Patents

Literature

379results about How to "Good heat sealing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the production of propylene terpolymers

InactiveUS6365682B1Excellent heat sealing propertyGood heat sealing performanceChemical/physical/physico-chemical stationary reactorsOlefin polymerizationChemistry

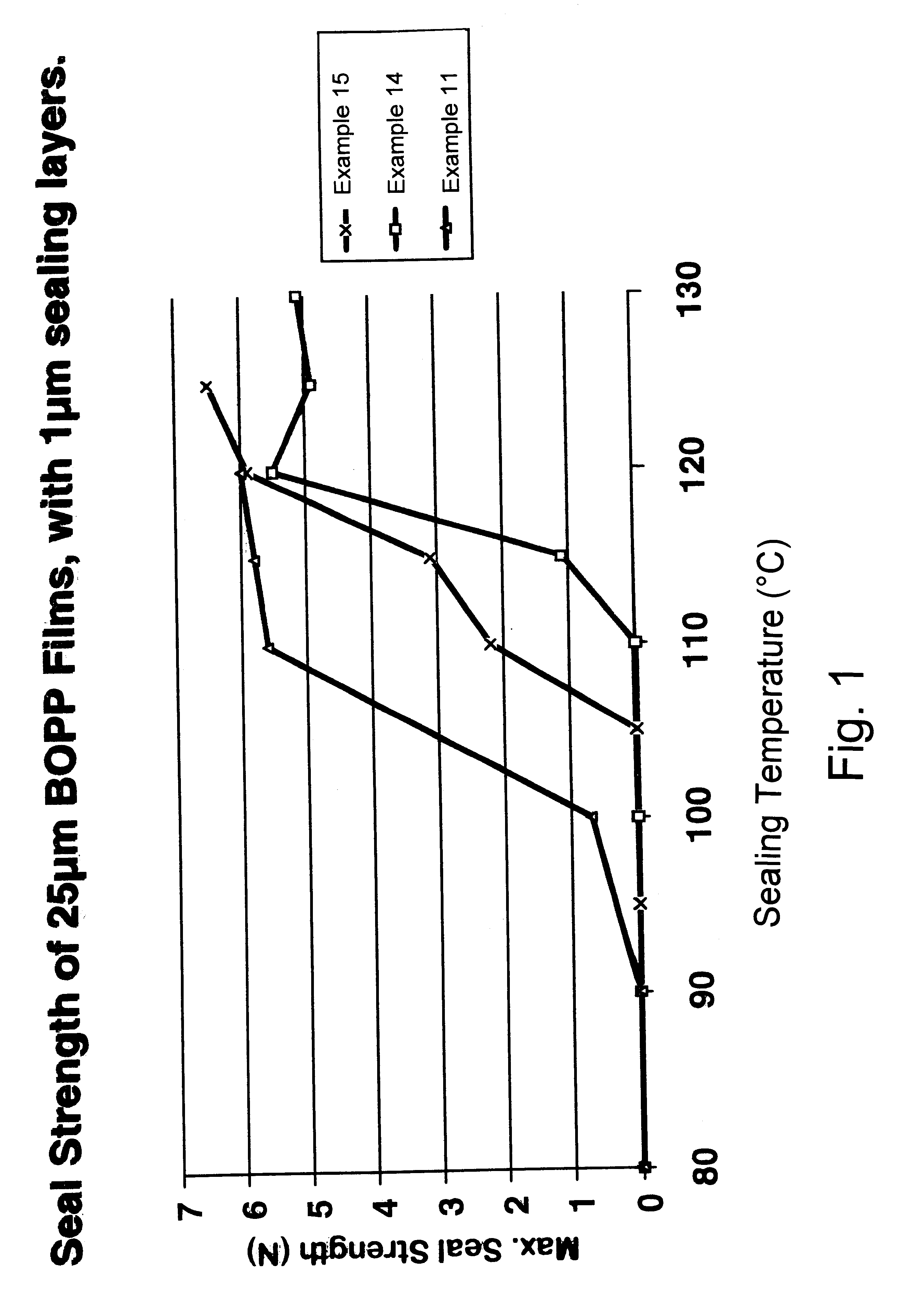

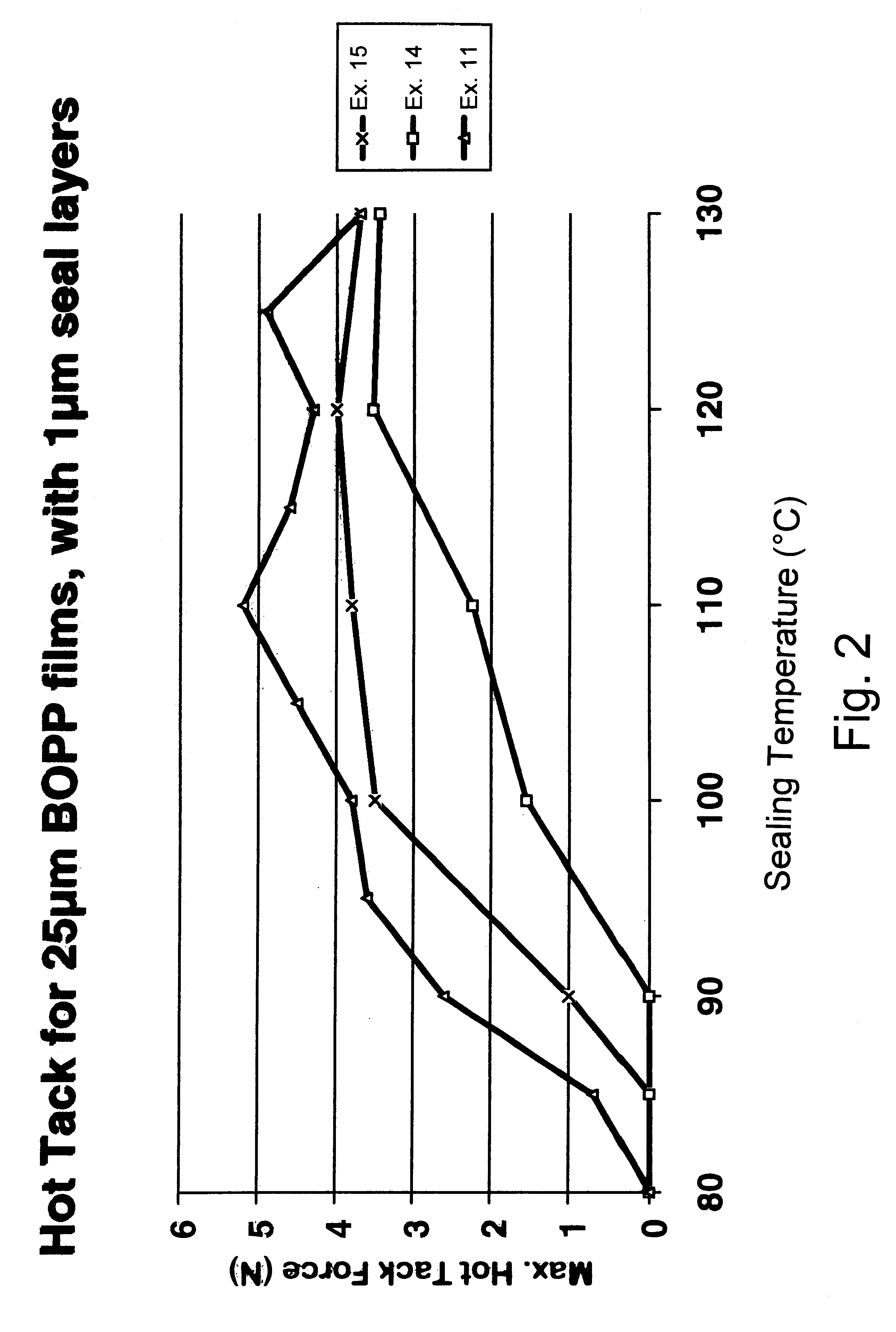

A process for producing terpolymers of propylene, comprising a) feeding into a slurry reactor a reaction mixture containing 50-85 w-% of propylene, 1-10 w-% of ethylene, 15-40 w-% of another C.sub.4 -C.sub.8 alpha-olefin, a catalyst system maintaining olefin polymerization at said temperature conditions, and optionally hydrogen, b) polymerizing said reaction mixture at a temperature of lower than 70.degree. C. a sufficient time to obtain a propylene terpolymer amounting to 50-99 w-% of the end product, c) transferring said reaction mixture into a gas phase reactor operating at a pressure of higher than 5 bars, preferably higher than 10 bars, optionally adding 0-30 w-% of ethylene, 0-10 w-% of another C.sub.4 -C.sub.8 alpha-olefin, 0-40 w-% of propylene and optionally hydrogen, and d) continuing polymerization in said gas phase reactor for obtaining a propylene terpolymer amounting to 1-50 wt-% of the end product. The terpolymer has a melting temperature a less than 135.degree. C., preferably less than 132.degree. C., and it can be used for manufacturing films having good sealing properties.

Owner:BOREALIS TECH OY

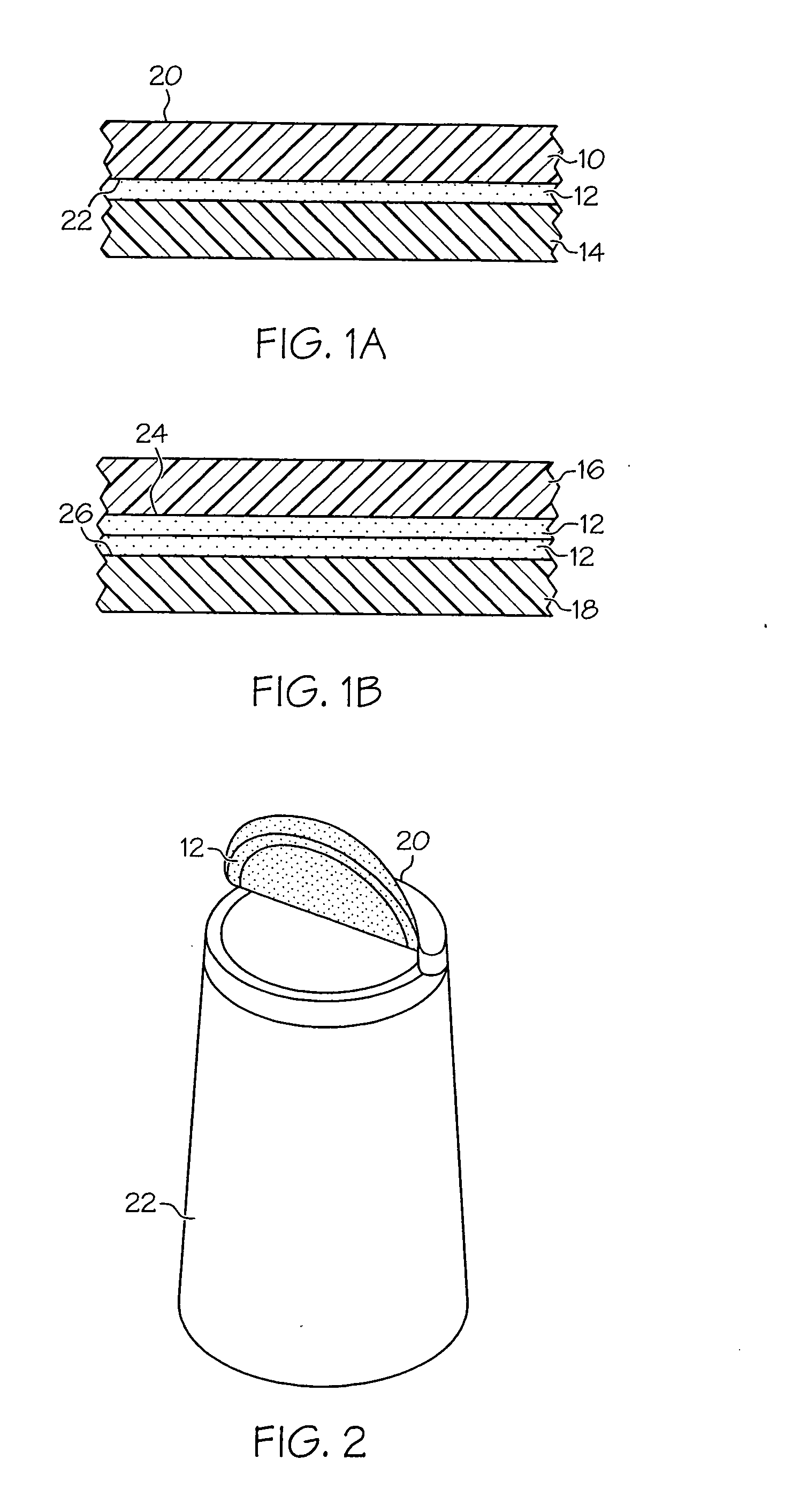

Heat sealable biaxially oriented polypropylene film

InactiveUS20050142367A1Low sealing temperatureSeal contaminationSynthetic resin layered productsDomestic containersButenePolyolefin

A polyolefin multilayer film comprising (a) a polyolefinic core layer and (b) at least one skin layer adjacent to the care layer comprising about 30%-90% by weight of a propylene-ethylene-butene terpolymer and about 10%-70% by weight of a metallocene catalyzed polyethylene or a metallocene catalyzed ethylene copolymer is disclosed. Preferably, a propylene-ethylene-butene terpolymer-containing component and a metallocene catalyzed polyethylene-containing component or a metallocene catalyzed ethylene copolymer-containing component are in distinct separate phases in an incompatible blend of the propylene-ethylene-butene terpolymer-containing component and the metallocene catalyzed polyethylene-containing component or the metallocene catalyzed ethylene copolymer-containing component.

Owner:TORAY PLASTICS AMERICA

Edible starch-based food packaging film and preparation method thereof

ActiveCN101899173AAvoid environmental pollutionAbundant sources of raw materialsFlexible coversWrappersFood packagingPlasticizer

The invention relates to an edible starch-based food packaging film and a preparation method thereof. The edible starch-based packaging film with high mechanical strength, barrier property, ageing resistance and heat sealability is prepared from a main film-forming raw material stabilized crosslinking compound modified starch, and auxiliary materials such as food grade plasticizers, lubricants, reinforcers, stabilizers and the like through high speed stirring and mixing, twin-screw extrusion granulation and single-screw extrusion blow molding. The preparation method has the characteristics of low energy consumption, high production efficiency and suitability for continuous industrialized production. The film has the advantages of edibility, full-degradable property, wide application for inner packaging of foods and no environmental pollution caused by non-degradable food packages.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Halogen-free flame-retardant acrylonitrile butadiene styrene (ABS)/polycarbonate (PC) alloy material for electrical engineering and preparation method thereof

InactiveCN102190854AMeet safety and environmental protection requirementsGood value for moneyAntioxidantPhosphate

The invention relates to a halogen-free flame-retardant acrylonitrile butadiene styrene (ABS) / polycarbonate (PC) alloy material for electrical engineering and a preparation method thereof. The halogen-free flame-retardant ABS / PC alloy material for electrical engineering comprises the following components in part by weight: 55 to 63 parts of ABS, 21 to 34 parts of PC, 2 to 7 parts of maleic anhydride grafted ABS compatilizer, 7 to 15 parts of organic phosphate flame retardant, 0.1 to 0.5 part of anti-dripping agent FA500B, 1.0 to 3.0 parts of organic silicon Dymgard and 0.2 to 0.5 part of composite antioxidant. In the preparation method, the halogen-free flame-retardant ABS / PC alloy material for electrical engineering is prepared by mixing, plastifying, extruding and pelleting at one step by using a double-single-screw double-step extruder. The comprehensive properties of the product can meet shell performance requirements of storage batteries special for subway engineering, electric locomotives and mobile stations.

