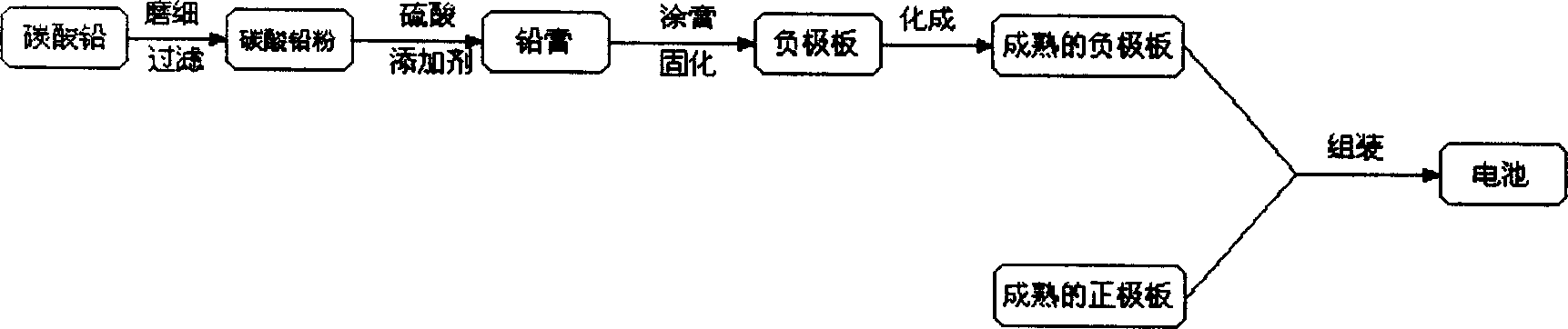

Method for preparing lead-acid battery negative pole

A lead-acid battery, negative electrode technology, applied in the field of chemical power supply and resource regeneration cycle, can solve the problems of low conversion current efficiency, low conversion success rate, no practical value, etc., to improve utilization, reduce production links, current efficiency and The effect of satisfying production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 14

