Patents

Literature

152 results about "Black lead" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

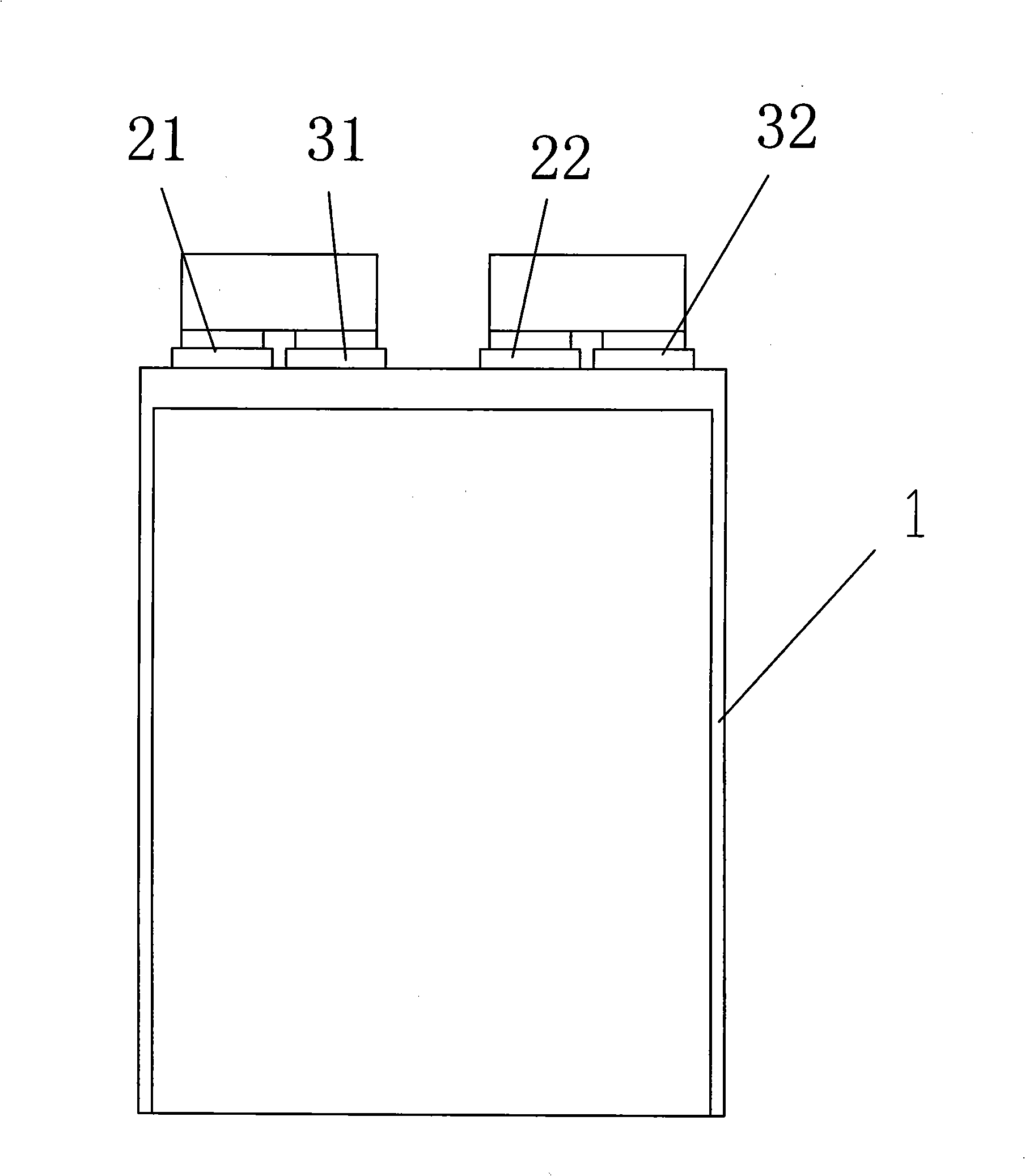

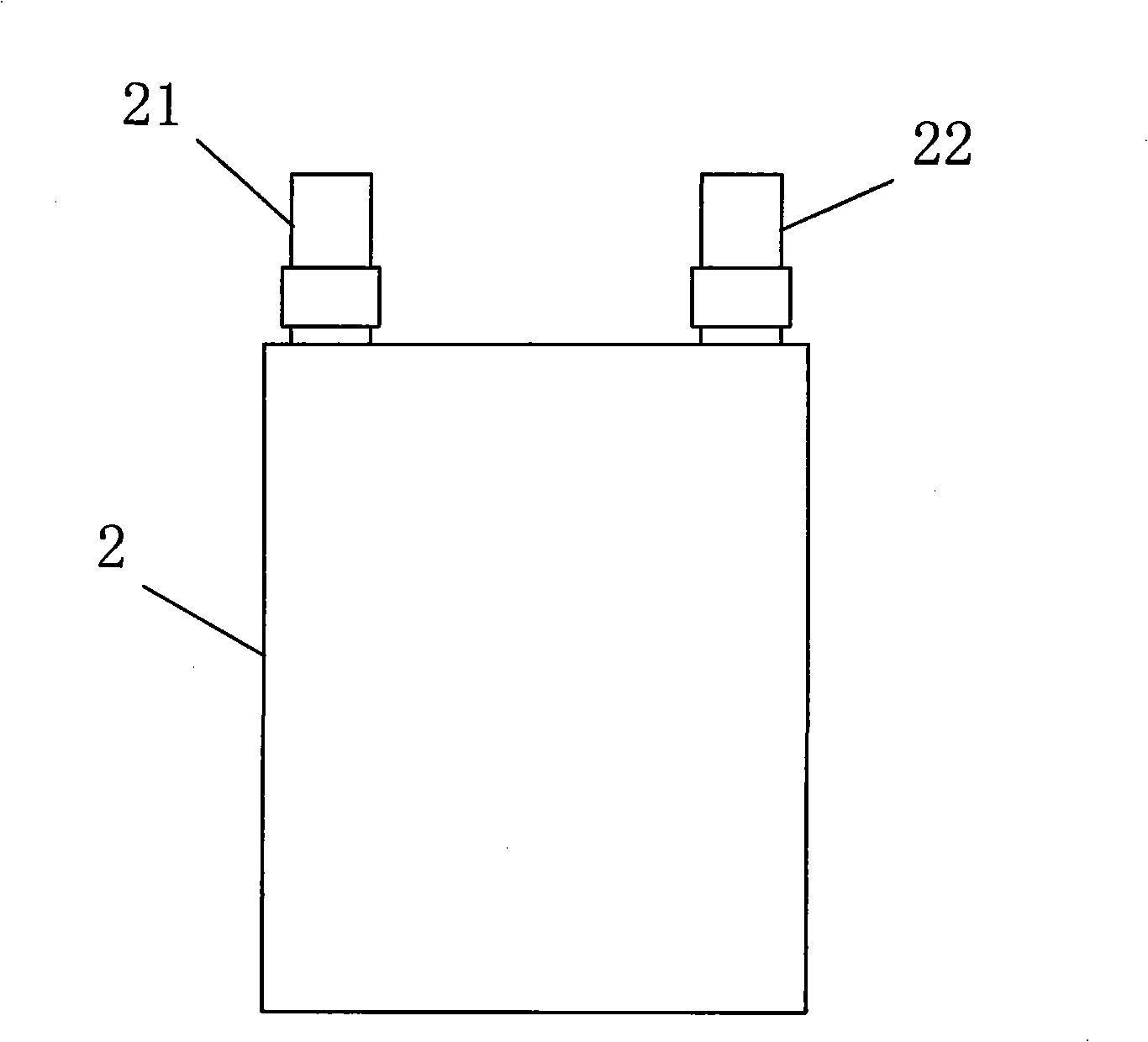

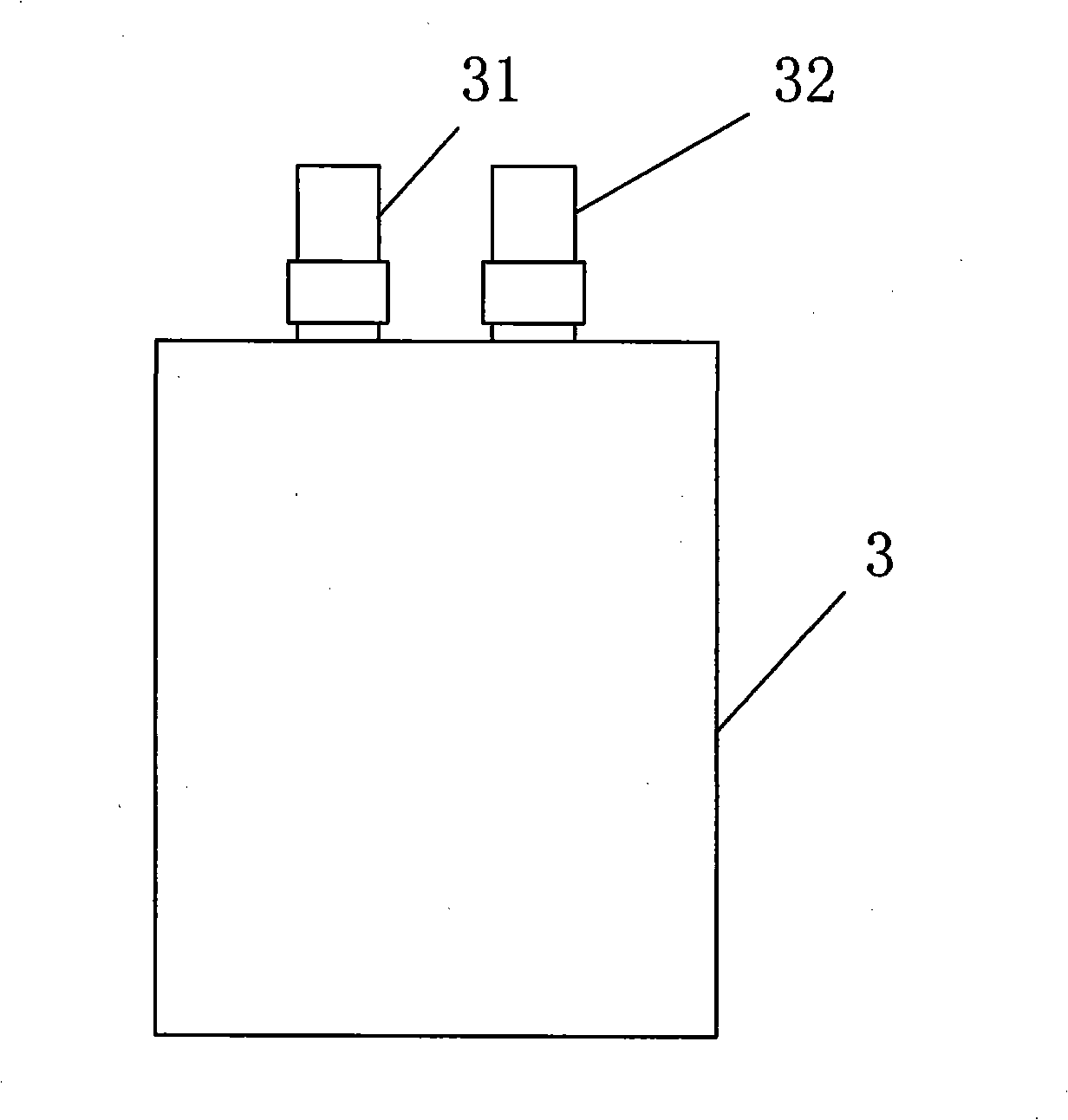

Large-capacity high power polymer ferric lithium phosphate power cell and preparation method thereof

InactiveCN101409369AImprove securityIncrease capacityElectrode manufacturing processesFinal product manufactureSlurryElectric vehicle

The invention discloses a large-capacity high-power polymer lithium iron phosphate power battery. The weight ratio of anode slurry is as follows: 81 to 85 percent of lithium iron phosphate, 1 to 5.5 percent of superconduction carbon, 0 to 2.5 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 0 to 2.5 percent of crystalline flake graphite, 0 to 2 percent of carbon nanometer tube as well as 6 to 7.5 percent of polyvinylidene fluoride; the weight ratio of cathode slurry is as follows: 89 to 91 percent of cathode material, 1 to 3.5 percent of superconduction carbon, 0 to 2 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 2.5 to 3.5 percent of styrene-butadiene rubber as well as 1.5 to 2 percent of sodium carboxymethyl cellulose; the steps for preparing the battery are as follows: preparing slurry, coating the anode and the cathode, rolling and pressing a polar plate, transversely and separately cutting the polar plate, baking the polar plate, welding the polar ears of the anode and the cathode, preparing a battery cell, putting the electric core into a shell and sealing, baking the electric core, injecting liquid into the battery as well as forming the battery and dividing the volume of the battery. The invention relates to a lithium-ion secondary battery which can provide drive energies for electric tools, electric bicycles, motor cars and electric vehicles.

