Patents

Literature

31results about How to "Less-expensive to maintain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

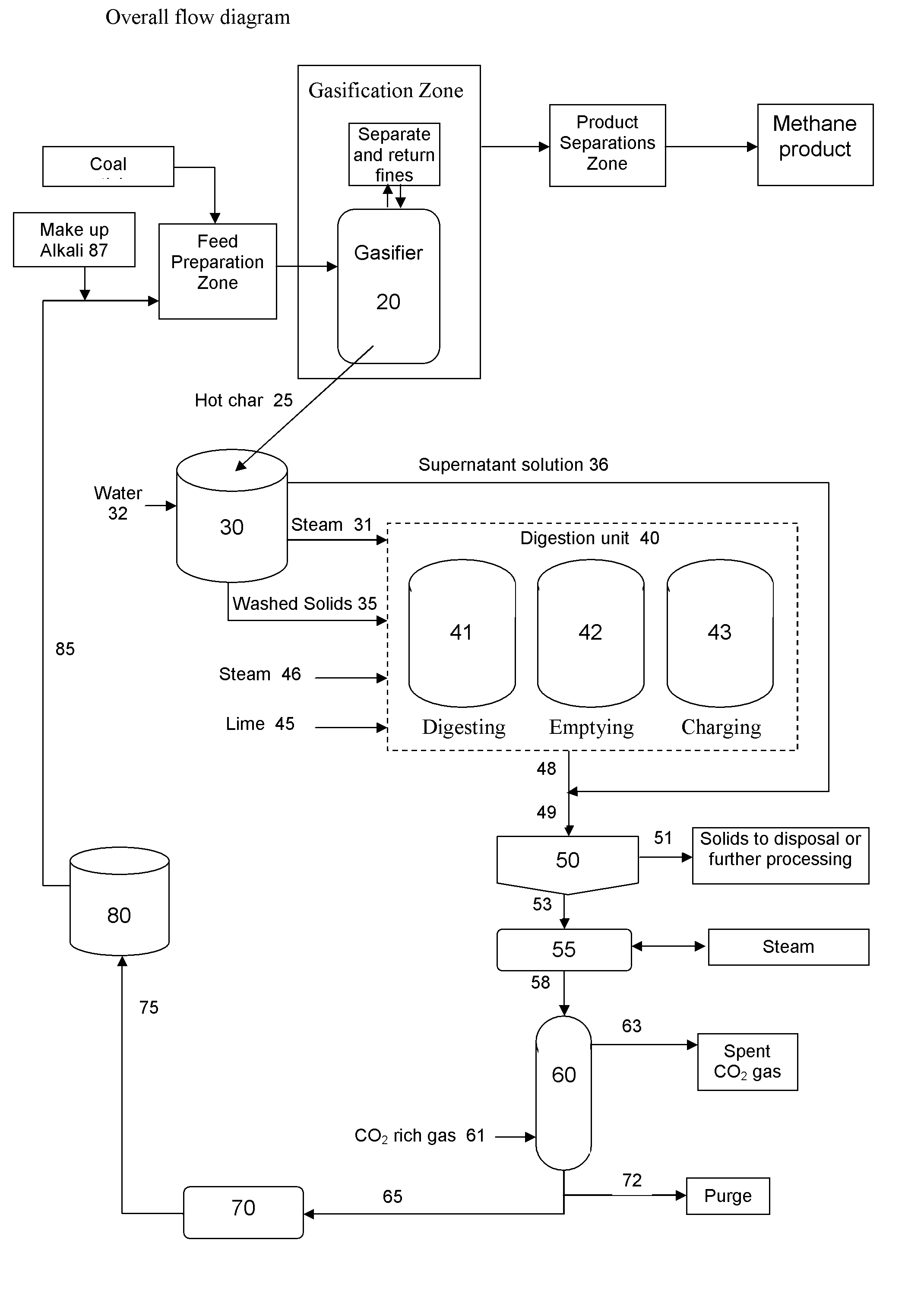

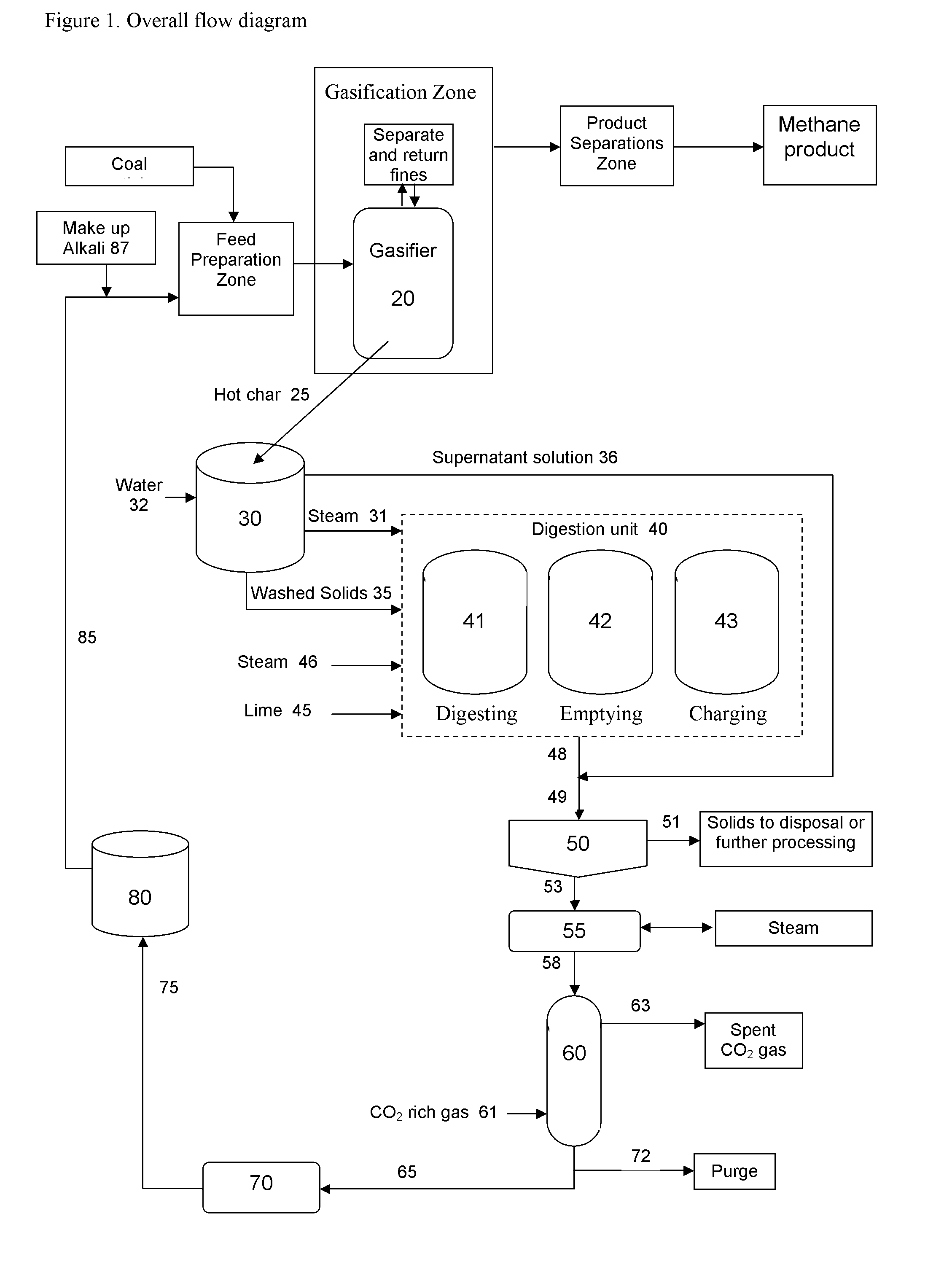

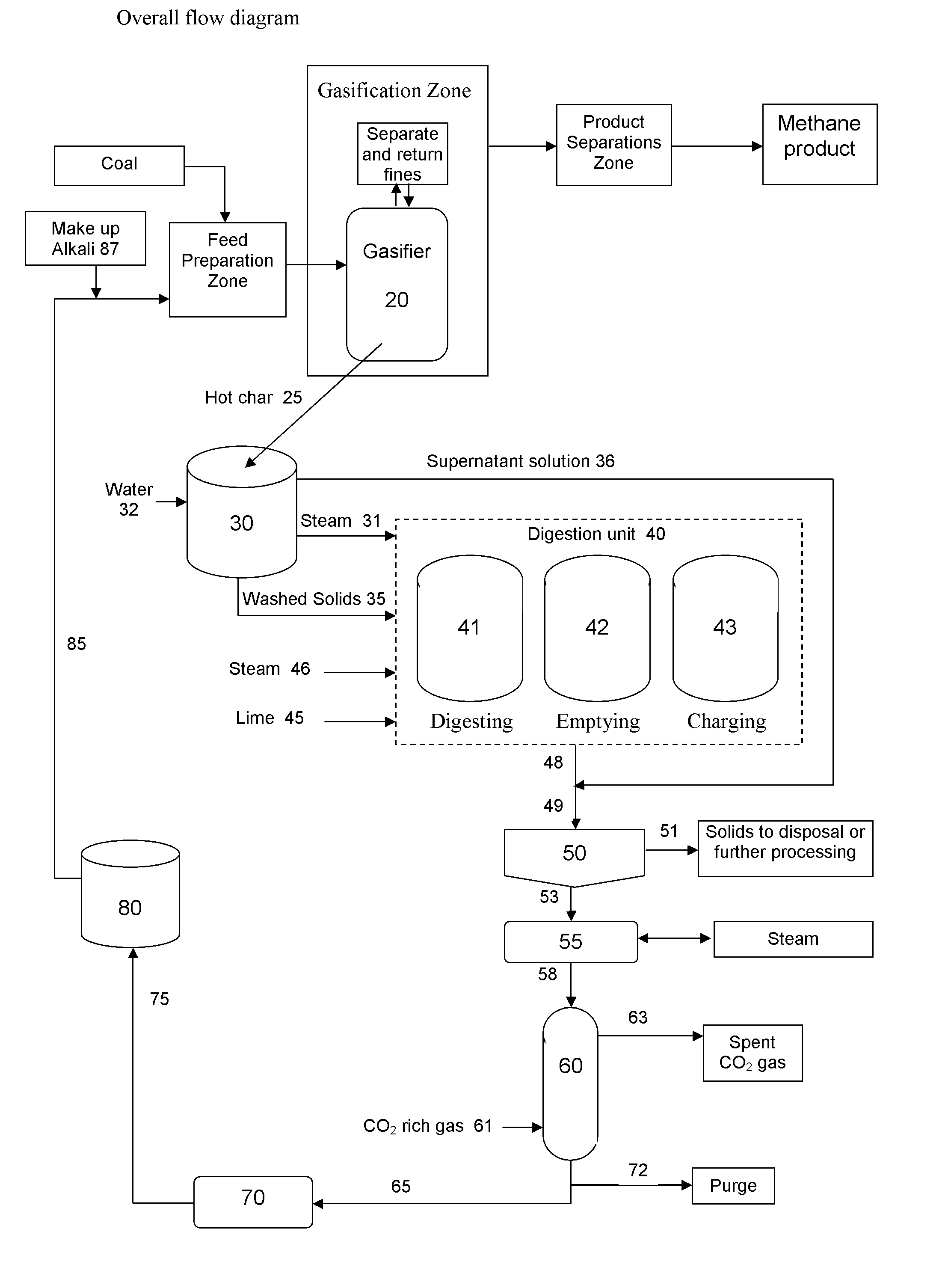

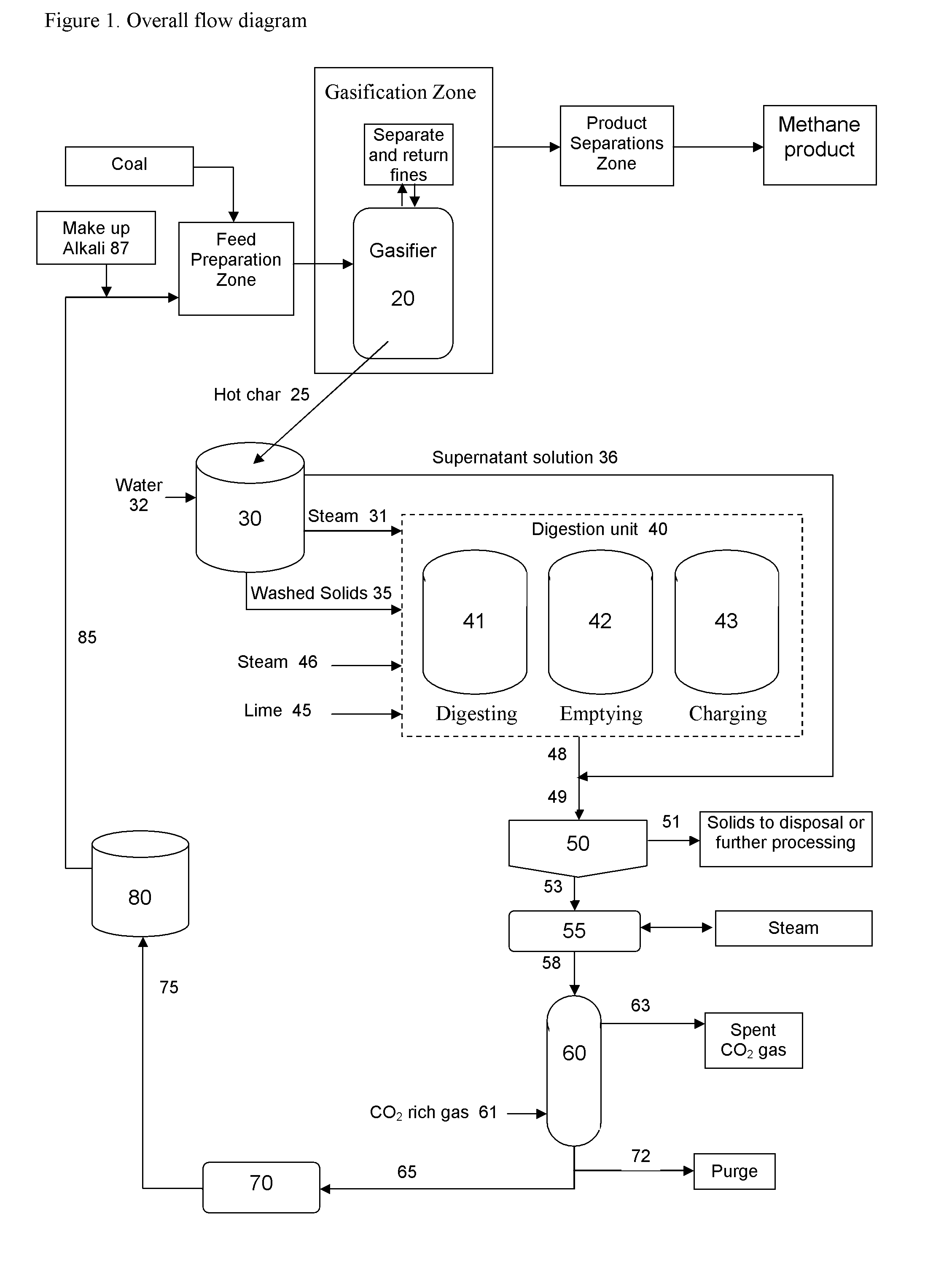

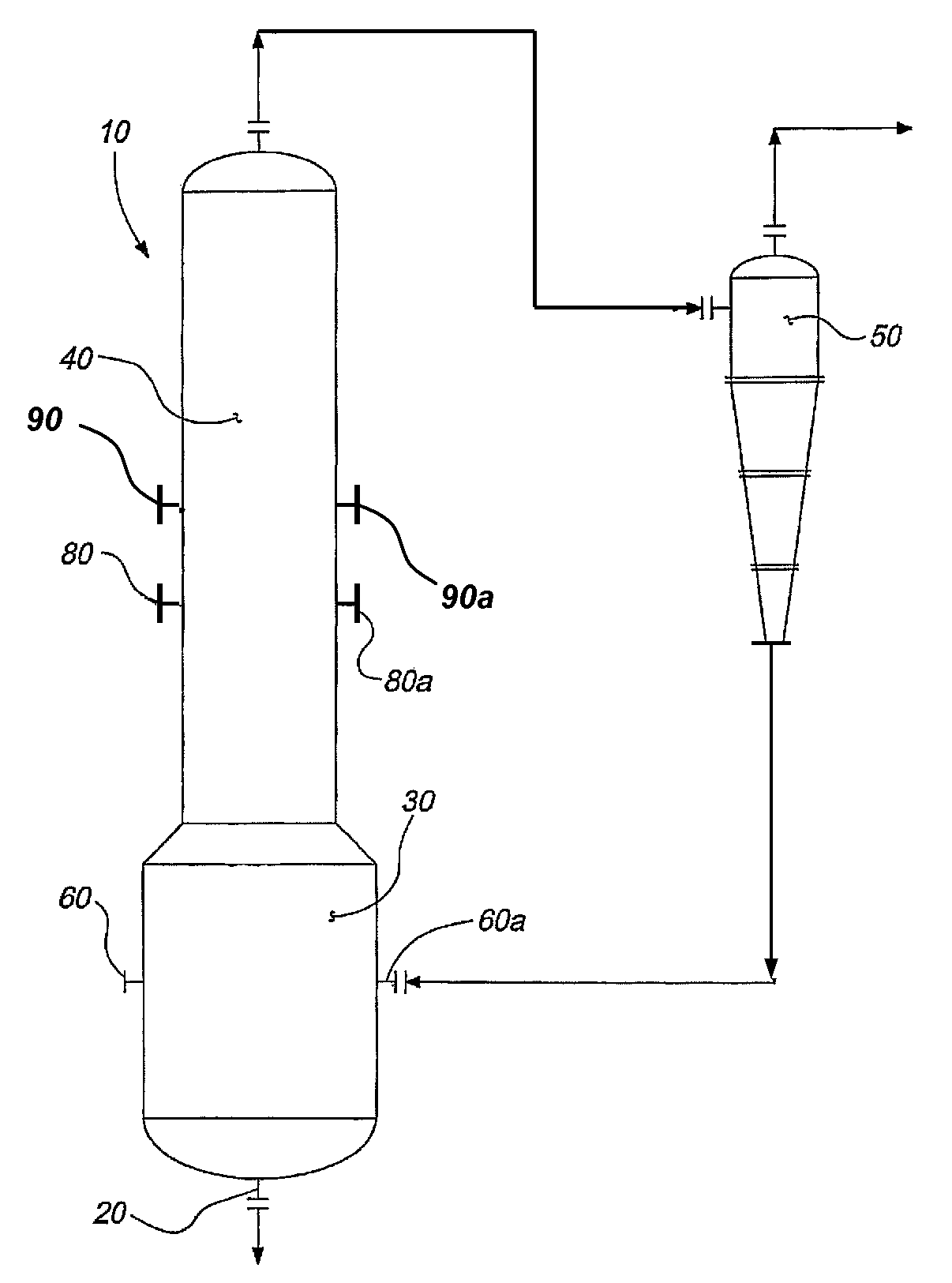

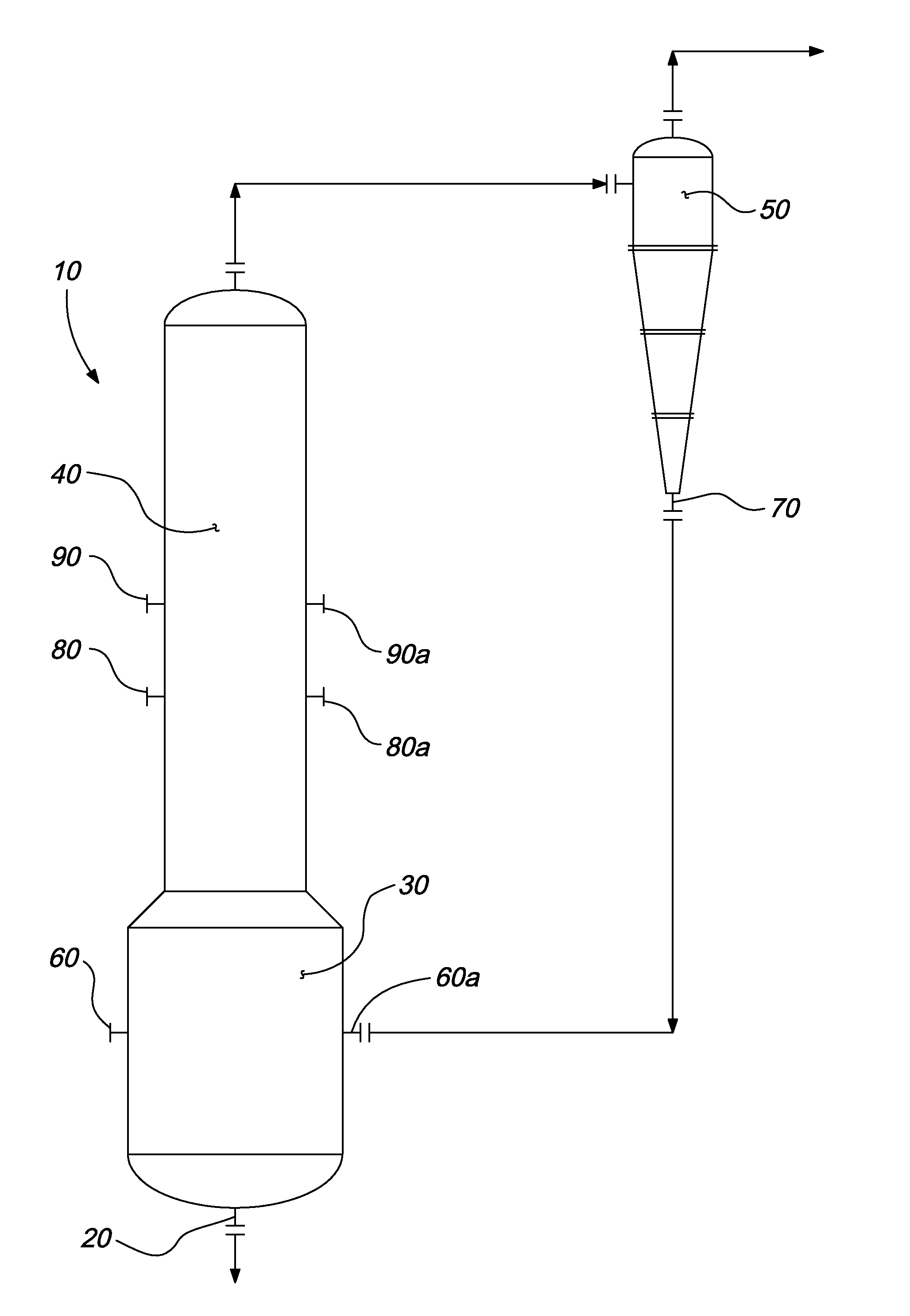

Catalytic steam gasification process with recovery and recycle of alkali metal compounds

ActiveUS20070277437A1Promote leachingLarge specific surface areaHydrogenGas modification by gas mixingCompound aAlkali metal

A high efficiency gasification process for converting carbonaceous solids to methane and apparatus for its practice are described. The process includes reacting steam and carbonaceous solids comprising ash in the presence of alkali metal catalyst in a gasification reactor to produce combustible gases and char particles comprising ash and alkali metal catalyst constituents, treating a stream of such char particles in an alkali metal catalyst recovery system to recover the catalyst constituents as alkali metal compounds, and recycling such recovered compounds. Within the alkali metal catalyst recovery system the process includes quenching the stream of char particles with water whereby such particles are cooled and fractured, dissolving soluble alkali metal catalyst constituents from the fractured solids to form a first alkali metal catalyst solution and washed solids, optionally reacting the washed solids in alkaline solution to form a second alkali metal catalyst solution, upgrading said first and optional second alkali solution to recover the alkali metal catalyst constituents as said alkali metal compounds.

Owner:SURE CHAMPION INVESTMENT LTD

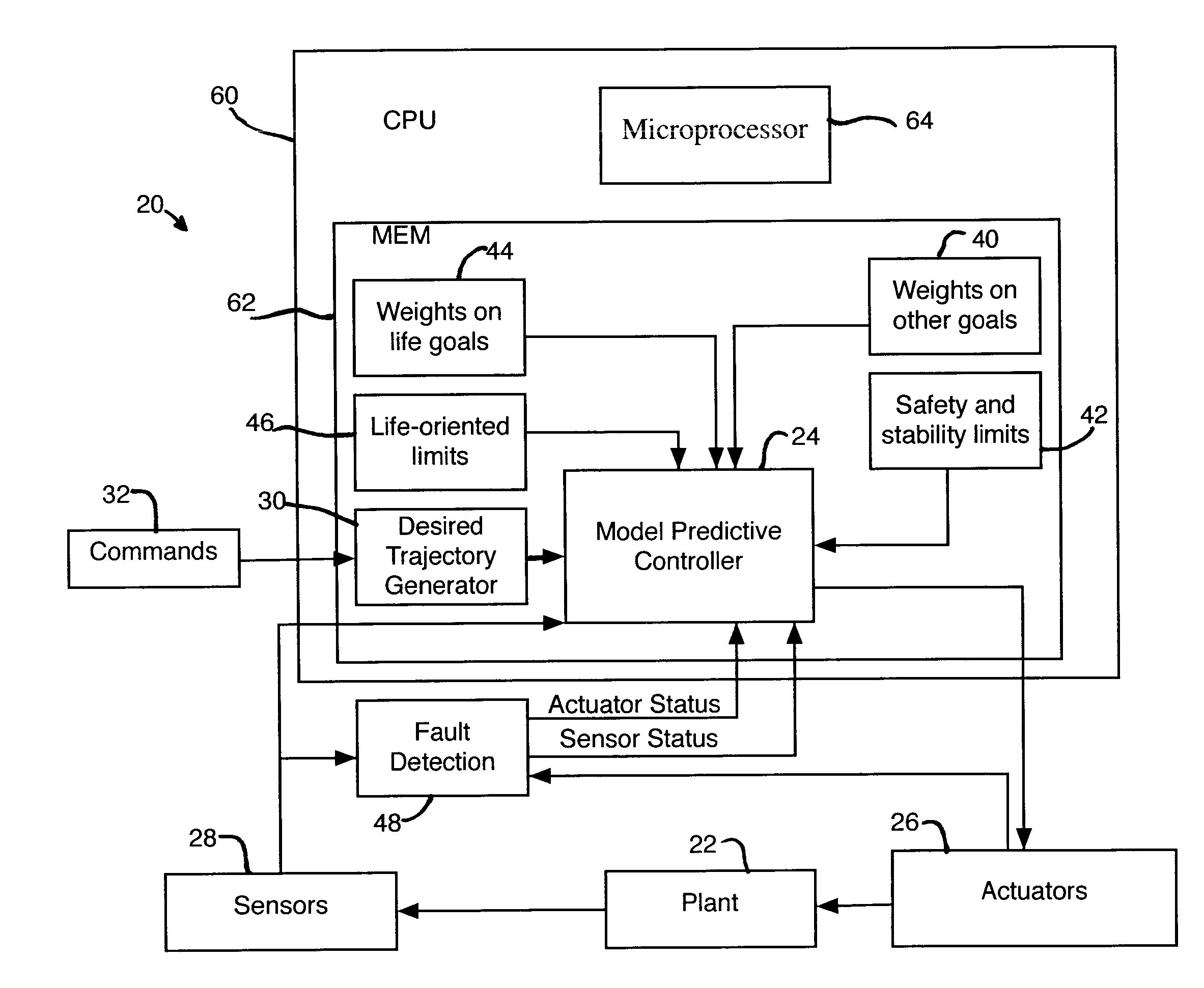

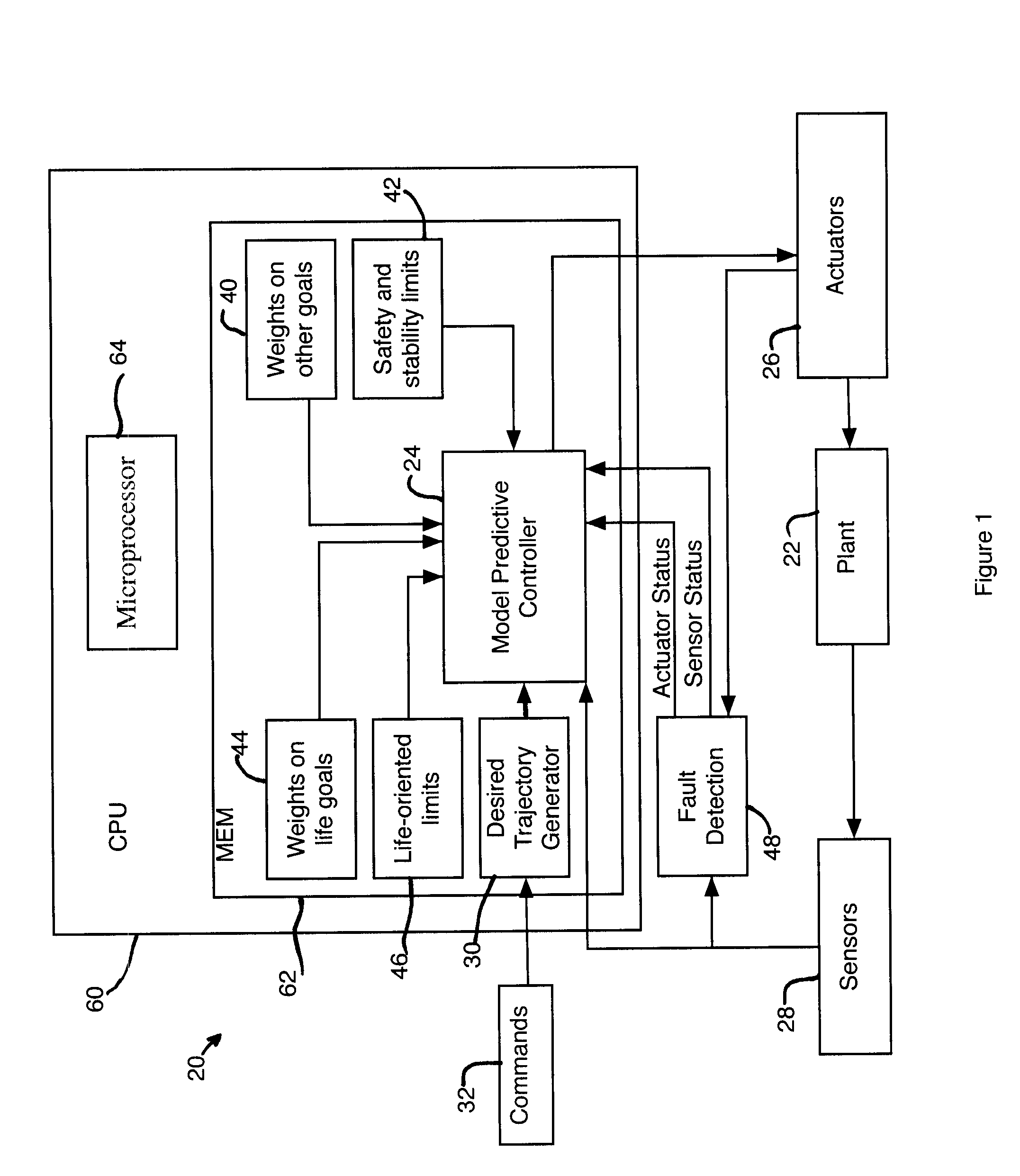

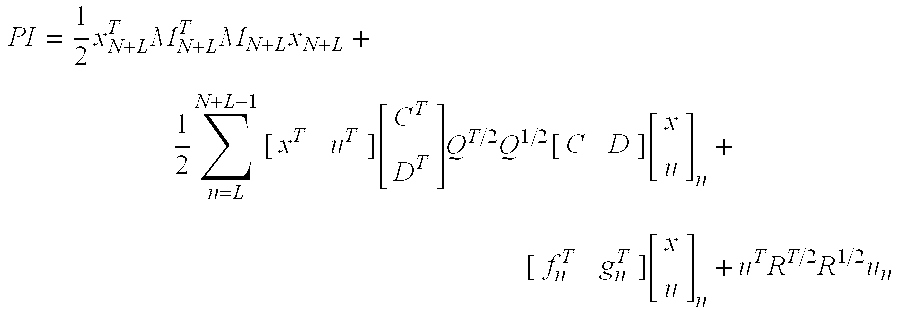

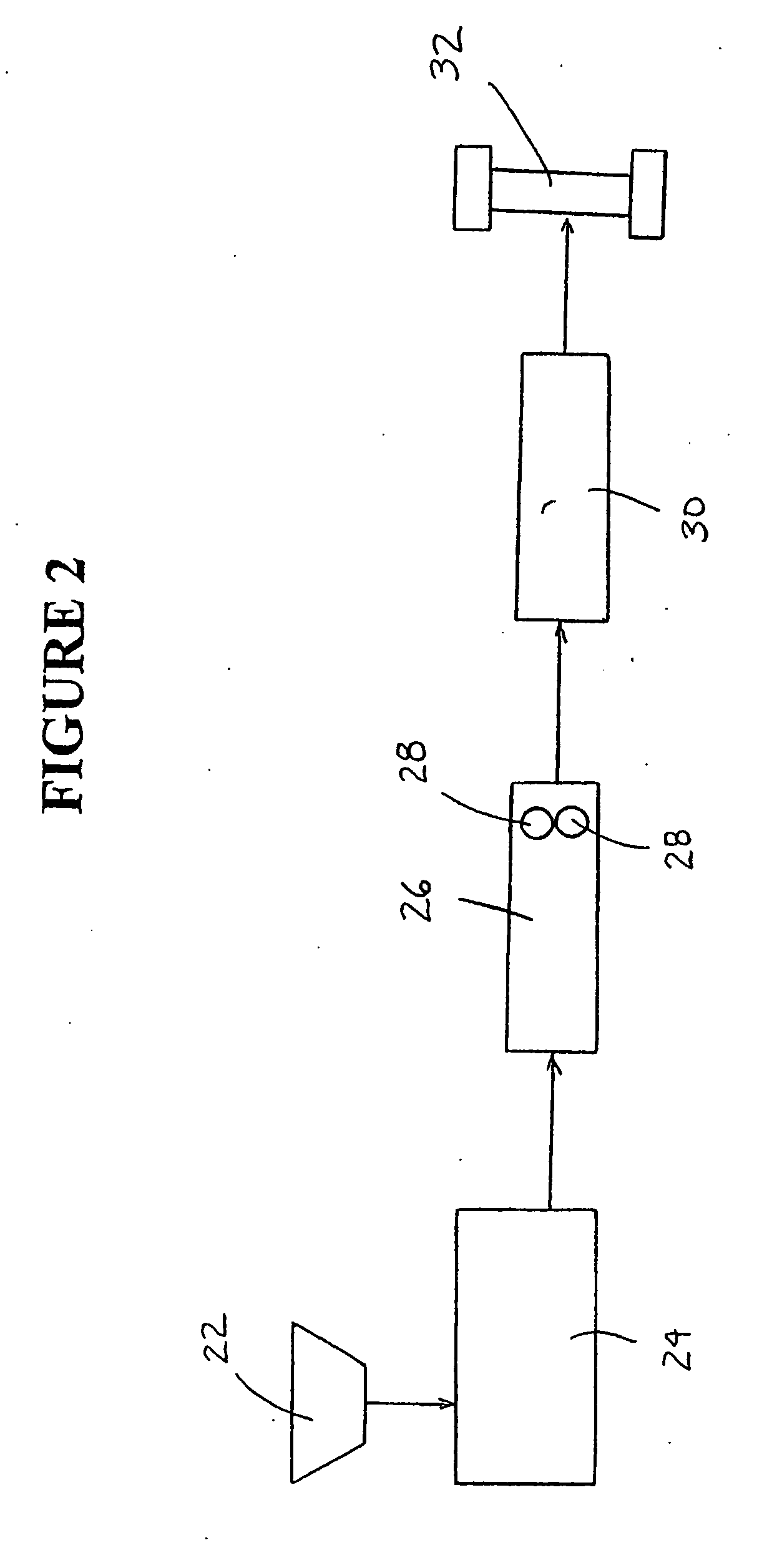

Model predictive controller with life extending control

ActiveUS7203554B2Reduce in quantityProlong lifeElectric testing/monitoringSpecial data processing applicationsControl systemPredictive controller

An MPC Control system provides a life extending control that includes life-extending goals in the performance index of the MPC controller and limits in the inequality equations. The MPC controller performs the normal functions of a control system for a physical system, but does so in a manner that extends the life or time-to-next maintenance or reduces the number of parts that need to be replaced. If the life extending functions do not degrade other control functions, they can be always enabled, making the system less expensive to maintain. If the life extending functions degrade some other control functions, they can be adjusted in-the-field or on-the-fly to stretch the time-until-maintenance until it is more convenient, but with some impact on performance.

