Patents

Literature

985 results about "Defective pixel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

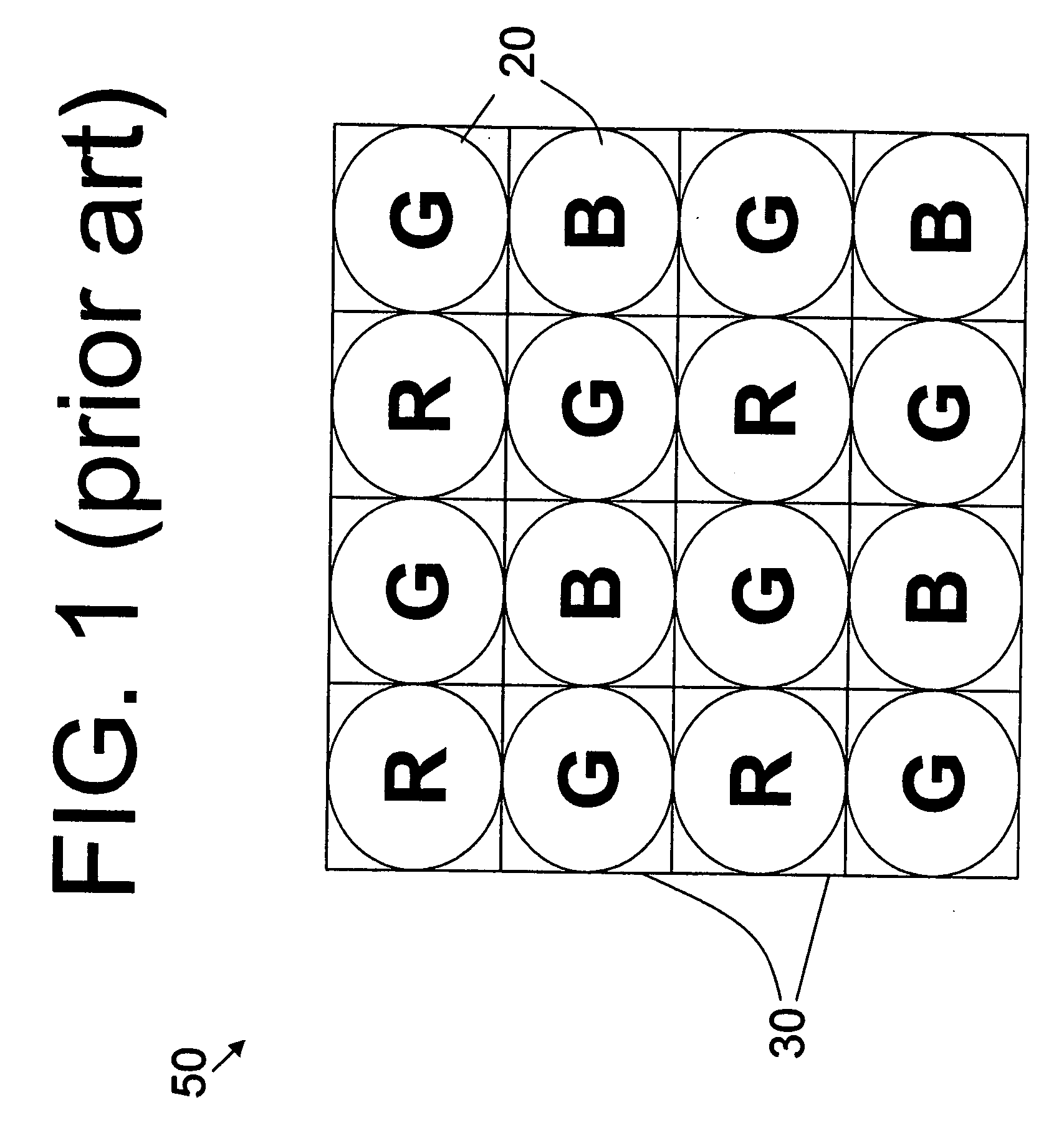

Defective pixels are pixels on a liquid crystal display (LCD) that are not performing as expected. The ISO standard ISO 13406-2 distinguishes between three different types of defective pixels, while hardware companies tend to have further distinguishing types.

Detection of Defective Pixels in an Image Sensor

ActiveUS20110043668A1Efficient detectionImprove the detection rateTelevision system detailsColor signal processing circuitsPattern recognitionDefective pixel

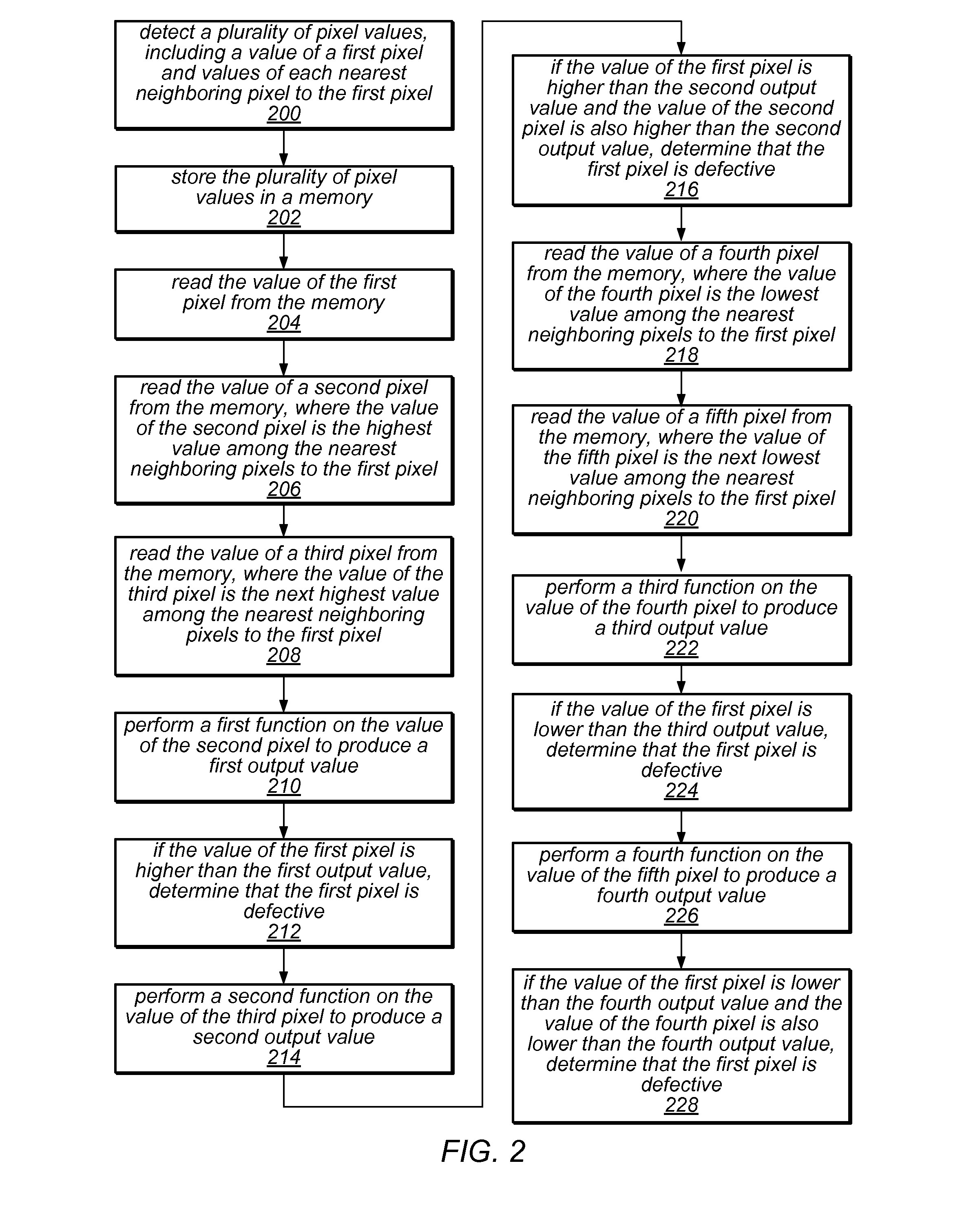

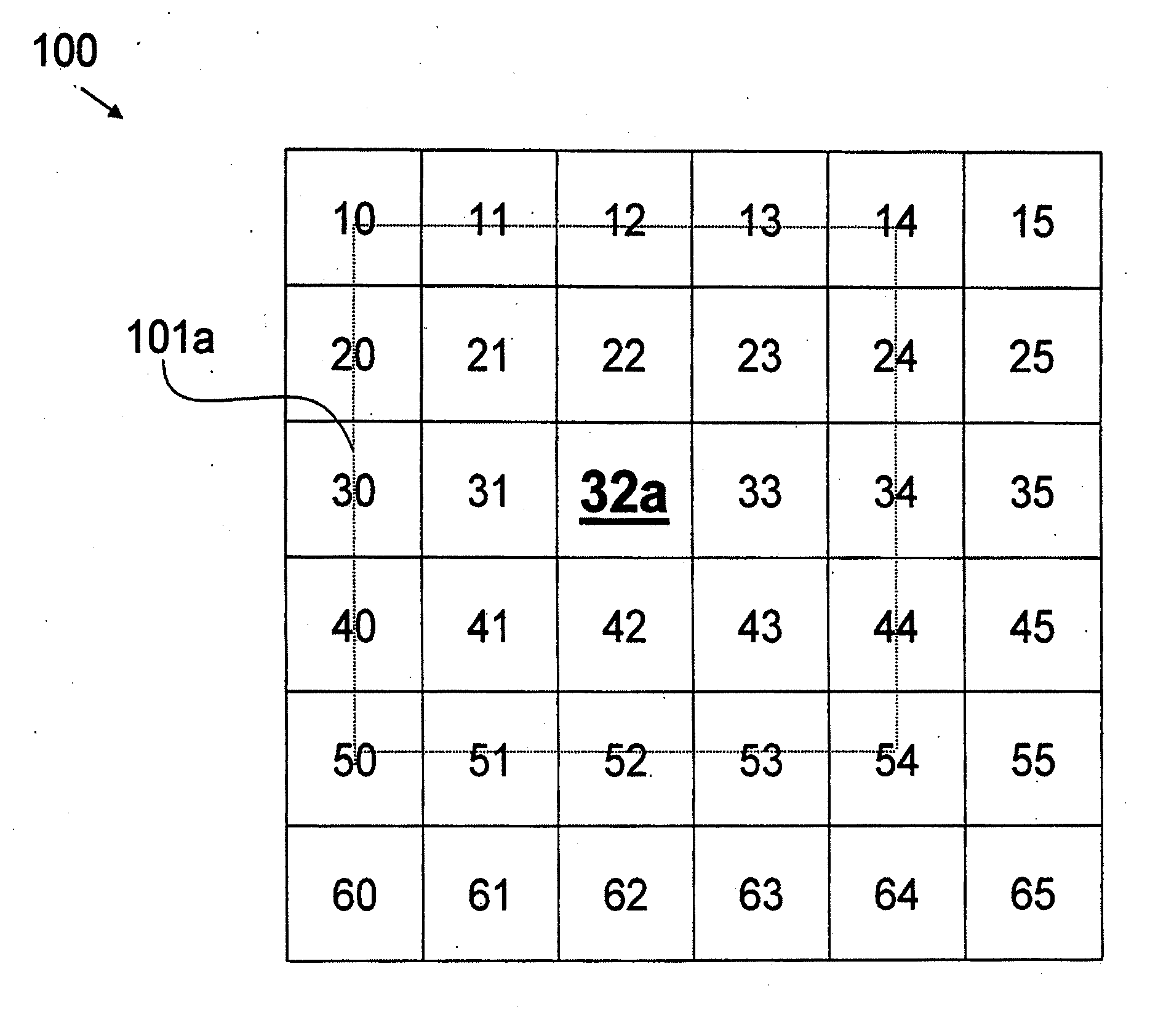

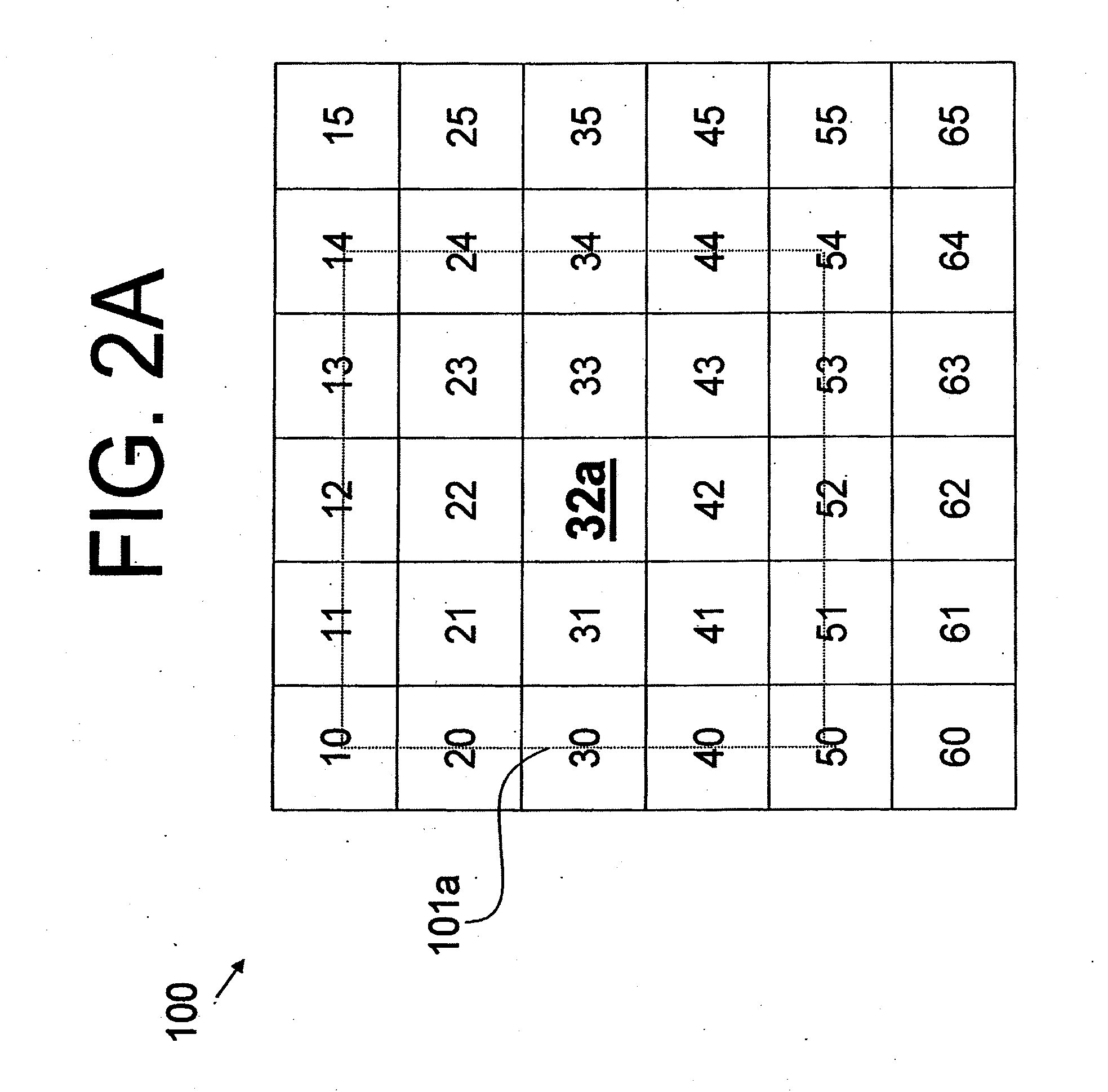

A system and method for detecting defective pixels in a sensor. A plurality of pixel values of the sensor may be detected. The values may include those of a first pixel and each nearest neighboring pixel to the first pixel. A second pixel may have the highest value of the neighboring pixels. A third pixel may have the next highest value of the neighboring pixels. A first function may be performed on the second pixel value, producing a first output value. A second function may be performed on the third pixel value, producing a second output value. If the first pixel value is higher than the first output value, or, if the first pixel value is higher than the second output value and the second pixel value is higher than the second output value, it may be determined that the first pixel is defective.

Owner:LIFESIZE INC

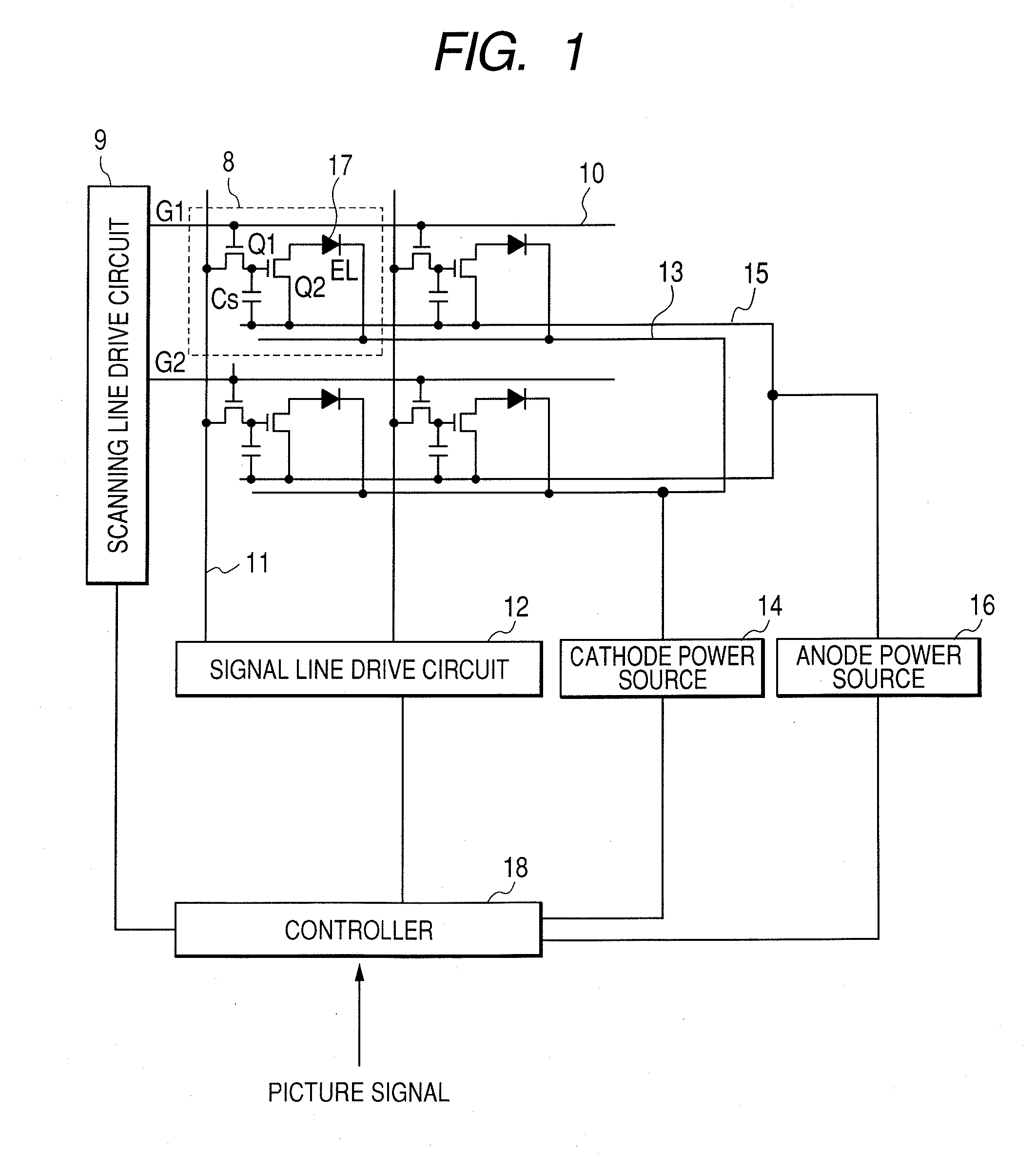

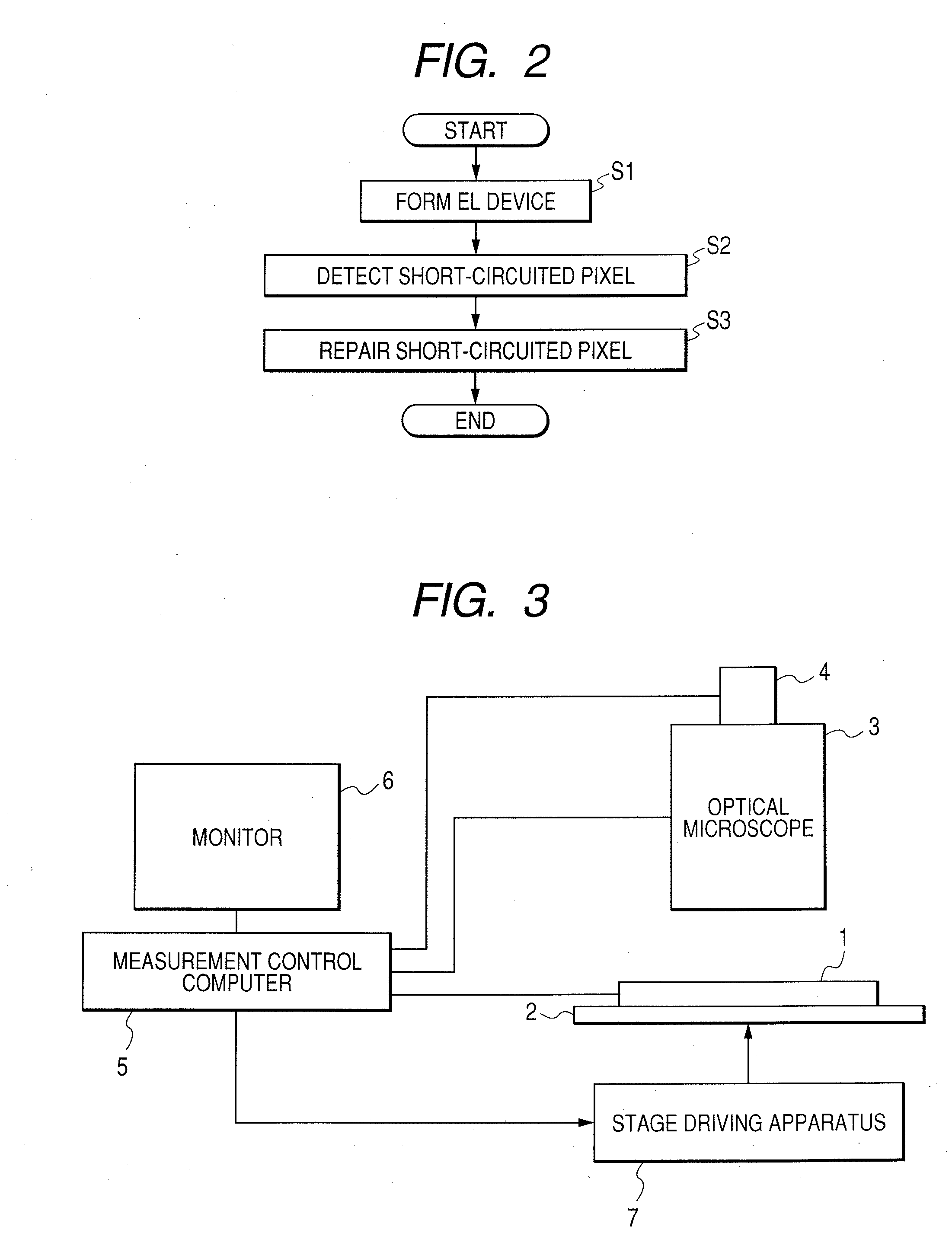

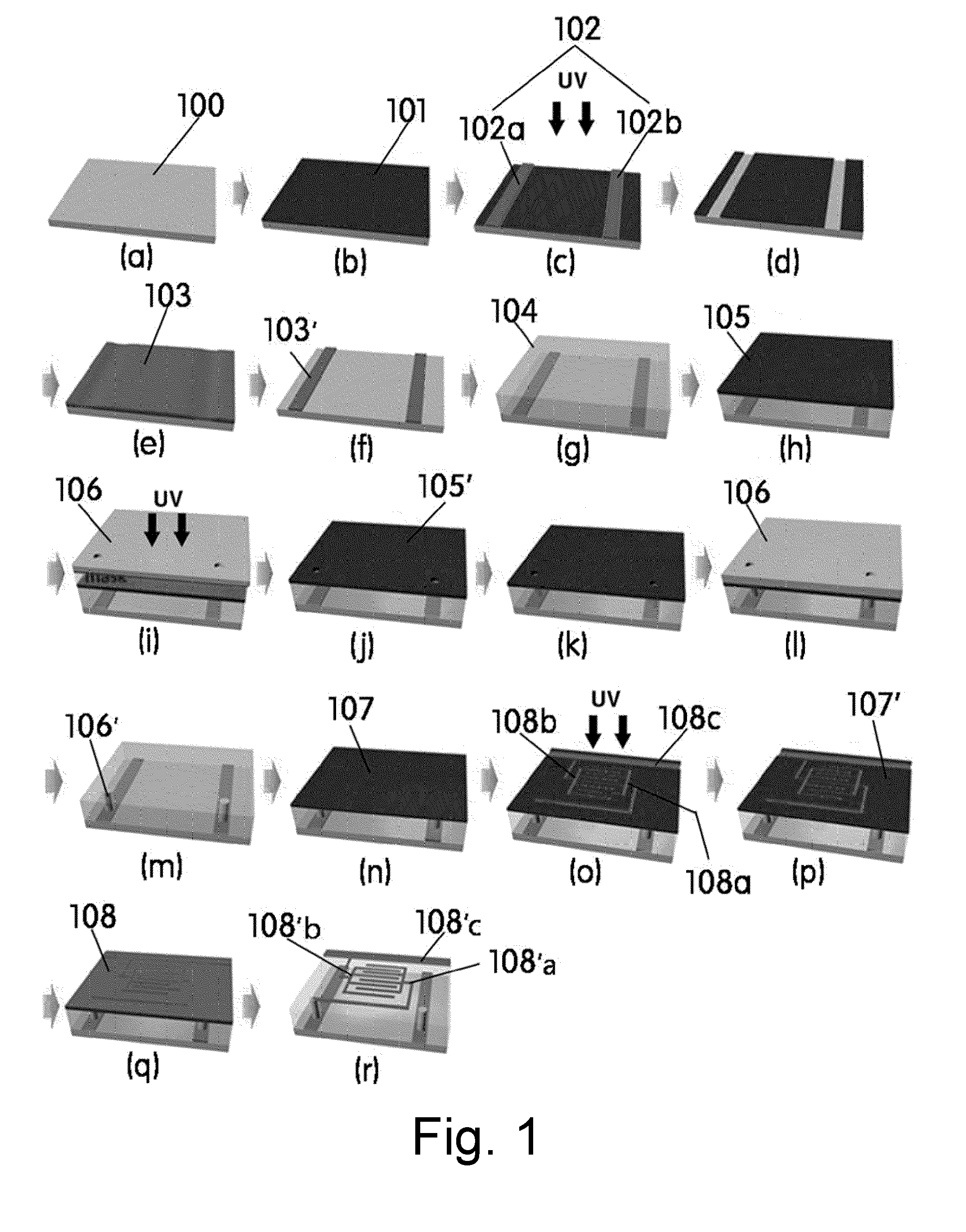

Organic elecroluminescence display apparatus, method of producing the same, and method of repairing a defect

InactiveUS20070273294A1Flowing through is suppressedIncrease costStatic indicating devicesOrganic semiconductor devicesDevice formEngineering

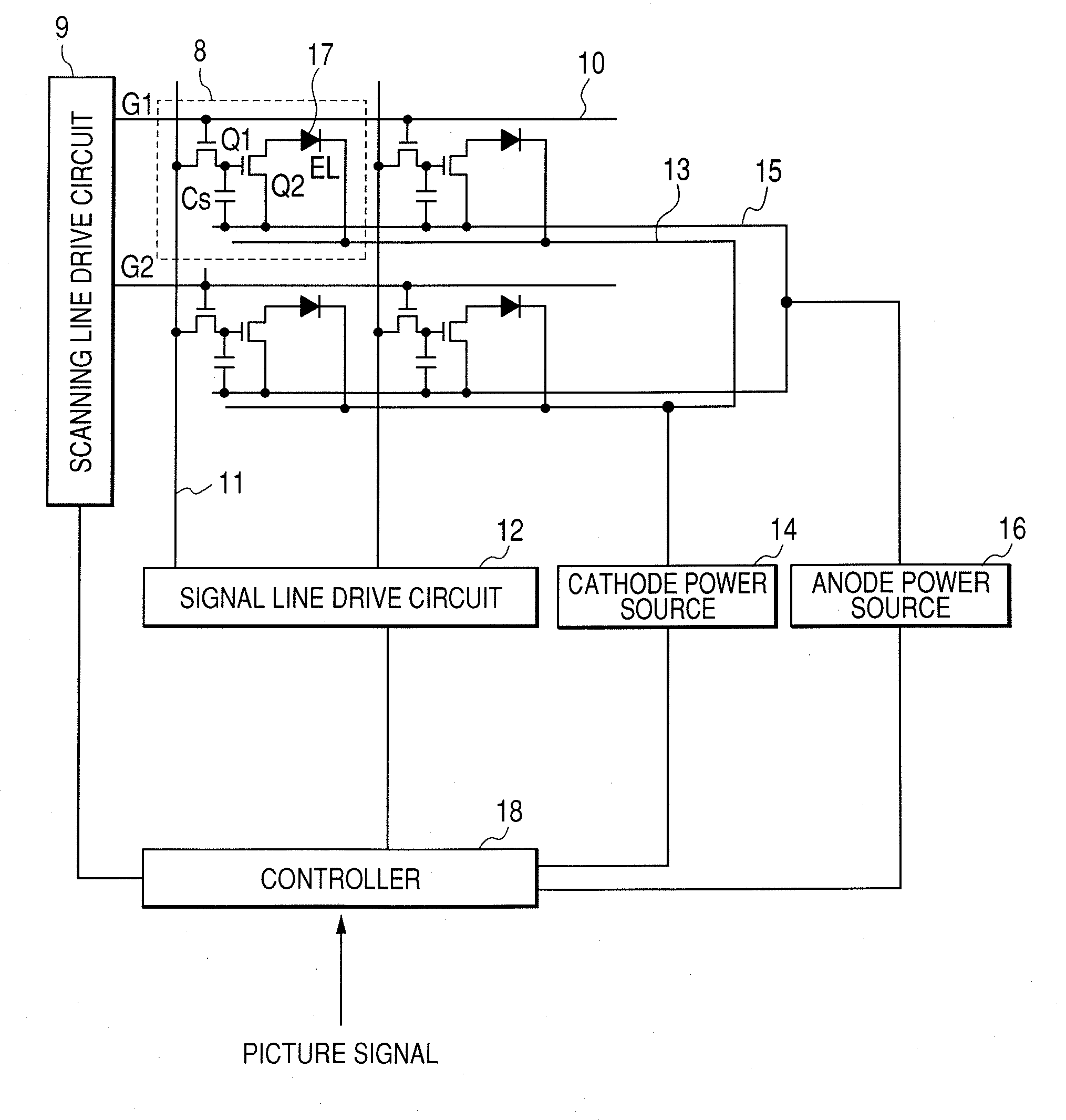

Provided is an organic EL display apparatus capable of opening and breaking a defective portion without degrading a normal portion of a pixel, and a method of producing the same. The method of producing an organic EL display apparatus in which a plurality of pixels including organic EL devices are arranged includes the steps of: forming an organic EL device formed of a light emitting layer made of an organic compound between a cathode electrode and an anode electrode (Step S1); detecting a defective pixel in which a cathode electrode and an anode electrode are short-circuited (Step 2); and repairing the defective pixel to be opened by selectively applying a voltage between the cathode electrode and the anode electrode with respect to the defective pixel (Step S3).

