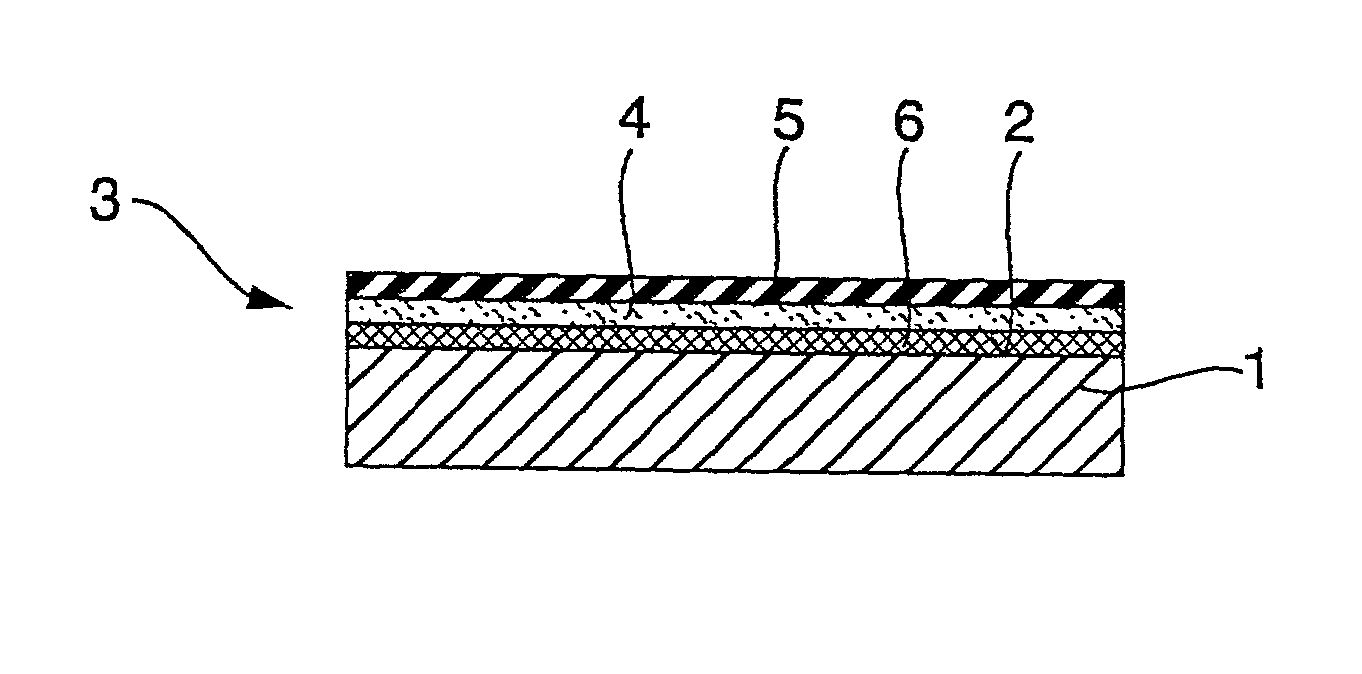

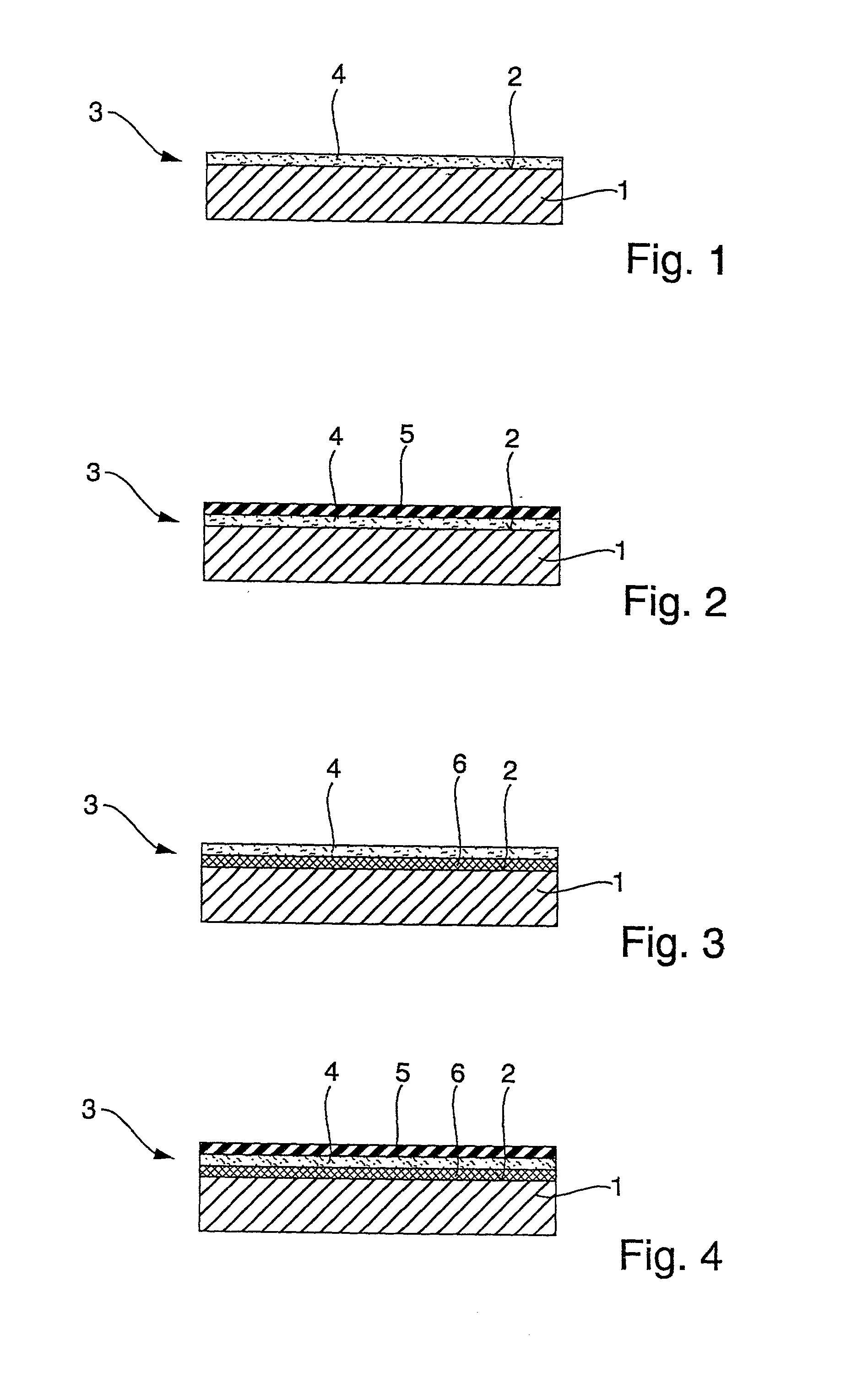

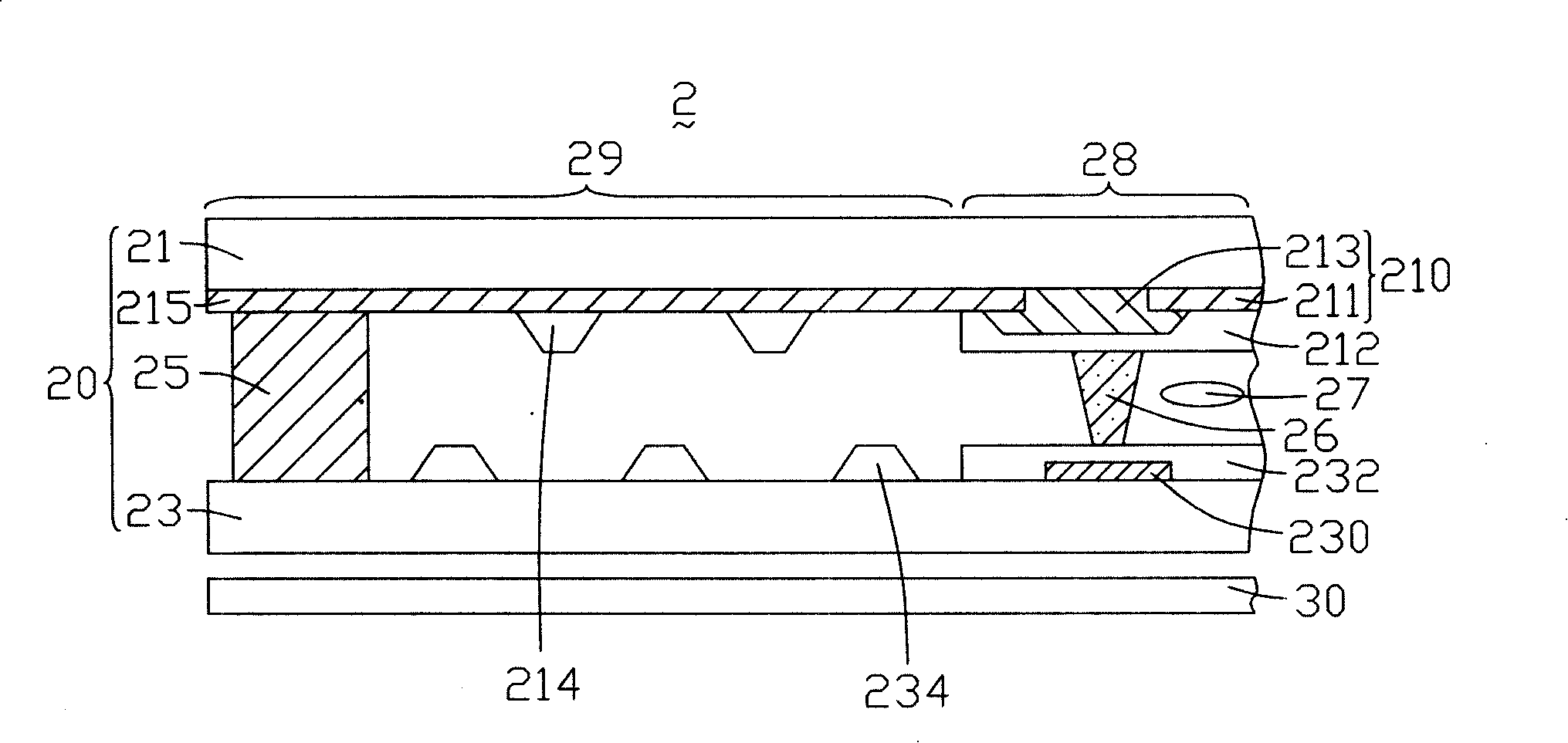

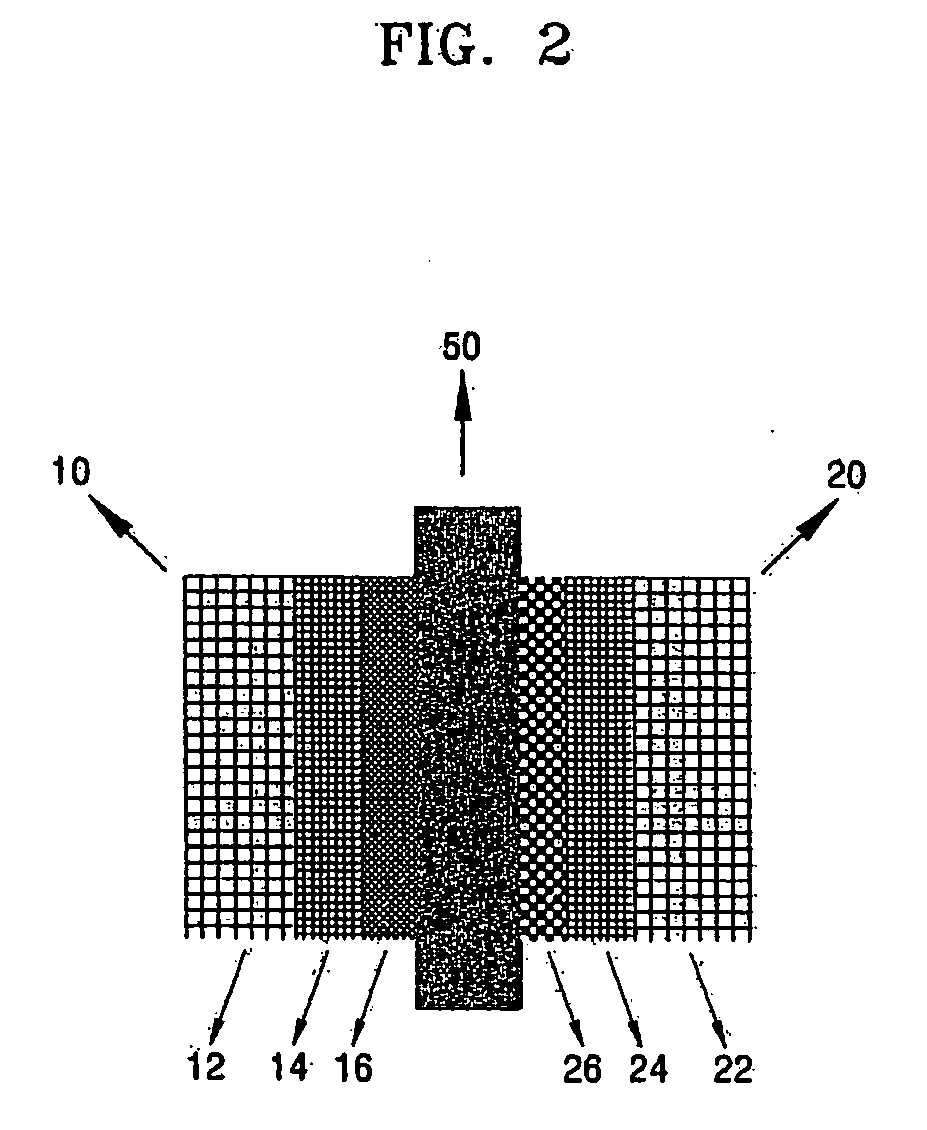

Electro-optical device and manufacturing method thereof

InactiveUS20050035708A1Simple formatEasy to operateVacuum tubesDischarge tube luminescnet screensDisplay deviceEngineering

The present invention aims to provide simple, high-speed processing for the formation of an EL layer by an ink-jet method. A method of manufacturing an electro-optical device having good operation performance and high reliability, and in particular, a method of manufacturing an EL display device, is provided. The present invention forms EL layers continuously across a plurality of pixels when the EL layers are formed by the ink-jet method. Specifically, with respect to m columns and n rows of pixel electrodes arranged in a matrix state, the EL layers are formed so as to form stripes with respect to one certain selected row or one column. The EL layers may also be formed having an oblong shape or a rectangular shape with respect to each pixel electrode.

Owner:SEMICON ENERGY LAB CO LTD

Electro-optical device having an EL layer over a plurality of pixels

InactiveUS7745991B2Simple formatEasy to operateDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceEngineering

The present invention aims to provide simple, high-speed processing for the formation of an EL layer by an ink-jet method. A method of manufacturing an electro-optical device having good operation performance and high reliability, and in particular, a method of manufacturing an EL display device, is provided. The present invention forms EL layers continuously across a plurality of pixels when the EL layers are formed by the ink-jet method. Specifically, with respect to m columns and n rows of pixel electrodes arranged in a matrix state, the EL layers are formed so as to form stripes with respect to one certain selected row or one column. The EL layers may also be formed having an oblong shape or a rectangular shape with respect to each pixel electrode.

Owner:SEMICON ENERGY LAB CO LTD

Halogen-free cleaning-free rosin flux, and preparation and application thereof

ActiveCN102513732ALess corrosiveSlow growth rateWelding/cutting media/materialsSoldering mediaSolventSolder paste

The invention discloses a halogen-free cleaning-free rosin flux, and preparation and application thereof, and particularly relates to a flux suitable for surface mount lead-free welding paste, preparation of the flux and application of the flux. The flux comprises 20-50% (mass fraction, the same below) of rosin, 5-25% of film-forming agent, 30-50% of high boiling solvent, 3-8% of activator and 2-5% of thixotropic agent, and the flux does not contain any halogen. In order to control growth of interface IMC (intermediate compound) during welding, 0.3-1% of combined inhibitor is added. The welding paste prepared with the flux and lead-free tin-silver-copper powder has the advantages of excellent printing performance, fine weldability, less post-weld residue, thin and even welding spot interface IMC and excellent mechanical property, and is capable of meeting the requirement of high-end electronic products on packaging.

Owner:CENT SOUTH UNIV

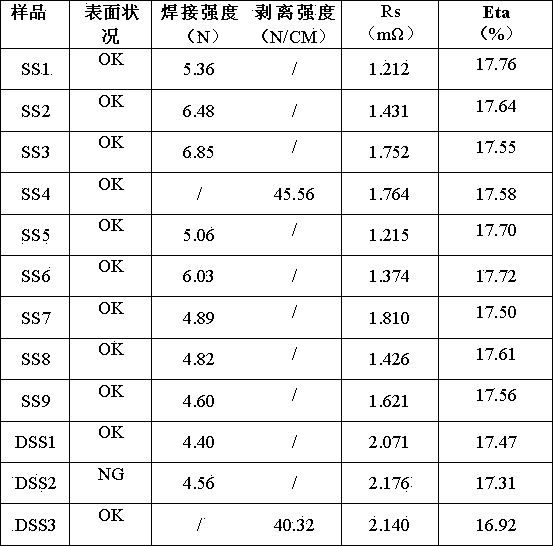

Conductive paste for crystalline silicon solar cell and preparation method of conductive paste

ActiveCN104078090AHigh tear strengthImprove adhesion strengthNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteConductive paste

The invention provides conductive paste for a crystalline silicon solar cell. The conductive paste comprises the following components in parts by weight: 100 parts of conductive metal powder, 1.0-10 parts of inorganic binder, 10-65 parts of organic carrier and 0.05-5.0 parts of conductive carbon. The conductive paste is excellent in conductivity; the photoelectric conversion efficiency of the cell is not influenced; and widely applied conductive paste for the crystalline silicon solar cell such as front-side silver paste, front-side seed layer silver paste, back-side silver paste and back electric field aluminum paste can be prepared.