Owner:RTX CORP

Catalytic steam gasification process with recovery and recycle of alkali metal compounds

ActiveUS7922782B2Promote leachingLarge specific surface areaHydrogenGaseous fuelsCompound aCombustible gas

A high efficiency gasification process for converting carbonaceous solids to methane and apparatus for its practice are described. The process includes reacting steam and carbonaceous solids comprising ash in the presence of alkali metal catalyst in a gasification reactor to produce combustible gases and char particles comprising ash and alkali metal catalyst constituents, treating a stream of such char particles in an alkali metal catalyst recovery system to recover the catalyst constituents as alkali metal compounds, and recycling such recovered compounds. Within the alkali metal catalyst recovery system the process includes quenching the stream of char particles with water whereby such particles are cooled and fractured, dissolving soluble alkali metal catalyst constituents from the fractured solids to form a first alkali metal catalyst solution and washed solids, optionally reacting the washed solids in alkaline solution to form a second alkali metal catalyst solution, upgrading said first and optional second alkali solution to recover the alkali metal catalyst constituents as said alkali metal compounds.

Owner:SURE CHAMPION INVESTMENT LTD

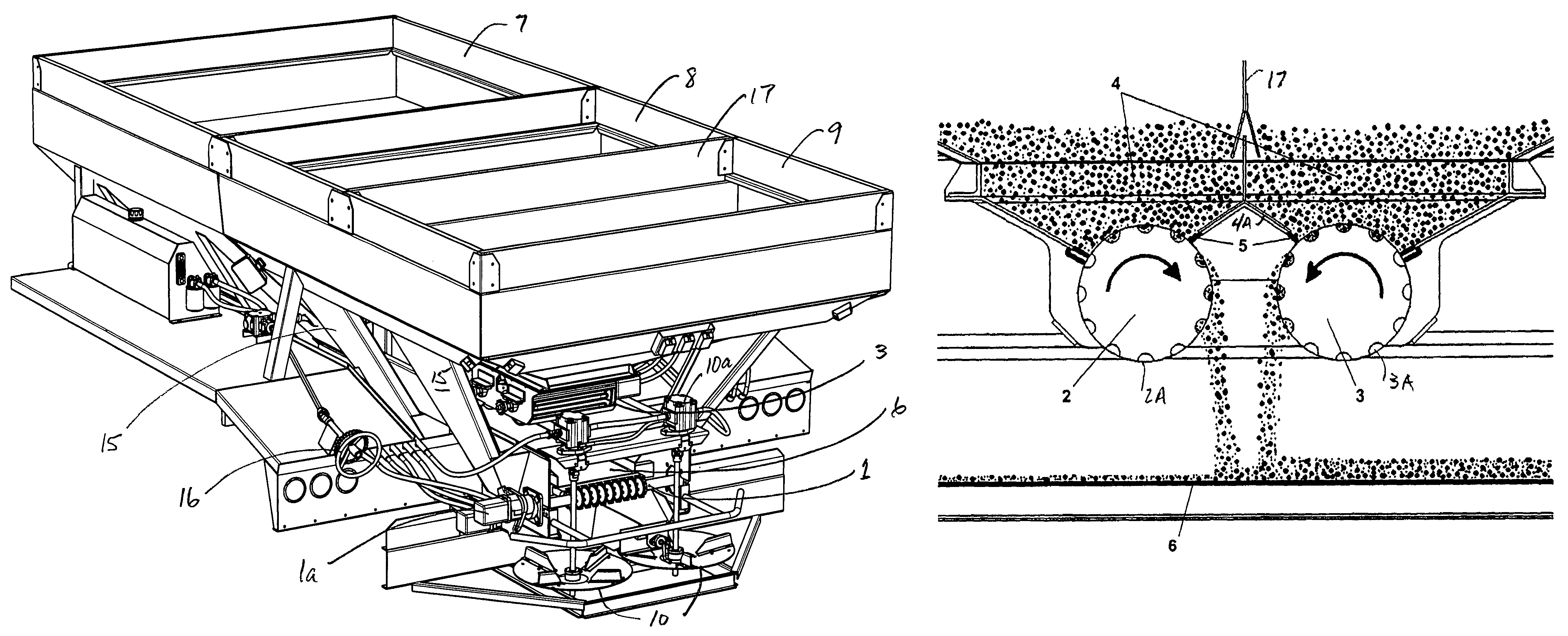

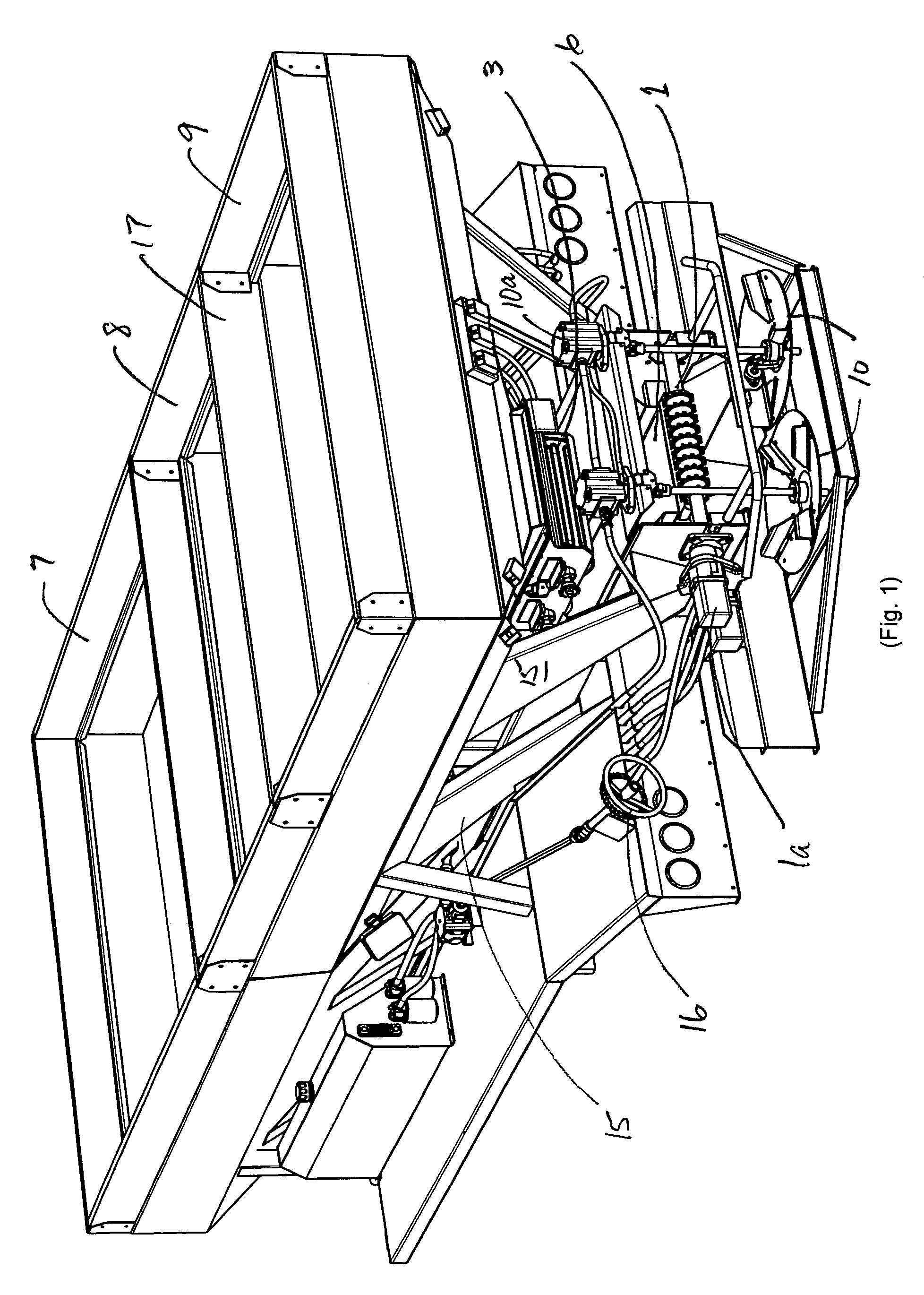

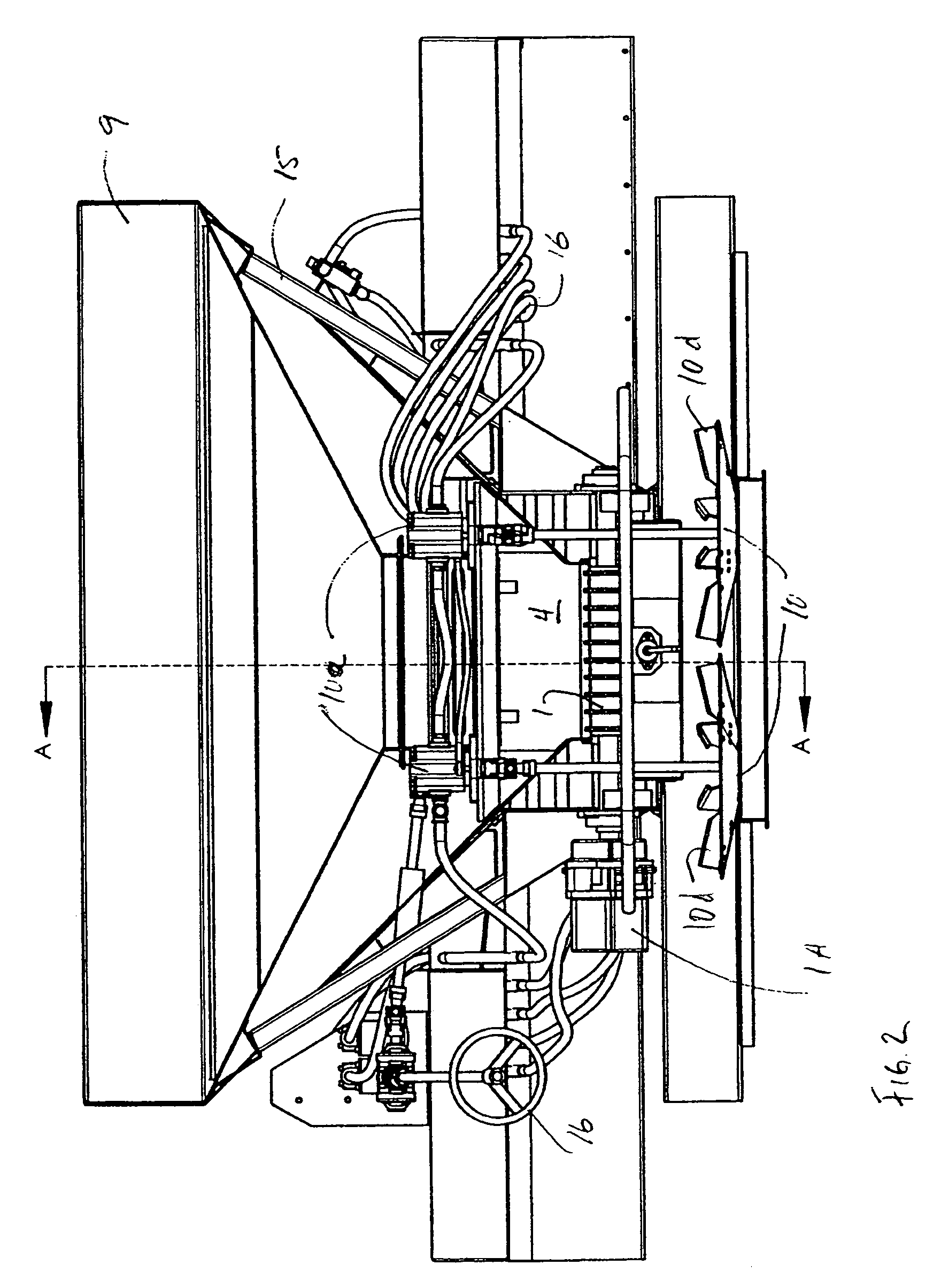

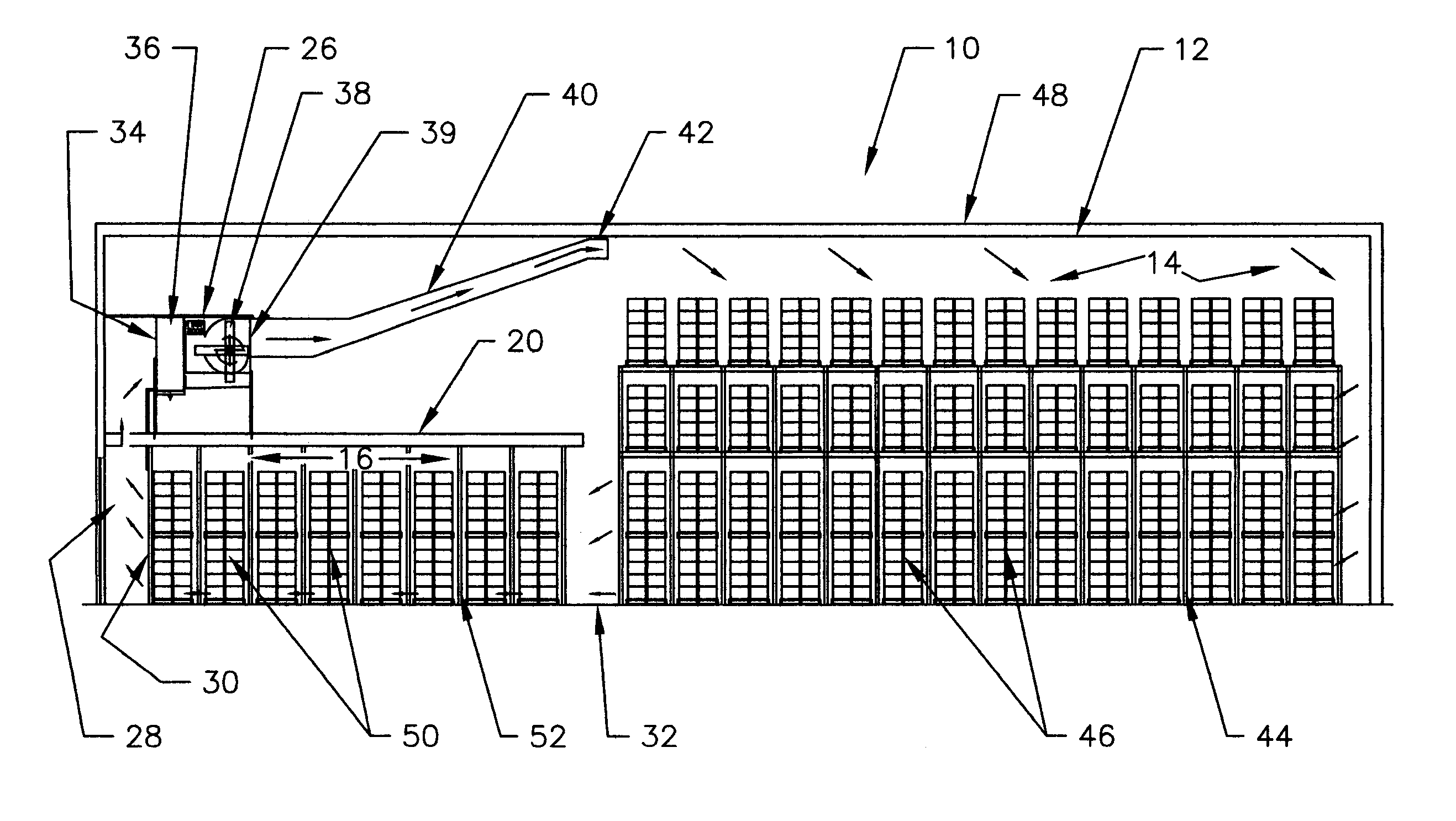

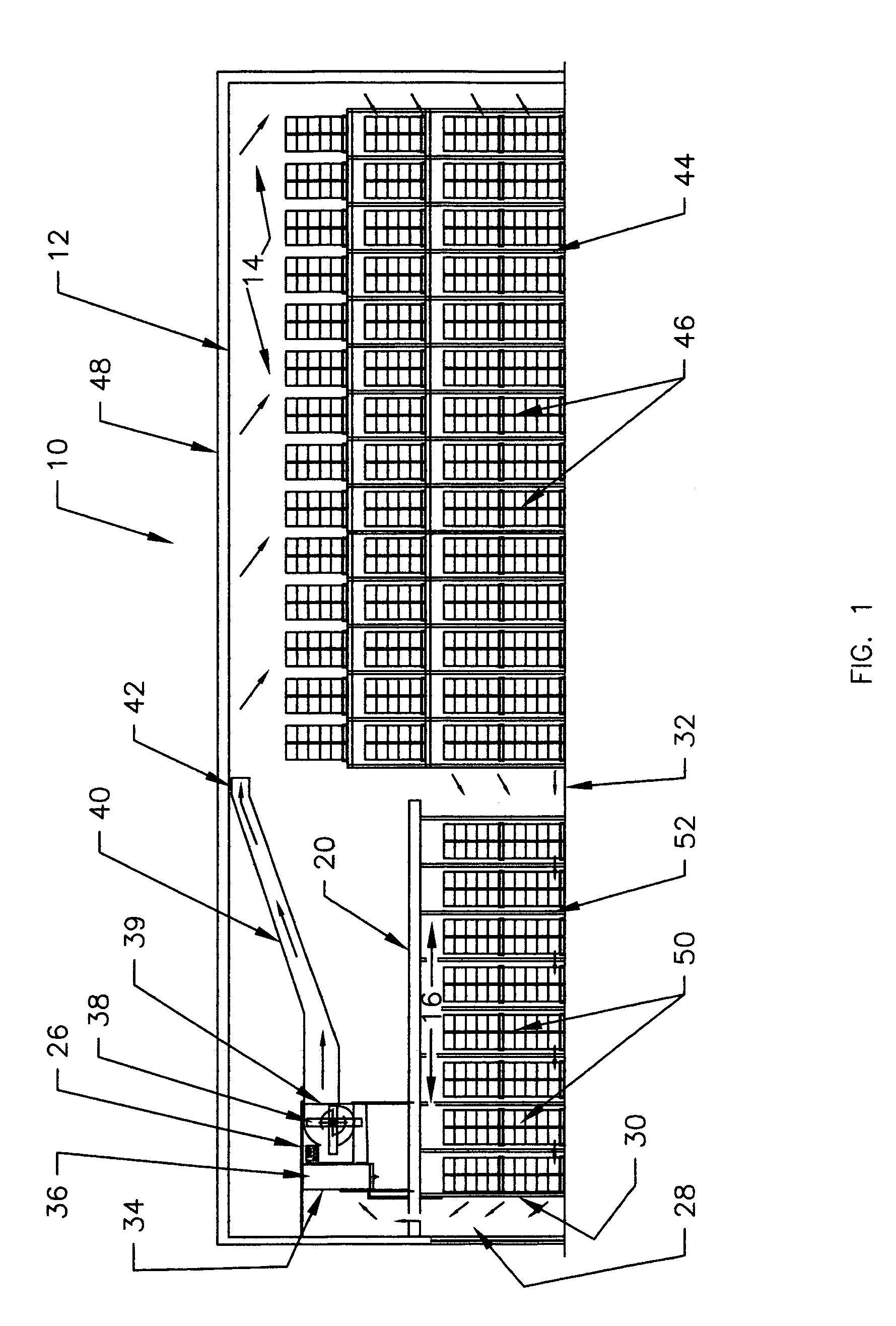

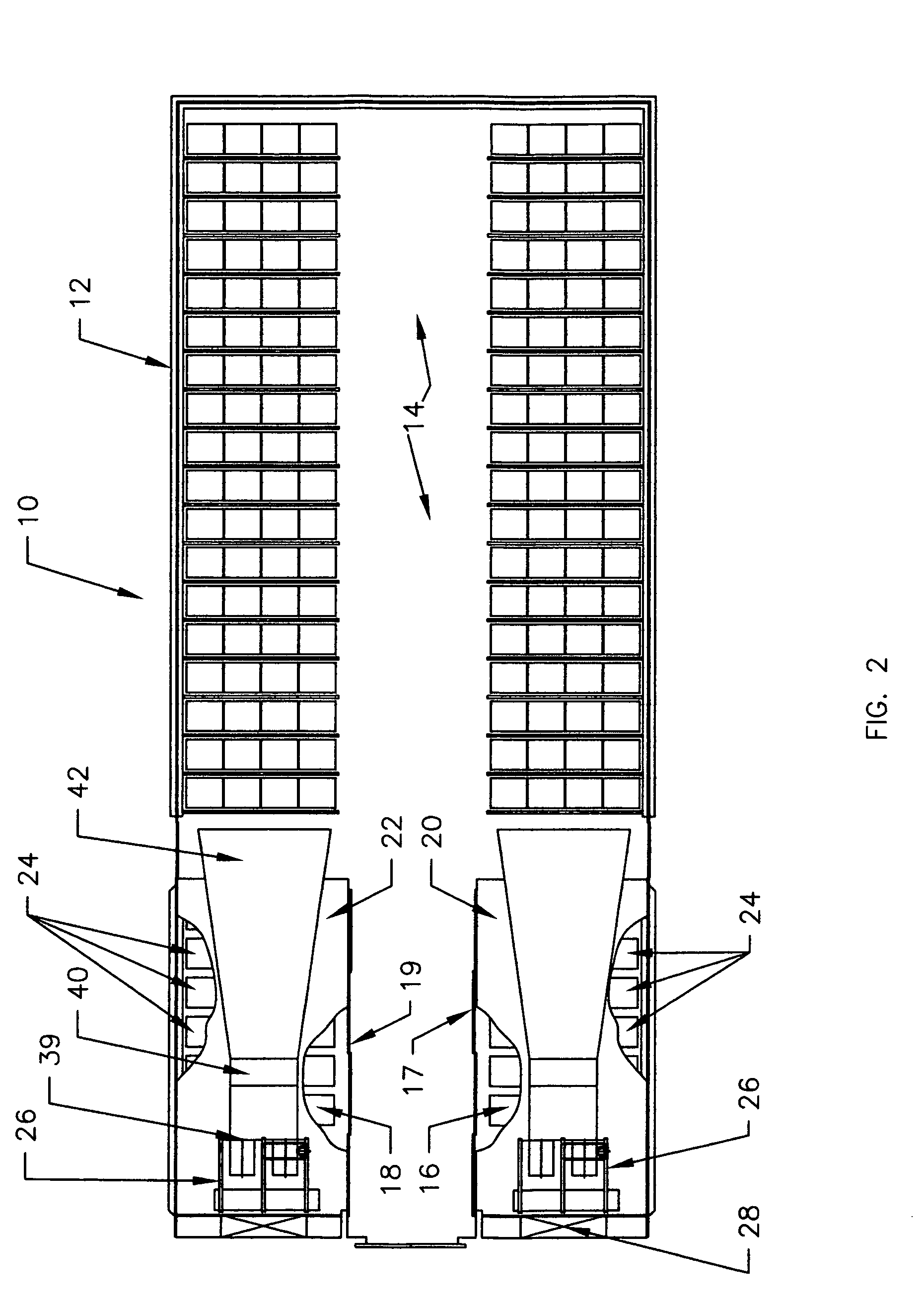

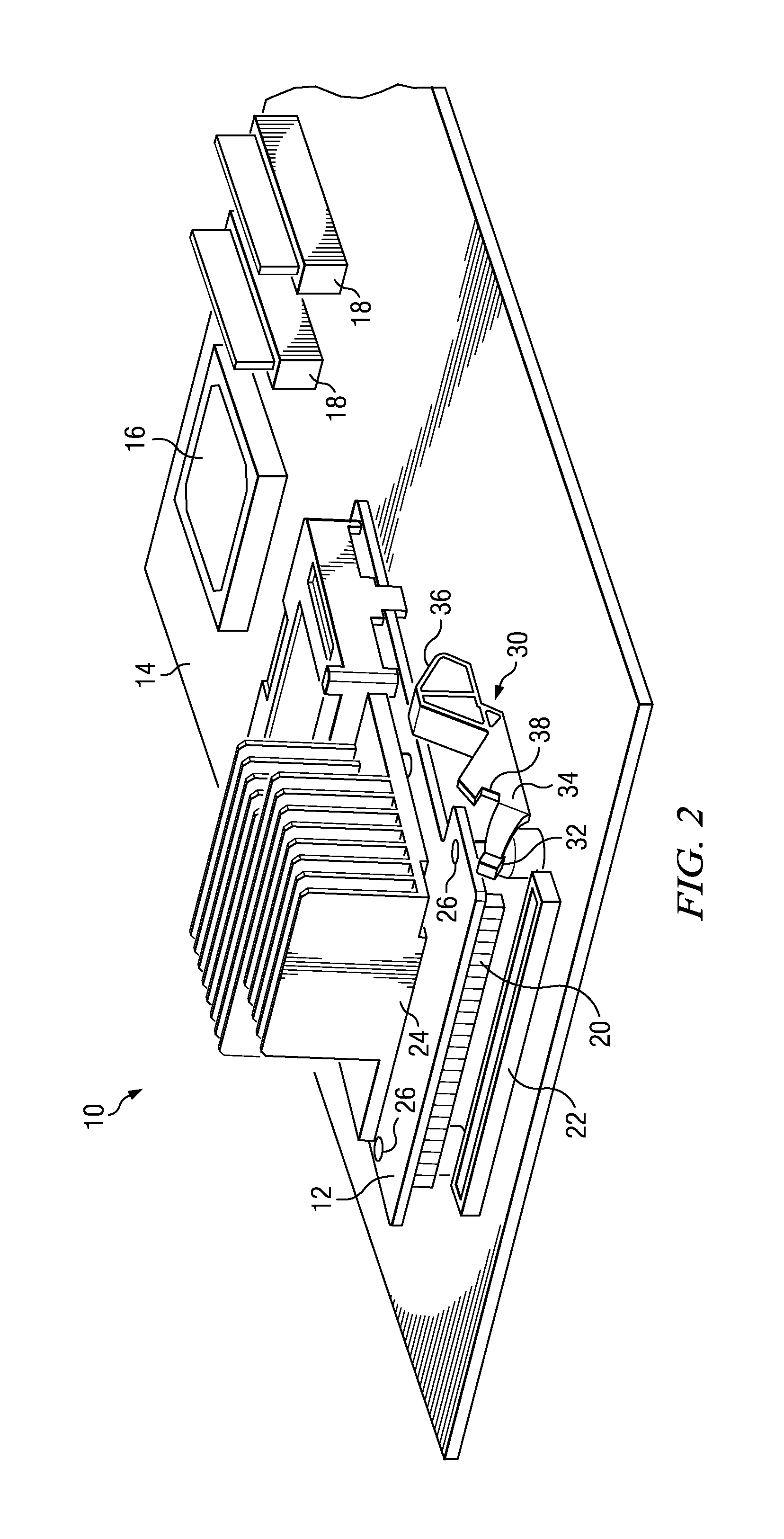

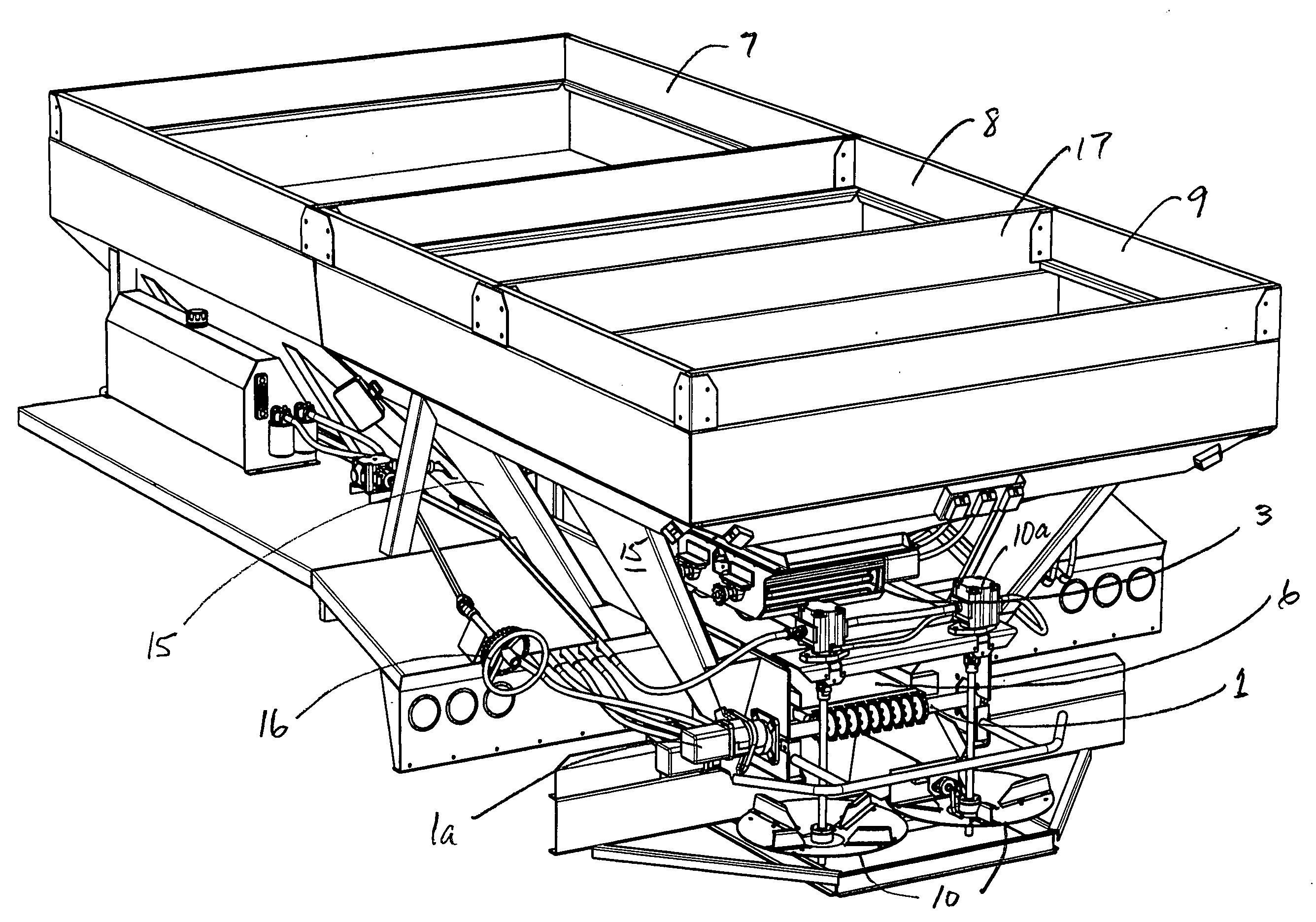

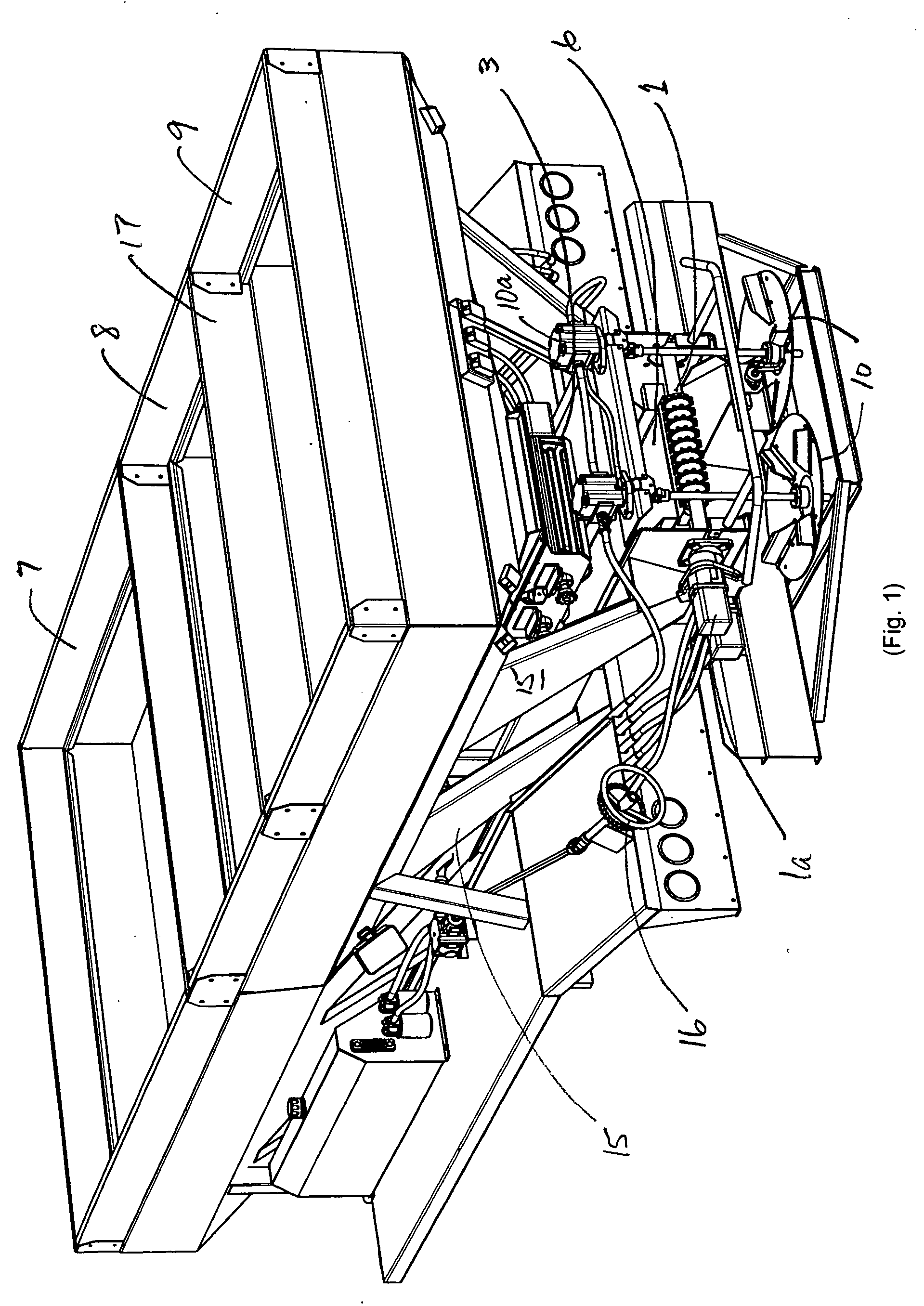

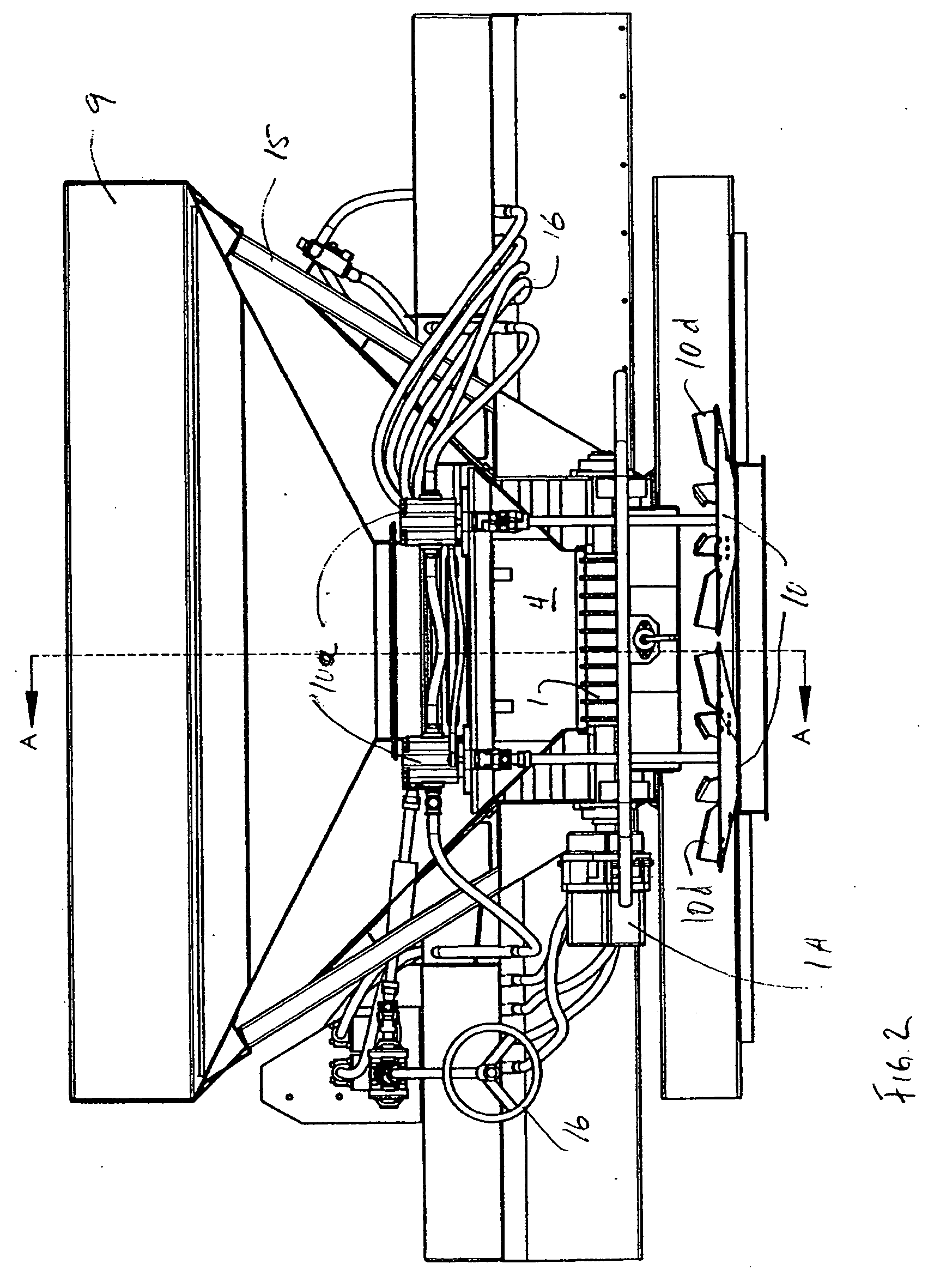

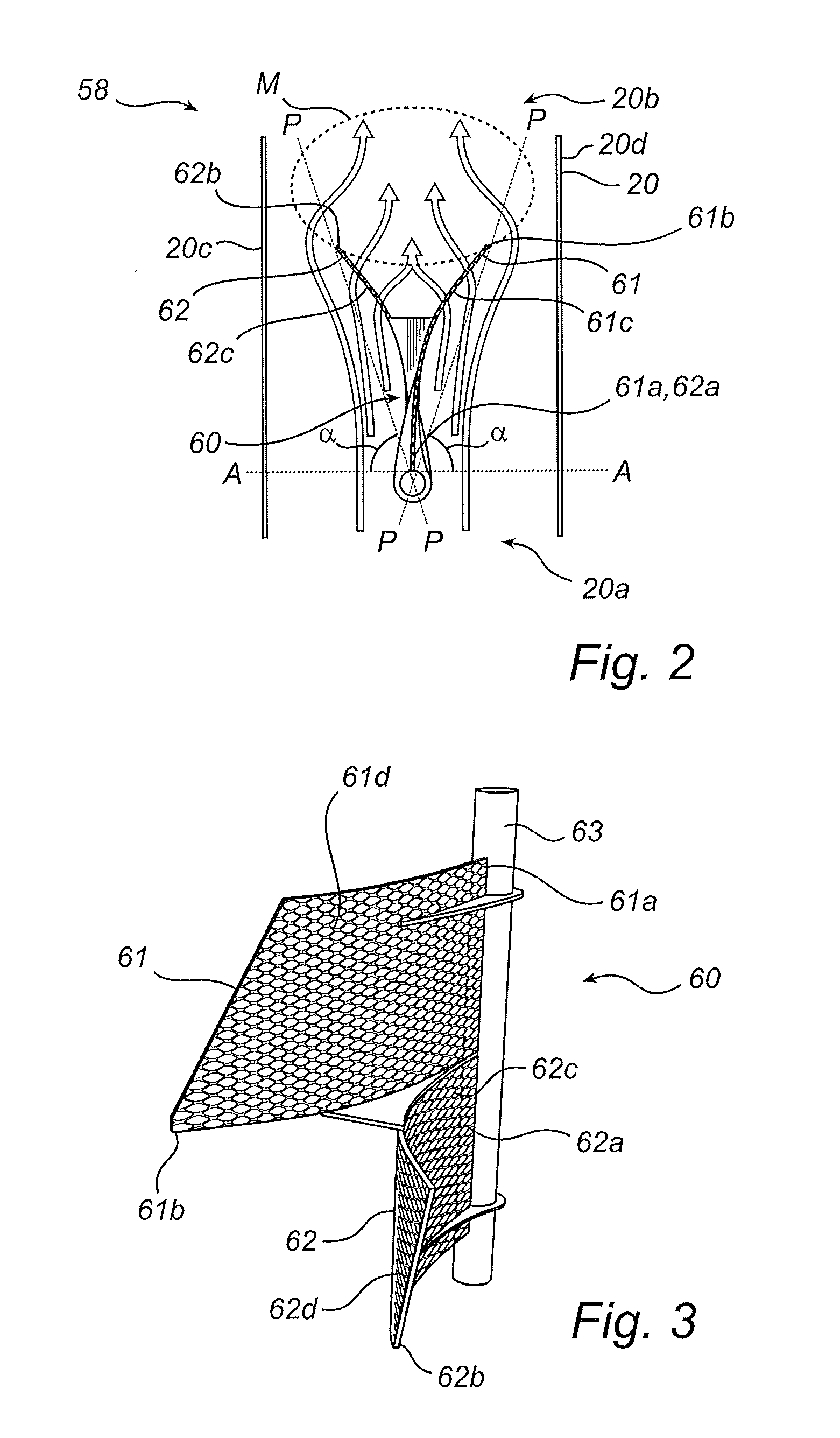

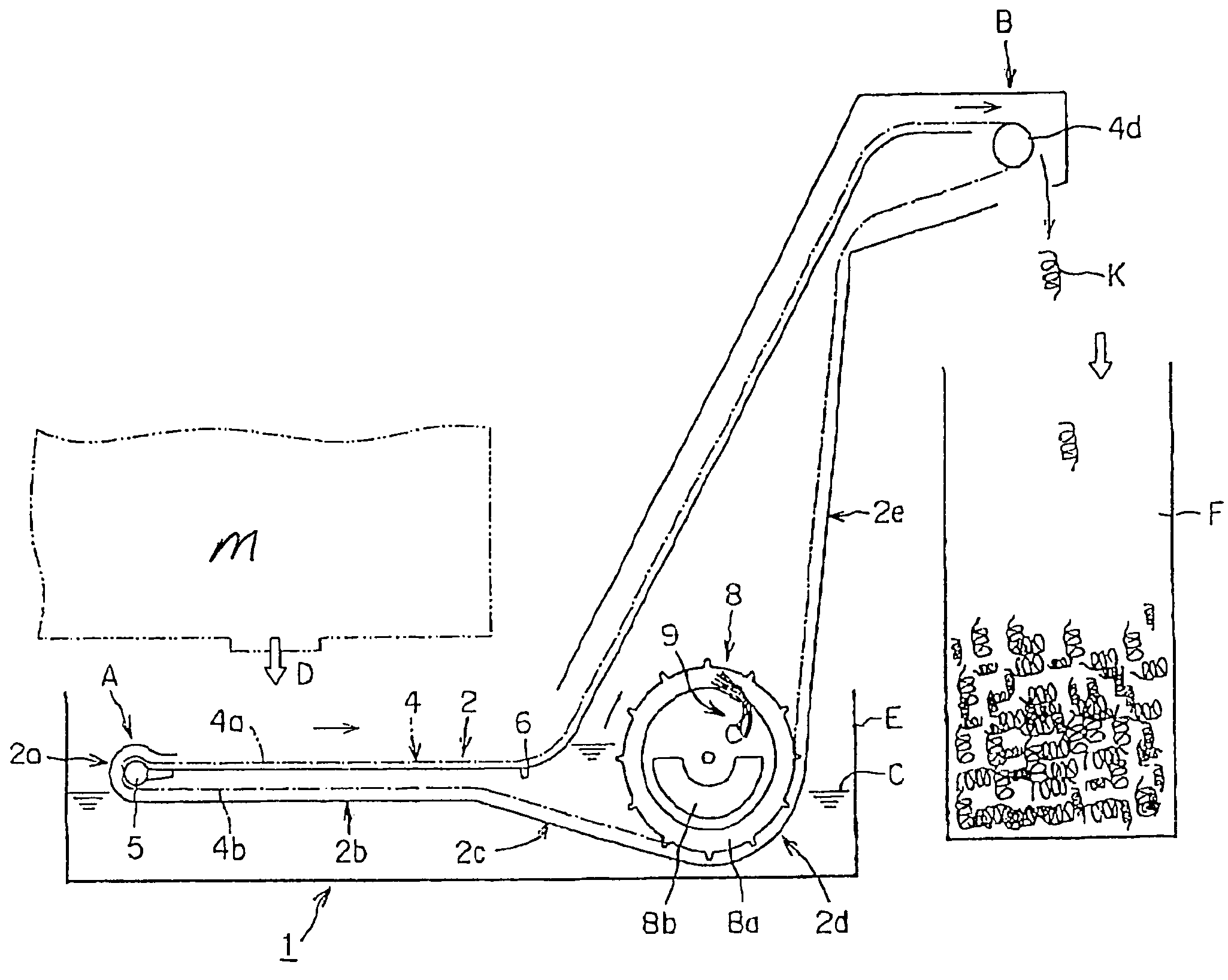

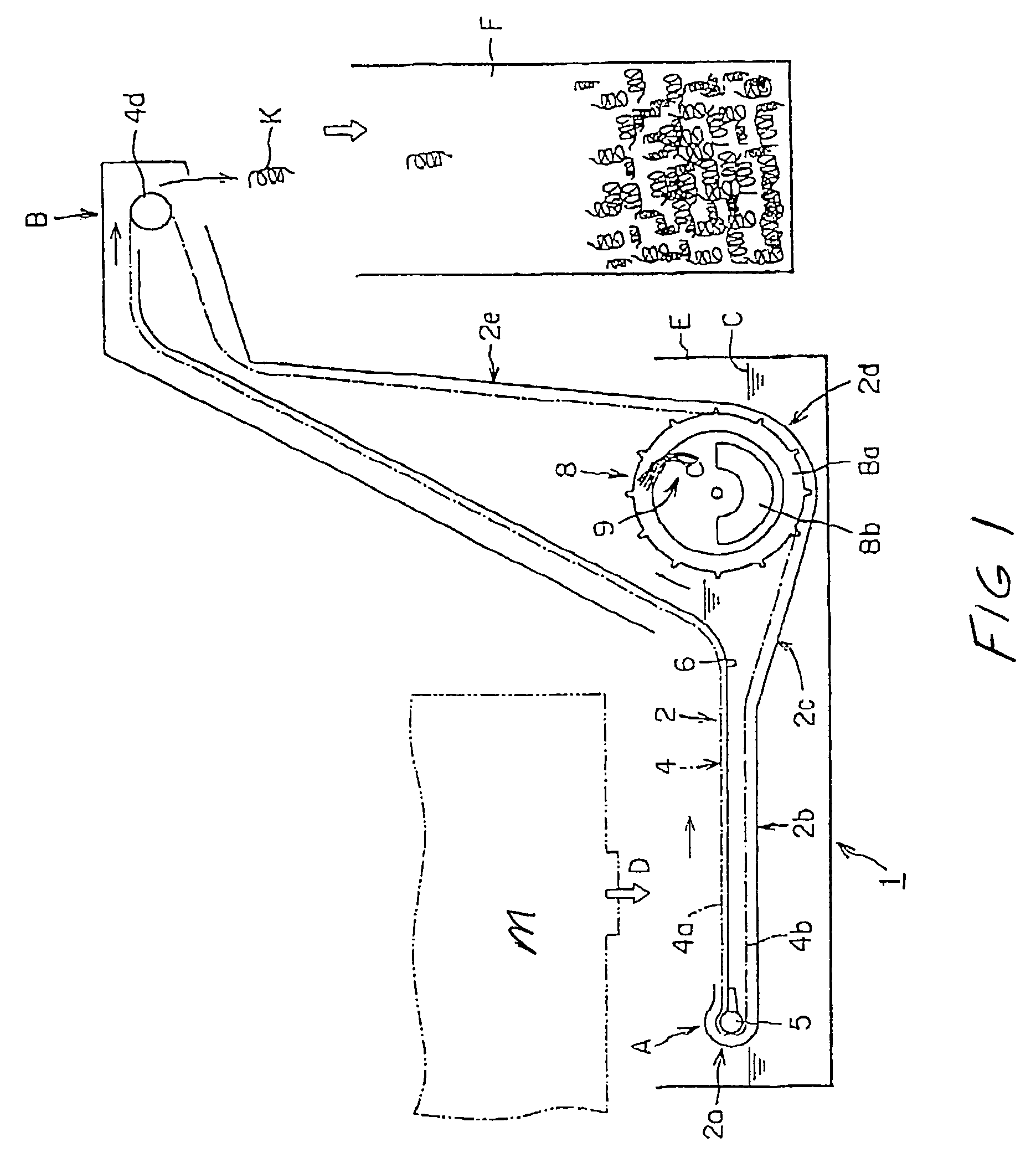

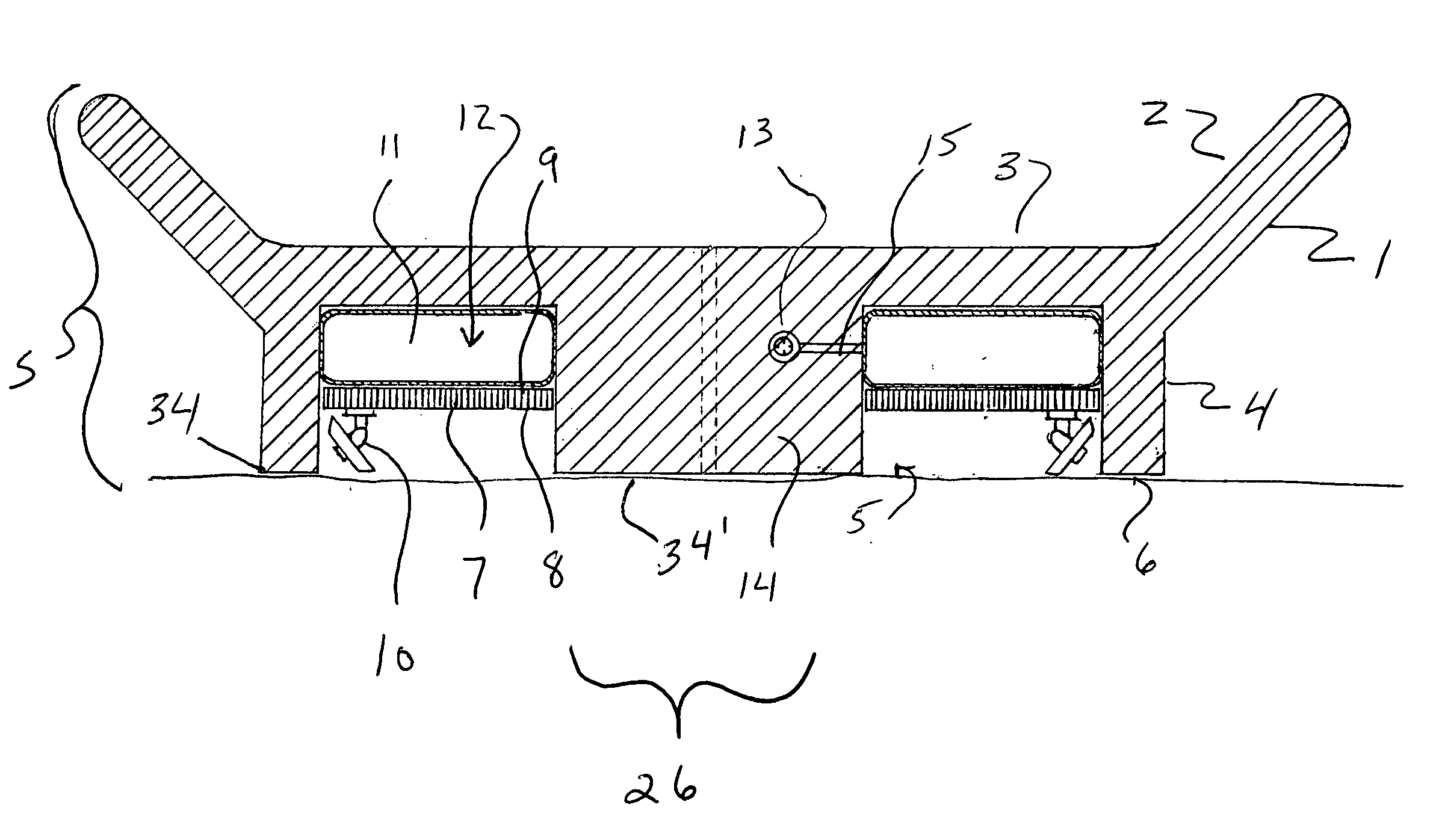

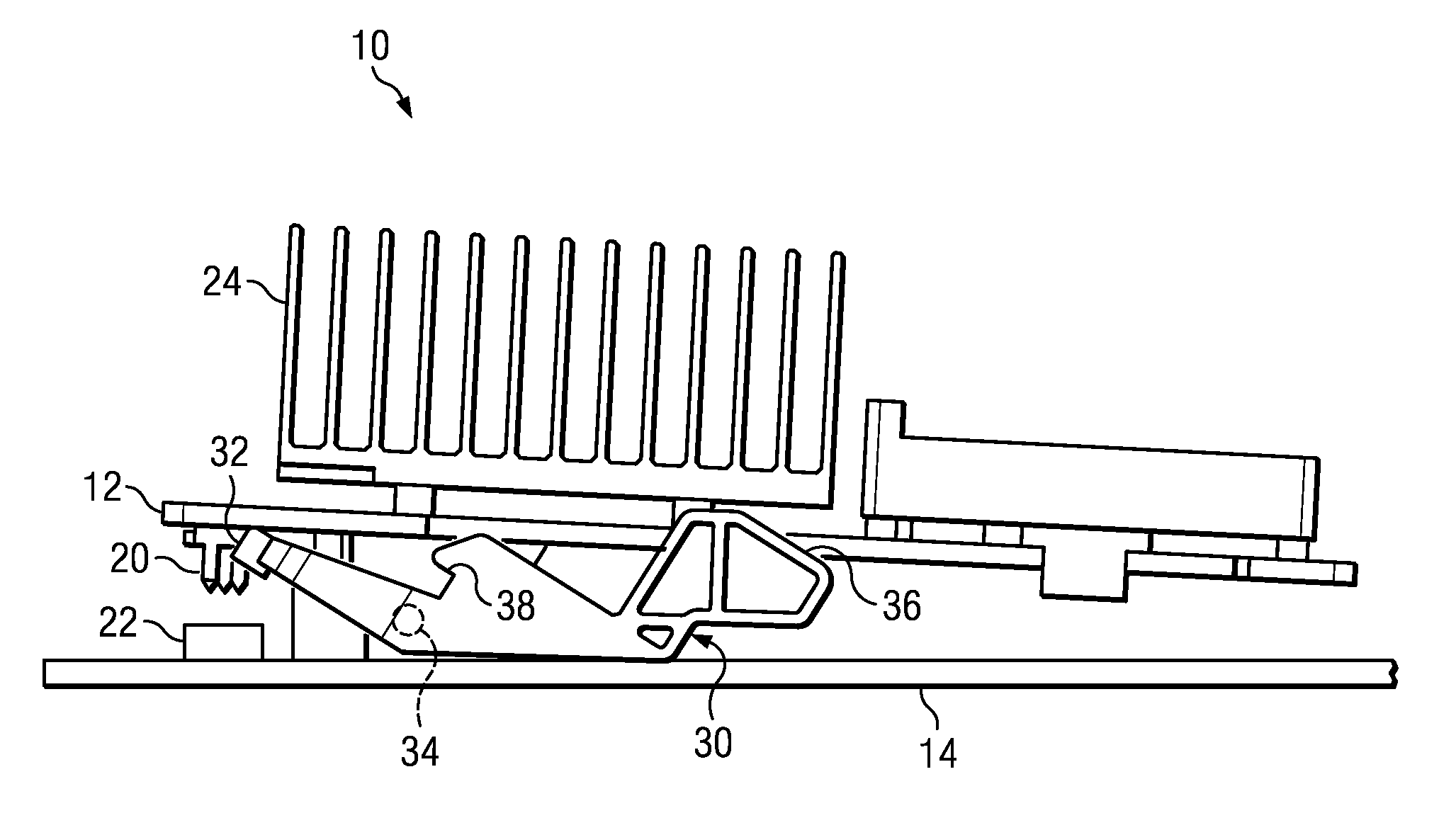

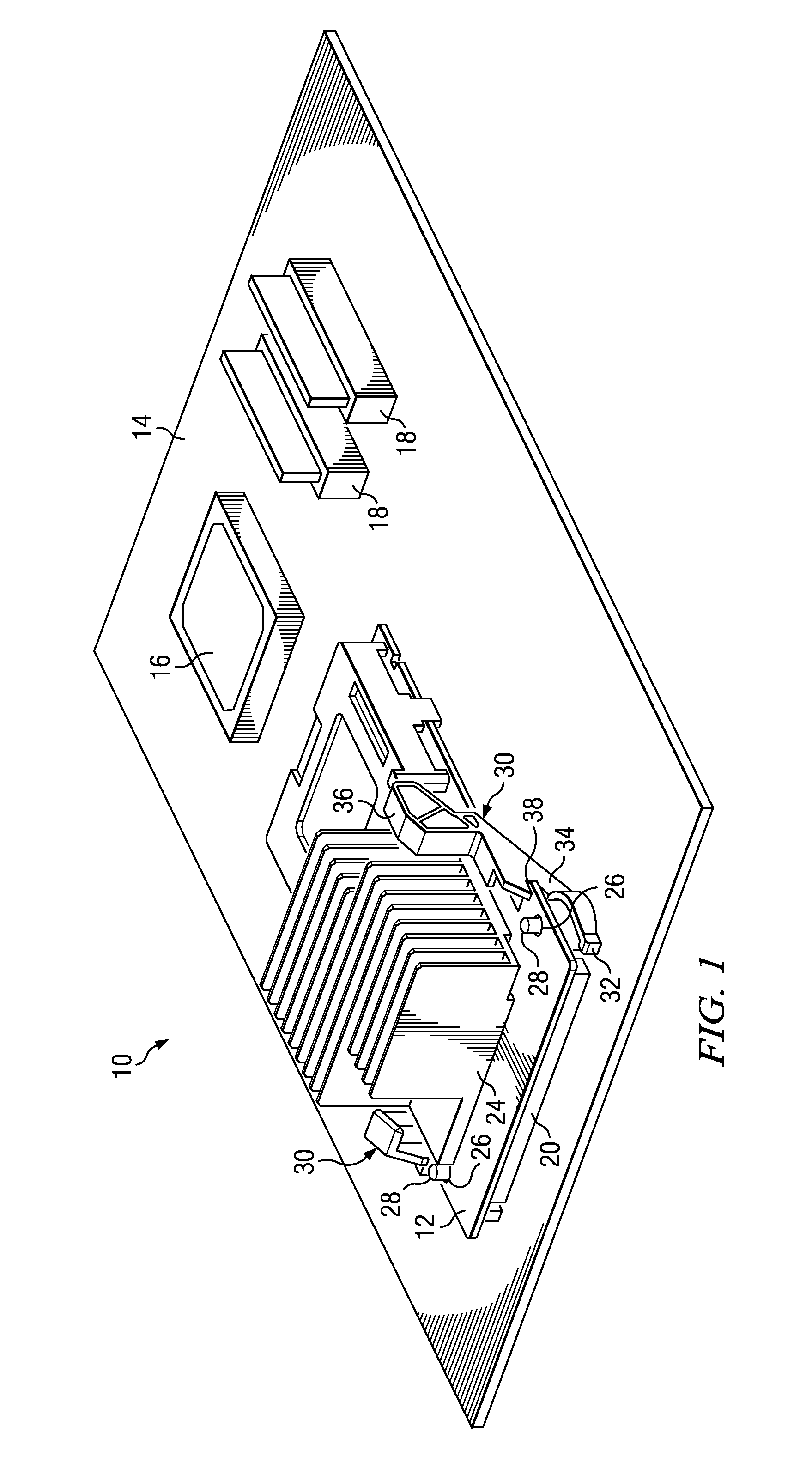

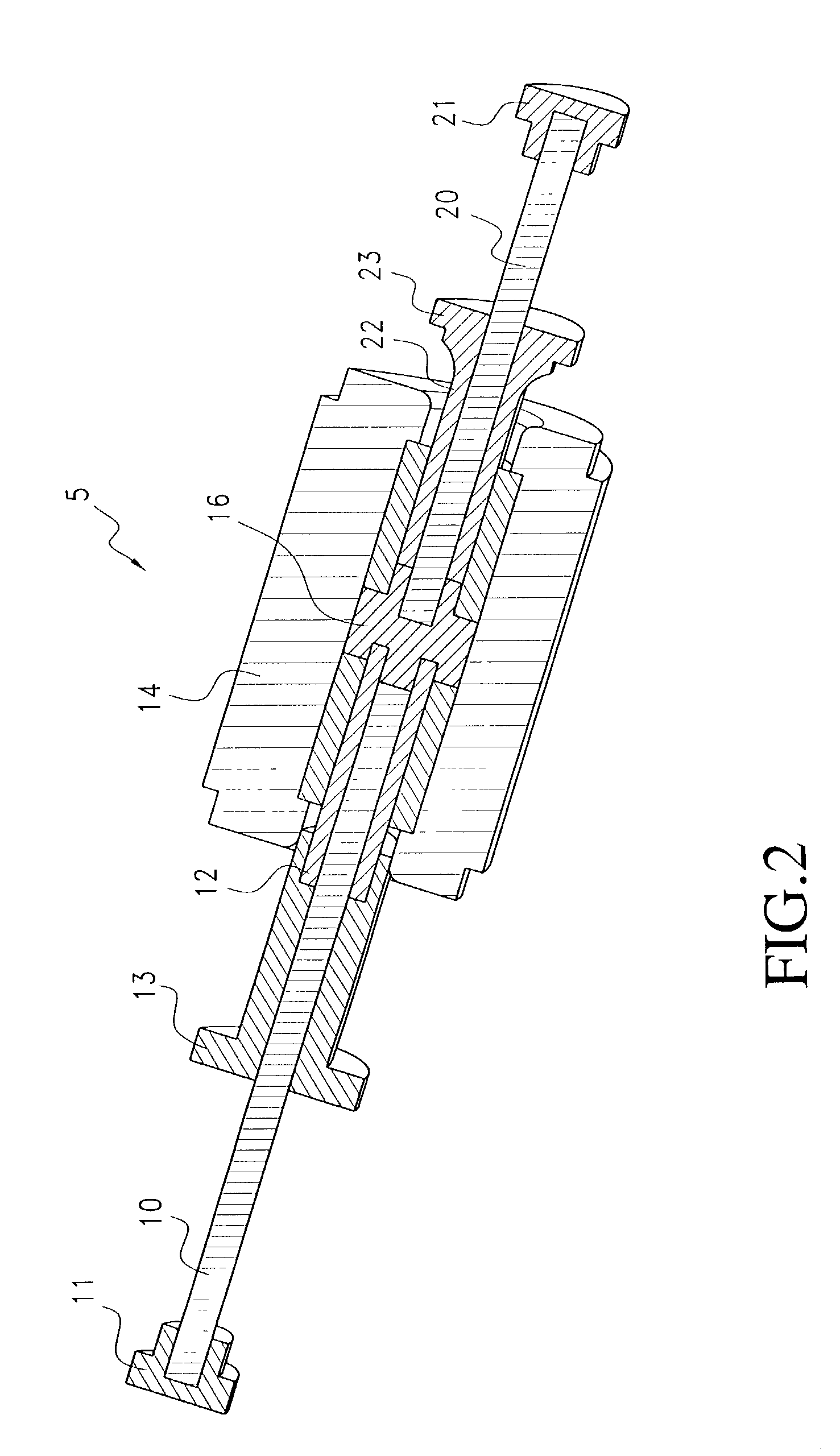

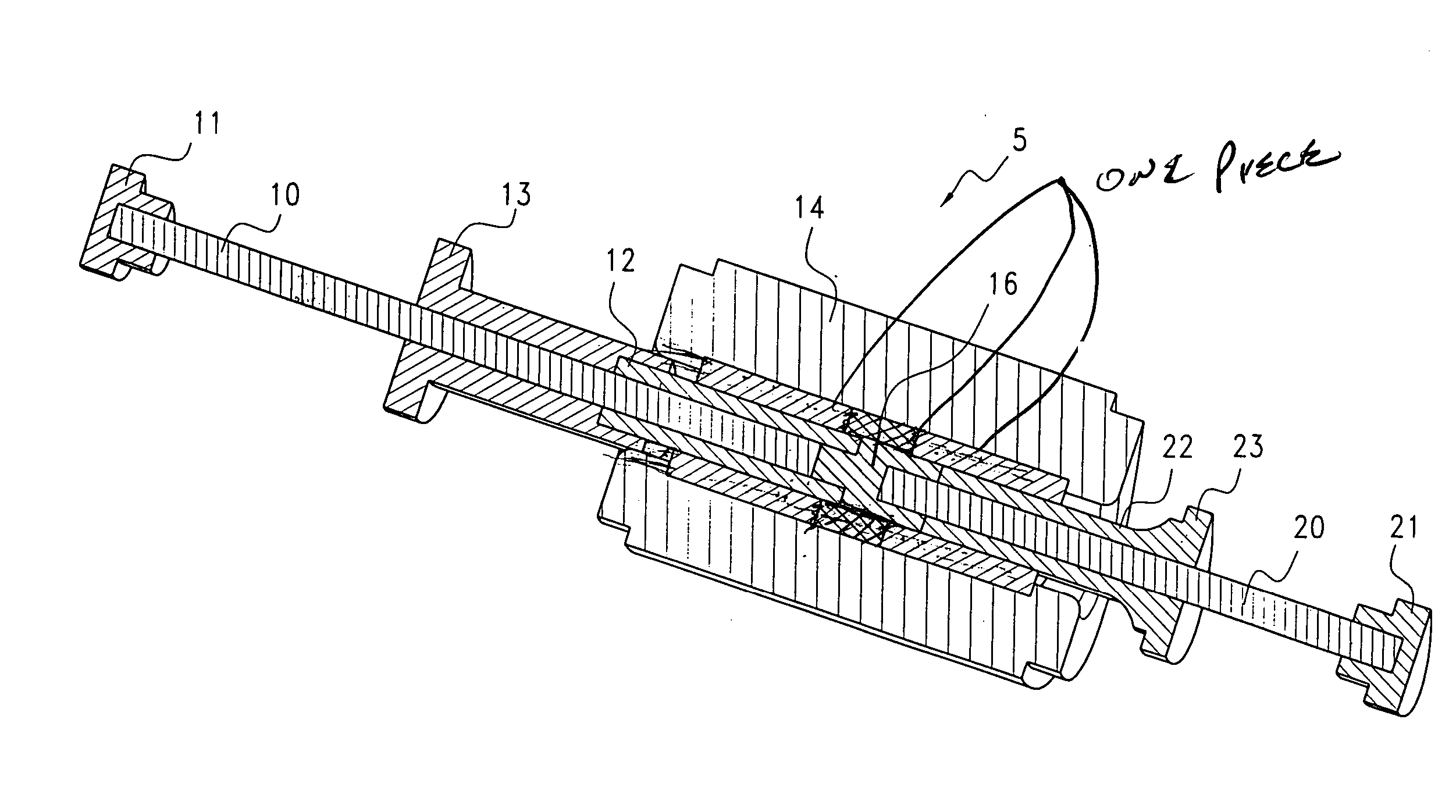

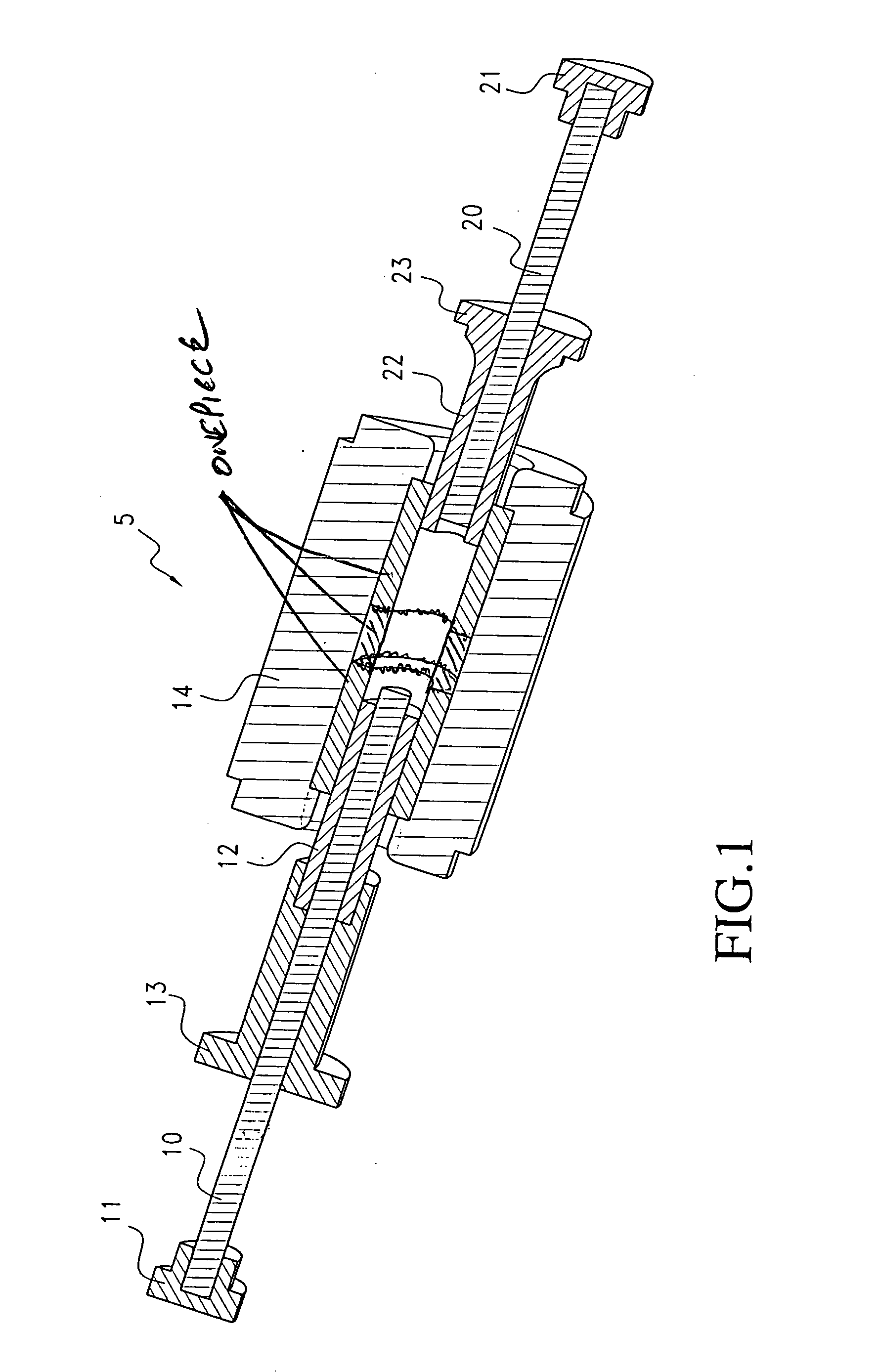

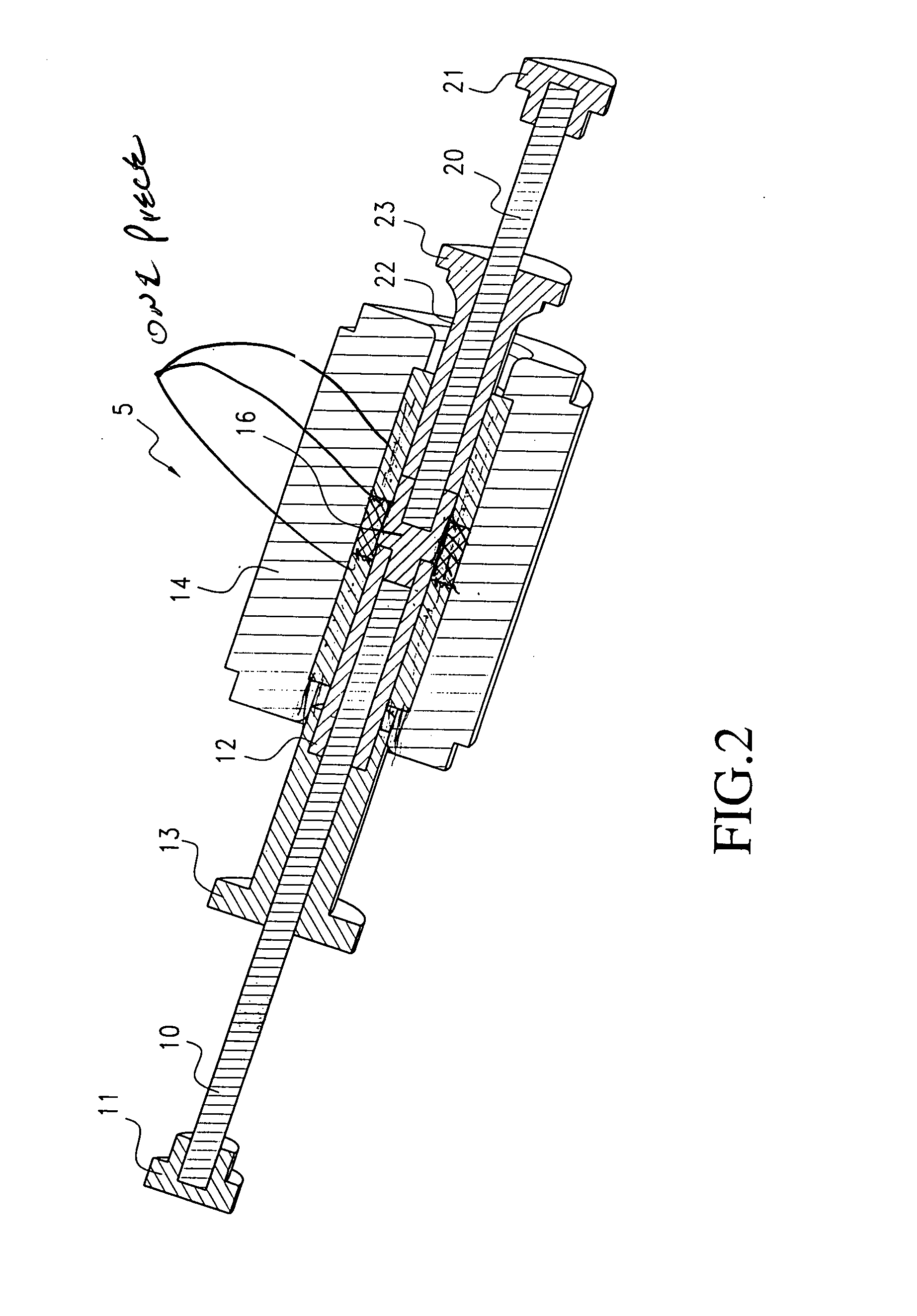

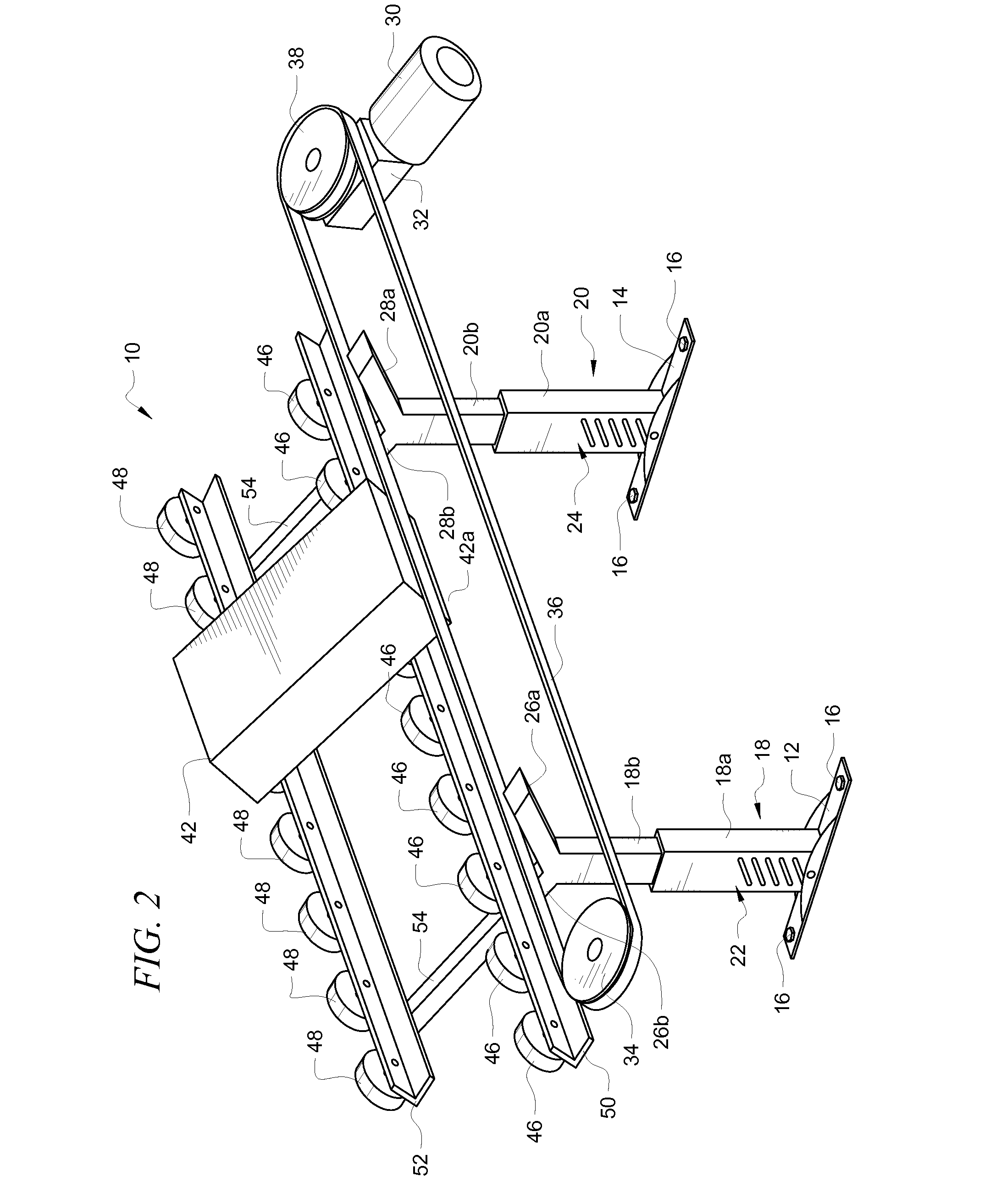

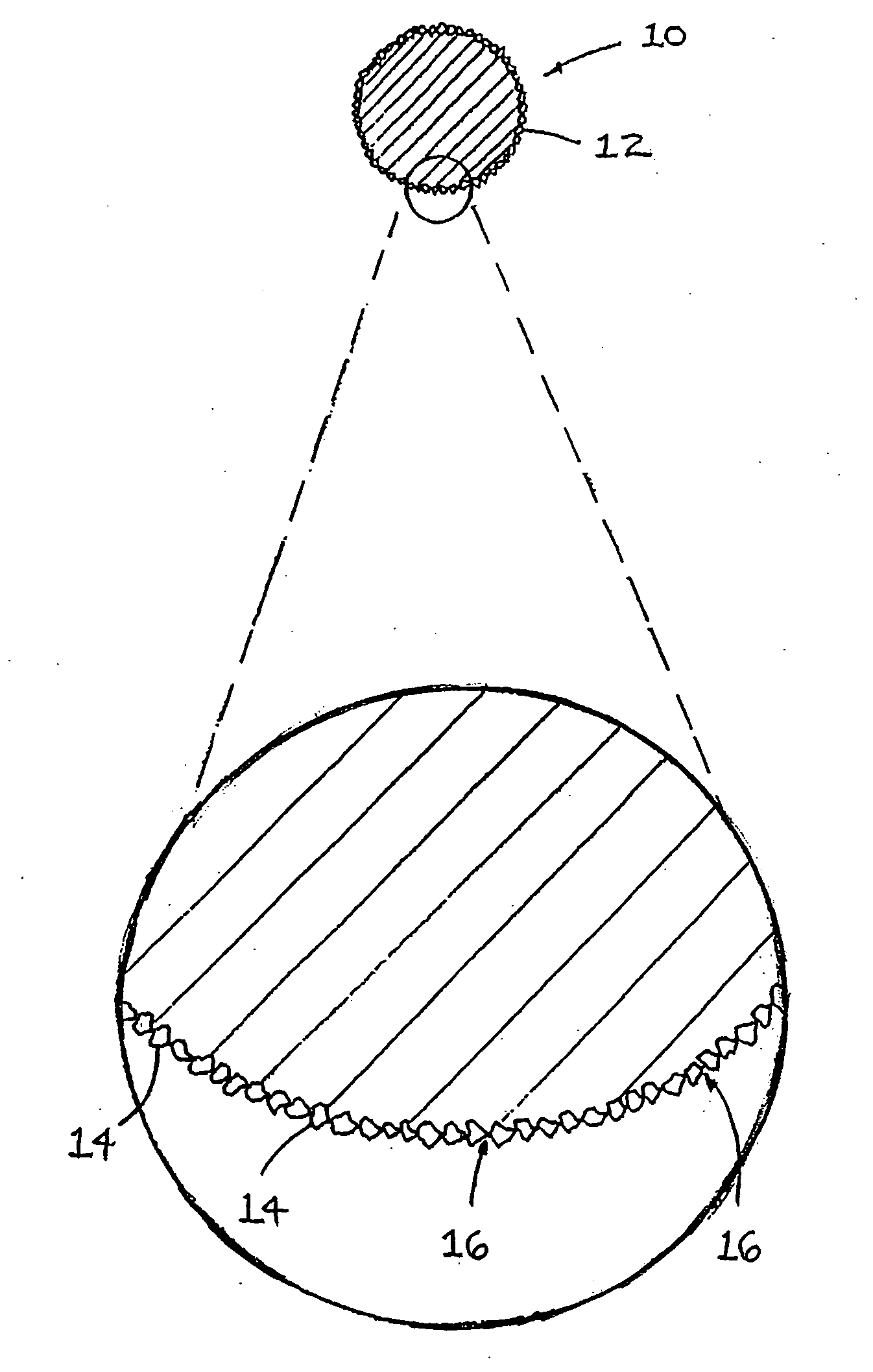

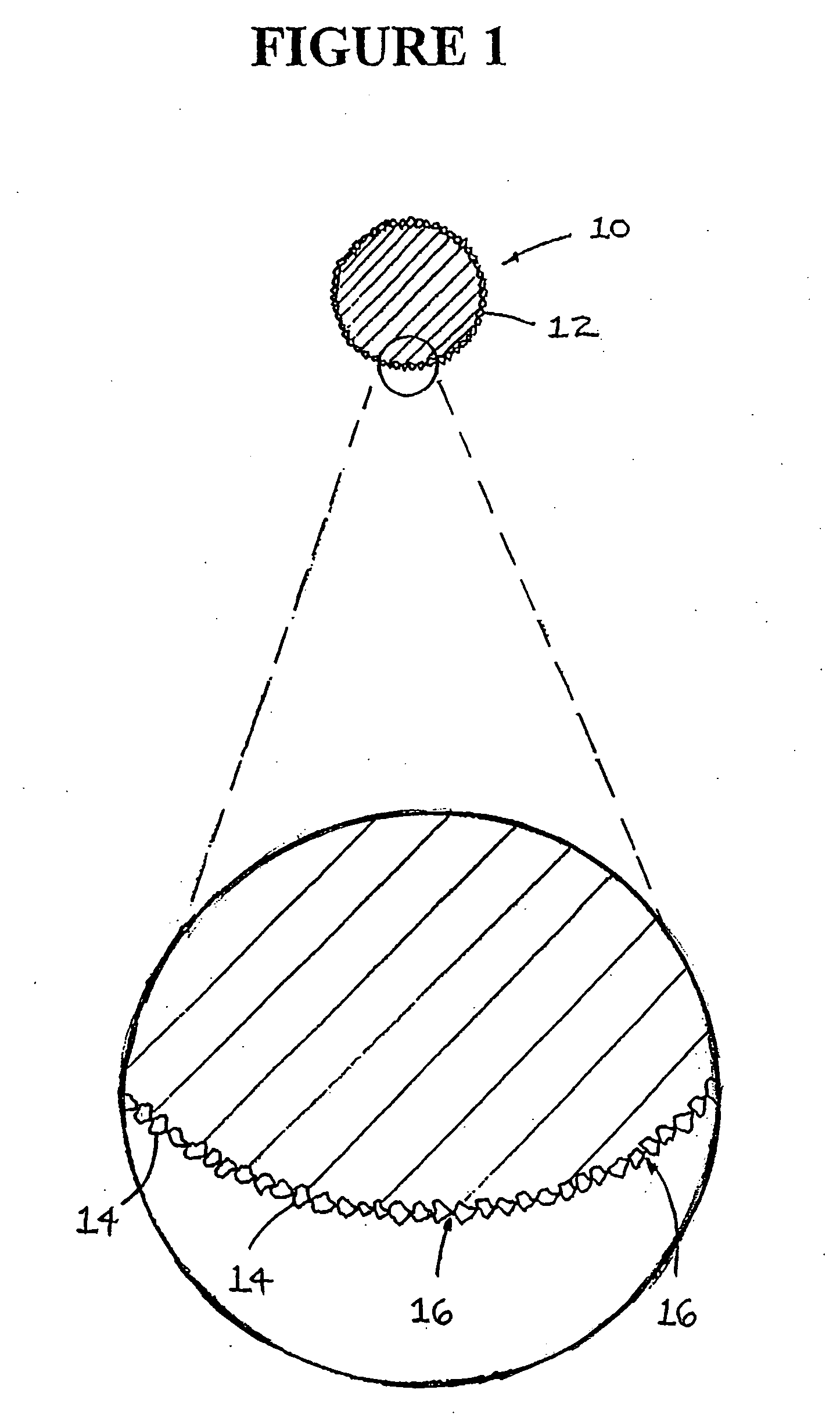

Plural bin metering system

ActiveUS7380733B2Low costLess-expensive to maintainFertiliser distributersCentrifugal wheel fertilisersOne passEngineering

