Patents

Literature

154results about How to "Guaranteed normal production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

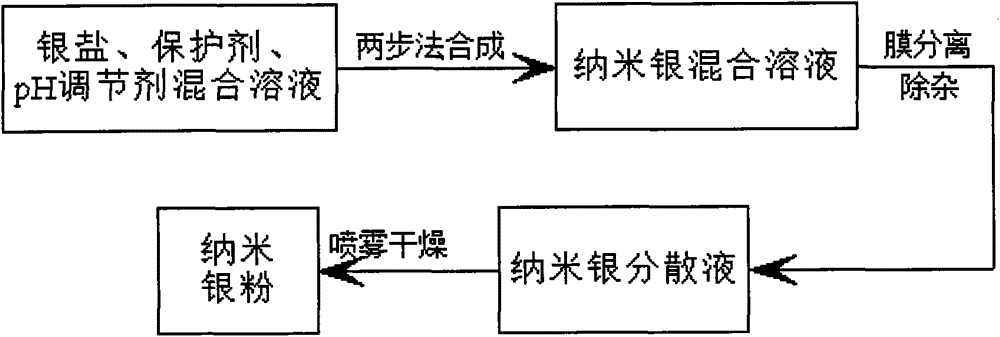

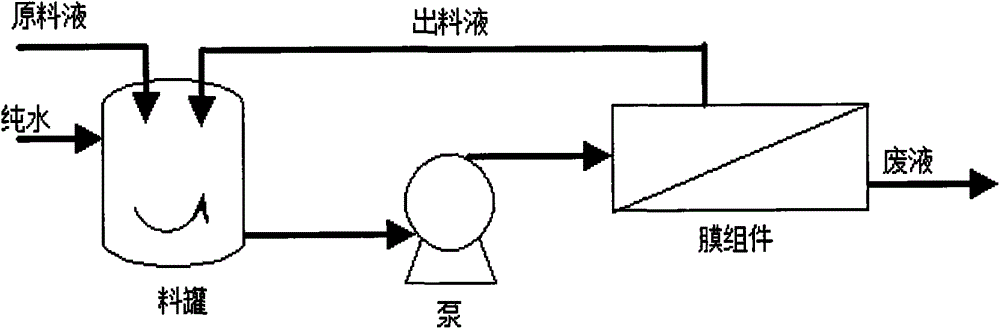

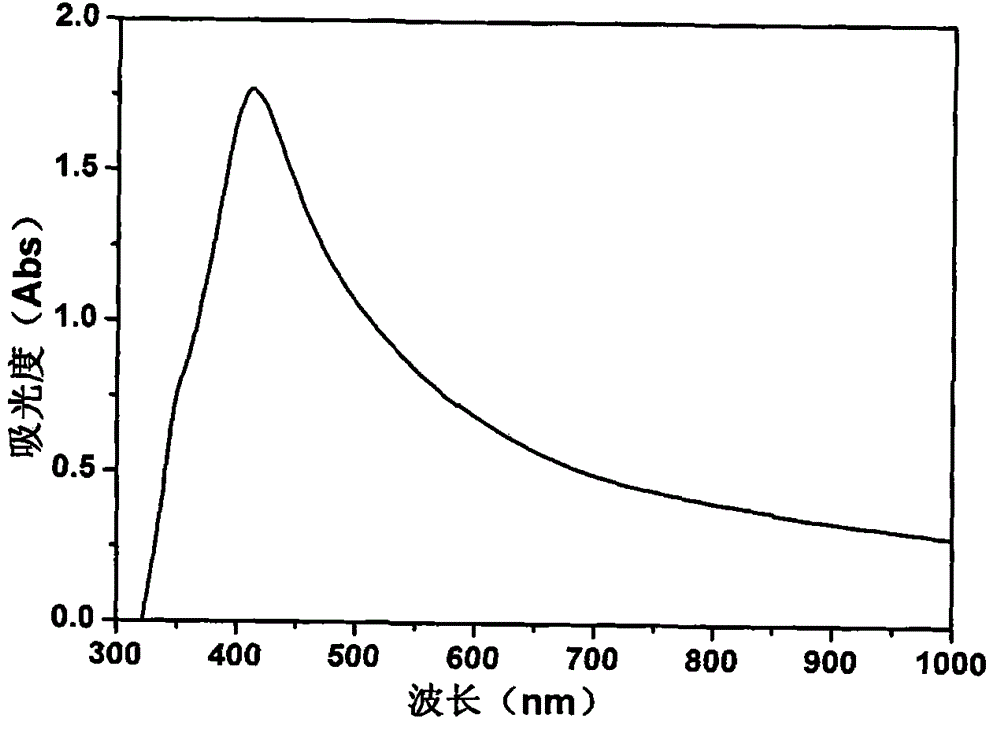

Method for preparing nanosilver powder in batches

ActiveCN104923801ASimple methodGuaranteed batch stabilityNanotechnologyBatch productionHigh concentration

The invention provides a method for preparing nanosilver powder in batches, belonging to the field of nano-material preparation. Nanosilver particles are synthetized in two steps, at first, a low-concentration reducing agent solution is slowly added into a solution mixed with silver salt, a protective agent, and a pH conditioning agent drop by drop, and then a high-concentration reducing agent solution is rapidly added drop by drop to obtain a nanosilver mixed solution; impurities in the nanosilver mixed solution are removed through a membrane separation device to obtain a nanosilver dispersion liquid; and at the end, absolute ethyl alcohol and a high-molecular dispersant are added into the nanosilver dispersion liquid, and spray drying is carried out by a spray drying device to obtain nanosilver powder in a certain particle size. The particle size of the prepared nanosilver powder is controllable, the batches are stable, the problems of non-uniform particle size during the synthesis of nanosilver, nanosilver separation, and agglomeration and acaking during powder preparation are solved, the preparation process and the operation are simple, and industrial and batches production is realized.

Owner:NANO TOP ELECTRONICS TECH

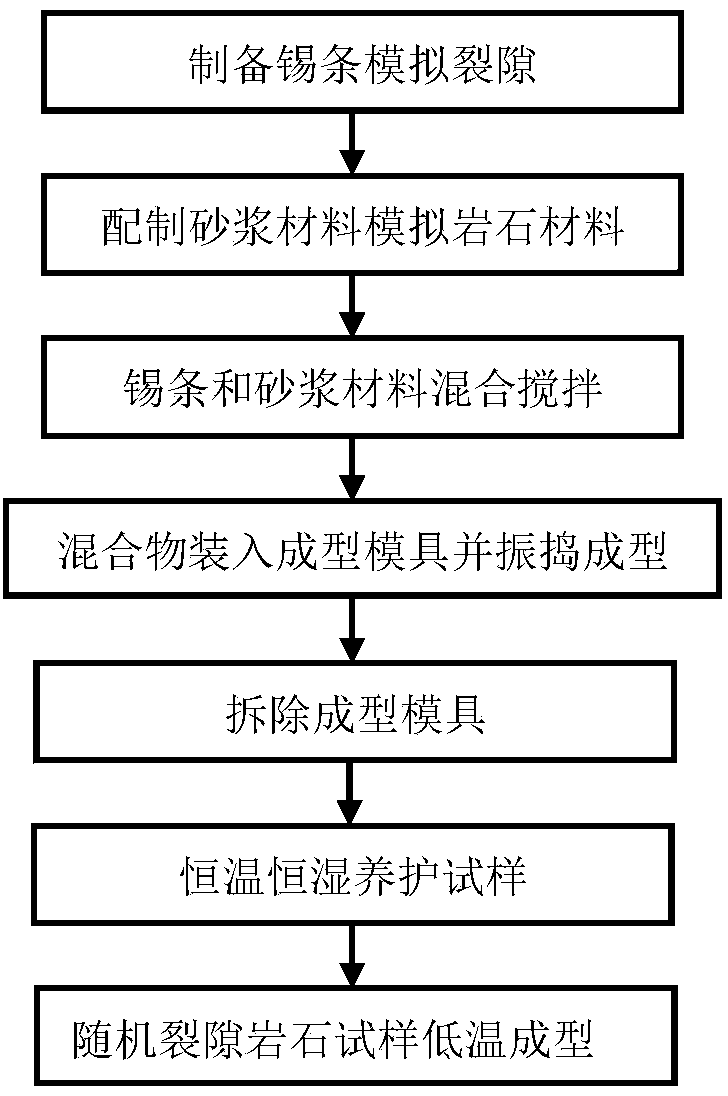

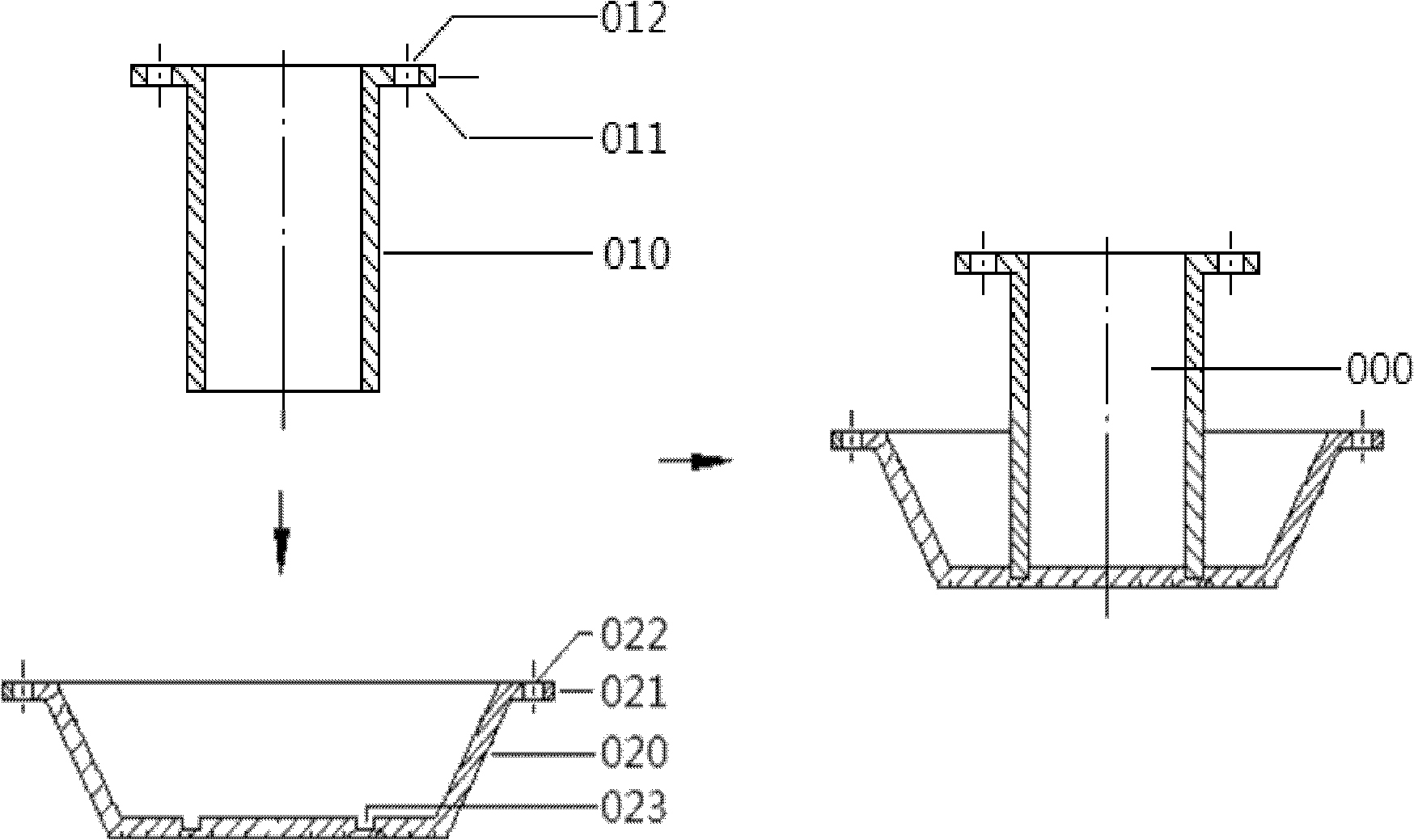

Manufacture method of rock sample with random fractures

InactiveCN103822808AGuaranteed normal productionEasy to adjust the probability density distributionPreparing sample for investigationRock engineeringRock sample

The invention belongs to the field of rock engineering, and specifically relates to a manufacture method of a rock sample with random fractures. The manufacture method comprises the following steps: (1) preparing a tin strip so as to simulate a crack; (2) preparing a mortar material so as to stimulate a rock material; (3) mixing and stirring the tin strip and the mortar material; (4) pouring the mixture into a forming mould so as to carry out a forming treatment through a vibrating and smashing method; (5) disassembling the forming mould; (6) maintaining the sample at a constant temperature under a constant humidity; (7) subjecting the random fracture rock sample to a low-temperature forming treatment. The manufacture method is capable of manufacturing a cracked rock with a large amount of random fractures, can conveniently modulate the probability density distribution of fractures so as to be accord with the actual situation of engineering rock, and has the advantages of simple operation, high efficiency, rapidness, and wide application range.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

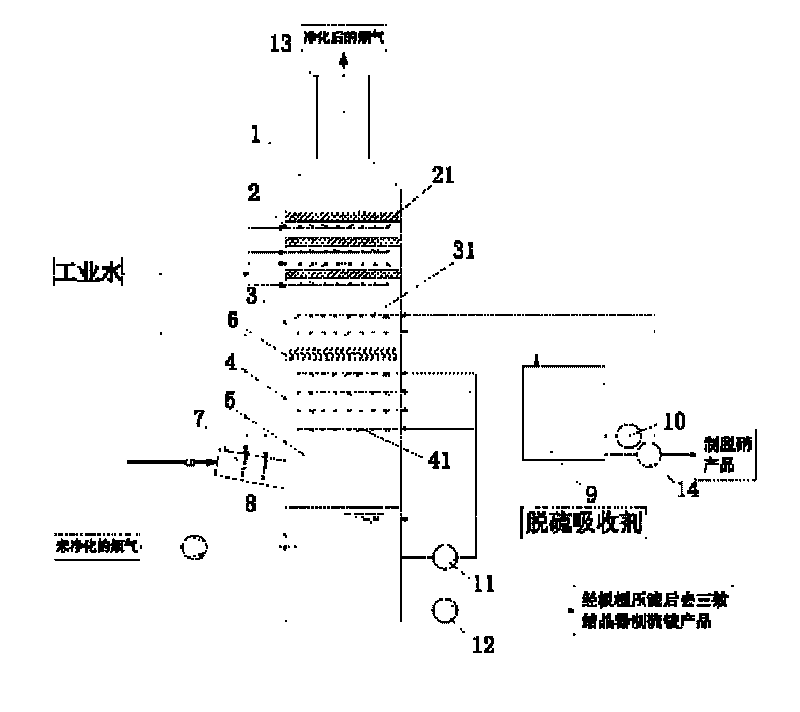

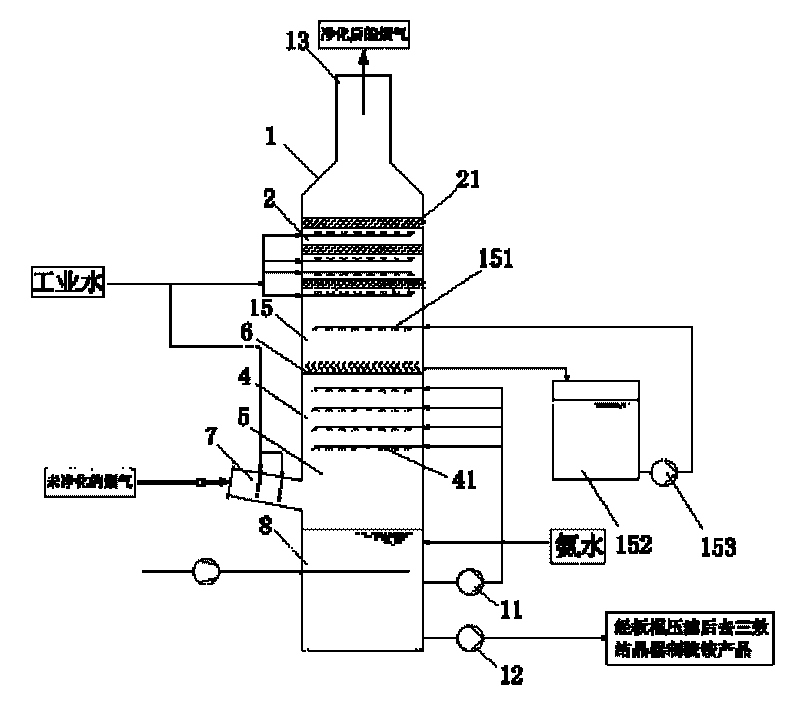

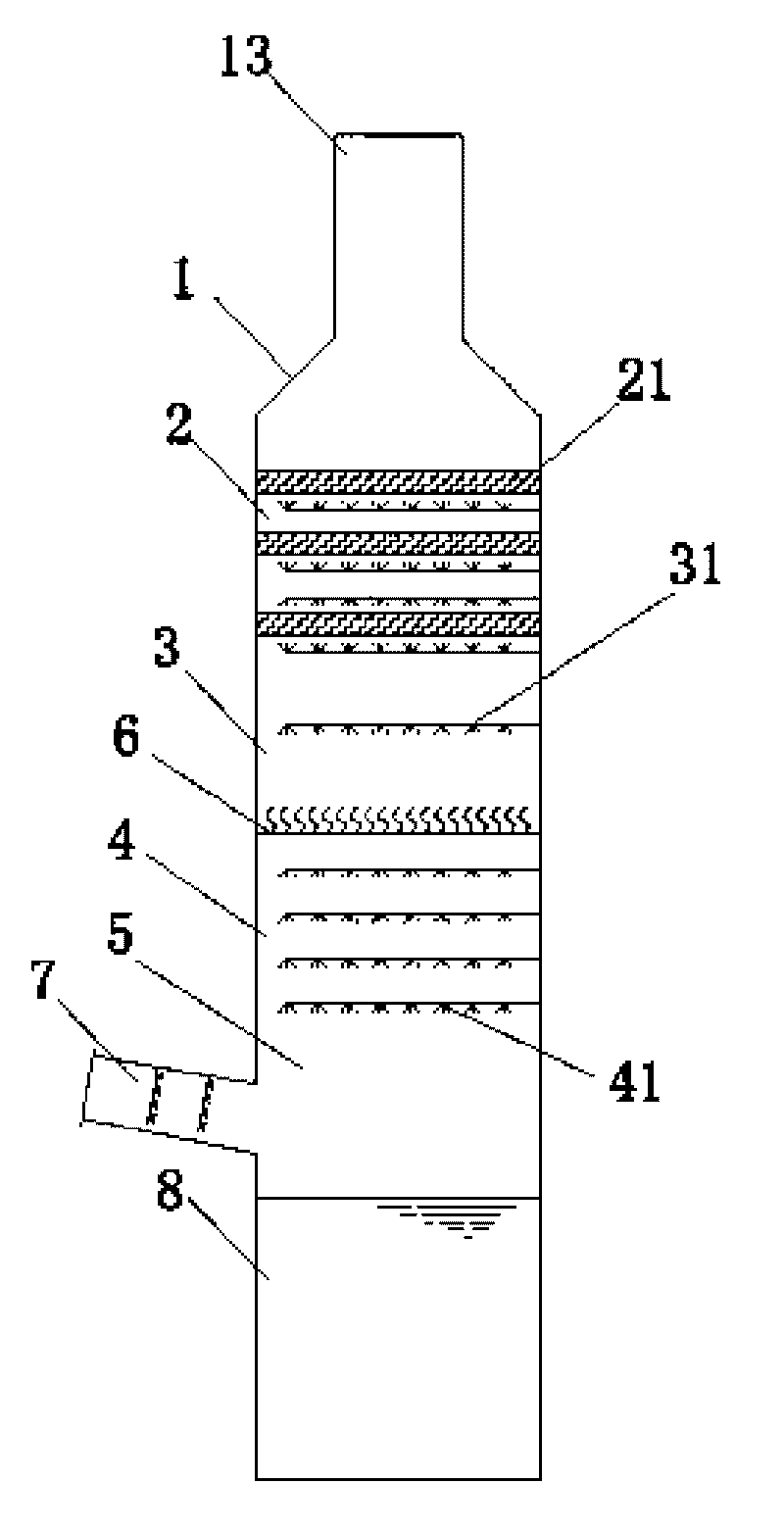

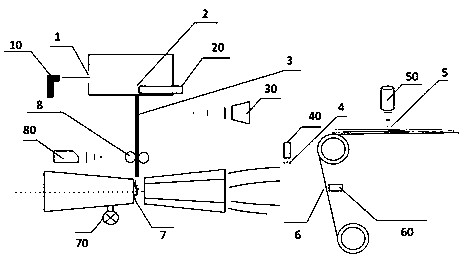

Treatment technique for pollutants in sinter fume and spraying and absorbing tower thereof

InactiveCN101708420AEasy to handleQuality improvementLighting and heating apparatusDispersed particle separationMulti pollutantEngineering

The invention discloses a treatment technique for pollutants in sinter fume and a spraying and absorbing tower thereof. After cooling and dedusting, the sinter fume is led into the spraying and absorbing tower, moves upwards to pass through at least two spraying and absorbing sections partitioned from up down in the spraying and absorbing tower, each spraying and absorbing section sprays and absorbs more than one pollutant in the sinter fume and the spraying and absorbing solution does not fall into the absorbing section of next layer, after passing through all the spraying and absorbing sections, the fume is demisted and exhausted from the top of the spraying and absorbing tower. The spraying and absorbing tower comprises a tower body, the tower body is partitioned into a demisting section, more than two spraying and absorbing sections and a fume inlet section from up down and a seriflux pool on the bottom of the tower body, and the adjacent spraying and absorbing sections are partitioned by a tower board assembly. The invention has the advantages that the loss of system resistance is small, the structure is simpler and more compact, the operation is convenient, the absorption effect is good, the treatment capacity is high and the like, and the invention can treat various pollutants in sinter fume.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

