Patents

Literature

927 results about "Workover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

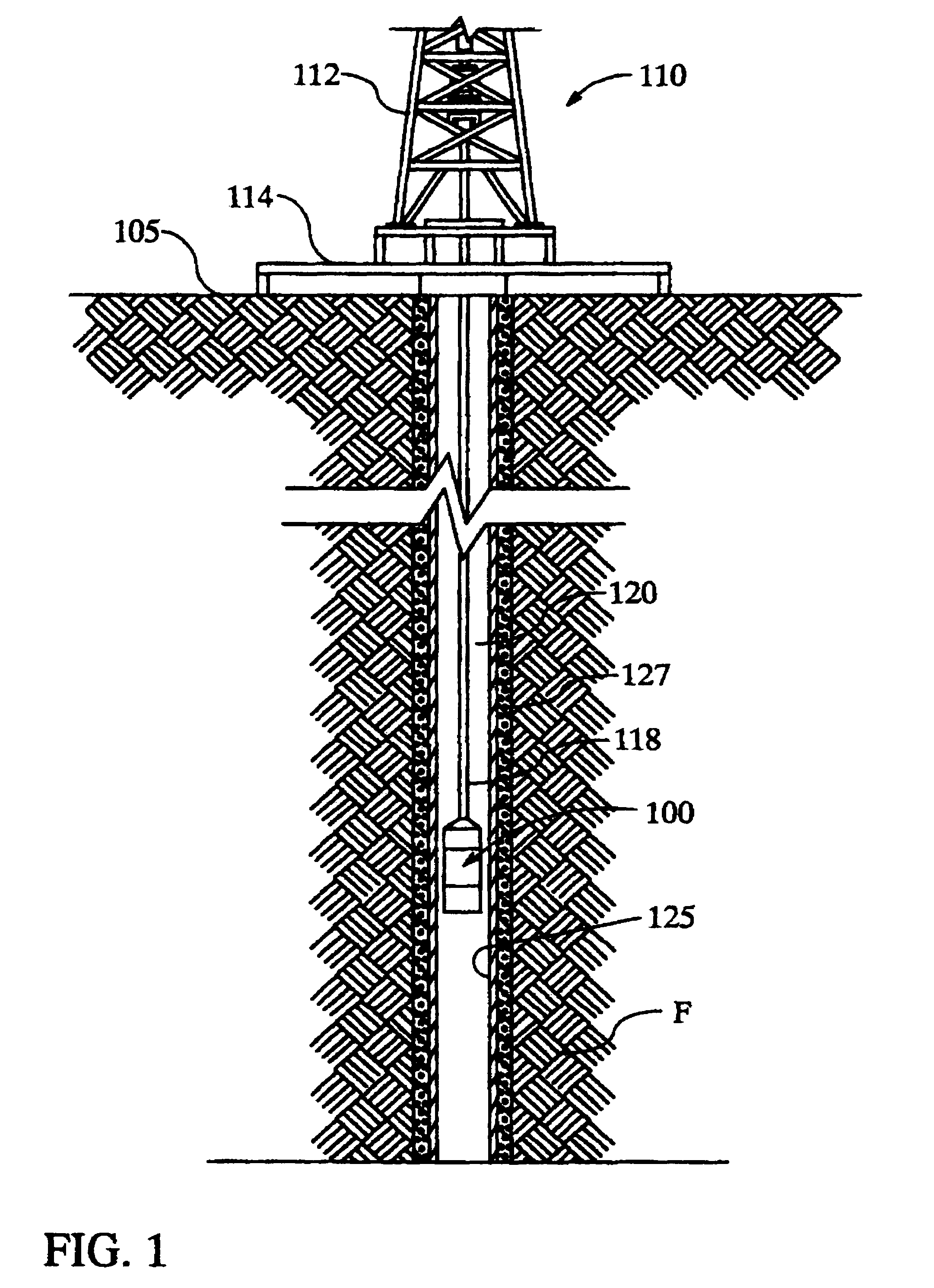

The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically, a workover refers to the expensive process of pulling and replacing completion or production hardware in order to extend the life of the well.

Downhole wellbore tools having deteriorable and water-swellable components thereof and methods of use

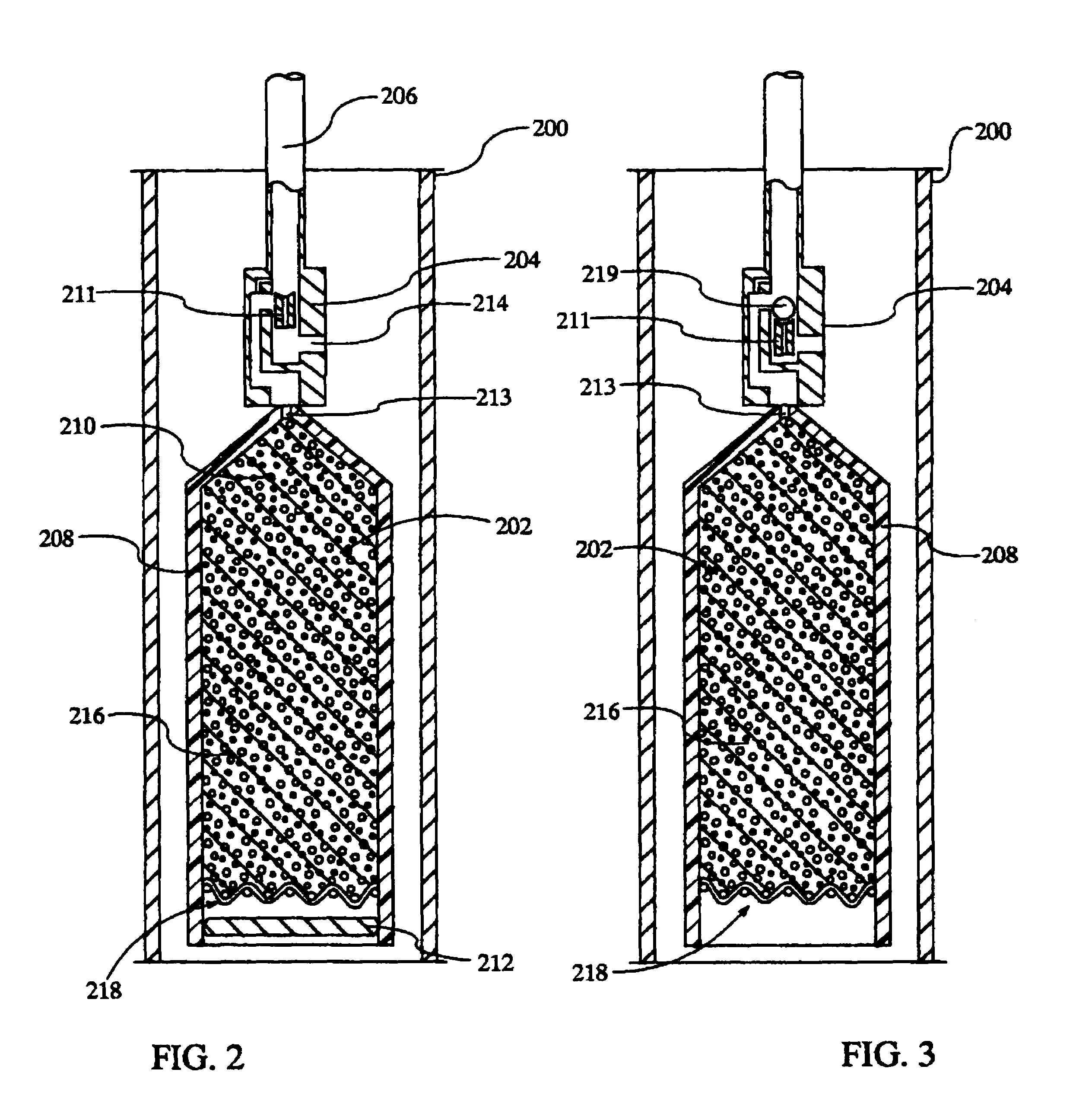

An apparatus is provided for use as a downhole tool or a component thereof for insertion into a wellbore. According to one aspect, the apparatus has a body having a chamber, wherein at least a portion of the body is radially expandable; and a water-swellable material in the chamber, wherein the water-swellable material is dissolvable in water. According to another aspect, the apparatus has a body having a chamber, wherein at least a portion of the body is radially expandable, and wherein at least a portion of the body is made with a material that is deteriorable by hydrolysis; and a water-swellable material in the chamber. According to a further aspect, the water-swellable material is dissolvable in water. A process of temporarily blocking or sealing a wellbore is also provided, including moving an apparatus according to the invention through a wellbore to a selected position in the wellbore; exposing the water-swellable material to water or an aqueous fluid to expand the apparatus into engagement with the wellbore; performing a well completion, servicing, or workover operation in which the apparatus is contacted with fluids; and thereafter, allowing the deteriorable material to deteriorate and / or allowing the water-swellable material to dissolve.

Owner:HALLIBURTON ENERGY SERVICES INC

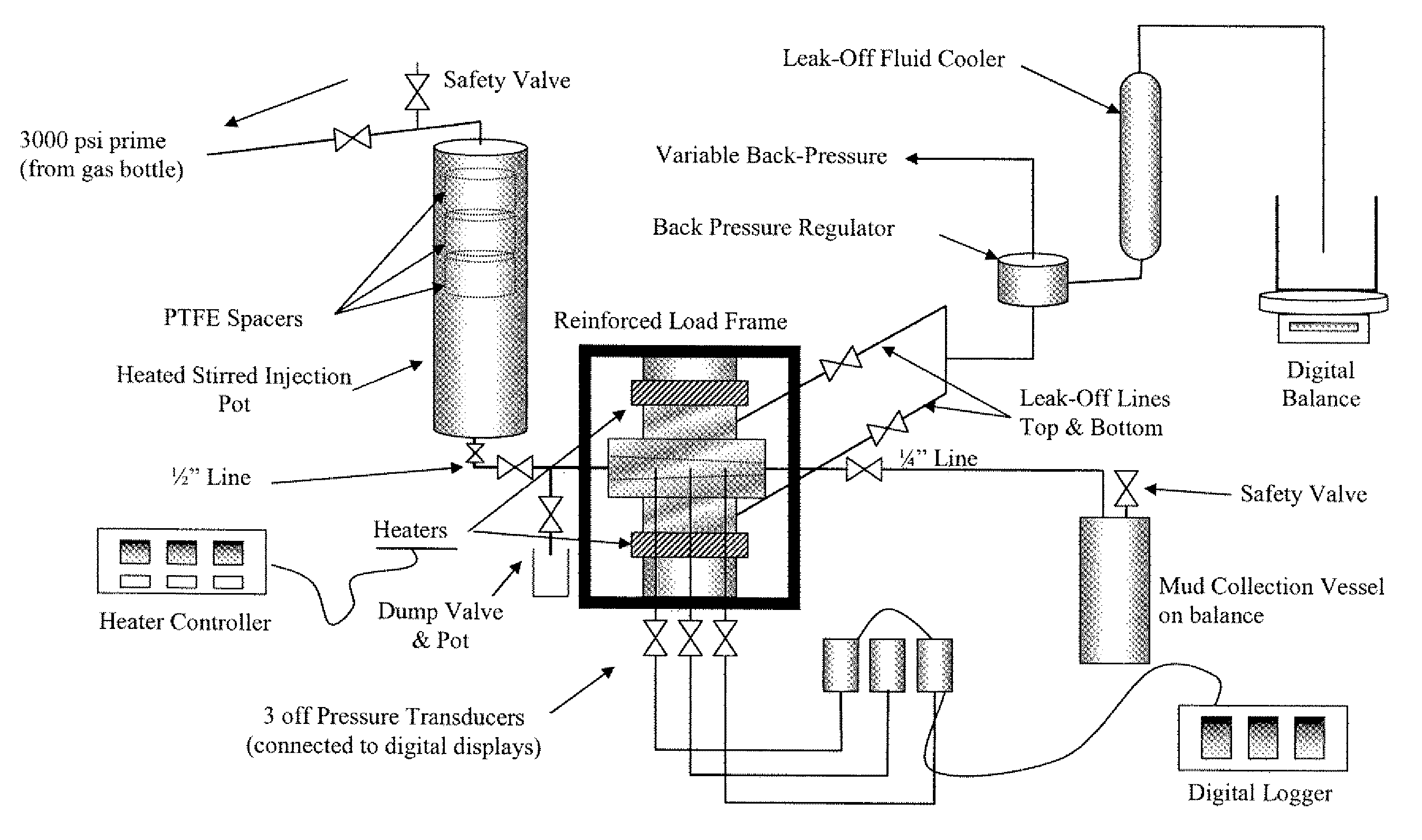

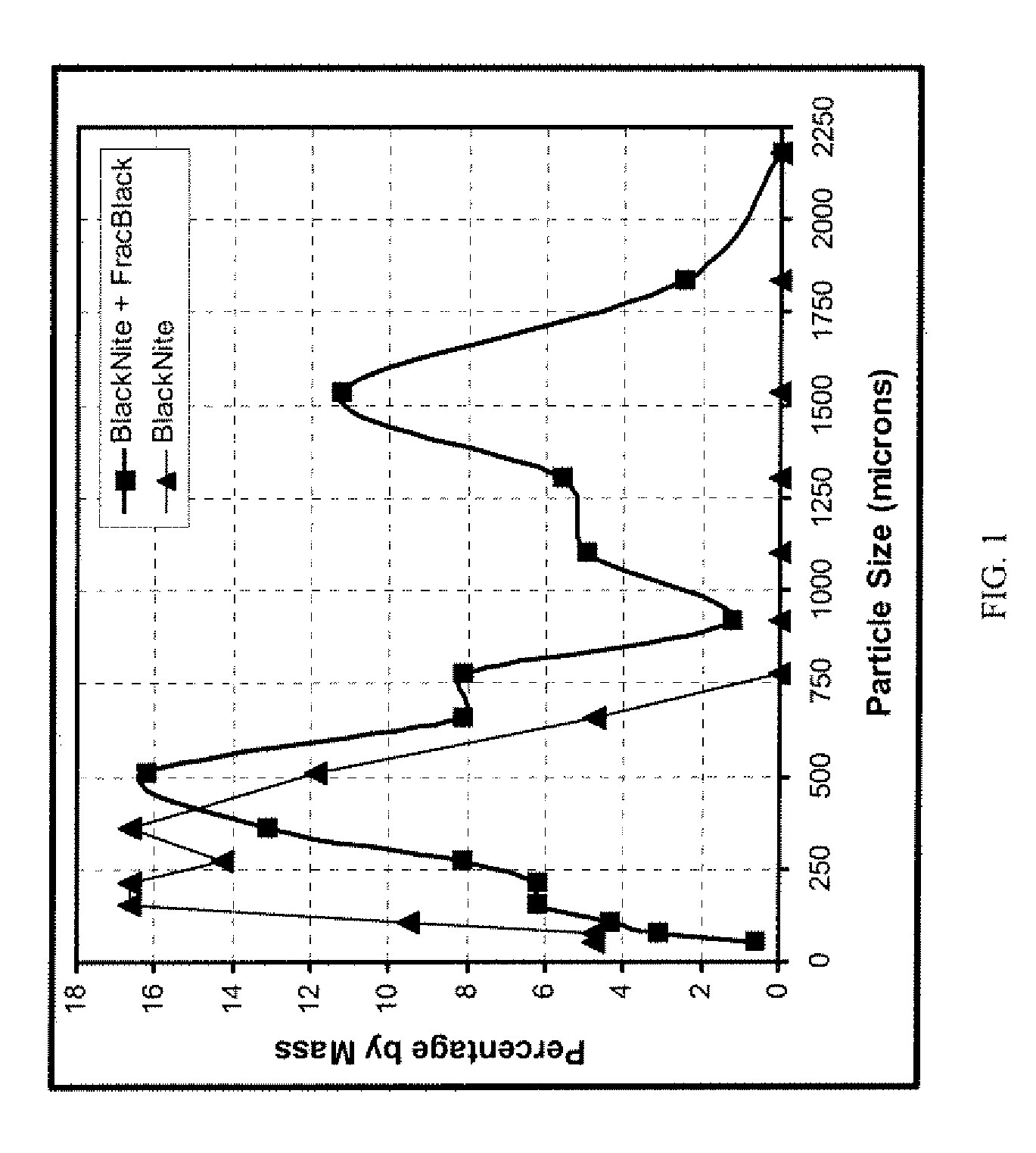

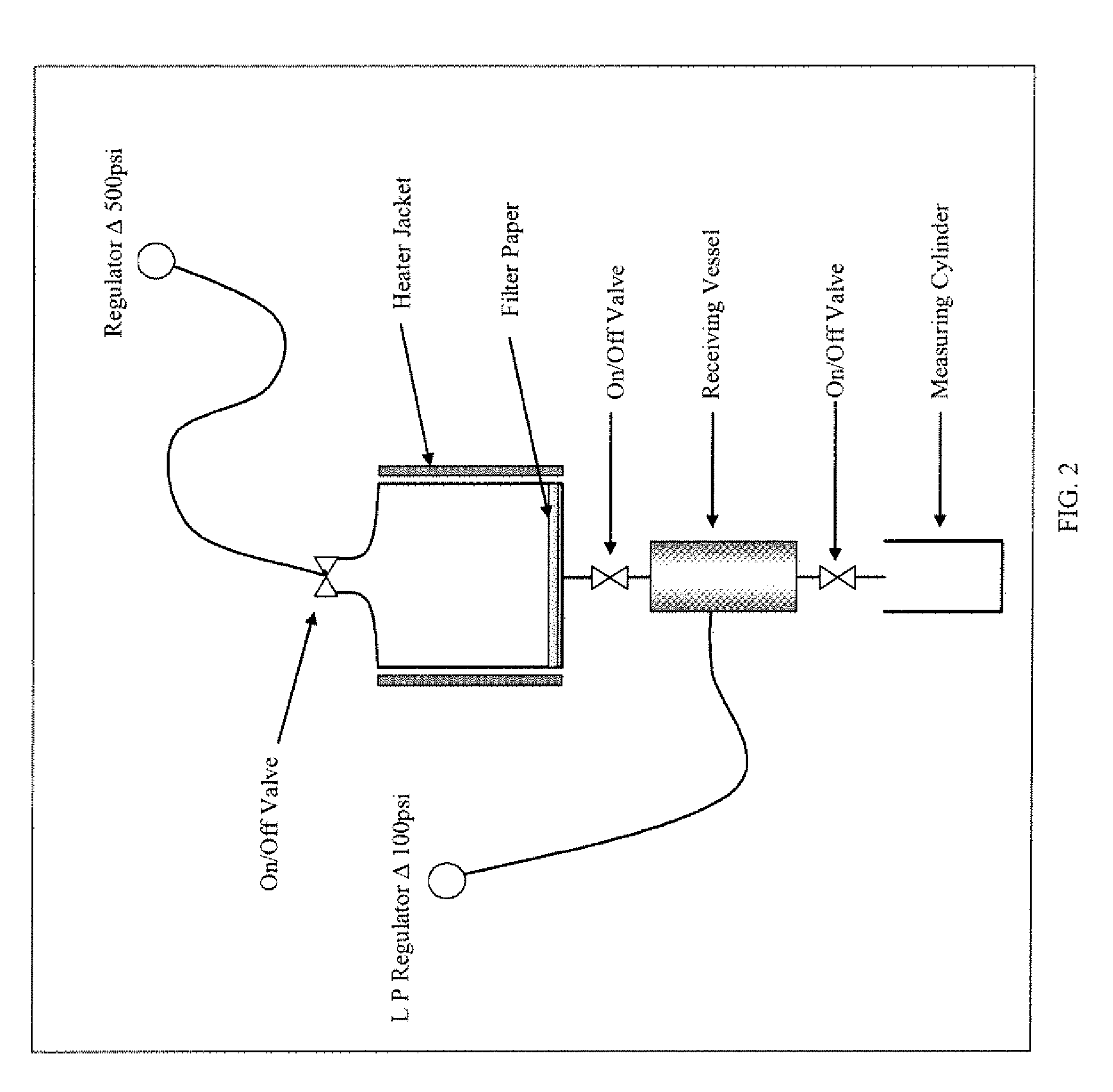

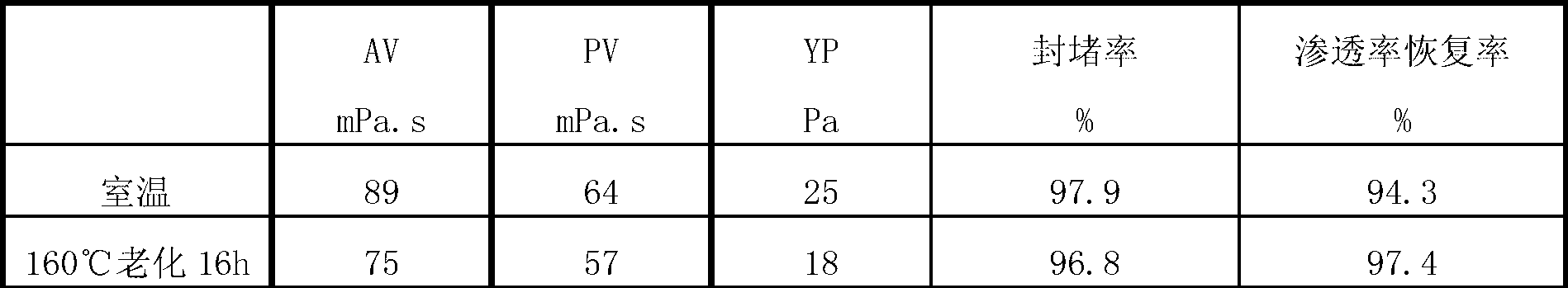

Drilling fluid, drill-in fluid, completition fluid, and workover fluid additive compositions containing thermoset nanocomposite particles; and applications for fluid loss control and wellbore strengthening

InactiveUS20090029878A1Loss in formationHigh strengthFlushingDrilling compositionWater basedDivinylbenzene

In one aspect, this invention relates to the use of thermoset nanocomposite particles as components of drilling fluid, drill-in fluid, completion fluid, and workover fluid additive packages to reduce fluid losses to a formation and / or to enhance a wellbore strength. In another aspect, this invention relates to the use particles of specific gravity ranging from about 0.75 to about 1.75 as components of drilling fluid, drill-in fluid, completion fluid, and workover fluid additive packages to reduce fluid losses to a formation and / or to enhance a wellbore strength. Using embodiments of the invention, reduction of fluid loss and / or enhancement of wellbore strength may be achieved while working with water-based, oil-based, invert emulsion, or synthetic drilling muds. The currently most preferred embodiments of the invention use substantially spherical thermoset nanocomposite particles, possessing a specific gravity from approximately 1.02 to approximately 1.15 wherein the matrix is a terpolymer of styrene, ethylvinylbenzene and divinylbenzene, and wherein carbon black particles possessing a length that is less than about 0.5 microns in at least one principal axis direction are incorporated as a nanofiller.

