Patents

Literature

2751results about "Fruits/vegetable preservation by freezing/cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of transporting or storing perishable produce

InactiveUS6615908B1Convenient infusionIncrease humiditySpace heating and ventilationOperation mode of machinesGas compositionProduct gas

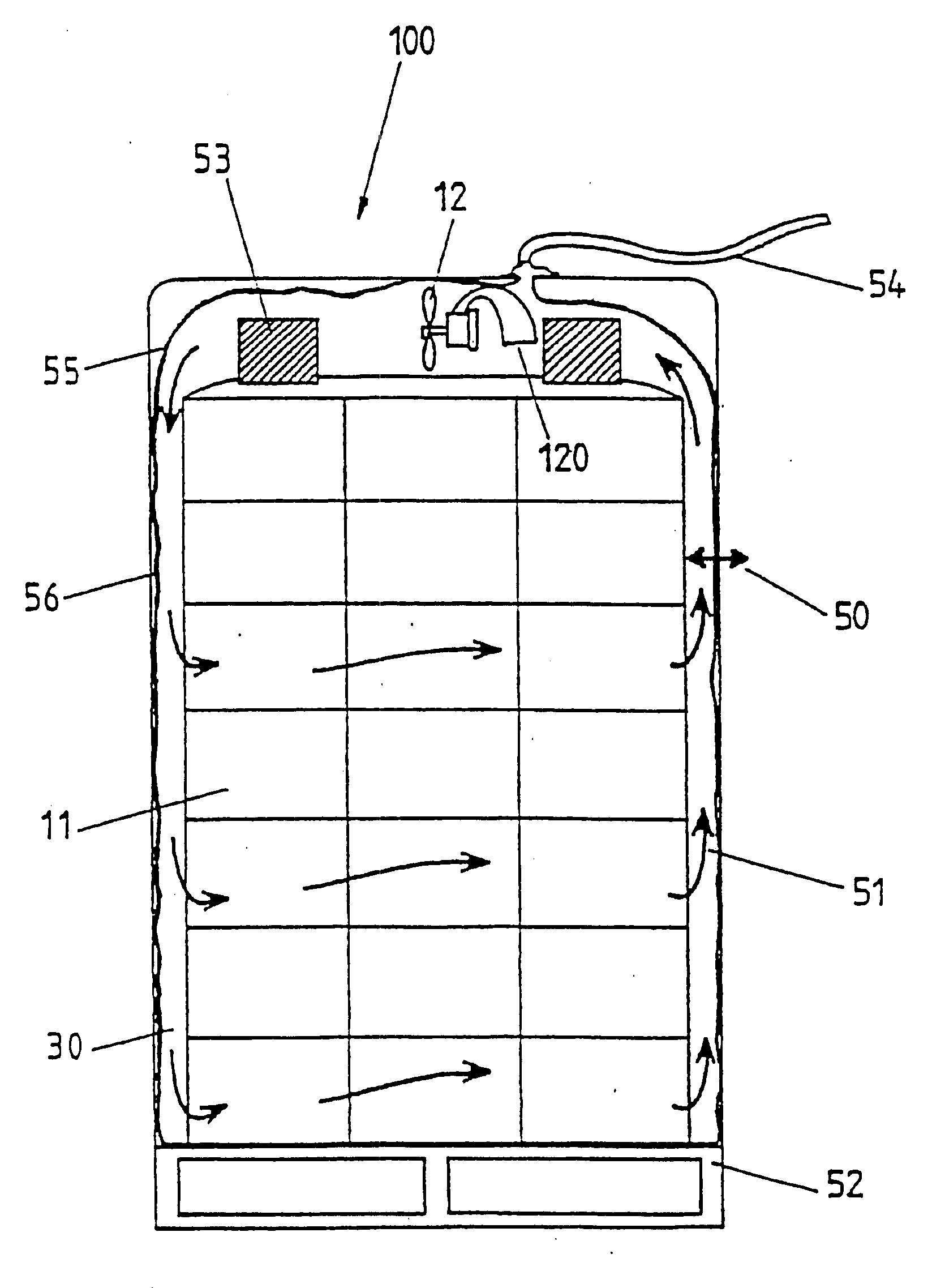

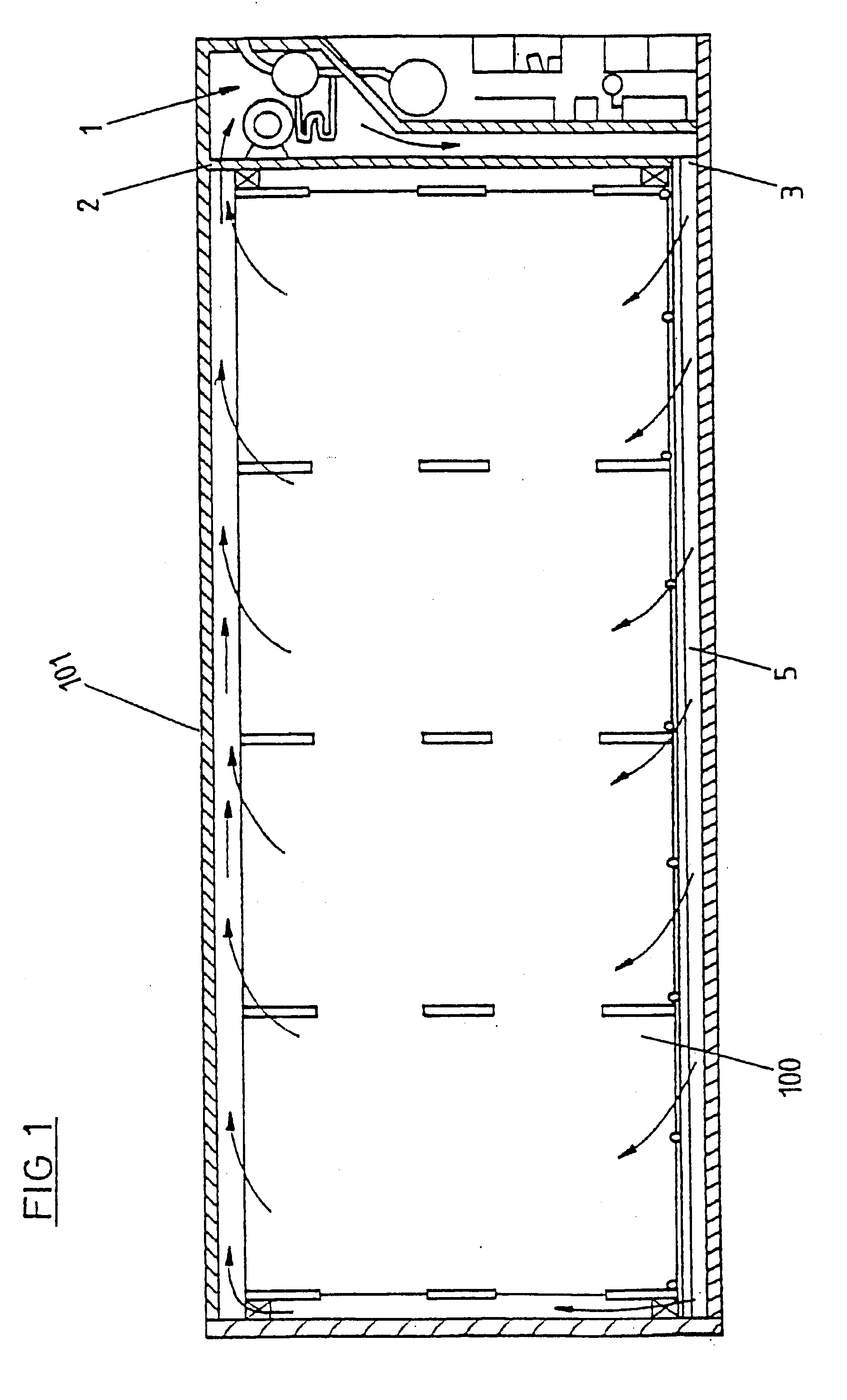

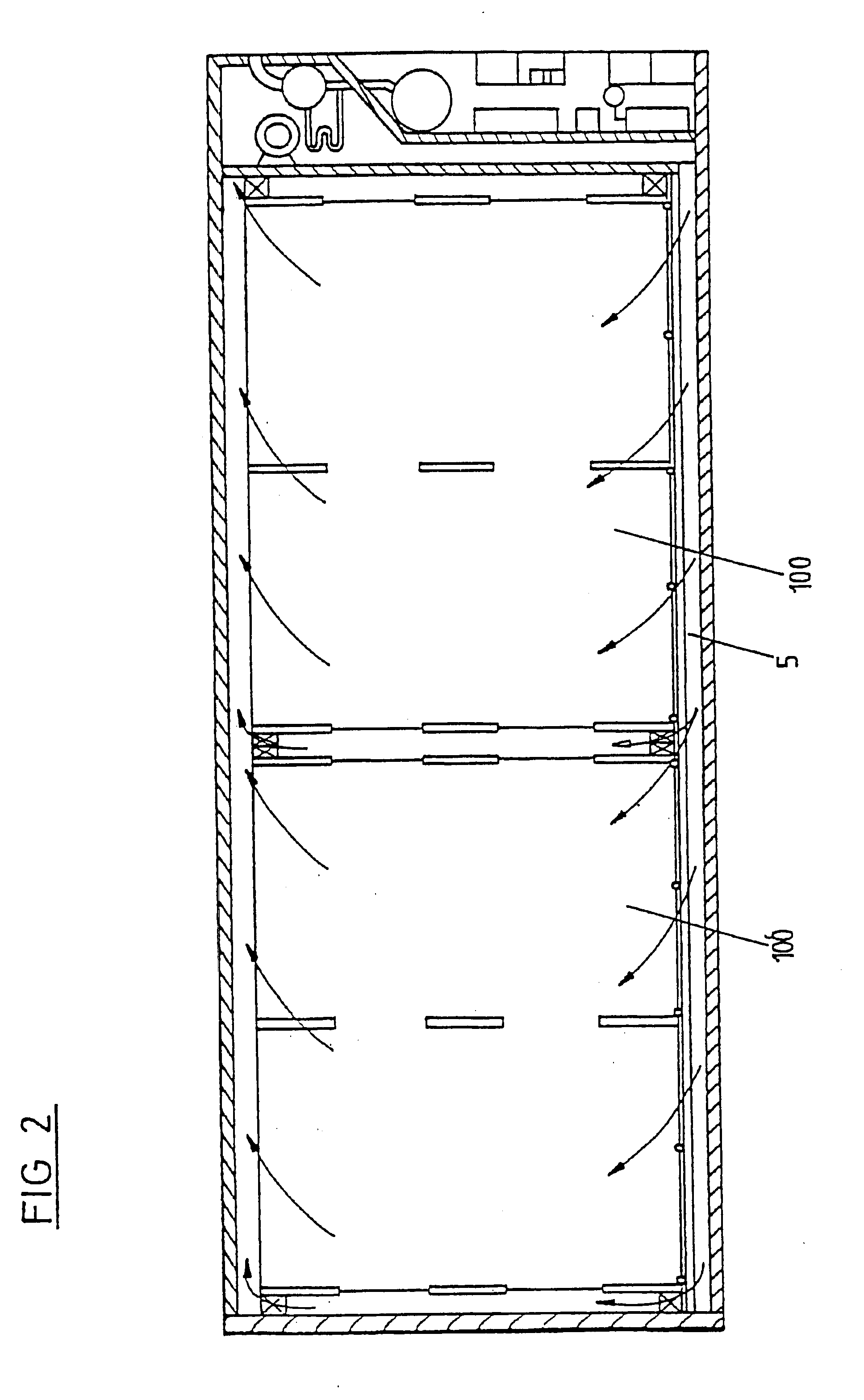

The invention allows cool rooms or sea containers designed for frozen goods to handle produce requiring more precisely controlled temperatures and conditions, e.g., vegetables and fruits requiring temperatures in the chilling range and often also needing control or modification of the atmosphere. Each load of produce (100) (e.g. of pallet size) is held in the sea container or cool room but is sealed from the air of the refrigerated environment by, for example, a plastics bag (56). The atmosphere within the bag is then circulated by a fan (12) (or by convection currents from a heating element) so as to pass through the load and around it via ducts (30) provided adjacent the bag (56). Heat exchange (50) between the circulating gas and the