Patents

Literature

512results about How to "Less equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

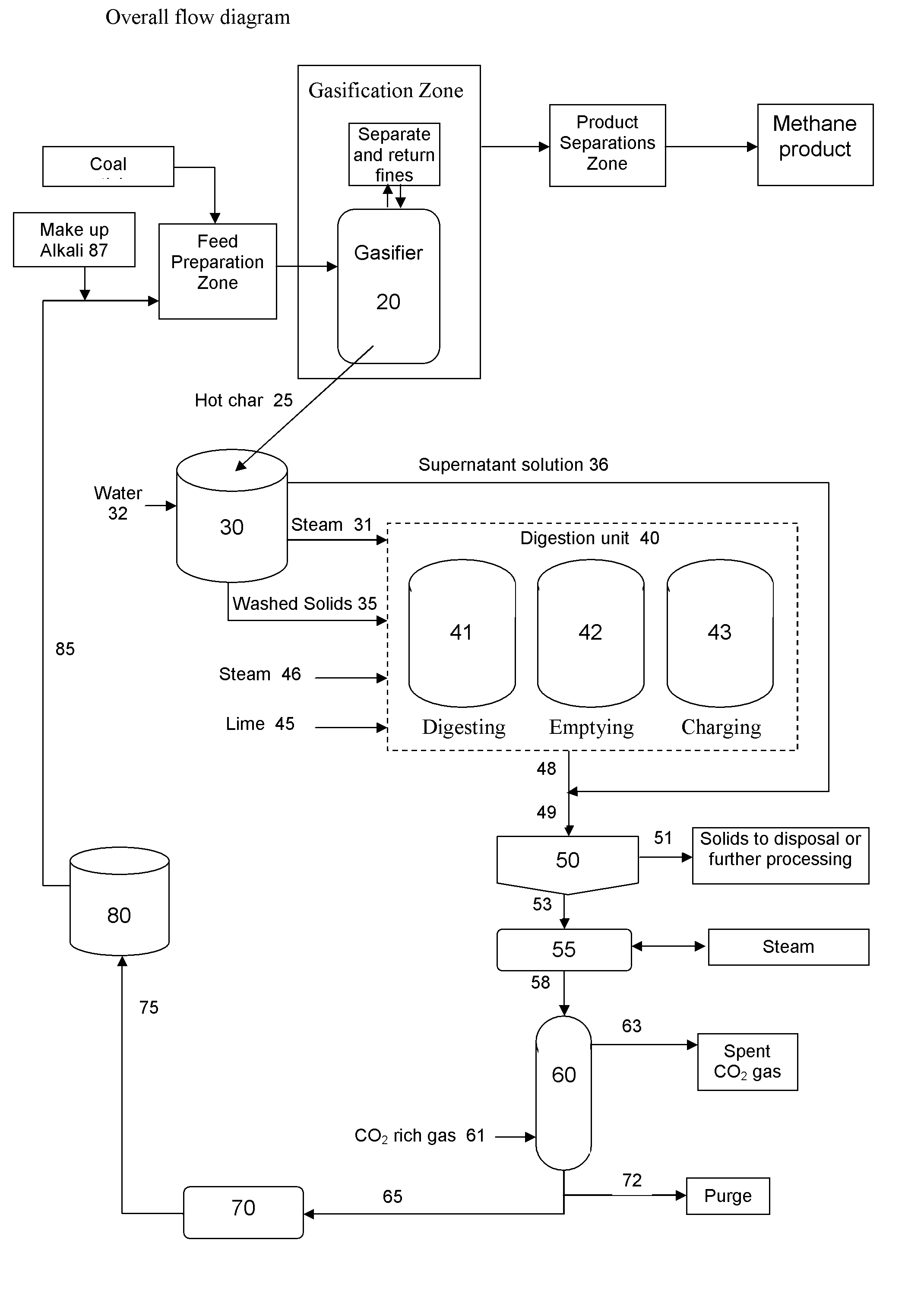

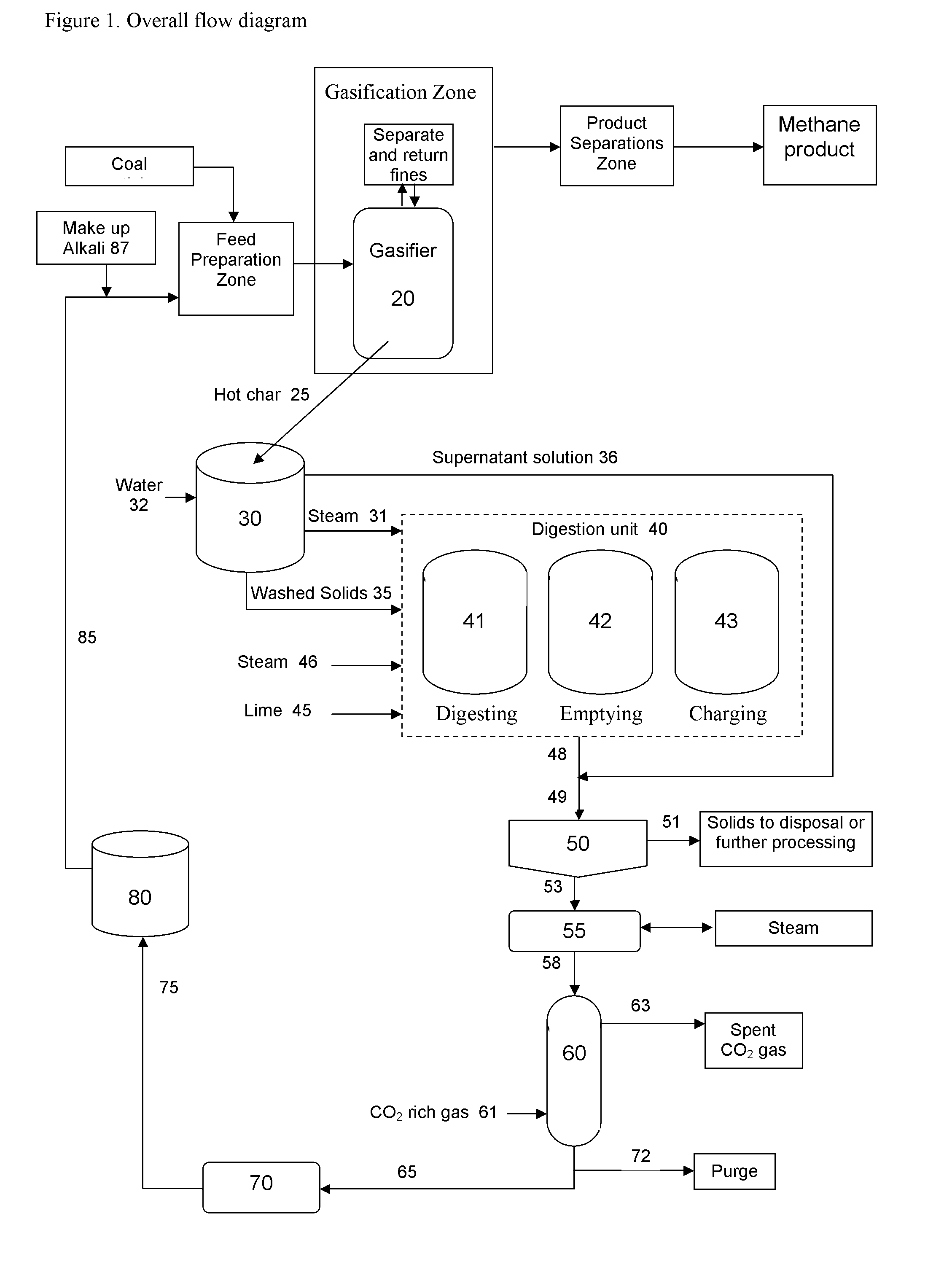

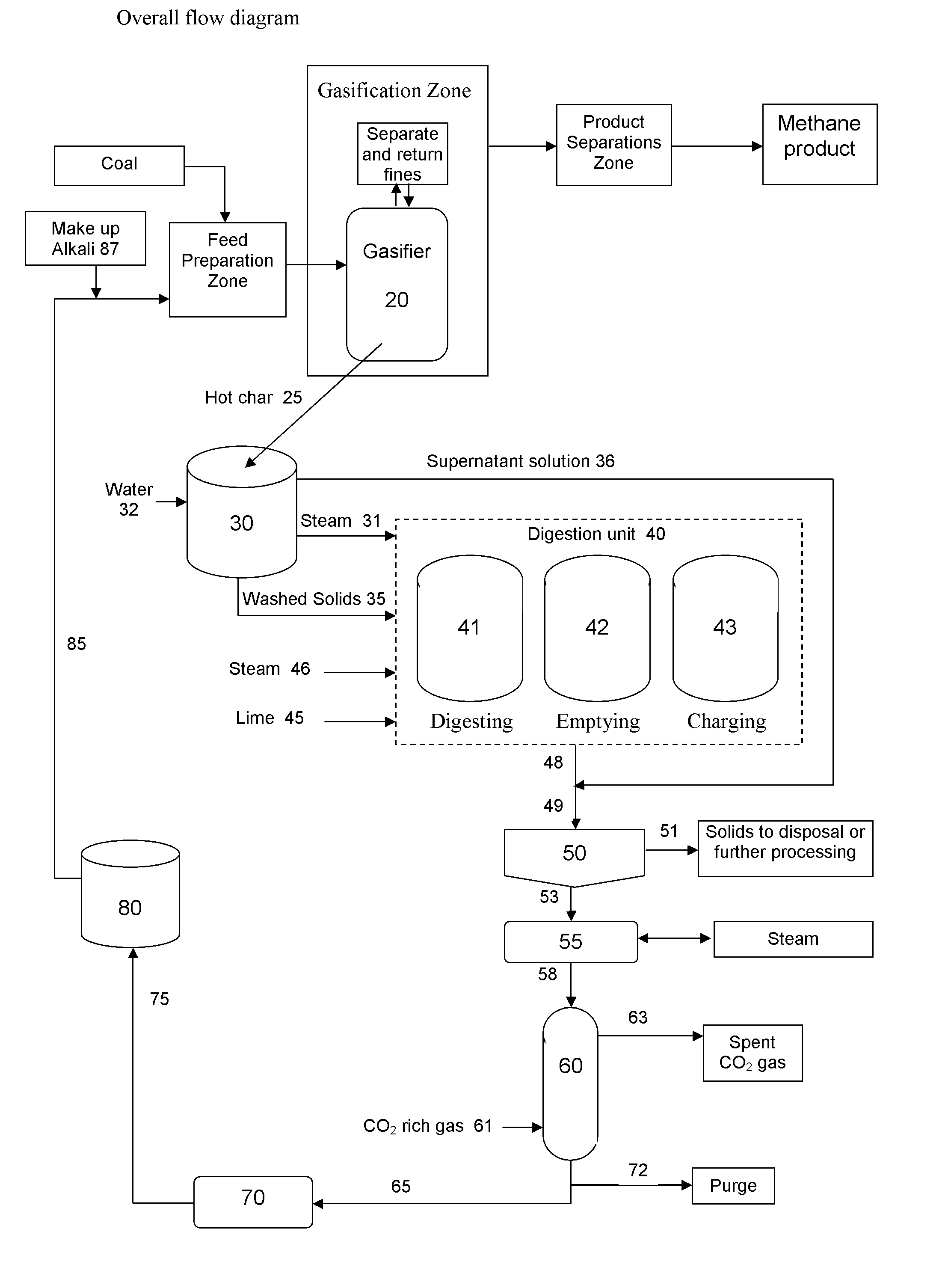

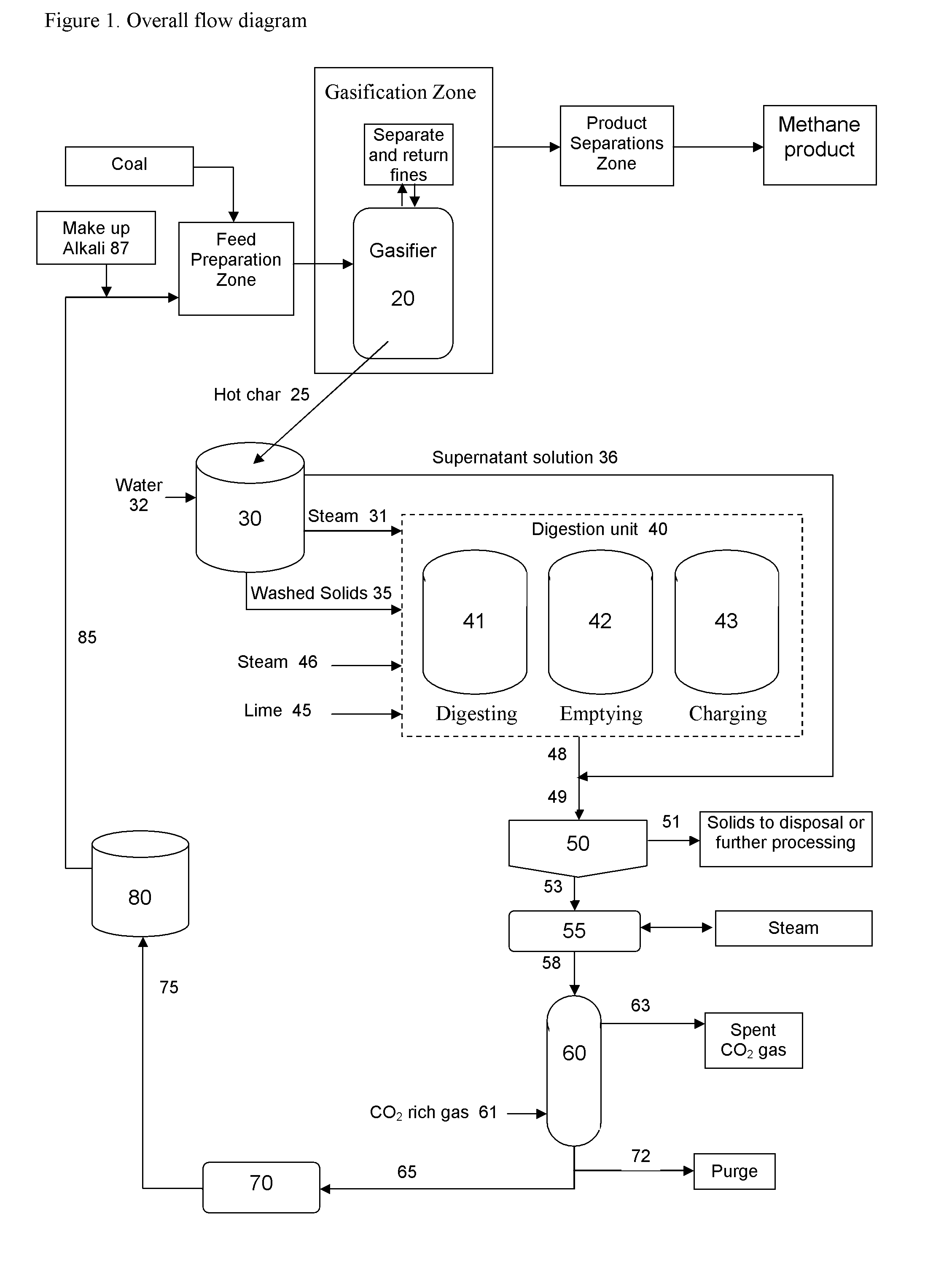

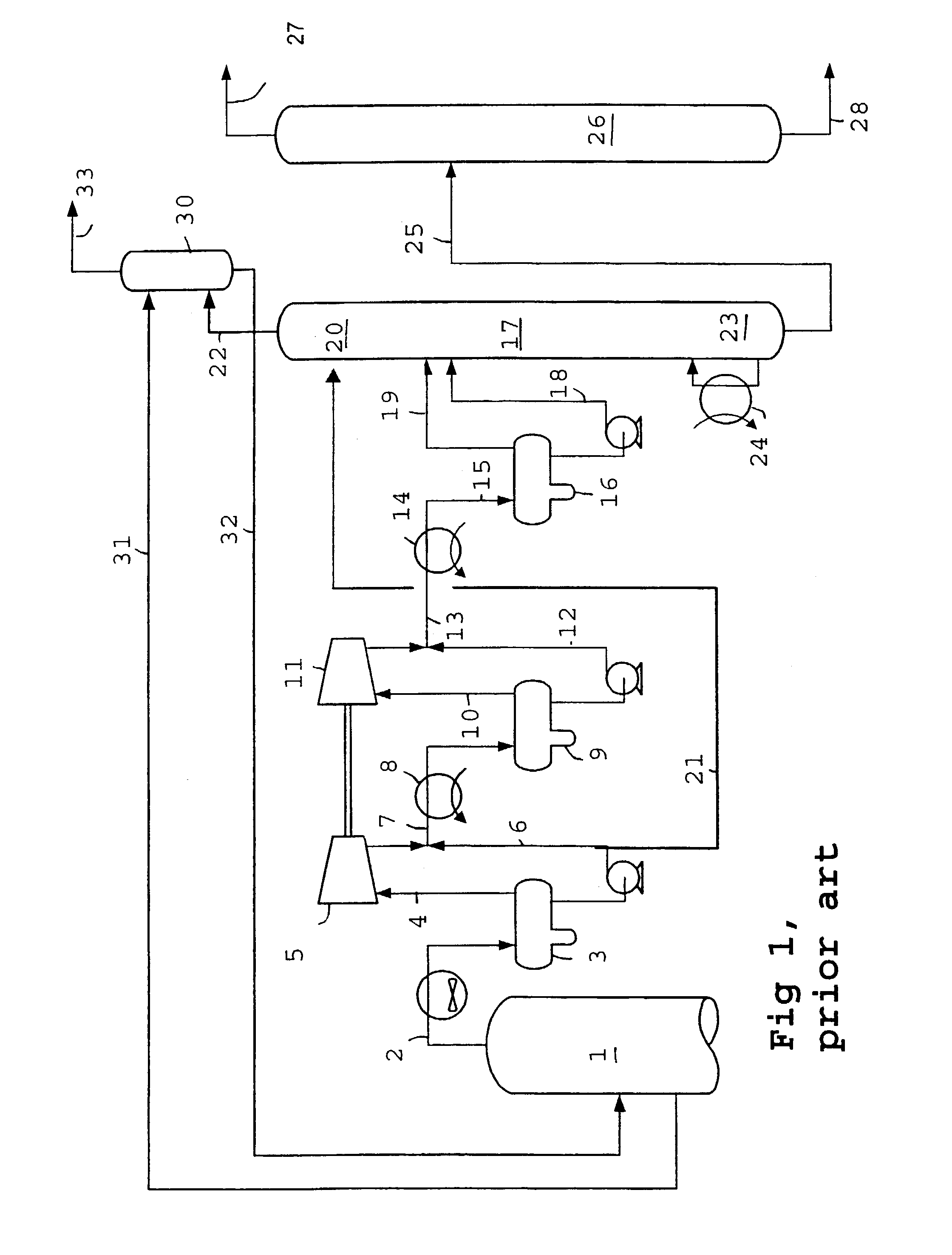

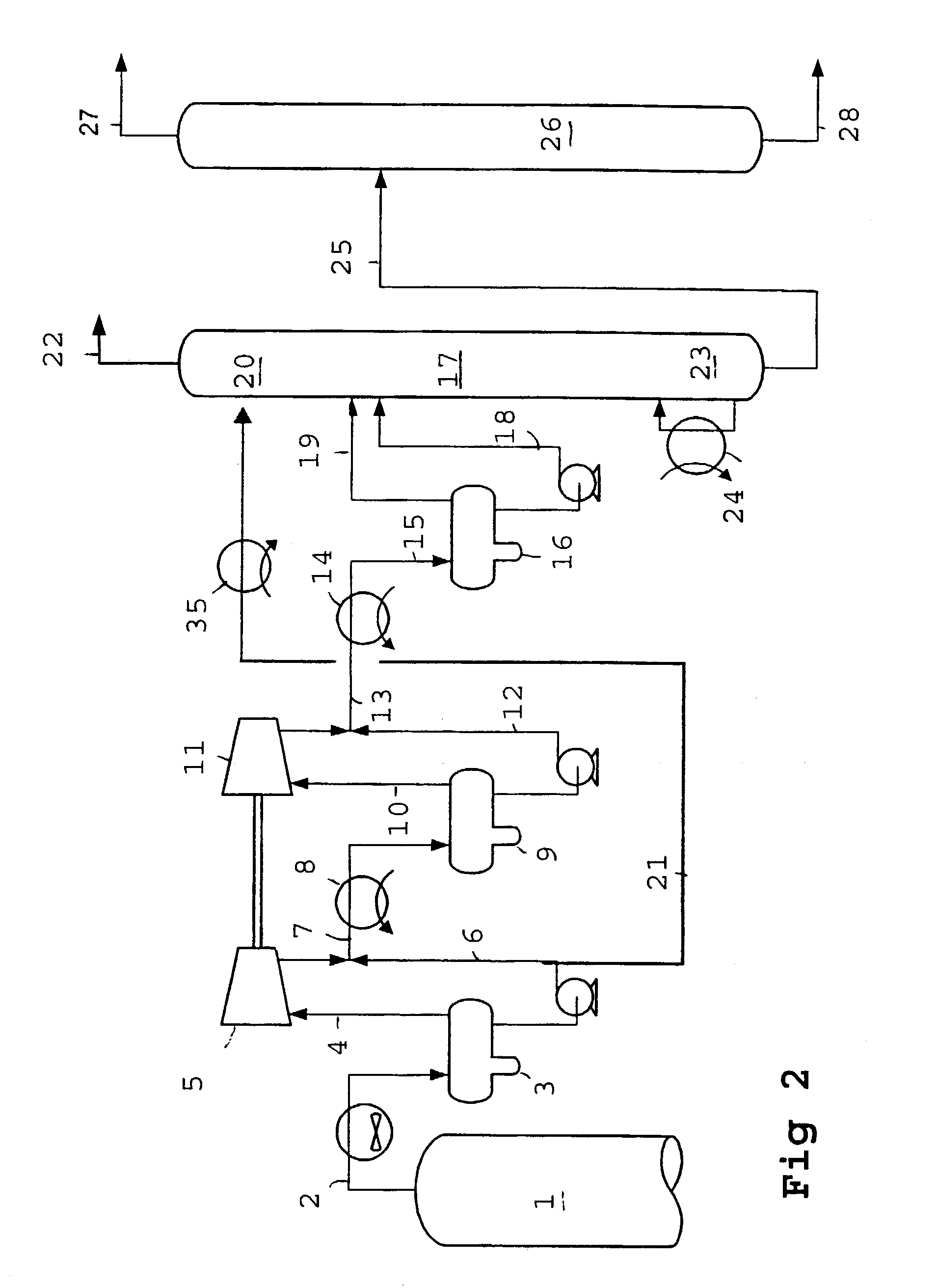

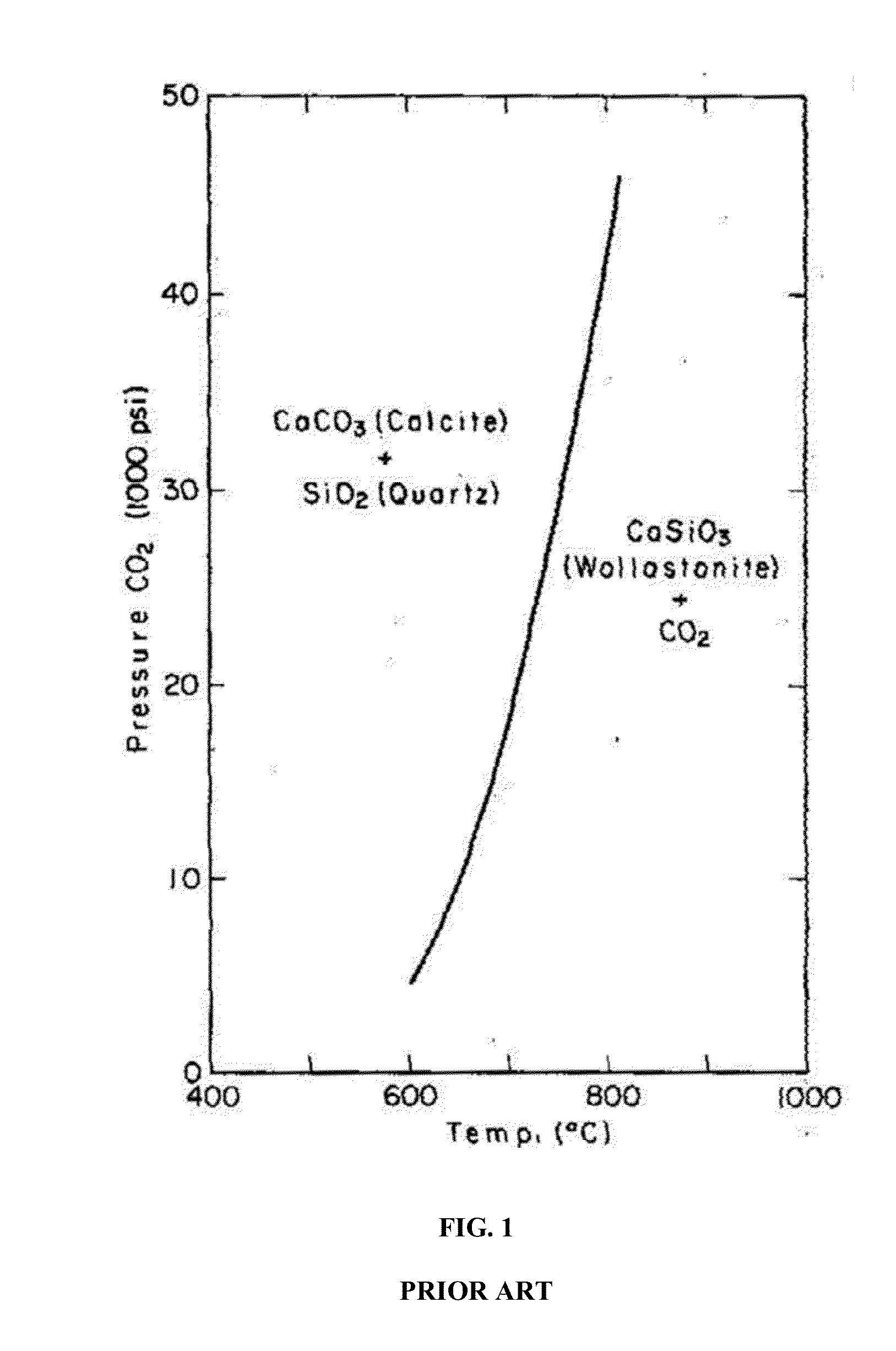

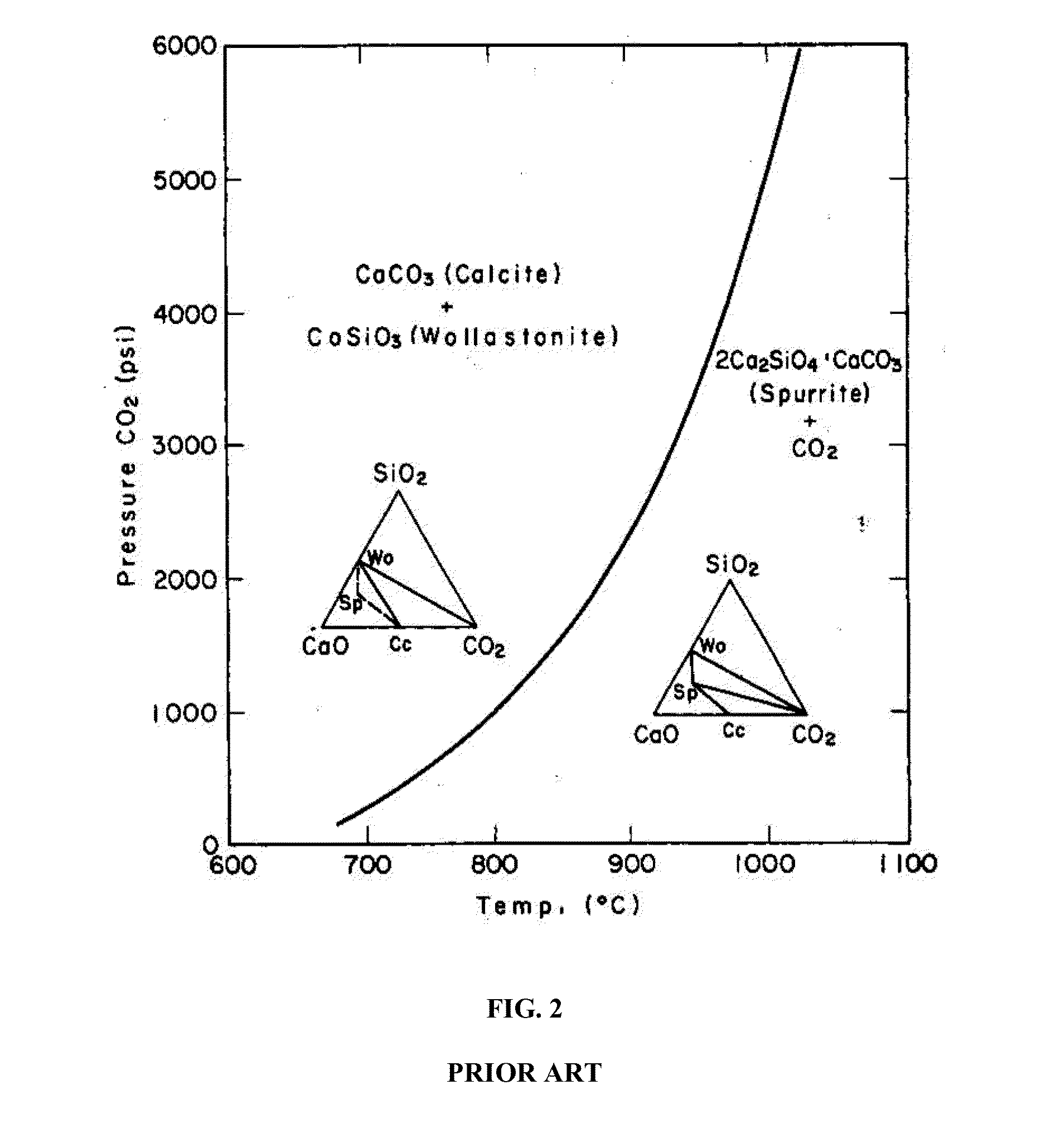

Catalytic steam gasification process with recovery and recycle of alkali metal compounds

ActiveUS20070277437A1Promote leachingLarge specific surface areaHydrogenGas modification by gas mixingCompound aAlkali metal

A high efficiency gasification process for converting carbonaceous solids to methane and apparatus for its practice are described. The process includes reacting steam and carbonaceous solids comprising ash in the presence of alkali metal catalyst in a gasification reactor to produce combustible gases and char particles comprising ash and alkali metal catalyst constituents, treating a stream of such char particles in an alkali metal catalyst recovery system to recover the catalyst constituents as alkali metal compounds, and recycling such recovered compounds. Within the alkali metal catalyst recovery system the process includes quenching the stream of char particles with water whereby such particles are cooled and fractured, dissolving soluble alkali metal catalyst constituents from the fractured solids to form a first alkali metal catalyst solution and washed solids, optionally reacting the washed solids in alkaline solution to form a second alkali metal catalyst solution, upgrading said first and optional second alkali solution to recover the alkali metal catalyst constituents as said alkali metal compounds.