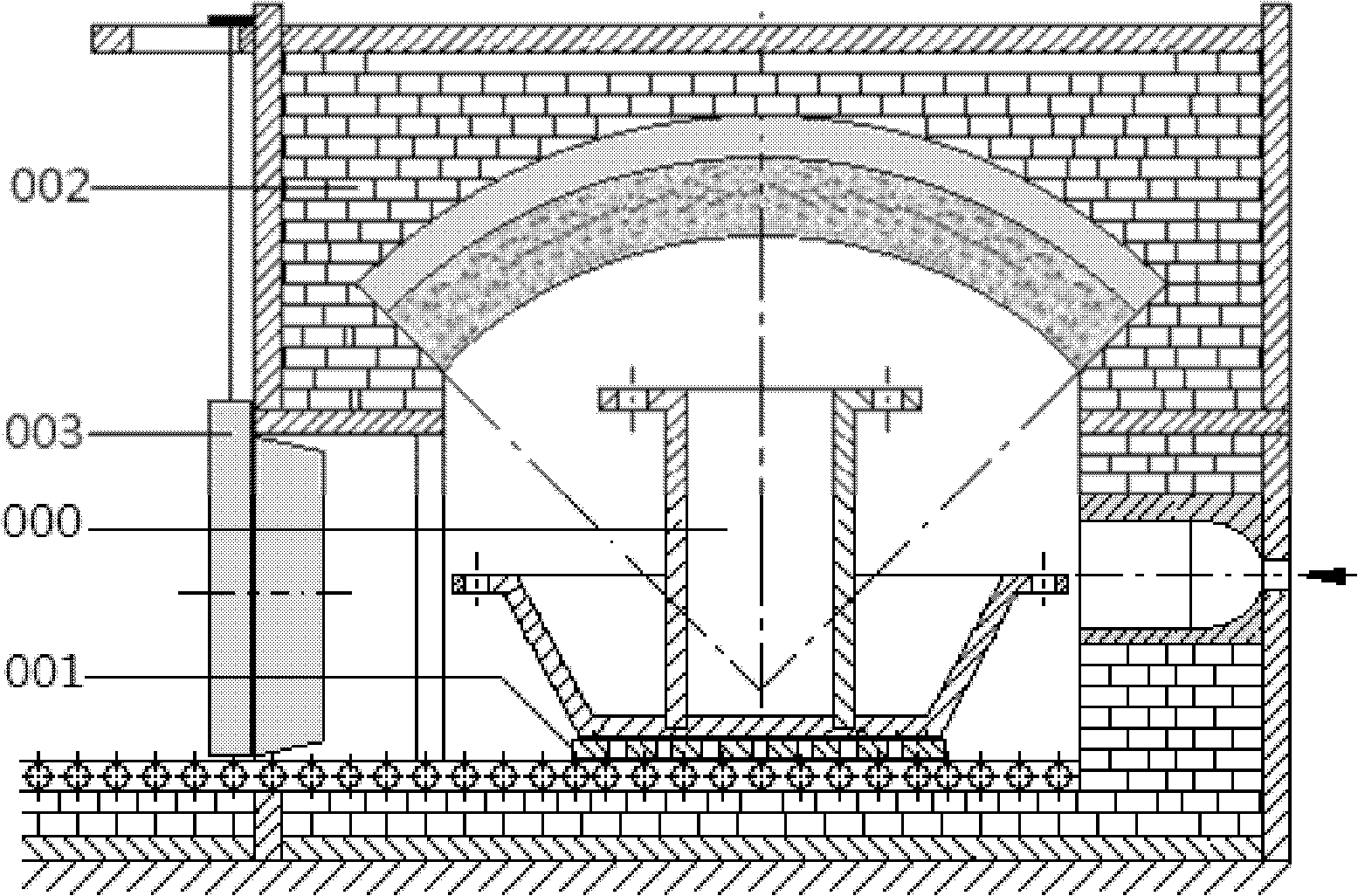

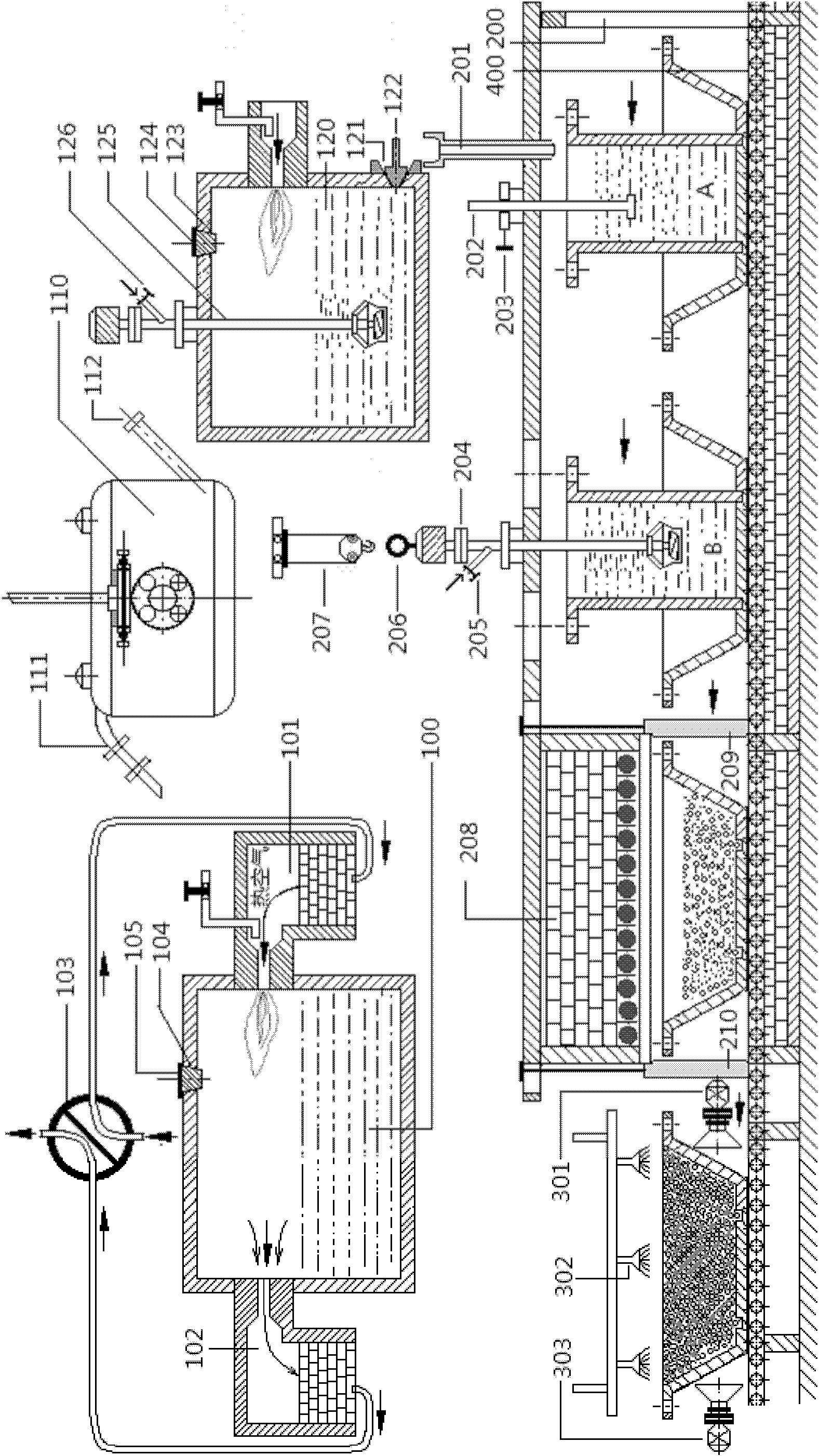

Semi-continuous production line of closed-cell aluminum foam

ActiveCN102586643AThe production process is easy to controlPrevent dumpingProduction lineFoaming agent

The invention discloses a semi-continuous production line of closed-cell aluminum foam. The semi-continuous production line comprises a composite die, a continuous preheating system of the composite die, a melt melting and distributing system, a melt foaming system and a full-automatic cooling system. The continuous preheating system comprises the composite die and a tunnel preheating kiln with amobile movable baseplate; and the composite die is formed by movably connecting a transition crucible without upper and lower cover plate with a filling die. The melt melting and distributing system comprises a melting furnace, a vacuum ladle and a tundish, a stirring device capable of sucking a tackifier in a negative pressure manner is arranged at the upper part of the tundish, and a flow port is arranged at the lower part of the tundish. The melting foaming system comprises a viscosity sensor, the stirring device capable of sucking a foaming agent in the negative pressure manner and a foaming furnace. The full-automatic cooling system comprises a cooling fan and a cooling pipe, wherein an atomizing shower head is arranged at the upper part of the cooling pipe. The semi-continuous production line disclosed by the invention can realize semi-continuous production of the aluminum foam, reduce labor intensity and further effectively ensure the consistency of product performances.

Owner:CENT SOUTH UNIV

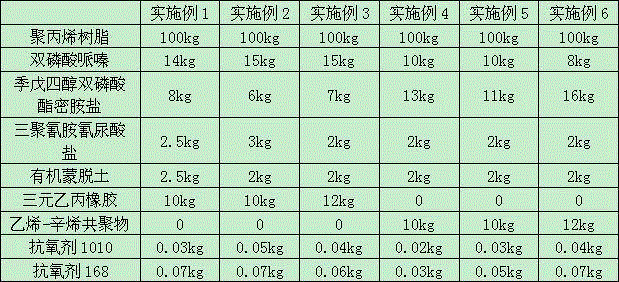

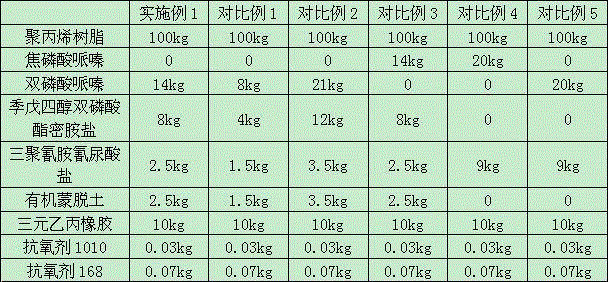

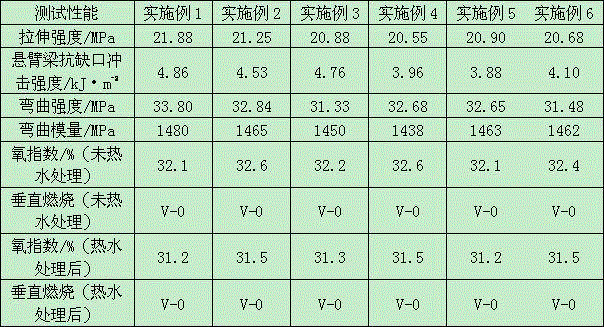

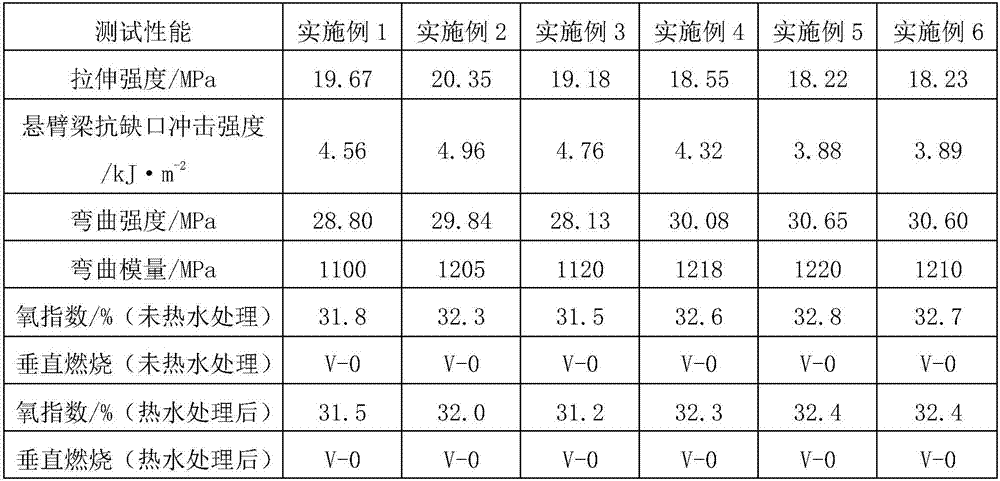

Halogen-free flame-retardant polypropylene material and preparation method thereof

ActiveCN105061887AGood flame retardant synergyImprove flame retardant performancePentaerythritolAntioxidant

The invention discloses a halogen-free flame-retardant polypropylene material and a preparation method thereof. The halogen-free flame-retardant polypropylene material comprises components in parts by weight as follows: 100 parts of polypropylene resin, 20-35 parts of a halogen-free composite flame retardant, 5-20 parts of a toughening agent and 0.05-0.12 parts of a complex antioxidant, wherein the halogen-free composite flame retardant comprises diphosphonate piperazine, pentaerythritol diphosphate melamine salt, melamine urate and organic montmorillonite in the weight ratio being (5-20) : (5-20) : (1-5) : (1:5). According to the halogen-free flame-retardant polypropylene material, a halogen-free composite flame retardant system comprises diphosphonate piperazine, pentaerythritol diphosphate melamine salt, melamine urate and organic montmorillonite and has an excellent flame-retardant synergistic effect and excellent high-temperature resistance, particularly, hydrolysis-resistant performance can be acquired without any treatment, and the flame retardant system is not easily hydrolyzed in the forming process.

Owner:JIANGYIN SULI CHEM

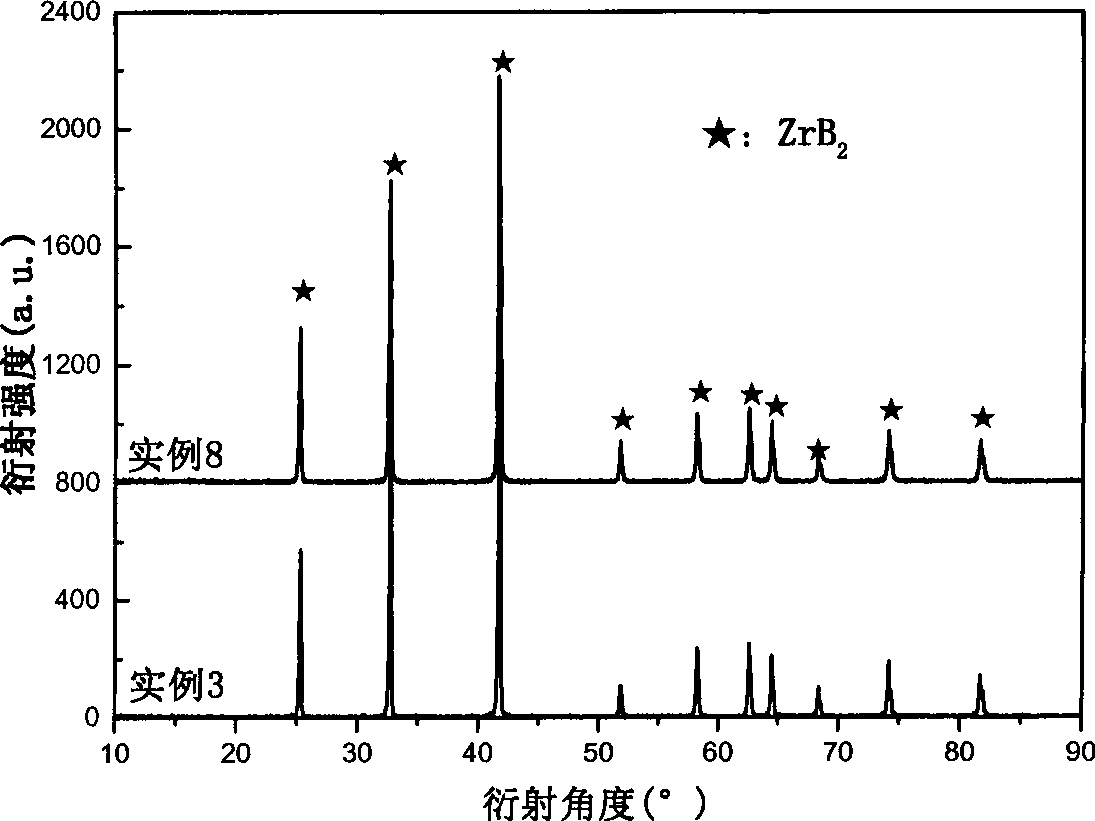

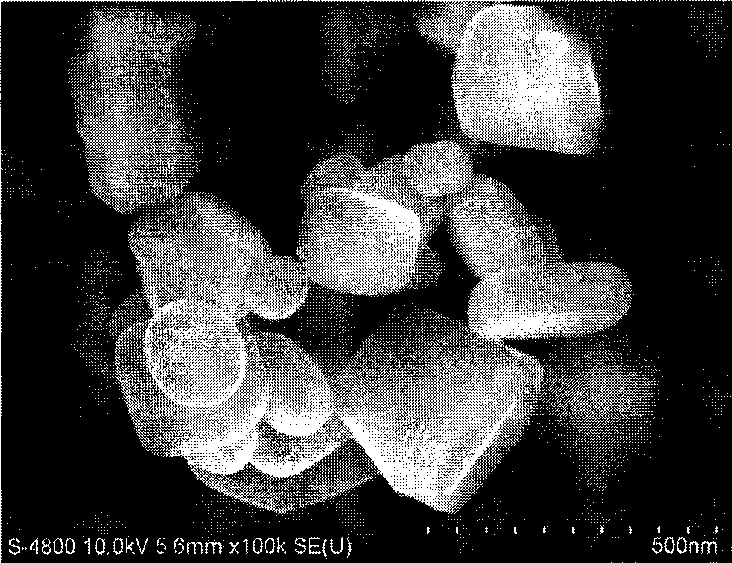

Preparation of nano zirconium diboride ceramic powder

InactiveCN101486577ASynthesis temperature is lowGuaranteed normal productionMetal boridesChemical treatmentCoprecipitation

The invention relates to a preparation method for nano zirconium diboride ceramic powder, which is characterized by comprising the following steps: 1) selecting materials: selecting according to a mol ratio of 1 : 3 to 1 : 5 between Zr and amorphous boron powder in soluble zirconium salt; 2) selecting one of the two methods as follows: a) using a coprecipitation method for gel forming to obtain xerogel; b) using a sol-gel method for gel forming to form the xerogel; 3) preparing precursor powder; 4) synthesizing quickly: arranging the materials into a large current reaction synthesizer; the inside of a black lead reactor is protected by vacuum or insert gases; applying a large current directly on the black lead reactor, quickly heating to 800 and 1500 DEG C at the temperature rising speed of 50 to 500 DEG C / min, preserving the temperature for 0 to 60 minutes to obtain a powder sample; and 5) chemical processing for obtaining the nano zirconium diboride ceramic powder. The method has the characteristics of quick synthesizing speed and high efficiency; the purity of the obtained nano zirconium diboride ceramic powder is high (equal to or more than 95 percent); and the grain diameters of the obtained nano zirconium diboride ceramic powder are uniform and thin(the average grain diameter is equal to or less than 300nm).

Owner:WUHAN UNIV OF TECH

Underwater installation method of ship rudder system

The invention discloses a method for the underwater installation of a ship rudder system, which comprises the following steps: 1. installing a rudder sleeve on the ship before launching, testing together with a rudder shaft, assembling a rudder stock and a rudder blade to a unit, installing the rudder system in mooring after launching; 2. regulating the ship trim by regulating ship ballast status; 3. horizontally moving the rudder blade and the rudder stock immediately below the rudder sleeve; 4. using the hand chain hoist of a tackle lifting mechanism at the ship stern to horizontally move the rudder stock / the rudder blade as a whole immediately below the rudder sleeve and meanwhile raising the hand chain hoist of a rudder cabin to lift the rudder blade to the top surface which has a certain distance with the bottom surface of the rudder sleeve; 5. sleeving lower rudder carrier parts on the rudder stock; 6. continuing to raise the rudder stock and the rudder blade, and installing a rudder carrier, a actuator and a jump stop block; 7. disassembling the tackle lifting mechanism at the ship stern, checking the whole rudder system, and finishing the whole work flow.