refrigerated environment, via the plastics film, serves to cool the load. However, if cooling is excessive a heating element can be used to raise the temperature of the circulating atmosphere. Gas composition of the atmosphere can be controlled by scrubbing, flushing, etc. via pipes from a central unit or at each load individually or by choosing semi-permeable plastic for the sealing bags.

Owner:TRANSPHERE SYST

Sulfurless preserved fruit confect and its producing method

The invention relates to preserved fruit without additive and a production method, which comprises that the raw material of the preserved fruit undergoes low-temperature refrigeration drying. The method realizes the production method of the preserved fruit without additive, in particular the sulfur-free production method, and meanwhile, the color of the raw material is maintained.

Owner:BEIJING YUSHIYUAN FOOD

Method for preparing frozen food

InactiveUS20040058037A1Water sublimation from food surface during frozen storage can be suppressedConfectionerySweetmeatsWater contentFood products

The present invention relates to a method for producing a frozen food and a frozen food produced by the process. There are provided a method for producing a frozen food characterized by subjecting a food to a contact treatment with an emulsifier-added fat or oil, and thereafter freezing the food; a frozen food produced by the method; and a method of preventing fluctuation in a water content of a frozen food, characterized by subjecting a food to a contact treatment with an emulsifier-added fat or oil, and thereafter freezing the food.

Owner:TAIYO KAGAKU CO LTD

Composite vegetable powder products and method for preparing the same

InactiveCN101095493ACompatibility is reasonablePreserve nutritional valueFruits/vegetable preservation by freezing/coolingFood preparationFlavorPre cooling

The invention relates to a kind of compound vegetable powder and the production method. The comprised components and their weight proportion are as follows: cabbage powder 20-85%, west orchid powder 0-50%, and other vegetable powder of cruciferae 0-30%. The method comprises following steps: picking raw material, selecting, pre-cooling, washing, blanching, cooling, cutting to sheet or block, freezing, subliming drying, hydrolyzing drying, grinding, matching, vacuum packing. The product is characterized by reasonable matching, flavor for absorption, health-care effect. The process is reasonable and the nutrition and biological activity in vegetable are retained at maximum degree because of the vacuum freezing technique.

Owner:SHANGHAI RIYI AGRI TECH

Productive technology for preserving and processing fruits and vegetables

InactiveCN101766209AMaintain nutritional qualityImprove food safetyFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingNutrition qualityNutritional quality

The invention belongs to productive technology for preserving and processing fruits and vegetables, mainly comprising the processes of grading selection, cleaning, arranging and splitting, preserving, dewatering and sterilizing, packing and refrigerating and the like. The technology is mainly characterized in that after two times of sterilizing by ozone and ultraviolet rays in sequence, the fruits and vegetables are soaked by an natural edible antistaling agent to form a film so as to carry out atmosphere packaging by mixed gas, thereby maximally maintaining nutritional quality of the fruits and vegetables, improving edible safety of the fruits and vegetables and prolonging sale and preservation period.

