Patents

Literature

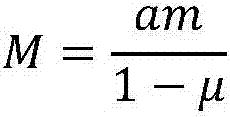

975results about How to "Not easy to layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

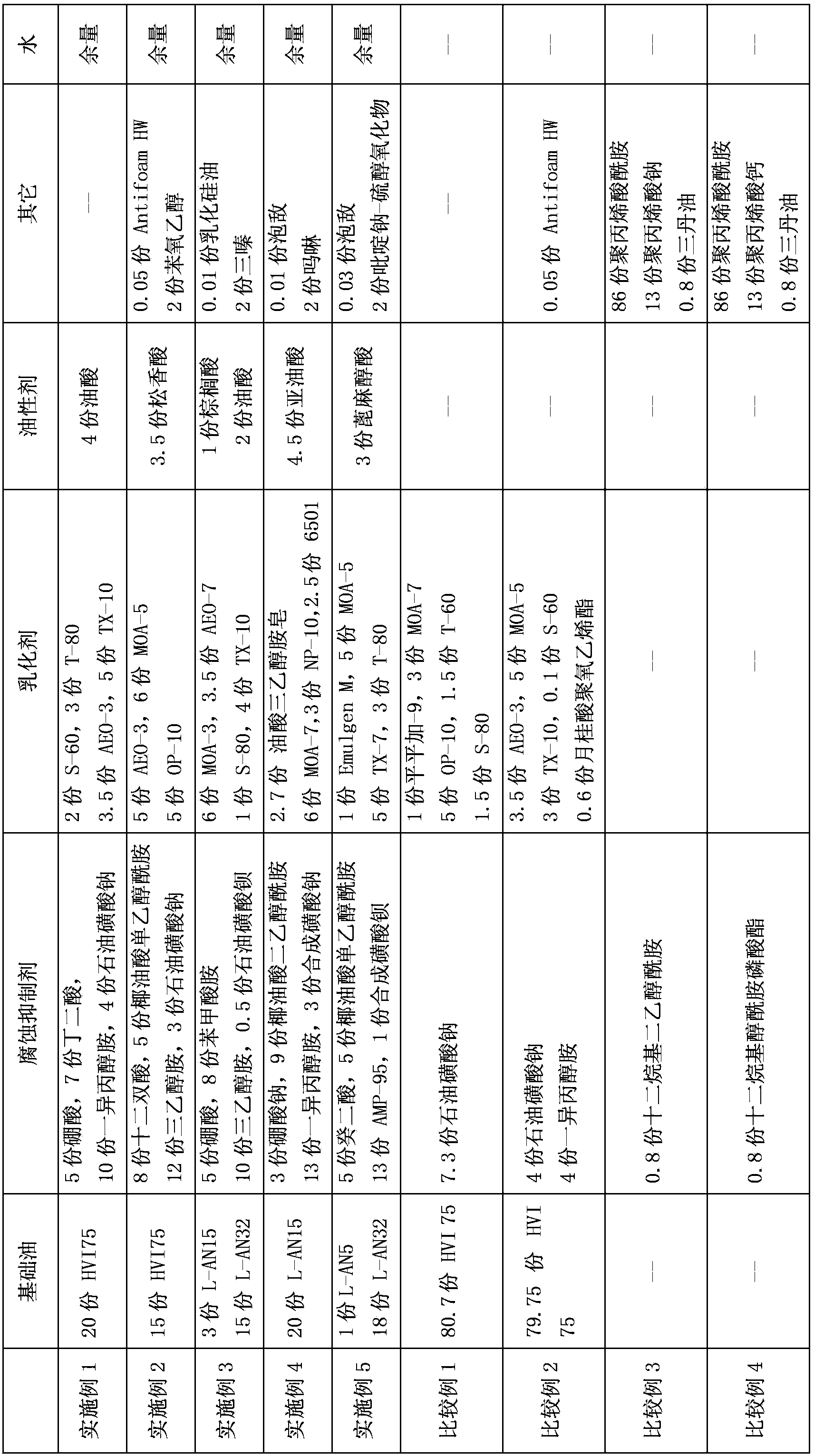

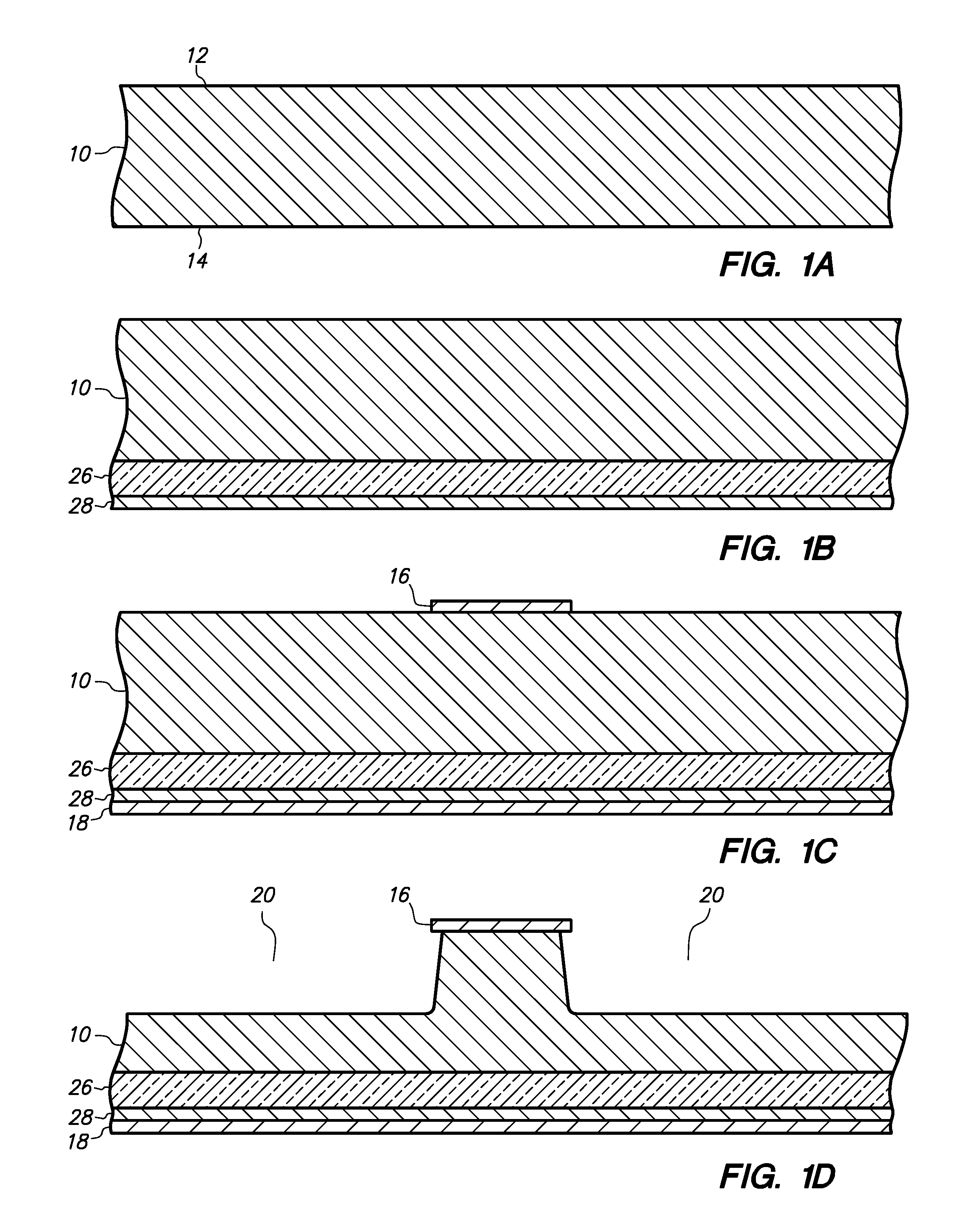

Lubricating oil composition and preparation method thereof

The invention relates to a lubricating oil composition and a preparation method thereof, and is mainly used for solving the problem that the lubricating oil in the prior art does not have anti-corrosive property to aluminum alloy and compatibility to rubber at the same time. The problem is well solved by the technical scheme that the lubricating oil composition comprises the following components in parts by weight: a) 10-30 parts of base oil, b) 15-35 parts of corrosion inhibitor, c) 8-20 parts of emulsifier, d) 1-6 parts of oil agent, and e) 5-40 parts of water. The lubricating oil composition can be applied to industrial production of the lubricating oil for automobile tire fitting.

Owner:CHINA PETROLEUM & CHEM CORP

Water high light wearable intaglio ink and preparing method thereof

The invention relates to a water-base printing ink and its producing method, especially water-base high light friction resistance gravure oil and the producing method thereof. The oil is suitable for packing print in the soft packing field such as food, drink, medicine, health products, chemicals and etc. The water-base high light friction resistance gravure oil is composed of acrylic resin, acrylic emulsion, dye, ethanol, built-up agent, dispersant, deionized water, water-base emulsifying wax, antifoamer, leveling agent. The inventive product completely meets the requirement of the gravure oil, has a reliable quality and can replace the solvent gravure oil, which can be dilute by the tap water of ethanol. The printing device can be washed directly by the tap water. The product has a high concentration, a low viscosity, a good printing adaptability has no harm to the environment and human body. The presswork has a clear pattern, a bright color, a powerful attached fastness, a good water resistance and friction resistance, has no harmful residue after drying and is not easy to fade and shed.