Owner:SUN DRILLING PRODS

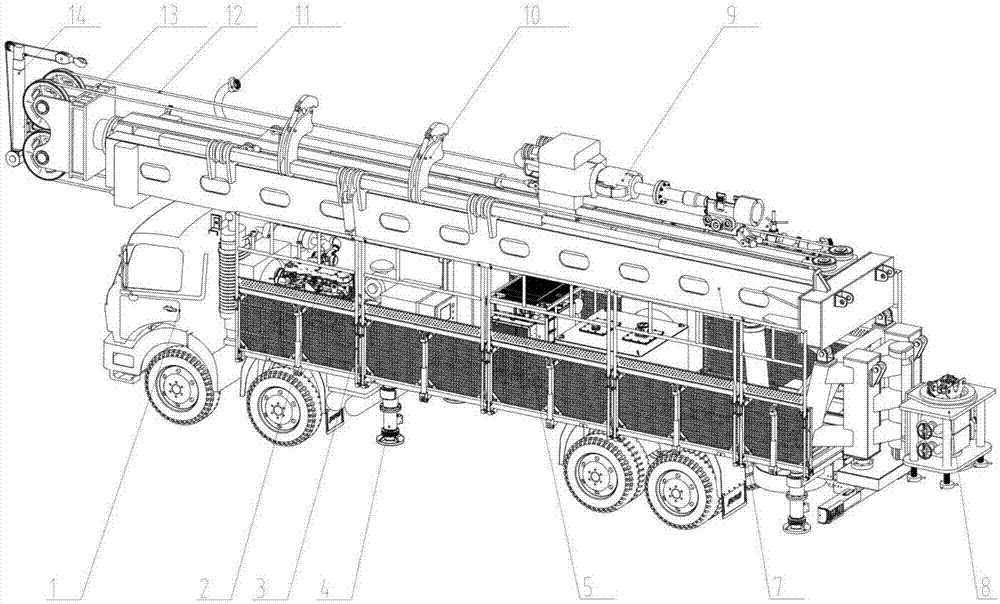

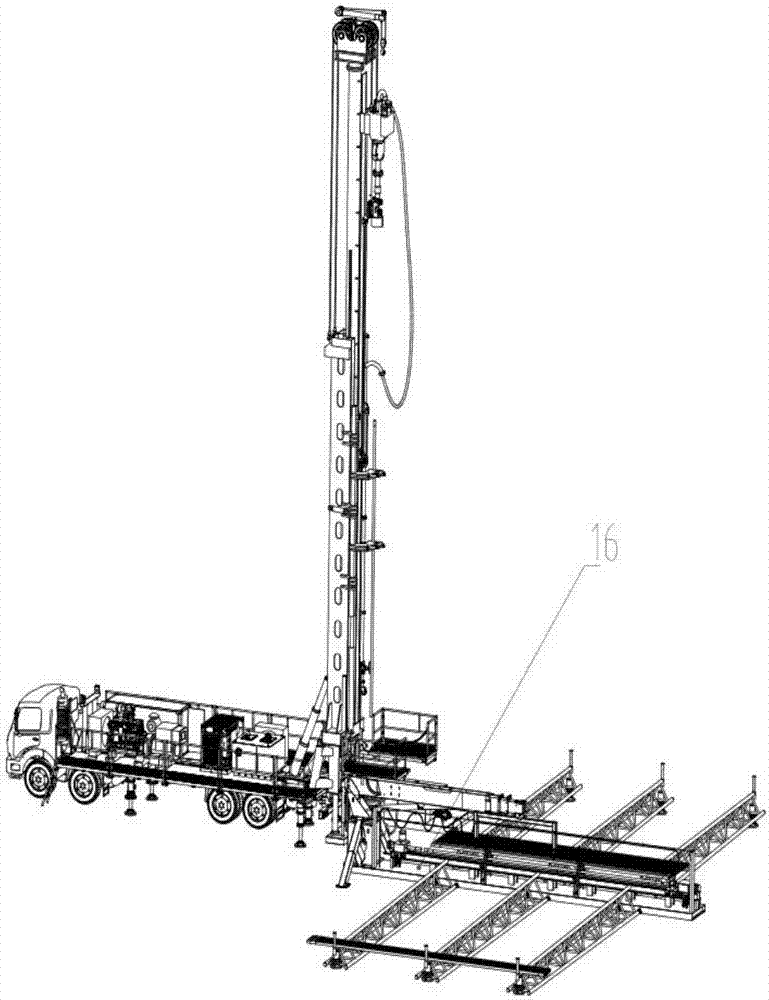

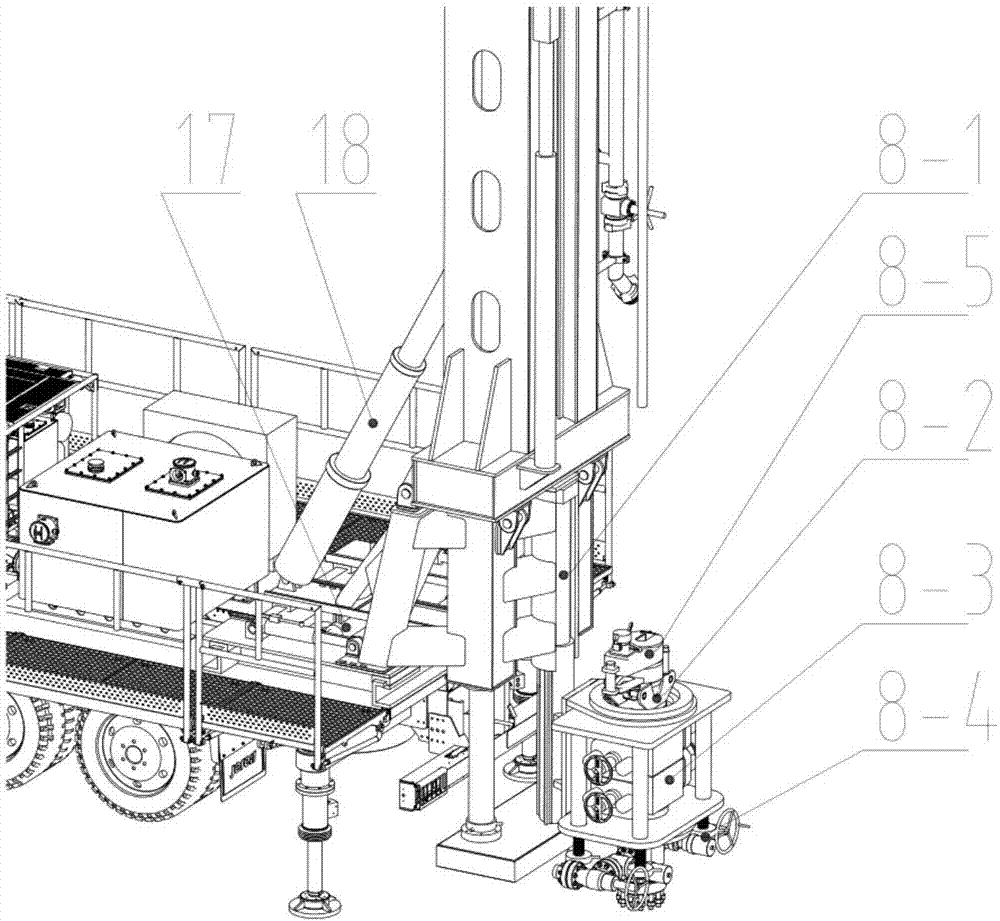

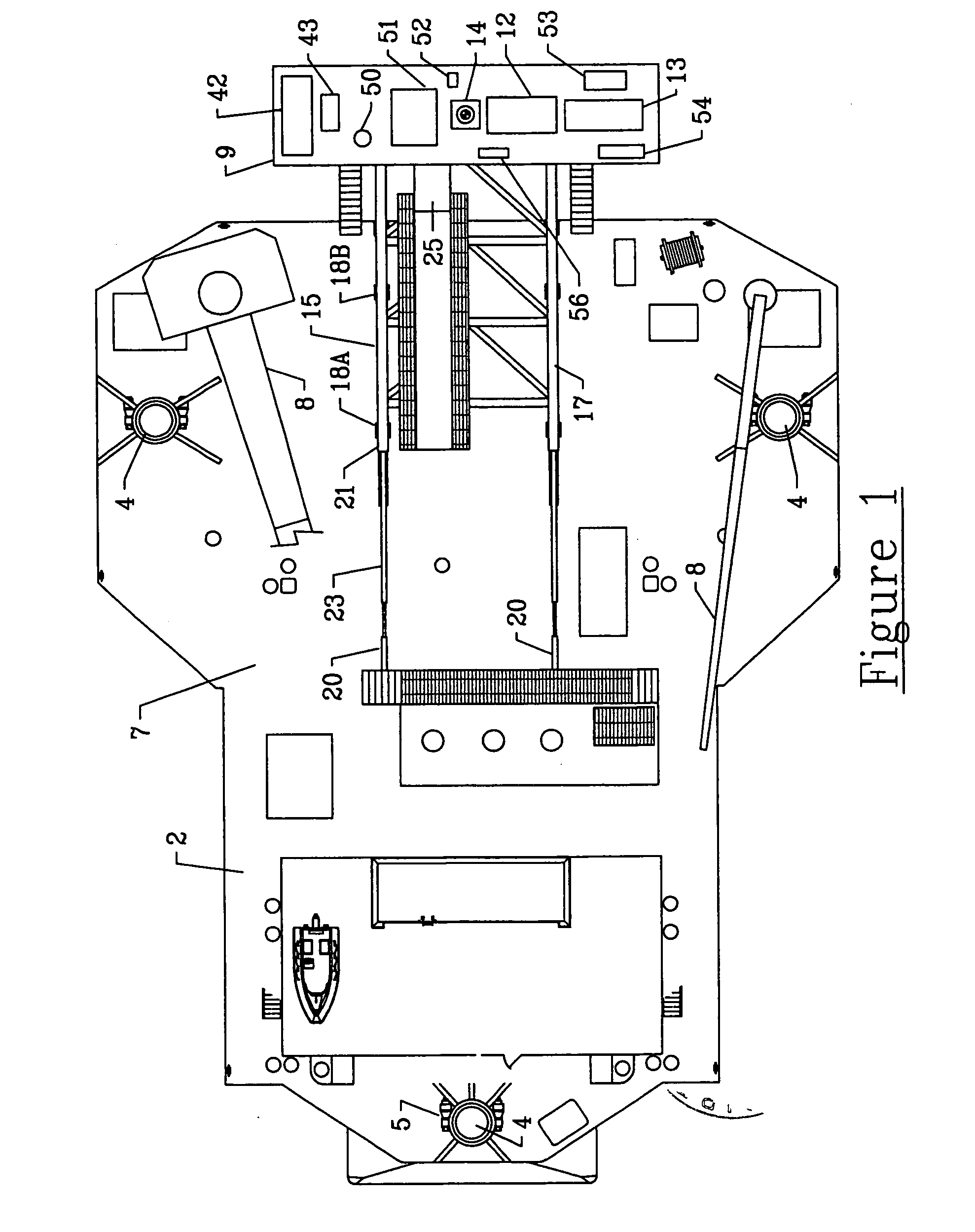

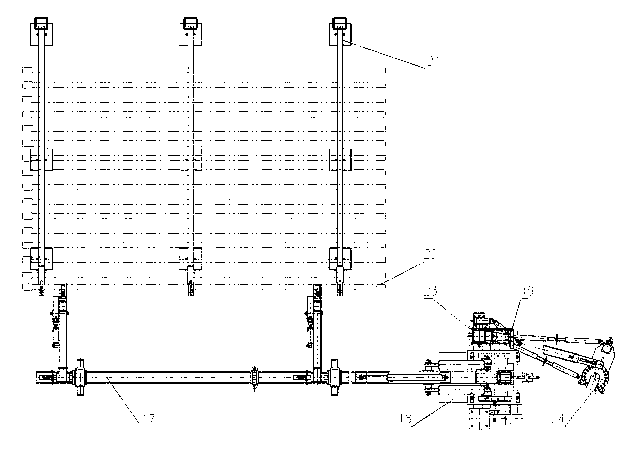

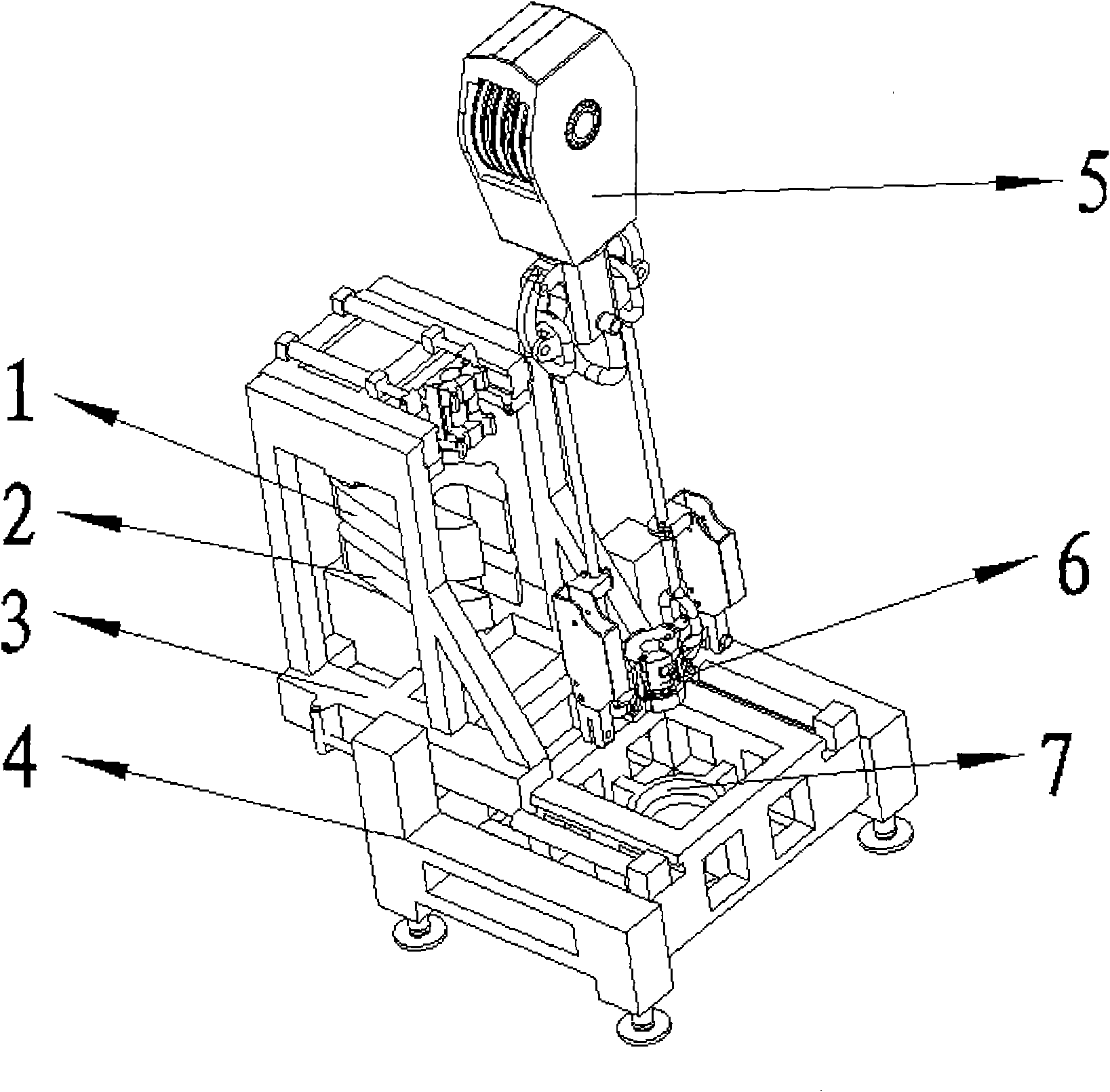

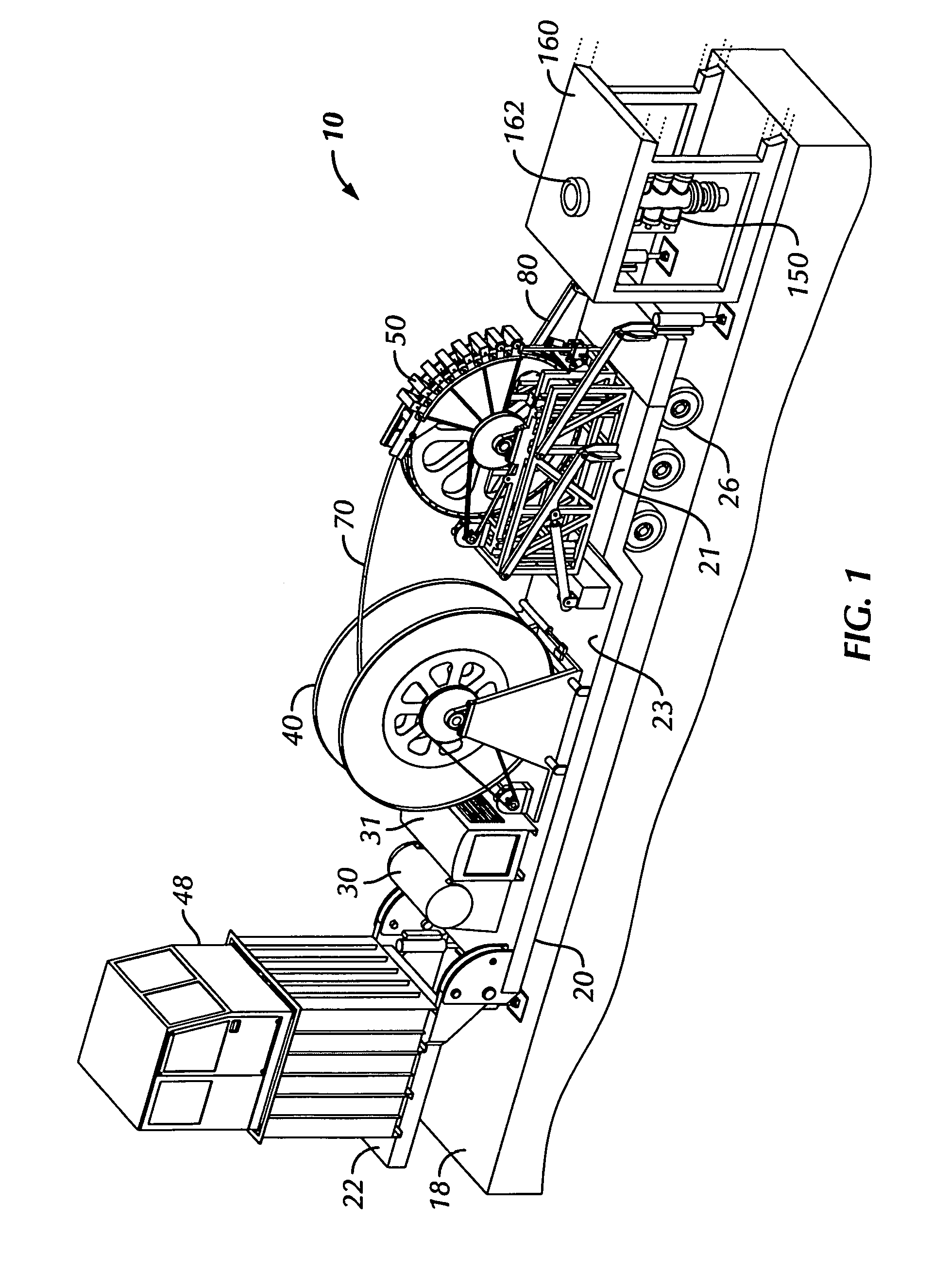

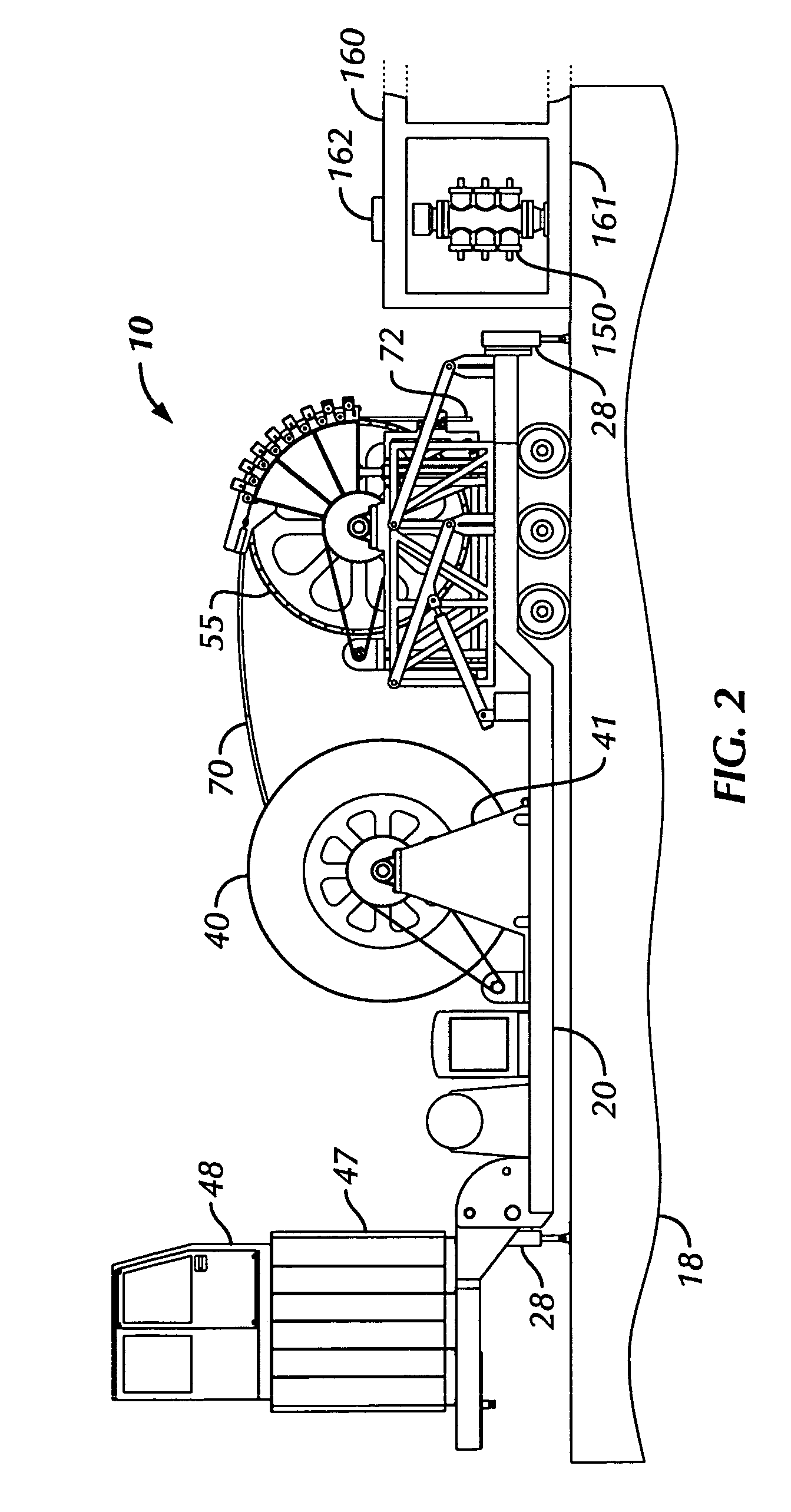

Fully hydraulic intelligent workover rig

InactiveCN107476769ARealize grabbingRealize pipe deliveryDrilling rodsDrilling casingsBlowout preventerTruck

The invention belongs to the field of oil equipment, and particularly relates to a fully hydraulic intelligent workover rig. The fully hydraulic intelligent workover rig is characterized in that an engine 2 and a hydraulic pressure station 5 are installed on a chassis truck 1, in the conveying state, a walkway is folded automatically and stored, a wellhead assembly is fixed to the tail of the chassis truck, after the hydraulic workover rig is moved to a well site, a wellhead is subjected to initial positioning through a reverse image in a cab and positioning and ranging, and then accurate positioning is conducted by moving a rapid positioning device through a derrick; by conducting height adjusting and supporting on a vehicle carrying chassis through hydraulic adjusting landing legs and conducting mechanical locking, rapid positioning and locking of the wellhead are achieved; the automatic folding walkway is designed, and convenient and labor-saving installation is achieved; increasing and decreasing of pressure of a string in a well and setting and control of bit pressure and drilling speed parameters can be achieved automatically, full automatic operations such as tubing string gripping and conveying, automatic fastening and unfastening, automatic discharging and automatic detection are achieved; integrated transport of a blowout preventer is achieved, and separate disassembly and transport are not needed.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

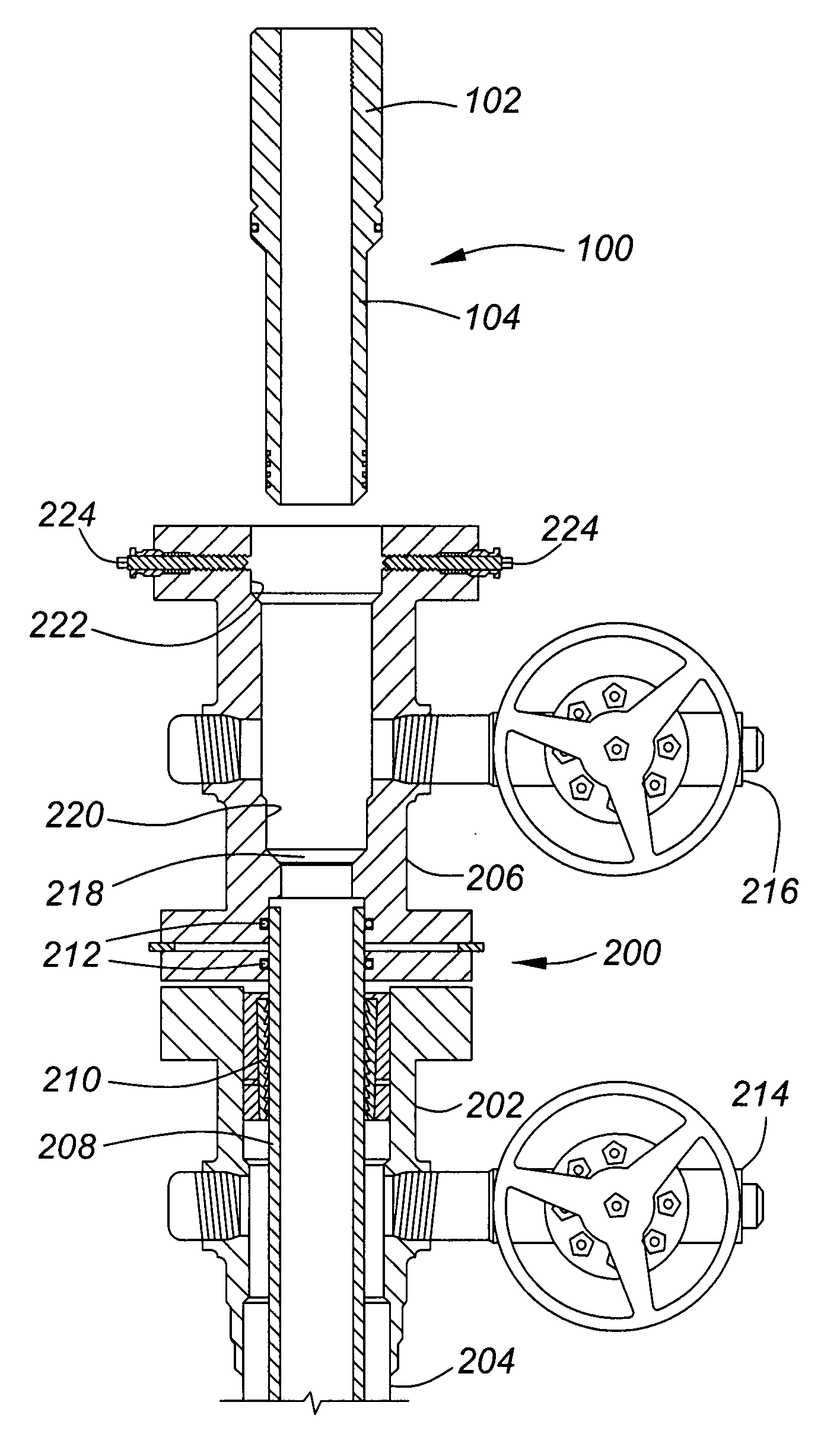

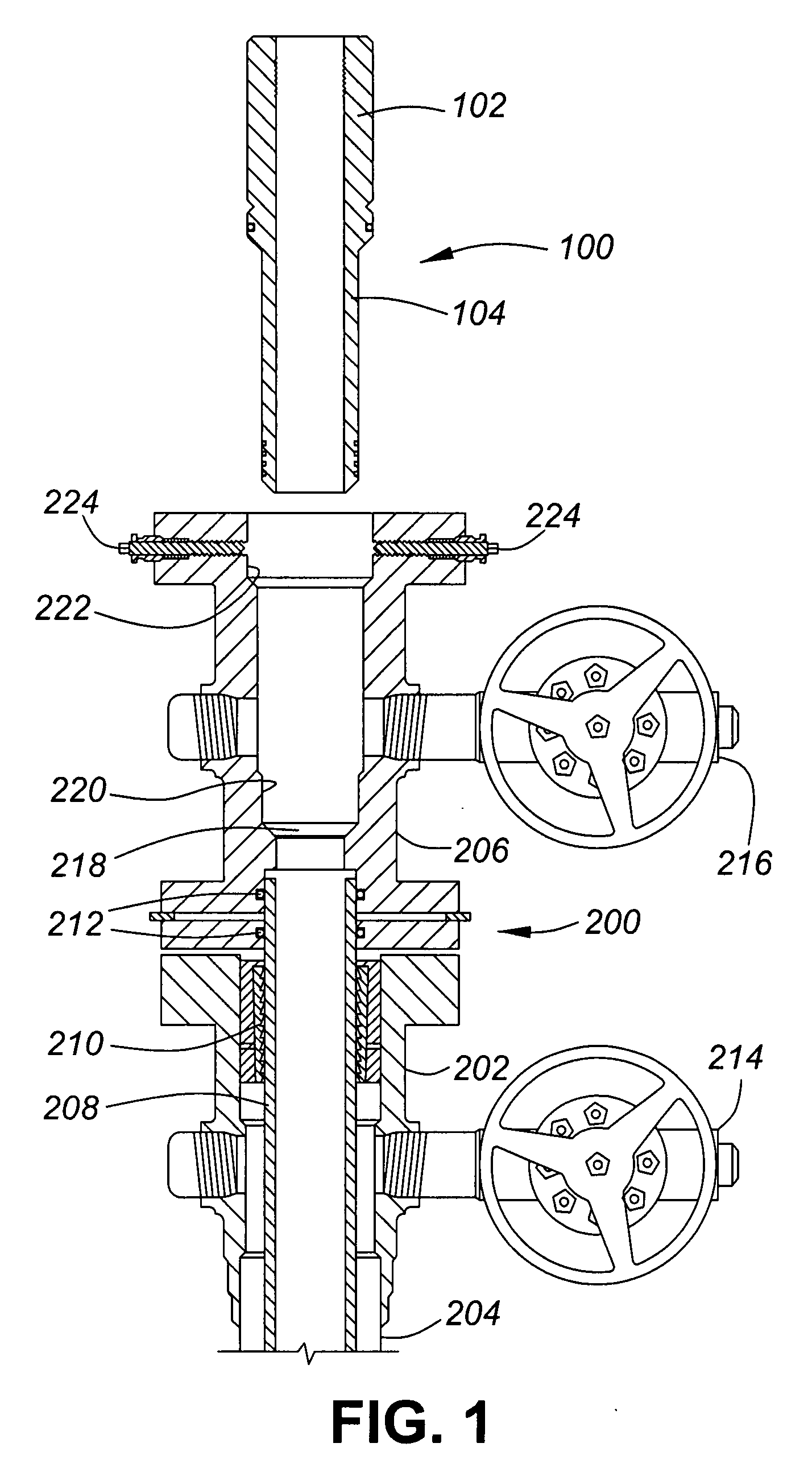

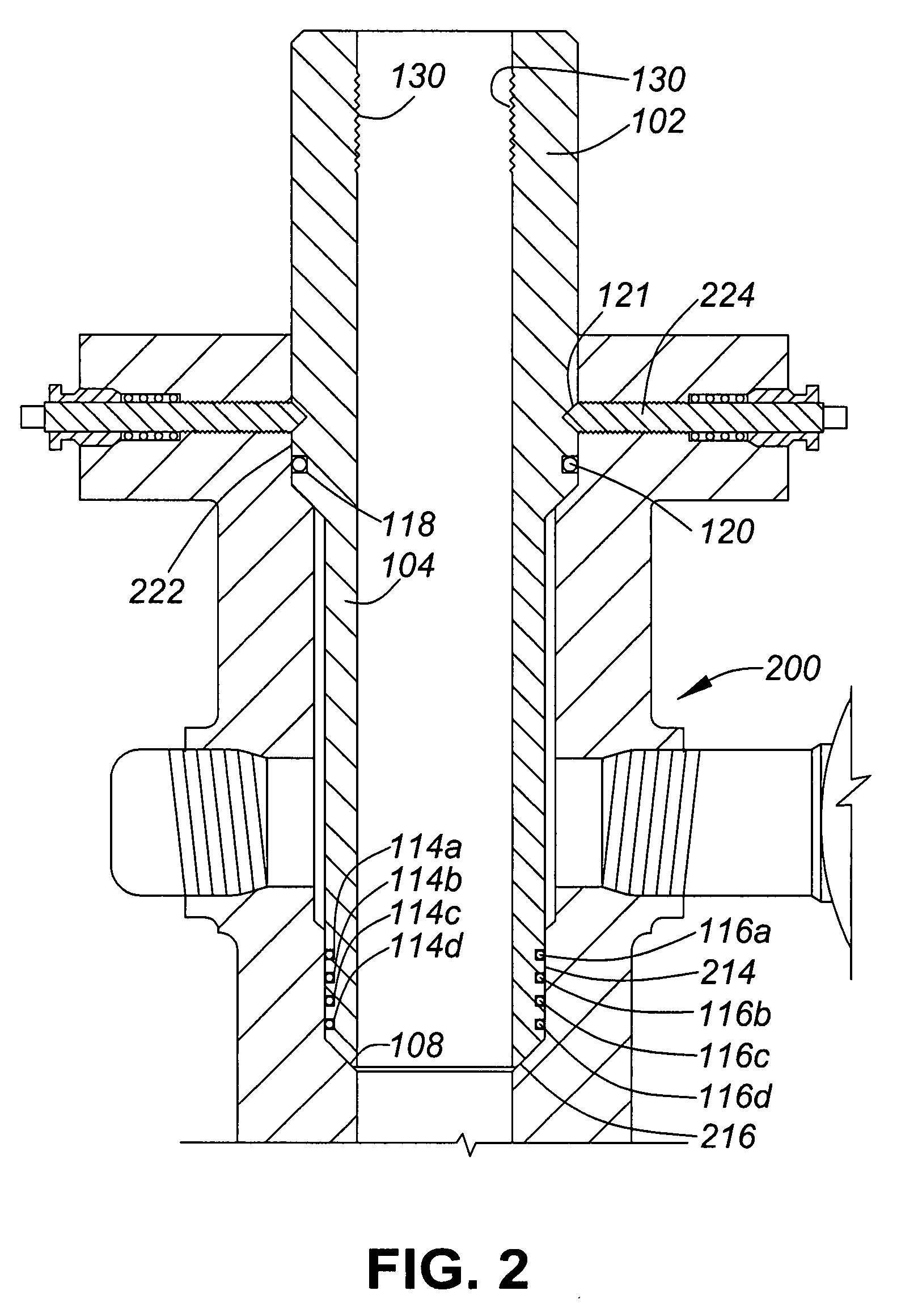

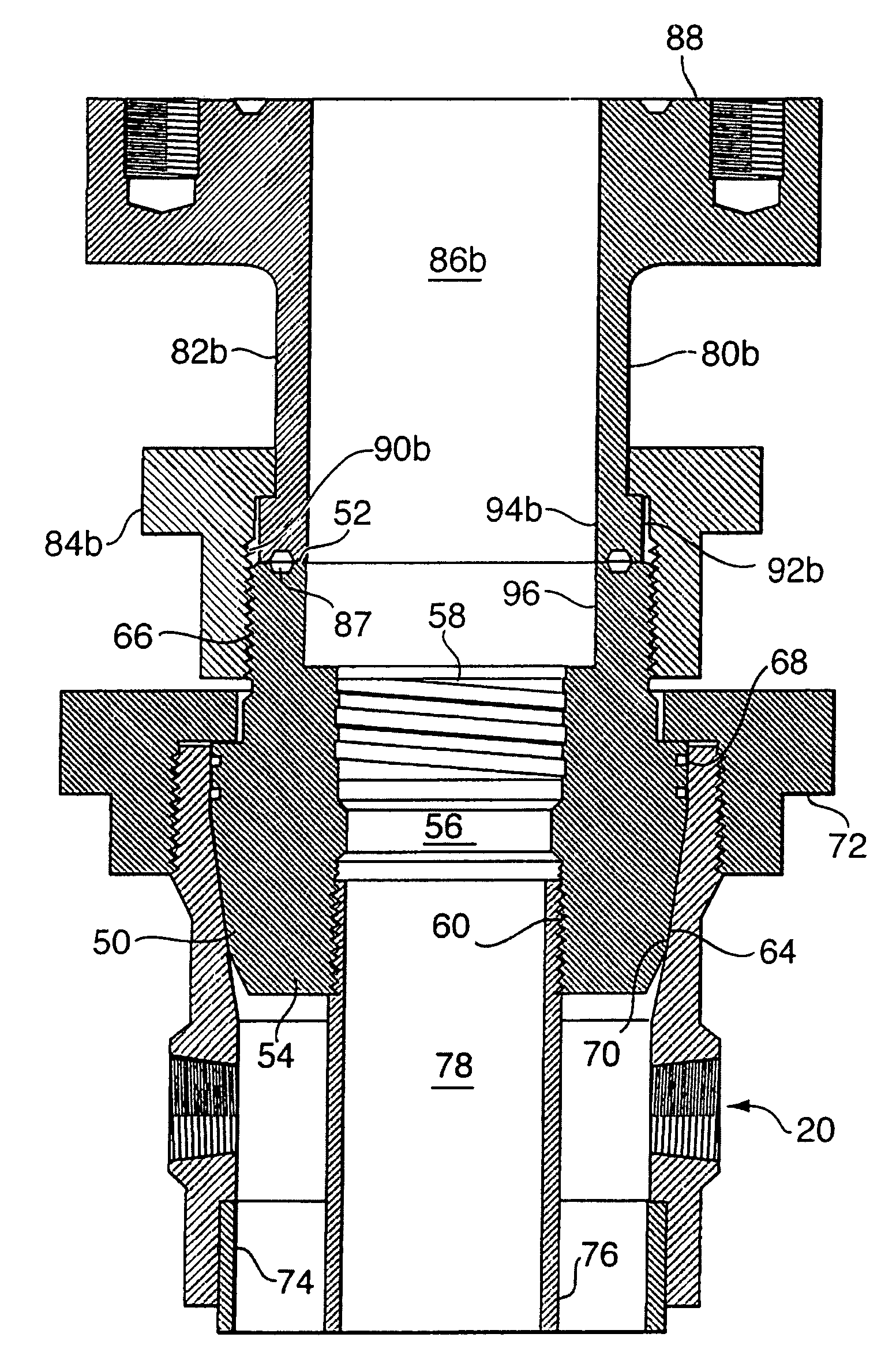

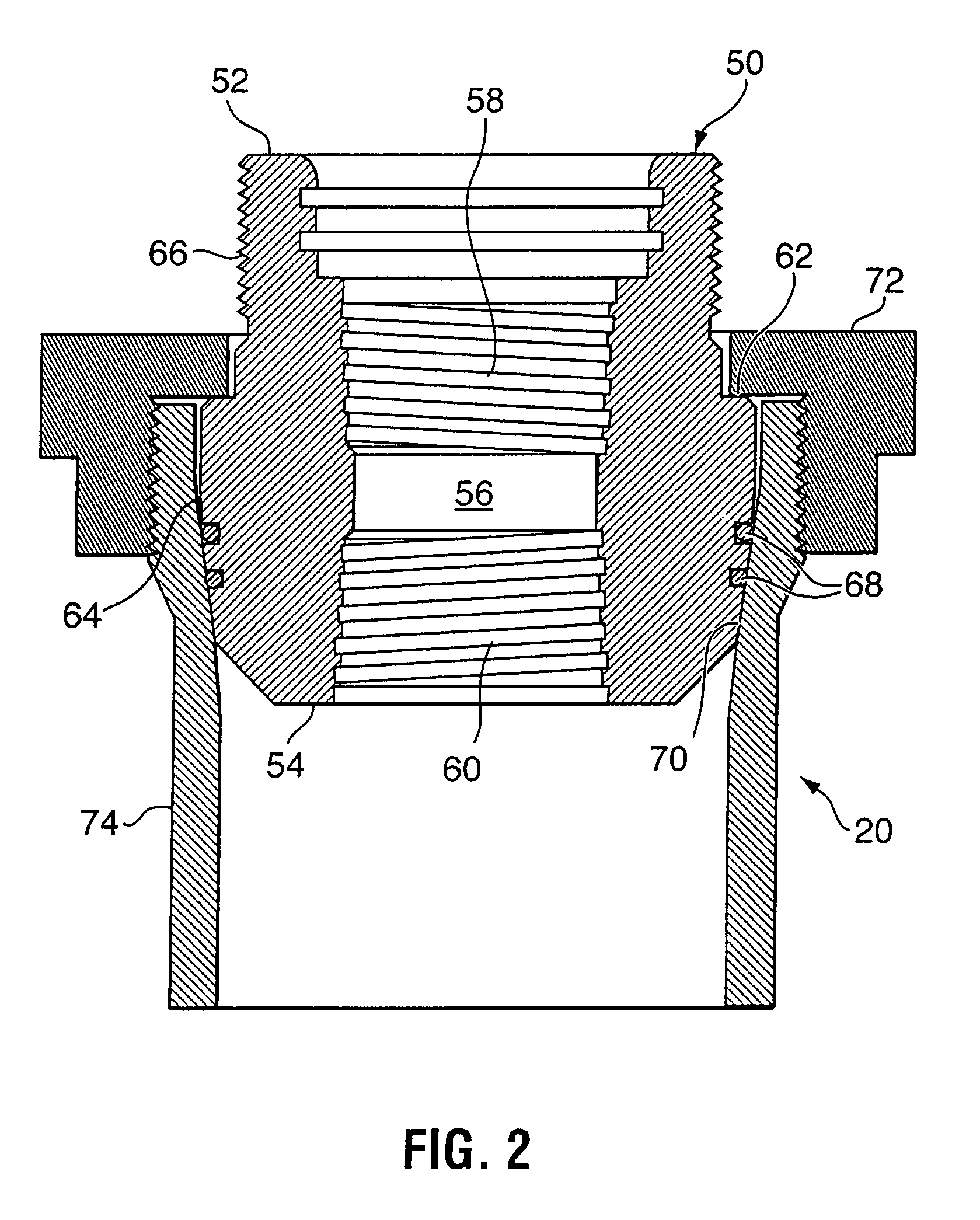

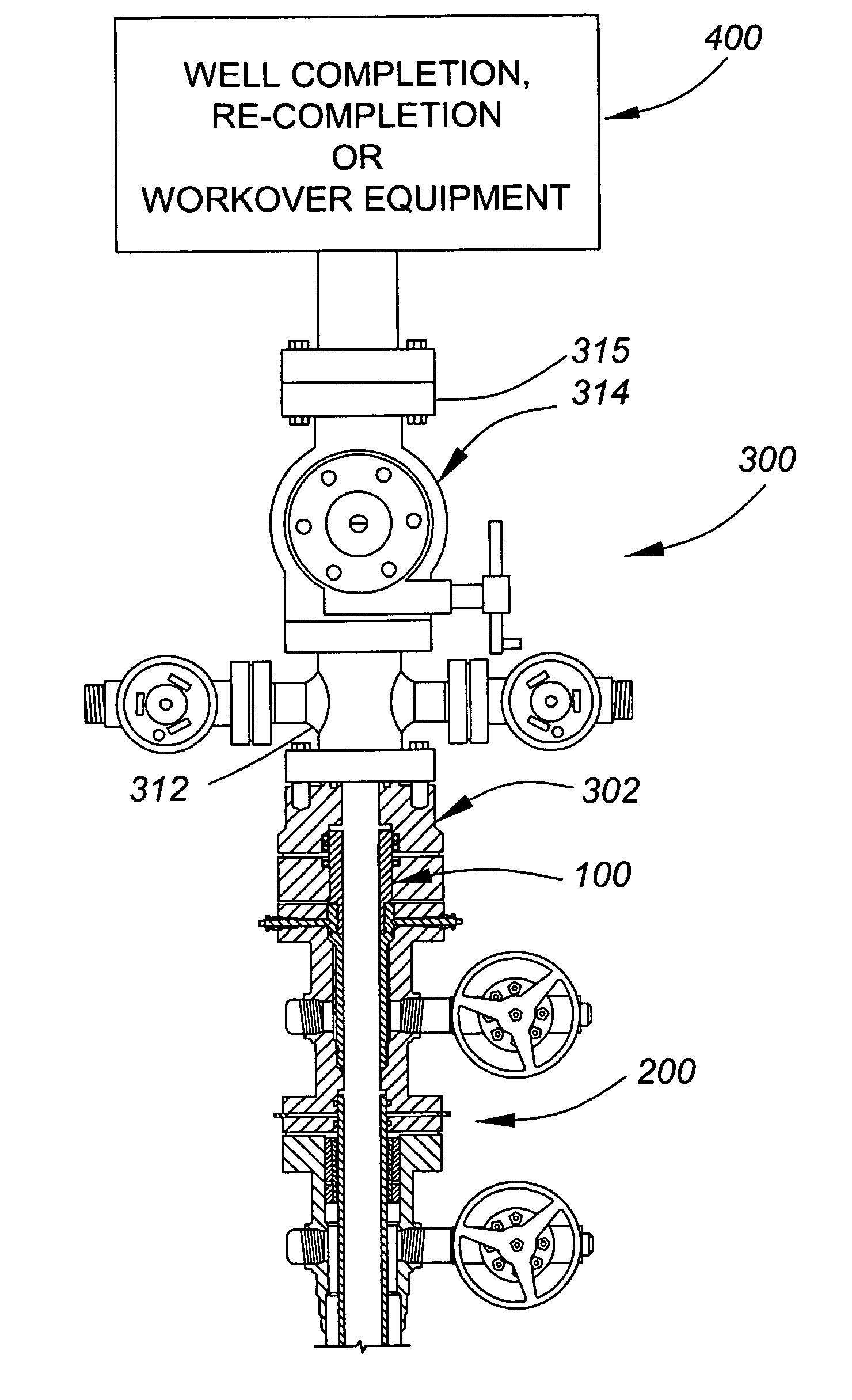

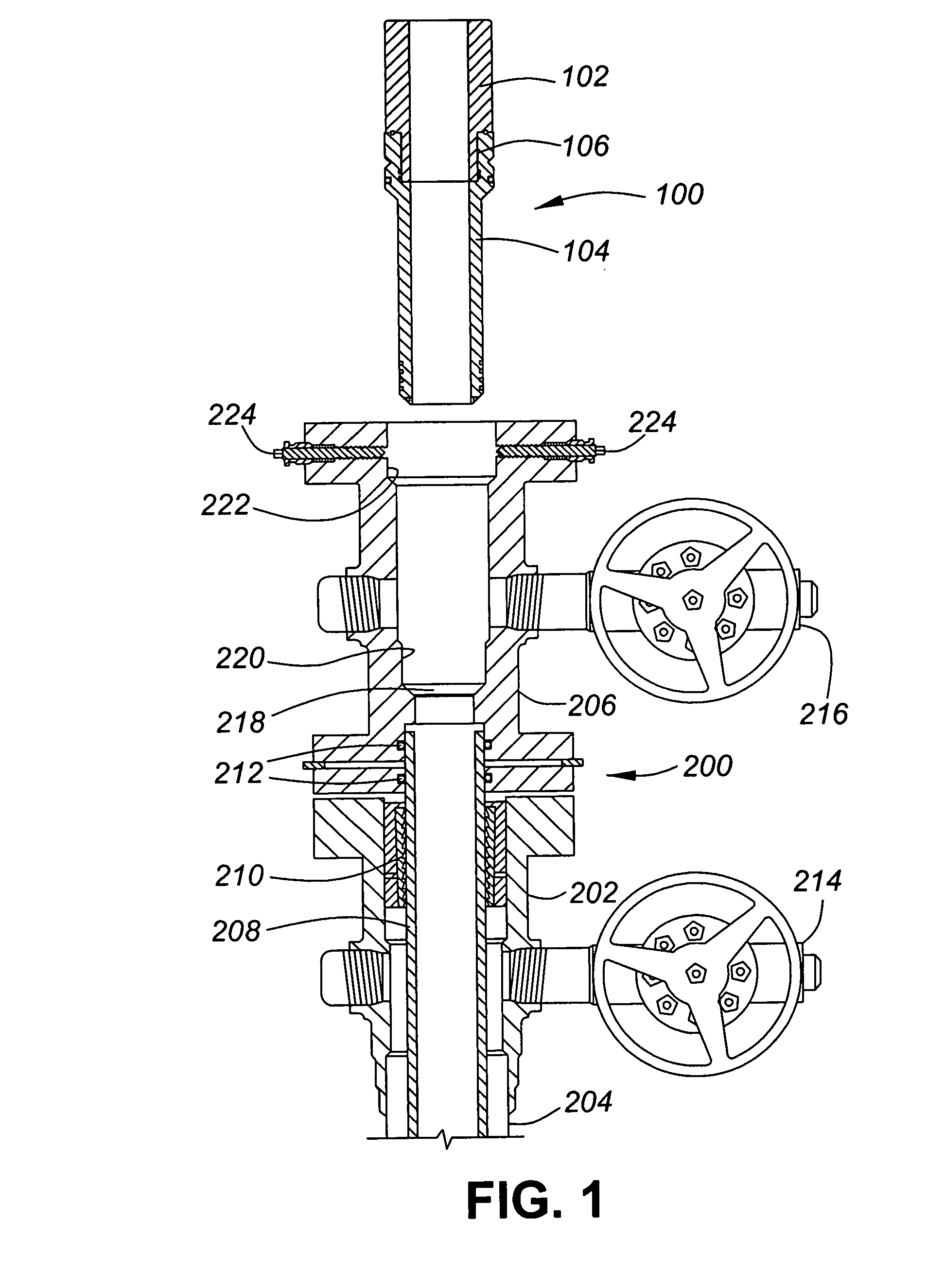

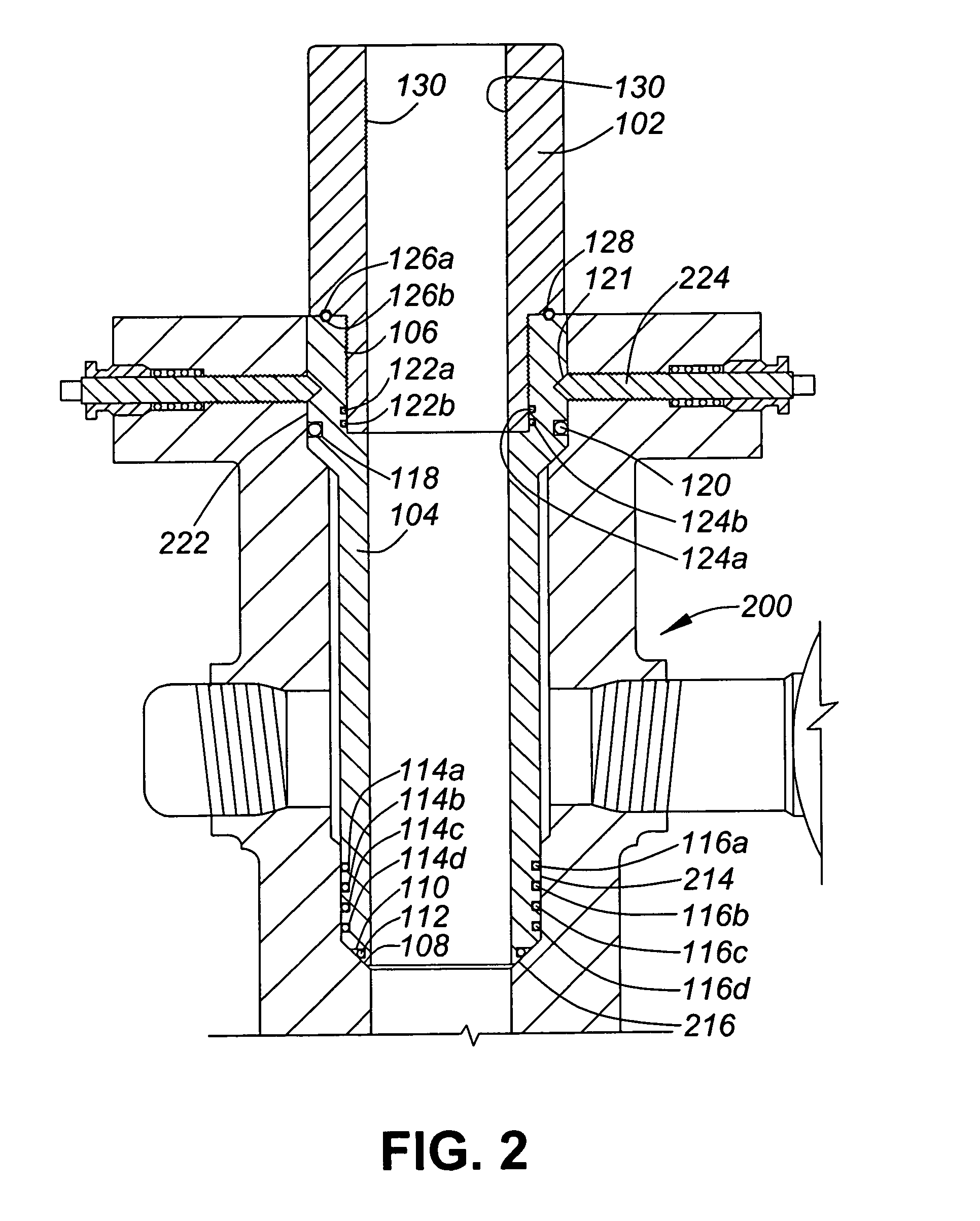

Retrievable frac mandrel and well control stack to facilitate well completion, re-completion or workover and method of use

A retrievable frac mandrel and a well control adapter are used to efficiently accomplish well completion, re-completion or workover. The retrievable frac mandrel is inserted in a tubing head spool of a well to be completed, re-completed or re-worked. The well control adapter is mounted to a top of the tubing head spool and seals off against a top of the retrievable frac mandrel. After well completion, re-completion or workover is completed, the frac mandrel can be retrieved from the tubing head spool without killing or plugging the well.

