Patents

Literature

427 results about "Ion beam irradiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

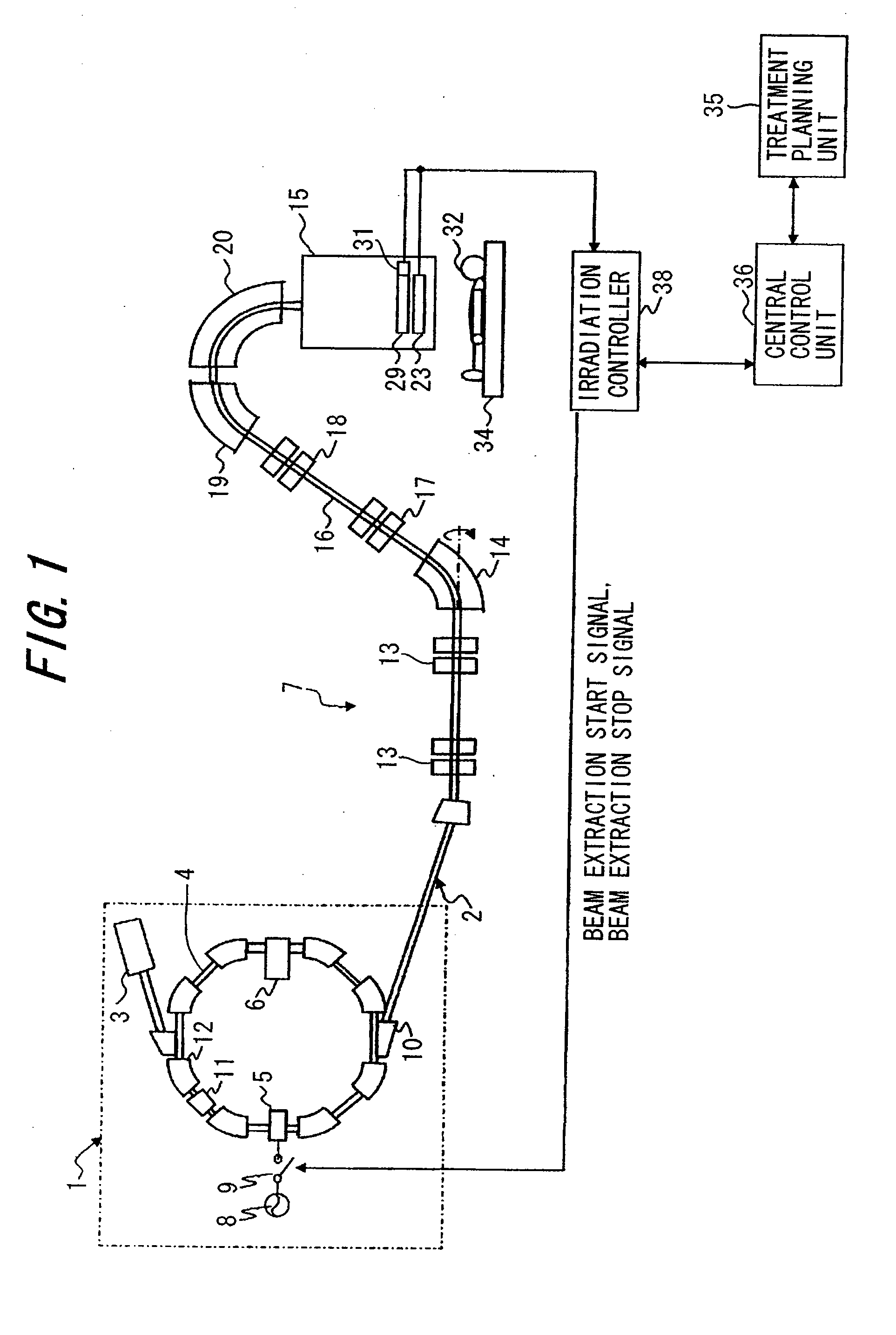

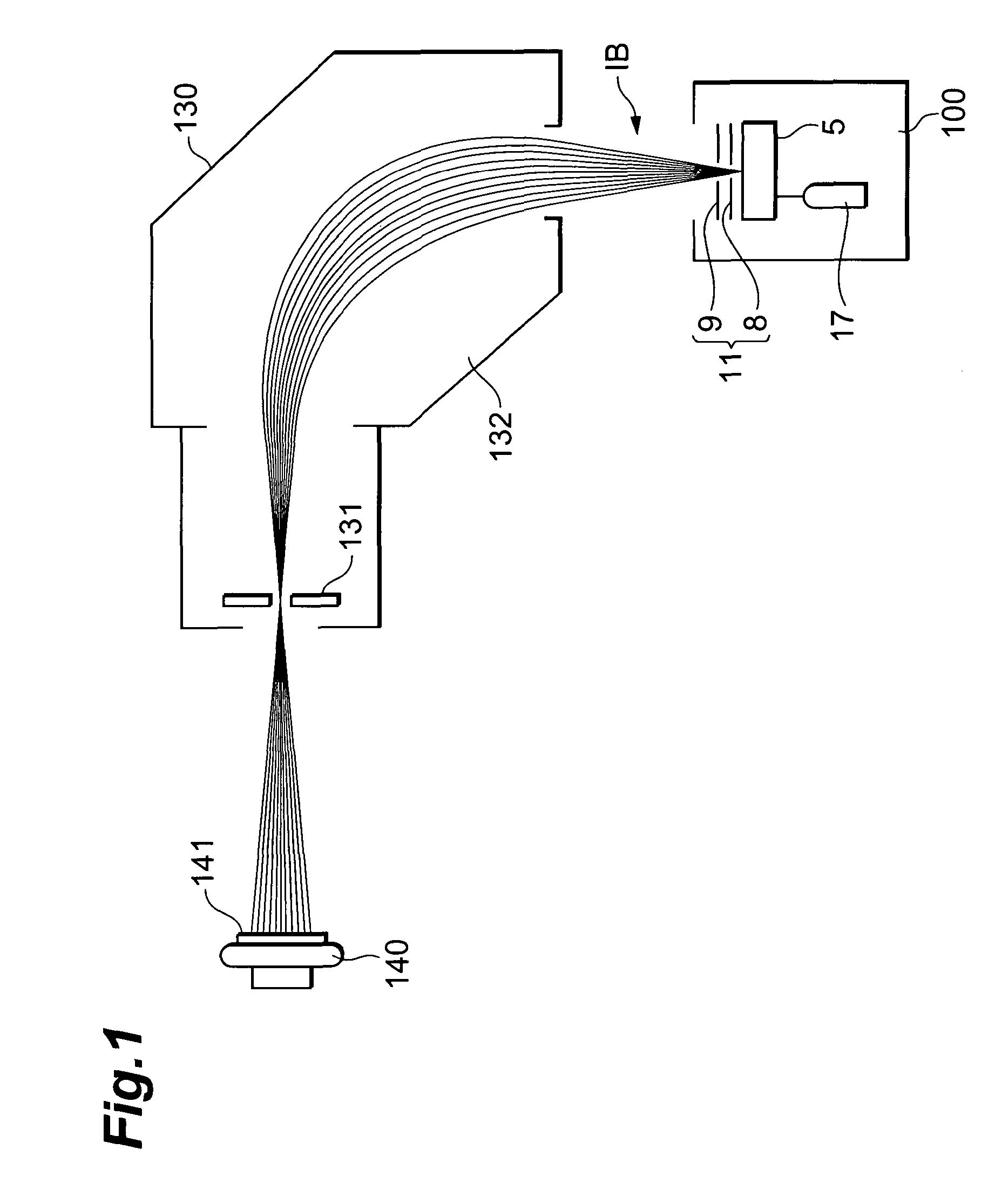

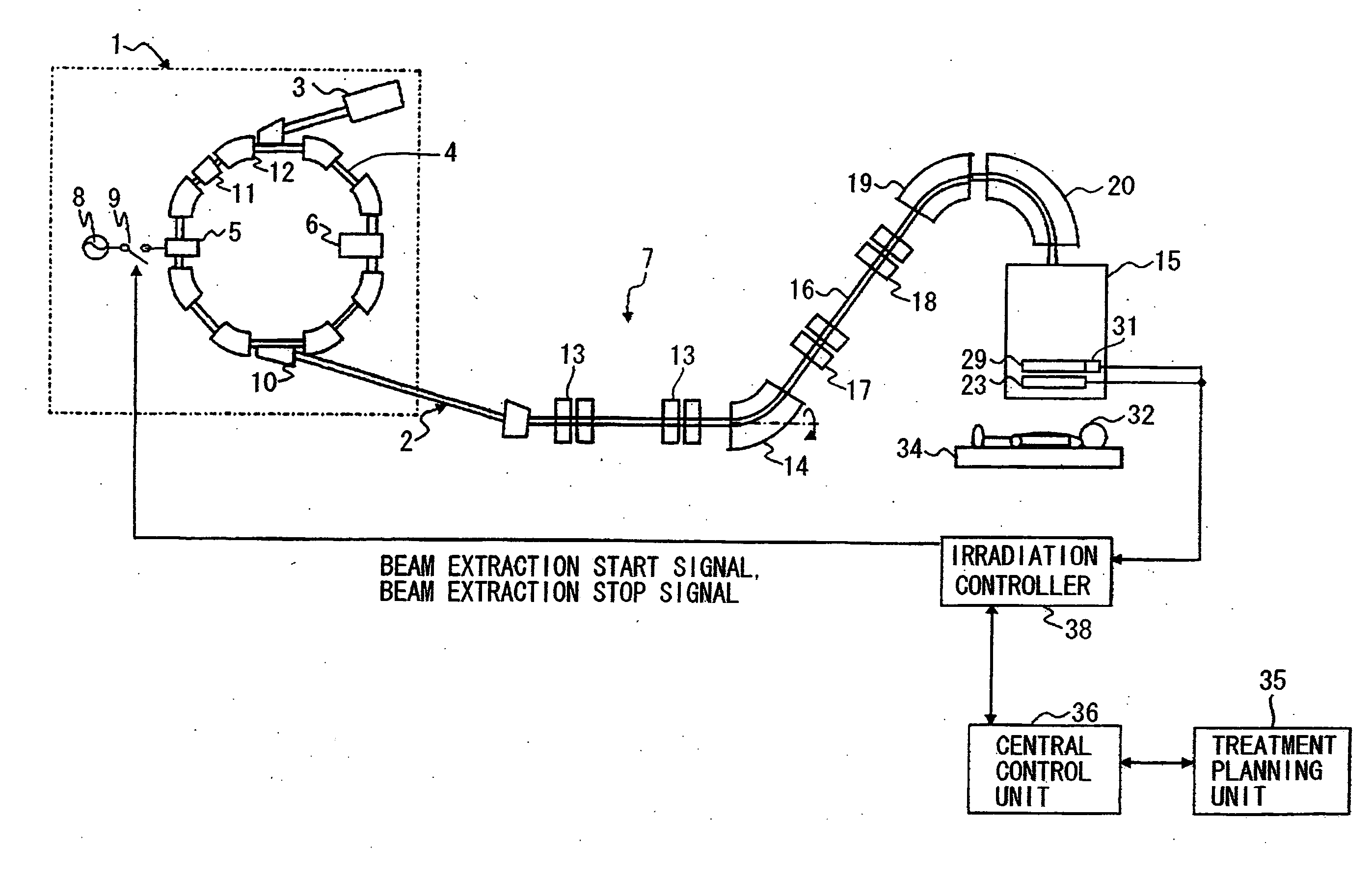

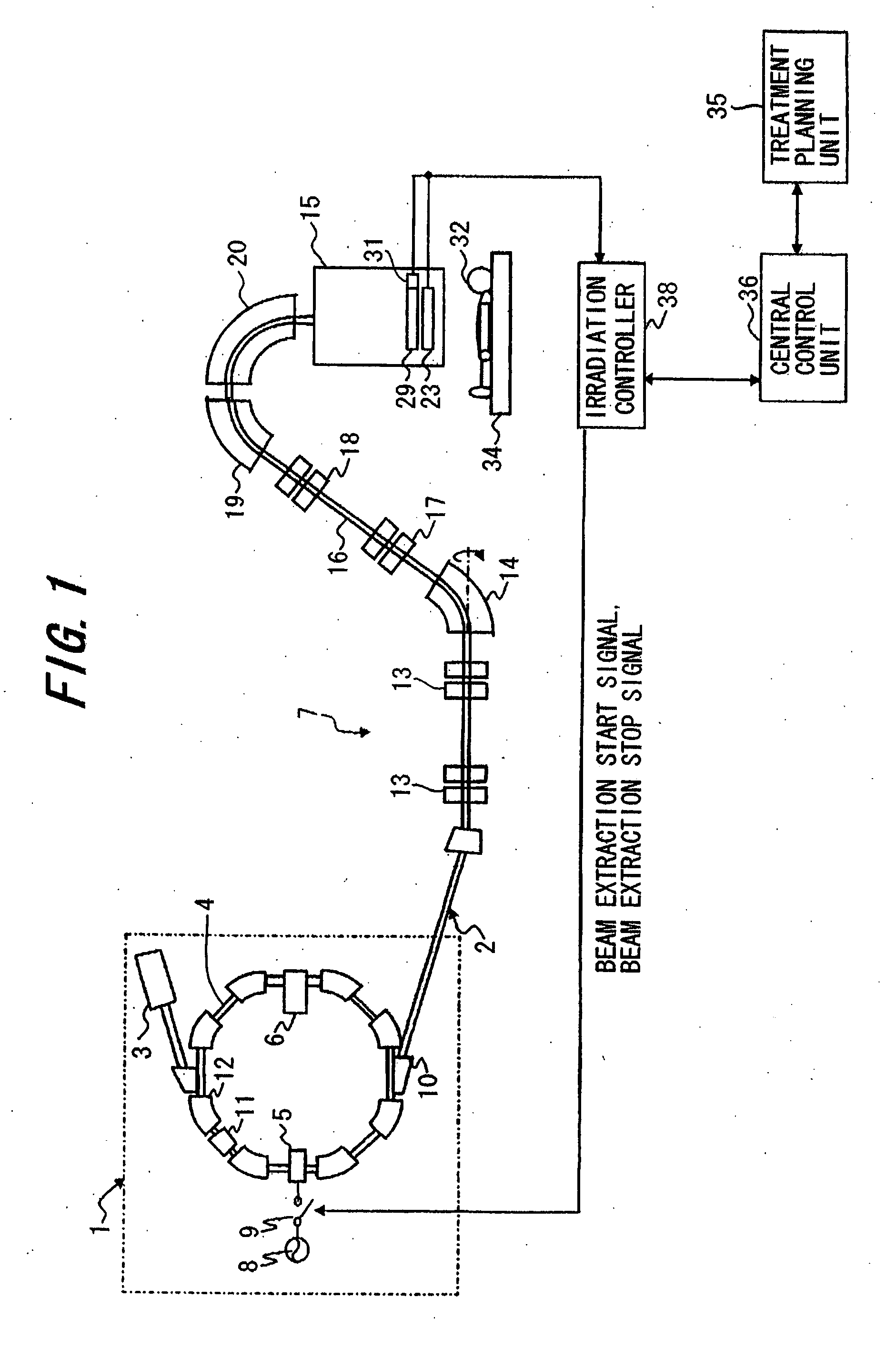

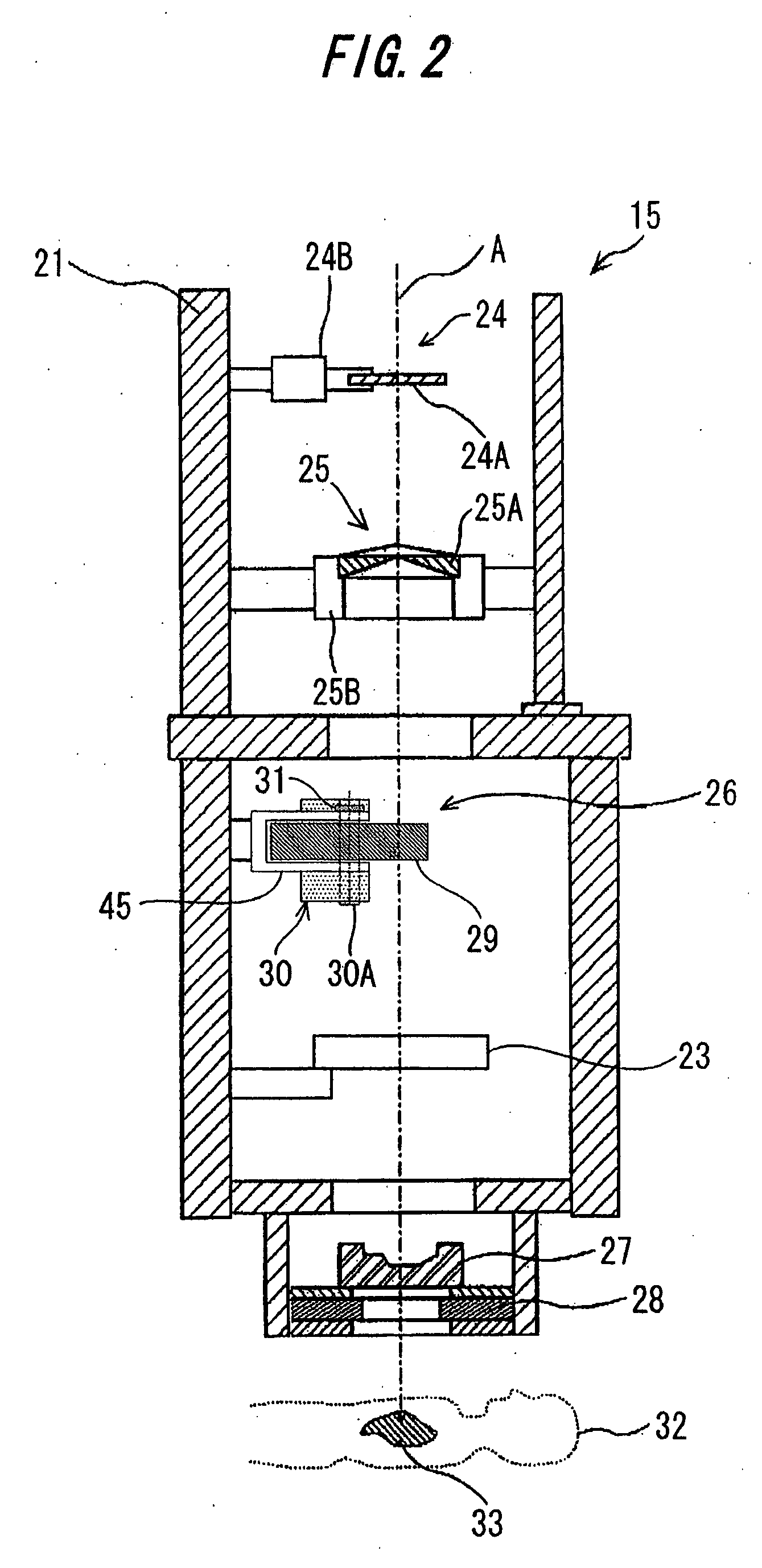

Charged particle irradiation system and method for controlling the same

ActiveUS20110073778A1Improve performanceEasy to operateChemical conversion by chemical reactionX-ray/gamma-ray/particle-irradiation therapyLight beamSynchrotron

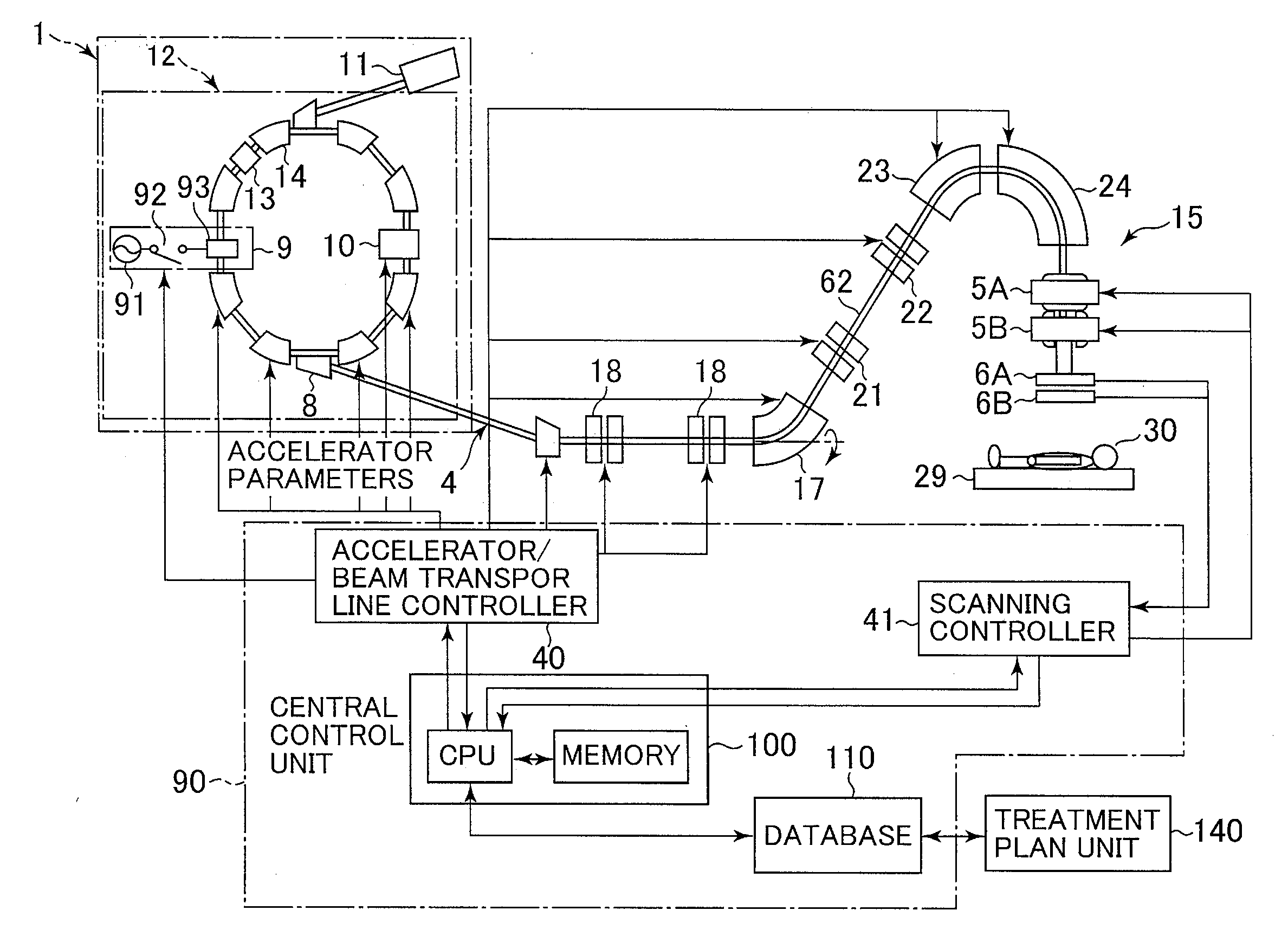

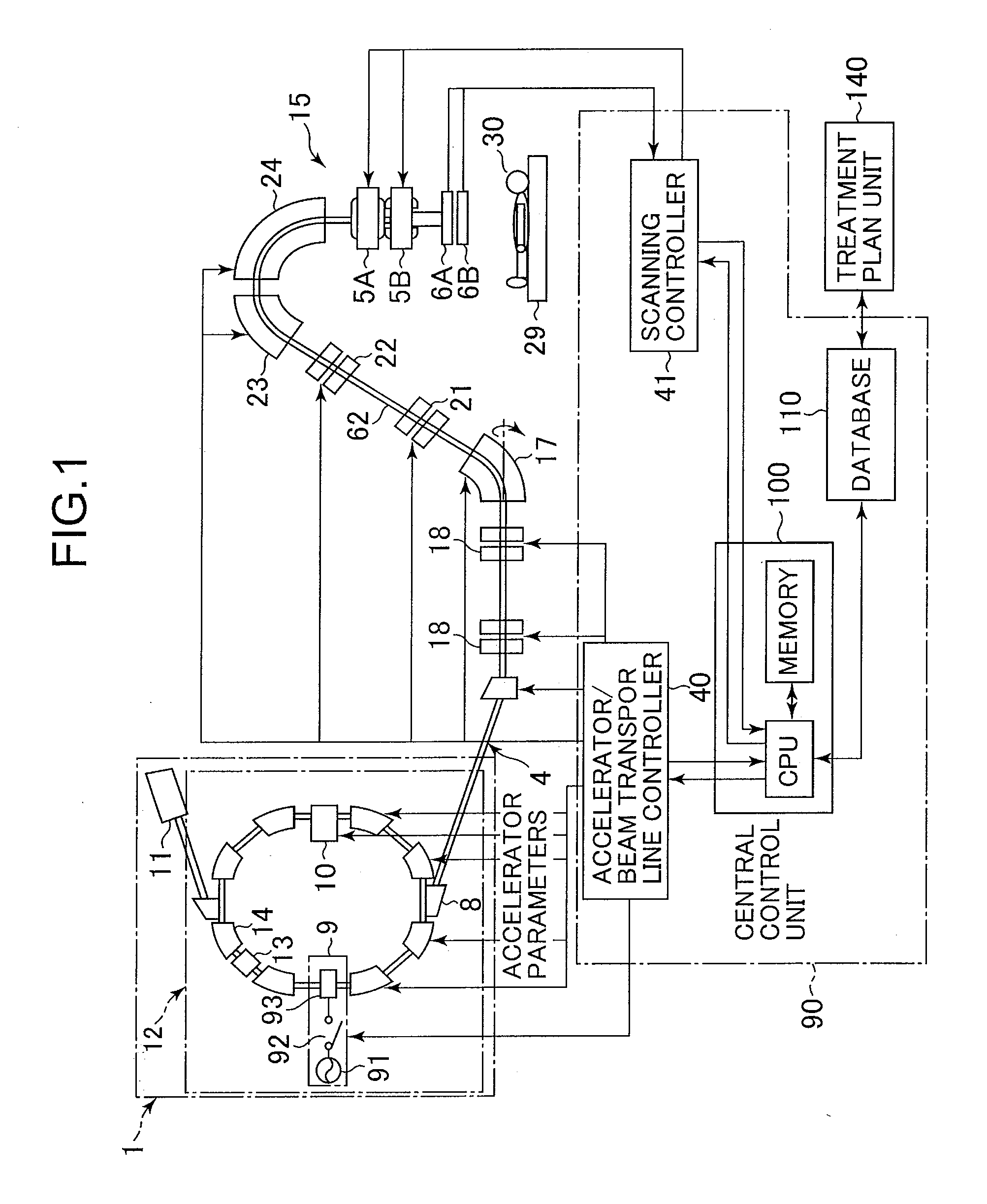

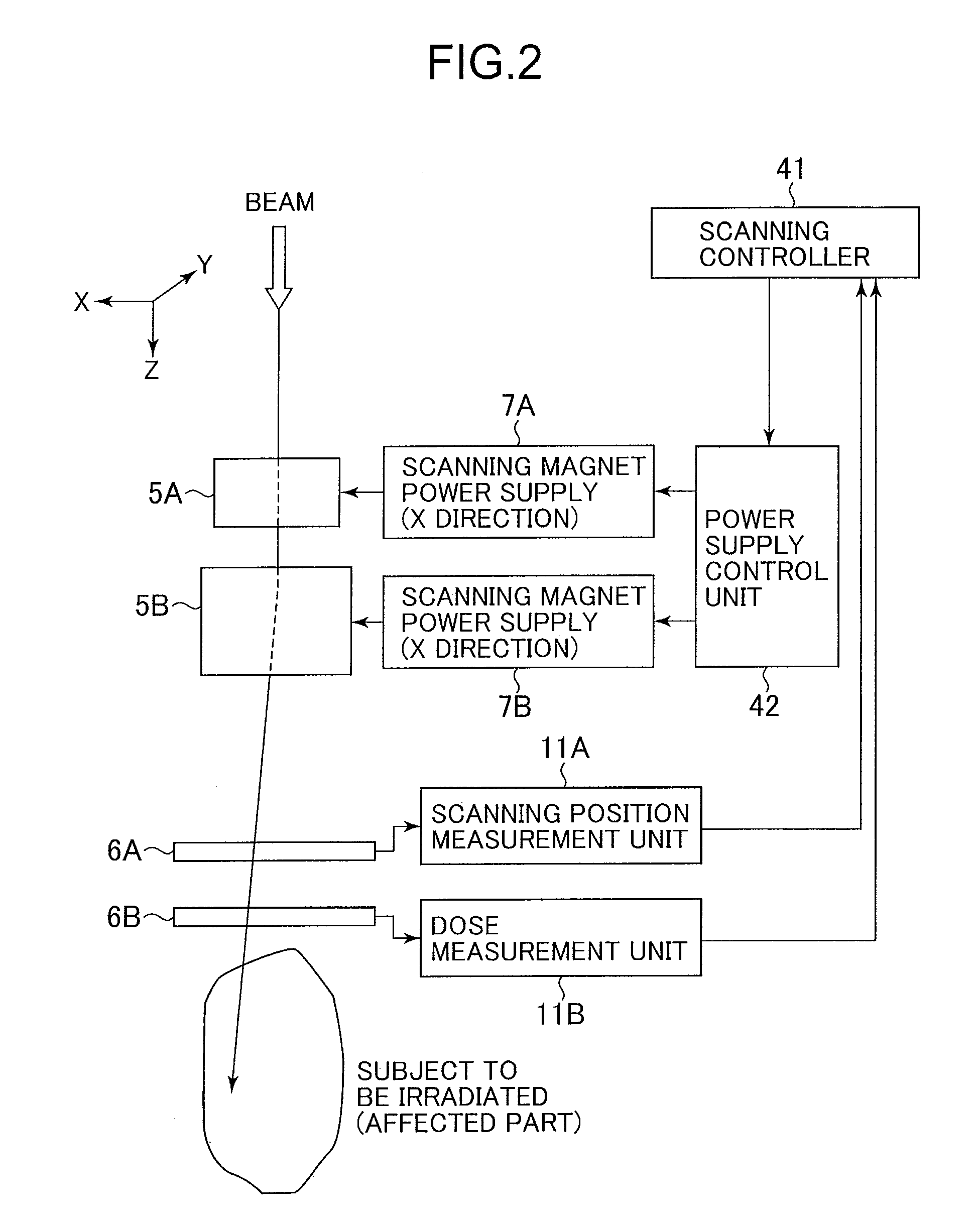

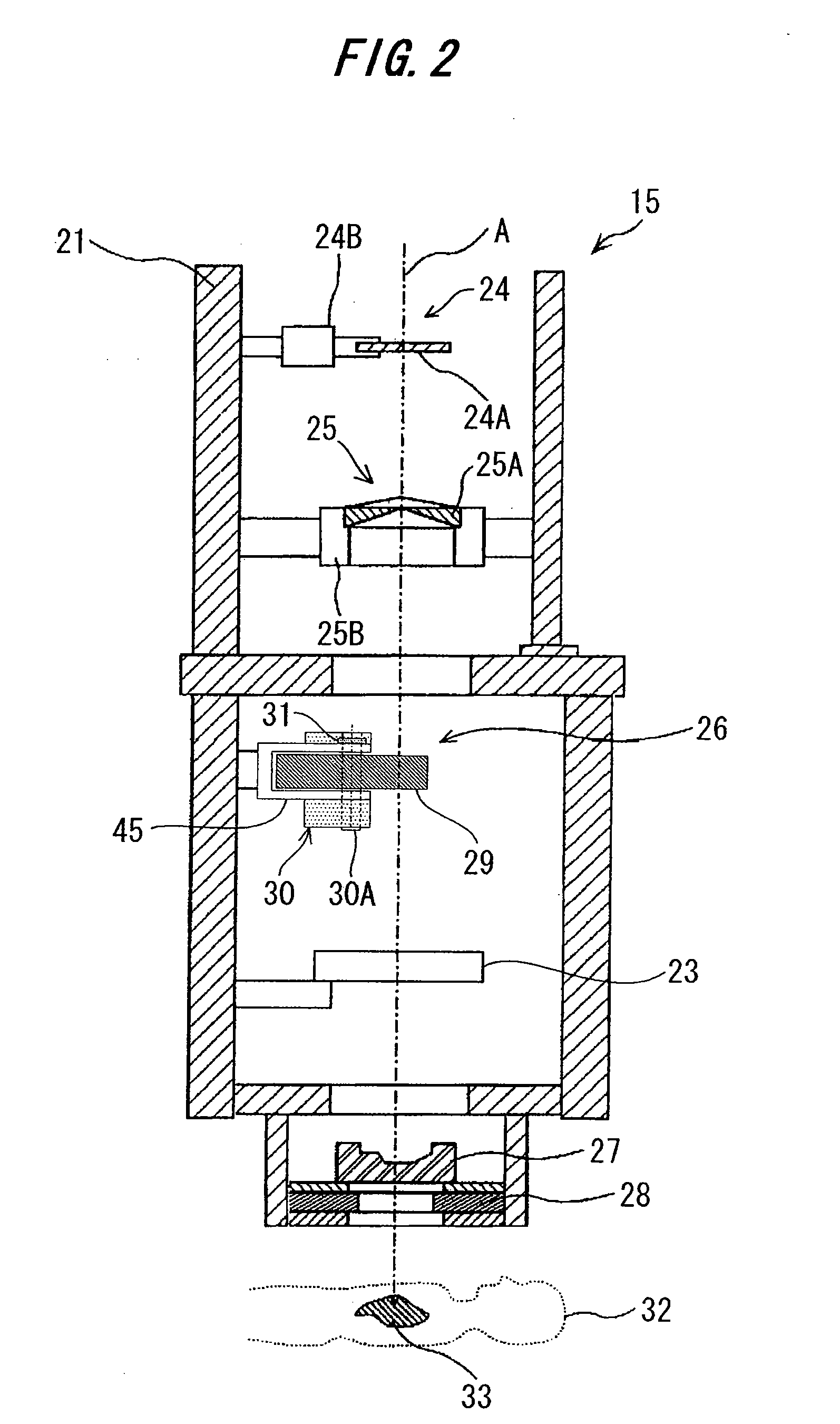

A beam extraction process (interruption and restart) is appropriately performed when a failure occurs during irradiation of a spot group. A charged particle irradiation system includes a synchrotron 12 and a scanning irradiation unit 15 that scans an ion beam extracted from the synchrotron over a subject. The extraction of the ion beam from the synchrotron is stopped on the basis of a beam extraction stop command. Scanning magnets 5A and 5B are controlled to change a point (spot) to be irradiated with the ion beam, while the extraction of the ion beam is stopped. The extraction of the ion beam from the synchrotron is restarted after the change of the spot to be irradiated. When a relatively minor failure in which continuous irradiation would be possible occurs during irradiation of a certain spot with the beam, the extraction of the beam is not immediately stopped.

Owner:HITACHI LTD

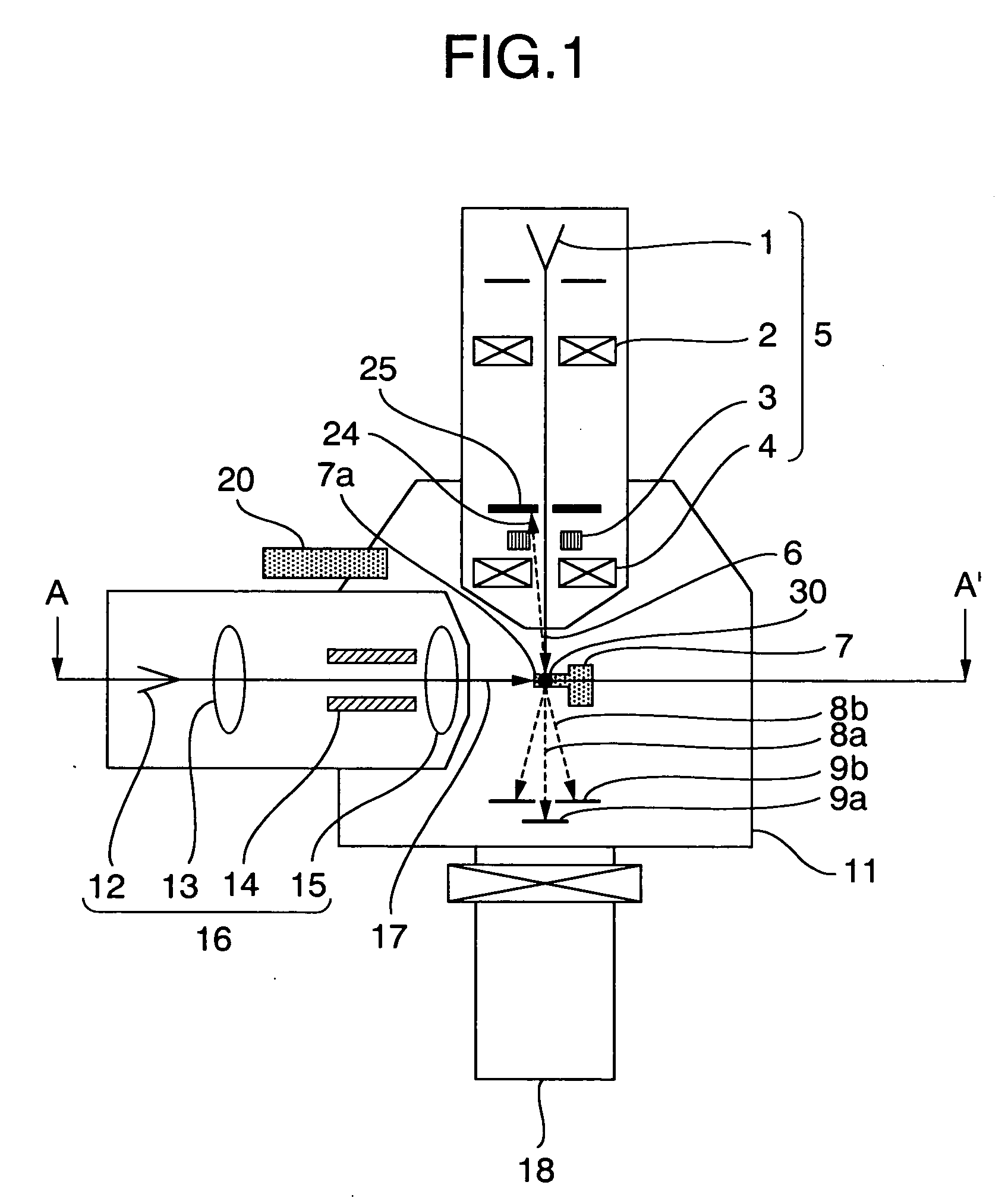

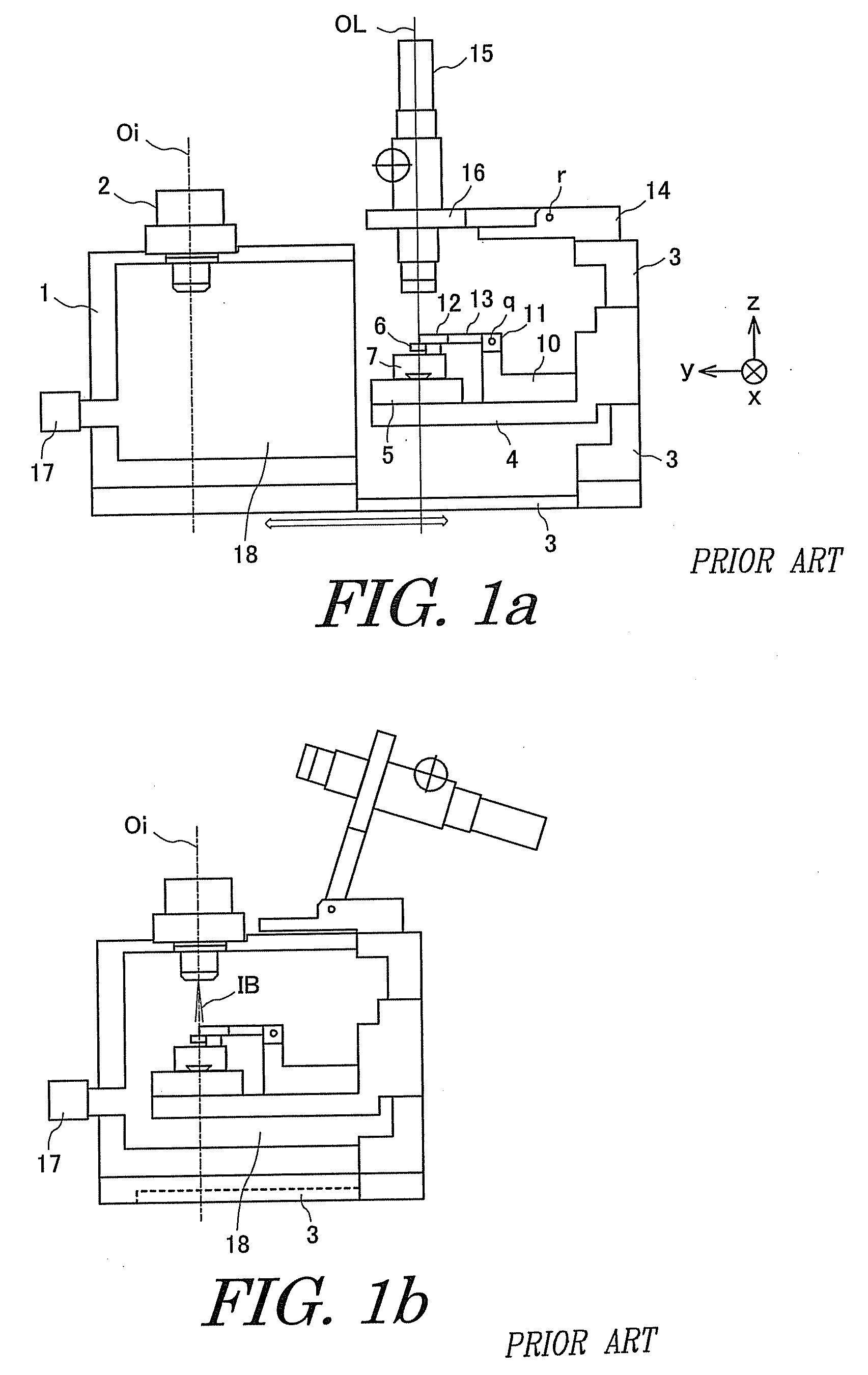

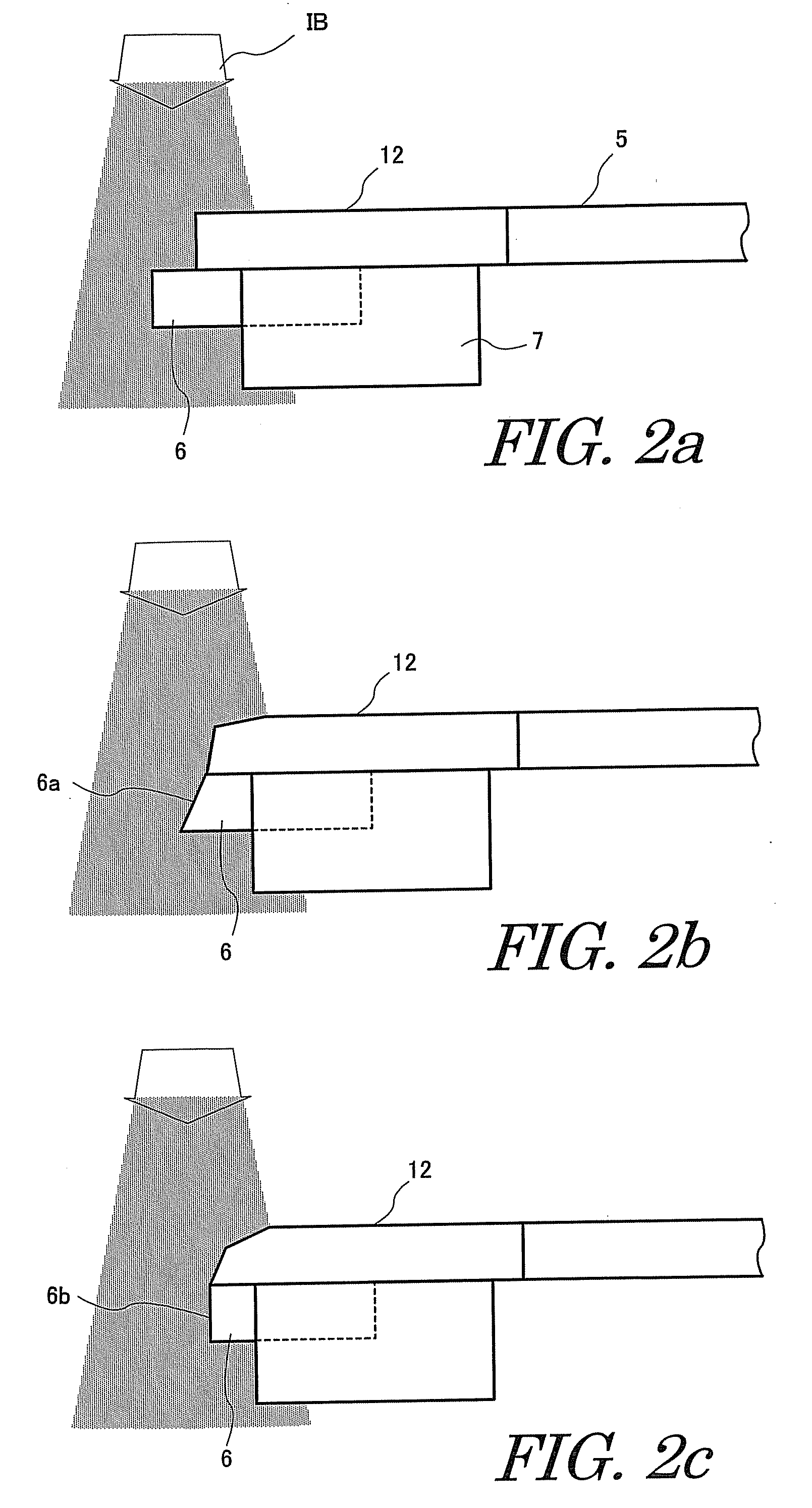

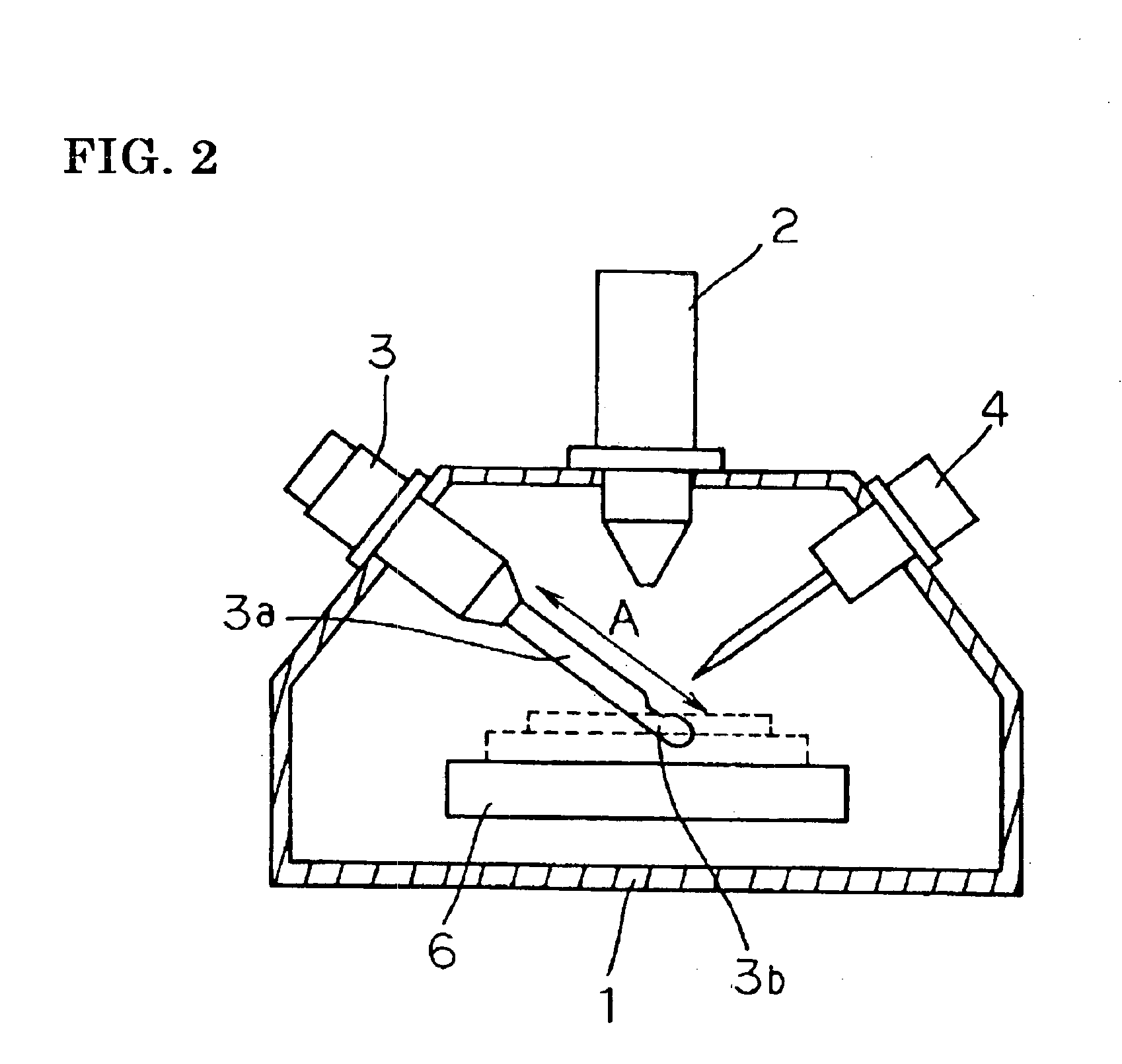

Charged particle beam apparatus and sample manufacturing method

ActiveUS20060097166A1Simplifying sample thickness optimization workReduced beam diameterMaterial analysis using wave/particle radiationElectric discharge tubesElectron beam irradiationIon beam irradiation

It is possible to carry out a highly accurate thin film machining by irradiation of an ion beam to a sample and a high-resolution STEM observation of the sample by irradiating an electron beam with a high throughput almost without moving the sample. The FIB irradiation system has an irradiation axis almost orthogonally intersecting an irradiation axis of the STEM observation electron beam irradiation system. The sample is arranged at the intersection point of the irradiation axes. The FIB machining plane of the sample is extracted from the thin film plane of the STEM observation sample. The transmitting / scattered beam detector are arranged at backward of the sample on the electron beam irradiation axis viewed from the electron beam irradiation direction.