Owner:浙江永在油墨有限公司

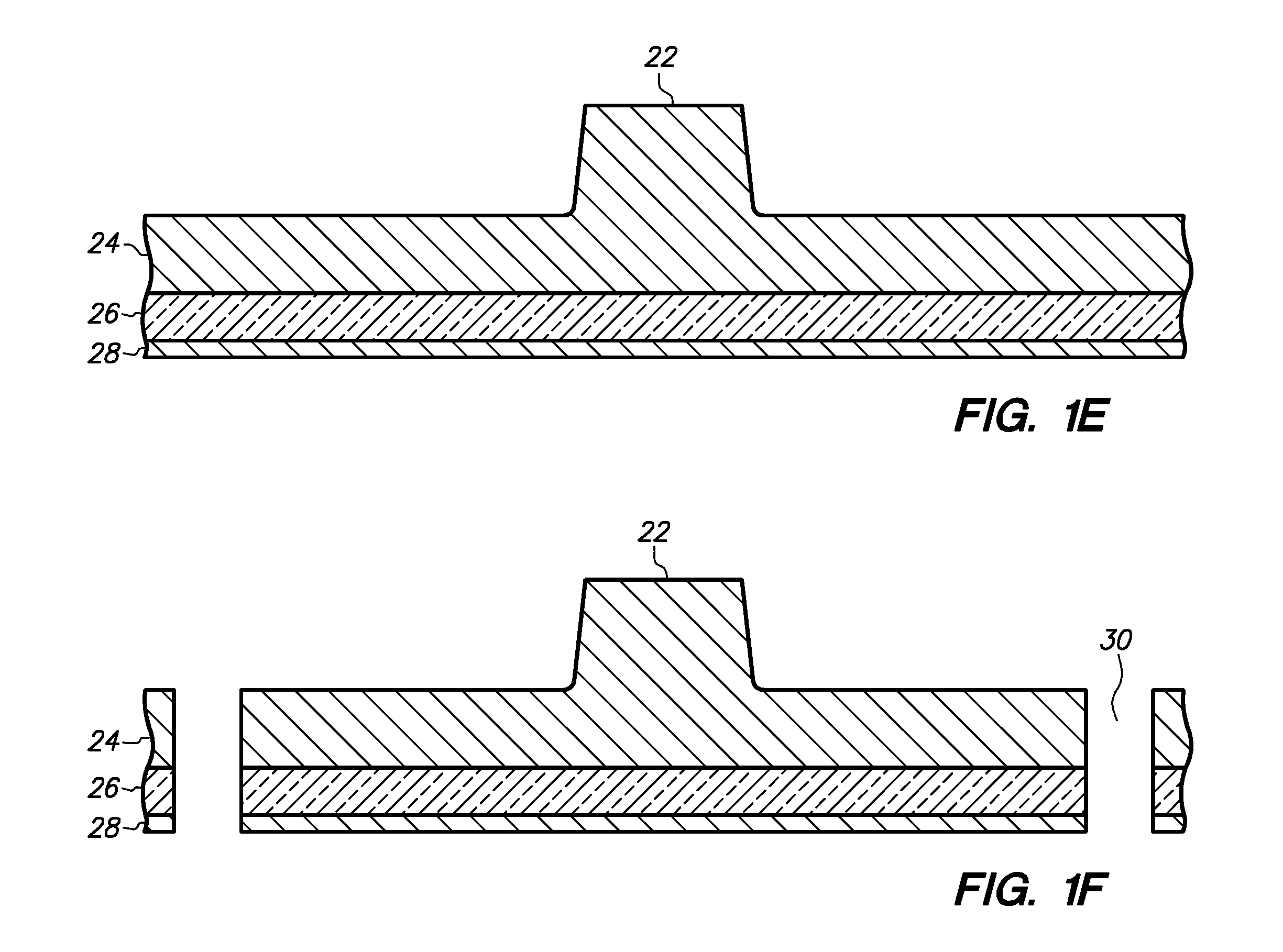

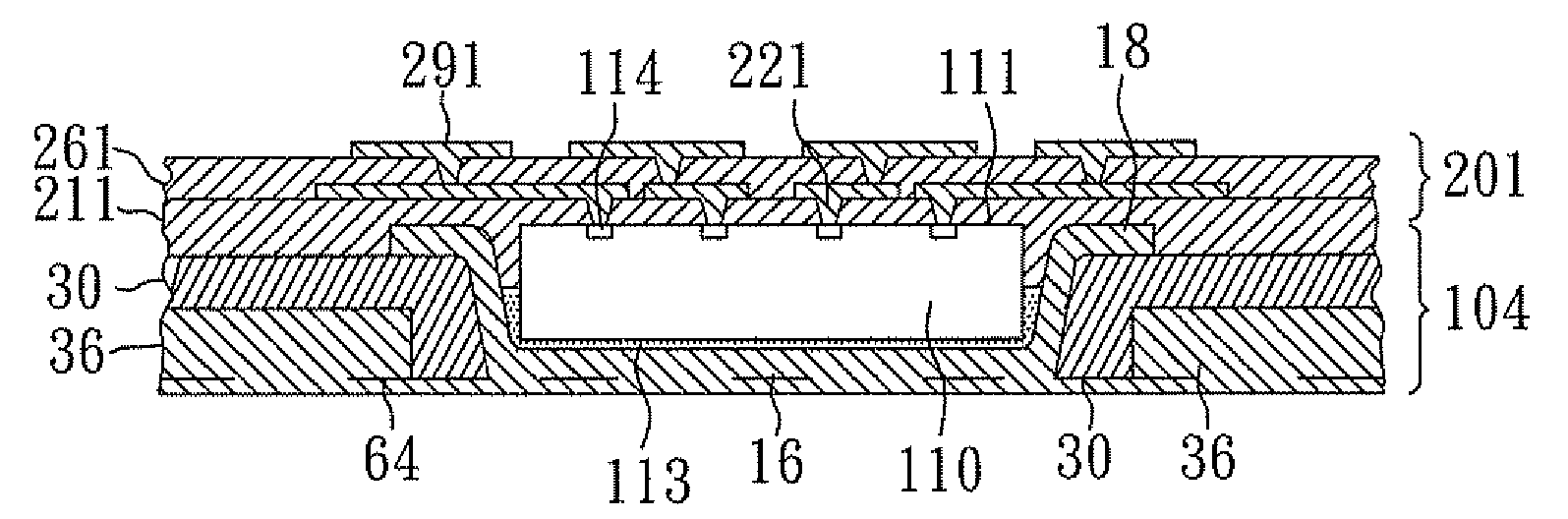

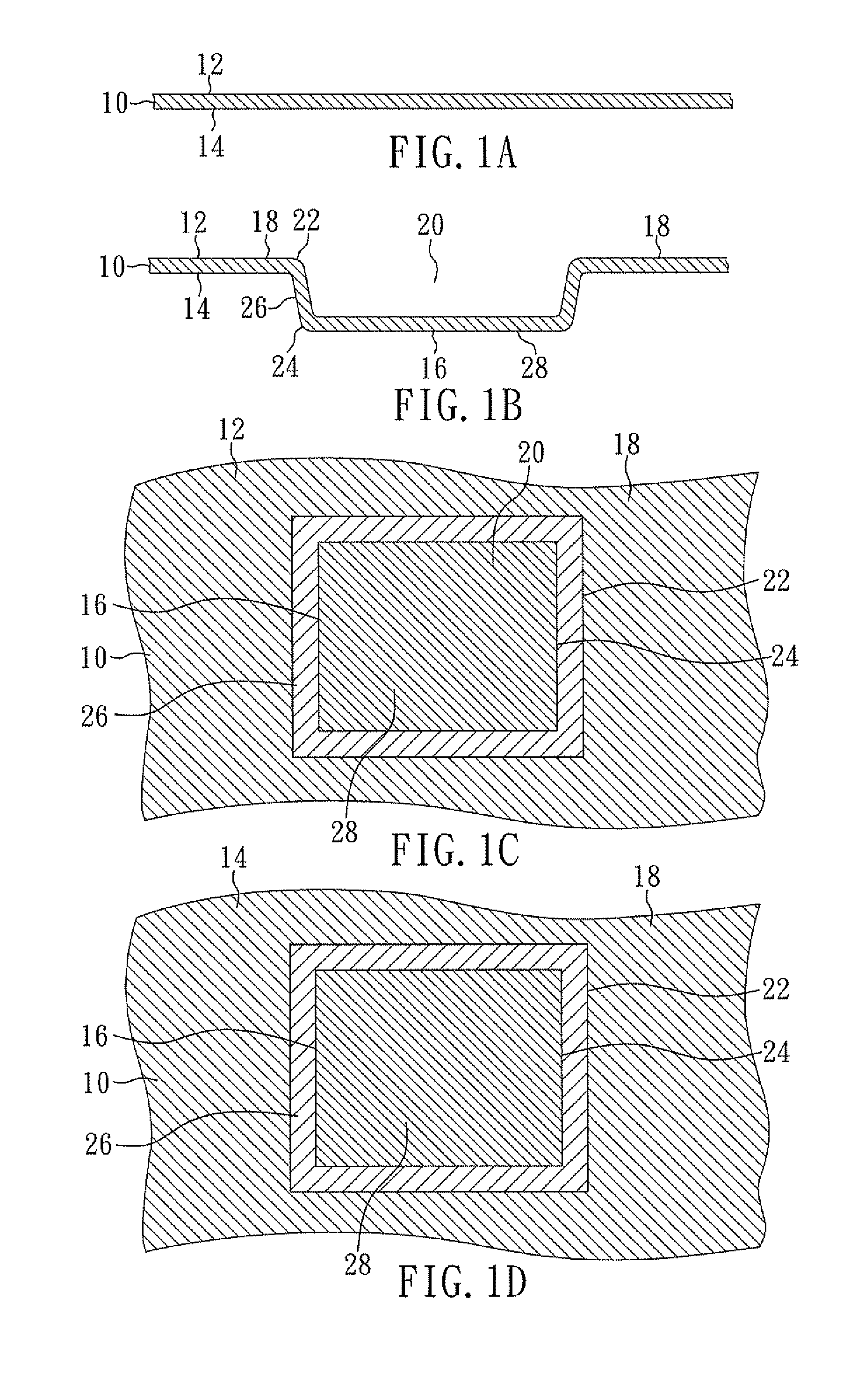

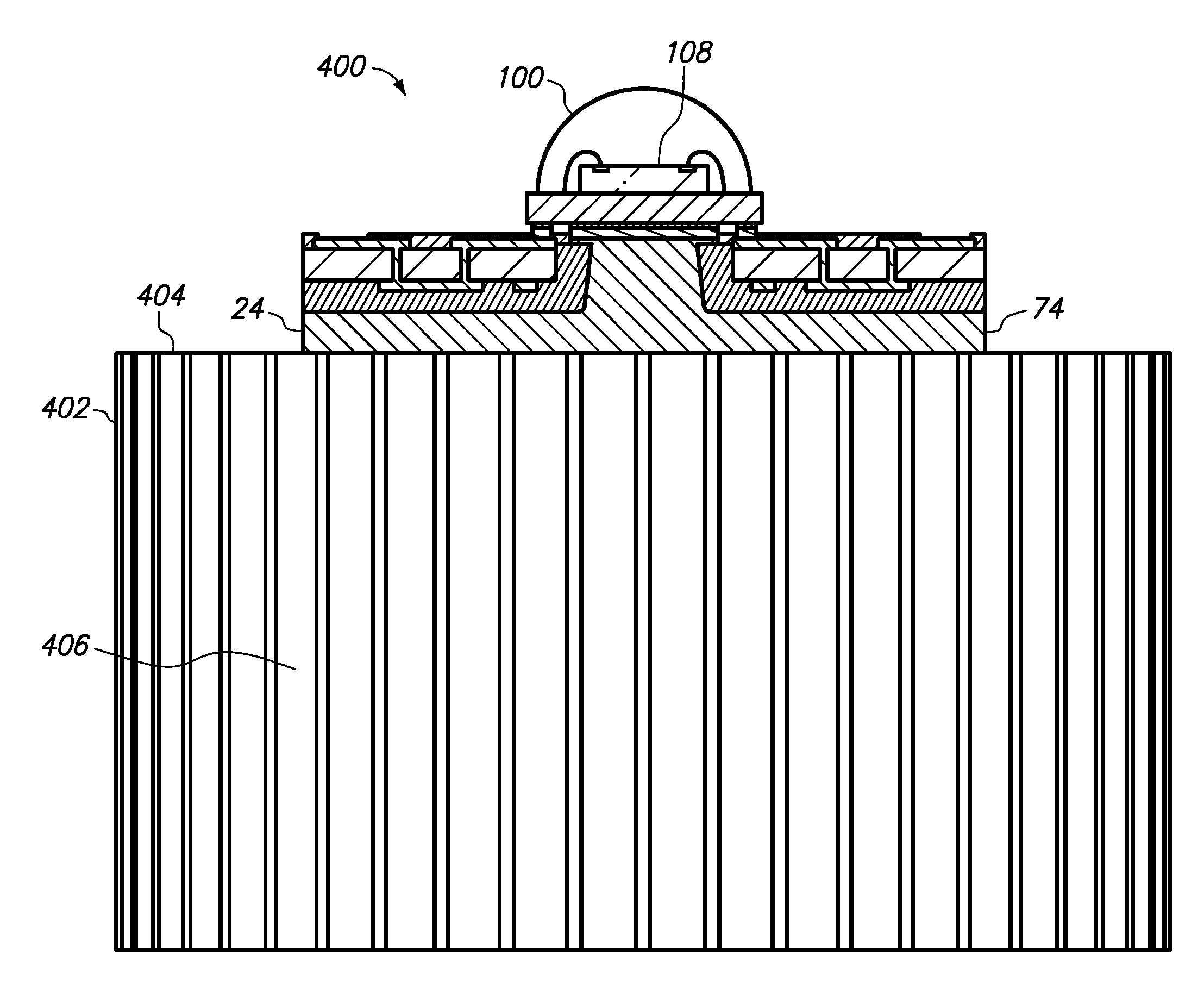

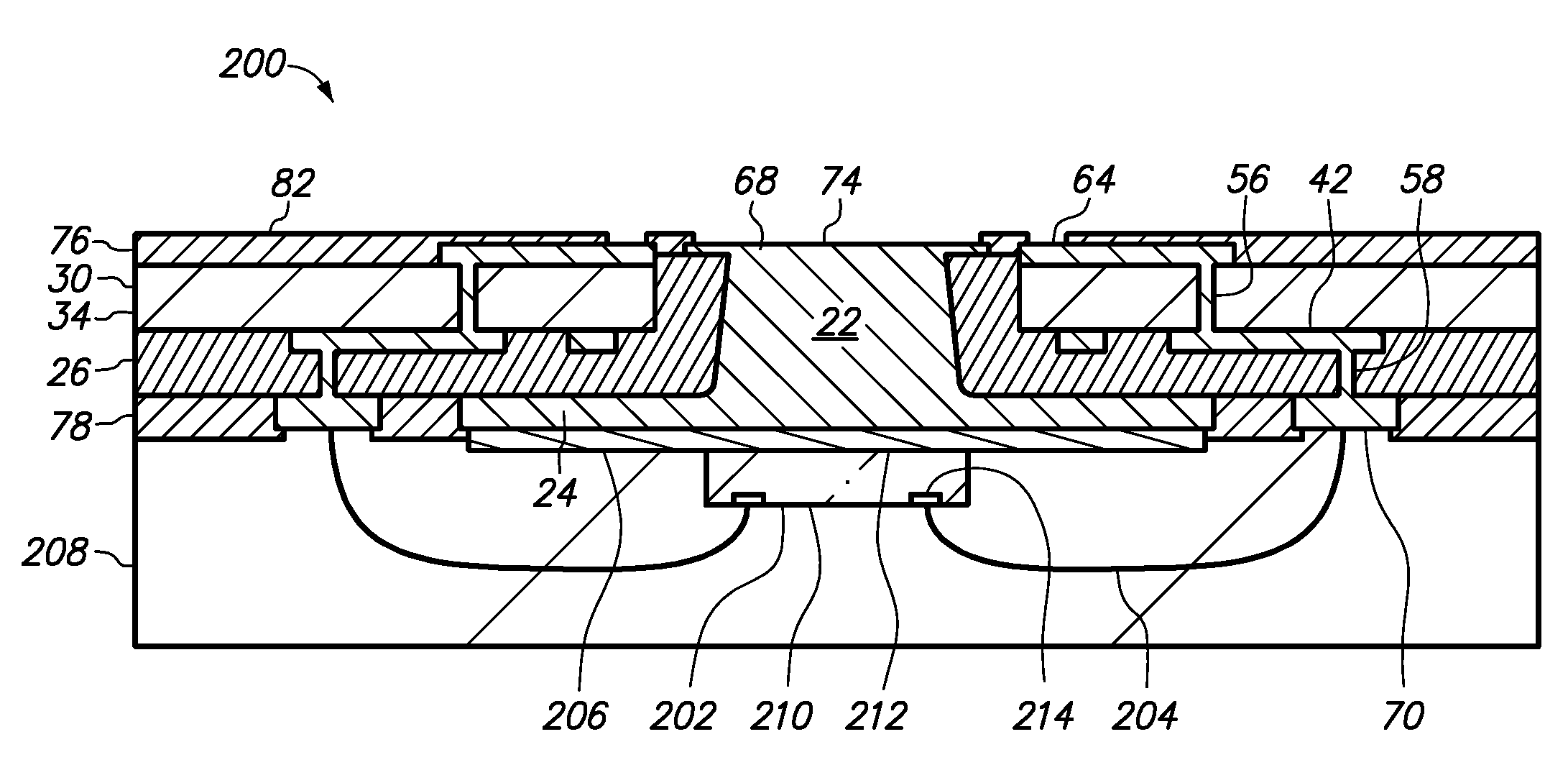

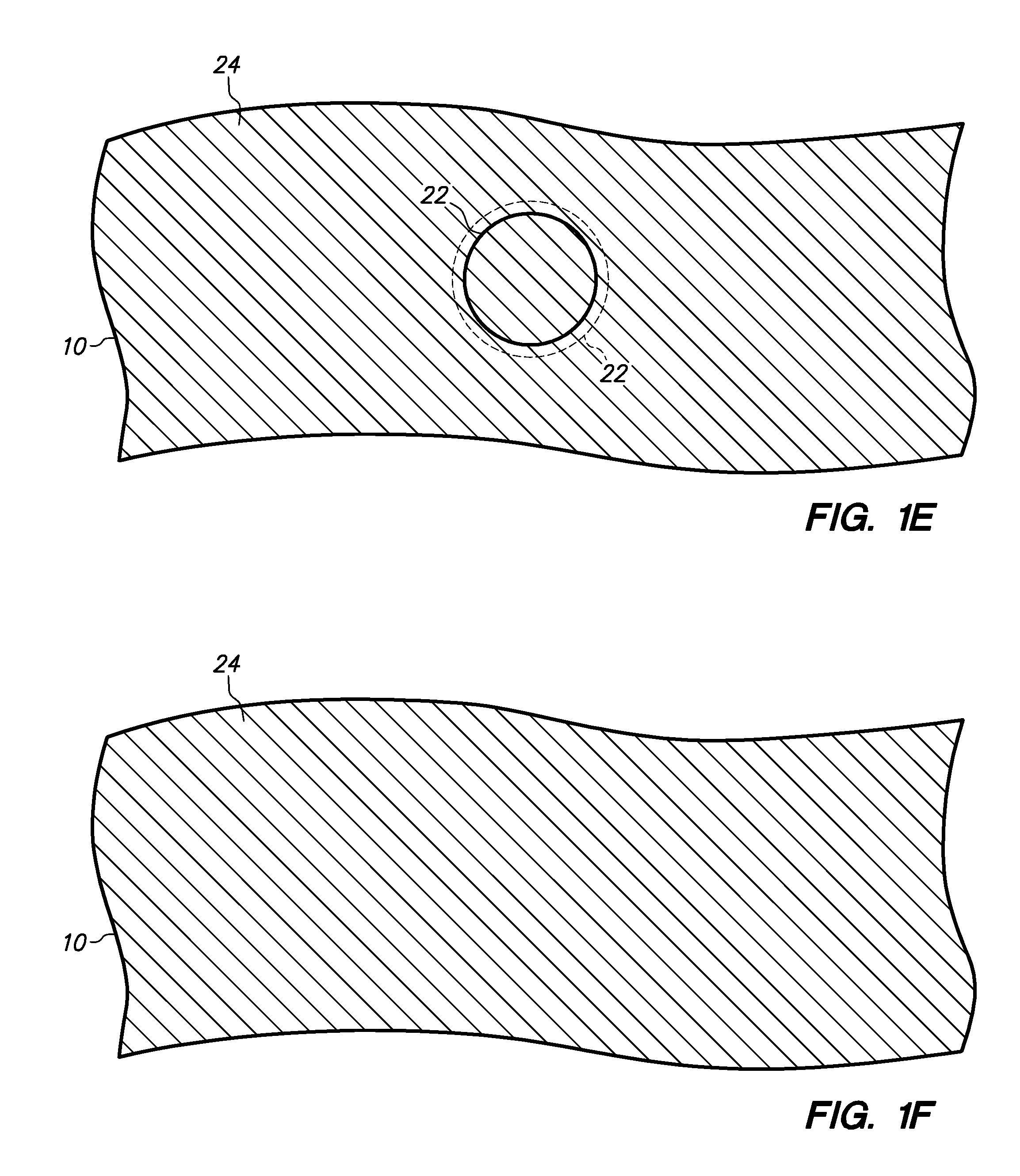

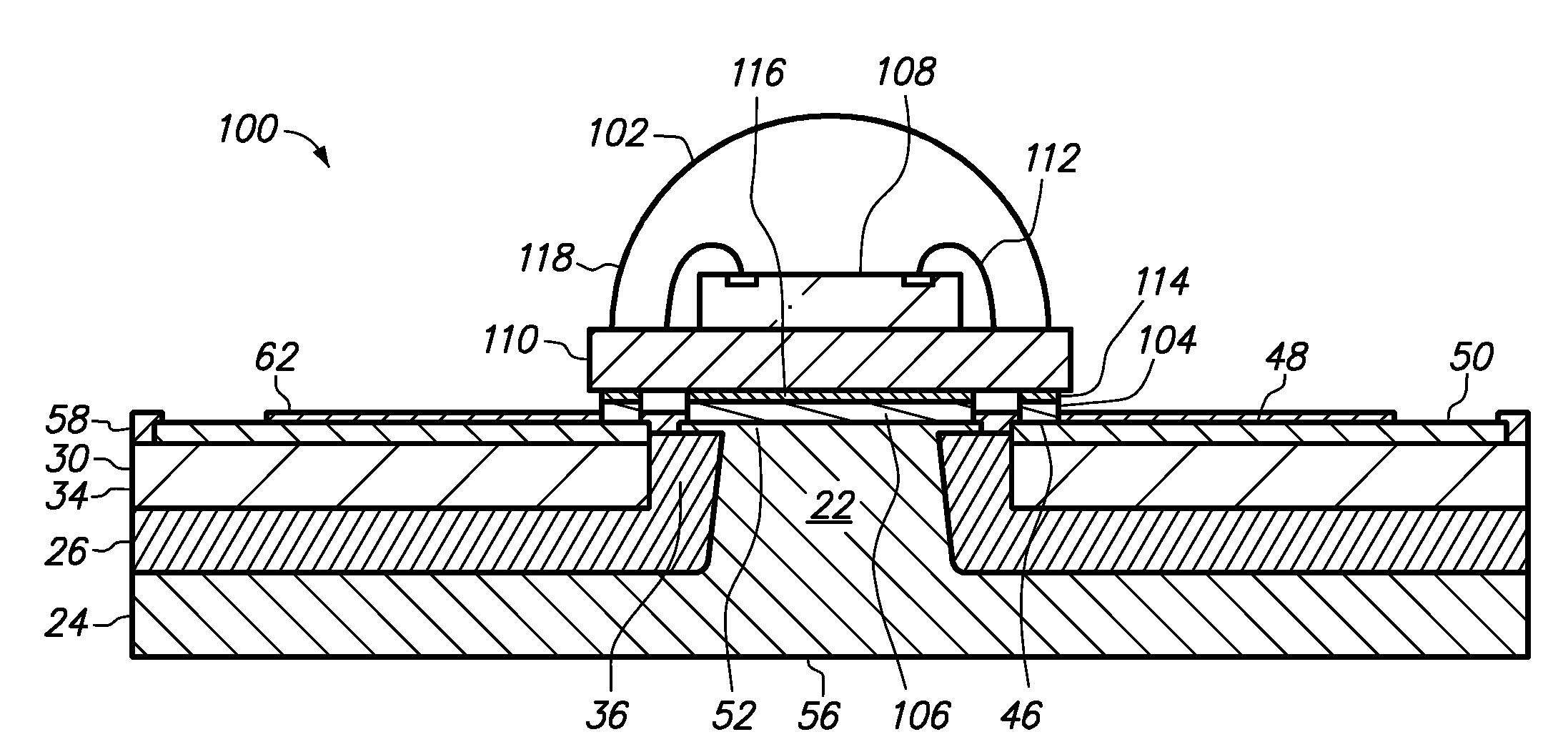

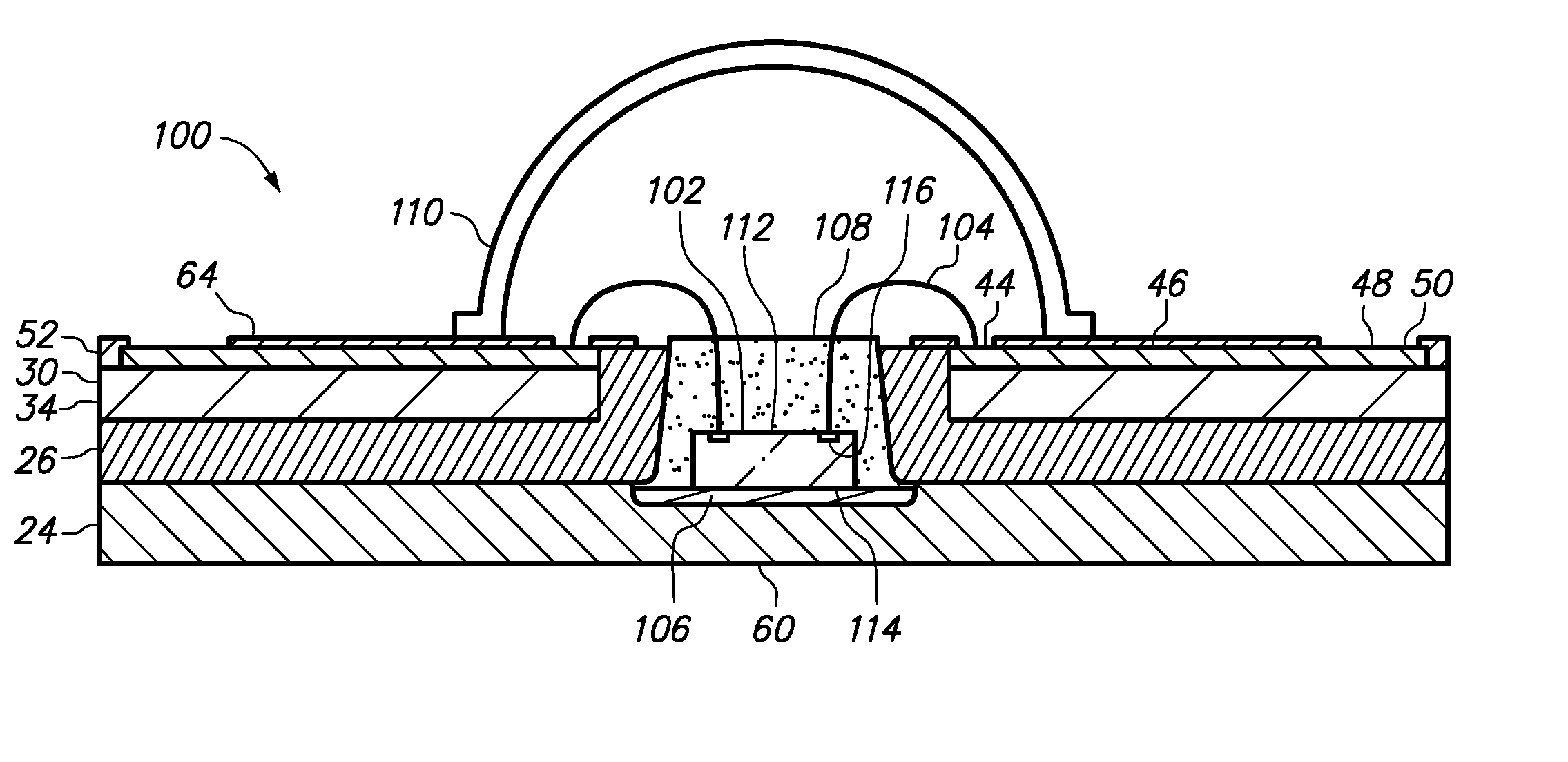

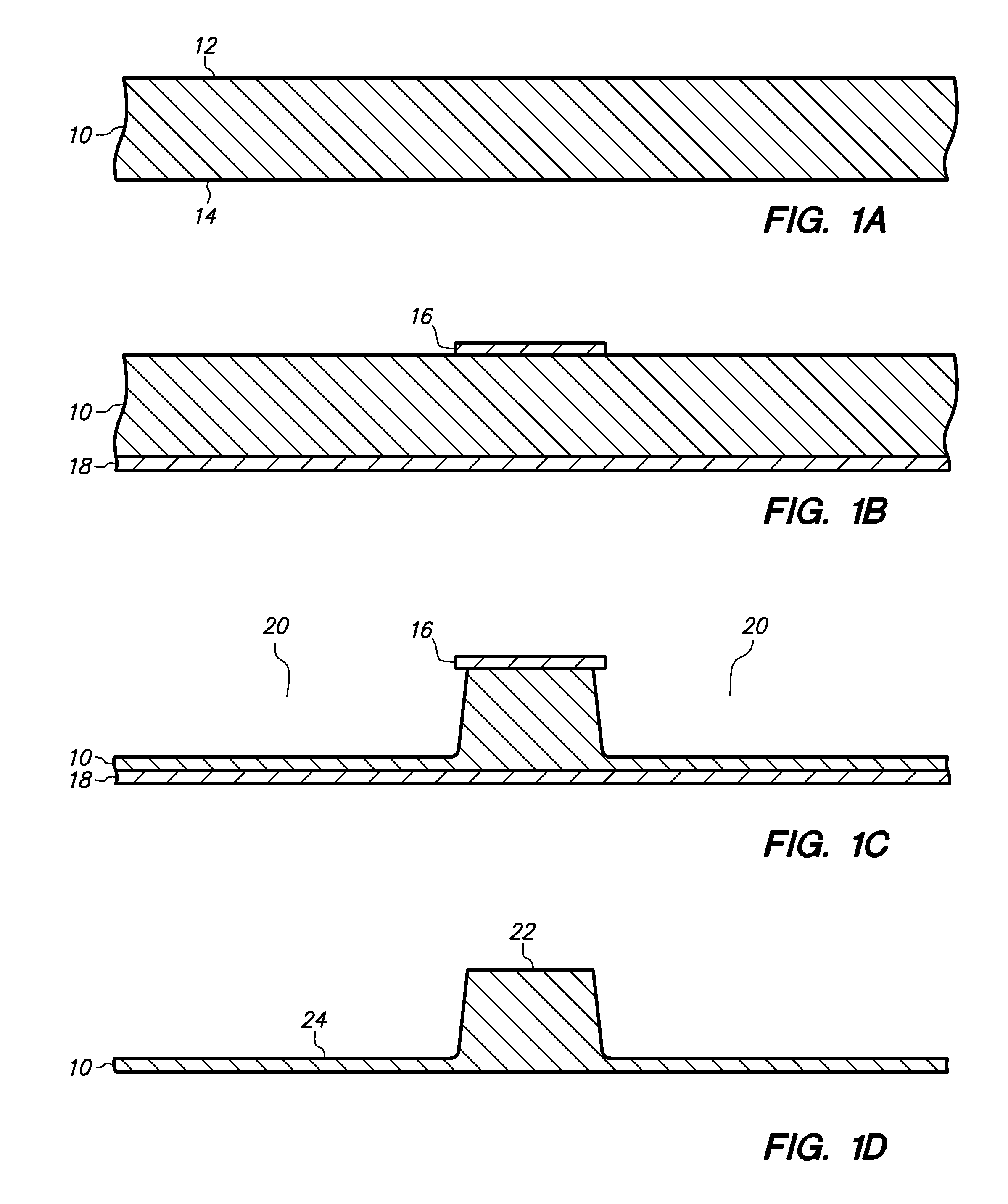

Semiconductor chip assembly with post/base heat spreader with ESD protection layer

InactiveUS20110089465A1Low costNot easy to layerSemiconductor/solid-state device detailsPrinted circuit aspectsSignal routingAdhesive

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and an adhesive. The heat spreader includes a post, a base, an ESD protection layer and an underlayer. The conductive trace includes a pad and a terminal. The semiconductor device is electrically connected to the conductive trace, electrically isolated from the underlayer and thermally connected to the heat spreader. The post extends upwardly from the base into an opening in the adhesive, the base extends laterally from the post and the ESD protection layer is sandwiched between the base and the underlayer. The conductive trace provides signal routing between the pad and the terminal.

Owner:BRIDGE SEMICON

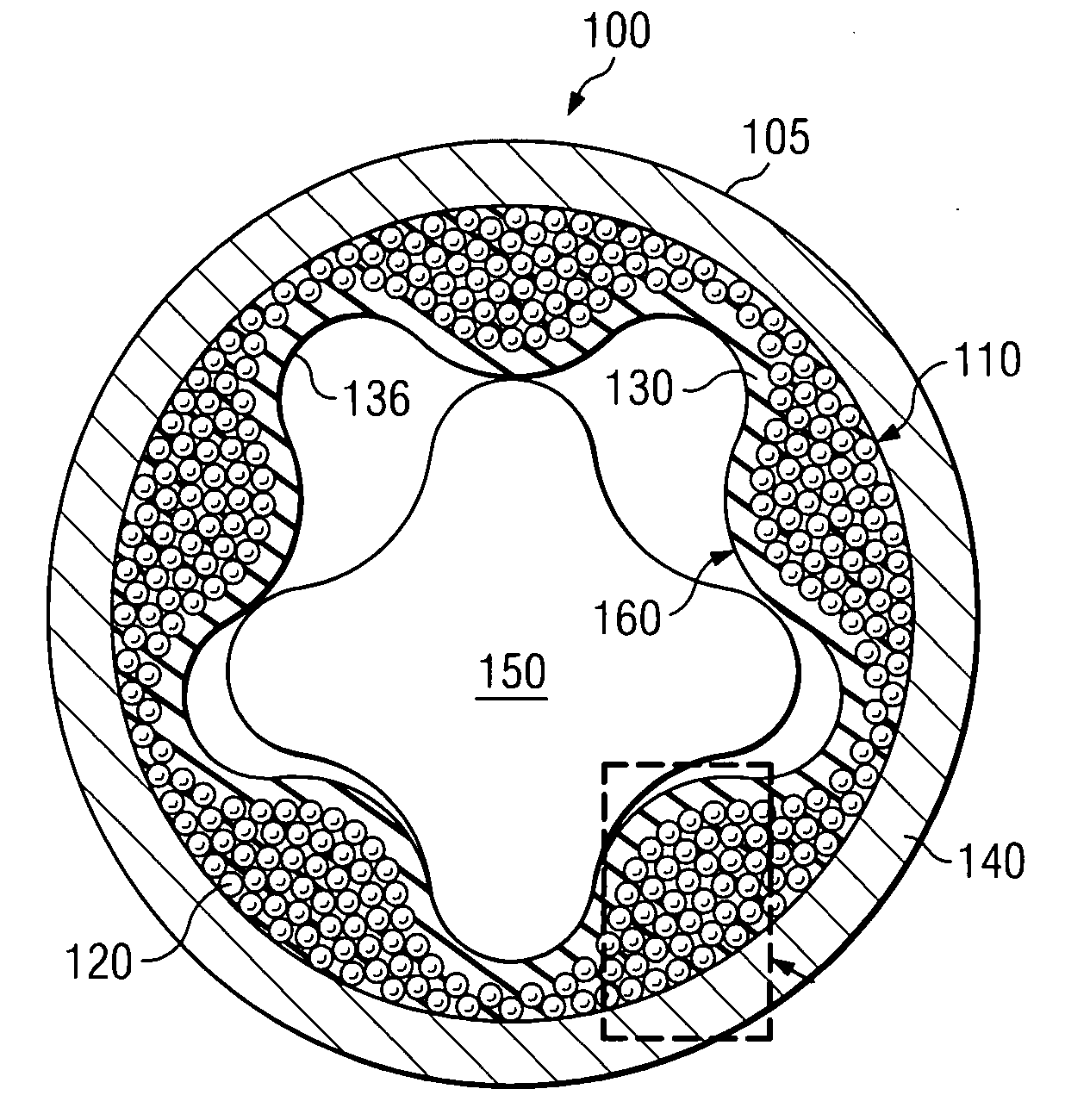

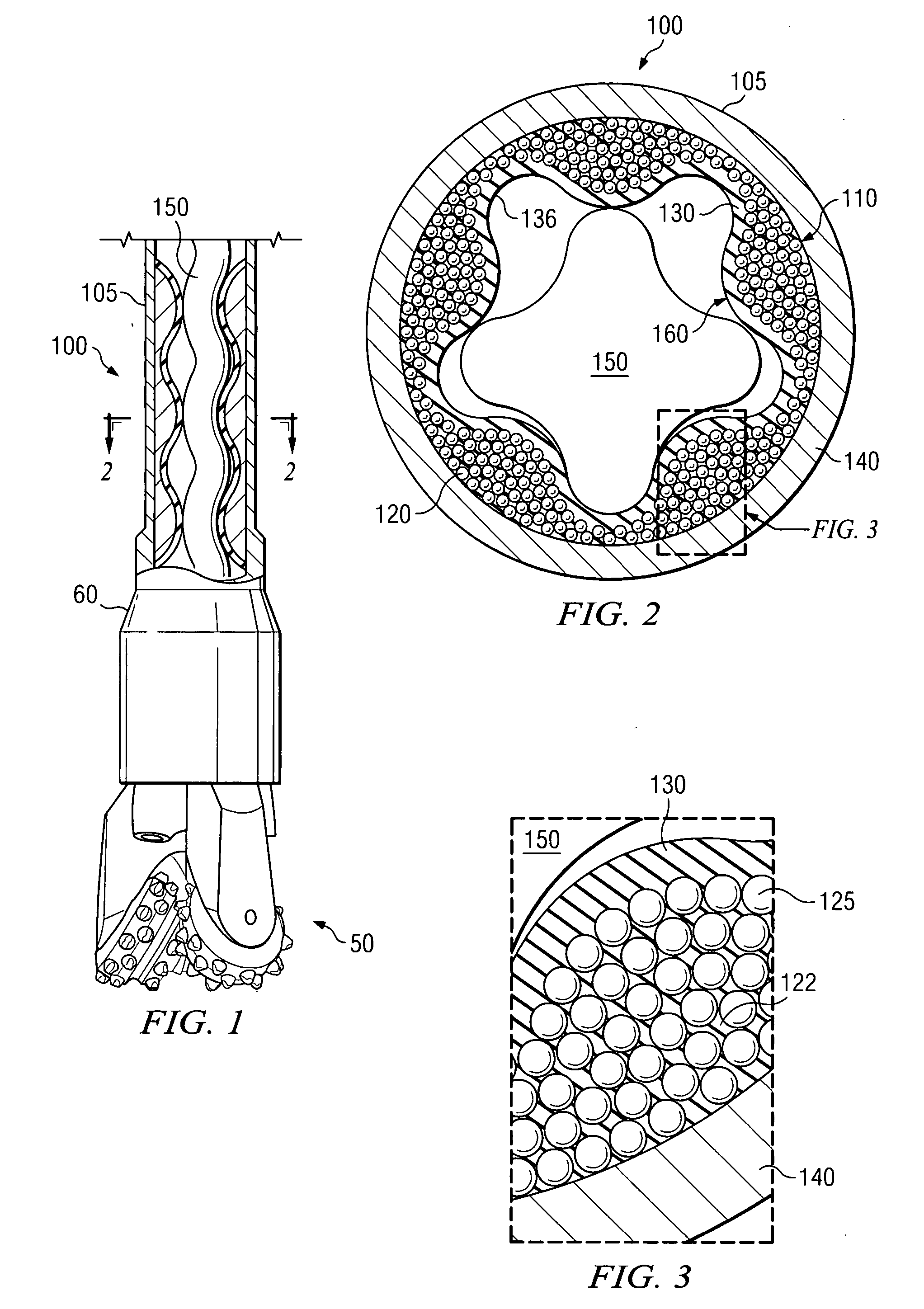

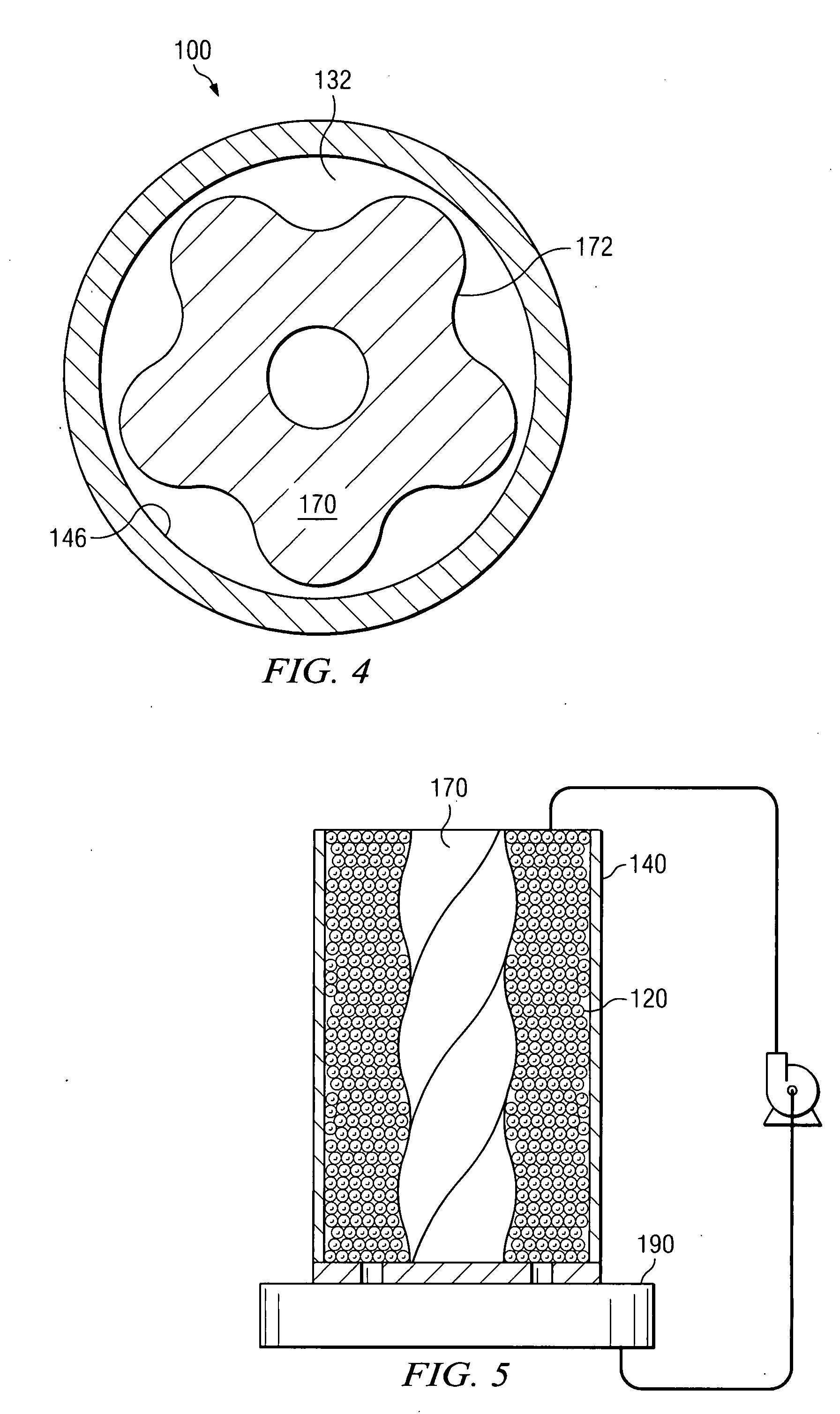

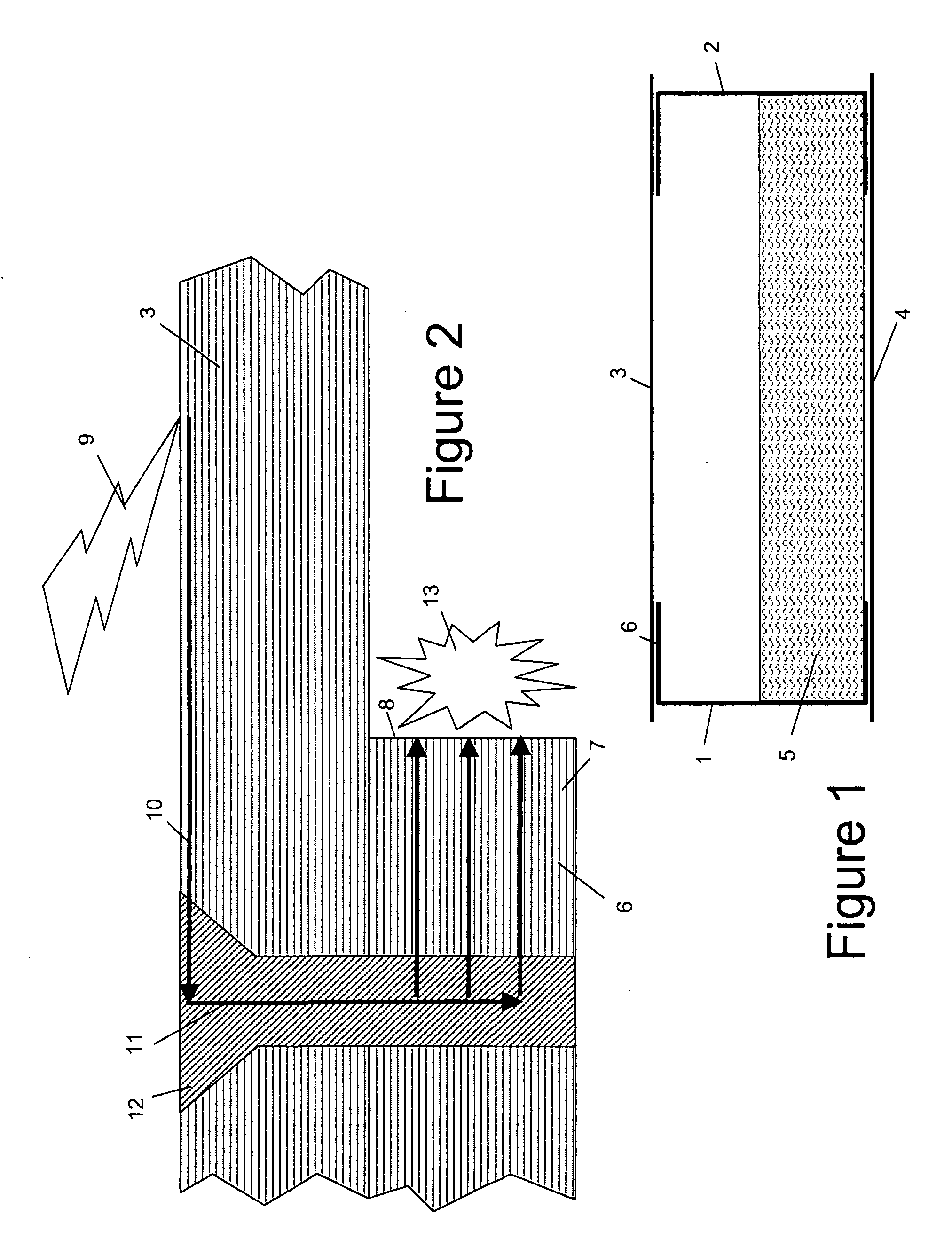

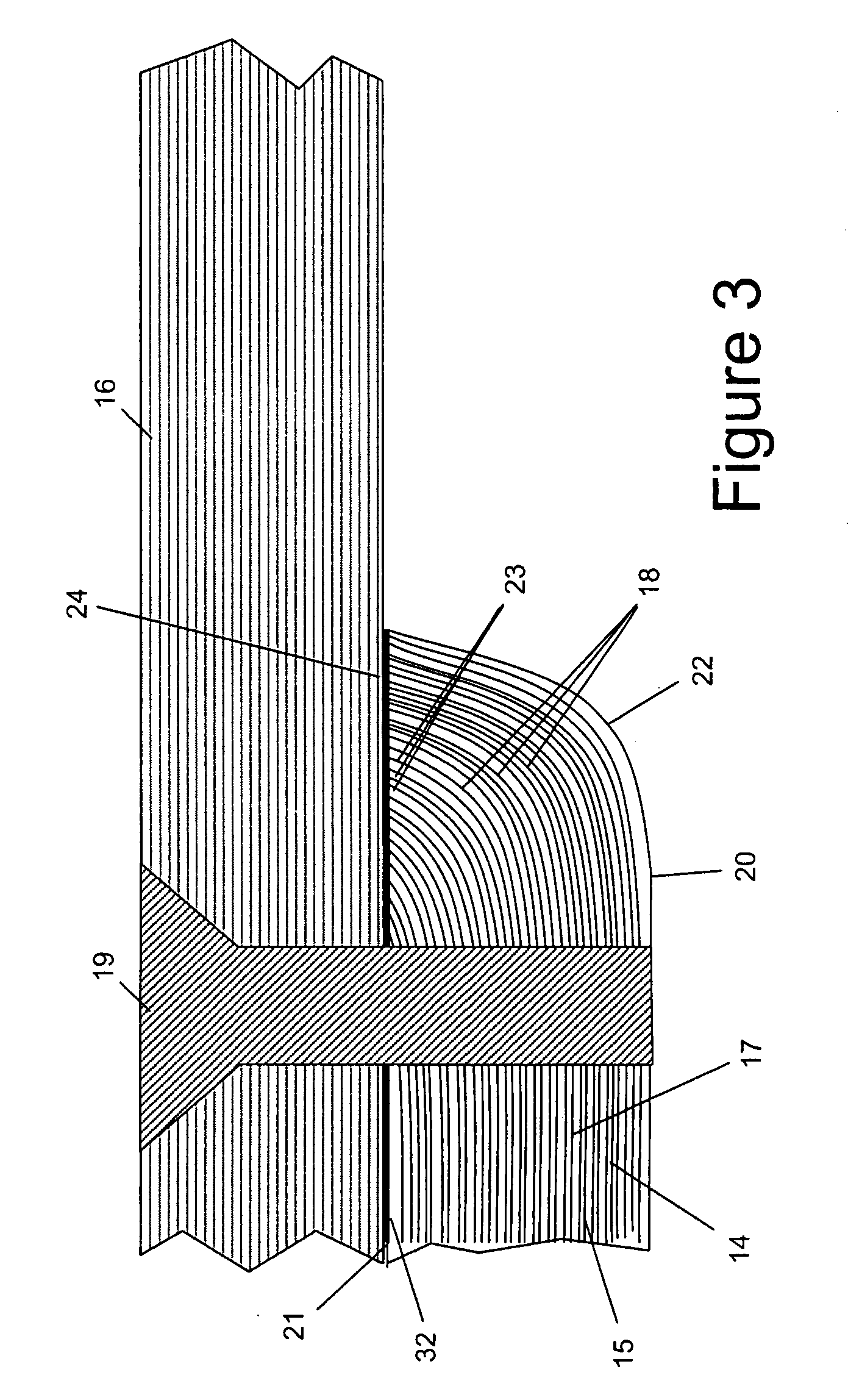

Moineu stator including a skeletal reinforcement

ActiveUS20080304991A1Extended service lifeNot easy to layerOscillating piston enginesEngine of intermeshing engagement typeElastomerInterference fit

A Moineau style stator includes a helical cavity component having reinforced helical lobes. The lobes are reinforced with a three-dimensional network of physically bonded aggregate particles. The network of bonded aggregate provides a porous skeletal-like structural reinforcement. Pore volume between the bonded aggregate particles may optionally be partially or substantially filled with an elastomer. An elastomer liner is typically deployed on an inner surface of the helical lobes to promote a rotational interference fit with a rotor.

