Patents

Literature

34results about How to "Less-expensive to build" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

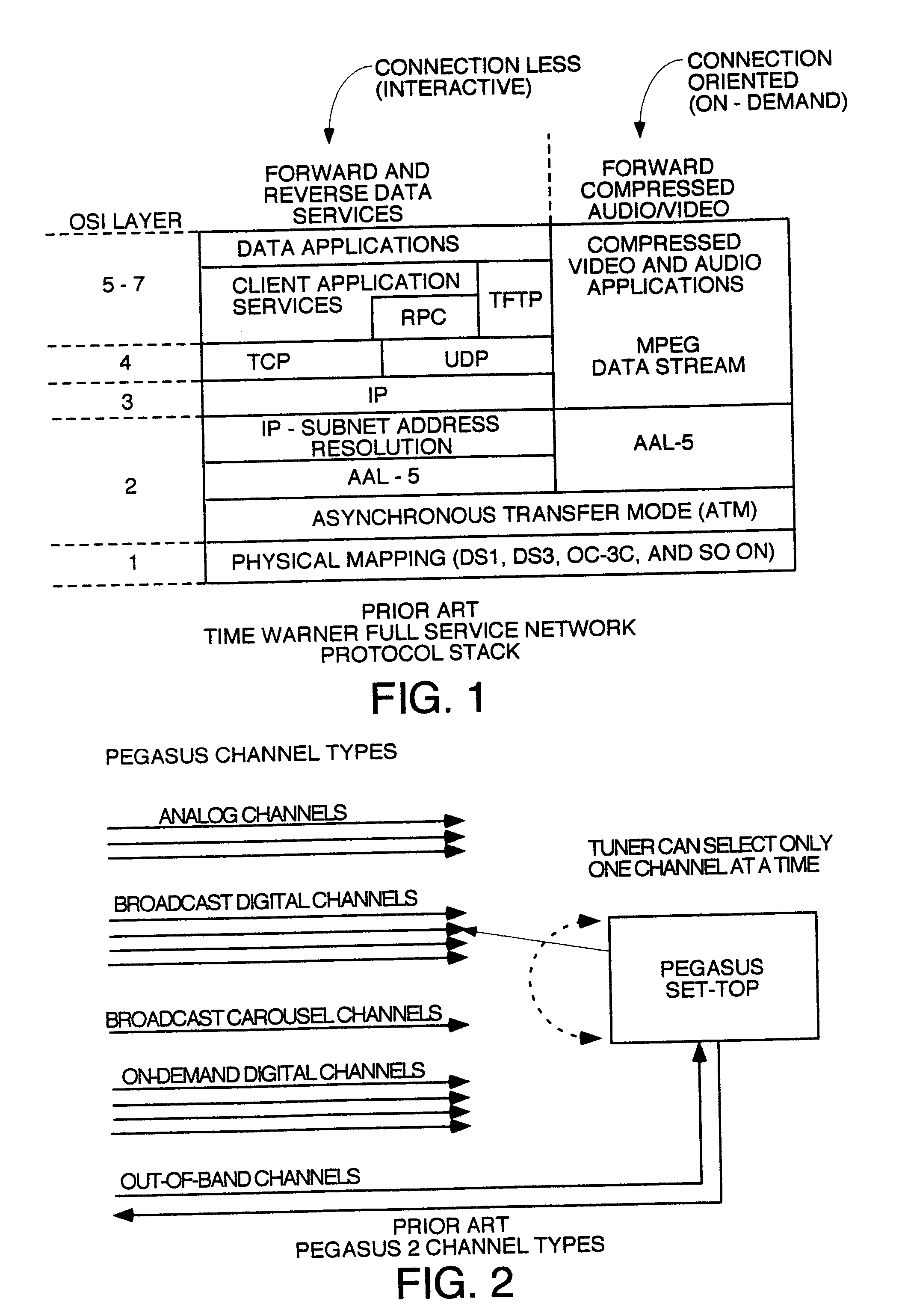

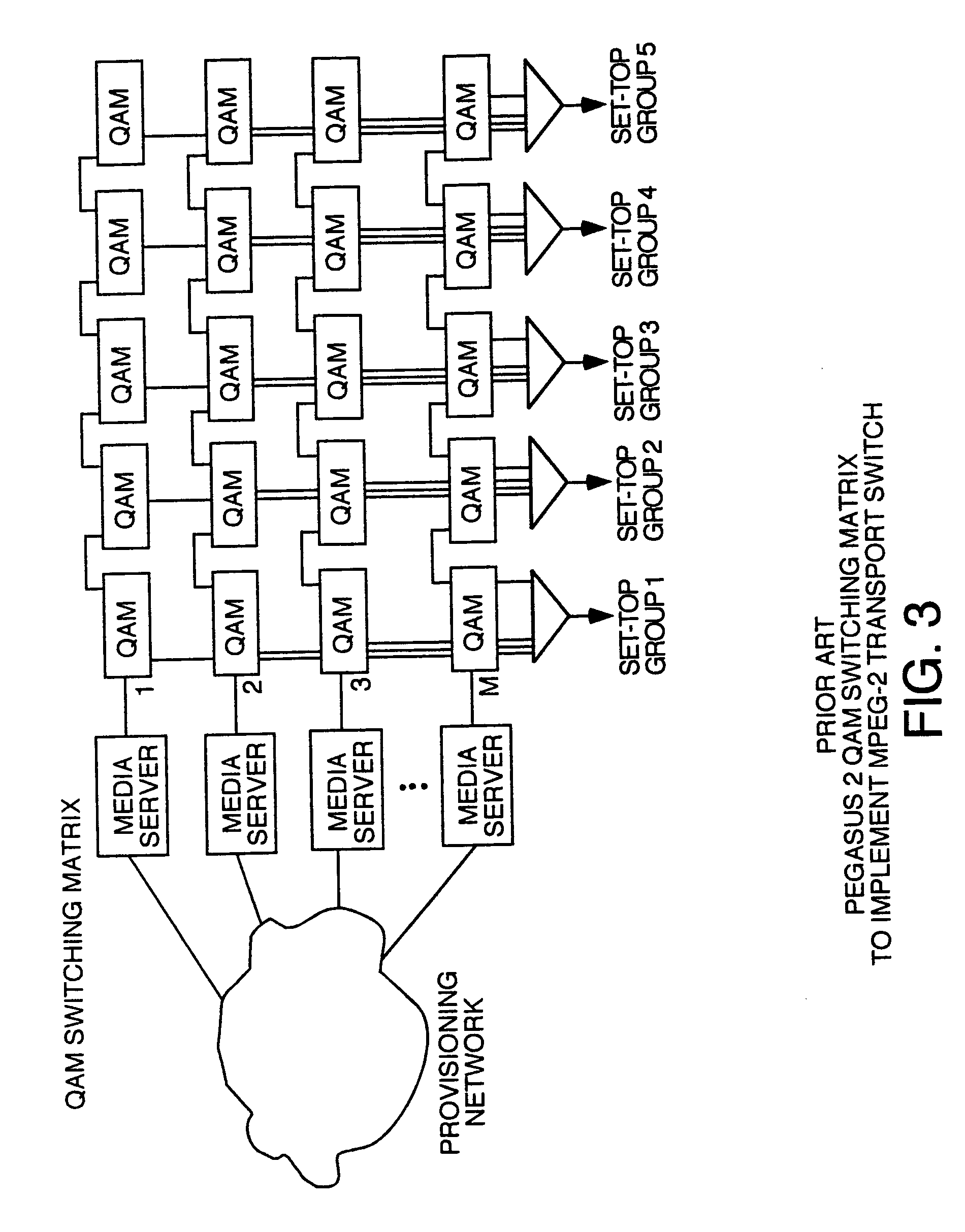

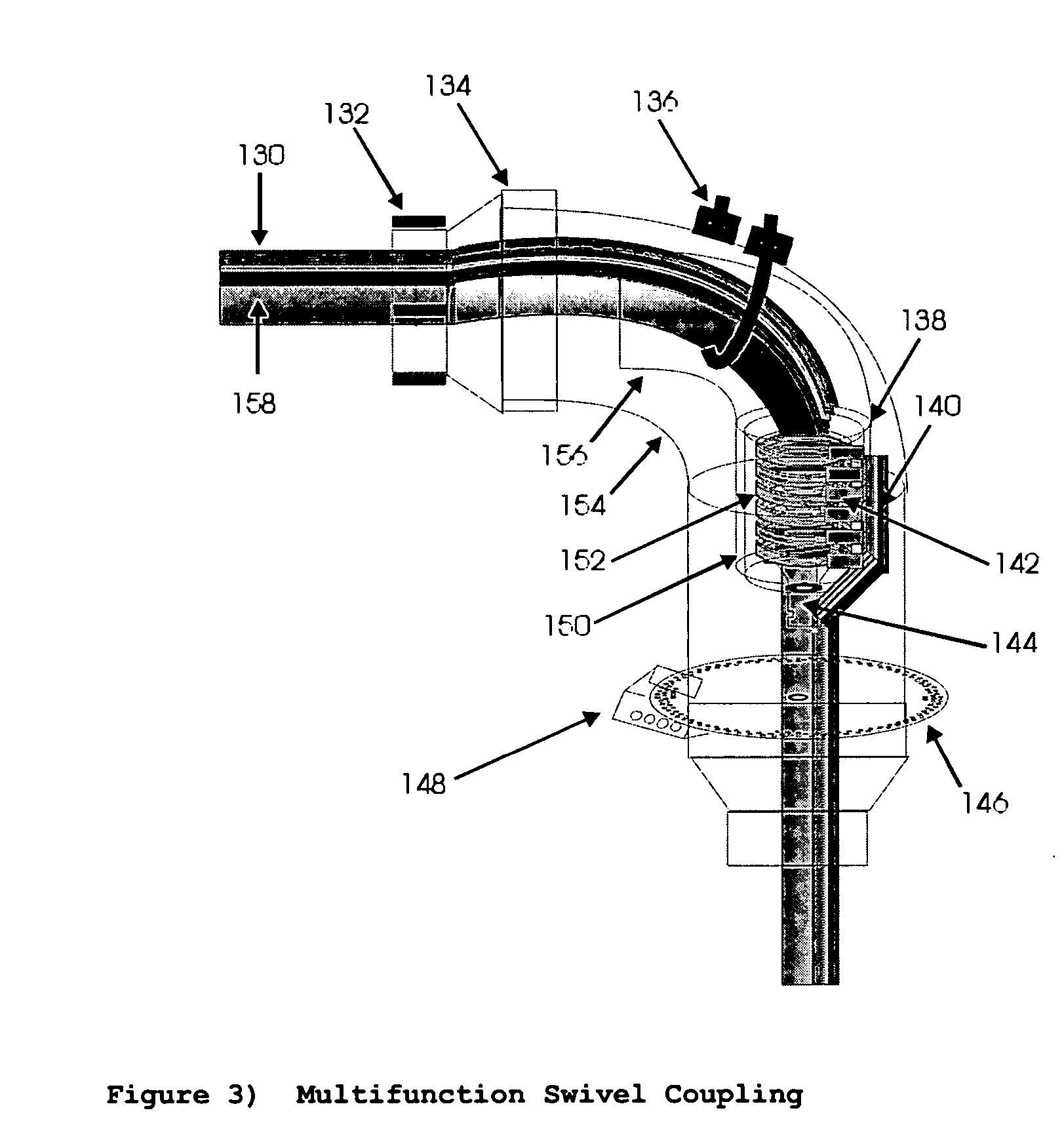

Thin DOCSIS in-band management for interactive HFC service delivery

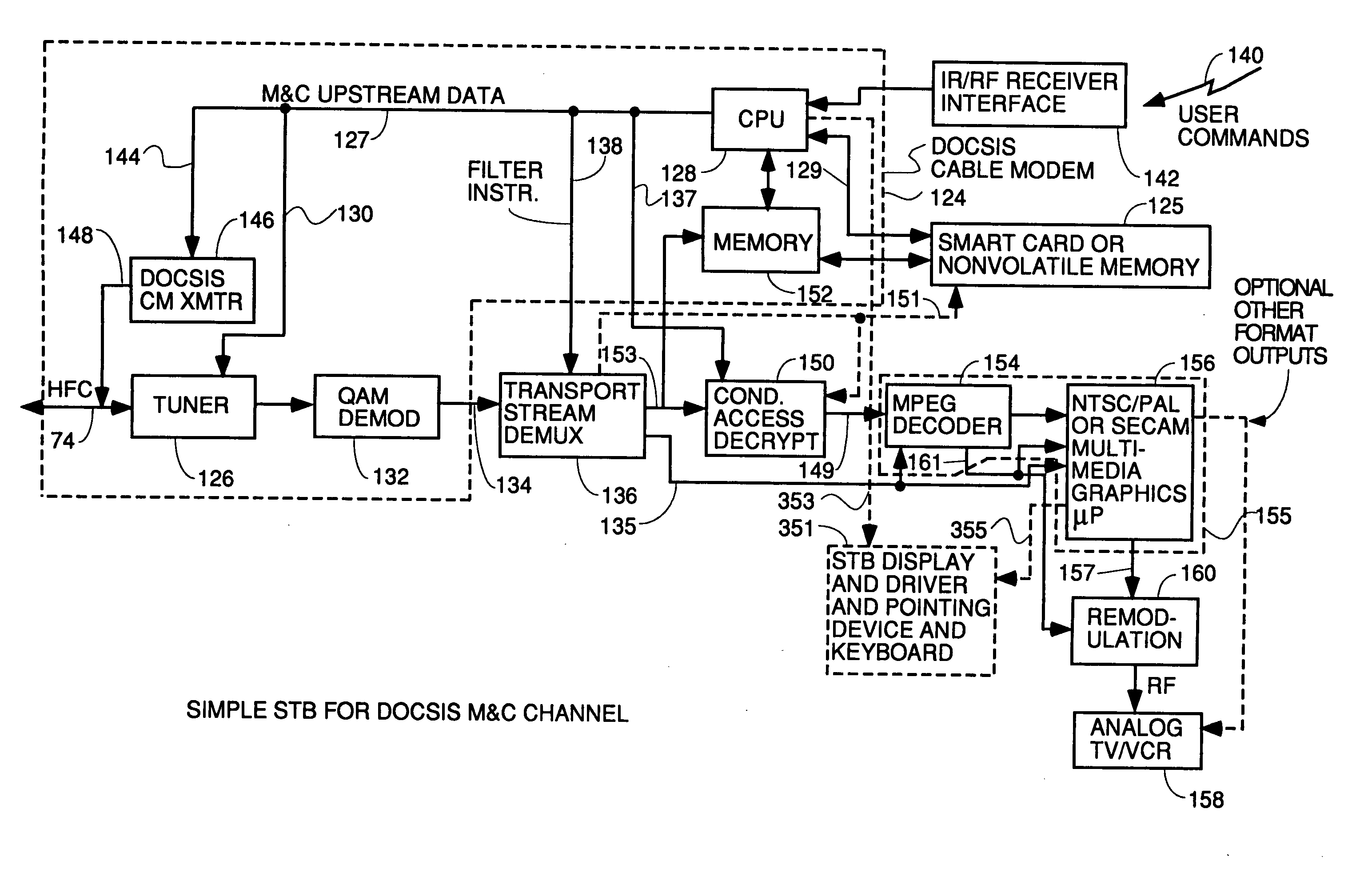

InactiveUS20040181800A1Simple processLess-expensive to buildAnalogue secracy/subscription systemsTwo-way working systemsModem deviceConditional access

Circuitry and processes carried out thereby are disclosed for implementing simple single tuner set top box decoders which do not require a separate tuner for an out of band management and control channel. Removable smart card conditional access circuitry and replaceable modules having decoding circuitry for different compression schemes and encoding circuitry for different format television circuits is disclosed. An embodiment with a single tuner and a full DOCSIS compatible modem which can interface to personal computers, etc. is also disclosed to make the set top box a simple, inexpensive home gateway is also disclosed.

Owner:TERAYON COMM SYST

Thin DOCSIS in-band management for interactive HFC service delivery

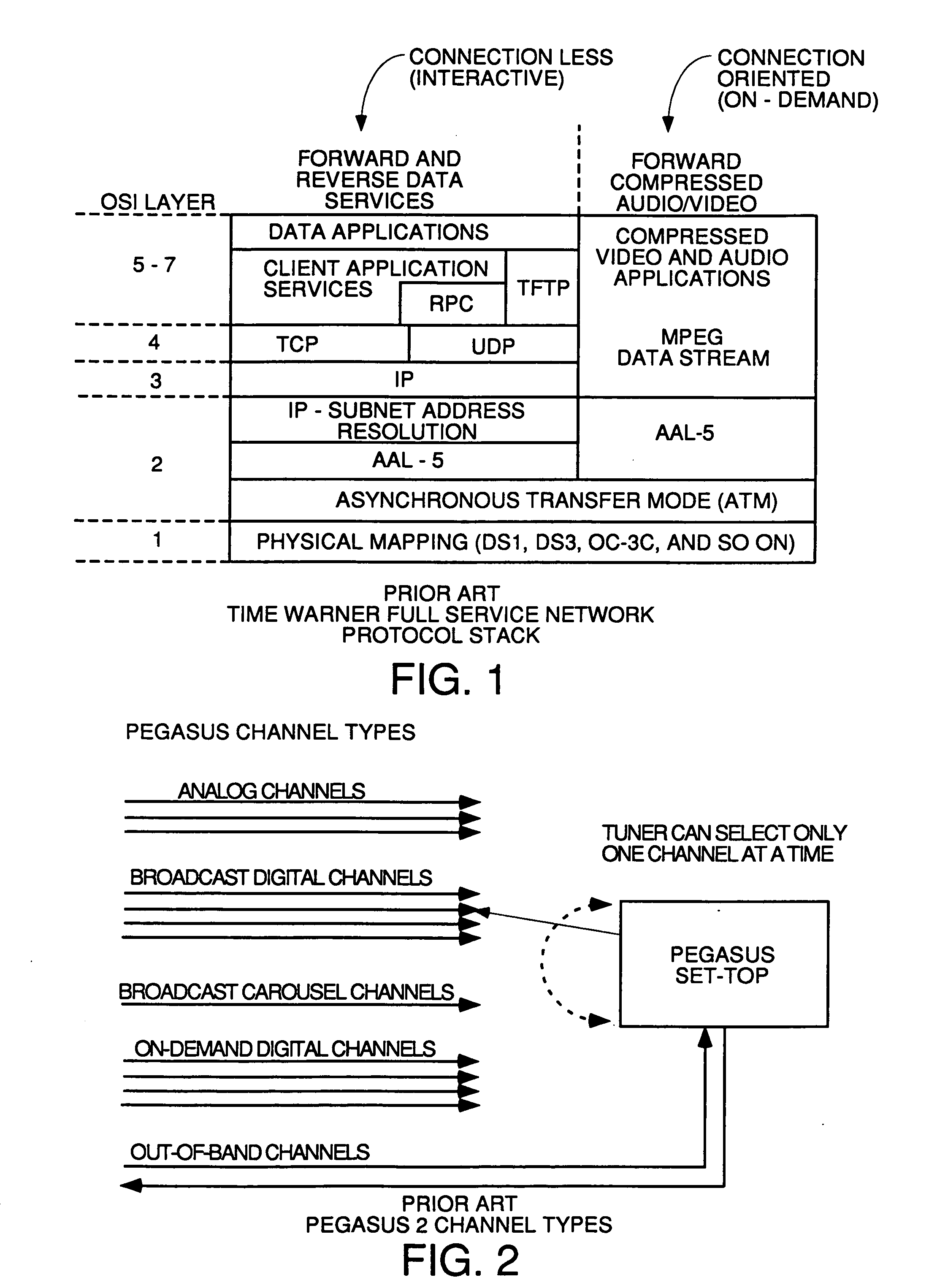

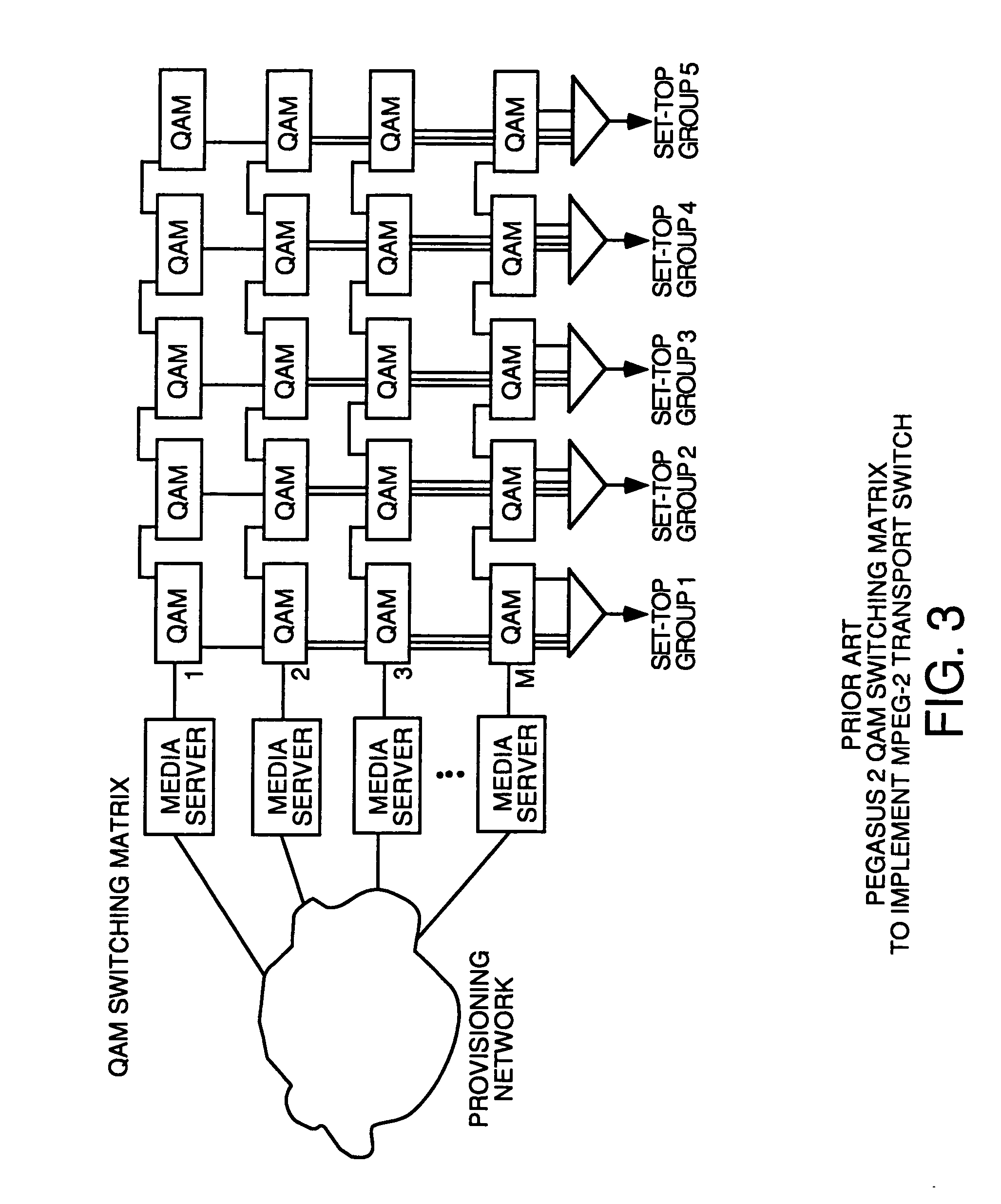

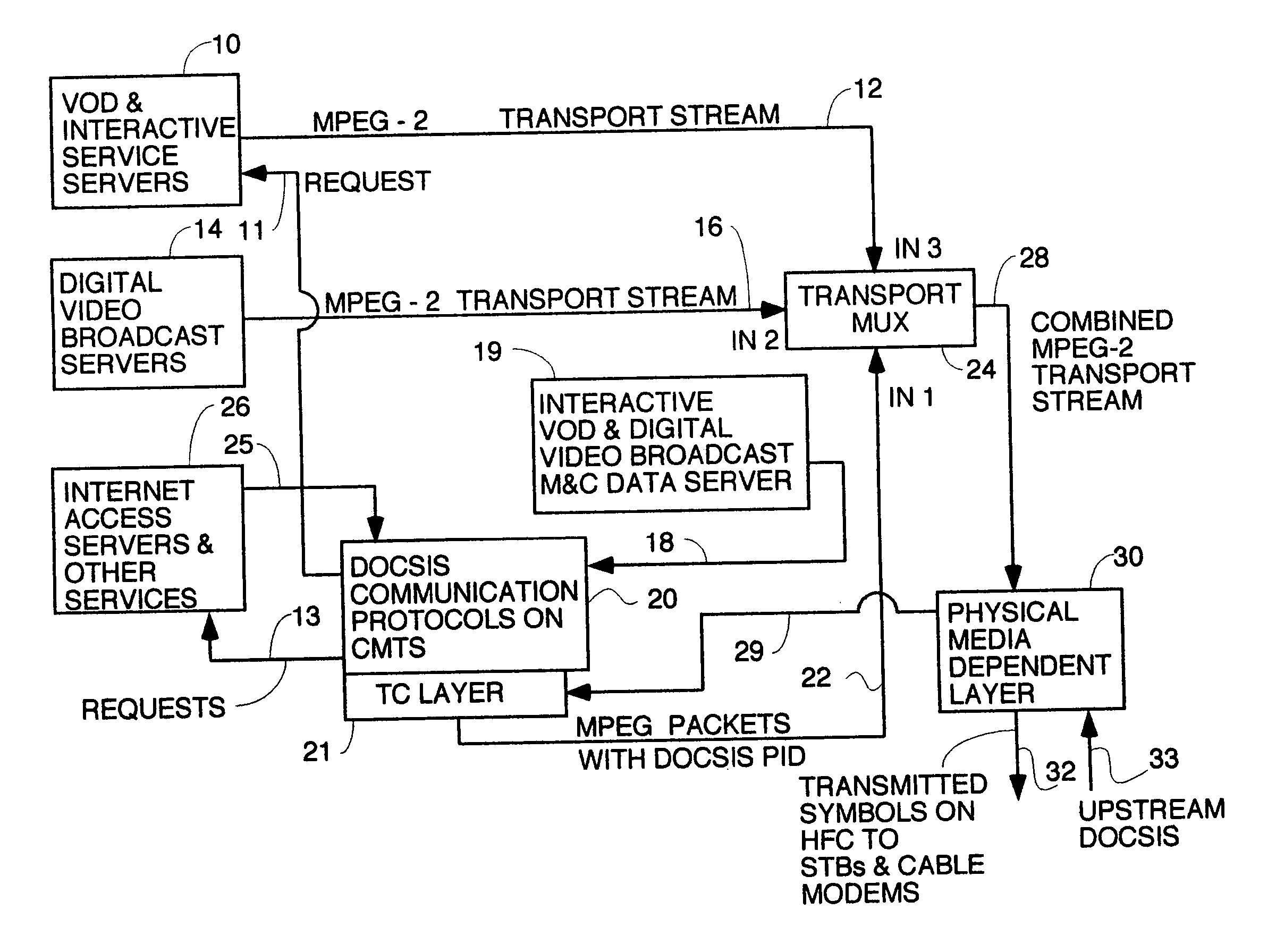

InactiveUS20040181811A1Simplifies STBsLess-expensive to buildAnalogue secracy/subscription systemsBroadcast information monitoringDOCSISMPEG transport stream

Circuitry and processed carried out thereby are disclosed for transmitting video-on-demand and interactive service data and other service data on an MPEG multiplex and sending management and control data including conditional access EMM key data in-band in said MPEG multiplex in MPEG packets having the DOCSIS PID. Processes to send conditional access data by sending ECM messages containing control words encrypted with session keys in said MPEG multiplex and sending EMM messages containing session keys encrypted with private set top box users keys are disclosed. The EMM messages are sent in-band in MPEG packets having the DOCSIS PID to only the set top boxes that request them and which have ordered an encrypted service. A head end with routing / switching capability to route MPEG transport streams encapsulated in IP packets is also disclosed.

Owner:TERAYON COMM SYST

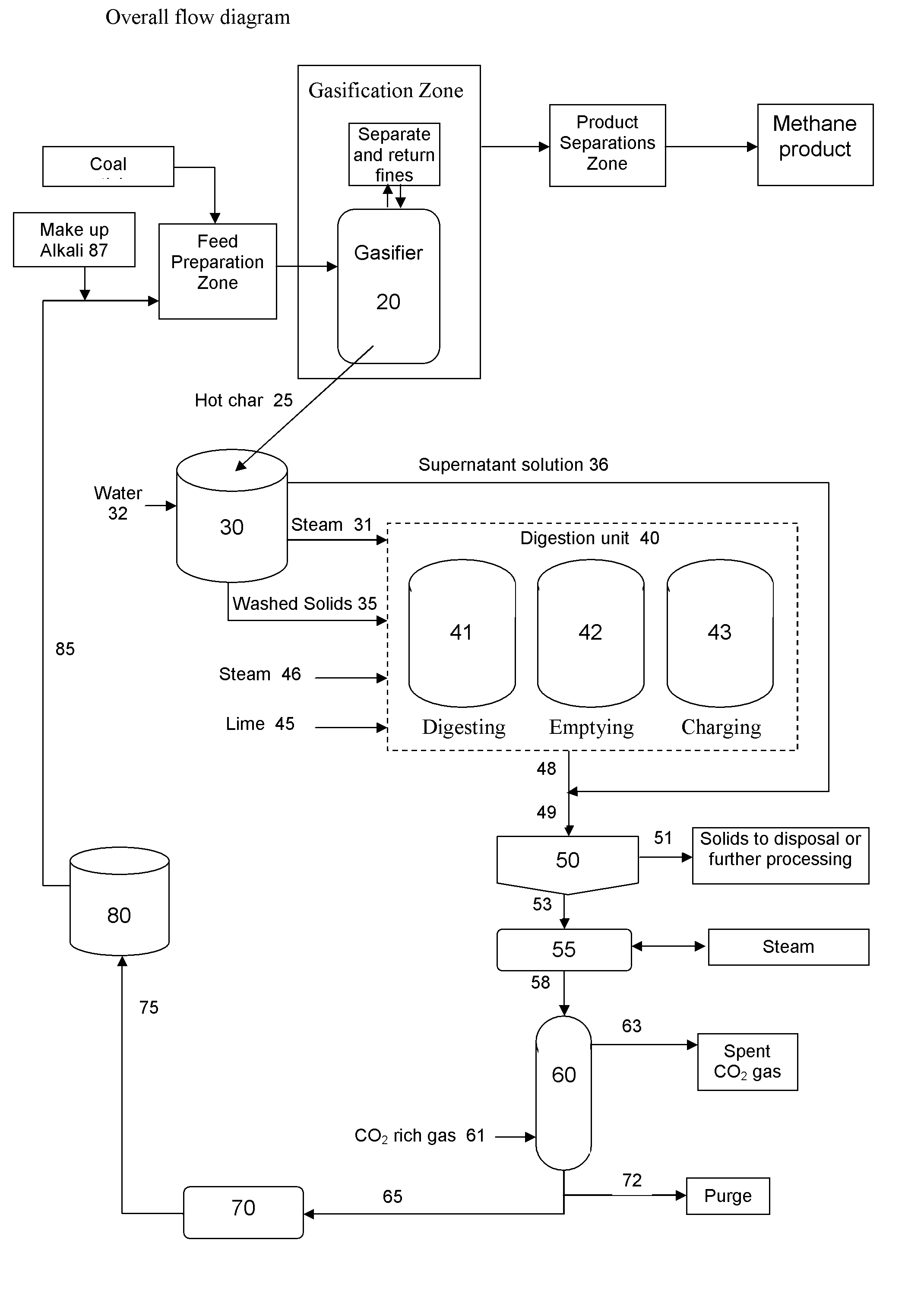

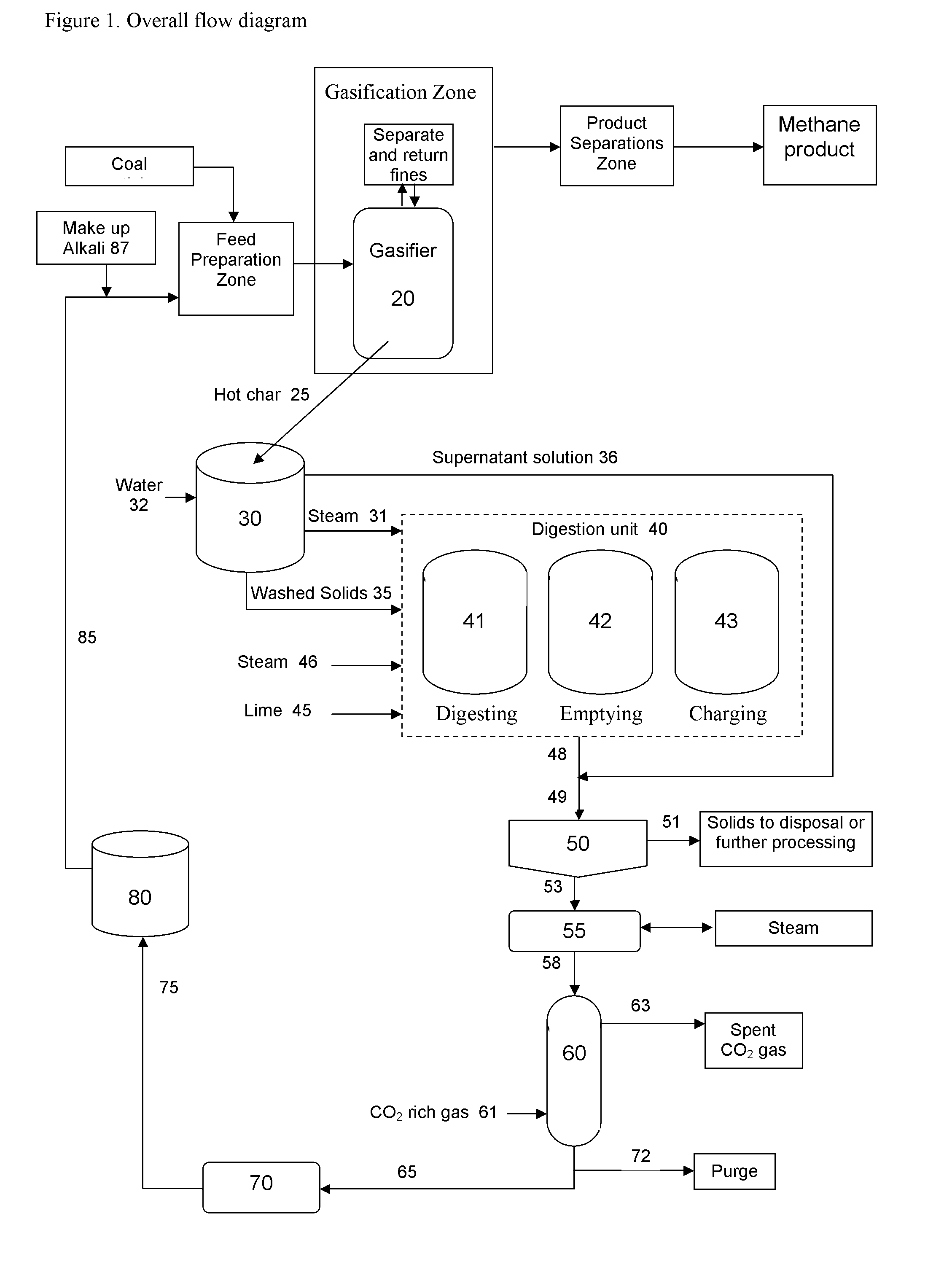

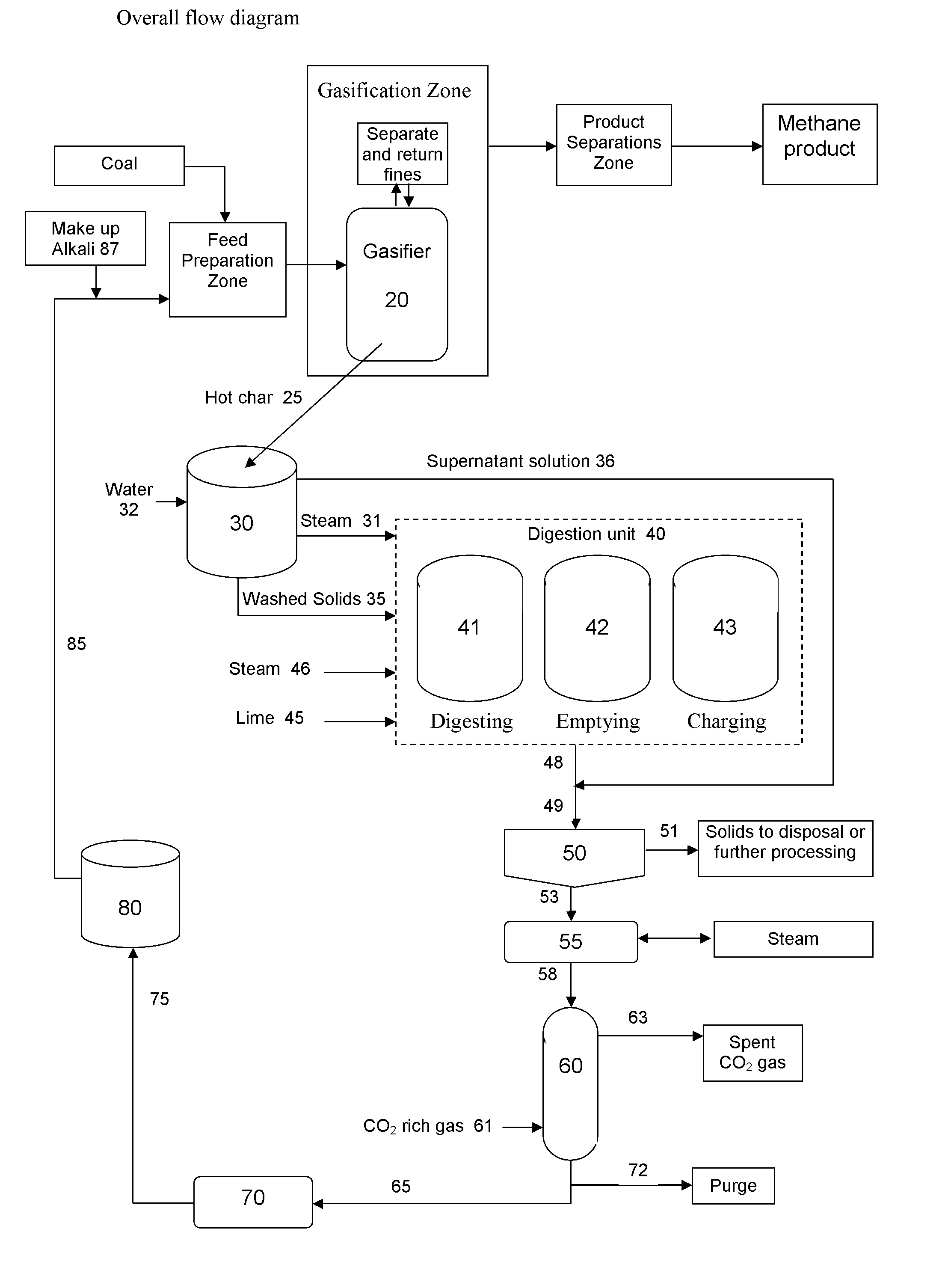

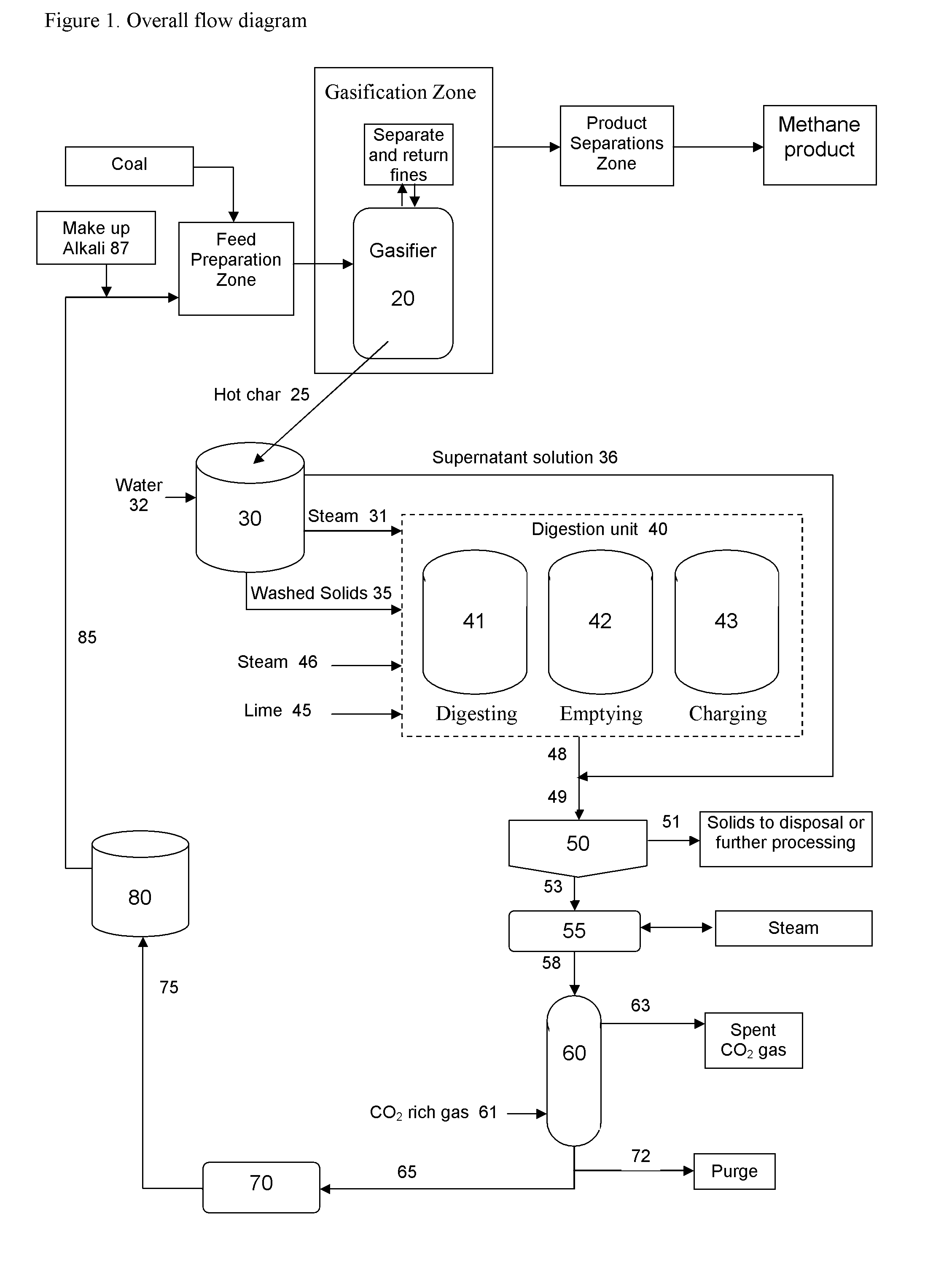

Catalytic steam gasification process with recovery and recycle of alkali metal compounds

ActiveUS20070277437A1Promote leachingLarge specific surface areaHydrogenGas modification by gas mixingCompound aAlkali metal

A high efficiency gasification process for converting carbonaceous solids to methane and apparatus for its practice are described. The process includes reacting steam and carbonaceous solids comprising ash in the presence of alkali metal catalyst in a gasification reactor to produce combustible gases and char particles comprising ash and alkali metal catalyst constituents, treating a stream of such char particles in an alkali metal catalyst recovery system to recover the catalyst constituents as alkali metal compounds, and recycling such recovered compounds. Within the alkali metal catalyst recovery system the process includes quenching the stream of char particles with water whereby such particles are cooled and fractured, dissolving soluble alkali metal catalyst constituents from the fractured solids to form a first alkali metal catalyst solution and washed solids, optionally reacting the washed solids in alkaline solution to form a second alkali metal catalyst solution, upgrading said first and optional second alkali solution to recover the alkali metal catalyst constituents as said alkali metal compounds.

