Rolling mill oil film bearing comprehensive test bench

A technology of comprehensive test bench and oil film bearing, which is applied in the field of comprehensive test bench for rolling mill oil film bearings, can solve the problem of inability to provide accurate and reliable test data for research on magnetic fluid lubrication oil film bearings, failure to fully reflect the influence of oil film bearing characteristics of high-speed heavy-duty rolling mills, failure Realize the problems of mechanical, electrical, hydraulic and pneumatic integration and joint control, and achieve the effects of easy and quick start, small static load and excitation load, and large braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

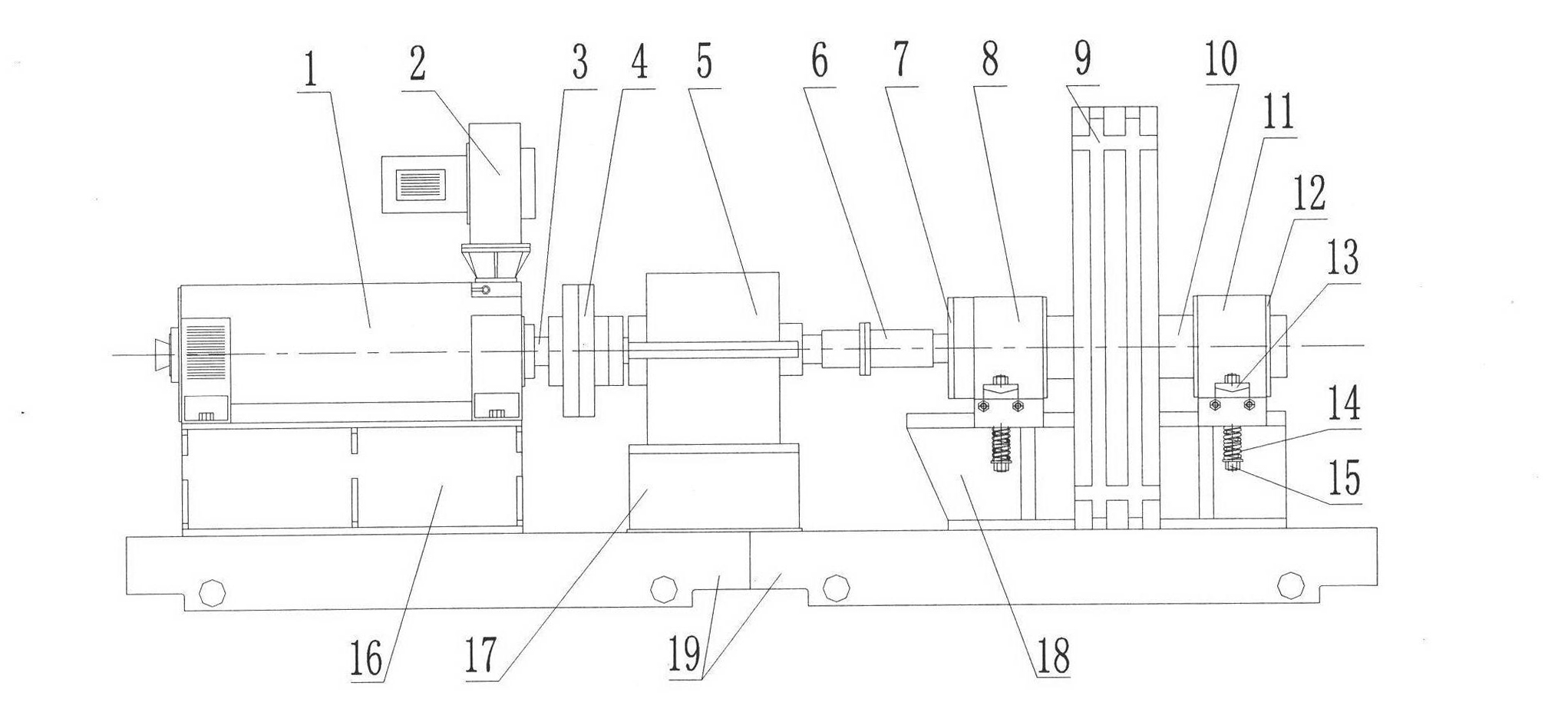

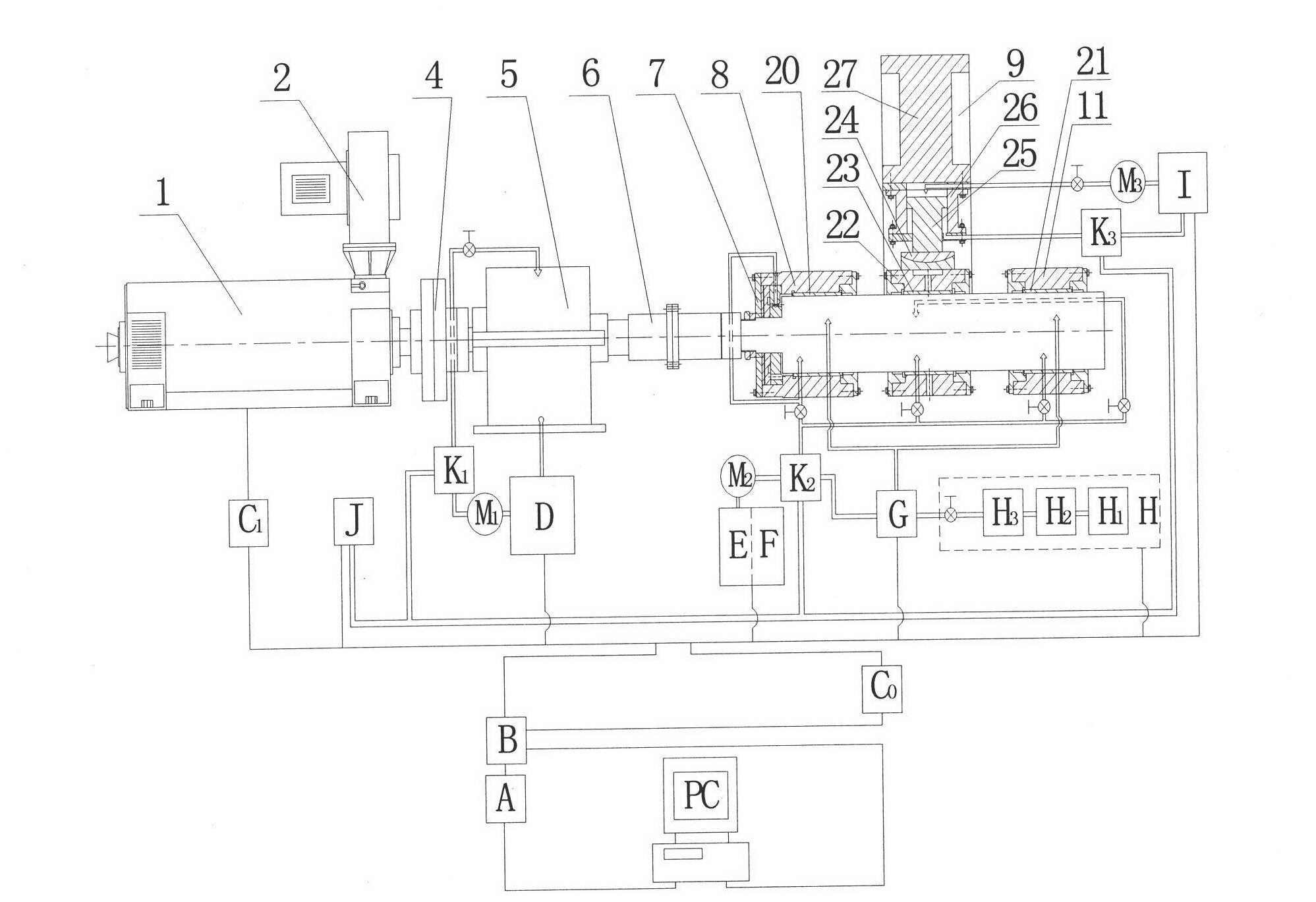

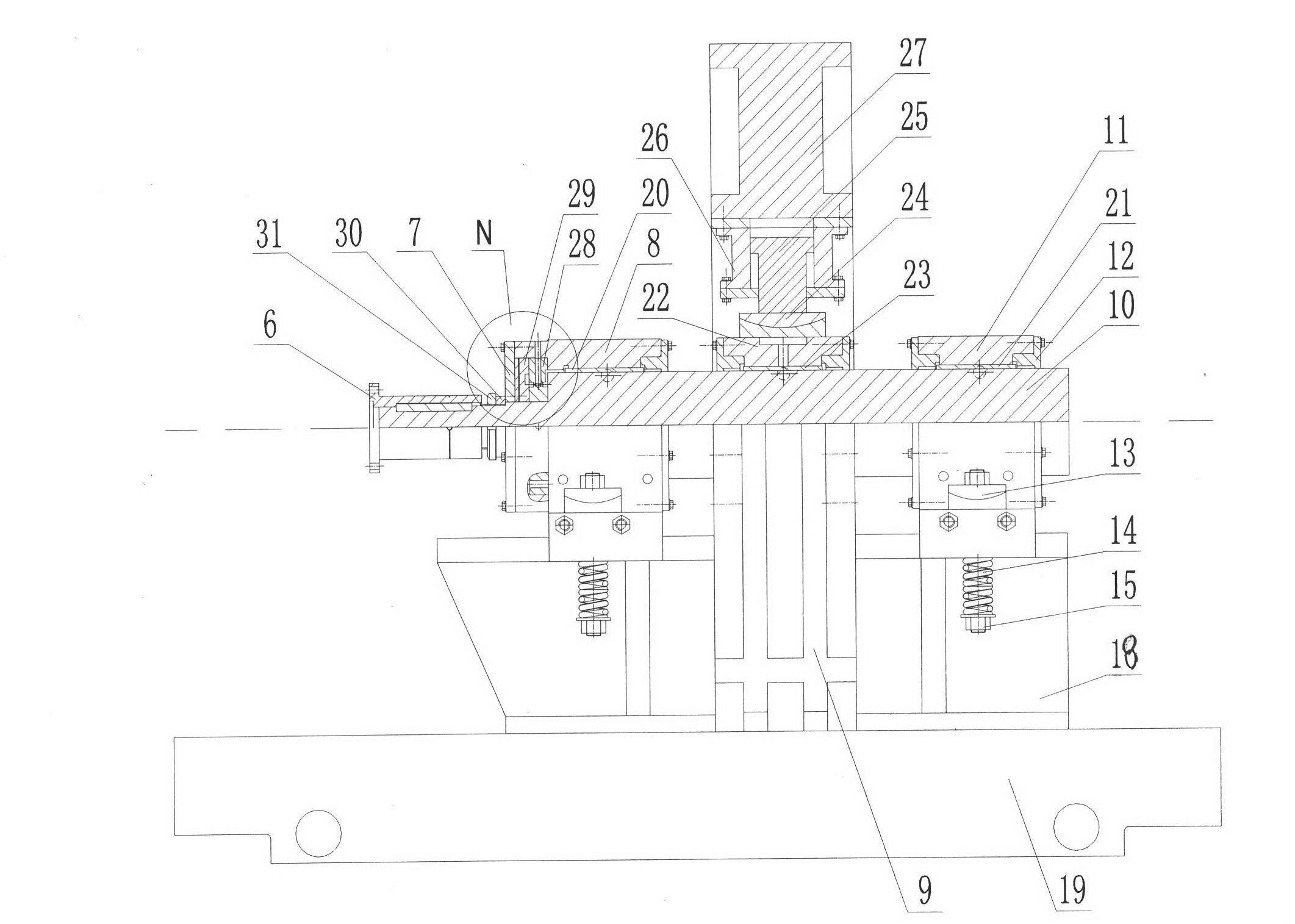

[0027] Such as figure 1 , figure 2 , image 3As shown, the bearing blocks 8, 11 are fixed on the base 18, the speed increaser 5 is installed on the base 17, the motor 1 is installed on the base 16, and the bases 16, 17, 18 can be placed on the horizontal slide table 19 Move and adjust left and right, fill cement below the horizontal slide table 19 to strengthen and resist vibration, and the dynamic pressure oil film bearing 23 and the left and right dynamic and static pressure oil film bearings 20, 21 are installed on the main shaft 10, and are installed on the respective corresponding dynamic pressure bearing seats 22 and the left and right dynamic and static pressure bearings together. Press the bearing seats 8 and 11, and then connect the main shaft 10 with the motor 1 on which the fan 2 is installed through the rigid coupling 6, the speed increaser 5 with a speed ratio of 1:8 and the elastic coupling 4, and ensure that the main shaft 10 and the motor shaft 3 of the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com