Owner:SMITH INT INC

Roasting sagger for circulating type lithium battery anode material and preparation method thereof

ActiveCN103311498AGood chemical inertnessStrong alkali corrosion resistanceElectrode manufacturing processesCharge supportsMulliteCordierites

The invention discloses and provides a roasting sagger for a circulating type lithium battery anode material, which is simple in manufacturing process and structure, does not easily react with a lithium battery material, can avoid polluting the lithium battery material, does not pollute the environment and can be recycled, and a preparation method thereof. The preparation method of the roasting sagger for the circulating type lithium battery anode material comprises the following steps of: (1) uniformly mixing mullite, cordierite, aluminum oxide, corundum, kaolin, active magnesium oxide, spodumene and a bonding agent; adding the materials into a metal mould according to the weight; and pressing and molding a blank by pressing and molding equipment; (2) uniformly mixing zirconium oxide, the spodumene, cerium oxide, the corundum and the bonding agent; uniformly distributing the materials on the surface of the blank by a material distribution machine or manpower and pressing again by the pressing and molding equipment to obtain a semi-finished sagger product; and (3) drying the sagger semi-finished product and sintering. The roasting sagger disclosed by the invention can be widely applied to the field of the sagger for the lithium battery anode material.

Owner:李艳晖

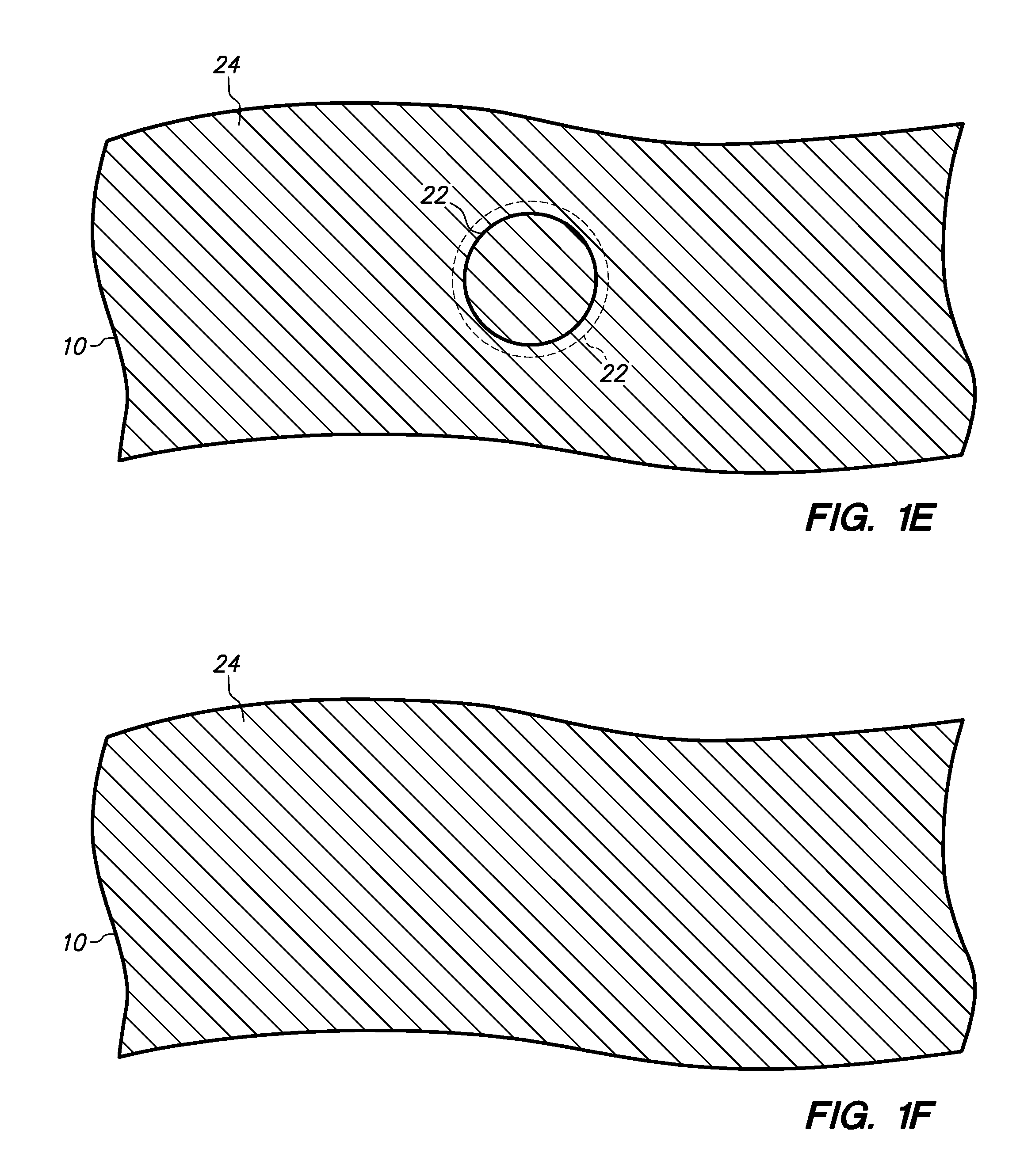

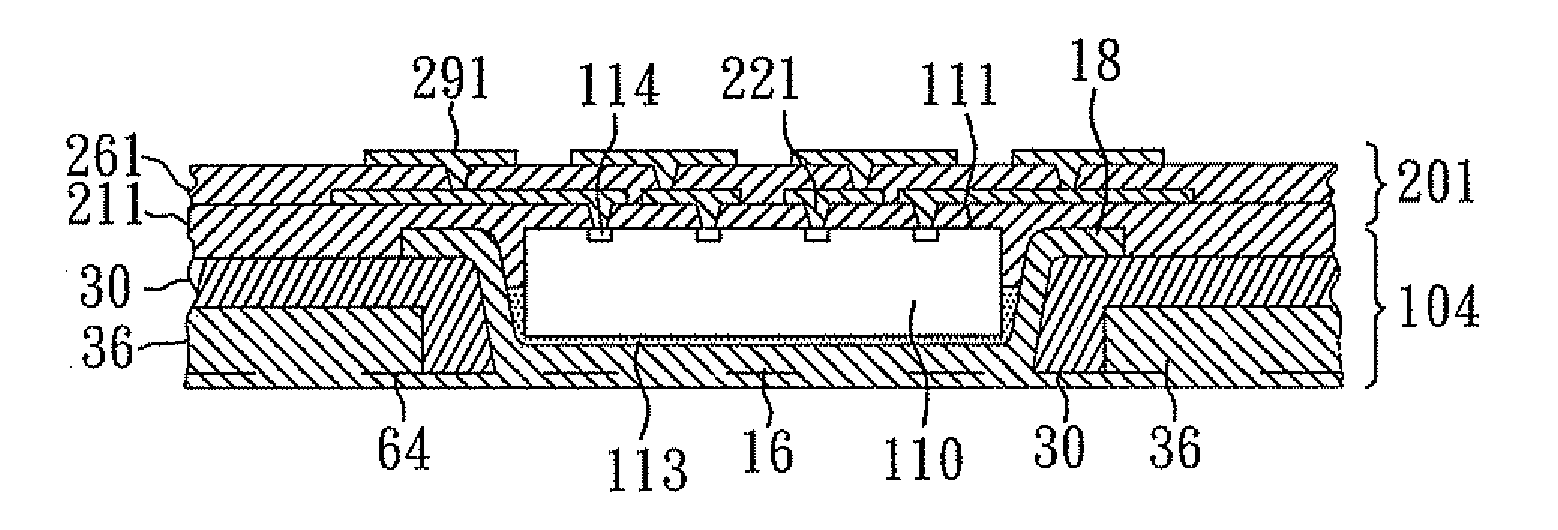

Method of making thermally enhanced semiconductor assembly with bump/base/flange heat spreader and build-up circuitry

InactiveUS20120129299A1Improve manufacturing yieldAccelerated dissipationSemiconductor/solid-state device detailsSolid-state devicesSignal routingElectricity

A method of making a semiconductor assembly that includes a semiconductor device, a heat spreader, an adhesive and a build-up circuitry is disclosed. The heat spreader includes a bump, a base and a flange. The bump defines a cavity. The semiconductor device is mounted on the bump at the cavity, electrically connected to the build-up circuitry and thermally connected to the bump. The bump extends from the base into an opening in the adhesive, the base extends vertically from the bump opposite the cavity and the flange extends laterally from the bump at the cavity entrance. The build-up circuitry includes a dielectric layer and conductive traces on the semiconductor device and the flange. The conductive traces provide signal routing for the semiconductor device.

Owner:BRIDGE SEMICON

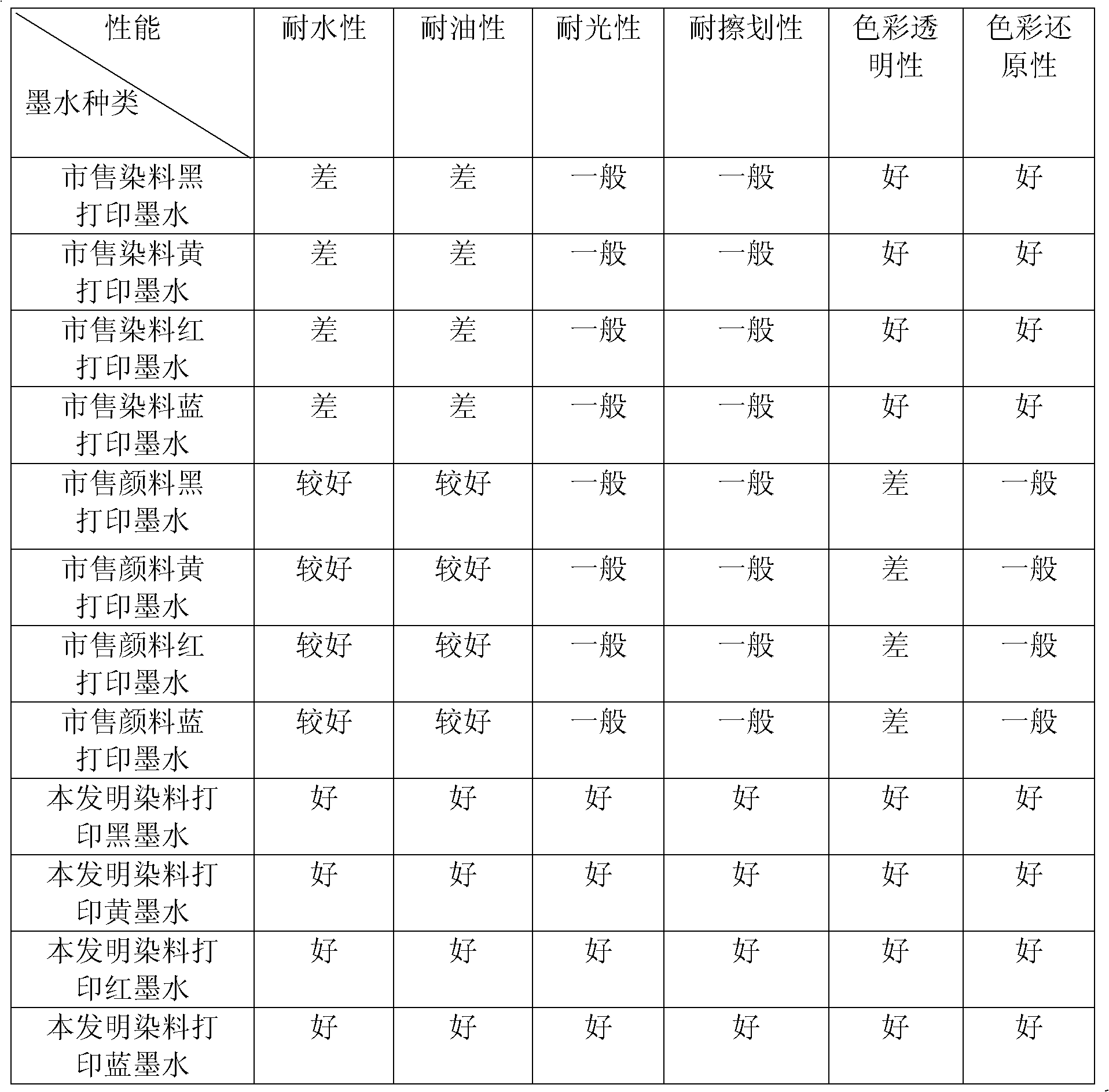

Water-based dye ink and application thereof

InactiveCN101805542AOvercome LightfastnessOvercome fading under lightInksDyeing processTextile printerWater based

The invention discloses a water-based dye ink and an application thereof. The water-based dye ink comprises the following components in percent by weight: 0.2 to 12 percent of water-soluble dye, 55 to 80 percent of modified acrylic resin emulsion, 0.01 to 1 percent of ultraviolet absorbent and balance of water, and different additives can be added. The dye ink can be applicable to the fields such as jet ink, cipher paint ink, textile printing ink, water-type printing ink, fountain pen ink and water ball pen ink, and has the advantages of water resistance, oil resistance, scratch resistance, illumination resistance, high temperature resistance, low temperature resistance, good color reducibility, duration and the like.

Owner:鲁继烈

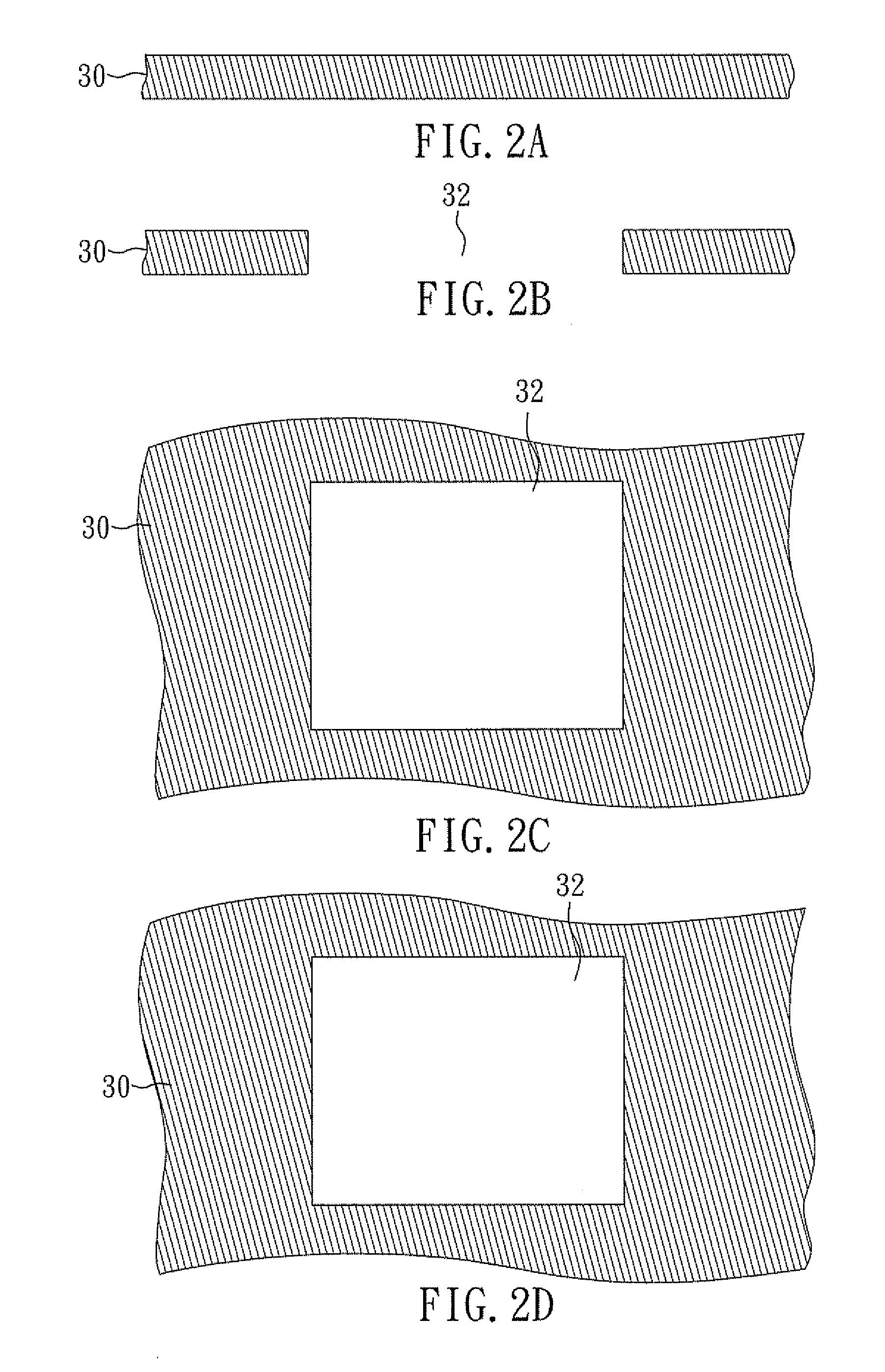

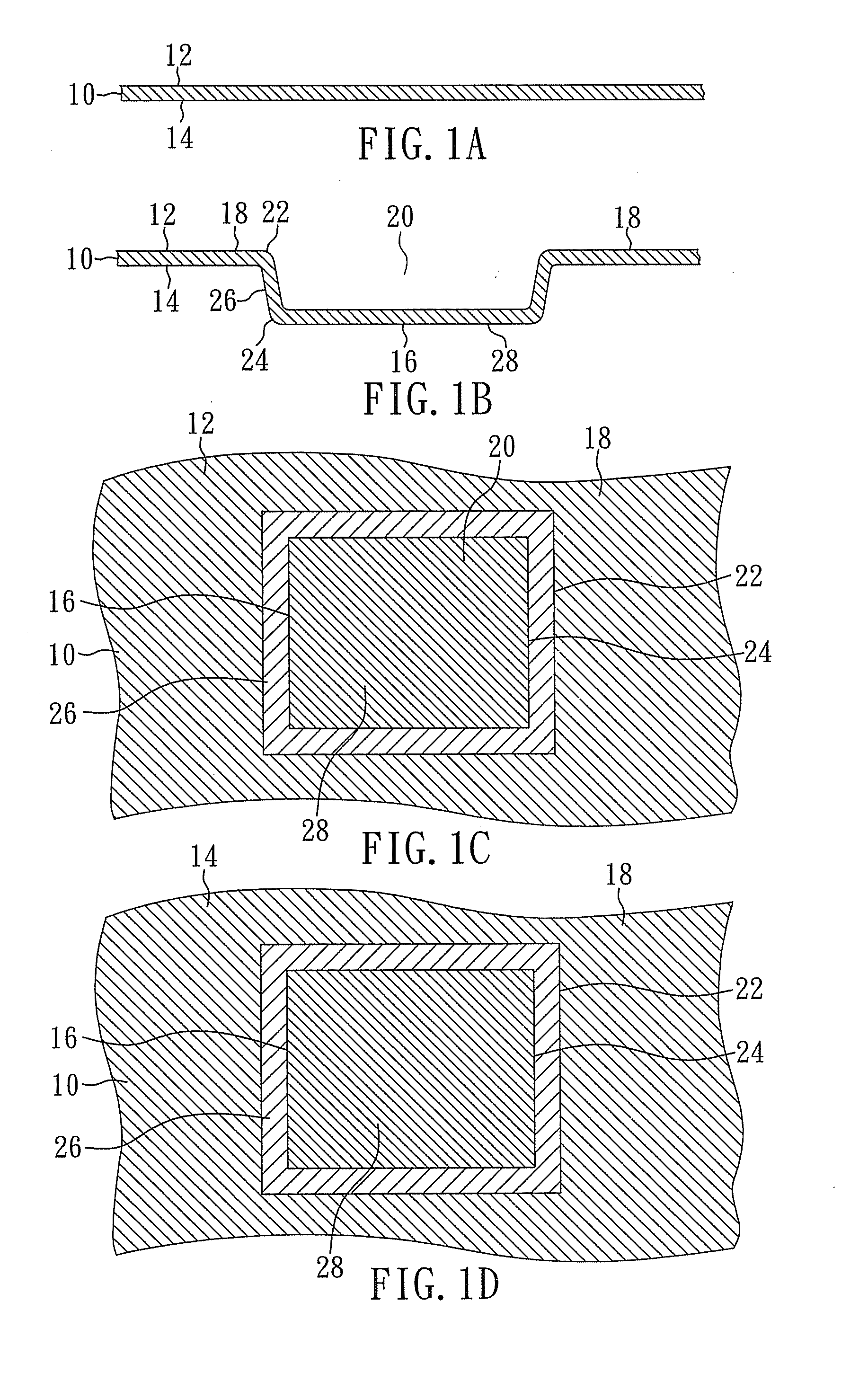

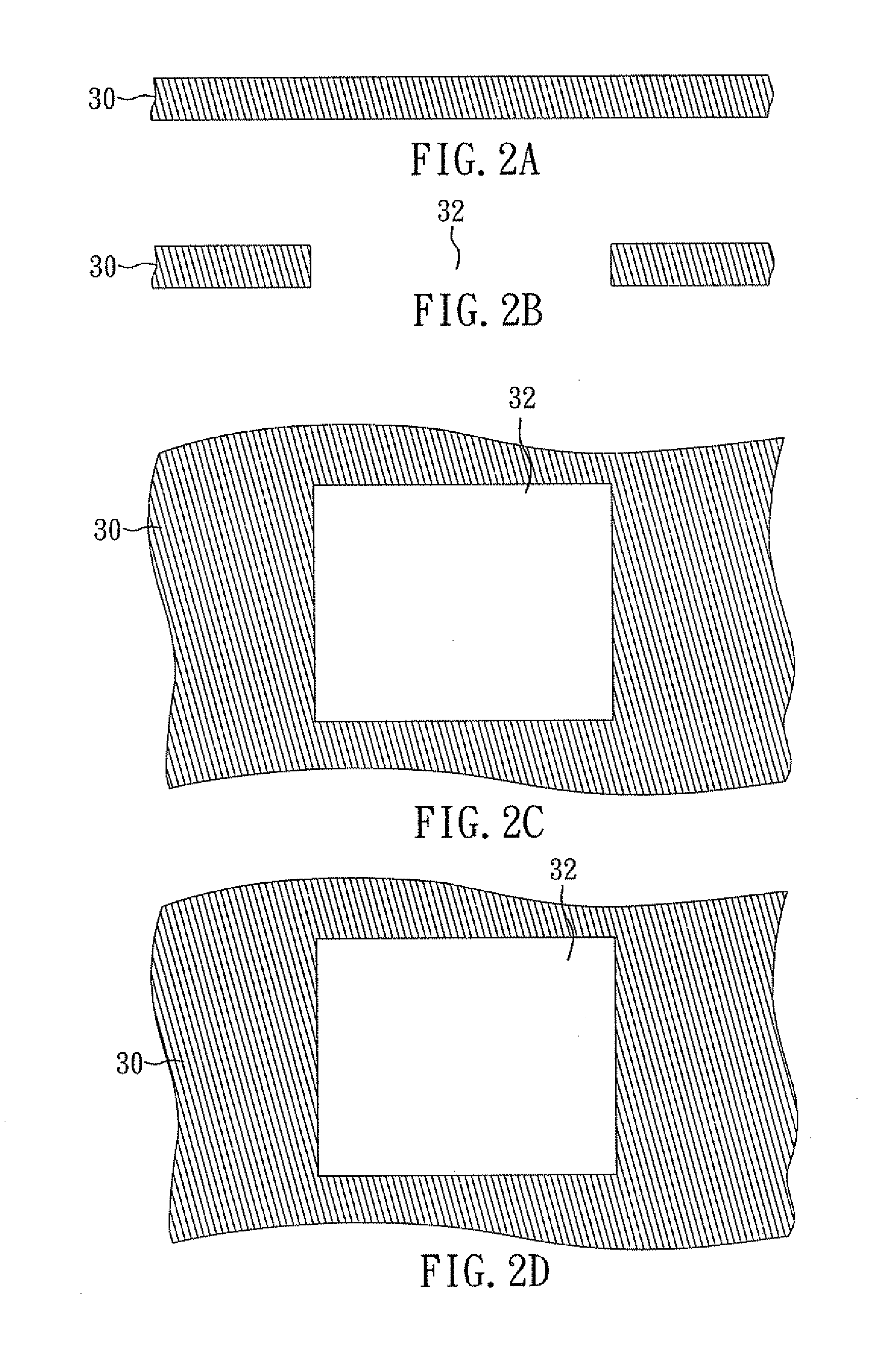

Semiconductor chip assembly with post/base heat spreader and horizontal signal routing

InactiveUS20100001309A1Enhance thermal connectionRobust mechanical bondSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringAdhesive

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a substrate and an adhesive. The semiconductor device is electrically connected to the substrate and thermally connected to the heat spreader. The heat spreader includes a post and a base. The post extends upwardly through an opening in the adhesive into an aperture in the substrate, and the base extends laterally from the post. The adhesive extends between the post and the substrate and between the base and the substrate. The substrate includes first and second conductive layers and a dielectric layer therebetween and provides horizontal signal routing between a pad and a terminal at the first conductive layer.