Owner:泰州口岸船舶有限公司

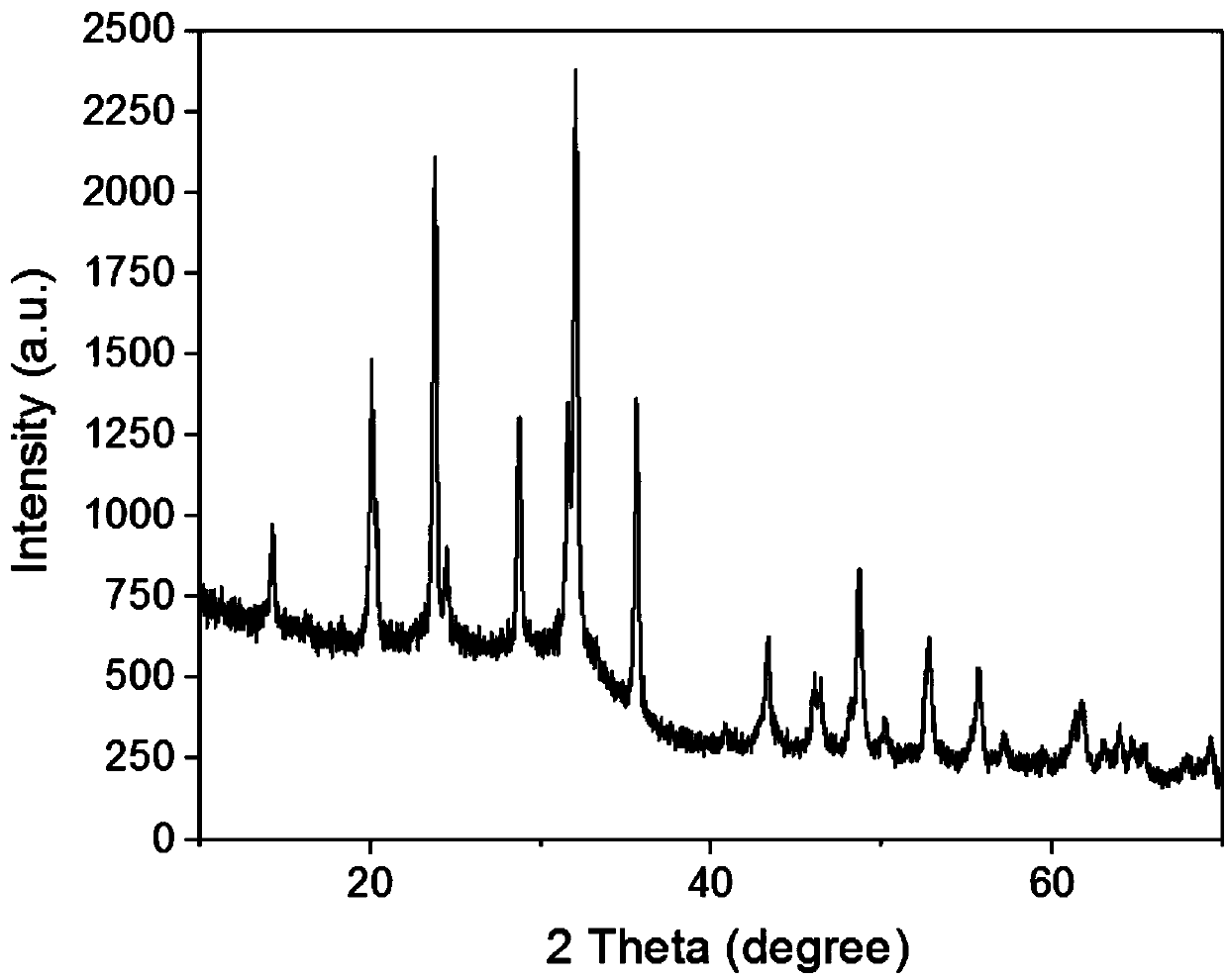

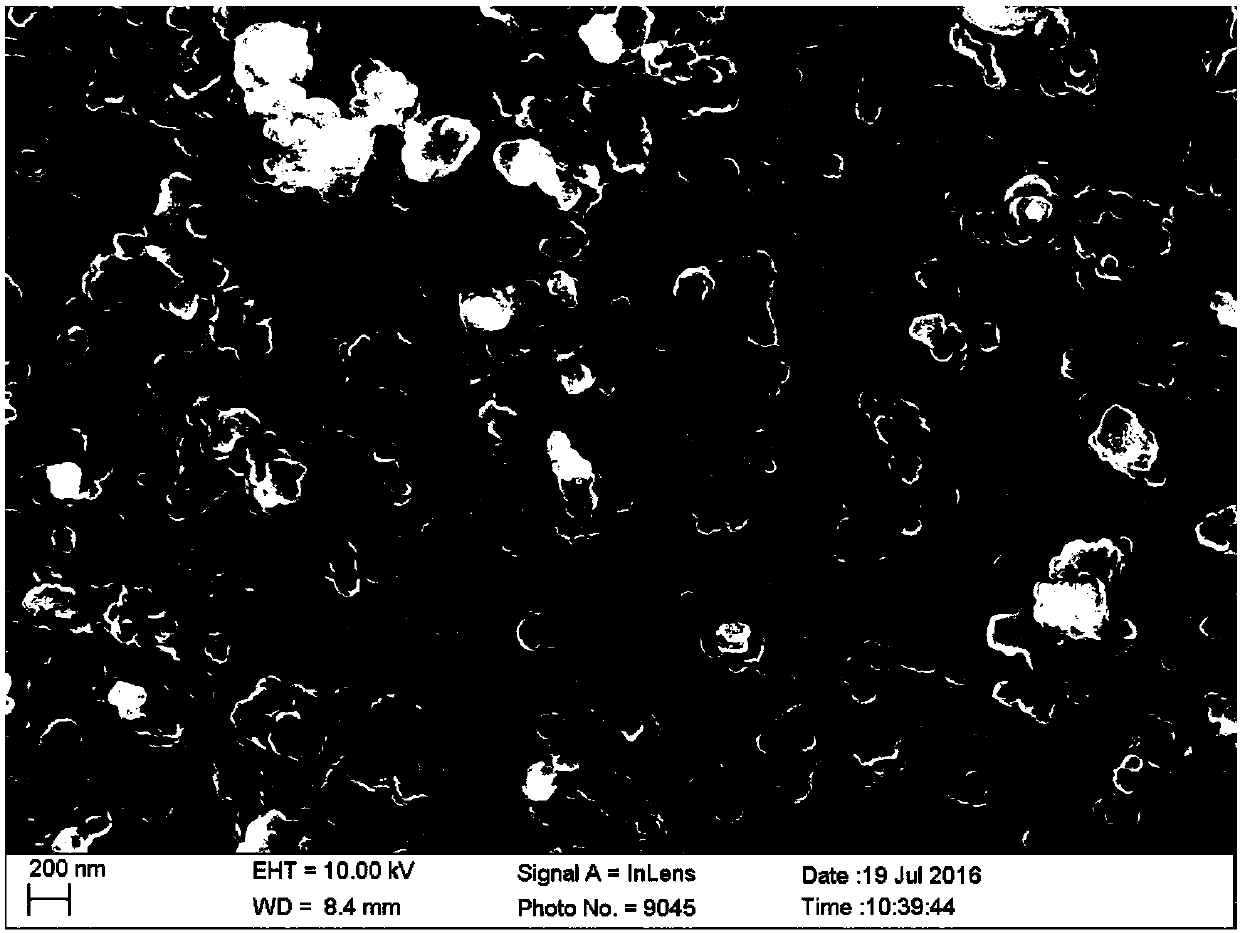

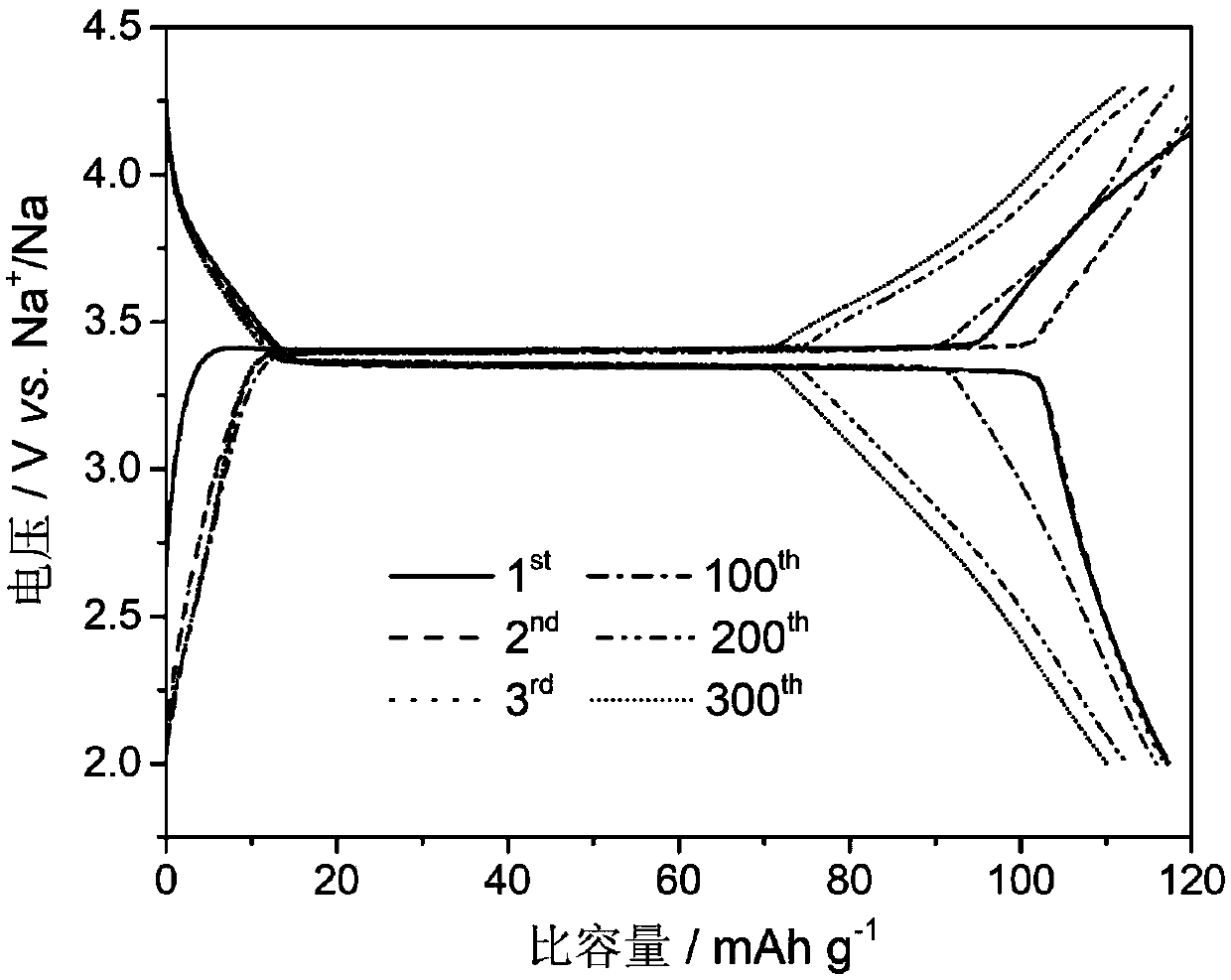

Metal-doped Na3V2(PO4)3 composite electrode material and preparation method and application thereof

InactiveCN107611390AImprove conductivityImprove cycle stabilityMaterial nanotechnologyCell electrodesMicro nanoCarbon source

The invention relates to a metal-doped Na3V2(PO4)3 composite electrode material and a preparation method and application thereof. The metal-doped Na3V2(PO4)3 composite electrode material is a Na3V<2-x>M<x>(PO4)3 / C composite electrode material in a micro-nano composite particle shape. According to the preparation method, an organic matter carbon source is added and can be coated on a surface of Na3V<2-x>M<x>(PO4)3 / C precursor particle in an in-situ way during the hydrothermal process, can be used for preventing the Na3V<2-x>M<x>(PO4)3 / C precursor particle from being grown and agglomerated and also can be decomposed to amorphous carbon during the thermal treatment process, the formation core is Na3V<2-x>M<x>(PO4)3 / C particle, and a shell is a core-shell structure of the amorphous carbon. Themetal-doped Na3V2(PO4)3 composite electrode material has the advantages of favorable conductivity, excellent cycle stability, rate performance and the like. The metal-doped Na3V2(PO4)3 composite electrode material belongs to the field of an electrode material.

Owner:UNIV OF SCI & TECH BEIJING

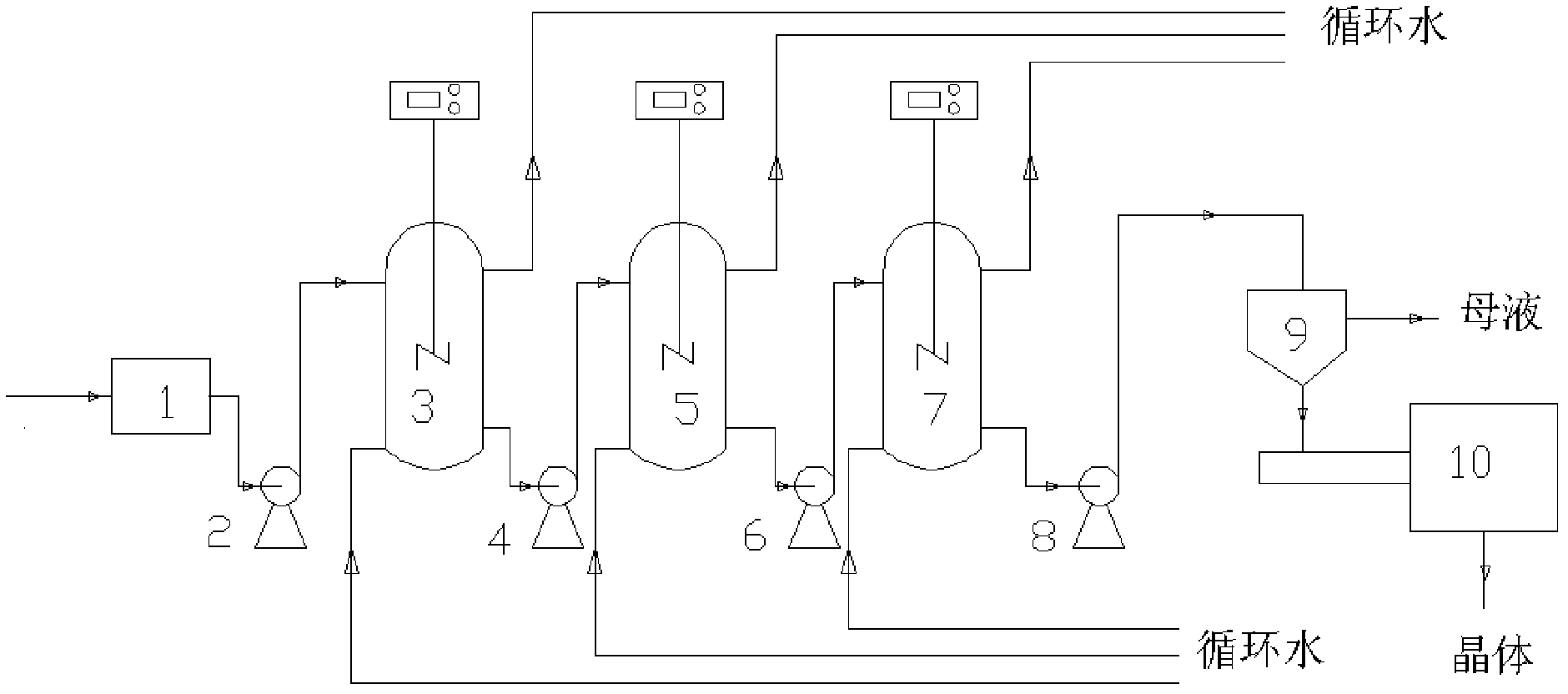

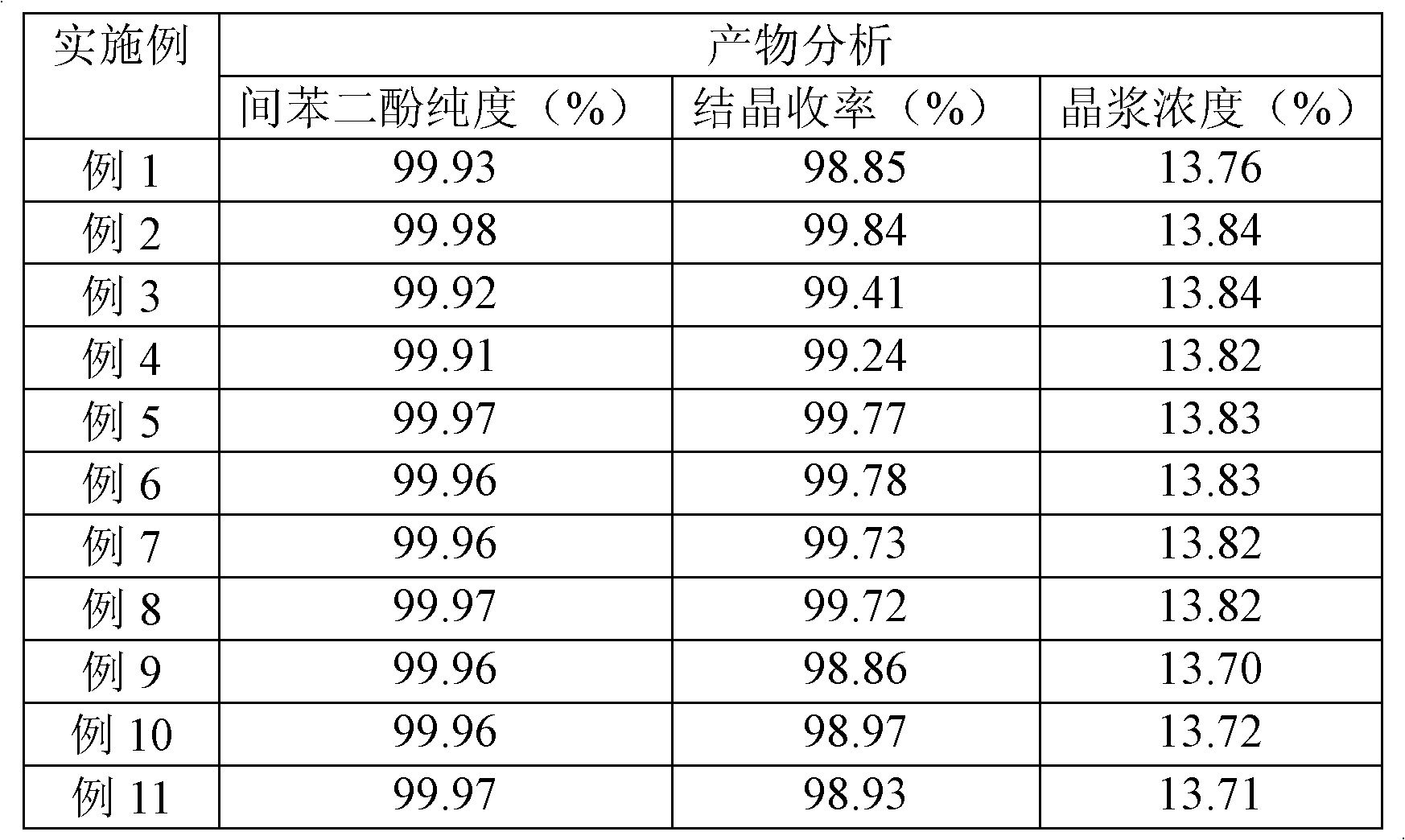

Method for purifying resorcinol by means of continuous crystallization

InactiveCN102643169AEffective growth rate controlGuaranteed stabilityOrganic chemistryOrganic compound preparationMagmaToluene

A method for purifying resorcinol by means of continuous crystallization belongs to the technical field of separation and purification of resorcinol, and includes: dissolving the resorcinol into methylbenzene in weight ratio of (6.0-6.1):1, and enabling solution to enter a primary crystallizer to crystallize with the temperature and stirring speed of the primary crystallizer constant; enabling magma to enter a secondary crystallizer, and crystallizing at a certain crystallizing temperature, at a certain stirring speed and by means of equal stop; enabling magma to enter a tertiary crystallizer, and crystallizing at a certain crystallizing temperature, at a certain stirring speed and by means of equal stop, wherein the temperature of the primary crystallizer, the temperature of the secondary crystallizer and the temperature of the tertiary crystallizer are sequentially decreased; and subjecting the magma to solid-liquid separation, and then scrubbing and drying obtained crystals by the methylbenzene. The method realizes continuous operation of crystallization and purification, operating cost is reduced, production capacity is improved, and stability of operating parameters is guaranteed.

