Preparation method and application of lamellar two-dimensional material MXene

A two-dimensional material, layered technology, applied in the field of chemical preparation, can solve the problems of complex equipment, unfavorable industrial promotion, easy operation and other problems, and achieve the effect of low equipment cost, lower threshold and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment prepares the layered two-dimensional material Ti 2 c. Concrete preparation steps are as follows:

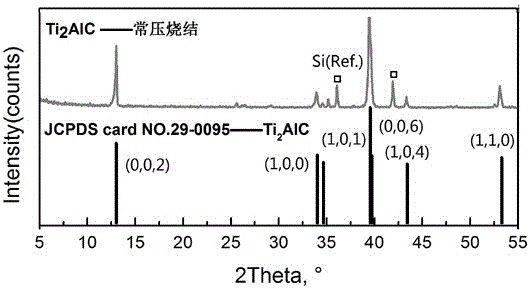

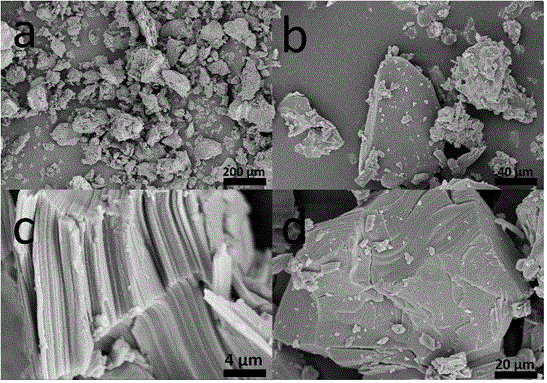

[0036] S100: Preparation of ternary material Ti by atmospheric pressure sintering process 2 AlC.

[0037] Wherein step S100 comprises following operation steps again:

[0038] S110: Weigh an appropriate amount of elemental powder Ti powder, pure Al powder and graphite powder; the Ti powder used in this example is (100 mesh, mass fraction 99.6%), and the pure Al powder is (200 mesh, mass fraction 99.7%) And graphite powder (400 mesh, mass fraction 99.85%). The specific operation is to weigh 11.05g of Ti powder; 3.57g of pure Al powder and 1.38g of graphite powder, according to the atomic ratio M:A:X is 2:1.15:1. The Al above the stoichiometric number here is mainly to prevent the evaporation of Al during the sintering process. What needs to be explained here is that the ratio of the elemental powder can be arbitrary, and the elemental powder exceeding ...

Embodiment 2

[0052] This embodiment prepares the layered two-dimensional material Ti 2 c. Concrete preparation steps are as follows:

[0053] S100: Preparation of ternary material Ti by atmospheric pressure sintering process 2 AlC.

[0054] Wherein step S100 comprises following operation steps again:

[0055] S110: Weigh an appropriate amount of elemental powder Ti powder, pure Al powder and graphite powder; the Ti powder used in this example is (100 mesh, mass fraction 99.6%), and the pure Al powder is (200 mesh, mass fraction 99.7%) And graphite powder (400 mesh, mass fraction 99.85%).

[0056] S120: uniformly mix the weighed multiple elemental powders and perform briquette processing to obtain a briquette. Before the briquetting process, it is best to use a high-speed ball mill to mill the mixture for 5-30 hours. The purpose of the ball milling process is to obtain a mixed powder with uniform particles. The briquetting treatment in this embodiment is to briquette the mixed powder ...

Embodiment 3

[0071] This embodiment prepares the layered two-dimensional material Ti 2 c. Concrete preparation steps are as follows:

[0072] S100: Preparation of ternary material Ti by atmospheric pressure sintering process 2 AlC. This step is the same as in Embodiment 1. But the atmospheric pressure sintering is carried out under the protection of nitrogen.

[0073] S200: Ternary material Ti obtained by sintering at atmospheric pressure 2 AlC is crushed into powder.

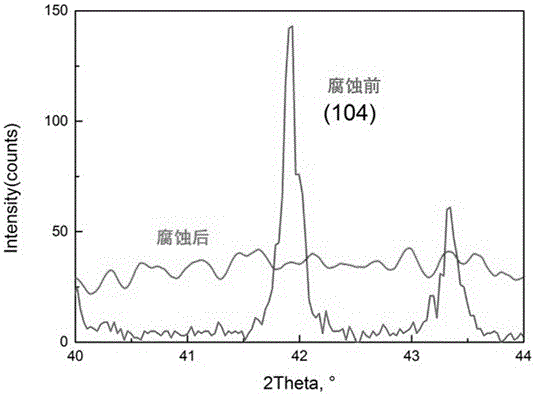

[0074] S300: Using HNO 3 Mix KF to perform etching treatment on the powder, and the etching treatment time is 50 hours.

[0075] The specific operation steps of etching treatment are: take 30 mL 6 M HNO 3 solution, 1.98 g of KF (analytical grade) was added to it. The sample powder obtained in step S200 is divided into several times, and a small amount is slowly added to the mixed etching solution each time, and magnetic stirring is performed at the same time to prevent bumping. The corrosion process lasted for 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com