Owner:SURE CHAMPION INVESTMENT LTD

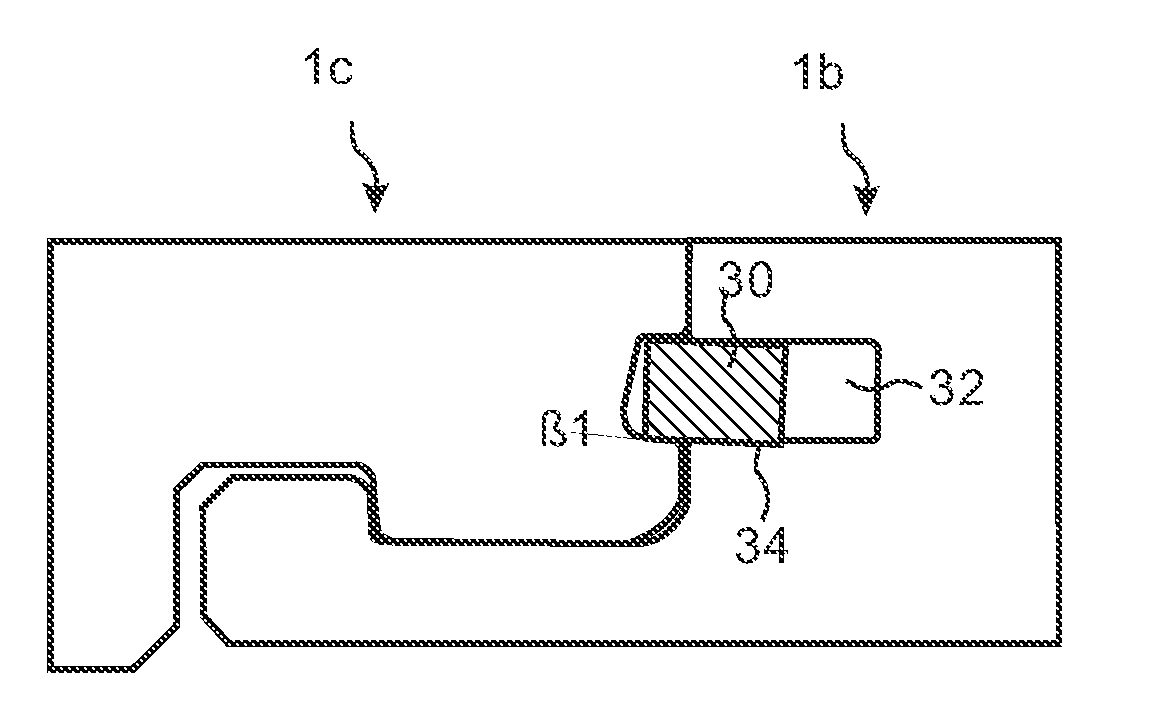

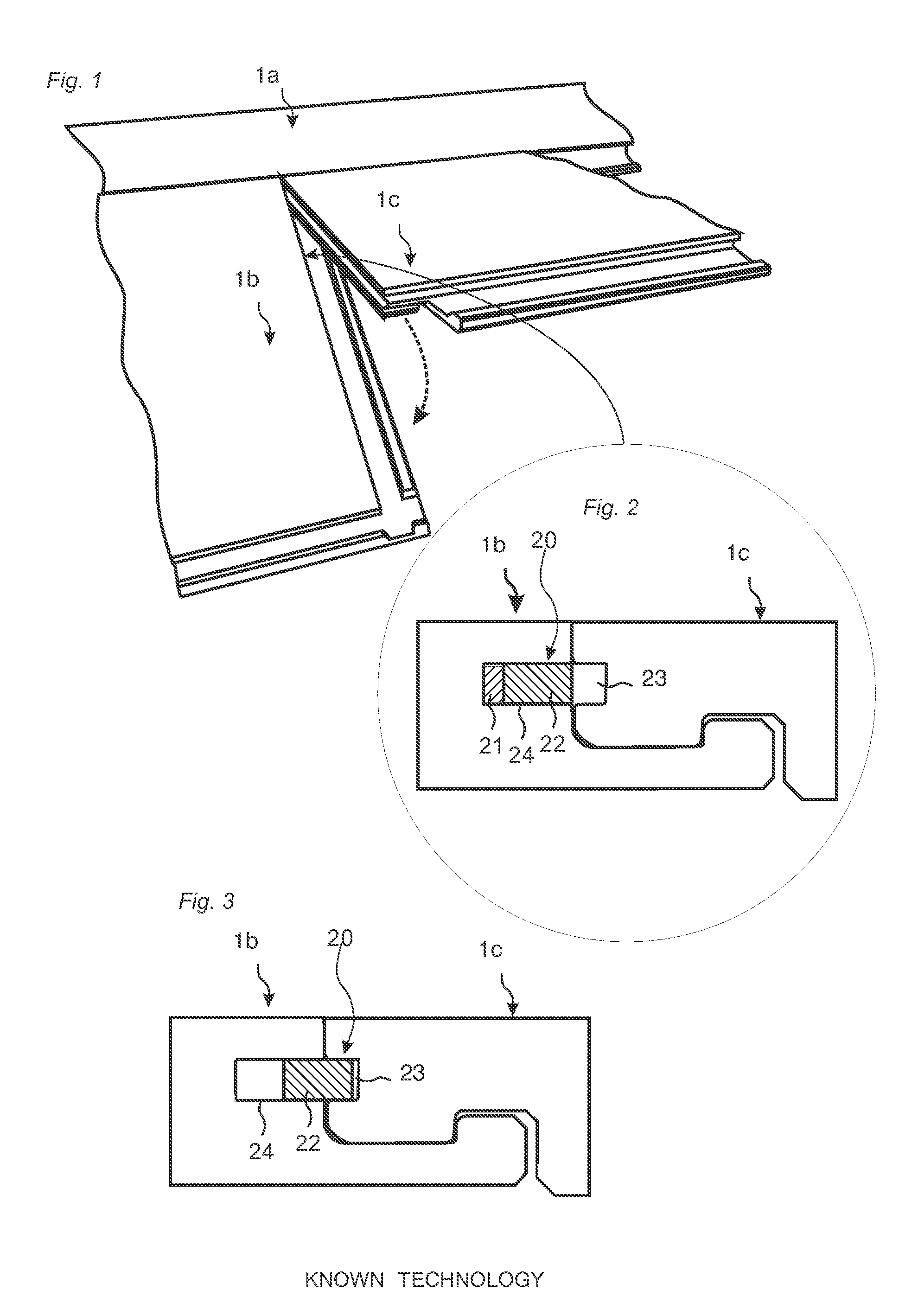

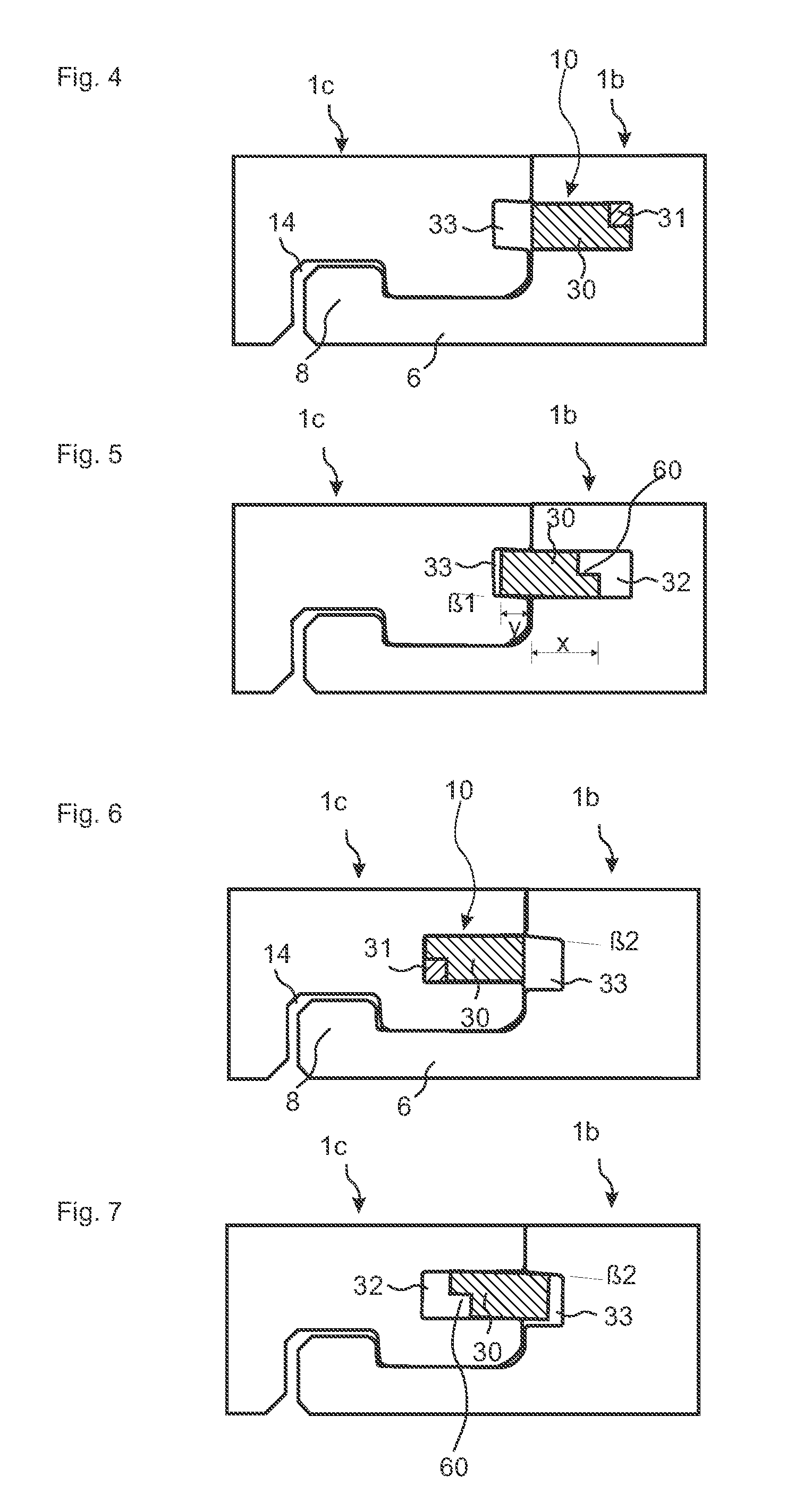

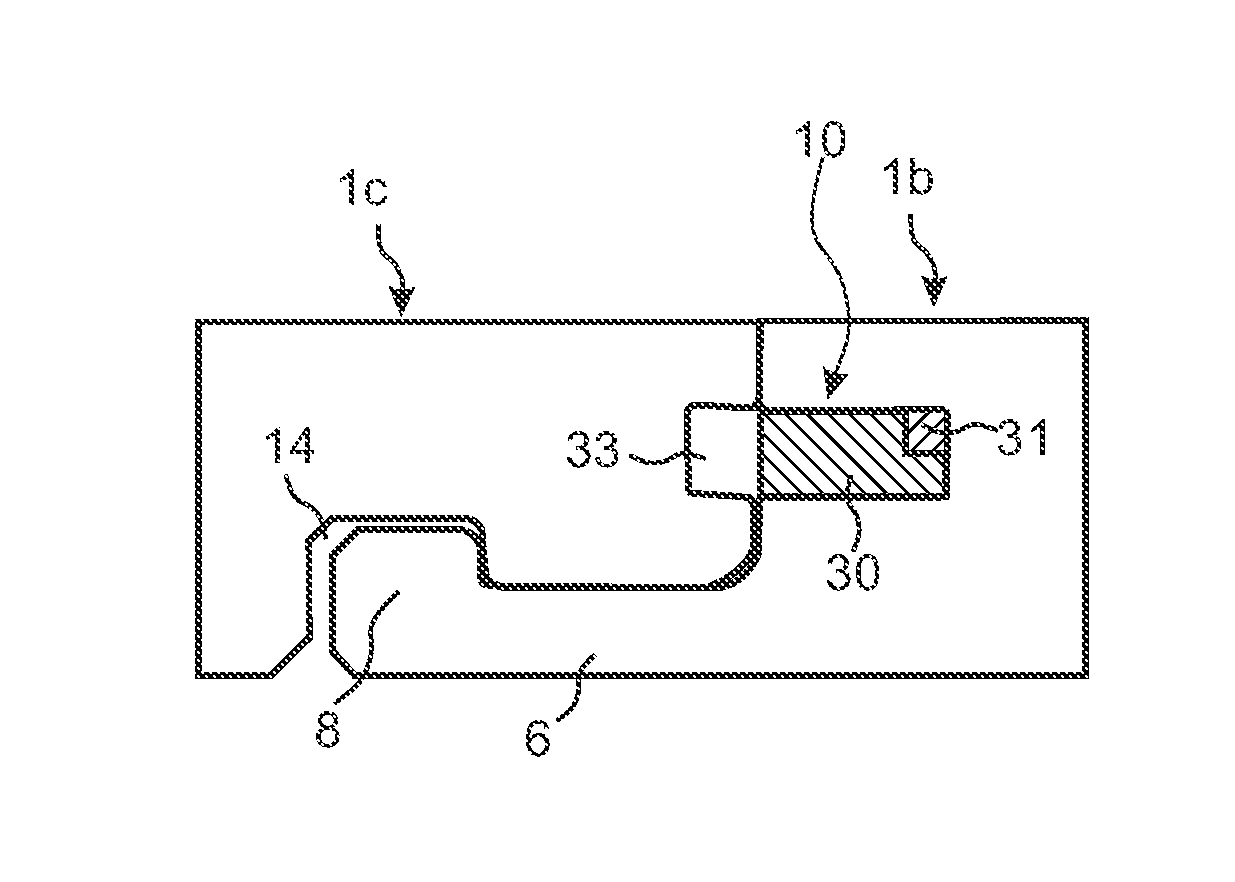

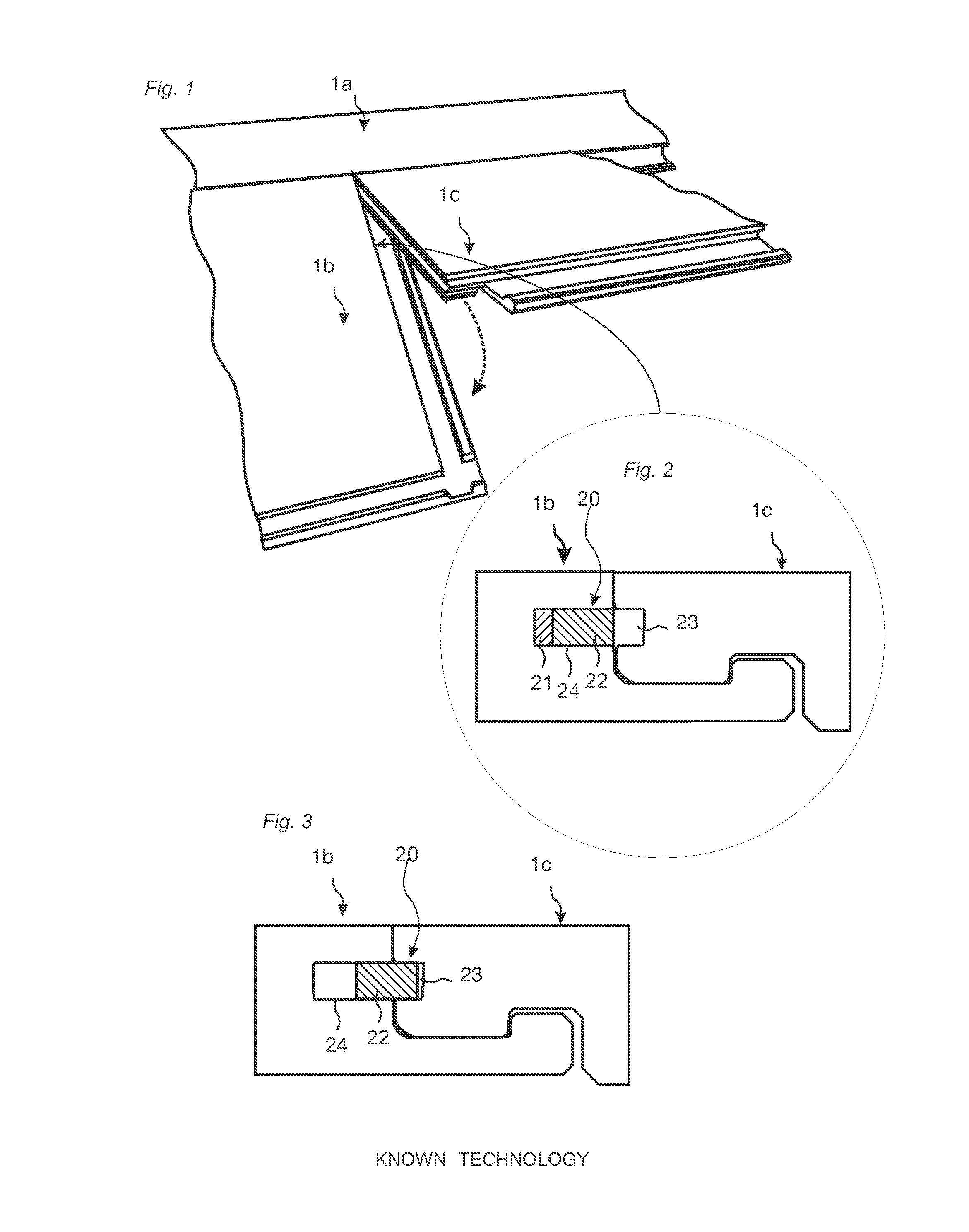

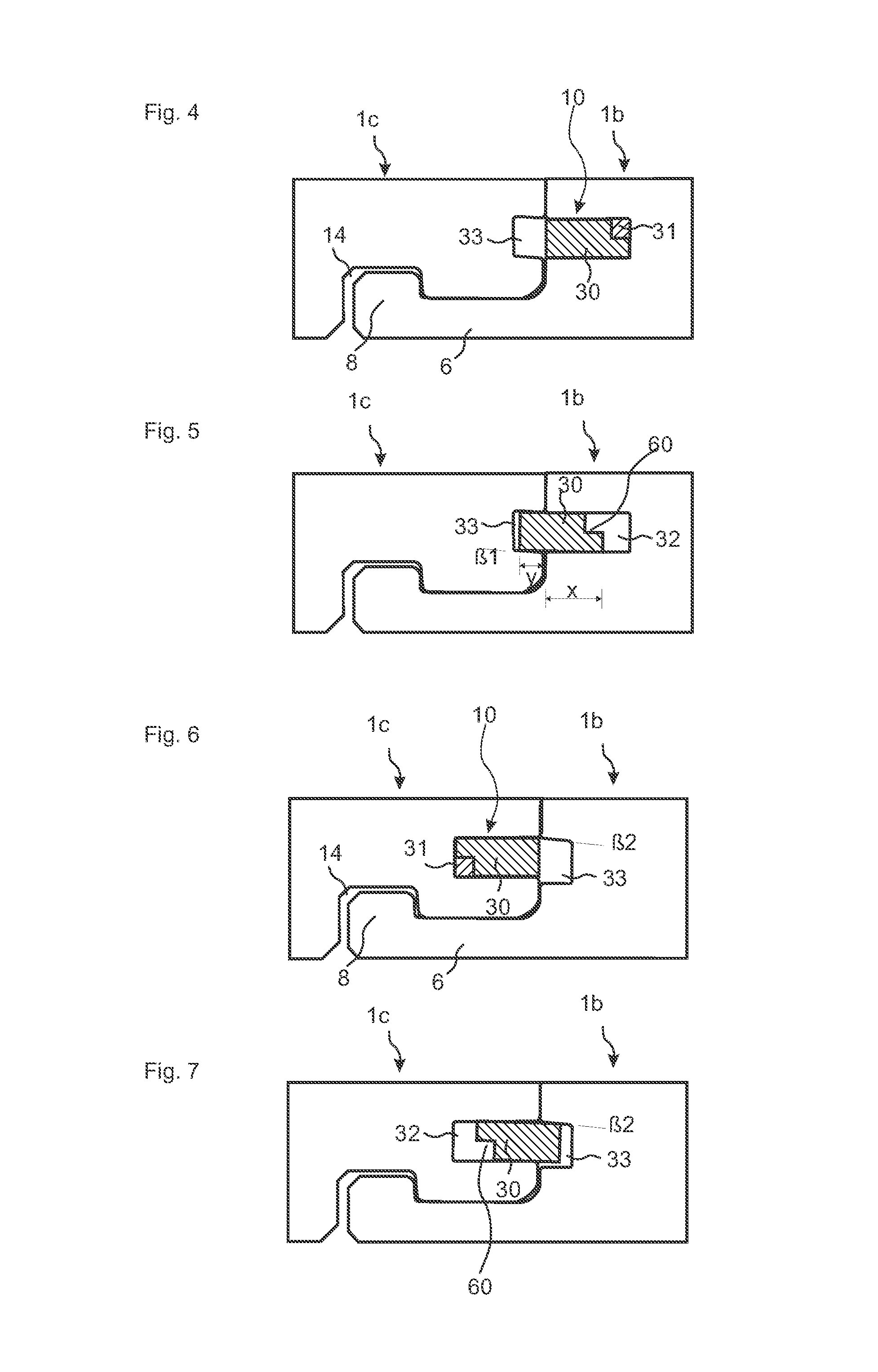

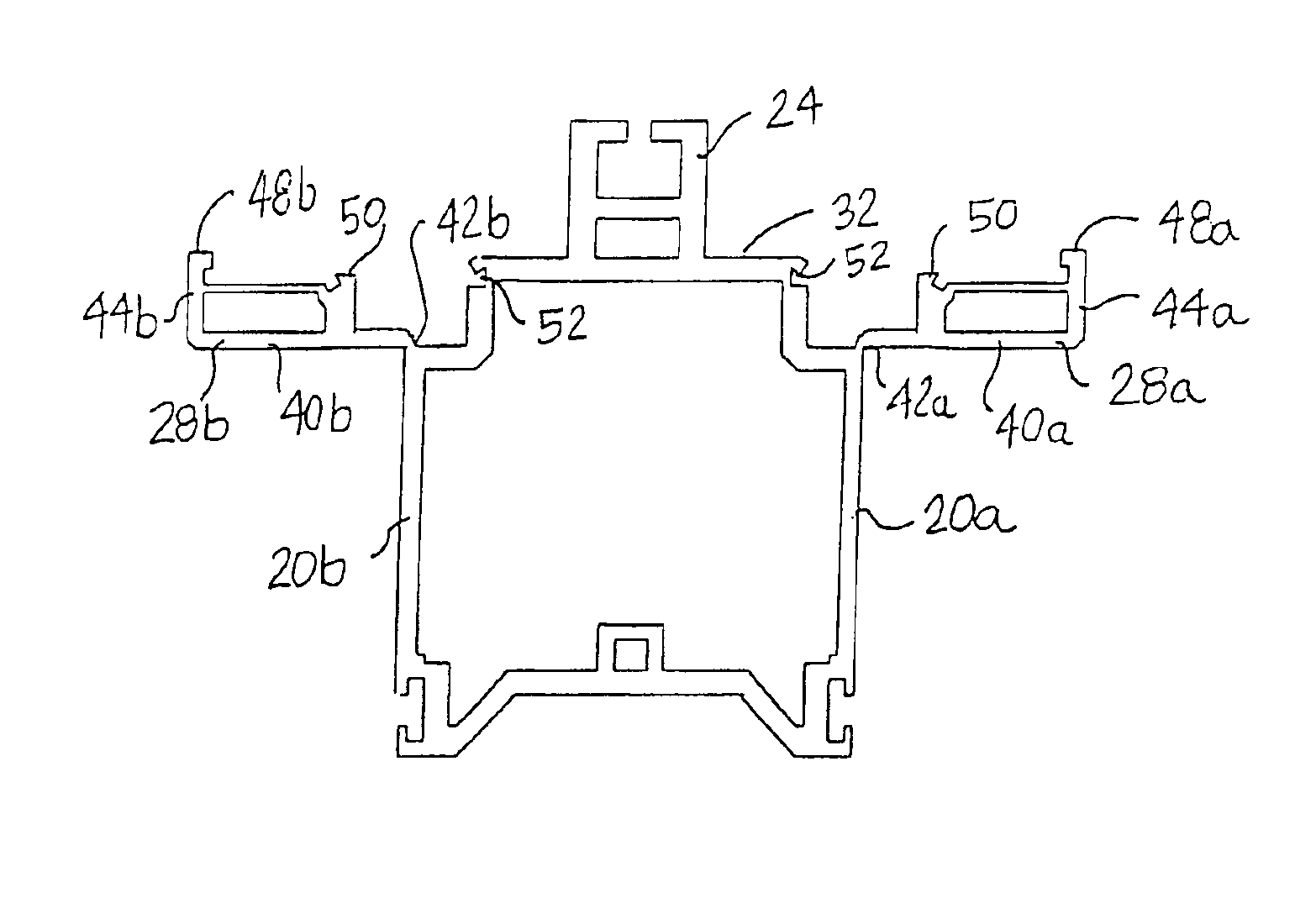

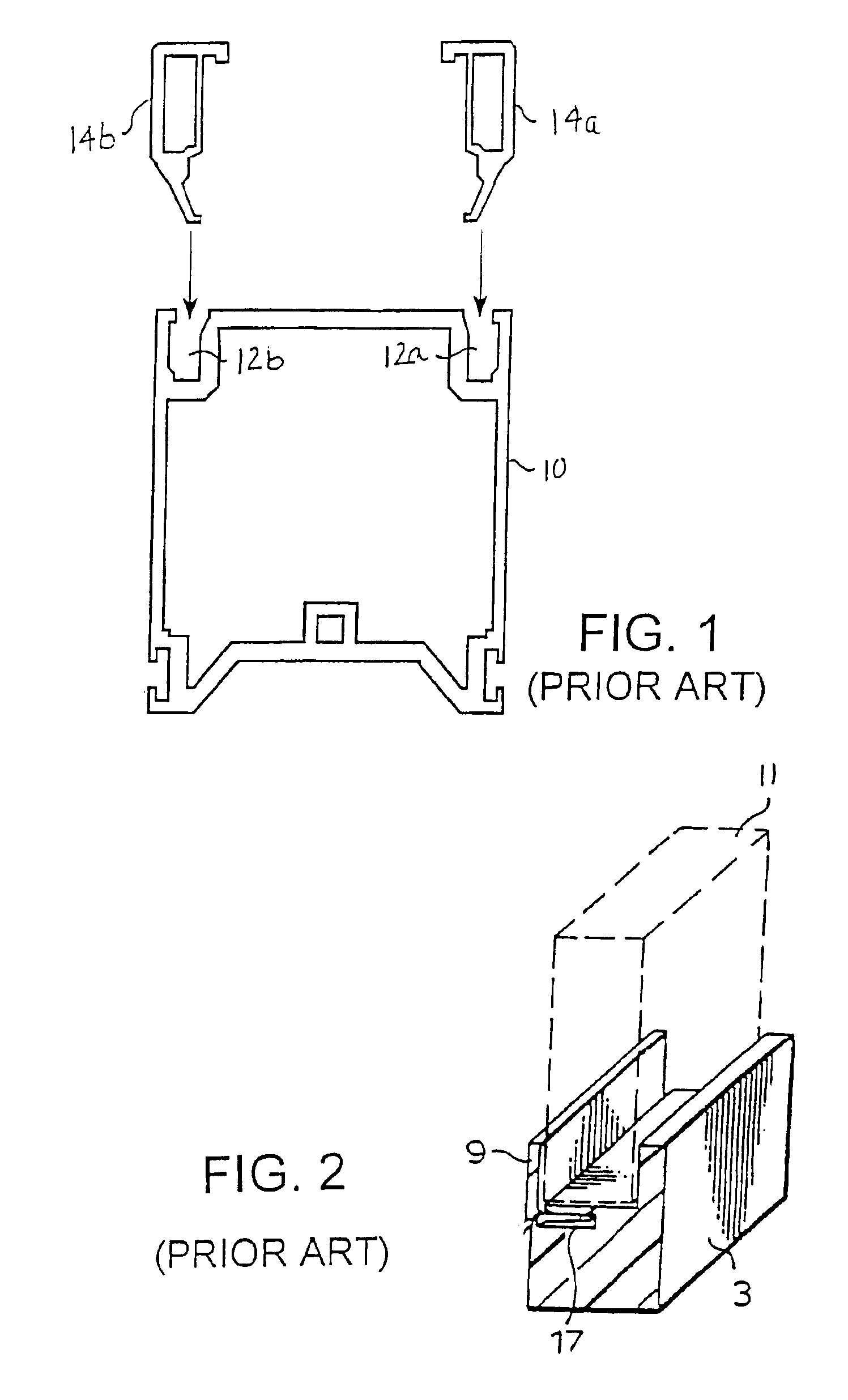

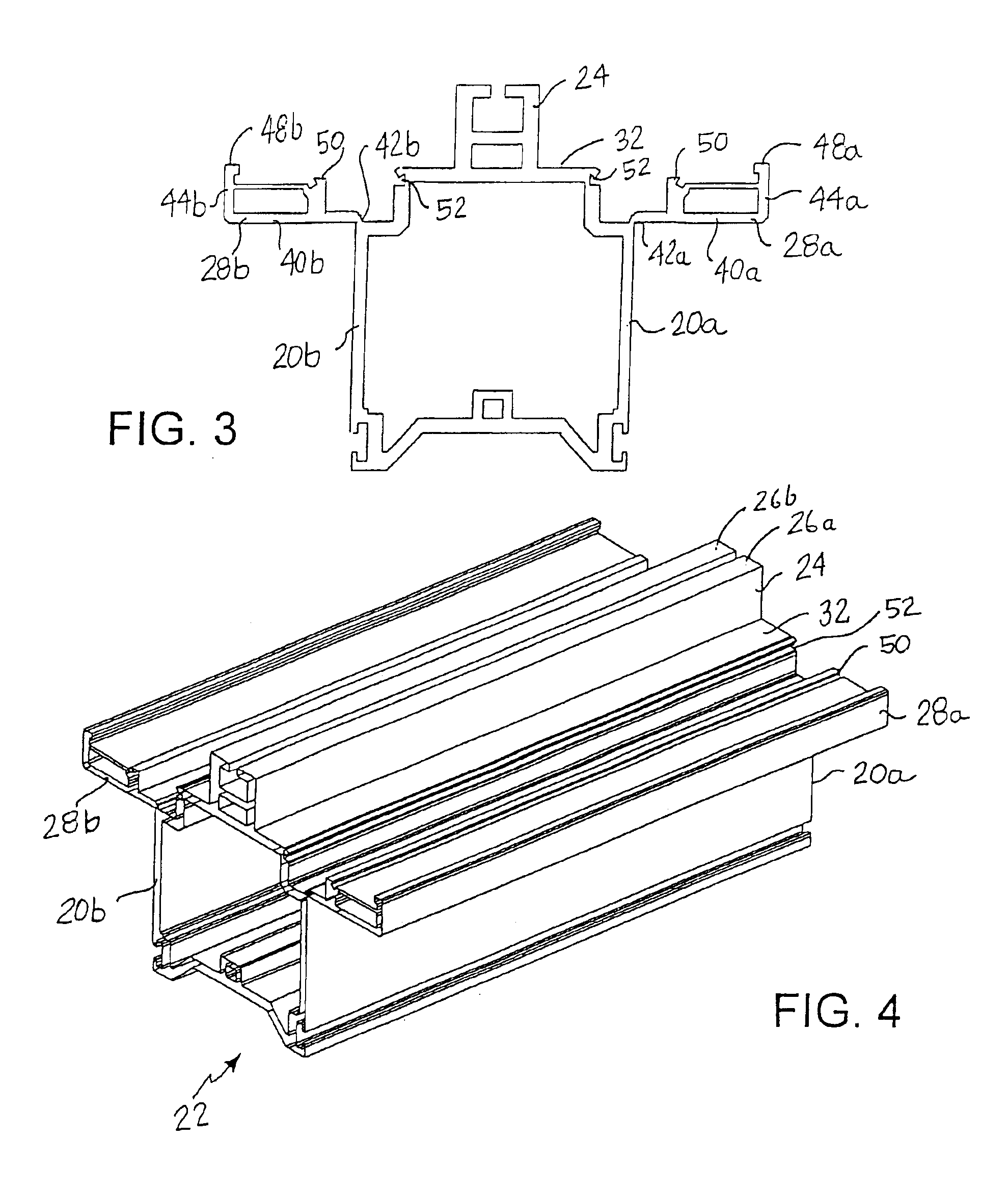

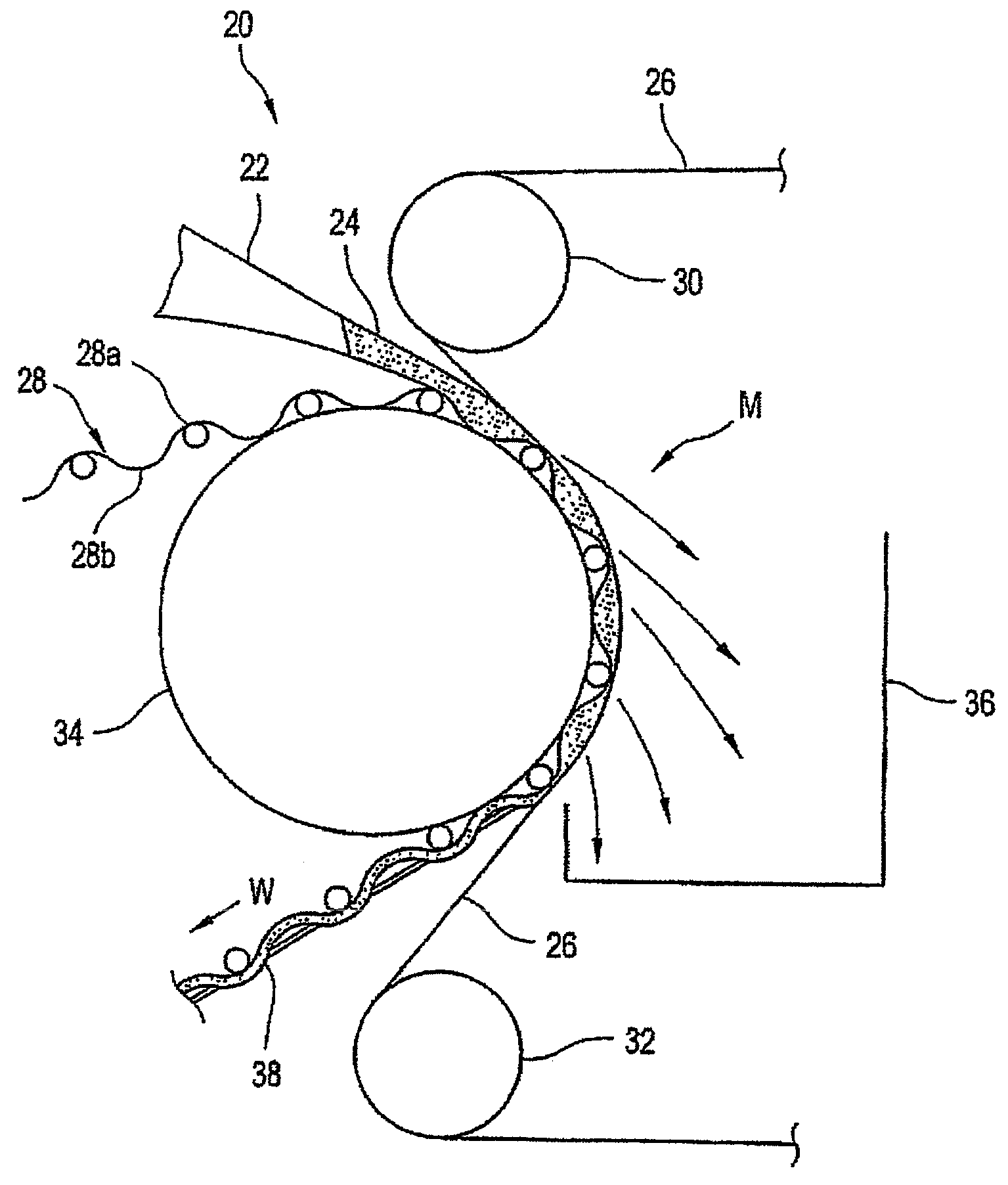

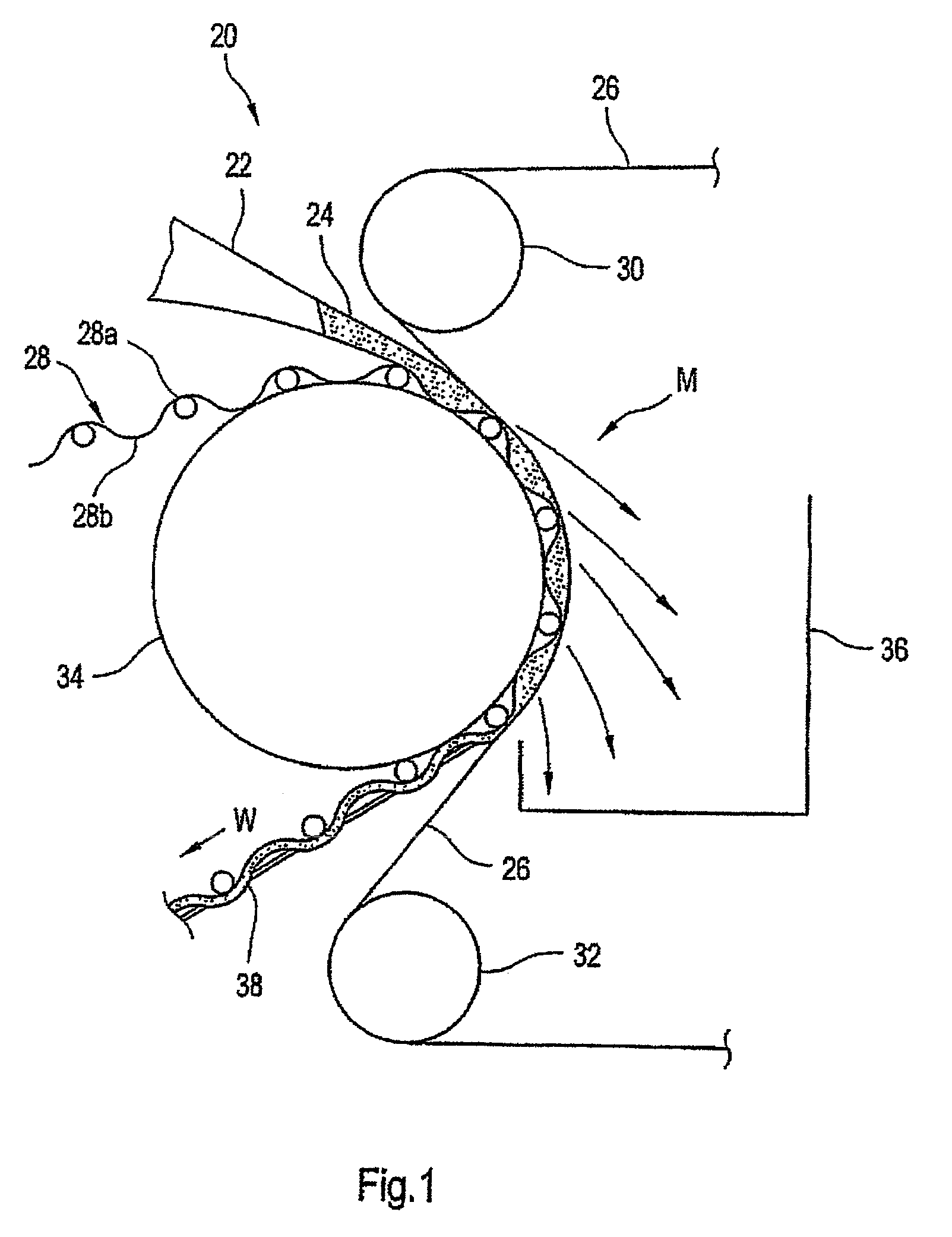

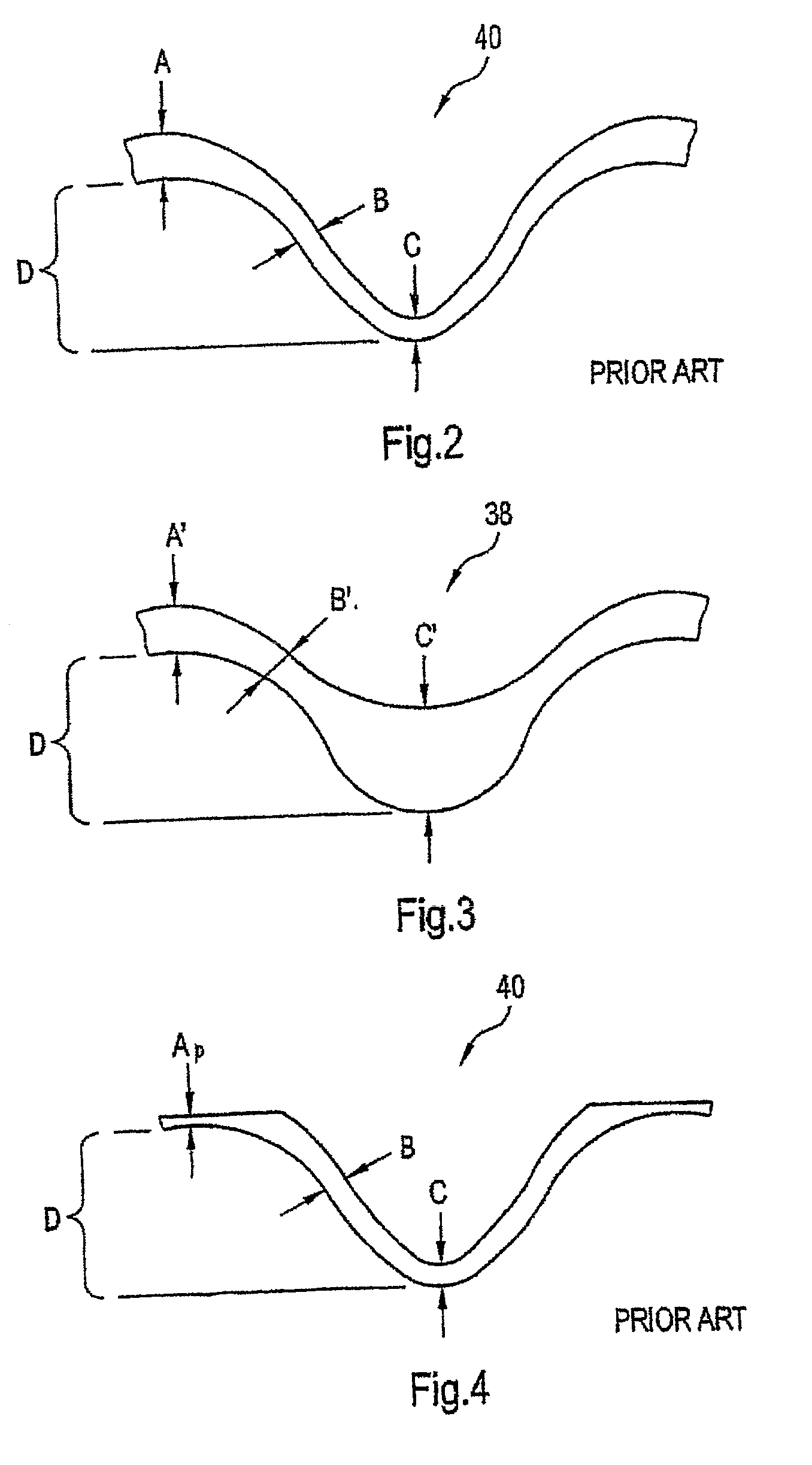

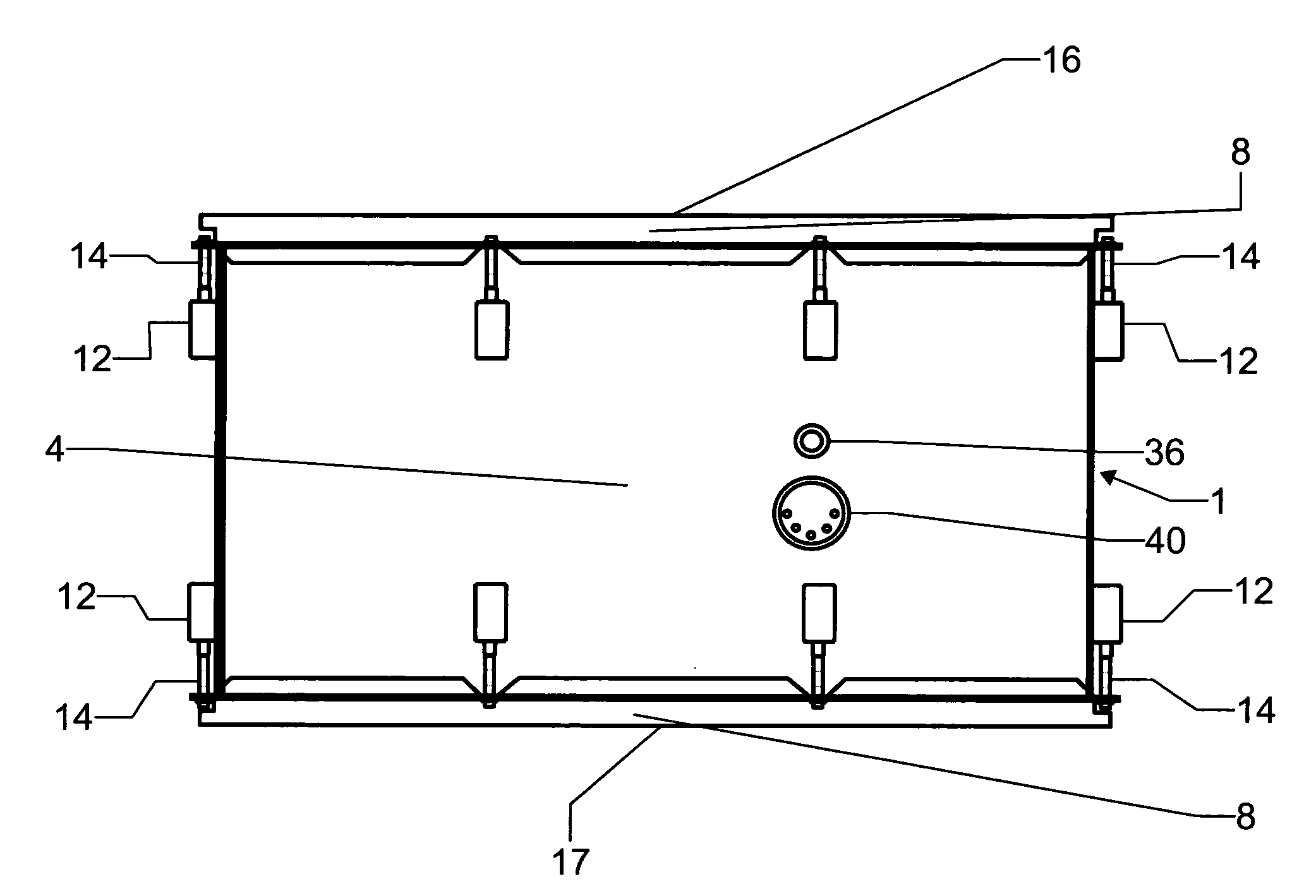

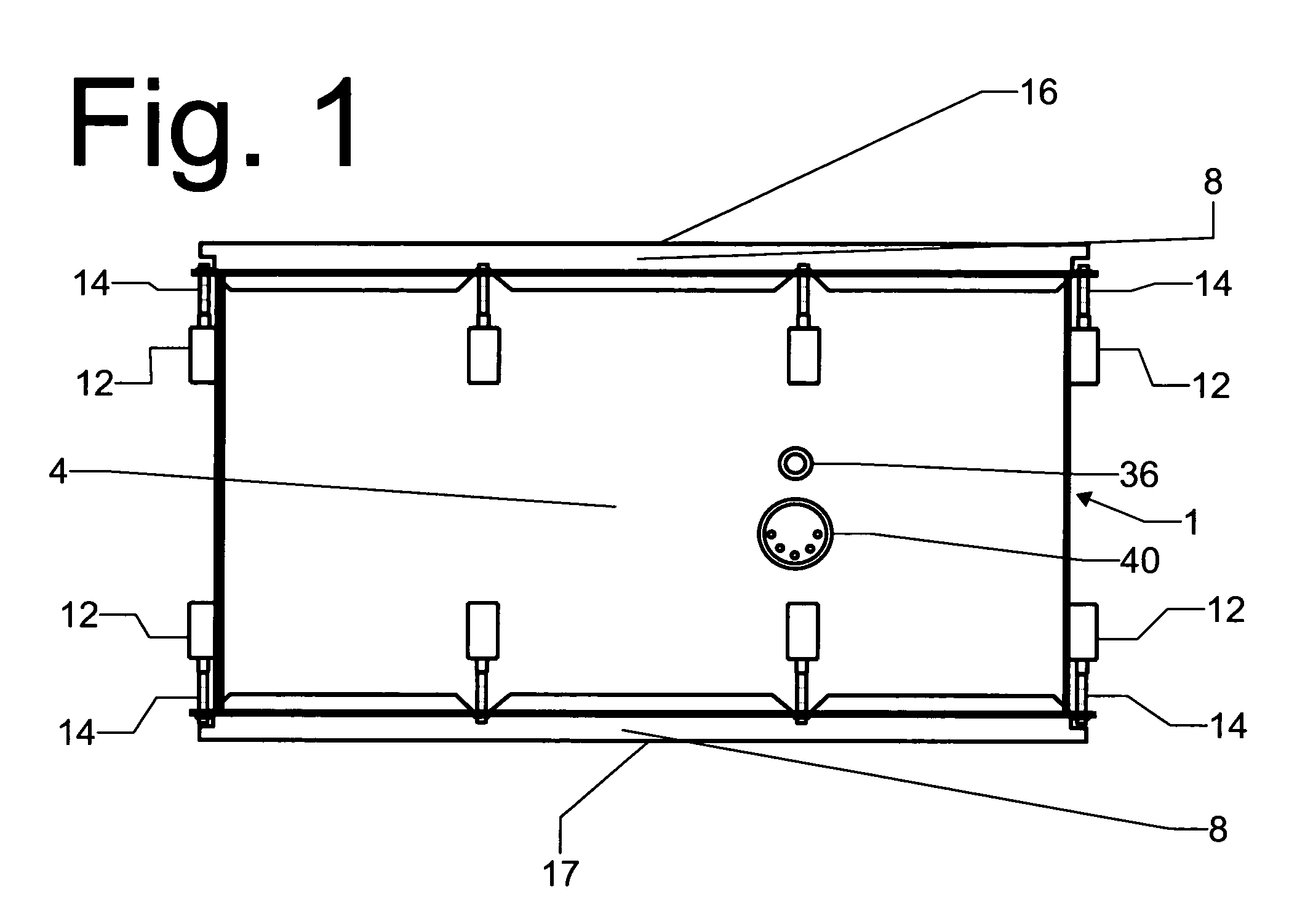

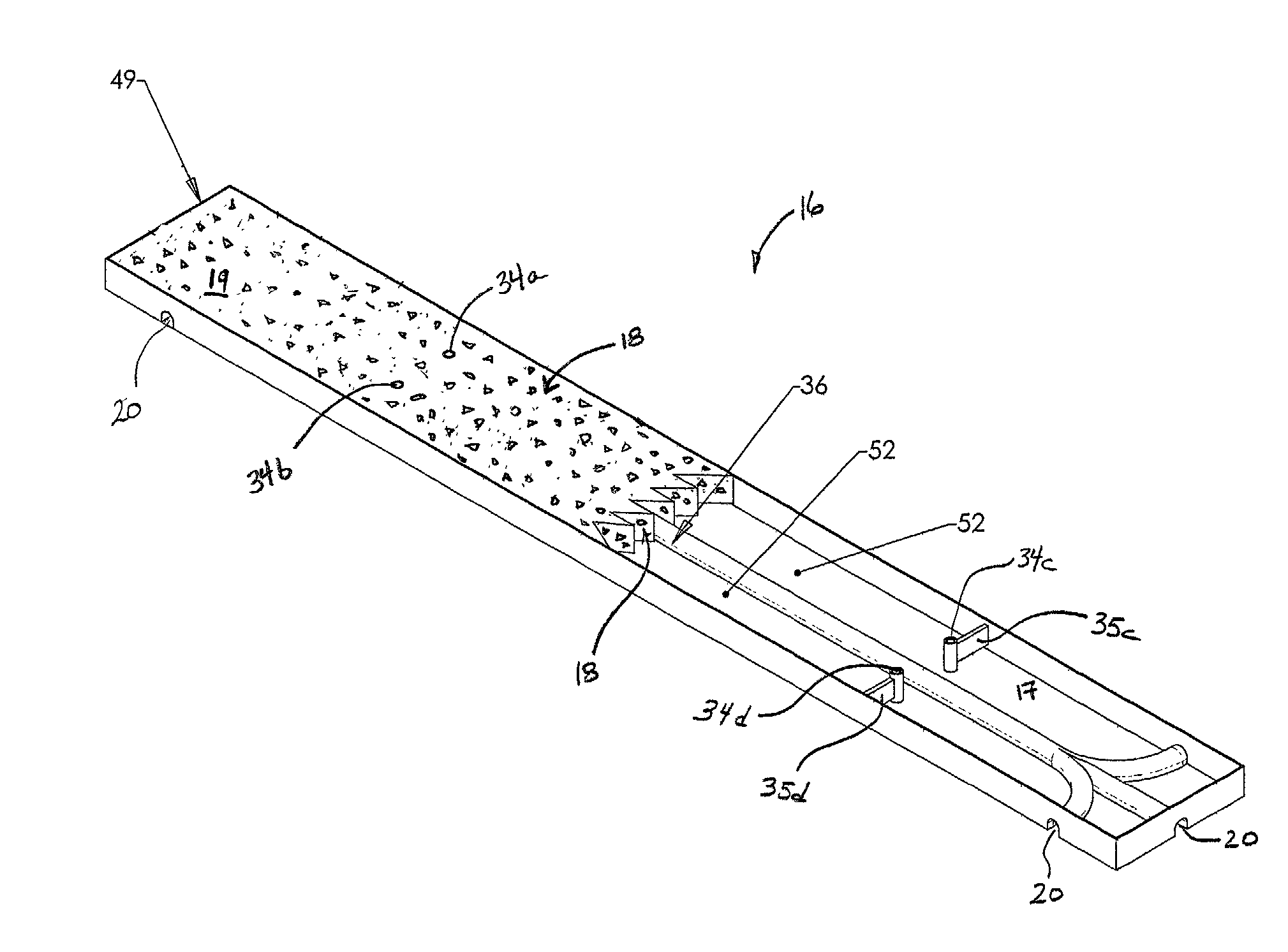

Building panels provided with a mechanical locking system

ActiveUS20140250813A1Improves vertical lockingLess complicatedFlooringEngineeringMechanical engineering

Building panels, such as floorboards, provided with a mechanical locking system. The mechanical locking system includes a displacement groove at a first edge of a first floorboard and a tongue groove at a second edge of a second floorboard A tongue is arranged in the displacement groove and is configured to cooperate, in a second position, with the tongue groove for vertical locking of the first and the second edge. The tongue includes, in a first position, an inner element and an outer element. The inner element is removable along the displacement groove, and is configured to cooperate with the outer element to obtain a displacement of the outer element towards the tongue groove and thereby obtain the second position. Said inner element and said outer element vertically overlap each other.

Owner:VÄLINGE INNOVATION AB

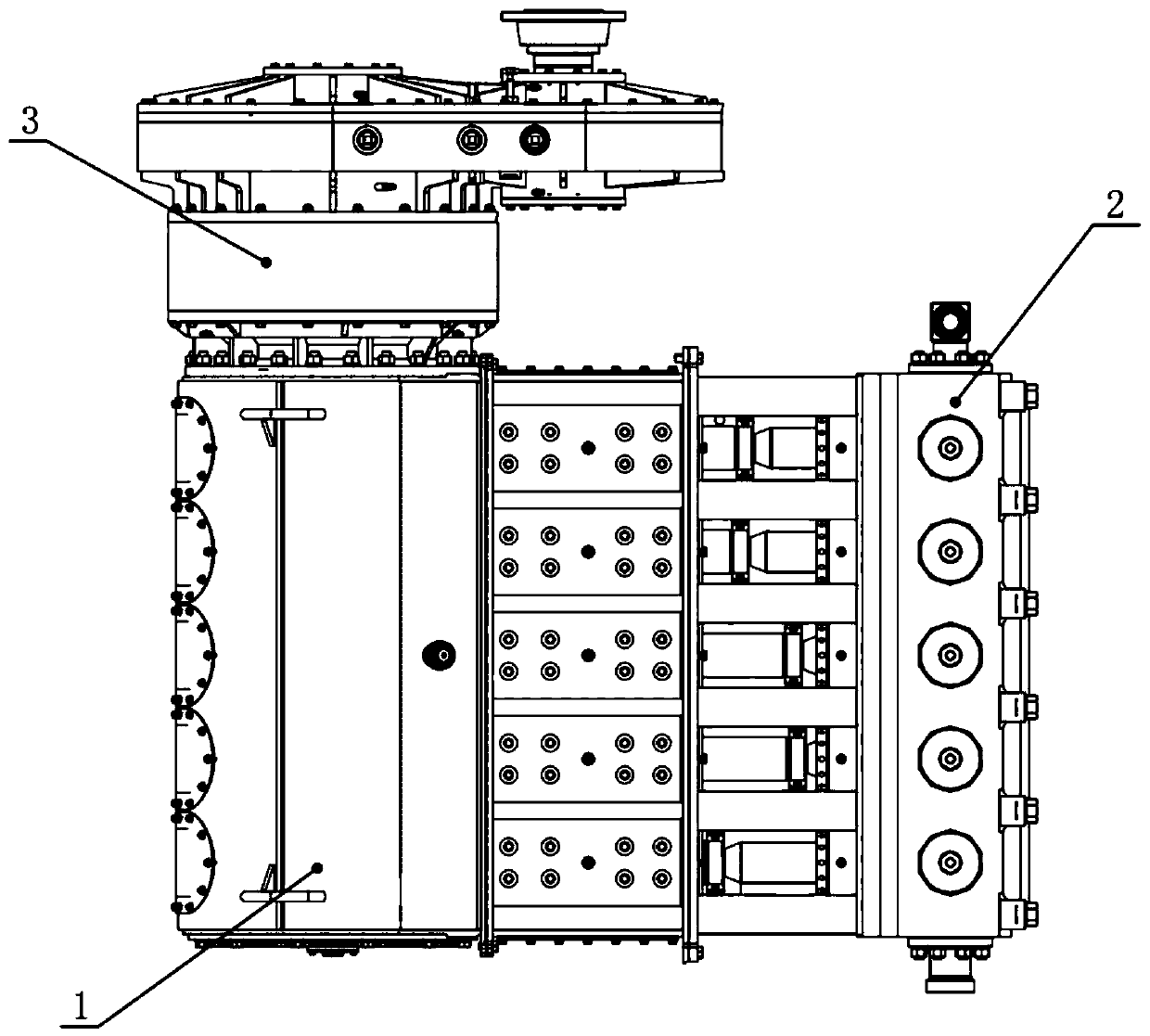

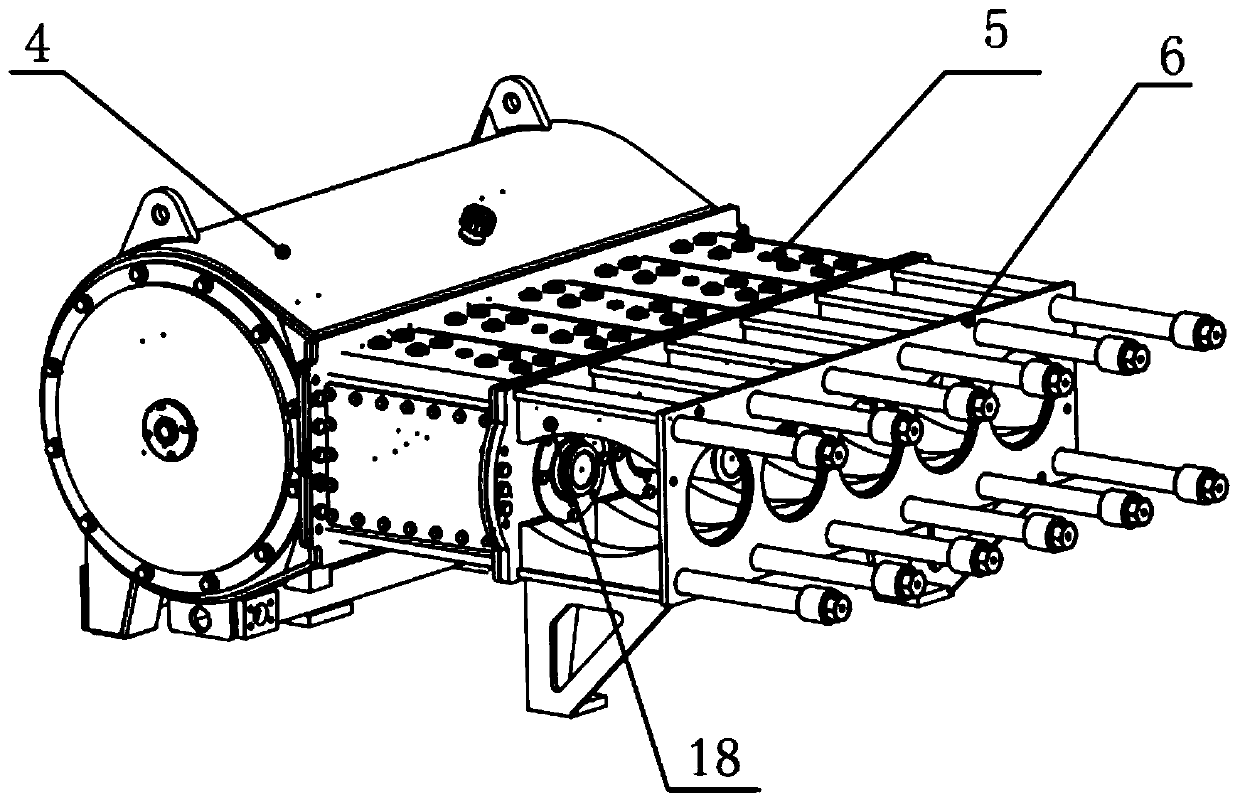

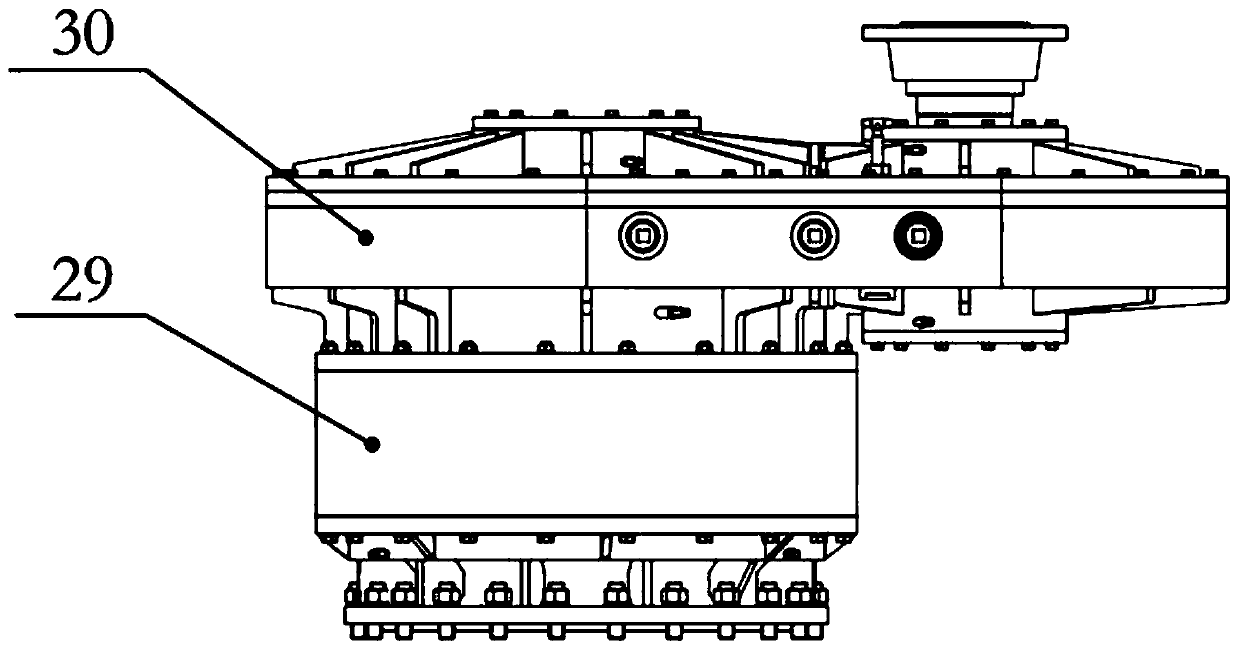

Super-power five-cylinder plunger pump

PendingCN109869294ALess equipmentSave on-site work spaceGearboxesPositive displacement pump componentsElectric driveCentre of rotation

