Preparation of nano zirconium diboride ceramic powder

A technology of zirconium diboride and ceramic powder is applied in the field of preparation of nano-zirconium diboride ceramic powder, which can solve the problems of difficult removal, slow reaction process, coarse product particles, etc. Rapid effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Zirconium oxychloride is selected as Zr source, and the molar ratio of Zr to amorphous boron powder in zirconium oxychloride is 1:3. Disperse 1.02g of amorphous boron powder in 100ml of distilled water (molar concentration is 0.3mol / L), adjust the pH value to 8 with a concentration of ammonia solution of 5mol / L, add 0.0102g of sodium dodecylbenzenesulfonate (SDBS ), magnetically stirred for 1 h to obtain an amorphous boron powder suspension; weigh 9.668 g of zirconium oxychloride and prepare a 0.3mol / L solution according to the formula, and add the prepared zirconium oxychloride solution to obtain the amorphous boron powder suspension Mix and magnetically stir for 1 hour to obtain a mixed solution; add dropwise ammonia water with a concentration of 5 mol / L to the mixed solution in a constant temperature water bath at 60°C until the pH value is 9, and magnetically stir for 6 hours to obtain a slurry; filter the slurry and wash with water , until no Cl is detected - So f...

Embodiment 2

[0031] Zirconium oxychloride is selected as Zr source, and the molar ratio of Zr to amorphous boron powder in zirconium oxychloride is 1:5. First weigh 1.70 g of amorphous boron powder after refinement (average particle size of amorphous boron powder is less than 200nm) according to the formula, put it into a beaker, and disperse amorphous boron powder in 100ml deionized water (molar concentration is 0.5mol / L), with a concentration of 10mol / L ammonia solution to adjust the pH value to 9, add 0.034g sodium dodecylbenzenesulfonate (SDBS), and magnetically stir for 1h to obtain a suspension of amorphous boron powder; take another beaker According to the formula, take 9.668g of zirconium oxychloride, prepare a 0.3mol / L solution of zirconium oxychloride, add the prepared zirconium salt solution into the suspension of amorphous boron powder and mix, and stir magnetically for 1h to obtain a mixed solution; Add ammonia water with a concentration of 10mol / L to the mixed solution dropw...

Embodiment 3

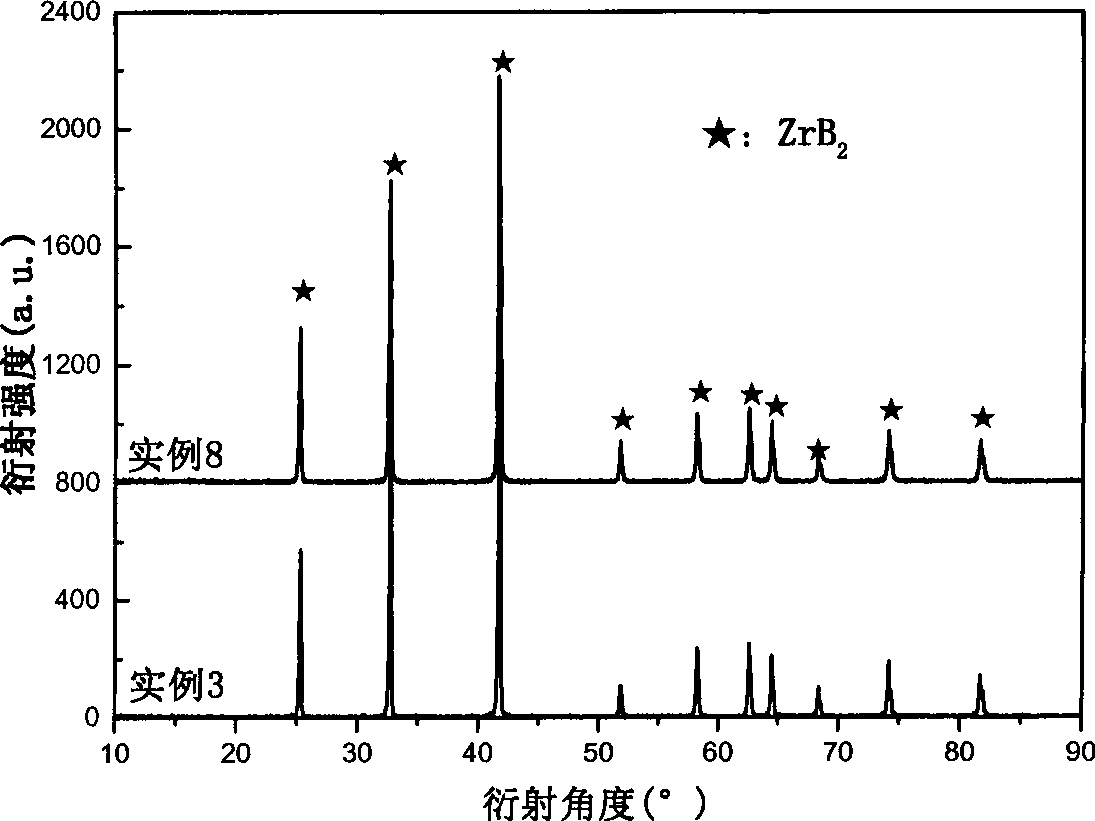

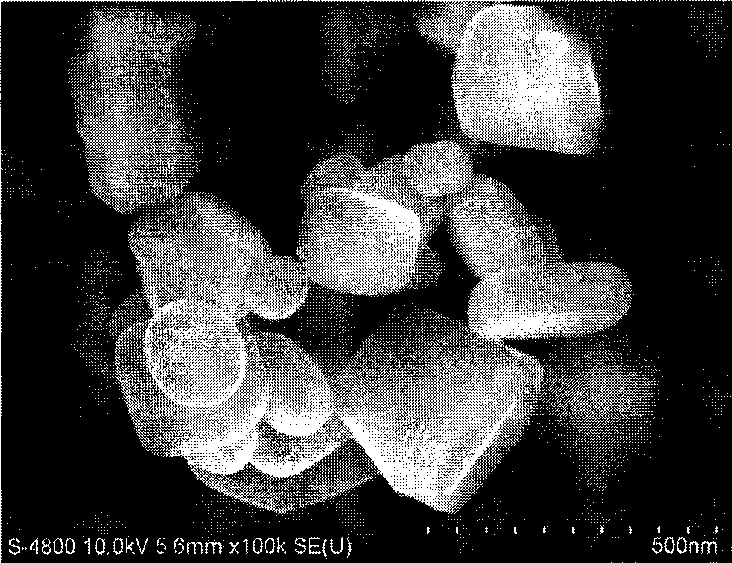

[0033] Zirconium oxychloride is selected as the Zr source, and the molar ratio of Zr to amorphous boron powder in zirconium oxychloride is 1:4. First weigh 1.27g of amorphous boron powder after refinement (the average particle size of amorphous boron powder is less than 200nm) according to the formula, put it into a beaker, and disperse the amorphous boron powder in 100ml deionized water (molar concentration is 0.4mol / L), with a concentration of 8mol / L ammonia solution to adjust the pH value to 8, add 0.01905g SDBS, and magnetically stir for 1h to obtain a suspension of amorphous boron powder; take another beaker, weigh zirconium oxychloride according to the formula, and Prepare a 0.3mol / L solution of zirconium oxychloride, add the prepared zirconium salt solution to the suspension of amorphous boron powder and mix, stir magnetically for 1 hour to obtain a mixed solution; add 8mol / L of ammonia solution to fully hydrolyze and precipitate the zirconium salt until the pH value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com