Owner:BEIJING UNIV OF CHEM TECH

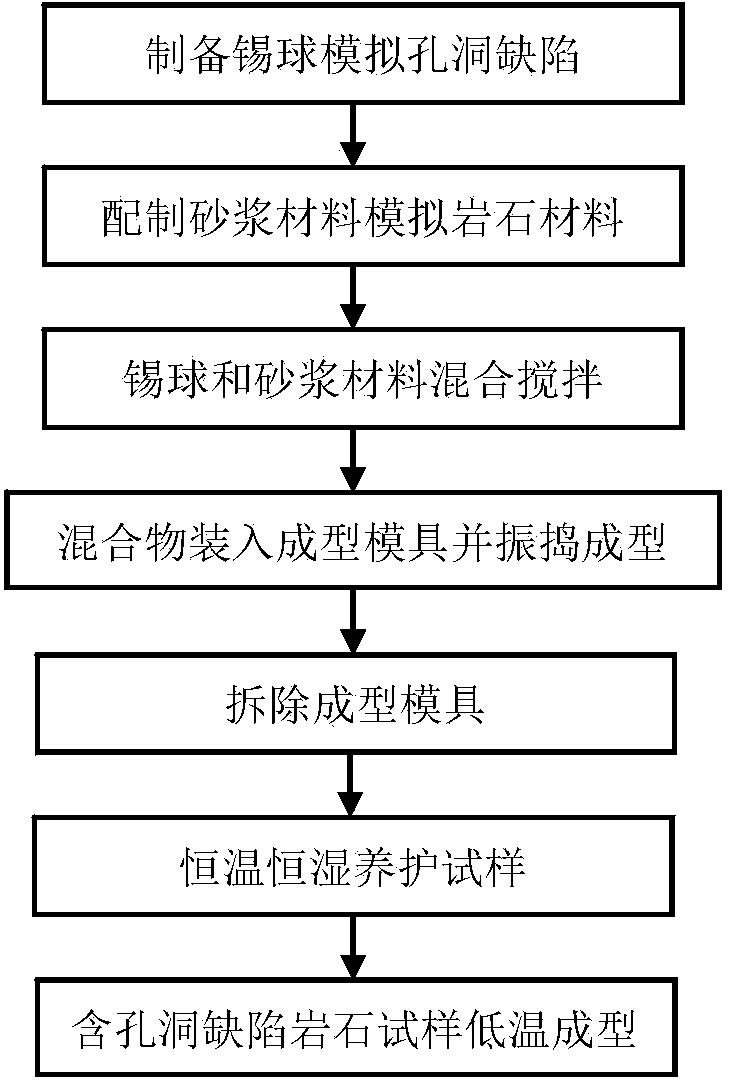

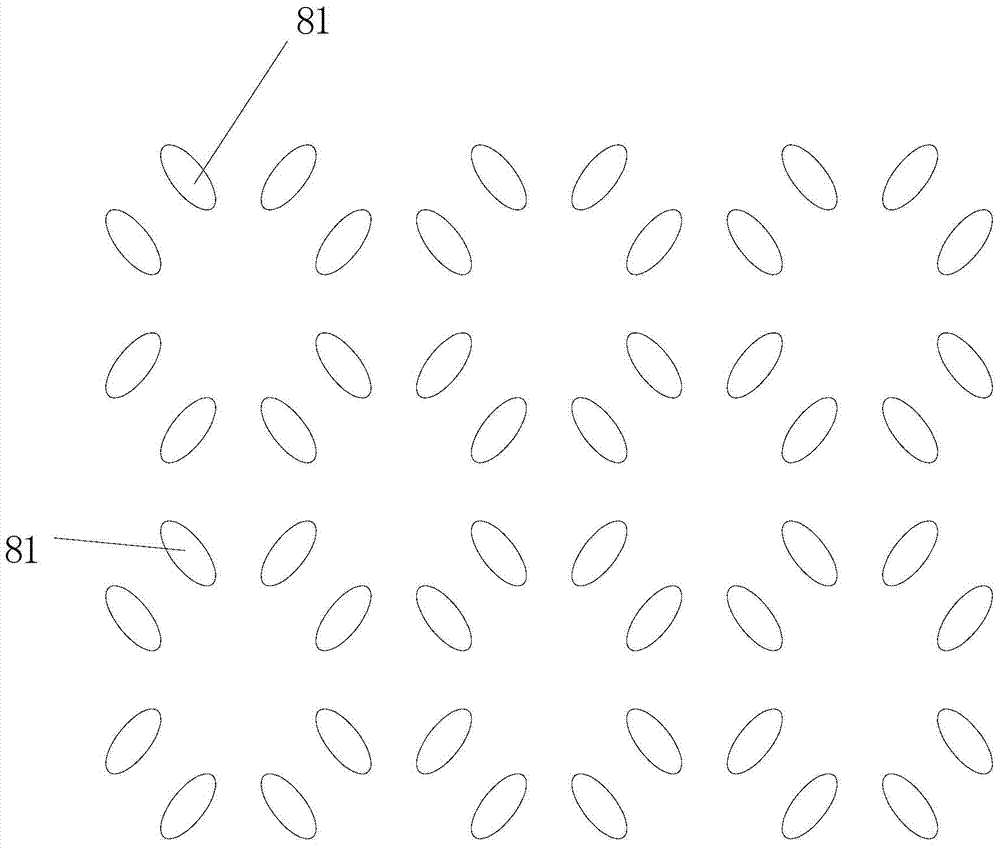

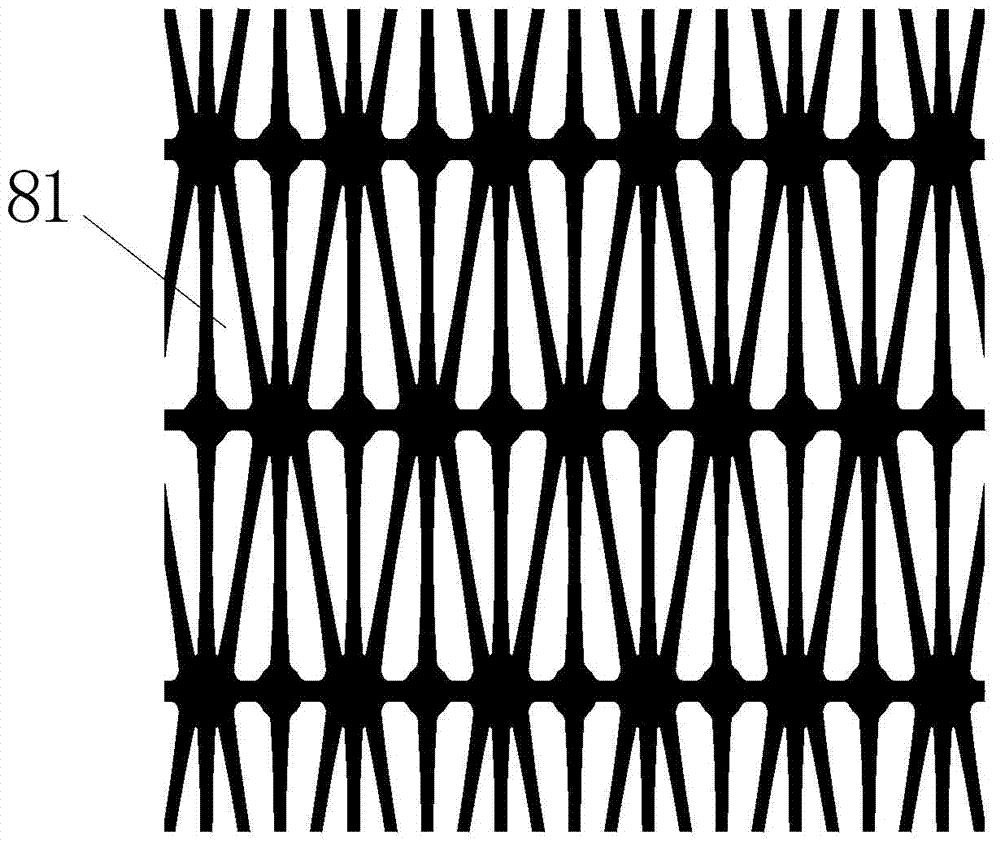

Manufacturing method for rock test sample containing hole defects

InactiveCN103837390AEasy to adjust the probability density distributionGuaranteed normal productionPreparing sample for investigationTest sampleMaterials science

The invention belongs to the field of geotechnical engineering and particularly relates to a manufacturing method for a rock test sample containing hole defects. The manufacturing method for the rock test sample containing the hole defects comprises the following steps: (1) preparing a tin ball for simulating the hole defects; (2) preparing a mortar material for simulating a rock material; (3) mixing and agitating the tin ball and the mortar material; (4) filling a molding mould with a mixture, and vibrating and molding; (5) detaching the molding mould; (6) curing the test sample under the conditions of constant temperature and constant humidity; and (7) molding the rock test sample containing the hole defects at a low temperature. According to the manufacturing method for the rock test sample containing the hole defects, the manufacturing of a plurality of the hole defects in an engineering rock body is guaranteed and the probability density distribution of the hole defects can be conveniently adjusted so as to meet the conditions of the actual engineering rock body; the operation method is simple, efficiency and rapid and the application range is wide.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

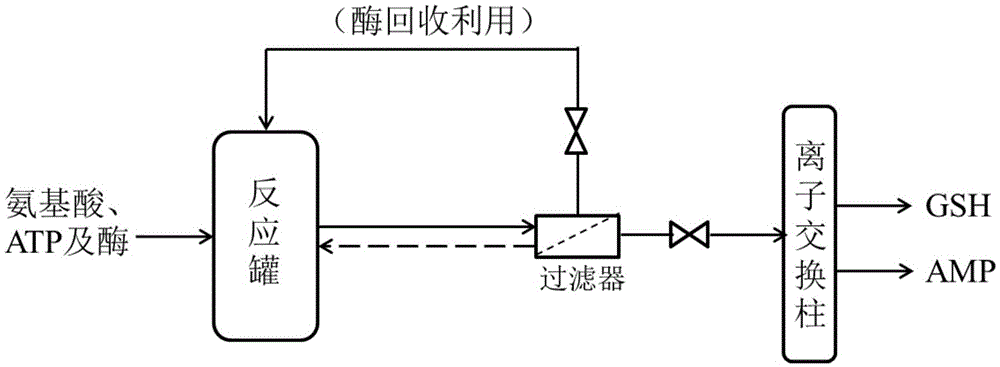

Enzymic method for simultaneously preparing glutathione and adenylate

ActiveCN105603028ASimple reaction conditionsIncrease concentrationPeptidesFermentationEnzymeAmino acid

The invention discloses an enzymic method for simultaneously preparing glutathione and adenylate. The enzymic method comprises the following steps: (1) generating glutathione and adenylate from GshF enzyme and Adk enzyme in a reaction tank; (2) separating the immobilized GshF enzyme and Adk enzyme in the reaction tank, or separating the free GshF enzyme and Adk enzyme by virtue of filtering equipment; and (3) separating products GSH and AMP. By virtue of the preparation method, the reaction condition in production of the GSH is optimized, the generation concentration of GSH reaches 30g / L-50g / L, and the utilization rate of amino acid is relatively high; meanwhile, by carrying out partial regeneration on ATP consumed in reaction by virtue of the Adk enzyme, the consumption of the ATP is reduced; and furthermore, the GSH and the AMP can be simultaneously prepared by virtue of the preparation method.

Owner:BEIJING TIANKAI YIDA BIOLOGICAL SCI & TECH

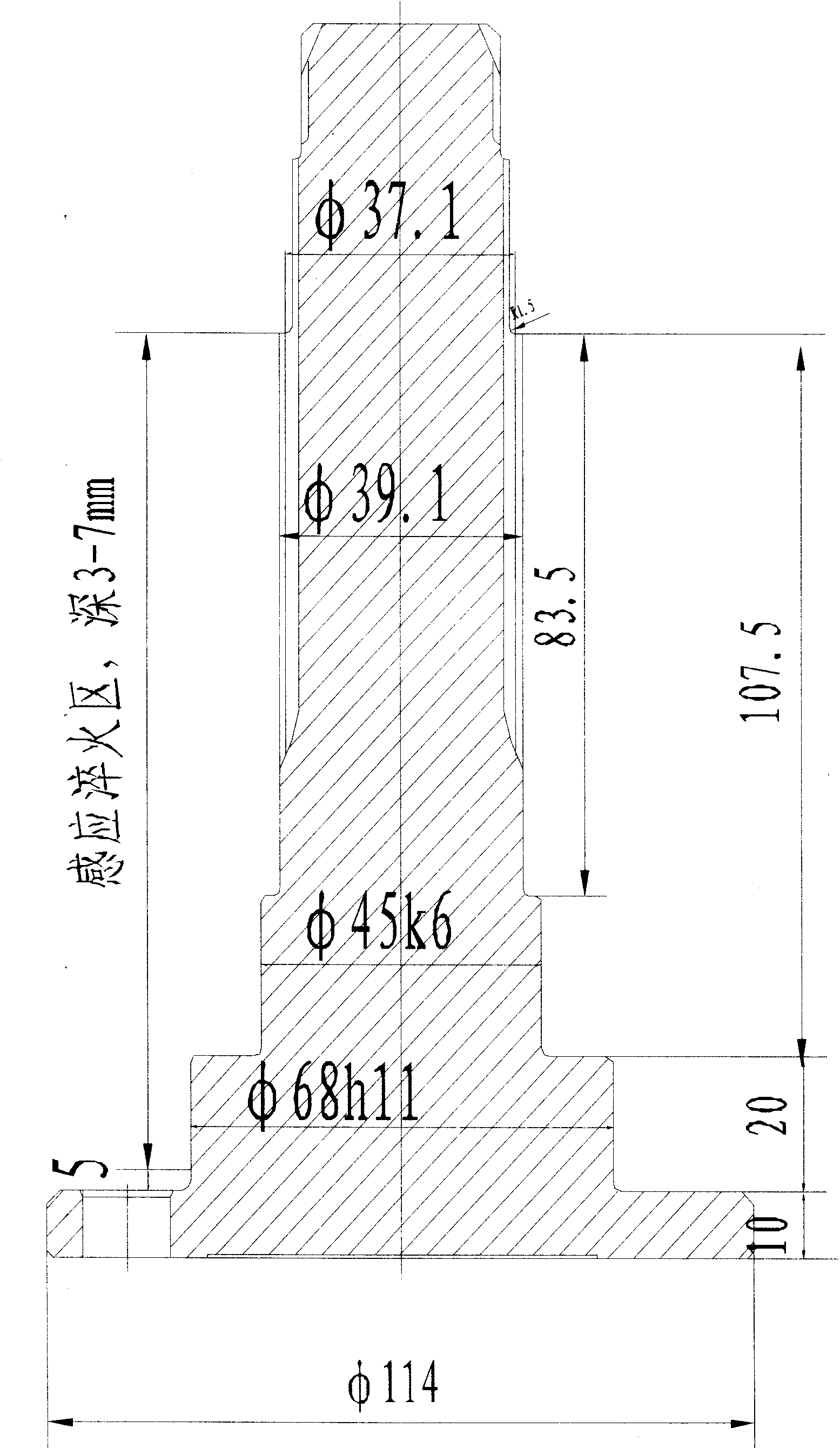

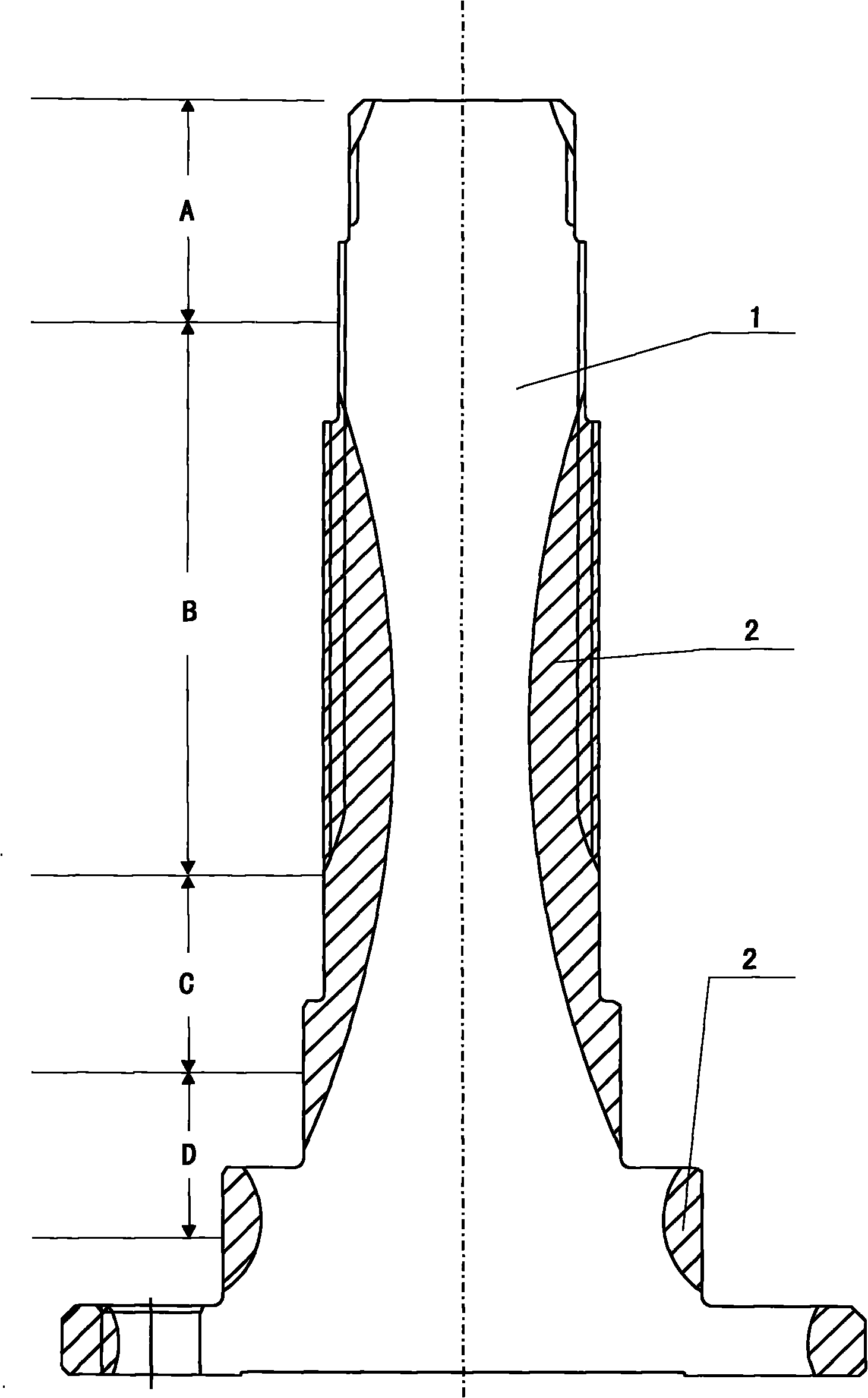

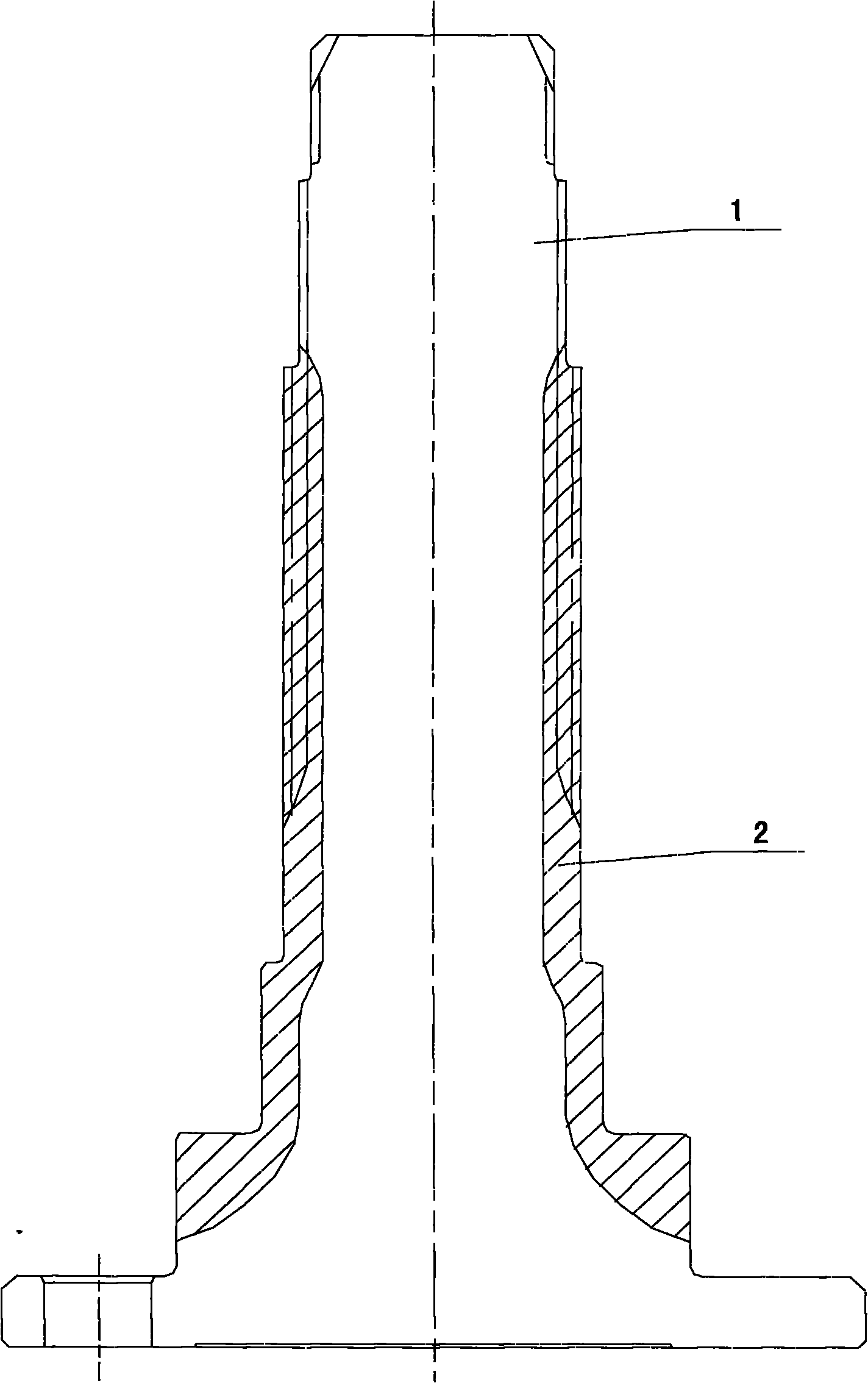

Large variable diameter shaft part induction heat-treatment and quenching technical method

InactiveCN101787425AImprove equipment utilizationLess investment in equipmentIncreasing energy efficiencyFurnace typesMoving speedMachine tool

The invention relates to a large variable diameter shaft part induction heat-treatment and quenching technical method. A power output driven shaft is taken as an example, a continuous heating quenching way and a liquid injecting cooling quenching way are adopted, and the action procedure of a machine tool comprises the steps of: preheating from the upper end of a spline and continuously walking at variable speed to the position of a shaft neck of phi 45; preheating, stagnating, and heating for a plurality of seconds 'determining according to the actual situation; heating, stopping heating, moving to the position of phi 68 for heating, lagging, heating and injecting liquid; moving to the position of 45 for continuously heating to 3-5mm of the upper end of the spline 'wherein the moving speed is different at the two sections of phi 45 and phi 37.1 andcan be shown in numerical control programming'; moving to a certain position of the upper end of phi 37.1 'in numerical control X is equal to -53'; injecting liquid for a plurality of seconds 'determining by experiment'; and returning to zero. The method has the advantages of saving energy and reducing consumption, being convenient for operation, lightening the labor intensity, improving the working environment and the like.