Owner:CANON KK

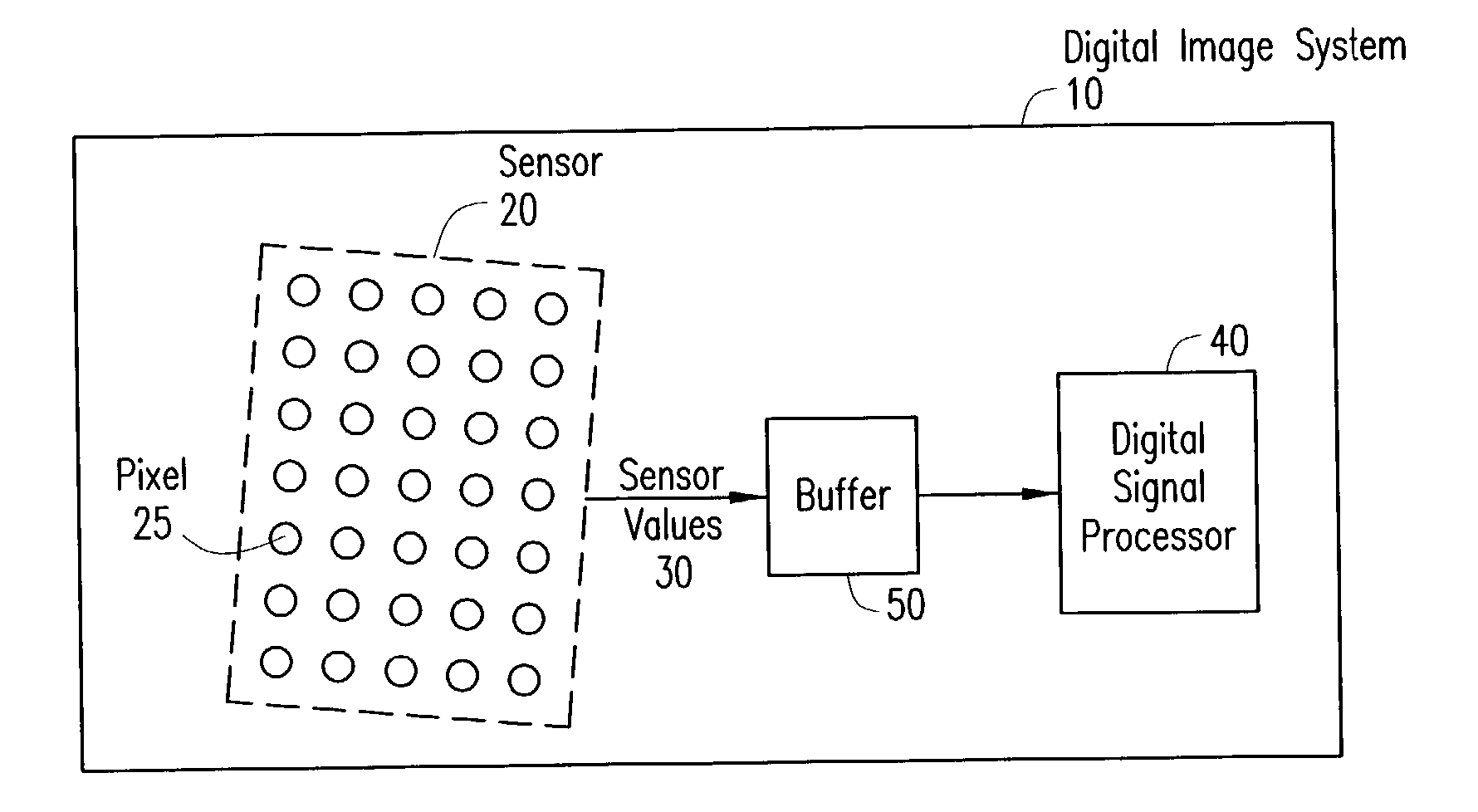

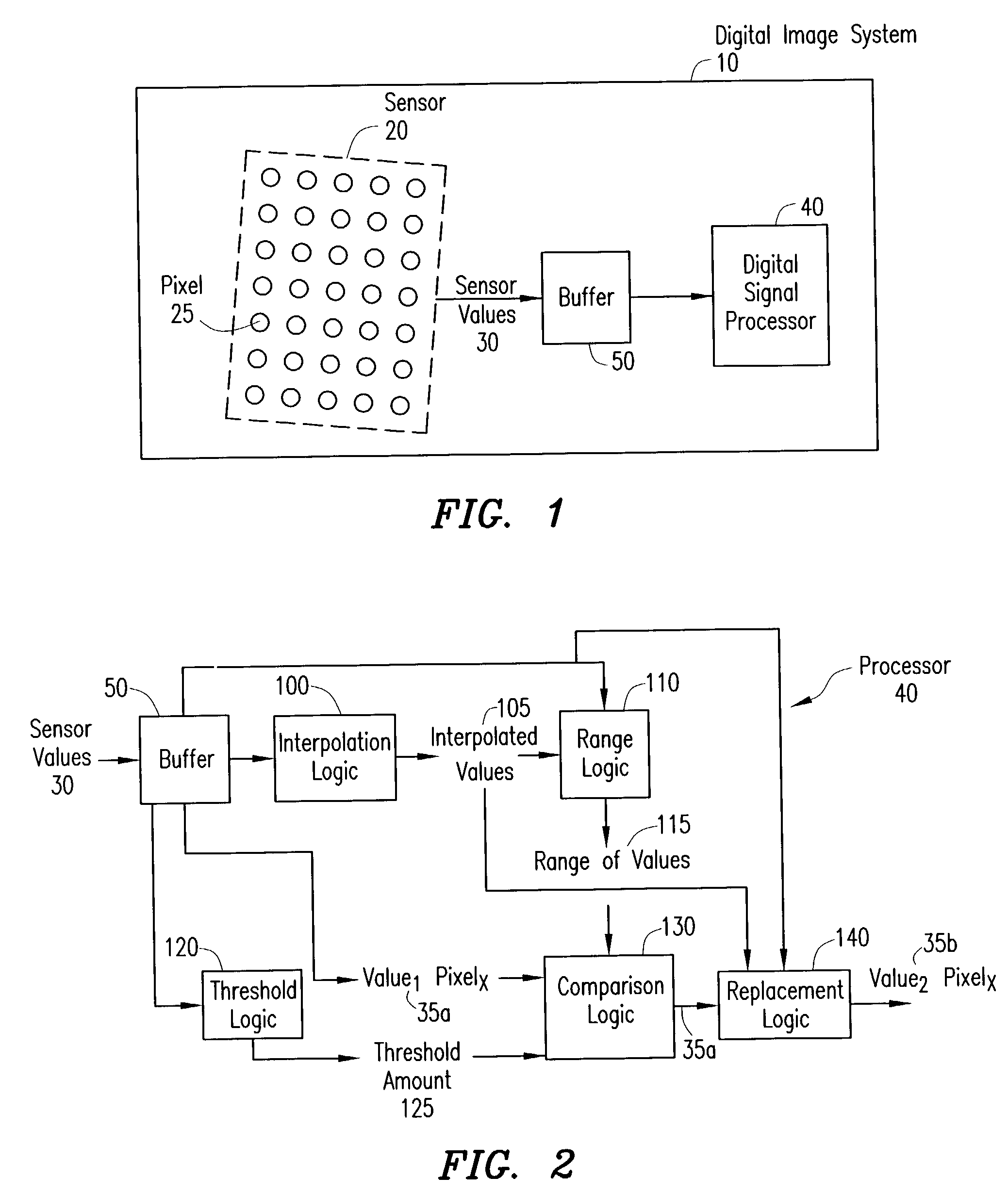

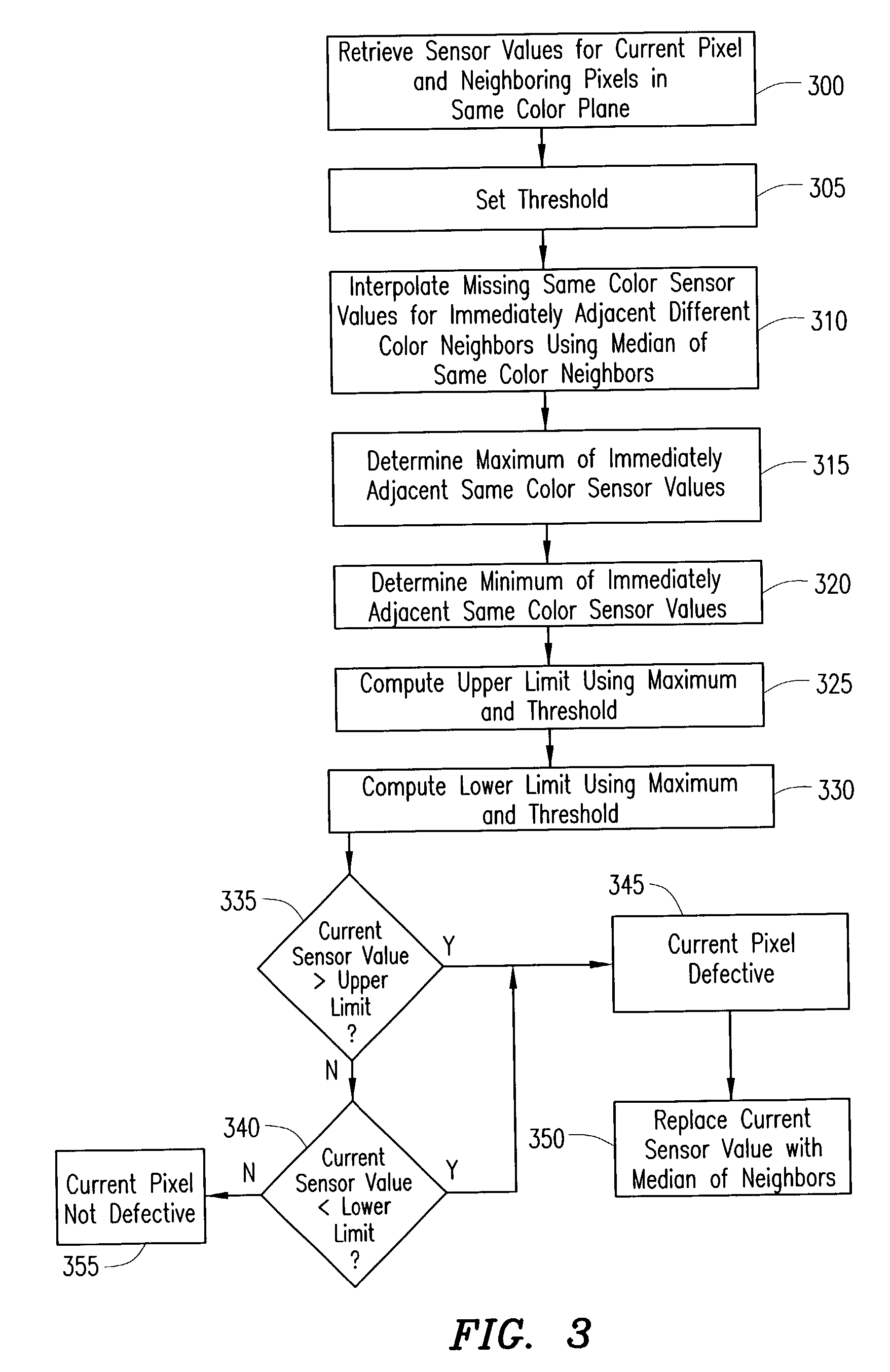

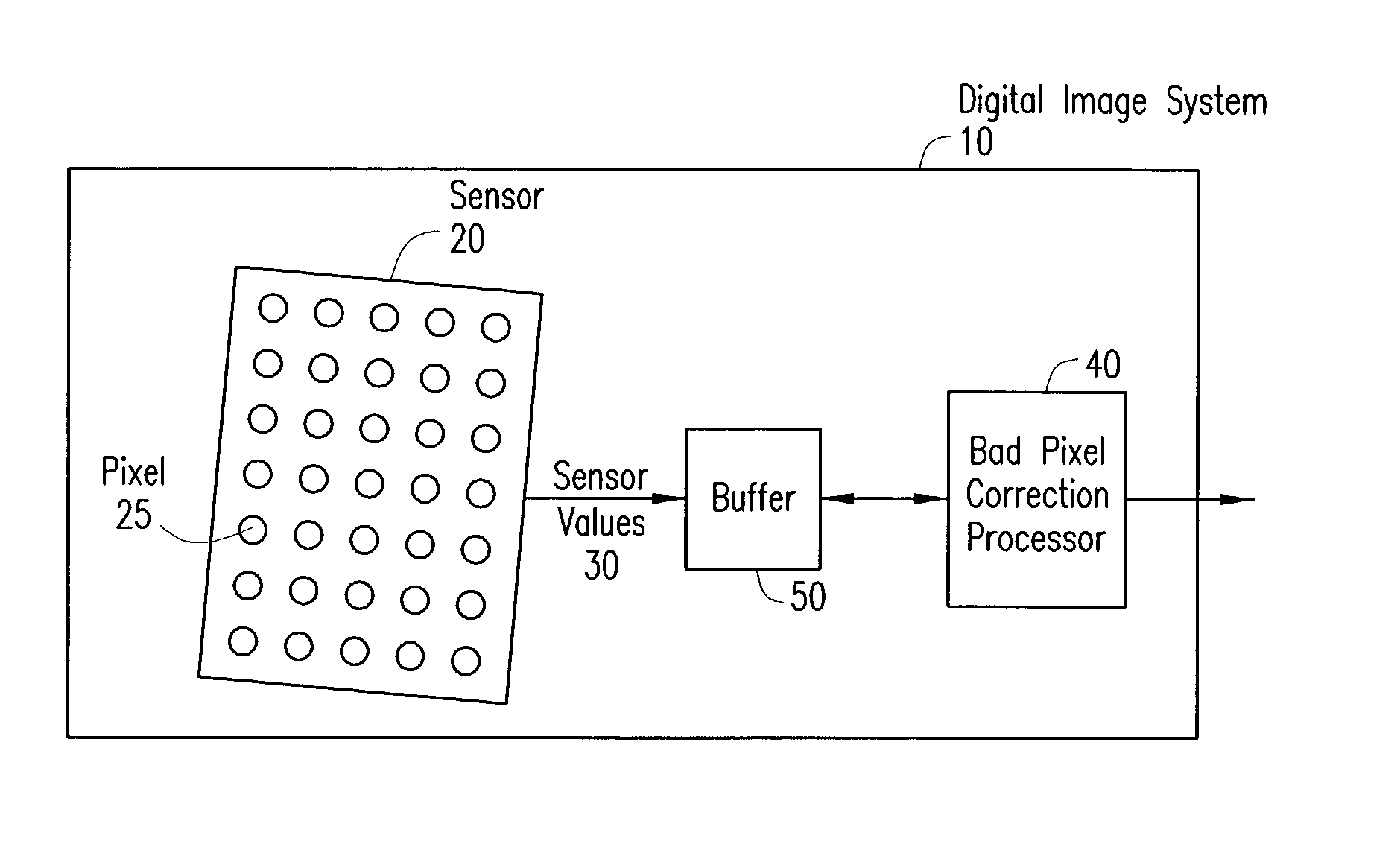

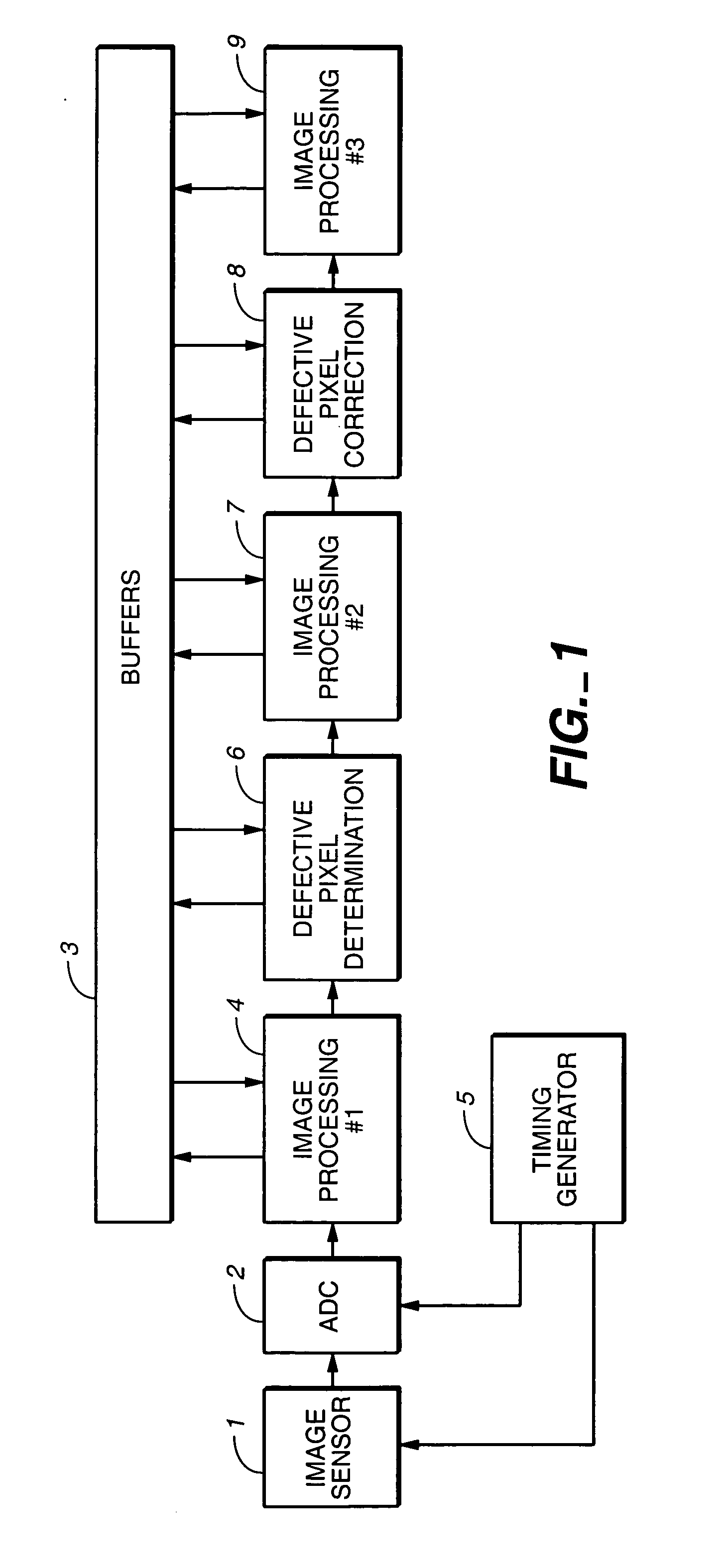

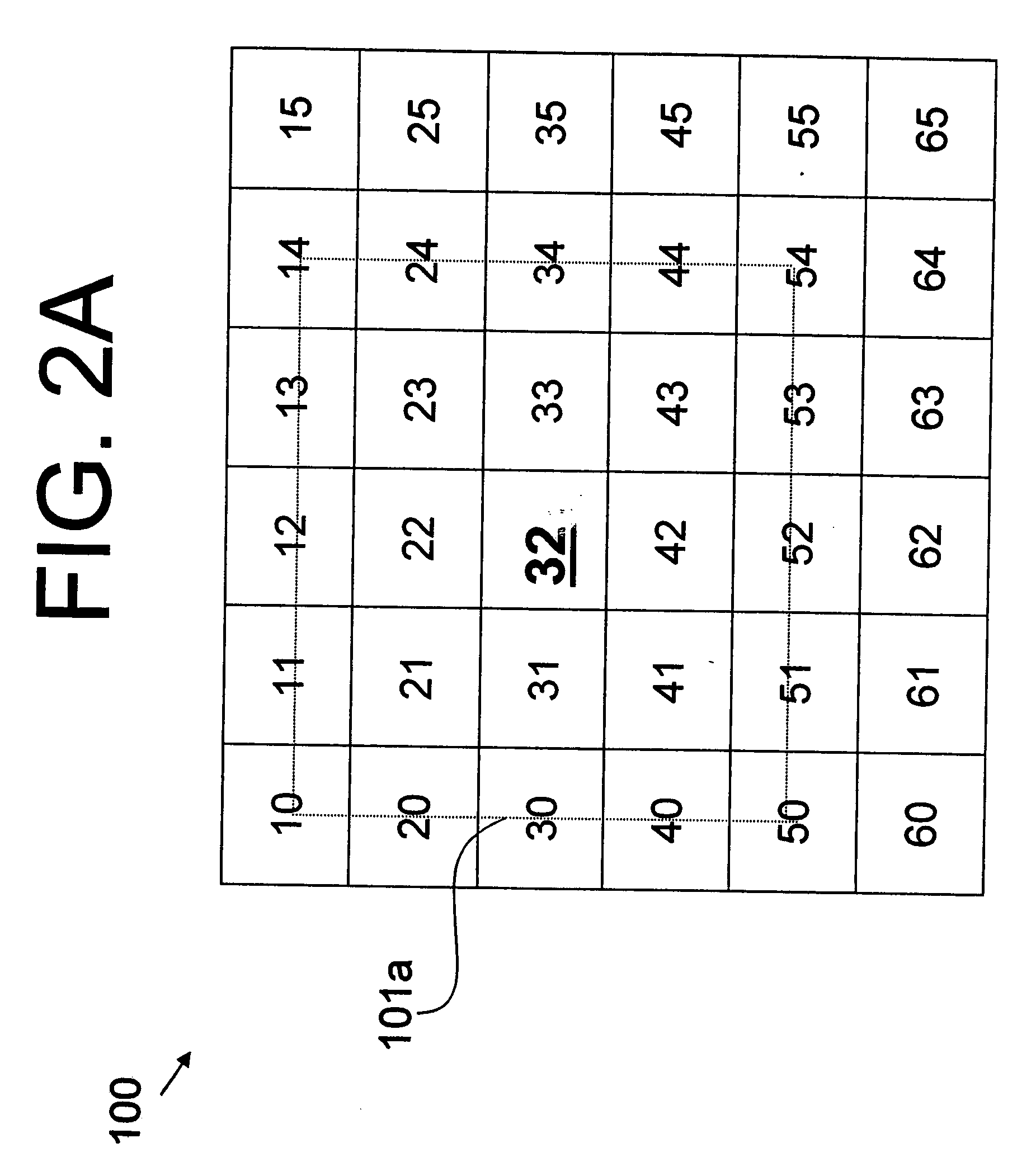

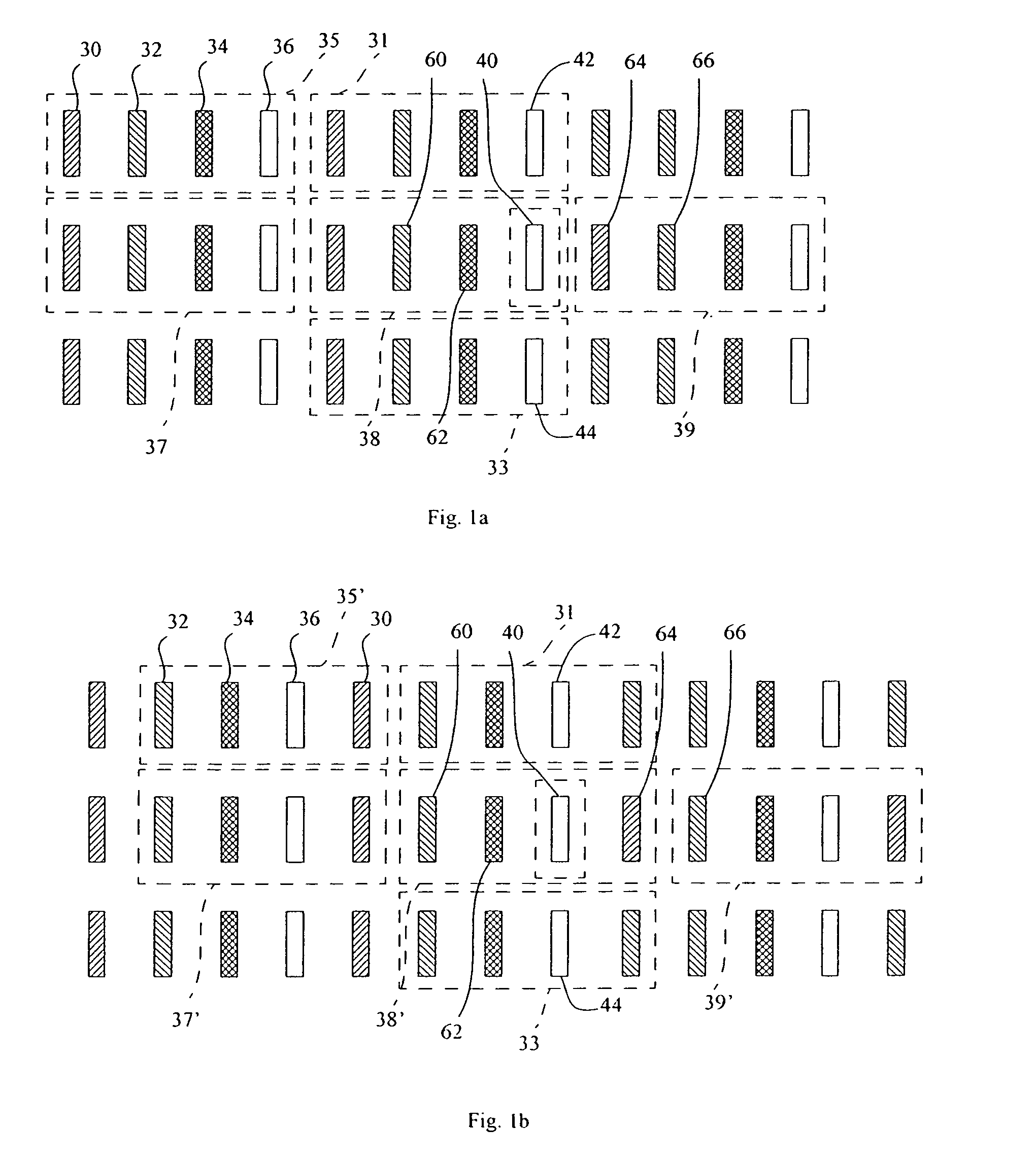

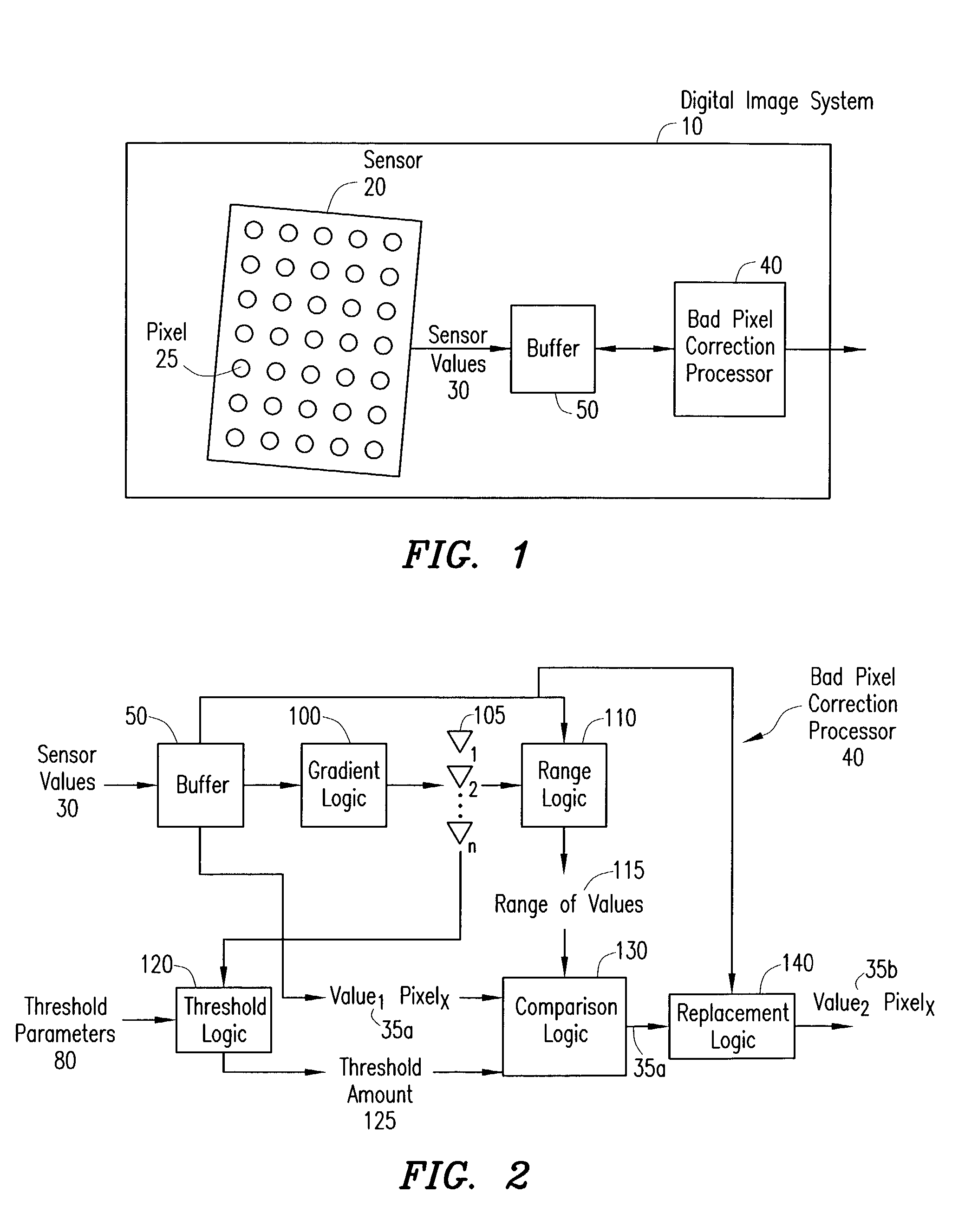

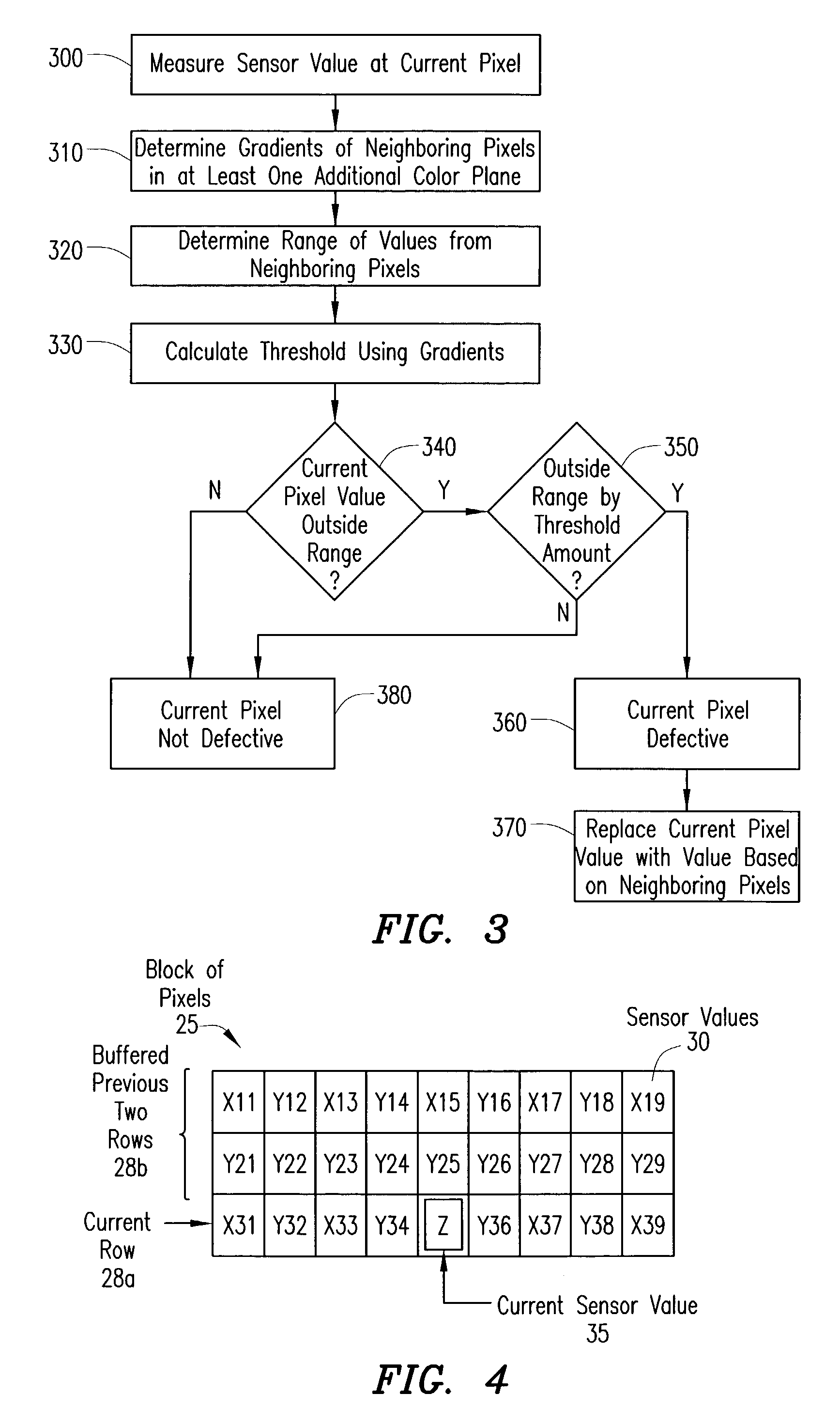

Digital image system and method for combining demosaicing and bad pixel correction

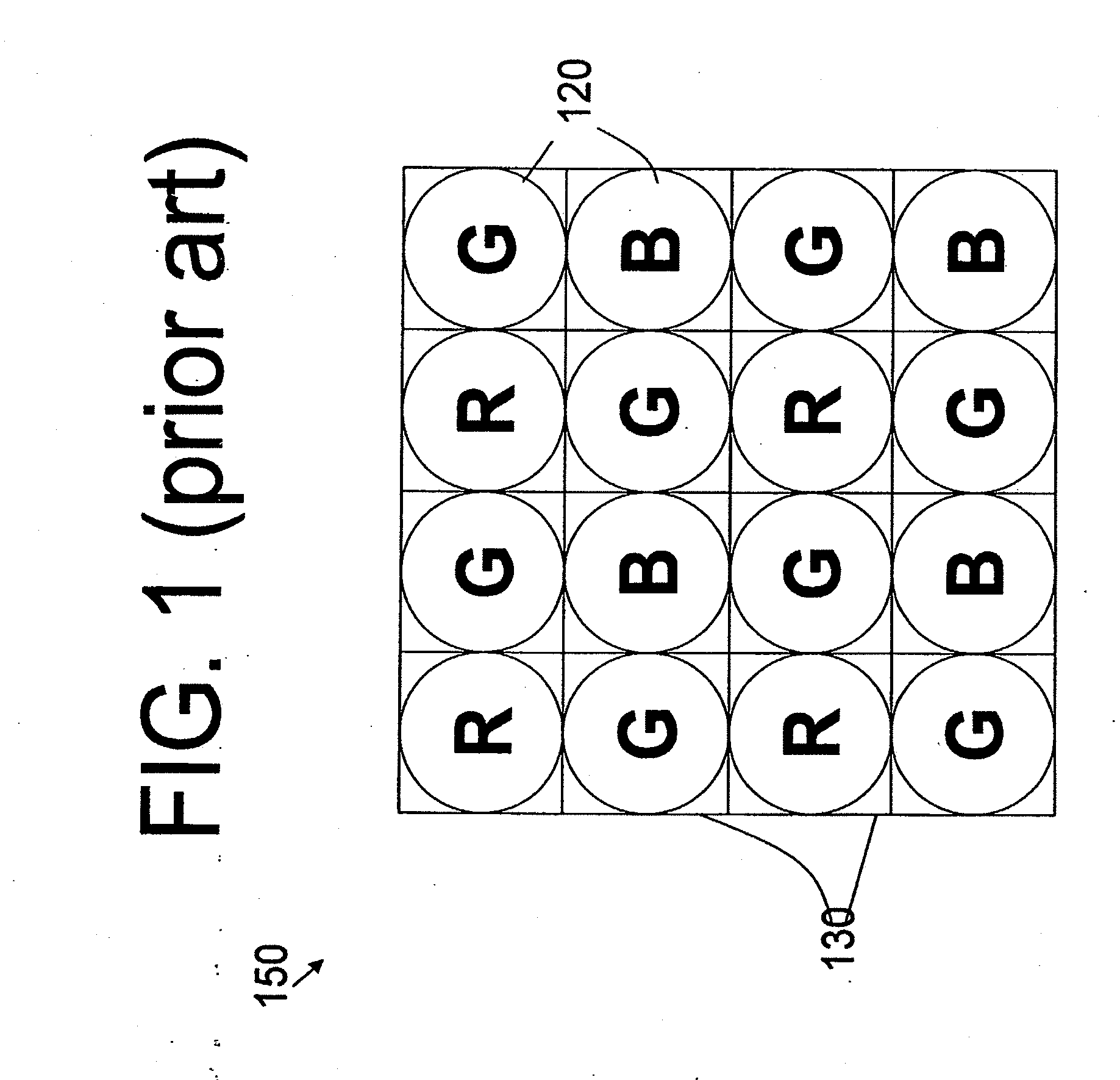

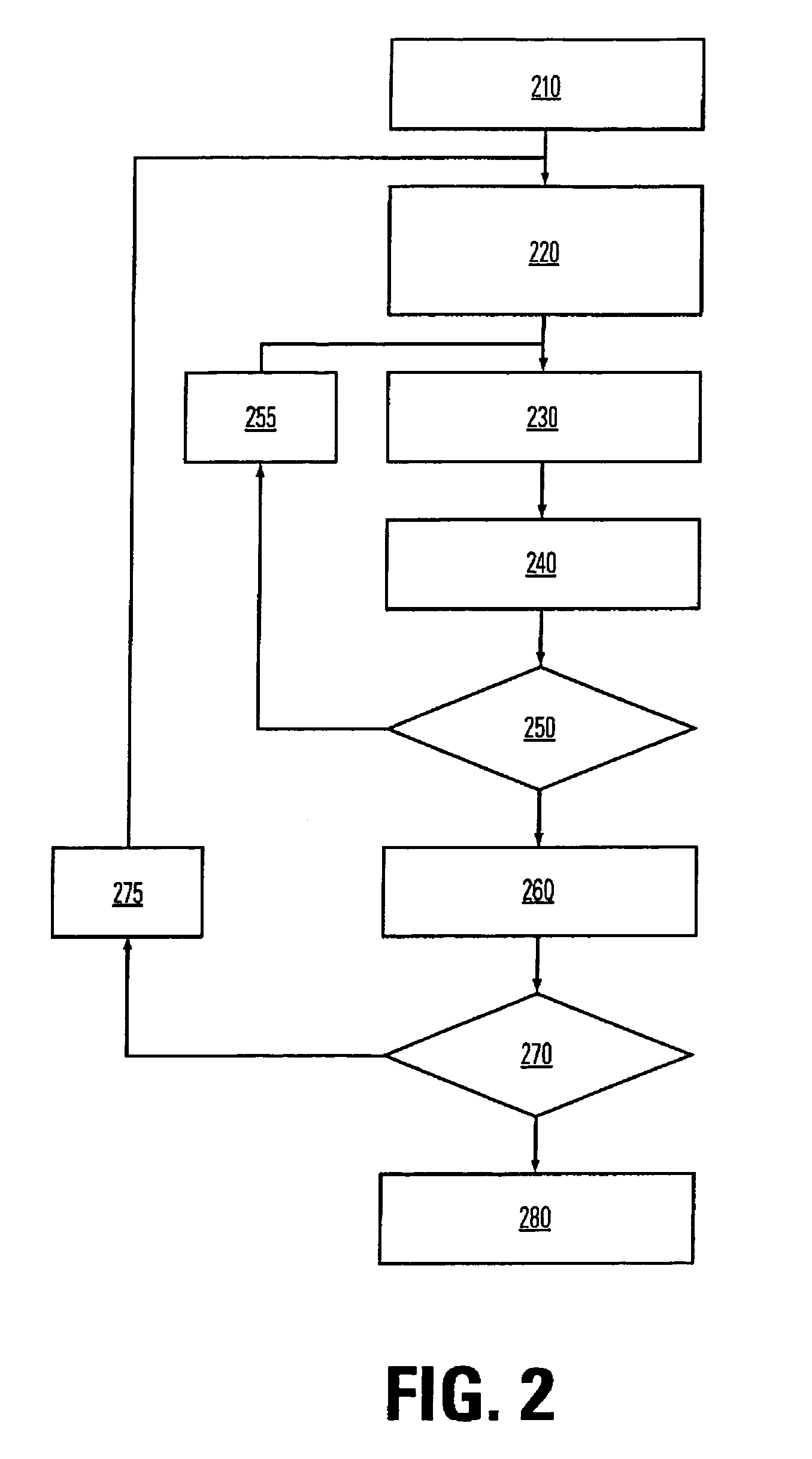

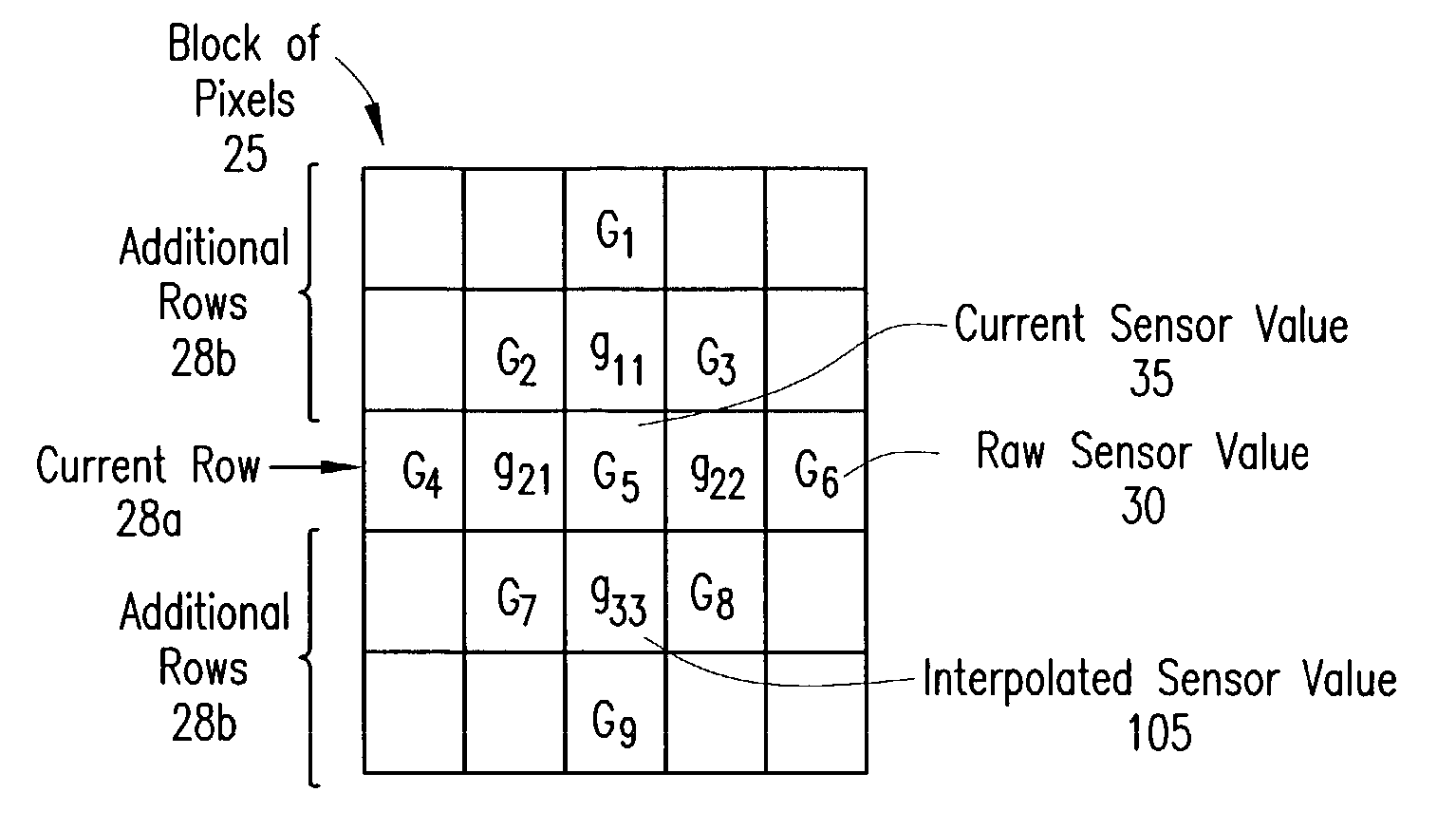

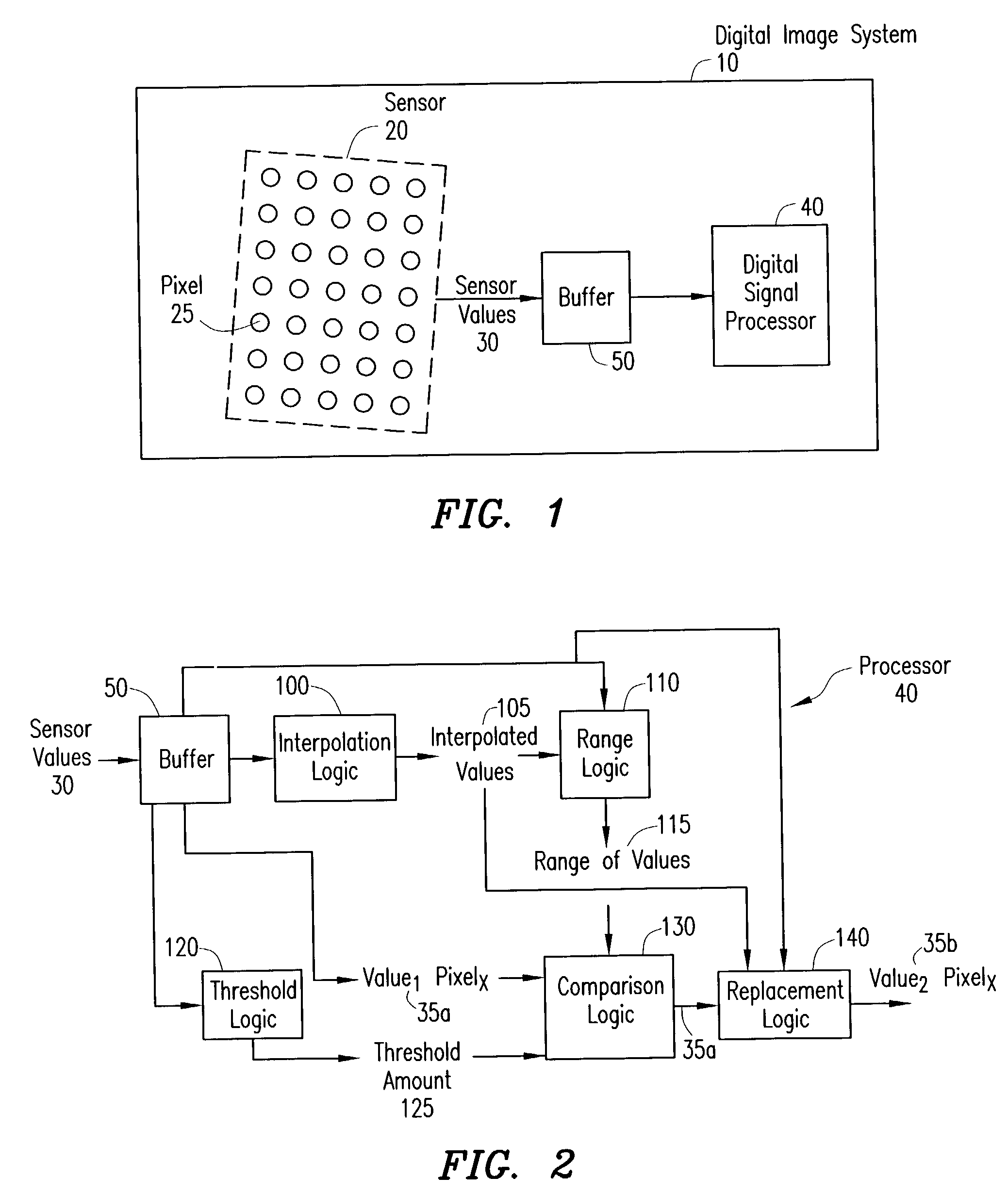

A digital image system and method for combining bad pixel correction and demosaicing in a single process is provided by interpolating sensor values for pixels immediately spatially adjacent to the current pixel being examined to detect defective pixels, and using the interpolated values for demosaicing. If the sensor value of the current pixel being examined is outside of a range of sensor values determined from the interpolated values by more than a configurable threshold amount, the current pixel is considered defective, and replaced using an estimated value from the neighboring pixels. The interpolated values calculated for use in detecting bad pixels can further be used as the interpolated values for demosaicing purposes