A plural bin metering system for broadcasting material ingredients contained therein over a ground surface. The system includes at least two material ingredient hoppers, each of the hoppers having a material ingredient discharge port. At least one of the material ingredient hoppers includes a variably controllable metering unit associated therewith for variably controlling the discharge of material ingredients therefrom independently from the rate of discharge of material ingredients from the other material ingredient hopper. A conveyor is disposed below the hoppers for receiving material ingredients discharged from the hoppers, and a material ingredient broadcasting device disposed off of one end of the conveyor for receiving material ingredients conveyed thereon, received from the hoppers, for broadcasting the material ingredients over a ground surface. The metering unit is capable of metering material ingredients from its associated hopper at ultra low rates. In a preferred embodiment the system has three hoppers for broadcasting, for example fertilizer across a field in one pass.

Owner:SALFORD BBI

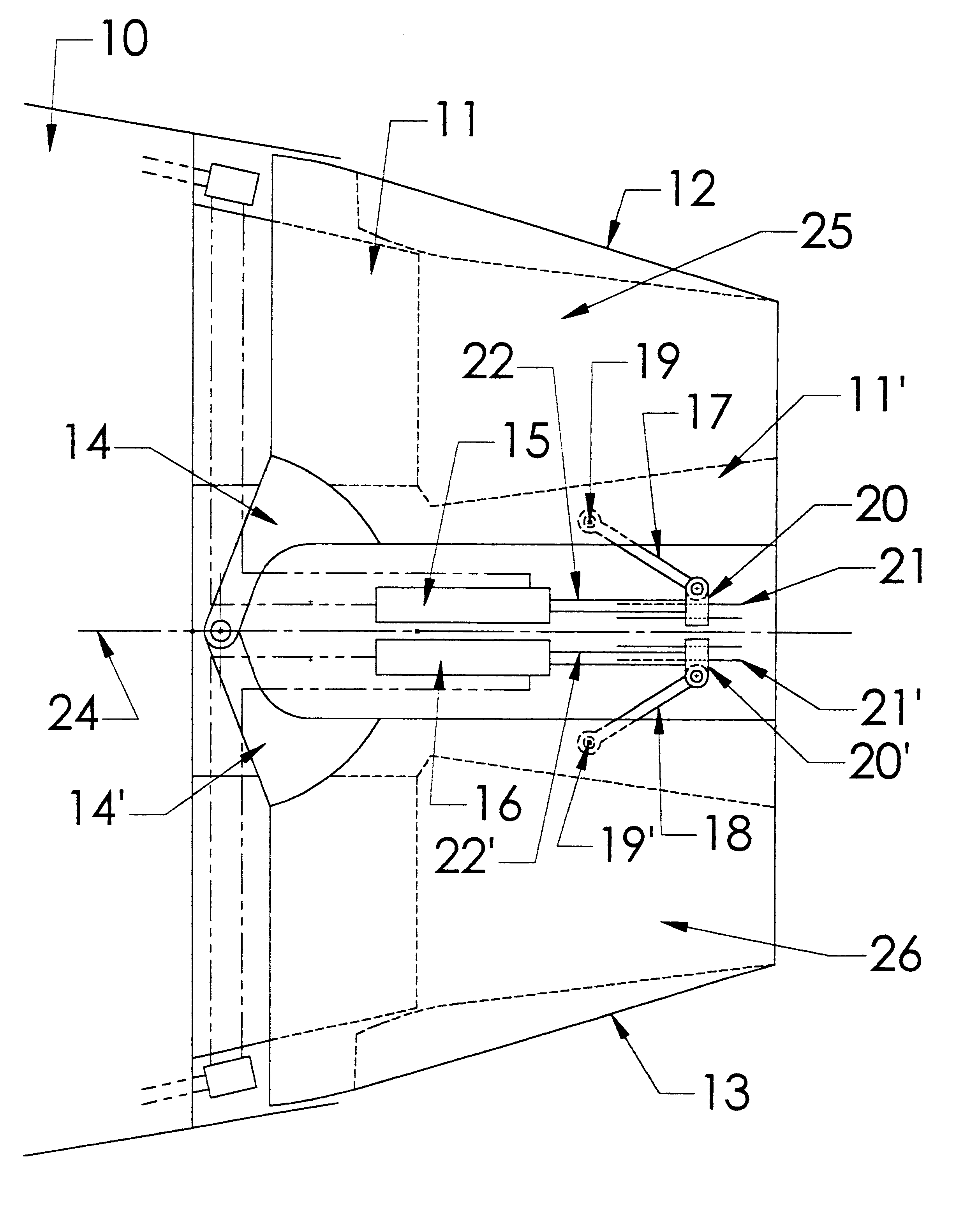

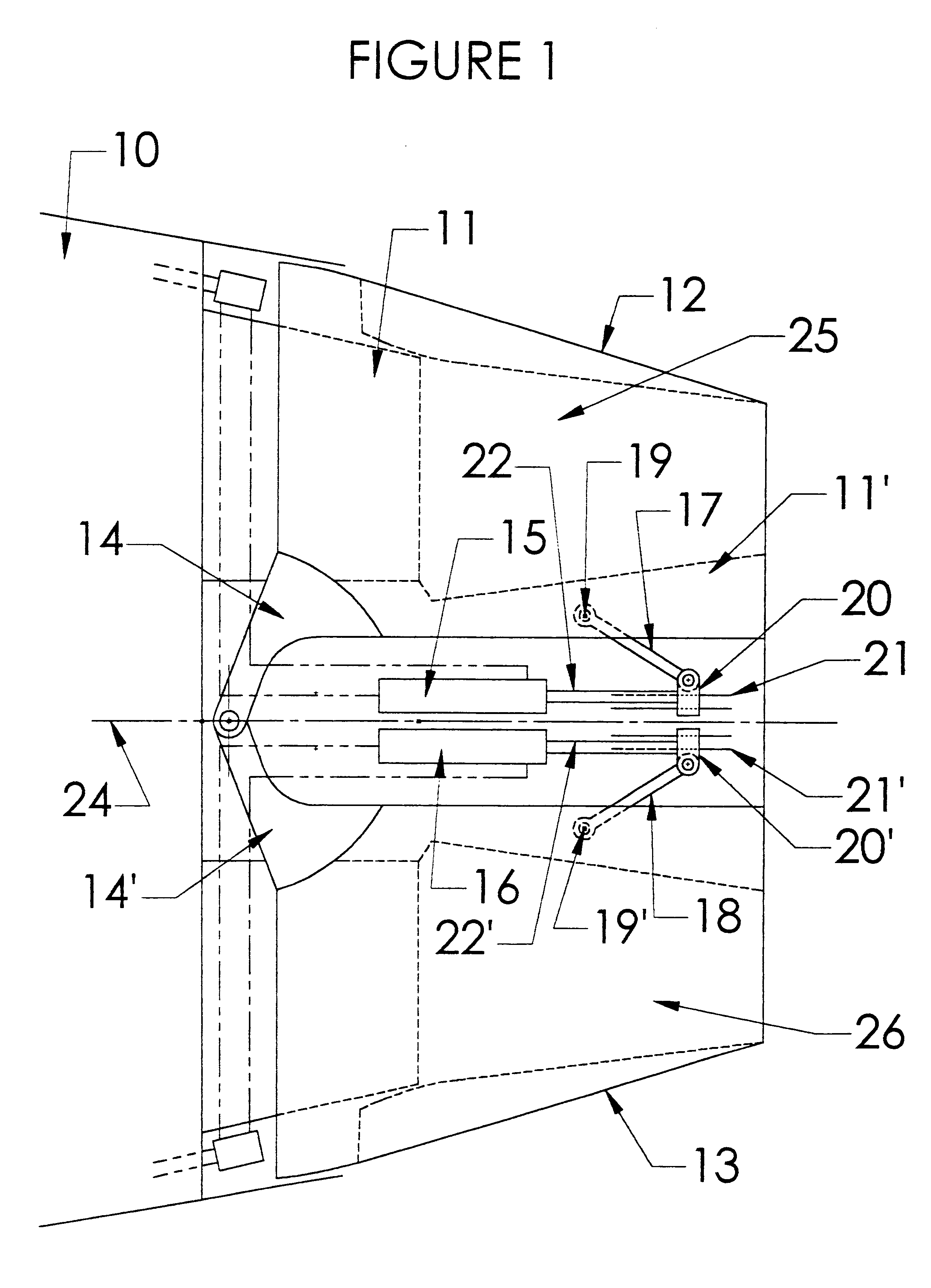

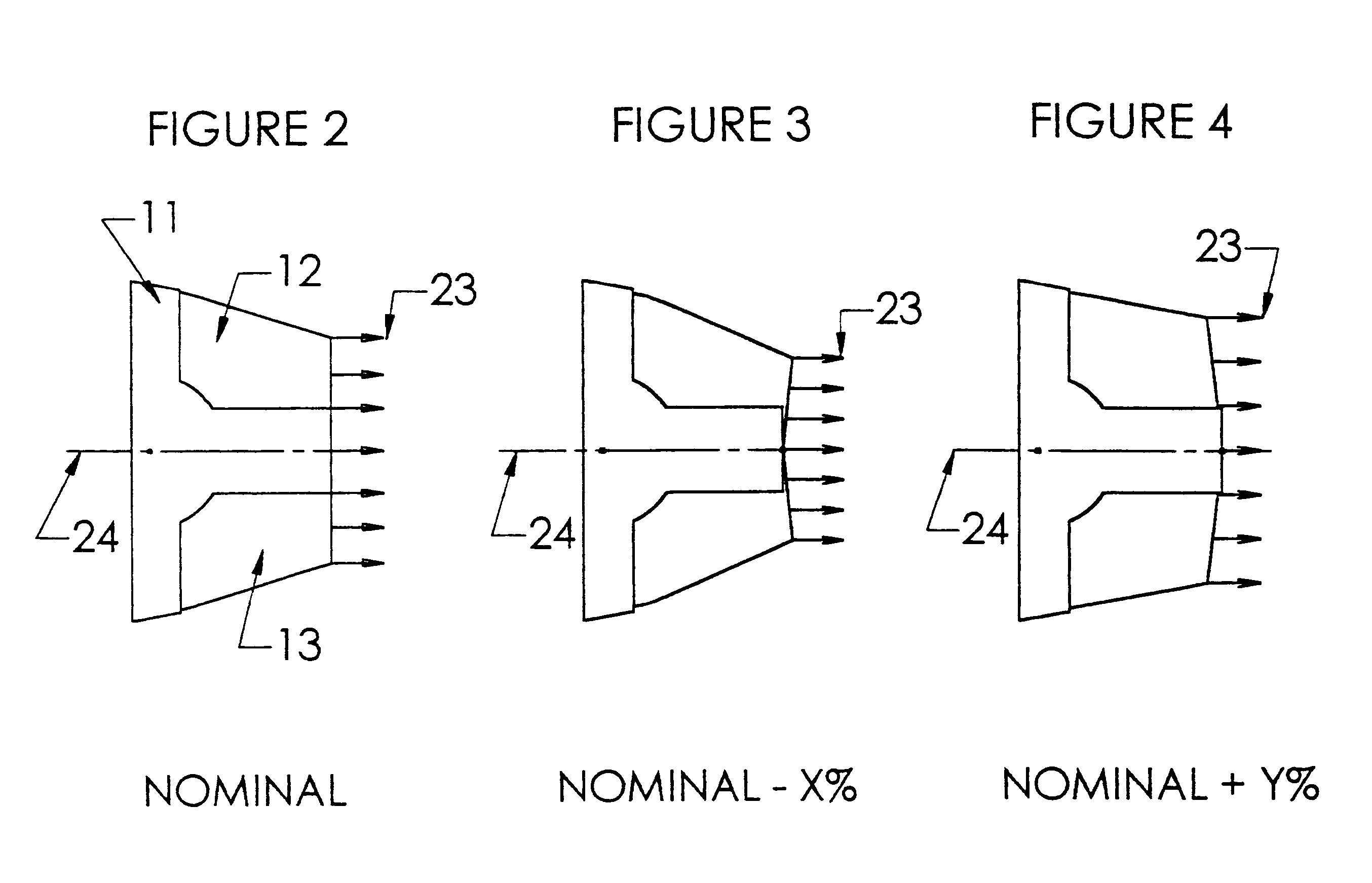

Jet engine nozzle with variable thrust vectoring and exhaust area

InactiveUS6546716B2Variable exhaust areaLess-expensiveAircraft navigation controlSpraying apparatusNacelleJet engine

