Patents

Literature

70 results about "Dose uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The uniformity of dosage units specification is not intended to apply to suspensions, emulsions, or gels in single-dose containers intended for cutaneous administration. The term “Uniformity of dosage unit” is defined as the degree of uniformity in the amount of the active substance among dosage units.

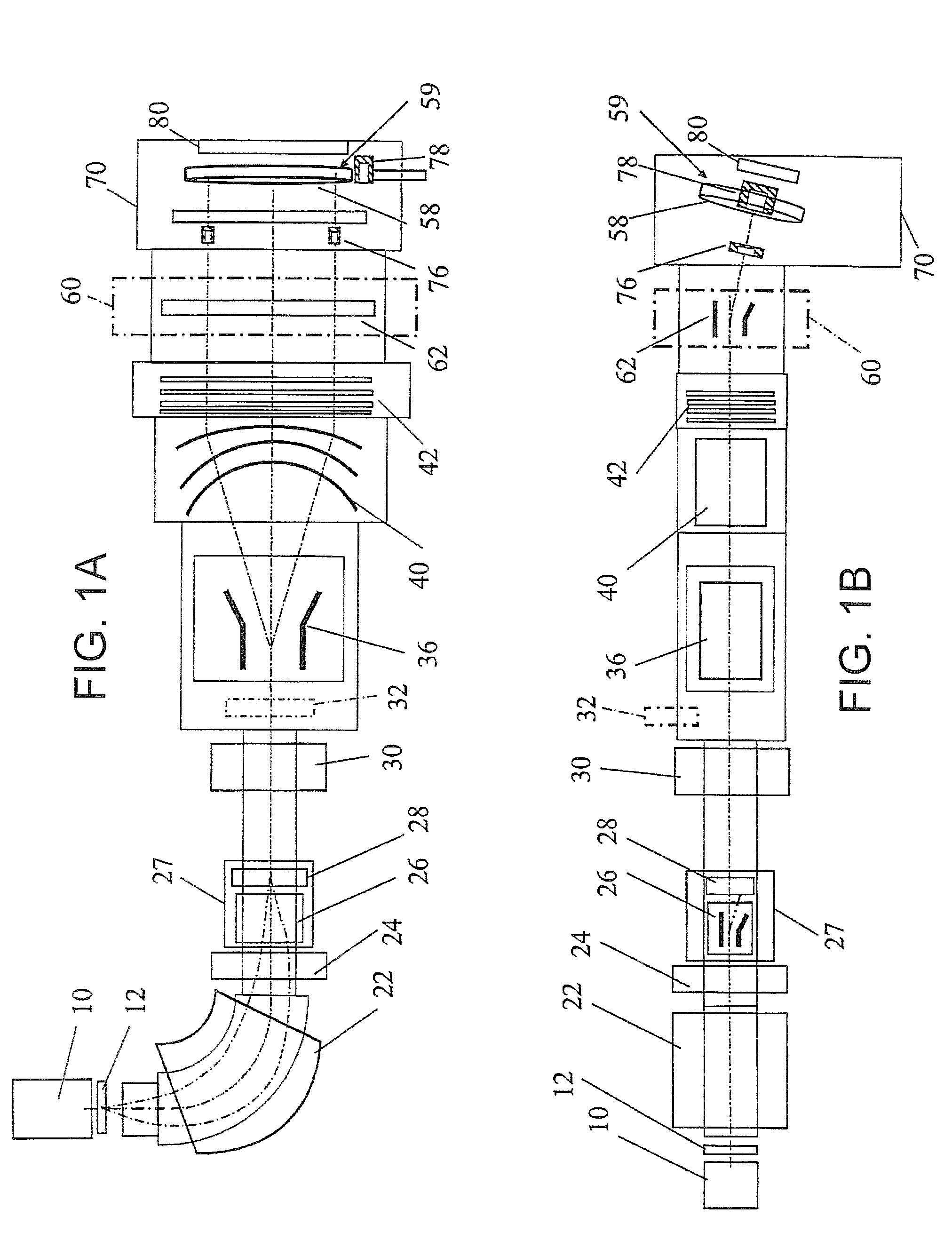

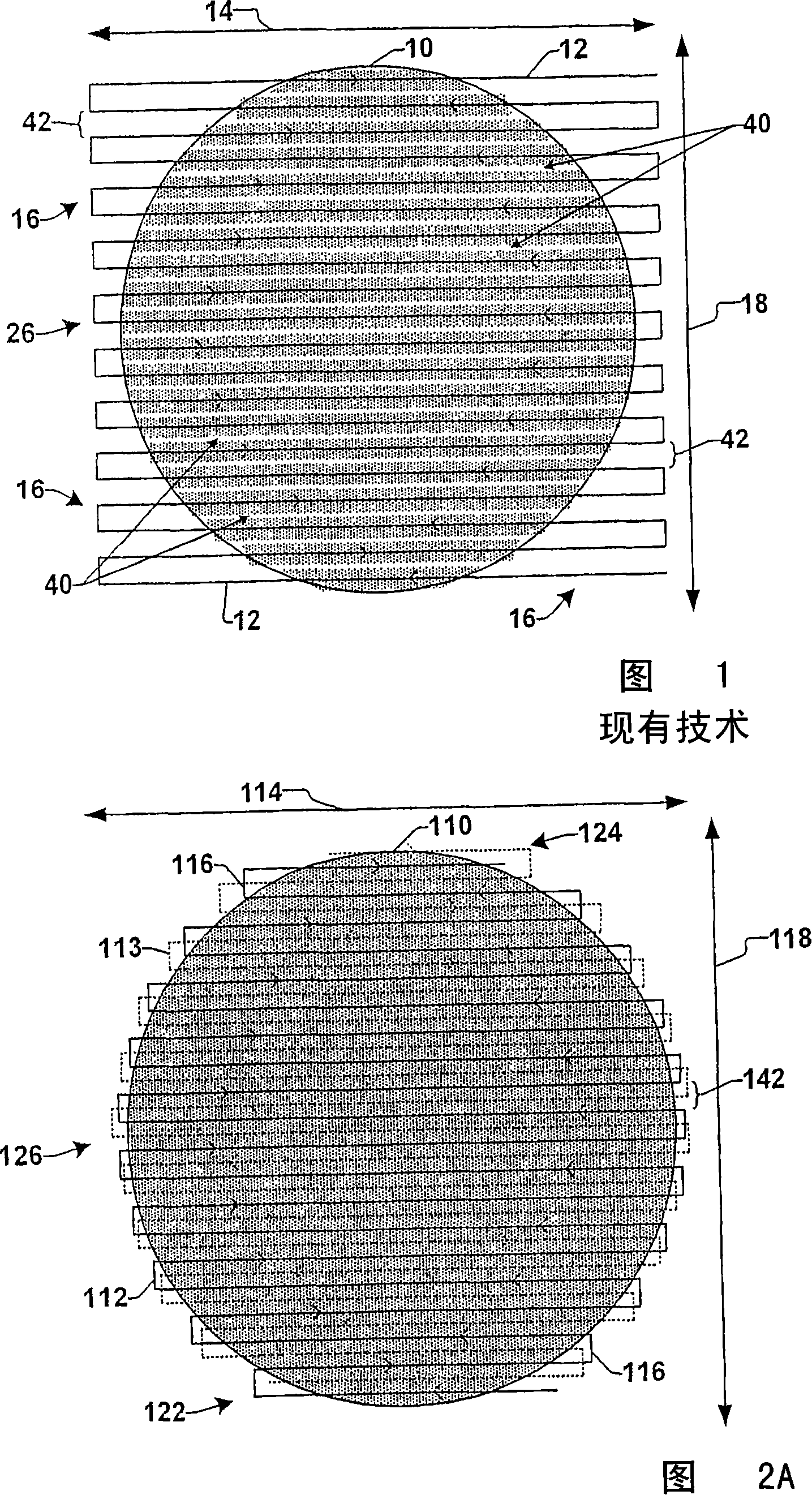

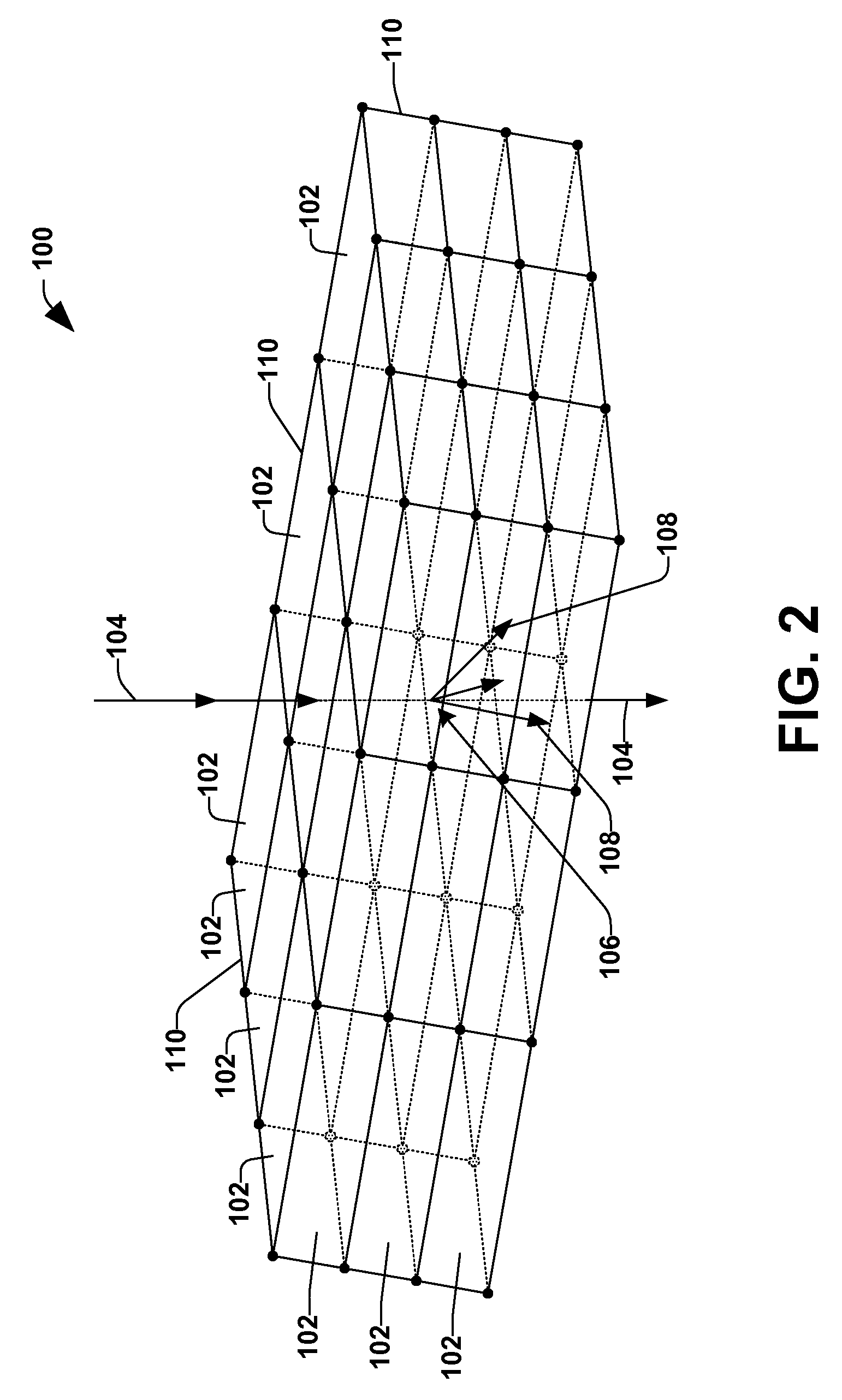

Method of determining dose uniformity of a scanning ion implanter

InactiveUS6965116B1Easy to monitorAccurately indicatedThermometer detailsBeam/ray focussing/reflecting arrangementsBeam instabilityDose uniformity

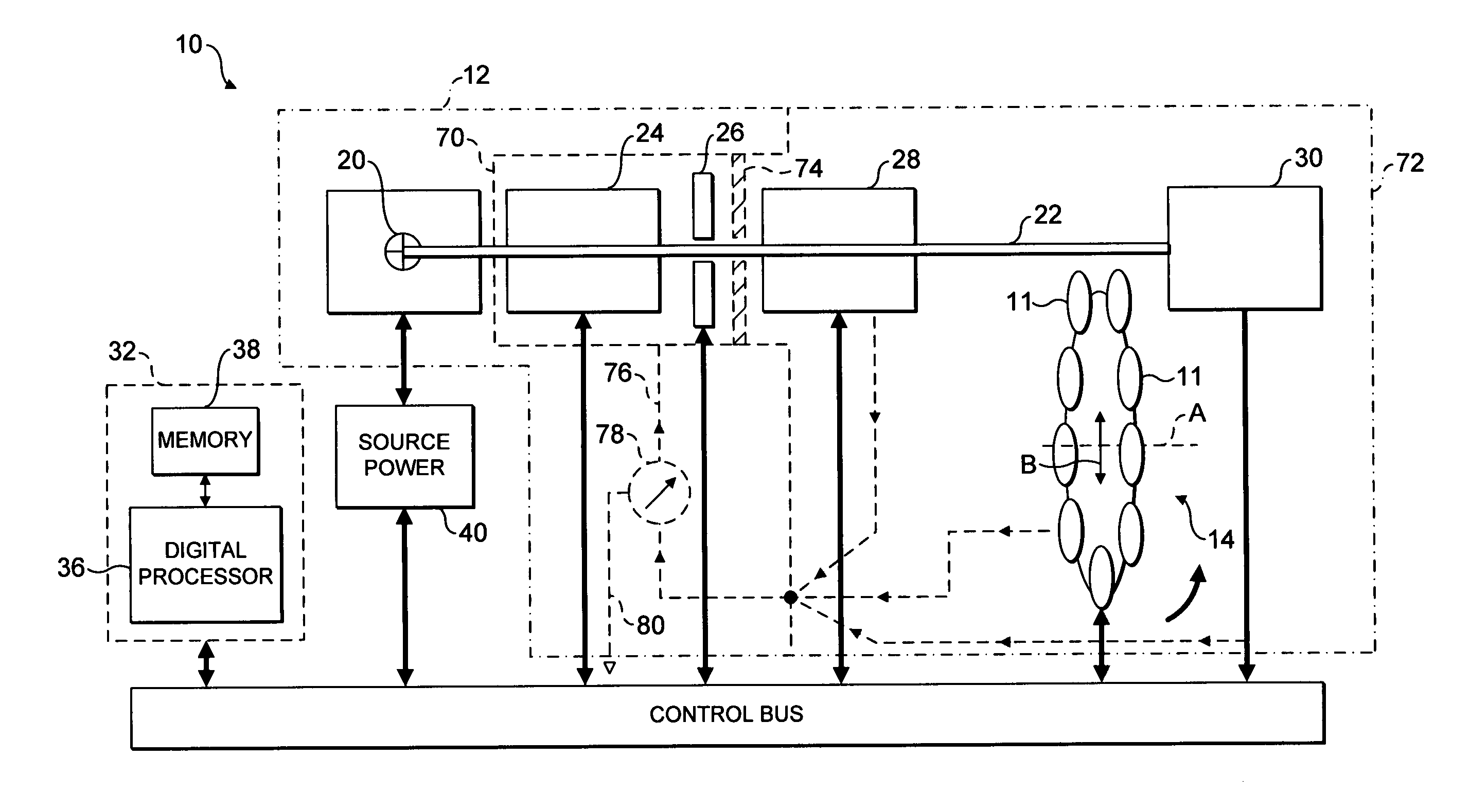

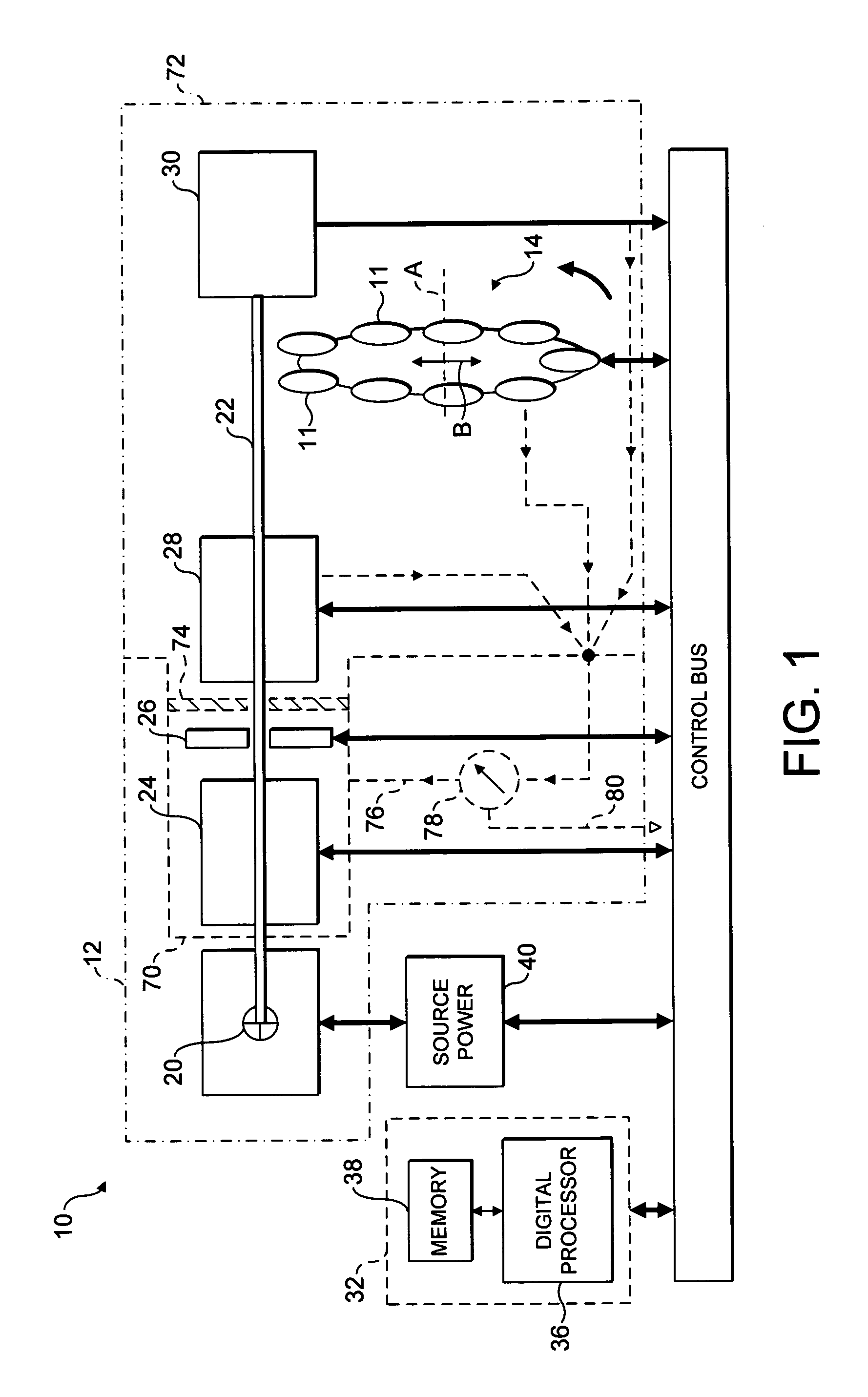

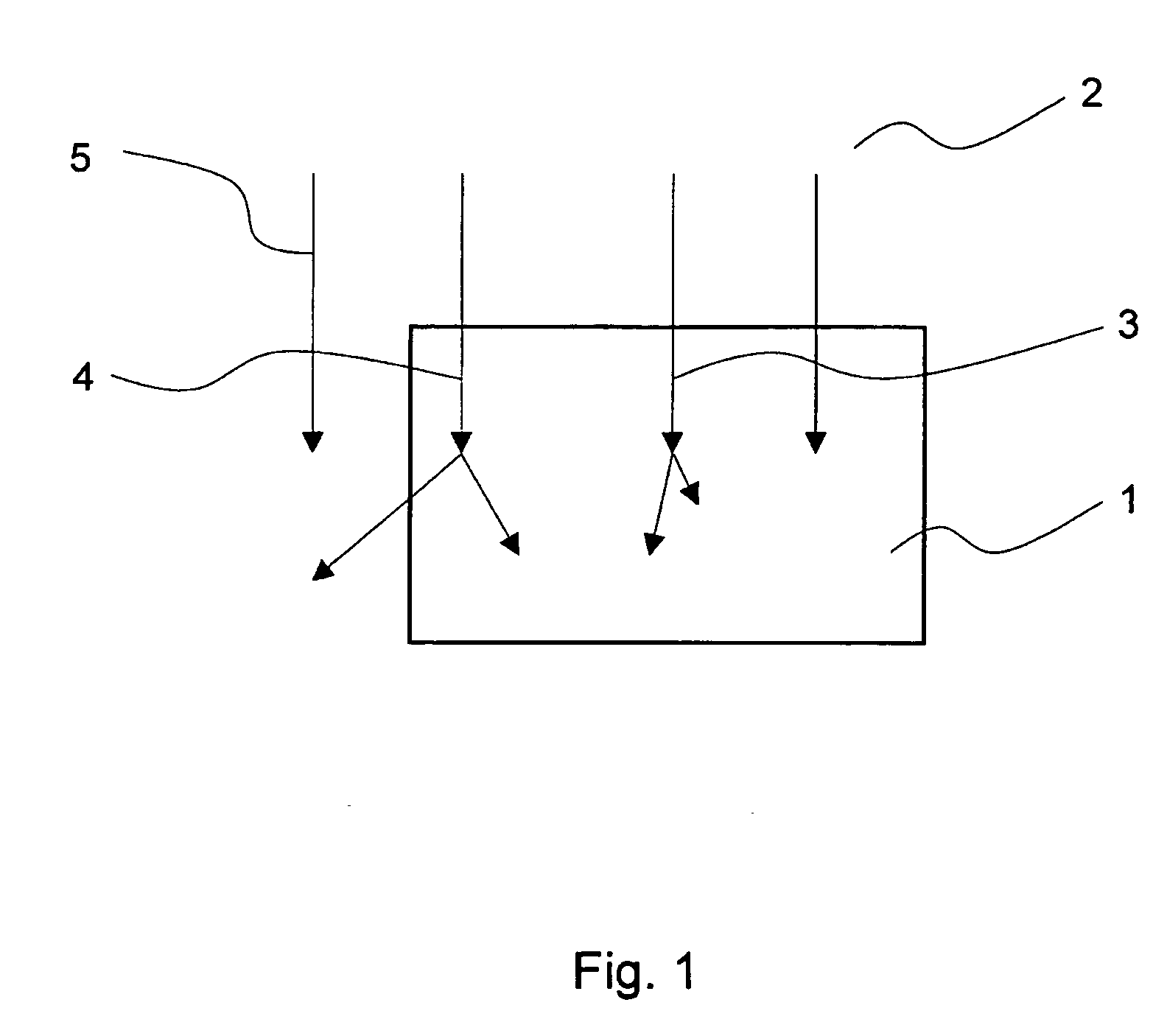

Dose uniformity of a scanning ion implanter is determined. A base beam current is measured at the beginning and / or the end of a complete scan over the whole substrate area. This base beam current is measured at a time when the measurement should be unaffected by outgassing from a substrate being implanted and a base dose distribution map is then calculated for the scan in question. During the scan itself beam instability events are detected and the magnitude and position in the scan of the detected instability events is measured. Corresponding deviations in the calculated base dose map are determined and subtracted from the previously calculated base dose distribution map to provide a corrected distribution map. By determining overall dose uniformity substractively in this way, good overall accuracy can be obtained with lesser accuracy in the measurement of the beam instability events.

Owner:APPLIED MATERIALS INC

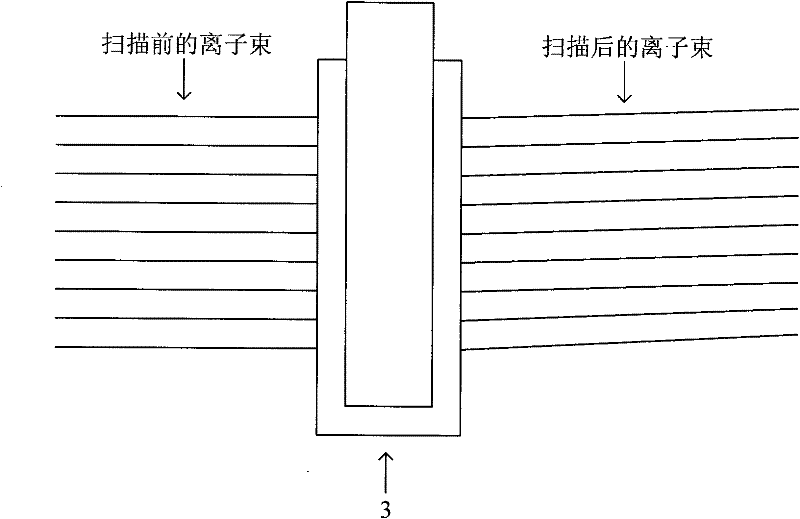

Ion beam irradiation system and ion beam irradiation method

ActiveUS20110297842A1Maintain uniformityImprove irradiation efficiencyElectric discharge tubesBeam/ray deflecting arrangementsMeasurement deviceDose uniformity

An ion beam irradiation method comprises calculating a scan voltage correction function with the maximum beam scan width depending on the measurement result of a beam current measurement device, calculating each of more than one scan voltage correction functions corresponding to each of scheduled beam scan widths depending on the calculated scan voltage correction functions while satisfying dose uniformity in the horizontal direction, measuring a mechanical Y-scan position during the ion implantation, changing the scan voltage correction function as a function of the measured mechanical Y-scan position so that the beam scan area becomes a D-shaped multistage beam scan area corresponding to an outer periphery of a half of the wafer to thereby reduce the beam scan width, and changing a mechanical Y-scan speed depending on the change of the measurement result of a side cup current measurement device to thereby keep the dose uniformity in the vertical direction.

Owner:SENCORP

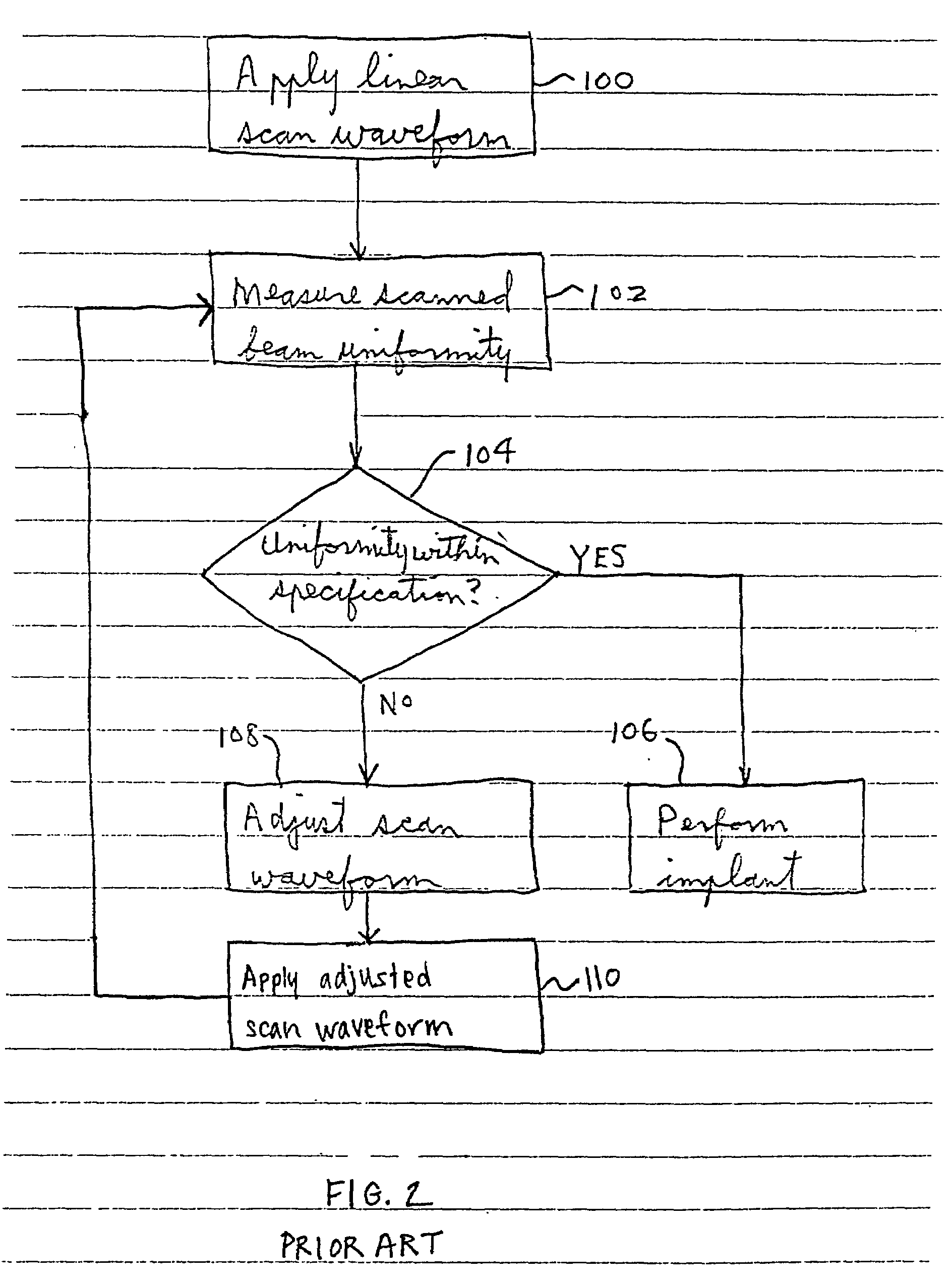

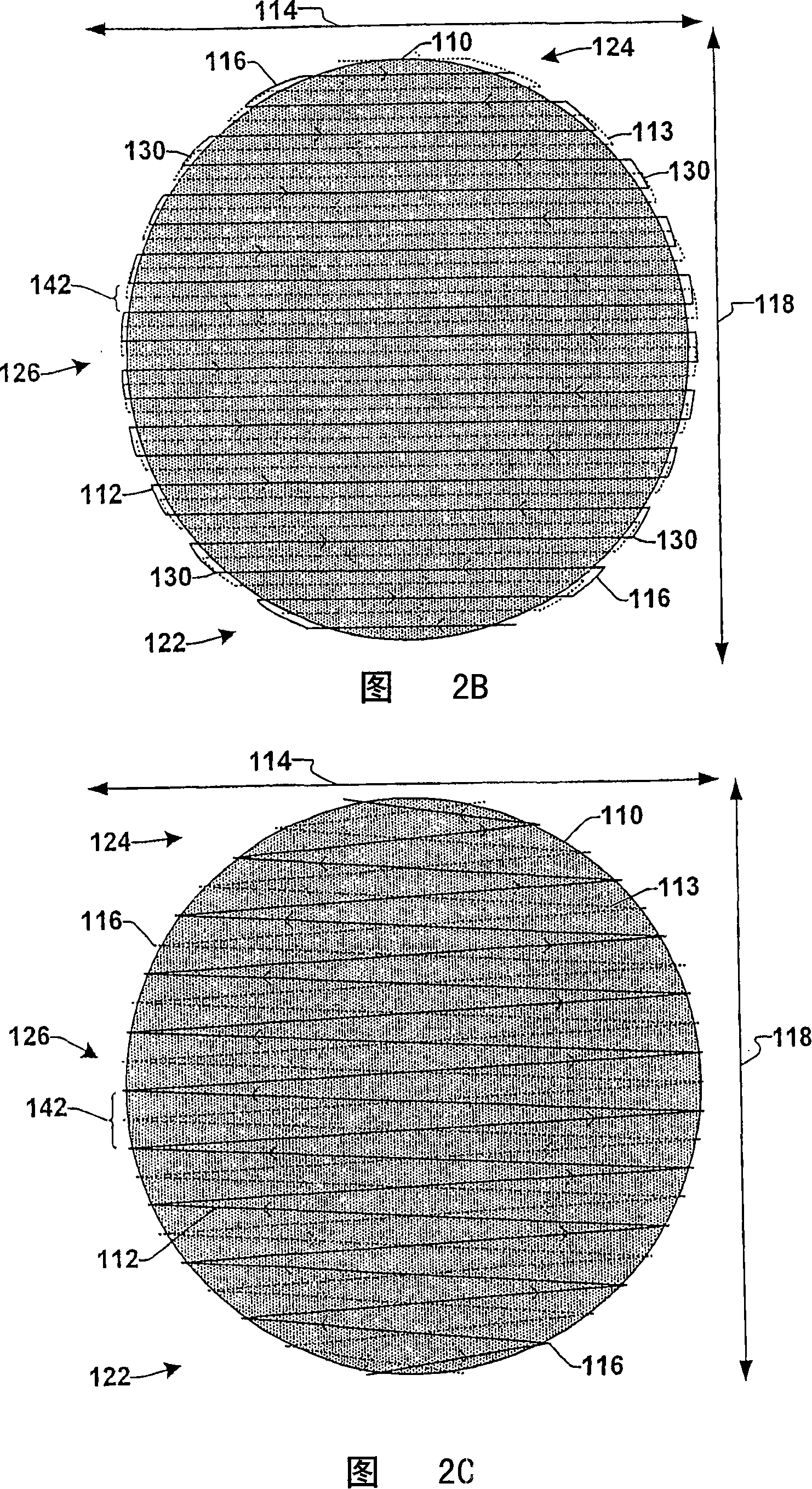

Dose uniformity during scanned ion implantation

InactiveUS20060097196A1Facilitates uniform ion implantationSave resourcesElectric discharge tubesSemiconductor/solid-state device manufacturingDose uniformityBiomedical engineering