Owner:APTINA IMAGING CORP

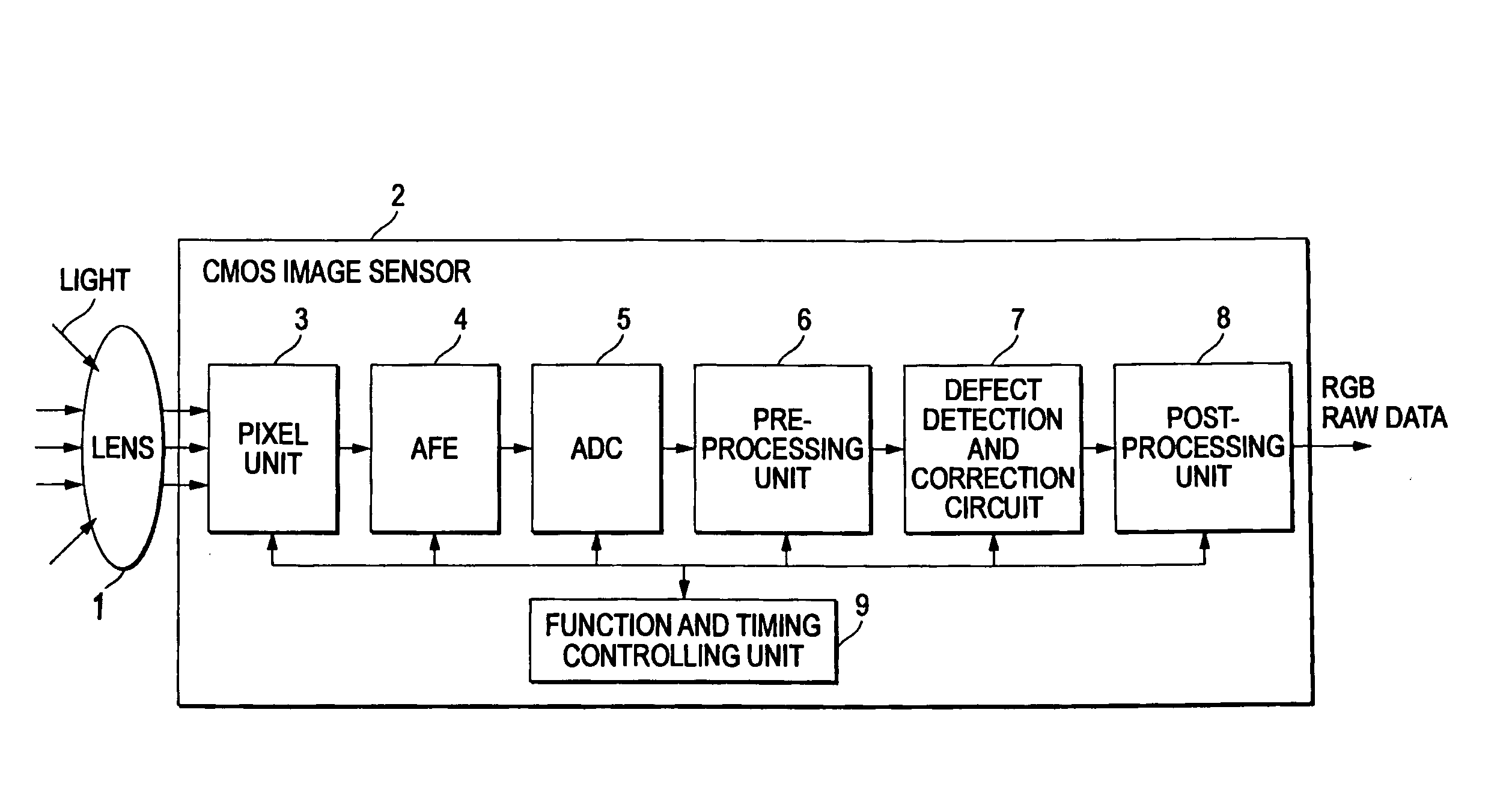

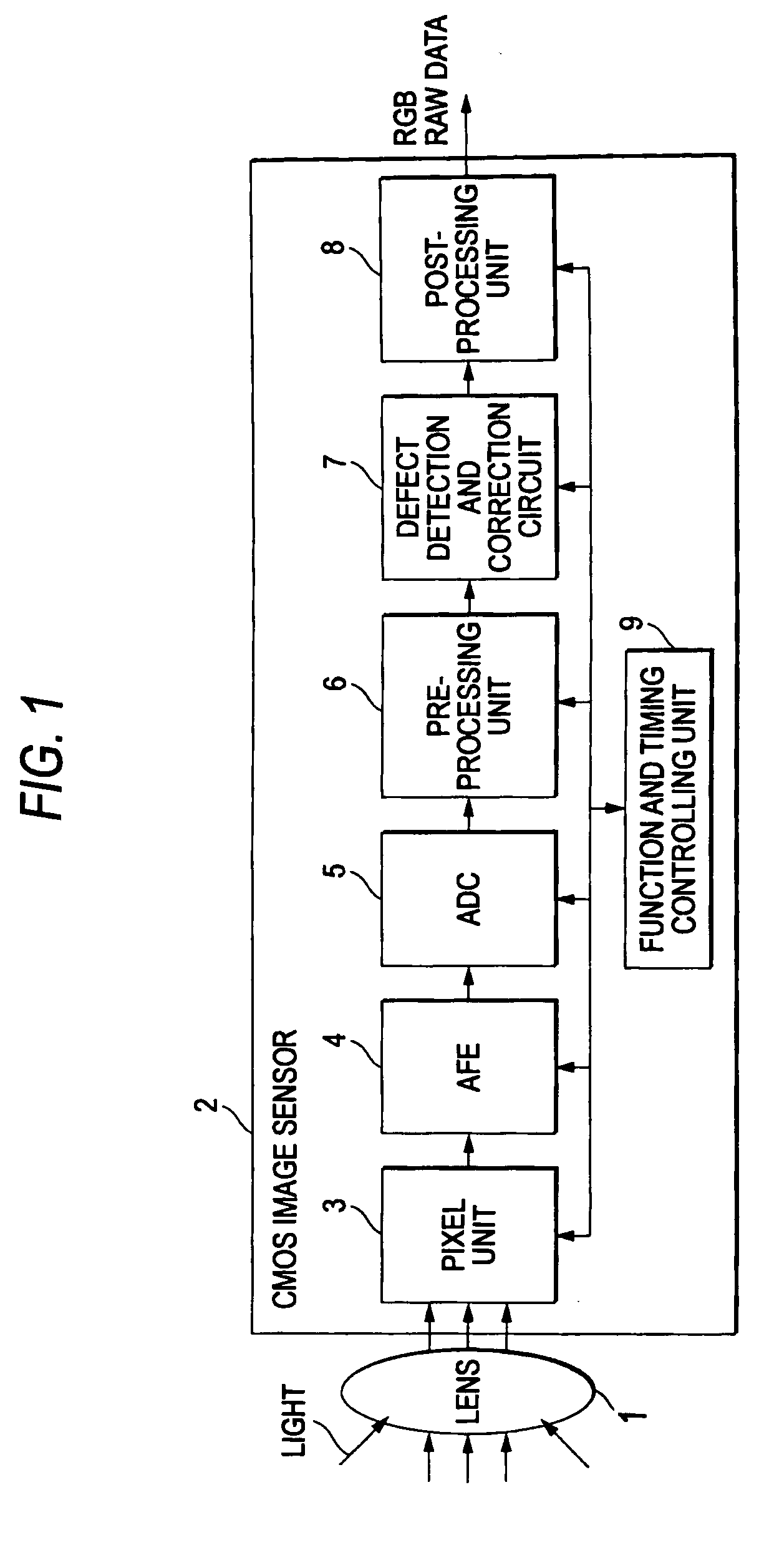

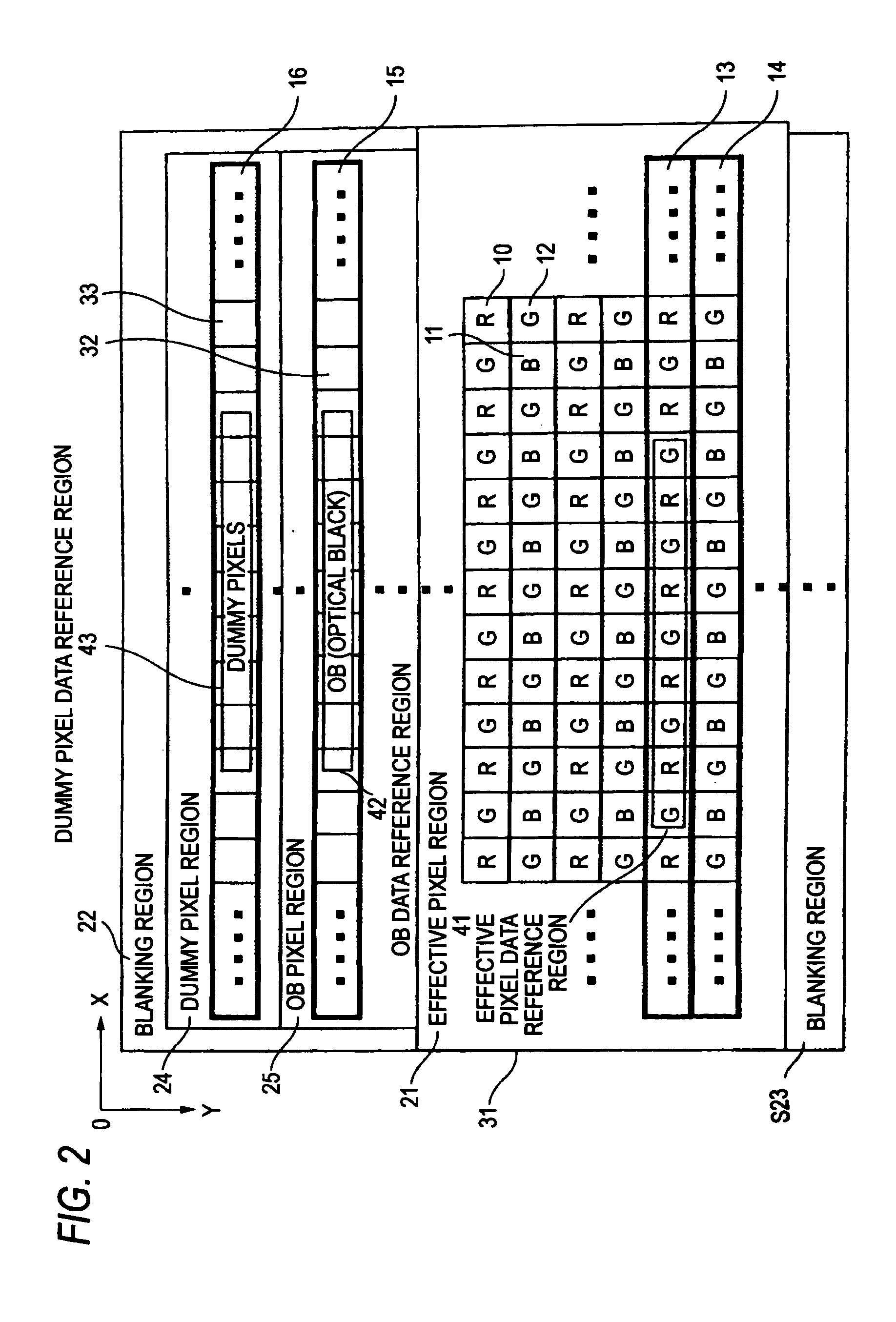

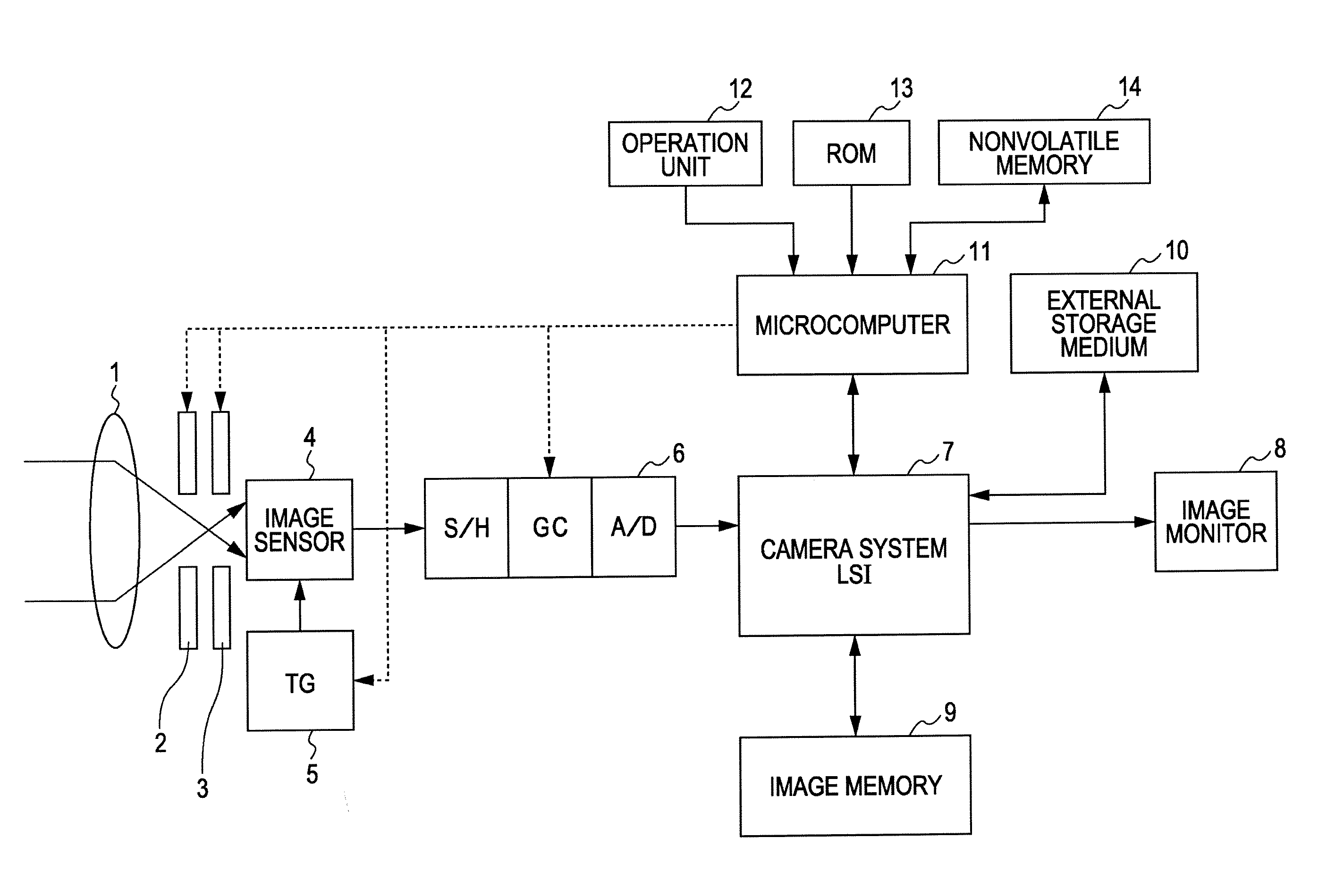

Image sensor

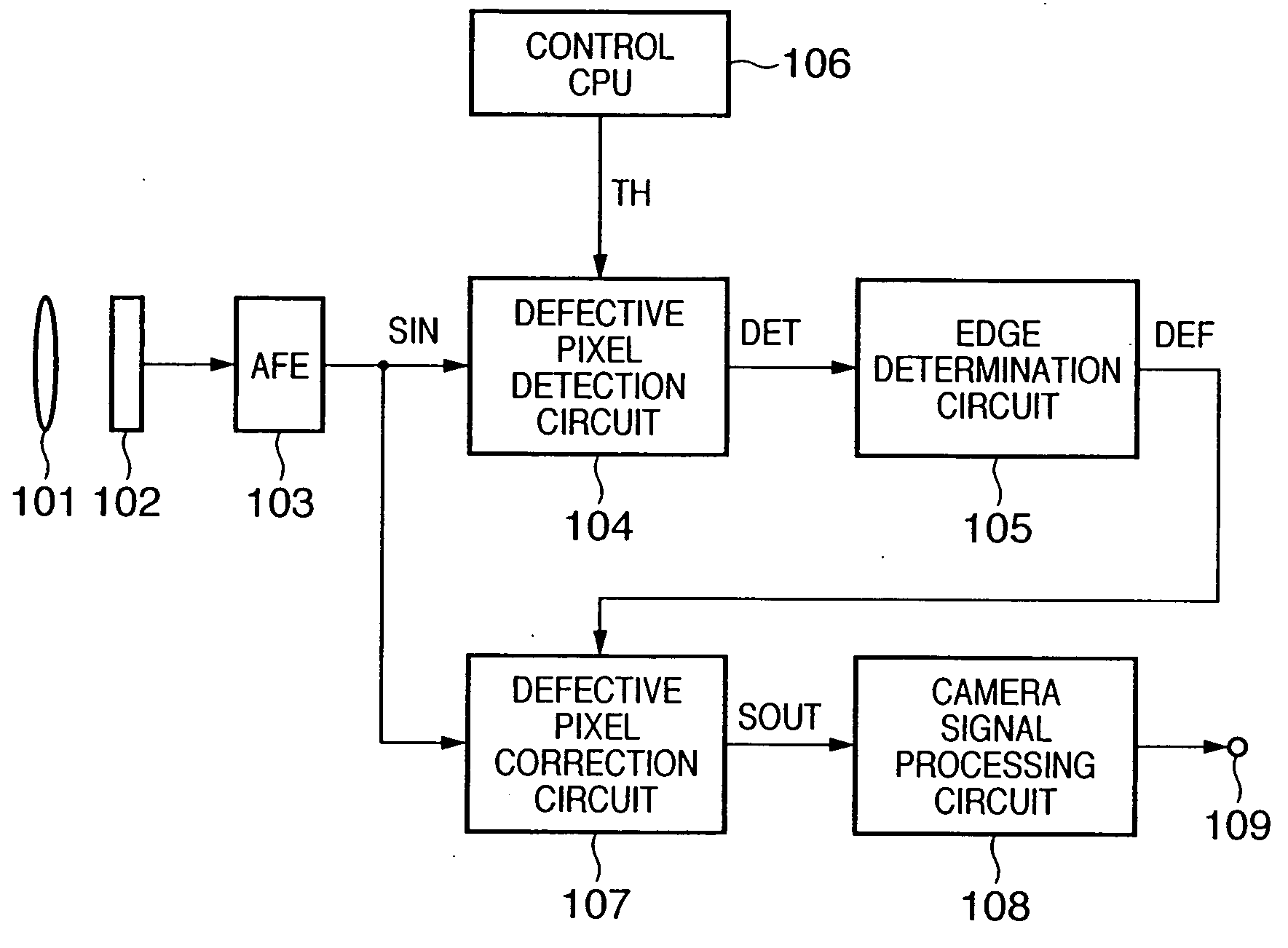

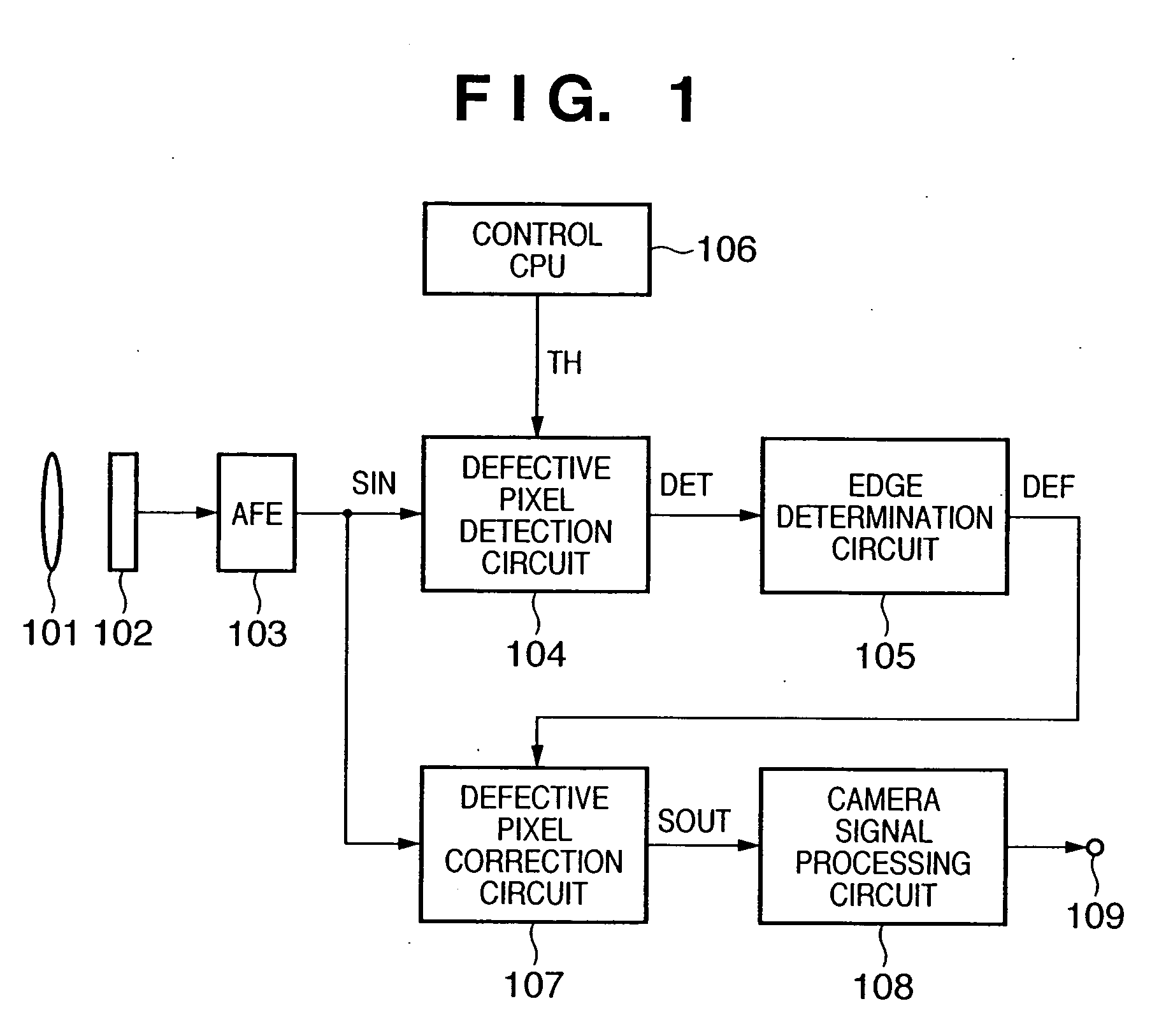

ActiveUS20060007331A1Suppress false detectionTelevision system detailsColor signal processing circuitsAudio power amplifierDefective pixel

An image sensor is disclosed, which includes: a pixel unit having a plurality of pixels each outputting incident light as a pixel signal; an amplifier amplifying the pixel signal output from the pixel unit; and a defective pixel detection circuit performing a defective pixel detection on signals output from the amplifier, wherein the defective pixel detection circuit adjusts the detection accuracy of the defective pixel detection in accordance with an exposure condition of the pixel unit.

Owner:SONY SEMICON SOLUTIONS CORP

Correction of cluster defects in imagers

A method and apparatus that allows for the correction of multiple defective pixels in an imager device. In one exemplary embodiment, the method includes the steps of selecting a correction kernel for a defective pixel, determining average and difference values for pixel pairs in the correction kernel, and substituting an average value from a pixel pair for the value of the defective pixel.

Owner:MICRON TECH INC

Defective pixel compensation method

InactiveUS6618185B2Microbiological testing/measurementSemiconductor/solid-state device manufacturingSpatial light modulatorFluence

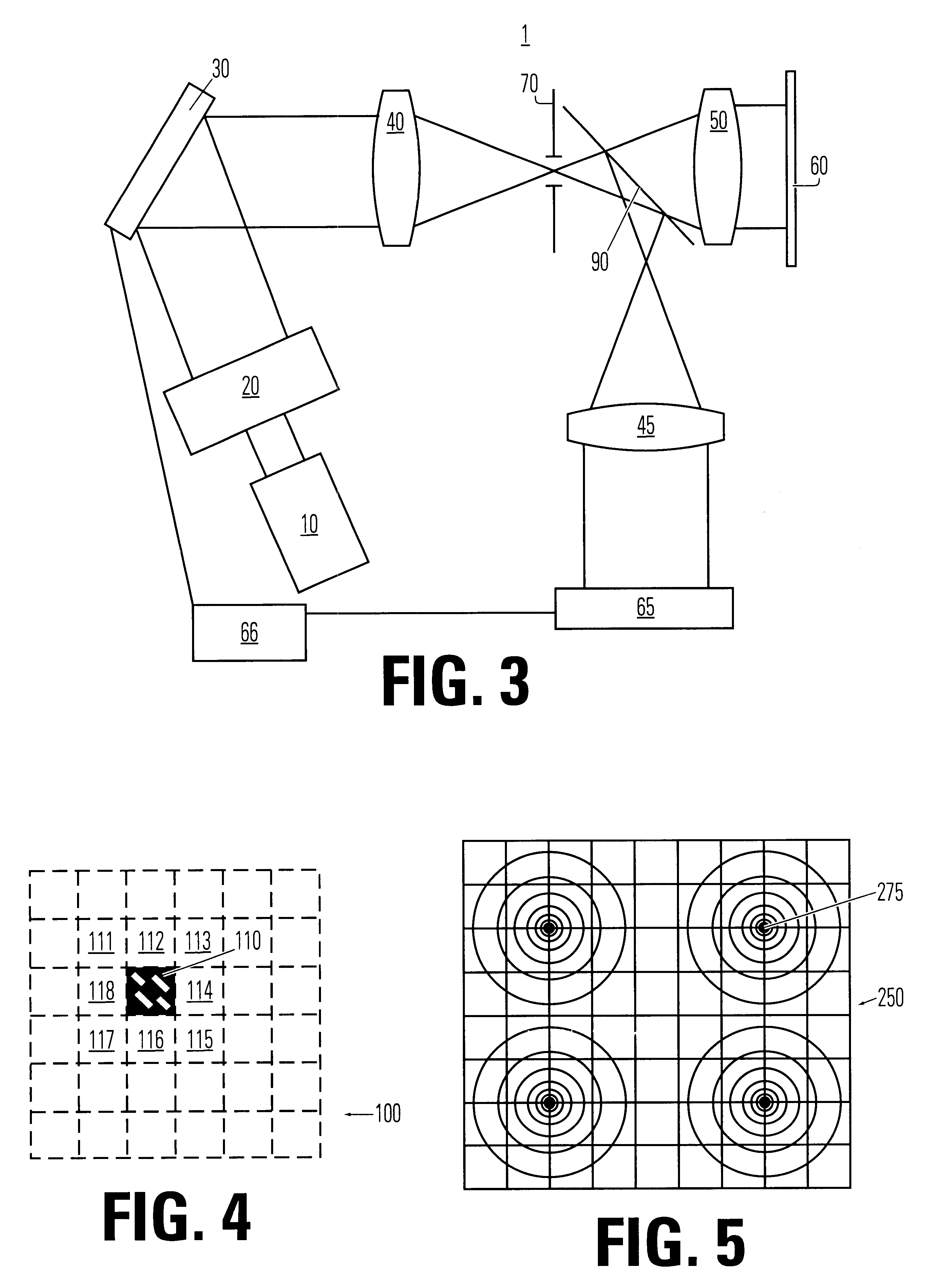

The present invention relates to a method for compensating the impact of at least one defective pixel with a known position in a spatial light modulator (SLM) when creating a pattern of the SLM on a work piece covered with a layer sensitive to electromagnetic radiation. A source for emitting electromagnetic radiation is provided. Said radiation is illuminating said SLM having a plurality of modulating elements (pixels). In a writing pass an image of said modulator is projected on said work piece. A compensation for defective pixels in at least one other writing pass is performed. The invention also relates to an apparatus for performing said method.

Owner:MICRONIC LASER SYST AB

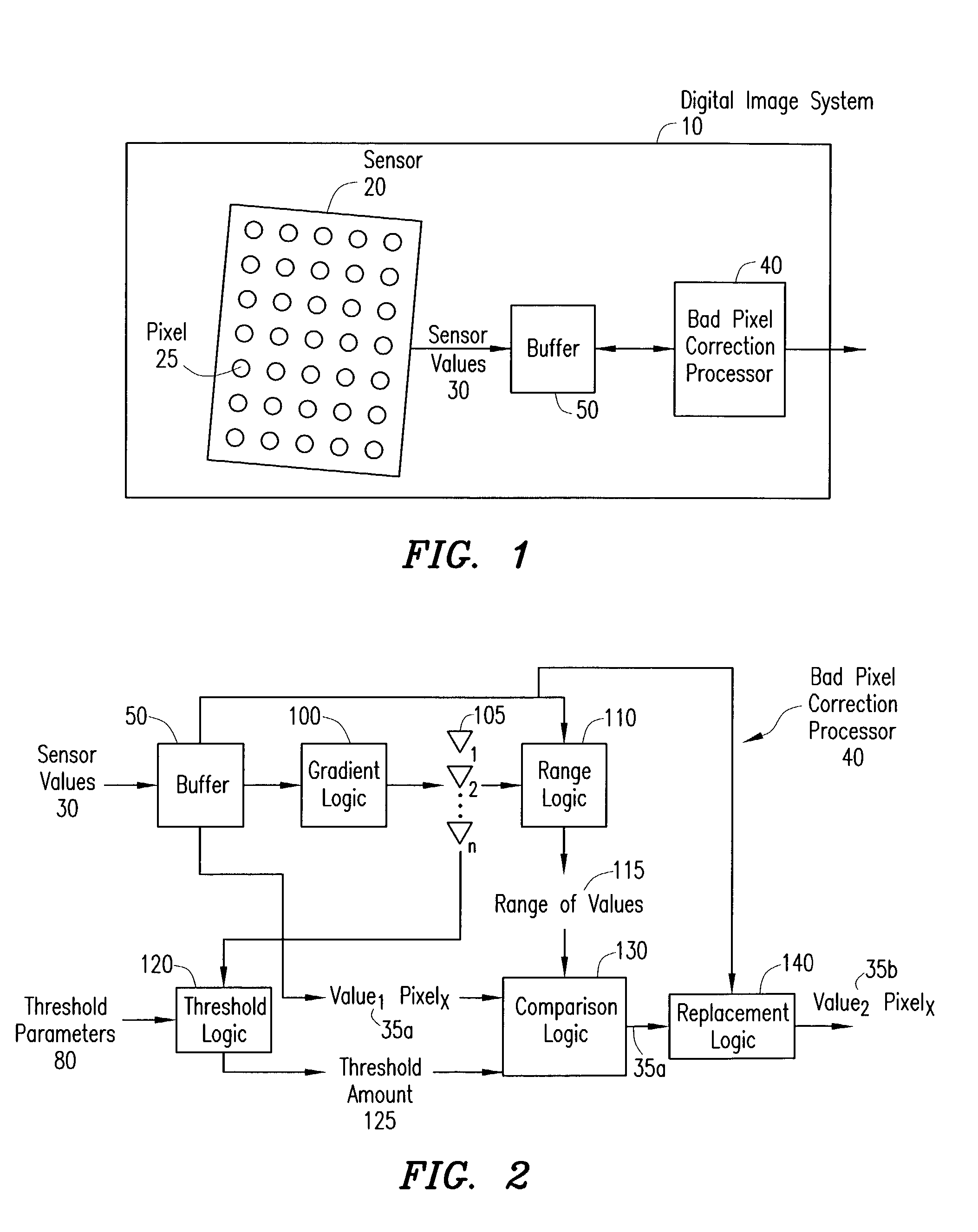

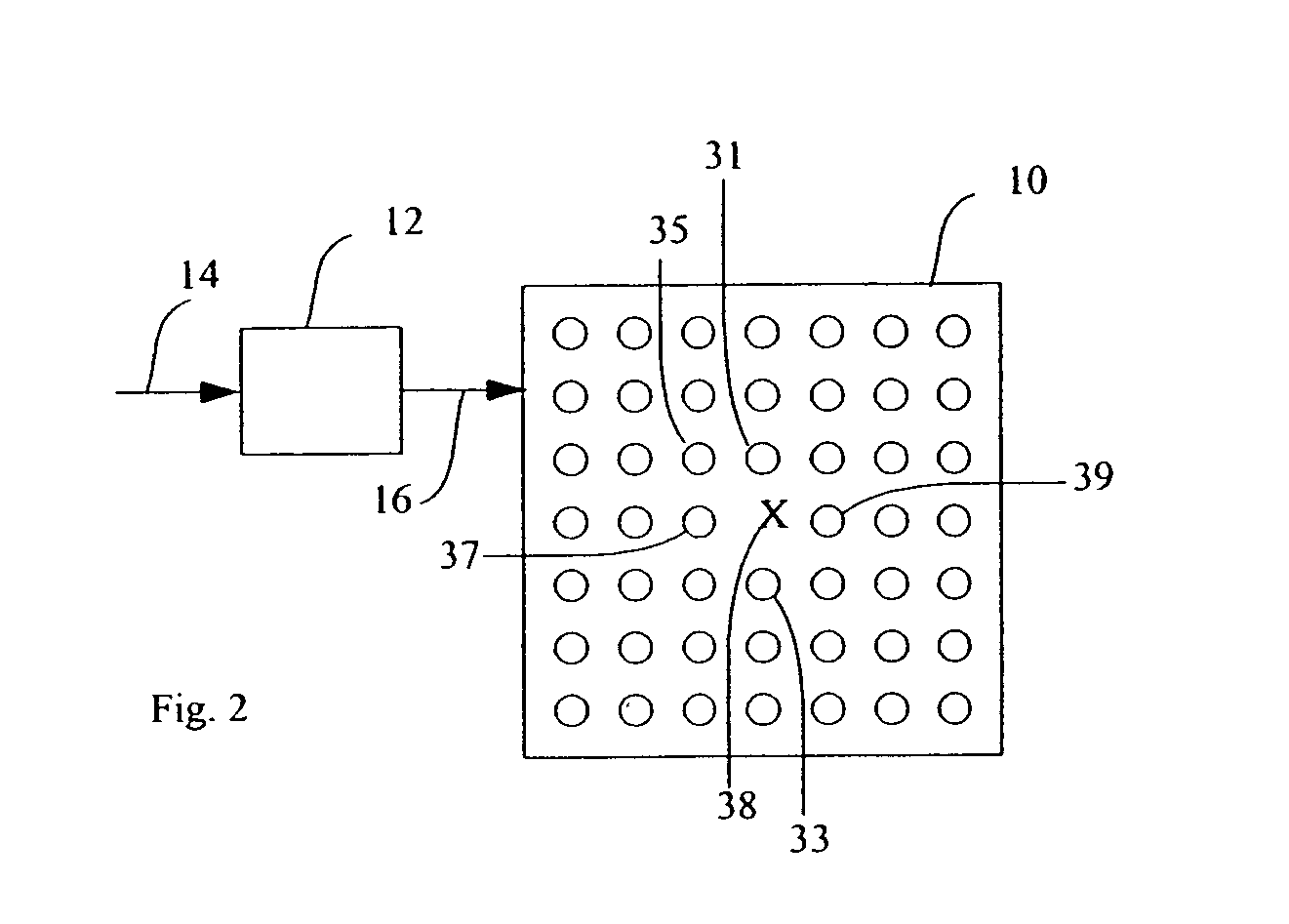

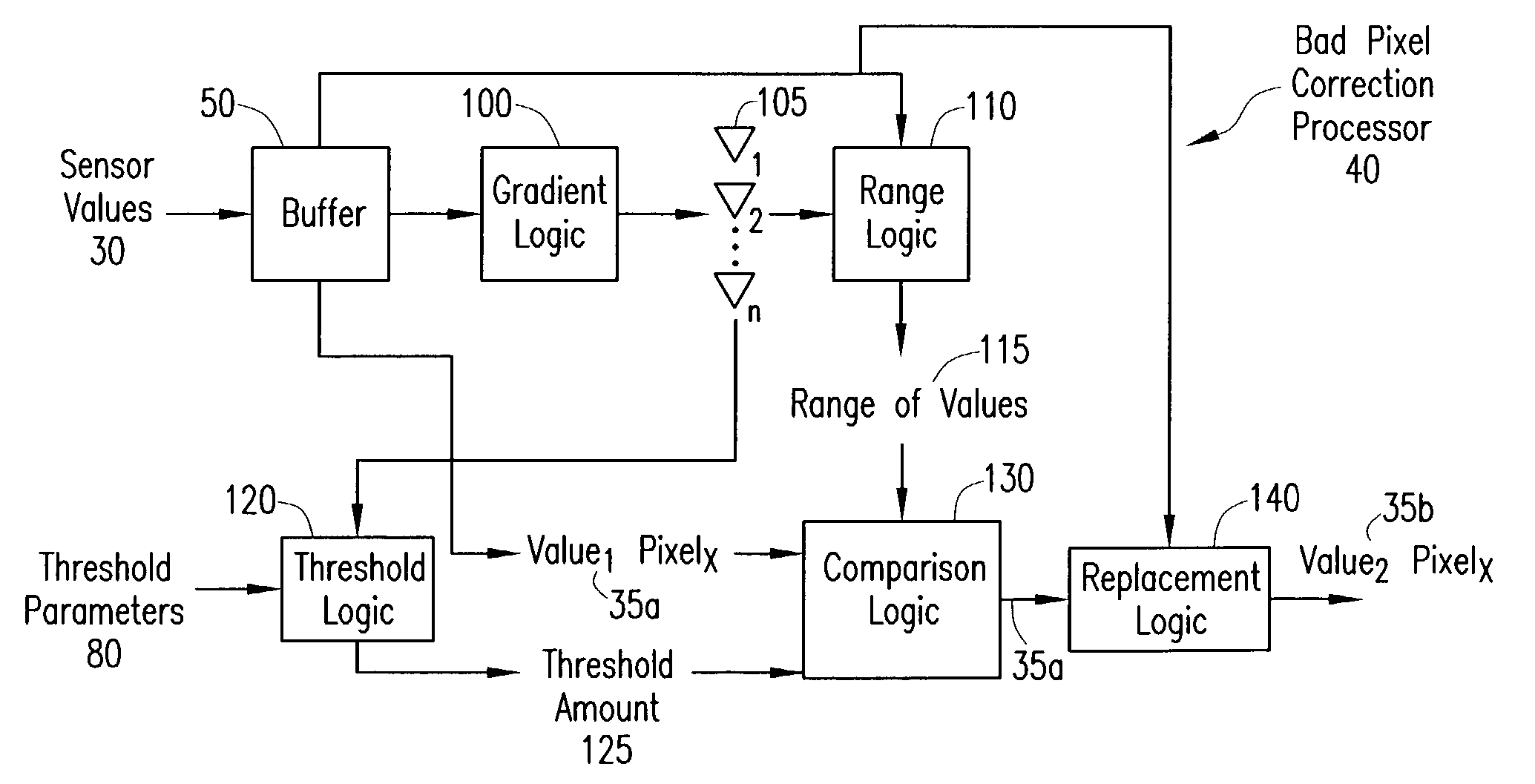

Method for detecting and correcting defective pixels in a digital image sensor

ActiveUS20040051798A1Television system detailsColor signal processing circuitsPattern recognitionColor image

