Patents

Literature

39results about How to "Remove defect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

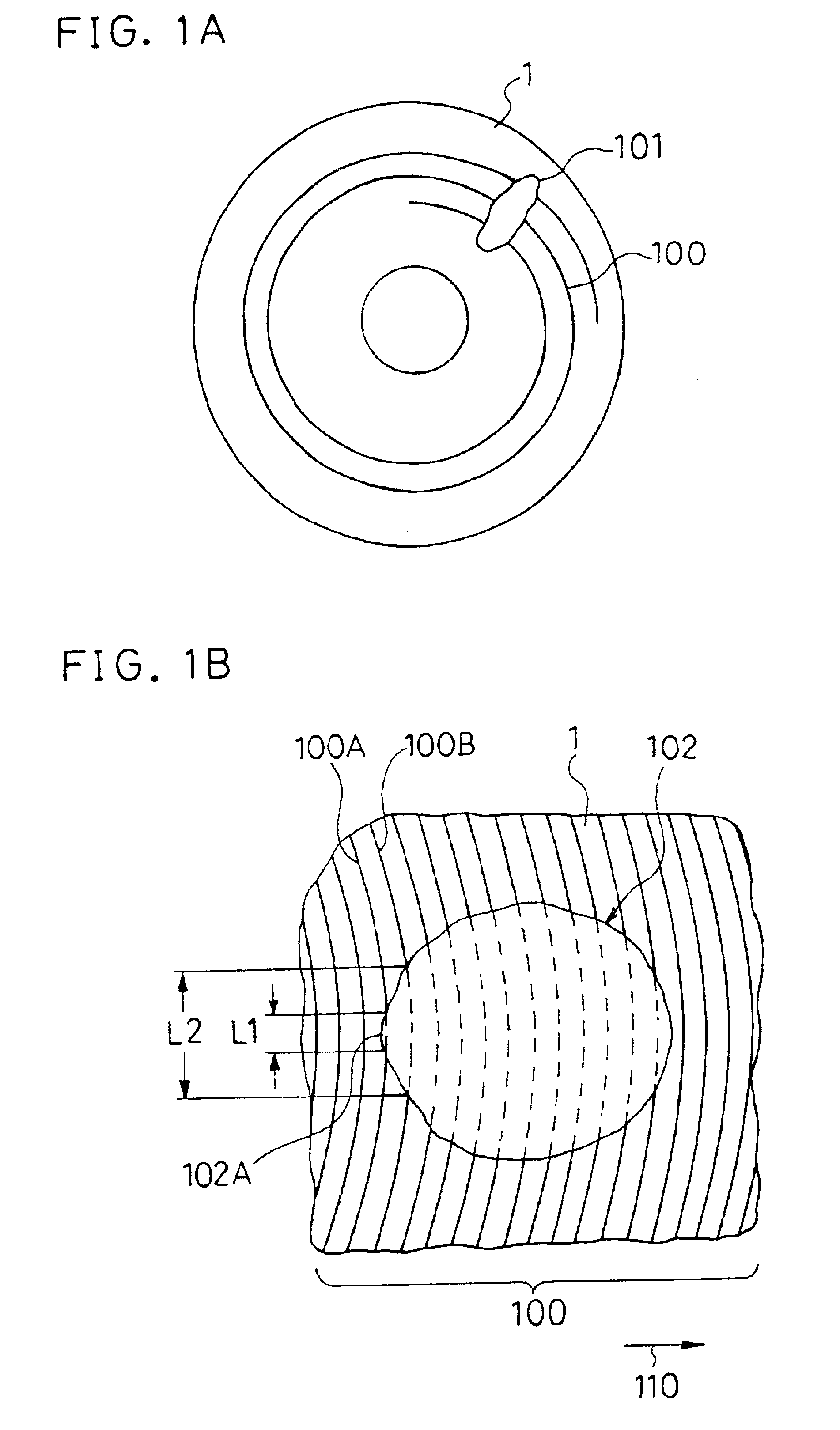

Automatic registration of images

ActiveUS20060276698A1Reliable measurementOptical density ratios are more reliably and easily obtainedDiagnostic recording/measuringSensorsVisual perceptionImage contrast

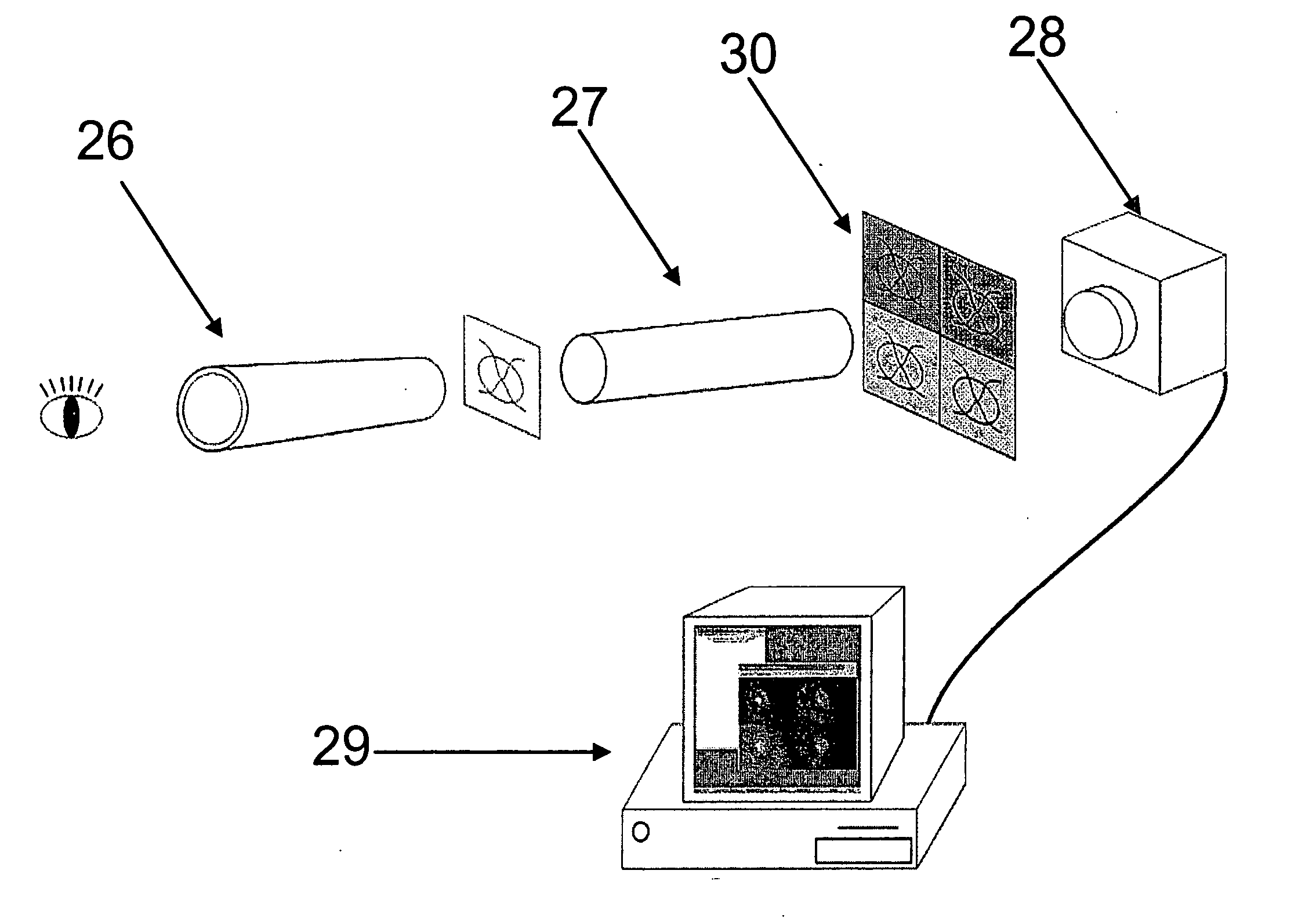

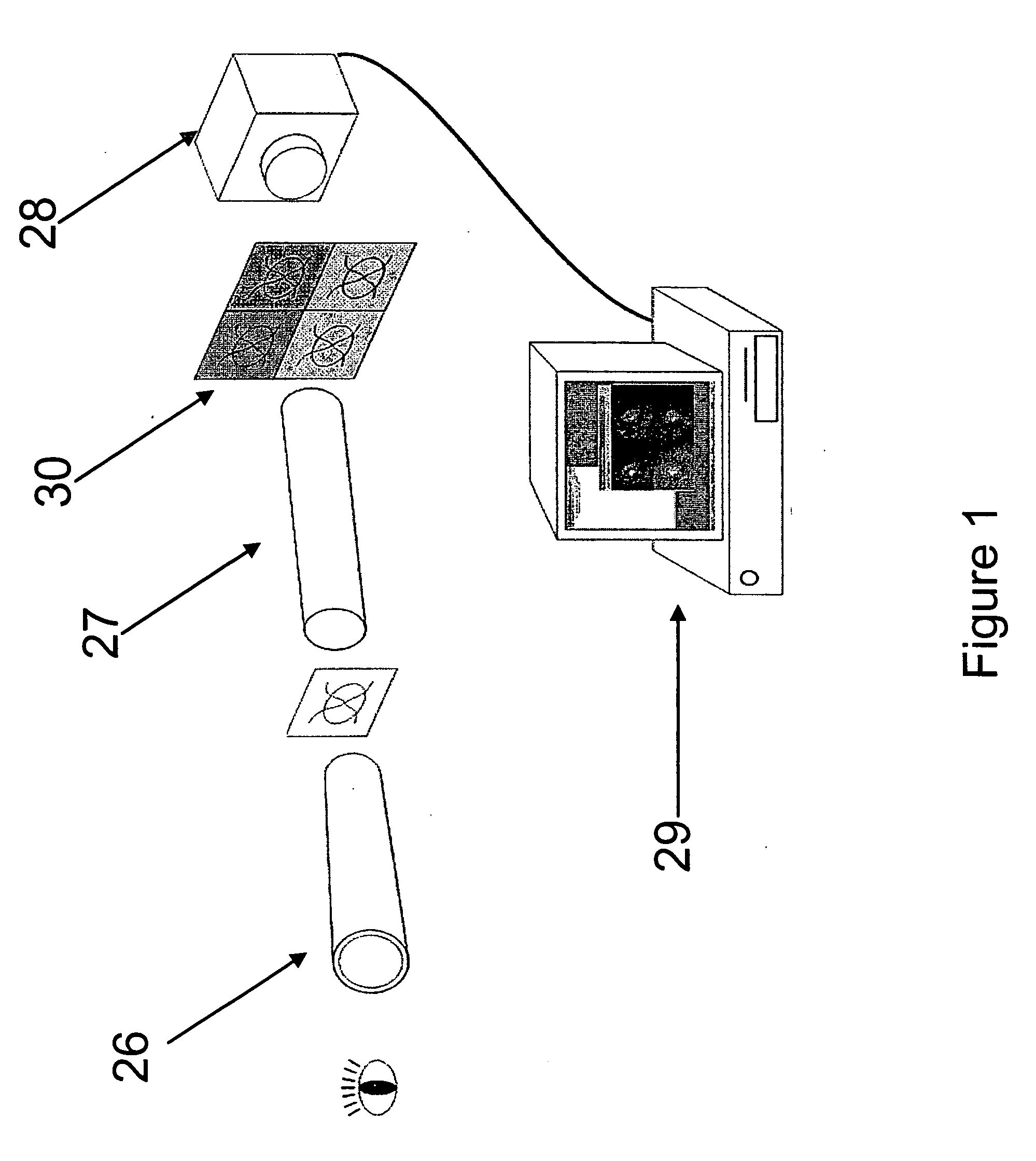

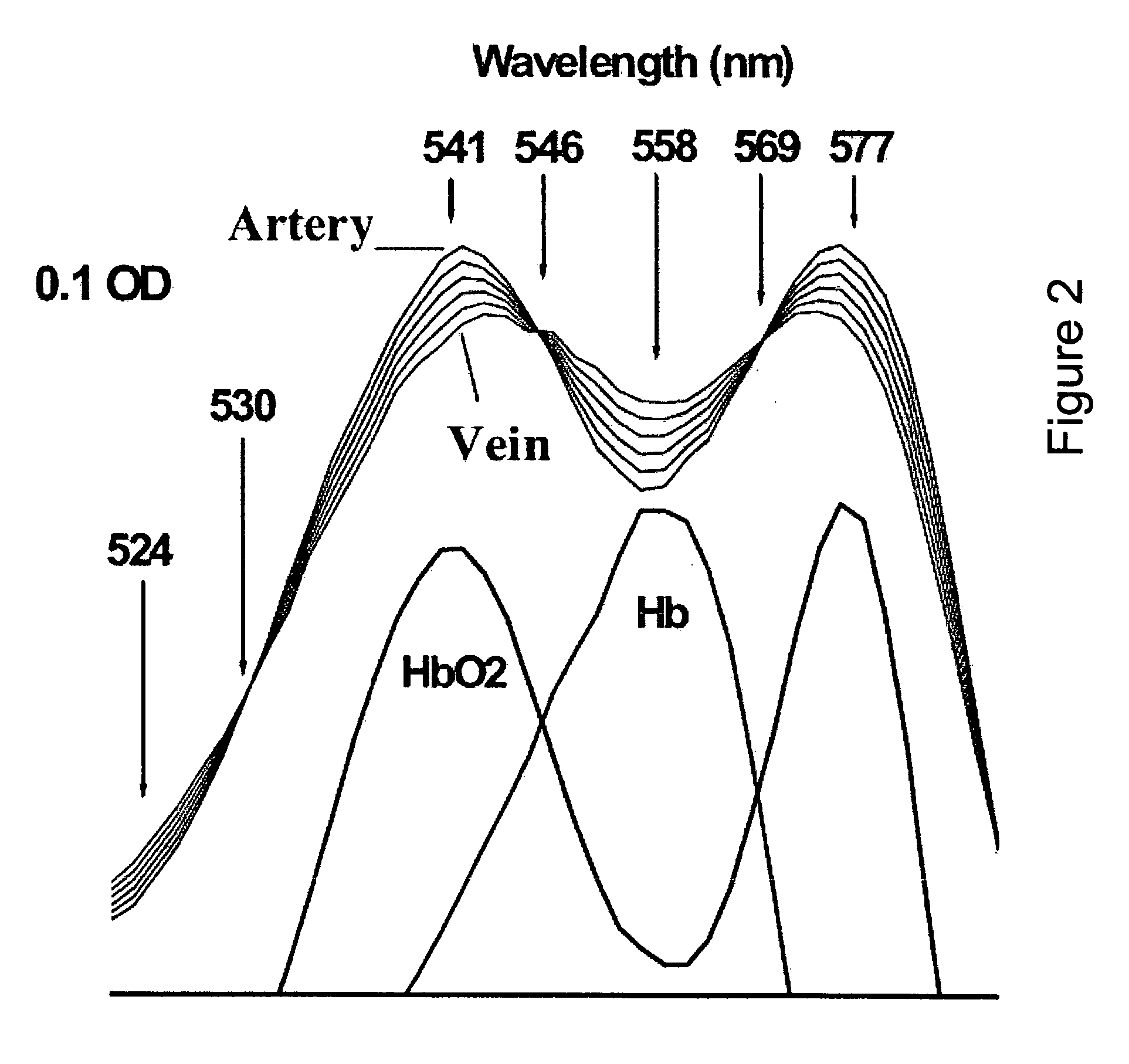

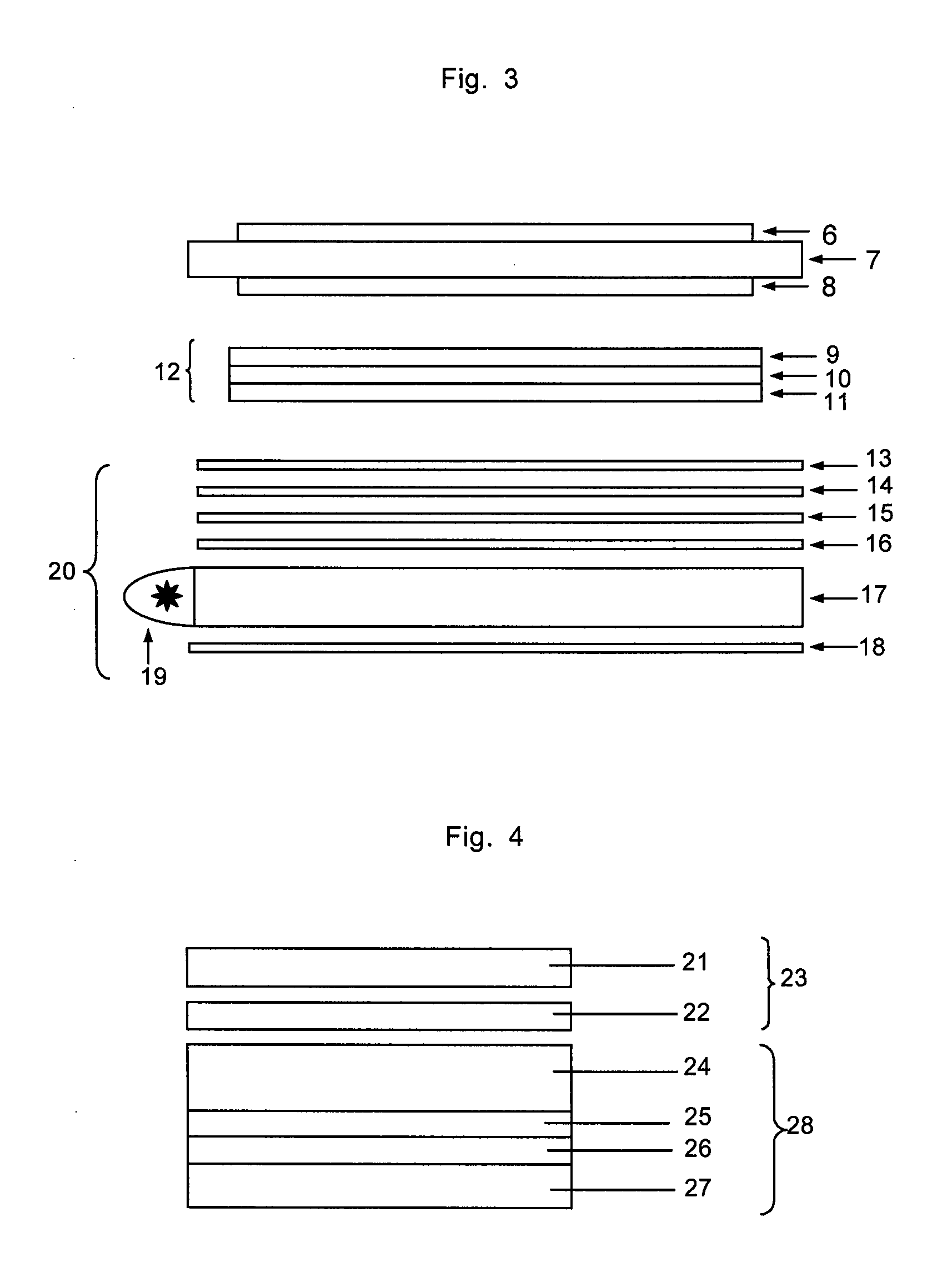

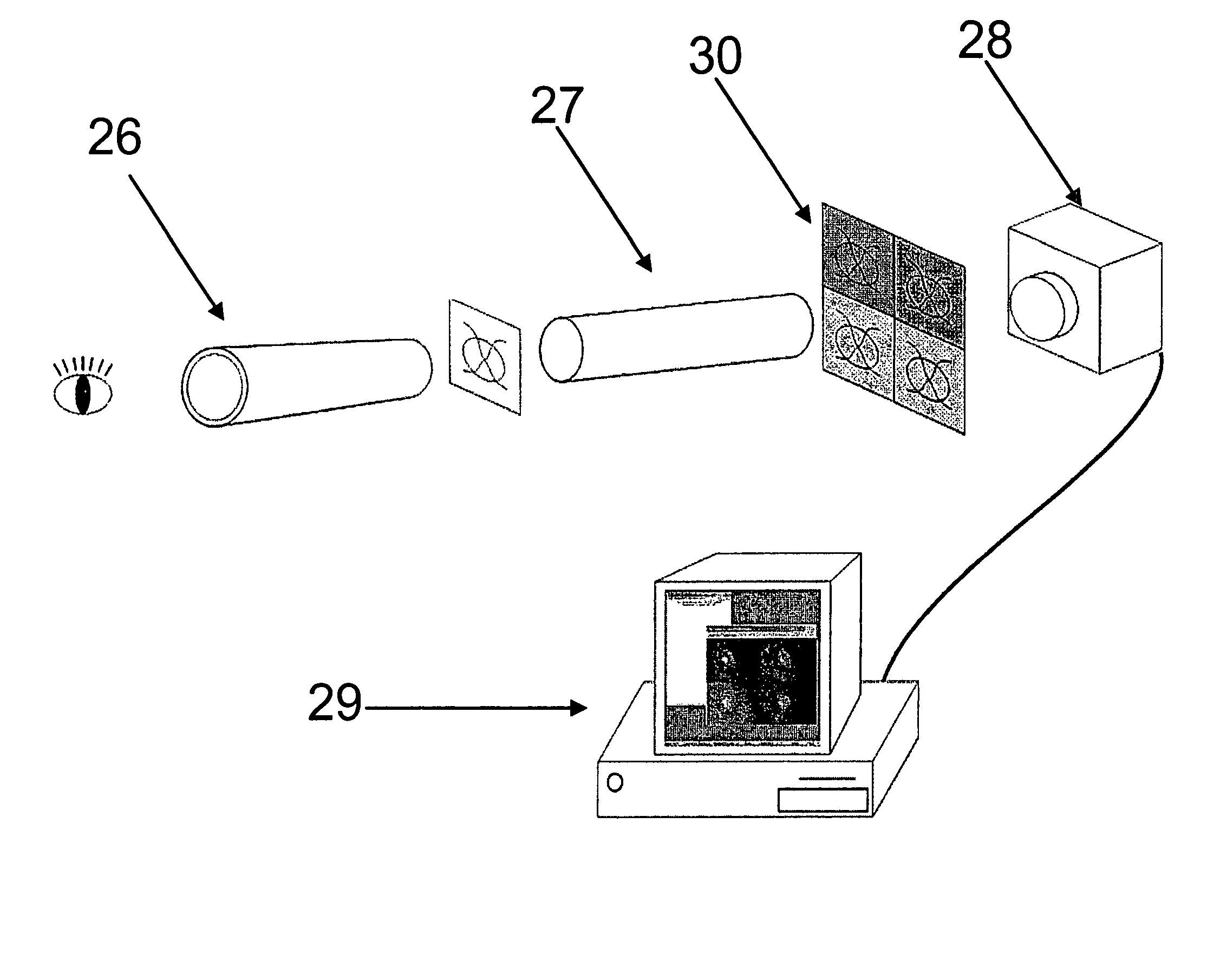

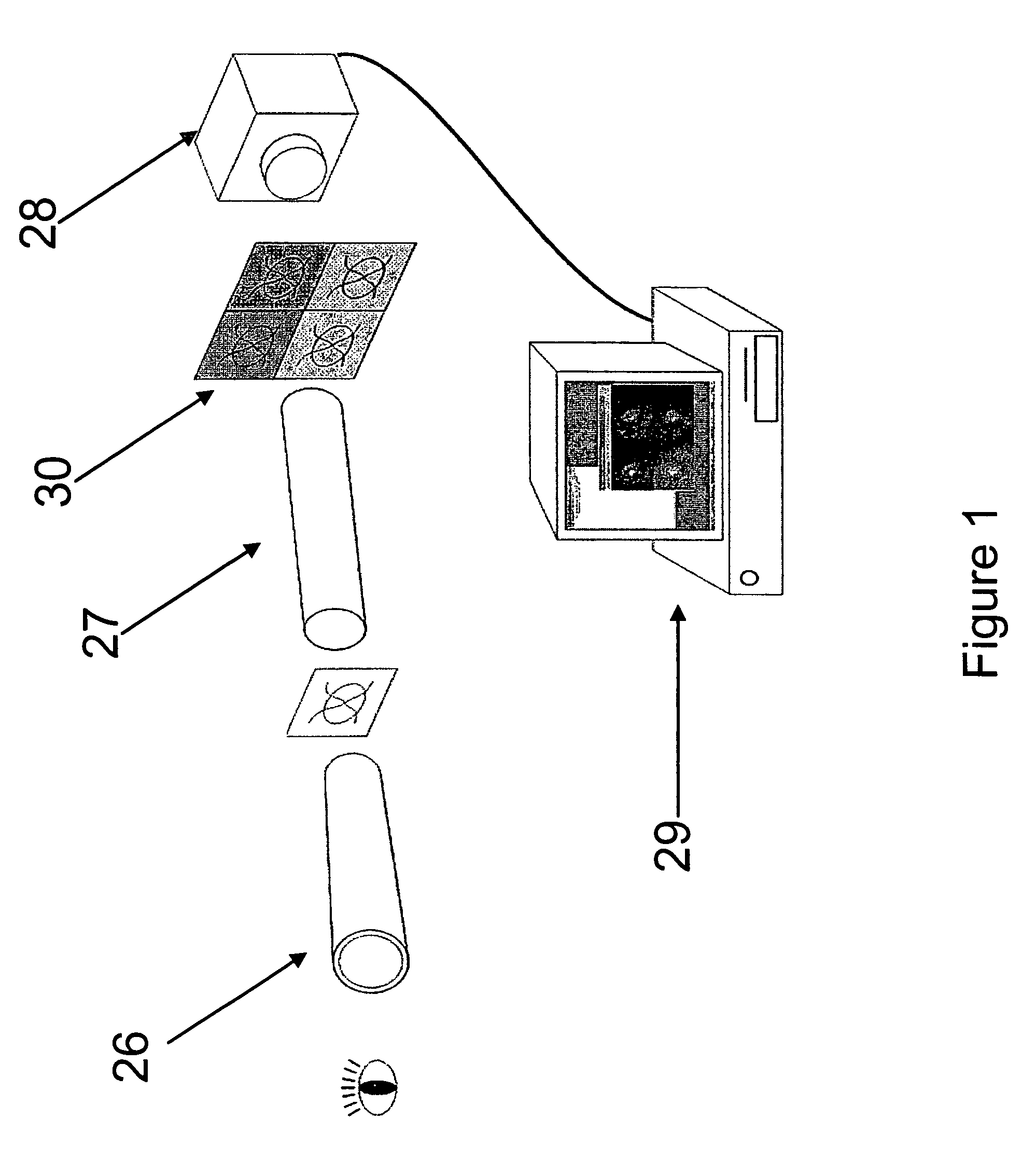

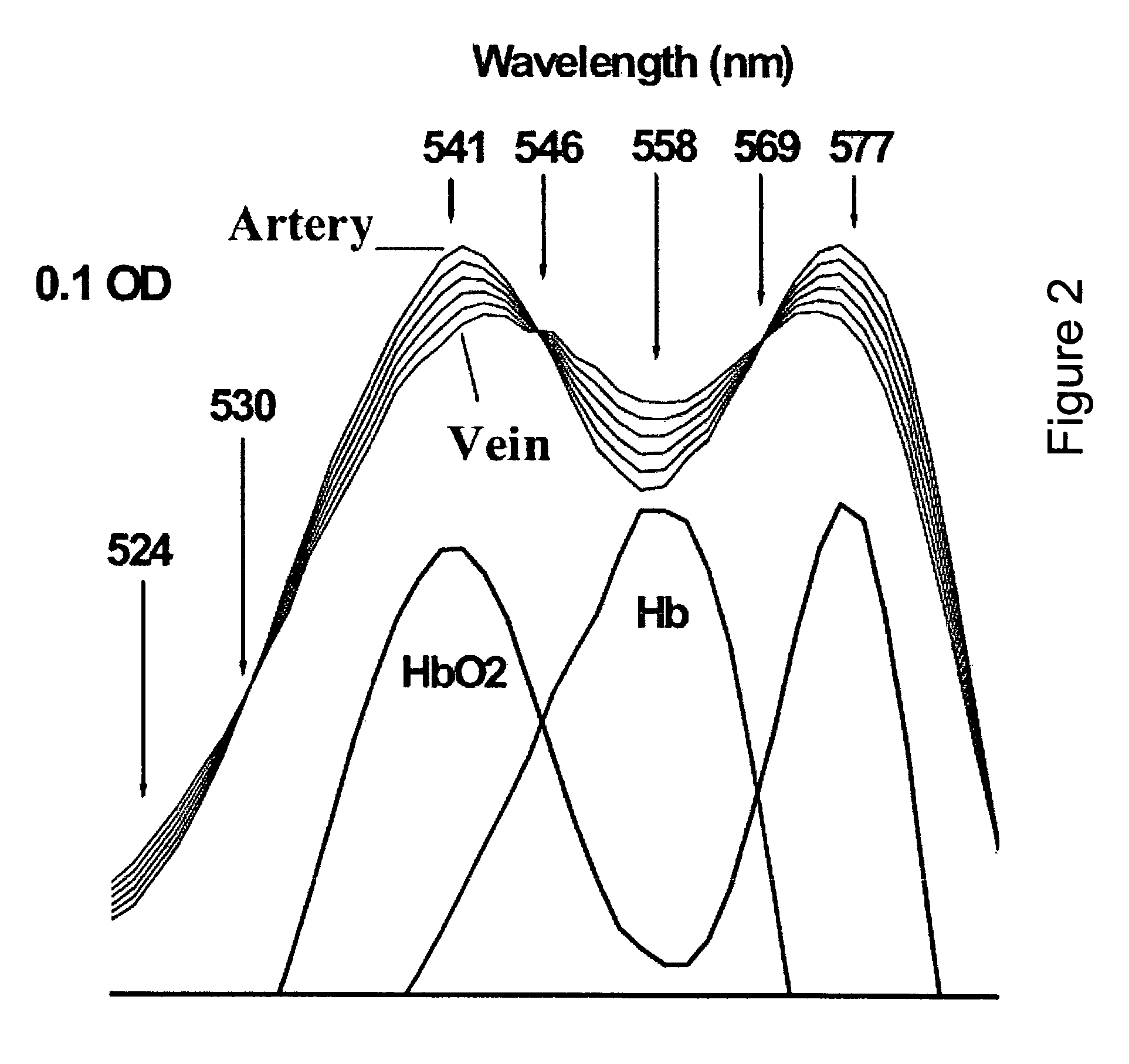

The present invention relates to a system for automatically evaluating oxygen saturation of the optic nerve and retina, said system comprising: image capturing system further comprising: a fundus camera (26), a four wavelengths beam splitter (27), a digital image capturing device (28), a computer system, image processing software performing in real-time the steps of: registering set of multi-spectral images (1) by, binarizing the multi-spectral image (7), find the all the border regions of each image by finding the region including the straight line that passes the most number of points in the region (8), use the orientation of the borders to evaluate the orientation of each spectral image (9), equalize the orientation of each spectral image by rotating the spectral image (10), edge detect each spectral image (11), estimate the translation between the spectral images based on the edges of adjacent images (12), transform the images to a stack of registered images (13), locating blood vessels (2) in each of the multi-spectral images by, retrieving registered spectral images (14), for each spectral image, remove defective pixels (15), enhance image contrast (16), perform top-hat transform using structuring element larger than the largest vessel diameter (17), binarize each image (18), apply filter for smoothing the image (19), combine all the spectral images using binary AND operator (20), skeletonize the resulting image (21), prune the skeleton image (22), re-grow the pruned image (23), locate junction points (24), evaluating the width of the blood vessels (3) by calculating the normal vector to the vessel direction to, estimate the direction and position of the vessel profile, evaluate positions of vessel walls based on the vessel profile obtained, evaluate vessel width based on the position of the vessel walls, selecting samples for calculating optical density, calculating the optical density ratio (4), evaluating oxygen saturation level (5), and presenting the results (6), wherein presenting the results may include presenting numerical and visual representation of the oxygen saturation.