Owner:AXCELIS TECHNOLOGIES

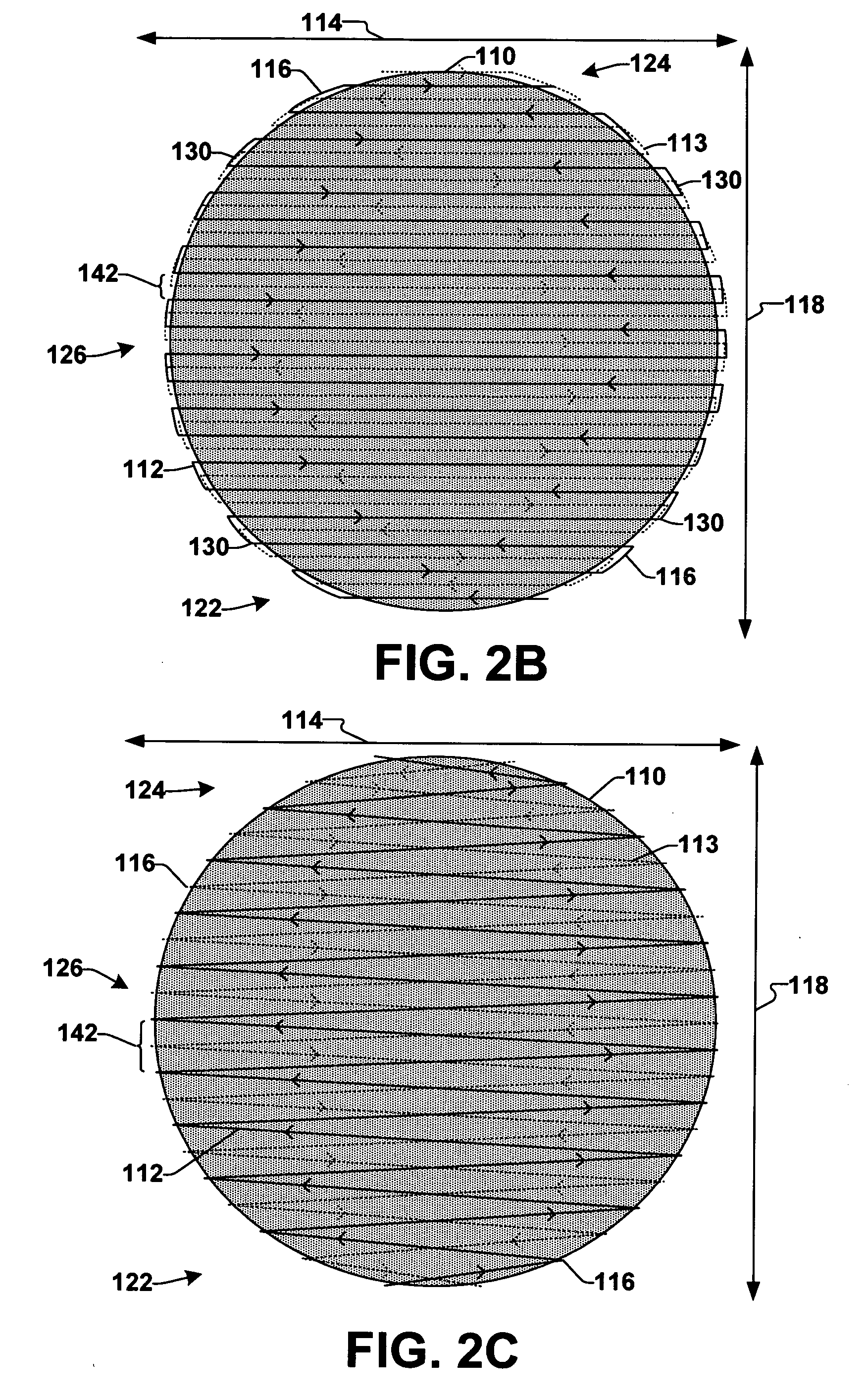

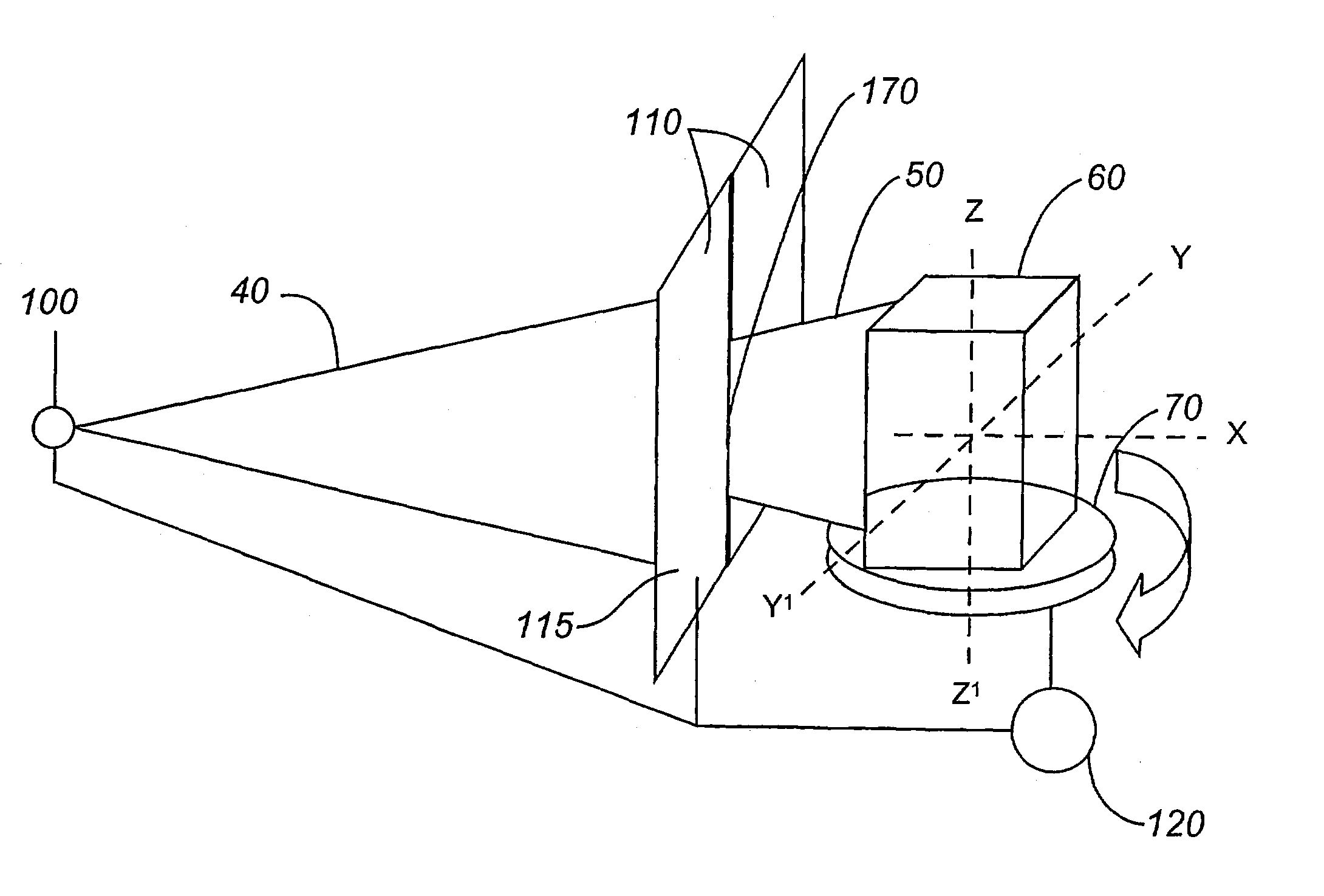

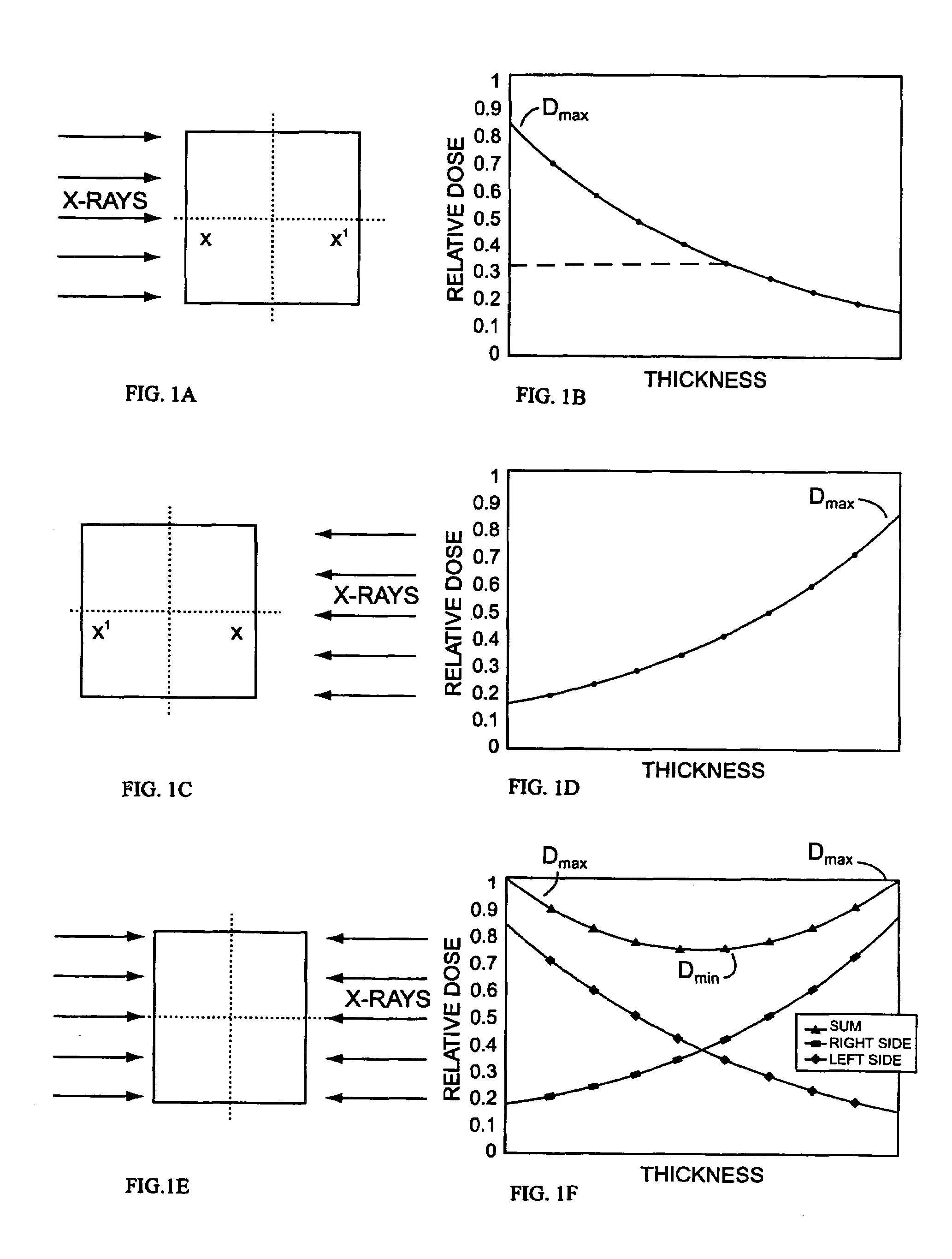

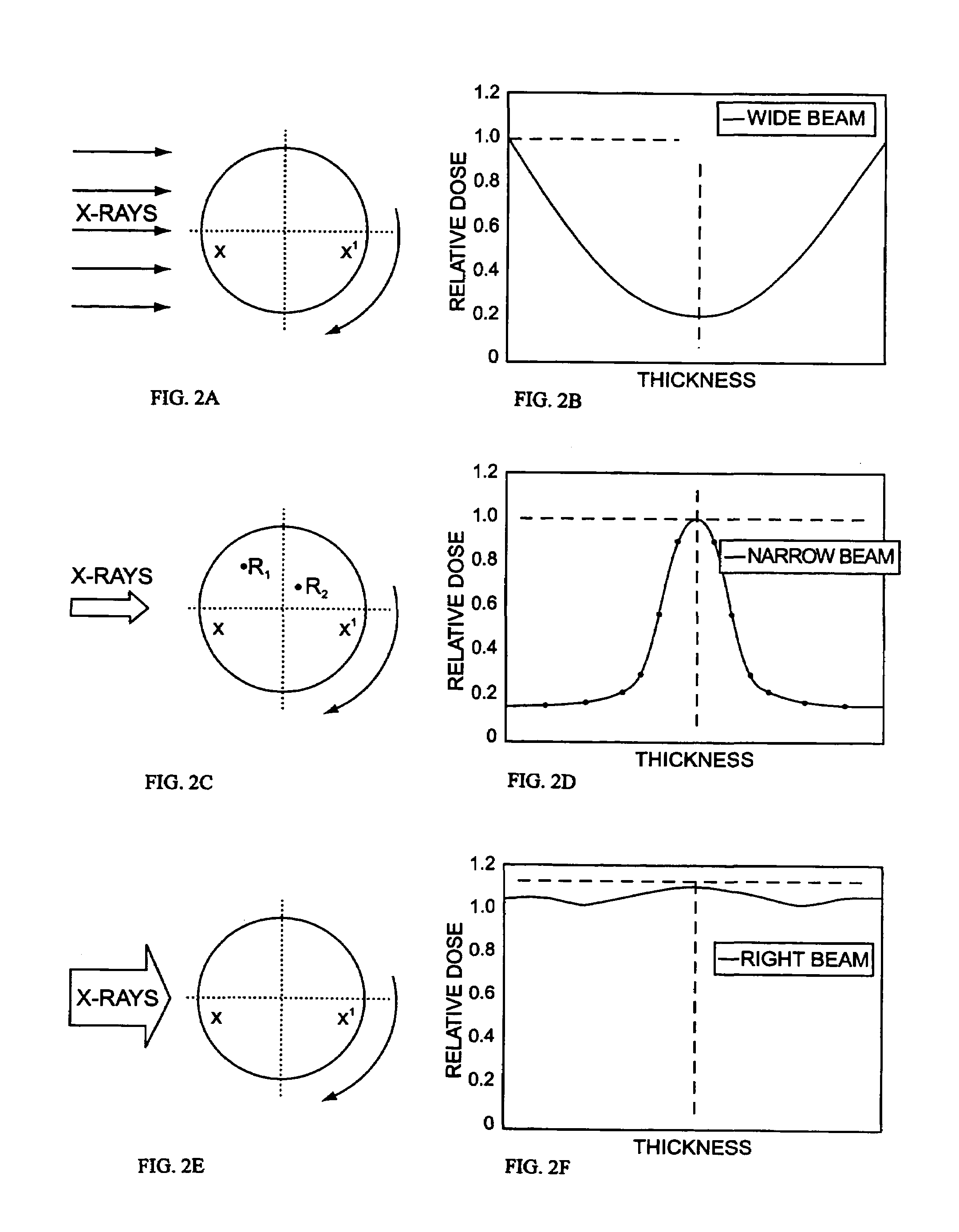

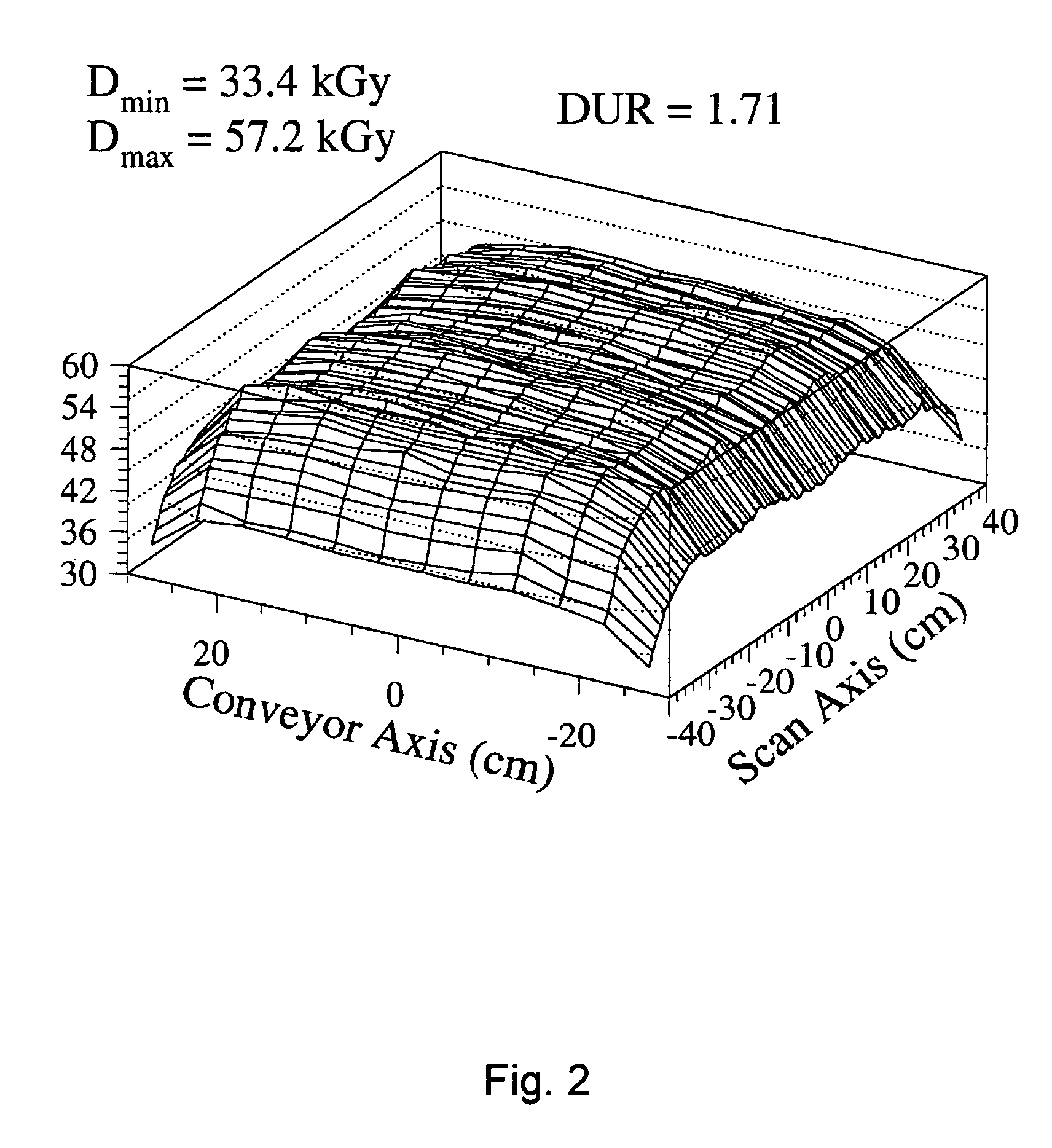

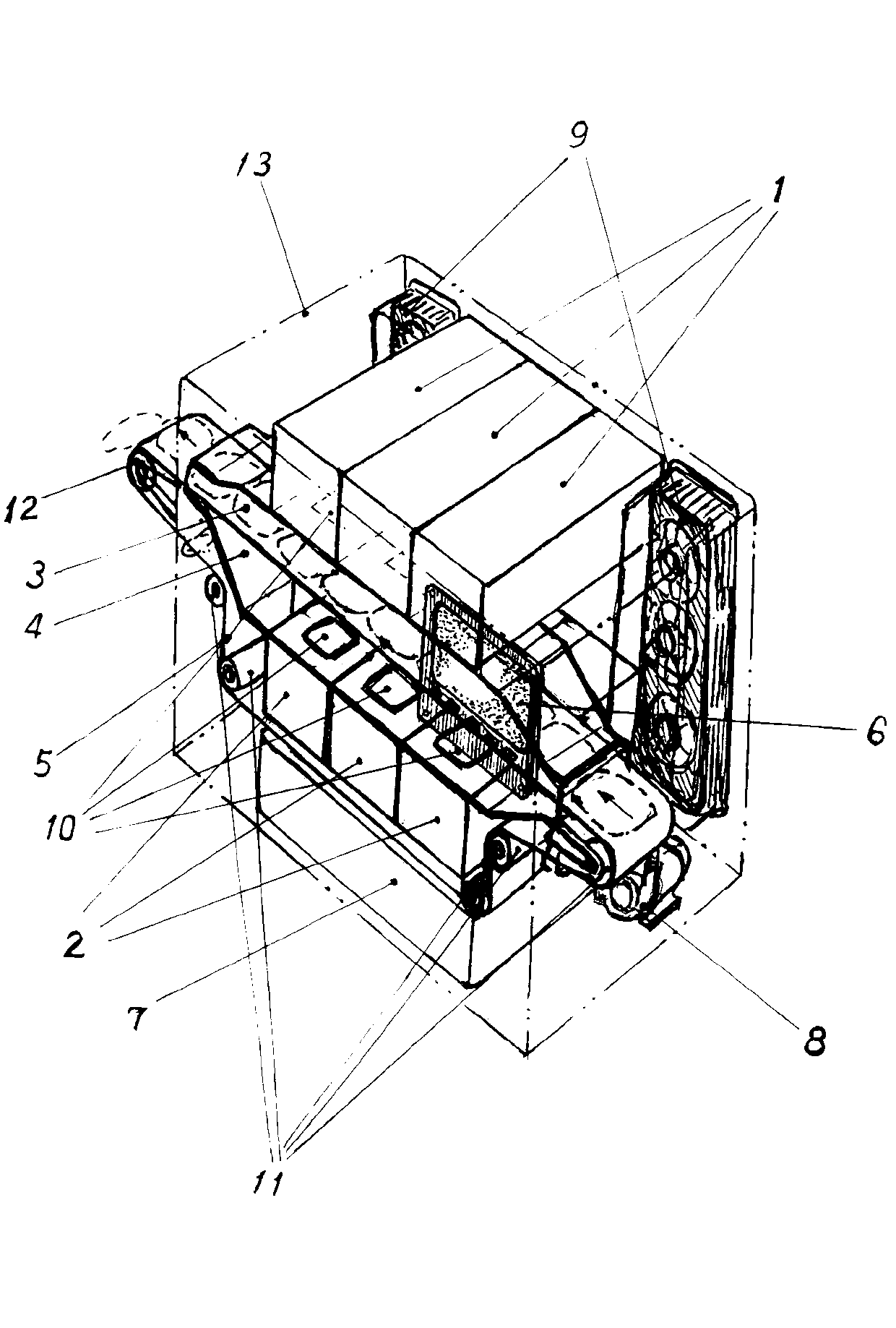

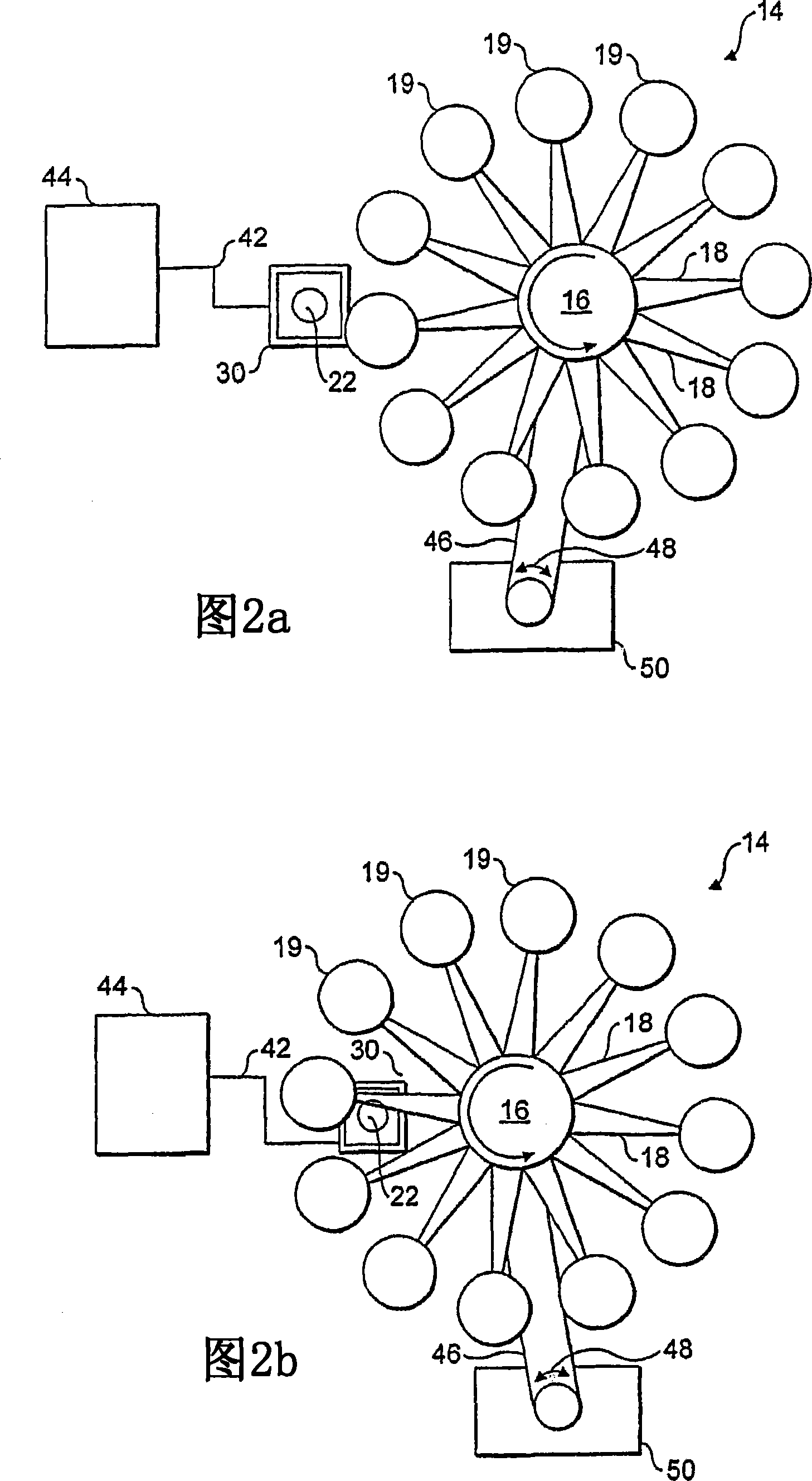

Product irradiator for optimizing dose uniformity in products

InactiveUS7187752B2Material analysis by optical meansIrradiation devicesDose uniformityControl system

An apparatus and method for irradiating a product or product stack with a relatively even radiation dose distribution is provided. The apparatus comprises a radiation source, an adjustable collimator, a turn-table capable of receiving a product stack and a control system capable of adjusting the adjustable collimator to vary the geometry of the radiation beam as the product stack is rotated in the radiation beam. Also disclosed is the modulation of the radiation beam energy and power and varying the angular rotational velocity of the product stack in a radiation beam to achieve a low dose uniformity ratio in the product stack.

Owner:MDS CANADA

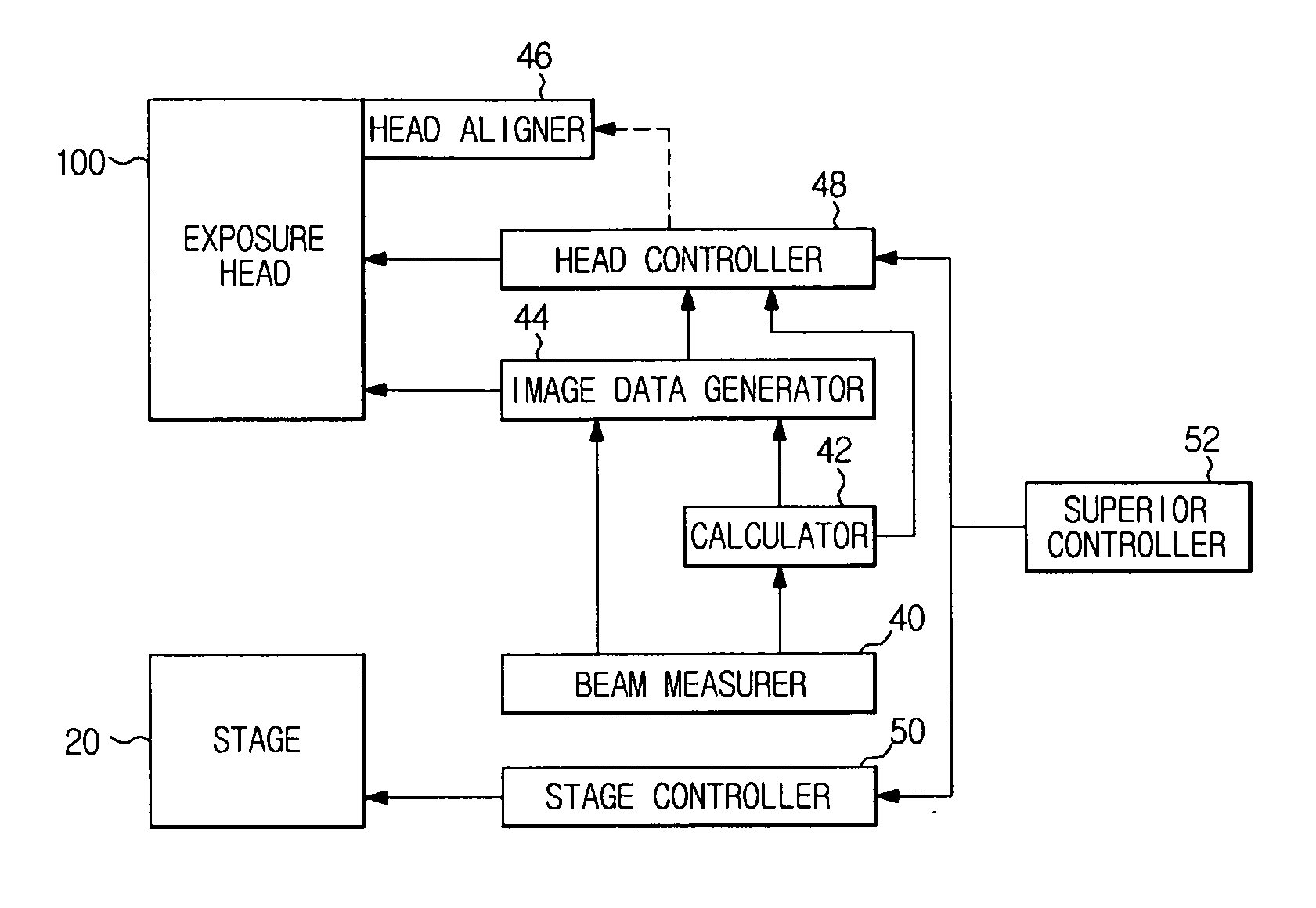

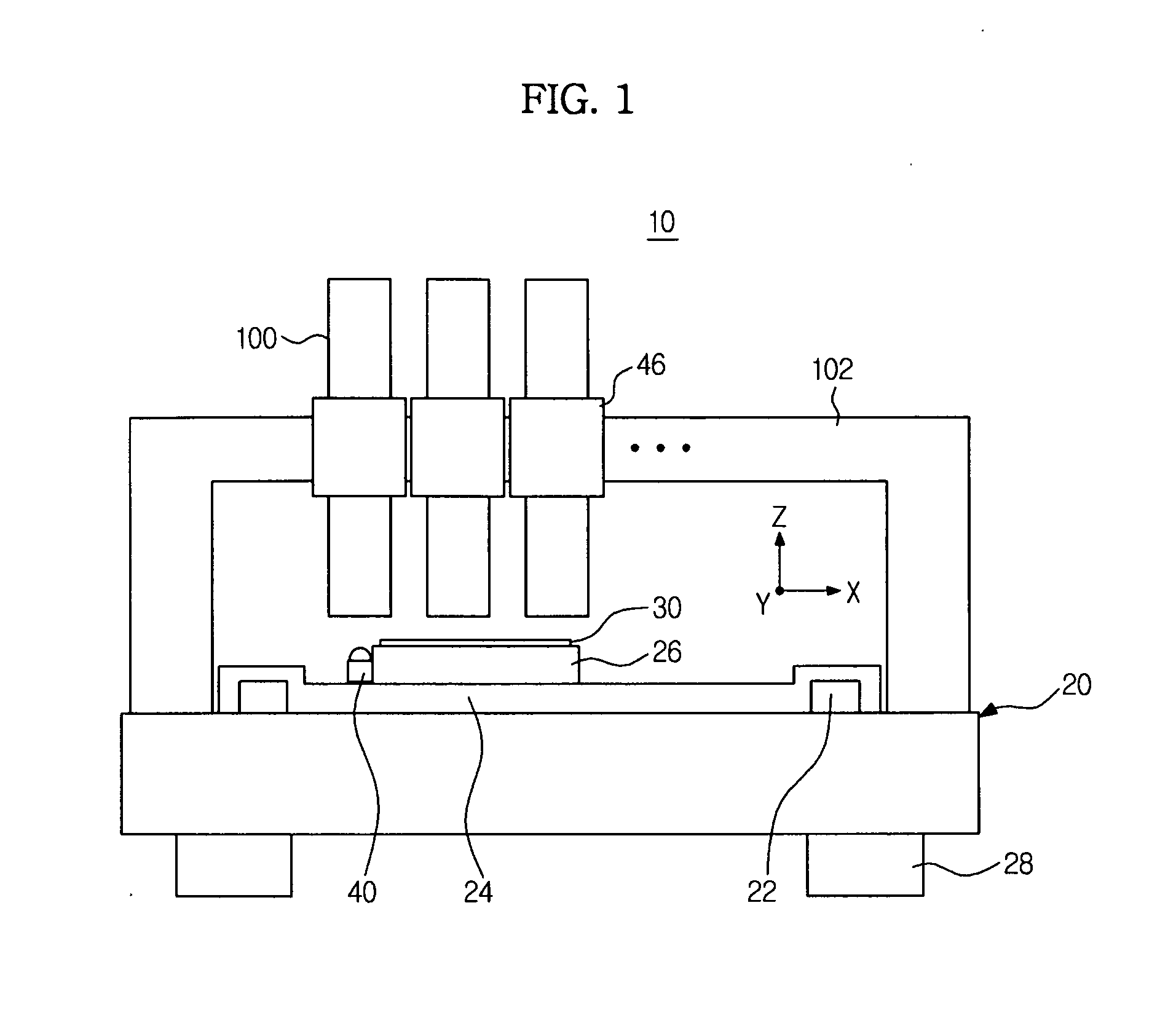

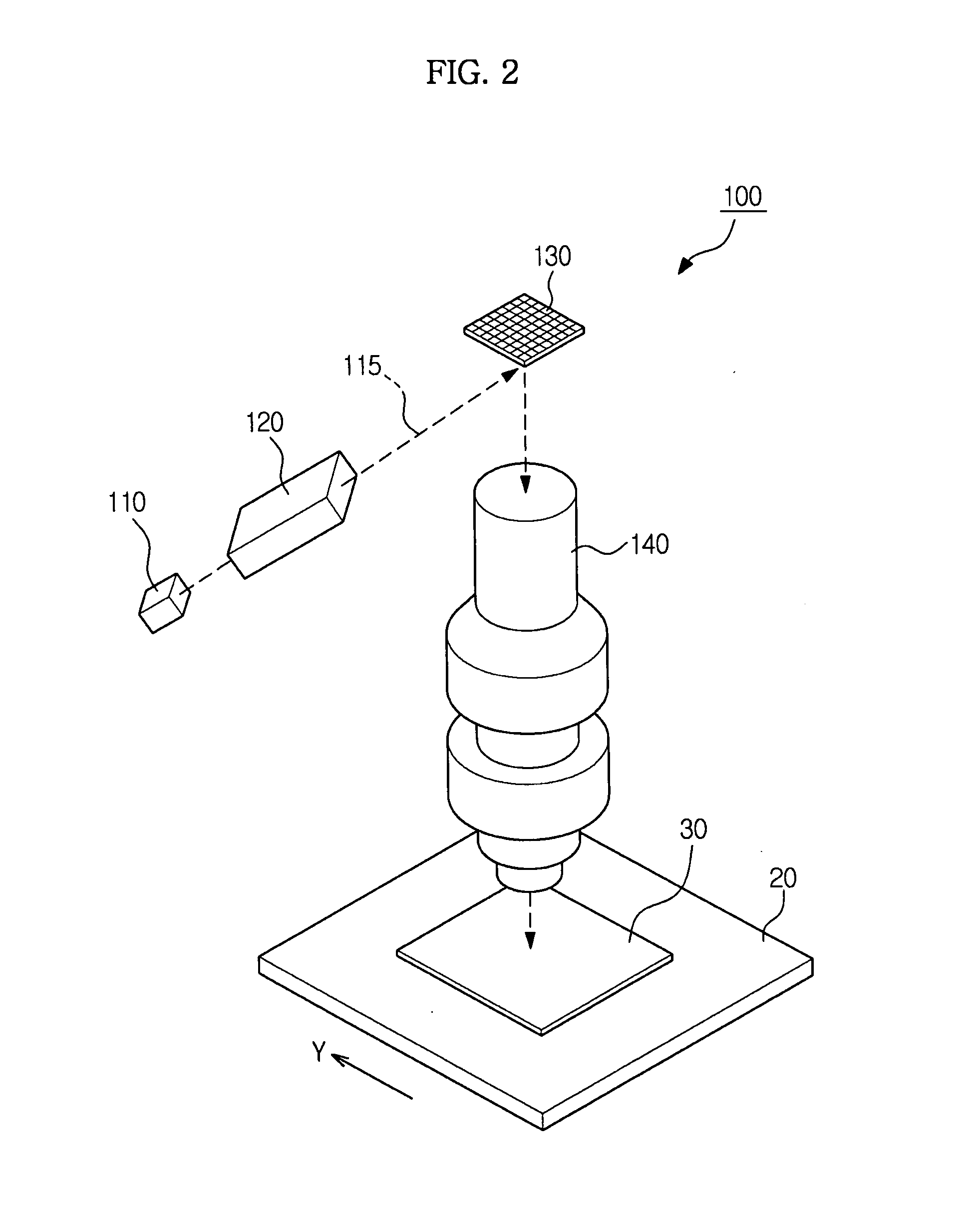

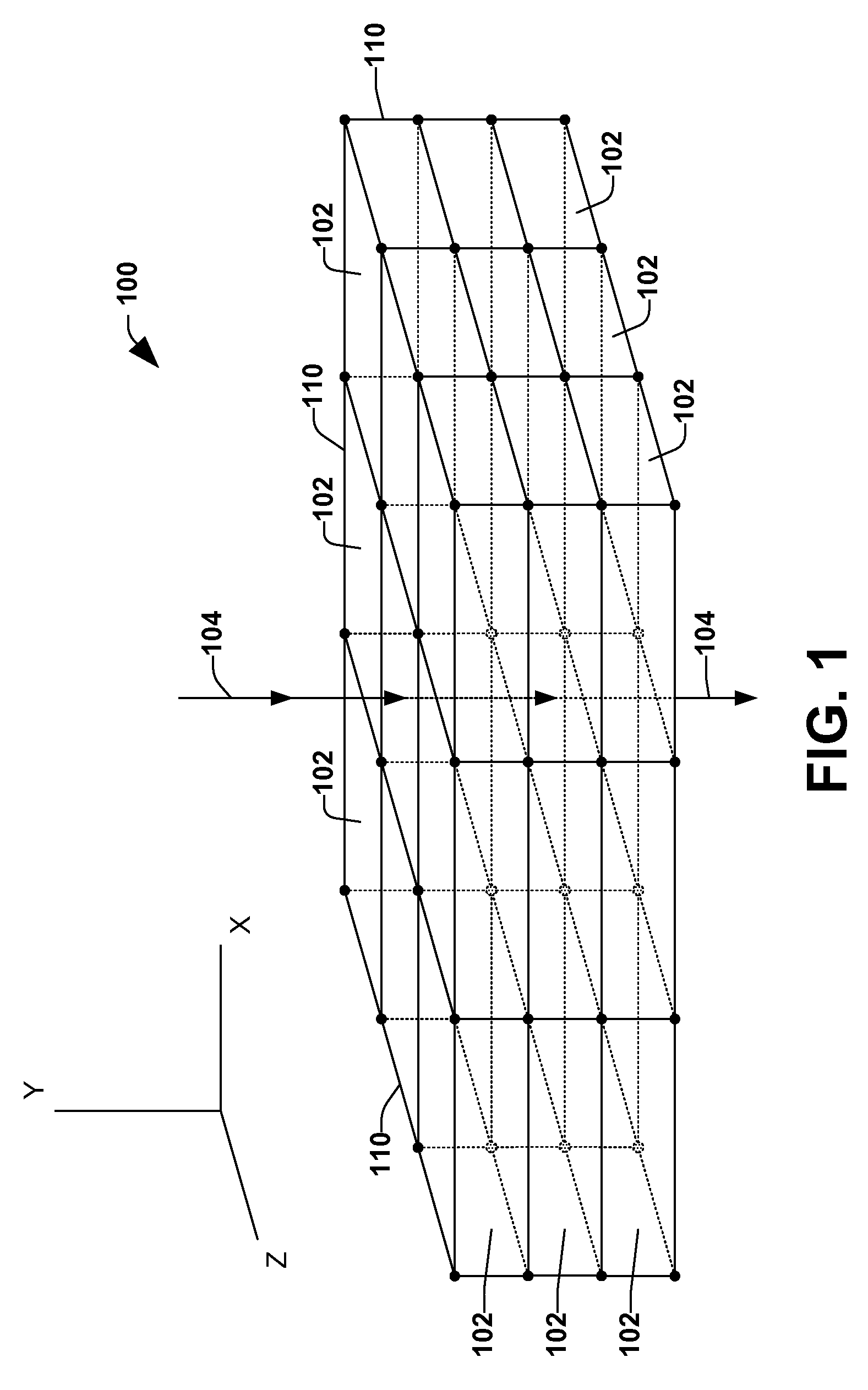

Maskless exposure apparatus and stitching exposure method using the same

ActiveUS20110267594A1Photomechanical apparatusSemiconductor/solid-state device manufacturingDose uniformityImaging data

Disclosed herein are a maskless exposure apparatus configured to perform exposure by tilting a beam spot array with respect to a scan direction (Y-axis direction) thus preventing stitching stripes and a stitching method using the same. A step distance, in which exposure dose uniformity in a stitching area is within a tolerance range, is calculated using actual position data of beam spots constituting the beam spot array on an exposure plane, and if necessary, using beam power data and / or beam size data. As exposure is performed based on image data conforming to the step distance, the stitching area has a uniform exposure dose, enabling exposure without stitching stripes.