Owner:HUNAN KEOCT MATERIALS

Biaxially oriented polylactic acid film with improved heat seal properties

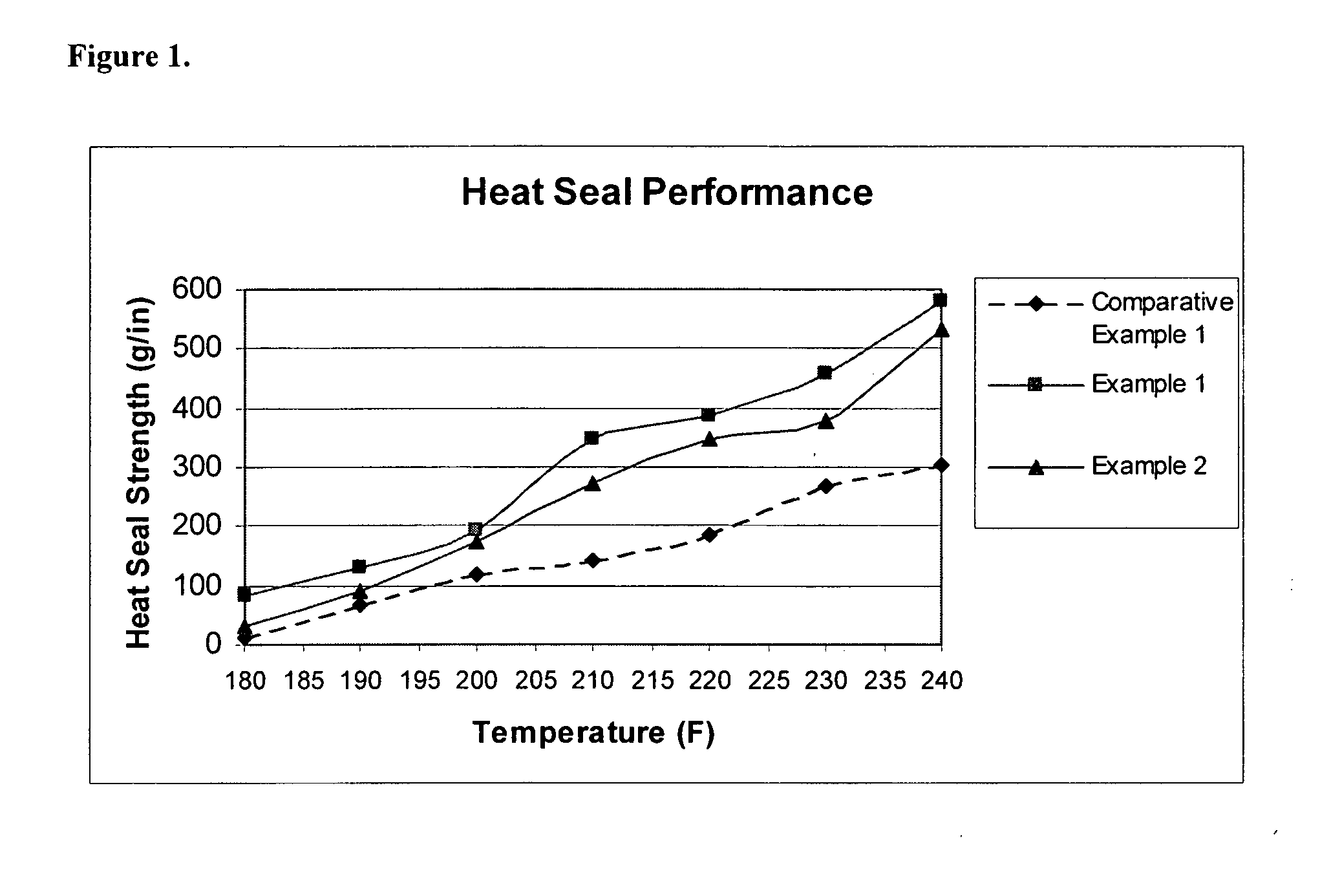

ActiveUS20100323196A1Lower heat seal initiation temperatureHeat seal rangeSynthetic resin layered productsLaminationPolybutylene adipate co-terephthalatePolylactic acid

Multi-layer biaxially oriented polylactic acid (BOPLA) film with a novel formulation improves the heat seal initiation temperature and heat seal performance of BOPLA films while maintaining good optical clarity. The film may include a core layer including polylactic acid base polymer resin, and a heat sealable layer including amorphous polylactic acid base polymer and a modifier comprising polycaprolactone or poly(butylene-adipate-co-butylene terephthalate).

Owner:TORAY PLASTICS AMERICA

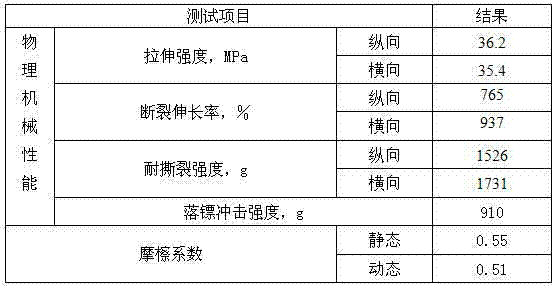

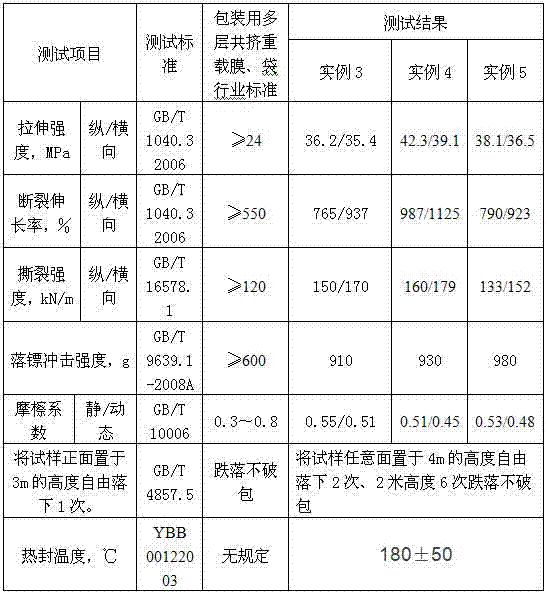

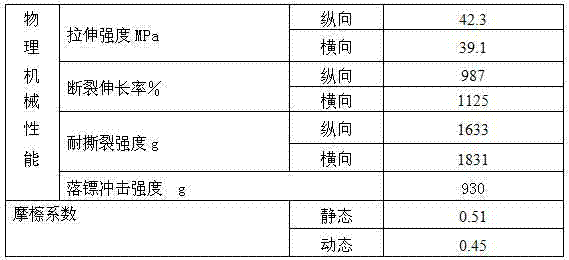

Three-layer coextrusion heavy packaging membrane and fabrication method thereof

The invention relates to the technical field of heavy packaging membranes, in particular to a three-layer coextrusion heavy packaging membrane and a fabrication method thereof. An inner layer of the three-layer coextrusion heavy packaging membrane contains LLDPE (linear low density polyethylene) and m-LLDPE (metallocene-linear low density polyethylene); a middle layer thereof contains m-LLDPE, LLDPE, MDPE (medium density polyethylene), EVA (ethylene-vinyl acetate) and a color masterbatch; and an outer layer thereof contains LLDPE, LDPE (low density polyethylene) and m-LLDPE. The fabrication method of the three-layer coextrusion heavy packaging membrane adopts the proportioning, and a product is fabricated on a certain technological condition. Compared with the prior art, the membrane has the characteristics that the membrane is excellent in mechanical property and good in deflexion; a skin-friction coefficient of the membrane is moderate; and a heat-seal window can reach 180 minus / plus 50 DEG C. The membrane can fully meet the requirement of normal use of downstream packaging, is particularly suitable for high-speed FFS (form-fill-seal) packaging, and has a good economic benefit and a social benefit.

Owner:GUANGDONG SUNION CHEM & PLASTIC

Ethylenic copolymer, composition containing said copolymer, and ethylenic copolymer film

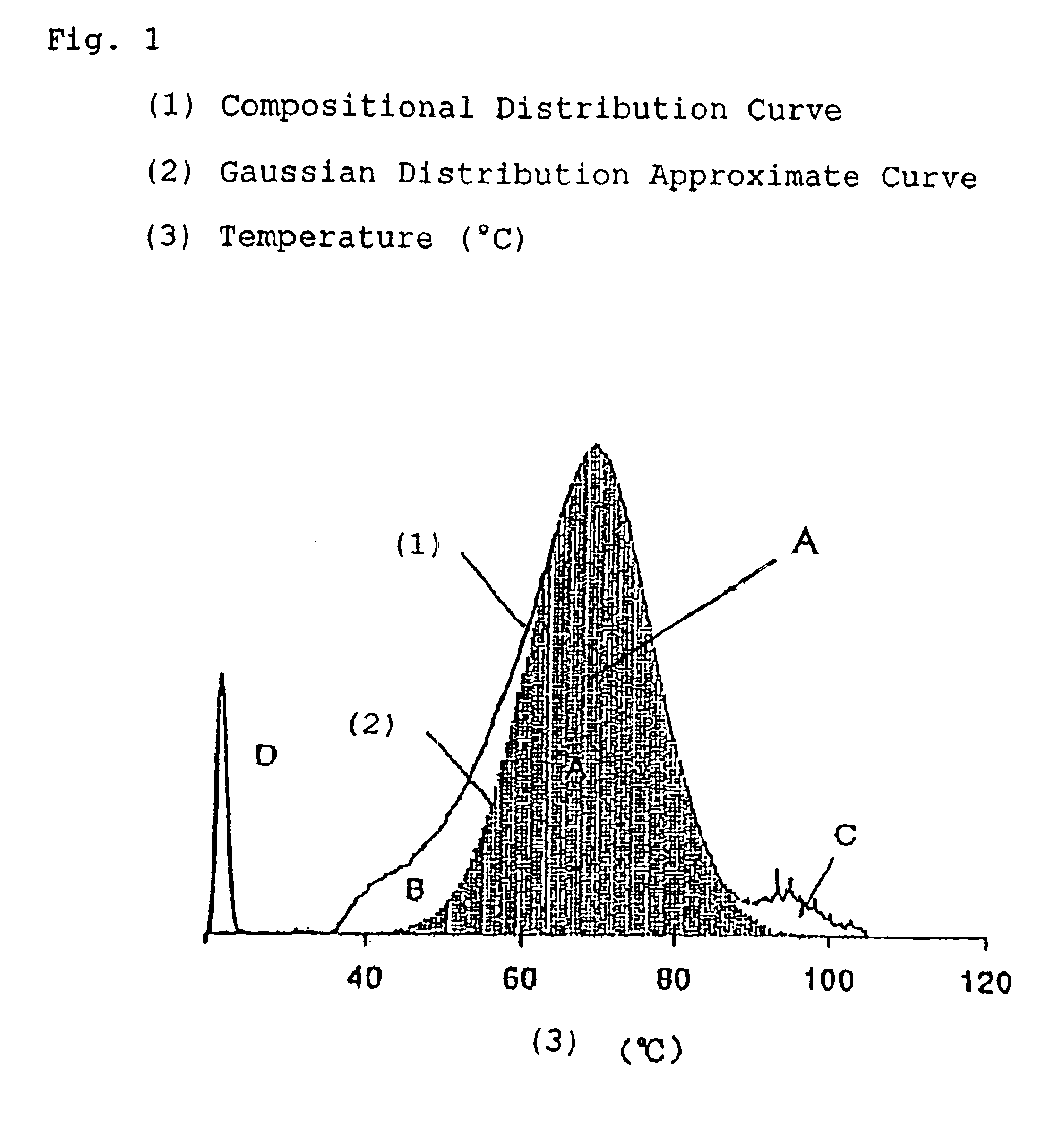

An ethylenic copolymer composition including an ethylenic copolymer having Mw / Mn of 1.5 to 4, Mw of 3,000 to 1,000,000, and a resin density of 0.85 to 0.95 g / cm3. The relationship between the half width at the half maximum [W / 2] of the Gaussian distribution curve, and the average, n, of short-chain branches in the copolymer satisfies the equation,0.704+0.147n=W / 2=−0.055+0.577n. The ethylenic copolymer composition also includes an ethylenic copolymer having an Mw of 3,000 to 1,000,000 and a resin density of 0.85 to 0.95 g / cm3.