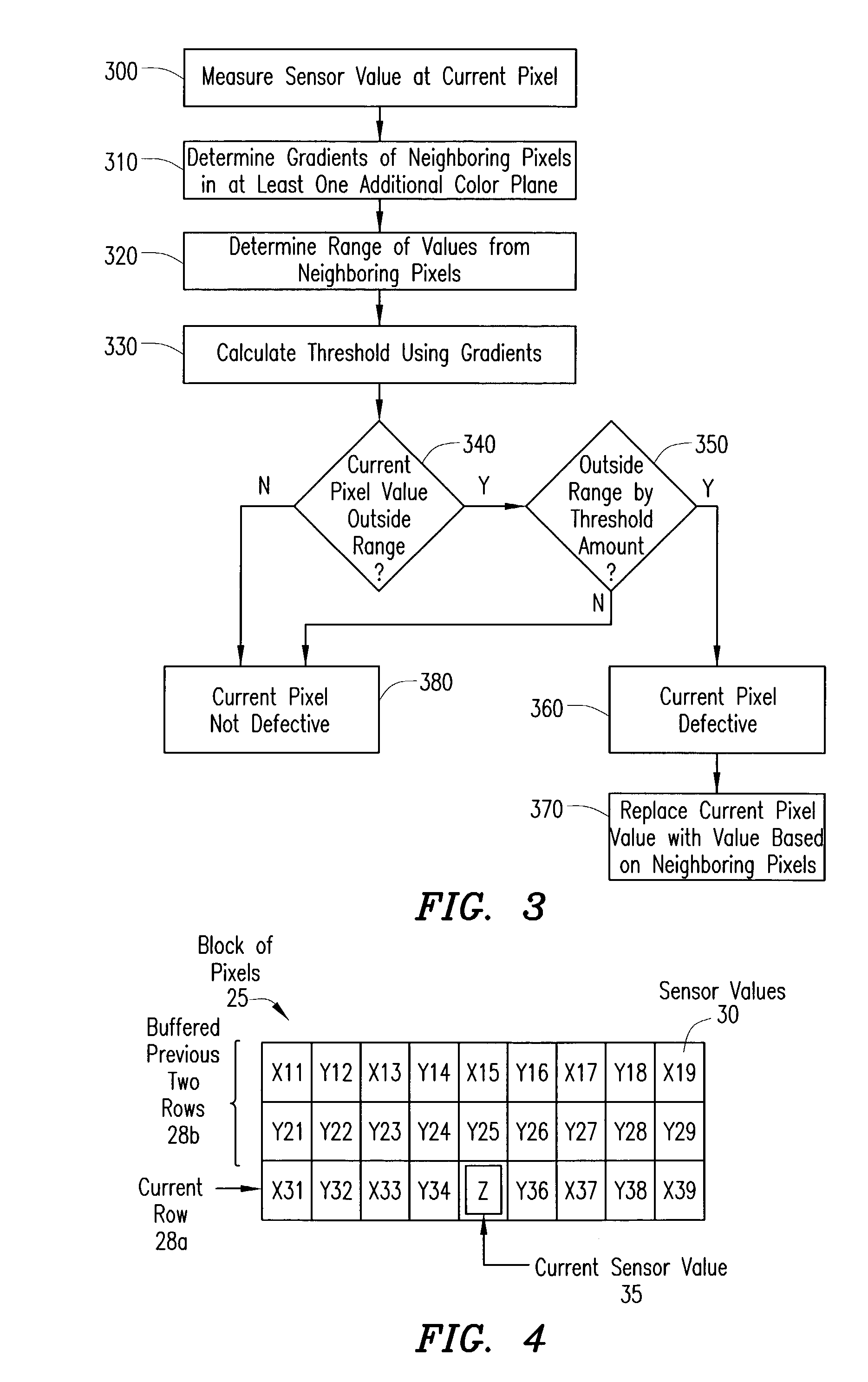

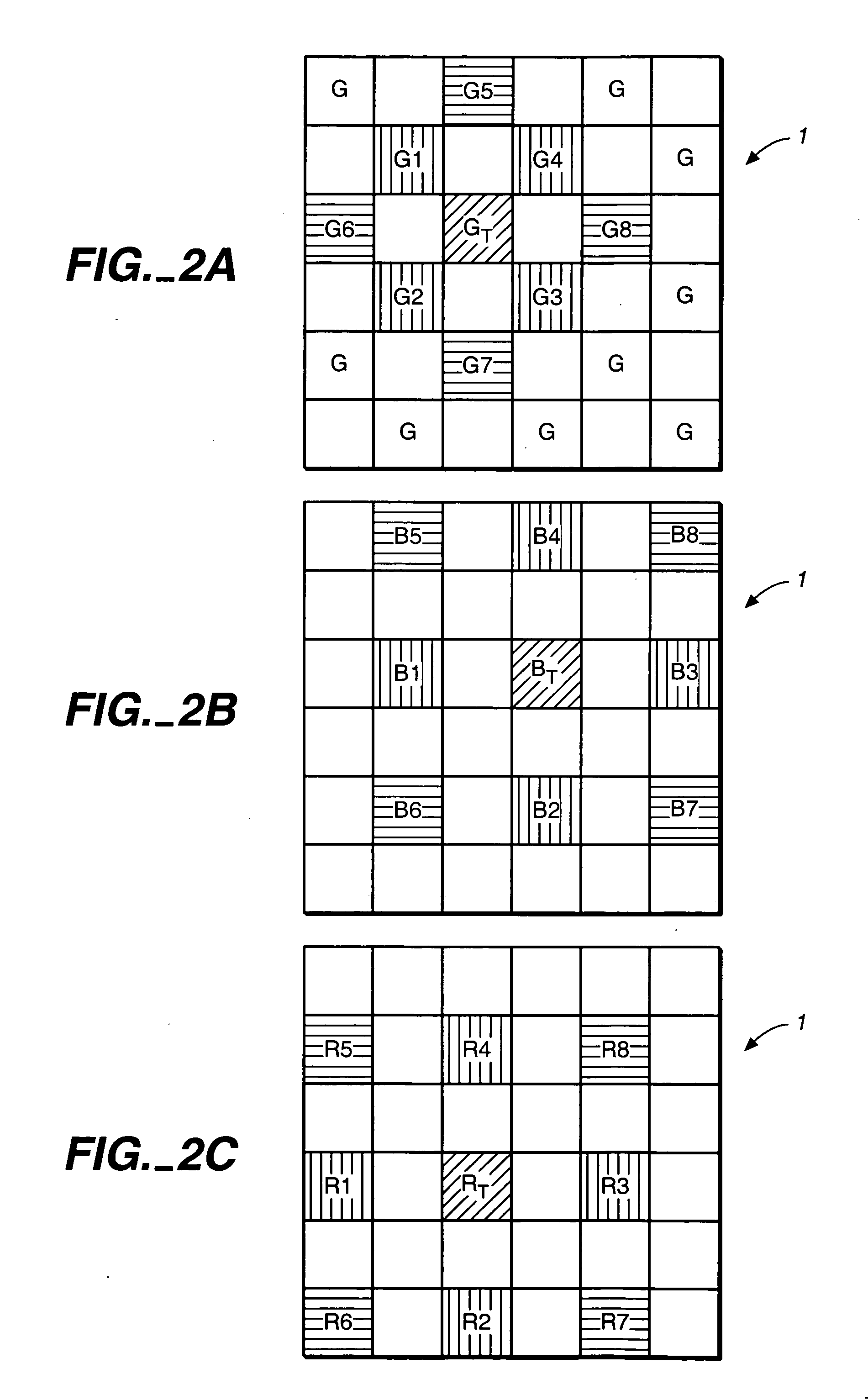

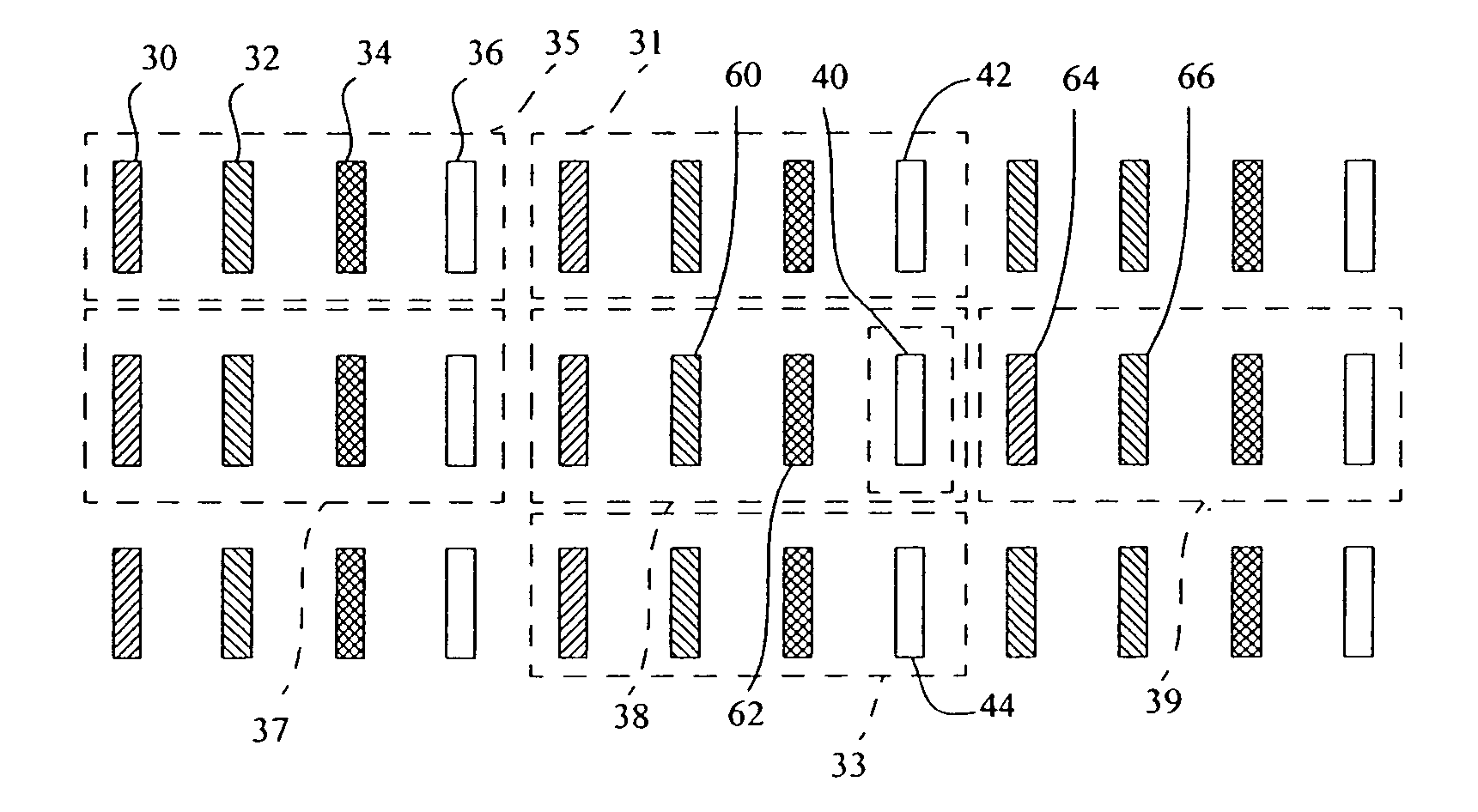

A bad pixel correction (BPC) algorithm that can be implemented on the image sensor chip is provided for detecting and correcting defective pixels in a digital color image sensor. Gradients of neighboring pixels in at least one other color plane than the color plane of a current pixel and a range of sensor values from neighboring pixels in the same color plane as the current pixel are determined. If the sensor value of the current pixel is outside of the range by a threshold amount that is calculated using one or more of the gradients, the current pixel is determined to be a defective pixel, and replaced using the sensor values of the neighboring pixels in the same color plane.

Owner:APTINA IMAGING CORP

Dynamic identification and correction of defective pixels

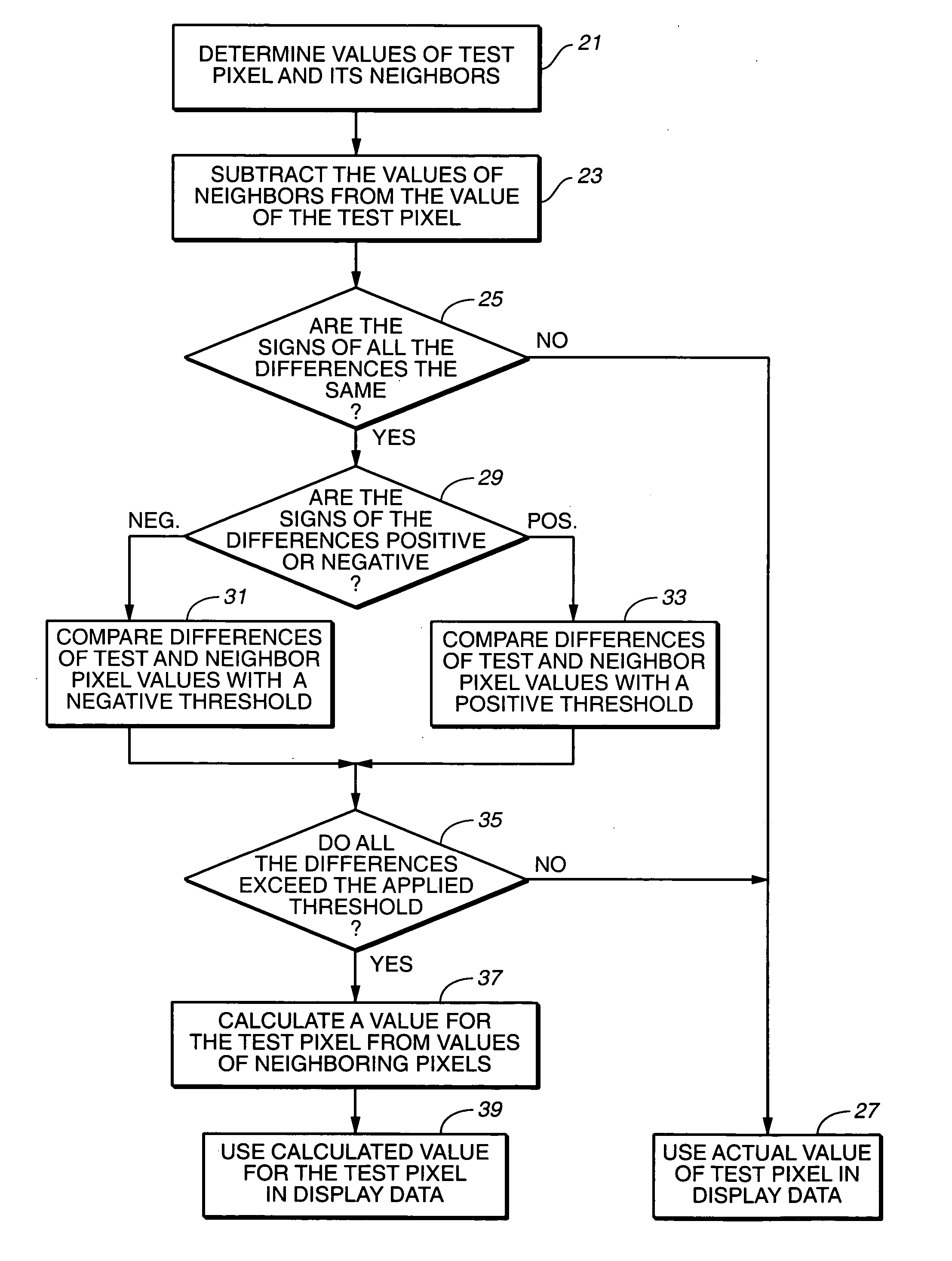

InactiveUS20050010621A1Reduce complexityLow costTelevision system detailsColor signal processing circuitsComputer scienceDefective pixel

Rather than storing a table within a digital camera or other optical device of defective pixels within its image sensor, defective pixels are dynamically identified by comparing the output values of individual pixels under test with those of neighboring pixels. If the neighbors are all above or below the pixel under test by a defined threshold amount, the output of the pixel under test is replaced with a value calculated from the outputs of neighboring pixels.

Owner:QUALCOMM INC

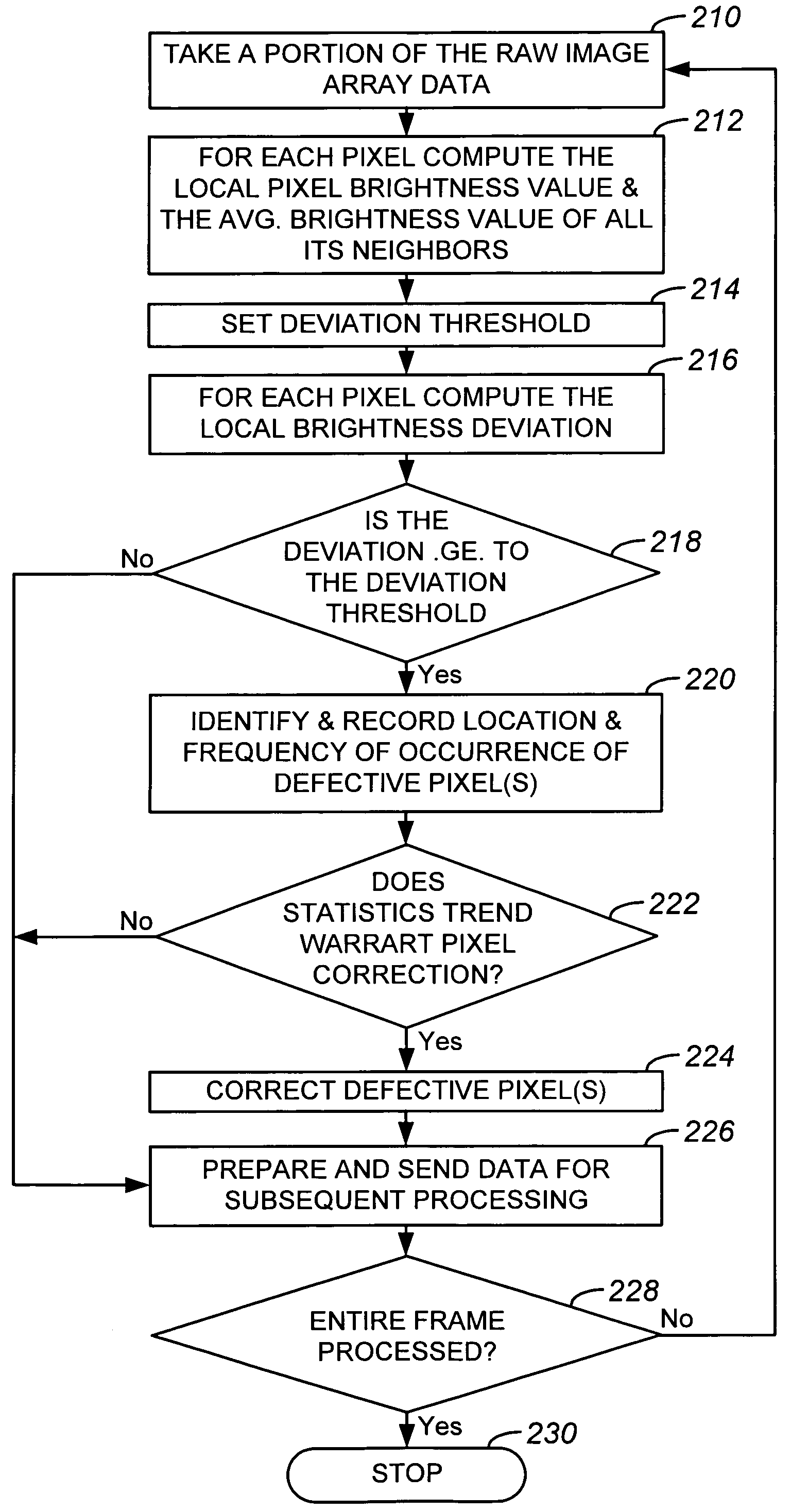

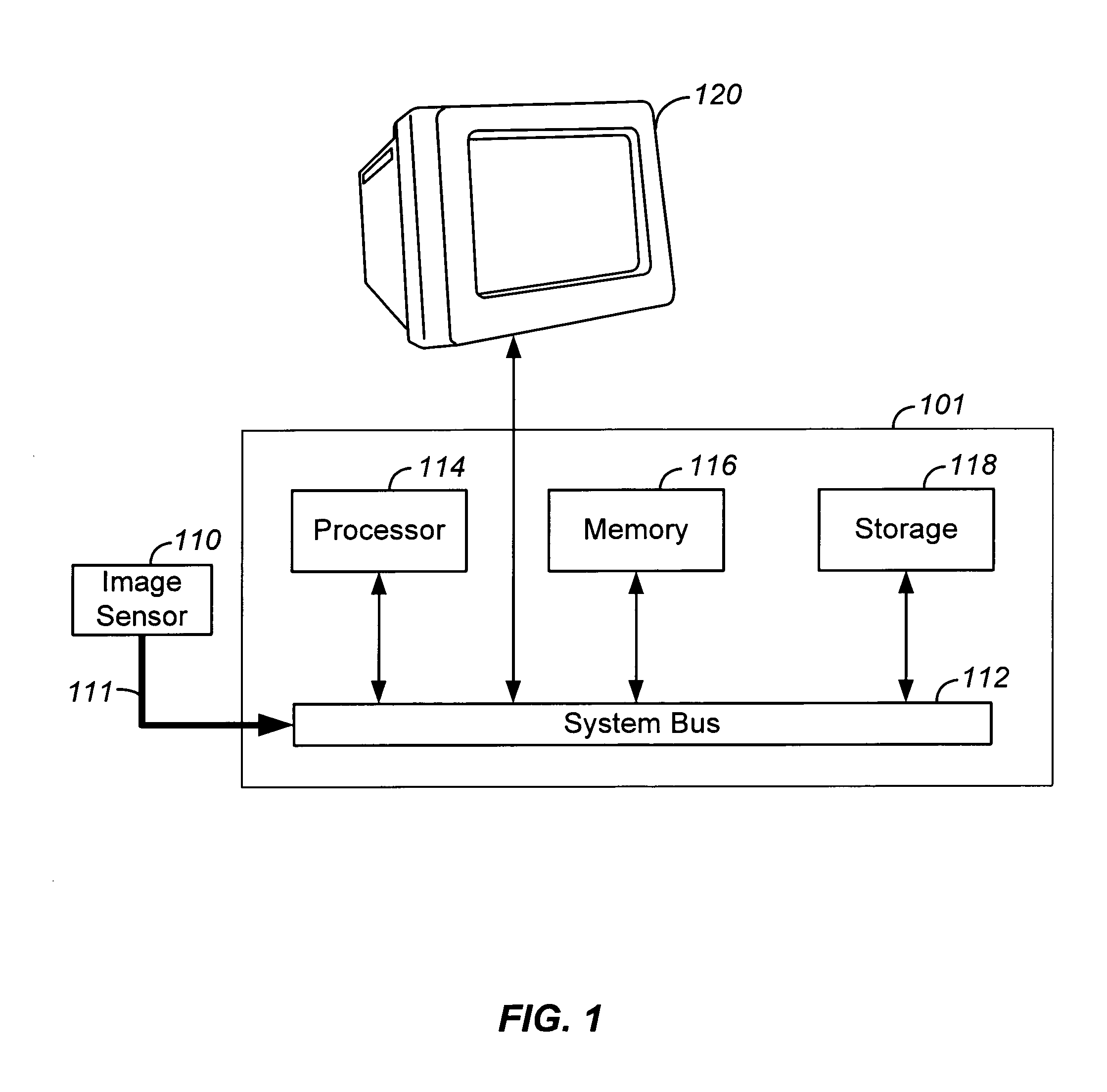

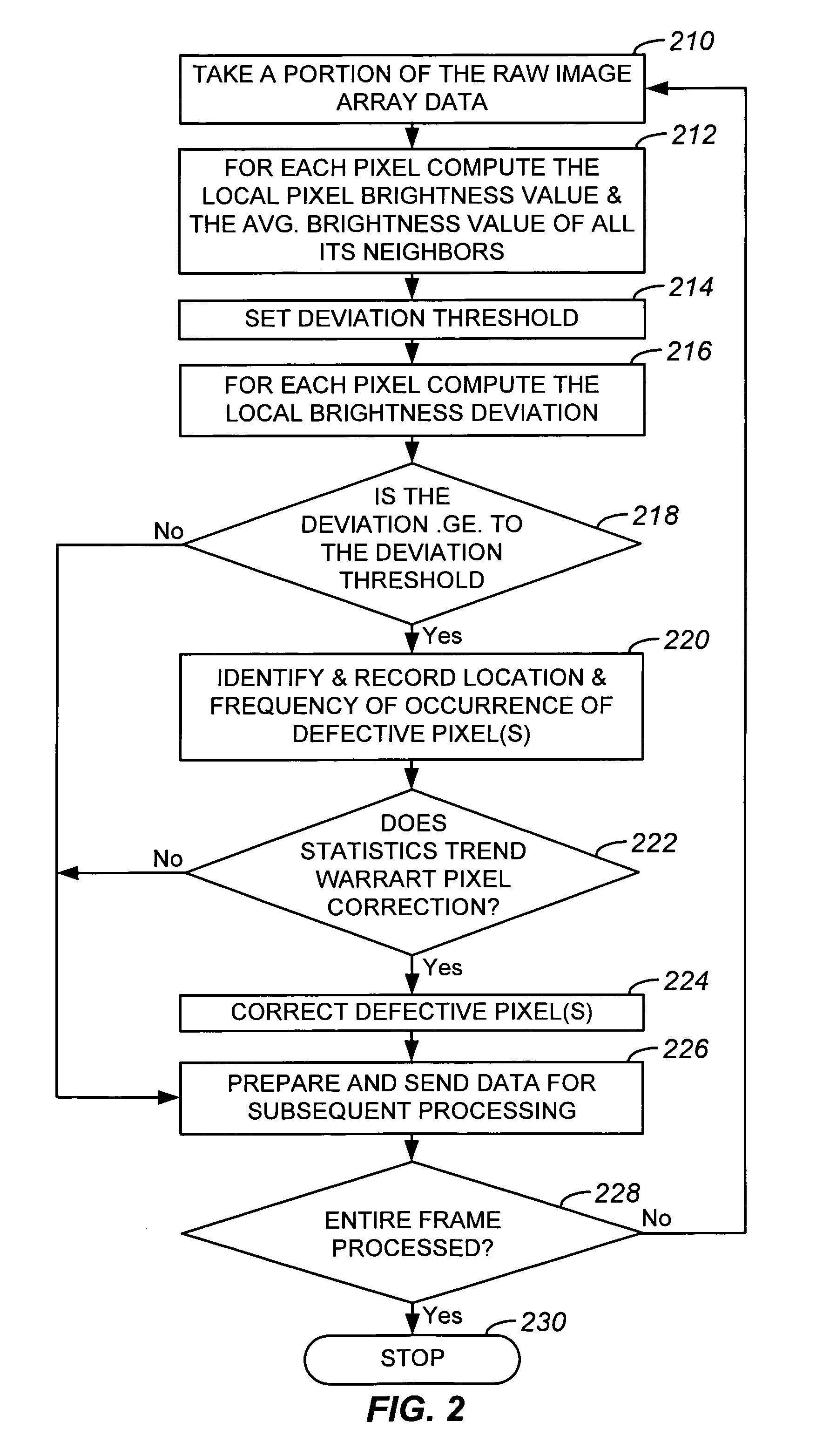

Dynamic anomalous pixel detection and correction

InactiveUS7009644B1Minimally affectedImpact rateTelevision system detailsColor signal processing circuitsPattern recognitionCMOS sensor

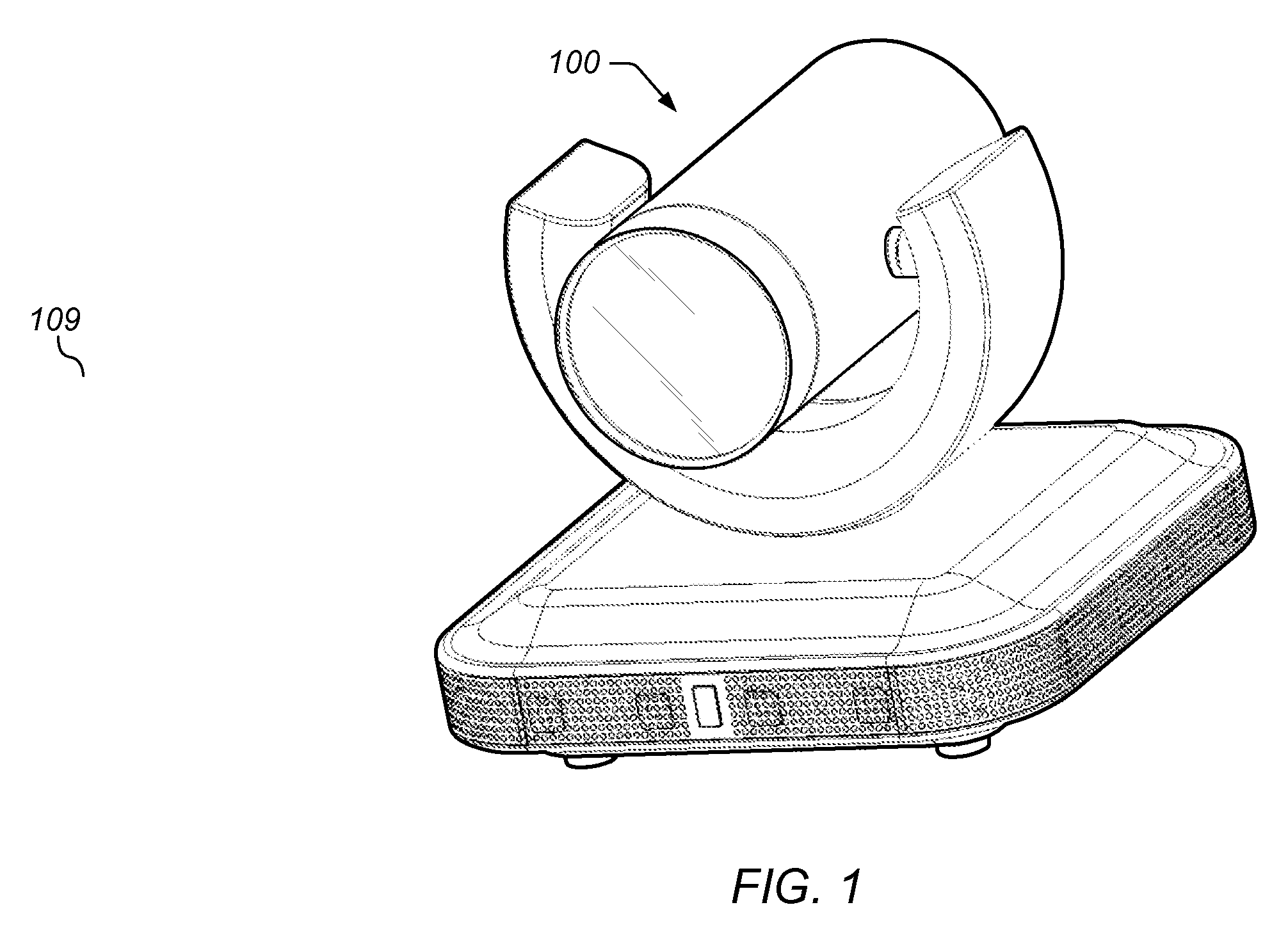

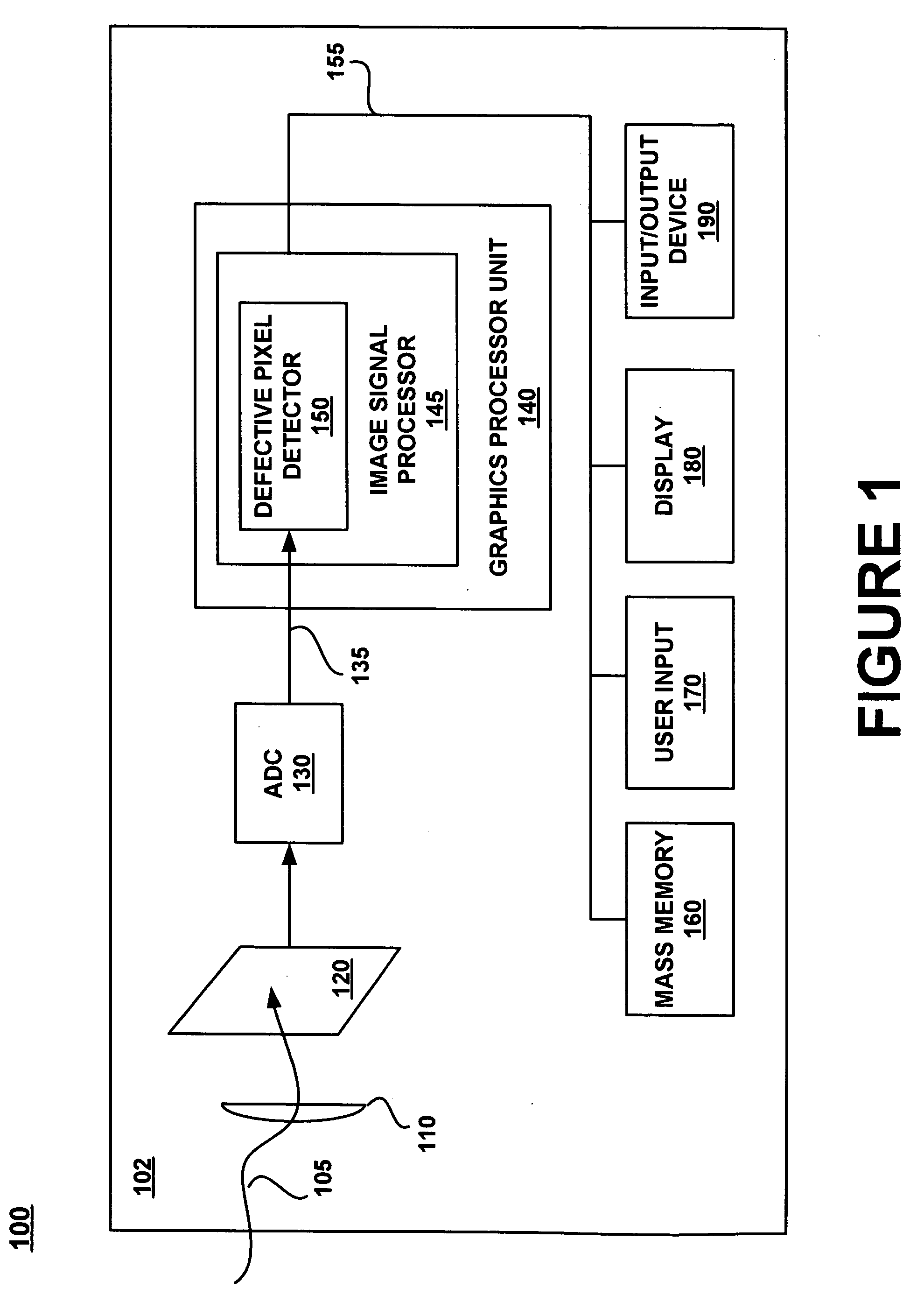

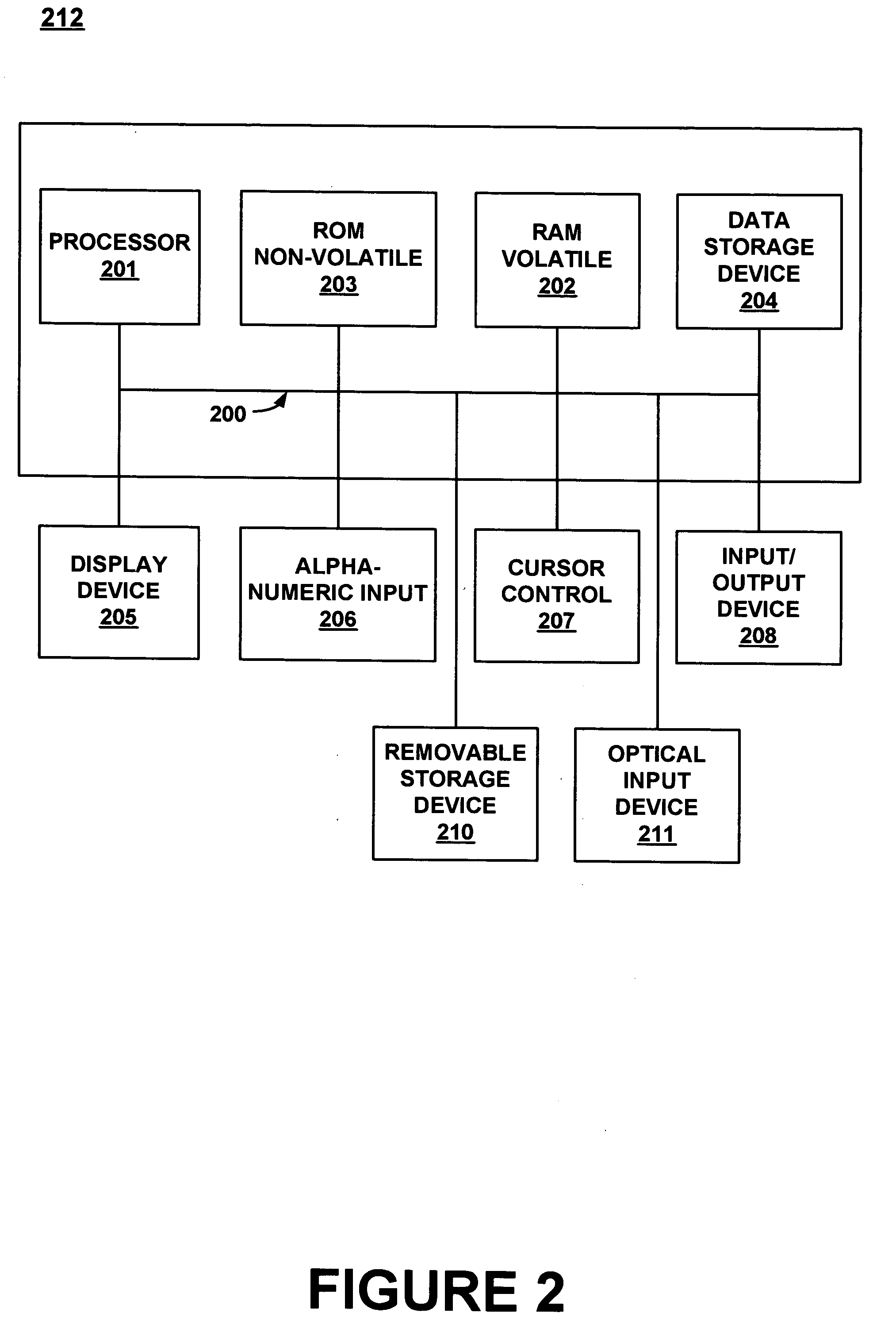

A method and a system for dynamically detecting and correcting anomalous pixels in the raw data taken from an image sensor array such as a CCD or a CMOS sensor array, thus allowing the use of dumb cameras to capture digital images for subsequent use by an intelligent host—such as being displayed on a computer monitor. This invention uses software algorithms running on an intelligent host processor to dynamically correct the anomalous pixels in the raw data taken from an image sensor array typical of those in a digital still or a video camera. Using the combination of a dumb camera which provides raw data to an intelligent host, which does all the subsequent image processing, the system works by scanning an image frame for pixels that vary more than a specified amount in their brightness value from their neighboring pixels and designating those as defective pixels. The location and frequency of the photosites sending the defective pixels are stored in a statistical database in the computer's memory. The brightness value of a defective pixel is then replaced by a local brightness value obtained from the defective pixel's neighboring pixels. The process includes video subsampling, meaning that the defective pixel detection is carried out and repeated at a pre-specified frame rate to ensure optimum detection and correction at a minimal level of scanning. A statistical database is kept so that truly anomalous pixels can over time be distinguished from false detection of true anomalies in the target image, lighting or other environmentally induced anomalies.