Owner:WELLS FARGO BANK NAT ASSOC +1

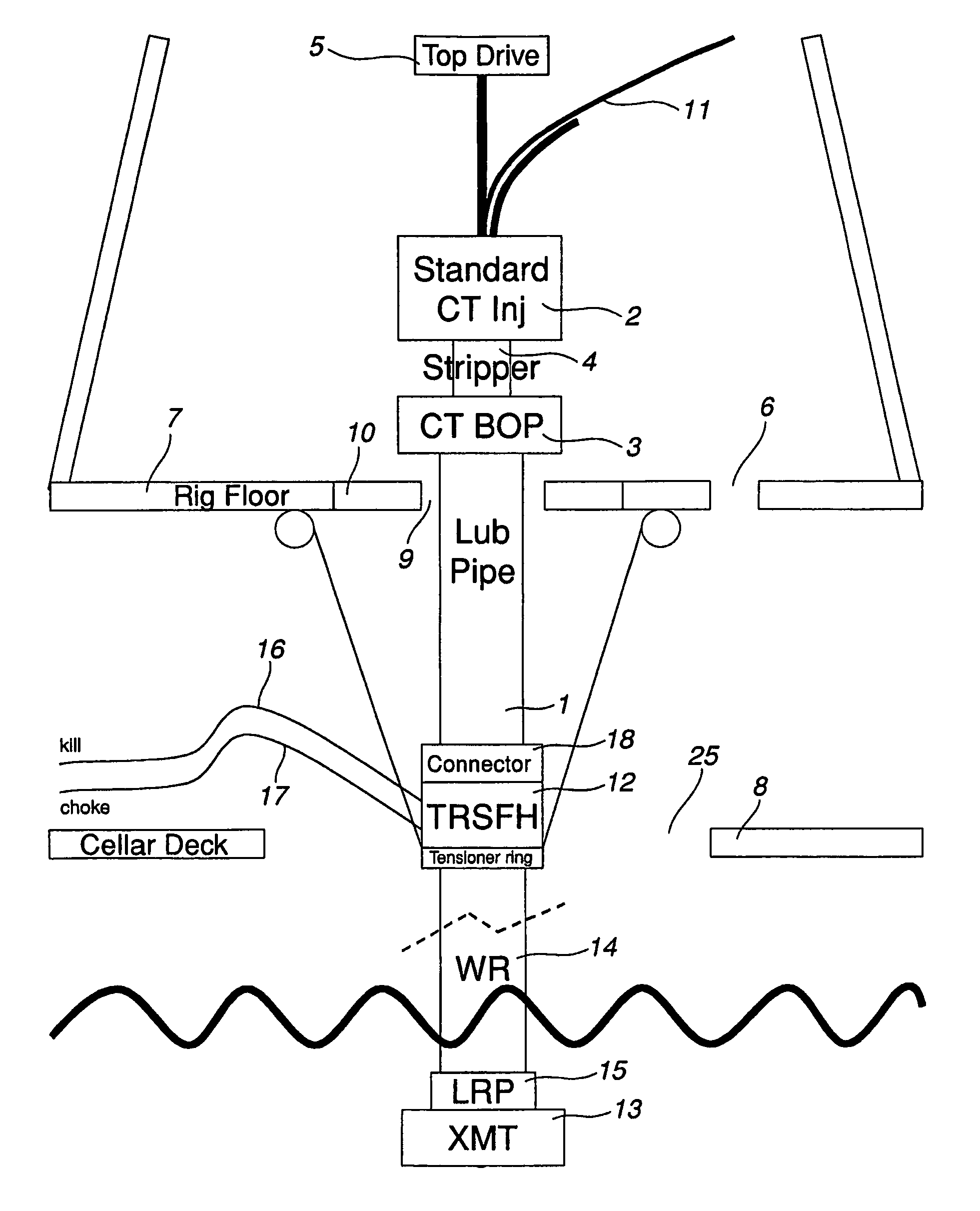

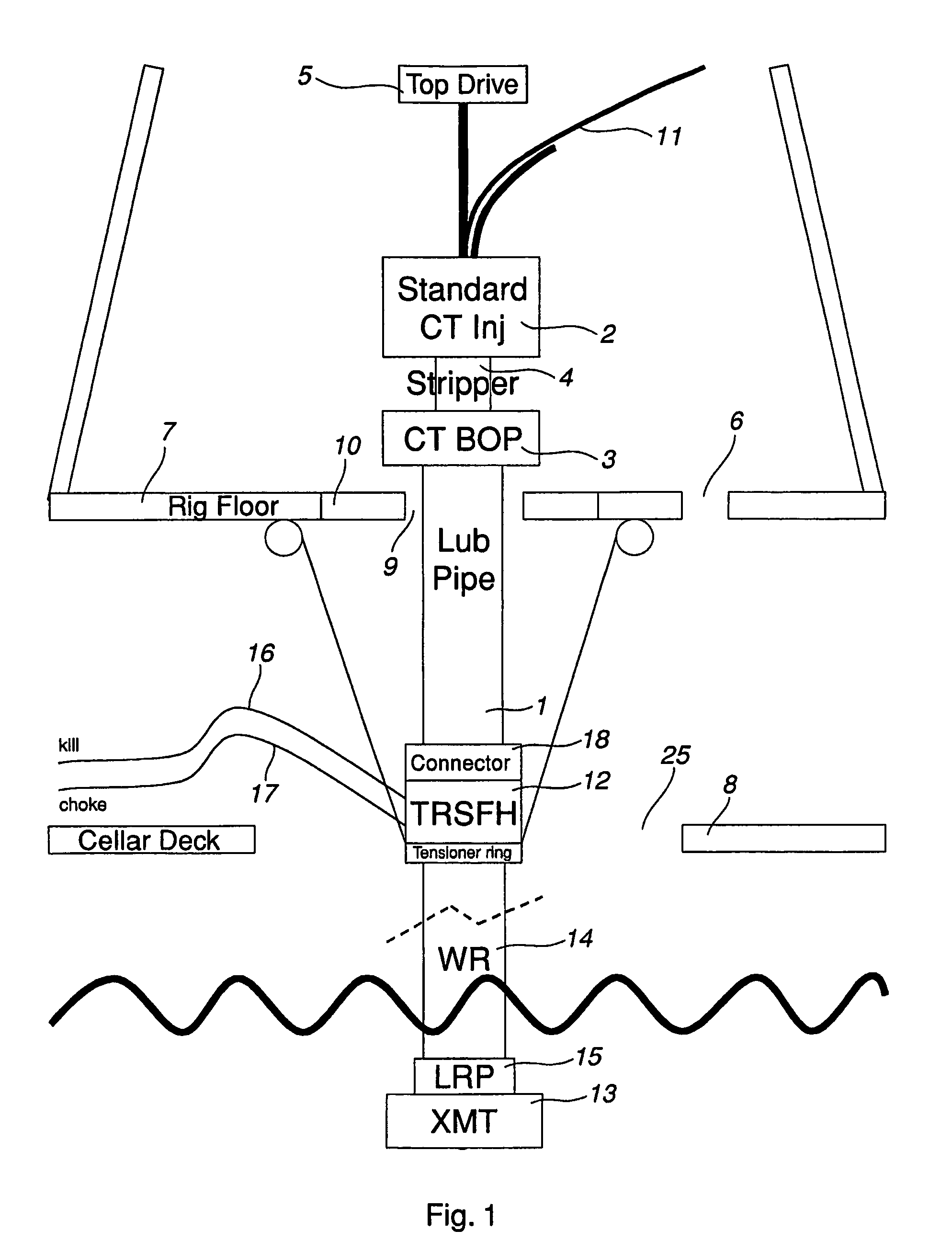

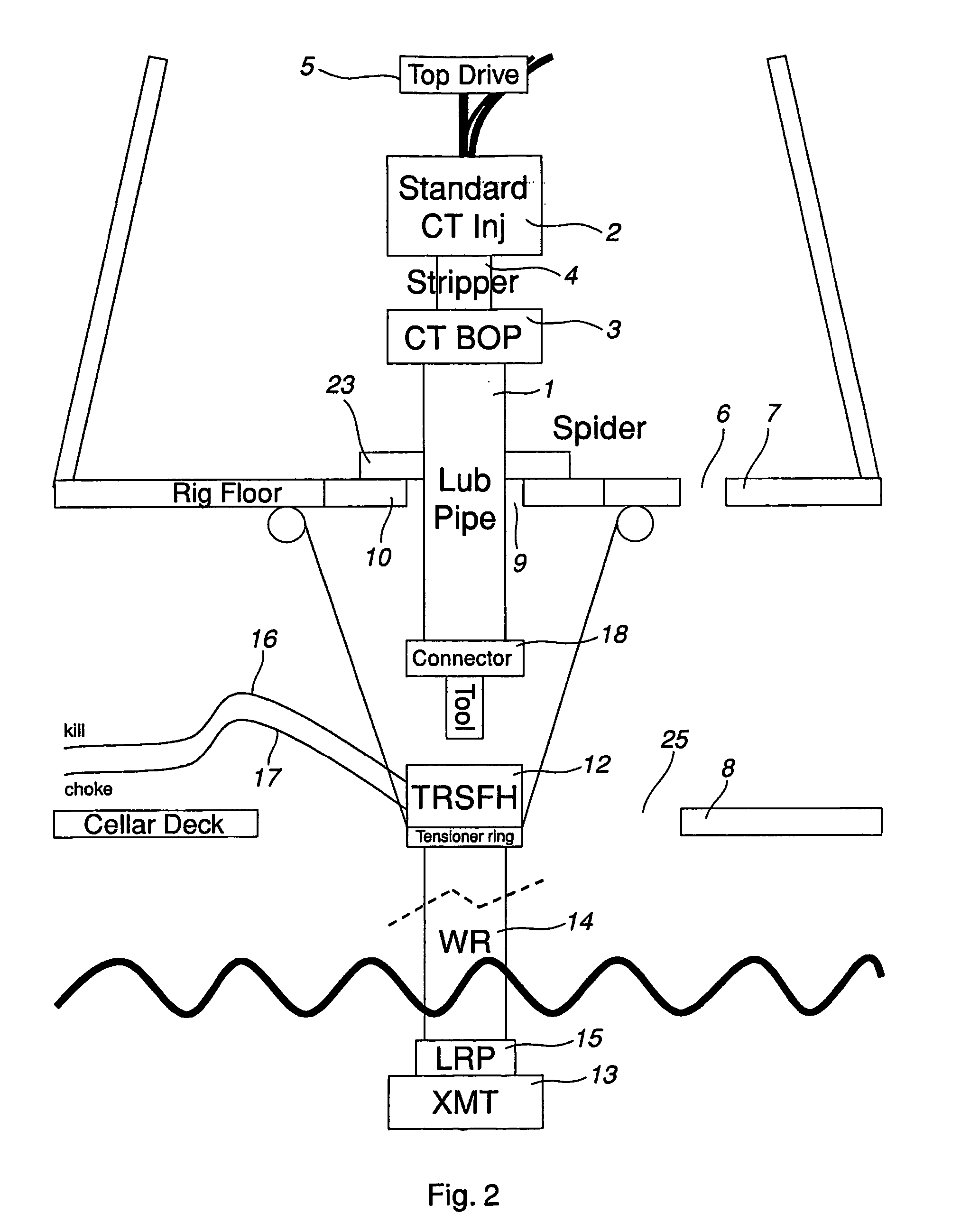

High pressure system

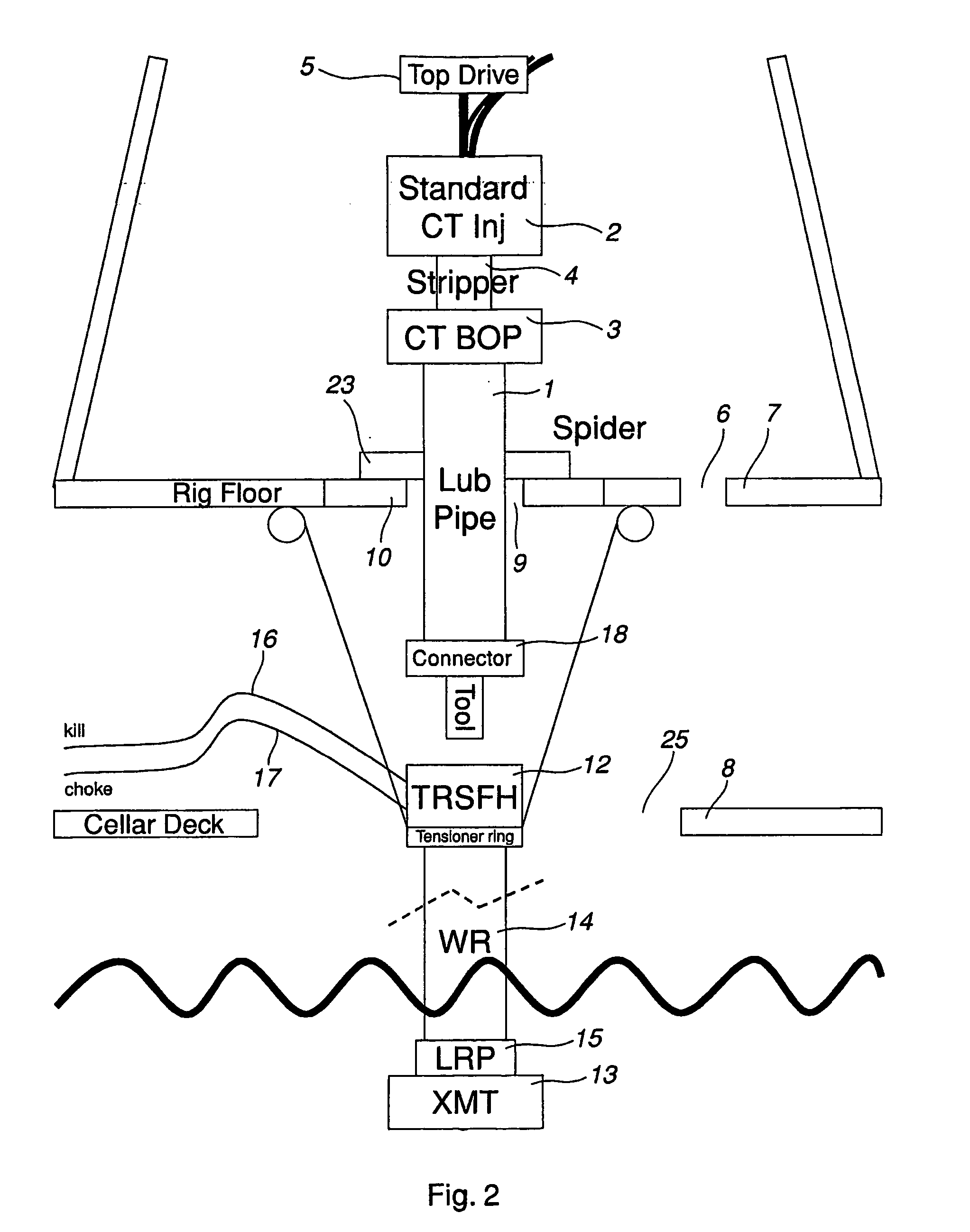

An arrangement and method for integrating a high pressure riser sleeve from the upper end of a high pressure drilling and workover riser terminated by an upper BOP close to sea level in one end and by a sub-sea blowout preventer BOP or a low riser package LRP close to the seabed in the lower end. The high pressure riser sleeve being installed, connected and integrated to the high pressure drilling and workover riser and extending up to and above the drill floor, inside a low pressure drilling riser slip joint which is connected to the drilling and workover riser. This relates to offshore drilling and well activities preformed from a floating drilling or workover rig or vessel. Operations can be switched from drilling with jointed drillpipe in a conventional manner, into performing underbalanced wireline and / or coiled tubing activities with full well pressure, much more effectively than with prior art.

Owner:ENHANCED DRILLING

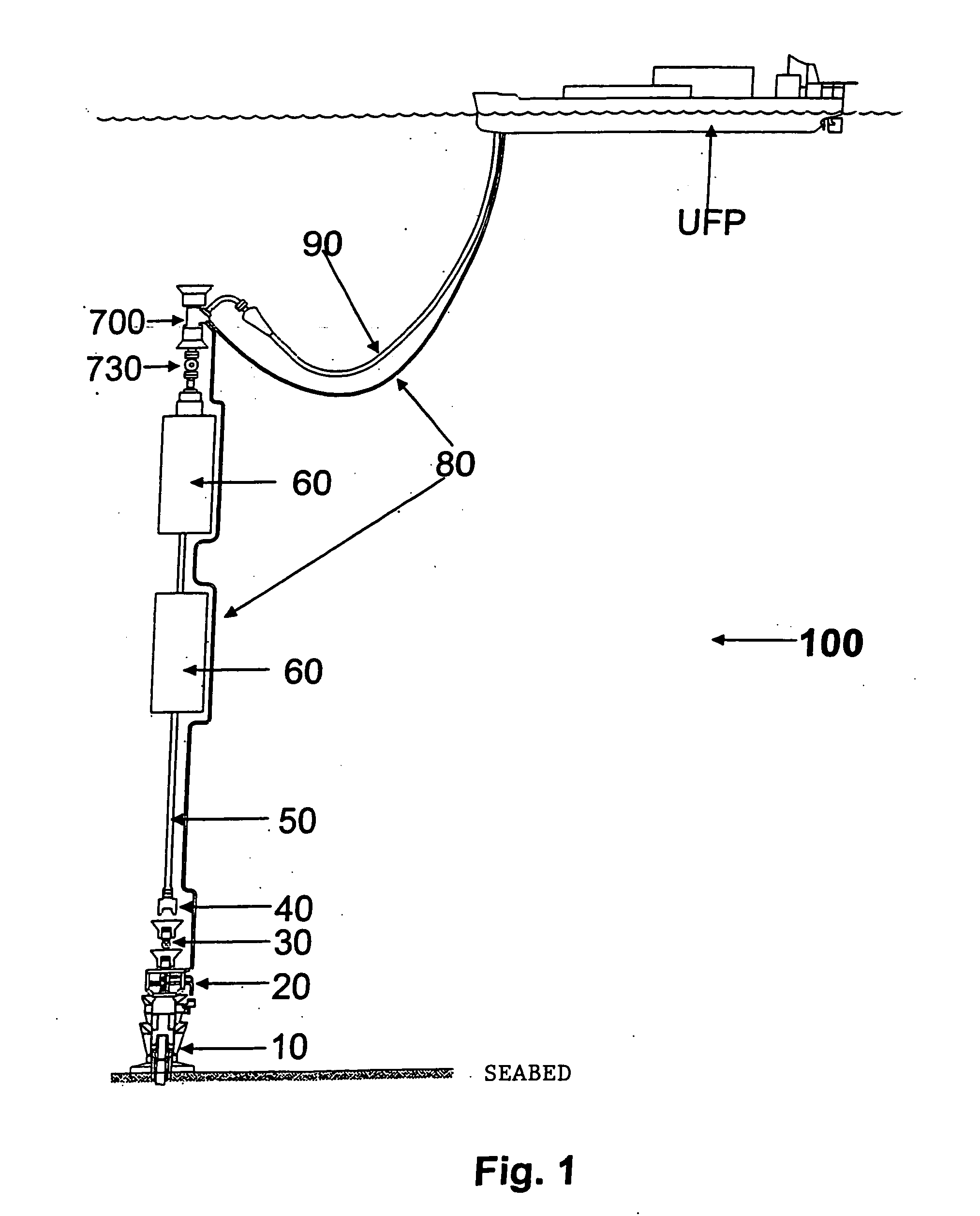

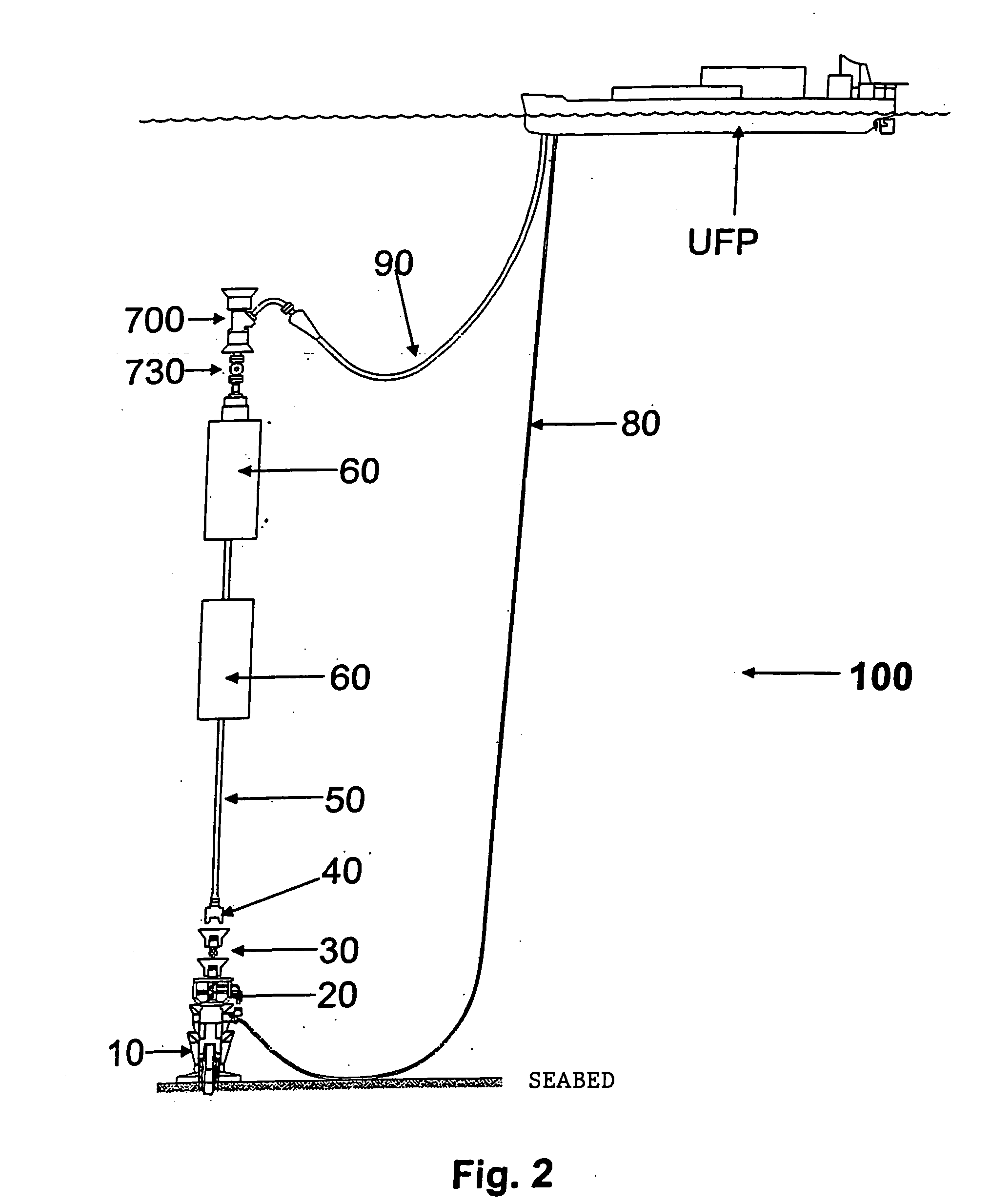

Self-supported riser system and method of installing same

InactiveUS20070044972A1Save rig timeReducing maneuvering stepCargo handling apparatusDrilling rodsBuoyPetroleum oil

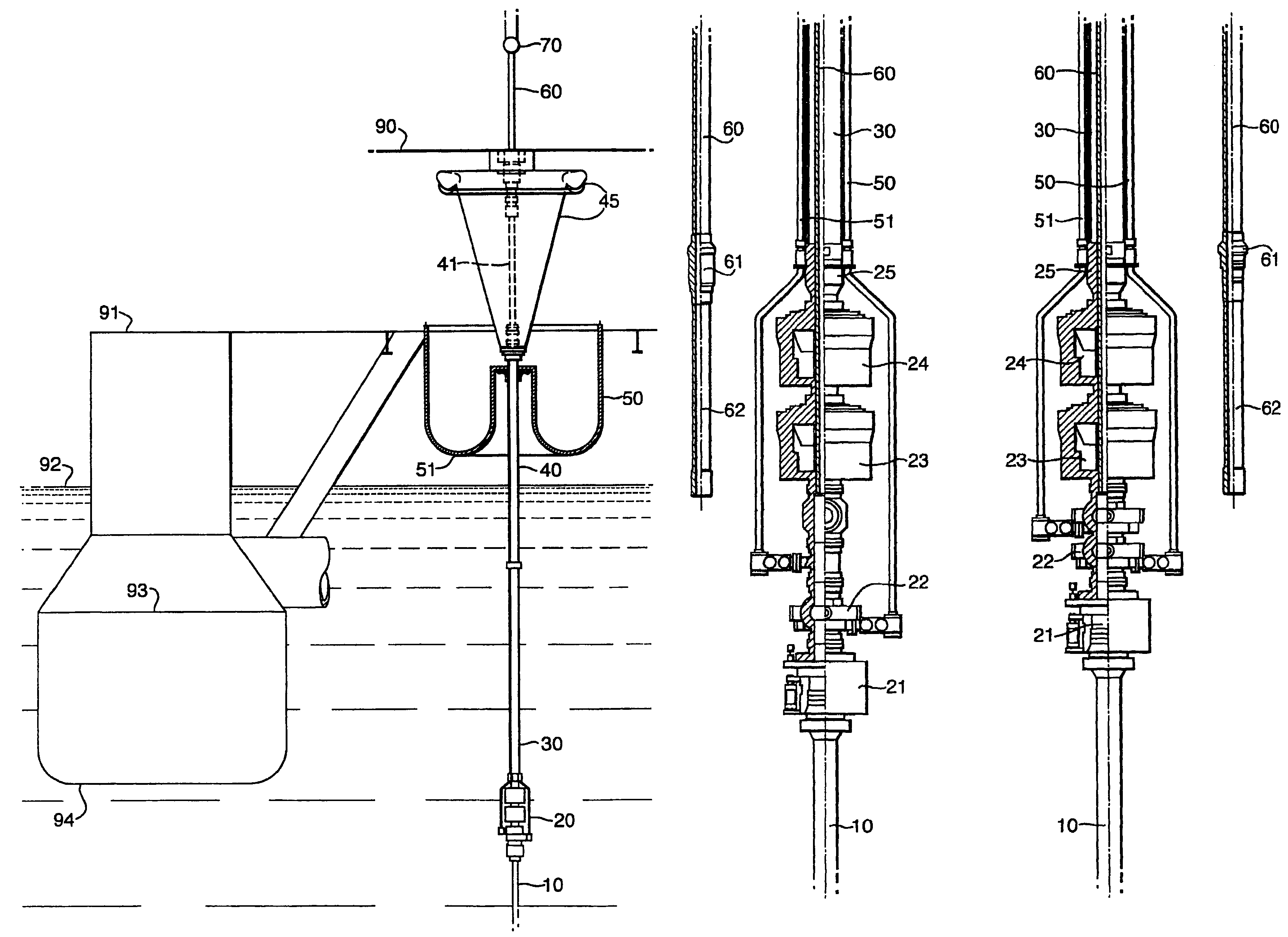

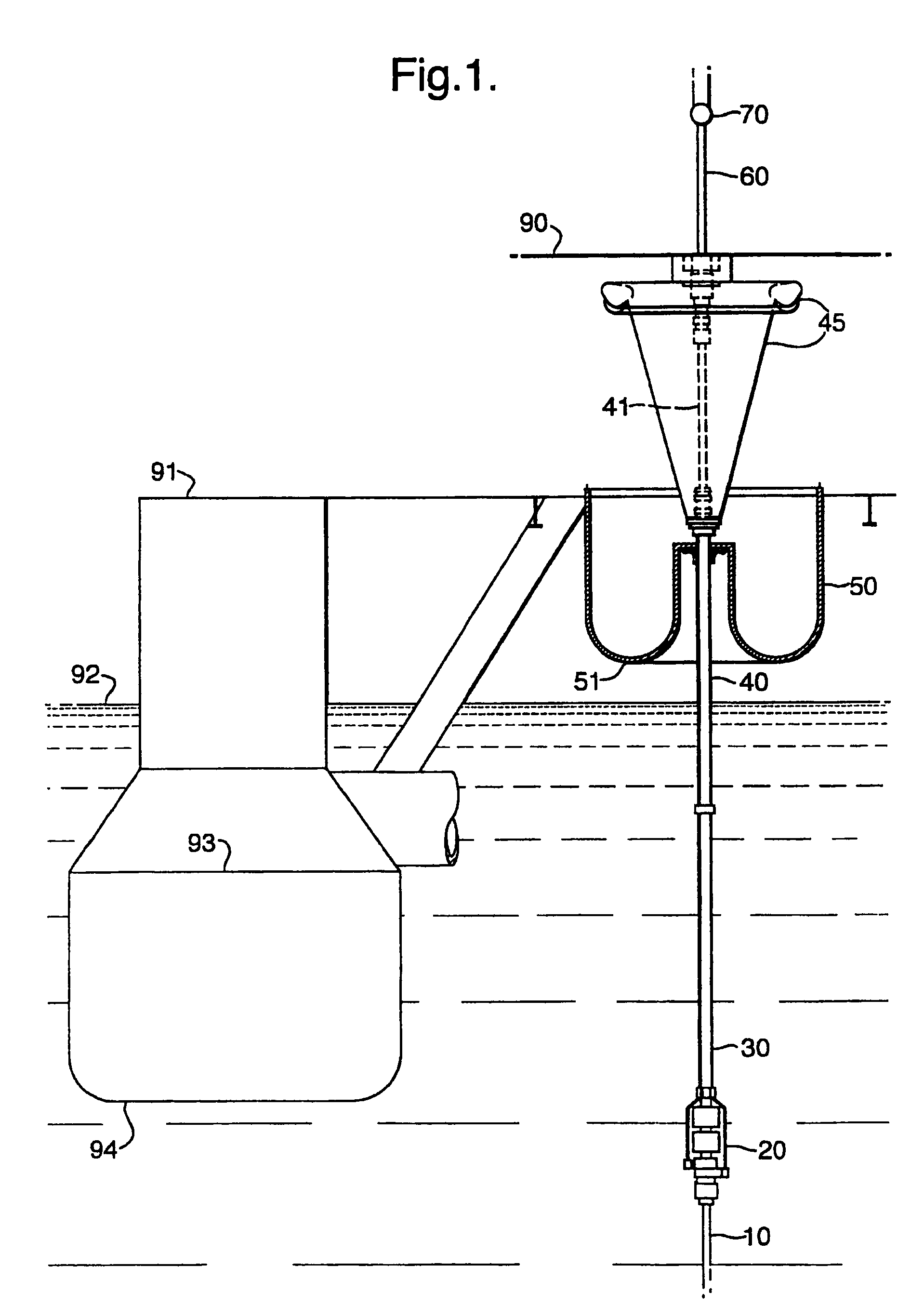

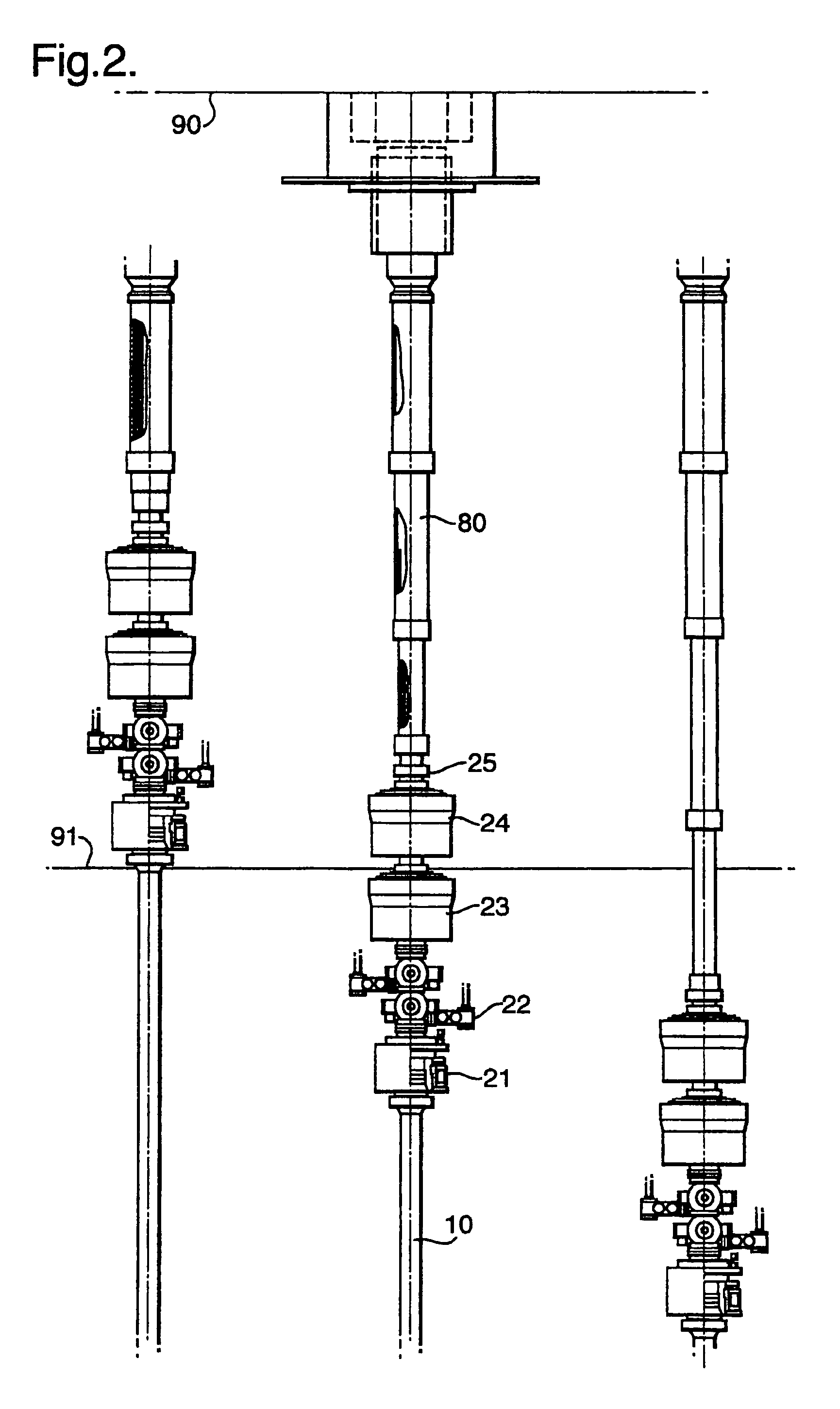

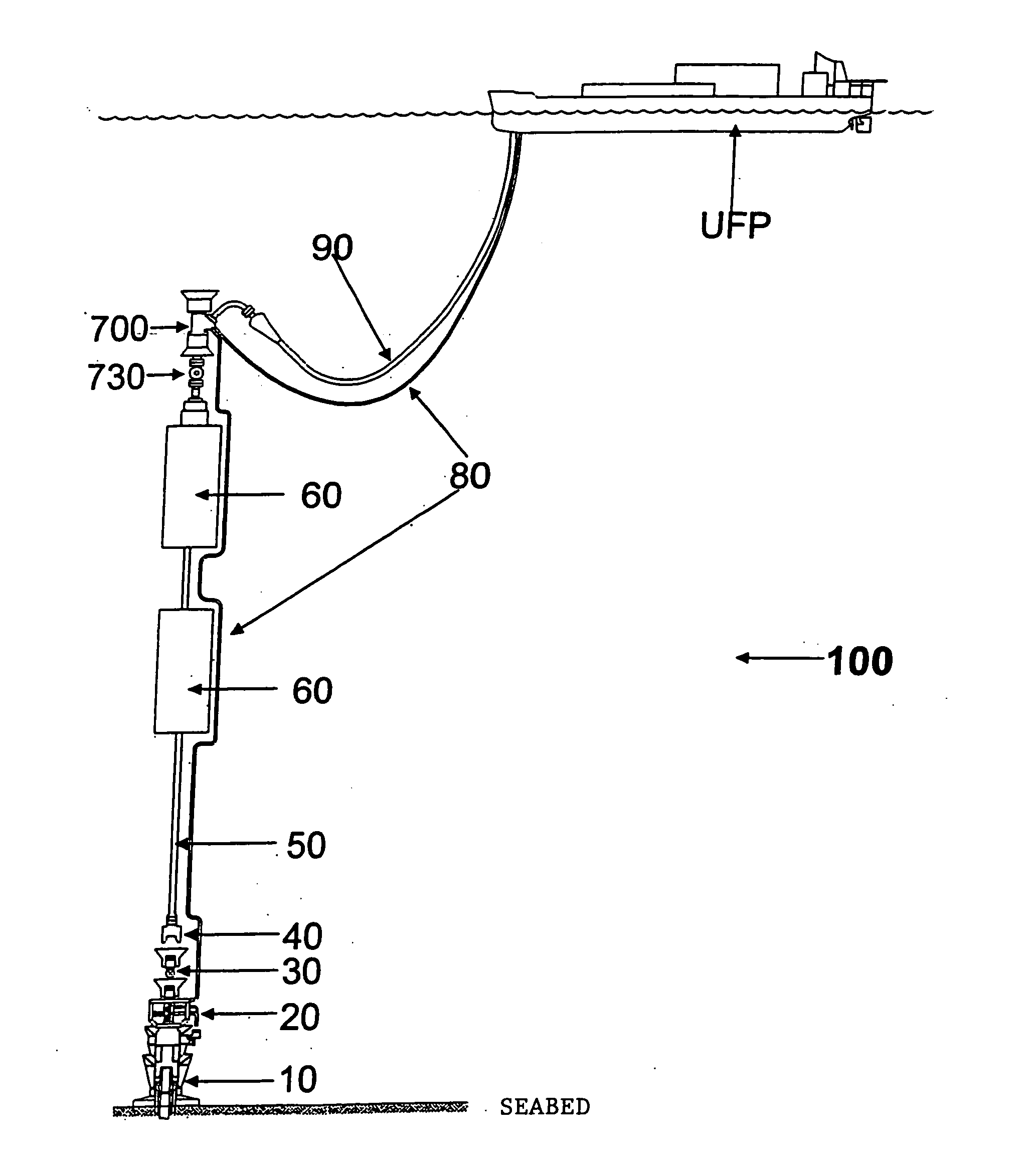

A self-supported riser system (100) for an Anticipated Production System (ASP) Test or a Long Duration Production (LDP) Test in a subsea petroleum production system, utilizing an ANM coupled to a wellhead and Floating Production Unit (FPU) is disclosed. The system includes a wellhead at the seabed, connected to an ANM (20) provided with a preventor (BOP of workover) (30). The preventor (30) is connected to a production riser (50) through a connection tool (40). The riser (50), mounted internally within a buoy assembly (60), is maintained under traction with the aid of a buoy assembly. The upper end of the riser (50) is provided with a Subsea Intervention Terminal (700), the Terminal being interlinked to the FPU by a flexible jumper (90) to carry the oil produced to the FPU. Two methods for installing the self-supported riser system (100) are also disclosed.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