Owner:MCNAIR TECH

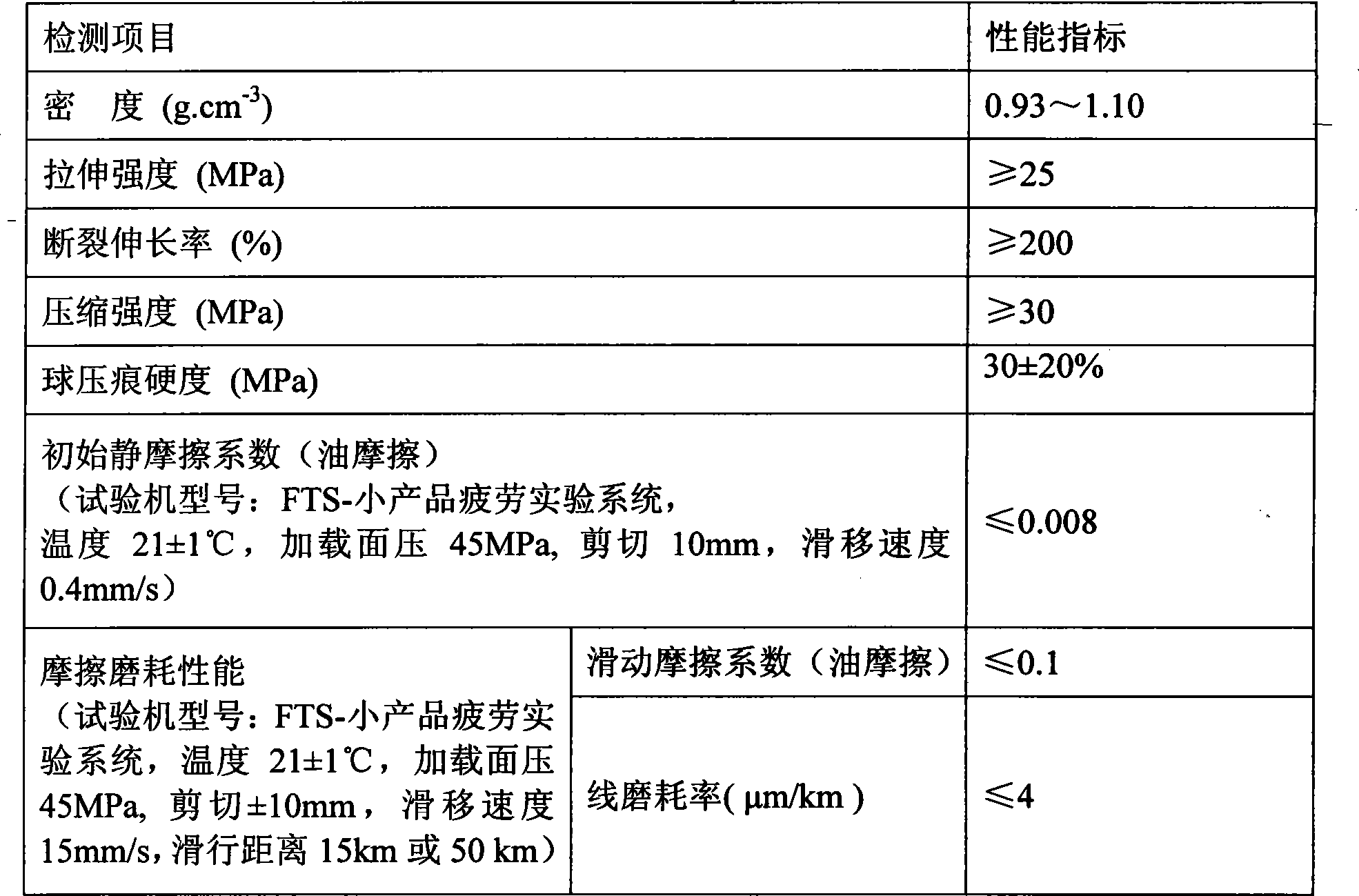

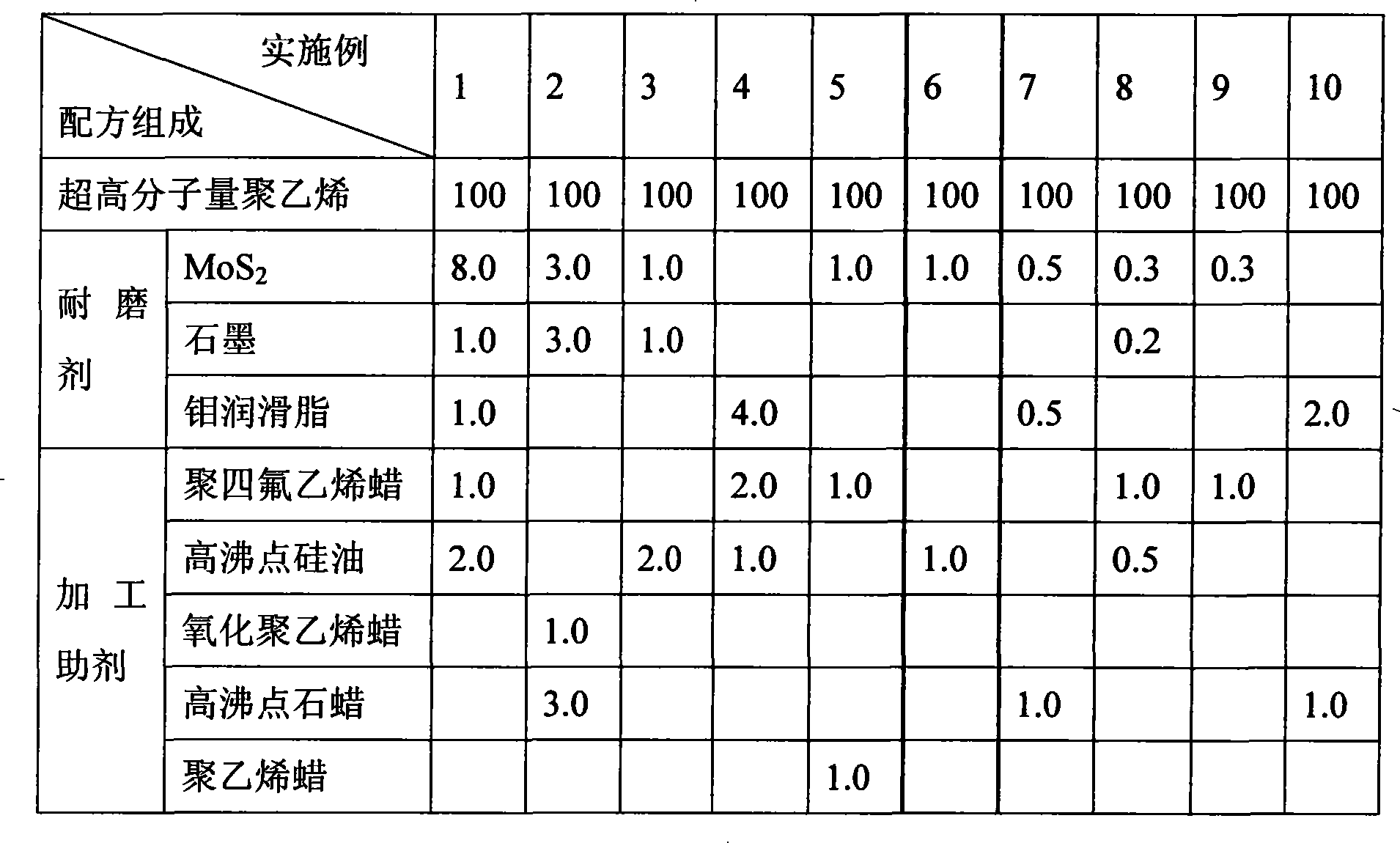

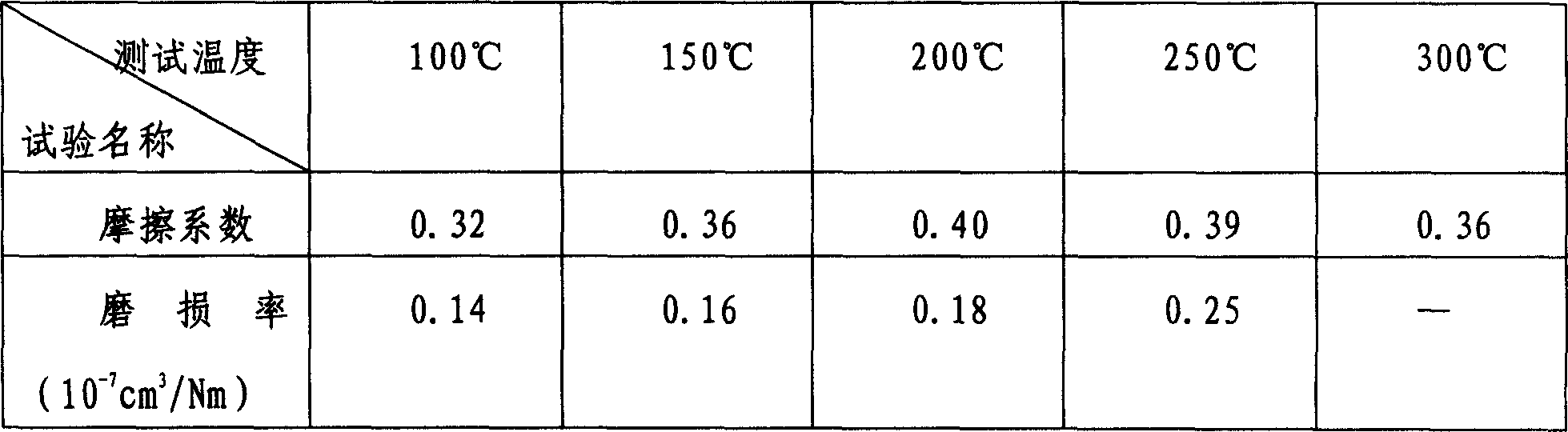

Super-high molecular weight polyethylene low frictional coefficient wearable composite material and its preparation and use

InactiveCN101240092AImprove performanceExcellent formulaBridge structural detailsParaffin waxProcedure Agents

Ultra high molecular weight polyethylene composite with low molar mass and high friction resistance, preparation and application thereof. Raw materials of 100 parts by weight of ultra high molecular weight polyethylene, 0.1-10 parts by weight of wear-resisting agent, 0.1-5.0 parts by weight of processing aid is prepared into highly friction resistant composite by mixing, chill-pressing, heating to melt, compression molding, cooling for shaping and cutting. The mentioned utra high molecular weight polyethylene has a matrix molecular weight of greater than 6 millionl. The mentioned wear-resisting agent is MoS2 surface treated by coupling agent, black lead, lubricating grease of molybdenum, copper powder, or mixture of more than two of them. The mentioned processing agent is organic silicon oil with high boiling point, polytetrafluroethylene, oxidized polyethylene wax, olefin or polyethylene wax with high boiling point, or mixture of more than two of them.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

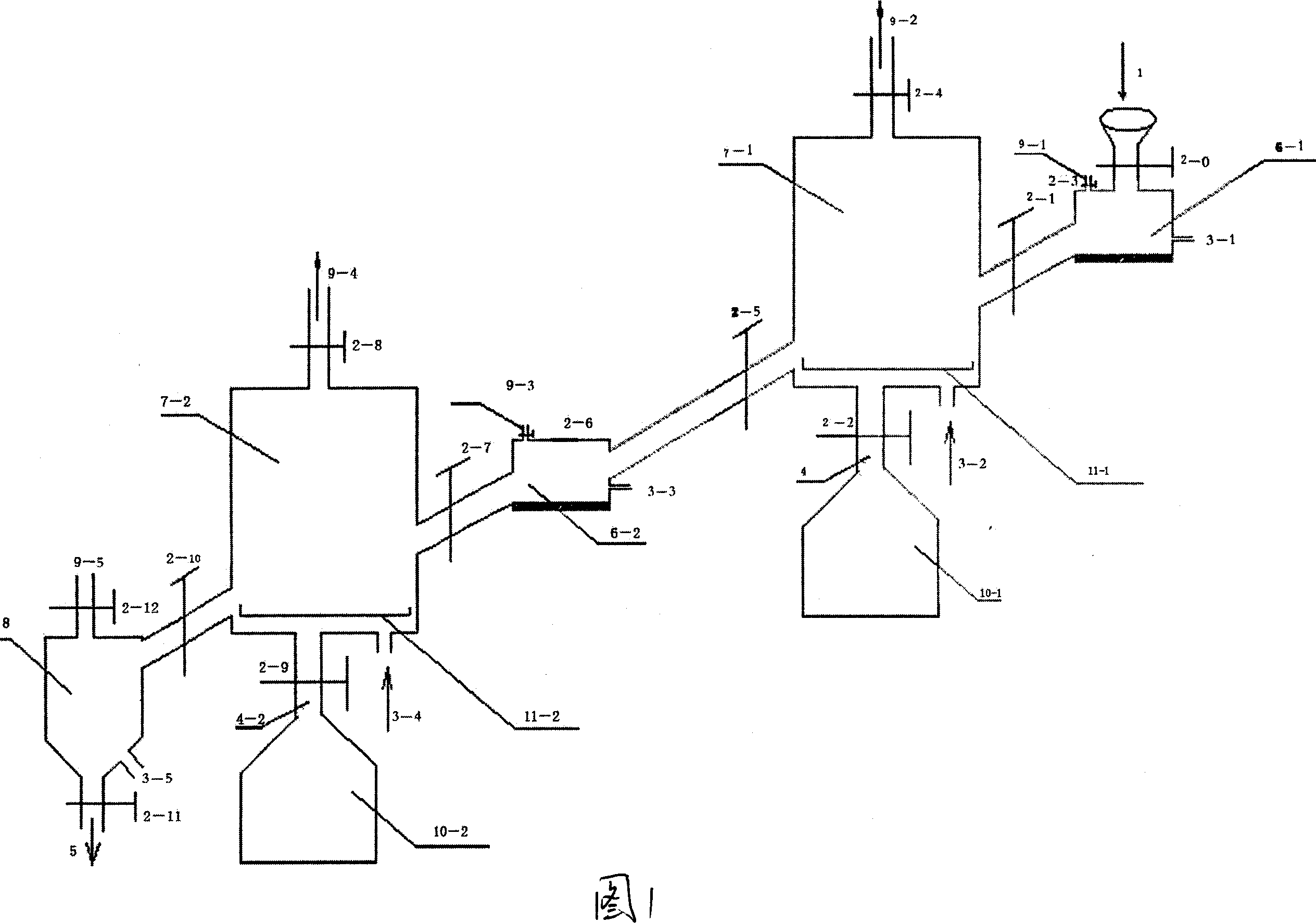

QTi3.5-10 graphite semi-solid size mechanical stirring producing method

InactiveCN1888801ASolve the problem that QTi3.5-10 graphite semi-solid slurry cannot be directly prepared from the liquid state”Mechanical apparatusStirring devicesLiquid stateSemi solid

A QTi3.5-10 black lead half-solid slurry mechanical whisk and preparation method belong to the QTi3.5-10 black lead half-solid research field. It uses peripheral and downward movements, which formed by the rotating of continuous up and down locomotive double arc straight blades, to break up the juvenile solid state formed during QTi3.5 melt solidification process and keep adding black lead grain to QTi3.5 melt. Change rotating way of the double arc straight blades to keep the disperse effect of the black lead grain, when QTi3.5 melt peripheral movement estate approaches the same estate of double arc straight blades. Use high viscosity of QTi3.5 melt and juvenile solid state grain to stop float of the black lead grain and get QTi3.5-10 black lead half-solid slurry, and also solve the problem that it couldn't get QTi3.5-10 black lead half-solid slurry directly form liquid state with conventionality engine.

