Beam transmission system and method

A technology of current transmission and beam current, which is applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of beam scanning and focusing, and cannot be realized simultaneously by a single beam optical device, so as to optimize uniformity, improve utilization efficiency, The effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

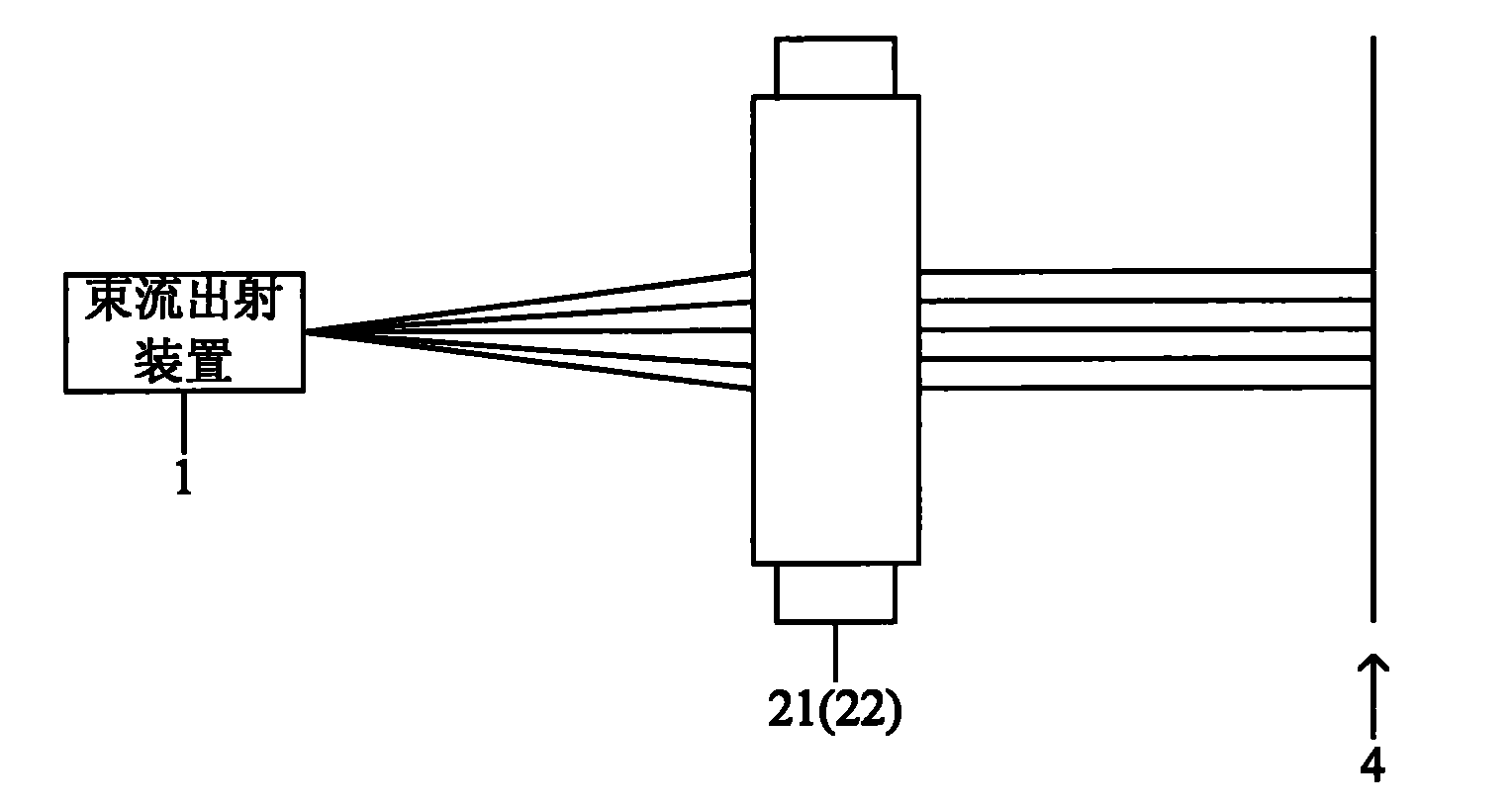

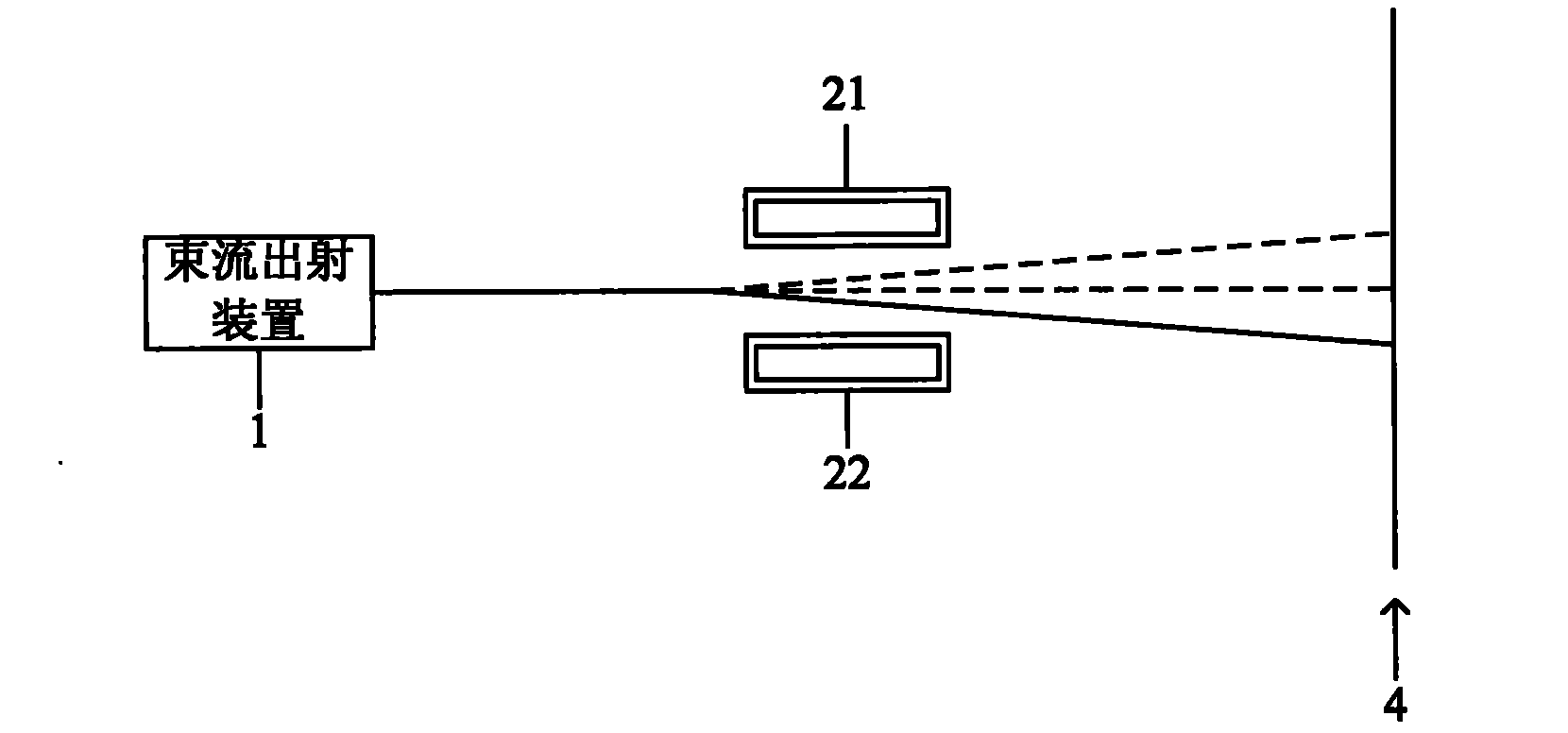