Owner:IDEMITSU KOSAN CO LTD

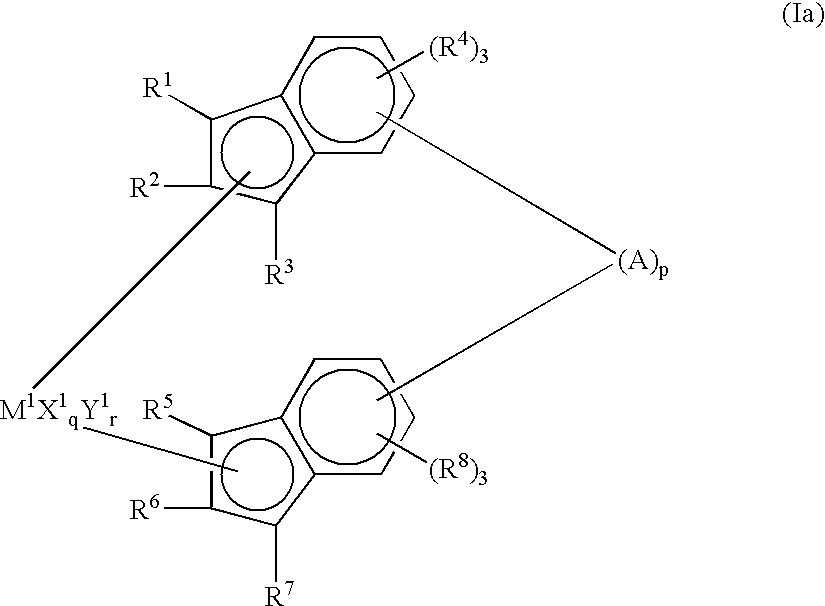

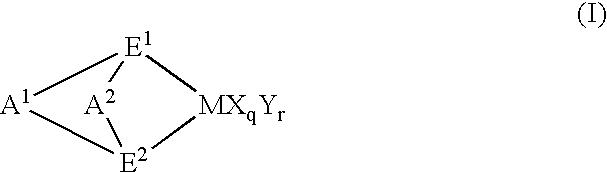

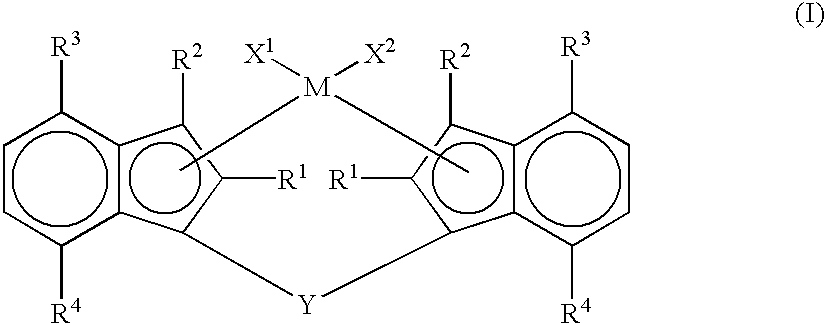

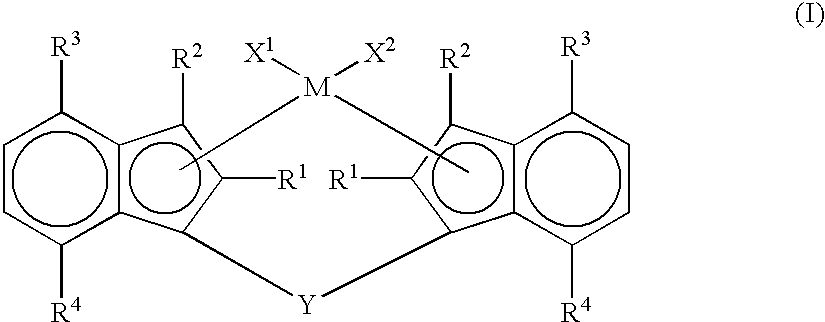

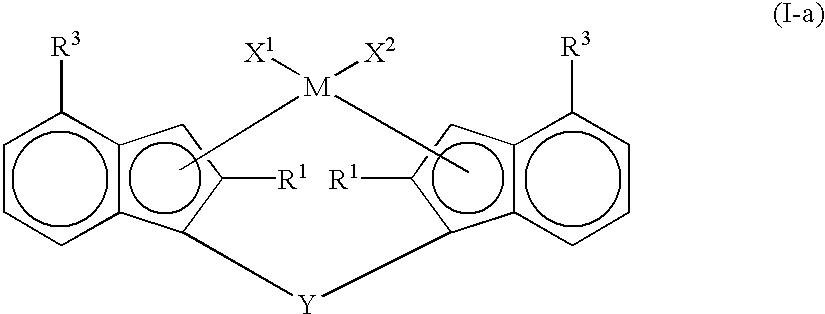

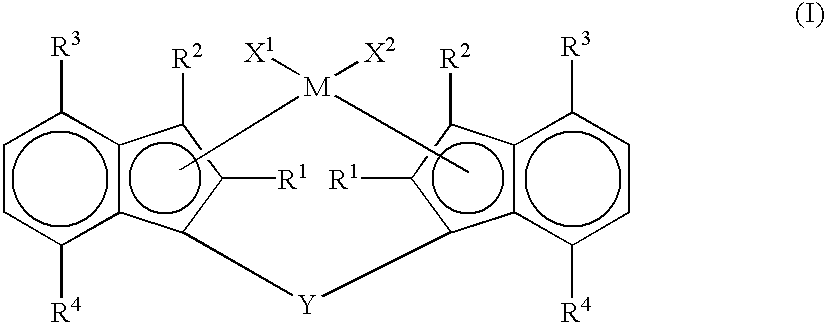

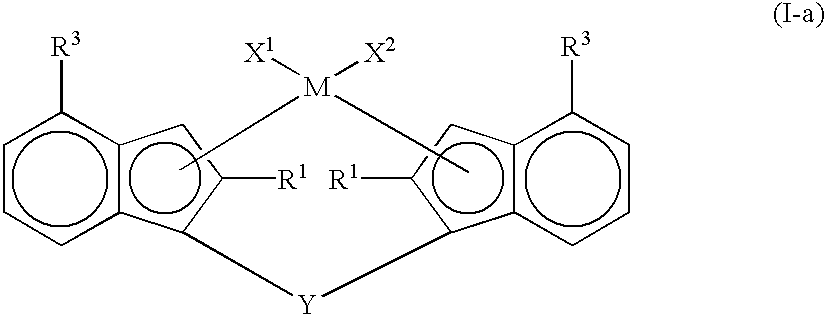

Propylene polymer and composition containing the same, molded object and laminate comprising these, and processes for producing propylene polymer and composition containing the same

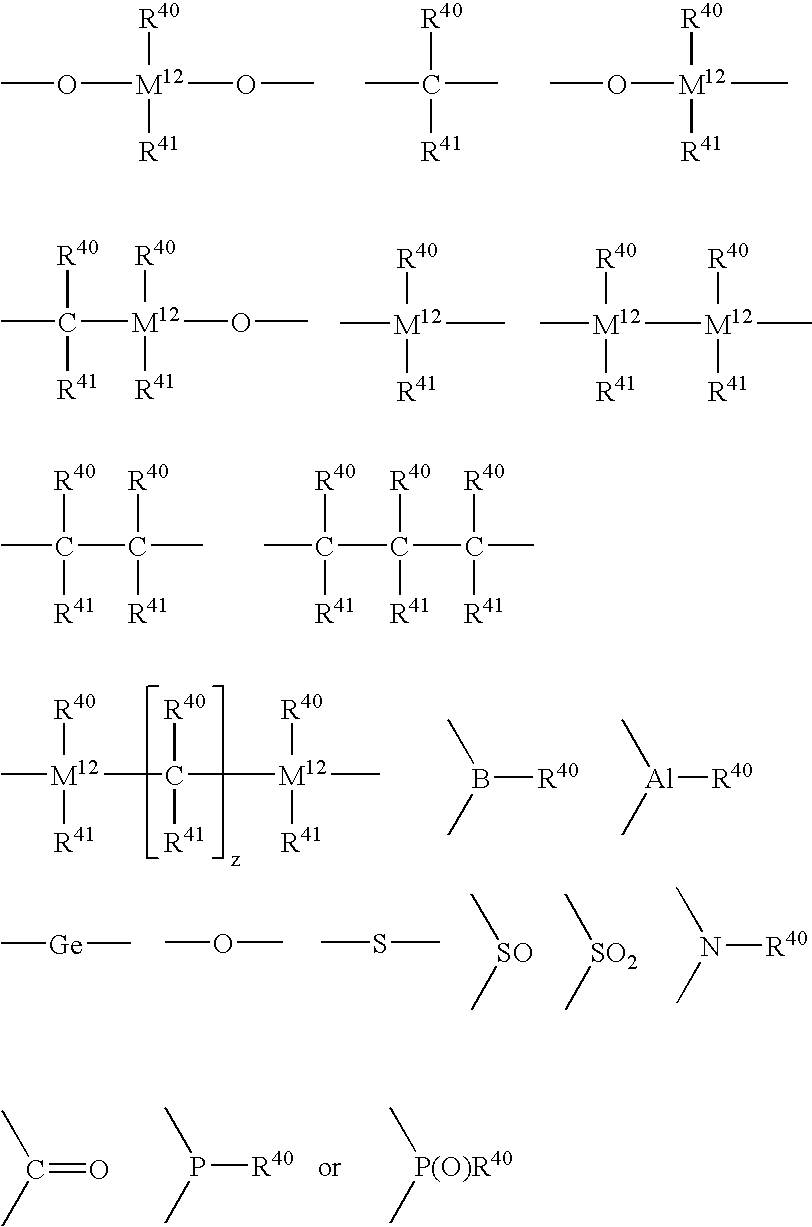

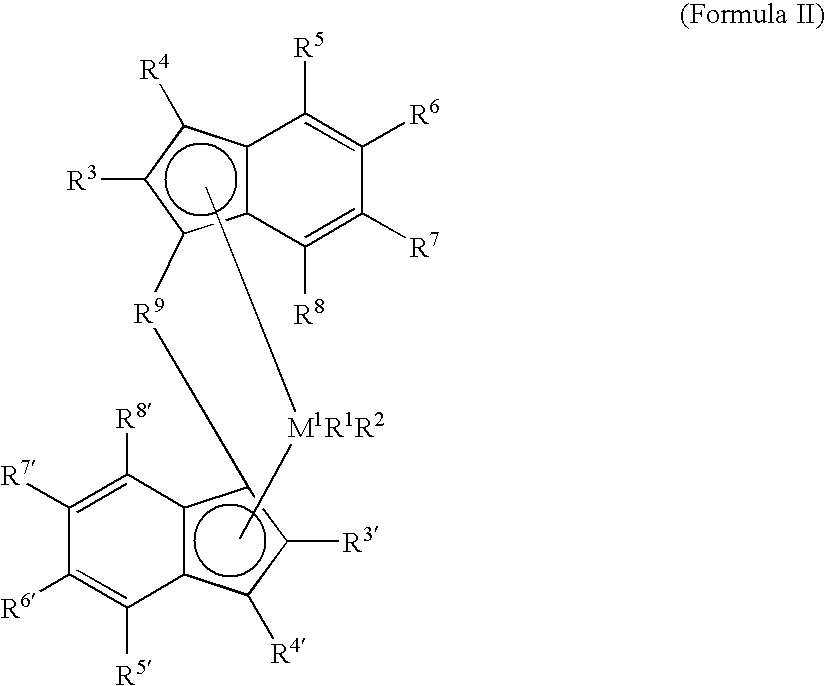

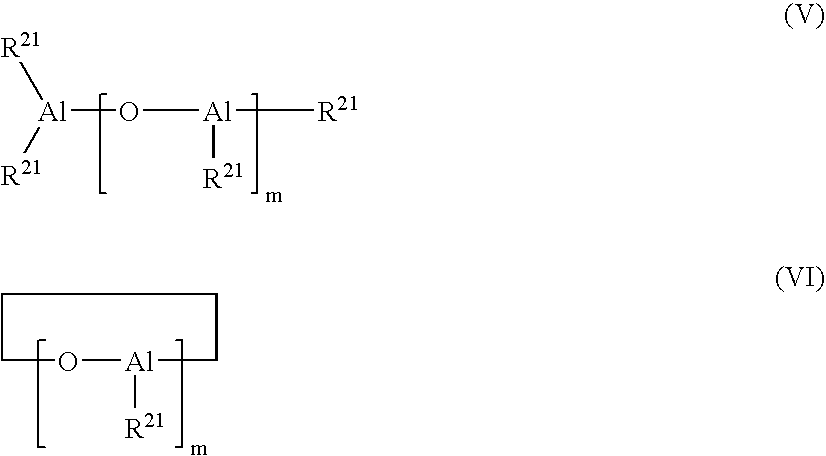

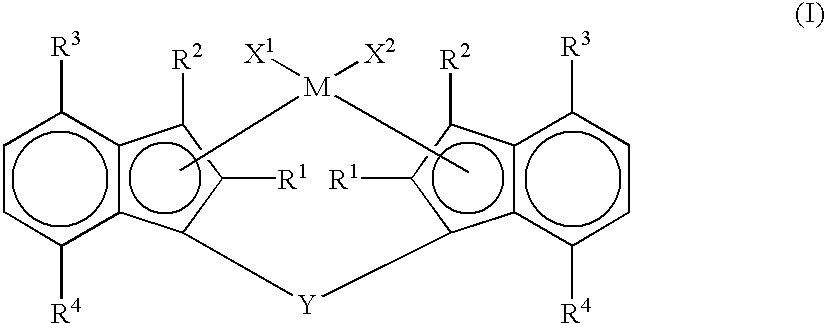

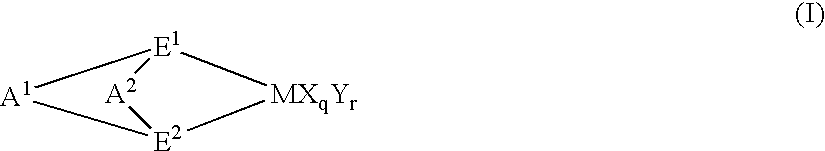

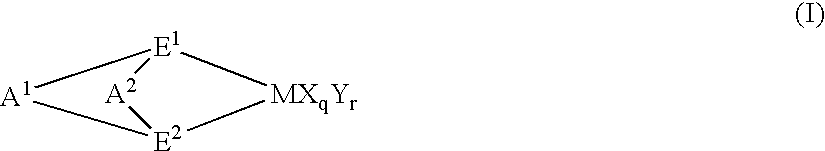

InactiveUS6906155B1Improve melt fluidityLess amountOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPliabilityPropylene Polymers

A propylenic polymer according to the present invention or a composition thereof have an excellent melt flowability and contains a less amount of stickiness-causing components, and also has a low modulus and is pliable, and is capable of providing a transparent molded article, thus being useful as a substitute for a pliable vinyl chloride resin. In addition, a molded article made therefrom exhibits an excellent heat seal performance at a low temperature, and is excellent in terms of transparency and rigidity. Specifically, it has an isotactic pentad fraction (mmmm), which indicates a stereoregulariry, of 30 to 80%, a molecular weight distribution (Mw / Mn) of 3.5 or less and an intrinsic viscosity [η] of 0.8 to 5 dl / g.

Owner:IDEMITSU KOSAN CO LTD

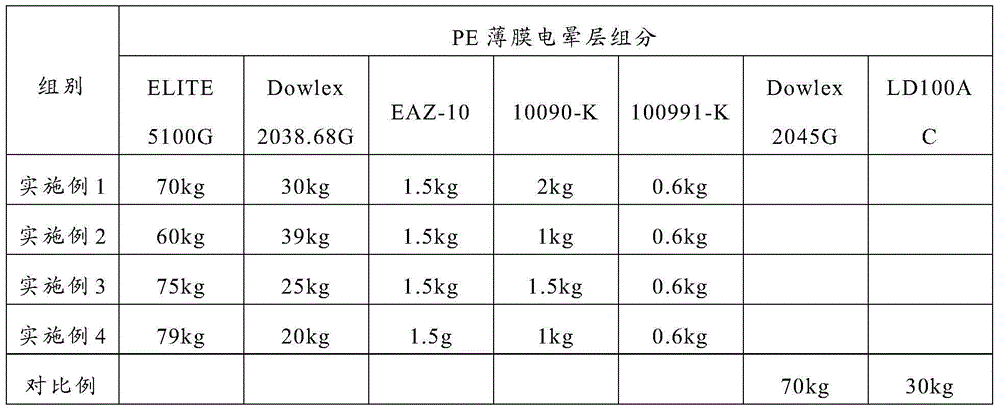

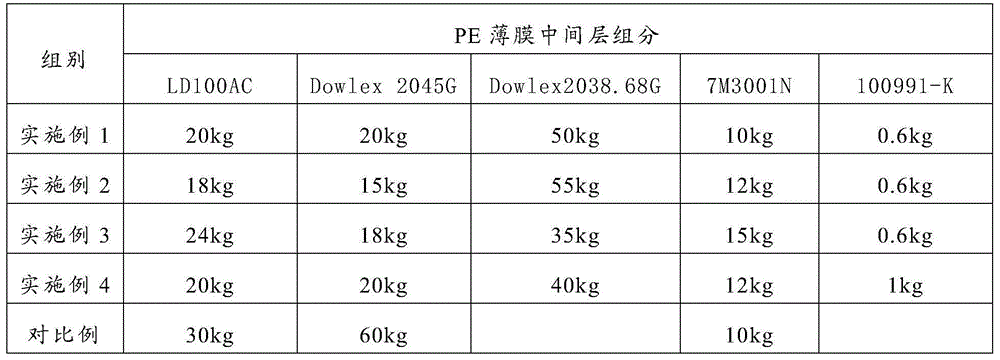

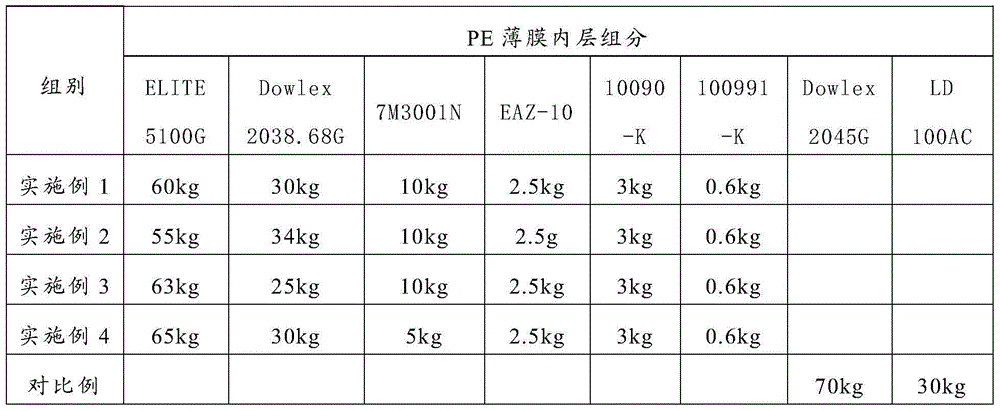

PE film and preparation method thereof

ActiveCN104476889AImprove stiffnessGood flexibilitySynthetic resin layered productsFlat articlesPliabilityMedium-density polyethylene

The invention provides a PE film which is formed by co-extruding a corona layer, a middle layer and an inner layer. The corona layer comprises metallocene linear low density polyethylene resin and medium density polyethylene resin. The middle layer comprises low density polyethylene resin, linear low density polyethylene resin and medium density polyethylene resin. The inner layer comprises metallocene linear low density polyethylene resin and medium density polyethylene resin. The corona layer and the inner layer each comprises the high-proportion metallocene linear low density polyethylene resin, so that the PE film has good heat sealing performance, and the medium density polyethylene resin added in the corona layer, the middle layer and the inner layer enable the film to have good stiffness and flexibility, and the PE film is suitable for package of hygienic products.