Owner:LOGITECH EURO SA

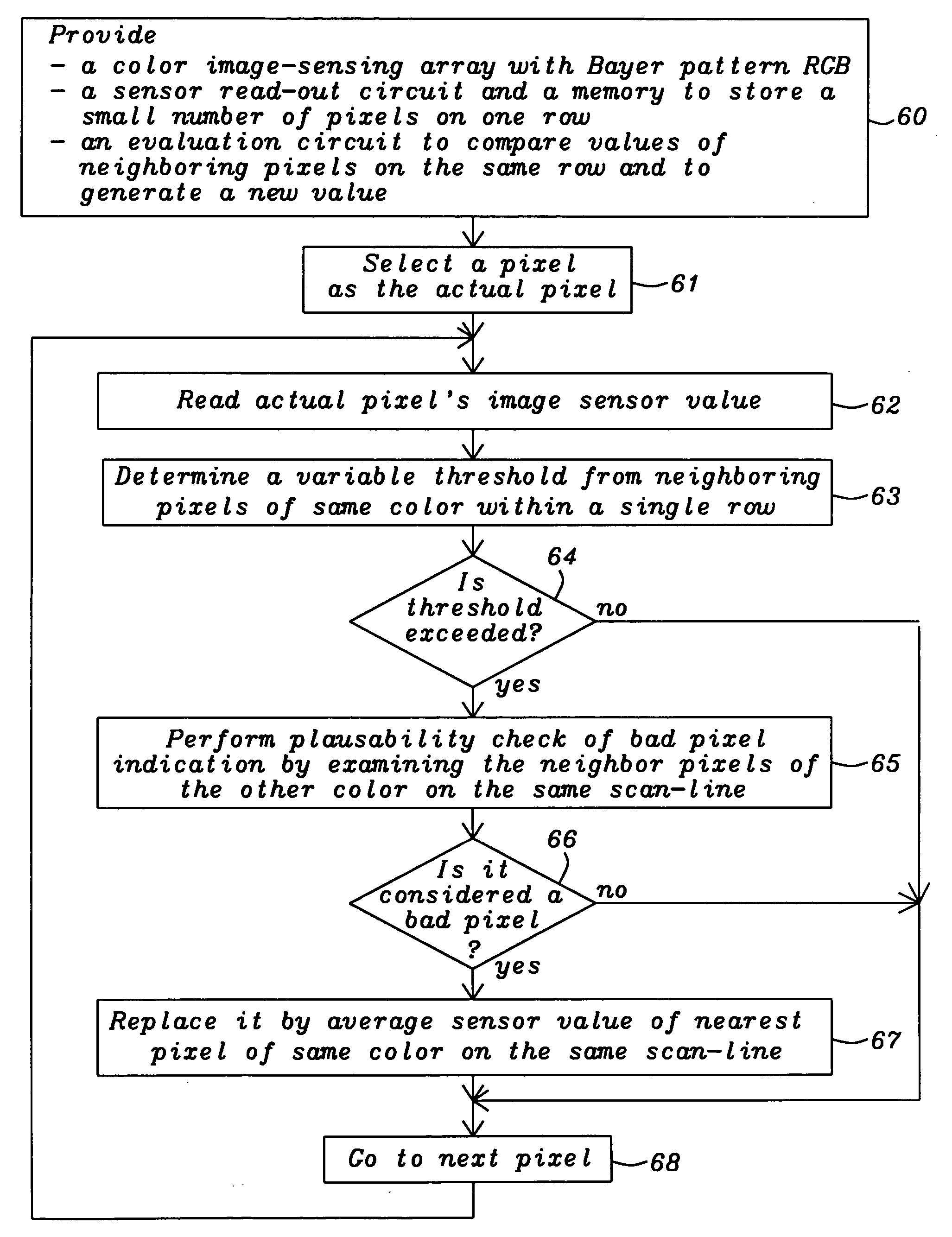

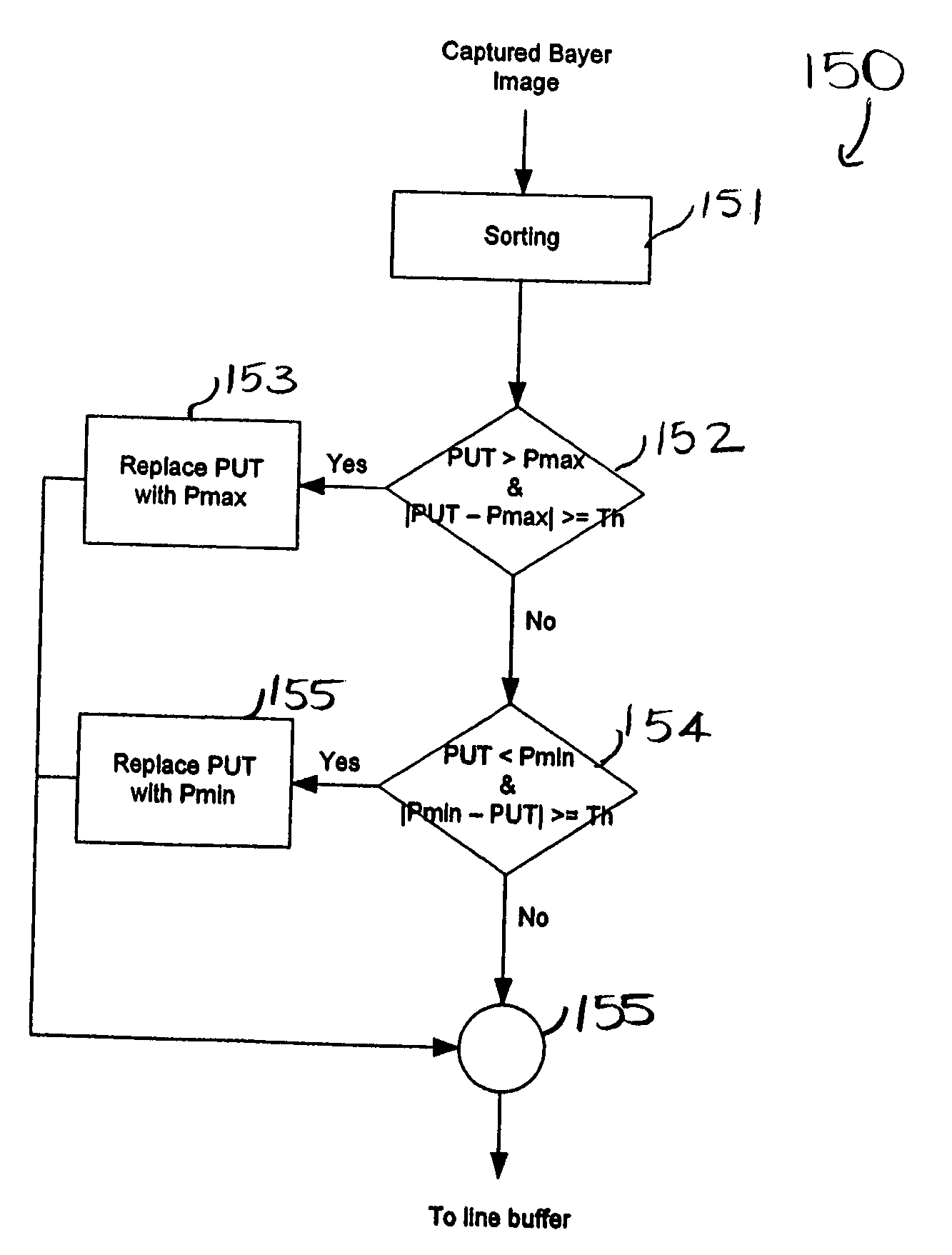

Single line bayer RGB bad pixel correction

InactiveUS20050248671A1Efficient detectionLow costTelevision system detailsColor signal processing circuitsPattern recognitionColor image

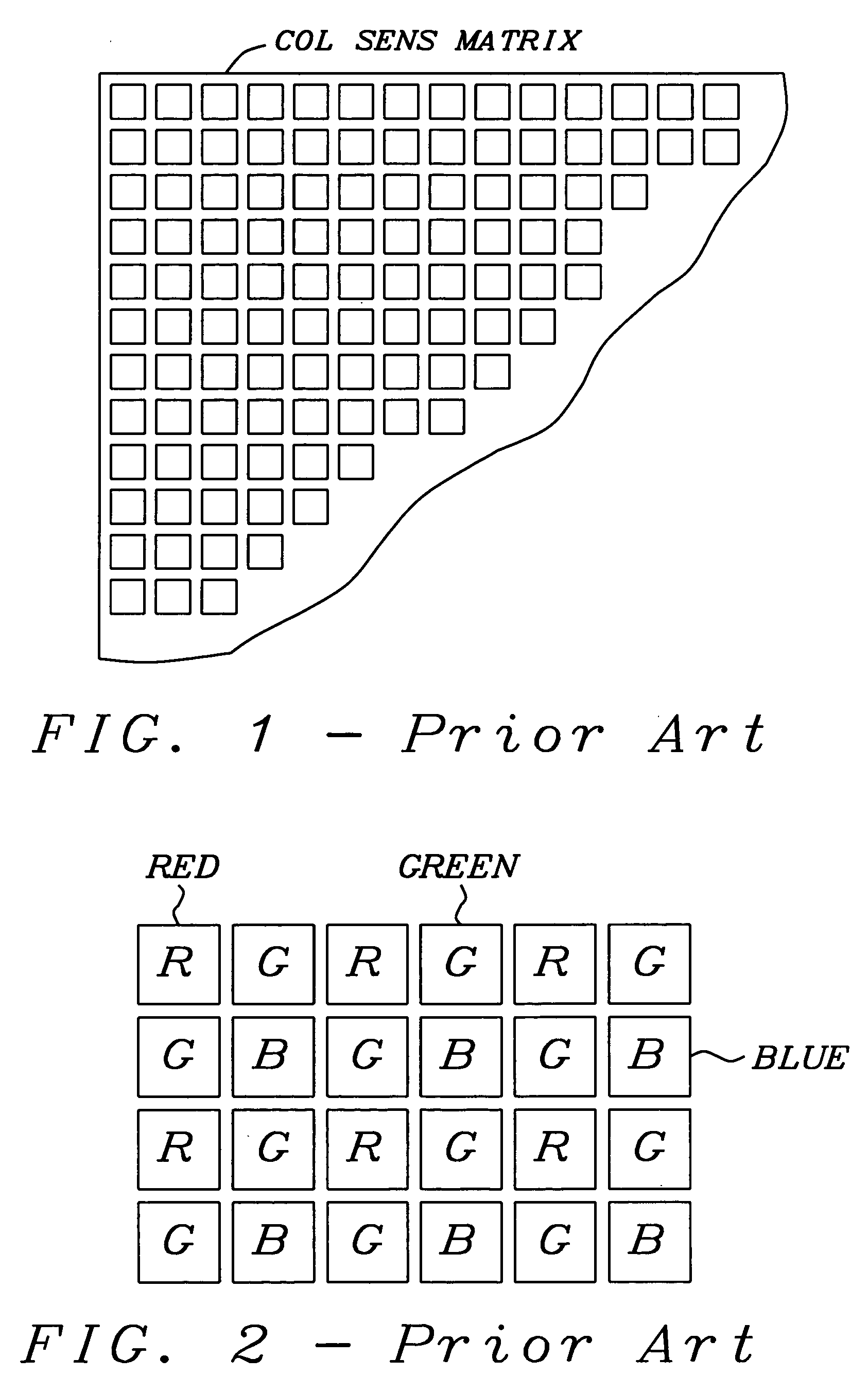

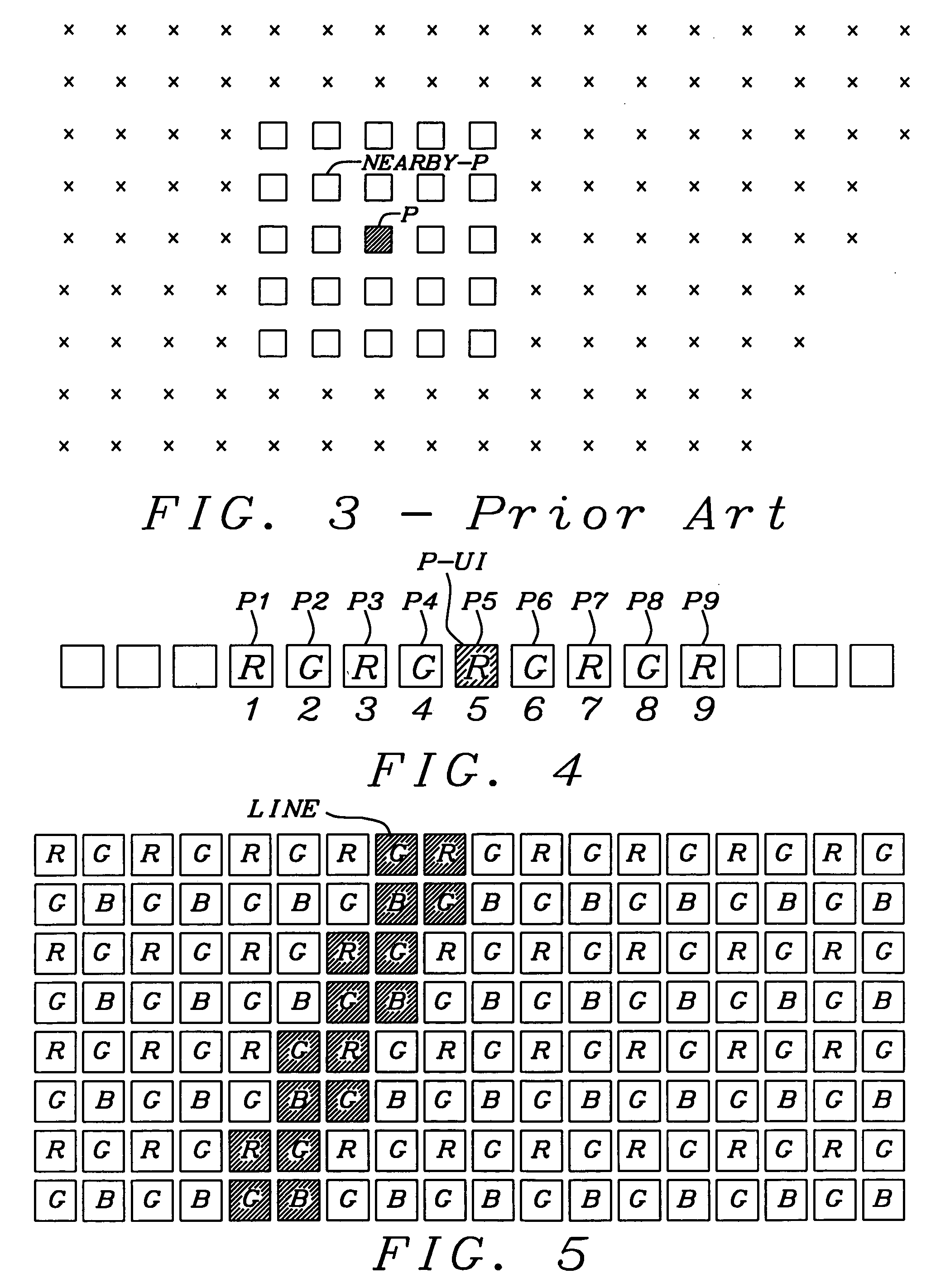

In large arrays of image sensing devices, like CCDs, a small number of defective image elements (pixels) must be tolerated and the resulting image degradation should be eliminated through bad pixel correction. The disclosed invention provides a mechanism to effectively detect defective pixels “on the fly” in a Bayer RGB type color image sensor, optimized for low cost applications. It calculates a variable threshold based on signal changes on nearby pixels of the same color within a single row and checks if the signal change of the pixel under test exceeds said variable threshold. It further performs a plausibility check using nearby pixels of an other color in the same row.

Owner:DIALOG IMAGING SYST

Method for correcting pixel defect in image sensing element, and image sensing apparatus using the same

InactiveUS20050030395A1Improve accuracyHigh-precision detectionTelevision system detailsColor signal processing circuitsImage sensingDefective pixel

An object of this invention is to provide an image sensing apparatus and image sensing method capable of eliminating a nonvolatile memory for storing position information of a defective pixel, and detecting a defective pixel at high precision even while sensing a complicated object. To achieve this object, there is provided an image sensing apparatus including a solid-state image sensing element having a plurality of pixels which output image sensing signals, a first determination device which determines whether a pixel of interest is a defective pixel candidate, by comparing the signal level of the pixel of interest subjected to defective pixel detection out of the plurality of pixels of the solid-state image sensing element, and the signal levels of a plurality of peripheral pixels around the pixel of interest, and a second determination device which, when the-first determination device determines that the pixel of interest is the defective pixel candidate, determines whether the determination result representing that the pixel of interest is the defective pixel candidate is erroneous detection, on the basis of the determination result of the first determination device representing whether a plurality of peripheral pixels around the pixel of interest are defective pixel candidates.

Owner:CANON KK

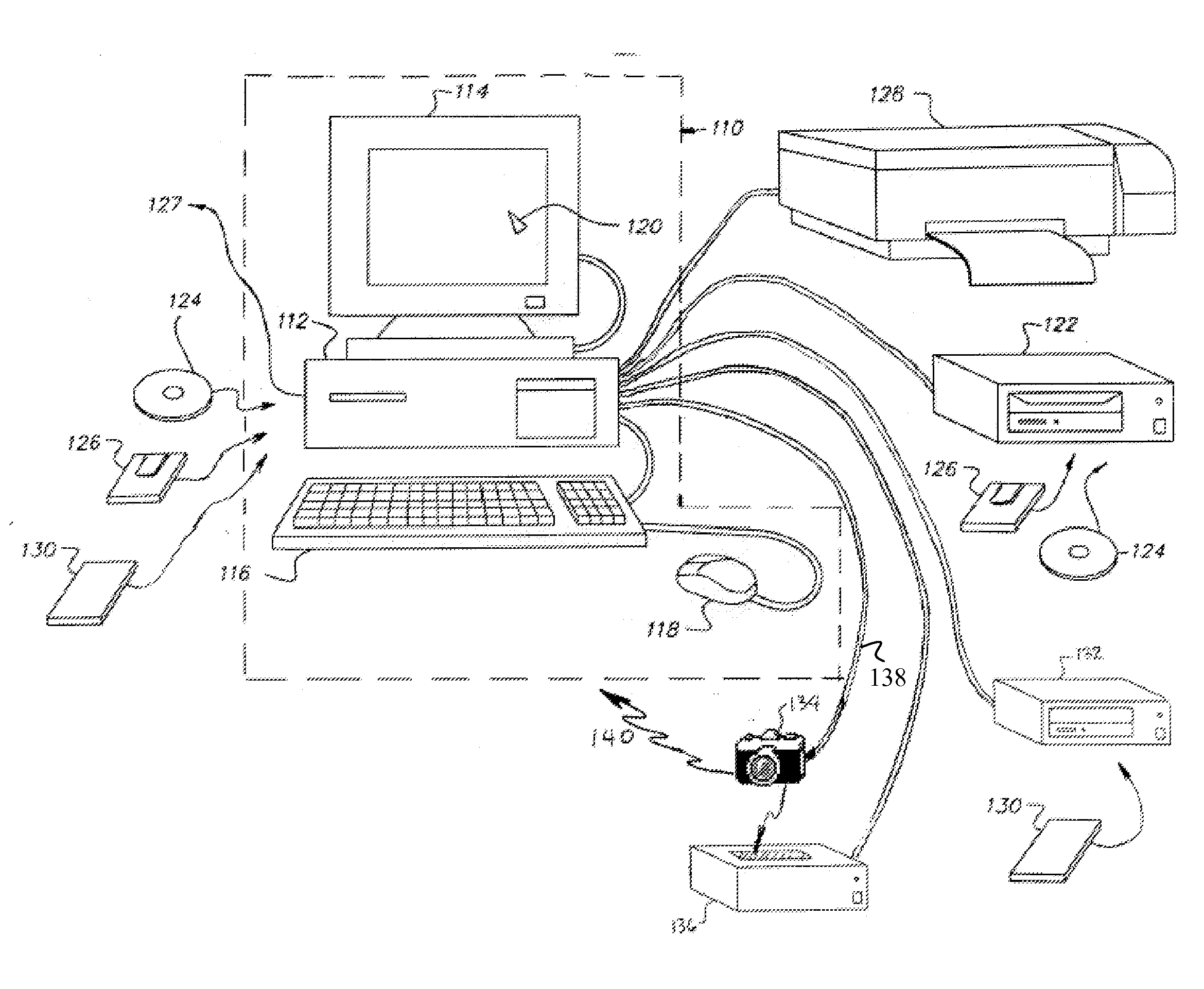

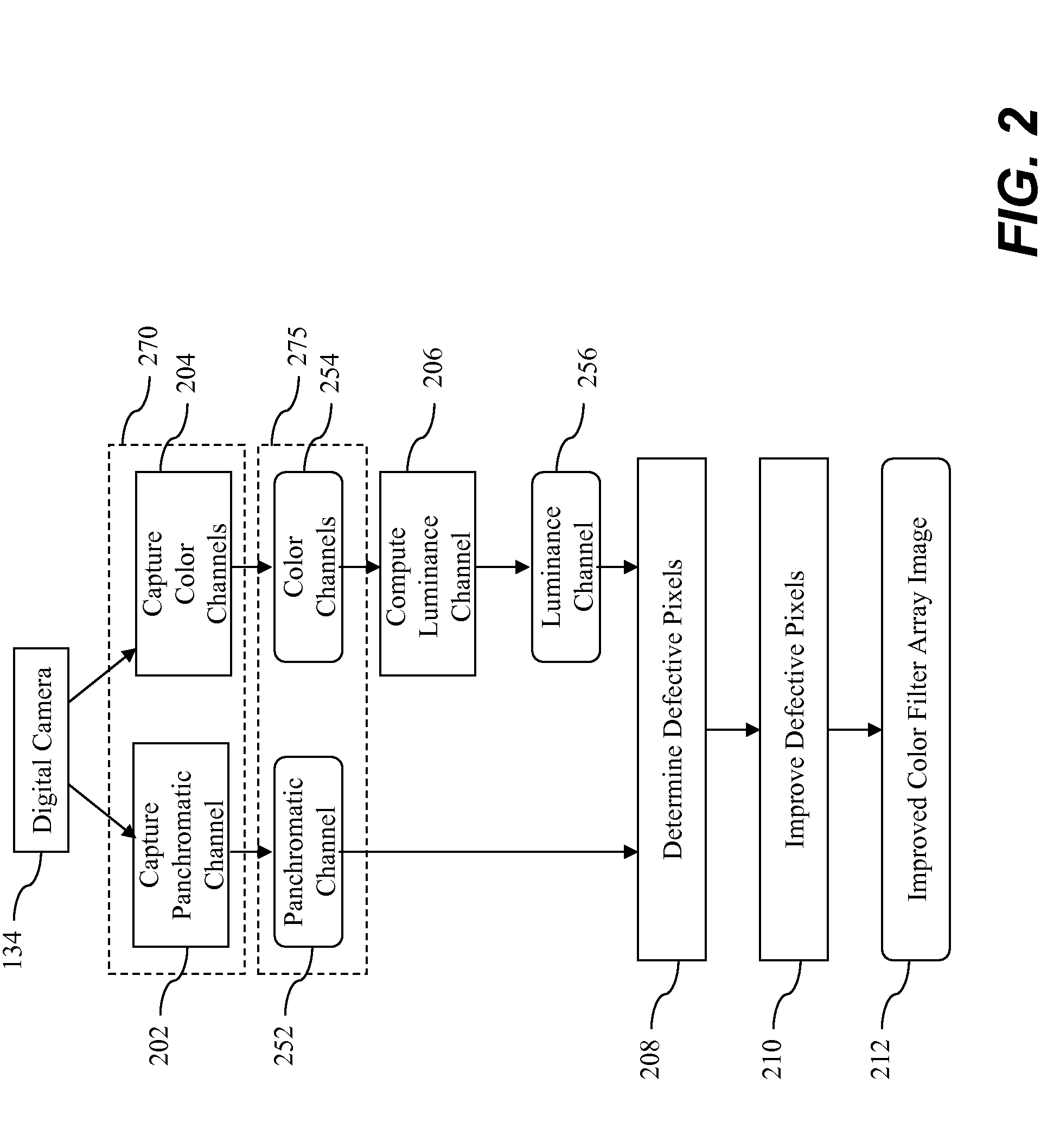

Defective color and panchromatic cfa image

ActiveUS20100104209A1Improved color filter array imageReduce blurTelevision system detailsColor signal processing circuitsColor imageColor filter array

A method of improving a first color filter array image from an image sensor having a plurality of color channels and a panchromatic channel, includes capturing the panchromatic channel at a different exposure time than at least one of the color channels with the image sensor; using the color channels to provide a luminance channel; and analyzing the color filter array image and the luminance channel to determine defective pixels in the color channels and using neighboring color and luminance pixel values to improve the defective pixels to produce a second color filter array image or full-color image having at least one improved channel.

Owner:OMNIVISION TECH INC

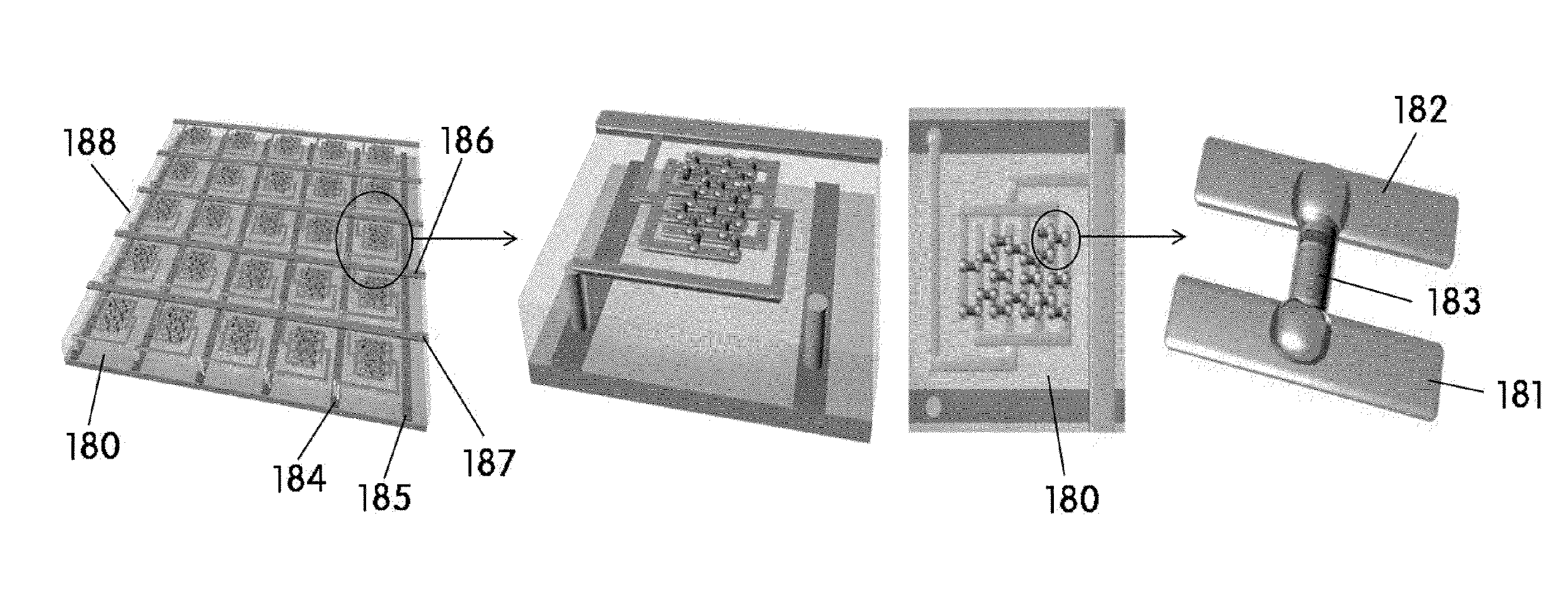

Display comprising ultra-small leds and method for manufacturing same

ActiveUS20160211245A1Light extraction efficiency can be maximizedMaximize efficiencySolid-state devicesSemiconductor/solid-state device manufacturingState of artDisplay device

Owner:SAMSUNG DISPLAY CO LTD

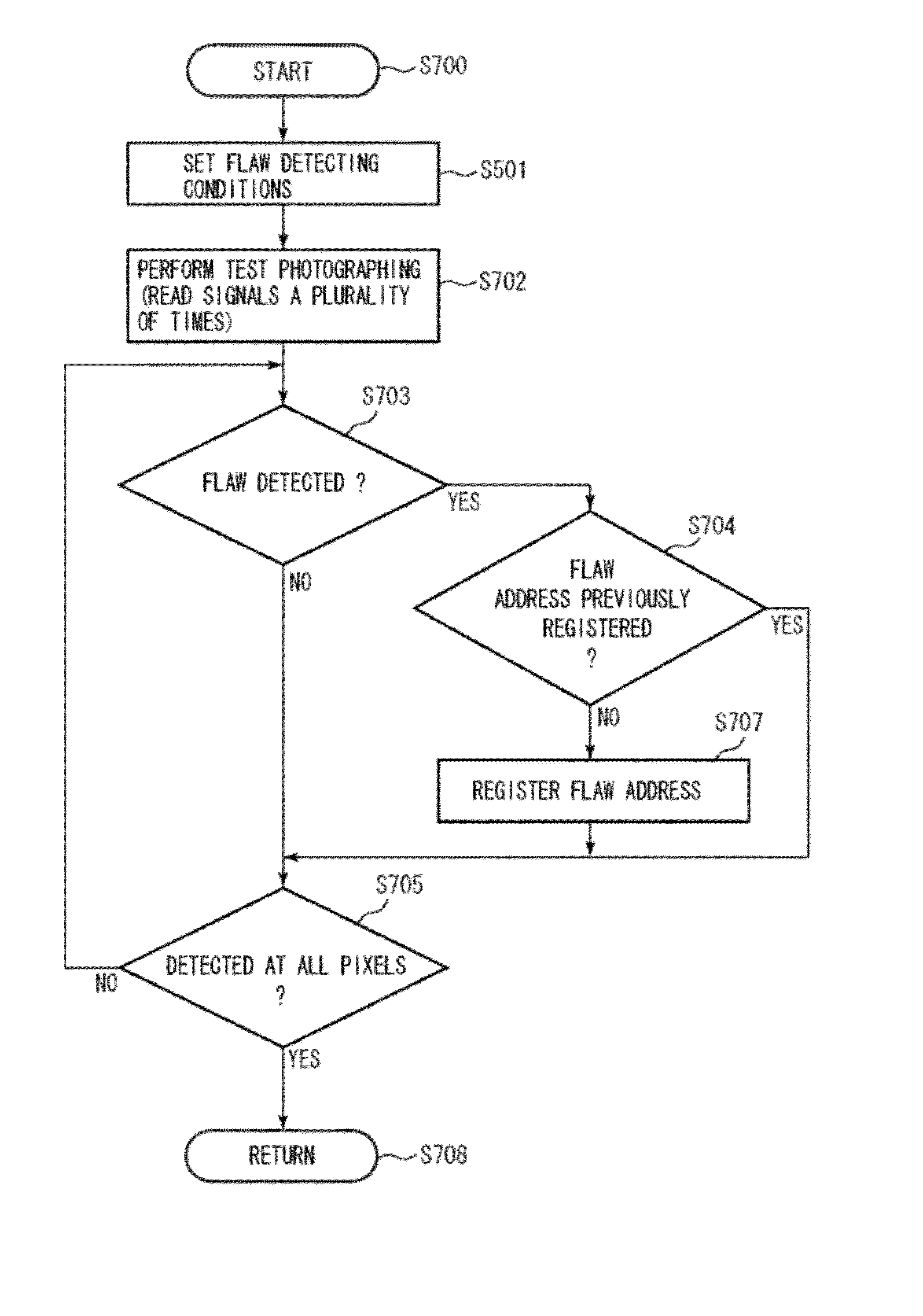

Image processing apparatus, image processing method, and program

InactiveUS20080117318A1Increase probabilityReduce probabilityTelevision system detailsColor signal processing circuitsImaging processingMaximum Pixel

In an image processing apparatus, a defect detection unit detects a defective pixel and a defect level thereof by comparing a maximum pixel value detected at each pixel position of a plurality of images captured via an image taking operation performed a plurality of times by an image sensor with a threshold value for detecting white defective pixels, and / or by comparing a minimum pixel value detected at each pixel position of the plurality of images with a threshold value for detecting black defective pixels. A defective pixel selection unit selects a predetermined plurality of defective pixels with high defect degrees, and registers defect data associated with the predetermined plurality of selected defective pixels in the defect data table. A defect correction unit corrects pixel values of pixels of the image output from the image sensor, in accordance with the defect data registered in the defect data table.

Owner:SONY CORP

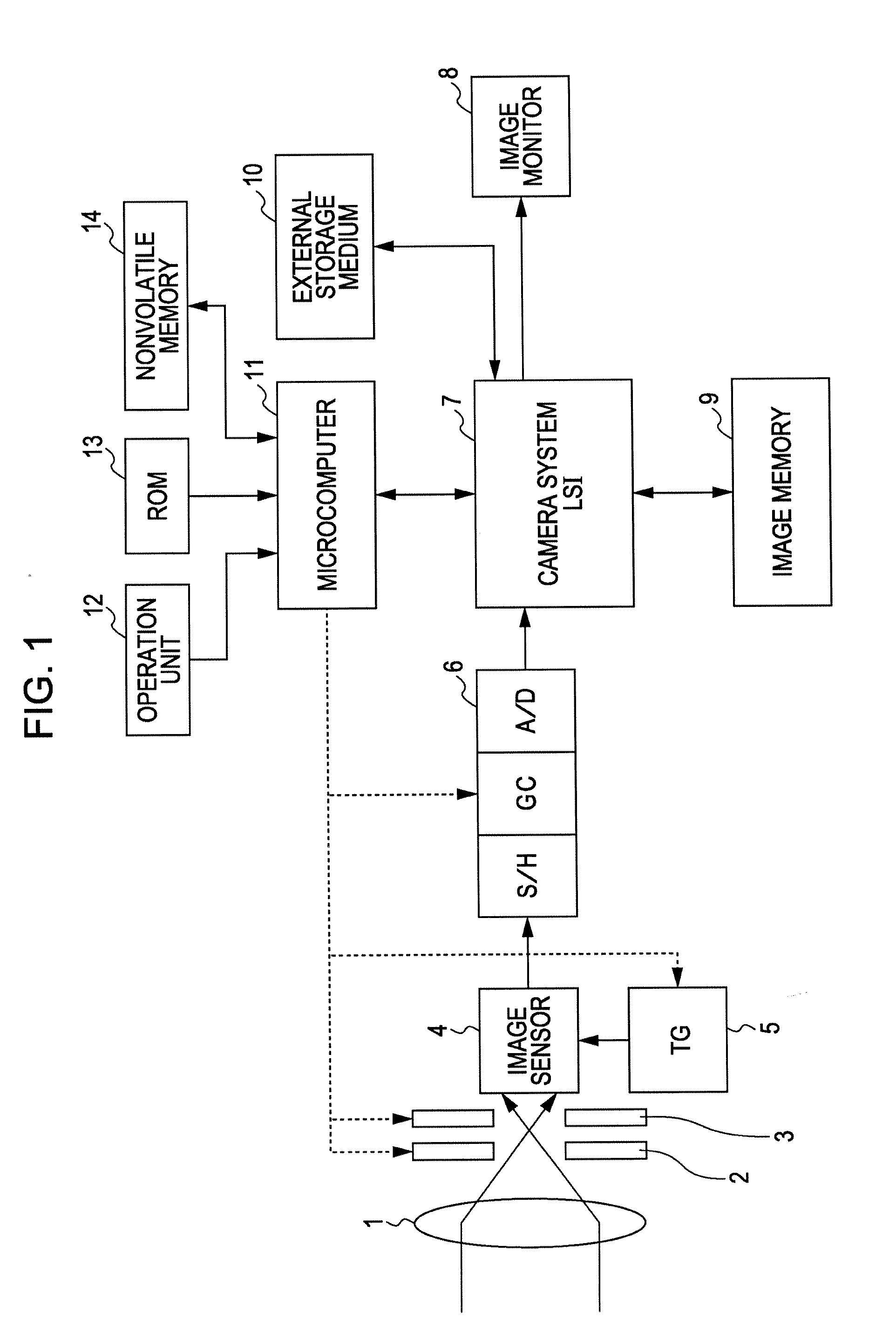

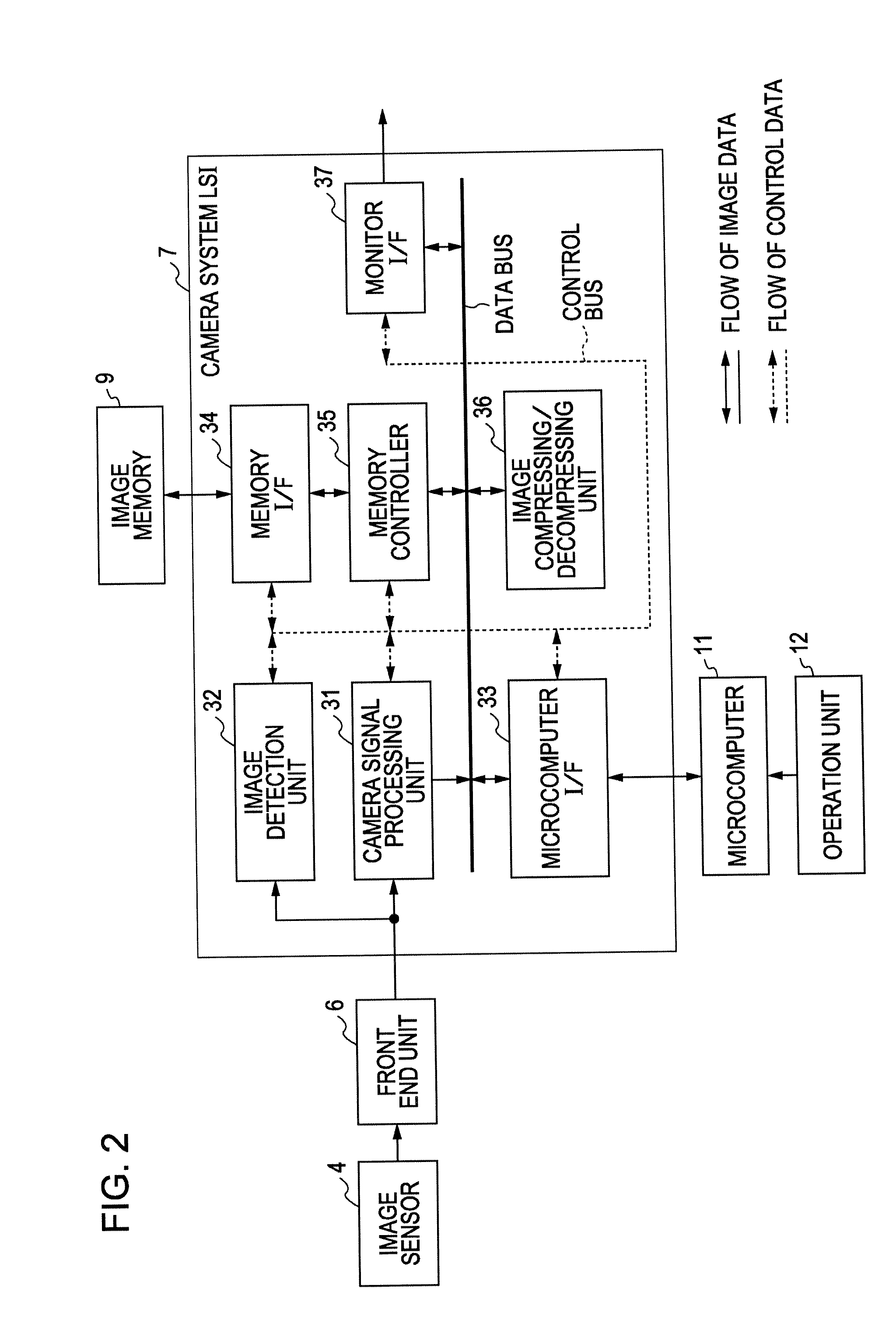

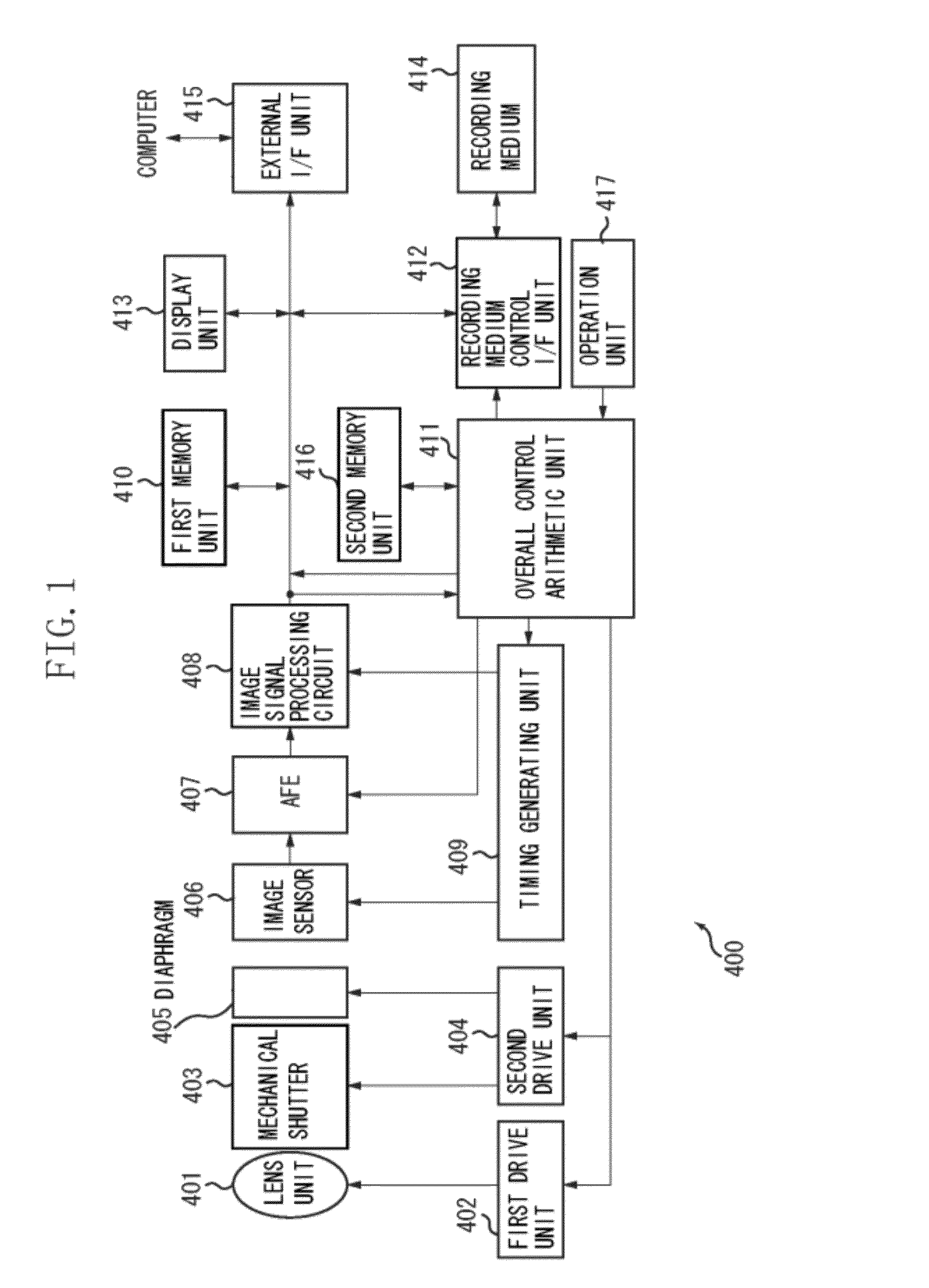

Image capture device and image data correction process of image capture device

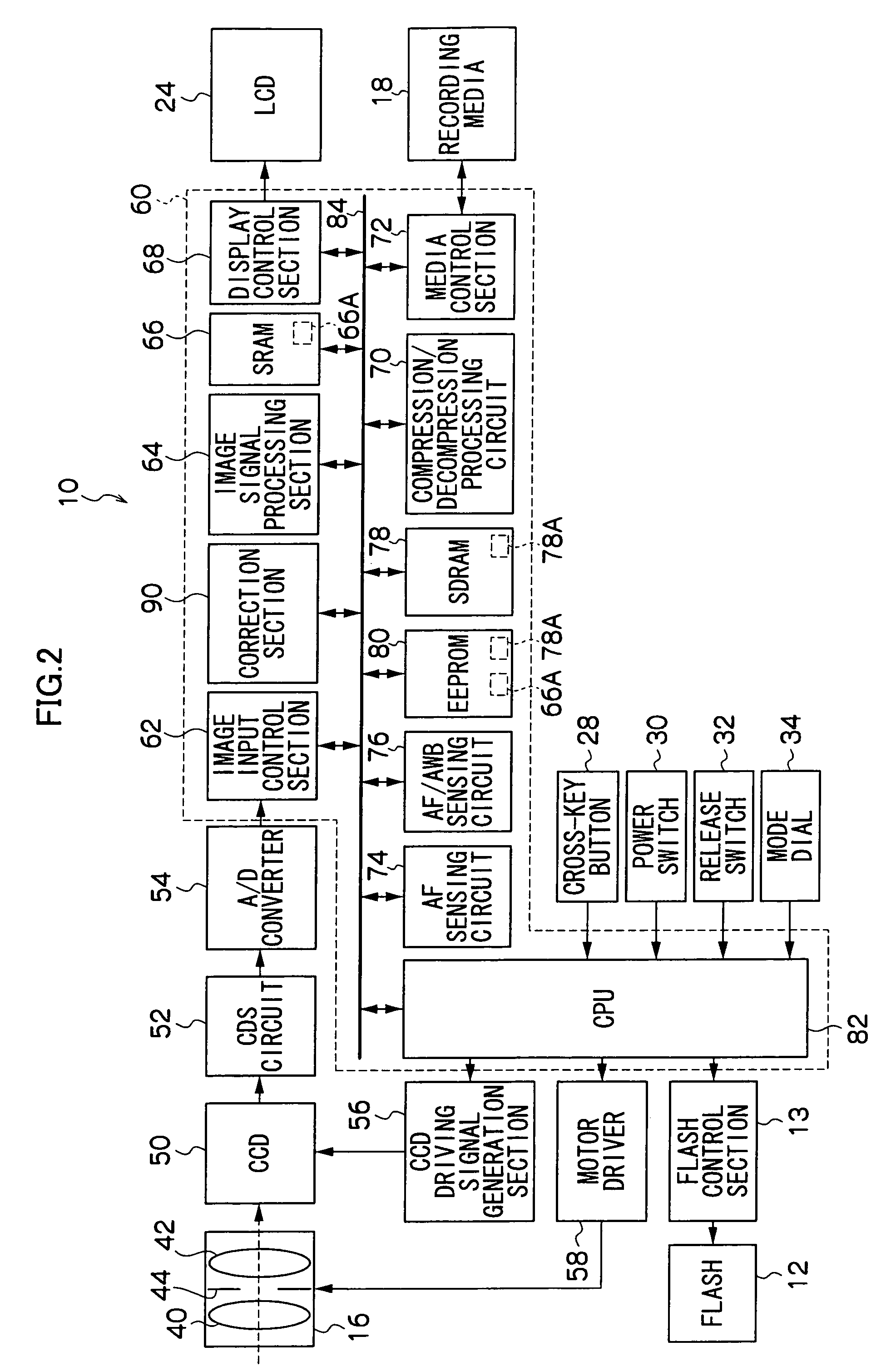

ActiveUS20060050158A1Memory capacity of memory can be assuredTime suppressionTelevision system detailsColor signal processing circuitsComputer hardwareComputer science

An image capture device provided with a first memory unit, which memorizes position information of non-continuous defective pixels of a solid-state image capture component, and a second memory unit with a higher access rate than the first memory unit, which memorizes position information of continuous defective pixels. When a continuous photography mode or a video photography mode is set, defective pixel correction processing is carried out on image data corresponding to each of defective pixels according to the defective pixel position information stored at the second memory unit. Alternatively, when a still photography mode is set, image data corresponding to all defective pixels is corrected, based on both the defective pixel position information stored at the first memory unit and the defective pixel position information stored at the second memory unit. As a result, it is possible to correct defective pixels with high efficiency in accordance with conditions of photography.