Owner:PROPULSION VECTORING

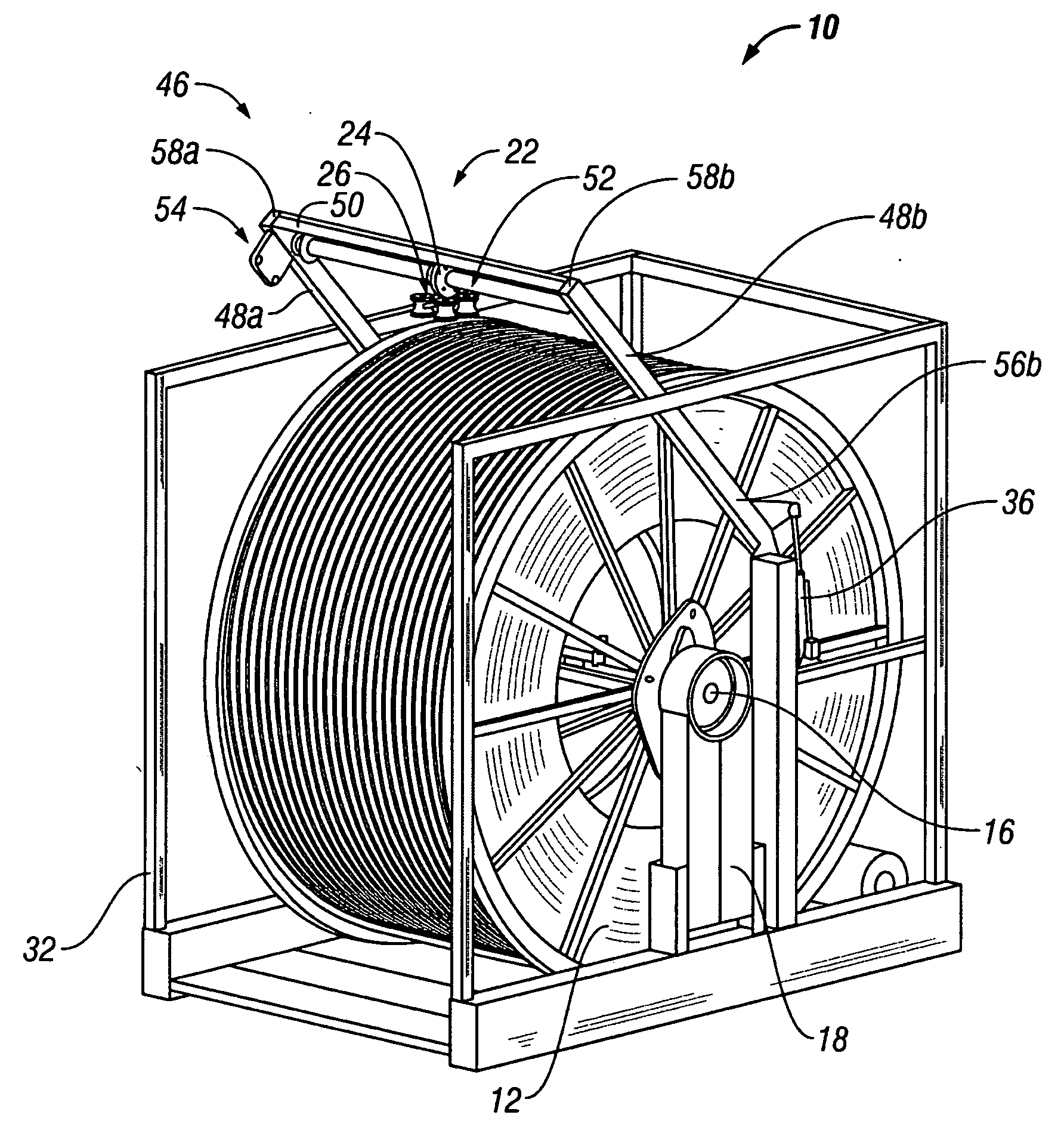

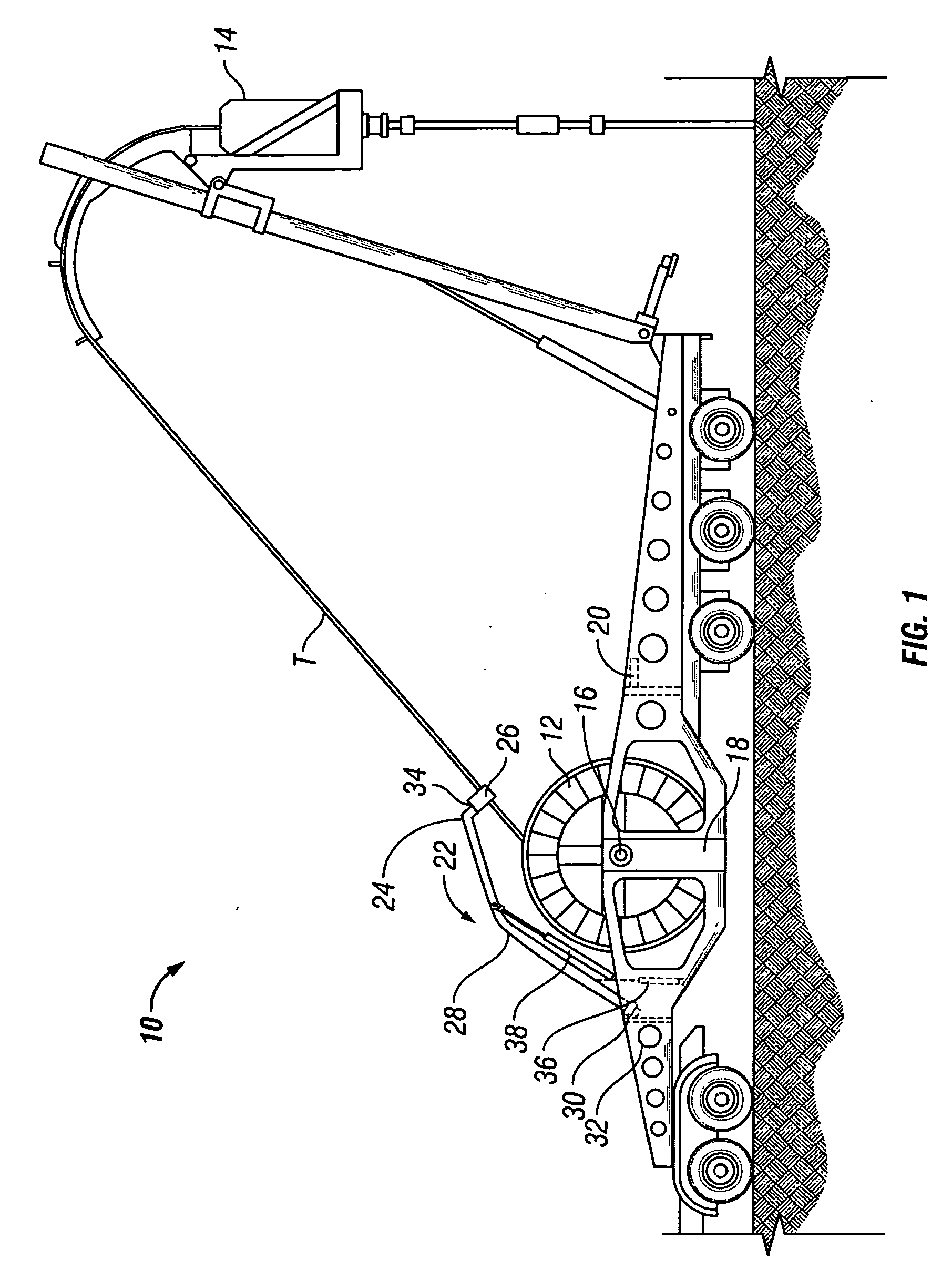

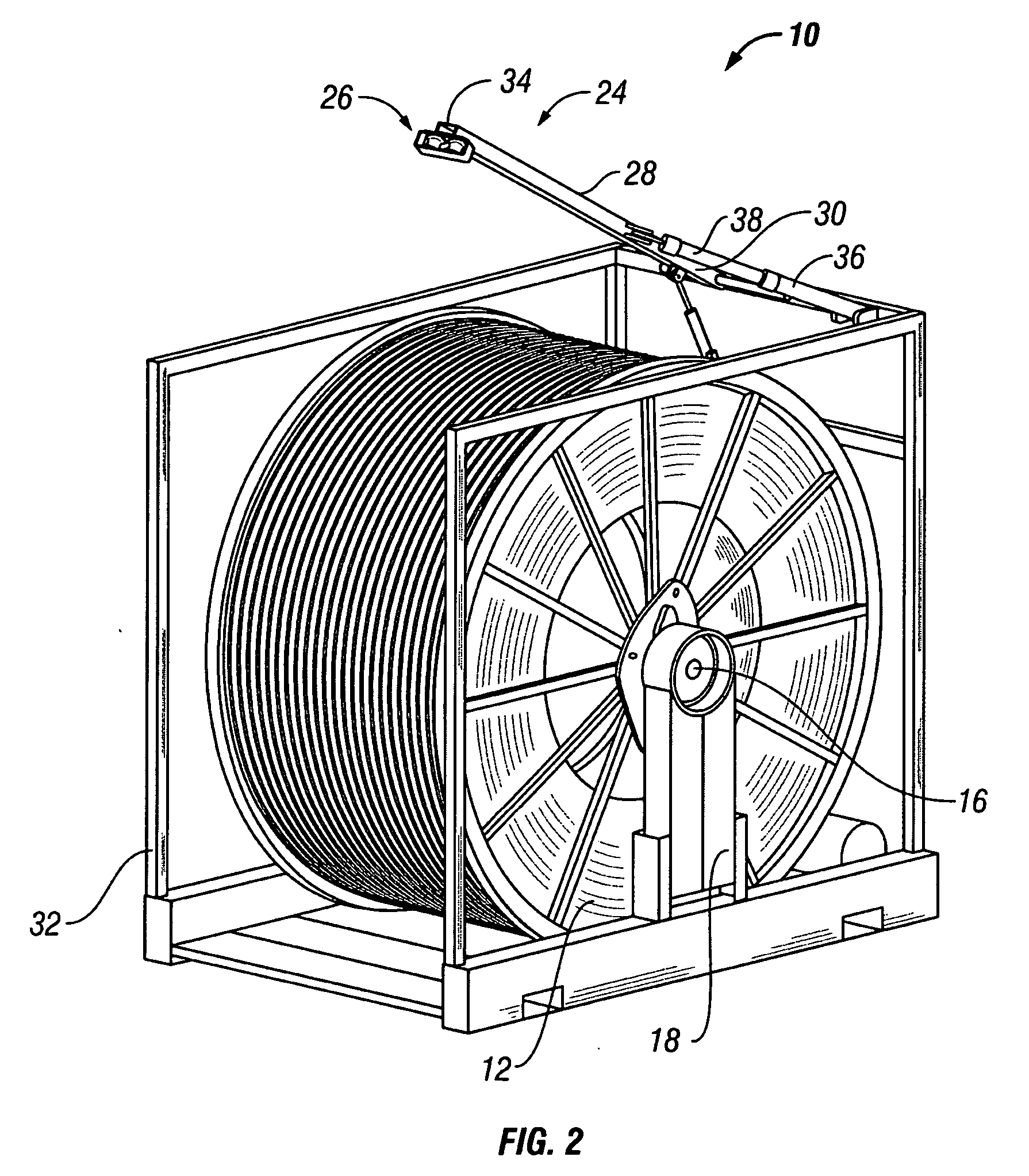

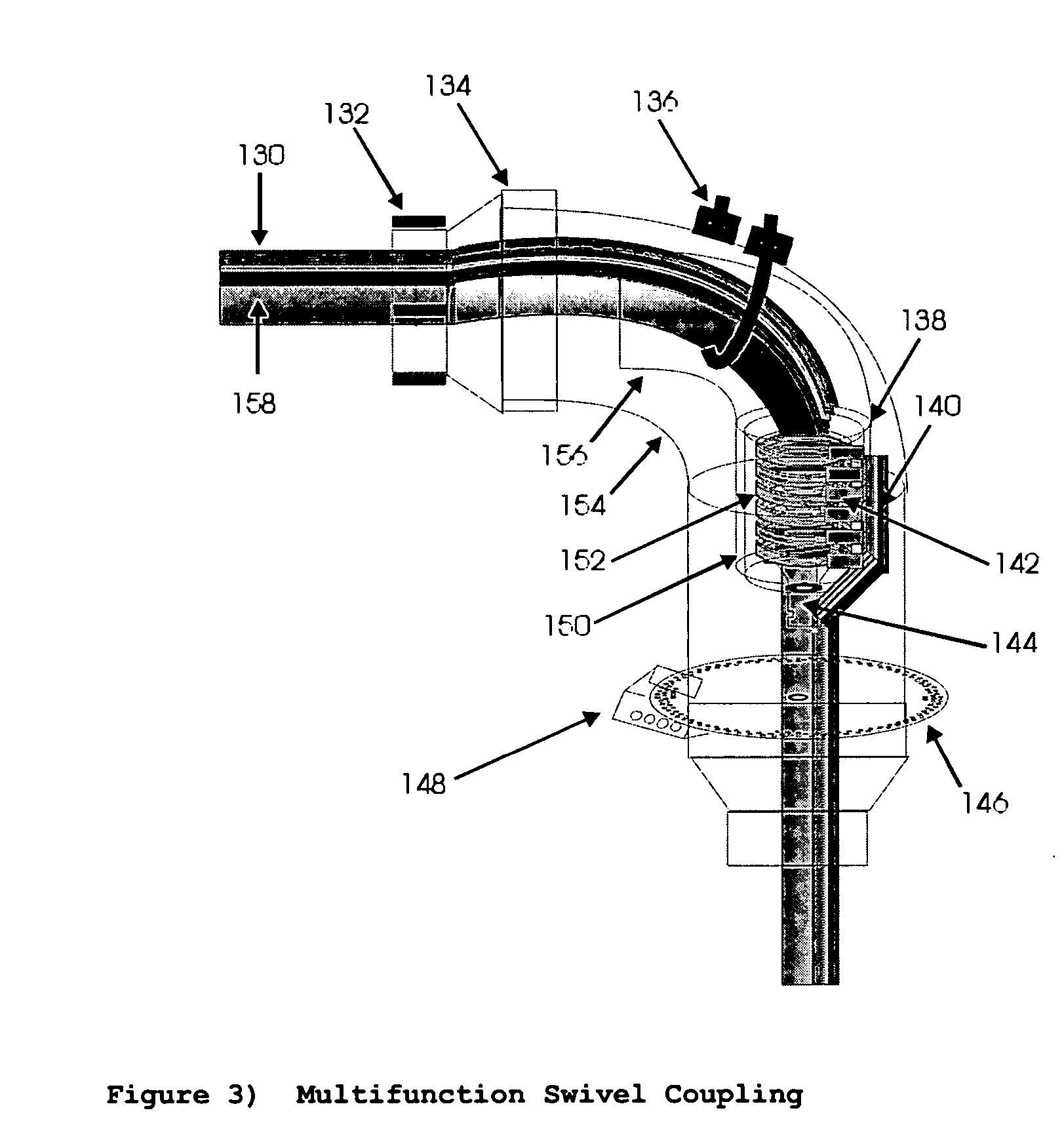

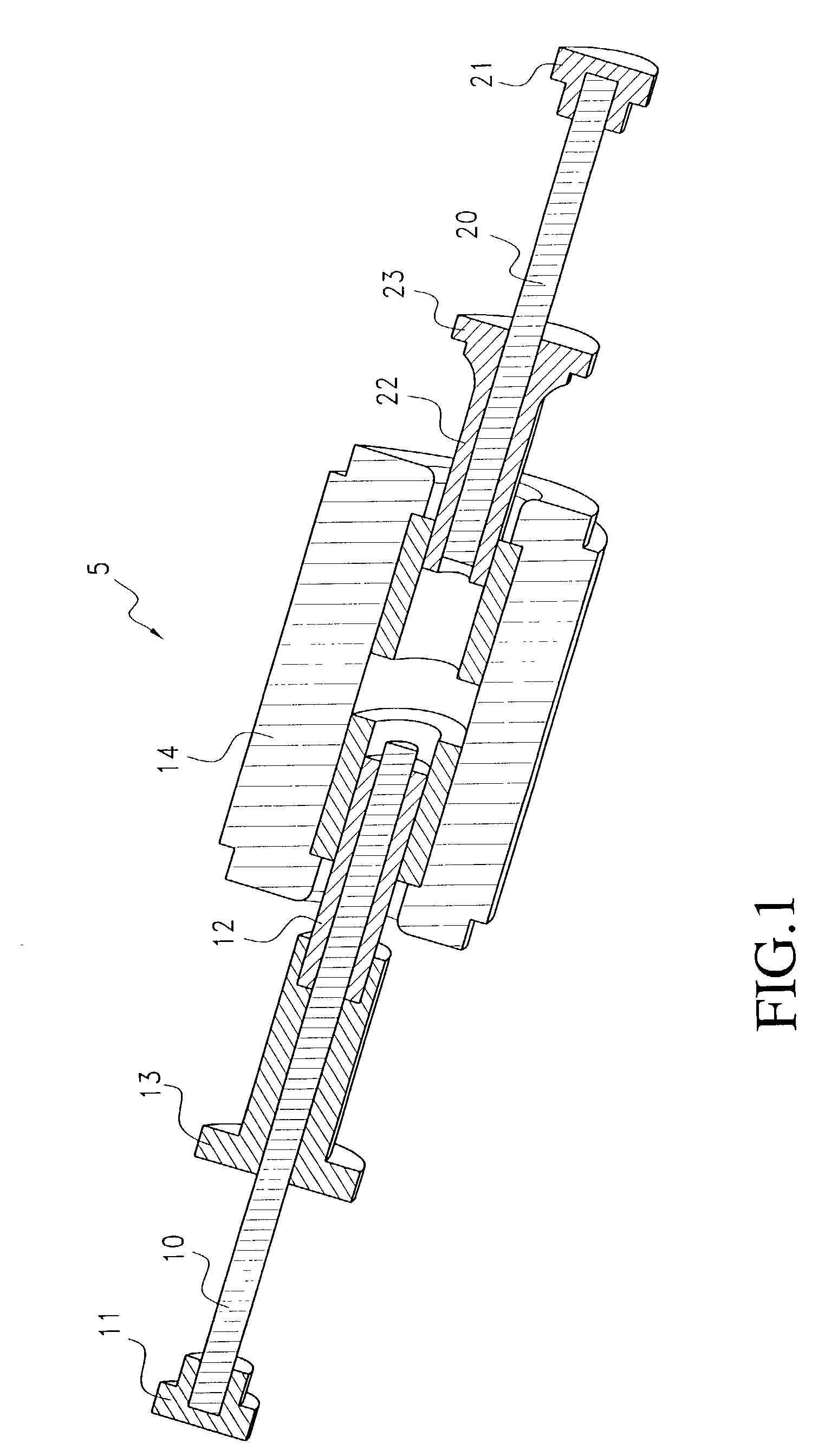

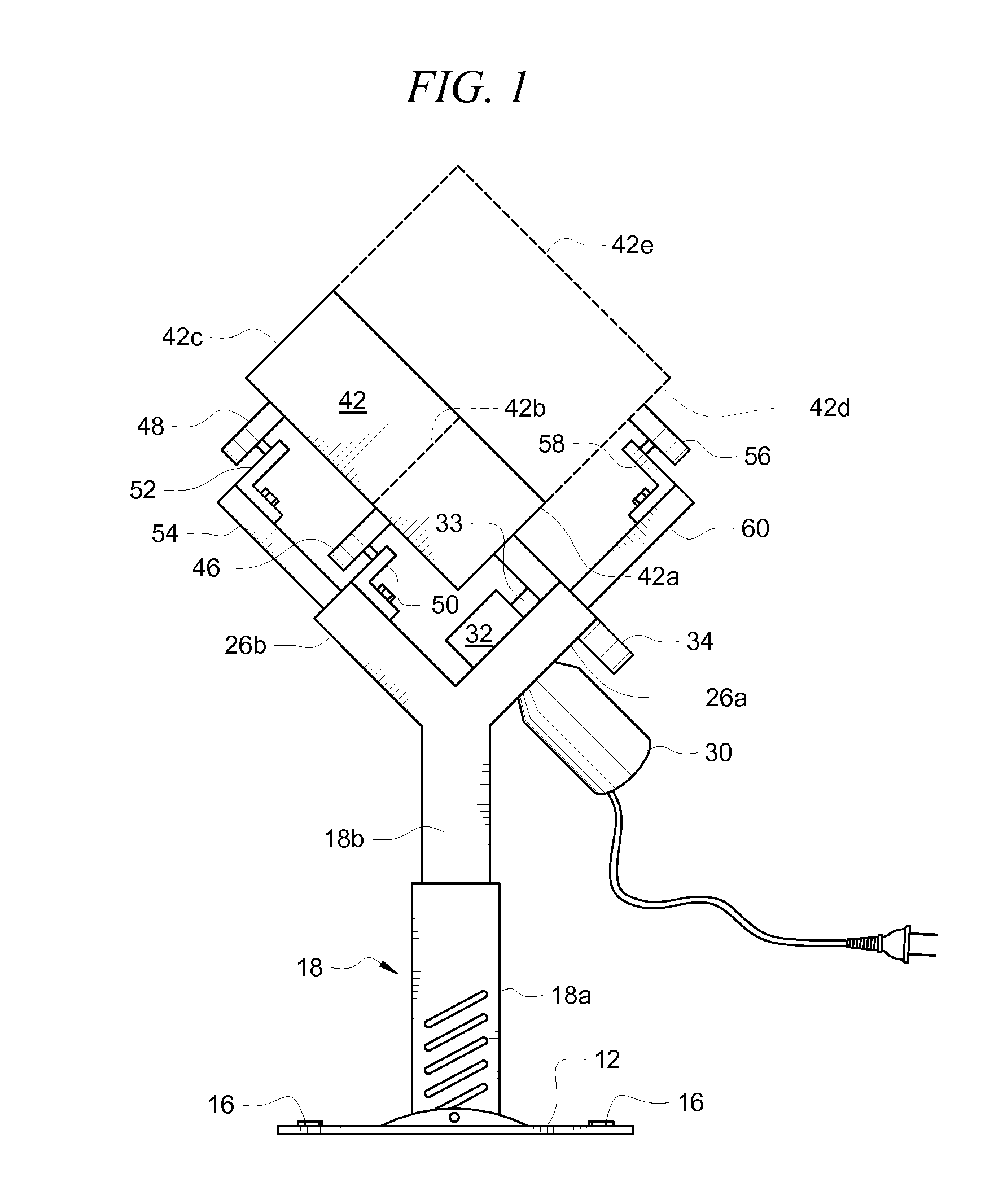

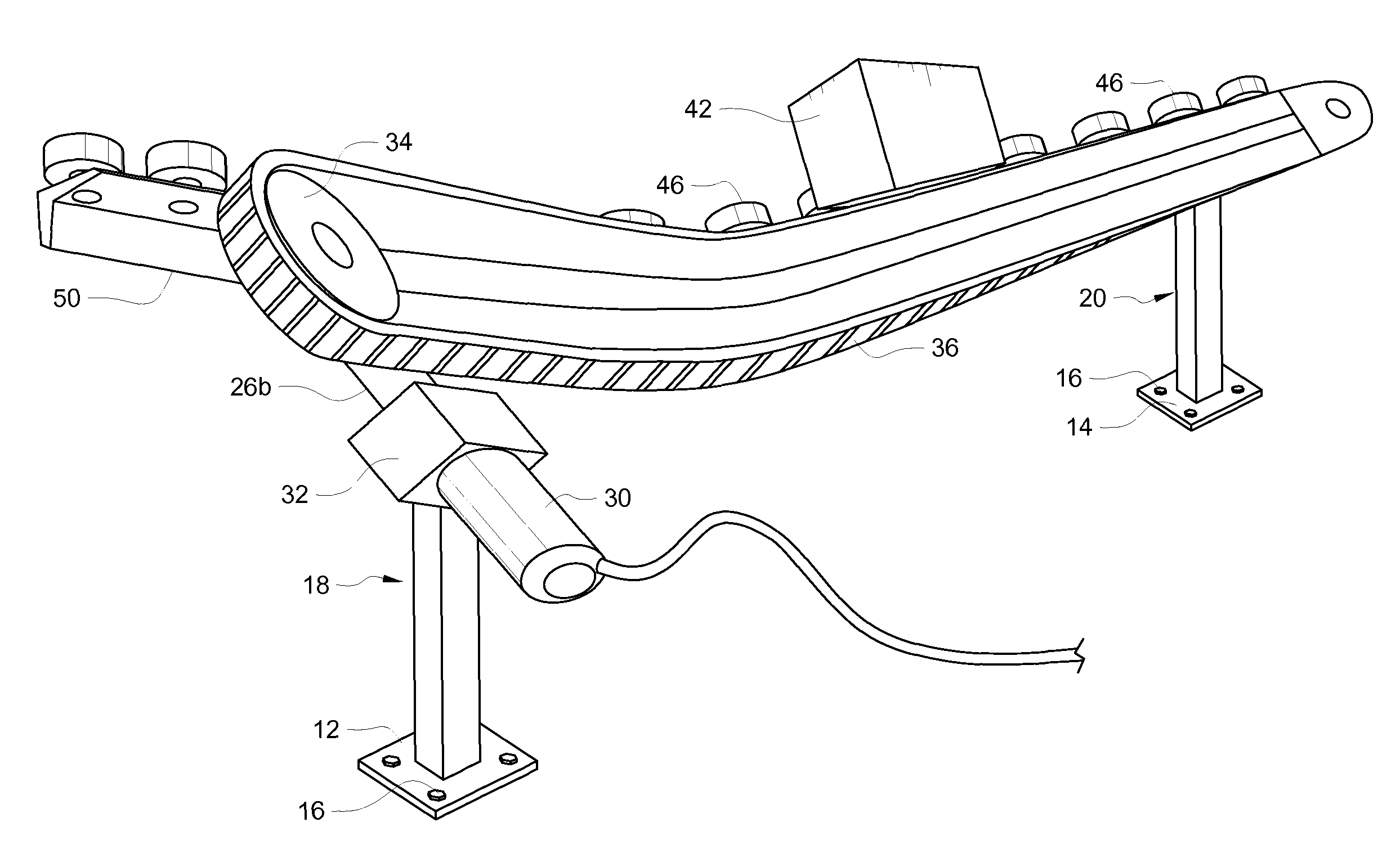

Level-wind system for coiled tubing

InactiveUS20060273213A1Less-expensive to manufactureLess-expensive to maintainDrilling rodsFilament handlingWind systemHorizontal axis

A level-wind head and system for coiled tubing the head adapted for passing coiled tubing of various outside diameters without repositioning or replacing the rollers. A system of an embodiment of the present invention includes a coiled tubing reel mounted for rotation about a horizontal axis, a level-wind head comprising only one pair rollers mounted in spaced relation to one another to form a throat sized to pass various outside diameter coiled tubing, without replacement or repositioning of the pair of rollers, to or from the reel, and a positioning system in connection with the level-wind head for selectively positioning the level-wind head proximate the reel.

Owner:SCHLUMBERGER TECH CORP

Freezer arrangement

ActiveUS7178356B1Less-expensive to buildLess-expensive to operateLighting and heating apparatusFood preservationEngineeringRefrigeration

A freezer arrangement includes a room having a storage area and a blast cell, with the volume of the storage area being greater than the volume of the blast cell. Frozen food product is positioned in the storage area. A refrigeration unit draws air from the storage area and through the blast cell to rapidly freeze the unfrozen food product. Air from the blast cell is chilled and blown back into the storage area. A method for rapidly freezing unfrozen food product includes providing a room with a large storage area and a smaller blast cell. Unfrozen food product is loaded into the blast cell and a refrigeration unit is operated to draw air from the large storage area, through the blast cell, chill the air, and exhaust the chilled air into the storage area, until the food product in the blast cell is cooled to a predetermined temperature.

Owner:LINGELBACH FREDRIC JOHN +1

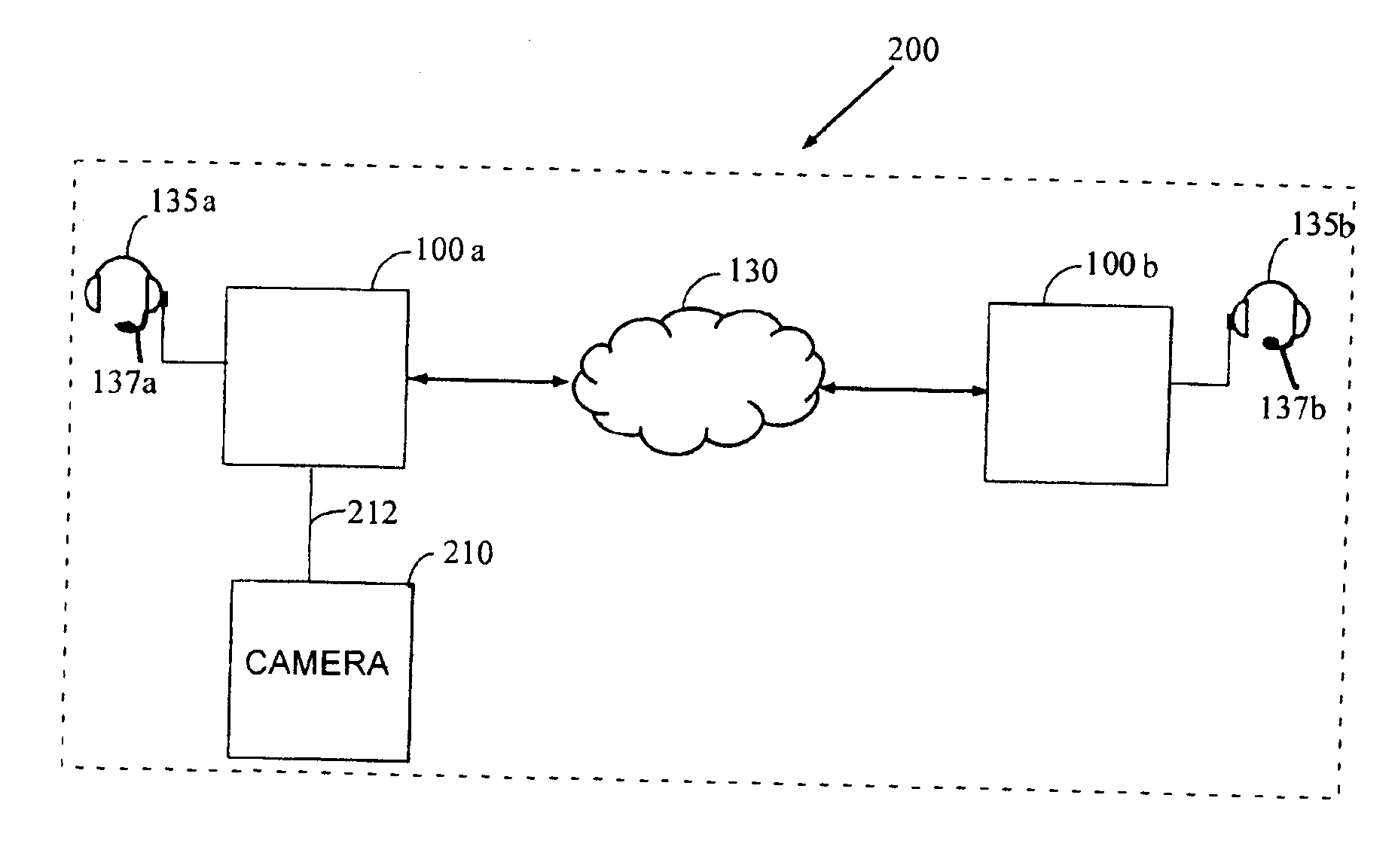

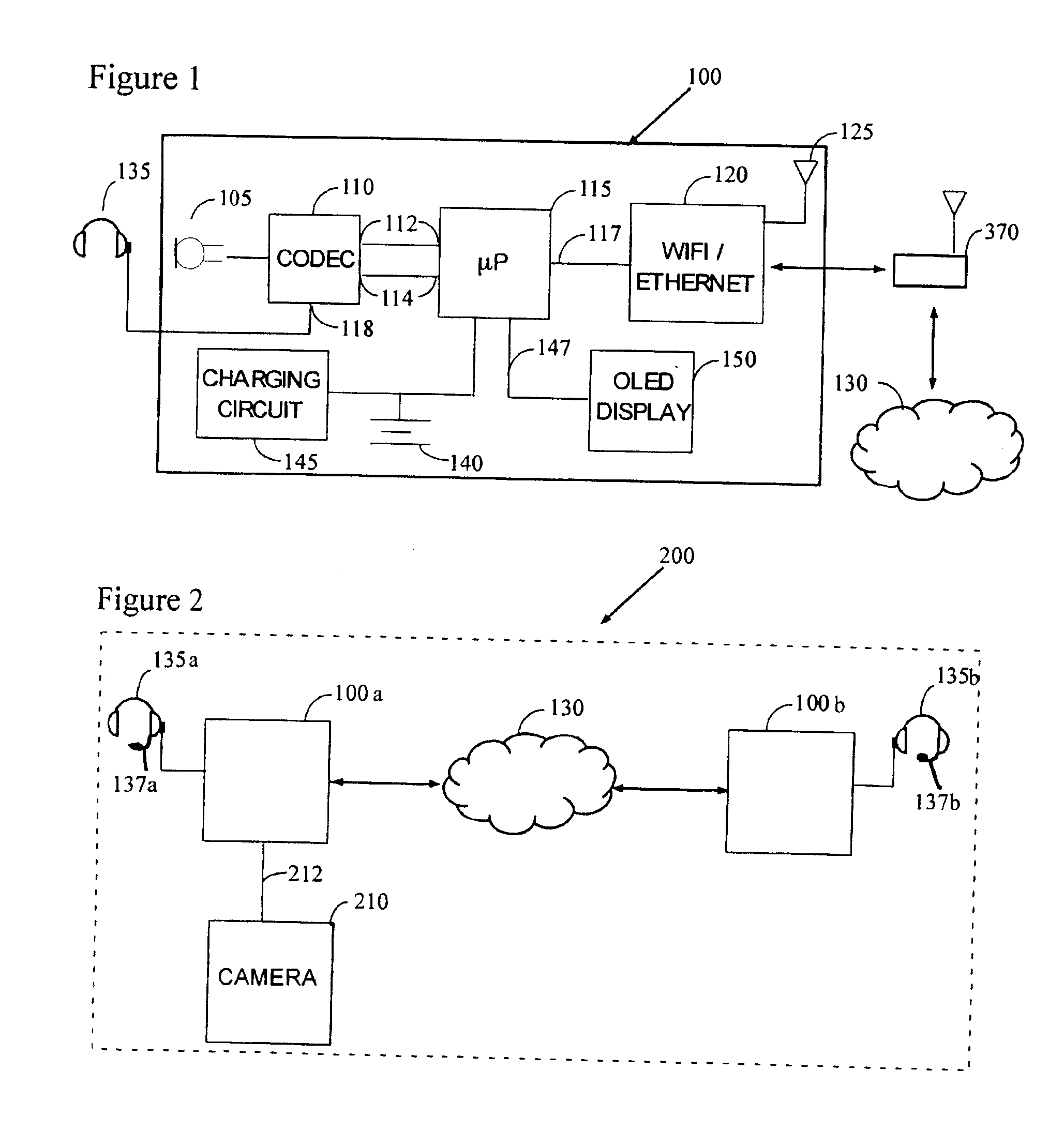

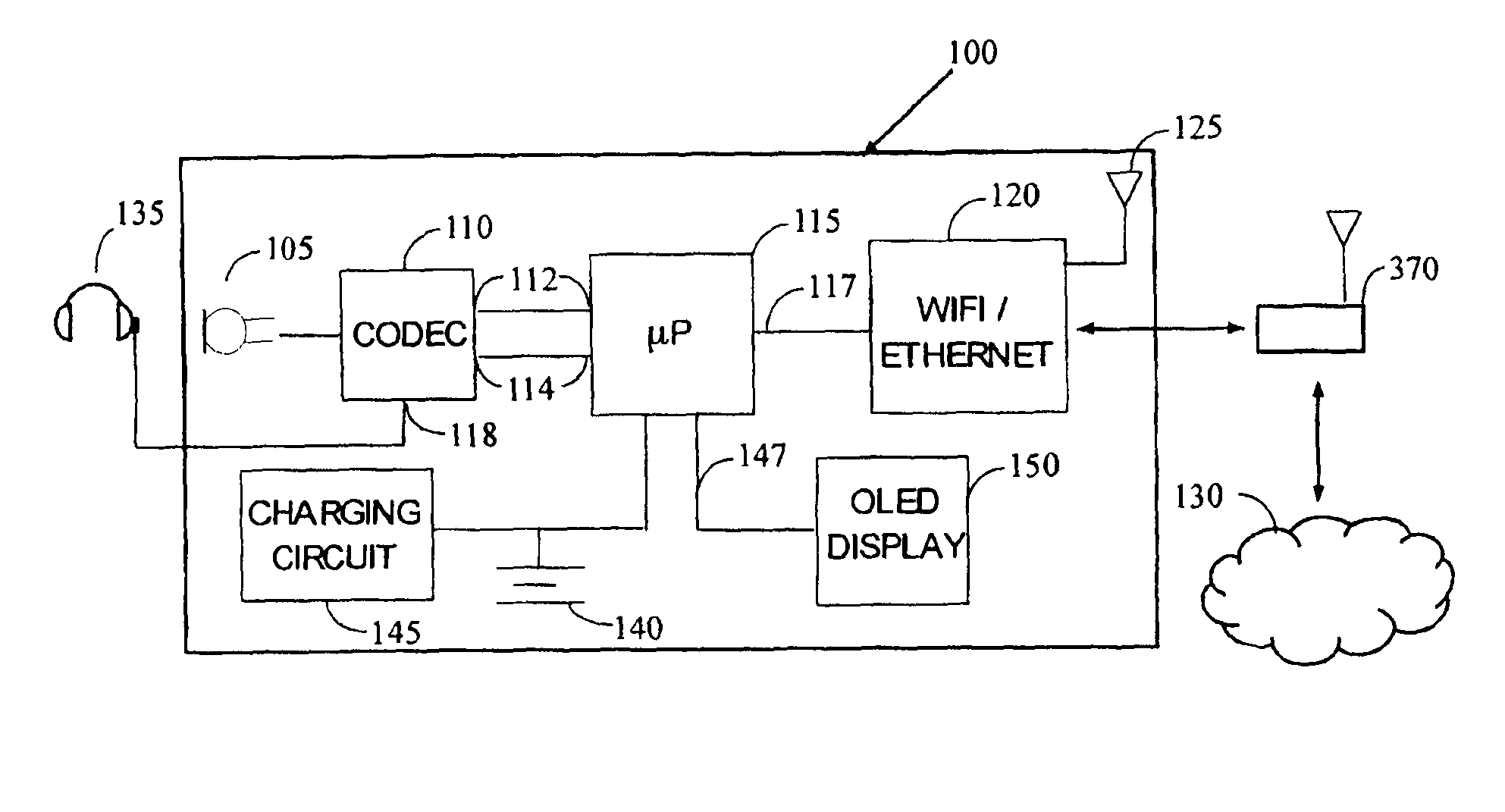

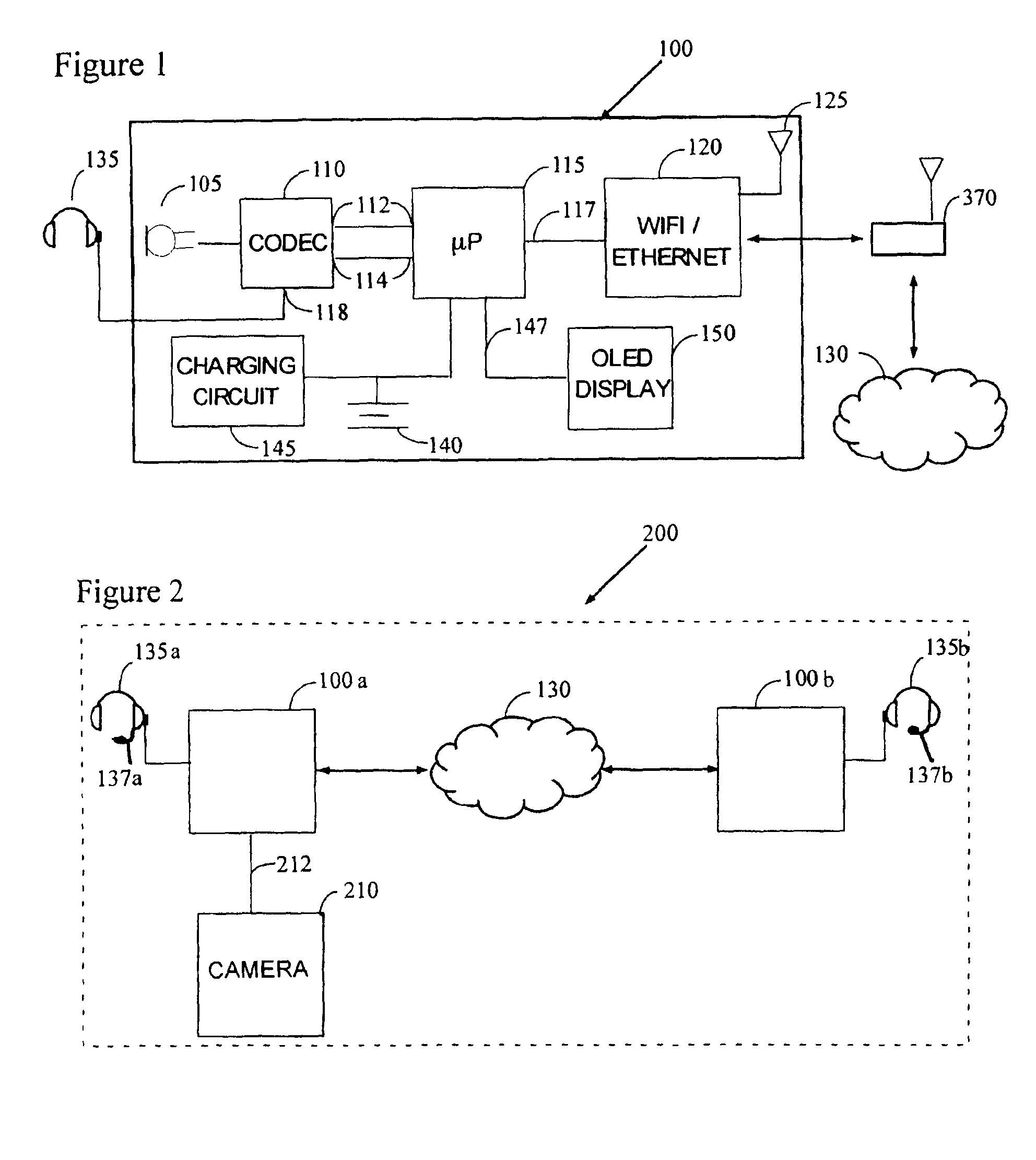

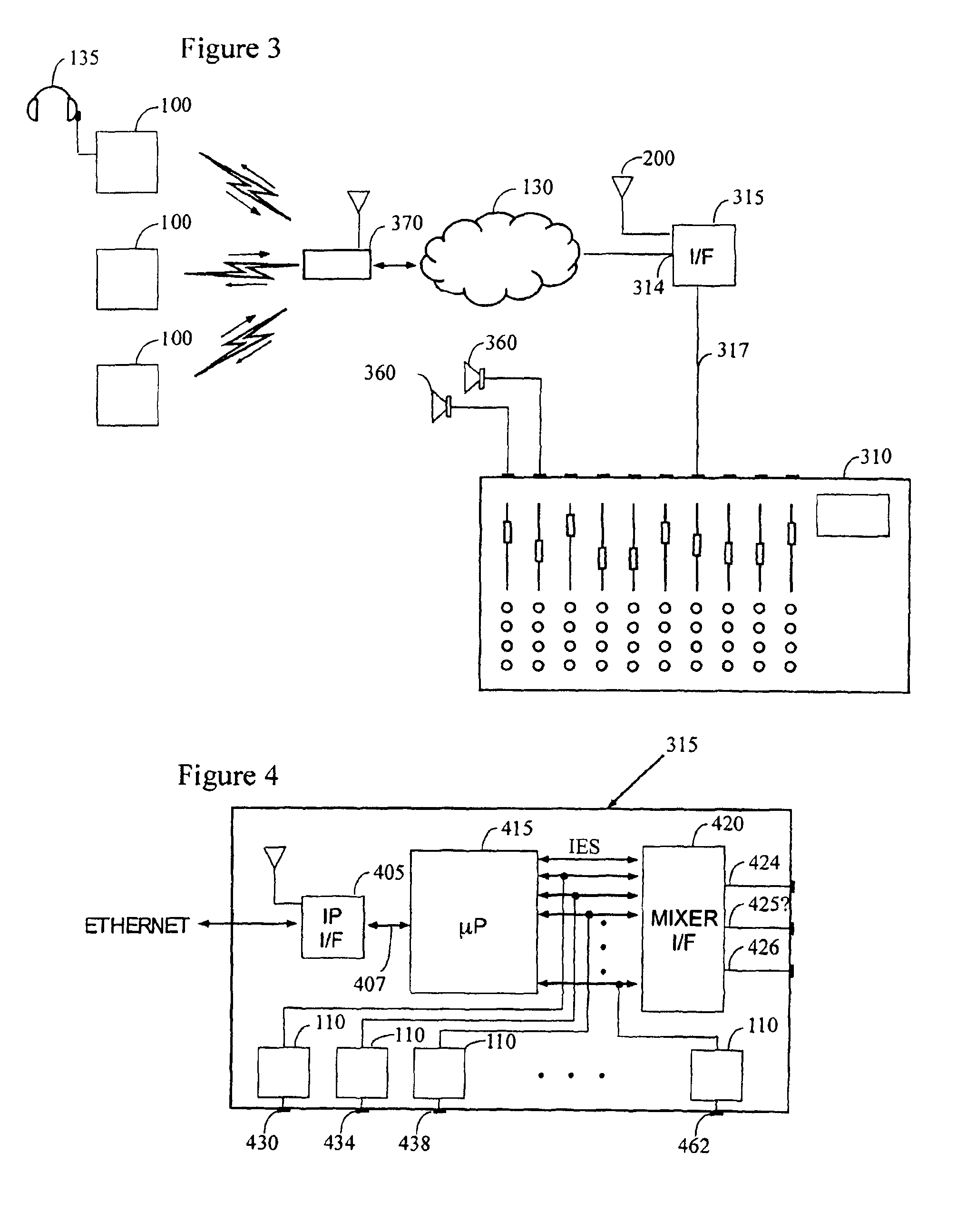

IP based microphone and intercom

InactiveUS20110211524A1Quality improvementLess-expensive to manufactureClosed circuit television systemsWireless commuication servicesMicrocontrollerTransceiver

A transceiver including, a codec, microcontroller, and radio. The codec including an analog to digital converter for receiving a first audio program and converting it to a first digital signal; a digital to analog converter for receiving a second digital audio signal and converting it to a second audio program; and, a control function for managing characteristics of the codec. The microcontroller is in electrical communication with the codec: for receiving the first digital audio signal from the codec and packetizing it into a first packet for transmission over a TCP / IP network; for receiving a second packet from network and converting it into the second digital audio signal and sending it to the codec; and for receiving control signals from the network. The radio is in electrical communication with the microcontroller for connection to the network to transmit the first packet to the network and receive the second packet from the network.