Owner:HITACHI HIGH-TECH CORP

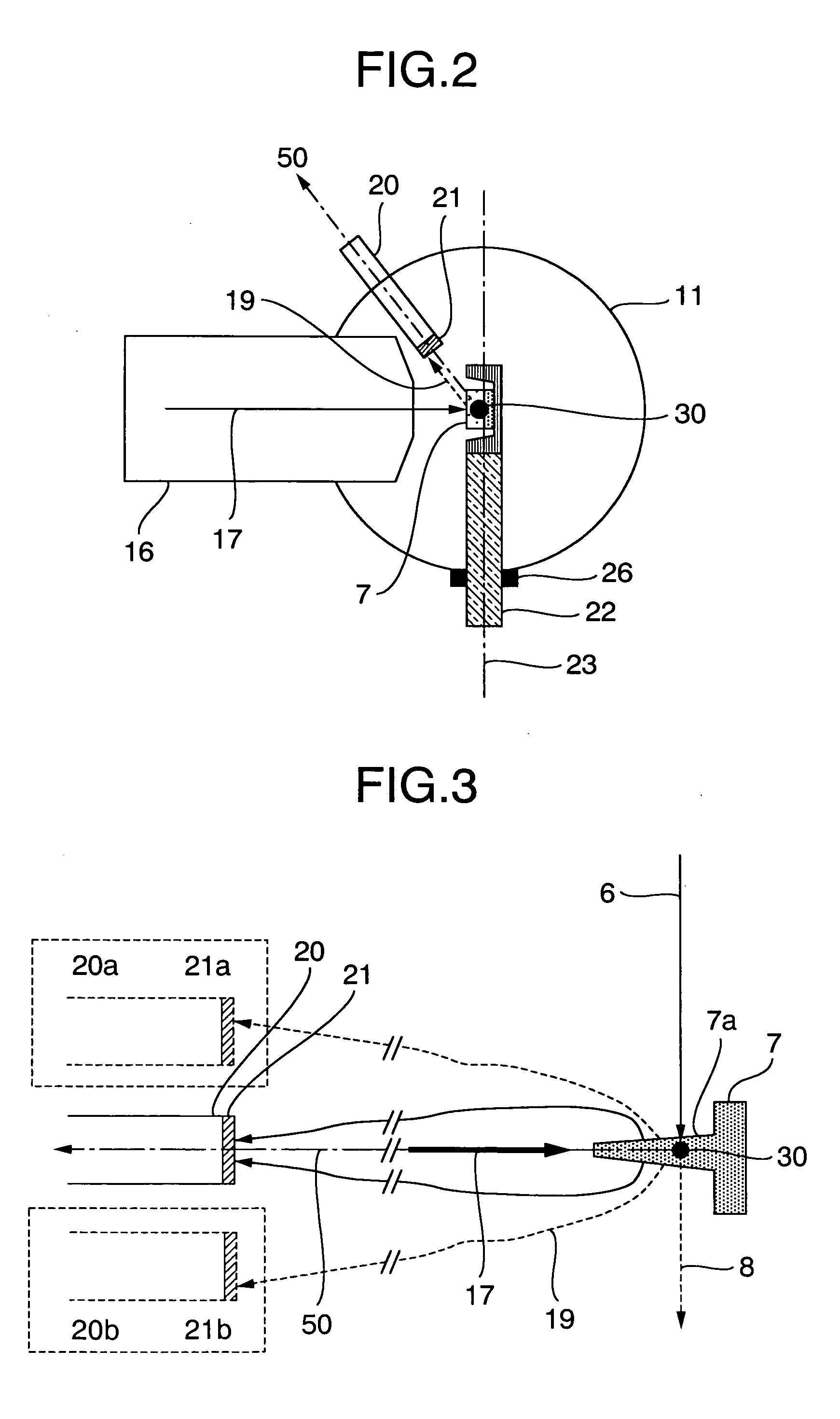

Ion beam delivery equipment and ion beam delivery method

ActiveUS20070228291A1Increase the number ofRadiation/particle handlingElectrode and associated part arrangementsVarying thicknessIrradiation

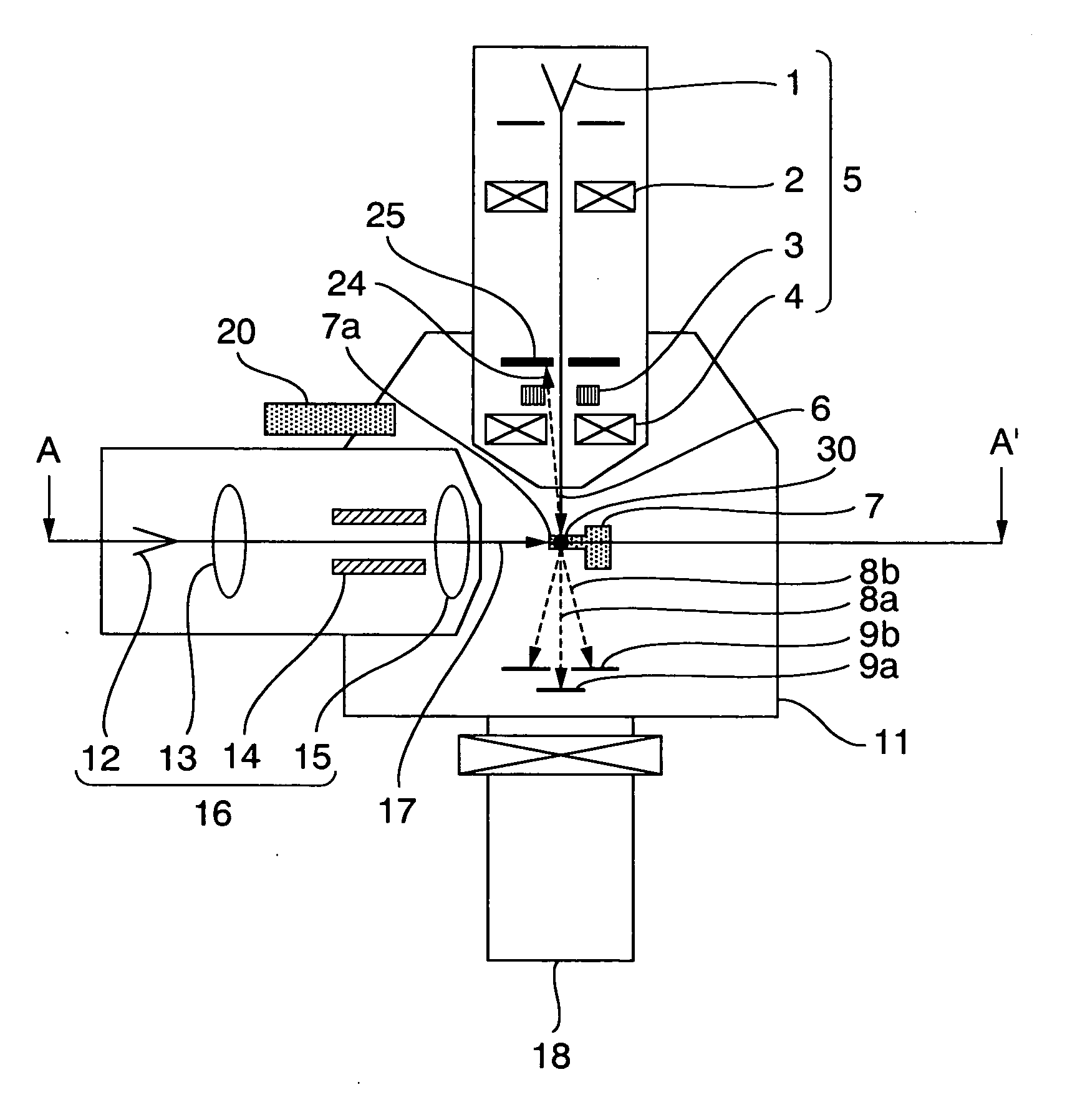

The invention is intended to increase the number of patients treatable using one wheel having a thickness varied in the rotating direction to change energy of an ion beam passing the wheel. Ion beam delivery equipment for irradiating an ion beam to a patient for treatment comprises a beam generator for producing and accelerating the ion beam, an beam delivery nozzle including a range modulation wheel which has a predetermined thickness distribution in the rotating direction and is rotated on a travel passage of the ion beam generated from the beam generator to control a range of the ion beam, and an irradiation controller for controlling the beam producing and accelerating operation of the beam generator in accordance with the phase of rotation of the range modulation wheel.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

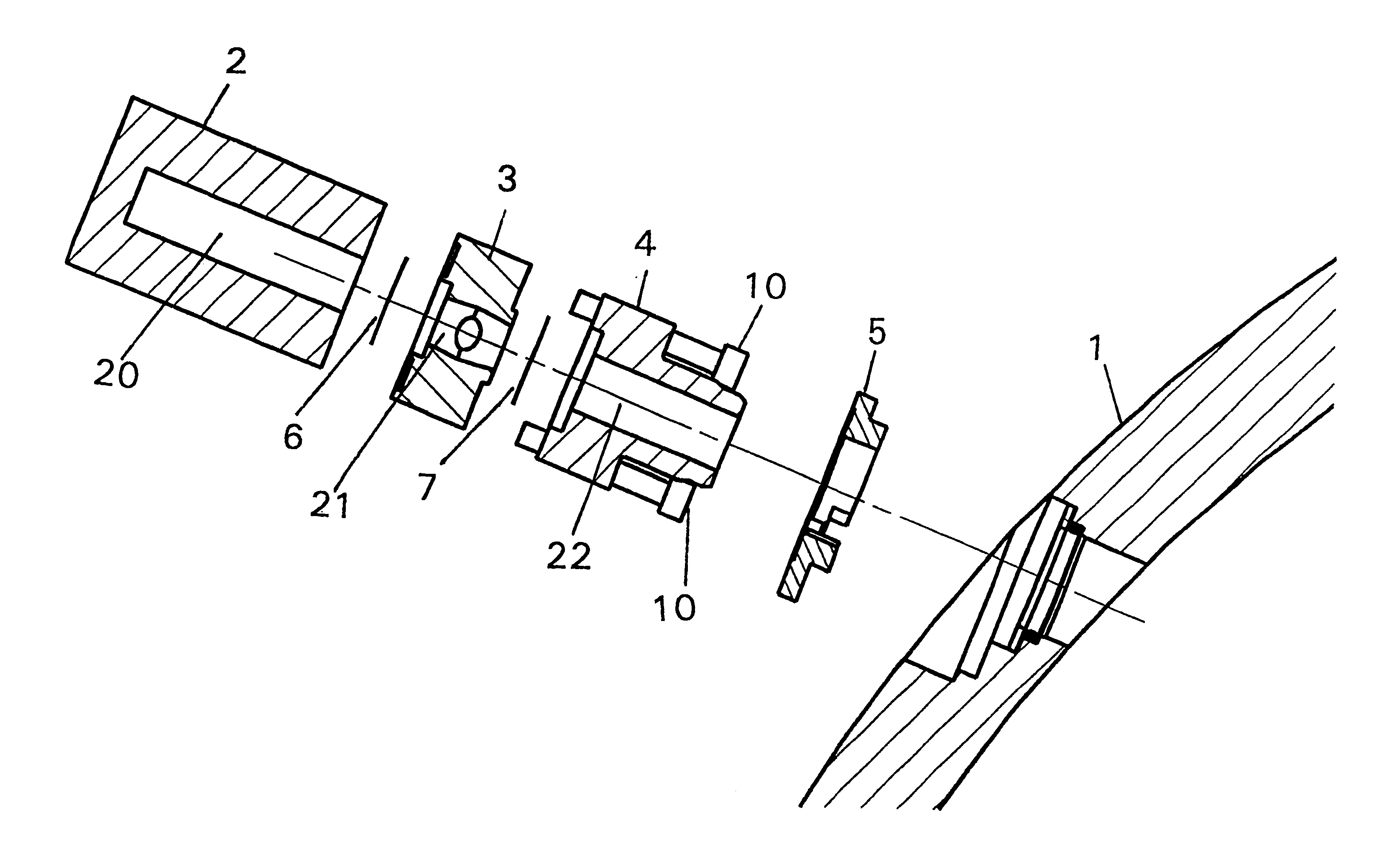

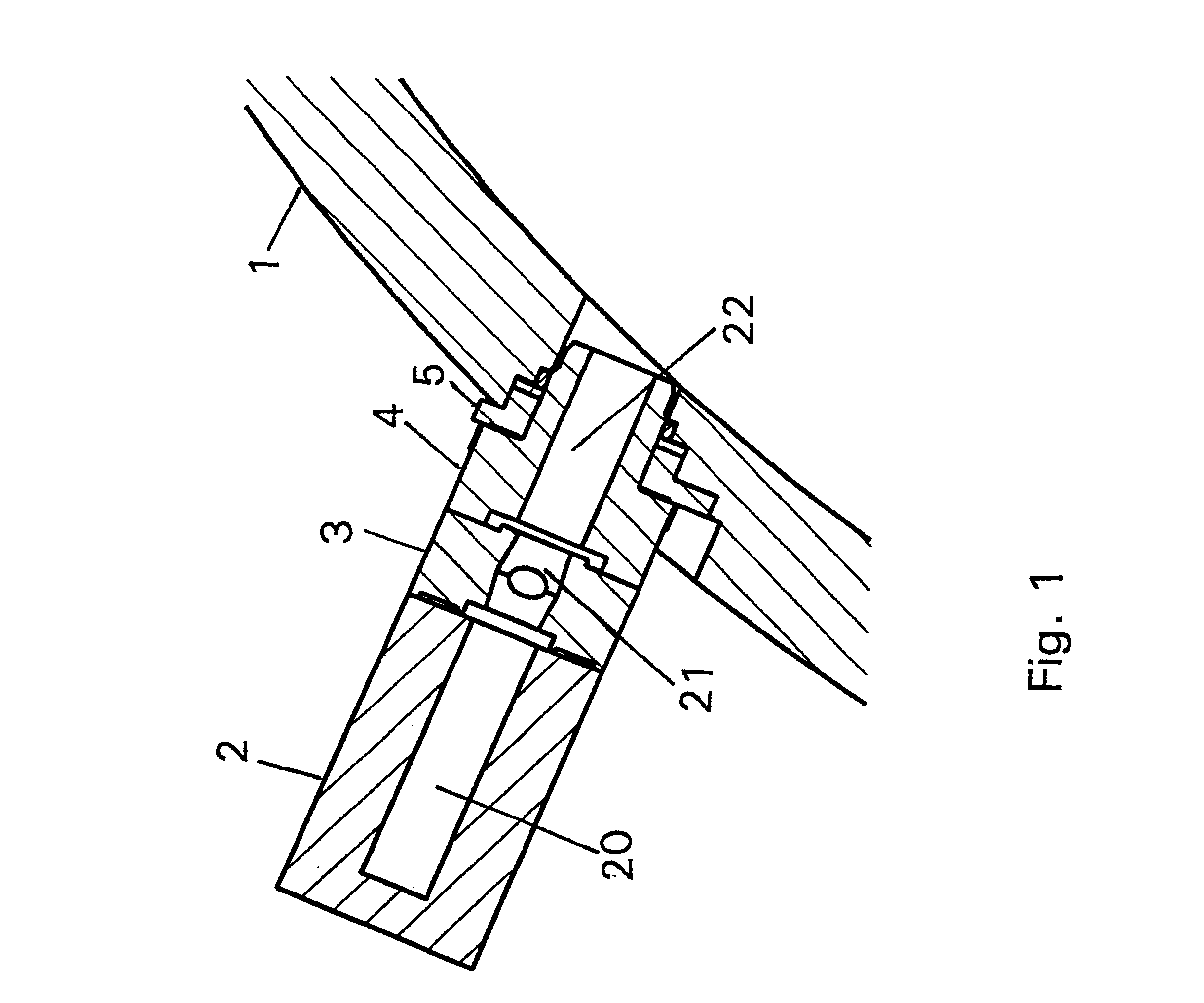

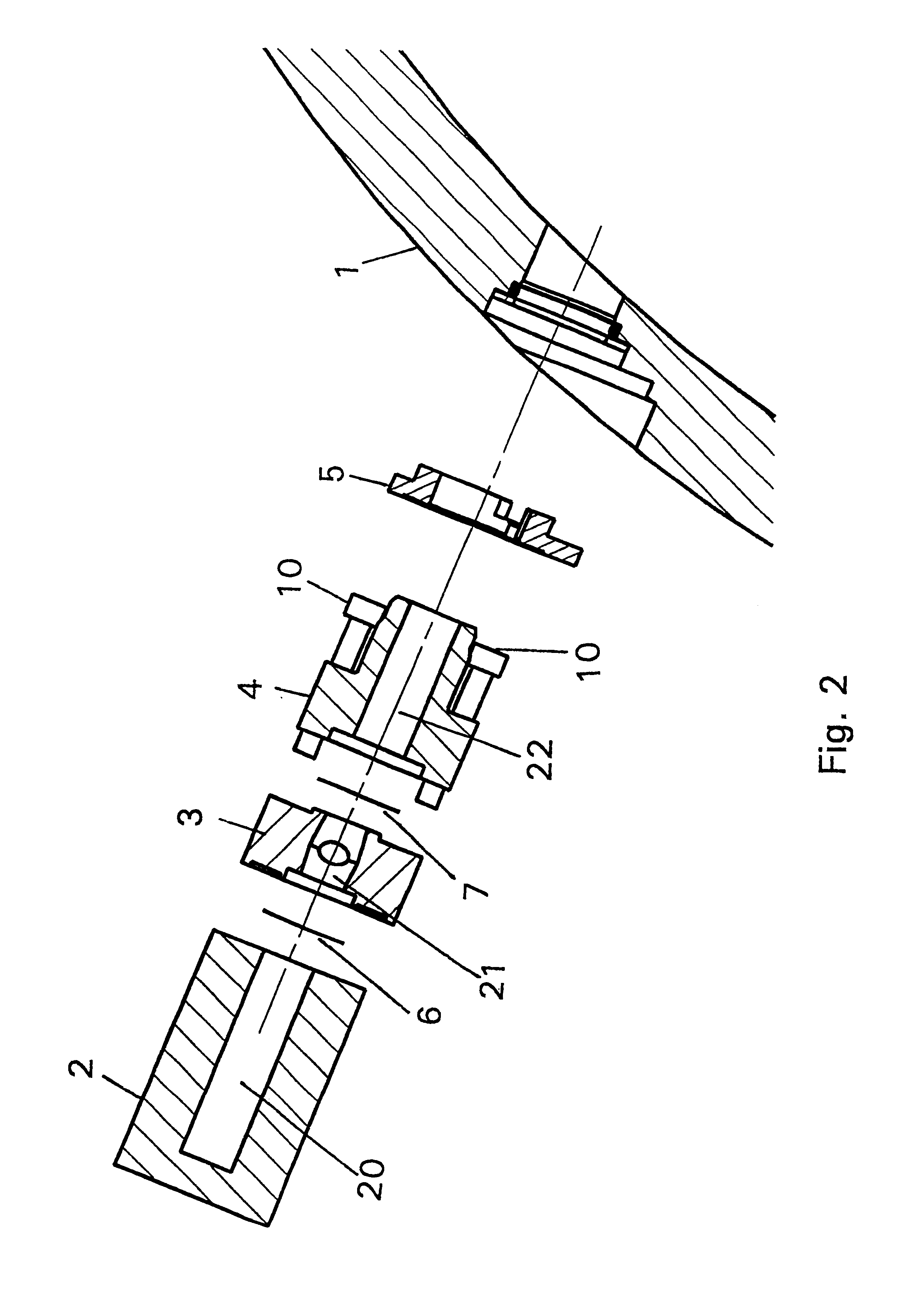

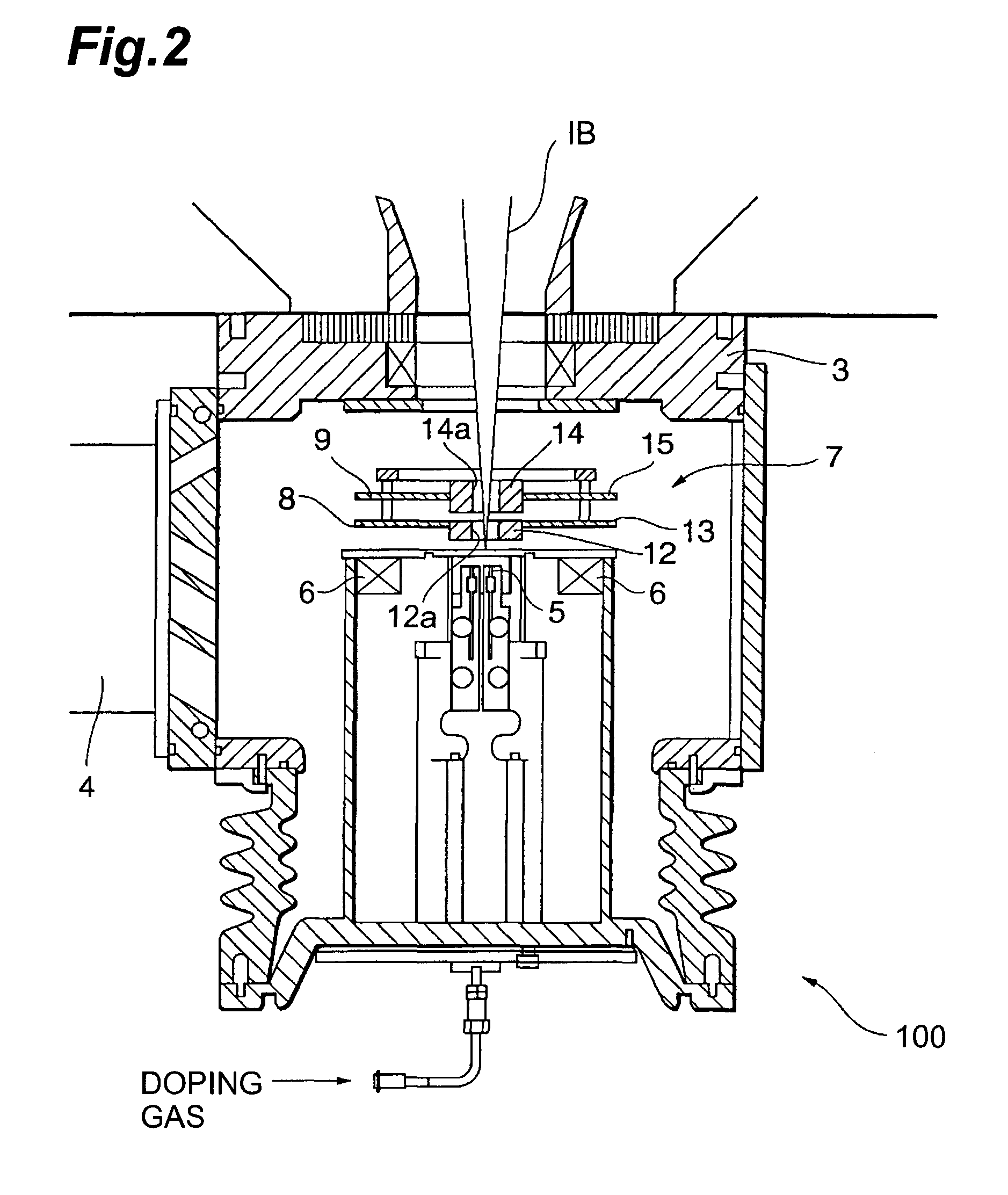

Device for fitting of a target in isotope production

InactiveUS6433495B1Minimize radiationFit fastThermometer detailsBeam/ray focussing/reflecting arrangementsInterior spaceIsotope

A device is disclosed for simple and quick disconnection of a target assembly at a cyclotron accelerator producing an ion beam irradiating the target assembly for PET radioisotope production. The device consists of a target body presenting a target space for introduction of target media to be irradiated by the ion beam from the cyclotron accelerator. The target body is separated into three portions by means of two separation window foils. The first separation window separates the internal space of a first body portion from a further internal space portion of a second target body portion and the second separation window separates a further internal space of the second target body portion from an internal space of a third target body portion being in communication with the vacuum space of the cyclotron. This third body portion forms a bayonet fitting to a corresponding bayonet fitting fixed to the cyclotron vacuum casing at a position where the ion beam is extracted, whereby the corresponding bayonet fitting also constitutes an insulating member. The device can by a small twisting be quickly released from the vacuum casing of the cyclotron after the vacuum has been removed for necessary maintenance and service.

Owner:GEMS PET SYST

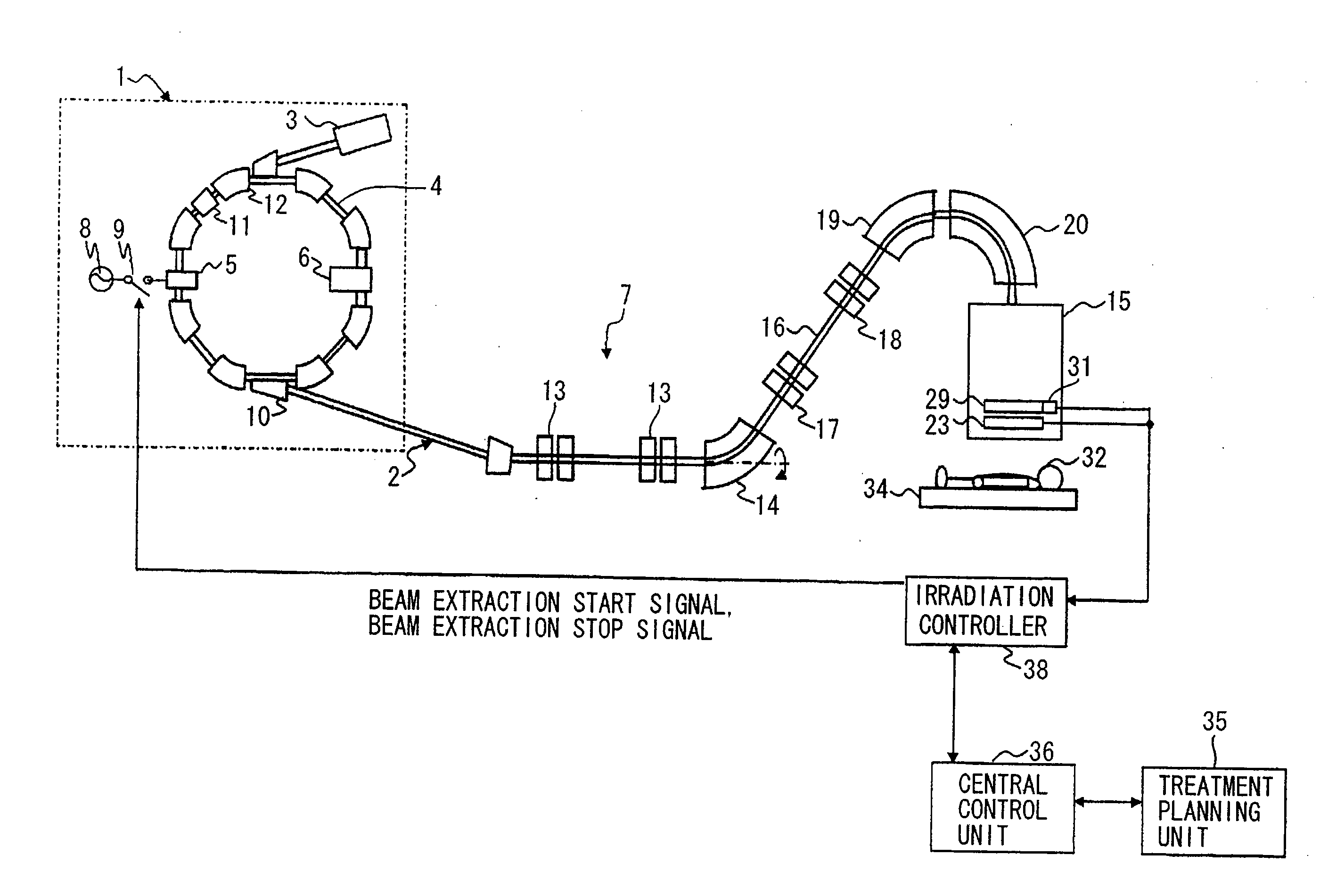

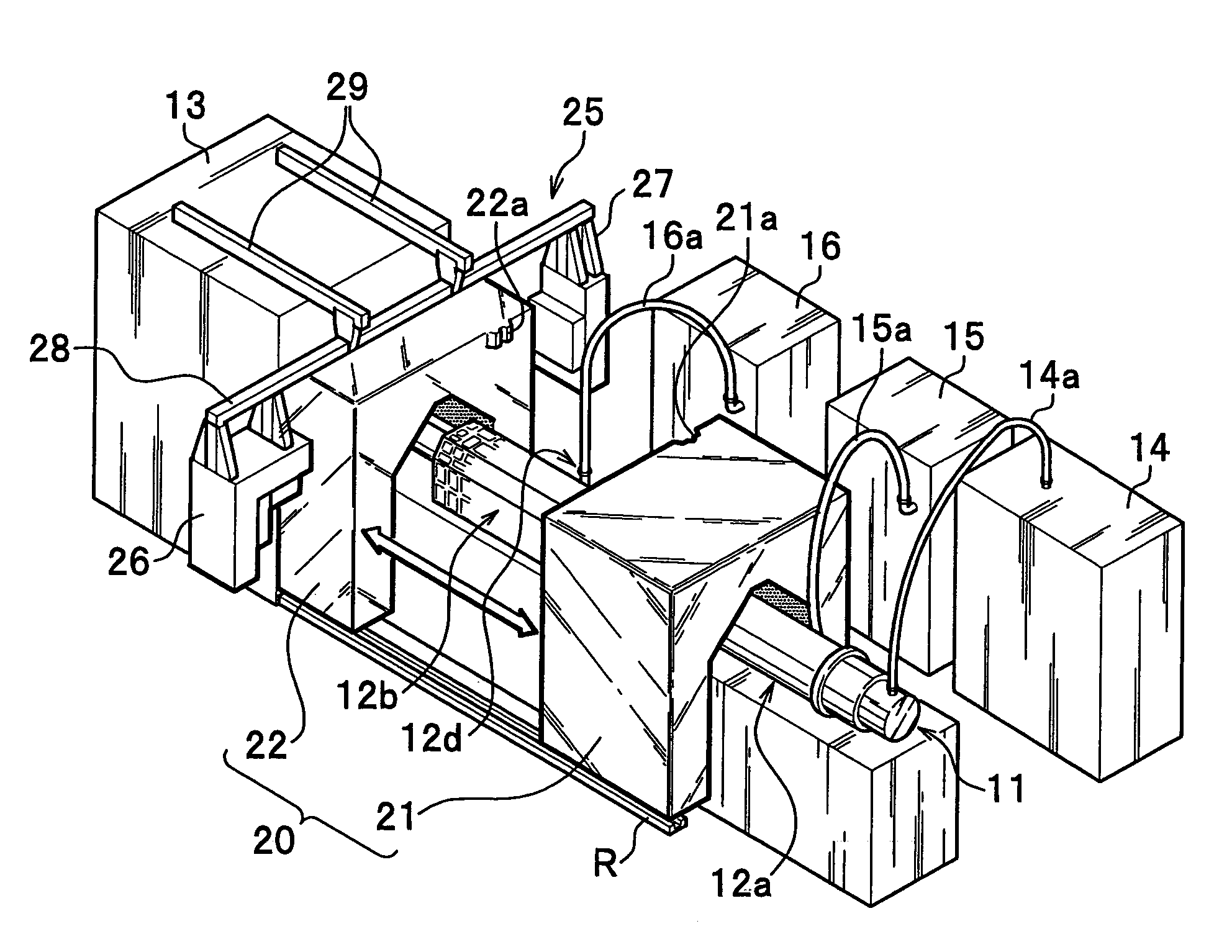

Particle therapy system

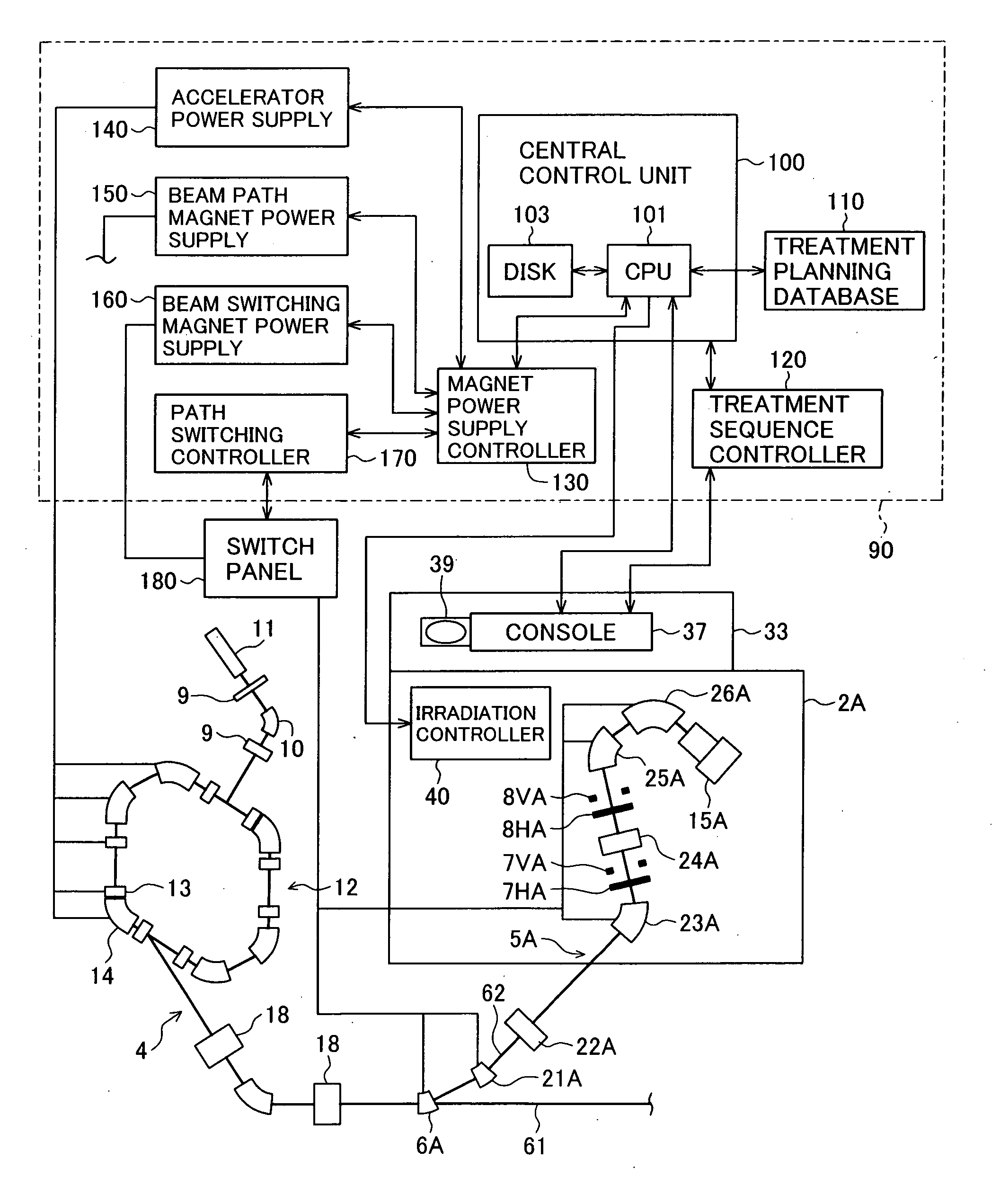

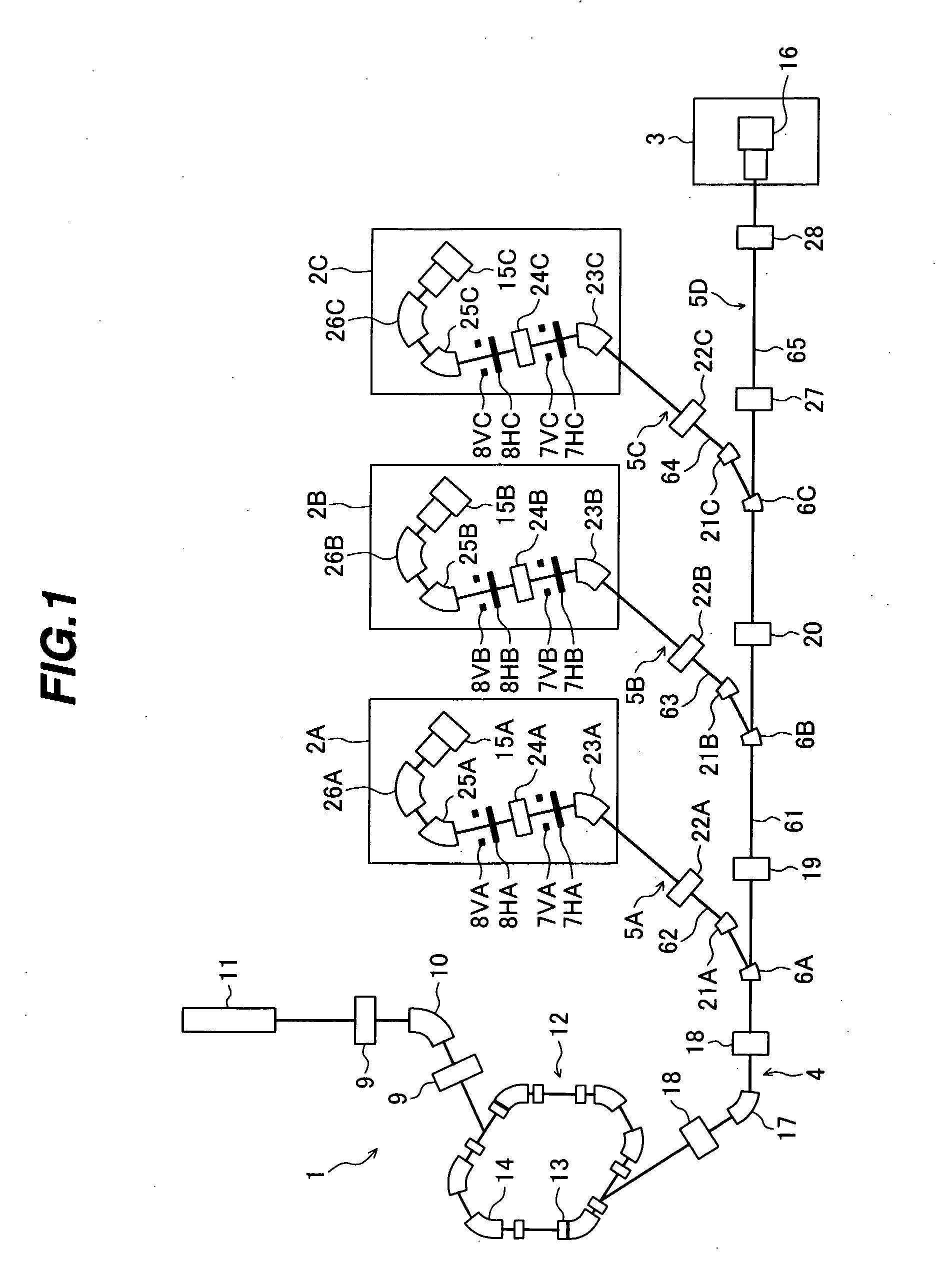

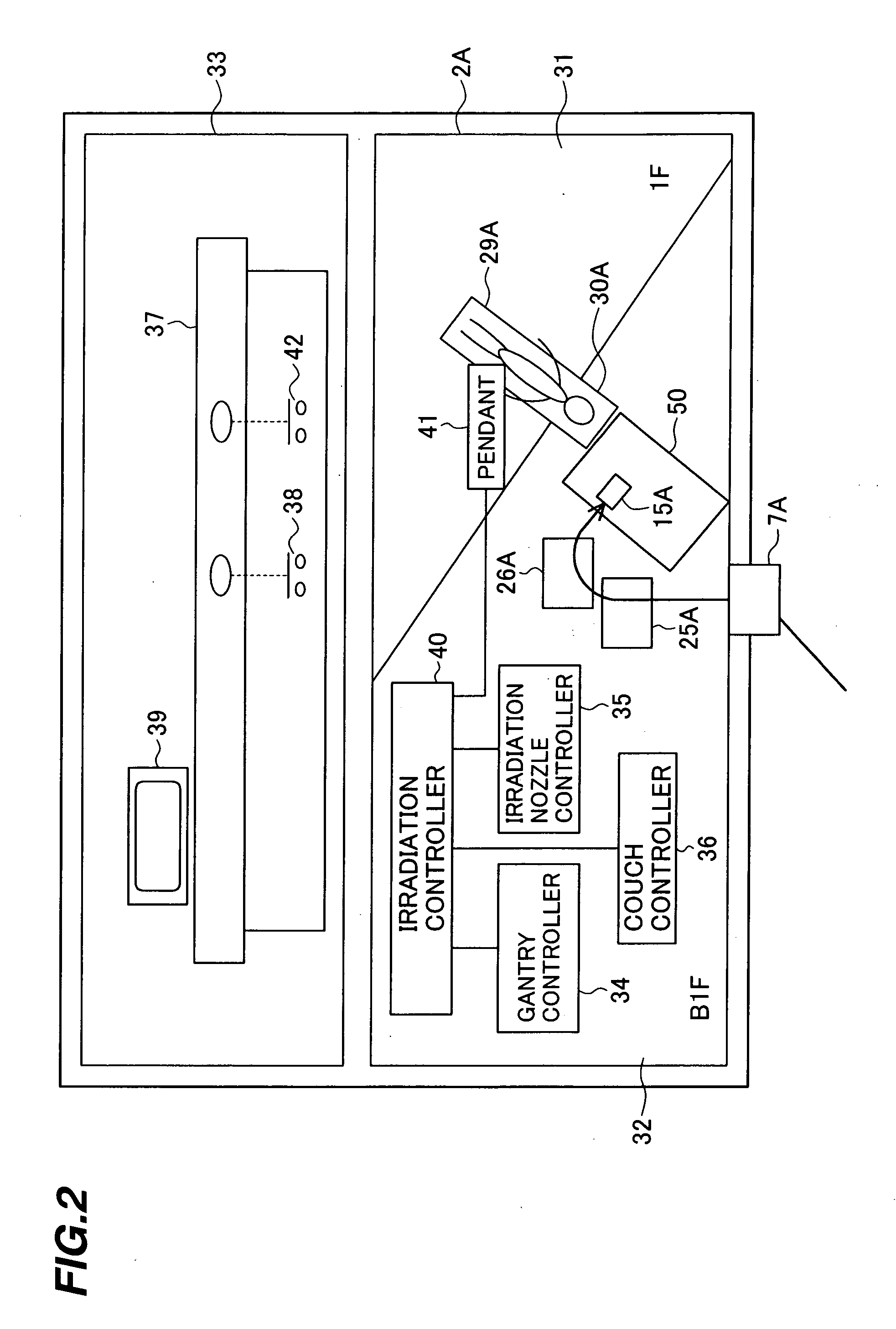

InactiveUS20050139787A1Time to setLow efficiencyThermometer detailsBeam/ray focussing/reflecting arrangementsTransport systemExcitation current

A particle therapy system capable of increasing the number of patients treated in one treatment room per unit time. The particle therapy system comprises a charged particle beam generator for generating an ion beam, an irradiation apparatus for irradiating the ion beam extracted from the charged particle beam generator to an irradiation target, a beam transport system for transporting the ion beam extracted from the charged particle beam generator to the irradiation apparatus, and a central control unit for producing a set of command data to command excitation currents for magnets disposed in the charged particle beam generator and the beam transport system, the set of command data being classified into group-1 data and group-2 data.

