Level-wind system for coiled tubing

a level-wind system and coil-type technology, applied in the field of coil-type tubing systems, can solve the problems of inability to adapt the tubing guide heads of these prior systems, subject to excess failure, and high cost of implementation, maintenance and operation of prior systems, and achieve the effect of less expensive manufacture, maintenance and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Refer now to the drawings wherein depicted elements are not necessarily shown to scale and wherein like or similar elements are designated by the same reference numeral through the several views.

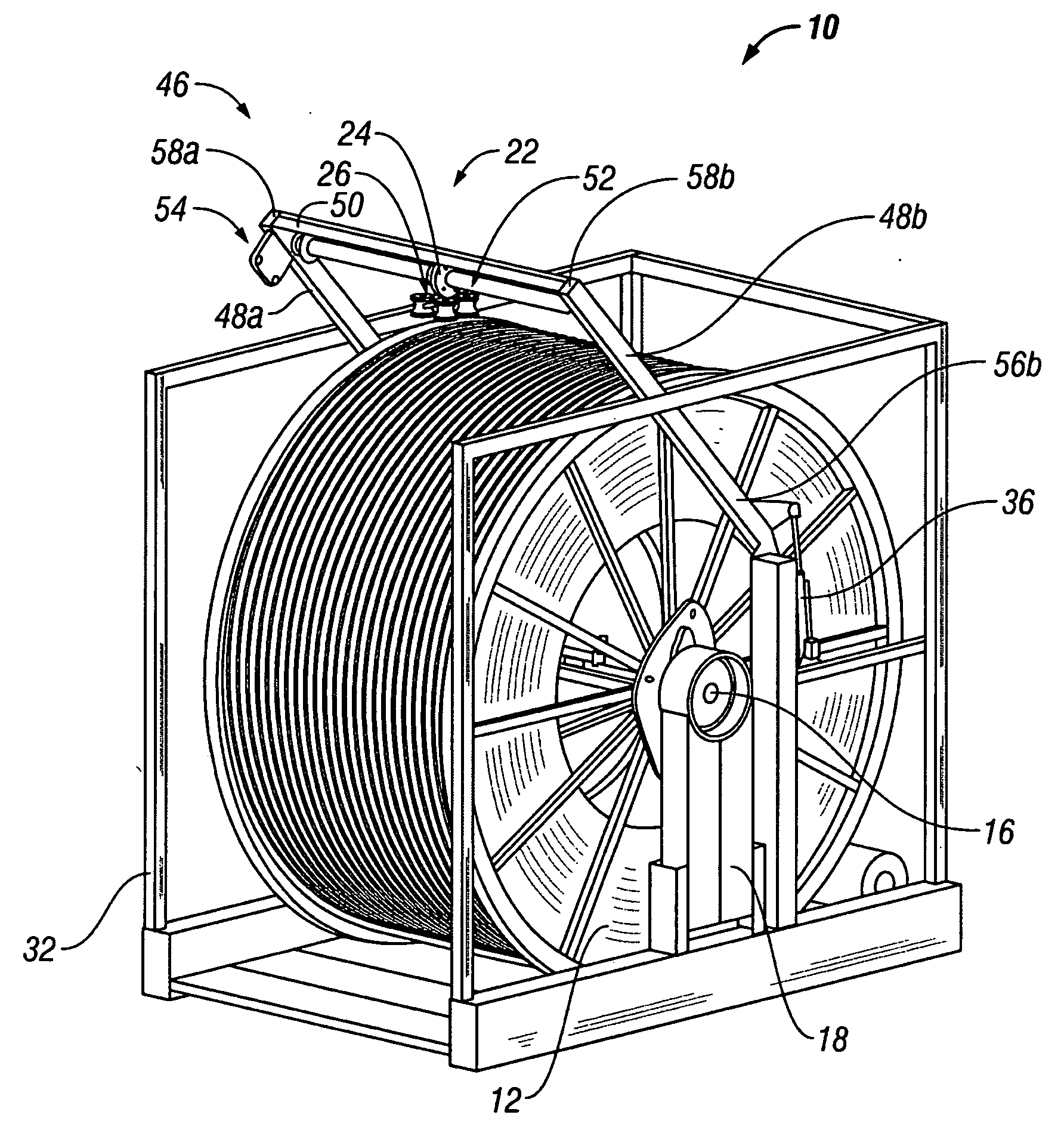

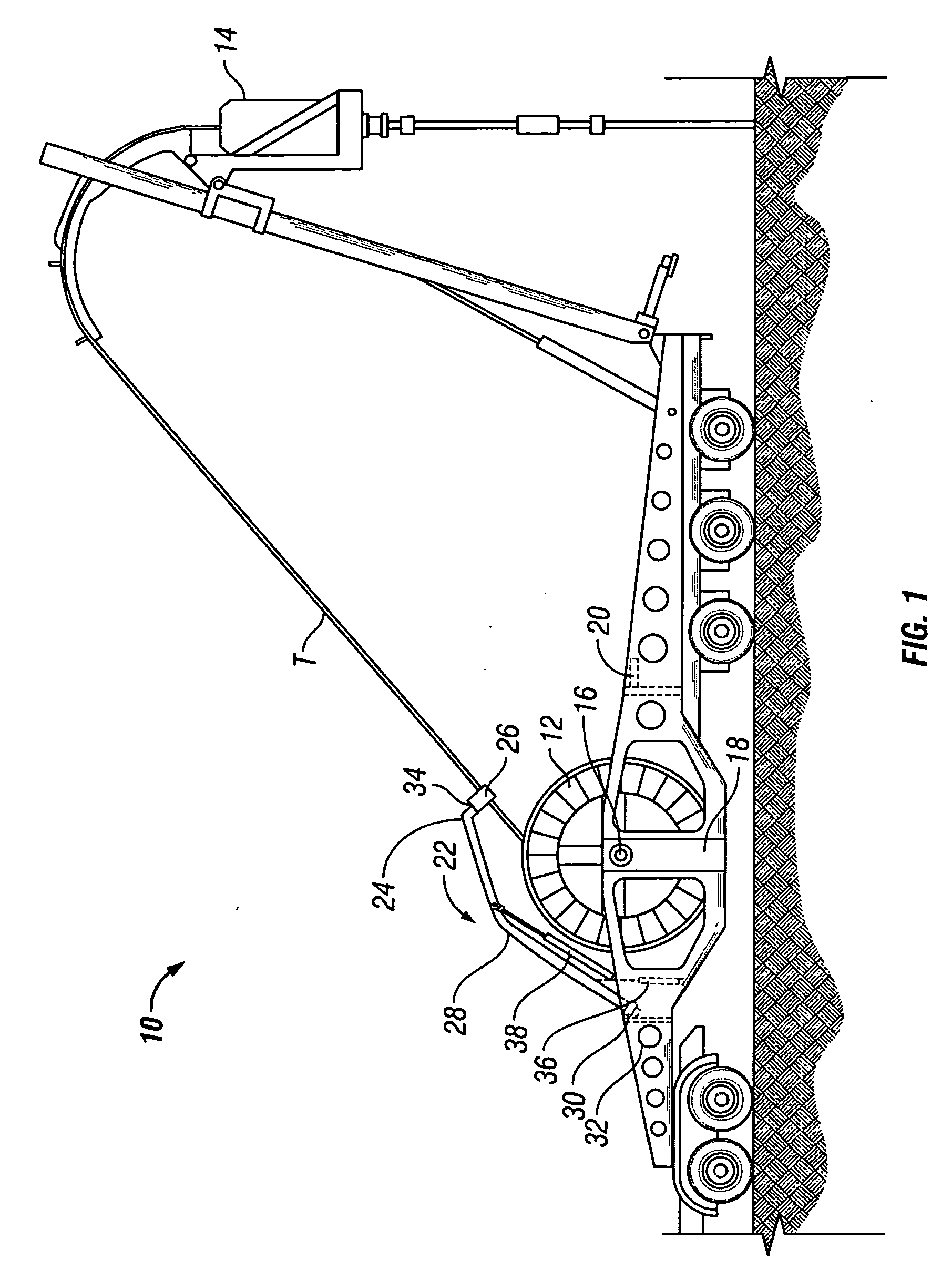

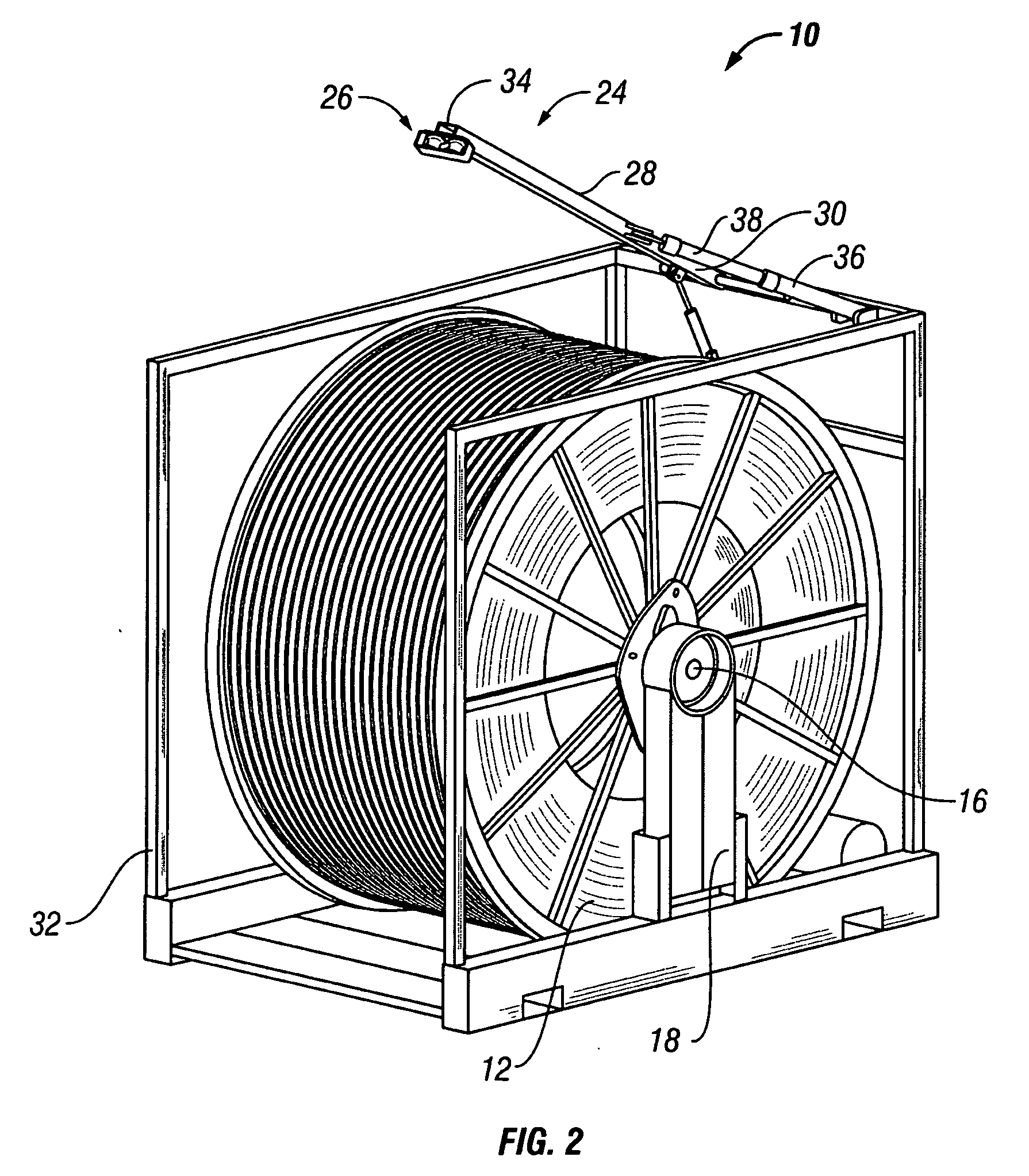

[0019]FIG. 1 is a side view of an embodiment of a trailer mounted coiled tubing unit of the present invention, generally designated by the numeral 10. A reel 12 for spooling coiled tubing T is mounted on a trailer. Coiled tubing T is spooled from reel 12 to injector 14 for injecting coiled tubing T into a well, and spooled onto reel 12 when removing coiled tubing T from the well. Reel 12 having an axle 16 is rotatably mounted on struts 18. Axle 16 defines the longitudinal axis of reel 12. A hydraulic motor 20 is connected to reel 12 for rotating reel 12. Hydraulic motor 20 and the drive connections, not shown, to reel 12 are generally referred to as the reel's drive mechanism.

[0020] A level-wind system 22 having an arm 24 and a level-wind head, or roller head, 26 is positioned proxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com