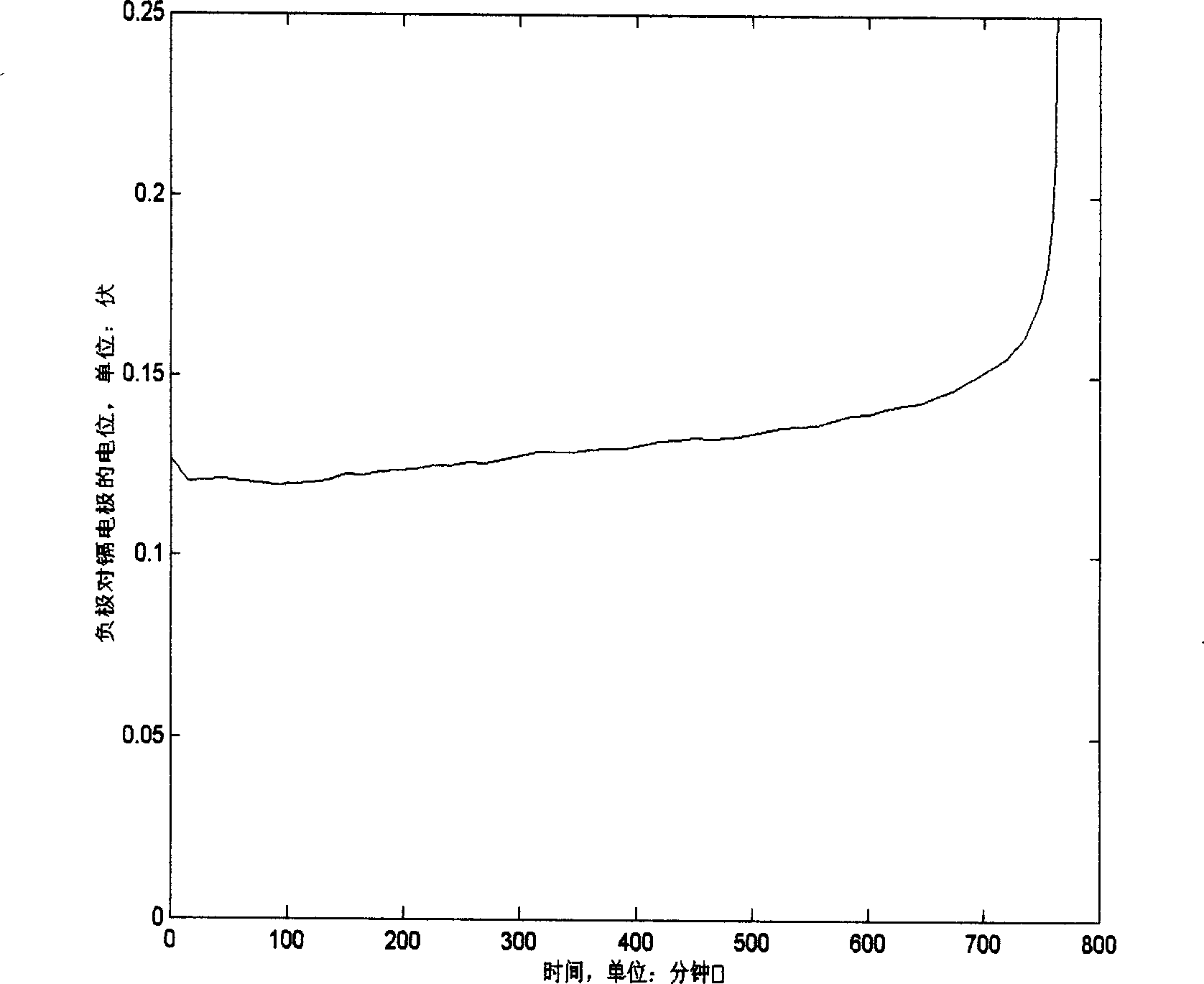

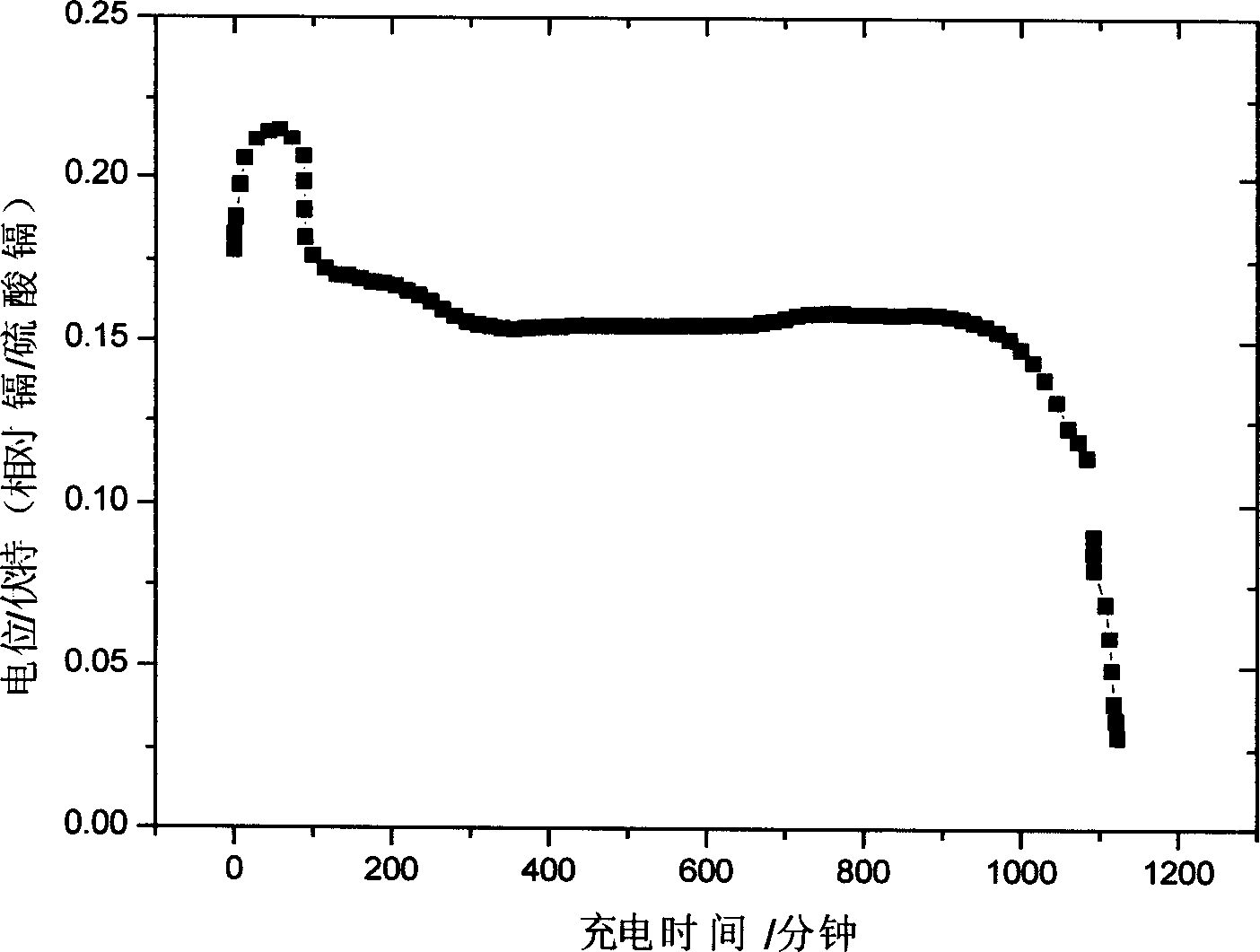

[0039] Embodiment 14 has provided the preparation process of making bigger pole plate (10Ah): Weigh lead carbonate 229.99 grams, additive 2.54 grams, 12mol / L H 2 SO 4 71.8ml (equivalent to 110% of stoichiometric). PbCO 3 Fully mix with additives, then slowly add sulfuric acid, and stir rapidly at the same time, the whole process of adding sulfuric acid lasts for about 6 minutes, continues to stir for about 10 minutes, and then stands for about 30 minutes to obtain 335.70 grams of lead paste. Spread about 120 grams of lead paste evenly on a 100*150mm Pb-Ca alloy grid, apply a pressure of 20MPa, and transfer to a drying room (temperature 30°C, relative humidity 90%) to cure for 24 hours. The resulting green plate was treated with 0.5mol / L Na 2 SO 4 The solution was energized at 900mA for 30 hours to obtain a cooked plate. The actual capacity measured in 5mol / L sulfuric acid solution is about 9.8Ah, and the utilization rate of active material is about 59.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com