Bimetallic metallurgical composite wear-resisting tube blank and manufacturing method thereof

A production method and technology for wear-resistant pipes are applied in the field of metal casting and can solve the problems of high melting point slag, low shear strength, inclusion and slag inclusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

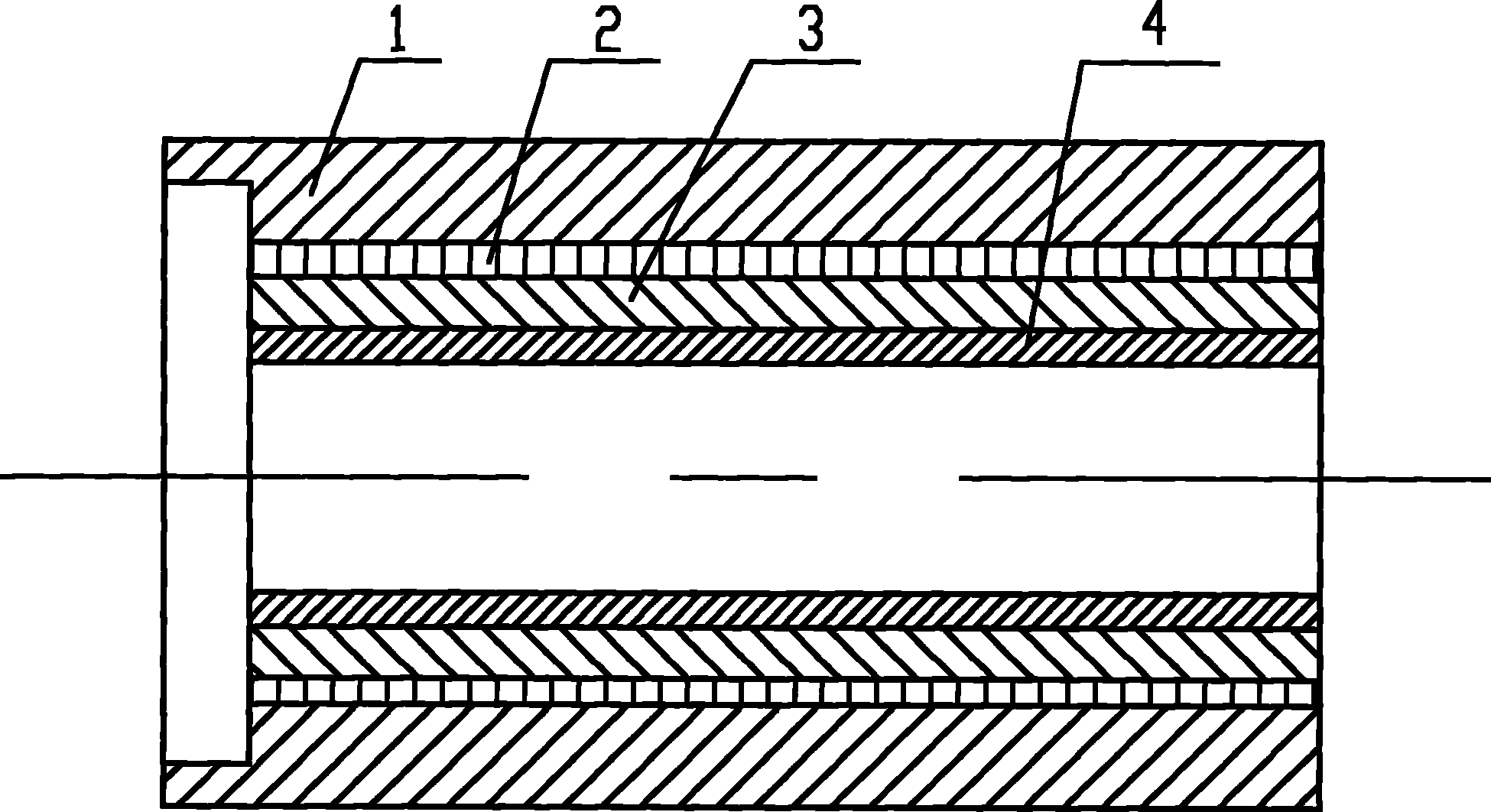

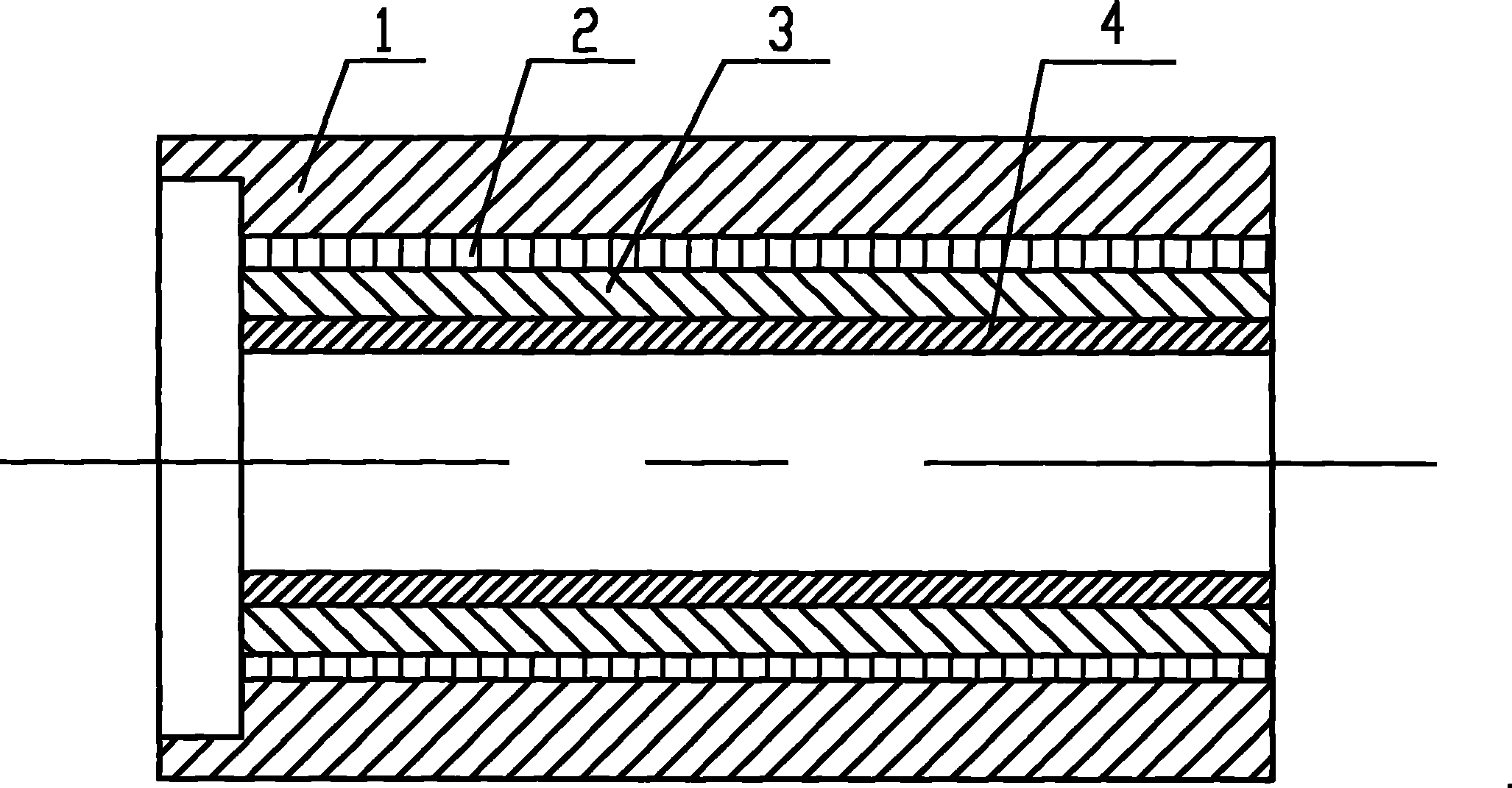

Image

Examples

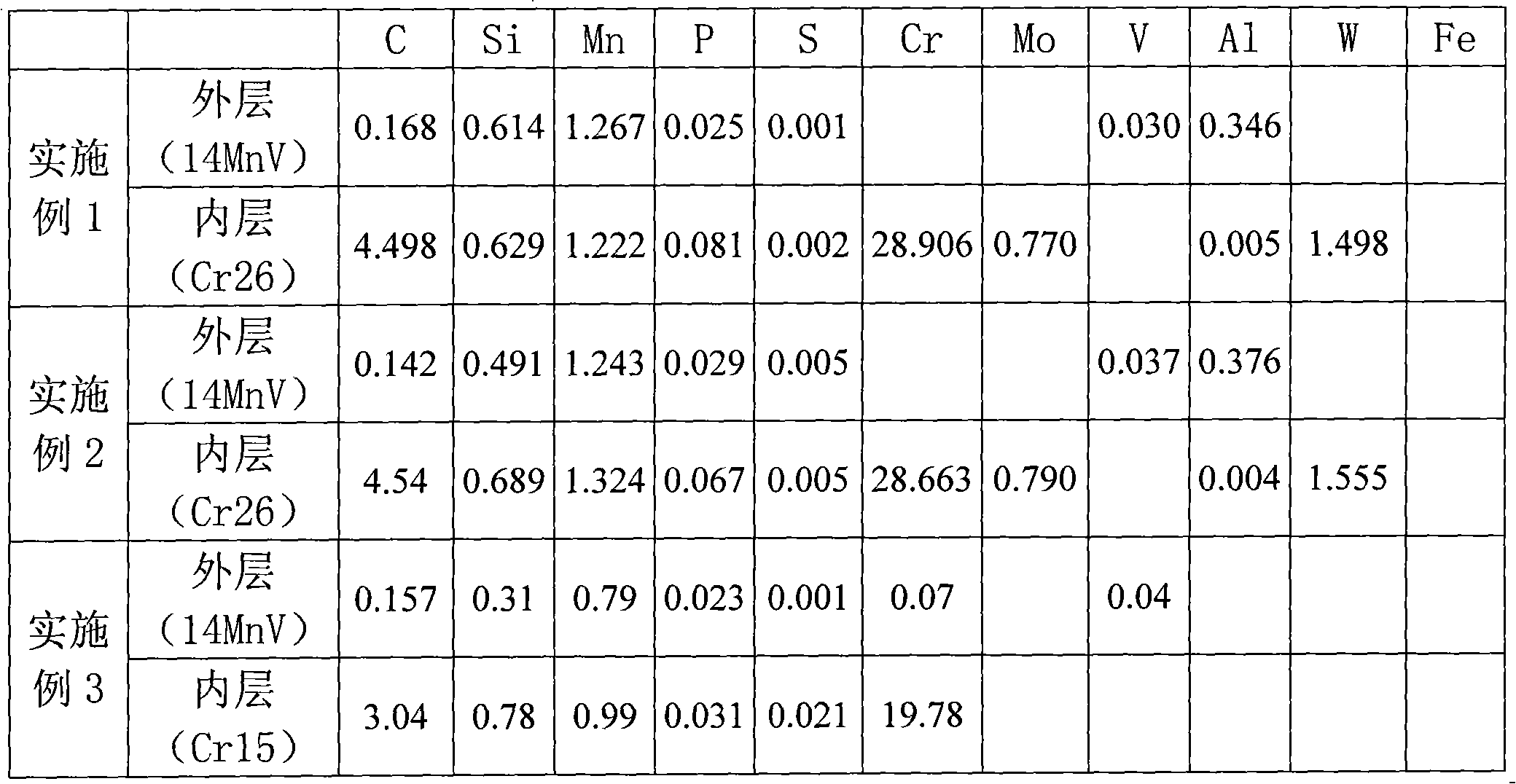

Embodiment 1

[0020] Example 1 (tube blank specification Φ617[outer diameter]×Φ589[medial diameter]×Φ563[inner diameter]×3100mm)

[0021] (1) After the metal pipe mold 1 is baked to 270°C, the water-based zirconium powder coating is sprayed with a thickness of 2.4 mm; the composition of the water-based zirconium powder coating should satisfy (ratio by weight): (zirconium) English powder: polyaluminum chloride: bentonite: water: active agent [washing powder or sodium sulfonate] = 100: 5-8: 12-15: 50: 0.5-0.8)