Owner:OXYMAP EHF

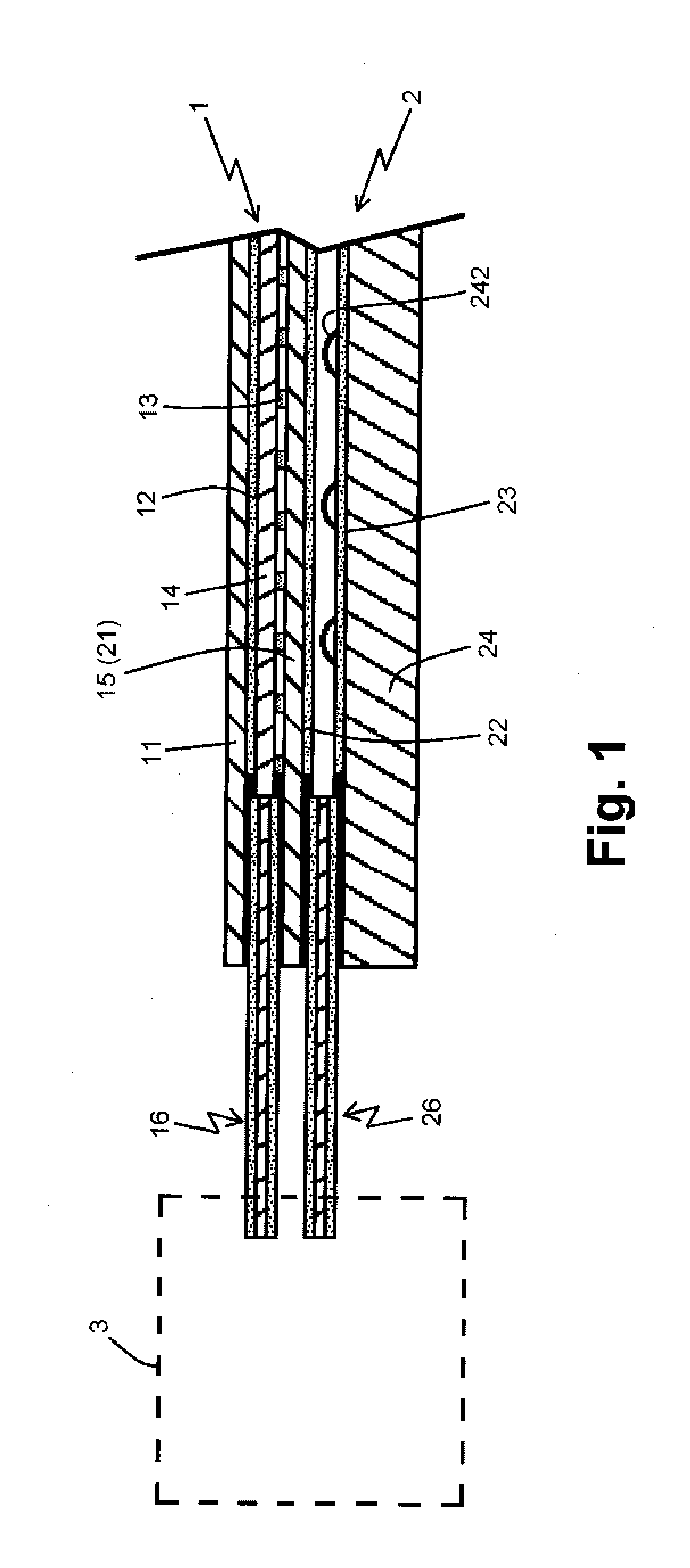

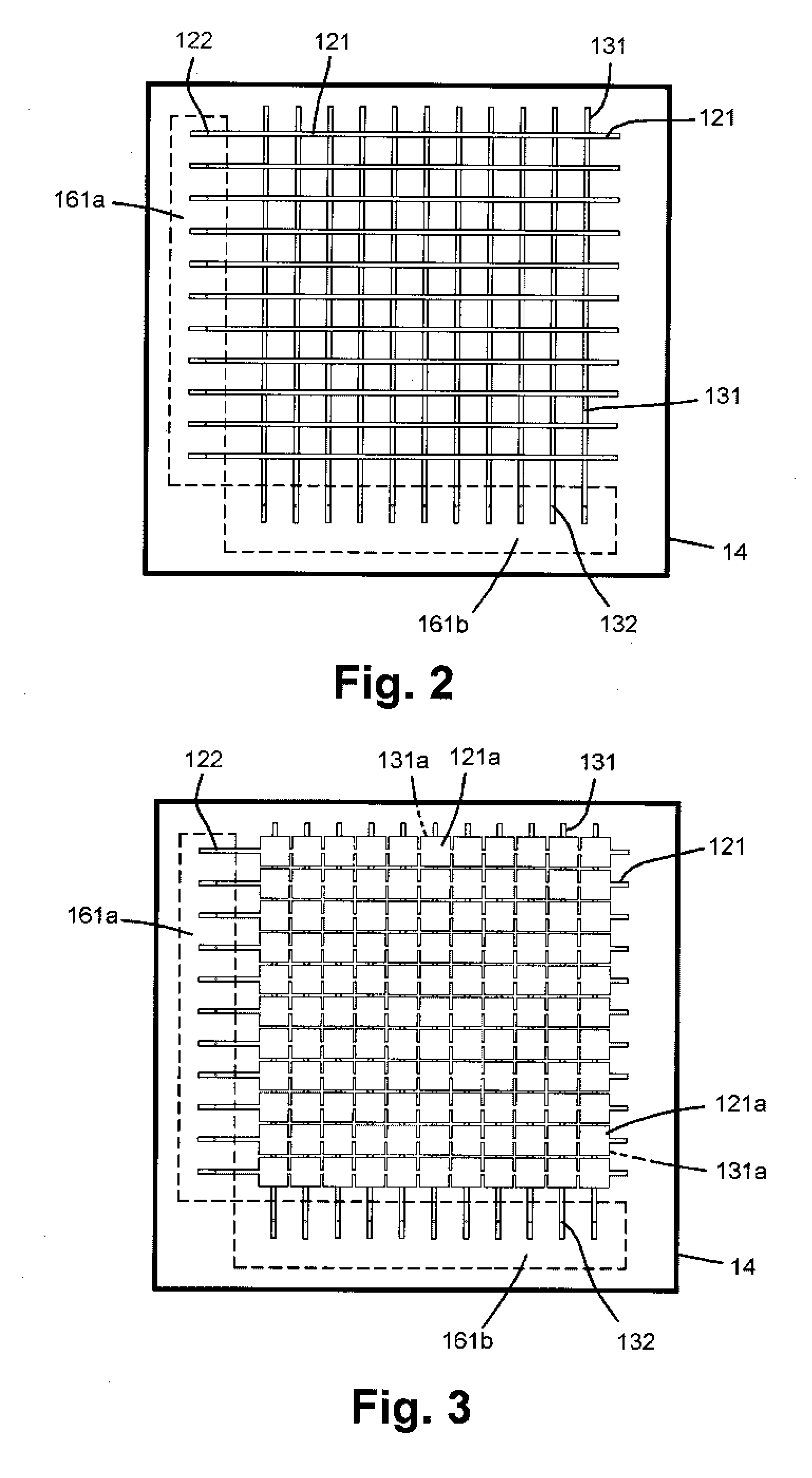

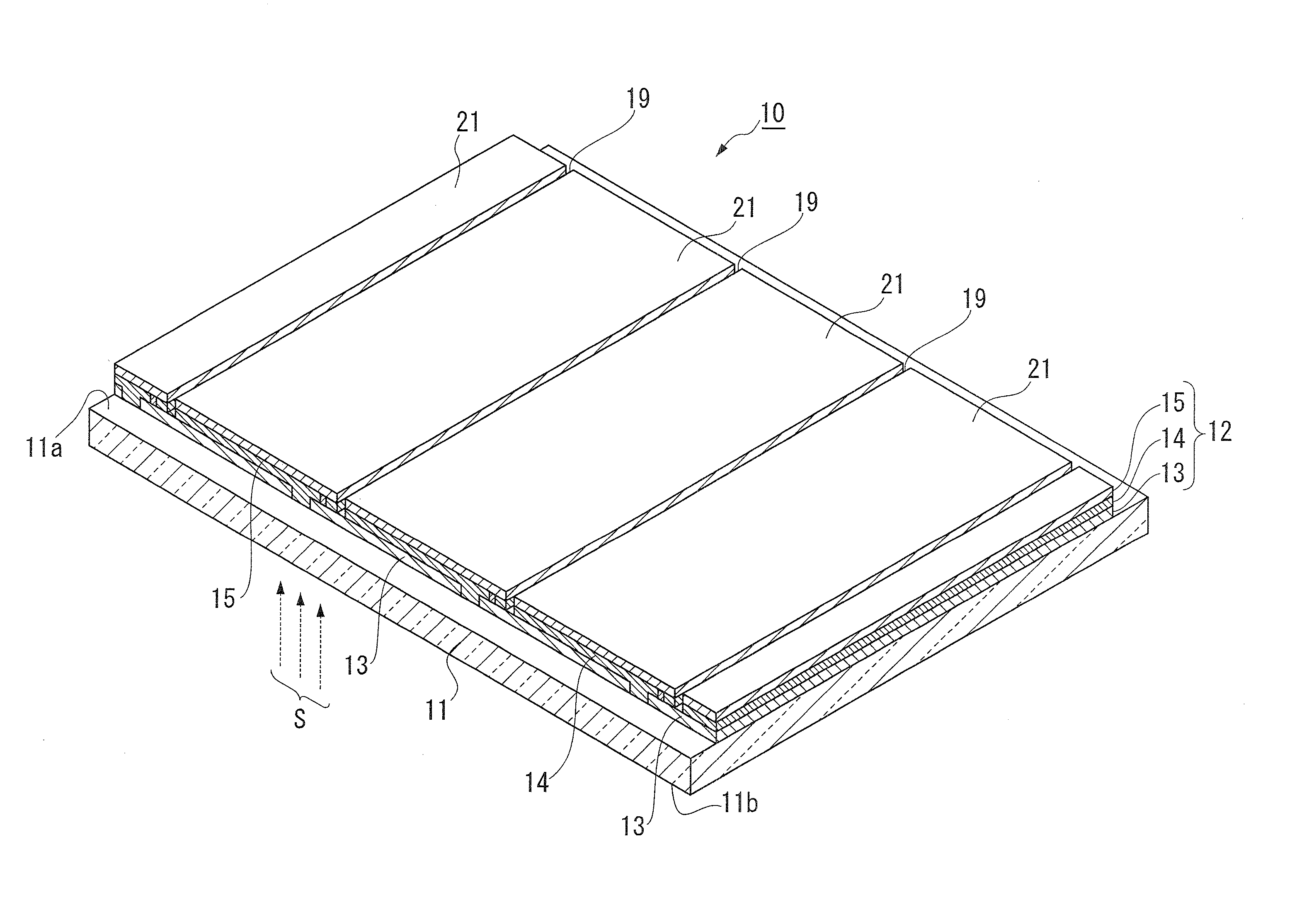

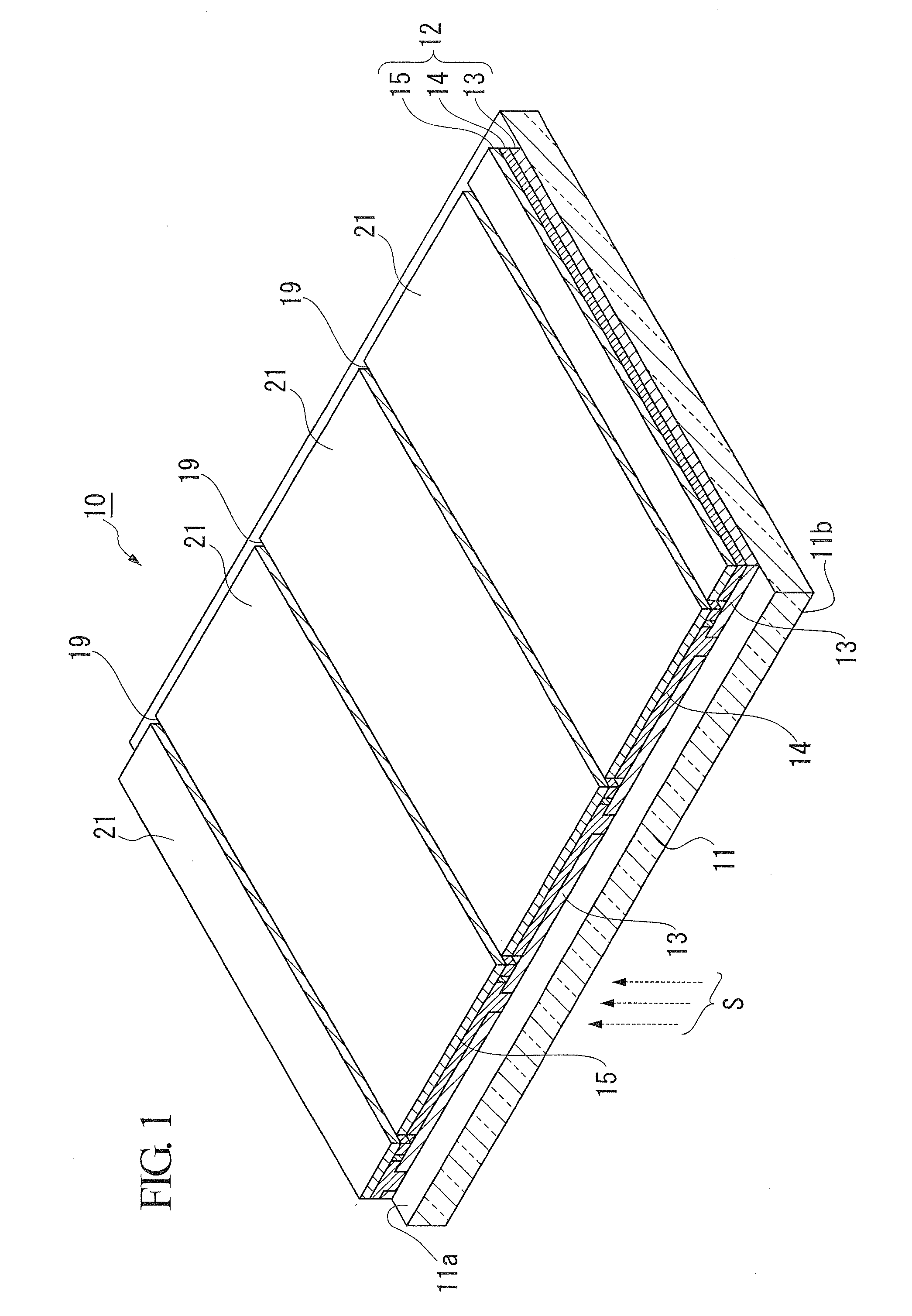

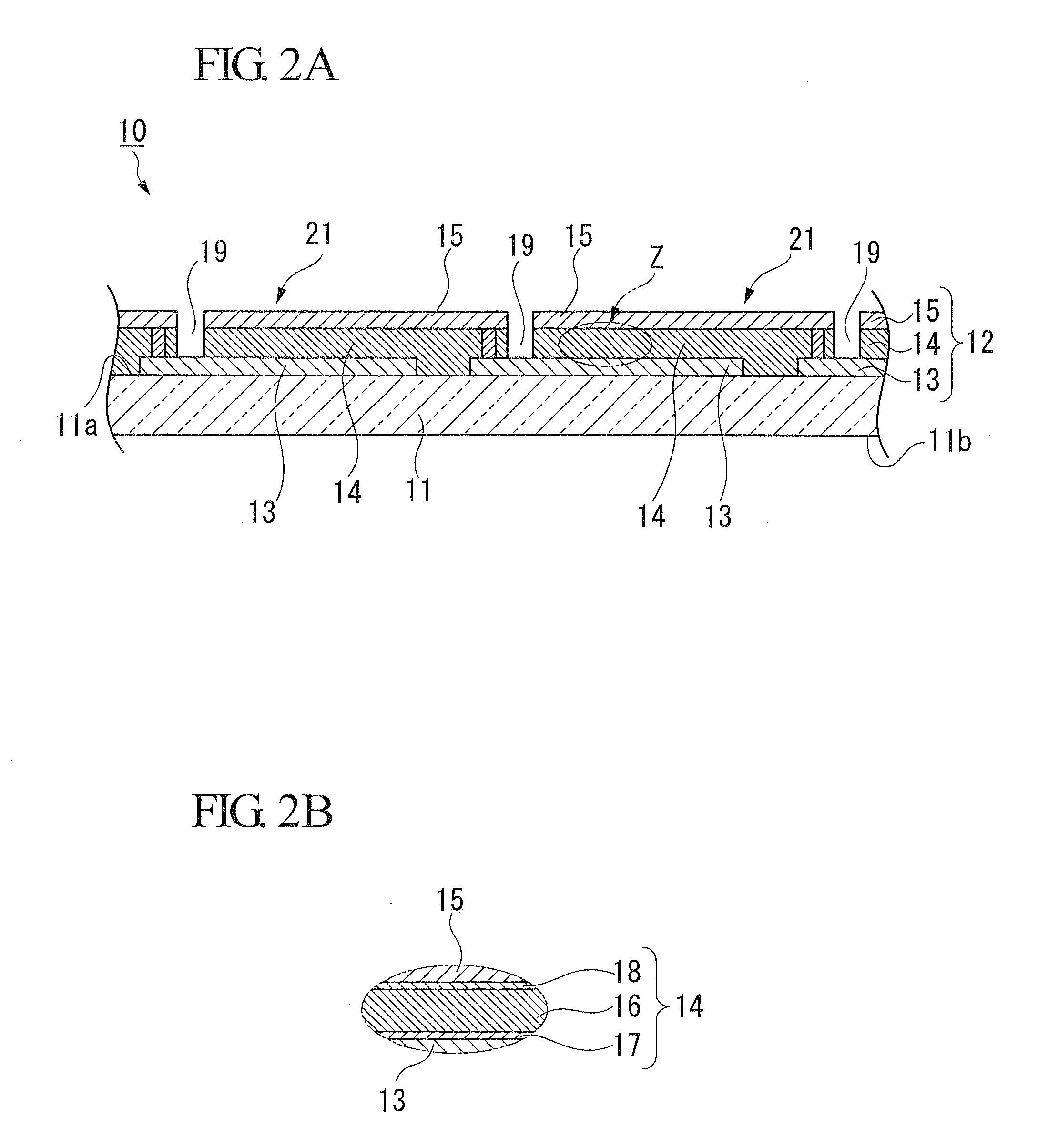

Duplex touch panel

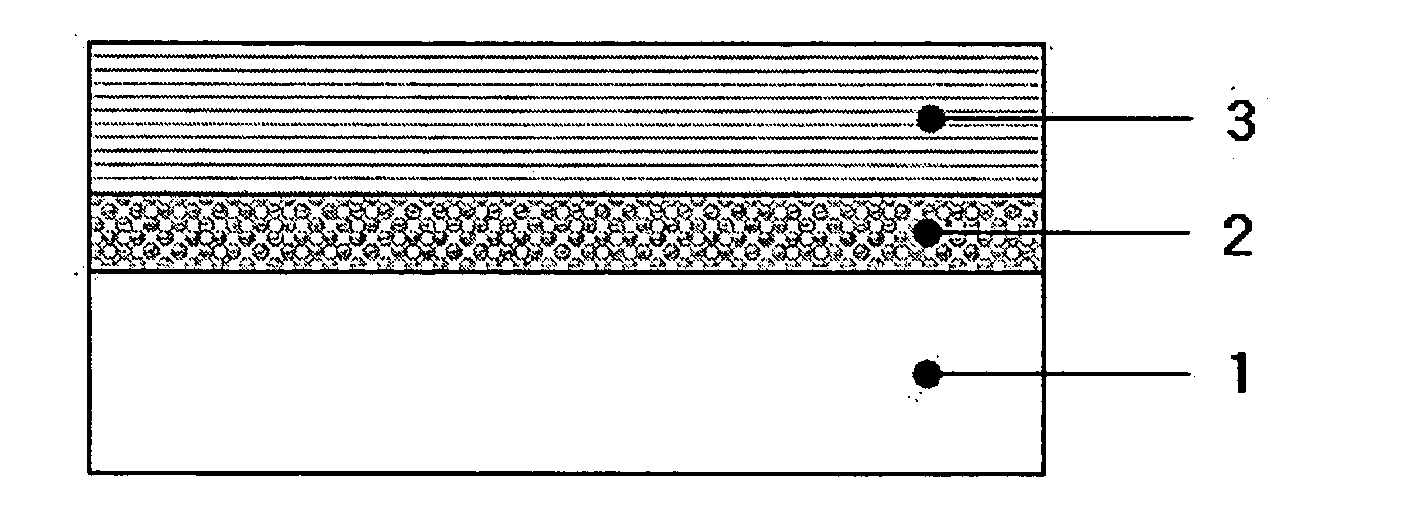

InactiveUS20090140987A1Uniform transparencyRemove defectInput/output processes for data processingTouch panelSurface layer

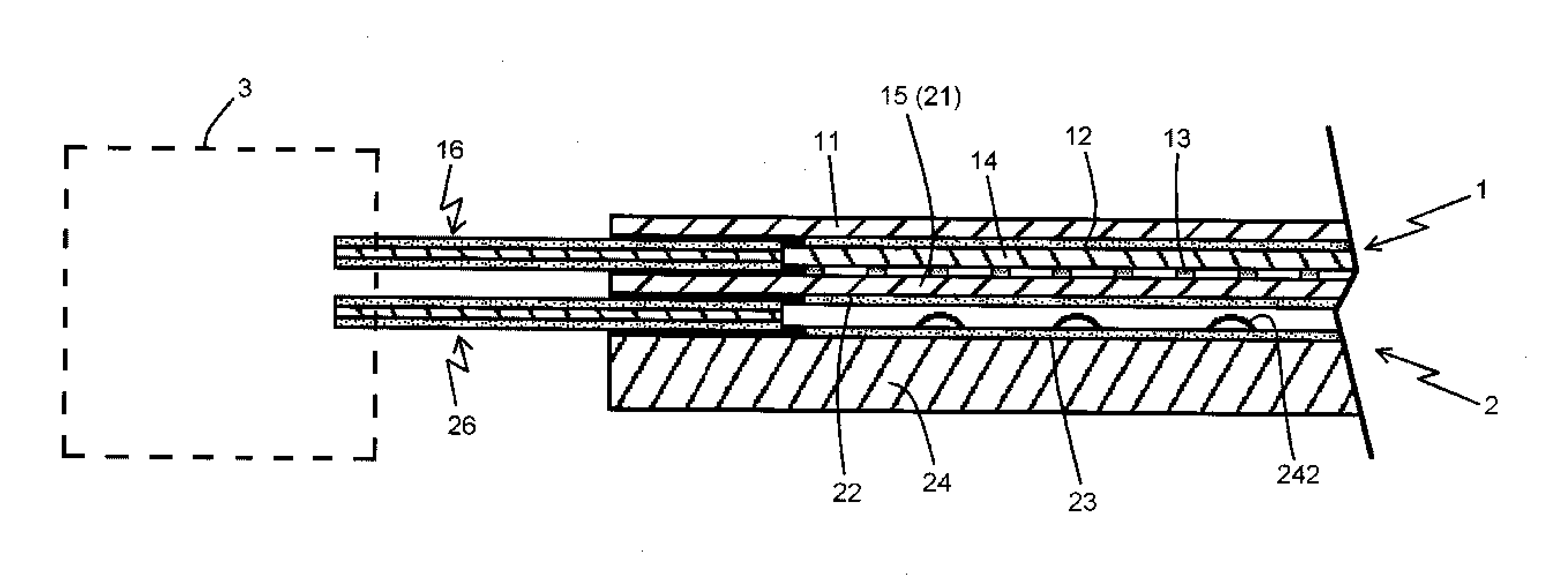

A duplex touch panel comprising: a capacitive touch panel unit; a resistive touch panel unit which is overlapped to the capacitive touch panel unit to be formed as a plate body; a signal processing unit received sensing signals from the capacitive touch panel unit and resistive touch panel unit; a surface layer; a first axis sensing layer being a transparent film; the first axis sensing layer having a plurality of first axis sensing traces; an insulation layer being a transparent insulated film layer; a second axis sensing layer being a transparent film; a base substrate being a flexible highly transparent insulated film; and a first signal output wire bank having a plurality of conductive paths; wherein the first axis sensing traces and second axis sensing traces being arranged along different vertical directions so as to form as a matrix.

Owner:YANG KAI TI

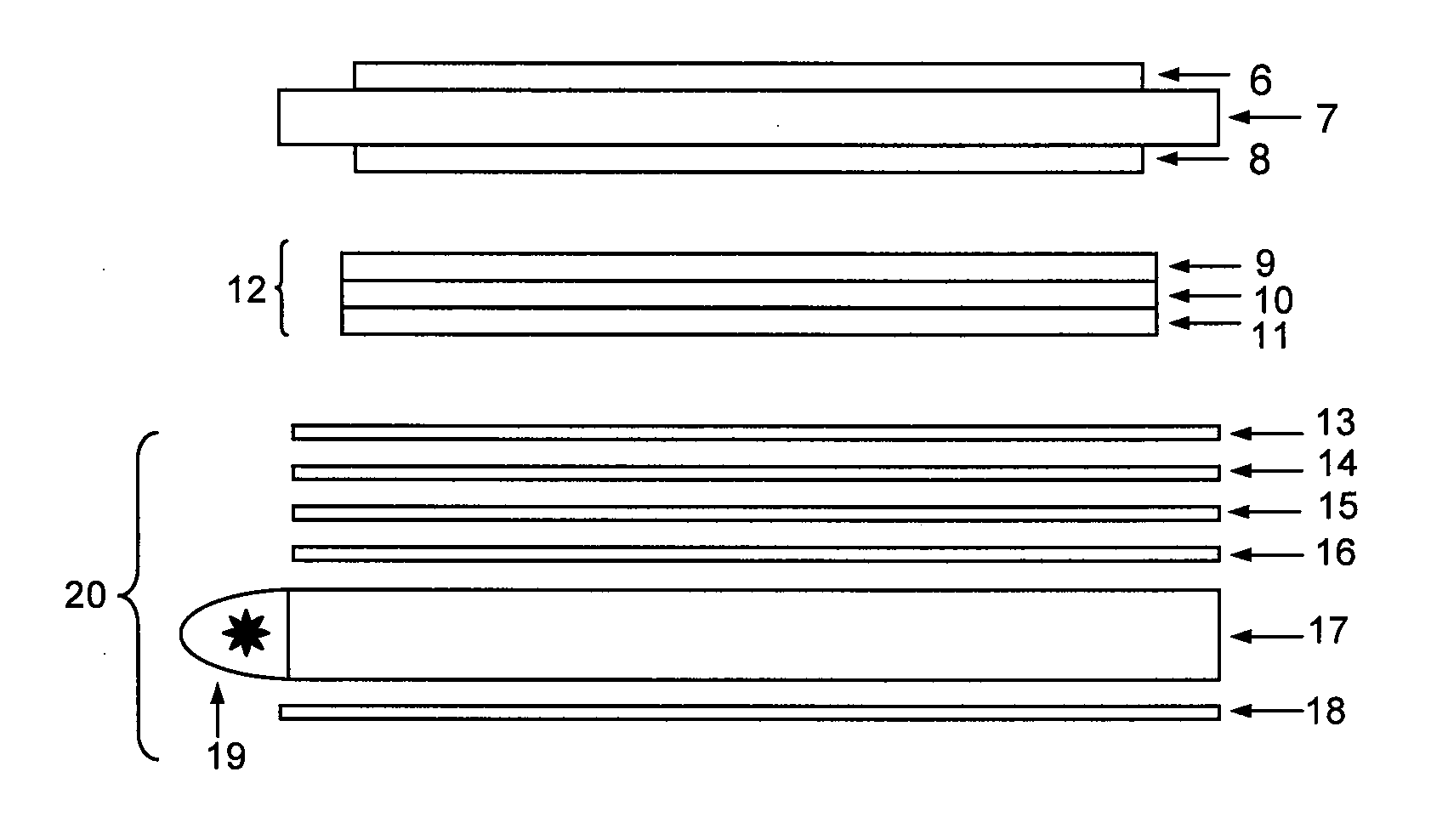

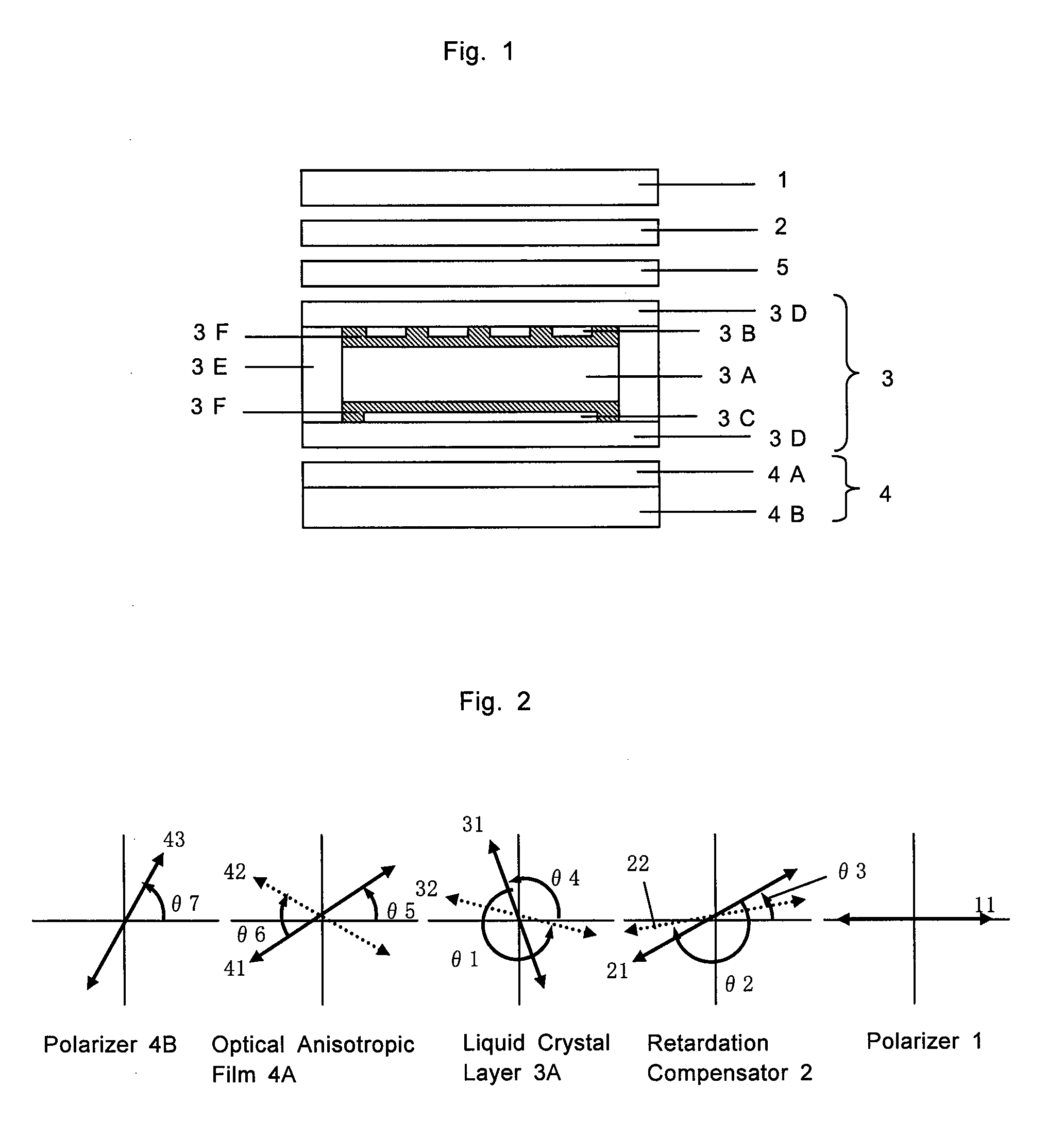

Circular Polarizer, Process for Producing the Same, Optical Film, Liquid Crystal Display Device and Electroluminescence Device

InactiveUS20080106675A1Less strainRemove defectLiquid crystal compositionsSolid-state devicesLiquid-crystal displayPolarizer

A circular polarizer includes at least an optically anisotropic element, a transmissive protection film and a polarizing element sandwiched therebetween. The optically anisotropic element has a liquid crystal layer aligned on a cellulose triacetate film and a retardation of approximately ¼ wavelength in the visible light region. The liquid crystal layer includes a liquid crystal film with a fixed twisted nematic alignment. The circular polarizer is suppressed in thickness by simplifying the layer structure without causing defects, such as peeling off the layers, even under elevated temperature and humidity condition and makes it possible to set arbitrarily the angle of the alignment axis direction of the optically anisotropic element including a liquid crystal layer with a fixed twisted alignment with respect to the absorption axis of the polarizing element, so that the optically anisotropic element and polarizing element both in the form of an elongate film can be laminated continuously to one another.

Owner:NIPPON OIL CORP

Conductive laminated body and method for preparing the same

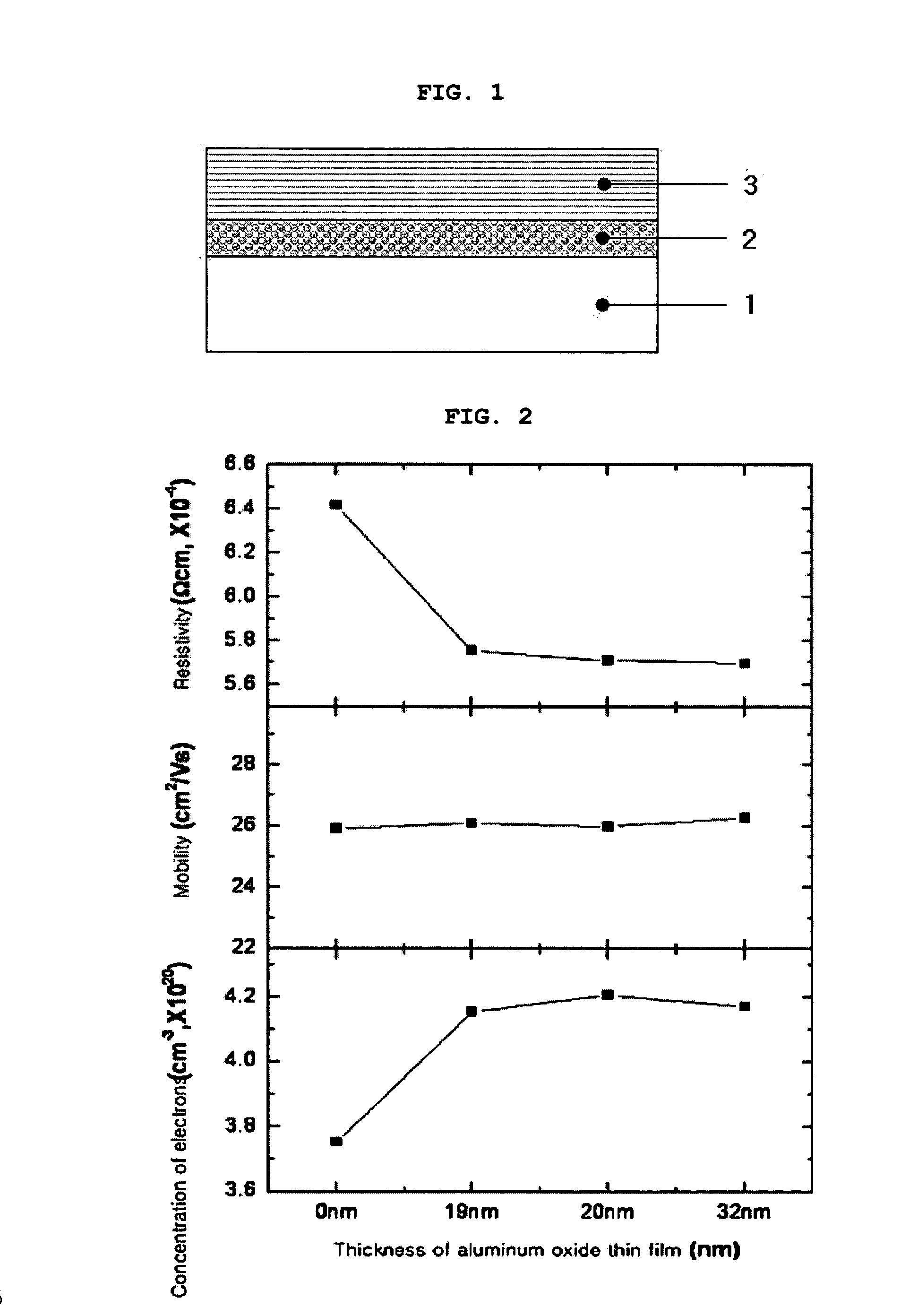

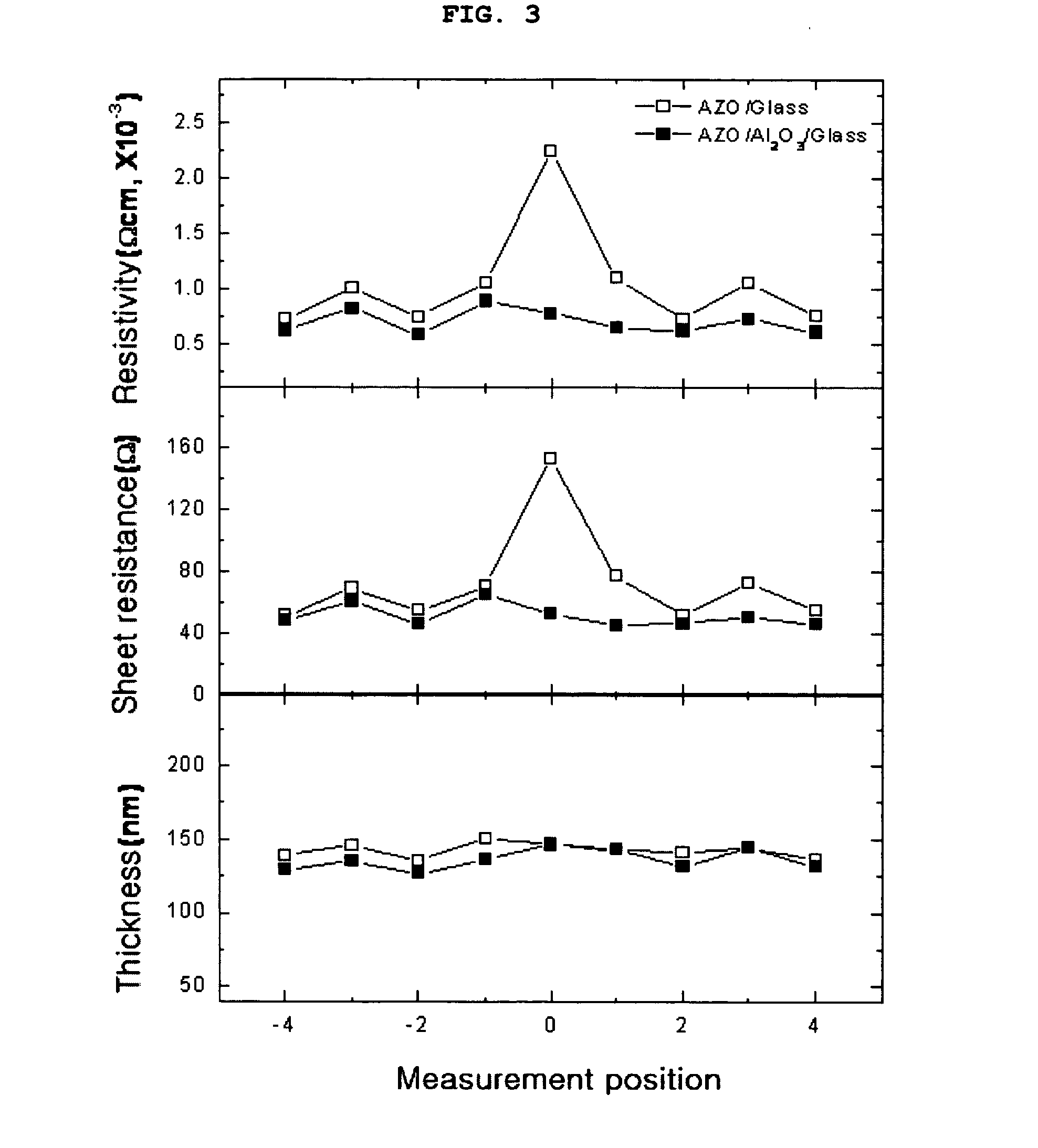

ActiveUS20100089623A1Increase electron concentrationLow mobilityConductive materialVacuum evaporation coatingHydrogenHeat resistance

Disclosed is a conductive laminated body, and a method for preparing the same, wherein the conductive laminated body including: a substrate; a zinc oxide-based thin film doped with an element M; and an interlayer including an oxide M′2O3, which is interposed between the substrate and the zinc oxide-based thin film. The disclosed conductive laminated body includes a metal oxide interlayer of an oxidation number +3, between a substrate and a zinc oxide layer. Therefore, it is possible to improve electrical properties of a transparent conductive thin film, especially, a resistivity property, and to minimize the unevenness in electrical properties between a middle portion and a circumferential portion on the surface of the thin film in sputtering deposition. Also, in deposition of a zinc oxide film, in addition to inert gas such as argon gas, the use of hydrogen gas can improve the concentration of electrons, and herein, the interposition of an interlayer including a metal oxide, between the substrate and the zinc oxide-based transparent conductive film, allows the heat-resistance / moisture-resistance stability and the uniformity of electrical properties.

Owner:LG CHEM LTD

Automatic registration of images

ActiveUS7774036B2Optical density ratios are more reliably and easily obtainedReliable measurementDiagnostic recording/measuringSensorsBeam splitterOptic nerve

The example embodiments relate to a system for automatically evaluating oxygen saturation of the optic nerve and retina, including an image capturing system which includes a fundus camera, a four wavelengths beam splitter, a digital image capturing device, a computer system, and image processing software for registering and analyzing multi-spectral images of the retina, and for evaluating oxygen saturation level.