Owner:SURE CHAMPION INVESTMENT LTD

Catalytic steam gasification process with recovery and recycle of alkali metal compounds

ActiveUS7922782B2Promote leachingLarge specific surface areaHydrogenGaseous fuelsCompound aCombustible gas

A high efficiency gasification process for converting carbonaceous solids to methane and apparatus for its practice are described. The process includes reacting steam and carbonaceous solids comprising ash in the presence of alkali metal catalyst in a gasification reactor to produce combustible gases and char particles comprising ash and alkali metal catalyst constituents, treating a stream of such char particles in an alkali metal catalyst recovery system to recover the catalyst constituents as alkali metal compounds, and recycling such recovered compounds. Within the alkali metal catalyst recovery system the process includes quenching the stream of char particles with water whereby such particles are cooled and fractured, dissolving soluble alkali metal catalyst constituents from the fractured solids to form a first alkali metal catalyst solution and washed solids, optionally reacting the washed solids in alkaline solution to form a second alkali metal catalyst solution, upgrading said first and optional second alkali solution to recover the alkali metal catalyst constituents as said alkali metal compounds.

Owner:SURE CHAMPION INVESTMENT LTD

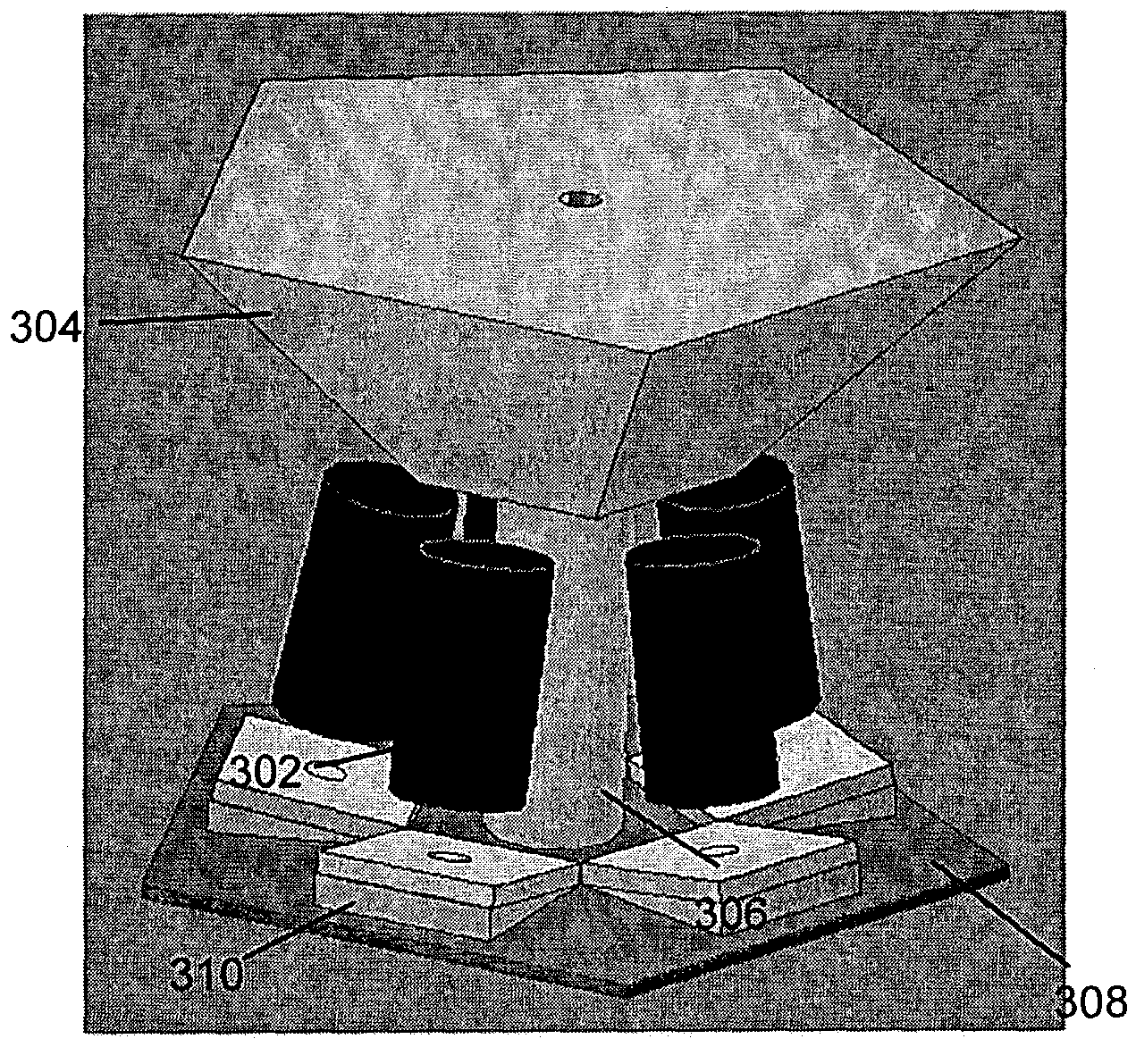

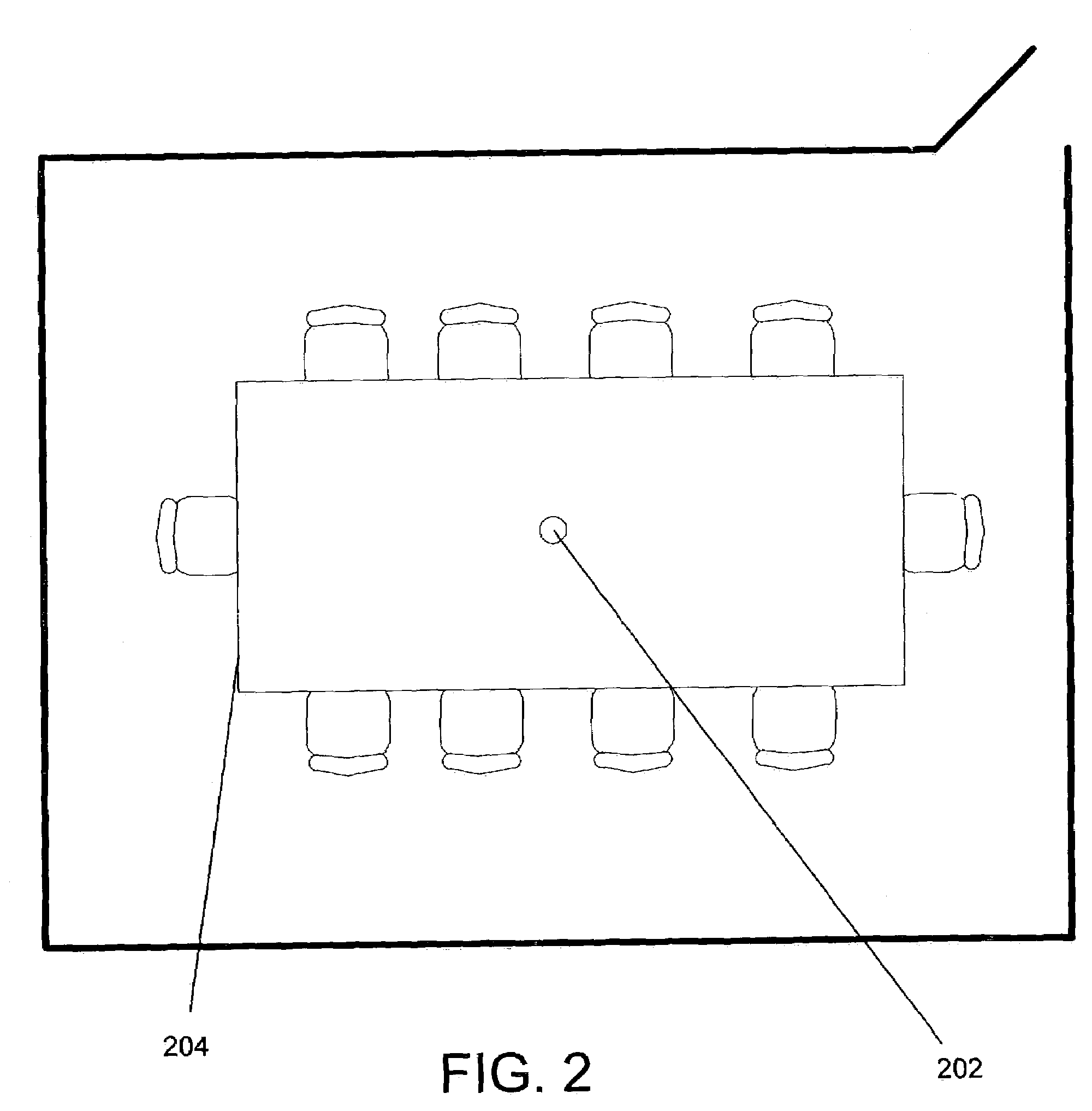

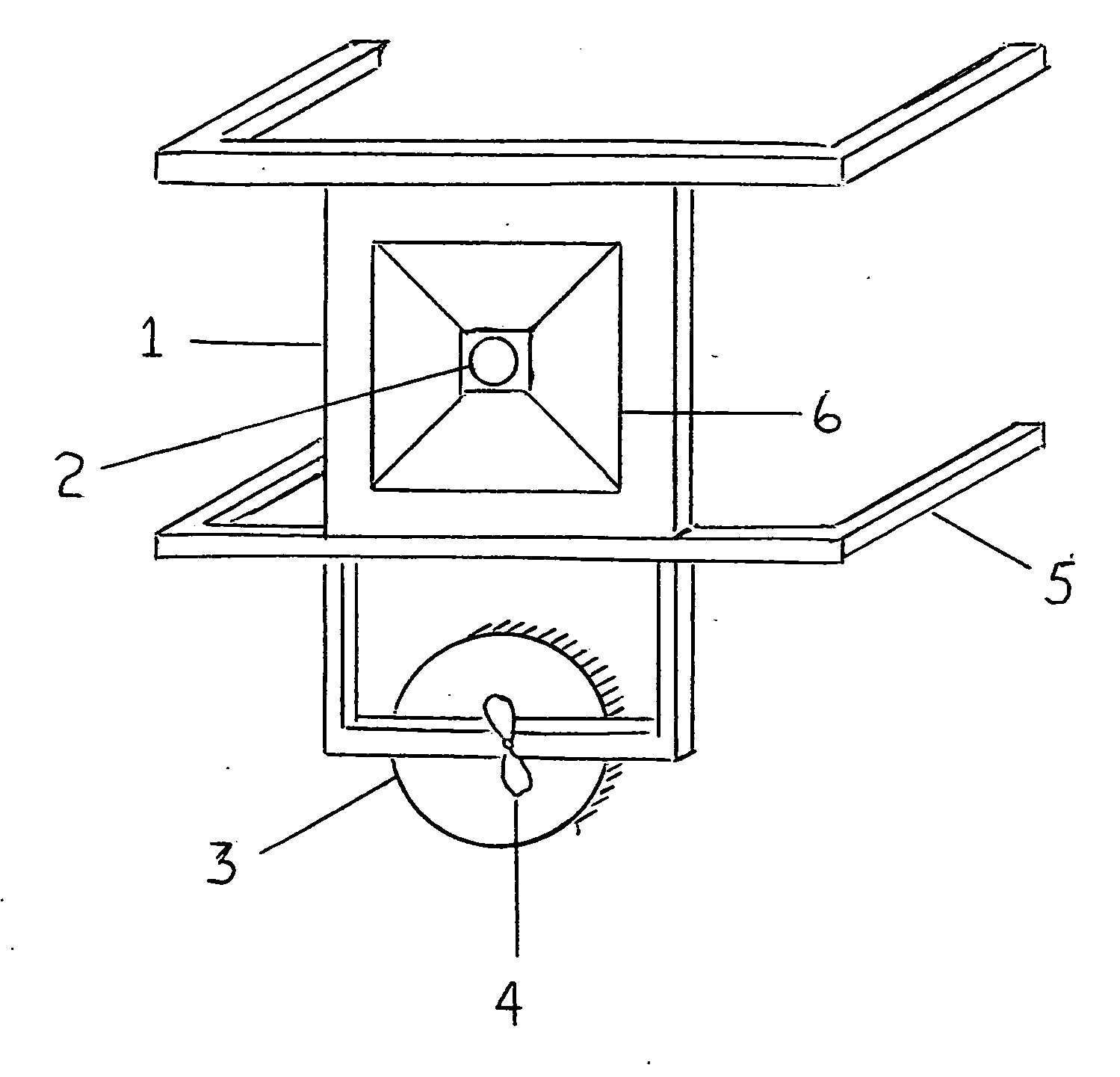

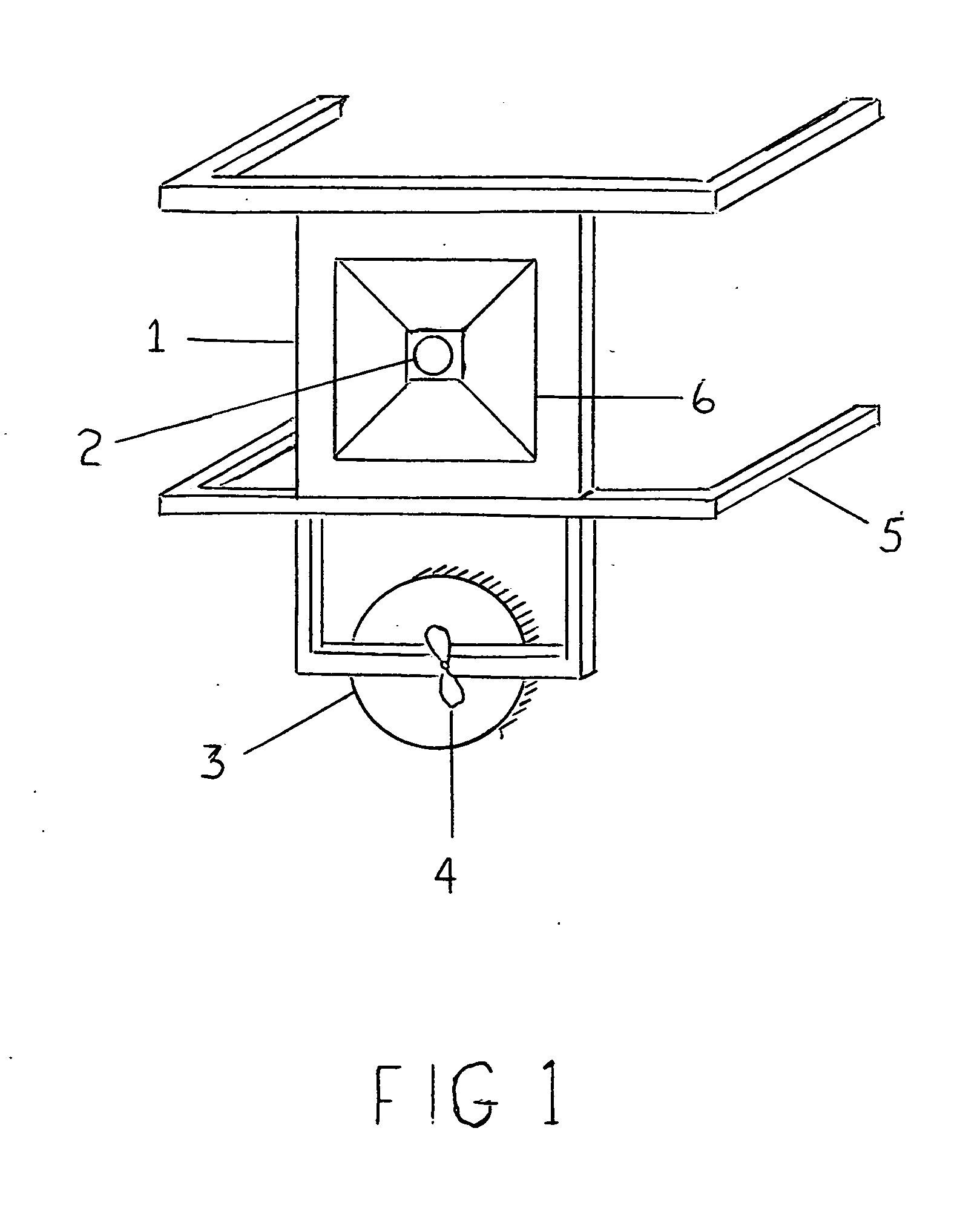

Omni-directional camera design for video conferencing

InactiveUS7298392B2Increase pixel resolutionLess-expensive to buildTelescopesTwo-way working systemsImage resolutionOmni directional

An omni-directional camera array that is very small and unobtrusive and allows for higher pixel resolution for the face of meeting participants sitting or standing around a conference room table, as would be typical in a video conferencing situation. The camera system of the invention uses N cameras and an N sided mirror to capture images of the surrounding scene. The cameras are arranged to have a small distance between their virtual centers of projection. The images from the N cameras are stitched together to create a 360-degree panorama using a calibration surface. To stitch the images together in real-time, a static image stitcher is used, which stitches images together perfectly for objects on a calibration surface. The calibration surface is typically defined by the boundary of the table the camera is sitting on.

Owner:MICROSOFT TECH LICENSING LLC

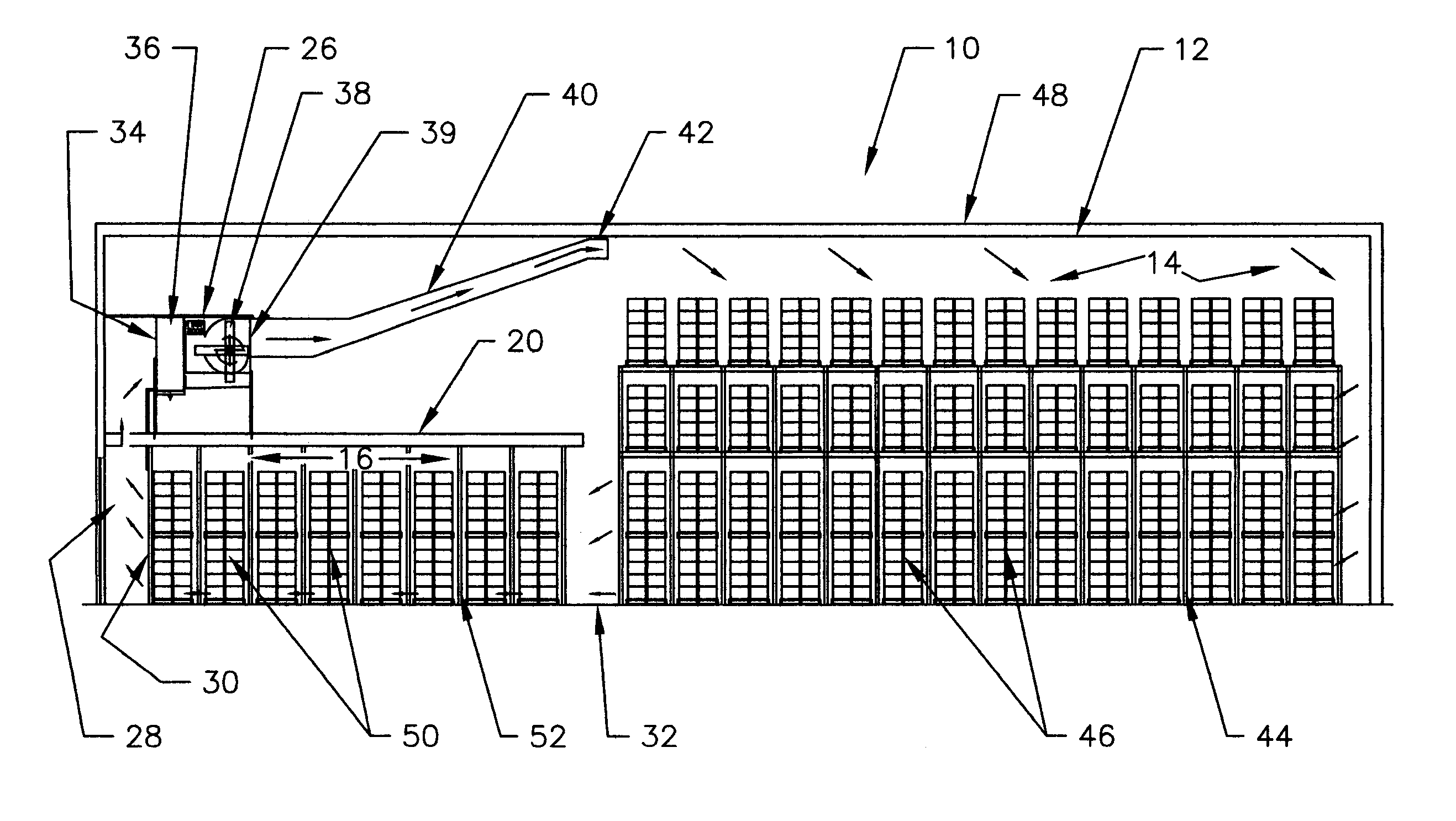

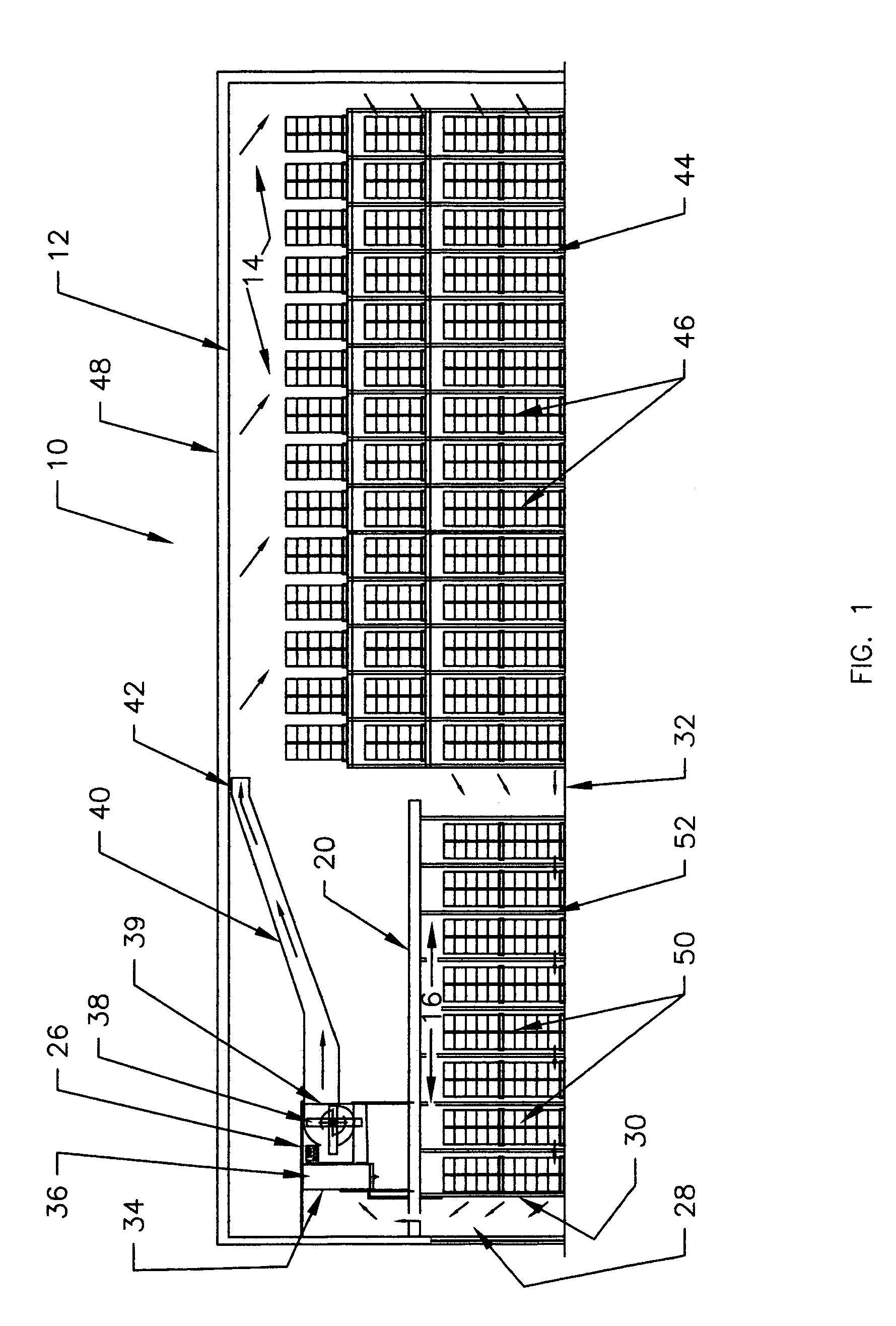

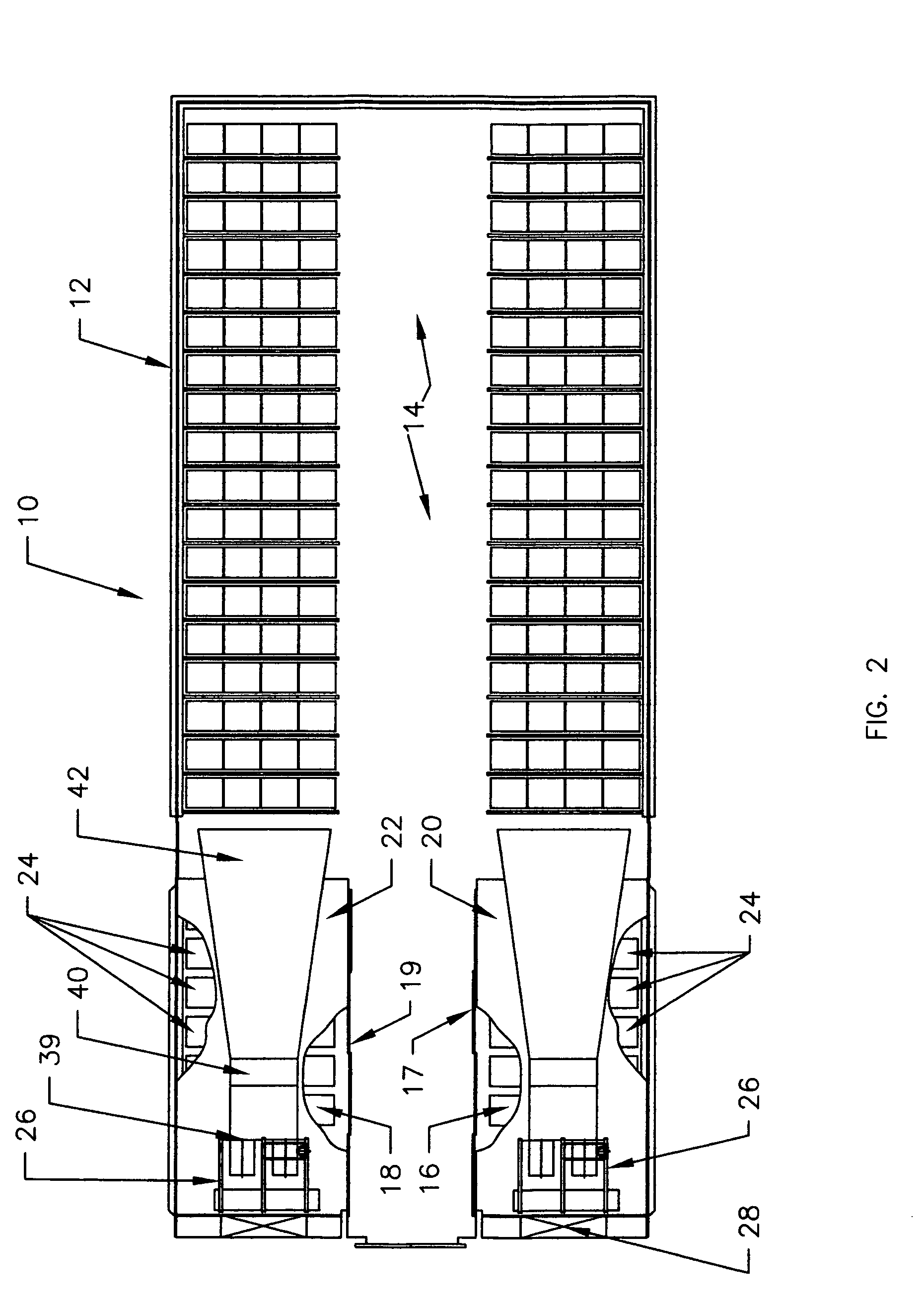

Freezer arrangement

ActiveUS7178356B1Less-expensive to buildLess-expensive to operateLighting and heating apparatusFood preservationEngineeringRefrigeration

A freezer arrangement includes a room having a storage area and a blast cell, with the volume of the storage area being greater than the volume of the blast cell. Frozen food product is positioned in the storage area. A refrigeration unit draws air from the storage area and through the blast cell to rapidly freeze the unfrozen food product. Air from the blast cell is chilled and blown back into the storage area. A method for rapidly freezing unfrozen food product includes providing a room with a large storage area and a smaller blast cell. Unfrozen food product is loaded into the blast cell and a refrigeration unit is operated to draw air from the large storage area, through the blast cell, chill the air, and exhaust the chilled air into the storage area, until the food product in the blast cell is cooled to a predetermined temperature.