Owner:BEIJING JIAOTONG UNIV

Graphite negative material of lithium ion battery and producing method thereof

InactiveCN1585172AGood compatibilityImprove efficiencyElectrode manufacturing processesTectorial membraneGraphite

To improve the stability of the graphite base body and the protecting film, the technical method is applied. The graphite negative material of the lithium ion battery is composed of the graphite and the shell covering the graphite. The shell is the carbon coverage with low crystallization disorderly layer structure. The producing procedure is as below: (1) Cover the bitumen onto the surface of the black lead particle. (2) Process the covered bitumen with heating processing. Compared with existed technology, the processed bitumen possesses the property of strong strong ability for combination and cycling stability with low cost.

Owner:BTR NEW MATERIAL GRP CO LTD

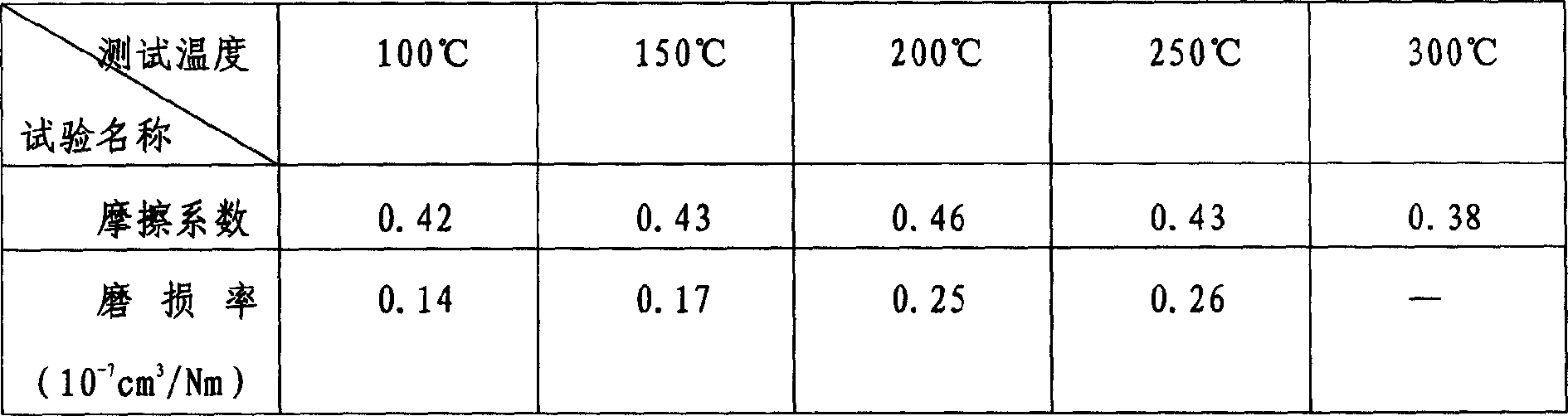

Automotiv non-asbestos high strength braking friction disk, and its prodn. method

InactiveCN1563735AImprove heat resistanceEnhancement effect is goodFriction liningHeat resistanceMetal fibers

The wearing piece of non-asbestos high srength material applies the high molecular compound, phenolic ressin as the agglomerant. The metal fiber or organic fiber is strengthen component. The stuffing applies regulator with frictional properties and barium sulfate, black lead, alumina as accessory ingredient. The production possesses excellent characteristic of physical chemical and mechanical and thermo-stability.

Owner:APPLIED PHYSICS INST OF GUANGXI ACADEMY OF SCI

Method for preparing conductive composite material by utilizing synergistic reaction of conductive filling material

InactiveCN101240091AImprove efficiencyImprove electrical performanceNon-conductive material with dispersed conductive materialFiberCarbon fibers

A preparation of electric conductive composite by synergism of conductive filler, particularly relates to a preparation of electric conductive composite by synergism between carbon nano-tube and conductive carbon filler. The preparation is characterized by using processing apparatus for high-molecular material to melt mix and granulate after mixing polymer, carbon nano-tube, carbon black, black lead, carbon fiber according to a definite ratio. The preparation is simple to operate, easy for application in industry, can further produce electric conductive composite with great electric conductivity and combination property, which can be widely used in automobile, electric and electronic apparatus, office equipment, industrial mechanism, and can satisfy and expand need of high-molecular materials in various application fields.

Owner:TSINGHUA UNIV

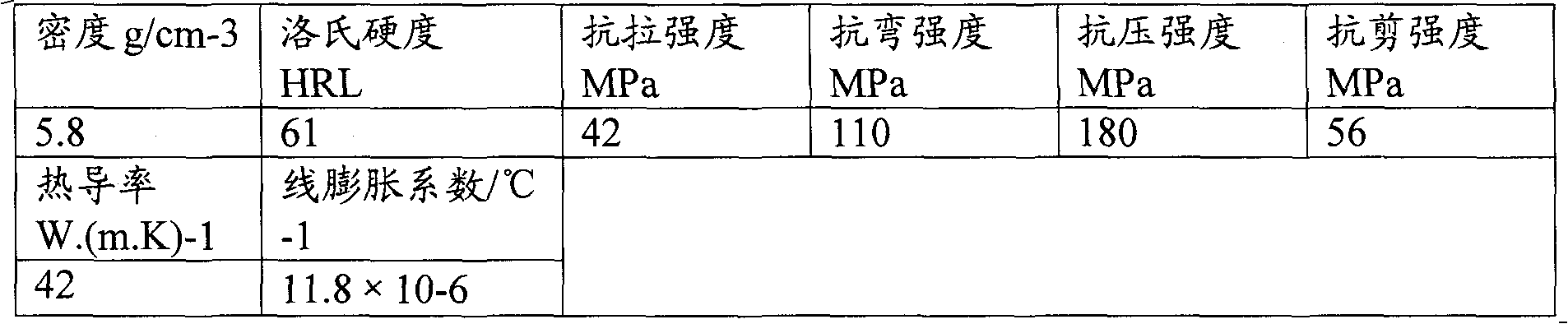

High-temperature brazing filler metal

ActiveCN101653884AMelt-holding vesselsWelding/cutting media/materialsRoom temperatureFlexural strength

The invention discloses a high-temperature brazing filler metal, relating to a brazing filler metal. The invention solves the problem that joints obtained by using the prior brazing filler composite material have low shearing strength. The brazing filler metal comprises Ti or TiH2, Ni and Nb. When the high-temperature brazing filler material is used to braze C / SiC composite material and the brazing joint of the C / SiC composite material, room temperature three-point bending strength reaches 50MPa-71MPa, and the room temperature shearing strength of the brazing joint of the C / SiC composite material and metal reaches 90MPa-180MPa, moreover, the retention rate of the 800 DEG C high-temperature shearing strength of the brazing joint is more than 69% and the retention rate of the 800 DEG C high-temperature shearing strength is more than 42%. When the high-temperature brazing filler material is used to braze black lead and the joint of Nb, the room temperature shearing strength reaches 30MPa-60MPa.

Owner:HARBIN INST OF TECH

Method for preparing artificial graphite cathode material of lithium ion battery

ActiveCN1691374AEasy to implementGood coating effectElectrode manufacturing processesNon-aqueous electrolyte accumulatorsGraphiteSodium-ion battery

The invention discloses a making method for lithium ion battery negative materials, comprising the steps of: (1) mixing the black lead, clad material and solvent, evacuating, stripping solvent and cladding the natural black lead in the clad materials; (2) polymerizing the materials and the surface of the natural black lead will get the microencapsulation cladding layer; (3) charring or charring the products of step (2) to get the carbon negative materials with the artificial black lead layer coated on the surface, this is the lithium ion battery negative materials. The detecting results of the battery negative materials are: tap density is more than 1.02, specific surface area is lese than 2.0, the first discharging capacity is more than 350mAh / g (non-reversible capacity is less than 25mAh / g), the first charging efficiency is more than 93%, after circulating 460 times, the rest first capacity is more than 90%.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

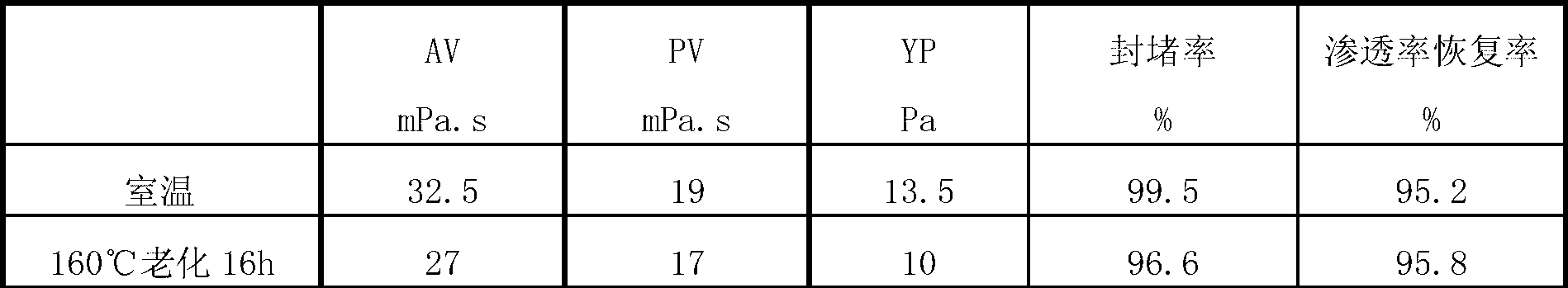

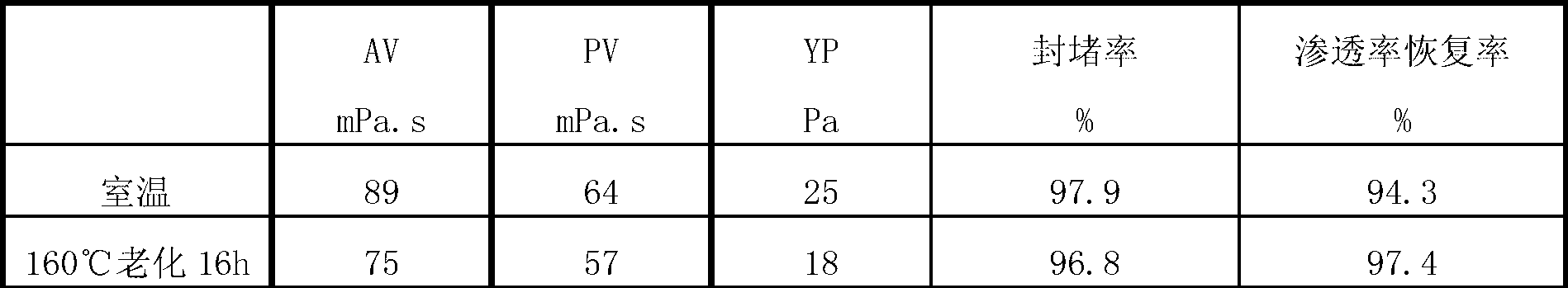

Nonclay one-way plugging drilling fluid

InactiveCN103013467ASuitable rheologyMeet drilling and completion requirementsDrilling compositionMicrospherePotassium

The invention relates to a nonclay one-way plugging drilling fluid. The raw material comprises the following components by mass part: 5-40 parts of main anchoring agent, 1-5 parts of auxiliary anchoring agent, 20-150 parts of one-way plugging agent, 5-20 parts of inhibiting agent, 0-20 parts of lubricating agent, 0-500 parts of weighting agent and 1000 parts of water, wherein the main anchoring agent is made of polyacrylamide, polyanionic cellulose or sulfonate copolymer fluid loss additive DSP-2; the auxiliary anchoring agent is made of xanthan gum or sodium carboxymethyl cellulose; the one-way plugging agent is made of polymer elastic microspheres SFH-1 or rubber particles; the inhibiting agent is made of amino polyol, potassium polyacrylate or polyhydric alcohols; the lubricating agent is made of the drilling fluid FYR lubricating agent, white oil or black lead; and the weighting agent is made of one of sodium formate and potassium formate or the mixture of sodium formate and potassium formate. The drilling fluid has the characteristic of one-way plugging, so as to be taken as drilling fluid, completion fluid or workover fluid; and the remarkable effects of improving the drilling rate, stabilizing the well wall and protecting a reservoir are achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