Owner:BRIDGE SEMICON

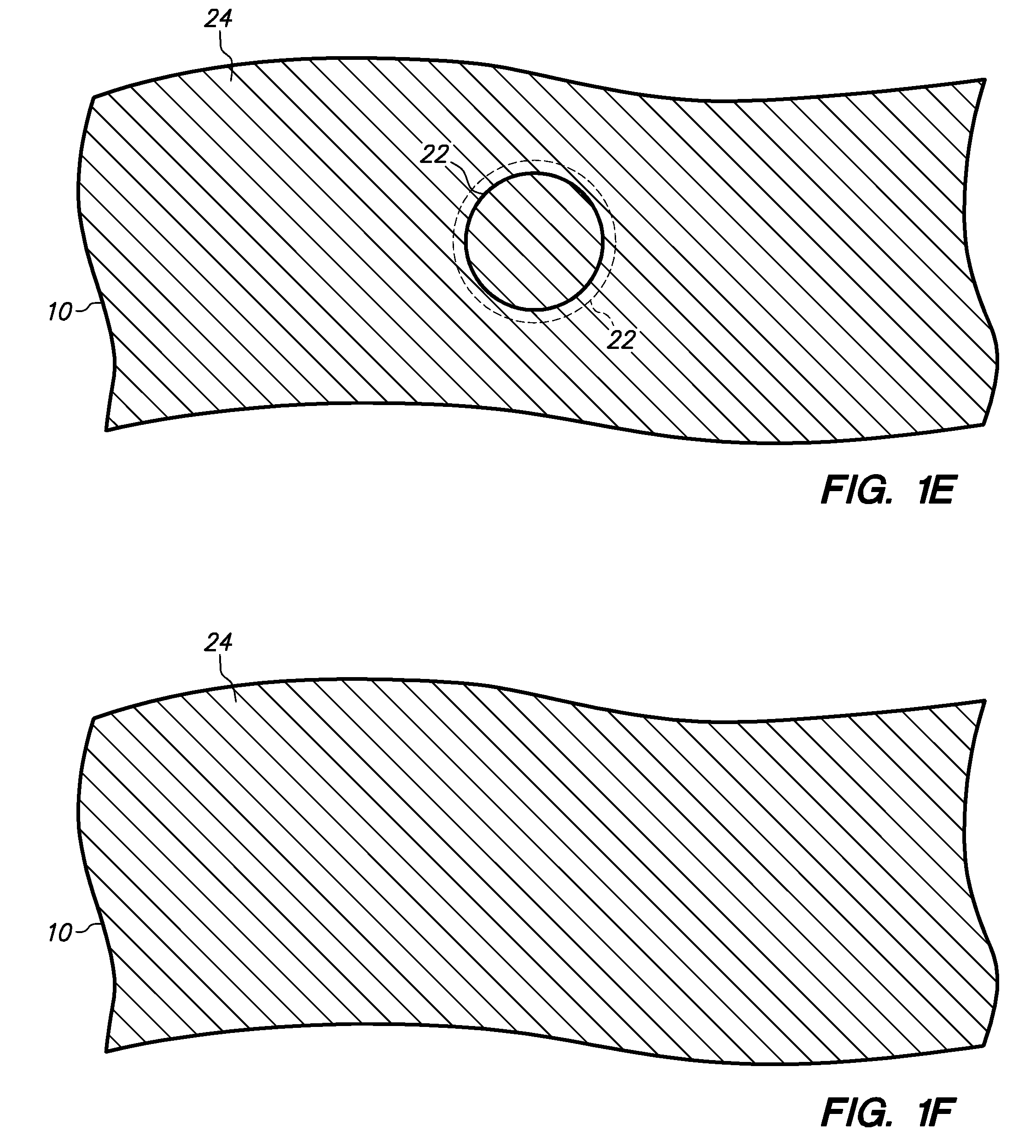

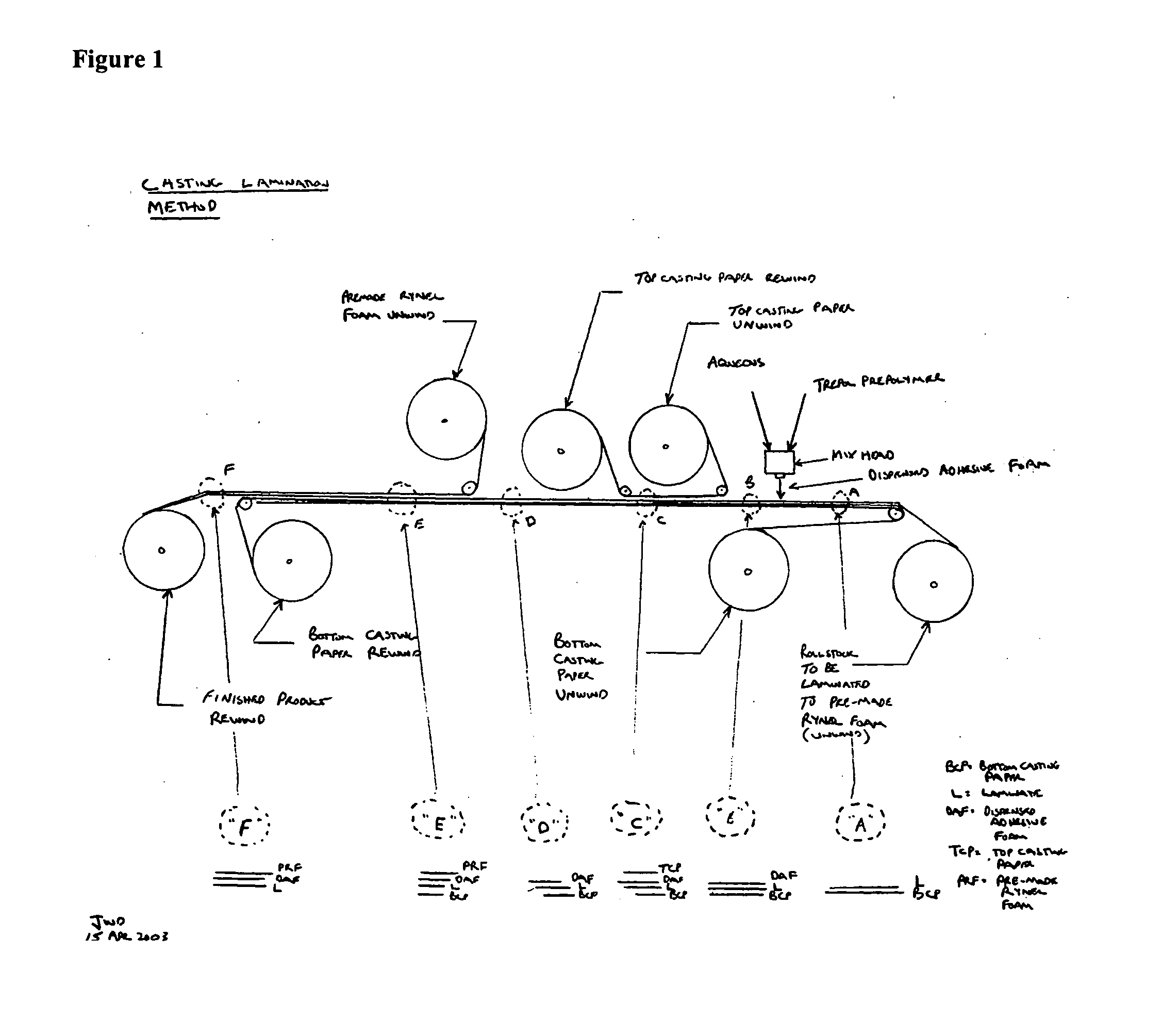

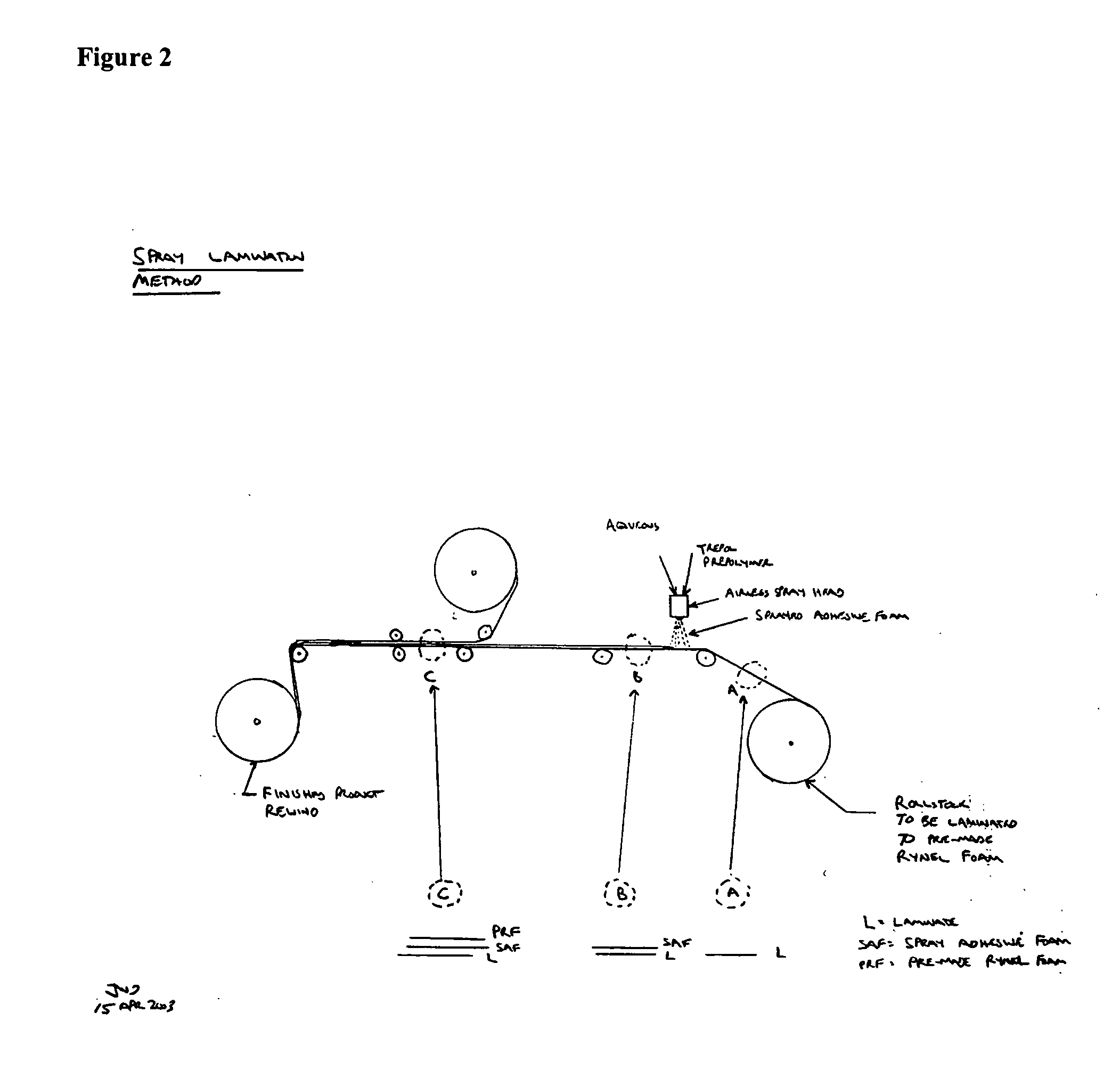

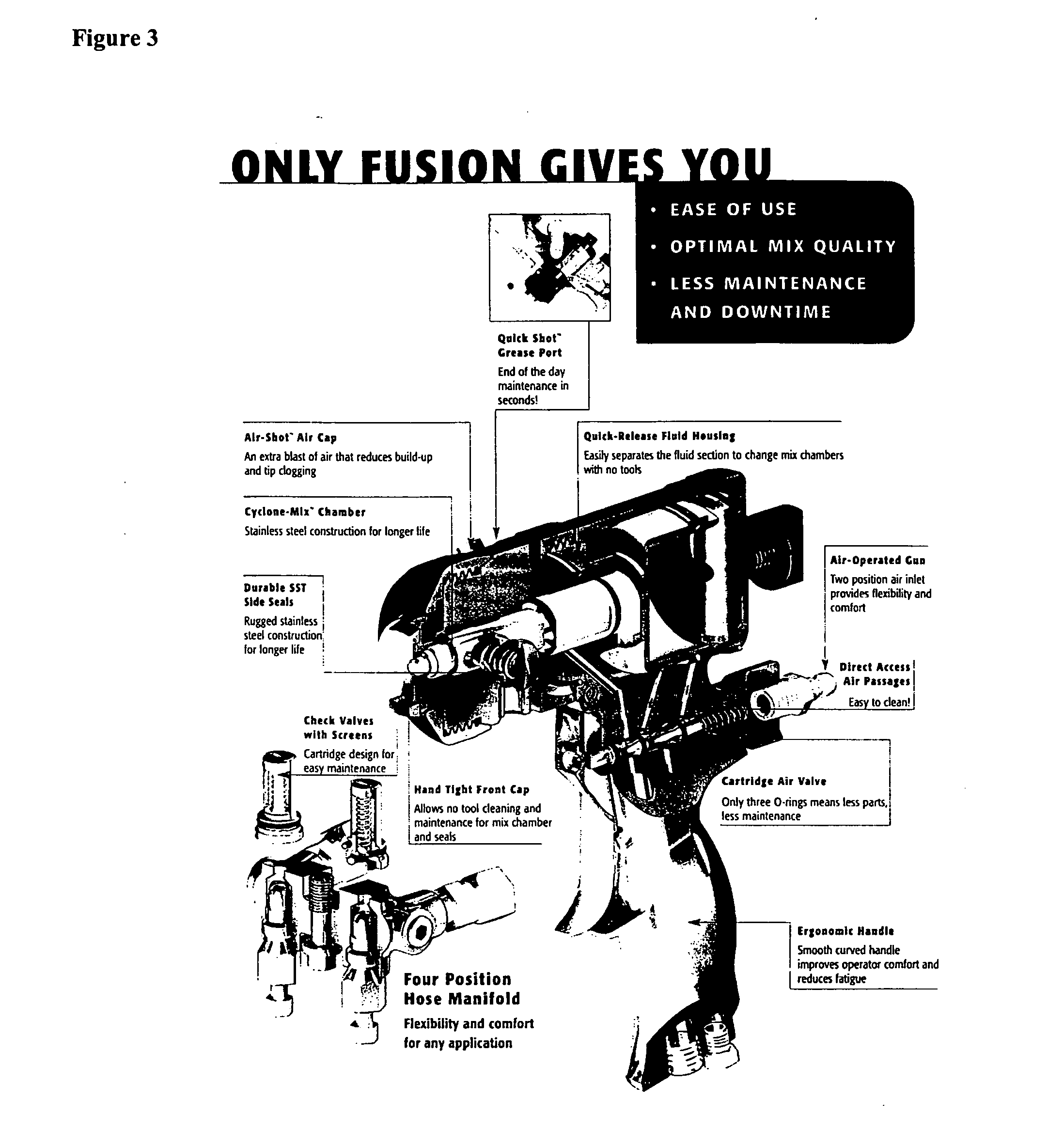

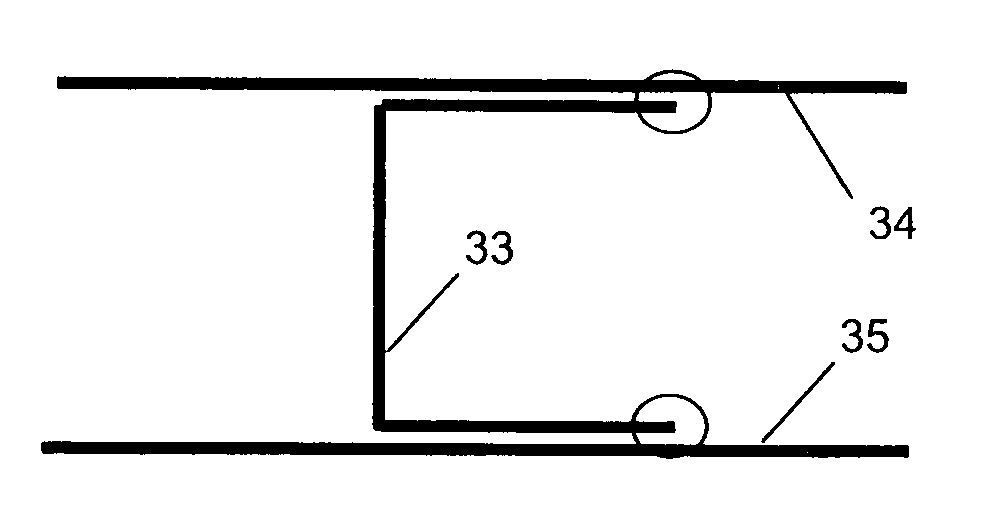

Apparatus and methods for the attachment of materials to polyurethane foam, and articles made using them

InactiveUS20050003178A1Low costEasy to useAdhesive processesSlide fastenersAdhesivePolymer chemistry

One aspect of the present invention relates to a laminated foam product, wherein the adhesive binding the foam to the laminate comprises the mixture from which the foam is made. Another aspect of the present invention relates to methods for making a laminated foam product. A third aspect of the present invention relates to an apparatus for making a laminated foam product.

Owner:RYNEL

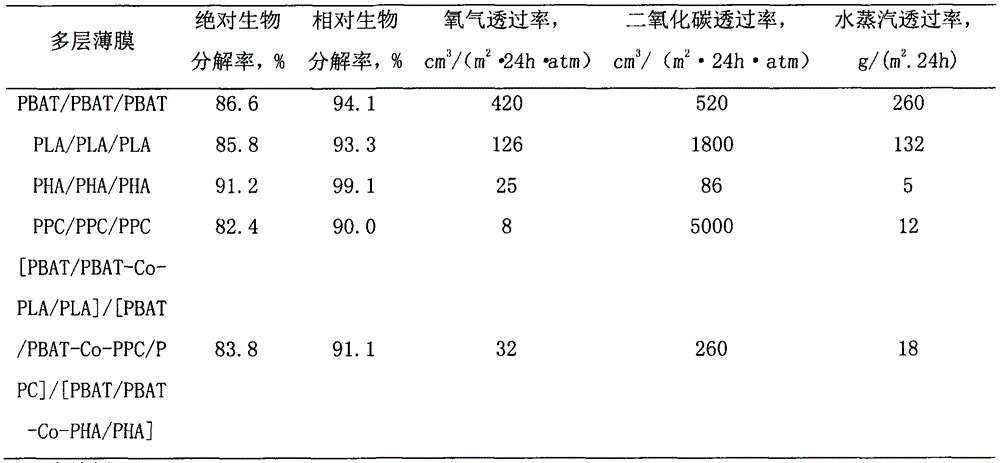

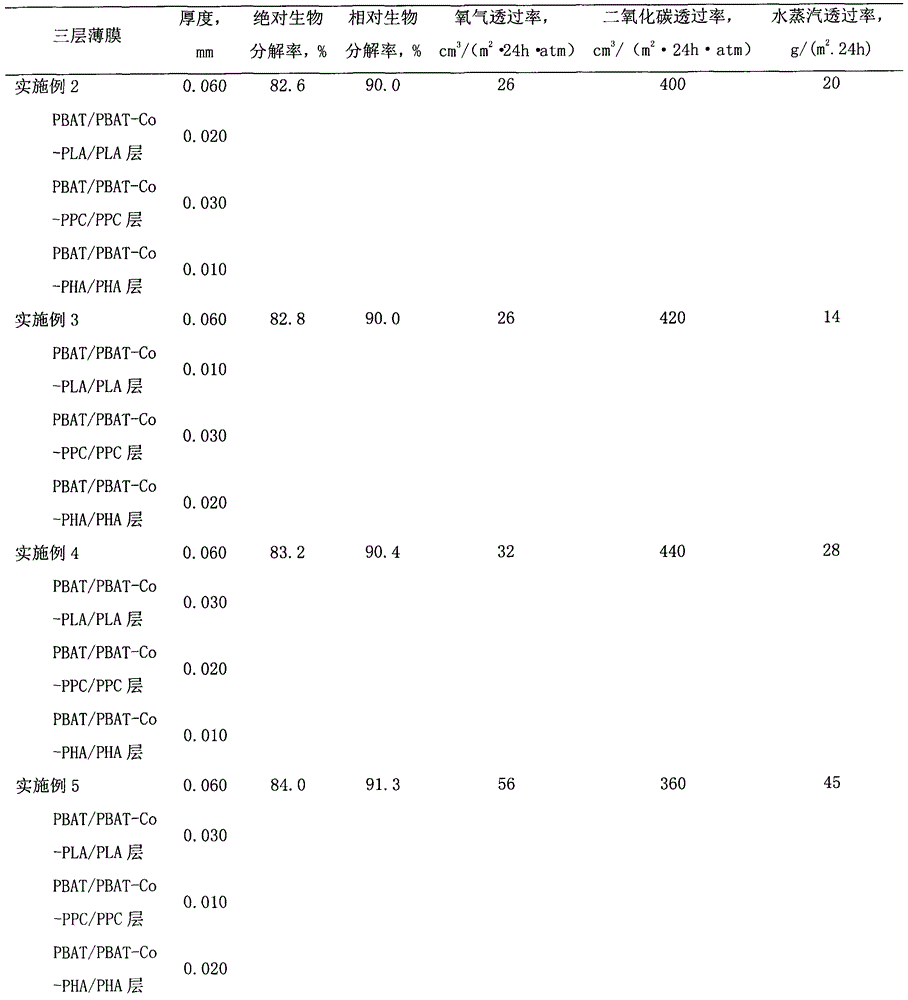

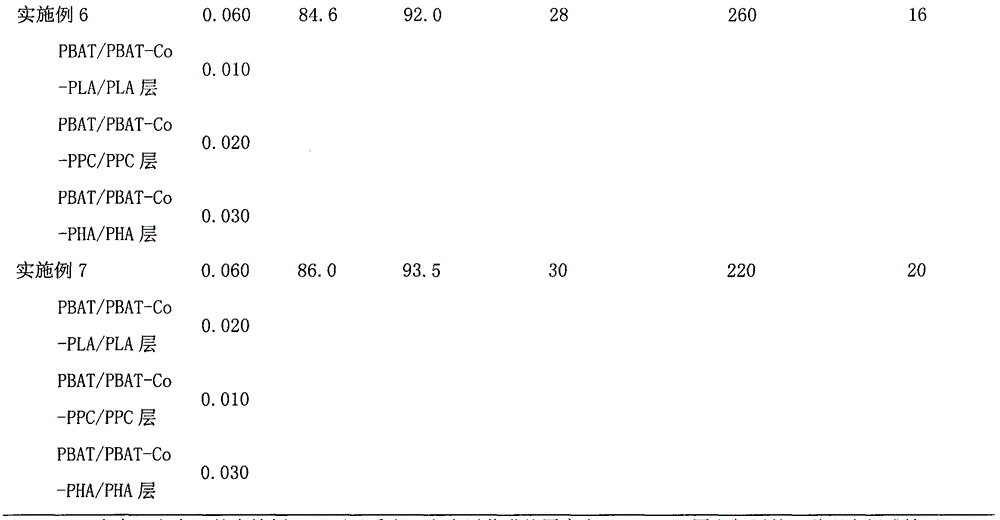

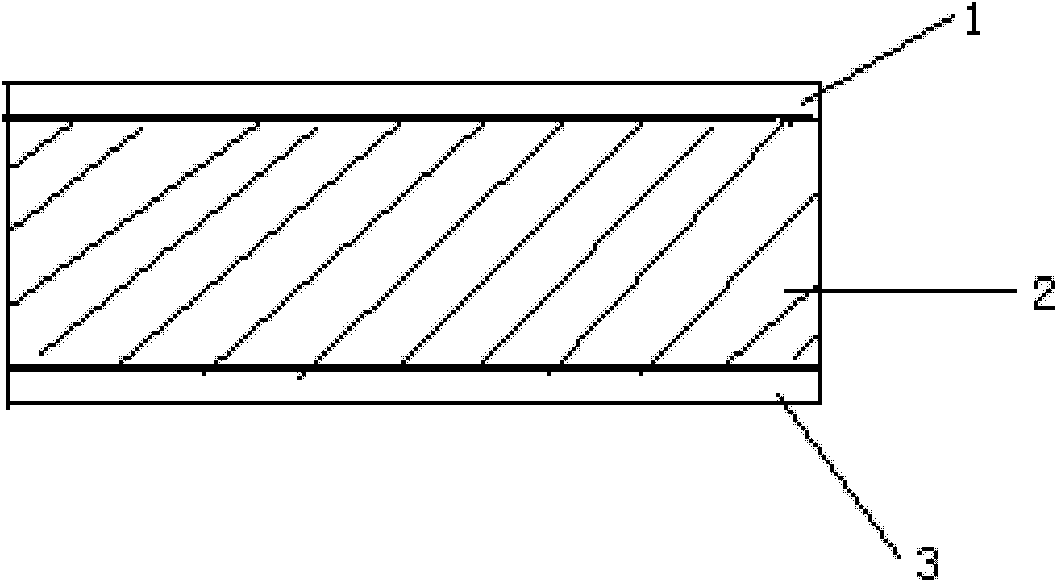

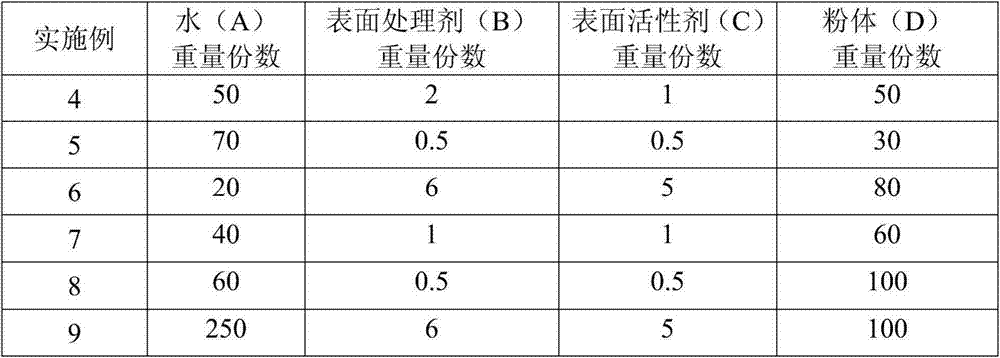

Biodegradable multilayer material with adjustable gas transmission rate and preparation method and applications thereof

ActiveCN104691067AStable physical propertiesNot easy to layerFlexible coversWrappersWater vaporOxygen

The invention relates to a biodegradable multilayer material, which can be a thin film material or a sheet material. The biodegradable multilayer material at least comprises one of an adipic butanediol terephthalate copolymer (PBAT) / PBAT-chain extender-polypropylene carbonate (PBAT-Co-PPC) / PPC blend layer, a PBAT / PBAT-chain extender-polylactic acid (PBAT-Co-PLA) / PLA blend layer and a PBAT / PBAT-chain extender-polyhydroxyalkanoate (PBAT-Co-PHA) / PHA blend layer, and blend resins are respectively prepared through twin-screw reactive extrusion. The multilayer material is produced by using extrusion and coextrusion methods, has a function that the transmission rates of oxygen, carbon dioxide and water vapor can be adjusted, and can be applied to the packaging field and the agriculture field, and especially applied to food packaging, pharmaceutical packaging, and ground film mulching.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Universal health-care board and preparation method thereof

ActiveCN102514254AGood elastic recoveryGood strength and elasticityStuffed mattressesLamination ancillary operationsFiberSurface layer