Owner:LINGELBACH FREDRIC JOHN +1

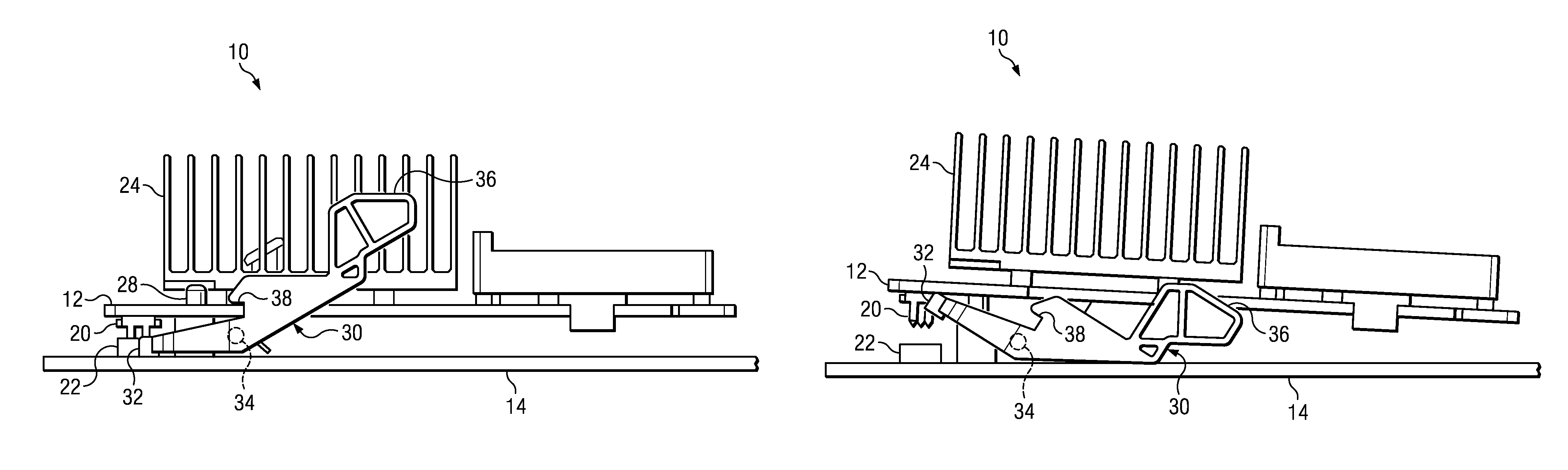

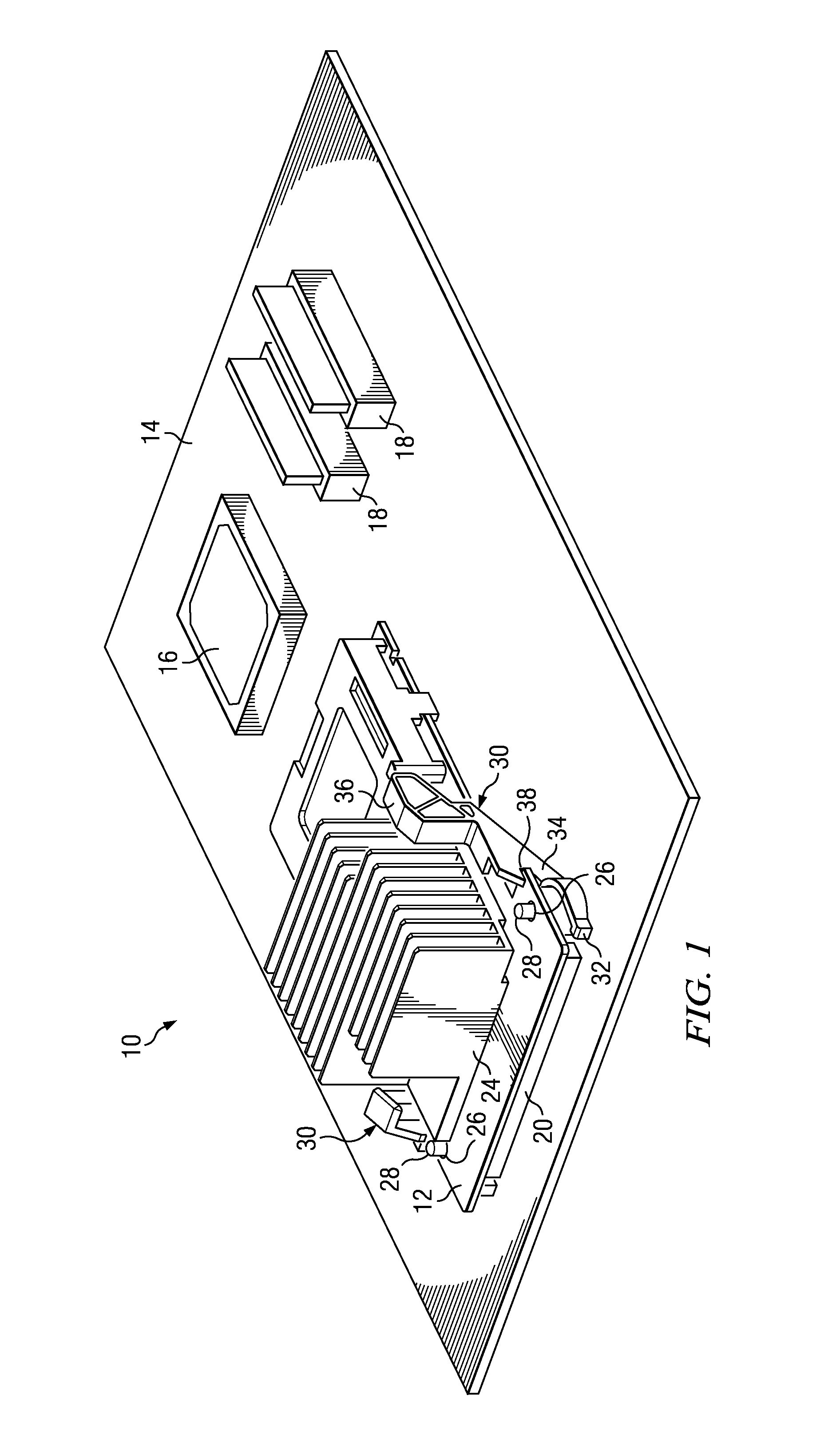

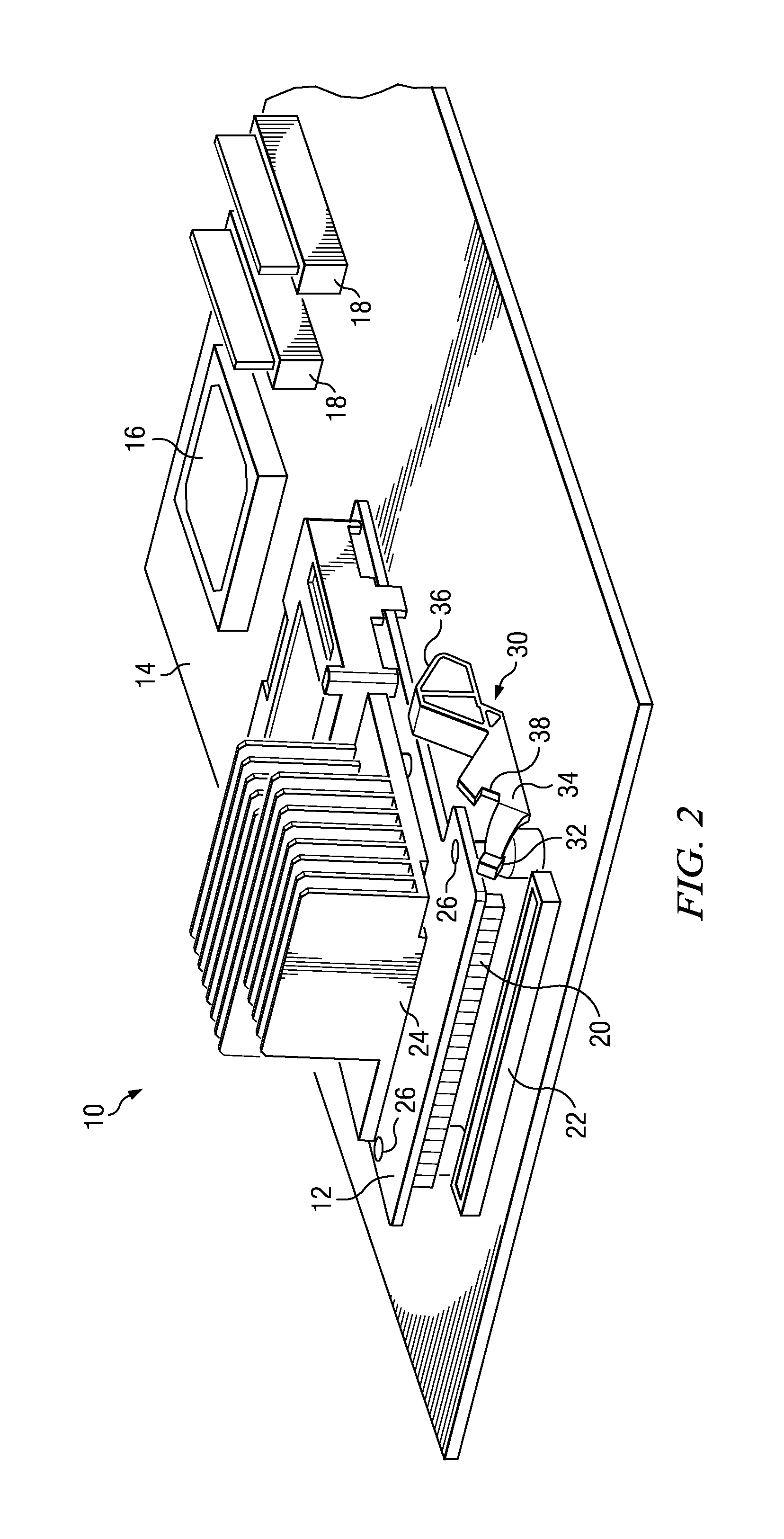

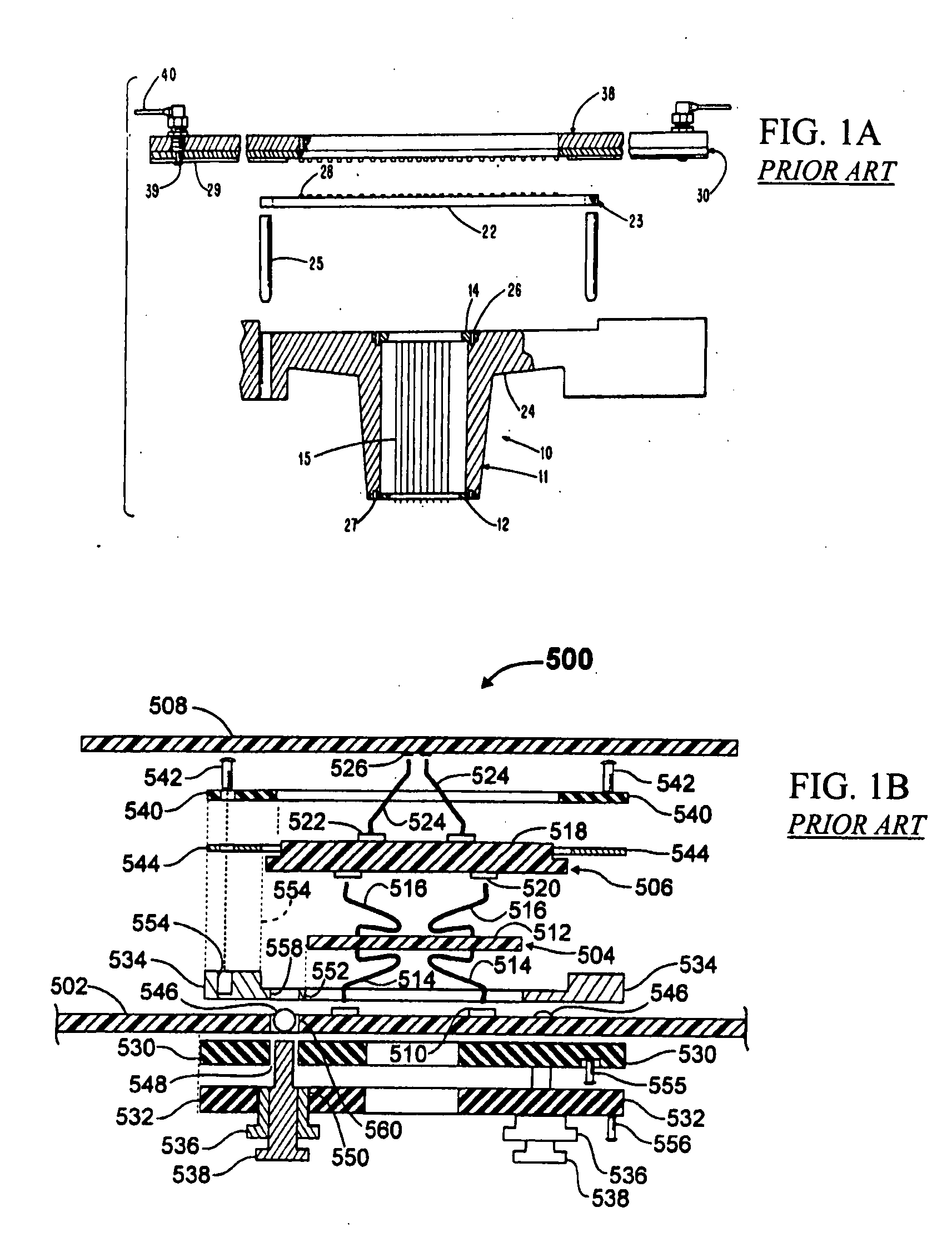

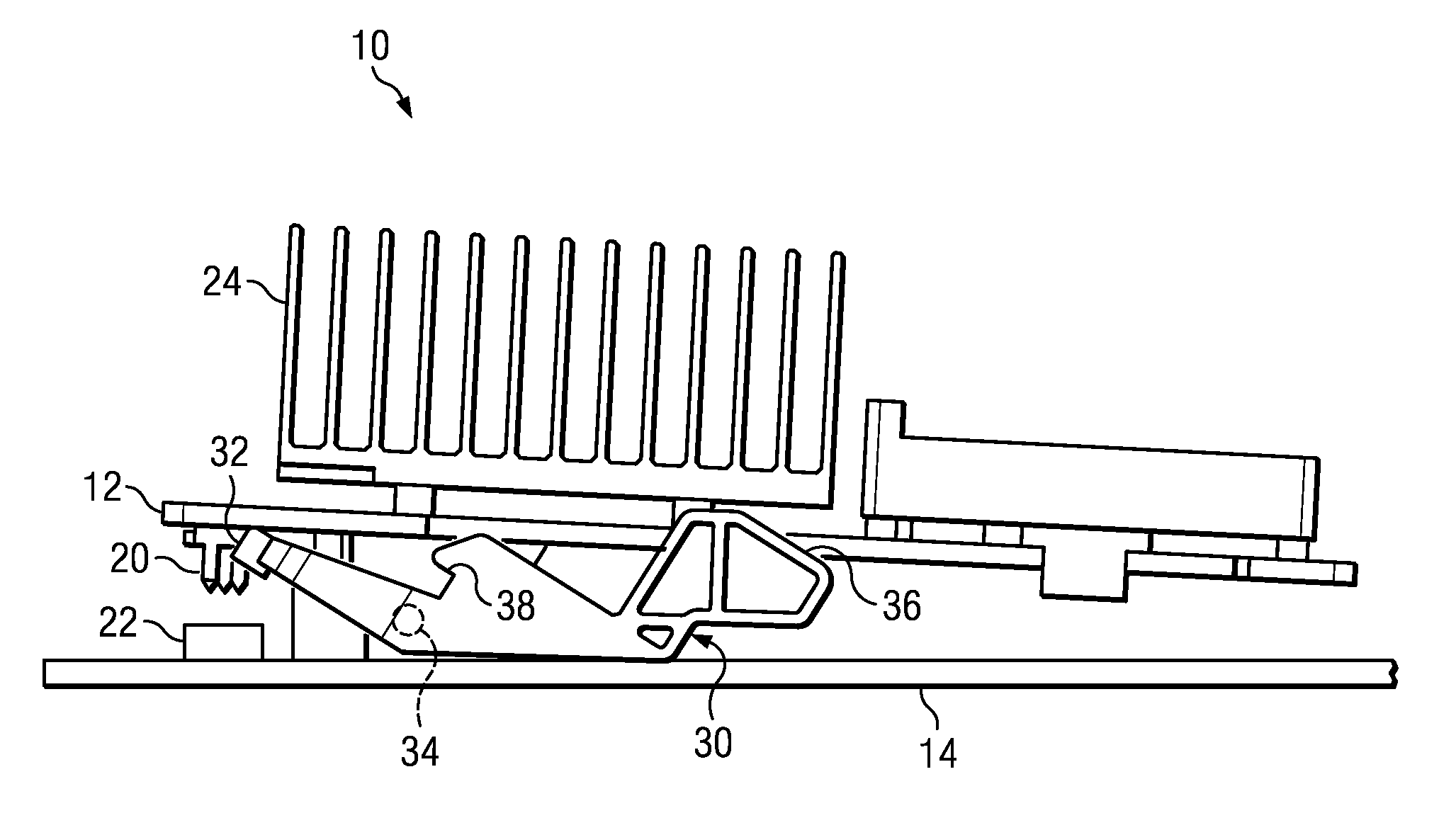

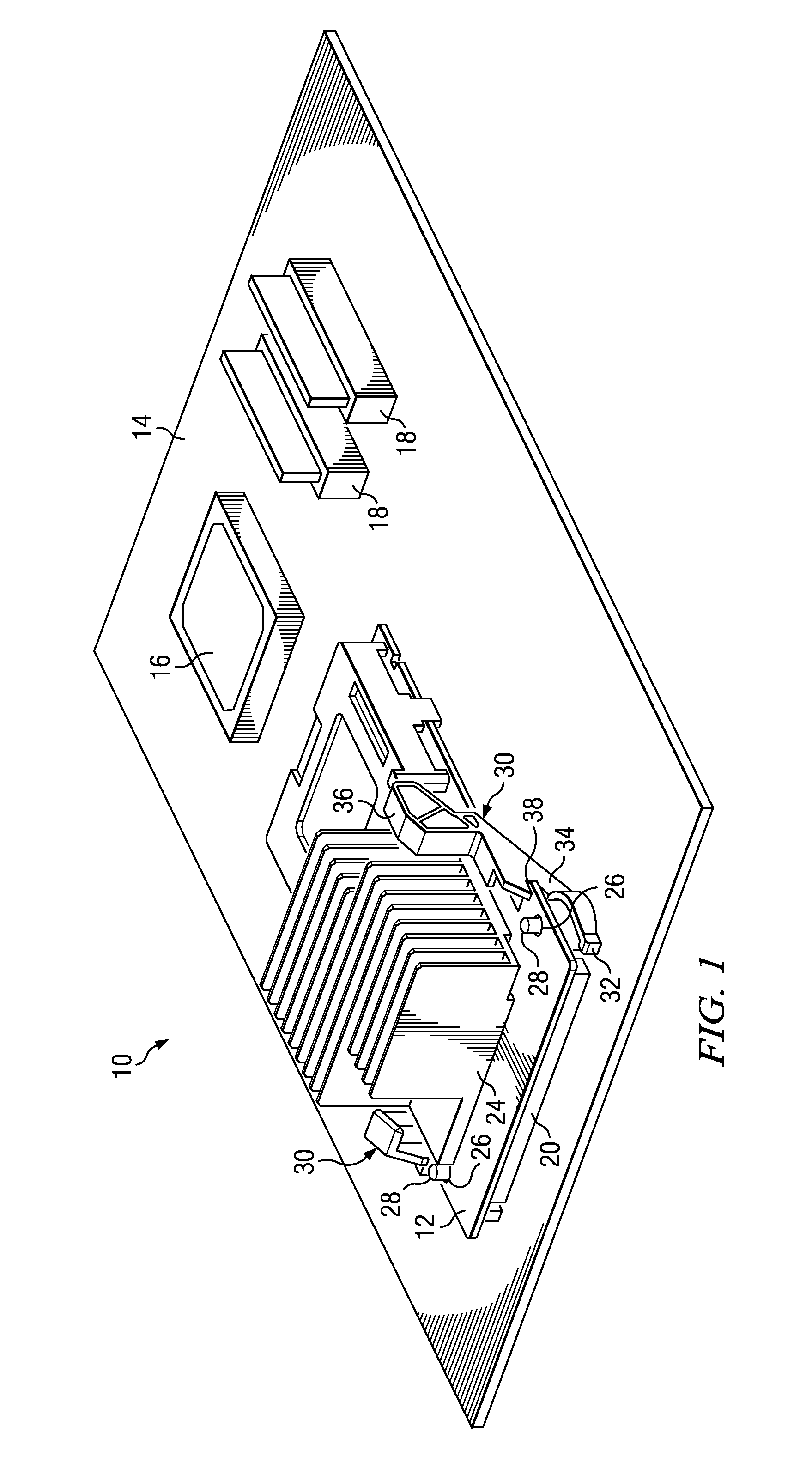

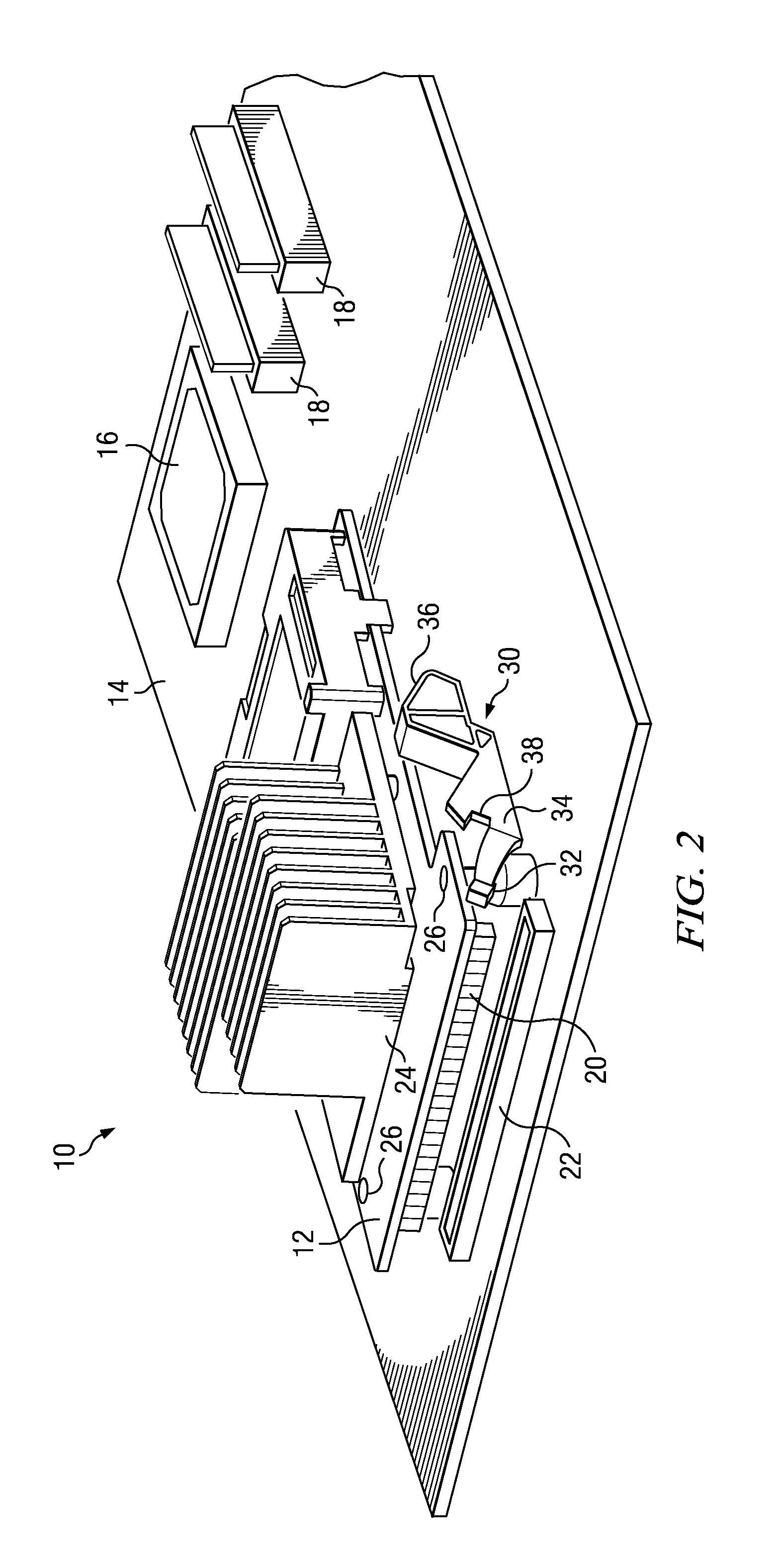

Retraction arm to extract a mezzanine circuit board connector from a motherboard connector

ActiveUS8366464B1Reduce disadvantagesReduce problemsEngagement/disengagement of coupling partsDigital data processing detailsEngineeringHandling system

An information handling system mezzanine circuit board disposed in a parallel configuration over a motherboard is selectively coupled and de-coupled at the motherboard with a retraction and latching device that translates retraction force applied at an accessible actuation portion to push upward from below the mezzanine circuit board. A retraction portion of the retraction and latching device provides an upward force at the bottom surface of the mezzanine circuit board to separate the mezzanine circuit board connector from the motherboard connector so that an end user can lift the mezzanine circuit board away from the motherboard.

Owner:DELL PROD LP

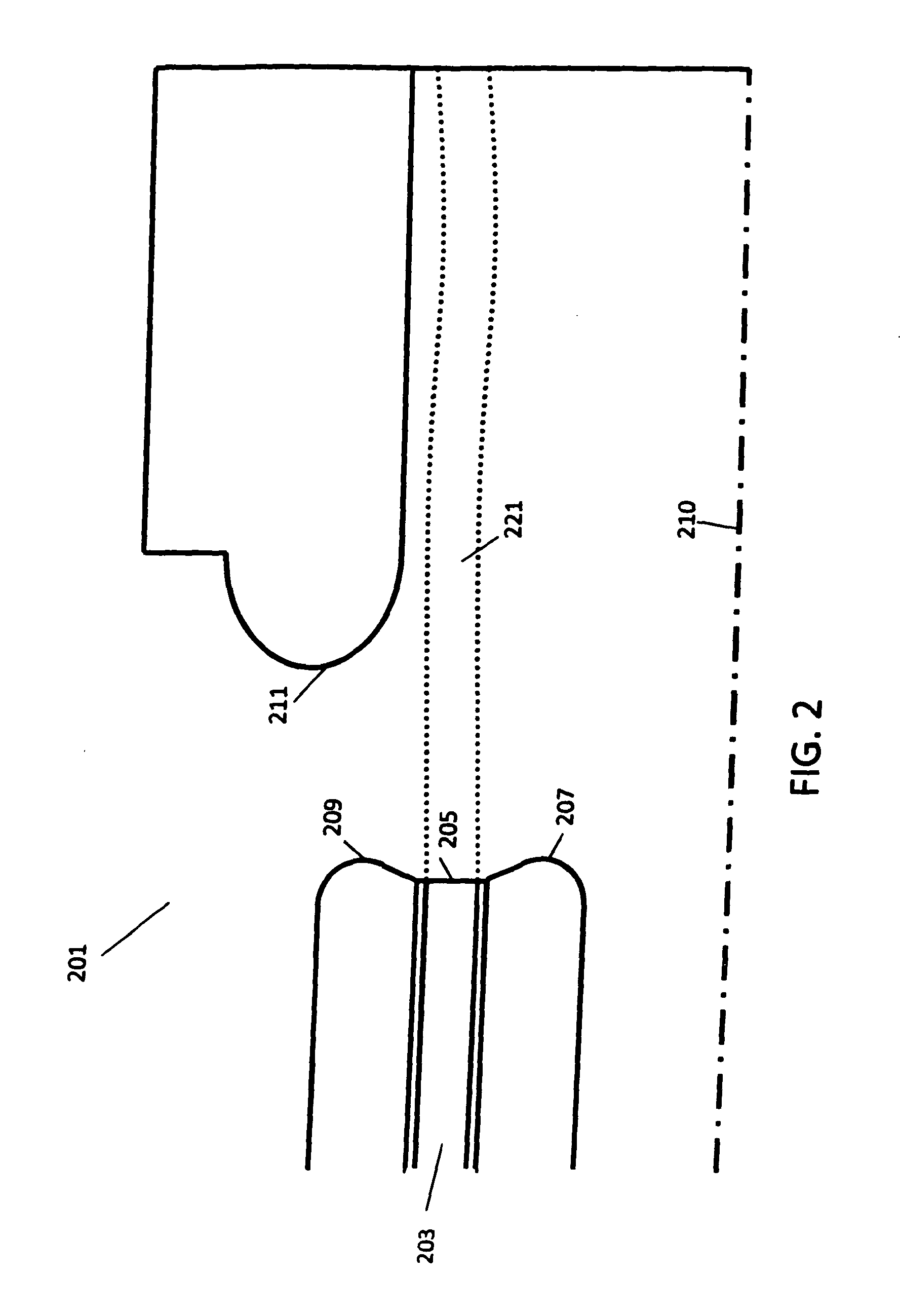

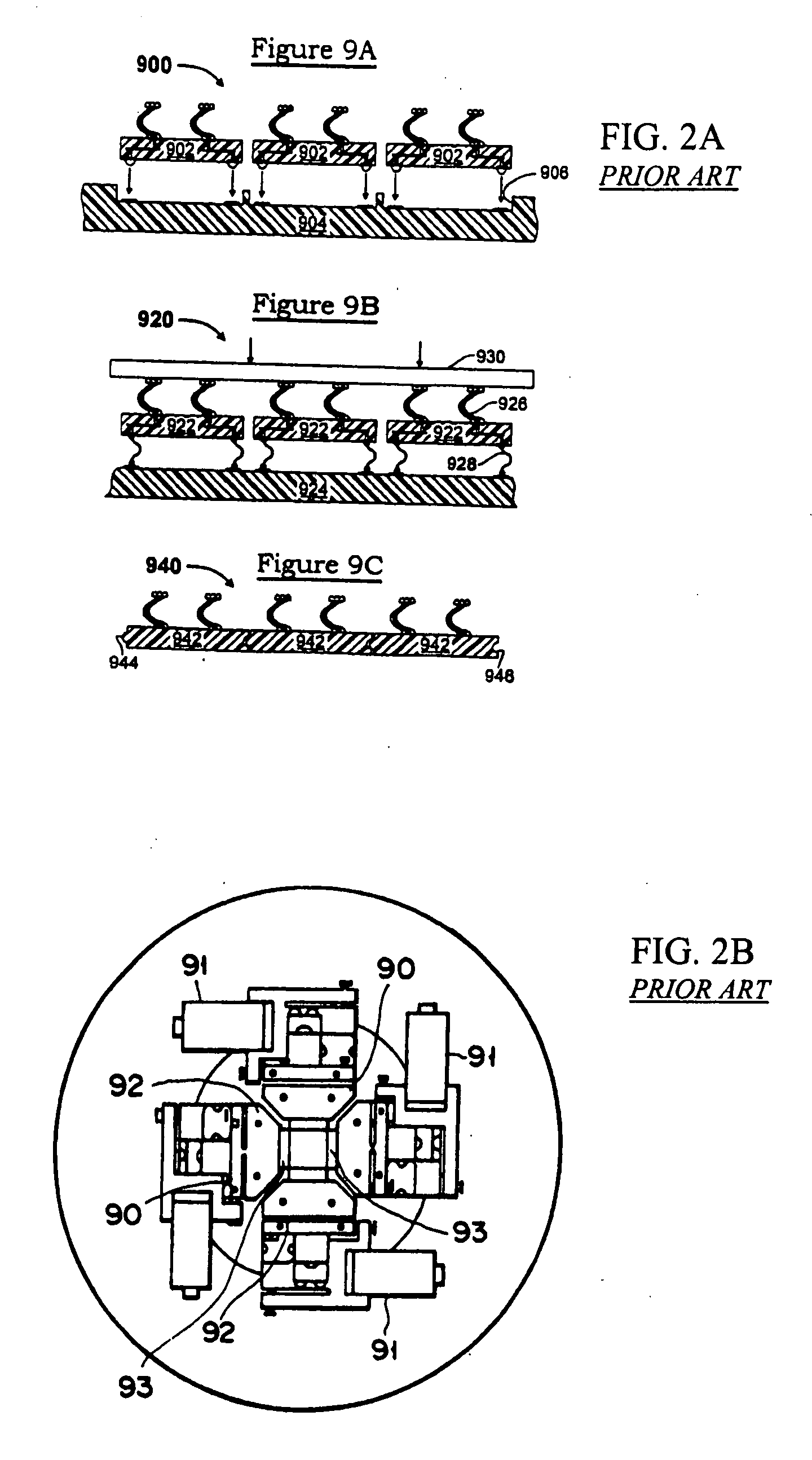

Probe card assembly

ActiveUS7365553B2Less-expensive to buildEasy to disassembleSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsProbe cardLocking mechanism

A probe card assembly has a probe contractor substrate having a plurality of probe contractor tips thereon and a probe card wiring board with an interposer disposed between the two. Support posts contacting the probe contractor substrate are vertically adjustable until secured by a locking mechanism which is coupled to the probe card wiring board. When the posts are secured in a fixed position, the position is one in which the plane of the plurality of probe contractor substrates is substantially parallel to a predetermined reference plane.

Owner:FORMFACTOR INC

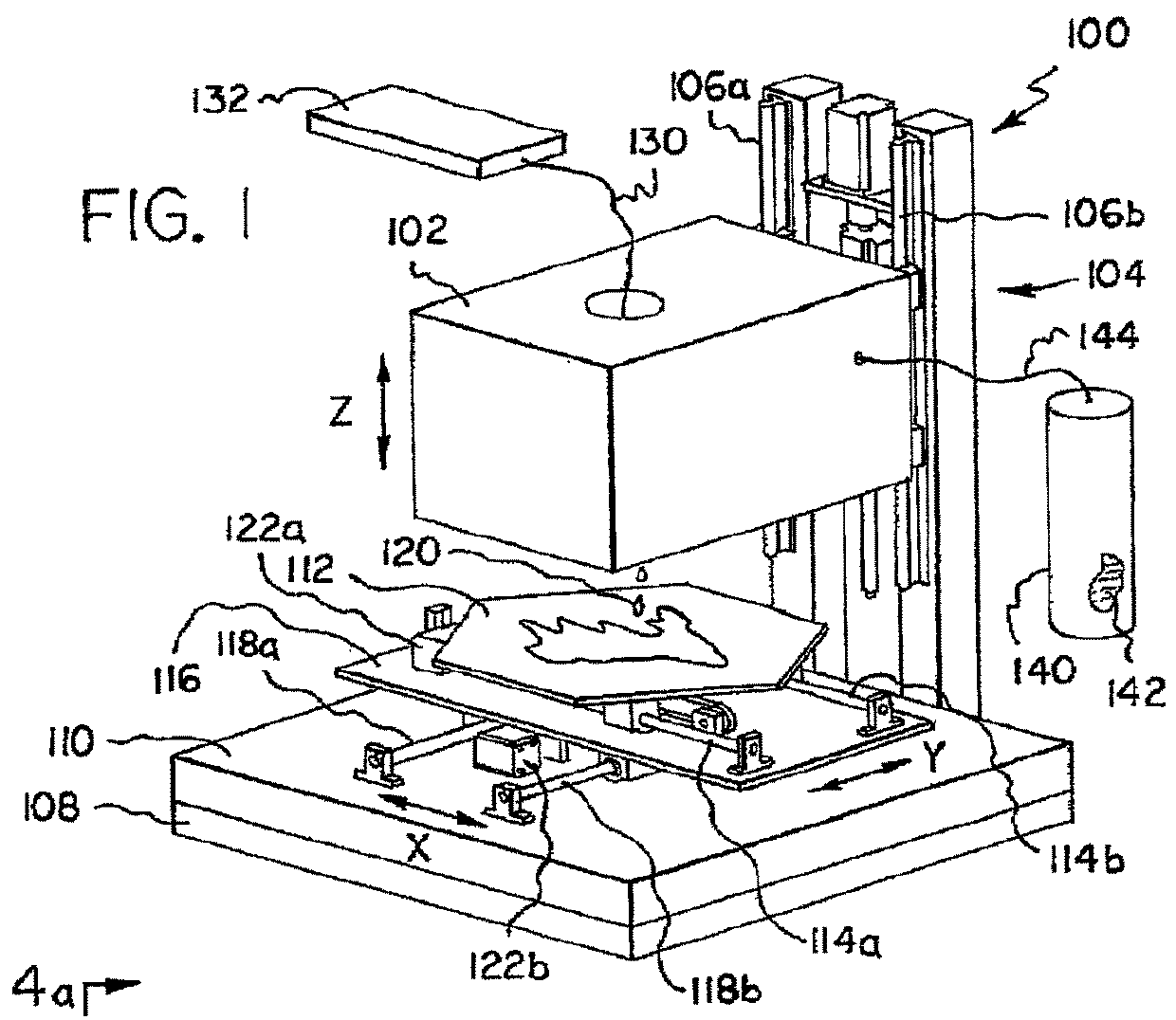

Conductive liquid three dimensional printer

ActiveUS10040119B2Less-expensive to buildOvercome disadvantagesAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringConductive materials