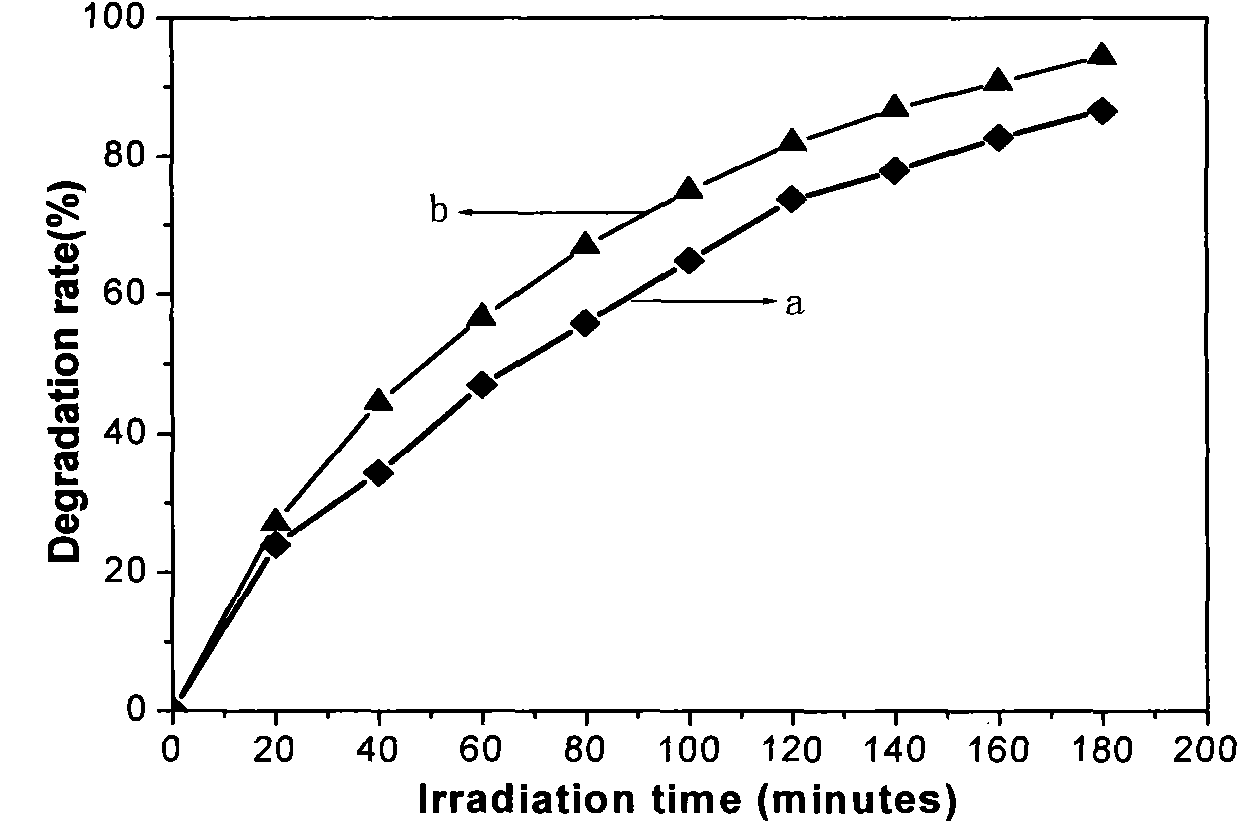

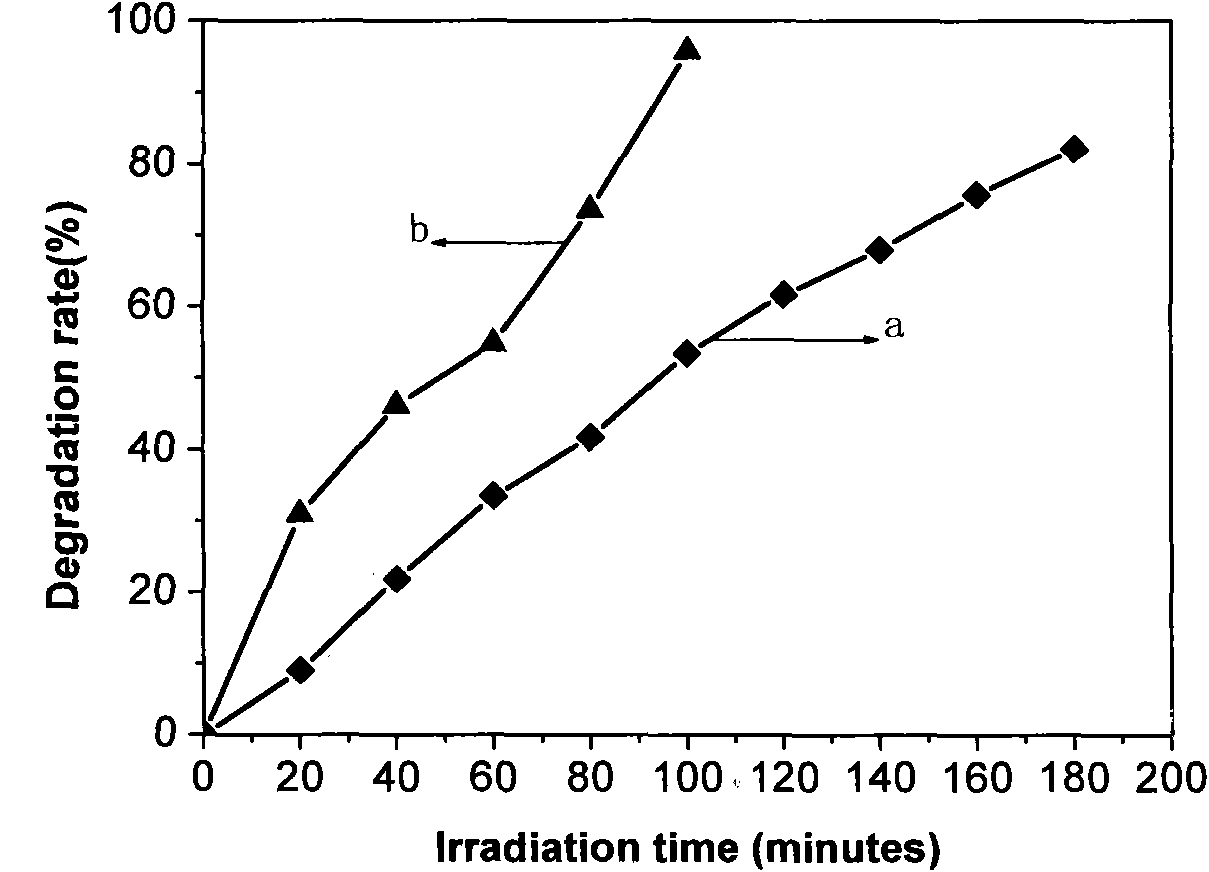

Method for treating industrial waste water by means of photoelectrocatalysis

InactiveCN101798126ANo physical transferHigh selectivityWater/sewage treatment by irradiationWater contaminantsOptical radiationTio2 nanotube

The invention provides a method for treating industrial waste water by means of chemical oxidation or chemical deoxidation in photoelectrocatalysis, belonging to the field of environmental protection. The method comprises the following steps of: taking a titanium positive electrode oxidation method-prepared high-ordered titanium-based TiO2 nanotube array thin film as an optical positive electrode or an optical negative electrode; taking high-purity black lead as an electrode; and degrading organic matter or heavy metal ion of the industrial waste water into H2O and CO2, low valent metal ion or metal simple substance under the conditions of the connection of an external circuit and the optical radiation. The invention has the advantages that: the adopted catalytic agent optical positive electrode is the high-ordered array thin film which is self assembled by anodic oxidation and is perpendicular to the bottom of the titanium base, thereby not only overcoming the defects of the existing powder body loading thin film optical positive electrode such as bad bond, easy falling and gradually-attenuated catalysis efficiency, but also being capable of directly using the sunlight by doping the modifying property to the array thin film, and being an advanced technology for treating single waste water (dye such as paper mill organic waste water, printing and dyeing mill organic waste water, or heavy metal ion such as electroplate factory chromium-containing waste water) or complex waste water with energy saving, high efficiency, high selectivity, cleaning and low cost.

Owner:SICHUAN UNIV

Method for direct making steel using induction furnace

The invention relates to the method of making steel directly using the inducing stove, the method of directly making steel using the iron ore, ferric oxide sheet, the steel dregs in the inducing stove is disclosed. It belongs to the metallurgy technical domain. The producing process includes the blow steps: 1. puddling: the iron ore, the ferric oxide sheet, the one or the three sorts of the scruff by the magnetism choosing or the steel dregs or the iron and the steel dregs, the black lead mine block and the limestone block are put in the inducing stove, the temperature is promoted to the 1350-1400 to melting to the molten iron and pushing aside the dregs, 2. steel-making: the limestone powder and the oxygen are added in the said molten iron to promote the temperature to 1650-1680, the molten steel is gained, thereinto, the quantity put of the limestone is the 2-5 percentage of the iron ore powder, the ferric oxide sheet, the one sort or the three sorts of the magnetism choosing scruff or the steel dregs or the iron and the steel dreg, 3. casting the steel ingot, the steel embryo or the cast steel piece. The energy consume of the invention is low.

Owner:徐建明

Method for direct making steel by converter using iron ore powder and anchracite duff batch briquette

InactiveCN1851000ALess investmentReduce energy consumptionManufacturing convertersIron powderGraphite

The invention deals with the method of using the combination of the iron ore powder and the blind mine powder to produce directly the iron and the steel by the converter, the steps are showed below: the step one, firstly, the blind mine block or the black lead mine block are added in the converter, secondly, the combination of the iron ore powder and the blind mine powder is added, the stream, the air or the oxygen are added from the roof, the stream, the oxygen or the azote and the combination of the air and the powder of the blind mine powder are added from the bottom of the stove, the process of blowing and smelting is keep 25-35 minutes, the temperature is promoted to the 1650-1680 to produce the molten iron, the molten iron is added in the ladle, the percentage of the outcome quantity of the molten iron accounts for the 70-90 compared with the overall molten iron; the step two, the blind coal block or the pot lead block, the limestone are added in the converter, then the combination of the iron ore powder and the blind mine powder is added, the step one is executed repeatedly. The invention has many merits such as the low invest and the low energy consuming.

Owner:徐建明

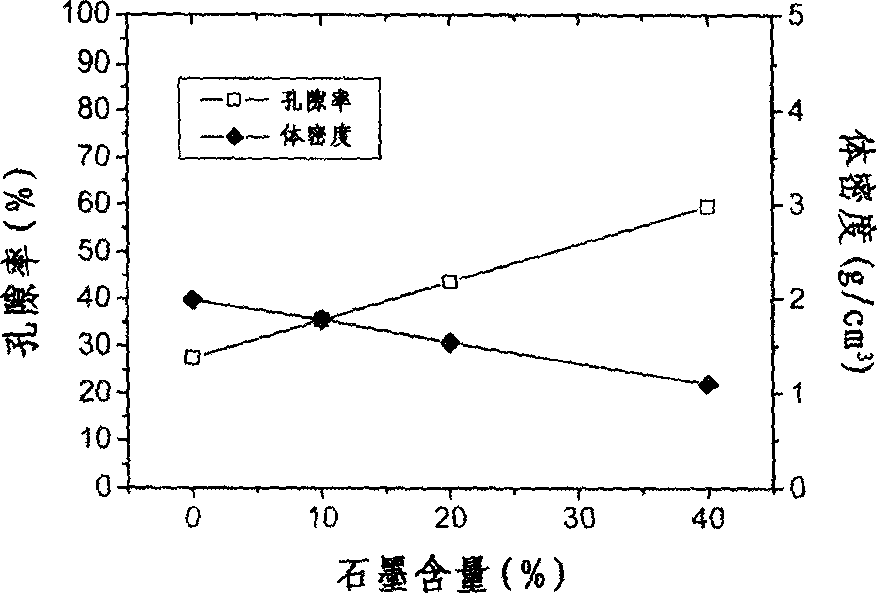

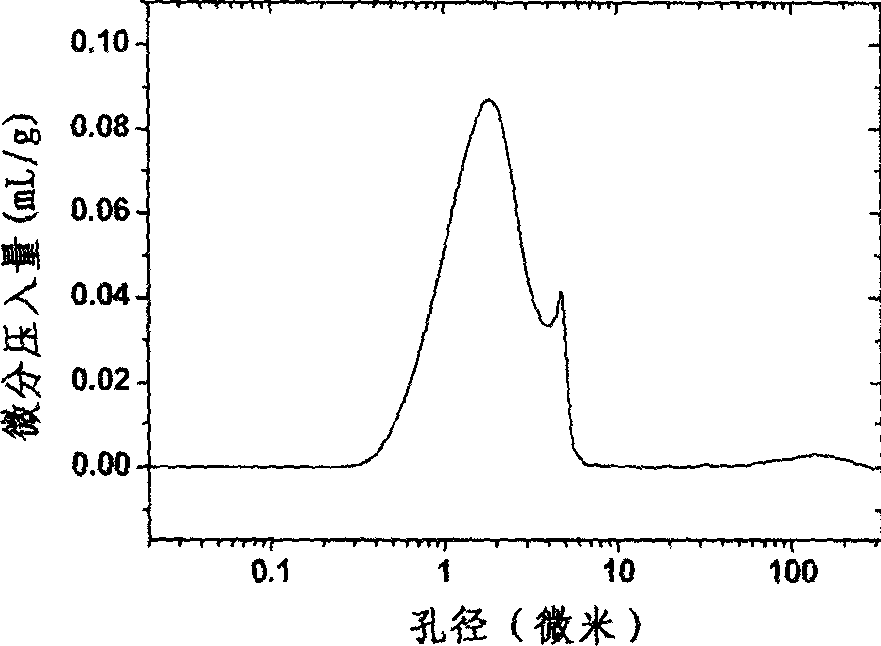

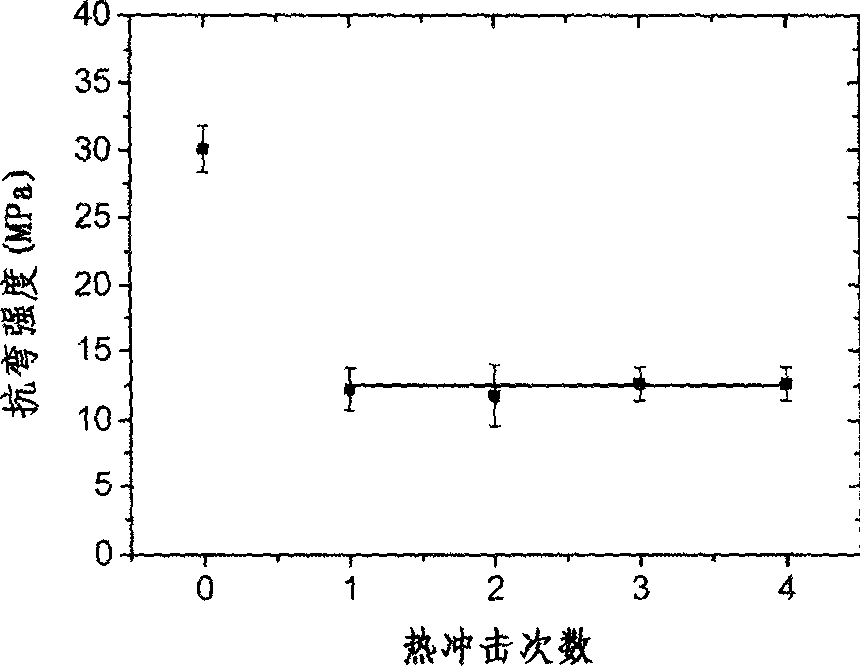

Silicon carbide-cordierite composite porous ceramic and its preparation method

InactiveCN1800097AImprove purification effectLower firing temperatureFiltration separationCeramicwareCordieriteThermal expansion