Owner:FUJIFILM CORP +1

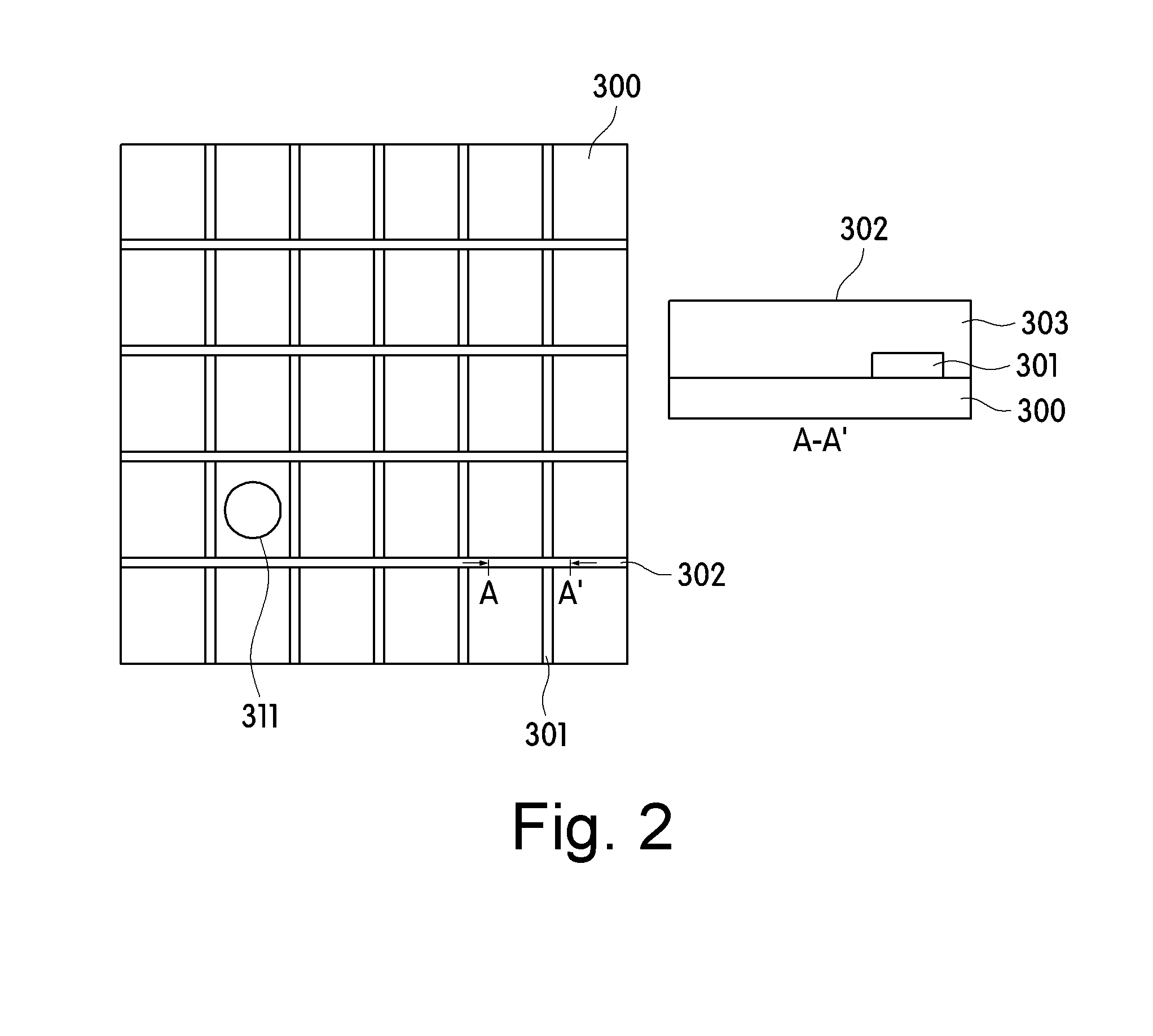

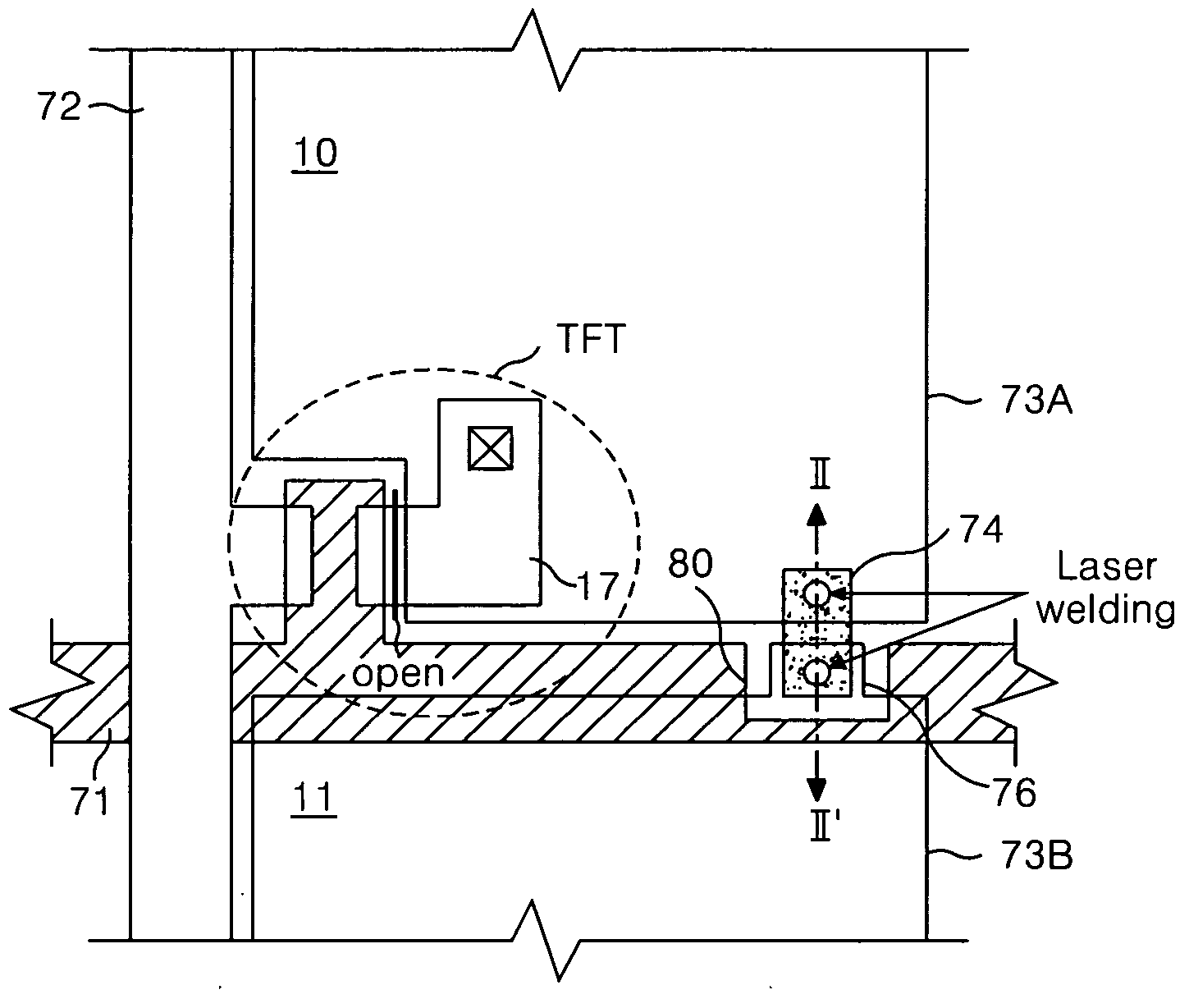

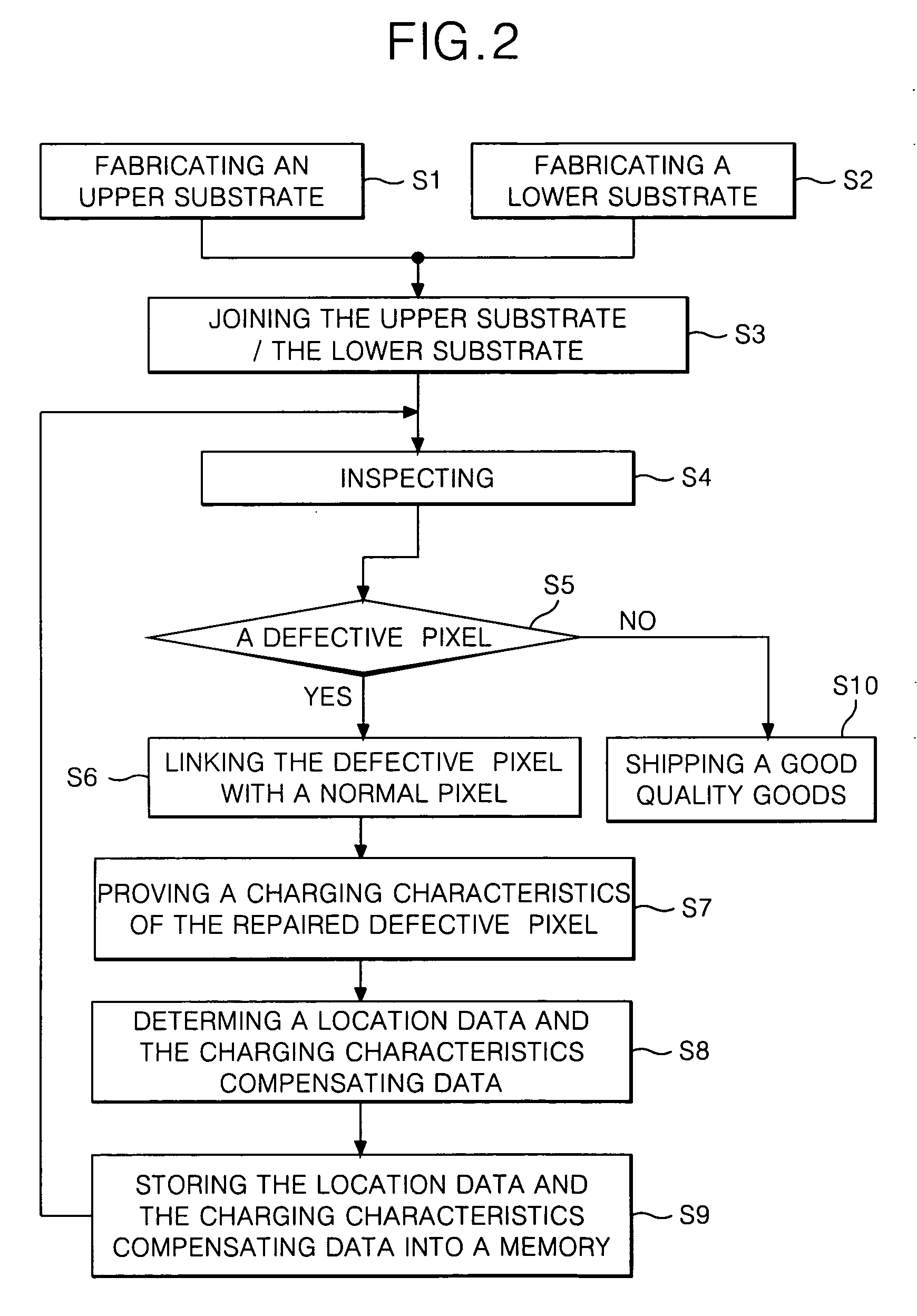

Flat panel display, fabricating method thereof, fabricating apparatus thereof, picture quality controlling method thereof, picture quality controlling apparatus

A flat panel display, a fabricating method thereof, a fabricating apparatus thereof, a picture quality controlling method thereof and a picture quality controlling apparatus for reducing a recognizing degree of a defective pixel and electrically compensating a charging characteristics of the defective pixel are provided. In the flat panel display, a display panel has a plurality of pixels. A defective pixel is electrically connected to an adjacent normal pixel. A memory stores a location data that indicates a location of the link pixel and a compensation data that compensates for charging characteristics of the link pixel. A compensation circuit modulates a digital video data to be displayed on the link pixel on the basis of the location data and the compensation data.

Owner:LG DISPLAY CO LTD

Correction method for defects in imagers

ActiveUS20060044425A1Television system detailsColor signal processing circuitsImaging equipmentComputer science

A method and apparatus that allows for the identification and correction of defective pixels and / or pixel clusters in an imaging device. The method, and implementing apparatus determines that a pixel is defective based upon a comparison of its pixel signal value with the value of neighboring pixels. In one exemplary embodiment, a pixel is defective if it is beyond a pre-determined threshold of either a high or low value from its neighboring, corrected pixels. Pixels identified as defective can be corrected using exemplary methods of the invention such as substituting a value of the defective pixel with a value of one of its non-defective neighbors.

Owner:APTINA IMAGING CORP

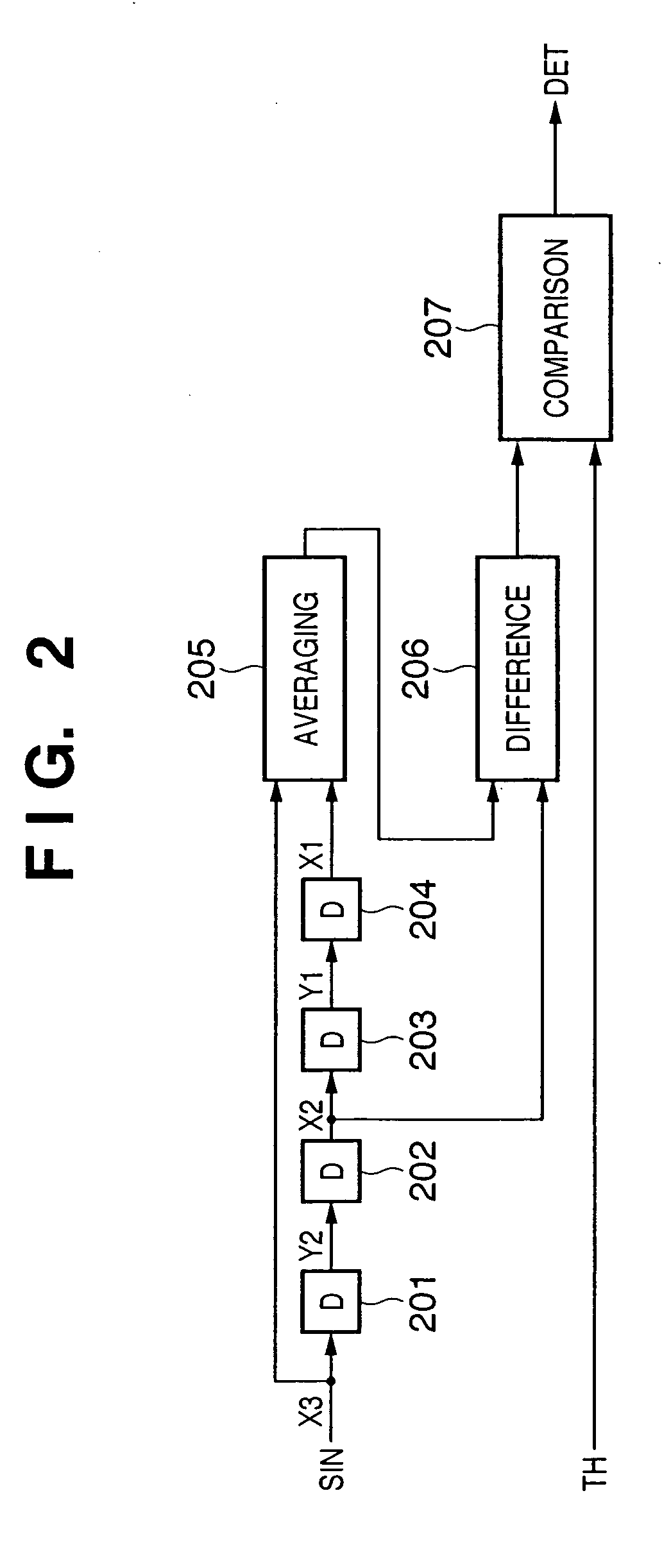

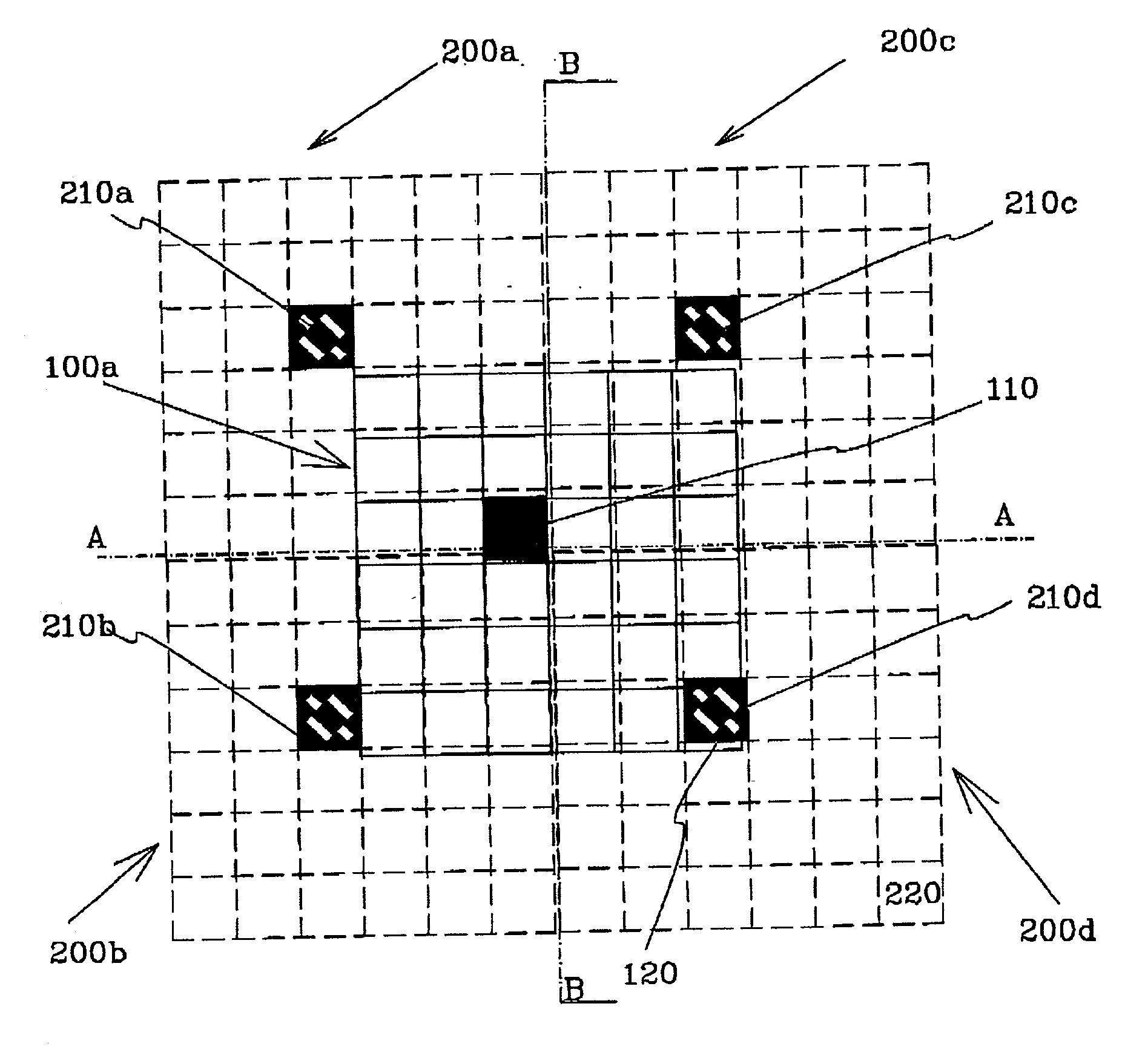

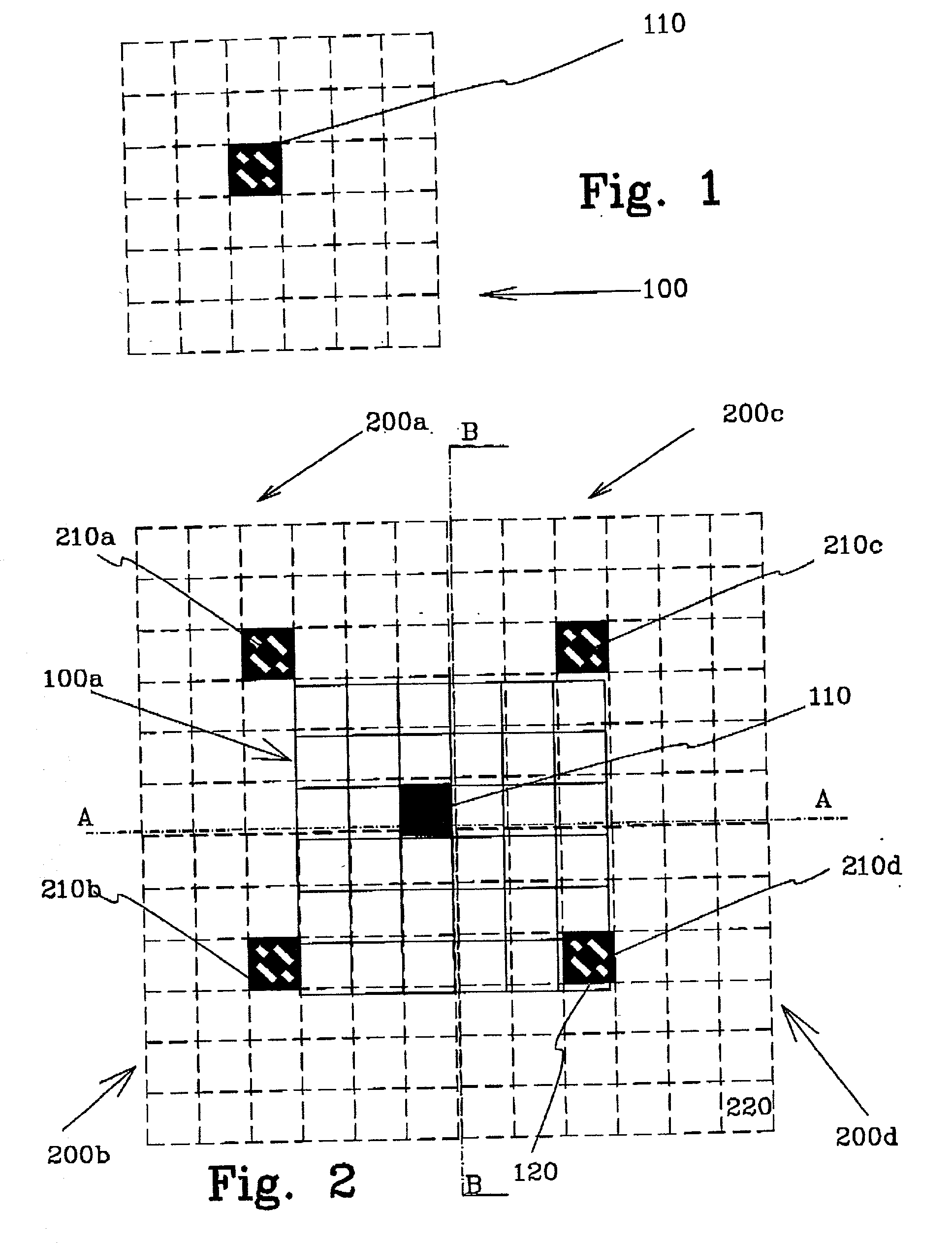

Method to detect a defective element

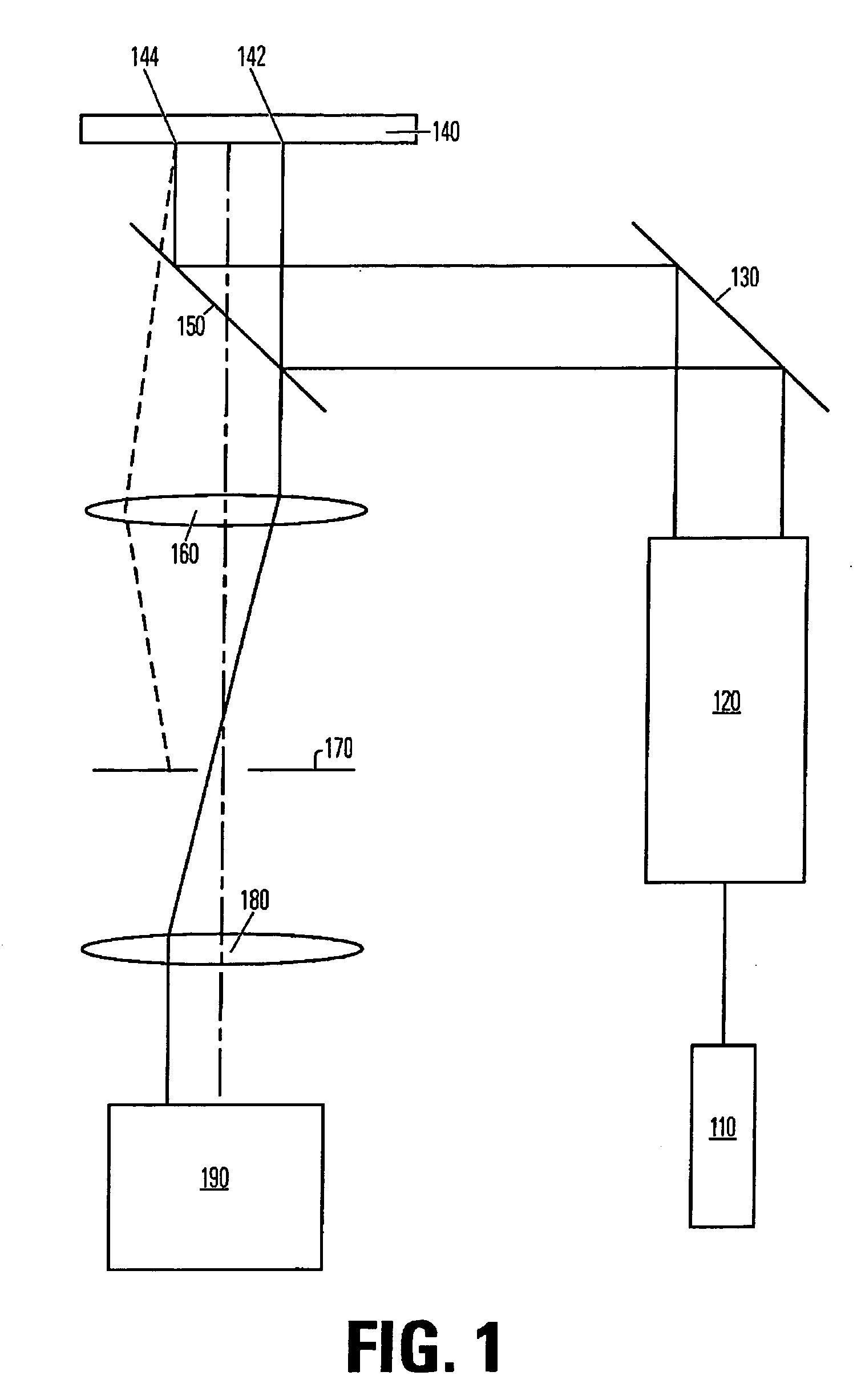

ActiveUS7061226B2Reduce processing timeStatic indicating devicesTelevision systemsSpatial light modulatorDefective pixel

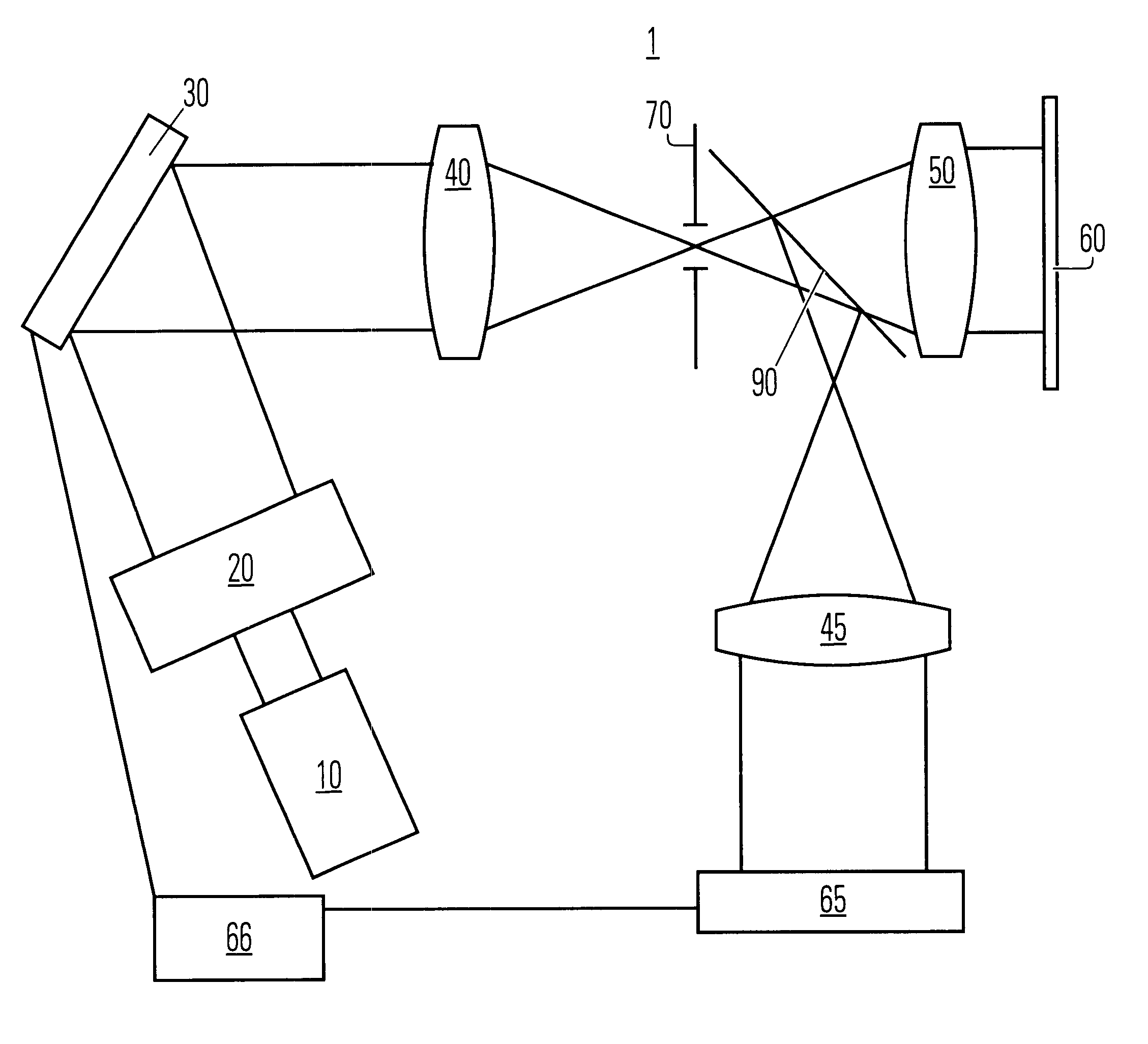

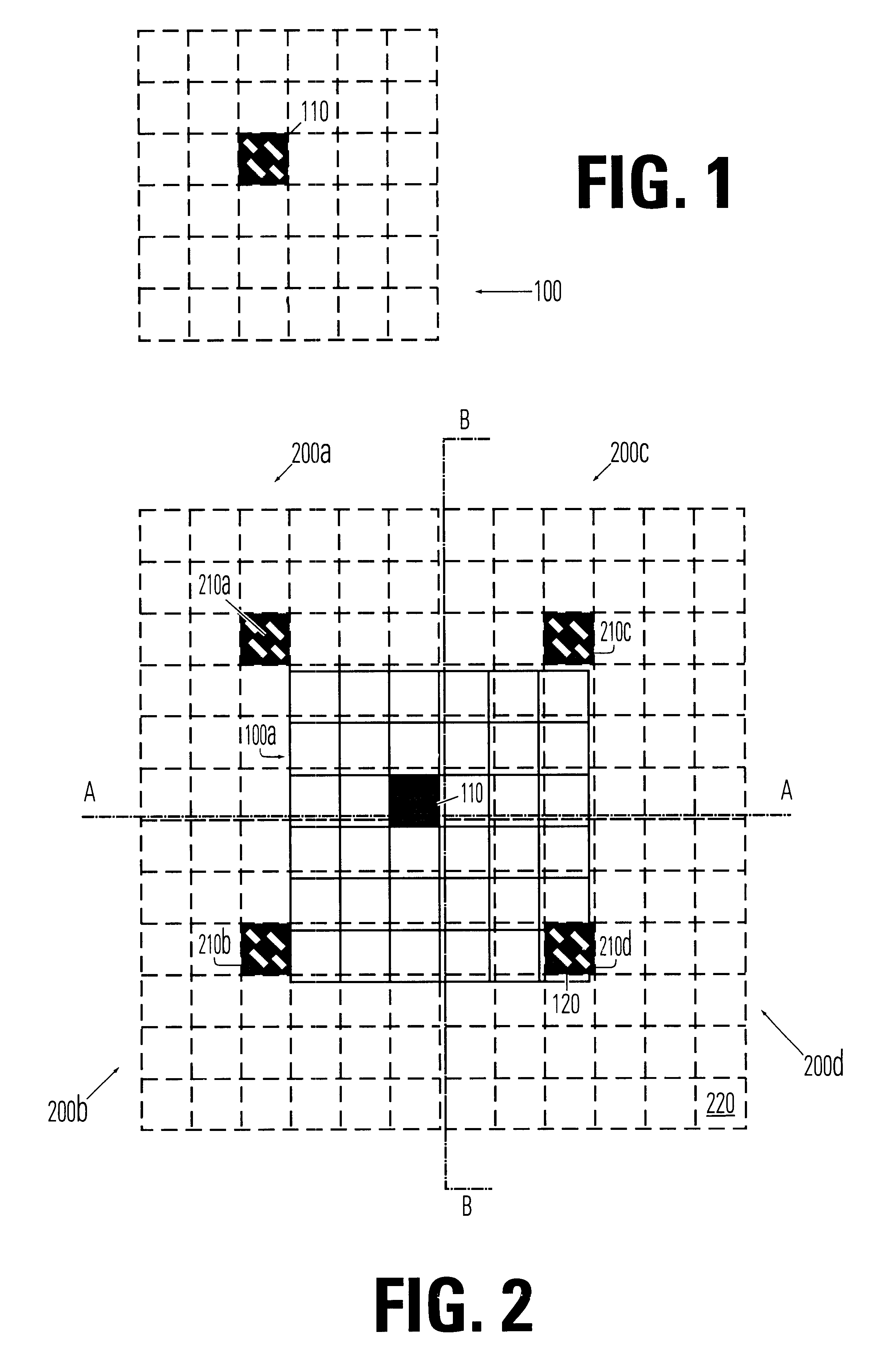

The present invention relates to a method to detect at least one defective pixel in a spatial light modulator comprising numerous pixel elements. The spatial light modulator is imaged to a detector. A relayed image of a first chess-board pattern of pixels in said spatial light modulator is detected by said detector. A relayed image of a second chess-board pattern of pixels in said spatial light modulator is detected, which is inverted to the first chessboard pattern, by said detector. The relayed images of said first and second chessboard patterns are analyzed to detect differences between said detected images and theoretical images thereof.

Owner:MICRONIC LASER SYST AB +1

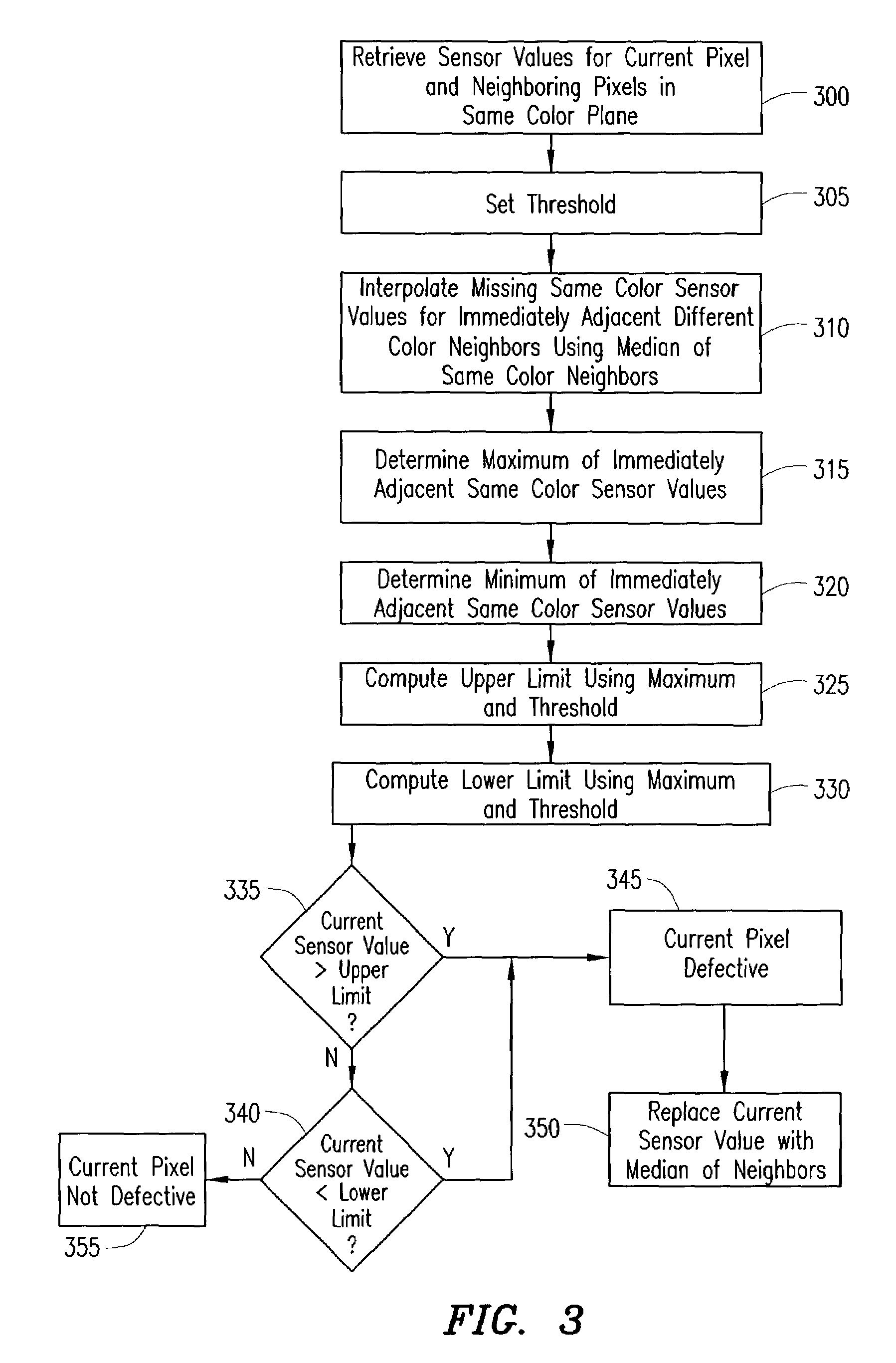

Digital image system and method for combining demosaicing and bad pixel correction

A digital image system and method for combining bad pixel correction and demosaicing in a single process is provided by interpolating sensor values for pixels immediately spatially adjacent to the current pixel being examined to detect defective pixels, and using the interpolated values for demosaicing. If the sensor value of the current pixel being examined is outside of a range of sensor values determined from the interpolated values by more than a configurable threshold amount, the current pixel is considered defective, and replaced using an estimated value from the neighboring pixels. The interpolated values calculated for use in detecting bad pixels can further be used as the interpolated values for demosaicing purposes

Owner:APTINA IMAGING CORP

Defective pixel compensation method

InactiveUS20030099026A1Microbiological testing/measurementSemiconductor/solid-state device manufacturingSpatial light modulatorFluence

The present invention relates to a method for compensating the impact of at least one defective pixel with a known position in a spatial light modulator (SLM) when creating a pattern of the SLM on a work piece covered with a layer sensitive to electromagnetic radiation. A source for emitting electromagnetic radiation is provided. Said radiation is illuminating said SLM having a plurality of modulating elements (pixels). In a writing pass an image of said modulator is projected on said work piece. A compensation for defective pixels in at least one other writing pass is performed. The invention also relates to an apparatus for performing said method.