Owner:HITACHI LTD

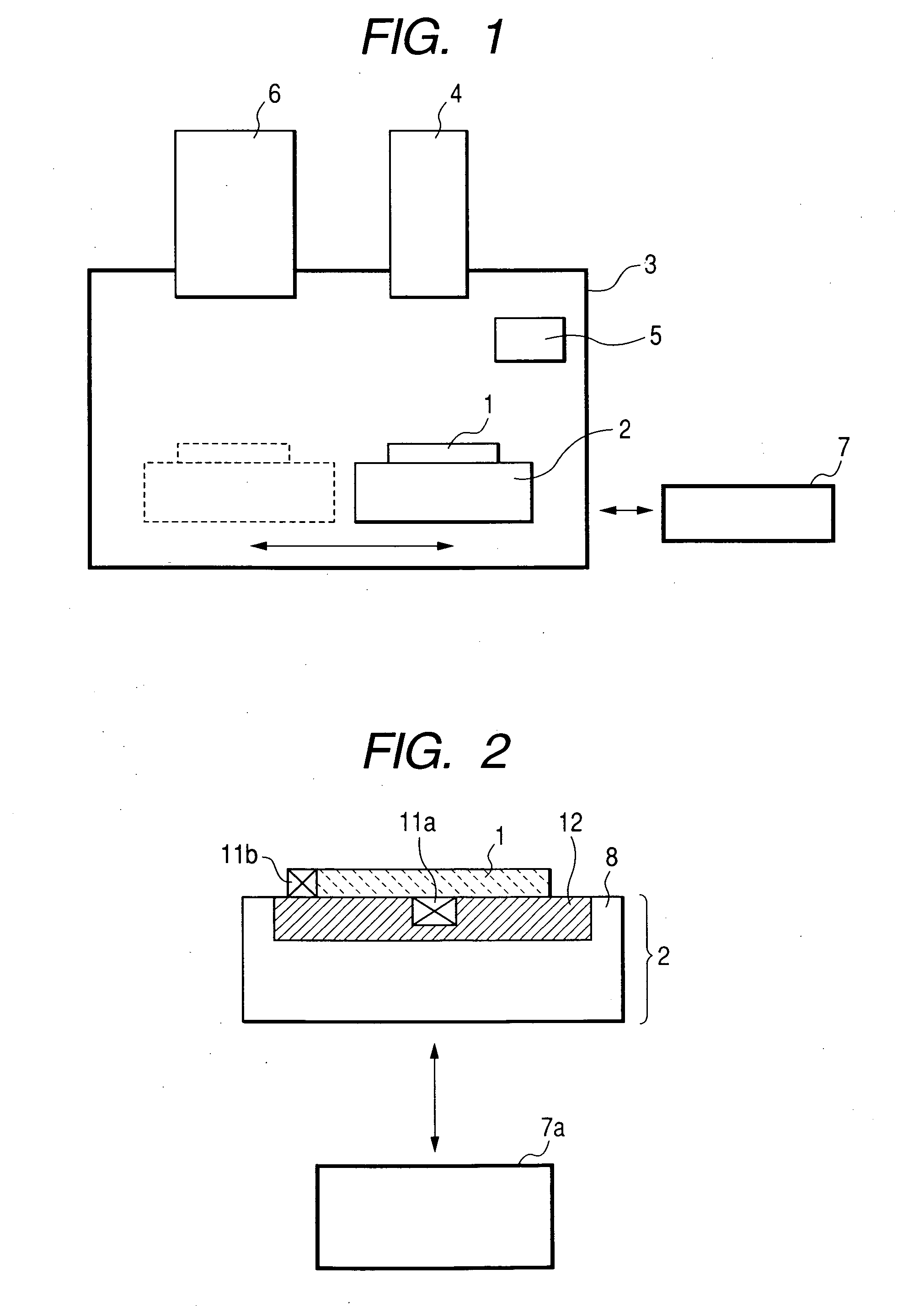

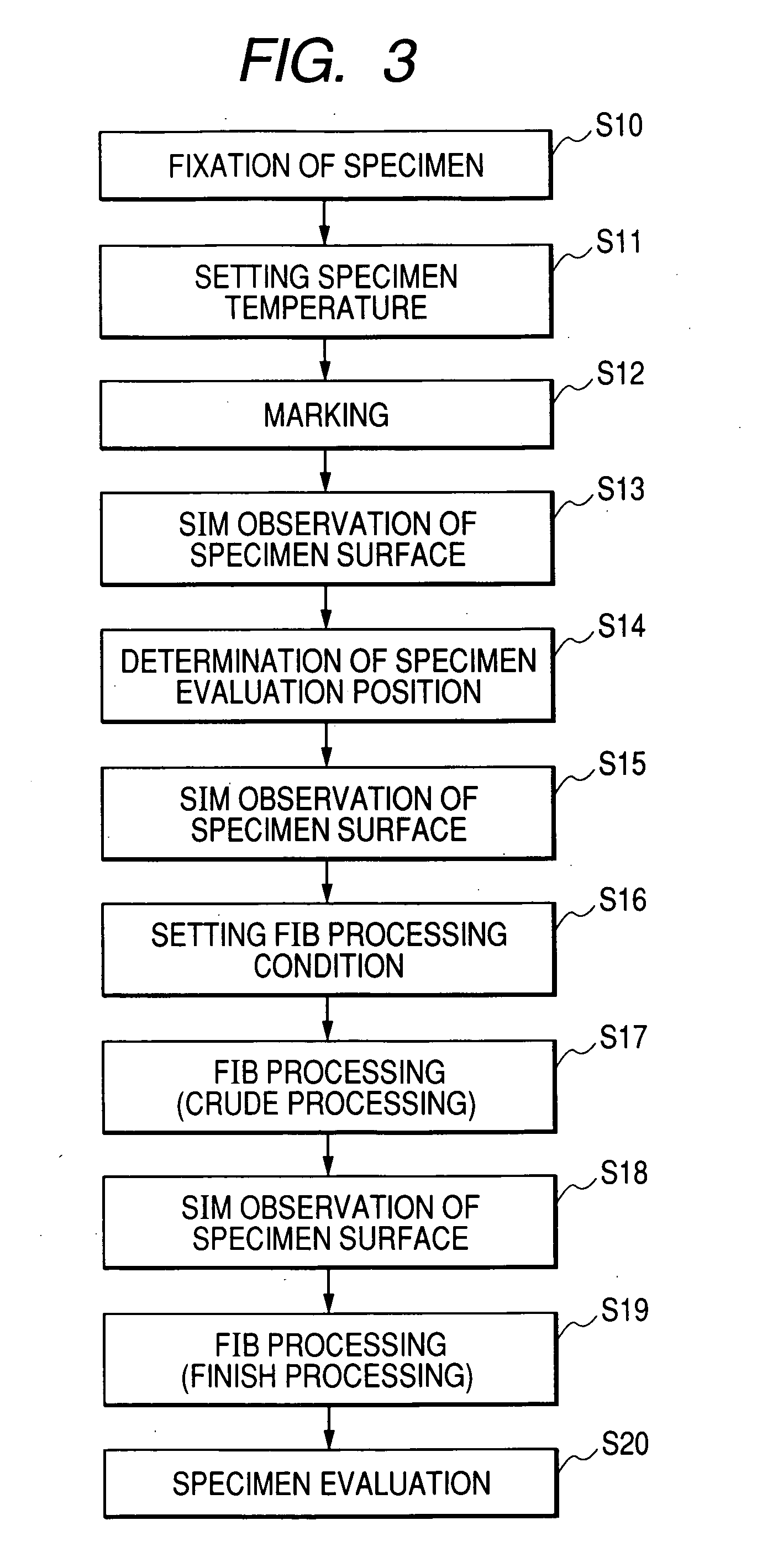

Apparatus and method for evaluating cross section of specimen

InactiveUS20060060777A1Effective evaluationEasy to identifyMaterial analysis using wave/particle radiationElectric discharge tubesIrradiationAtomic physics

An apparatus for evaluating a cross section of a specimen in a specimen chamber wherein the apparatus comprises a specimen stage for placing the specimen, temperature regulation means for regulating the temperature of the specimen, ion beam generation means for irradiating the specimen with an ion beam thereby performing cross section processing and observation of the specimen, detection means for detecting emission signals emitted from the specimen in response to the irradiation of the ion beam for observing the specimen and marking means for marking the specimen.

Owner:CANON KK

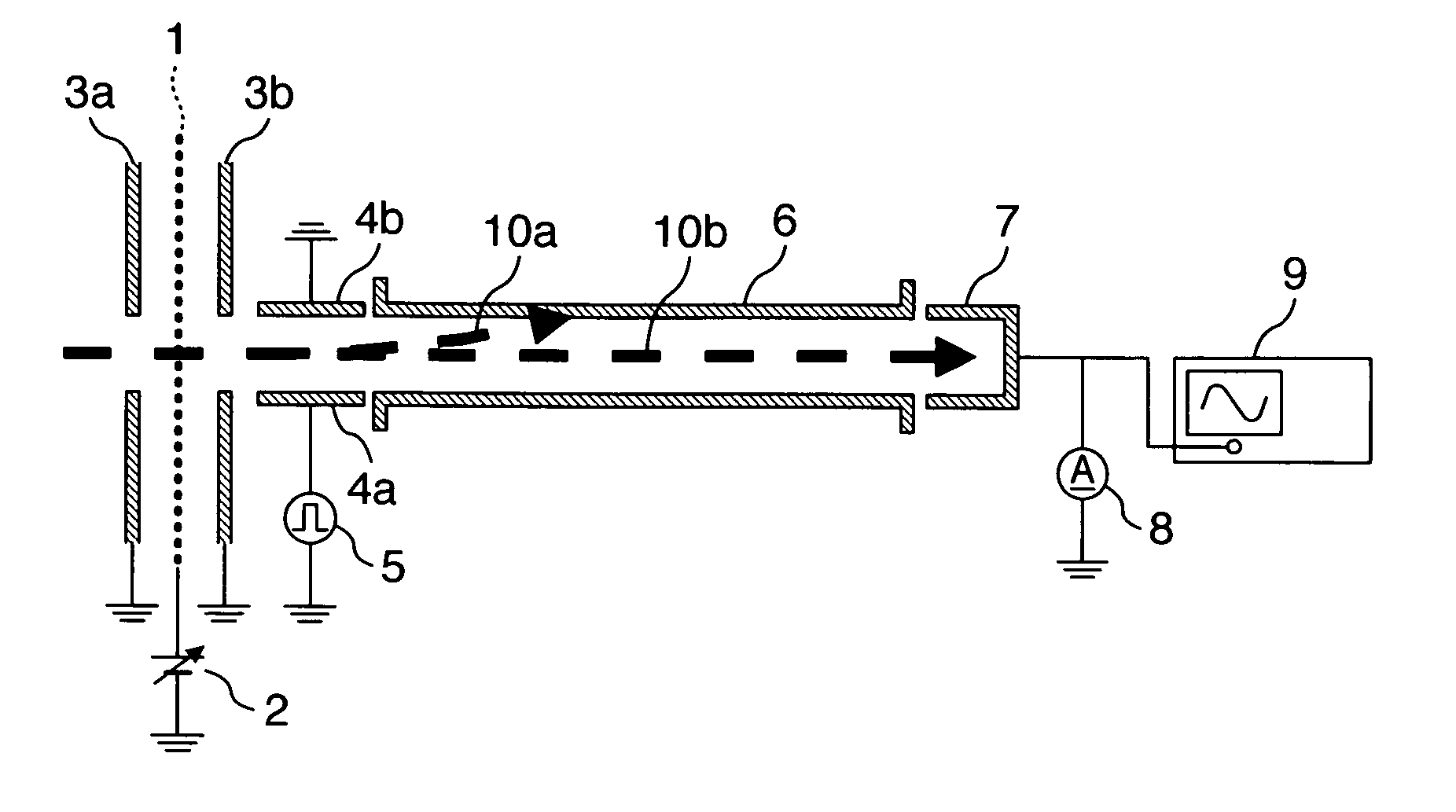

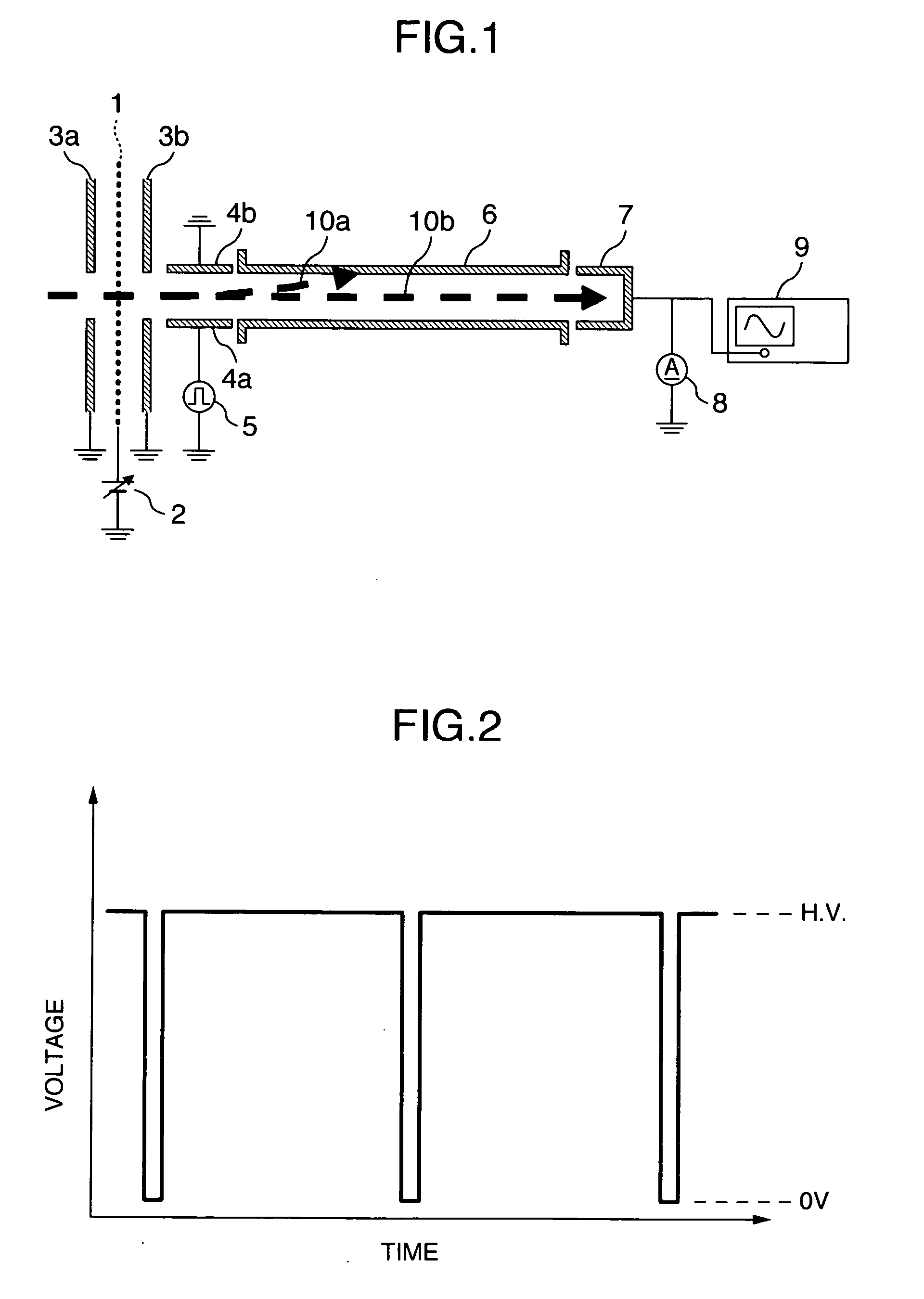

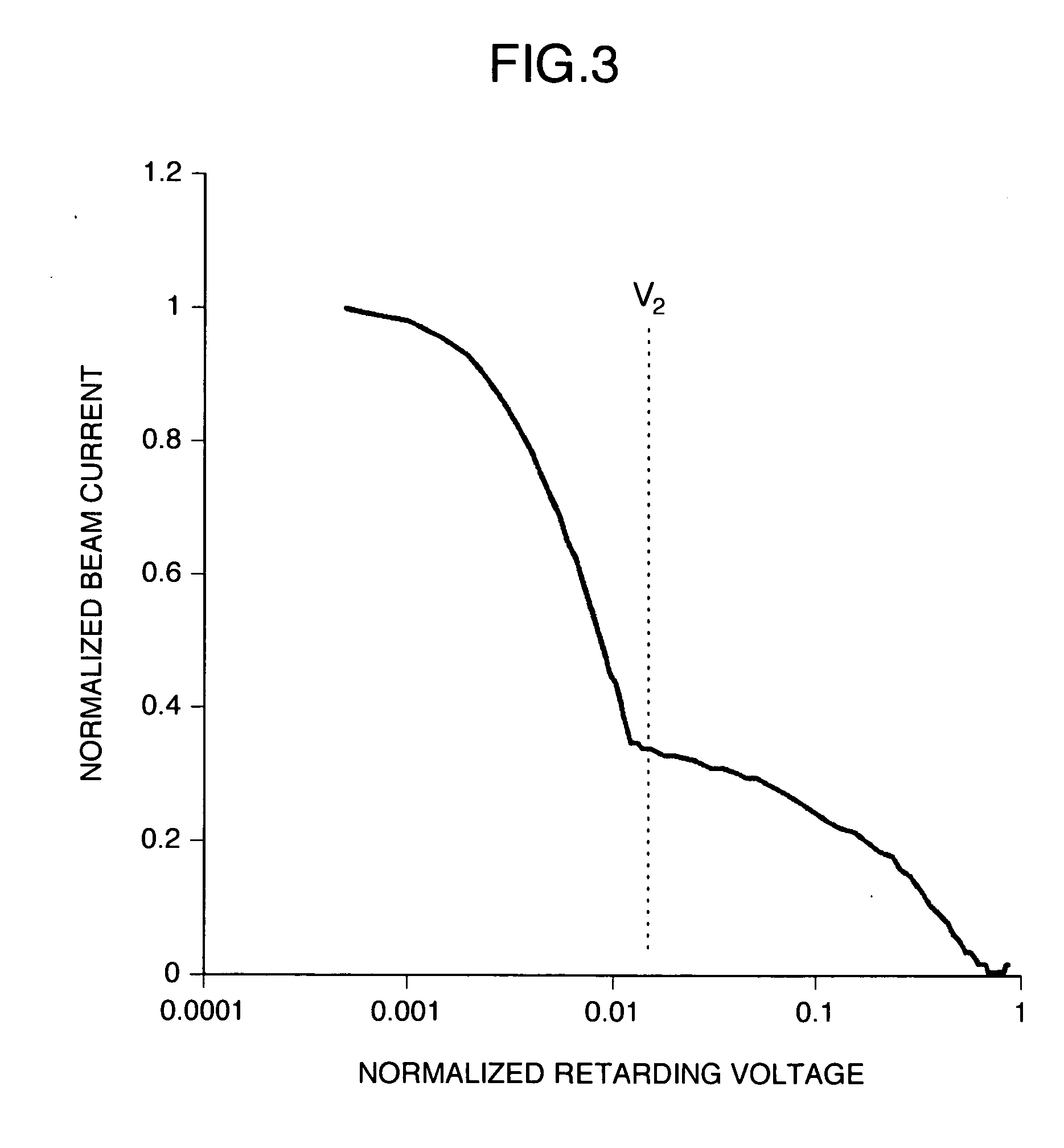

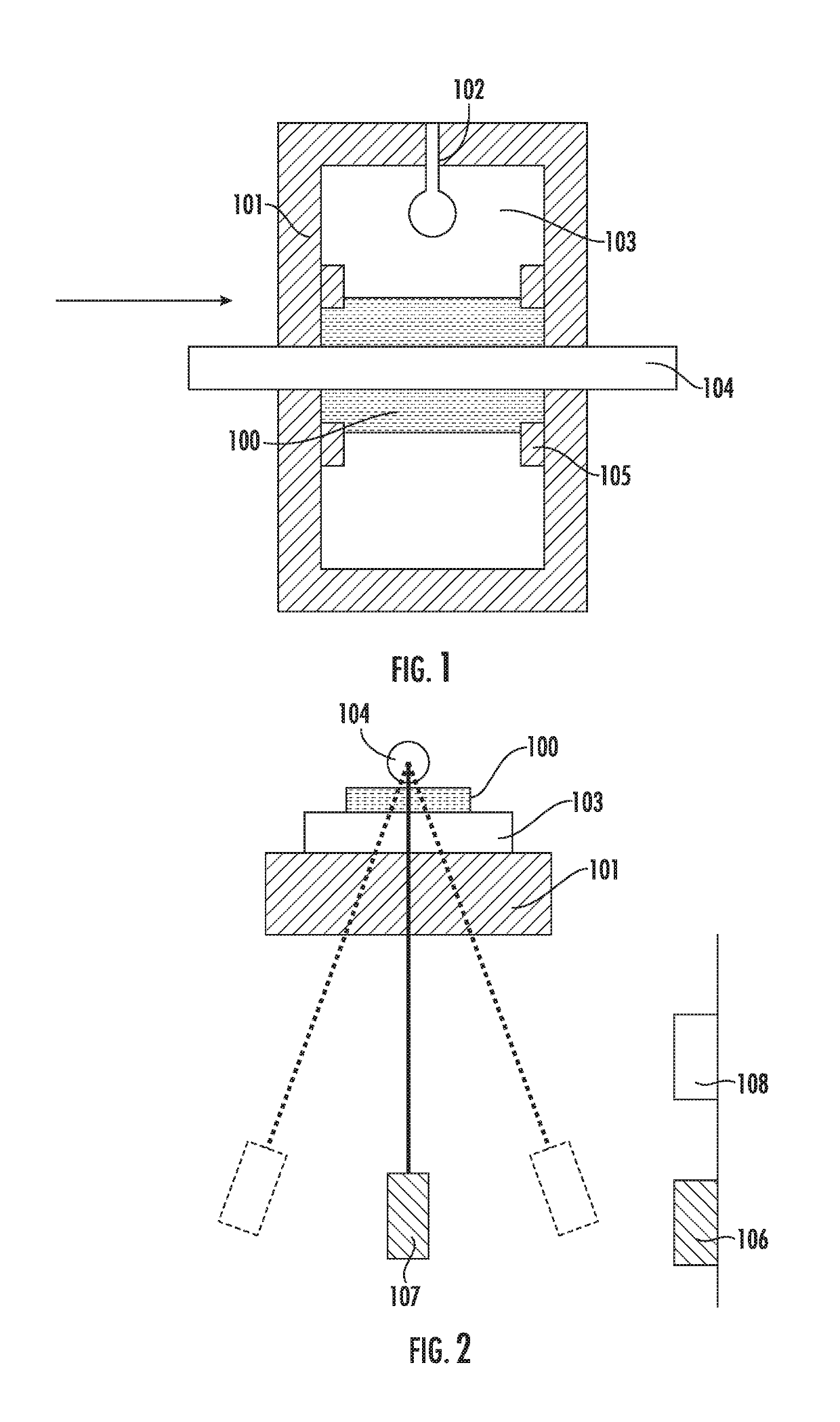

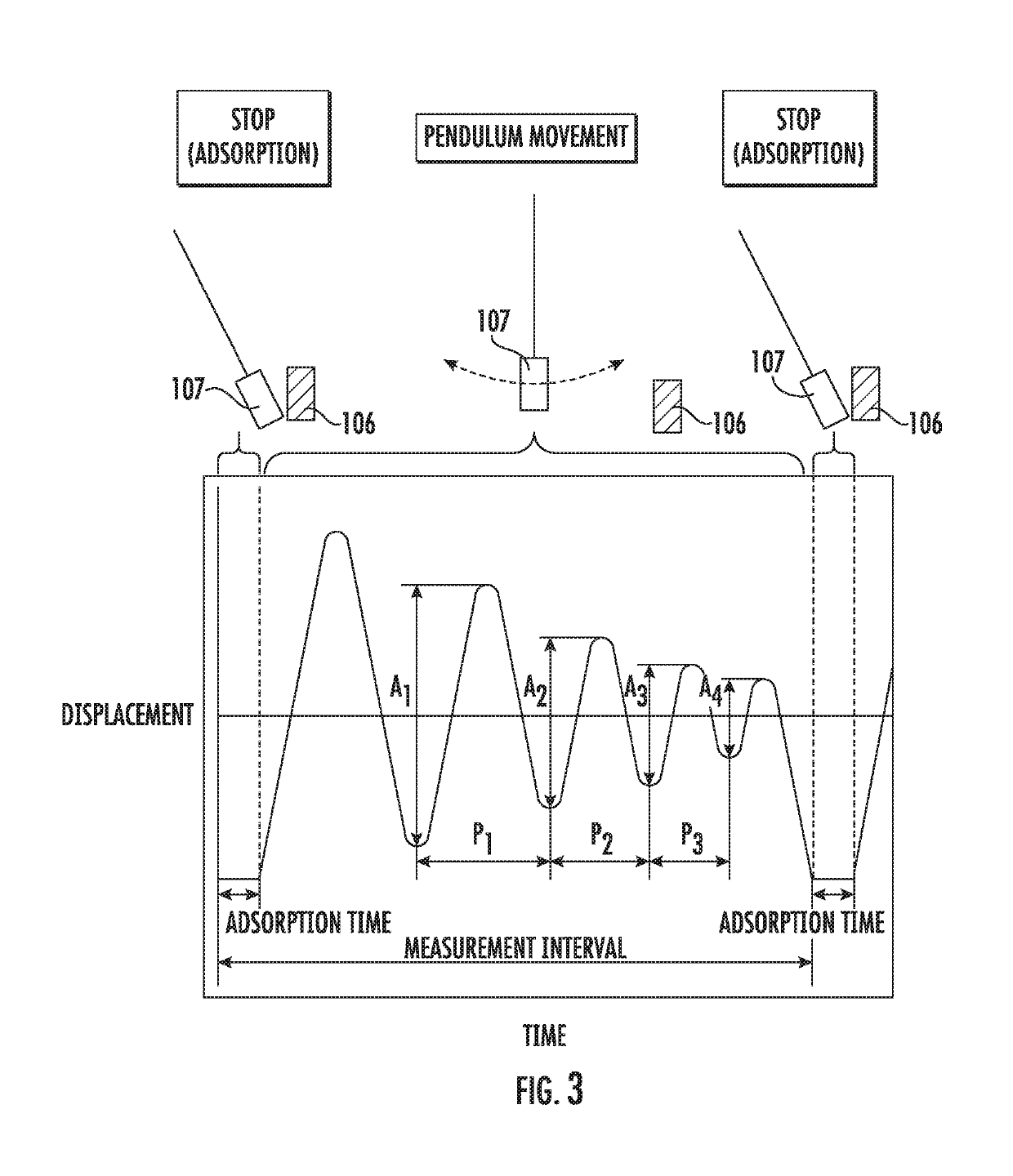

Cluster-ion beam irradiation apparatus and method for manufacturing magnetic head element using the same

InactiveUS20060043317A1Good effectSmall sizeParticle separator tubesIsotope separationMeasuring instrumentDrift tube

In a cluster ion beam irradiation apparatus including an apparatus for measuring size and energy distribution of gas cluster ions by using the time of flight (TOF) mass spectrometry, a unit for applying a retarding voltage is disposed in a stage preceding a TOF measuring instrument including a drift tube and a current measuring instrument. By measuring the size and energy distribution of the gas cluster ions and adjusting ionization conditions, cluster ions having predetermined energy and size are supplied to a work surface. In addition, a product of a pressure in an ion transportation device and an ion transportation length is controlled so as to satisfy the relation P×L≦30 / N2 / 3 / E1 / 2 Pa.m, where N is the size of gas cluster ions used for irradiation, and E is kinetic energy (eV) of the gas cluster ions.

Owner:HITACHI LTD

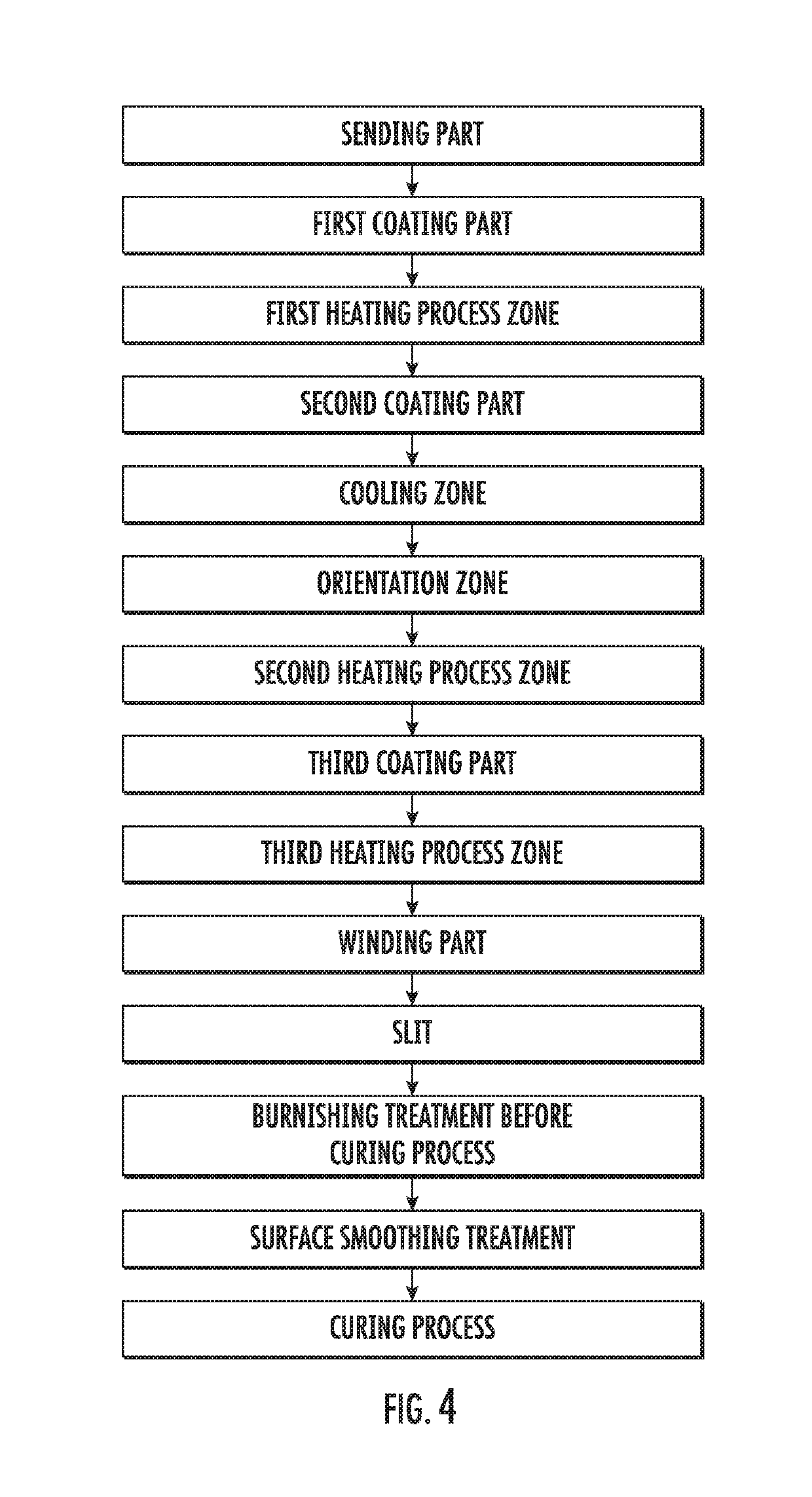

Magnetic tape having characterized magnetic layer and magnetic recording and reproducing device

ActiveUS10515657B2Excellent electromagnetic conversion characteristicAvoid it happening againDisposition/mounting of recording headsMagnetic materials for record carriersMagnetic tapeViscoelasticity

Owner:FUJIFILM CORP

Blazed holographic grating, method for producing the same and replica grating

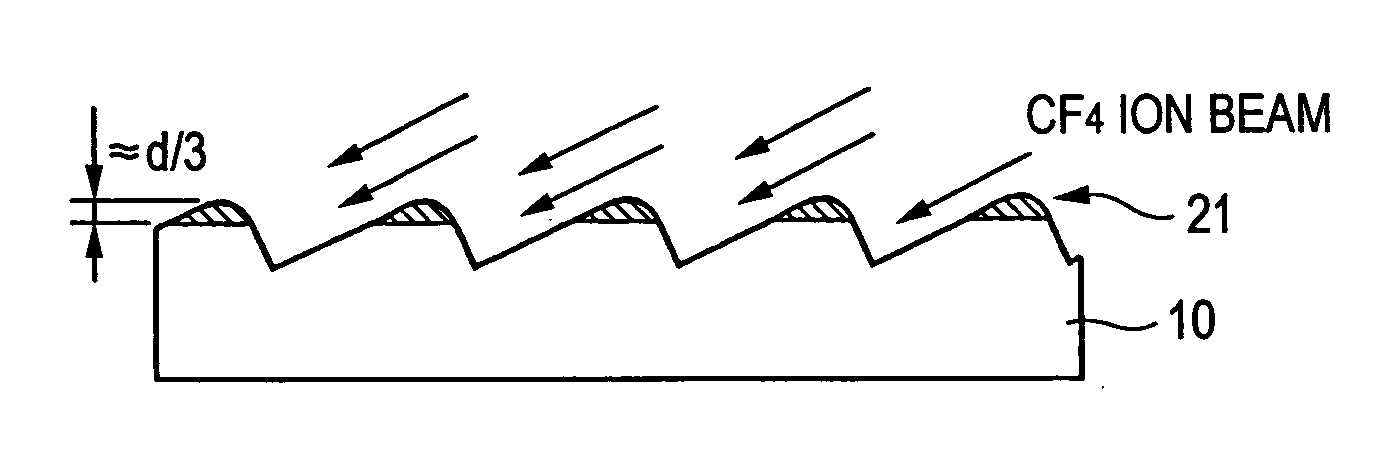

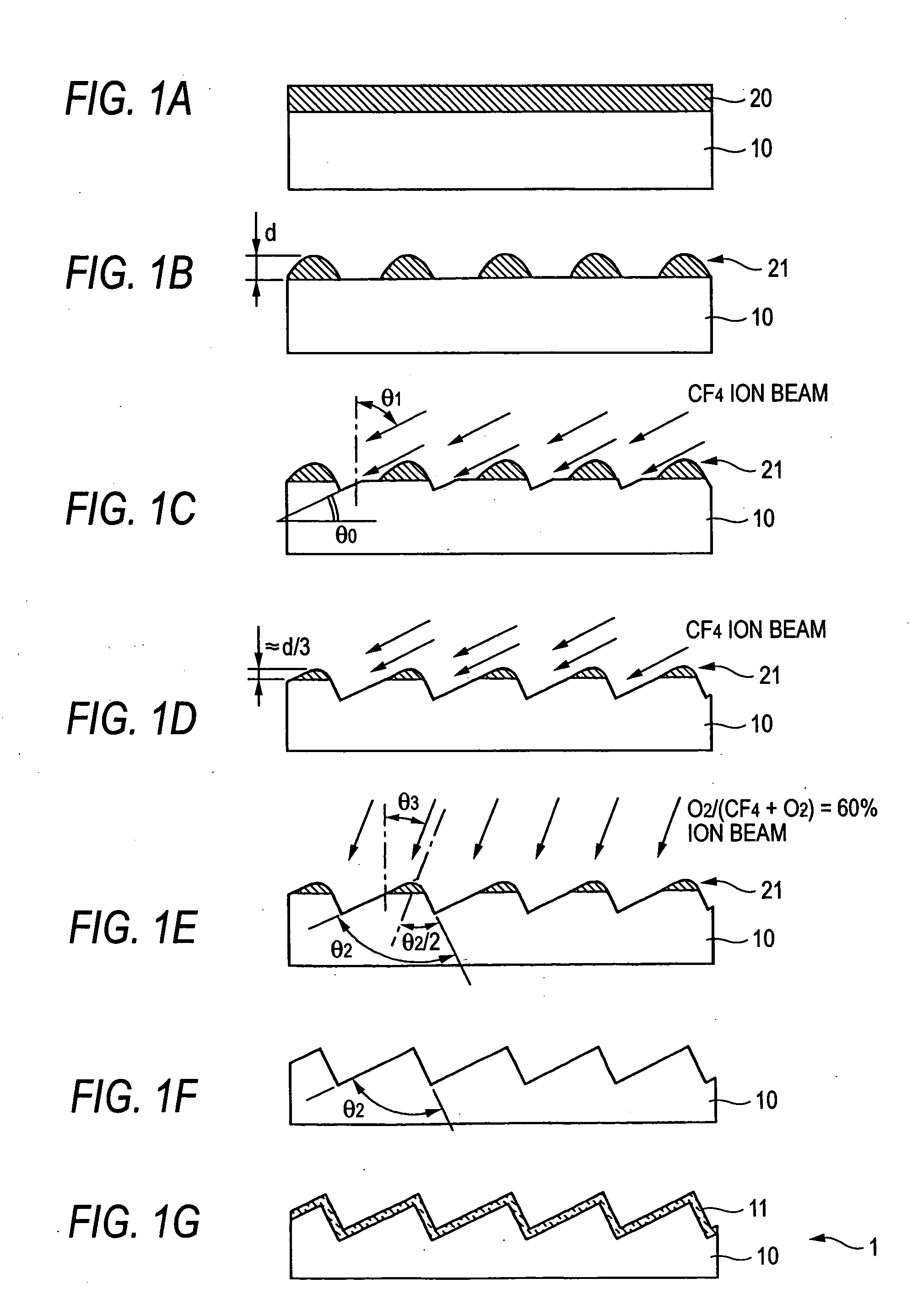

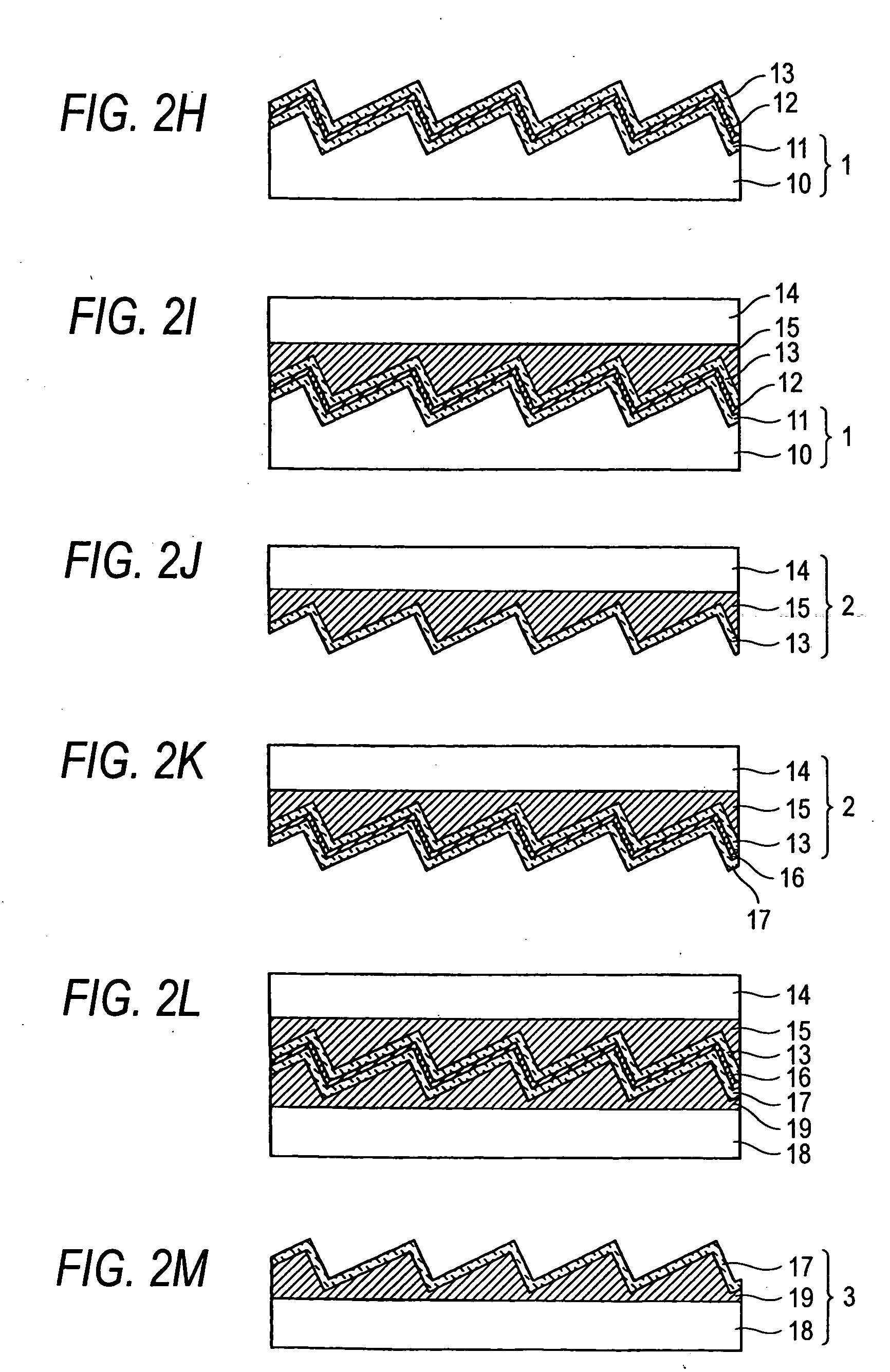

InactiveUS20050130072A1High diffraction efficiencyImprove linearityOptical articlesDiffraction gratingsResistIon beam irradiation

A substrate is subjected to holographic exposure to a sinusoidal or half-sinusoidal resist pattern corresponding to grating groove thereon. Thereafter, the substrate and the resist pattern are subjected to a first etching step at which they are irradiated with an ion beam obliquely at an angle that is identical to the blaze angle in the presence of CF4 as an etching gas, whereby they are cut until the height of the resist is about ⅓ of the initial value. Thereafter, the substrate is subjected to a second etching step at which the substrate is irradiated with an ion beam in the direction corresponding to the bisector of the vertex in the presence of a mixture of CF4 and O2 as an etching gas, whereby the substrate is cut until the resist disappears completely to an extent such that some overetching occurs.