Owner:LP PARTNERS

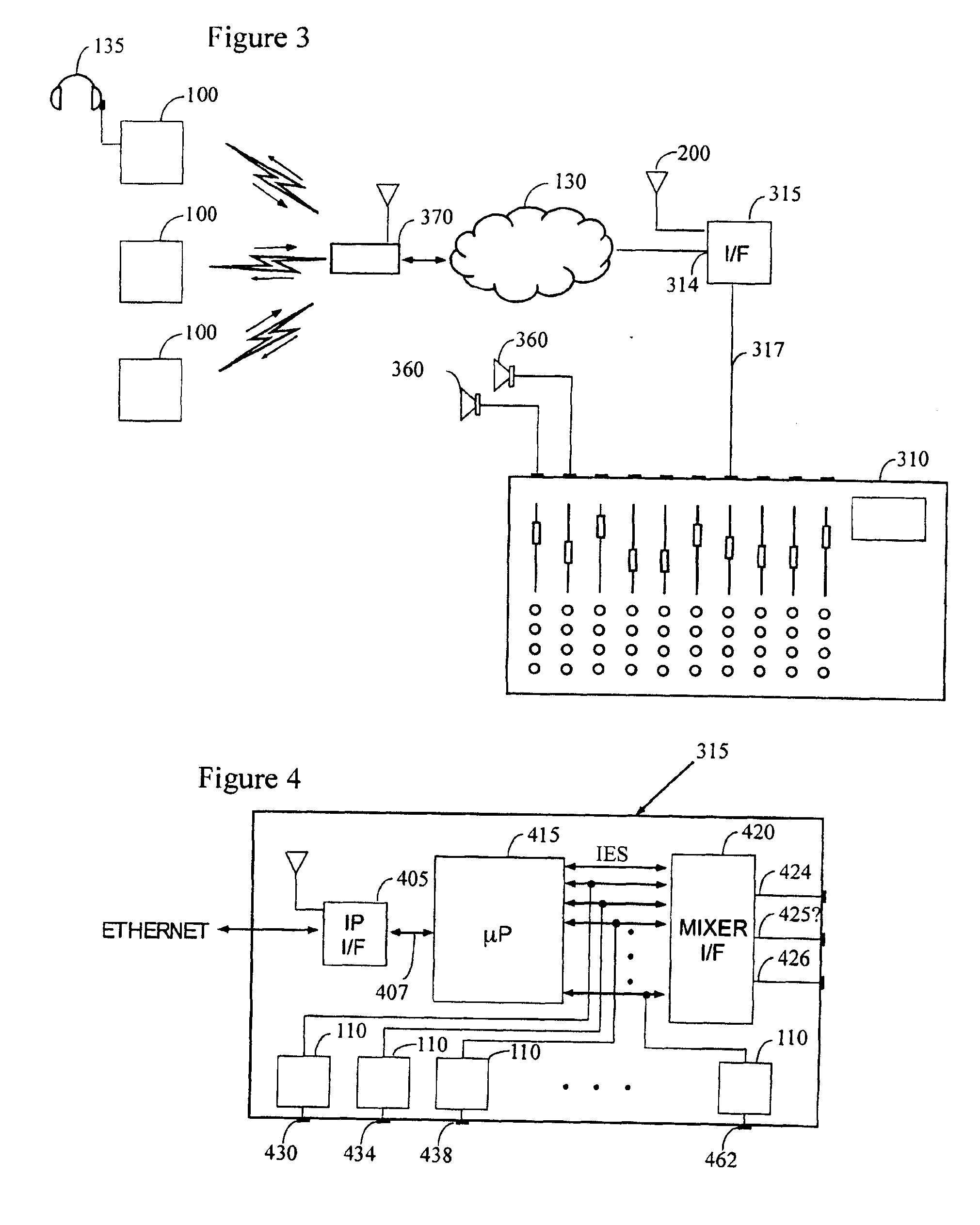

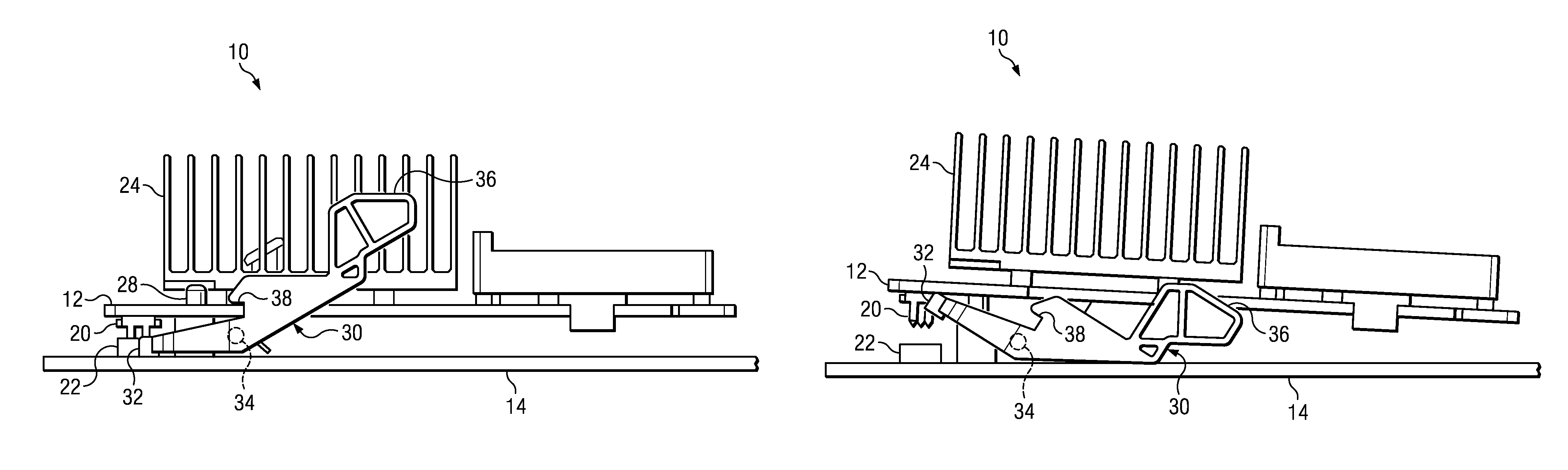

Retraction arm to extract a mezzanine circuit board connector from a motherboard connector

ActiveUS8366464B1Reduce disadvantagesReduce problemsEngagement/disengagement of coupling partsDigital data processing detailsEngineeringHandling system

An information handling system mezzanine circuit board disposed in a parallel configuration over a motherboard is selectively coupled and de-coupled at the motherboard with a retraction and latching device that translates retraction force applied at an accessible actuation portion to push upward from below the mezzanine circuit board. A retraction portion of the retraction and latching device provides an upward force at the bottom surface of the mezzanine circuit board to separate the mezzanine circuit board connector from the motherboard connector so that an end user can lift the mezzanine circuit board away from the motherboard.

Owner:DELL PROD LP

Plural bin metering system

ActiveUS20070034721A1Low costLess-expensive to maintainFertiliser distributersCentrifugal wheel fertilisersOne passAdditive ingredient

A plural bin metering system for broadcasting material ingredients contained therein over a ground surface. The system includes at least two material ingredient hoppers, each of the hoppers having a material ingredient discharge port. At least one of the material ingredient hoppers includes a variably controllable metering unit associated therewith for variably controlling the discharge of material ingredients therefrom independently from the rate of discharge of material ingredients from the other material ingredient hopper. A conveyor is disposed below the hoppers for receiving material ingredients discharged from the hoppers, and a material ingredient broadcasting device disposed off of one end of the conveyor for receiving material ingredients conveyed thereon, received from the hoppers, for broadcasting the material ingredients over a ground surface. The metering unit is capable of metering material ingredients from its associated hopper at ultra low rates. In a preferred embodiment the system has three hoppers for broadcasting, for example fertilizer across a field in one pass.

Owner:SALFORD BBI

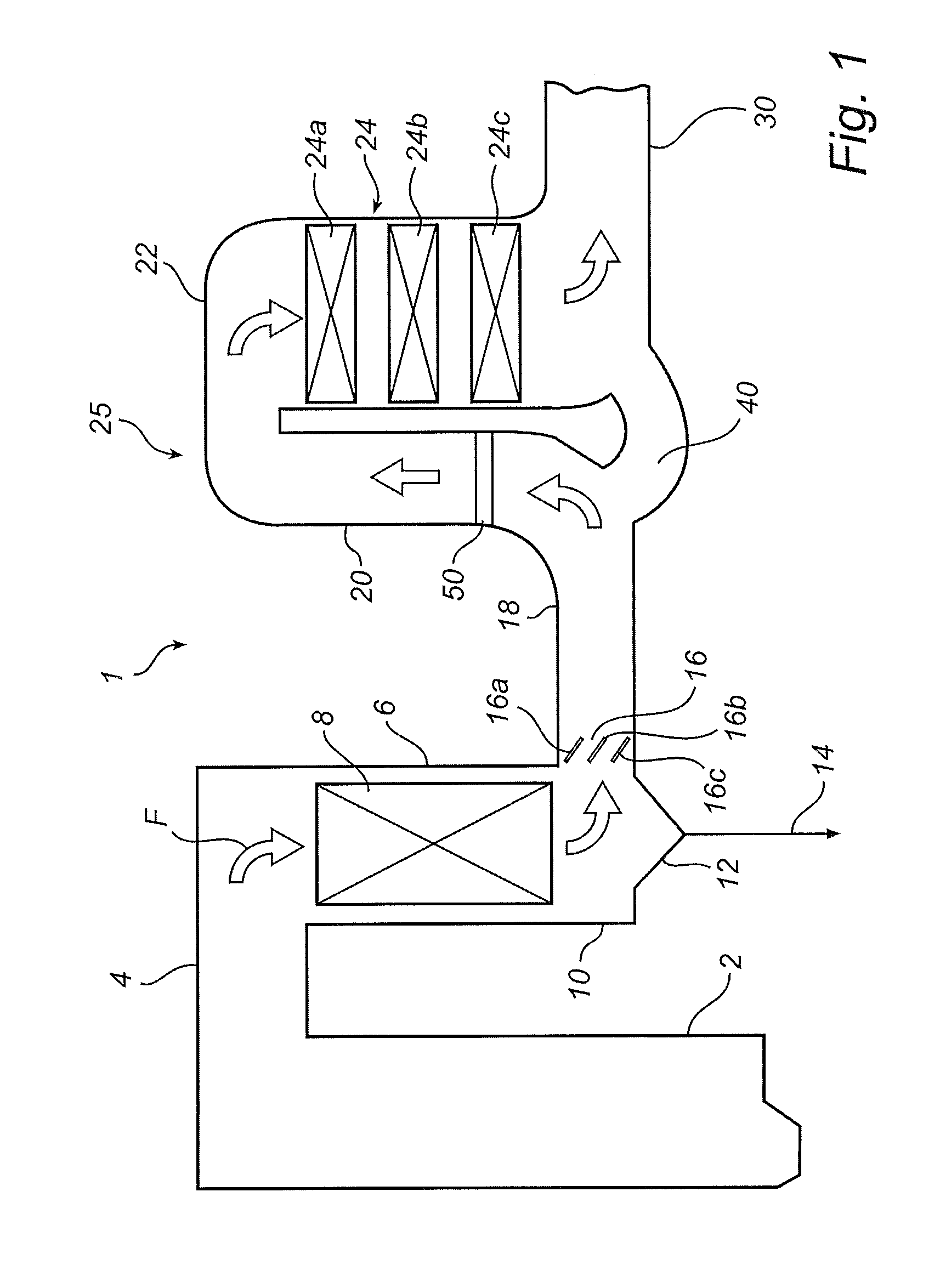

Gas flow control arrangement

InactiveUS20120073666A1Decrease pressure dropEnhance performanceCombination devicesFlow mixersExhaust gasFlue

A gas flow control arrangement for use in an exhaust gas cleaning system, comprising a duct (20) through which flue gases flow from a first end (20a) toward a second end (20b). The duct is configured to have a longitudinal expanse between its first end and its second end, and a gas flow control device (80) arranged therein. The gas flow control device further comprises at least one expanded screen (81, 82, 83, 84) arranged at an angle within the duct to distribute gas flow. A method for controlling gas flow in an exhaust gas cleaning system is also described.

Owner:ALSTOM TECH LTD

Cell culture methods for producing recombinant proteins in the presence of reduced levels of one or more contaminants

InactiveUS20090181426A1Lower Level RequirementsPromote growthAnimal cellsGenetically modified cellsBiotechnologyTherapeutic protein

Owner:MILLIPORE CORP

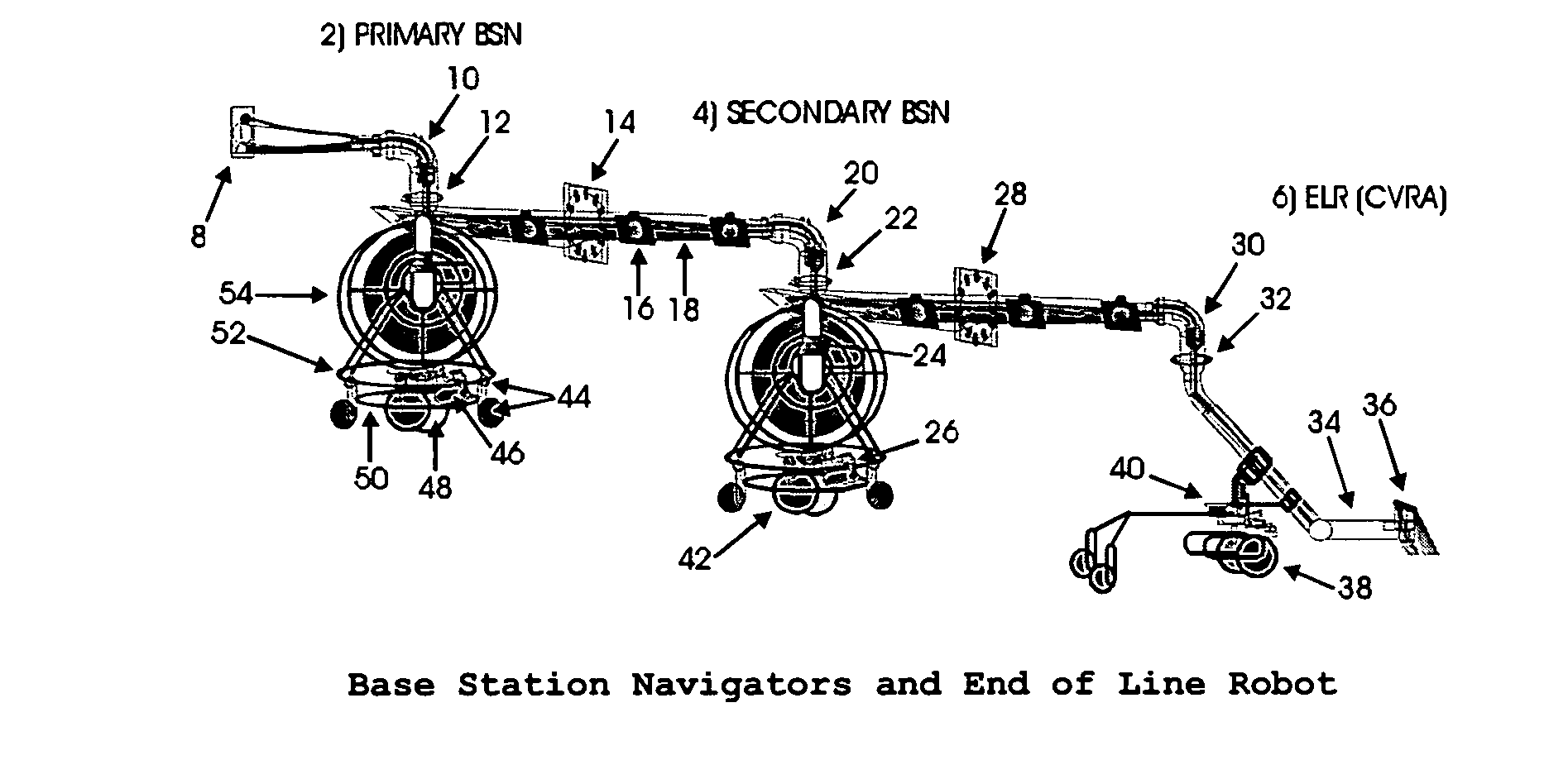

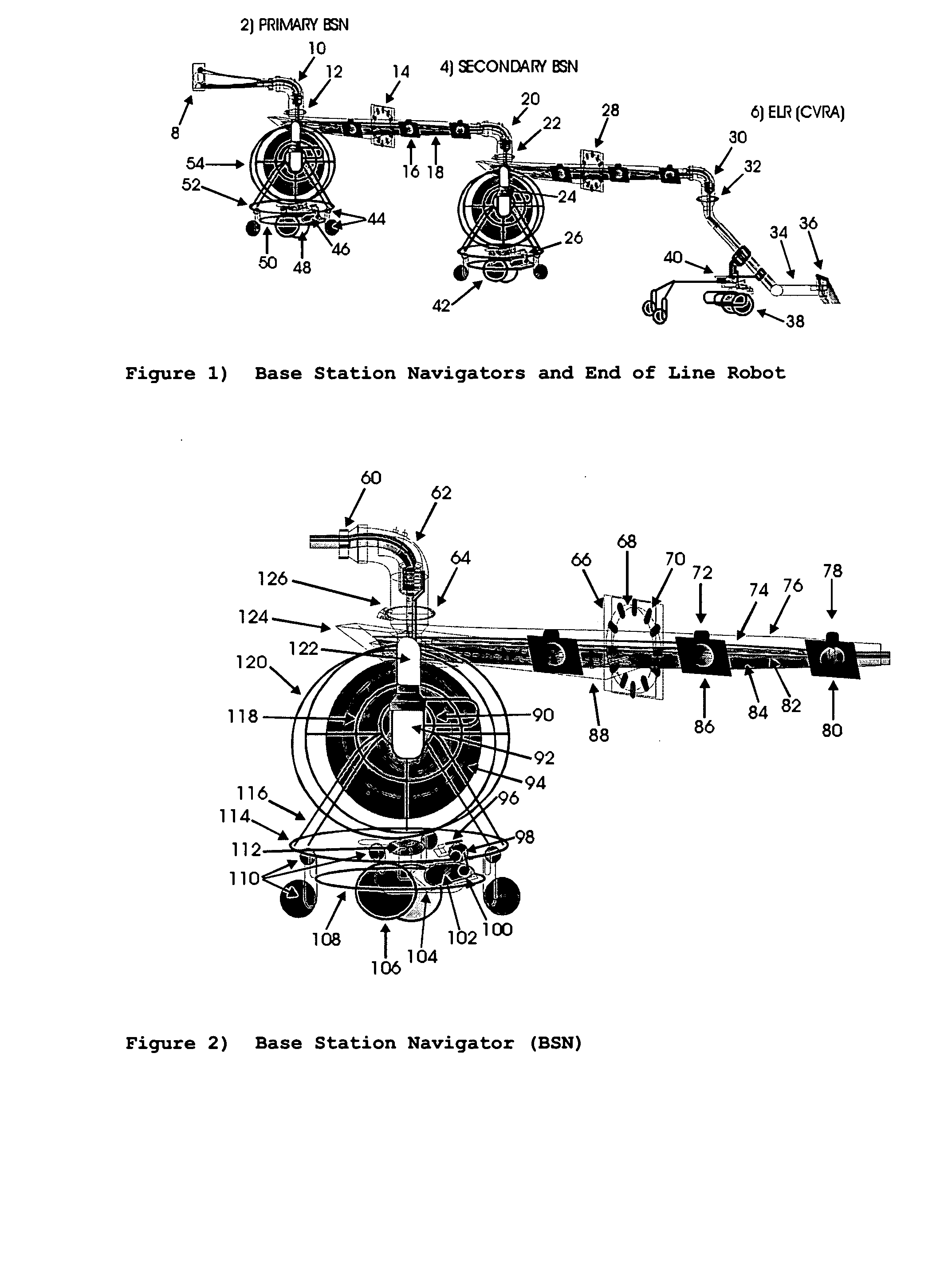

Guidance system for a robot

InactiveUS20060009876A1Less-expensive to buildLess-expensive to operateNavigation instrumentsTension measurementGuidance systemTelecommunications link

A guidance system for a robot includes a main monitoring station and an unmanned movable base station, which is in communication with the main monitoring station. A robot is provided which is adapted to operate within a predetermined radius of the base station. Either an umbilical cord connection or a wireless communication link can be provided for dynamically determining the distance and orbital positioning of the robot relative to the base station.

Owner:MCNEIL DEAN

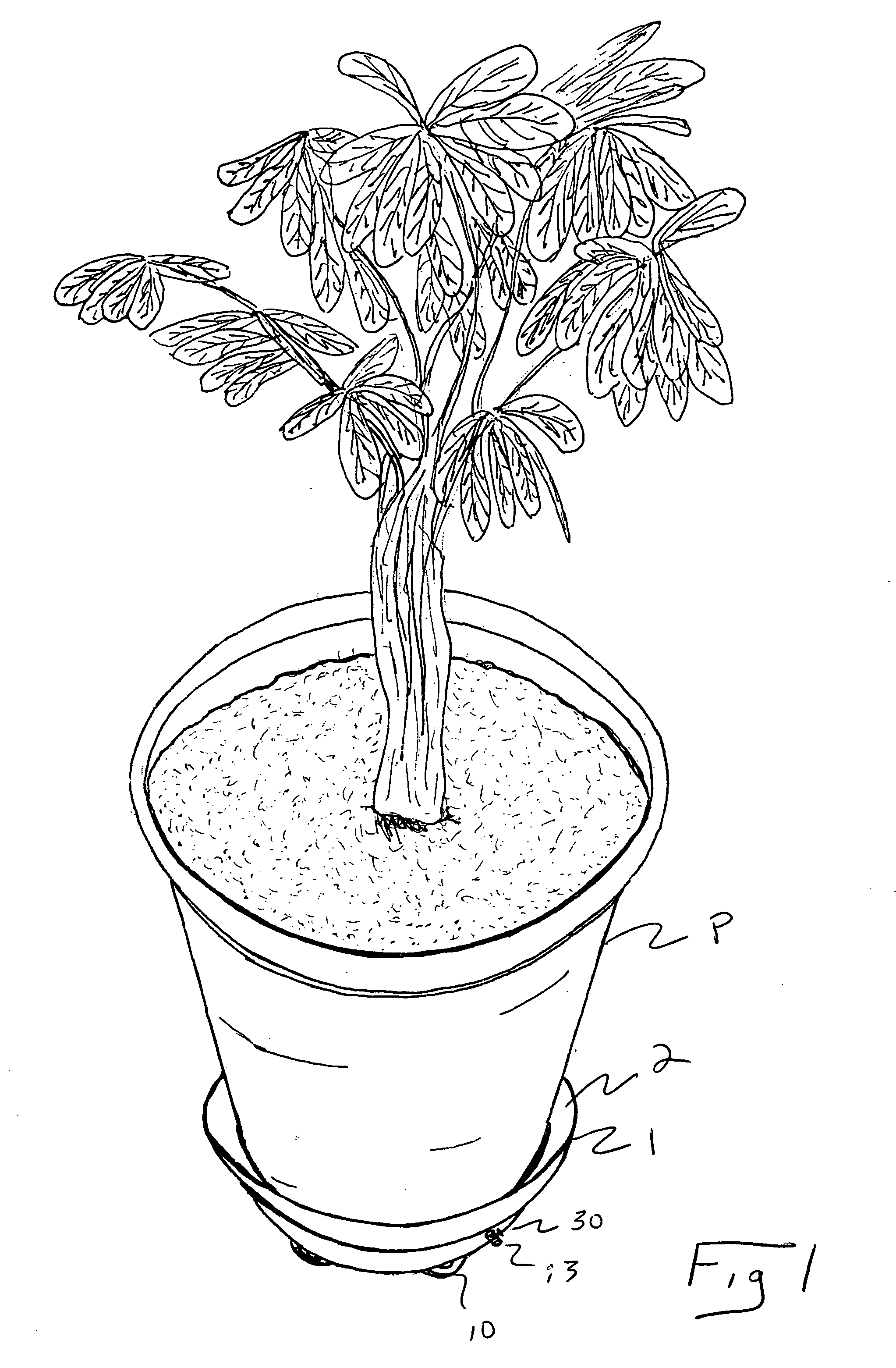

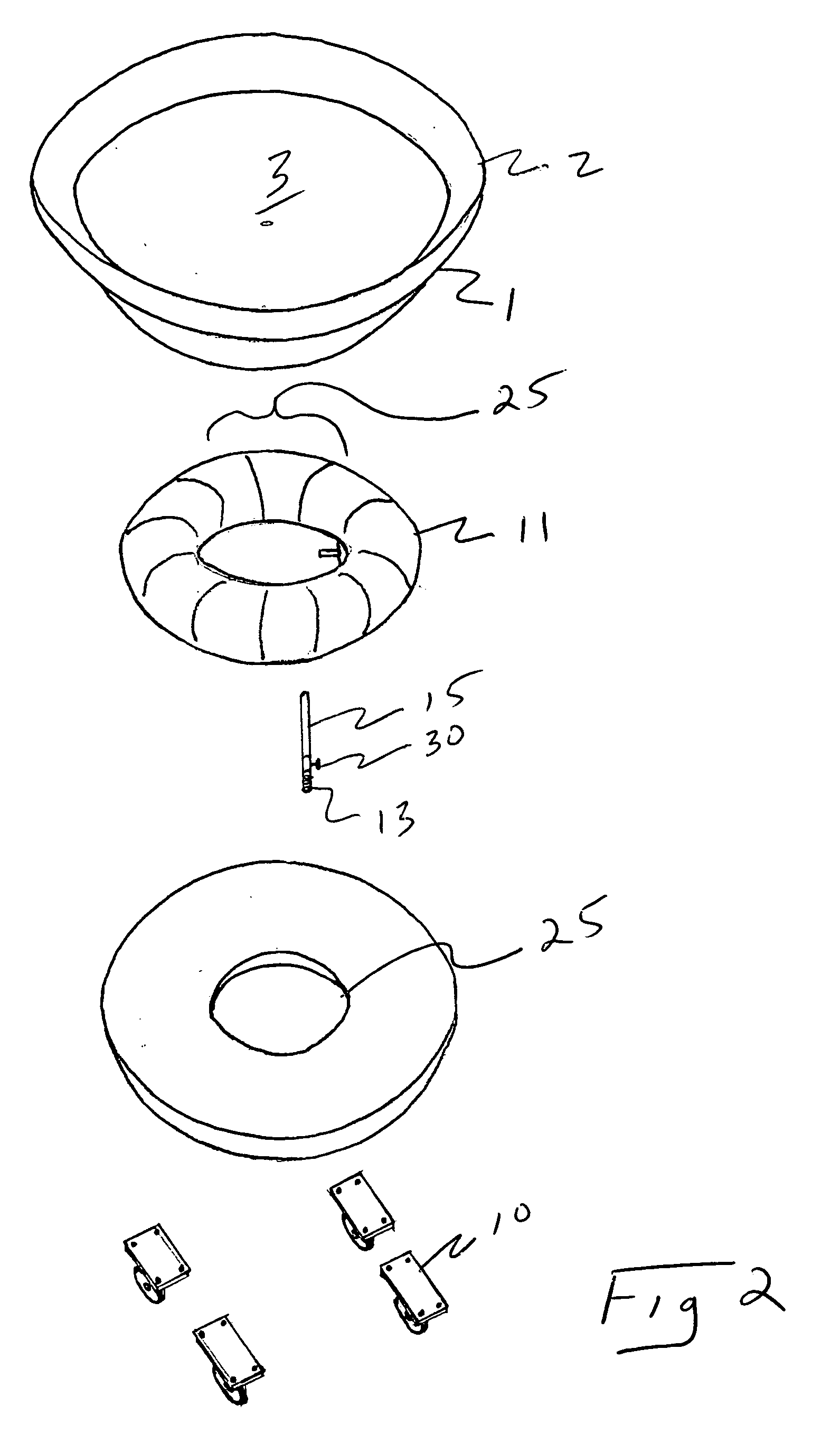

Pneumatic lifting system and method

ActiveUS20060042878A1Easy to implementEasy to operateCarpet cleanersFloor cleanersAirbag deploymentLift system

A lifting device and method therefore utilizing an air bag or the like for lifting an object supported by a wheeled platform or the like, from a stationary, parked configuration wherein the object conceals the wheeled platform and supports the object, to a lifted, configuration whereby the wheeled platform supports the object, allowing same to be easily moved via the wheeled platform. The preferred embodiment of the present invention contemplates a planter unit comprising a pot or the like for containing a plant, said pot having a false bottom wherein there is situated a support platform having castors or the like thereon, and an air bag or other flexible container configured to be filled with fluid situated between the wheeled platform and the underside of the pot. In use, the false bottom has a cavity formed therein to enclose the wheeled platform, the false bottom having a lower edge supporting the pot when the air bag is uninflated. To lift the pot and raise the lower edge of the false bottom from the floor, the air bag or the like is filled with air via a hand pump or compressed air source, which expands the bag so as to lift the planter such that the wheeled support then supports the planter. The walls forming the false bottom surround the air bag in its inflated condition, stabilizing the unit so that it may be wheeled to its desired location, and preventing “rolling” of the airbag and planter from the platform.

Owner:COSSE III IRVY E +1

Method and System for Communication Between Devices

InactiveUS20120159604A1Less-expensive to maintainImprove securityDigital data processing detailsMultiple digital computer combinationsDigital dataEngineering

An embodiment of the present invention includes a system for communicating digital data from a preferably small battery powered device (e.g., key-chain or pocket-sized form-factor) to a personal electronic device (e.g., a smartphone such as an iPhone or a Nexus One). The communication mechanism of the present invention can be used as second factor authentication. The present invention can also be used as a key for accessing physical locations such as building. Alternatively, the present invention can be used as a manner for transmitting digital data to a personal electronic device such as a smart phone.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Retraction arm to extract a mezzanine circuit board connector from a motherboard connector

ActiveUS20130052847A1Reduce disadvantagesReduce problemsEngagement/disengagement of coupling partsDigital data processing detailsEngineeringHandling system

An information handling system mezzanine circuit board disposed in a parallel configuration over a motherboard is selectively coupled and de-coupled at the motherboard with a retraction and latching device that translates retraction force applied at an accessible actuation portion to push upward from below the mezzanine circuit board. A retraction portion of the retraction and latching device provides an upward force at the bottom surface of the mezzanine circuit board to separate the mezzanine circuit board connector from the motherboard connector so that an end user can lift the mezzanine circuit board away from the motherboard.