Owner:MICRONIC LASER SYST AB

Method for rectifying missing pixels and image sensor

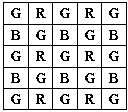

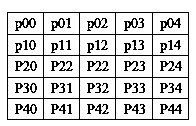

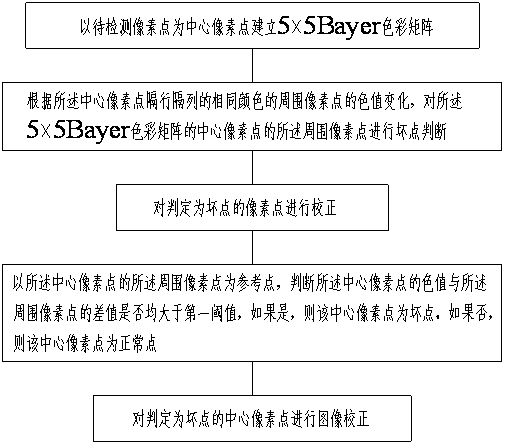

ActiveCN103475828AAccurate judgmentImprove image qualityTelevision system detailsColor television detailsImage correctionDefective pixel

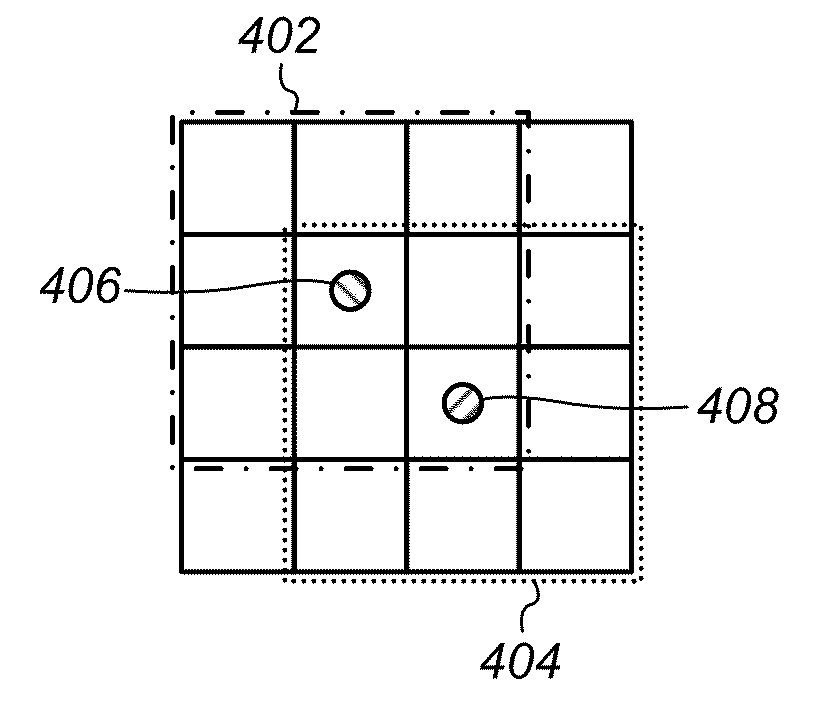

The invention discloses a method for rectifying missing pixels and an image sensor. The method for rectifying missing pixels and the image sensor are efficient and accurate. According to the method for rectifying missing pixels, a 5*5Bayer color matrix is established with a pixel to be detected as a center pixel. Firstly, missing pixel rectifying is performed on pixels surrounding the center pixel of the 5*5Bayer color matrix; the pixels surrounding the center pixel of the 5*5Bayer color matrix server as reference points and whether the differential values between the color value of the center pixel and the color values of the surrounding pixels are larger than a first threshold value or not is judged, if yes, the center pixel is determined as a missing pixel and if not, the center pixel is determined as a normal pixel; the center pixel determined as the missing pixel undergoes image rectifying. The method for rectifying missing pixels is accurate in judgment of missing pixels, high in speed and good in effect of rectifying missing pixels.

Owner:深圳市三宝创新机器人有限公司

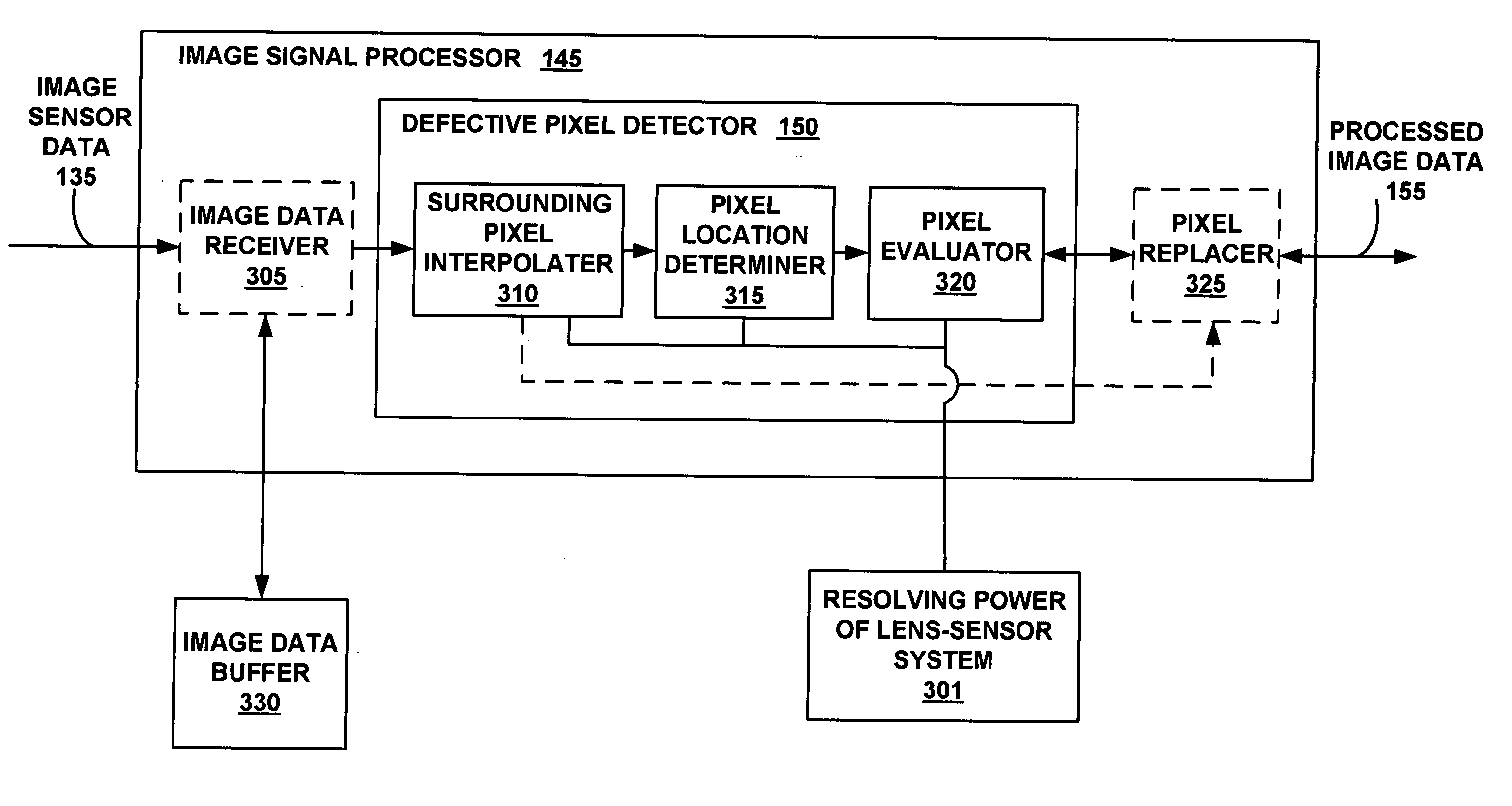

Methods and devices for defective pixel detection

ActiveUS20070091187A1Quickly and efficiently operateTelevision system detailsColor signal processing circuitsMethod of imagesDigital image

In a method of image signal processing, defective pixels are determined on-the-fly in a digital image representation based on a comparison of a pixel under evaluation with its surrounding pixels, with reference to a known resolving capability of a lens-sensor arrangement that captured the digital image representation. In response to the determination of defective pixels, the defective pixels are corrected.

Owner:NVIDIA CORP

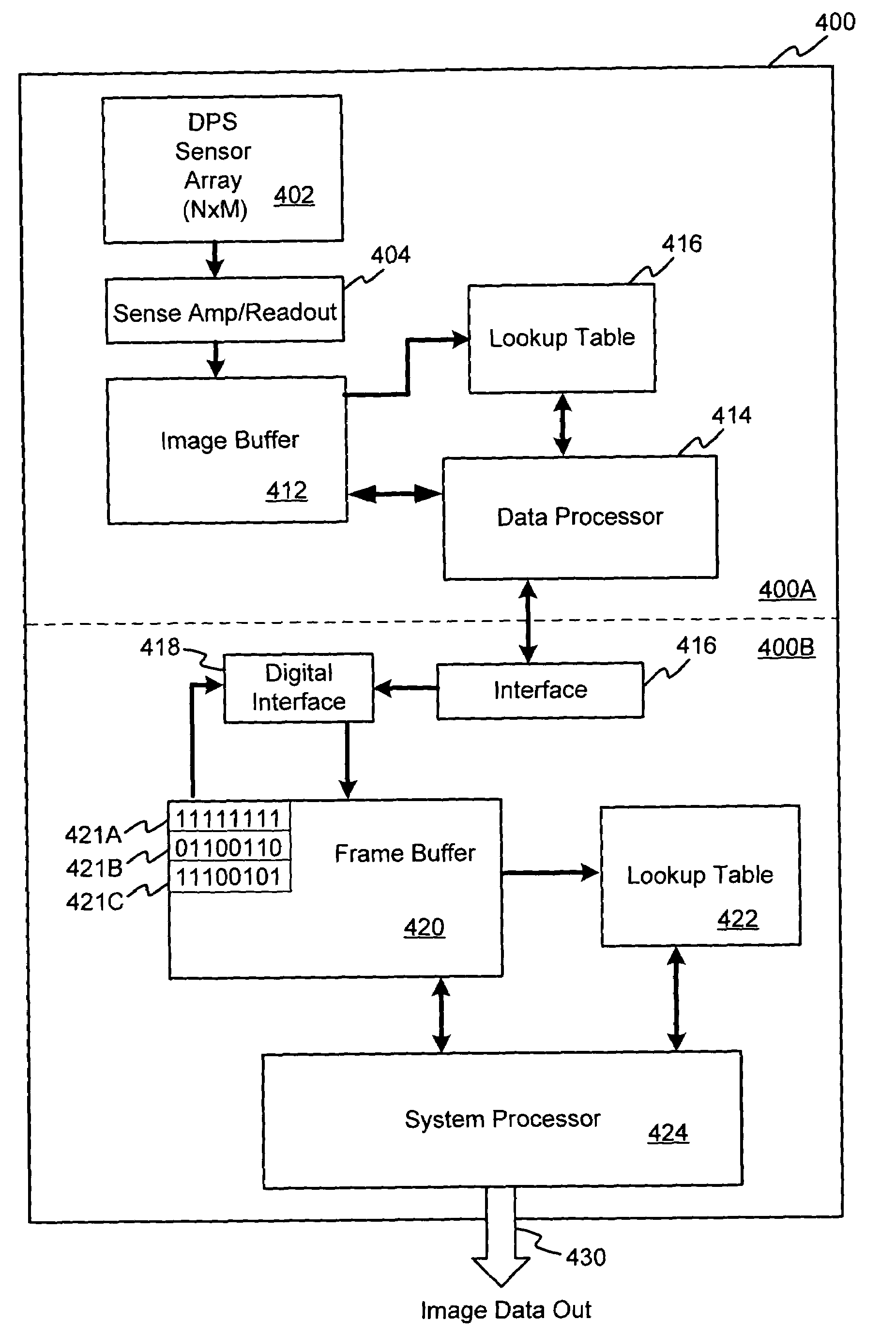

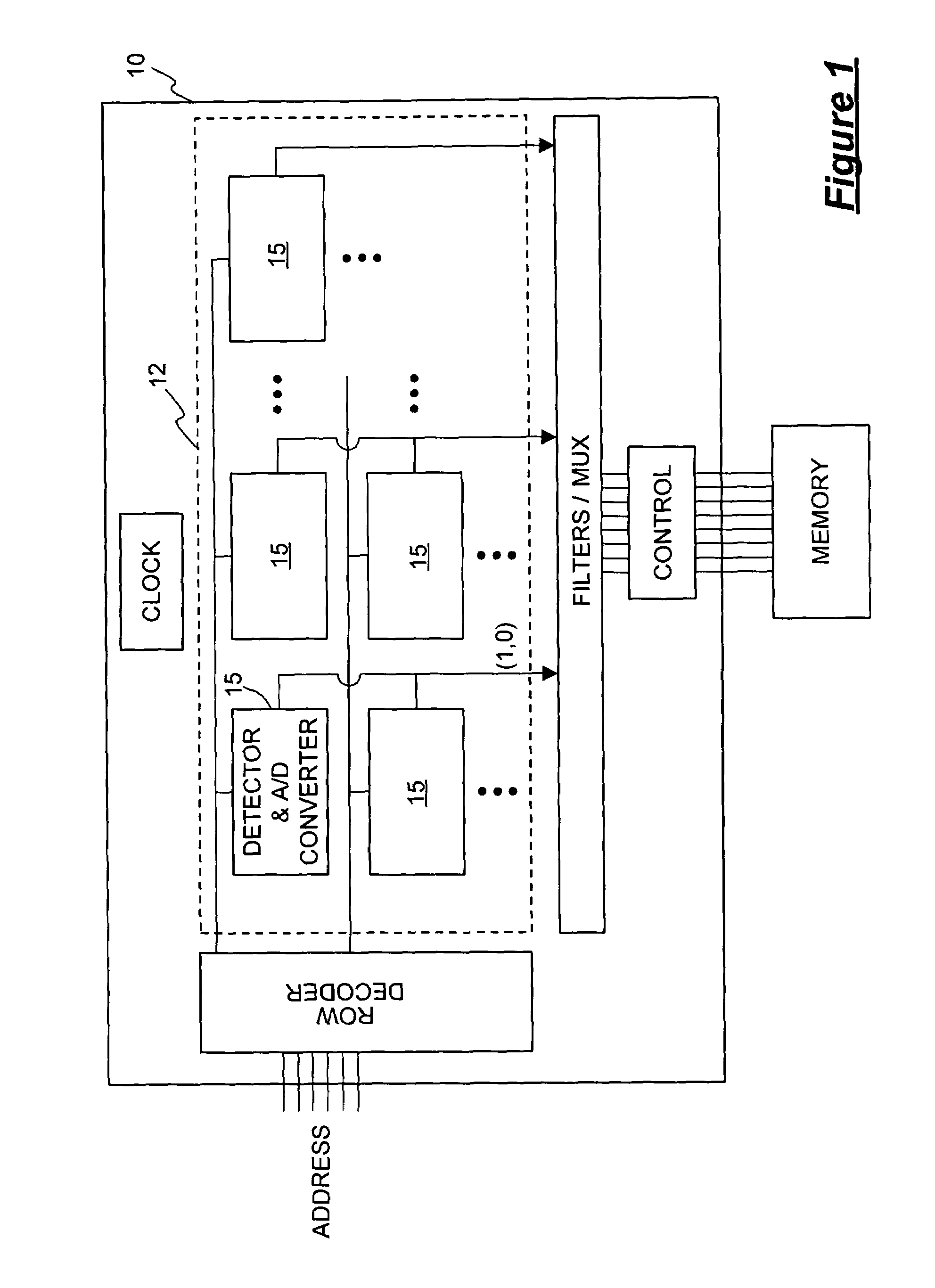

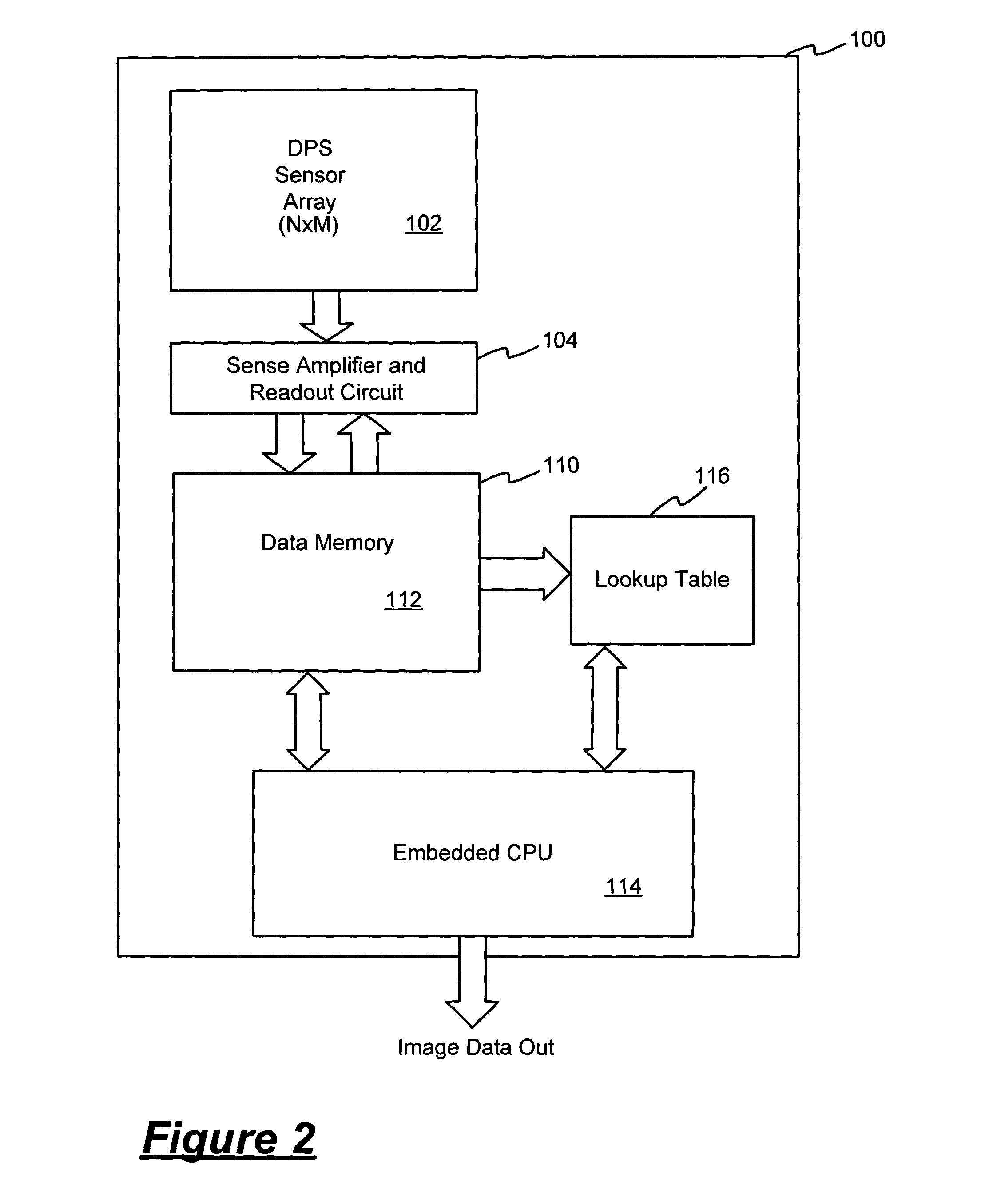

Digital CMOS image sensor incorporating a programmable multi-functional lookup table

A system-on-chip imaging system includes an image sensor of a two-dimensional array of pixel elements providing pixel data representing an image of a scene, a data memory for storing pixel codewords whereby at least some of the pixel codewords are indicative of the pixel data, a programmable lookup table for providing LUT codewords as output data, and a processing unit for receiving LUT codewords from the lookup table and generating output image data. In operation, a first pixel codeword stored in the data memory is used to index the lookup table for causing the lookup table to provide a respective LUT codeword to the processing unit. The processing unit operates to perform one or more image processing functions in response to the LUT codeword. The lookup table can be programmed to perform a variety of image processing functions, including defective pixel correction, CDS subtraction, privacy masking and dark signal subtraction.

Owner:PIXIM

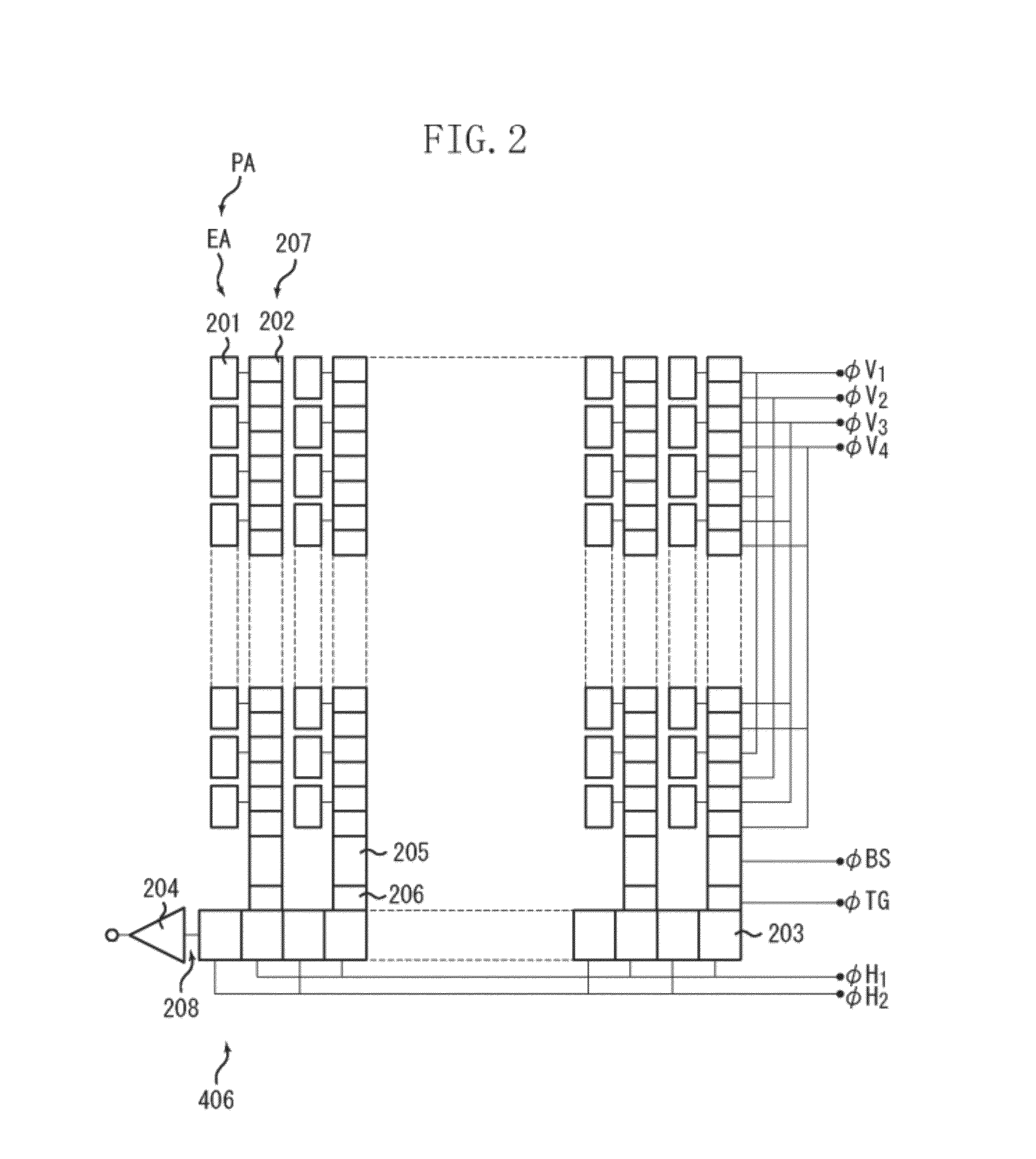

Image sensing apparatus and control method for the image sensing apparatus

InactiveUS8159570B2Improve detection accuracyShorten the timeTelevision system detailsColor signal processing circuitsComputer scienceImage sensing

An image sensing apparatus includes an image sensor including a pixel array, on which a plurality of pixels are arranged, and a reading section configured to read a signal from the pixel array, a detection unit configured to detect a defective pixel in the pixel array based on a signal read from the pixel array by the reading section under a condition that the pixel array is shielded from light, and a control unit configured to control the reading section to read a signal from the pixel array under a condition that a defect tends to occur when the detection unit detects the defective pixel.

Owner:CANON KK

Method and apparatus for defect correction in a display

ActiveUS20070109327A1Cathode-ray tube indicatorsInput/output processes for data processingPattern recognitionGamut

A full-color display device, comprising: a) a display having a plurality of sub-pixels formed in rows or columns in a first dimension including at least three different color sub-pixels forming a color gamut, and grouped into pixels within each row or column, each pixel including at least two of the gamut-specifying color sub-pixels and at least one additional sub-pixel having a color within the gamut and an efficiency higher than at least one of the color sub-pixels, wherein at least one pixel is defective and comprises one defective additional in-gamut sub-pixel; and b) a controller for driving the display pixels and for transforming an input signal into a compensated signal for selectively modifying the output of at least one color sub-pixel in the defective pixel, at least one other, but not all, of the color sub-pixels in a neighboring pixel in the first dimension, and additional in-gamut sub-pixels in neighboring pixels in a second dimension, the at least one other color sub-pixel including the sub-pixel in the neighboring pixel that is closest to the defective sub-pixel, to compensate for the output of the defective sub-pixel(s).

Owner:GLOBAL OLED TECH

Method for detecting and correcting defective pixels in a digital image sensor

ActiveUS7283164B2Accurate predictionEasy to implementTelevision system detailsTelevision system scanning detailsPattern recognitionColor image

A bad pixel correction (BPC) algorithm that can be implemented on the image sensor chip is provided for detecting and correcting defective pixels in a digital color image sensor. Gradients of neighboring pixels in at least one other color plane than the color plane of a current pixel and a range of sensor values from neighboring pixels in the same color plane as the current pixel are determined. If the sensor value of the current pixel is outside of the range by a threshold amount that is calculated using one or more of the gradients, the current pixel is determined to be a defective pixel, and replaced using the sensor values of the neighboring pixels in the same color plane.

Owner:APTINA IMAGING CORP

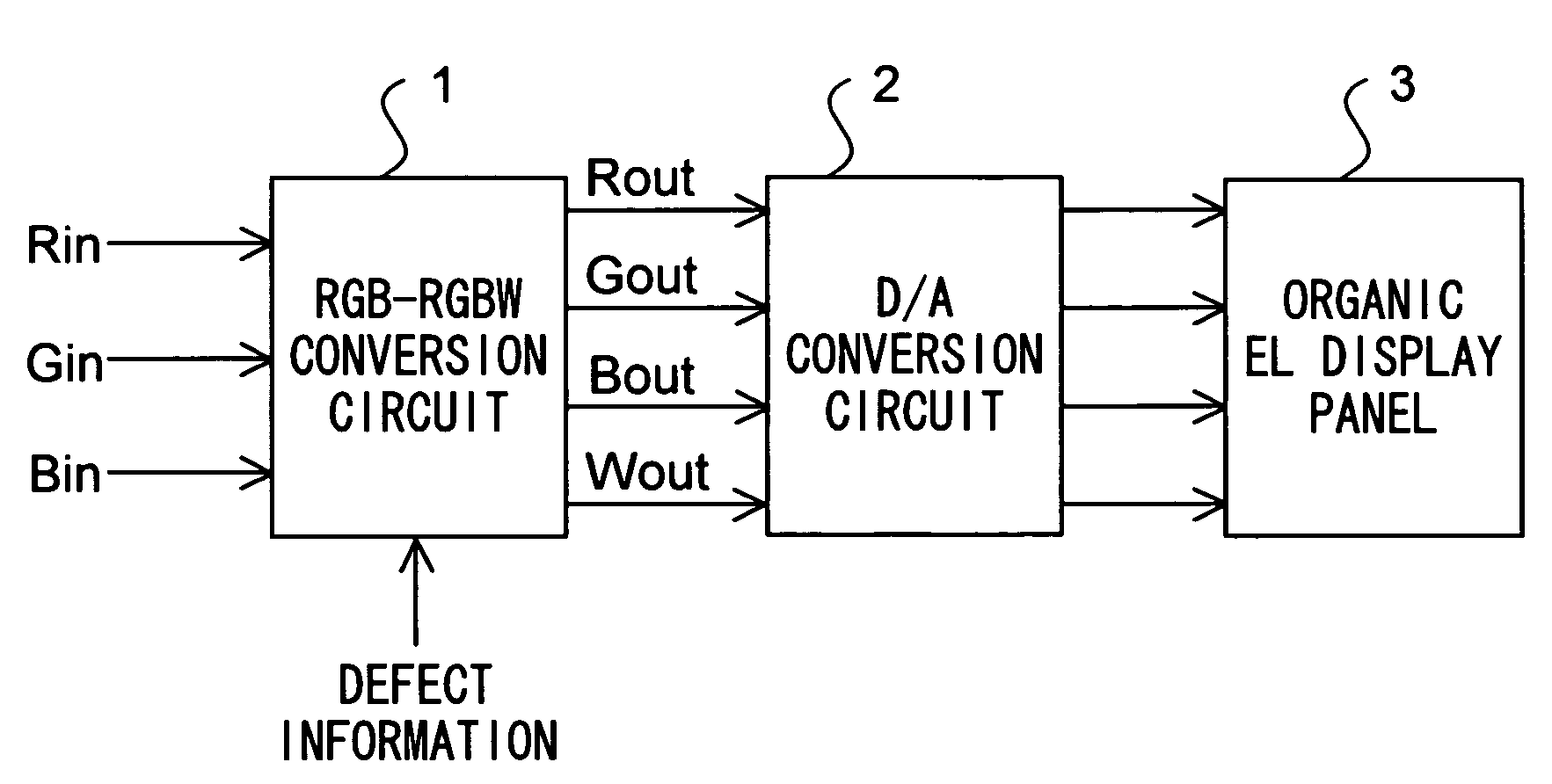

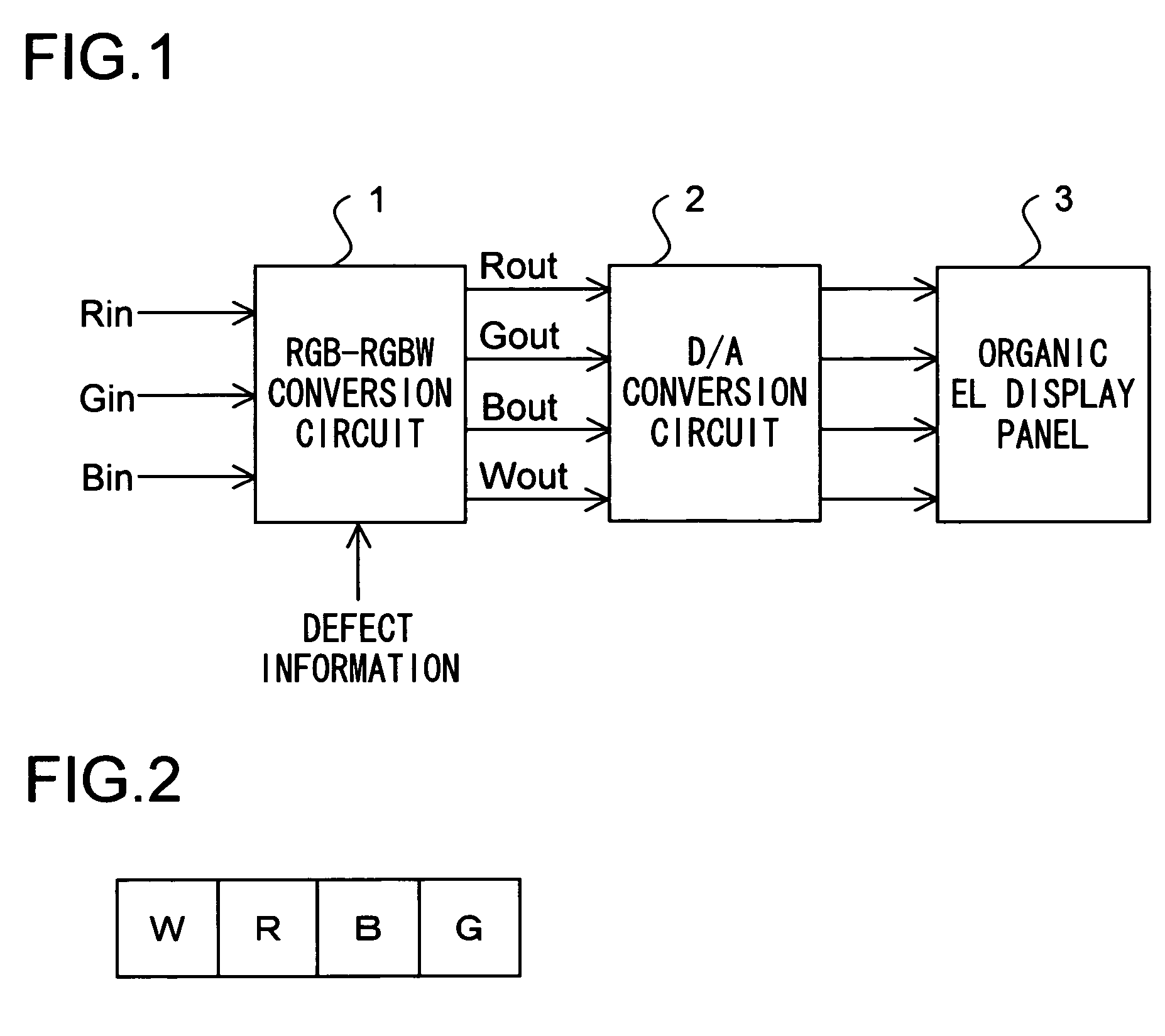

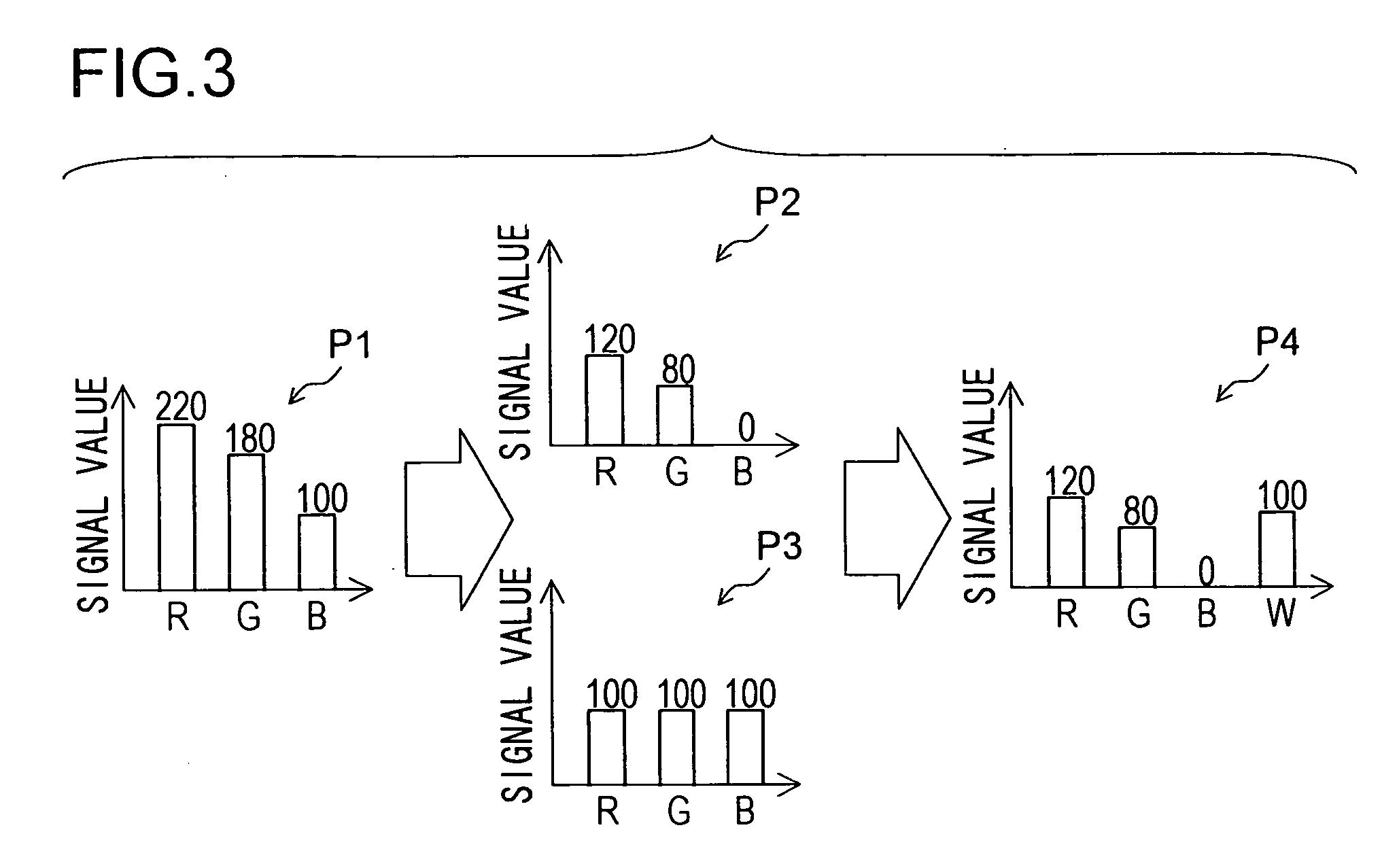

Display device

ActiveUS20060268003A1Alleviate degradation in display quality of displayReduce morbidityTelevision system detailsElectroluminescent light sourcesDisplay devicePosition control

A display device has: an RGB-RGBW conversion circuit that converts RGB signals fed thereto into RGBW signals; a display panel that has a plurality of dots each composed of four, namely R, G, B, and W, unit pixels and that displays an image based on the RGBW signals; a defect position specifier that specifies, if a unit pixel is found defective, a position of the defective pixel on the display panel; and a conversion rate controller that controls the rate at which, when the RGB signals are converted into the RGBW signals, the RGB signals are converted into a W signal according to the position of the defective pixel. If the defective pixel is a W pixel, the conversion rate for pixels adjacent thereto is made lower than the standard conversion rate set for the entire display panel.