Owner:SAMSUNG ELECTRONICS CO LTD

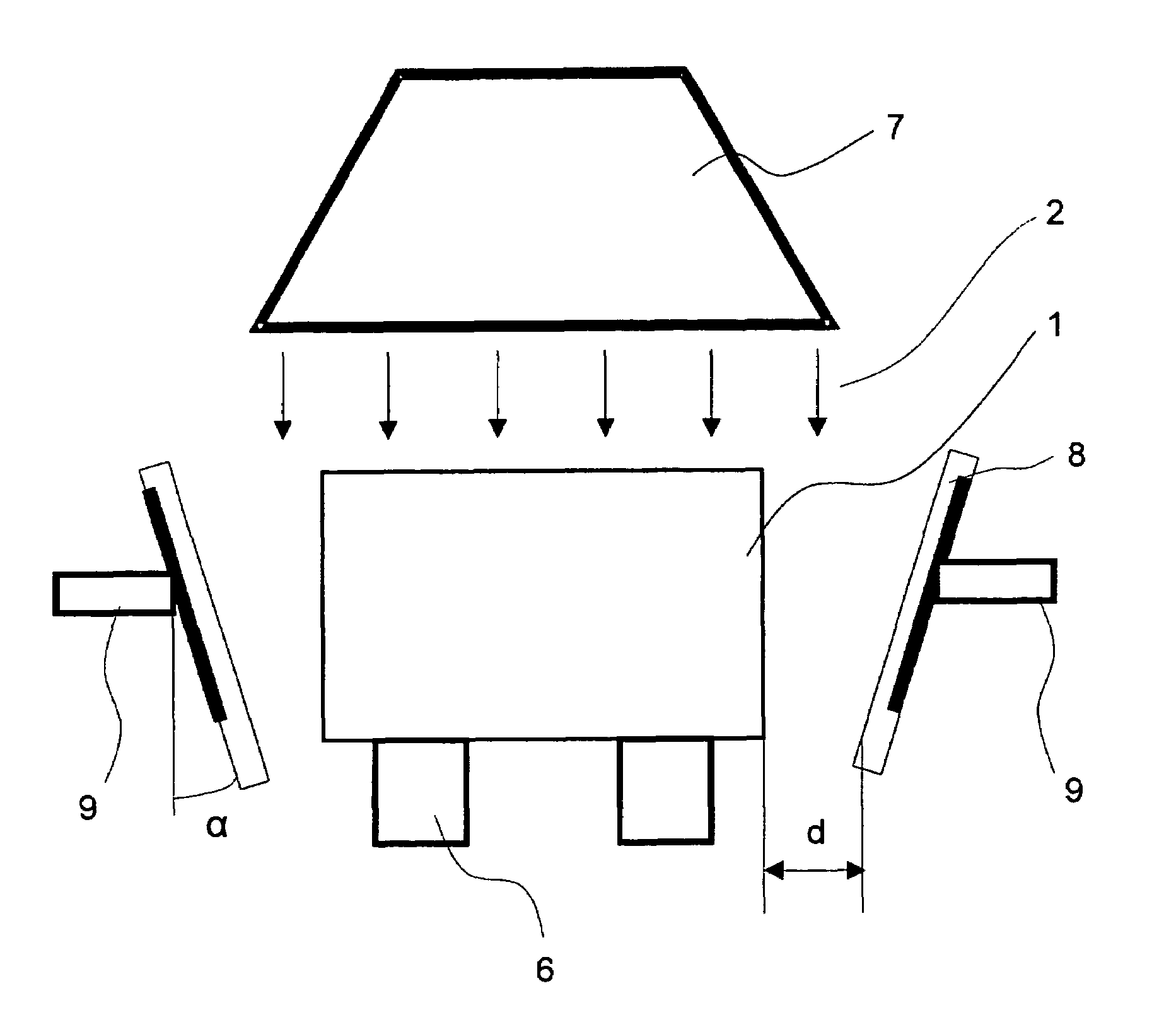

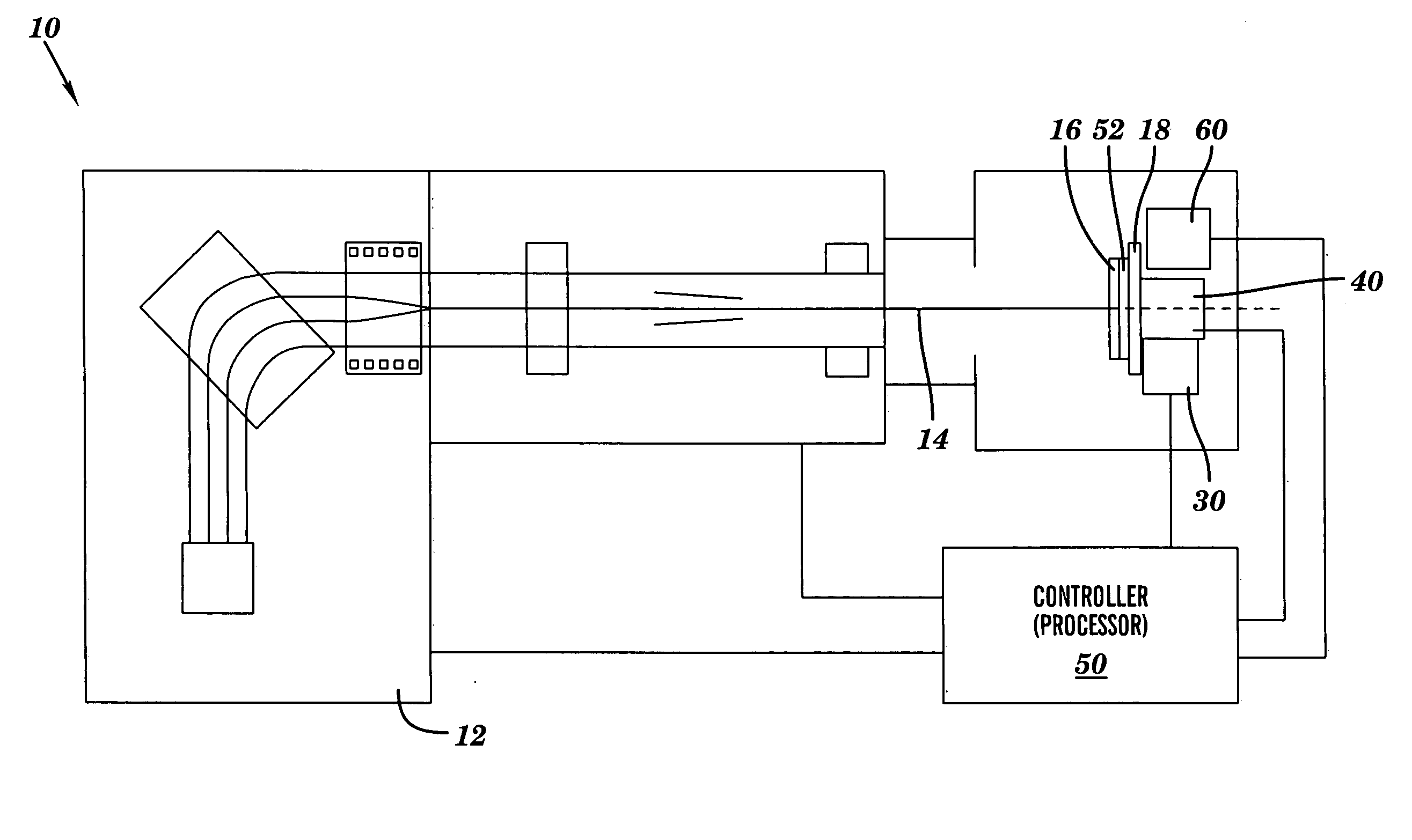

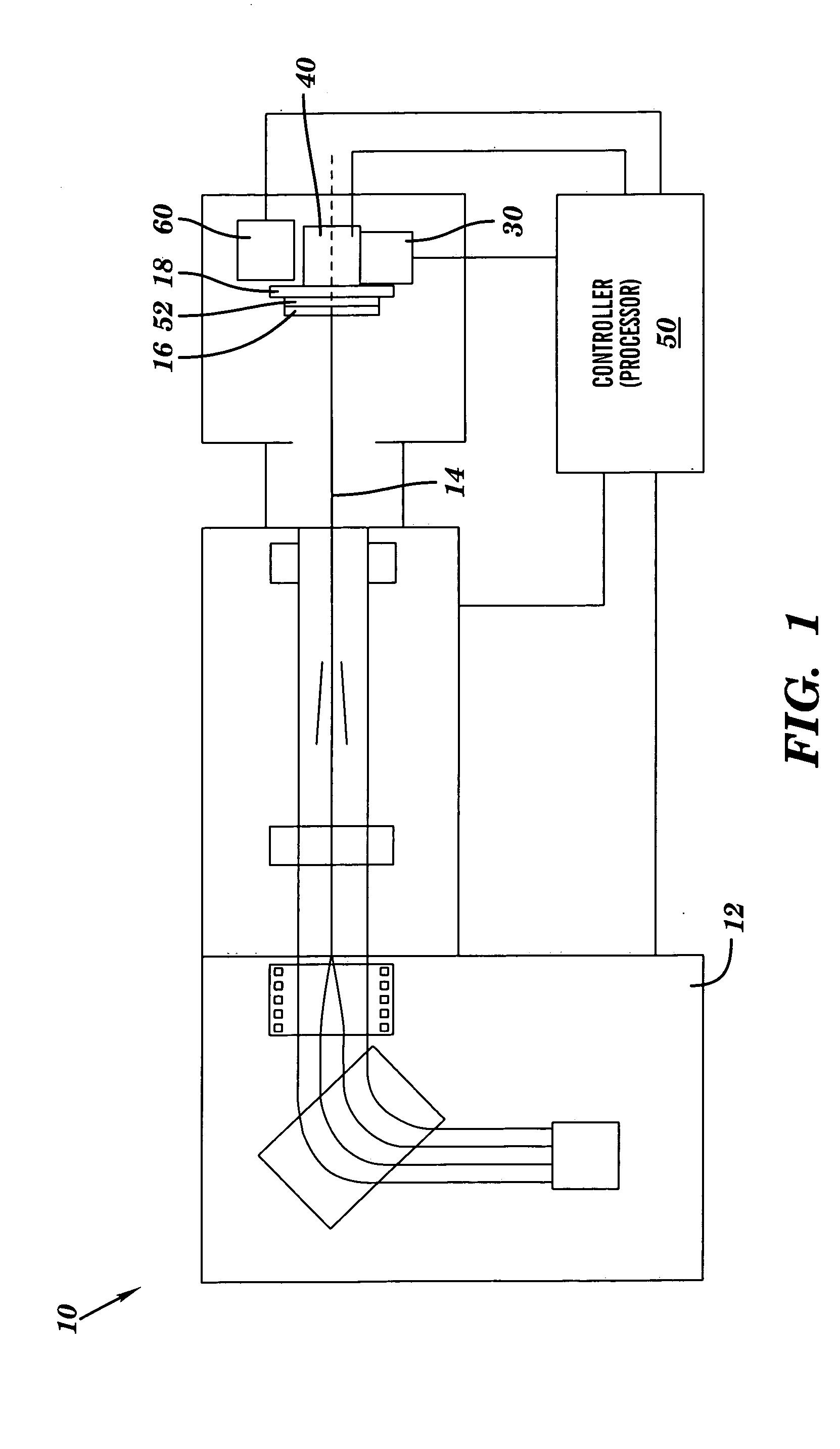

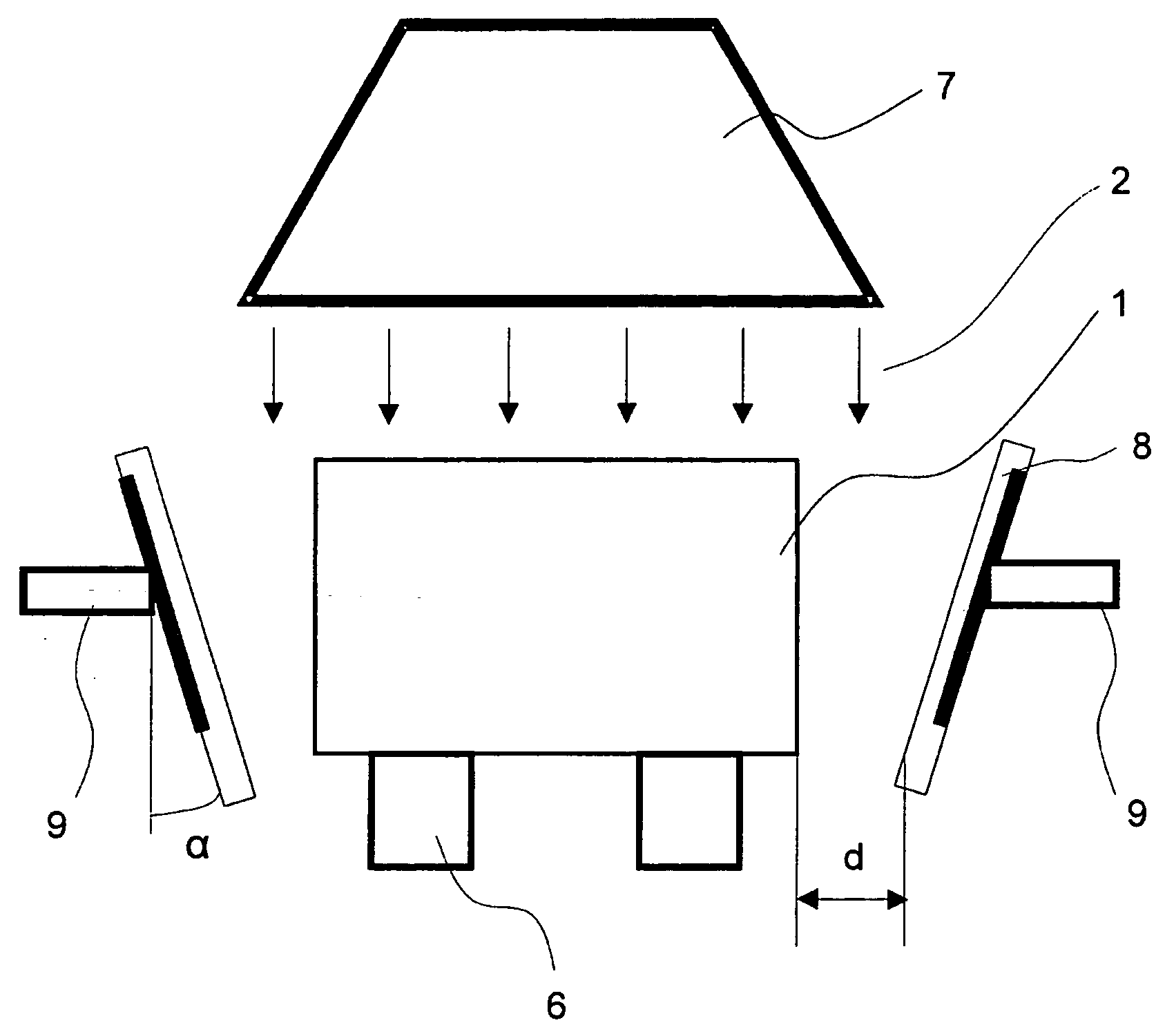

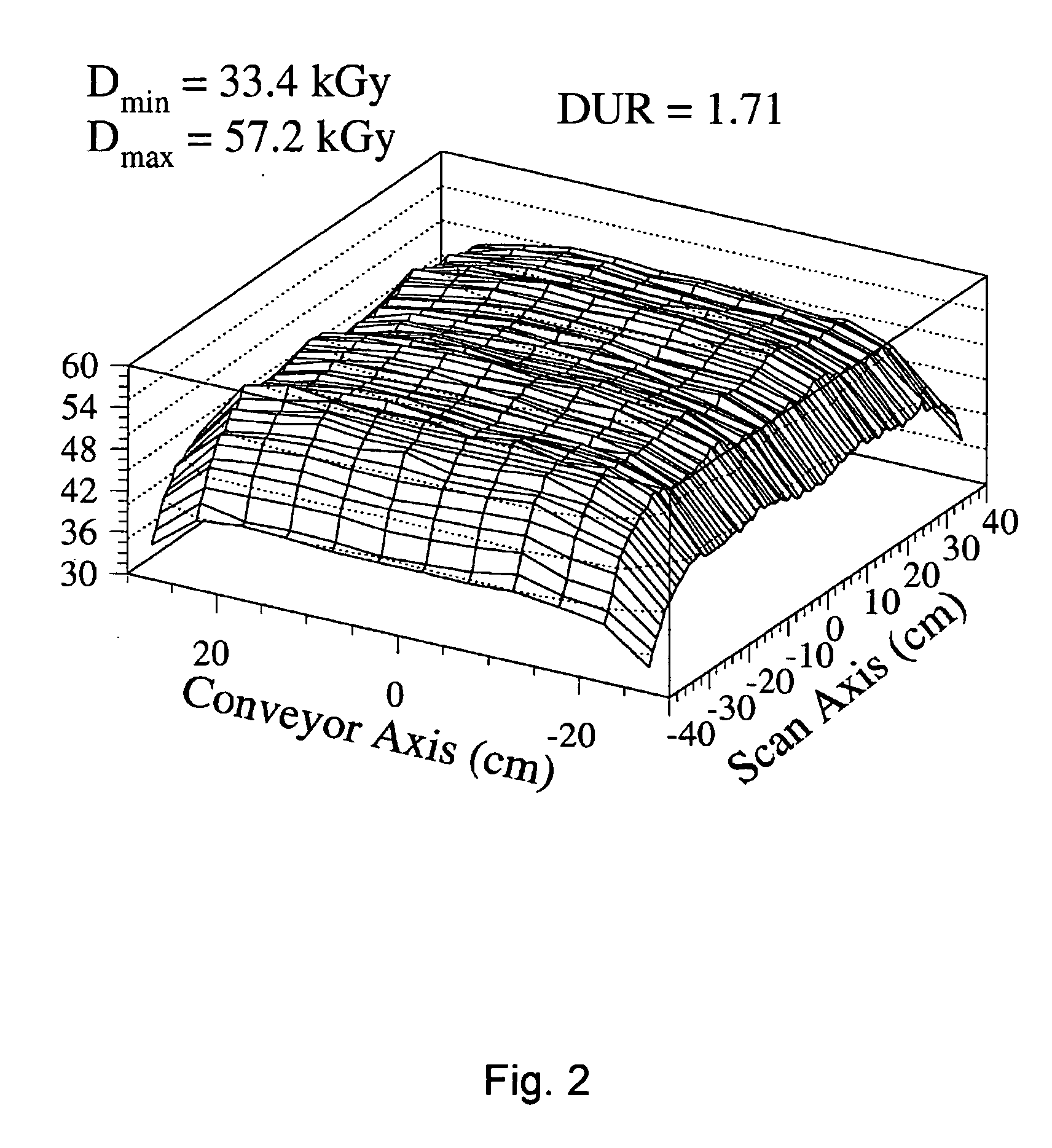

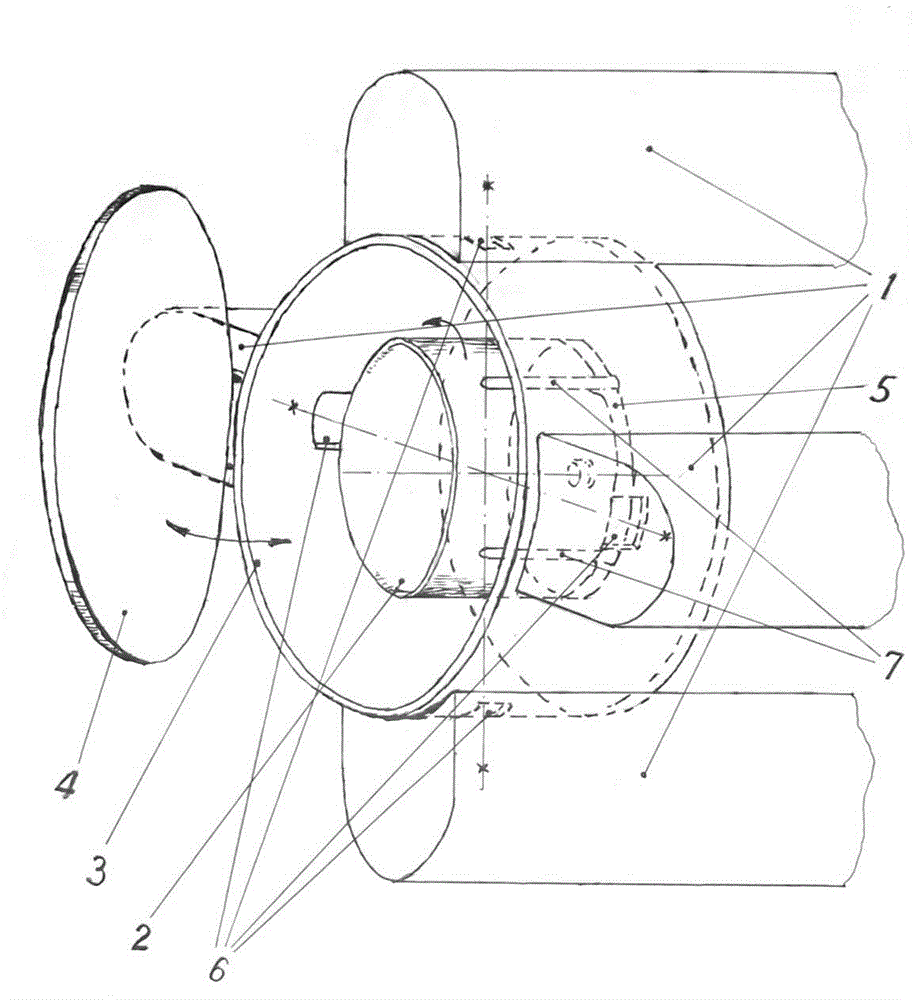

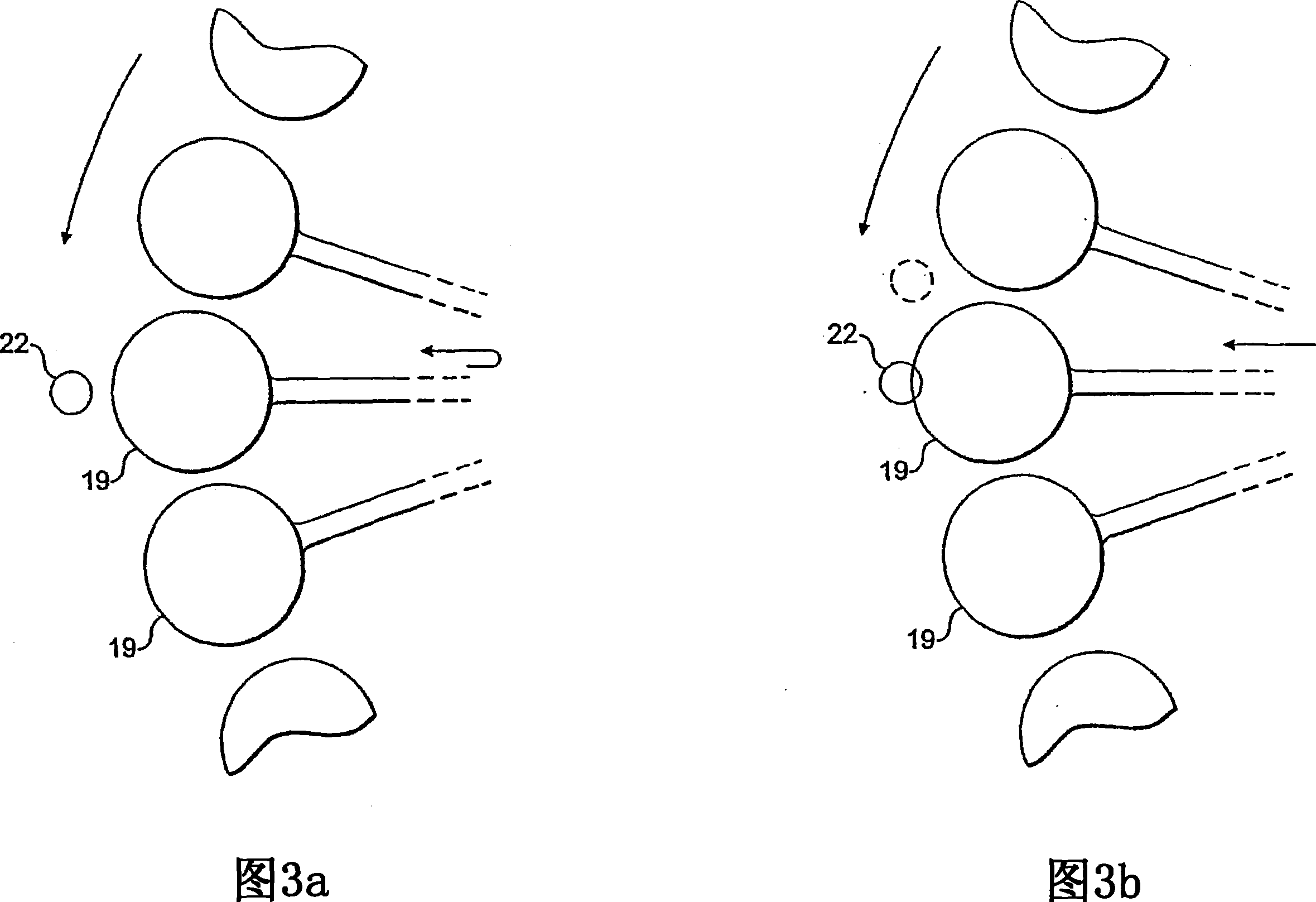

Apparatus and method for electron beam irradiation having improved dose uniformity ratio

InactiveUS7067827B2Distance minimizationOptical radiation measurementPackage sterilisationDose uniformityBeam direction

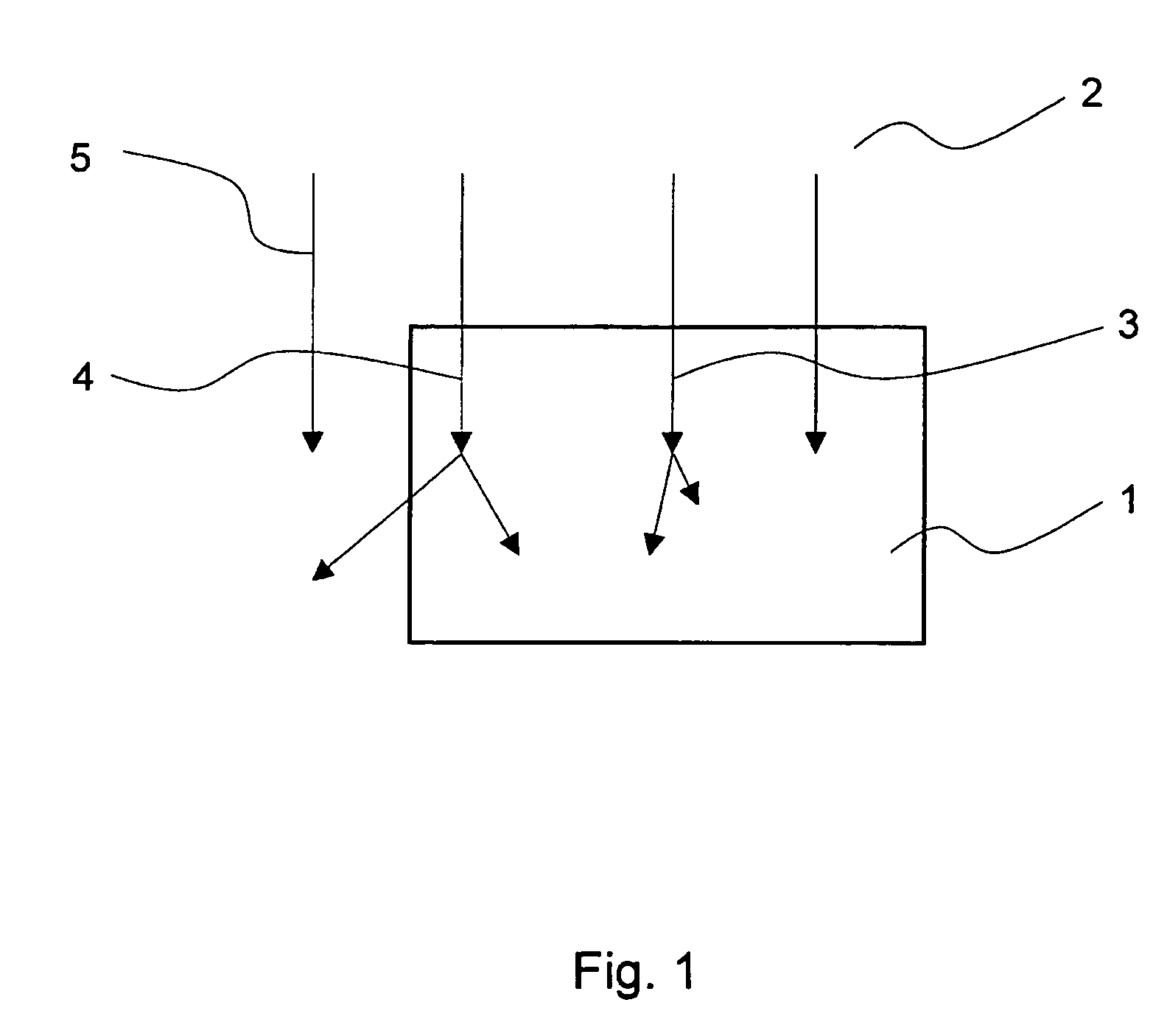

The present invention is related to an apparatus and method for irradiating a product package, comprising a radiation source directing a radiation beam along a beam direction towards said product package, conveying means for transporting said product package past said radiation source along a transport path, and reflecting means located on at least one side of the plane formed by said beam direction and said transport path. By adjusting the distance and angle of the reflecting means to the conveyor and beam, and improved dose uniformity ratio is obtained.

