Polymer viscous acid

A technology of thickening acid and polymer, which is applied in the direction of drilling compositions, chemical instruments and methods, etc. It can solve the limitation of thickening stability of thickening agent, high temperature resistance, insufficient salt resistance, viscosity of thickened acid system Not high enough to achieve the effect of strong ability to suspend fine sand, low filtration loss, and improve temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of above-mentioned hydrophobic association polymer, comprises the following steps:

[0043] The hydrophilic monomer, the cationic hydrophobic monomer and the functional monomer are mixed in a solvent, and an initiator is added to carry out a polymerization reaction to obtain a hydrophobic association polymer.

[0044] Preferably, adiabatic polymerization is adopted, and solvent, hydrophilic monomer, functional monomer and hydrophobic monomer are sequentially added, and when the temperature is adjusted to -5°C to 50°C in a water bath, an initiator is added to carry out polymerization reaction.

[0045] The solvent is preferably water.

[0046] The hydrophilic monomer, cationic hydrophobic monomer and functional monomer are the same as above, and will not be repeated here.

[0047] When z is 0, no functional monomer is added during the preparation process.

[0048] The dosage of each monomer can be proportioned according to the mole percentage of ...

Embodiment 1

[0073] Dissolve acrylamide and 0.1mol% acryloyloxyethyl dodecyl ammonium chloride in a 5000mL beaker with pure water to prepare a solution with a concentration of 25wt%, and add the initiator ammonium persulfate after keeping the temperature in a water bath to -5°C 1. Sodium bisulfite initiates polymerization, the concentration of oxidant is 0.012% of the monomer mass, the polymerization reaction is carried out in an adiabatic environment, a thermometer is inserted in the center of the reaction system to monitor the progress of the polymerization reaction, the reaction time is about 4-8h, when the temperature within 30 minutes The polymerization reaction is considered to be substantially complete when the rise does not exceed 1°C. One hour after the completion of the polymerization reaction, take out the colloid, cut the colloid into 3-5mm size particles, spread the colloid on a 500-mesh screen, put it in an oven at a constant temperature of 90°C and dry it for 40-90 minutes, t...

Embodiment 2~12

[0076] According to the method of Example 1, the hydrophobic association polymer was prepared using the raw material ratio in Table 1. The results are shown in Table 1. Table 1 is a summary of the raw material ratios in Examples 2-12.

[0077] The raw material proportioning of table 1 embodiment 2~12

[0078]

[0079]

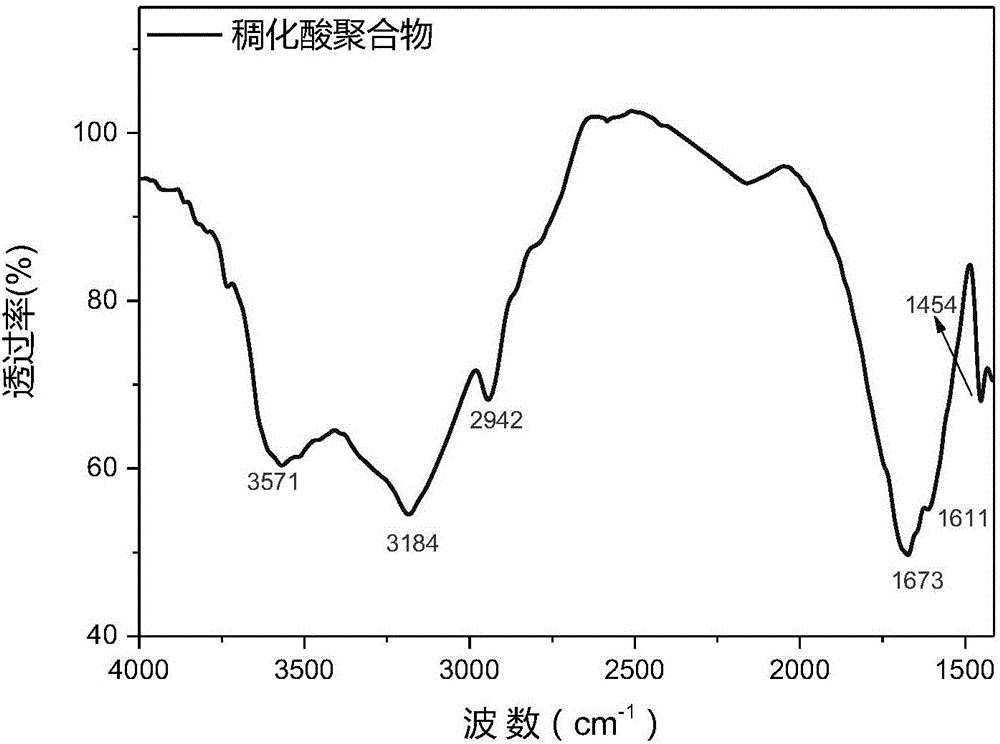

[0080] Adopt infrared spectrum to carry out structure detection to the polymkeric substance prepared in embodiment 2, the results are shown in figure 1 , figure 1 It is the infrared absorption spectrum of the polymer prepared in Example 2.

[0081] figure 1 Middle, in the Fourier transform infrared spectrum, 3571cm -1 and 3184cm -1 Antisymmetric and symmetric stretch vibration peaks attributable to N-H bonds; 2942cm -1 and 1454cm -1 Stretching vibration peak and bending vibration peak respectively attributed to C-H bond, 1673cm -1 It belongs to the stretching vibration peak of amide I band C=O, 1611cm -1 Assigned to the N-H bending vibration peak ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com