The invention discloses a super-power five-cylinder plunger pump. The super-power five-cylinder plunger pump comprises a power end assembly, a fluid-power end assembly and a reduction box assembly; the power end assembly adopting a sectional type structure design includes a crankshaft box body, a crosshead box body and a space-stop rack, one end of the crosshead box body is connected with the crankshaft box body, and the other end of the crosshead box body is connected with the space-stop rack; the fluid-power end assembly is arranged at one end of the space-stop rack, and the fluid-power endassembly passes through the space-stop rack and the crosshead box body in sequence and is connected with the crankshaft box body through bolts; and the reduction box assembly is connected with the crankshaft box body, a crankshaft in the crankshaft box body is forging alloy steel, the crankshaft includes six shaft necks and five crank threw, each crank throw is arranged between two adjacent shaftnecks, and the distance between the crank threw and the rotating center of the crankshaft is 110mm to 160 mm. The super-power five-cylinder plunger pump has the beneficial effects that the rated inputpower of the super-power five-cylinder plunger pump is 5000 hp, so that the problem that high-power motors cannot be matched with the plunger pumps of corresponding specifications in electric drive fracturing is solved, and the contradictions that the conditions in oil and gas well fields are limited and the matching of fracturing equipment is much is further solved at the same time.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

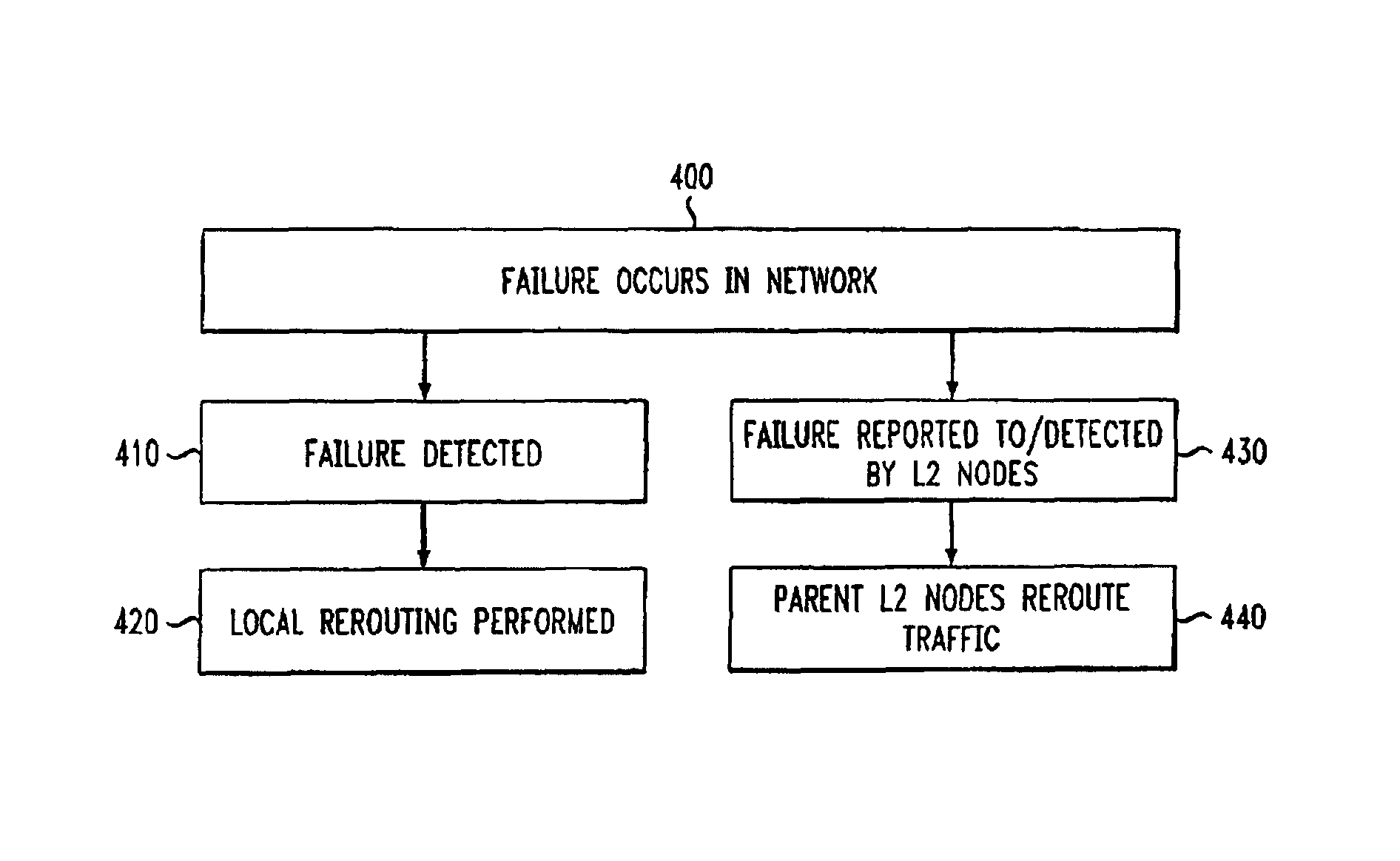

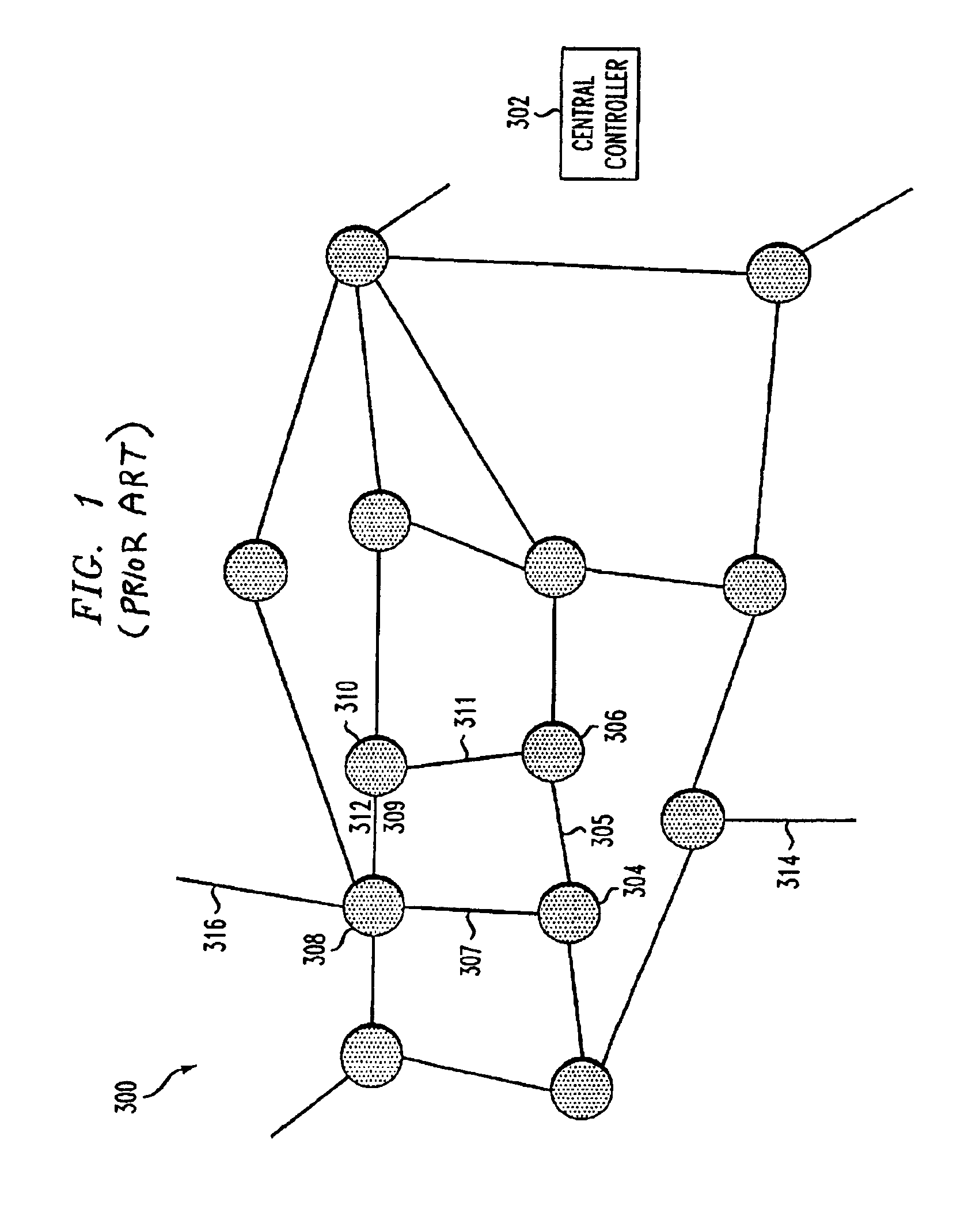

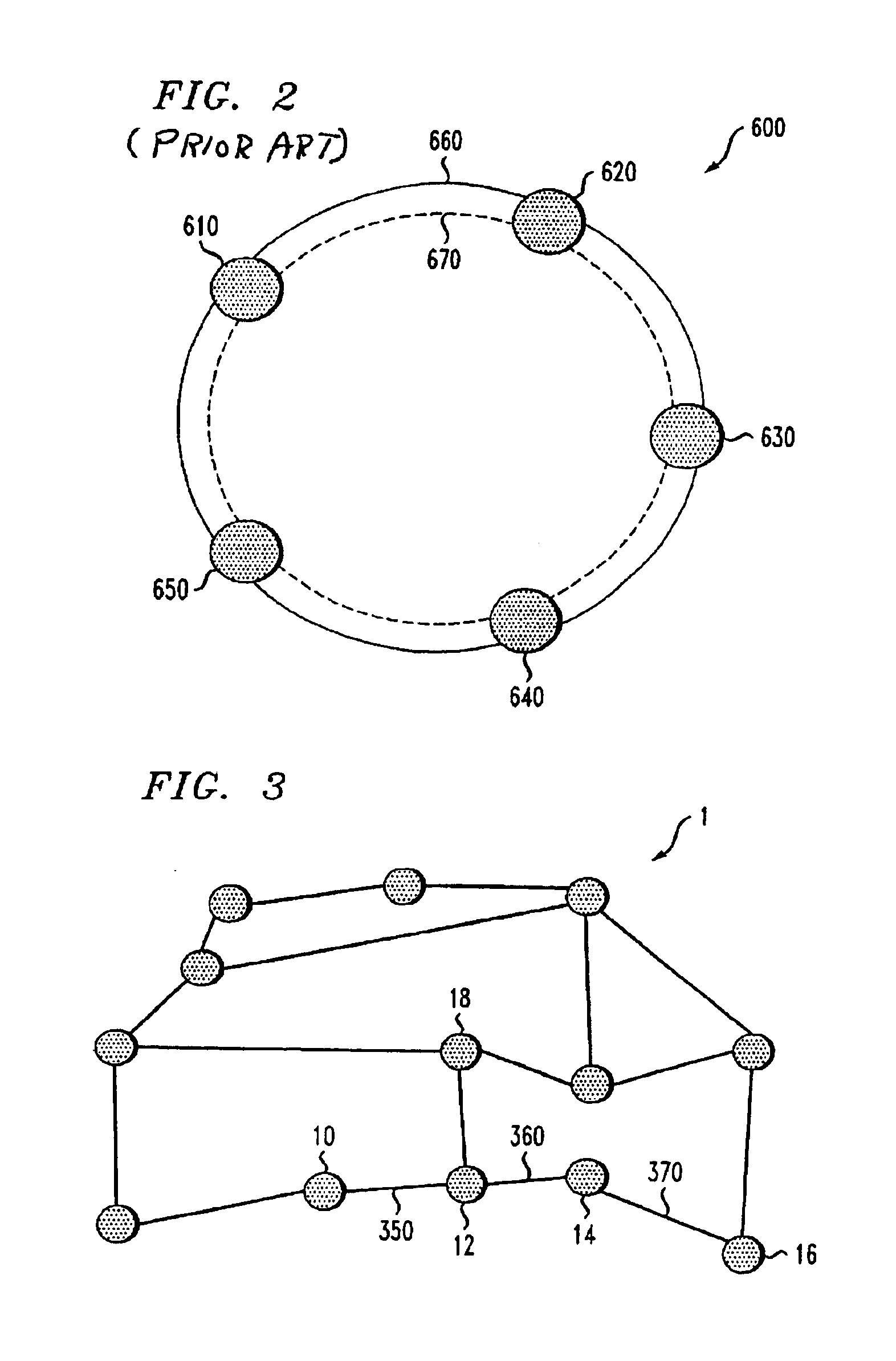

Hierarchical telecommunications network with fault recovery

InactiveUS6862263B1Less equipmentLess susceptibleInterconnection arrangementsError preventionTraffic volumeDevice failure