Owner:OXYMAP EHF

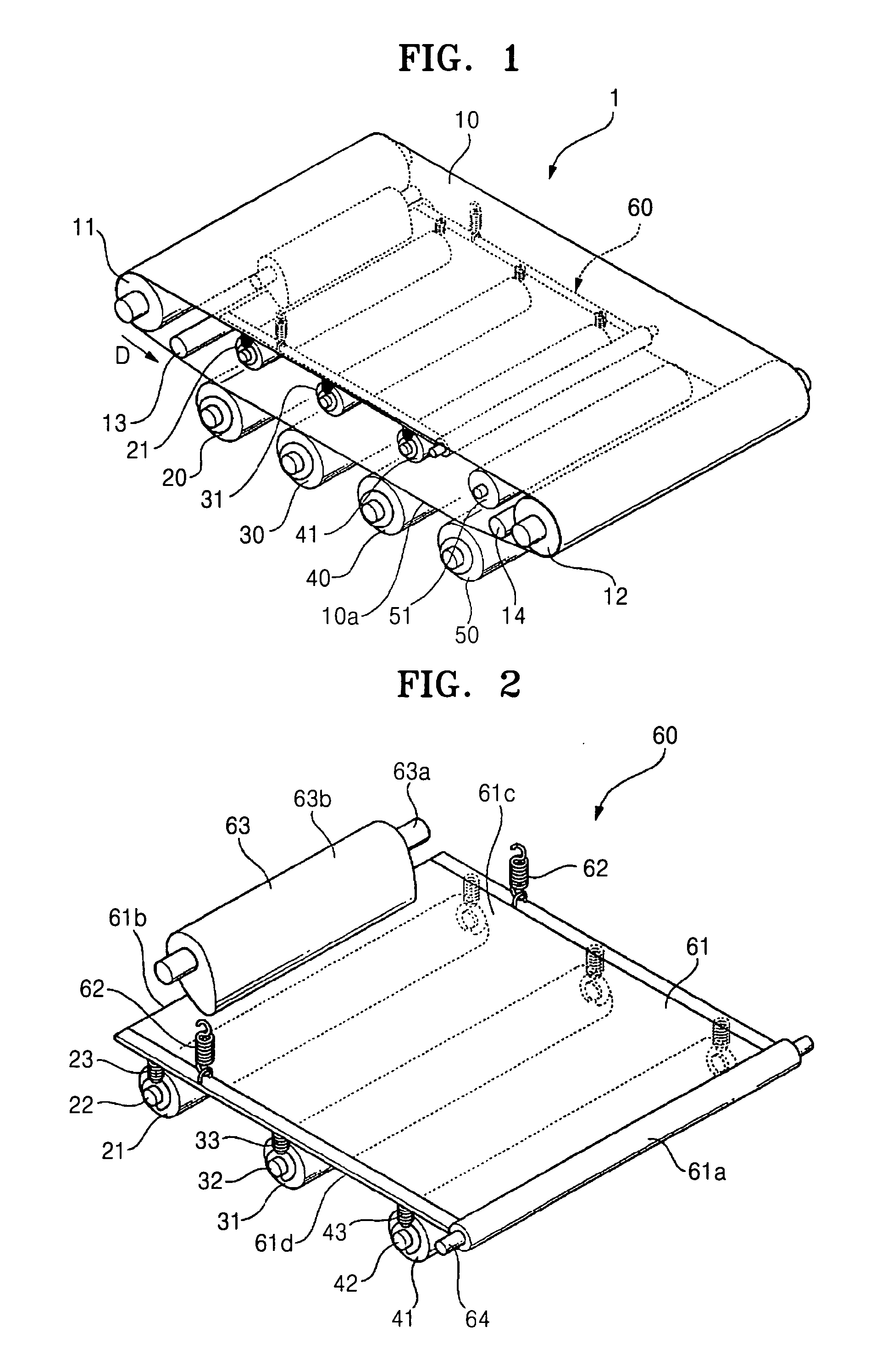

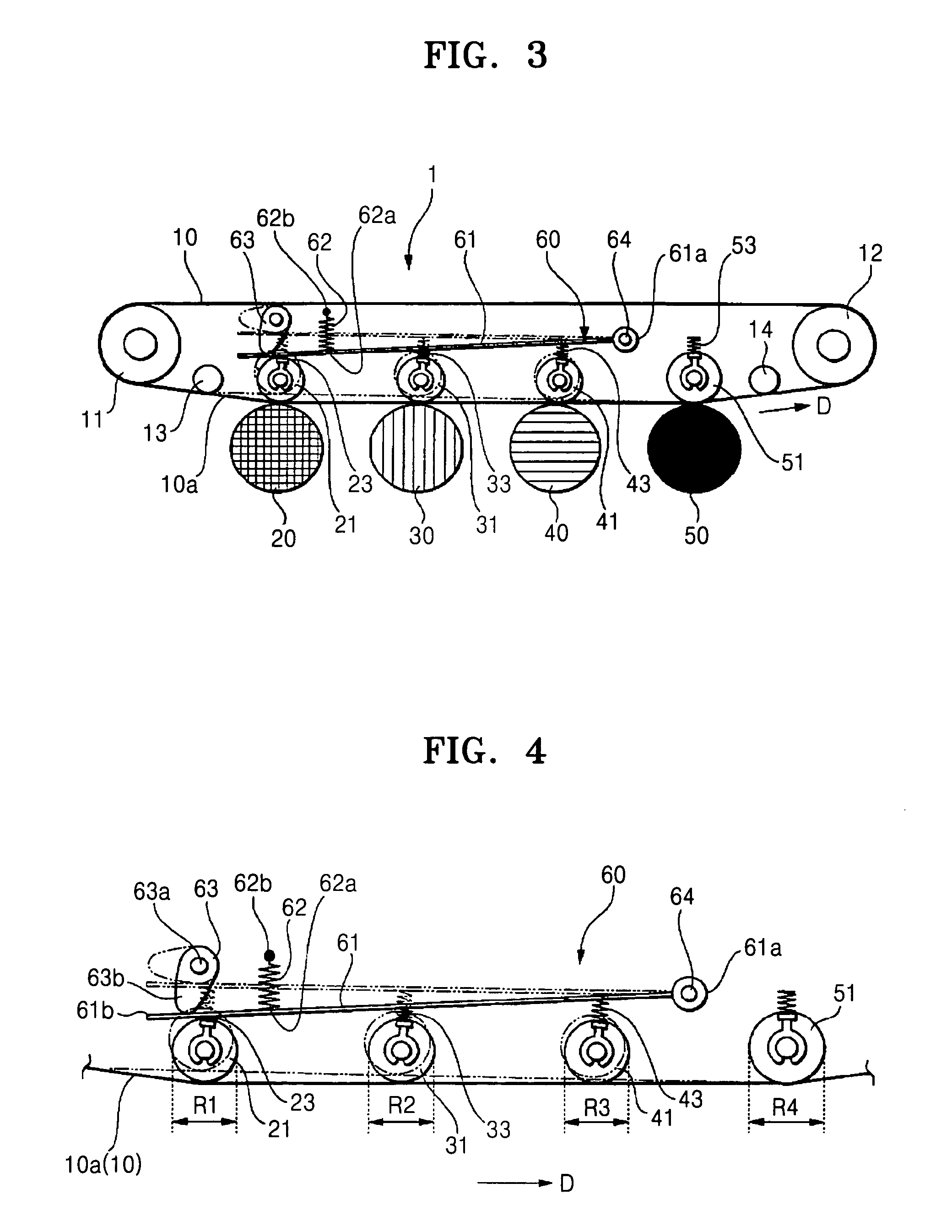

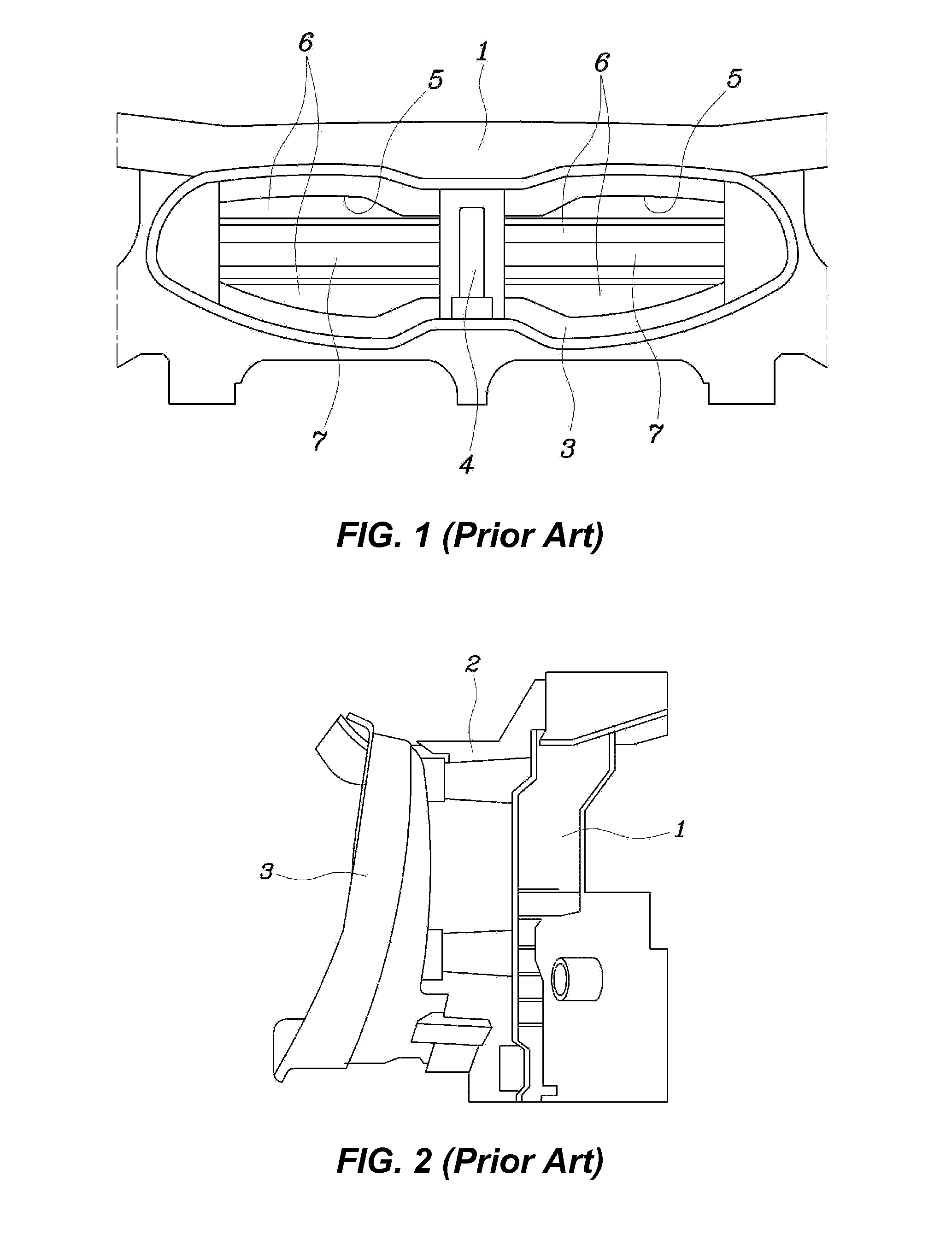

Image forming apparatus

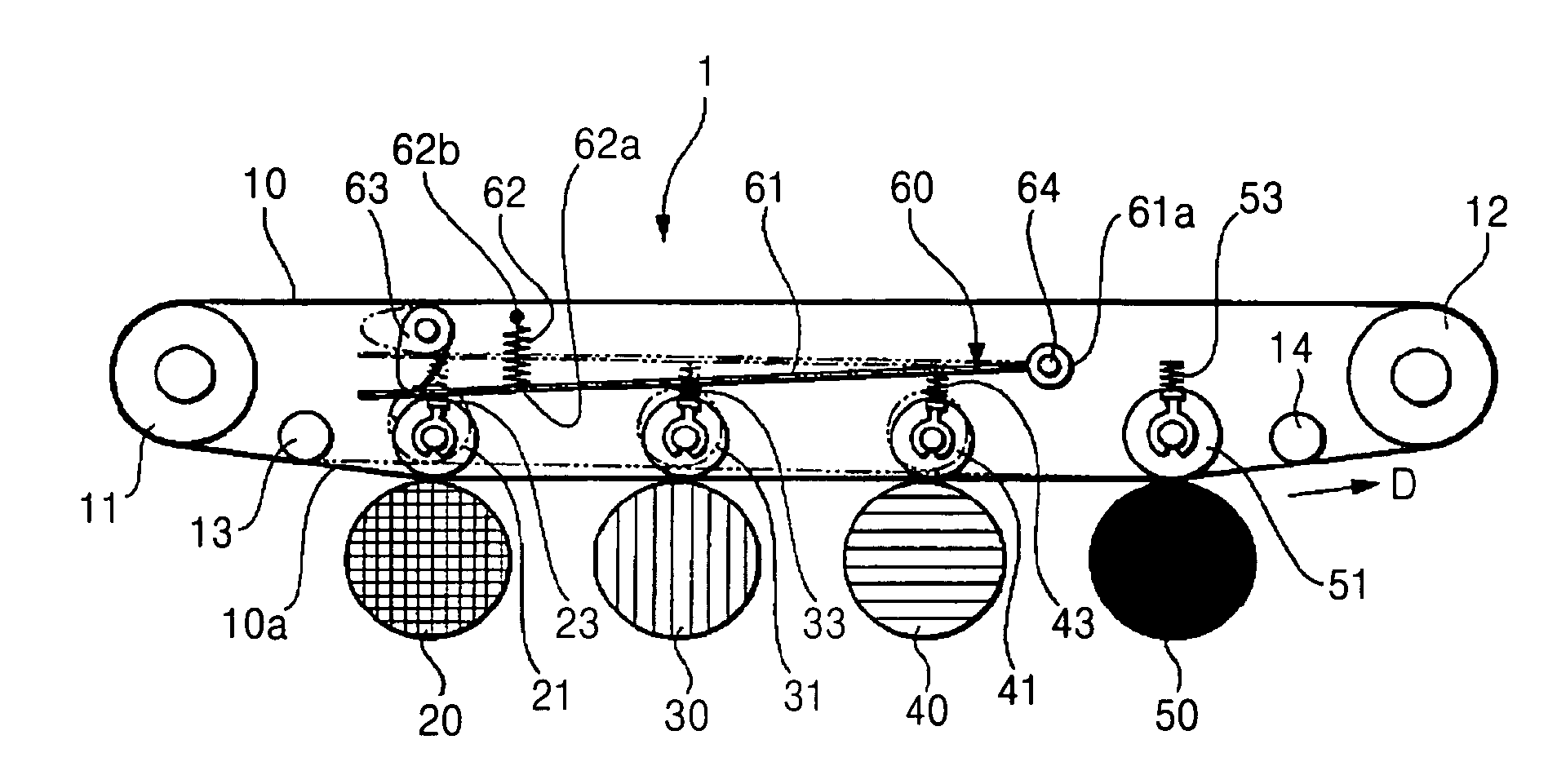

InactiveUS20070134028A1Quality improvementRemove hollow defectElectrographic process apparatusLatent imageImage formation

An image forming apparatus such as a tandem type color image forming apparatus is provided. The image forming apparatus includes a transfer belt that rotates in a rotating direction in which a toner image is transferred. A plurality of color latent image carrying members are arranged successively along the rotating direction so as to form various color toner images, and a monochrome latent image carrying member is located at any one end of the color latent image carrying members so as to form a monochrome toner image. A plurality of color transfer rollers and a monochrome transfer roller are arranged opposite to the color image carrying members and the monochrome image carrying member, respectively, with the transfer belt therebetween. A roller supporting member supports all of the color transfer rollers. A roller shifting unit moves the roller supporting member in a direction in which the color transfer rollers move toward or away from the color latent image carrying members. The diameters of the color transfer rollers are smaller than the diameter of the monochrome transfer roller. The color transfer rollers press against the color image carrying members with an appropriate force so that hollow defects are prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

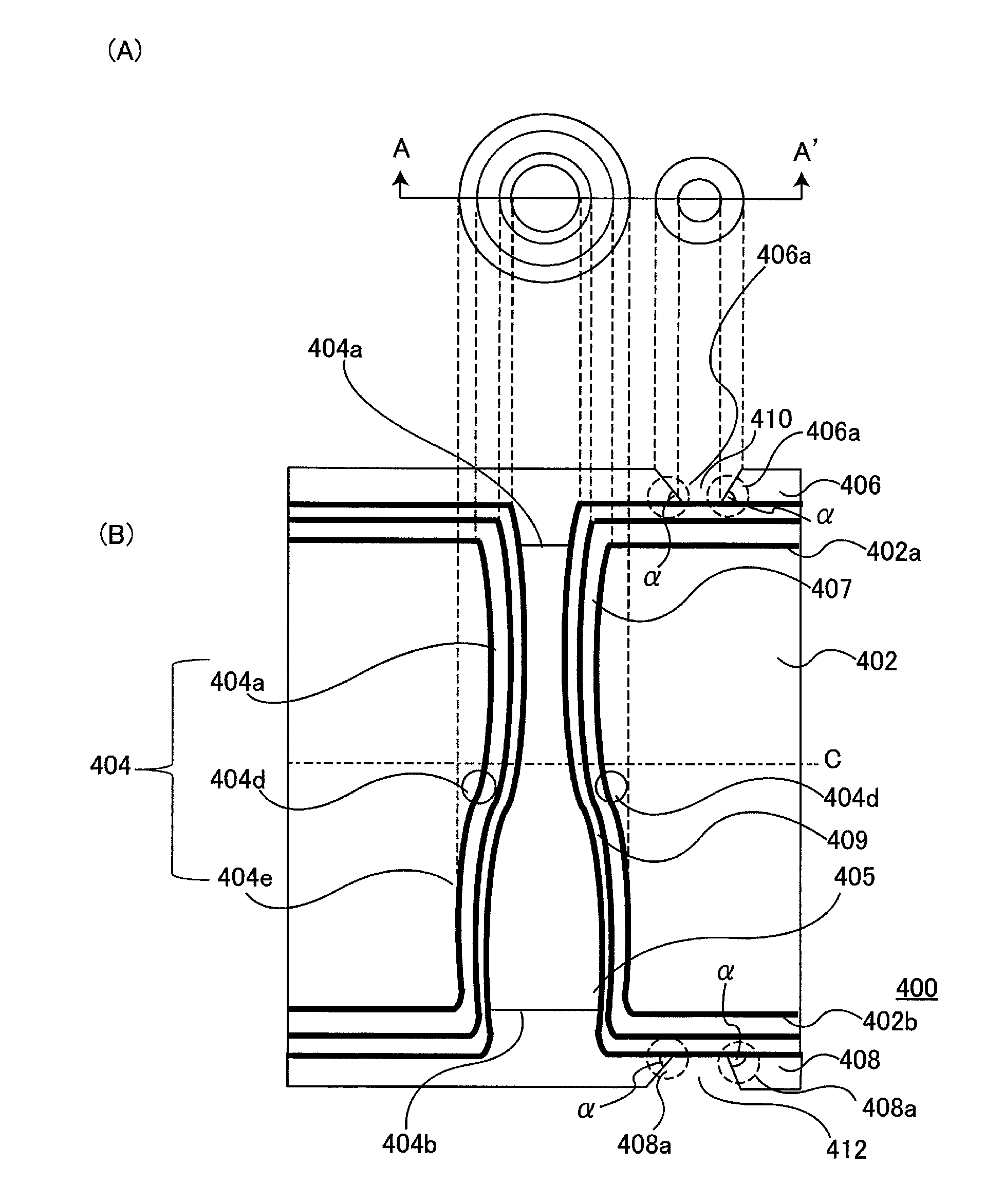

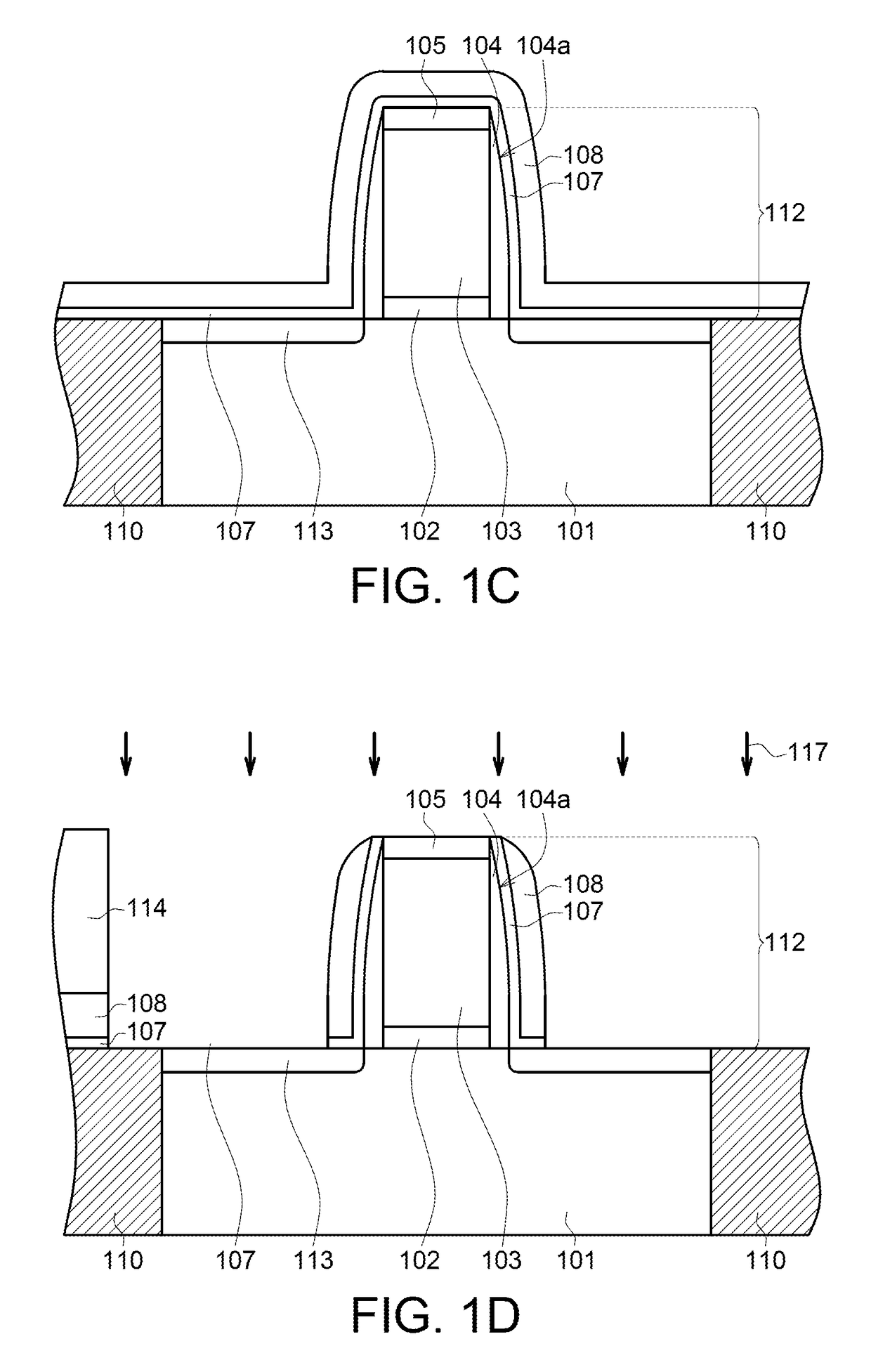

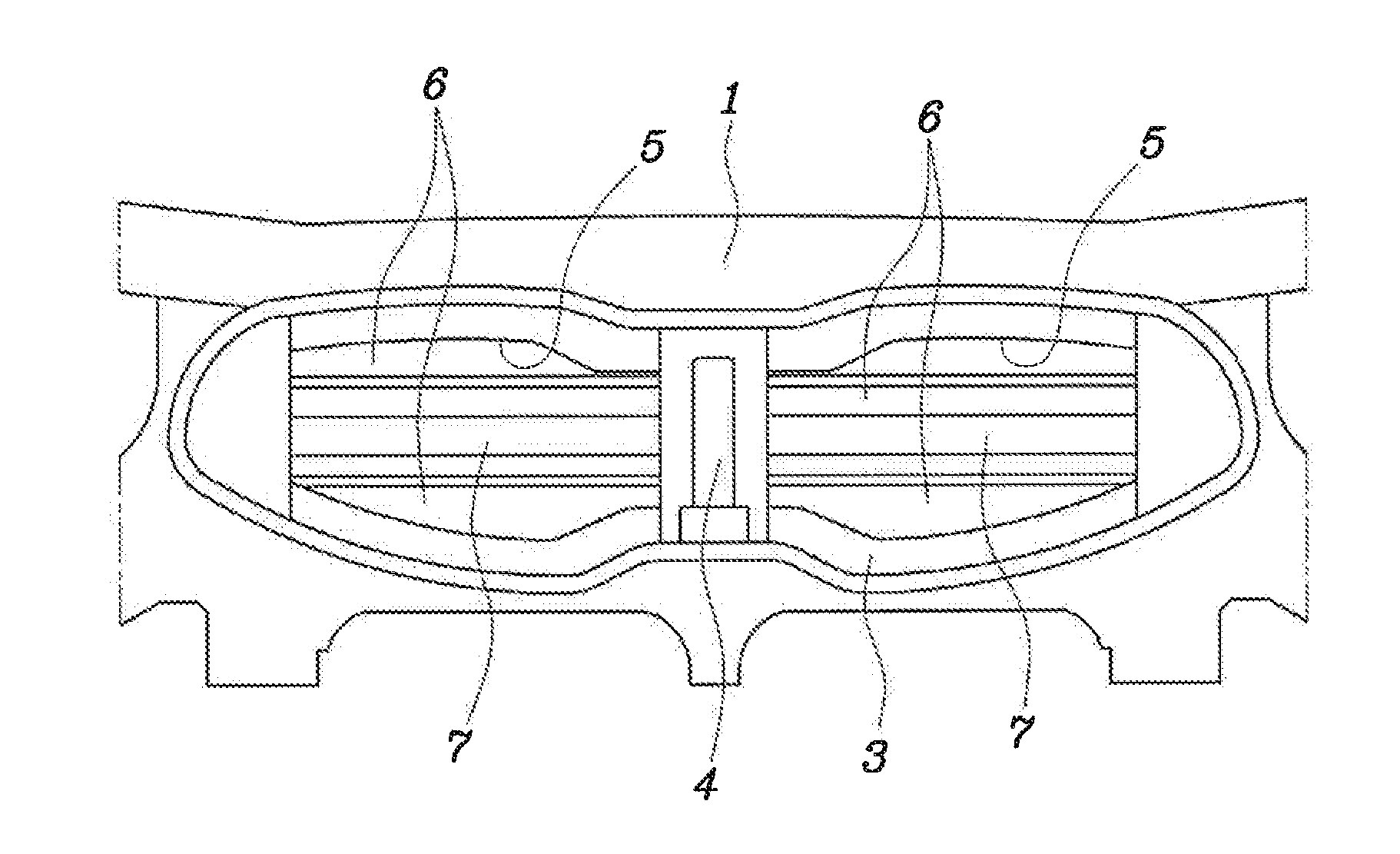

Photovoltaic cell manufacturing method

InactiveUS20110151591A1Reliable removalReliable separationFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The present invention provides a photovoltaic cell manufacturing method, the photovoltaic cell including: a photoelectric converter in which at least a first electrode layer, a semiconductor layer, and a second electrode layer are stacked in layers in this order being formed on a face of a substrate; and a connection portion of the first electrode layer and the second electrode layer, the photoelectric converter having a plurality of compartment elements which are electrically separated by a predetermined size using scribing lines at which the semiconductor layer and the second electrode layer are removed, adjacent compartment elements being electrically connected to each other, the photovoltaic cell manufacturing method comprising: a defect region specifying step in which a region at which the structural defect exists is specified in the photoelectric converter; and a repairing step in which at least three repair lines in which the semiconductor layer and the second electrode layer are removed are formed by irradiating the photoelectric converter with a laser, the region at which the structural defect exists is surrounded by at least three repair lines described above and one of the scribing lines, and the structural defect is removed or separated off, wherein one of at least three repair lines described above are formed at a region between the structural defect and the connection portion and at a region α including a contact portion of the semiconductor layer and the substrate in the photoelectric converter.

Owner:ULVAC INC

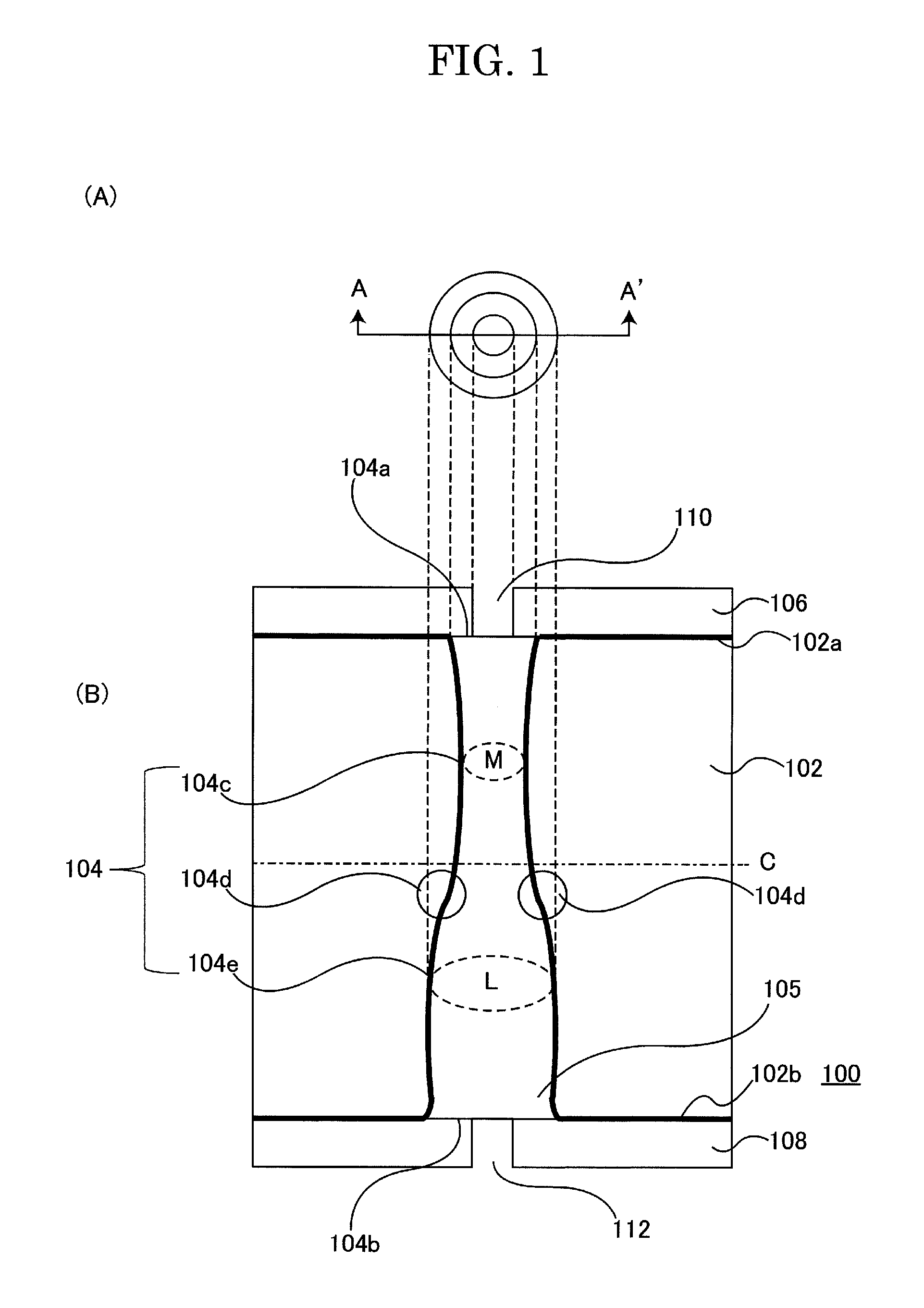

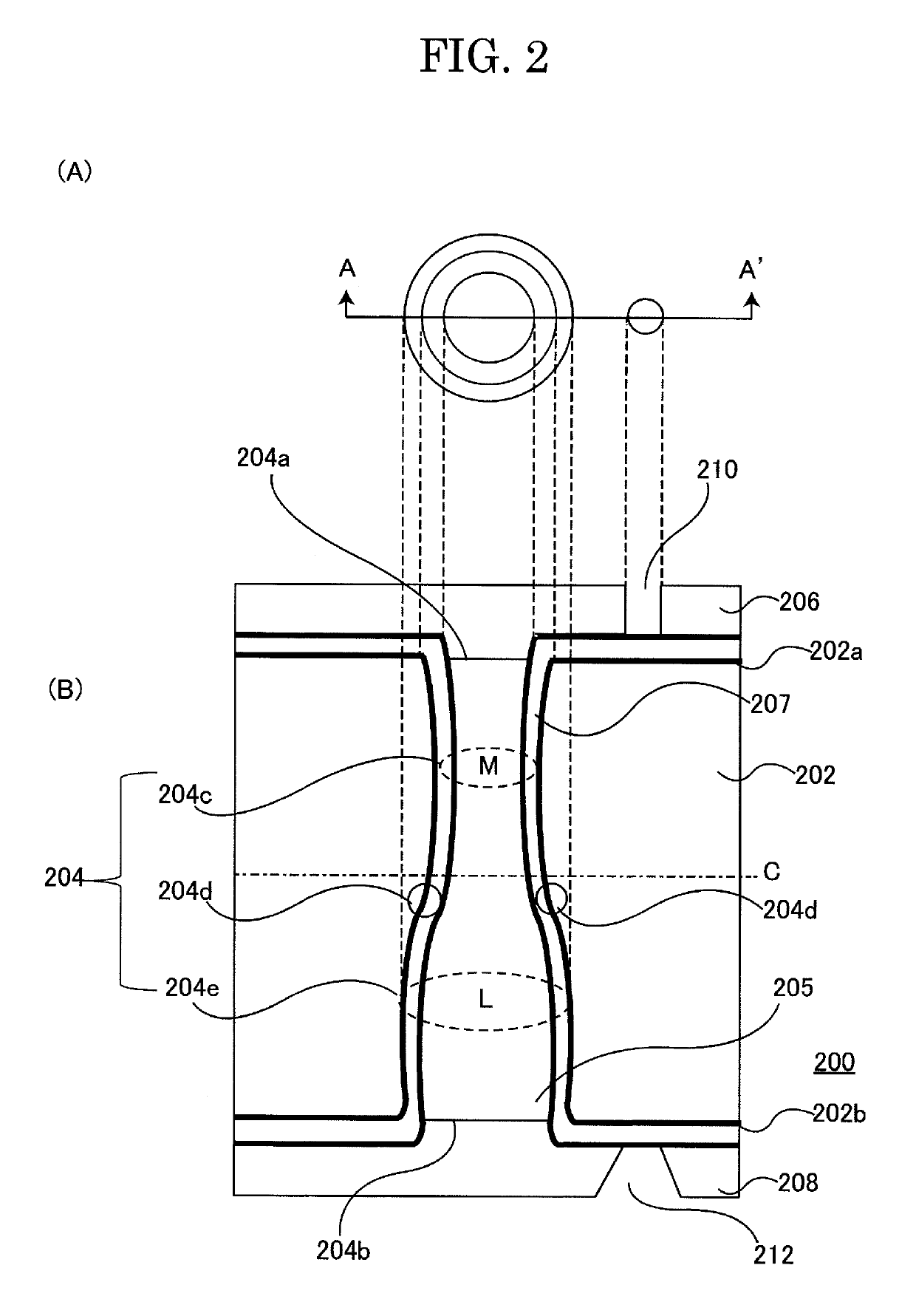

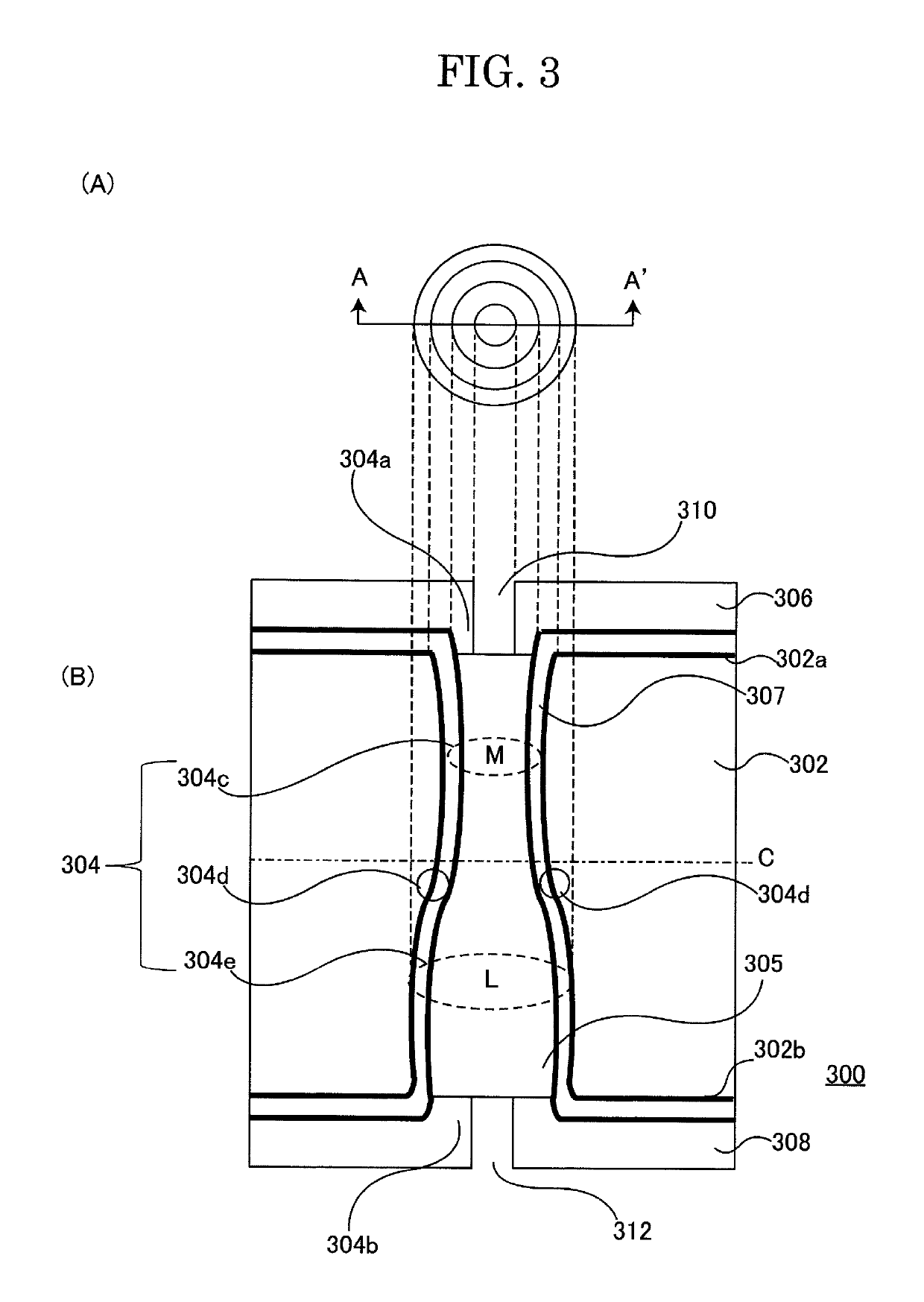

Through electrode substrate and semiconductor device using through electrode substrate

ActiveUS20160276257A1Increase in sizeRemove defectSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductorSemiconductor device

A through-hole electrode substrate includes a substrate including a through-hole extending from a first aperture of a first surface to a second aperture of a second surface, an area of the second aperture being larger than that of the first aperture, the through-hole having a minimum aperture part between the first aperture and the second aperture, wherein an area of the minimum aperture part in a planer view is smallest among a plurality of areas of the through-hole in a planer view, a filler arranged within the through-hole, and at least one gas discharge member contacting the filler exposed to one of the first surface and the second surface.

Owner:DAI NIPPON PRINTING CO LTD

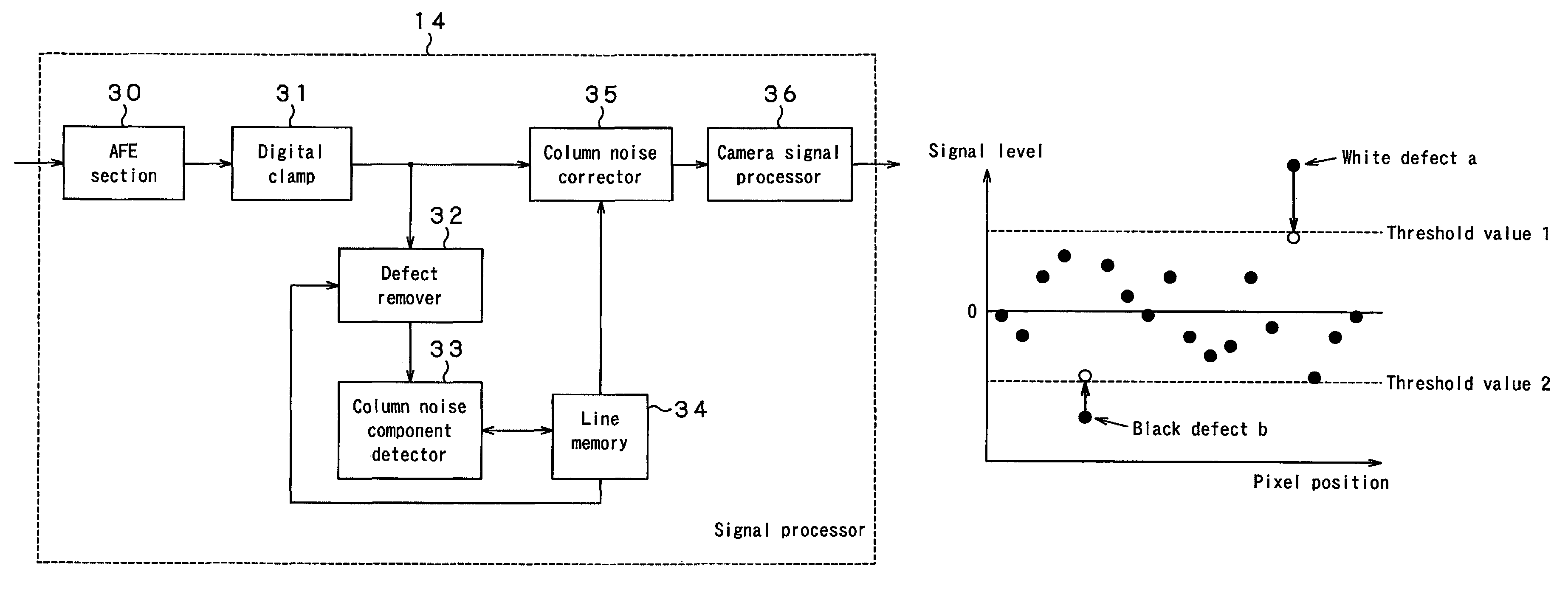

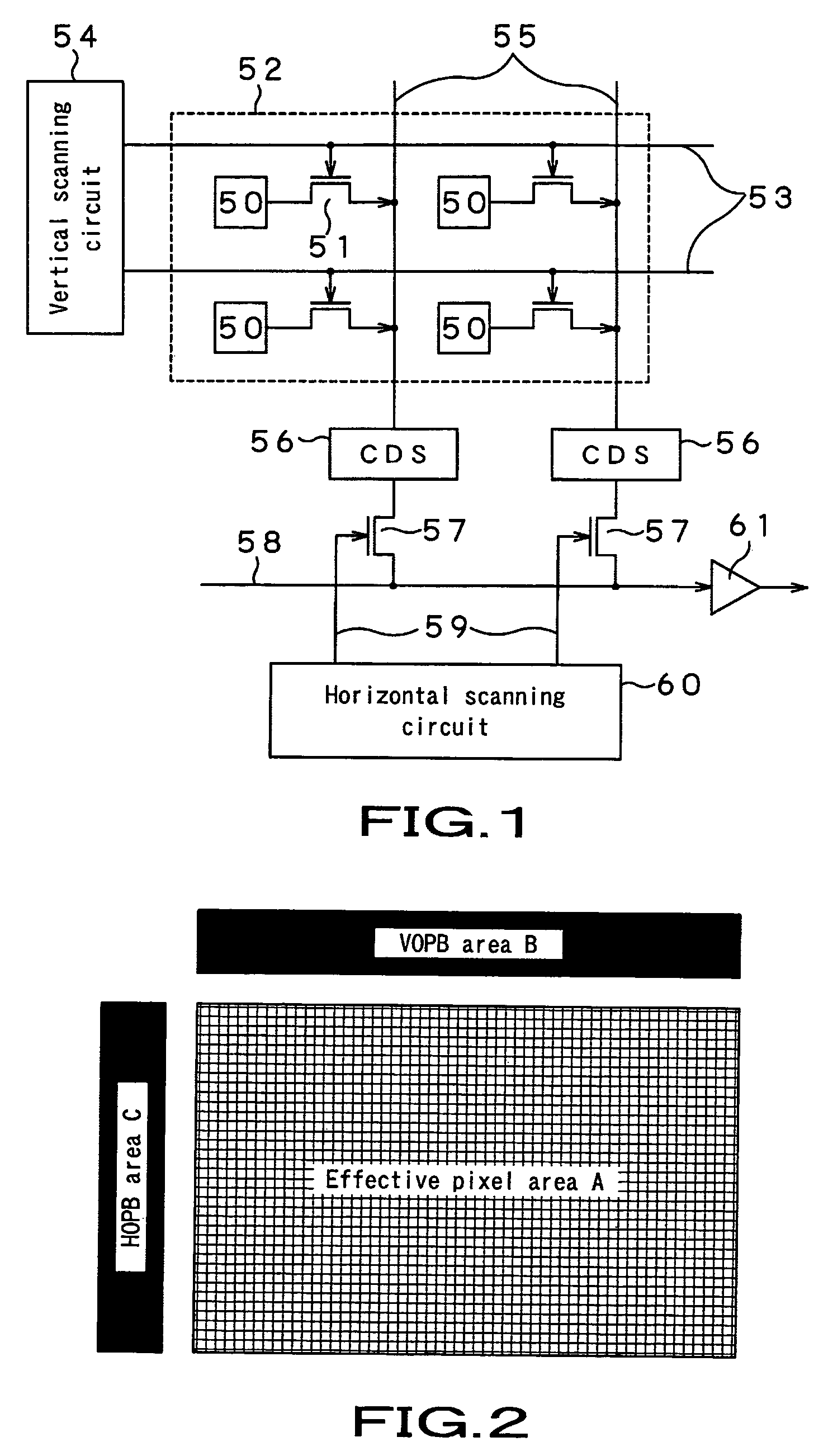

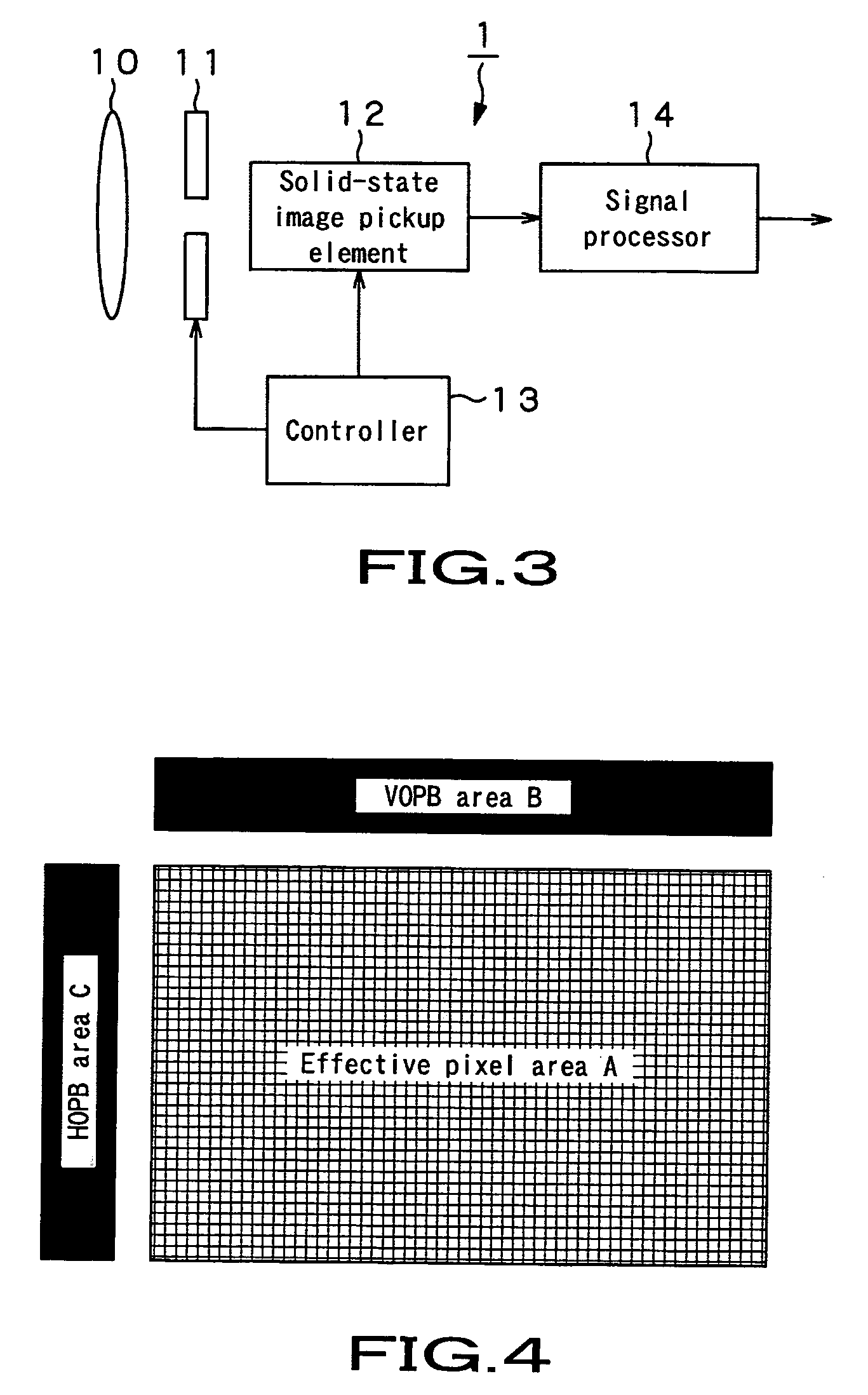

Signal processing device and method for reducing influence on column noise detection from defective pixels

InactiveUS7623162B2Column noiseRemove defectTelevision system detailsColor signal processing circuitsOn columnNoise detection

The present invention provides a signal processing device which, even when a defective pixel exists in the VOPB area B, can detect column noise accurately, and can carry out column noise correction. The signal processing device includes a solid-state image pickup element having a pixel part including an effective pixel area to be irradiated with light, and a vertical light-shielded pixel area where irradiation of light is shielded, a vertical scanning circuit, a horizontal scanning circuit, and an output circuit, a clamp section which clamps, to a predetermined reference value, black level values of pixel signals from the vertical light-shielded pixel area and effective pixel area, a threshold determination section which determines a threshold value, based on the predetermined reference value, a determination section which determines whether or not pixel signals from the vertical light-shielded pixel area that have the black level value clamped to the reference value by the clamp section exceed the threshold value determined by the threshold determination section, a defective pixel detector which detects a defective pixel among pixels arranged in the vertical light-shielded pixel area, and a signal processor which performs a predetermined signal processing on pixel signals from the vertical light-shielded pixel area that have a black level value clamped to the reference value by the clamp section.