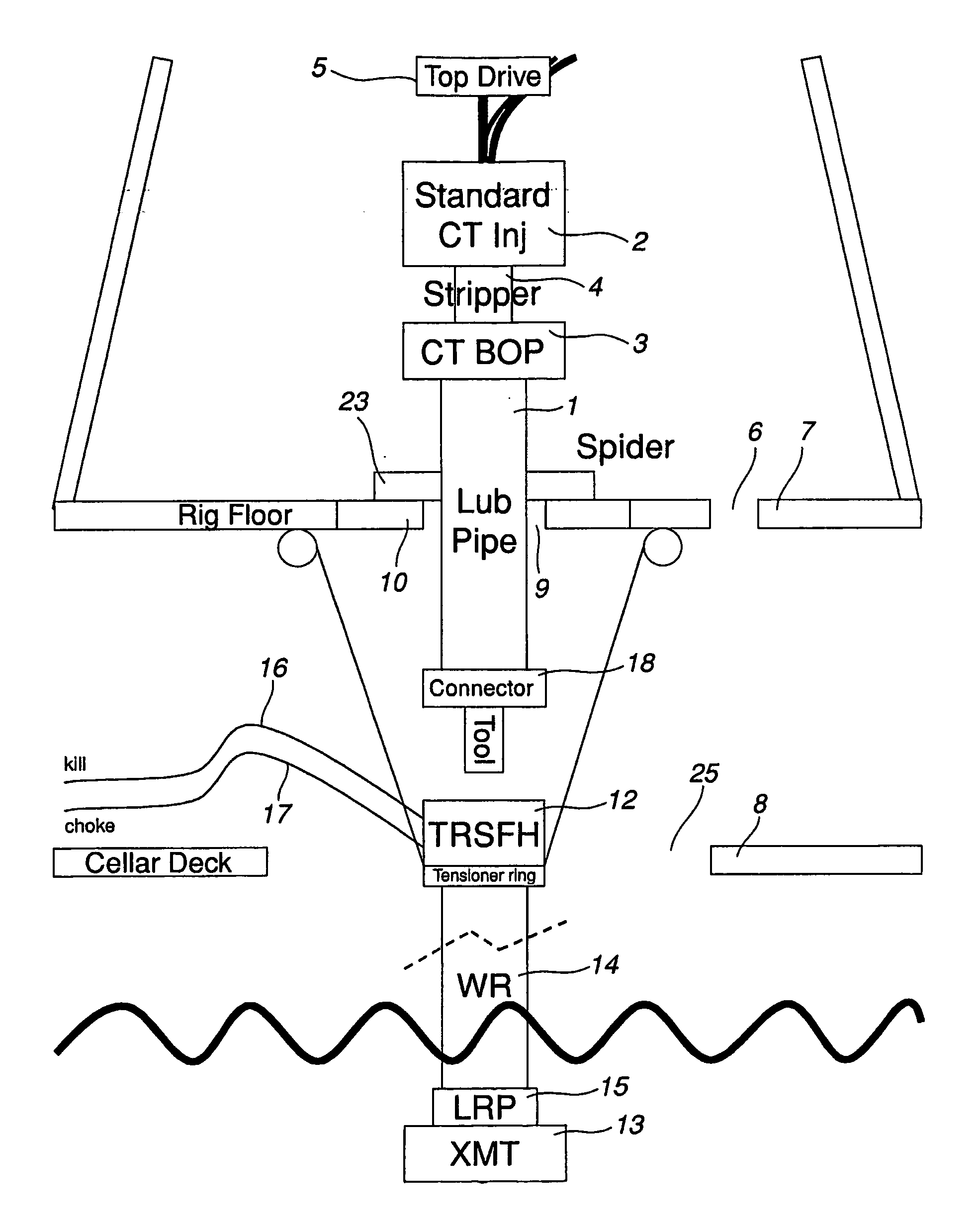

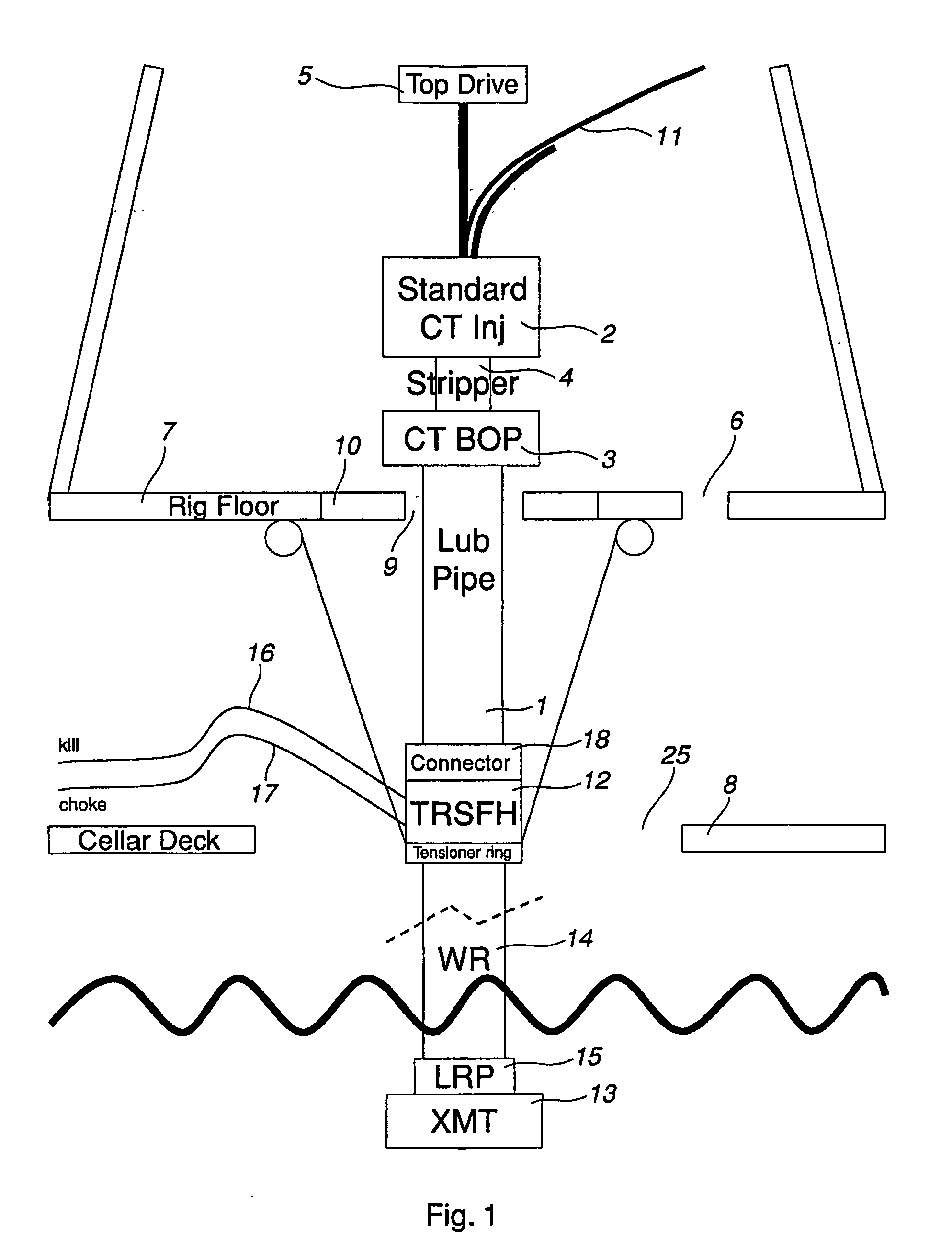

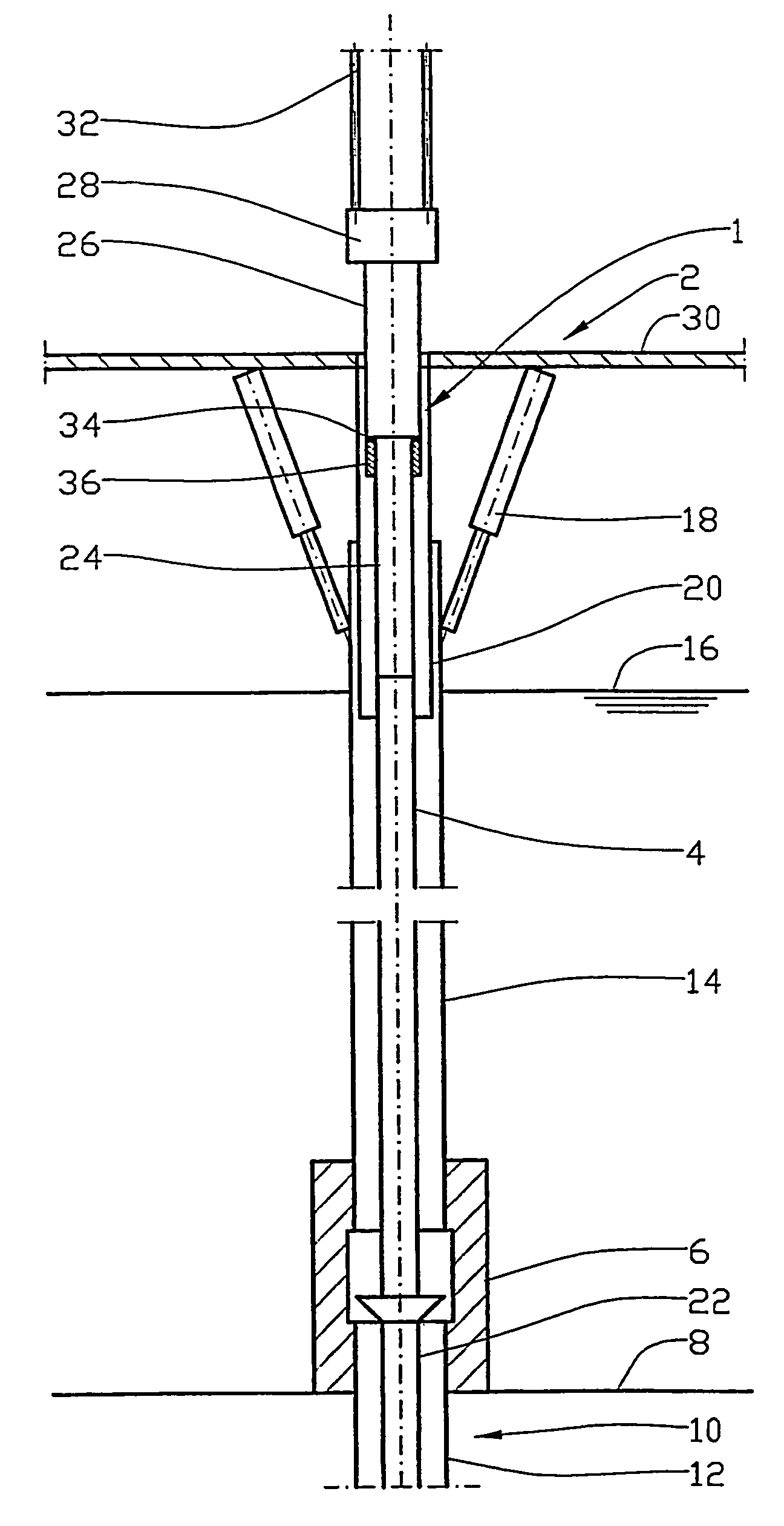

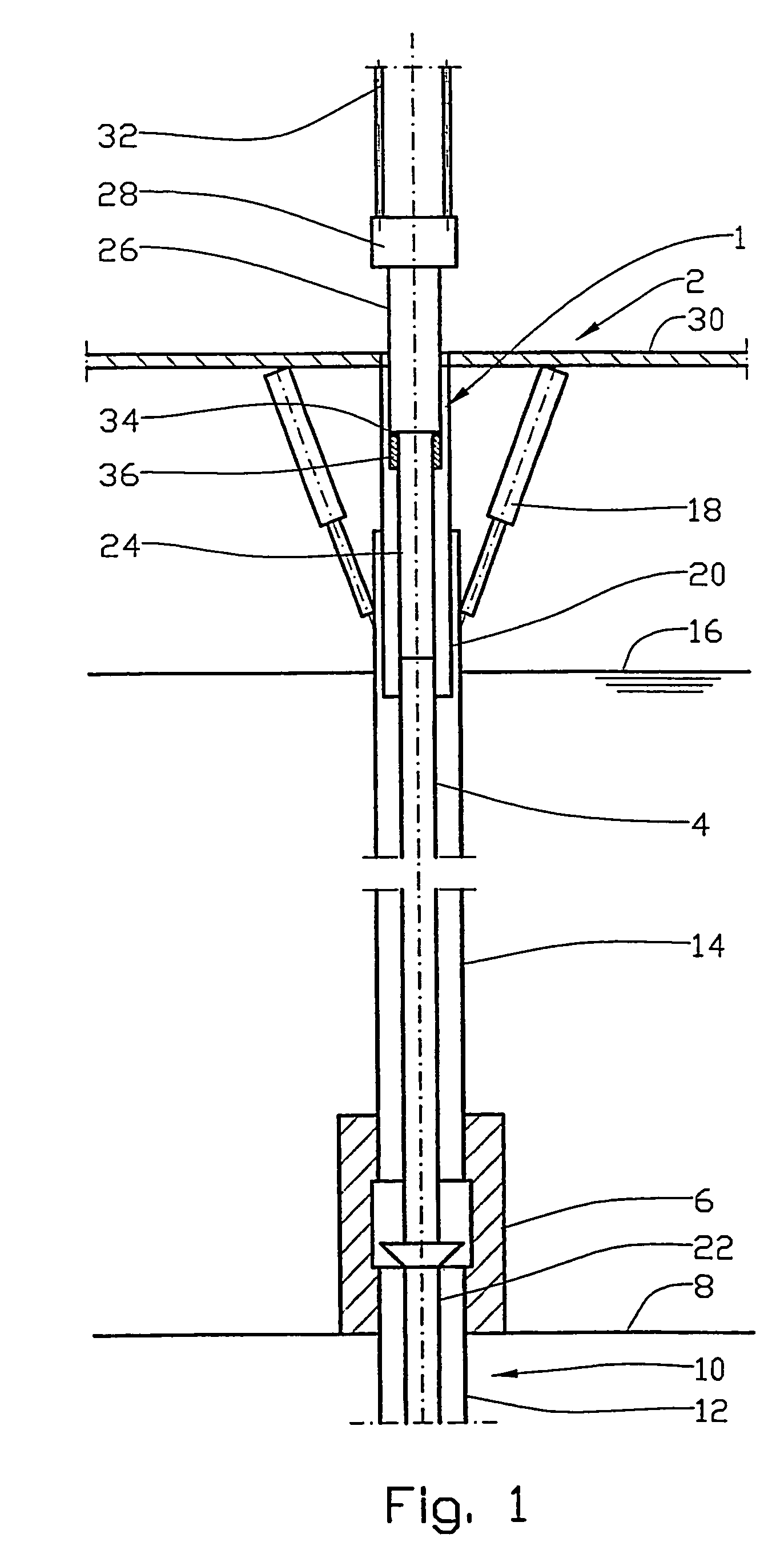

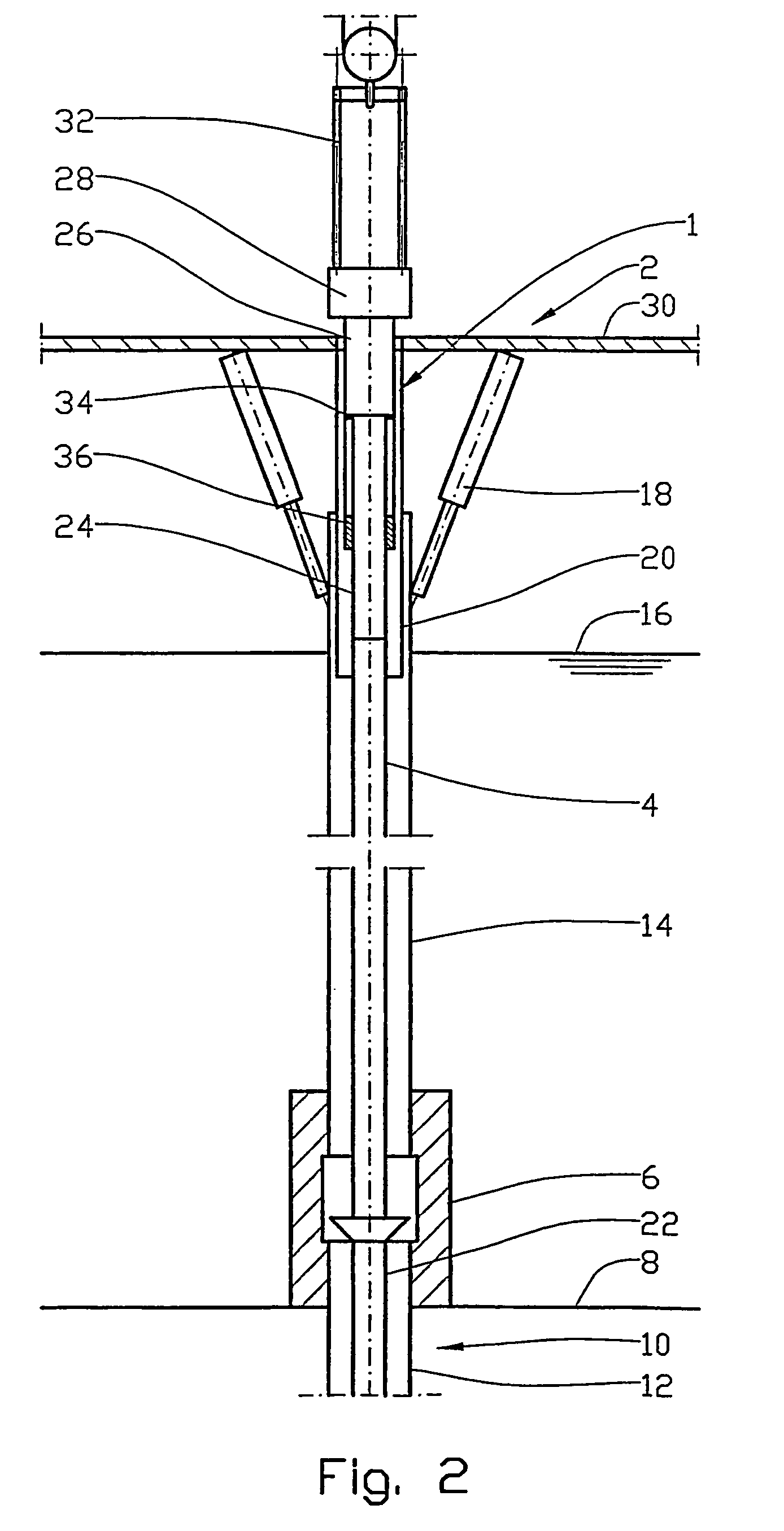

System And Method For Rigging Up Well Workover Equipment

InactiveUS20070284113A1Facilitate riggingSimple and safe processDrilling rodsFluid removalVertical tubeCoiled tubing

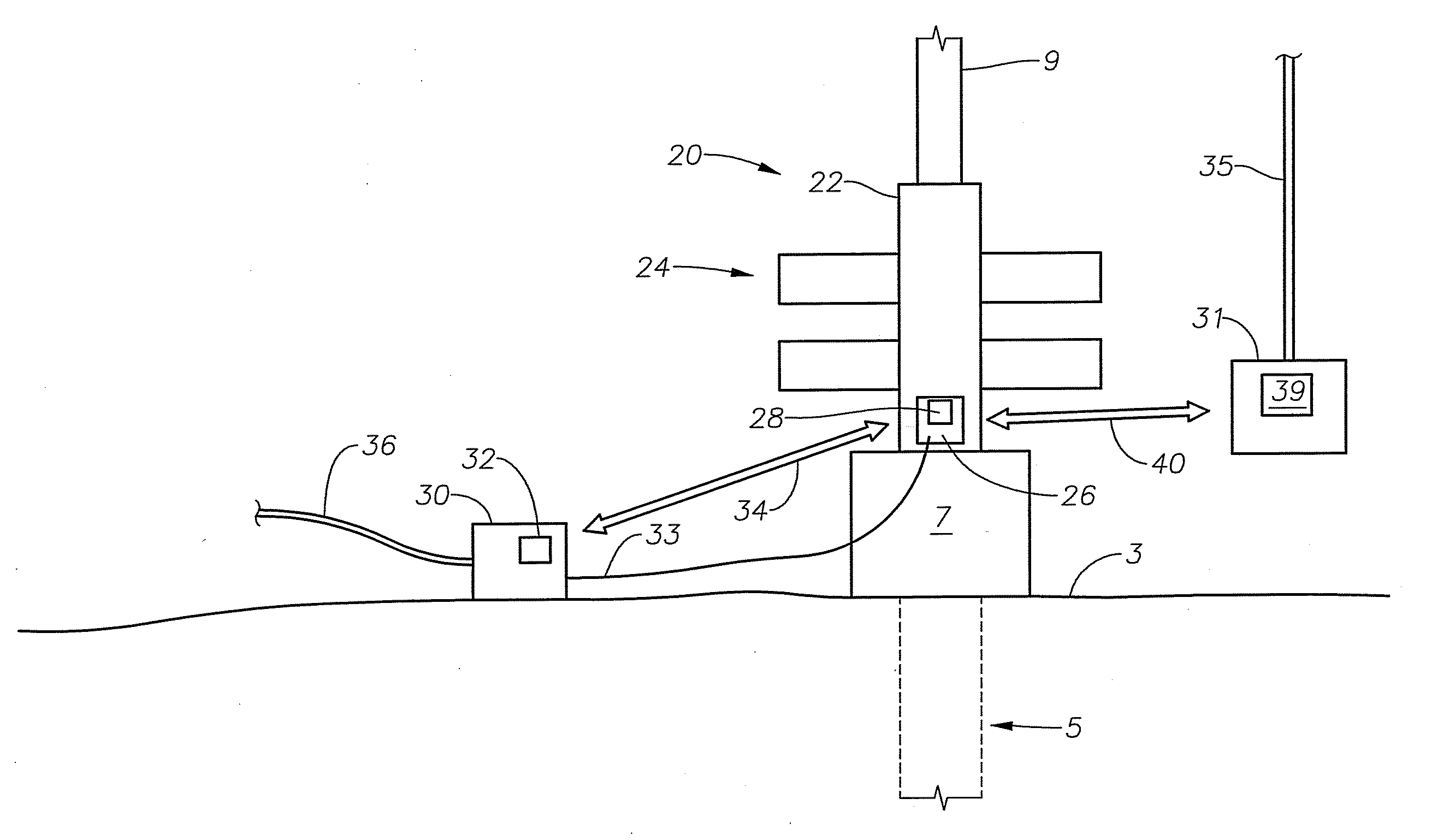

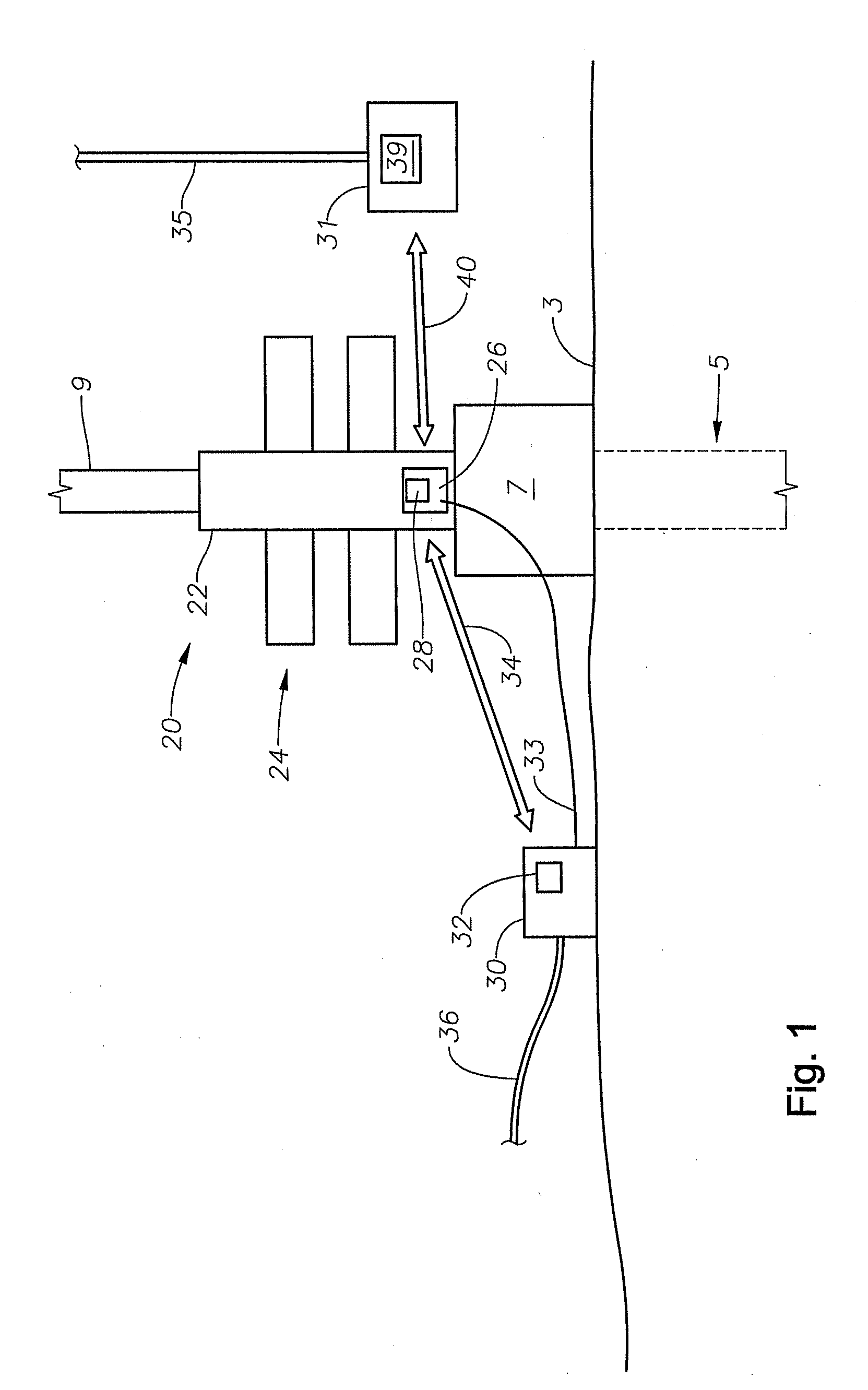

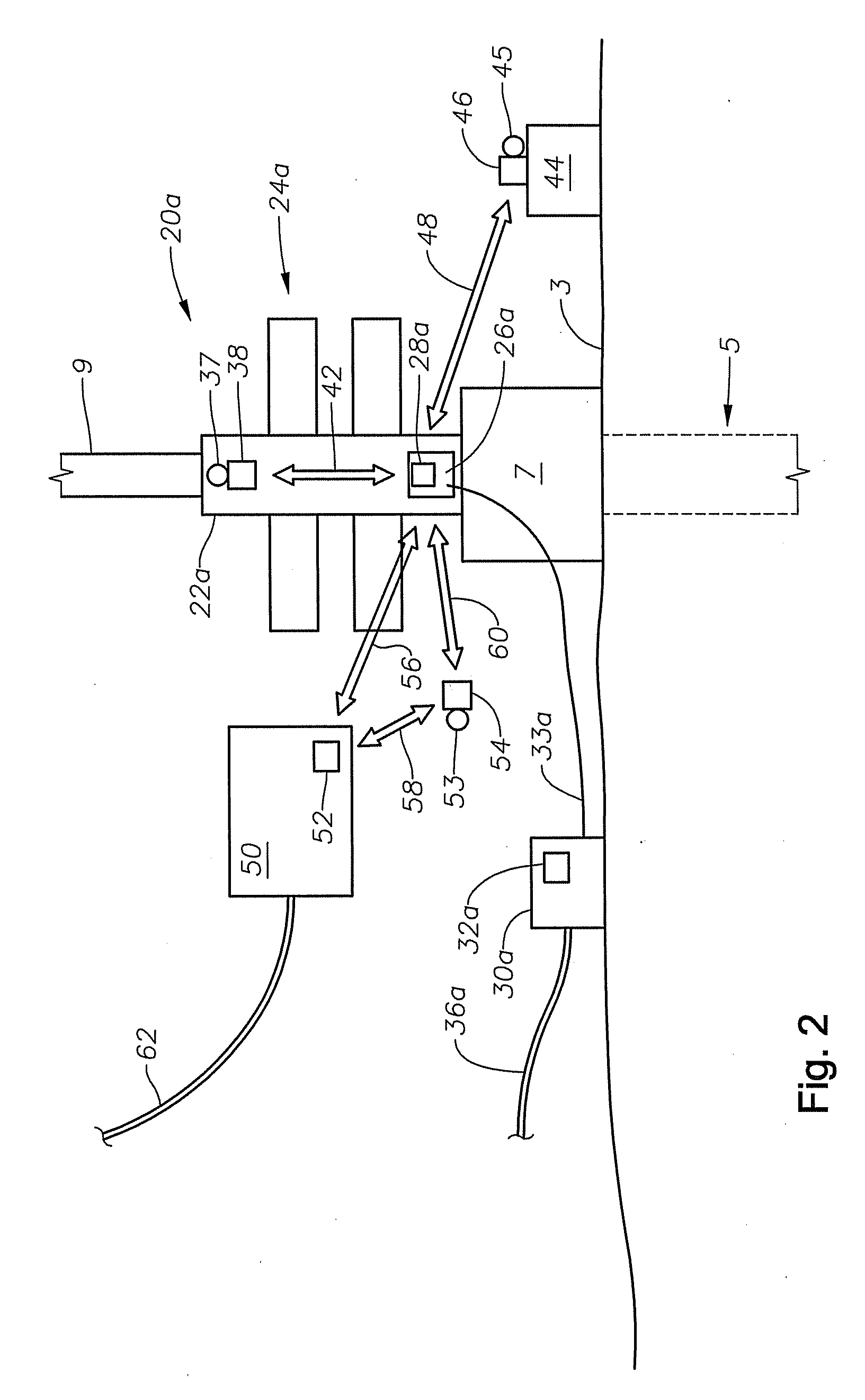

A gas and oil recovery system including a vessel, platform or rig, with a rig floor, a riser including a pipe that extends from the vessel, platform or rig to a x-mas tree on top of a well head and via which a wire or coiled tubing is fed down into a well. The riser is movable through an opening in the rig floor, and a surface flow head connected to the riser and to a wire line or coiled tubing equipment. The surface flow head is arranged to be run through the opening in the rig floor.

Owner:VETCO GRAY SCANDINAVIA

Underwater Communications Using RF

A subsea production system adapted for wireless communication so that production tree operation can be controlled locally wirelessly from a workover umbilical or remotely controlled vehicle. The production system includes a wellhead assembly and an umbilical termination connected to an umbilical that extends to above the sea surface. Dedicated wireless communication devices can be attached to one or both of the wellhead assembly and the umbilical termination. The wireless communication devices can include a radio frequency modem, a sonar device, an infrared communication device, a light emitting diode, an optical modem, and combinations thereof; the wireless communication can include radio frequency waves, acoustic waves, and electromagnetic waves. A subsea control module can be included for controlling / actuating devices in or associated with the production system. The subsea control module can be adapted for wireless communication.

Owner:VETCO GRAY

Method for using a multipurpose system

The invention is a method for drilling a well and for well intervention using a multipurpose system on a pivoting, slidable cantilever on a platform to drill a well and to perform well intervention operations, wherein the method involves pulling a completion tubing out of the well; forming completion tubing segments pulled from the well; setting back the segments into a storage area; running the coiled tubulars into the well; removing used completion equipment from the well; preparing the well for new completion equipment with the coiled tubulars; pulling segments of new completion tubing from the storage area and breaking segments of new completion tubing into individual joints and removing the individual joints from the cantilever; running into the well with coiled tubulars and installing the new completion equipment; building segments from individual joints and setting the segments in the storage area; and running segments and new completion equipment into the well.