[0022] (2) After spraying, bake the metal pipe mold to 280°C and centrifugally pour the outer metal liquid. The pouring weight is 710kg, and the pouring temperature is 1610°C. Melting point mold flux, the composition of low melting point mold flux is (in percent by weight): CaO: 34.1%; SiO 2 : 29.8%; Al 2 o 3 : 2.51%; CaF 2 : 7.94%; Na2O: 14.57%; MgO: 2.51%; BaO: 8.57%;

[0023] (3) When the temperature of the inner surface of the outer layer is cooled to 50-60°C lower than the m...

Embodiment 2

[0024] Example 2 (tube blank specification Φ617[outer diameter]×Φ571[middle diameter]×Φ537[inner diameter]×3100mm)

[0025] (1) After baking the metal pipe mold to 285°C, spray water-based zircon powder coating with a thickness of 2.1 mm; the composition of water-based zircon powder coating should satisfy (ratio by weight): (zircon powder: polyaluminum chloride: bentonite: water: active agent [washing powder or sodium sulfonate]=100:5-8:12-15:50:0.5-0.8).

[0026] (2) After spraying, bake the metal pipe mold to 295°C and centrifugally pour the outer metal liquid. The pouring weight is 1036kg, and the pouring temperature is 1587°C. Melting point mold flux, low melting point mold flux consists of (weight percentage): CaO: 34.1%; SiO 2 : 29.8%; Al 2 O3: 2.51%; CaF 2 : 7.94%; Na 2 O: 14.57%; MgO: 2.51%; BaO: 8.57%.

[0027] (3) When the temperature of the inner surface of the outer layer is cooled to 110-120°C lower than the melting point of the outer layer of molten metal, s...

Embodiment 3

[0028] Example 3 (tube blank specification Φ222[outer diameter]×Φ193[medial diameter]×Φ184[inner diameter]×2100mm)

[0029] (1) After baking the metal pipe mold to 280°C, spray water-based zircon powder coating with a thickness of 1.3 mm; the composition of water-based zircon powder coating should satisfy (ratio by weight): (zircon powder: polyaluminum chloride: bentonite: water: active agent [washing powder or sodium sulfonate]=100:5-8:12-15:50:0.5-0.8).

[0030](2) After spraying, bake the metal pipe mold to 310°C and centrifugally pour the outer metal liquid. The pouring weight is 230kg, and the pouring temperature is 1644°C. Cool after pouring. Melting point mold flux, low melting point mold flux consists of (weight percentage): CaO: 34.1%; SiO 2 : 29.8%; Al 2 o 3 : 2.51%; CaF2: 7.94%; Na 2 O: 14.57%; MgO: 2.51%; BaO: 8.57%.

[0031] (3) When the temperature of the inner surface of the outer layer is cooled to 50-60°C lower than the melting point of the outer layer of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com