Owner:SONY CORP

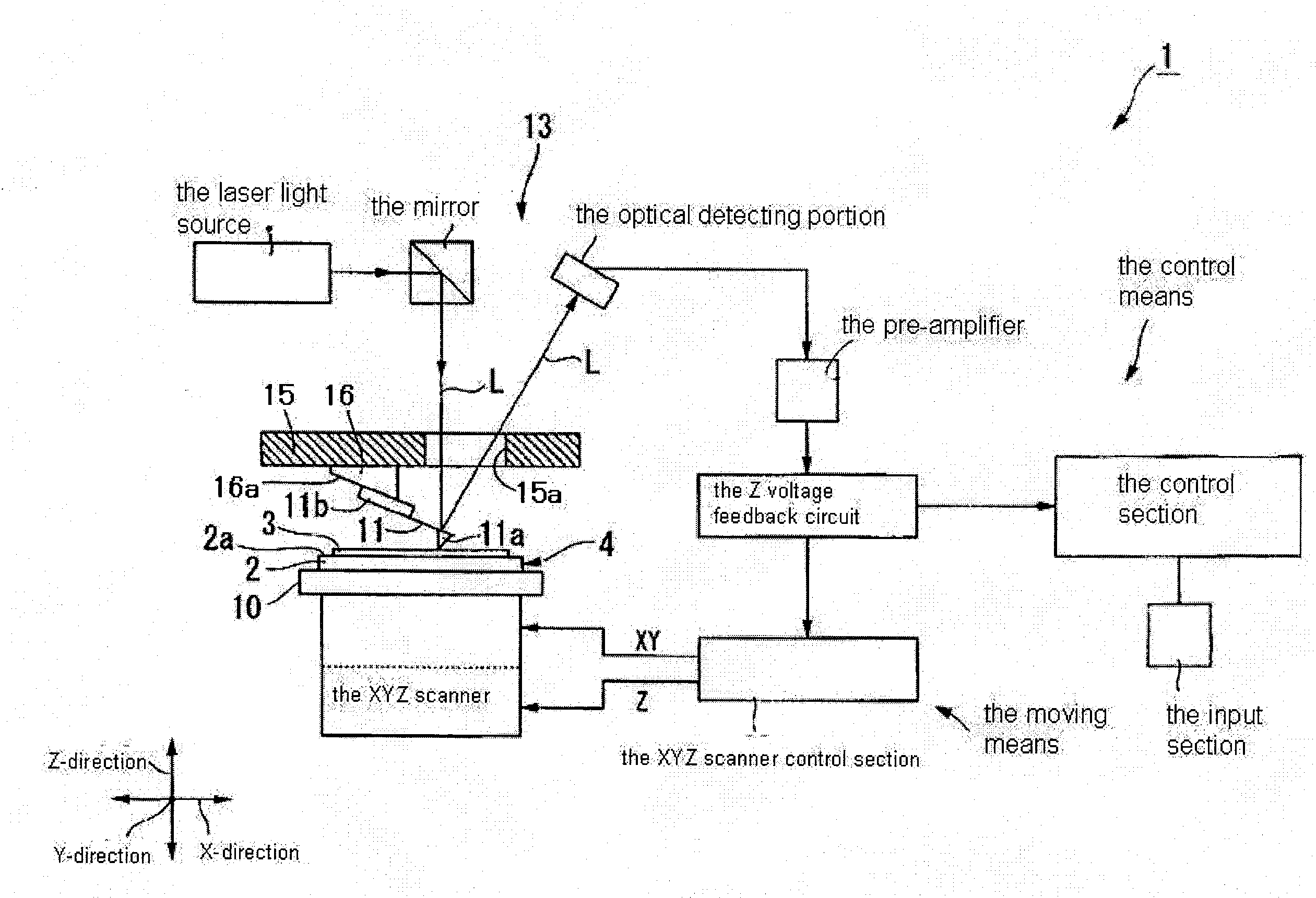

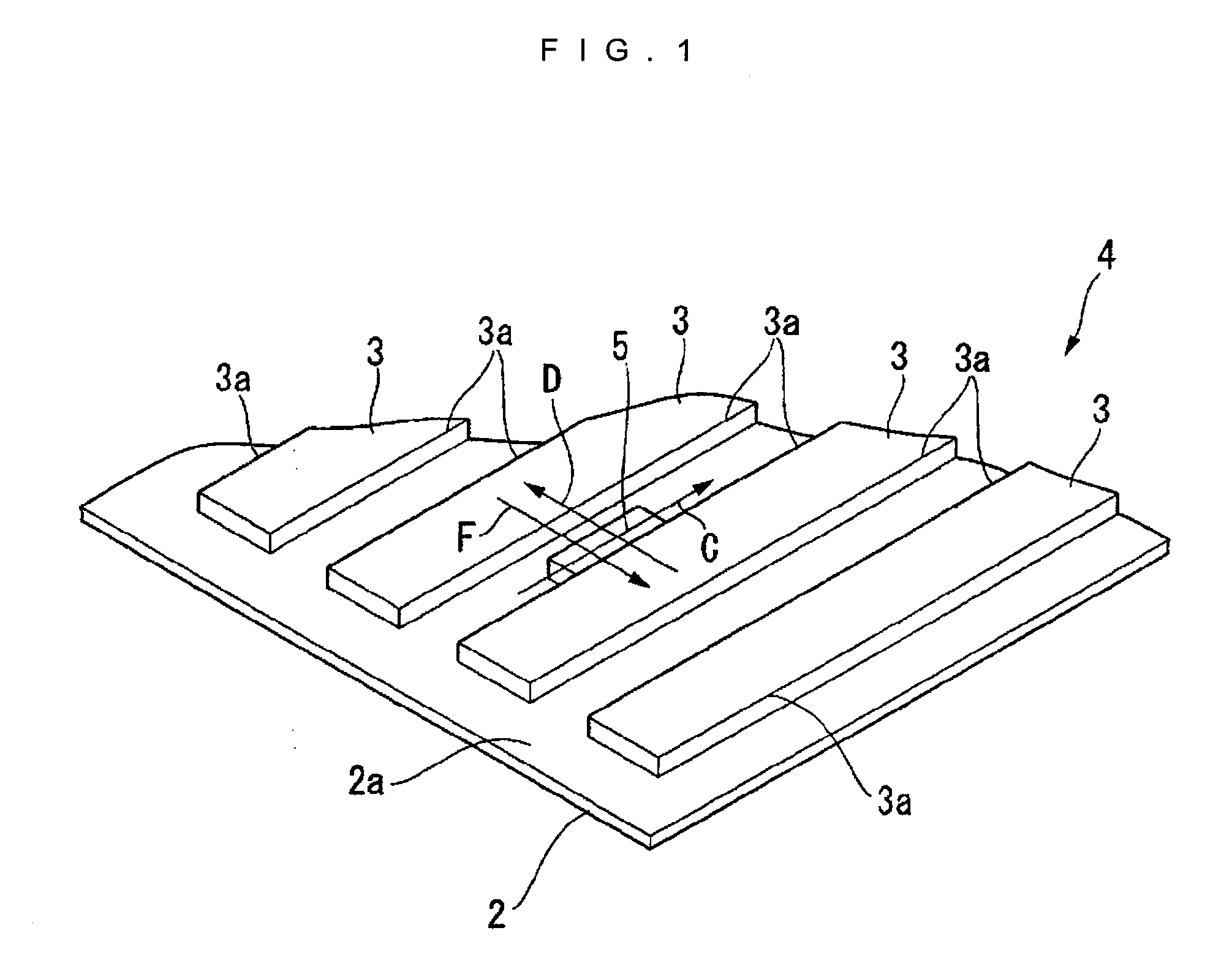

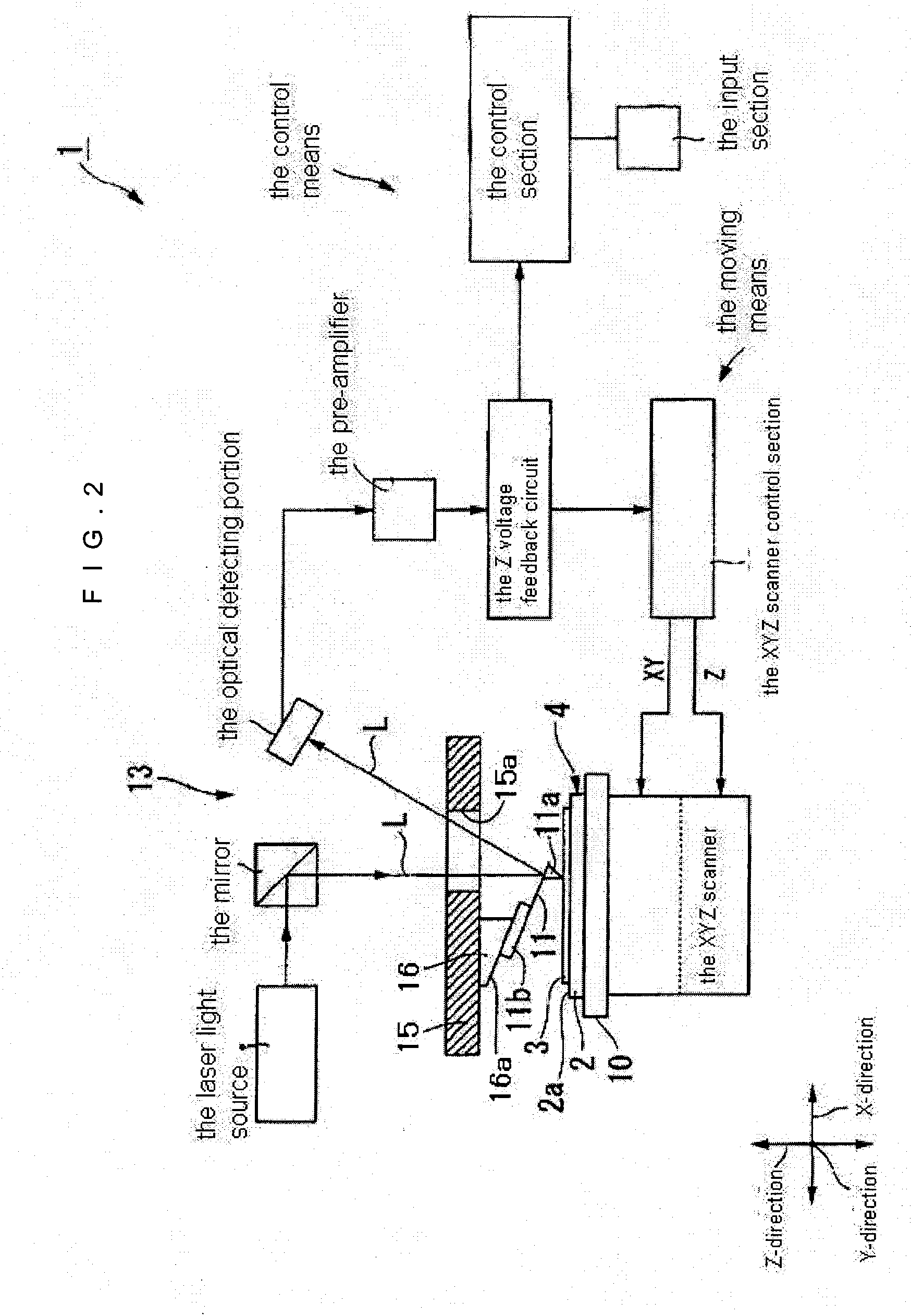

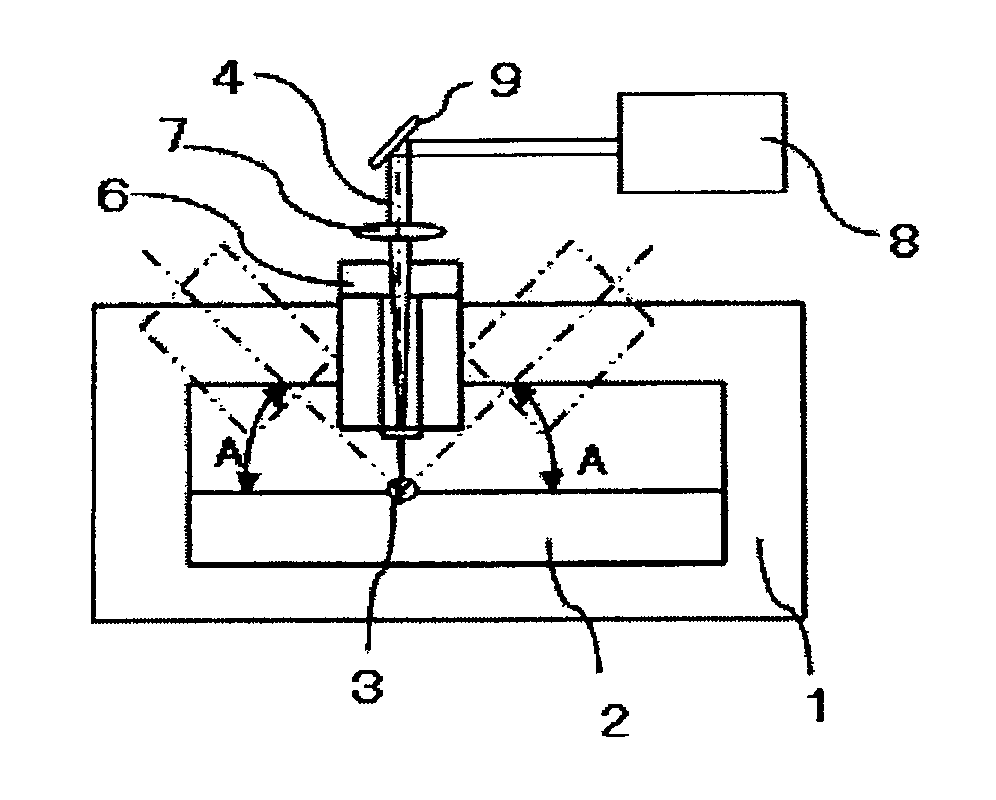

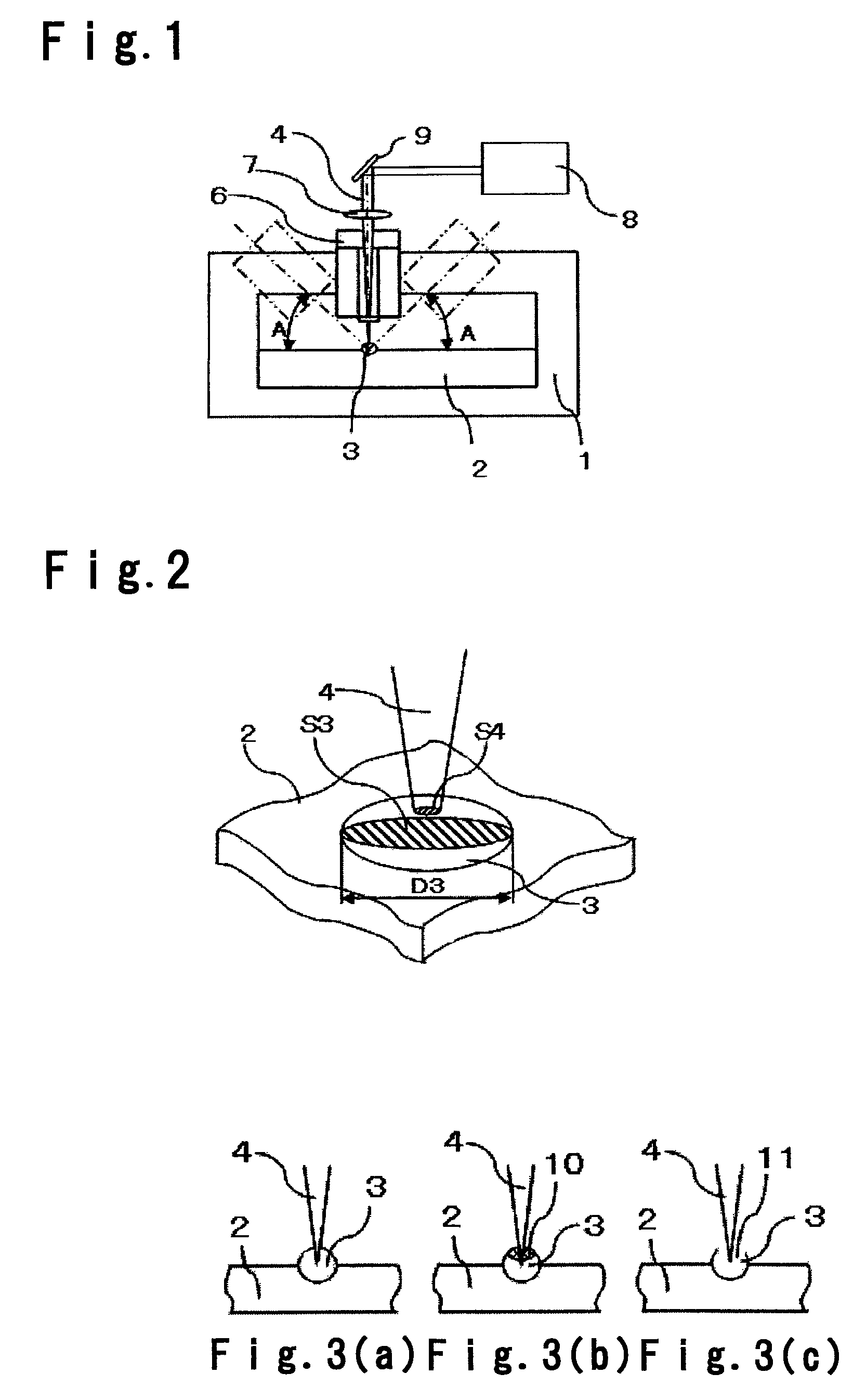

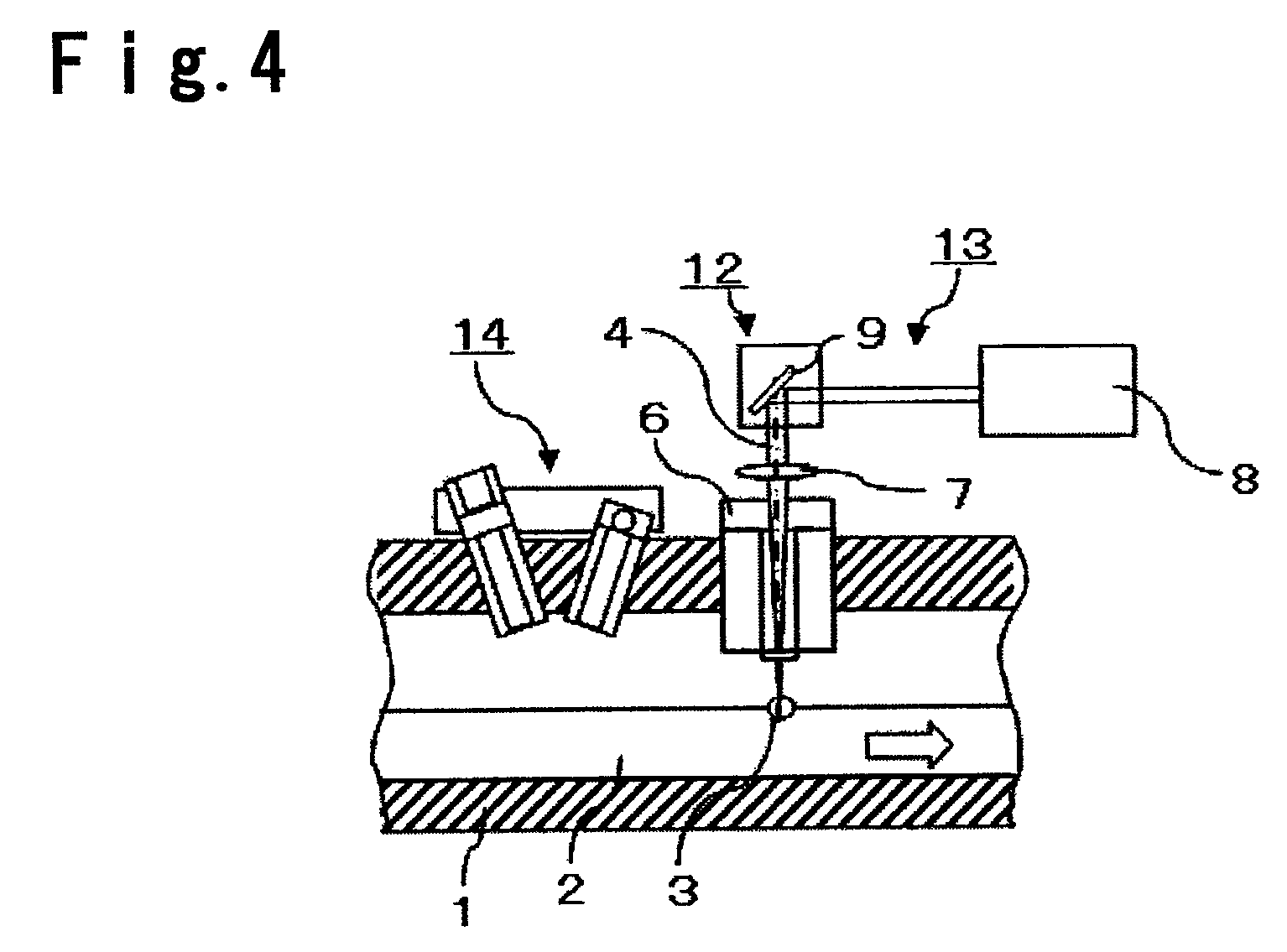

Photomask defect correction device and photomask defect correction method

InactiveUS20090038383A1High accuracyRemove defectNanoinformaticsSemiconductor/solid-state device manufacturingCorrection methodBiomedical engineering

Provided is a photomask defect correction method including: an observing step of scanning plurality of lines one after another while controlling a distance between the probe tip and a surface (2a) of the substrate so that displacement of the probe becomes constant to recognize a shape of the defect portion (5) through AFM observation; and a processing step of scanning a plurality of lines one after another while pressing the probe tip to the recognized defect portion with a predetermined force to subject the defect portion to cutting and removing processing, in which, at the observing step, the scanning for every one line is set in a parallel direction (C direction) to an edge (3a) of a mask pattern (3), and the scanning of the plurality of lines is performed one after another from the mask pattern side towards a tip side (D direction) of the defect portion.

Owner:SII NANOTECHNOLOGY INC

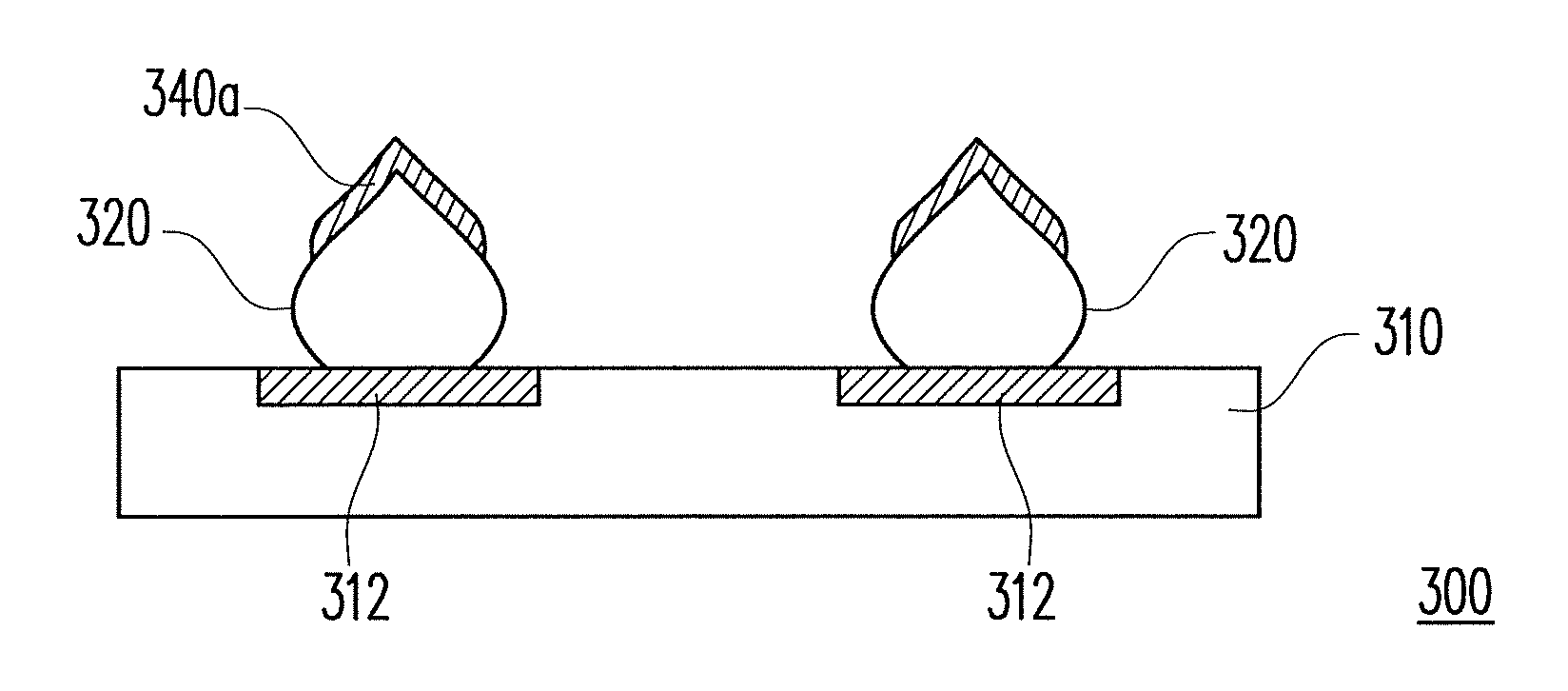

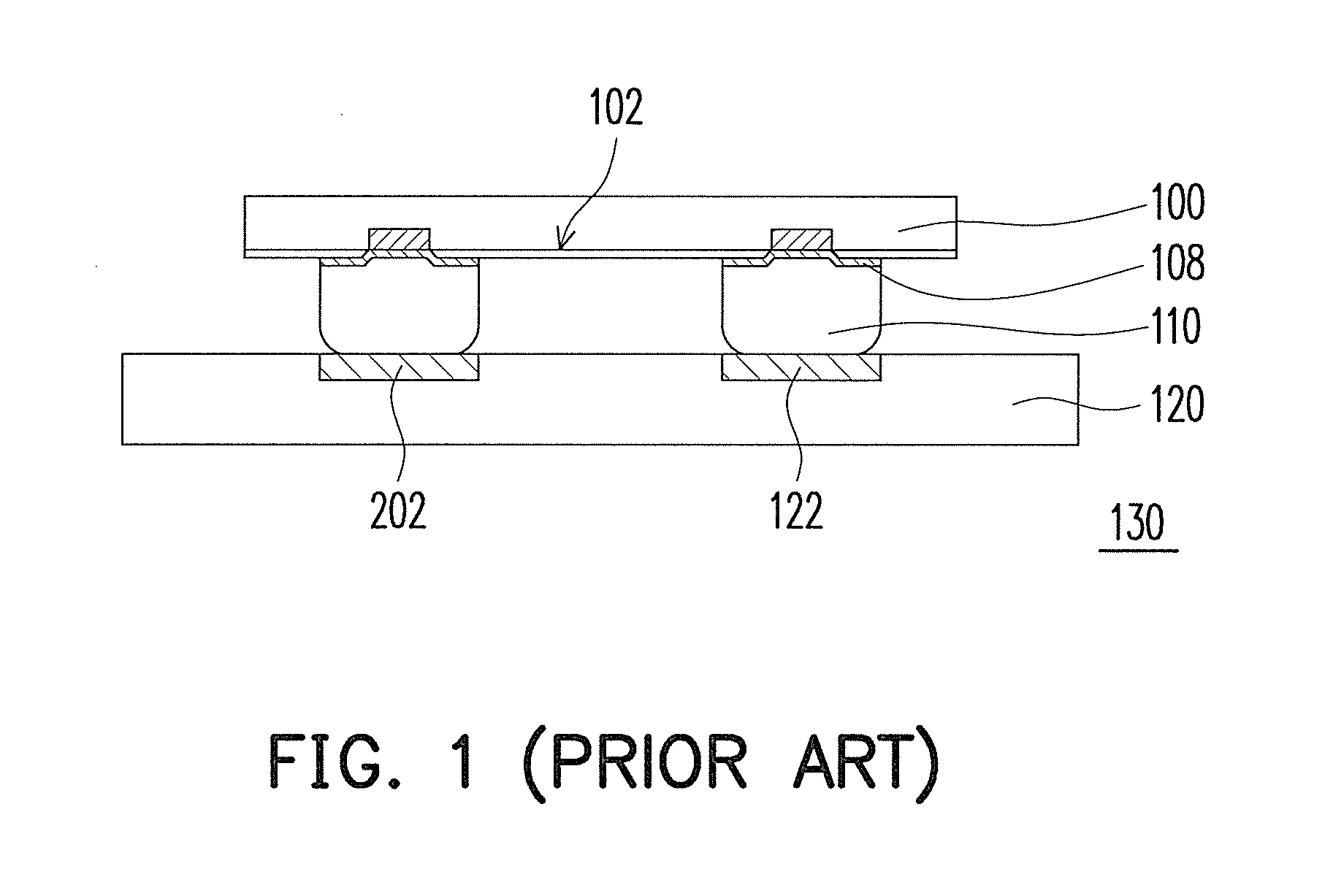

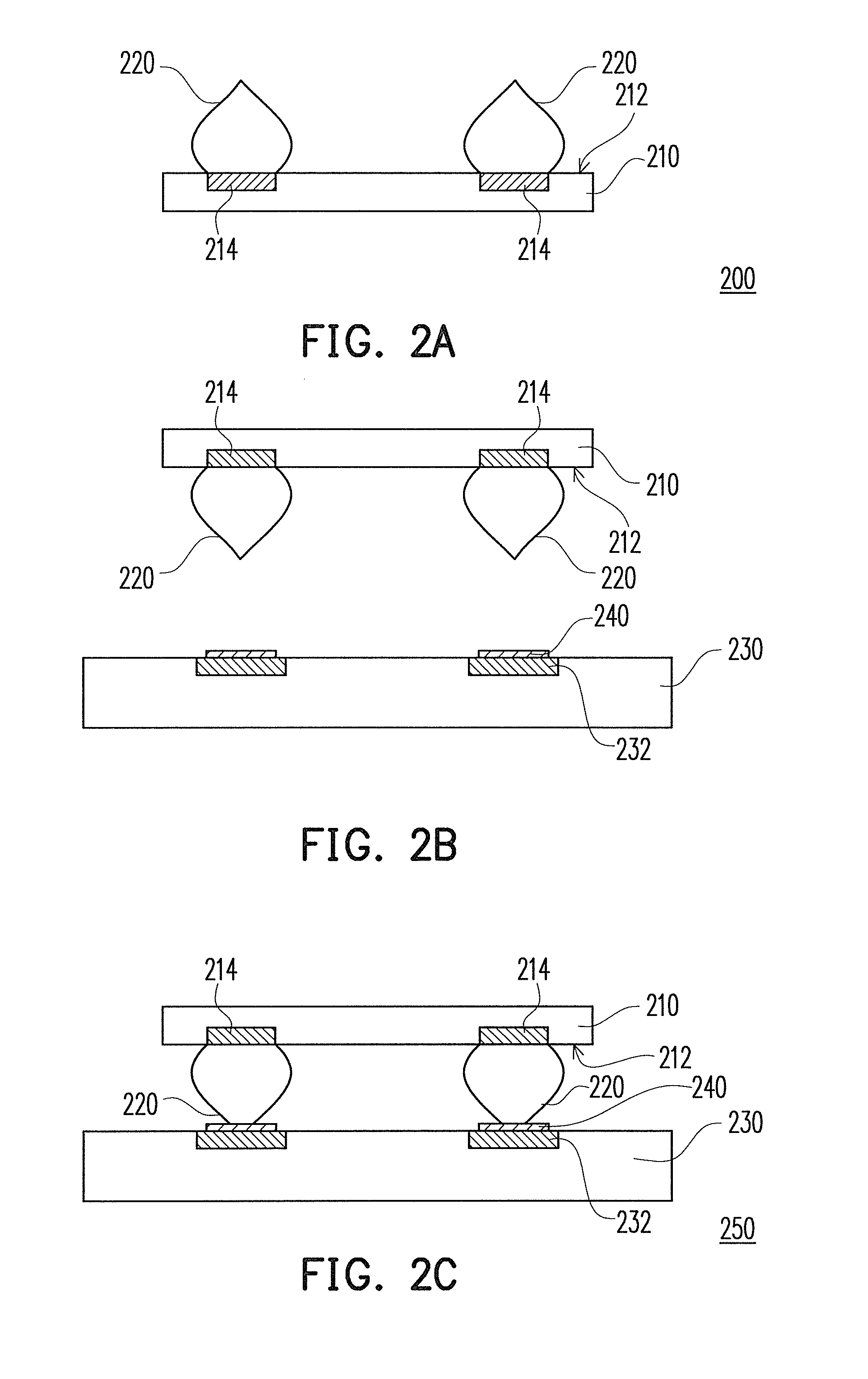

Chip structure, substrate structure, chip package structure and process thereof

InactiveUS20090127706A1Improve reliabilityRemove defectSemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

A chip package structure and process are provided; the structure includes a substrate, a chip, a solder layer and at least a stud bump. The substrate has at least a contact pad, and the chip has an active surface where at least a bonding pad is disposed. The stud bump is disposed on the bonding pad of the chip or on the contact pad of the substrate, and the stud bump joints with the solder layer to fix the chip on the substrate. The stud bump is made of gold-silver alloy containing silver below 15% by weight.