Owner:CHINA YITUO GROUP

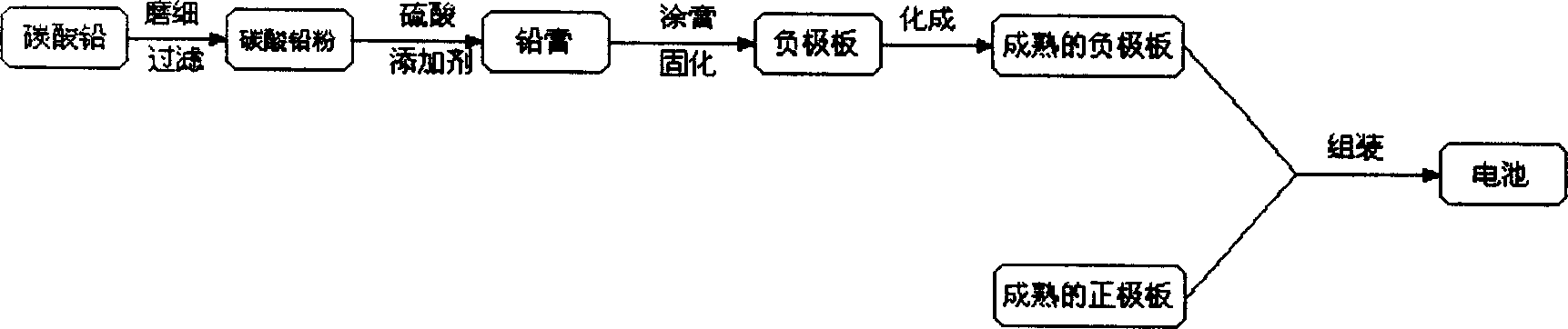

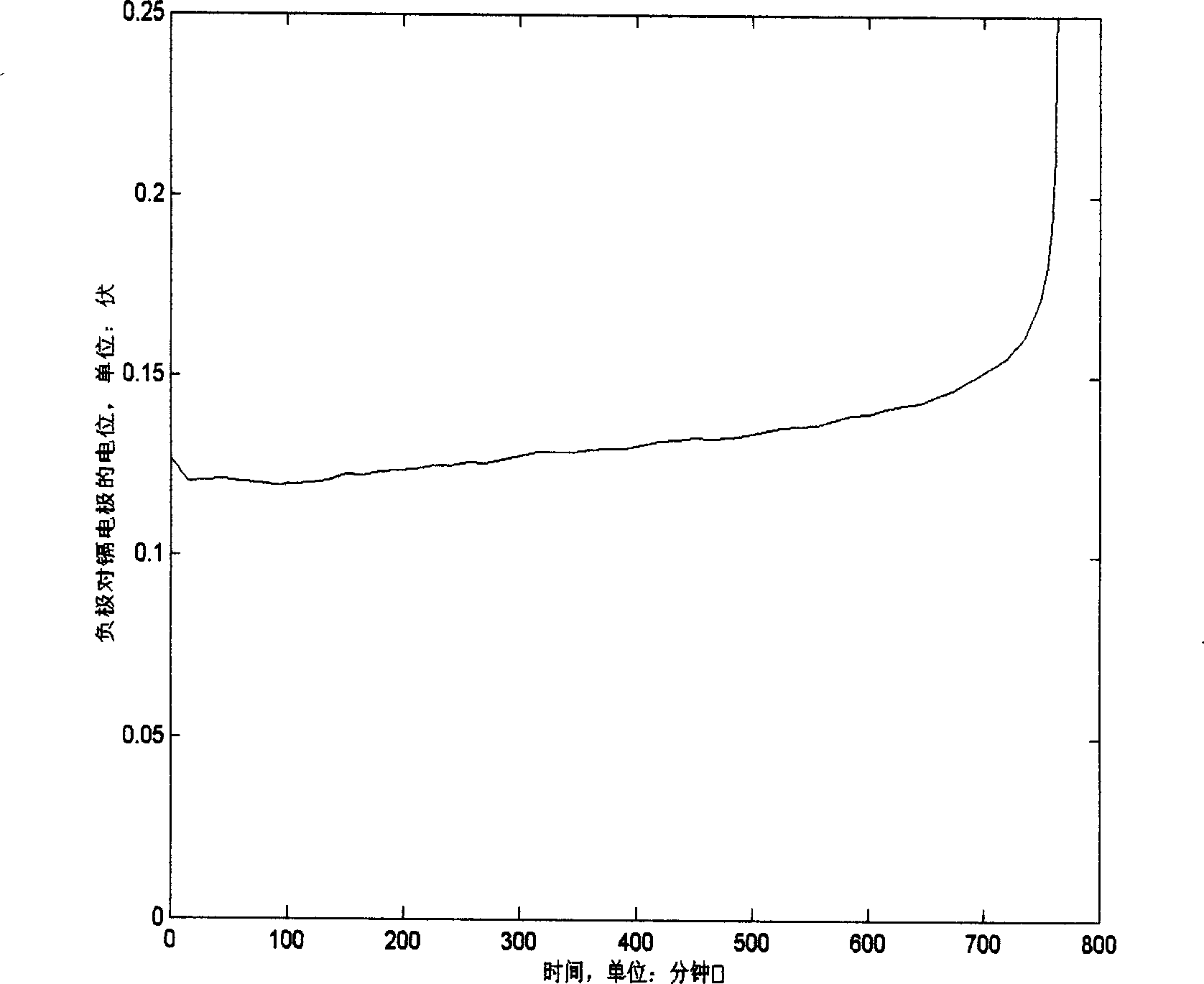

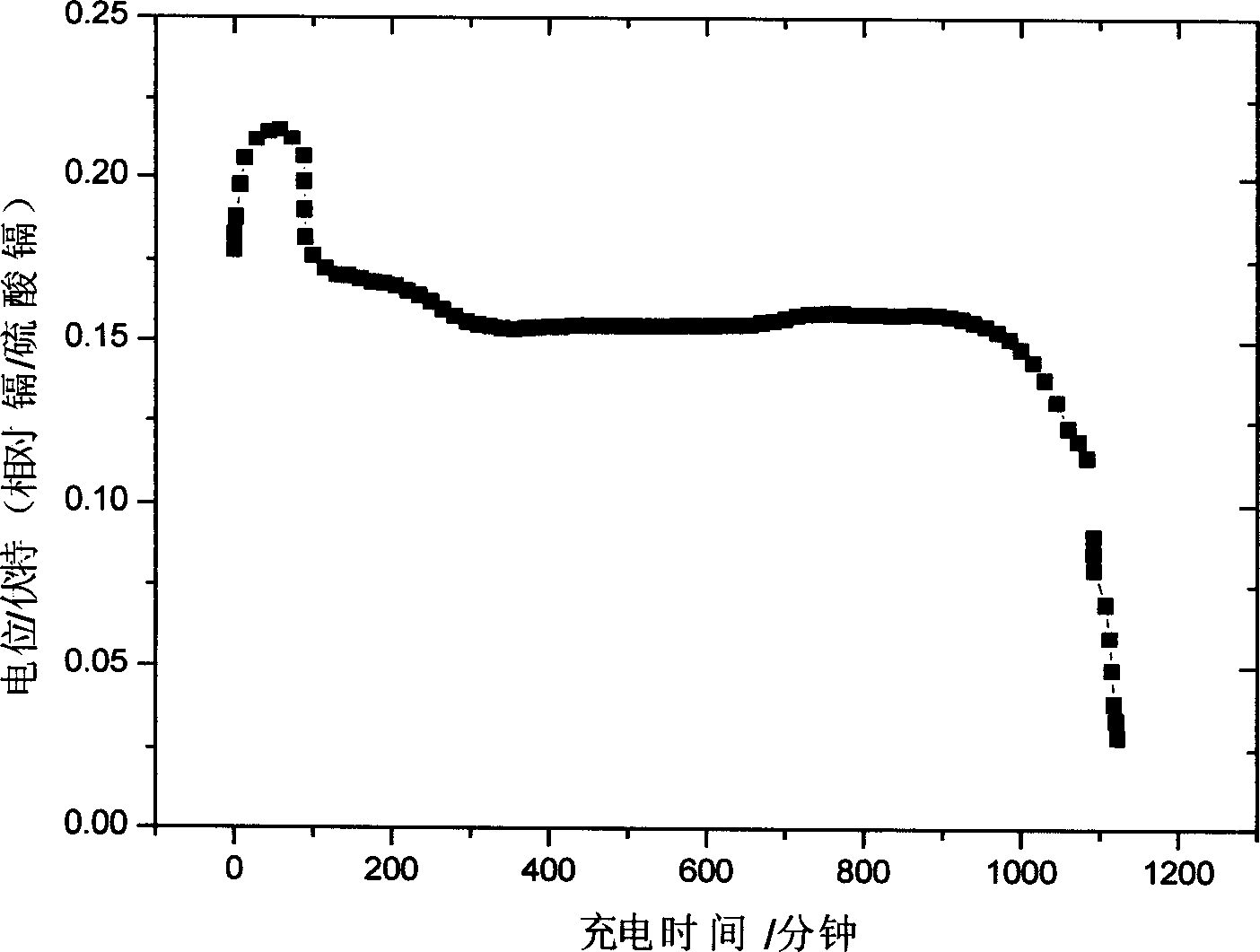

Method for preparing lead-acid battery negative pole

InactiveCN1426122AReduce production linksIncrease profitLead-acid accumulator electrodesElectricityLead carbonate

The present invention relates to the perparation process of lead-acid accumulator negative pole with lead carbaonate as material. It includes the following steps: grinding and sieving lead carbonate; imxing with additives and reaction with sulfuric acid to produce lead paste; painting the lead paste to Pb-Sb or Pb-Ca alloy slab lattice; setting the slab lattice into sodium sulfate and / or sulfuric acid solution for constant current compounding to obtain the negative pole board. Compared with traditional preparation process, the present invention has less steps, lower power consumption, high material utilizatino and thus lower production cost. The production process may be combined with the recovery of waste lead-acid accumulator to reuse material and reduce pollution.

Owner:WUHAN UNIV

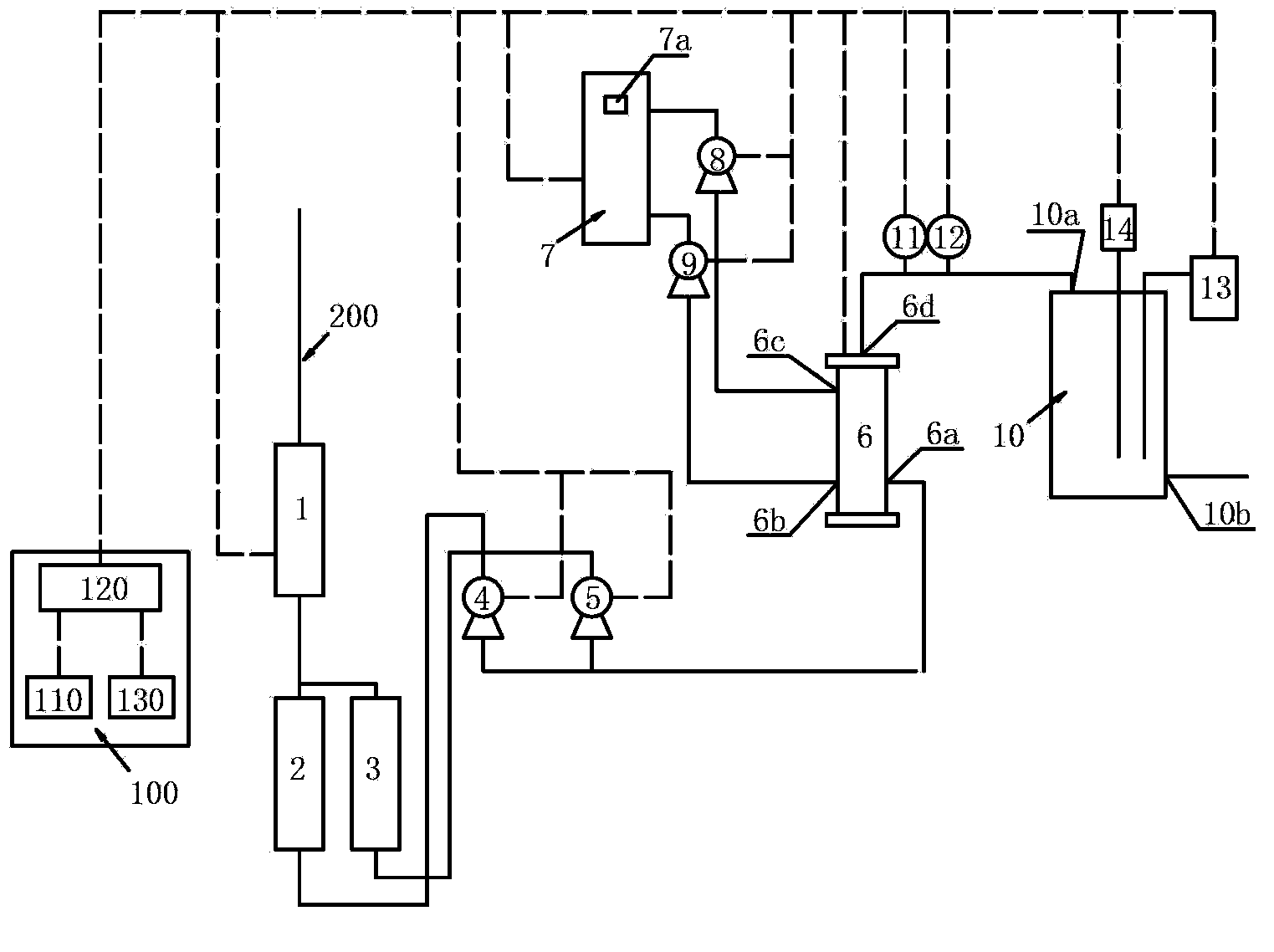

Diaphragm-free type device for circularly electrolyzing hypochlorous acid and sodium hypochlorite

ActiveCN104342715ASolve the problem of temperature riseSolve the problem of pickling and descalingCellsWater storage tankHypochlorous acid

The invention provides a diaphragm-free type device for circularly electrolyzing hypochlorous acid and sodium hypochlorite. The device comprises a water softener, a water storage tank, a sodium chloride storage tank, a water supply pump, a saline water conveying pump, a diaphragm-free type electrolytic cell, a hypochlorous acid and sodium hypochlorite storage tank and an electrical control system. The device is characterized in that the diaphragm-free type electrolytic cell is provided with a cooling electrolyte flow-in opening and an electrolyte flow-out opening; an electrolyte output pump, a heat exchanger and an electrolyte input pump are sequentially connected between the electrolyte flow-out opening and the cooling electrolyte flow-in opening; the electrical control system comprises a touch screen, a PLC control module and a rectifier; and control circuits are arranged among the PLC control module, the touch screen, the rectifier, the water softener, the water supply pump, the saline water conveying pump, a conductive electrode of the diaphragm-free type electrolytic cell, the heat exchanger, the electrolyte output pump and the electrolyte input pump. The diaphragm-free type device is high in electrolytic reaction speed, high in hypochlorous acid and sodium hypochlorite yield, high in conversion rate and low in running cost.

