Modified atmosphere freshness-retaining method for strawberry

A modified atmosphere preservation and strawberry technology, which is applied in the fields of fruit and vegetable preservation, food preservation, fruit/vegetable preservation through freezing/refrigeration, etc., to achieve the effects of good heat sealing, control of bacterial reproduction, and good commodity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

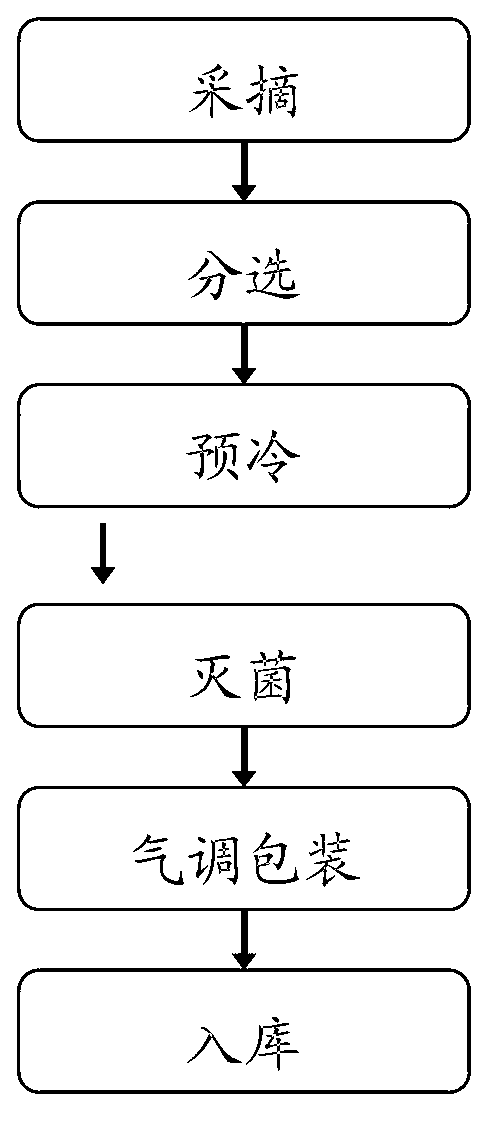

[0021] Such as figure 1 Shown is a modified atmosphere fresh-keeping method for strawberries. Freshly picked strawberries are pre-cooled and placed in a packaging container, and a mixed gas of oxygen, carbon dioxide and nitrogen is introduced into the packaging container, so that the packaging The concentration of nitrogen in the container is 85-95%, the concentration of oxygen is 1-8%, and the concentration of carbon dioxide is 1-6%. Put the packaged strawberries into a refrigerator at 0-2°C for refrigeration.

[0022] The freshly picked strawberries are strawberries with an eighth degree of maturity.

[0023] When the strawberries are pre-cooled, the temperature of the pre-cooling store is 0-2°C, and the pre-cooling time is greater than or equal to 24 hours.

[0024] When the strawberries are precooled, an air sterilization system is configured in the precooler, and ozone is used for sterilization.

[0025] The packaging container is a packaging bag. The packaging contain...

Embodiment 2

[0027] Embodiment two: a kind of modified atmosphere fresh-keeping method of strawberry,

[0028] Such as figure 1 shown, including the following steps:

[0029] 1. Picking: When picking, choose strawberries that are about 80% ripe.

[0030] 2. Sorting: Screening and removal of damaged and rotten strawberries to prevent mutual influence.

[0031] 3. Pre-cooling: Pre-cooling in time after picking, the temperature of the pre-cooling room is 0-2°C, and the pre-cooling time is more than 24 hours. While preventing cold damage, ensure that the central temperature of strawberries meets the requirements; the temperature of pre-cooling and packaging, Humidity should be maintained to prevent condensation.

[0032] 4. Sterilization: The pre-cooler is equipped with an air sterilization system, and a certain concentration of ozone is used for sterilization.

[0033] 5. Modified atmosphere packaging: Pre-cooled and sterilized strawberries are packaged in modified atmosphere packaging. T...

Embodiment 3

[0035] Embodiment three: a kind of modified atmosphere fresh-keeping method of strawberry,

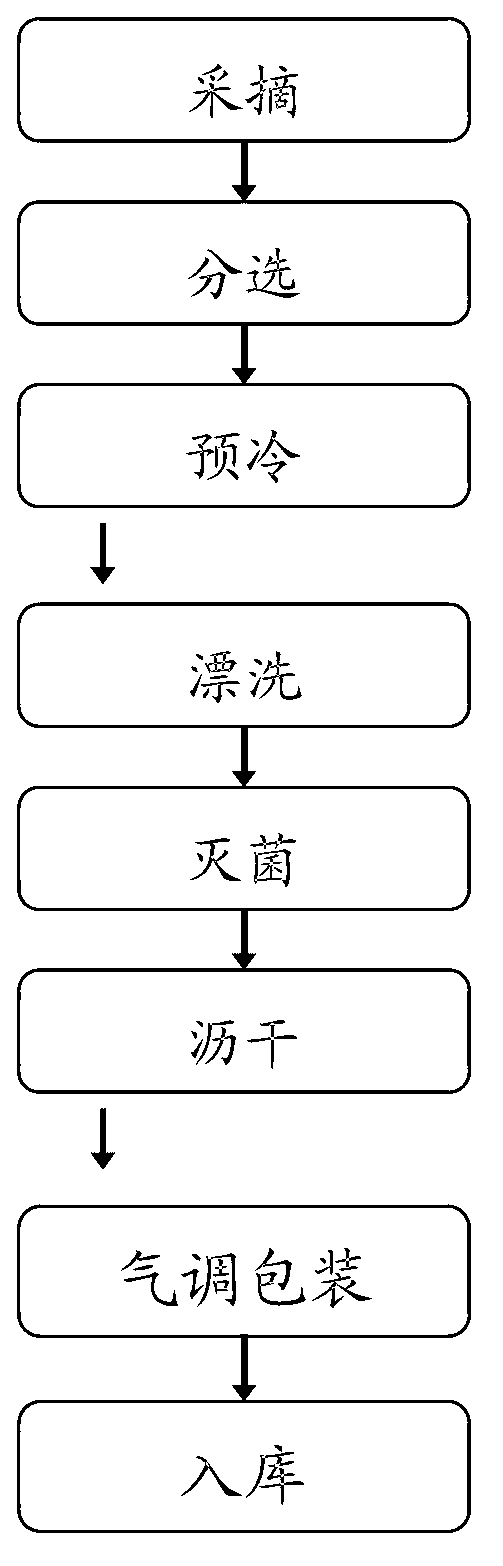

[0036] Such as figure 2 shown, including the following steps:

[0037] 1. Picking: When picking, choose strawberries that are about 80% ripe.

[0038] 2. Sorting: Screening and removal of damaged and rotten strawberries to prevent mutual influence.

[0039] 3. Pre-cooling: Pre-cooling in time after picking, the temperature of the pre-cooling room is 0-2°C, and the pre-cooling time is more than 24 hours. While preventing cold damage, ensure that the central temperature of strawberries meets the requirements; the temperature of pre-cooling and packaging, Humidity should be maintained to prevent condensation.

[0040] 4. Rinse: Rinse the strawberries with sterile purified water.

[0041] 5. Sterilization: The pre-cooler is equipped with an air sterilization system, and a certain concentration of ozone is used for sterilization.

[0042] 6. Drain: Spread the sterilized strawberries o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com