Owner:SHIMADZU CORP

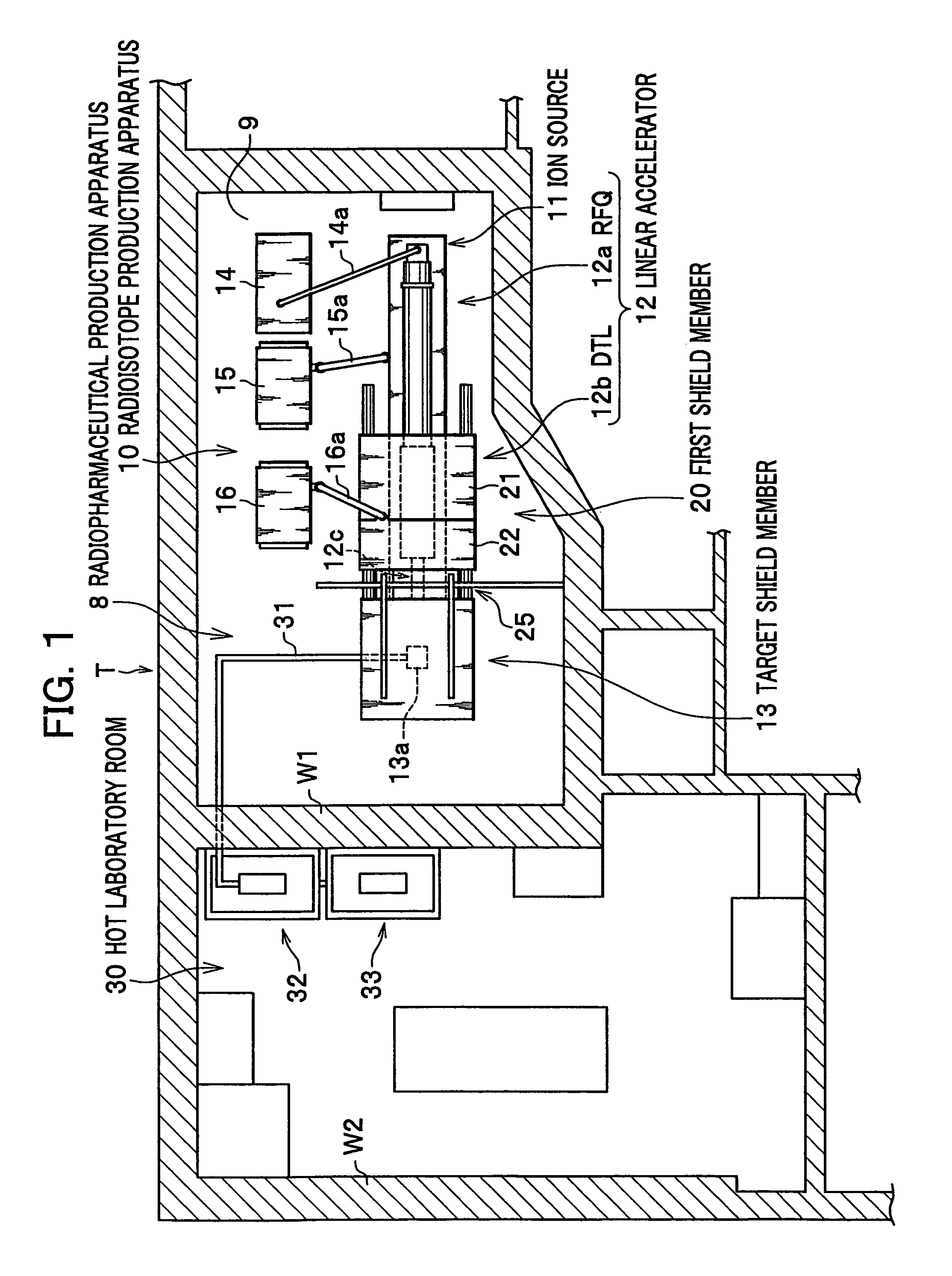

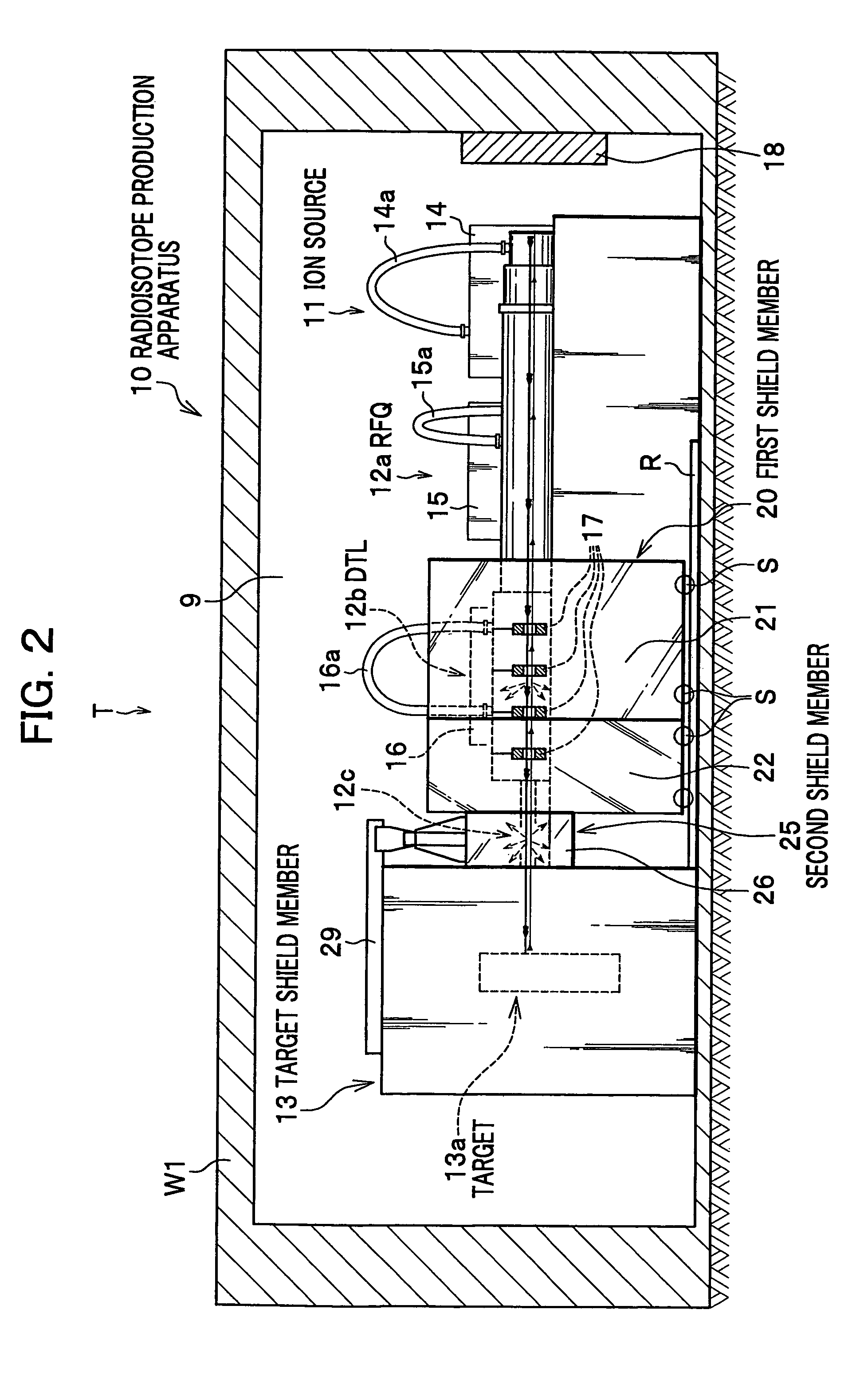

Radioisotope production apparatus and radiopharmaceutical production apparatus

InactiveUS7394081B2Reduce construction costsImprove abilitiesLaser detailsConversion outside reactor/acceleratorsEngineeringRadio frequency

A radioisotope production apparatus includes: a linear accelerator for accelerating an ion beam and irradiating a target with the ion beam, radio frequency power supplies for supplying radio frequency waves through coaxial tubes and the linear accelerator, a target shield member containing the target, a first radiation shield member covering the linear accelerator, and a movable second radiation shield member covering the side of target shield member of the linear accelerator between the first radiation shield member and the target shield member. The first radiation shield member is movably divided in opposite directions, respectively, of the axial direction of the linear accelerator from the base point of the connection point of the coaxial tube connected to the linear accelerator.

Owner:HITACHI LTD

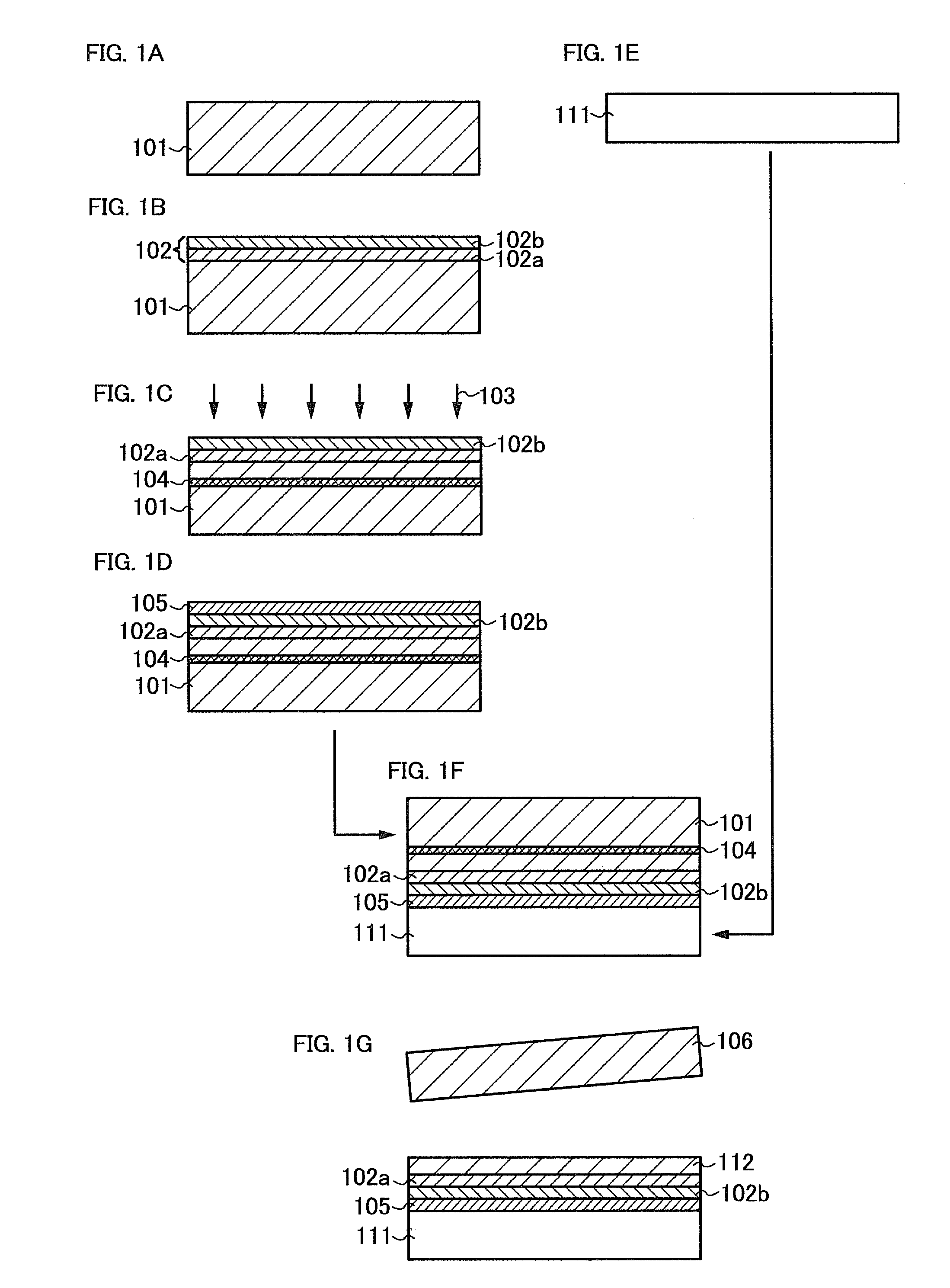

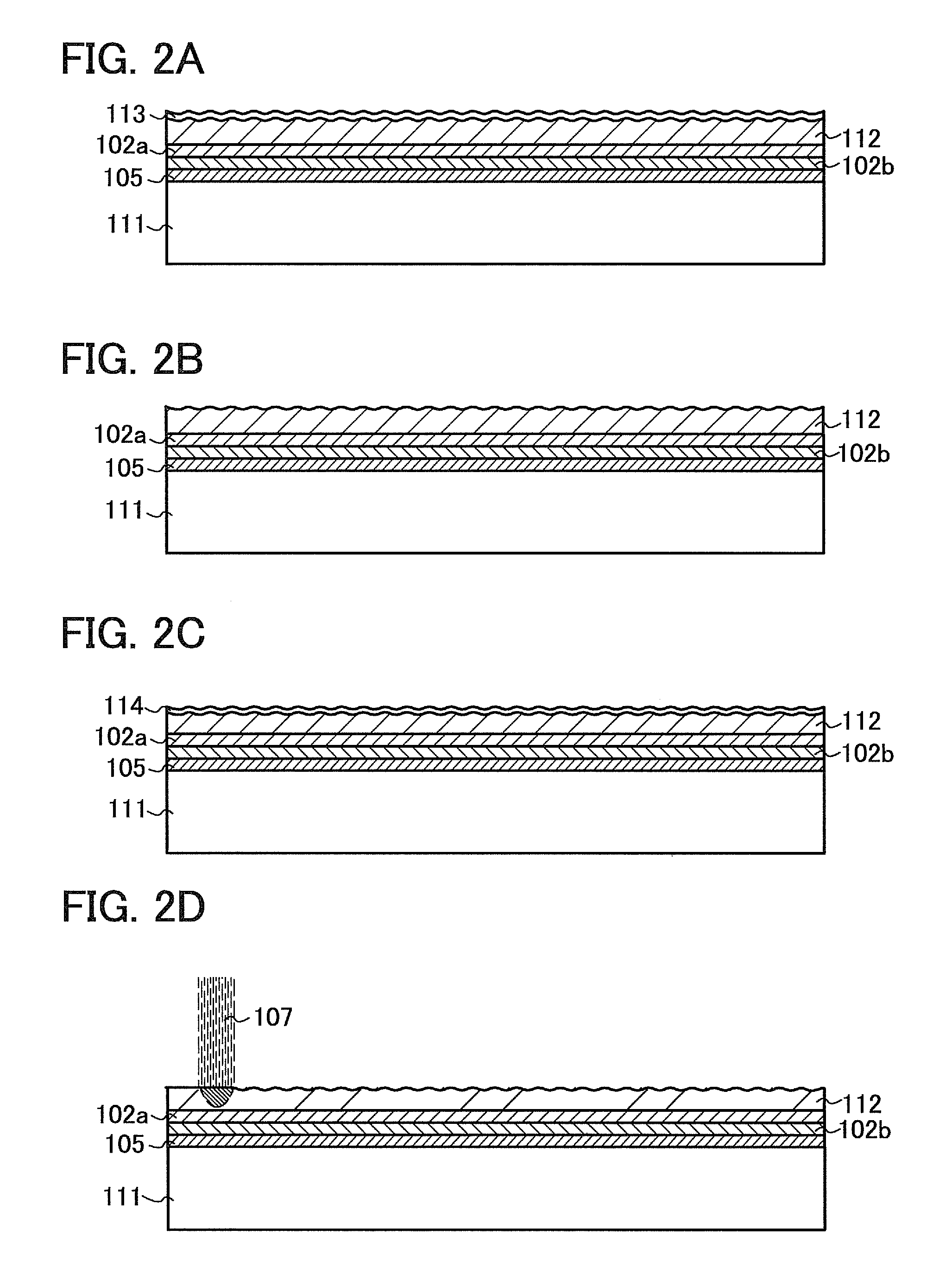

Method for manufacturing soi substrate

ActiveUS20090239354A1Remove defectDefect damage of surfaceSemiconductor/solid-state device manufacturingLaser lightSingle crystal

Forming an insulating film on a surface of the single crystal semiconductor substrate, forming a fragile region in the single crystal semiconductor substrate by irradiating the single crystal semiconductor substrate with an ion beam through the insulating film, forming a bonding layer over the insulating film, bonding a supporting substrate to the single crystal semiconductor substrate by interposing the bonding layer between the supporting substrate and the single crystal semiconductor substrate, dividing the single crystal semiconductor substrate at the fragile region to separate the single crystal semiconductor substrate into a single crystal semiconductor layer attached to the supporting substrate, performing first dry etching treatment on a part of the fragile region remaining on the single crystal semiconductor layer, performing second dry etching treatment on a surface of the single crystal semiconductor layer subjected to the first etching treatment, and irradiating the single crystal semiconductor layer with laser light.

Owner:SEMICON ENERGY LAB CO LTD

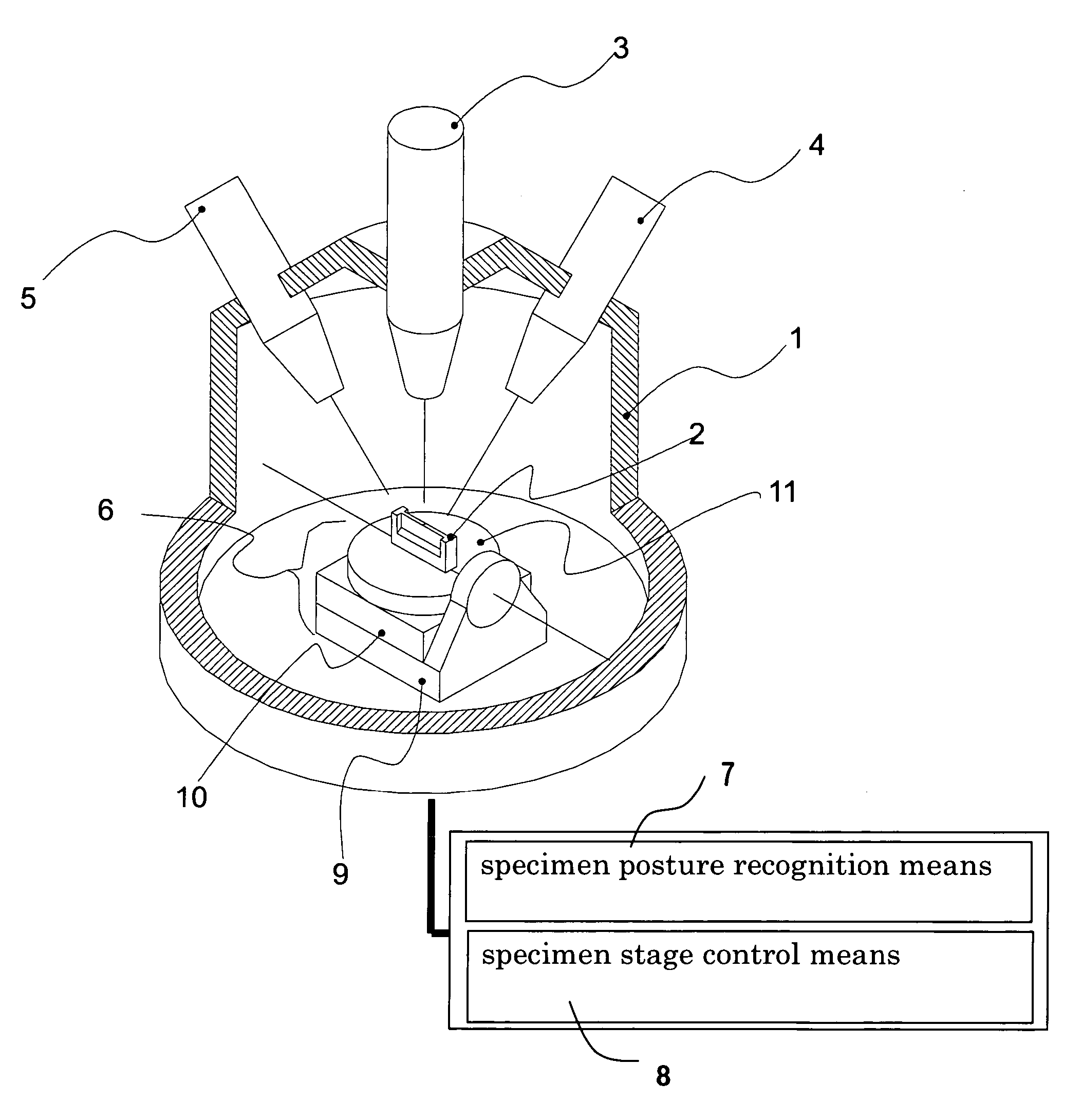

Ion beam apparatus, ion beam processing method and sample holder member

InactiveUS6838685B1Suppressing re-attachmentElectric discharge tubesPreparing sample for investigationIon beam processingIrradiation

An ion beam processing device has a sample holder for fixing a sample on which a section has been formed by irradiation of a specified focused ion beam from a surface side, and gas ion beam irradiation device for irradiating a gas ion beam to a region of the sample fixing using the holder member that contains the section to remove a damage layer on the section. The gas ion beam from the gas ion beam irradiation device irradiates the section from a rear surface side of the sample at a specified incident angle.