Owner:ADVANCED SEMICON ENG INC

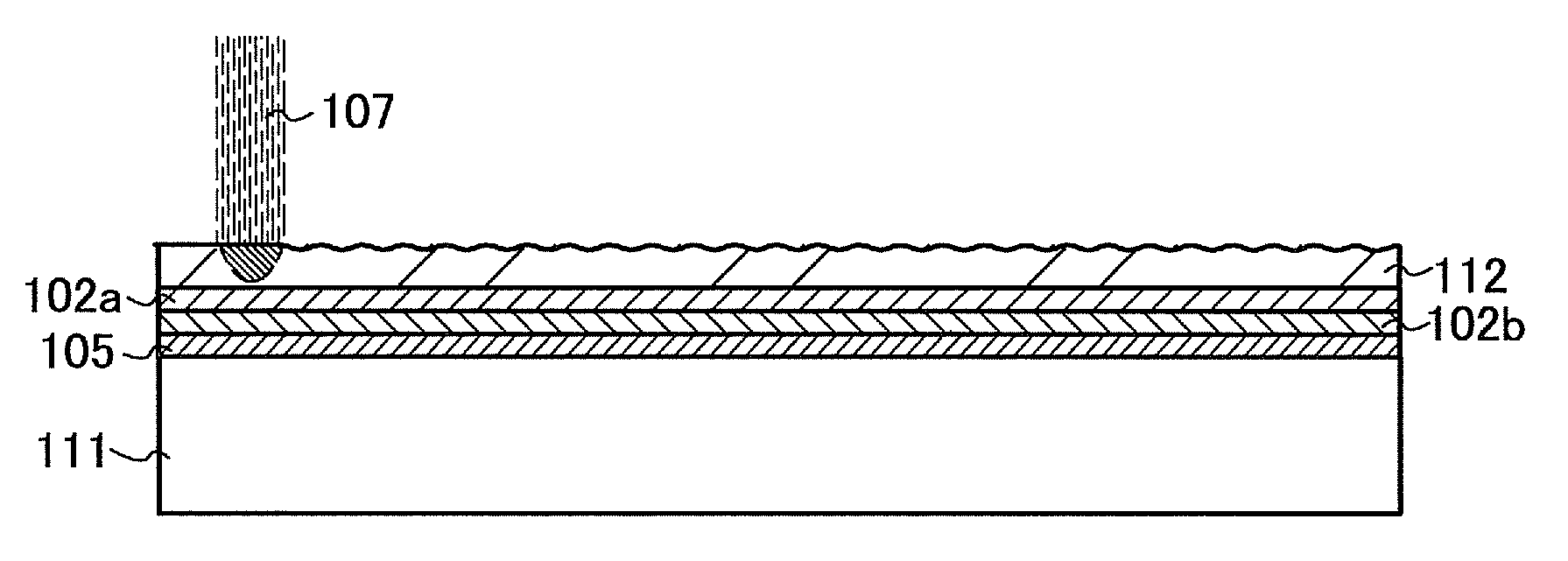

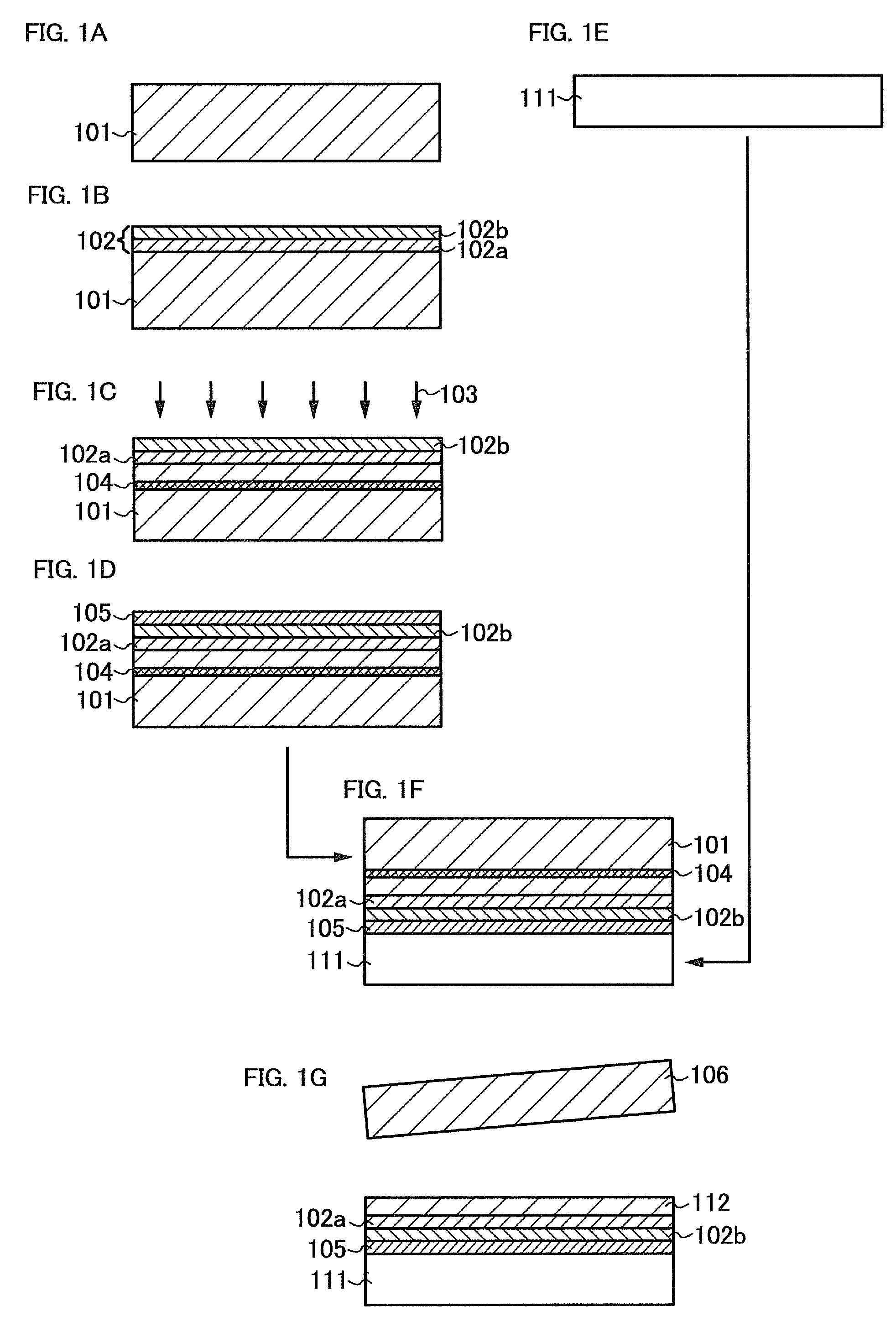

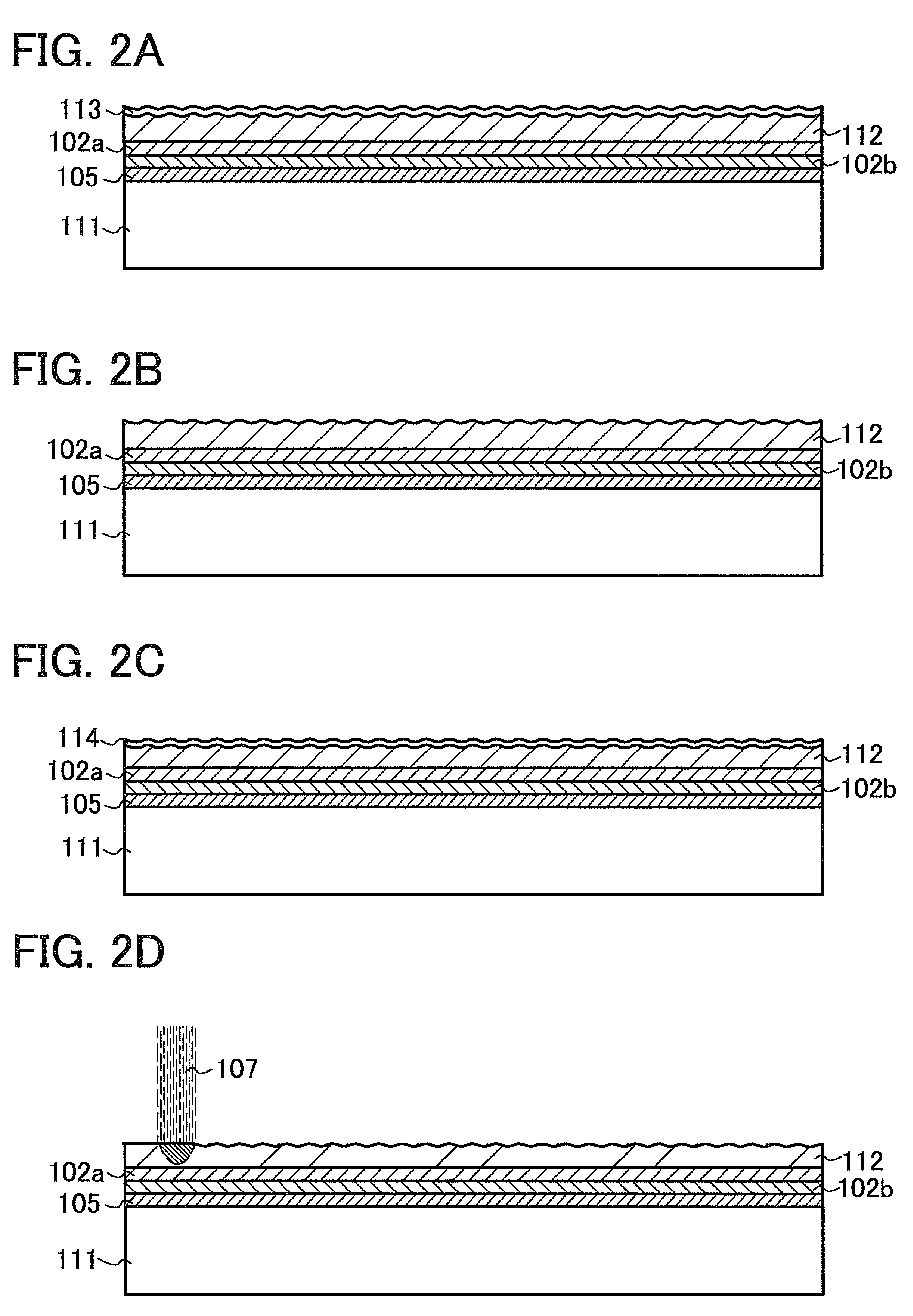

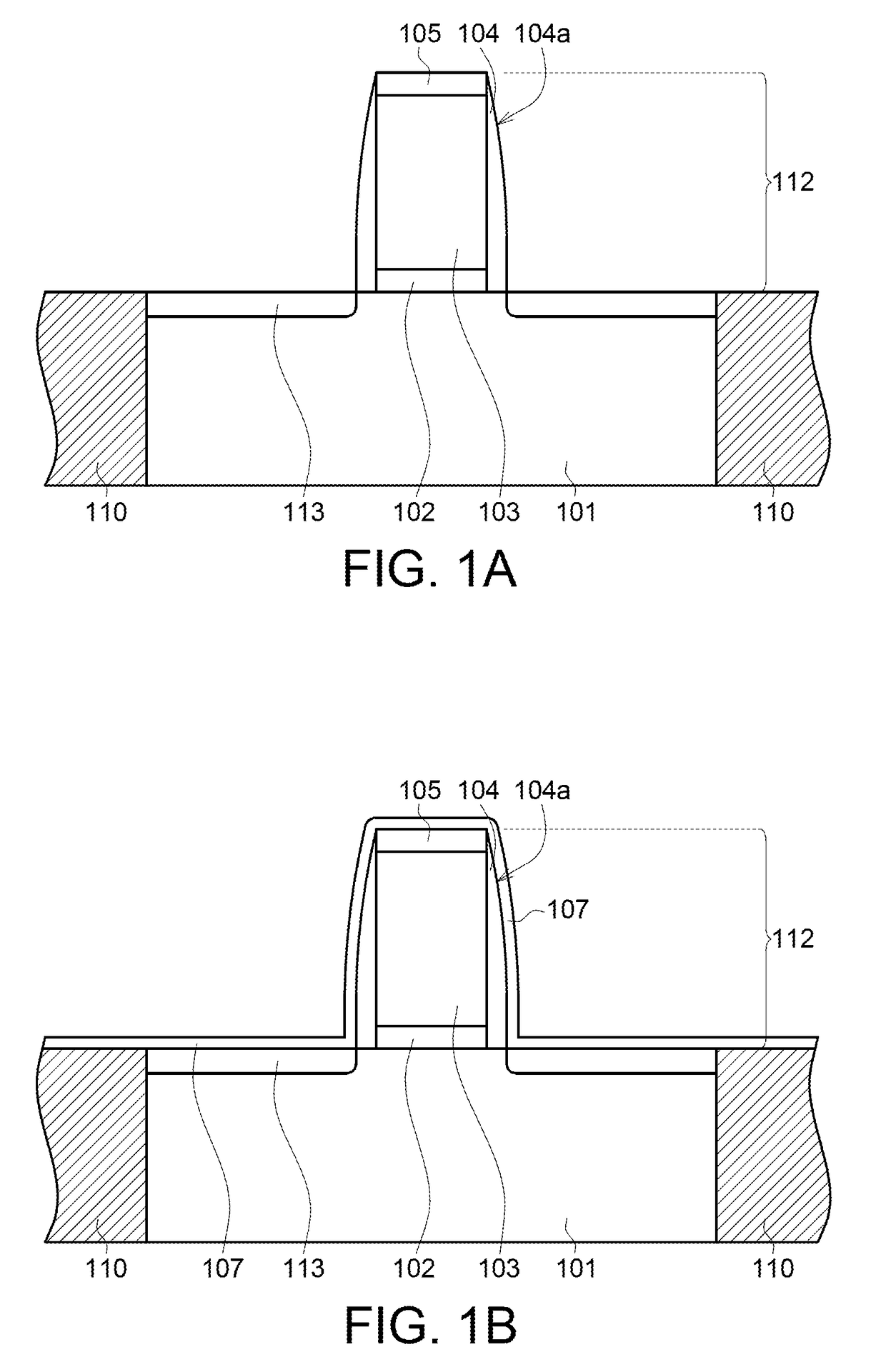

Method for manufacturing SOI substrate

InactiveUS8003483B2Defect damageRemove defectSemiconductor/solid-state device manufacturingSoi substrateSingle crystal

Forming an insulating film on a surface of the single crystal semiconductor substrate, forming a fragile region in the single crystal semiconductor substrate by irradiating the single crystal semiconductor substrate with an ion beam through the insulating film, forming a bonding layer over the insulating film, bonding a supporting substrate to the single crystal semiconductor substrate by interposing the bonding layer between the supporting substrate and the single crystal semiconductor substrate, dividing the single crystal semiconductor substrate at the fragile region to separate the single crystal semiconductor substrate into a single crystal semiconductor layer attached to the supporting substrate, performing first dry etching treatment on a part of the fragile region remaining on the single crystal semiconductor layer, performing second dry etching treatment on a surface of the single crystal semiconductor layer subjected to the first etching treatment, and irradiating the single crystal semiconductor layer with laser light.

Owner:SEMICON ENERGY LAB CO LTD

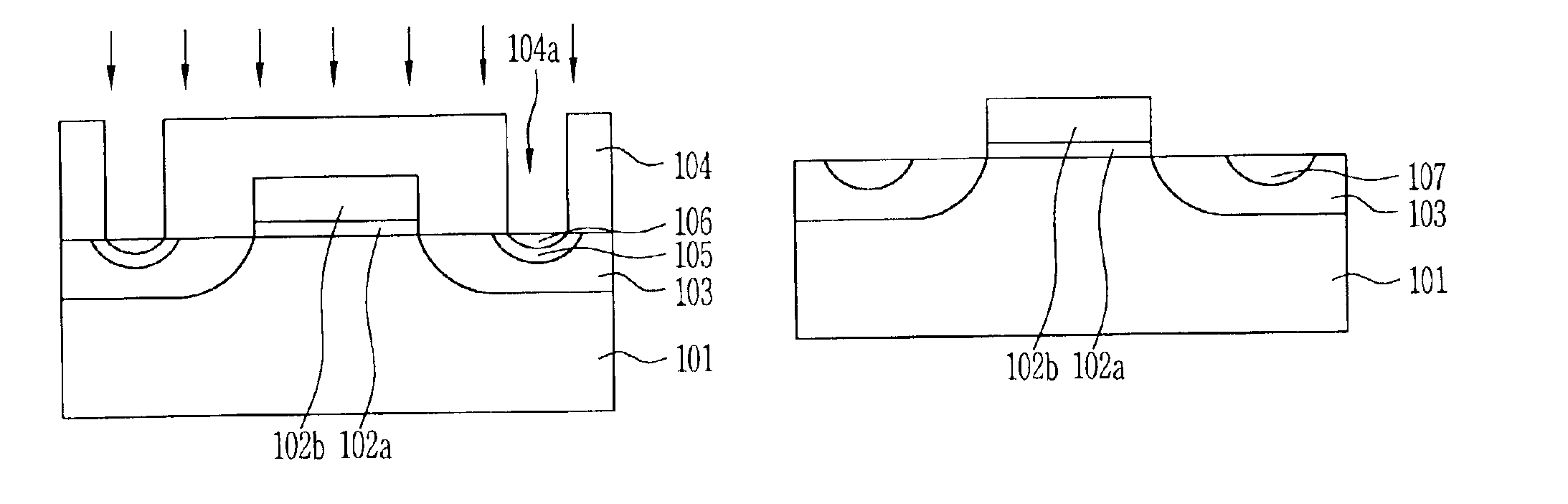

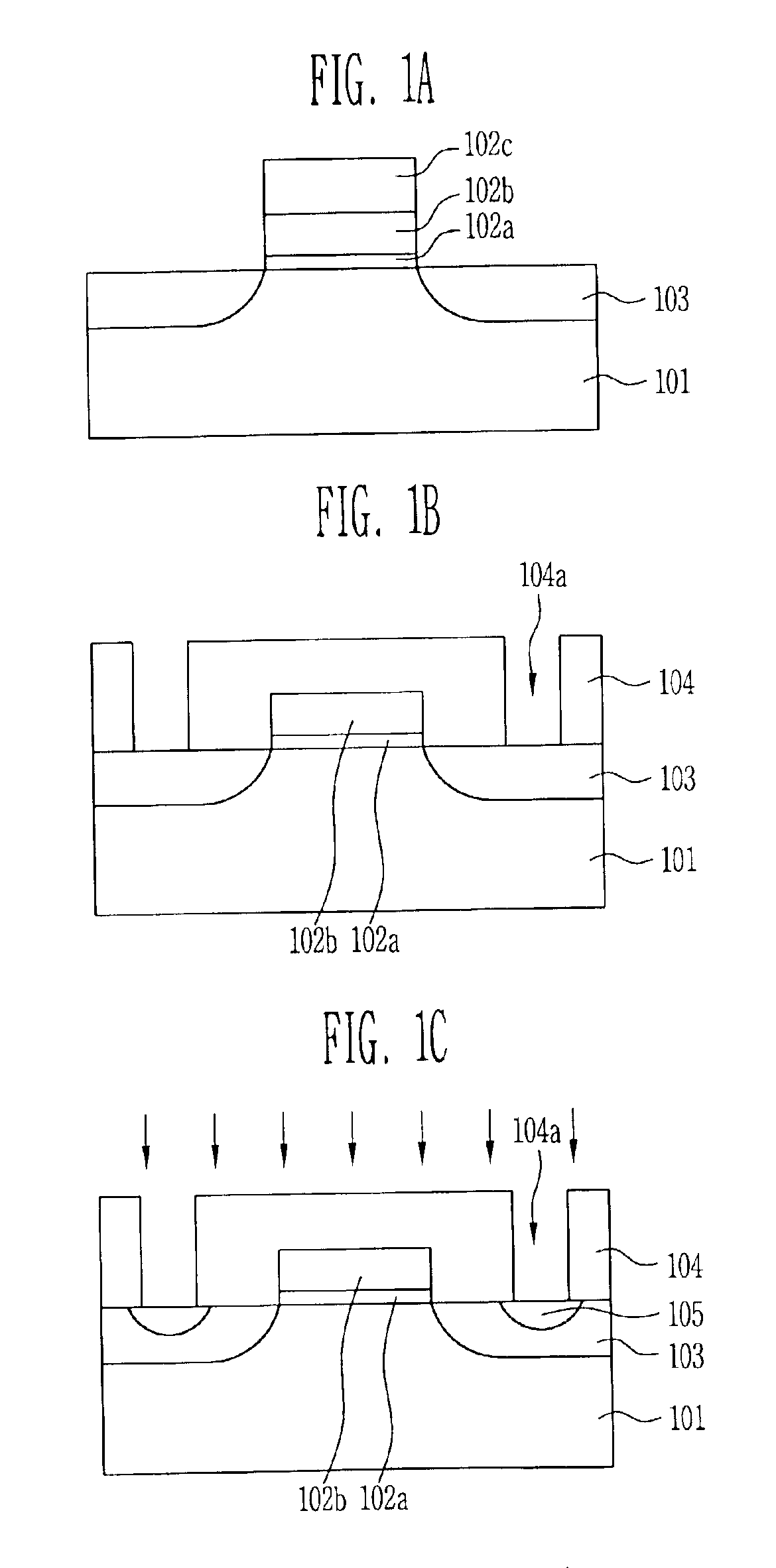

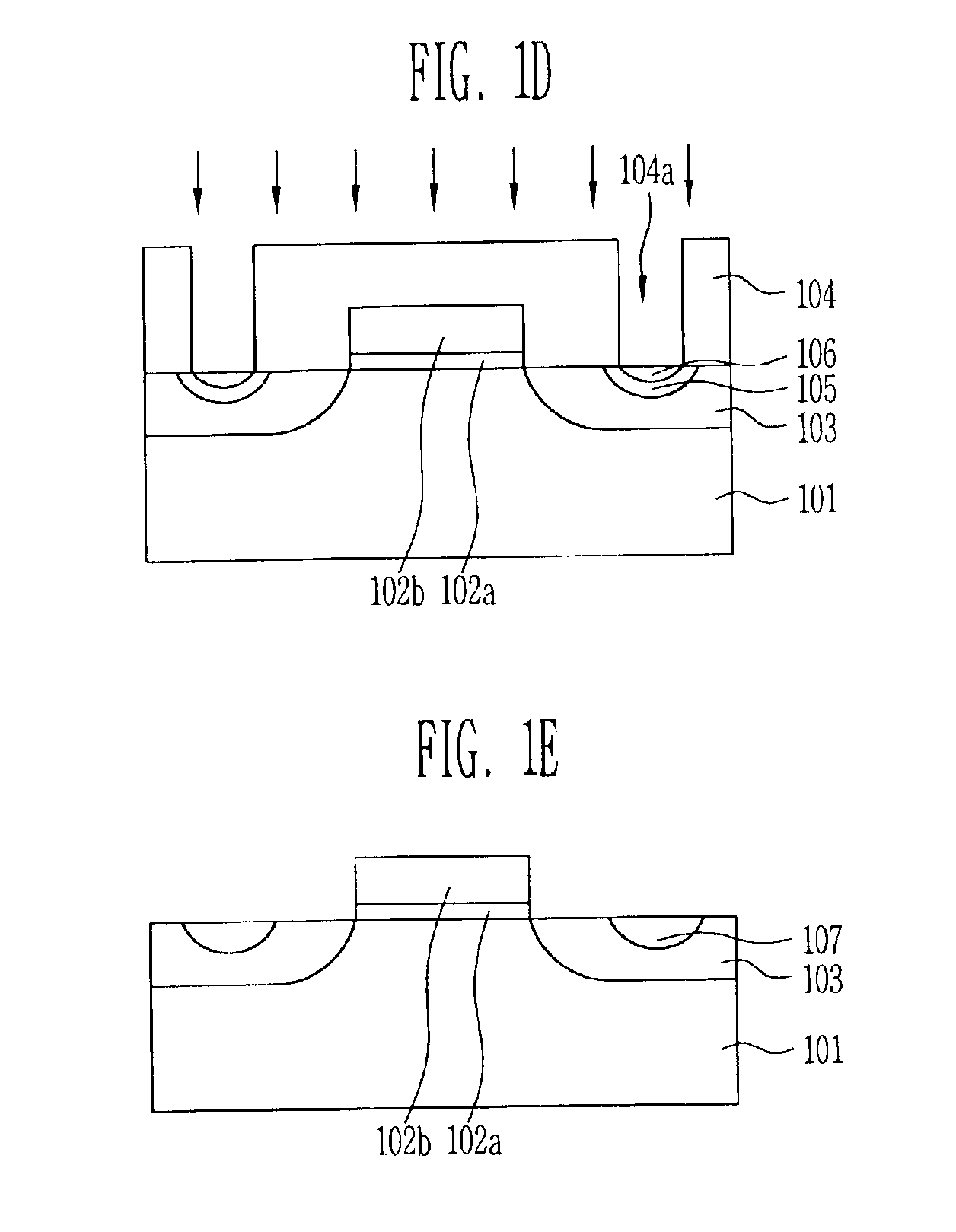

Method of forming high voltage junction in semiconductor device

InactiveUS6878596B2Reduce sheet resistanceRemove crystal defectSemiconductor/solid-state device manufacturingSemiconductor devicesSheet resistanceEngineering

The present invention relates to a method of forming a high voltage junction in a semiconductor device. The method includes forming a double diffused drain junction, and making amorphous the double diffused drain junction to a first depth by implanting an impurity having a high atomic weight than an impurity injected into the double diffused drain junction, implanting an impurity so that the concentration of the concentration of an impurity to a second depth lower than the first depth and then activating the impurities. Thus, the present invention can reduce the sheet resistance by prohibiting diffusion of an impurity, prohibit a channeling phenomenon by lowering the depth of the junction, and remove crystal defects by sufficiently activating an impurity and since a subsequent annealing process for activation can be performed at a high temperature, and thus improve reliability of a process and an electrical characteristic of the device.

Owner:SK HYNIX INC

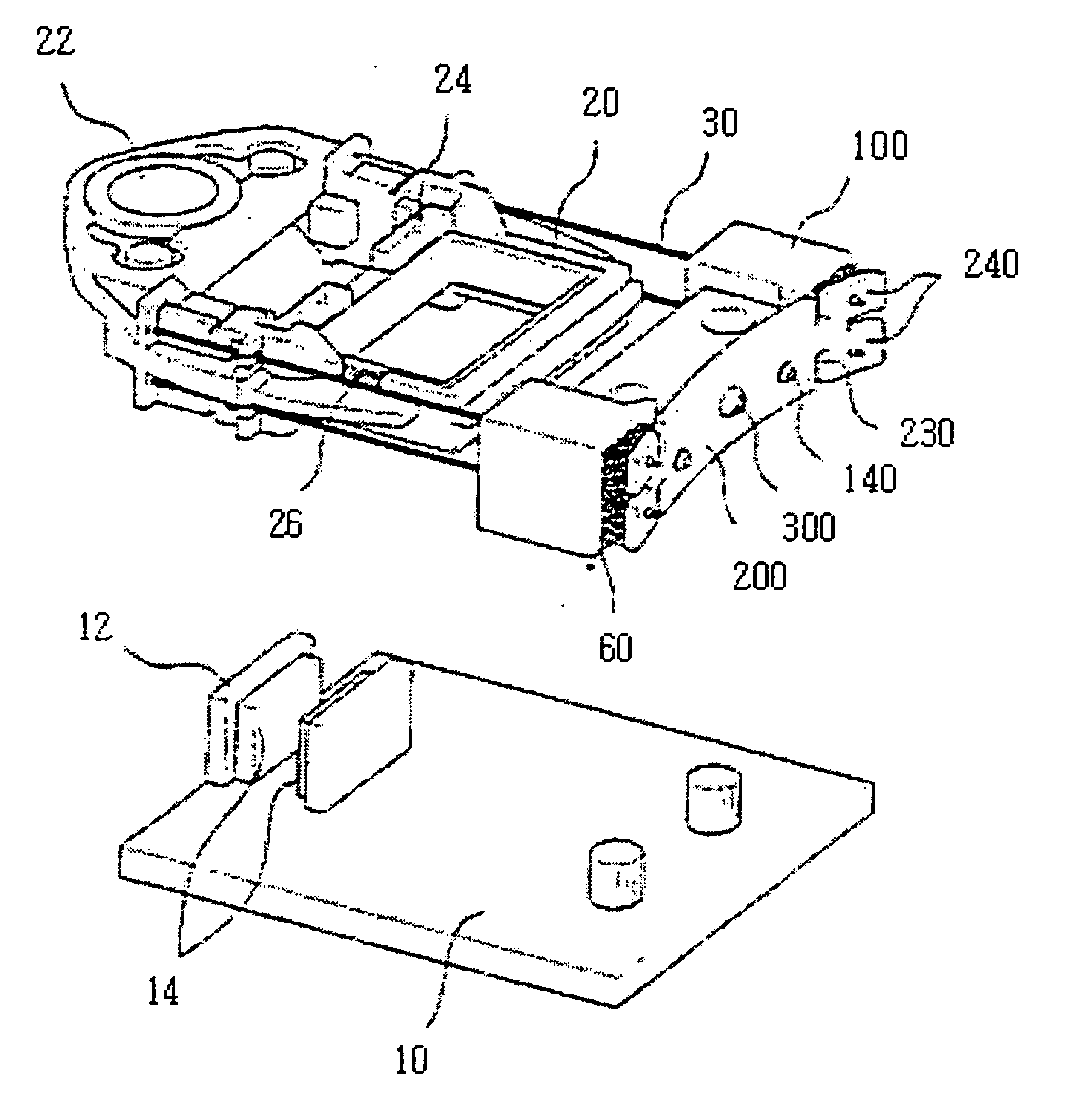

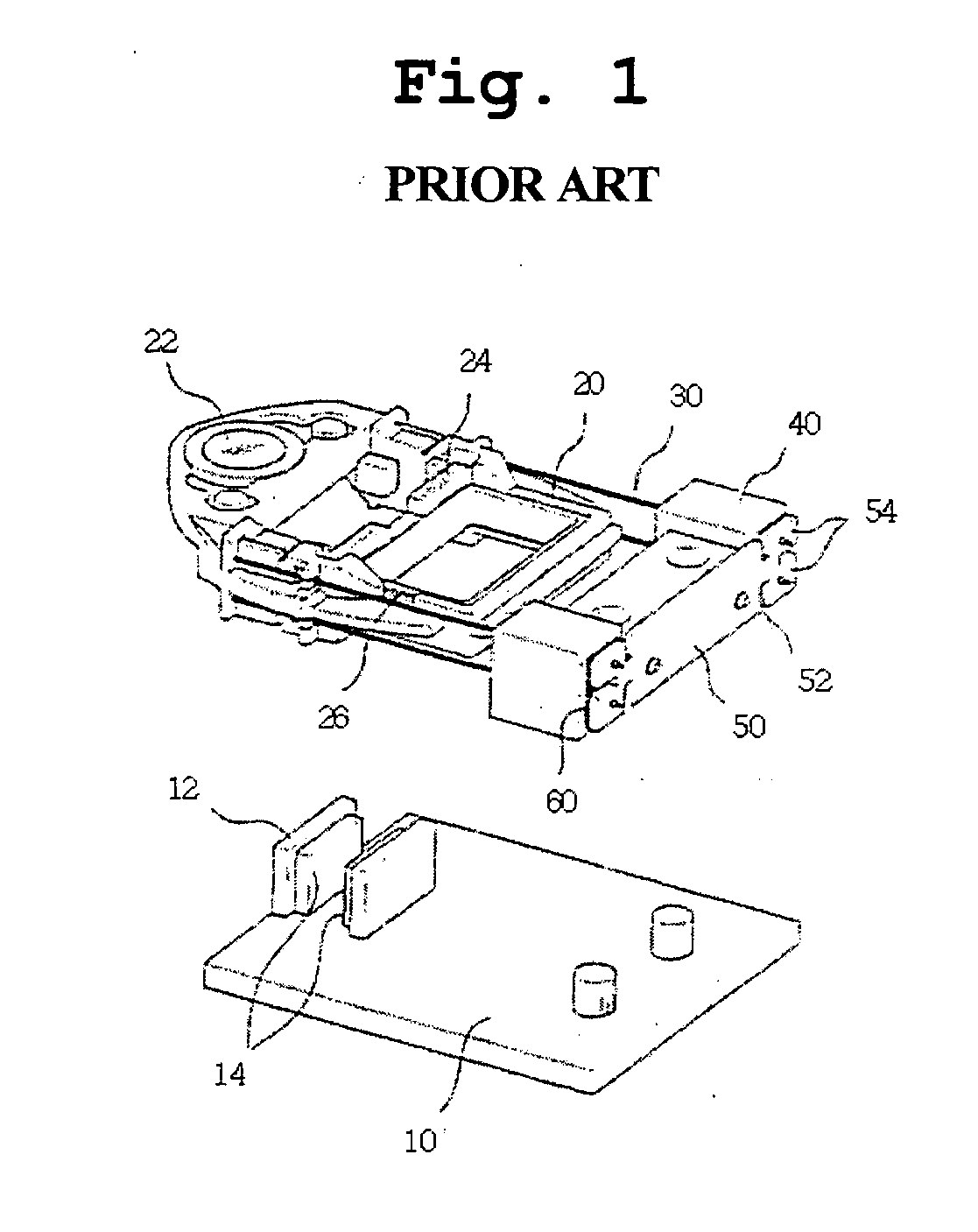

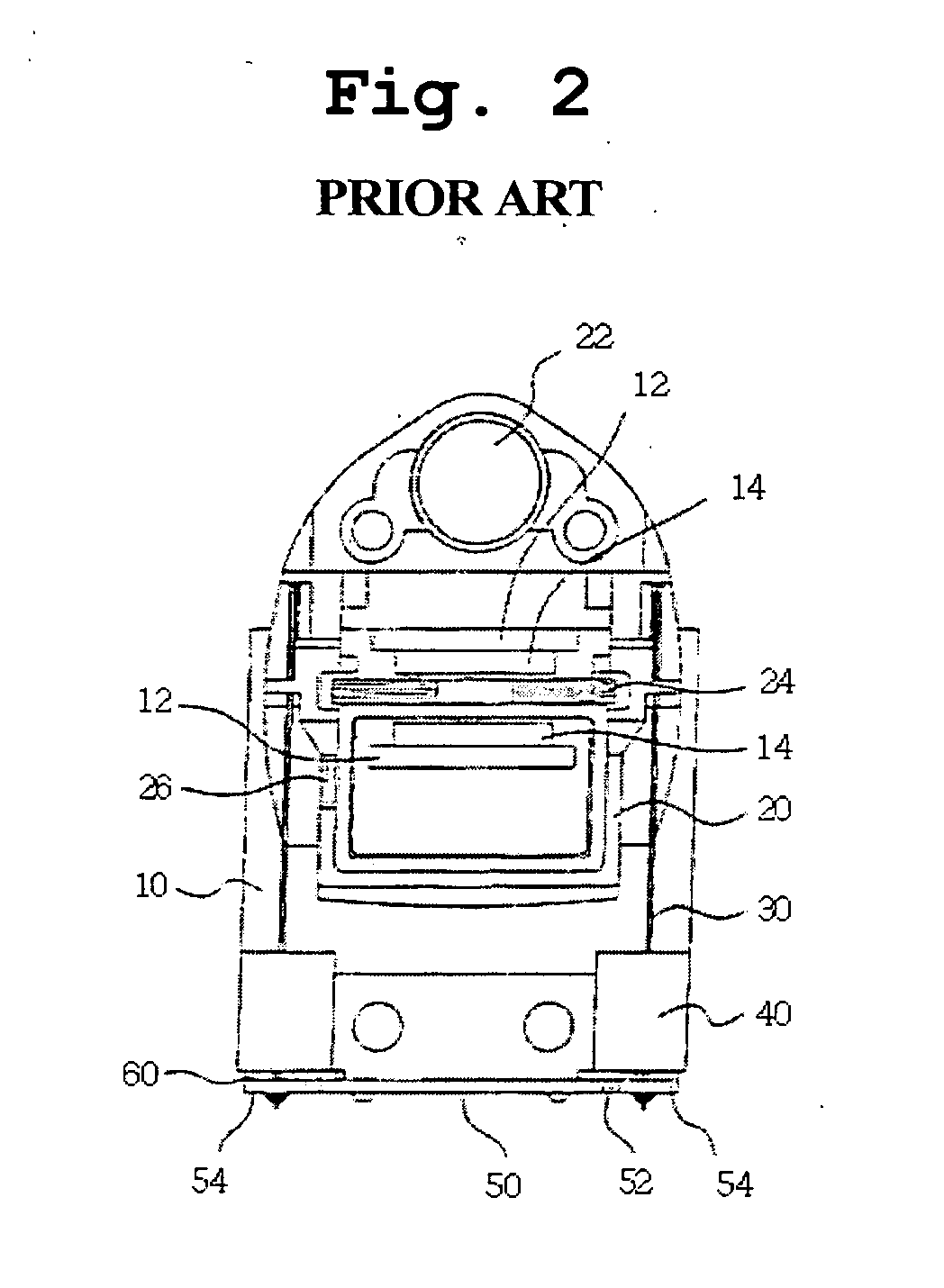

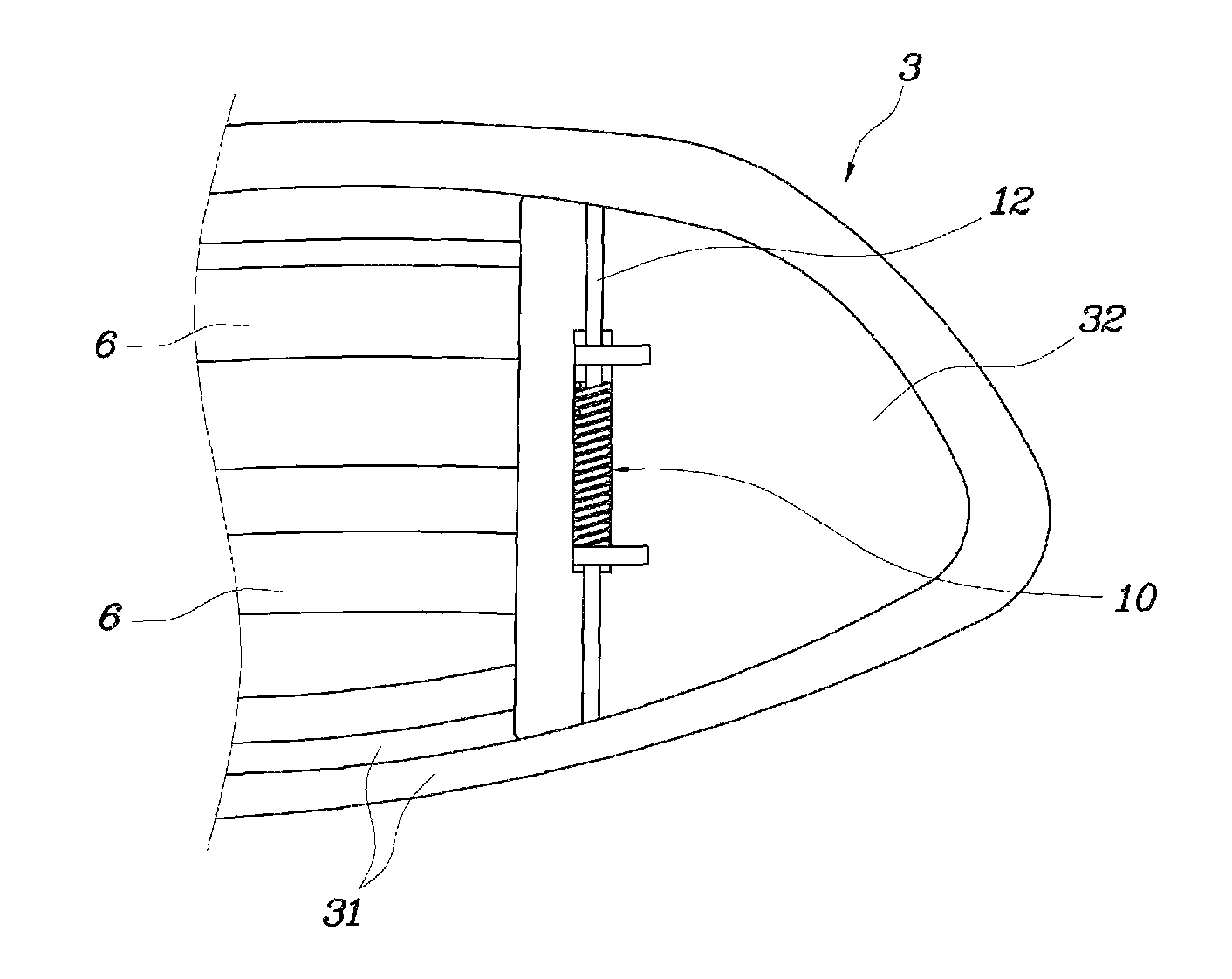

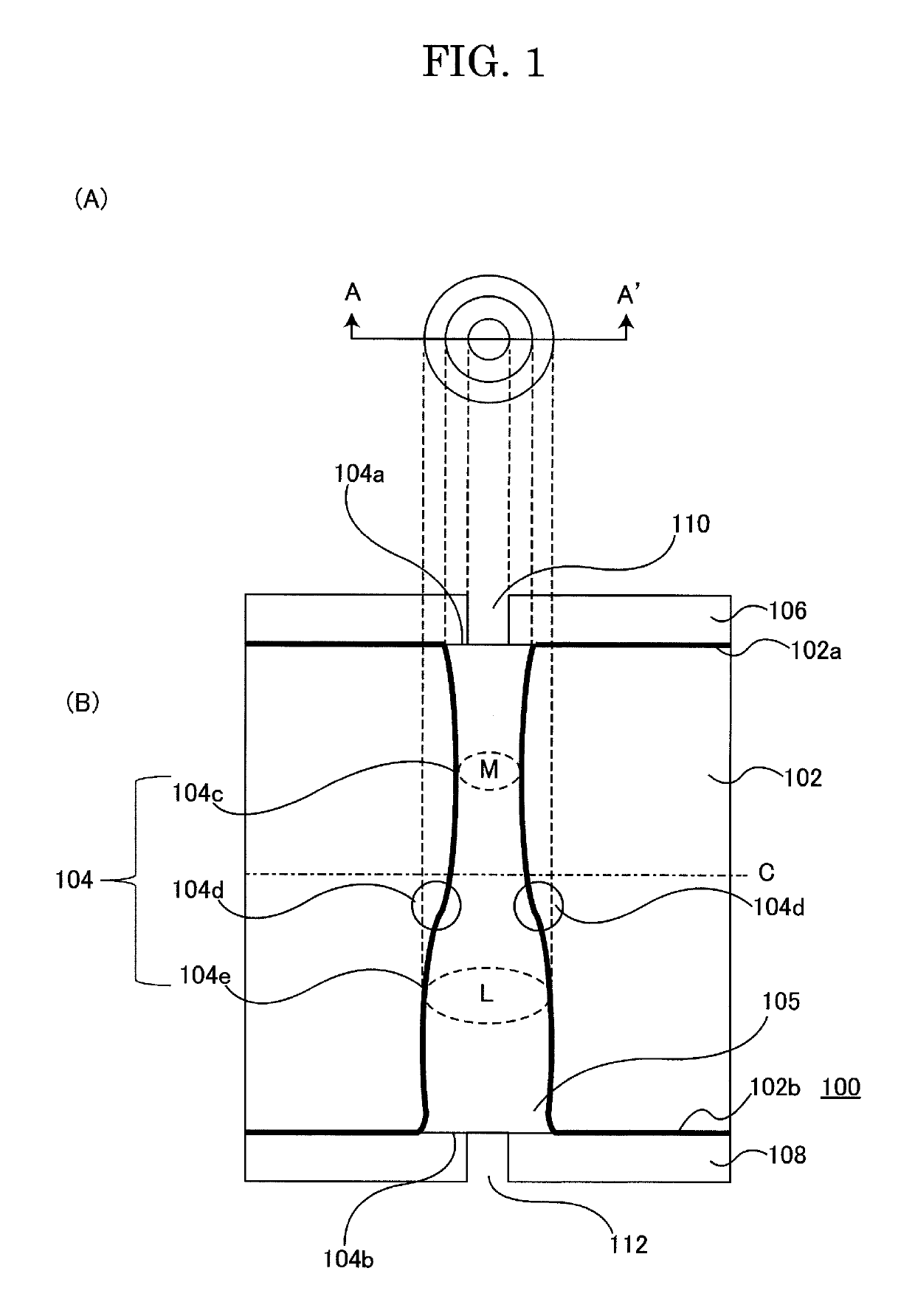

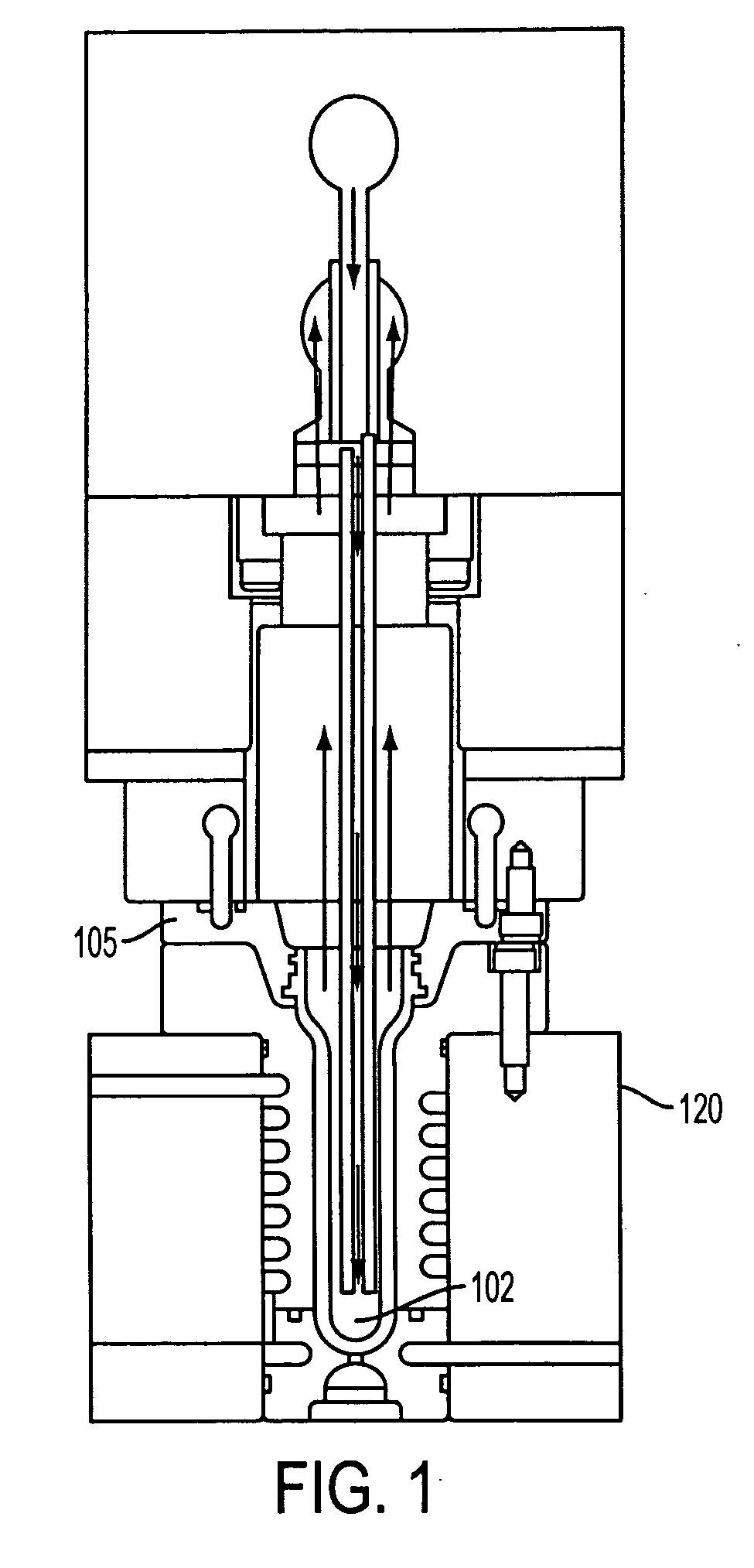

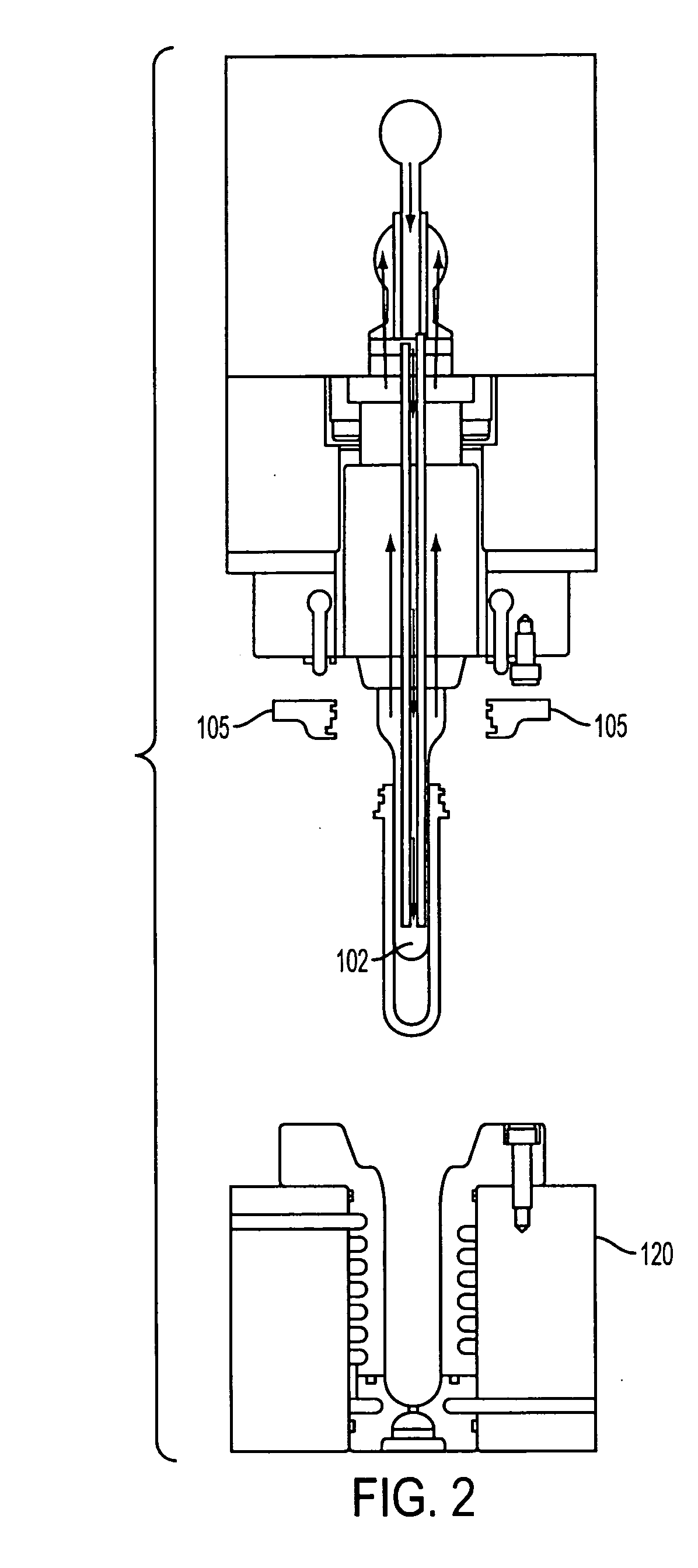

Optical pickup actuator

InactiveUS20050128894A1Avoid vibrationKeep gapPrinted circuit assemblingPrinted circuit aspectsOptical pickupBobbin