Owner:ITREC BV

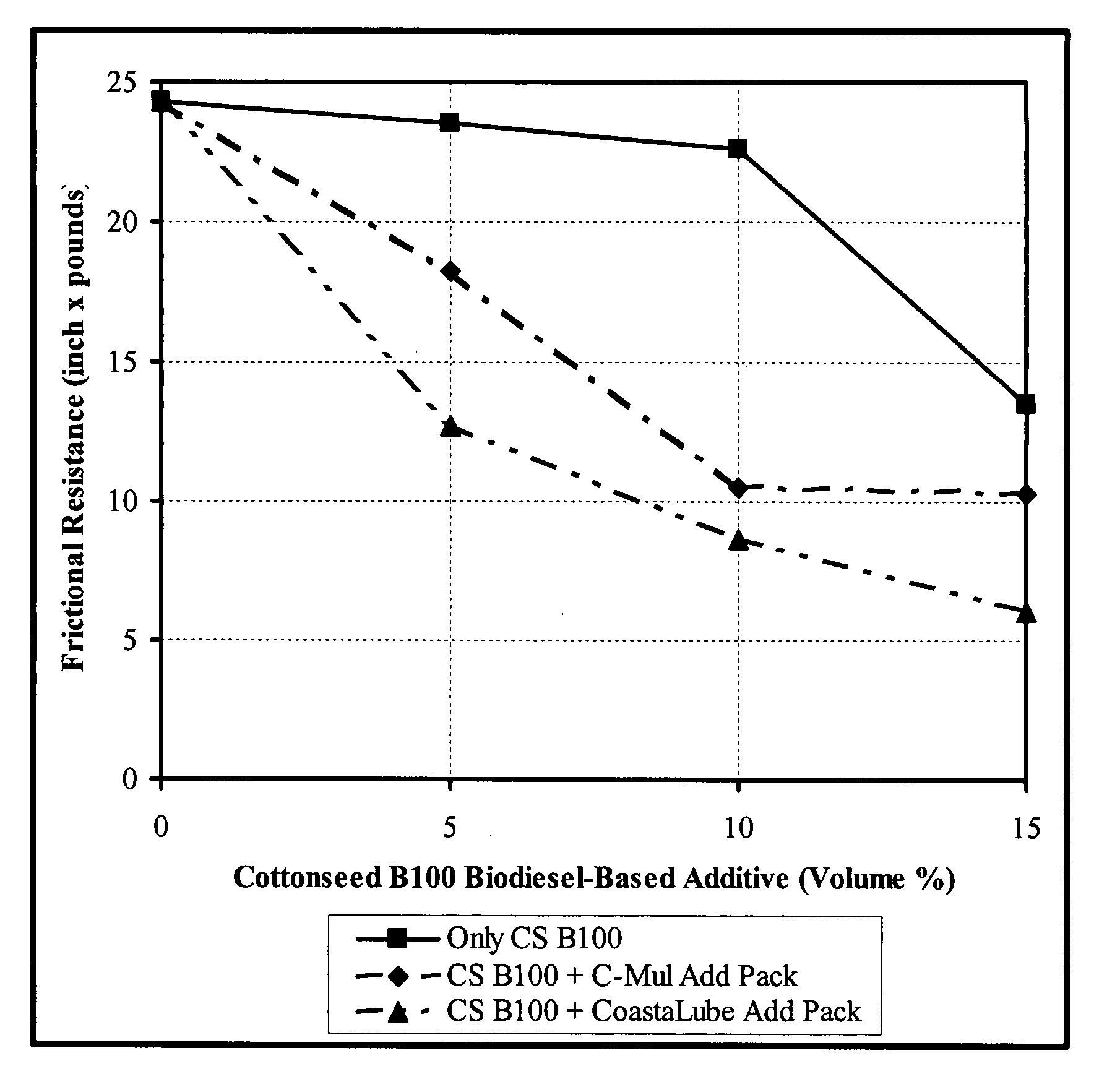

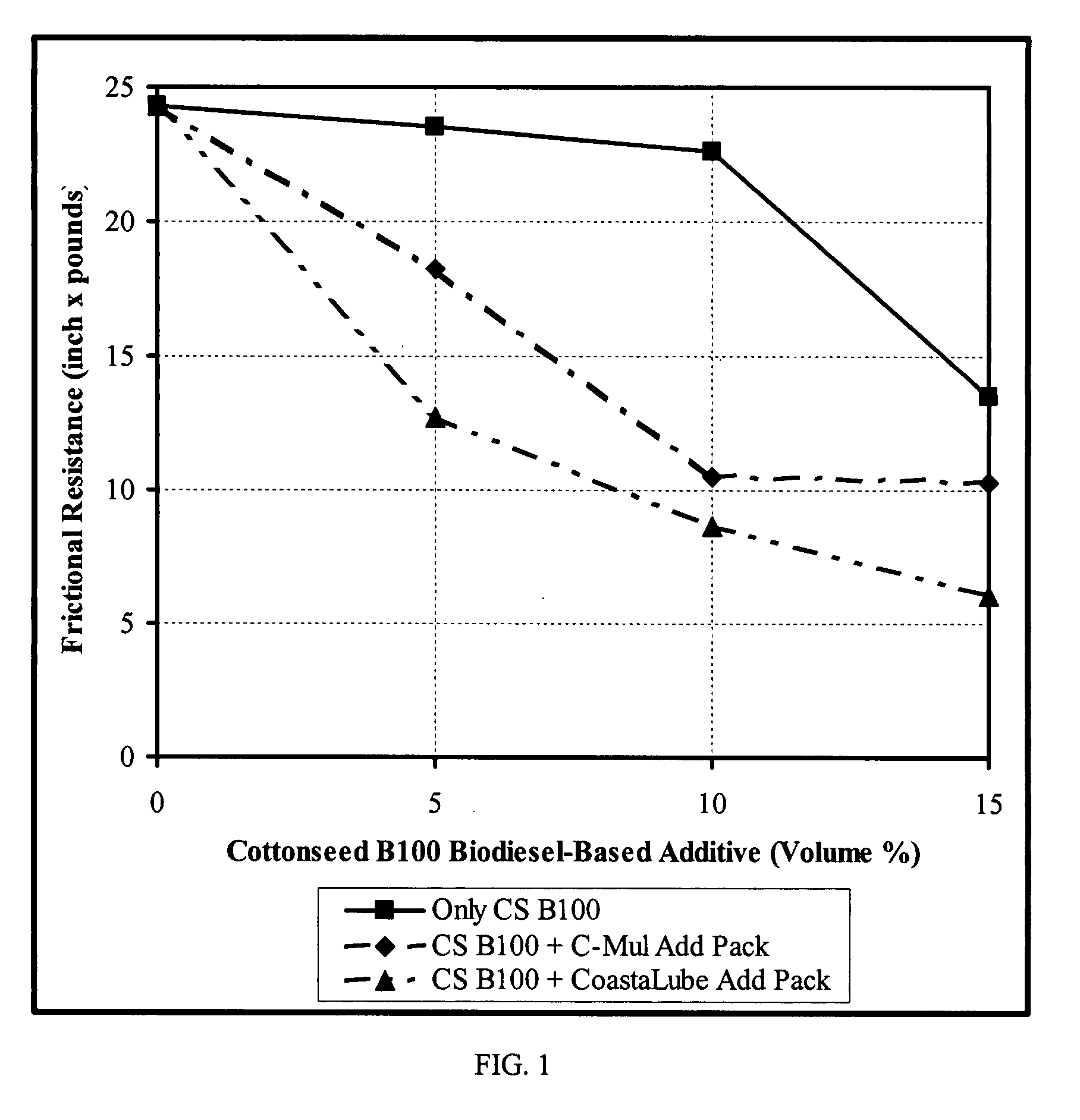

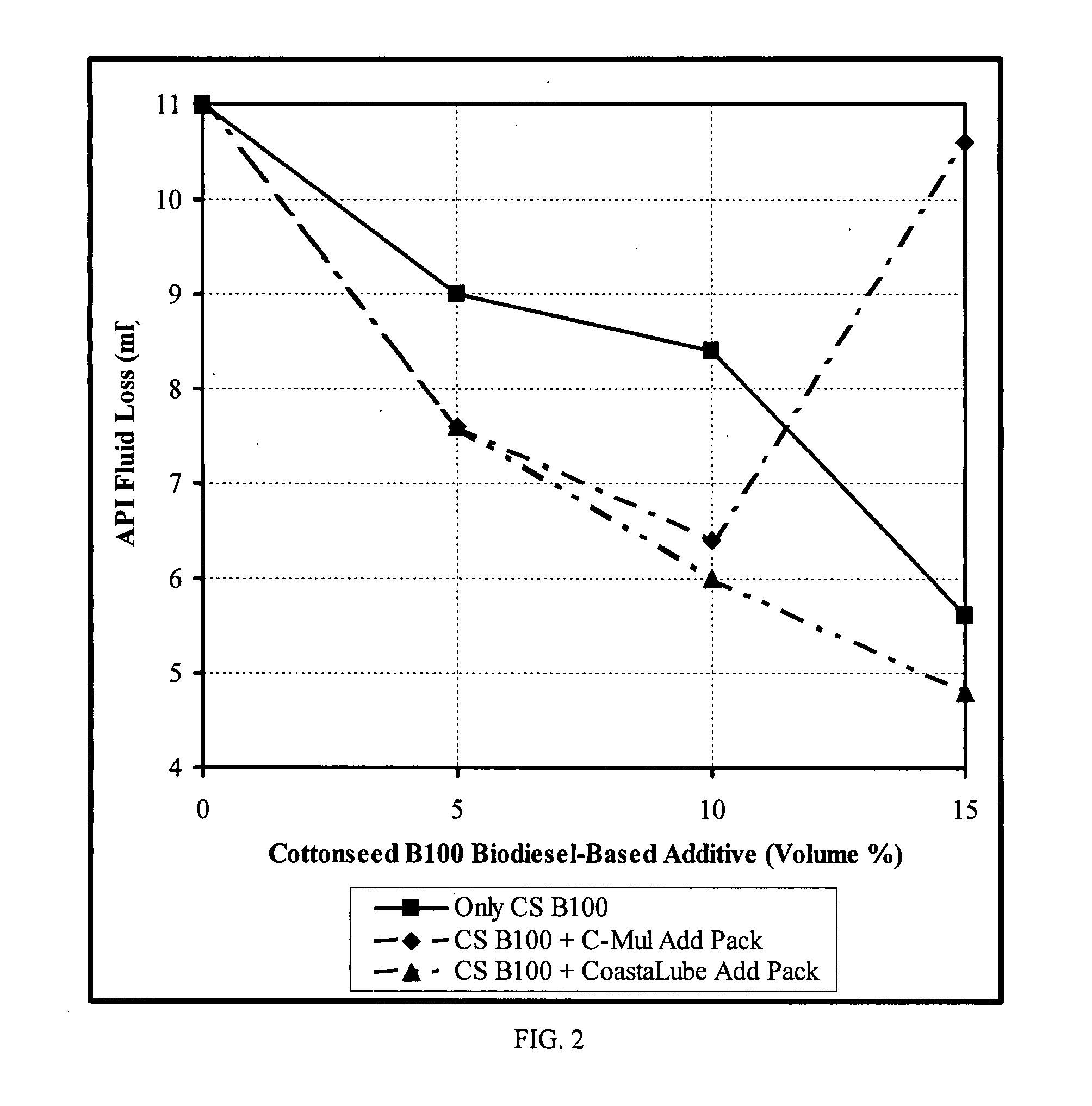

Drilling fluid additive and base fluid compositions of matter containing B100 biodiesels; and applications of such compositions of matter in well drilling, completion, and workover operations

InactiveUS20070287636A1Reducing differential pressure bondReduce fluid lossFluid removalFlushingWater basedBiodiesel

A drilling fluid compound, for use as an additive in a water-based drilling mud system, comprises a neat (B100) biodiesel liquid at a concentration of at least 5% by volume, and is useful in downhole applications such as lubrication, spotting, shale inhibition, fluid loss control, and rate of penetration enhancement. A base fluid for a synthetic-based drilling mud system comprises a B100 biodiesel liquid at a concentration of at least 5% by volume. A polyalphaolefin, another isomerized olefin, a petrodiesel, a mineral oil, a mineral oil derivative, or combinations thereof, may also be included in the drilling fluid compound or in the base fluid, within suitable ranges. The compositions of matter satisfy the current environmental standards defined by the U.S. Environmental Protection Agency for drilling fluids.

Owner:SUN DRILLING PRODS

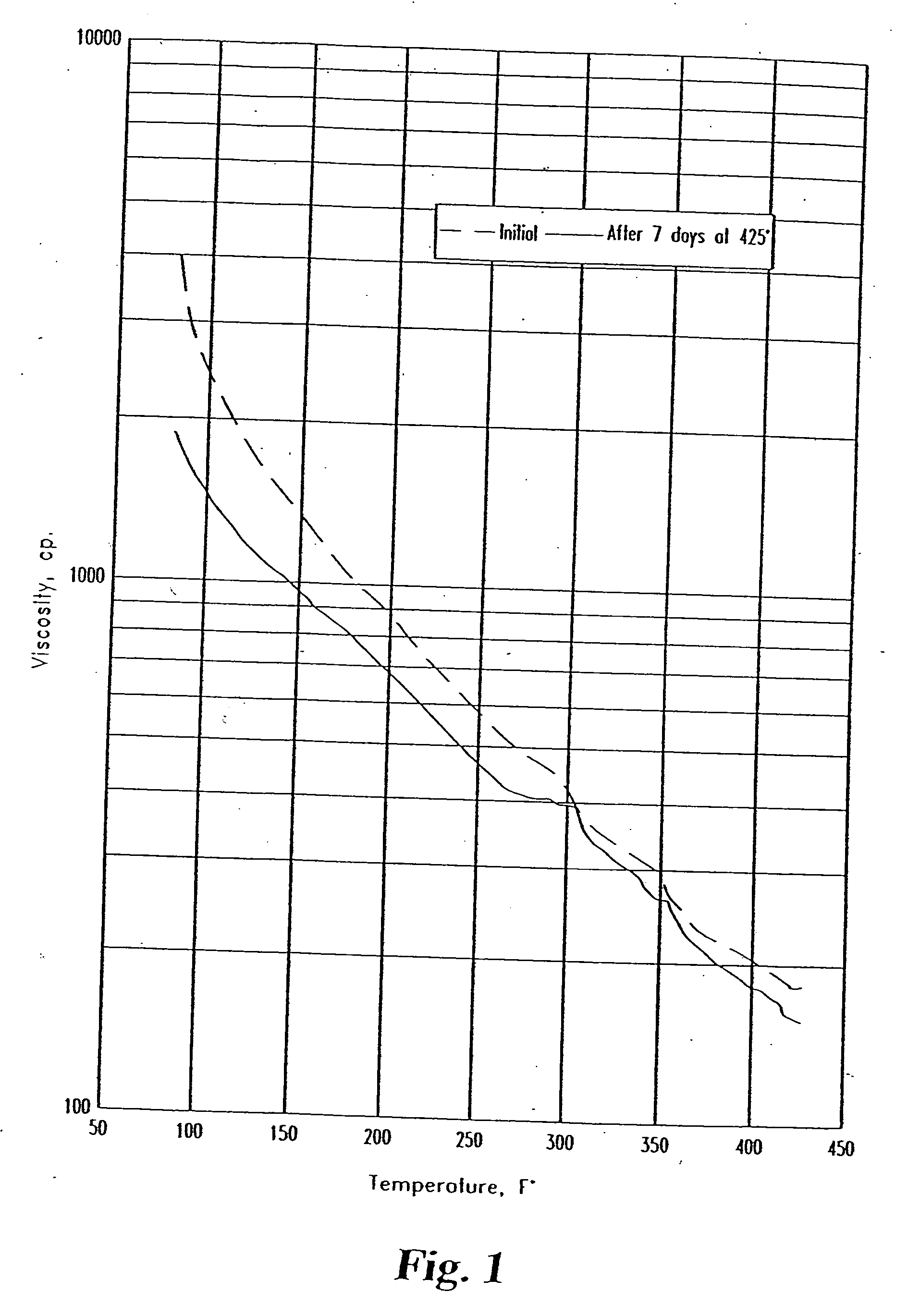

Method for reducing sag in drilling, completion and workover fluids

InactiveUS6861393B2Reduce saggingHigh viscosityDrilling compositionBorehole/well accessoriesWell drillingFluid viscosity

A method is disclosed for reducing sag in drilling and completion fluids and in workover fluids. The method employs a drilling fluid comprising a low molecular weight polyalkyl methacrylate with an average molecular weight ranging from about 40,000 to about 90,000. This additive does not result in increased viscosity of the fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

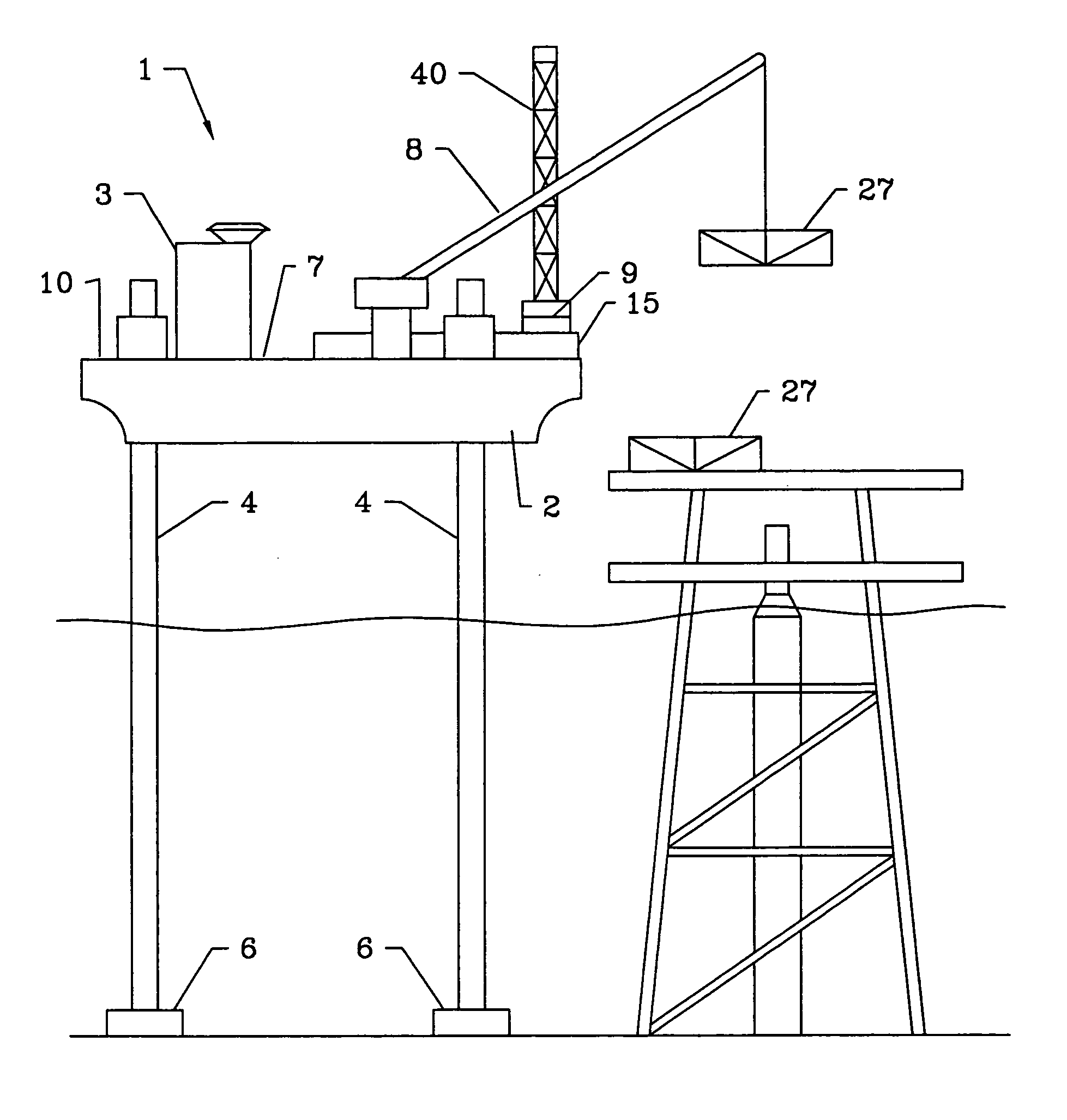

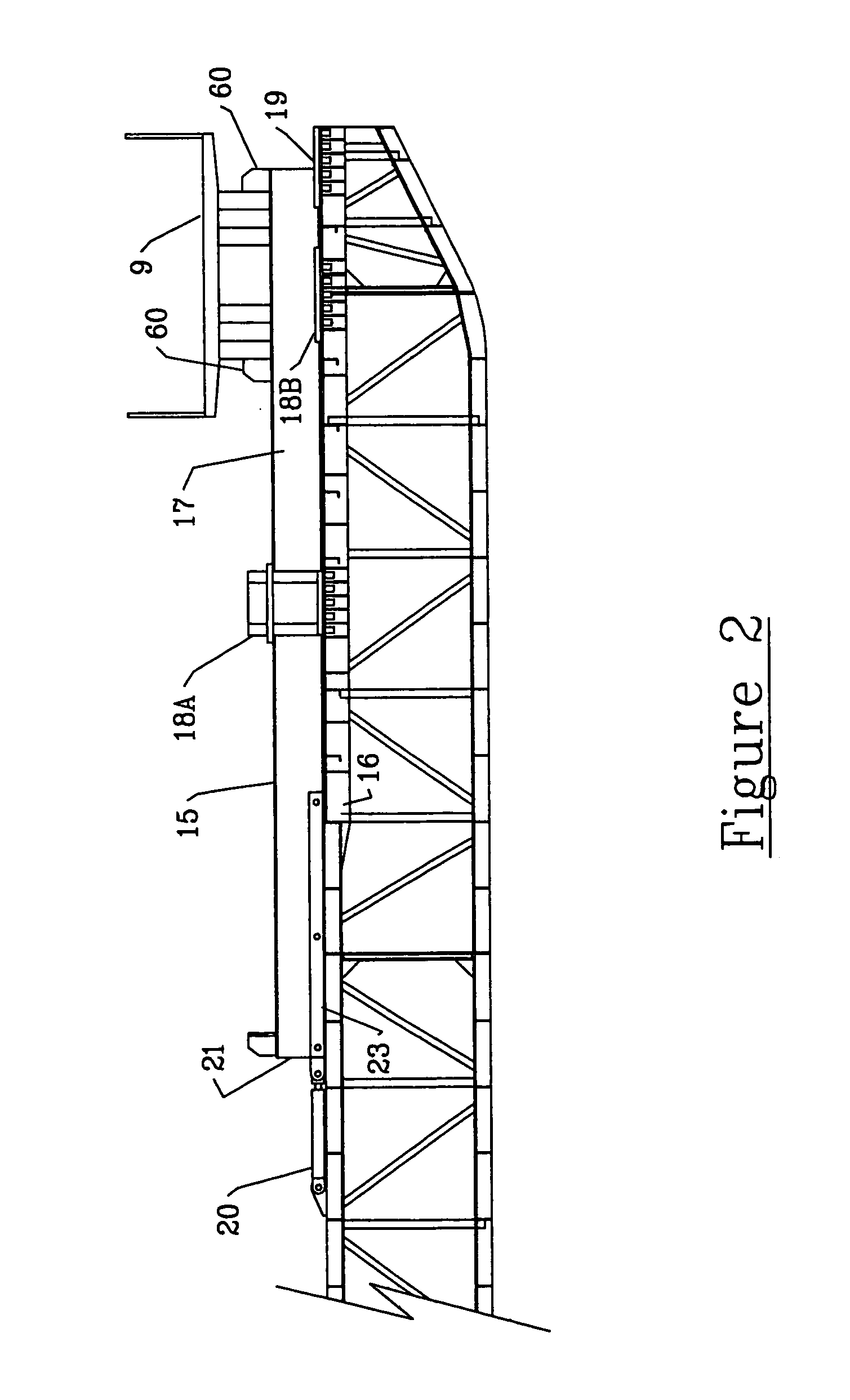

Jack up workover rig with removable workover floor unit

InactiveUS6926097B1Low costEasy to installArtificial islandsDerricks/mastsIt equipmentMarine engineering

An offshore jack-up workover rig. The workover rig includes a vessel which may be self powered or powered by a tug. The vessel may be raised above the surface of a water body by extending the legs until they reach the water body bed and then continuing to extend the legs. The workover rig contains a workover floor unit which includes at least a drawworks, a drawworks motor, and a well aperture. The workover rig is detachably mounted on an extensible cantilevered frame. The frame may be extended to position the workover floor unit over an offshore platform to be serviced. The workover floor unit is also configured to mover laterally relative to the extensible frame. The vessel is also provided with a crane. The crane may be used to lift the detachable workover floor unit from the vessel and deposit it, including its equipment, on the platform.

Owner:BLAKE MICHAEL E

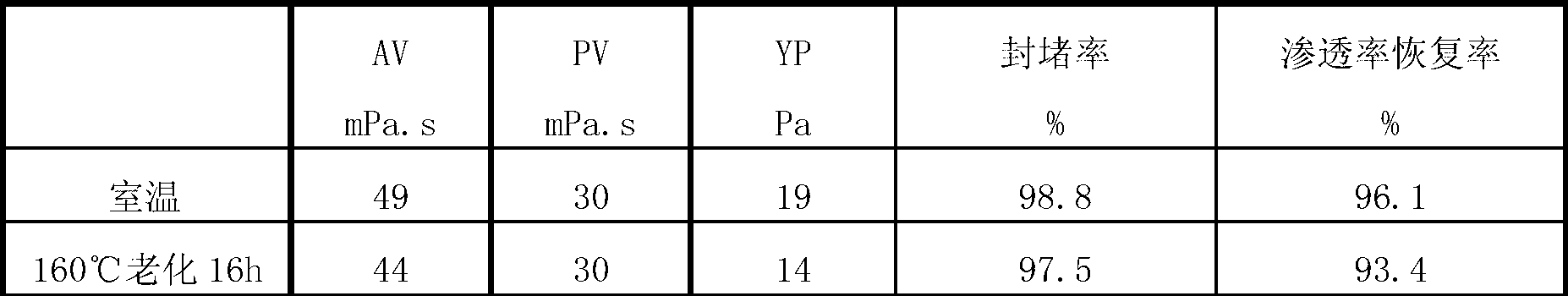

Hydrolysiable high elastic well remending liquid temperary blocking agent

ActiveCN1869147APrevent leakageRestore permeabilityDrilling compositionSulfateMethylene bisacrylamide

The invention relates to hydrolysable high elasticity well workover liquid temporary blocking agent used in oil field workover treatment. It is made up of 40-80% de-ionized water, 10-30% acrylic acid, 8-30% starch, 0.1-1.5% sodium per-sulfate, and 0.1-1.0% N,N-methylene-bisacrylamide. The water-bearing of the product is 40%-80%. It can be degraded easily in water, and can lose full strength in 24 hours below 60 centigrade degree. The degraded residue is little and has low system viscosity.

Owner:PETROCHINA CO LTD

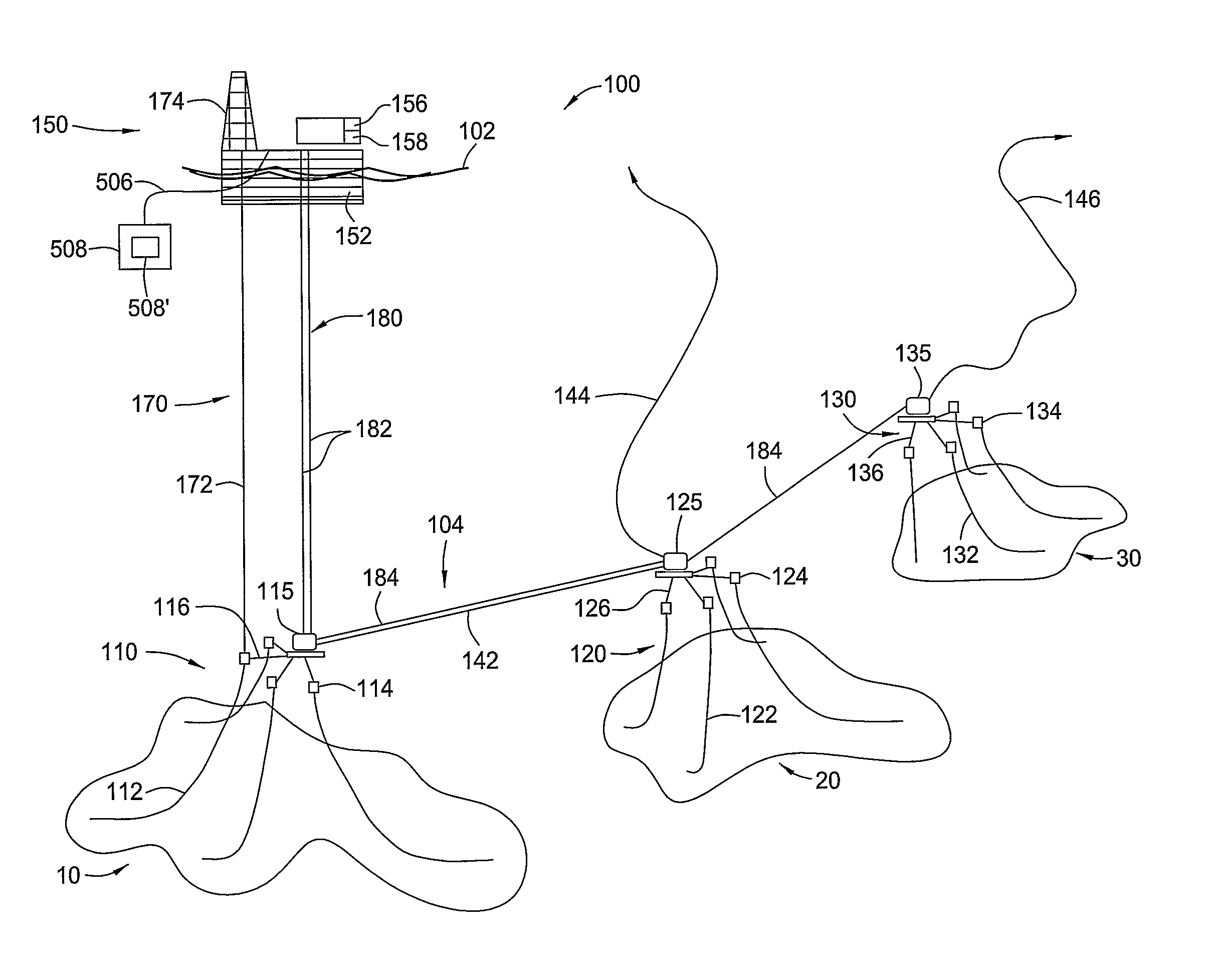

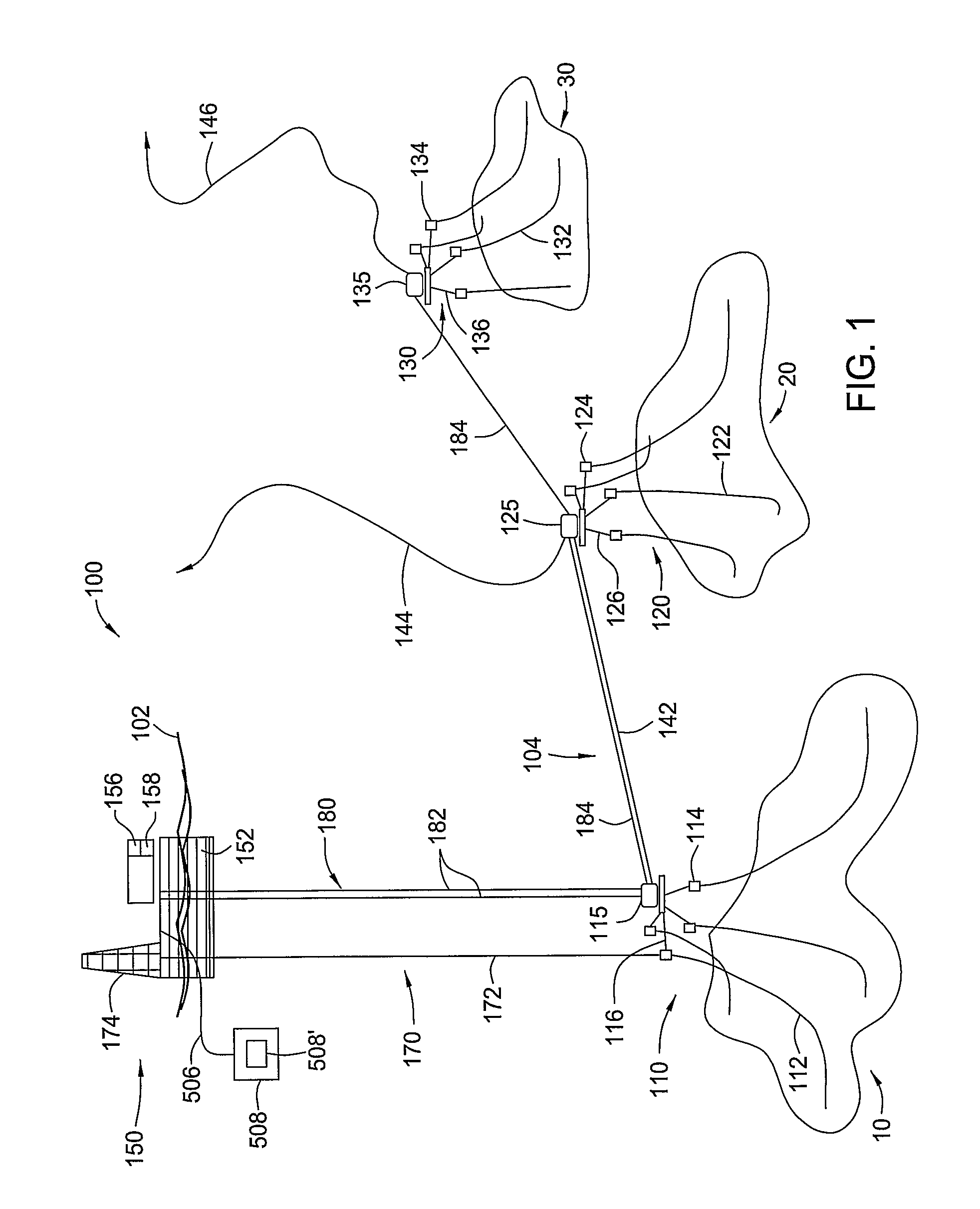

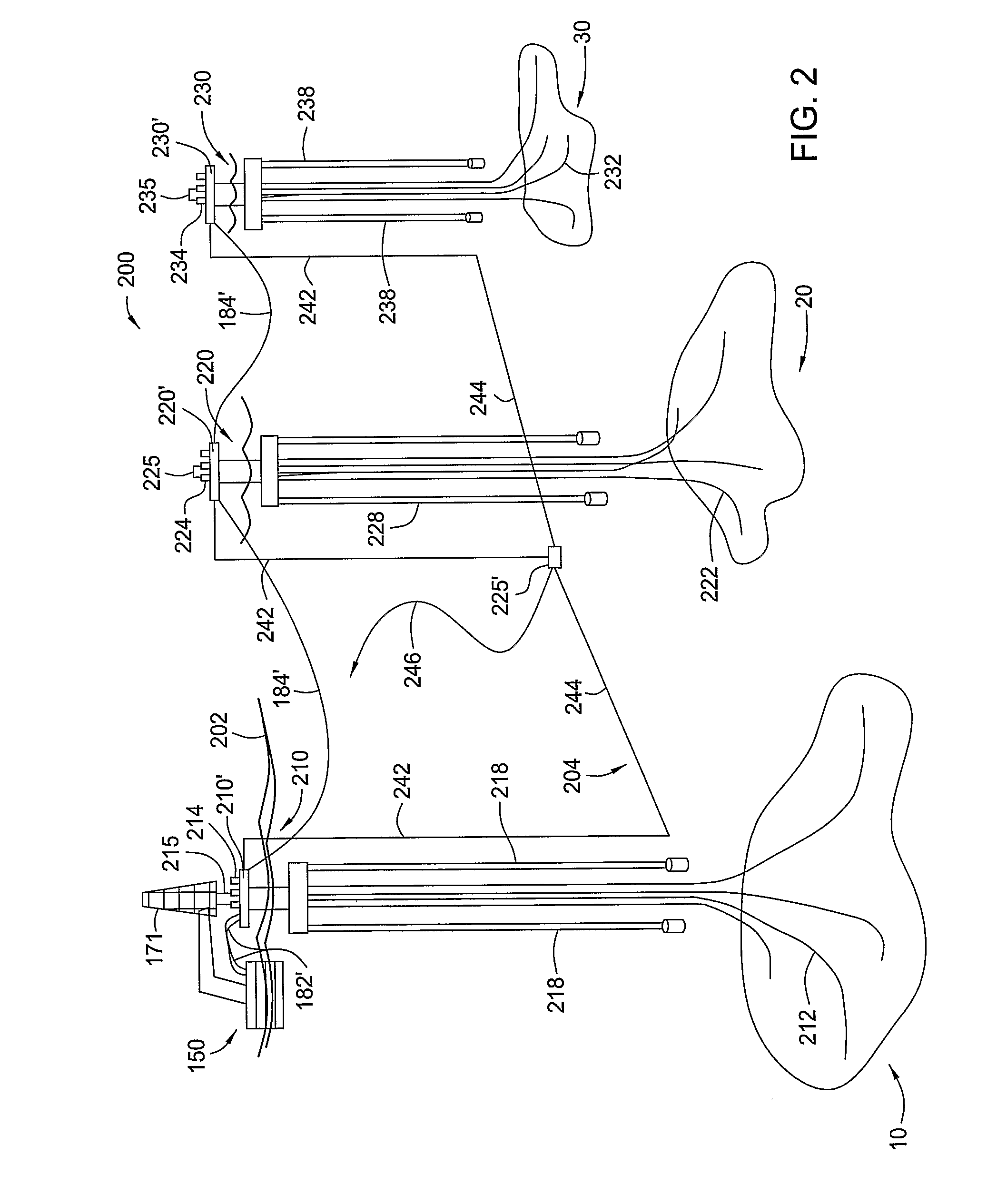

System and vessel for supporting offshore fields

Owner:EXXONMOBIL UPSTREAM RES CO

Method and arrangement by a workover riser connection

A slip joint for a riser between a well and a floating petroleum installation, for example an oil platform. The slip joint includes, an outer pipe and an inner pipe, the pipes arranged to enable telescopic movement relative to one another in order to compensate for a change in distance between the sea bottom and the platform. The inner pipe is connected to a piston, the piston being operable in response to hydraulic pressure for inflicting a tensile force on riser. The outer diameter of the inner pipe is adapted to the diameter of outer pipe so as to form an annulus between the pipes. The piston is fixedly connected to inner pipe at or close to a downwardly directed end thereof, the annulus and the piston being subjected to hydraulic pressure. A protective sleeve is provided below the piston, which is slippingly arranged within outer pipe.

Owner:BLAFRO TOOLS

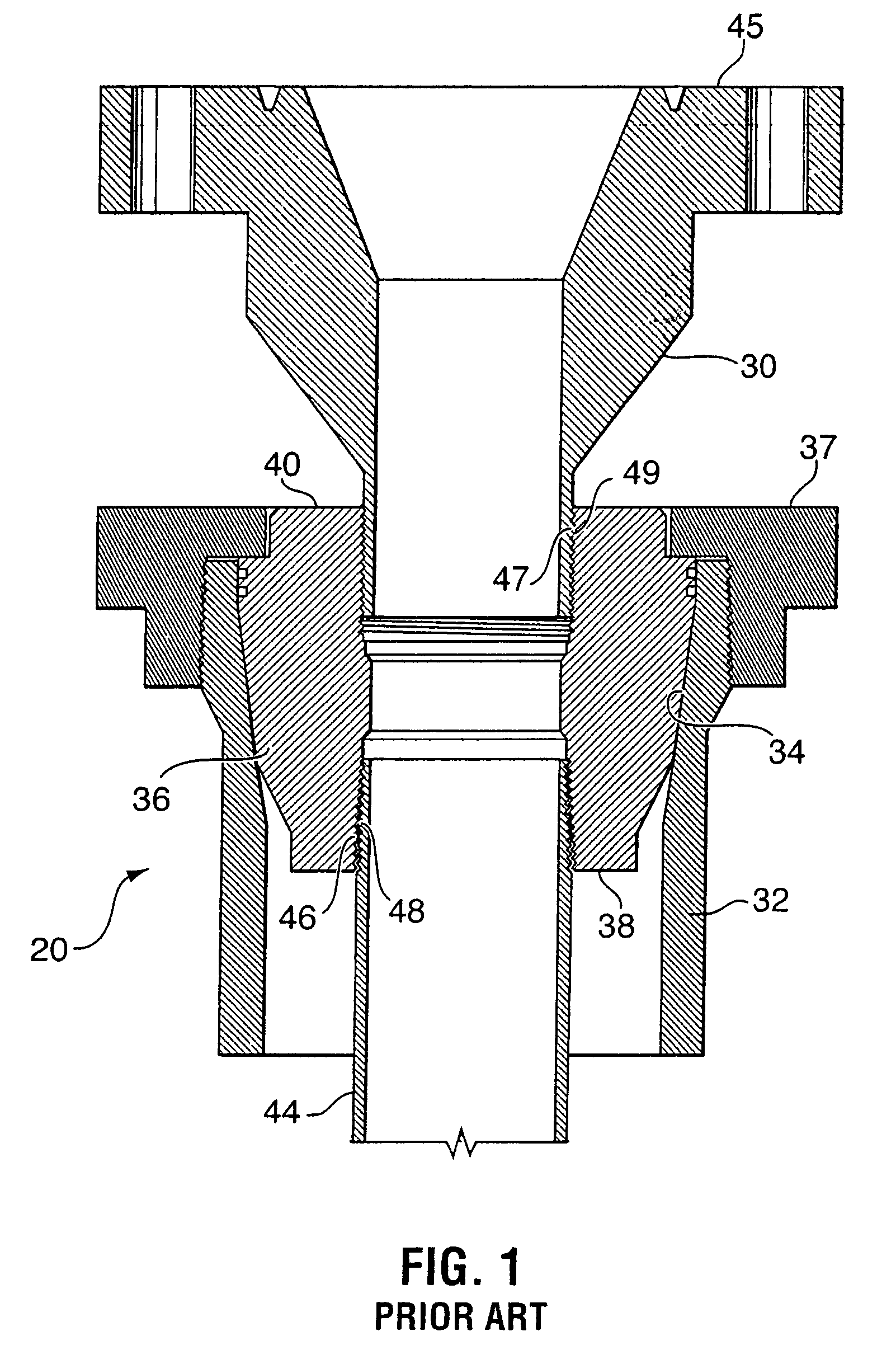

Casing mandrel for facilitating well completion, re-completion or workover

A casing mandrel for an independent screwed wellhead includes a seal bore for receiving a fixed-point packoff connected to a high-pressure mandrel of a pressure isolation tool, and a pin thread adapted for engagement with a box thread of a tubing head supported by the casing mandrel.