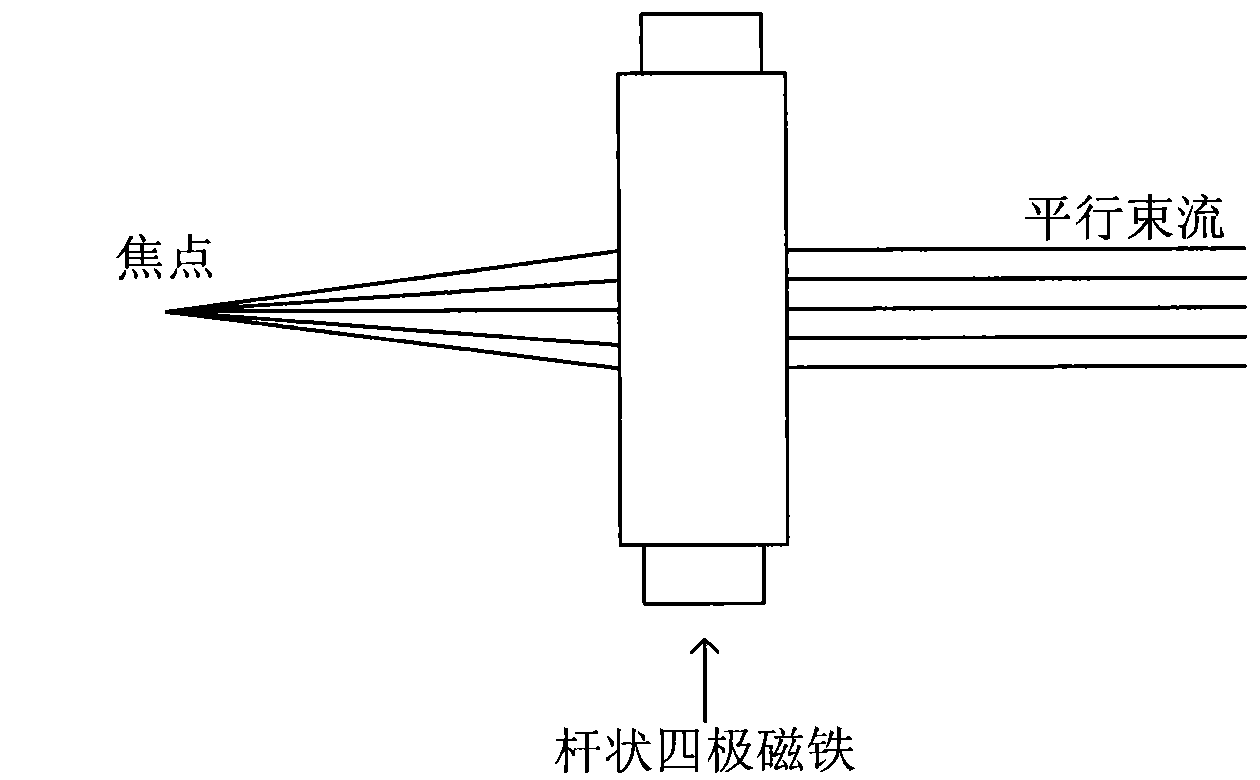

[0030] Figure 1a and Figure 1b Shown are side and top views, respectively, of a first embodiment of the beam delivery system of the present invention. After the beam emitted by the beam emitting device 1 is transmitted on the beam path, it finally reaches the target workpiece 4 according to the preset intensity distribution and angle distribution requirements to complete the processing of the workpiece. The beam emitting device 1 can be an ion source or an electron source, and correspondingly, the transmitted beam can be an ion beam or an electron beam. In the present invention, a pair of first rod-shaped quadrupole magnets 21 and 22 parallel to each other and located on both sides of the beam path are arranged between the beam emitting device 1 and the target workpiece 4 .

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com