Owner:HITACHI HIGH TECH SCI CORP

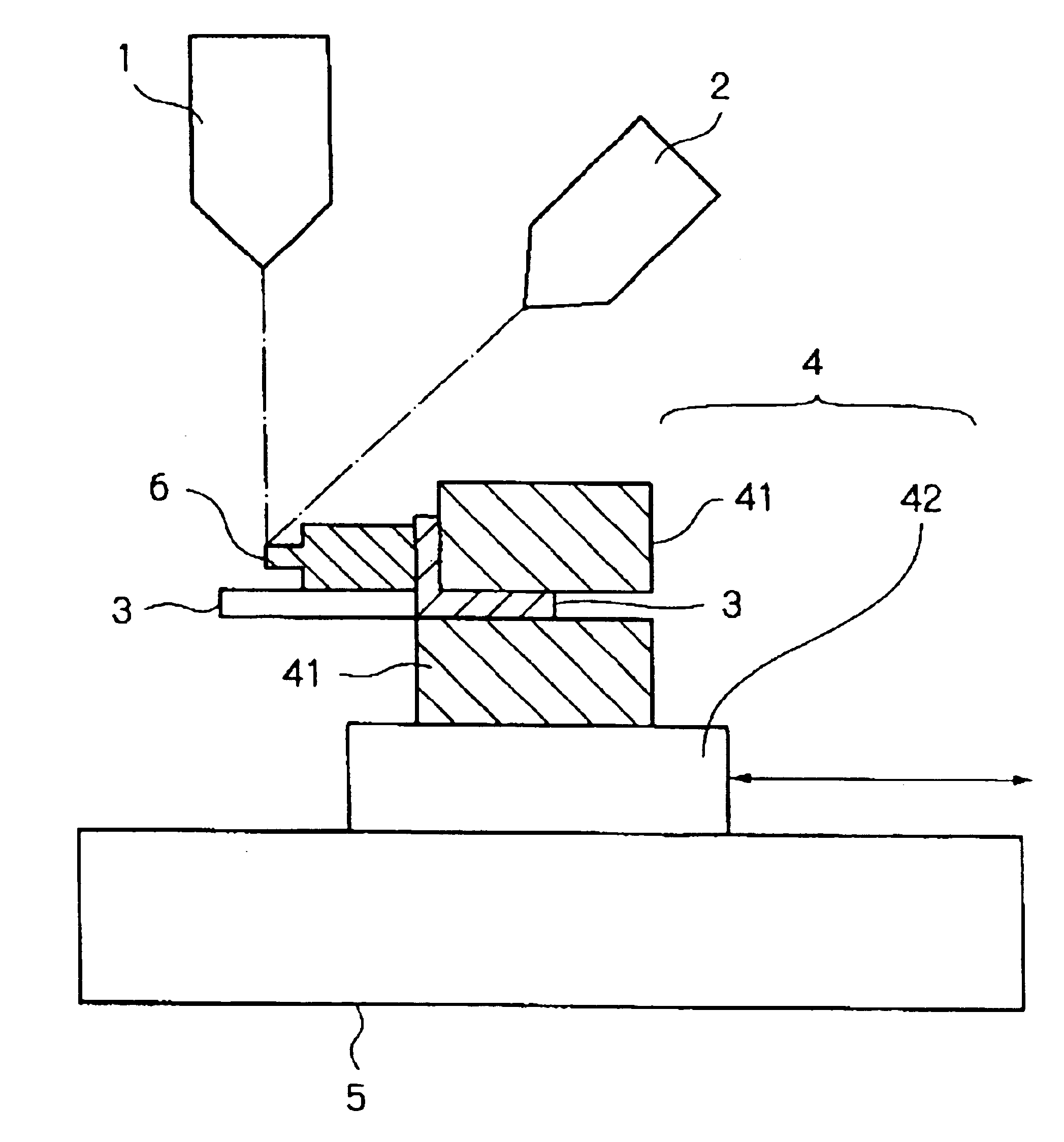

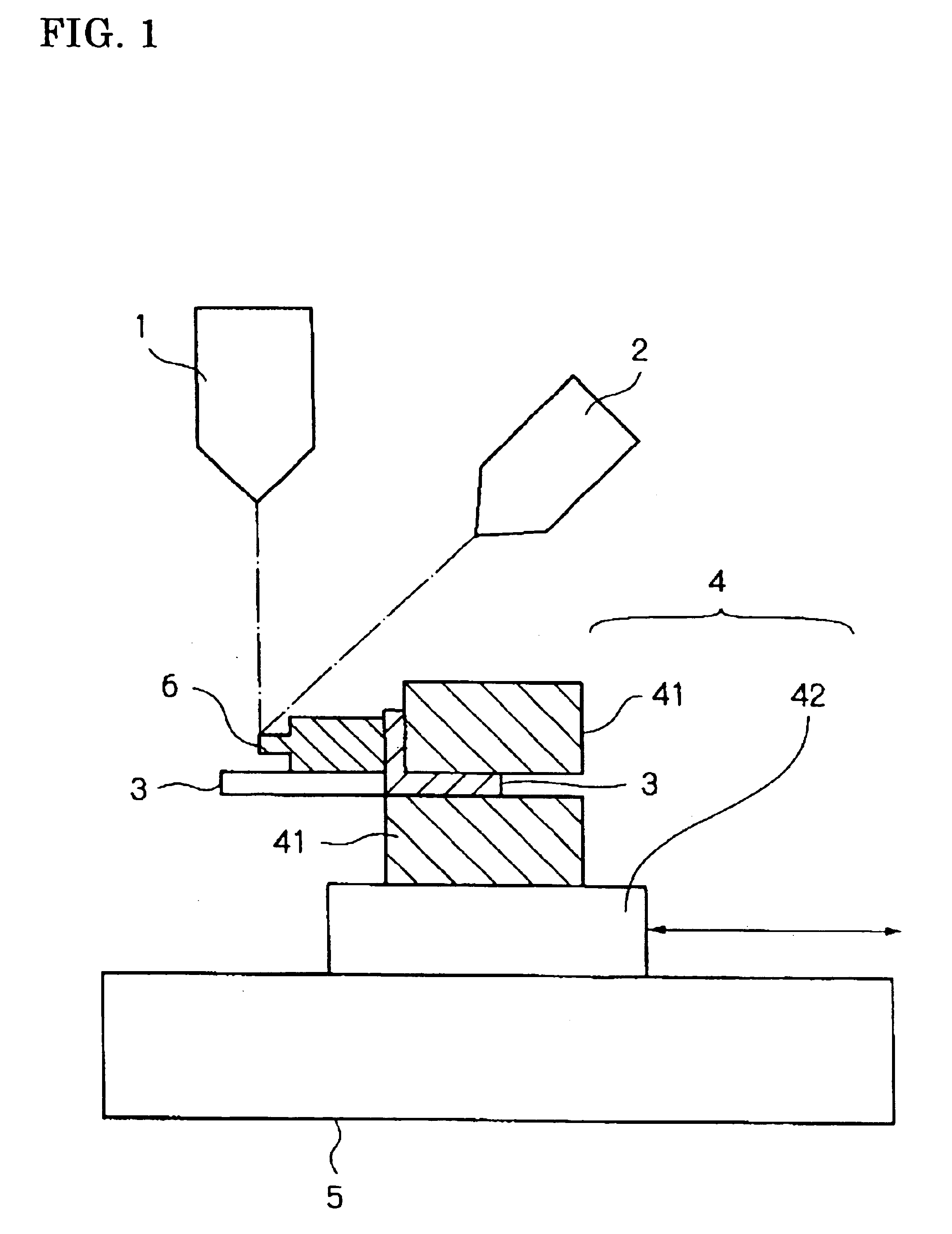

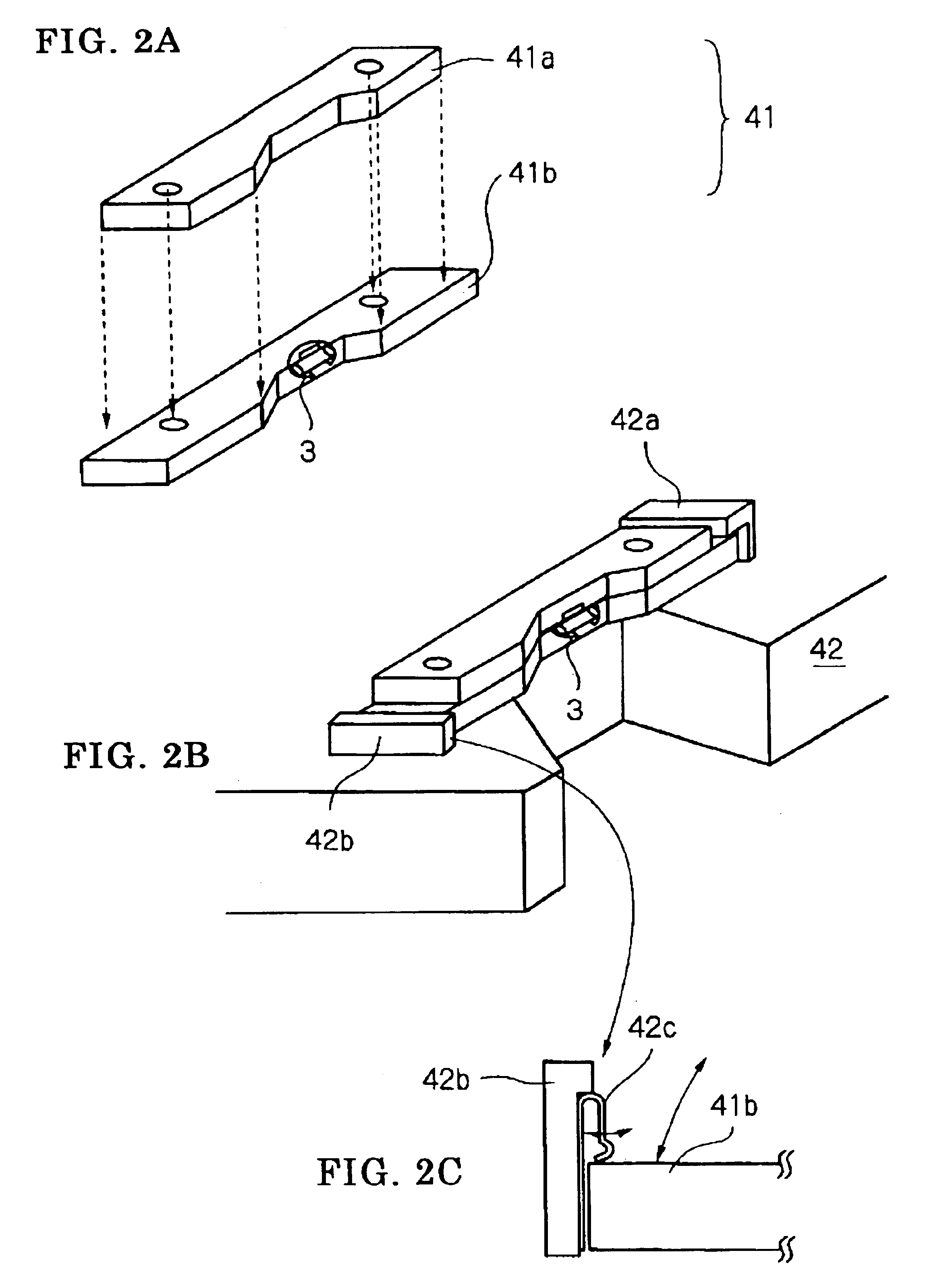

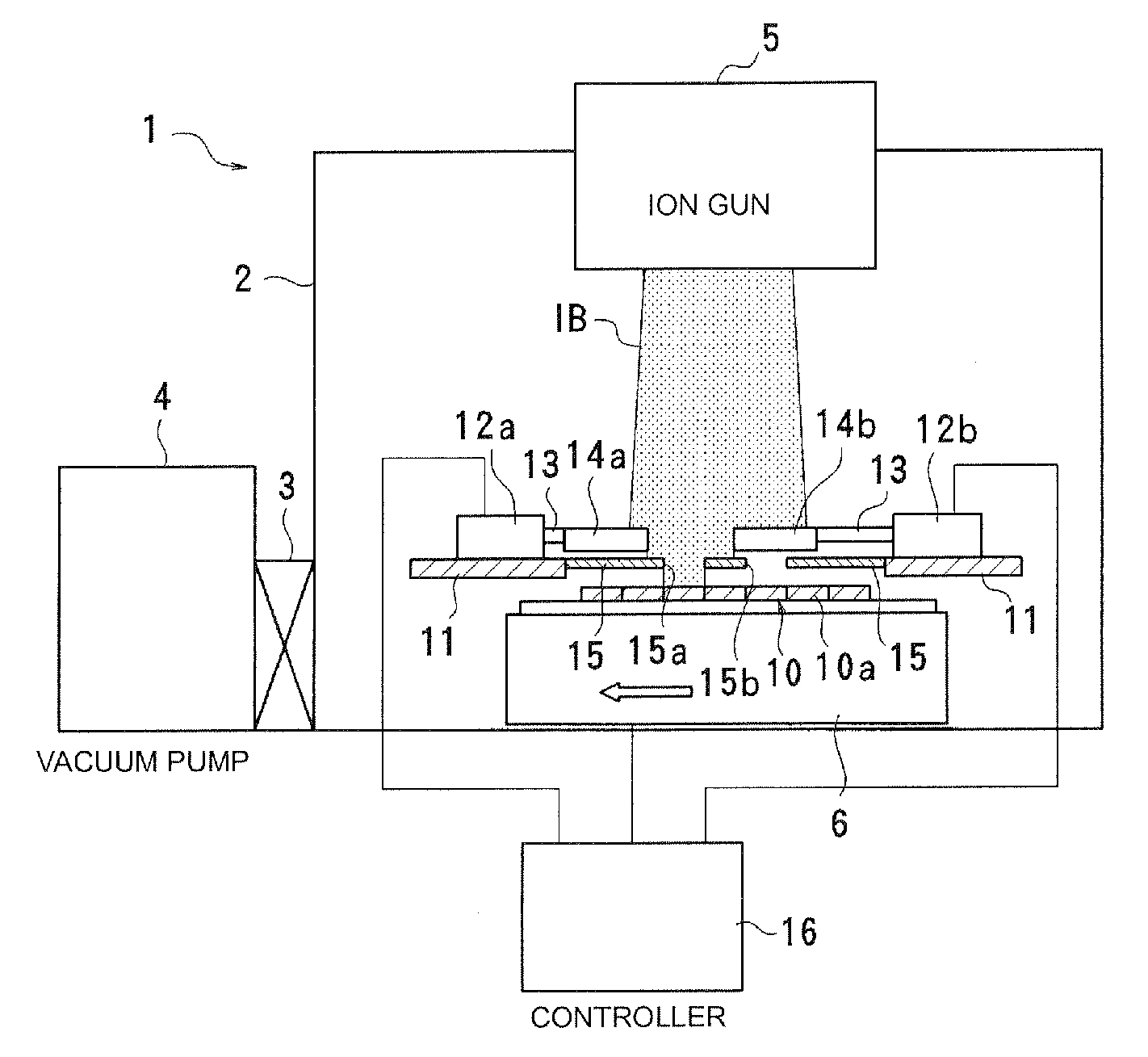

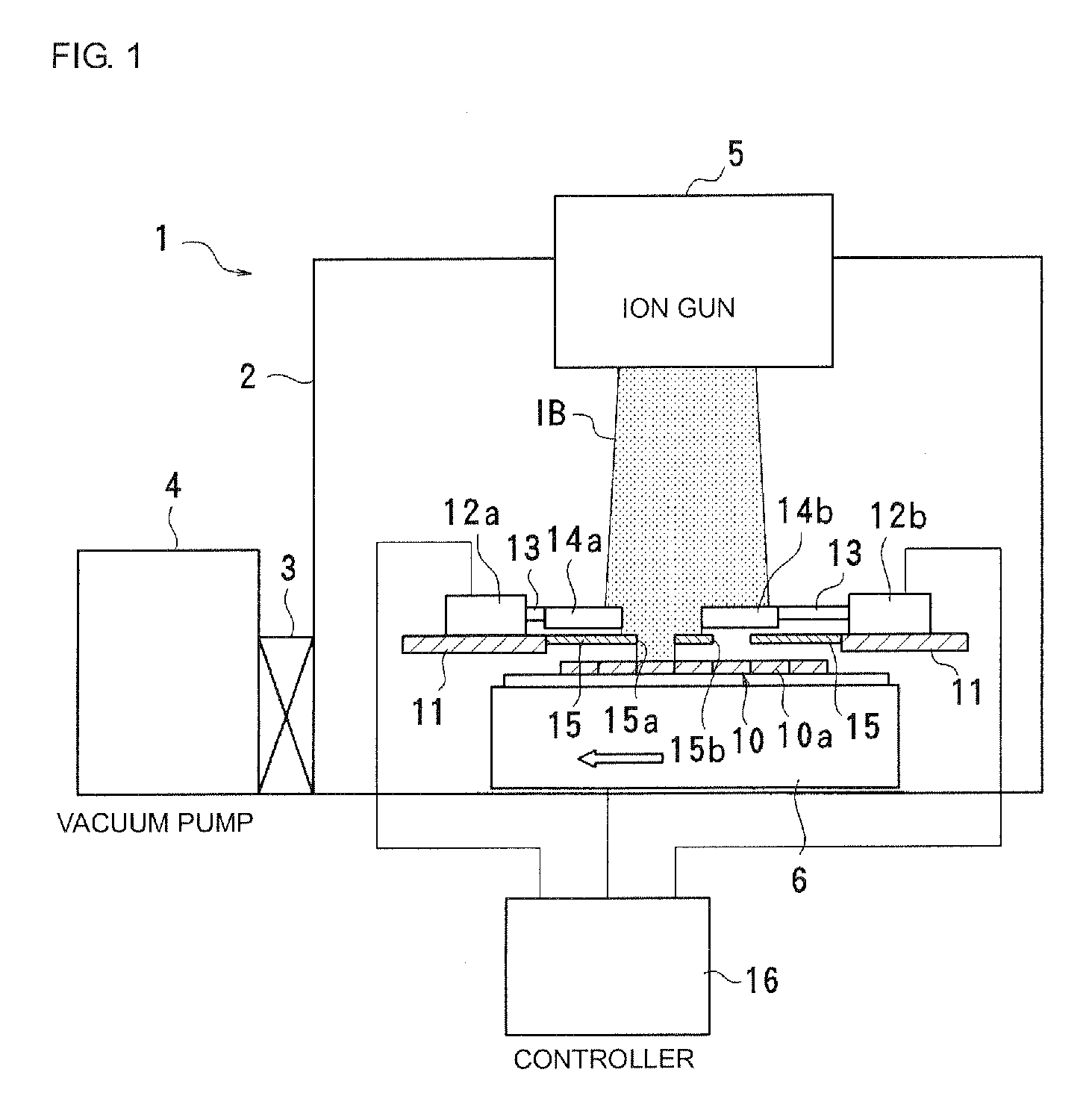

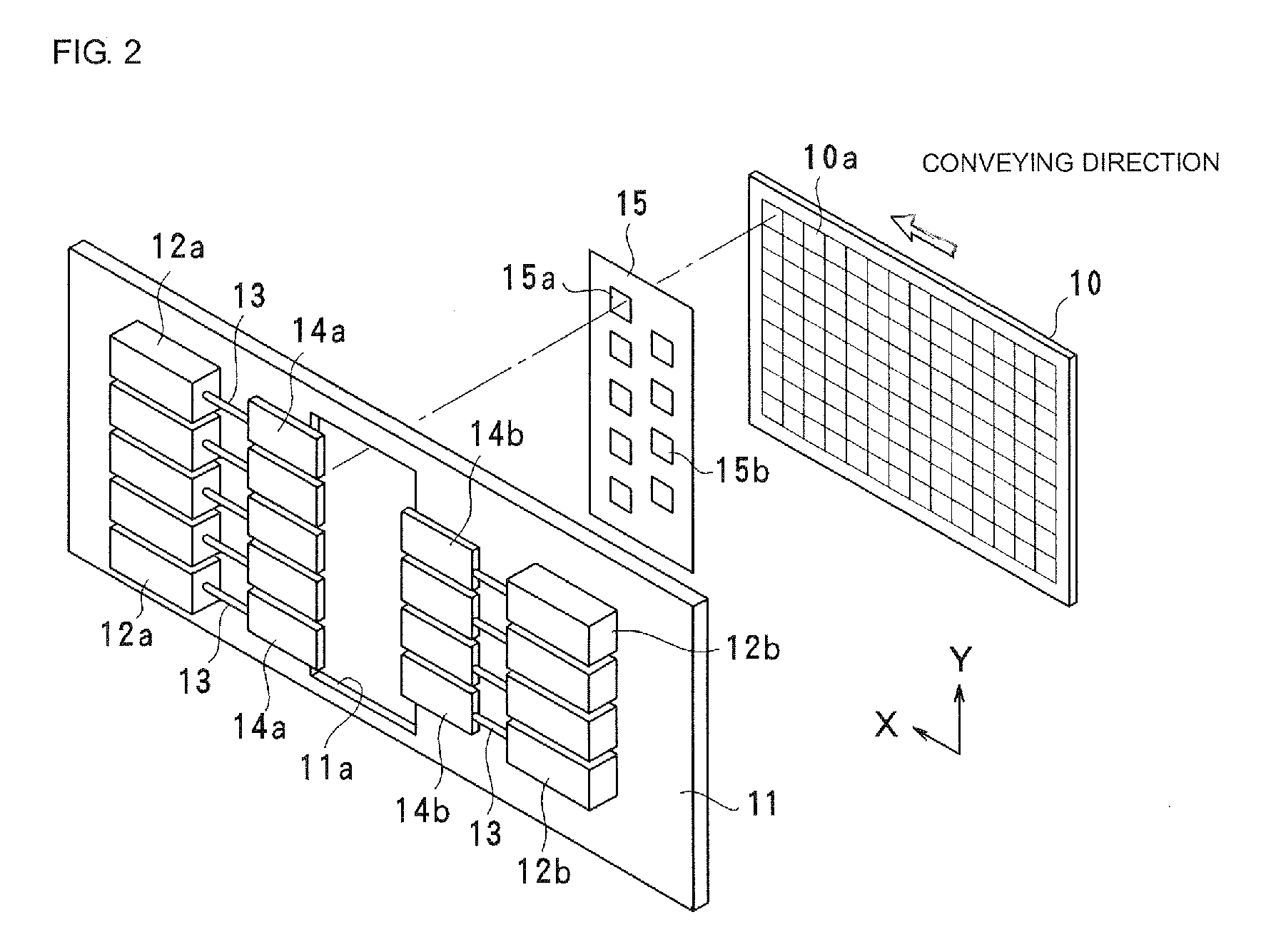

Frequency adjusting apparatus

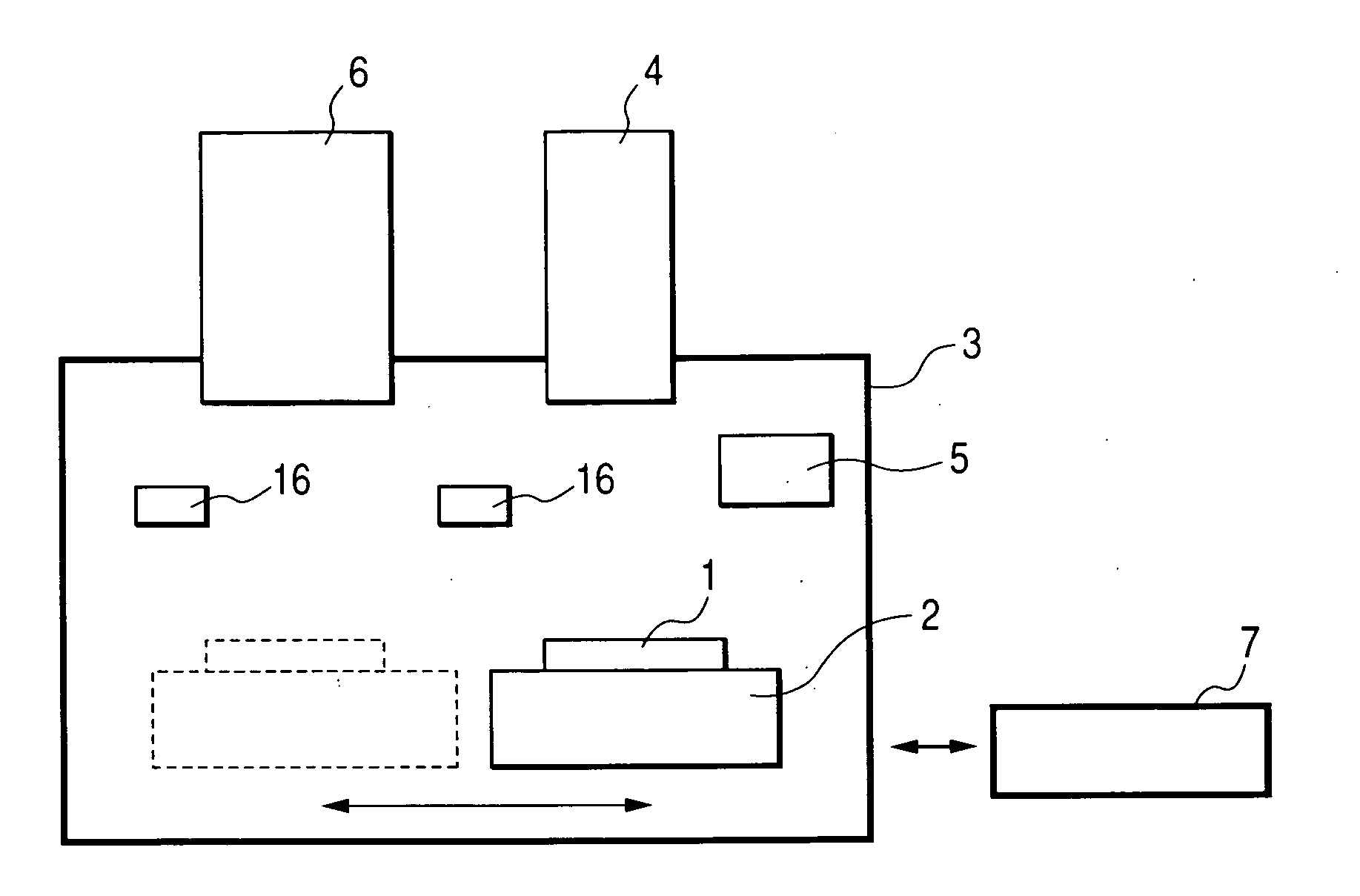

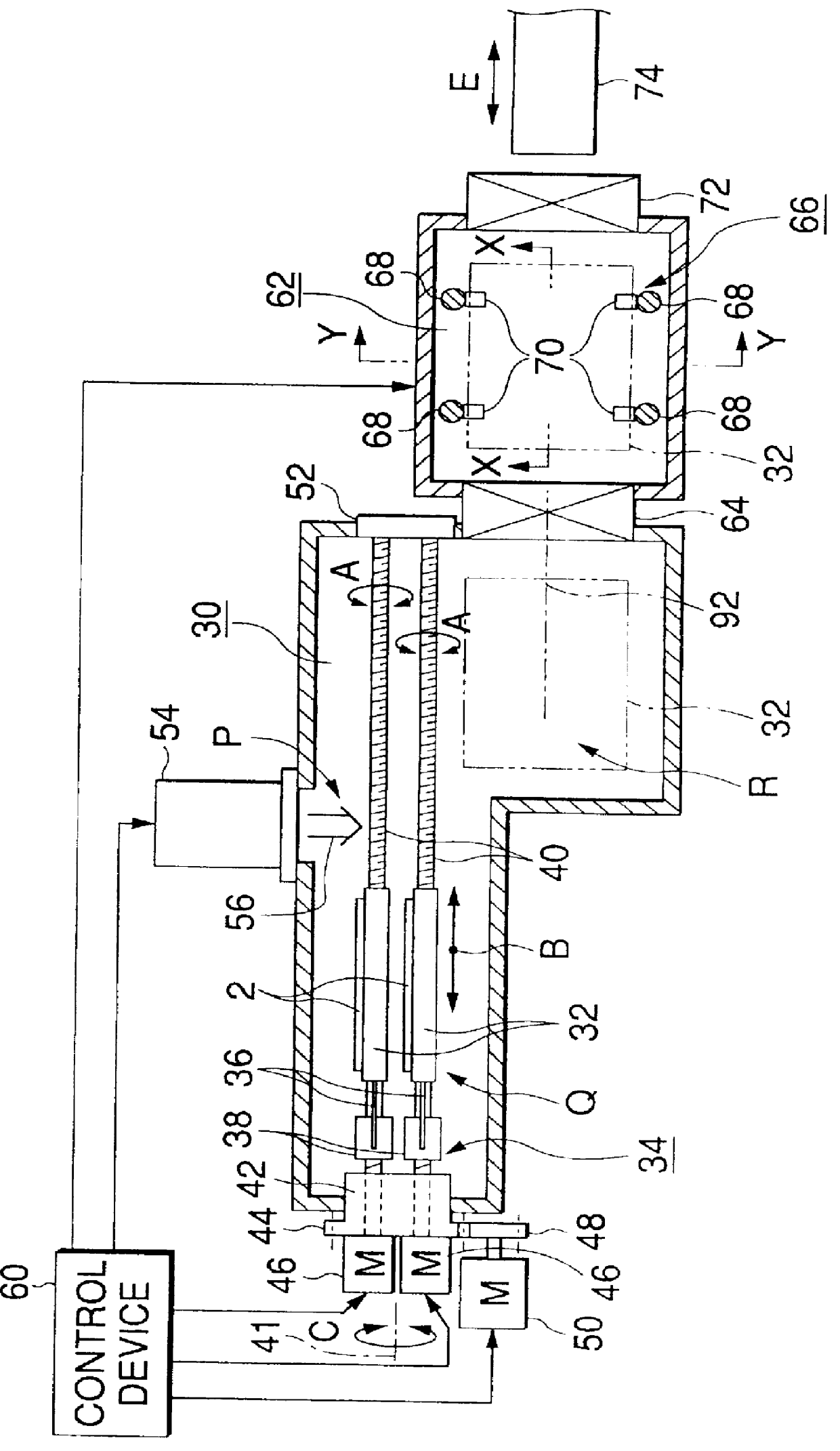

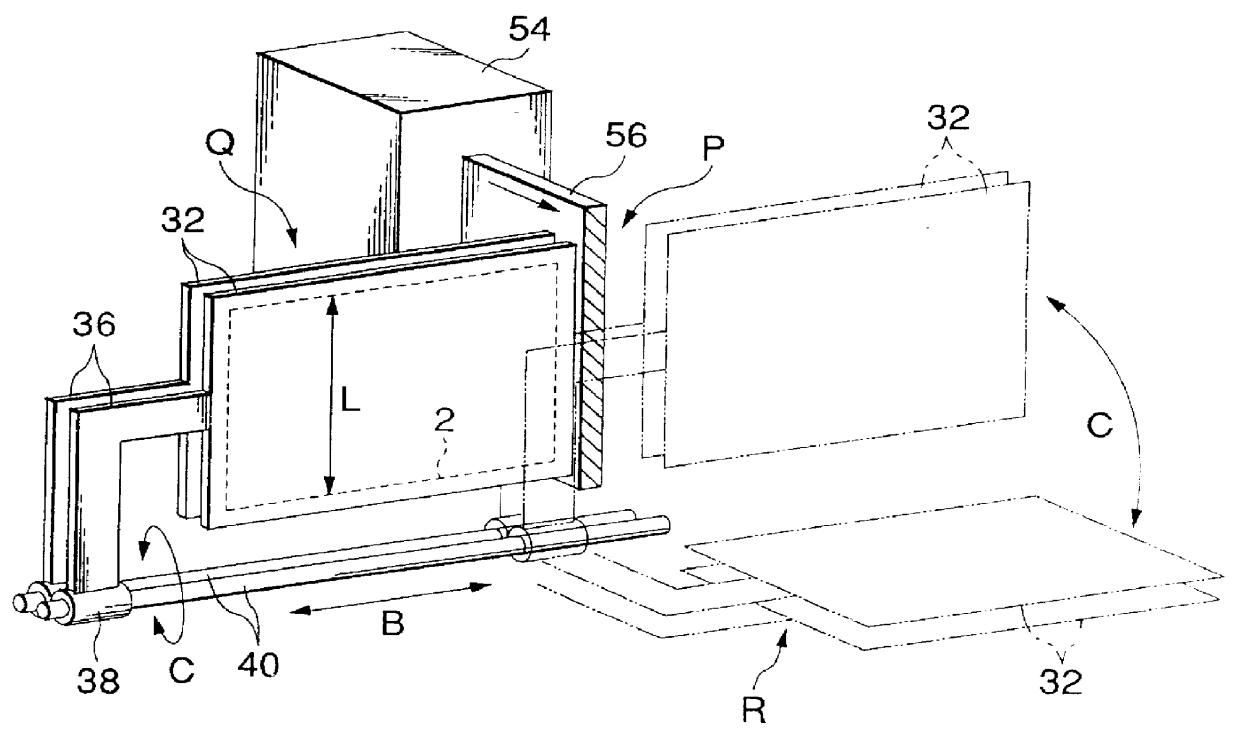

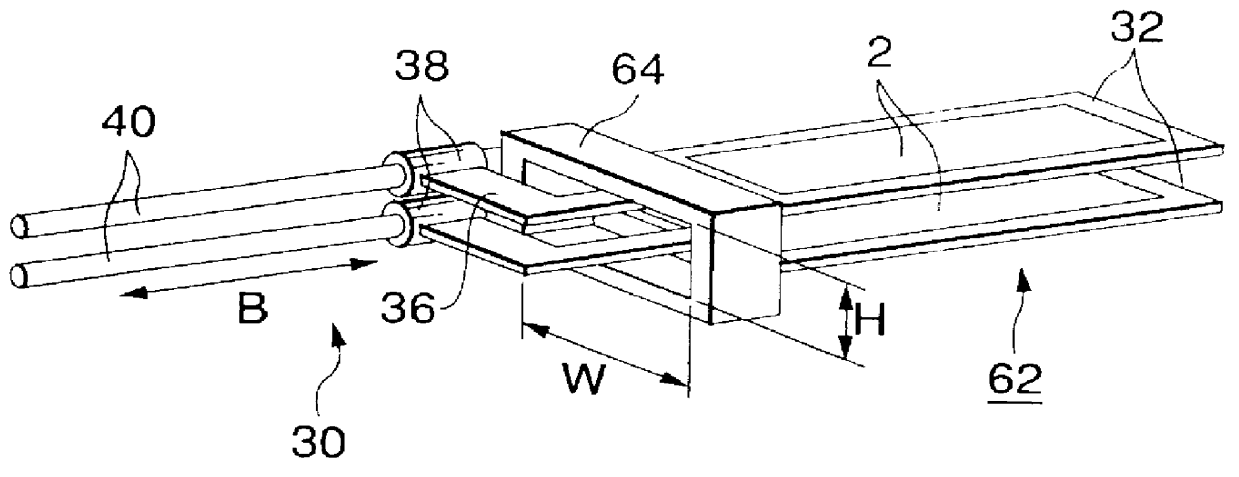

A wafer having a plurality of elements closely arranged thereon is irradiated with an ion beam while being conveyed in one direction by a conveying unit. Each of shutters adjusts an irradiation time during which a target area of the wafer is irradiated with the ion beam. Thus, a frequency in the target area is adjusted. Each of a plurality of mask holes in a pattern mask disposed between the wafer and the shutters corresponds to one area of the wafer. The mask holes are alternately displaced in a wafer conveying direction in which the wafer is conveyed, and are arranged in a plurality of columns perpendicular to the wafer conveying direction. To individually open and close the mask holes, the shutters are arranged to correspond to the respective mask holes. Thus, frequency adjustment, for areas in one column perpendicular to the wafer conveying direction, is performed in multiple steps.

Owner:MURATA MFG CO LTD

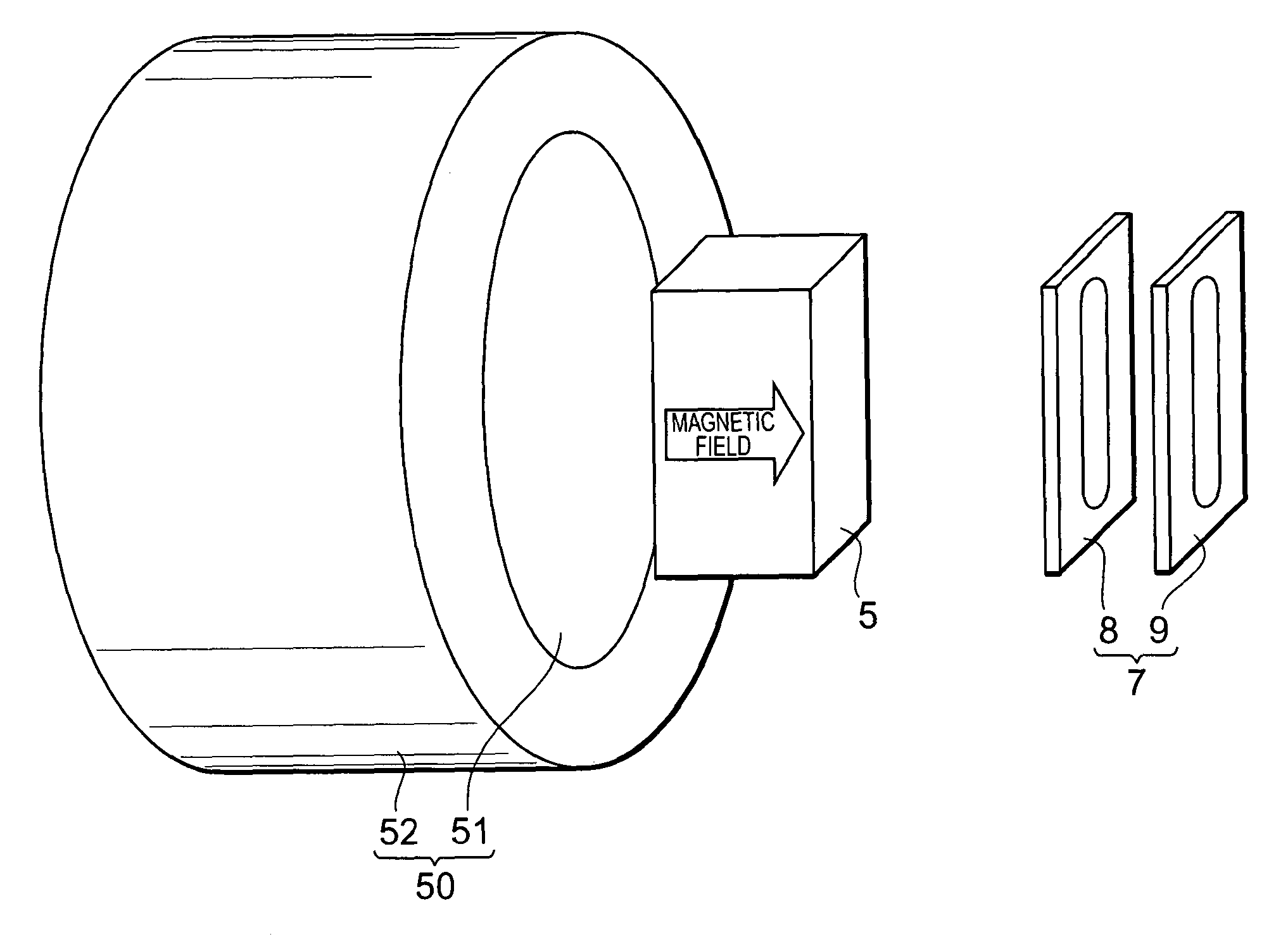

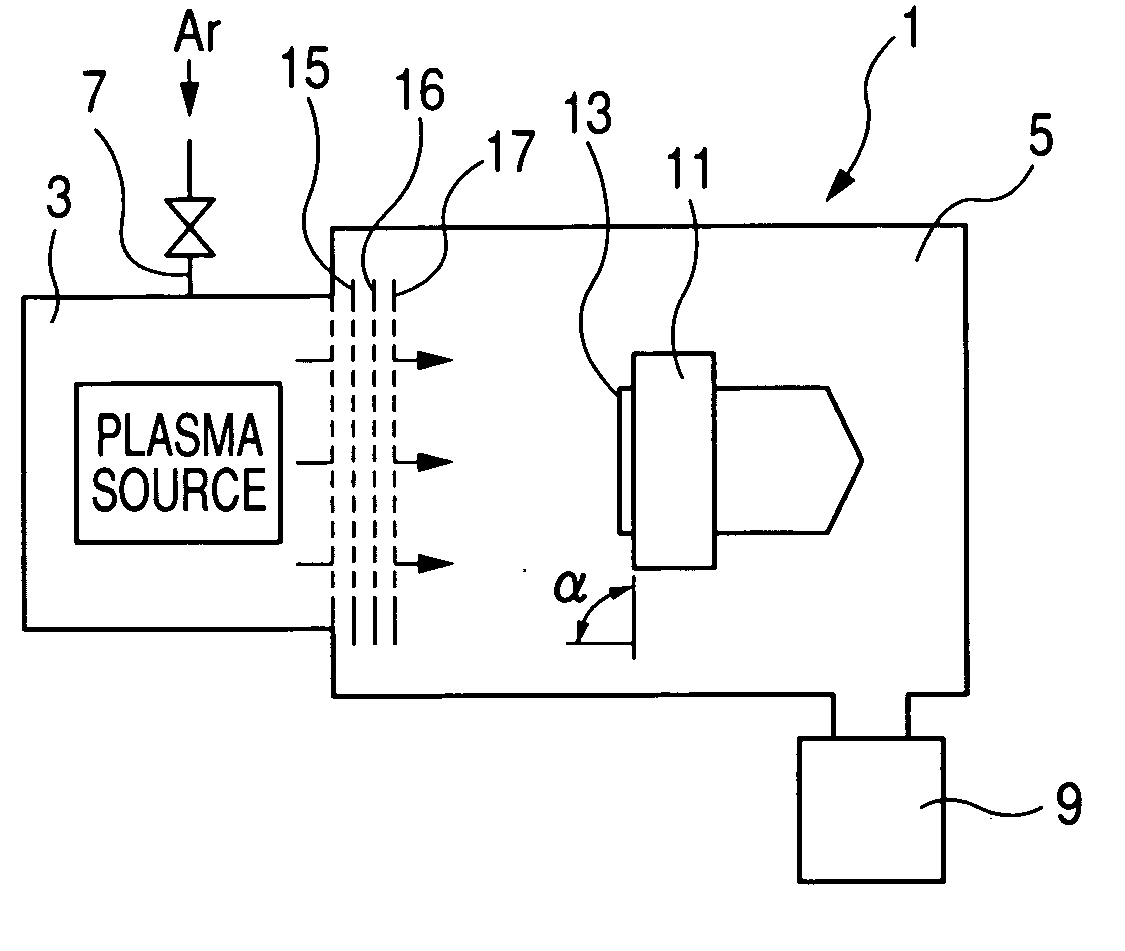

Ion implantation method, SOI wafer manufacturing method and ion implantation system

ActiveUS7064049B2Sufficient throughputIncrease currentVacuum evaporation coatingSputtering coatingMass numberIon implantation

The present invention provides an ion implantation method which can achieve sufficient throughput by increasing a beam current even in the case of ions with a small mass number or low-energy ions, an SOI wafer manufacturing method, and an ion implantation system. When ions are implanted by irradiating a semiconductor substrate with an ion beam, predetermined gas is excited in a pressure-reduced chamber to generate plasma containing predetermined ions, a magnetic field is formed by a solenoid coil or the like along an extraction direction when the ions are extracted to the outside of the chamber, and the ions are extracted from the chamber with predetermined extraction energy. The formation of the magnetic field promotes ion extraction, but this magnetic field has no influence on an advancing direction of the extracted ions. Therefore, the ion beam current can be kept at a high level-to contribute to the ion implantation.

Owner:APPLIED MATERIALS INC

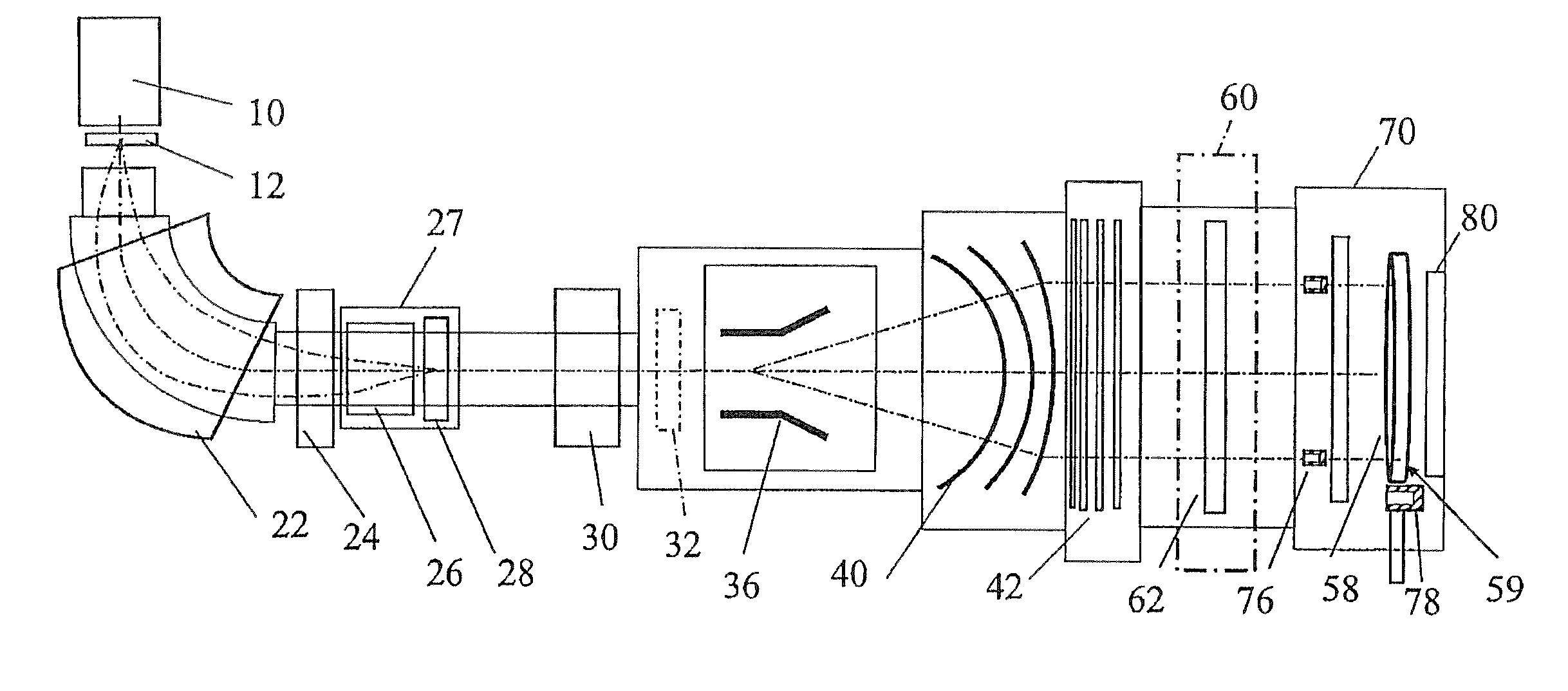

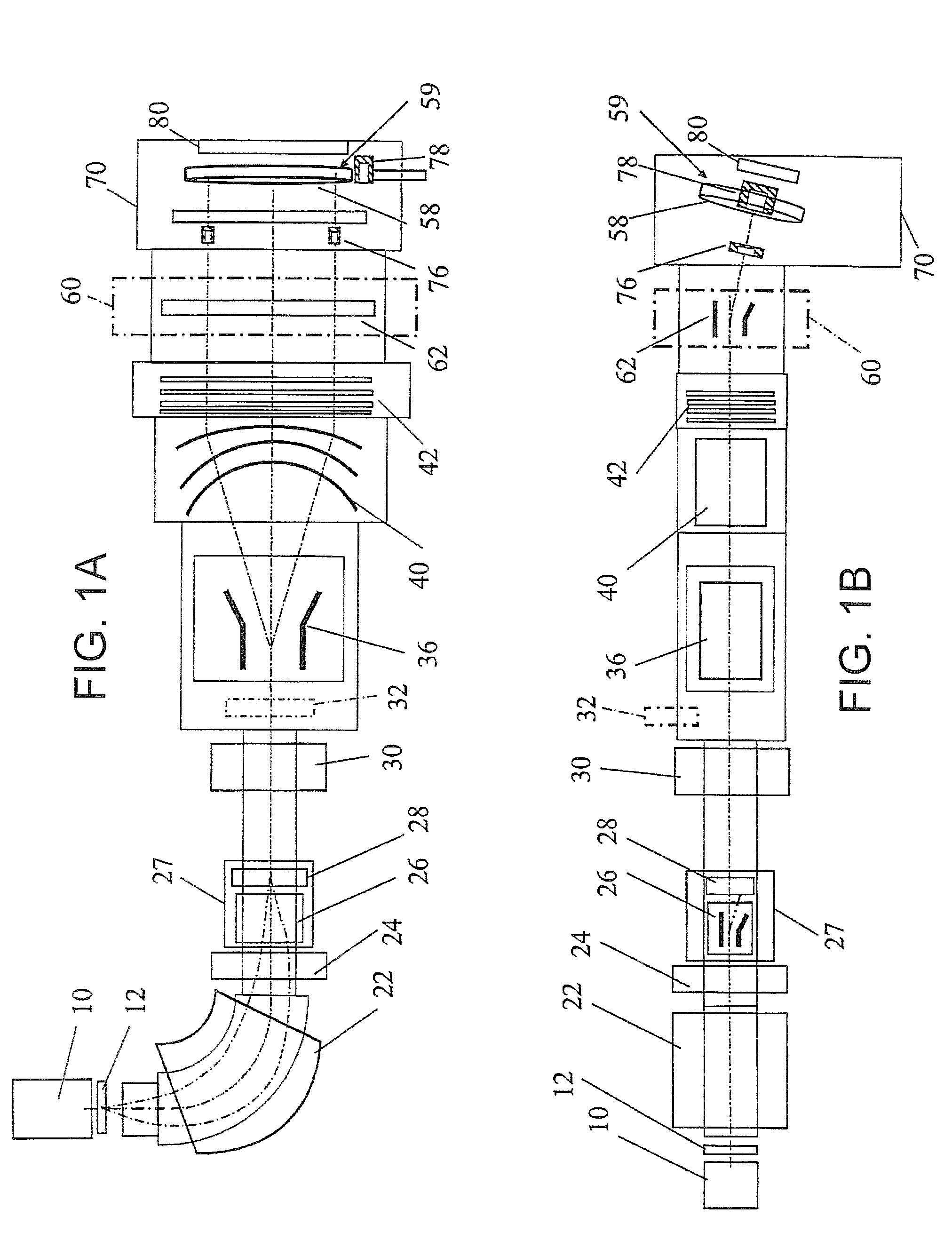

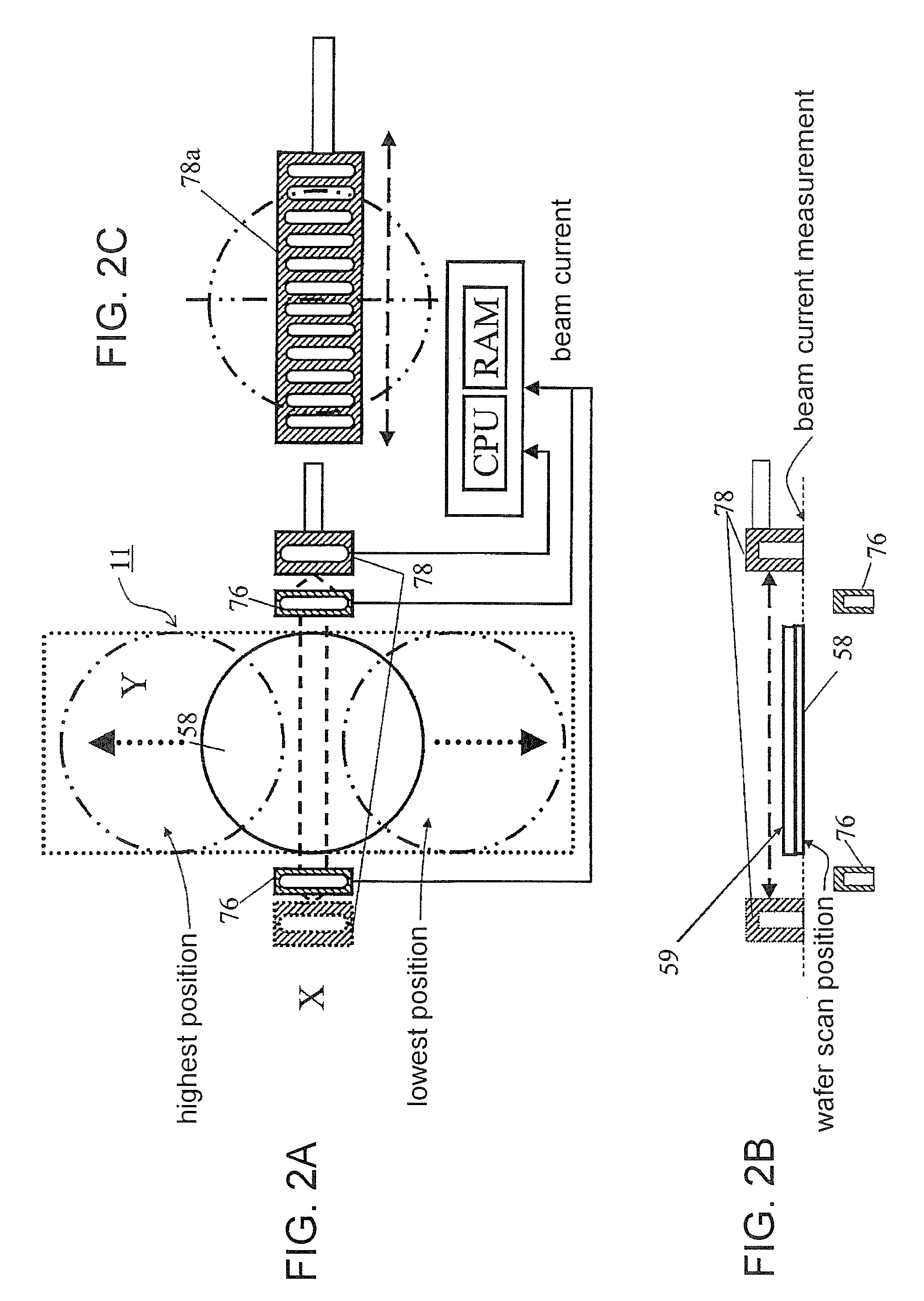

Ion beam irradiation system and ion beam irradiation method

ActiveUS20110297842A1Maintain uniformityImprove irradiation efficiencyElectric discharge tubesBeam/ray deflecting arrangementsMeasurement deviceDose uniformity

An ion beam irradiation method comprises calculating a scan voltage correction function with the maximum beam scan width depending on the measurement result of a beam current measurement device, calculating each of more than one scan voltage correction functions corresponding to each of scheduled beam scan widths depending on the calculated scan voltage correction functions while satisfying dose uniformity in the horizontal direction, measuring a mechanical Y-scan position during the ion implantation, changing the scan voltage correction function as a function of the measured mechanical Y-scan position so that the beam scan area becomes a D-shaped multistage beam scan area corresponding to an outer periphery of a half of the wafer to thereby reduce the beam scan width, and changing a mechanical Y-scan speed depending on the change of the measurement result of a side cup current measurement device to thereby keep the dose uniformity in the vertical direction.

Owner:SENCORP

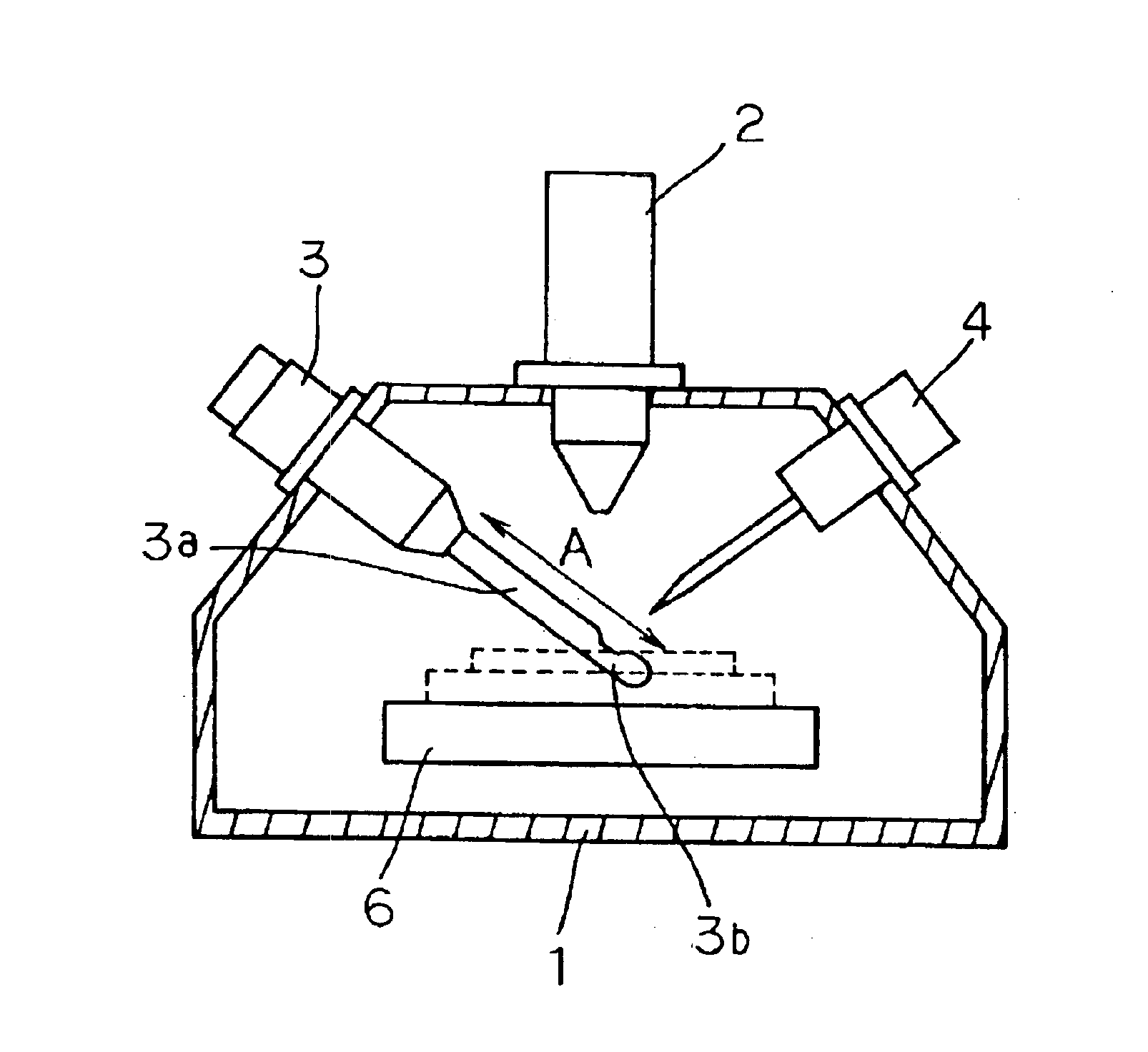

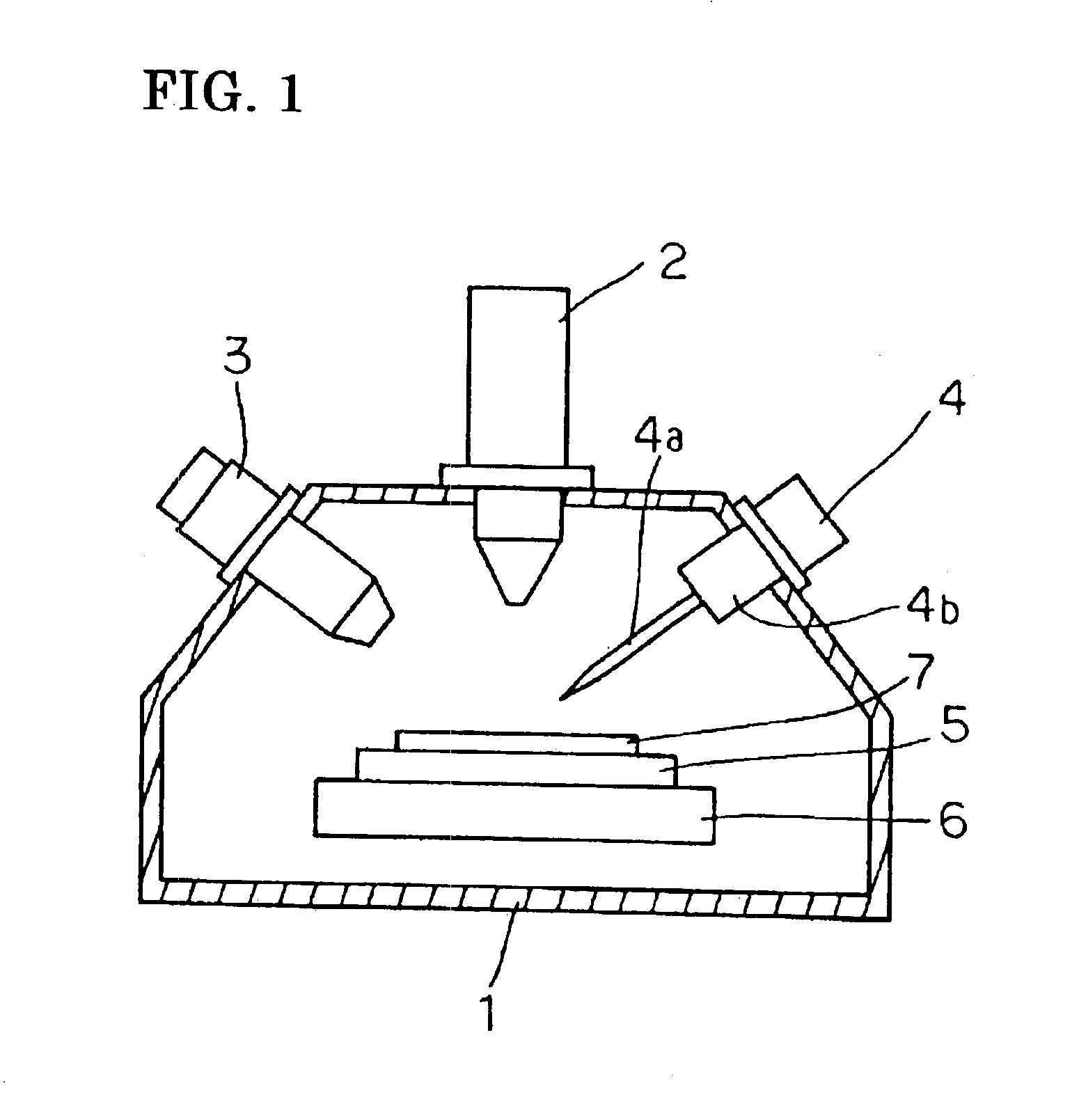

Apparatus for Preparing Cross-Sectional Specimen Using Ion Beam

InactiveUS20080067443A1Progress of quickly and easilyPrecise positioningSamplingElectric discharge tubesSpecimen preparationOptical observation

There is disclosed a cross-sectional specimen preparation apparatus. The milling position can be modified or corrected in a short time. Also, the internal structure of the specimen can be known. The apparatus has an optical observation device for observing a cross section of the specimen milled by the ion beam. During ion beam irradiation or when the irradiation is interrupted, a shutter is opened. The cross section of the specimen can be observed while maintaining the vacuum inside a processing chamber. The apparatus further includes an adjusting mechanism for varying the relative position between the specimen and the shielding material. Whenever one sectioning operation ends, an image of the cross section is accepted and the milling position is moved an incremental distance. A three-dimensional image of the specimen is constructed from obtained plural images.