Owner:SANYO ELECTRIC CO LTD

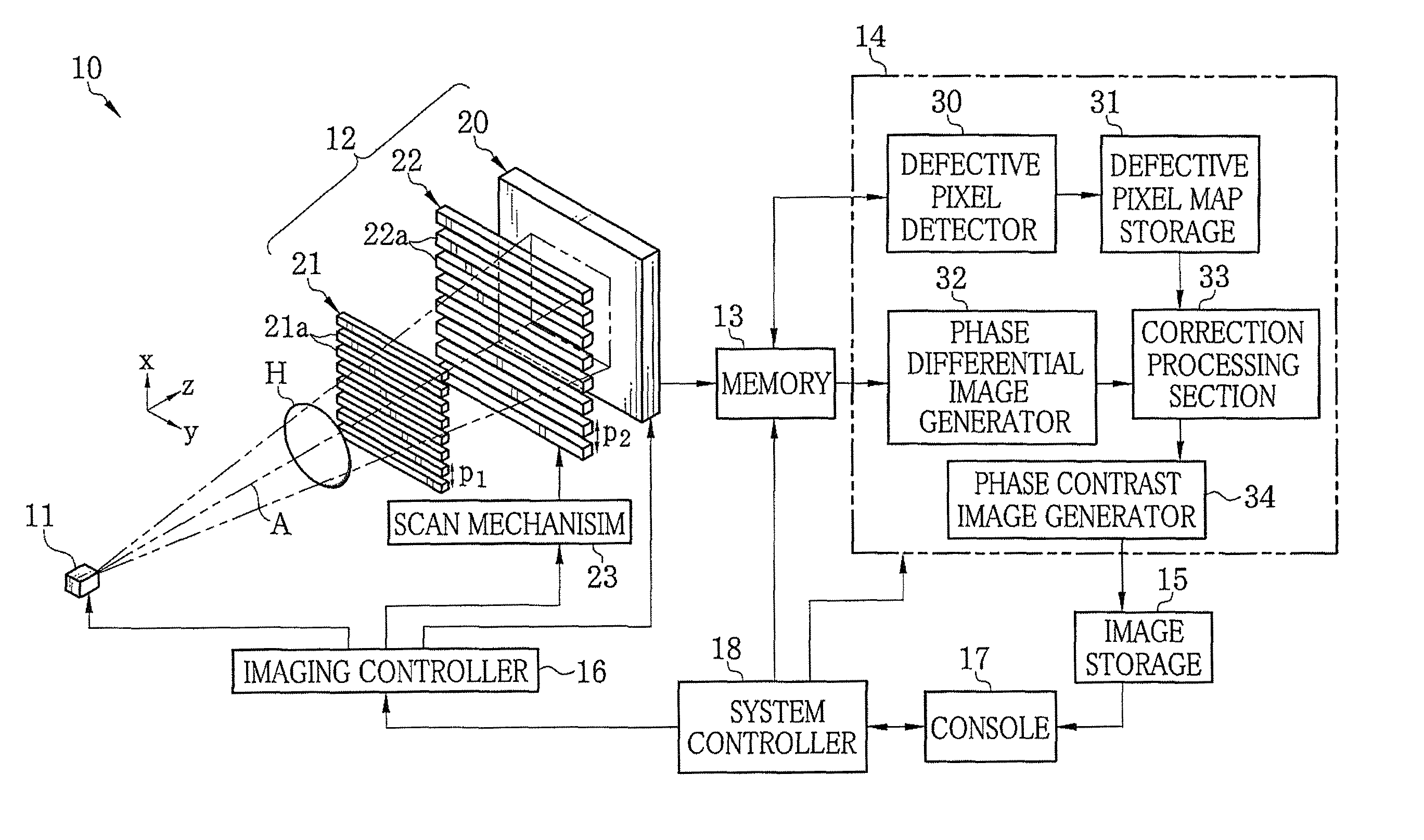

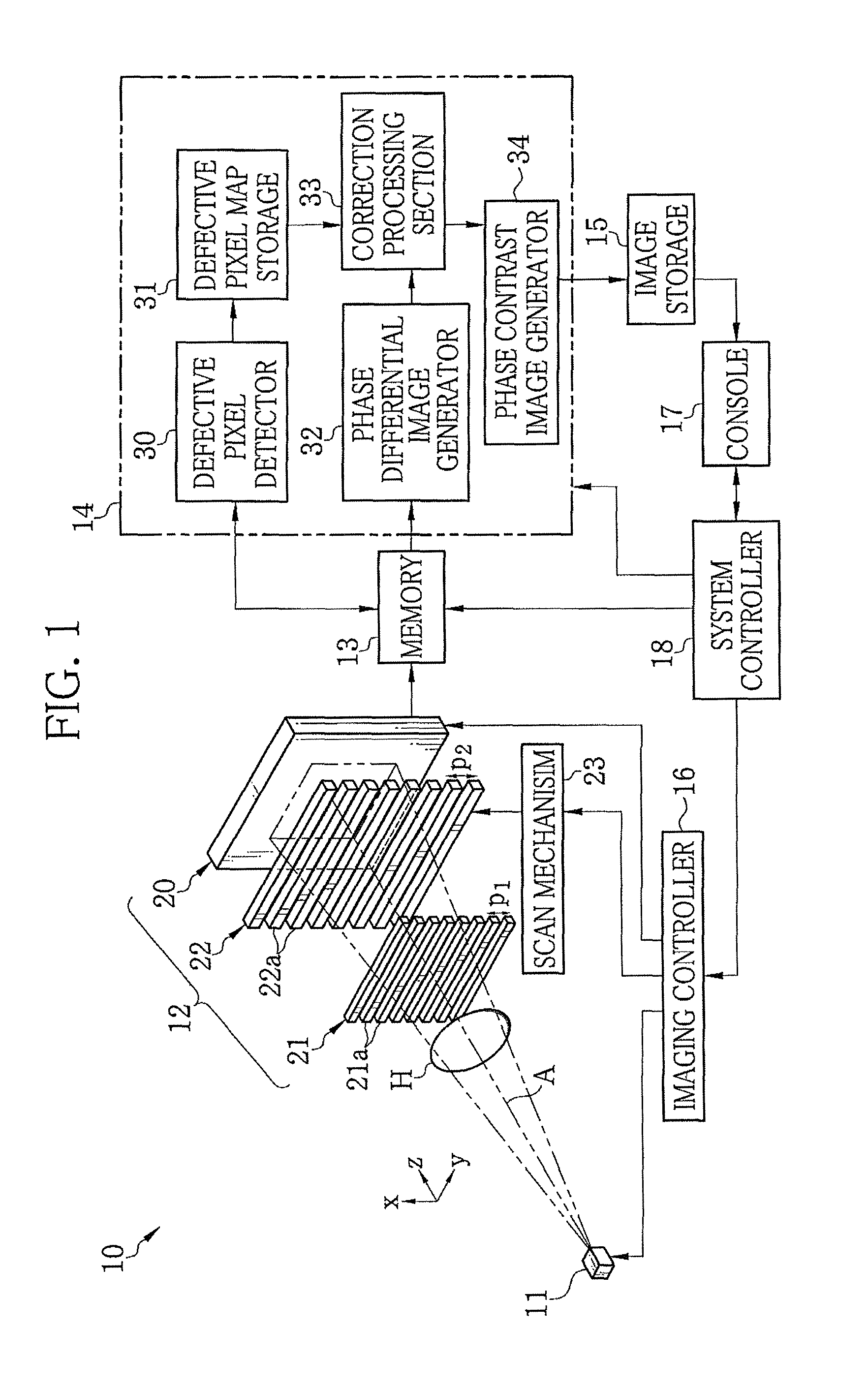

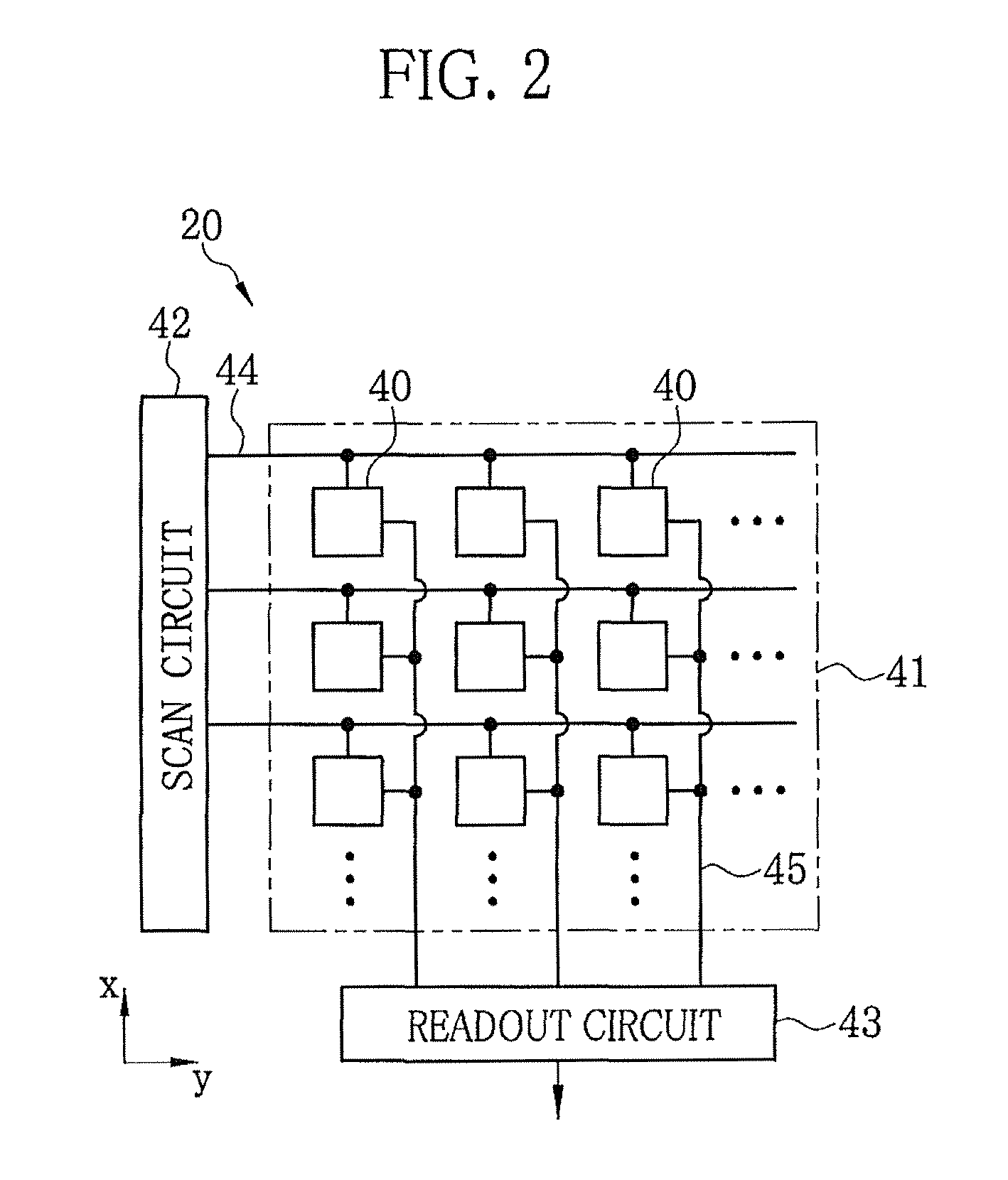

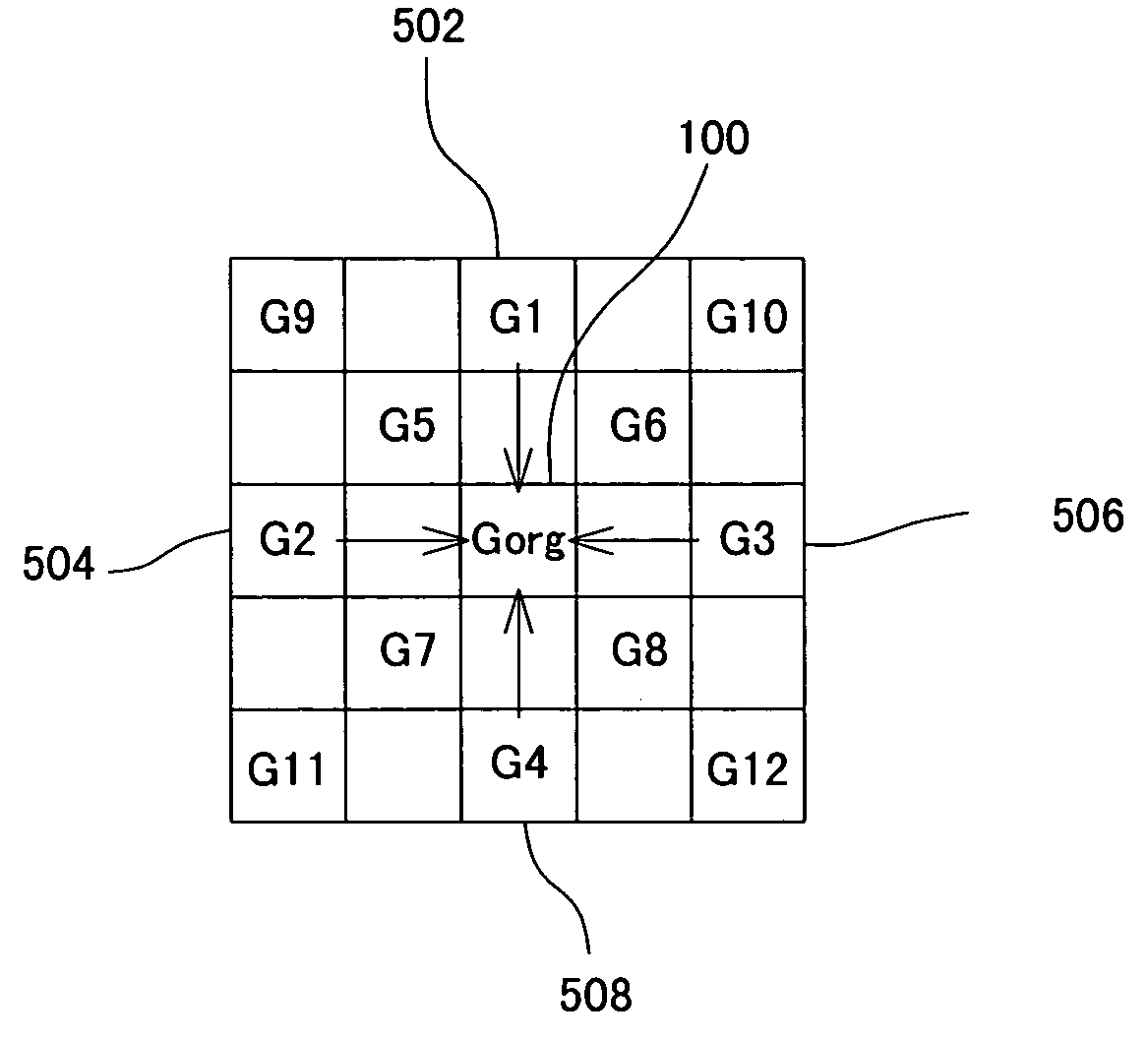

Radiation imaging system and apparatus and method for detecting defective pixel

InactiveUS8591108B2Improve accuracyX/gamma/cosmic radiation measurmentMaterial analysis by transmitting radiationAcquired characteristicGrating

An X-ray imaging system includes an X-ray source, first and second absorption gratings, and an FPD. The first absorption grating passes X-ray emitted from the X-ray source to form a G1 image. The second absorption grating modulates intensity of the G1 image at each of relative positions to form two or more fringe images. The relative positions differ in phase with respect to a period pattern of the G1 image. The FPD detects two or more frames of image data of the fringe images. A defective pixel detector reads two or more frames of image data stored in a memory and obtains a characteristic value of an intensity modulated signal on a pixel-by-pixel basis based on the read image data. The defective pixel detector detects a defective pixel based on the characteristic value obtained.

Owner:FUJIFILM CORP

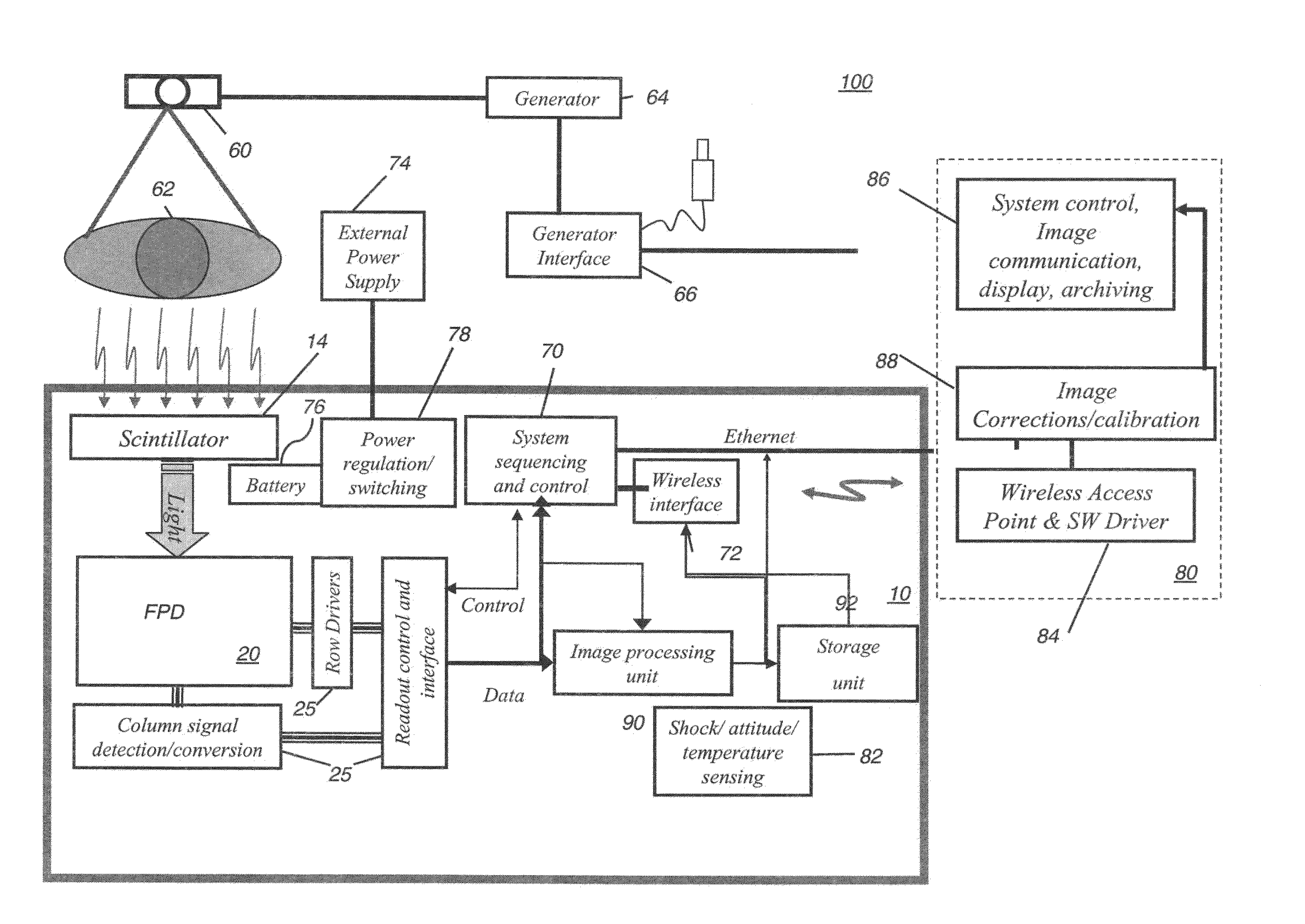

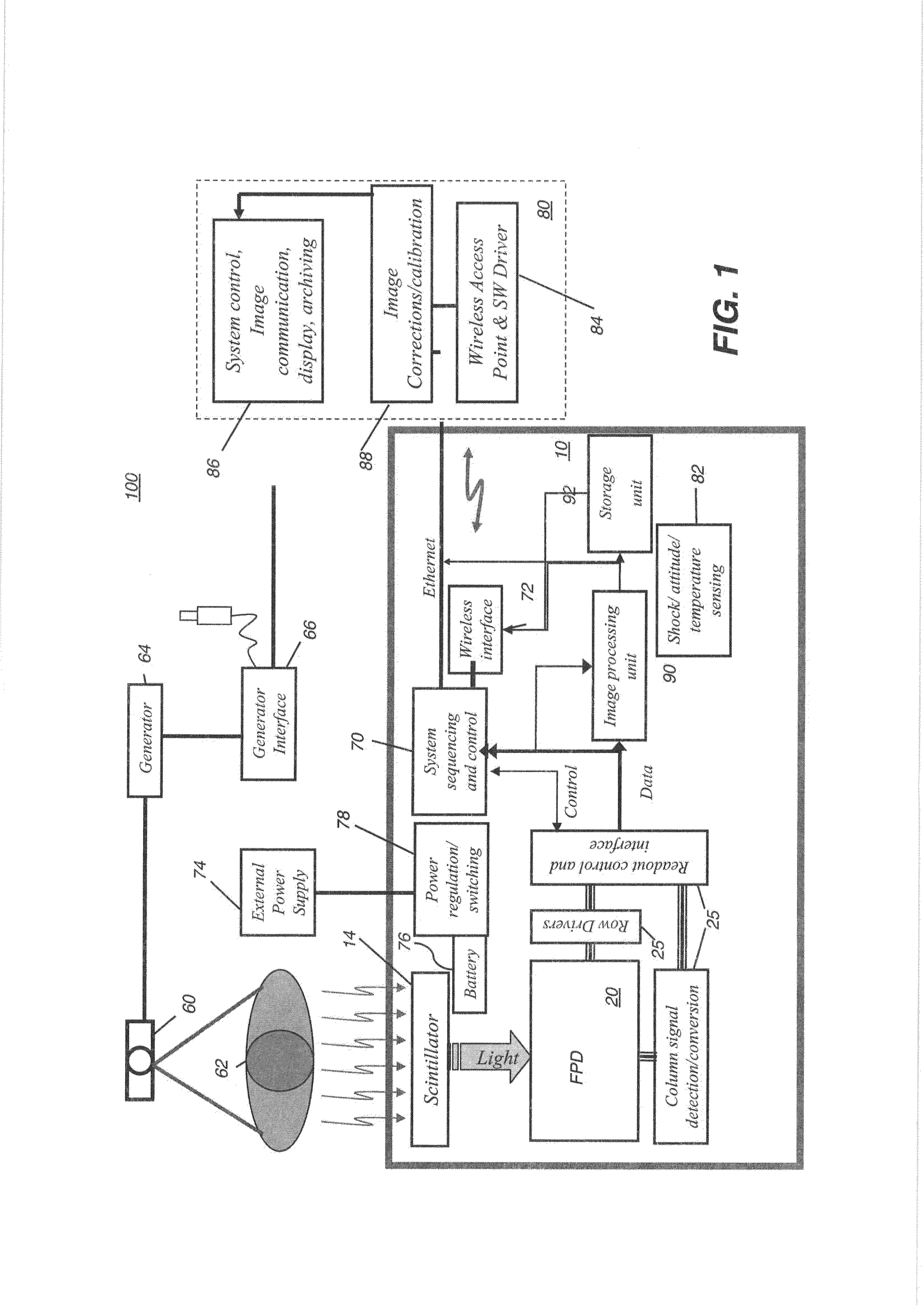

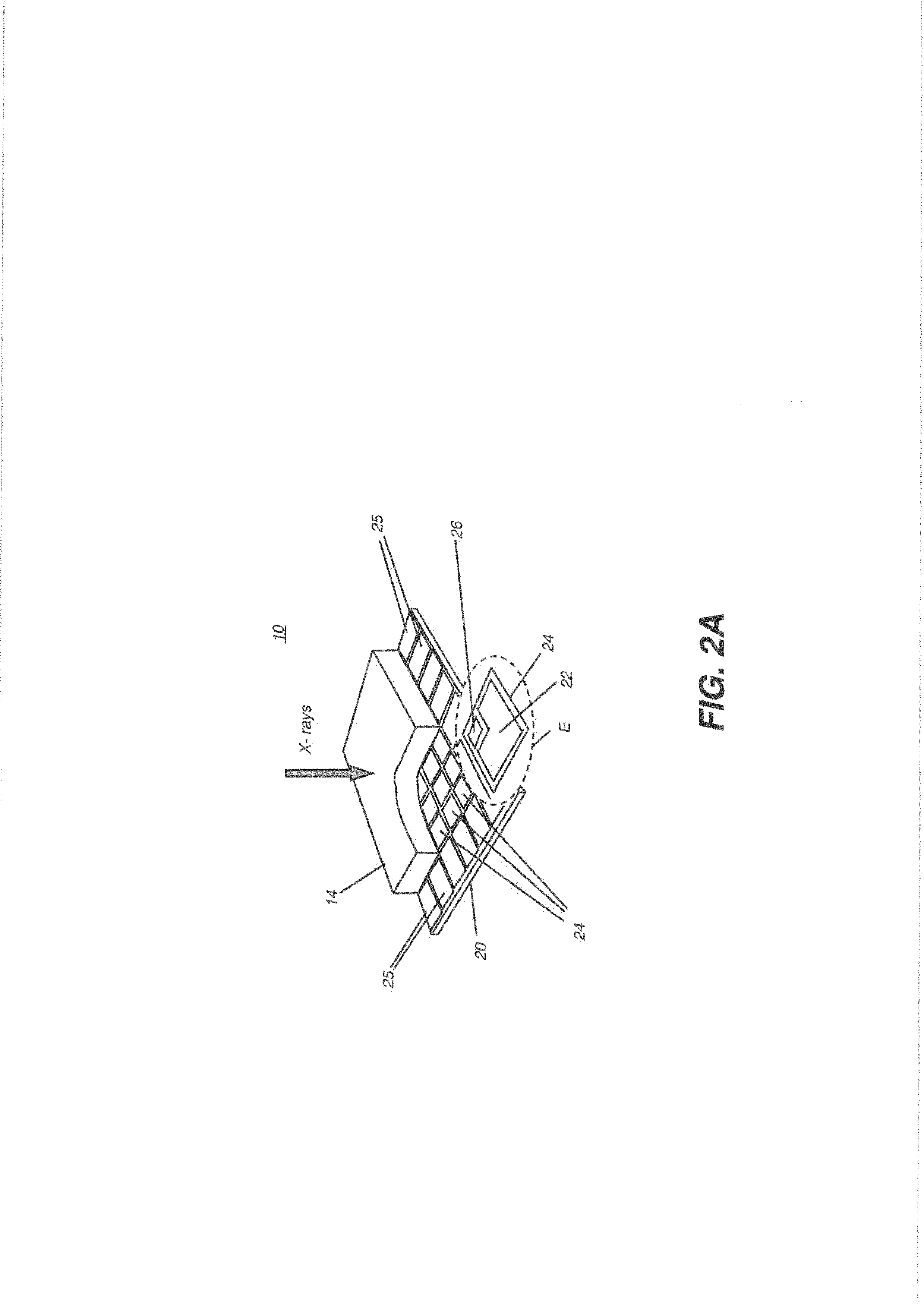

Self correcting portable digital radiography detector, methods and systems for same

Embodiments of radiographic imaging systems and / or methods can monitor the state of calibration of a digital x-ray detector, the detector including a solid state sensor with a plurality of pixels, an optional scintillating screen and at least one embedded microprocessor. In one embodiment, a method can use a computer or the embedded microprocessor or both, for setting a calibration operating mode of the portable detector; taking a plurality of dark images in the calibration mode; determining a dark difference image between pixel readings between two of the plurality of dark images; identifying pixels in the dark difference image that differ by over a threshold amount from at least some surrounding pixels in the dark difference image as defective pixels.

Owner:CARESTREAM HEALTH INC

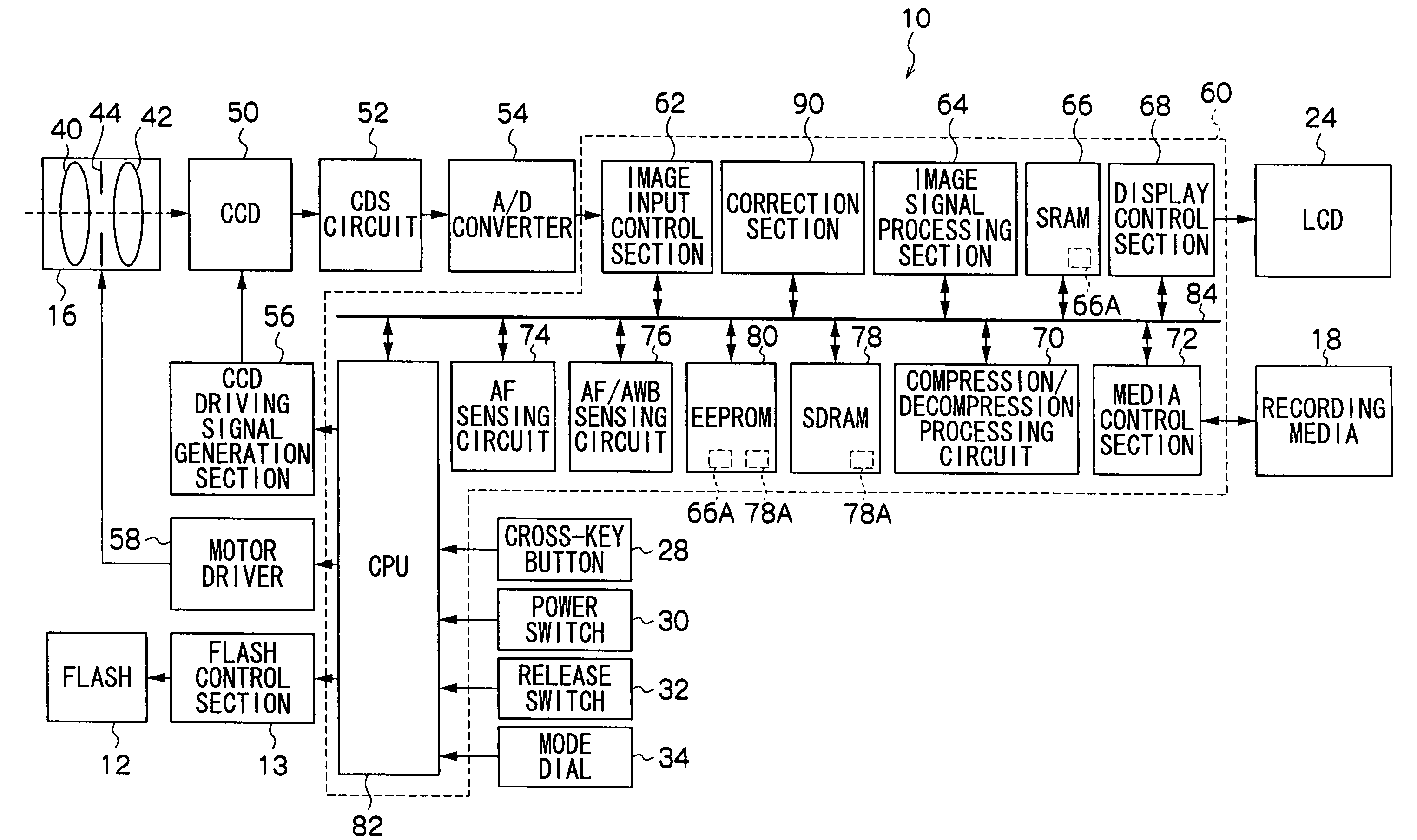

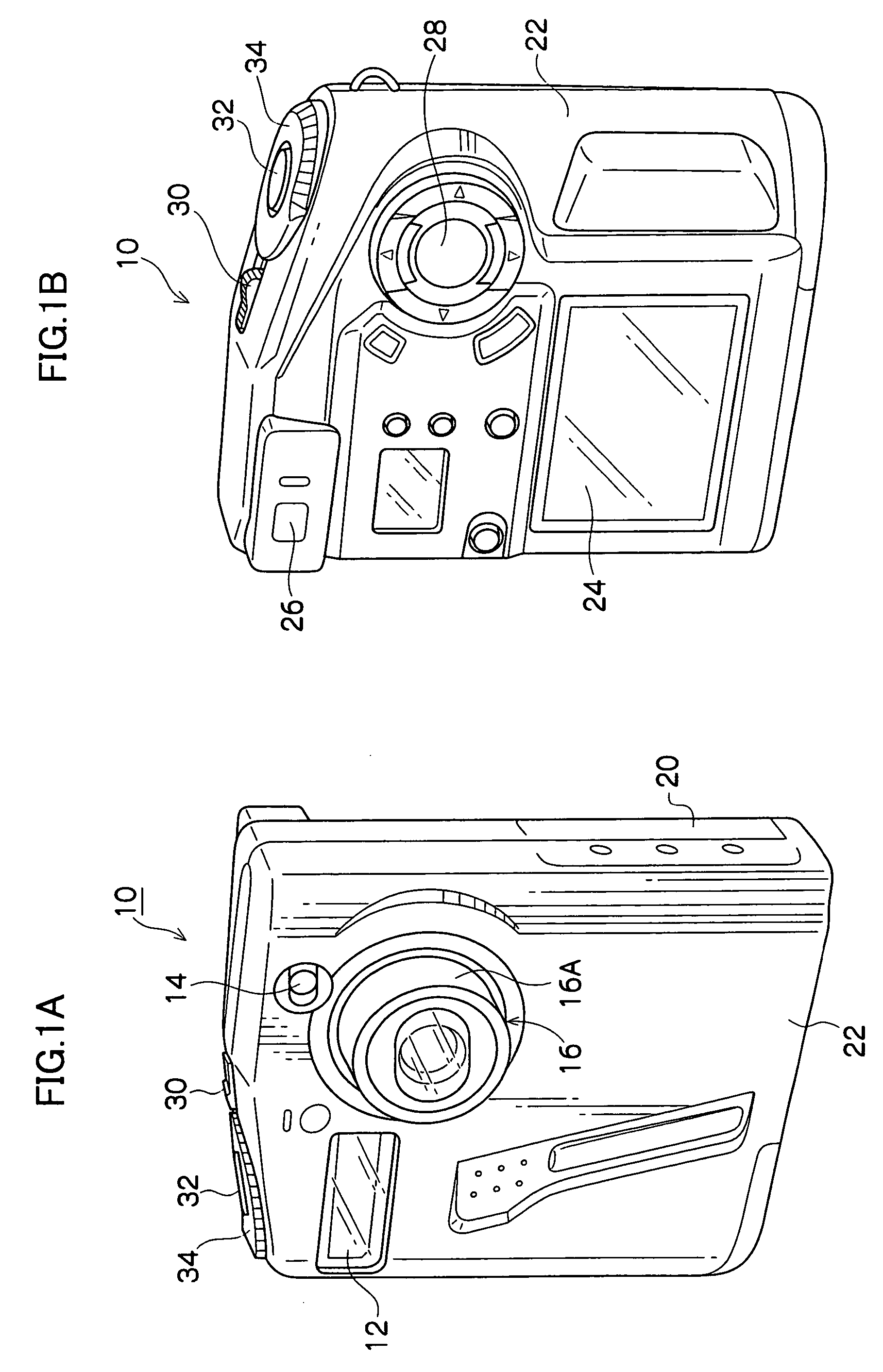

Pixel defect correction device

InactiveUS20060238629A1Improve calibration accuracyTelevision system detailsColor signal processing circuitsDiagonalImage storage

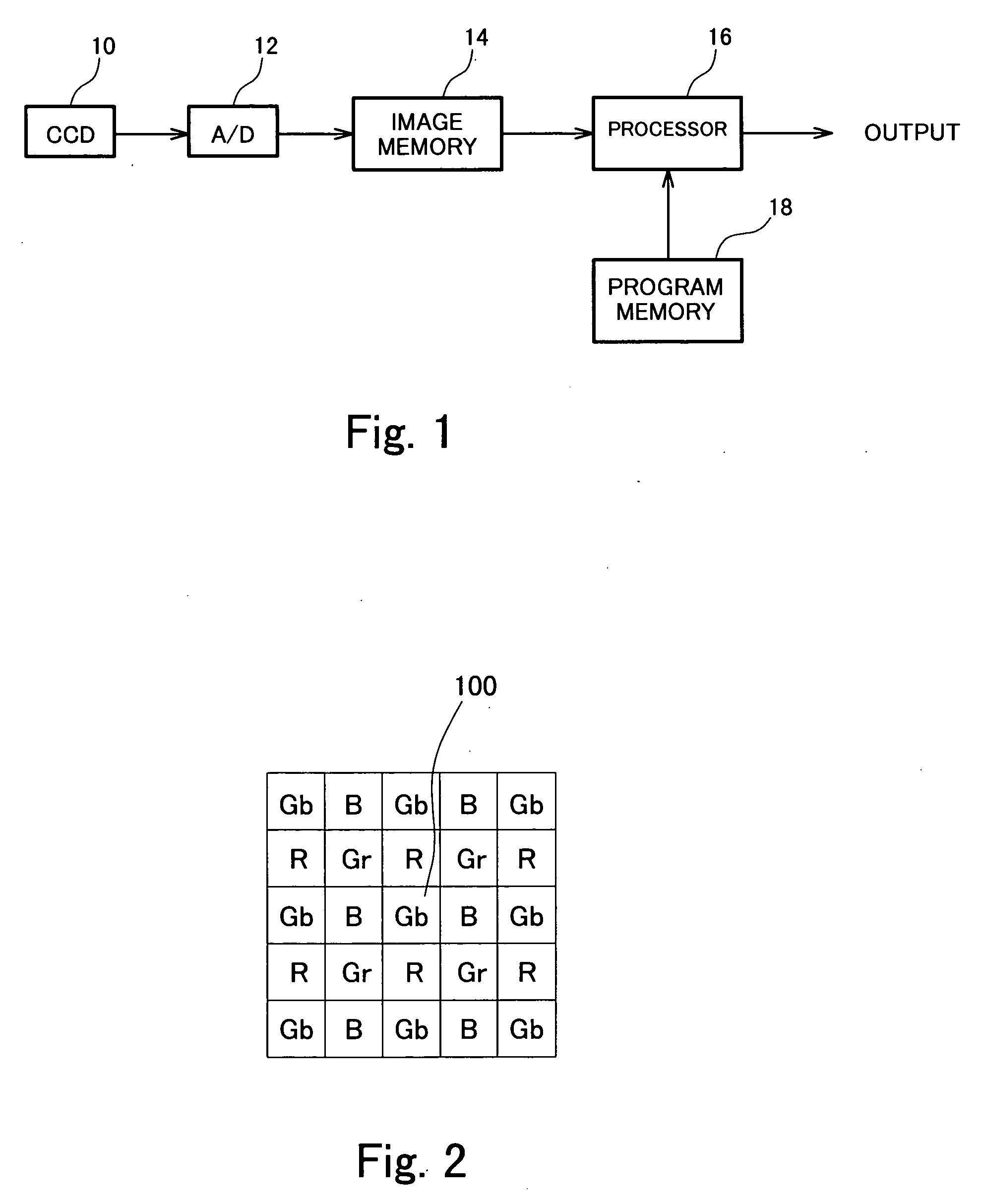

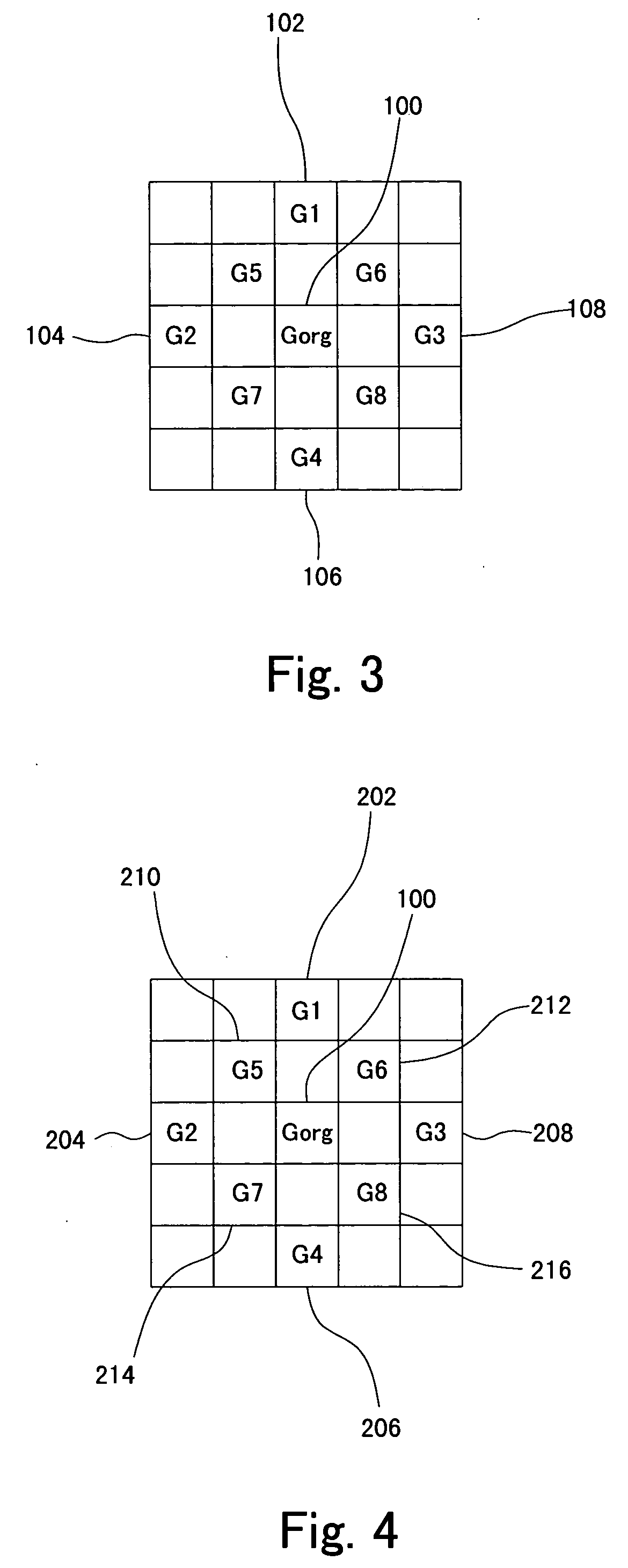

To enhance accuracy in correction of a defective pixel. An image of an object is captured using a digital camera, and stored in an image memory 14. A processor 16 detects a defect, using pixels located in the vertical and horizontal directions relative to, in lines of the same color as, and separated by one line from, the focused line. With any defect found, the presence or absence of line crawl is next determined. When it is determined that line crawl is present, the presence or absence of a diagonal edge is then determined. Subsequently, the surrounding pixels used to correct a defective pixel are selected in consideration of whether or not line crawl or a diagonal edge are present.

Owner:MONUMENT PEAK VENTURES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com