Owner:永新股份(黄山)包装有限公司

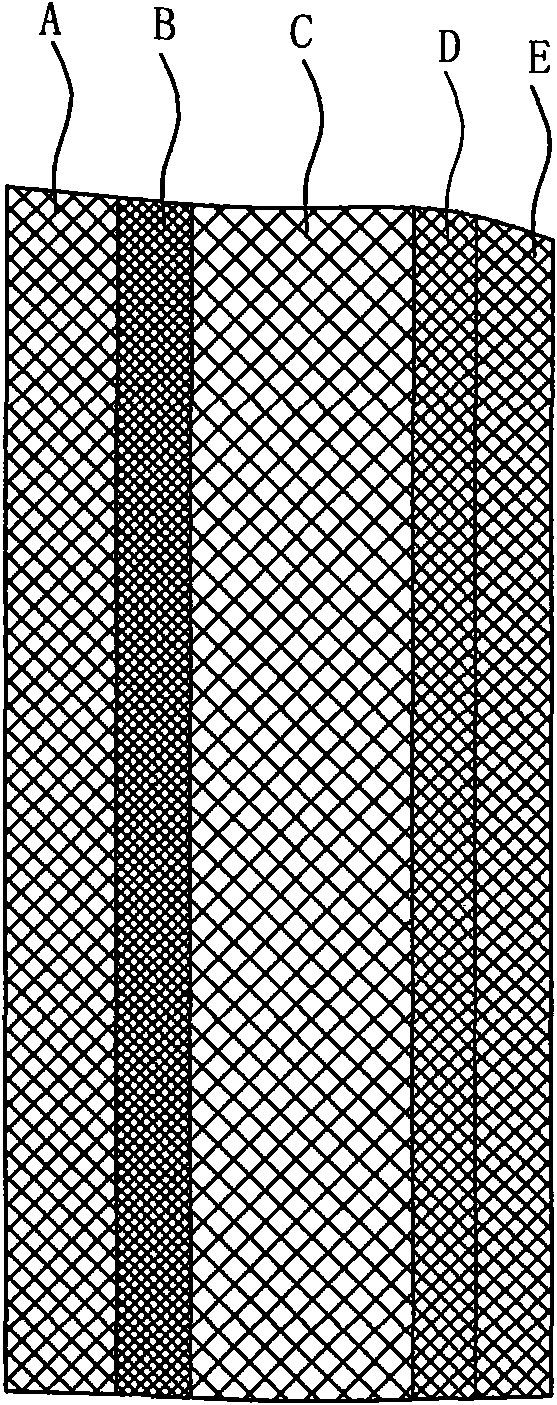

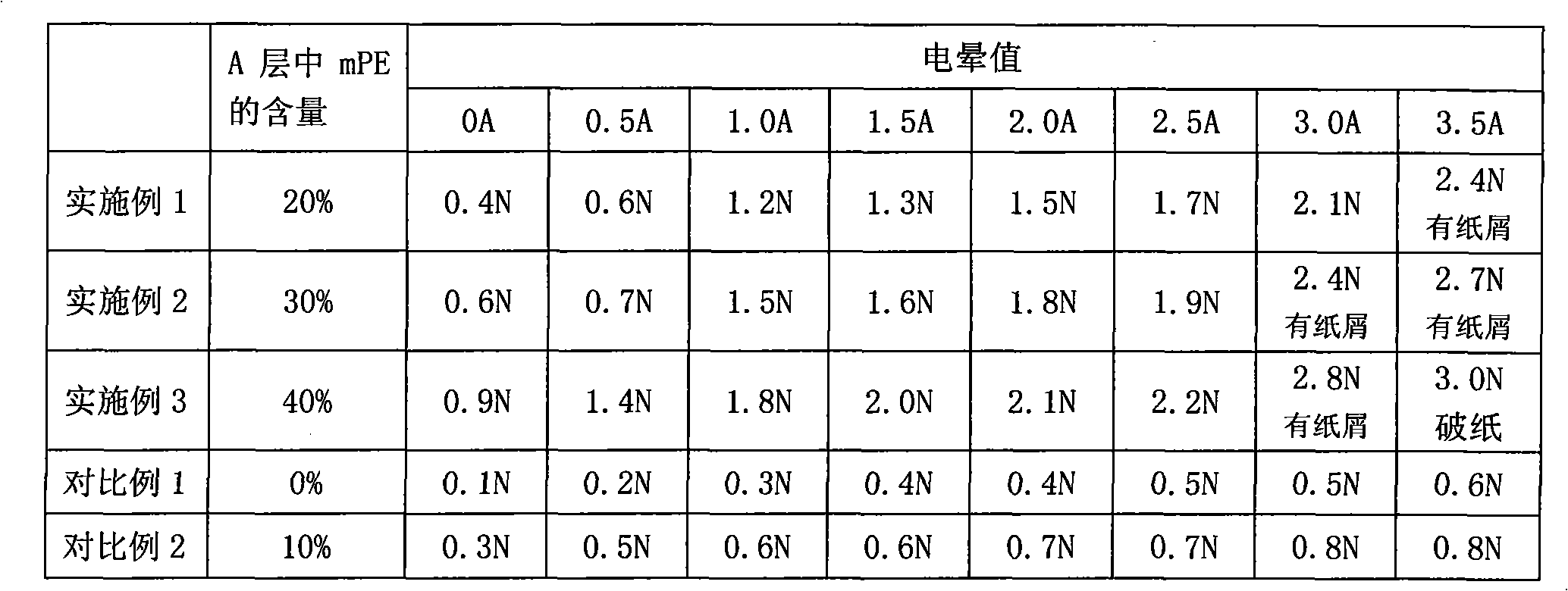

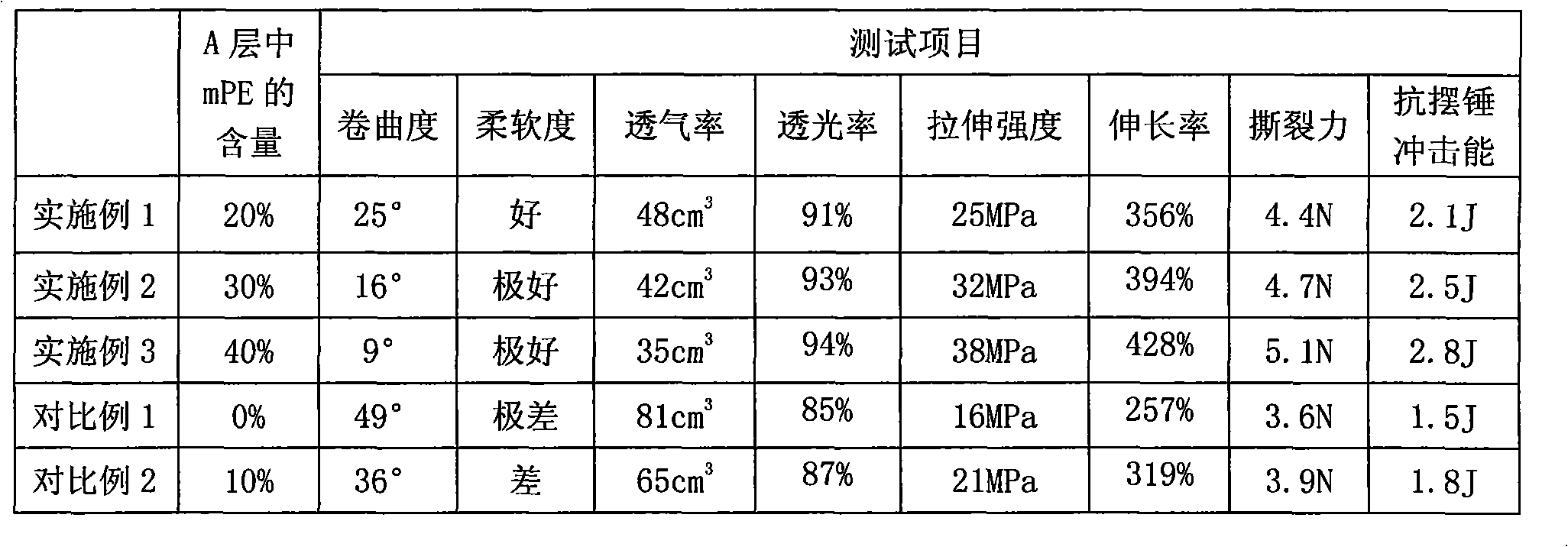

Film for suction plastic packaging of medical equipment and method for preparing same

InactiveCN101559854AGood heat sealing effectReduce production linksFlexible coversWrappersMaleic anhydrideMetal