Owner:上海洁循实业有限公司

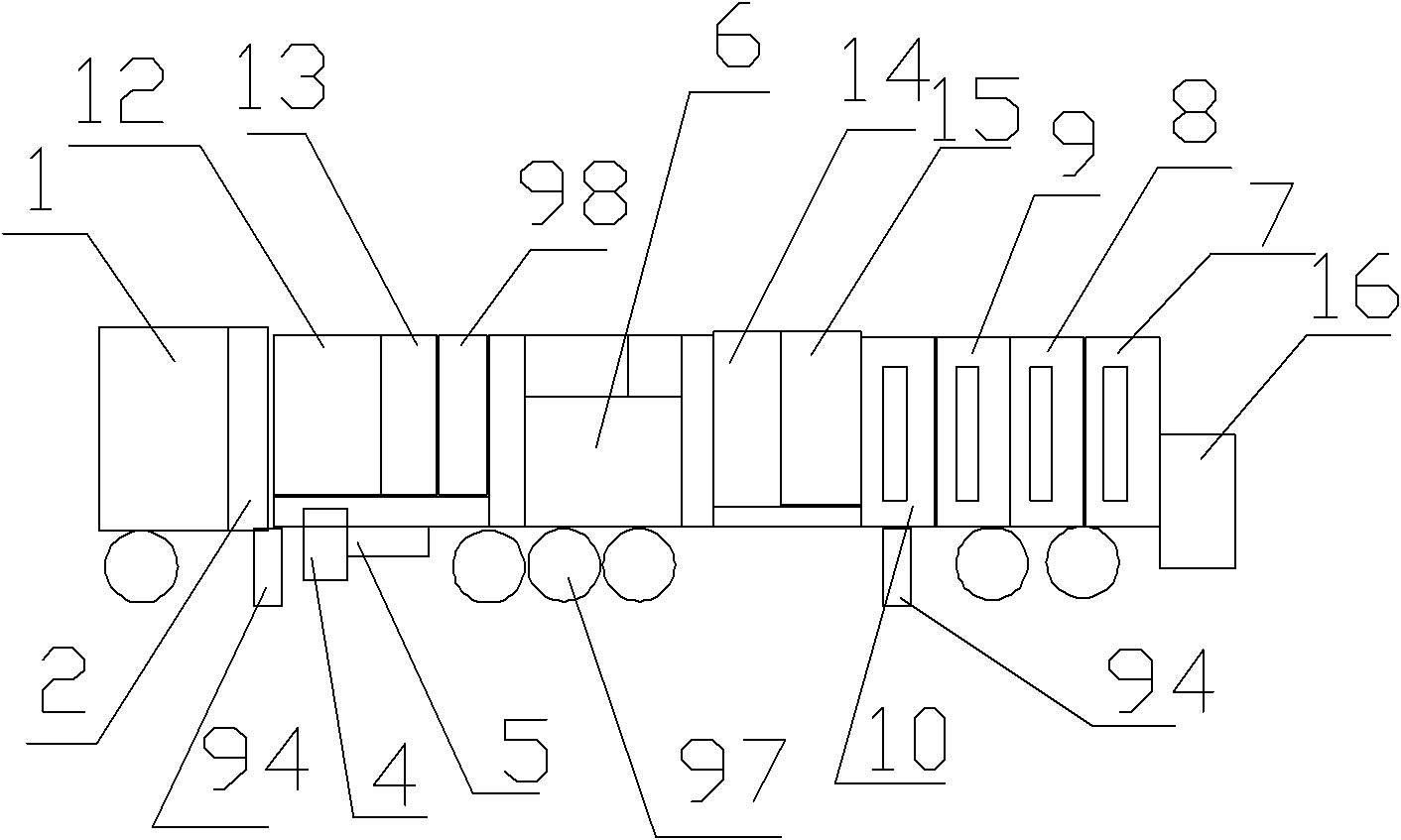

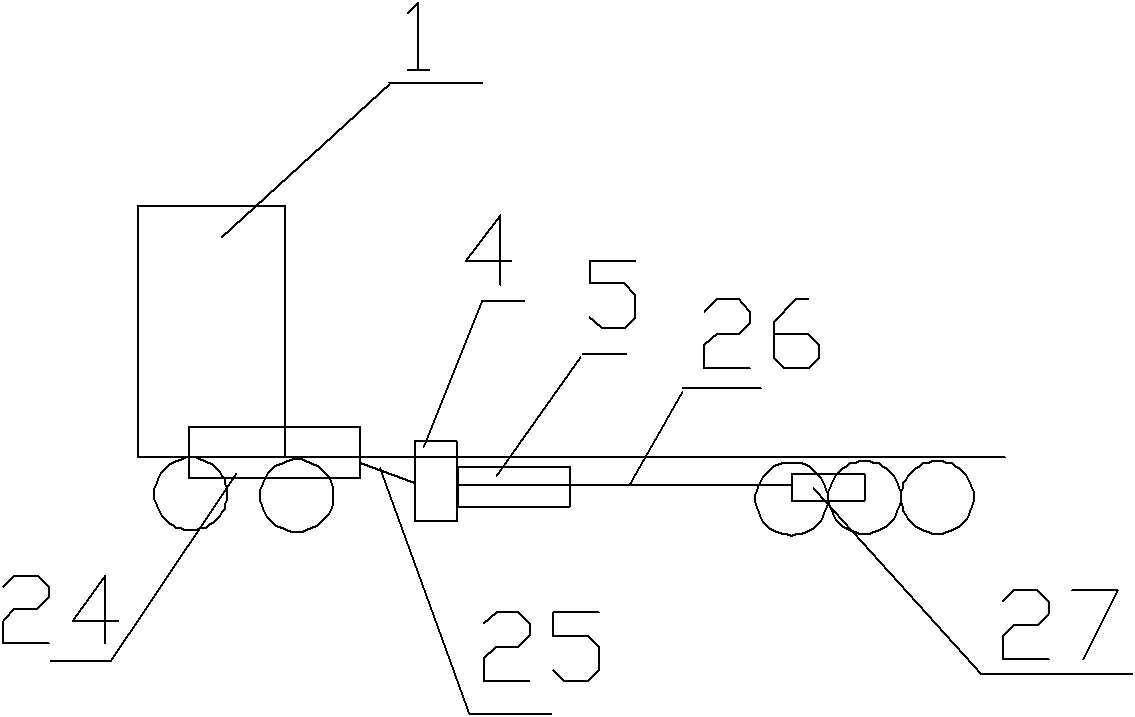

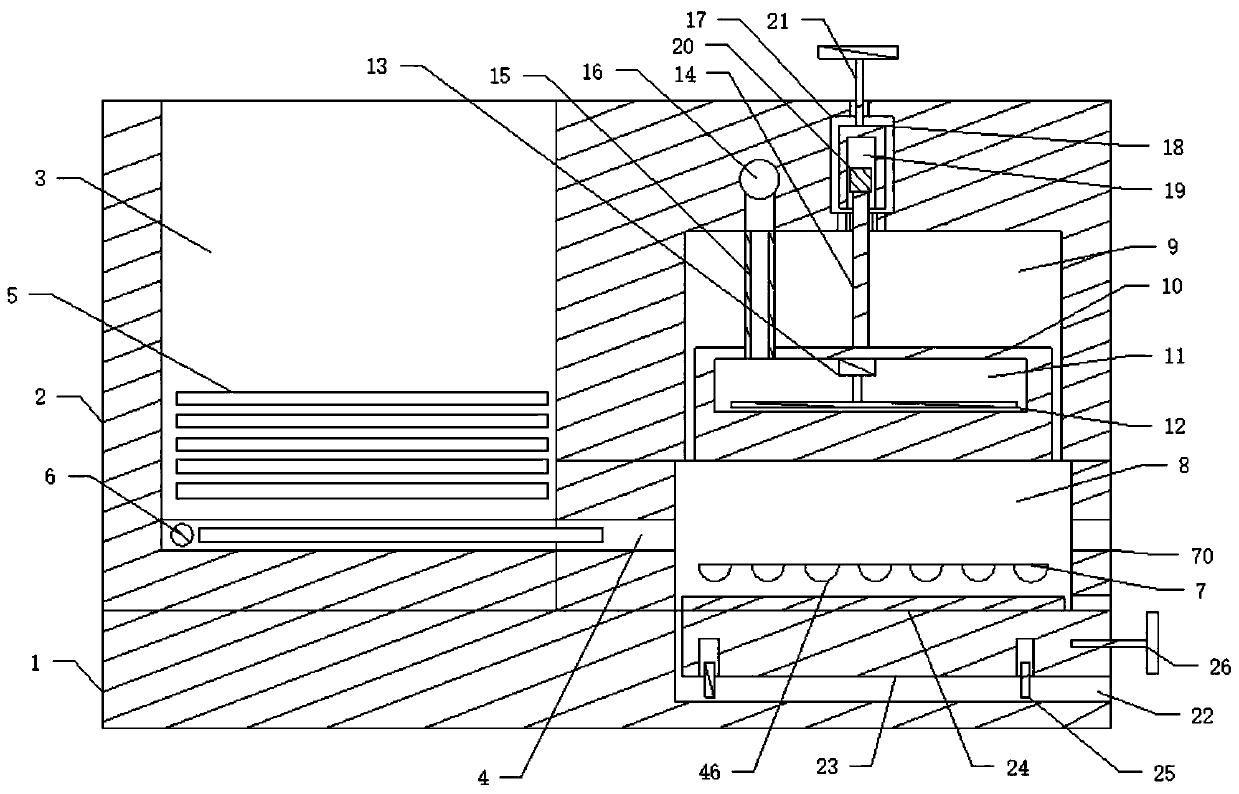

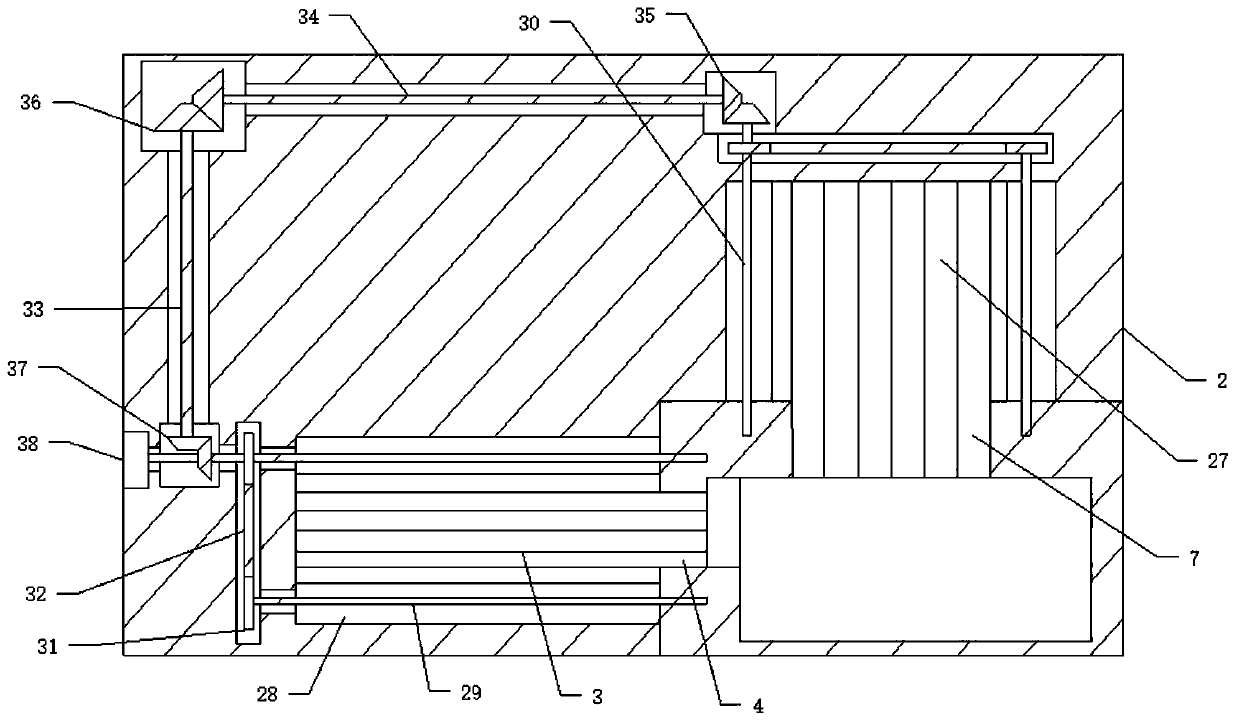

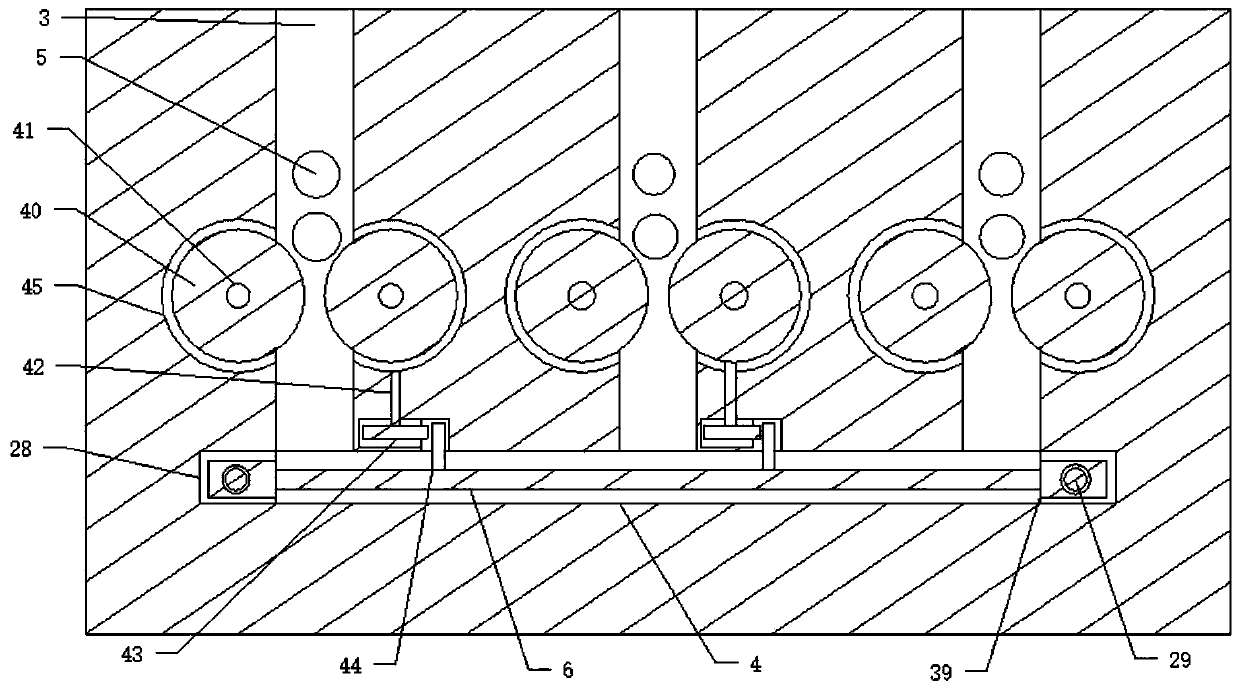

Arm support type concrete mixing pump truck

InactiveCN102094530ASimplify the manufacturing processGuaranteed normal productionBuilding material handlingEngineeringElectric control

The invention relates to a movable concrete mixing pump truck integrating concrete production with pumping into a whole, comprising an automobile cassis, wherein an electric control chamber, a power supplying device, a concrete mixing and pumping device, a powder storing device, a powder conveying device, a powder weighting device, an aggregate continuous loading device, an aggregate weighting device, an aggregate conveying device, a clear water storing device and a clear water weighting device are arranged on the automobile chassis; the powder conveying device is connected with the powder storing device and the powder weighting device; the powder weighting device is connected with an inlet of a mixing main machine; the aggregate continuous loading device is connected with the aggregate weighting device; and the aggregate weighting device is connected with the inlet of the mixing main machine through the aggregate conveying device. According to the arm support type concrete mixing pump truck, the functions of continuous loading, raw material storing, weighting, concrete mixing, conveying, concrete pumping, and the like on the concrete as the raw material are integrated on freely-movable equipment; and the arm support type concrete mixing pump truck has a simple structure and is practical.

Owner:金朝福

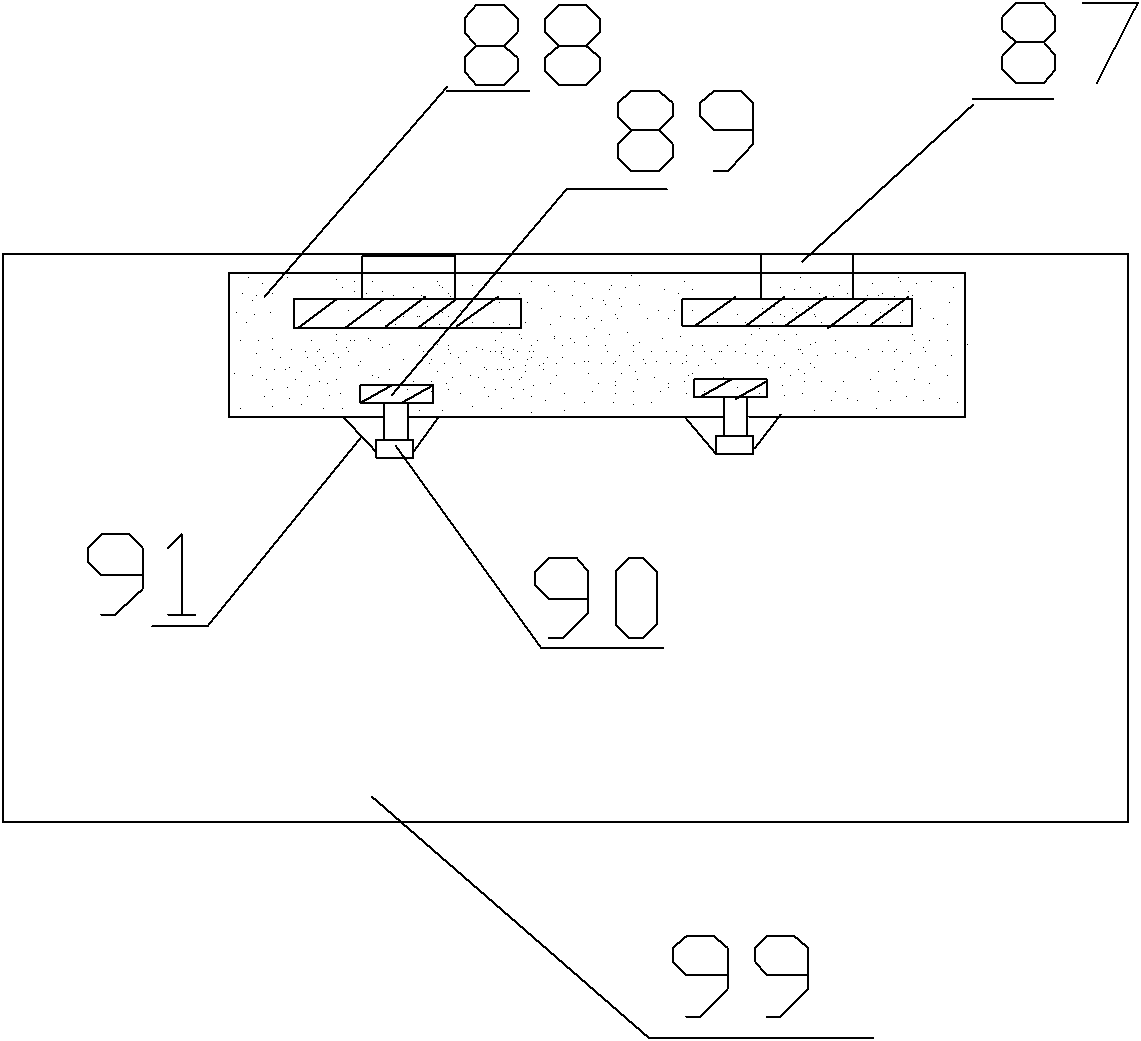

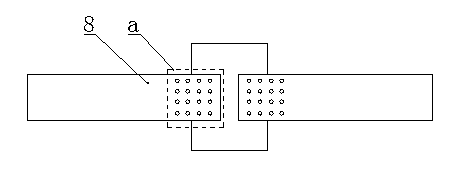

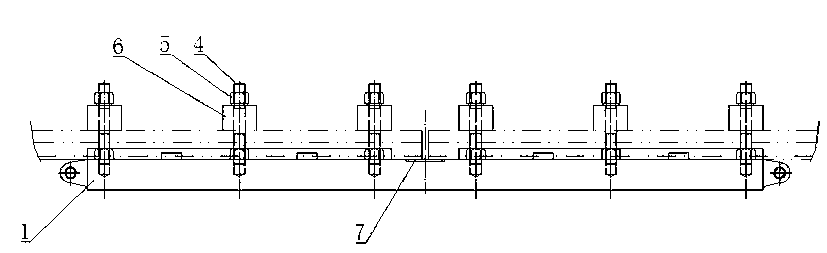

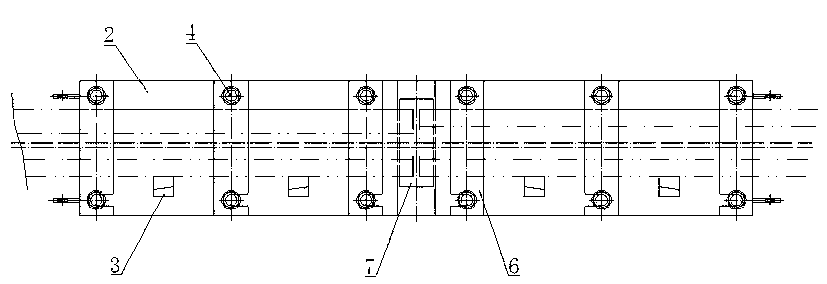

Wharf ship loader telescoping mechanism rail production process and special rail butt joint tool thereof

ActiveCN103192236AExtend your lifeReach the hardness requirementWelding/cutting auxillary devicesAuxillary welding devicesButt jointMedium frequency

The invention relates to a wharf ship loader telescoping mechanism rail production process and a special rail butt joint tool thereof. The production process includes the steps: producing two rail subsections; performing hardening and hardness measurement to the rail subsections; carrying out preparations before rail subsection welding, clamping the two rail subsections by the aid of the special rail butt joint tool to enable ends of the two rail subsections to be aligned and gapped, and performing weld preheating for the rail subsections; welding the rail subsections; performing postwelding heat insulation; and finally performing postwelding polishing and inspection. The machined rail subsections are subjected to medium-frequency hardening and then are in butt joint to form a whole. Joints are gapless, corrosion is less prone to occur, and service life of a rail is prolonged. Hardening of the whole rail is not needed, production cost is reduced, requirement on rail hardness is net, joints are less prone to cracks, and product quality is guaranteed.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

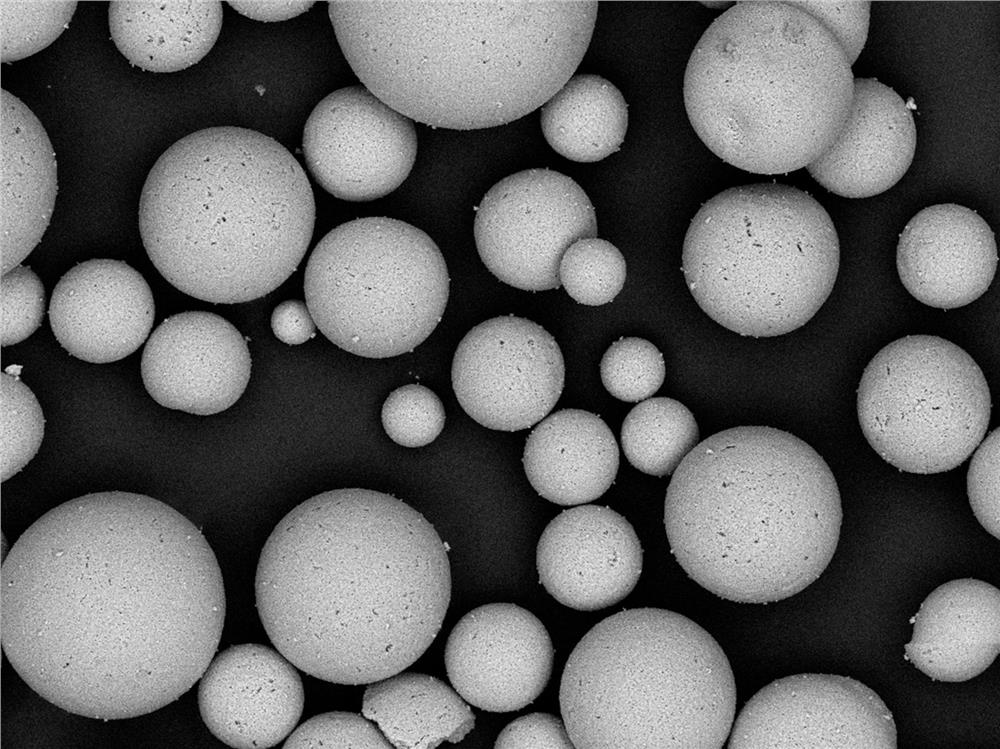

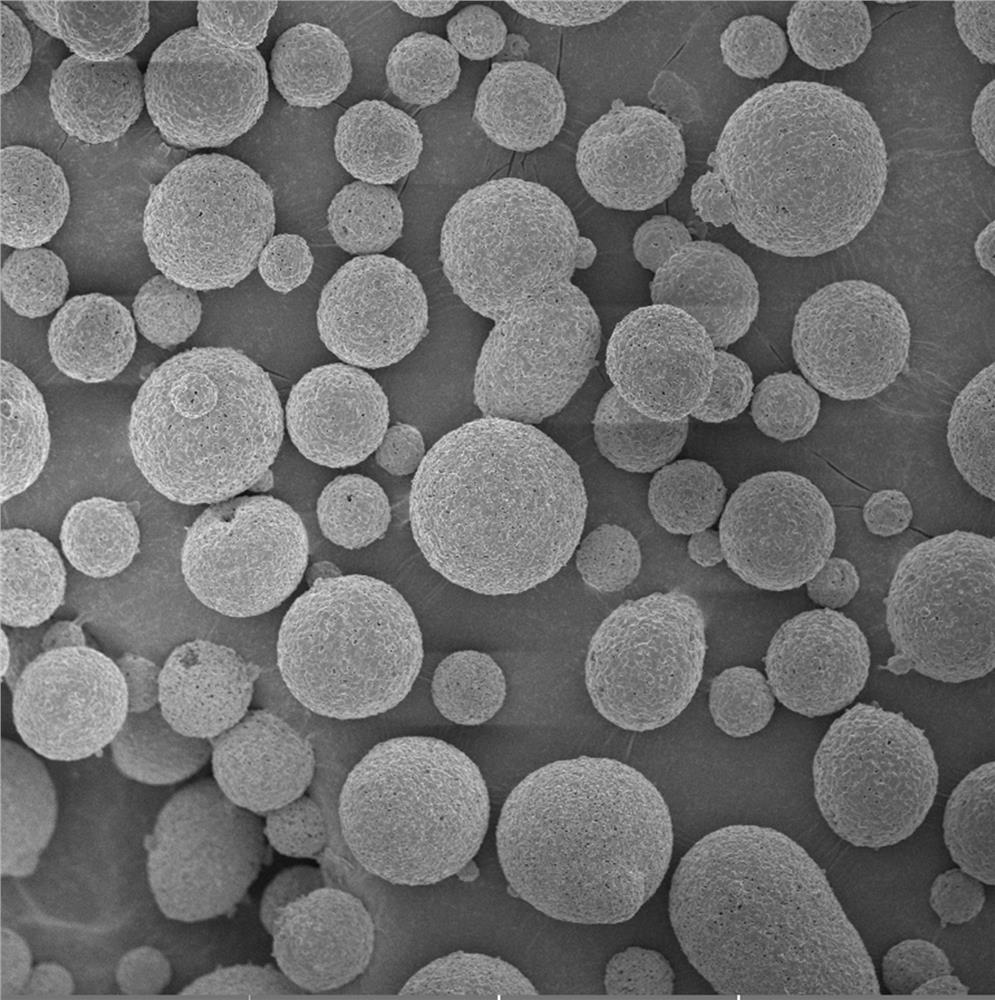

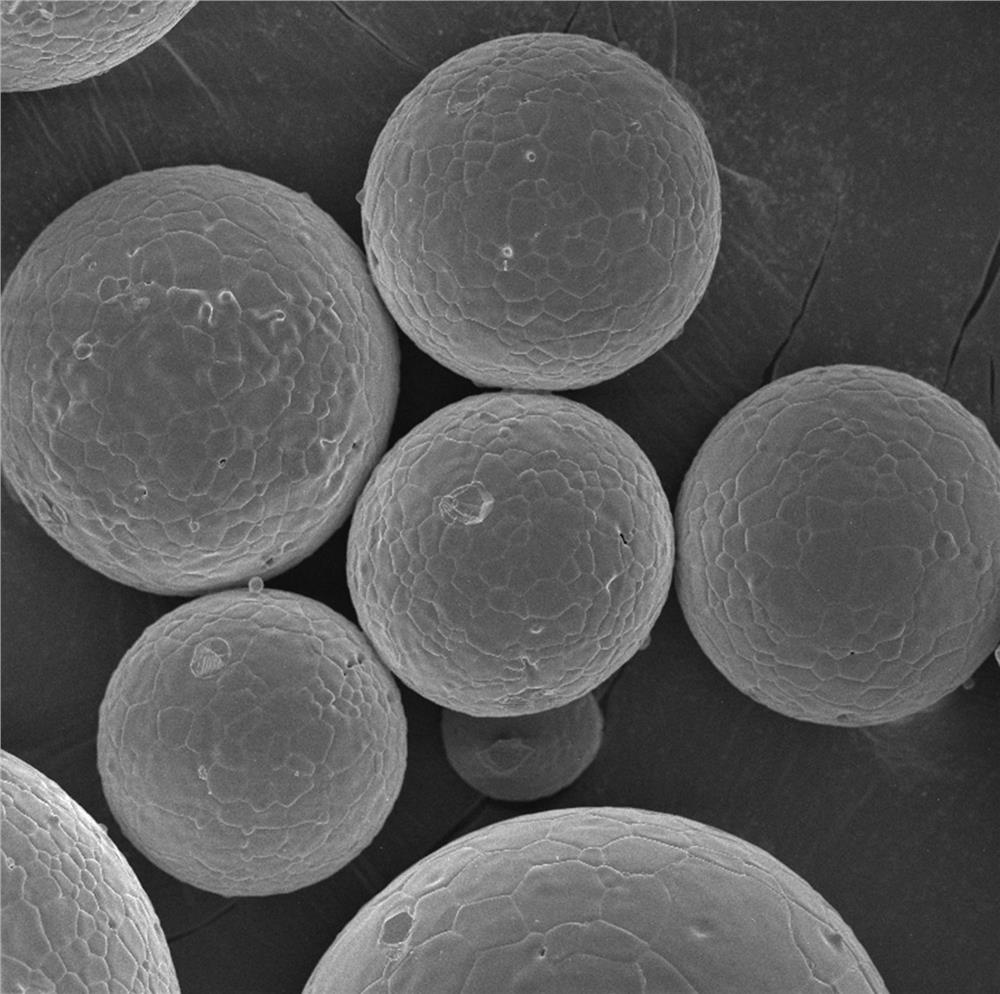

Preparation method of spherical yttrium oxide powder for high apparent density thermal spraying