The present invention is a telecommunications network having a hierarchical architecture which reduces the amount of equipment and processing required to recover from network failures. In an exemplary embodiment, the nodes of the network are divided into high level nodes and low level nodes. High granularity traffic is collected, routed and manipulated at high level nodes, but generally passes through low level nodes, which generally lack the capability for routing and manipulating such high granularity traffic. Equipment savings results from low level nodes lacking the capability to manipulate traffic other than traffic relevant to those nodes or nearby nodes. Each high level node pair is connected by at least three node disjoint paths of low level nodes and links. Less protection capacity is needed, as each node disjoint path is expected to handle only a portion of rerouted traffic in the event of a network equipment failure. Recovery is decentralized, and is thus faster, requires less equipment, and is less susceptible to the failure of a centralized controller than with networks using centralized recovery processing.

Owner:RED HAT

Building panels provided with a mechanical locking system

Building panels, such as floorboards, provided with a mechanical locking system. The mechanical locking system includes a displacement groove at a first edge of a first floorboard and a tongue groove at a second edge of a second floorboard A tongue is arranged in the displacement groove and is configured to cooperate, in a second position, with the tongue groove for vertical locking of the first and the second edge. The tongue includes, in a first position, an inner element and an outer element. The inner element is removable along the displacement groove, and is configured to cooperate with the outer element to obtain a displacement of the outer element towards the tongue groove and thereby obtain the second position. Said inner element and said outer element vertically overlap each other.

Owner:VÄLINGE INNOVATION AB

Catalytic steam gasification process with recovery and recycle of alkali metal compounds

ActiveUS7922782B2Promote leachingLarge specific surface areaHydrogenGaseous fuelsCompound aCombustible gas

A high efficiency gasification process for converting carbonaceous solids to methane and apparatus for its practice are described. The process includes reacting steam and carbonaceous solids comprising ash in the presence of alkali metal catalyst in a gasification reactor to produce combustible gases and char particles comprising ash and alkali metal catalyst constituents, treating a stream of such char particles in an alkali metal catalyst recovery system to recover the catalyst constituents as alkali metal compounds, and recycling such recovered compounds. Within the alkali metal catalyst recovery system the process includes quenching the stream of char particles with water whereby such particles are cooled and fractured, dissolving soluble alkali metal catalyst constituents from the fractured solids to form a first alkali metal catalyst solution and washed solids, optionally reacting the washed solids in alkaline solution to form a second alkali metal catalyst solution, upgrading said first and optional second alkali solution to recover the alkali metal catalyst constituents as said alkali metal compounds.

Owner:SURE CHAMPION INVESTMENT LTD

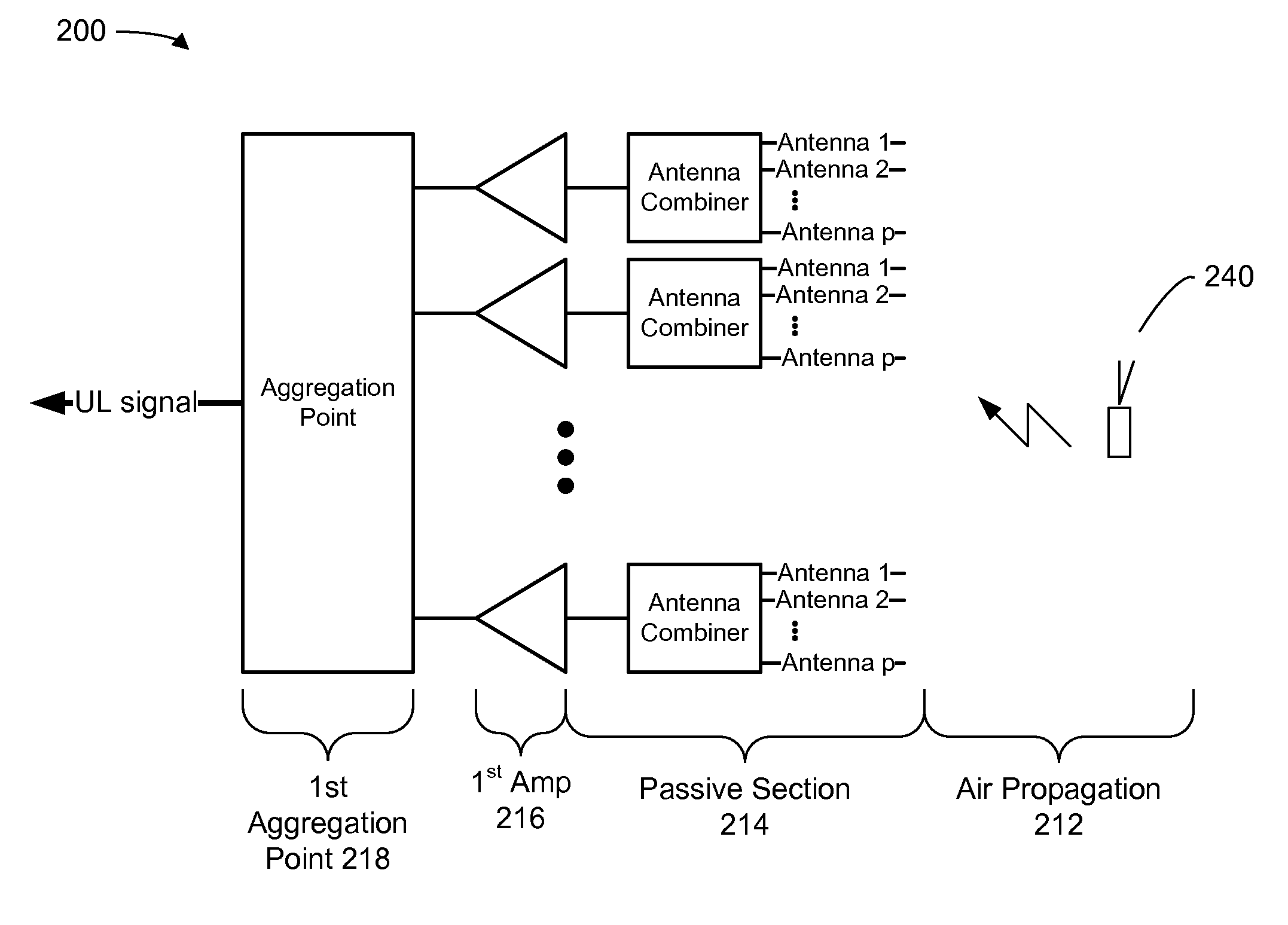

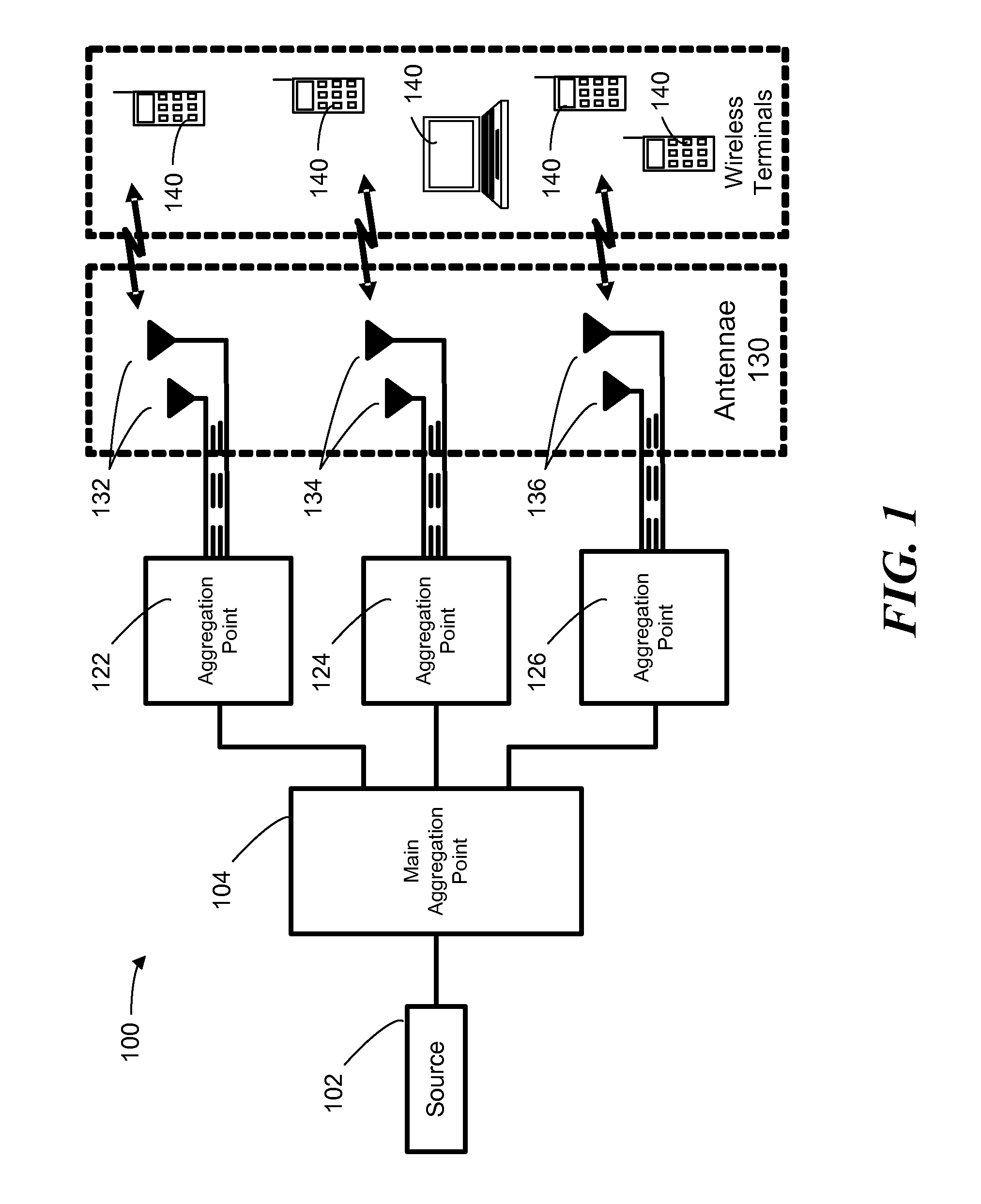

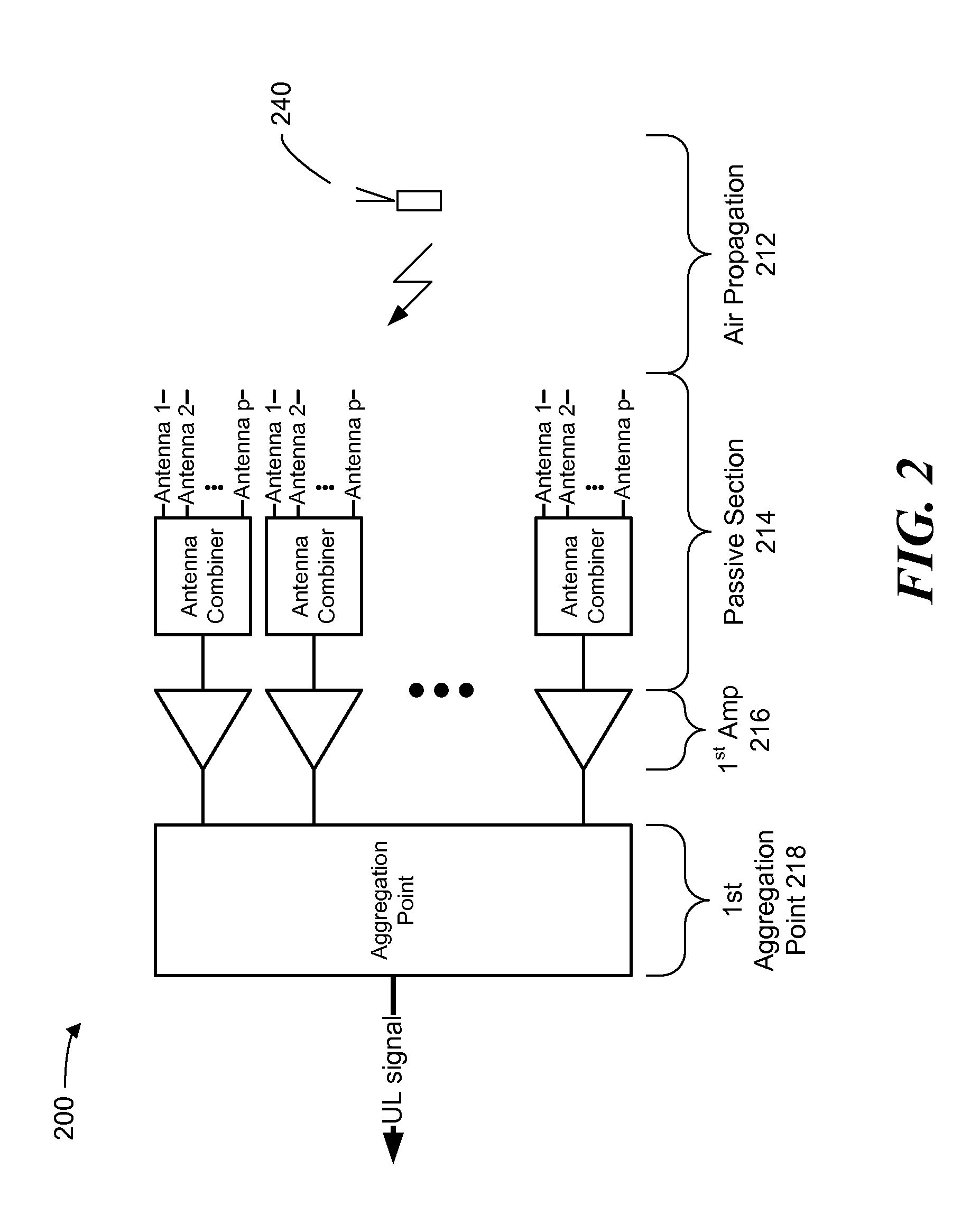

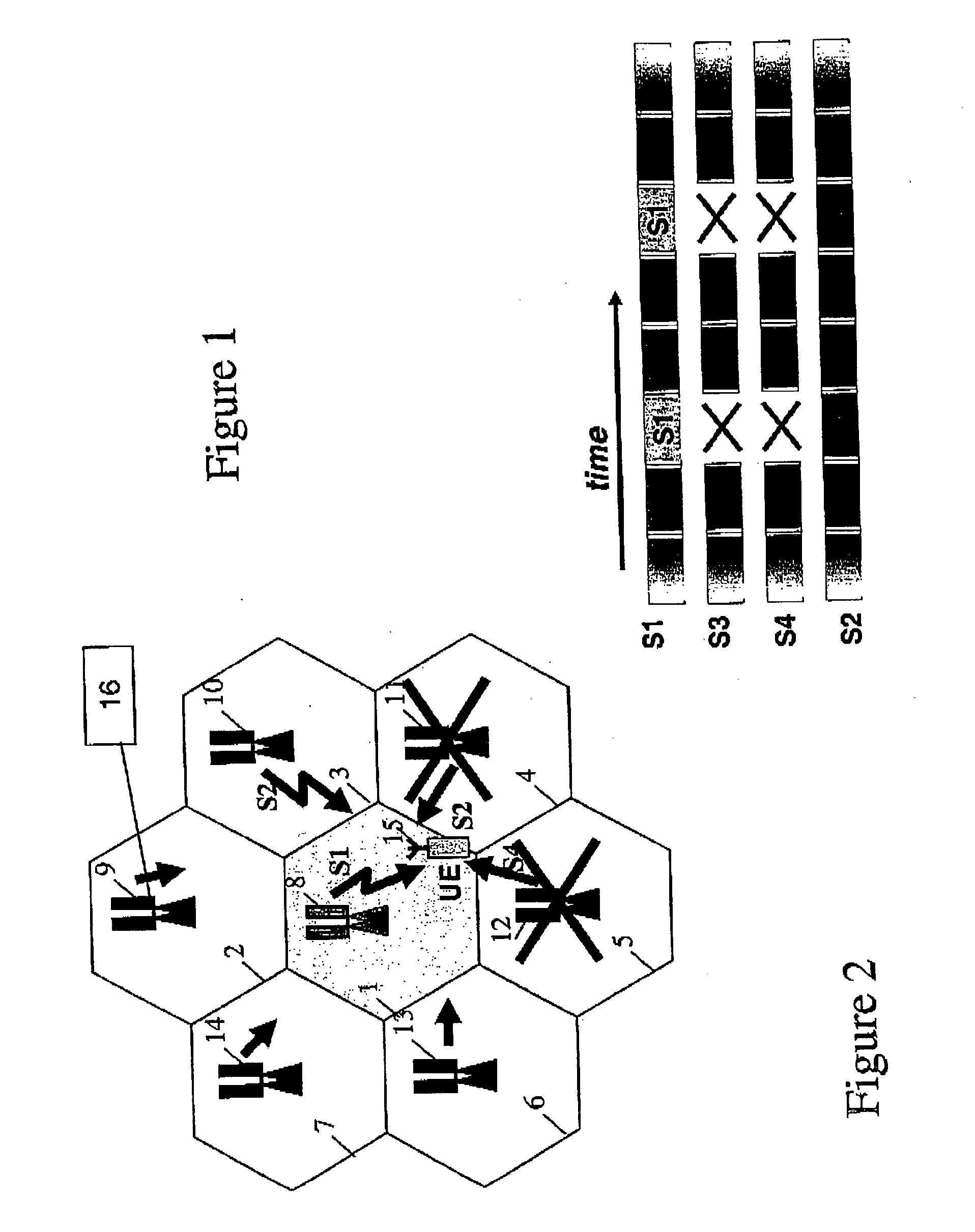

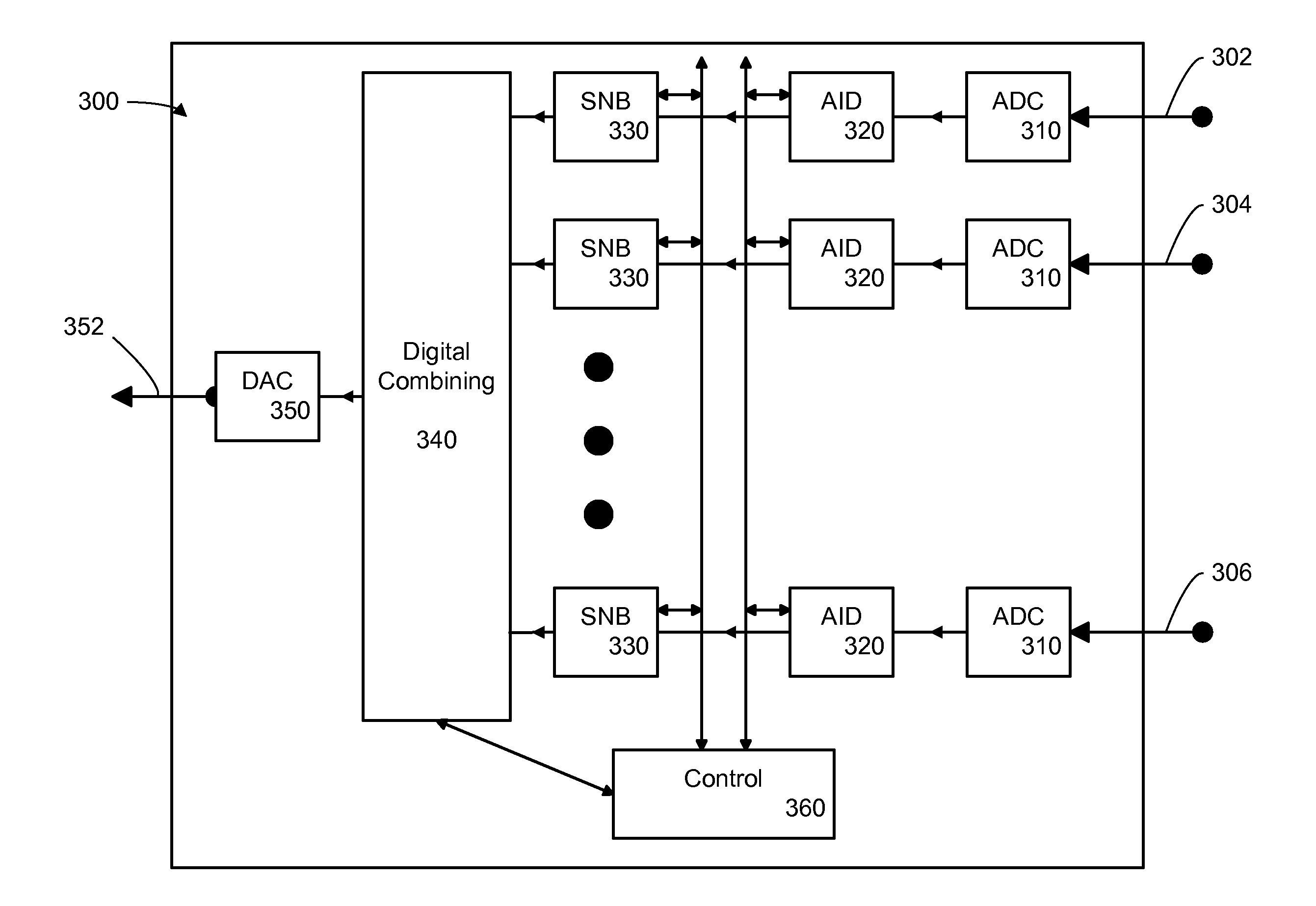

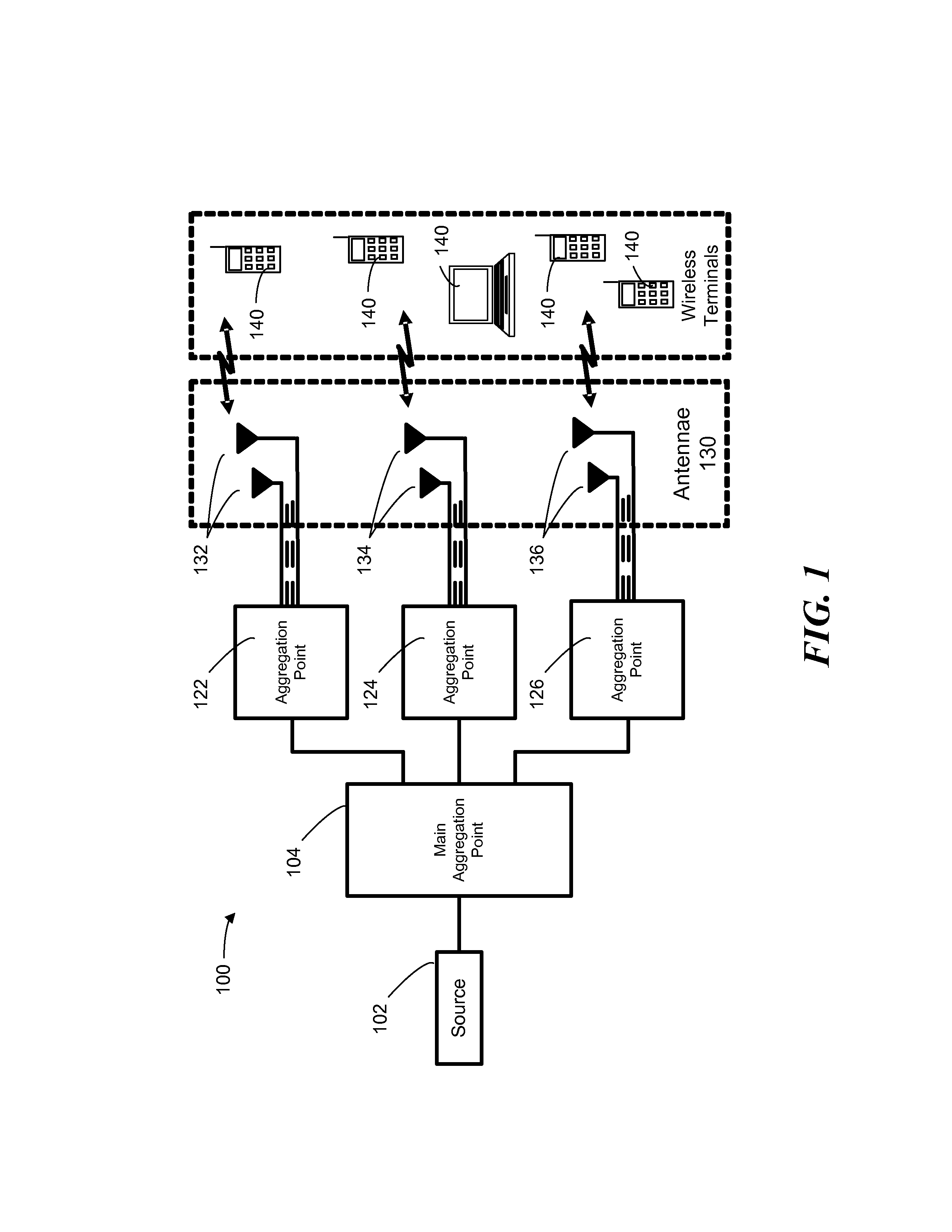

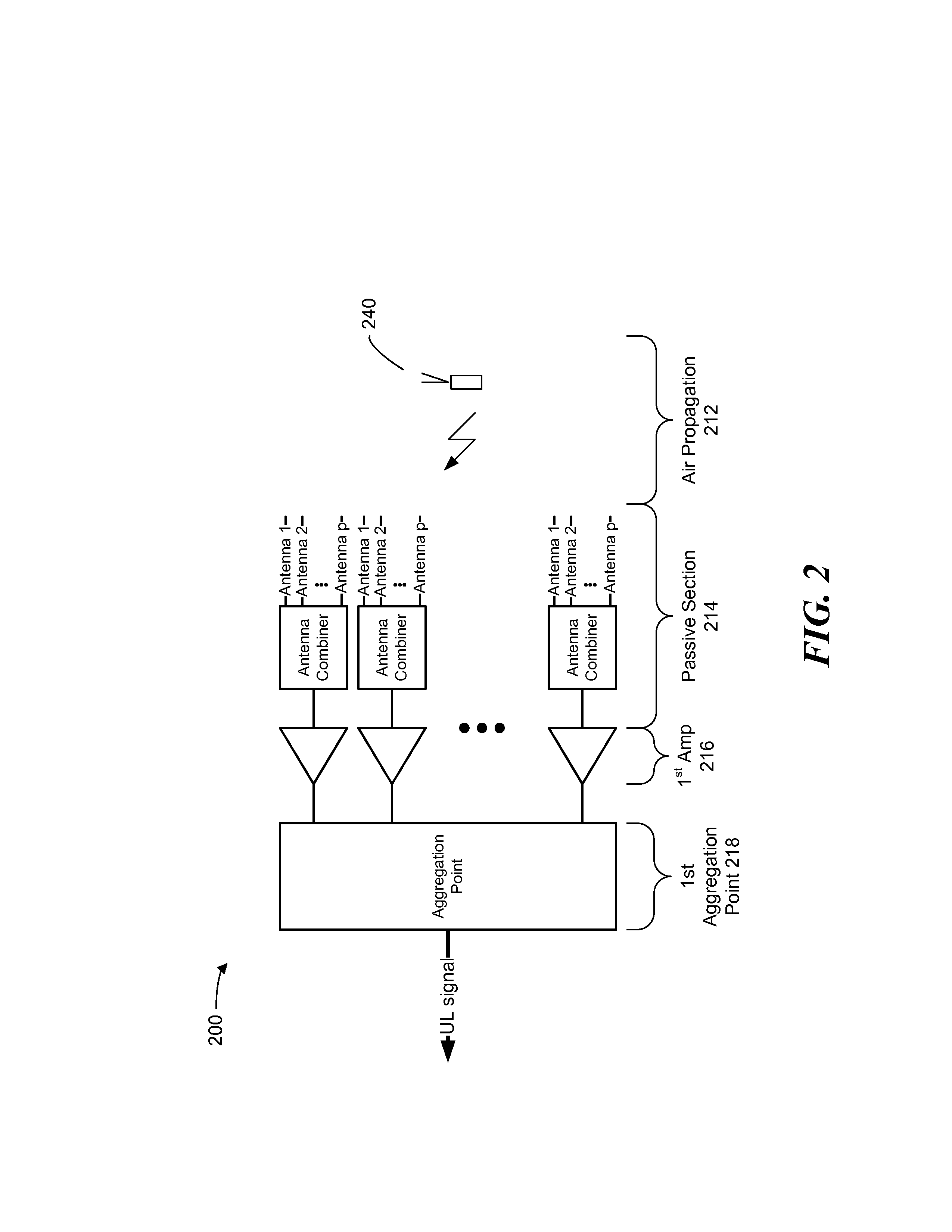

Method and system for improving uplink performance

ActiveUS20080198955A1Limited dynamic rangeReduce distanceSite diversityPolarisation/directional diversityDistributed antenna systemComputer science

The present invention is directed to improvements for distributed antenna systems and more particularly to methods and systems for improving uplink communications. In one embodiment, Aggregation Point Noise Blocking provides for blocking or filtering the noise contributed by one or more of the branches coupled to an aggregation point that are not carrying the signal from a particular terminal. Signal activity from a given terminal on a particular branch can be identified and that information can be used to selectively block or filter the signal noise contributed by the other branches to an aggregation point. The selective blocking or filtering can also include an attenuation function to attenuate the signal and provide dynamic range smoothing. In another embodiment the signal can be regenerated to produce a signal that has a restored or very high SNR. An uplink regeneration block can be provided which demodulates the uplink signal to recover the transmitted information and then re-modulates the transmitted information to regenerate a signal at a restored or very high SNR.

Owner:CORNING OPTICAL COMM WIRELESS

Window sash frame with hinged components

InactiveUS6928776B2Less capital intensiveLess equipmentInsect protectionGlass/slag layered productsEngineeringMechanical engineering

Methods and apparatus are provided for mounting one or more glazing panes or insulating glass units into a window sash frame member having spaced side walls joined by an inner facing frame surface with a spacing structure disposed on the frame surface. Glazing panes are placed against strips of adhesive sealant within the window sash frame. Folding glazing beads hingedly attached to the side or inner walls of the frame member are folded against the glazing panes to secure them to the window sash frame member and / or to cover the glazing pane edges.