Owner:JIANGSU REDBUD DYEING TECH CO LTD

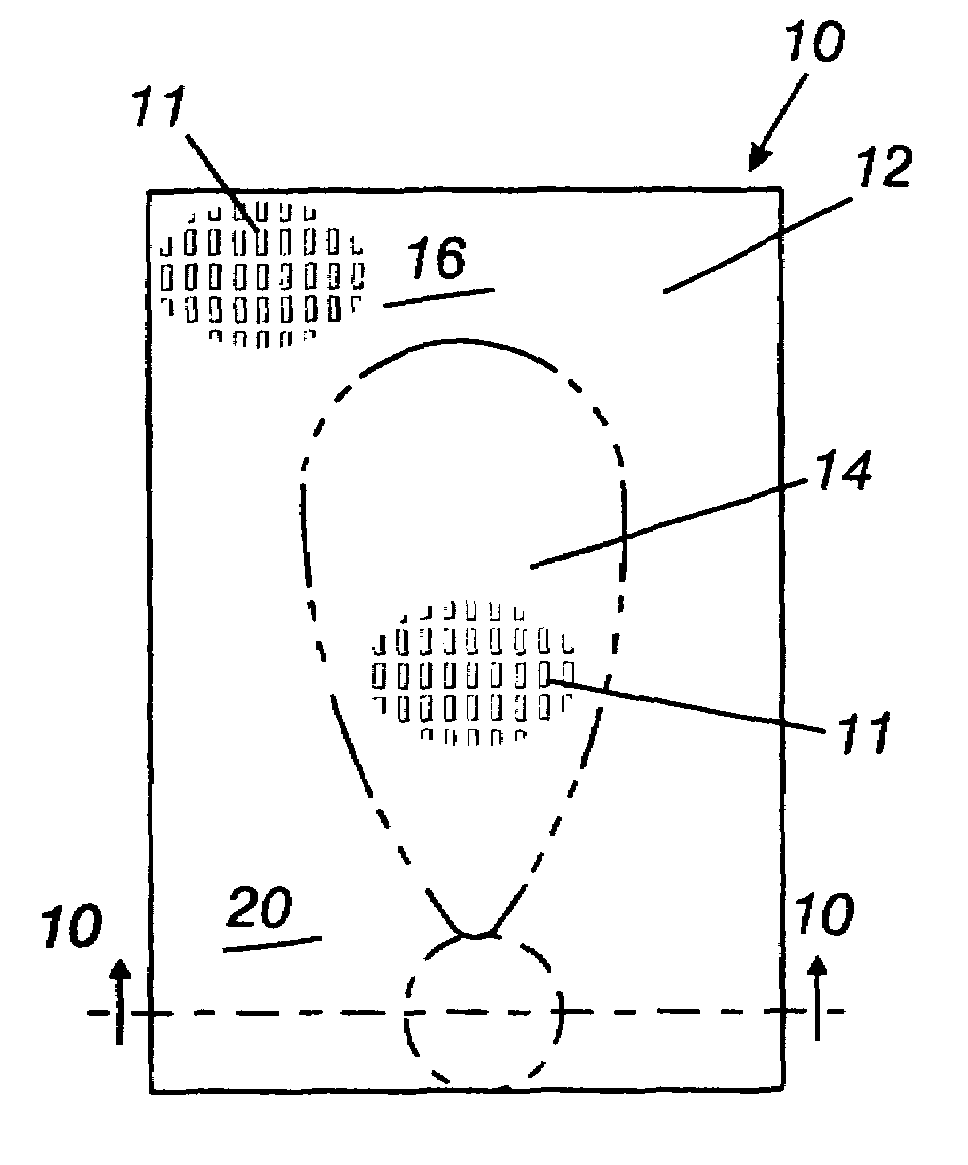

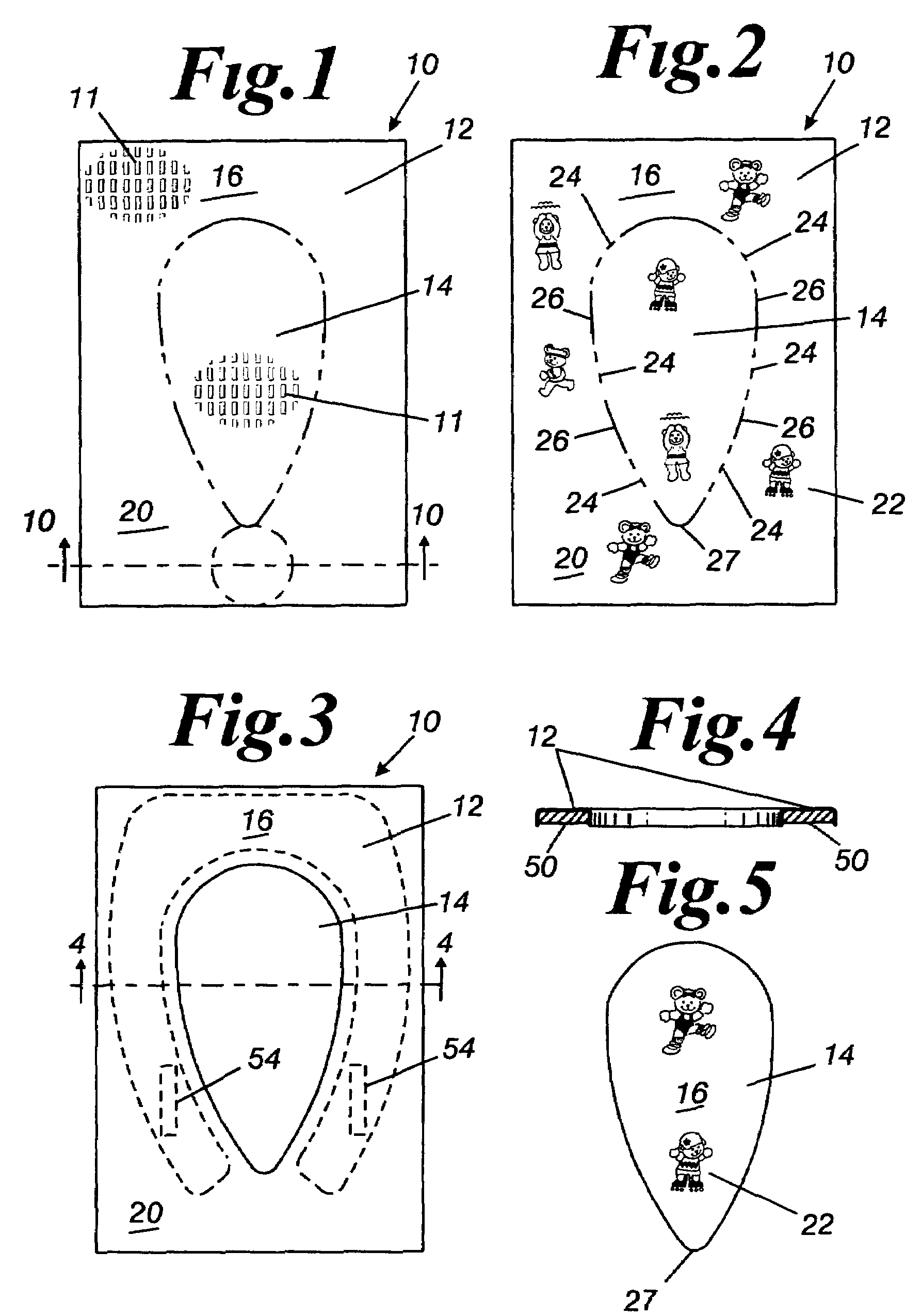

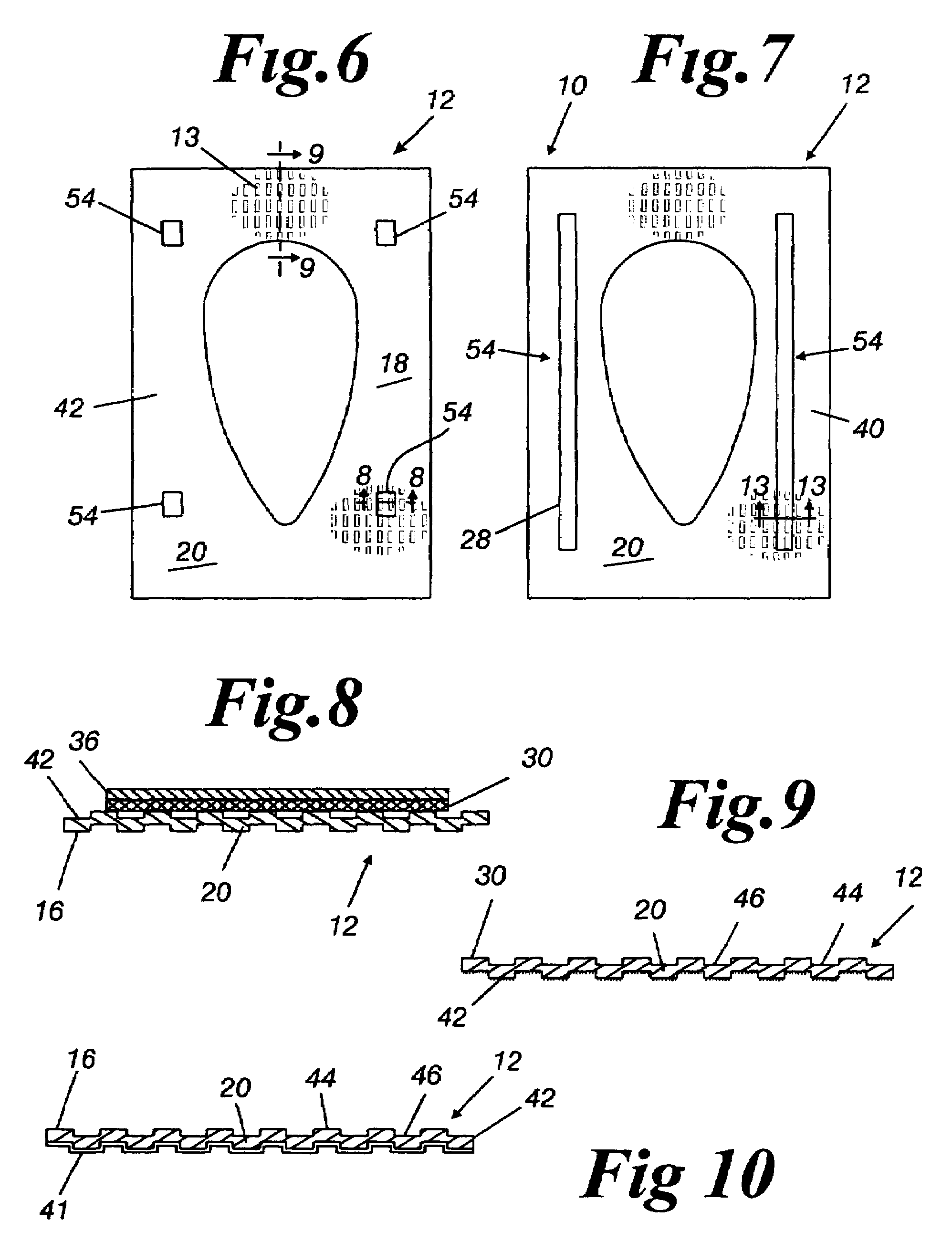

Sanitary, portable and disposable toilet seat cover, with attached wipe

InactiveUS7247360B1Improve absorbencyAdd to thicknessStampsFlexible coversTowelettesBiomedical engineering

The invention is an easy to fold sanitary toilet seat cover for preventing direct contact between an individual's skin and the top and the side surfaces of a toilet seat. When unfolded, the toilet seat cover is sufficiently large to not only cover the entire elongated toilet seat, but also cover the sides of the seat. The disposable toilet seat cover comprises a polygonal annulus that is comprised of a quilted multilayer sheet having a water impervious layer and an absorbent layer, a wipe that is a detachable inner oval section that provides an opening to the toilet, and an adhesive fastening means for temporarily securing the polygonal annulus toilet seat. The water impervious layer comprises a coated layer and / or a filmic layer. The wipe detaches from an inner ovalled edge of the annulus, and is functional as a sanitary wipe or towel.

Owner:HAMCO

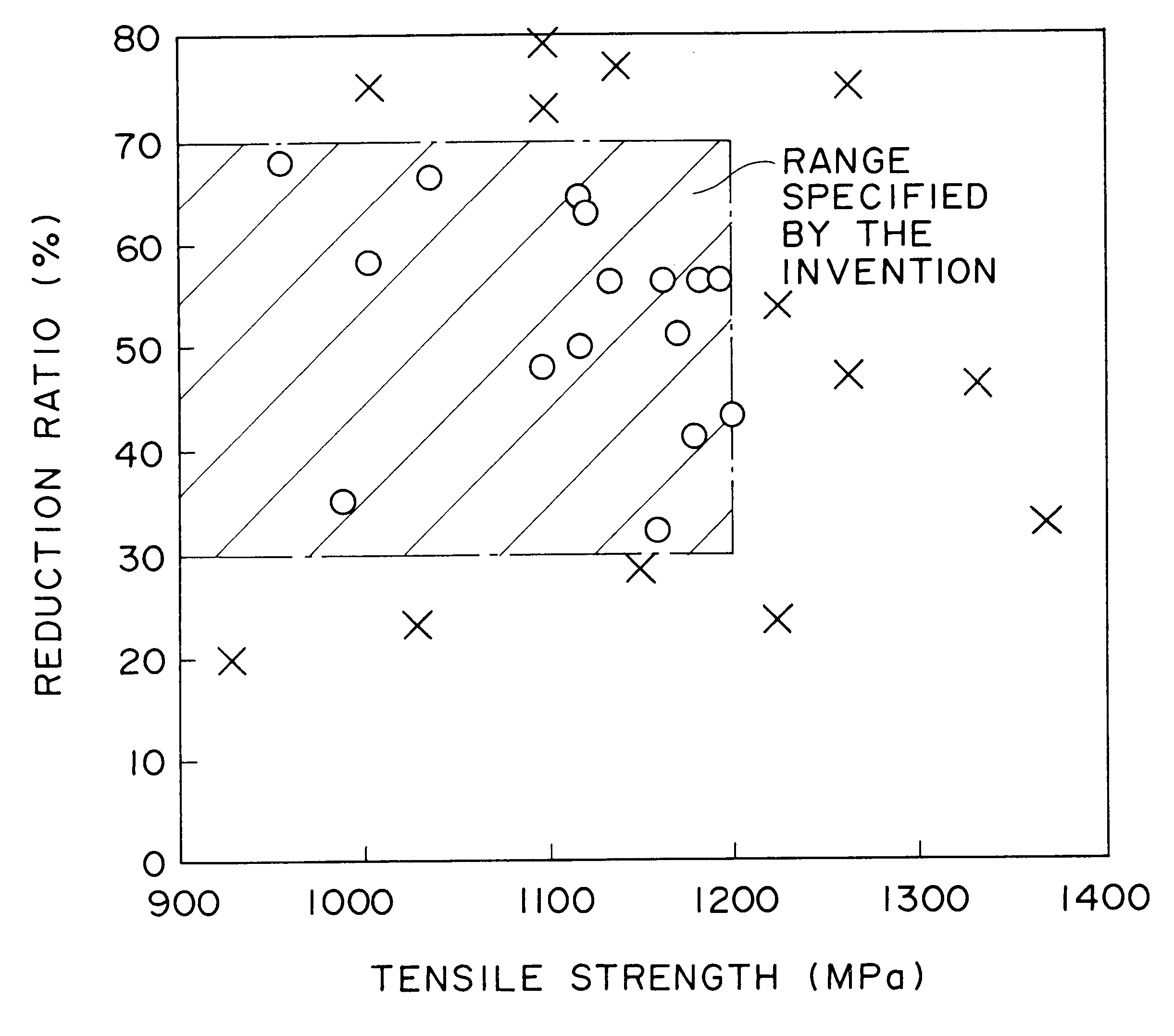

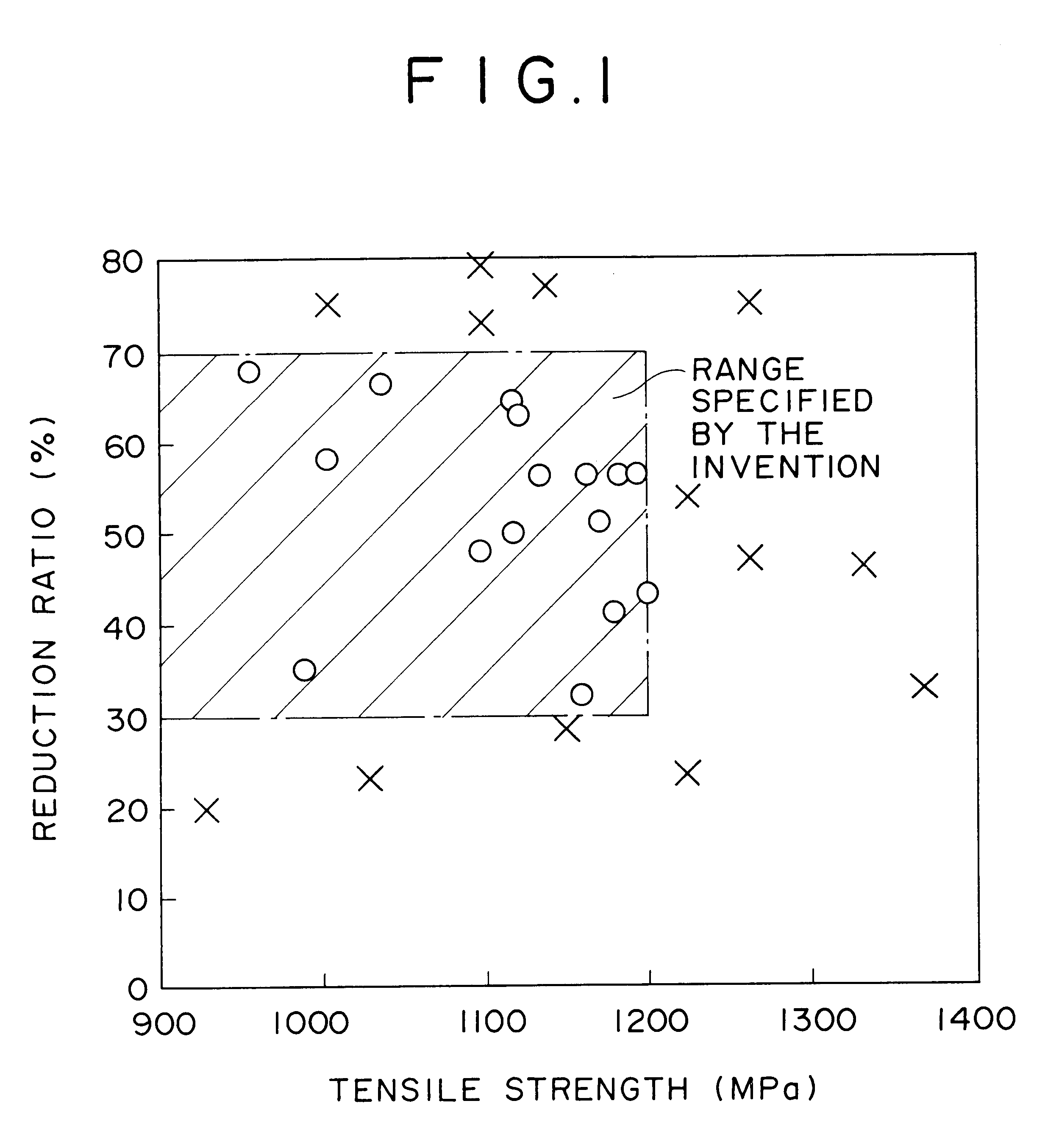

Spring steel superior in workability

A spring steel which is superior in both shaving properties and green drawing properties, which are important in spring production. A process for making the spring steel into wire rods for good springs. A rolled spring steel superior in workability characterized in that it has the following mechanical properties.Tensile strength<=1200 MPa30%<=reduction of area<=70%A process for producing a steel wire rod for springs from said spring steel, said process comprising drawing, shaving, and oil tempering, which are carried out sequentially, said drawing being optionally followed by prescribed treatment.