Owner:BYD CO LTD

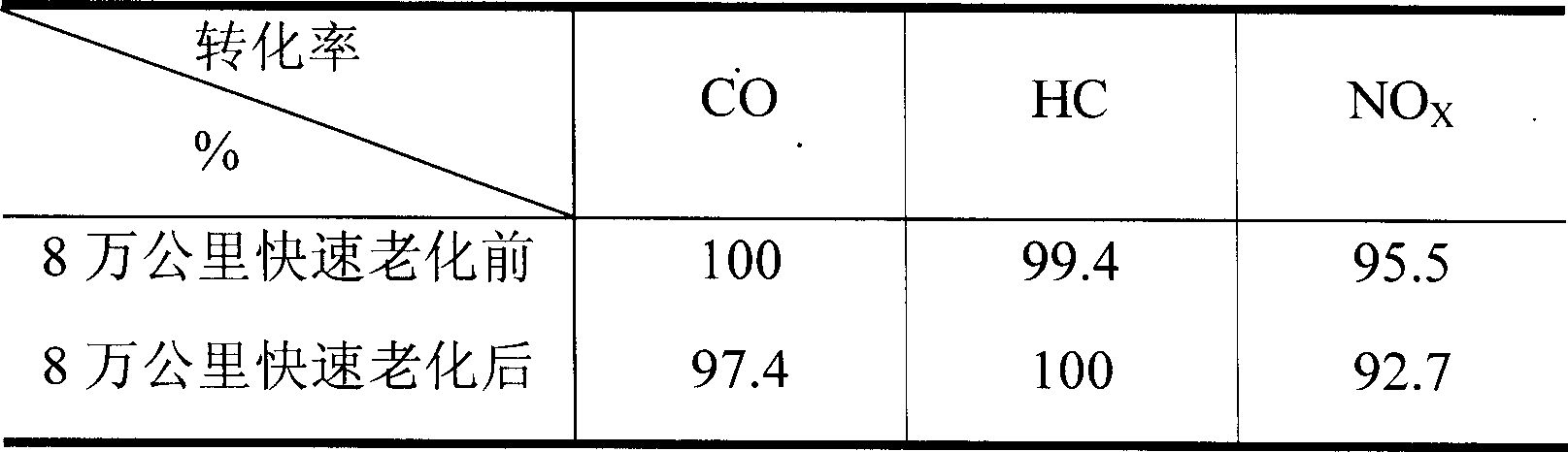

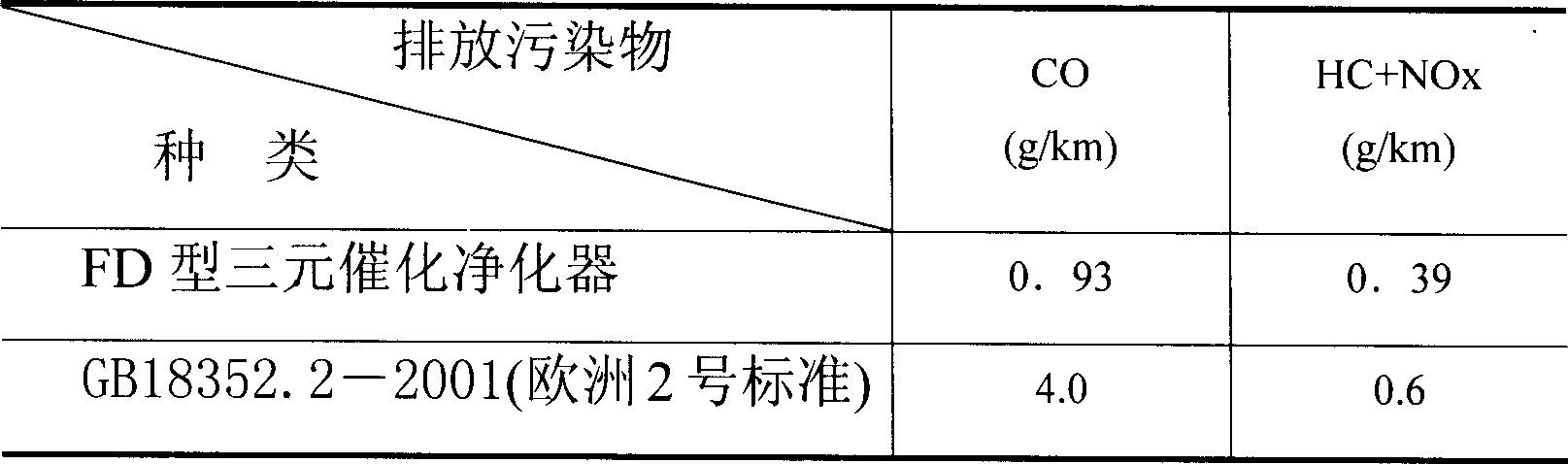

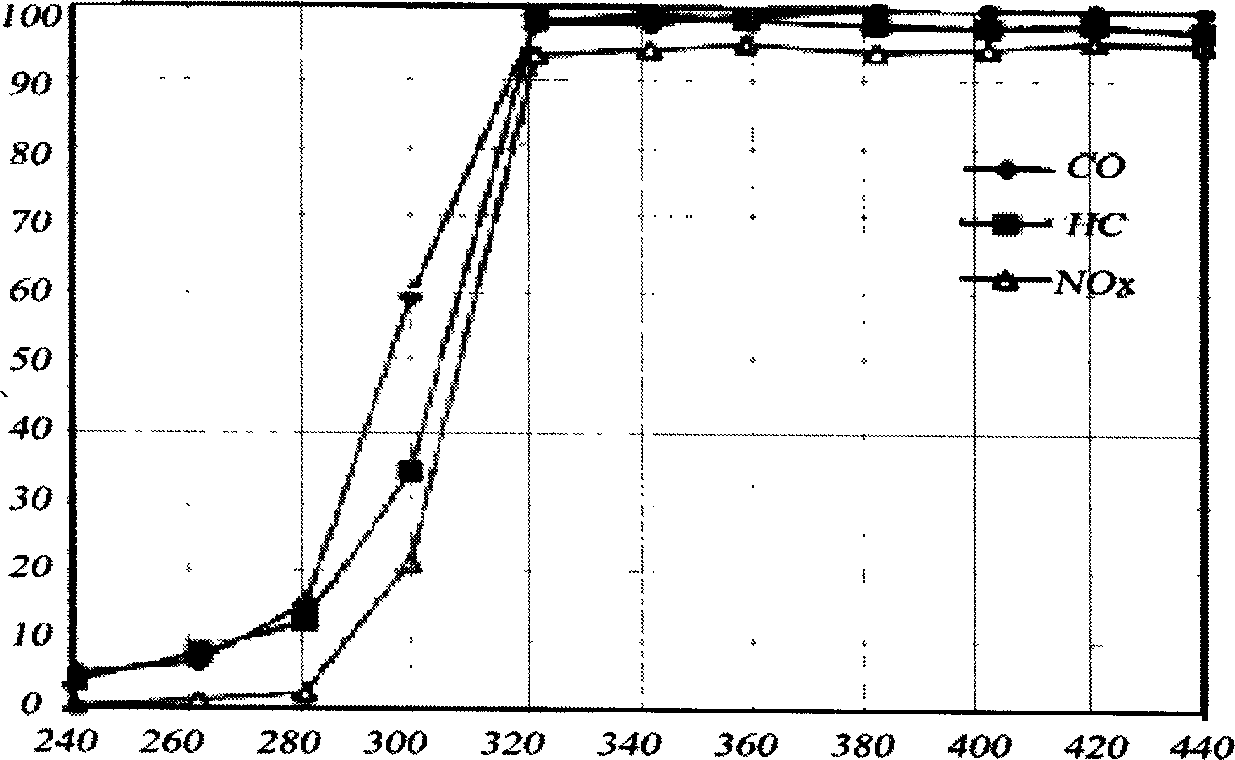

Ternary catalyst for automobile tail gas and its preparation method

InactiveCN1413769AIncrease profitSmall metal particlesCatalyst carriersDispersed particle separationActive componentCordierite

A three-element catalyst for cleaning the tail gas of car features that the cellular cordierite ceramics modified by the RE tailing mixture or transition metal oxide is ued as the first carrier, the internal and external modified alumina coating layers are used as the second carrier, and the noble metal Pt, Rh or Pd is used as its active component.

Owner:FUZHOU UNIV

Silver alloy wire and preparation method thereof

The invention relates to a silver alloy wire and a preparation method thereof. The silver alloy wire is prepared from the following components of 0.5-10 percent of Au, 0-1 percent of Pt, 1-6 percent of Pd, 0-1 percent of Rh, 0-1 percent of Cu, 0-500ppm of Ln, 0-200ppm of Ce, 0-0.5 percent of Al, 0.7-3 percent of Ti, 0-0.2 percent of Si, 0-0.3 percent of Zn, 0-1 percent of Sn, 0-10 percent of Be and the balance of Ag. A directional continuous casting process is adopted. The prepared silver alloy wire overcomes the problem that the bonded silver wire is easily subjected to sulfur corrosion in the prior art, and has a series of other excellent characteristics.

Owner:YANTAI YINUO SEMICON MATERIAL CO LTD

Protective coating for a thermally stressed component, particularly a turbine component

The invention relates to a sealing coating for a thermally stressed component, particularly a turbine component, for protection from corrosion and / or oxidation and / or erosion. To improve the life of the protective coating or of the component, the protective coating has a single-layer or multilayer sealing coating of an amorphous material.

Owner:ALSTOM (SWITZERLAND) LTD

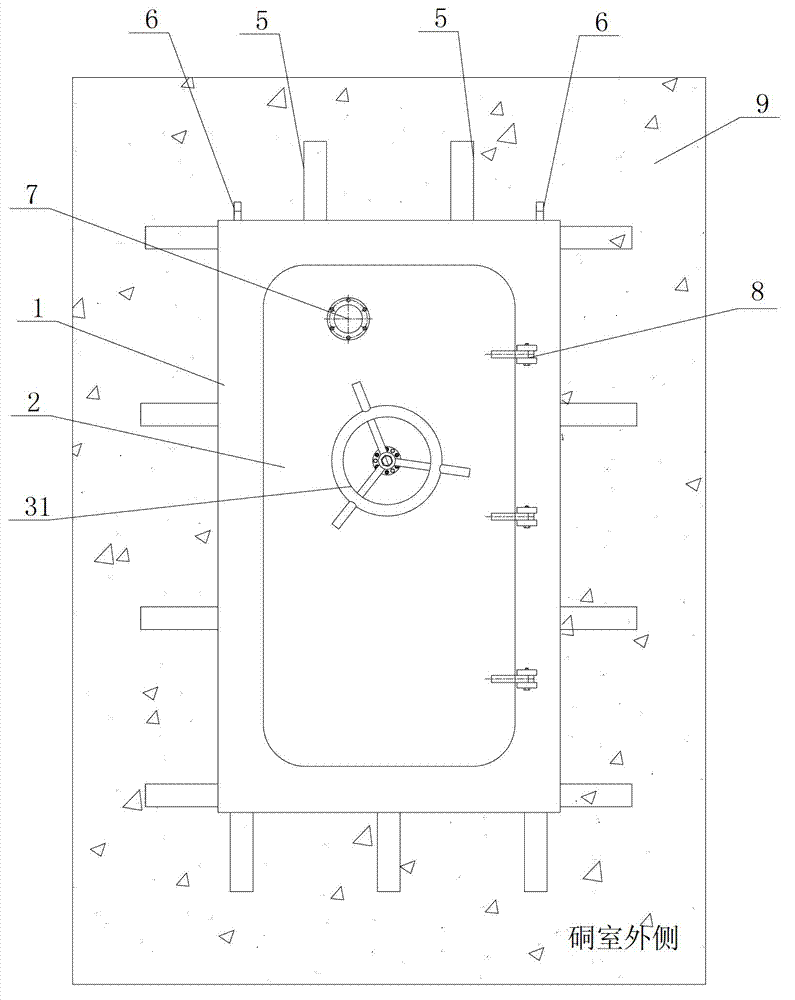

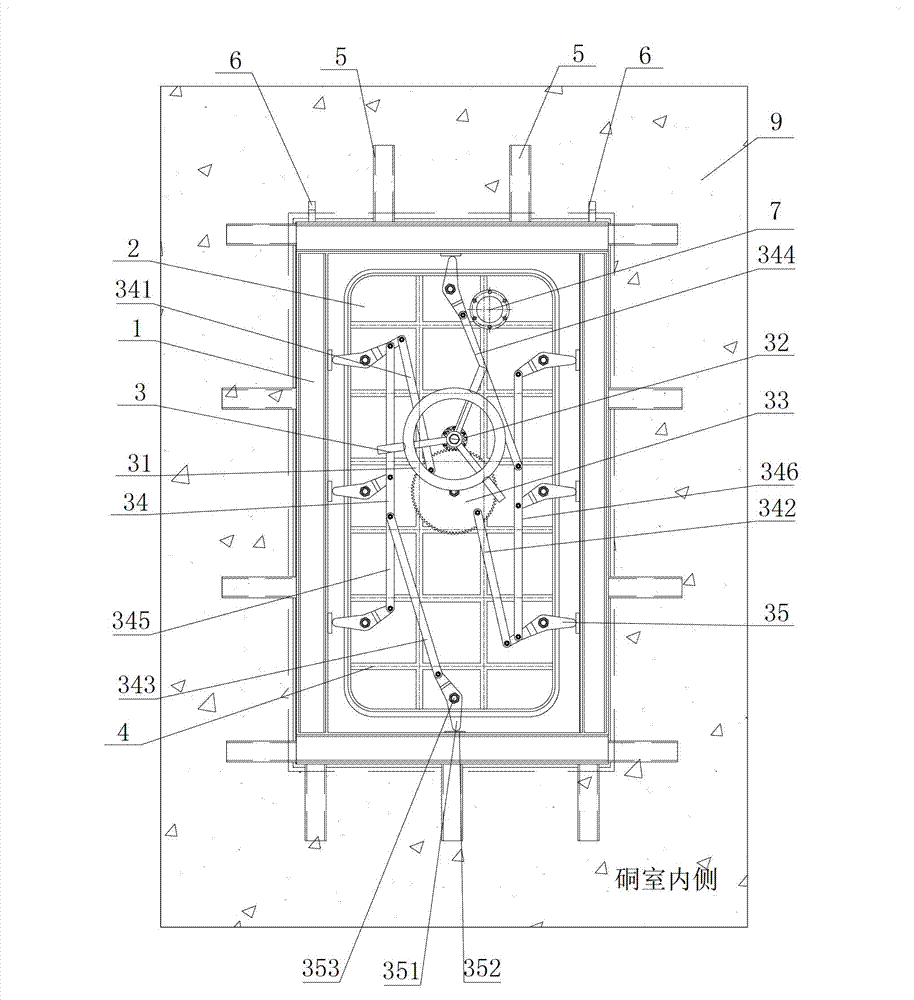

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

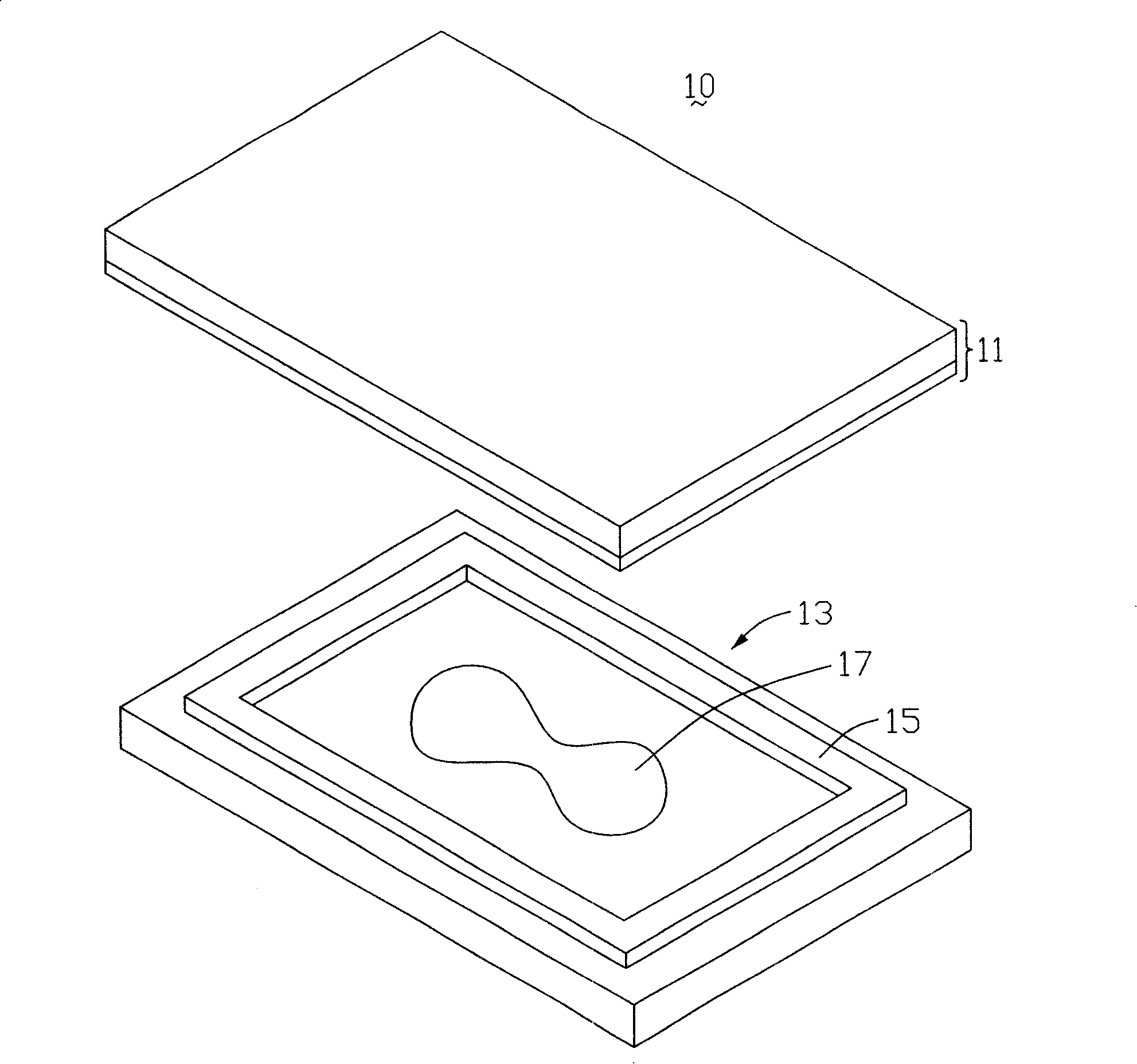

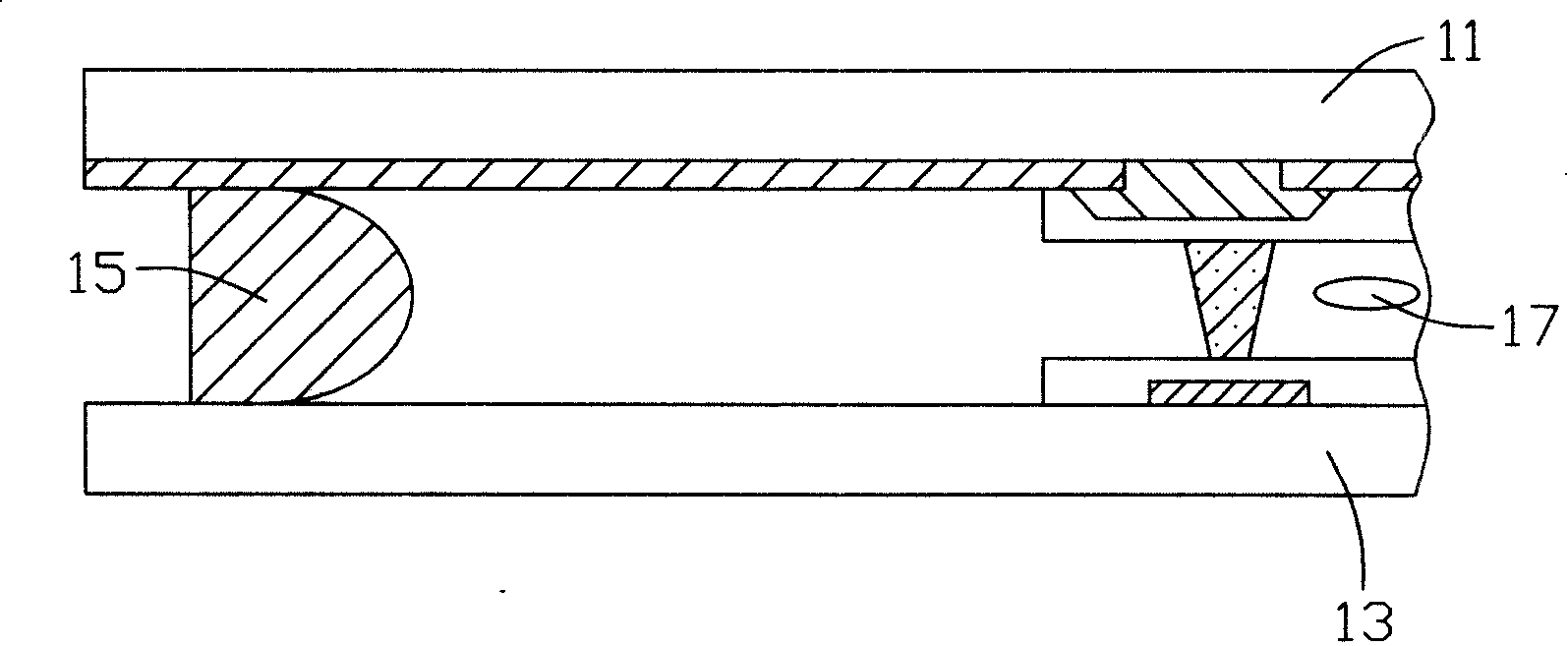

LCD display panel and device

InactiveCN101191958AReduce scrap rateReduce impactNon-linear opticsLiquid-crystal displayEngineering

The present invention relates to a liquid crystal display panel having a display area. The liquid crystal display panel comprises a first base plate, a second base plate, a glue frame and a liquid crystal layer. The second base plate and the first base plate are oppositely arranged; the glue frame is used to joint the first base plate and the second base plate; the first base plate and the second base plate form a liquid crystal box; the liquid crystal layer is arranged inside the liquid crystal box, wherein, the first base plate and the second base plate respectively comprise a plurality of protuberances which are arranged between the glue frame and the display area. The present invention also provides a liquid crystal display adopting the liquid crystal display panel. The liquid crystal display panel and the liquid crystal display can effectively decrease the damage phenomena of the glue frame.

