Method for detecting phthalate ester plasticizer in plastic

A technology of phthalic acid and ester plasticizers, which can be used in measurement devices, analytical materials, solid solvent extraction, etc. The effect of fast measurement speed, reduced inspection investment and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In order to realize the rapid and sensitive detection of plasticizers in plastic products, the present invention uses ion mobility spectrometry as an analysis method, which is combined with the simple sample pretreatment technology of solvent extraction.

[0029]This method has low requirements for sample pretreatment, and can be extracted with organic solvent methanol. The specific steps are as follows: Accurately weigh 0.5g of plastic sample and place it in a test tube, add 10mL of analytically pure organic solvent methanol to extract for 0.1-2min (special material plastic products take longer), the extract can be directly used for detection and analysis.

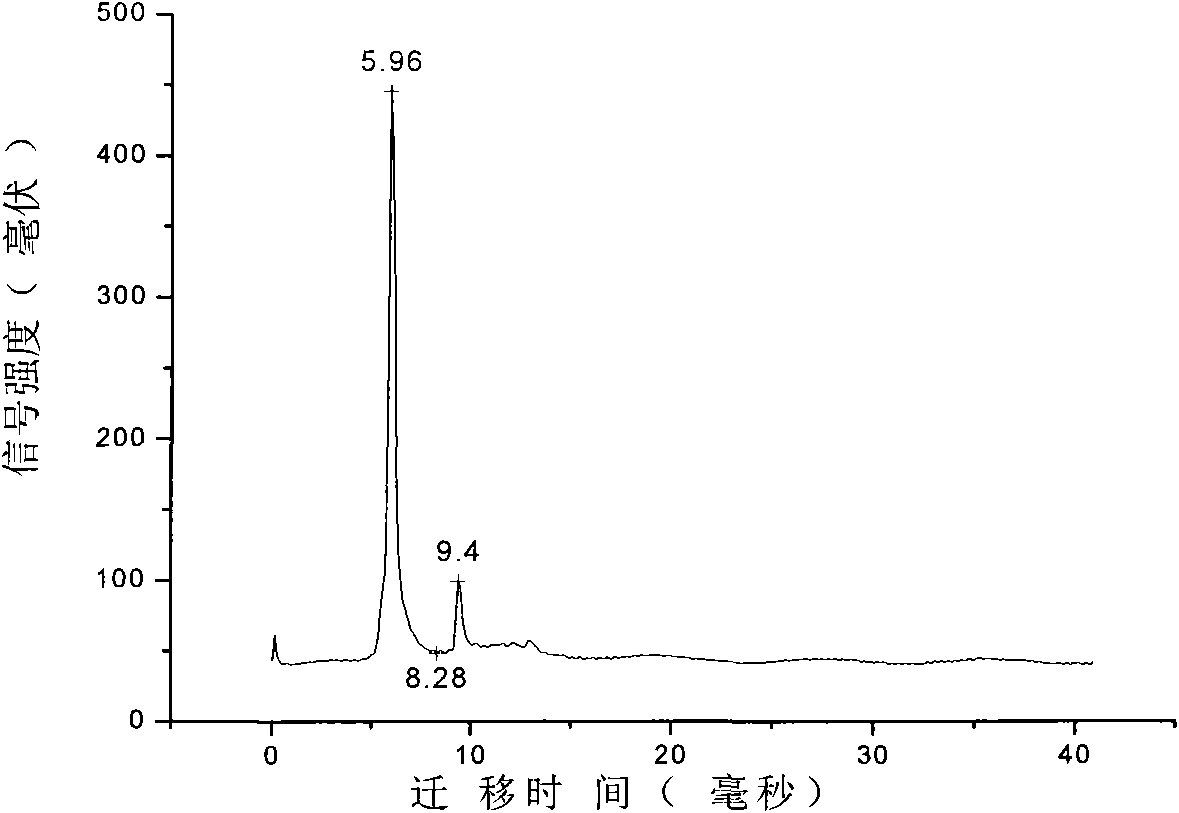

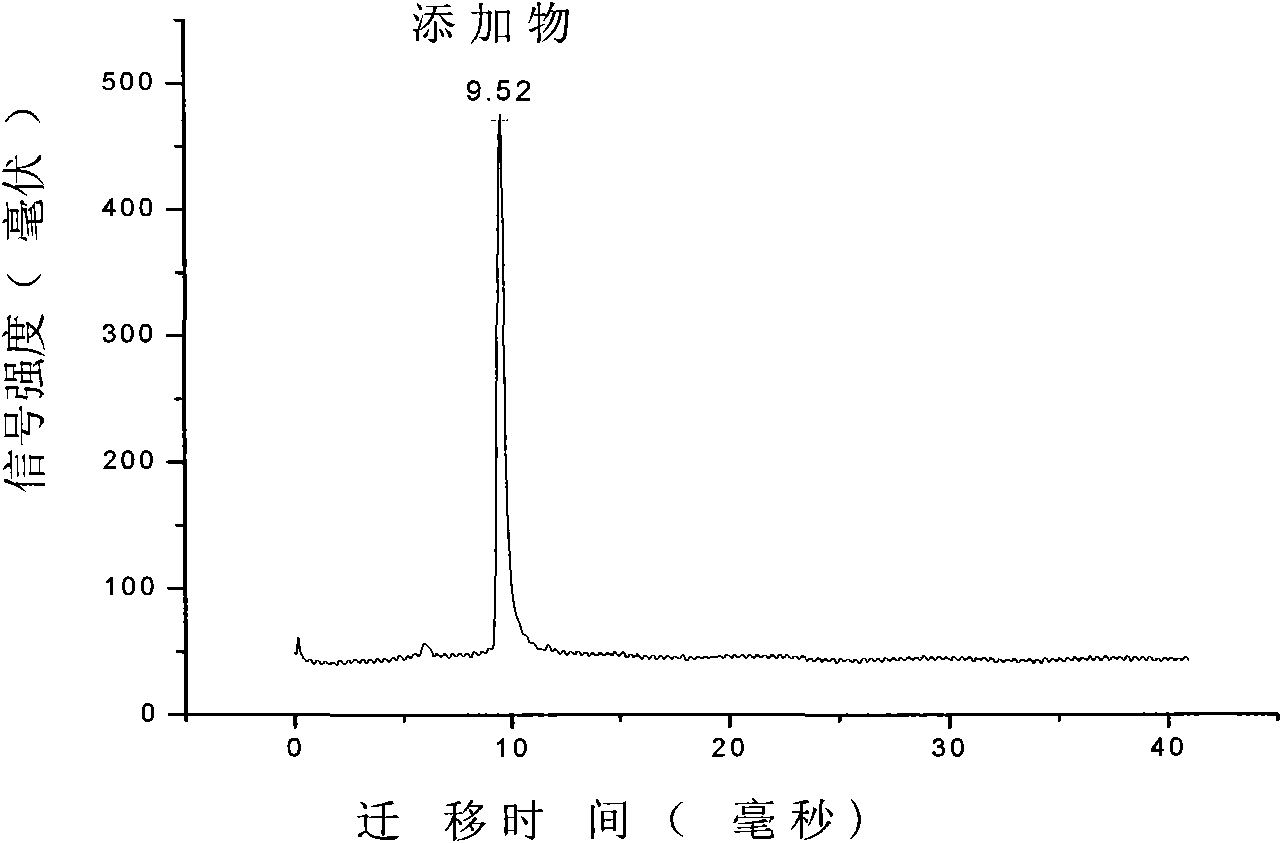

[0030] The process of using ion mobility spectrometer to detect phthalates is as follows: extract 20-50 μL of the above extract, drop it on a clean PTFE sheet, evaporate methanol, and then insert it into the sample inlet of the instrument. The sample containing phthalates is quickly vaporized by a built-in thermal ...