Owner:JEOL LTD

Apparatus and method for processing substrate

A substrate processing apparatus includes a processing chamber and a vacuum spare chamber adjacent thereto through a vacuum valve. The processing chamber houses two holders for holding substrates on their surfaces on the same side. The processing chamber is provided with an ion source for irradiating the substrate on each holder having reached a processing position P with an ion beam so that it is subjected to ion implantation. The processing chamber is internally provided with a holder moving mechanism for performing the operation of moving the two holders in parallel independently from each other so that they traverse the processing position P, and moving the two holders in parallel simultaneously between the insides of the processing chamber and vacuum spare chamber through the vacuum valve. The vacuum spare chamber is internally provided with a substrate replacing mechanism for replacing processed substrates and non-processed substrates with each other collectively for the two holders in cooperation with the holder moving mechanism.

Owner:NISSIN ELECTRIC CO LTD

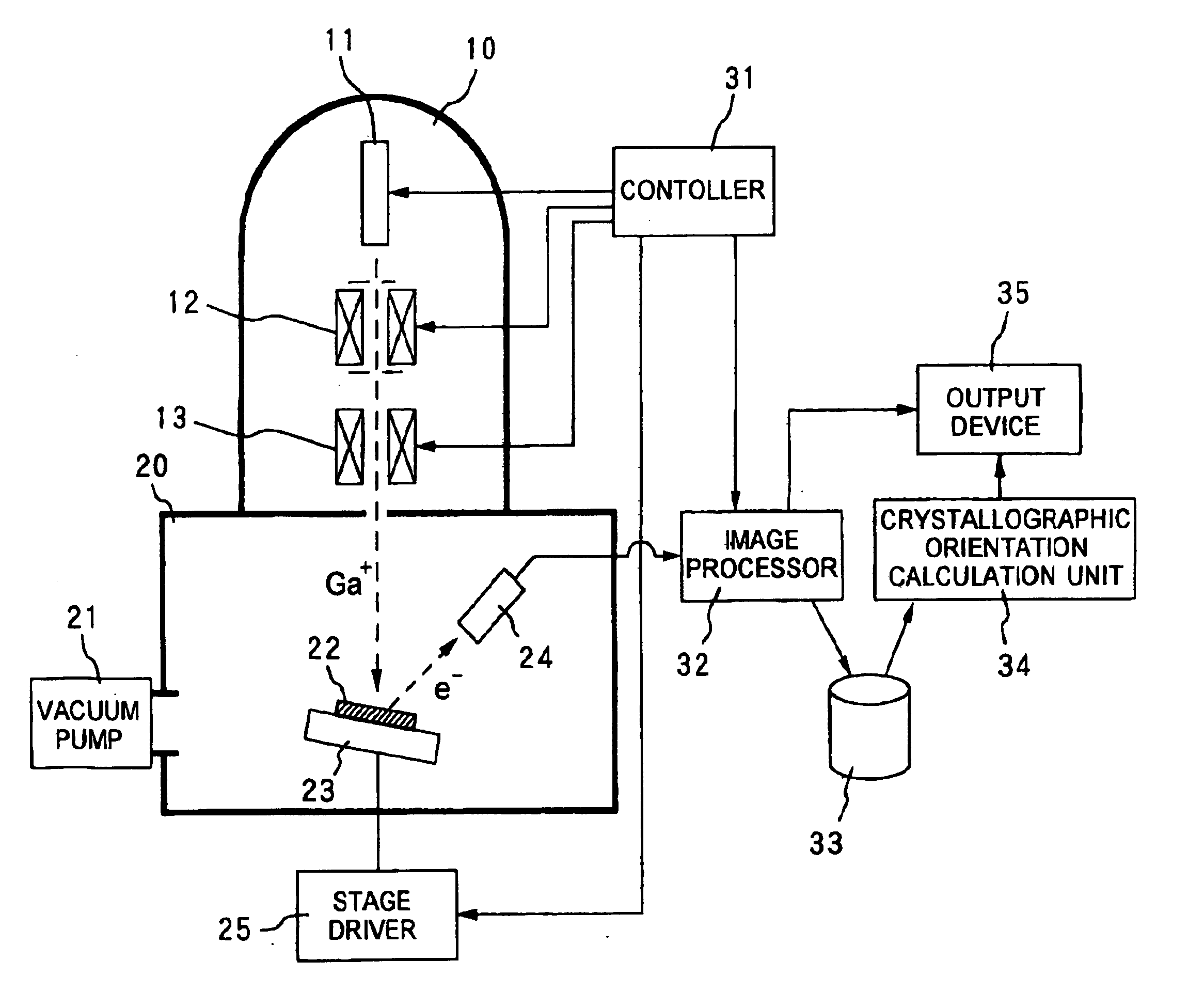

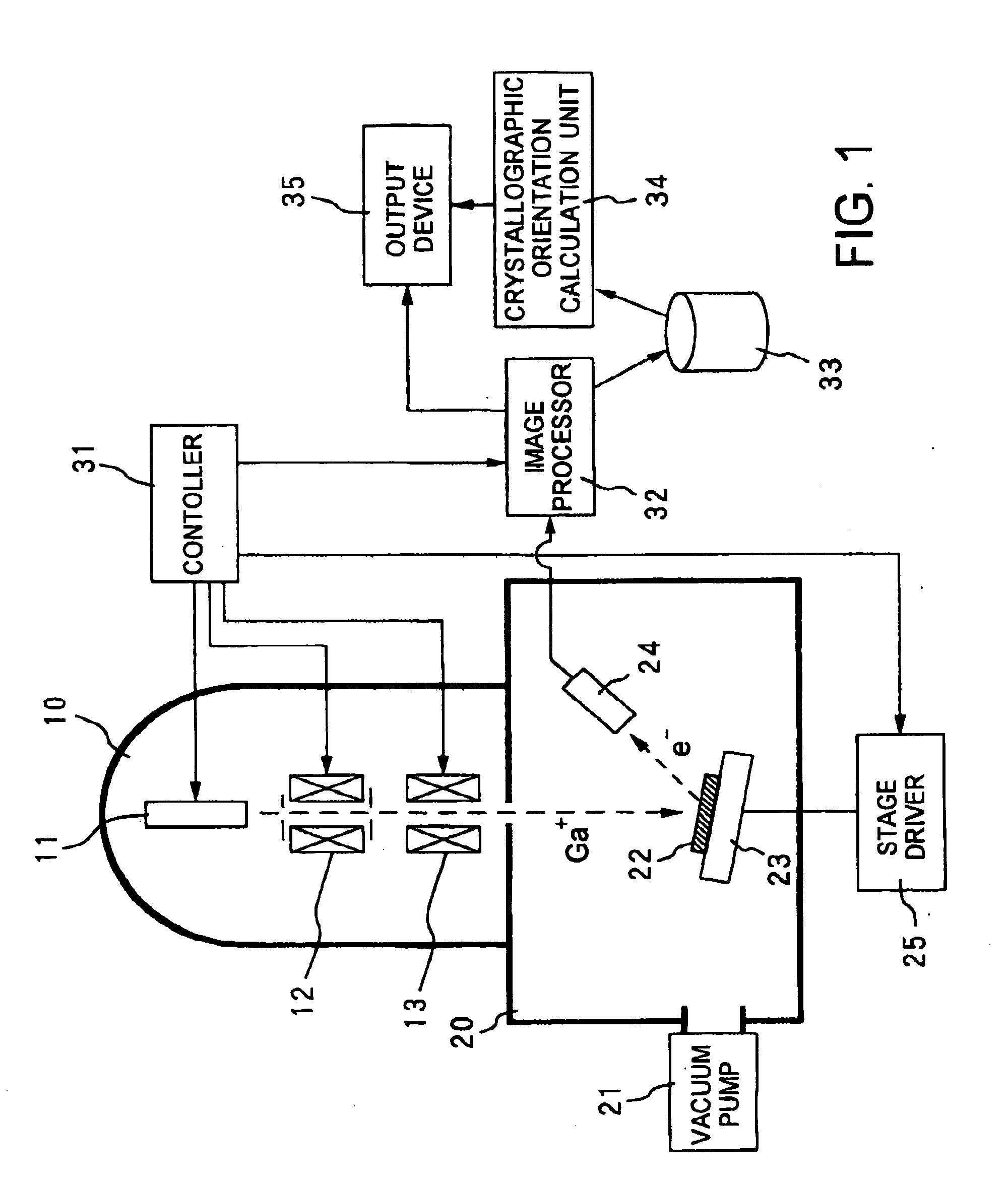

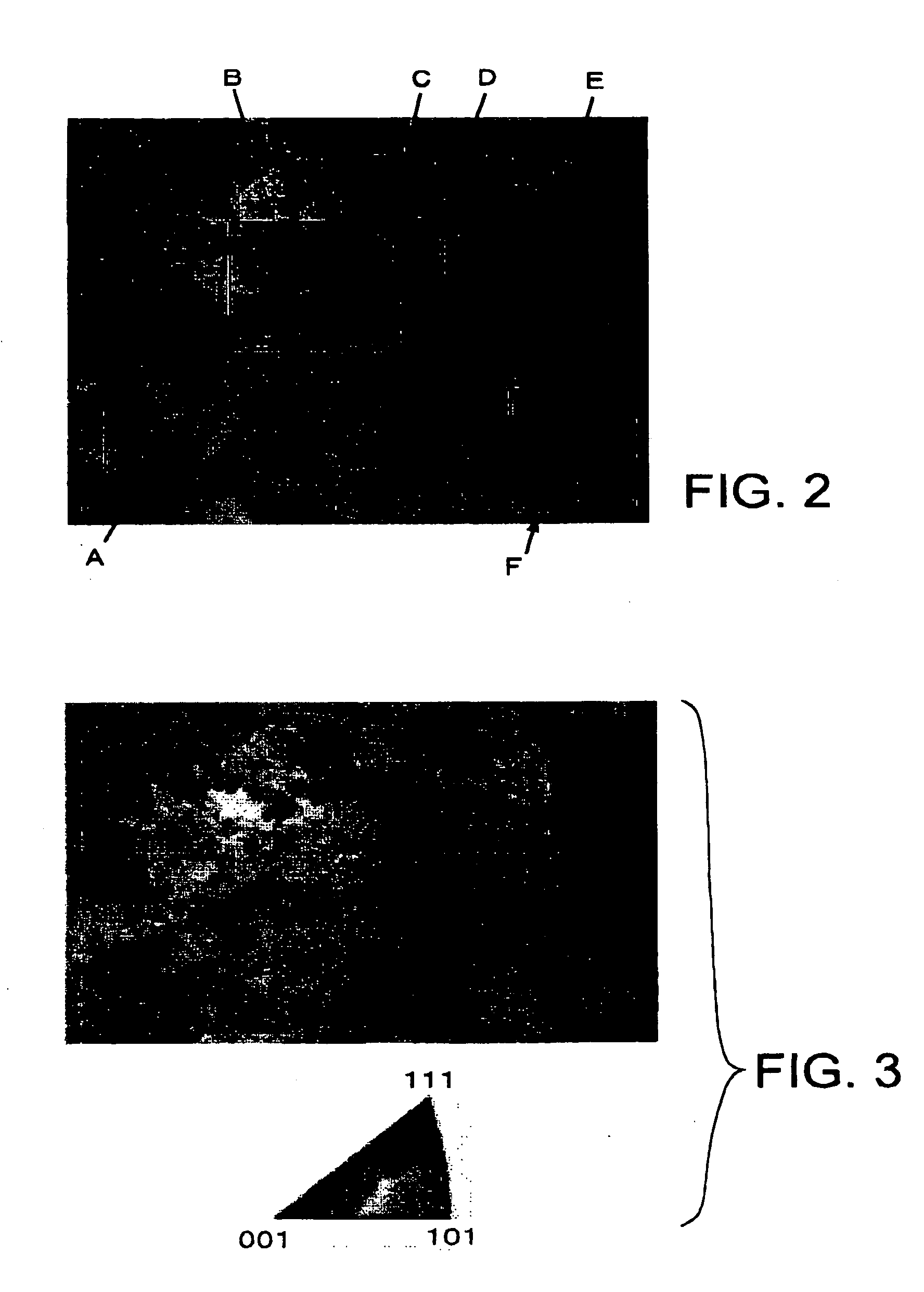

Method and apparatus for crystal analysis

InactiveUS20050103995A1High resolutionEasy to measureMaterial analysis using wave/particle radiationElectric discharge tubesCrystal systemAngle of incidence

The method of measuring crystallographic orientations, crystal systems or the like of the surface of a specimen has steps of: irradiating the specimen with an ion beam; measuring tho secondary electrons generated by the irradiation of the ion beam; repeating the irradiation of the ion beam and the measurement of the secondary electrons with each variation in an angle of incidence of the ion beam with respect to the specimen; and determining the crystalline state based on the variation in the amount of the secondary electrons corresponding to the variation of the angle of incidence.

Owner:TDK CORPARATION

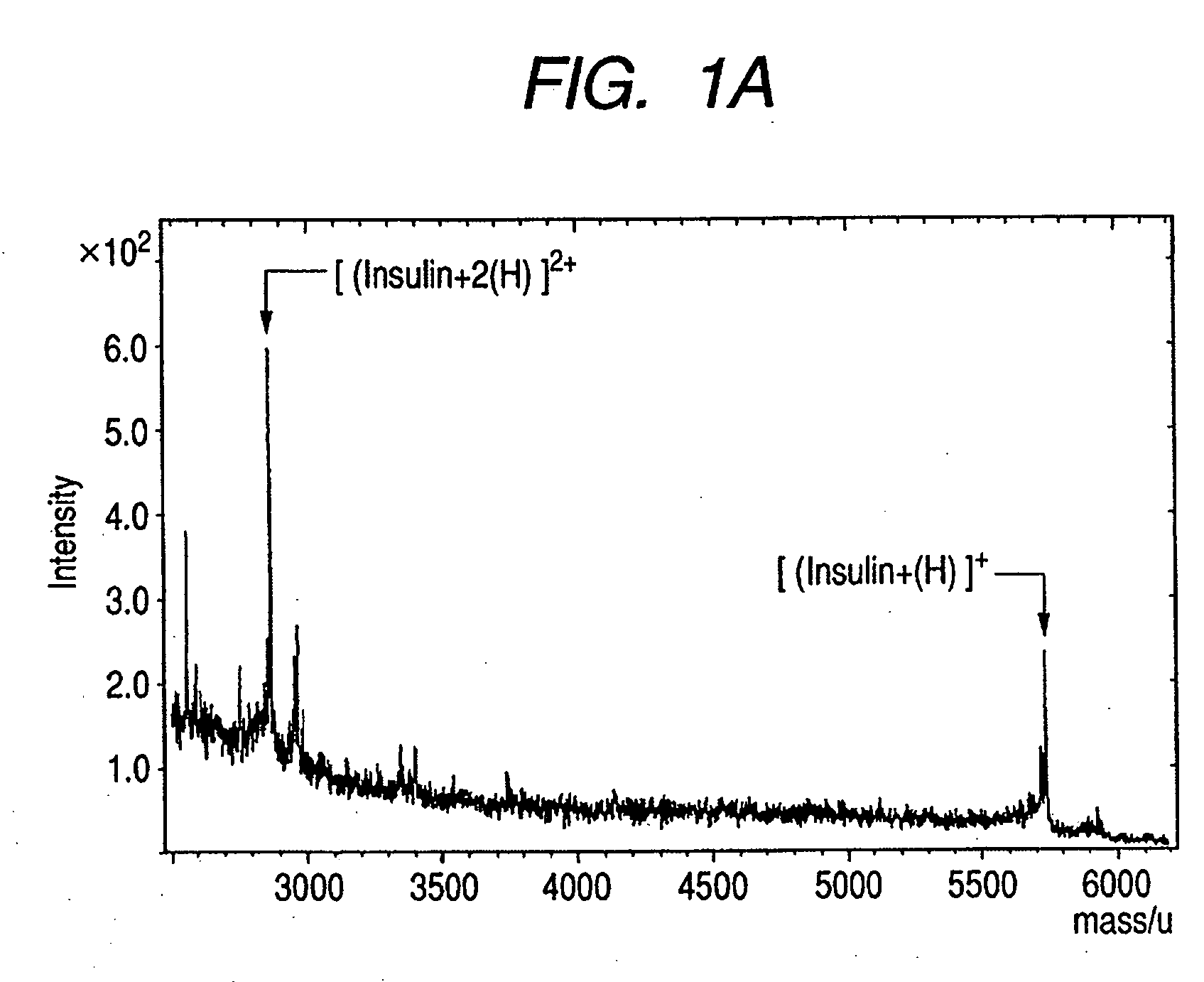

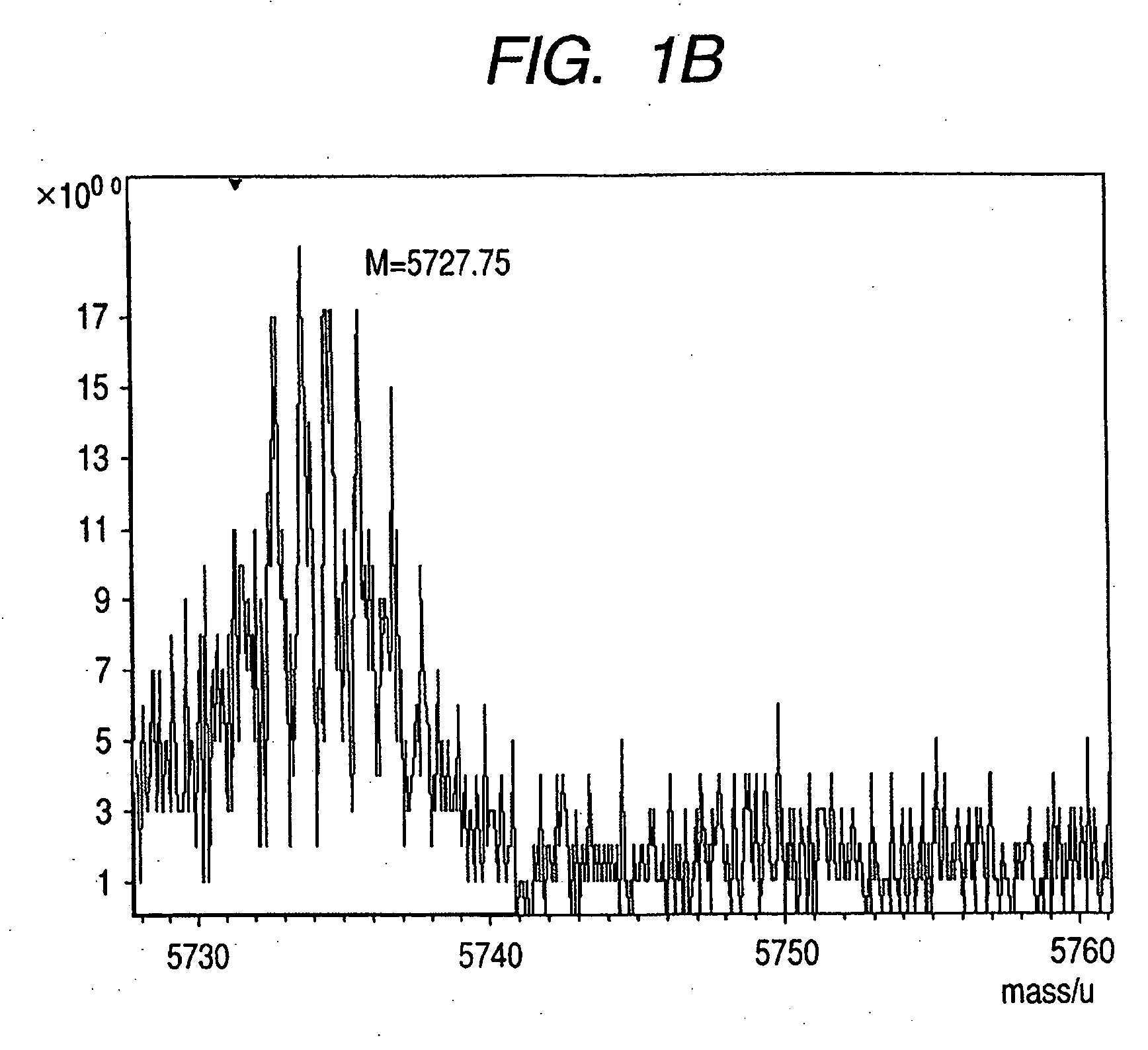

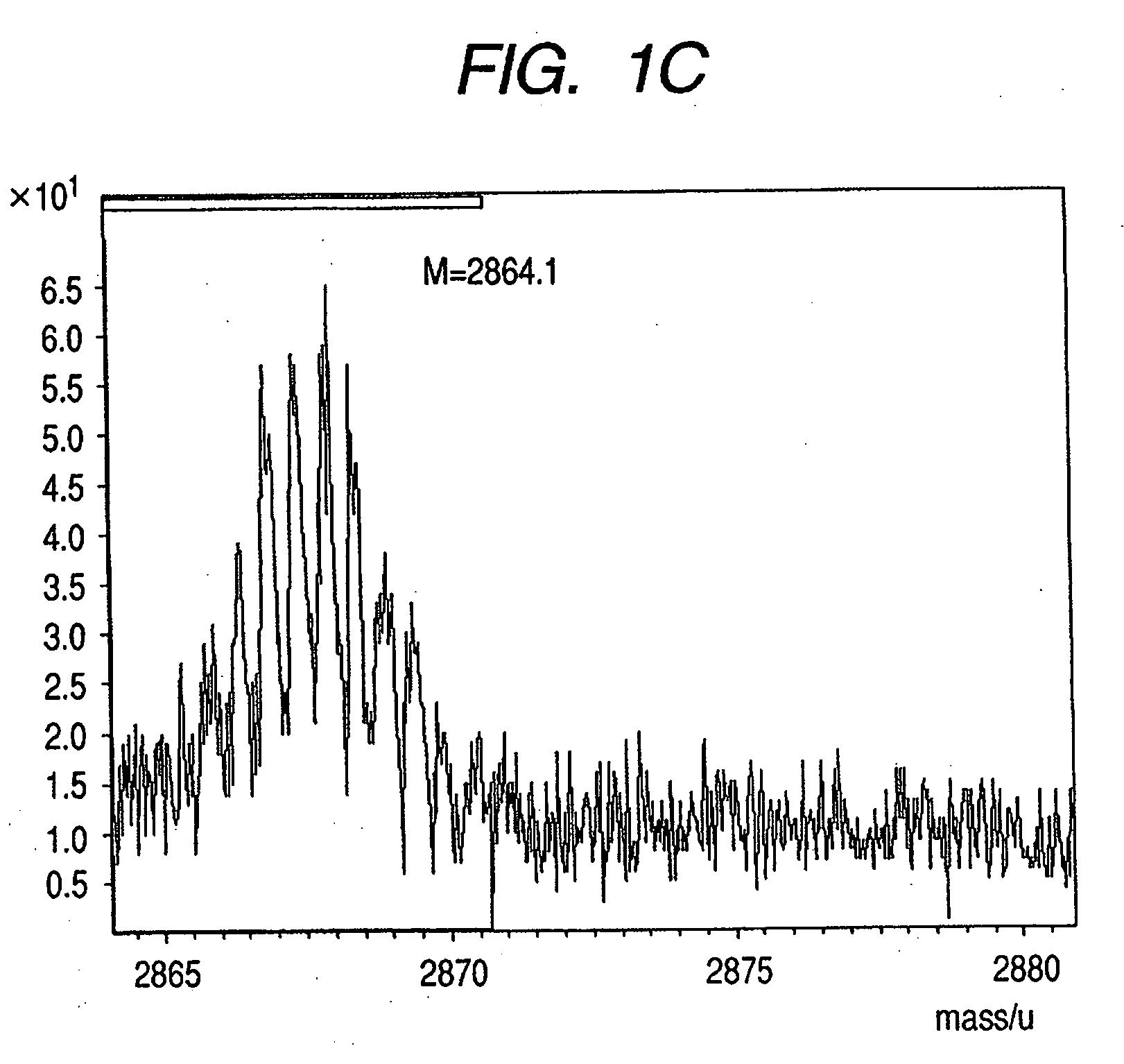

In-plane distribution measurement method

InactiveUS20060118711A1Generate efficientlyTime-of-flight spectrometersMaterial analysis using wave/particle radiationIn planeTime of flight

In-plane distribution of a target objectcontained in a sample is measured. The sample dispersedly placed on a substrate is treated to promote ionization of the target object, then the mass and flying amount of an ion containing the target object or a component of the target object is determined by irradiating an ion beam to the sample and performing time-of-flight secondary ion mass spectrometry of the ion that flies from a portion in the sample where the ion beam is irradiated, and the in-plane distribution of the target object is determined from the mass and flying amount data obtained at plural portions by scanning the beam on the sample plane. The step of treating the sample to promote ionization of the target object includes contacting an aqueous solution of an acid that does not crystallize at ordinary temperature with the sample. A high spatial resolution two-dimensional image can be obtained.

