Water covering type explosive welding method of metal compound

A technology of explosive welding and metal cladding, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve problems such as the health impact of on-site operators, the difficulty of dust falling down quickly, and the reduction of the energy utilization rate of explosives. The effect of using amount, protecting health and improving the utilization rate of explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

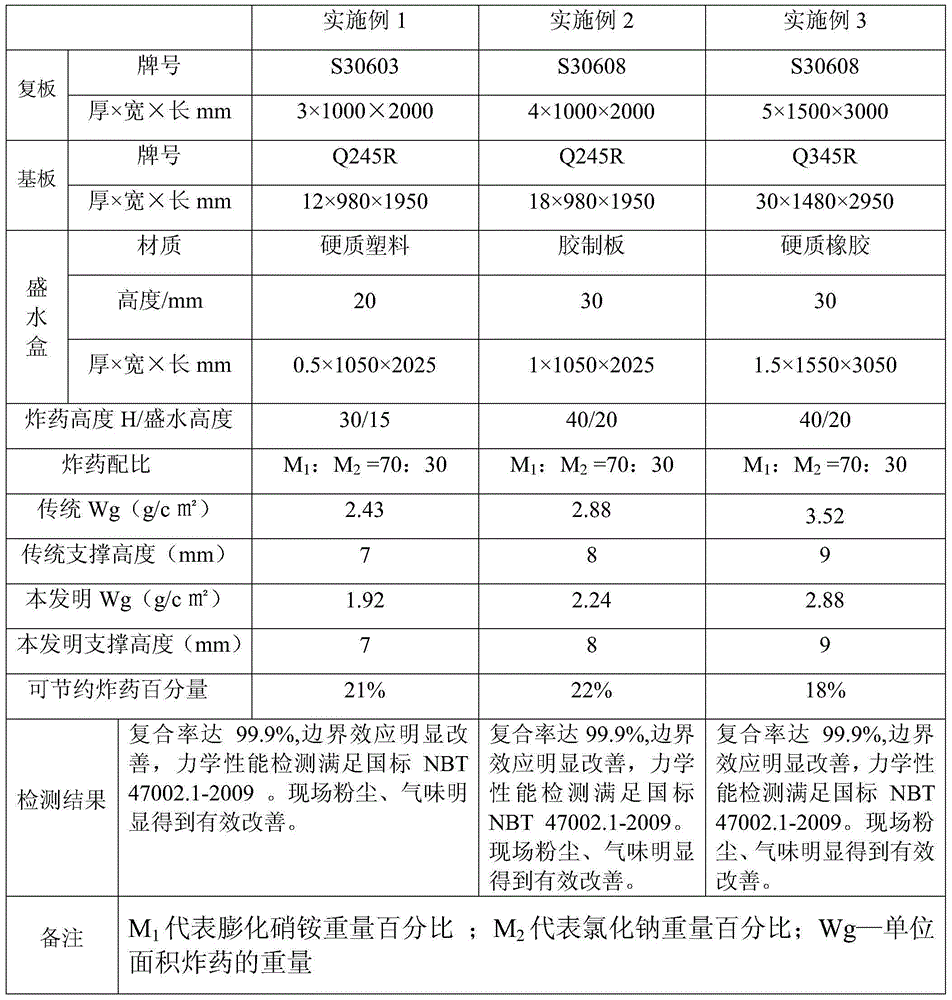

[0023] The invention relates to a water-covered metal compound explosive welding method. The method uses a base plate, a double plate, and a support. The base plate is made of carbon steel, the double plate is made of stainless steel, and the support is made of a copper sheet, or an aluminum sheet, or an iron sheet. .

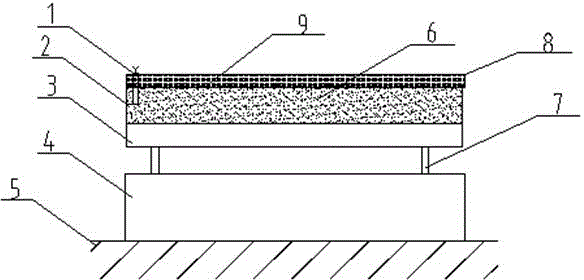

[0024] to combine figure 1 First, polish the surface to be welded of the substrate 4 and place it horizontally on the clay foundation 5, and evenly distribute several supports 7 of equal height on the surface to be welded of the substrate 4. The supports 7 are single sheets, and each support is superimposed on each other. The total height is controlled at 5-10mm, and the doubler board 3 is placed flat on the base plate 4 through several supports 7 and aligned with the base plate 4, and the medicine frame 2 is pasted with a plastic bag along the length and width of the doubler board, and then the explosives 6 are spread evenly On the upper end face of the doubl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com