Owner:ION BEAM APPL

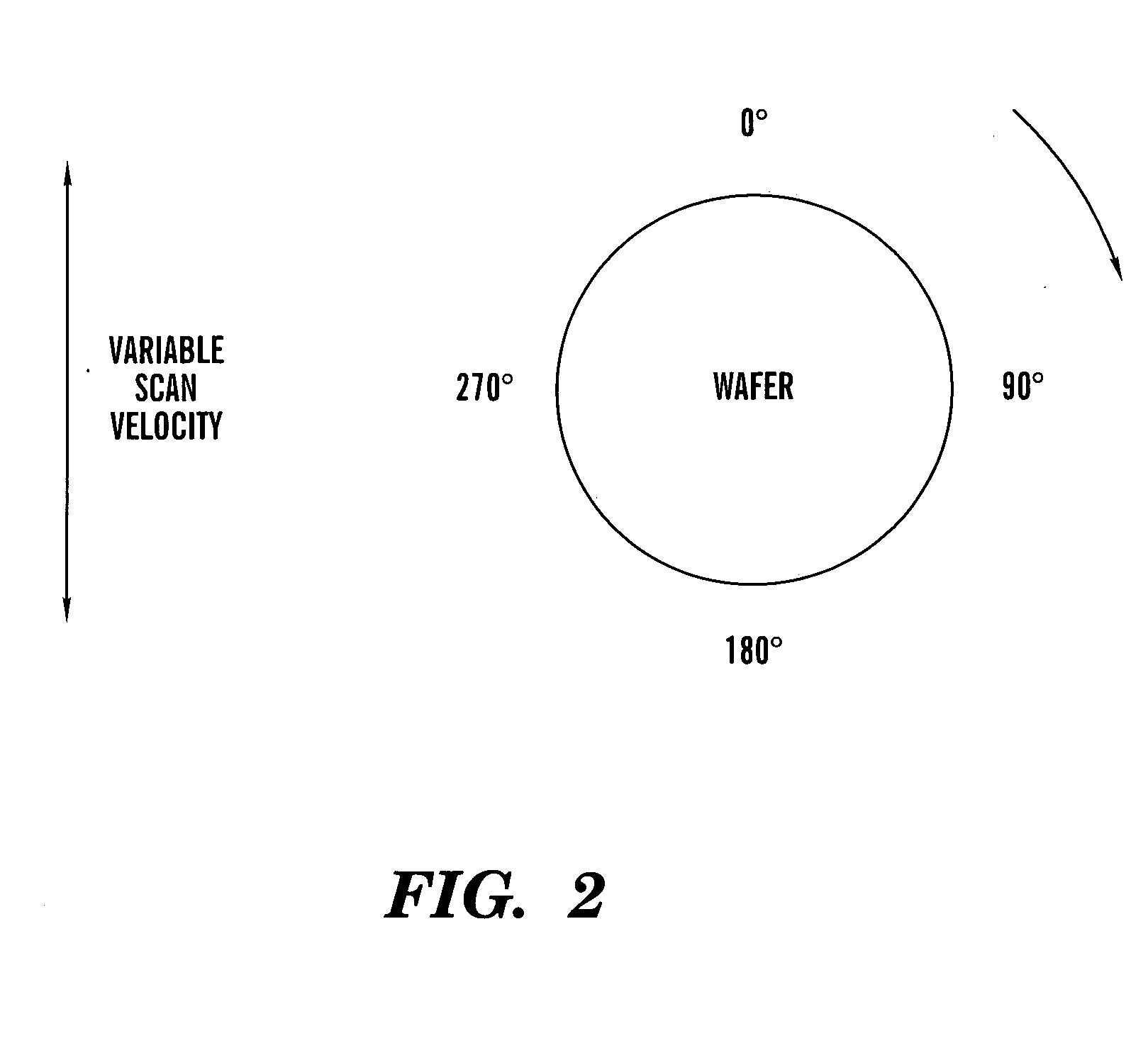

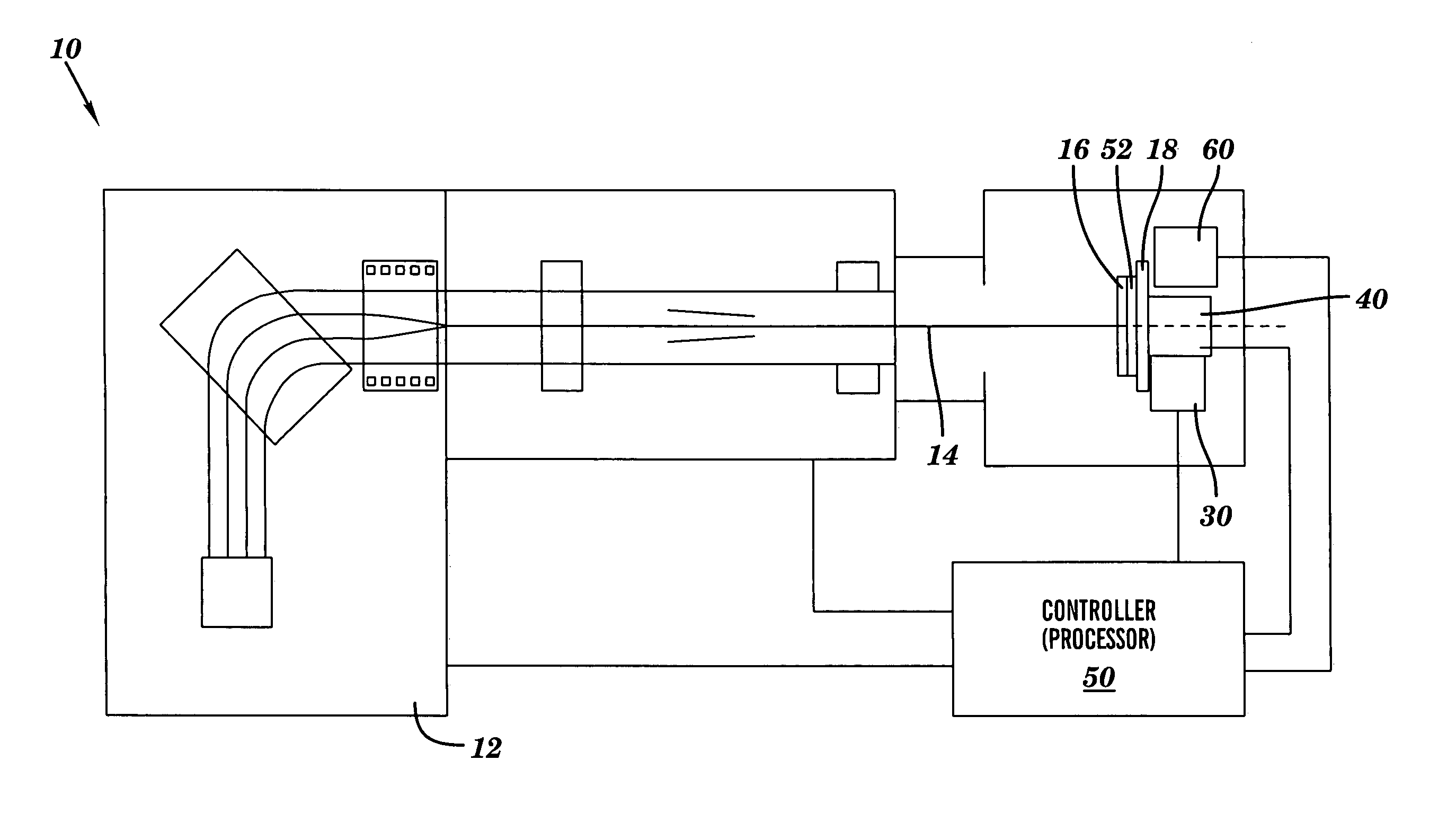

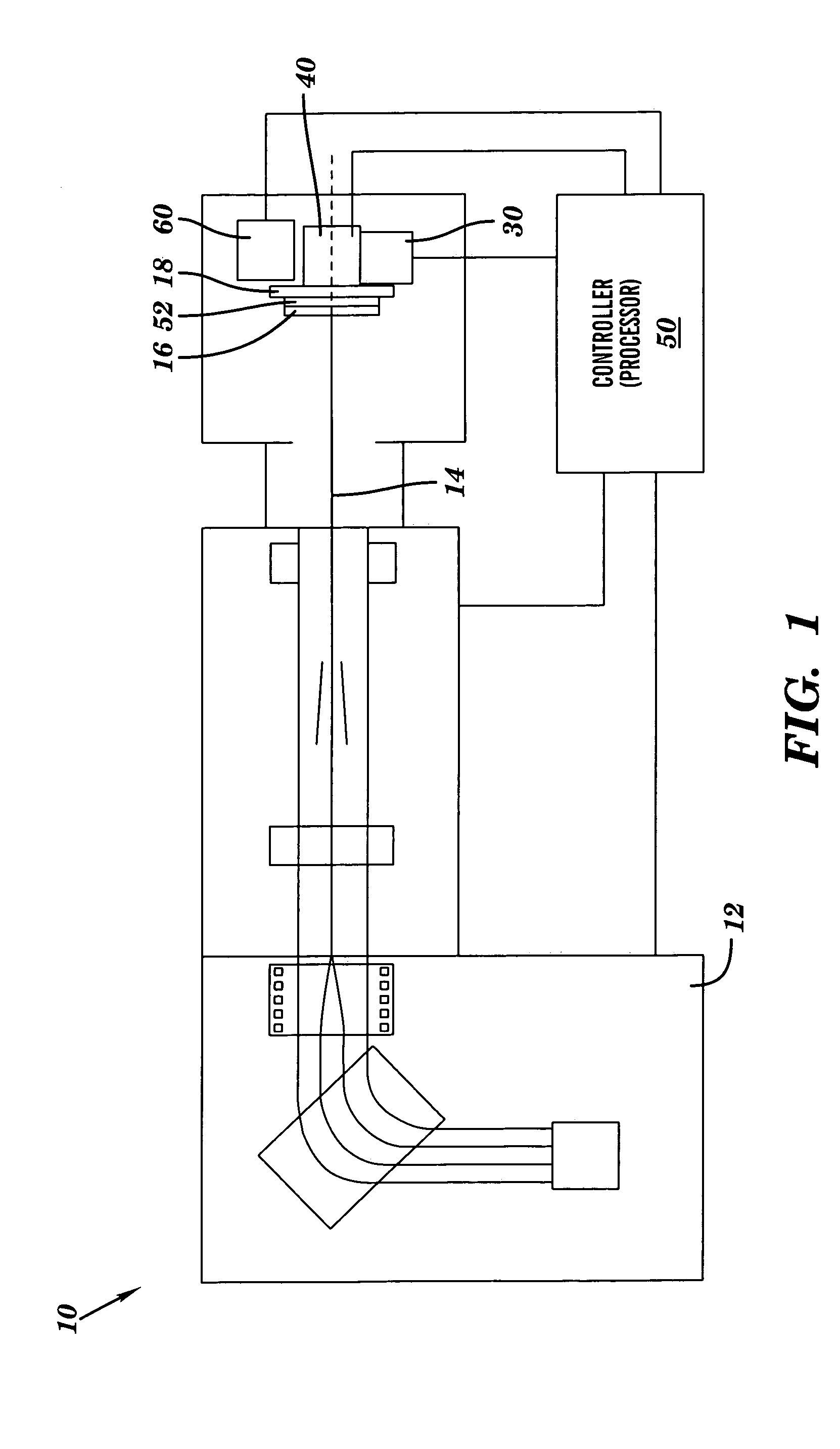

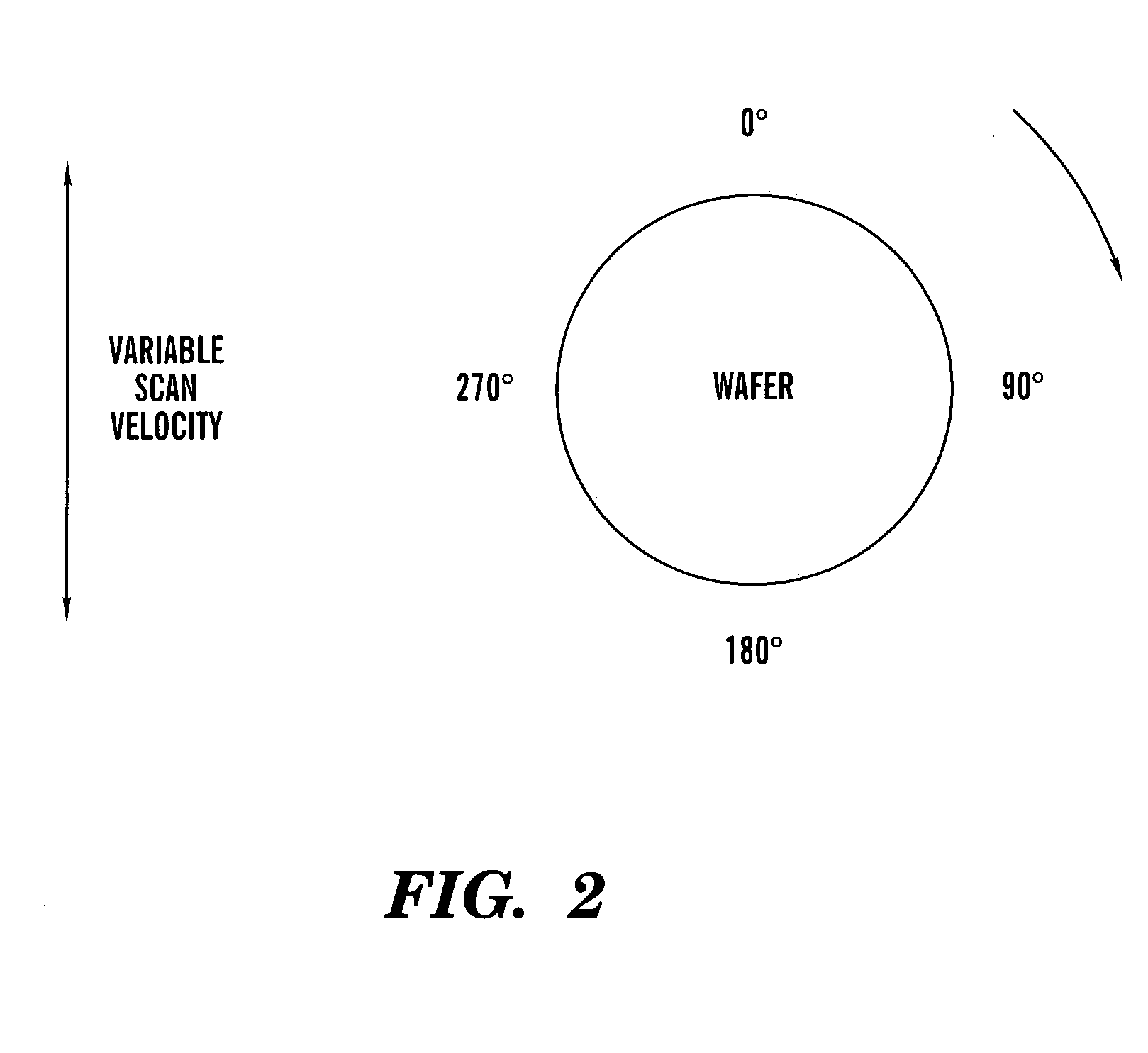

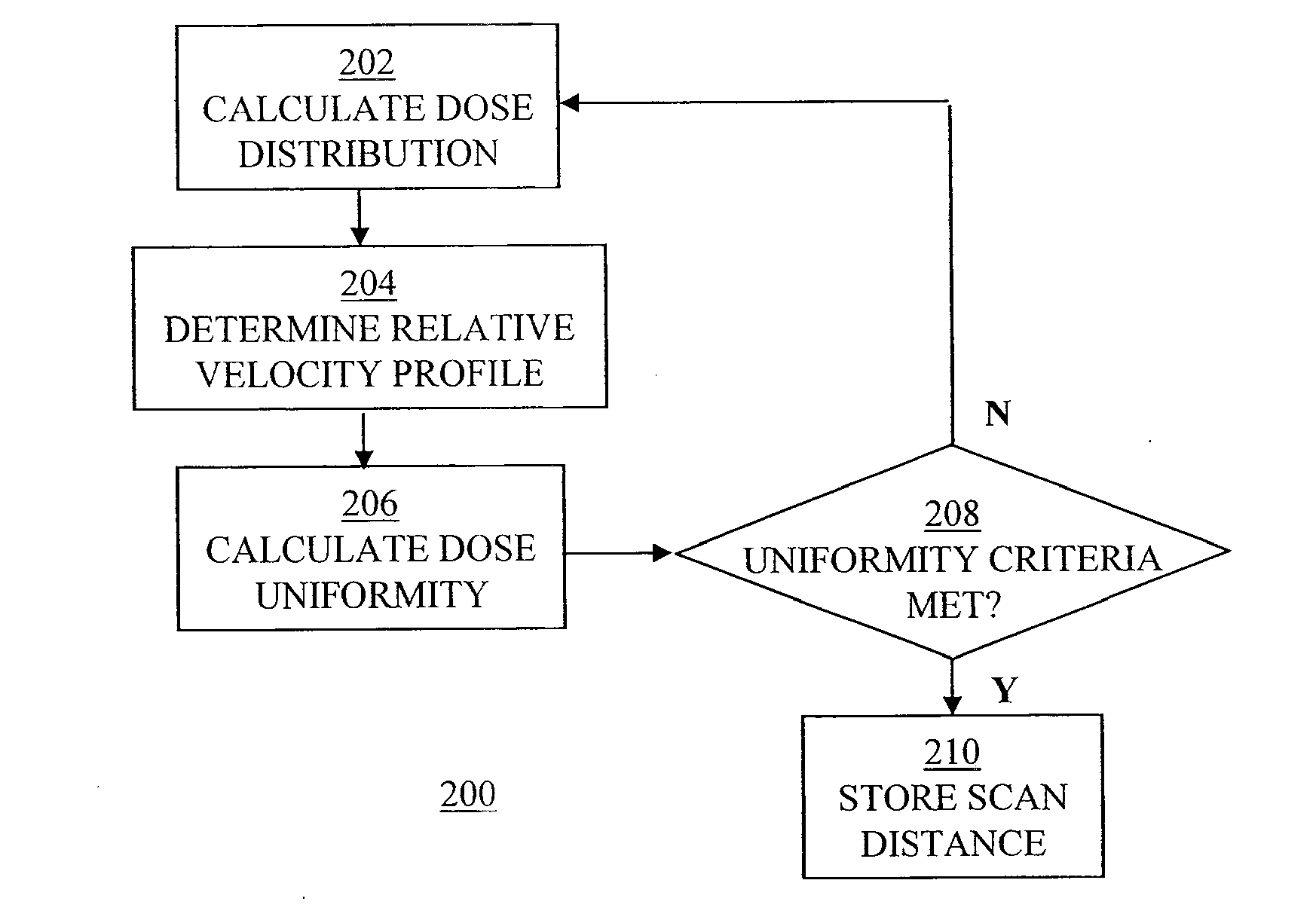

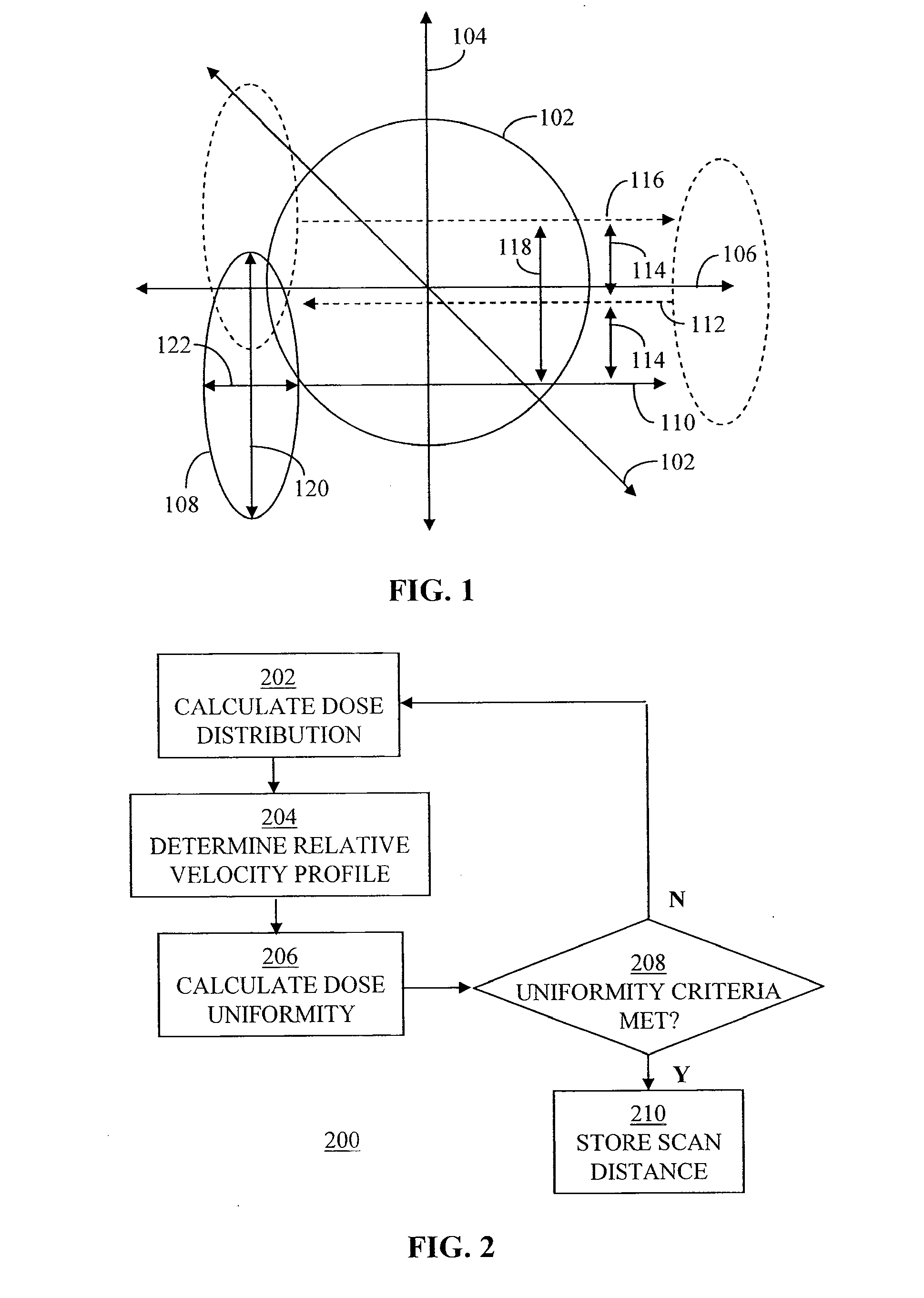

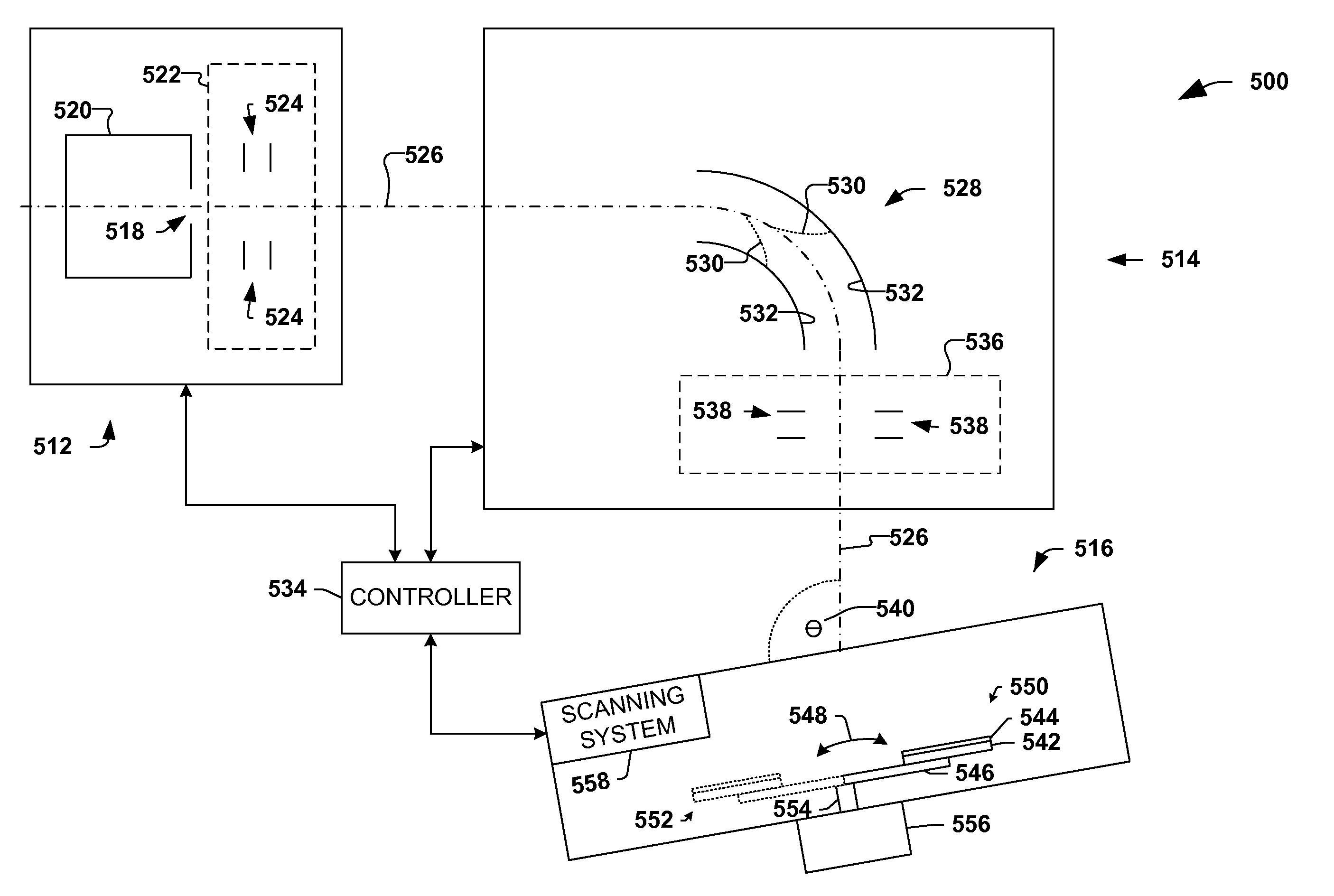

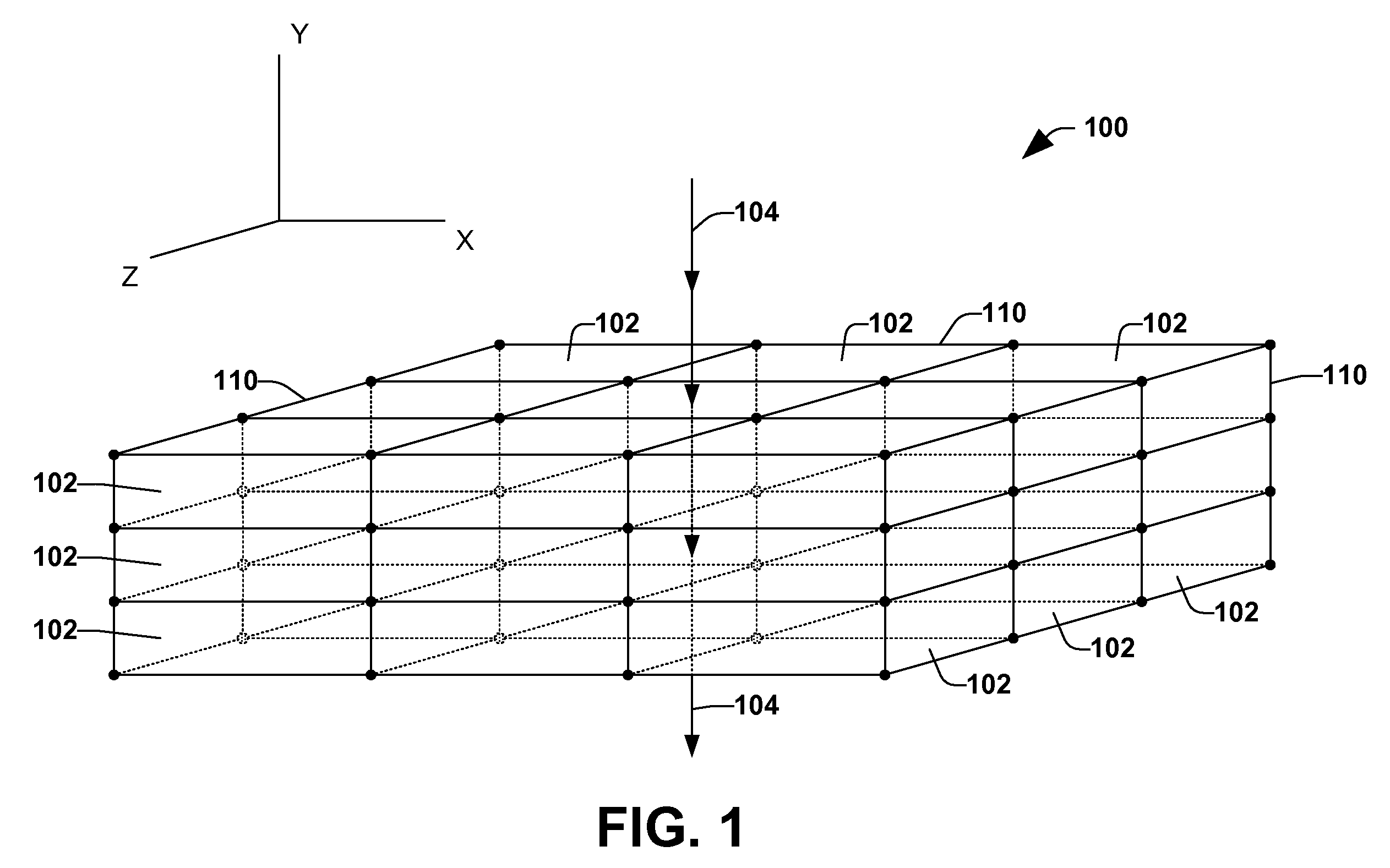

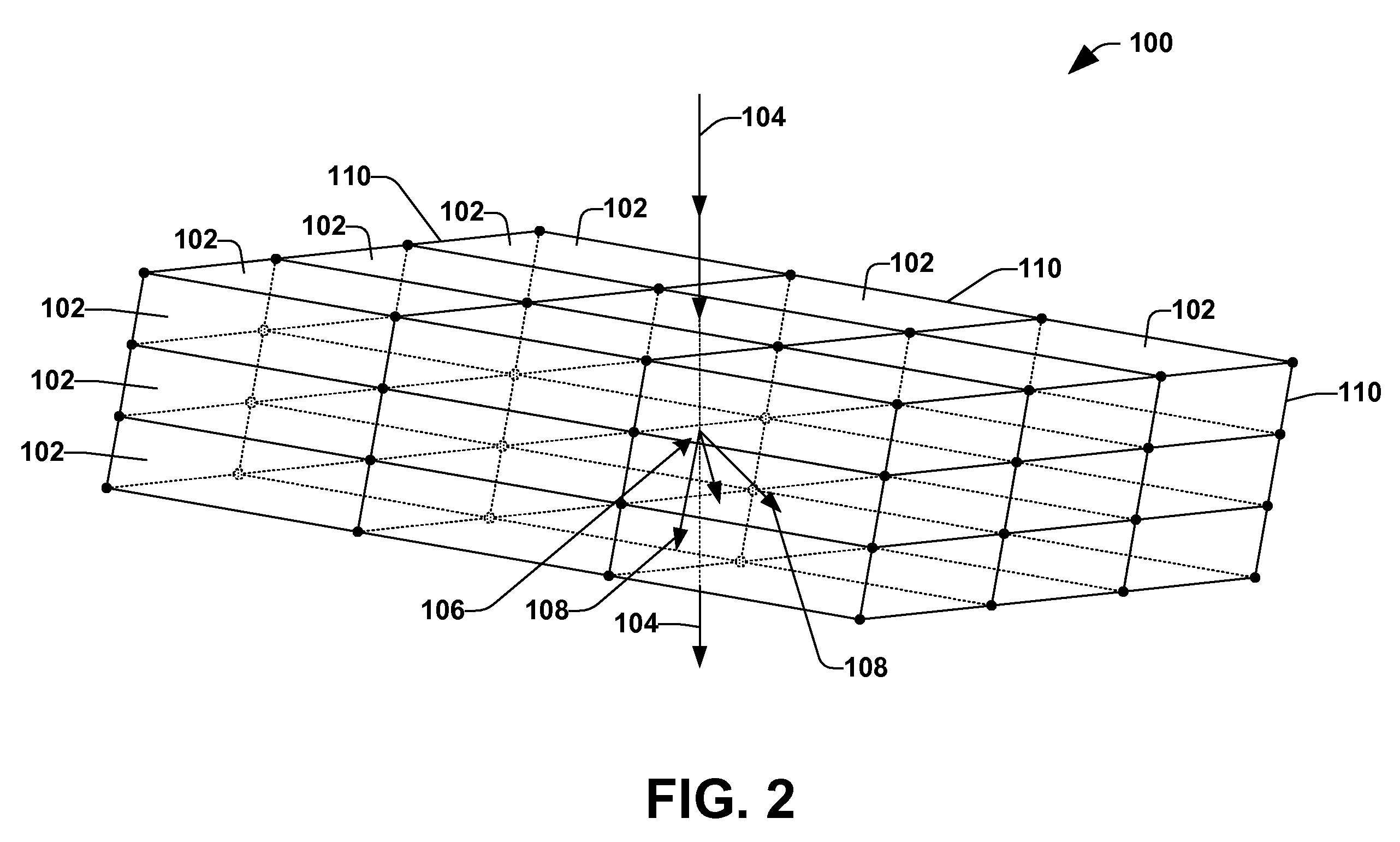

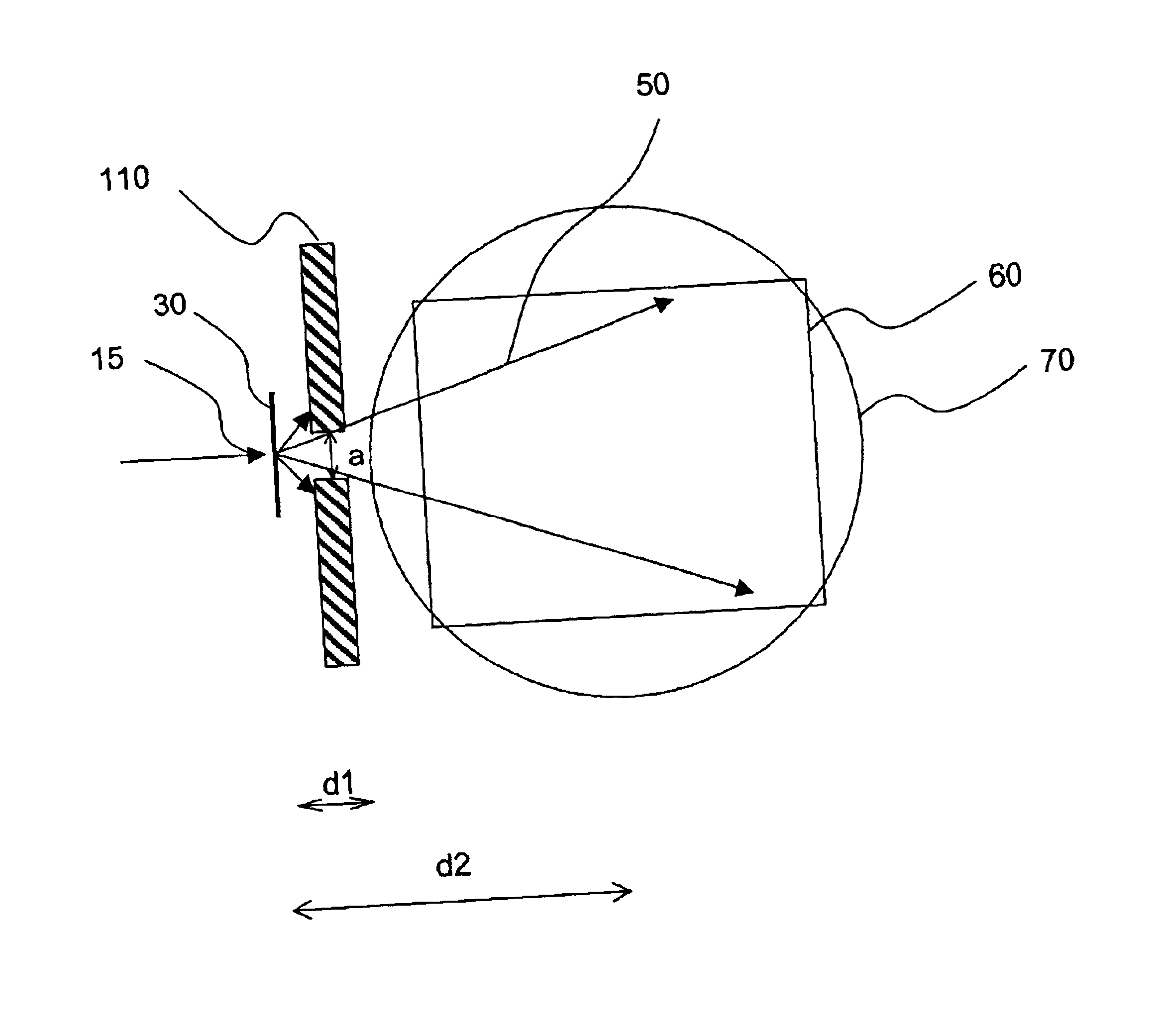

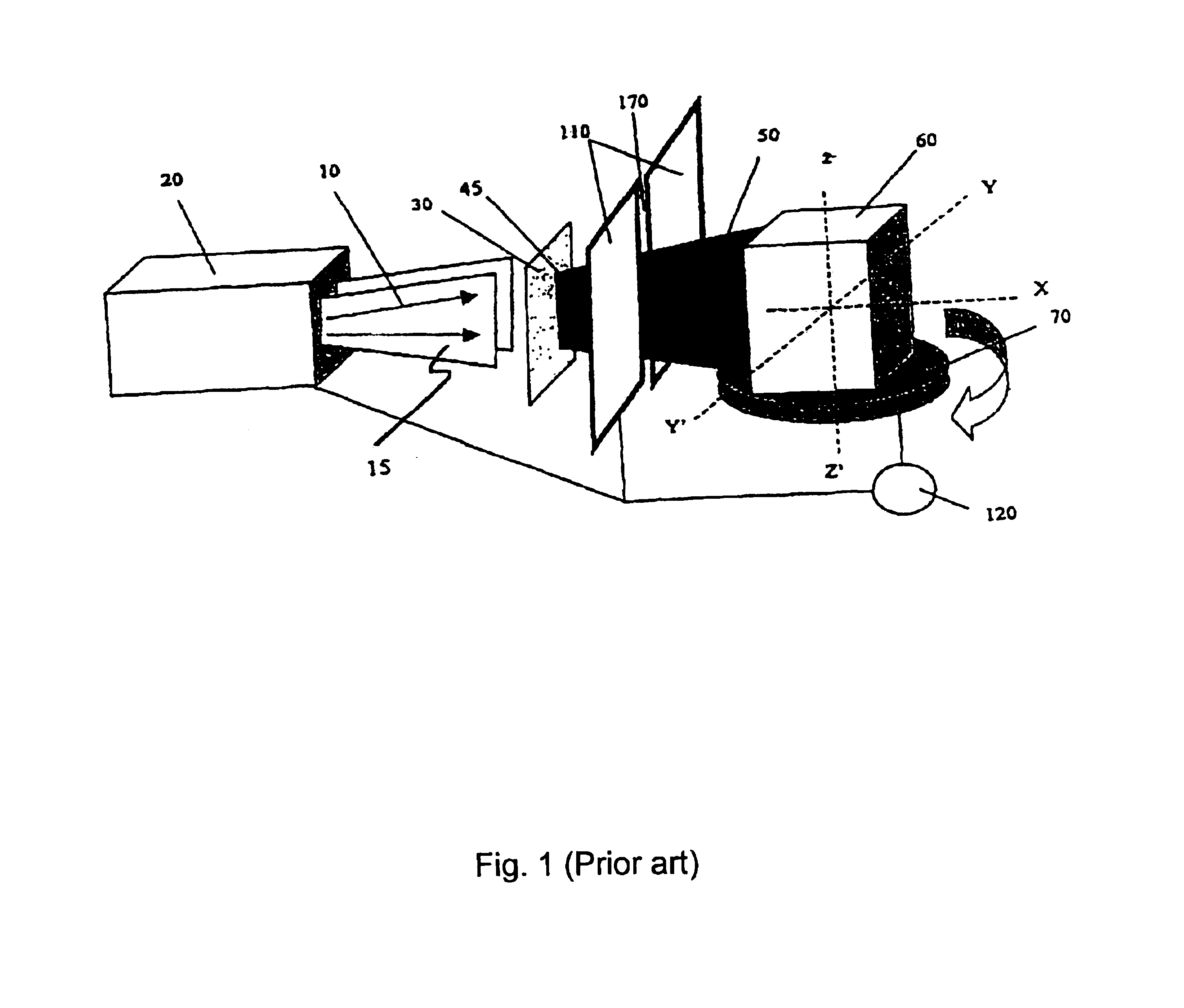

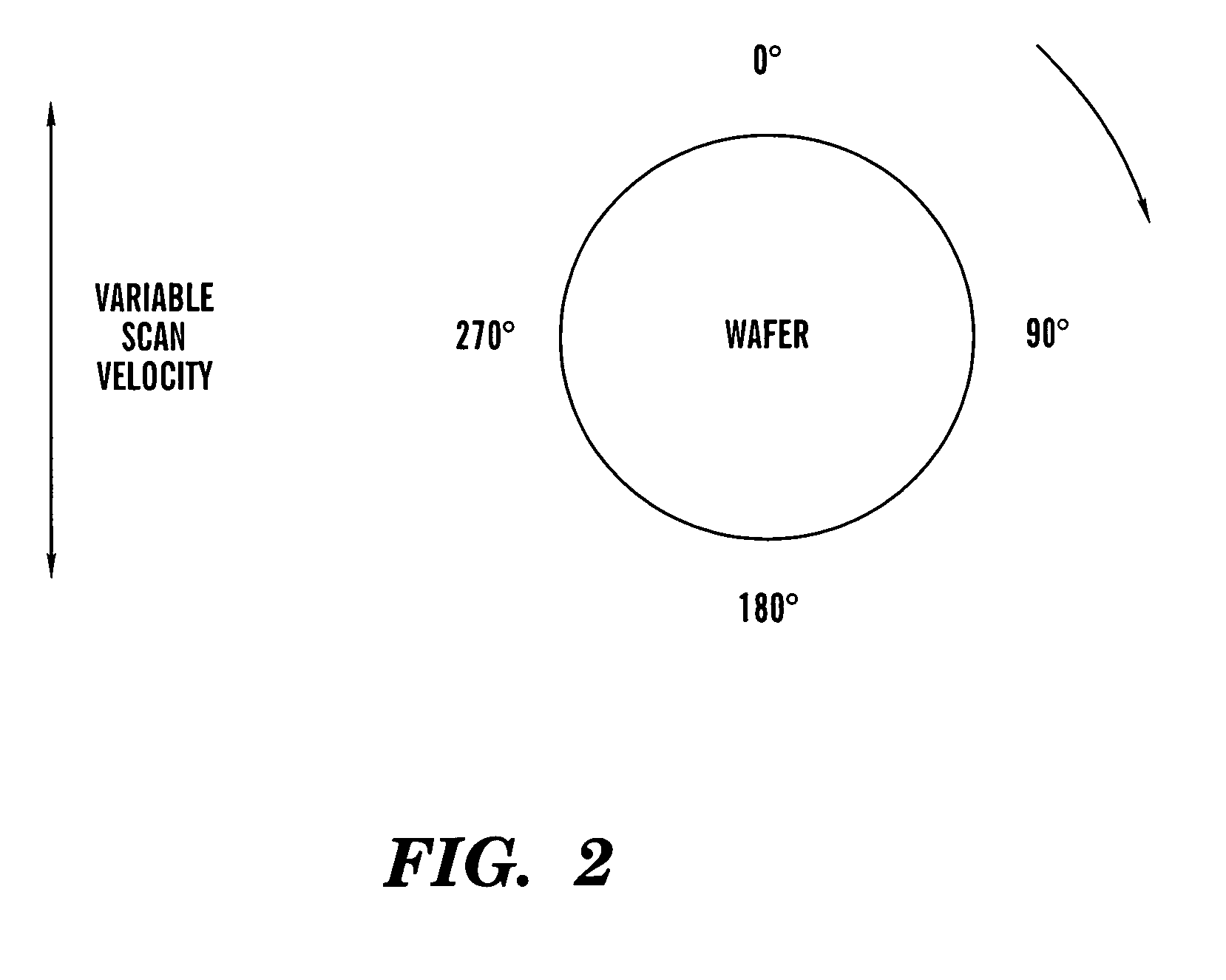

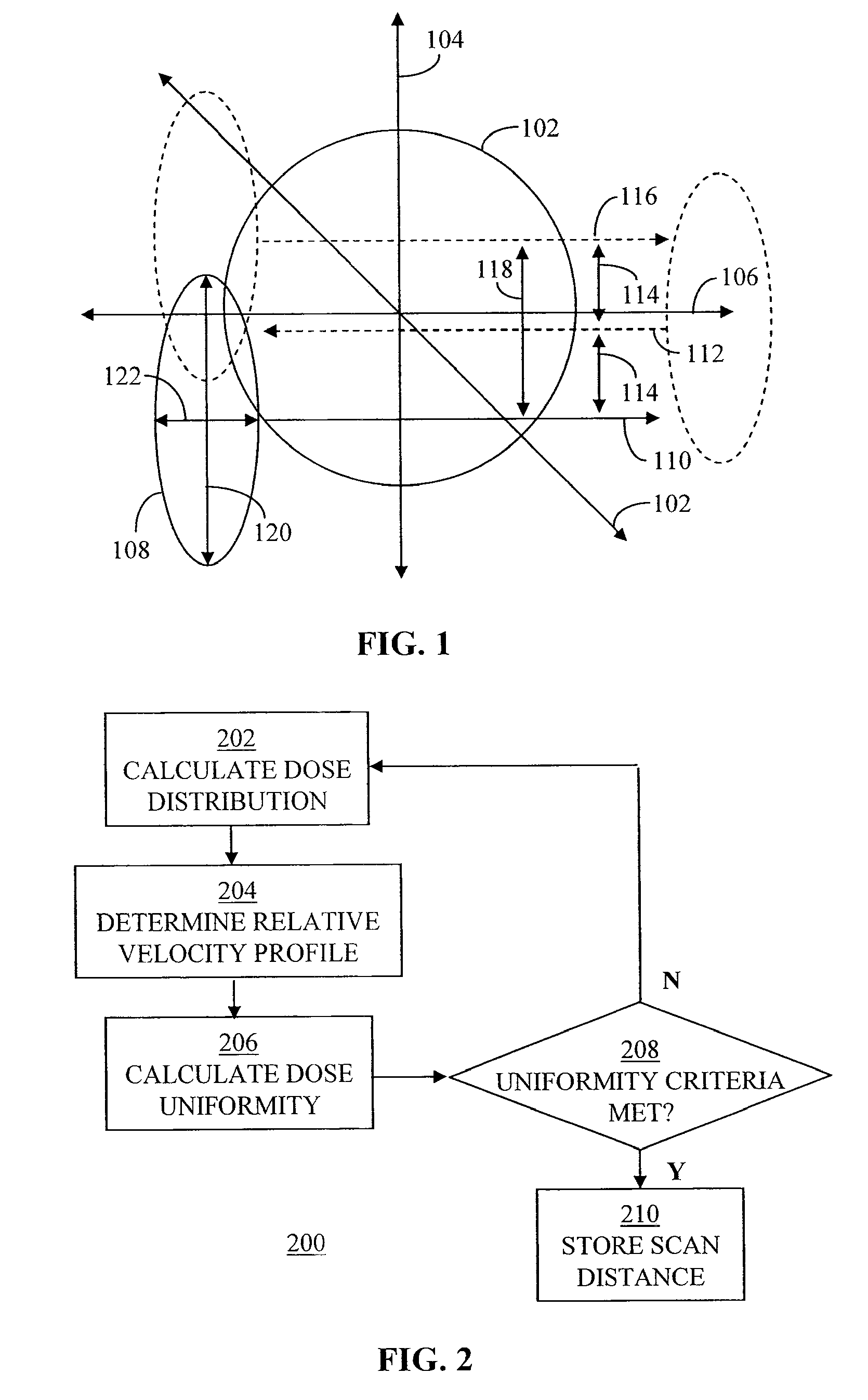

Uniformity control using multiple tilt axes, rotating wafer and variable scan velocity