Owner:SASHLITE

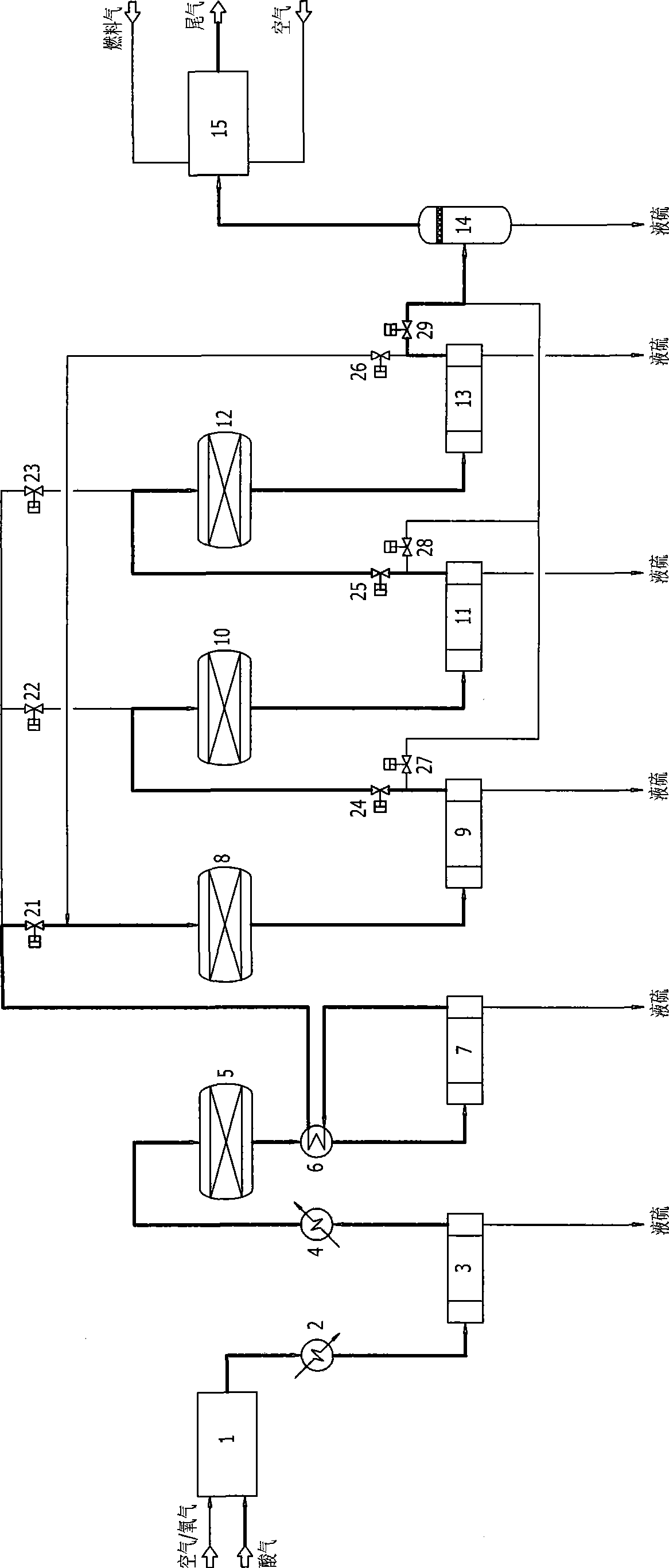

Low temperature Claus sulfur recovery process and device therefor

InactiveCN101519192AAchieve regenerationImprove conversion rateEnergy inputSulfur preparation/purificationReaction temperatureOxygen

Owner:CHENGDU SEPMEM SCI & TECH

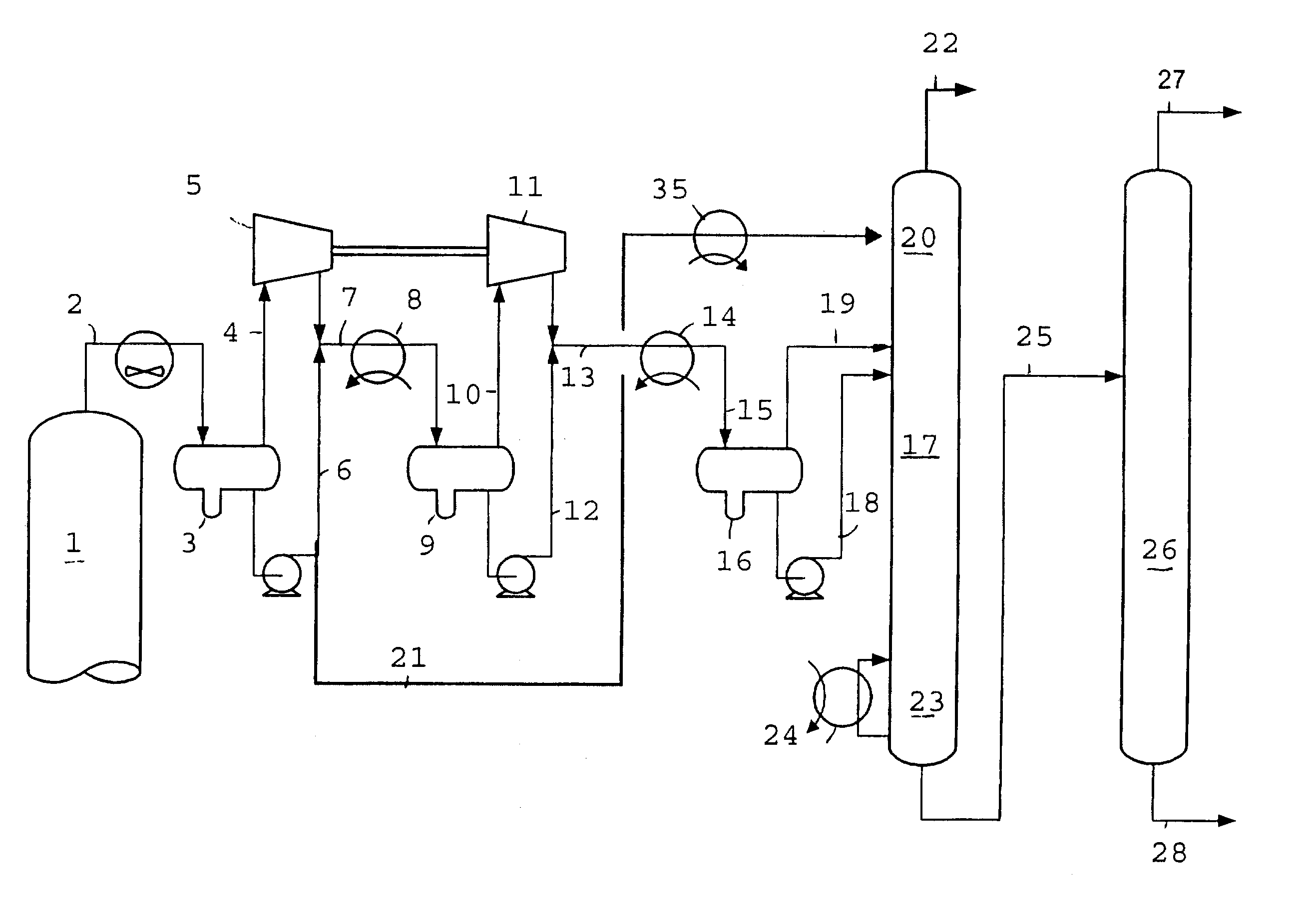

Use of low pressure distillate as absorber oil in a FCC recovery section

InactiveUS7074323B2Less equipmentImprove throughputThermal non-catalytic crackingCatalytic crackingNaphthaDistillation

A process for the recovery of gaseous products from the product mixture obtained by contacting a hydrocarbon feed with a catalyst in a fluid catalytic cracking process, wherein the liquid, obtained by separating the top product of main fractionators into gaseous and liquid fraction, when supplied to the absorber has a temperature of between about 8–25 DEG C. This liquid may be pre-saturated with gaseous top product from absorber; or also a high boiling fraction (cat cracker naphtha / light cycle oil) may be first separated from this liquid by distillation.

Owner:SHELL OIL CO

Forming fabric with extended surface

InactiveUS20090205797A1Large capacityQuality bulkSynthetic resin layered productsMachine wet endMechanical engineeringPolymer

A fabric for an advanced dewatering system having a woven fabric, the woven fabric having a paper side and a roll side, the paper side having a paper side surface and the roll side having a roll side surface and a polymer material. The polymer material is deposited onto the fabric and extends above the paper side surface. The polymer material has at least one of a random pattern, a random motif, a pseudo-random pattern, a pseudo-random motif, a predetermined pattern, and a predetermined motif.

Owner:VOITH PATENT GMBH

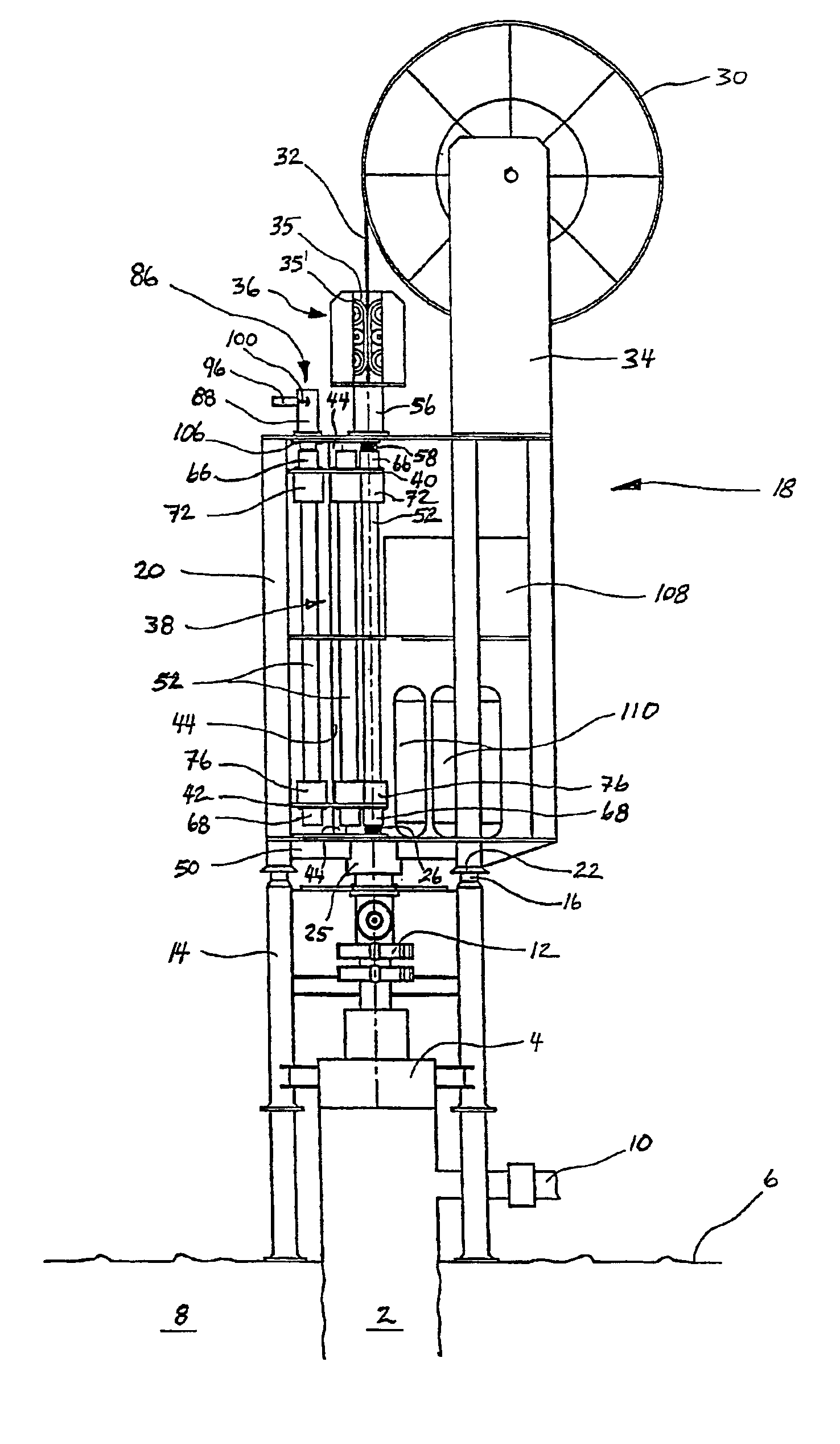

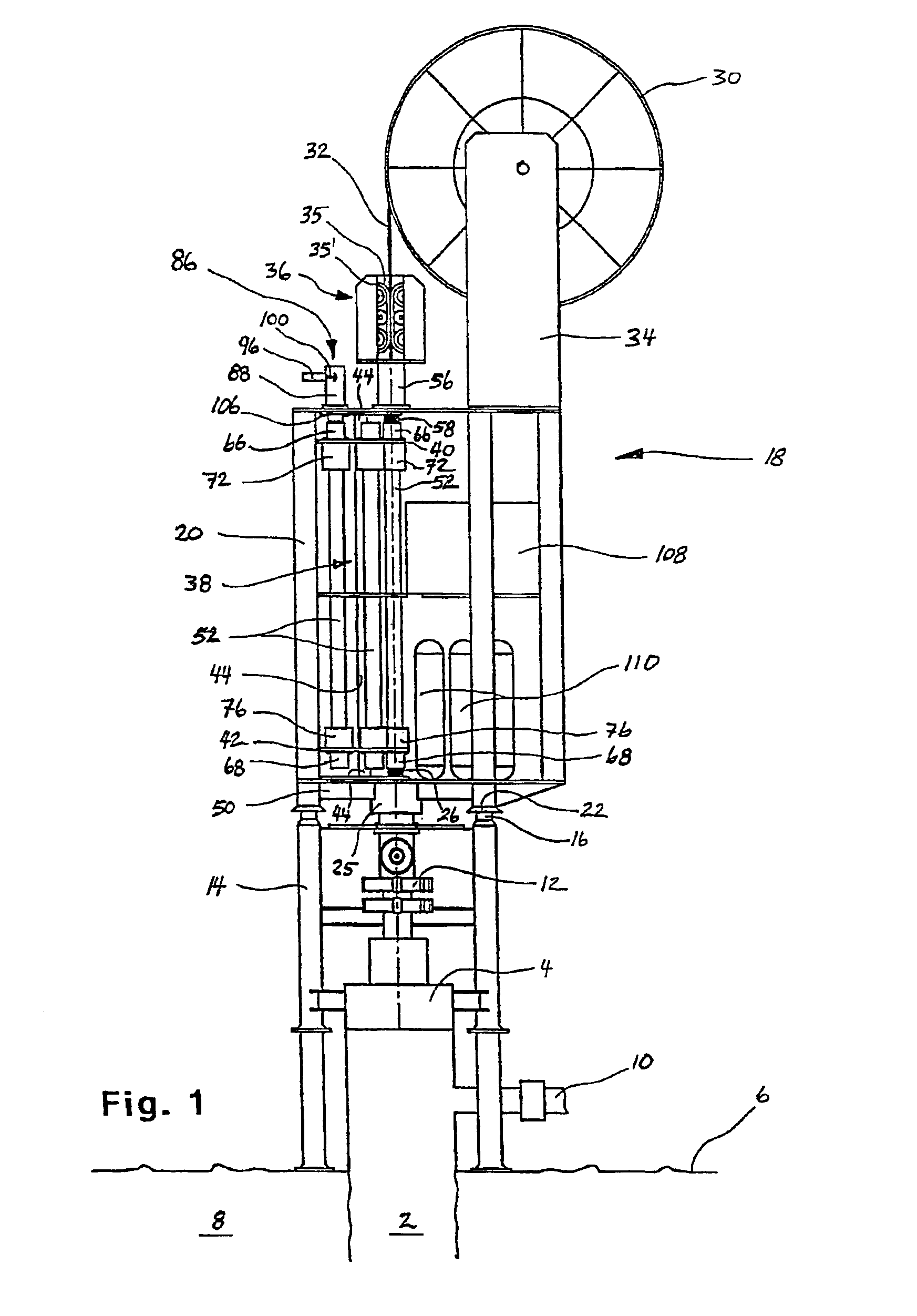

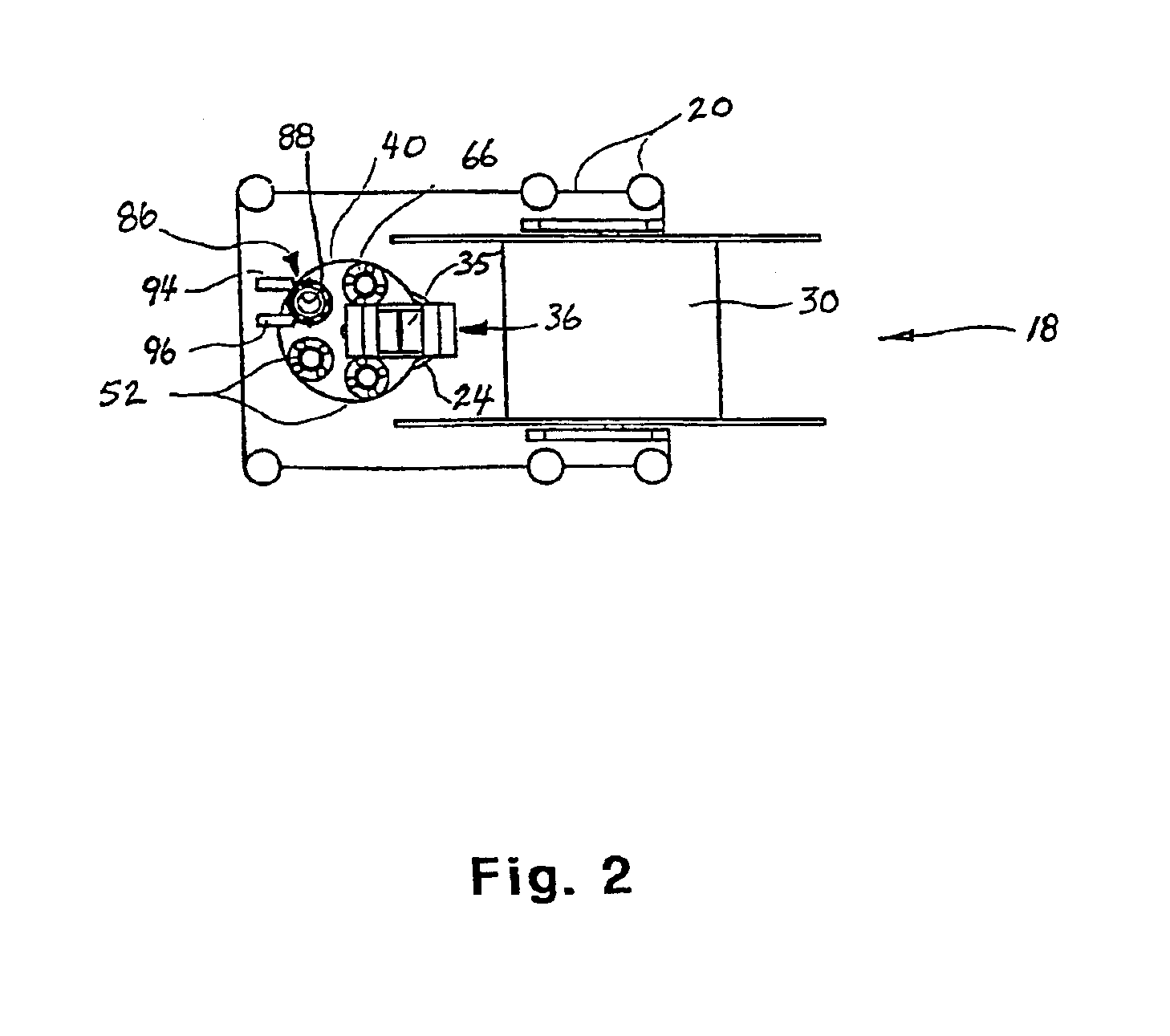

Intervention module for a well

The invention relates to an intervention module (18) for well intervention operations in preferably a pressurized subsea well (2) with a wellhead (4) disposed on a water floor. The intervention module (18) is provided with necessary equipment to replace, under water, intervention tools (54) and thereby perform several well intervention operations in one run, without the supply of equipment from a surface vessel. The module (18) is lowered from a surface vessel and placed on the wellhead (4), possibly a BOP (12), of the well (2). The intervention module (18) is connected to the surface vessel through a connecting line / hose or a wireless connection which communicates, as a minimum, necessary control and feed-back signals. The module (18) is provided with i.e. a rotatable tool magazine (38) arranged with several storage pipes (52) for intervention tools (54), the relevant storage pipe (52) being rotatable into a position immediately above the well bore (24) of the well (2), after which the intervention tool (54) is connected to a supply string (32), whereas the storage pipe (52) is connected in a pressure-sealing manner to the well bore (24) below and a pressure safety device above, through which the supply string (32) is passed, so that the intervention tool (54) may be inserted safely into the well (2).

Owner:OFFSHORE & MARINE

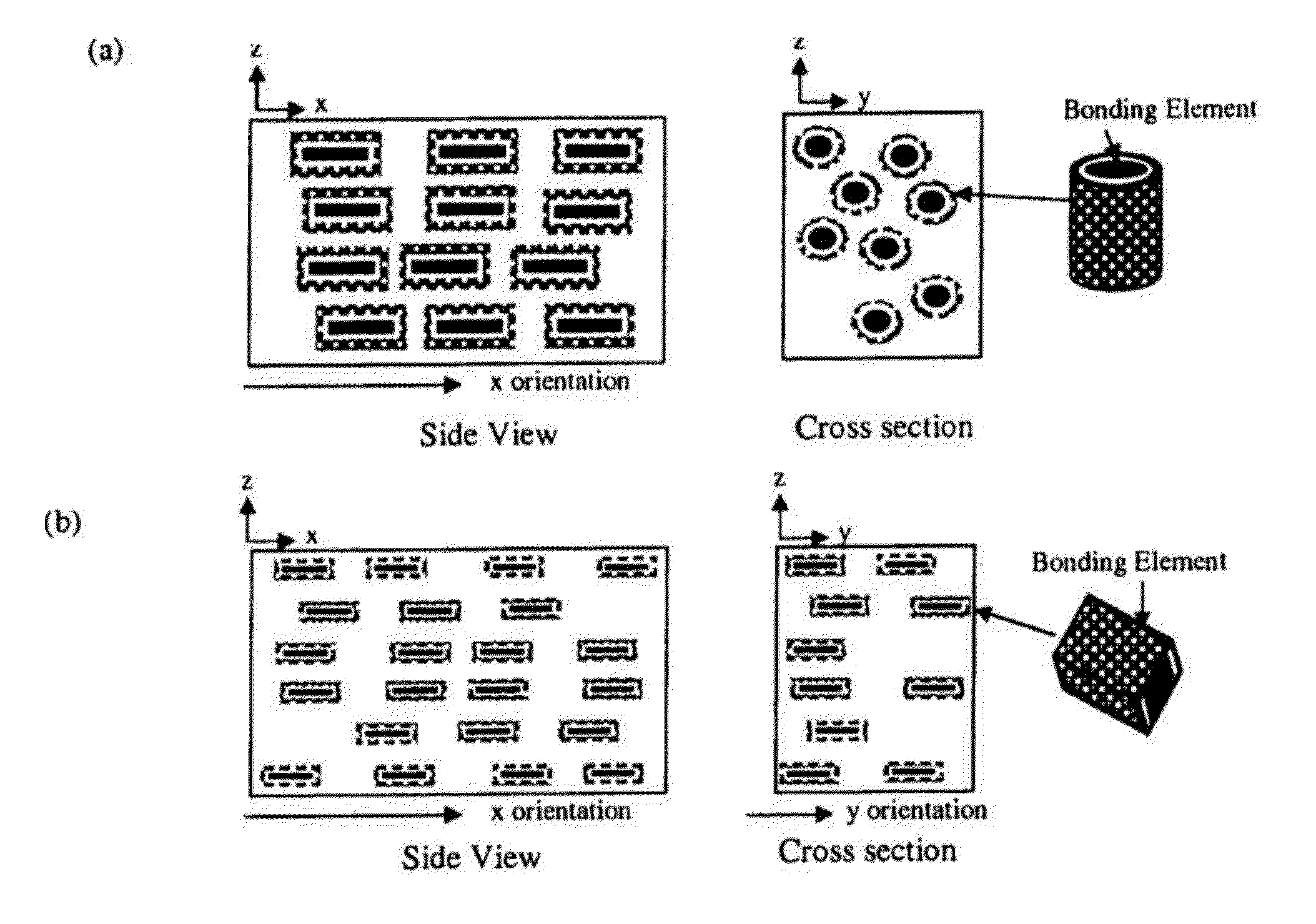

Aerated composite materials, methods of production and uses thereof

ActiveUS20150056437A1Excellent physicalExcellent performance characteristicSolid waste managementLayered productsEnergy consumptionMethods of production

The invention provides novel aerated composite materials that possess excellent physical and performance characteristics of aerated concretes, and methods of production and uses thereof. These composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production with improved energy consumption, desirable carbon footprint and minimal environmental impact.

Owner:SOLIDIA TECH

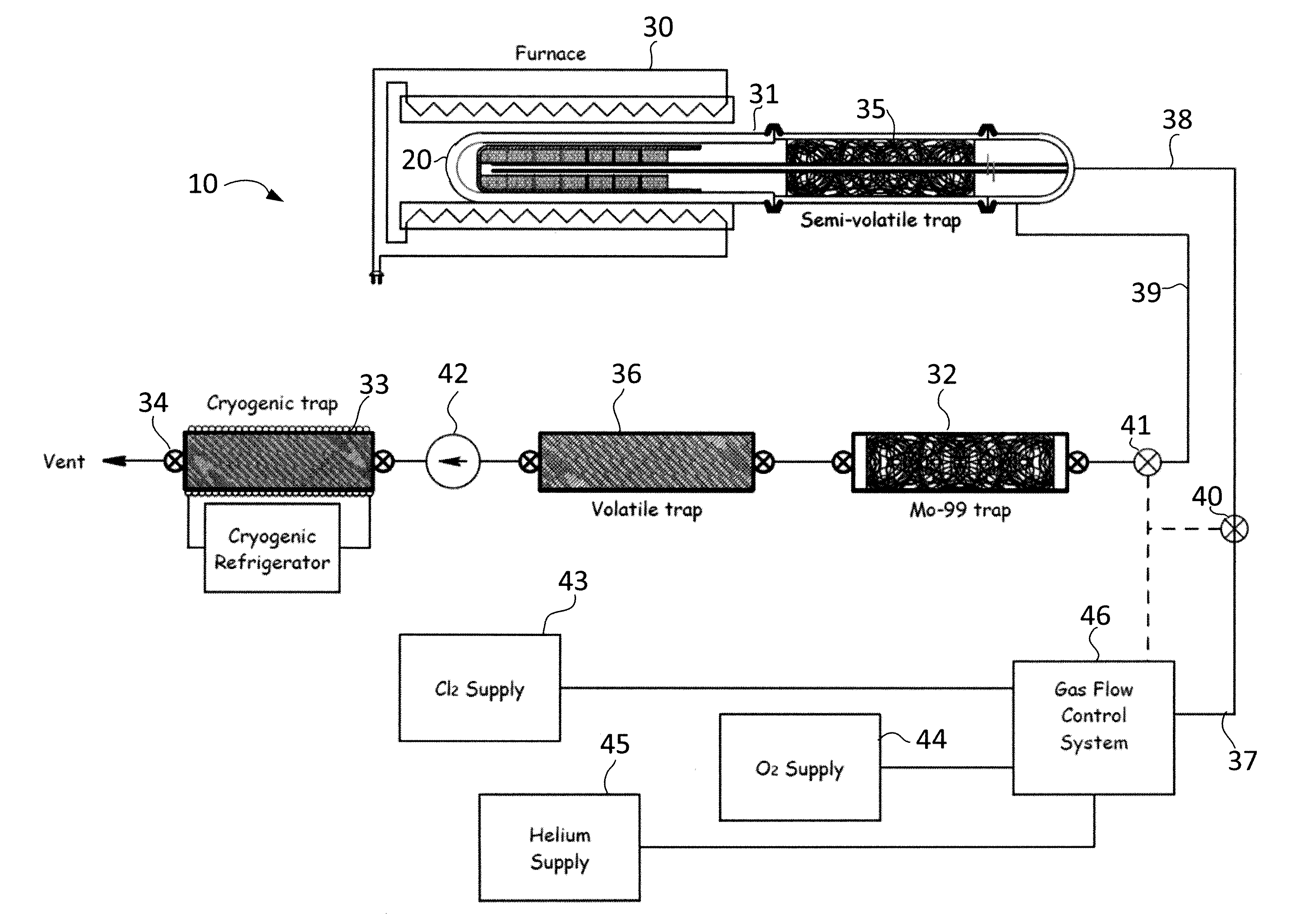

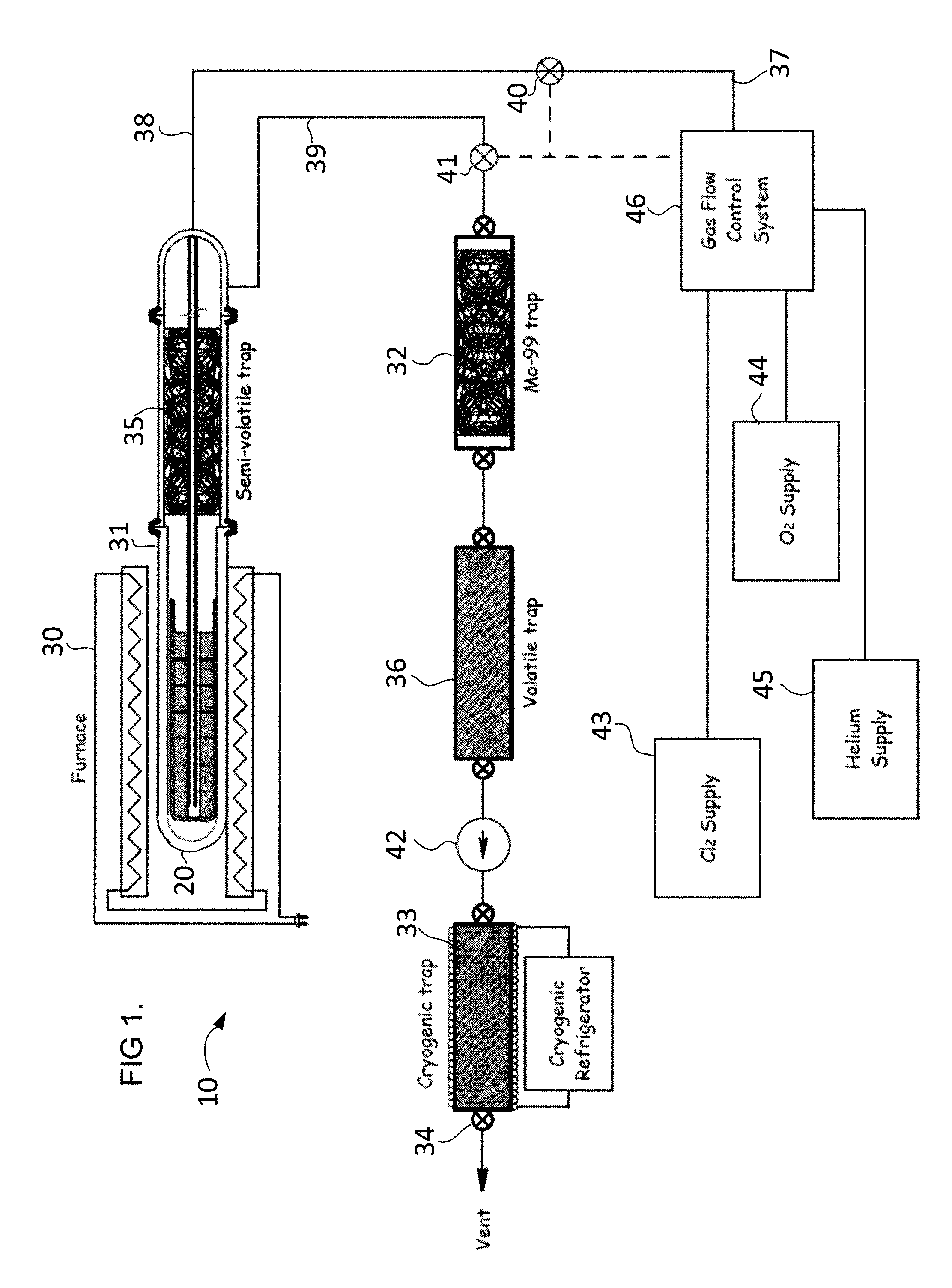

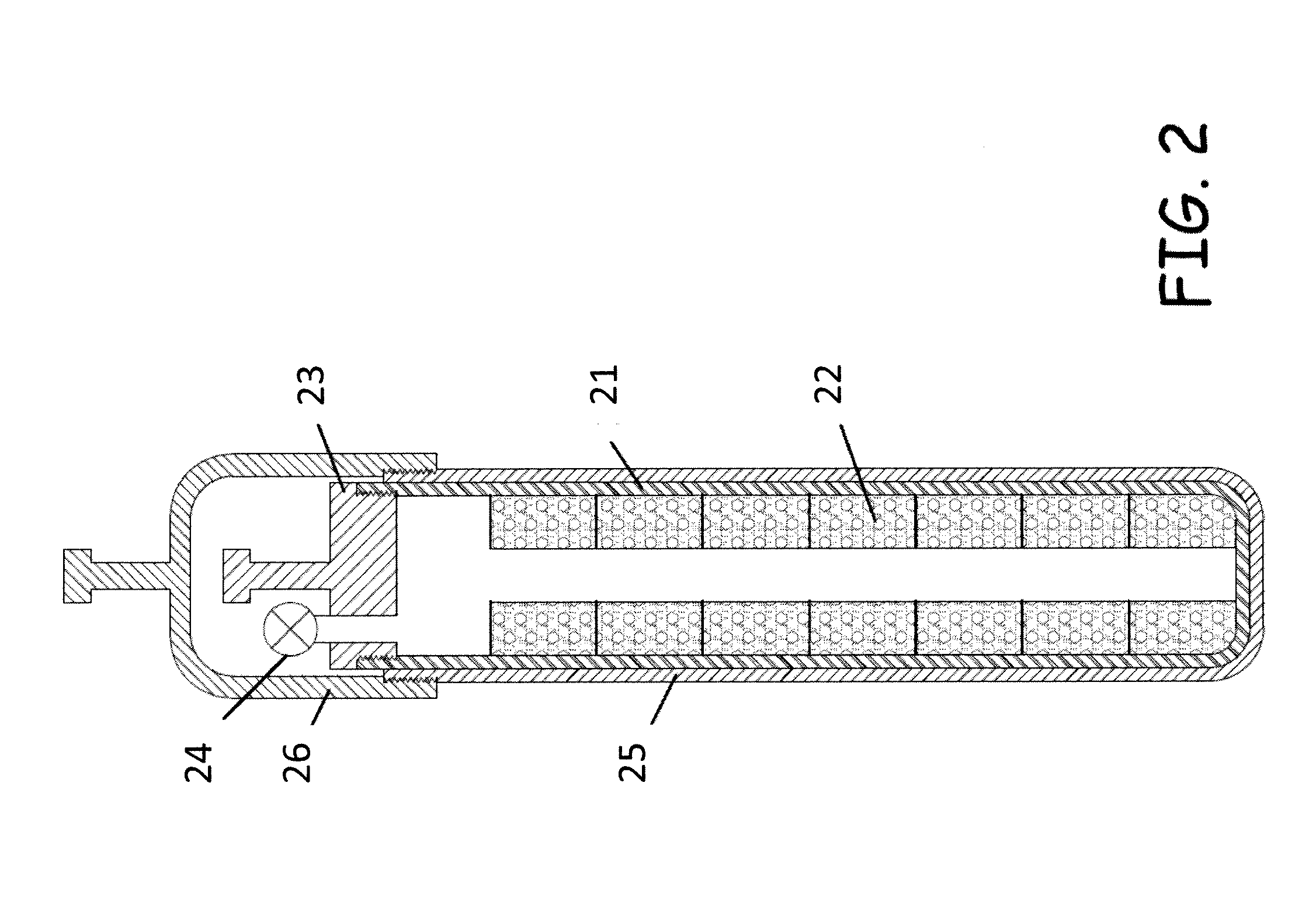

Methods and apparatus for selective gaseous extraction of molybdenum-99 and other fission product radioisotopes

ActiveUS20110305309A1Less capital equipmentRapid productionSpecific isotope recoveryConversion outside reactor/acceleratorsChemistryGaseous substance

Methods and apparatus are provided for producing and extracting Mo-99 and other radioisotopes from fission products that overcome the drawbacks of previously-known systems, especially the excessive generation of radioactive wastes, by providing gas-phase extraction of fission product radioisotopes from a nuclear fuel target using a mixture including halide and an oxygen-containing species with heat to convert the fission product radioisotopes to gas (e.g., Mo-99 to MoO2Cl2 gas). The gaseous species are evacuated to a recovery chamber where the radioisotopes solidify for subsequent processing, while the substantially intact uranium target made available for further irradiation and extraction cycles.