Owner:CANON KK

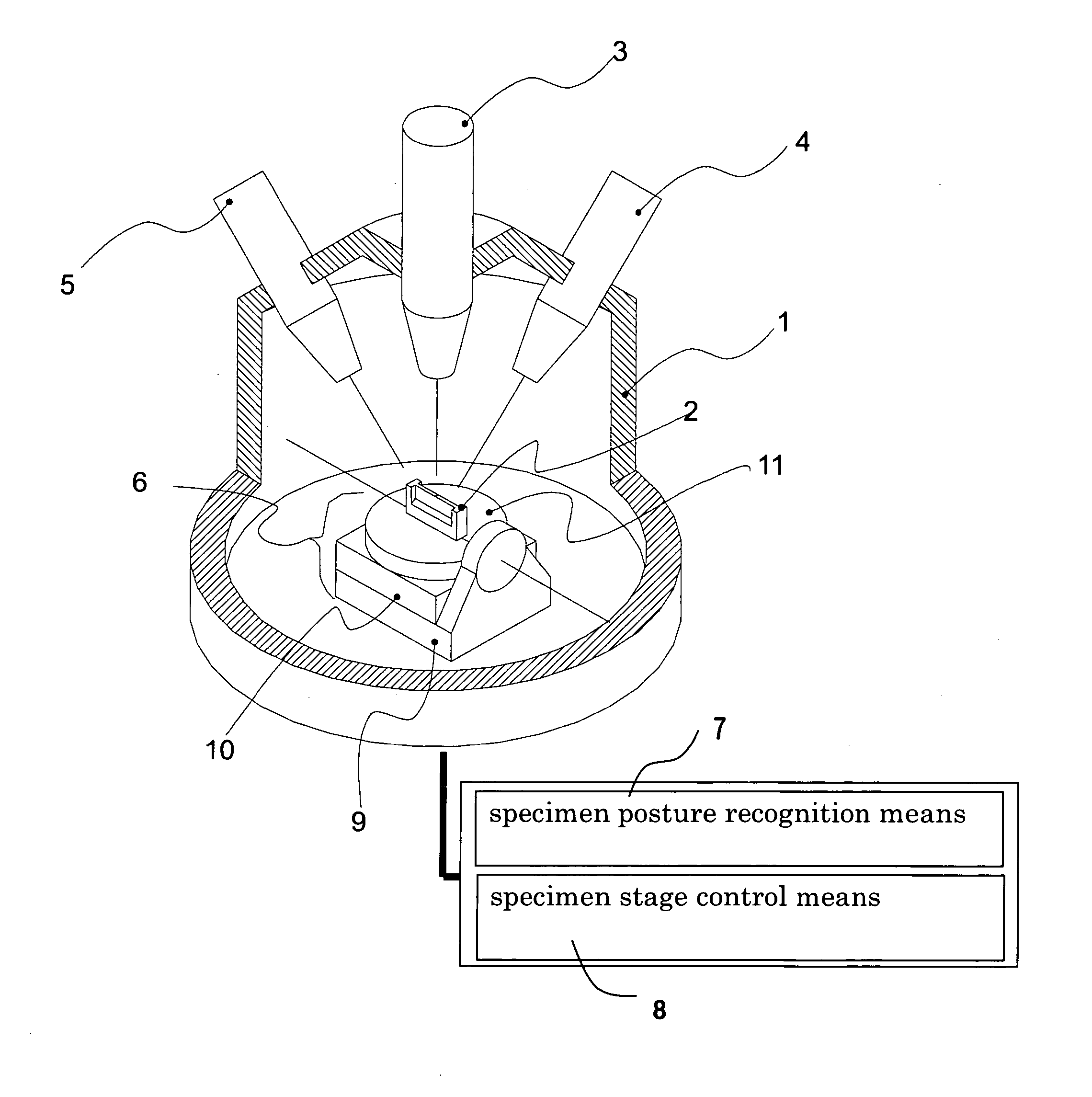

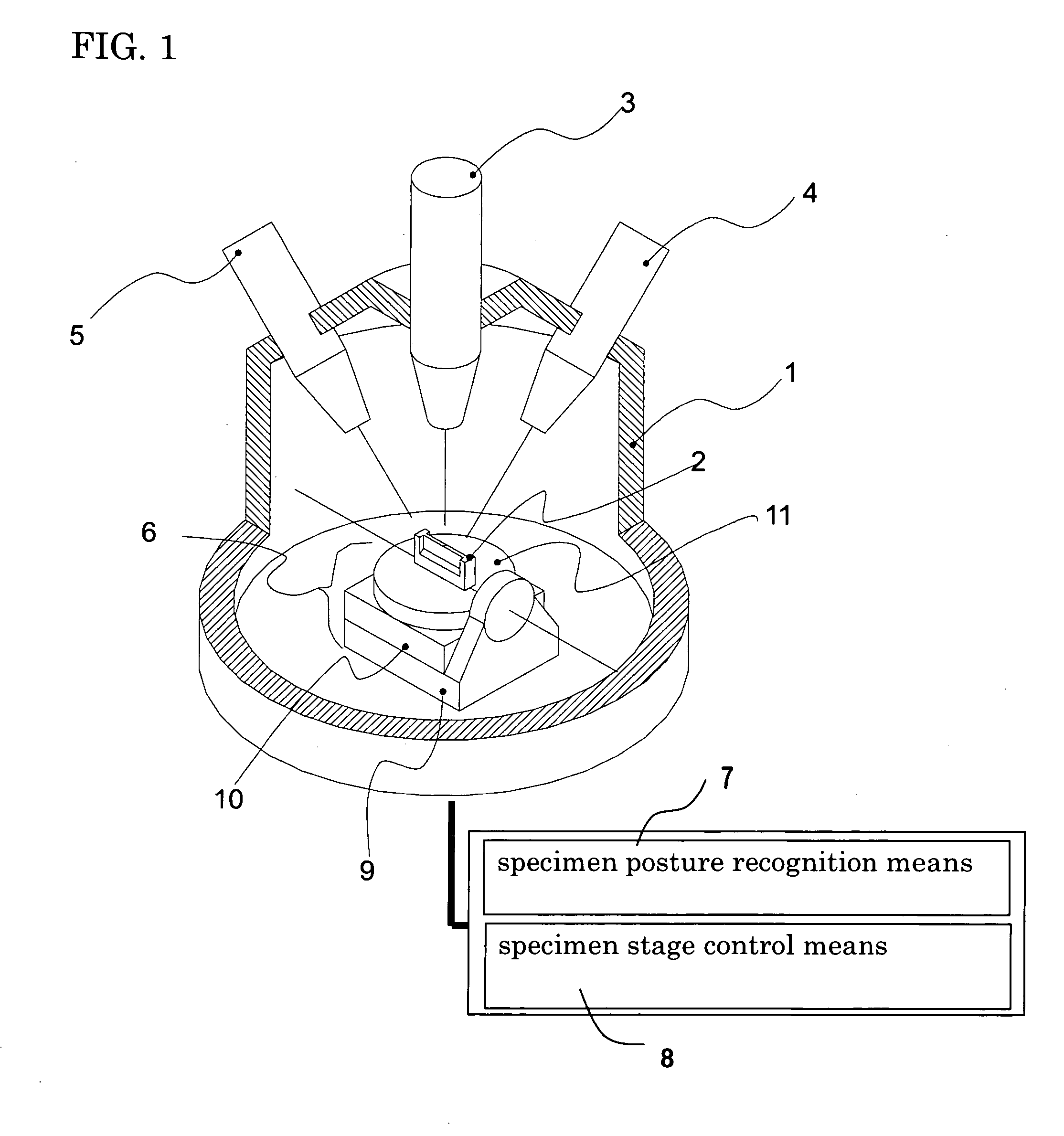

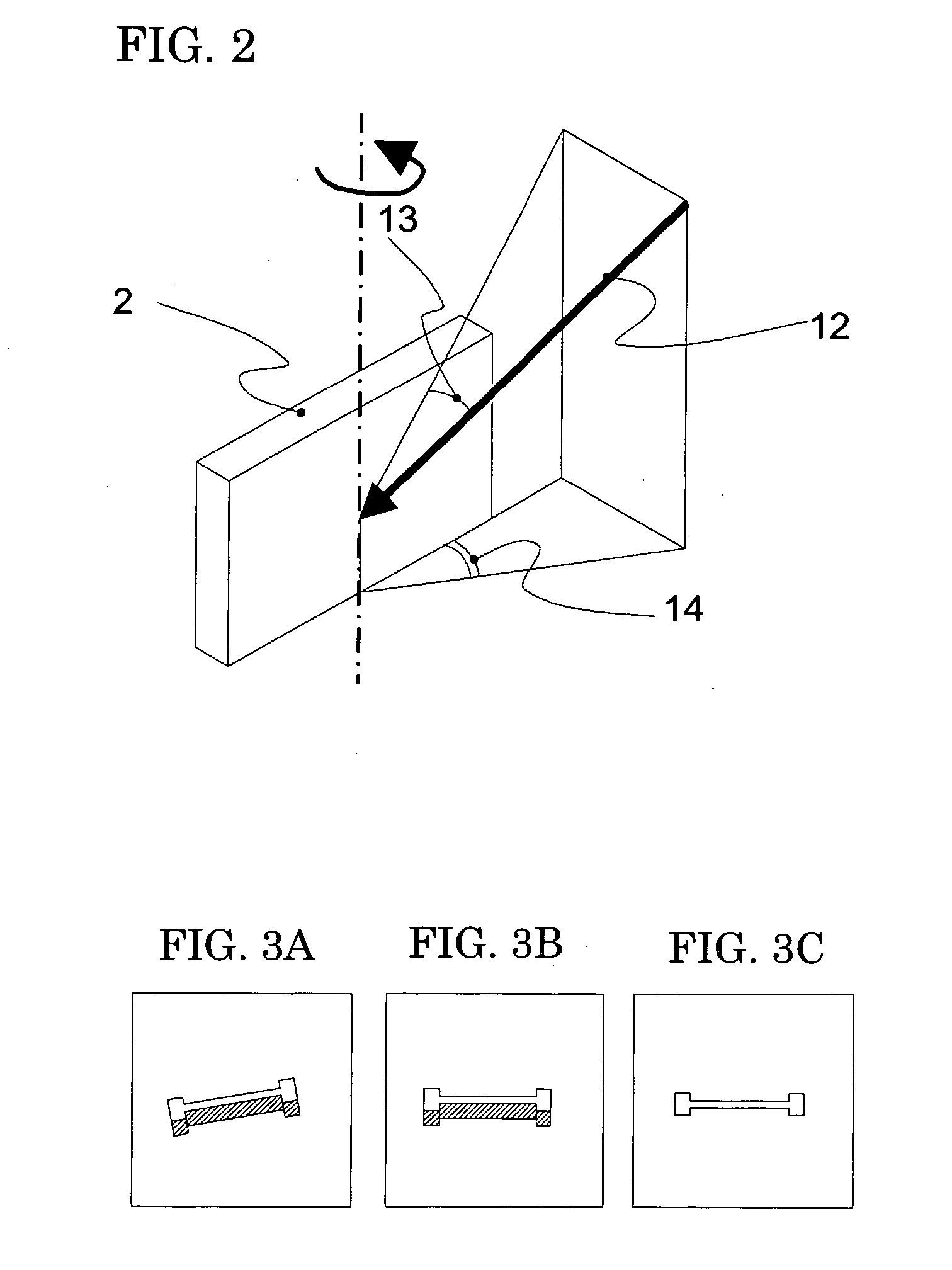

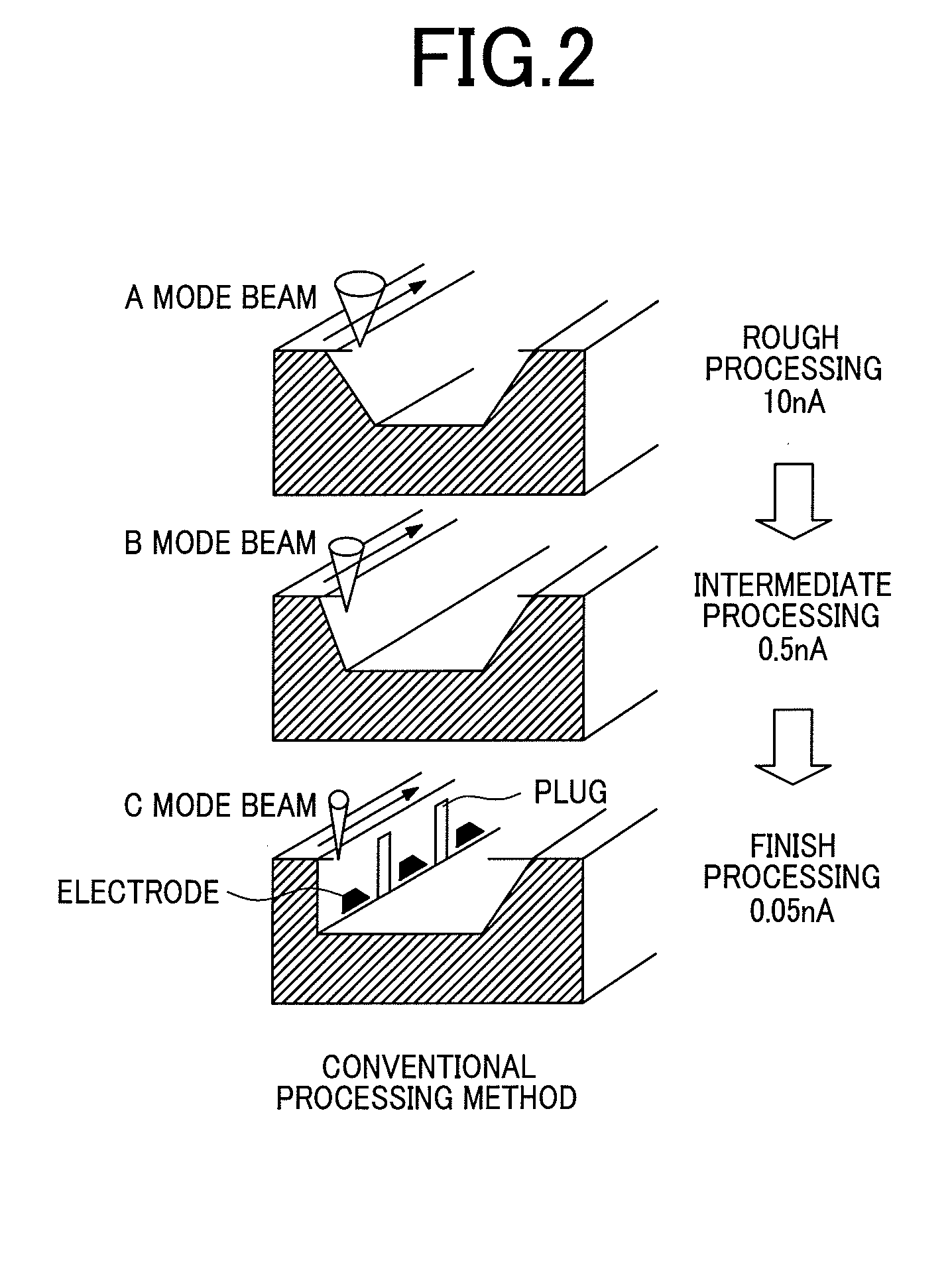

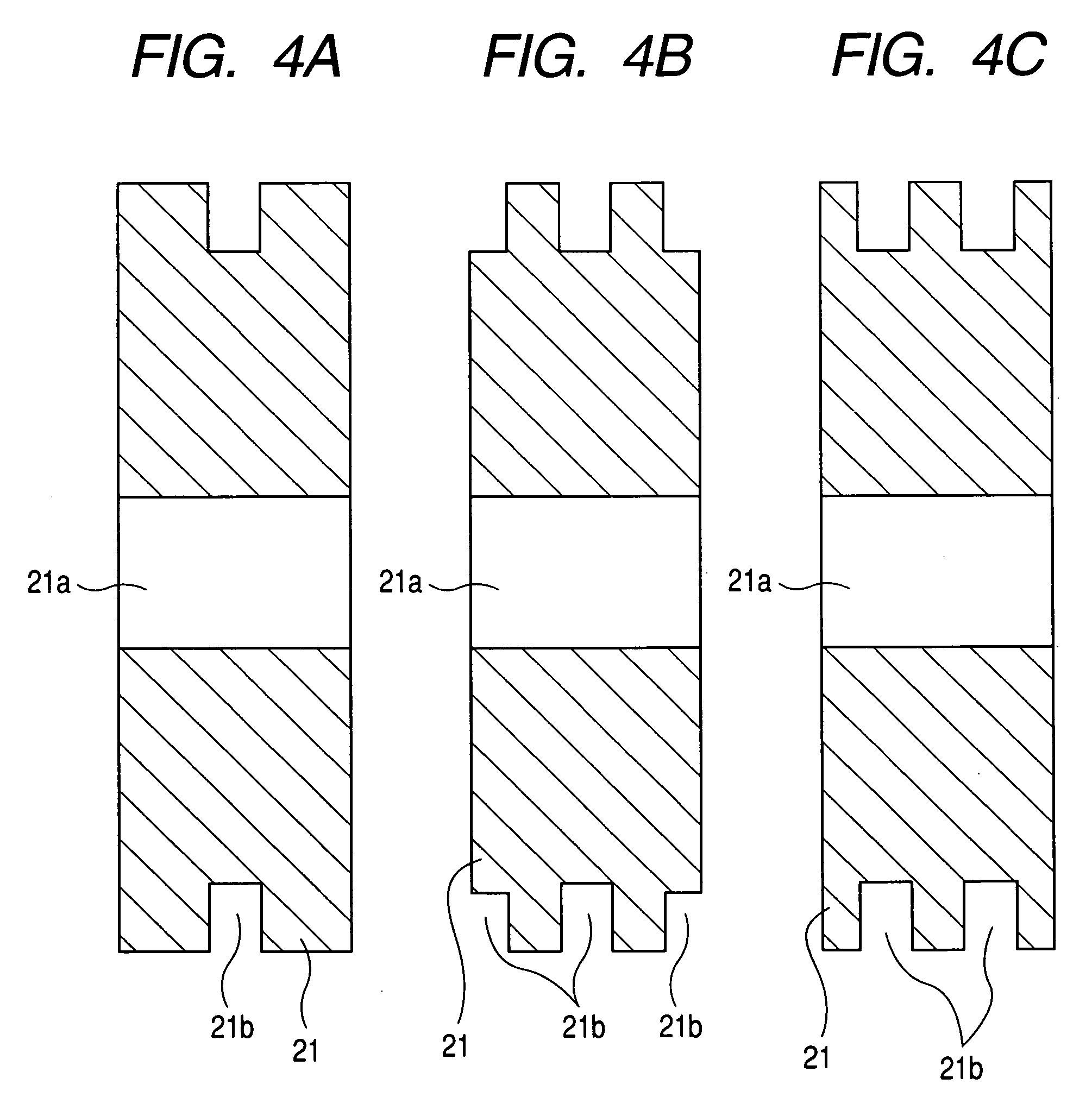

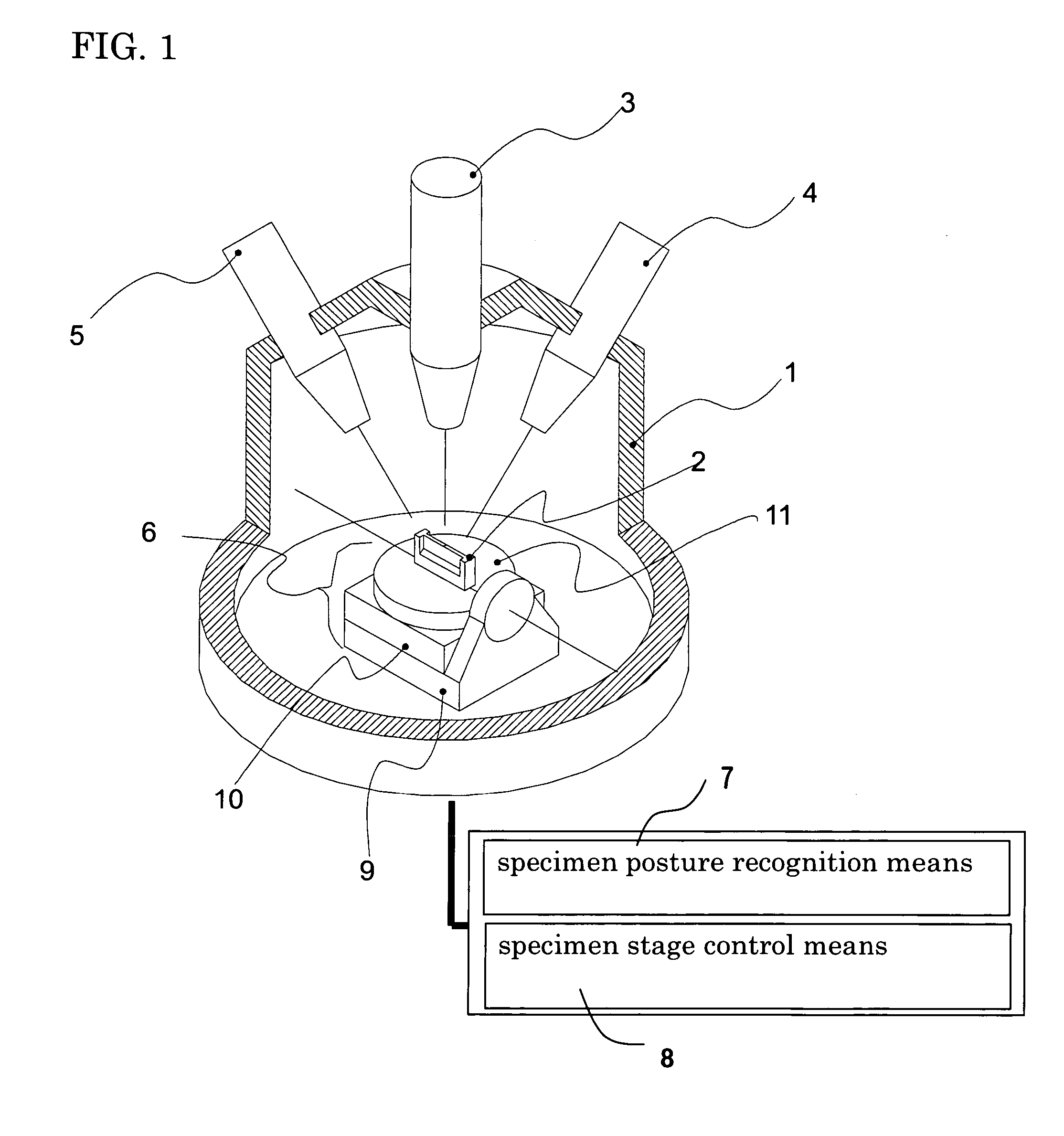

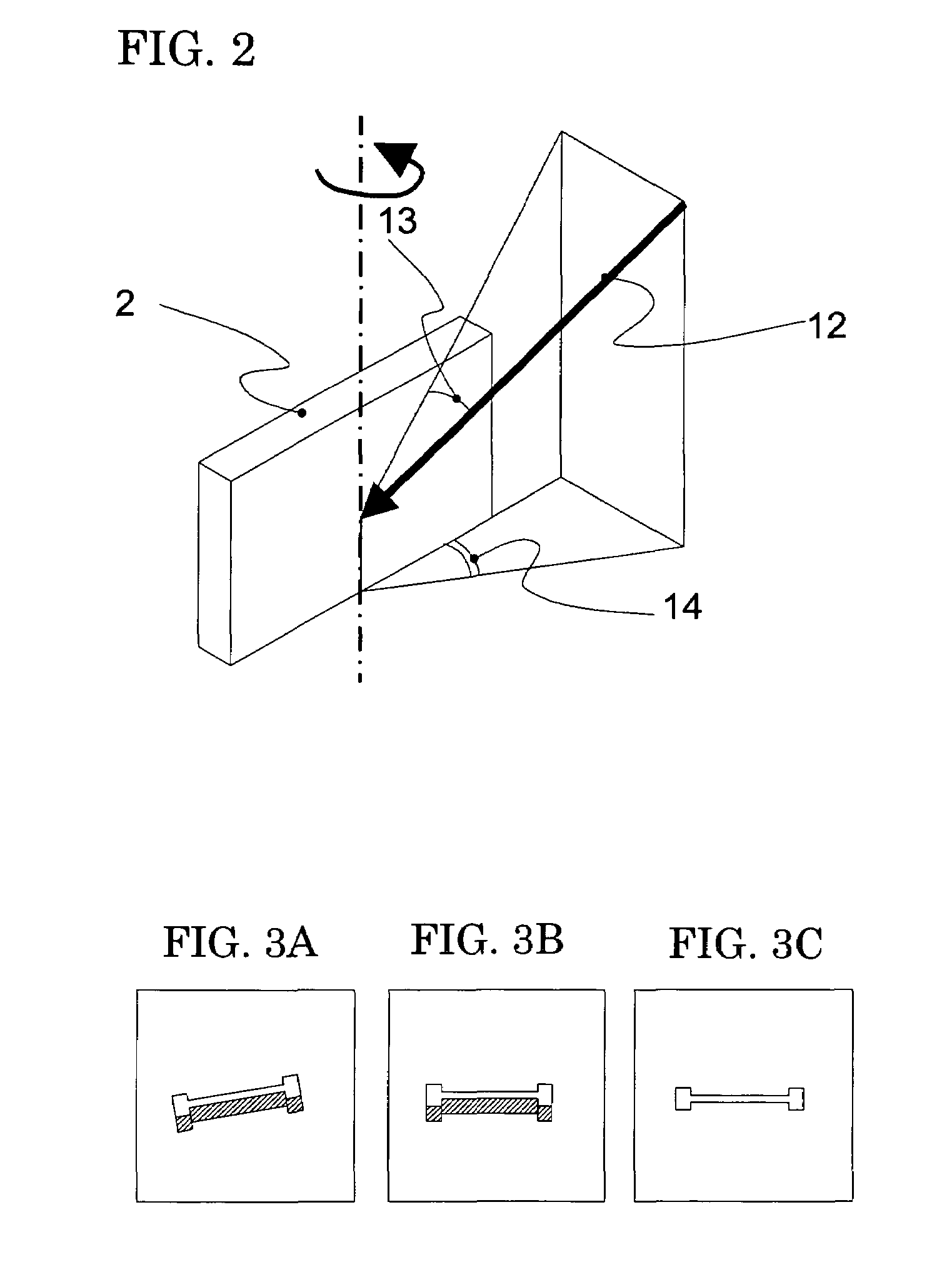

Charged particle beam apparatus

ActiveUS20070045560A1Irradiation angle is somewhat limitedMaterial analysis using wave/particle radiationPreparing sample for investigationScanning electron microscopeElectron microscope

To include a focused ion beam apparatus fabricating a sliced specimen by processing a specimen as well as observing the sliced specimen, a scanning electron microscope observing the slice specimen, a gas-ion beam irradiation apparatus performing finishing processing by irradiating a gas-ion beam onto a surface of the sliced specimen, a specimen stage on which the sliced specimen is fixed and having at least one or more rotation axis, a specimen posture recognition means recognizing positional relation of the sliced specimen with respect to the specimen stage and a specimen stage control means controlling the specimen stage based on a specimen posture recognized by the posture recognition means and an installation angle of the gas-ion beam irradiation apparatus in order to allow an incident angle of the gas-ion beam with respect to the obverse or the reverse of the sliced specimen to be a desired value.

Owner:HITACHI HIGH TECH SCI CORP

Sample milling/observing apparatus and method of observing sample

InactiveUS20060226376A1Simply and easily adjustedEasy to observeMaterial analysis using wave/particle radiationElectric discharge tubesIrradiationElectron

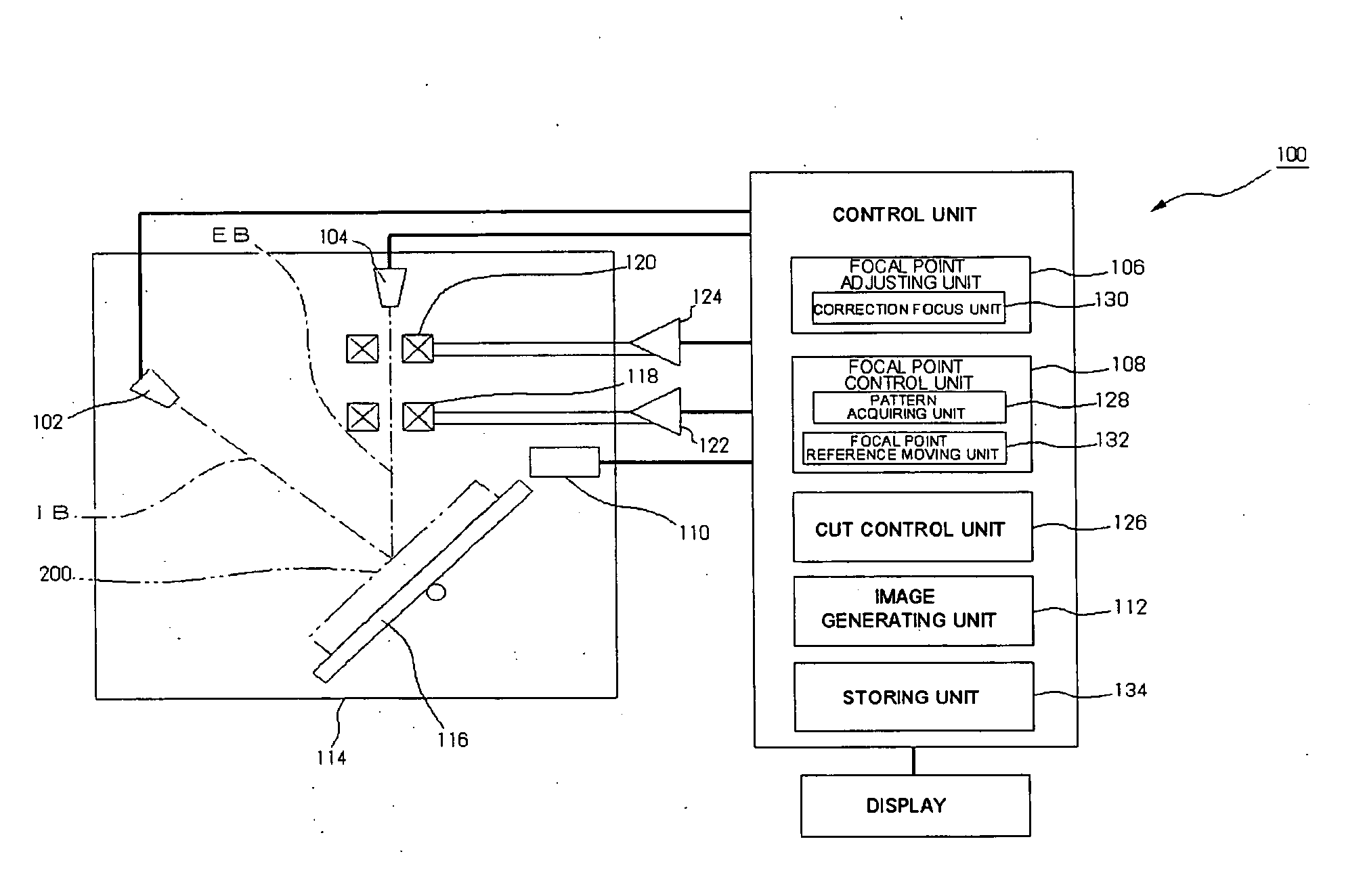

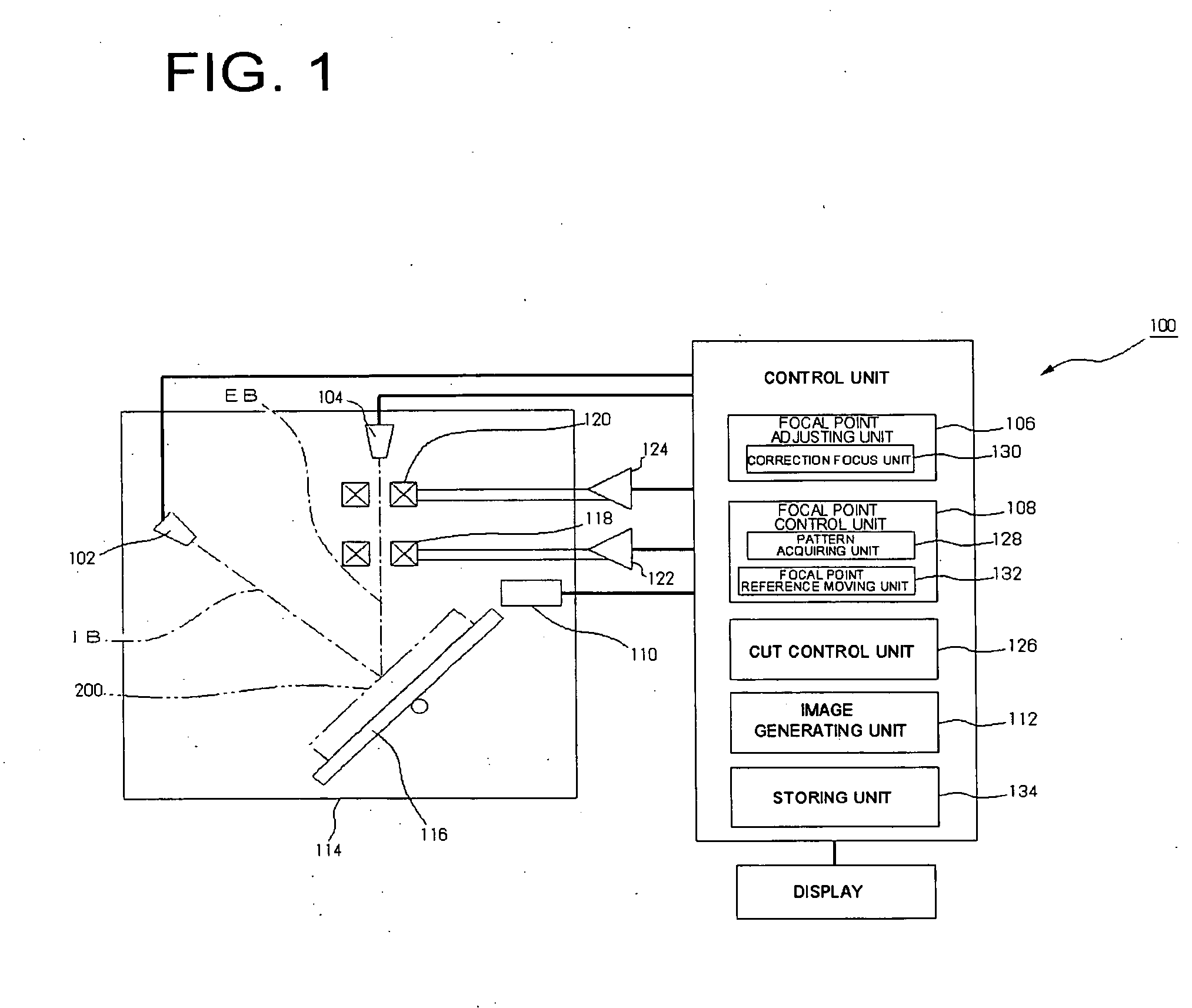

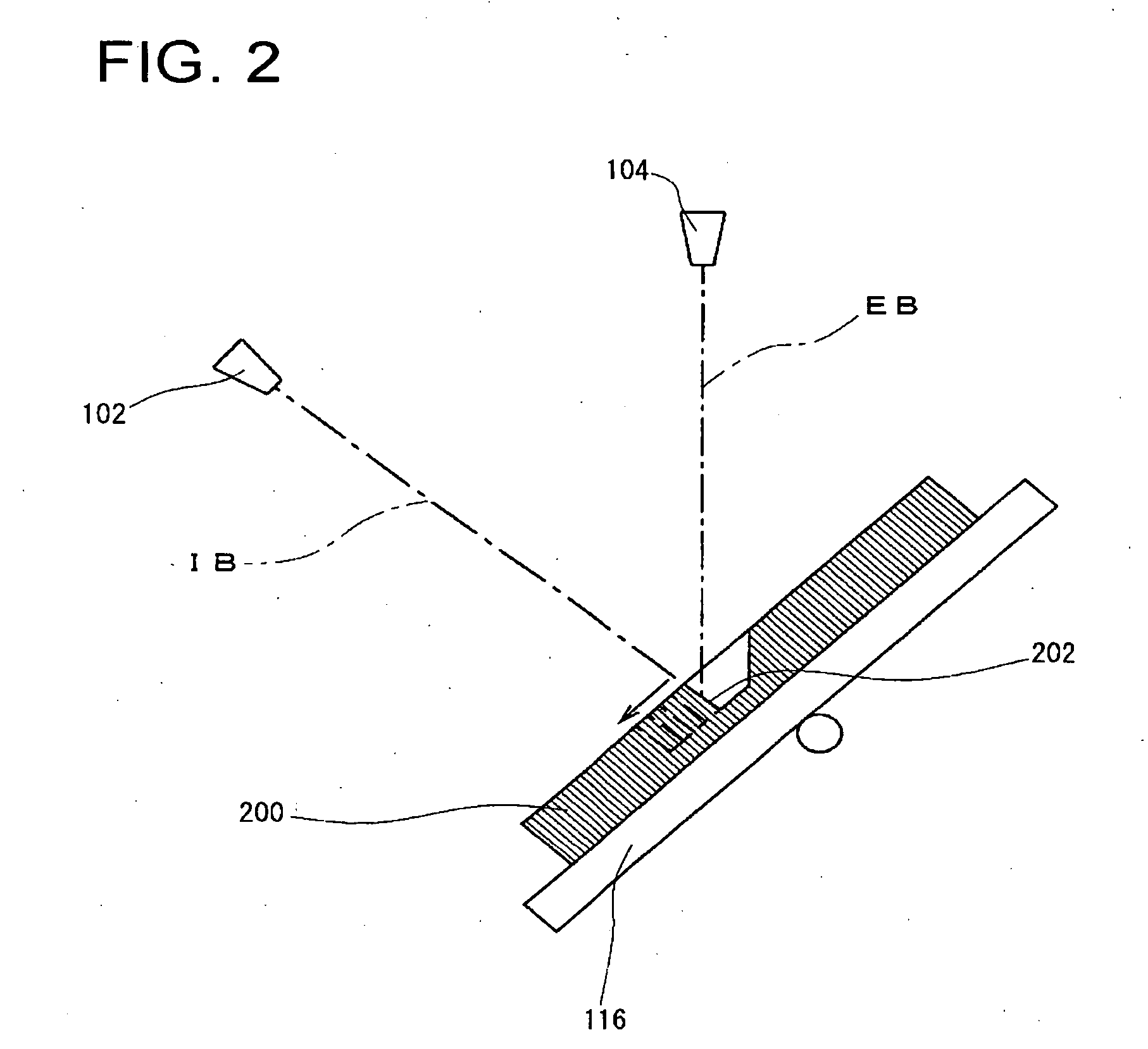

When a sample is cut to update an observed section, an electron beam is focused on the observed section. An apparatus of the invention includes an ion gun 102 which irradiates an ion beam onto a sample 200 to form an observed section 202, an electron gun 104 which irradiates an electron beam EB onto the observed section 202 formed by the ion gun 102, a focal point adjusting unit 106 which adjusts a relationship between the observed section 202 and a focal point of the electron beam EB, and a focal point control unit 108 which controls the focal point adjusting unit 106 on the basis of an amount of cut of the sample 200 obtained by irradiation of the ion beam IB obtained by the ion gun 102.

Owner:RENESAS ELECTRONICS CORP

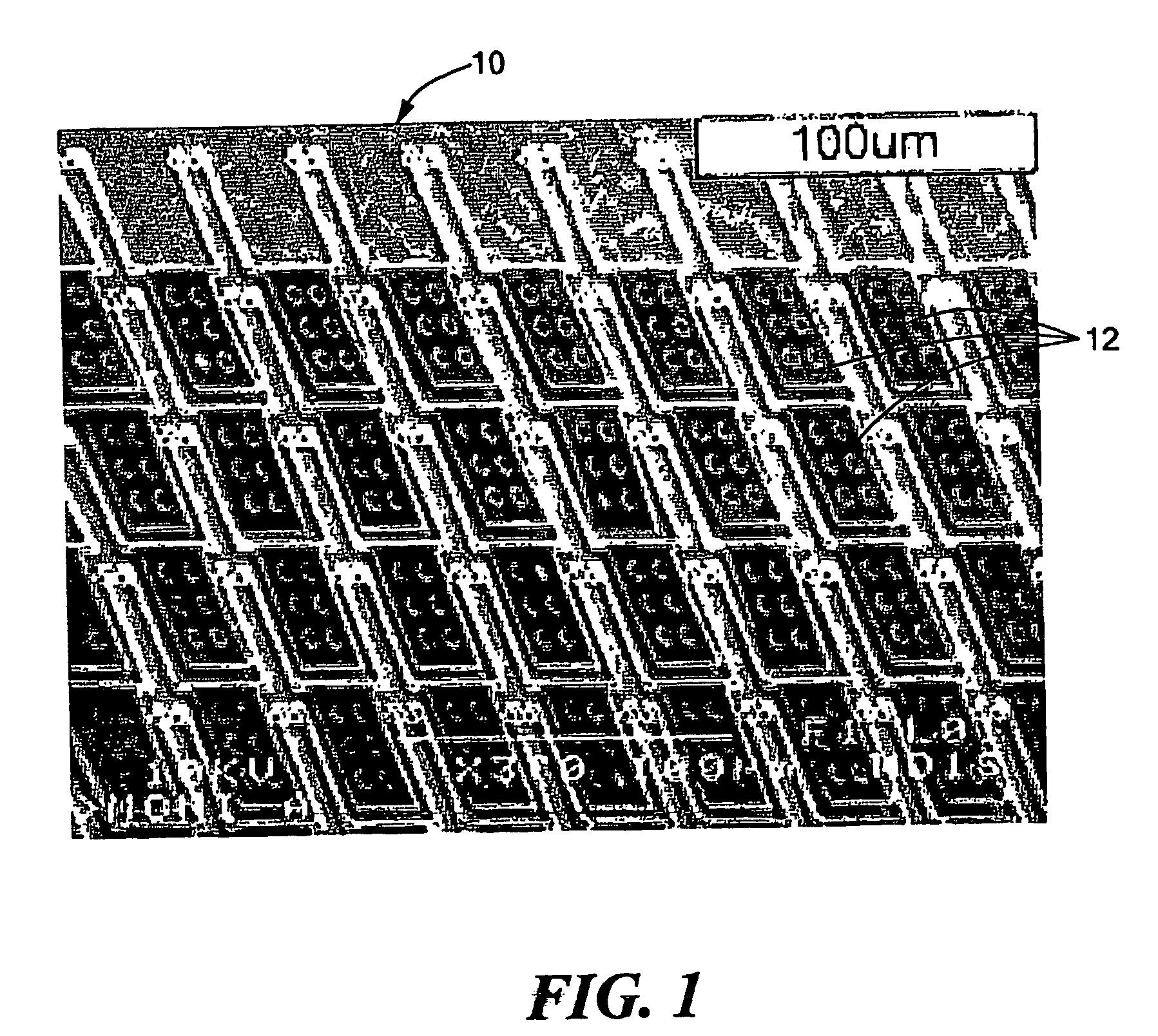

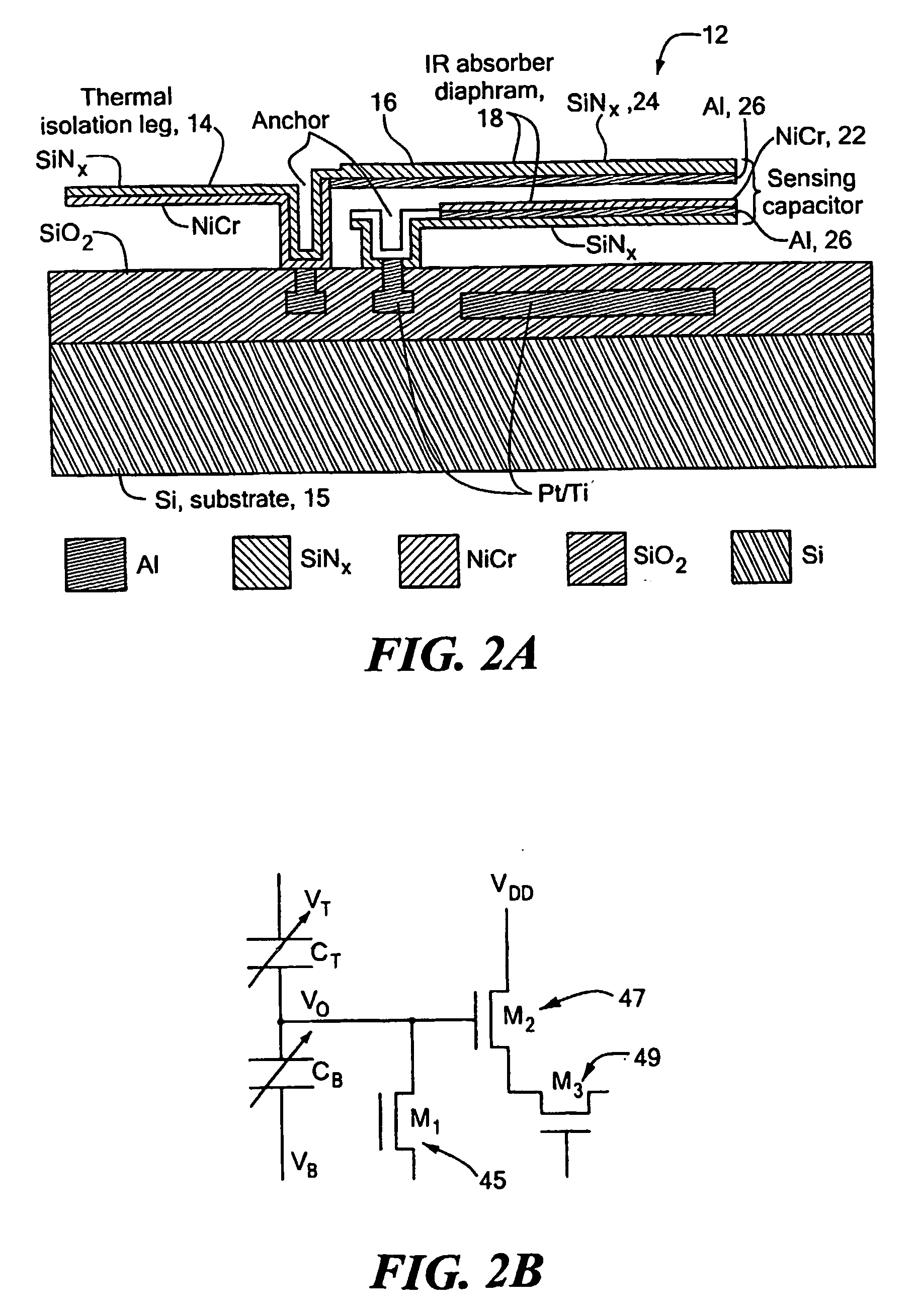

Uncooled Cantilever Microbolometer Focal Plane Array with Mk Temperature Resolutions and Method of Manufacturing Microcantilever

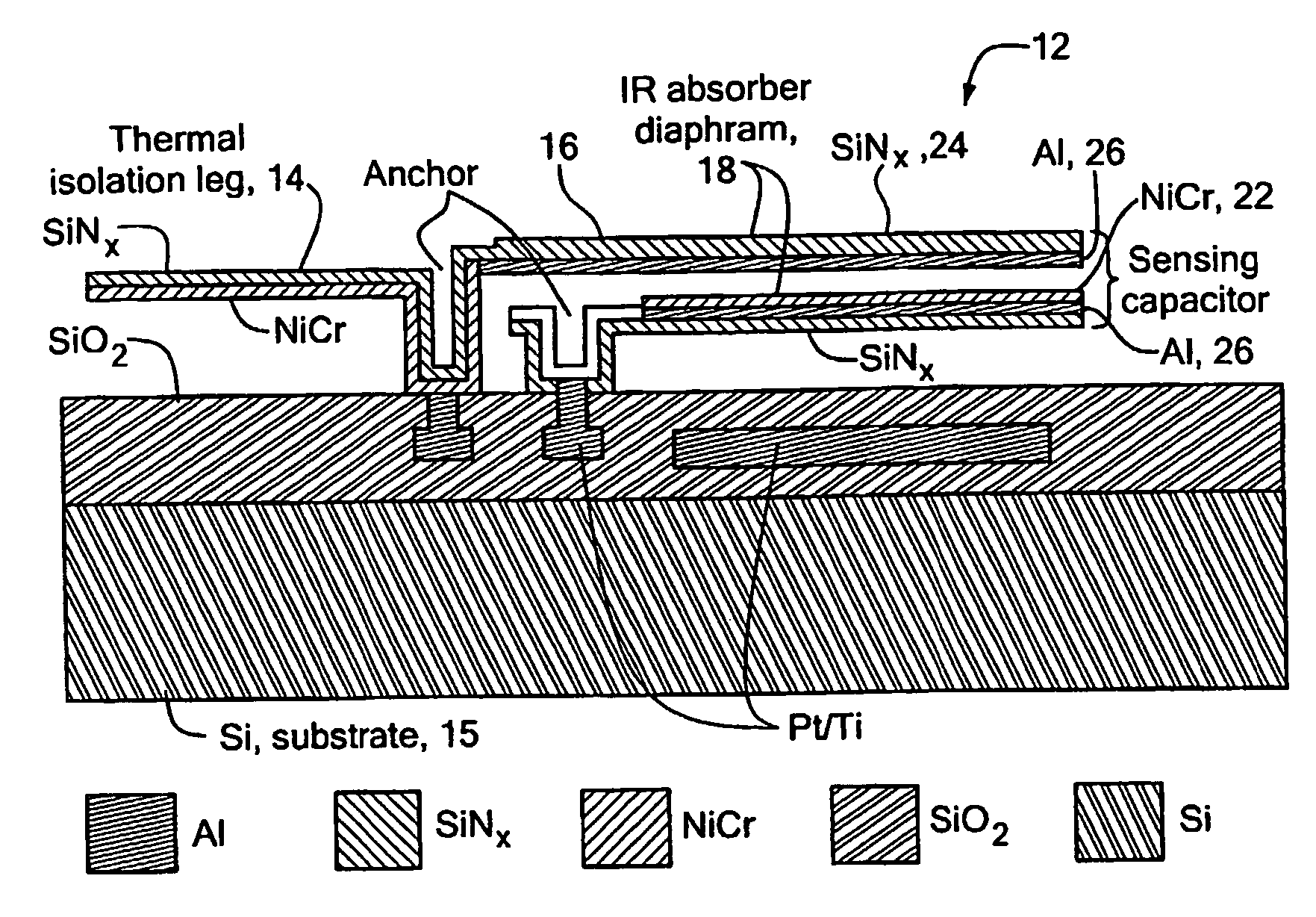

InactiveUS20070272864A1Reliable and straightforward manufacturing technologyHigh sensitivitySolid-state devicesSemiconductor/solid-state device manufacturingCantilevered beamMicrobolometer

A microbolometer sensor has a first cantilever supported above a substrate and formed of a bimaterial so as to deform in a first direction in response to incident radiation, and a second cantilever supported above the substrate and formed of a bimaterial so oriented as to cause the second cantilever to deflect oppositely to the first cantilever in response to radiation. The first and second cantilevers have a spacing therebetween that varies as a function of radiation incident on said first and second cantilevers. Means for sensing the deflection of the first and second cantilevers to provide an indication of the incident radiation is provided. A process of forming a micromechanical cantilever structure is also providing by irradiating a cantilever with an ion beam, whereby the cantilever is flattened. Also, the cantilever can be annealed in a rapid thermal annealing process to flatten the cantilever.

