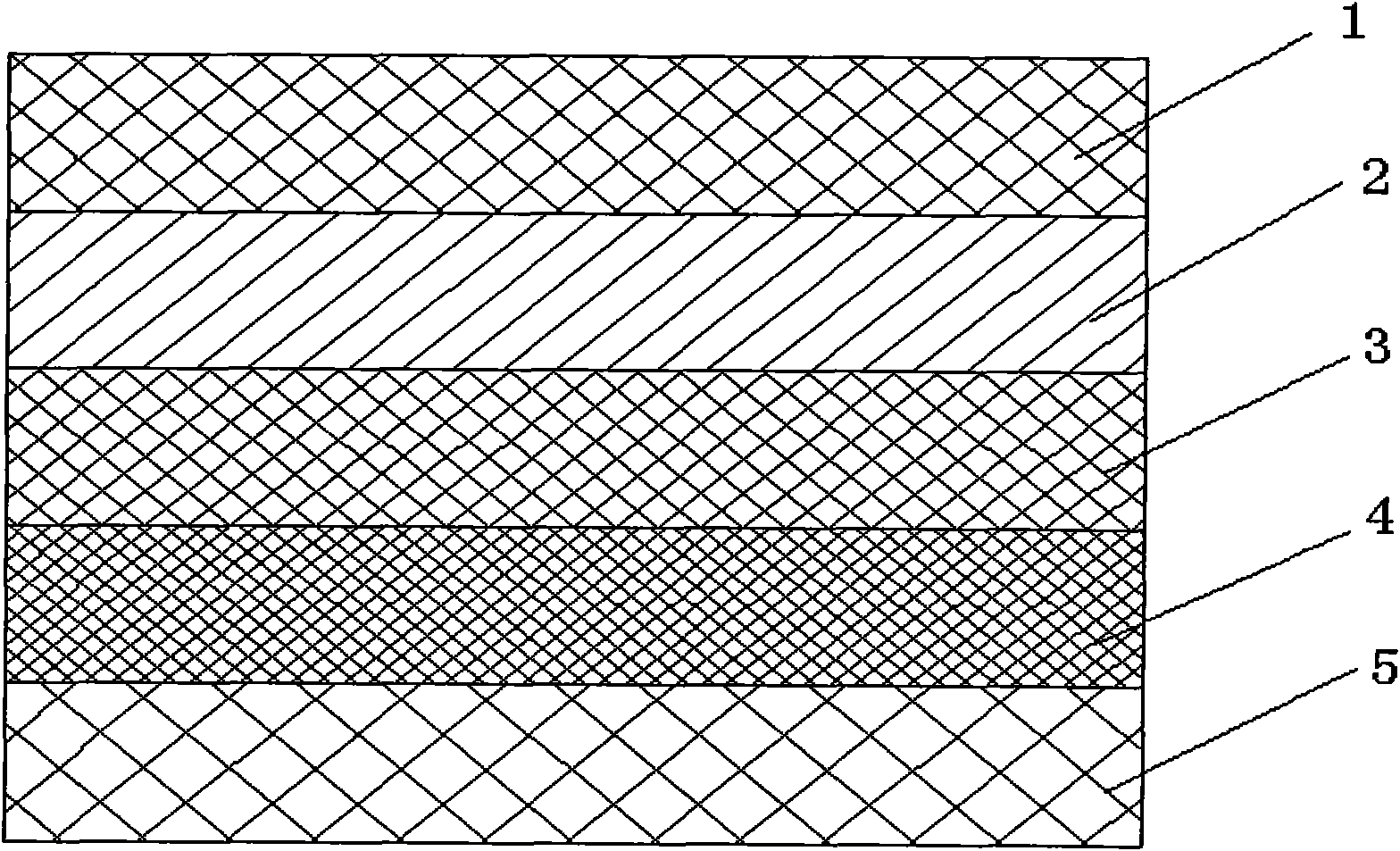

Composite membrane for sauce and preparation method thereof

A composite film and sauce technology, applied in chemical instruments and methods, synthetic resin layered products, flexible coverings, etc. Heat sealing effect, good anti-pollution performance, not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