Owner:GENERAL ATOMICS

Capacitive electric musical instrument vibration transducer

InactiveUS7408109B1Low costImprove fidelityElectrophonic musical instrumentsLinear/angular speed measurementParallel plateElectronic instrument

A capacitive electric musical instrument vibration transducer contains one or more parallel plate variable capacitors. Each variable capacitor contains one vibrating variable capacitor plate, an electrically conducting surface that comprises, covers, or is embedded within an acoustically emitting vibrating surface on a musical instrument (such as a drumhead or soundboard), and one fixed variable capacitor plate comprising a rigid electrically conducting surface held a fixed distance away. When the instrument is played, the vibrating surface causes vibrations directly (without using airborne sound as an intermediary) in the vibrating variable capacitor plates, thus causing time-varying voltage oscillations in the parallel plate variable capacitors reflecting the vibrational state, and therefore the sound, of the instrument. An electric circuit in the transducer converts these voltage oscillations into the same kinds of signals produced by microphones and magnetic pickups.

Owner:FREITAS PAUL JOHN

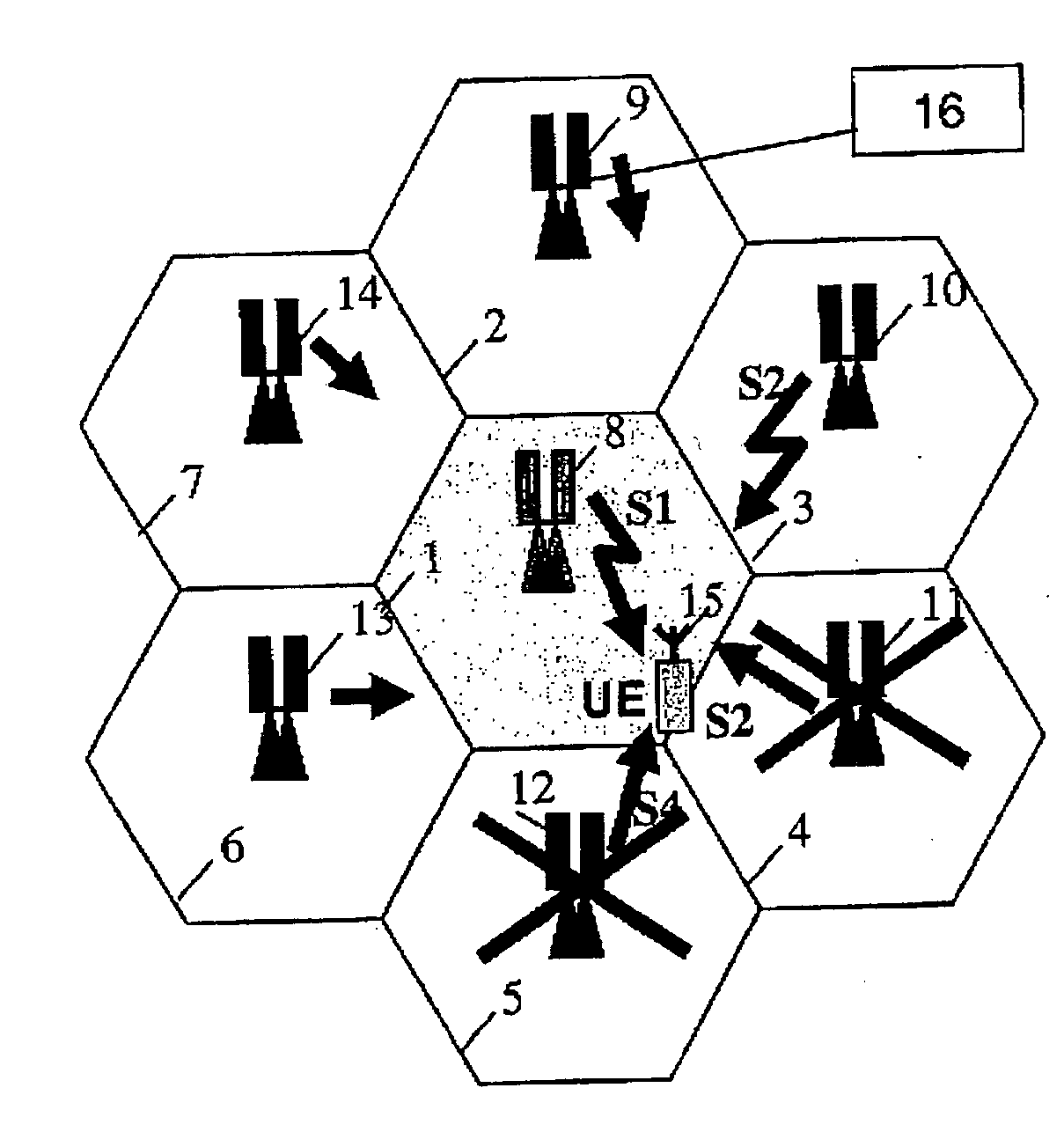

Method and apparatus for improving a transmission signal characteristic of a downlink signal in a time division multiple access wireless communication system

ActiveUS20040125773A1Enhanced signalImproving C/IEnergy efficient ICTTime-division multiplexCommunications systemTime division multiple access

The invention relates to improving the quality of a received downlink signal in a time division multiple access wireless cellular communications network. The method of the invention comprises measuring a signal quality characteristic at a user equipment and comparing this to a threshold to determine it a desired signal quality level exists. It so then a certain level or type of service on the downlink can be effected. It not, the method comprises identifying an interferer signal or signals and removing at least one of such interferer signals by arranging for it to either not be transmitted on the same TDMA timeslot as the downlink signal or to be transmitted at a lower power, for example, in said timeslot.

Owner:APPLE INC

Pervious composite materials, methods of production and uses thereof

ActiveUS20140363665A1Excellent physical and performance characteristicEasy to produceRecord information storageCeramic shaping apparatusEnvironmental effectCarbon footprint

The invention provides novel pervious composite materials that possess excellent physical and performance characteristics of conventional pervious concretes, and methods of production and uses thereof. These composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production with improved energy consumption, desirable carbon footprint and minimal environmental impact.

Owner:SOLIDIA TECH

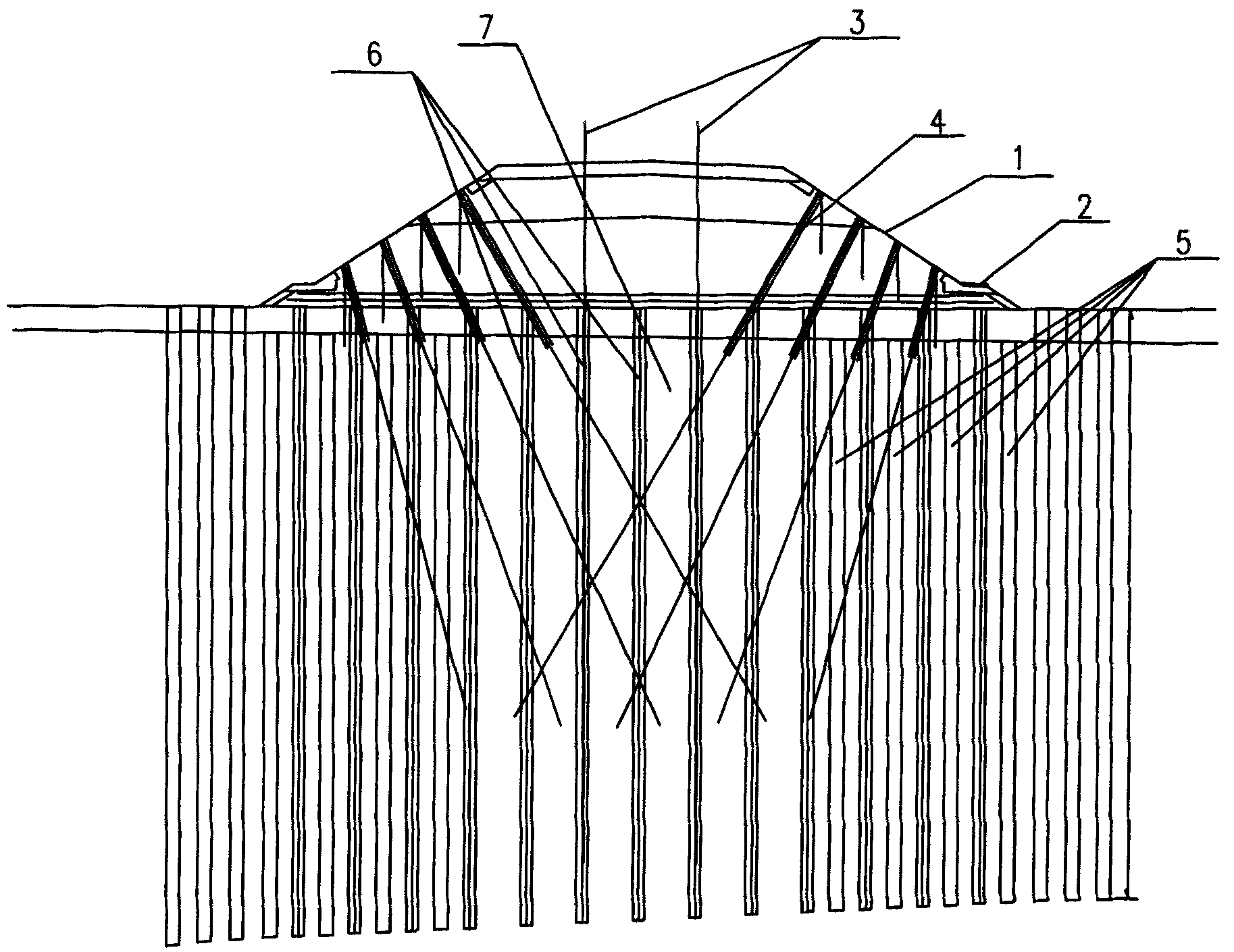

Soft foundation reinforcing method of existing railway or highway subgrade construction

ActiveCN101886382AAvoid traffic disturbanceLess equipmentBulkheads/pilesSoil preservationEngineeringSizing

The invention relates to a soft foundation reinforcing method of the existing railway or highway subgrade construction, which comprises the following steps of: constructing vertical chemical churning piles on the side slope and the slope toe of a subgrade to be reinforced; after the vertical chemical churning piles are cured, drilling a plug hole tilting toward the center line of a track and extending into the soft foundation in the side slope by using a drilling machine; and performing shock tube grouting in the plug hole. A sizing agent in the plug hole permeates towards the periphery of the foundation, the cured sizing agent, the vertical chemical churning piles and the foundation form an integrated reinforcing block, and thus, the reinforcement of the railway or highway subgrade construction is completed. Compared with the traditional single technique, the method has the advantages of no construction transition, no traveling interruption and no reinforcing dead zone by adopting the vertical chemical churning piles together with a shock tube grouting technique. The advantages of both the vertical chemical churning piles and the shock tube grouting technique are fully exerted, and the safety and the quality are controllable.

Owner:广东省铁路规划设计研究院有限公司

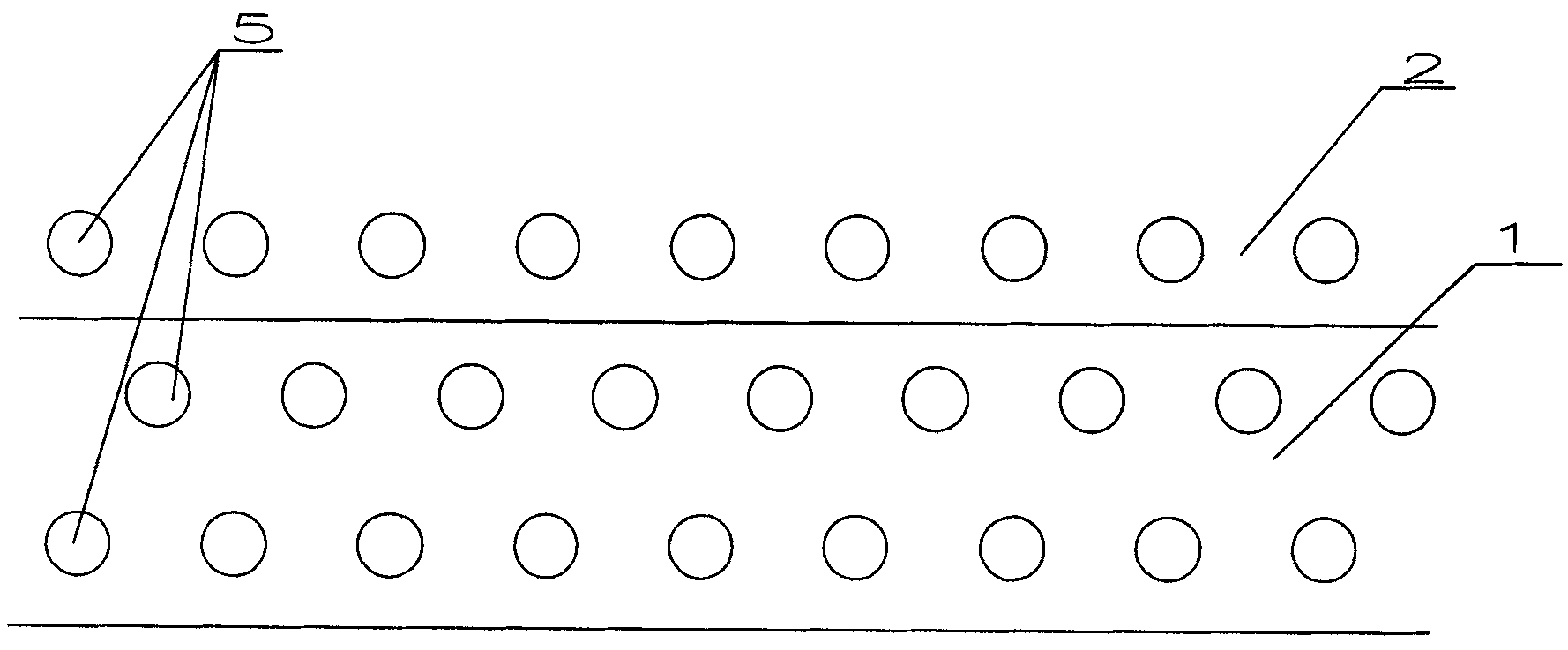

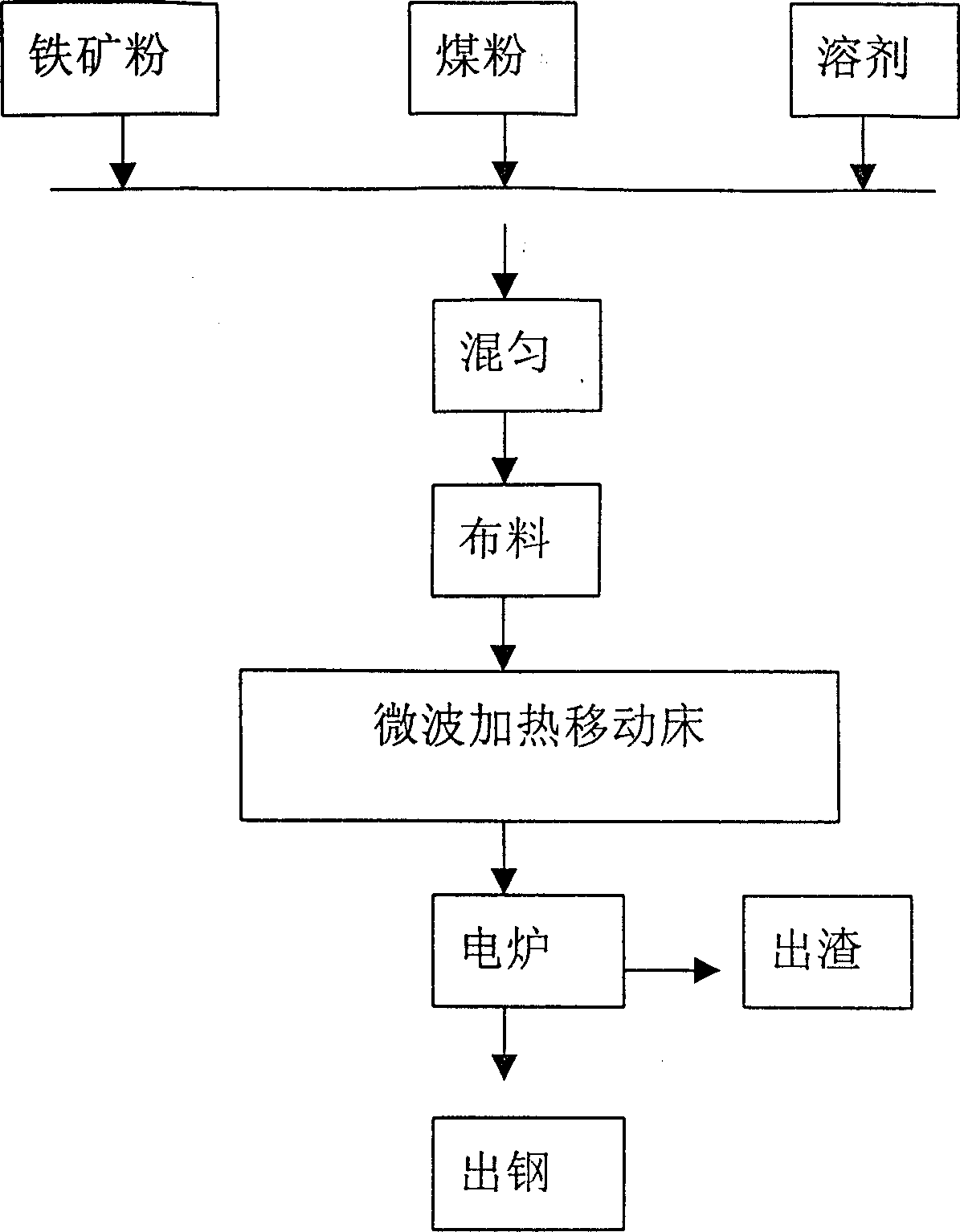

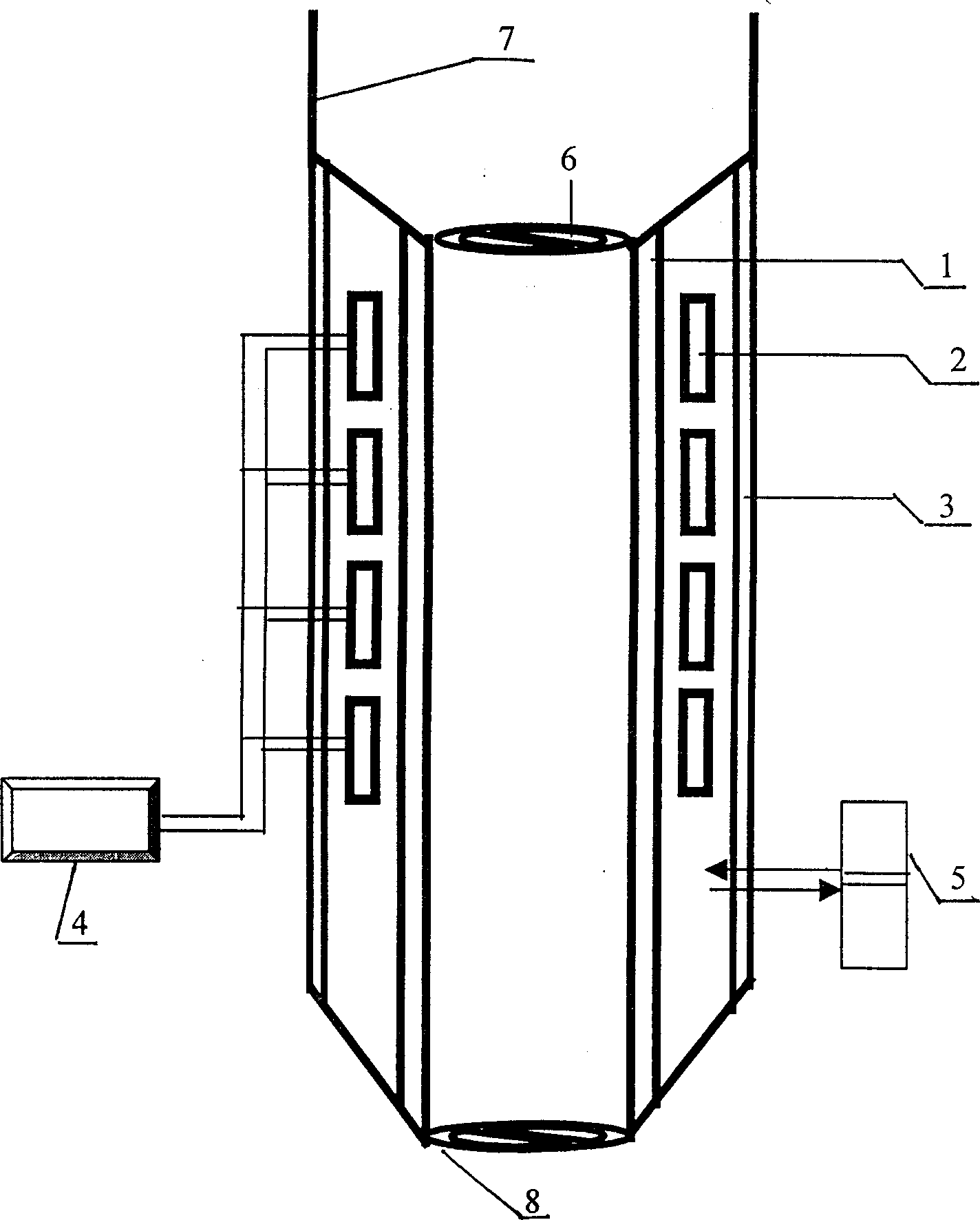

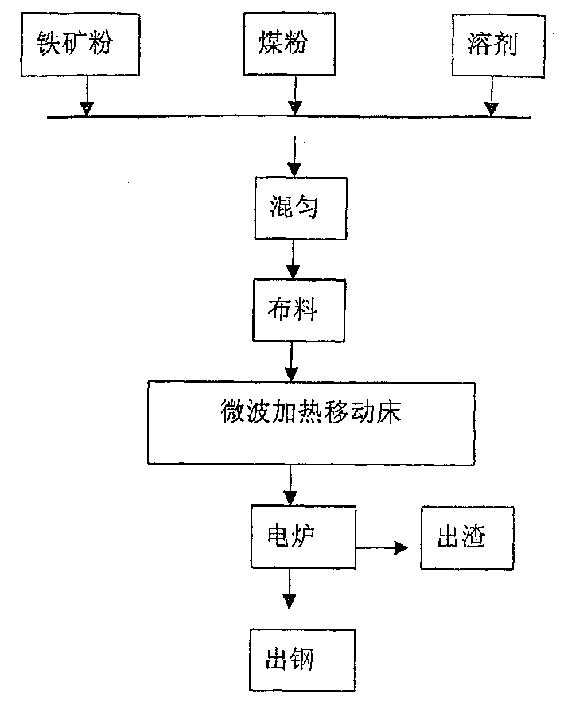

Coal-iron ore microwave reduction and electric furnace steel-making method and equipment

The present invention is microwave reduction and electric furnace steel-making method and equipment. Certain amount of coal, iron ore and flux and mixed, set on microwave heating bed and heated to 800-1300 deg.c for 10-20 min to produce reduced iron material; and the iron material is heated in an electric arc furnace to 1400-1600 deg.c for 1-2 hr and slag-steel separated. The equipment includes microwave heating movable bed with refractory inner wall, protecting outer metal wall, microwave heater between the inner wall and the outer wall, air cooling circulator between the two walls, mixing feeder over the movable bed and high temperature discharger. The present invention has less investment, simple process, high efficiency, low power consumption and no waste exhaust and is suitable for production in different scale.

Owner:任瑞刚 +3

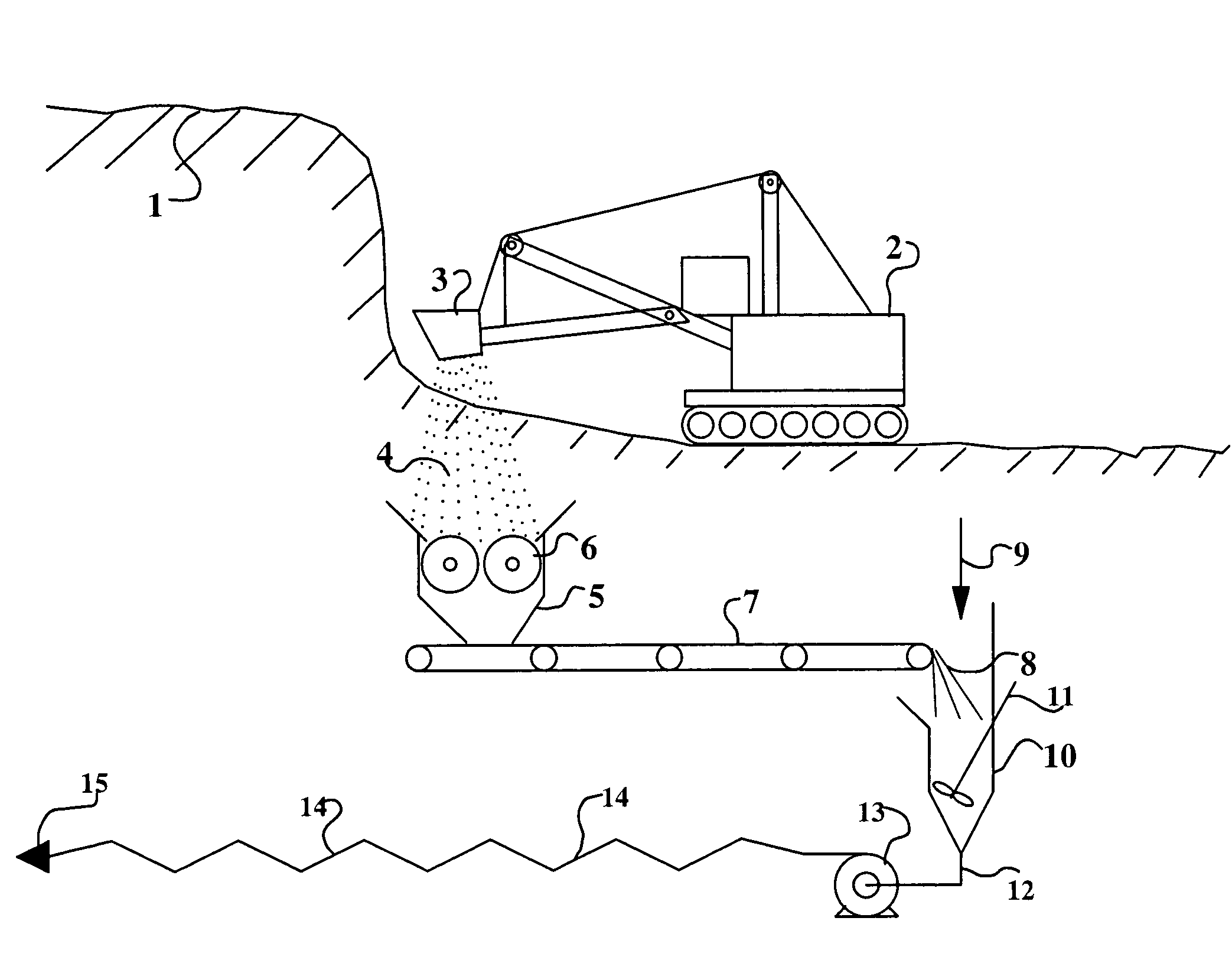

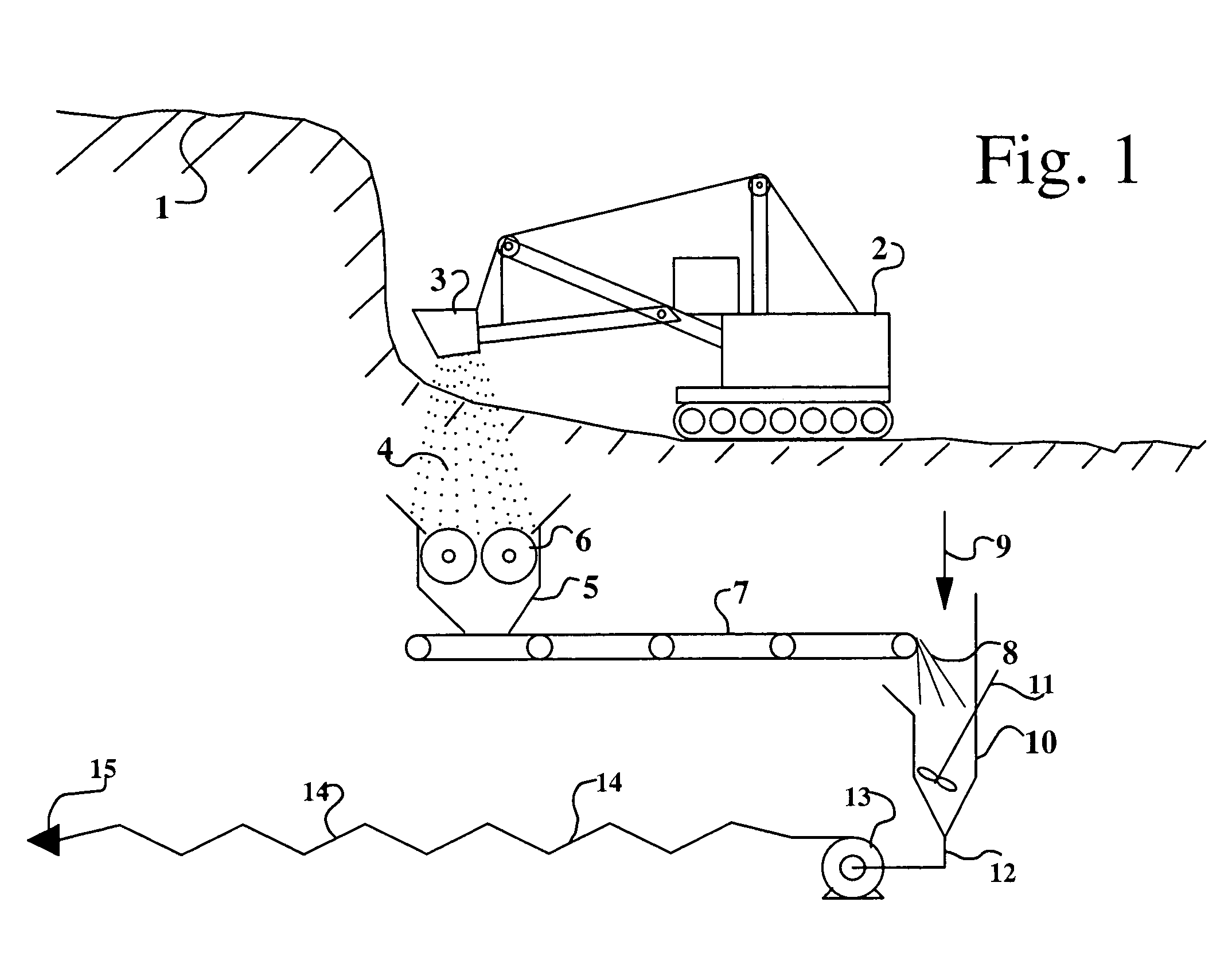

Isoelectric separation of oil sands

InactiveUS20090139906A1Reduced effectivenessReduce recoveryWater/sewage treatmentLiquid hydrocarbon mixture productionSlurryFroth flotation

A process and system for substantially isoelectric separation of an oil sand slurry is disclosed and described. The process can include mining oil sand, crushing the oil sands, forming a slurry of the oil sands, and transporting the oil sands slurry to a sinusoidal pipe. The sinusoidal pipe acts to digest the slurry from which bitumen can be separated using a hydrocyclone. Overflow from the hydrocyclone can be further treated using a revolving oleophilic device from which bitumen is recovered. Various optional further treatments can be used to dewater and / or further treat the bitumen and other process streams. The use of caustic soda, long-term tailing ponds, and froth flotation can be avoided resulting in an effective production of oil using less water than currently conventional processes.