Owner:DELL PROD LP

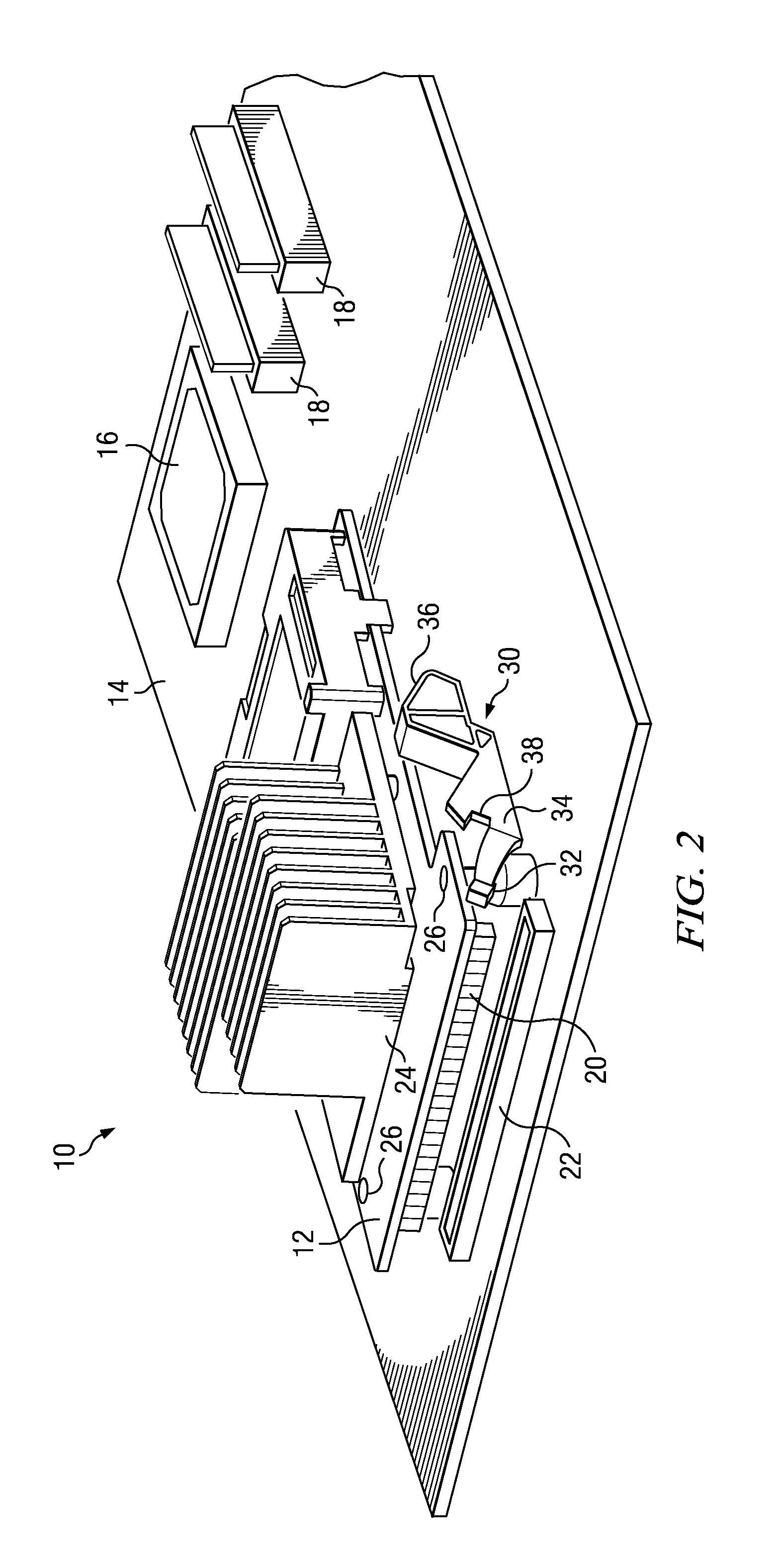

Cold forging apparatus and method for forming complex articles

InactiveUS20040089047A1Good flexibilityLess complexExtrusion diesForging hammersComputerized systemSingle station

A cold forging apparatus for forming complex shapes at a single station includes a pair of confronting multiple function punch assemblies disposed on a common axis. Each of the multiple function punch assemblies includes an inner or a center punch and an outer or ring-shaped punch surrounding and in sliding contact with the inner punch. The apparatus also includes a die holder for positioning a mass or slug of metal between the punches. A computer system controls movement of the punches and is programmable to form parts of different shapes at a single station.

Owner:TRAVIS RAY +1

Cold forging apparatus and method for forming complex articles

InactiveUS20040089048A1Good flexibilityLess complexExtrusion diesForging hammersComputerized systemEngineering

A cold forging apparatus for forming complex shapes at a single station includes a plurality of multiple function punch assemblies disposed on intersecting axes. Each of the multiple function punch assemblies includes an inner or a center punch and an outer or ring-shaped punch surrounding and in sliding contact with the inner punch. The apparatus also includes a die holder for positioning a mass or slug of metal between the punches. A computer system controls movement of the punches and is programmable to form parts of different shapes at a single station. Off axis punches and angularly offset punches and an additional punch or punch assembly are also disclosed.

Owner:TRAVIS RAY +1

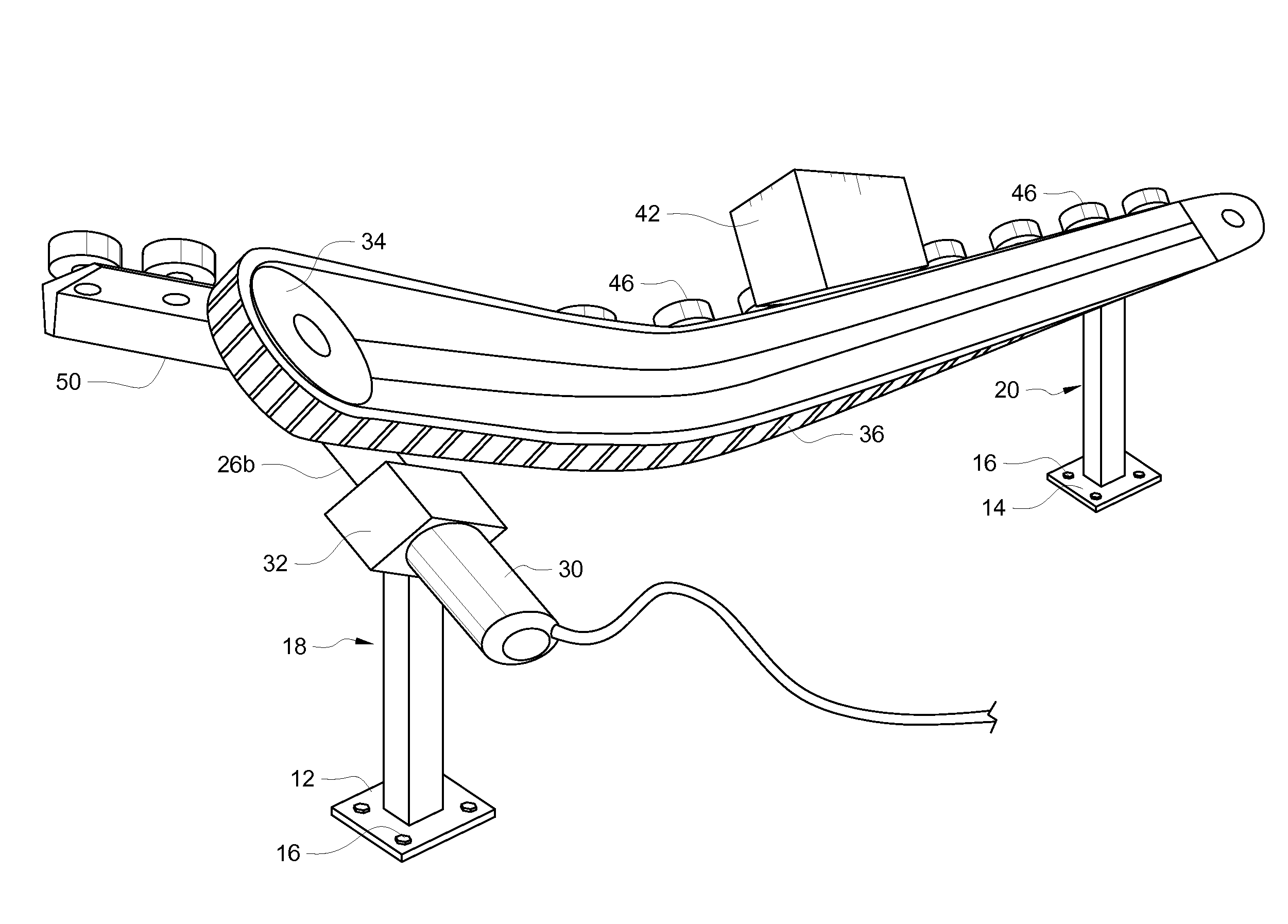

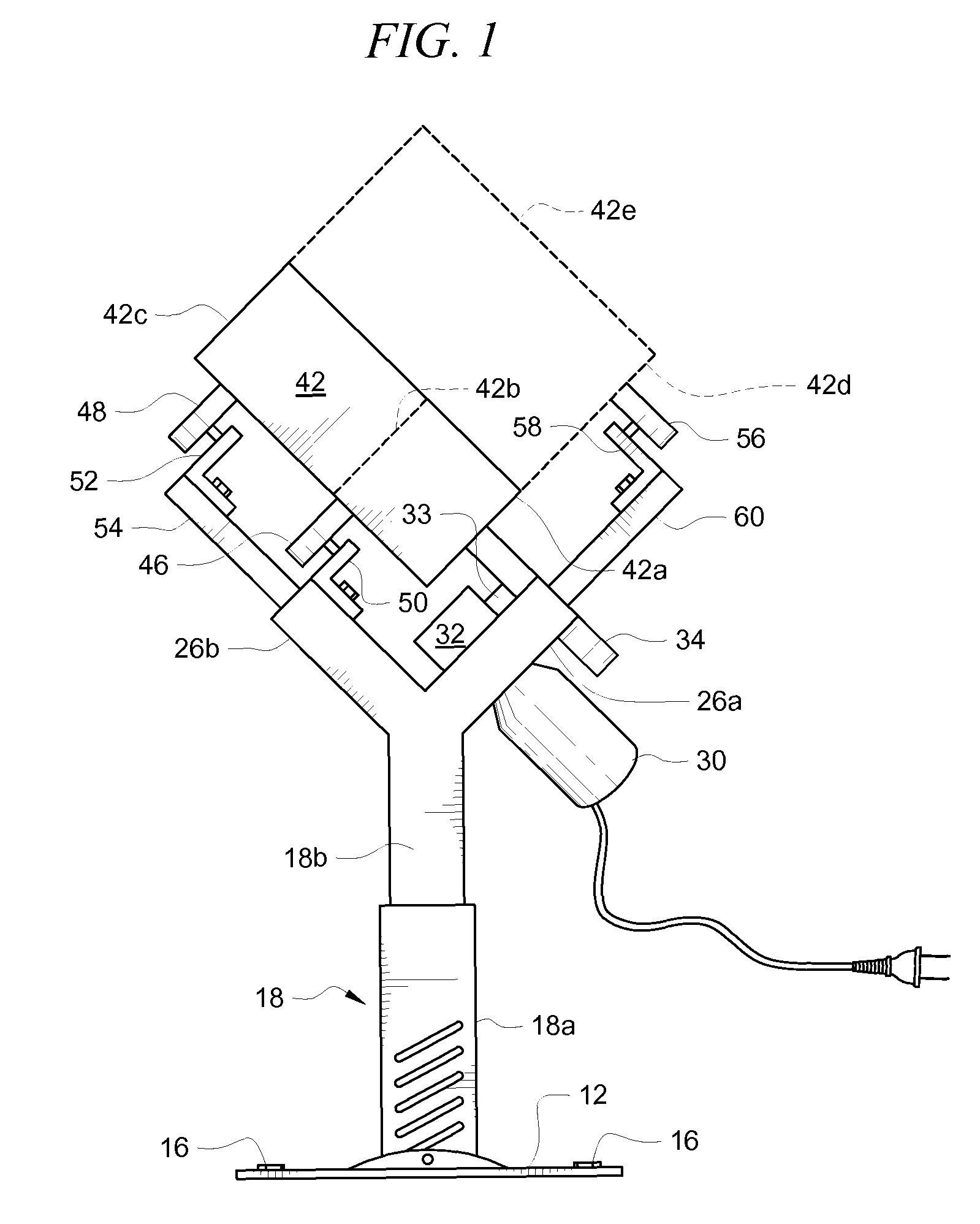

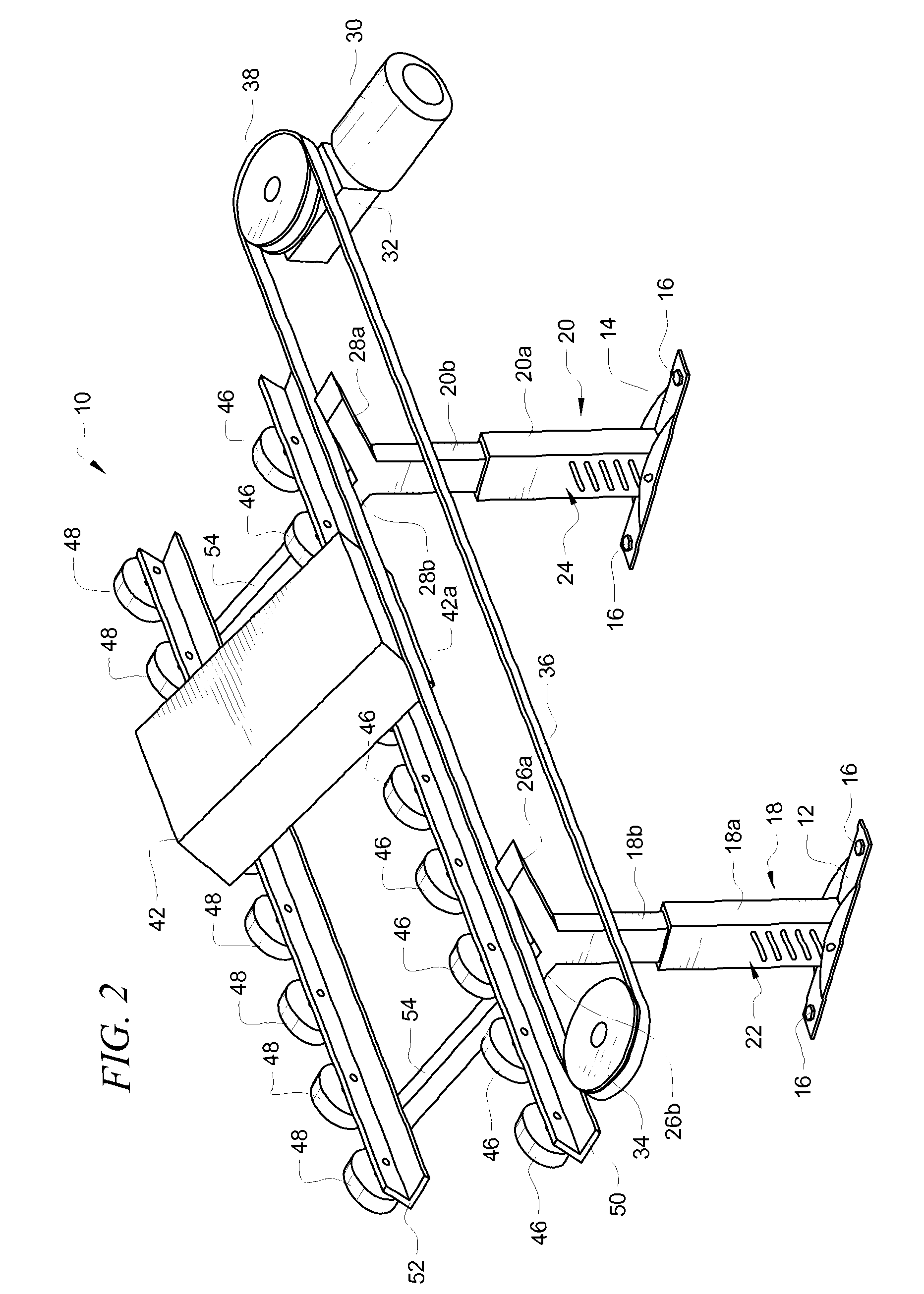

V-Shaped Product Conveyor

InactiveUS20090000919A1Easy to adjustHigh profileConveyorsSupporting framesDelivery systemProduct Containers

A conveyor system includes first and second upstanding posts disposed in longitudinally spaced apart relation to one another. Each post is surmounted by forward and rearward support arms that form a “V”-shape. A forward drive belt is mounted for rotation along a path of travel perpendicular to the forward support arms. A first embodiment cradles a product container between the forward drive belt and a rearward primary support arm. A second embodiment includes the first embodiment structure and adds a rearward secondary support arm. A third embodiment includes the primary but not the rearward secondary support arm, the forward drive belt and a forward secondary support arm. A fourth embodiment includes the rearward primary and secondary support arms, the forward drive belt and a forward secondary support arm. The product container is tilted from vertical so that the conveyor follows a path of travel including curvatures having no guide rails.

Owner:RINNE RHETT L

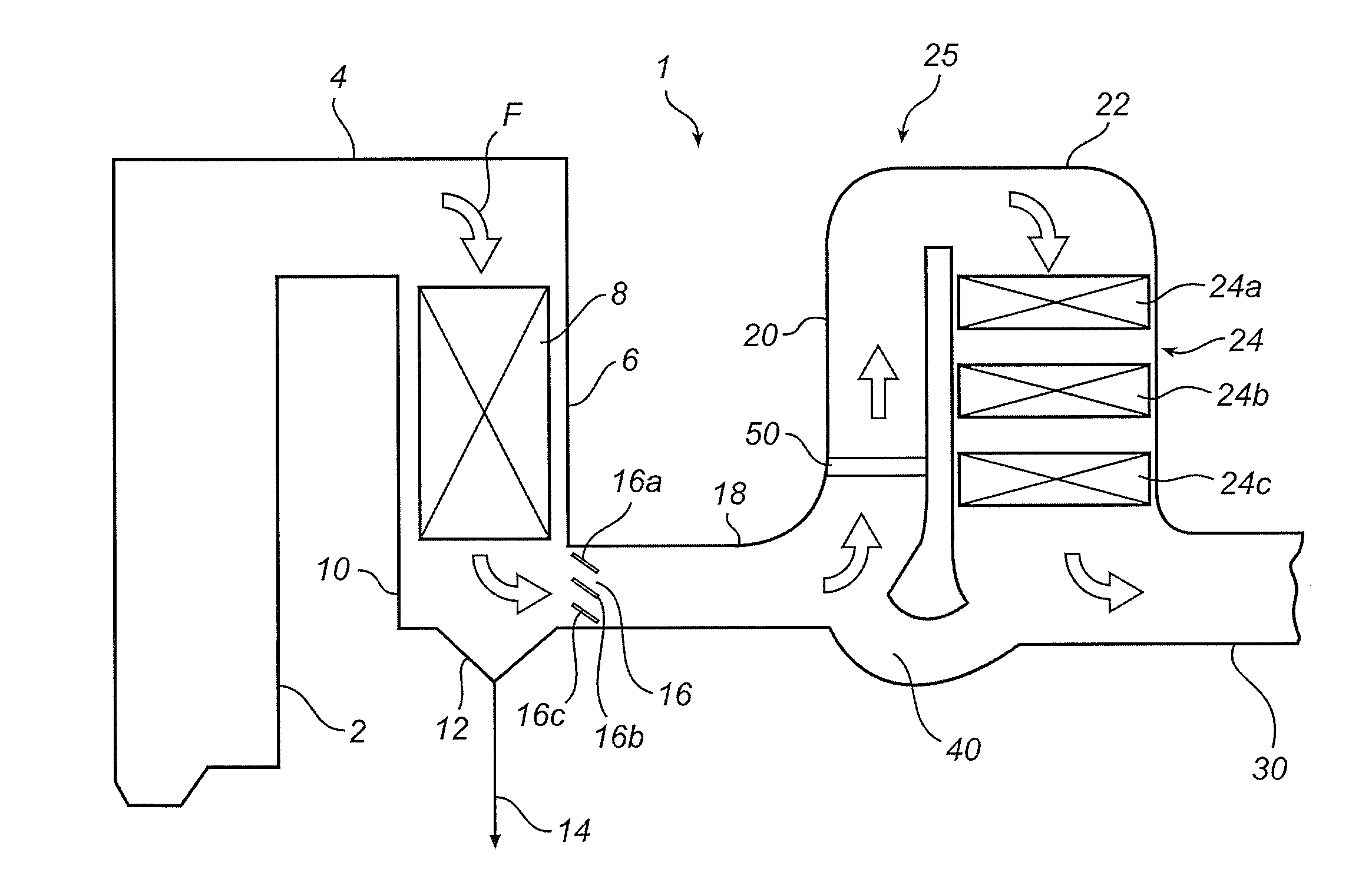

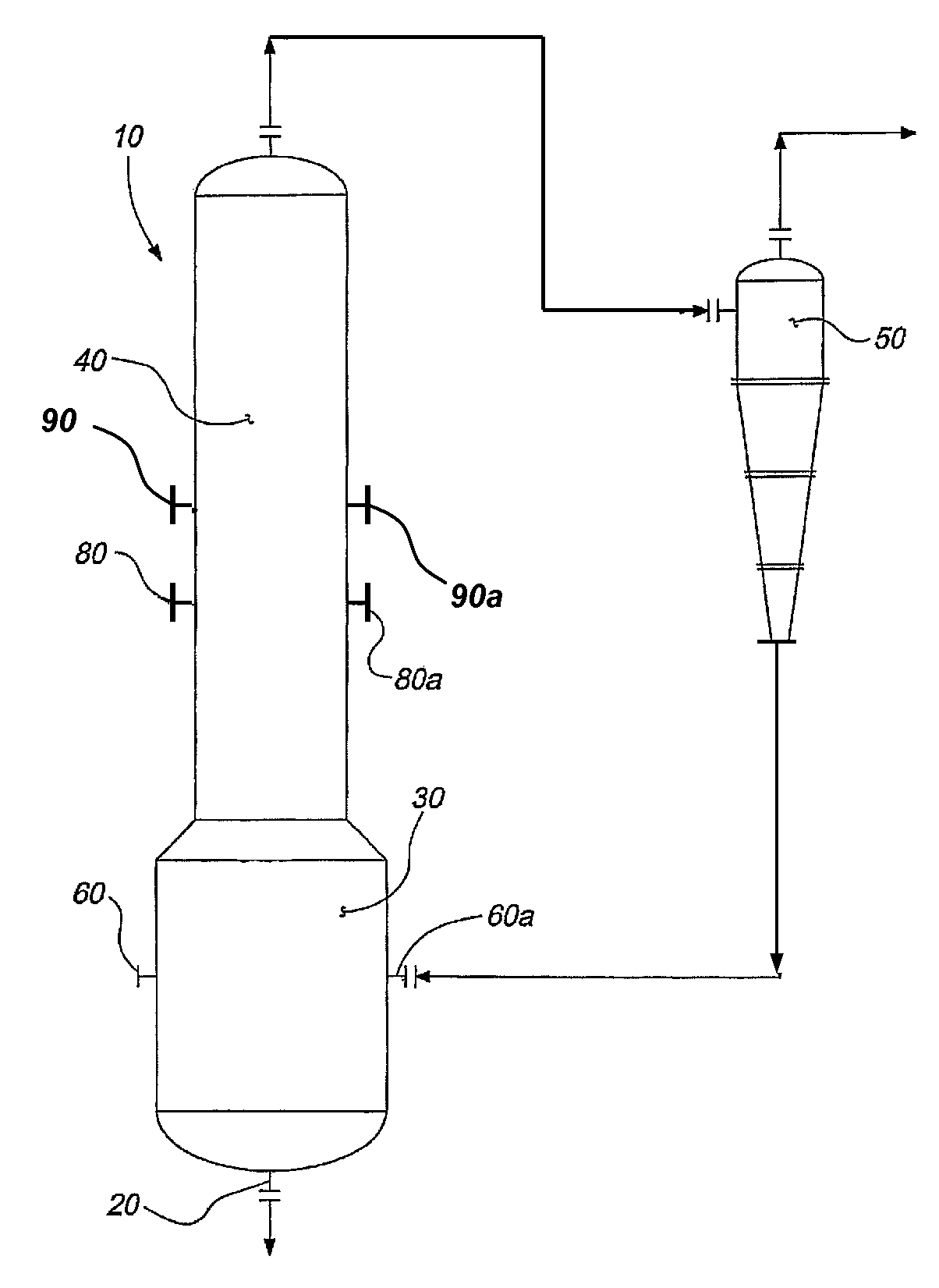

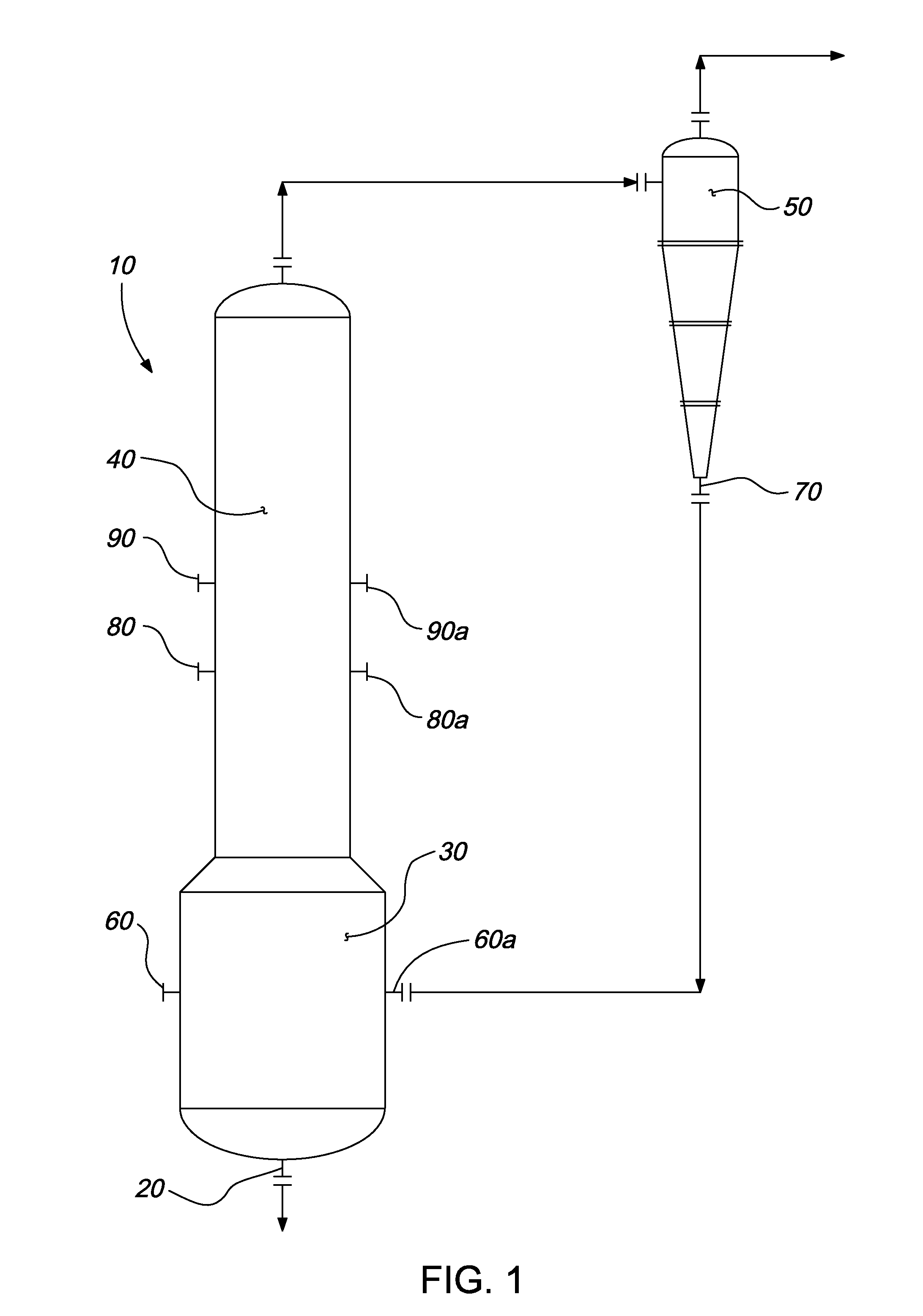

Tar-free gasification system and process

ActiveUS8252073B2Less-expensive to constructLess-expensive to maintainHydrocarbon from carbon oxidesGas modification by gas mixingSyngasCombustion

A novel tar-free gasification process and system is disclosed that involves the partial combustion of recycled dry solids and the drying of a slurry feedstock comprising carbonaceous material in two separate reactor zones in a two stage gasifier, thereby producing mixture products comprising synthesis gas. The synthesis gas produced from the high temperature first stage reaction zone is then quenched in the second stage reaction zone of the gasifier prior to introduction of a slurry feedstock. The temperature of the final syngas exiting the second stage reaction zone of the gasifier is thereby moderated to be in the range of about 350-900° F., which is below the temperature range at which tar is readily formed, depending upon the type of carbonaceous feedstock utilized.

Owner:LUMMUS TECH INC

Tar-free gasification system and process

ActiveUS20100155669A1Less-expensive to constructLess-expensive to maintainHydrocarbon from carbon oxidesGas modification by gas mixingSyngasCombustion

A novel tar-free gasification process and system is disclosed that involves the partial combustion of recycled dry solids and the drying of a slurry feedstock comprising carbonaceous material in two separate reactor zones in a two stage gasifier, thereby producing mixture products comprising synthesis gas. The synthesis gas produced from the high temperature first stage reaction zone is then quenched in the second stage reaction zone of the gasifier prior to introduction of a slurry feedstock. The temperature of the final syngas exiting the second stage reaction zone of the gasifier is thereby moderated to be in the range of about 350-900° F., which is below the temperature range at which tar is readily formed, depending upon the type of carbonaceous feedstock utilized.

Owner:LUMMUS TECH INC

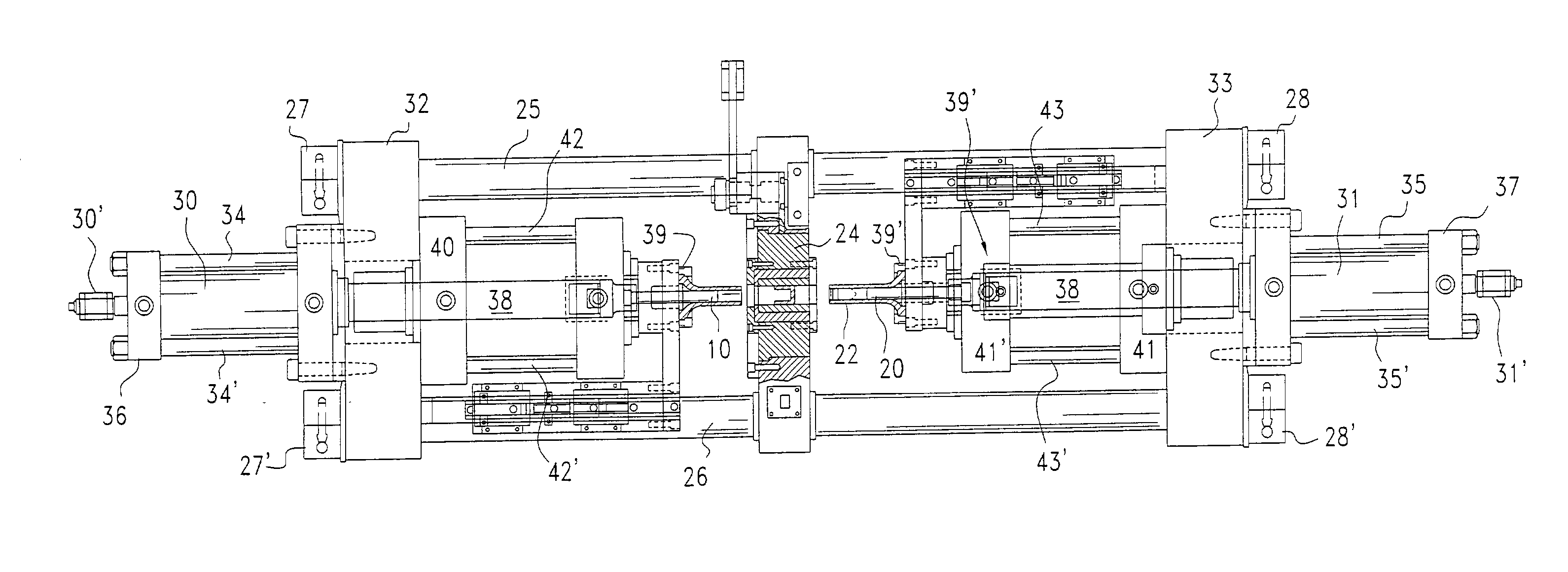

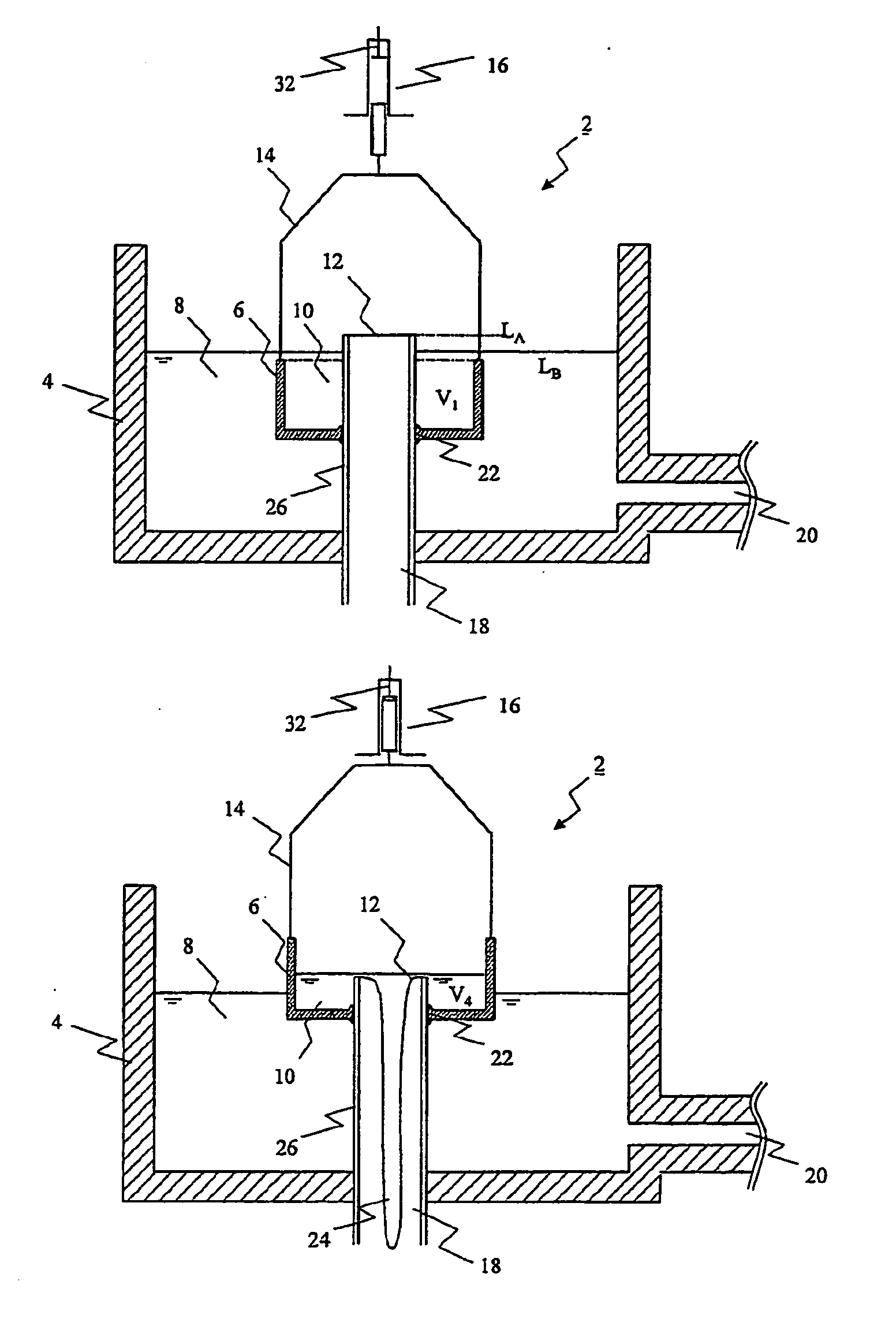

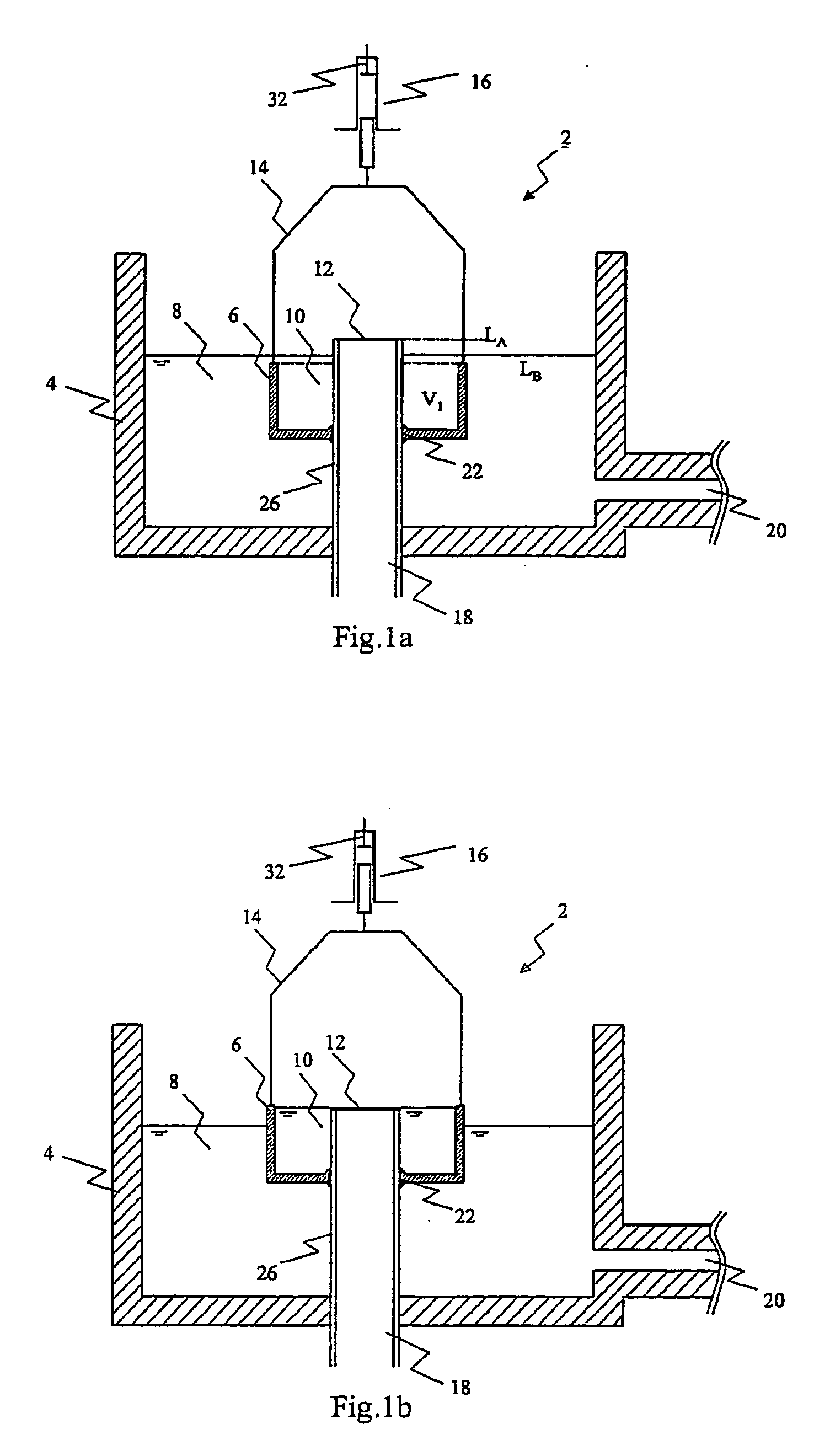

Tapping and pouring system for molten metals

InactiveUS20060113058A1Less-expensiveLess-expensive to installMelt-holding vesselsMolten metal pouring equipmentsMolten bathEngineering

System (2) for tapping a high-temperature molten material, especially a molten metal, from a bath (8) and pouring it into a mould, comprising a mobile container (6) capable of moving with respect to an element (26) in such as way as, on the one hand, said container (6) may be plunged into the bath (8) to take some liquid and, on the other hand, lift the container (6) above a particular level for forcing the liquid to fall down with gravity through an aperture (10) along the wall. The system (2) does not imply high costs and allows to pour accurate volumes of molten material.