Owner:乔维汉 +2

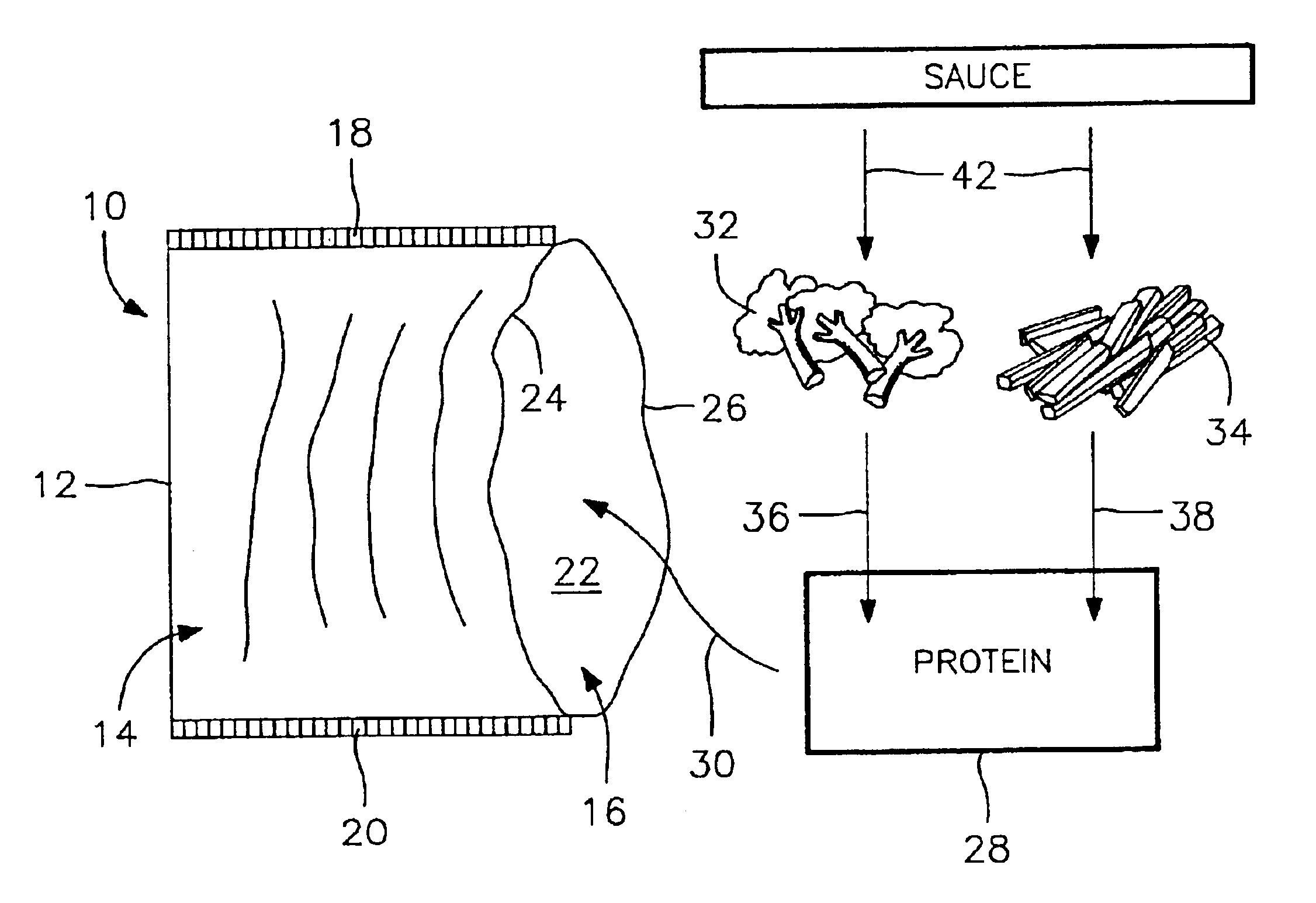