The invention provides a composite porous ceramic of silicon carbide-cordierite, its preparing method and application; during the production of said composite porous ceramic, we take silicon carbide particles as the first phase, and cordierite as the second phase. The cordierite phase is made by clay, talcum and aluminum oxide, etc, through burning at the temperature of about 1400 Deg C; during the formation of cordierite phase, silicon carbide particles are connected together through cordierite phase and form porous ceramic with certain strength; in order to enhance the factor of porosity of said porous ceramic, we need to add some black lead particles as pore-creating agent; the porous ceramic produced in this way is made up of 10-90wt% cordierite and 90-10wt% silicon carbide, whose factor of porosity is 24~65%, pore size distribution is double quotidian mode, and bending strength is 4~55MPa, coefficient of thermal expansion is 1.71~6.26*10-6K-1 (20~800 Deg C), thermal-shock resista nce at the temperature of 1000 Deg C could reach more than 5 times; The porous ceramic provided in said invention could be used to produce wall-flowing mode honeycomb ceramic and enhance the purification capacity to end gas and waste gas.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Light high heat conducting nano composite material and preparation thereof

The invention discloses a light high-heat conducive nano composite material and a preparation method thereof; wherein, the composite material is formed by mixing 50 to 99 wt (weight percent) percent of black lead powder basic body material and 1 to 50 wt percent of nano materials with high-heat conducive performance. The preparation method comprises: a. selecting the black lead powder with a granularity between 0.1 and 100 microns and the nano carborundum powder and nano silicon powder with a granularity between 10 and 500 nanometers; b. mixing the black lead powder, the carborundum powder and the silicon powder materials under a stirring condition; simultaneously adding a macromolecular caking agent and obtaining the precursor powder of the composite material by carrying out drying and dispersing to the mixed materials; and c. thermosetting and shaping the precursor powder under an oxygen-free atmosphere. The composite material of the invention has the characteristics of easily-obtained and cheap materials, low production cost, light weight, and good heat radiation effect, and can partially or completely replace a metal heat radiating material.

Owner:深圳市东维丰电子科技股份有限公司 +1

Calcium-expanding black lead mixed adsorbent

InactiveCN1613551AImprove permeabilityIncrease in sizeOther chemical processesAdsorption refrigerationSorbent

A mixed adsorbent for the absorption bed of air conditioner is prepared from calcium chloride and expanded graphite in the weight ratio of (60-80%):(20-40%) for the bulk one or (55.1-67.7%):(17.2-32.7%) for the solid one. Its advantages are high gas osmosis, high heat conductivity and high refrigerating efficiency.

Owner:SHANGHAI JIAO TONG UNIV

Copper-base high-temperature self-lubricating composite material

InactiveCN1641237AIncrease the maximum use temperatureIncrease temperatureBearing componentsChemical compositionGraphite

The invention is a type of composite material with properties as aldary palosome, resistance to high temperature and self lubricating capability. It has following characters: its palosome is aldary while component element of self-lubricating is black lead and the percentages by weight of its composition is respectively: Ni 5-15+C 5-15+Sn 4-8+Zn 4-8+Pb 2-5+Mn 0.5-3+Fe 1-3+Cu. This type of composite material has inoxidizability, resistance to corrosion, resistance to high temperature and wearability etc. It mainly used to axletrees and leading cover with the temperature between 200-500Deg.C.

Owner:合肥波林新材料股份有限公司

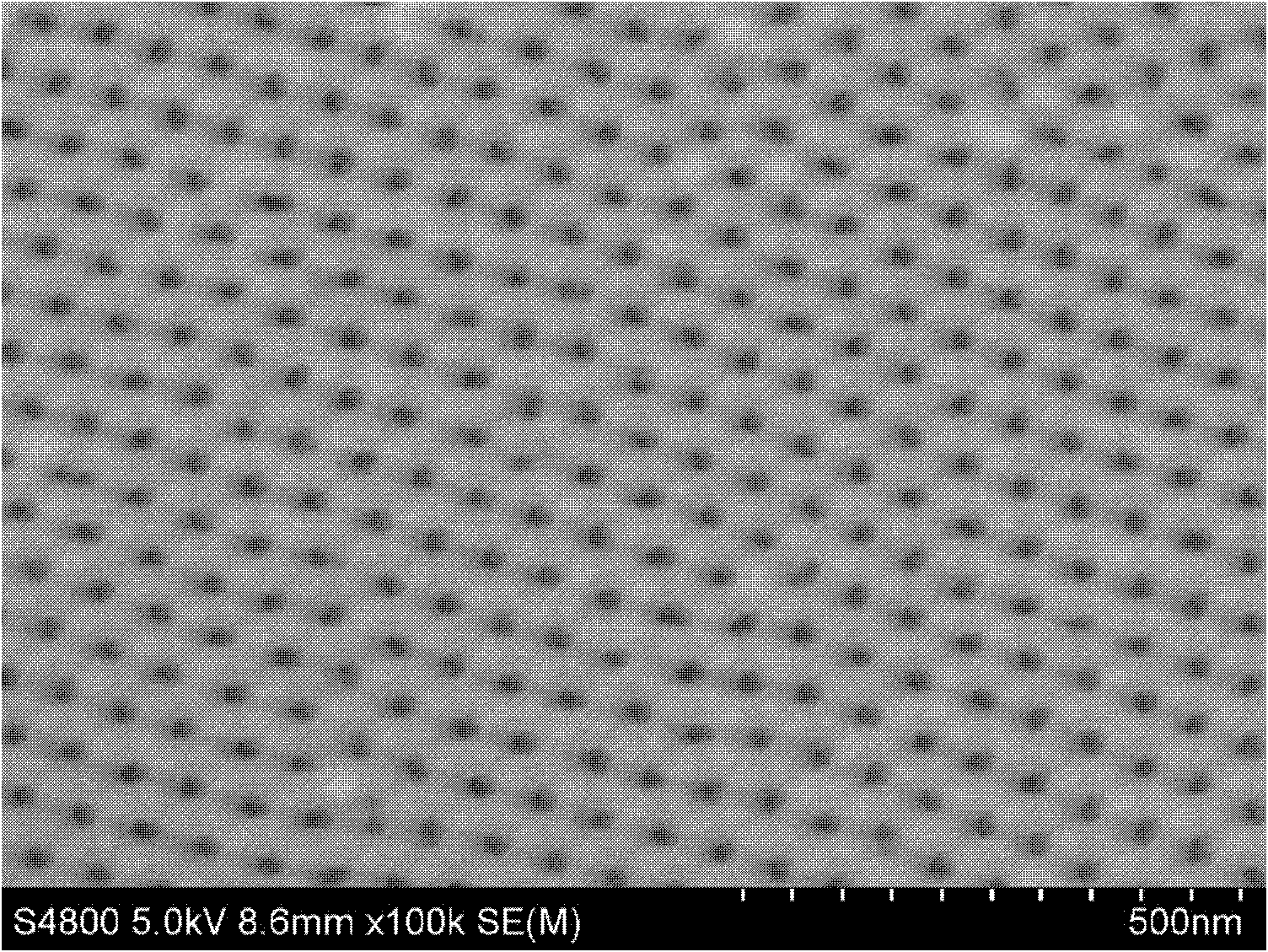

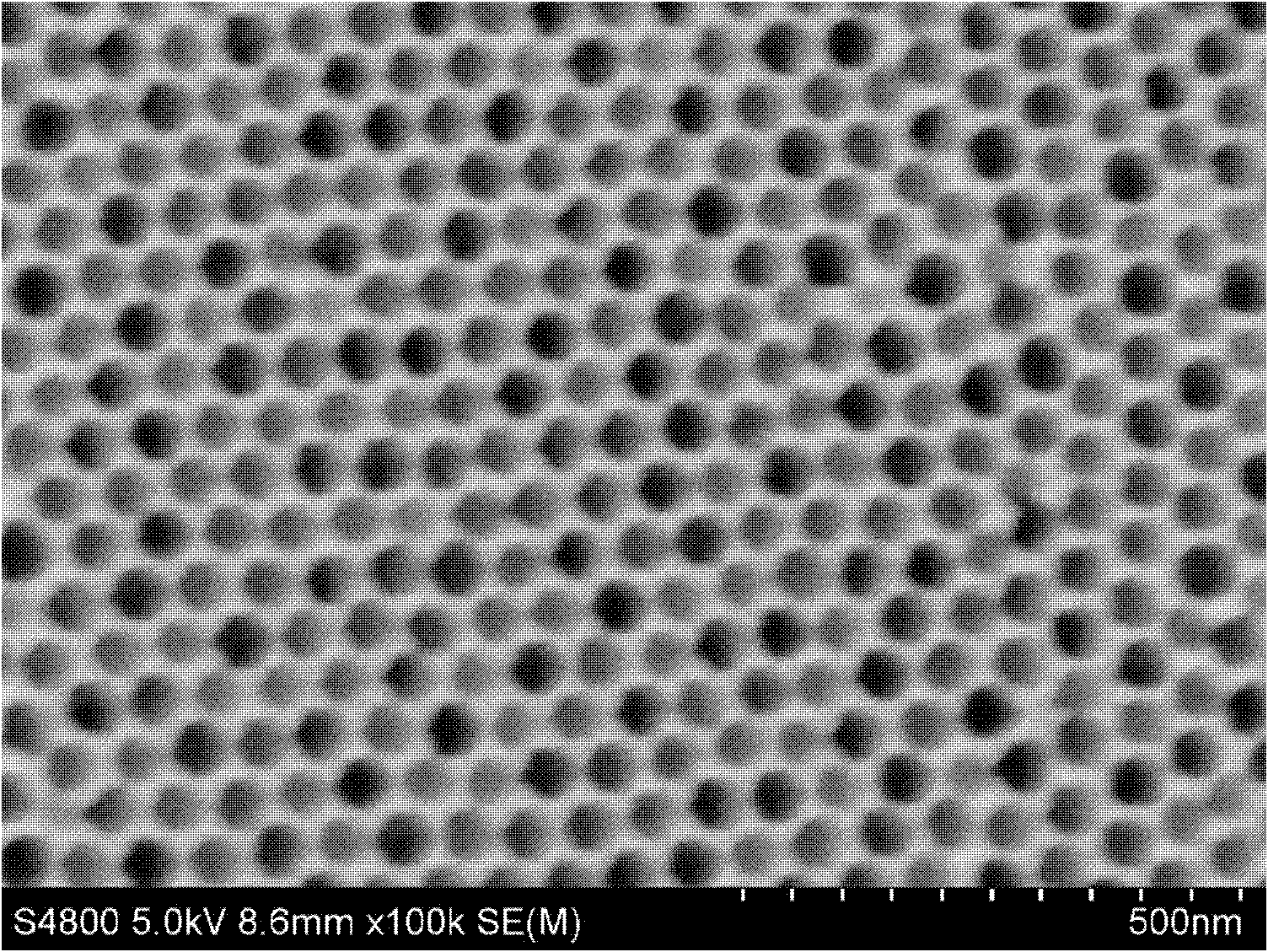

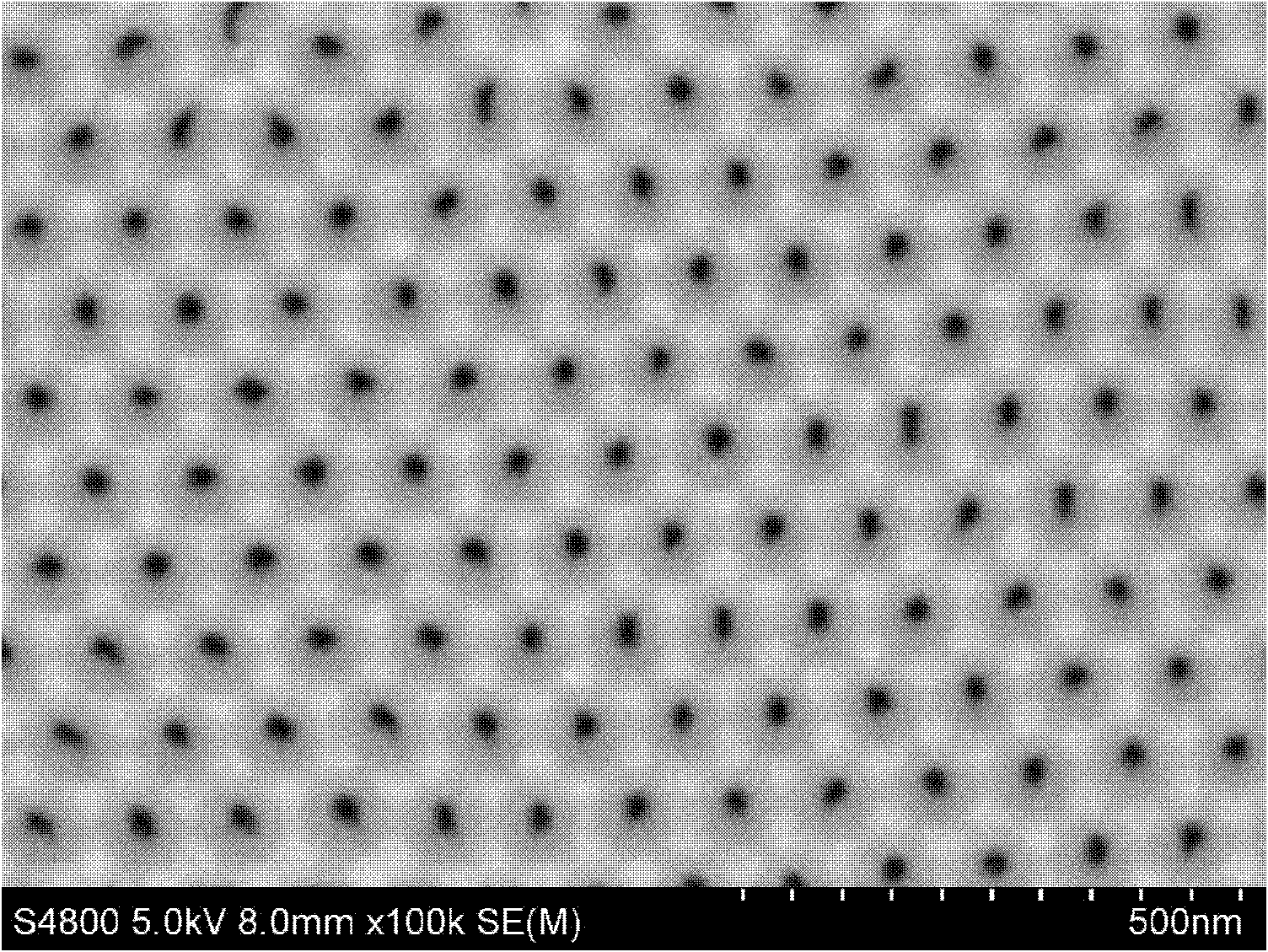

Method for preparing highly ordered aluminum oxide template by asymmetric two-step anodization