PendingCN112209419AGuaranteed uniformityLow bulk densityRare earth metal compounds preparation/treatmentYittrium oxides/hydroxidesMicrowave sinteringSpray dried

The invention discloses a preparation method of spherical yttrium oxide powder for high apparent density thermal spraying. The method comprises the following steps: 1, preparation of yttrium oxide slurry: adding high-purity yttrium oxide serving as a raw material into a mixing container, adding deionized water into the mixing container, stirring, blending into slurry, adding a binder into the slurry, uniformly mixing, putting the mixed slurry into a sand mill, and carrying out high-speed ball milling to obtain yttrium oxide slurry; then guiding the slurry obtained after high-speed ball millingout of a sand mill, and obtaining yttrium oxide slurry; 2, spray granulation: putting the yttrium oxide slurry obtained in the step 1 into a spray dryer to prepare spherical yttrium oxide powder; and3, high-temperature sintering: placing the spherical yttrium oxide powder obtained in the second step in a high-temperature sintering furnace to be sintered, and performing high-temperature sinteringin two stages. According to the method, the solid content of the slurry is increased and microwave sintering is adopted in the preparation process, so that the spherical yttrium oxide powder for thermal spraying with high apparent density can be prepared, and the method is simple in process, free of chemical reaction and controllable in process adjustment.

Owner:湖南威斯康新材料科技有限公司

Method for preparing dipeptidyl peptidase IV (DPP-IV) inhibitory peptide through using hairtail

ActiveCN103333940BCompletely hydrolyzedFacilitated releasePeptide preparation methodsFermentationDipeptidyl peptidaseEnzymatic hydrolysis

The invention discloses a method for preparing a DPP-IV inhibitory peptide through using hairtail. The method is characterized in that the method comprises the following steps: adding water to hairtail, and rubbing to form a uniform fish flesh pulp; putting the fish flesh pulp in an enzymatic hydrolysis tank, adding endo protease, and carrying out stirring hydrolysis for 4-12h to obtain a hydrolysate; heating to 95-100DEG C, and maintaining the temperature unchanged for 10-15min for enzyme killing; cooling the hydrolysate to 40-60DEG C, adding exoproteinase, and carrying out stirring hydrolysis for 2-8h; heating to 95-100DEG C, and maintaining the temperature unchanged for 10-15min for enzyme killing; centrifuging the obtained enzyme-killed hydrolysate, and taking the obtained supernatant; adding the supernatant to an ultrafilter membrane separator, adjusting the pressure and the interception molecular weight of the ultrafilter membrane to 0.05-0.1MPa and 3000Da respectively, and collecting an ultrafilter membrane permeate liquid; and separating and purifying the DPP-IV inhibitory peptide through adopting an affinity chromatography process. The method has the advantages of simple technology, low production cost and short production period.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

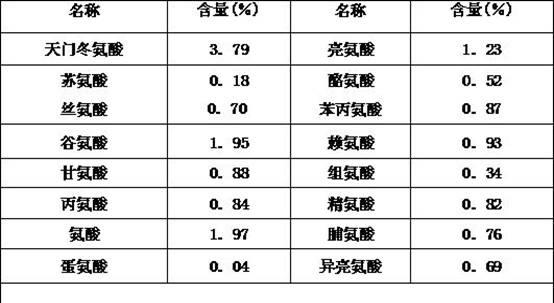

Method for preparing Gynura divaricata tea

InactiveCN102578334ASolve carrying problemsGuaranteed normal productionTea substituesAir blowerMechanical engineering

The invention relates to a method for preparing Gynura divaricata tea, comprising the following steps: (1) withering slightly: spreading the fresh leaves of Gynura divaricata on a meshed bed plate uniformly, and blowing the Gynura divaricata leaves from the bottom surface of the meshed bed plate by using an air blower; (2) deactivating enzyme in the Gynura divaricata leaves: arranging an air blower on the inlet of an enzyme deactivating machine and a water vapor discharge device on the tail part of the enzyme deactivating machine, and discharging the water vapor in the enzyme deactivating machine rapidly; (3) rolling and twisting the Gynura divaricata leaves: putting the Gynura divaricata leaves into a rolling and twisting machine, and rolling and twisting the Gynura divaricata leaves; (4) drying the Gynura divaricata leaves: making the rolled and twisted Gynura divaricata leaves dried nearly; and (5) frying and shaping the Gynura divaricata leaves: putting the Gynura divaricata leaves in a frying rotary drum, frying, shaping and polishing. Due to the adoption of the industrial method, the loss of a variety of amino acids and trace elements in the Gynura divaricata tea is slight. The Gynura divaricata tea prepared by adopting the method is very convenient to drink, store and carry.

Owner:BENGBU BUILD GOLD MOON GRASS SCI & TECH DEV

Manufacturing method of large ink

The invention relates to a manufacturing method of large ink. The manufacturing method mainly comprises the steps of making a pattern, refining smoke, mixing glue, pestling, making ink and molding, sizing and drying the ink, wherein the step of mixing glue means that a smoke material and a sizing material are stirred for 6-8 minutes by using a blender, the step of making ink and molding means that a molded ink blank is put on a mass fire plate, two to four 300W-electric furnaces are arranged under the mass fire plate for heating the mass fire plate to reach 70 DEG C to 90 DEG C, the step of sizing means that compression molding is carried out on the ink blank by using a four-bar ink pressing machine for 0.5-3 hours, and the step of drying ink means that the ink is dried for 6-12 months in a natural indirect ventilation condition. The ink manufactured by the method is larger in appearance, different in shape and convenient to enjoy and store; and the additional value of the product is improved.

Owner:HUANGSHAN SHEXIAN JUMOTANG INK IND

Zinc oxide resistor disc and preparation method and application thereof

ActiveCN111606703AThe content is easy to controlRaise the potential gradientResistor manufactureVaristor coresElectrical resistance and conductanceElectrical current

The invention relates to the technical field of piezoresistor discs for lightning arresters, in particular to a zinc oxide resistor disc and a preparation method and application thereof. The zinc oxide resistor disc provided by the invention is prepared from the following raw materials in percentage by mole: 85-95% of ZnO, 0.01-4.0% of Bi2O3, 0.01-4.0% of Sb2O3, 0.05-3.0% of Co2O3, 0.01-2.0% of MnO2, 0.01-3.0% of NiO, 0.01-2.0% of Fe2O3, 0.01-2.0% of A12O3, and 0.01-2.0% of Dy2O3. According to the zinc oxide resistor disc provided by the invention, a toxic substance Cr2O3 does not need to be added, various components including ZnO, Bi2O3, Sb2O3, Co2O3, MnO2, NiO, Fe2O3, Al2O3 and Dy2O3 cooperate with each other, such that the zinc oxide resistor disc has the excellent performances of highpotential gradient, high square wave through-flow capacity, low residual voltage, high square wave current and large current impact resistance, good aging resistance and the like.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +6

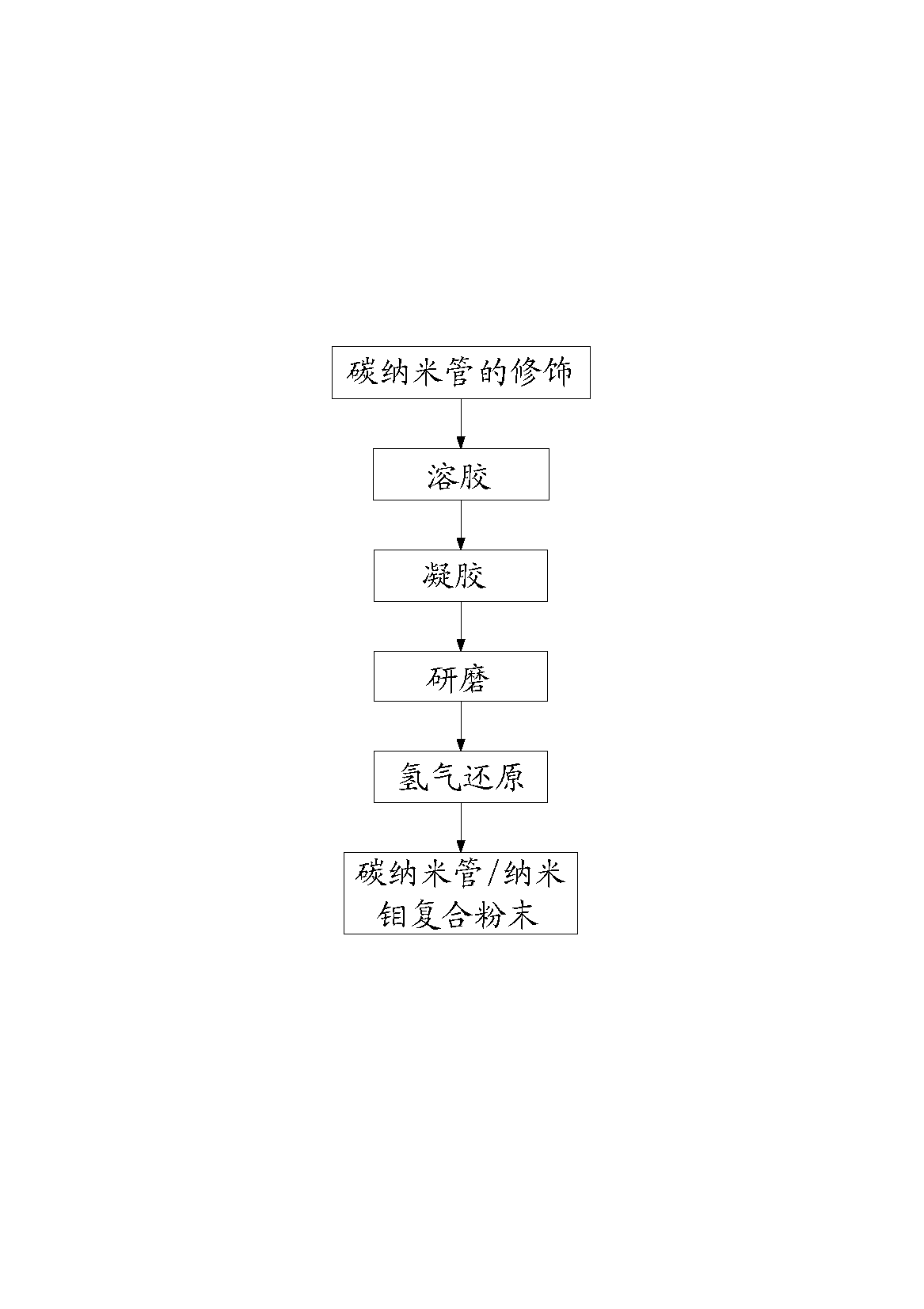

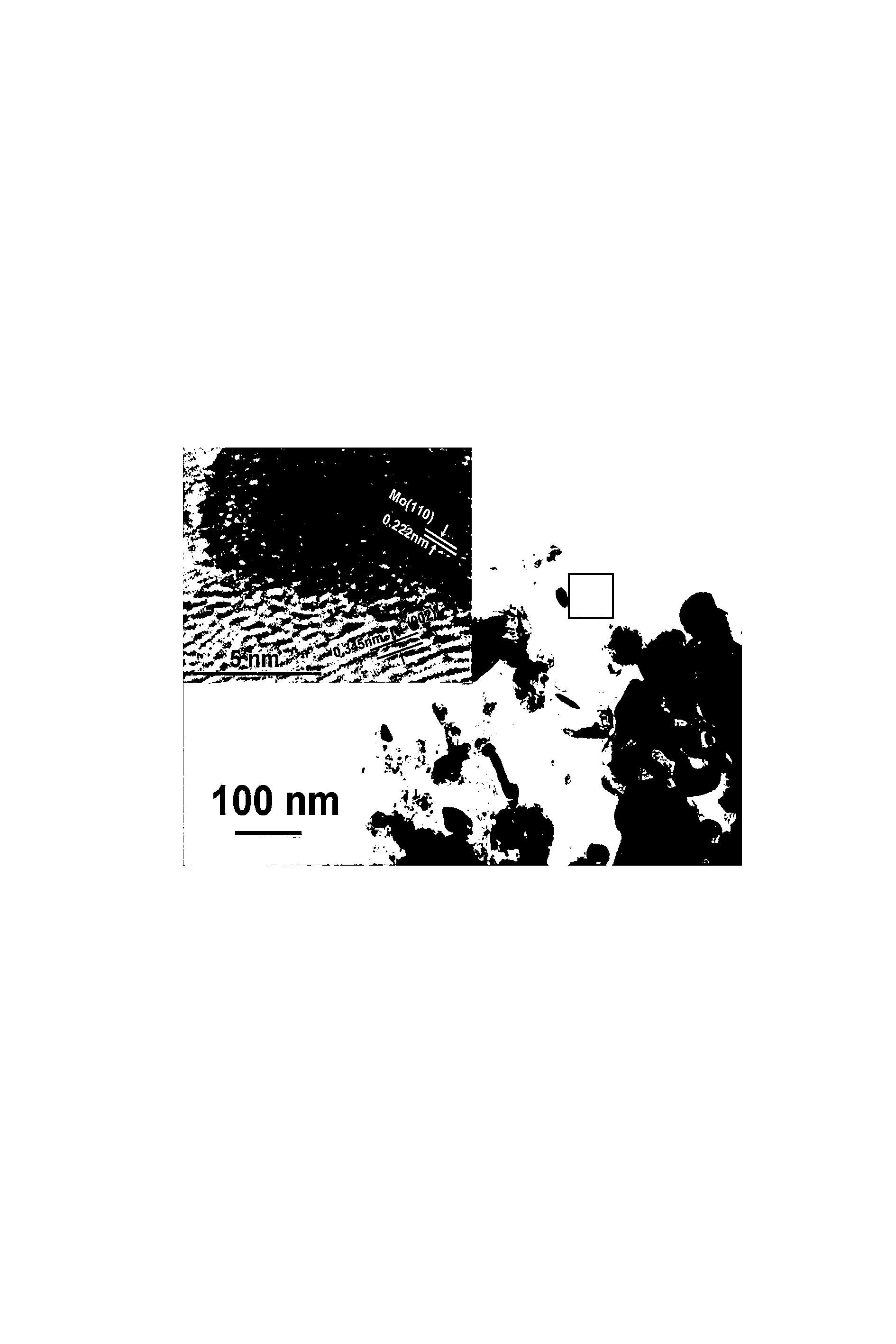

Preparation method of nanometer molybdenum powder containing homodisperse carbon nano tubes

The invention discloses a preparation method of nanometer molybdenum powder containing homodisperse carbon nano tubes. The carbon nano tubes and ammonium paramolybdate are selected as raw materials, hydrogen is used as reduction carrier gas, adsorption characteristics of the carbon nano tubes on nanometer molybdenum particles are utilized, and then carbon nano tube / nanometer molybdenum powder composite powder is prepared by utilizing the adsorption characteristics of the carbon nano tubes on the nanometer molybdenum particles. The preparation technology process is modification of the carbon nano tubes-gel dissolving-gel coagulation-grinding-hydrogen gas reduction-carbon nano tube / nanometer molybdenum powder composite powder. According to the preparation method, the carbon nano tube / nanometer molybdenum powder composite powder is prepared by utilizing the adsorption characteristics of the carbon nano tubes on the nanometer molybdenum particles, through modification on the carbon nano tubes and mixing the carbon nano tubes and ammonium paramolybdate solution, and by adopting gel dissolving and gel coagulation and reduction process. The average grain diameter of the prepared molybdenum powder is 20-80nm, the carbon nano tubes can be dispersed evenly in the nanometer molybdenum powder, and industrial mass production can be achieved easily.

Owner:XIAMEN UNIV OF TECH

High-yield synthetic method for DD3R molecular sieve film

ActiveCN106621858AEasy to synthesizeSmall fluxMembranesSemi-permeable membranesMolecular sieveInorganic particle

The invention discloses a high-yield synthetic method for a DD3R molecular sieve film. The high-yield synthetic method comprises the following steps: mixing a sigma-1 molecular sieve with inorganic particles to prepare a carrier; further crystalizing a DD3R molecular sieve layer on the carrier by adopting a secondary growth method; finally preparing the DD3R molecular sieve film layer by adopting a hierarchical sintering method. The molecular sieve film prepared by the method has the advantages of prevention of defects and high yield.

Owner:山东嘉驰新材料股份有限公司

Internet of Things system for flame glass fiber production

InactiveCN108900592AEasy to useGuaranteed normal productionGlass making apparatusTransmissionAutomatic controlInternet of Things

The invention discloses an Internet of Things system for flame glass fiber production, which is composed of three parts of a material homogenization Internet of Things subsystem, a flame injection Internet of Things subsystem and a glue-spreading collecting cotton Internet of Things subsystem. A signal acquisition module acquires state signals in the material homogenization Internet of Things subsystem, the flame injection Internet of Things subsystem and the glue-spreading collecting cotton Internet of Things subsystem, the signals are transmitted through a signal transmission module connected with the signal acquisition module, the signals are processed by a signal processing module connected with the signal transmission module, the transmitted data information can be subjected to algorithm analysis according to a large database, a regulation instruction is formed, feedback is carried out by an information feedback module, the response adjustment time is shortened, the information feedback module feeds the data information back to the material homogenization Internet of Things subsystem, the flame injection Internet of Things subsystem and the glue-spreading collecting cotton Internet of Things subsystem, and closed-loop automatic control is realized.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

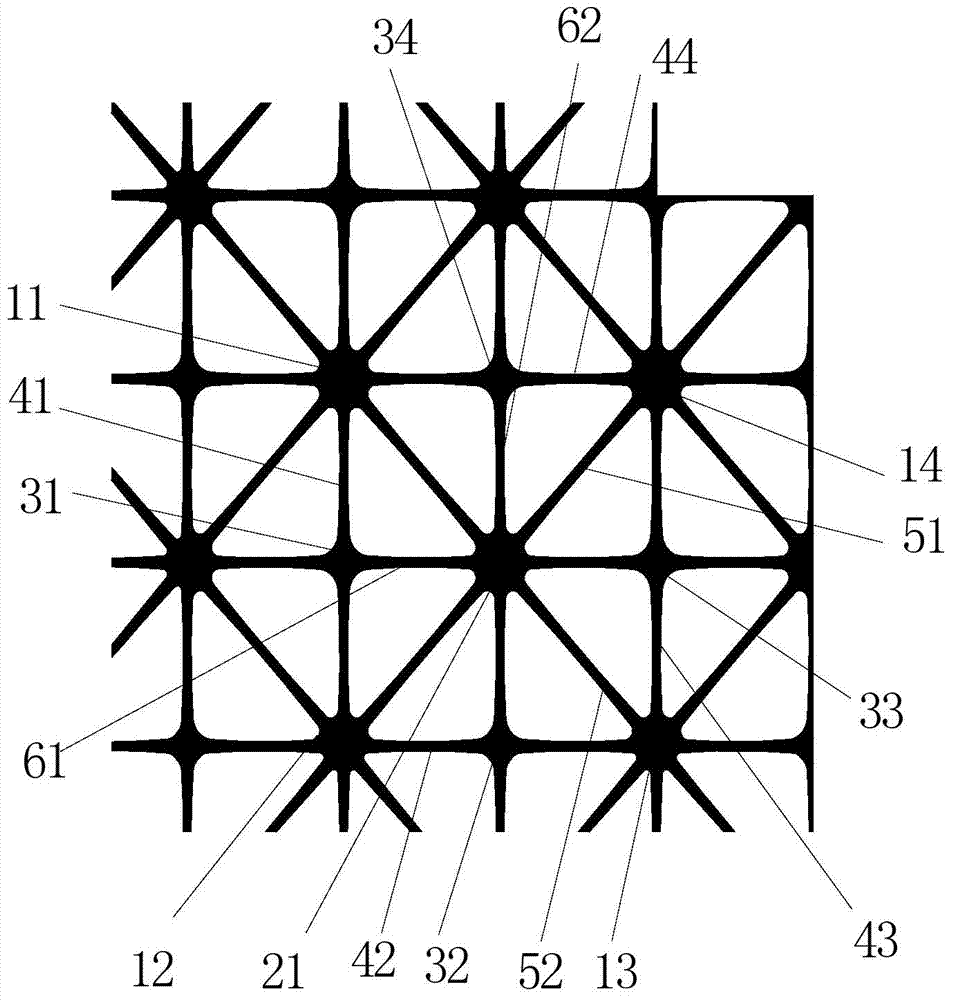

Four-directional grille

A four-way grid, comprising a plurality of nodes and a plurality of ribs, wherein the nodes and the ribs are connected to form a plurality of rectangular units. Each of the rectangular units comprises four first nodes (11, 12, 13, 14) which are located at four vertexes of a rectangle, and a second node (21) which is located at the point of intersection of diagonal lines of the rectangle, and also comprises first ribs (41, 42, 43, 44) which are located in the directions of the sides of the rectangle and are connected to every two adjacent first nodes of the first nodes (11, 12, 13, 14), third nodes (31, 32, 33, 34) which are located at the midpoints of all of the sides of the rectangle, second ribs (51, 52) which are located on the diagonal lines of the rectangle, and third ribs (61, 62) which pass through the second nodes (21) and are connected to each of the third nodes (31, 32, 33, 34), wherein the thickness of each of the nodes is greater than that of each of the ribs.