ActiveUS20050263721A1Thermometer detailsBeam/ray focussing/reflecting arrangementsDose uniformityIon beam

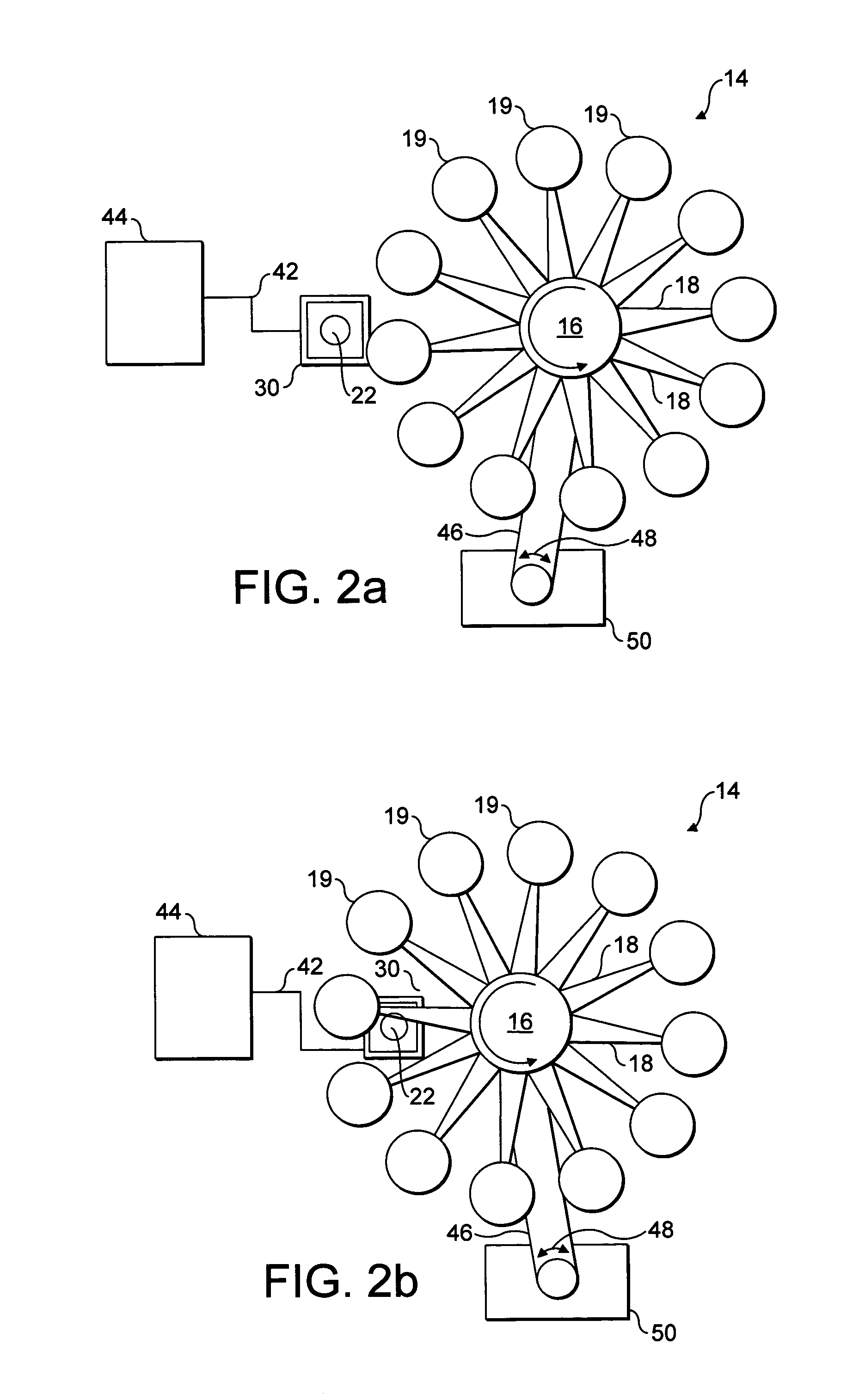

A system, method and program product for enhancing dose uniformity during ion implantation are disclosed. The present invention is directed to allowing the use of an at least partially untuned ion beam to obtain a uniform implant by scanning the beam in multiple rotationally-fixed orientations (scan directions) of the target at variable or non-uniform scan velocities. The non-uniform scan velocities are dictated by a scan velocity profile that is generated based on the ion beam profile and / or the scan direction. The beam can be of any size, shape or tuning. A platen holding a wafer is rotated to a new desired rotationally-fixed orientation after a scan, and a subsequent scan occurs at the same scan velocity profile or a different scan velocity profile. Also included is a method, system and program product for conducting a uniform dose ion implantation in which the target is rotated and tilted about greater than one axes relative to the ion beam.

Owner:VARIAN SEMICON EQUIP ASSOC INC

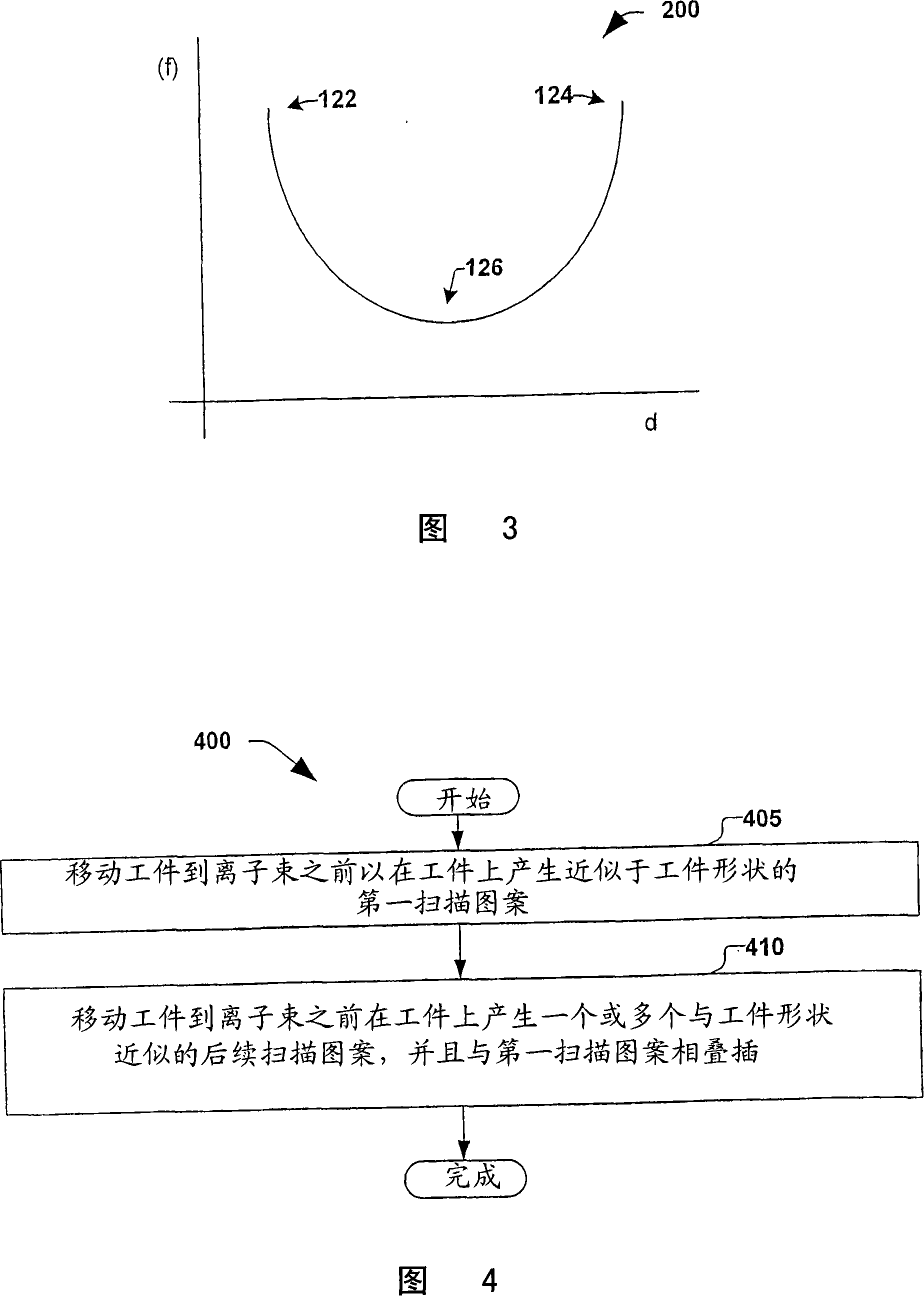

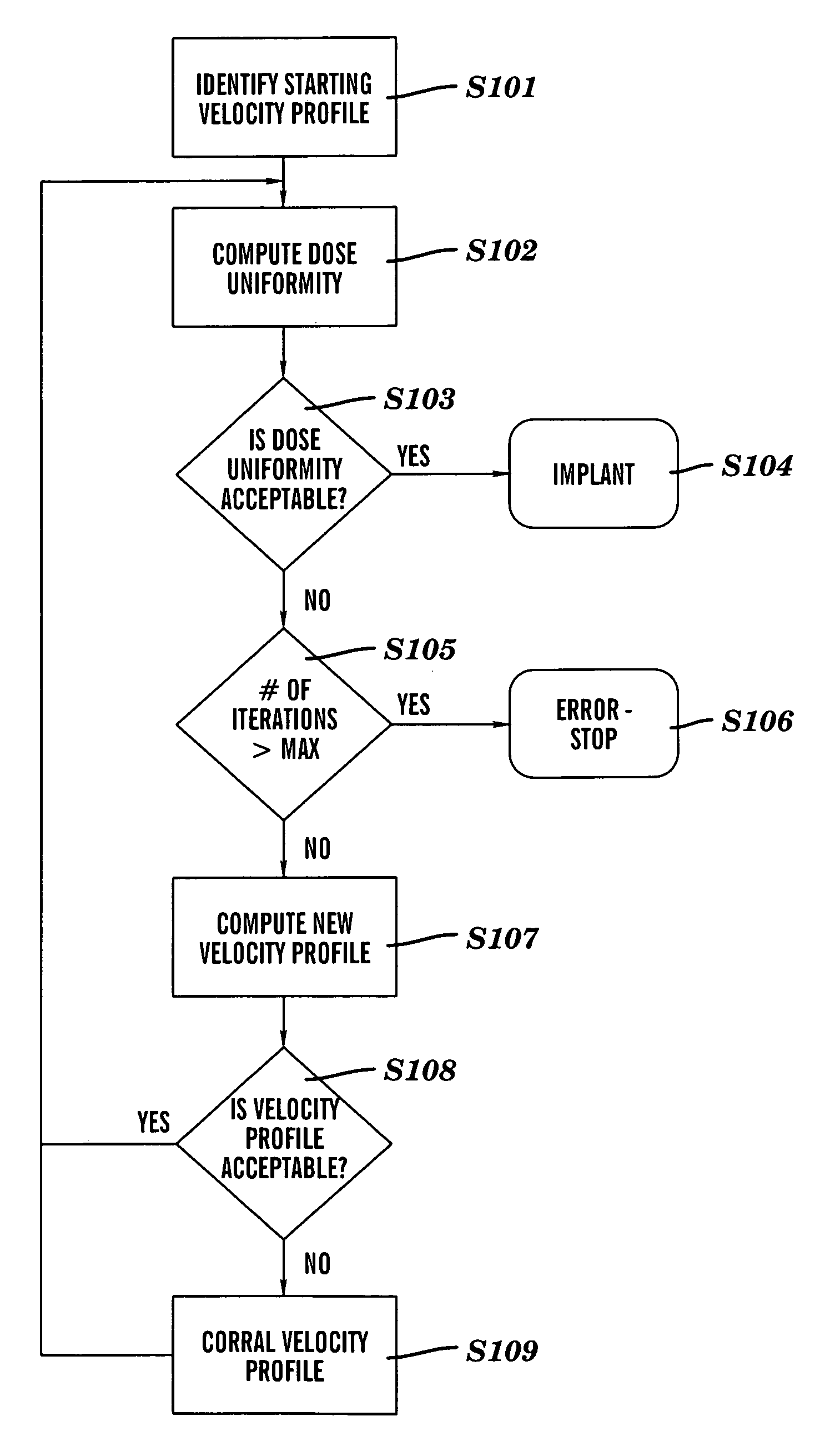

Technique for improving ion implantation throughput and dose uniformity

ActiveUS20080078953A1Improve device yieldImprove beam utilizationElectric discharge tubesIrradiation devicesDensity distributionDose uniformity

A technique for improving ion implantation throughput and dose uniformity is disclosed. In one exemplary embodiment, a method for improving ion implantation throughput and dose uniformity may comprise measuring an ion beam density distribution in an ion beam. The method may also comprise calculating an ion dose distribution across a predetermined region of a workpiece that results from a scan velocity profile, wherein the scan velocity profile comprises a first component and a second component that control a relative movement between the ion beam and the workpiece in a first direction and a second direction respectively, and wherein the ion dose distribution is based at least in part on the ion beam density distribution. The method may further comprise adjusting at least one of the first component and the second component of the scan velocity profile to achieve a desired ion dose distribution in the predetermined region of the workpiece.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Uniformity control multiple tilt axes, rotating wafer and variable scan velocity

ActiveUS7166854B2Thermometer detailsBeam/ray focussing/reflecting arrangementsDose uniformityLight beam

A system, method and program product for enhancing dose uniformity during ion implantation are disclosed. The present invention is directed to allowing the use of an at least partially untuned ion beam to obtain a uniform implant by scanning the beam in multiple rotationally-fixed orientations (scan directions) of the target at variable or non-uniform scan velocities. The non-uniform scan velocities are dictated by a scan velocity profile that is generated based on the ion beam profile and / or the scan direction. The beam can be of any size, shape or tuning. A platen holding a wafer is rotated to a new desired rotationally-fixed orientation after a scan, and a subsequent scan occurs at the same scan velocity profile or a different scan velocity profile. Also included is a method, system and program product for conducting a uniform dose ion implantation in which the target is rotated and tilted about greater than one axes relative to the ion beam.

Owner:VARIAN SEMICON EQUIP ASSOC INC

X-ray source module pair linear assembly continuous inlet-outlet sample irradiating machine

ActiveCN103745901AHigh radiation conversion efficiencyImprove efficiencyX-ray tube electrodesNuclear radiationDose uniformity

The invention relates to an X-ray source module pair linear assembly continuous inlet-outlet sample irradiating machine, in particular to a special continuous inlet-outlet sample irradiating device for irradiating bagged blood or Chinese patent medicine and bulk food (such as garlic). The device comprises a linear assembly, an irradiating chamber upper protection cover, an irradiating chamber lower protection cover, a circulating sample conveyor belt, a control table-board and an anode water-cooling circulating system, wherein the linear assembly consists of a plurality of pairs of upper X-ray source modules and lower X-ray source modules. The X-ray source module pair linear assembly continuous inlet-outlet sample irradiating machine has the advantages of high irradiating conversion efficiency, large irradiating angle, continuity for irradiating the sample which is automatically inputted and outputted, uniformity in irradiating dose and the like and is used for substituting the existing widely-used radioactive nuclear radiation source blood irradiating machine, so that the dependence of the irradiating device on the nuclear radiation source can be finally thoroughly avoided, and the potential danger for producing radioactive nuclear pollution to the environment can be eliminated.

Owner:汇佳生物仪器(上海)有限公司

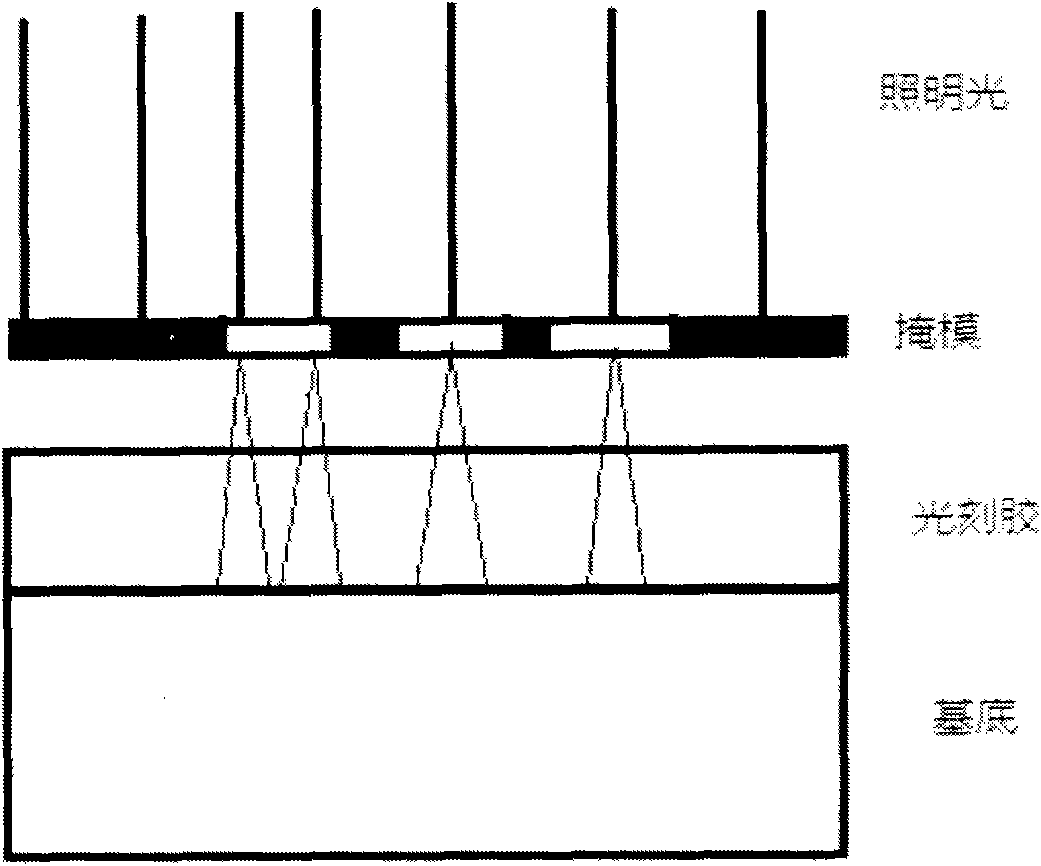

Proximity contact scan exposure device and method

ActiveCN102736421AImprove dose uniformityImprove line width uniformityPhotomechanical exposure apparatusMicrolithography exposure apparatusOptical propagationDose uniformity

The invention discloses a proximity contact scan exposure device which successively comprises the following parts along the optical propagation direction: an illumination system which is used for outputting parallel lights; a mask which is irradiated by the parallel lights to generate emergent light output; a substrate which is positioned below the mask and is irradiated by the emergent lights emitted from the mask; and a working table which supports the mask and the substrate. When the scan exposure device is in use, the mask and the substrate synchronously move with the working table. In comparison with a traditional aligned mask aligner, although the yield of the device provided by the invention is a little lower, dose uniformity is raised such that linewidth uniformity (CDU) is improved. In comparison with a traditional projection type mask aligner, although precision of the device provided by the invention is not such high, projection lens is not required so as to reduce the cost.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

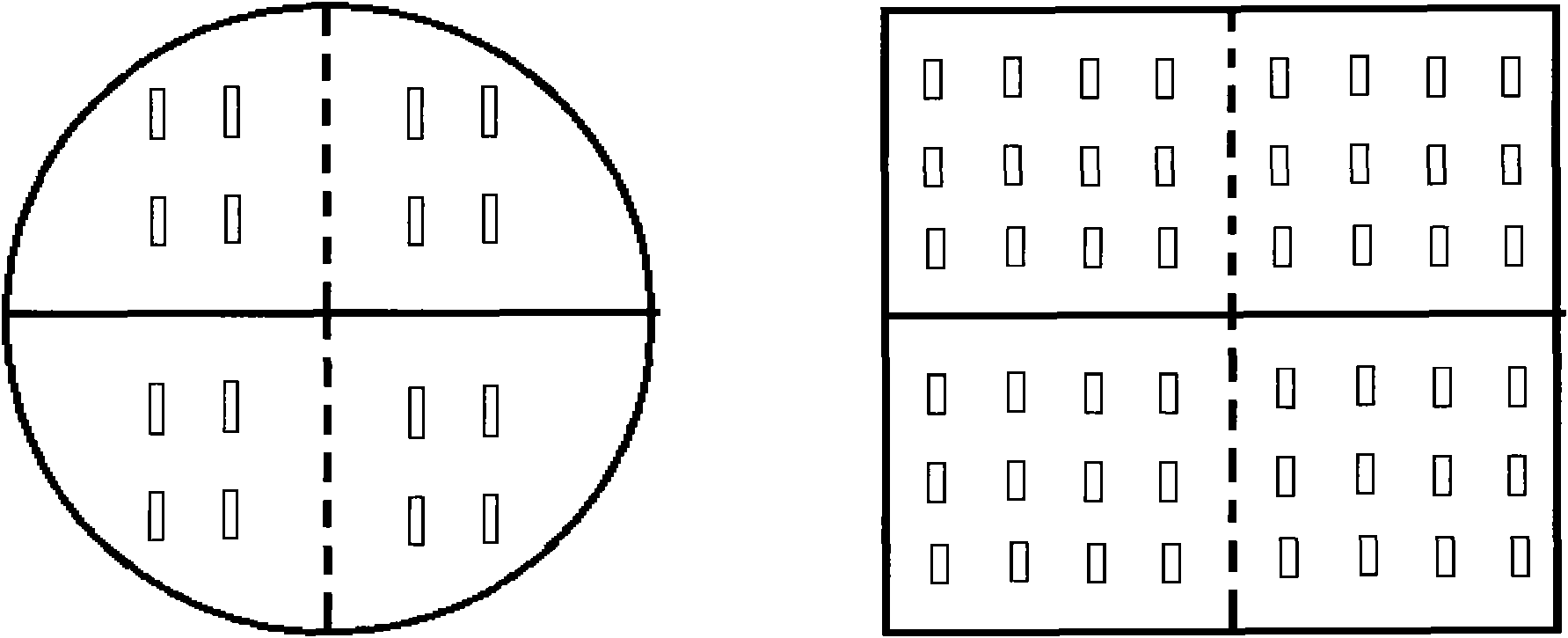

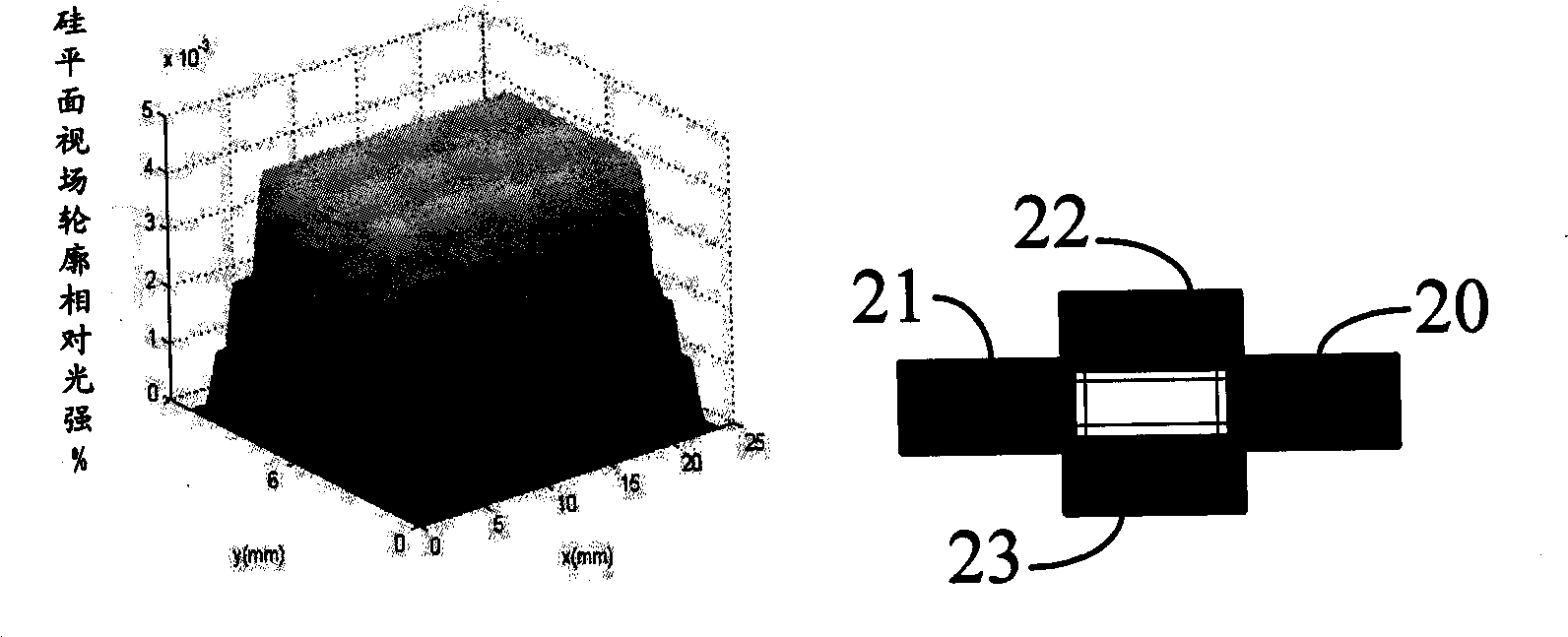

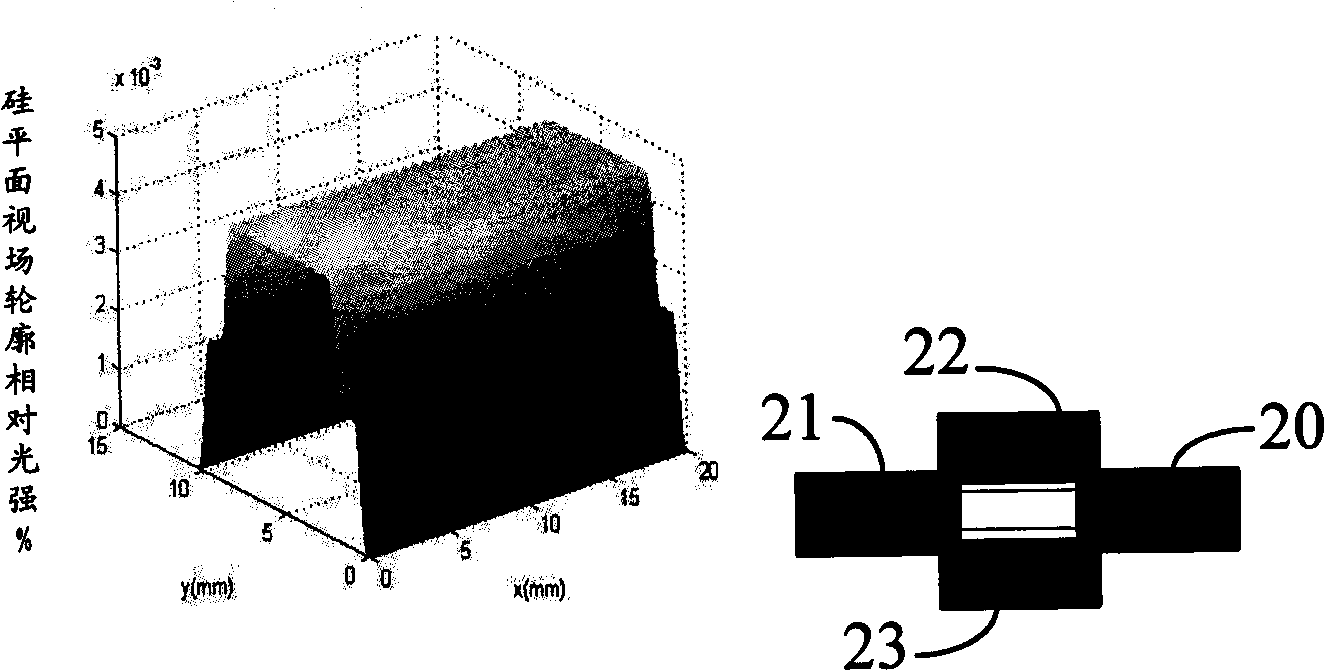

Scanning exposure method for photo-etching machine

ActiveCN101487988AImprove dose uniformityImprove uniformityPhotomechanical exposure apparatusMicrolithography exposure apparatusDose uniformityLine width

The invention provides a scanning and exposure method of a photoetching machine. The method comprises the following steps: two directions which are mutually orthogonal are arranged on a silicon plain of the photoetching machine and the silicon plain is divided into a plurality of exposure field areas, a changeable narrow slit is arranged on the photoetching machine, the changeable narrow slit is provided with cutting lips in the two mutually orthogonal directions, scanning and exposure are carried out on one direction of the exposure field area and then on the other direction of the same exposure field area; when the scanning and exposure are carried out on one direction of the exposure field area, the cutting lips of the changeable narrow slit in the direction are gradually opened to the maximum and then gradually folded to be closed. In the invention, the scanning and exposure are first carried out on one direction of the exposure field area and then on the other direction of the same exposure field area, therefore, dose uniformity of both X direction and Y direction of the exposure field areas are improved, thus improving system performance of exposure dose and uniformity of photoetching line width.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