Owner:TRUSTEES OF BOSTON UNIV +1

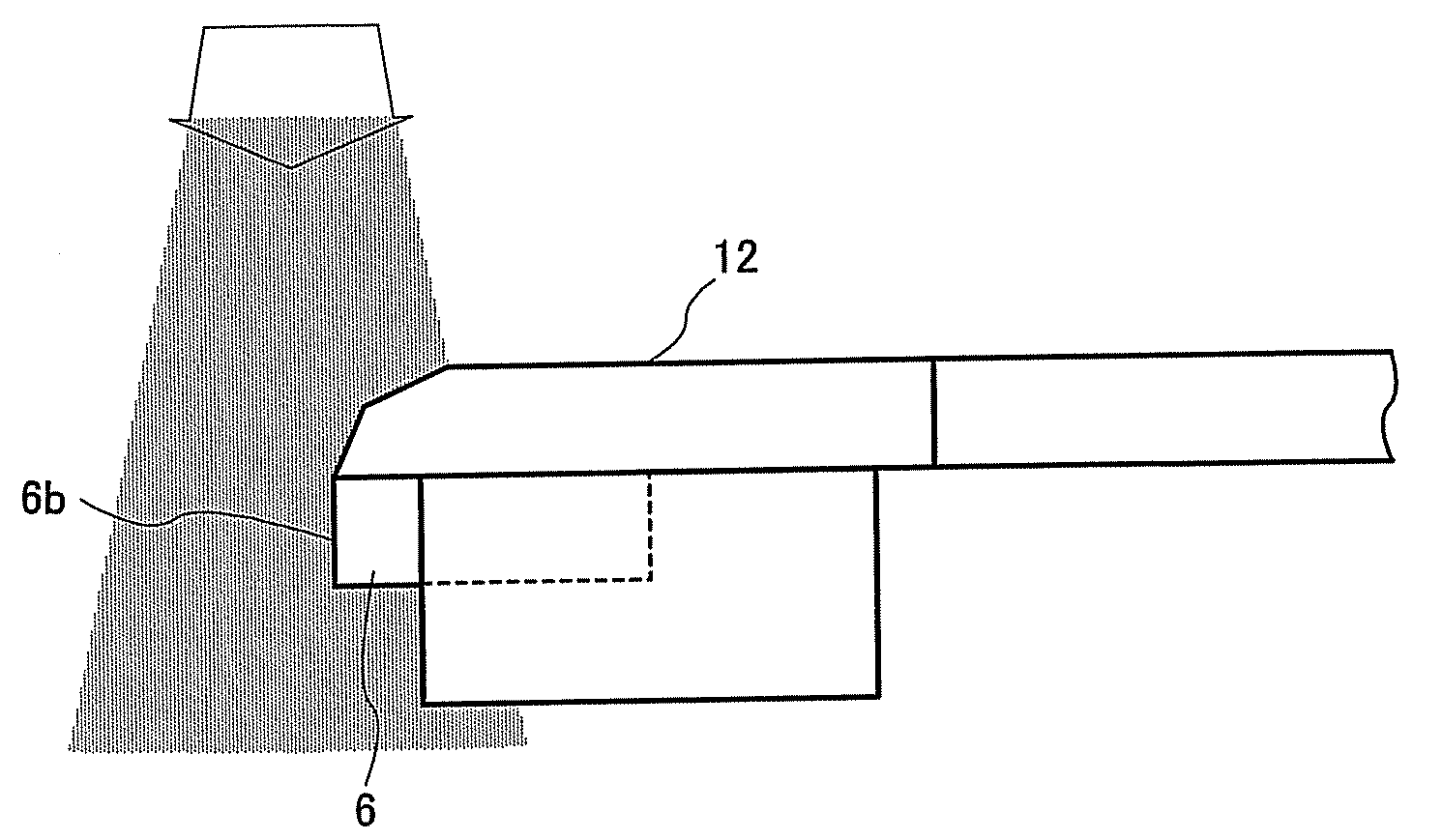

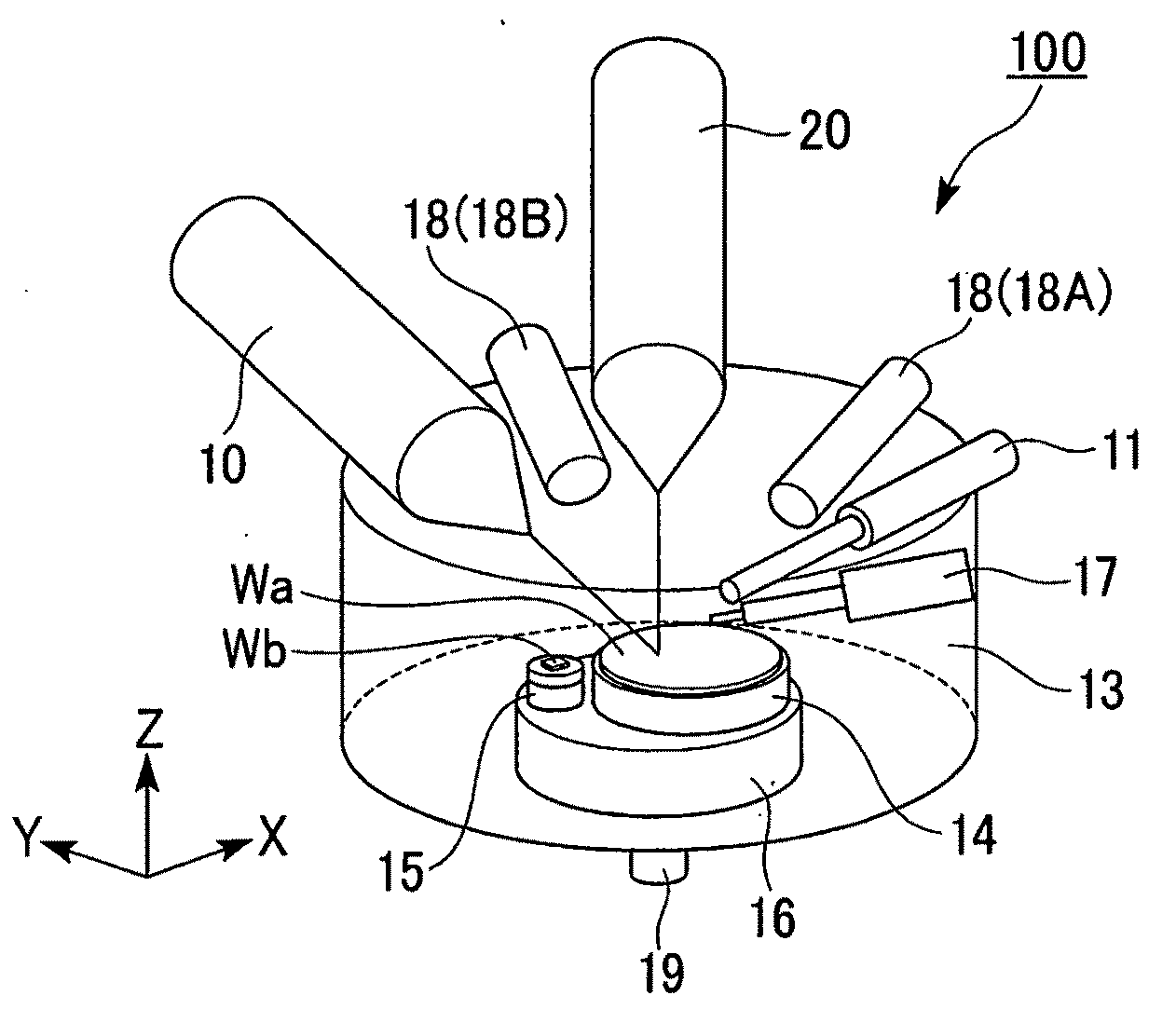

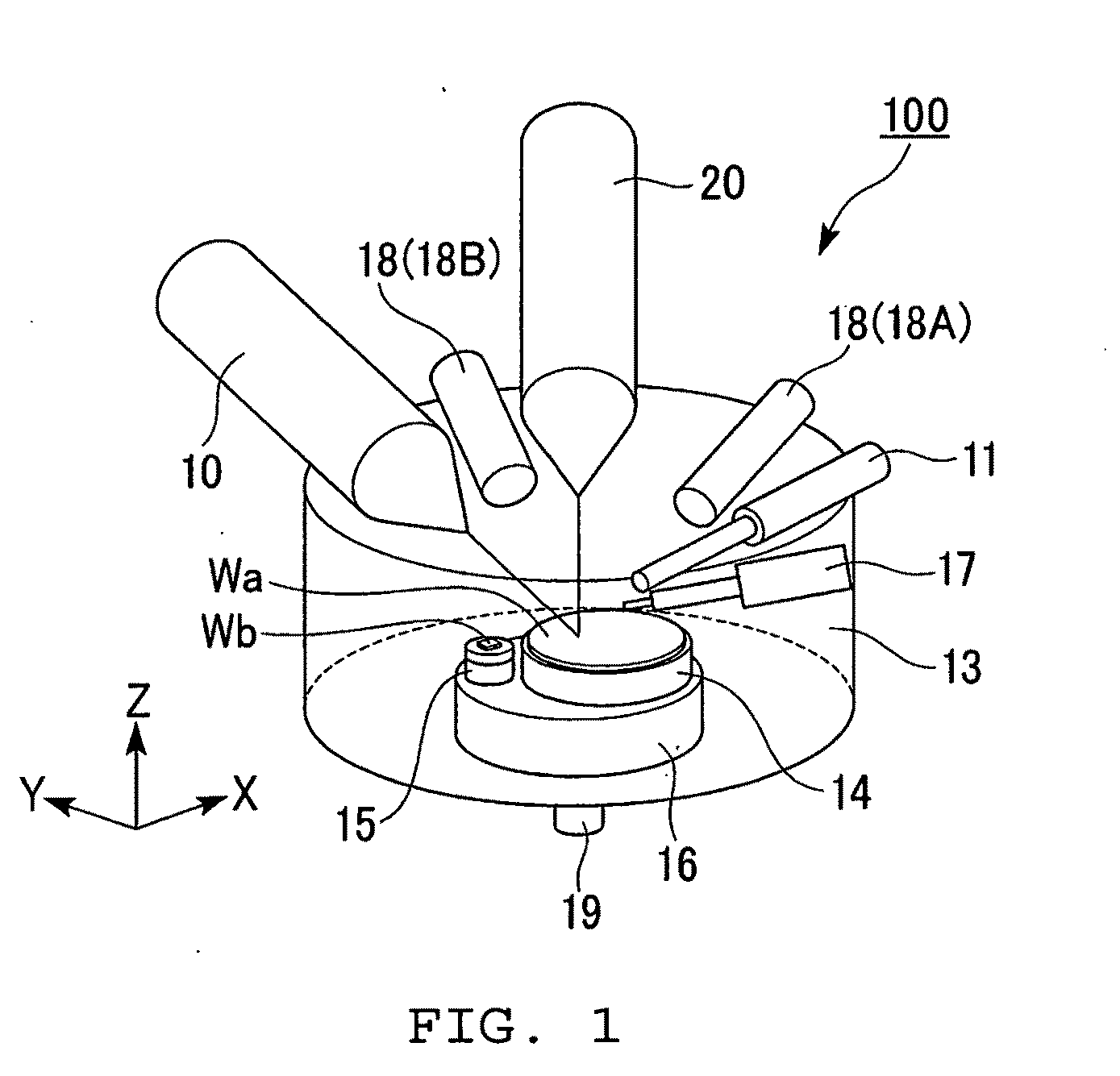

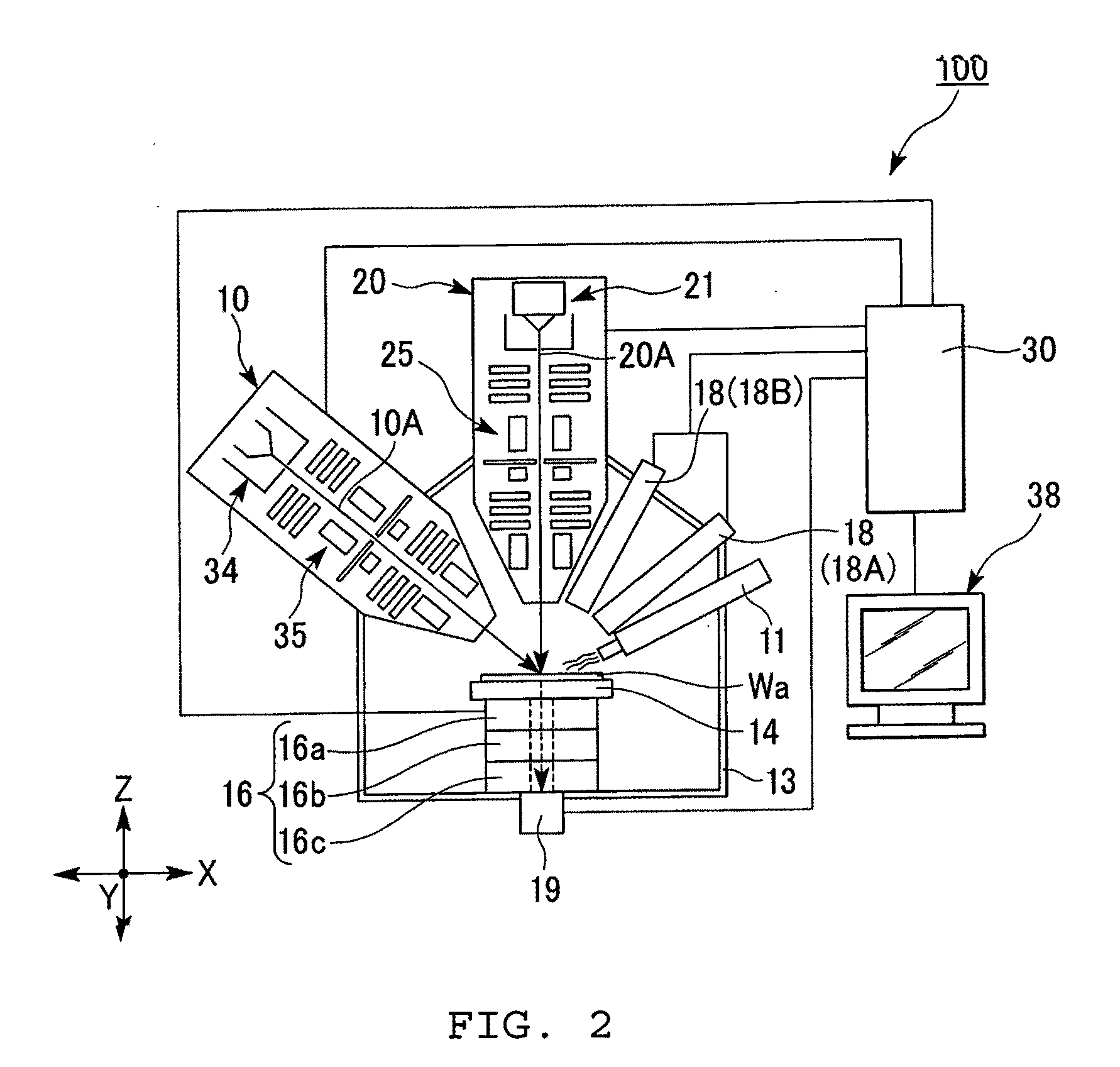

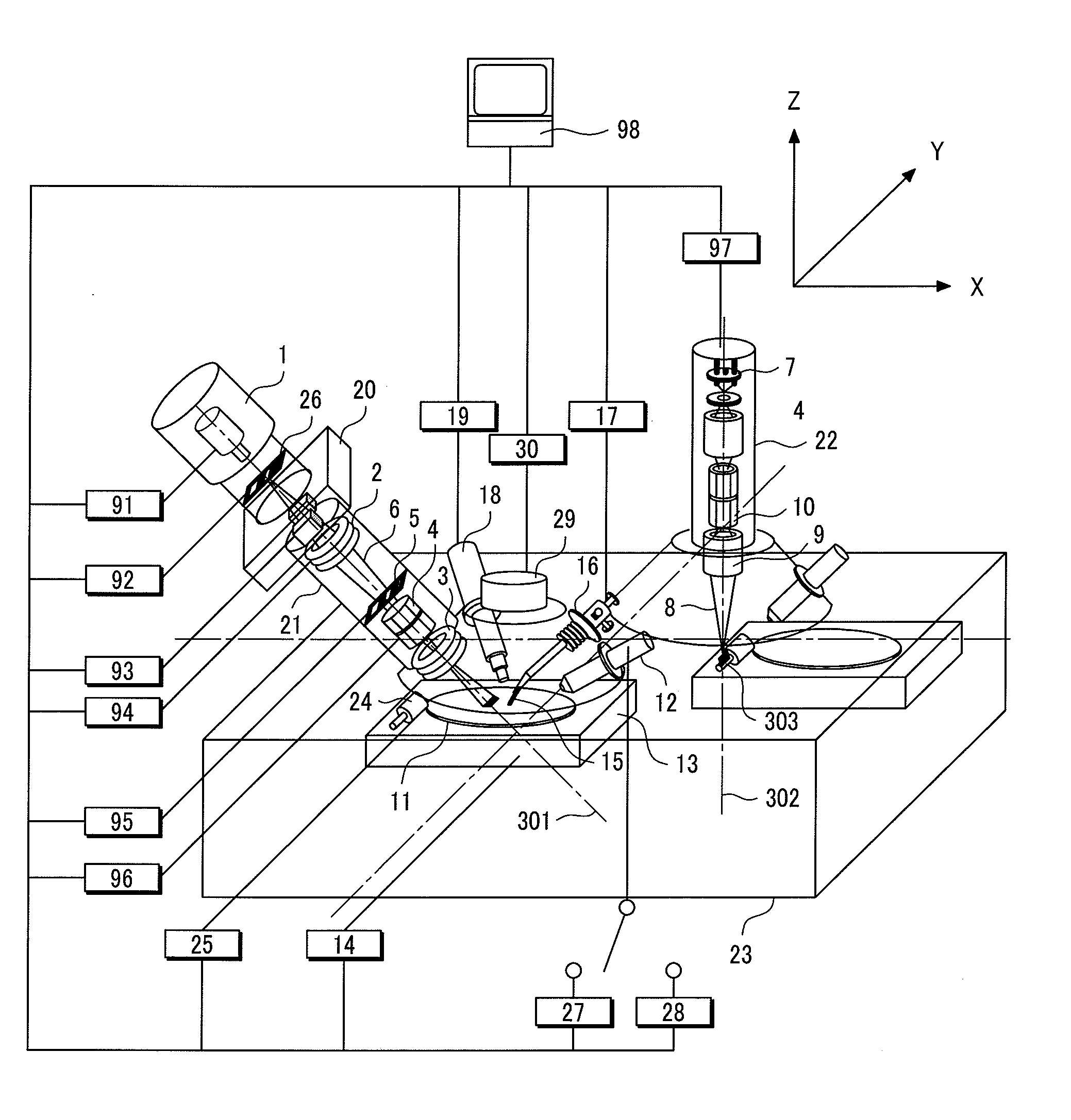

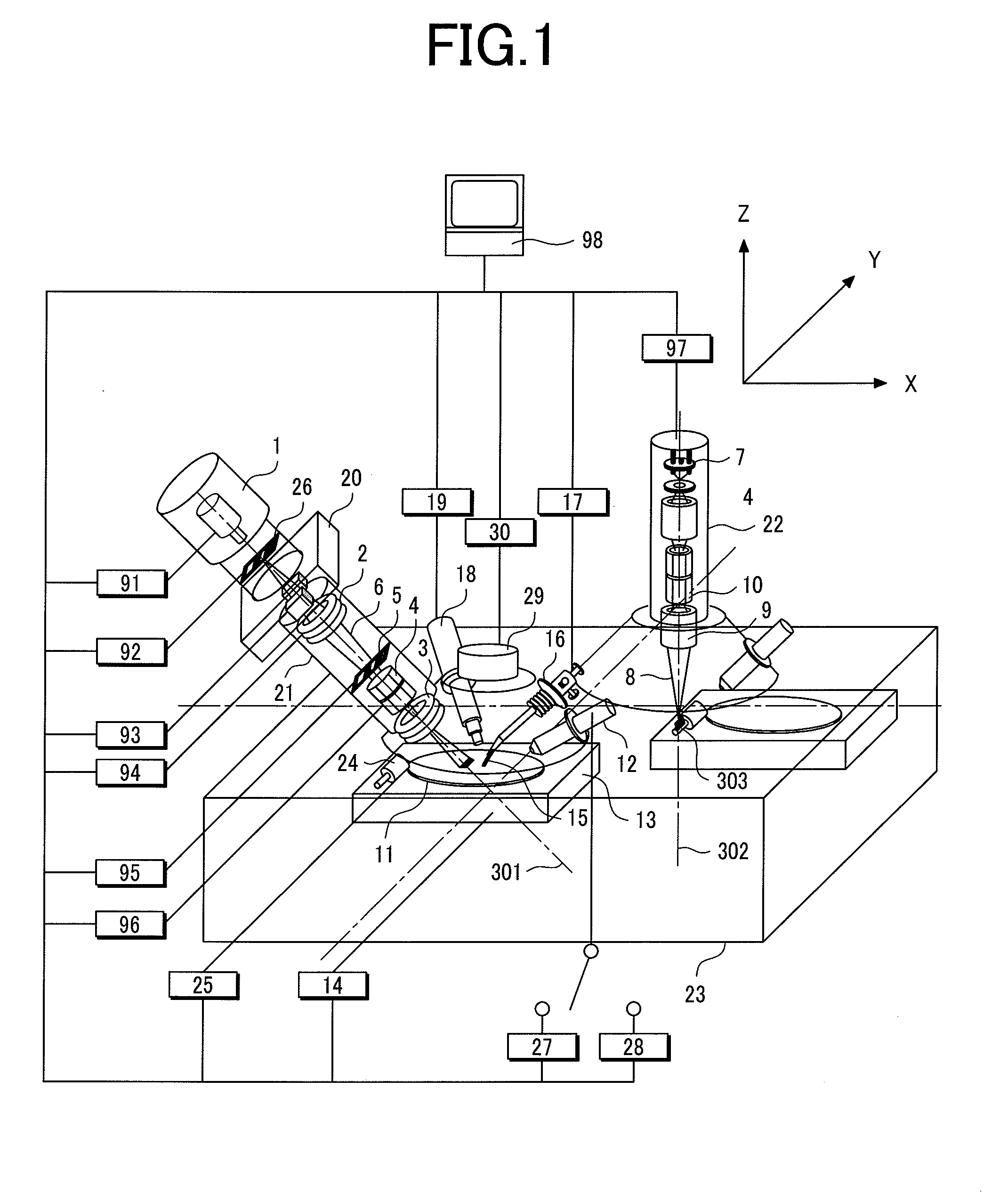

Composite focused ion beam device, and processing observation method and processing method using the same

ActiveUS20100176296A1Good for observationSuper high resolutionMaterial analysis using wave/particle radiationPreparing sample for investigationLiquid metal ion sourceBeam diameter

A composite focused ion beam device includes a first ion beam irradiation system 10 including a liquid metal ion source for generating a first ion, and a second ion beam irradiation system 20 including a gas field ion source for generating a second ion, and a beam diameter of the second ion beam 20A emitted from the second ion beam irradiation system 20 is less than that of the first ion beam 10A emitted from the first ion beam irradiation system 10.

Owner:HITACHI HIGH TECH SCI CORP

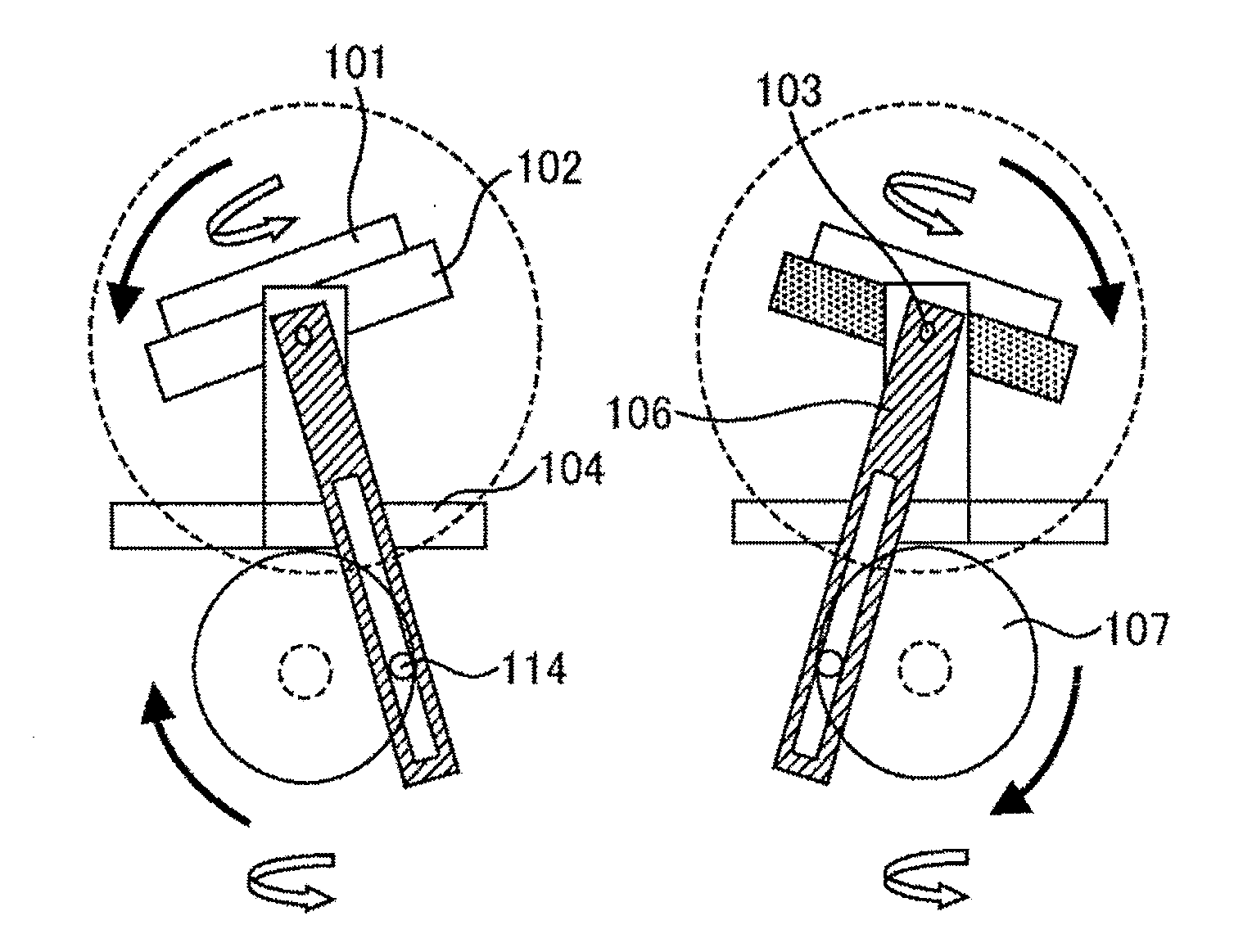

Ion Milling Device, Sample Processing Method, Processing Device, and Sample Drive Mechanism

InactiveUS20120298884A1Possible to detectElectric discharge tubesPreparing sample for investigationIon beam irradiationParticle physics

In view of the above-mentioned problems, an object of the present invention is to provide a processing method that is not dependent on the material or the ion beam irradiation angle. In order to achieve the object above, the present invention provides a processing device that processes a sample by irradiating the sample with an ion beam, the processing device comprising a sample tilting / rotating mechanism that rotates / tilts the sample relative to the ion beam, wherein the sample rotating mechanism comprises a rotating shaft that rotates the sample relative to the ion beam, and a tilting shaft that is orthogonal to the rotating shaft and that tilts the sample relative to the ion beam, the sample rotating mechanism being adapted to simultaneously perform the rotating and tilting of the sample.

Owner:HITACHI HIGH-TECH CORP

Ion beam processing apparatus

InactiveUS20080073582A1Precise processingShorten the timeMaterial analysis using wave/particle radiationElectric discharge tubesIon beam processingIrradiation

The present invention provides an ion beam processing technology for improving the precision in processing a section of a sample using an ion beam without making a processing time longer than a conventionally required processing time, and for shortening the time required for separating a micro test piece without breaking the sample or the time required for making preparations for the separation. An ion beam processing apparatus is structured so that an axis along which an ion beam is drawn out of an ion source and an ion beam irradiation axis along which the ion beam is irradiated to a sample mounted on a first sample stage will meet at an angle. Furthermore, the ion beam processing apparatus has a tilting ability to vary an angle of irradiation, at which the ion beam is irradiated to the sample, by rotating a second sample stage, on which a test piece extracted from the sample by performing ion beam processing is mounted, about the tilting axis of the second sample stage. The ion beam processing apparatus is structured so that a segment drawn by projecting the axis, along which the ion beam is drawn out of the ion source, on a plane perpendicular to the ion beam irradiation axis can be at least substantially parallel to a segment drawn by projecting the tilting axis of the second sample stage on the plane perpendicular to the ion beam irradiation axis.

Owner:HITACHI HIGH-TECH CORP

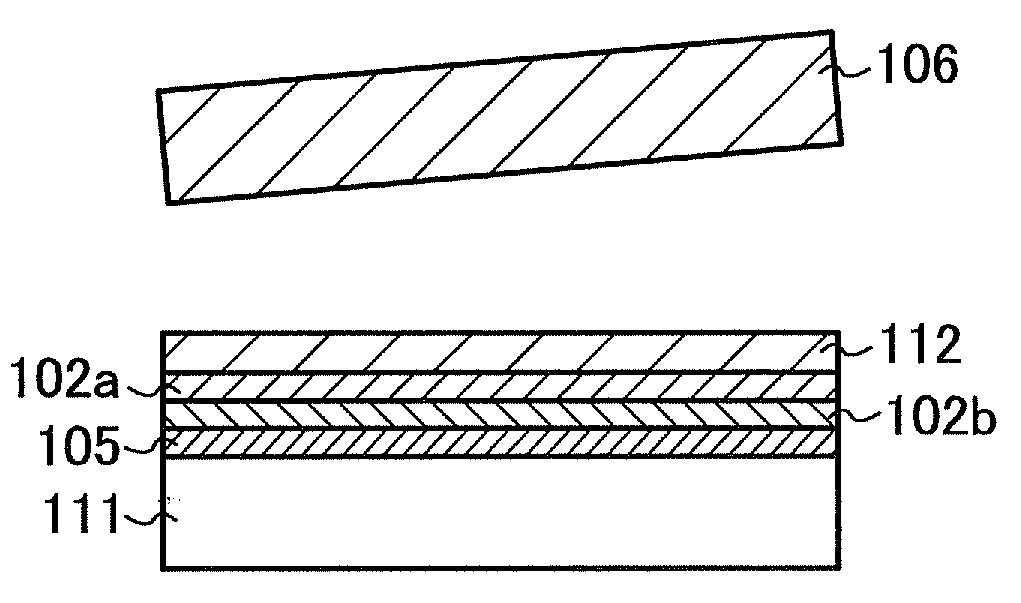

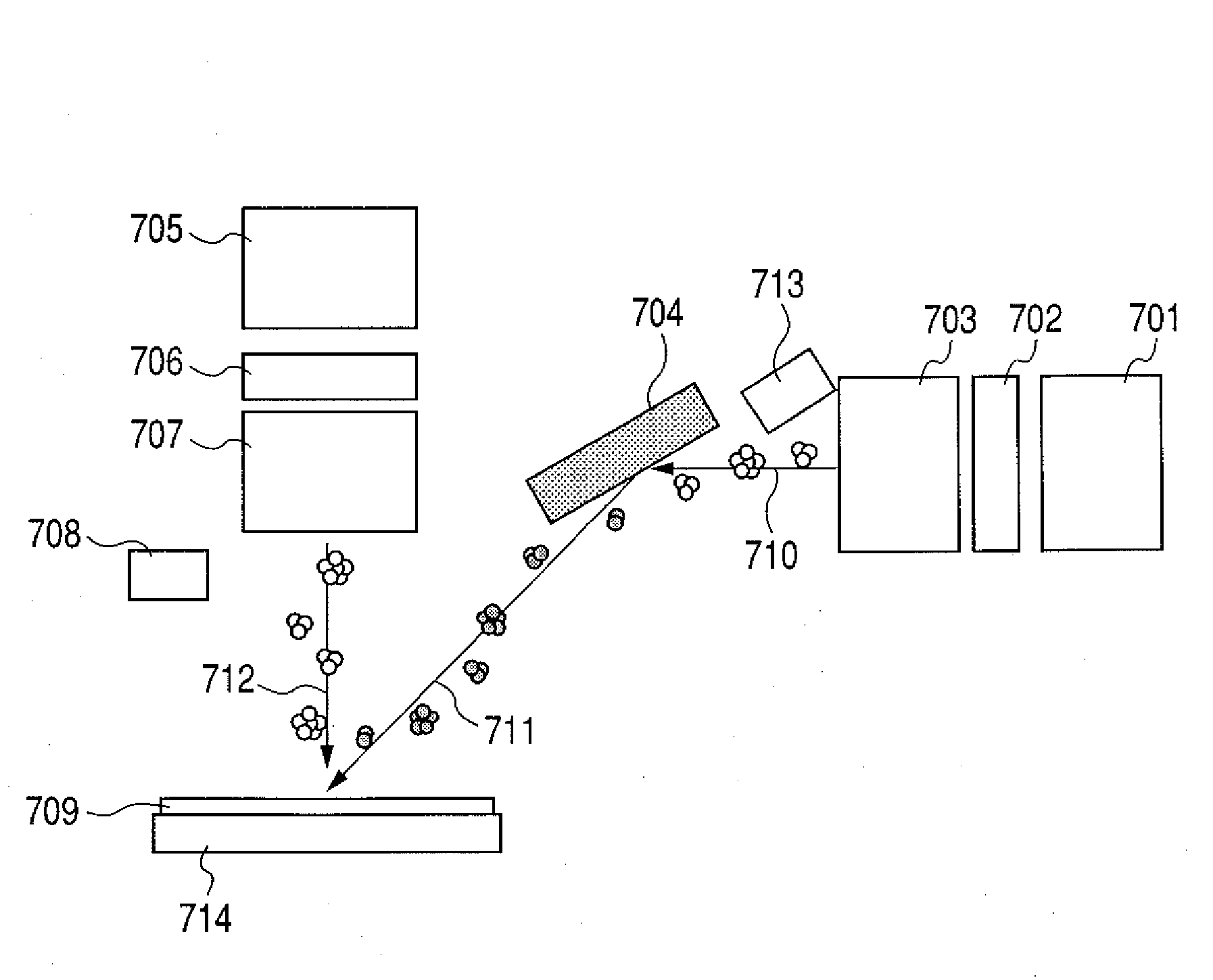

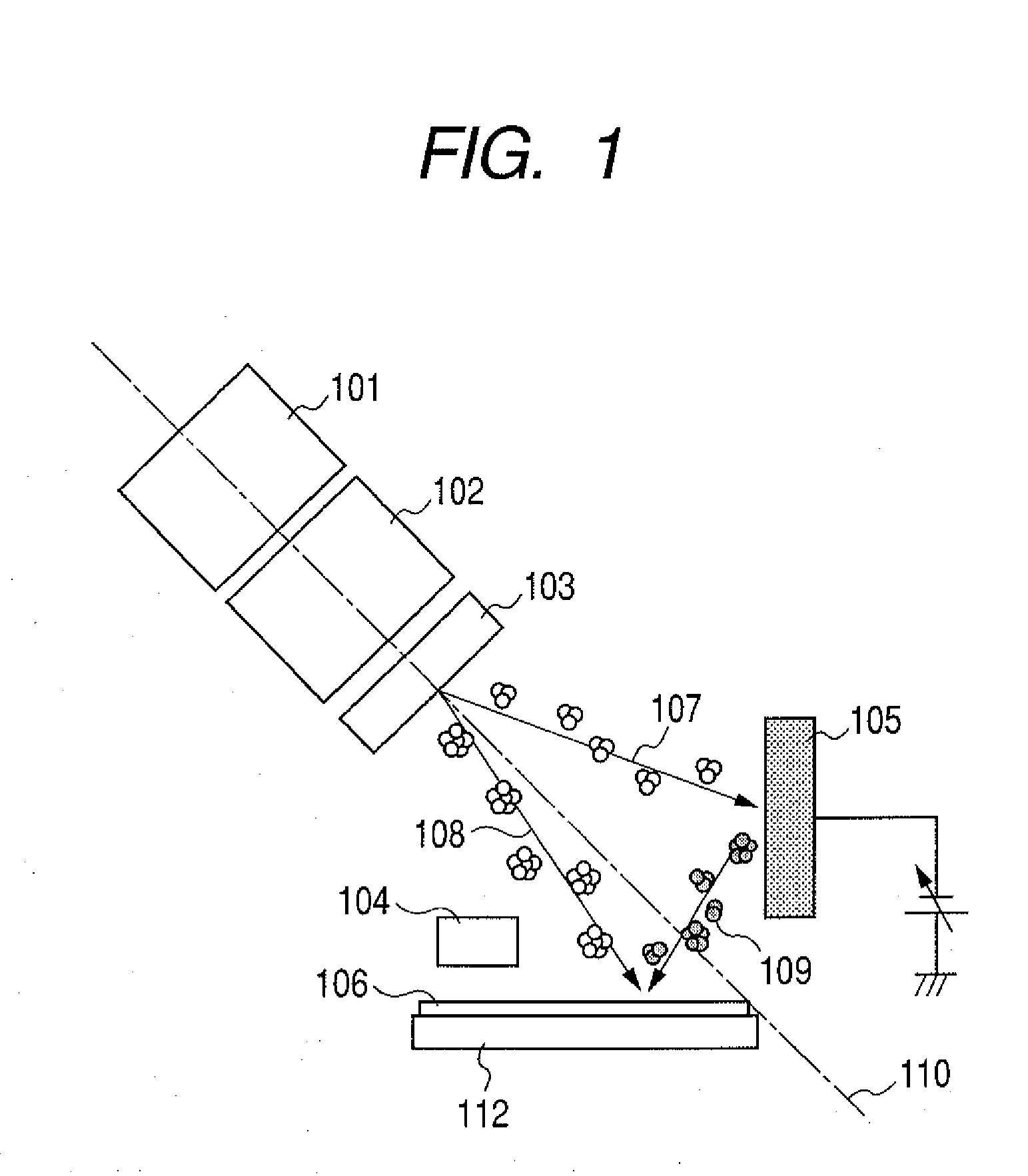

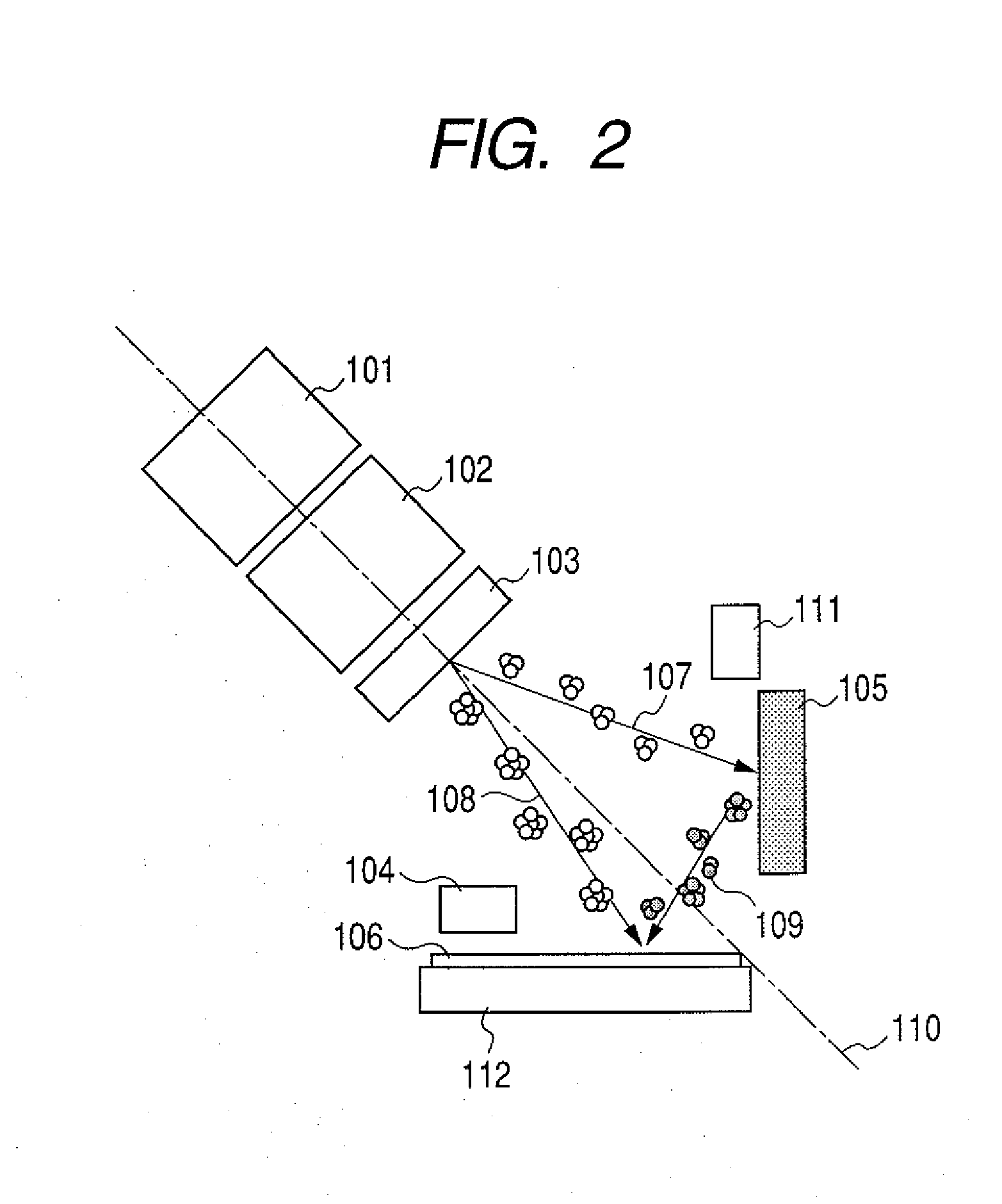

Film deposition apparatus and method of film deposition

InactiveUS20090071818A1Quality improvementCellsElectric discharge tubesOptoelectronicsIon beam sputtering

An ion beam sputtering film deposition apparatus is provided which can form a high-quality thin film that is dense, smooth and faultless. The film deposition apparatus has ion beam irradiating unit, a target 105 containing a film forming substance to be sputtered, and holding unit 112 to hold a substrate 106 on which the sputtered film forming substance is deposited. The ion beam irradiating unit irradiates gas cluster ions to both the target 105 and the substrate 106.

Owner:CANON KK

Apparatus for processing and observing a sample

InactiveUS6870161B2Not easy to interfereAvoid interferenceMaterial analysis using wave/particle radiationElectric discharge tubesOptical axisIrradiation

An apparatus for processing and observing a sample has a sample stage for supporting a sample at a preselected location thereof, a focused ion beam irradiation system for irradiating the sample with a focused ion beam along an optical axis to cut out a portion from the sample, and a side entry stage disposed over the sample stage and extending slantingly with respect to the optical axis of the focused ion beam irradiated by the focused ion beam irradiation system. The side entry stage has a microscope sample holder for picking up the cut-out sample portion directly from the preselected location of the sample and for supporting the sample portion. The microscope sample holder is configured to be removed from the side entry stage while supporting the sample portion and to be connected to an entry stage of a microscope device for observing the sample portion.

Owner:HITACHI HIGH TECH SCI CORP

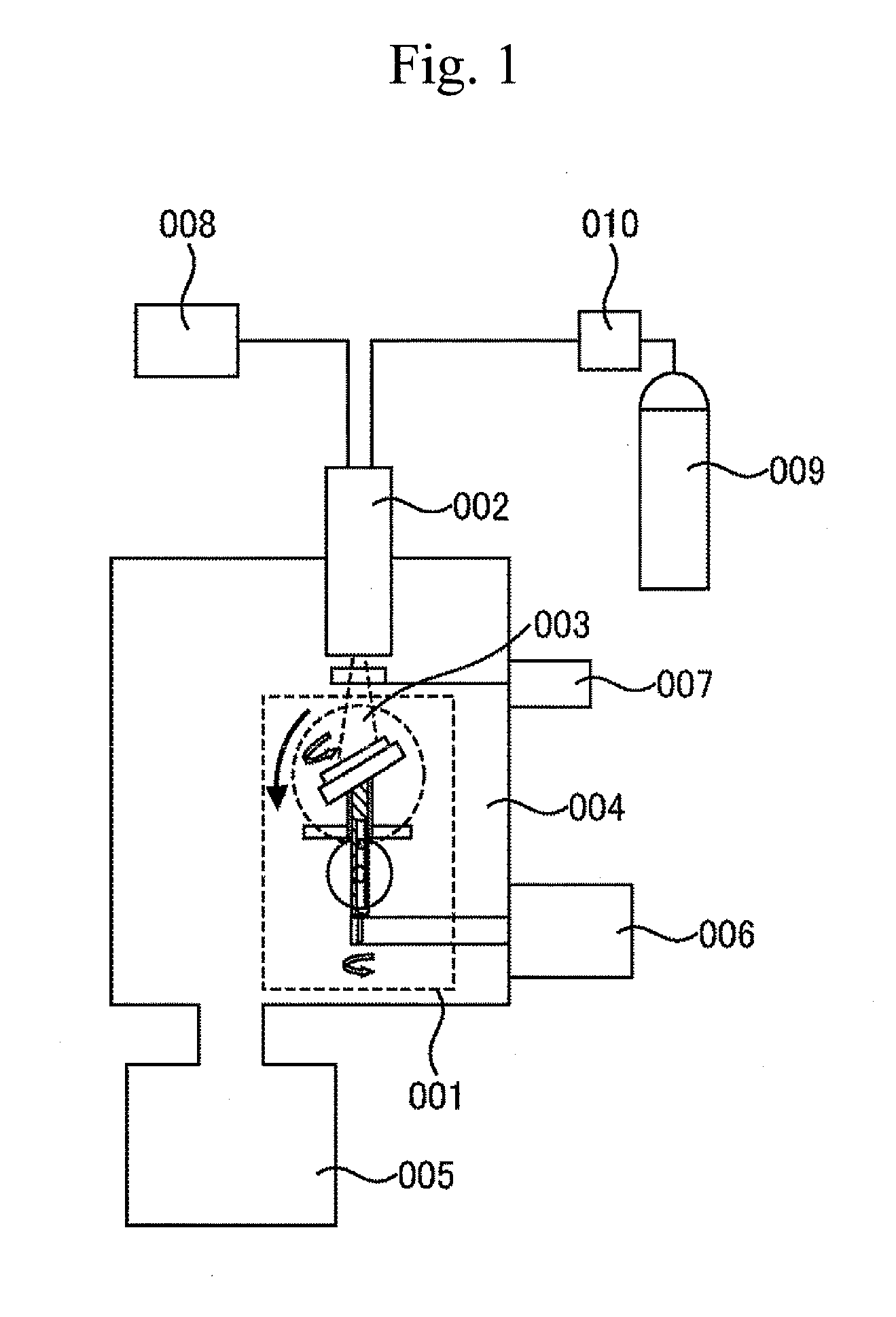

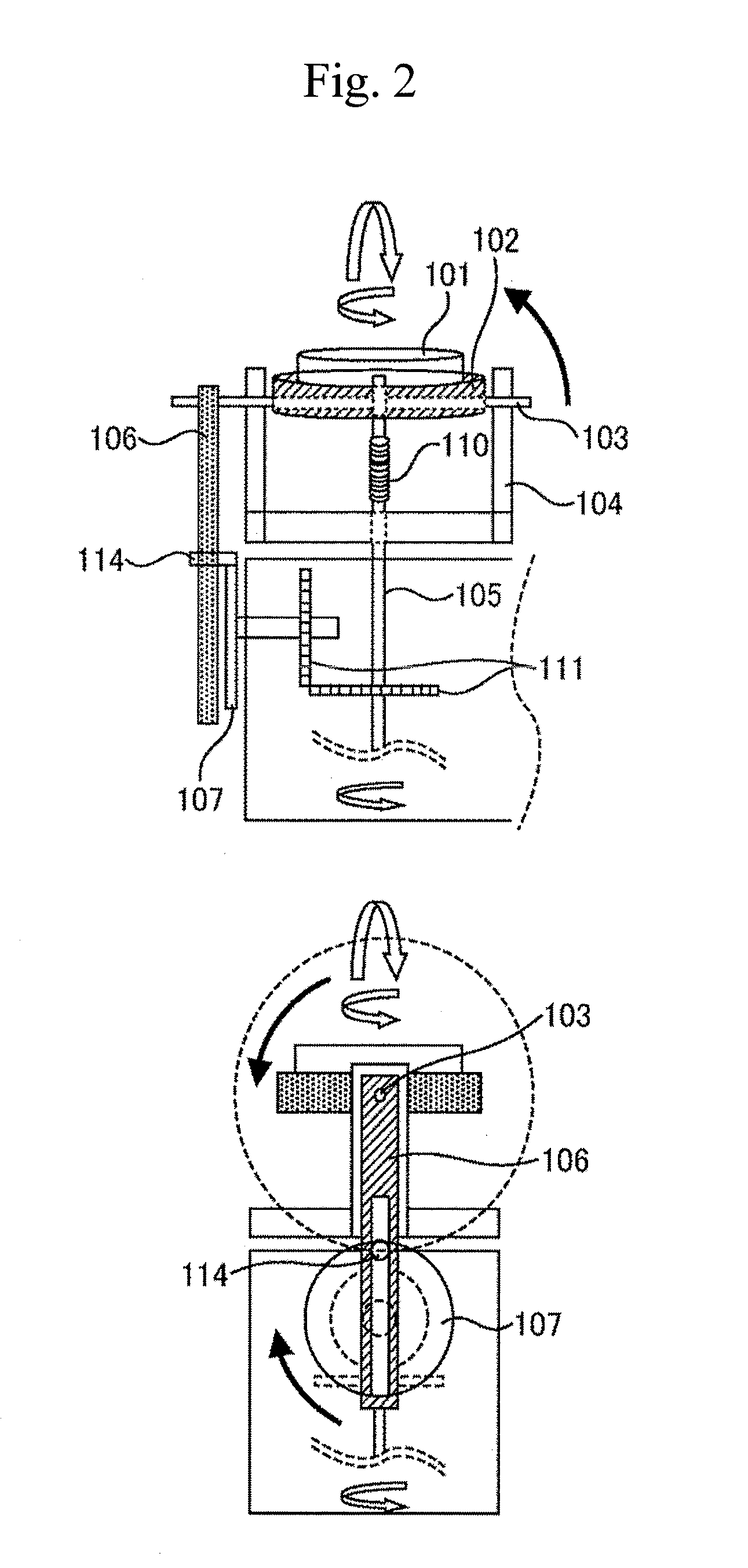

Ion beam delivery equipment and an ion beam delivery method

ActiveUS20070158592A1Increase the number ofElectric discharge tubesAcceleratorsVarying thicknessIrradiation

The invention is intended to increase the number of patients treatable using one wheel having a thickness varied in the rotating direction to change energy of an ion beam passing the wheel. Ion beam delivery equipment for irradiating an ion beam to a patient for treatment comprises a beam generator for producing and accelerating the ion beam, an beam delivery nozzle including a range modulation wheel which has a predetermined thickness distribution in the rotating direction and is rotated on a travel passage of the ion beam generated from the beam generator to control a range of the ion beam, and an irradiation controller for controlling the beam producing and accelerating operation of the beam generator in accordance with the phase of rotation of the range modulation wheel.

Owner:HITACHI LTD +1

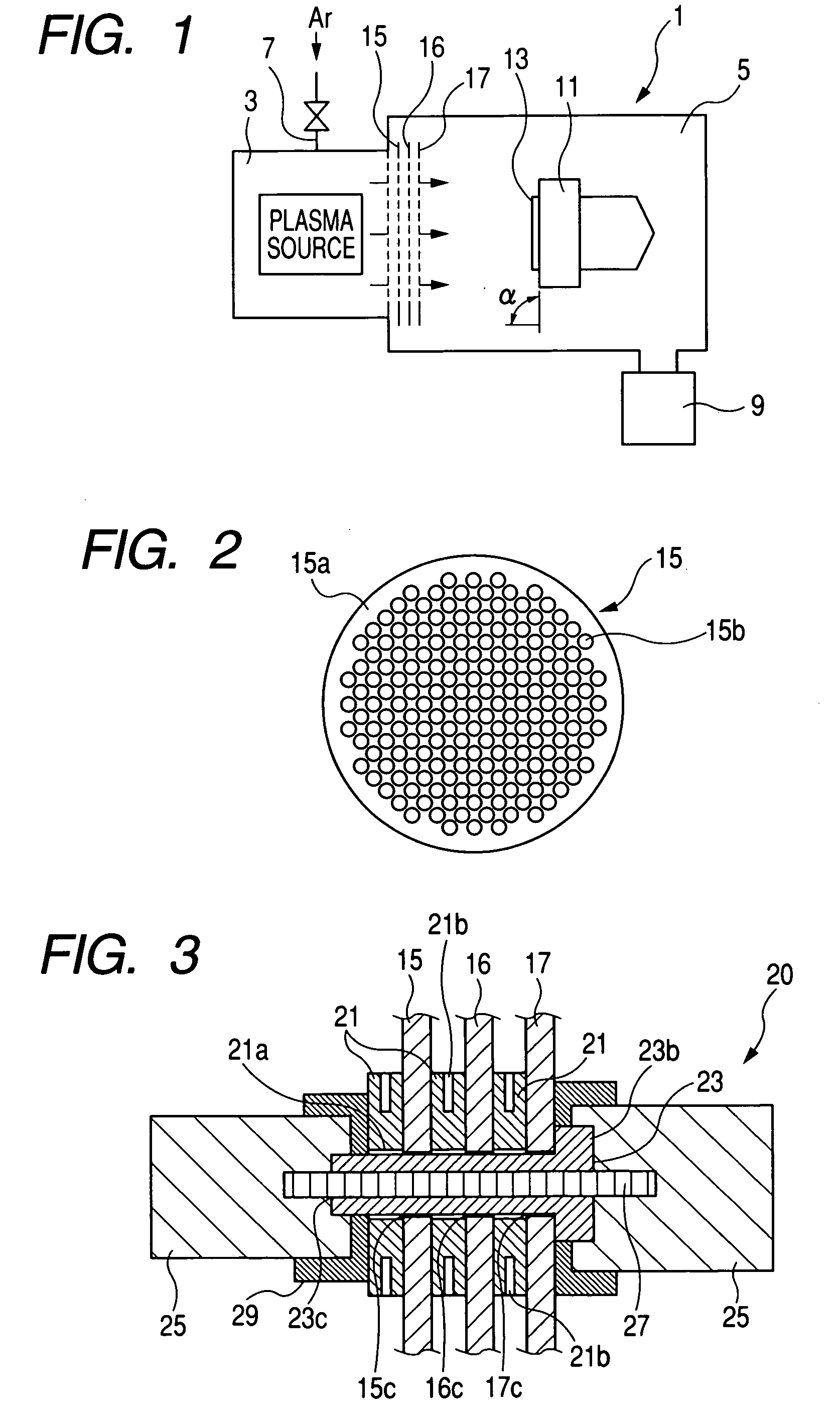

Ion beam irradiation apparatus and insulating spacer for the same

InactiveUS20050211926A1Reduce the amount requiredIncrease profitElectric arc lampsIon beam tubesAtomic physicsMesh grid

The frequency of replacement of an insulating spacer disposed between grids of an ion beam irradiation apparatus is to be reduced. In addition, the intervals of the multiple grids in the ion beam irradiation apparatus are to be kept constant. To achieve these objects, in a so-called insulating spacer provided for maintaining insulation between the grids, a groove portion having a bottom onto which sputtered materials are hard to adhere is provided on the central portion of the side surface of the insulating spacer all along its circumference.

Owner:TDK CORPARATION

Charged particle beam apparatus

ActiveUS7442942B2Irradiation angle is somewhat limitedMaterial analysis using wave/particle radiationPreparing sample for investigationScanning electron microscopeElectron microscope

To include a focused ion beam apparatus fabricating a sliced specimen by processing a specimen as well as observing the sliced specimen, a scanning electron microscope observing the slice specimen, a gas-ion beam irradiation apparatus performing finishing processing by irradiating a gas-ion beam onto a surface of the sliced specimen, a specimen stage on which the sliced specimen is fixed and having at least one or more rotation axis, a specimen posture recognition means recognizing positional relation of the sliced specimen with respect to the specimen stage and a specimen stage control means controlling the specimen stage based on a specimen posture recognized by the posture recognition means and an installation angle of the gas-ion beam irradiation apparatus in order to allow an incident angle of the gas-ion beam with respect to the obverse or the reverse of the sliced specimen to be a desired value.

Owner:HITACHI HIGH TECH SCI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com