Ion beam irradiation apparatus and insulating spacer for the same

a technology insulating spacer, which is applied in the field of ion beam irradiation apparatus and insulating spacer for the same, can solve the problems of short circuit of grids, deterioration of insulating performance, and deterioration of insulating spacers, so as to reduce the amount of ions blocked by grids, improve ion utilization efficiency, and uniform milling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

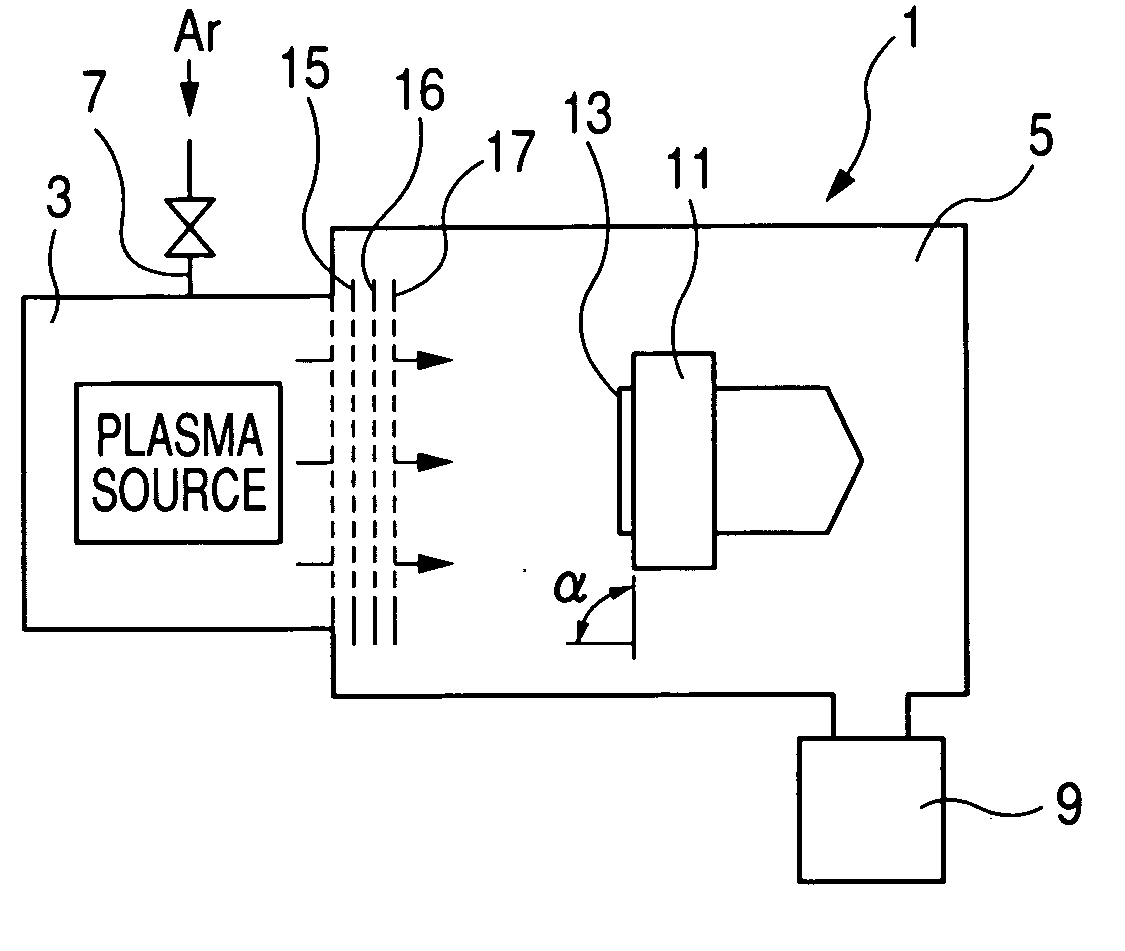

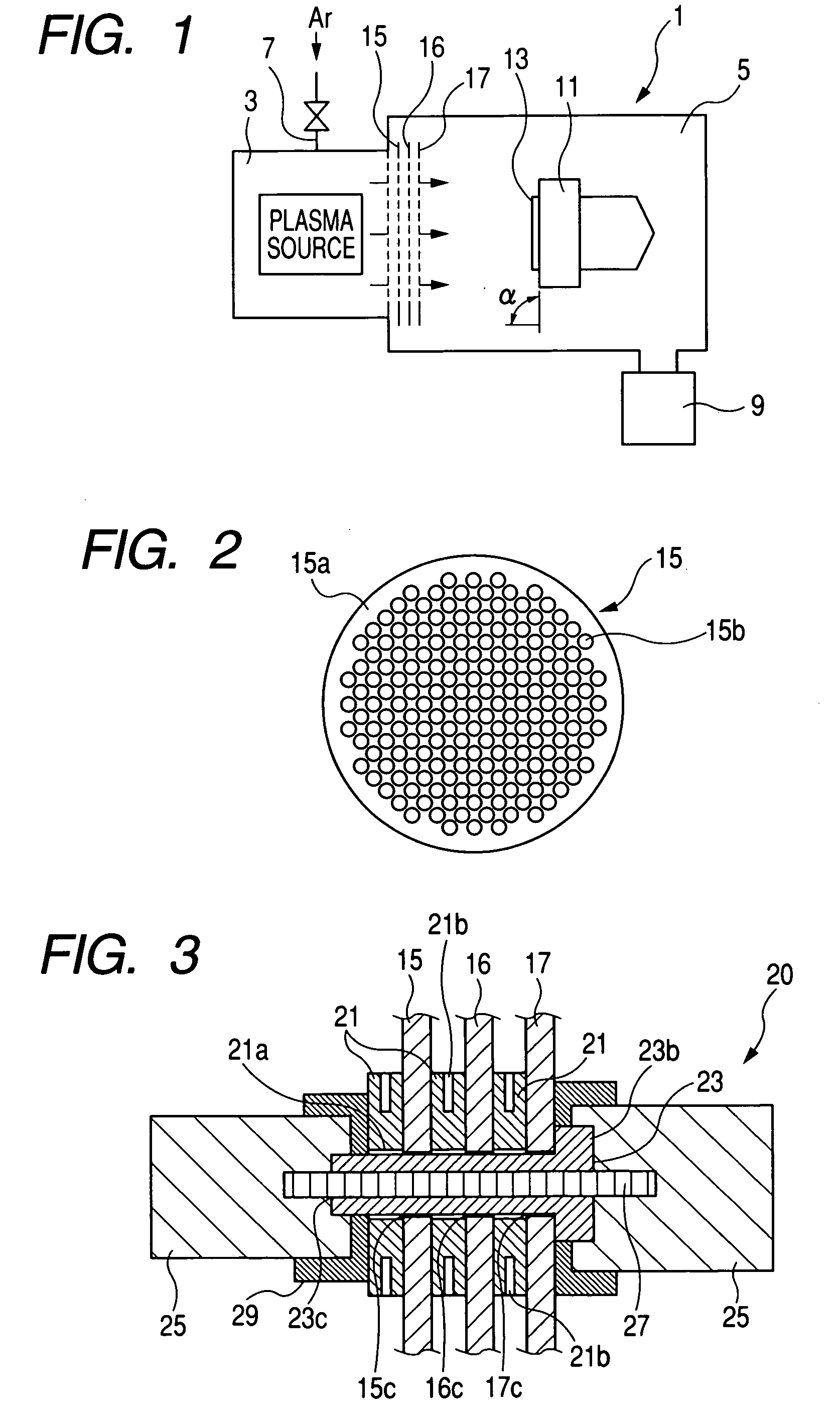

[0052] In the following, embodiments of the present invention will be described with reference to the drawings. FIG. 1 schematically shows the outline of an ion milling apparatus 1 equipped with,as an ion source, an ion beam irradiation apparatus having insulating spacers according the present invention. The apparatus 1 is composed of two chambers, that is, a plasma generation chamber 3 and a process chamber 5. In the plasma generation chamber 3 in this embodiment, for example argon gas is supplied to the plasma generation chamber through a gas supply system 7 as the gas to be subjected to plasma generation. There are various methods of generating a plasma such as the Kaufmann type, the bucket type, the ICP type and the ECR type, and any of these method may be employed. In this embodiment, the plasma is generated by an IPC type system in which the possibility of inclusion of impurity elements in the ion beam is relatively low and the structure of the apparatus is simple. The process...