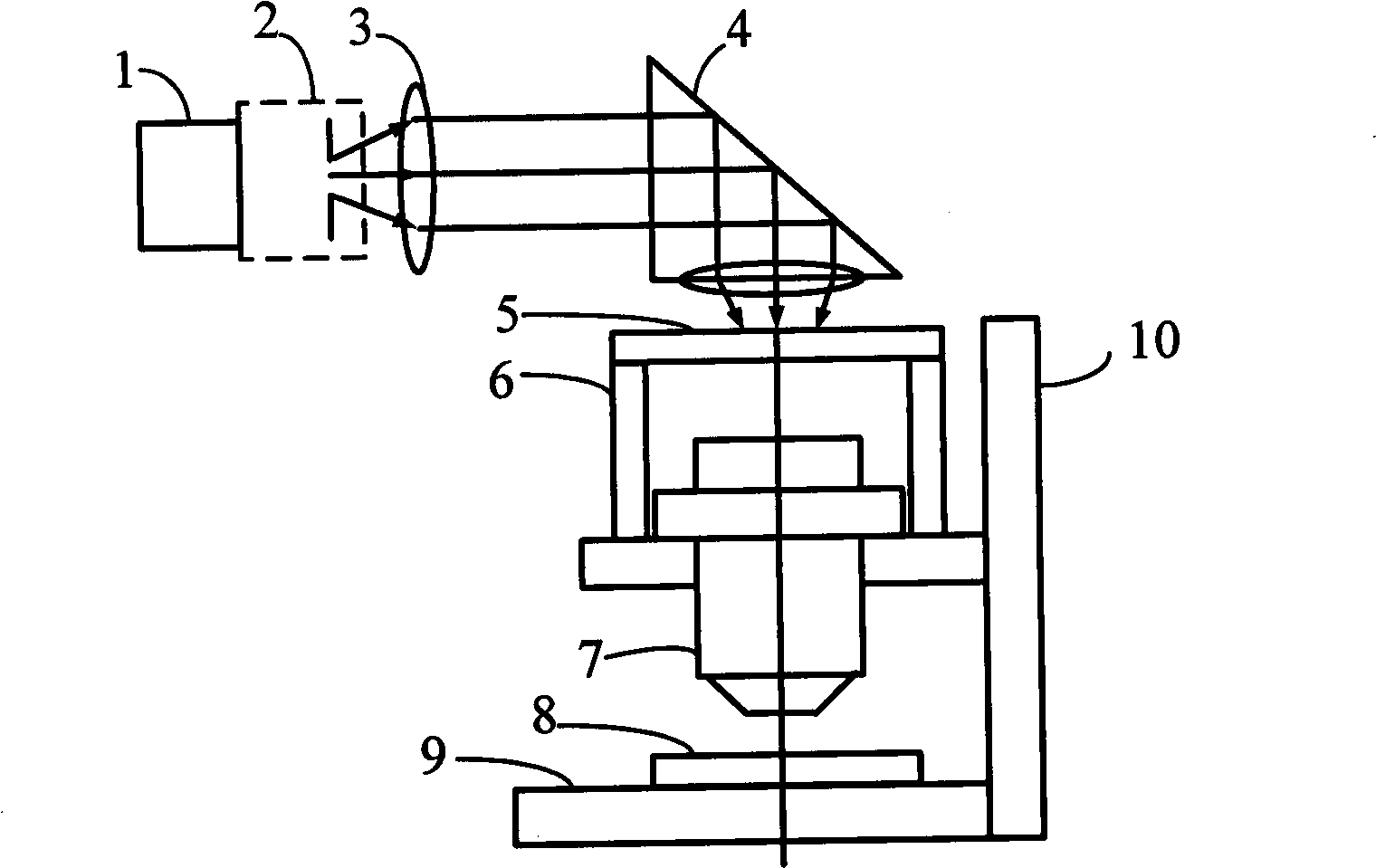

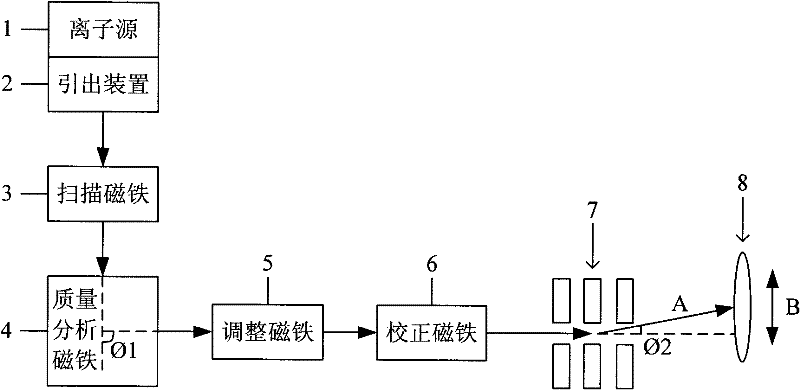

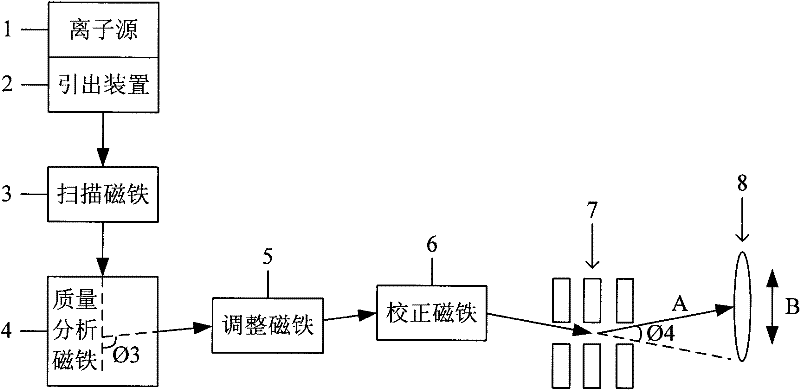

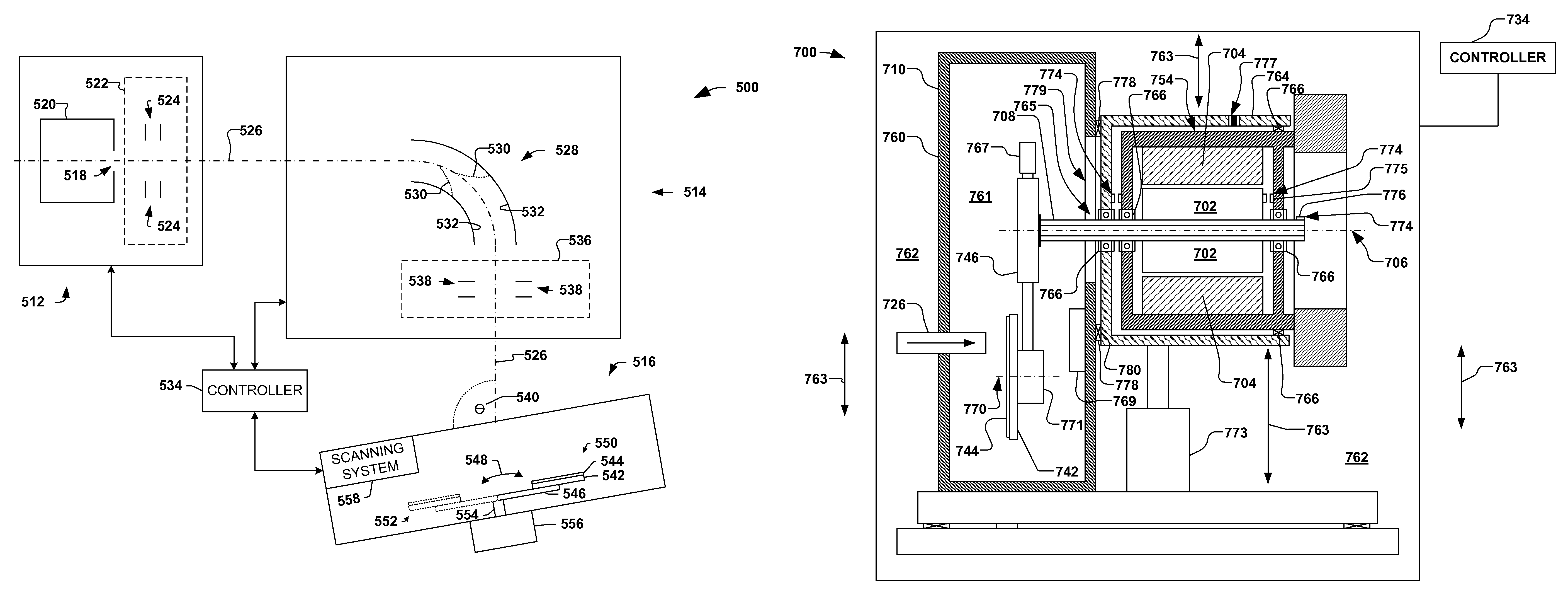

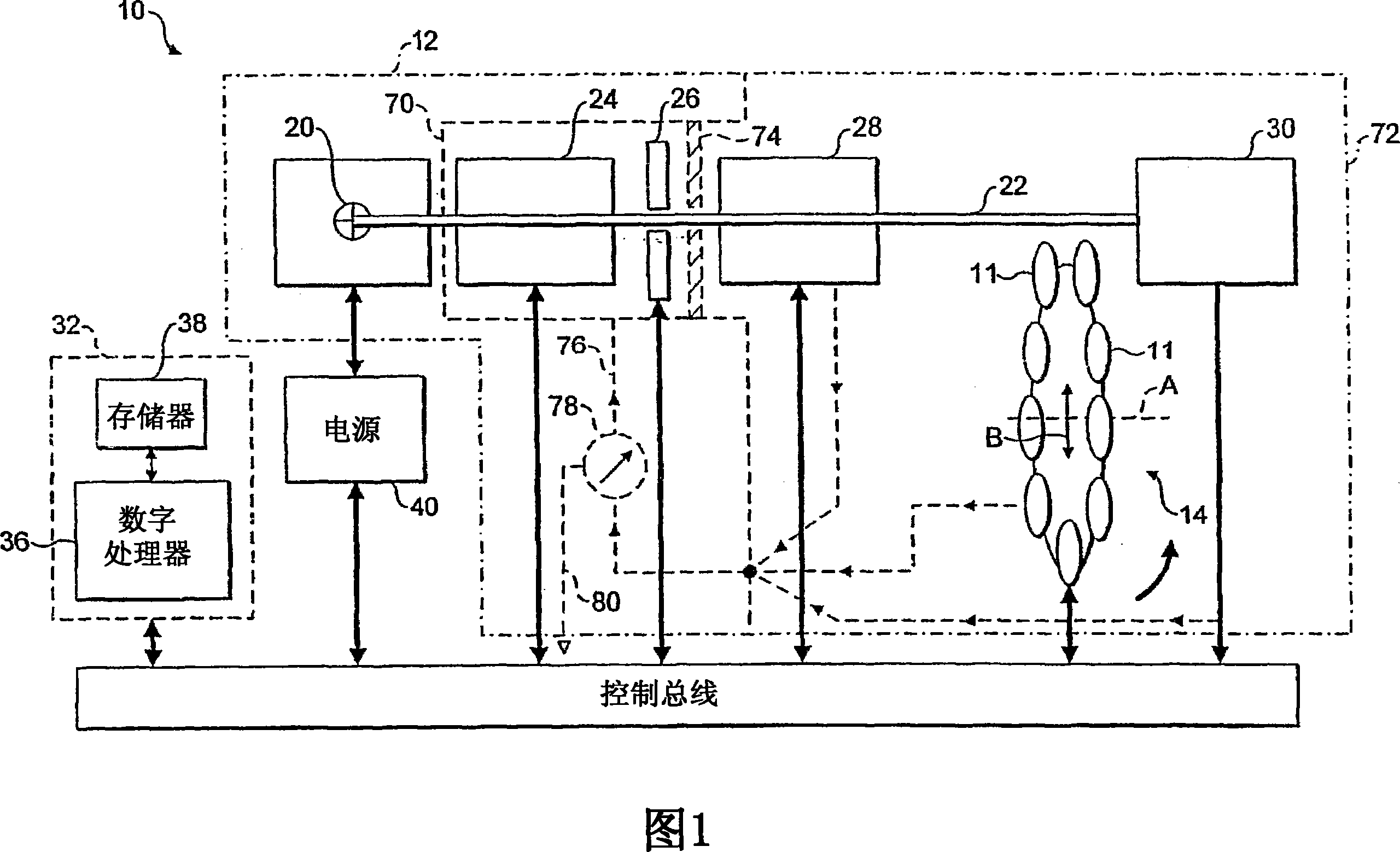

Ion implantation system and method

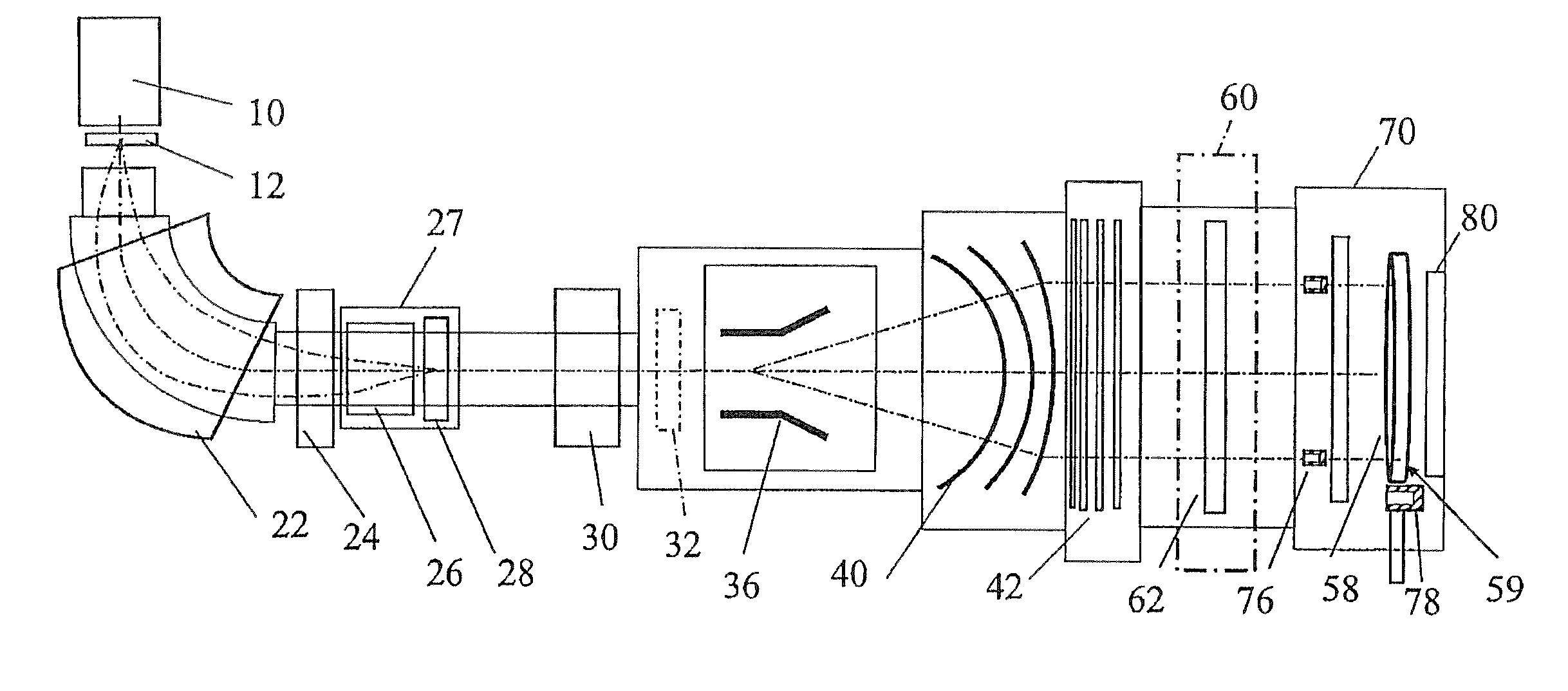

ActiveCN102237243AReduce hysteresisReduce design sizeElectric discharge tubesSemiconductor/solid-state device manufacturingDose uniformityIon beam

The invention discloses an ion implantation system comprising an ion source and a leading-out device, wherein a scanning magnet, a mass analysis magnet, a correcting magnet, a speed changing device and a workpiece scanning device are arranged on a transmission path of an ion beam current in sequence; the system also comprises an adjusting magnet arranged on a beam current transmission path between the mass analysis magnet and the correcting magnet; and the adjusting magnet is used for diverging or gathering beam currents in the scanning direction. The invention also discloses an ion implantation method realized by using the ion implantation system. According to the invention, lower energy consumption and higher beam current utilization efficiency are obtained so that the production efficiency can be largely enhanced; in addition, the ion implantation system and method, disclosed by the invention, are also beneficial for optimizing the dose uniformity and the angle uniformity of the beam currents.

Owner:KINGSTONE SEMICONDUCTOR LIMITED COMPANY

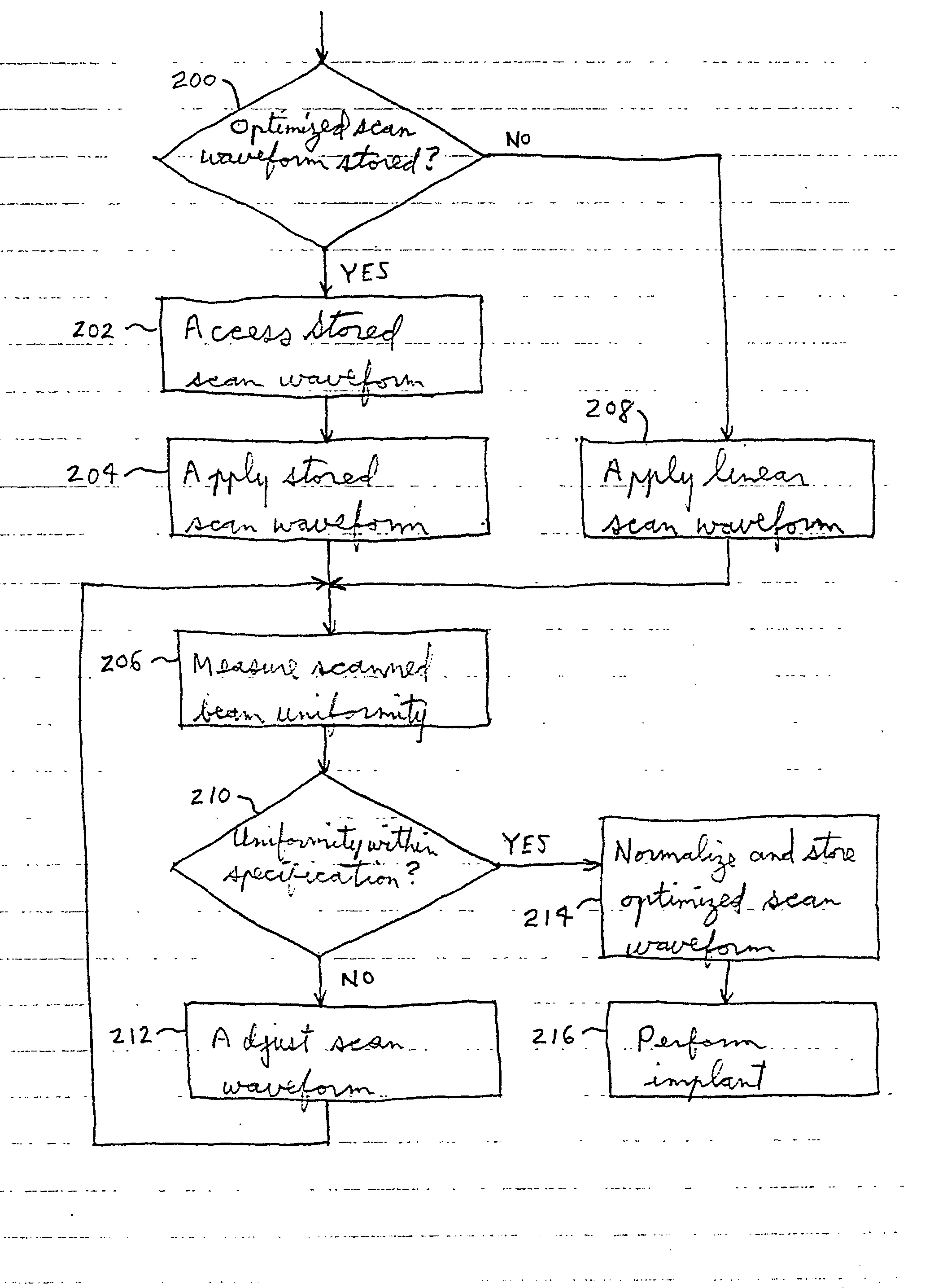

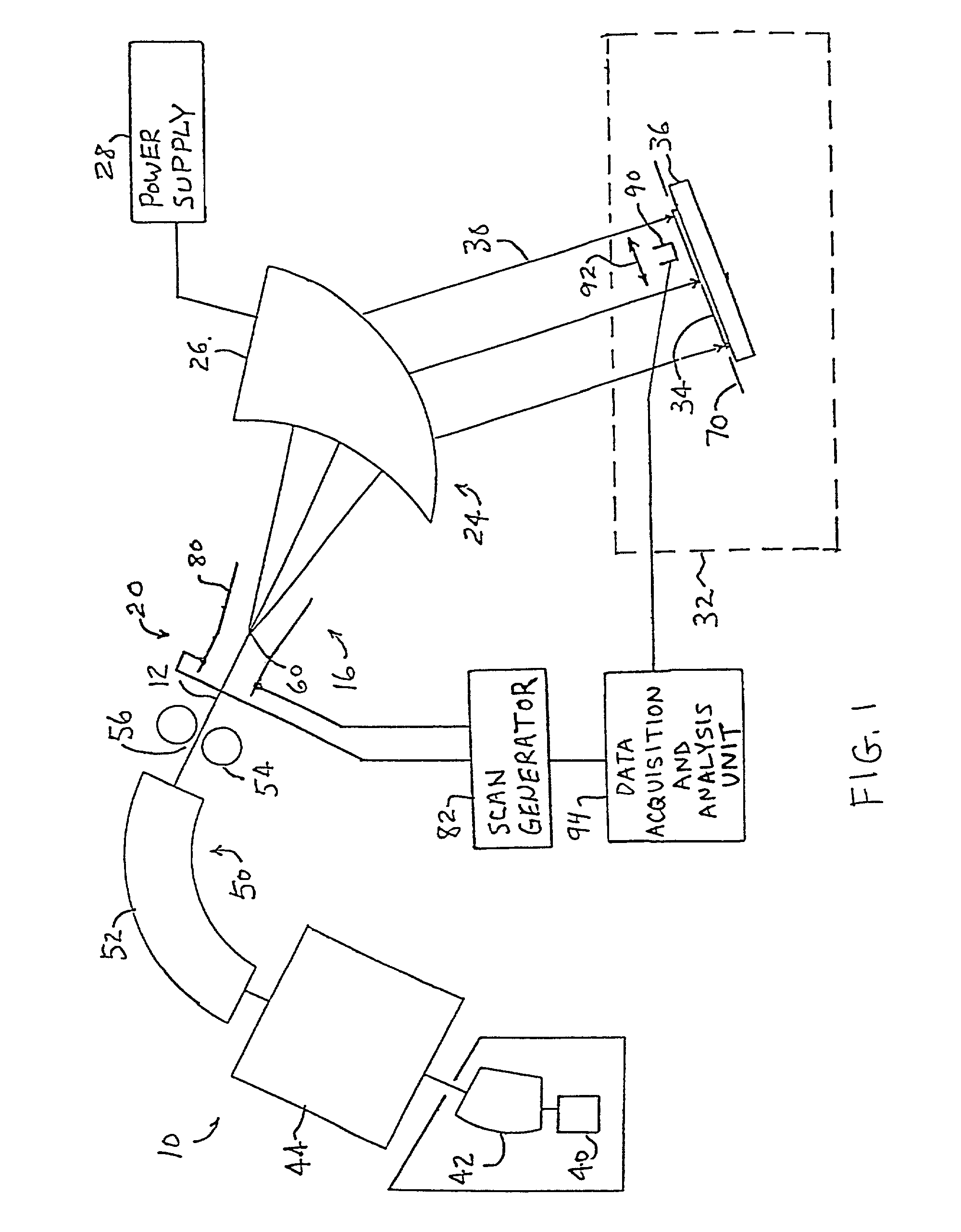

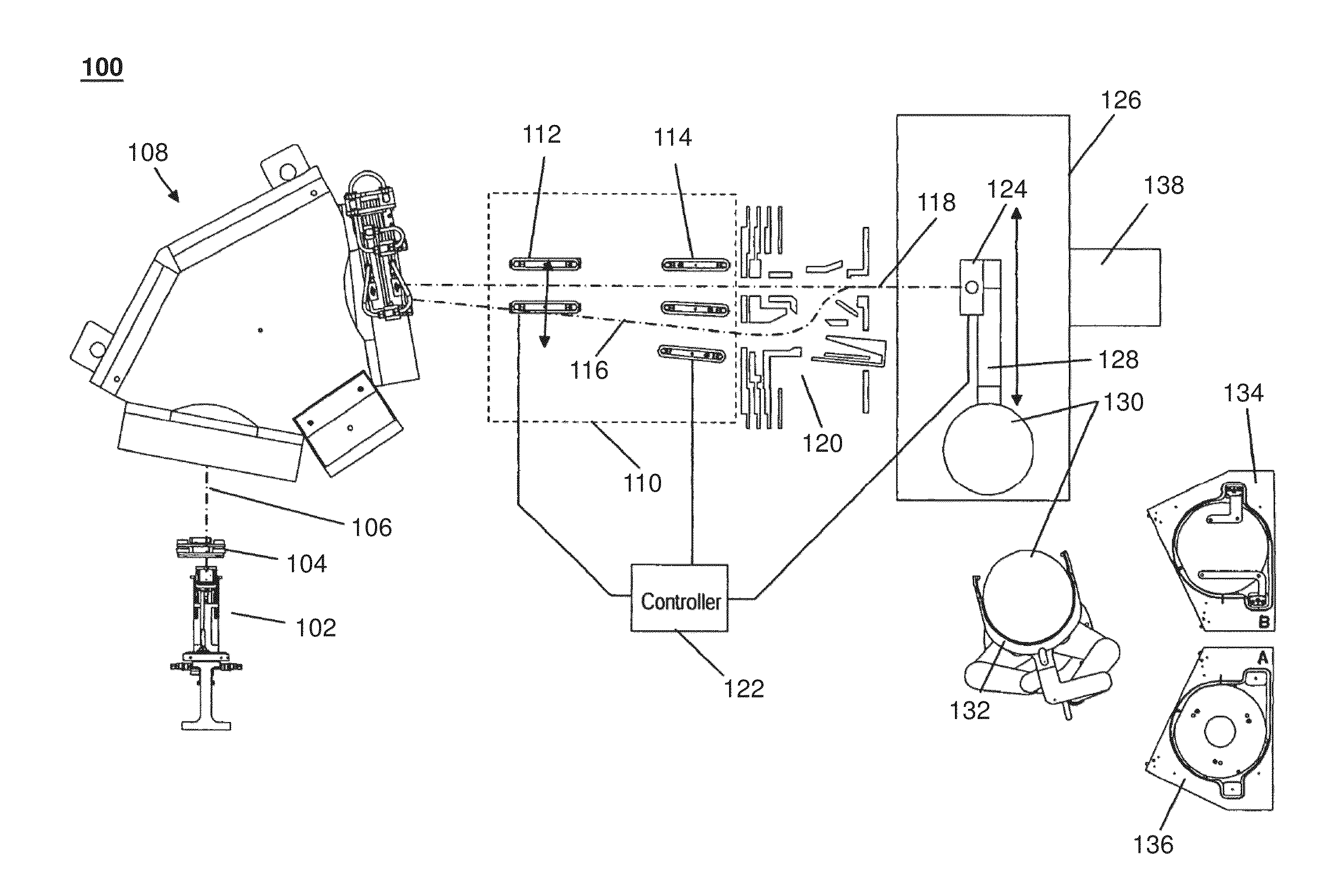

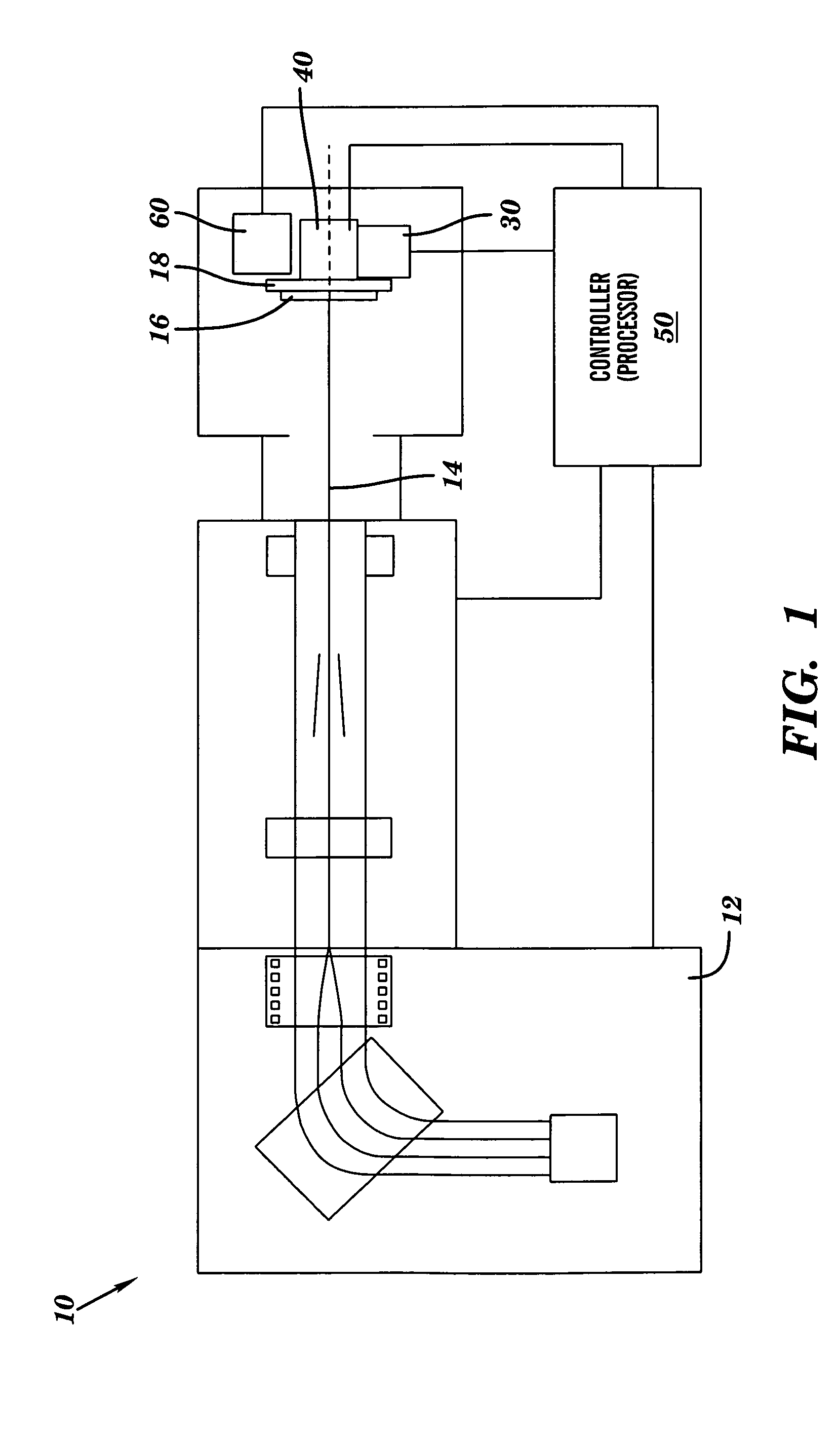

Ion implanter optimizer scan waveform retention and recovery

Methods and apparatus are provided for controlling dose uniformity in an ion implantation system. According to one embodiment of the invention, an initial scan waveform is adjusted to obtain a desired uniformity for use in a first implant process, and the adjusted scan waveform is stored. The stored scan waveform is recalled and used in a second implant process. According to a another embodiment of the invention, desired beam parameters are identified and, based on the desired beam parameters, a stored scan waveform is recalled for use in a uniformity adjustment process, and the uniformity adjustment process is performed. According to a further embodiment of the invention, an apparatus is provided that includes a beam profiler for measuring a current distribution of a scanned ion beam. The apparatus also includes a data acquisition and analysis unit for adjusting an initial scan waveform based on a desired current distribution and the measured current distribution for use in a first implant process, storing the adjusted scan waveform, recalling the stored scan waveform, and using the recalled scan waveform in a second implant process.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Magnetic field fluctuation for beam smoothing

ActiveUS20140212595A1Liquid surface applicatorsElectrode and associated part arrangementsDose uniformityParticle physics

The time-averaged ion beam profile of an ion beam for implanting ions on a work piece may be smoothed to reduce noise, spikes, peaks, and the like and to improve dosage uniformity. Auxiliary magnetic field devices, such as electromagnets, may be located along an ion beam path and may be driven by periodic signals to generate a fluctuating magnetic field to smooth the ion beam profile (i.e., beam current density profile). The auxiliary magnetic field devices may be positioned outside the width and height of the ion beam, and may generate a non-uniform fluctuating magnetic field that may be strongest near the center of the ion beam where the highest concentration of ions may be positioned. The fluctuating magnetic field may cause the beam profile shape to change continuously, thereby averaging out noise over time.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