Owner:KOBE STEEL LTD

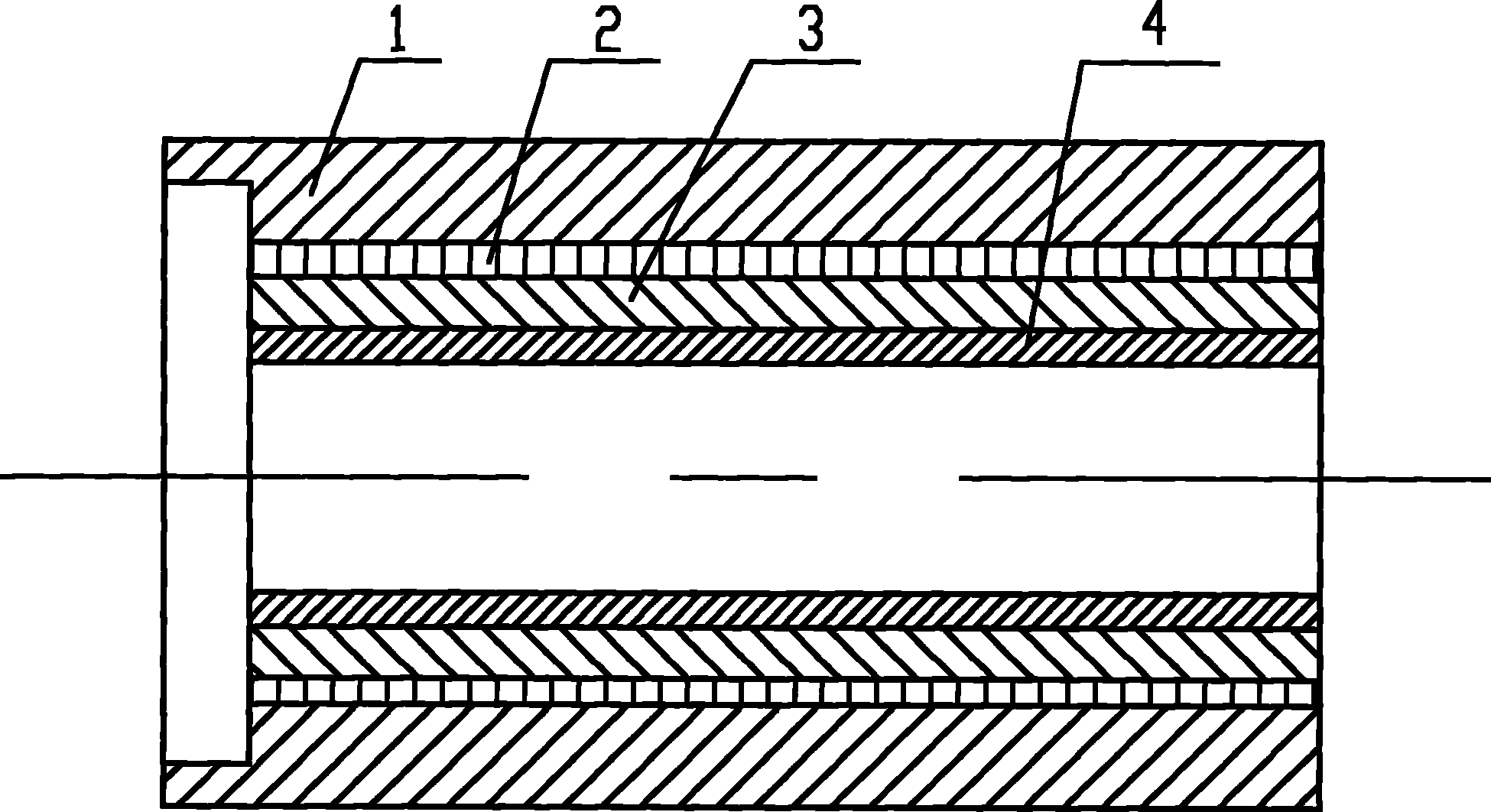

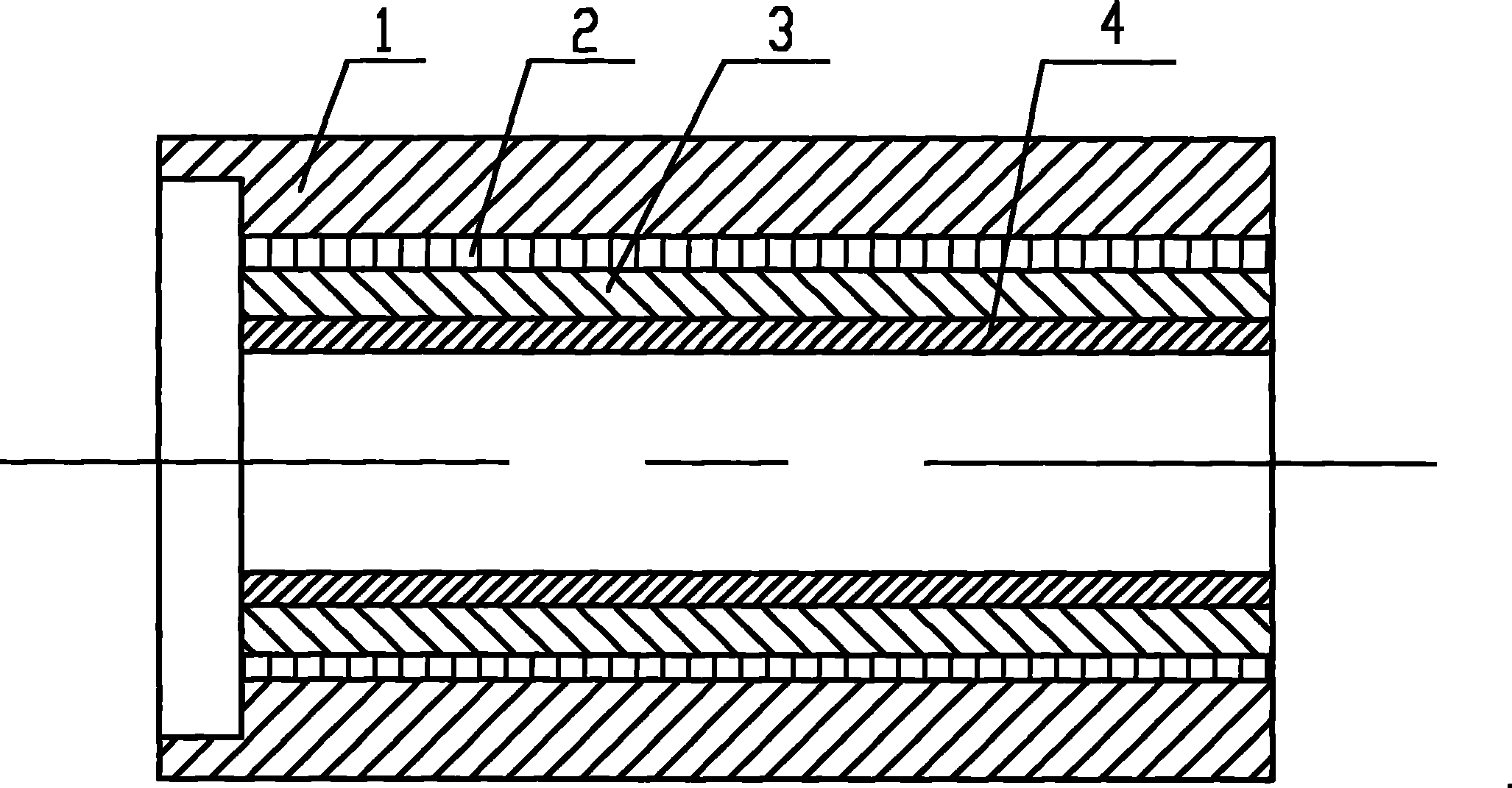

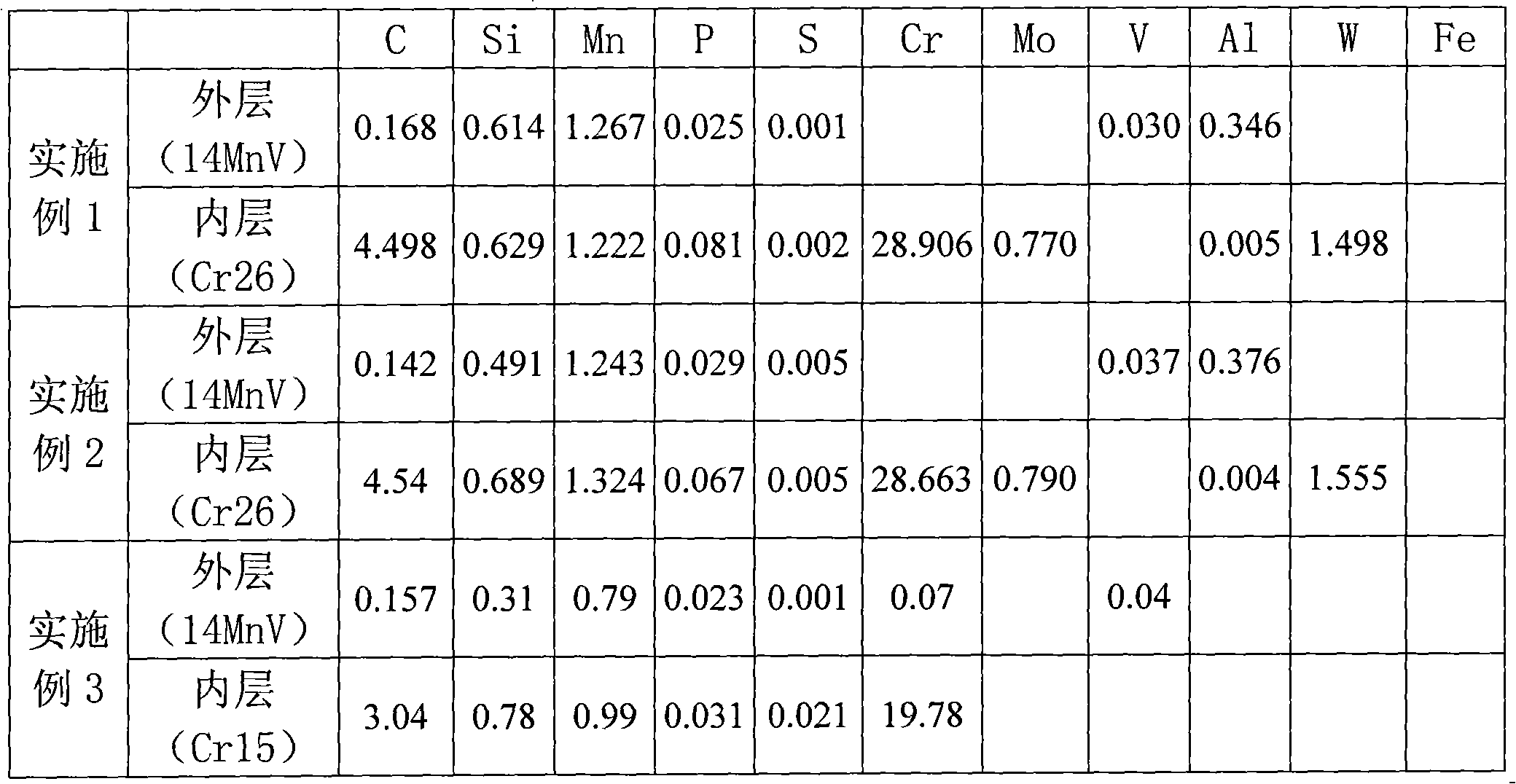

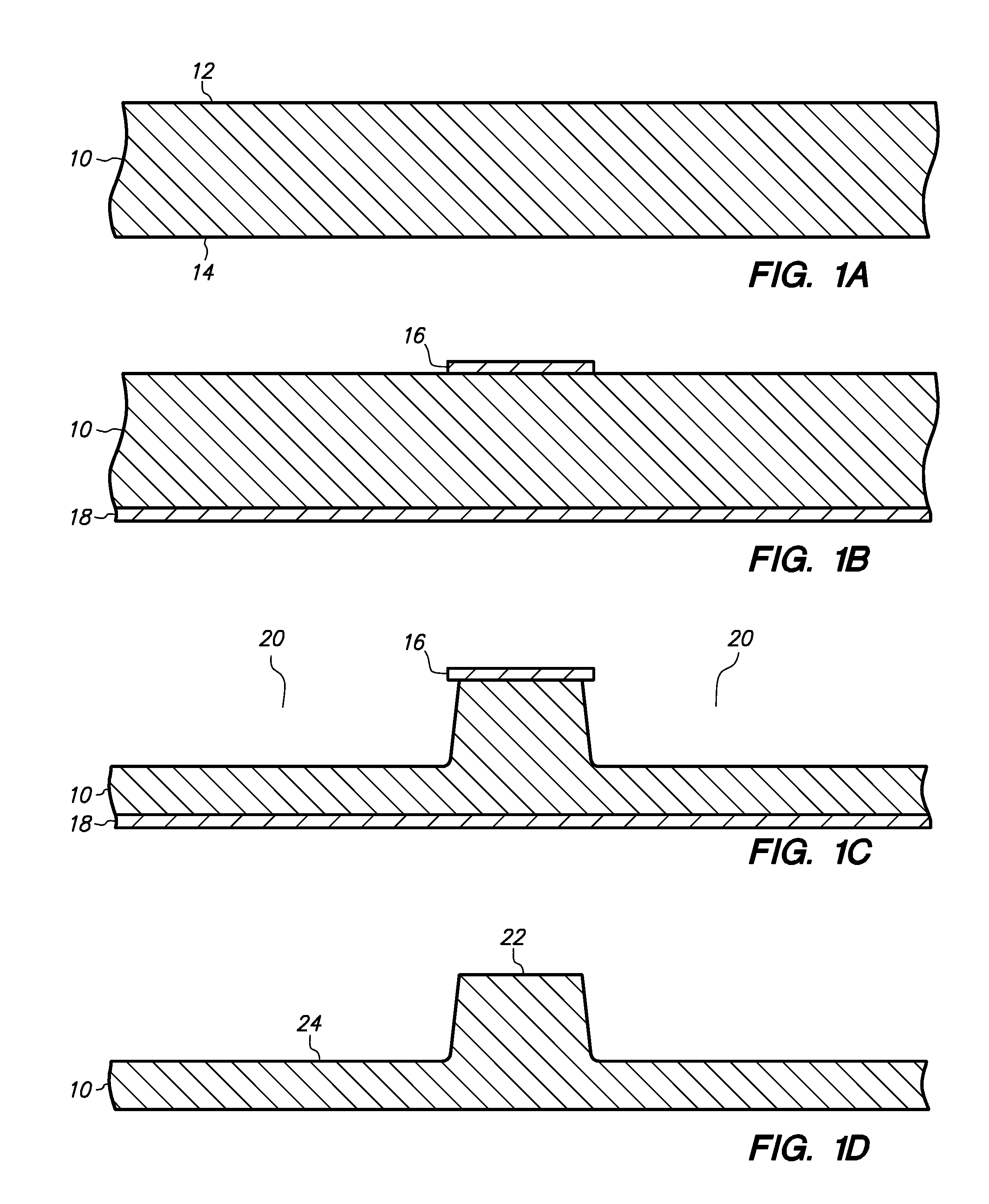

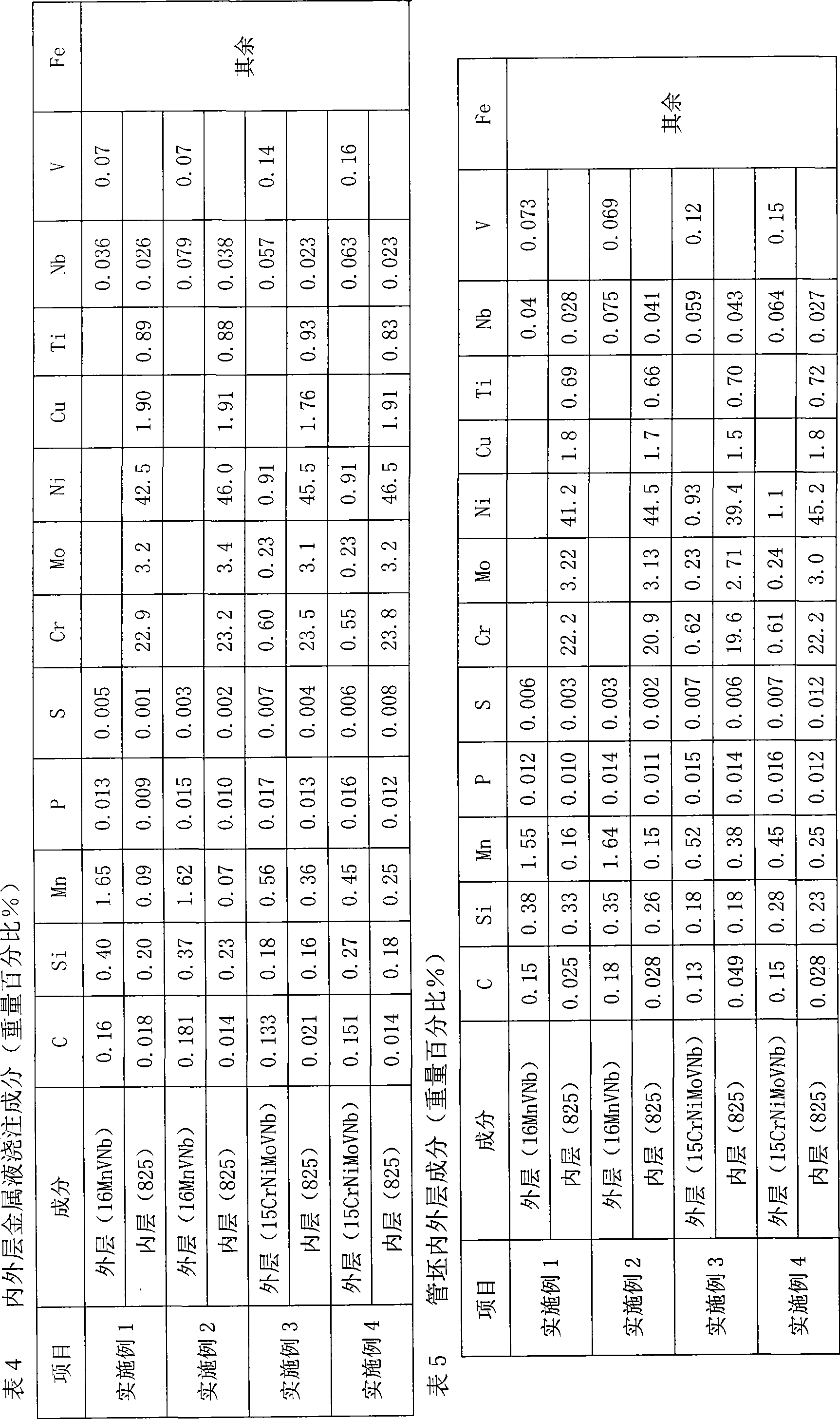

Bimetallic metallurgical composite wear-resisting tube blank and manufacturing method thereof

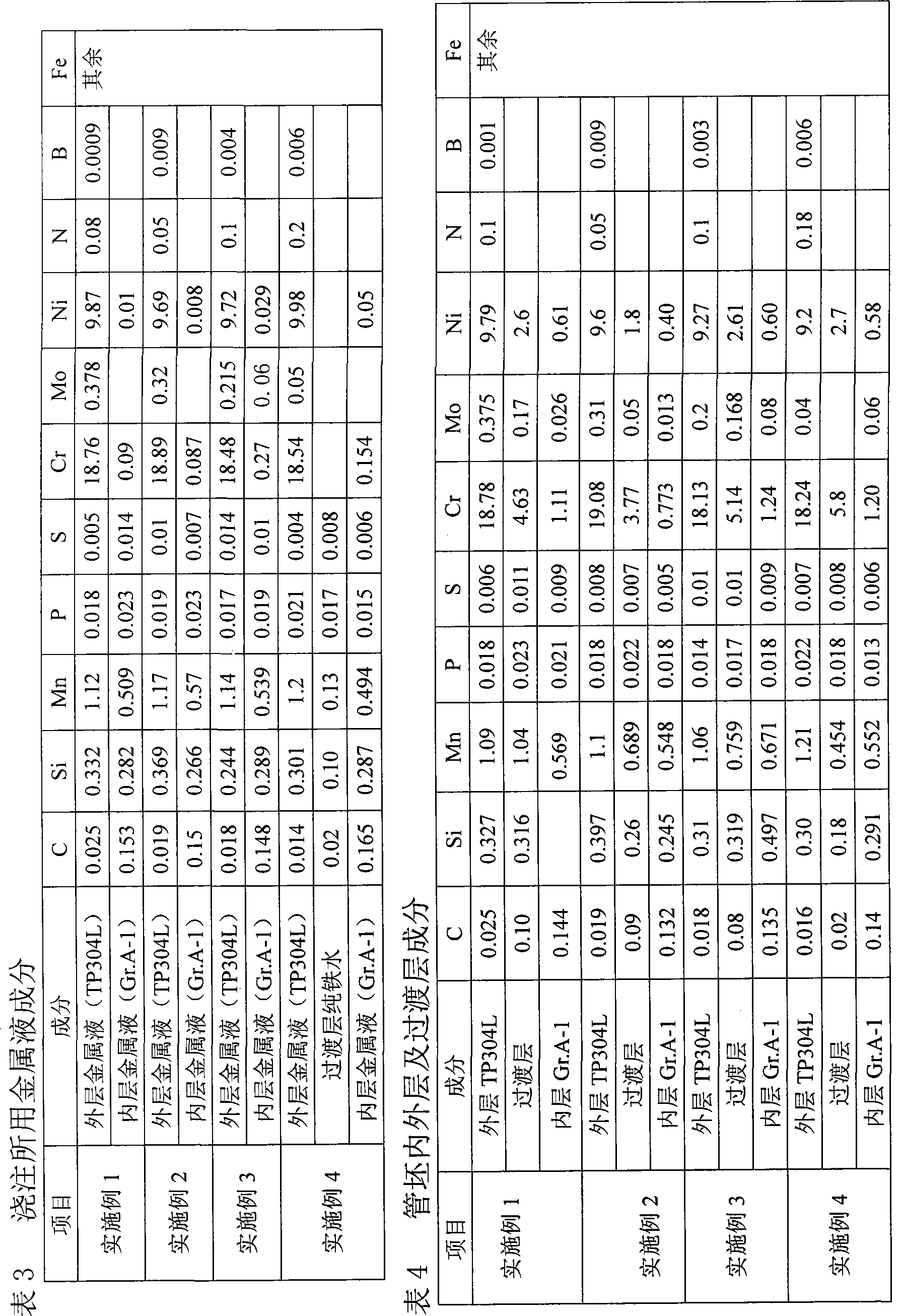

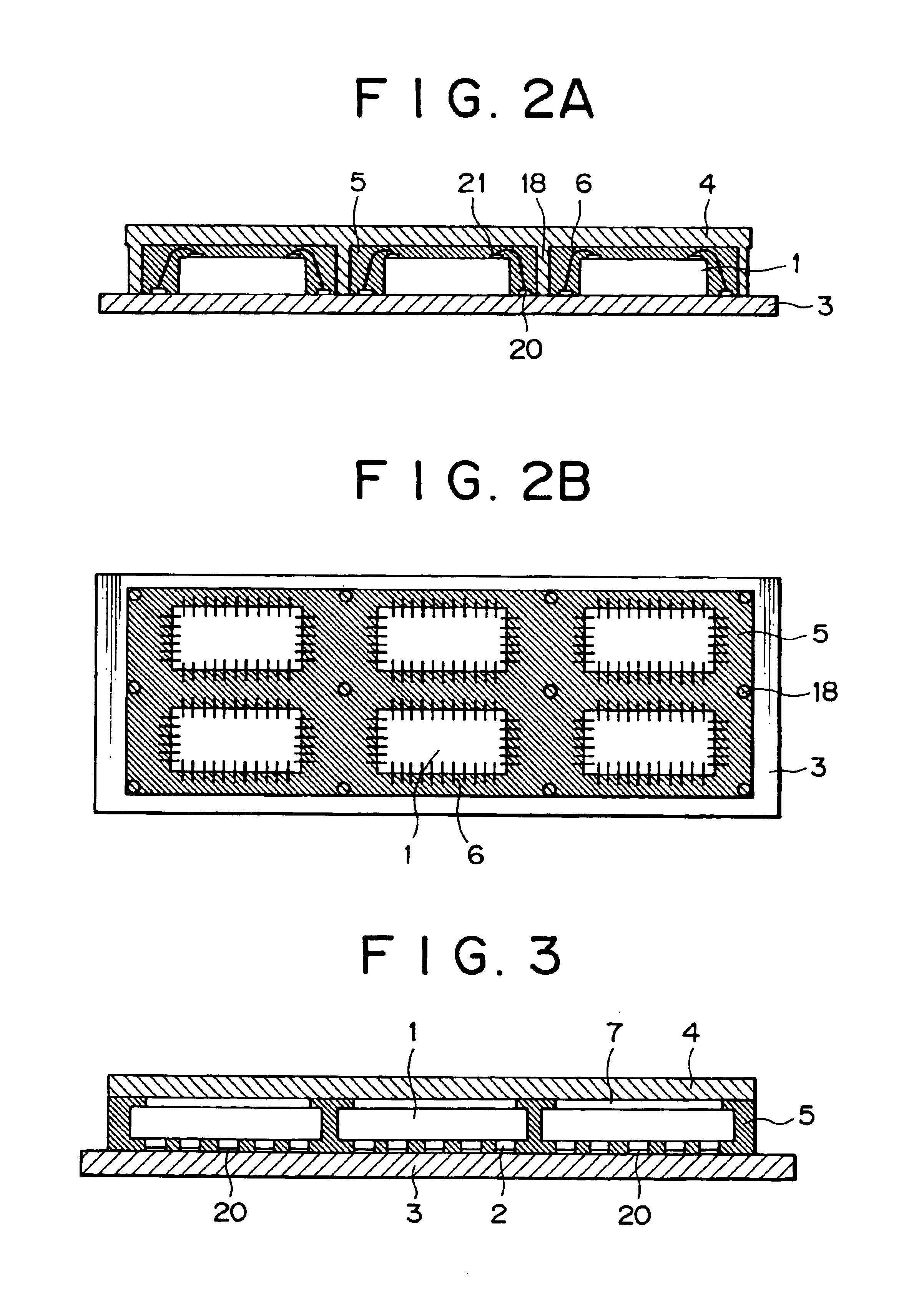

The invention discloses a method for manufacturing a bimetallic metallurgical composite wear-resisting tube blank, which comprises the following steps: firstly, spraying a water-based zircon powder coating onto a metal tube die after being baked to between 200 and 300 DEG C, wherein the spraying thickness is 1.0 to 3.0mm; secondly, centrifugally casting external liquid metal on the metal tube die after being baked to between 200 and 350 DEG C, cooling the metal tube die after casting, beginning to cast internal liquid metal into the metal tube die when an internal surface temperature of the outer layer is cooled to a temperature lower than a solidus temperature of the external metal; and finally, pouring the internal liquid metal into the metal tube die for centrifugal casting, cooling the metal tube die after casting, and stopping cooling when the outer layer and the inner layer are completely solidified, then the outer layer and the inner layer are metallurgically fused completely, wherein the outer layer is made of a plain carbon steel material or a low-alloy high-strength steel material and the inner layer is made of a high-chromium white cast iron material. The invention also discloses the bimetallic metallurgical composite wear-resisting tube blank manufactured by the method. The outer-layer metal and the inner-layer metal of the tube blank manufactured by the method can be metallurgically fused completely; the qualification rate is improved; and the use safety is high.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

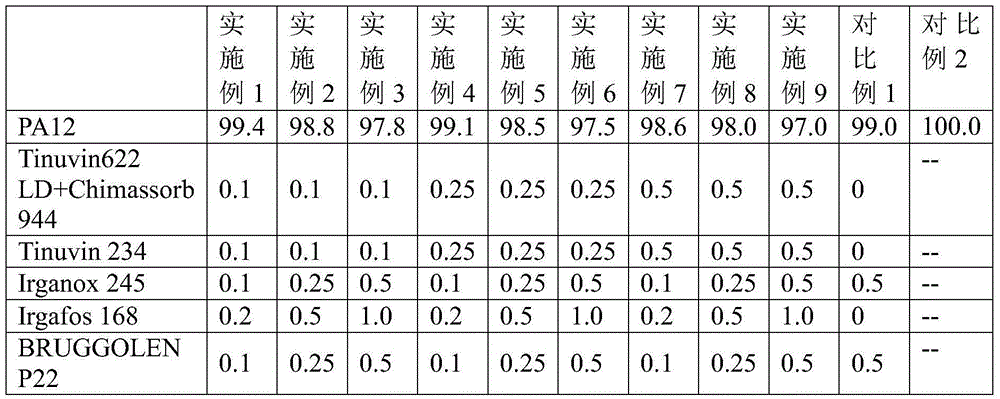

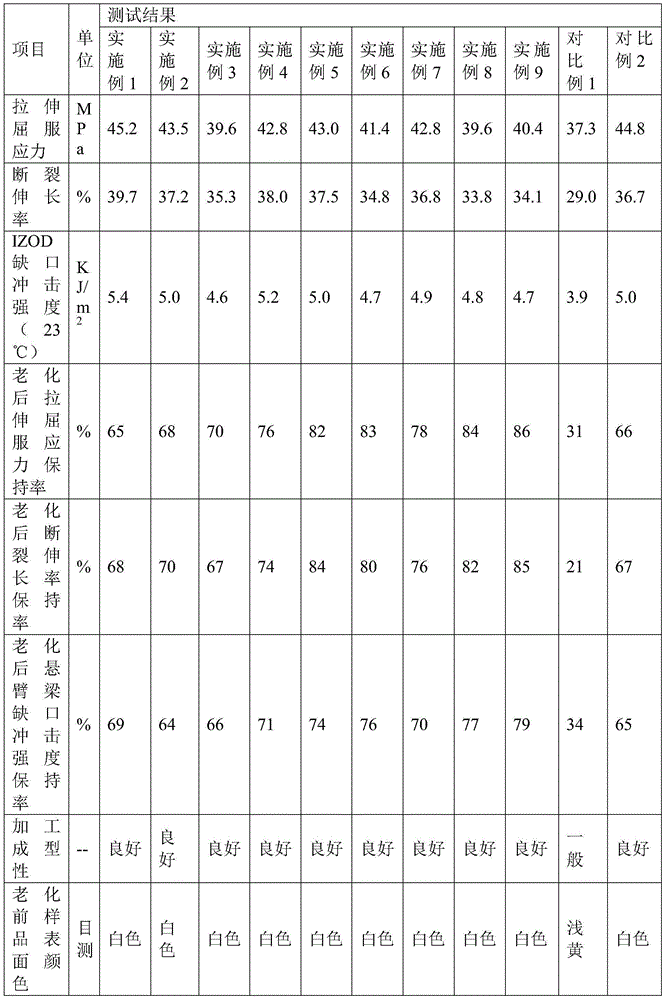

3D printing weather-resistant nylon powder composite material and preparation method thereof

The invention discloses a 3D printing weather-resistant nylon powder composite material and a preparation method thereof. The 3D printing weather-resistant nylon powder composite material is characterized by being prepared from the following components in percentage by mass: 97-99.4wt% of nylon, 0.1-0.5wt% of a hindered amine light stabilizer, 0.1-0.5wt% of an ultraviolet light absorber, 0.1-0.5wt% of a hindered phenol antioxidant, 0.2-1.0wt% of a phosphite ester antioxidant and 0.1-0.5wt% of other additives, wherein the other additives comprise one or combination of multiple components of a dispersing agent, a nucleating agent and a lubricant. With the combination of the hindered amine light stabilizer, the ultraviolet light absorber, the hindered phenol antioxidant and the phosphite ester antioxidant, the 3D printing weather-resistant nylon powder composite material prepared through spray-drying is excellent in weather resistance and small in mechanical property change before and after being modified, can be recycled and reused for multiple times, is narrow in spherical granule distribution, good in flowing property, free of layering or powder dropping, and moreover is high in preparation efficiency, small in energy consumption and simple and easy to process.

Owner:QINGDAO UNIV OF SCI & TECH +2

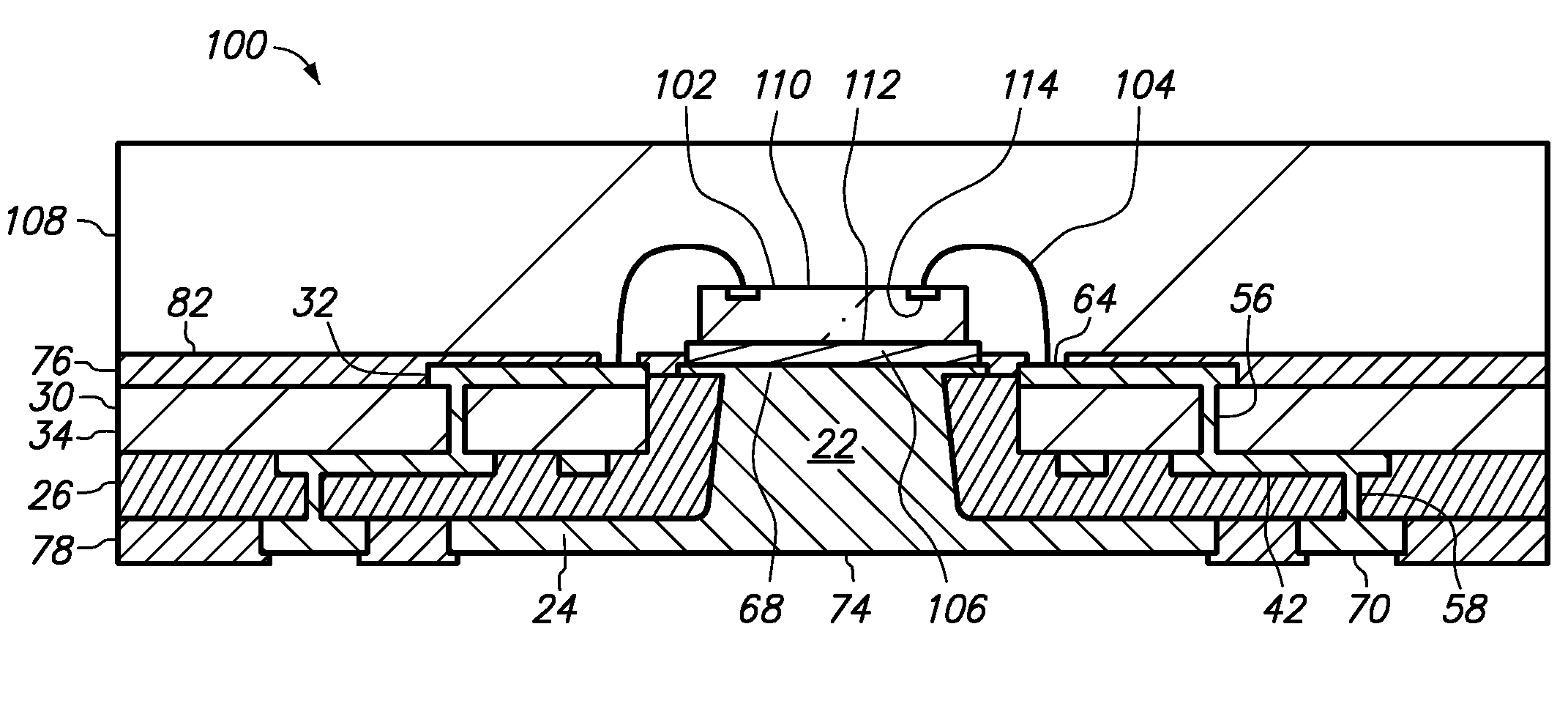

Semiconductor chip assembly with post/base heat spreader and vertical signal routing

InactiveUS20100001395A1Excellent heat spreading heatImprove cooling effectSemiconductor/solid-state device detailsPrinted circuit aspectsSignal routingAdhesive

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a substrate and an adhesive. The semiconductor device is electrically connected to the substrate and thermally connected to the heat spreader. The heat spreader includes a post and a base. The post extends upwardly through an opening in the adhesive into an aperture in the substrate, and the base extends laterally and supports the substrate. The adhesive extends between the post and the substrate and between the base and the substrate. The substrate includes first and second conductive layers and a dielectric layer therebetween, and the assembly provides vertical signal routing between a pad at the first conductive layer and a terminal below the adhesive.

Owner:BRIDGE SEMICON

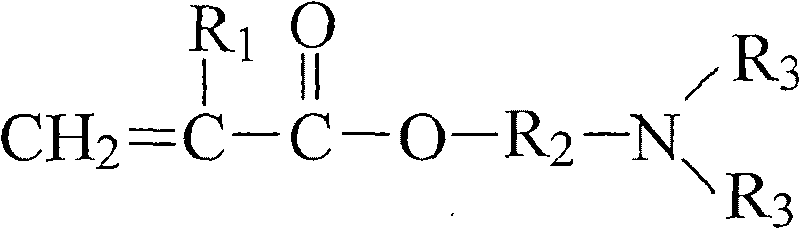

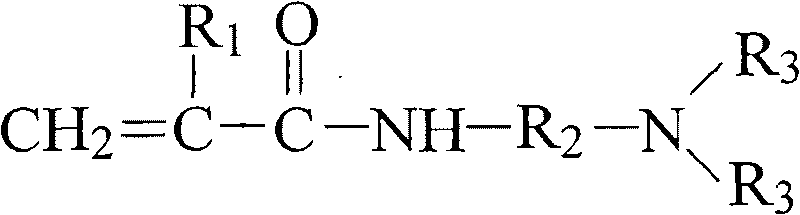

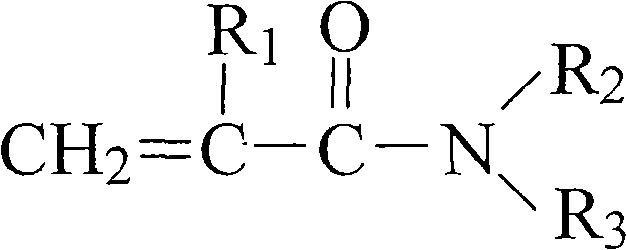

Preparation method of water-soluble polymer dispersion

The invention relates to a preparation method of a water-soluble polymer dispersion. The water-soluble monomer is dispersed in a solution polymerization system containing a dispersant, an initiator and a metal ion scavenger to perform polymerization and obtain the water-soluble polymer dispersion, wherein the dispersant is a composite dispersant system and contains at least one kind of water-insoluble inorganic macroparticles and at least one water-soluble polymer dispersant. The invention utilizes the composite dispersant system in which the water-insoluble inorganic macroparticles are matched with the polymer dispersant to form dispersion coating mechanism so as to reduce the concentration of high molecular polymer in continuous phase and ensure that the rolling friction and rigid impact are mainly adopted between the polymer molecule chain and the macroparticles. Therefore, the viscosity of the dispersion is effectively reduced while the molecular weight of polyacrylamide polymer in the dispersion is not reduced, and the water-soluble polymer dispersion with high concentration, good solubility, uniform dispersion, high efficiency and full water-solubility can be prepared.