The invention discloses a method for preparing a highly ordered aluminum oxide template by asymmetric two-step anodization, which is characterized by comprising the following steps of: carrying out high-temperature annealing treatment on a highly pure aluminum sheet, and then carrying out electrochemistry polishing treatment, wherein the highly pure aluminum sheet has the purity being larger than or equal to 99.99wt%; anodizing for the first time in electrolyte by taking the highly pure aluminum sheet treated in the last step as the anode and a black lead as the cathode; dipping the highly pure aluminum sheet anodized for the first time into a mixed solution of phosphoric acid and chromic acid so as to remove an oxidation film on the surface of the highly pure aluminum sheet; anodizing for the second time in electrolyte different from the electrolyte for anodizing for the first time to obtain the aluminum oxide template, and then cleaning the aluminum oxide template to obtain the highly ordered aluminum oxide template. The invention widens the range of oxidation voltage for preparing aluminum oxide templates in electrolyte and realizes the modulation on the distance and the aperture between every two template holes to the larger extent.

Owner:CENT SOUTH UNIV

Micro fine-grained titanium-nickel-niobium shape memory alloy block material preparing method

The invention is a manufacturing method for a kind of micron tiny crystal titanium nickel-niobium shape memorizing alloy block materials, 45%-50% titanium, 40%-45% nickel, 5%-10% niobium are melted and produced into titanium nickel-niobium alloy cast ingot, and cuts the titanium nickel-niobium alloy block material into blank, and carries on surface finish process, and paints with glass lubricate, uses isometric curved squeezing mould with 90-120 degrees channel angle, the mould cavity surface is painted with black lead lubricate, the blank and mould are heated and carries on temperature reservation, and takes them out to be squeezed at the same time, finally gets the product. The invention solves the problem that the bad plastic property of titanium nickel-niobium shape memorizing alloy in room temperature, enhances the alloy mechanical performance, and lowers the cost.

Owner:SHANGHAI JIAO TONG UNIV

Artificial diamond purification technique

The invention discloses a process to purify diamond, which comprises the following steps: grinding diamond synthesized block into particles; putting into autoclave; adding into the water solution of sulfuric acid or azotic acid or alcaine with density at 10-20%; reacting at normal temperature for 36-48 h; stripping metal; balling; sluicing; clearing black lead; drying; getting the purified diamond. This method does not use concentrated nitric sulfuric mixed acid and can eliminate a good deal of yellow acid mist, which can improve the safety in industrial process.

Owner:ZHONGNAN DIAMOND CO LTD

Putamen type carbon cathode material for lithium ion secondary battery and preparation method thereof

InactiveCN1547278AAvoid re-exposureReduce the first irreversible capacityElectrode manufacturing processesCarbonizationAsphalt

The invention discloses a kind of kernel shell type carbon negative material of a kind of lithium ion secondary cell and the manufacturing method. The materials are manmade black lead or natural black lead powder with particle size of 5-50ª–m, the shell is carbonized material which uses asphalt thermal fasculation reaction resultants and whose thickness is 0.01-0.2ª–m. The manufacturing method includes: crushing the black lead, the thermal fasculation reaction, rinsing and eliminating the asphalt component and the carbonization process to the covered black lead micro powder. The merits of the invention lie in: the efficiency is high and the circular performance is excellent. The method is simple and the energy consumption is low, and the cost is low.

Owner:TIANJIN UNIV

Silver-graphitic electrical contact composite plating layer and method of preparing the same

InactiveCN101256903AEvenly distributedFlat surfaceContact materialsConductive materialAdditive ingredientMetallic materials

Silver -black lead electrical contact composite plating and manufacture method thereof, which belongs to metallic material technology field. The steps are: confecting compound plating solution, black lead granule dispersing, and substrate preprocess, compound plating solution ingredient: methane sulfonic acid silver 0.05M / L, succinimide 0.15M / L-1.5M / L, composite plating. boracic acid 0.5M / L-0.5M / L, black lead content in solution 2g / L-50g / L. The composite plating is made up of silver and black lead, wherein the black lead volume percent is: 1-15%, silver volume fraction 85%-99%, contact resistance 1.2-2m Omega, hardness 70-100Hv, density more than 99.9%. The present invention plating solution is protection environment and non-toxic; the ultrasonic energy promoting adequate distribution of black lead granule, the produced composite plating has smooth surface and high density.