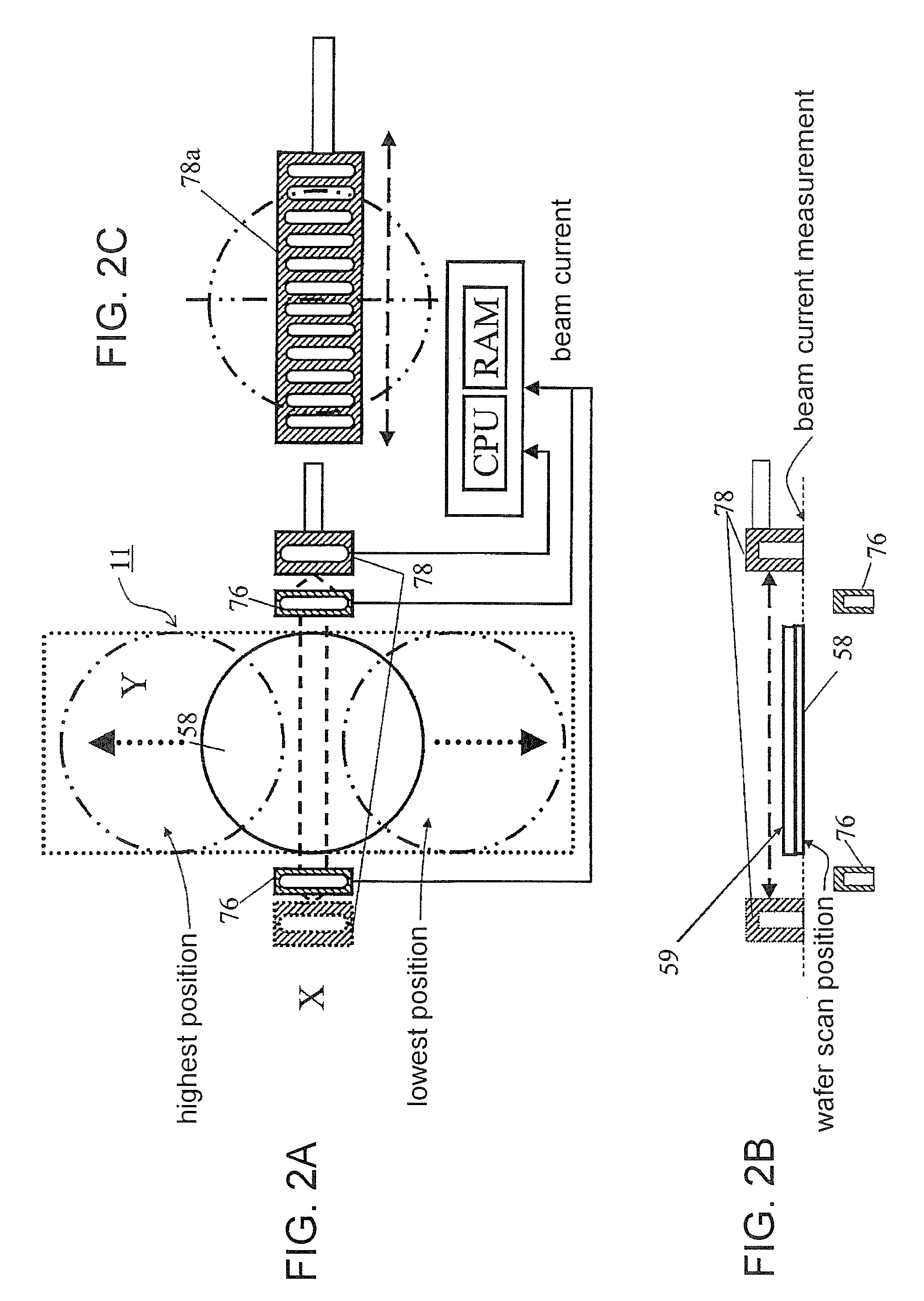

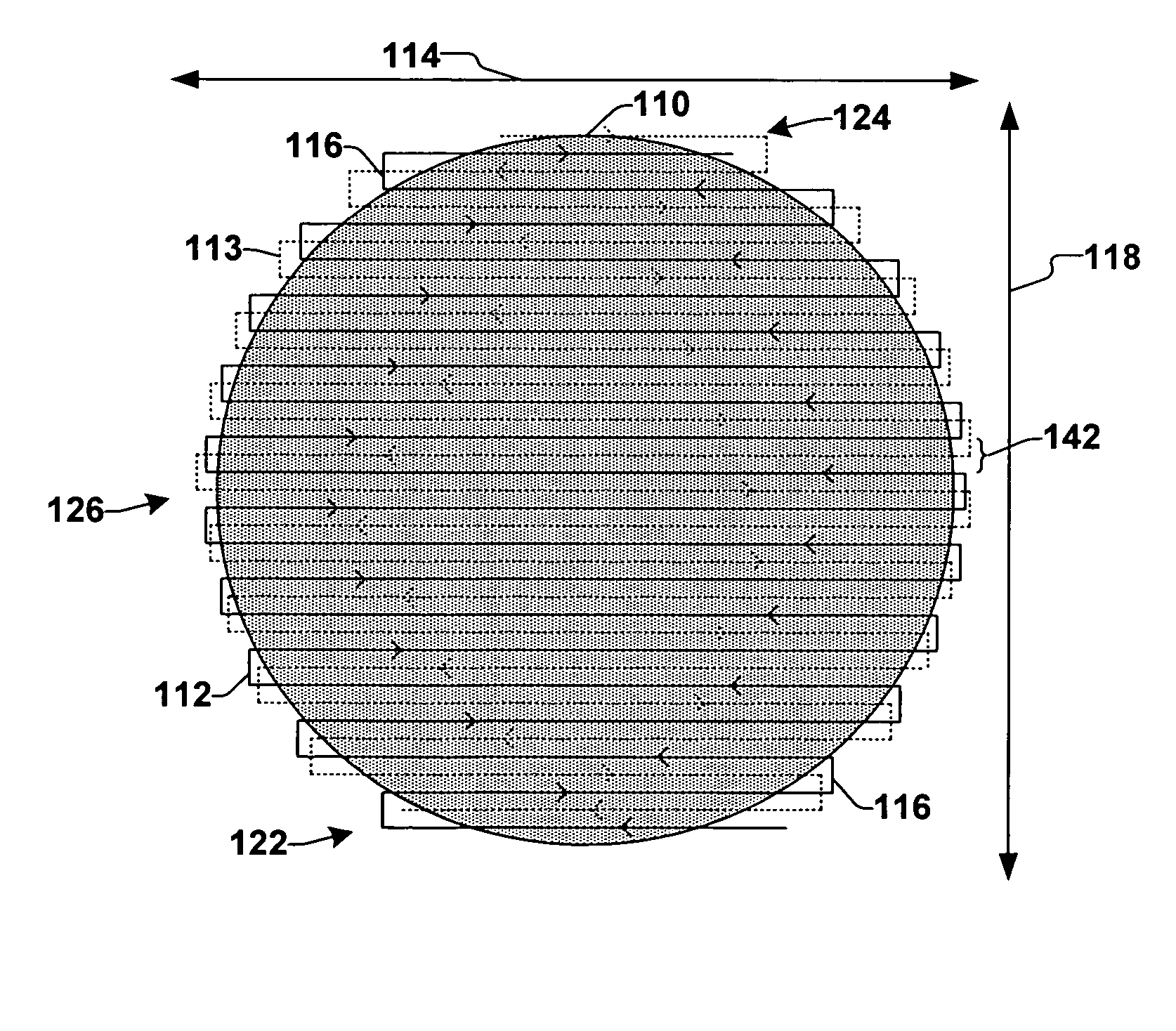

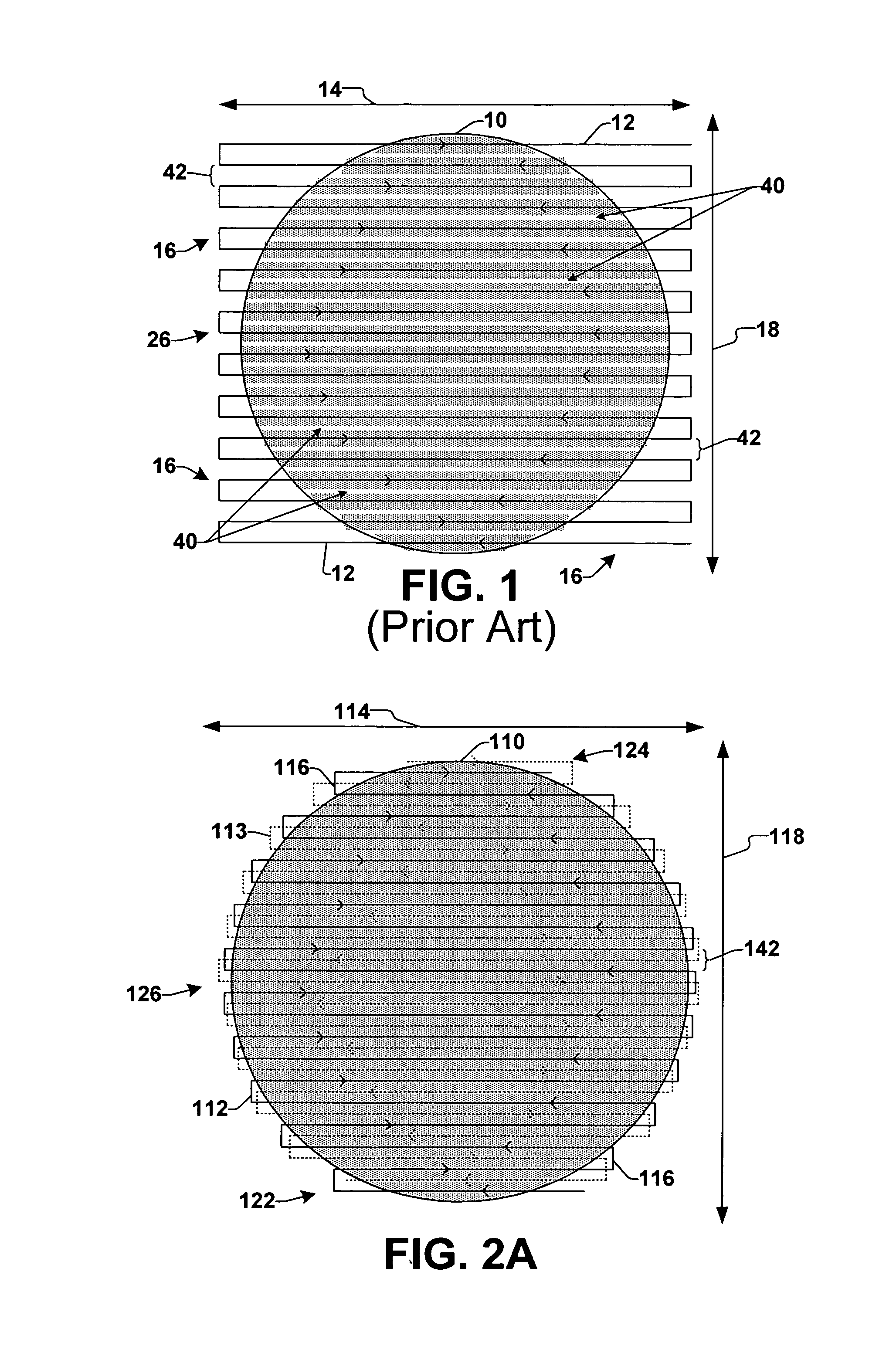

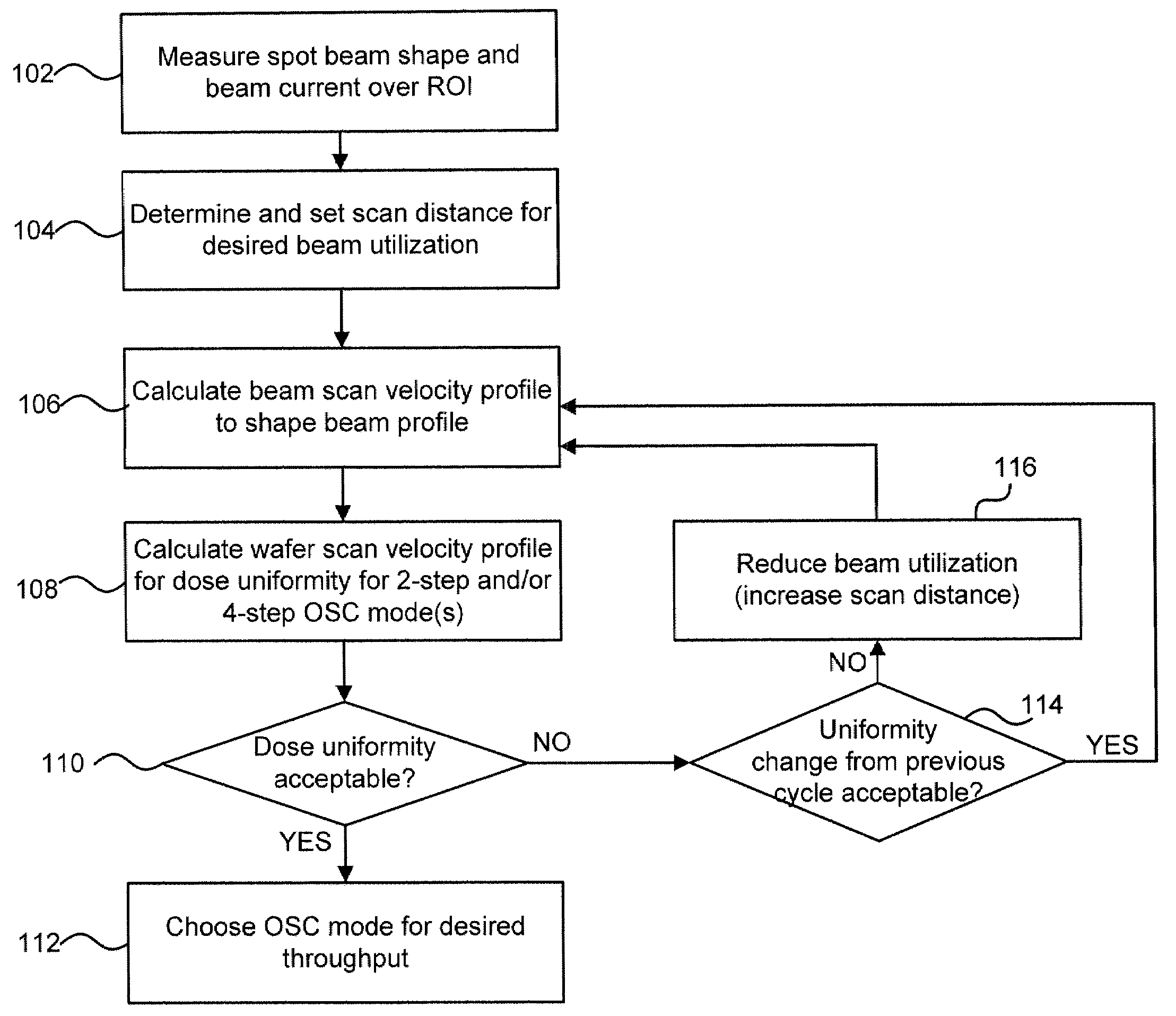

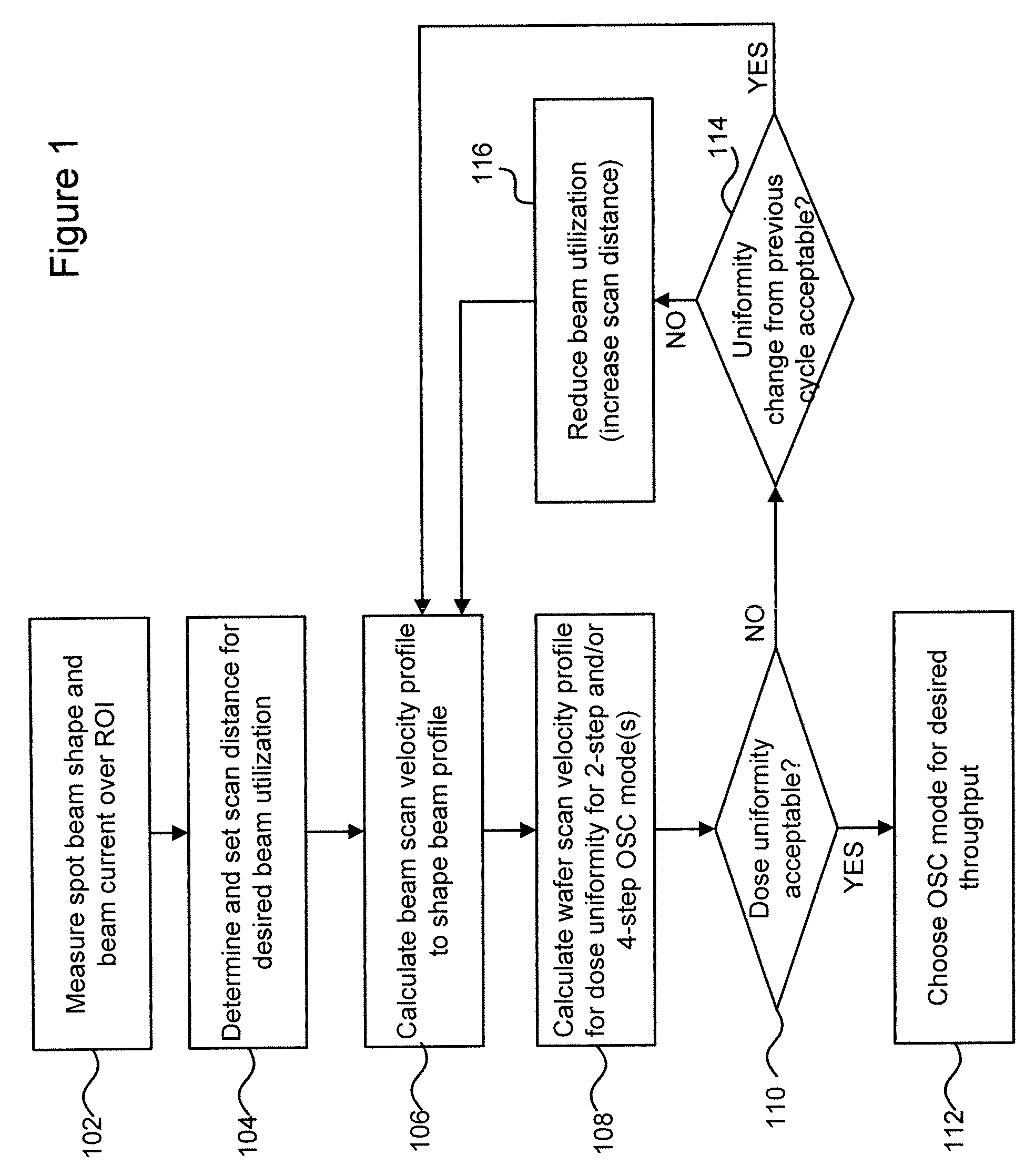

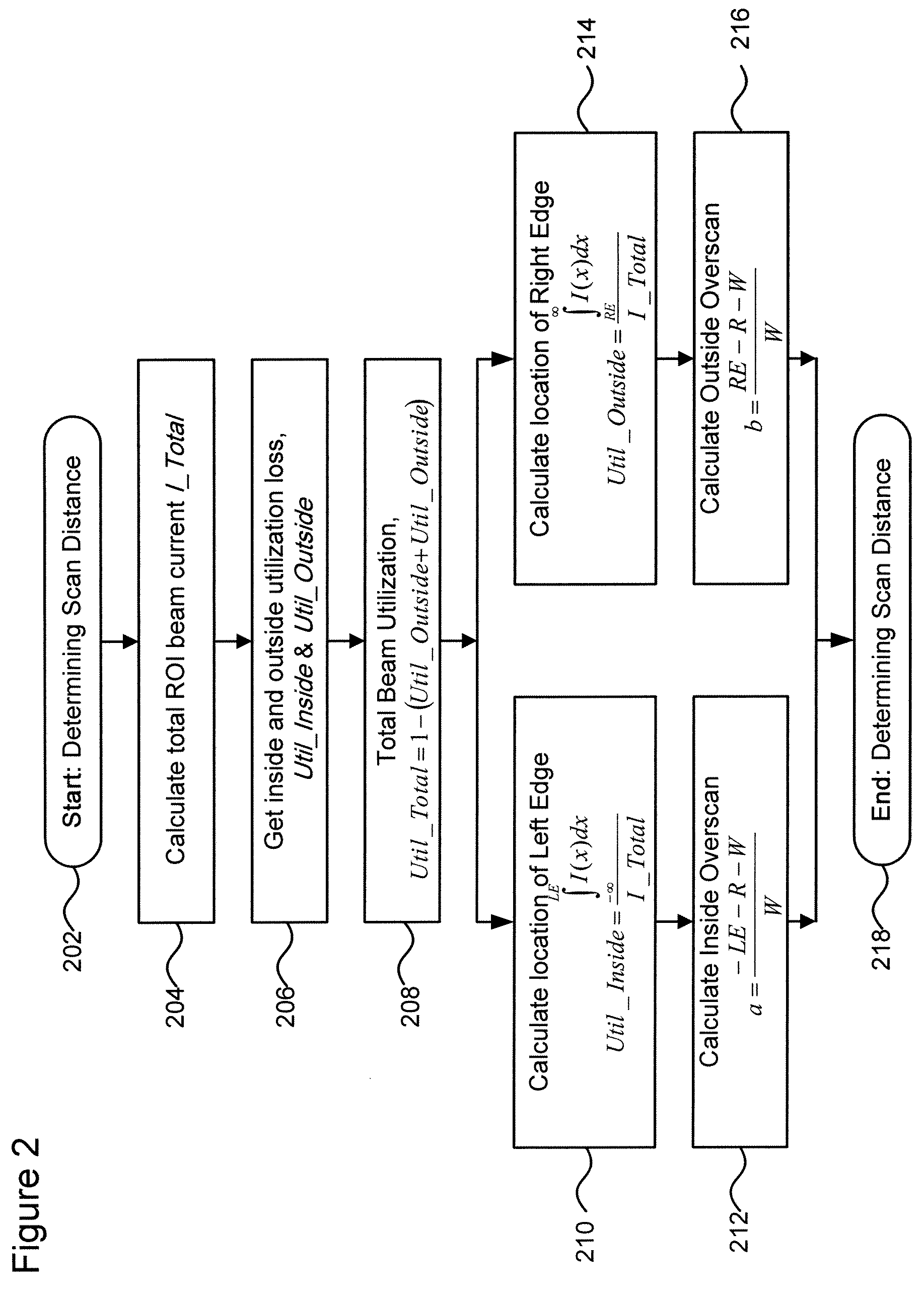

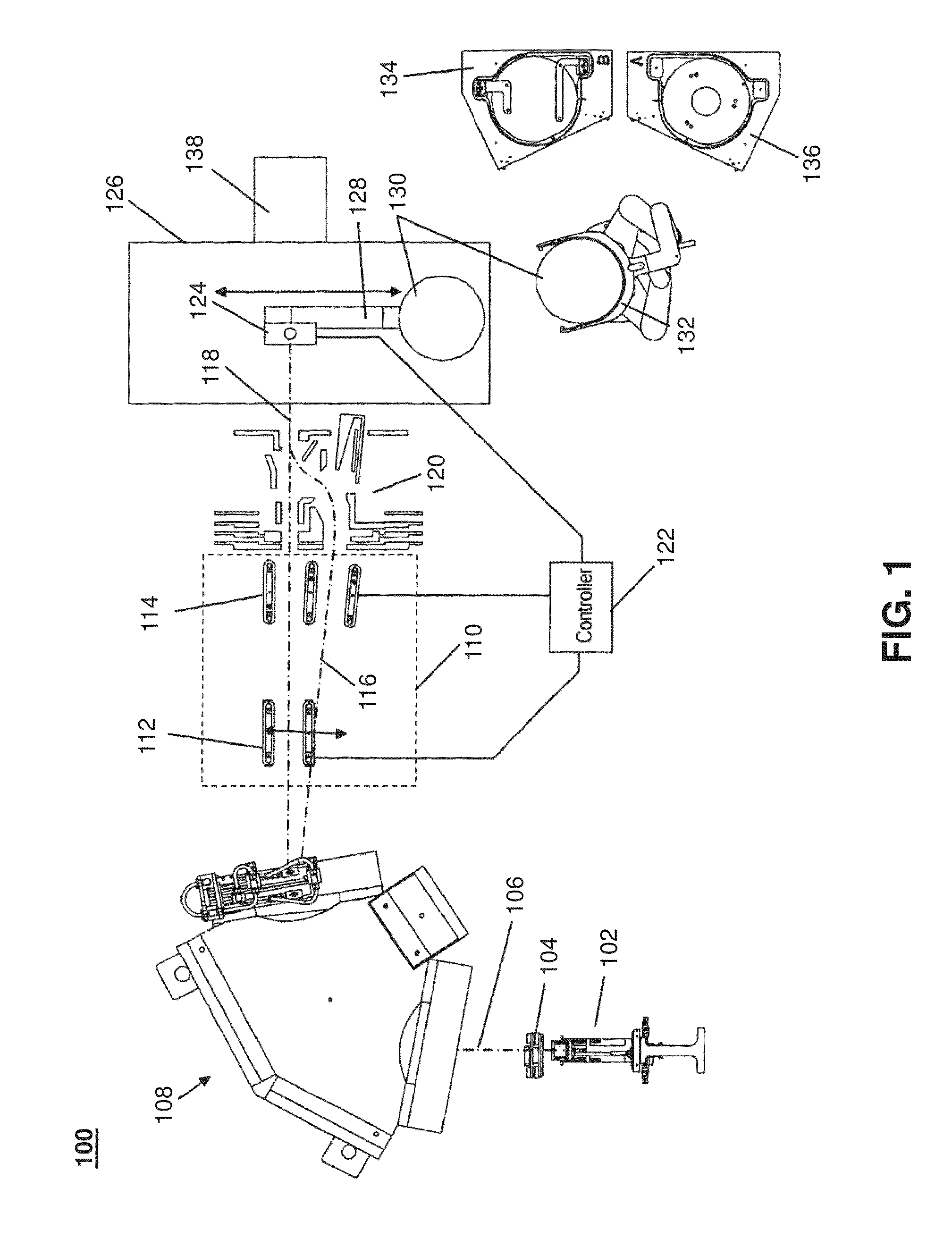

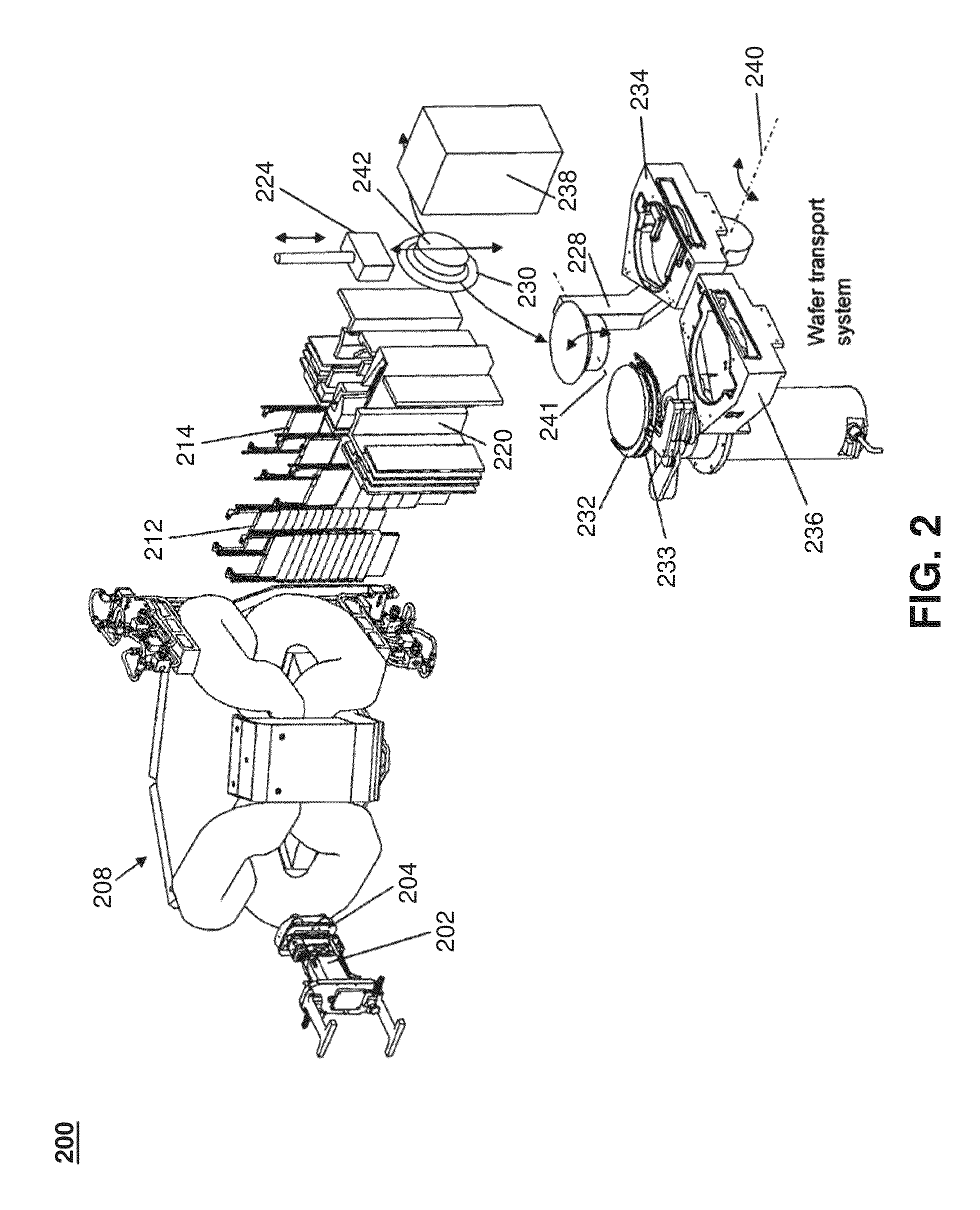

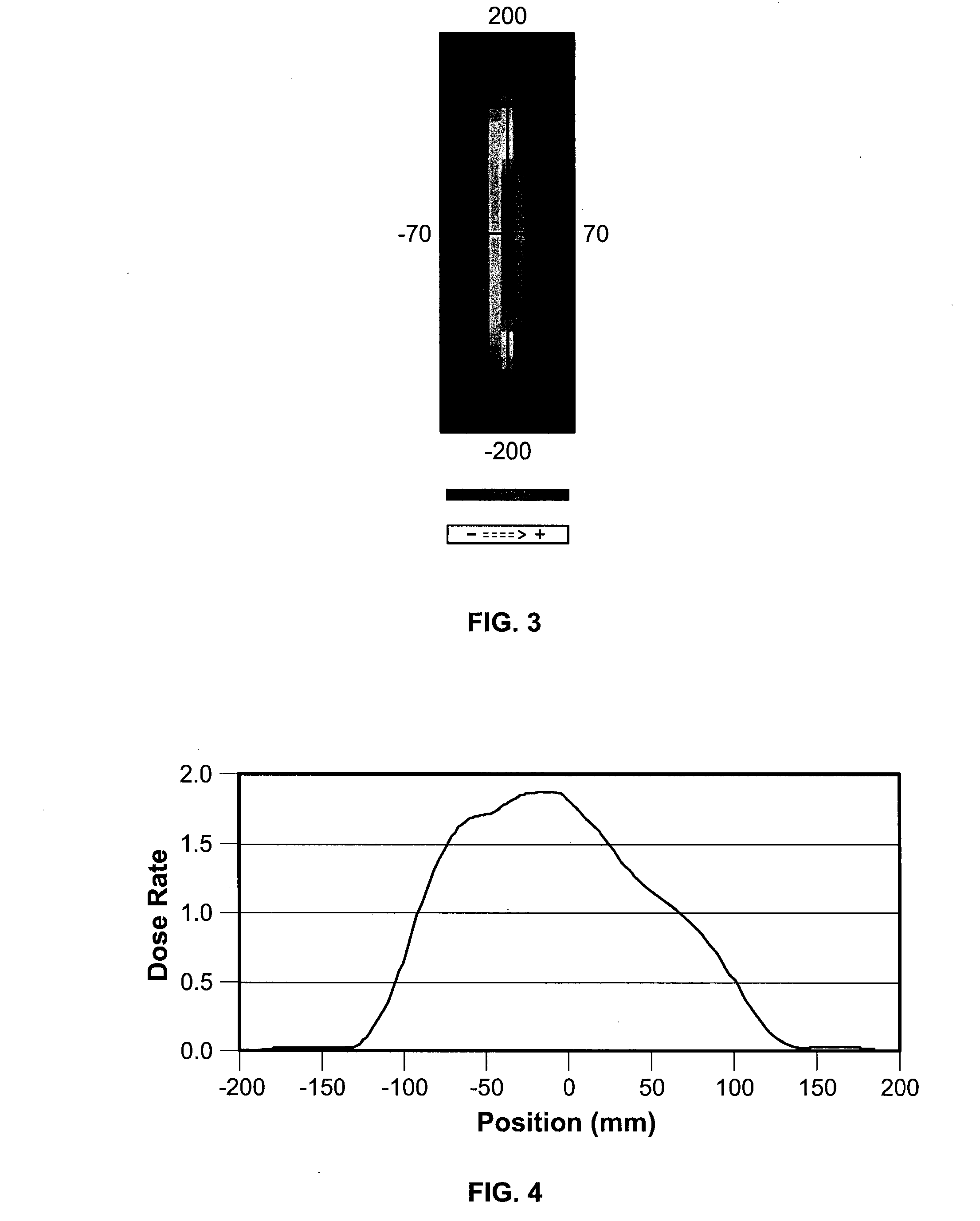

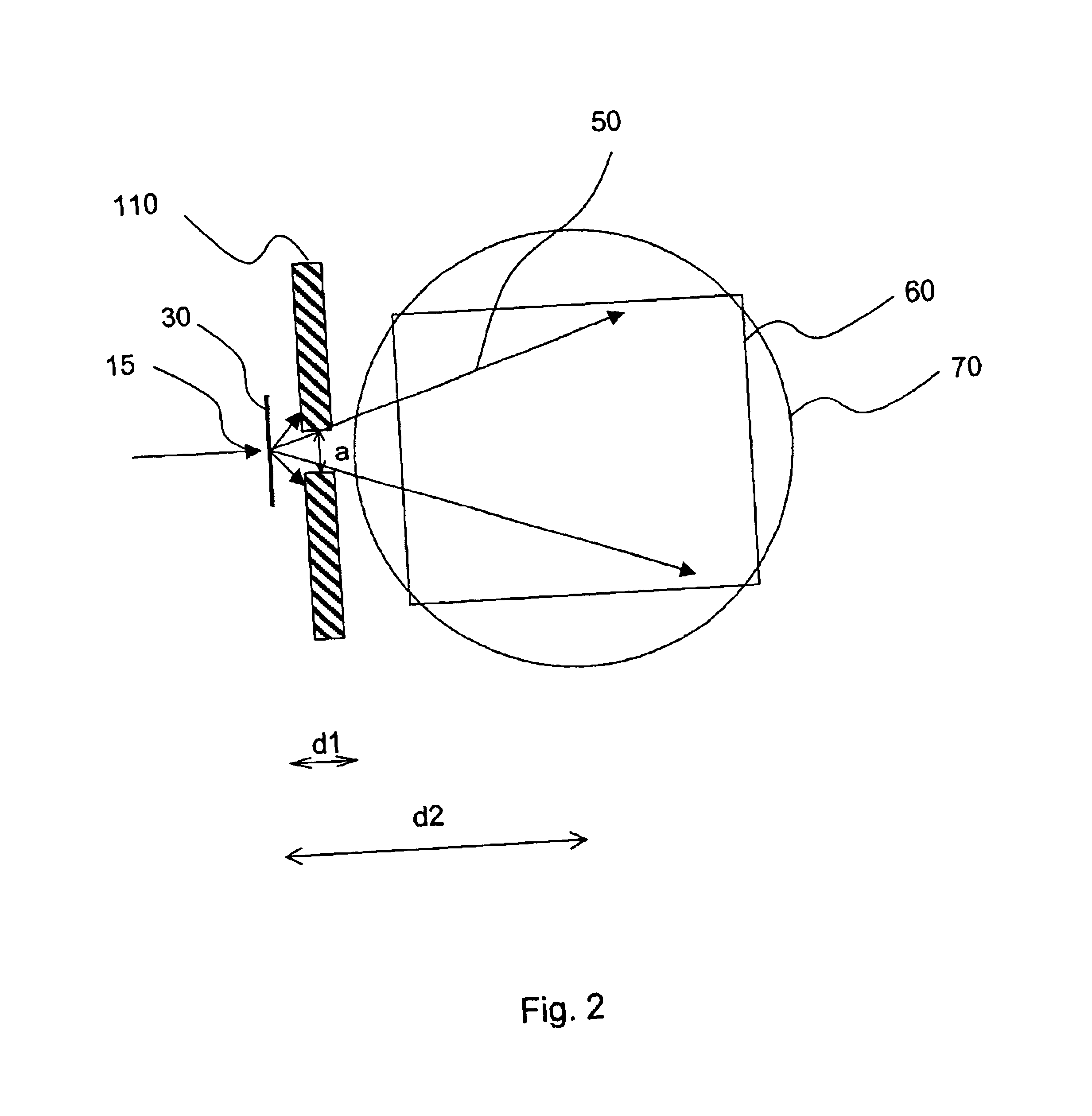

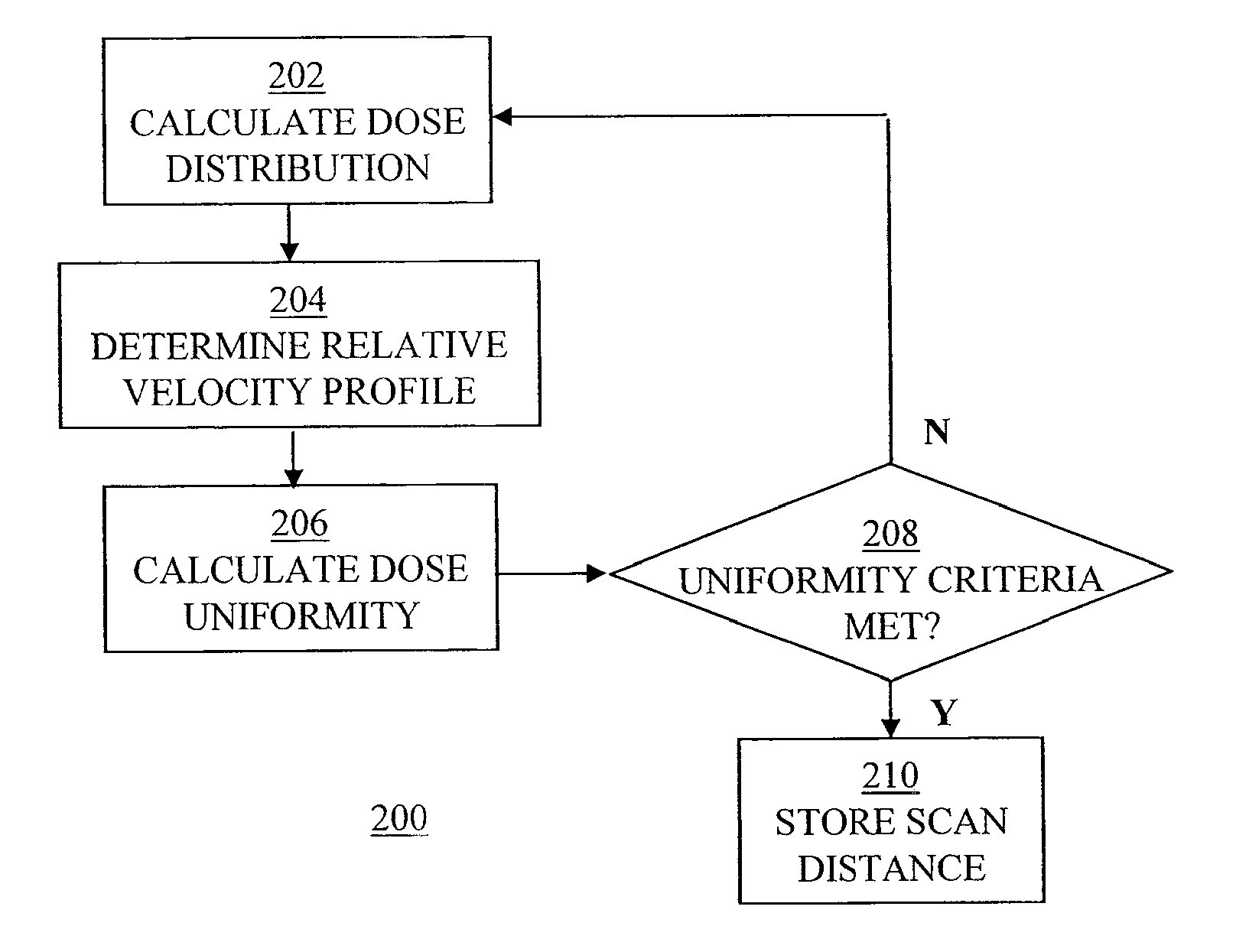

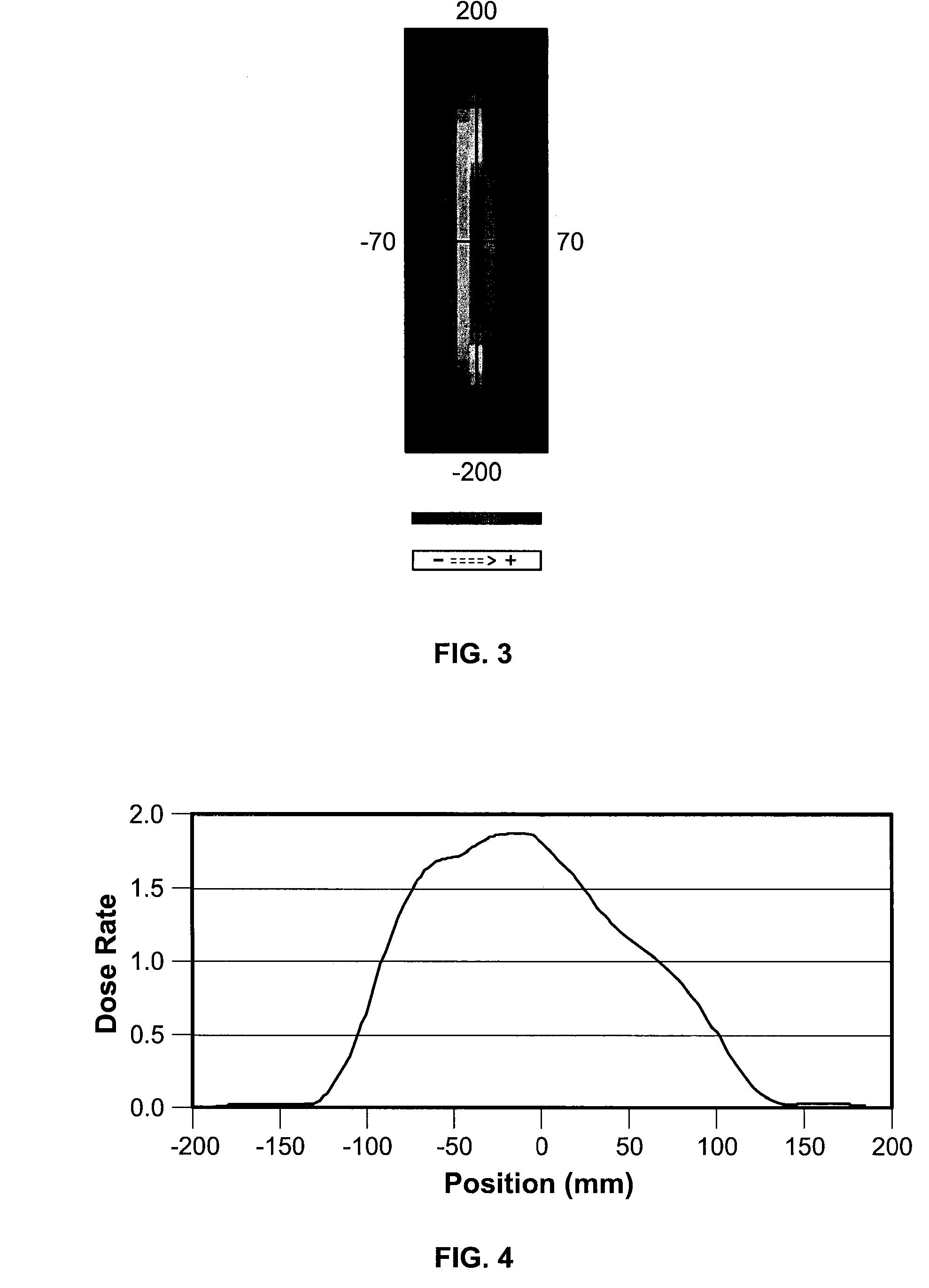

Implant beam utilization in an ion implanter

ActiveUS20090090876A1Electric discharge tubesSemiconductor/solid-state device manufacturingDose uniformityBeam scanning

To select a scan distance to be used in scanning a wafer with an implant beam, a dose distribution along a first direction is calculated based on size or intensity of the implant beam and a scan distance. The scan distance is the distance measured in the first direction between a first path and a final path of the implant beam scanning the wafer along a second direction in multiple paths. A relative velocity profile along the second direction is determined based on the dose distribution. Dose uniformity on the wafer is calculated based on the wafer being scanned using the relative velocity profile and the determined dose distribution. The scan distance is adjusted and the preceding steps are repeated until the calculated dose uniformity meets one or more uniformity criteria.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

Apparatus and method for electron beam irradiation having improved dose uniformity ratio

InactiveUS20050098740A1Distance minimizationPackage sterilisationRadiation therapyDose uniformityLight beam

The present invention is related to an apparatus and method for irradiating a product package, comprising a radiation source directing a radiation beam along a beam direction towards said product package, conveying means for transporting said product package past said radiation source along a transport path, and reflecting means located on at least one side of the plane formed by said beam direction and said transport path. By adjusting the distance and angle of the reflecting means to the conveyor and beam, and improved dose uniformity ratio is obtained.