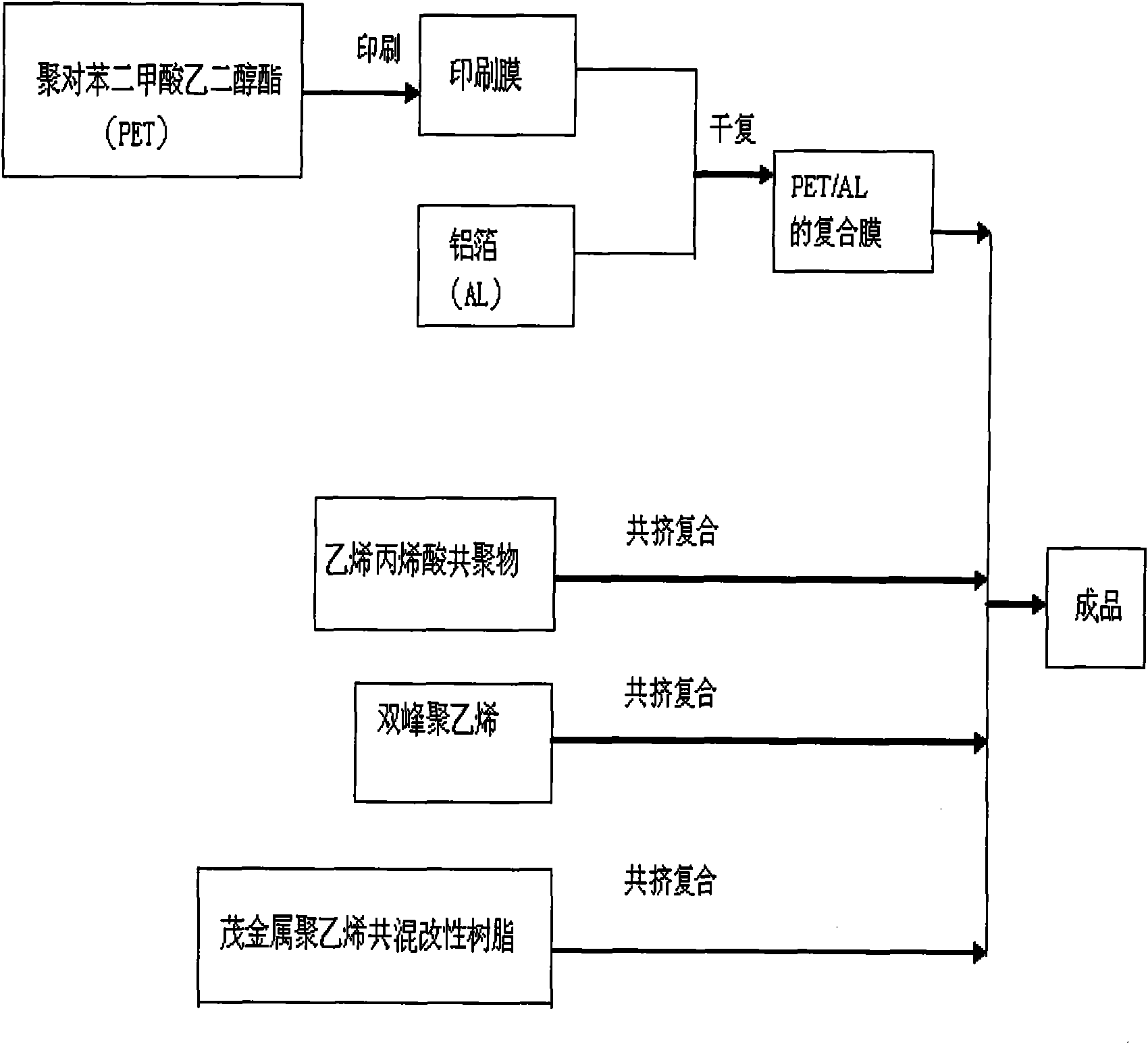

[0049] Composite film for seasoning sauce packaging, including the following processes:

[0050] 1. Dry compounding process: Print on polyethylene terephthalate (PET) film; dry compound the PET film and AL to form a PET / AL composite film, and the composite adhesive is two-component polyurethane Adhesive, the manufacturer is Henkel, Germany, the brand is UK3640;

[0051] 2. The preparation process of the metallocene polyethylene blended modified resin layer is as follows: the pellets of each layer are mixed and blown according to the following ratio;