Owner:ALLOY ACQUISITION CORP LLC

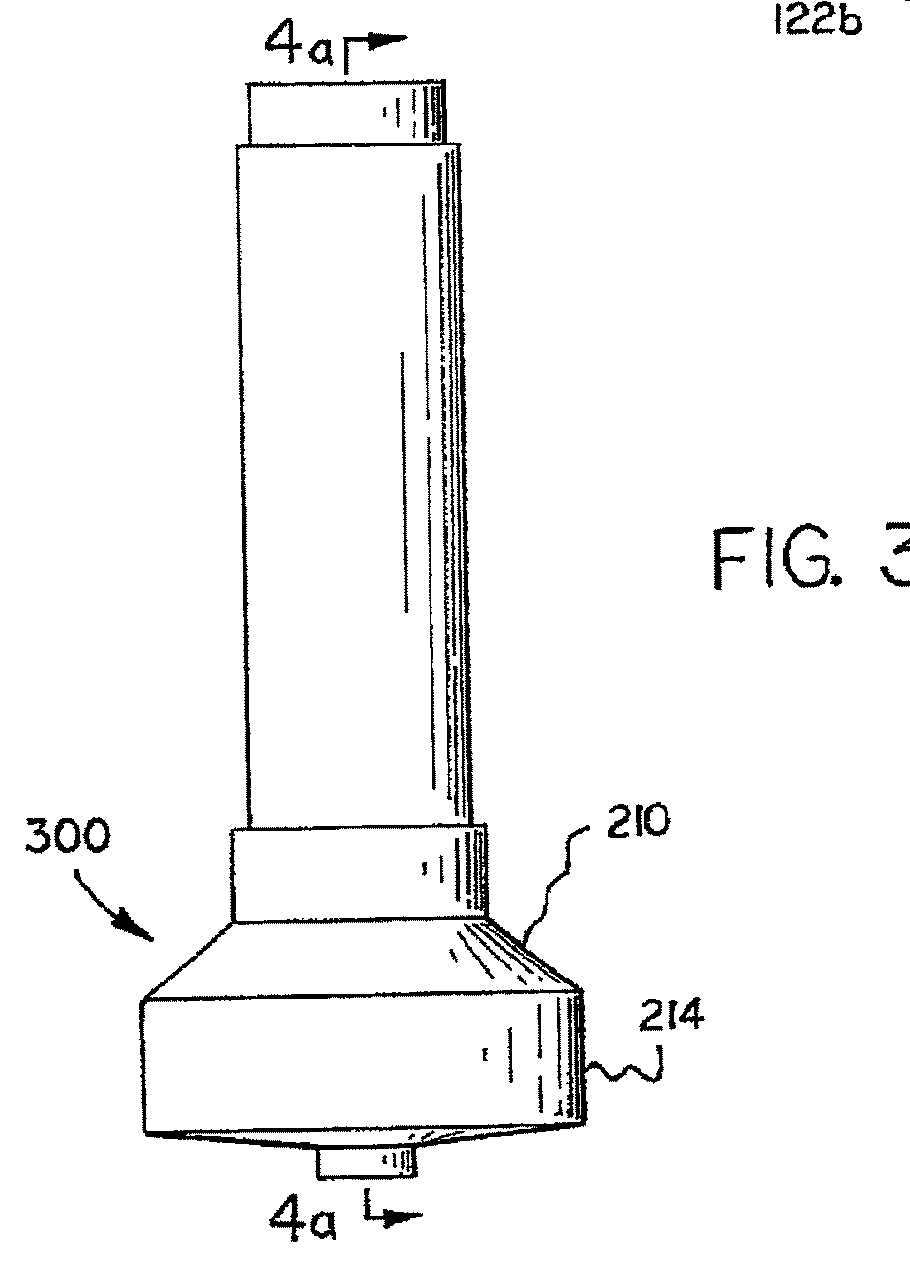

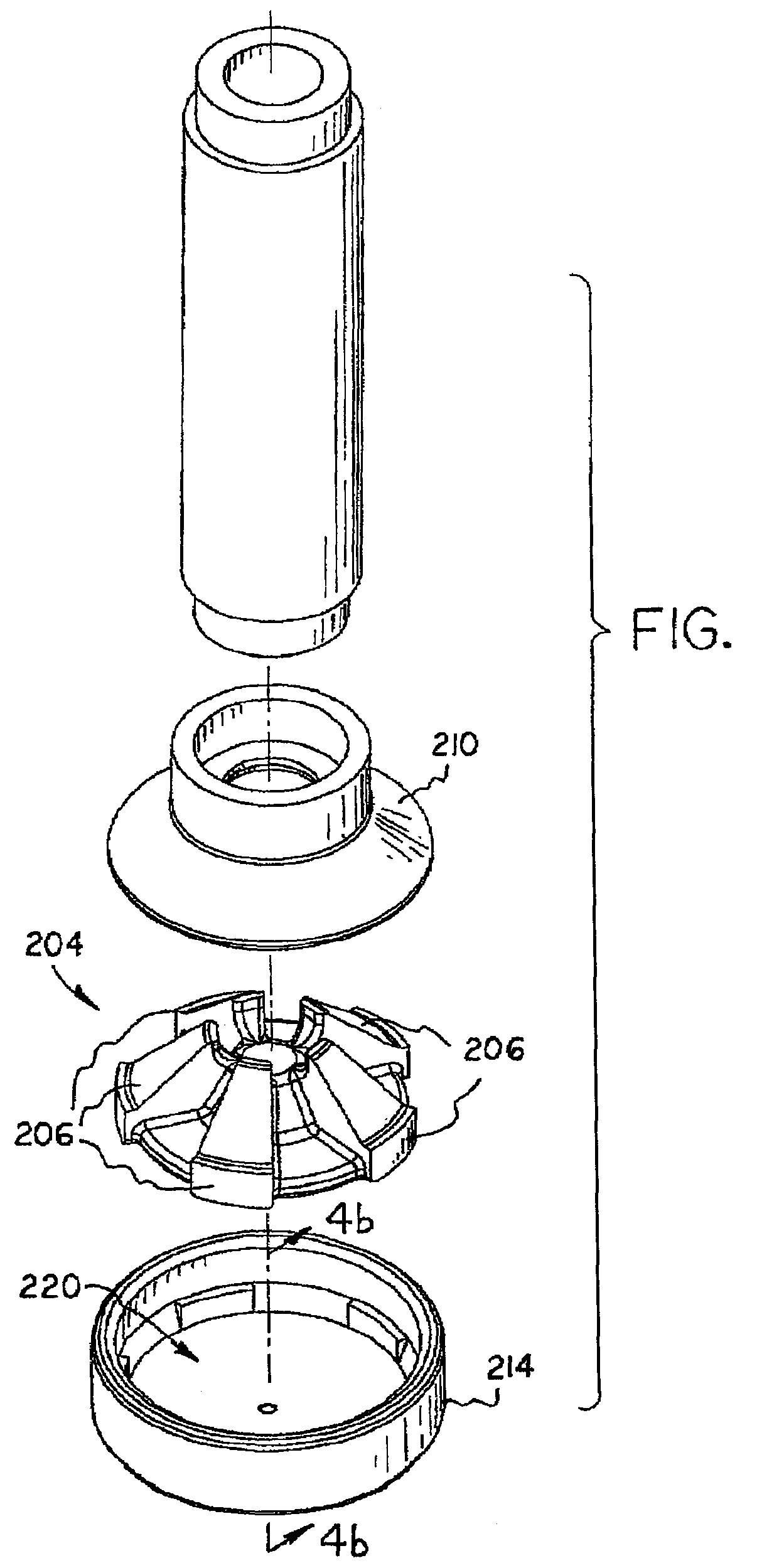

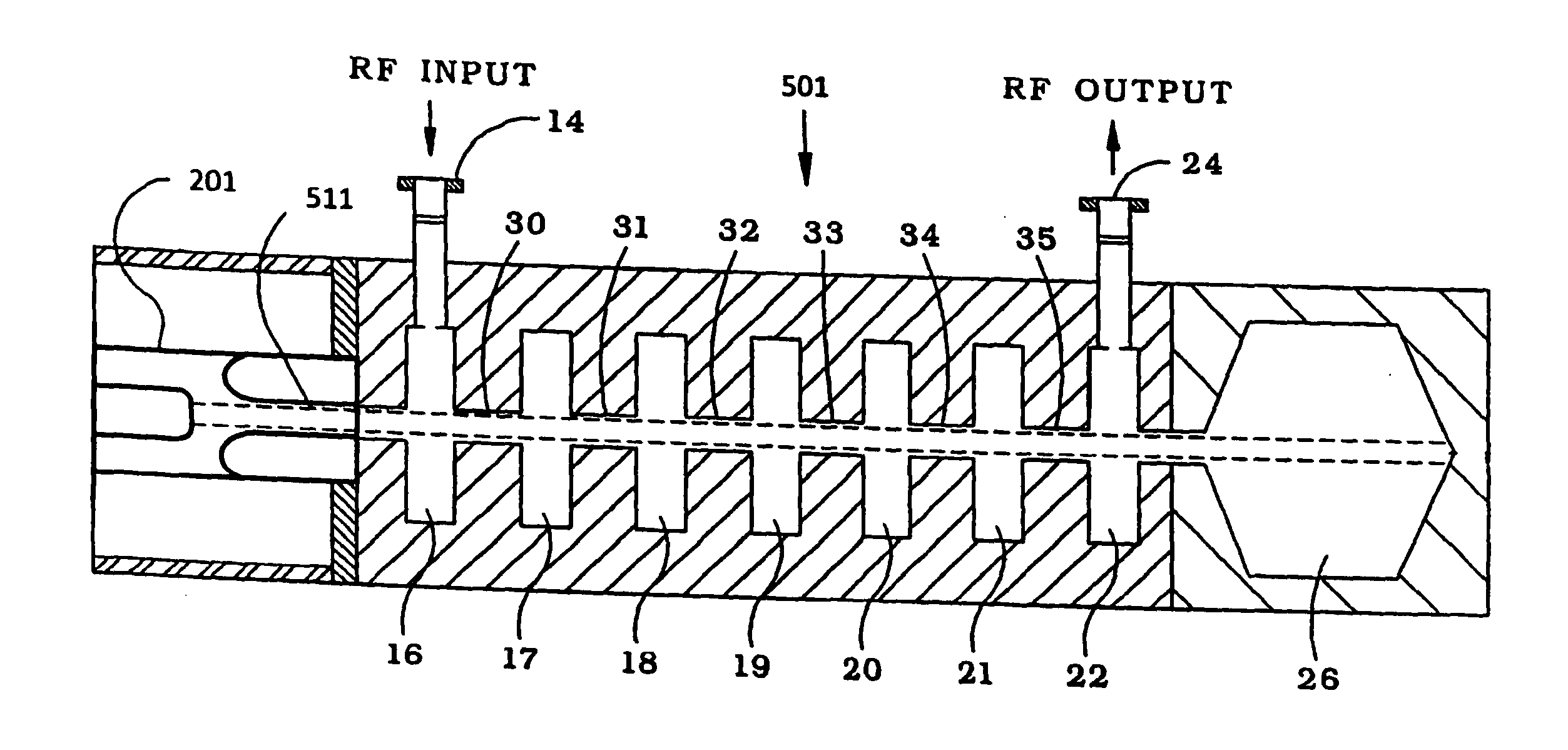

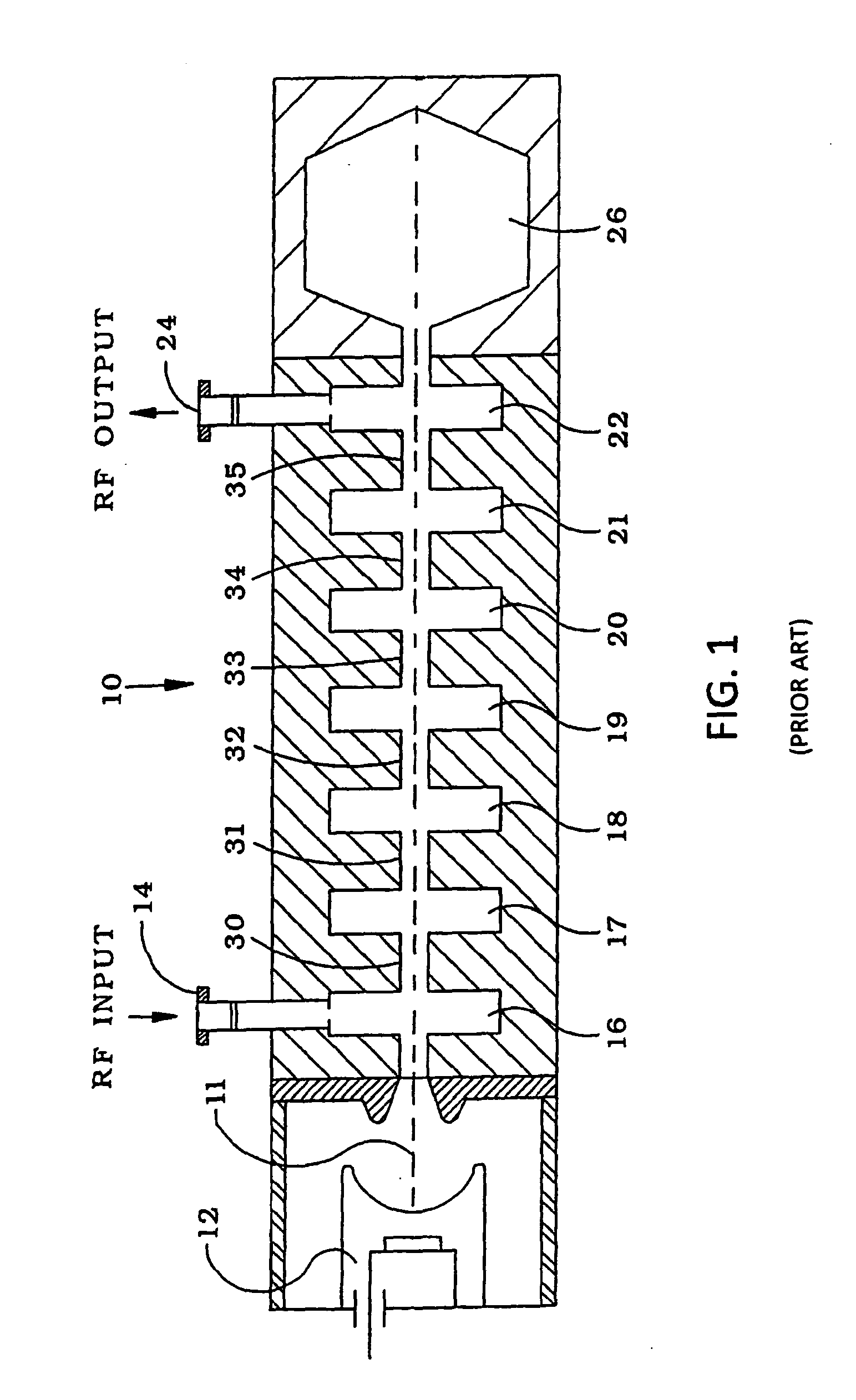

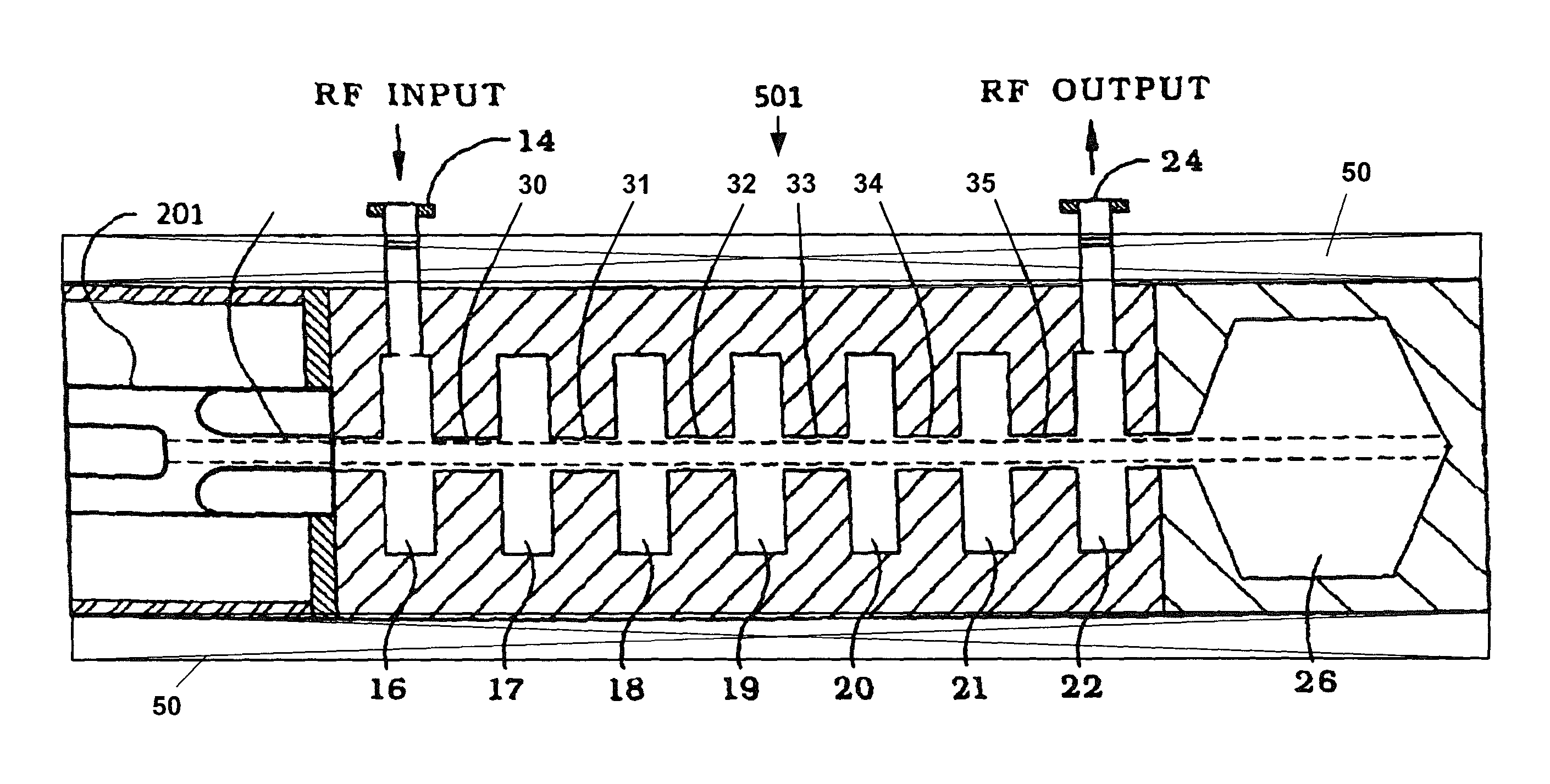

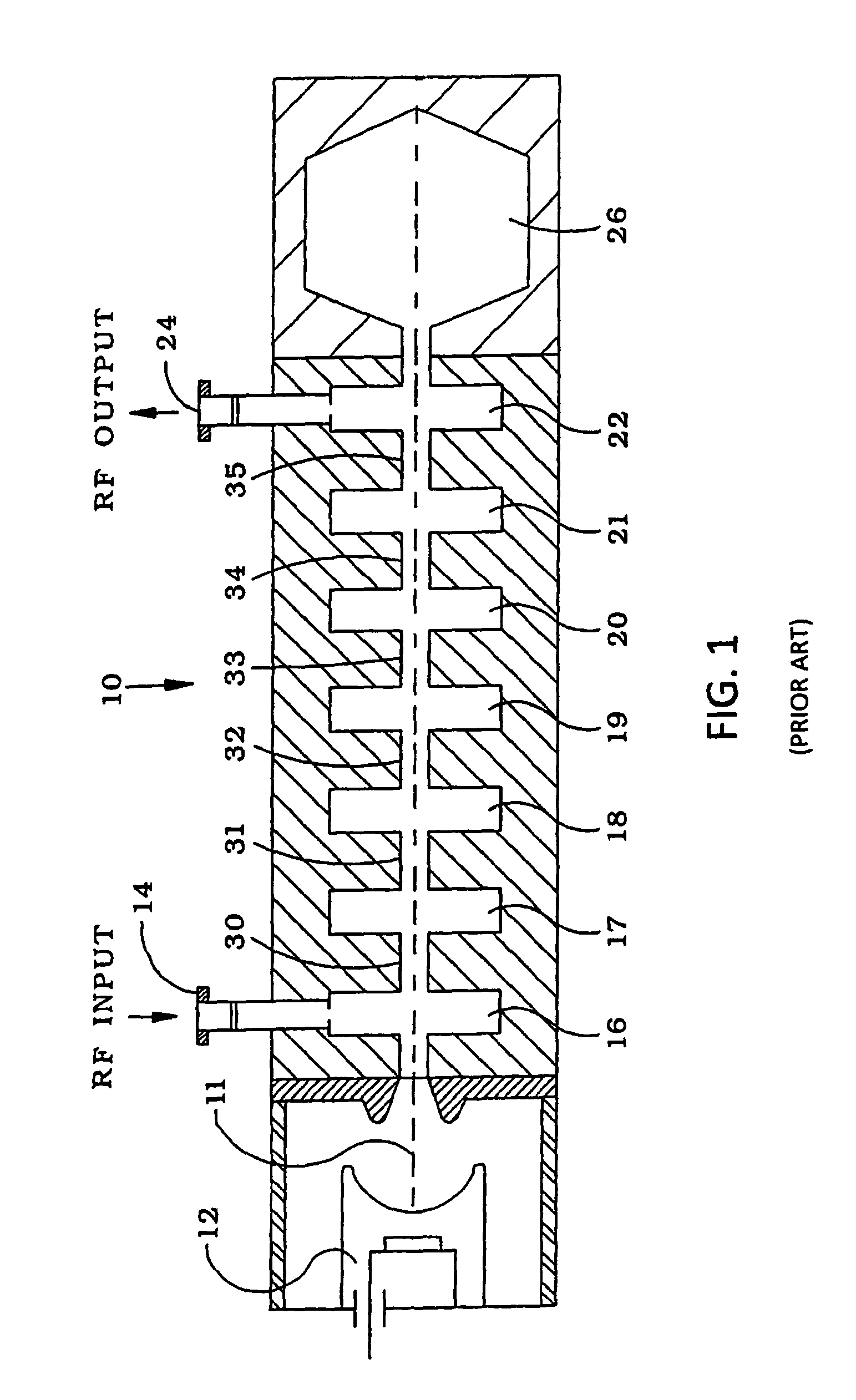

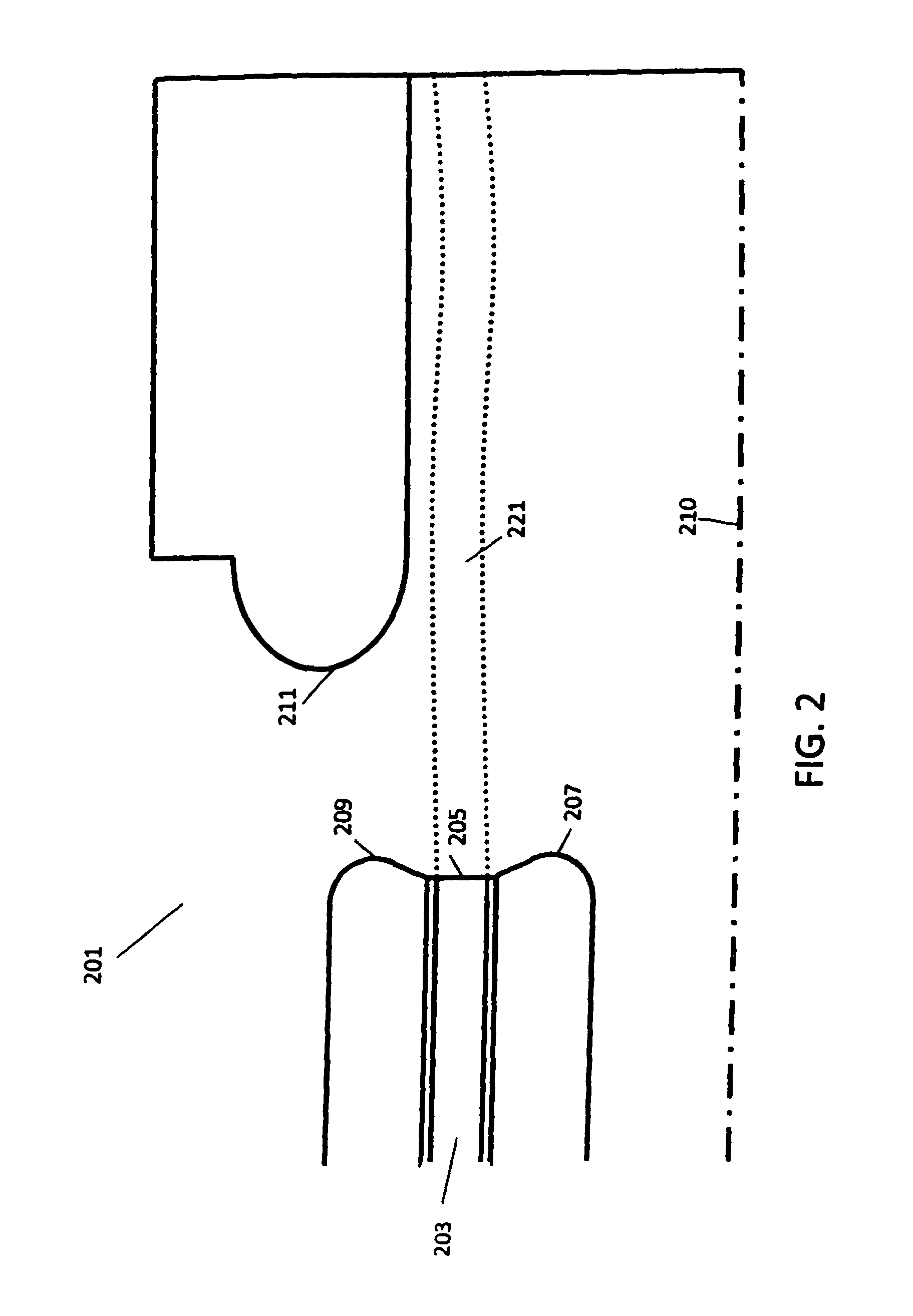

Hollow beam electron gun for use in a klystron

InactiveUS20110006678A1Short RF interaction circuit lengthLess-expensive to buildTransit-tube electron/ion gunsTransit-tube focussing arrangementsKlystronDrift tube

A klystron has a hollow beam electron gun that has a circular planar electron emitting surface. A hollow electron beam is directed from the electron gun through a plurality of drift tubes, resonant chambers and magnetic fields to a collector. The hollow electron beam does not experience significant radial movement and can operate at a lower beam voltage which reduces the required length of the RF interaction circuit and lowers the risks of RF arcing.

Owner:FERGUSON PATRICK

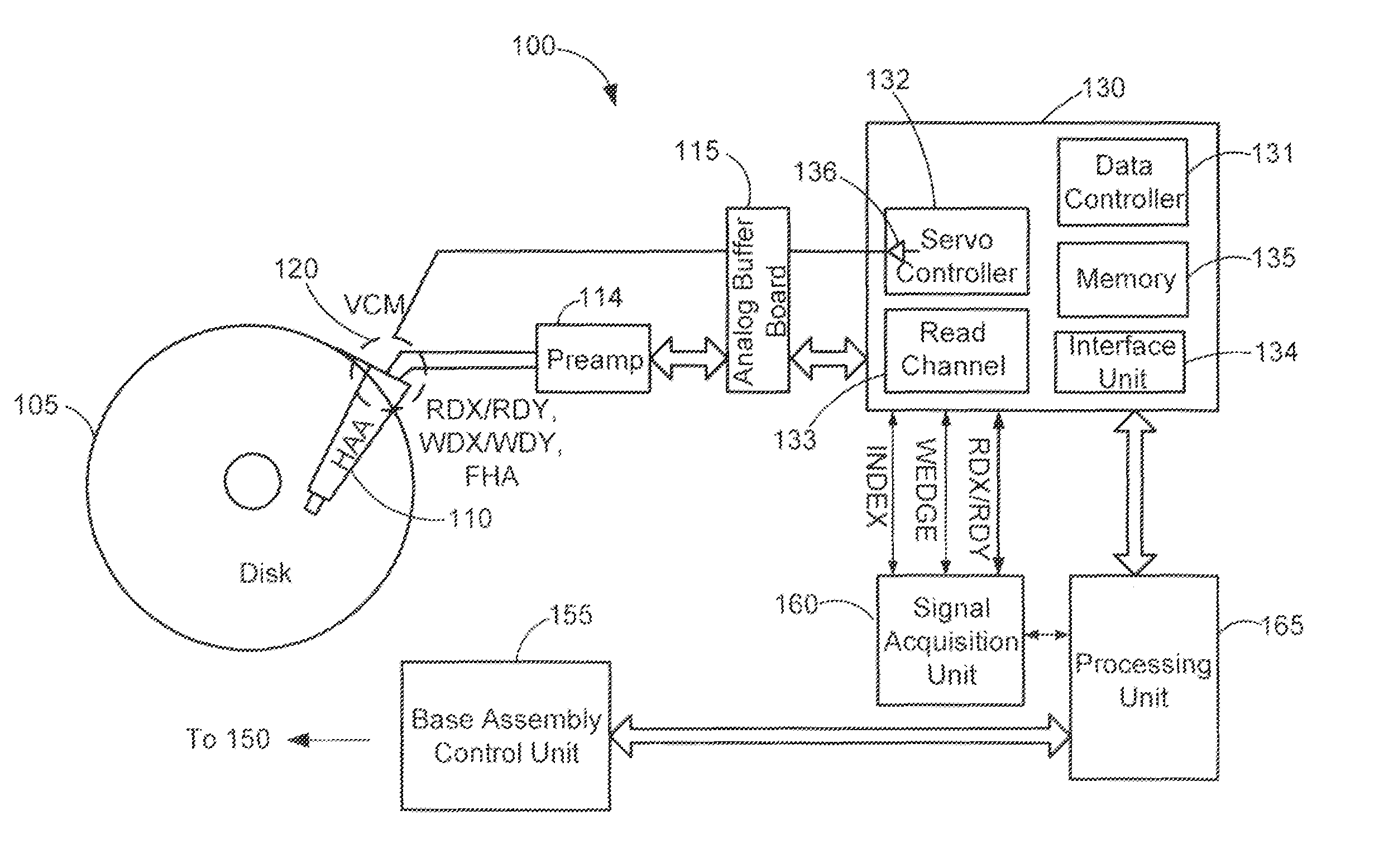

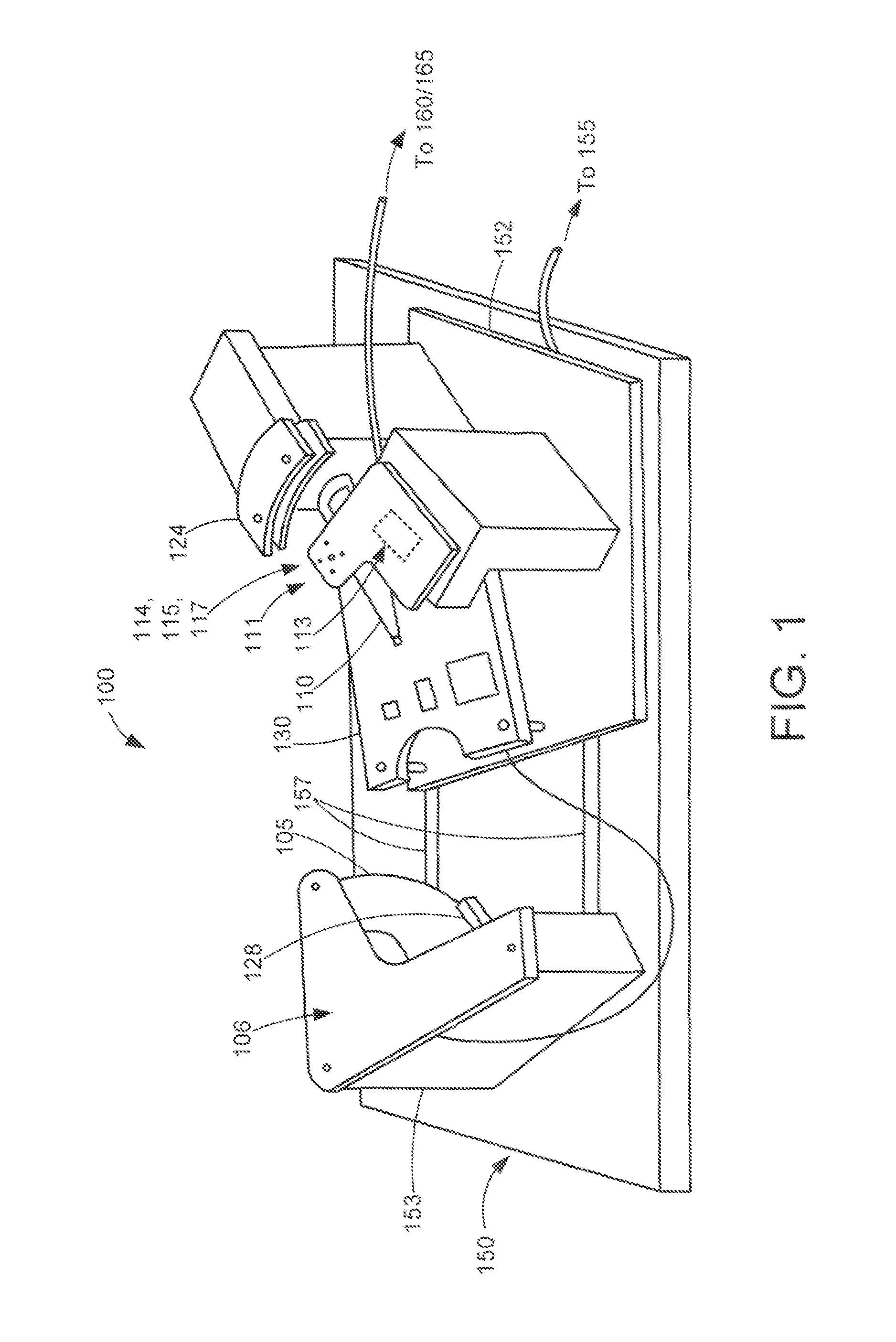

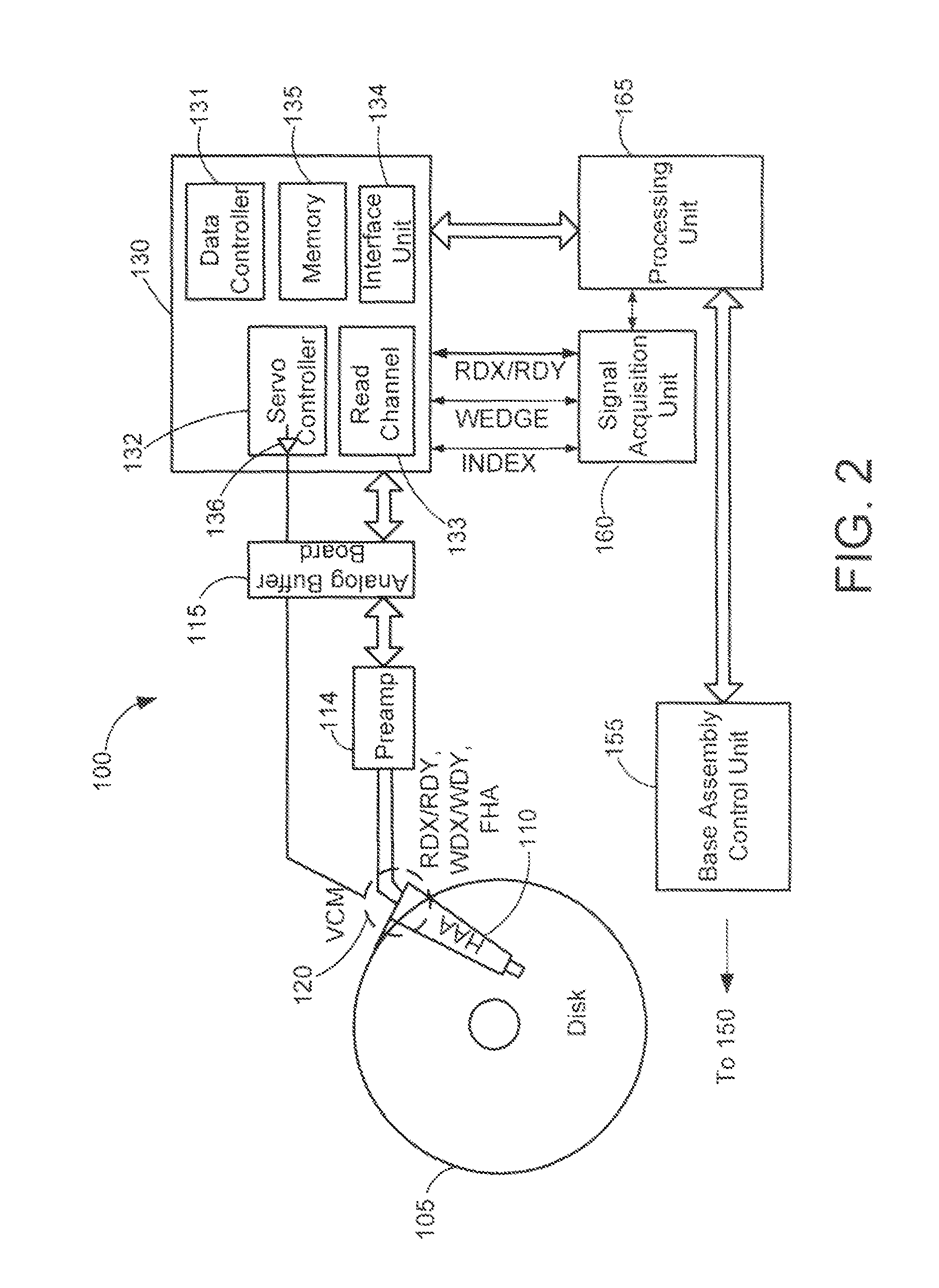

Apparatus and method for testing magnetic disk drive components using drive-based parts

InactiveUS7705588B2Less timeLess costRecord information storageMagnetic property measurementsEngineeringMagnetic disks