Owner:JIANGSU FEYMER TECH

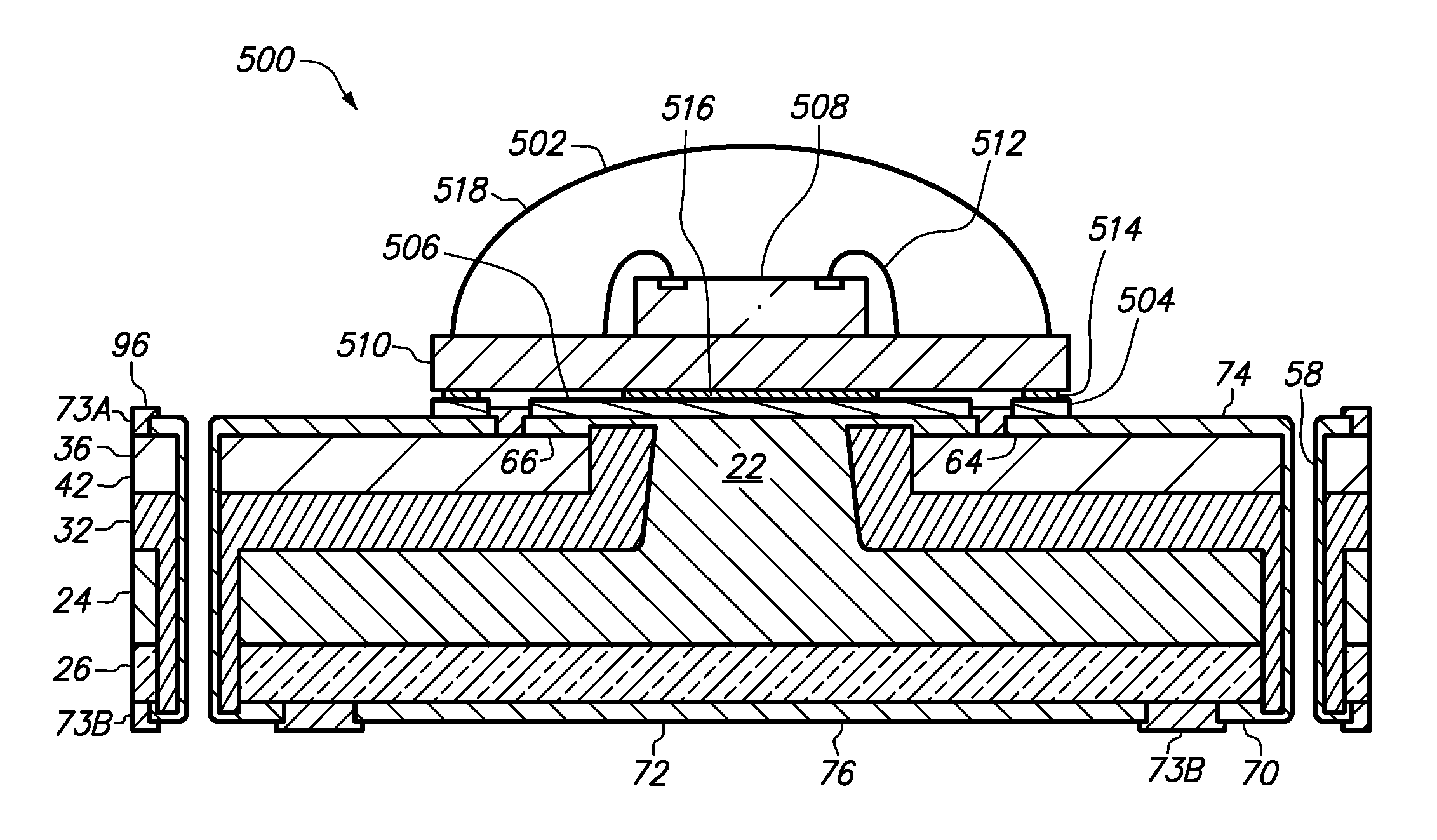

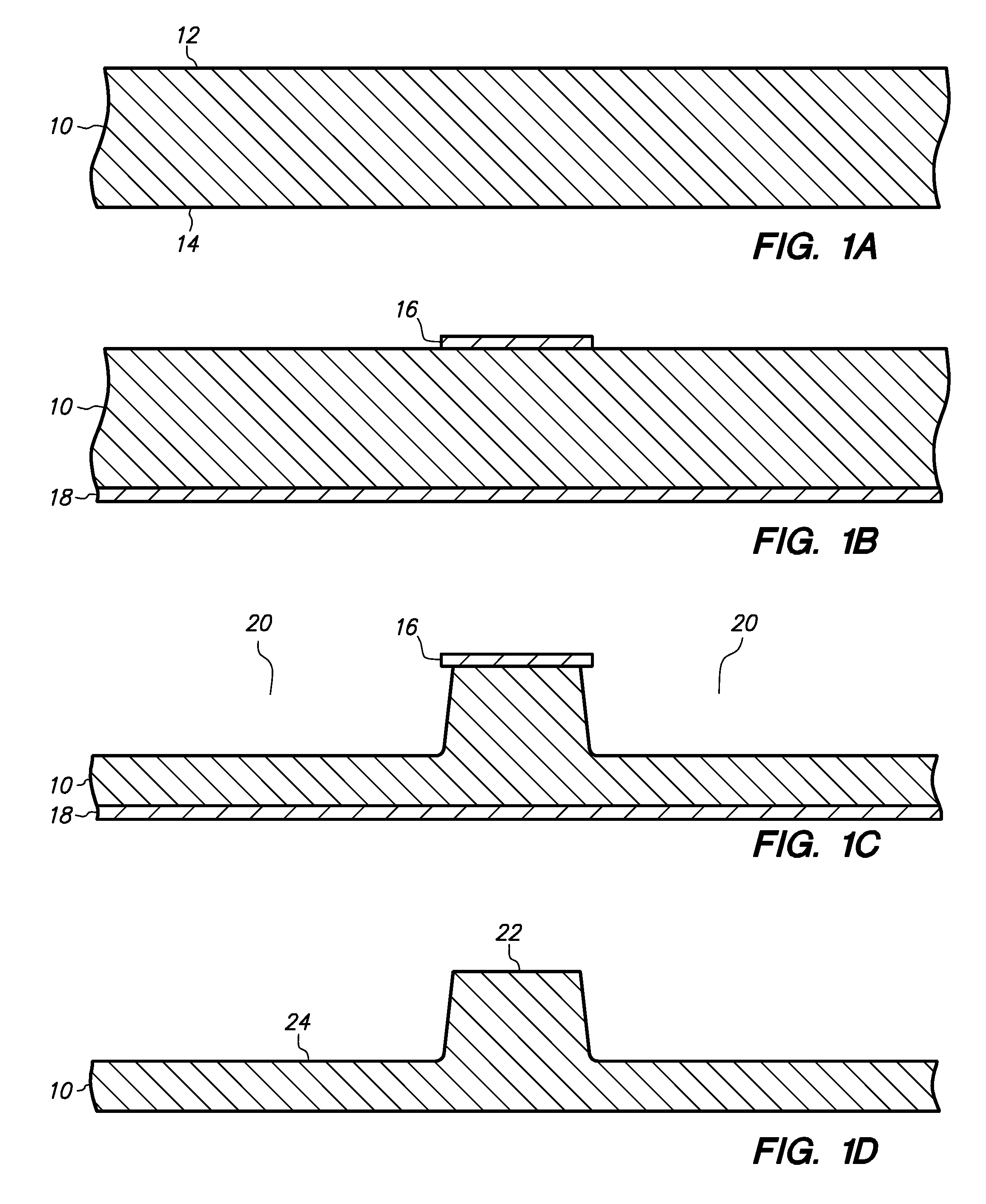

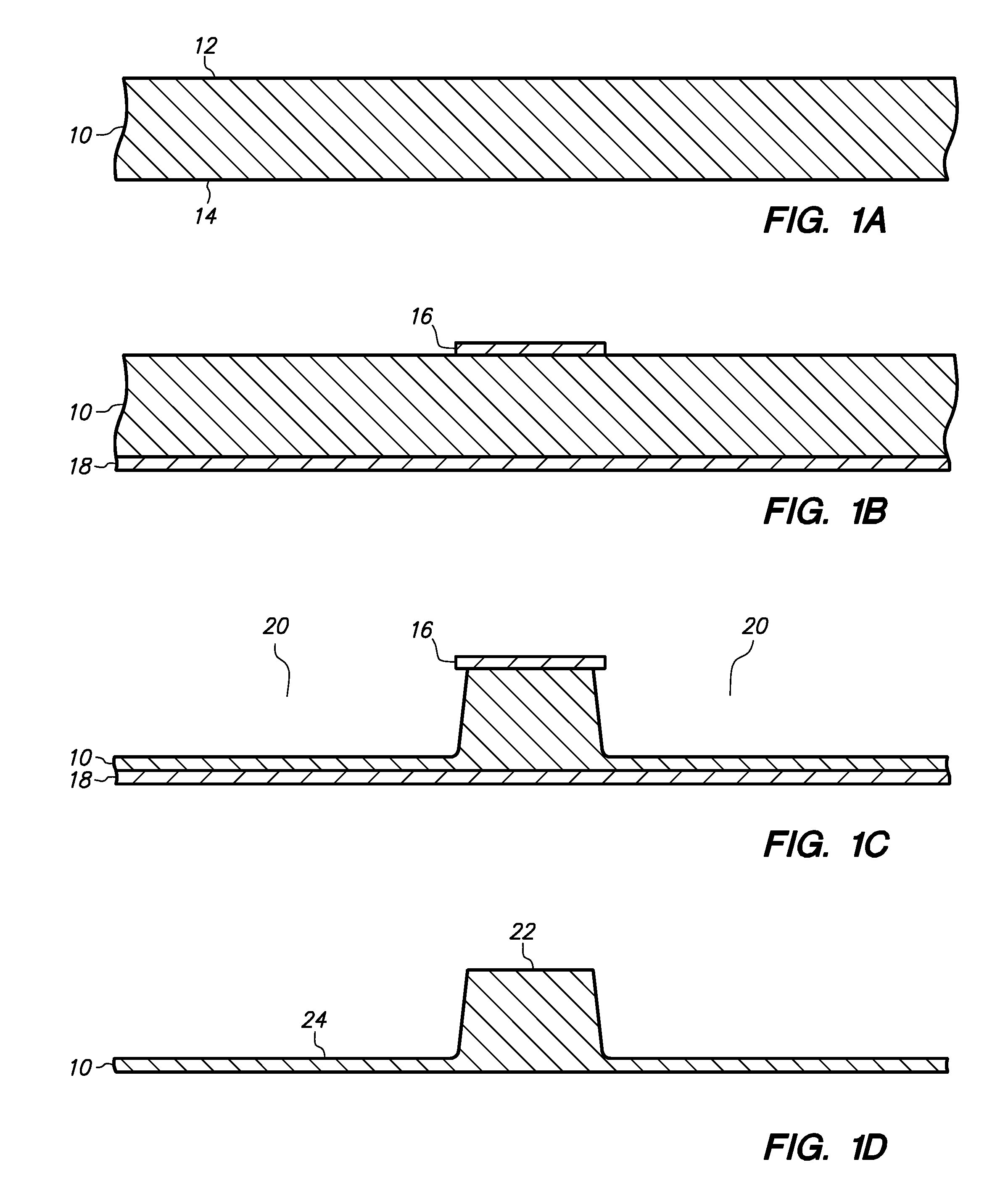

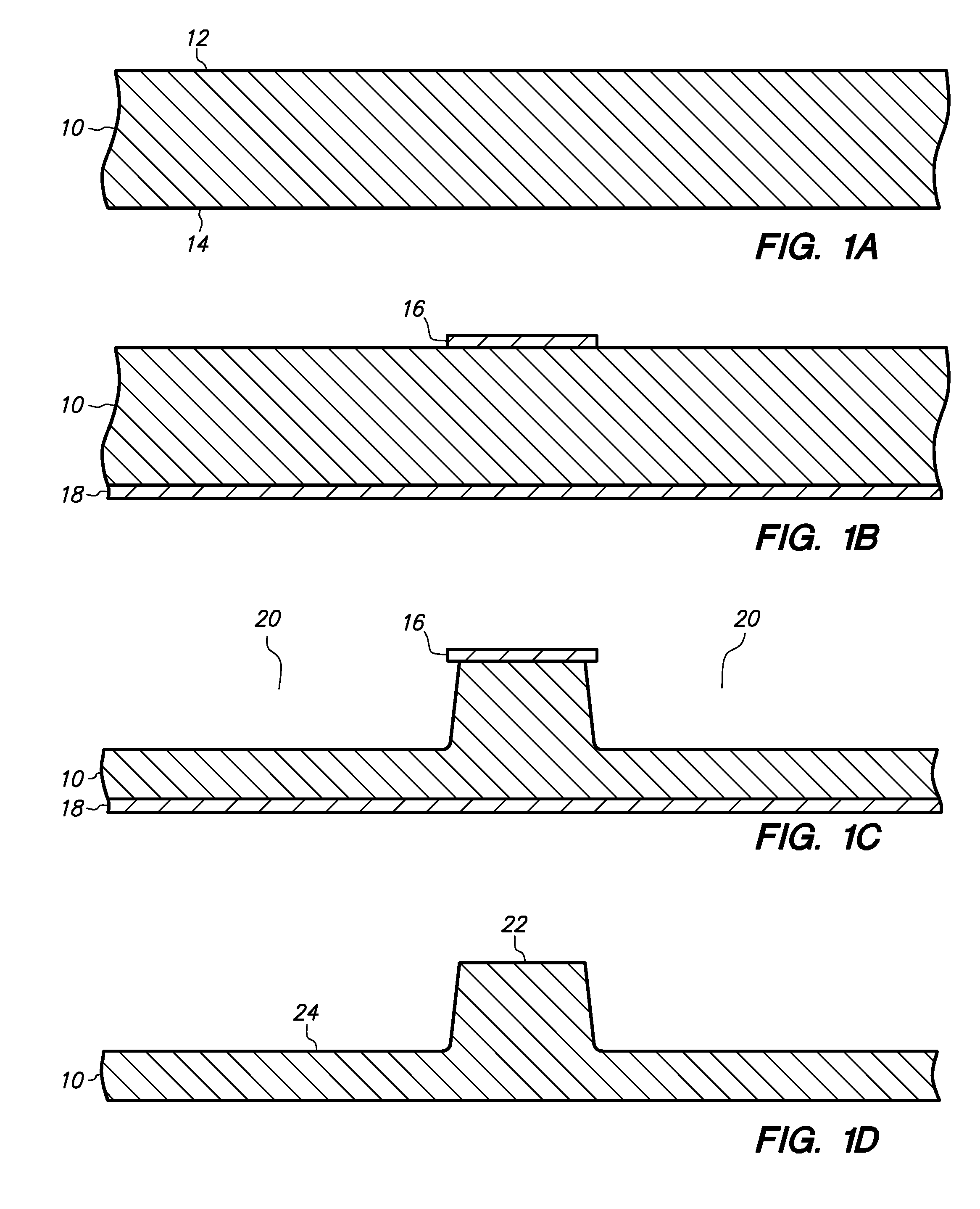

Method of making a semiconductor chip assembly with a post/base heat spreader and a substrate

InactiveUS20100055811A1Low costNot easy to layerSemiconductor/solid-state device detailsPrinted circuit aspectsAdhesiveSemiconductor chip

A method of making a semiconductor chip assembly includes providing a post and a base, mounting an adhesive on the base including inserting the post through an opening in the adhesive, mounting a substrate on the adhesive including inserting the post into an aperture in the substrate to form a gap in the aperture between the post and the substrate, then flowing the adhesive into and upward in the gap, solidifying the adhesive, then mounting a semiconductor device on a heat spreader that includes the post and the base, electrically connecting the semiconductor device to the substrate and thermally connecting the semiconductor device to the heat spreader.

Owner:BRIDGE SEMICON

Corrosion-resistant dual metal clad tube blank and manufacturing method thereof

InactiveCN101530898ANot easy to layerImprove securityRigid pipesExplosion weldingCorrosion resistant

A manufacturing method of a corrosion-resistant dual metal clad tube blank comprises the following steps: outer-layer molten metal is pumped into a pipe die for centrifugal pouring, the molten metal is cooled after pouring, and inner-layer molten metal is poured when internal surface temperature of the outer layer is cooled to be lower than 50-70 DEG C which is the melting point of the outer-layer molten metal; inner-layer molten metal is pumped into the pipe die for centrifugal pouring, the molten metal is cooled after pouring; cooling is stopped after the outer layer and the inner layer are completely solidified, at the moment, the inner layer and the outer layer achieve complete metallurgical bonding; wherein, the outer layer is made of X52 or X60 steel and the inner layer is made of 825 steel. A metallurgical bonding layer of a production tube obtained by carrying out extrusion or hot rolling on the tube blank manufactured by the method is several times or dozens of times as thick as a bonding layer of the dual metal tube obtained by the explosive welding process; the transition of the ingredients on the inner and outer layers is gentle, thus greatly relieving the interfacial stress between the inner layer and the outer layer, facilitating the inner layer and the outer layer not to be layered easily, improving the safety of the use of the production tube and prolonging the service life of the production tube.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

Semiconductor chip assembly with base heat spreader and cavity in base

InactiveUS20100155769A1Excellent heat spreading heatImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesSignal routingAdhesive

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and an adhesive. The heat spreader includes a base. A cavity extends through the adhesive into the base. The semiconductor device extends into the cavity, is electrically connected to the conductive trace and is thermally connected to the heat spreader. The adhesive extends between the cavity and the conductive trace and between the base and the conductive trace. The conductive trace is located outside the cavity and provides signal routing between a pad and a terminal.

Owner:BRIDGE SEMICON

Semiconductor chip assembly with post/base heat spreader and vertical signal routing

InactiveUS7948076B2Low costNot easy to layerSemiconductor/solid-state device detailsPrinted circuit aspectsSignal routingAdhesive

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a substrate and an adhesive. The semiconductor device is electrically connected to the substrate and thermally connected to the heat spreader. The heat spreader includes a post and a base. The post extends upwardly through an opening in the adhesive into an aperture in the substrate, and the base extends laterally and supports the substrate. The adhesive extends between the post and the substrate and between the base and the substrate. The substrate includes first and second conductive layers and a dielectric layer therebetween, and the assembly provides vertical signal routing between a pad at the first conductive layer and a terminal below the adhesive.

Owner:BRIDGE SEMICON

Edge glow protection for composite component

InactiveUS20110008587A1Reduce voidsImproves Structural IntegrityAircraft lighting protectorsCellulosic plastic layered productsComposite laminatesEngineering

A composite component comprises a co-cured stack of composite laminate plies, and has a lateral edge between opposing first and second surfaces. The lateral edge is free of laterally facing cut ply edges, and at least one of the plies has a cut ply edge substantially flush with and facing outwardly from the second surface. The component may be joined to a second component such that the one or more outwardly facing cut ply edges face towards the second component. Eliminating exposed cut ply edges protects against edge glow. Also, methods of forming the composite component.

Owner:AIRBUS OPERATIONS LTD

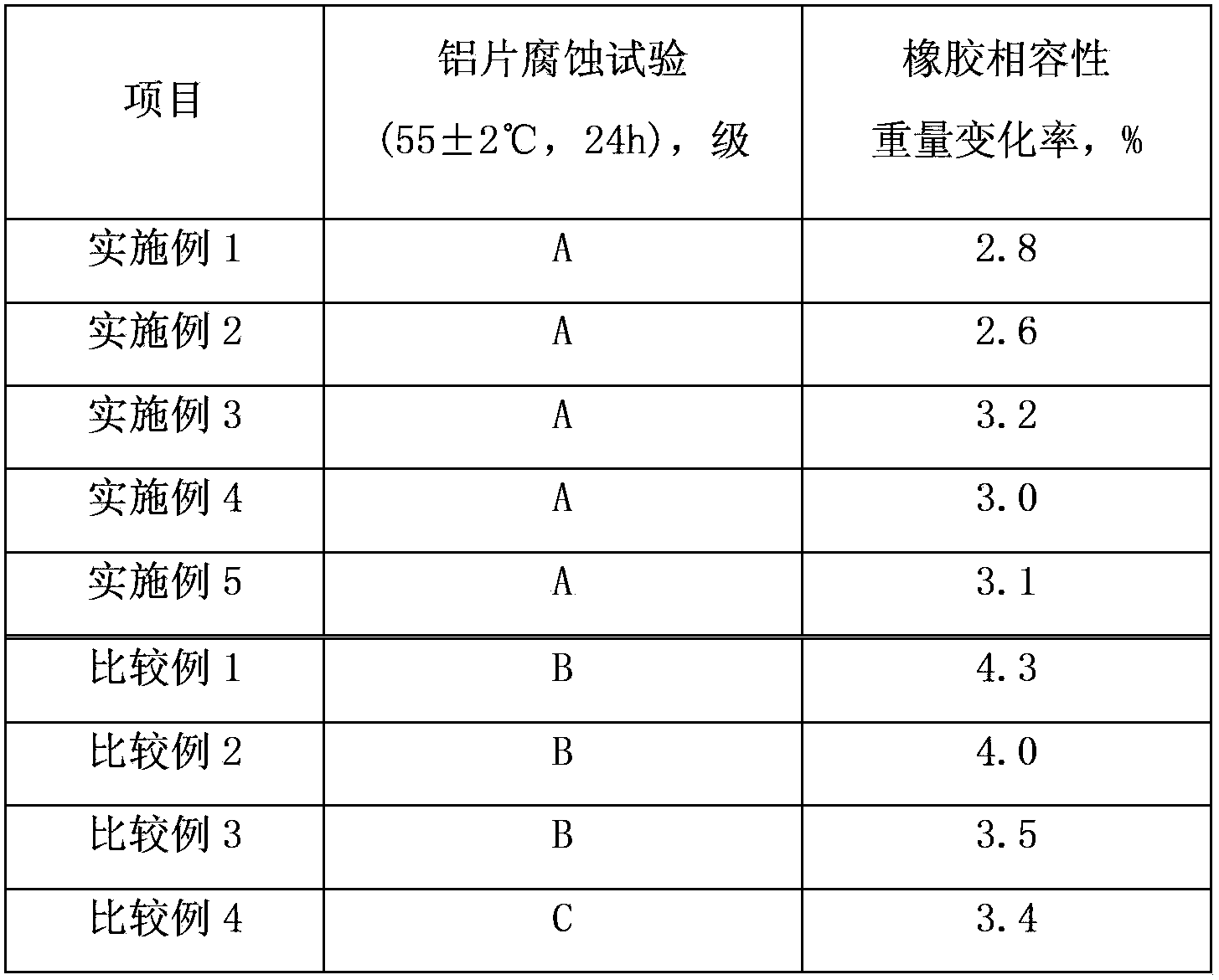

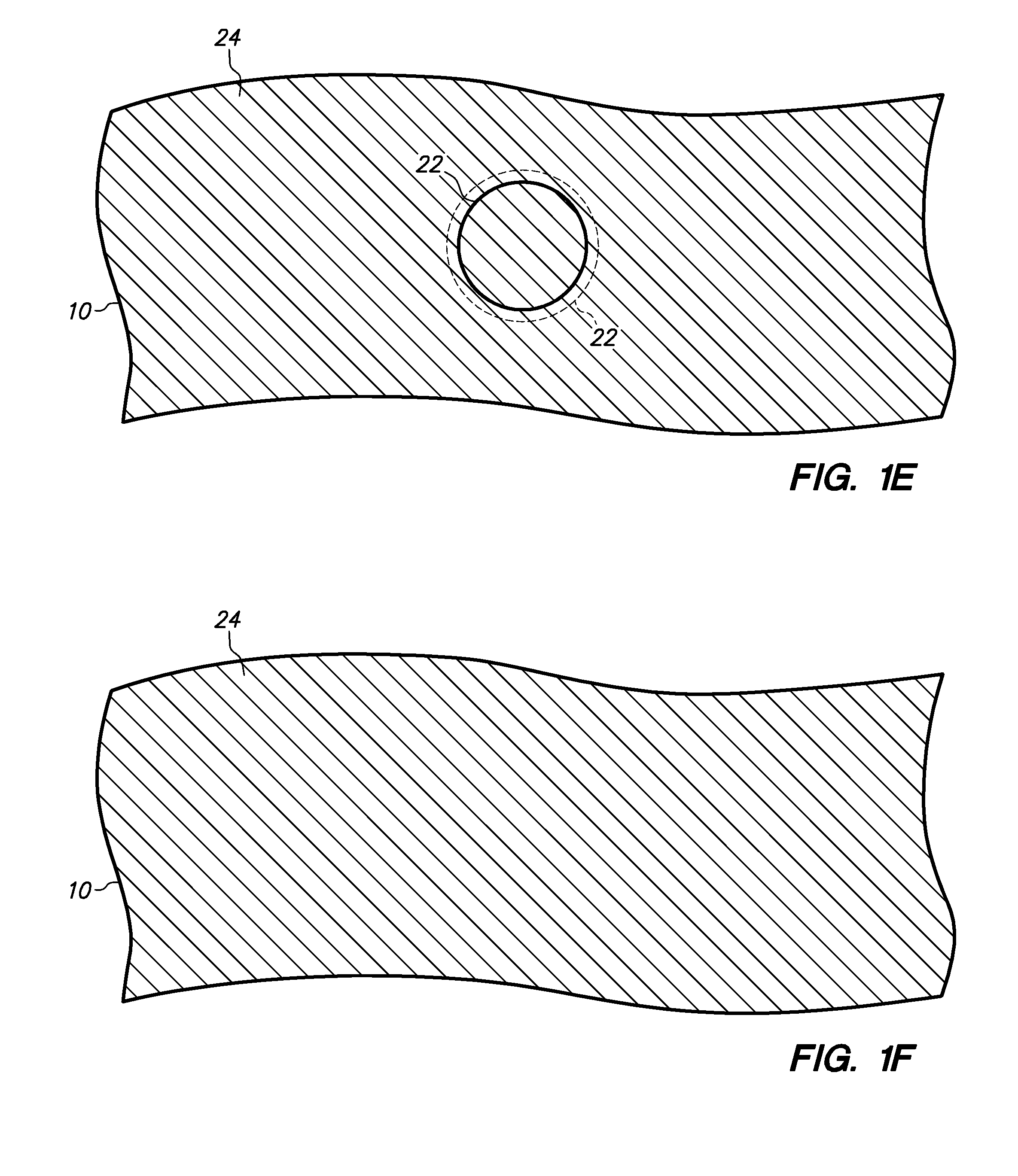

Thermally enhanced semiconductor assembly with bump/base/flange heat spreader and build-up circuitry

InactiveUS20120126399A1Low costNot easy to layerSemiconductor/solid-state device detailsSolid-state devicesSignal routingDevice material

A semiconductor assembly includes a semiconductor device, a heat spreader, an adhesive and a build-up circuitry. The heat spreader includes a bump, a base and a flange. The bump defines a cavity. The semiconductor device is mounted on the bump at the cavity, electrically connected to the build-up circuitry and thermally connected to the bump. The bump extends from the base into an opening in the adhesive, the base extends vertically from the bump opposite the cavity and the flange extends laterally from the bump at the cavity entrance. The build-up circuitry includes a dielectric layer and conductive traces on the semiconductor device and the flange. The conductive traces provide signal routing for the semiconductor device.