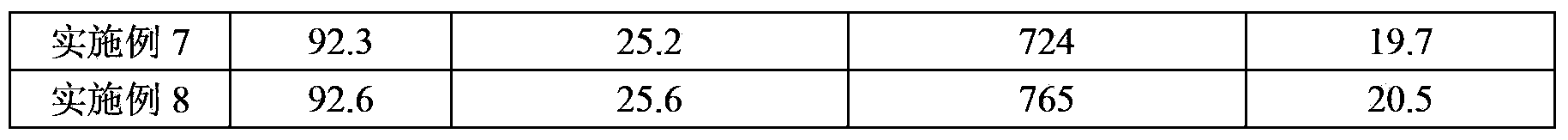

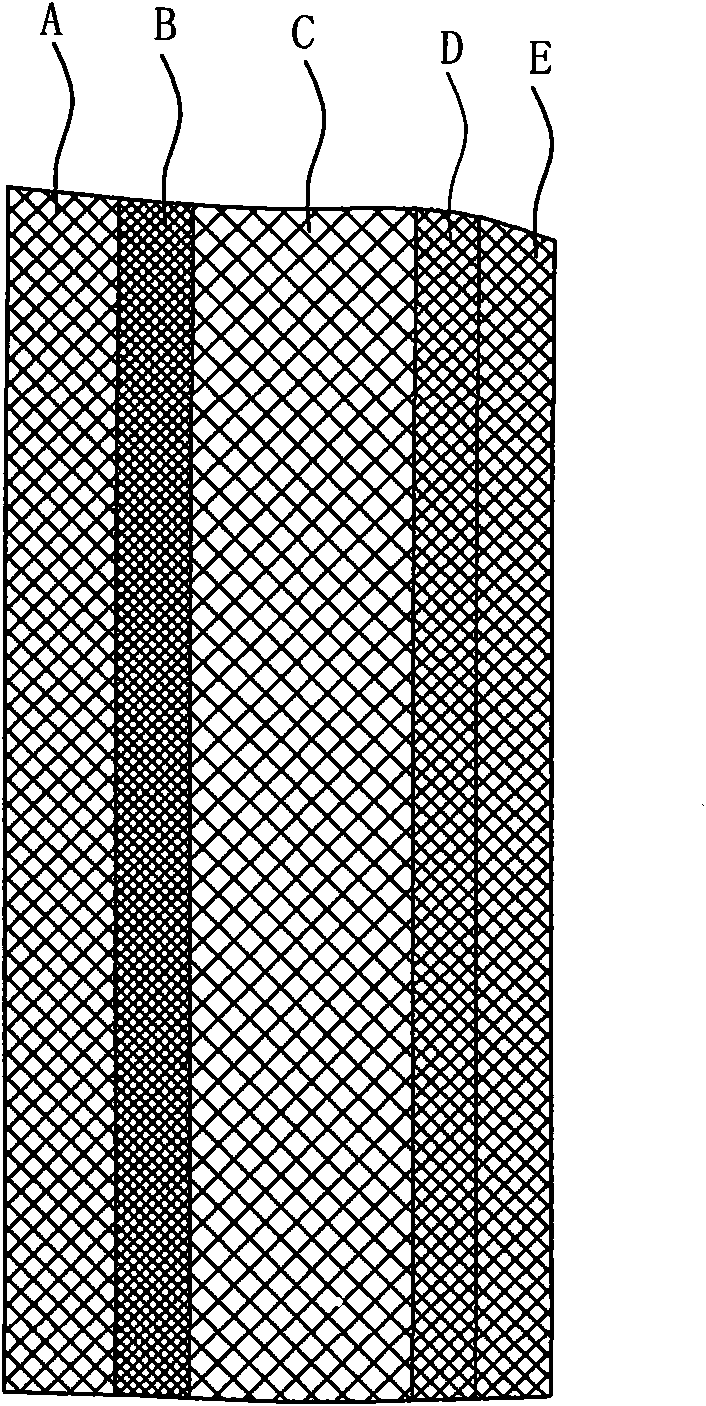

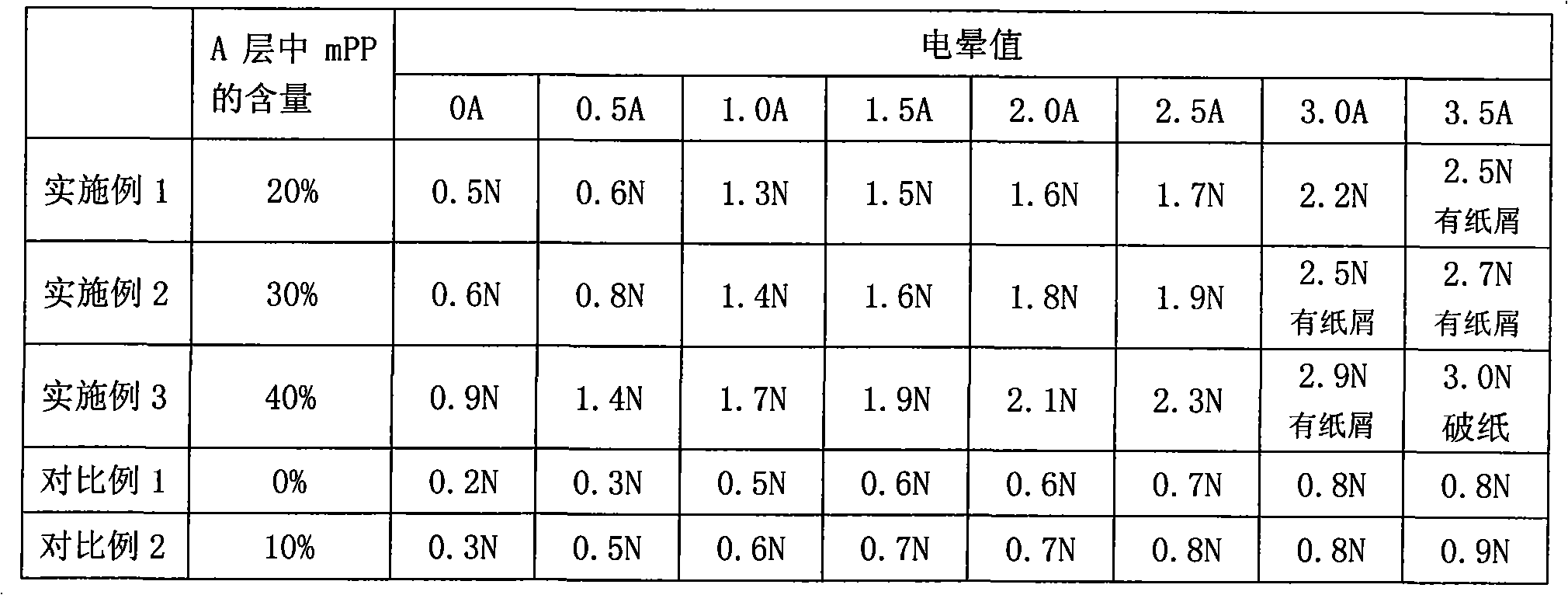

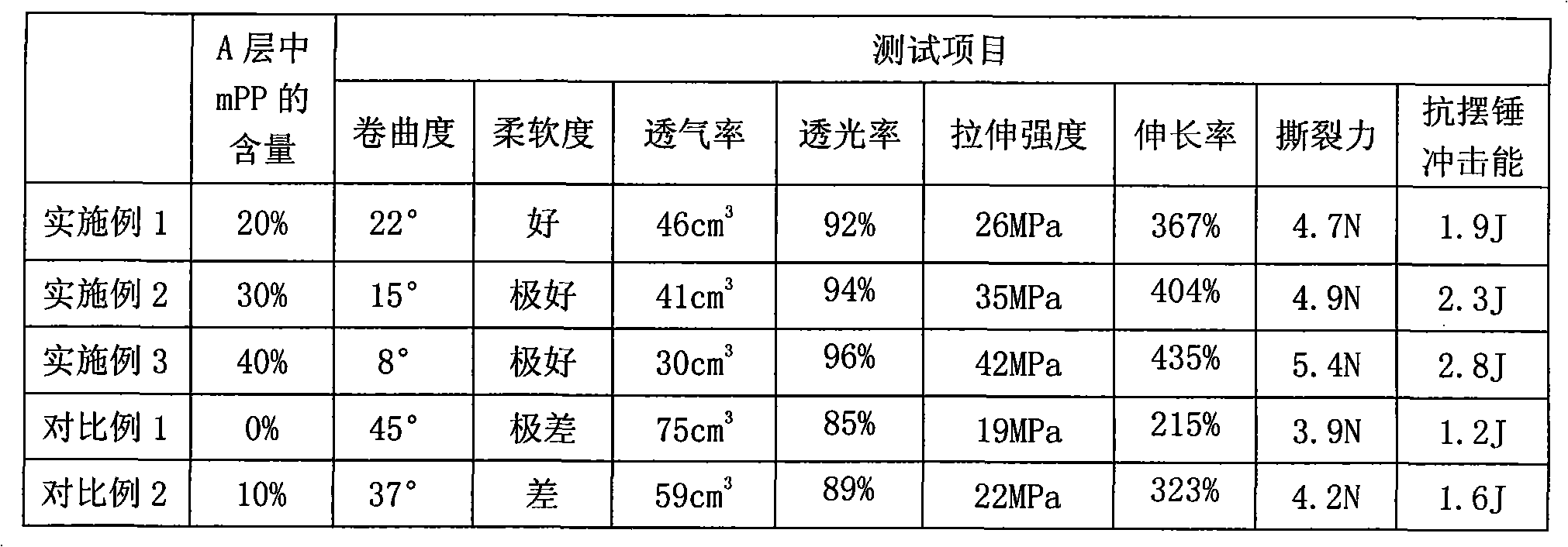

The invention relates to a film for suction plastic packaging of medical equipment and a method for preparing the same. The film adopts a five-layer structure; the first layer is a heat seal layer A, of which the component is co-mixing resin of linear low-density polyethylene and metallocene catalytic polyethylene taking octene as a comonomer, wherein the content of the metallocene catalytic polyethylene in the co-mixing resin is 20 to 40 weight percent; the second layer is an inner layer B, of which the component is linear low-density polyethylene containing a hexene comonomer; the third layer is a core layer, of which the component is linear low-density polyethylene containing a butene comonomer; the fourth layer is a bonding layer D, of which the component is maleic anhydride grafted polyethylene; and the fifth layer is a weathering resistant layer E, of which the component is nylon 6 or 66. The preparation method comprises the following steps that: the bottom blowing water cooling type co-extrusion process or flow casting method is adopted, and the plastics is subjected to fusion and die inflation or flow casting, and quick cooling at water temperature of between 15 and 18 DEG C. The film and the preparation method have the advantages that: the method is simple; the products have merits of various resins; the film can be thermally sealed with the dialyzing paper without glum spreading; and moreover, the method and the film also have the advantages of low film thickness, good comprehensive property and reutilization.

Owner:NINGBO HUAFENG PACKAGE

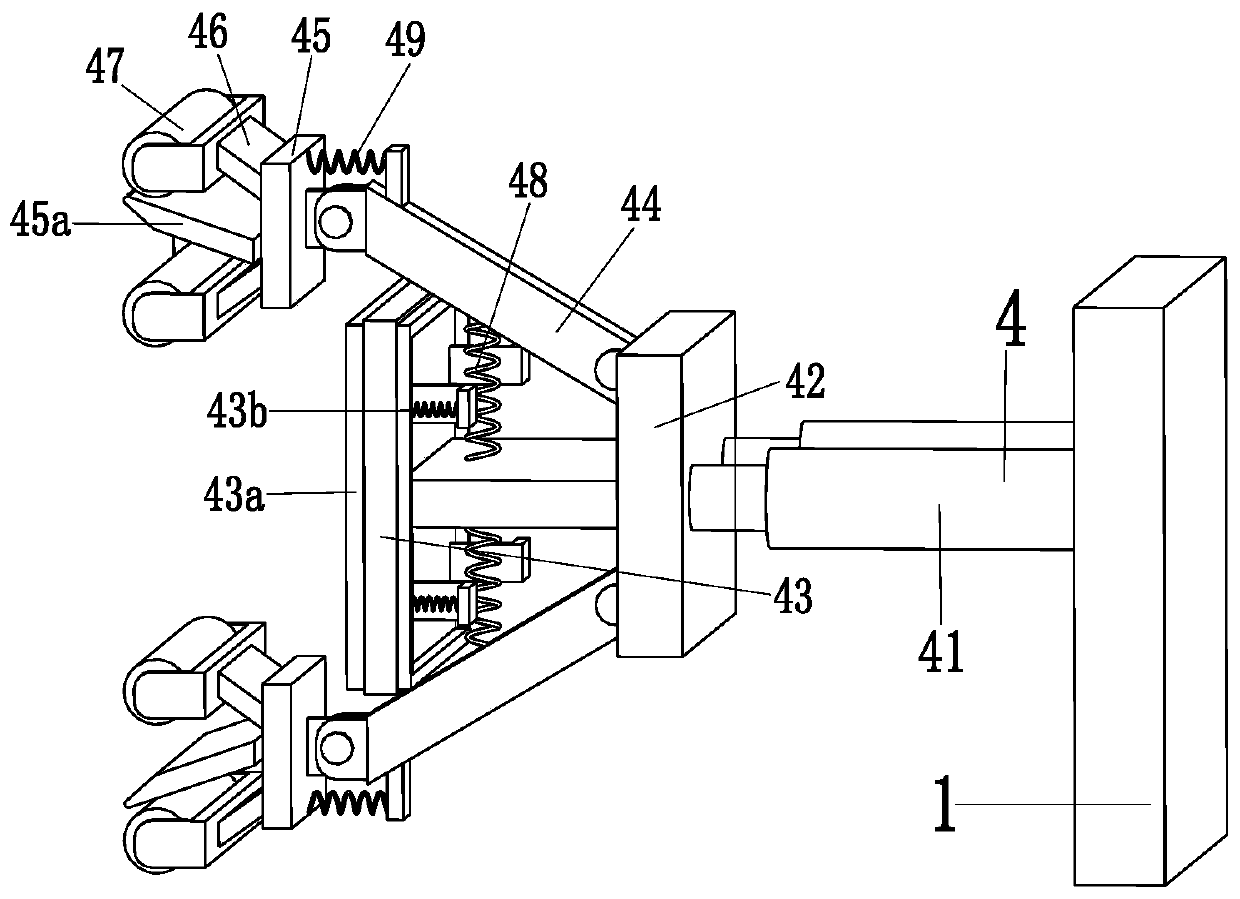

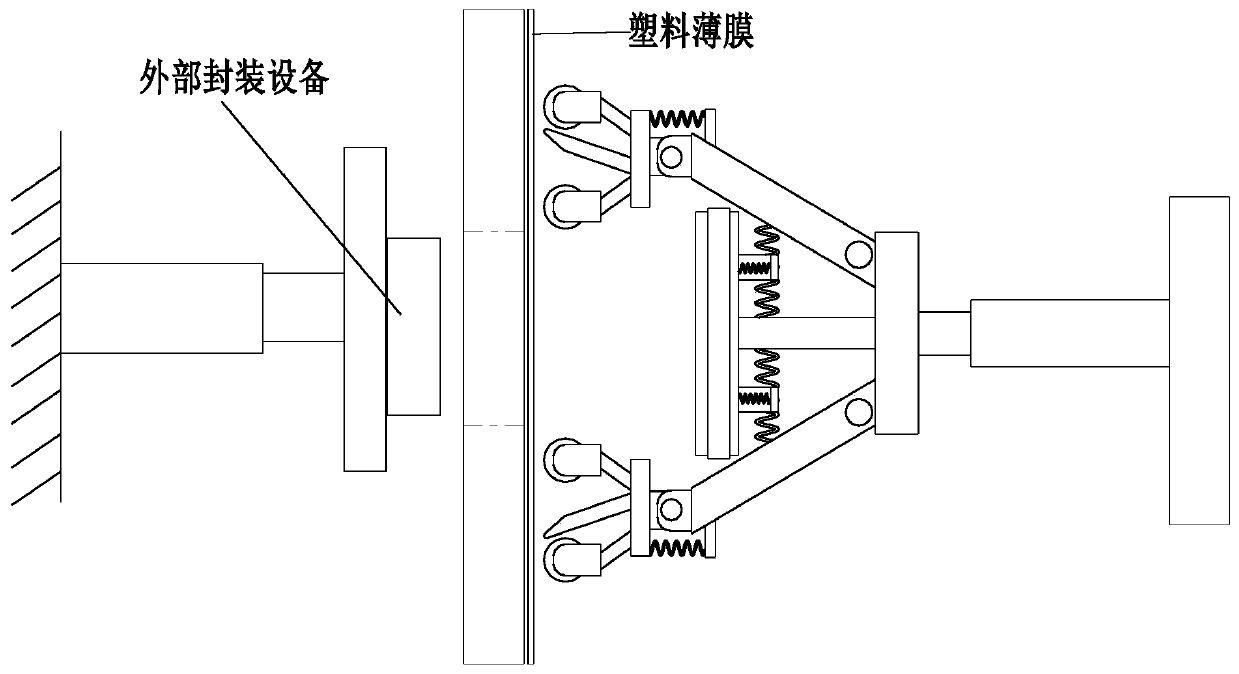

Fold-preventing spreading device for plastic film

InactiveCN110203744AImprove stabilityImprove heat sealing effectBag making operationsPaper-makingThin membranePlastic film

The invention relates to a fold-preventing spreading device for a plastic film. The fold-preventing spreading device comprises a supporting frame and a spreading device. The spreading device is installed on the left side face of the right end of the supporting frame. The spreading device comprises a spreading air cylinder, a pressing support, a supporting plate, a guide pillar, a spreading connecting plate, a wheel connecting pillar, a spreading wheel and a spreading spring. The spreading device can be used for evenly spreading the plastic film so that the plastic film can be subjected to thehot sealing action flatly. The outer end of the supporting plate is connected with a pressing frame in a sliding manner. The right end of the pressing frame is installed on the right side face of thesupporting plate through a pressing spring. The pressing frame can press the plastic film needing to be subjected to hot sealing in a stressed manner, and the hot sealing effect of the plastic film isfurther improved. By means of the fold-preventing spreading device for the plastic film, the problems that when an existing plastic film is subjected to hot sealing, spreading cannot be conducted atthe upper portion and the lower portion of the plastic film at the same time, folds can occur on the plastic film, and the hot sealing area of the plastic film cannot be limited in a stressed manner can be solved.

Owner:安庆市明盛塑业有限公司

High-transparency polytene thermocontracted film and producing method thereof

The transparent heat shrinkable polyethylene film is prepared with the mixture comprising metallocene LDPE, linear LDPE, LDPE and assistant, and through compounding material, mixing, extruding with a single-screw extruder and blow molding at 160-200 deg.c. The product of the present invention has high transparency, and may be used in printing bright pattern and packing with stable stacking and is suitable for mechanical production. The product of the present invention may be used in packing various products, such as farm product, domestic article, cosmetic, detergent, food, medicine, beverage, etc.