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

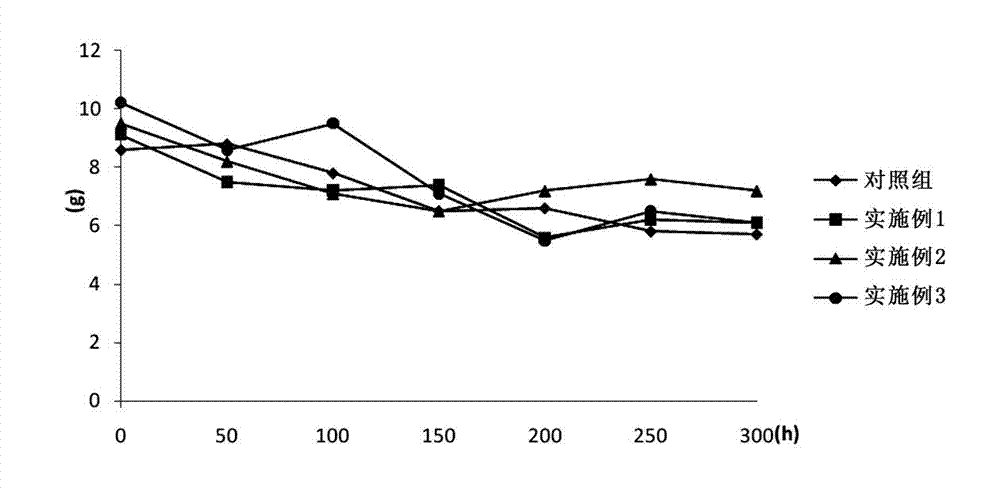

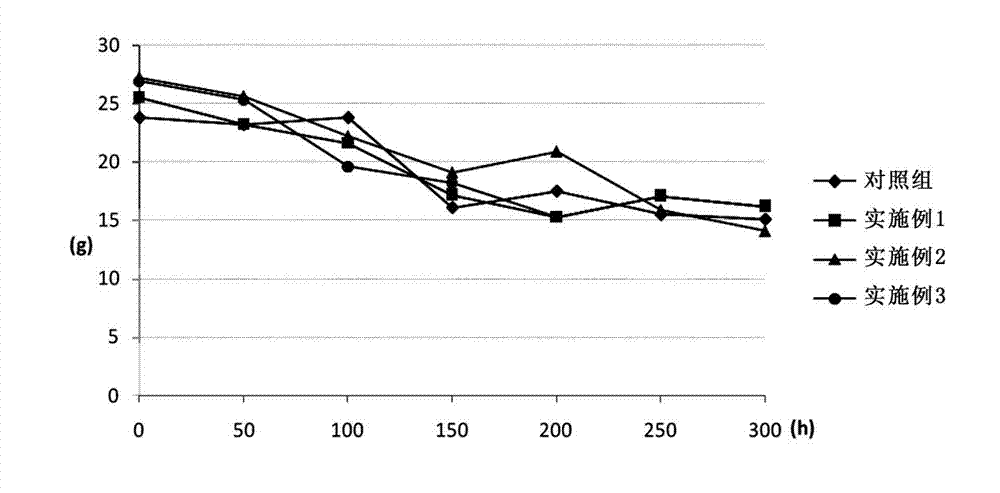

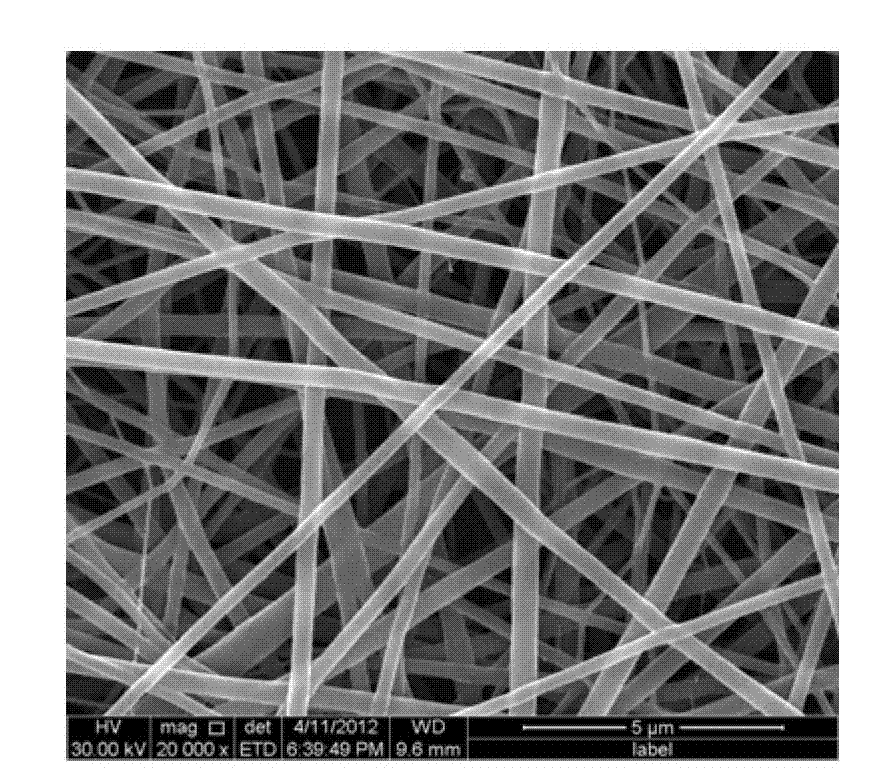

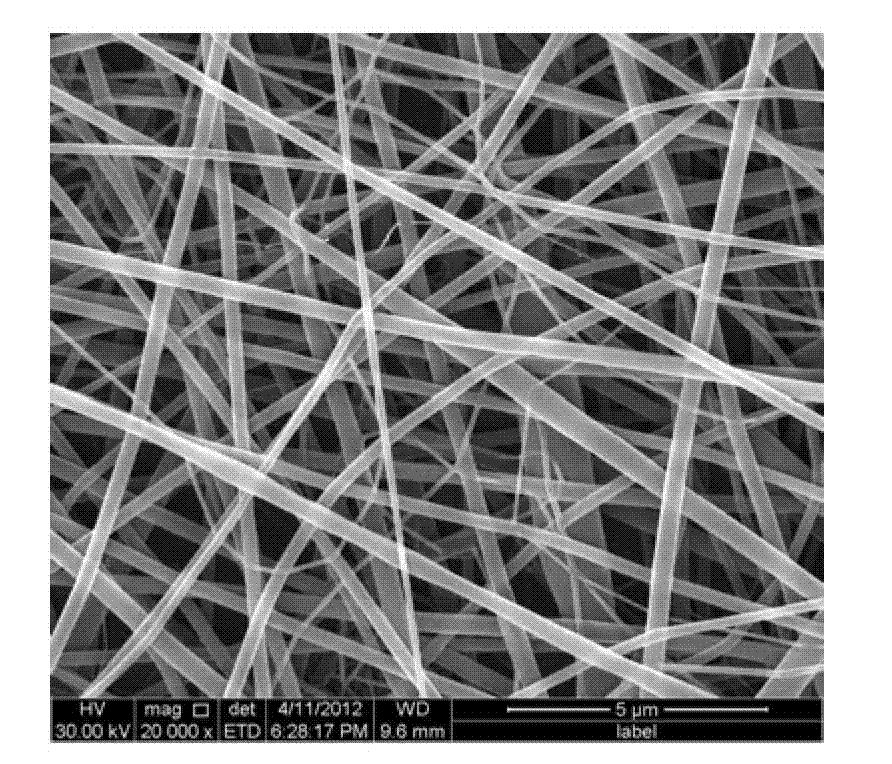

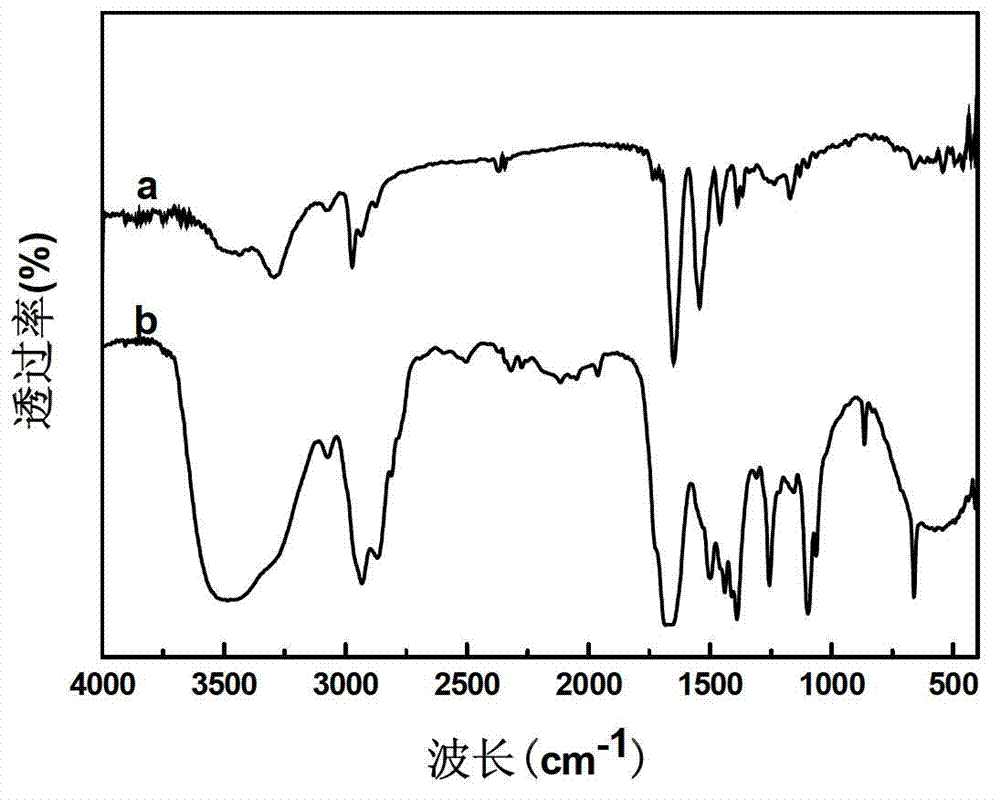

Thermo-sensitive poly N-isopropylacrylamide/polyurethane medicine-loading electro-spun fibrous membrane and preparation method thereof

ActiveCN102733088ALarge specific surface areaHigh drug loadingOrganic active ingredientsFilament/thread formingN dimethylformamideElectrospinning

The invention relates to a thermo-sensitive poly N-isopropylacrylamide / polyurethane medicine-loading electro-spun fibrous membrane and a preparation method thereof, relating to a medicine-loading electro-spun fibrous membrane and a preparation method thereof and aiming to solve problems of poor mechanical property of existing poly N-isopropylacrylamide medicine-loading electro-spun fibrous membrane and no temperature sensitivity of a polyurethane medicine-loading electro-spun fibrous membrane. The thermo-sensitive poly N-isopropylacrylamide / polyurethane medicine-loading electro-spun fibrous membrane is prepared by poly N-isopropylacrylamide, polyurethane, N,N-dimethylformamide and a medicine; the preparation method comprises the following steps: 1, preparing static spinning solution; 2, dissolving the medicine so as to obtain the static spinning solution containing the medicine; 3, carrying out electrospinning; and 4, carrying out dry treatment to obtain the thermo-sensitive poly N-isopropylacrylamide / polyurethane medicine-loading electro-spun fibrous membrane. According to the invention, the preparation method is mainly used for preparing the thermo-sensitive poly N-isopropylacrylamide / polyurethane medicine-loading electro-spun fibrous membrane.

Owner:HARBIN INST OF TECH

Ca and heavy rare earth Gd-containing die-casting heat resisting magnesium alloy and preparation thereof

The invention relates to a die-casting heat resistant magnesium alloy containing Ca and heavy rare earth element Gd and a preparation method thereof, pertaining to the metal material technical field. The components and weight percentage thereof of the alloy are: 3.0 to 8.0 percent of Al, 0.1 to 3.0 percent of Ca, 0.1 to 3.0 percent of Gd, 0 to 0.5 percent of Mn, lower than 0.02 percent of impurity elements and the rest is Mg. The preparation method of the alloy comprises the following steps: the materials are weighed, and industrial pure Mg is heated under the protection of the mixed gas of N2 and 0.2 percent of SF6; after Mg is wholly melted, industrial pure Al, industrial pure Ca and Al-Mn interalloy are added at the temperature of 650 to 680 DEG C, Mg-Gd interalloy is added at the temperature of 660 to 680 DEG C, the temperature is increased to 740 to 760 DEG C, and when the Mg liquid is cooled to 670 to 690 DEG C, the mixture carries out die casting. The preparation method of the invention has the advantages of low cost and high production efficiency, obviously increases the tensile strength, the yield strength, the elongation percentage and the creep resistance of the alloy at room temperature, and has excellent die-casting performance.

Owner:SHANGHAI JIAO TONG UNIV

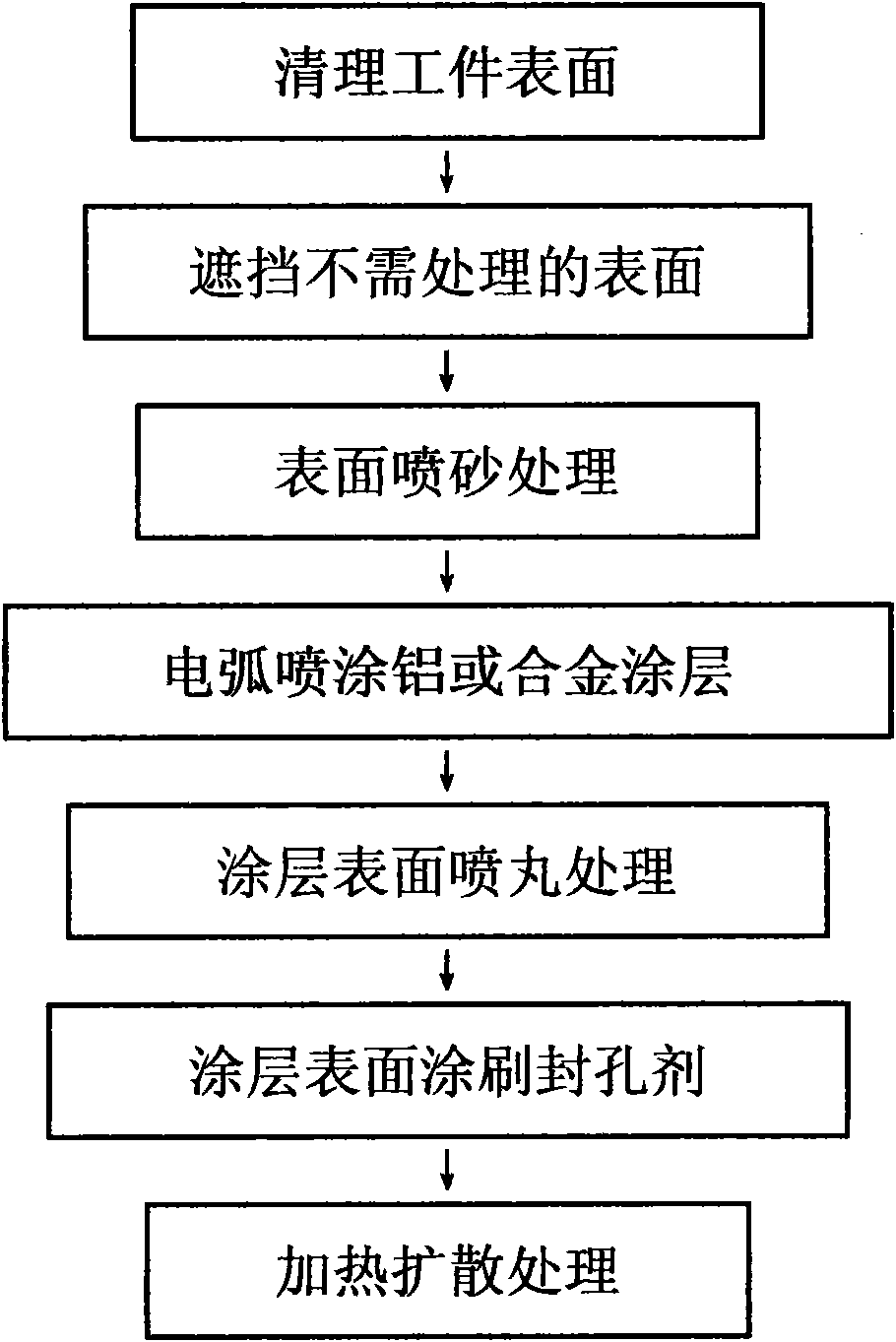

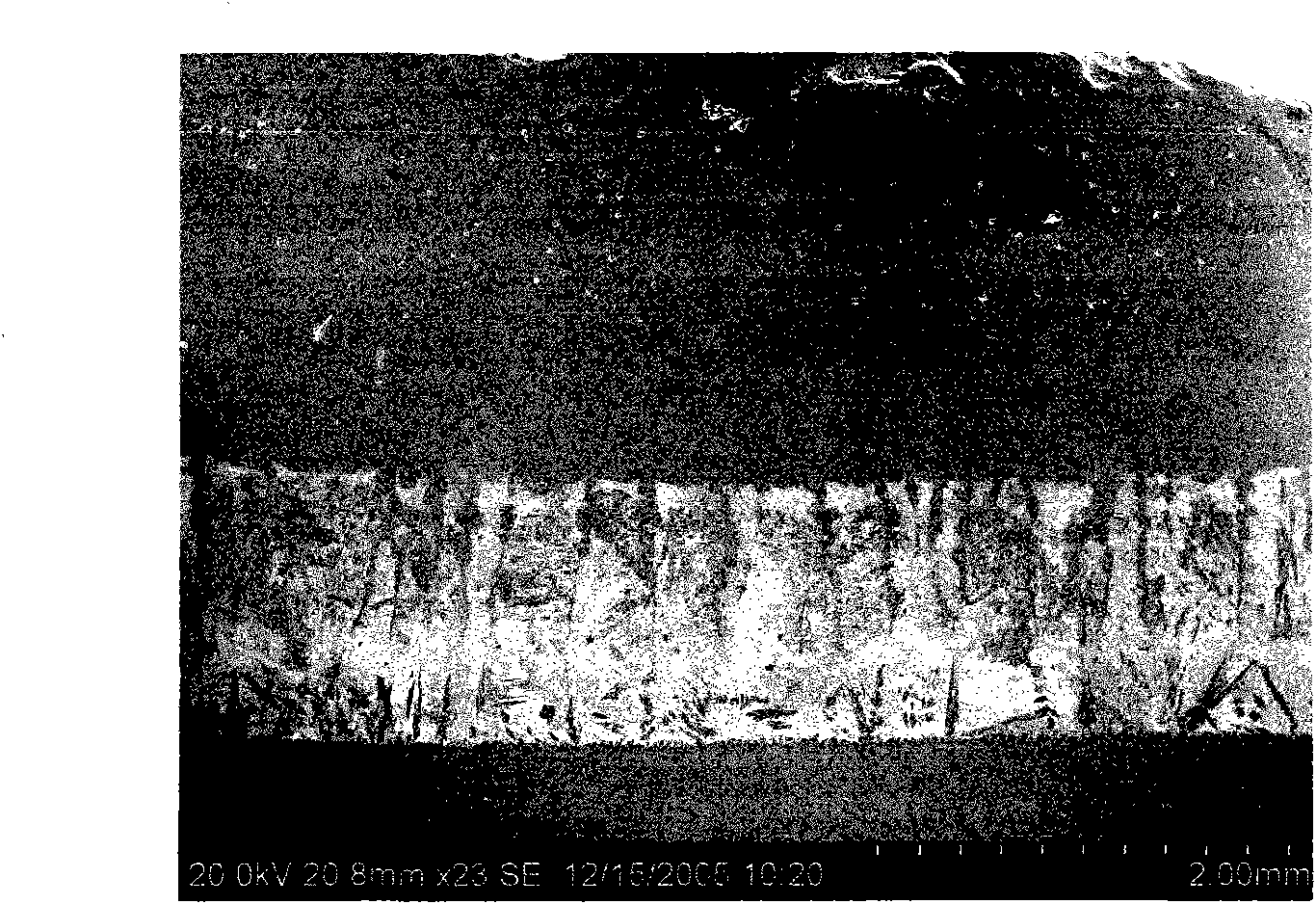

Process for preparing antioxidant and wear-resistant layer on surface of copper

InactiveCN101638788AImprove the protective effectExtend protection lifeMolten spray coatingThermal sprayingWear resistant

The invention provides a process method for preparing an aluminide penetrating layer on the surface of pure copper or a copper alloy by combining the thermal spraying technology and the thermal treatment technology, which comprises the following steps: firstly, spraying a layer of pure aluminium coating on the surface of a copper product through arc; secondly, performing shot blasting and sealingagent coating treatment on the surface of the coating; and finally, performing thermal treatment at a temperature of between 800 and 900 DEG C, maintaining the temperature for 2 to 4 hours, and obtaining an aluminide layer over 3mm on the surface of the pure copper. The aluminide layer prepared by the method has good combination with a copper substrate, good antioxidant performance and good wear resistance. The method can prepare the aluminide penetrating layer, and also can prepare aluminium-molybdenum, aluminium-silicone, aluminium-chromium binary or multi-metallic diffusion layers.

Owner:SHENYANG POLYTECHNIC UNIV

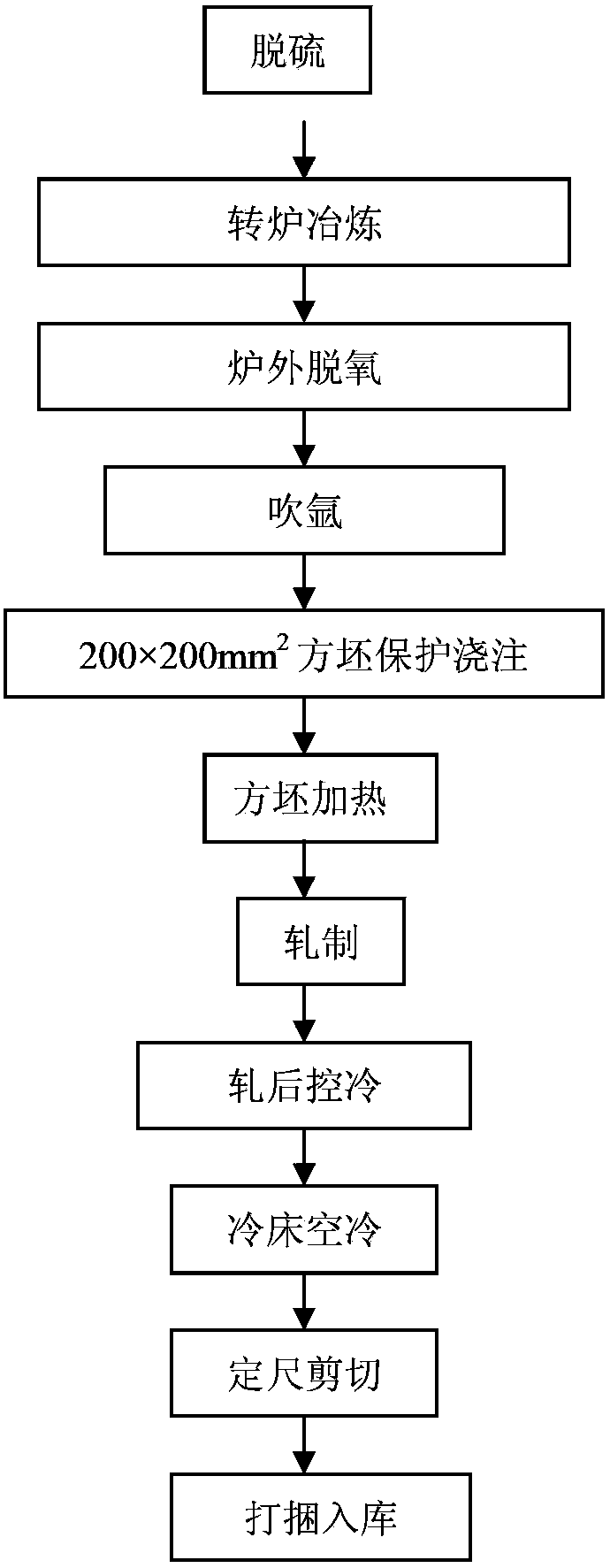

600MPa hot-rolled ribbed steel bar and preparation method thereof

The invention provides a 600MPa hot-rolled ribbed steel bar and a preparation method thereof. The steel comprises the following chemical components in percentage by weight: 0.06-0.15% of C, 0.2-0.5% of Si, 1.2-1.6% of Mn, less than or equal to 0.04% of P, less than or equal to 0.04% of S, 0.001-0.04% of B, 0.03-0.05% of Nb, 0.02-0.05% of V, 0.01-0.04% of Ti, 0.005-0.009% of N, and the balance of Fe and inevitable impurities. The preparation method of the 600MPa hot-rolled ribbed steel bar comprises the steps of molten iron desulphurization, converter smelting, nitrogen blowing, continuous casting, square billet heating, rolling, cooling control and cooling bed air-cooling. The steel not only has good comprehensive mechanical properties, but also has better cold bending properties.