Owner:WELLS FARGO BANK NAT ASSOC +1

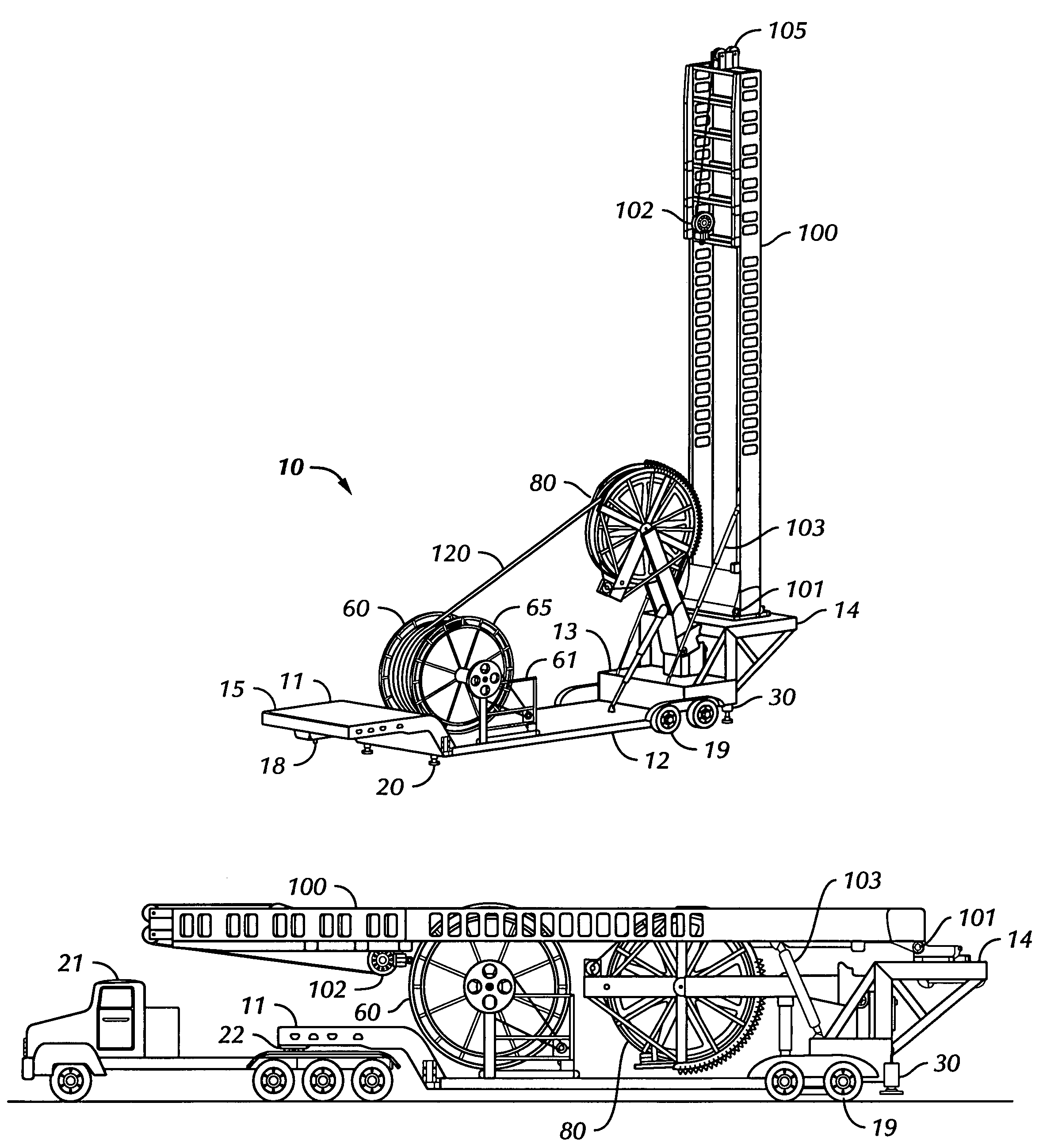

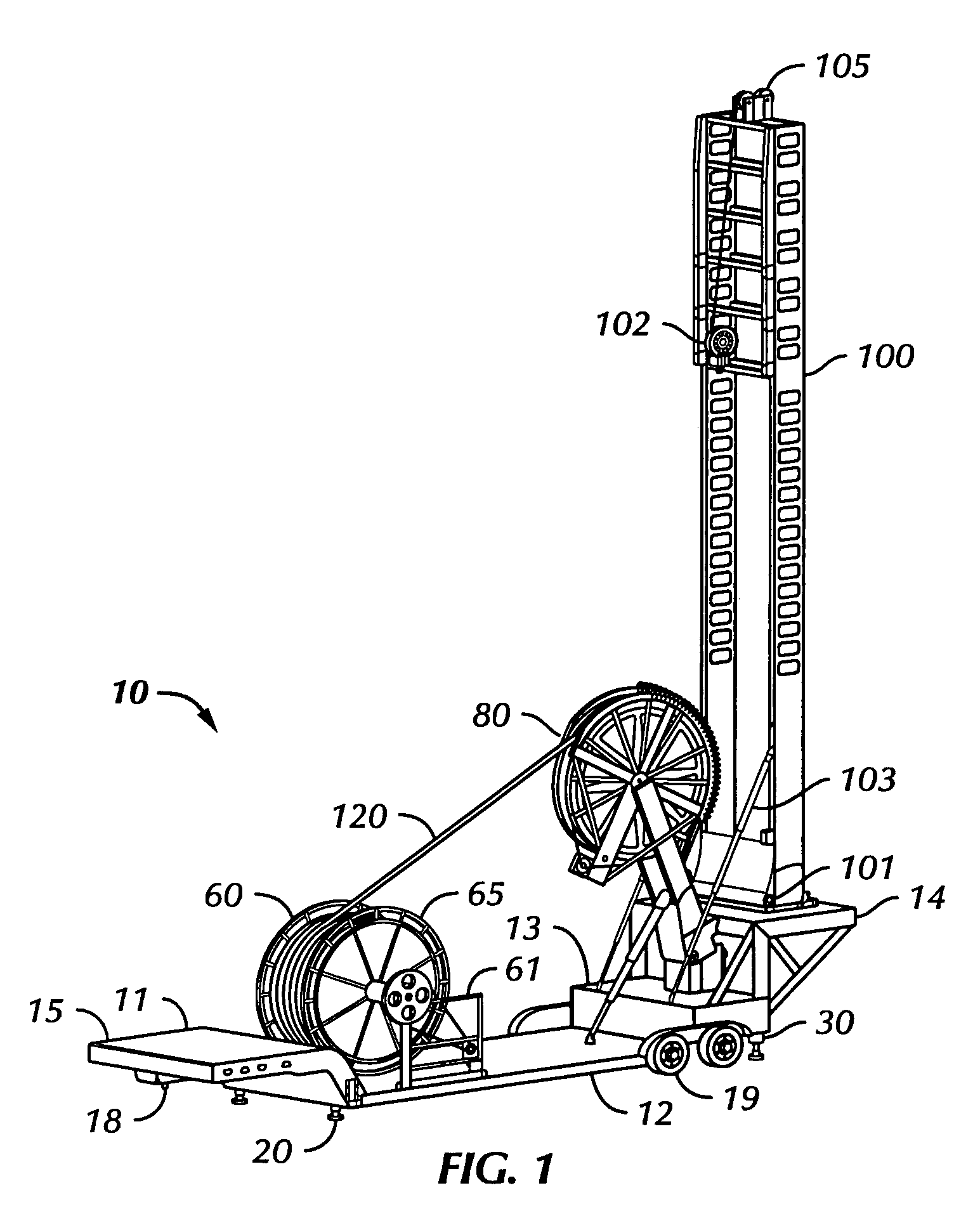

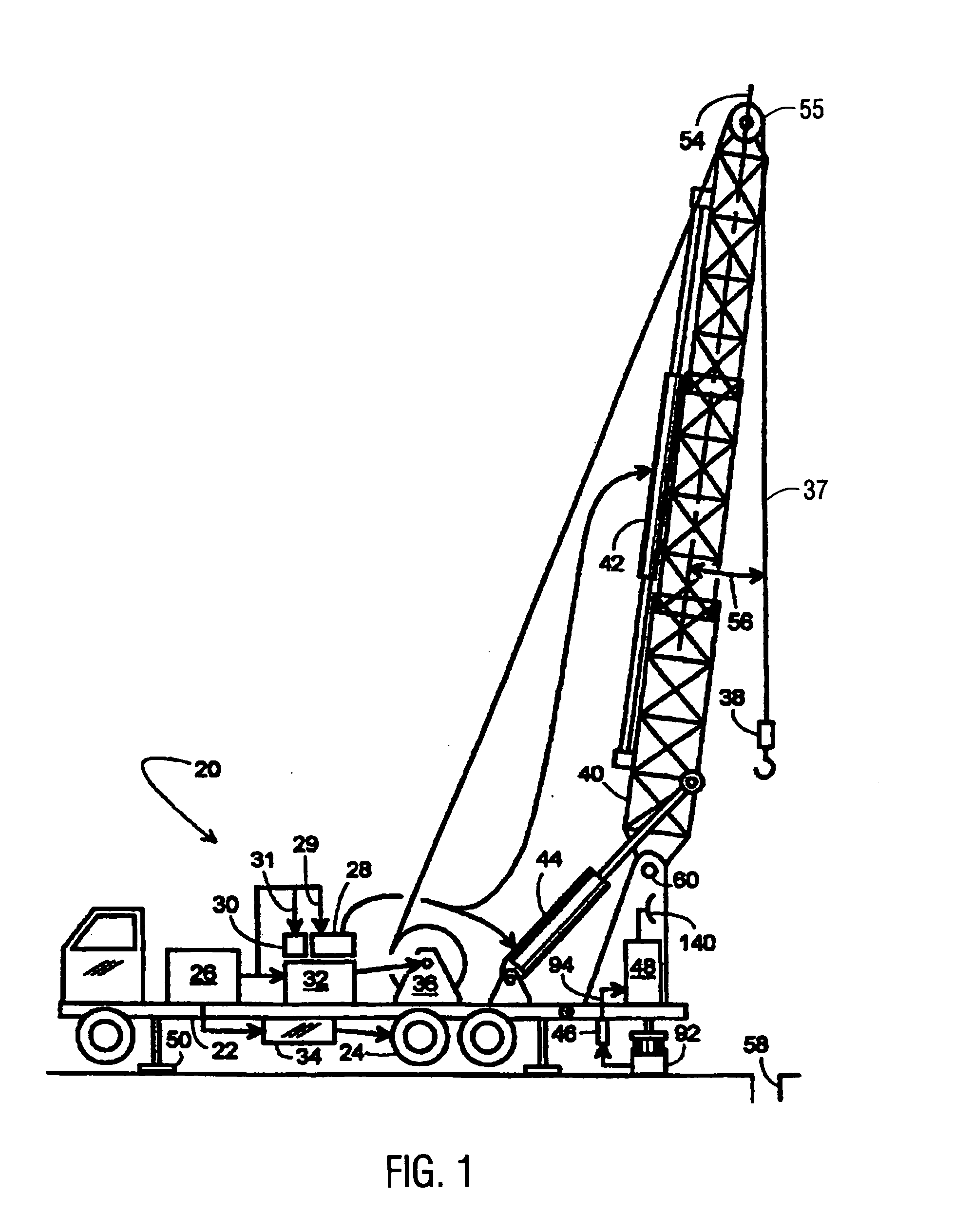

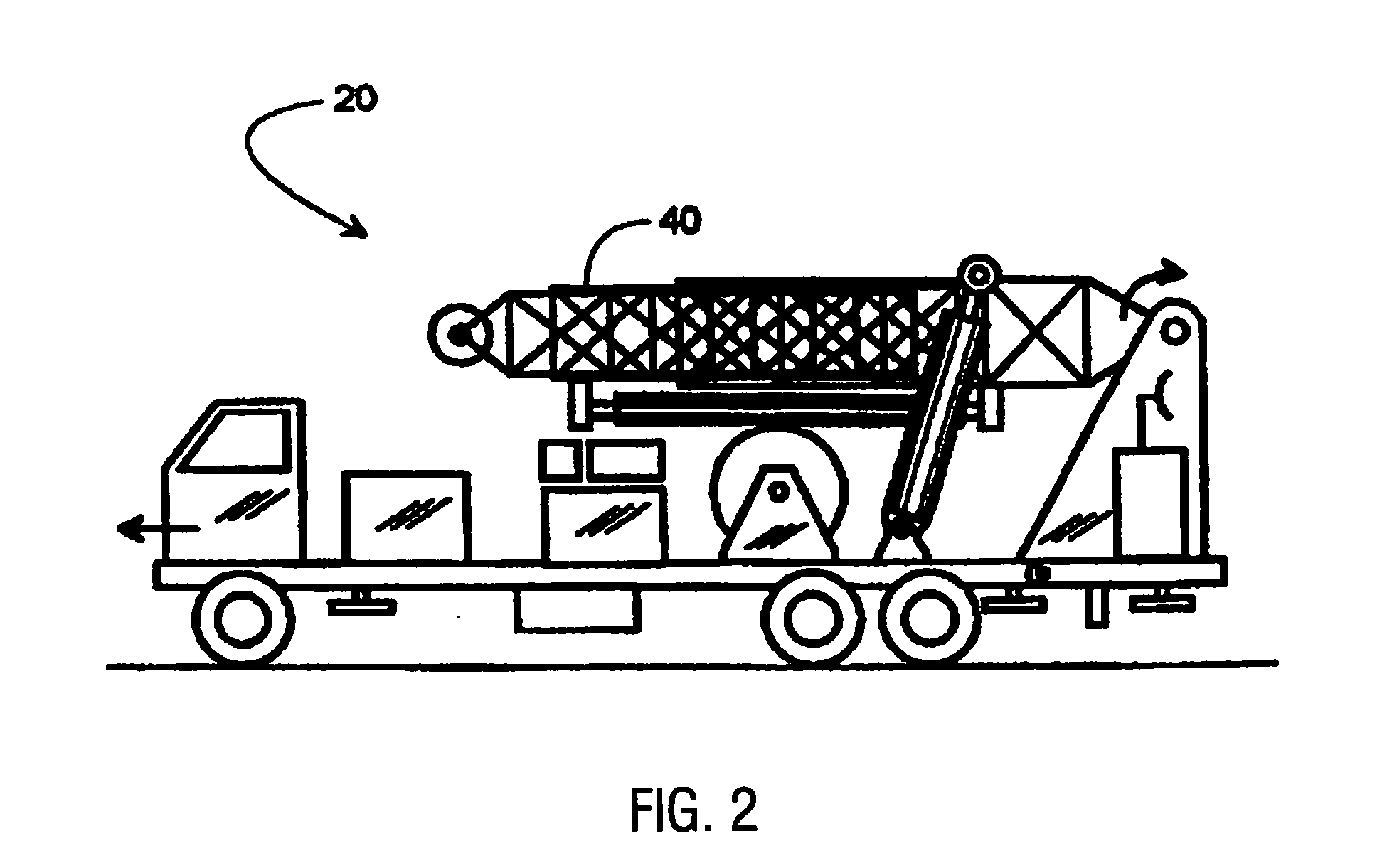

Combination workover and drilling rig

The combination workover and drilling rig of the present invention combines a capability to drill a well, as well as perform well maintenance and service, using either or both tubing with threaded tubular connections or coiled tubing. A mast and a coiled tubing injector are independently mounted to a support platform and can be operated independently of each other. The coiled tubing injector is selectably elevatable into a stowed position, a ready position, or an operating position.

Owner:TOM C GIPSON

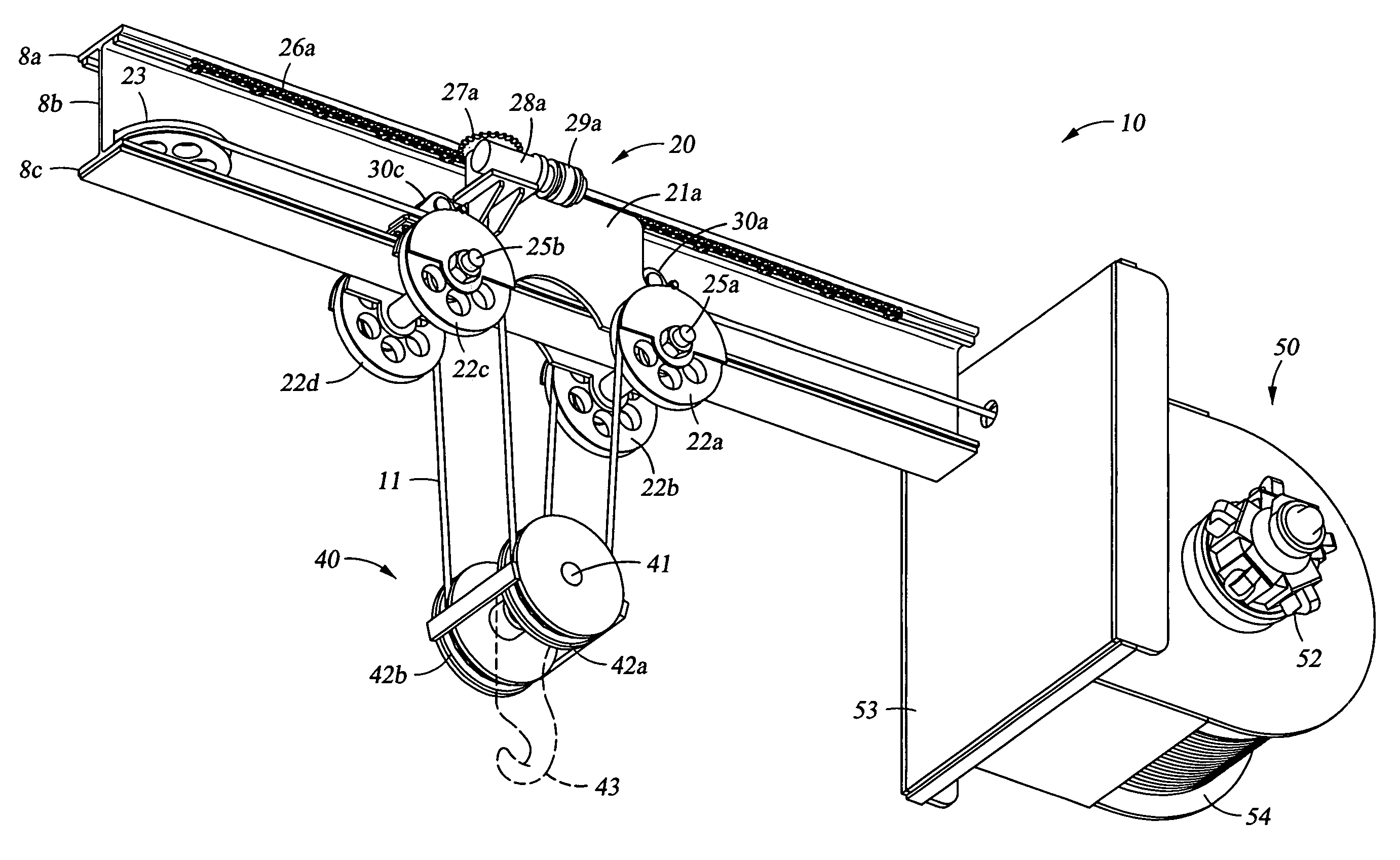

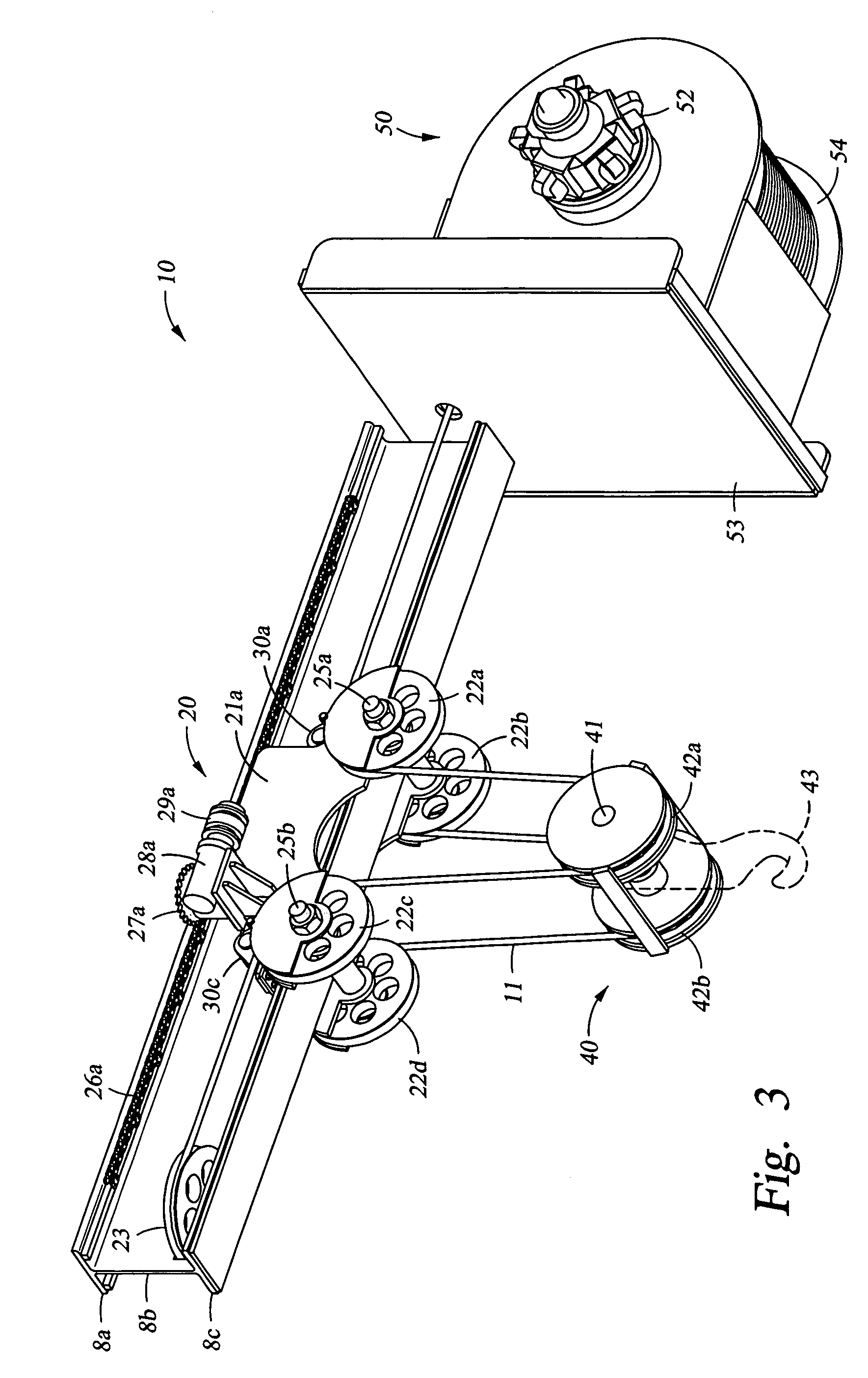

Compact hoist for drilling or workover rig

InactiveUS20060180564A1Expands vertical and horizontal rangeExpanding the range of operation increases usable rig storage spaceTrolley cranesTravelling gearLifting capacityWell drilling

The present invention provides a compact hoist system for use on a drilling or workover rig. The present invention eliminates problems related to chain failures in hoist systems by incorporating wire rope in a vertically and horizontally compacted arrangement to provide maximum vertical lift capacity and improved versatility. Caterpillar bearings, wire rope tension equalizing sheaves and a winch coupled to a axially movable spiral-grooved drum are combined to provide a system that enables cantilever jack-up rigs to handle blow-out preventer stacks of increased height and size.

Owner:KEPPEL JAMES R

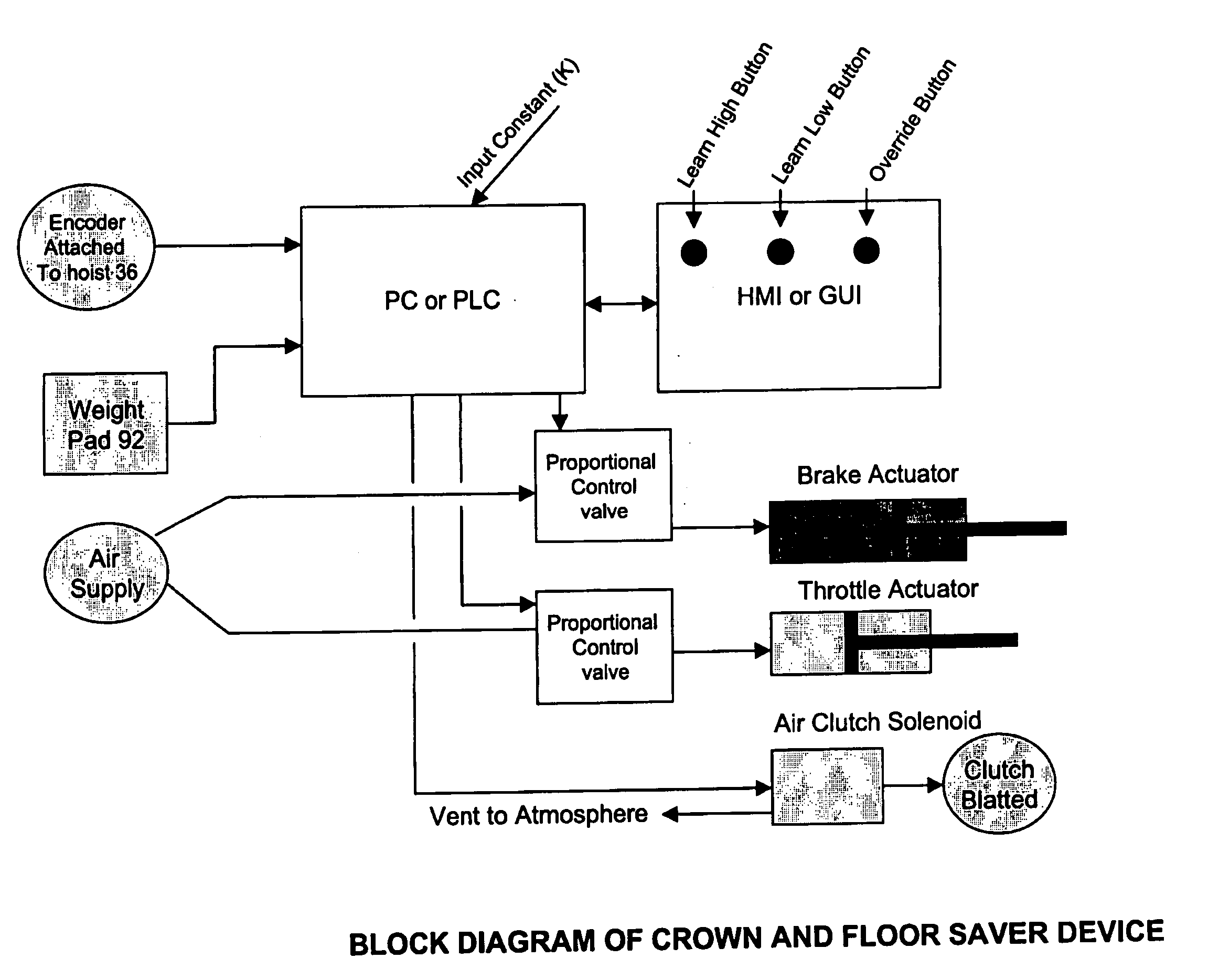

Multiple sensor for preventing a crown-block incursion on an oil well rig

ActiveUS20050114001A1Easy to useOperational securityDrilling rodsAnalogue computers for trafficMultiple sensorOil drilling

The technology disclosed herein provides a multiple sensor system that prevents crown incursion by a traveling block in an oil rig. This system calculates traveling block position, traveling block velocity and weight supported by the traveling block, and uses this information to calculate emergency stopping positions to prevent crown out by the traveling block. The system takes all these parameters into consideration when slowing and / or stopping the traveling block when it reaches a crown out position. The result is much safer operation of the traveling block on a workover rig, as well as on an oil drilling rig.

Owner:KEY ENERGY SERVICES

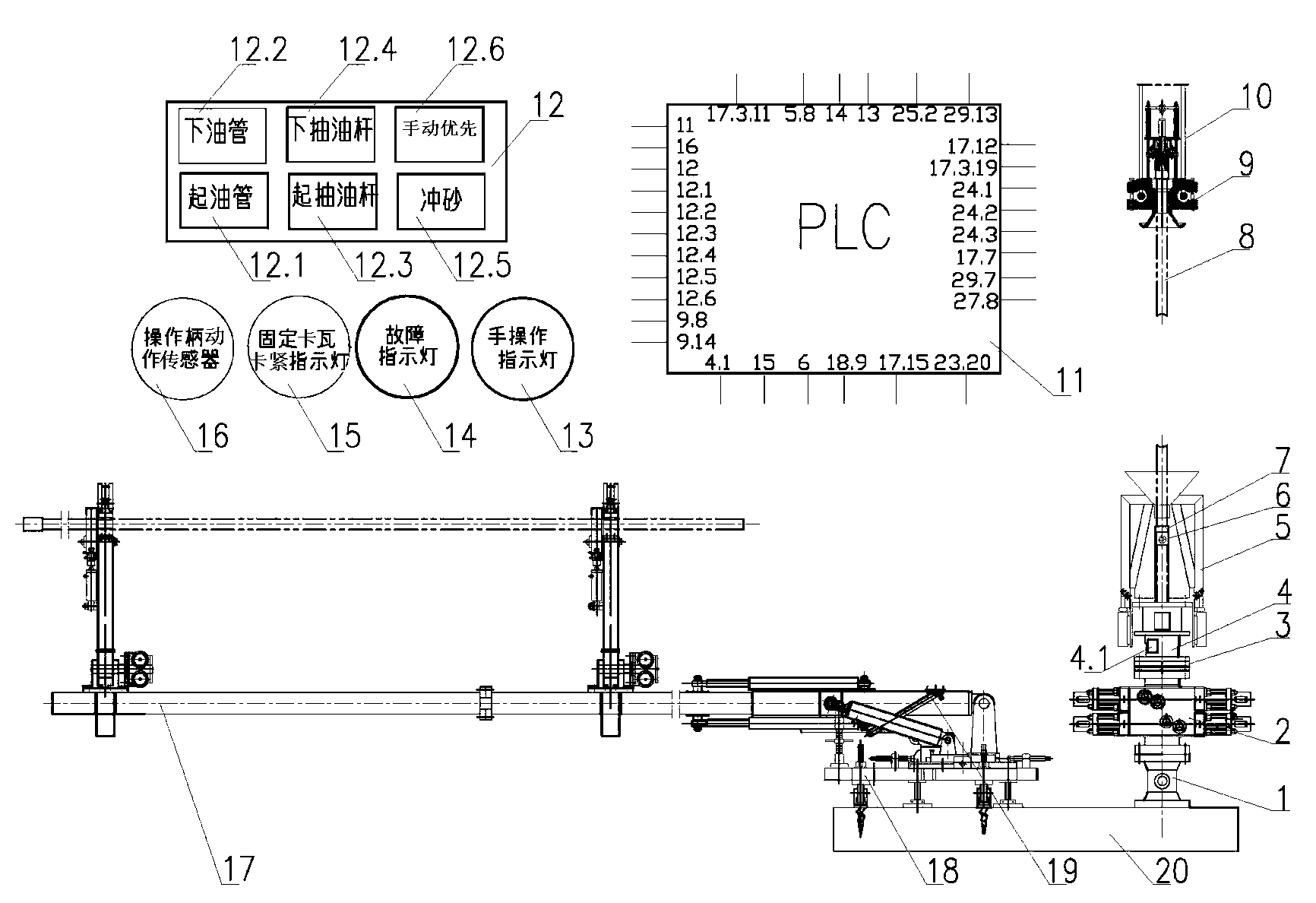

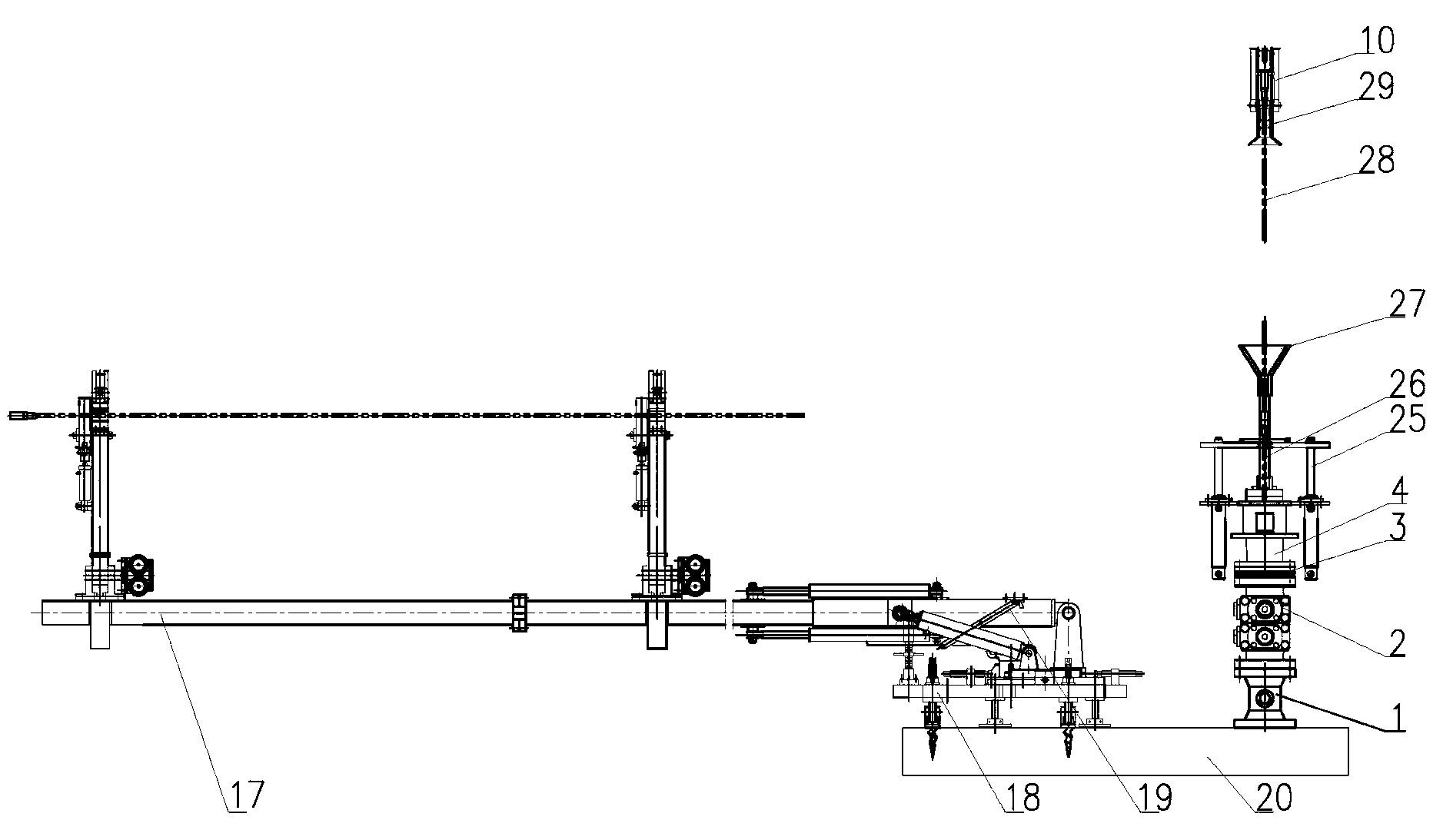

Automatic running and pulling system of oilfield workover string

InactiveCN103061692APrevent airborne sprayReduce pollutionDrilling rodsDrilling casingsButt jointControl system

The invention relates to an automatic running and pulling system of an oilfield workover string, which comprises a blowout preventer, fixing slips, an oil pipe / sucker rod guide mechanism, an oil pipe / sucker rod locating mechanism, an oil pipe / sucker rod elevator component, a mechanical arm component, hydraulic clamps, a hydraulic clamps bracket, a control system, a base component and a string bent, wherein the mechanical arm component and the hydraulic clamps bracket are installed on the base component and are connected through a linkage component to carry out linkage movement, and the string bent is arranged on the side surface of the mechanical arm component and moves in match with the mechanical arm component. With the adoption of the automatic running and pulling system of the oilfield workover string, the automation of movements of snatching up, butt joint, clamping, upper unloading, elevating, lowering, arrangement and the like can be realized, manual string running and pulling operation at a wellhead is replaced, an equipment mechanism is simplified as much as possible, and an operation program is optimized.