Owner:SHANGHAI ZIQUAN LABEL CO LTD

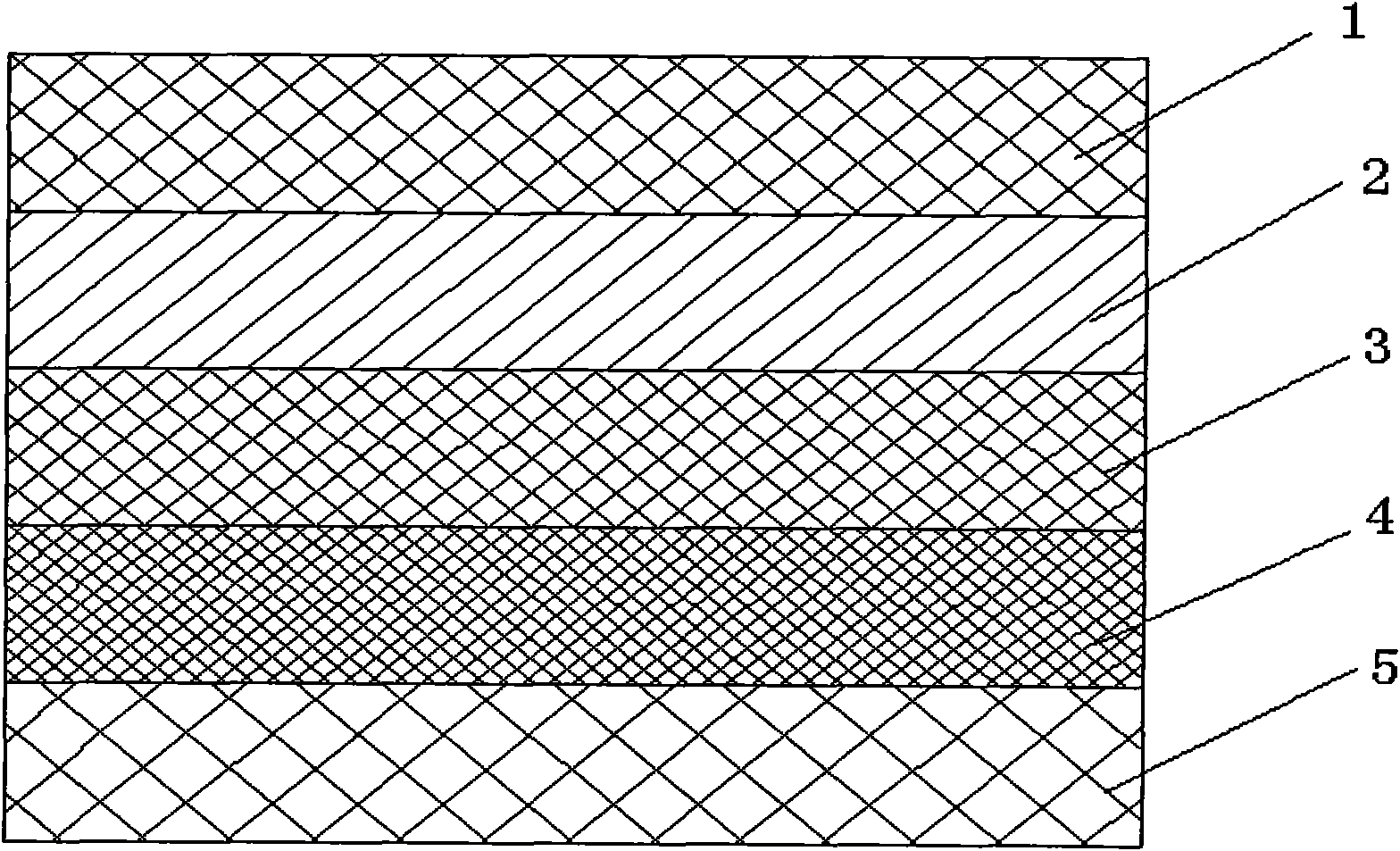

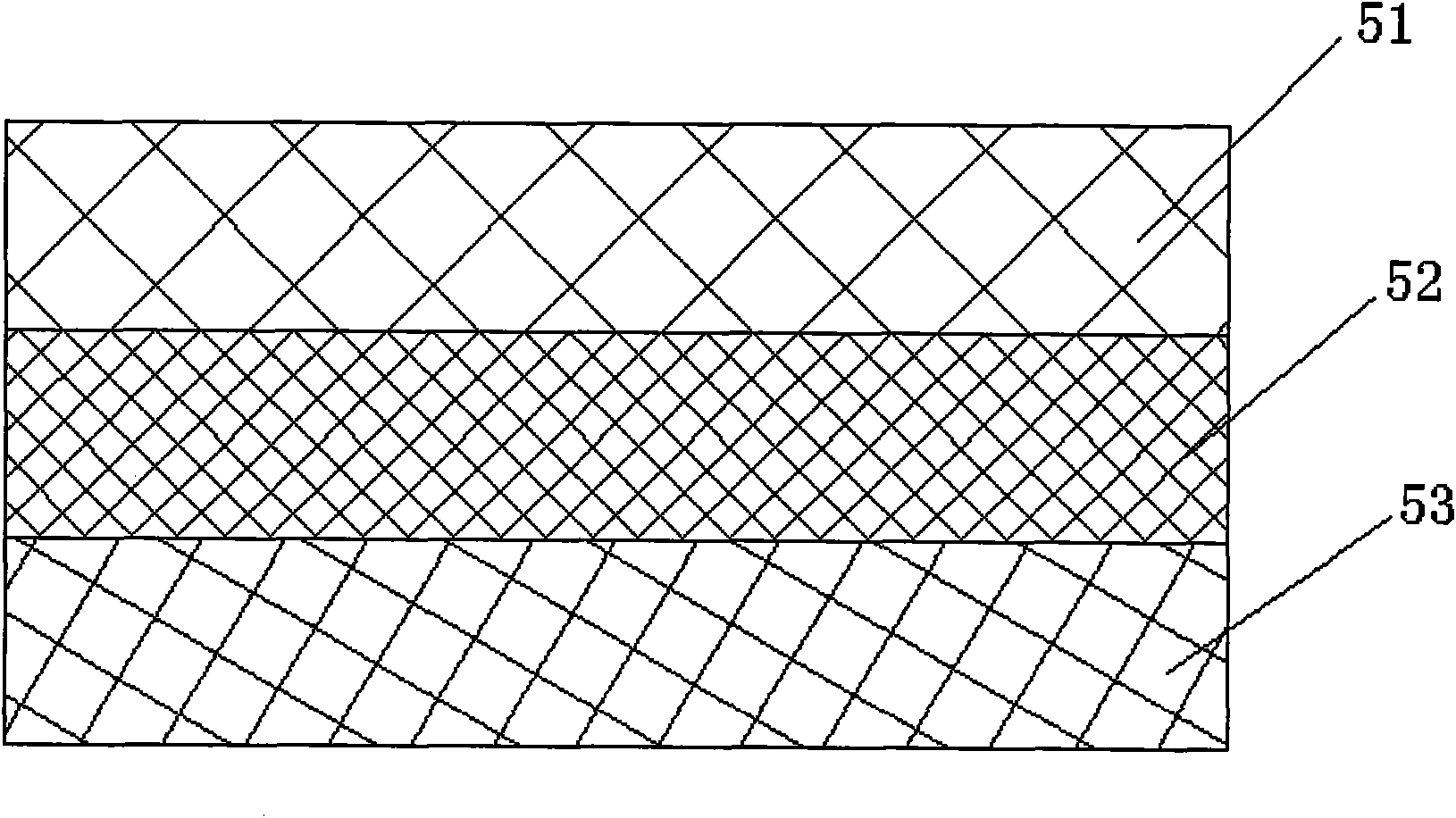

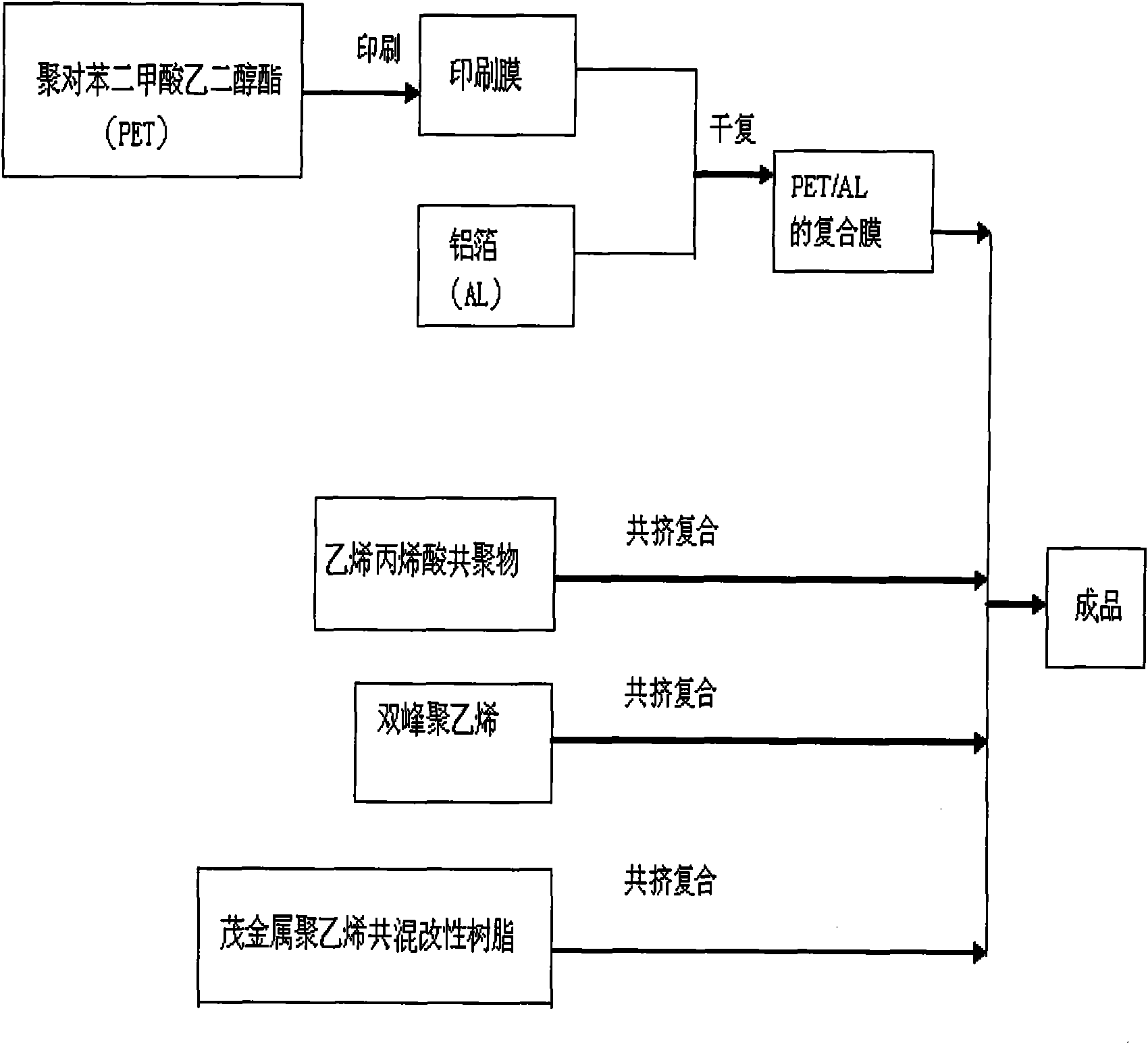

Composite membrane for sauce and preparation method thereof

ActiveCN101624112AGood fragrance retentionGood low temperature heat sealabilityFlexible coversWrappersLow-density polyethylenePolyethylene terephthalate

The invention discloses a composite membrane for sauce and a preparation method thereof. The composite membrane sequentially comprises a polyethylene glycol terephthalate layer, an aluminum foil layer, an ethylene acrylic multipolymer layer, a double-peak low-density polyethylene layer and a metallocene polyethylene blending and modifying resin layer. The preparation method is characterized by comprising the following steps: dry compounding, preparing the metallocene polyethylene blending and modifying resin layer and blending and compounding. Compared with the prior art, the composite membrane for sauce has high sealing strength, short hot seal time, good sealing effect, good sealing planeness, good pollution resistance, medium resistance, low cost, no delamination, and the like.

Owner:HUANGSHAN NOVEL

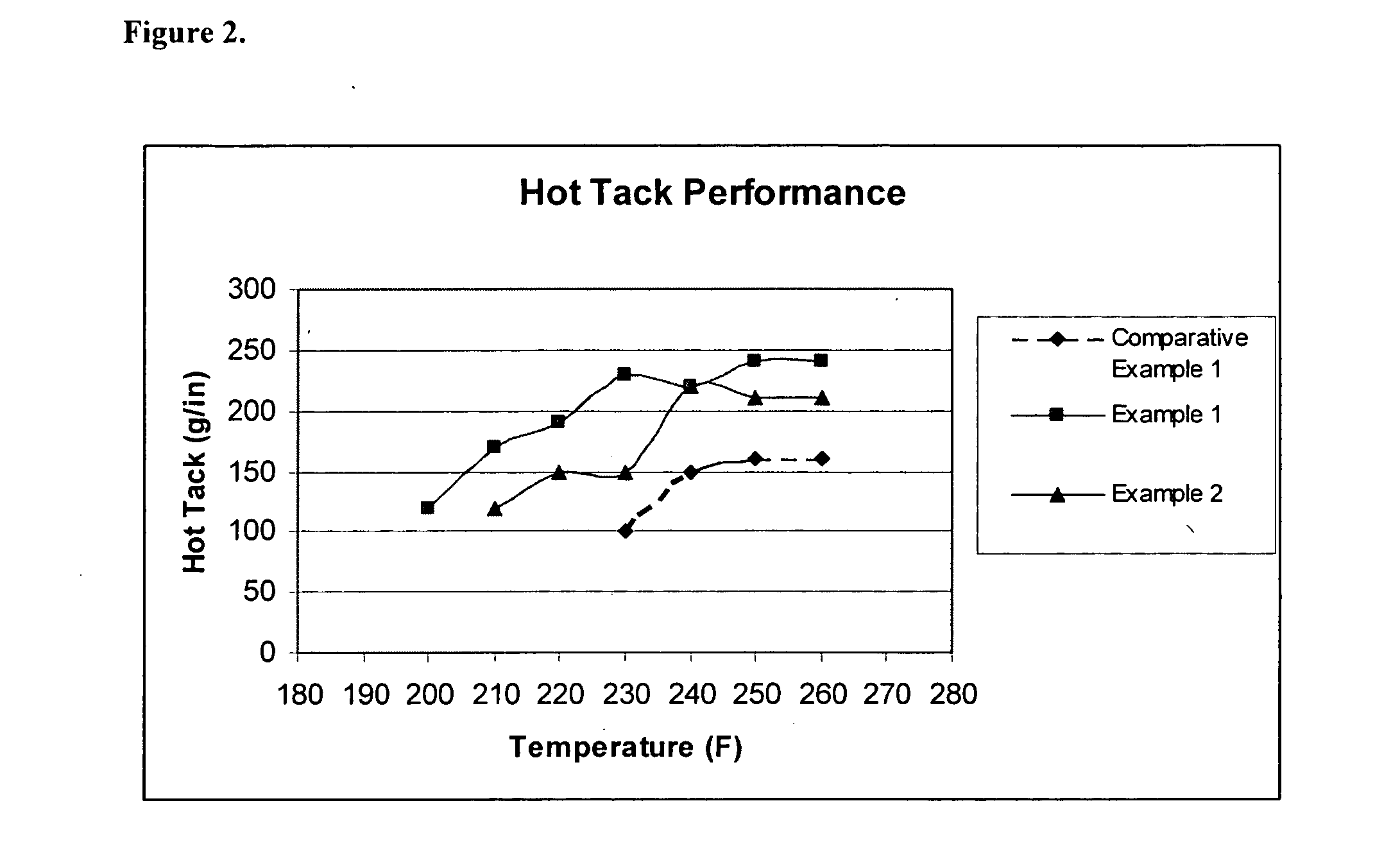

Coating for enhancing low temperature heat sealability and high hot tack to polymeric substrates

ActiveUS20070087189A1High hot tackGood heat sealing performanceSynthetic resin layered productsCellulosic plastic layered productsCelluloseWater based

A coating is provided for enhancing low temperature heat sealability and providing high hot tack to polymeric substrates. The coating is water-based and includes a dispersion of a copolymer of ethylene and acrylic or methacrylic acid, and a compatible adhesion enhancer which is an aliphatic polyurethane emulsion. The coating may also include additives such as wetting agents, matting agents, antiblocking agents, and tackifying resins. The coating may be applied to a variety of polymeric substrates and may be heat sealed to itself, or to polymeric substrates, cellulosic substrates, and metal substrates.

Owner:MICHELMAN INC

Polypropylene composite film

InactiveUS20020182426A1Good heat sealing performanceHigh heat sealing strengthSynthetic resin layered productsDomestic containersFiberPolymer science

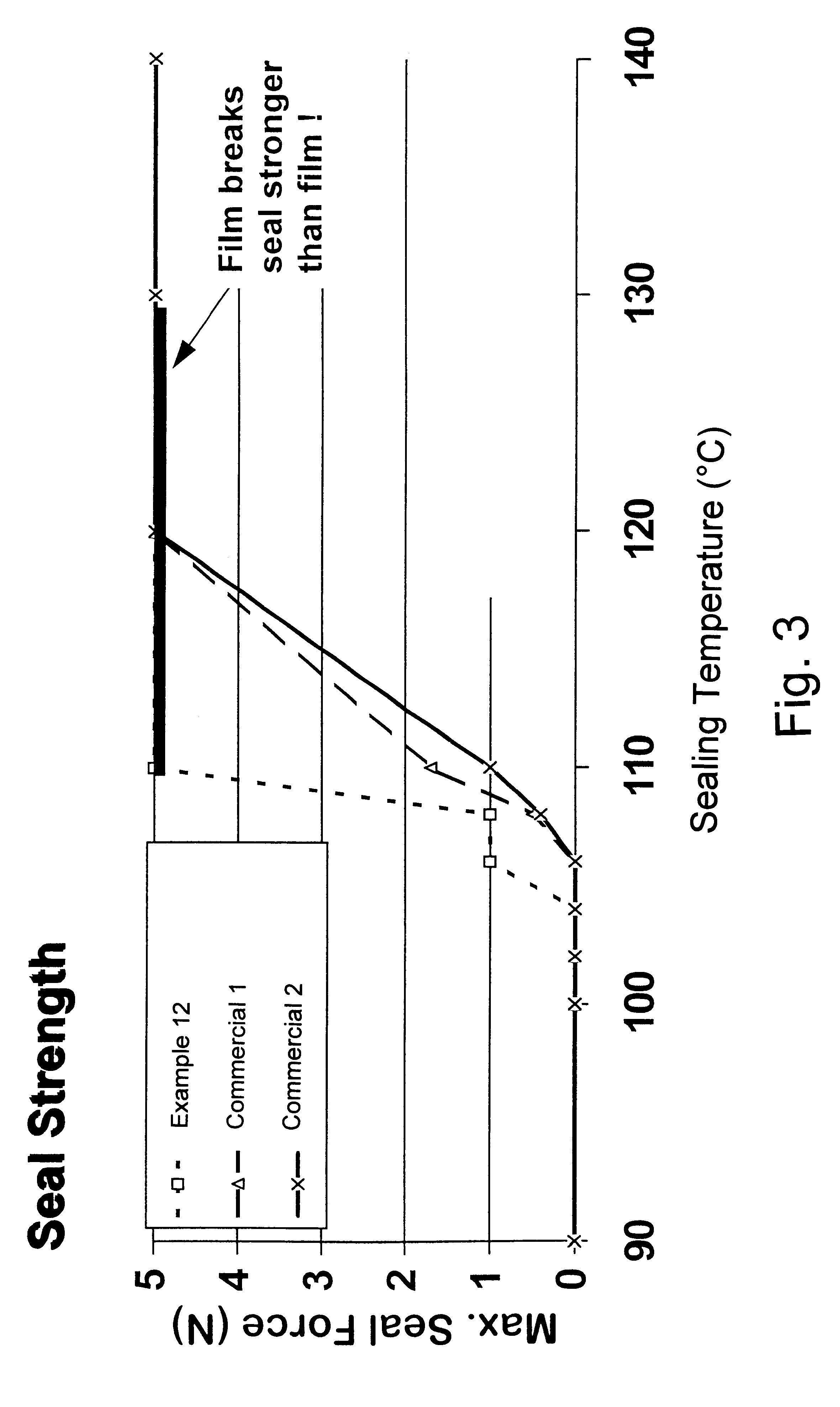

The polypropylene composite film of the present invention comprises (A) a crystalline polypropylene layer and (B) a propylene-1-butene random copolymer layer which is laminated on at least one surface of the crystalline polypropylene layer (A). The propylene / 1-butene random copolymer (B) has the following properties: (1) the copolymer comprises 50 to 95% by mol of constituent units derived from propylene and 50 to 5% by mol of constituent units derived from 1-butene, (2) the intrinsic viscosity is 0.1 to 5 dl / g, (3) the molecular weight distribution (Mw / Mn) is not less than 3, and (4) the parameter B value is 1.0 to 1.5. The crystalline polypropylene layer (A) of this composite film may be unstretched, monoaxially stretched or biaxially oriented. The polypropylene composite film has excellent heat-sealing properties, such as low-temperature heat-sealing properties and heat-sealing strength, and hot tack properties. The polypropylene composite film is almost free from surface tackiness and shows good slip properties and high blocking resistance at high temperatures, so that it is suitable for high-speed packaging. In addition, this composite film also has good transparency and scratch resistance. The polypropylene composite film of the invention having the above-mentioned excellent properties can be favorably used for packaging of foods, fill packaging and fiber packaging.