Owner:ION BEAM APPL

Dose uniformity correction technique

InactiveUS20080067438A1Facilitate uniform ion implantationUniform ion implantationElectric discharge tubesSemiconductor/solid-state device manufacturingDose uniformityCorrection technique

Non uniform ion implantations in a pendulum type of ion implantation are mitigated by adjusting movement of a wafer according to a corresponding non uniform function. More particularly, a non uniform ion implantation function is obtained by measuring and / or modeling ion implantations. Then, movement of a wafer along a second non arcuate scan path is adjusted according to the non uniform ion implantation function to facilitate uniform ion implantations.

Owner:AXCELIS TECHNOLOGIES

Dose uniformity during scanned ion implantation

InactiveCN101124649AElectric discharge tubesSemiconductor/solid-state device manufacturingDose uniformityBiomedical engineering

Owner:AXCELIS TECHNOLOGIES

Method and apparatus for X-ray irradiation having improved throughput and dose uniformity ratio

InactiveUS6940944B2Maximize throughputLess complex to maintainPackage sterilisationIrradiation devicesDose uniformityX-ray

The present invention is related to a method and apparatus of radiation processing of a product package in a device having a radiation source, a collimator having a variable aperture, and a turntable, said radiation processing resulting in a point in the product package where the dose is minimal (Dmin point) and a point in said product package where the dose is maximal (Dmax point) comprising the steps of:determining a first value of the collimator aperture, by increasing said aperture from a small value, where the Dmax point is located near the centre of the product package, up to a value where the Dmax point moves near to the centre of a small side of said package's rectangular horizontal cross-section;determining a second value of the collimator aperture, by further increasing the collimator aperture up to a point where the Dmin point moves from a point near the corner of the product package to the centre of said package;processing said package with radiation, the collimator aperture being kept at a constant value comprised between said first and said second value, the turntable being rotated at a variable speed.

Owner:ION BEAM APPL

Uniformity control using multiple fixed wafer orientations and variable scan velocity

ActiveUS7161161B2Thermometer detailsBeam/ray focussing/reflecting arrangementsDose uniformityIon beam

A system, method and program product for enhancing dose uniformity during ion implantation are disclosed. The present invention is directed to allowing the use of an at least partially un-tuned ion beam to obtain a uniform implant by scanning the beam in multiple rotationally-fixed orientations (scan directions) of the target at variable or non-uniform scan velocities. The non-uniform scan velocities are dictated by a scan velocity profile that is generated based on the ion beam profile and / or the scan direction. The beam can be of any size, shape or tuning. A platen holding a wafer is rotated to a new desired rotationally-fixed orientation after a scan, and a subsequent scan occurs at the same scan velocity profile or a different scan velocity profile. This technique may be used independently or in conjunction with other uniformity approaches to achieve the required level of uniformity.

Owner:VARIAN SEMICON EQUIP ASSOC INC

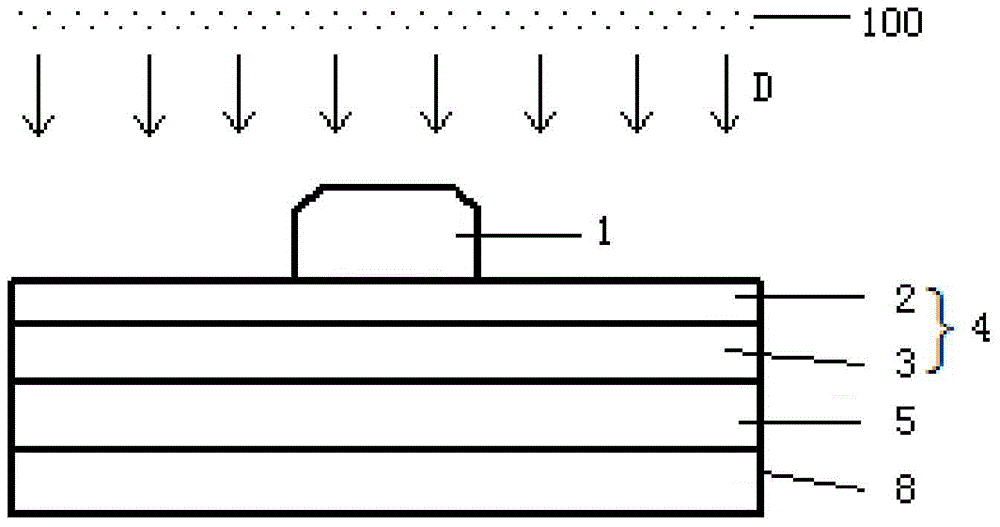

Manufacturing method for low temperature polycrystalline silicon thin film transistors

InactiveCN105097544ASolve the problem of production capacityIncrease production capacitySemiconductor/solid-state device manufacturingElectricityInsulation layer

The present invention provides a manufacturing method for low temperature polycrystalline silicon thin film transistors, and the method is characterized by including the following steps: a polycrystalline silicon layer, a gate insulation layer and a gate metal layer are formed on a substrate in sequence; one part of the gate metal layer is removed so as to expose one part of the gate insulating layer; and doping ions penetrate the exposed part of the gate insulation layer by the adoption of an ion-injection method. According to the invention, a metal layer is etched only but a silicon nitride and silicon oxide layer is not etched, a dose uniformity of the doping ion injecting is increased, and therefore, an electricity uniformity of the low temperature polycrystalline silicon thin film transistors is improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

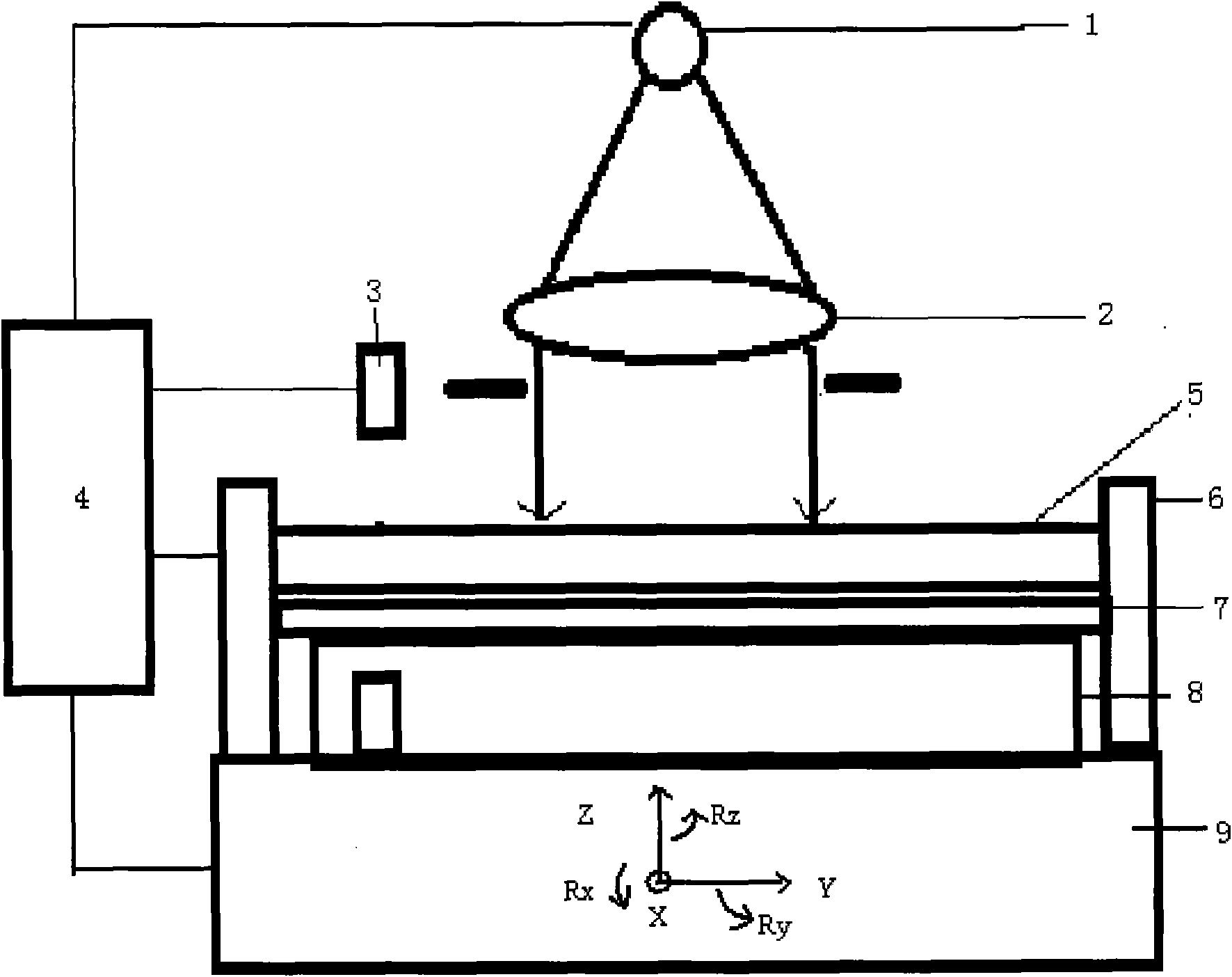

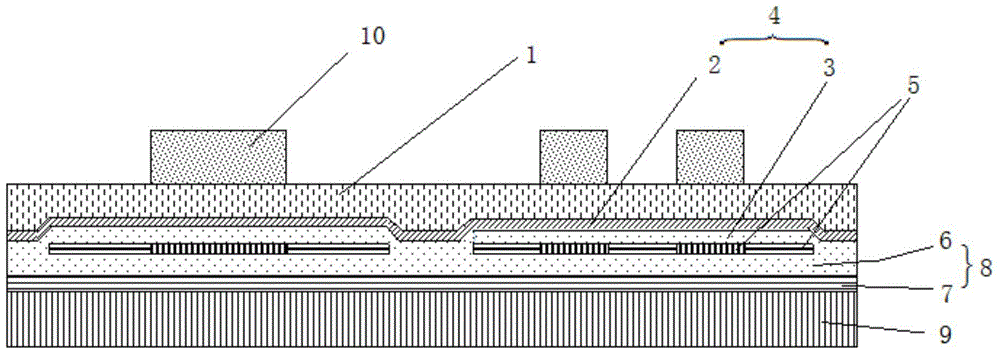

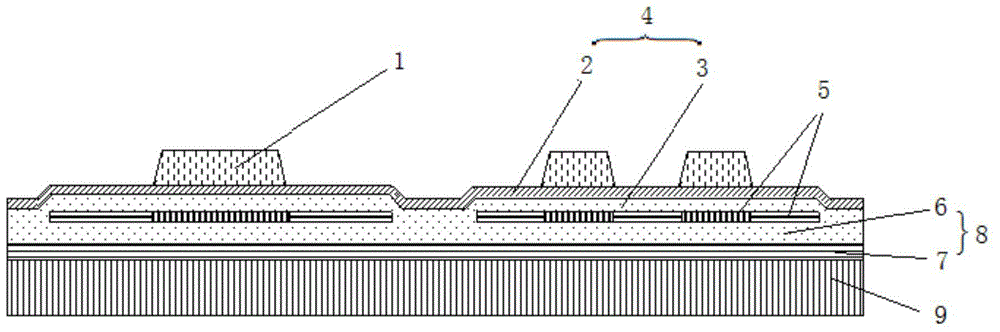

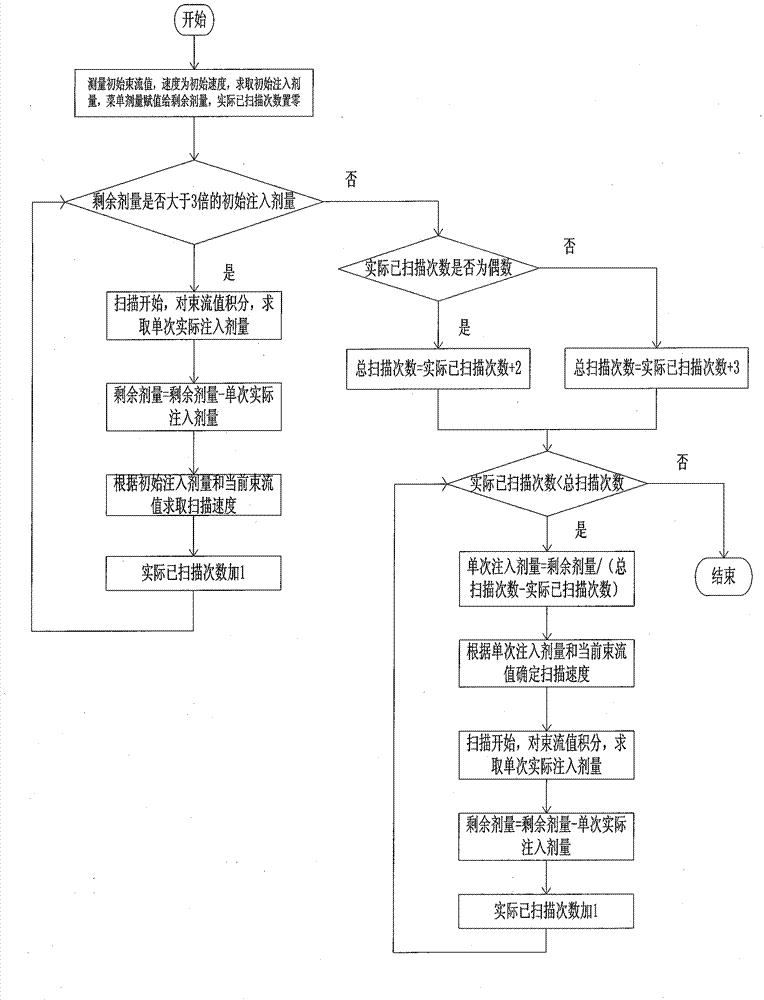

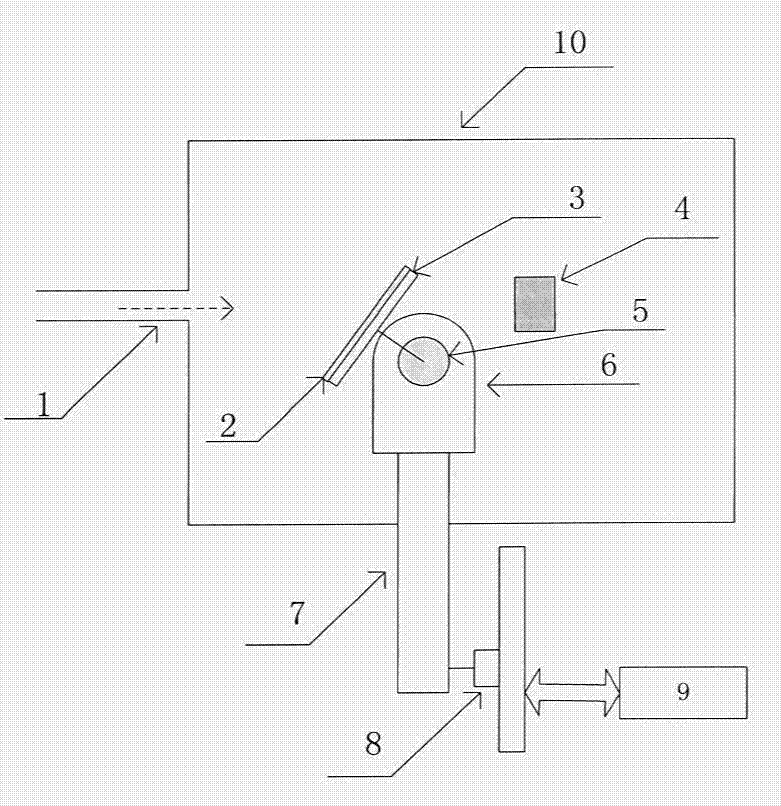

Method for controlling wafer ion implantation dosage

ActiveCN103779163APass through at a constant speedElectric discharge tubesAir bearingDose uniformity

The invention discloses a method for controlling the wafer ion implantation dosage. The hardware comprises an ion beam (1), a wafer (2), a target disk (3), a closed-loop Faraday cup (4), an X-Tilt motor (5), a target platform (6), a linear motor (8), a PMAC controller (9), and a vacuum target chamber (10). In order to reduce particle impurities, process of ion implantation is carried out in the vacuum target chamber. The beam is generated by an ion source, and the processed ion beam (1) should meet requirements in uniformity and parallelism in order to arrive at the target chamber. According to process requirements, an included angle is reserved between the wafer (2) and the vertical direction. The linear motor (8) drives an air bearing to move up and down, and the wafer is ensured to move at constant speed when passing through a beam area. The implantation dosage at a single time and the total number N of scanning times are coordinated, and the N is an even number. According to the method, the scanning speed and the total number of scanning times of the motor are controlled through controlling the implantation dosage at a single time, thereby realizing purposes of being accurate in implantation dosage and improving the dosage uniformity.

Owner:BEIJING SHUOKE ZHONGKEXIN ELECTRONICS EQUIP CO LTD

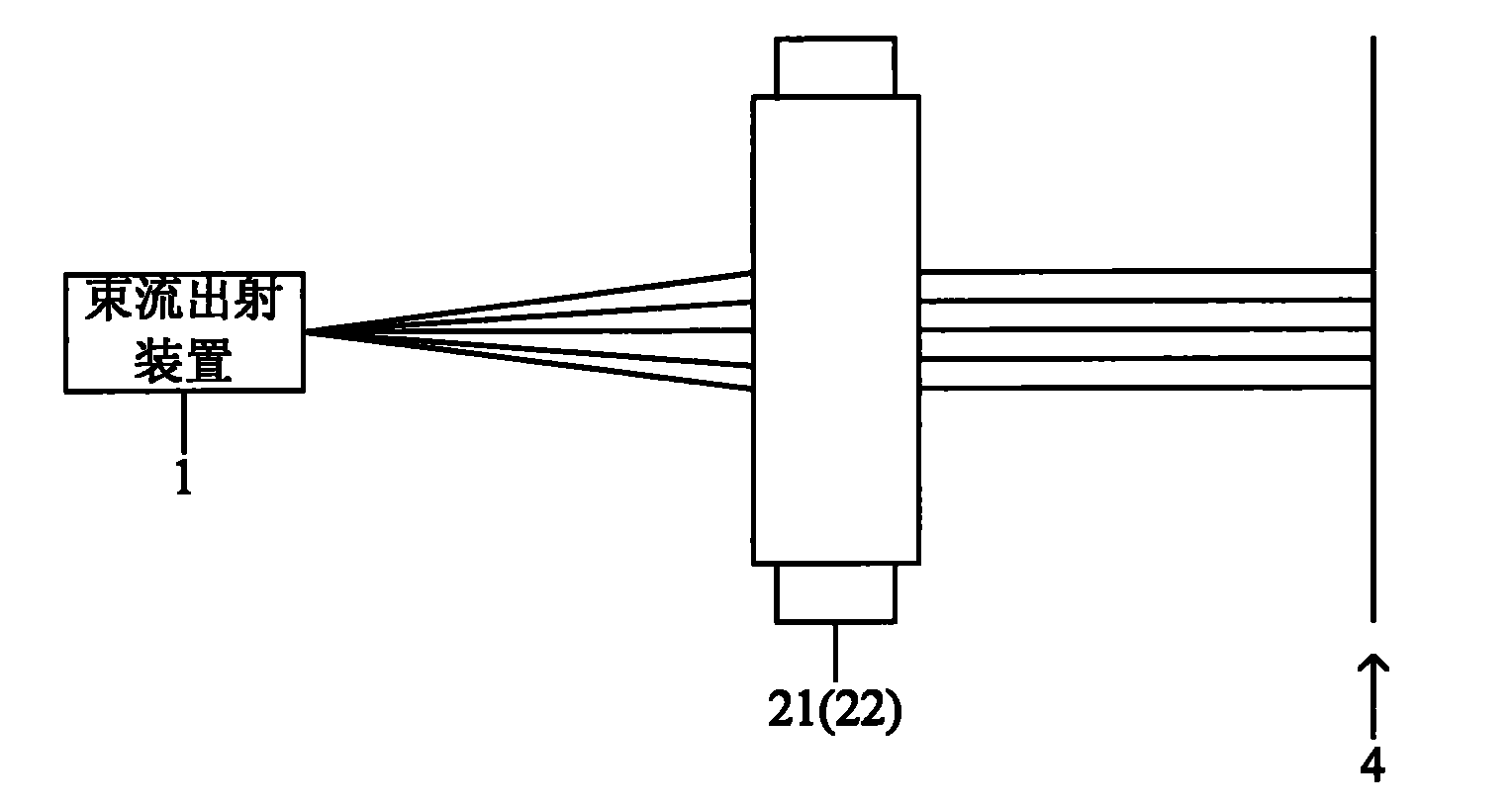

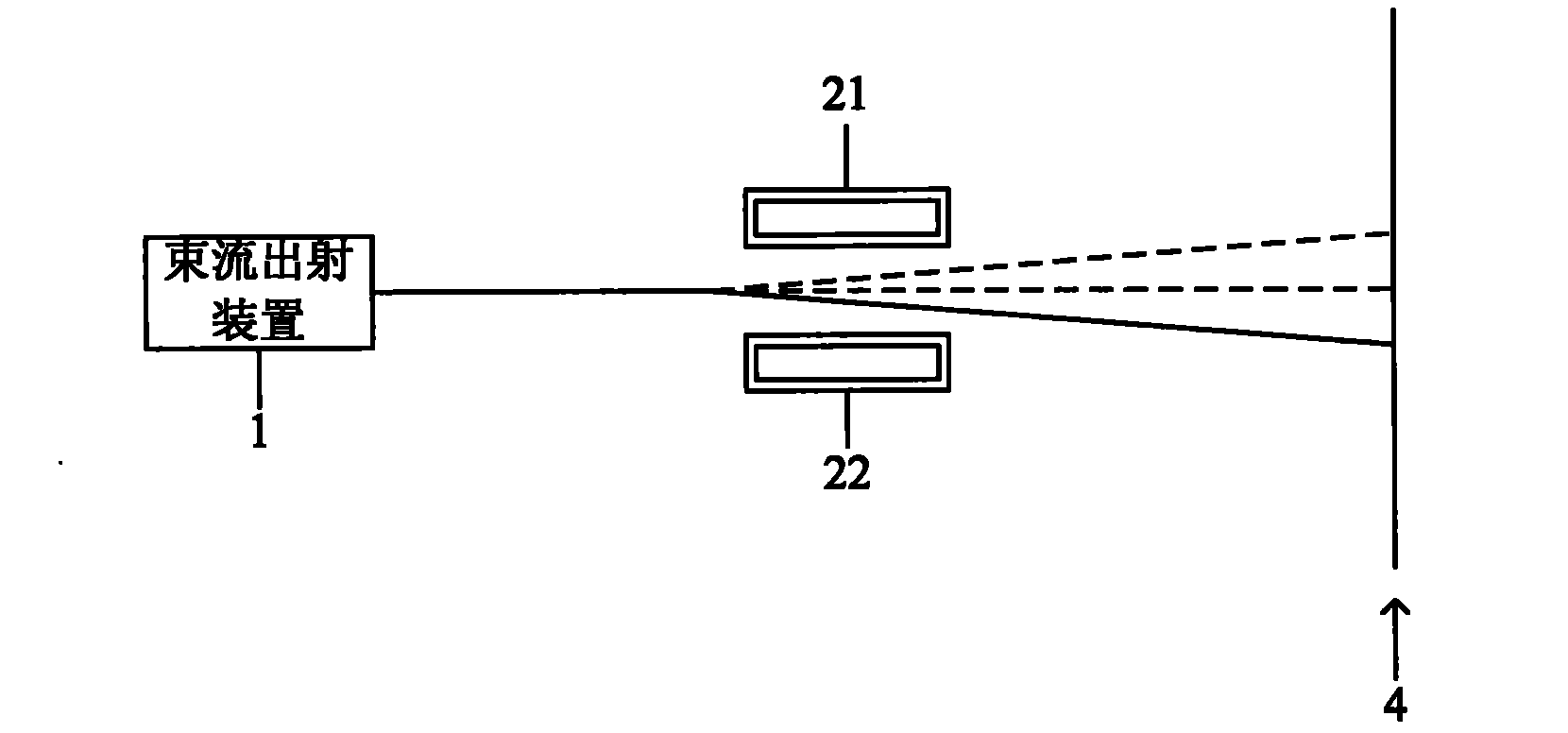

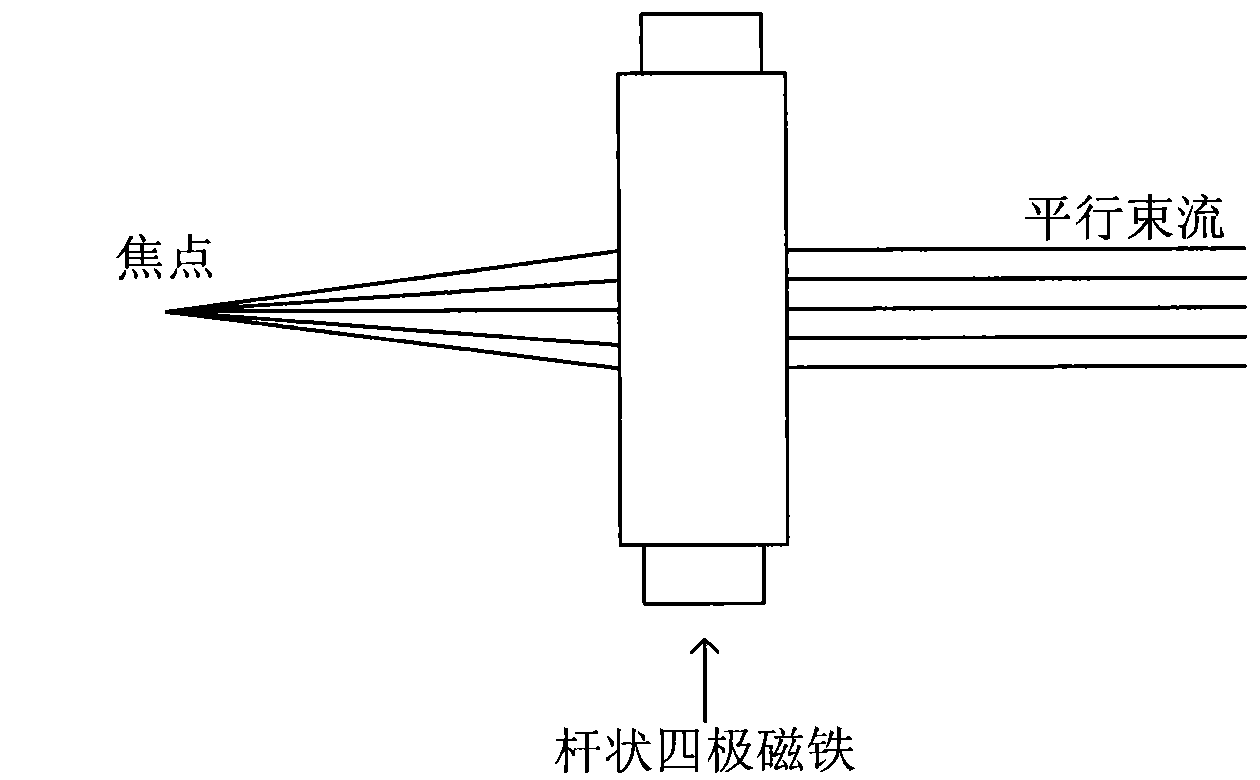

Beam transmission system and method

ActiveCN102110568AImprove utilization efficiencyImprove transmission efficiencyElectric discharge tubesLower limitTransport system

The invention discloses a beam transmission system, which comprises a beam jetting device and a target workpiece as a beam transmission terminal. A pair of parallel first rod-shaped quadrupole magnets positioned on the two sides of a beam path respectively is arranged between the beam jetting device and the target workpiece, the sum of the current values in the coils of the two first rod-shaped quadrupole magnets is kept at a first preset value, and the current value in the coil of each first rod-shaped quadrupole magnet constantly changes between a preset upper limit and a preset lower limit. The invention also discloses a beam transmission method realized by utilizing the beam transmission system. According to the invention, the intensity distribution and the angle distribution of the beam can be controlled by controlling the current values of one or two pairs of rod-shaped quadrupole magnets, so as to improve the beam utilization efficiency and further facilitate the optimization of the dose uniformity and the angle uniformity of the beam. Meanwhile, because of the focusing effect of the rod-shaped quadrupole magnets, the beam transmission efficiency is improved, and the beam intensity when the beam is transmitted to the workpiece is increased.

Owner:KINGSTONE SEMICONDUCTOR LIMITED COMPANY

Drum irradiation machine for intensively irradiating multiple X-ray source modules

ActiveCN104701119AHigh radiation conversion efficiencyRaise the radiation dose rateX-ray tube electrodesNuclear radiationDose uniformity

The invention discloses a drum irradiation machine for intensively irradiating multiple X-ray source modules, and the concentrated irradiation drum irradiation machine can be used as special irradiation equipment for irradiating bagged blood or Chinese patent medicines and unpacked foods (such as garlic) and other samples. The equipment comprises concentrated irradiation combinations of multiple X-ray source modules, a sample drum rotating on a central turntable, a cylindrical irradiation chamber protection cover with a circular bottom, a circular irradiation chamber protection cover, the central turntable, an anode water cooling circulation system and a total control console; the drum irradiation machine operates in a way that said multiple X-ray source modules are intensively irradiated and the sample drum rotates in the direction perpendicular to the outgoing centre line of the X-ray source. The drum irradiation machine is high in radiation conversion efficiency, large in irradiation depth, and excellent in uniformity of irradiation dose, thus the drum irradiation machine is used for replacing a radioactive nuclear irradiation source blood irradiation machine widely used at present, finally, the irradiation equipment can completely get rid of the nuclear irradiation source, and potential menaces such as operators suffer from nuclear radiation caused by exchanging the sample drum and the surrounding environment generates the radioactive nuclear contamination can be eliminated.

Owner:汇佳生物仪器(上海)有限公司

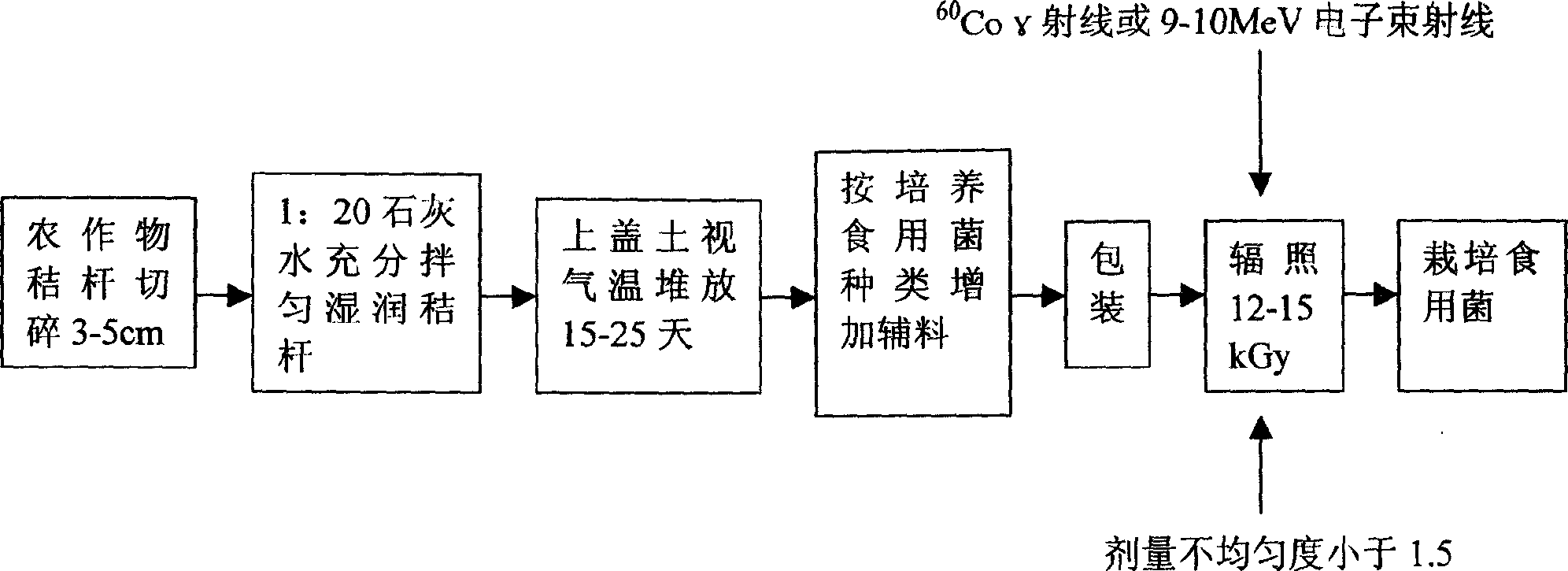

Method of irradiation degrading crop stalk to prepare edible fungus culturing material

InactiveCN1887047ABio-organic fraction processingOrganic fertiliser preparationDose uniformityOrganism

The present invention belongs to the field of irradiation treating technology, and is especially method of irradiation degrading crop stalk to prepare edible fungus culturing material. The present invention opens one new way of utilizing crop stalk. The method includes cutting stalk into 3-5 cm long, mixing with 1 / 20 concentration lime water to alkalize, piling to ferment for 15-25 days, compounding with supplementary material determined based on the variety of edible fungus to be cultured, hermetically packing and irradiating in the irradiation dose of 12-15 kGy and irradiation dose uniformity within 1.5, and using the irradiated material for culturing edible fungus. Or, the crop stalk is fermented preferably in a fermenting tank before compounding material, irradiation degrading and sterilizing to produce the edible fungus culturing material.

Owner:宁波超能科技股份有限公司

Implant beam utilization in an ion implanter

ActiveUS7772571B2Electric discharge tubesSemiconductor/solid-state device manufacturingDose uniformityBeam scanning

To select a scan distance to be used in scanning a wafer with an implant beam, a dose distribution along a first direction is calculated based on size or intensity of the implant beam and a scan distance. The scan distance is the distance measured in the first direction between a first path and a final path of the implant beam scanning the wafer along a second direction in multiple paths. A relative velocity profile along the second direction is determined based on the dose distribution. Dose uniformity on the wafer is calculated based on the wafer being scanned using the relative velocity profile and the determined dose distribution. The scan distance is adjusted and the preceding steps are repeated until the calculated dose uniformity meets one or more uniformity criteria.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

Dose uniformity correction technique

InactiveUS7692164B2Uniform ion implantationElectric discharge tubesSemiconductor/solid-state device manufacturingDose uniformityCorrection technique

Owner:AXCELIS TECHNOLOGIES

Laser packaging device and method

ActiveCN109093251AImprove sealingSolve the bubblesSolid-state devicesSemiconductor/solid-state device manufacturingDose uniformityOptoelectronics

The invention provides a laser packaging device and method. The laser packaging device is used for shooting a laser beam to a packaging base to form a light spot, the light intensity is gradually reduced from the edge of the light spot to the center of the light spot on the surface perpendicular to the direction of the advancing path of the laser beam, and the light spot comprises a first sectionclose to the edge of the light spot and a second section close to the center of the light spot. The light intensity reducing rate of the first section is smaller than that of the second section, and the boundary position of the first section and the second section is a first inflection point. The laser beam with the light spot is used for packaging the packaging base to effectively improve the uniformity of the dosage irradiated to a glass material, and thus the airtightness of the glass material is further improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Method of determining dose uniformity of a scanning ion implanter

Dose uniformity of a scanning ion implanter is determined. A base beam current is measured at the beginning and / or the end of a complete scan over the whole substrate area. This base beam current is measured at a time when the measurement should be unaffected by outgassing from a substrate being implanted and a base dose distribution map is then calculated for the scan in question. During the scan itself beam instability events are detected and the magnitude and position in the scan of the detected instability events is measured. Corresponding deviations in the calculated base dose map are determined and subtracted from the previously calculated base dose distribution map to provide a corrected distribution map. By determining overall dose uniformity substractively in this way, good overall accuracy can be obtained with lesser accuracy in the measurement of the beam instability events.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com