Owner:武汉钢铁有限公司

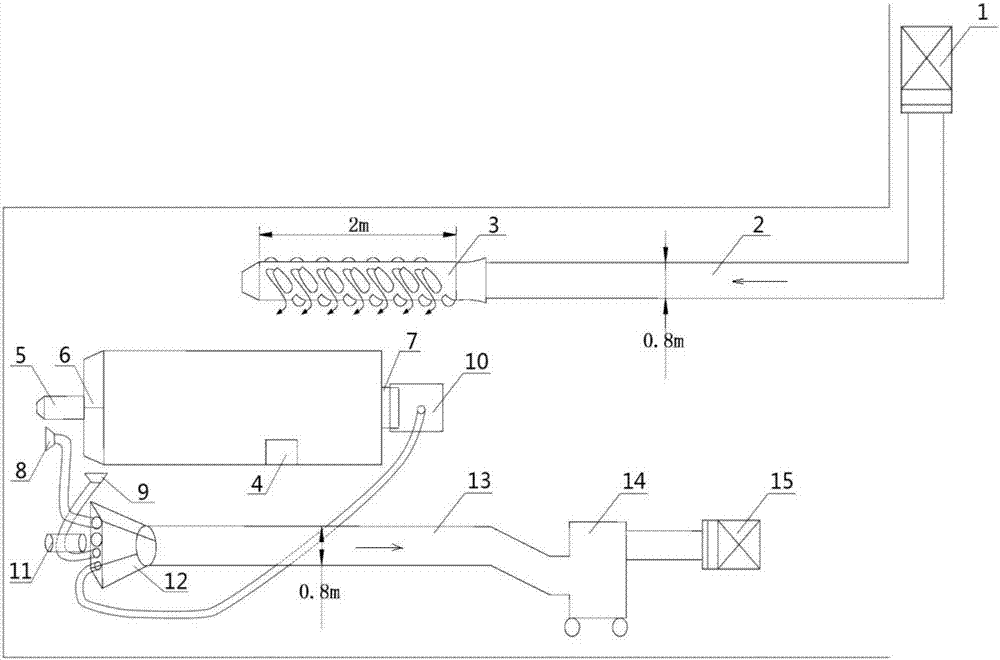

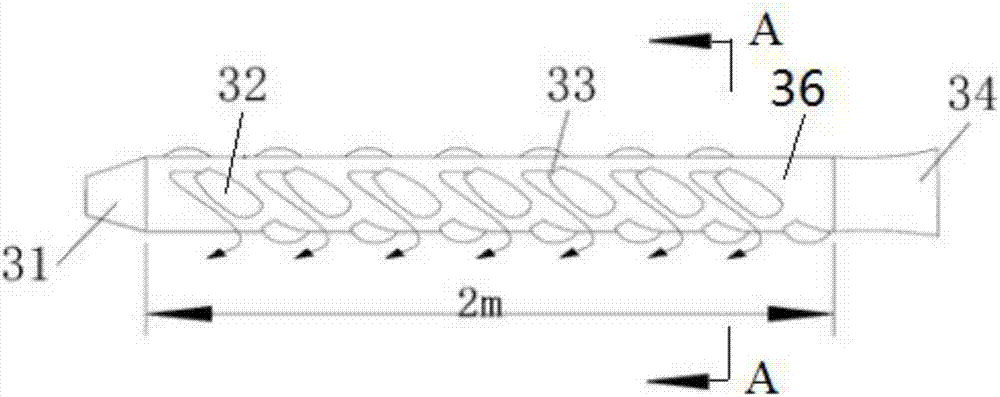

Dust removing system for fully-mechanized coal mining workface

PendingCN107218074AImprove working environmentReduce dust concentrationDust removalFire preventionMining engineeringDust control

The invention discloses a dust removing system for a fully-mechanized coal mining workface. The system includes a dust control system installed on one side of a roadheader, a dust suction system and a dust collecting system installed on the other side of the roadheader, wherein the dust control system comprises a press-in type fan, a press-in type air duct and a wall-attached air duct which are connected with each other in turns; the dust suction system comprises a first suction hood for sucking dust on the cutting head position of the roadheader, a second suction hood for sucking dust on the insertion board position of the roadheader, a third suction hood for sucking dust on the break-of-bulk-point position of a scraper conveyor and belt conveyor, a dust suction air duct and a suction hood assembly box, and the first suction hood, the second suction hood, the third suction hood and the dust suction air duct are all connected to the suction hood assembly box; the dust collecting system comprises an extraction type air duct, a dust remover and an extraction type fan which are connected with each other in turns, and the extraction type air duct is connected to the suction hood assembly box. The dust removing system for the fully-mechanized coal mining workface can effectively control diffusing and spreading of dust in underground roadways, has a good dust suction effect and high dust collecting efficiency, and can greatly reduce the dust concentration of the fully-mechanized coal mining workface.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

A homogeneous coagulation molding method for polyacrylonitrile precursor

InactiveCN102260919AAchieve homogenizationImprove performanceWet spinning methodsPolymer scienceDouble diffusion

The invention discloses a method for homogenizing, solidifying and forming polyacrylonitrile precursor. By adopting a wet spinning technology, a polyacrylonitrile spinning solution trickles in a coagulating bath to be subjected to double diffusions through solvent and precipitator and then solidified and separated so that the polyacrylonitrile precursor is formed. According to the method disclosed by the invention, an ammonia-containing compound is added in the a coagulating bath; the ammonia-containing compound is served as a third component and can be used for retarding the double-diffusion speed in the solidification process of the polyacrylonitrile spinning solution; therefore, the solidifying and forming homogenization is realized; and the high-performance polyacrylonitrile precursor and carbon fibre can be obtained.

Owner:ZHEJIANG TAIXIAN NEW MATERIAL

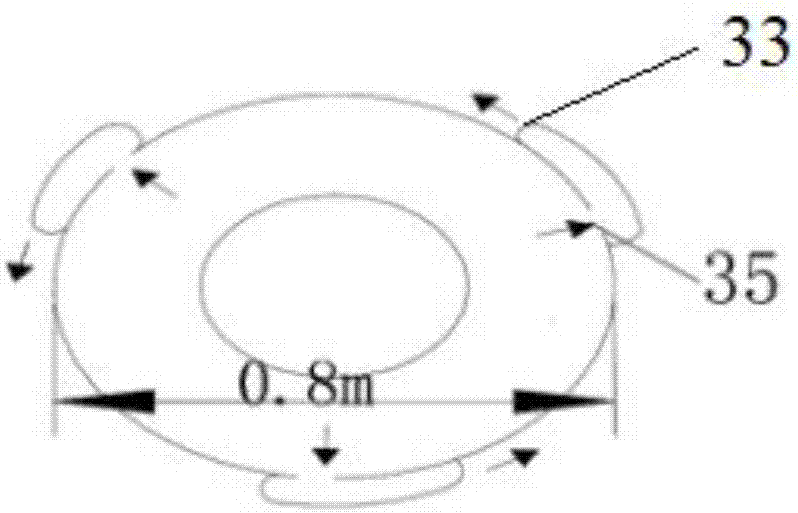

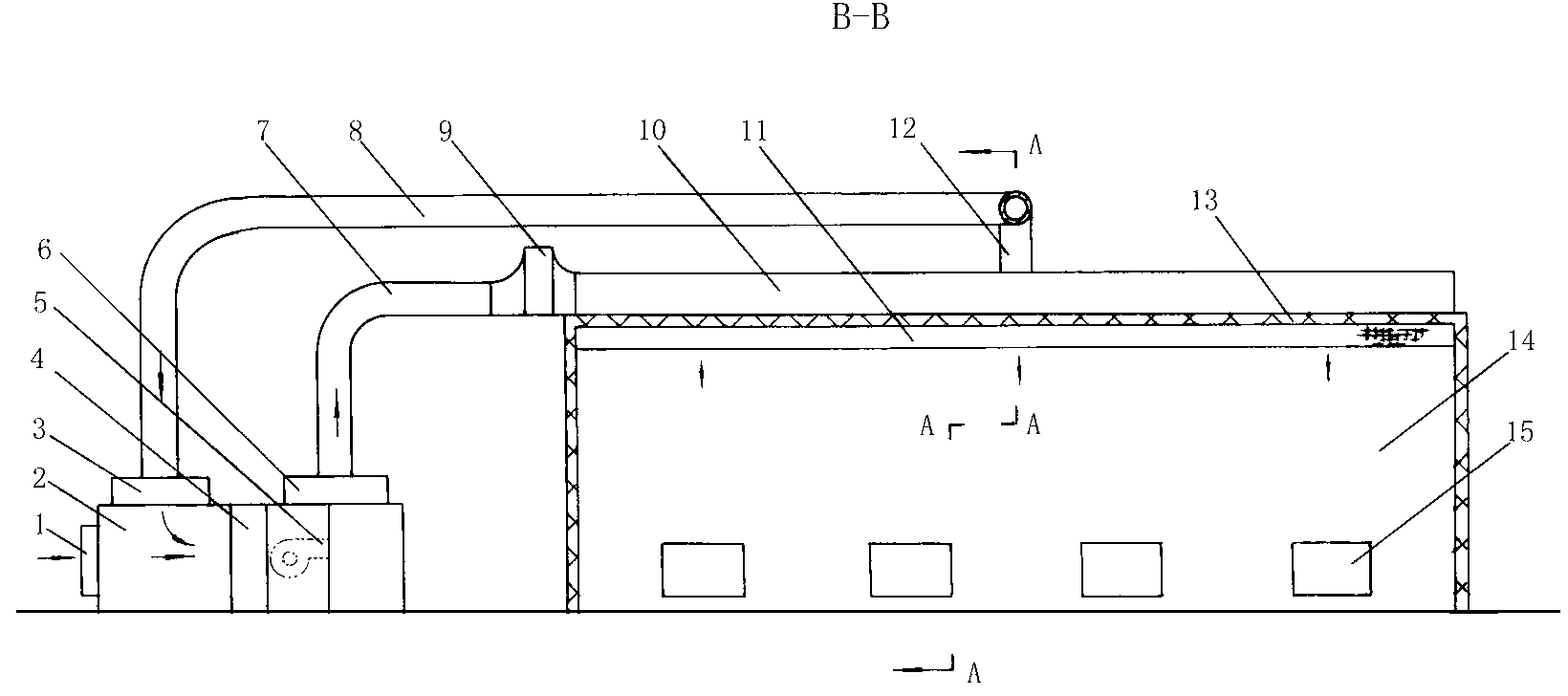

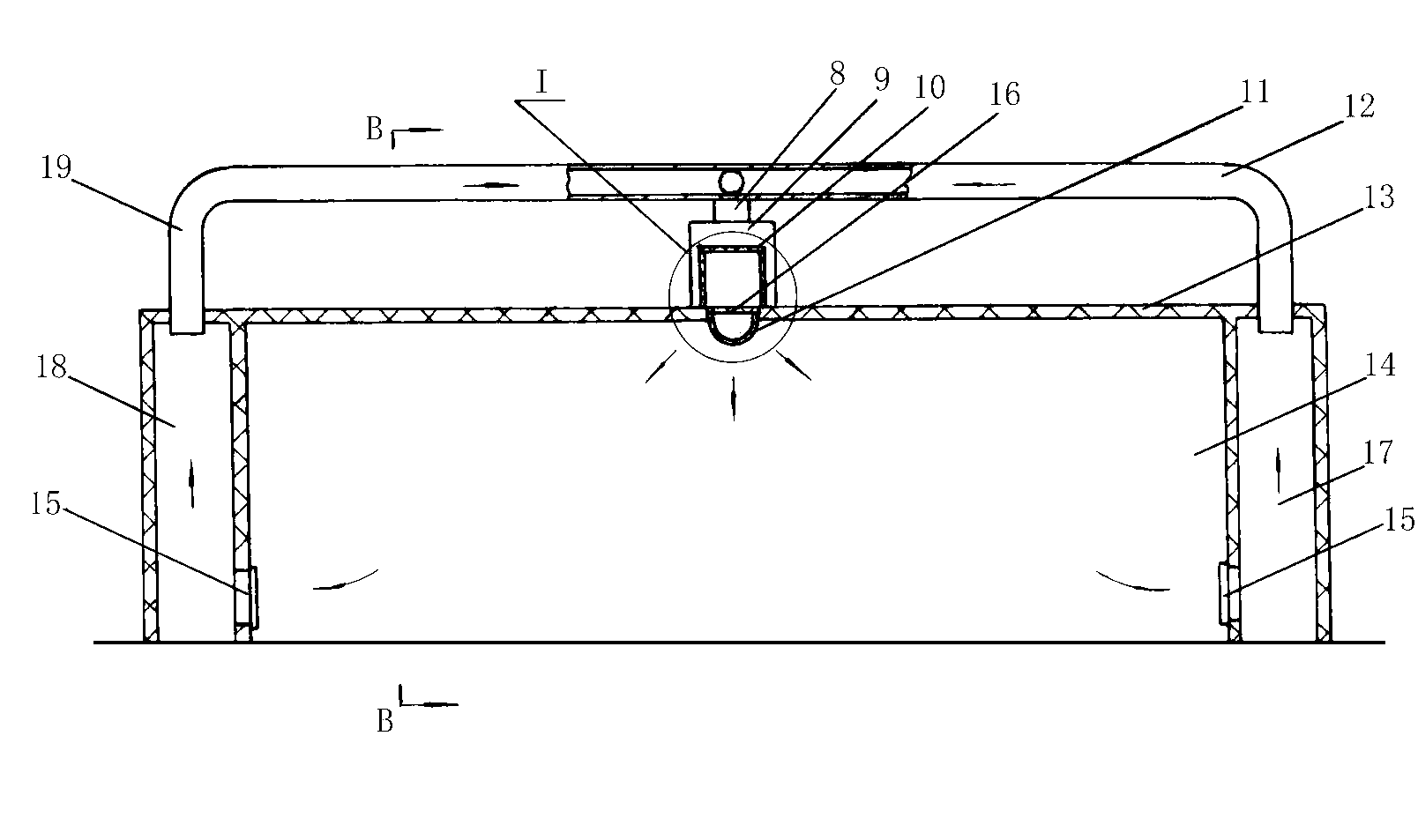

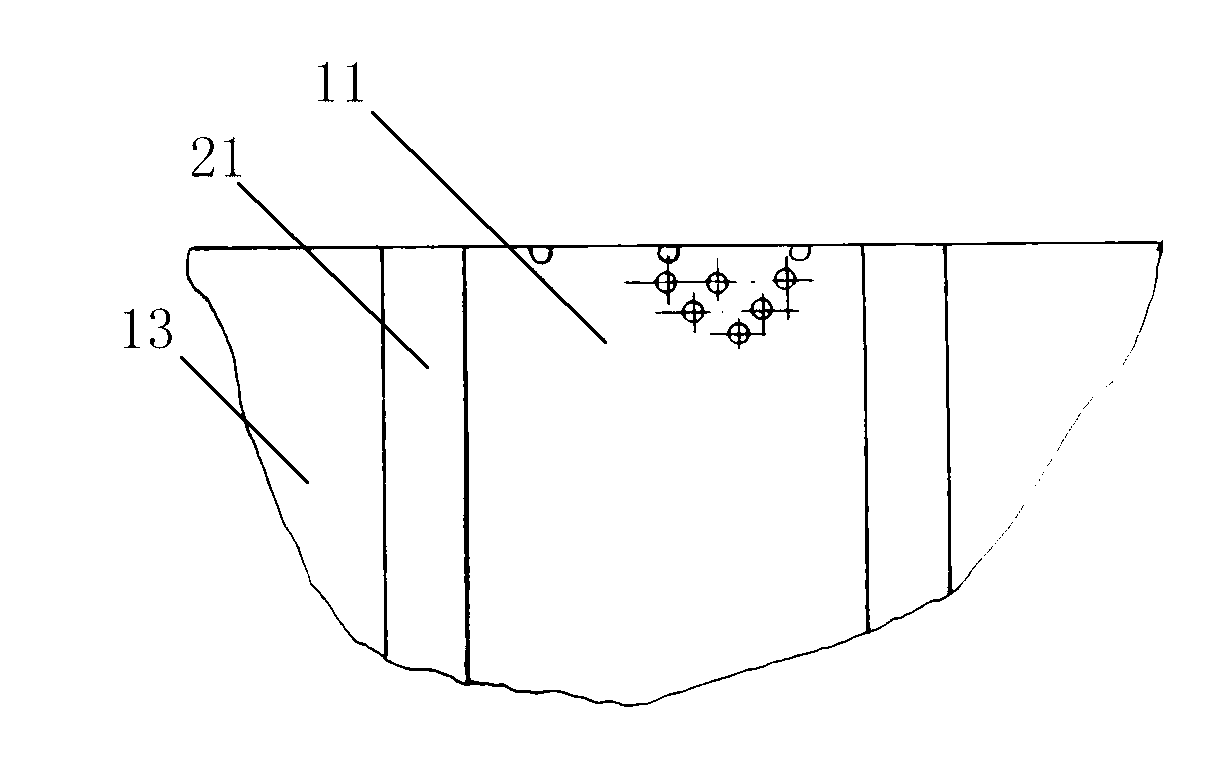

Low steady-speed radial flow clean room air-conditioning air supply and return system

ActiveCN103322657ASmall running resistanceSlow down the spreadDucting arrangementsLighting and heating apparatusSuspended particlesFresh air

The invention relates to a low steady-speed radial flow clean room air-conditioning air supply and return system which comprises a radial flow air supply channel device, a wall-mounted air return channel device, an air-conditioning outlet static pressure box, an air-conditioning air return port static pressure box and an air-conditioning fresh air port filtering device, the radial flow air supply channel device comprises a clean room roof, a static pressure box type air supply channel, a pressure equalizing partition plate, an arc-shaped radial flow cover, a damping layer and a high efficiency filter bank, and the wall-mounted air return channel device comprises a sandwich wall type air return duct and a filtering device mounted at an air return port of the lower end of the sandwich wall type air return duct. The air supply and return system has the advantages that the operation resistance of the air supply and return system is reduced, the diffusion speed of harmful suspended particles in a clean room is the lowest, fewer high efficiency filter banks are used, the clean room is low in construction investment, energy-saving in operation and convenient to maintain, the air cleanliness class of the clean room is improved by more than 30% as compared with that of a mixed airflow clean room, clean time can be shortened by more than 40%, and airflow in the clean room is reasonably distributed.

Owner:SHIJIAZHUANG AOXIANG MEDICAL ENG

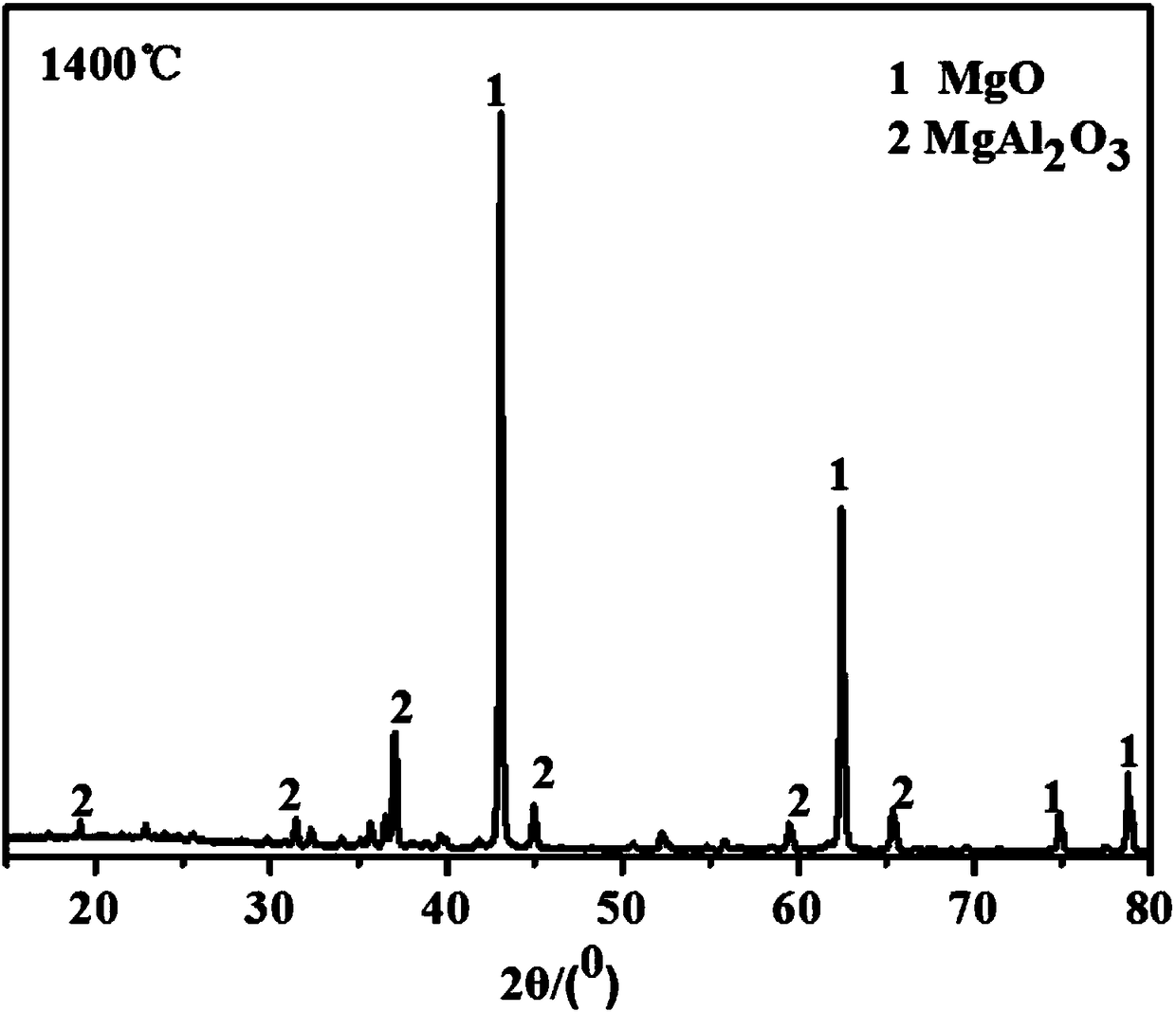

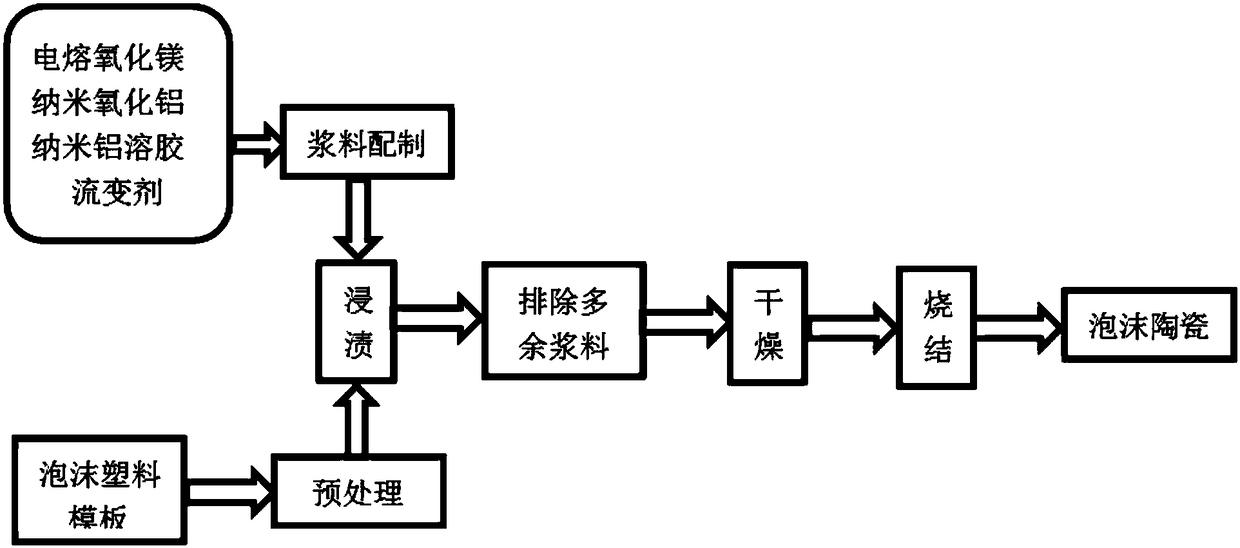

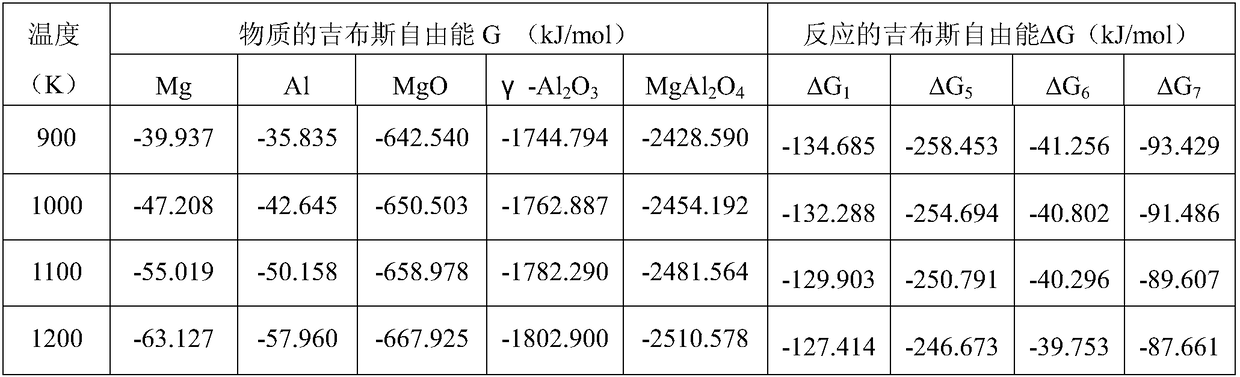

Magnesium aluminate spinel enhanced magnesia-based foamed ceramic filter and preparation method thereof