Owner:MITSUI CHEM INC

Polypropylene resin composition

A polymer blend includes a first random copolymer of propylene and one or more C2-C20 α-olefins other than propylene having a melting point of above 116° C. and up to about 145° C. and which constitutes from about 60 weight percent to about 95 weight percent of the composition, and a second random copolymer of propylene and one or more C2-C20 α-olefins other than propylene having a melting point of from about 70° C. to no more than 116° C. and which constitutes from about 5 weight percent to about 40 weight percent of the composition. The polymer blend includes a xylene soluble fraction having a weight average molecular weight of above about 100 kg / mol and an intrinsic viscosity of above about 1.0 dl / g.

Owner:LUMMUS NOVOLEN TECH

Polypropylene composite film

InactiveUS6686055B2Good heat sealing performanceHigh heat sealing strengthSynthetic resin layered productsDomestic containersPolypropylene compositesPolymer science

The polypropylene composite film of the present invention comprises (A) a crystalline polypropylene layer and (B) a propylene-1-butene random copolymer layer which is laminated on at least one surface of the crystalline polypropylene layer (A). The propylene / 1-butene random copolymer (B) has the following properties: (1) the copolymer comprises 50 to 95% by mol of constituent units derived from propylene and 50 to 5% by mol of constituent units derived from 1-butene, (2) the intrinsic viscosity is 0.1 to 5 dl / g, (3) the molecular weight distribution (Mw / Mn) is not less than 3, and (4) the parameter B value is 1.0 to 1.5. The crystalline polypropylene layer (A) of this composite film may be unstretched, monoaxially stretched or biaxially oriented. The polypropylene composite film has excellent heat-sealing properties, such as low-temperature heat-sealing properties and heat-sealing strength, and hot tack properties. The polypropylene composite film is almost free from surface tackiness and shows good slip properties and high blocking resistance at high temperatures, so that it is suitable for high-speed packaging. In addition, this composite film also has good transparency and scratch resistance. The polypropylene composite film of the invention having the above-mentioned excellent properties can be favorably used for packaging of foods, fill packaging and fiber packaging.

Owner:MITSUI CHEM INC

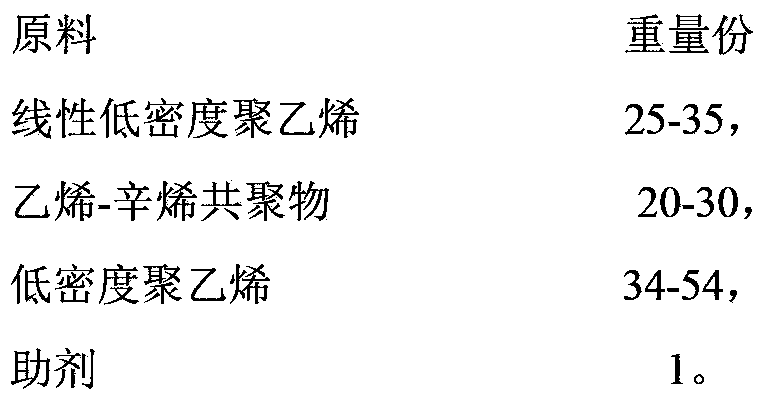

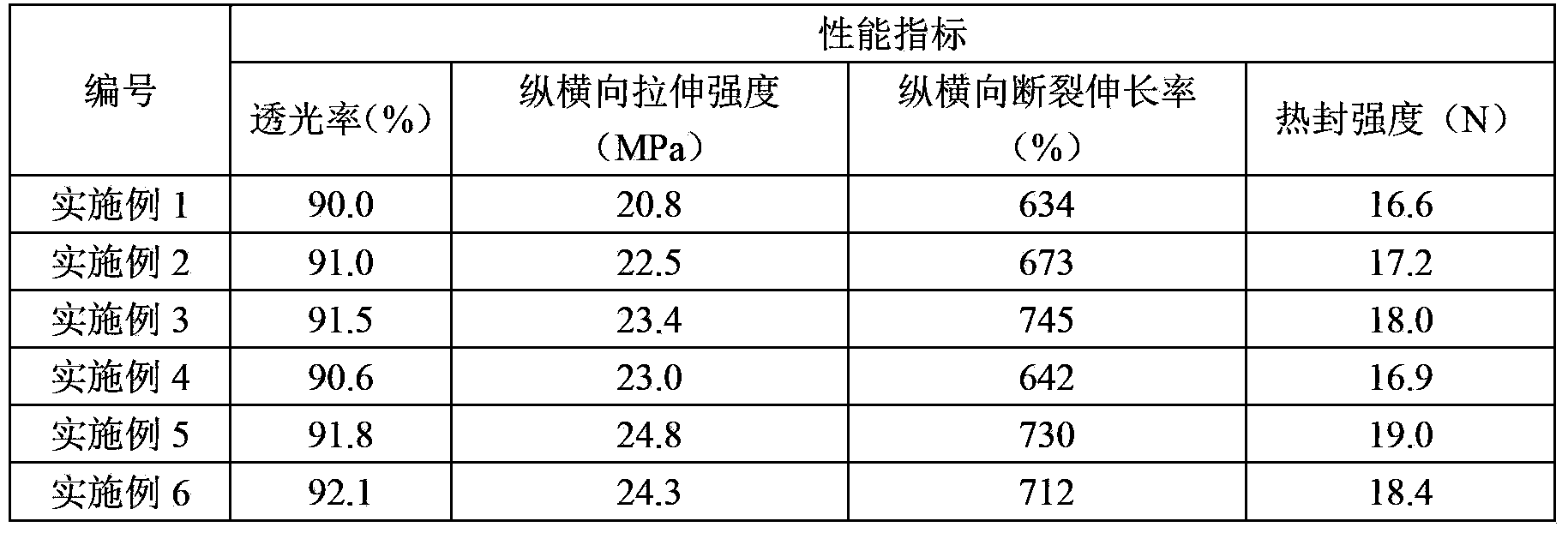

High-transparency polyolefin heat shrinkage film and production method thereof

ActiveCN103360664AGood heat sealing performanceHigh transparencyLow-density polyethyleneLinear low-density polyethylene

The invention belongs to the technical field of a production method of a polymer film material for packaging and in particular discloses a high-transparency polyolefin heat shrinkage film and a production method thereof. The production method of the high-transparency polyolefin heat shrinkage film comprises the following steps of: extruding 25-35 parts by weight of linear low-density polyethylene, 20-30 parts by weight of ethylene-octylene copolymer, 34-54 parts by weight of low-density polyethylene and 1 part by weight of auxiliaries by a single-screw extruder; extruding the materials into a tube blank by an extruding mould head of a single-layer film blowing machine; cooling and pulling the tube blank into a stretching oven for carrying out transverse and longitudinal stretching of a certain times. According to the high-transparency polyolefin heat shrinkage film provided by the invention, the transparency of the film is improved for enabling the packaging of the printed goods to be more attractive; the strength of the film is improved to broaden the application field; the heat sealing performance of the film is improved for adapting to the mechanical production and improving the packaging resilience; and the product has a constant longitudinal-transverse shrinkage rate, so that the packaging stability can be ensured.

Owner:HUBEI ENG UNIV

Coextruded Heat-Shrinkable Polyester Film

ActiveUS20090017245A1Good heat sealing performanceImprove stabilityStampsWrappers shrinkagePolyesterMicrowave

Coextruded, biaxially oriented, heat-shrinkable films having a base layer comprising a polyester having an intrinsic viscosity greater than 0.75 and at least one outer heat-sealable layer directly adhered to the base layer are disclosed. The outer layer is heat-sealable and optionally peelable in particular to polyester containers. The invention further relates to a process for producing the film and to packages comprising a container, a product and the coextruded, biaxially-oriented heat-shrinkable film sealed onto the container. The packages are suitable for use with ready-prepared foods, so-called “ready-meals”, which are intended to be warmed in a microwave or in a conventional oven.

Owner:CRYOVAC ILLC

High barrier heat sealable film with linear tear properties

ActiveUS20120028058A1Improve water vapor barrier performanceExcellent linear tear propertySynthetic resin layered productsVacuum evaporation coatingLow-density polyethylenePolymer science

A monoaxially oriented film including a metallized layer; a gas barrier layer; and a propylene-based random copolymer and at least about 3 wt % of a low density polyethylene which is oriented at least about 2.5 times in one direction and exhibits excellent linear directional tear properties parallel to the orientation direction and excellent heat seal performance in terms of high heat seal strengths and low seal initiation temperature. This film formulation and orientation is suitable for pouch applications requiring high gas and moisture barrier, an “easy-tear” linear tear feature, and excellent hermetic seal properties.

Owner:TORAY PLASTICS AMERICA

Biaxially oriented high density polyethylene film with improved sealant layer

ActiveUS20160031191A1Good heat sealing performanceSacrificing optical properties such as transparency and clarity of the filmSynthetic resin layered productsLabelsPolymer sciencePolyolefin

A multi-layer biaxially oriented high density polyethylene (OHDPE) film with a novel formulation which exhibits superior heat seal properties is disclosed. This improved formulation comprises a blend of a single grade of high density polyethylene (HDPE) or several grades of high density polyethylene (HDPE) with a nucleating agent (NA) used in the core layer to achieve a lower sealing initiation temperature, higher heat seal strength and broader sealing temperature range HDPE-based film that still exhibits typical properties of OHDPE films and a lower haze than conventional OHDPE films. The multi-layer BOPP film has additional layers such as a third polyolefin resin-containing layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

High temperature resistance film for blister package of medical equipment and preparation method thereof

InactiveCN101607616AChange the phenomenon of weak heat sealIncrease the effect of sterilization penetrationFlexible coversWrappersMedical equipmentEngineering

The invention relates to a high temperature resistance film for blister package of medical sterilization equipment and a preparation method thereof. The first layer of the film is a heat-sealing layer A, and comprises blending resin of block copolymerized polypropylene and metallocene catalyzed polypropylene (mPP), wherein, the melting point of the block copolymerized polypropylene is more than 131 DEG C; the dosage of the mPP accounts for 20 to 50 percent of the blending rein by weight; the second layer of the film is a secondary inner layer B, and comprises homopolymerized polypropylene; the third layer of the film is an intermediate layer C, and comprises homopolymerized polypropylene; the fourth layer of the film is a binding layer D, and comprises polypropylene grafted by maleic anhydride; and the fifth layer is a weather resistance layer E, and comprises nylon 6 or 66. The film is prepared by adopting a bottom blowing water cooling type co-extrusion process or a casting method, wherein, after plastic is sufficiently melted, is inflated or cast by a die, the plastic is cooled at water temperature of between 15 and 18 DEG C. The preparation method is simple, and the product can endure high temperature steam sterilization for long time, and has good heat-sealing performance of dialyzing paper.

Owner:NINGBO HUAFENG PACKAGE

Shrink package color film and production method thereof

ActiveCN103264553AHigh transparencyThe overall thickness is thinFlexible coversWrappersLow-density polyethyleneHigh resistance

The invention relates to a shrink package color film and a production method thereof. The shrink package color film comprises a color printing layer and a heat shrinkage film. For the heat shrinkage film, MPE metallocene polyethylene is employed and LDPE high pressure polyethylene, HDPE low pressure polyethylene and LLDPE linear low density polyethylene with different melt indexes are cooperatively used, so the shrink package color film provided by the invention has high resistance to impact and tear, high transparency and good heat sealability; thus, the shrink package color film is thinner and has more uniform thickness, packaging requirements of high-quality products are met, and production cost is reduced.

Owner:无锡市方成彩印包装有限公司

Propylene polymer and composition containing the same, molded object and laminate comprising these, and processes for producing propylene polymer and composition containing the same

InactiveUS20050043495A1Improve melt fluidityLess amountMetallocenesPropylene PolymersIntrinsic viscosity

A propylenic polymer according to the present invention or a composition thereof have an excellent melt flowability and contains a less amount of stickiness-causing components, and also has a low modulus and is pliable, and is capable of providing a transparent molded article, thus being useful as a substitute for a pliable vinyl chloride resin. In addition, a molded article made therefrom exhibits an excellent heat seal performance at a low temperature, and is excellent in terms of transparency and rigidity. Specifically, it has an isotactic pentad fraction (mmmm), which indicates a stereoregulariry, of 30 to 80%, a molecular weight distribution (Mw / Mn) of 3.5 or less and an intrinsic viscosity [η] of 0.8 to 5 dl / g.