Owner:VERVIER JACQUES

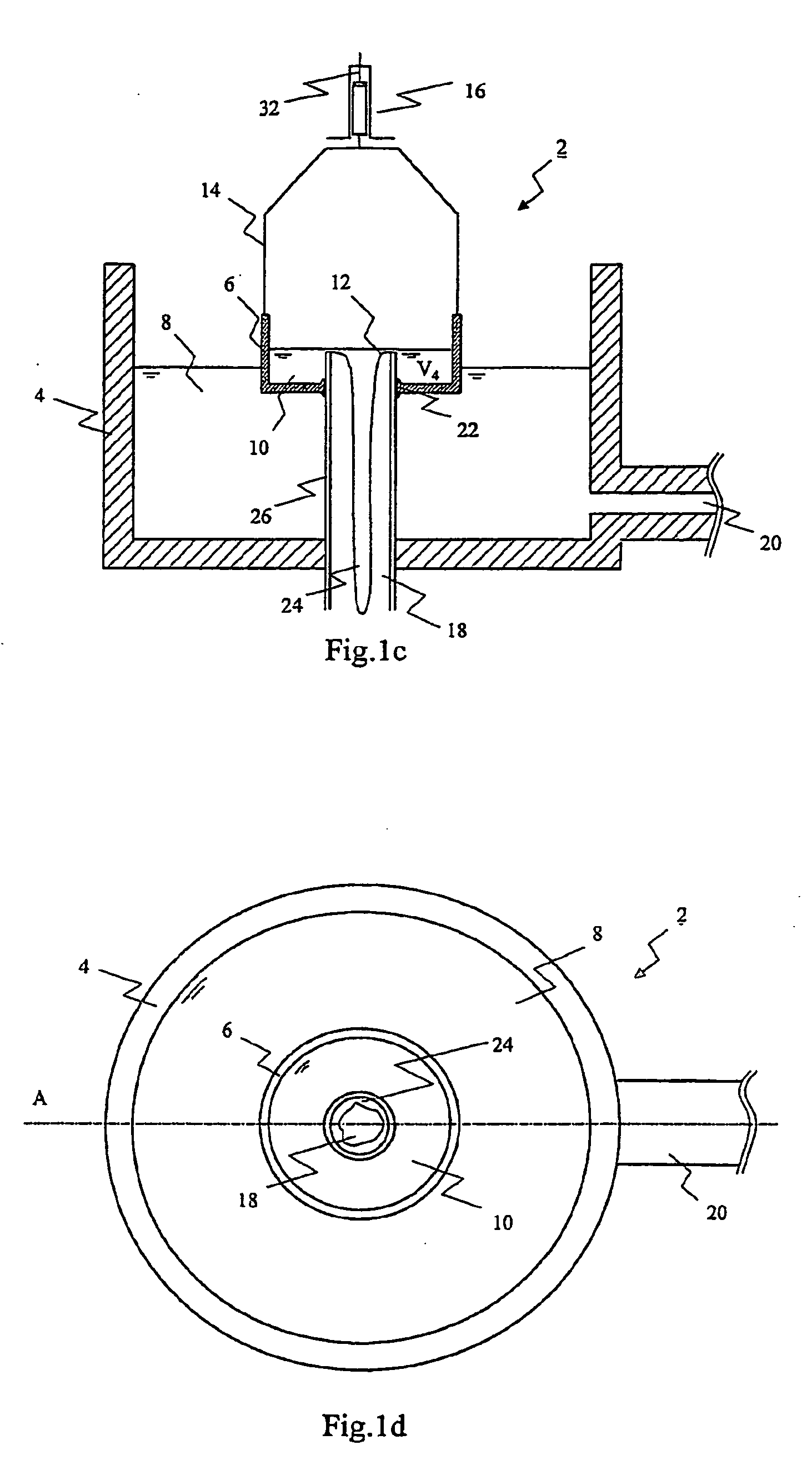

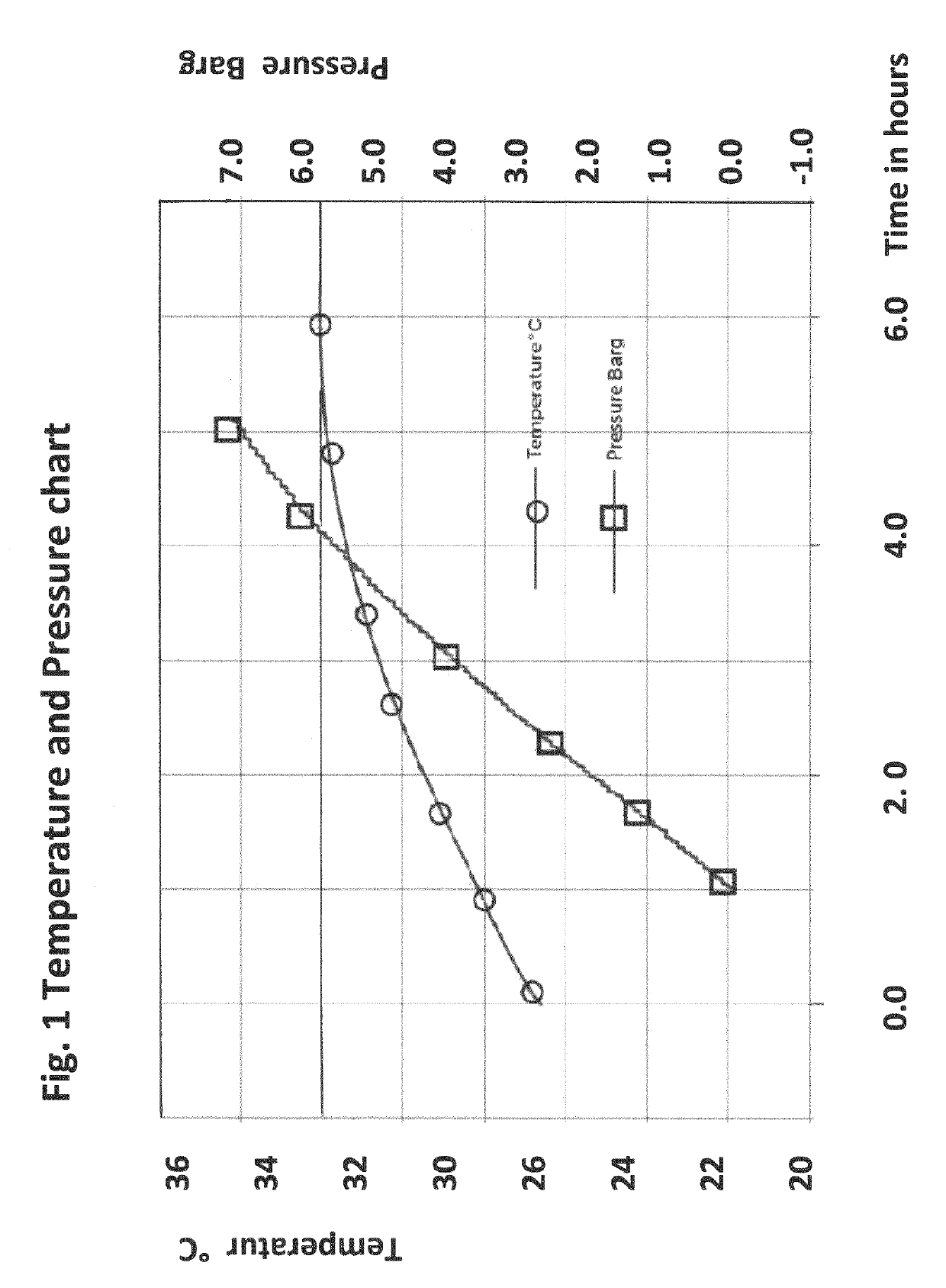

Vertical plug-flow process for simultaneous production of ethanol and a fermented, solid transformation product of the substrate

ActiveUS20190309244A1Simple reactor designLess-expensive in investmentAntibacterial agentsBioreactor/fermenter combinationsYeastHelianthus annuus seed

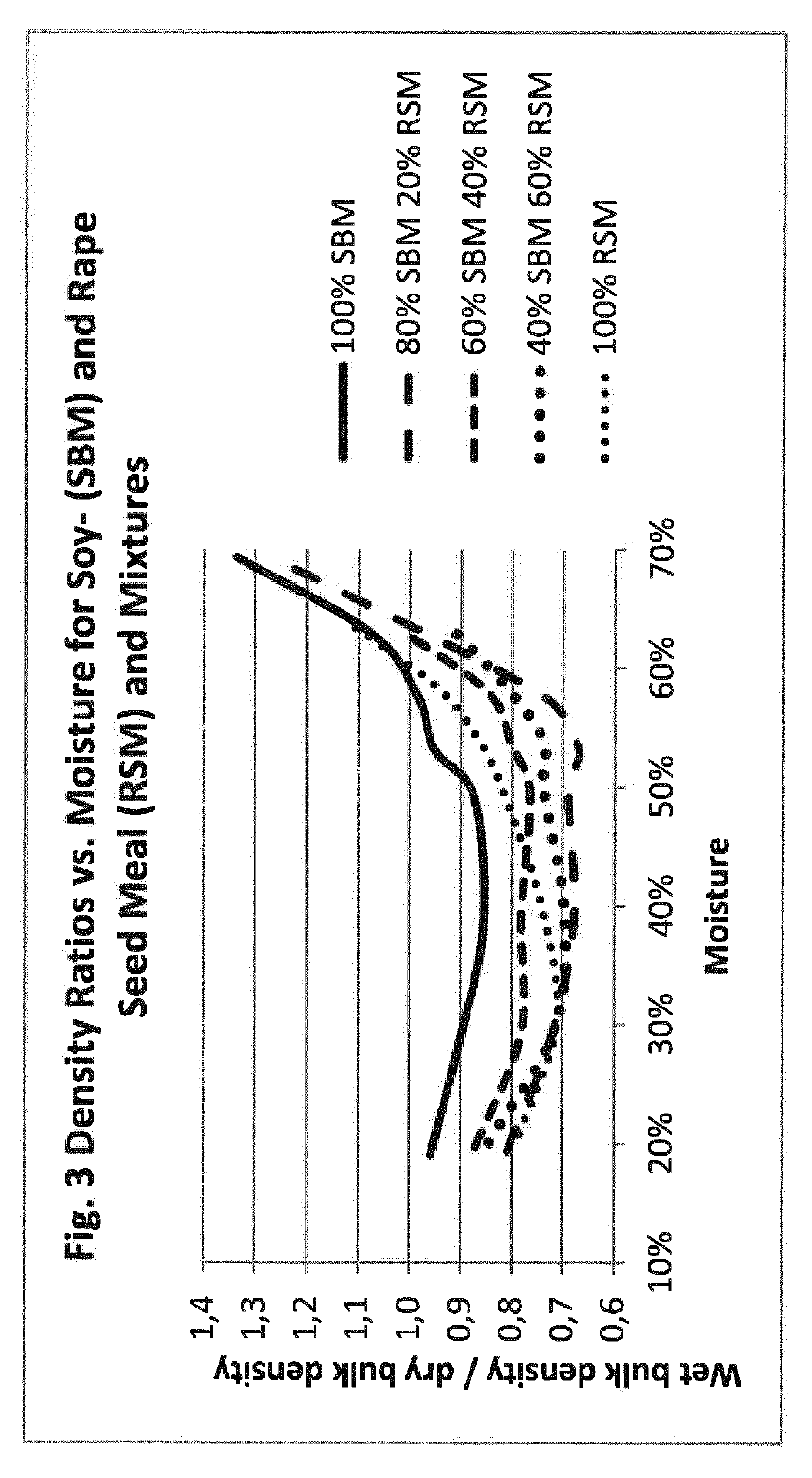

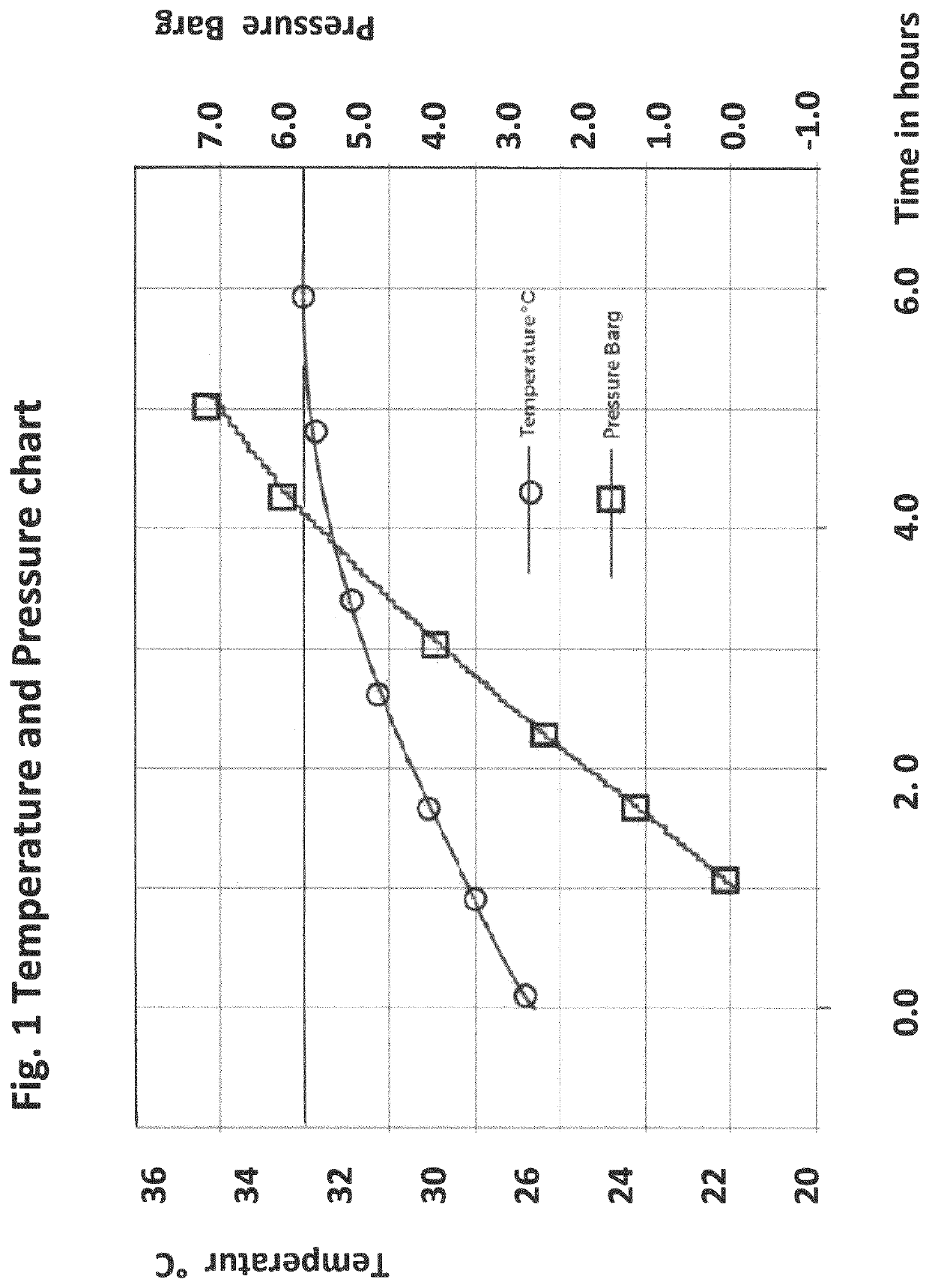

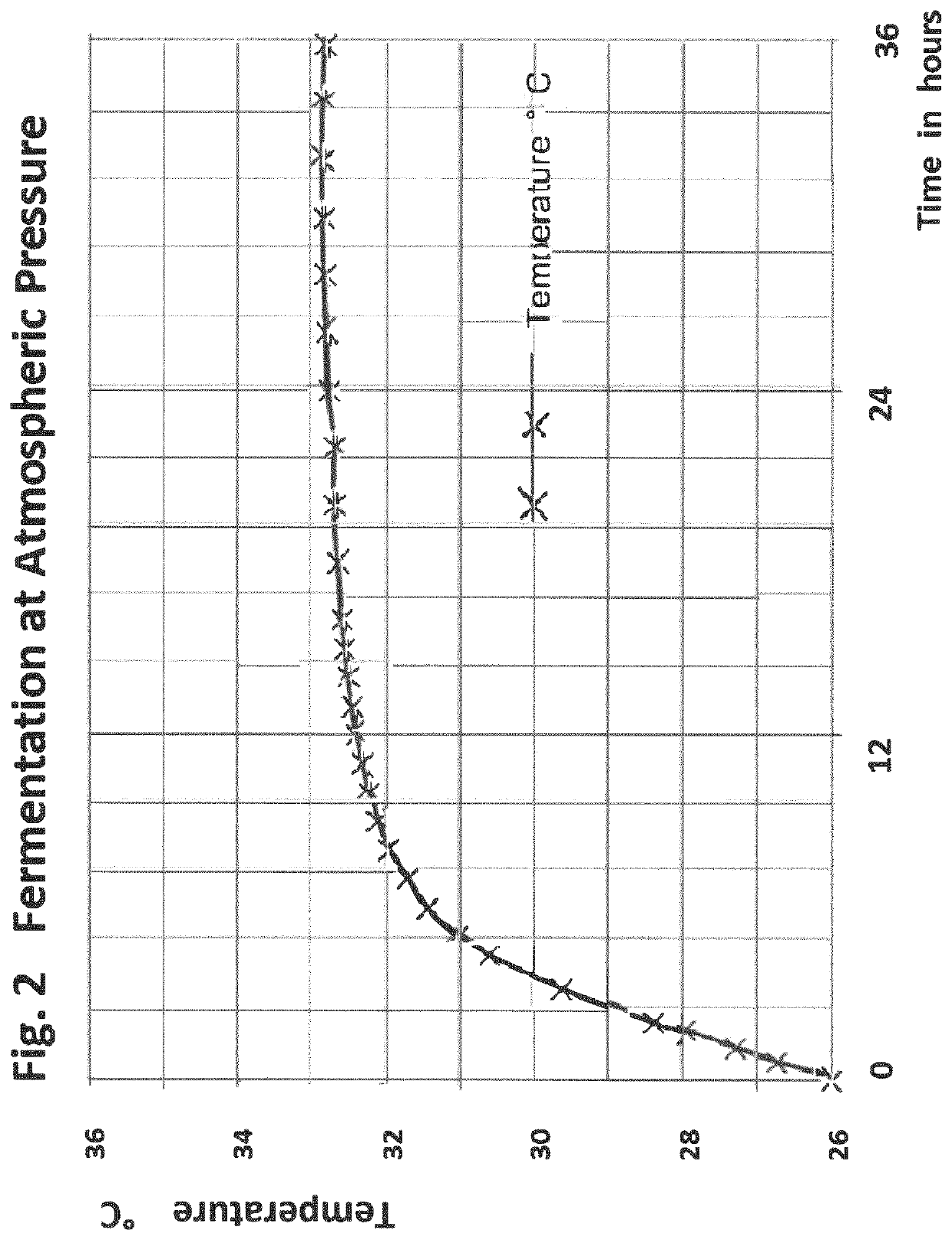

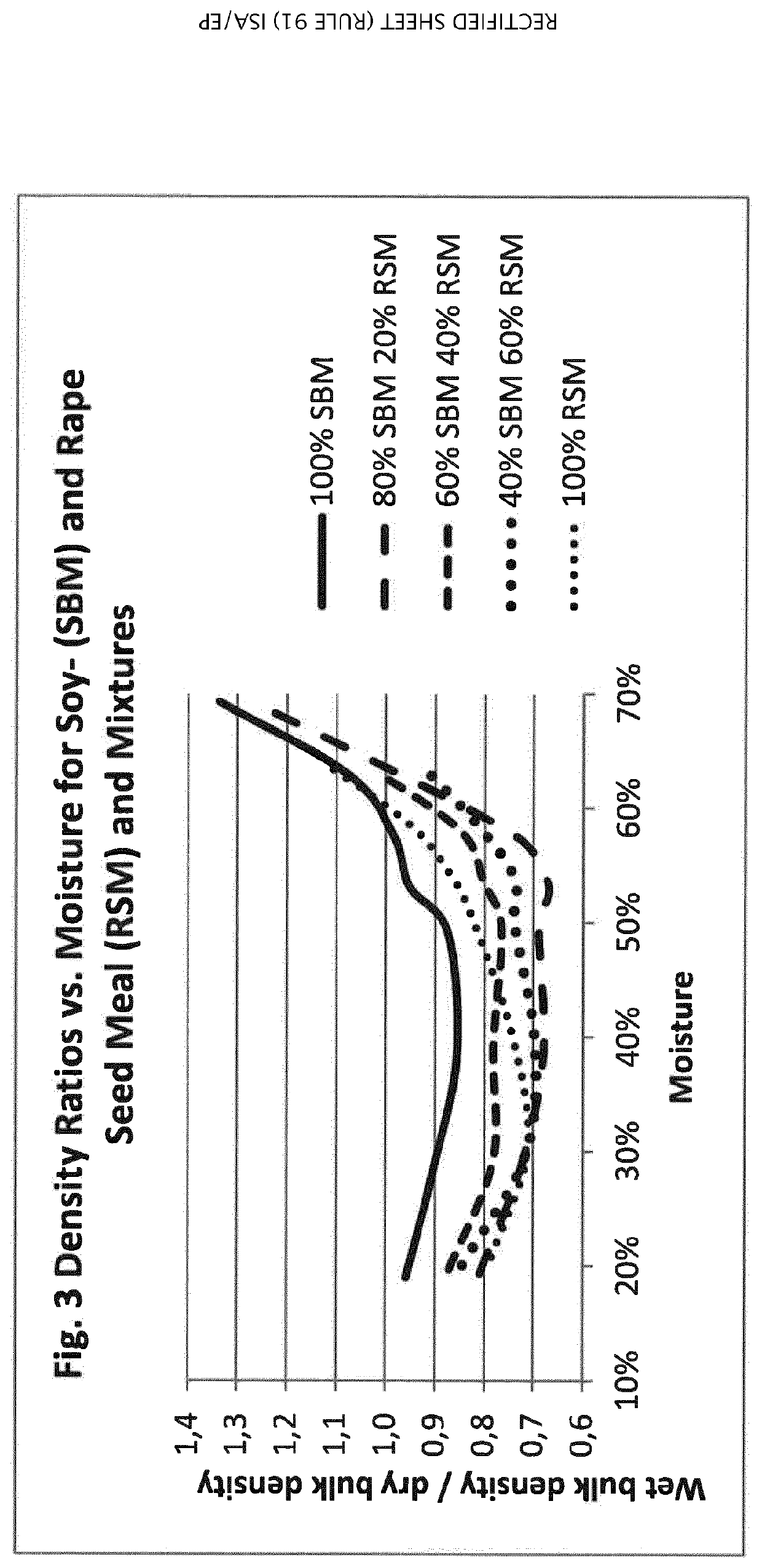

The invention relates to a method for the simultaneous production of a solid transformation product of the substrate and crude ethanol comprising the following steps: • preparing a substrate from milled or flaked biomass comprising proteinaceous matter which originates from soya bean, rape seed, or mixtures thereof, optionally in further mixture with proteinaceous matter originating from fava beans, peas, sunflower seeds, lupine, cereals, and / or grasses, • mixing said substrate with live yeast in a dry matter ratio of from 1:1 to 10,000:1 and adding water in an amount which provides a ratio of wet bulk density to dry bulk density from 0.60 to 1.45 in the resulting mixture; • incubating said mixture for 1-48 hours at a temperature of about 20-60° C.; and • separating crude ethanol and wet solid transformation product from said mixture; further comprising that the incubation is performed as a continuous plug-flow process in a vertical, non-agitated, closed incubation tank with inlet means for said mixture and additives and outlet means for the solid transformation product and crude ethanol. The invention further relates to the products of this method as well as uses thereof.

Owner:HAMLET PROTEIN AS

Vertical plug-flow process for simultaneous production of ethanol and a fermented, solid transformation product of the substrate

ActiveUS11180723B2Less-expensive in investmentLarge capacityAntibacterial agentsBioreactor/fermenter combinationsRapeseedCereal grain

The invention relates to a method for the simultaneous production of a solid transformation product of the substrate and crude ethanol comprising the following steps: •preparing a substrate from milled or flaked biomass comprising proteinaceous matter which originates from soya bean, rape seed, or mixtures thereof, optionally in further mixture with proteinaceous matter originating from fava beans, peas, sunflower seeds, lupine, cereals, and / or grasses, •mixing said substrate with live yeast in a dry matter ratio of from 1:1 to 10,000:1 and adding water in an amount which provides a ratio of wet bulk density to dry bulk density from 0.60 to 1.45 in the resulting mixture; •incubating said mixture for 1-48 hours at a temperature of about 20-60° C.; and •separating crude ethanol and wet solid transformation product from said mixture; further comprising that the incubation is performed as a continuous plug-flow process in a vertical, non-agitated, closed incubation tank with inlet means for said mixture and additives and outlet means for the solid transformation product and crude ethanol. The invention further relates to the products of this method as well as uses thereof.

Owner:HAMLET PROTEIN AS

Cell culture methods for producing recombinant proteins in the presence of reduced levels of one or more contaminants

InactiveUS8058027B2Lower Level RequirementsPromote growthAnimal cellsGenetically modified cellsBiotechnologyTherapeutic protein

Owner:MILLIPORE CORP

V-shaped product conveyor

InactiveUS7870950B2Convenience to workReducing resistance to movementConveyorsSupporting framesEngineeringProduct Containers

A conveyor system includes first and second upstanding posts disposed in longitudinally spaced apart relation to one another. Each post is surmounted by forward and rearward support arms that form a “V”-shape. A forward drive belt is mounted for rotation along a path of travel perpendicular to the forward support arms. A first embodiment cradles a product container between the forward drive belt and a rearward primary support arm. A second embodiment includes the first embodiment structure and adds a rearward secondary support arm. A third embodiment includes the primary but not the rearward secondary support arm, the forward drive belt and a forward secondary support arm. A fourth embodiment includes the rearward primary and secondary support arms, the forward drive belt and a forward secondary support arm. The product container is tilted from vertical so that the conveyor follows a path of travel including curvatures having no guide rails.

Owner:RINNE RHETT L

Vertical plug-flow process for bio-conversion employing microorganisms

ActiveUS20210000137A1Simple reactor designLess-expensive in investmentProtein composition from vegetable seedsBiofuelsSunflower seedProtein protein

The invention relates to a method for producing a solid transformation product of a substrate comprising the following steps: • preparing a substrate of biomass comprising carbohydrates and proteinaceous matter that originates from soya bean, rape seed, or mixtures thereof, optionally in further mixture with carbohydrates and proteinaceous matter originating from fava beans, peas, sunflower seeds, lupine, cereals, and / or grasses, • mixing said substrate with a live microorganism or a combination of live microorganisms, which live microorganism or mixture of live microorganisms is not live yeast, and adding water in an amount which provides an initial incubation mixture having a water content from 30 to 70% by weight, and a ratio of wet bulk density to dry bulk density from 0.60 to 1.45 in the resulting mixture; • incubating said initial incubation mixture for 1-240 hours at a temperature of 15-70° C.; and thereafter recovering wet solid transformation product from the incubation mixture; further comprising that the incubating step is performed as a continuous plug-flow process in a vertical, non-agitated incubation tank with inlet means for said mixture and additives and outlet means for said solid transformation product.

Owner:HAMLET PROTEIN AS

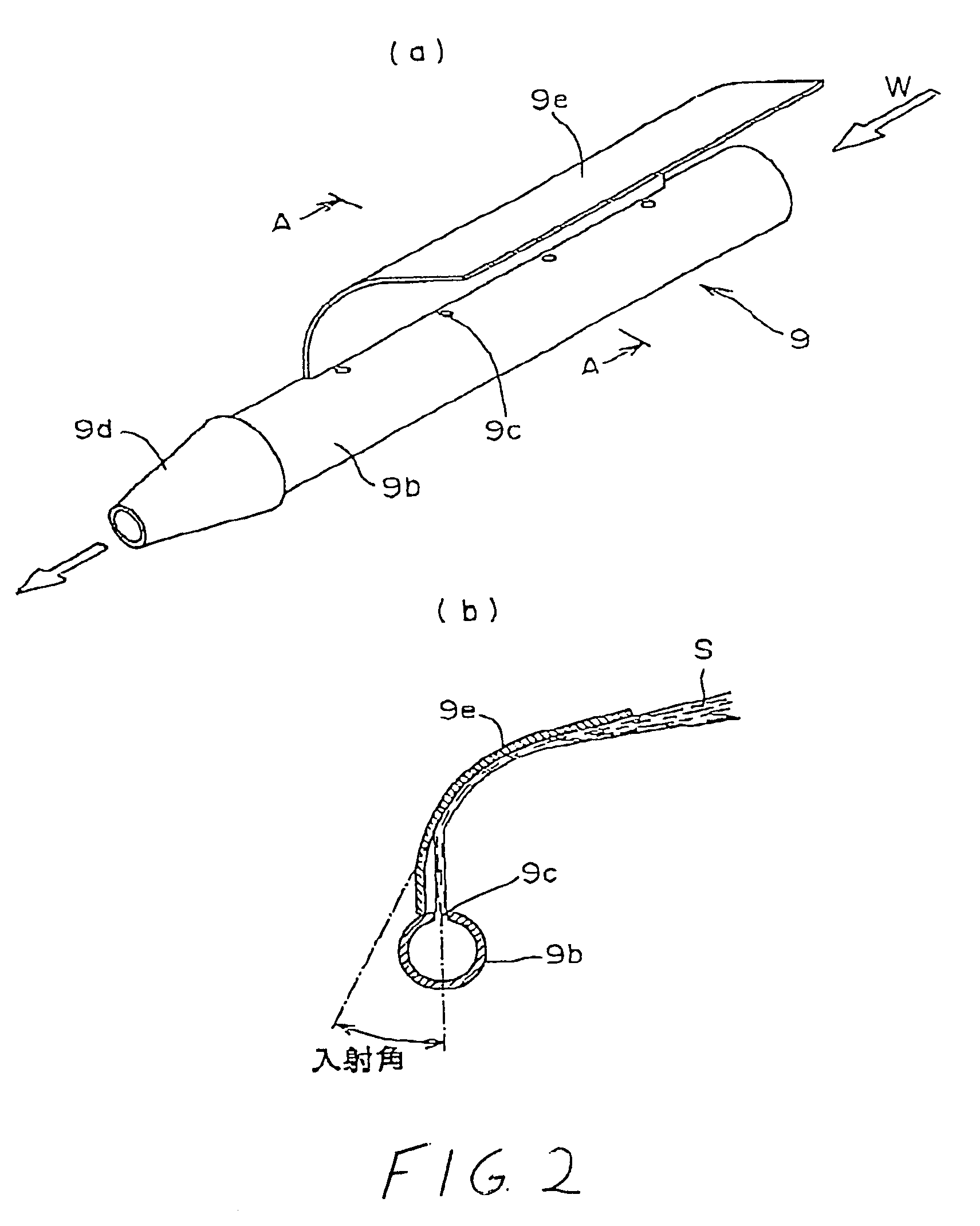

Spooled cutting string for string trimmer

InactiveUS20110061244A1Resists meltingResists fusionMowersMetal working apparatusEngineeringAbrasive

A novel abrasive cutting string for use in a string trimmer provides for a thermoplastic string with abrasives in the surface, but not in the central core of the string, the string being wound on a spool for rotation and incremental extension of at least one extremity in combination with the operation of the string trimmer.

Owner:WOOD LARRY +1

IP based microphone and intercom

InactiveUS9001729B2Less-expensive to manufactureLess-expensive to maintainBroadcast transmission systemsClosed circuit television systemsMicrocontrollerTransceiver

A transceiver including, a codec, microcontroller, and radio. The codec including an analog to digital converter for receiving a first audio program and converting it to a first digital signal; a digital to analog converter for receiving a second digital audio signal and converting it to a second audio program; and, a control function for managing characteristics of the codec. The microcontroller is in electrical communication with the codec: for receiving the first digital audio signal from the codec and packetizing it into a first packet for transmission over a TCP / IP network; for receiving a second packet from network and converting it into the second digital audio signal and sending it to the codec; and for receiving control signals from the network. The radio is in electrical communication with the microcontroller for connection to the network to transmit the first packet to the network and receive the second packet from the network.

Owner:LP PARTNERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com