The present invention relates, in general, to an optical pickup actuator and, more particularly, to an optical pickup actuator, in which a depression (120) is formed in a center portion of a rear surface of a wire holder (100) to be depressed, and the position of a bobbin (20) is adjusted by straining wires (30) while a center portion of a printed circuit board (200), closely attached to the rear surface of the wire holder, is pressurized using a control screw (300) to allow the printed circuit board to be arcuately deformed.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

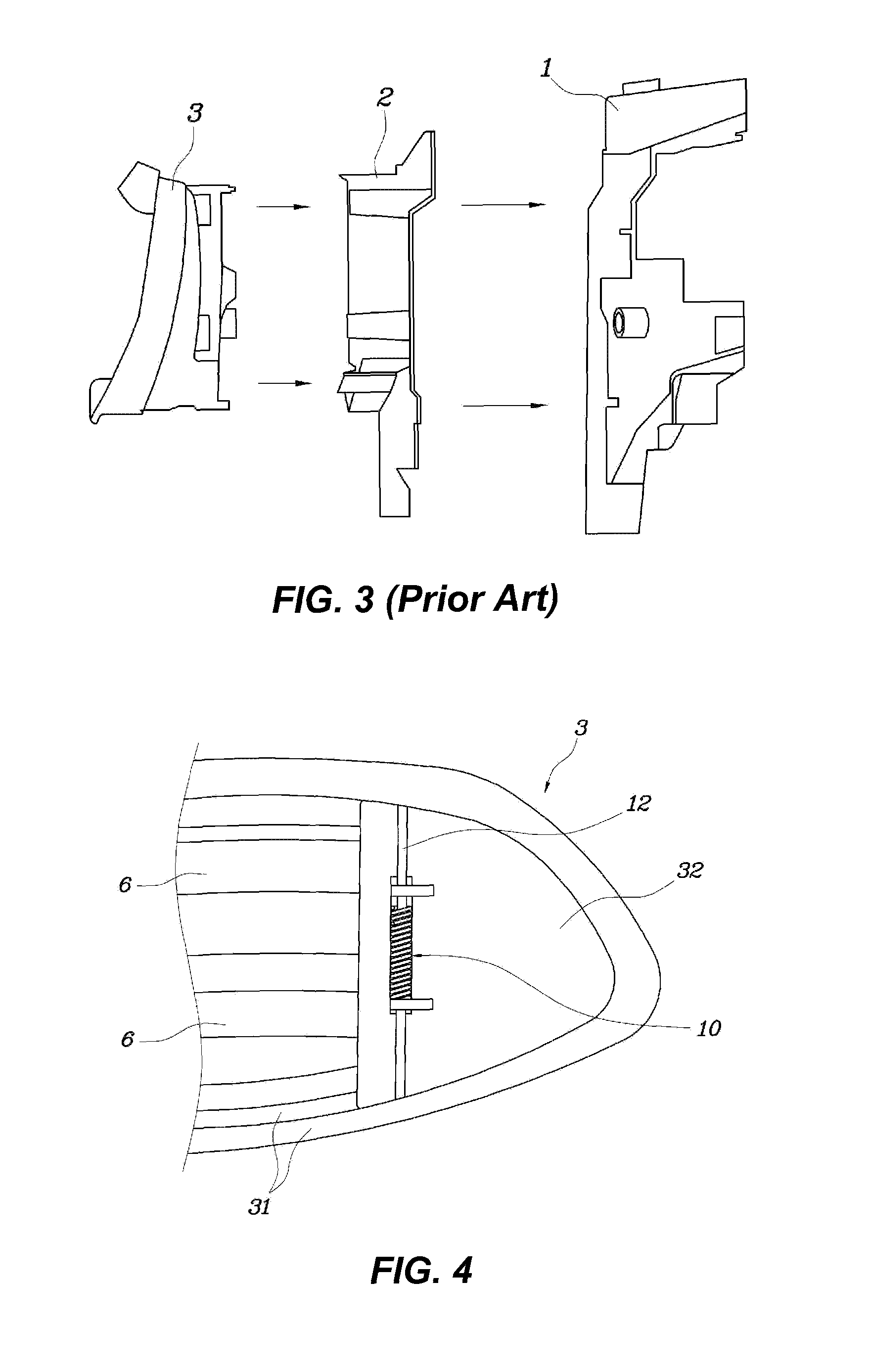

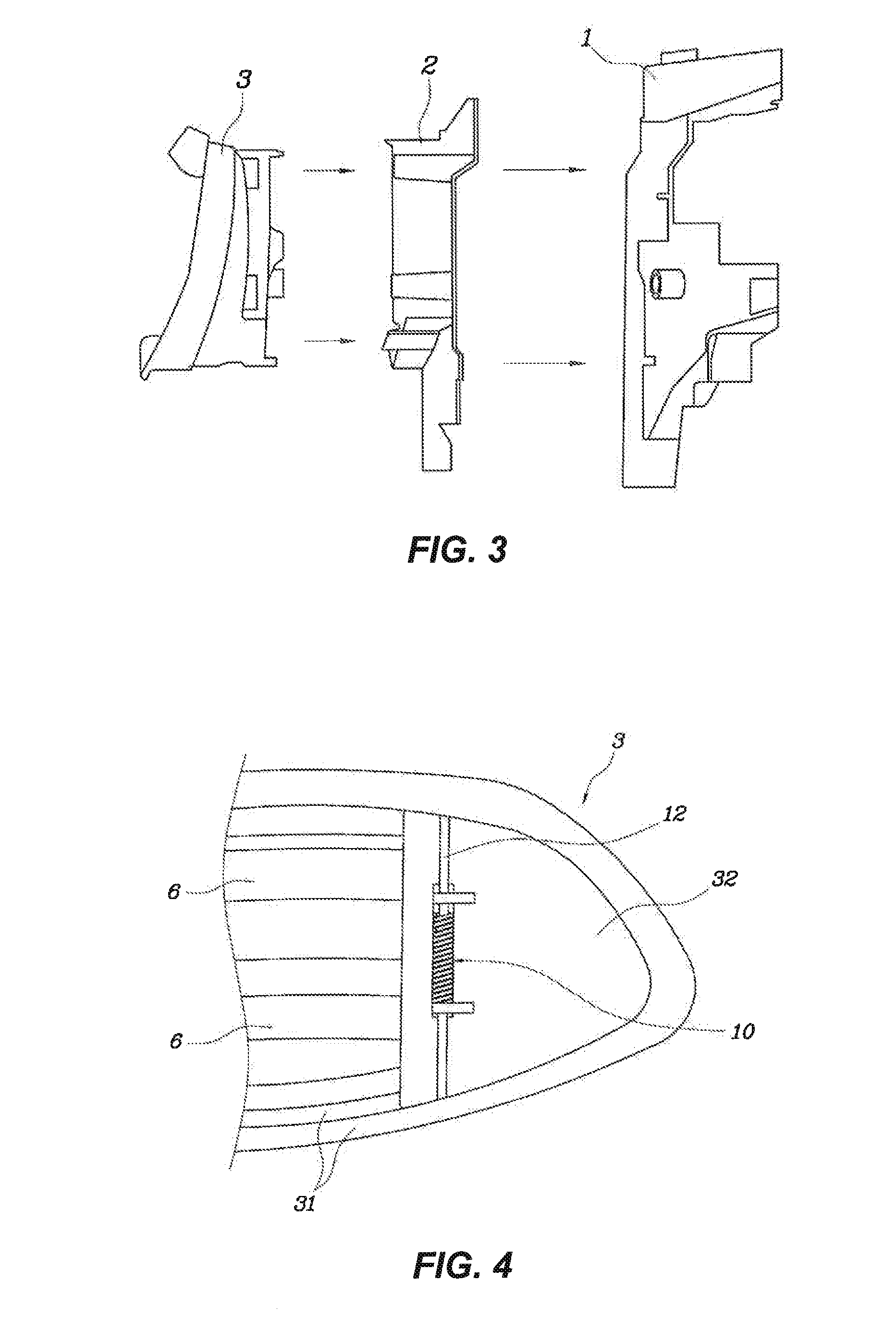

Active air flap apparatus for vehicle

ActiveUS8887846B2Remove defectMinimize injurySuperstructure subunitsComponent optimizationPedestrianImpact energy

Owner:HYUNDAI MOTOR CO LTD

Method for removing bubbles from molten glass and process for producing glass

InactiveUS8109118B2Quality improvementImprove productivityGlass furnace apparatusElectric furnaceProduction rateLaser beams

It is an object of the present invention to provide a method and apparatus for efficiently remove bubbles present on a surface of molten glass, which can solve a problem that bubbles remaining on a surface of molten glass are get inside at a time of forming the glass to cause inside bubbles, to thereby provide a glass substrate of good quality, and which can improve productivity of glass substrates; and to provide a process for producing glass employing the above method for removing bubbles. The present invention provides a method for removing bubbles from molten glass, which is a method for removing floating bubbles on a surface of molten glass, wherein a floating bubble on the surface of molten glass is irradiated with at least one laser beam.

Owner:ASAHI GLASS CO LTD

Optical modulation device and driving method thereof

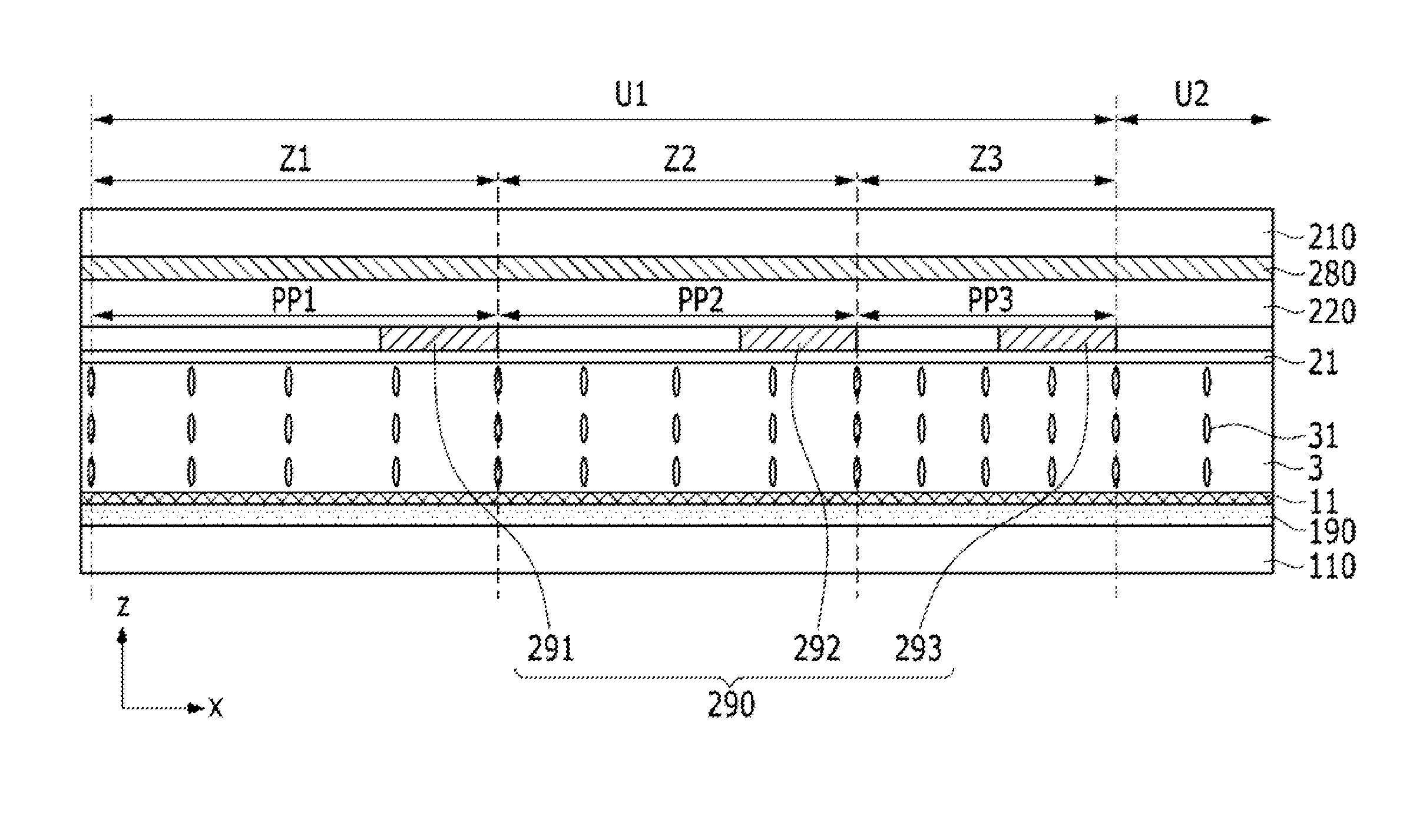

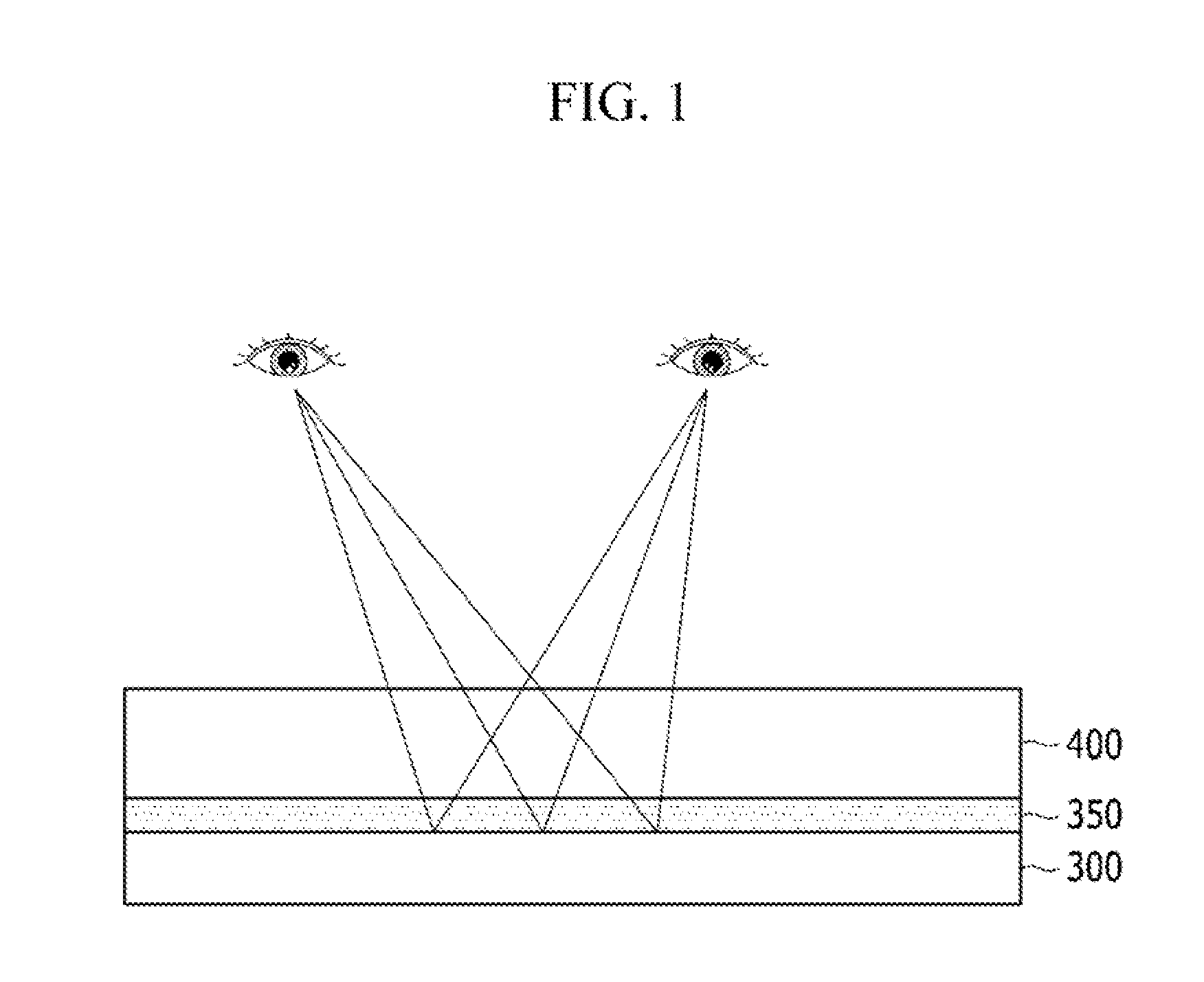

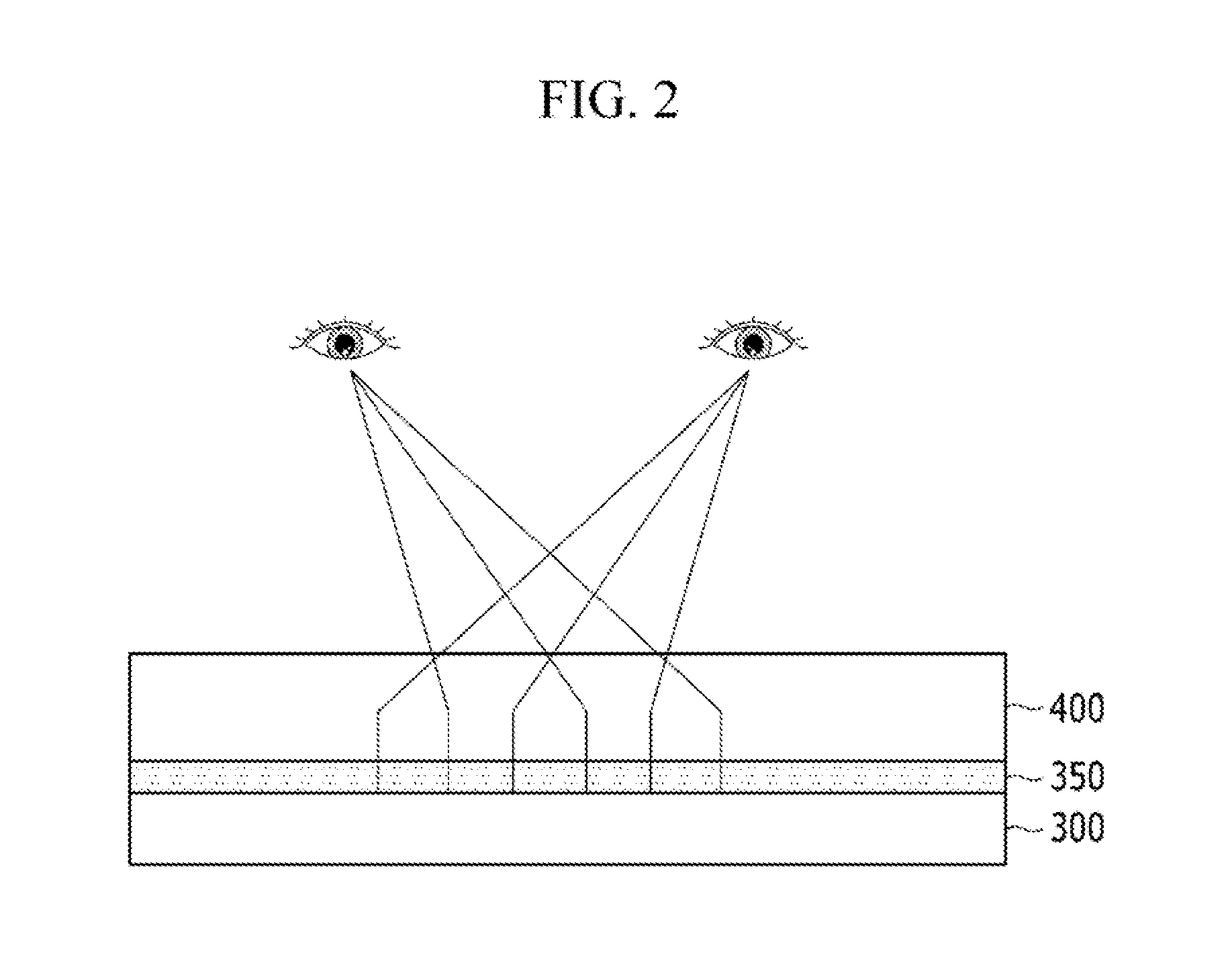

ActiveUS20160246083A1Simple processShorten production timeNon-linear opticsEngineeringLiquid crystal molecule

An optical modulation device includes: a first substrate and a second substrate that face each other; and a liquid crystal layer provided between the first substrate and the second substrate that includes a plurality of liquid crystal molecules. The first substrate includes a plurality of unit regions, a common electrode and a first aligner, and the second substrate includes a plurality of unit regions, a plurality of upper-plate electrodes that include a plurality of first electrodes extending in a first direction and a plurality of second electrodes extending in a second direction crossing the first direction, and a second aligner.

Owner:SAMSUNG DISPLAY CO LTD

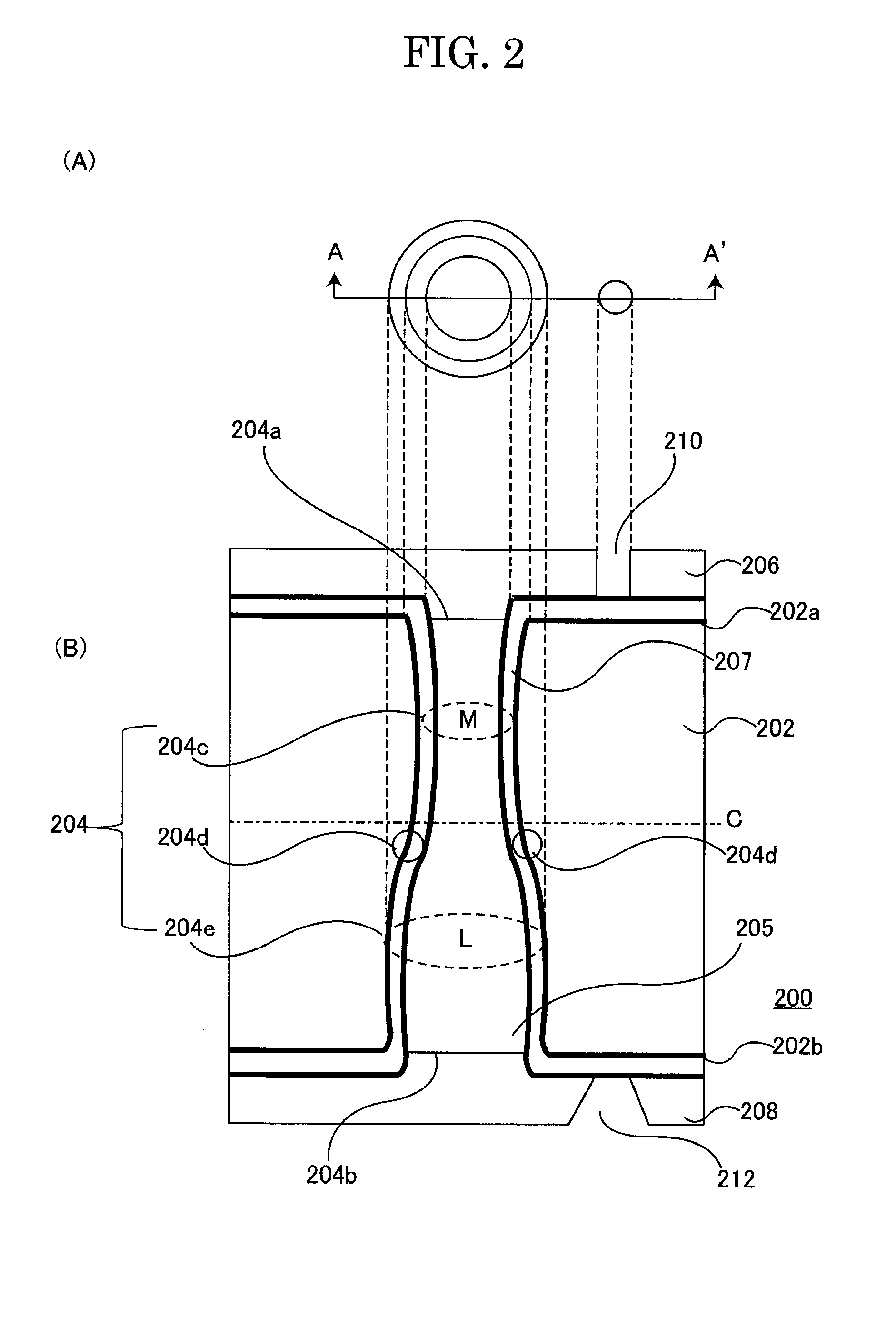

Through-hole electrode substrate and semiconductor device using through-hole electrode substrate

ActiveUS10256176B2Remove defectImprove reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductorSemiconductor device

A through-hole electrode substrate includes a substrate including a through-hole extending from a first aperture of a first surface to a second aperture of a second surface, an area of the second aperture 5 being larger than that of the first aperture, the through-hole having a minimum aperture part between the first aperture and the second aperture, wherein an area of the minimum aperture part in a planar view is smallest among a plurality of areas of the through-hole in a planar view, a filler arranged within the 10 through-hole, and at least one gas discharge member contacting the filler exposed to one of the first surface and the second surface.

Owner:DAI NIPPON PRINTING CO LTD

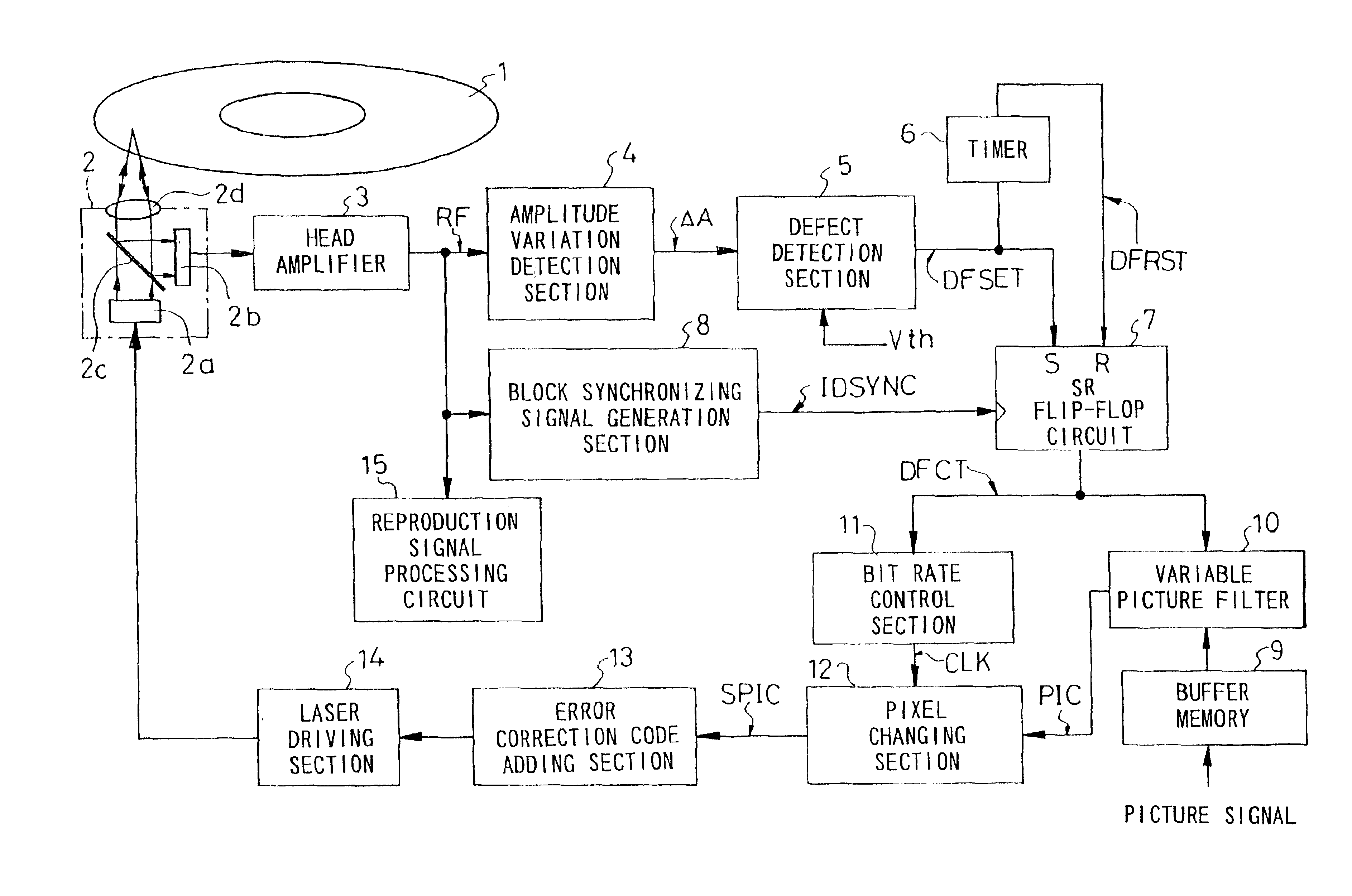

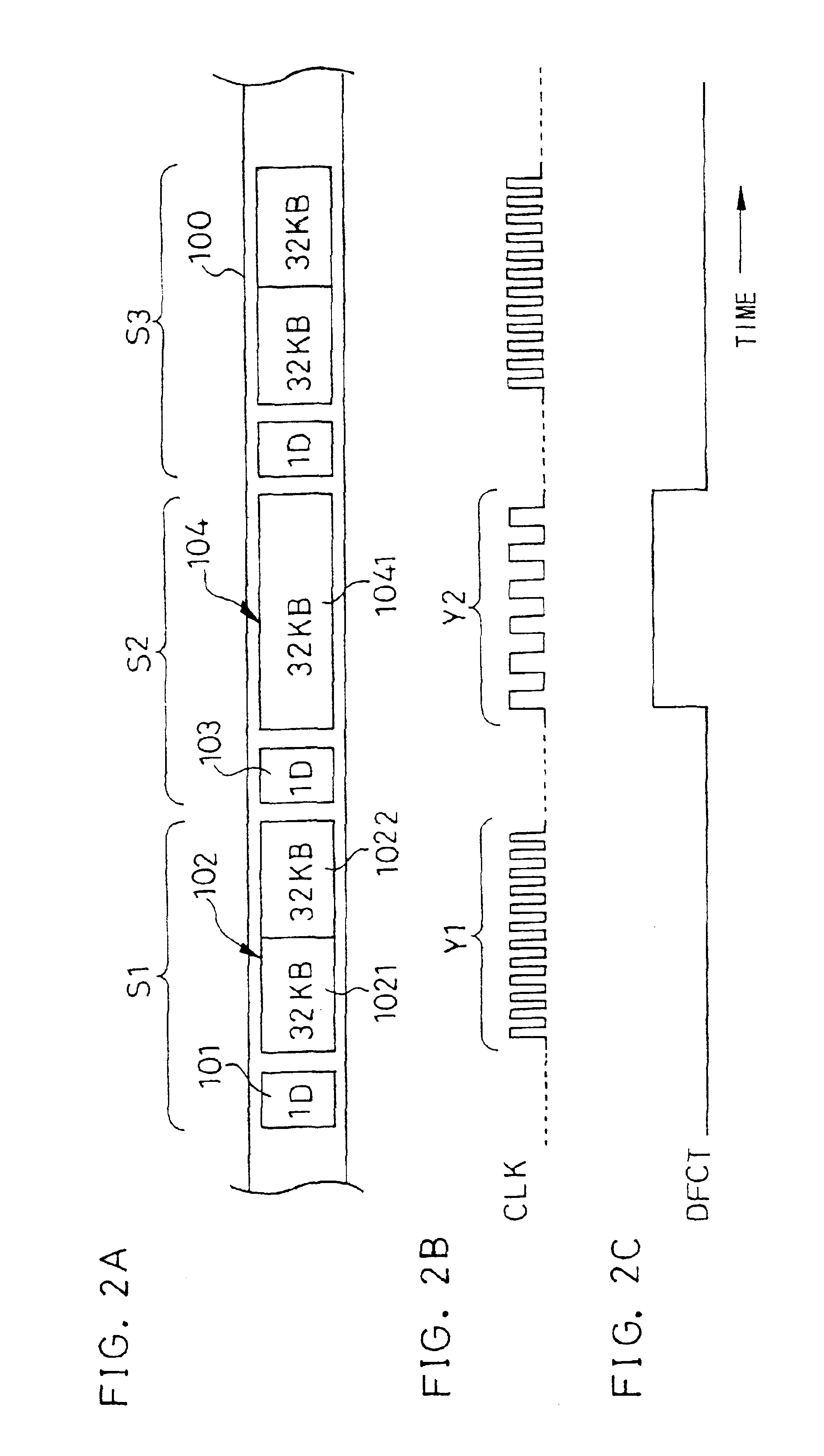

Method for information recording and apparatus therefor

InactiveUS7020385B2Remove defectReduce decreaseCombination recordingTelevision system detailsDigital videoRecording density

In areas on an optical disk wherein defects are detected frequently, recording is carried out while the recording density of information blocks is lowered and the amount of picture information is reduced at the same time so that digital video signals can be recorded even when defects owing to dust and flaws are present on the optical disk and so that picture losses can be prevented from occurring during reproduction.