Owner:SHANGHAI JIAO TONG UNIV

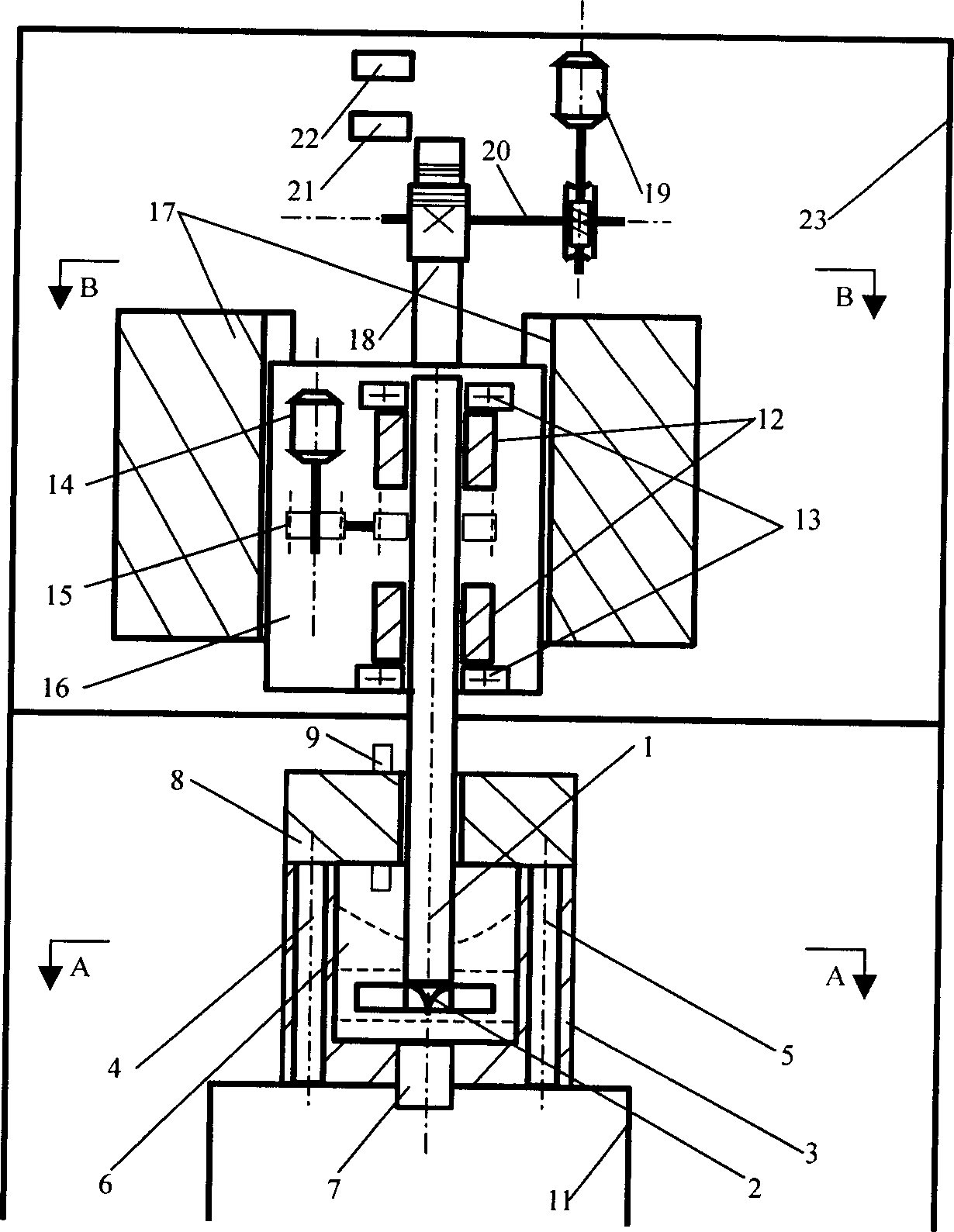

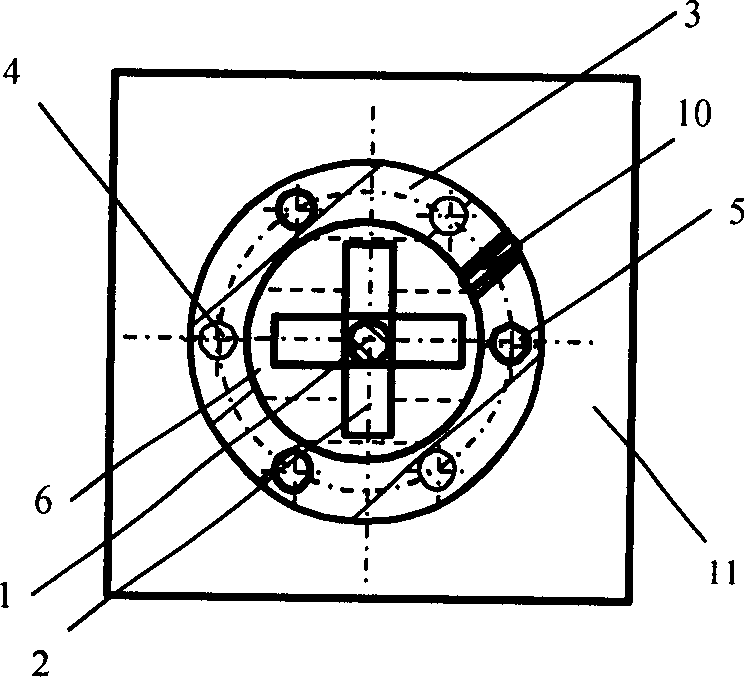

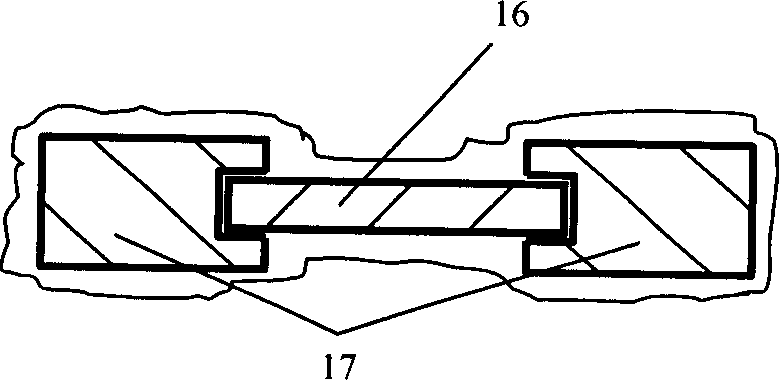

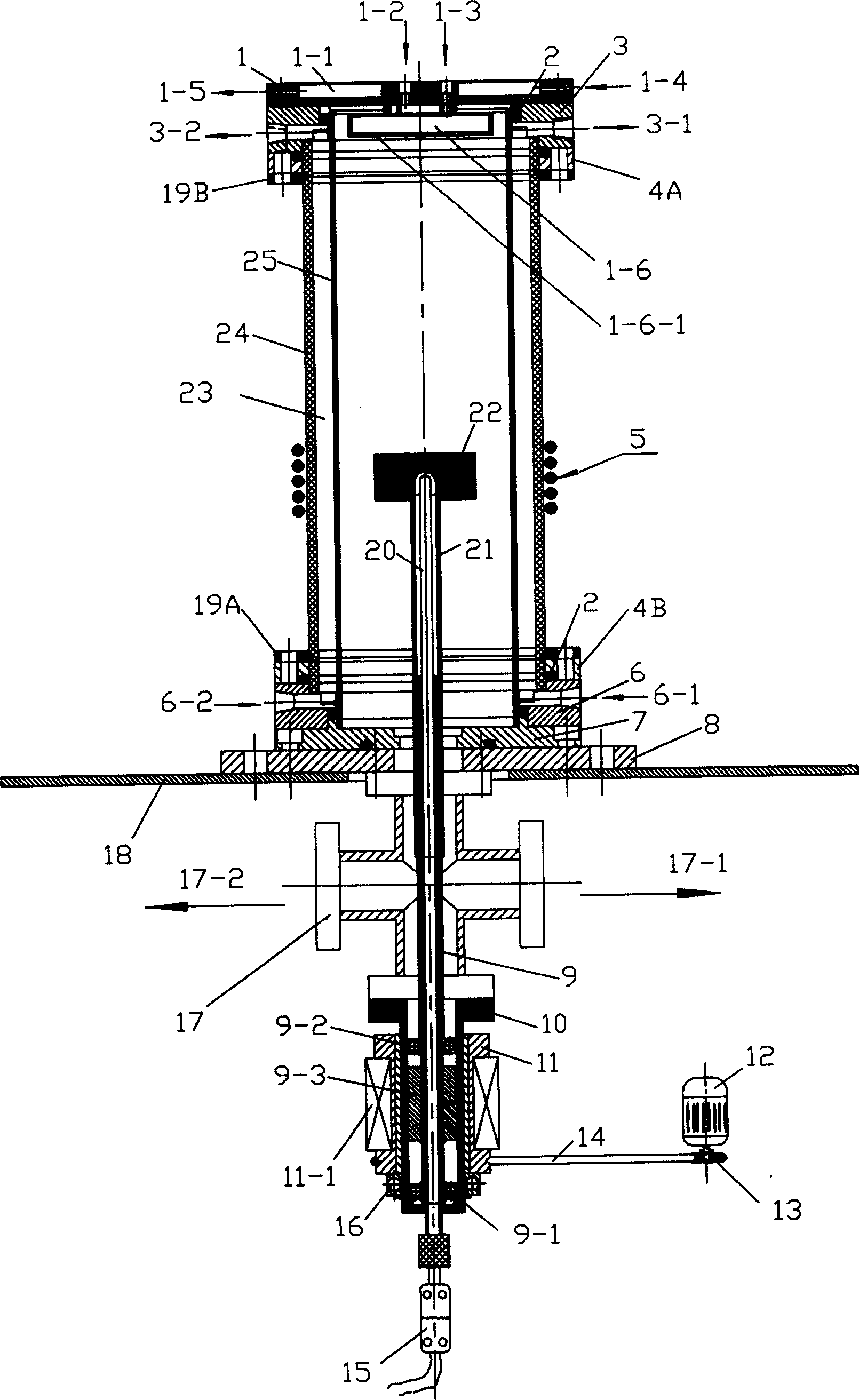

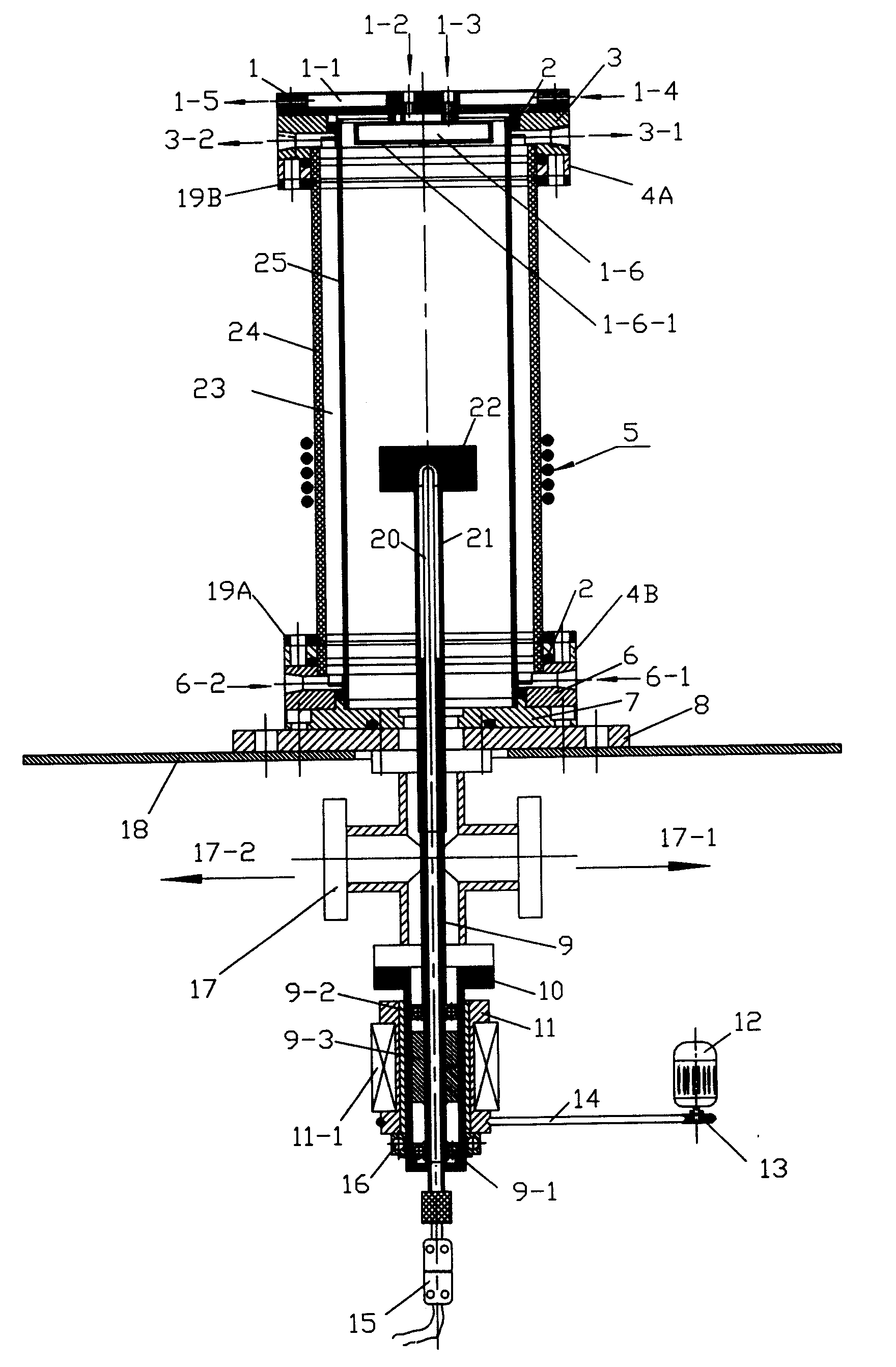

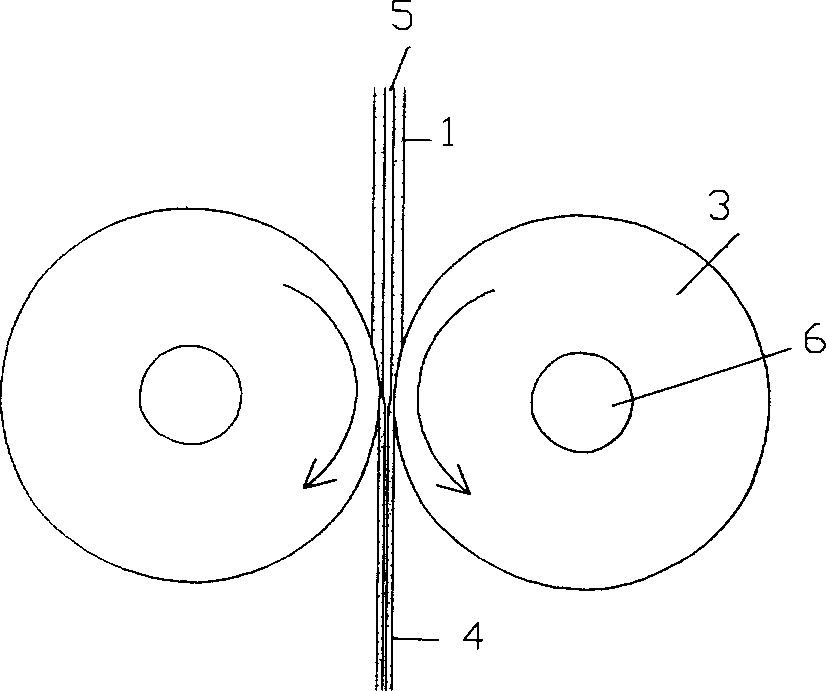

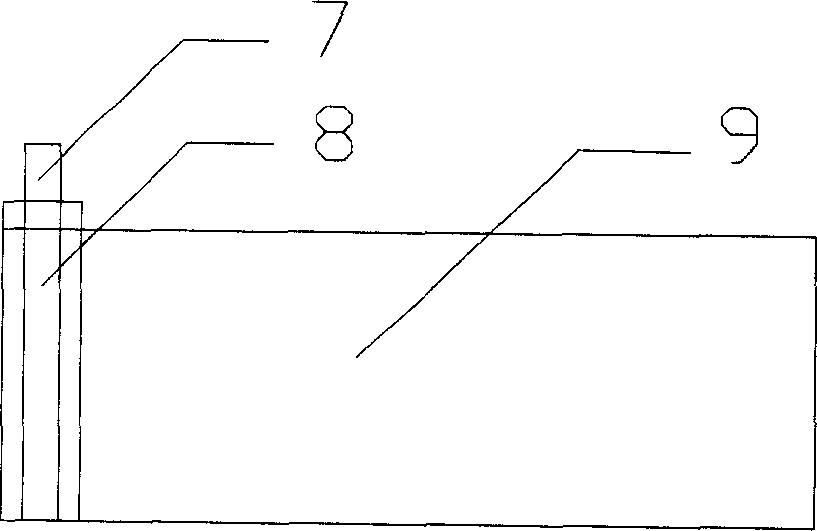

Preparing method and device of composite material of black lead for synthesizing diamond and catalyst

ActiveCN101015783ASimple processUltra-high pressure processesCatalyst activation/preparationLower limitDiamond crystal

Owner:JIANGSU TIANYI ULTRA FINE METAL POWDER

High temperature separating material for preventing cinder and steel from staining to cinder ladle

InactiveCN1593816AGood slag resistanceImprove peeling resistanceMelt-holding vesselsFoundry mouldsCarboxymethyl celluloseSodium Bentonite

The invention makes public a kind of high temperature separating material which can prevent dregs from adhering the dregs pot. The material includes 30~50 units of dolomite, 30~45 units of bentonite, 18~28 units of clay, 1.0~2.5 units of trimer sodium phosphate, 0.5~3.0 units of carboxymethyl cellulose and 135~220 units of water in proportion of weight. All water-fast particles' size should not lesser than 180 eyes. And about 0.5~5 units of black lead can be joined in the material. The material has good property of high temperature, dregs proof, and anti-strip. It can prevent the pot from being dregs adhered effectively, so it can make sure turning dregs automatically and high velocity of the pot. Adhering degree of the material is moderate, and no deposition and delamination in 72 hours. The material has good working performance.

Owner:武汉钢实星源工业总公司

Gallium nitride base film epitaxial growth apparatus by metal organic chemical vapor deposition

InactiveCN1528948AControlling Epitaxial Growth TemperatureGuaranteed uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseEngineering

The invention is a extension growing device for metal organic chemical gas phase deposition kalium nitride base film, it includes reactor, whose character lies in: the reacting room is tube type double layer structure, and it is made up interior tube and exterior tube, the interior tube cavity is reacting cavity, the interior and exterior are inserted in the upper and subjacent fixing device, there is cooling water cavity between the interior and the exterior, the outer wall of exterior tube is winded with conduction heating coil, there sets a black lead base in the interior tube, the black lead is set on a ceramic tube, the ceramic tube connects with gearing part. The reactor has water cooling system, in order to maintain the low temperature within reactor, especially the part above crystal piece and gas mixing room; it can prevent the occurrence of pre-reaction.