Owner:IDEMITSU KOSAN CO LTD

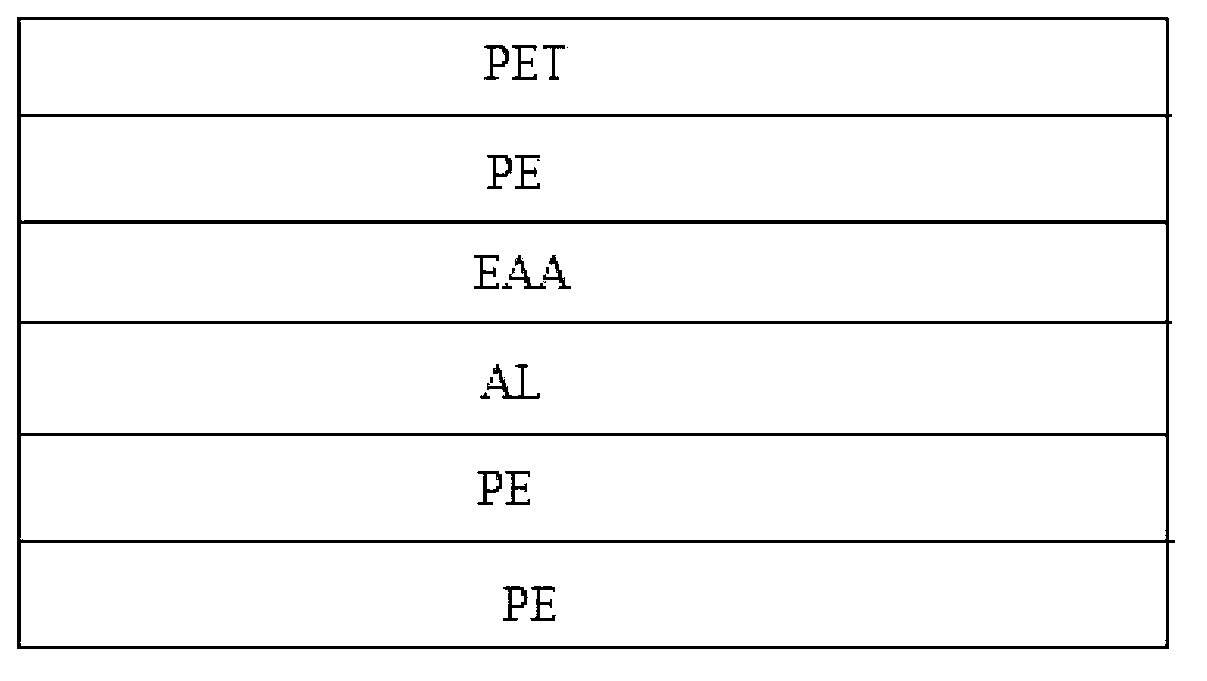

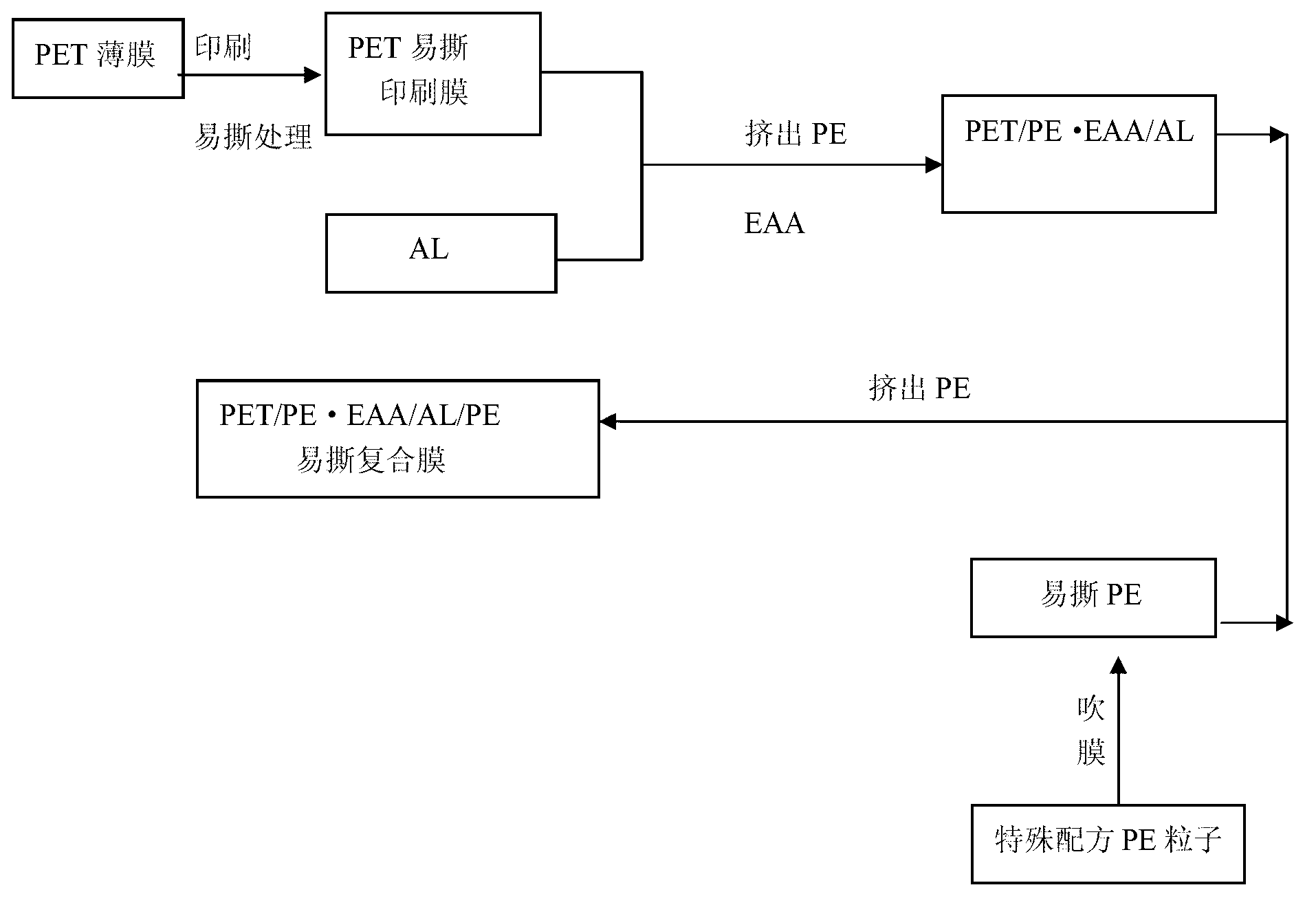

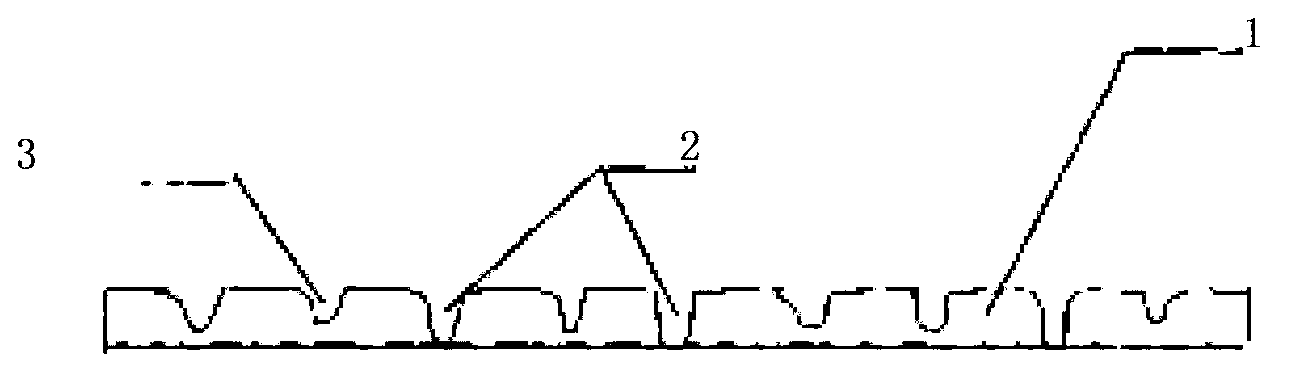

Shredded composite packaging film in arbitrary direction and preparation method thereof

ActiveCN103192564AImprove integrityIntegrity guaranteedSynthetic resin layered productsMetal layered productsEthyleneComposite structure

The invention discloses a shredded composite packaging film in arbitrary direction, and the shredded composite packaging film is of a PET / PE.EAA / AL / PE / PE (poly(ethylene terephthalate) / polyethylene.ethylene acrylic acid / aluminum / polyethylene / polyethylene) composite structure compounded by three layers of base materials with different performances. The shredded composite packaging film comprises an outer layer, PET, a first protective layer, PE.EAA, a barrier layer, an AL foil, a second protective layer, PE, an inner layer and PE. The invention further discloses a preparation method of the shredded composite packaging film in arbitrary direction. The shredded composite packaging film has the advantages of good shelf effect, excellent barrier property, strong packaging tightness without a gap, and excellent protecting effect; the grade of the product can be improved; the quality guarantee period of a packaging content can be ensured; and the packaging integrity can be kept in transporting and moving processes.

Owner:HUANGSHAN NOVEL

Film for flexible bags

InactiveUS20140138406A1Relieves any residual pressurePreventing product weepingLiquid transferring devicesVolume meteringHermetic sealPuncture resistance

Embodiments relate to a film used to form a flexible bag including an inner sealant layer capable of providing a hermetic seal; an oxygen barrier layer capable of extending the shelf life of a food product; and an outer layer capable of providing abrasion and puncture resistance and tacking to the specialized tacky polymer strip mounted on the dispensing device.

Owner:CLEAR LAM PACKAGING

Hot pressing bag making equipment for packaging bags

PendingCN111331927AIncrease productivityGuaranteed installation stabilityBag making operationsPaper-makingHeat sealerPunching

The invention discloses hot pressing bag making equipment for packaging bags, relates to packaging bag production, and aims to solve the problem that the prior art lacks equipment for directly processing plastic bag films. According to the technical scheme, the hot pressing bag making equipment for packaging bags comprises a feeding device, a strip detaching device, a punching mechanism, an incision mechanism, a traction mechanism, a hot pressing cutting device and a blanking mechanism; the strip detaching device comprises an upward guide frame, guide rollers, a material pulling mechanism anda coil cutting mechanism; the incision mechanism comprises incision supporting rollers, tooth blade cutter discs and incision motors; the hot pressing cutting device comprises a heat sealing mechanism, a cutting mechanism, a crankshaft transmission mechanism and an alternating current motor. The hot pressing bag making equipment for packaging bags provided by the invention has the functions of detachment of waste strips, punching, incision and heat sealing cutting, so that the technical effect that packaging bags disclosed in the background technology can be produced by single equipment is realized, and the production efficiency is effectively improved.

Owner:嘉兴华悦包装用品有限公司

Biologically degradable starch film and its prepn

InactiveCN1453303AHigh mechanical strengthGood heat sealing performanceCross-linkWater soluble polysaccharides

The biologically degradable starch film consists of starch polysaccharide hydrolyzing product 5-70 wt%, natural gelatin hydrolyzing product 0.2-3 wt%, PVA 18-85 wt%, cross linking agent 0.2-0.3 wt% and water 8-14 wt%, its preparation includes the following steps: mixing starch polysaccharide, natural gelatin, water and proper amount of polysaccharidase to obtain water soluble polysaccharide sol;mixing PVA and water to obtain PVA sol; mixing the polysaccharide sol and the PVA sol and adding proper amount of cross linking agent to form mixed sol; forming film with the mixed sol via dry curtain coating, drying, stretching, and hot setting to form the film with water content of 8-14 wt%. The film has the excellent performance similar to that of chemical plastic film, can be decomposed and absorbed by microbe in soil and has low production cost.

Owner:WUHAN JINBAO ENVIRONMENTAL BIOTECH

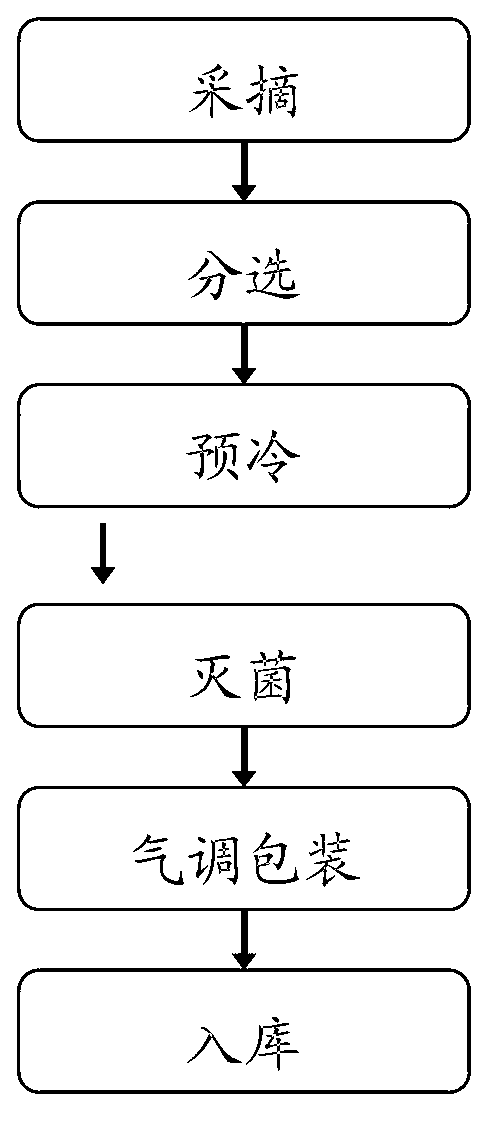

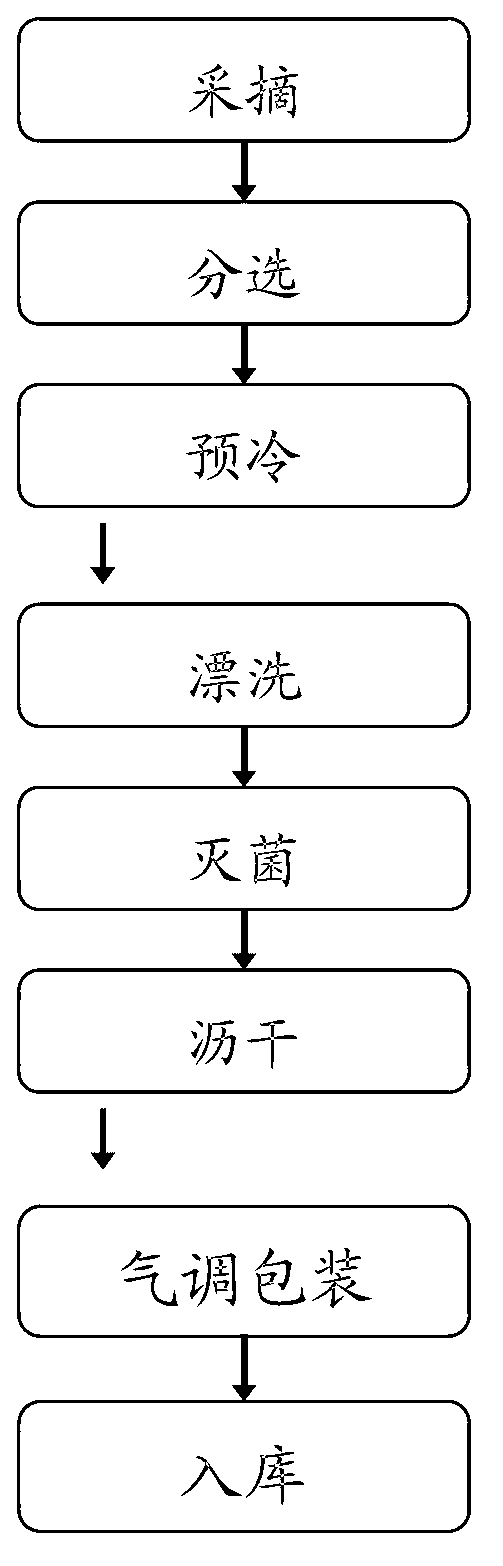

Modified atmosphere freshness-retaining method for strawberry

InactiveCN102793005ASlow breathingControlled reproductionFruits/vegetable preservation by freezing/coolingFragariaNitrogen

The invention discloses a modified atmosphere freshness-retaining method for strawberry. Freshly picked strawberry is pre-cooled and put in a packaging container and the mixed gas of oxygen, carbon dioxide and nitrogen is introduced into the packaging container to lead the nitrogen concentration to be 85-95%, the oxygen concentration to be 1-8% and the carbon dioxide concentration to be 1-6%. The packaged strawberry is put in a refrigerator for cold storage at the temperature of 0-2 DEG C. The method leads the strawberry which is liable to oxidation stain to keep fresh and unchanged color and taste within 25 days, thus the product quality is ensured.

Owner:SUZHOU YAHE PRESERVATION TECH

High-strength high-breathability polrvinyl chloride (PVC) preservative film

InactiveCN101948592AGood moisture permeabilityHigh mechanical strengthFruit and vegetables preservationZinc compoundsPolyvinyl chloride

The invention relates to a high-strength high-breathability polrvinyl chloride preservative film which comprises the following components in parts by weight: 100 parts of PVC resin (SG-4 type), 4-6 parts of calcium-zinc compound stabilizing agent, 0.5-1 part of stearic acid, 25-30 parts of dioctyl phthalate (DOP), 20-25 parts of 1,2-propylene glycol adipate, 2-5 parts of nano scale silicon dioxide (SiO2), 1-3 parts of silane coupling agent, 2-5 parts of nano scale calcium carbonate (CaCO3) and 1-3 parts of titanate coupling agent. The components are prepared into a film with a certain thickness through the working procedures of mediating, extruding, blow molding, and the like, and the film is used for retaining the freshness of agricultural products. The preservative film has the main technical characteristics that the tensile strength and the elongation at break of the preservative film are 10-30 percent higher than that of ordinary preservative films, the breathability rate is improved by 10-20 percent, and the preservative film has better packability to the agricultural products and good breathability and can effectively prevent frosting.

Owner:天津市食品加工工程中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com