Intelligent robot routing inspection system and method for railway machine room

A technology of intelligent robot and inspection system, applied in CCTV systems, signal transmission systems, general control systems, etc., can solve problems such as inability to accurately locate and eliminate faults, low technical level of maintenance personnel, etc. The effect of less equipment and clear system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in combination with specific embodiments.

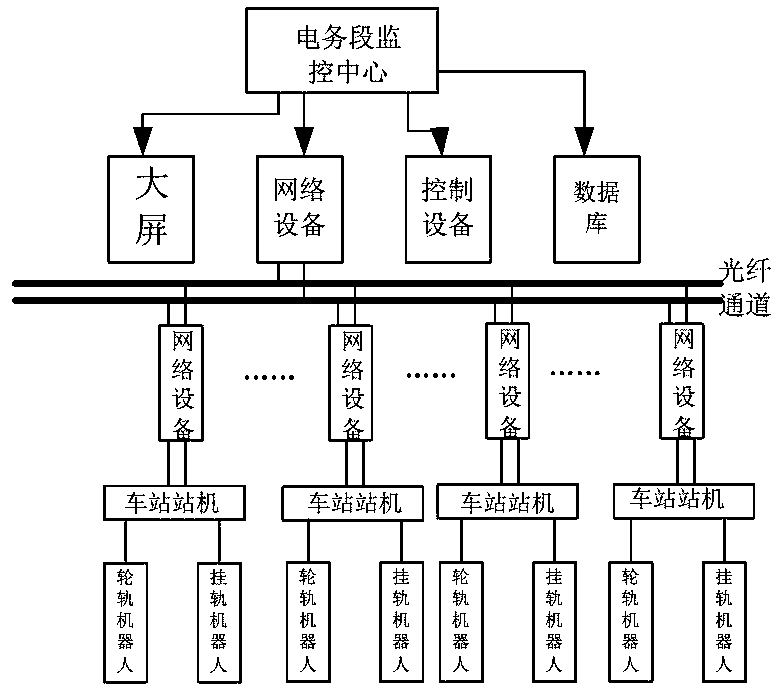

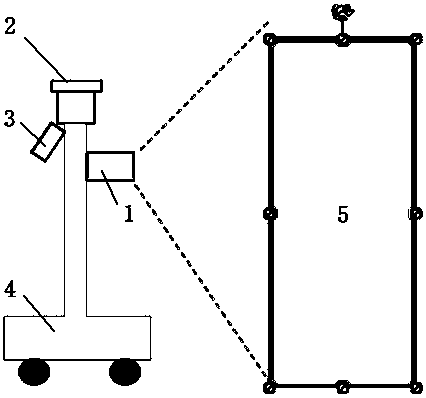

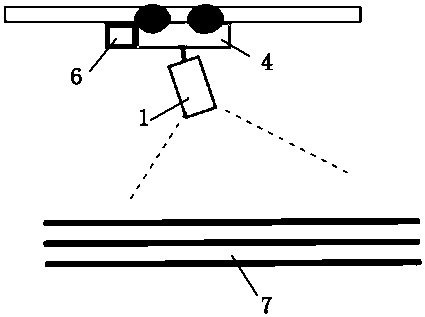

[0039] The invention relates to an intelligent robot inspection system and method for a railway machine room, an automatic robot inspection system for a railway machine room using multi-sensor fusion technology, electromagnetic compatibility technology, navigation machine behavior planning technology, robot vision technology, security technology and stable wireless transmission technology . Through the monitoring of the equipment and the environment of the computer room by the wheel-rail robot on the anti-static floor, and the monitoring of the cable status of the cable channel by the hanging-rail robot under the anti-static floor, images, data and equipment status are effectively collected, and the collected The received equipment information is entered into the database server, and the fault information in the expert knowledge base is used for comparison and judgment, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com