Gallium nitride base film epitaxial growth apparatus by metal organic chemical vapor deposition

A technology of chemical vapor deposition and metal organics, which is applied in the direction of gaseous chemical plating, metal material coating technology, electrical components, etc., can solve the problems of difficult processing, poor growth repeatability, and high growth cost, and achieve uniform doping Uniformity and growth, airflow stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

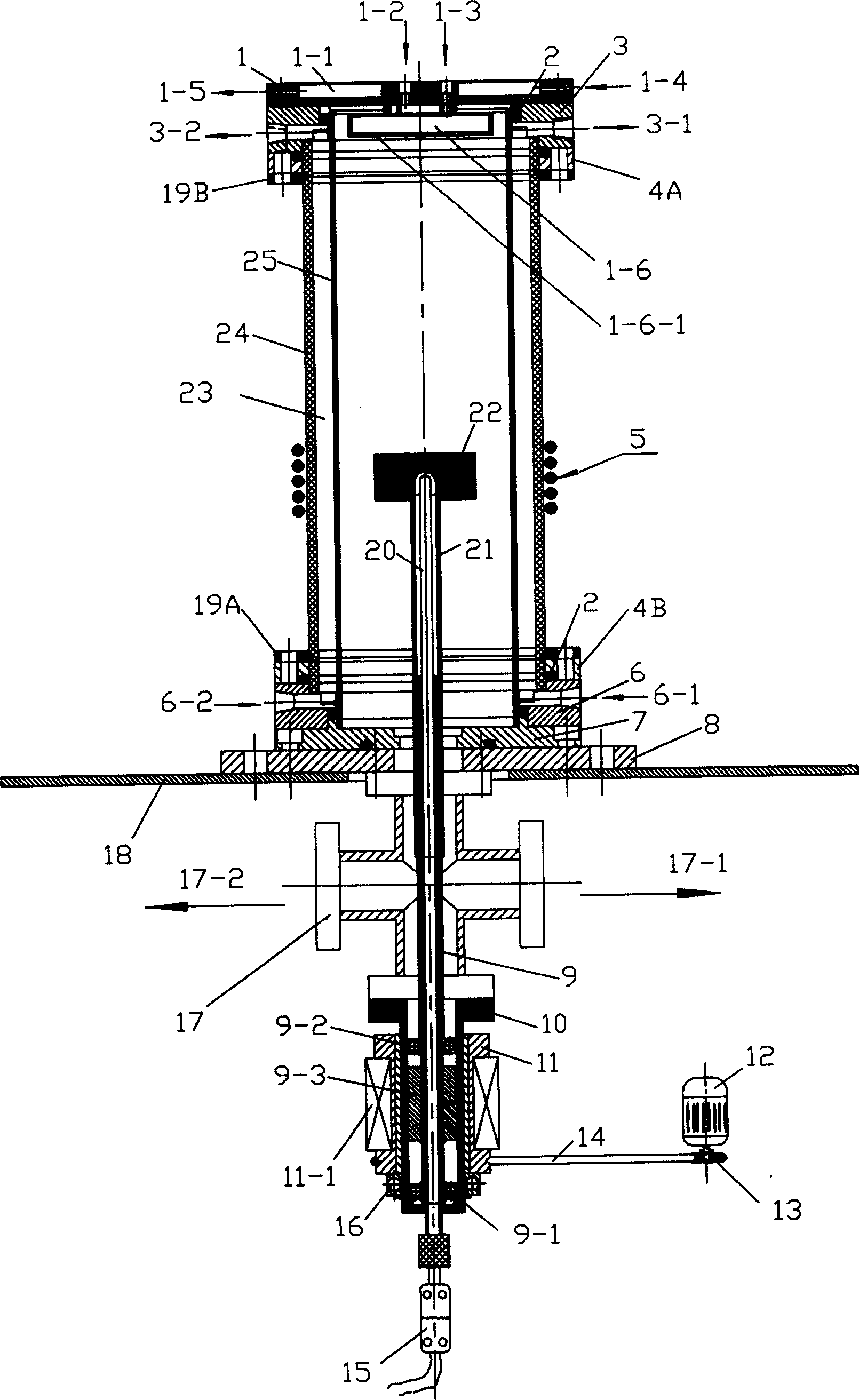

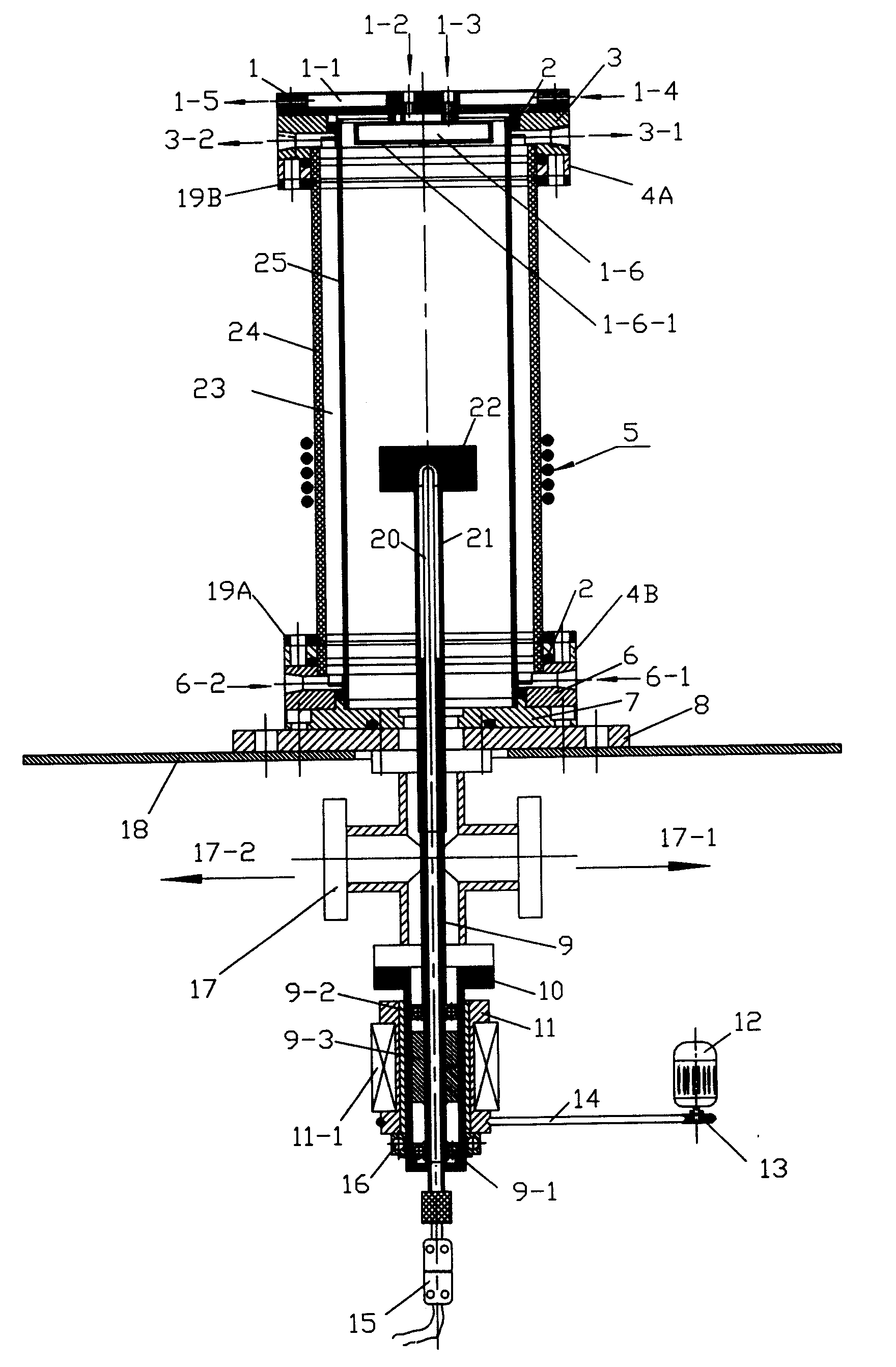

[0017] 1. Top air chamber; 1-1. Cooling water chamber; 1-2. MO air inlet; 1-3. NH 3 Air inlet; 1-4. Cooling water inlet; 1-5. Cooling water outlet; 1-6. Mixed air chamber; 1-6-1. Air hole; 2. O-shaped sealing ring; 3. Upper aluminum ring; 3 -1. Cooling water outlet; 3-2. Cooling water outlet; 4A. Upper sealing ring; 4B. Lower sealing ring; 5. Induction heating coil; 6. Lower aluminum ring; 6-1. Cooling water inlet; 6-2 .Cooling water inlet; 7. Pipe seat; 8. Base; 9. Transmission shaft; 9-1. Ball bearing; 9-2. Ball bearing; 9-3. Rotating block; 10. Shaft seat; 11-1. Strong magnet; 12. Motor; 13. Pulley; 14. Belt; 15. Thermocouple; 16. Thrust ball bearing; 17. Four-way pipe joint; 17-1. Main vacuum pump; 18. Support plate; 19A. Lower positioning ring; 19B. Upper positioning ring; 20. Glass tube; 21. Ceramic tube; 22. Graphite base; 23. Cooling water cavity; 24. Outer tube 25. Inner tube .

[0018] see figure 1 , The invention is an innovative design of the reactor structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com