Welding quality monitoring system and method

A welding quality and monitoring system technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as inaccurate welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

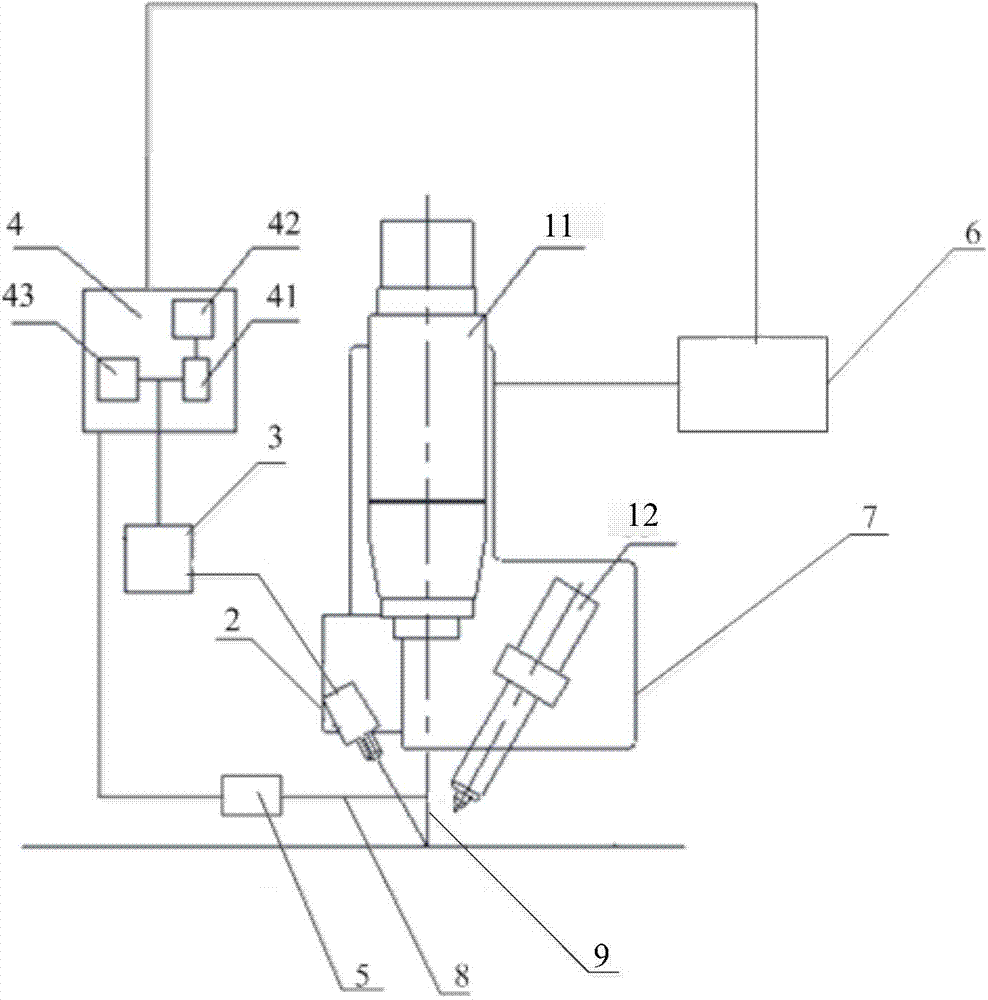

[0035] This embodiment provides a welding quality monitoring system, such as figure 1 As shown, the system includes: a welding torch 1, an infrared thermal imager 2, an image acquisition card 3, and an image processing computer 4; wherein,

[0036] The welding torch 1 is used to weld the welding spot; the welding torch 1 includes: a laser welding torch 11 and an arc welding torch 12 .

[0037] The thermal imaging camera 2 is used to record the molten pool infrared thermal imaging data of the welding spot and the welding seam forming process during the welding process of the welding torch 1;

[0038] After the infrared thermal imager 2 has recorded the infrared thermal imaging data of the melting pool and the welding seam forming process, the image acquisition card 3 is specifically used for: collecting the infrared thermal imaging data of the molten pool and welding seam forming process, sending the welding seam forming process of the molten pool infrared thermal imaging data...

Embodiment 2

[0088] Corresponding to Embodiment 1, this embodiment also provides a welding quality monitoring method, such as Figure 4 As shown, the method includes the following steps:

[0089] Step 410, using a welding torch to weld the spot;

[0090] In this step, the welding torch includes a laser welding torch and an arc welding torch.

[0091] Step 411, recording infrared thermal imaging data of the molten pool of the solder joint;

[0092] In this step, during the welding process of the welding torch, an infrared imager is used to record the infrared thermal imaging data of the molten pool of the welding spot and the welding seam forming process.

[0093] Step 412, collecting and sending the infrared thermal imaging data of the melting pool;

[0094] After the infrared thermal imager has recorded the infrared thermal imaging data of the molten pool and the weld forming process, the image acquisition card is used to collect the infrared thermal imaging data of the molten pool and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com