ActiveCN108516803AAct as a binderAvoid damageFiltration separationCeramicwareOxide ceramicNano al2o3

The invention discloses a magnesium aluminate spinel enhanced magnesia-based foamed ceramic filter with capability of realizing sintering at low temperature, excellent chemical stability and excellentthermal shock resistant performance, and a preparation method thereof. The preparation method comprises the following steps that (1) 10 to 20 percent of nanometer alumina sol, 0.8 to 1.5 percent of rheological agents and the balance of magnesium oxide ceramic powder containing a nanometer aluminum oxide sintering aid are proportioned; deionized water is added; ball milling and uniform mixing areperformed; then, through vacuum exhaust, ceramic slurry with the solid content being 60 to 70 percent is prepared; (2) a polyurethane foamed plastic template is soaked into the ceramic slurry; the polyurethane foamed plastic template is extruded through a roller press for removing the redundant leaching hanging slurry; then, biscuit is prepared; then, the biscuit is heated to 80 to 120 DEG C for drying; (3) the dried biscuit is put into a sintering furnace; the temperature is raised to 1400 to 1600 DEG C; high-temperature sintering is performed; cooling is performed along with the furnace to room temperature; the magnesia-based foamed ceramic filter is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

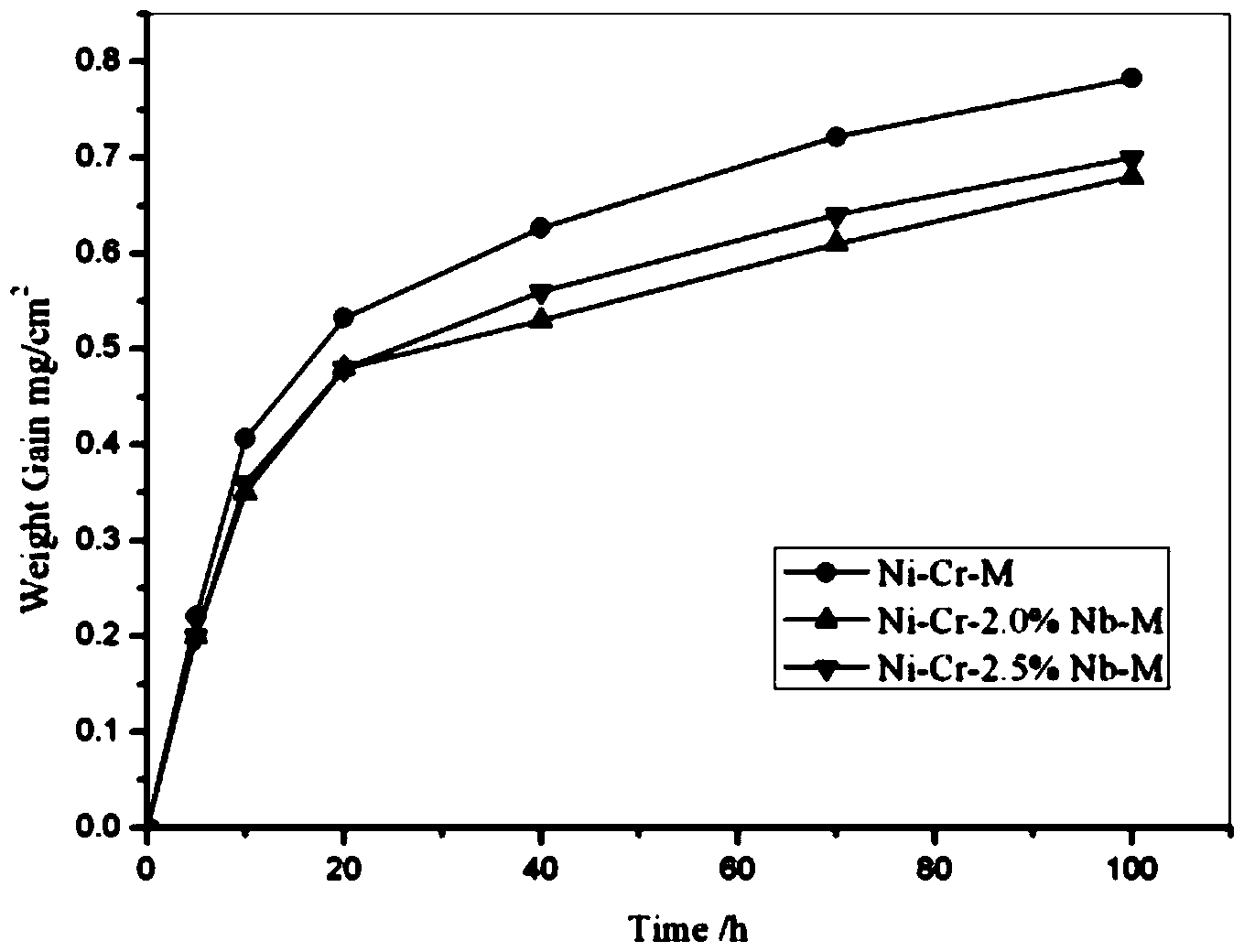

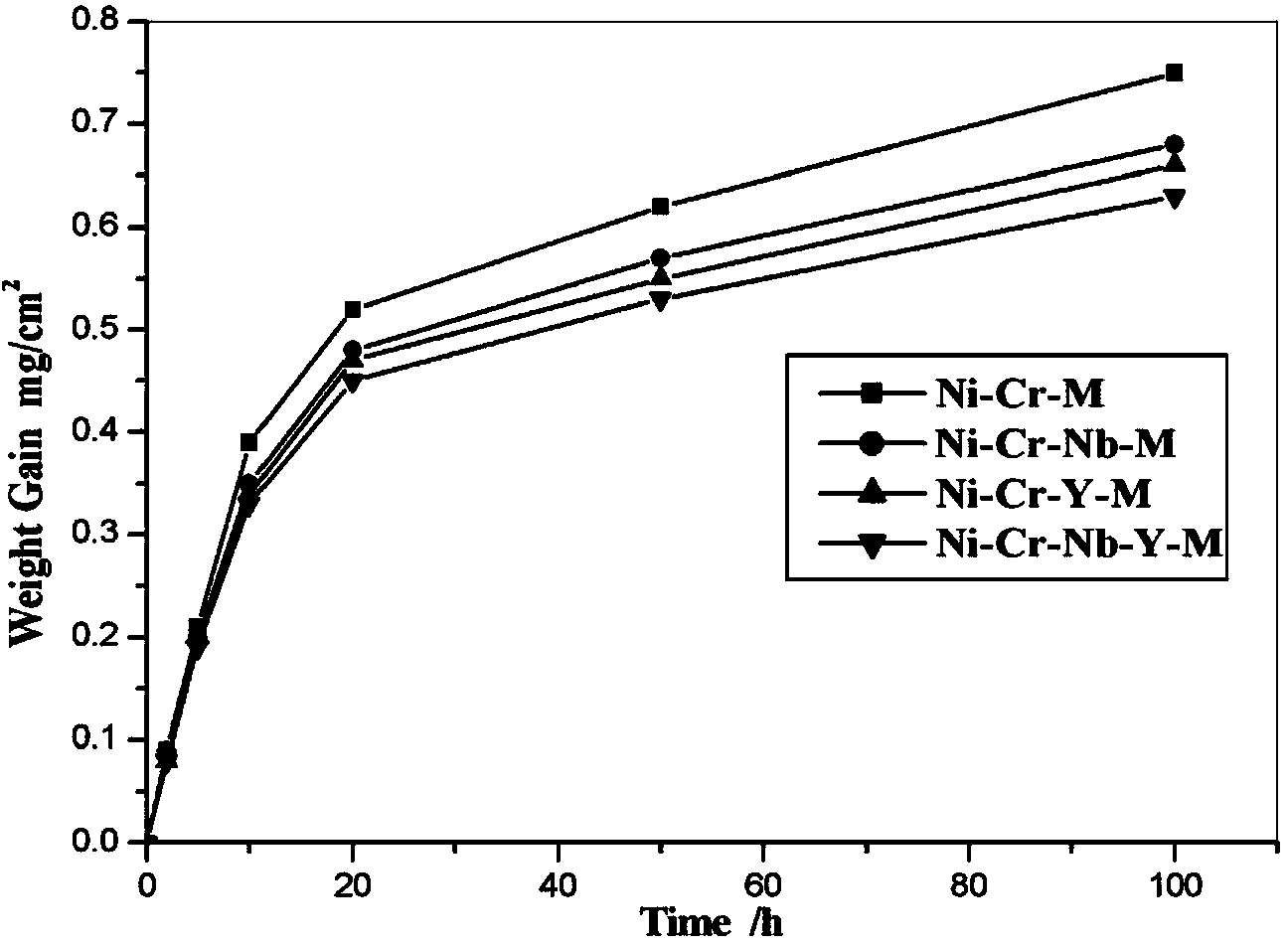

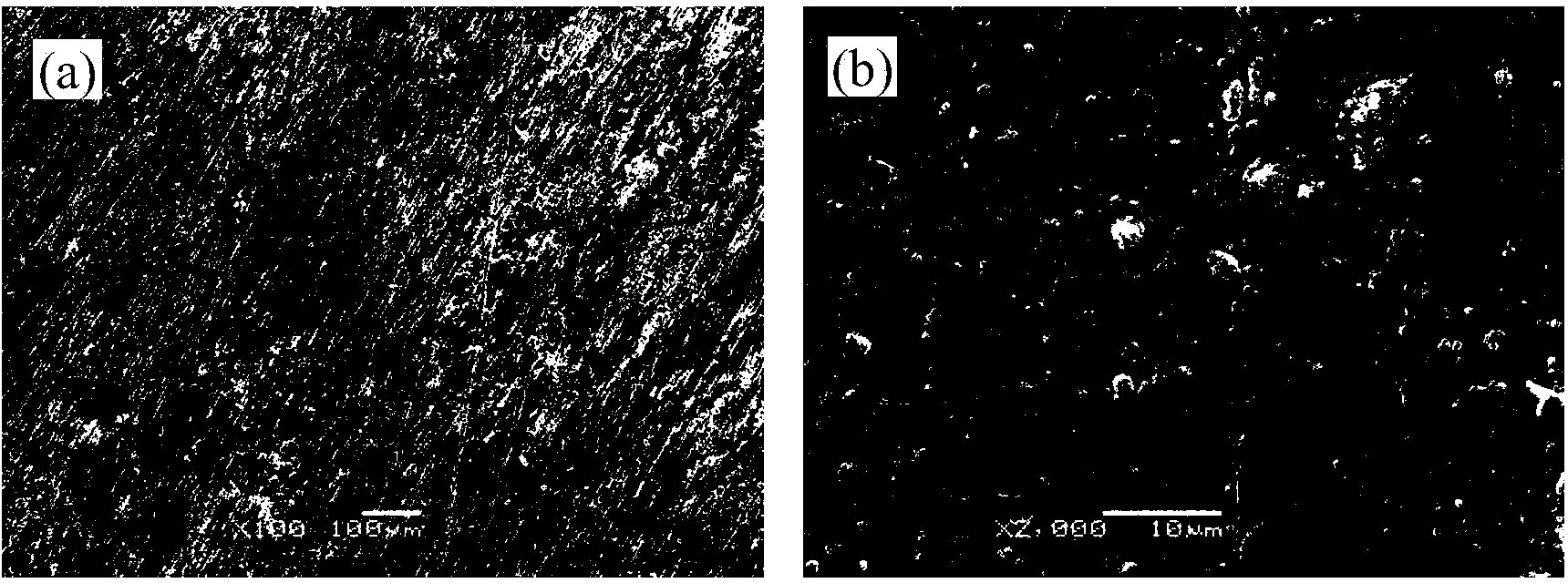

Nickel-based high temperature alloy, preparation method thereof as well as application thereof in spark plug electrode

The invention relates to a nickel-based high temperature alloy, a preparation method thereof as well as application thereof in a spark plug electrode. The nickel-based high temperature alloy contains the following components in percent by weight: 0.04%-0.06% of C, 19%-21% of Cr, 7%-9% of W, 5%-7% of Mo, 1%-2% of Ti, 0.5%-2% of Al, 0.004%-0.006% of B, 0.03%-0.05% of Zr, 0.7%-0.9% of Fe, 0-3% of Nb, 0-1% of Y, and the balance of Ni and inevitable impurities. The preparation method of the nickel-based high temperature alloy comprises the following steps of: mixing the components in a vacuum electric-arc melting furnace according to a proportion, smelting, getting out and forming; heating up to 1200 DEG C in a heating furnace, carrying out thermal-insulation solid-solution treatment for 4 hours, and carrying out air-cooling; and carrying out thermal-insulation aging treatment for 10 hours at 800 DEG C, and carrying out air-cooling to prepare the nickel-based high temperature alloy. The nickel-based high temperature alloy disclosed by the invention has good high-temperature oxidation resistance and corrosion resistance, and can be applied to the spark plug electrode material so as to prolong the service life of an electrode and the service life of a spark plug.