Owner:SEAGATE TECH LLC

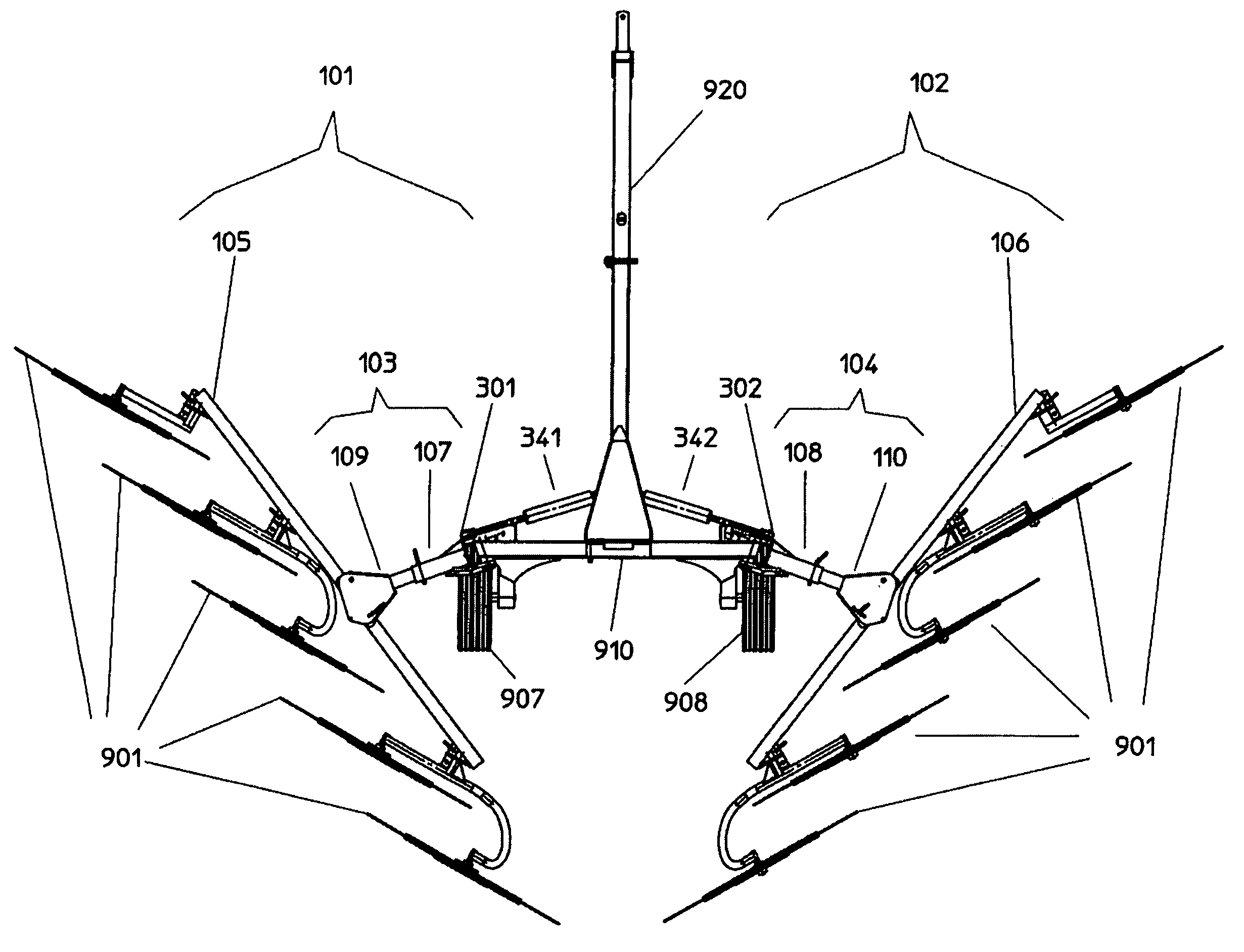

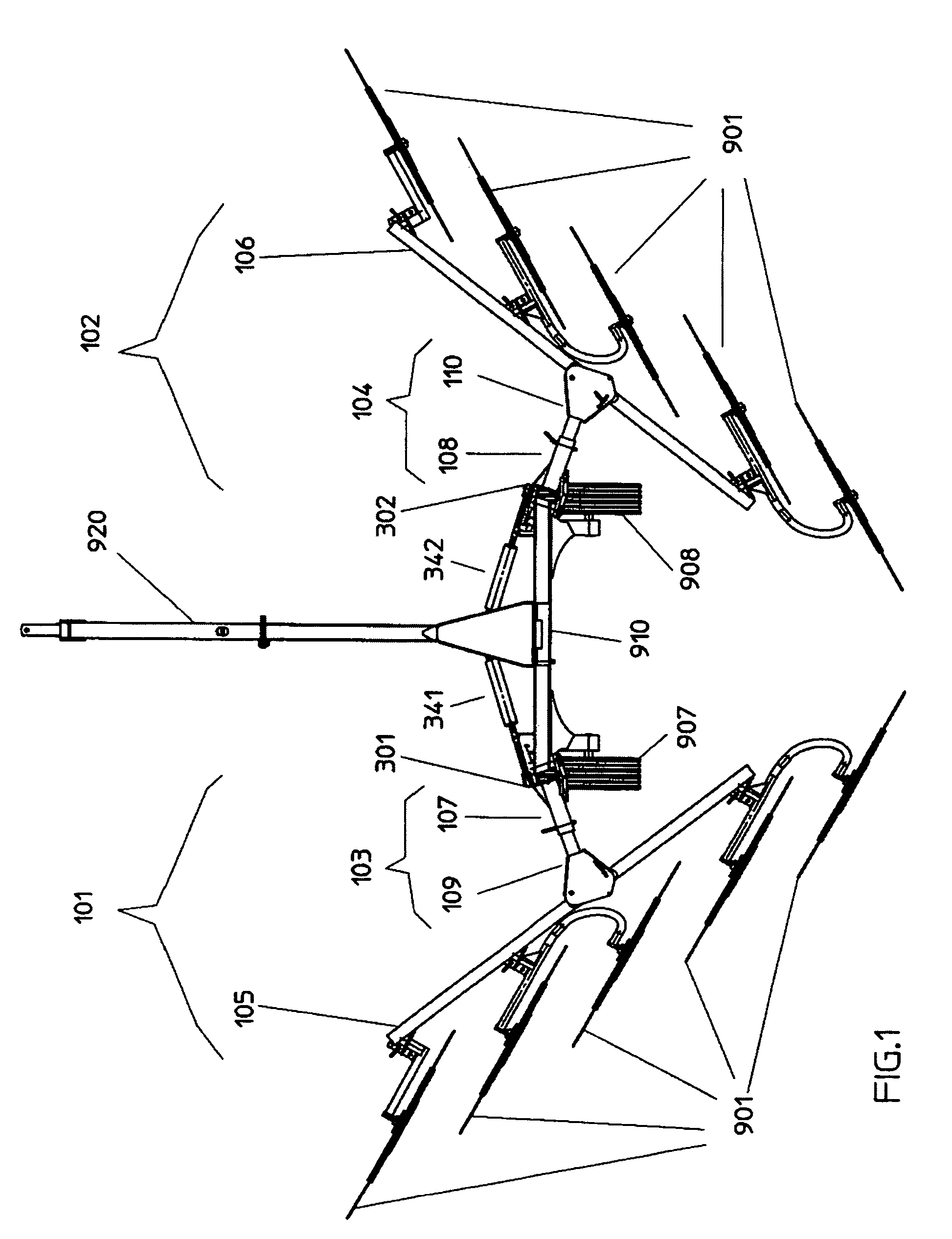

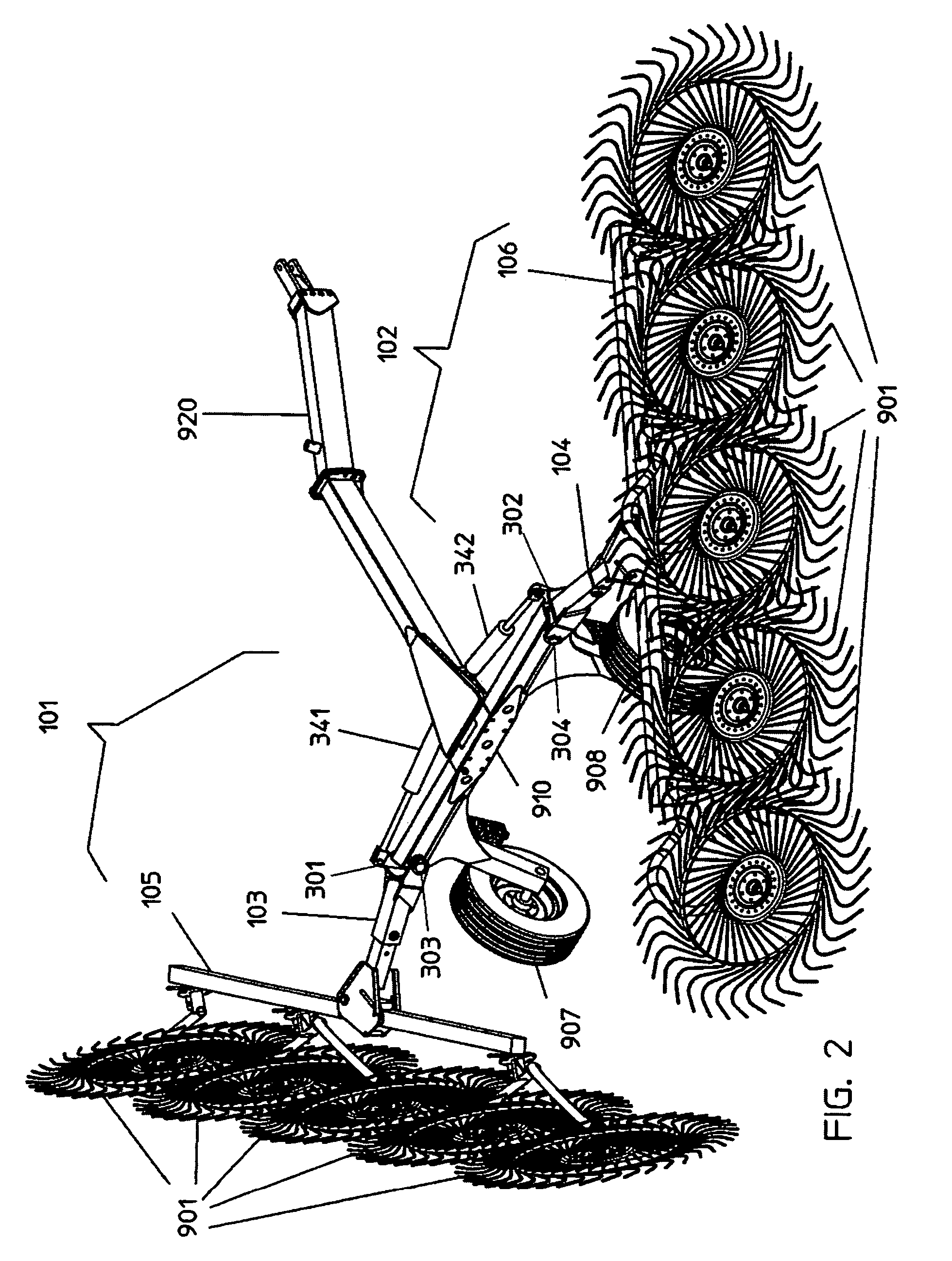

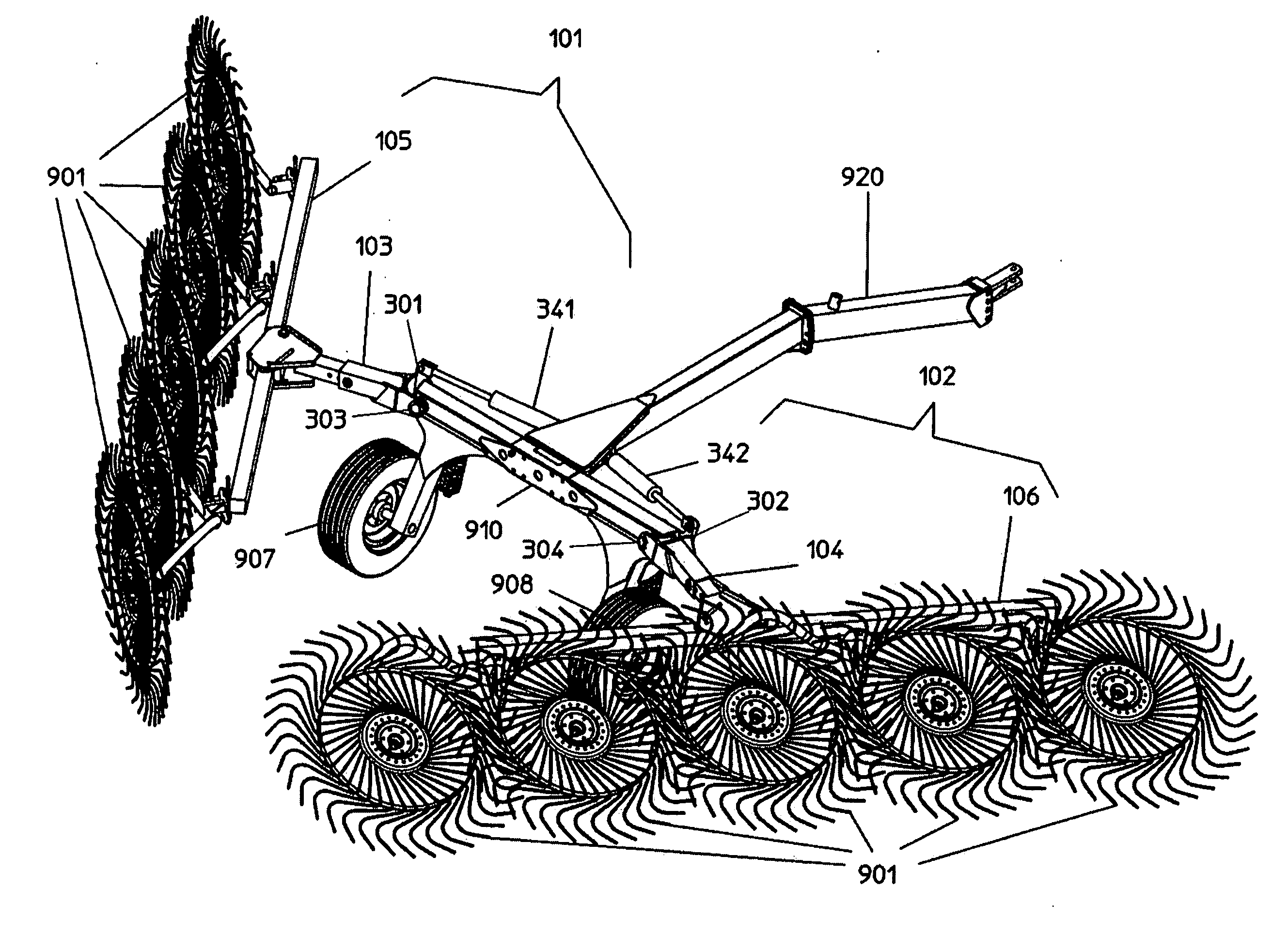

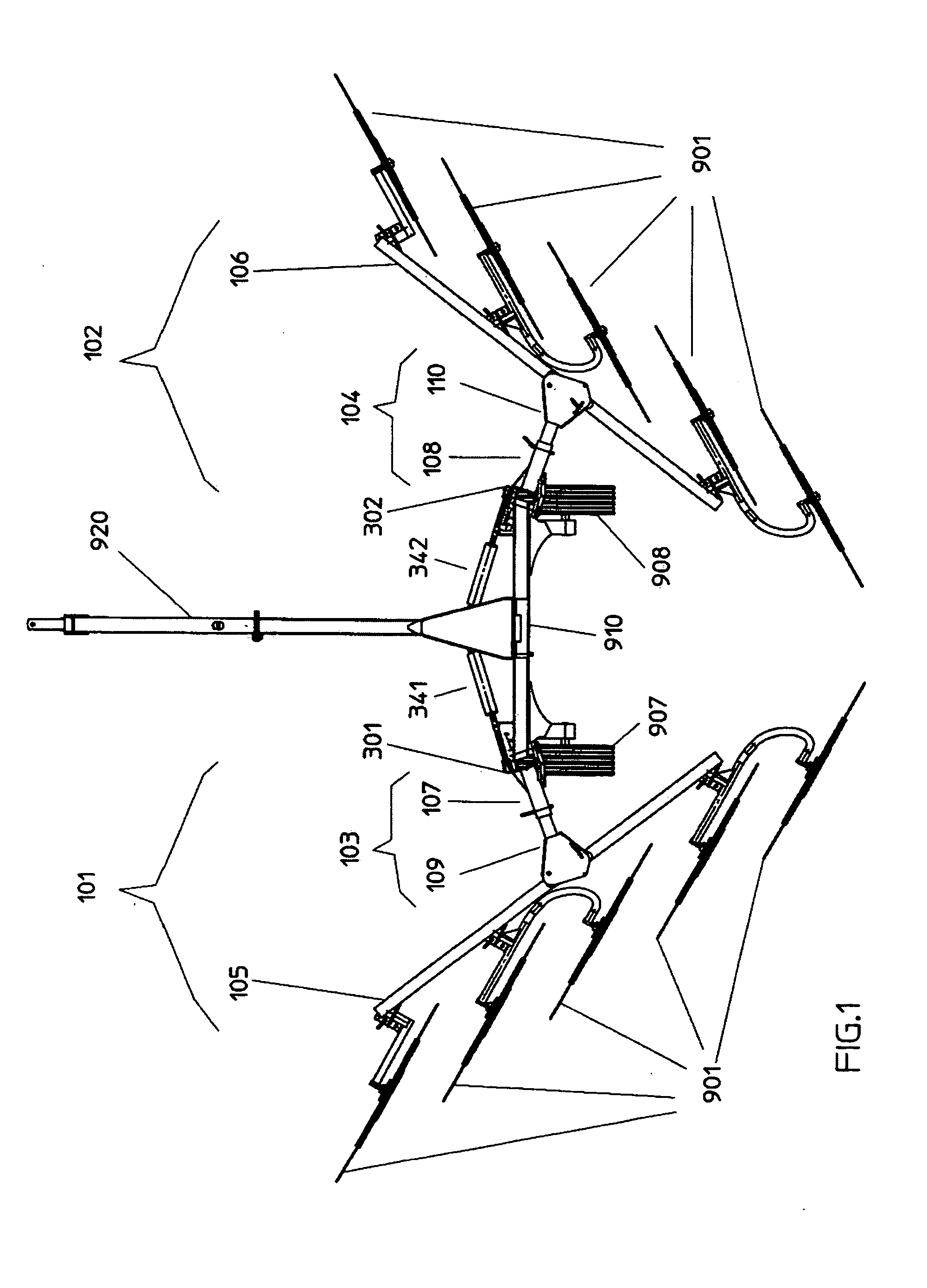

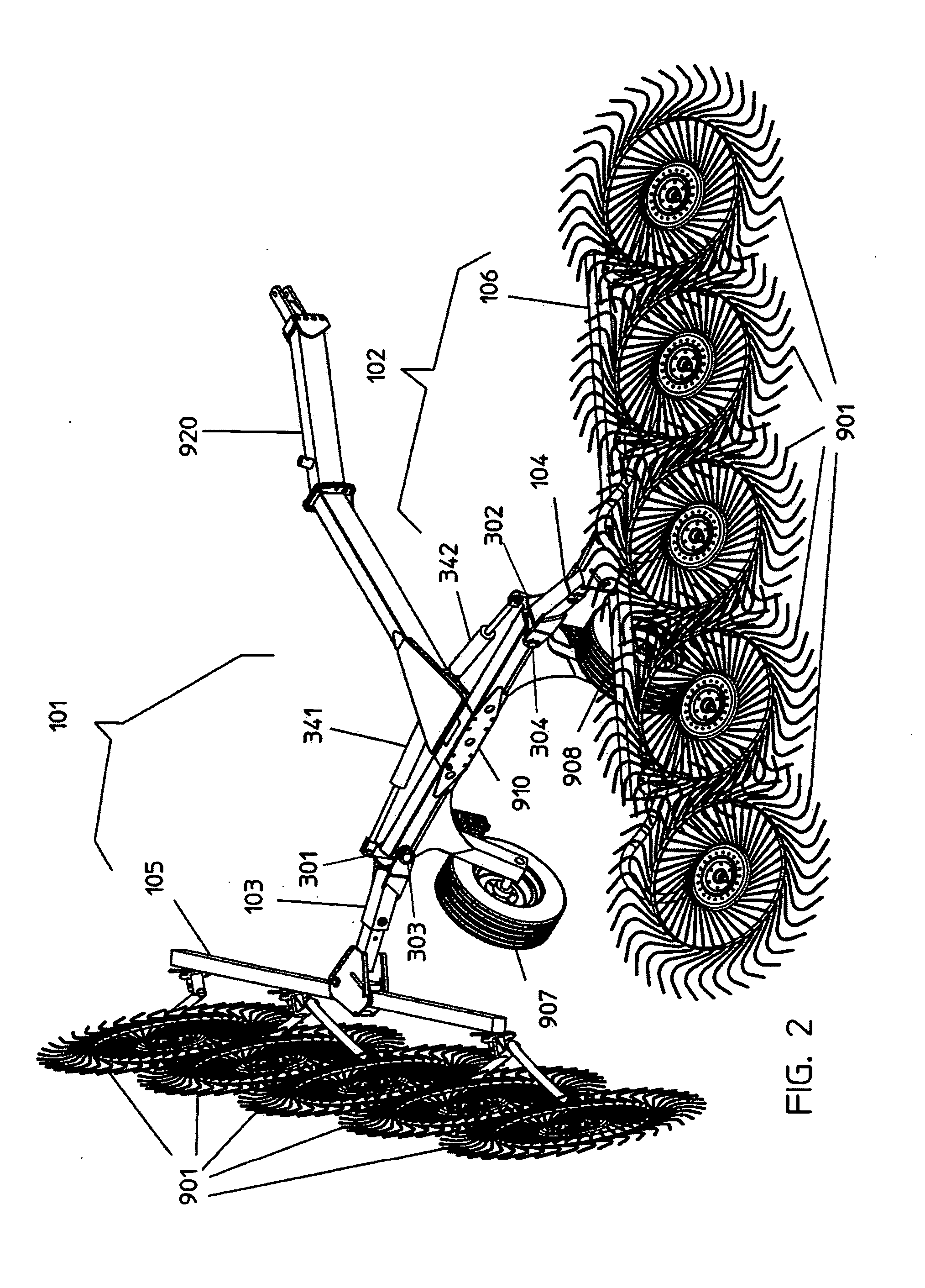

Adjustable and foldable V-shaped hay rake

ActiveUS8001755B2Less-expensive to buildHighly effectiveCarriage/perambulator accessoriesAgricultural machinesEngineeringHay

Owner:SITREX

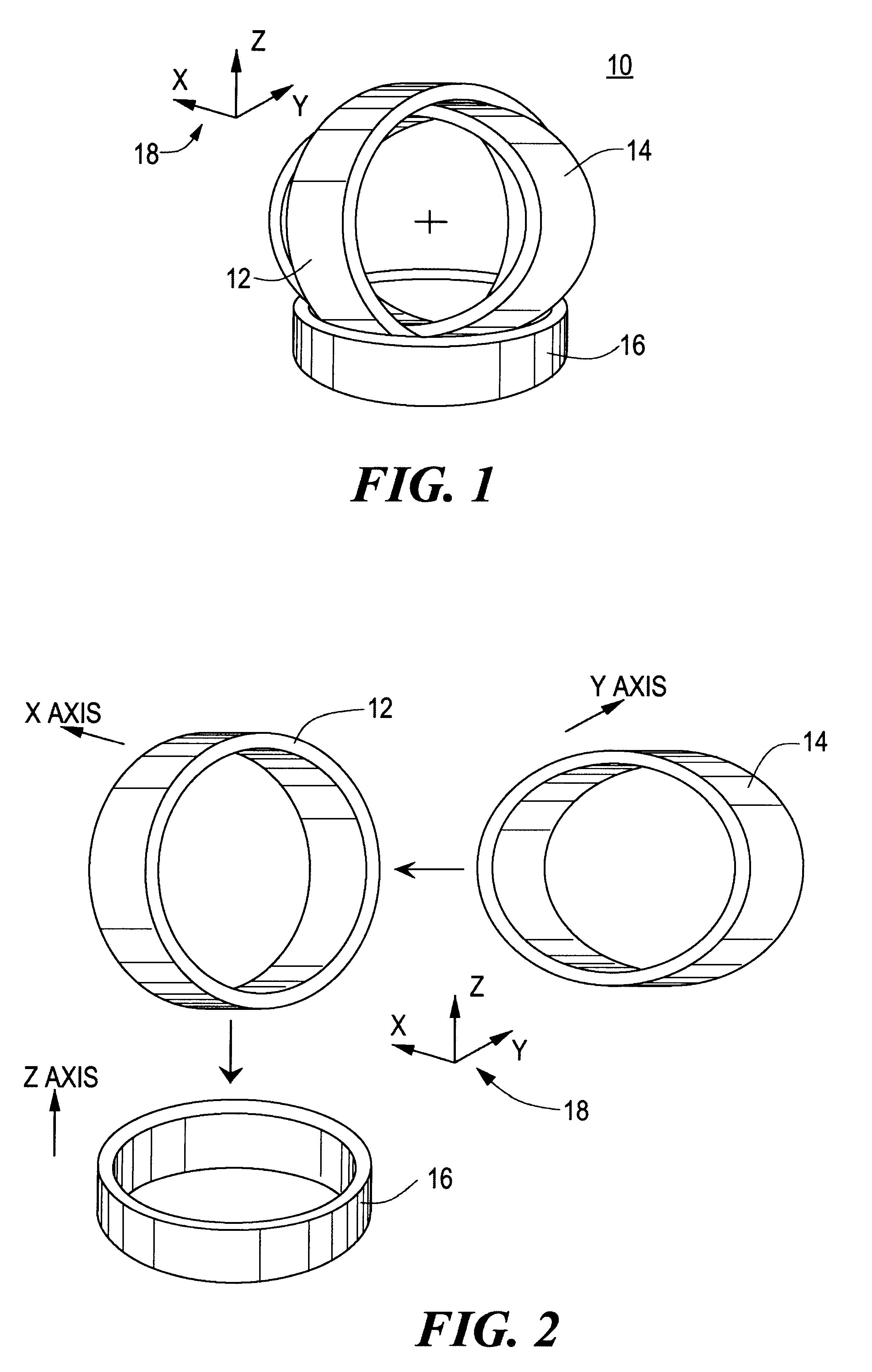

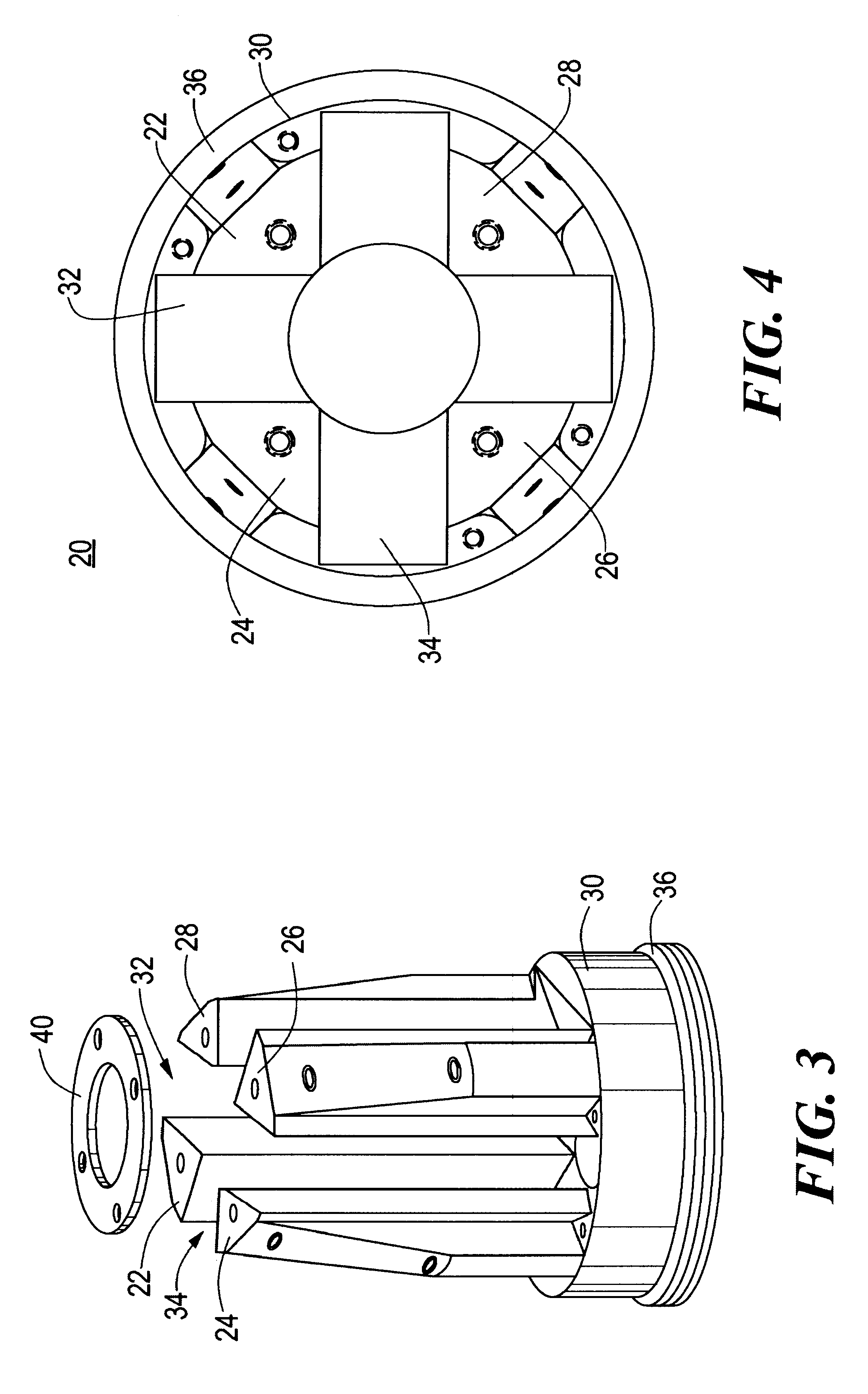

Nested fiber optic gyro system

InactiveUS6198094B1Much of lightLess-expensive to buildRadiation pyrometryMaterial analysis by optical meansFiberEngineering

Owner:GILMORE JEROLD PHILIP +2

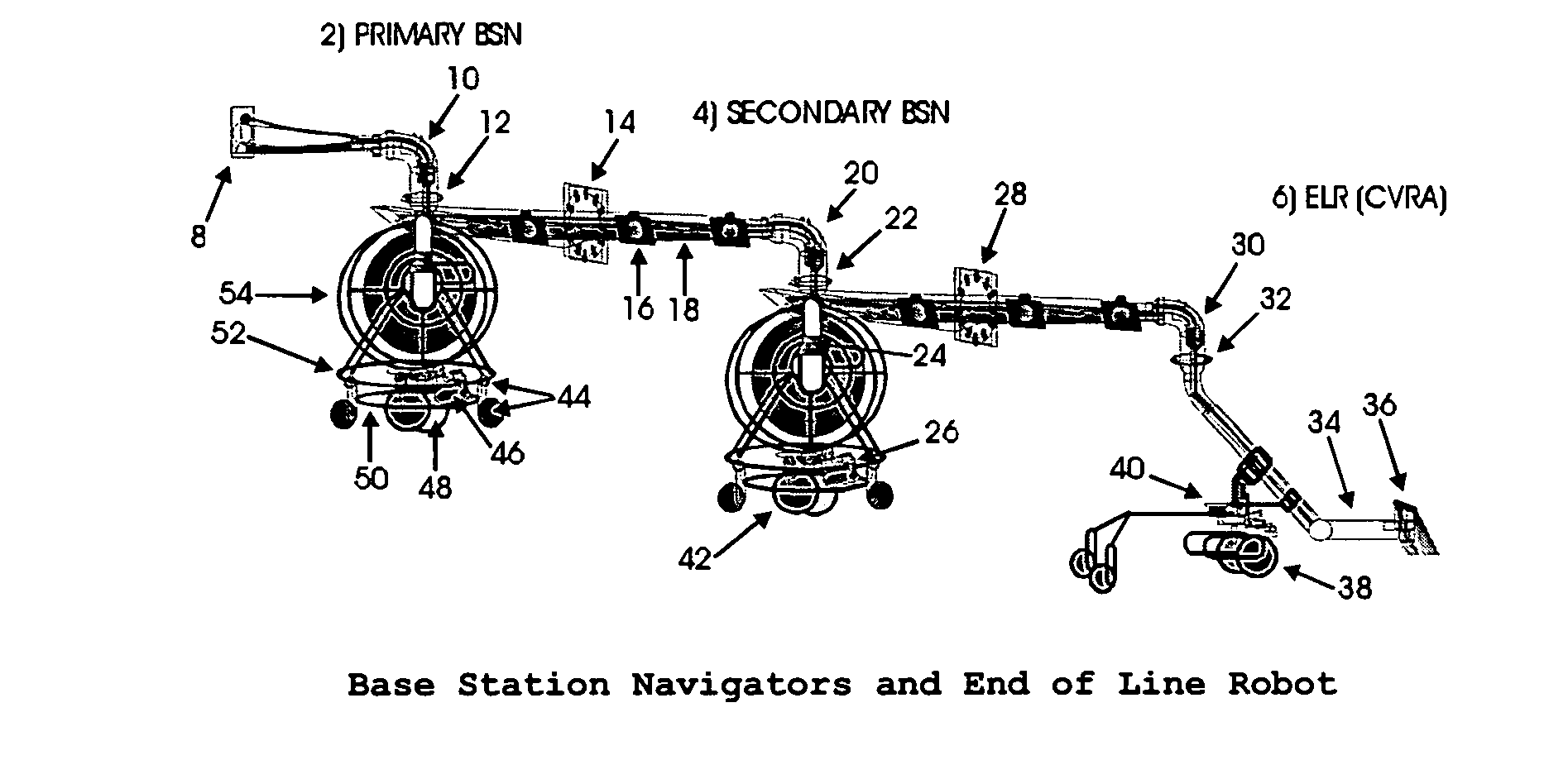

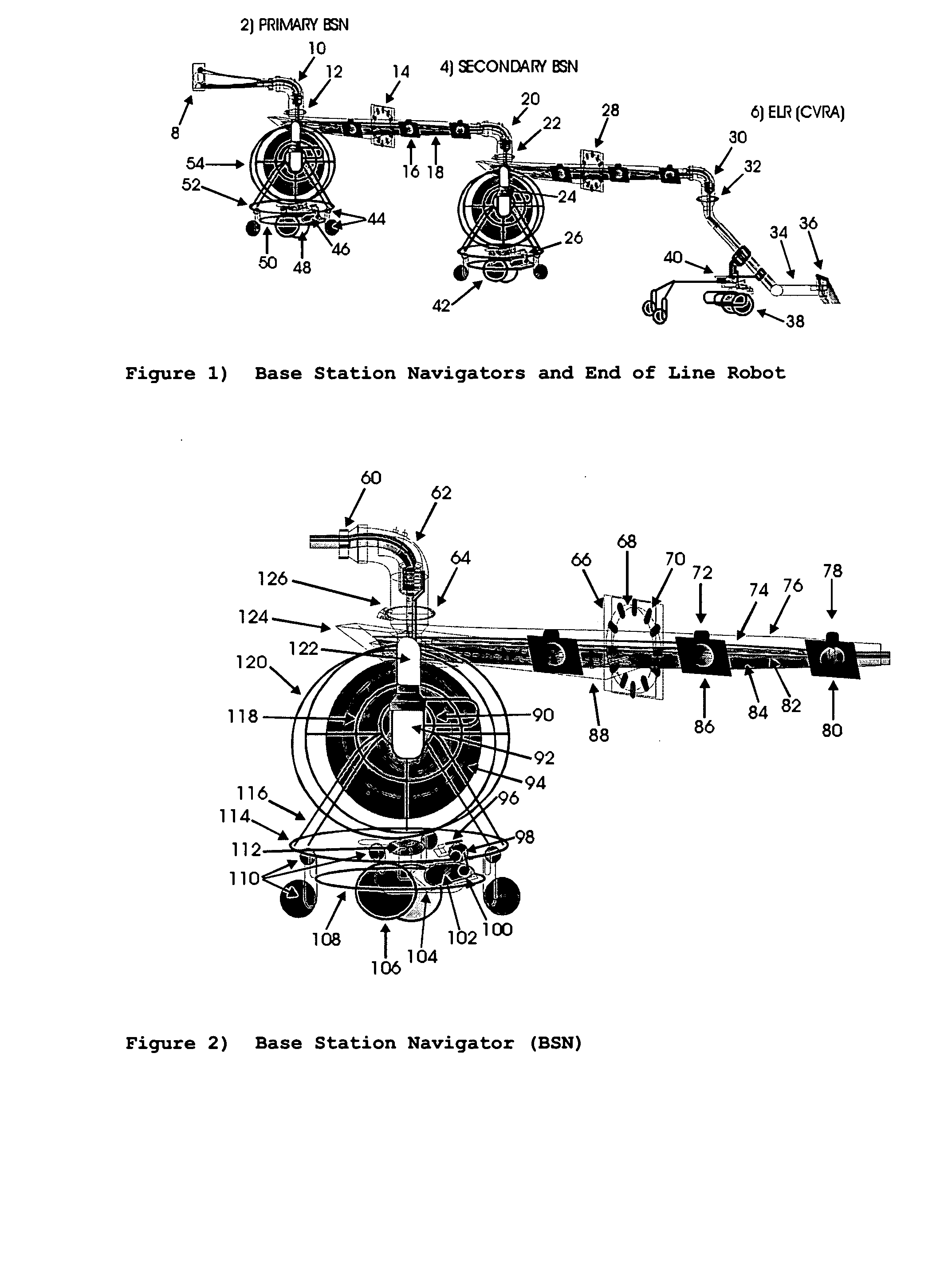

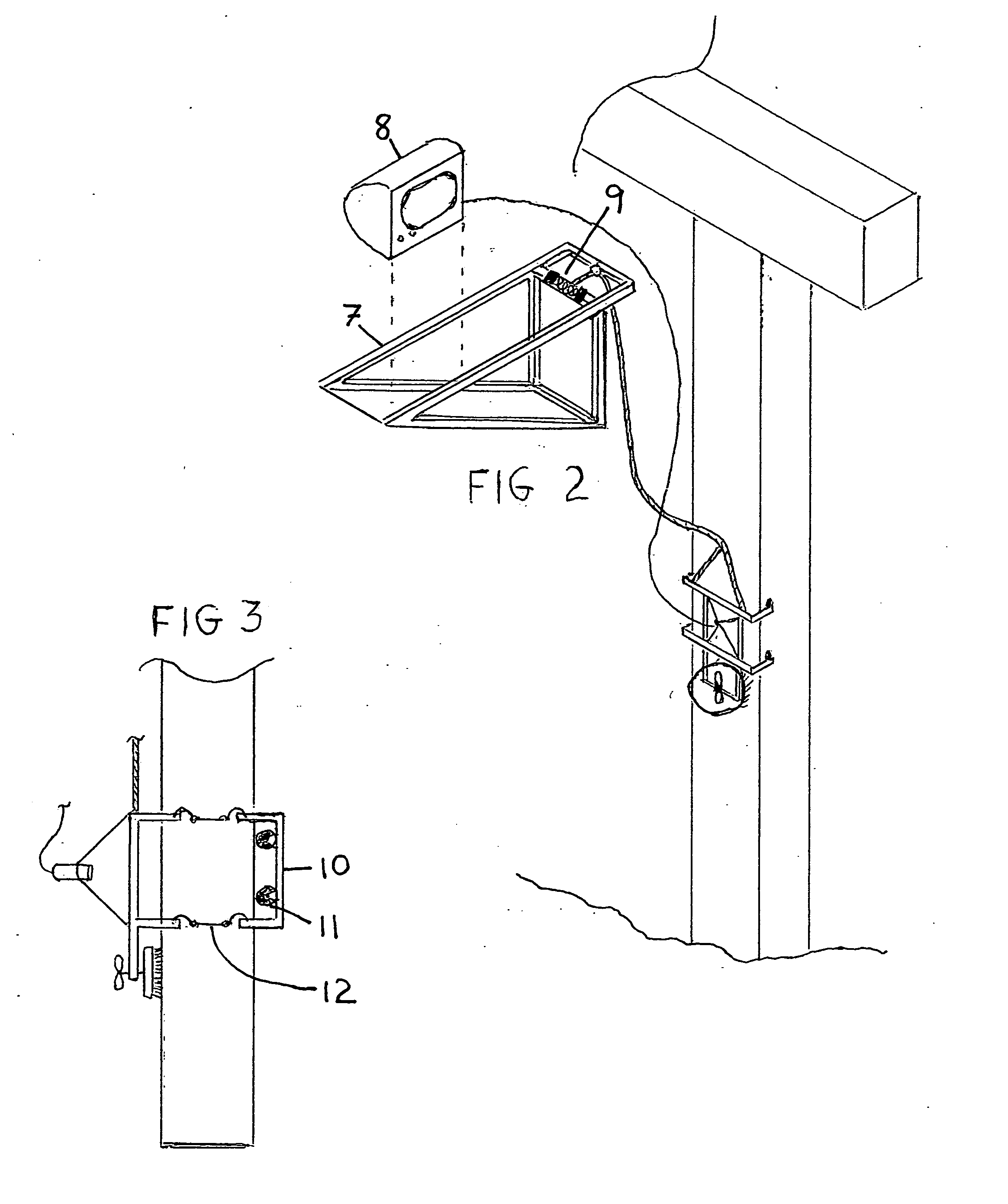

Guidance system for a robot

InactiveUS20060009876A1Less-expensive to buildLess-expensive to operateNavigation instrumentsTension measurementGuidance systemTelecommunications link

A guidance system for a robot includes a main monitoring station and an unmanned movable base station, which is in communication with the main monitoring station. A robot is provided which is adapted to operate within a predetermined radius of the base station. Either an umbilical cord connection or a wireless communication link can be provided for dynamically determining the distance and orbital positioning of the robot relative to the base station.

Owner:MCNEIL DEAN

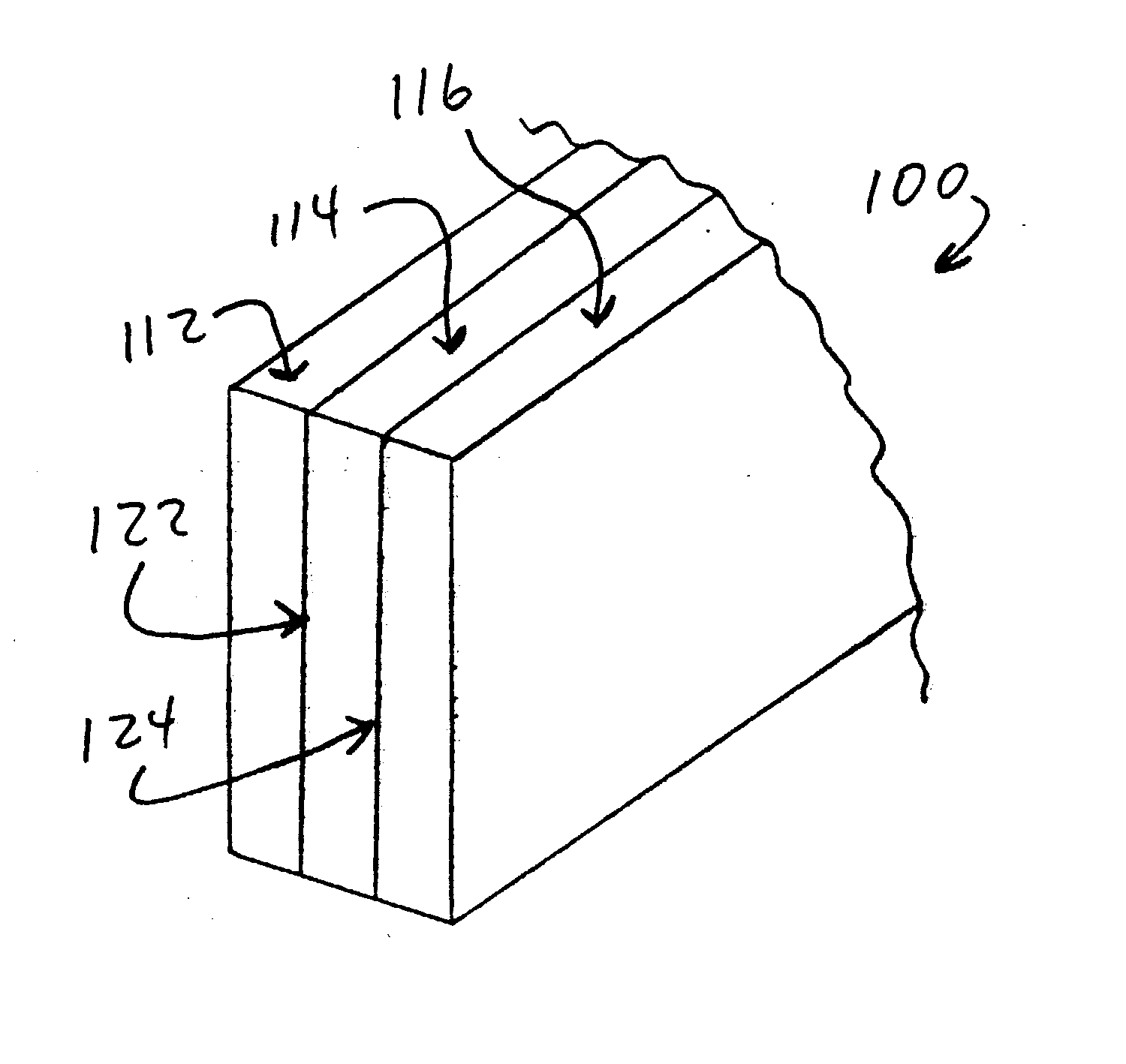

Laminated beams, boards, planks, and rails with enhanced stiffness and strength, made from nylon fiber composites

InactiveUS20050170166A1Increase stiffnessGreat strength and durabilitySynthetic resin layered productsThin material handlingAdhesiveBuilding design

Synthetic fiber composites (preferably containing nylon fibers obtained from recycled carpets) are made in laminated forms that can substitute for wooden boards, and even for structural beams (including studs, rafters, joists, etc.) in a framed house or other building. These laminates can be made from needle-punched fiber mats, which provide more extensive fiber intertwining than air-laid, bat-formed, or other fiber mats. In a preferred method of manufacture, sheets or wide strips are glued together, under pressure and using a non-foaming adhesive, to form oversized laminates having any desired thickness and desired length. The laminated sheets or strips are then sawed (such as by gang-ripping) into desired widths, to form edges that will not need additional trimming to remove excess adhesive. If suitable adhesives are used to form the adhesive layers, lamination can provide increased stiffness, compared to single-layer sheets having the same thickness. This increased stiffness can provide these laminated items with greater ability to withstand bending moments, torsional forces, and heavy longitudinal compression. These materials can also enable improved building designs and constructions that use less material, such as by increasing the spacings between adjacent studs, joists, and rafters.

Owner:BACON FORREST C +1

Method of forming probe card assembly

ActiveUS20080007281A1Less-expensive to buildEasy to disassembleLine/current collector detailsSemiconductor/solid-state device testing/measurementProbe cardLocking mechanism

A probe card assembly has a probe contactor substrate having a plurality of probe contactor tips thereon and a probe card wiring board with an interposer disposed between the two. Support posts contacting the probe contactor substrate are vertically adjustable until secured by a locking mechanism which is coupled to the probe card wiring board. When the posts are secured in a fixed position, the position is one in which the plane of the plurality of probe contactor substrates is substantially parallel to a predetermined reference plane.

Owner:FORMFACTOR INC

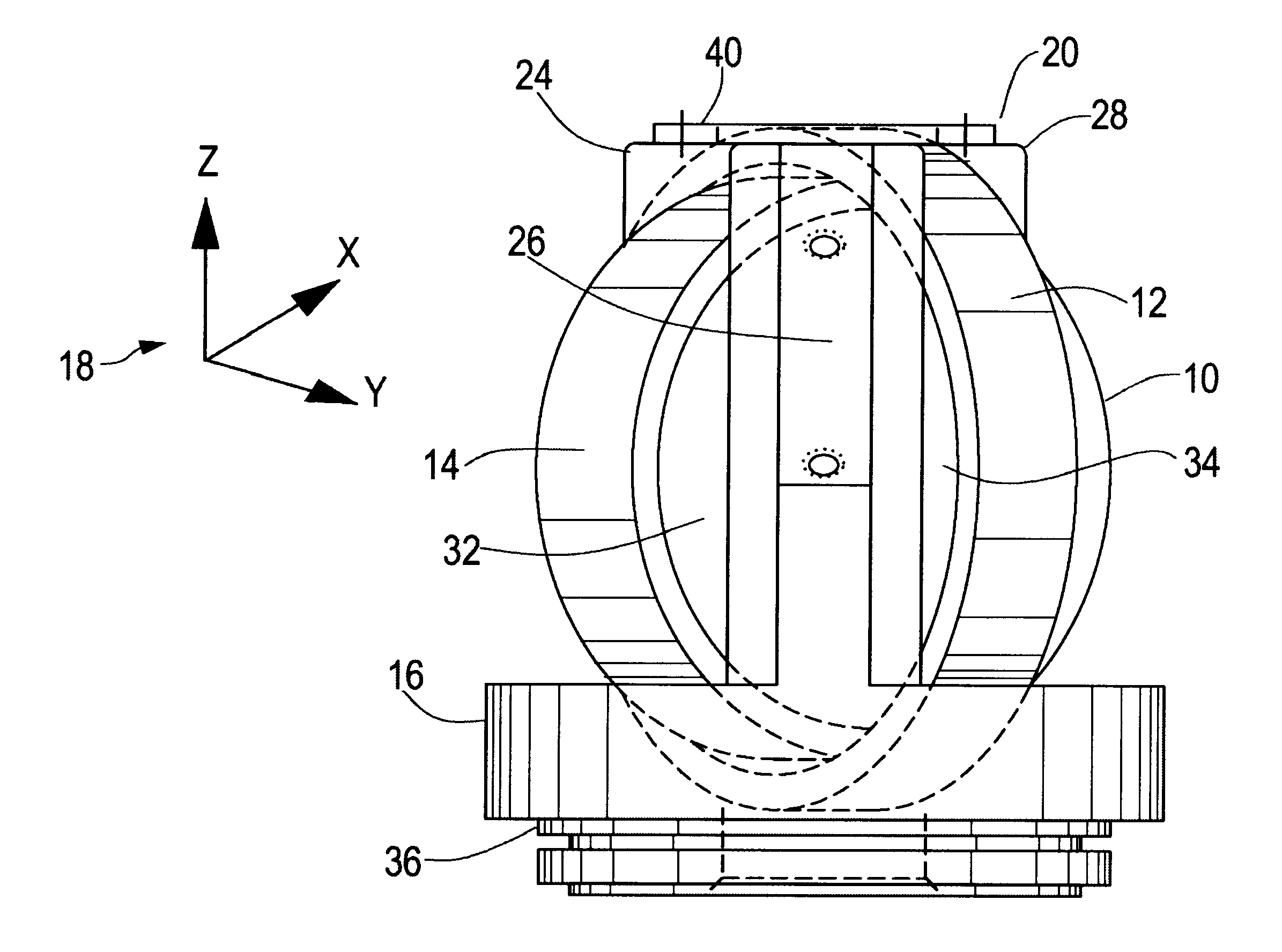

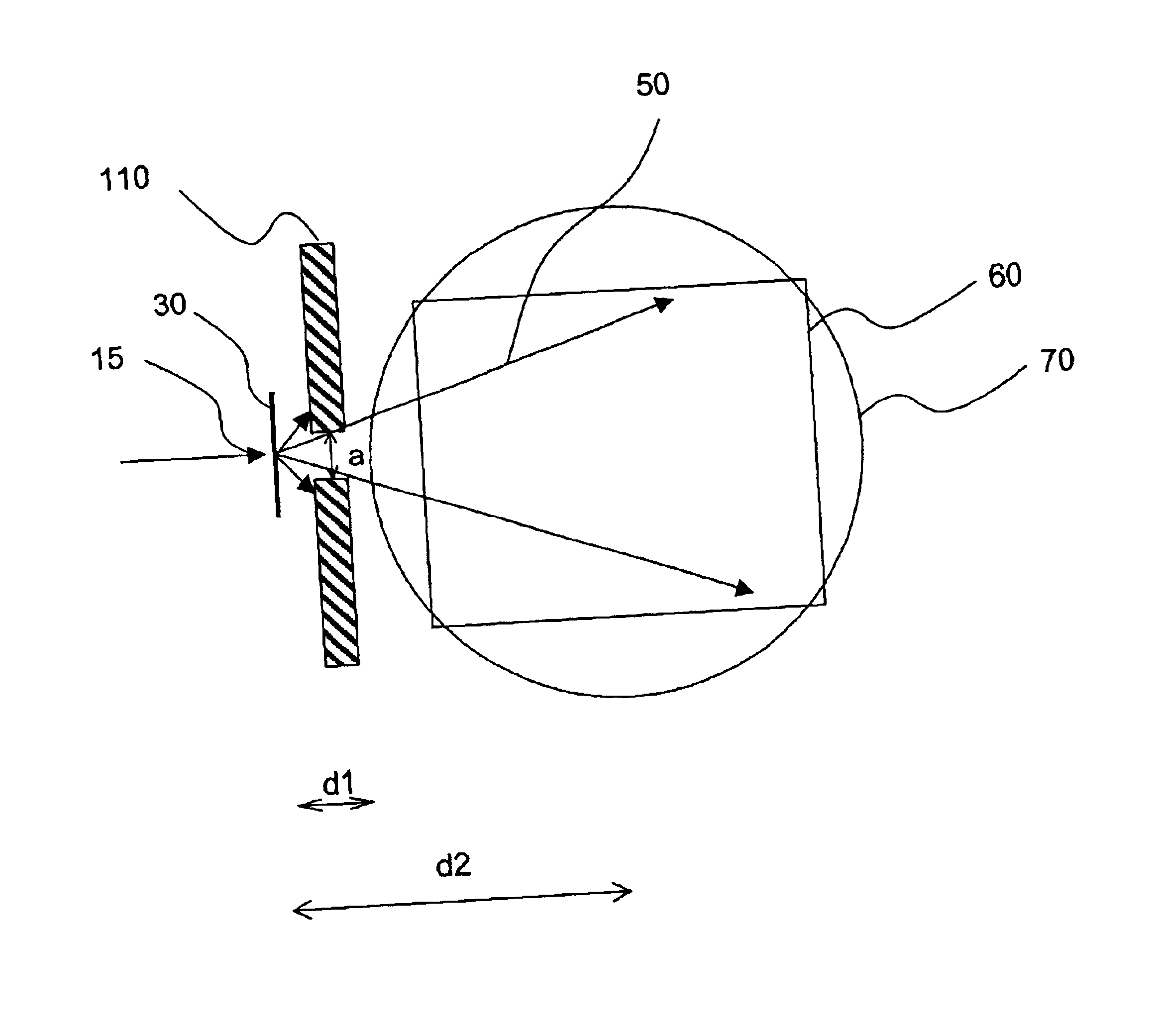

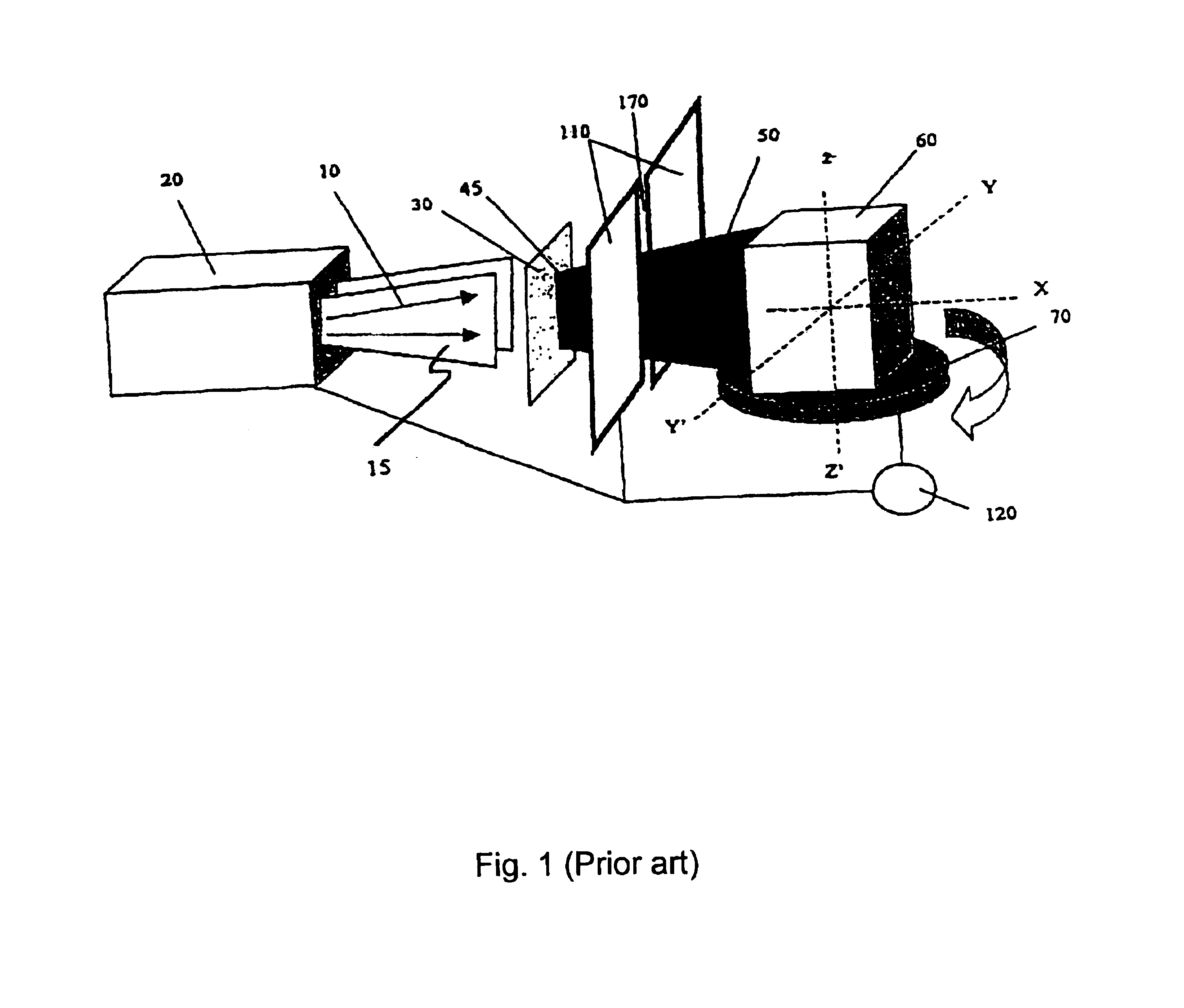

Method and apparatus for X-ray irradiation having improved throughput and dose uniformity ratio