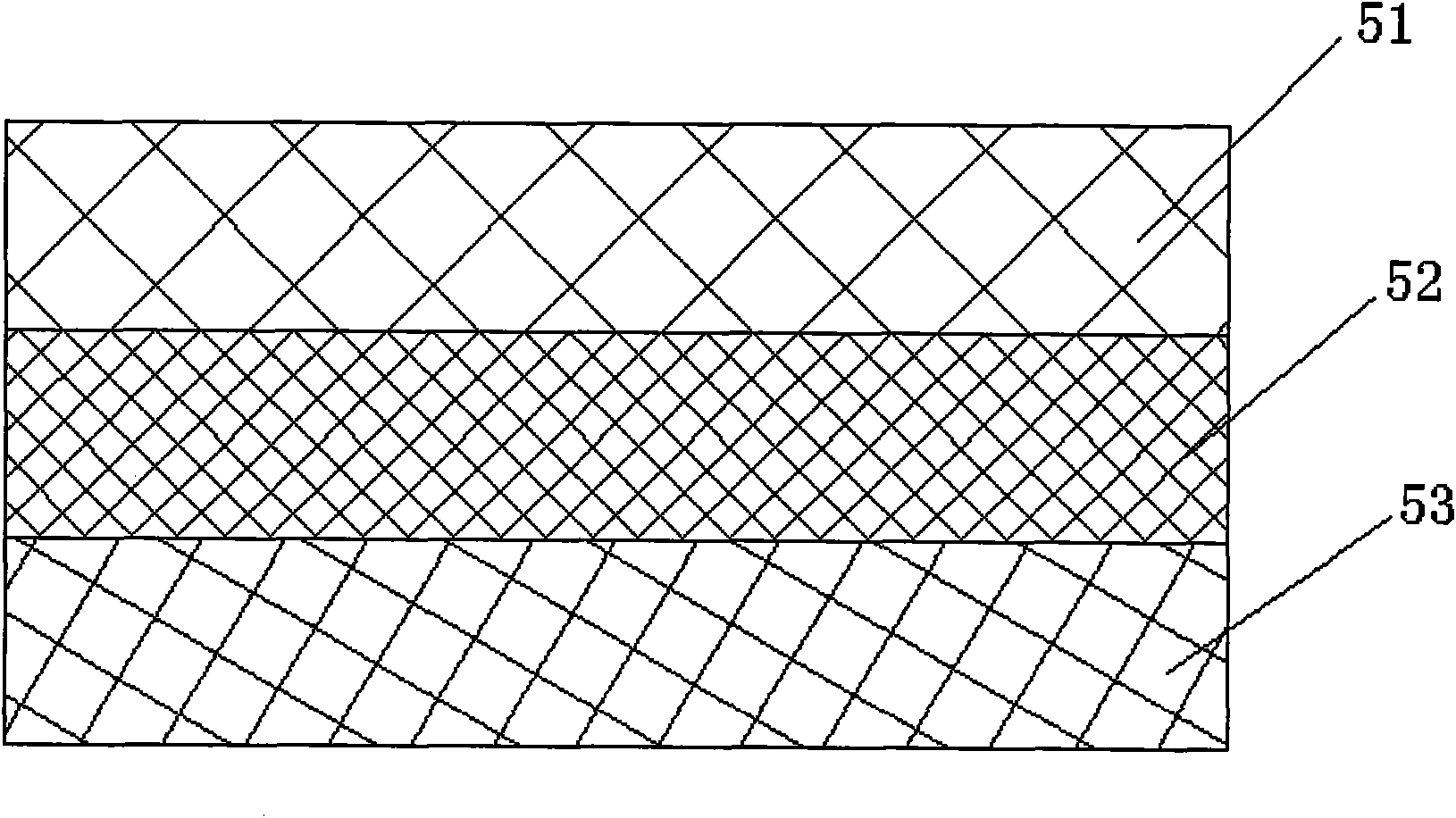

[0052] The proportion of the outer layer 51 is: 50Kg low-density polyethylene (TN00)+50Kg linear low-density polyethylene (7042); the thickness of the outer layer is 7 μm.

[0053] The proportion of the middle layer 52 is: 50Kg low density polyethylene (Q281)+50Kg metallocene polyethylene (1881)+25Kg medium density polyethylene (SP4020), the thickness of the middle layer is 8 μm.

[0054] The proportion of the inner layer 53 is...

Embodiment 2

[0058] Except that the thickness of the EAA layer 3 is 15 μm and the thickness of the SPPE layer 4 is 12 μm, the rest is the same as that of the embodiment 1.

Embodiment 3

[0060] Except that the thickness of the EAA layer 3 is 20 μm, and the thickness of the SPPE layer 4 is 18 μm, the rest is the same as that of the embodiment 1.

[0061] The technical index of embodiment 1-3 is as shown in table 6:

[0062] Table 6:

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com