Owner:SHANDONG UNIV

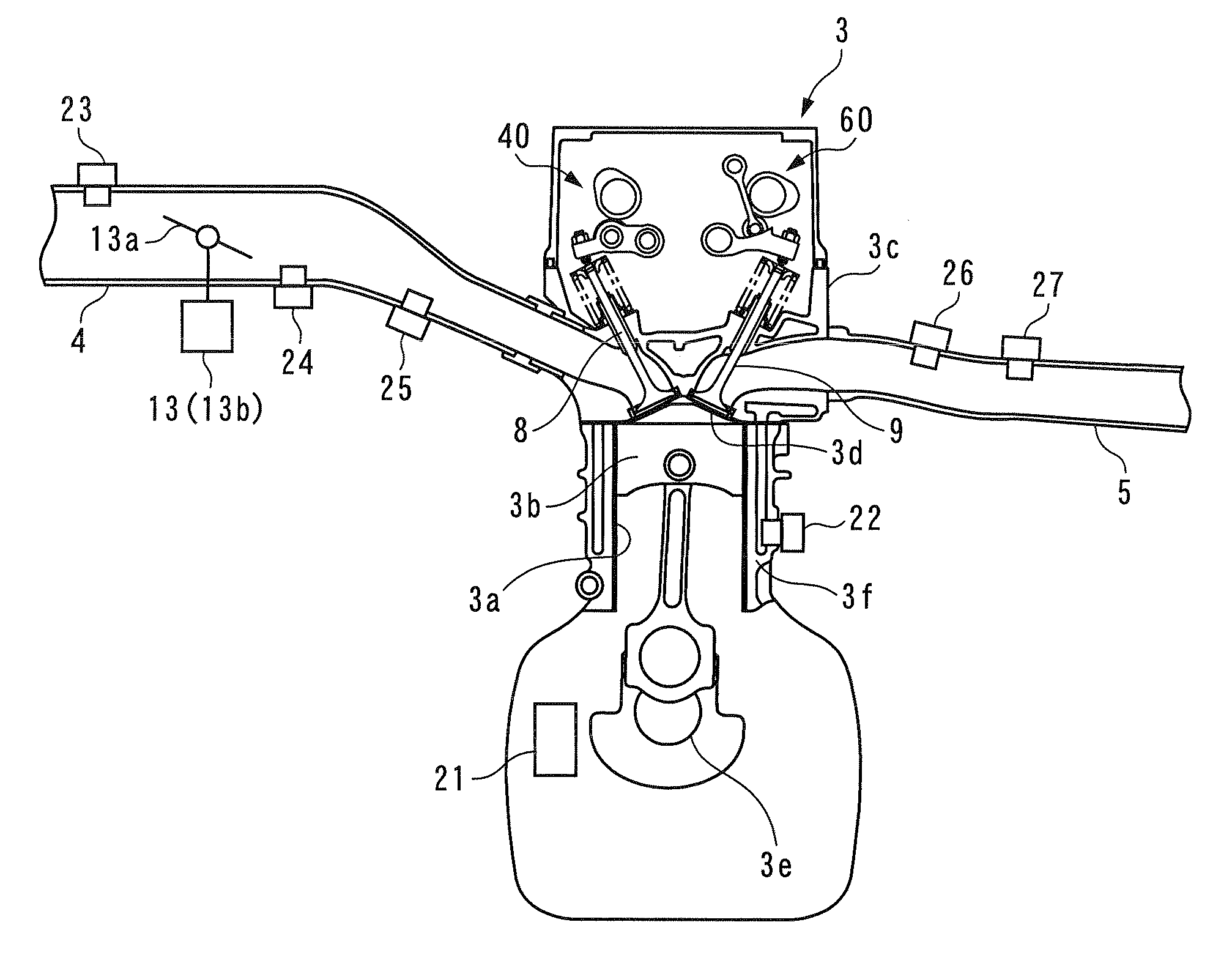

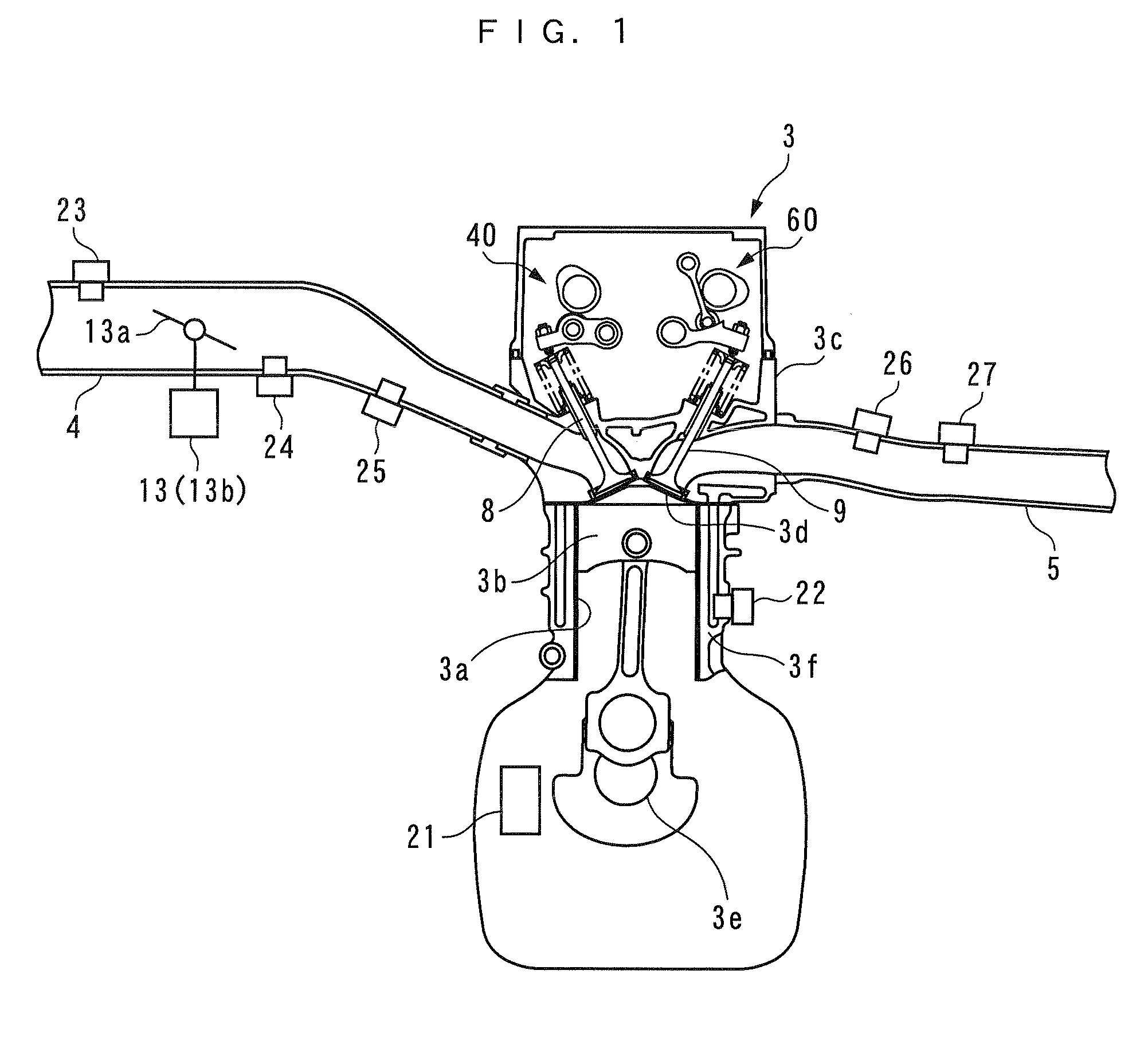

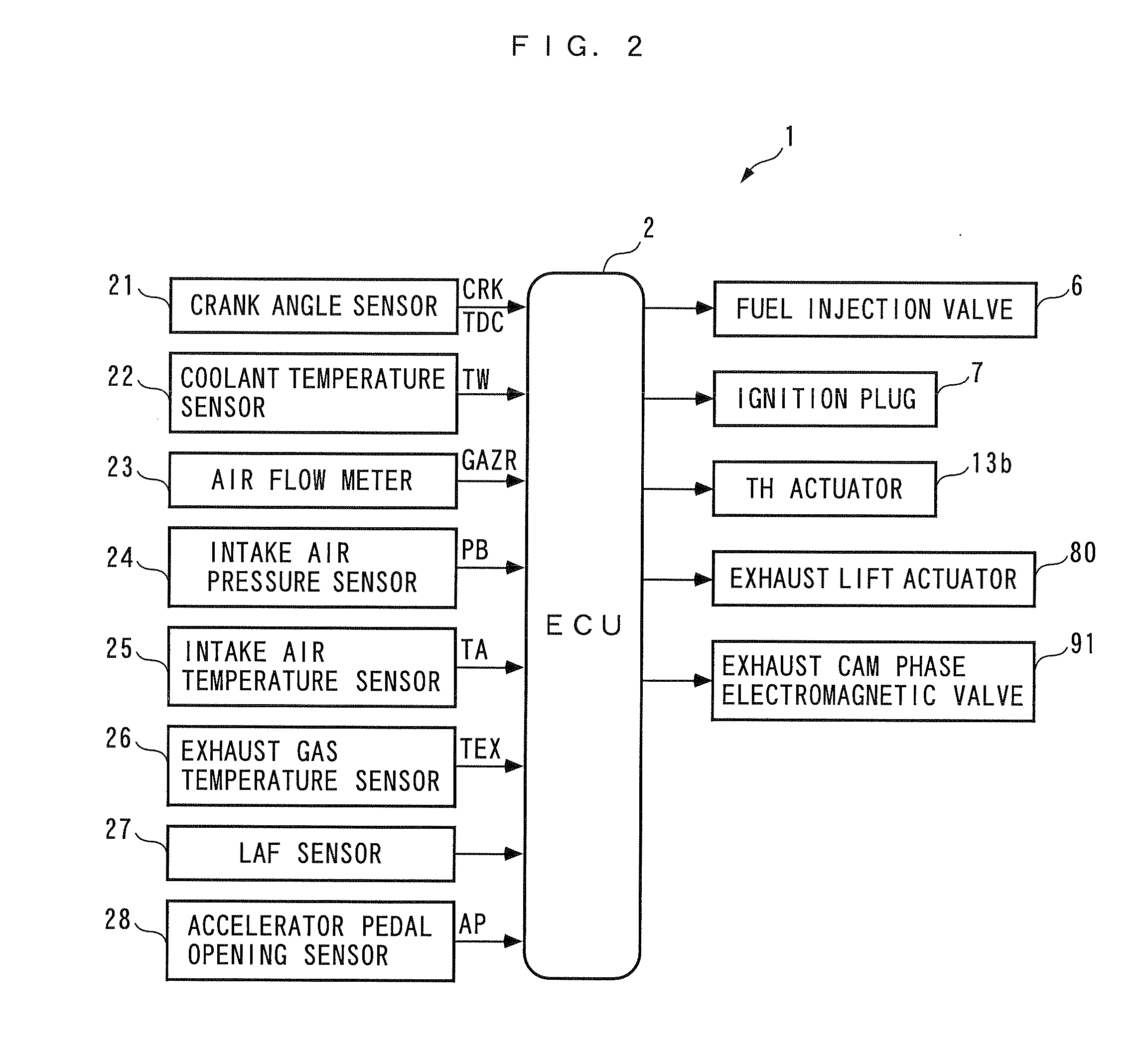

Ignition timing control system for internal combustion engine

InactiveUS20100274463A1Stable combustionImprove drivabilityAnalogue computers for vehiclesElectrical controlControl systemTime control

To provide an ignition timing control system for an internal combustion engine, which is capable of ensuring stable combustion without causing a misfire or knocking, by properly setting ignition timing in the compression stroke injection mode, thereby making it possible to improve drivability. The ignition timing control system for the engine 3 that directly injects fuel into cylinders 3a and is operated by switching the fuel injection mode between an intake stroke injection mode and a compression stroke injection mode comprises fuel injection timing-setting means 2 for setting a fuel injection timing INJOBJ according to an engine speed NE of the engine 3 and a fuel injection amount GFUEL, basic value-setting means 2 for setting a basic value IGBASE of ignition timing according to the engine speed NE of the engine 3 and the fuel injection timing INJOBJ, and ignition timing-setting means 2 for setting ignition timing IGCOMP in the compression stroke injection mode by correcting the basic value IGBASE according to a detected air-fuel ratio AF.

Owner:HONDA MOTOR CO LTD

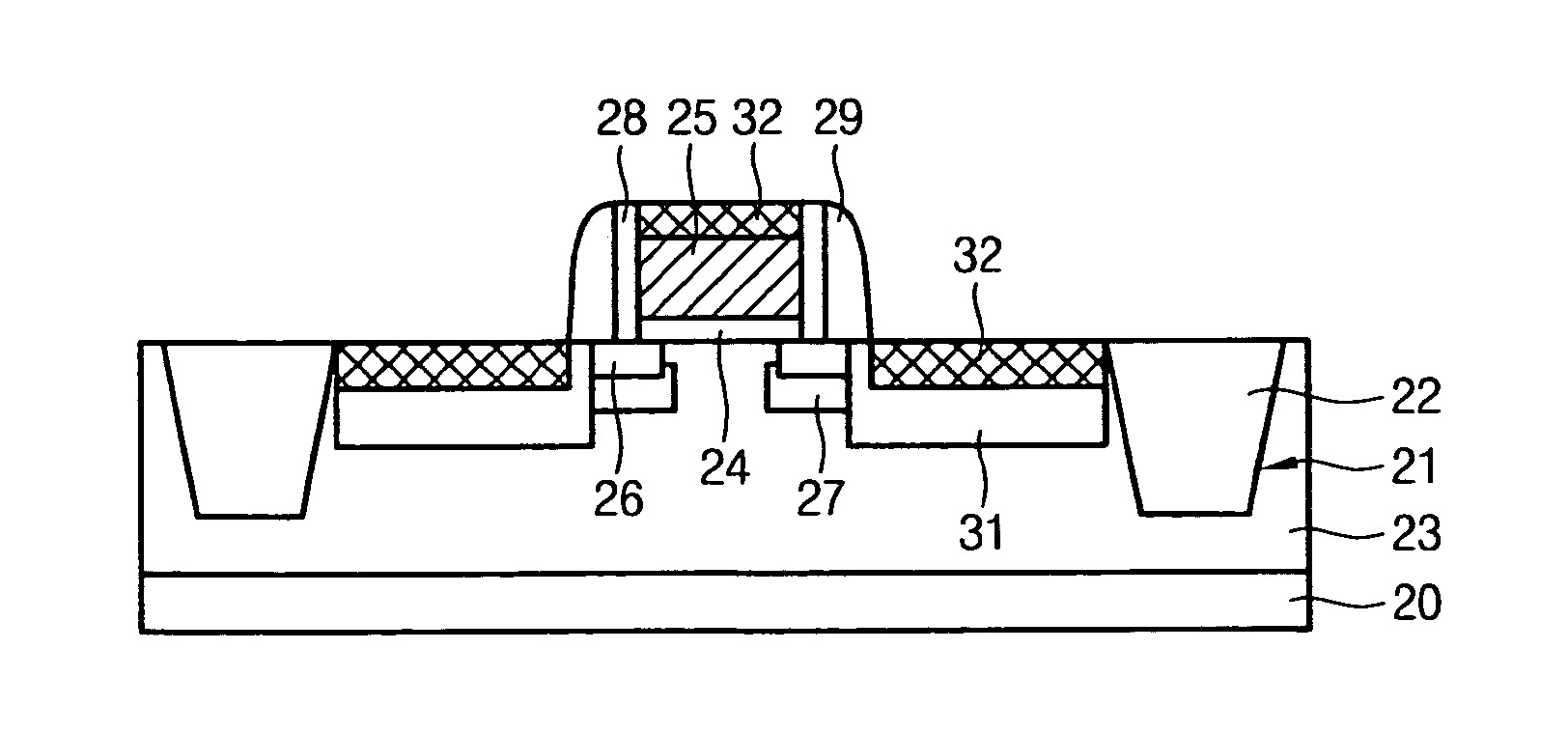

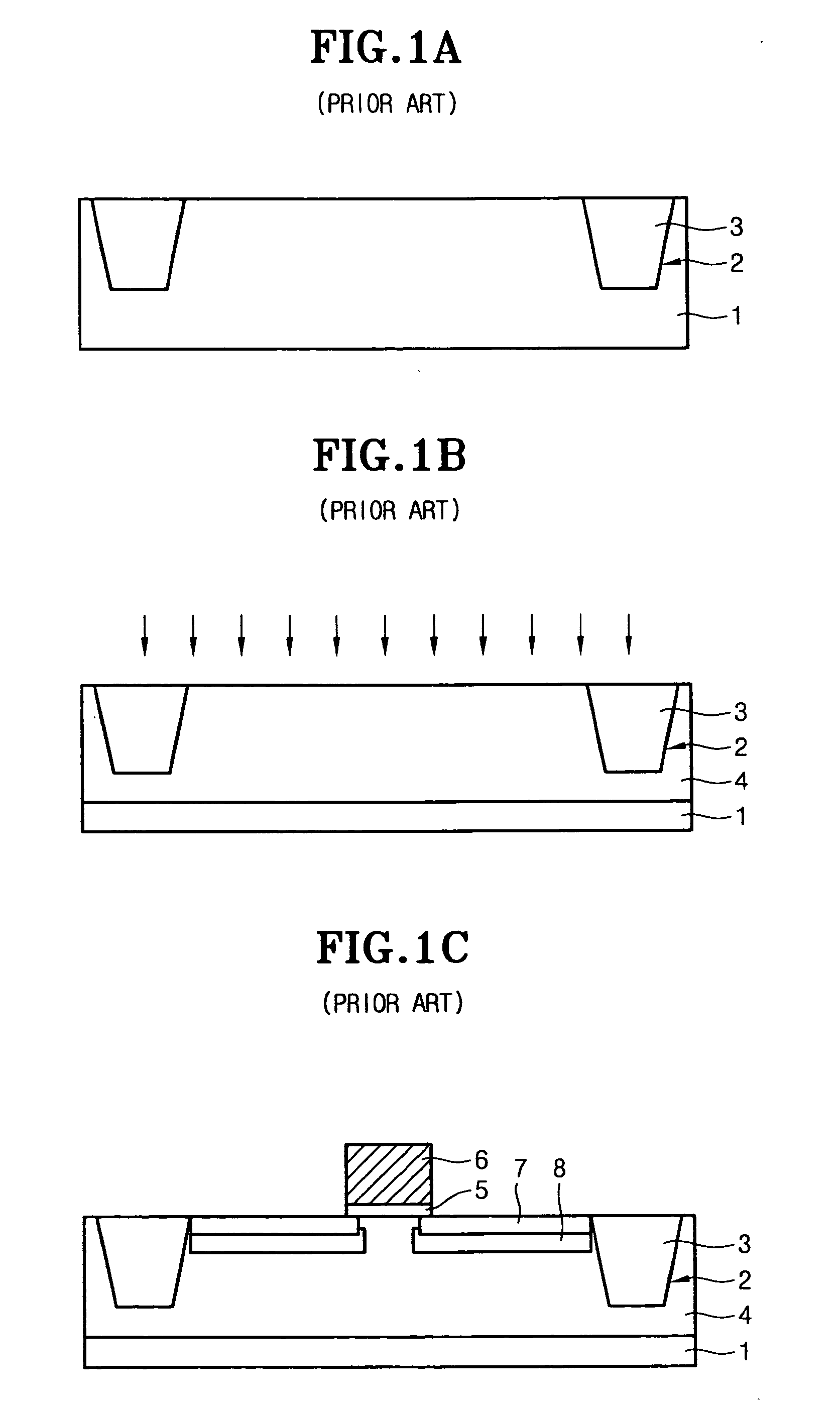

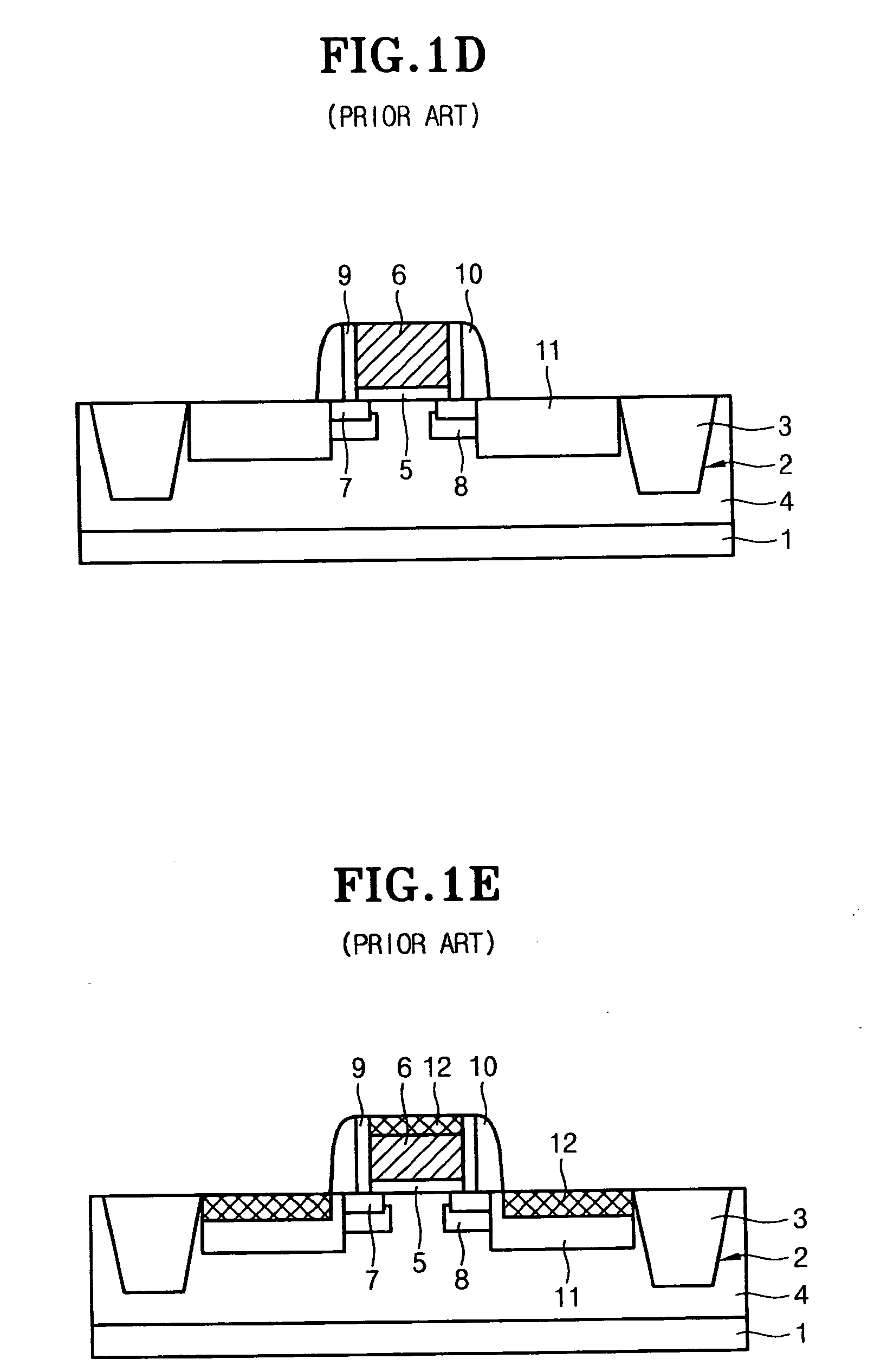

Method for fabricating transistor of semiconductor device

ActiveUS20050112835A1Slow down the spreadImprove short channel effectTransistorSemiconductor/solid-state device manufacturingSalicideHigh density

Disclosed is a method for fabricating a transistor of a semiconductor device, the method comprising the steps of: providing a semiconductor; forming a gate electrode; performing a low-density ion implantation process with respect to the substrate, thereby forming an LDD ion implantation layer; forming an insulation spacer on a sidewall of the gate electrode; forming a diffusion barrier; performing a high-density ion implantation process with respect to the substrate, thereby forming a source / drain; performing a first thermal treatment process with respect to a resultant structure, so as to activate impurities in the source / drain, and simultaneously causing a diffusion velocity of the impurities in the source / drain to be reduced by the diffusion barrier; and forming a salicide layer.

Owner:ATRIA TECH INC

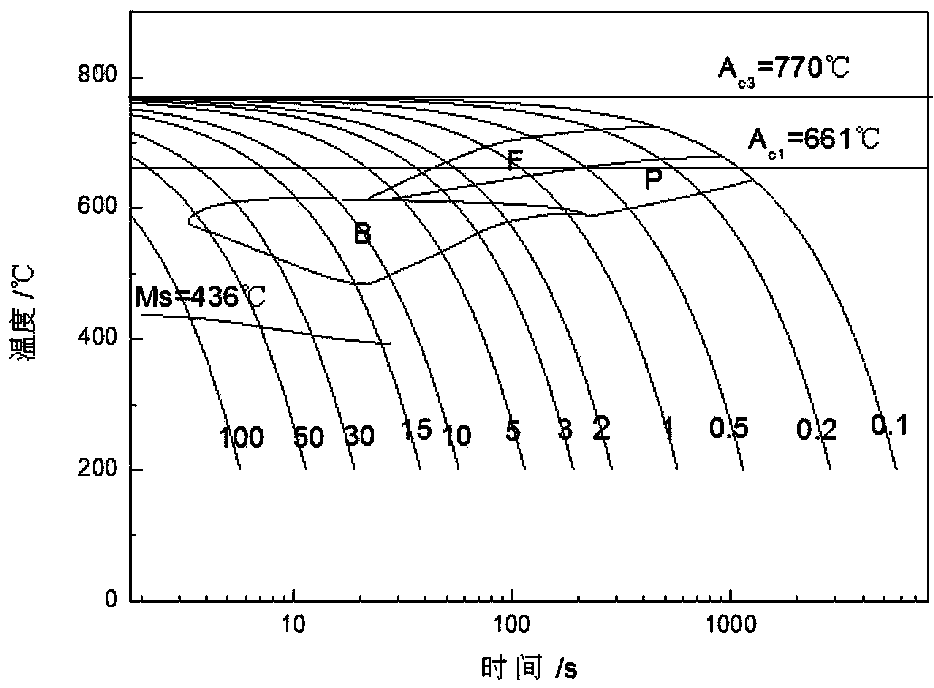

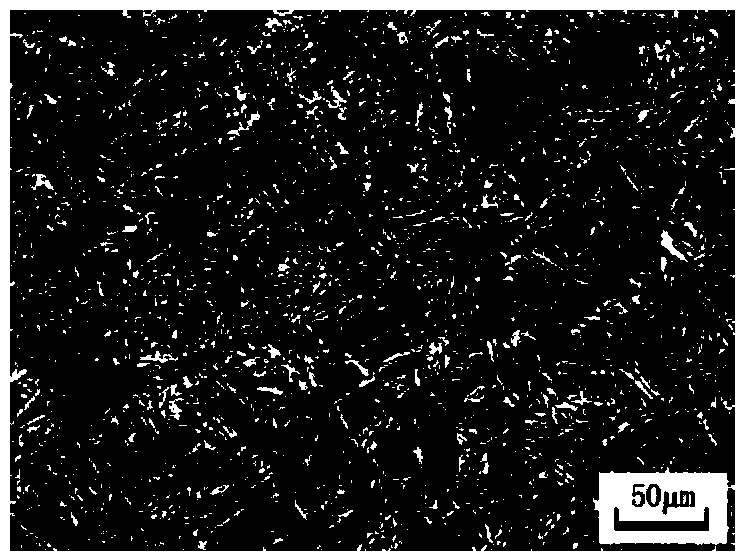

HRB500 reinforcing steel bar and preparation method thereof

The invention discloses an HRB500 reinforcing steel bar and a preparation method thereof. The reinforcing steel bar comprises the following chemical components in percentage by weight: 0.10-0.18% of C, 0.2-0.8% of Si, 1.2-1.6% of Mn, less than or equal to 0.04% of P, less than or equal to 0.04% of S, 0.001-0.005% of B and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: heating a billet to 1,150-1,250 DEG C in a furnace; performing heat preservation for 100-120 minutes; taking the billet out of the furnace; rolling when the temperature is within 1,050-1,150 DEG C; rolling, and cogging for two times, wherein the billet is rolled for 14-18 times in all roughly, moderately and finely, and the total compression ratio is 64-156; cooling to 600-680 DEG C at a speed of 8-12 DEG C / s after the fine rolling is finished; finally air-cooling to the room temperature. According to the HRB500 reinforcing steel bar and the preparation method, the strength of the reinforcing steel bar is improved through tissue phase change. Compared with the prior art, the HRB500 reinforcing steel bar is smelted by using a smelting method for ordinary steel, and is subsequently cast into the billet, and meanwhile the alloy content is reduced, so that the product cost is lowered.