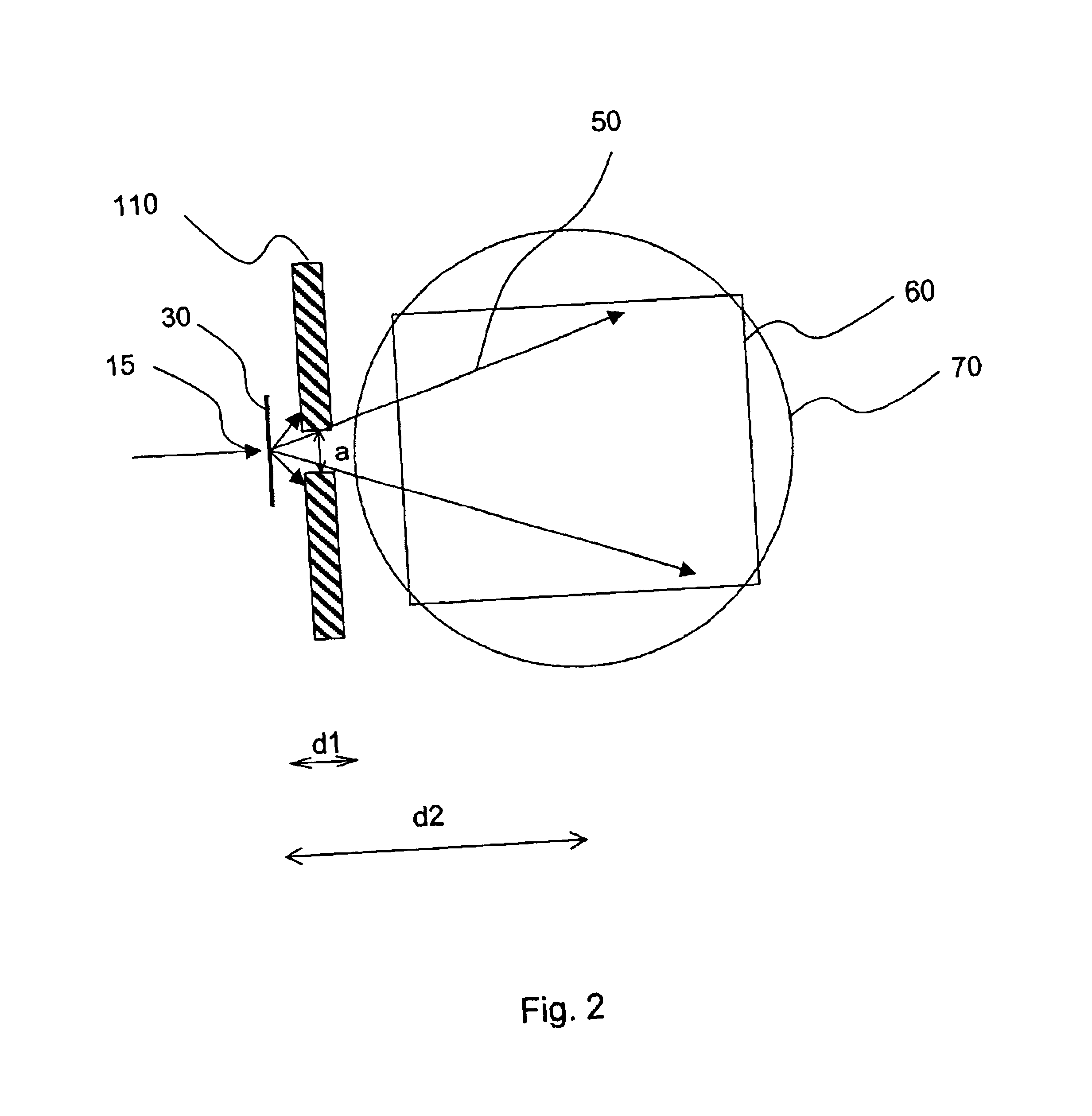

InactiveUS6940944B2Maximize throughputLess complex to maintainPackage sterilisationIrradiation devicesDose uniformityX-ray

The present invention is related to a method and apparatus of radiation processing of a product package in a device having a radiation source, a collimator having a variable aperture, and a turntable, said radiation processing resulting in a point in the product package where the dose is minimal (Dmin point) and a point in said product package where the dose is maximal (Dmax point) comprising the steps of:determining a first value of the collimator aperture, by increasing said aperture from a small value, where the Dmax point is located near the centre of the product package, up to a value where the Dmax point moves near to the centre of a small side of said package's rectangular horizontal cross-section;determining a second value of the collimator aperture, by further increasing the collimator aperture up to a point where the Dmin point moves from a point near the corner of the product package to the centre of said package;processing said package with radiation, the collimator aperture being kept at a constant value comprised between said first and said second value, the turntable being rotated at a variable speed.

Owner:ION BEAM APPL

Retraction arm to extract a mezzanine circuit board connector from a motherboard connector

ActiveUS20130052847A1Reduce disadvantagesReduce problemsEngagement/disengagement of coupling partsDigital data processing detailsEngineeringHandling system

An information handling system mezzanine circuit board disposed in a parallel configuration over a motherboard is selectively coupled and de-coupled at the motherboard with a retraction and latching device that translates retraction force applied at an accessible actuation portion to push upward from below the mezzanine circuit board. A retraction portion of the retraction and latching device provides an upward force at the bottom surface of the mezzanine circuit board to separate the mezzanine circuit board connector from the motherboard connector so that an end user can lift the mezzanine circuit board away from the motherboard.

Owner:DELL PROD LP

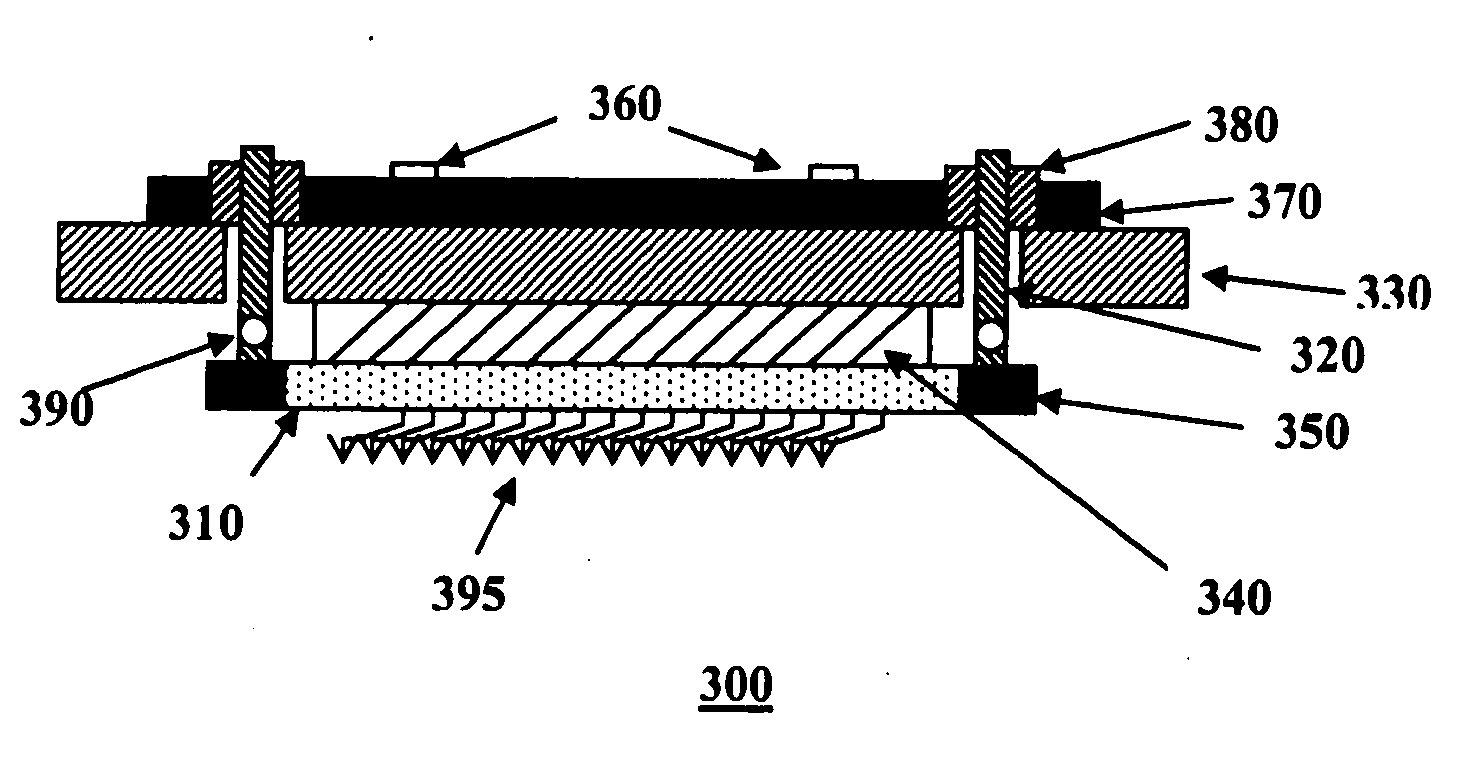

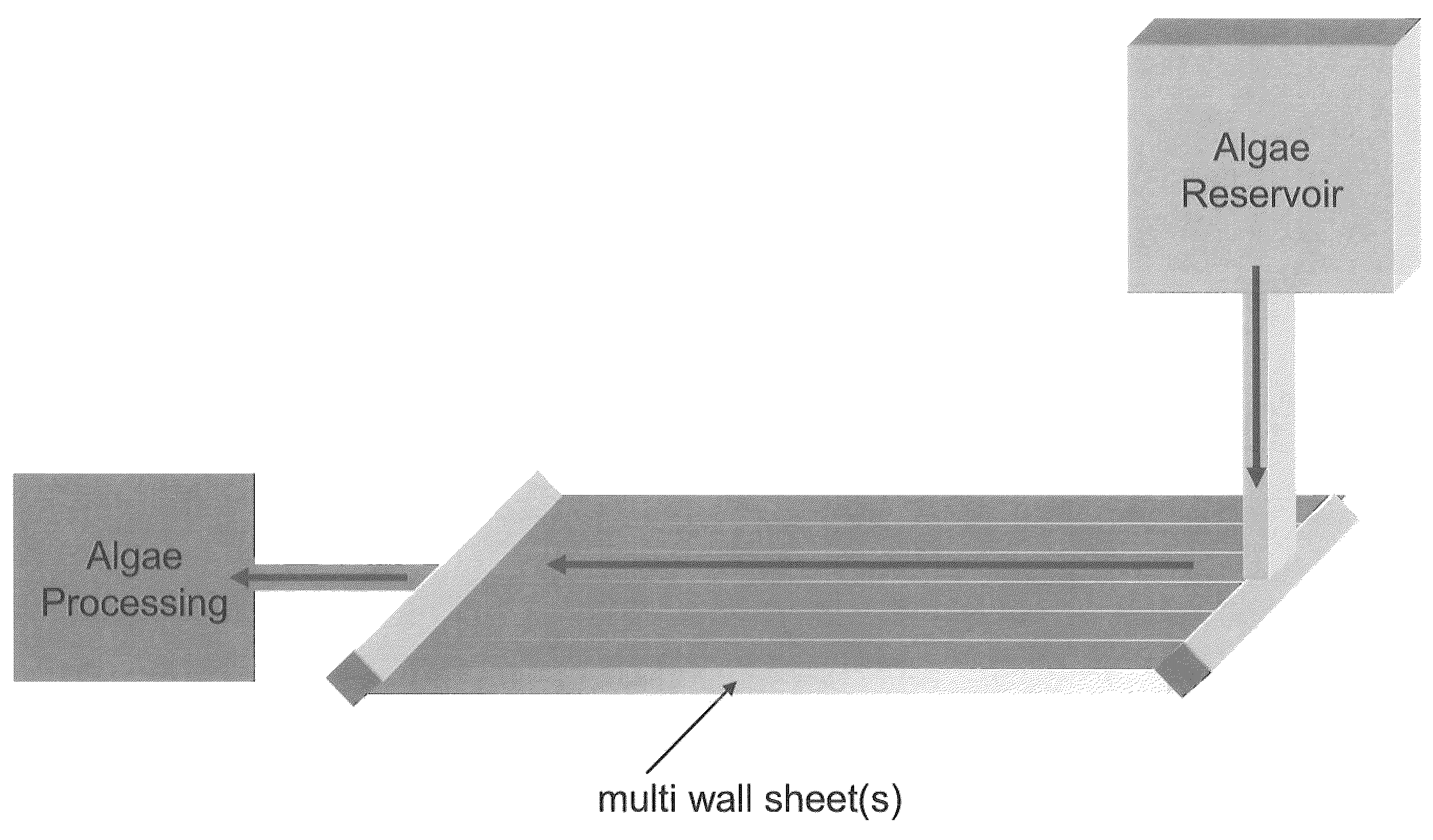

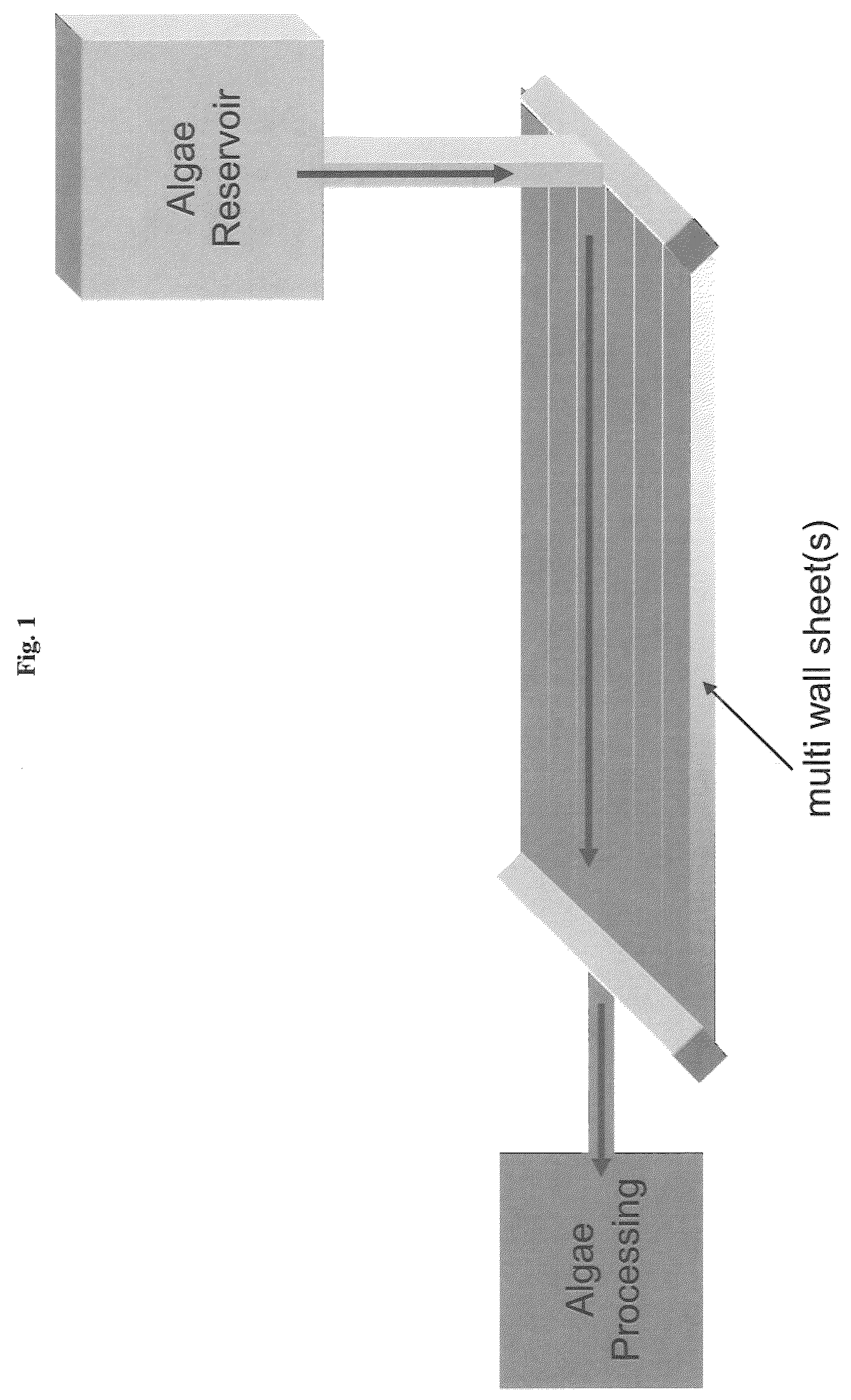

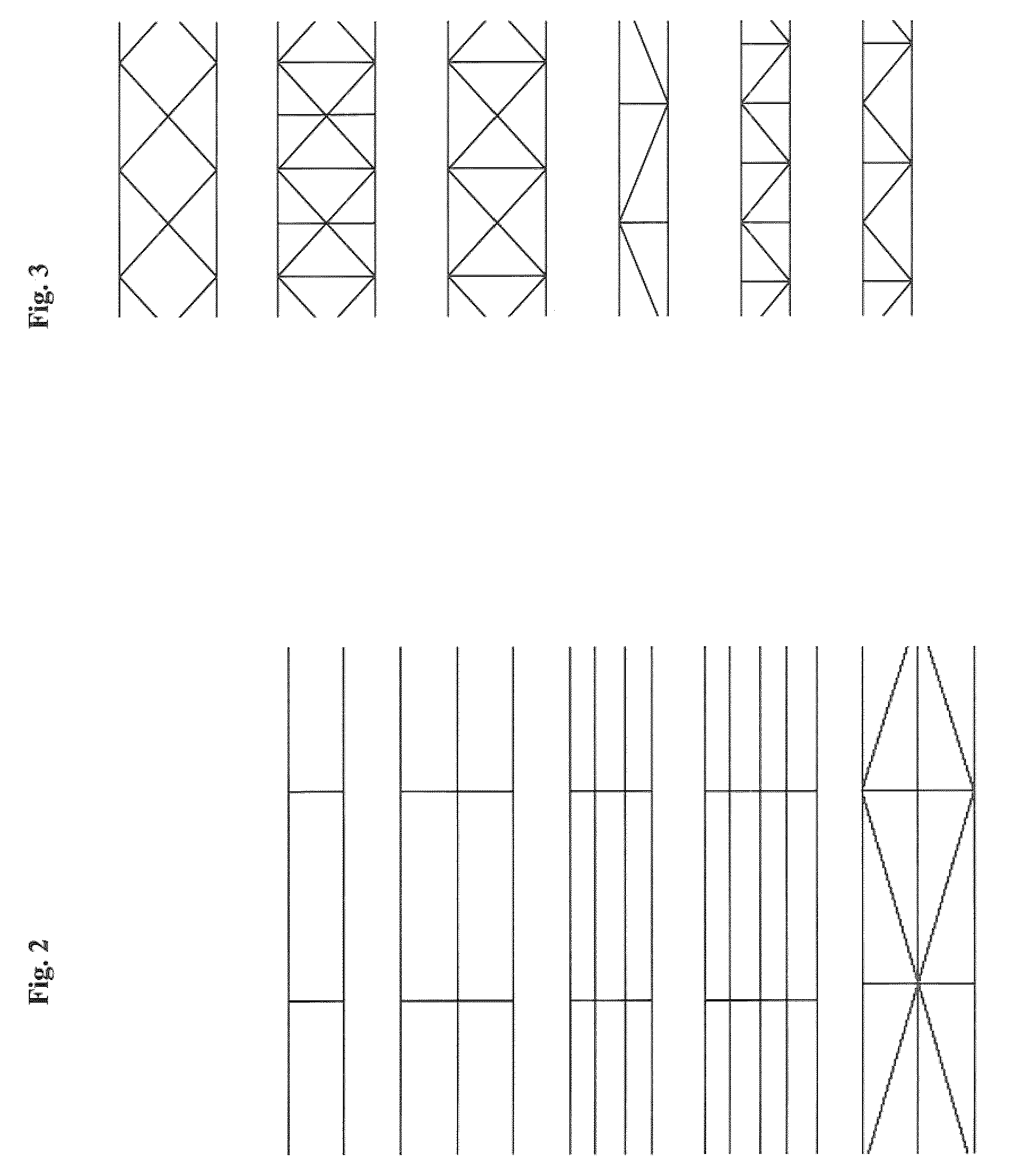

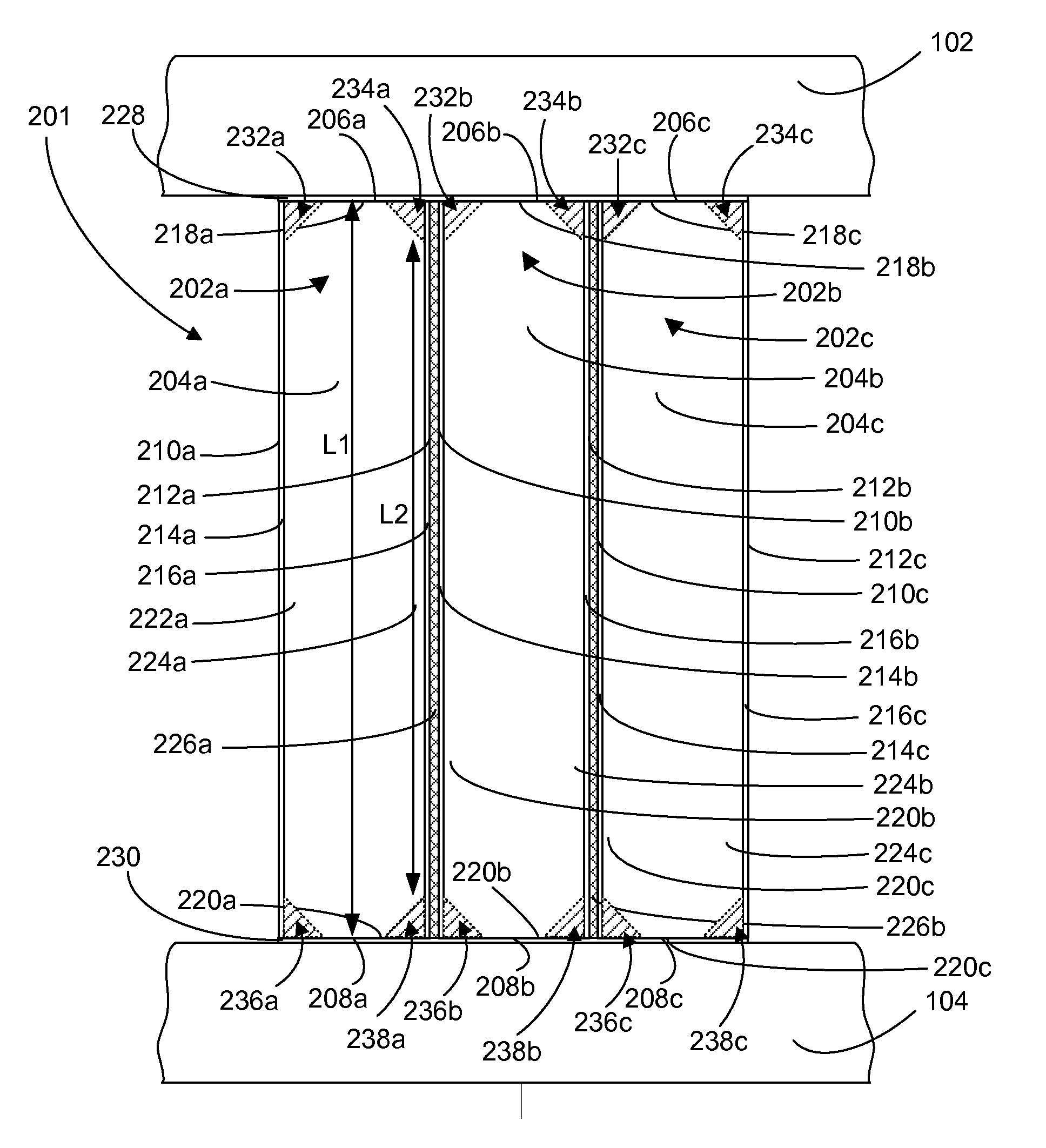

Photobioreactor for algae growth

InactiveUS8658420B2Less-expensive to buildReduce energy costsBioreactor/fermenter combinationsBiological substance pretreatmentsGravity assistBiofuel

The present invention provides a flow-through photobioreactor containing at least one thermoplastic multi-wall sheet having an upper layer and a lower layer having arranged there between at least two sidewalls, at least one inner wall and two or more end caps. Also provided is a process for the production of a biofuel with the inventive photobioreactor. The photobioreactor and process of the present invention have the following advantages: genetically engineered microbes that give higher yields cannot escape into the environment, water in the system does not evaporate, no weeding (presence of unwanted algae), UV light from the sun is filtered out by the reactor walls, temperature control is possible, CO2 from power plants, breweries, etc. can be artificially fed to increase yield. The inventive photobioreactor is also less expensive to build than pipe reactors and may have low energy costs to operate, because little or no energy is needed for agitation and pumping in a preferred gravity assisted embodiment.

Owner:COVESTRO LLC

Adjustable and foldable V-shaped hay rake

ActiveUS20100032924A1Less-expensive to buildHighly effectiveCarriage/perambulator accessoriesAgricultural machinesEngineeringUltimate tensile strength

The adjustable and foldable V-shaped hay rake which is the object of this invention is an agricultural tool used for raking hay on fields, in which, for each arm of the hay rake, all the mechanisms for moving the arm are centered on a single master support plate, that can simultaneously, both be very effectively used and easily adjusted, as well as providing the advantages of great simplicity of construction, great strength and a very economical cost of production.

Owner:SITREX

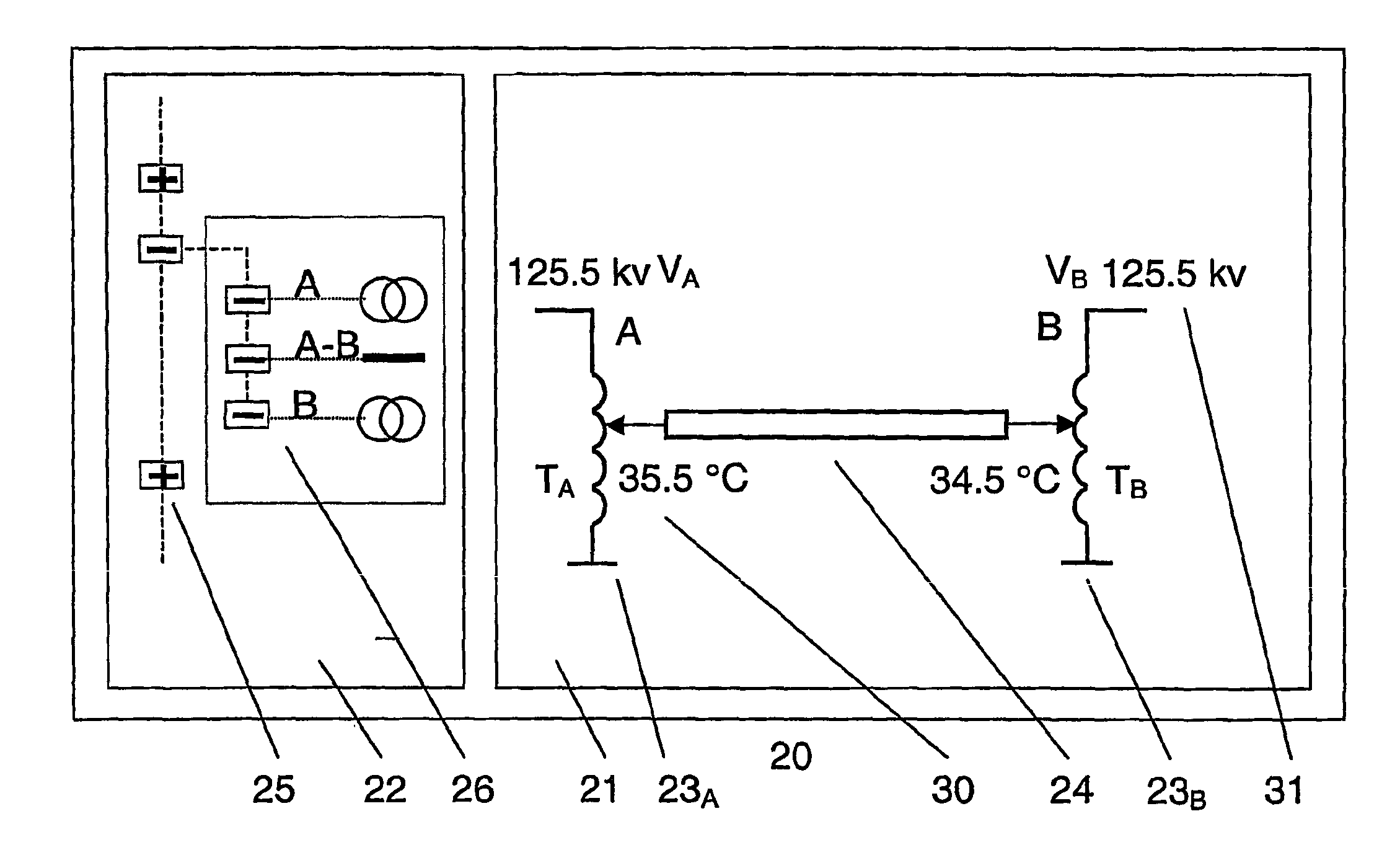

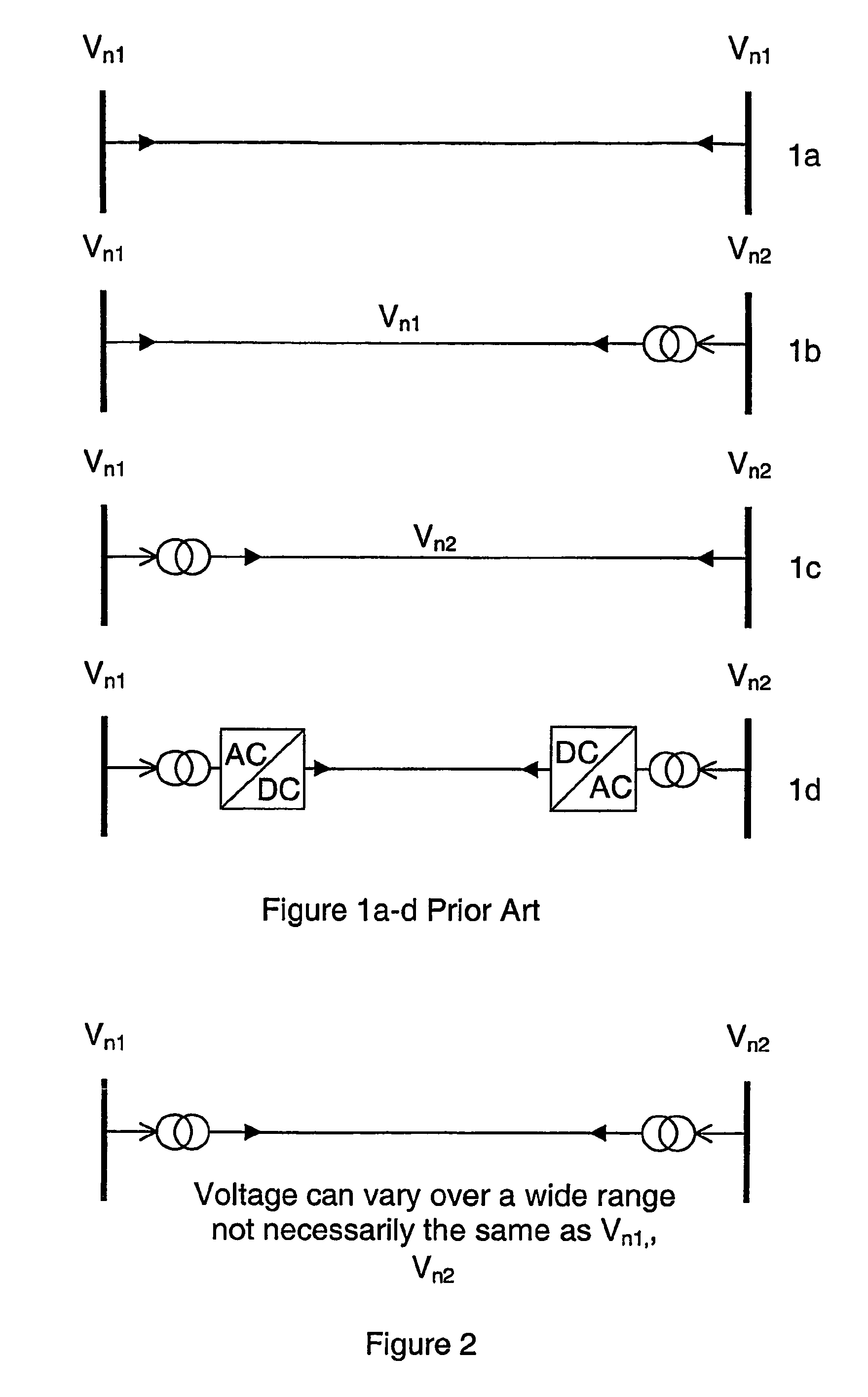

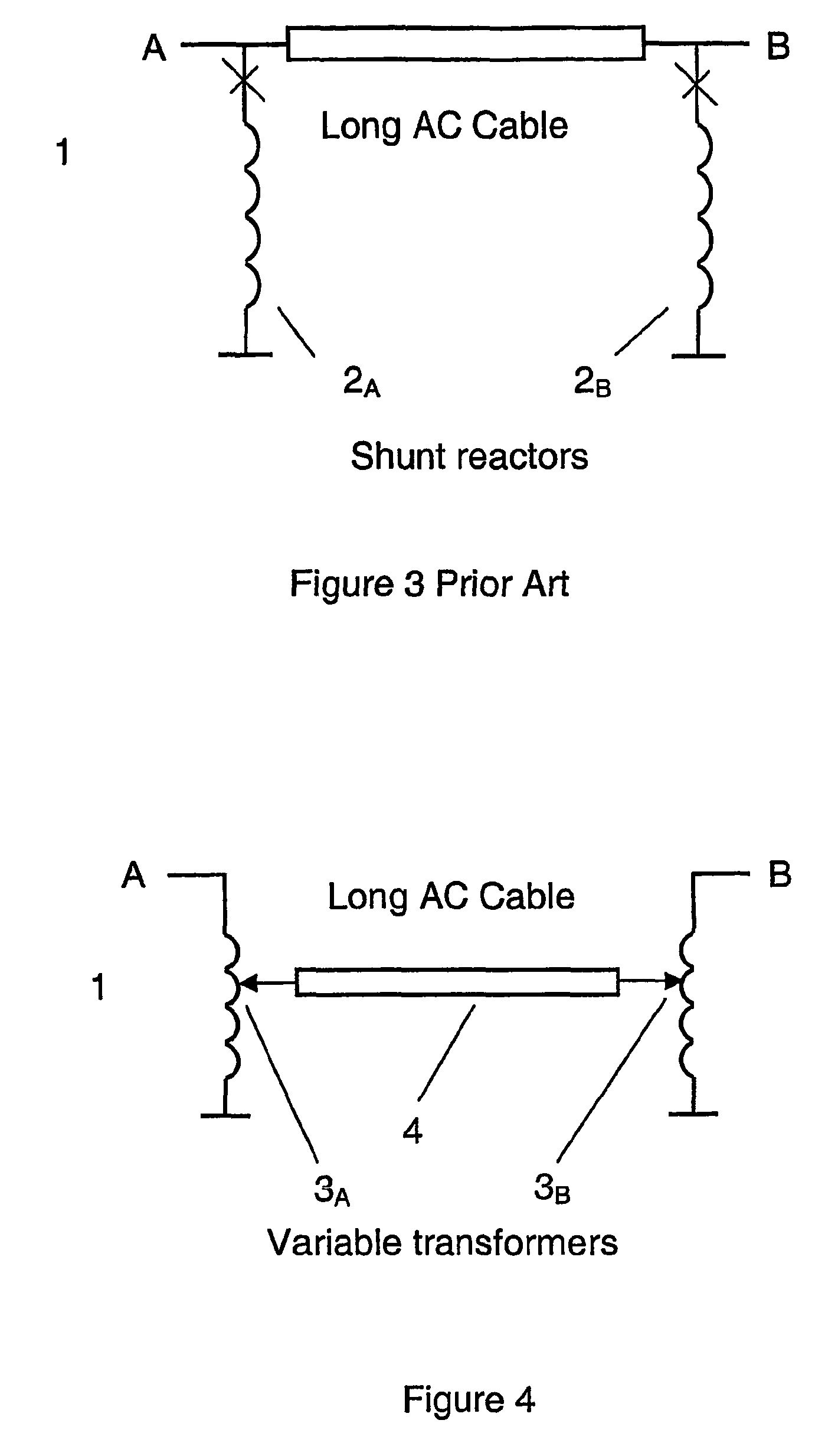

System for transmission of electric power

InactiveUS7759910B2Minimal power lossReduce power consumptionReactive power adjustment/elimination/compensationElectric variable regulationElectric power transmissionElectric power system

A high voltage AC transmission cable system for transmitting power between two points, each connected to one or more power networks, and a method to operate the system. At least one transformer is arranged at each end of the AC transmission cable, wherein at least one of the transformers is arranged to operate the transformer at a voltage whereby losses due to reactive power transport and dielectric losses are minimized. The AC cable is run at a variable voltage regulated such that the voltage is a function of the load for the transmission cable. This operating voltage is not necessarily the same as the nominal voltages in the connection points. A control and communication system and a graphical user interface for carrying out the method are also provided.