Owner:QINGDAO JASON ELECTRIC

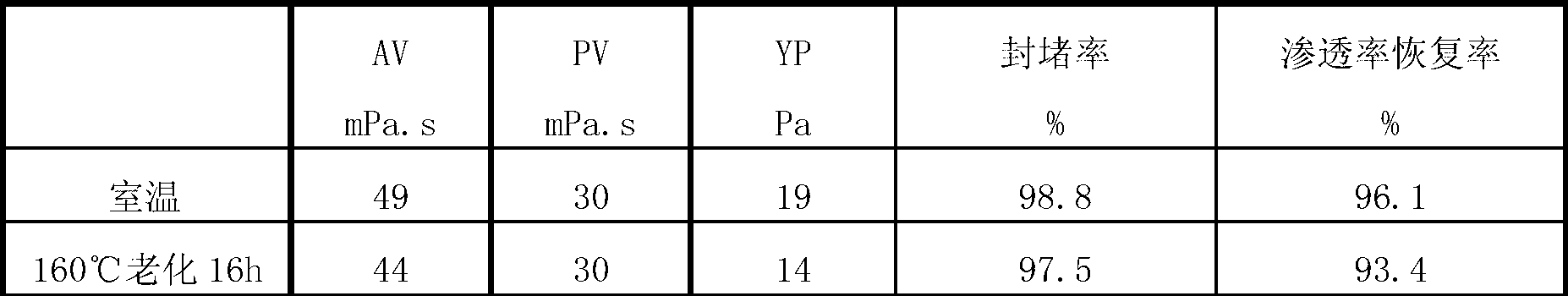

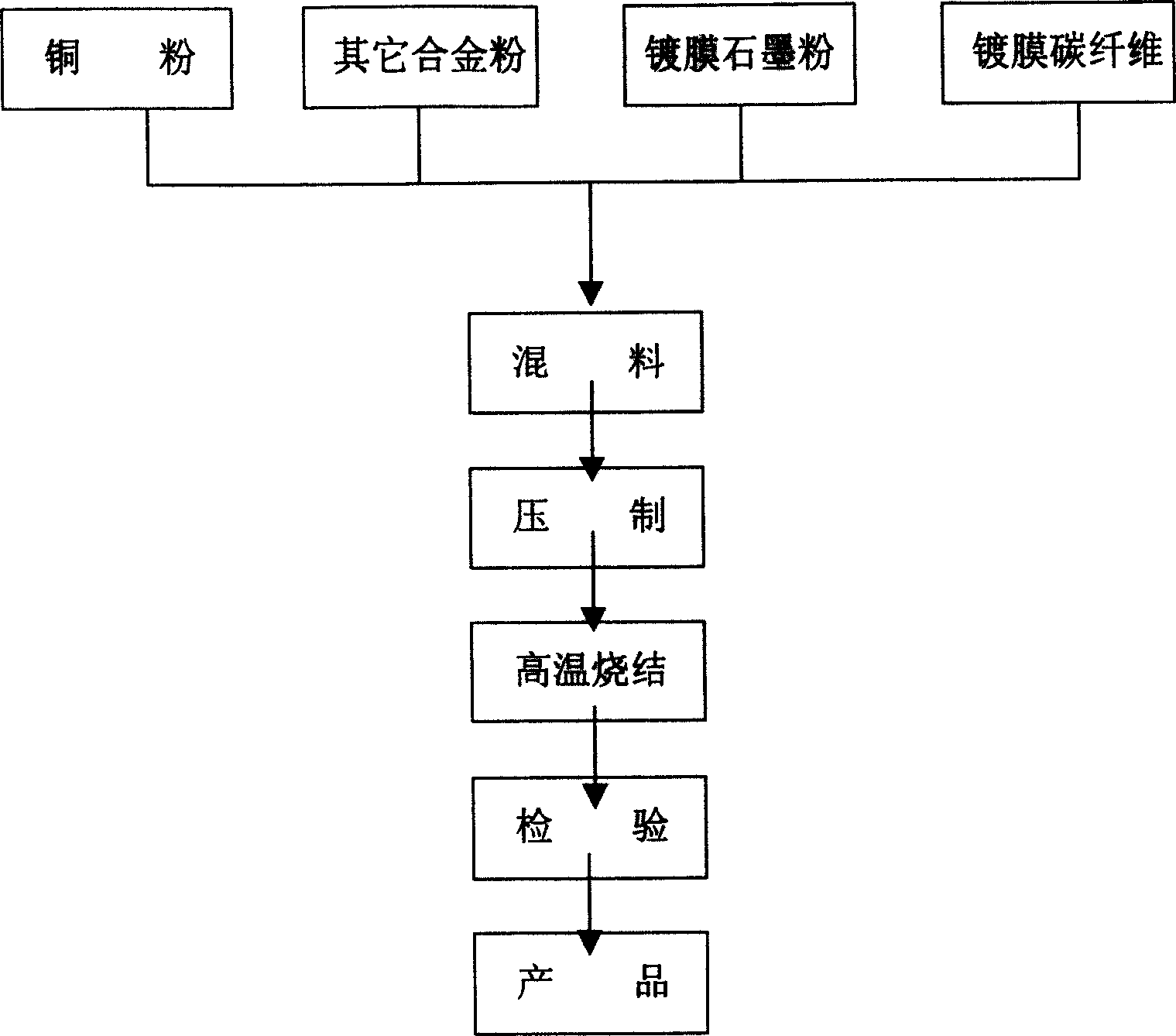

High speed train powder metallurgy brake pad and preparation technology thereof

ActiveCN101839295AImprove thermal conductivityImprove plasticityFriction liningSilicon dioxideLubrication

The invention embodiment discloses a high speed train powder metallurgy brake pad. The material of the brake pad comprises the following powder raw material by weight percent: 60 to 70 copper powder, 4 to 10 tin powder, 4 to 6 ferrous powder, 4 to 9 black lead, 2 to 3 silicon dioxide, 2 to 6 zinc powder, 3 to 5 molybdenum disulfide and 2 to 6 zircon. The invention further discloses the preparation technology of the powder metallurgy brake pad. The invention has the advantages that the copper with high thermal conductivity and good plasticity is used to be matrix, tin and zinc are added and alloyed in the sintering process, the sintering temperature is reduced, the abrasion performance is improved, the silicon dioxide and the zircon are added to improve friction coefficient, the black lead and the molybdenum disulfide serve as a lubrication component to protect duality and stabilize the friction coefficient. The abrasion of the brake pad produced through the method on a dual disc is small. The invention has the advantages of stable friction coefficient, small abnormal wear and noise occurrence probability and environmental protection and the brake performance thereof can meet the requirement of the high speed train.

Owner:SHANDONG GOLD PHOENIX

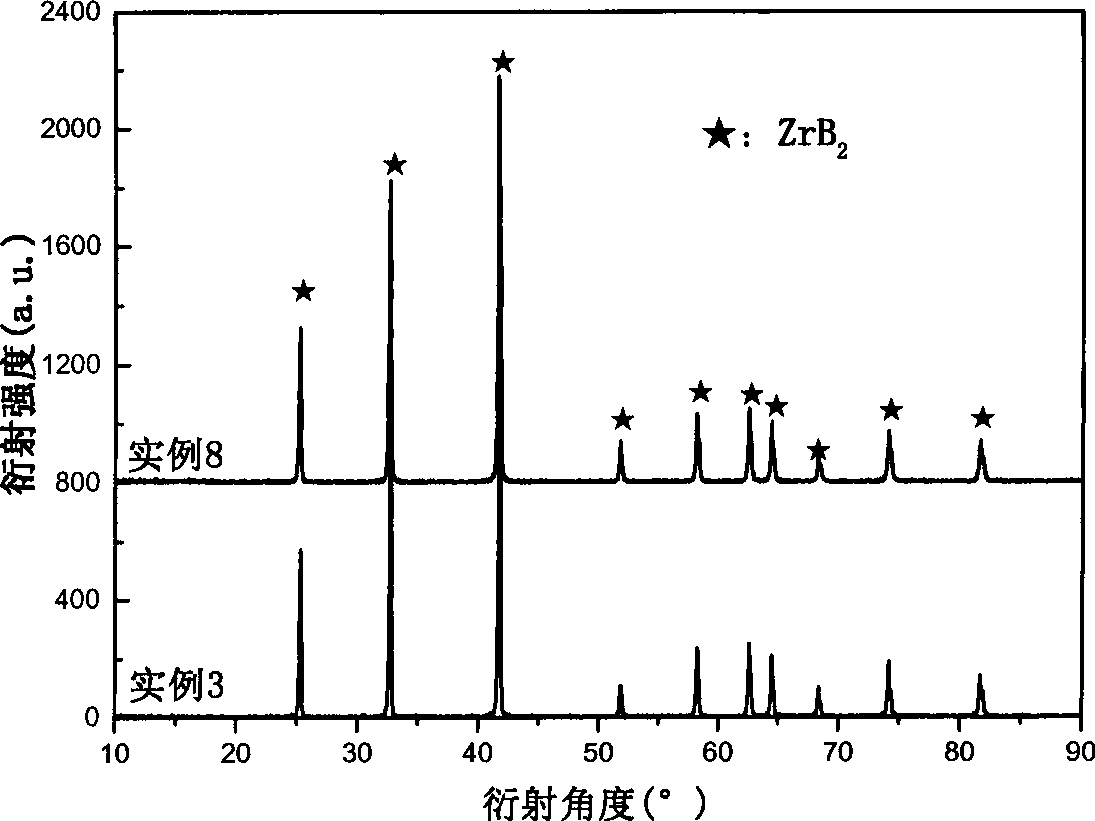

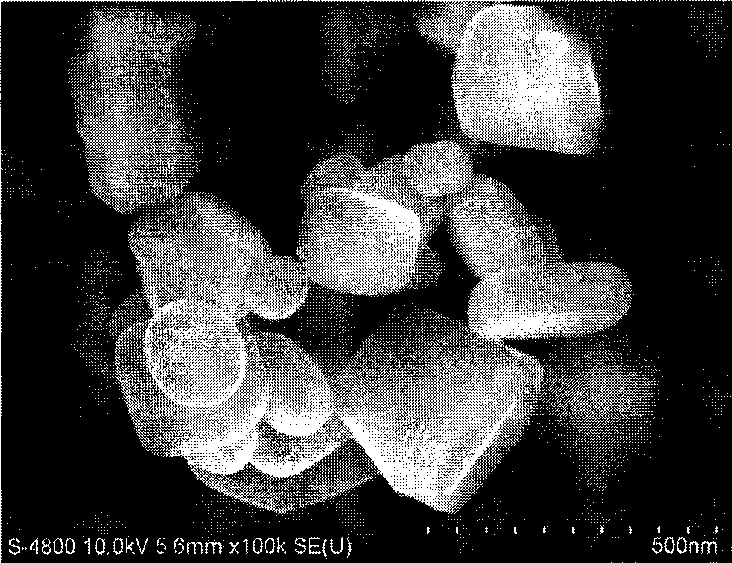

Preparation of nano zirconium diboride ceramic powder

InactiveCN101486577ASynthesis temperature is lowGuaranteed normal productionMetal boridesChemical treatmentCoprecipitation

The invention relates to a preparation method for nano zirconium diboride ceramic powder, which is characterized by comprising the following steps: 1) selecting materials: selecting according to a mol ratio of 1 : 3 to 1 : 5 between Zr and amorphous boron powder in soluble zirconium salt; 2) selecting one of the two methods as follows: a) using a coprecipitation method for gel forming to obtain xerogel; b) using a sol-gel method for gel forming to form the xerogel; 3) preparing precursor powder; 4) synthesizing quickly: arranging the materials into a large current reaction synthesizer; the inside of a black lead reactor is protected by vacuum or insert gases; applying a large current directly on the black lead reactor, quickly heating to 800 and 1500 DEG C at the temperature rising speed of 50 to 500 DEG C / min, preserving the temperature for 0 to 60 minutes to obtain a powder sample; and 5) chemical processing for obtaining the nano zirconium diboride ceramic powder. The method has the characteristics of quick synthesizing speed and high efficiency; the purity of the obtained nano zirconium diboride ceramic powder is high (equal to or more than 95 percent); and the grain diameters of the obtained nano zirconium diboride ceramic powder are uniform and thin(the average grain diameter is equal to or less than 300nm).

Owner:WUHAN UNIV OF TECH

Carbonaceous fibre filling polytetrafluoroethylene and method of producing the same

The invention discloses an oil-free lubrication element material-low cost carbon fiber filling politef and preparing method on general purpose reciprocated compressor, which is characterized by the following: comprising with 60-80% politef, 10-35% sum of carbon fiber and carbon powder and not more than 15% filling agent; setting carbon fiber : carbon powder as 1 : 0. 5-1. 5; choosing the filling agent from one or more than one black lead, glass fiber, molybdenum disulfide and copper powder; mixing at normal temperature; getting the product. This invention possesses long lifespan, low cost and wide applicability.

Owner:沈阳气体压缩机股份有限公司

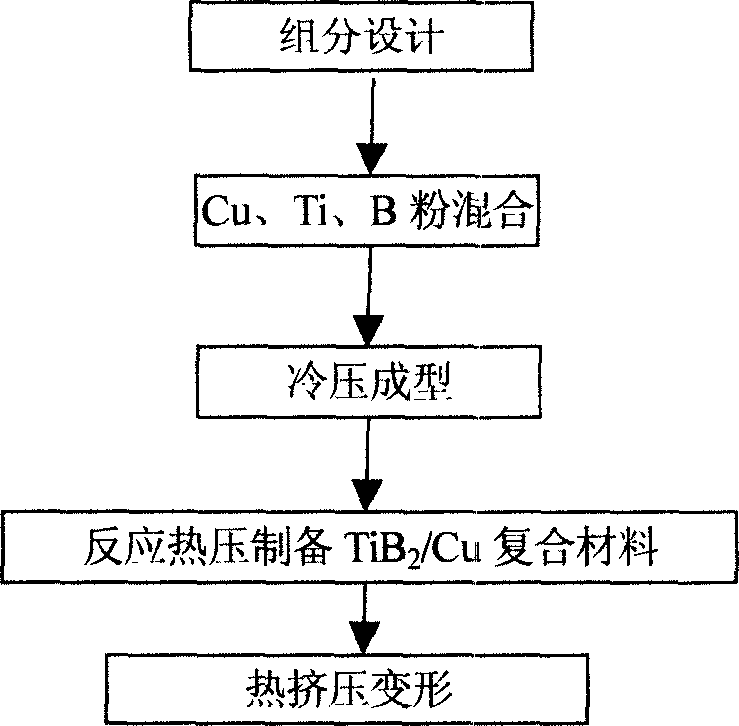

Method for preparing reactive hot-press in-situ autogenesis copper-base composite material

The invention discloses a preparation technique of reaction heat pressing original position autogeny copper base material, relates to preparation technique of a copper base material applied to micro electric industry. Focusing on the problem that existing original position autogeny preparation technique is of expensive devices, complex operation while the product is hard to specify. The technique is achieved through following steps: a, put powder of Ti, B, Cu into ball milling cylinder and vacuum the cylinder, aerate with argon gas, blend the mixed powder for 6 to 12 hours for while the ratio of grinding media to material is 1 to 20 : 1 and rotating speed at 200 to 400 round per minutes; b: shape the blended powder in black lead moulds making the density to 20 to 40 percent; c, sinter the powder together with the mould into vacuum heat press furnace and make the density to 90 to 99 percent, furnace cool to room temperature, unmould to acquire the TiB2 / Cu complex material. The device in the invention is of simple and easy operation, the volume fraction is easy to control while the reaction temperature needs not to be very high and without side reaction product.

Owner:HARBIN INST OF TECH

Fiber-Reinforced Resin Composition and Molded Body Thereof

Disclosed is a fiber-reinforced polyolefin resin composition containing (A) 1-20 mass % of carbon fibers having a fiber diameter of 3-20 μm, (B) 3-50 mass % of black lead (graphite) having an average particle diameter of 1-100 μm, and (C) 25-95 mass % of a polyolefin resin, wherein the mass ratio of the black lead (graphite) (B) (Wg) to the carbon fibers (A) (Wcf), namely mass ratio (Wg / Wcf), is 1-10. Also disclosed is a molded body of such a fiber-reinforced polyolefin resin composition.

Owner:PRIME POLYMER CO LTD

Production for positive electrode piece of cylindrical winding lithium-ferrite disulfide battery

InactiveCN1645650ALow costSimple production processElectrode manufacturing processesPyritePole piece

The pole piece of anode is composed of pyrite, acetylene black, black lead, binding agent and additive. After the pyrite is taken by heat treatment, it mixes with compression-treated acetylene black, black lead and additive. Two methods are used in making the anode powder piece. One is slurry method: after the anode powder mixes with deionized water and industrial spirit, the Teflon liquid cream is added to form a cream; first pressing it to form film and then making it into piece. The second method is rolling forming: after the industrial spirit, Teflon liquid cream are added into the anode powder, first pressing it into film; then making it into pieces; the pieces are put into bake oven to remove water and then put into vacuum case for drying.

Owner:惠州德赛能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com