Owner:武汉钢铁有限公司

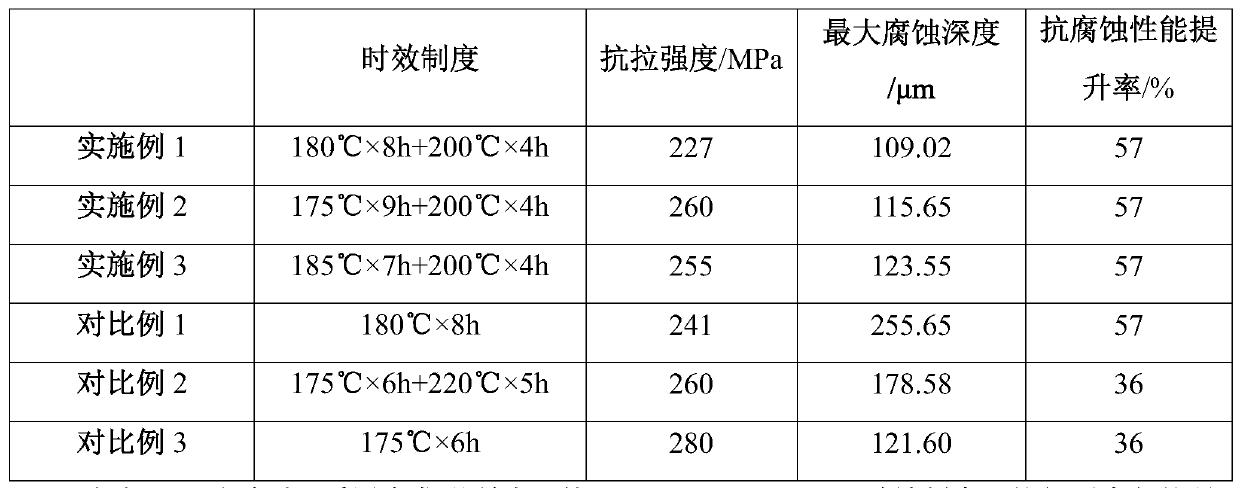

Production process for improving intergranular corrosion resistance of 6 series aluminum alloys

The invention belongs to the technical field of metal heat treatment, and relates to a production process for improving the intergranular corrosion resistance of 6 series aluminum alloys. The 6-seriesaluminum alloys are prepared from the raw materials: 0.5% to 0.9% of Si, less than or equal to 0.35% of Fe, less than or equal to 0.30% of Cu, less than or equal to 0.50% of Mn, 0.4% to 0.7% of Mg, less than or equal to 0.30% of Cr, 0.1% of Ti, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of total impurity and the balance of Al; a preparation method includes the steps of ingredient melting and casting, homogenization, extrusion, solution quenching, stretching, two-stage aging and detection; and the two-stage aging system is (175-185 DEG C)*(7-9h)+200 DEG C*(3-5h), and the heating time from the first-stage aging to the second-stage aging does not exceed 15min. The two-stage aging is a best aging mode, and the tensile strength and the intergranular corrosion resistance are the best match.

Owner:CHINA ZHONGWANG

Concrete-curing agent applicable to strong-wind arid area and preparation method thereof

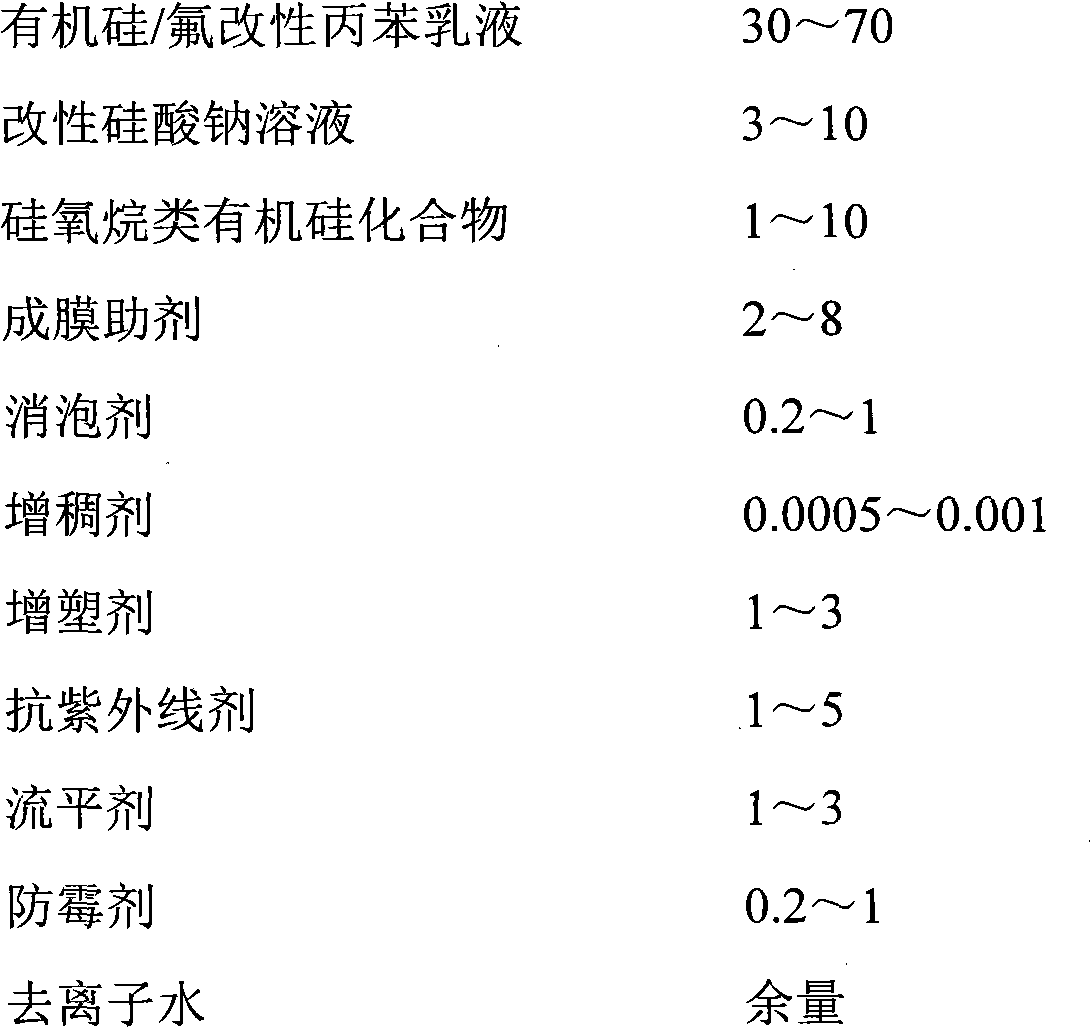

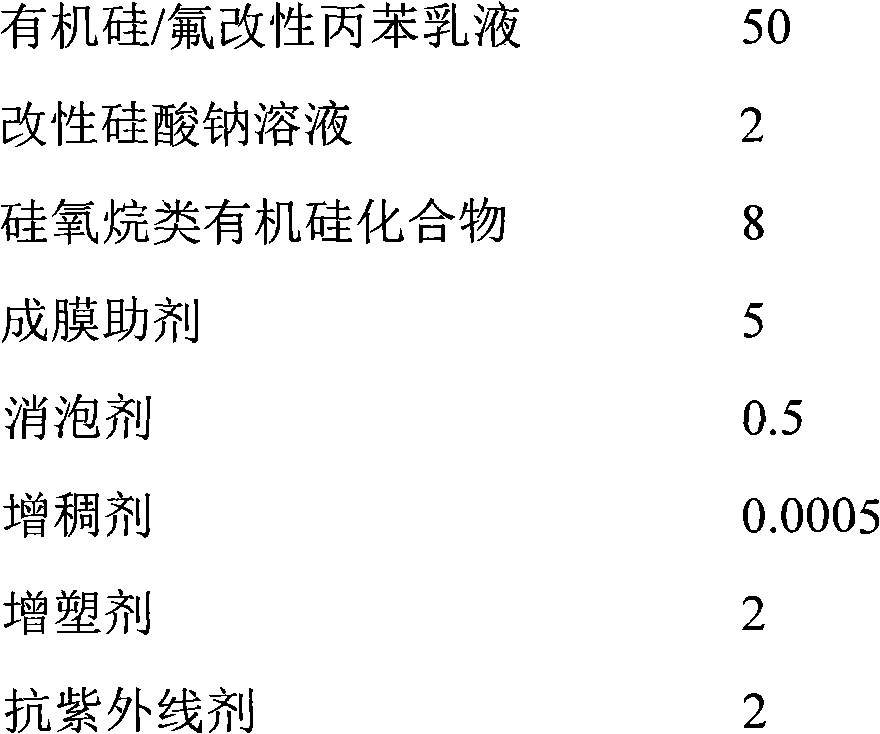

The invention relates to a concrete-curing agent applicable to a strong-wind arid area and a preparation method thereof. The curing agent is prepared through the following steps of: by using an organic / inorganic composite system with an organic-silicon / fluorine modified propyl-benzene emulsion and active aluminum-silicate modified sodium-silicate solution as a main fluid and adopting a siloxane organic-silicon compound with a certain reactive group as a cross-linked component, compounding with a film-forming aid, a defoaming agent, a thickening agent, a wetting and dispersing agent, a mildew-proof agent, a flatting agent, an ultraviolet-resisting agent and deionized water under the condition at a normal temperature. The production process of the concrete-curing agent is simple, and reaction conditions are easy to control. The water-resisting property, the scrubbing-resisting property, the durability and the flexibility of a film after the film of the curing agent is formed are improved by introducing the propyl-benzene emulsion of organic silicon / fluorine onto a high-molecular chain; and the compactness of the film is enhanced by introducing the modified sodium-silicate solution, thereby the water evaporation of a concrete surface is greatly reduced. The curing agent has the technical characteristics that the curing agent can be sprayed after concrete is finished, the film-forming speed is high, the water retention rate is high, ultraviolet rays are resisted, and the like, and is applicable to the concrete curing of western strong-wind arid areas.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

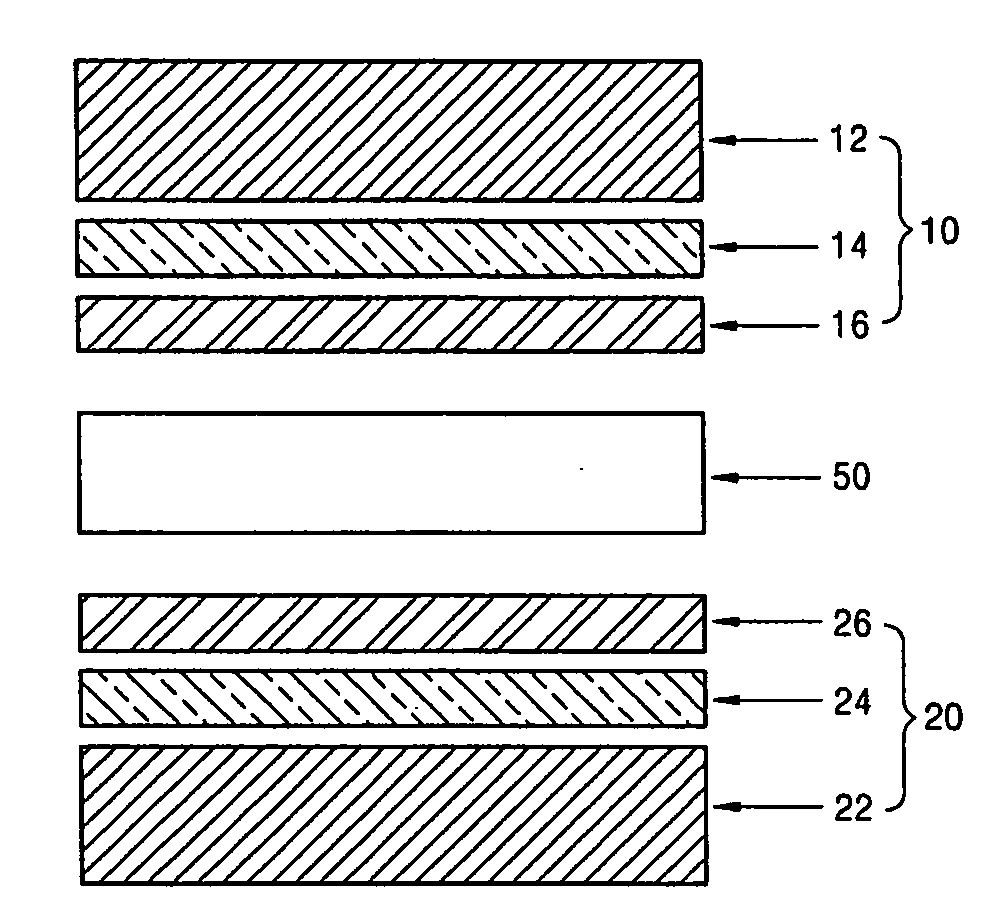

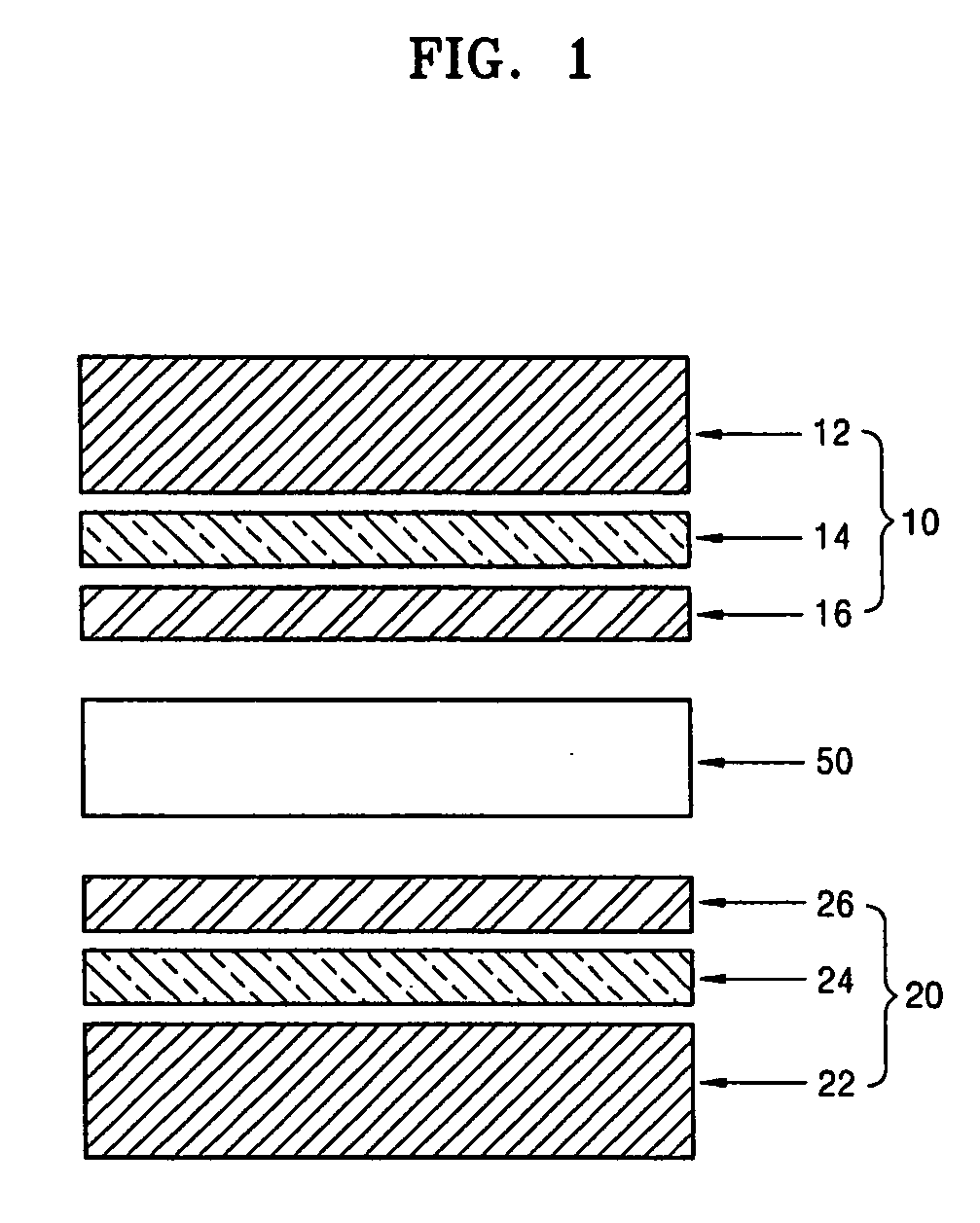

Membrane electrode assembly for fuel cell, method of preparing the same, and fuel cell using the membrane electrode assembly for fuel cell

InactiveUS20070184336A1High membrane performanceReduce diffusion speedFinal product manufactureWater management in fuel cellsCathode catalystMembrane configuration

A membrane electrode assembly for a fuel cell, a method of preparing the same, and a fuel cell using the membrane electrode assembly for a fuel cell. The membrane electrode assembly includes an anode comprising an anode substrate, an anode diffusion layer, and an anode catalyst layer having pores; a cathode comprising a cathode substrate, a cathode diffusion layer, and a cathode catalyst layer having pores; and an electrolyte membrane interposed between the cathode and the anode, wherein the anode diffusion layer is hydrophilic and the cathode diffusion layer is hydrophobic, and the average diameter of the pores of the anode catalyst layer is smaller than the average diameter of the pores of the cathode catalyst layer. In the membrane electrode assembly, air can be easily supplied to the cathode and water can easily flow out of the cathode, thereby obtaining high performance of the membrane electrode assembly, and the anode catalyst layer has relatively small pores, thereby improving durability of the anode and reducing the diffusion speed of methanol in the anode catalyst layer to maintain the initial performance of a battery for a long time.

Owner:SAMSUNG SDI CO LTD

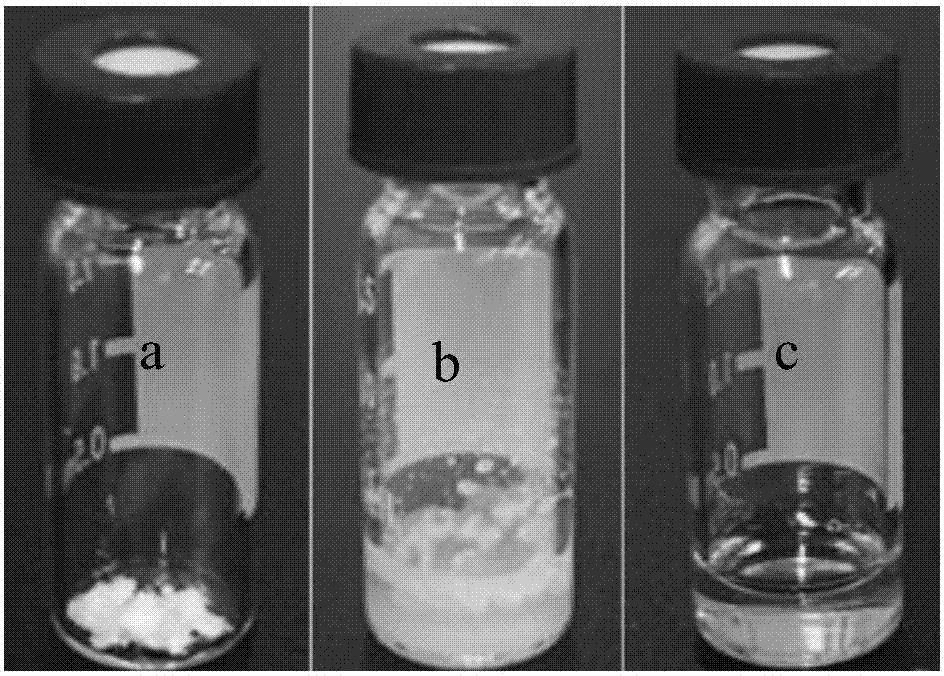

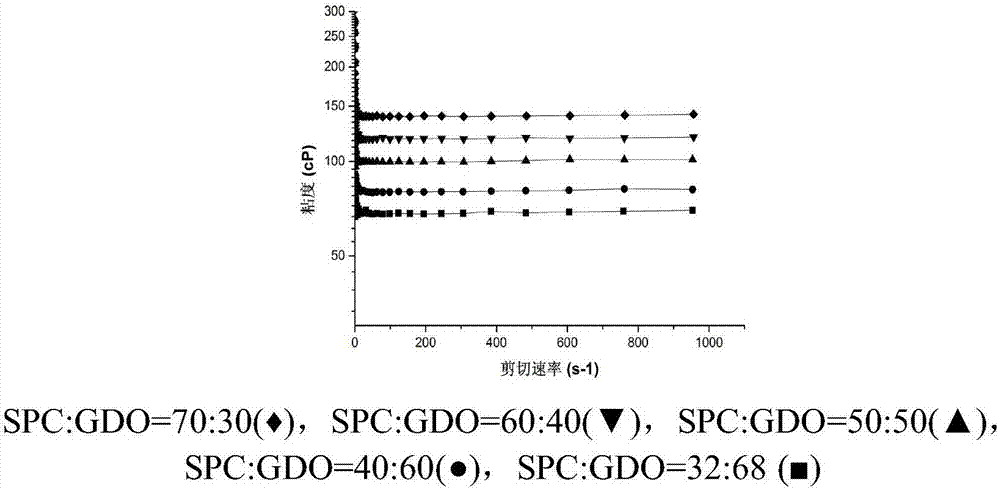

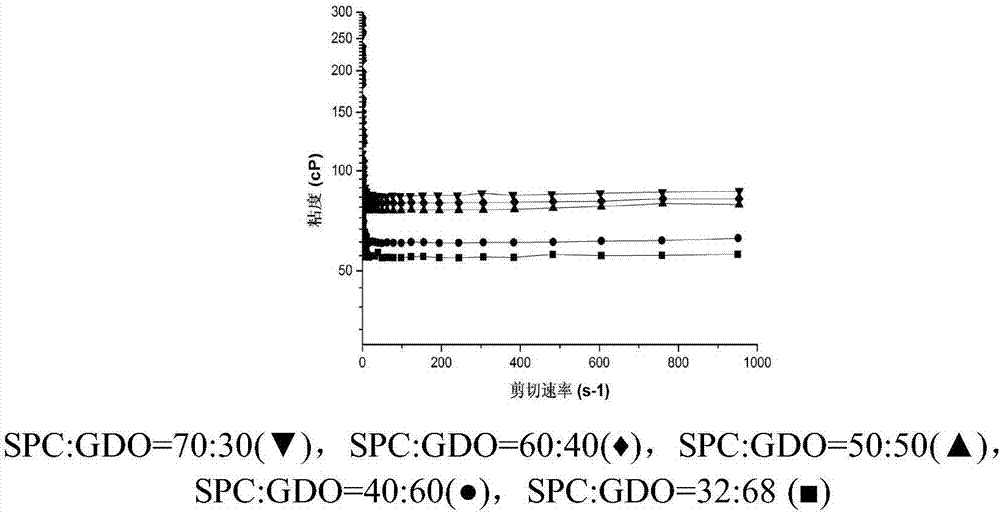

Huperzine a lyotropic liquid crystal preparation and preparation method thereof

ActiveCN106924172AImprove solubilityOvercome the disadvantages of insoluble in waterOrganic active ingredientsNervous disorderTO-18Organic solvent

The invention provides a huperzine a lyotropic liquid crystal preparation and a preparation method thereof. The huperzine a lyotropic liquid crystal preparation is prepared from the following components in parts by weight: 0.12 to 0.7 part of huperzine a, 10 to 18 parts of organic solvent, 12 to 70 parts of phospholipid, and 12 to 59.5 parts of grease. According to the huperzine a lyotropic liquid crystal preparation provided by the invention, the phospholipid, the grease and the organic solvent are used as carriers of the huperzine a, so that the solubleness of the huperzine a is effectively improved, the defect that the huperzine a is insoluble in water is overcome, the pharmacological function of the huperzine a is played favorably; meanwhile, under the condition of the limited component proportion, the huperzine a lyotropic liquid crystal preparation encounters water to form a lyotropic liquid crystal after being injected into a human body, so that the adhesion of a medicine and the preparation is improved, the medicine diffusion speed is retarded, the administration period is increased, the administration times are reduced, and thus the compliance of a patient is greatly improved.