Owner:ABB RES LTD

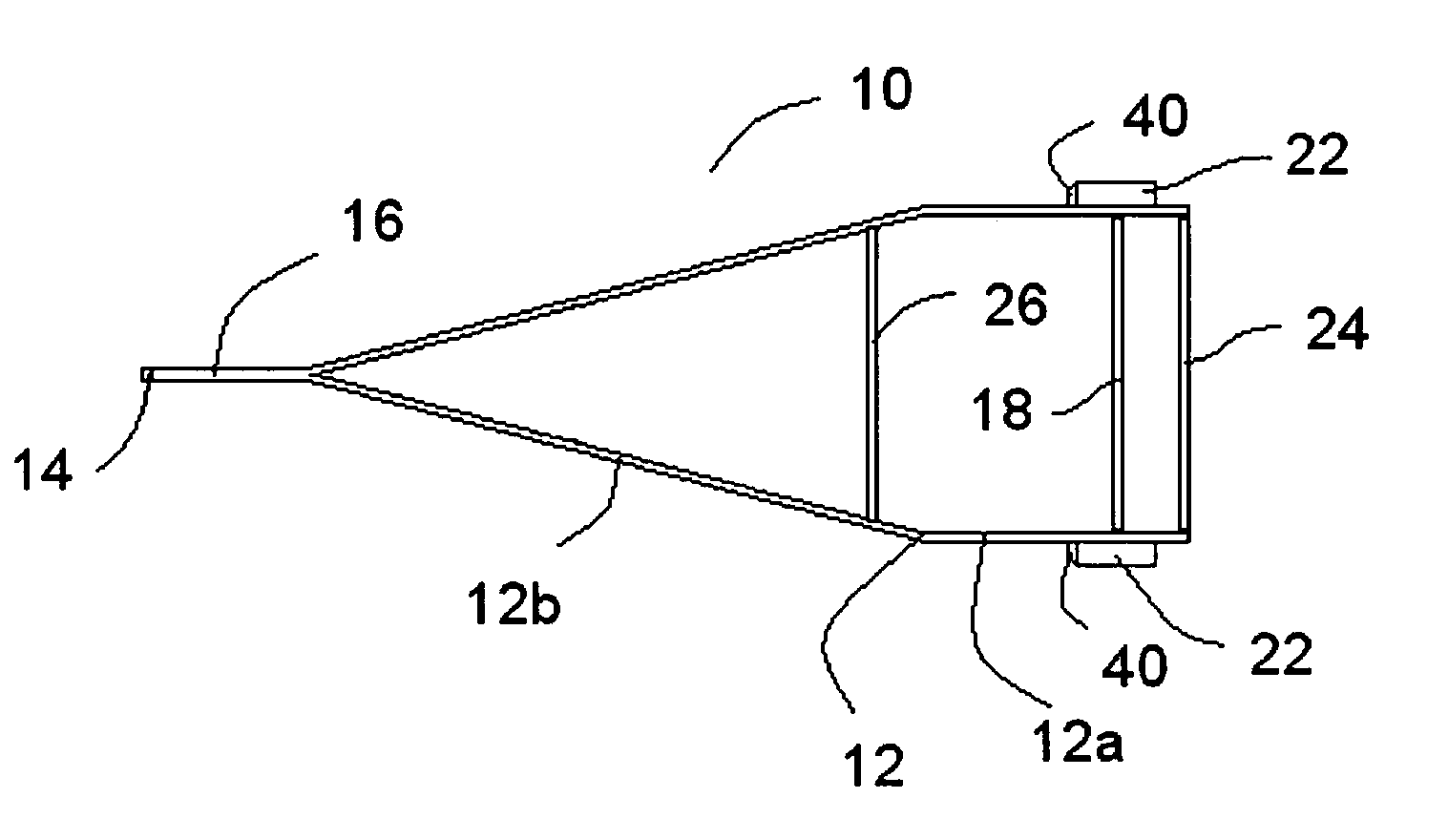

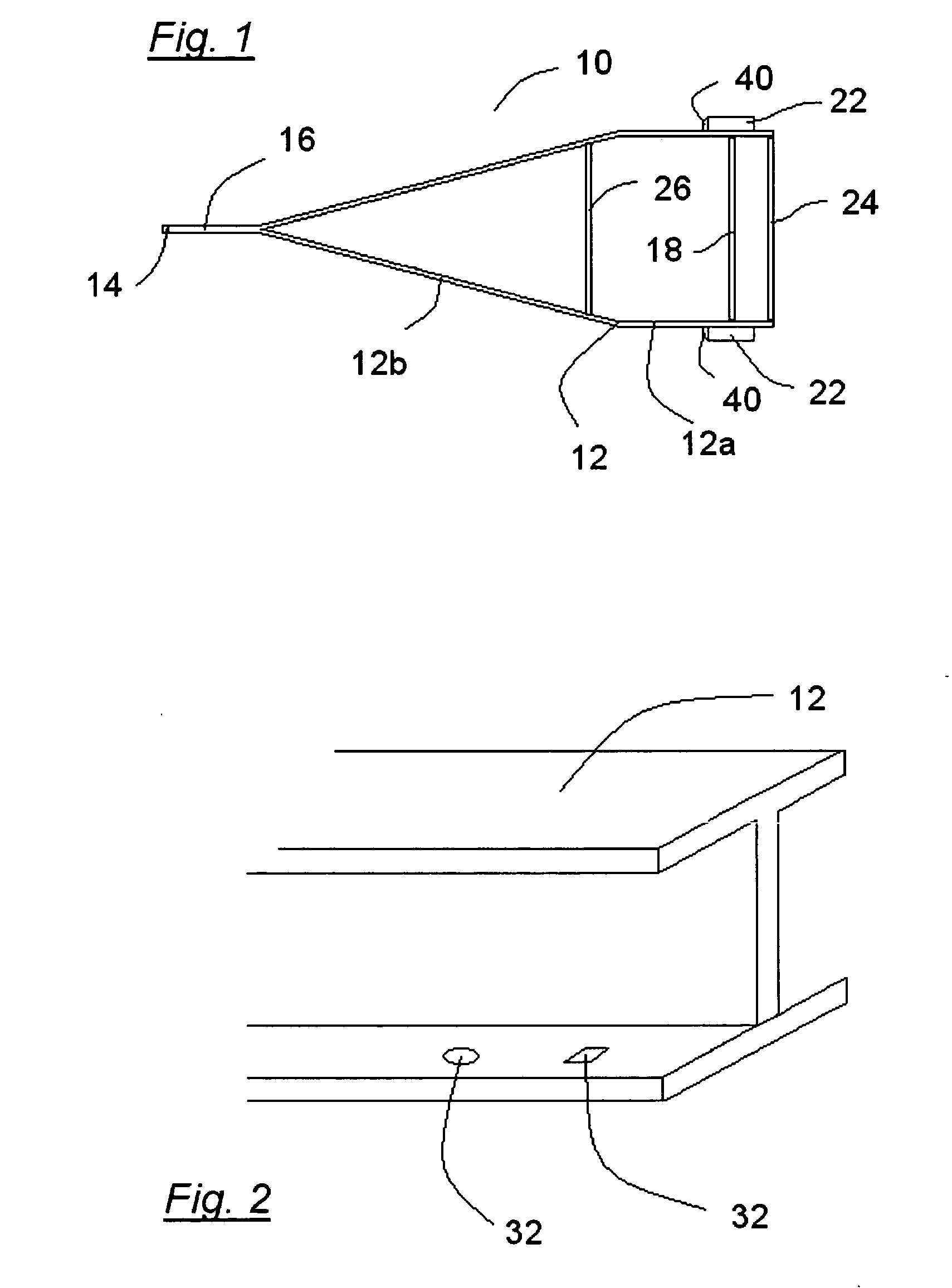

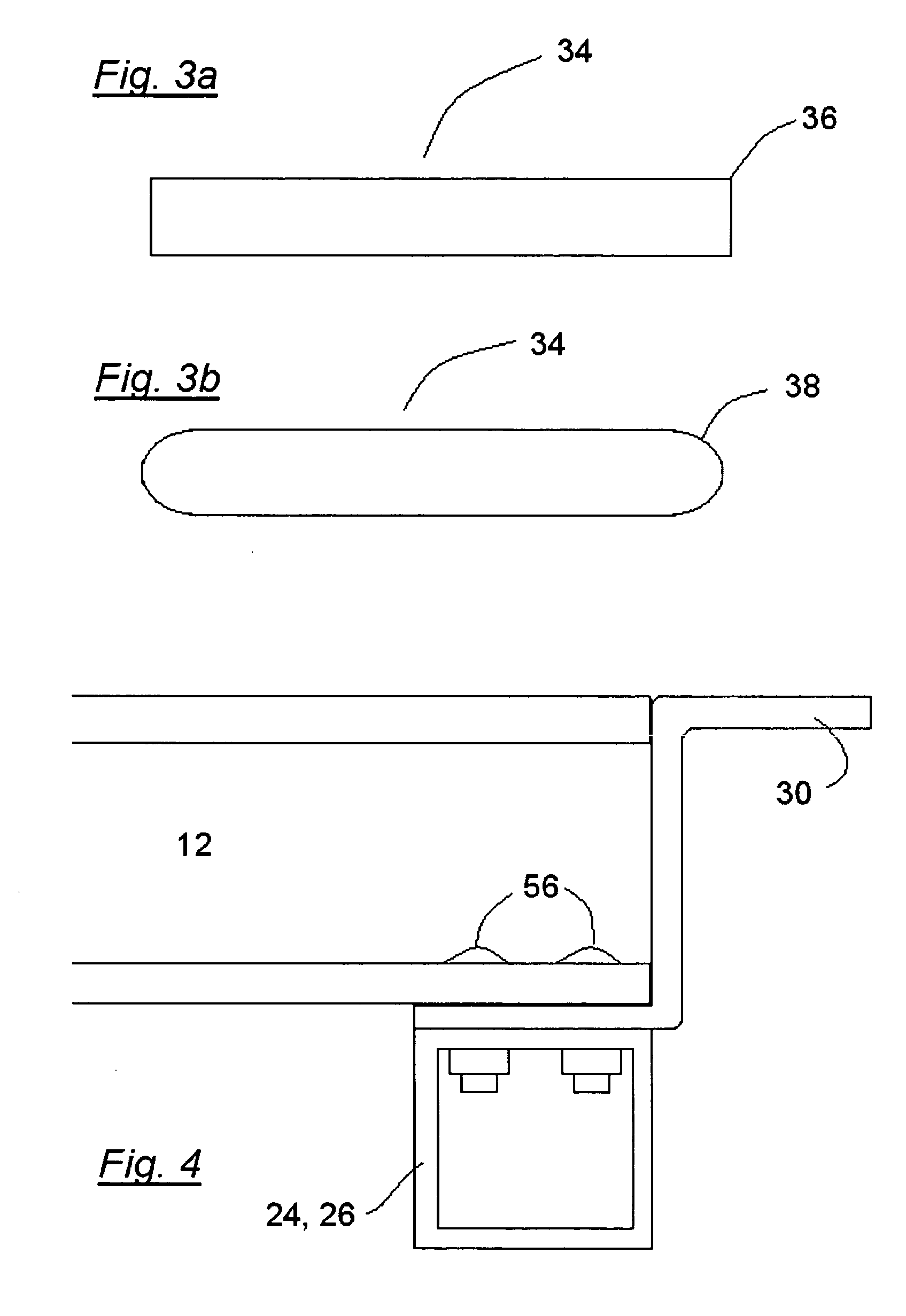

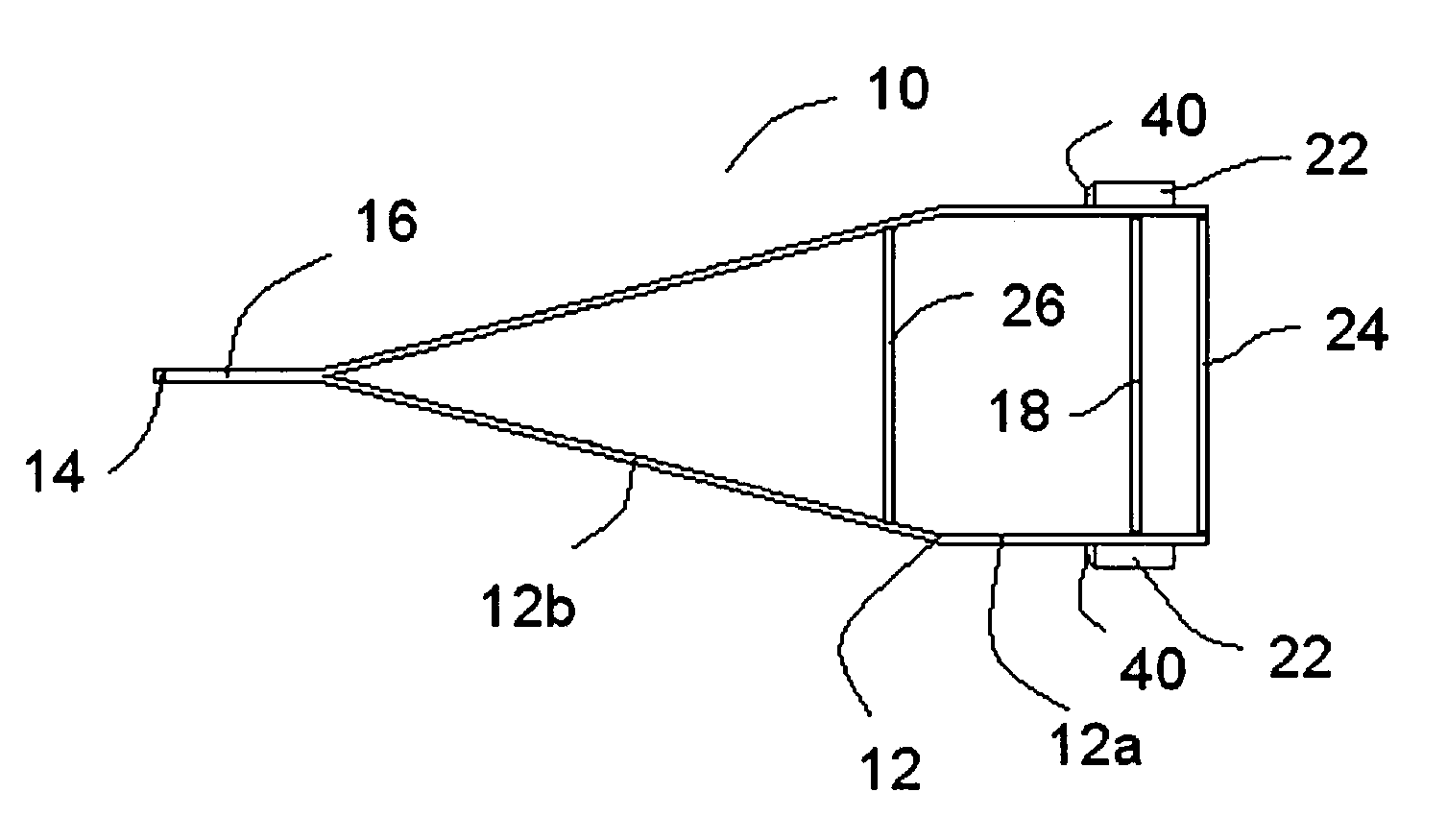

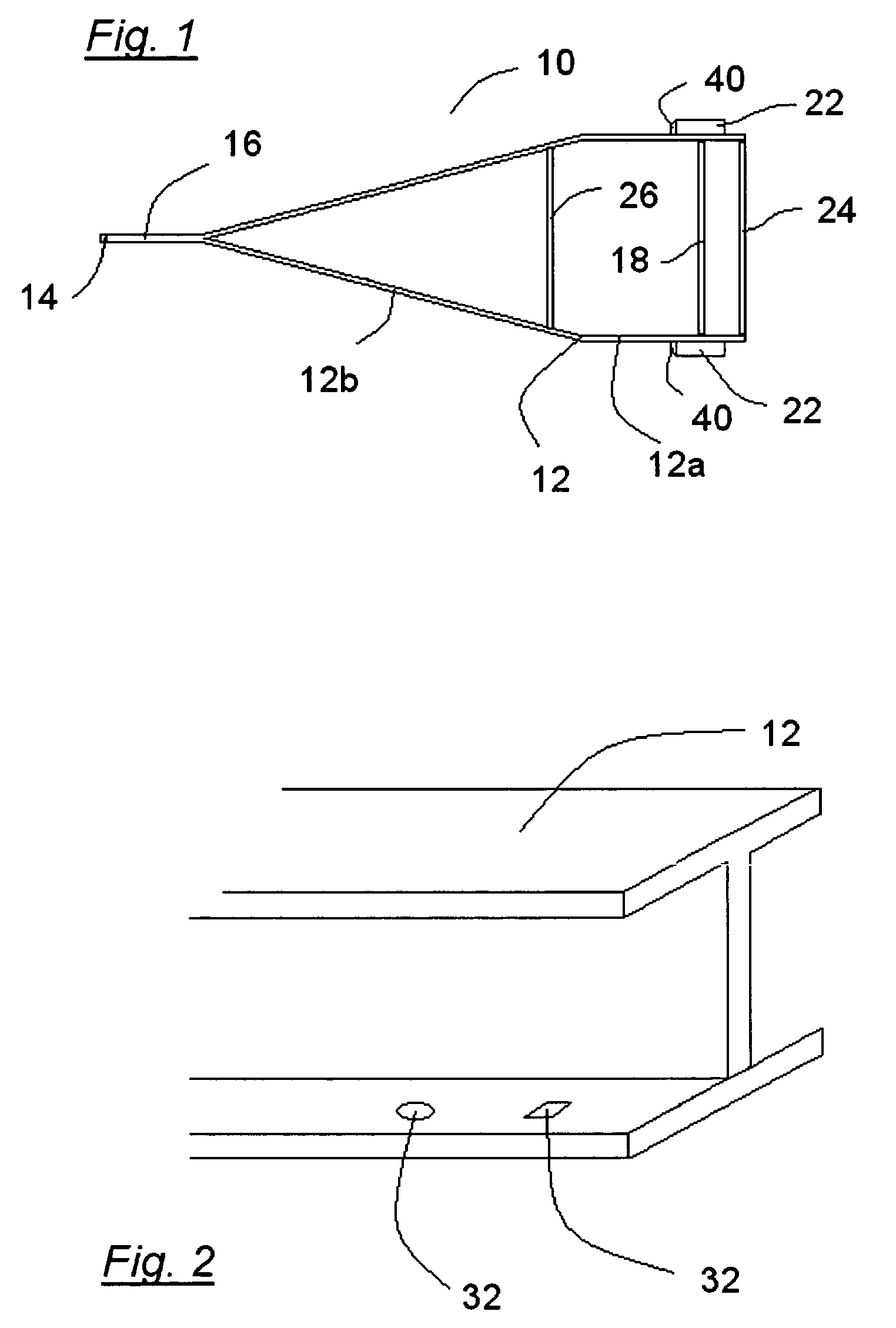

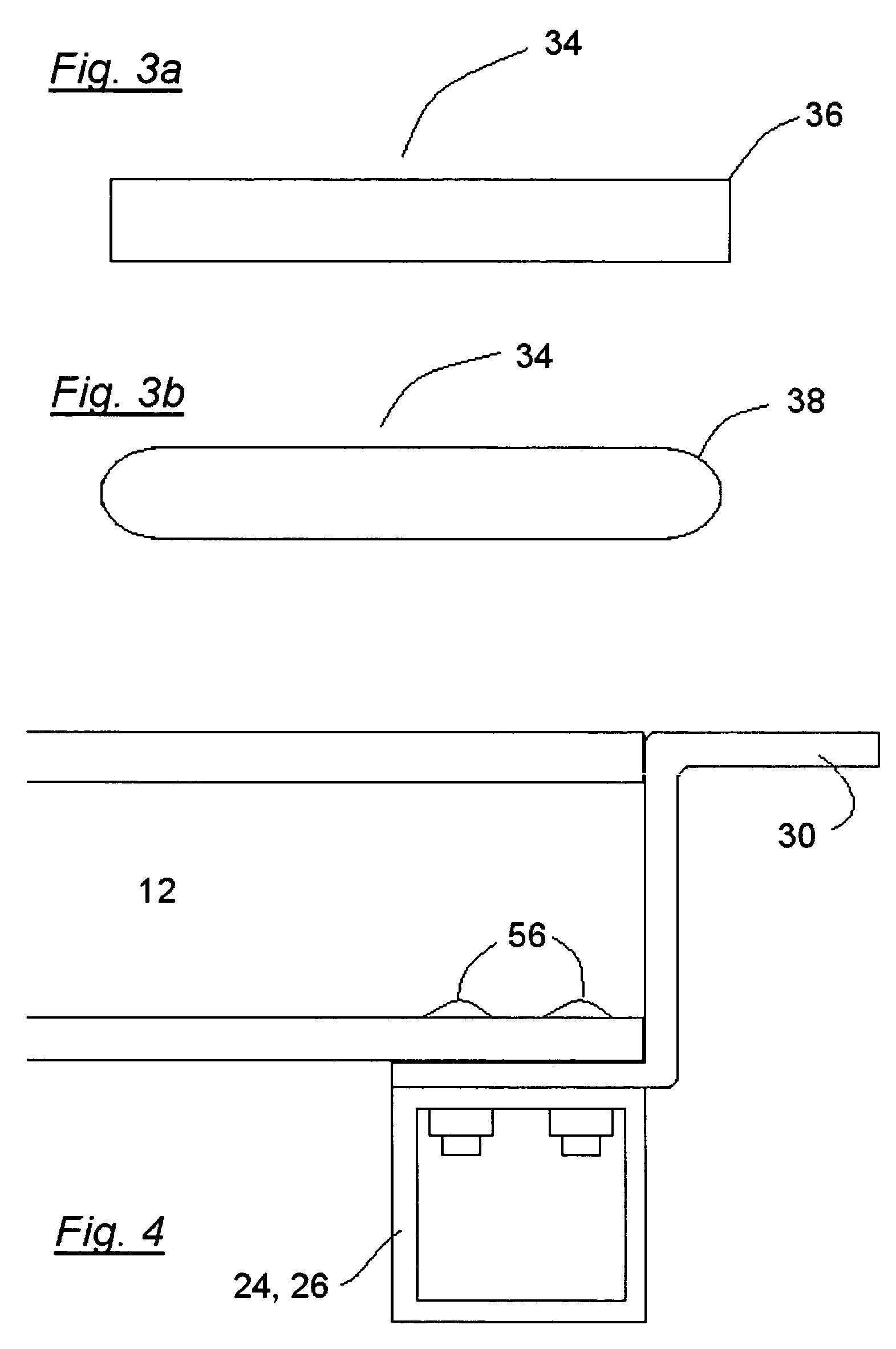

Boat trailer

InactiveUS20050179231A1Improve securityIncrease costUnderstructuresItem transportation vehiclesEngineeringMechanical engineering

A boat trailer comprising two side beams positioned adjacent to each other, wherein each of the side beams has a forward tongue forming portion converging toward the other side beam. The side beams can be connected to a towing vehicle and the side beams may also have a trailing boat-supporting portion. The trailer also includes at least one cross bar member extending between the boat-supporting portion of one of the side beams and the boat-supporting portion of the other side beam. The various members of the trailer may be punched with holes in a standard pattern.