Owner:PANASONIC CORP

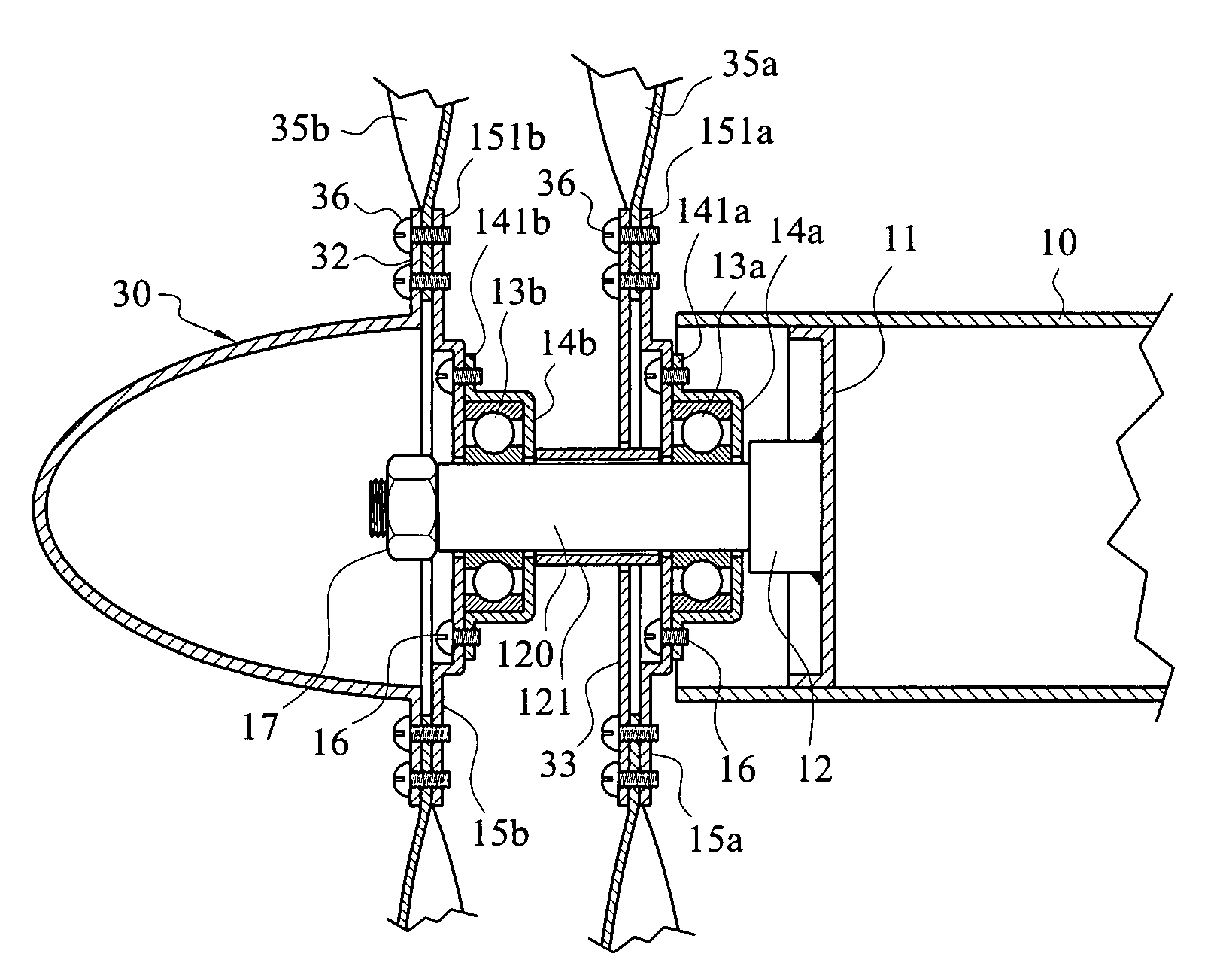

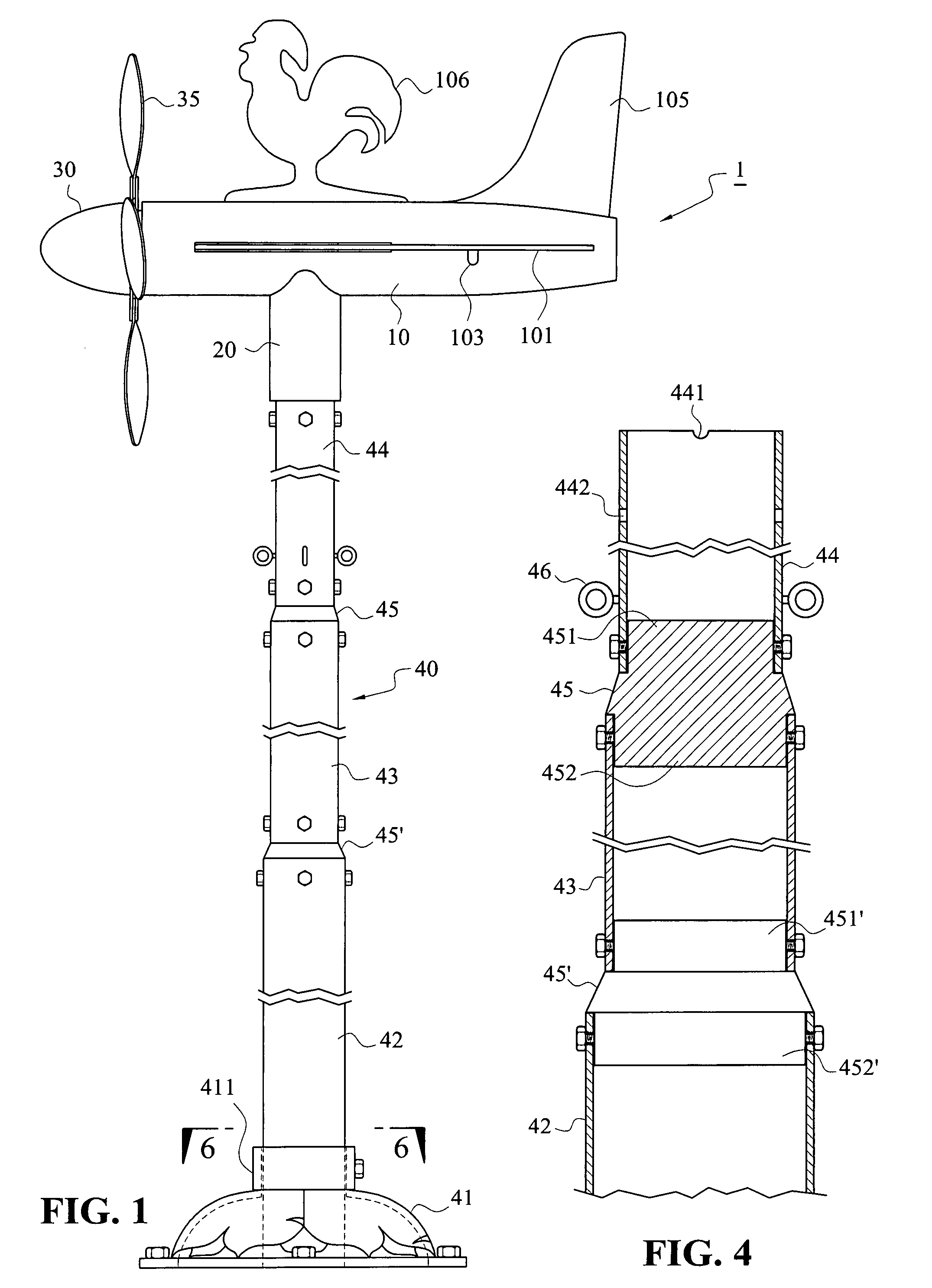

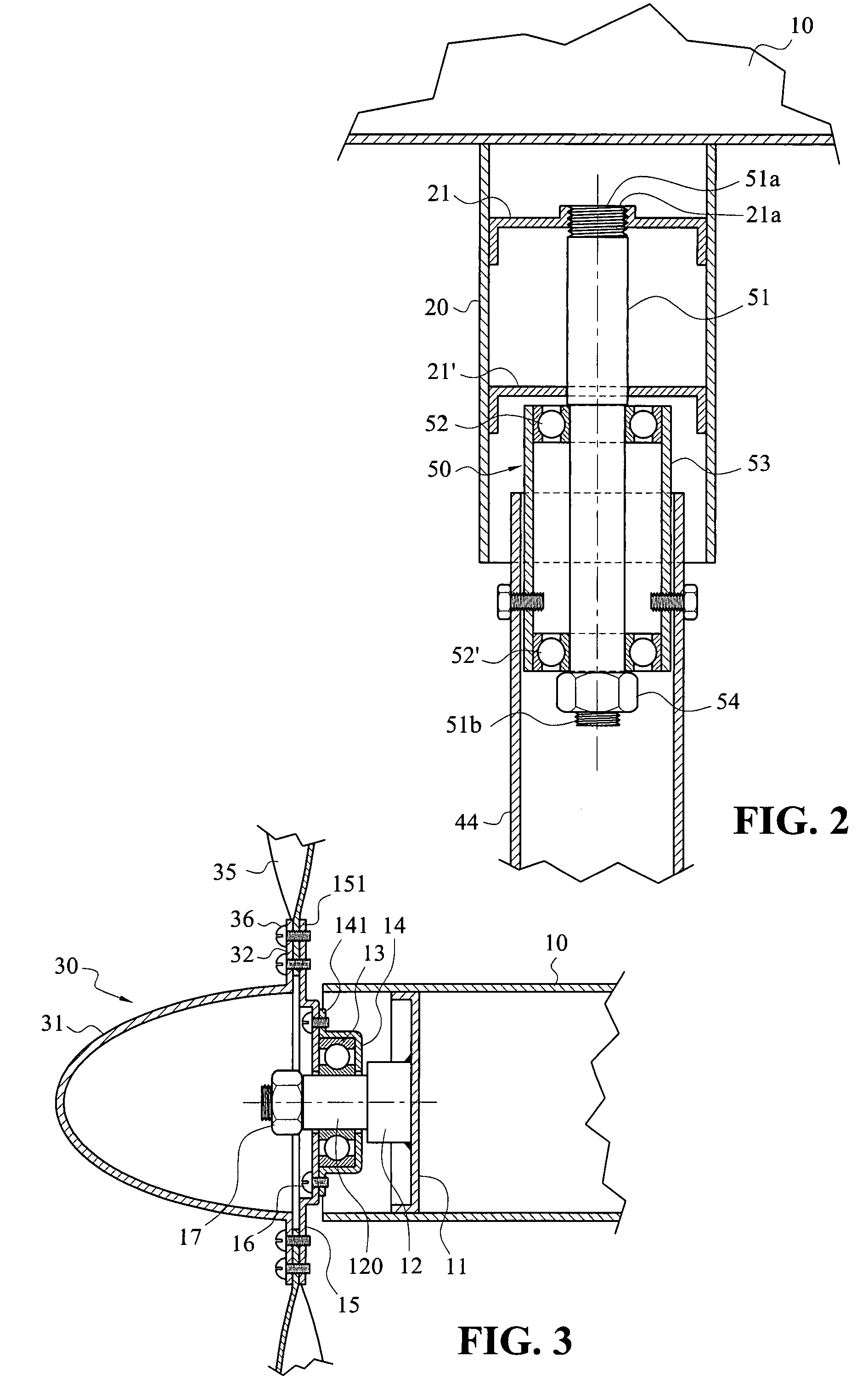

Wind vane device

InactiveUS7437924B2Easy to assemble/disassembleRemove defectIndication/recording movementFluid speed measurementPropellerEngineering

Owner:CHEN FU LIANG

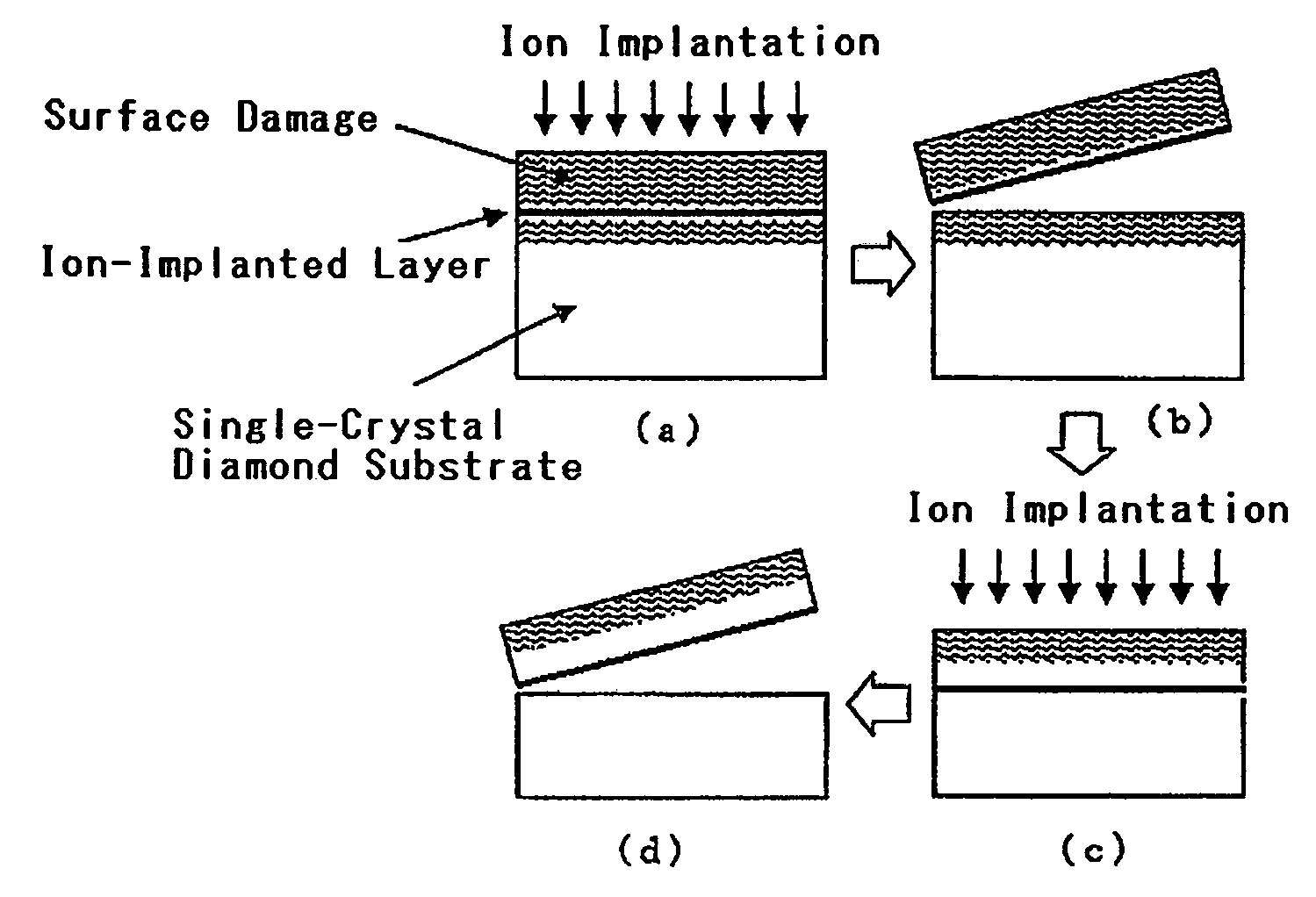

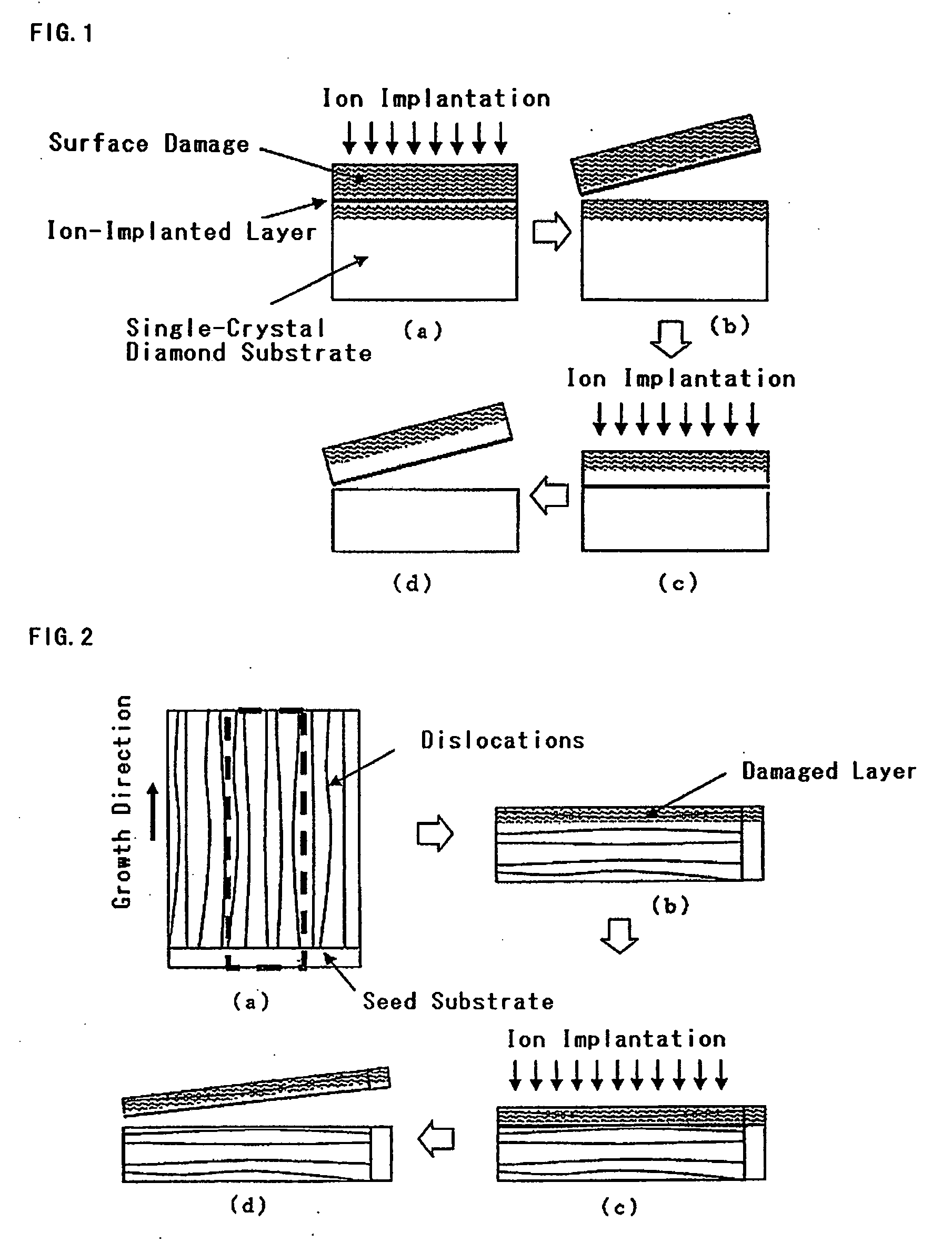

Removal method of surface damage of single crystal diamond

InactiveUS20100000967A1Reduce defectsHigh crystallinityDecorative surface effectsSemiconductor/solid-state device manufacturingCrystallographySurface layer

The present invention provides a process for removing surface damage of a single-crystal diamond, which comprises implanting ions into a single-crystal diamond to form a non-diamond layer near a surface of the diamond, graphitizing the non-diamond layer, and removing a surface layer by etching. According to the invention, the surface damage can be removed or reduced without increasing the surface roughness of a single crystal diamond.

Owner:NAT INST OF ADVANCED IND SCI & TECH

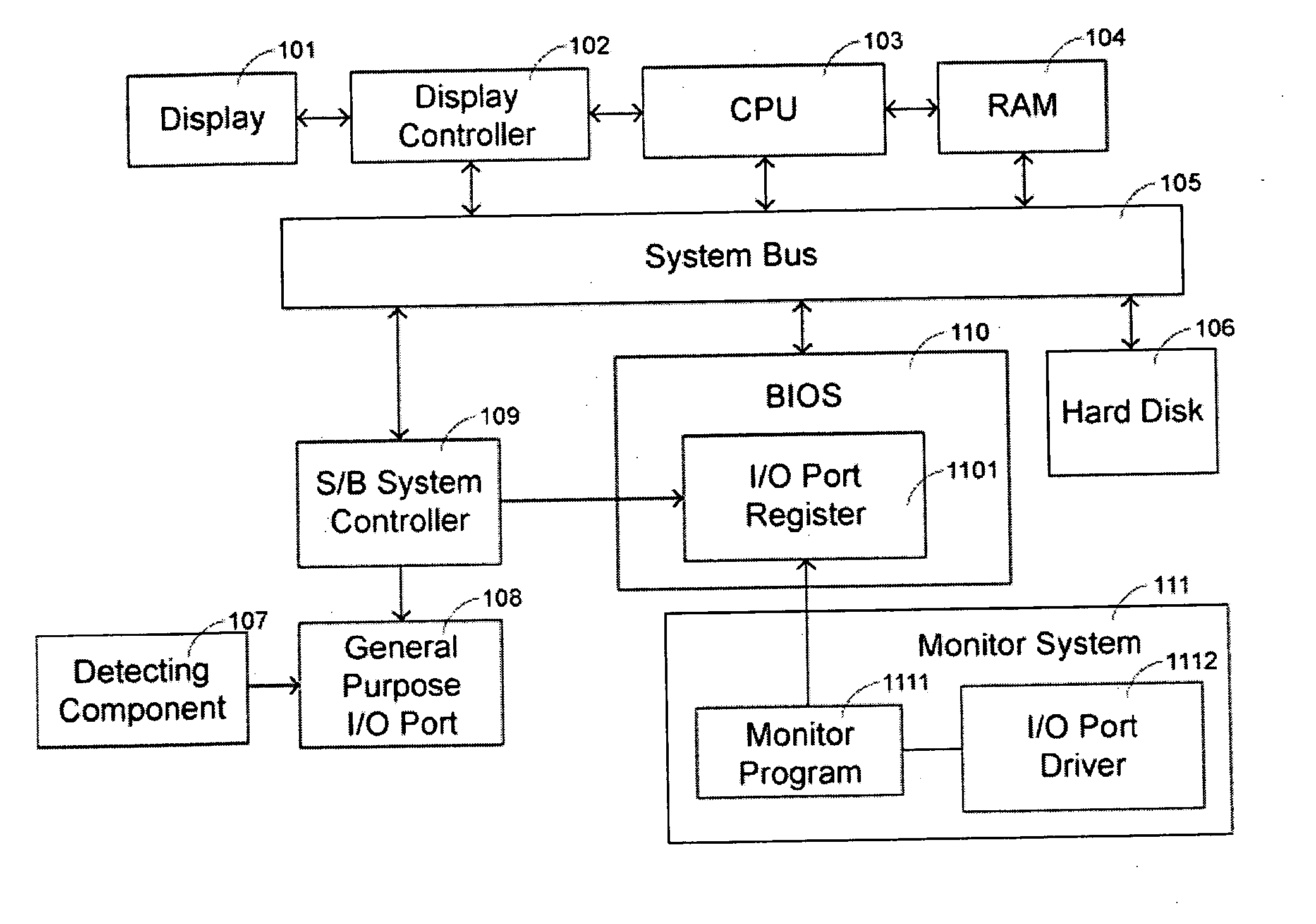

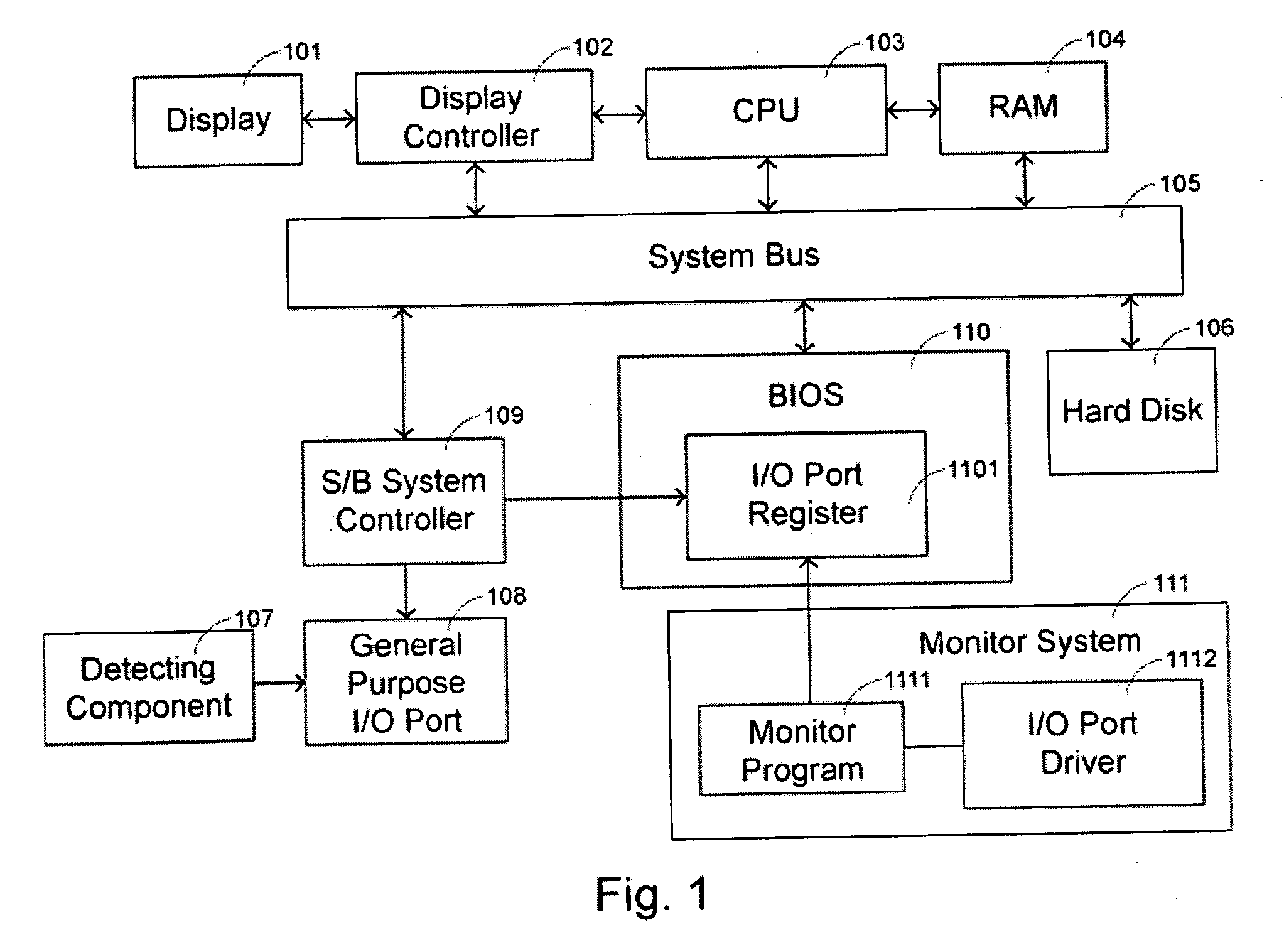

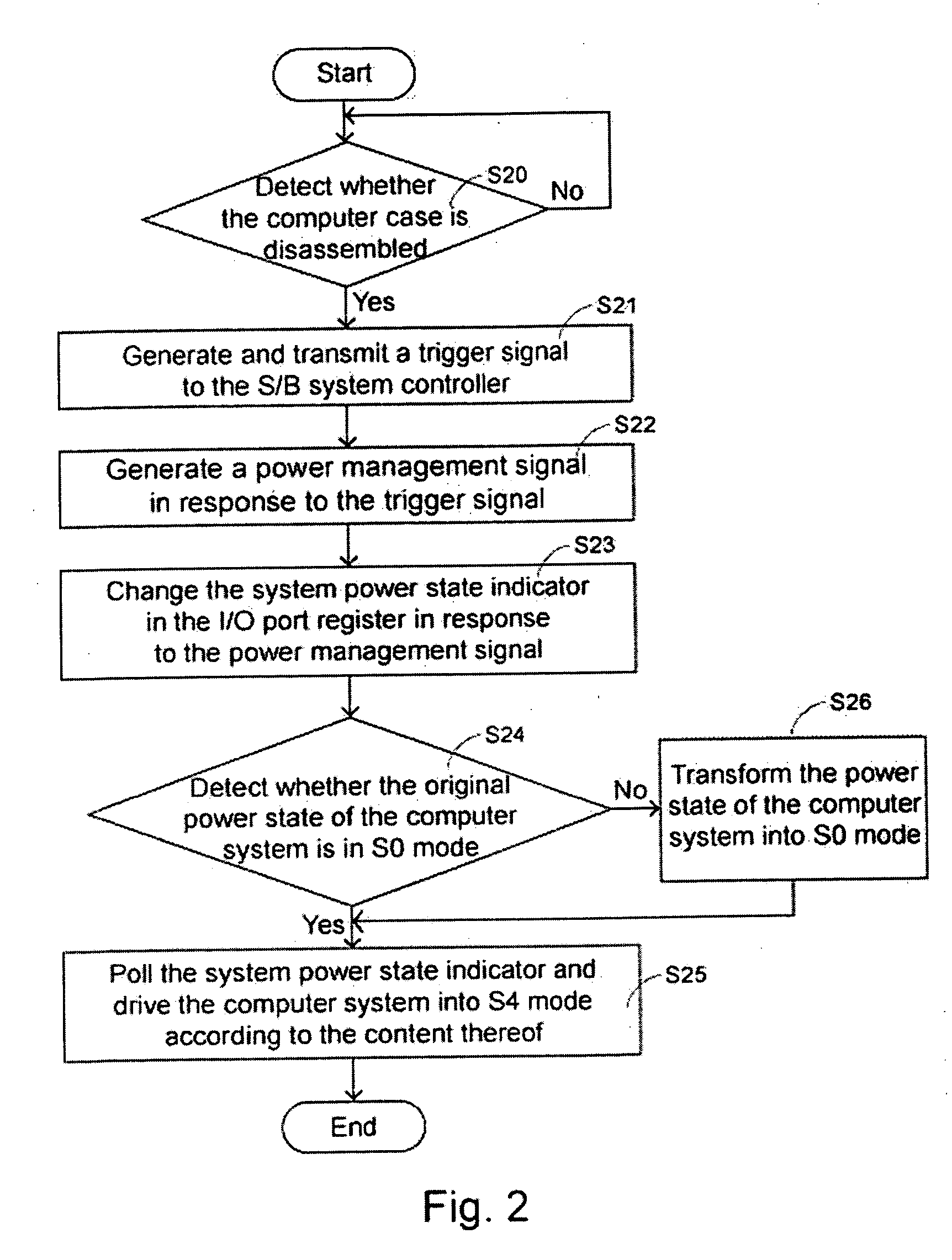

Method and apparatus for monitoring the power state of computer system

ActiveUS20050268184A1Remove defectReduce defectsElectronic circuit testingVolume/mass flow measurementComputer casePower management

A monitoring method and apparatus applied to a computer system having a computer case, a controller and a register for changing the power state of the computer system according to the assembling state of the computer case is disclosed. The method comprises steps of detecting whether the computer case of the computer system is disassembled, generating a trigger signal to the controller when the computer case of the computer system is disassembled, generating a power management signal in response to the trigger signal for changing a system power state indicator of the register, and polling the system power state indicator and driving the computer system into a hibernation mode according to the change of the system power state indicator.

Owner:ACER INC

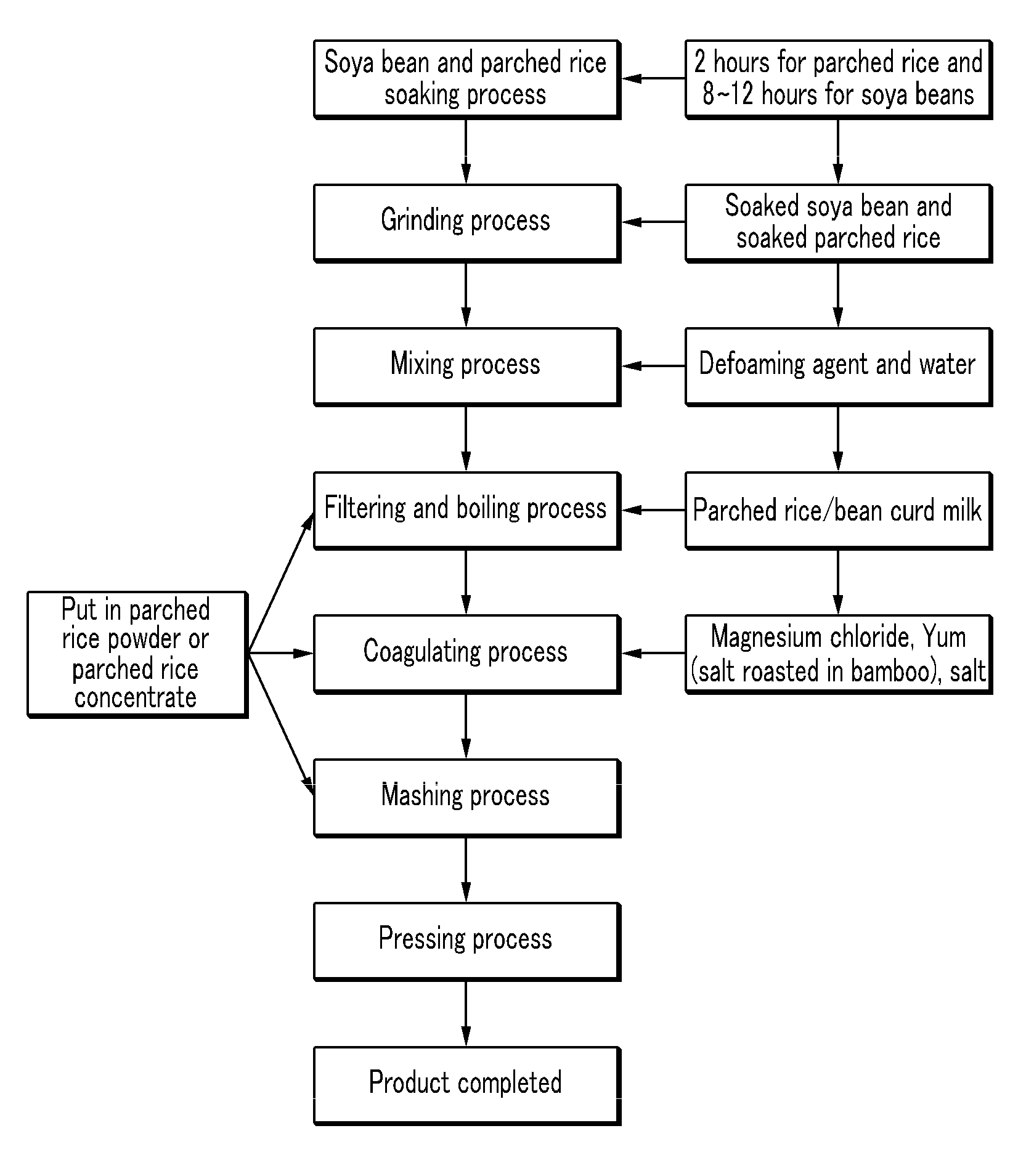

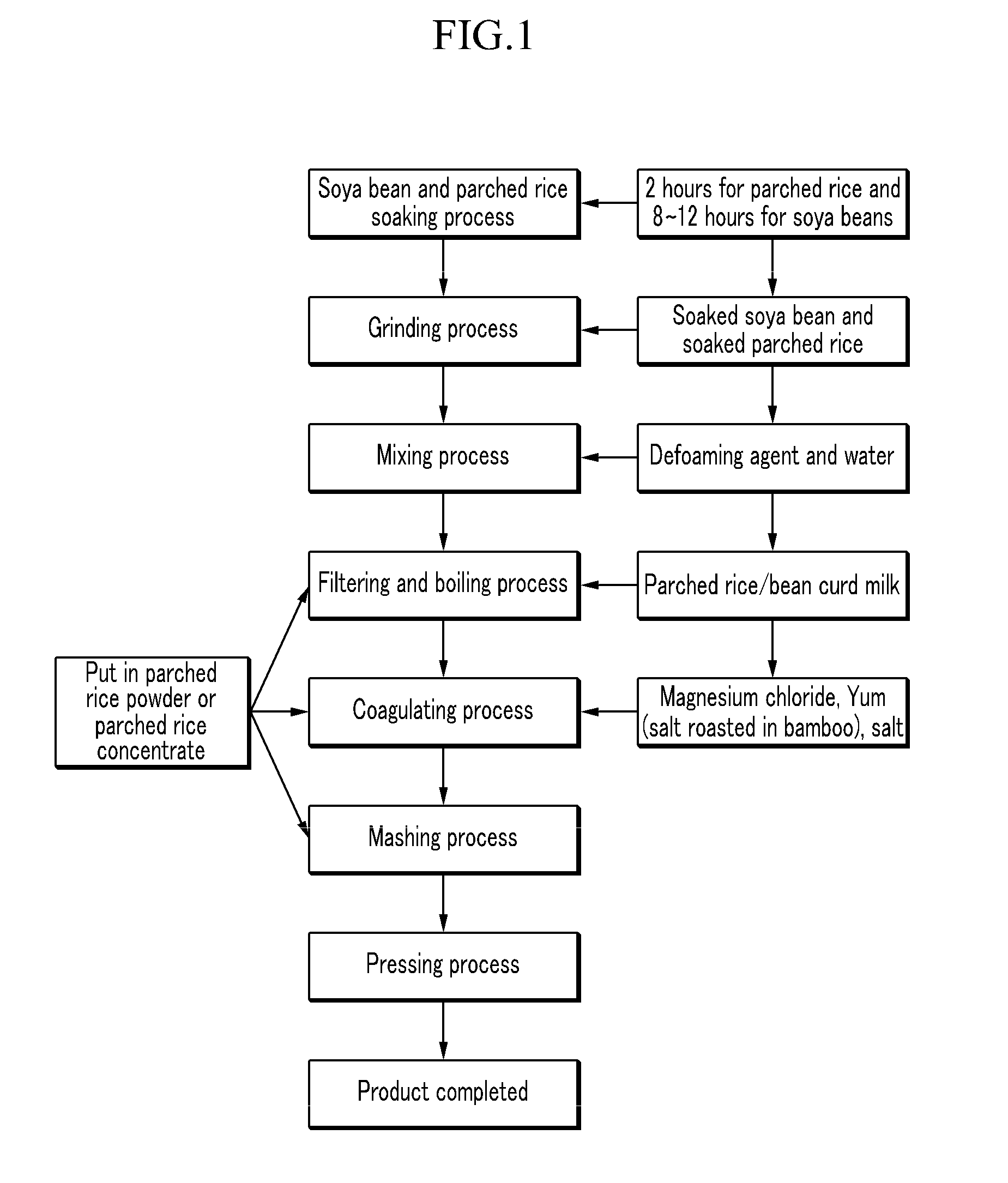

Manufacturing process of a bean curd for using a rice

InactiveUS20100316779A1Increase consumptionGood for healthMilk preservationFood thermal treatmentRice dishesDefoaming Agents

The present invention relates to a method of making bean curd using rice, in which 65-70 wt % of soya beans and 30-35 wt % of parched rice in about a total weight of 5 kg for one block of bean curd are soaked, and in which the soya beans are soaked for about 8-12 hours and the parched rice is soaked for about 2 hours in water.The soya beans and parched rice are mixed and the mixture is put into a mill to grind it into powder, and then 15 g of a defoaming agent that suppresses foaming and 60 g of water are added into the mixture of ground soya beans and parched rice and they are mixed evenly.Bean curd refuse is filtered by passing the mixture through a filter, and then the remaining parched rice / soya bean milk is boiled at 80-99° C.42 g of magnesium chloride, which is a coagulant, is added to the heated parched rice / bean curd milk, 14 g of salt or JukYum (salt roasted in bamboo) is added together with 45 g of water, and they are mixed and coagulated.The coagulated parched rice / bean curd milk is mashed to have a diameter of about 3-4 cm and then the mashed rice-bean curd is pressed, such that bean curd using rice is completed.Accordingly, consumers' health can be improved by the bean curd containing rice, and it is possible to satisfy various tastes of the consumers by providing high-quality bean curd.