Owner:KRUYER JAN

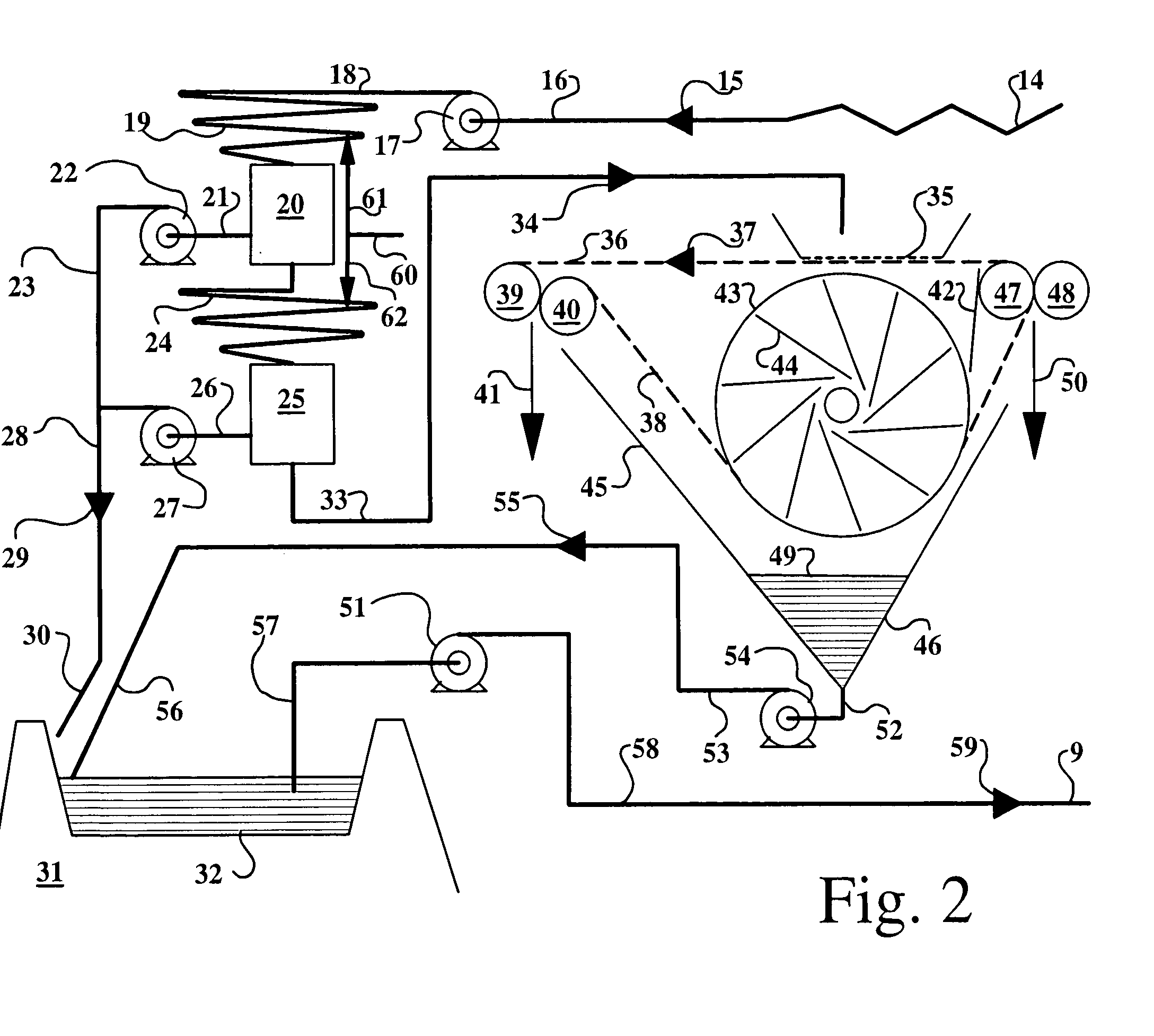

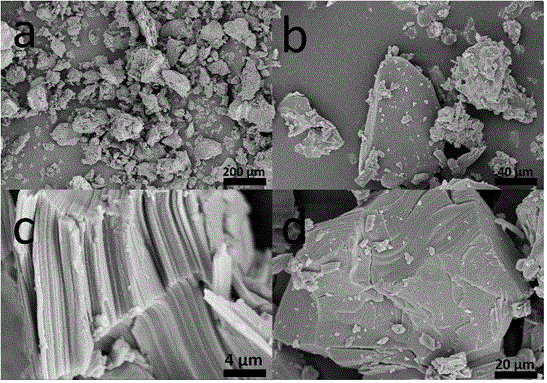

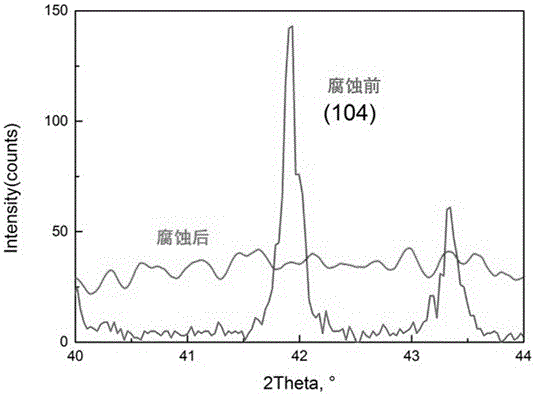

Preparation method and application of lamellar two-dimensional material MXene

InactiveCN107522202ALower barriers to entry and complexityLess equipmentTitanium carbideEquipment useSintering

The invention provides a preparation method of a lamellar two-dimensional material MXene. The preparation method comprises the following steps: S100: preparing a ternary material Mn+1AXn by adopting a normal-pressure sintering technology, wherein M is transition metal, A is a third or fourth main group element, X is an element C or N and n is 1, 2 or 3; S200: crushing the ternary material Mn+1AXn which is obtained by normal-pressure sintering into powder; S300: carrying out etching treatment on the powder, wherein the time for the etching treatment is 8h to 50h; S400: carrying out washing treatment and drying treatment on a powder mixed solution subjected to the etching treatment to obtain the lamellar two-dimensional material MXene. According to the preparation method provided by the invention, a pressurizing flow in a high-temperature process is replaced through a separation and pressurization and heating manner, so that the threshold and the complexity of preparing a precursor are reduced. Furthermore, equipment used for normal-pressure sintering is relatively low, so that the preparation method is especially suitable for industrial production.

Owner:SICHUAN UNIV

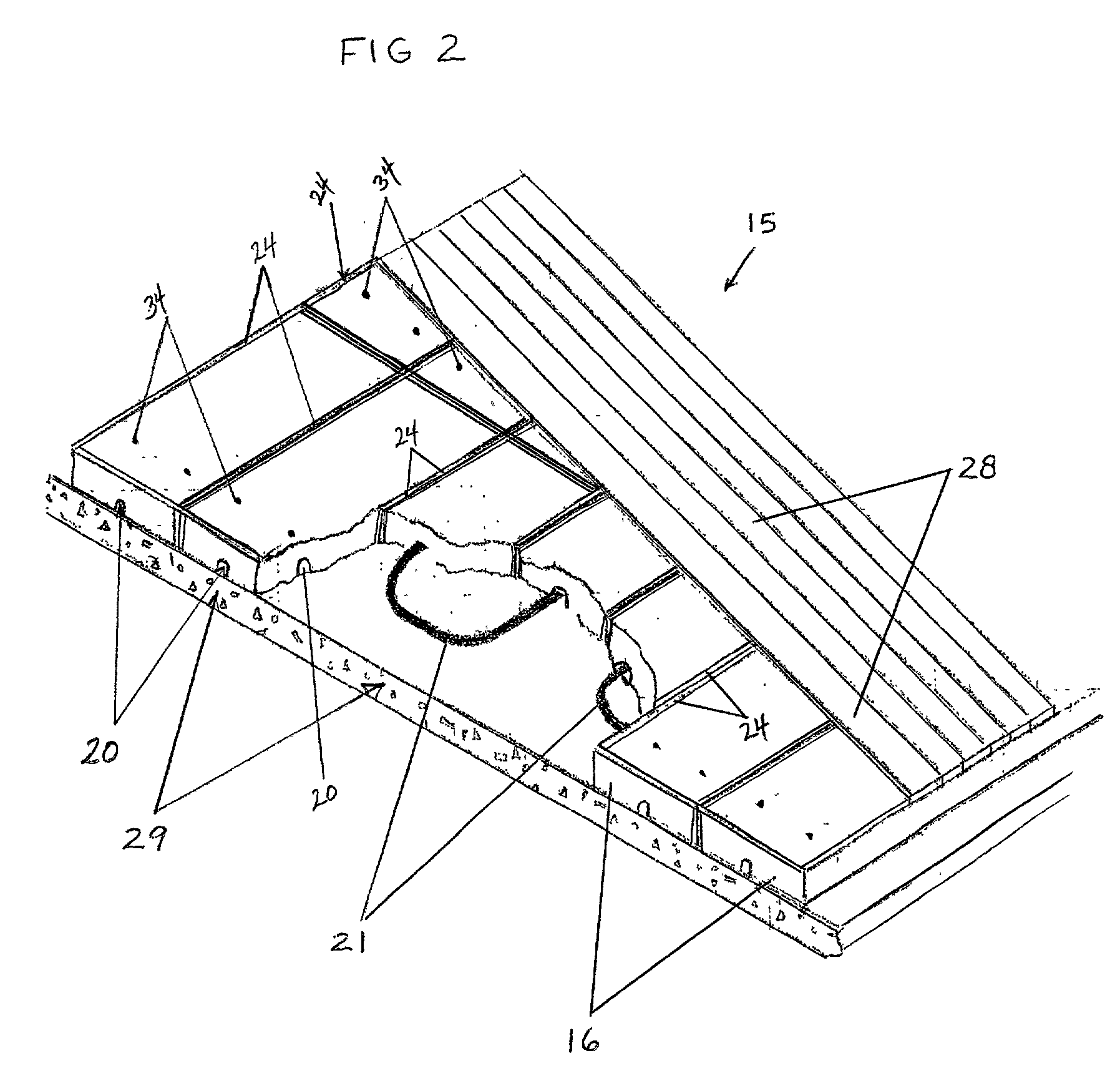

Modular radiant heat panel system

The invention is directed to modular radiant heat panel system. In the preferred embodiment, the system comprises multiple radiant heat transfer panels (16), each of the panels having a thermal mass (18) and a conduit channel (20); a fluid conduit (21), the conduit communicating with an apparatus (23) for heating fluid (22) in the conduit; the multiple panels positioned adjacent each other such that the conduit extends through a series of the conduit channels; the panels, conduit and apparatus so configured and arranged to permit heat transfer from the fluid to the thermal mass of the panel, whereby heat radiates from the panel. The present invention also discloses a radiant heat transfer panel for engagement with a fluid conduit comprising: a formed tray (24); the tray defining a thermal volume (17) and a conduit channel; the volume containing a thermal mass; and the channel, volume and thermal mass configured and arranged to permit heat transfer between the conduit and the thermal mass. The invention also discloses a method for installing a modular radiant heat panel system comprising the steps of: providing an under-layer having a given area (44); providing multiple panels having a thermal mass and a conduit channel; providing conduit; position the conduit over or under the under-layer in a predetermined pattern; and positioning the panels on or under the under-layer such that the conduit extends through at least a portion of the conduit channel of the panels.

Owner:HYDOCK GARY J

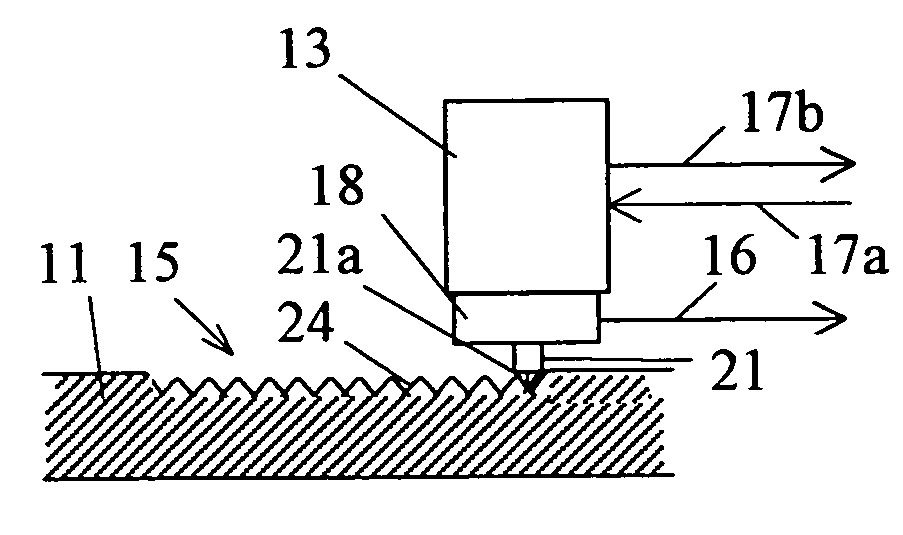

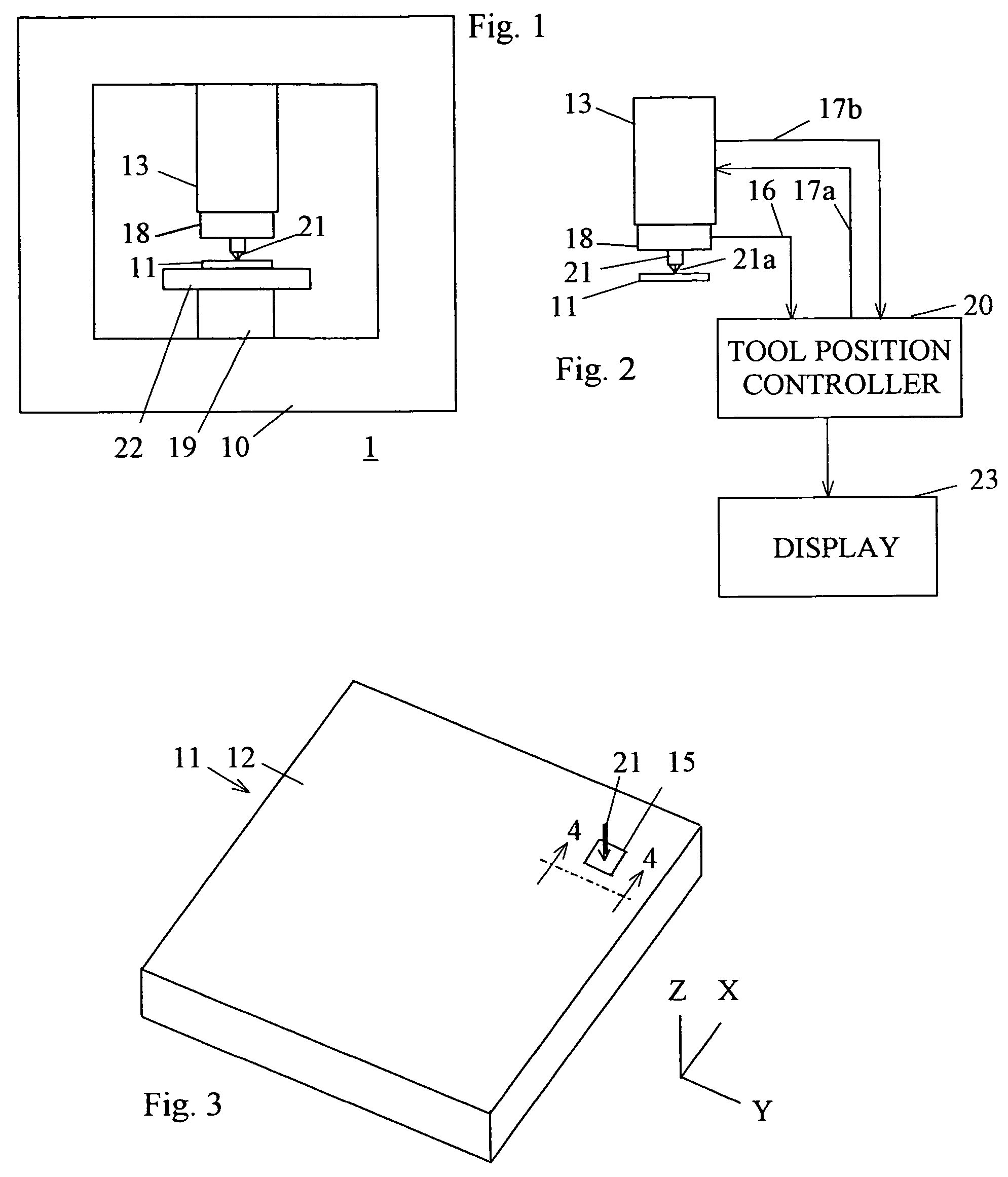

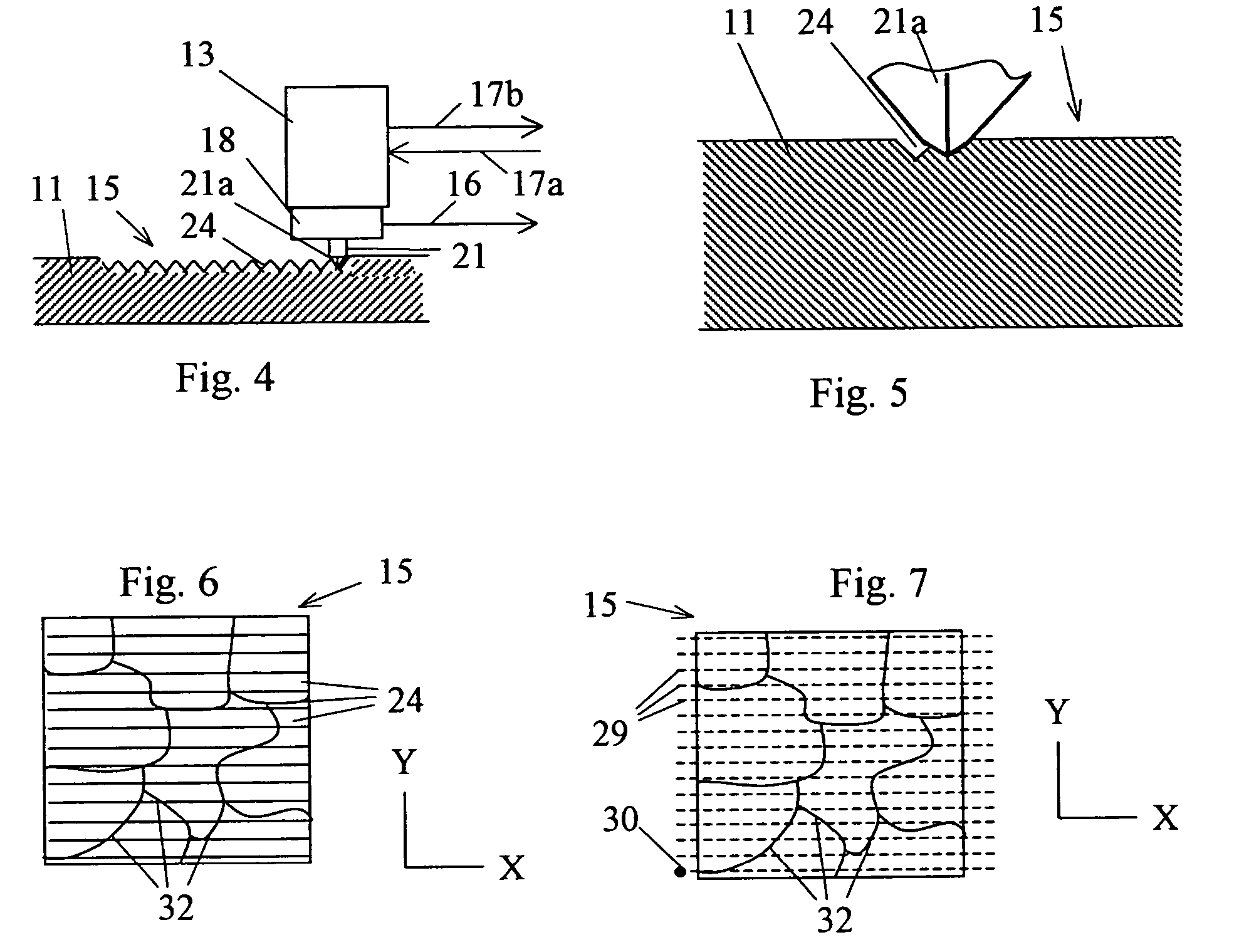

Method for observation of microstructural surface features in heterogeneous materials

ActiveUS7107694B2Increase speedLess equipmentWriting aidsMechanical counters/curvatures measurementsConstant forceMachined surface

Owner:BRUKER NANO INC

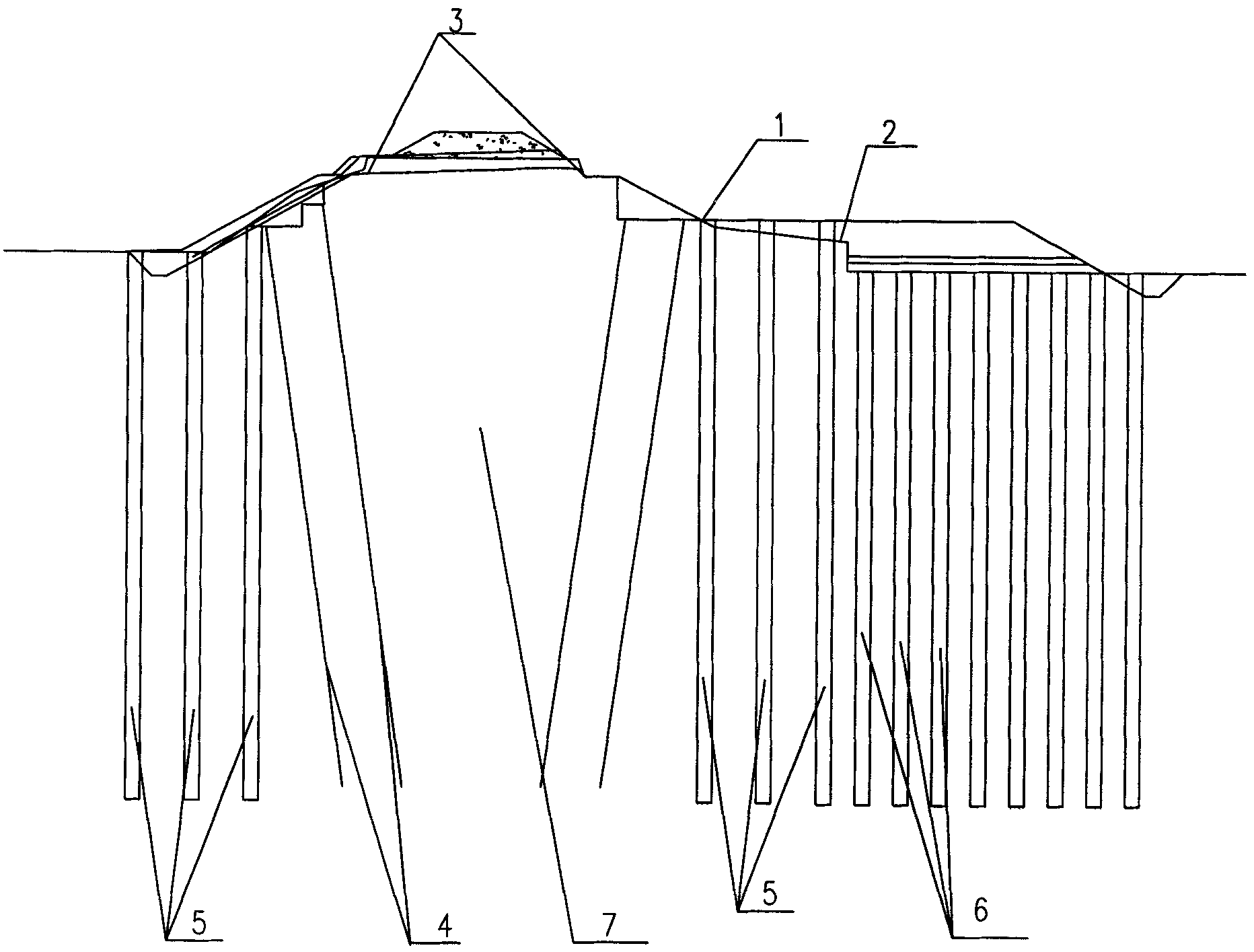

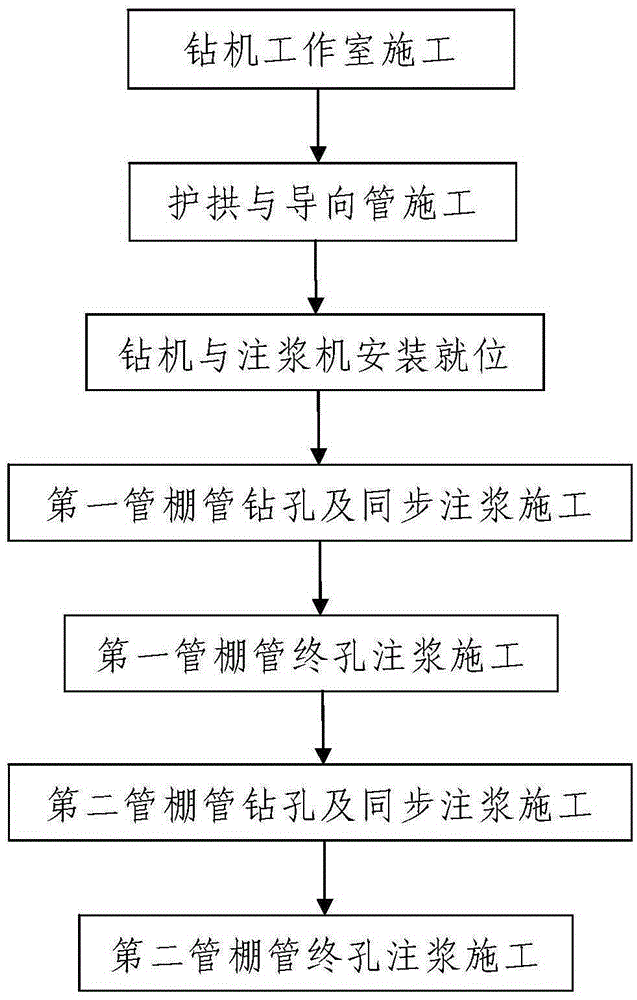

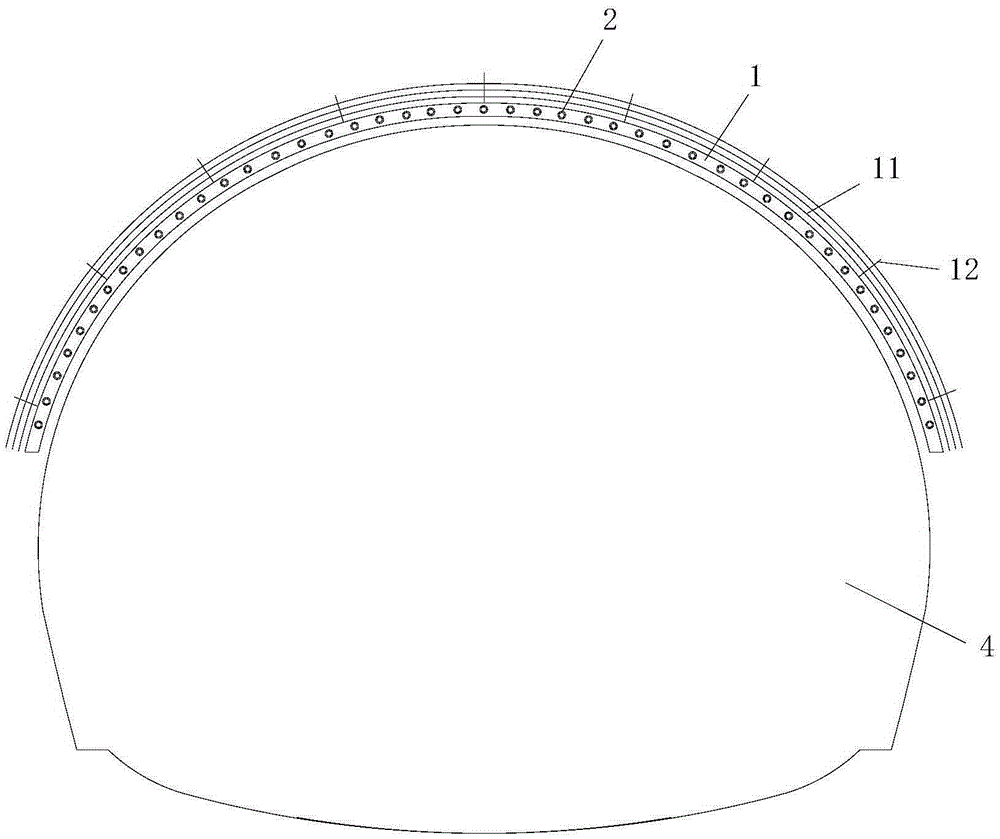

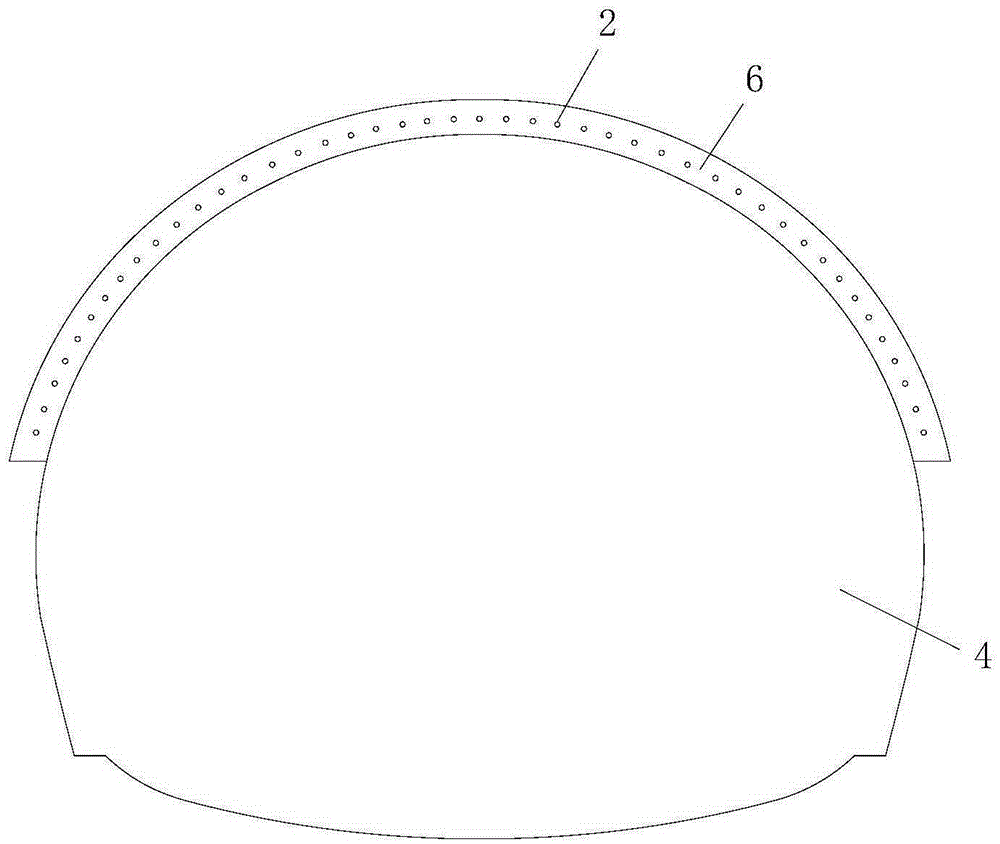

Soft and weak wall rock tunnel advance reinforced support construction method

InactiveCN105298517AThe method steps are simpleEasy to implementUnderground chambersTunnel liningGuide tubeDrilling machines

The invention discloses a soft and weak wall rock tunnel advance reinforced support construction method. When a pipe roof advance support construction is carried out on one segment of the constructed tunnel, the construction method comprises the following steps: (1) support arch and guide pipe construction, wherein a plurality of guide tubes for carrying out guiding on a plurality of pipe roof pipes are arranged on a support arch; each pipe roof pipe comprises a pipe body and a drill bit; each pipe body is formed by splicing a plurality of pipe joints; each drill bit is coaxially arranged at the front end of the pipe body; the pipe joints are spiral steel pipes; the pipe roof pipes are first pipe roof pipes or second pipe roof pipes; and the first pipe roof pipes and the second pipe roof pipes are staggered; (2) drilling machine and slip casting machine installation and emplacement; (3) pipe roof advance support construction, which comprises the following processes: first pipe roof pipe drilling and synchronous grouting construction, final hole grouting construction of the first pipe roof pipes, second pipe roof pipe drilling and synchronous grouting construction and final hole grouting construction of the second pipe roof pipes. The method disclosed by the invention is simple in steps, reasonable in design, simple and convenient to construct and good in support effect; and the soft and weak wall rock tunnel advance reinforced support process can be simply, conveniently and quickly finished.