Owner:武汉百纳礼康生物制药有限公司

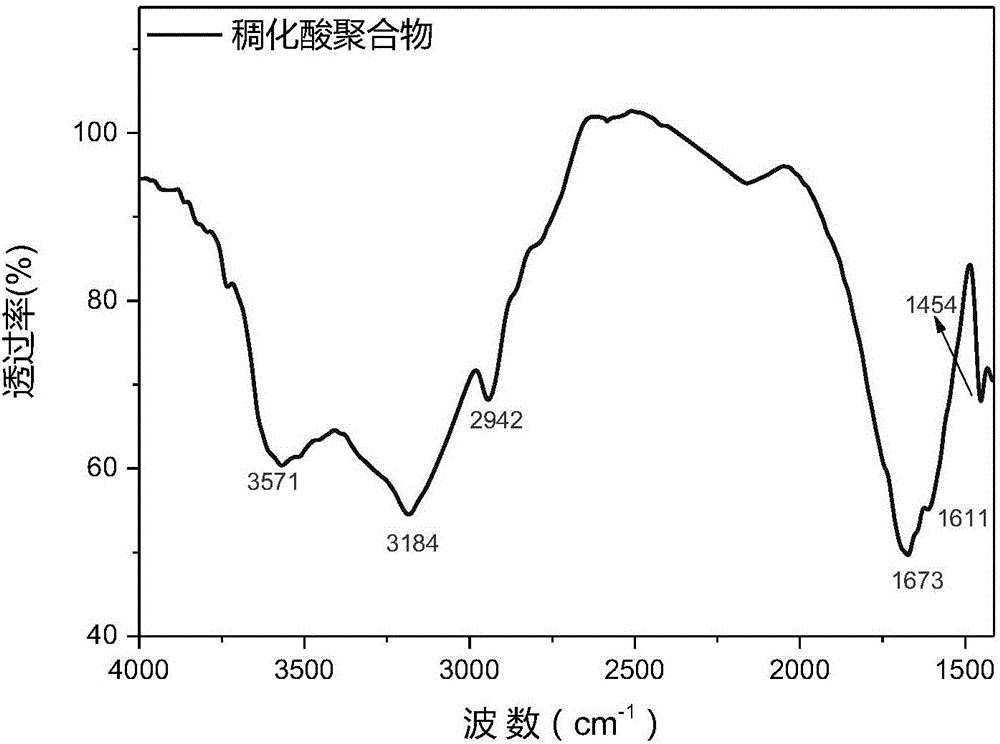

Polymer viscous acid

PendingCN106433606AReduce frictionStrong ability to suspend fine sandDrilling compositionPolymer scienceFiltration

The invention provides a polymer viscous acid. The polymer viscous acid comprises acid, a hydrophobic associative polymer thickener, a corrosion inhibitor and an iron ion stabilizer. According to the invention, the hydrophobic associative polymer thickener is adopted as a thickening agent of the viscous acid. Hydrophobic groups of the polymer are associated together in the acid liquid, such that a huge space network structure is formed in the solution, and solution thickening property is improved. The diffusion speed of hydrogen ions in the acid liquid to cracks and gaps is reduced. Also, a formed associated network structure assists in effectively limiting the activity of hydrogen ions. Therefore, acid liquid consumption rate is greatly reduced, effective action distance is increased, acid rock reaction is retarded, crack width is increased, and stratum permeability is improved. The association of hydrophobic groups also assists in improving the temperature resistance and salt resistance of the solution. The formed associative polymer has lower hydrogen ion mass transfer coefficient under high temperature and better high-temperature resistance. The prepared viscous acid has the characteristics of low filtration loss, low friction resistance and high fine sand suspension capacity, such that secondary stratum damage can be retarded.

Owner:SICHUAN GUANGYA POLYMER CHEM

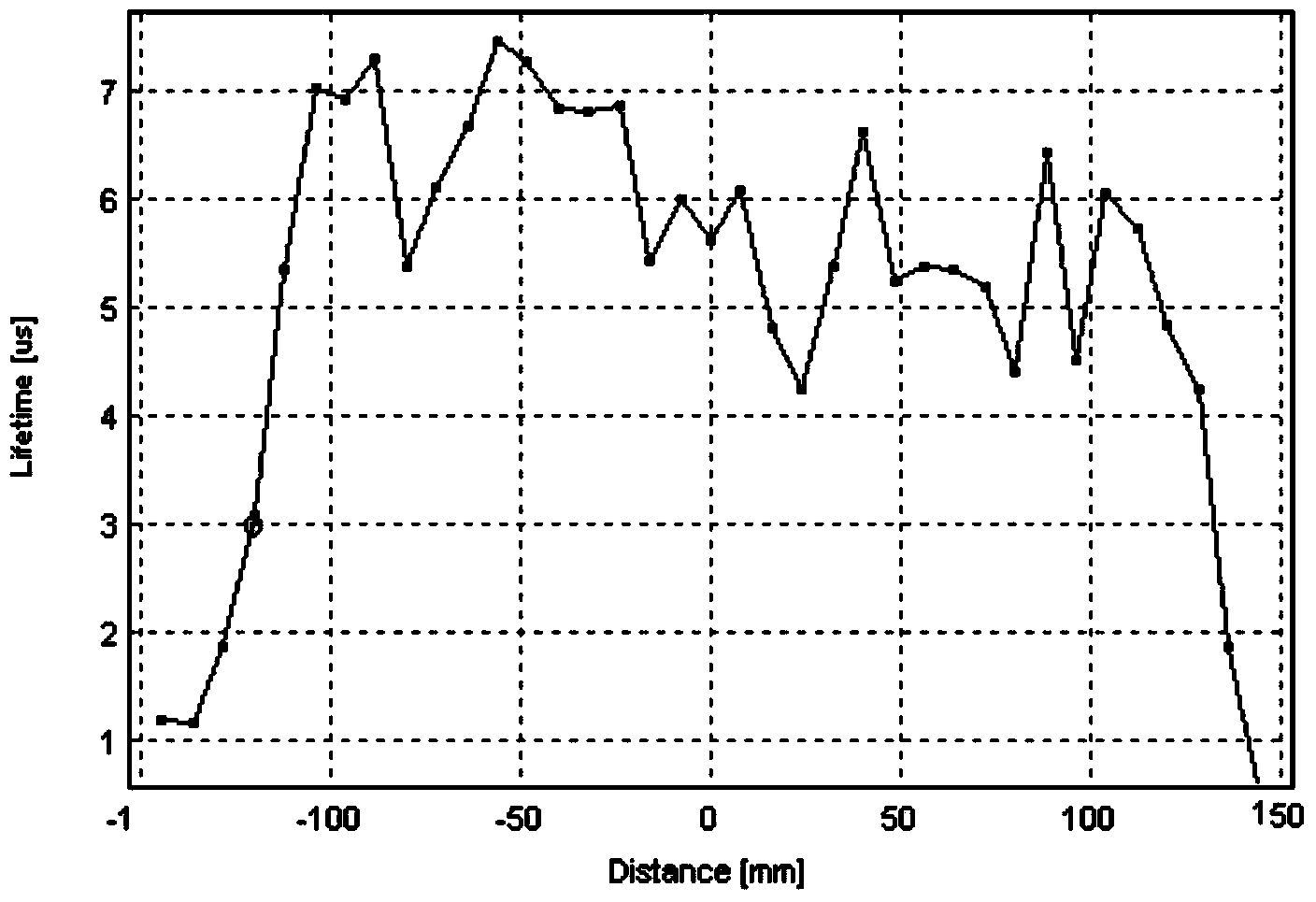

Quartz crucible and manufacturing method thereof

InactiveCN103484935ALow content of metal impuritiesSlow down the spreadPolycrystalline material growthSingle crystal growth detailsMetallurgyMetal impurities

The invention discloses a quartz crucible and a manufacturing method of the quartz crucible. A glass sand coating coats the inner surface of a common quartz crucible body and plays a role in shielding between the common quartz crucible body and polycrystalline silicon ingot crystals, the speed of metal impurities diffusing toward the polycrystalline silicon ingot crystals in the common quartz crucible body is reduced, then the content of the metal impurities in the polycrystalline silicon ingot crystals is reduced, and therefore the purpose of improving service life of a non-equilibrium minority carrier is achieved. On the basis of the manufacturing method, the number of unqualified parts of the bottom surface and the side faces in the manufactured qualified polycrystalline silicon ingot crystals is reduced, the usage rate is improved, and production cost is reduced.

Owner:镇江荣德新能源科技有限公司

Hard carbon-metal oxide-soft carbon composite material and preparation method and application thereof

ActiveCN107240680AHigh specific capacitySmall specific surface areaCell electrodesSecondary cellsCarbon compositesSodium-ion battery

The invention discloses a hard carbon-metal oxide-soft carbon composite material and a preparation method and application thereof. The preparation method comprises the steps of firstly, performing a hydrothermal method on hydrocarbon in a reaction kettle to prepare a hard carbon precursor; secondly, pre-coating the hard carbon precursor and a titanium salt, placing asphalt in a muffle furnace for low-temperature pyrolysis reaction to obtain a soft carbon precursor; and finally, fully mixing the pre-coated hard carbon precursor and the soft carbon precursor, and performing high-temperature pyrolysis reaction under protection of an inert gas to obtain the product, wherein the product is the hard carbon-metal oxide-soft carbon composite material. The material can be used as a negative active material of a sodium ion battery. The preparation method is wide in raw material source and low in cost, and the prepared hard carbon-metal oxide-soft carbon composite material has the advantages of large reversible capacity, high initial charge-discharge coulombic efficiency, good cycle property and the like in the sodium ion battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

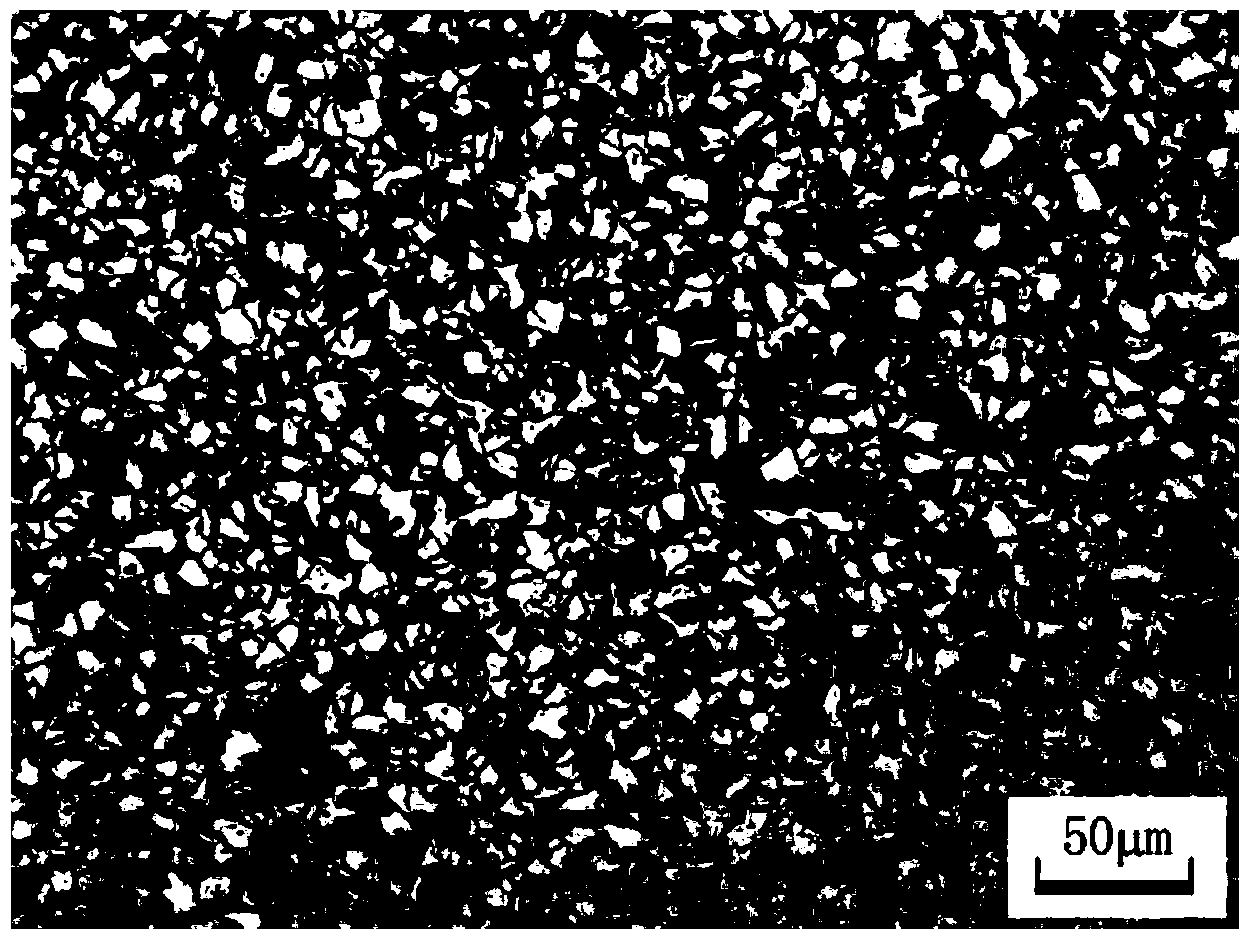

Preparation process of tissue-controllable high-aluminum-content Cu-Al2O3 nano dispersion copper alloy

ActiveCN109207766AEffective control of conductivityPrevent precipitationTransportation and packagingMetal-working apparatusNew energyHigh-voltage direct current

The invention discloses a preparation process of a tissue-controllable high-aluminum-content Cu-Al2O3 nano dispersion copper alloy. According to the preparation process, the Cu-Al2O3 nano dispersion copper alloy is prepared by performing ball milling activation and two-stage internal oxidation on Cu-Al alloy powder of which the Al content is 0.5 to 1.0 percent by weight; the tensile strength of the Cu-Al2O3 nano dispersion copper alloy at room temperature is larger than or equal to 550Mpa, the elongation rate is larger than 20 percent, and the electric conductivity is larger than 78 percent IACS; when the Cu-Al2O3 nano dispersion copper alloy is tensioned at a temperature of 700 DEG C, the tensile strength is larger than or equal to 245MPa. The preparation process is reasonable, and is convenient to operate, the formation of Al2O3 particles which are distributed continuously or densely along a crystal boundary in a high-temperature internal oxidation process can be effectively avoided;a prepared material has the advantages of high electric conductivity and high room temperature and high-temperature strength and elongation rate, so that the prepared Cu-Al2O3 nano dispersion copperalloy has superior performance, high strength and high electric conductivity. Thus, urgently needed raw materials are provided for the assembly of spot-welding electrodes, electrovacuum devices and high-voltage direct-current relays on an automatic welding production line in industries such as electronics, appliances, electric vacuum, batteries and new energy automobiles, and the preparation process is suitable for industrial production.

Owner:湖南高创科惟新材料股份有限公司

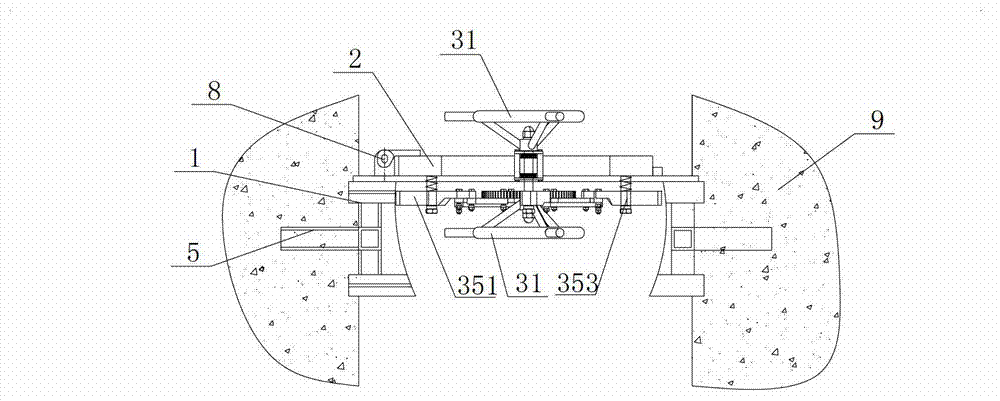

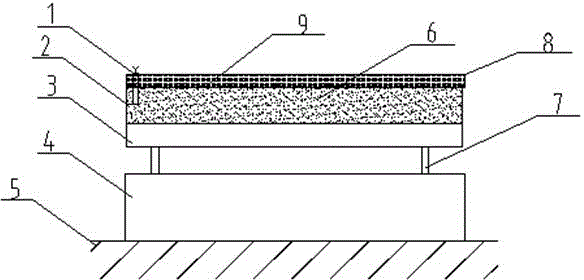

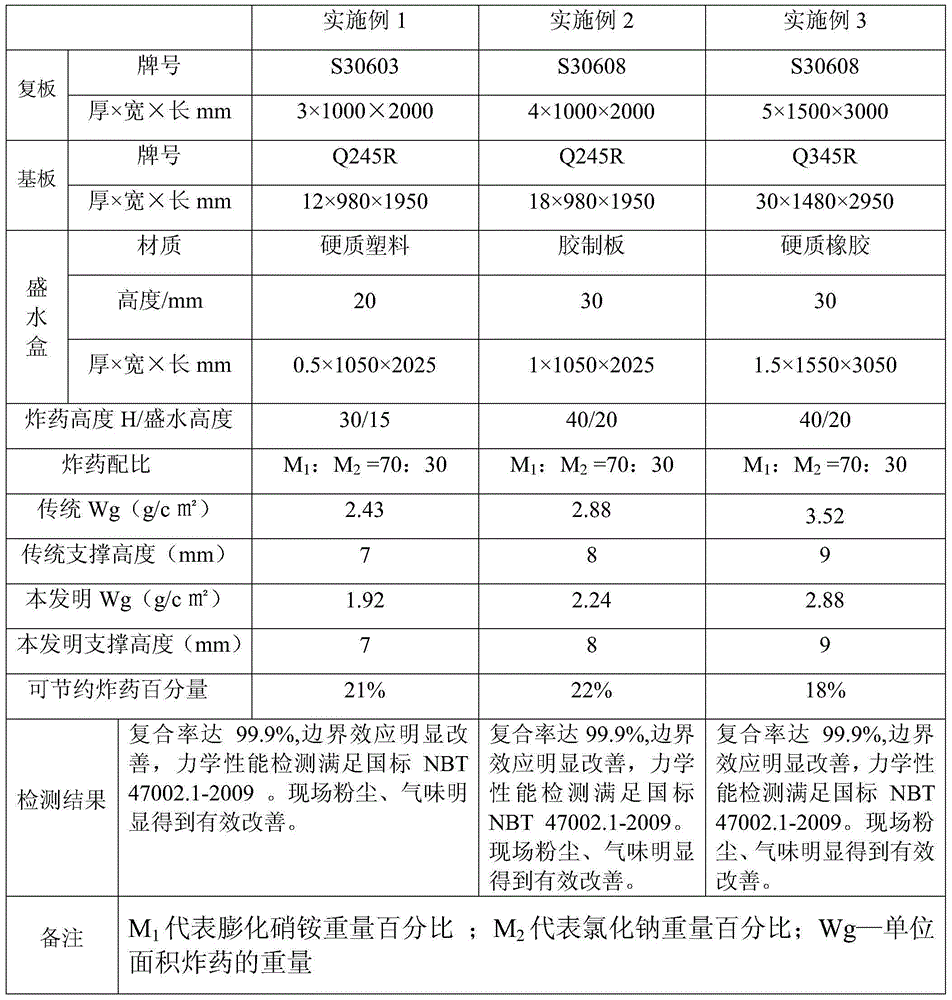

Water covering type explosive welding method of metal compound

InactiveCN104475961ASlow down the spreadIncrease profitNon-electric welding apparatusDetonatorWorking environment

The invention provides a water covering type explosive welding method of a metal compound. The method comprises the steps of polishing a base plate (1) and horizontally arranging on a clay foundation (5); uniformly arranging a plurality of supports (7) on the base plate; horizontally arranging a compound plate (3) on the base plate through the plurality of supports; adhering an explosive frame (2) to the surrounding of the compound plate through an adhesive bag in the length and width directions; uniformly paving explosive (6), wherein the explosive is paved and controlled to be 2.4 to 4.0g / cm<2> in height H; arranging a water box (8) on the explosive frame and staggering to form a gap for storing detonator (1); slowly pouring water (9) into the water box and keeping the depth less than or equal to H / 2; detonating the explosive through the detonator during explosive welding. According to the method, water in the water box can slow down the explosive energy upwards diffusing and can also raise the explosive utilization rate during explosive welding; meanwhile, water can be atomized when the explosive is detonated, and therefore, a large amount of poisonous gas generated by explosive welding can be absorbed by the atomized water, and moreover, lots of clay dust and explosion-caused dust can be collected so as to reduce the pollution to the working environment.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com