Owner:OH KYUNG SIK

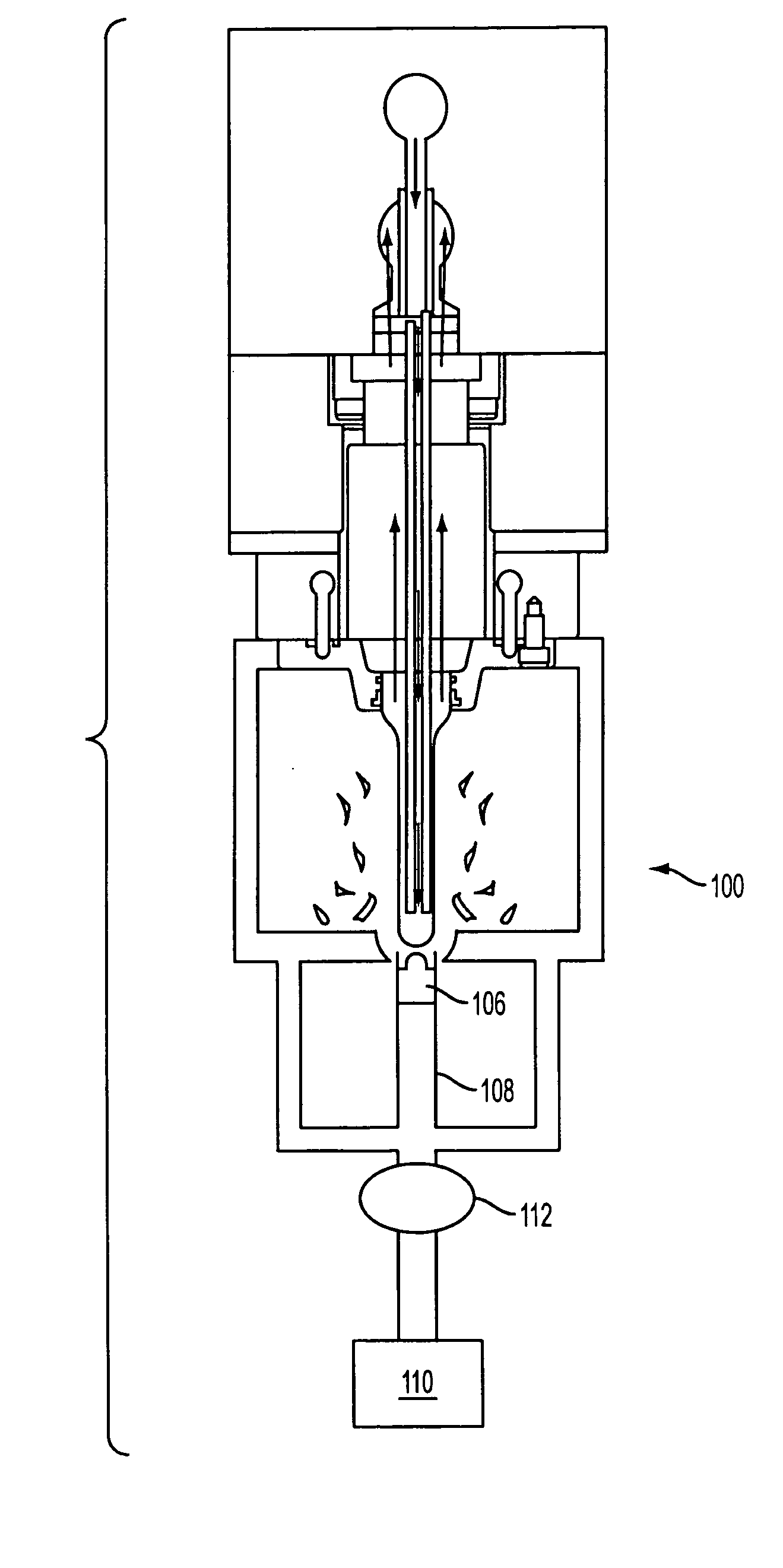

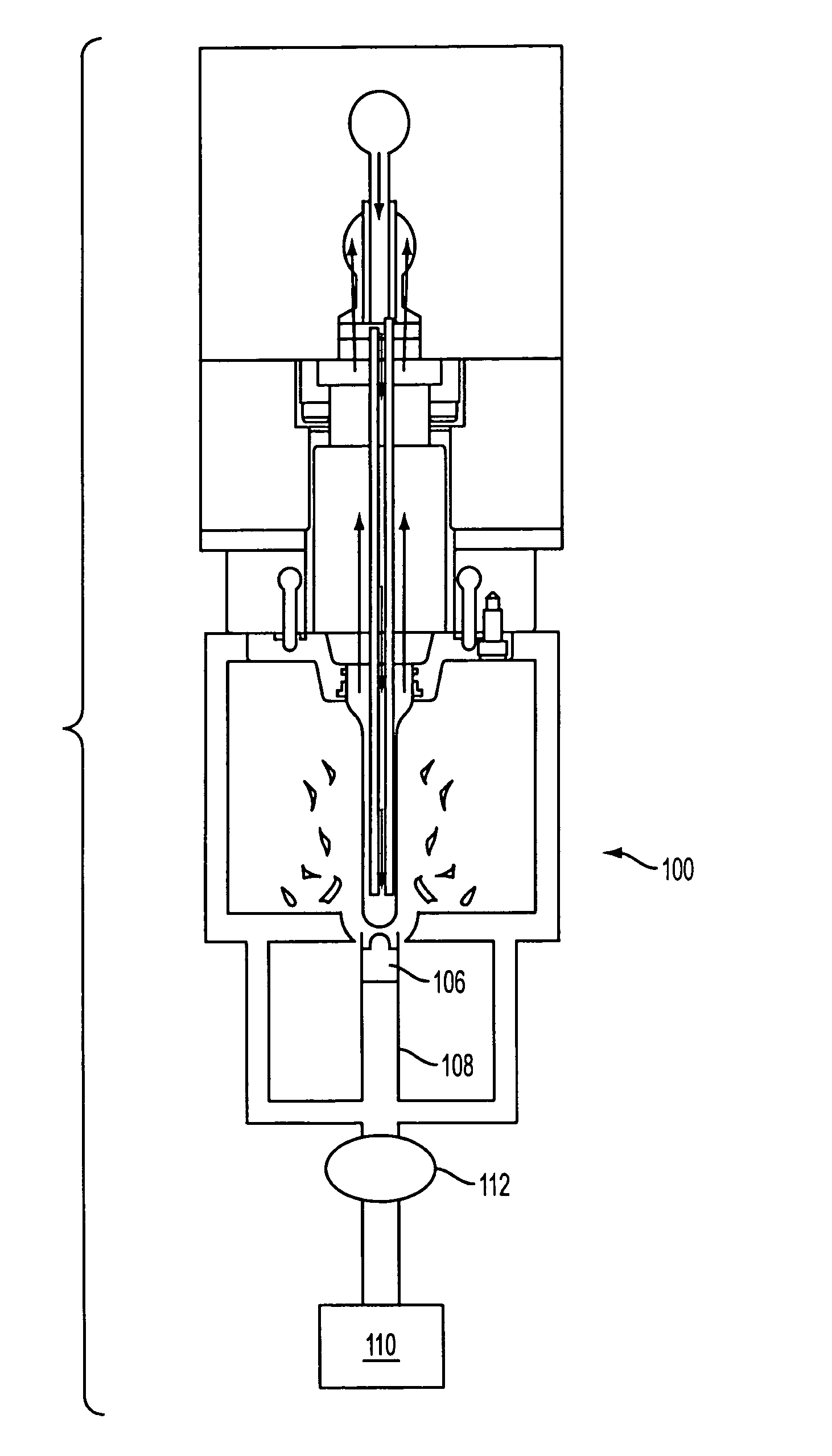

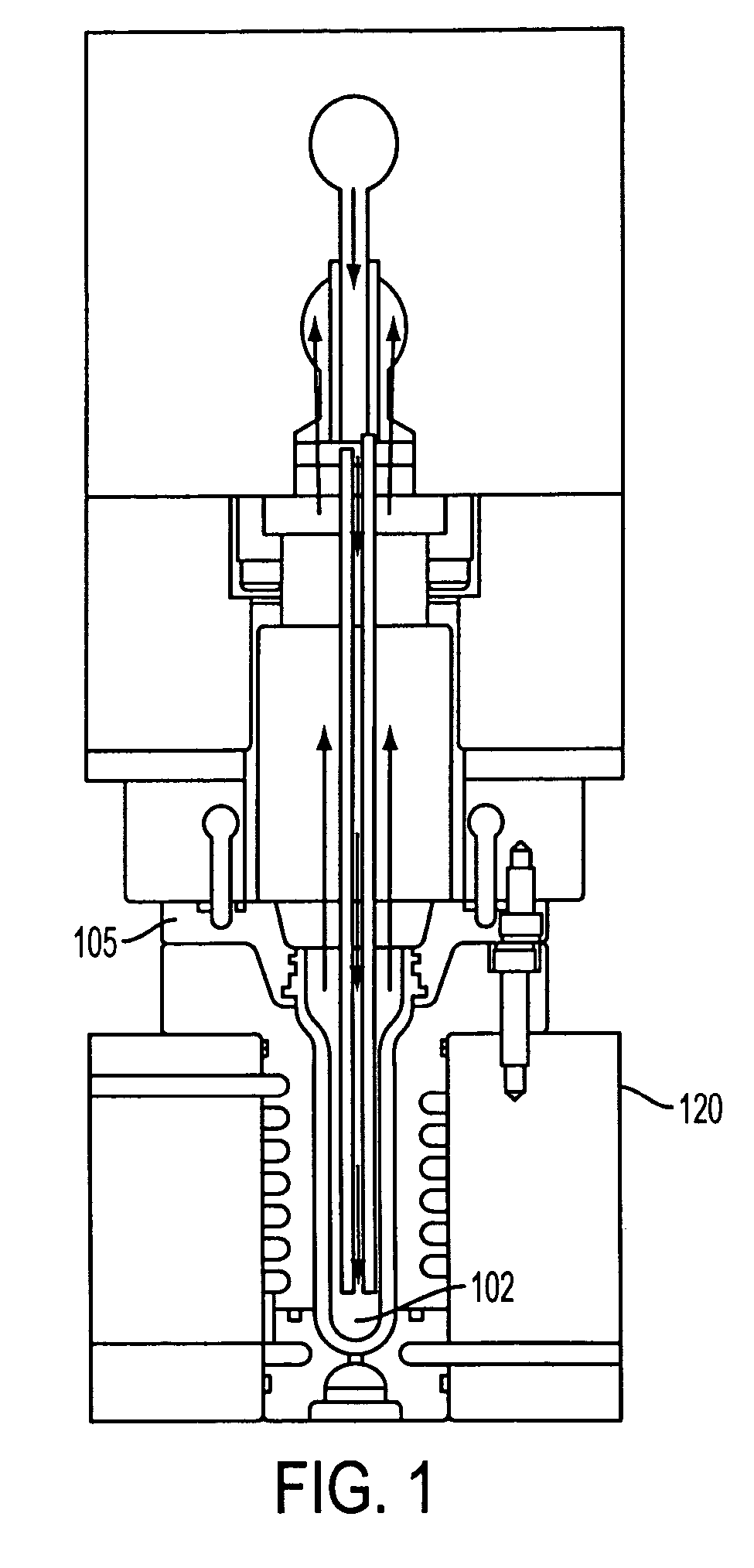

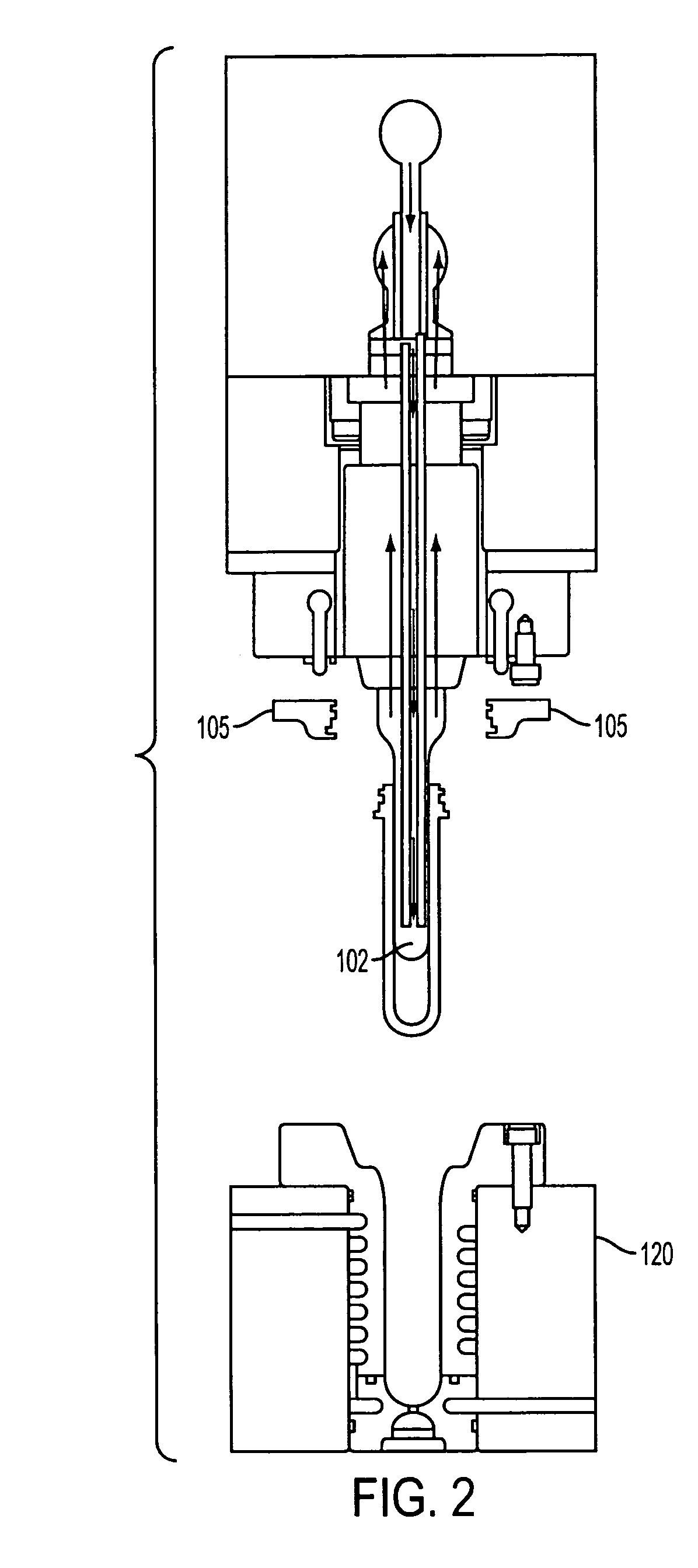

Device and method for removal of preforms

InactiveUS20060068051A1Shorten cycle timeCool more quicklyMouldsConfectioneryEngineeringInjection moulding

A device for fracturing a defective preform for use in blowmolding is claimed. The preform has head end and a tail end and the device comprises a tube with walls defining a cavity for accepting the defective preform while the defective preform is on a core of an injection molding apparatus, an attachment element that attaches the tube to the injection molding apparatus, and locates the tube relative to the core; and a percussion instrument that contacts and breaks the defective preform at the tail end of the preform.

Owner:GRAHAM PACKAGING CO LP

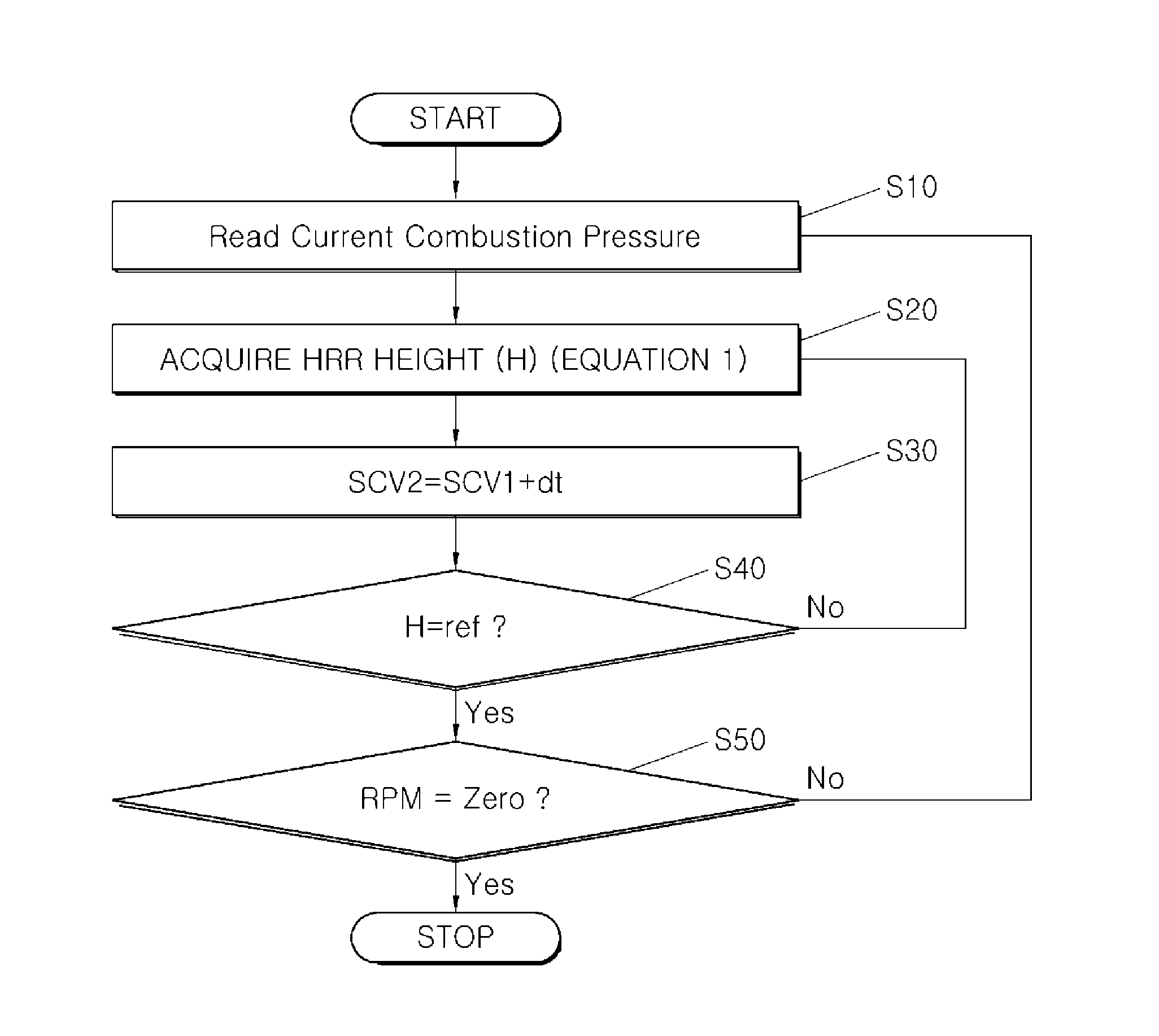

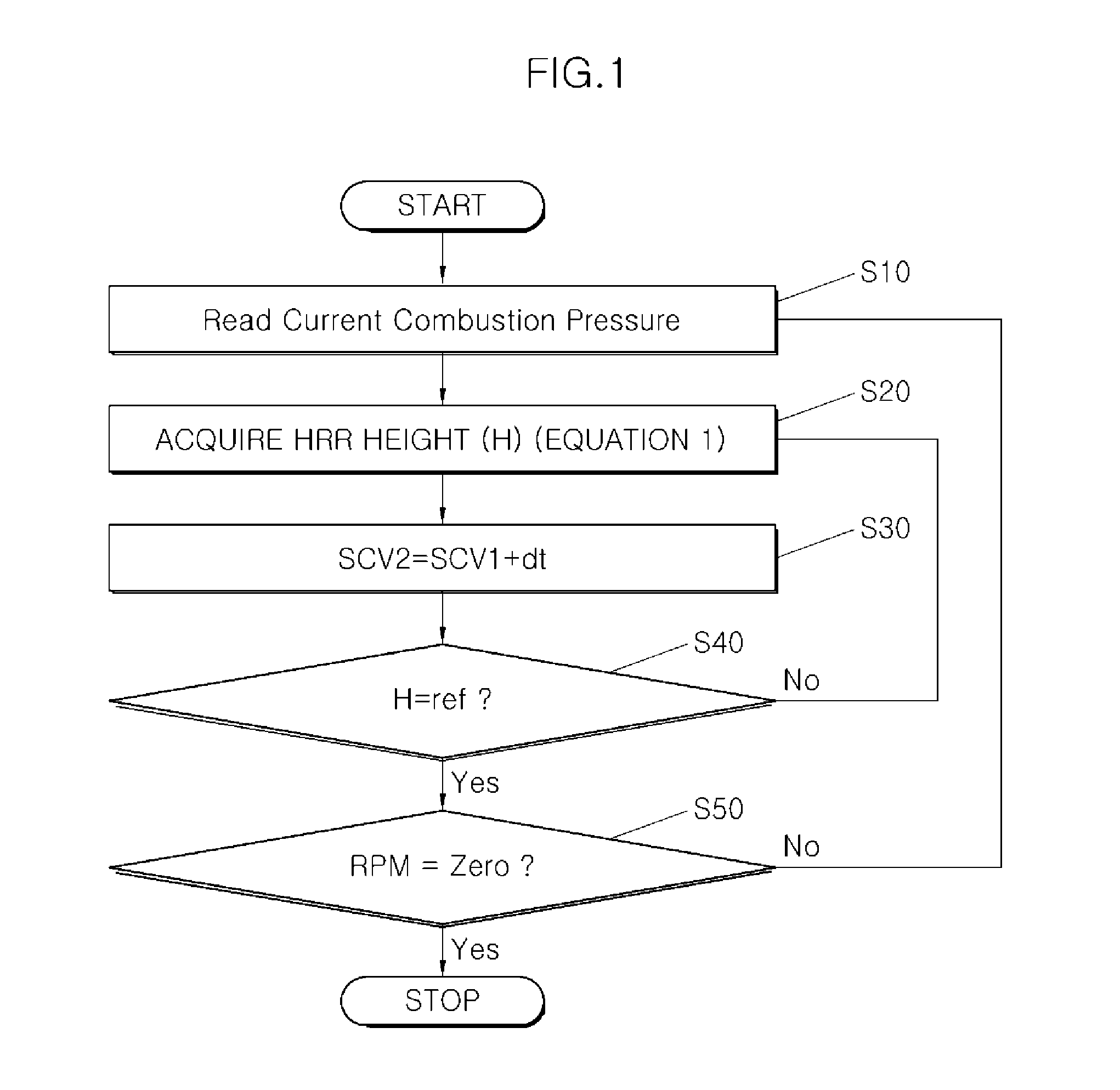

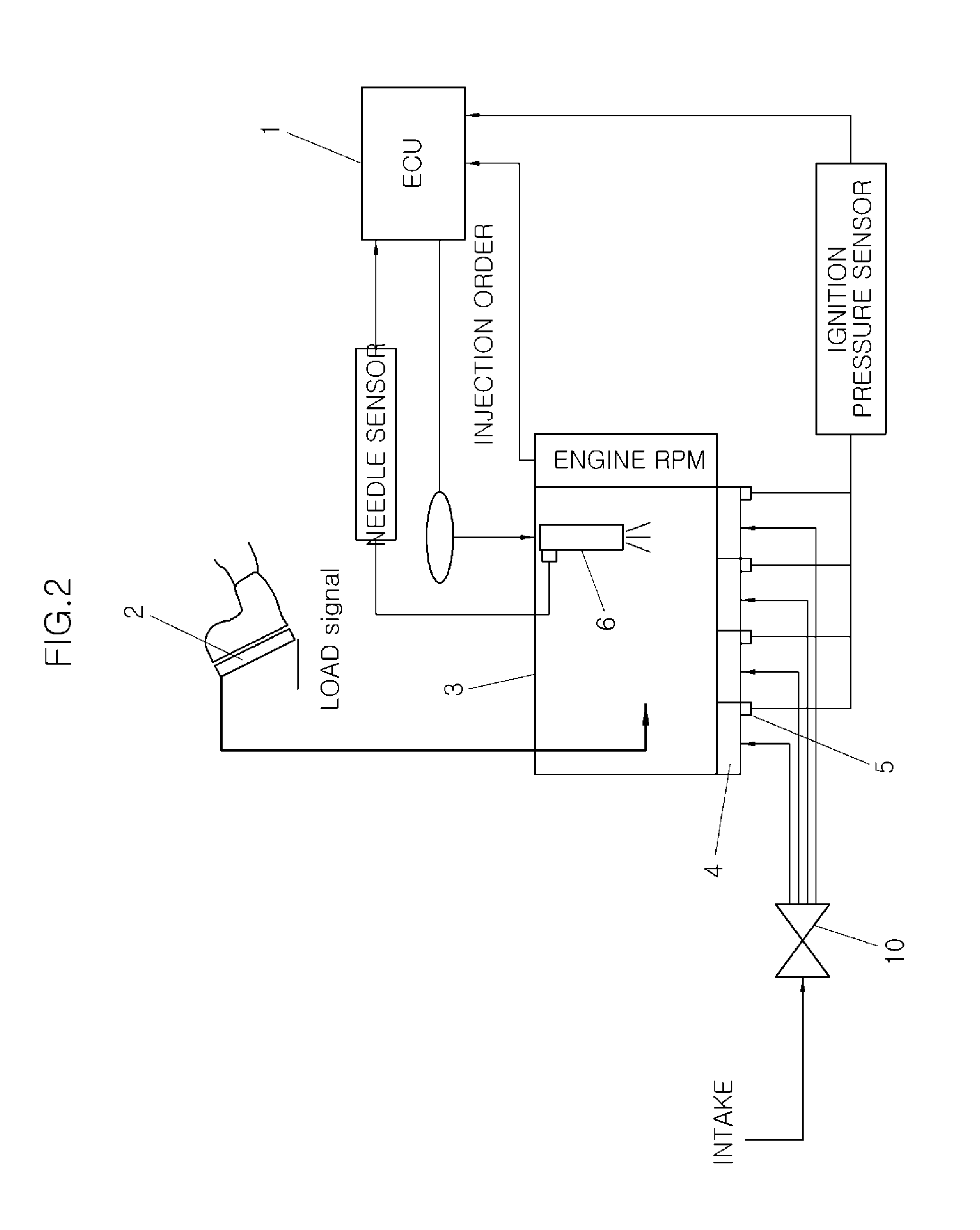

Method for pre-mixed ignition strength control using swirl control and engine control system thereby

InactiveUS20160138512A1Large calculation errorRemove defectElectrical controlInternal combustion piston enginesCombustionControl system

An engine control system may includes a meted for performing pre-mixed ignition strength using swirl control, in which when an ECU determines the difference between the initial optimum level and a detected pre-mixed ignition strength due to ignition pressure of cylinders, the opening amount of Swirl Control Valve is controlled by the ECU on the basis of swirls changing turbulent intensity of the air around fuel flowing into the cylinders and a swirl control optimization mode for matching the pre-mixed ignition strength with the initial optimum level through the control of the opening amount of the SCV is implemented, such that combustion keeps with the pre-mixed ignition strength maintained the initial optimum level.

Owner:HYUNDAI MOTOR CO LTD

Device and method for removal of preforms

A device for fracturing a defective preform for use in blowmolding is claimed. The preform has head end and a tail end and the device comprises a tube with walls defining a cavity for accepting the defective preform while the defective preform is on a core of an injection molding apparatus, an attachment element that attaches the tube to the injection molding apparatus, and locates the tube relative to the core; and a percussion instrument that contacts and breaks the defective preform at the tail end of the preform.

Owner:GRAHAM PACKAGING CO LP

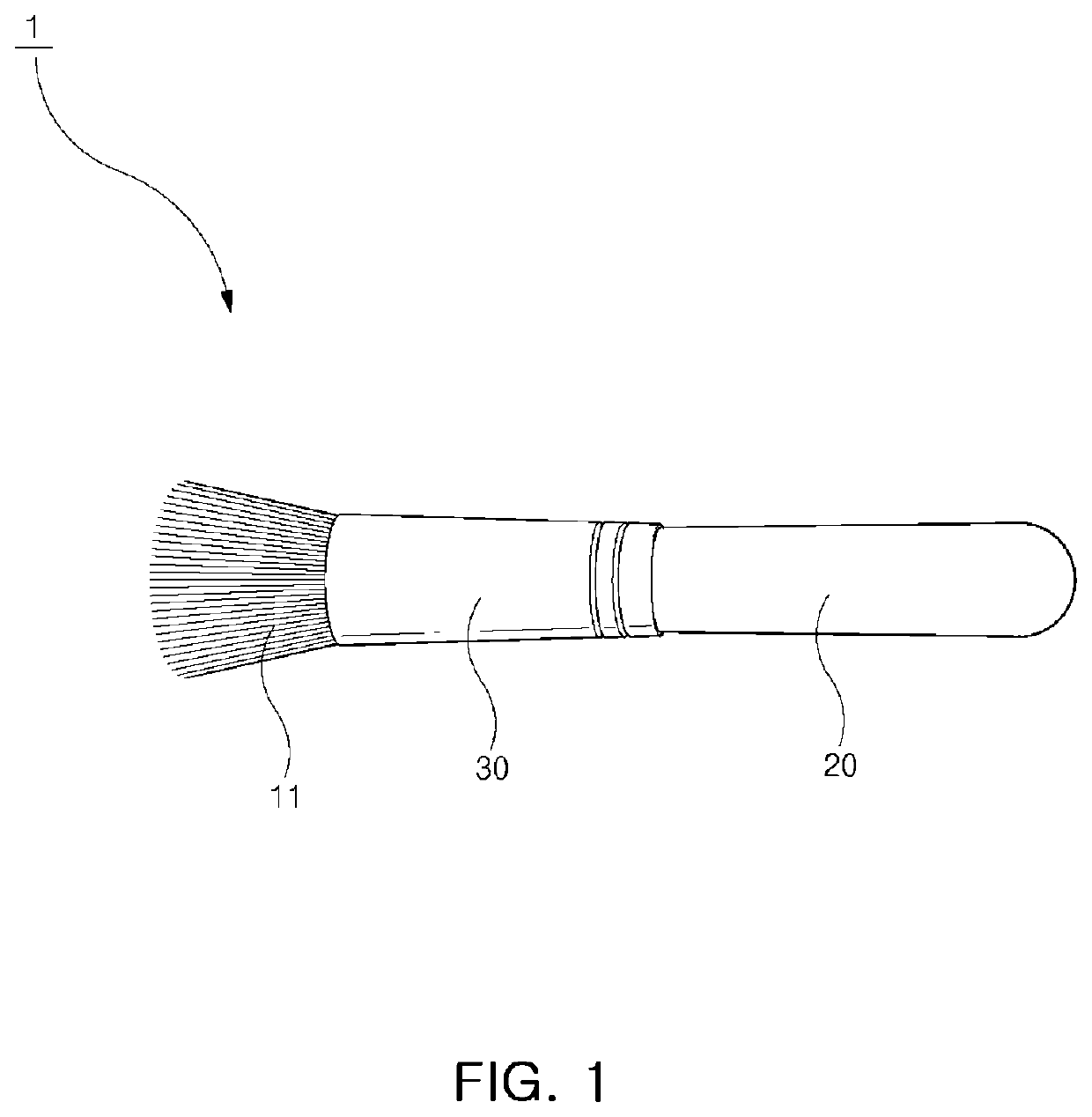

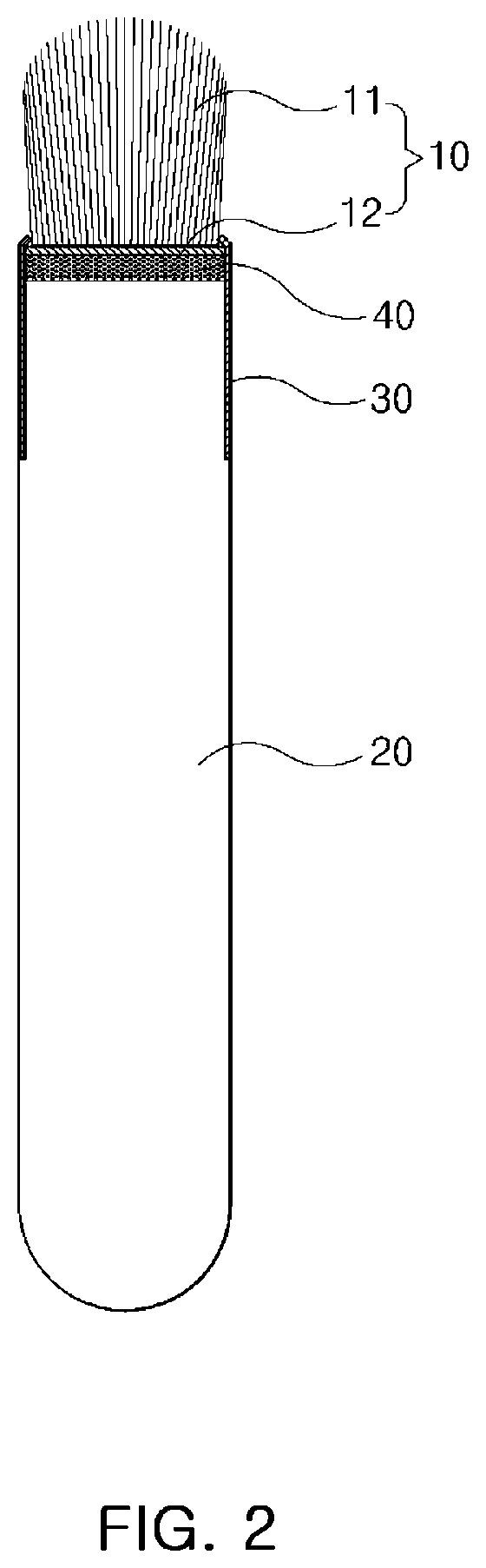

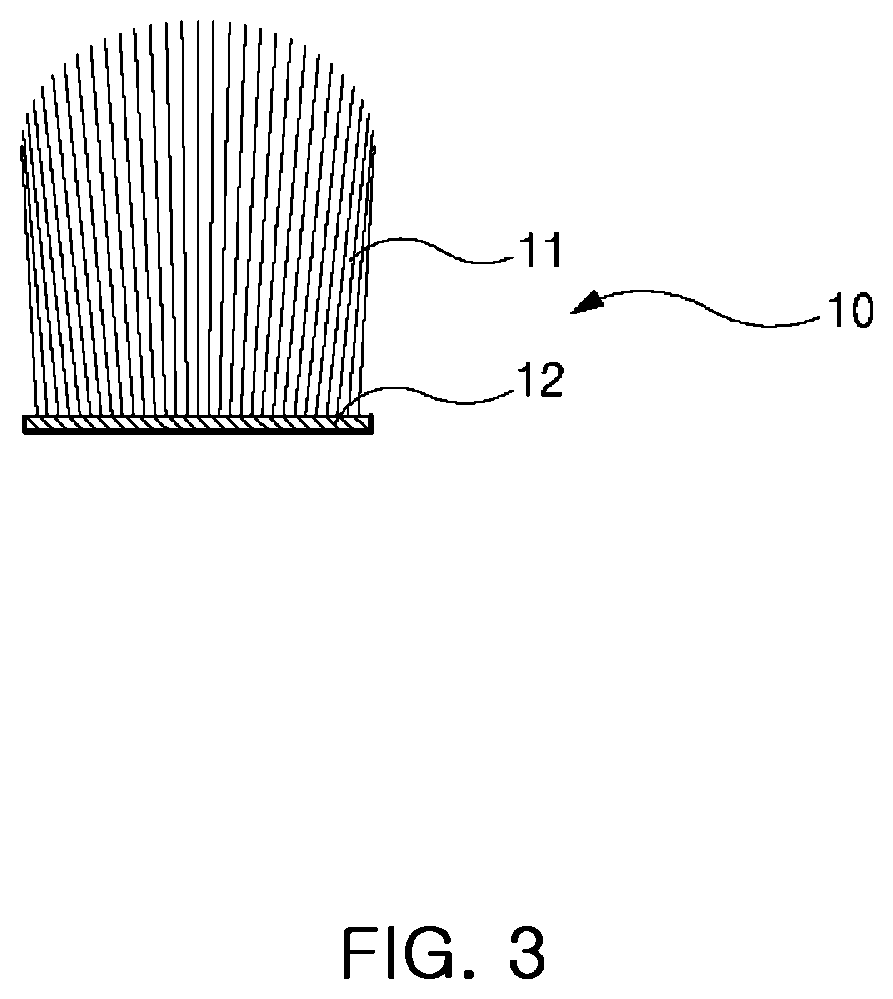

Brush and its manufacturing method

ActiveUS10517382B2Remove defectAvoid shakingBrush bodiesBristle carriersEngineeringMechanical engineering

The present invention provides a brush and a manufacturing method thereof. A brush of the present invention includes: brush hairs; a brush hair part that has a brush coupler to which the brush hairs are attached; a brush body that support an end of the brush coupler; a coupling member that has a first part coupled to the brush body and a second part coupled to the edge of the brush coupler and has a metallic tube; and a fixing member that prevents shaking of the brush coupler between the brush body and the brush coupler, in which the coupling member and the brush body are combined by pressing the portion of the coupling member where the coupling member and the brush body are in contact with each other.

Owner:F S KOREA IND

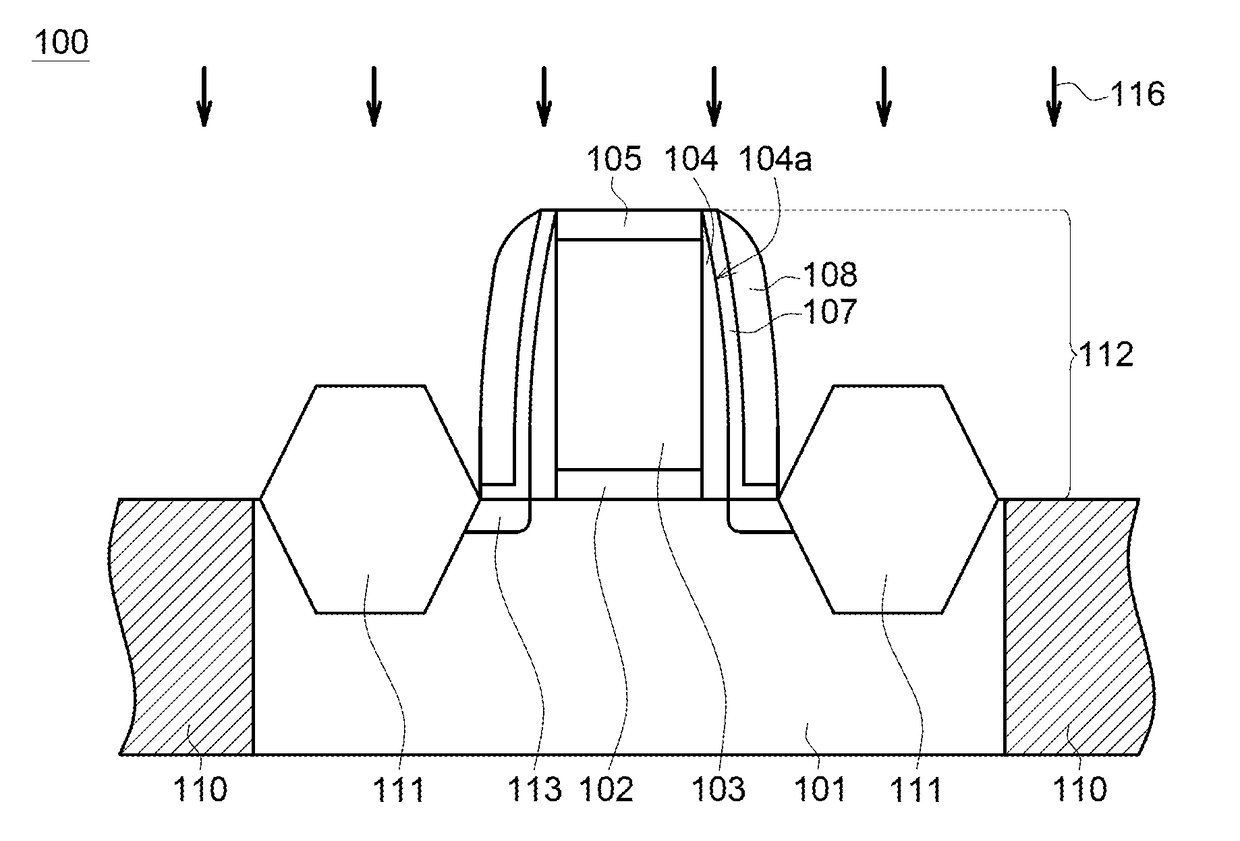

Method for fabricating semiconductor device

ActiveUS20170179286A1Not easy to layerRemove defectSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorSemiconductor device

A method for forming a semiconductor device includes steps as follows: Firstly, a semiconductor substrate having a circuit element with at least one spacer formed thereon is provided. Next, an acid treatment is performed on a surface of the spacer. A disposable layer is then formed on the circuit element and the spacer. Thereafter, an etching process is performed to form at least one recess in the semiconductor substrate adjacent to the circuit element. Subsequently, a selective epitaxial growth (SEG) process is performed to form an epitaxial layer in the recess.

Owner:UNITED MICROELECTRONICS CORP

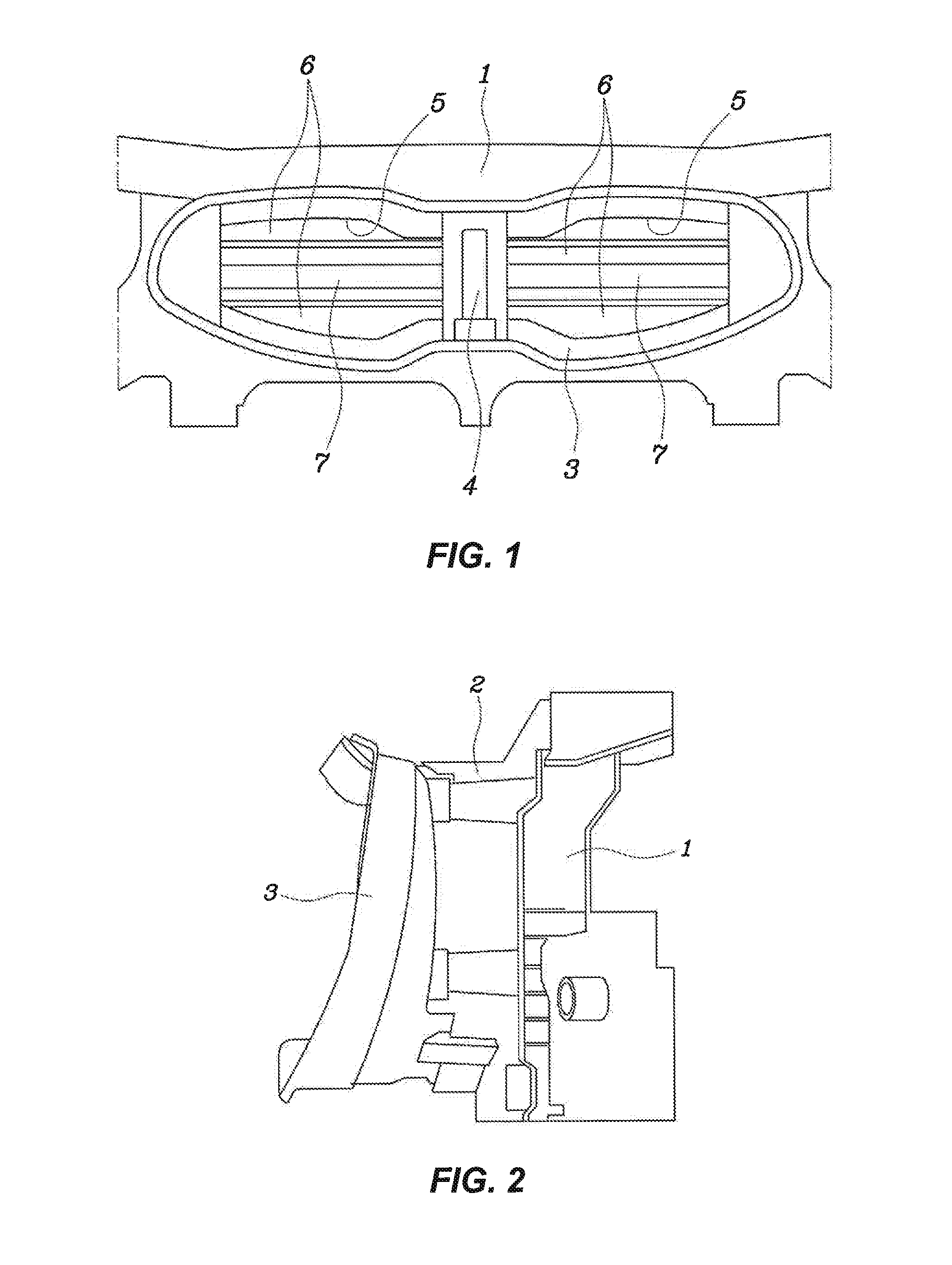

Active air flap apparatus for vehicle

ActiveUS20140117709A1Remove defectMinimize pedestrian injuryVehicle seatsWindowsAerospace engineeringPedestrian

An active air flap for a vehicle can absorb shock energy by means of a wing of a housing which pivots in a collision with a pedestrian and can minimize the pedestrian injury as possible.

Owner:HYUNDAI MOTOR CO LTD

Polishing composition

InactiveUS20200299543A1Increase speedRemove defectOther chemical processesSemiconductor/solid-state device manufacturingSilica particleOrganic acid

Provided is a polishing composition which can sufficiently remove defects remaining on the surface of a polished object and which can make the polishing speeds of the respective materials substantially equal to each other when polishing the object to be polished containing a plurality of materials.A polishing composition used for polishing an object to be polished containing a material having a silicon-silicon bond, a material having a silicon-nitrogen bond, and a material having a silicon-oxygen bond, the polishing composition including: organic acid surface-immobilized silica particles; a wetting agent; and a polishing speed inhibitor for the material having a silicon-silicon bond, wherein the polishing composition has a pH of less than 7.

Owner:FUJIMI INCORPORATED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com