Owner:中铁二十局集团第二工程有限公司

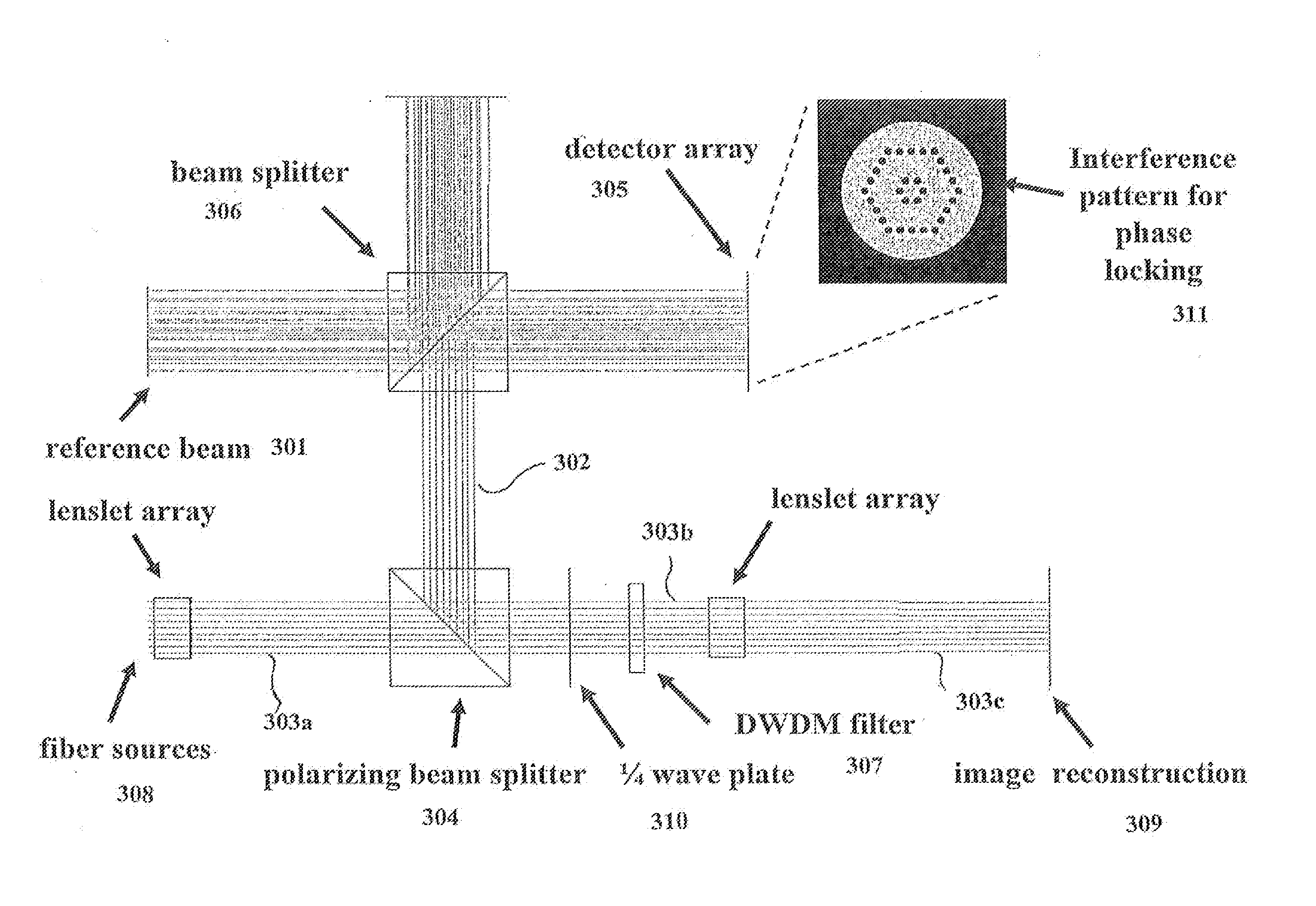

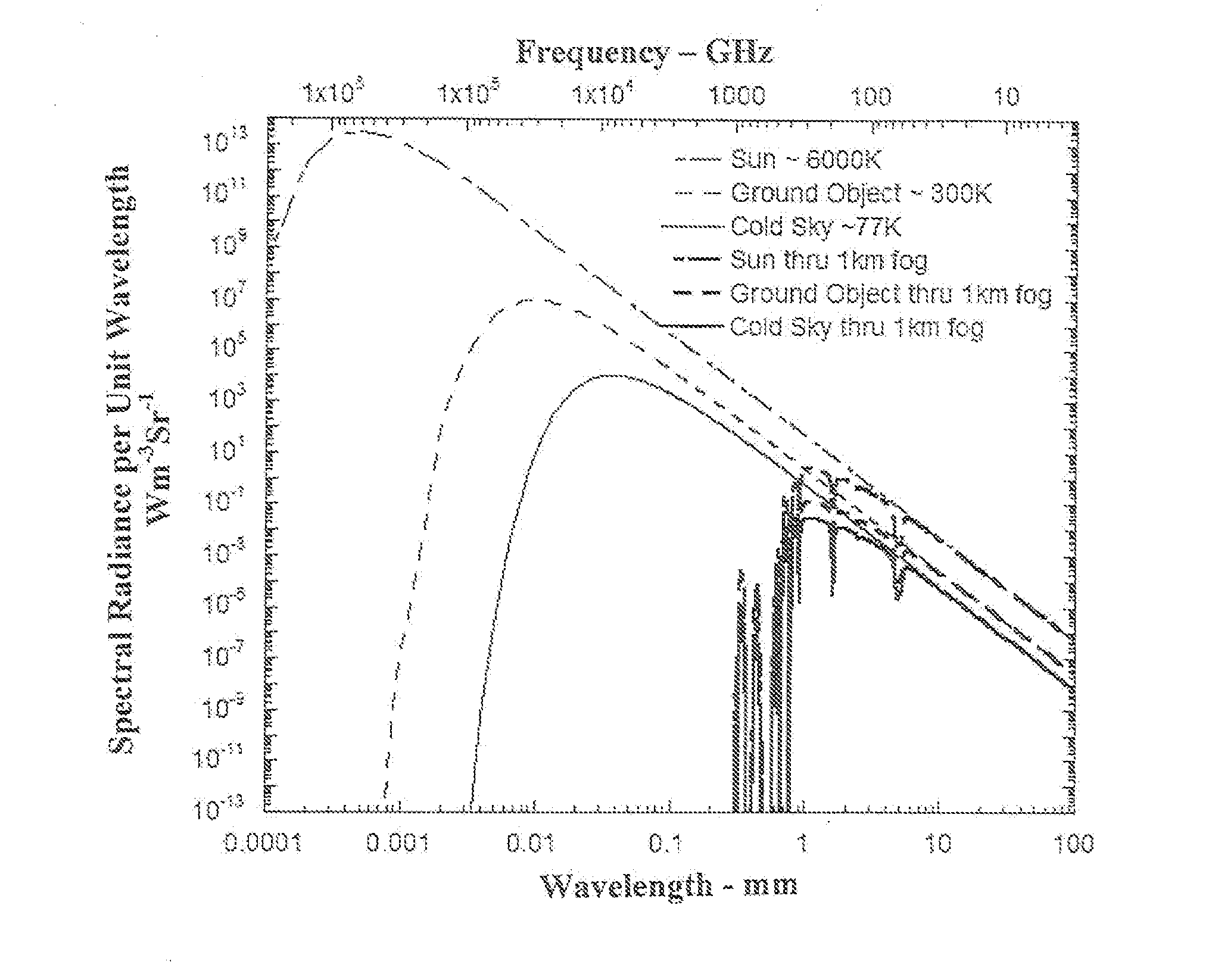

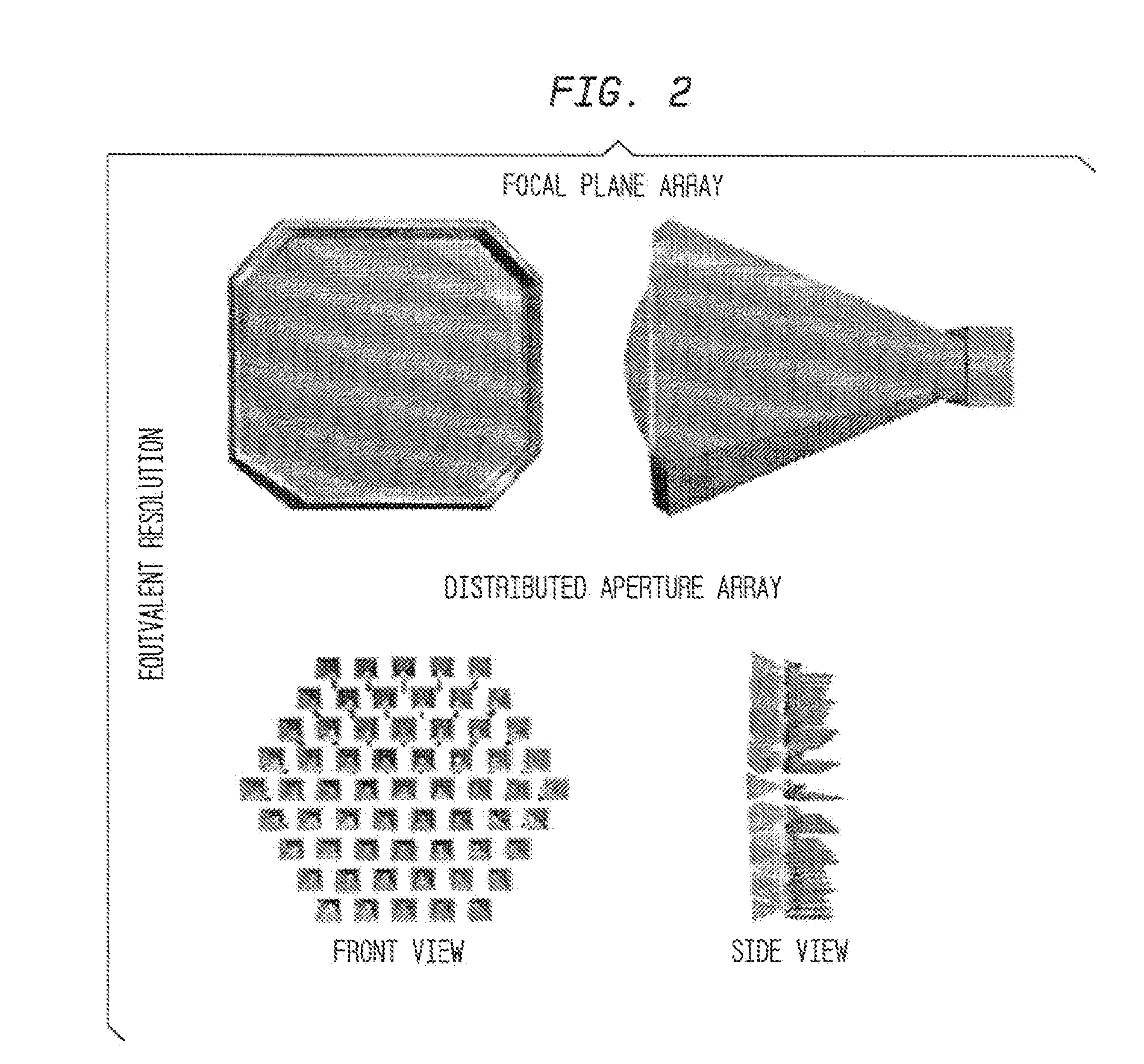

Method for controlling the phase of optical carriers in millimeter wave imaging systems using optical upconversion

ActiveUS20110073772A1Less expensiveLess equipmentLaser detailsConverting sensor ouput using wave/particle radiationRelative phasePhase change

A system and method for locking the relative phase of multiple coherent optical signals, which compensates for optical phase changes induced by vibration or thermal changes in the environment.

Owner:PHASE SENSITIVE INNOVATIONS

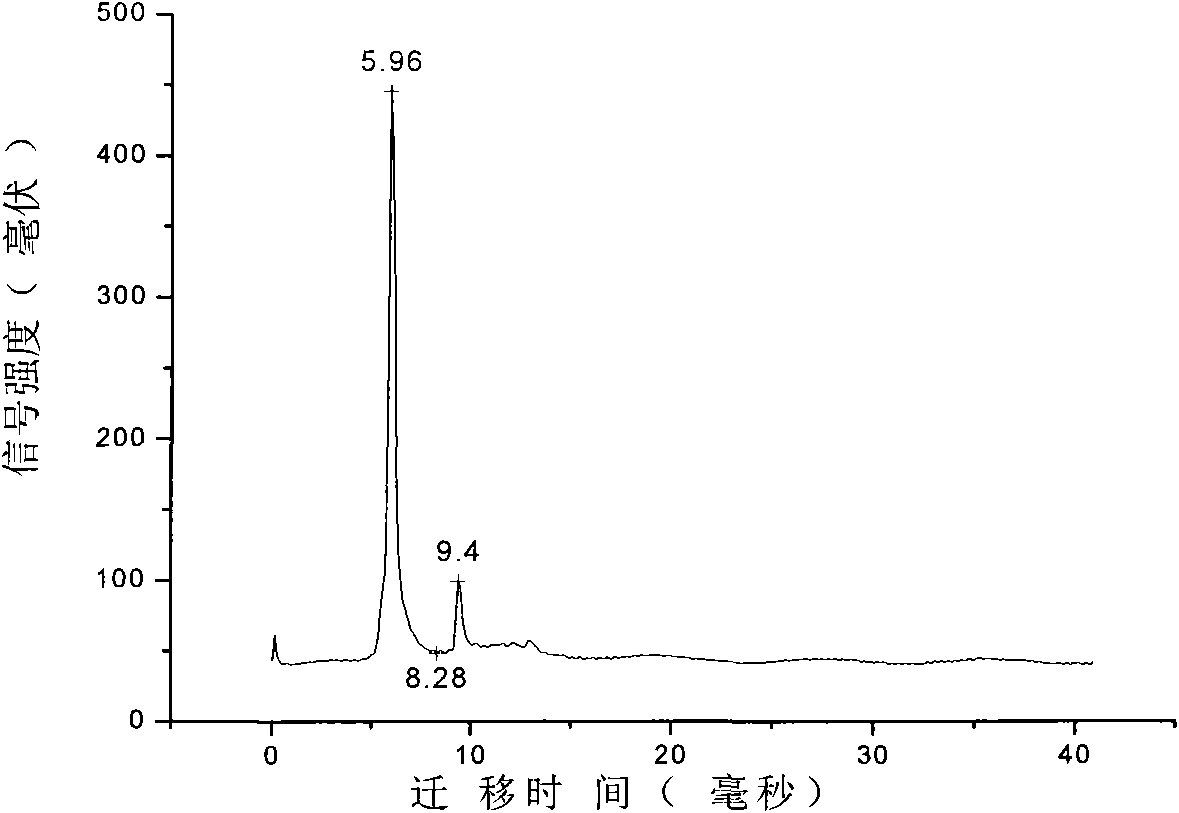

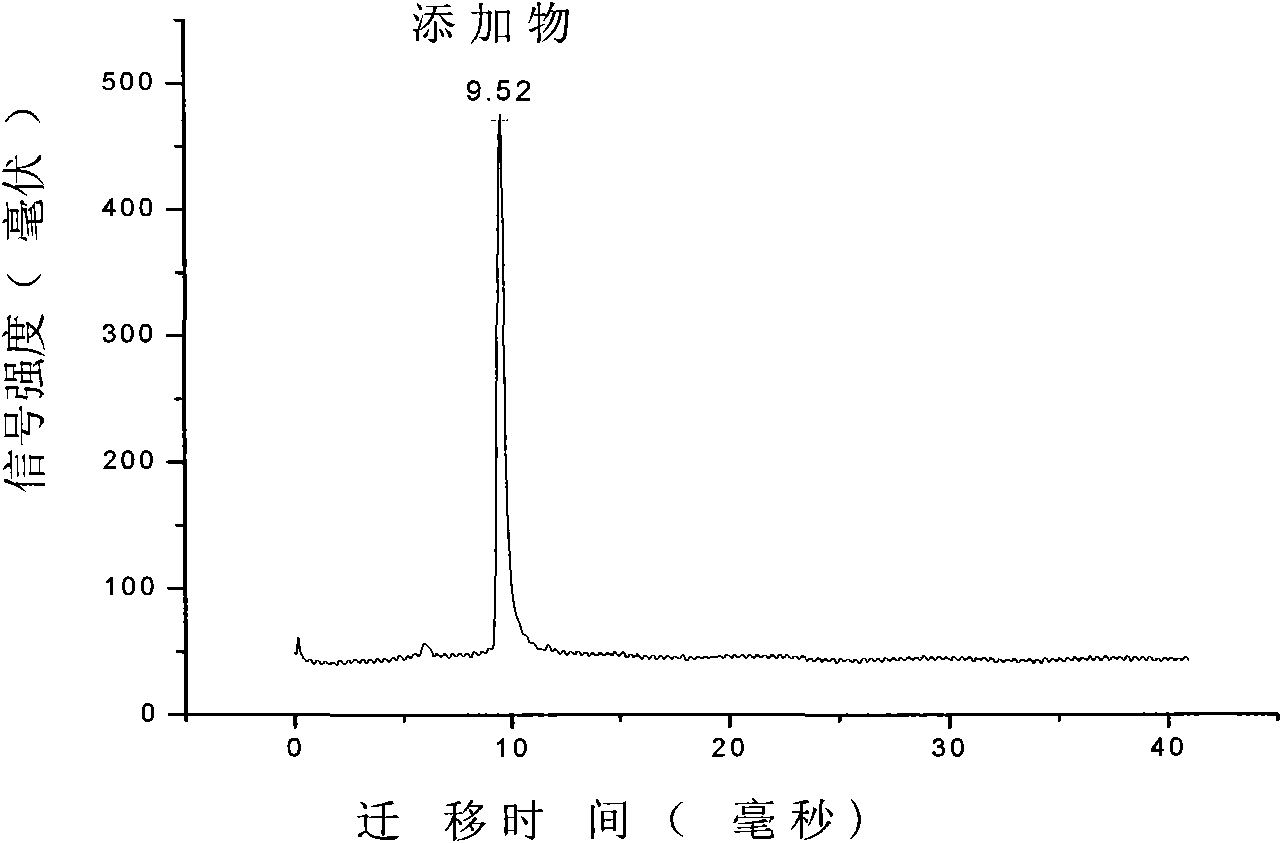

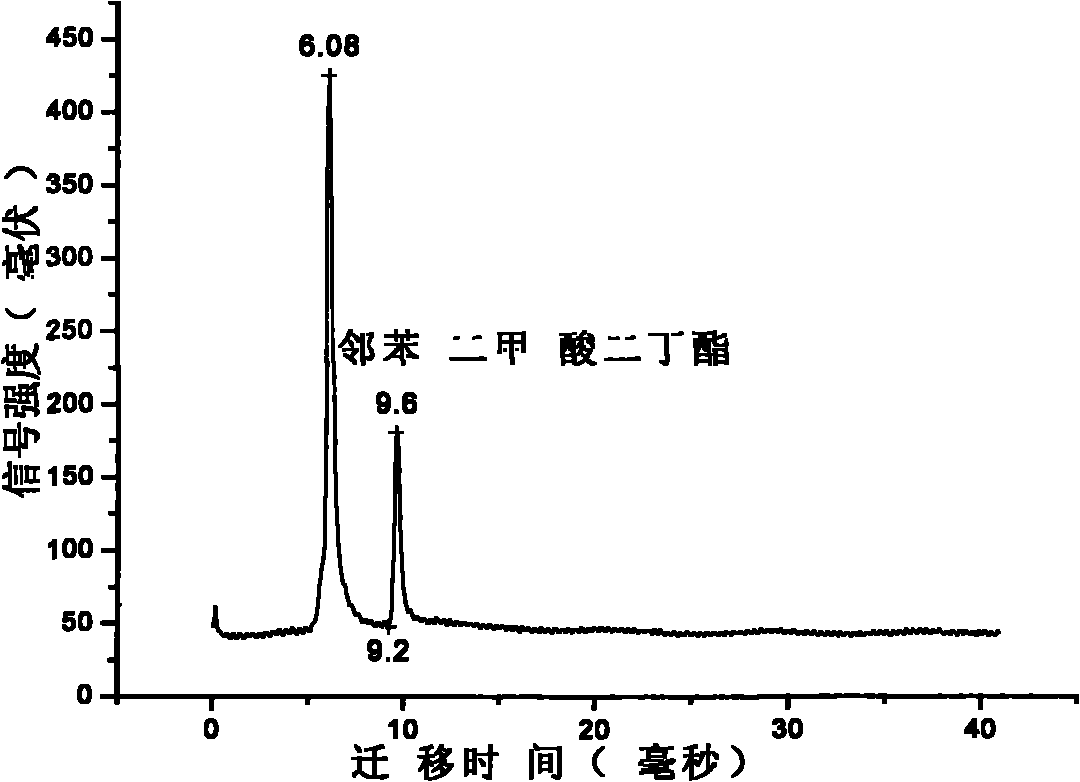

Method for detecting phthalate ester plasticizer in plastic

InactiveCN101852766AEasy to carrySmall and portableMaterial analysis by electric/magnetic meansSolid solvent extractionPlasticizerPretreatment method

The invention discloses a simple, fast and sensitive method for detecting a plasticizer (phthalate ester) in plastic, which is based on ion mobility spectrometry and detects phthalate ester in an extracting solution using a fast ion mobility spectrometry detector in combination with a simple organic solvent extraction pretreatment method. The measurement method is simple, fast and reliable. The analysis time of the method is only 0.5min, the requirement on a sample pretreatment is low, the detection time is short, the sensitivity is high, and the detection limit can be up to 1ppb.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

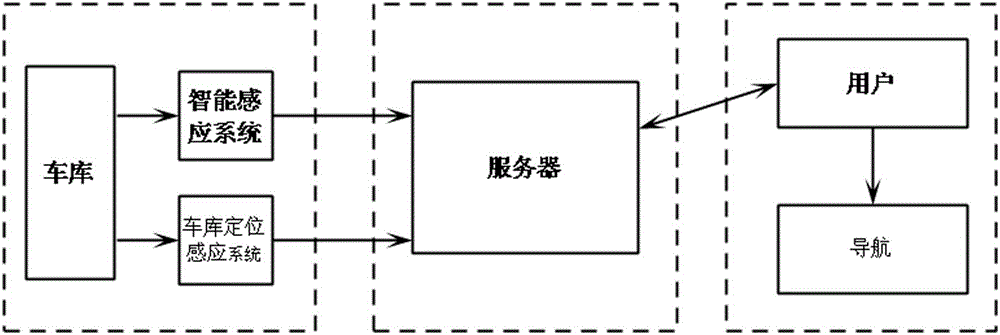

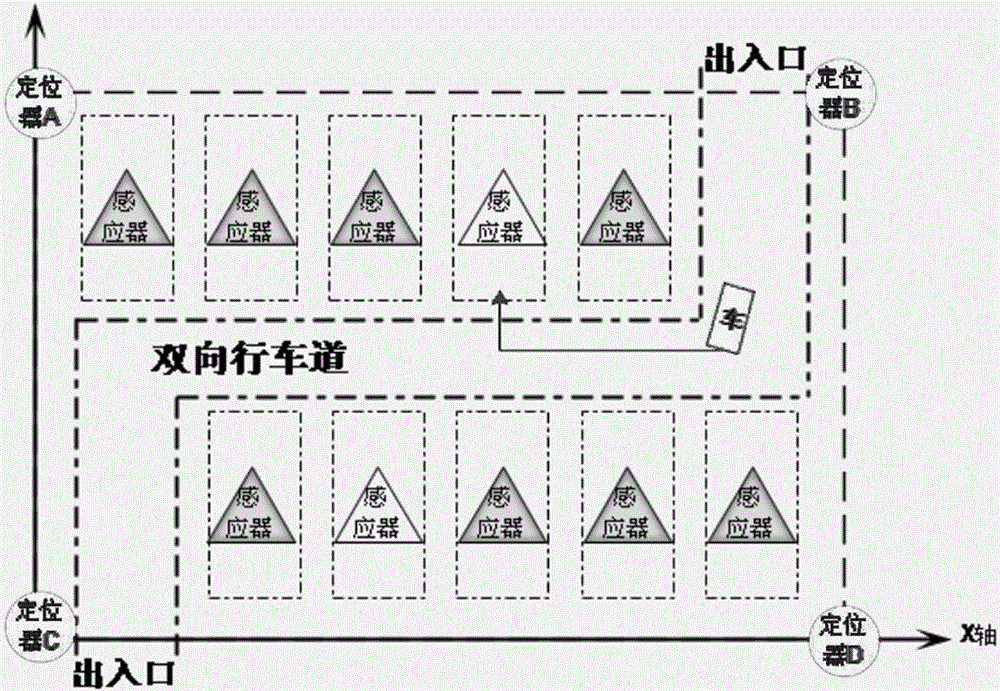

Parking navigation method and device based on intelligent terminal

PendingCN105702085AOvercome problemsRealize the display effectIndication of parksing free spacesParking spaceNavigation system

A conventional parking navigation system has the problems of too much hardware equipment, impossibility of reliable implementing a wireless positioning sensor mode, too much reading heads, complex devices and wiring and high cost. The invention provides a parking navigation method and device based on an intelligent terminal. A complete technical scheme is designed, and an integral and practical parking space booking and parking navigation technical solution is provided, so that the problems of the conventional parking navigation system are effectively overcome. The intelligent terminal cooperates with a few intelligent detection modules to realize display of free parking spaces and parking navigation. Hardware equipment, devices and wiring are less, and the cost is low.

Owner:重庆喜玛拉雅科技有限公司

Method and system for improving uplink performance

InactiveUS20130329825A1Reduce in quantityLow costSite diversitySpatial transmit diversityDistributed antenna systemComputer science

Distributed antenna systems and more particularly to methods and systems for improving uplink communications are disclosed. In one embodiment, Aggregation Point Noise Blocking provides for blocking or filtering of the noise contributed by one or more of the branches coupled to an aggregation point that are not carrying the signal from a particular terminal. Signal activity from a given terminal on a particular branch can be identified and that information can be used to selectively block or filter the signal noise contributed by the other branches to an aggregation point. The selective blocking or filtering can also include an attenuation function to attenuate the signal and provide dynamic range smoothing.

Owner:CORNING OPTICAL COMM WIRELESS

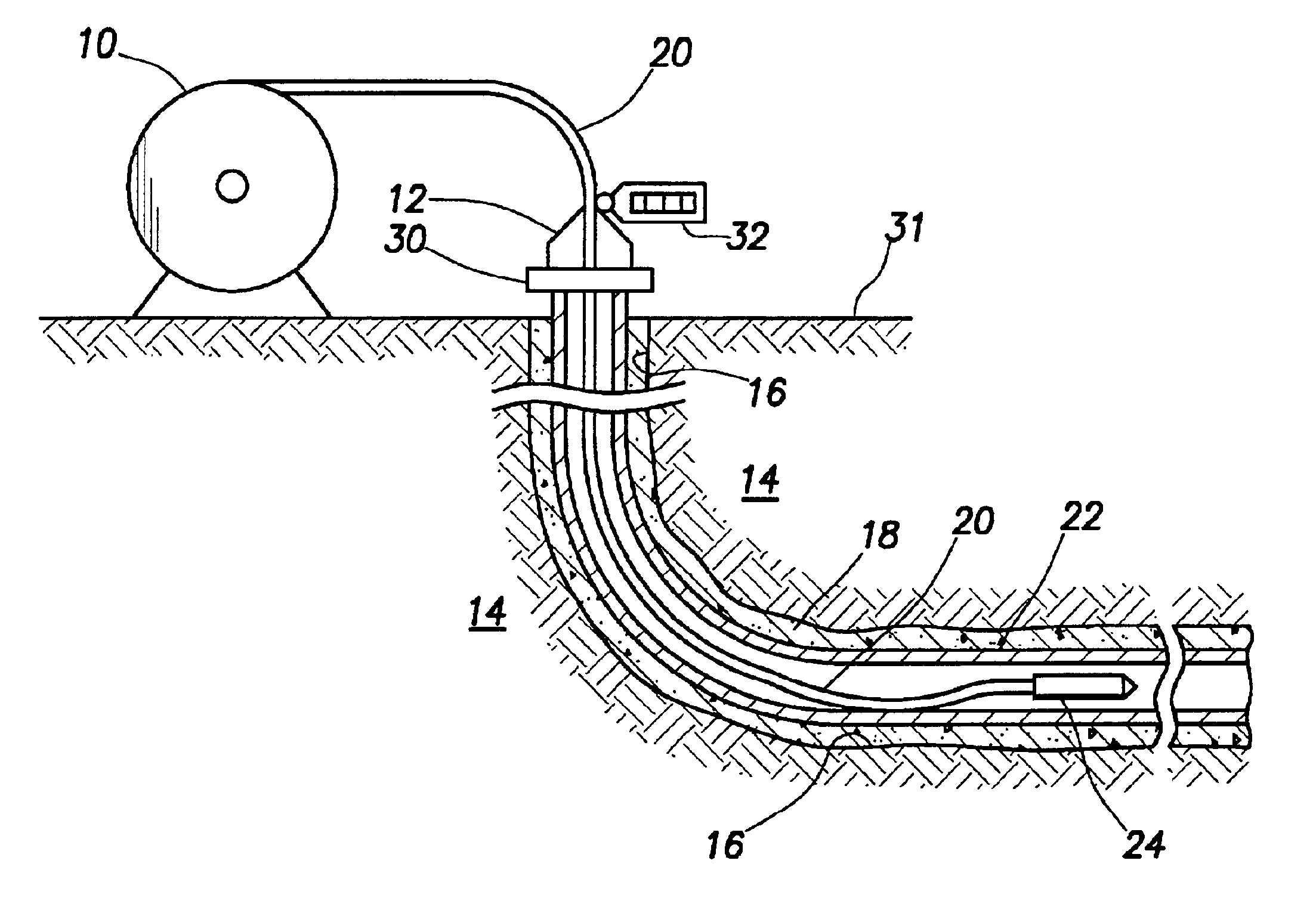

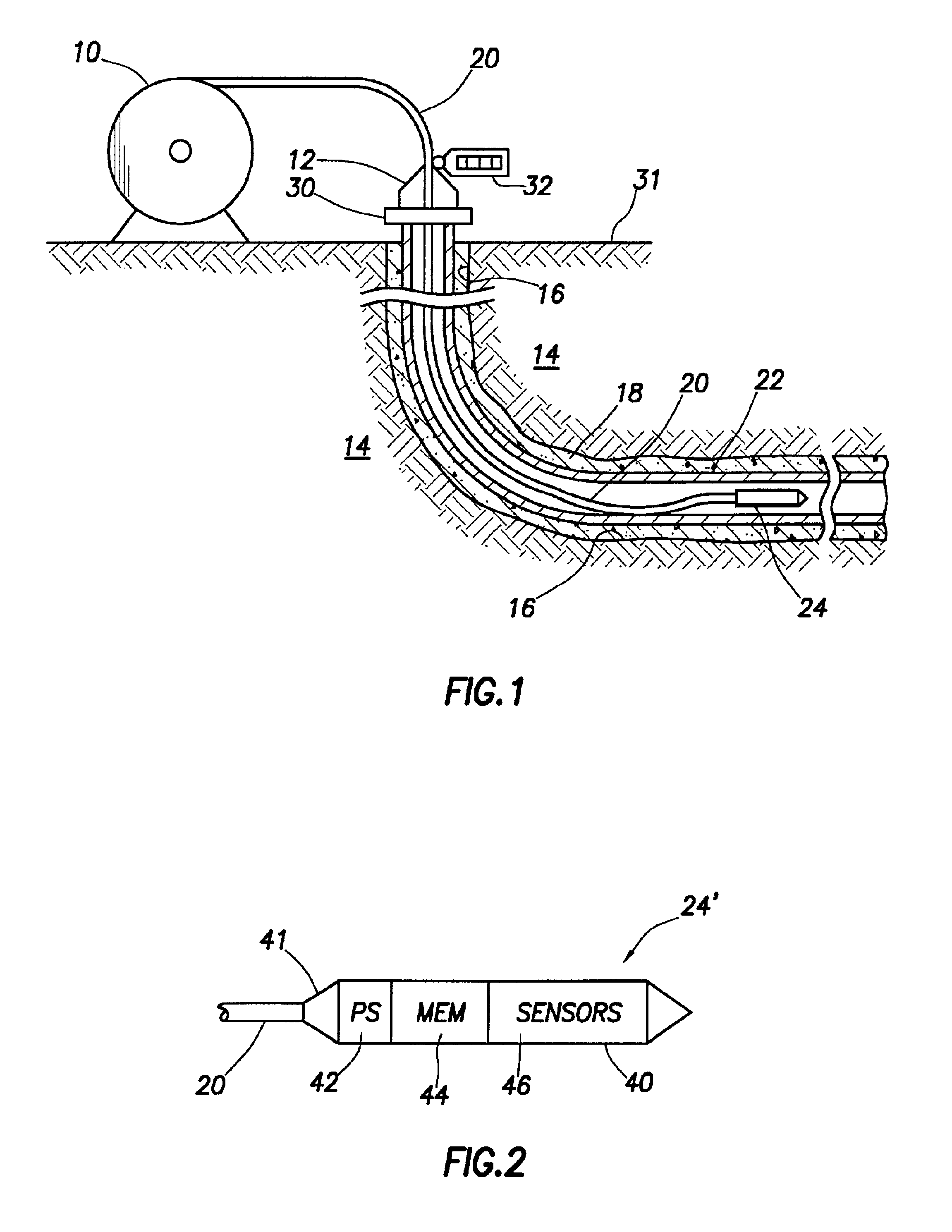

Apparatus and methods for conveying instrumentation within a borehole using continuous sucker rod

The present invention provides an apparatus and method for conveying downhole tools within a borehole using a continuous rod. The apparatus may include a continuous rod, a downhole tool attached to one end of the continuous rod, and a delivery rig for lowering the continuous rod and downhole tool into the wellbore.

Owner:WEATHERFORD TECH HLDG LLC

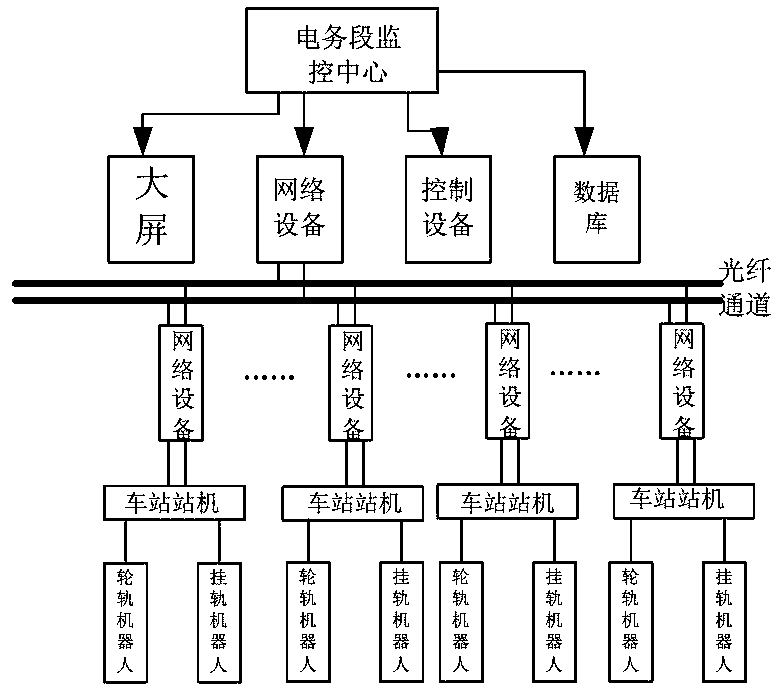

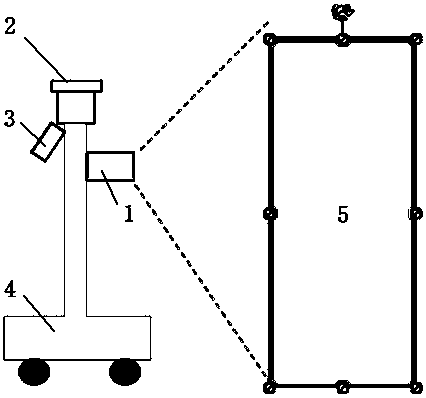

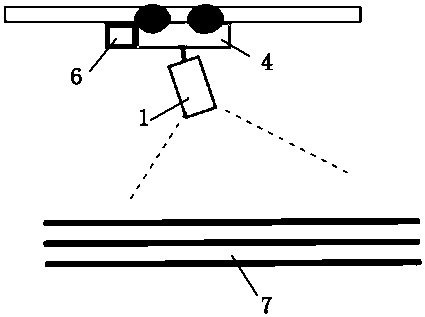

Intelligent robot routing inspection system and method for railway machine room

PendingCN108388194AImprove monitoring efficiencyHigh precisionProgramme controlRadiation pyrometryDatabase serverSimulation

The invention relates to an intelligent robot routing inspection system and method for a railway machine room, and the system comprises a communication and signaling section monitoring center, networkequipment, and a routing inspection robot. The routing inspection robot comprises a wheel rail robot and a robot hung on a rail, wherein the information collected by the two robots is transmitted tothe communication and signaling section monitoring center through the network equipment. According to the invention, the wheel rail robot on an anti-electrostatic floor is used for monitoring the equipment and the environment of a machine room, and the robot hung on a rail below the anti-electrostatic floor is used for monitoring the state of a cable of a cable duct. The system effectively collects the image, data and equipment state, records the collected equipment information into a database server, compares the collected equipment information with fault information, and carries out the prejudgment or proposes a solution to a fault and feeds back the solution to an intelligent display terminal, so as to guide a signal maintainer to process the fault, thereby effectively reducing the fault rate, and improving the maintenance efficiency.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com