second embodiment

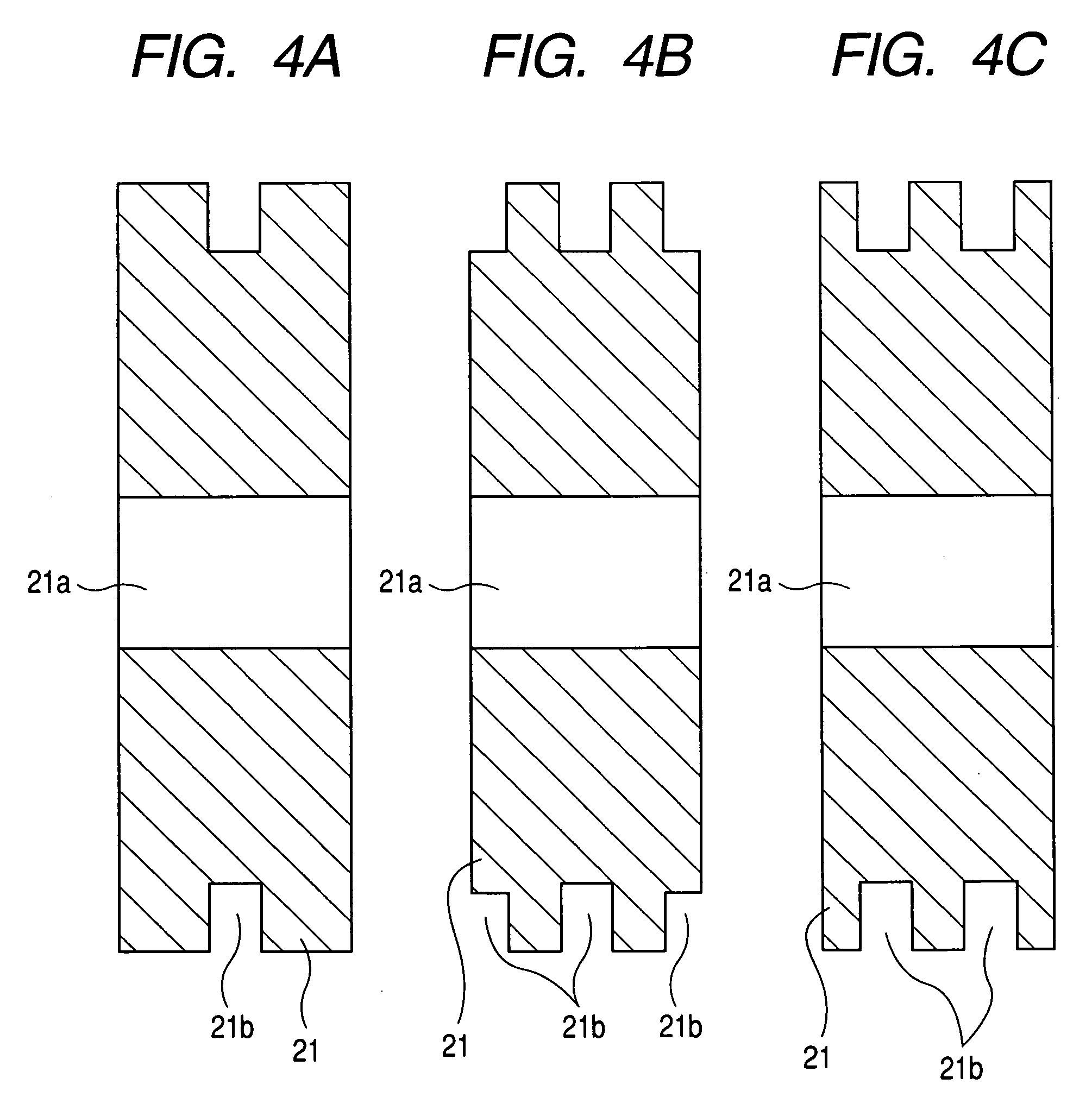

[0066]FIG. 7 schematically shows the structure of a fixing apparatus for fixing the first to third grids 15, 16, 17 at predetermined intervals and fixing insulating spacers between the grids. The fixing apparatus 120 is composed of insulating spacers 121, an insulating member 23, insulating caps 25, a screw rod 27 and grooved washers 29. The insulating spacer 121 is a disk like member with parallel end faces made of an insulating material such as alumina. The insulating spacer 121 has a through hole 121a with a predetermined diameter that passes through its top and bottom surfaces, formed at its center. The thickness of the disk corresponds to the distance between the grids. The insulating member 23 is a substantially cylindrical member including a shaft portion 23a having an outer diameter that can pass through the through hole 121a of the insulating spacer 121 and an enlarged diameter portion 23b having an enlarged diameter formed at one end thereof. The insulating member 23 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com