Owner:BRIDGE SEMICON

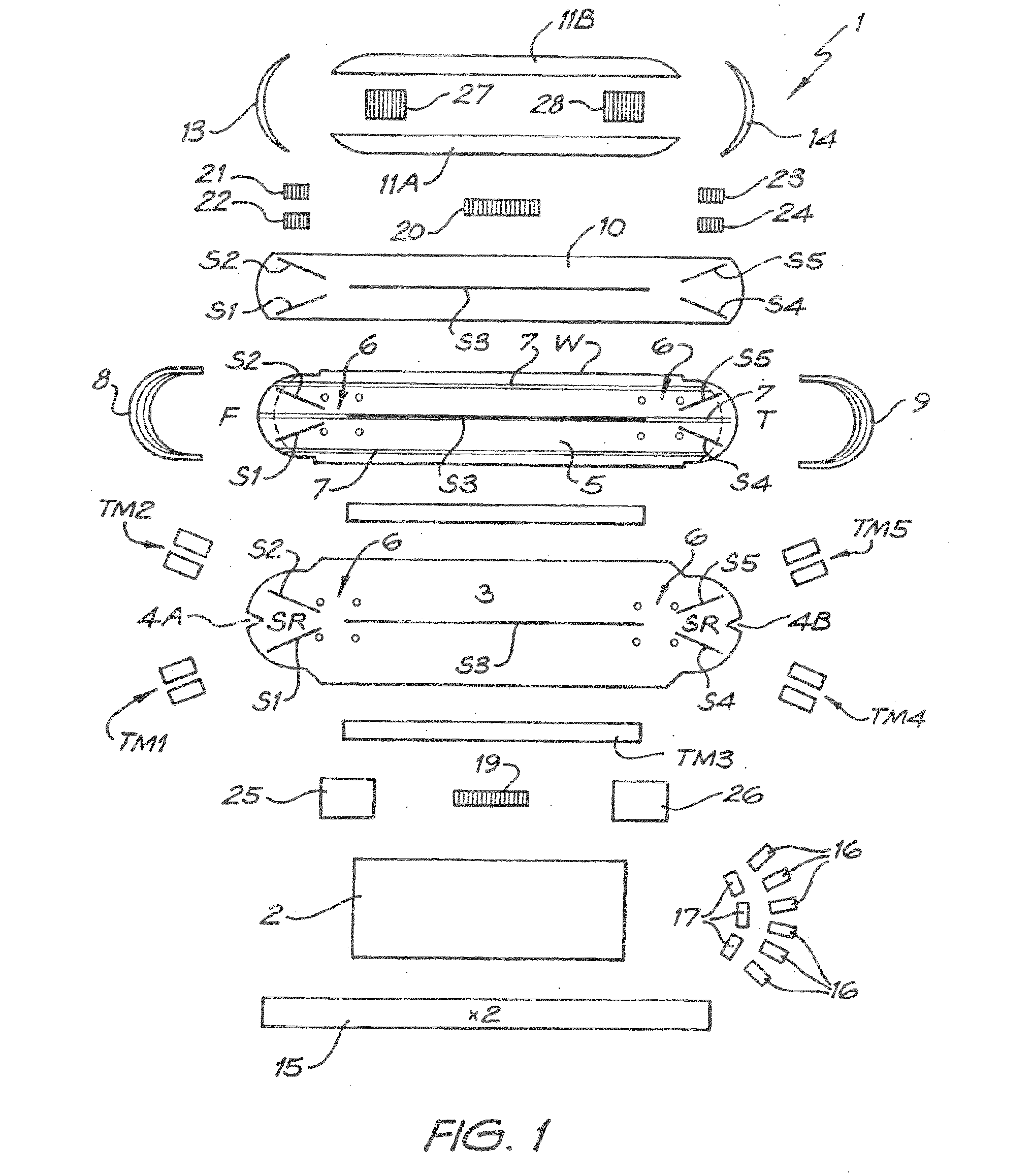

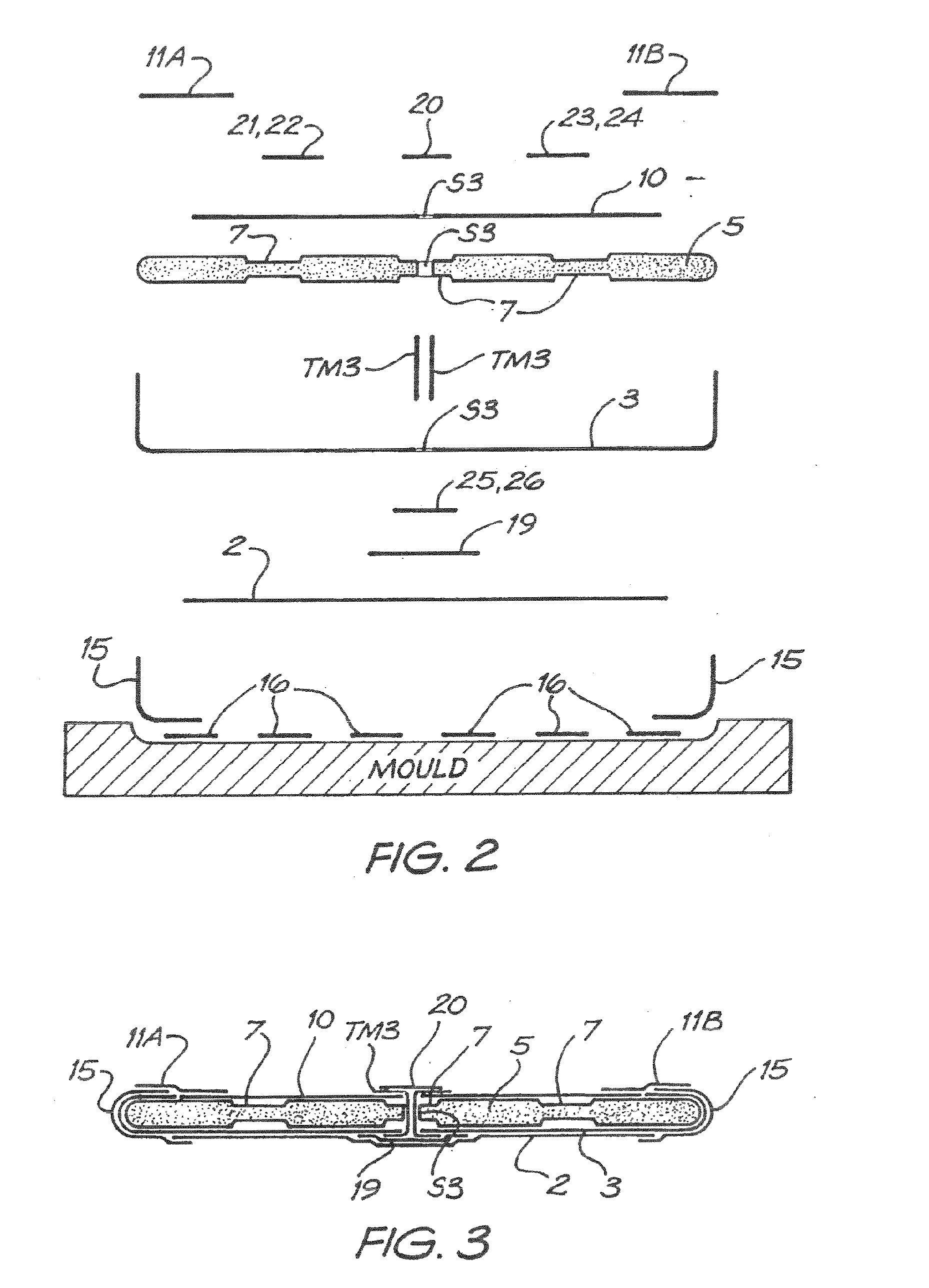

Alternative gripping for skateboard

InactiveUS20140103613A1High strengthGood resiliencyDead plant preservationArtificial flowers and garlandsAdhesiveArtificial turf

This invention relates to a composite board including: a core having upper and lower surfaces and at least one aperture extending therebetween, at cast one upper reinforcing layer disposed on the upper surface of the core and at least one lower reinforcing layer disposed on the lower surface of the core, at least one tie member passing through the substantially aligned apertures, each said tie member having a first end portion protruding through said aligned apertures from said upper reinforcing layer and a second end portion protruding through aligned apertures from a lower reinforcing layer, with the surface covered by artificial turf as a means of alternative gripping for the rider. The artificial turf is secured to the upper layer of the skateboard by an adhesive. A process for preparing the composite board and skateboard deck formed from the composite board and artificial turf surface are disclosed.

Owner:GOMEZ JOSE ALEJANDRO

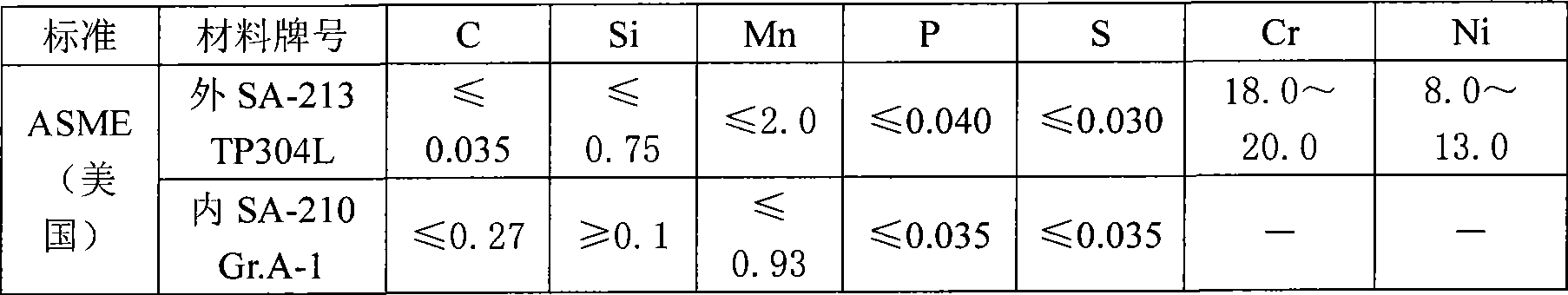

Clad tube blank of dual metal seamless steel tube used for boiler and manufacturing method thereof

InactiveCN101530907ANot easy to layerExtended service lifeRigid pipesMetal layered productsJoint surfaceTransition layer

A clad tube blank of a dual metal seamless steel tube used for a boiler comprises an inner layer and an outer layer; a transition layer is arranged between the inner layer and the outer layer and is respectively bonded with the inner layer and the outer layer completely and metallurgically; the inner layer is cast by a Gr.A-1 material; the transition layer is cast by ferrite or inner layer materials. The transition layer is arranged between the inner layer and the outer layer of the clad tube blank and is respectively bonded with the inner layer and the outer layer completely and metallurgically, therefore, interfacial stress between joint surfaces of the inner layer and the outer layer is reduced, the tube blank is not easy to be layered and the service life of production tubes used for boilers and manufactured by the tube blank is greatly increased.

Owner:XINXING DUCTILE IRON PIPES CO LTD +1

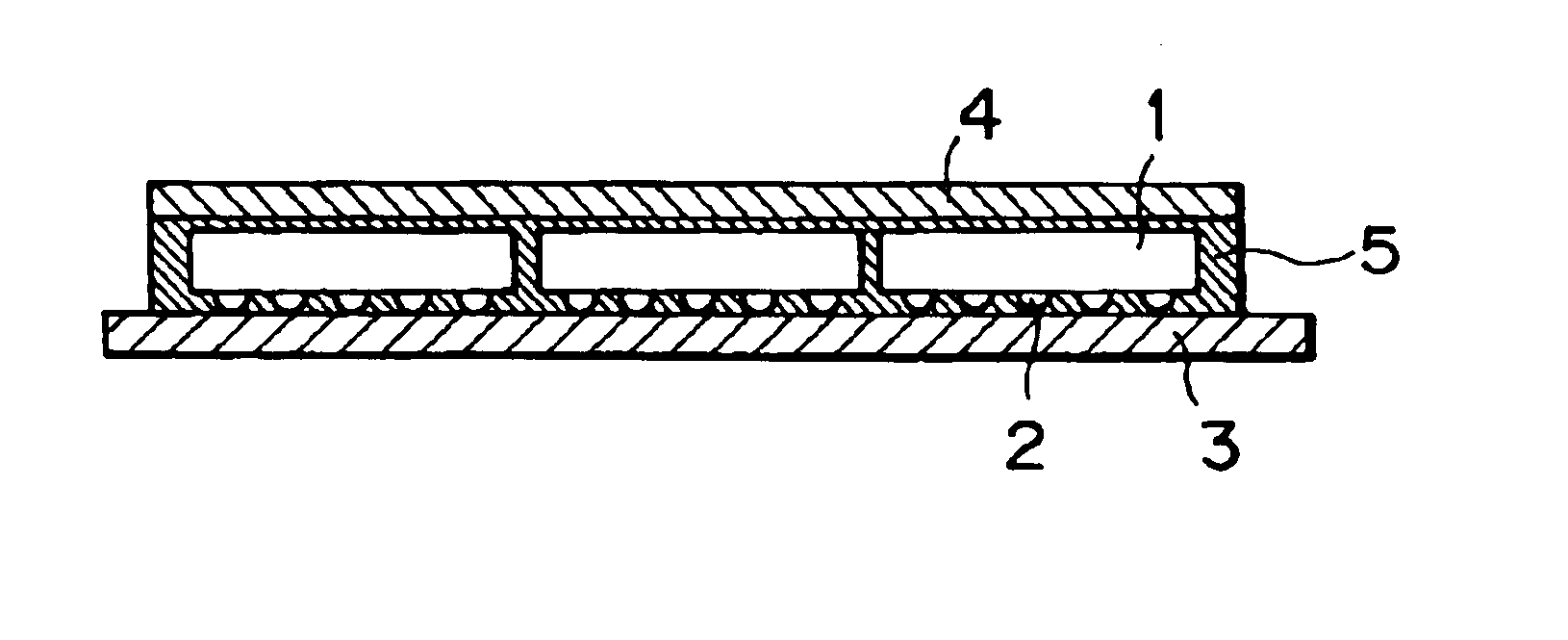

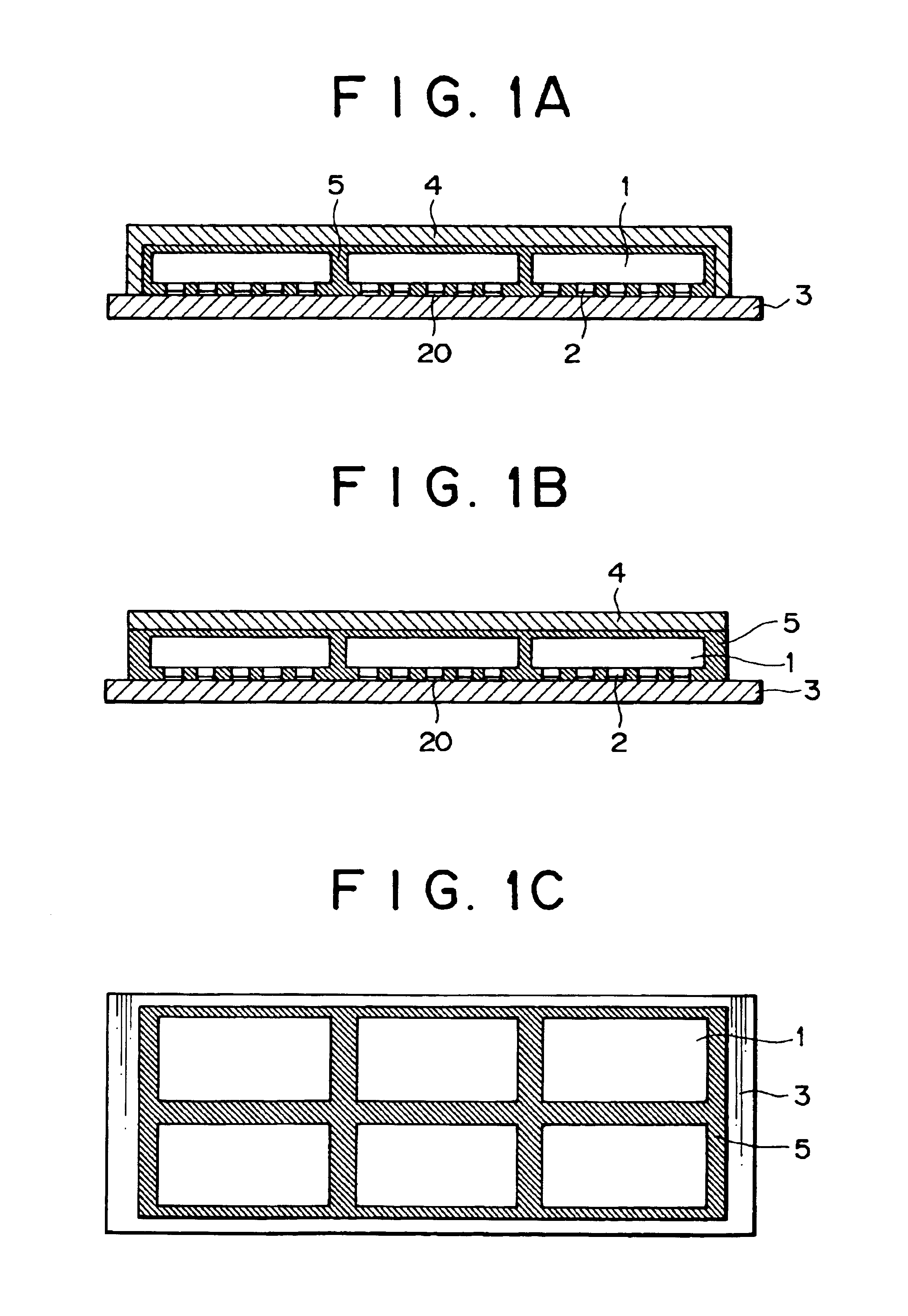

Semiconductor module and mounting method for same

InactiveUS6940162B2Low costImprove heat resistanceSemiconductor/solid-state device detailsSolid-state devicesStress concentrationSingle process

In a multi chip module of a structure wherein a plurality of bare or packaged semiconductor chips are mounted on a single wiring board and upper surfaces of the semiconductor chips are covered with a single heat spread plate, the whole space around the semiconductor chips thus sandwiched between the wiring board and the heat spread plate is filled with resin.By so doing, the semiconductor chips are interconnected through the resin, so that even if a stress is exerted on any of the chips, it is dispersed and therefore it is possible to diminish the occurrence of cracks in the chips and the heat spread plate caused by stress concentration. Besides, since the semiconductor chips and the heat spread plate are bonded together with resin, even if there are variations in size of the chips, both can be bonded easily. Further, the bonding of all the chips and the heat spread plate can be done in a single process.

Owner:RENESAS ELECTRONICS CORP

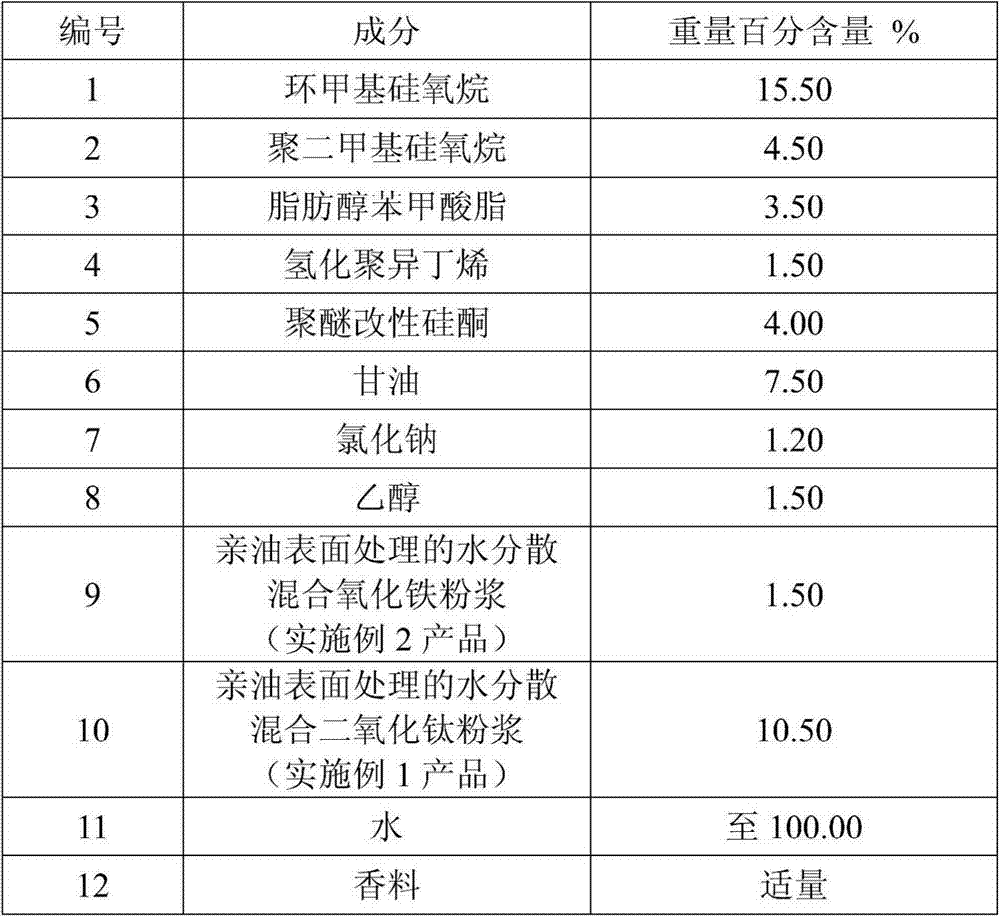

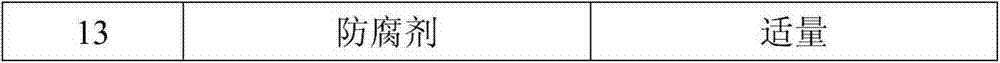

Water dispersible powder syrup for oleophylic treatment and product applying powder syrup

InactiveCN103919693AImprove stabilityNot easy to layerCosmetic preparationsMake-upWater dispersibleSurface finishing

The invention discloses water dispersible powder syrup for oleophylic surface treatment and a product produced by the powder syrup. The water dispersible powder syrup for oleophylic surface treatment is obtained by carrying out surface treatment on powder (D) by adopting a mixture formed by water (A) as a dispersant and a reaction carrier, organosiloxane (B) and a surfactant (C). The treated water dispersible powder syrup is particularly suitable for the industries such as daily chemical, texture, coating and the like. The water dispersible powder syrup for oleophylic surface treatment, disclosed by the invention, has excellent dispersibility and water resistance, and the cosmetic added with the water dispersible powder syrup is good in dispersibility and excellent in skin touch, skin adhesion and water resistance. The water dispersible powder syrup has the advantages of simple and safe operating process, no organic solvent pollution, low cost and the like, and is an energy-saving environment-friendly product.

Owner:SHANGHAI DELTA IND

Electrode production of fuel battery membrane with proton exchange membrane

ActiveCN1713424AIncrease contactTightly boundCell electrodesFinal product manufacturePtru catalystNafion

The method includes following steps: 1) the carbon paper or carbon fabric is dipped in PTFE latex, and then dried to get conduction base; 2) the VXCÊ72 carbon black or acetylene black is mixed with PTFE latex to form synthetic size that is coated on the conducting base; after drying, forms a gas diffusion layer; 3) prepares catalyst slurry; 4) the catalyst slurry is coated on the diffused layer; after hot pressing, it is cooled at the condition of keeping pressure, and the gas diffusion electrode is formed; 5) the Nafion film is set between two gas diffusion electrodes with catalysis layer; after hot pressing, it is cooled at the condition of keeping pressure.

Owner:BYD CO LTD

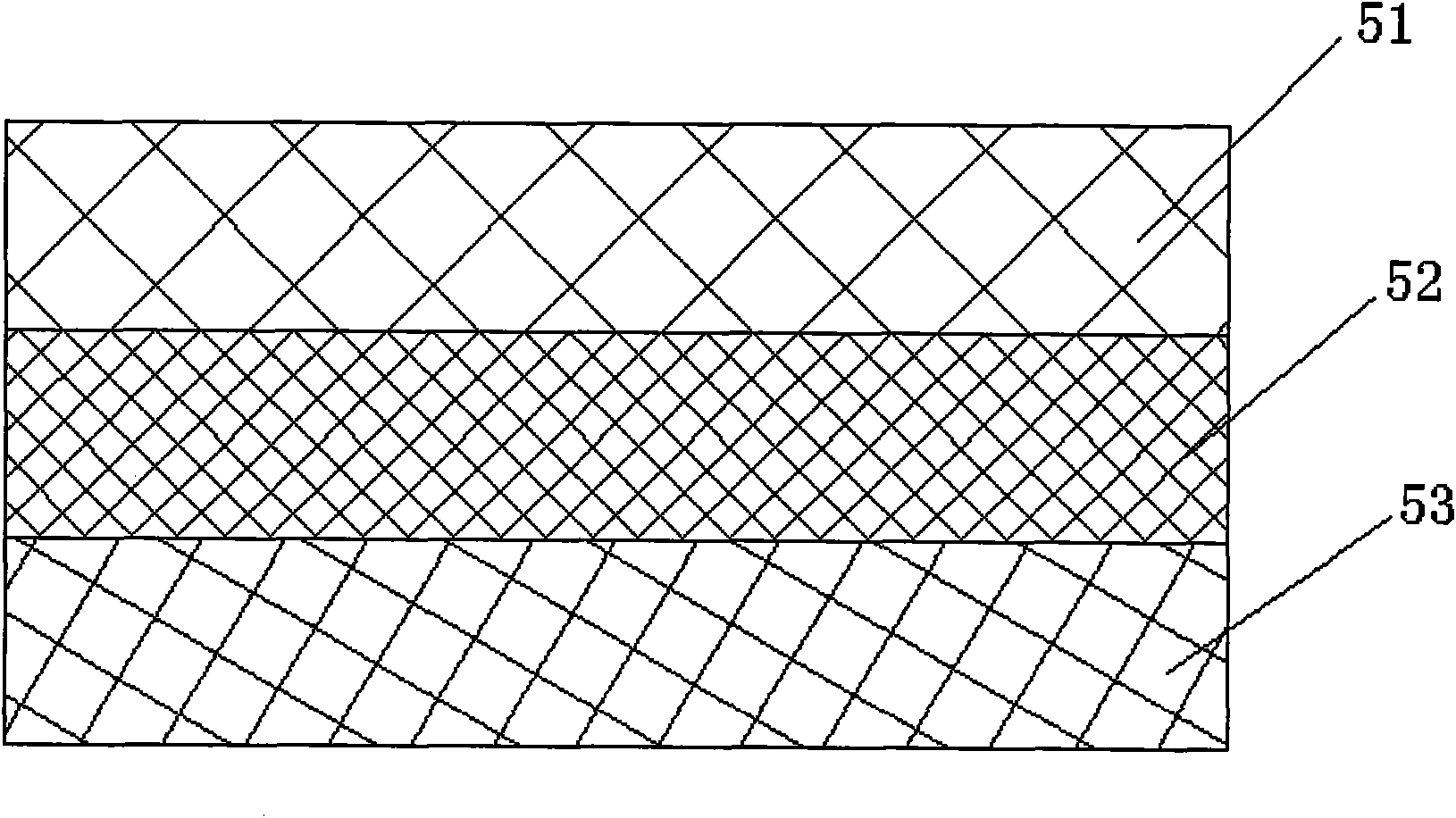

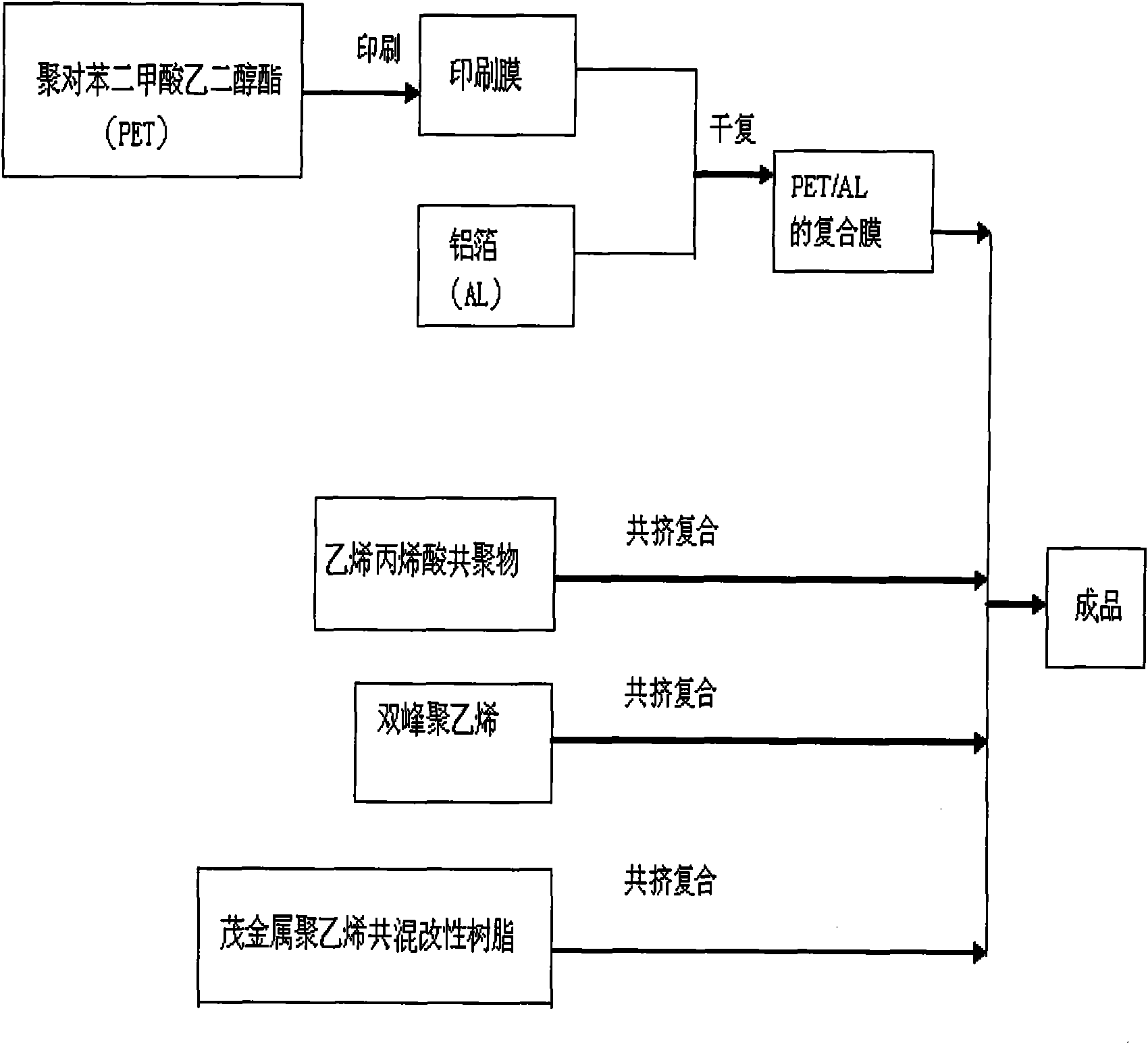

Composite membrane for sauce and preparation method thereof

ActiveCN101624112AGood fragrance retentionGood low temperature heat sealabilityFlexible coversWrappersLow-density polyethylenePolyethylene terephthalate

The invention discloses a composite membrane for sauce and a preparation method thereof. The composite membrane sequentially comprises a polyethylene glycol terephthalate layer, an aluminum foil layer, an ethylene acrylic multipolymer layer, a double-peak low-density polyethylene layer and a metallocene polyethylene blending and modifying resin layer. The preparation method is characterized by comprising the following steps: dry compounding, preparing the metallocene polyethylene blending and modifying resin layer and blending and compounding. Compared with the prior art, the composite membrane for sauce has high sealing strength, short hot seal time, good sealing effect, good sealing planeness, good pollution resistance, medium resistance, low cost, no delamination, and the like.

Owner:HUANGSHAN NOVEL

Shield synchronous grouting slurry prepared from shield waste slurry and construction method thereof

The invention discloses shield synchronous grouting slurry prepared from shield waste slurry and a construction method thereof, each cubic meter of the shield synchronous grouting slurry comprises the following components: 100-200kg of cement or 40-100kg of lime, 300-450kg of fly ash, 200-750kg of the waste slurry, 600-1300kg of sand, 0-450kg of water and 0-12kg of a water reducer. The waste slurry pollution problems can be alleviated, the amount of raw materials of mortar can be reduced, the shield waste slurry is mainly used in backwall grouting material for replacement of bentonite and arts of water in backwall grouting mortar, and the environmental pollution problems caused by the waste slurry can be reduced.

Owner:CCCC SECOND HARBOR ENG +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com