Owner:TAIAN MODERN PLASTIC

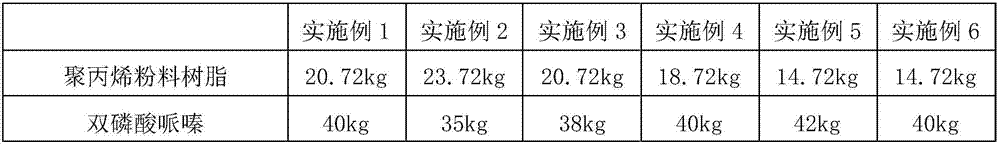

Halogen-free flame-retardant polypropylene master batch and preparation method thereof

ActiveCN107266786AGood flame retardant synergyImprove flame retardant performancePentaerythritolPolypropylene

The invention discloses a halogen-free flame-retardant polypropylene master batch and a preparation method thereof. According to the halogen-free flame-retardant polypropylene master batch, a halogen-free composite flame retardation system is composed of piperazine diphosphate, a melamine salt of pentaerythritol diphosphate, melamine cyanurate and triphenyl phosphate; and the flame retardation system has good flame retardation synergism and good high temperature resistance and can obtain good resistance to hydrolysis precipitation without any treatment, so the flame retardation system is not prone to hydrolysis precipitation in the forming process of the master batch.

Owner:南通顺裕包装材料有限公司

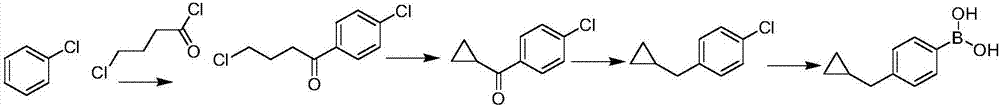

Method for preparing 4-cypro methylene phenylboronic acid

InactiveCN106986887AGuaranteed normal productionReduce manufacturing costGroup 3/13 element organic compoundsPhenylboronic acidChlorobenzene

The invention discloses a method for preparing a 4-cypro methylene phenylboronic acid, and relates to the technical field of organic synthesis. The chlorobenzene is taken as the starting material, is subjected to a friedel-crafts reaction to generate 4-butanoyl chloride chlorobenzene, is subjected to a ring-closure reaction to generate 4-cypro formyl chlorobenzene, is subjected to a reduction reaction to generate 4-cypro methylene chlorobenzene, and is finally subjected to a Grignard boric acid reaction to generate the 4-cypro methylene phenylboronic acid. The cheap chlorobenzene, which is easy to get, is taken as the starting material, the preparation cost is remarkably lowered, the total molar yield of the product of 4-cypro methylene phenylboronic acid prepared through the 4-cypro methylene phenylboronic acid, the ring-closure reaction, the reduction reaction and the Grignard boric acid reaction is more than 35%, the production of the product is guaranteed on the basis of the low cost, and the method is suitable for industrial production.

Owner:BENGBU CHINA SYNCHEM TECH CO LTD

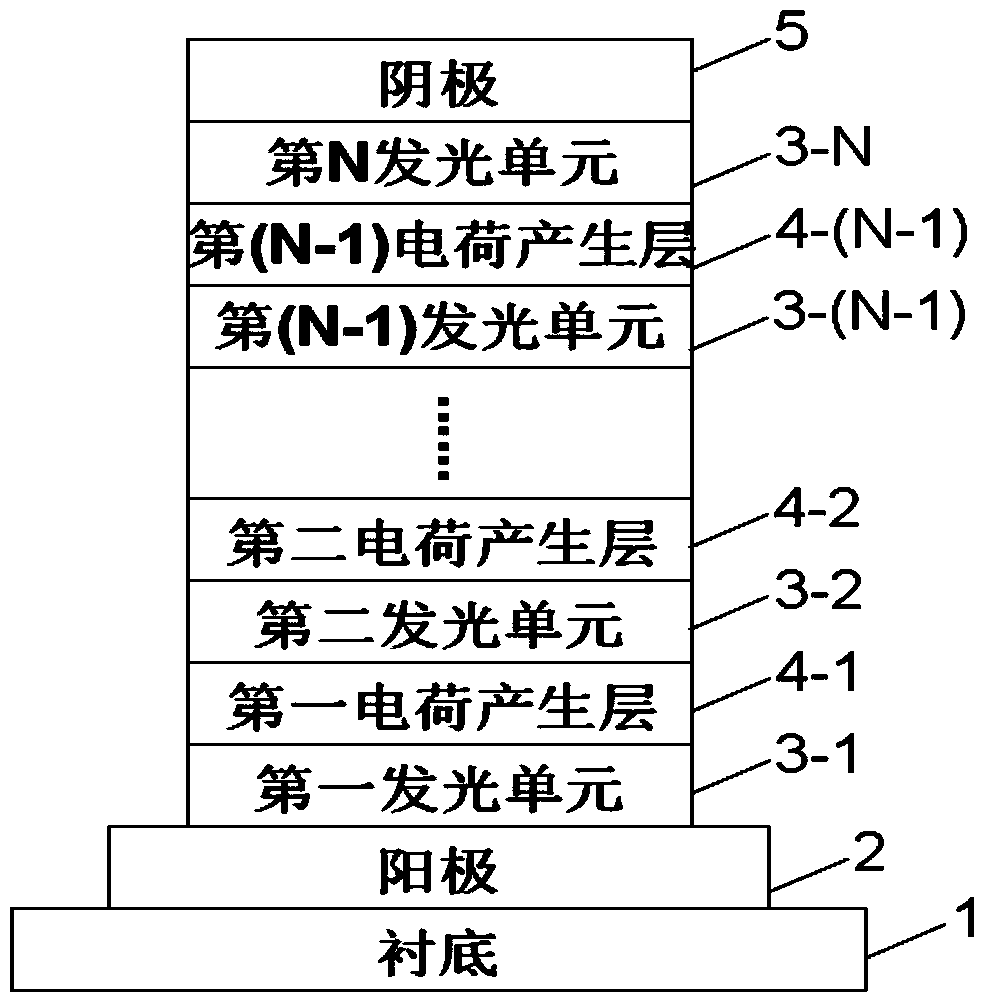

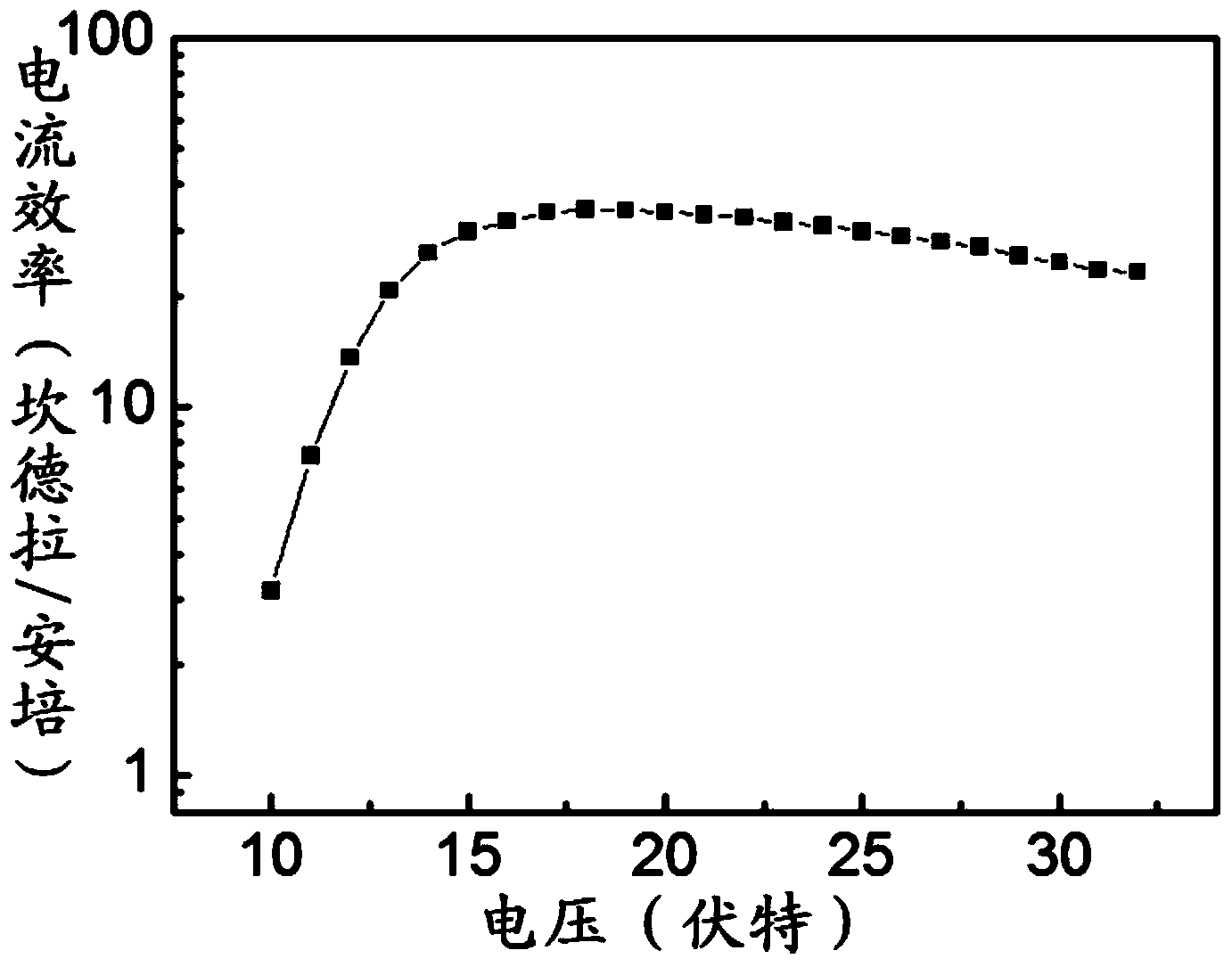

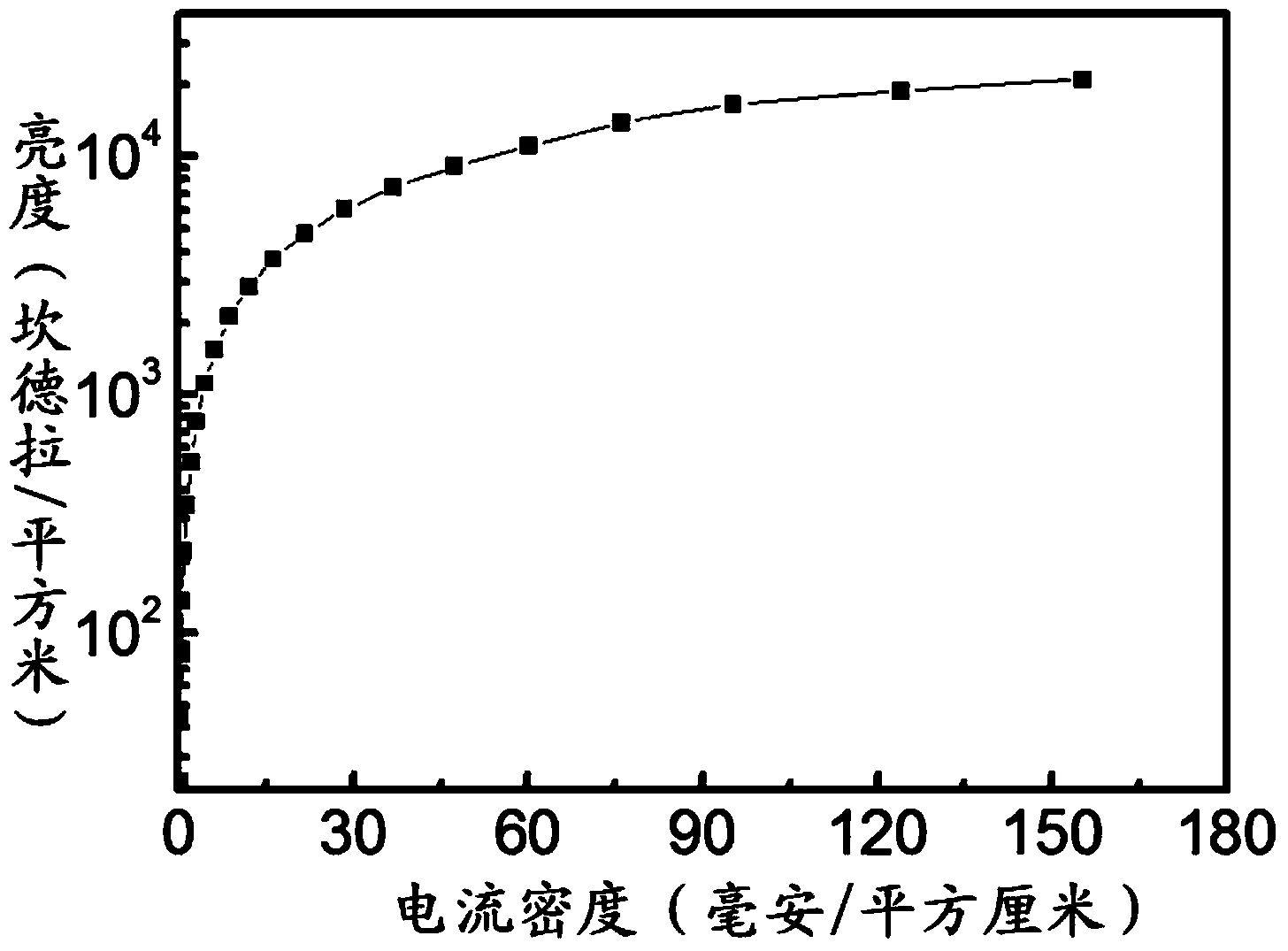

Laminated organic electroluminescent device based on single-layer light emitting units

InactiveCN103730588AReduce in quantityEasy to manufactureSolid-state devicesSemiconductor/solid-state device manufacturingDopantCharge carrier

The invention discloses a laminated organic electroluminescent device based on single-layer light emitting units, and belongs to the technical field of organic electroluminescent devices. The device is composed of a substrate, an anode, the single-layer organic light emitting units, electric charge generating layers and a cathode in sequence. The single-layer organic light emitting units and the electric charge generating layers are arranged alternately. The single-layer organic light emitting units are formed by doping organic luminescent dye in parent materials as dopant, organic materials with the high hole mobility are adopted as the parent materials of the light emitting units on odd layers, and organic materials with the high electronic mobility are adopted as the parent materials of the light emitting units on even layers. Due to the fact that the single-layer structure is adopted in the light emitting units, the number of the function layers of the laminated device is reduced, and the laminated device can be manufactured conveniently. In addition, due to the fact that the carrier transport polarity of the organic materials adopted by the electric charge generating layers is inconsistent with that of the parent materials of the adjacent single-layer light emitting units, it is guaranteed that the exciton recombination area of each light emitting unit is far away from the anode and the cathode, the exciton cancellation effect in a traditional single-layer device is weakened, and it is guaranteed that the laminated device of the structure has good performance.

Owner:JILIN UNIV

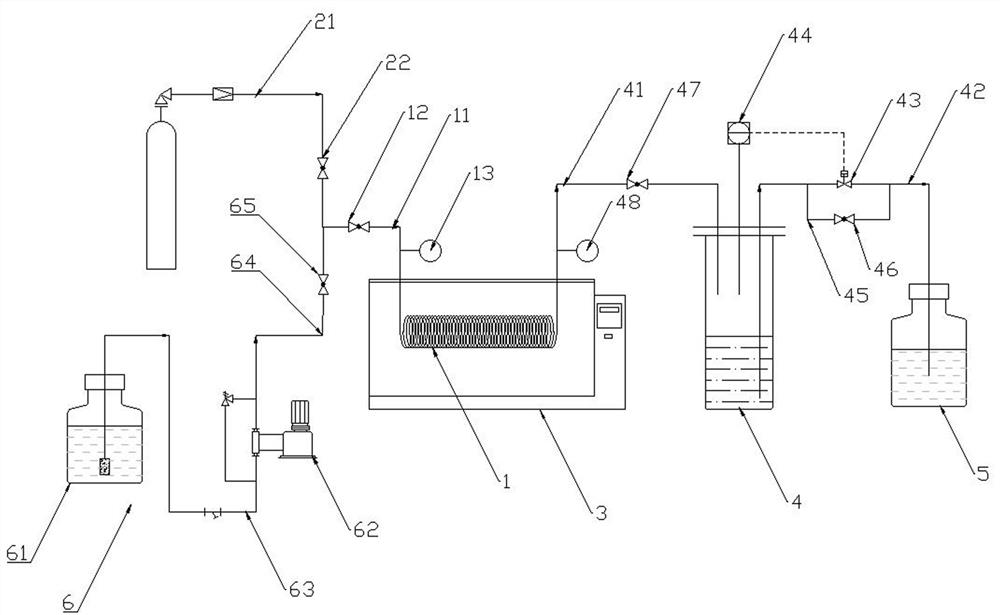

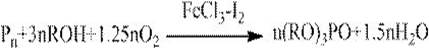

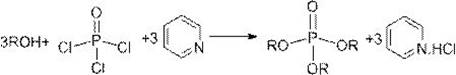

Pipelined continuous preparation method and device of triisoamyl phosphate for spent fuel post-treatment

ActiveCN112225754ARealize continuous productionGuaranteed normal productionGroup 5/15 element organic compoundsPressure vessels for chemical processFuel reprocessingPhosphate

The invention provides a preparation device of triisopentyl phosphate. The device comprises: a reaction coil pipe used as a reaction container of a mixed solution; an air source communicated with theinlet of the reaction coil pipe through an air inlet pipe, wherein an air inlet switch is arranged on the air inlet pipe; a heating unit used for heating the reaction coil pipe; a high-pressure buffertank, wherein the upper portion of the space in the high-pressure buffer tank is communicated with the outlet of the reaction coil pipe through a first liquid outlet pipe; a reaction liquid collecting tank communicated with the bottom of the space in the high-pressure buffer tank through a second liquid outlet pipe, wherein a first liquid outlet switch is arranged on the second liquid outlet pipe; a feeding unit used for conveying the mixed solution into the reaction coil pipe; and a first pressure gauge arranged on the high-pressure buffer tank and used for measuring the pressure of the reaction environment. The invention also provides a method for preparing triisopentyl phosphate by adopting the device. According to the invention, continuous industrial production of triisopentyl phosphate is realized, the generated byproduct methanol does not react with triisopentyl phosphate, the yield is high, and the process risk is low.

Owner:HANGZHOU JINGYE INTELLIGENT TECH CO LTD

An automatic manufacturing machine for building sewage tank cement partitions

ActiveCN108789814BAvoid troubleReduce workloadDischarging arrangementFeeding arrangmentsArchitectural engineeringMachine

The invention discloses an intelligent automatic manufacturing machine for building sewer tank cement clapboards. The machine comprises a fixed base, wherein a machine body is arranged on the fixed base, a board manufacturing tank is arranged in the machine body, a first conveying tank and a second conveying tank corresponding to the board manufacturing tank are further arranged on the machine body, and supporting steel bars are respectively arranged in the first conveying tank and the second conveying tank; a first sliding groove correspondingly communicating with the first conveying tank isarranged in the machine body; a second sliding groove correspondingly communicating with the second conveying tank is arranged in the machine body; two sliding push rods are respectively arranged in the first sliding groove and the second sliding groove; and the push rods synchronously slide and respectively press the supporting steel bars. The supporting steel bars can be further pushed to slidethrough the sliding of the push rods, so that the supporting steel bars are pushed into the board manufacturing tank, and the increase of the workload caused by manually arranging the supporting steelbars is avoided.

Owner:江西抚州中恒管桩有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com