Owner:崔诗光

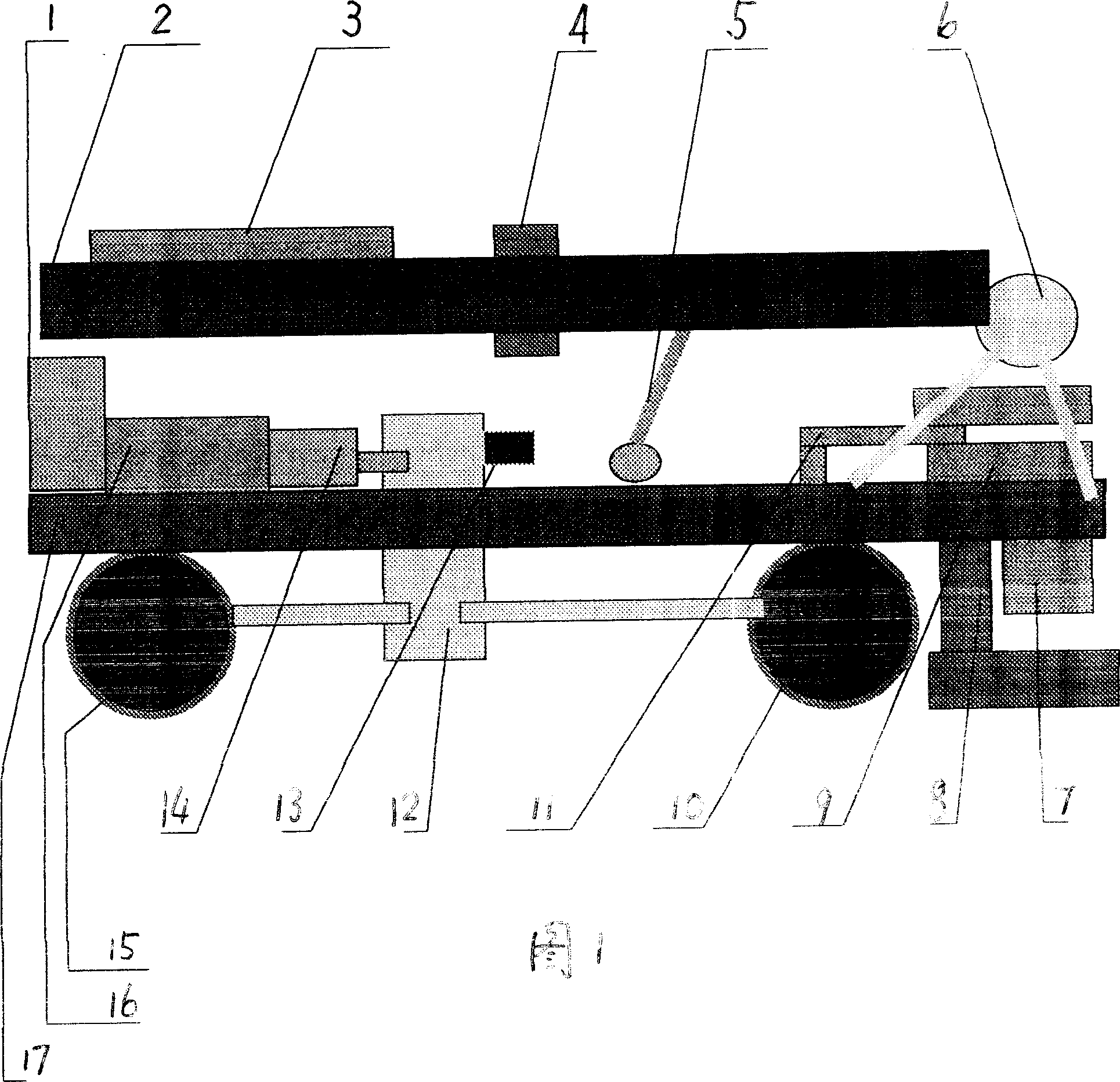

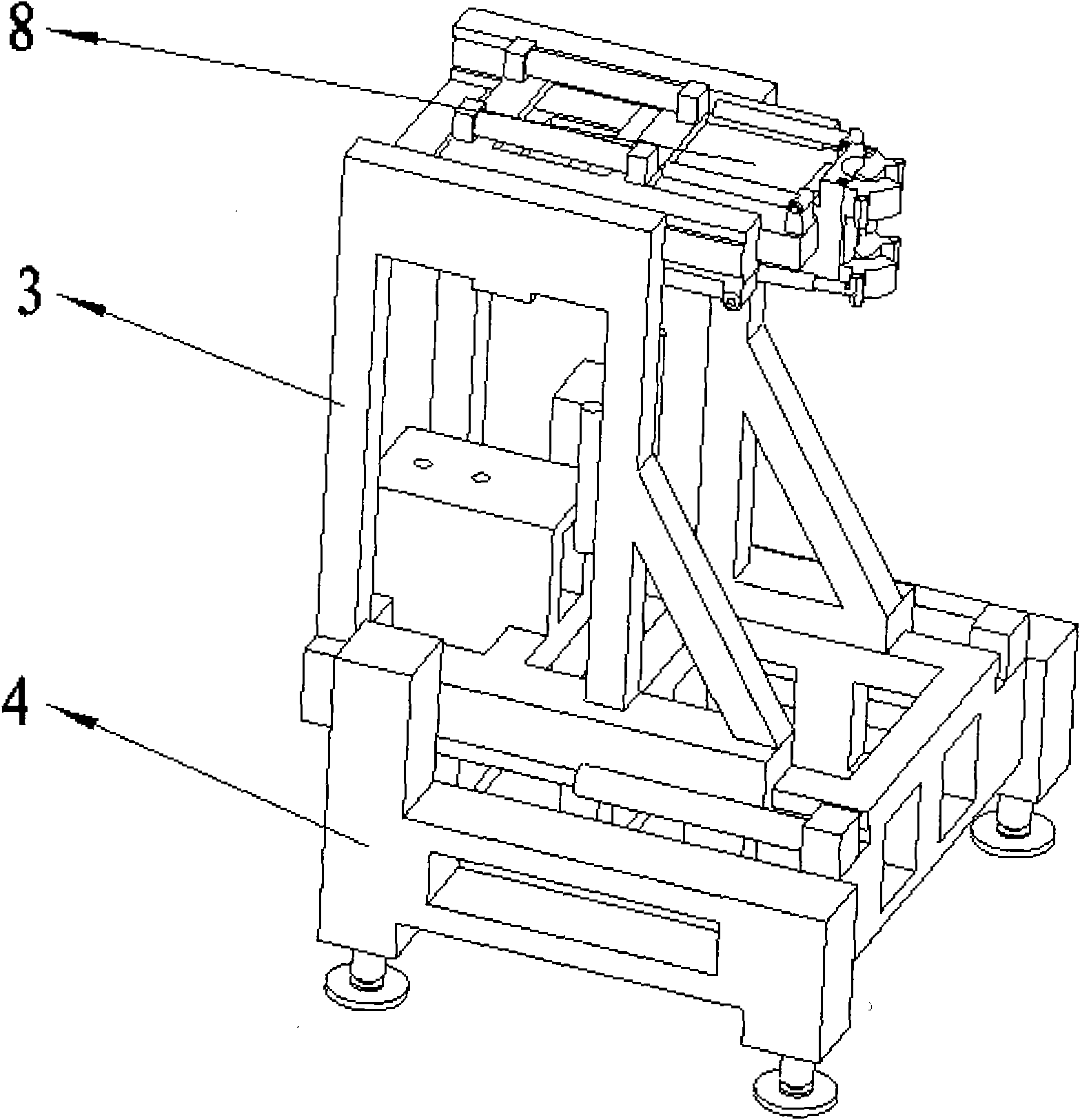

Drill floor well repairing machine without manual operation in well mouth

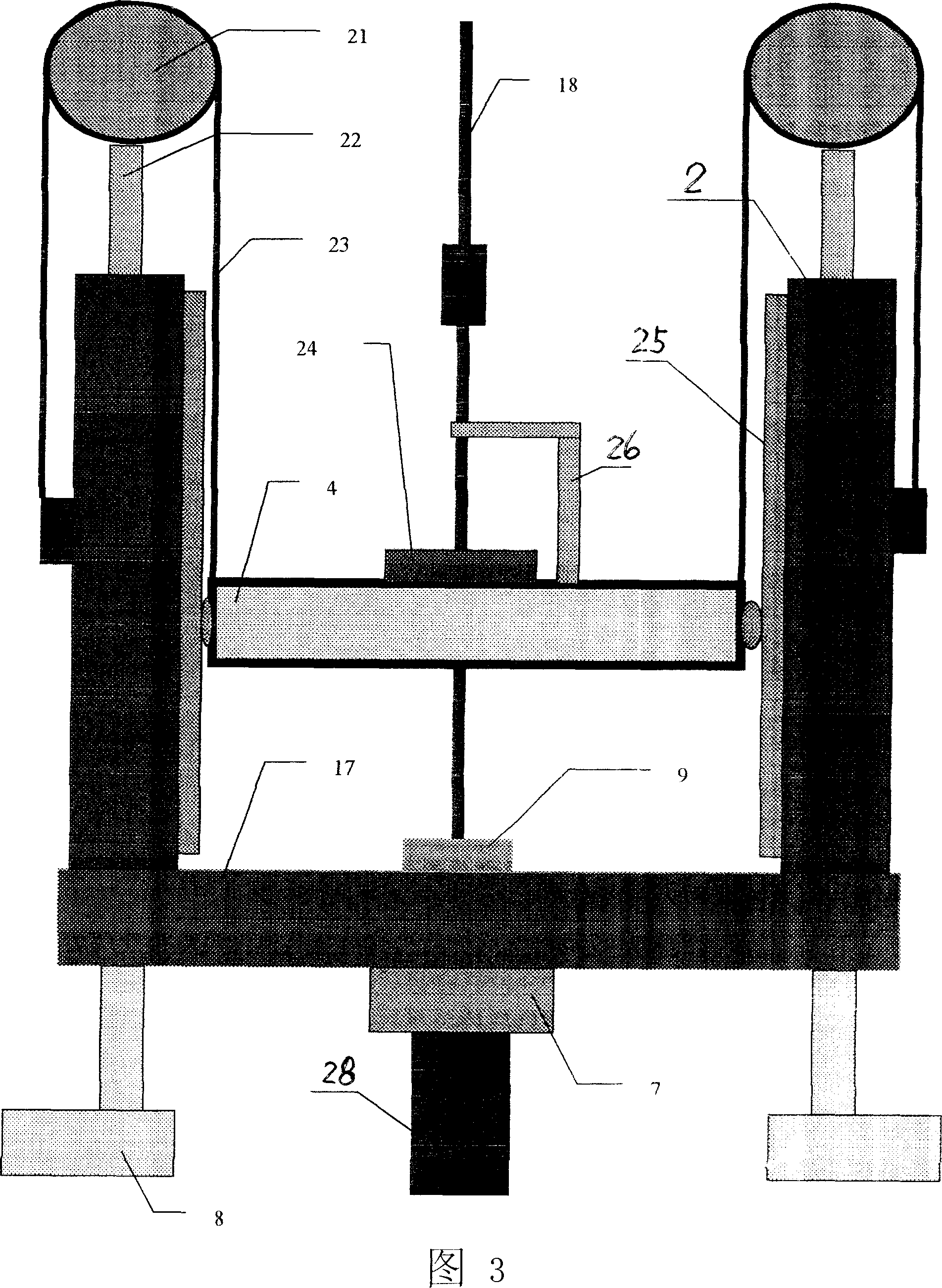

InactiveCN1920239AReduce labor intensityImprove workover efficiencyDrilling rodsDrilling casingsHydraulic cylinderVehicle frame

The invention relates to a workover device in drill floor type, used in non-manned operation under the oil well, wherein it is formed by driving control room 1, thick support post 2, discharge tube 3, lifter 4, amplitude-variable hydraulic cylinder 5, support post base 6, well-open hydraulic blowout preventer 7, drill floor hydraulic base 8, fixing hydraulic clamp disc 9, back tyre, back driving bridge 10, hydraulic clamper 11 with flexible sliding channel 11, hydraulic gear box 12, high-pressure gear pump 13, hydraulic torque converter 14, front tyre, front driving bridge 15, engine 16, frame and drill floor 17; the front part of frame 17 is arranged with driving control room 1, engine 16, hydraulic torque converter 14, hydraulic gear box 12 and high-pressure gear pump 13, while the back part has fixing hydraulic clamp disc 19, support post base 6, and hydraulic clamper 11; the support post base 6 is mounted with thick support post 2, discharge tube 3 and lifter 4. The invention can automatically set discharge tube and improve the working efficiency.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

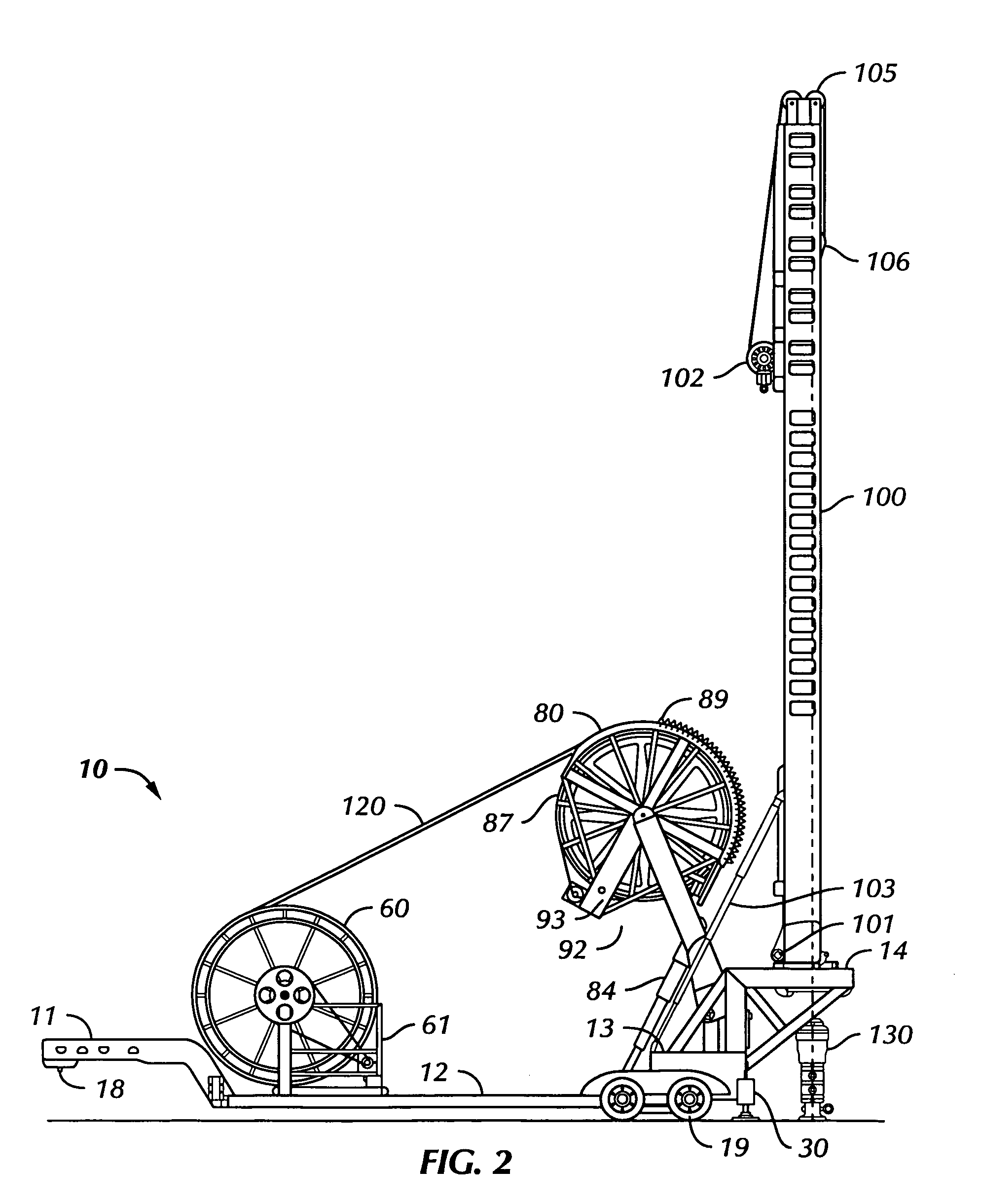

Mobile hydraulic workover rig

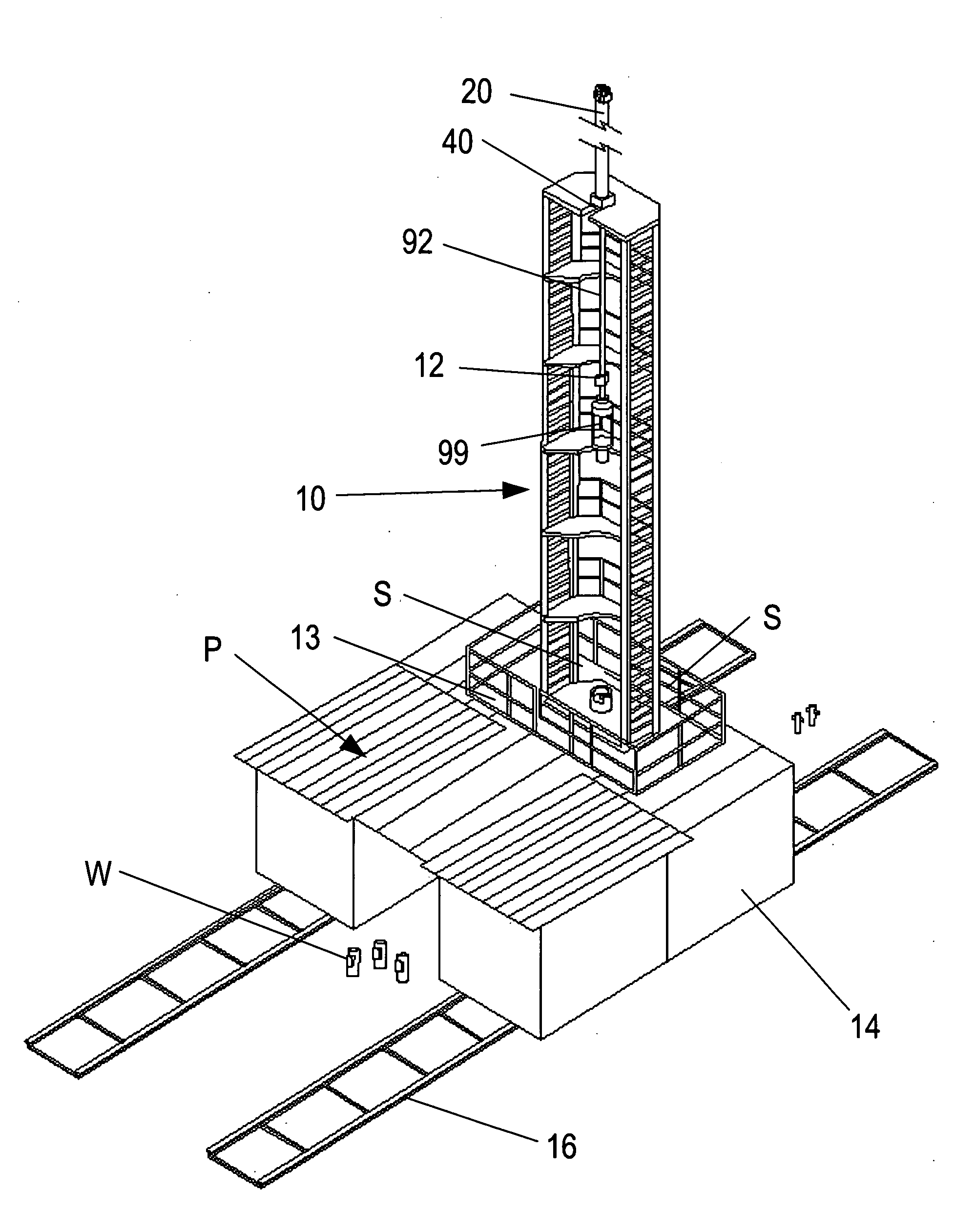

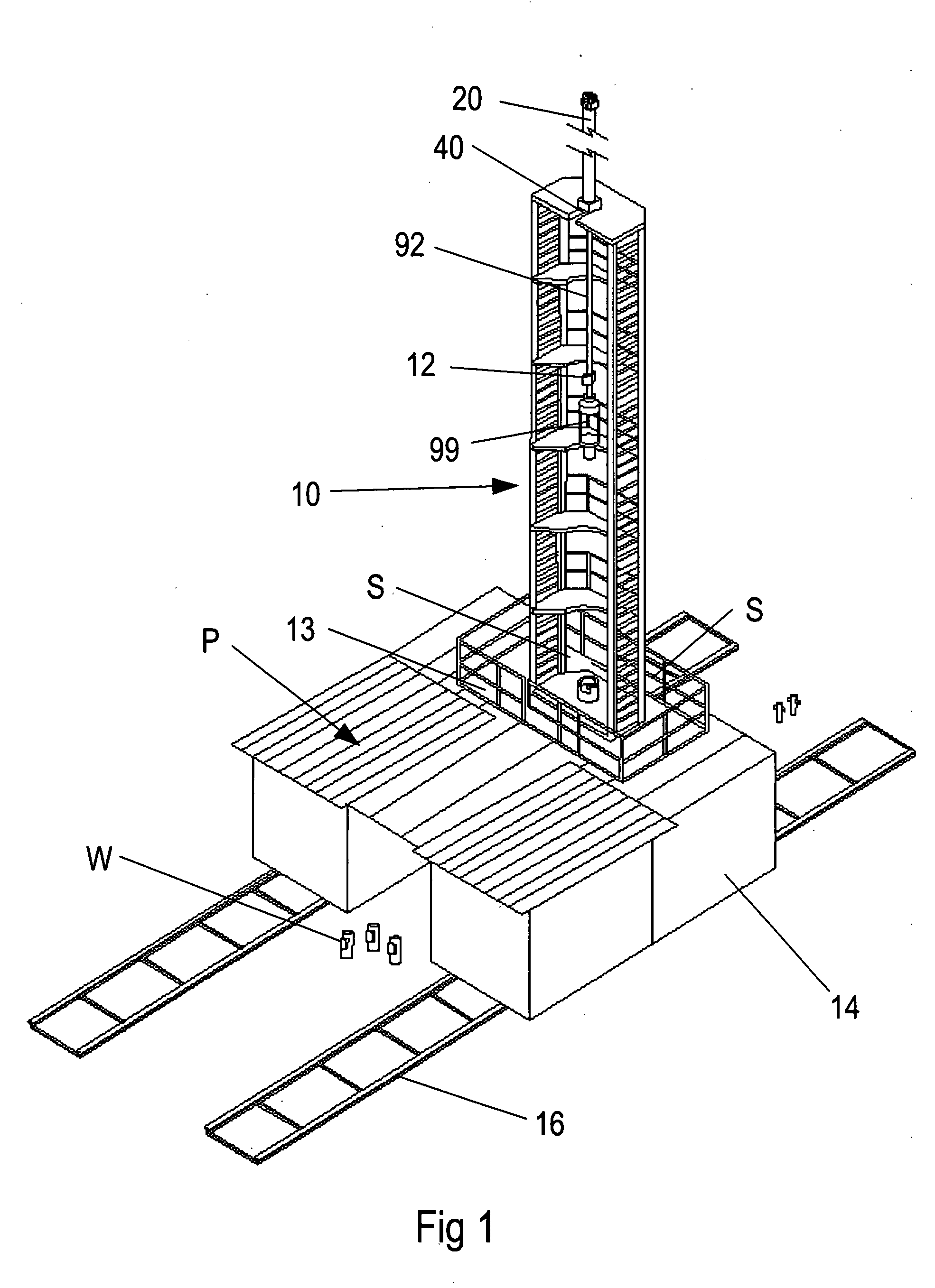

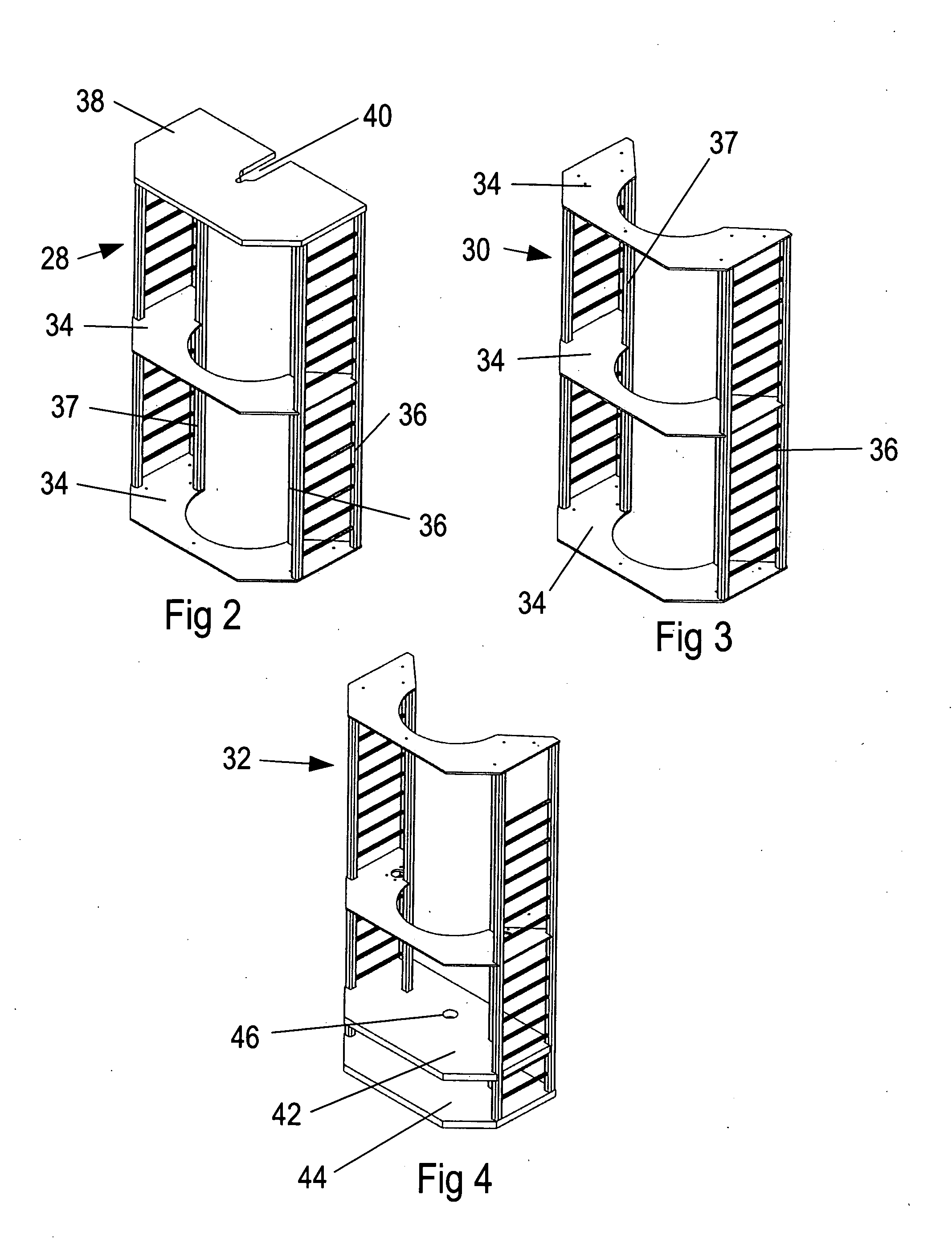

InactiveUS20090272540A1Reliable and efficient mannerEfficient and reliableDrilling rodsConstructionsHydraulic cylinderMarine engineering

A portable hydraulic rig for workover, drilling or other operations on existing wells in which the rig has a derrick elevated on a base structure comprised of containers for equipment used in association with drilling or workover activities, a work platform including pipe rack sections for storing a plurality of pipes, the derrick being open-sided with a power cylinder at its upper end for lifting and lowering pipe sections away from and into each well, and hydraulic drive cylinders for advancing the rig between wells without telescoping or pivoting the derrick into a travel position, all of the hydraulic components being controlled from a central control panel on the work platform.

Owner:RODGERS TECH

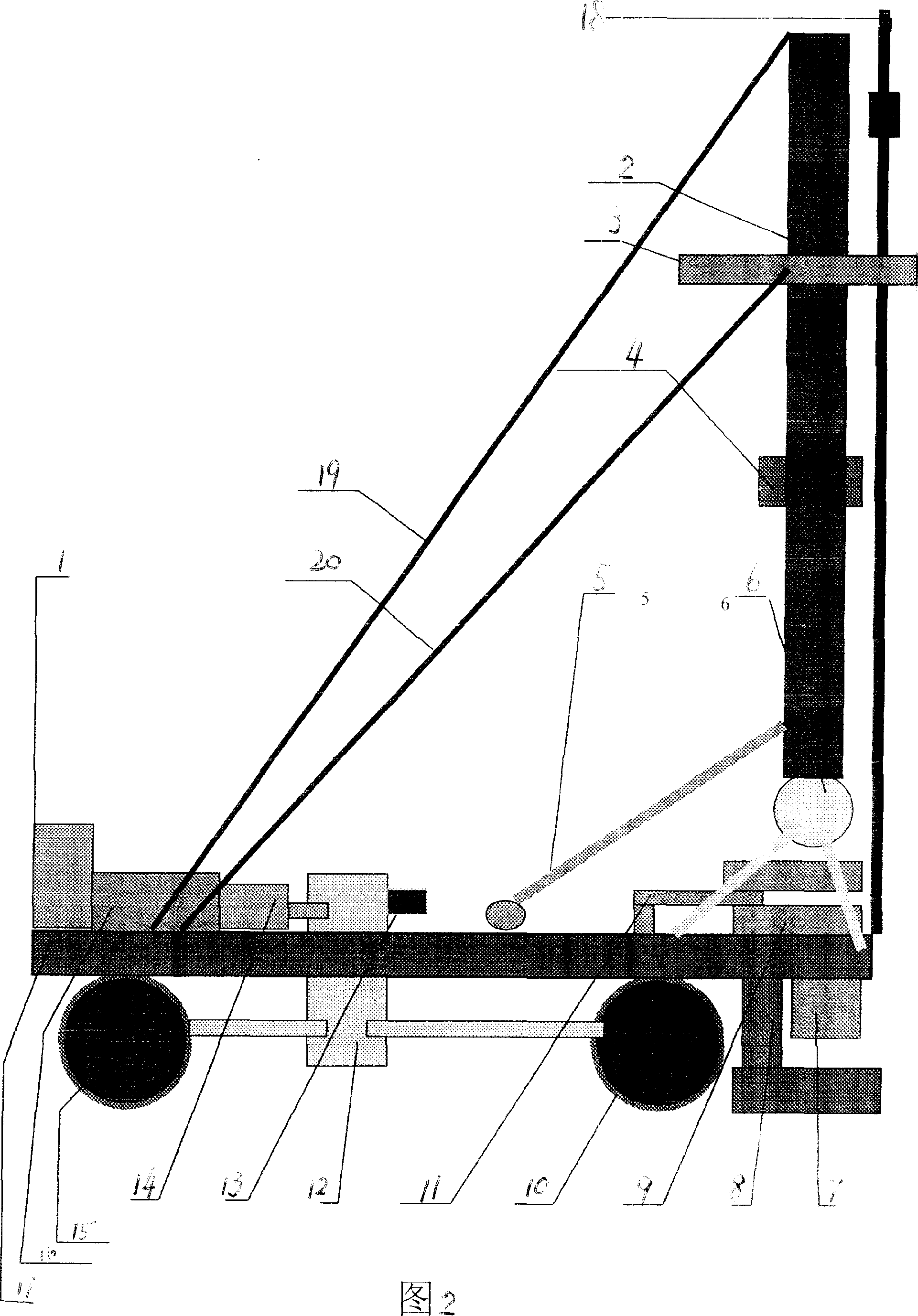

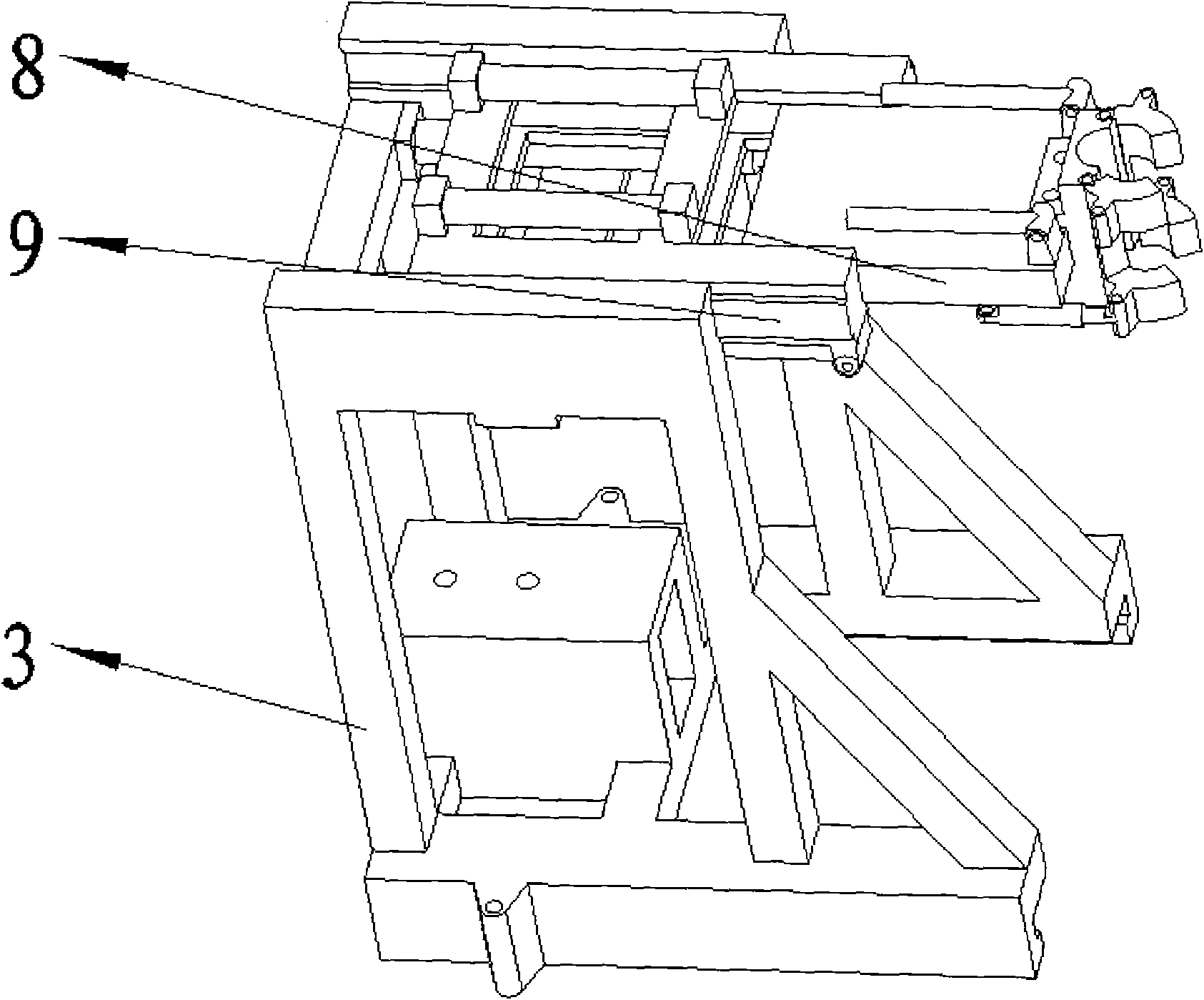

Workover operation mechanization system replacing well mouth manual operation

InactiveCN101672168AHigh degree of automationImprove mechanical propertiesDrilling rodsDrilling casingsEconomic benefitsRelative motion

The invention discloses a workover operation mechanization system replacing well mouth manual operation, which mainly solves the problem that mechanization and automation can not be realized when the well mouth operation is carried out in the existing well reparation. In the invention, an opening power tong, a power slip, a lift sub for conveying tubular column and a mobile mechanism of a conveying power tong are integrated; the power tong comprises a main tong and a backup tong, and is installed on the mobile mechanism; the lift sub is connected on a derrick through a big hook; the upper layer of a mobile mechanism is a working machine; the lower layer thereof is a base; the two layers can move relatively; the power tong is installed on the upper layer; the top part of the upper layer isprovided with a righting machine hand used for adjusting the position when the tubular column is loaded and uploaded; the movement of the power tong is finished through the mobile mechanism when the tubular column is loaded and uploaded; and the top part of the mobile mechanism is provided with a righting machine hand which is matched with the lift sub to move the tubular column when the tubular column is loaded and uploaded. The system of the invention improves automation degree of the tubular column loading and uploading, and improves the accuracy of the position of tubular column movement of the tubular column loading and uploading, and increases economic benefits.

Owner:DAQING GASOLINEEUM INST

Well treatment fluid

InactiveUS20050113264A1Improve thermal stabilityAvoid stress crackingFluid removalFlushingProduction rateWell drilling

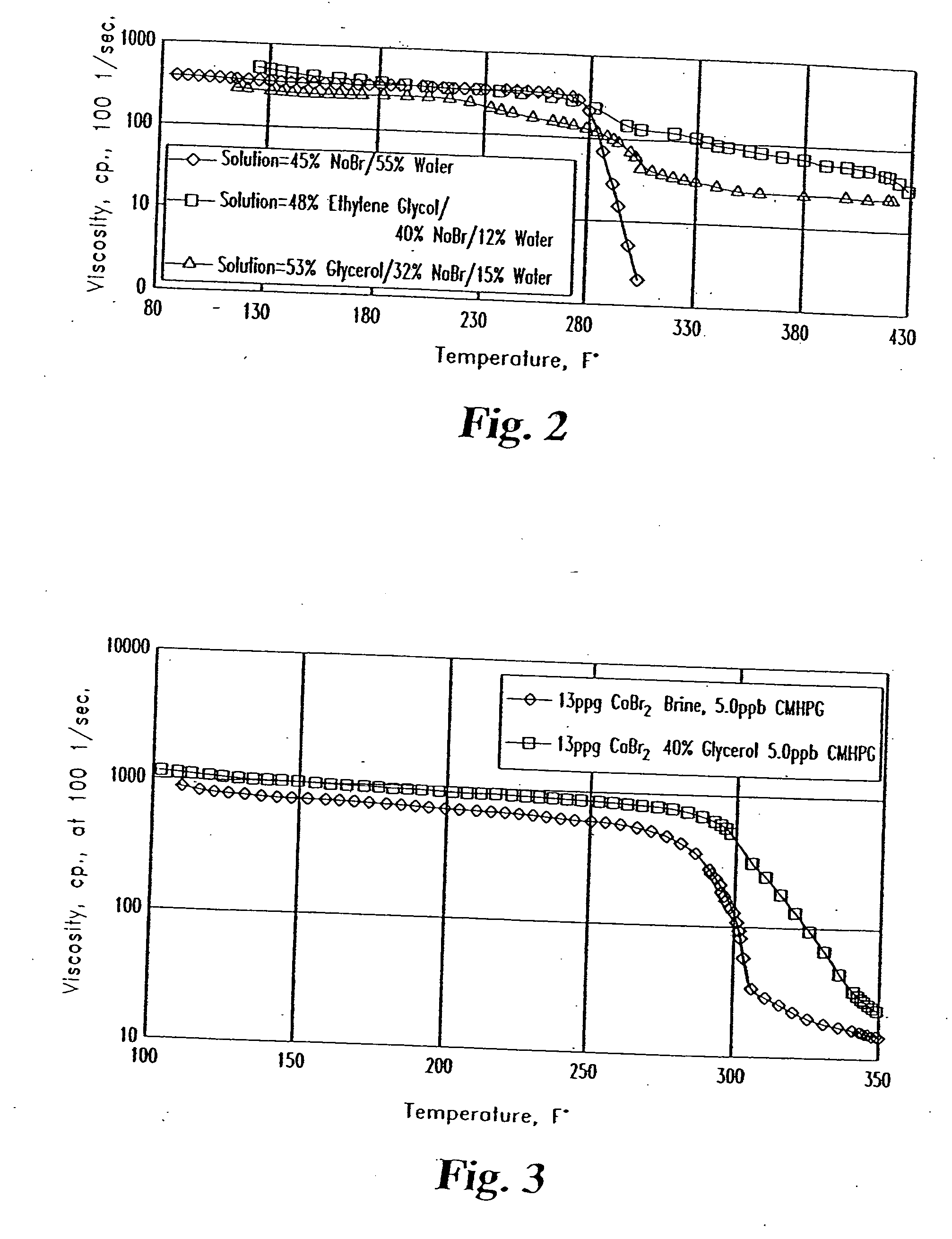

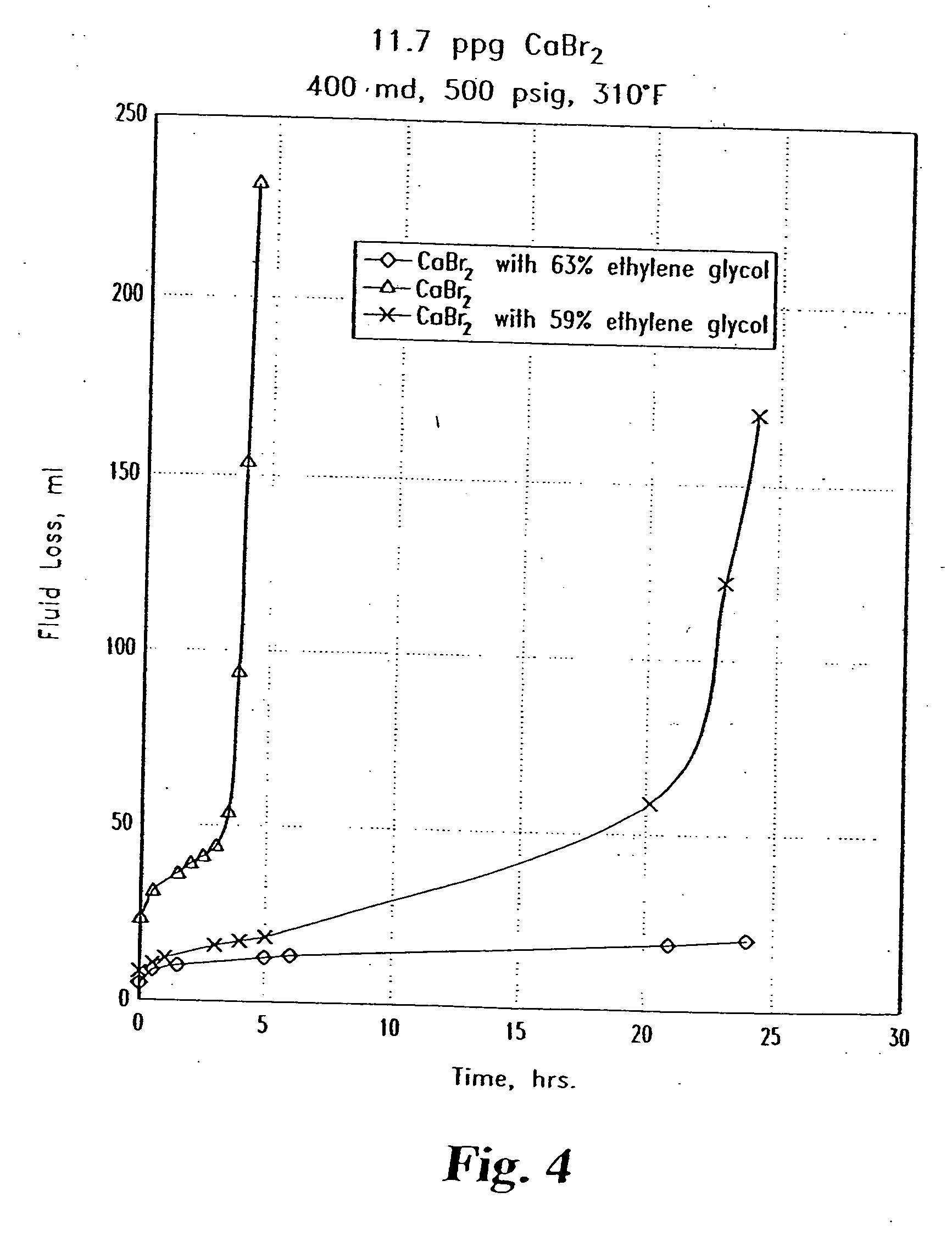

This invention relates to a wellbore treatment fluid and a method of enhancing wellbore treatment fluids to increase efficiency and productivity of wells. More specifically this invention provides methods for enhancing the thermal stability of wellbore treatment fluids such as drill-in, completion, workover, packer, well treating, testing, spacer or hole abandonment fluids. The methods include providing a wellbore treatment fluid that comprises polyol, polysaccharide, weighting agent, and water, wherein the fluid is solids free.

