Surface defect detection algorithm based on machine vision

A defect detection and machine vision technology, used in optical testing flaws/defects, instruments, measuring devices, etc., can solve problems such as unreliability, instability, and inability to achieve real-time detection requirements, achieve good real-time performance, and meet online detection. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below. The description herein is only used to explain the present invention when referring to specific examples, and does not limit the present invention.

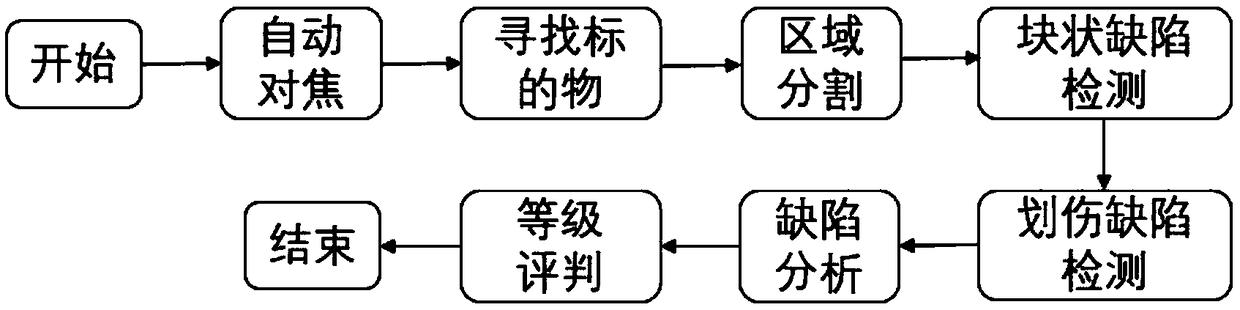

[0072] figure 1 Schematic flow chart of the surface defect detection algorithm of the present invention; the steps included are:

[0073] (a): Use CCD or CMOS sensor to collect the surface image of the object surface, judge the clarity of the collected image, and adjust the focus state according to the clarity of the image;

[0074] (b): Using the auto-focus algorithm, find the clearest image among the multiple collected object surface images, and send it to the next step of the defect detection algorithm;

[0075] (c): Use the target matching positioning algorithm to find the area with the highest similarity with the corresponding target or template image in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com