Owner:ROBERTS JR RONALD E

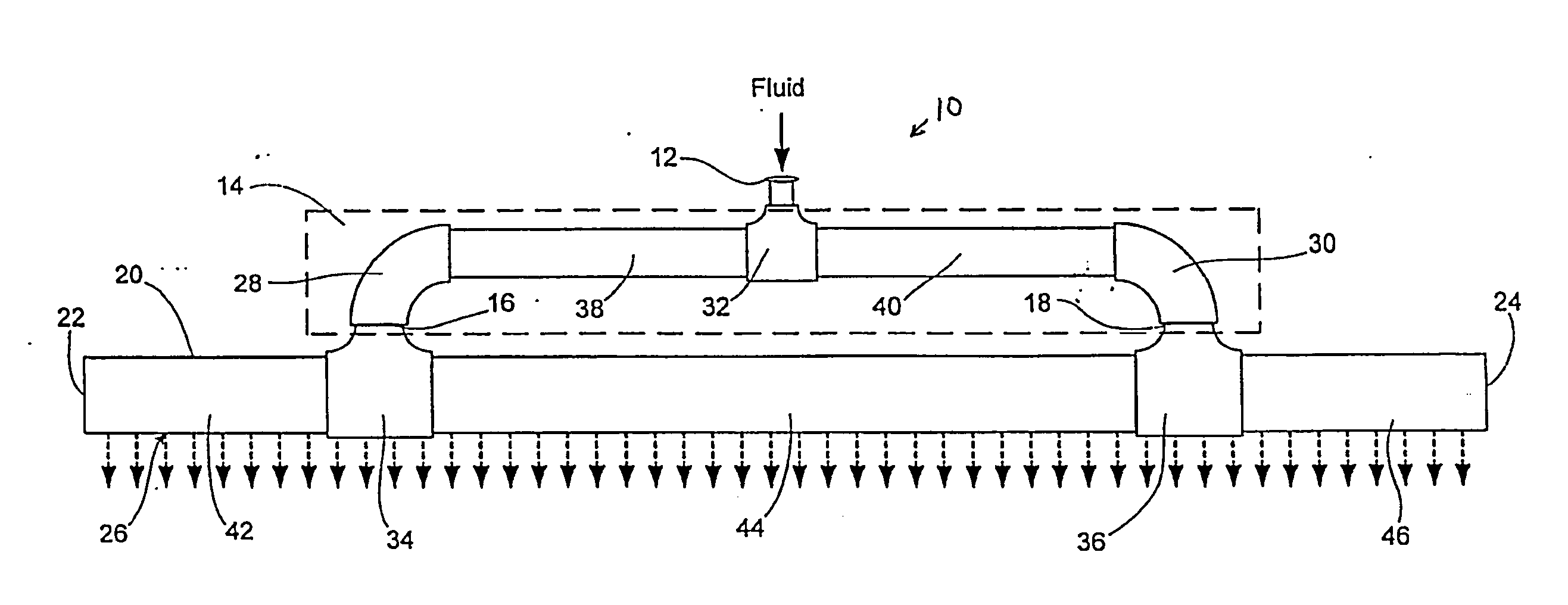

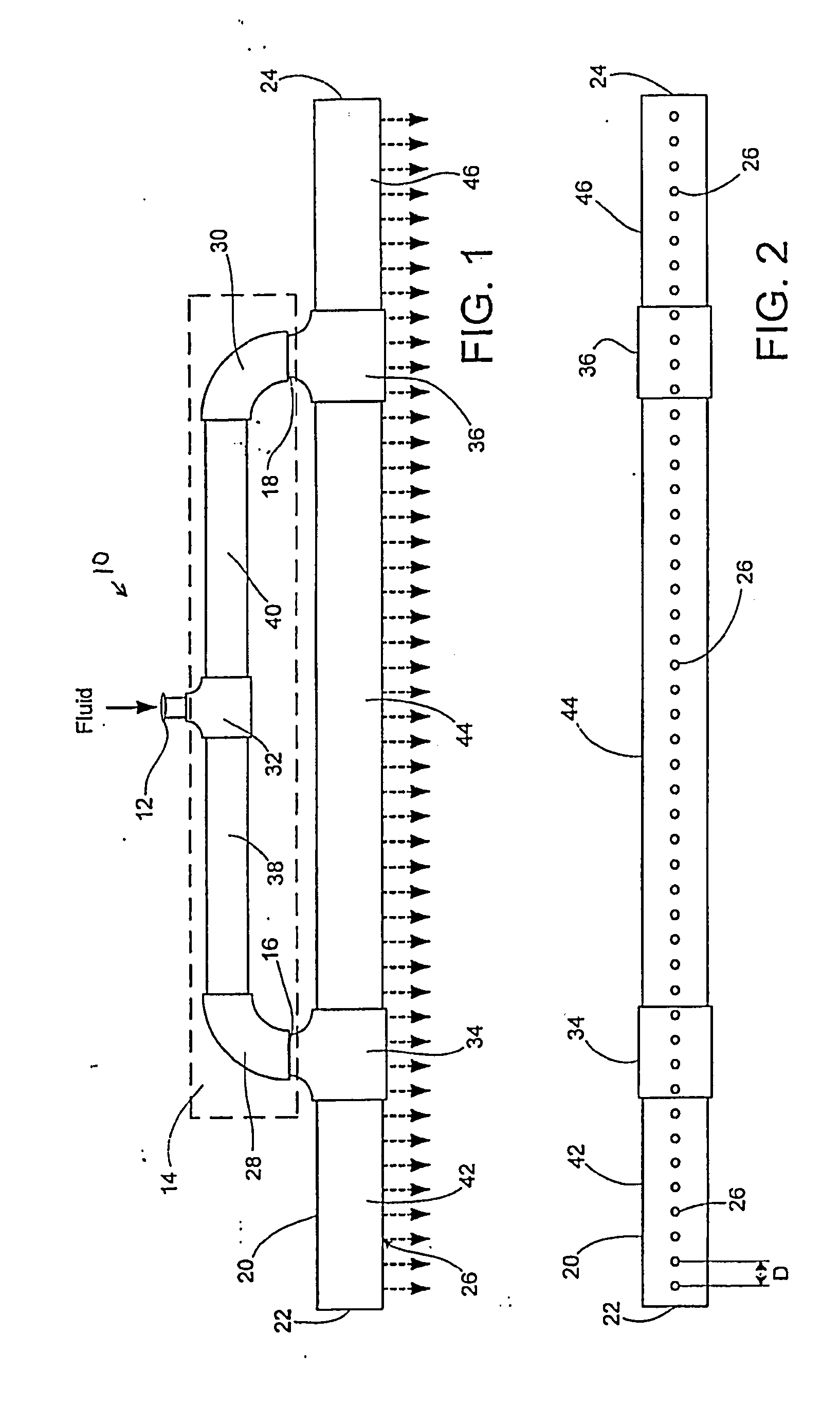

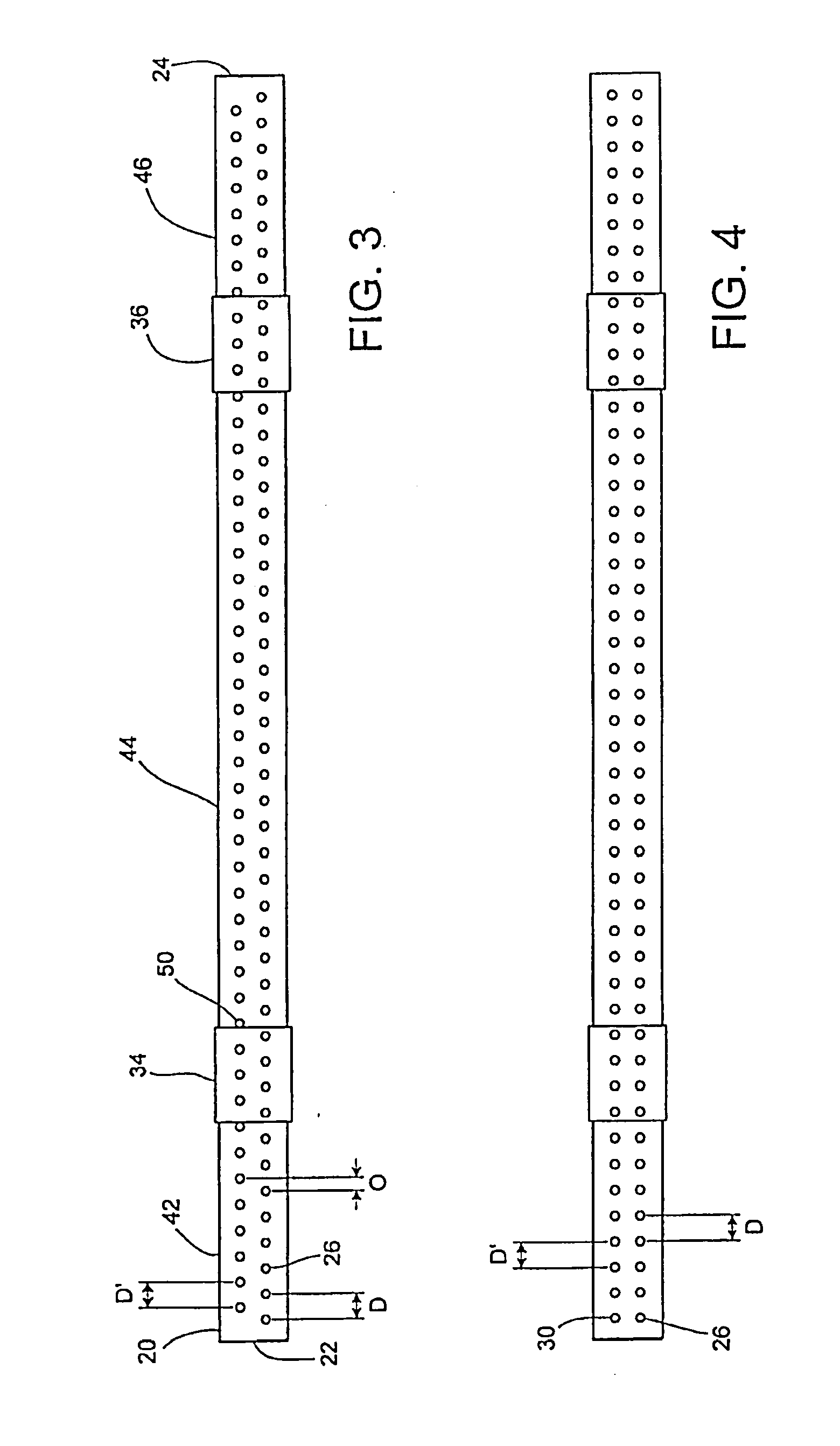

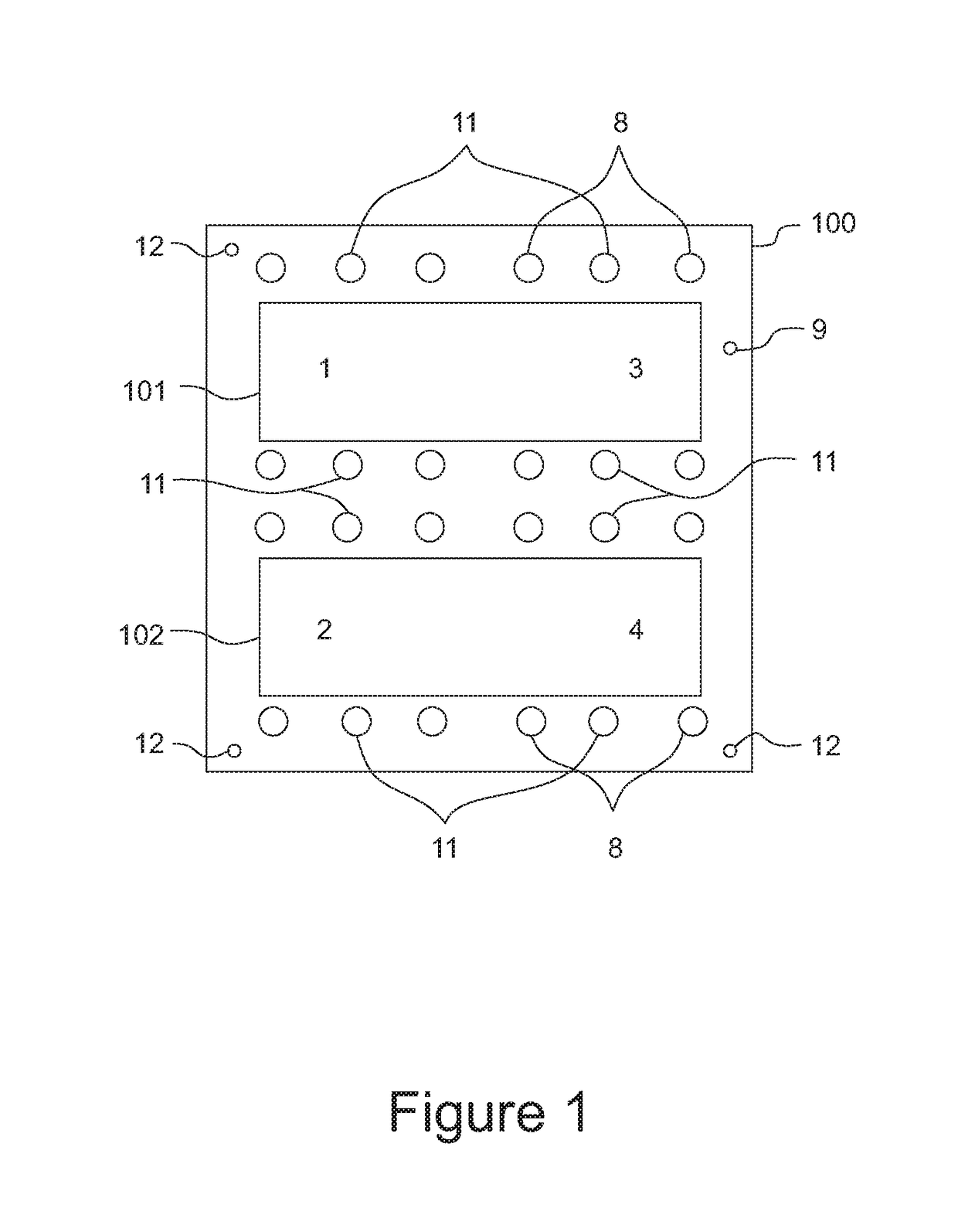

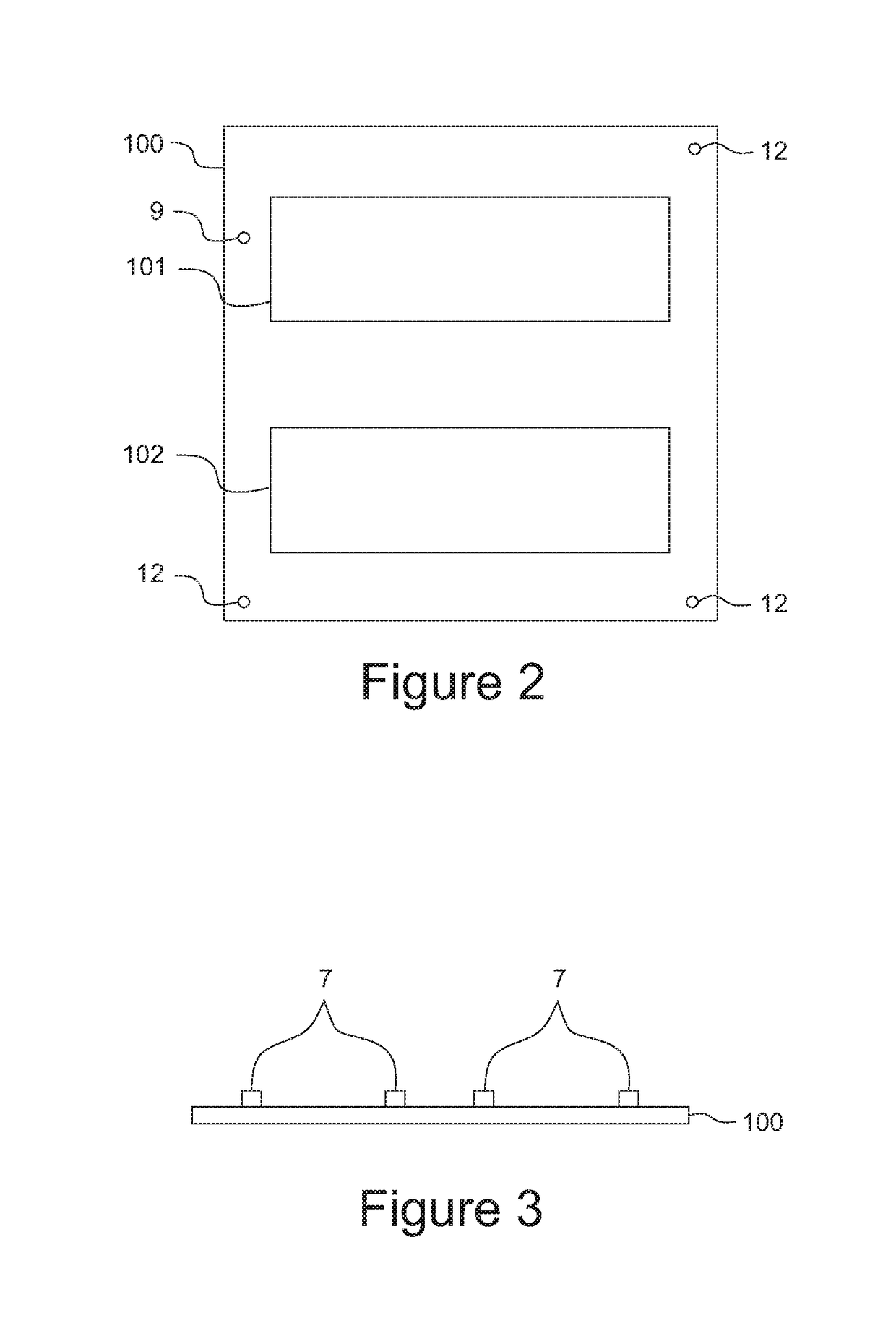

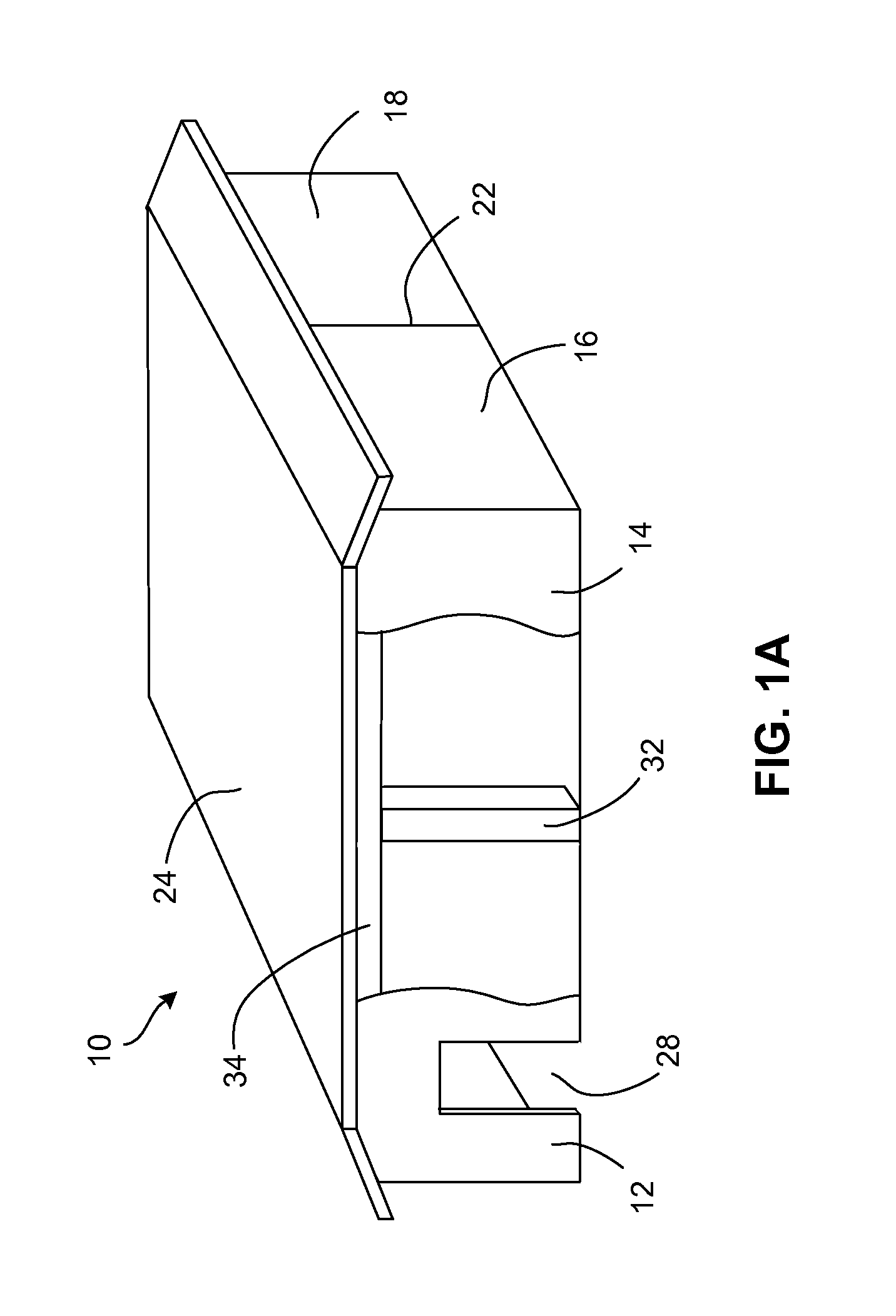

Nozzle system and method for manufacturing composite sandwich panels

InactiveUS20140263759A1Great strength-to-weight ratioLight weightSpray nozzlesBuilding componentsEngineeringSandwich panel

A nozzle and system for manufacturing composite sandwich panels, including an input port configured to receive a fluidic production material for forming a composite sandwich panel; a branching element coupled to the input port, wherein the production material that enters the branching element is output from a first end and a second end of the branching element; and an elongate tubular member coupled to the first end and the second end of the branching element for receiving the production material, wherein the elongate tubular member has a first end; a second end and a plurality of openings formed in the elongate tubular member such that the received production material is output through the plurality of openings. In another embodiment, the nozzle includes a second plurality of openings formed in the elongate tubular member.

Owner:MILLPORT ASSOC

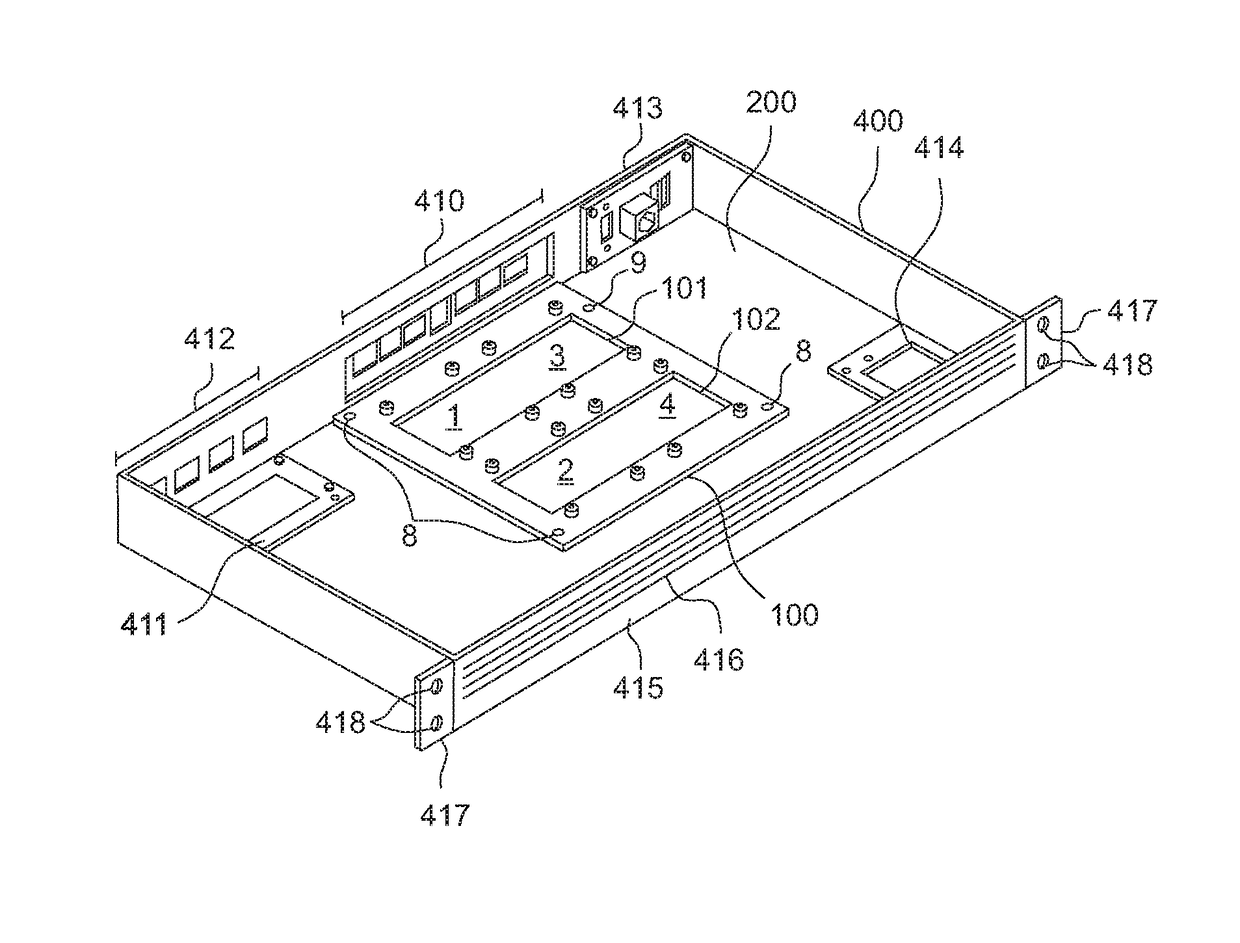

Server using single board computer

ActiveUS10019042B1Less energyLess-expensive to buildServersSubstation/switching arrangement detailsSingle-board computerMonoboard

Owner:FRANKLIN DAVID

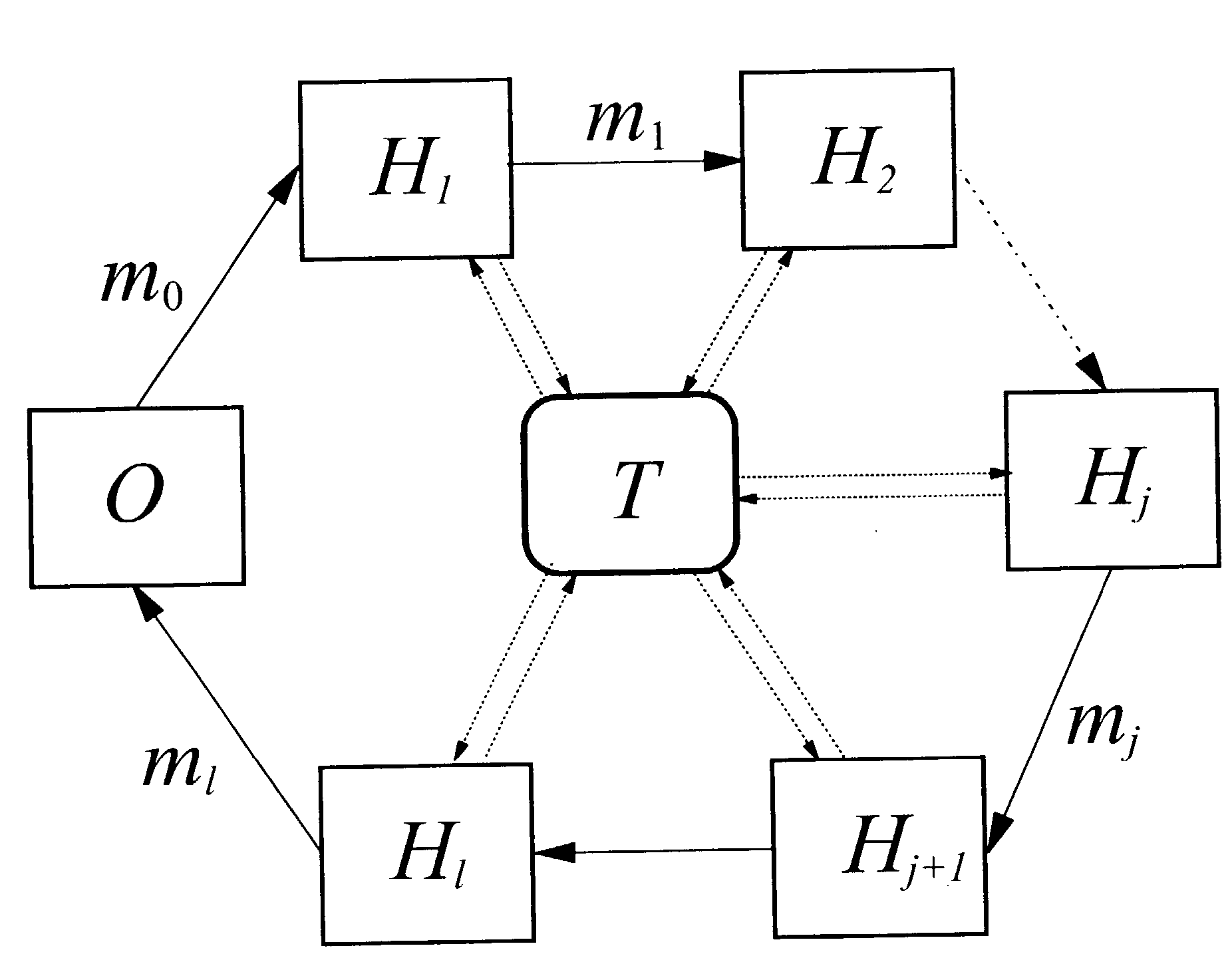

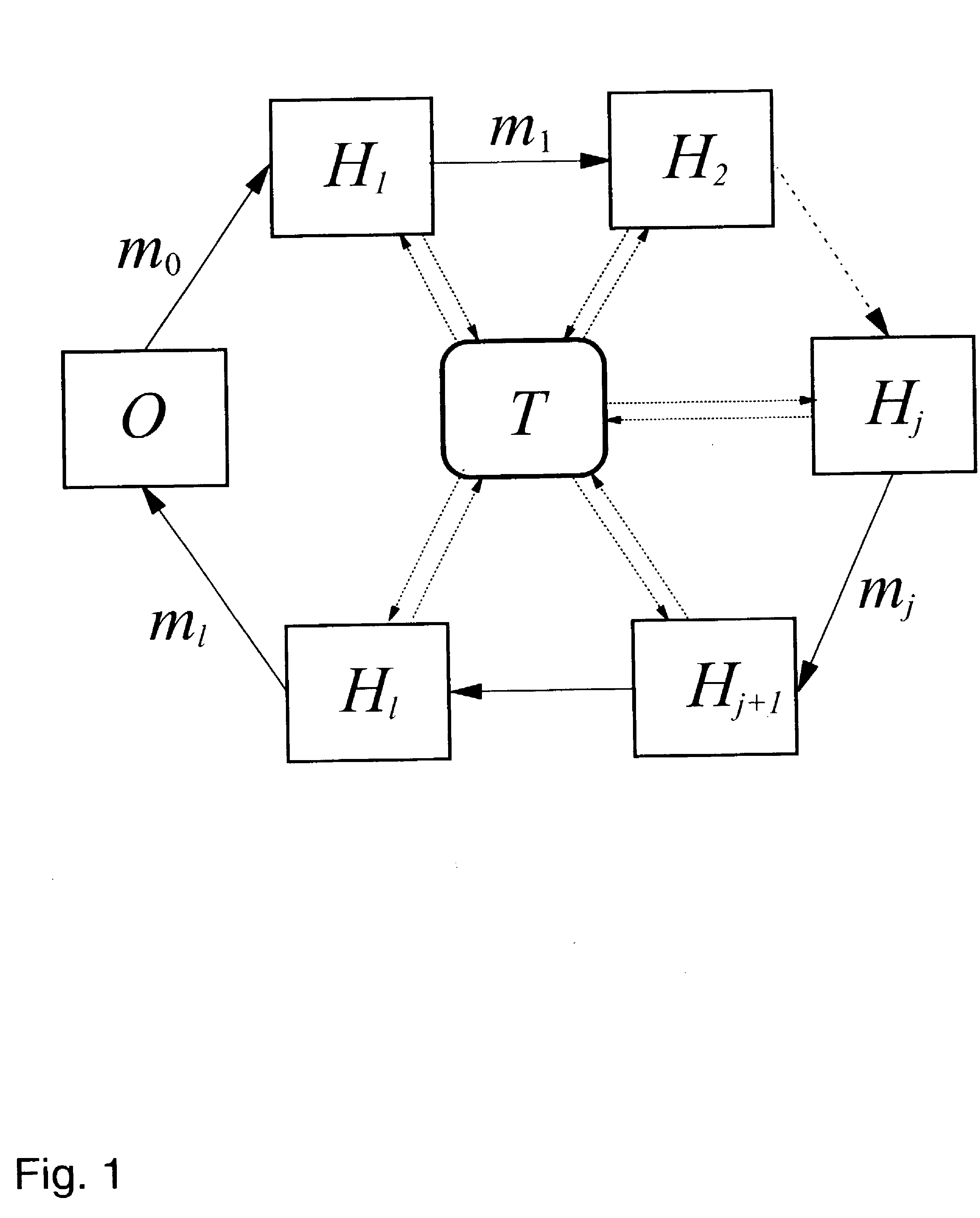

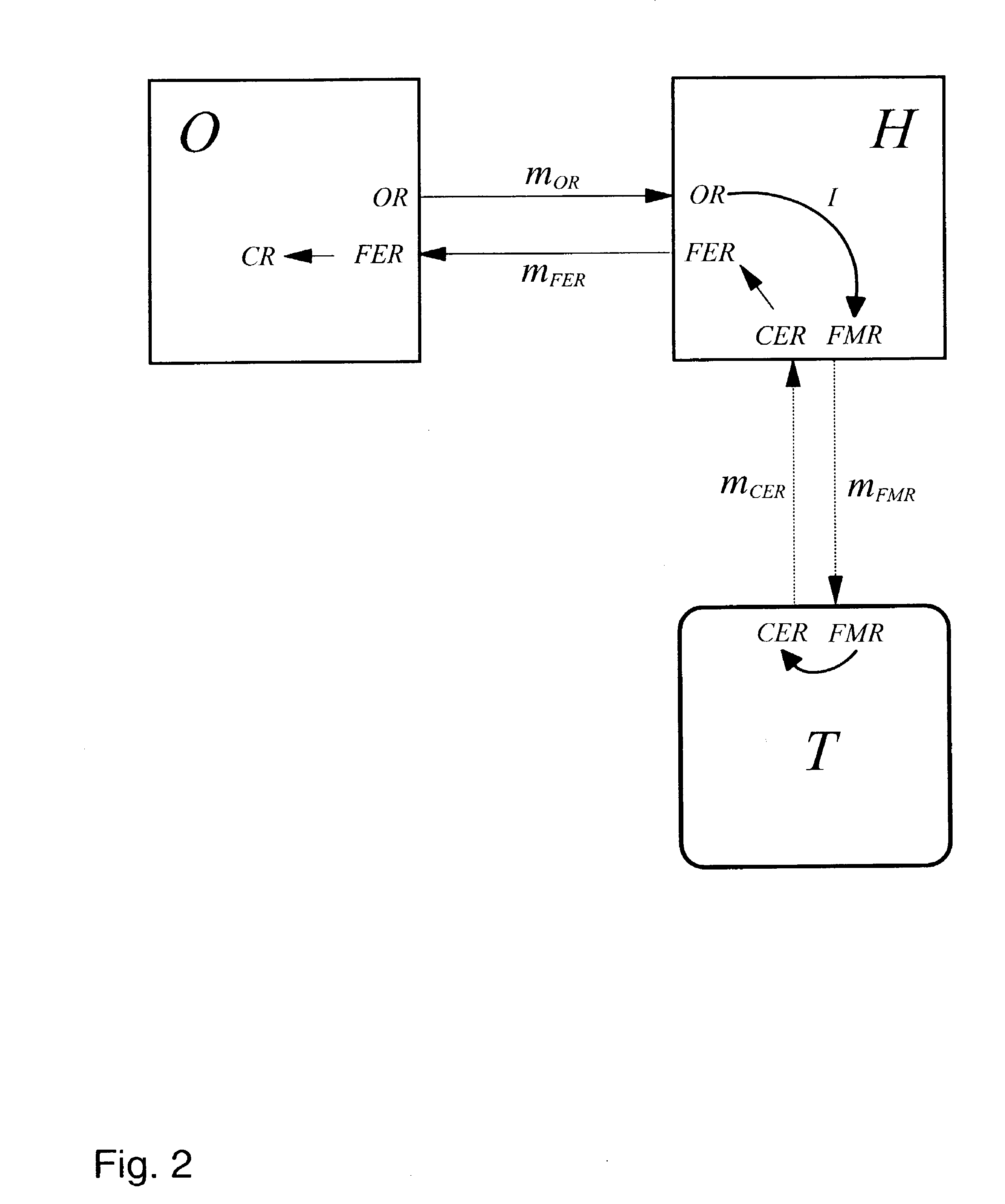

Method and system for processing a request of a customer

InactiveUS7844496B2Less-expensive to buildLess-expensive to operateBuying/selling/leasing transactionsComputer scienceReceipt

The invention provides methods, apparatus and systems for securely processing an originator request of a customer. This originator request can be sent to at least one first entity. An example of a method for processing the originator request comprises the steps of a) sending from the customer the originator request to each first entity; b) connecting each first entity to a computation entity; c) each first entity, adding, on receipt of the originator request, information concerning the originator request thereby forming a first-modified request; d) sending at least part of the first-modified request to at least the computation entity; e) the computation entity having received at least part of the first-modified request deriving a computation-entity result from the at least part of the first-modified request; f) sending at least part of the computation-entity result to each first entity; g) each first entity having received at least part of the computation-entity result deriving therefrom a first-entity result and forwarding it at least in part; and h) the customer having received at least part of the first-entity result, deriving therefrom a customer result.

Owner:IBM CORP

Hollow beam electron gun for use in a klystron

InactiveUS8258725B2Low efficiencyShort RF interaction circuit lengthTransit-tube electron/ion gunsTransit-tube focussing arrangementsKlystronDrift tube

A klystron has a hollow beam electron gun that has a circular planar electron emitting surface. A hollow electron beam is directed from the electron gun through a plurality of drift tubes, resonant chambers and magnetic fields to a collector. The hollow electron beam does not experience significant radial movement and can operate at a lower beam voltage which reduces the required length of the RF interaction circuit and lowers the risks of RF arcing.

Owner:FERGUSON PATRICK

Boat trailer

InactiveUS7070195B2Easy to assembleLess-expensive to manufactureUnderstructuresItem transportation vehiclesMechanical engineeringMarine engineering

A boat trailer comprising two side beams positioned adjacent to each other, wherein each of the side beams has a forward tongue forming portion converging toward the other side beam. The side beams can be connected to a towing vehicle and the side beams may also have a trailing boat-supporting portion. The trailer also includes at least one cross bar member extending between the boat-supporting portion of one of the side beams and the boat-supporting portion of the other side beam. The various members of the trailer may be punched with holes in a standard pattern.

Owner:ROBERTS JR RONALD E

Method & Apparatus for Remote Cleaning & Inspection of Underwater Structures

InactiveUS20120272889A1Less-expensive to buildLess complexVessel cleaningHullsMarine engineeringWater velocity

An underwater structure inspection vehicle that uses a rotating brush to clean the structure for camera inspection. Unlike underwater vehicles currently being used that are positioned by thrusters, this vehicle will be positioned in three different planes by three different means. The first is by mechanically raising and lowering it. The second is by a propulsion system pushing it into the structure. The third is by lateral guidance bars being engaged by the rotating forces of the propulsion system. In areas of high water velocity, an optional back-side platform may be used to assist the propulsion system by locking the vehicle onto the structure.

Owner:PANNING DONALD CHRISTOPHER

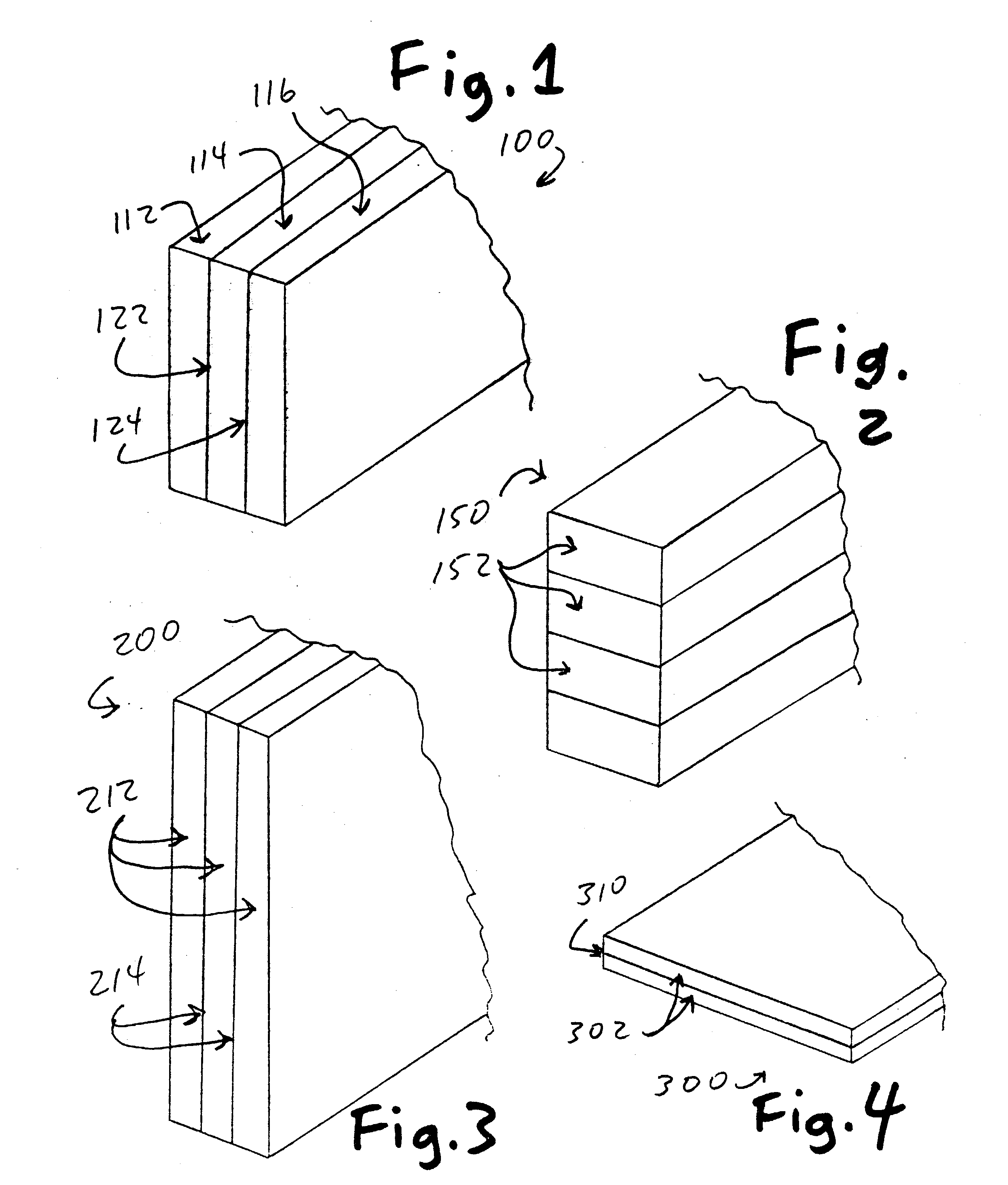

Multiple panel column and methods

InactiveUS20140260081A1Great strength-to-weight ratioLight weightStrutsLaminationEngineeringSurface plate

A support column and method for making a support column, the support column having a plurality of panels arranged side by side. The panels each have a core of insulative material and outer laminate layers laminated to the core. The panels are adhered to one another.

Owner:MILLPORT ASSOC

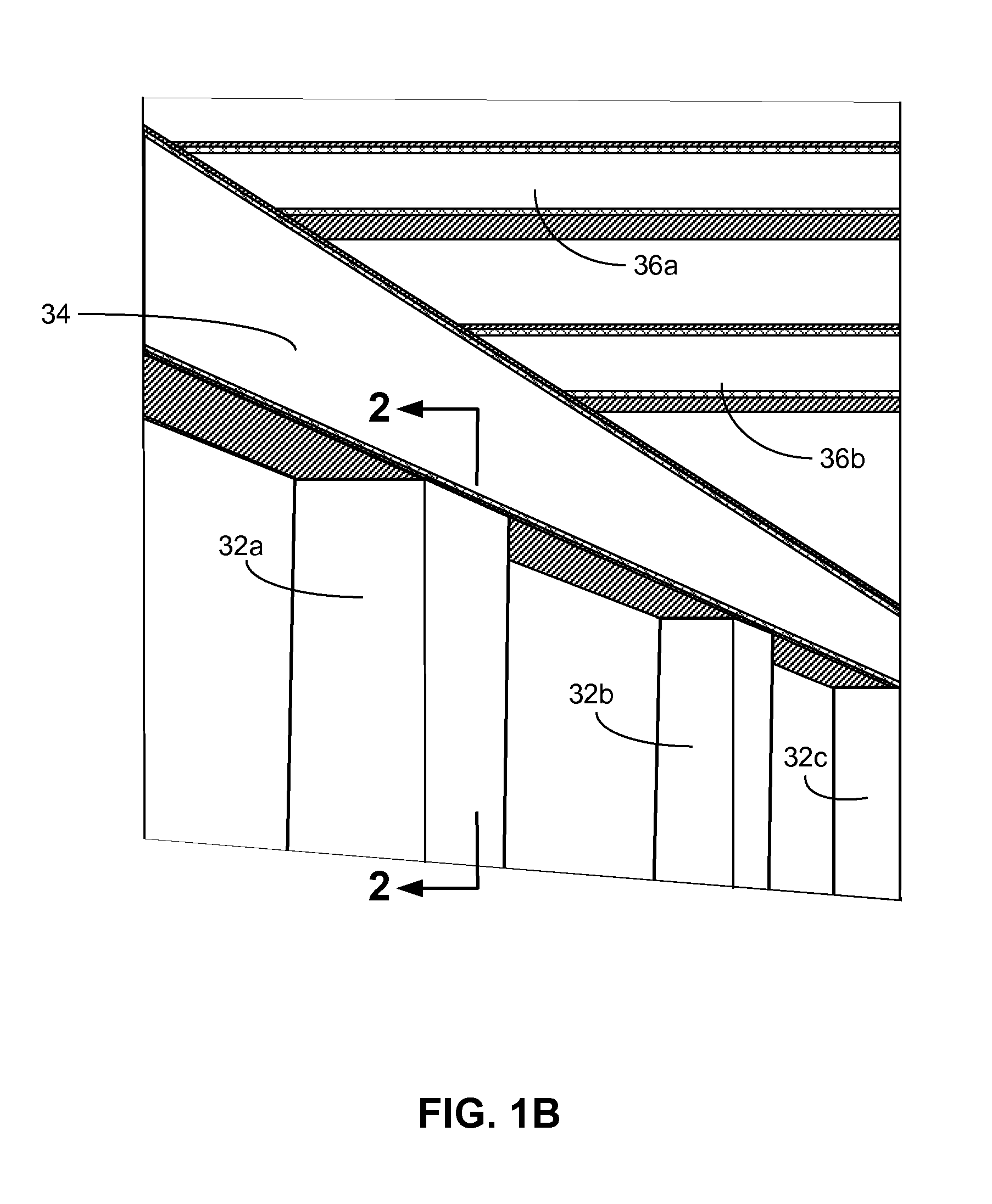

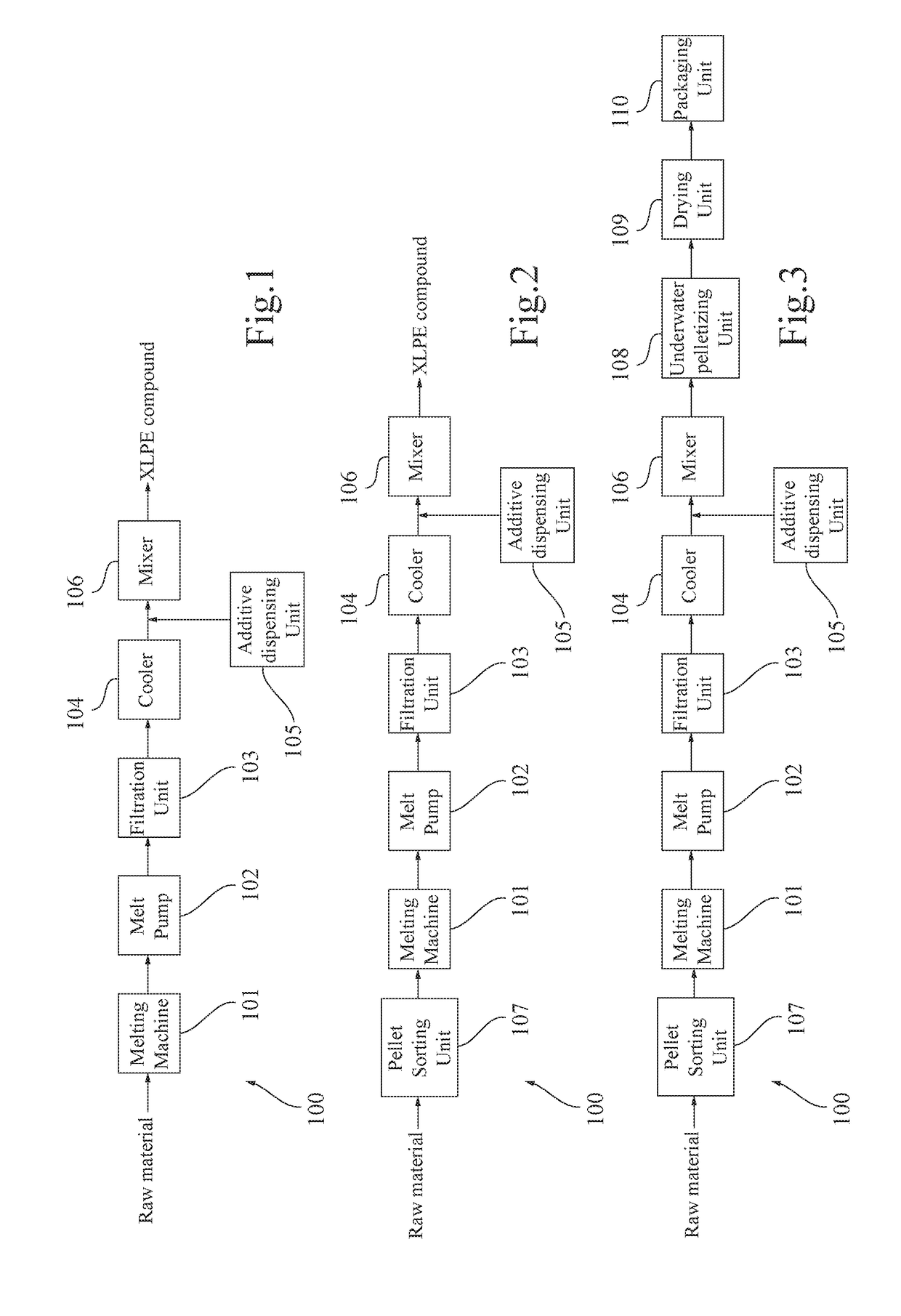

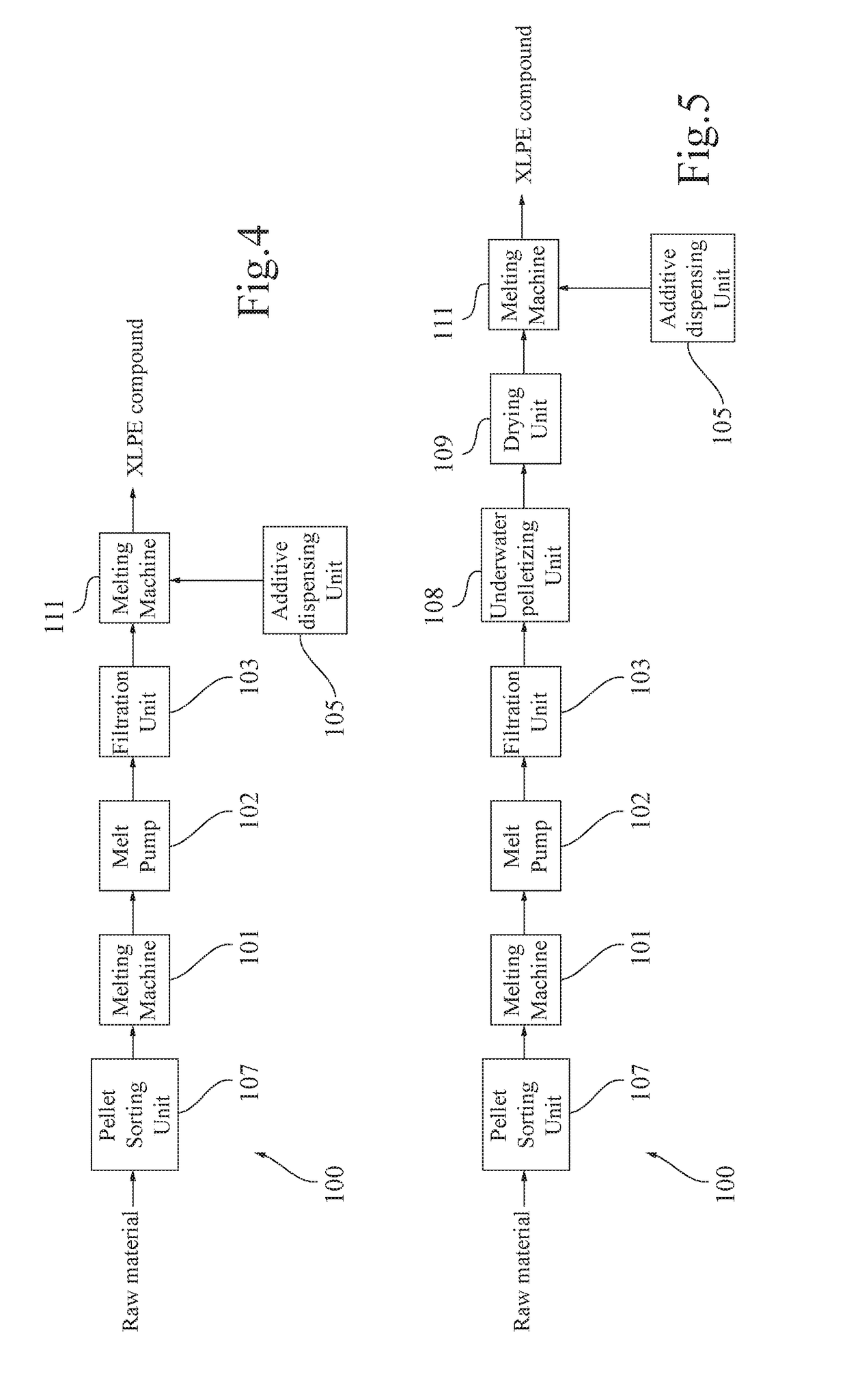

Installation and method for manufacturing cross-linkable polyethylene compounds

ActiveUS20190070752A1Less-expensive to buildQuality improvementPlastic recyclingPower cableFiltration

Installation for manufacturing cross-linkable polyethylene compounds which comprises a melting machine (101), a melt pump (102) and a filtration unit (103). The installation allows to produce cross-linkable polyethylene compounds that may be further used for manufacturing insulating parts of medium, high and extra-high voltage power cables. A method for manufacturing cross-linkable polyethylene compounds is further provided.

Owner:BUSS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com