Owner:BSA ACQUISITION

Nonclay one-way plugging drilling fluid

InactiveCN103013467ASuitable rheologyMeet drilling and completion requirementsDrilling compositionMicrospherePotassium

The invention relates to a nonclay one-way plugging drilling fluid. The raw material comprises the following components by mass part: 5-40 parts of main anchoring agent, 1-5 parts of auxiliary anchoring agent, 20-150 parts of one-way plugging agent, 5-20 parts of inhibiting agent, 0-20 parts of lubricating agent, 0-500 parts of weighting agent and 1000 parts of water, wherein the main anchoring agent is made of polyacrylamide, polyanionic cellulose or sulfonate copolymer fluid loss additive DSP-2; the auxiliary anchoring agent is made of xanthan gum or sodium carboxymethyl cellulose; the one-way plugging agent is made of polymer elastic microspheres SFH-1 or rubber particles; the inhibiting agent is made of amino polyol, potassium polyacrylate or polyhydric alcohols; the lubricating agent is made of the drilling fluid FYR lubricating agent, white oil or black lead; and the weighting agent is made of one of sodium formate and potassium formate or the mixture of sodium formate and potassium formate. The drilling fluid has the characteristic of one-way plugging, so as to be taken as drilling fluid, completion fluid or workover fluid; and the remarkable effects of improving the drilling rate, stabilizing the well wall and protecting a reservoir are achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

System and method for rigging up well workover equipment

InactiveUS8127854B2Facilitate riggingSimple and safe processDrilling rodsFluid removalCoiled tubingEngineering

A gas and oil recovery system including a vessel, platform or rig, with a rig floor, a riser including a pipe that extends from the vessel, platform or rig to a x-mas tree on top of a well head and via which a wire or coiled tubing is fed down into a well. The riser is movable through an opening in the rig floor, and a surface flow head connected to the riser and to a wire line or coiled tubing equipment. The surface flow head is arranged to be run through the opening in the rig floor.

Owner:VETCO GRAY SCANDINAVIA

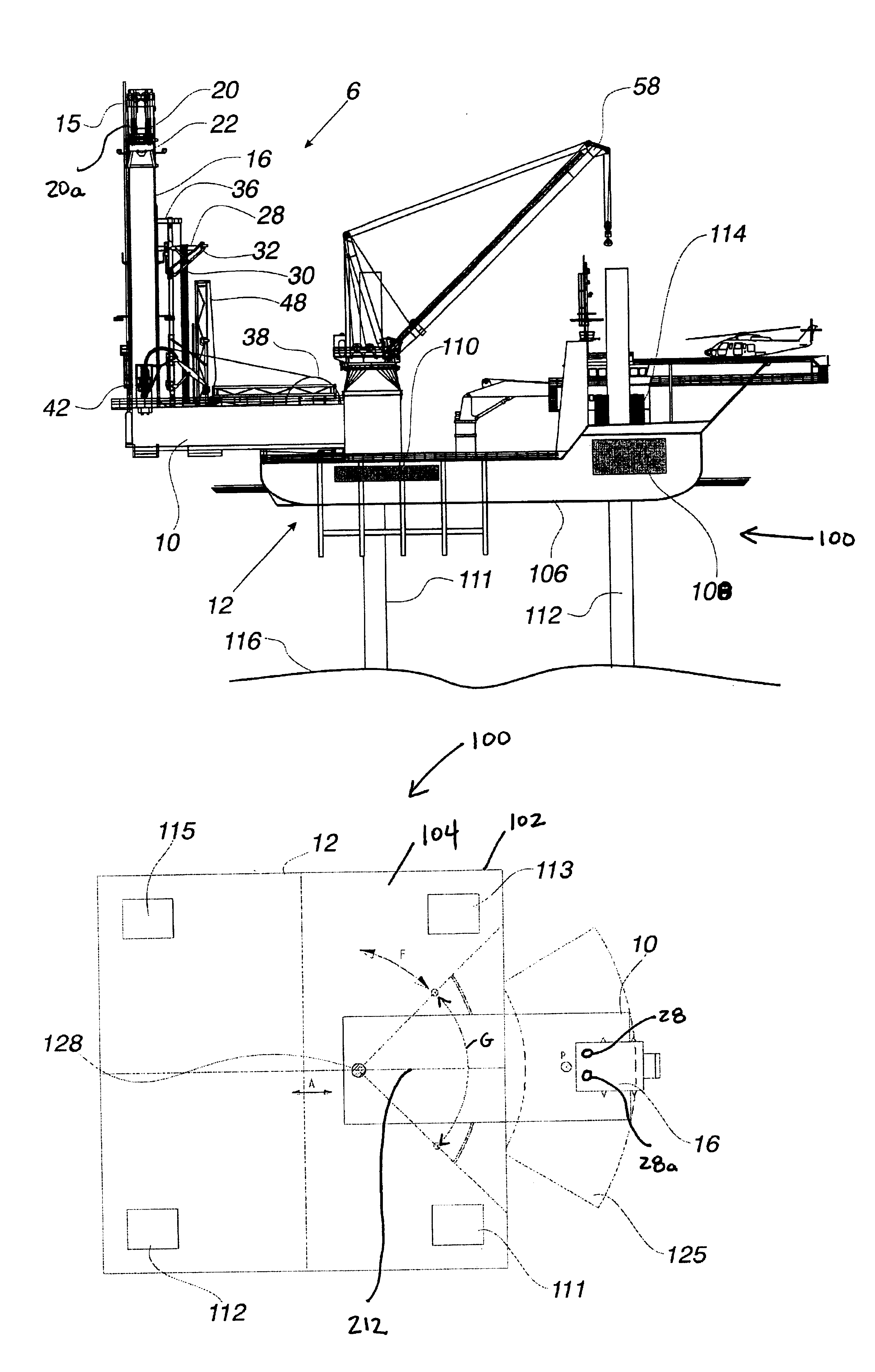

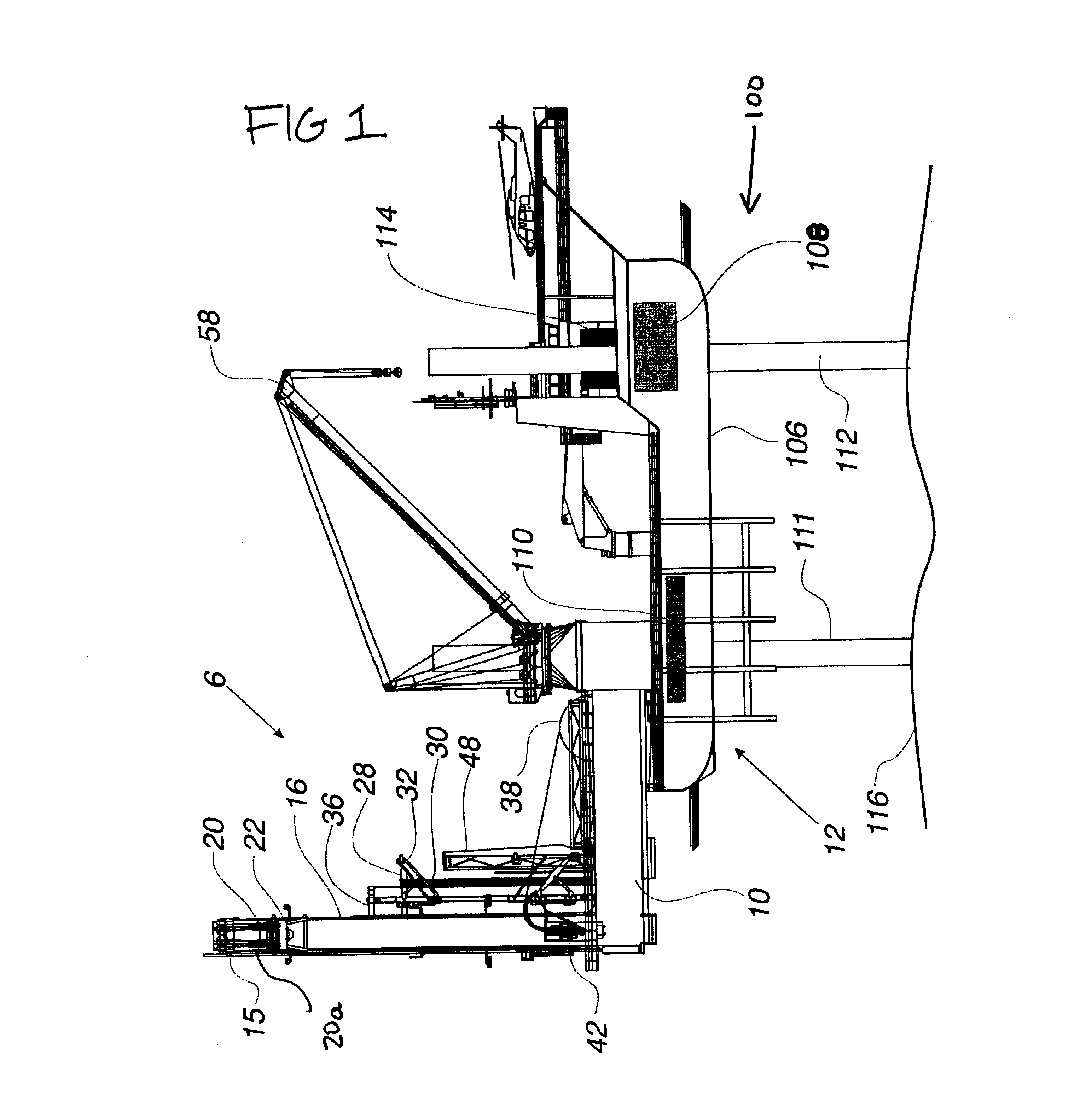

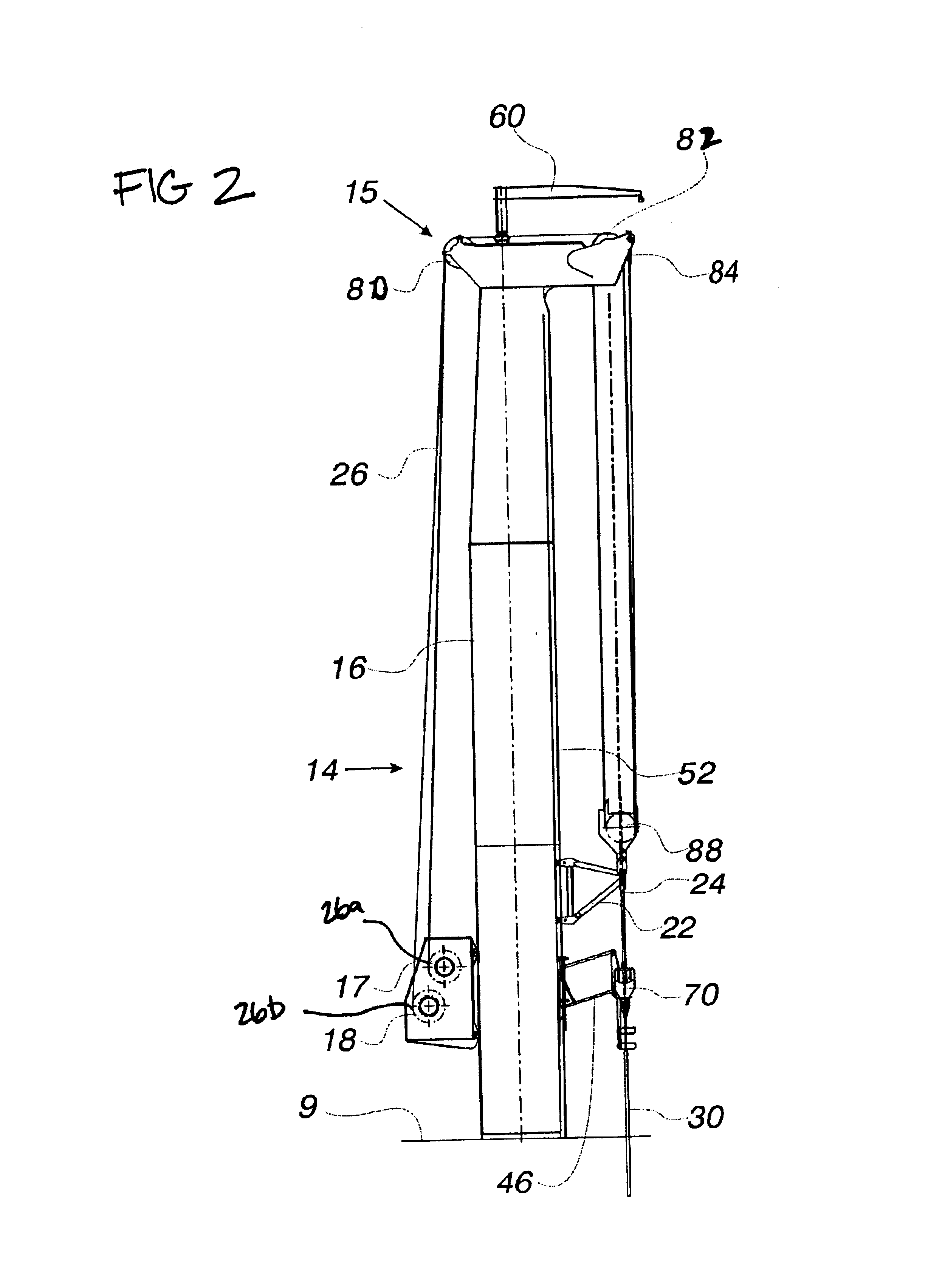

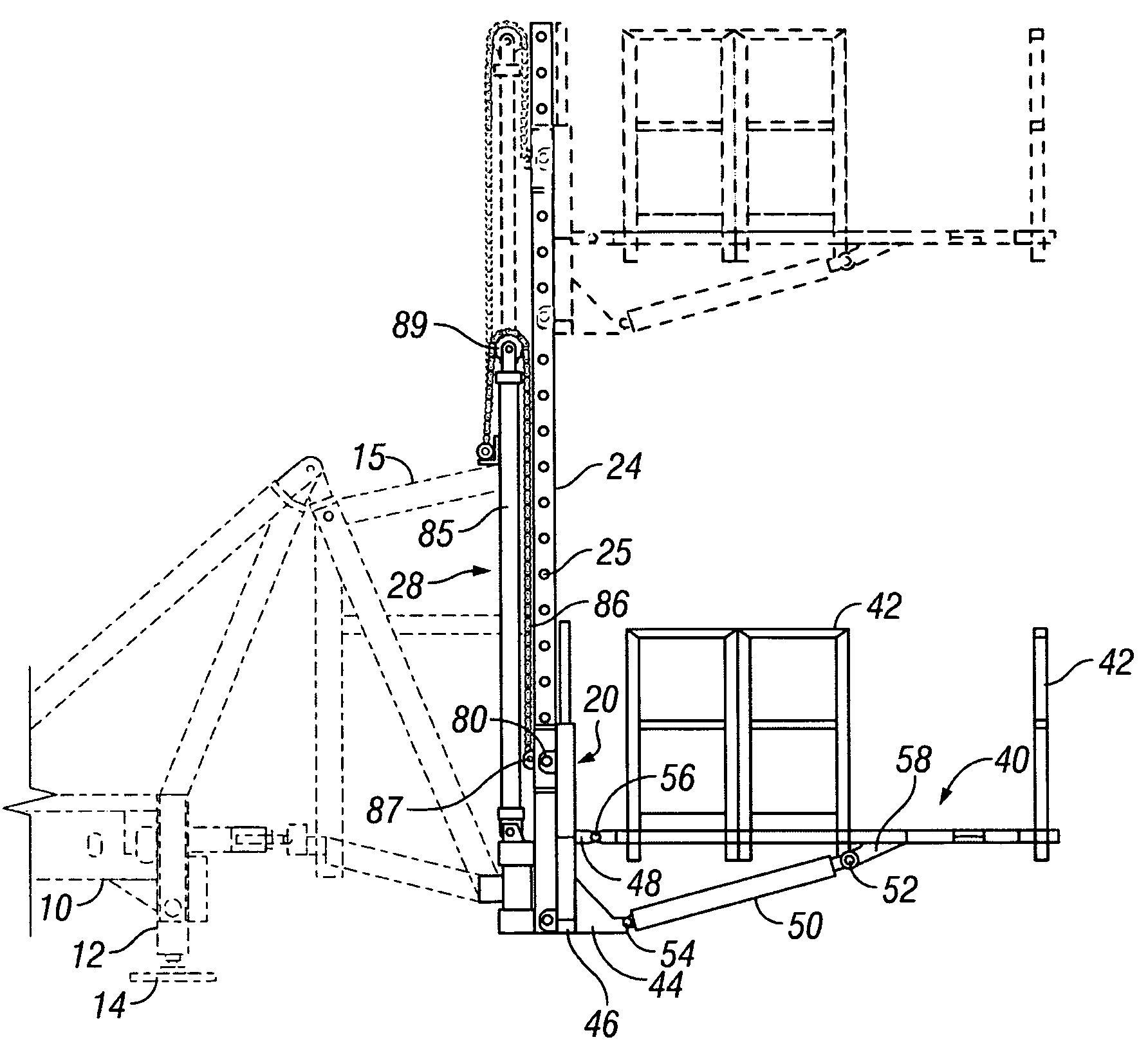

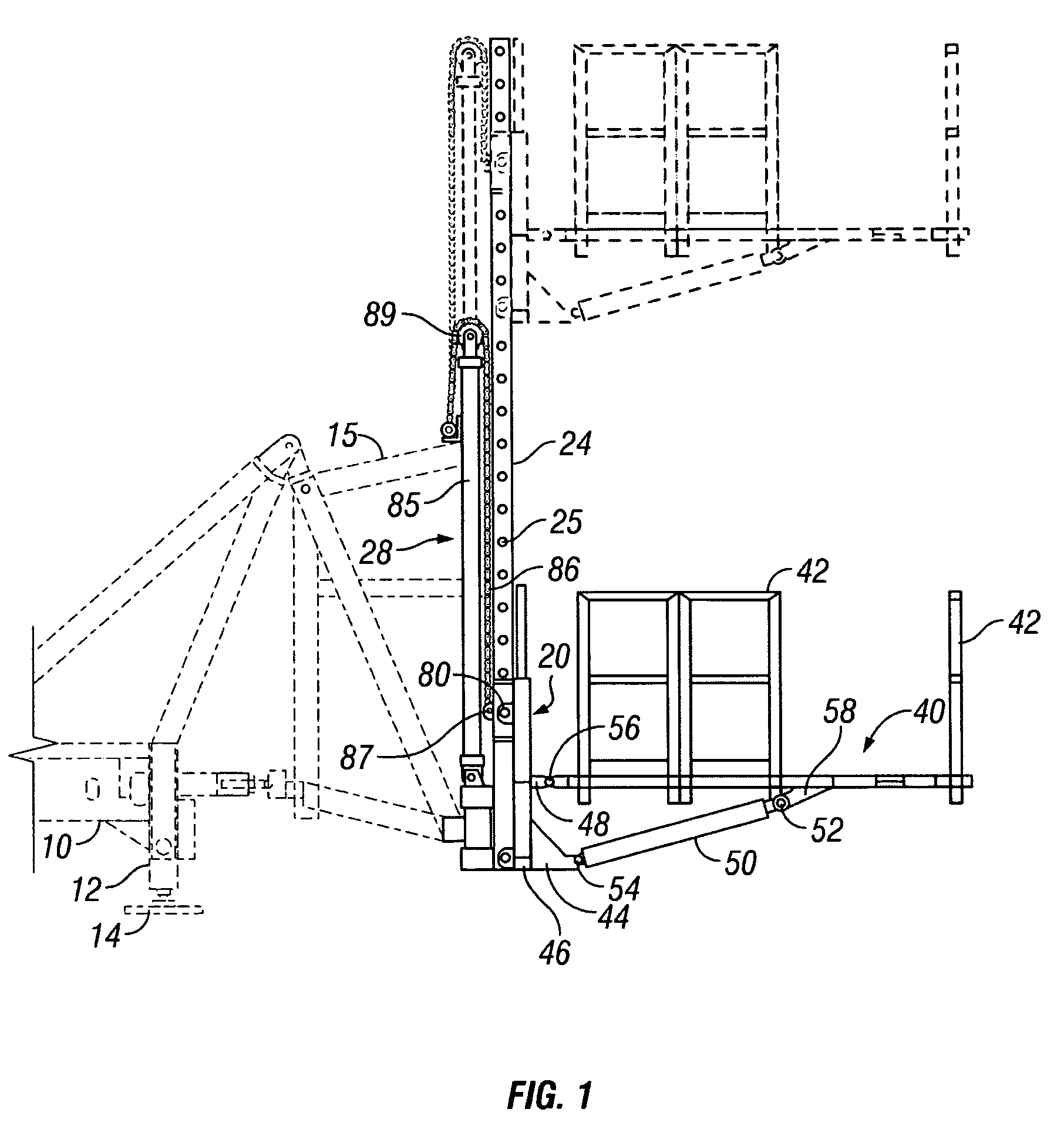

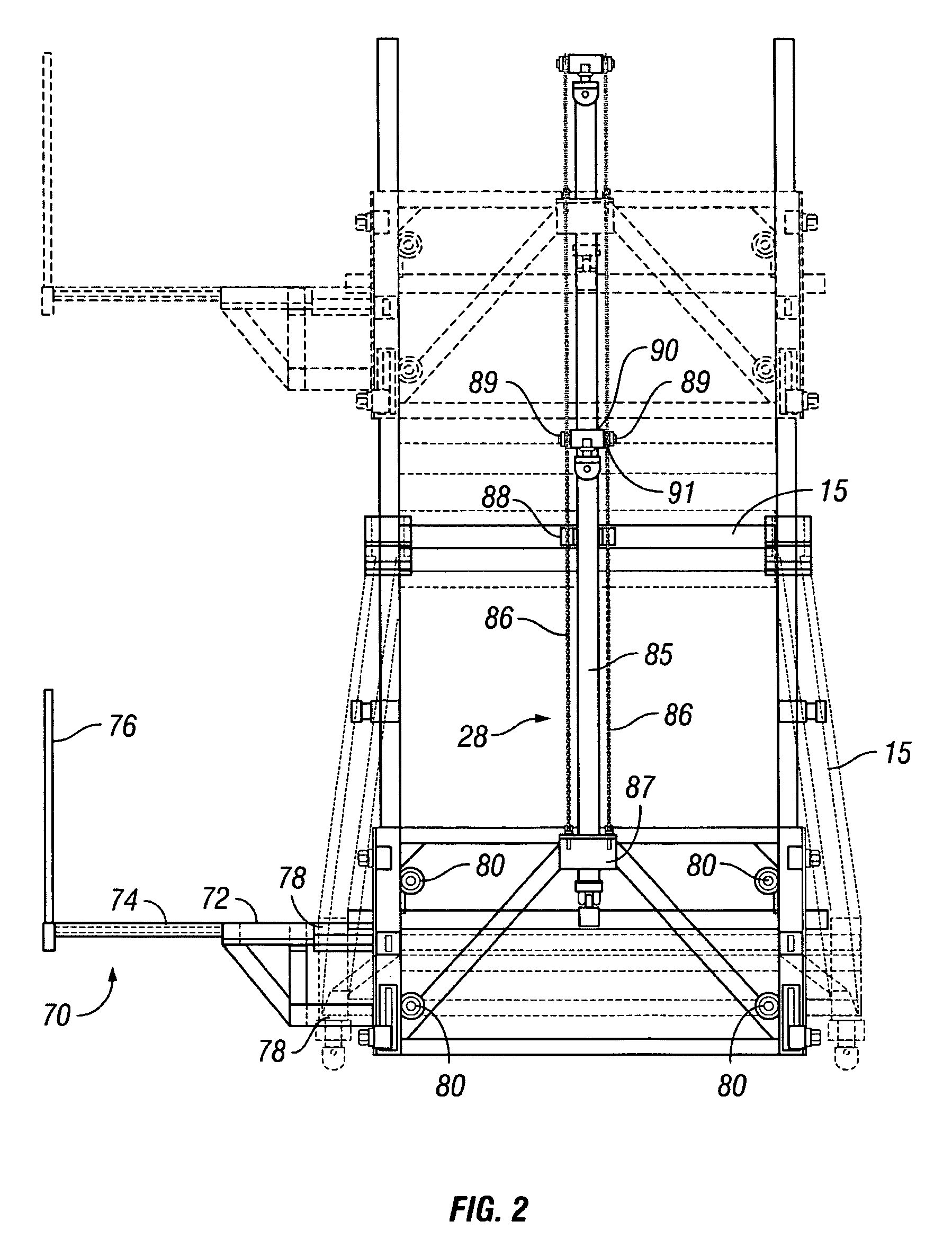

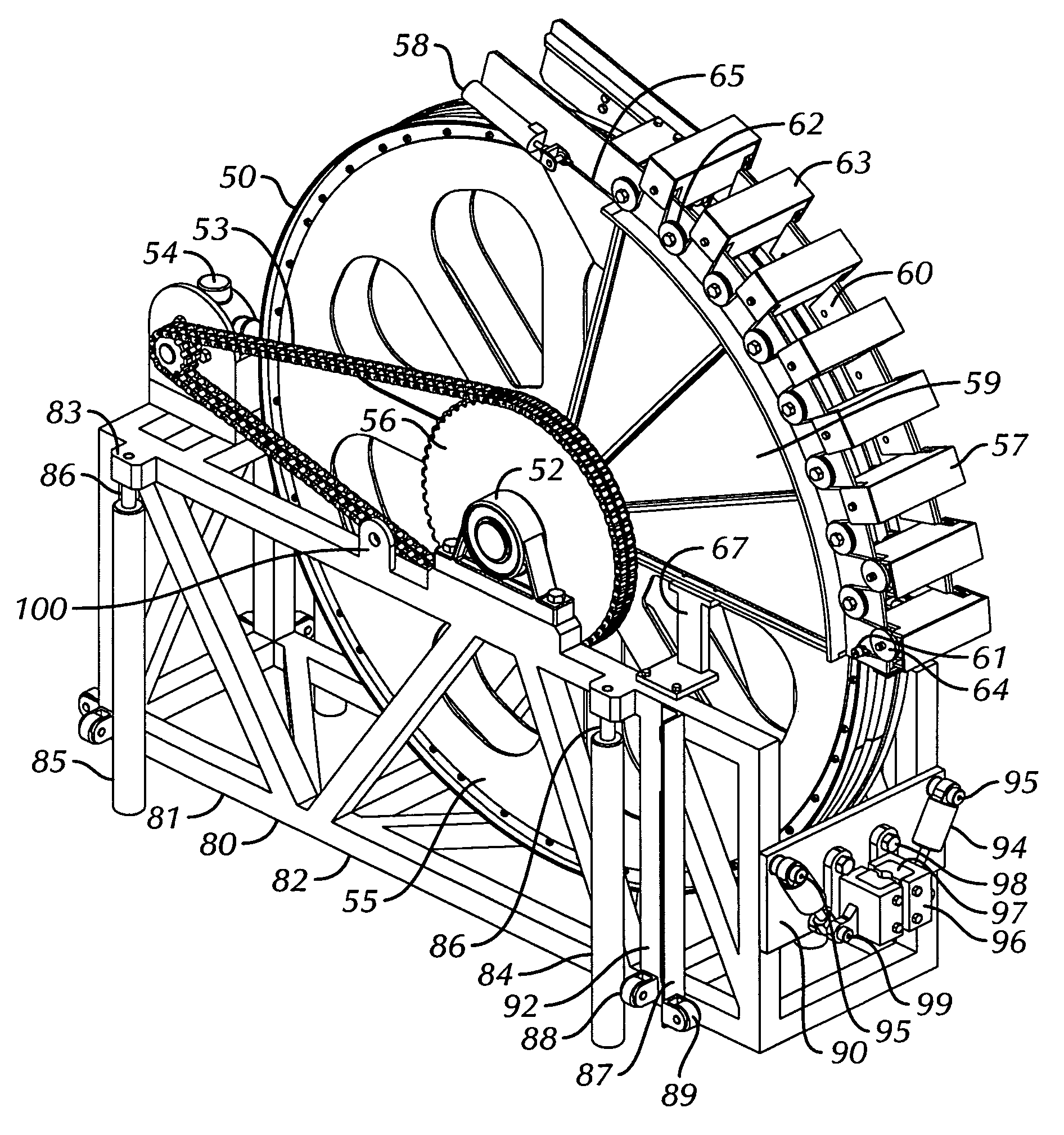

Automated system for positioning and supporting the work platform of a mobile workover and well-servicing rig

ActiveUS7293607B2Shorten the timeReduce the risk of injuryDrilling rodsDerricks/mastsMarine engineeringPositioning system

Owner:NAT OILWELL DHT

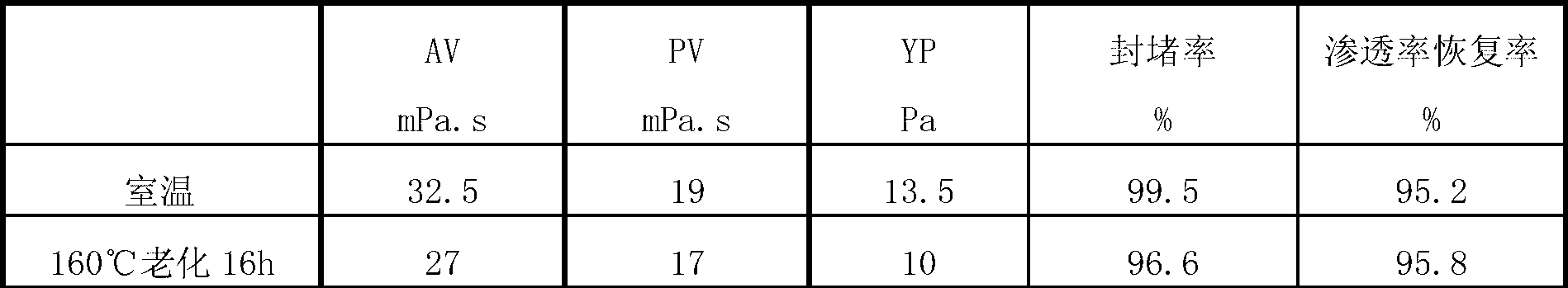

Method of decreasing the loss of fluid during workover and completion operations

InactiveUS6325149B1Avoid damageReduce differential pressureFluid removalFlushingHydrostatic pressurePolyethylene glycol

The invention provides solids-free, viscous fluids (pills) for use in various well workover and completion operations including as displacement spacer pills, standard fluid loss control pills, post gravel pack in-screen pills, perforation sealing, and the like. The pills comprise a viscous solution of a polyethylene glycol having a molecular weight of 1,000 to 8,000,000 in an aqueous liquid comprising a solution of one or more soluble bromide salts having a density sufficient to provide the desired hydrostatic pressure at the location of use of the fluid in a well. The minimum concentration of the polyethylene glycol in the pill varies with the average molecular weight as follows: MW=1,000 to 10,000=100 ppb; MW=10,001 to 100,000=75 ppb; MW=100,001 to 250,000=50 ppb; MW=250,001 to 500,000=10 ppb; MW=500,001 to 8,000,000=5 ppb.

Owner:TUCC TECH LLC

Selectably elevatable injector for coiled tubing

A selectably elevatable coiled tubing injector is described that is suitable for a mobile self-contained unitized coil tubing rig for the drilling and workover of petroleum wells. The selectably elevatable coiled tubing injector includes a mechanism for positioning a trailer mounted coiled tubing injector either in a first stowed position on the deck of the transport trailer or in a second position resting on an elevated rig floor of a drilling rig. Furthermore, the selectably elevatable coiled tubing injector includes a further mechanism for selectably elevating the injector above its second position on the rig floor while clamping the tubing in order to provide additional tension on the tubing string or to raise the tubing deployed within a well.

Owner:TOM C GIPSON

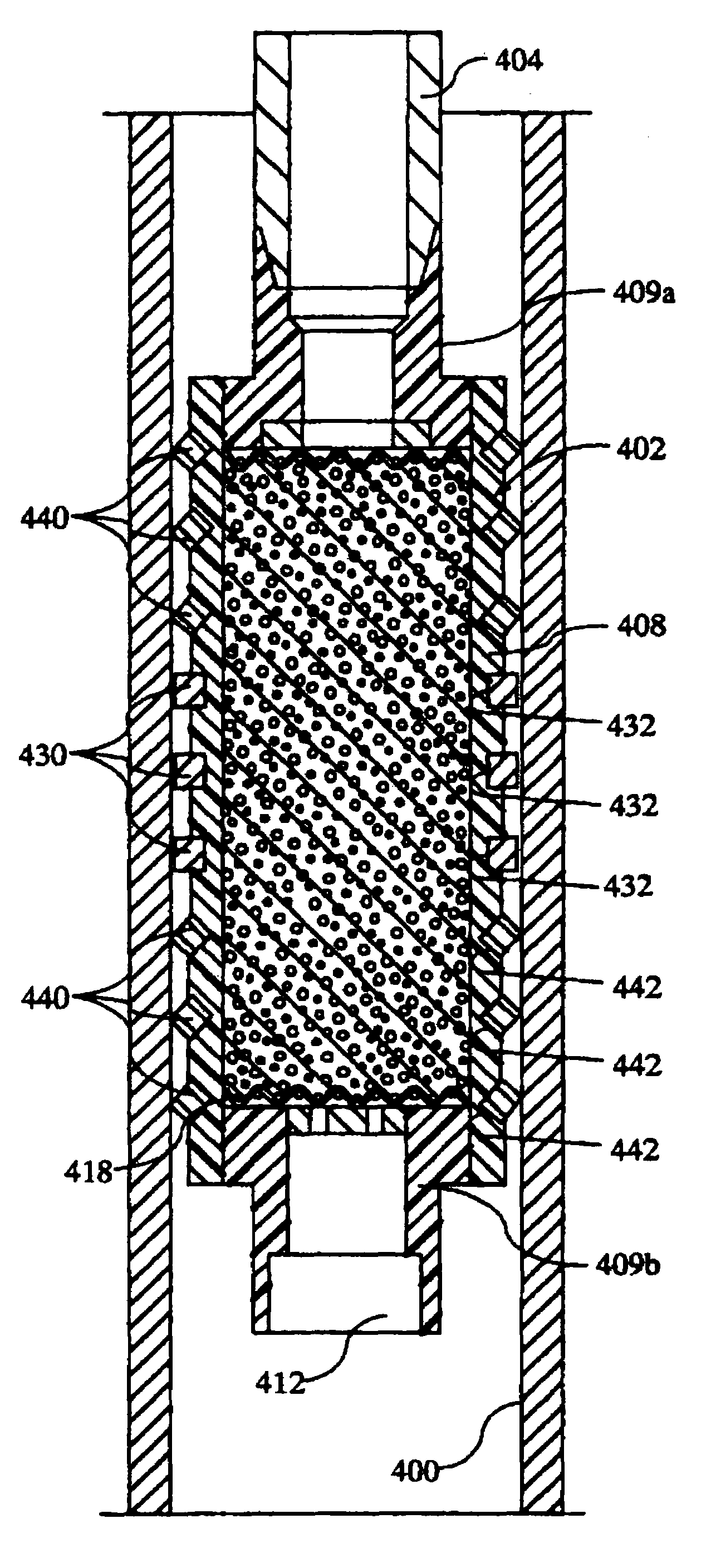

Retrievable frac mandrel and well control stack to facilitate well completion, re-completion or workover and method of use

A retrievable frac mandrel and a well control stack are used to efficiently accomplish well completion, re-completion or workover. The retrievable frac mandrel is inserted in a tubing head spool of a well to be completed, re-completed or re-worked. The well control stack is mounted to a top of the tubing head spool and seals off against a top of the retrievable frac mandrel. Once well completion, re-completion or workover is completed, the frac mandrel can be retrieved from the tubing head spool without killing or plugging the well.

Owner:WELLS FARGO BANK NAT ASSOC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com