Embodiment 2

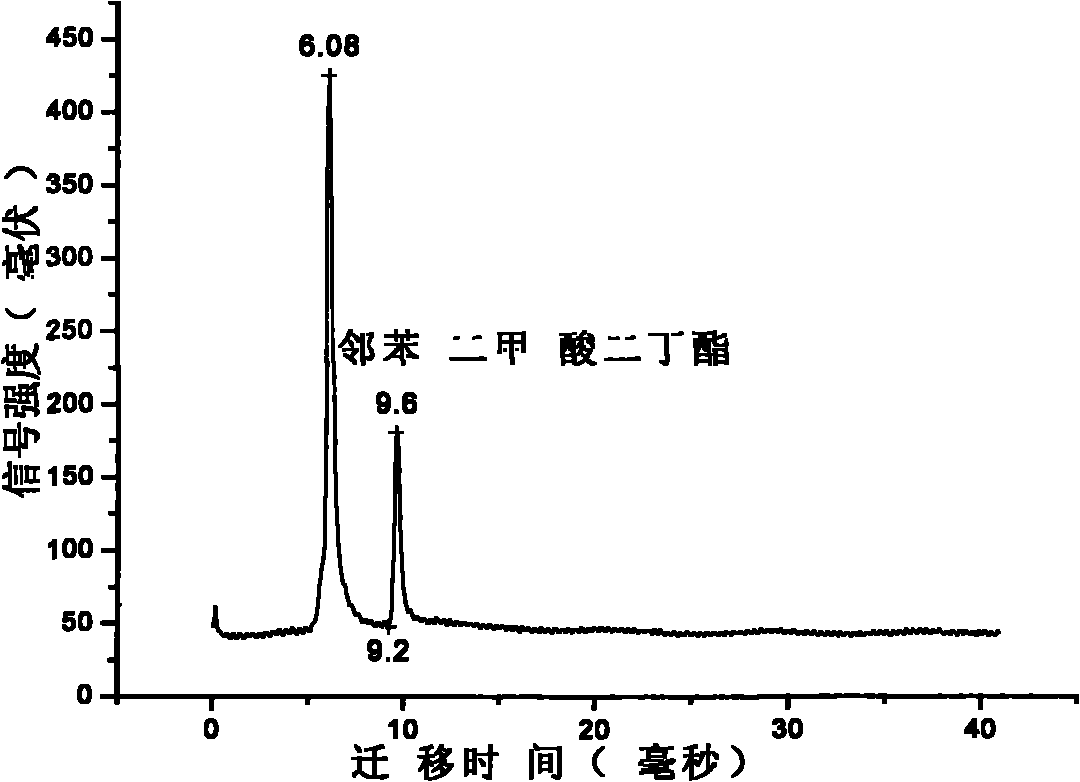

[0035] Different plasticizers (phthalates) have different peak times, which can be used for qualitative analysis. Moreover, when the sample contains two or more phthalate plasticizers, it can be detected by ion mobility spectrometer at the same time, and the analysis and test method is the same as in Example 1.

[0036] image 3 Shown is the control migration spectrum of different phthalates detected by ion mobility spectrometer. The three esters shown in the figure are well detected, the characteristic peak of dibutyl phthalate is at 9.6ms, while the characteristic peak of dinonyl phthalate is at 13.1ms, and the characteristic peak of didecyl phthalate is The characteristic peak is at 13.5ms.

[0037] Figure 4 Shown is the migration spectrum of an experiment separating two phthalates. For phthalate plasticizers with different peak times, they can be detected and separated at the same time.

Embodiment 3

[0039] In life, people tend to use plastic and water more often. Therefore, the dissolution and detection of plasticizers under this condition were studied.

[0040] In life, if plastic lasts for a certain period of time in boiling water or certain plastic products are used in a microwave oven. The plasticizers in its plastic are oozing out.

[0041] The difference from Example 1 is that the sample pretreatment steps are as follows: Accurately weigh 1g of plastic sample (cut into small pieces, about 0.5mm*0.5mm in size), soak in water (10mL), heat and boil for more than 5min or Microwave treatment for 0.5-2min (or longer) to dissolve the phthalate plasticizer in the plastic sample in water, and then use an organic solvent (dichloromethane) for liquid-liquid extraction; take 20-50μL for extraction The final organic solvent is put into the injector of the ion mobility spectrometer rapid detector, and can be directly used for detection;

[0042] Figure 5 shows the plasticizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com