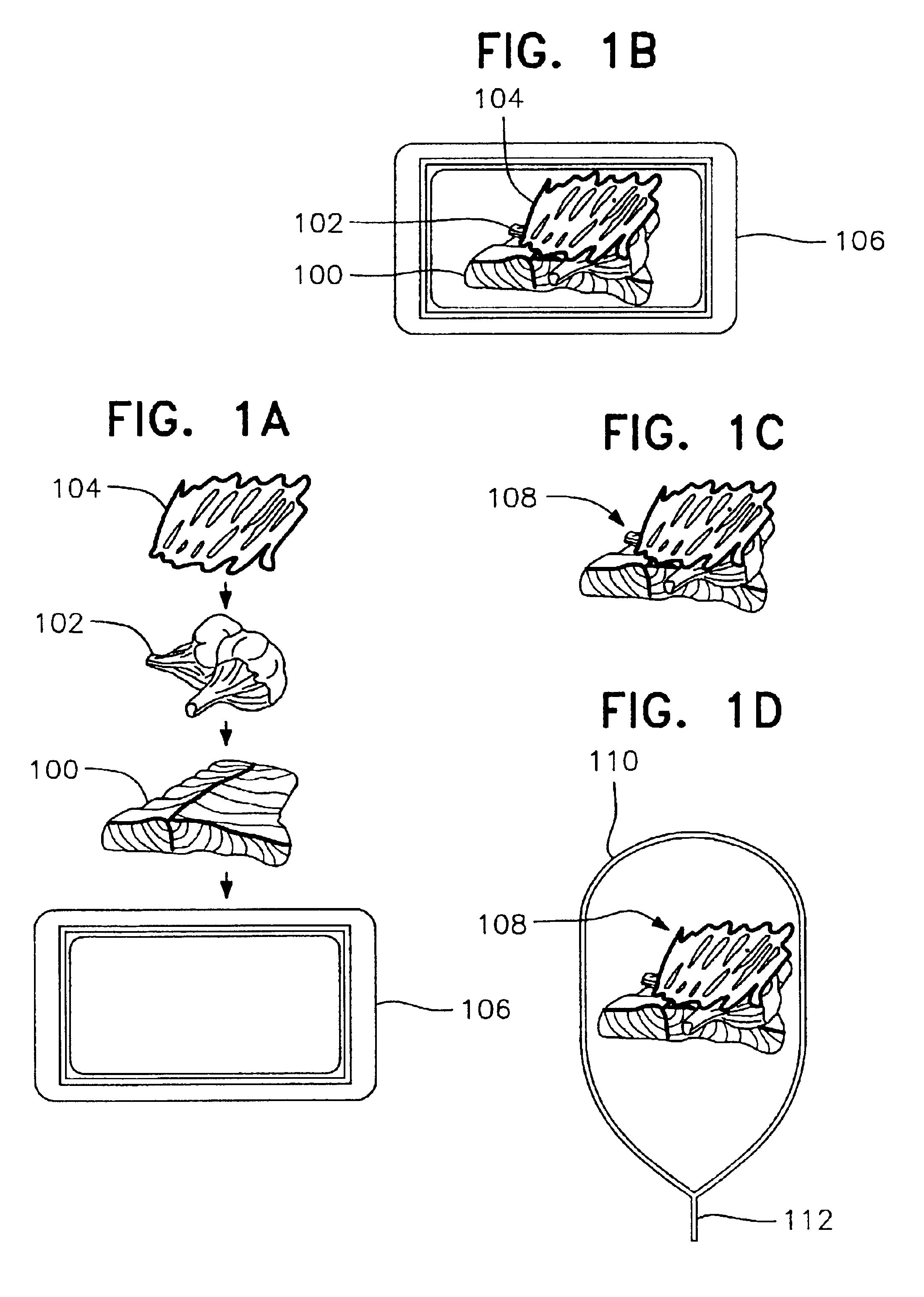

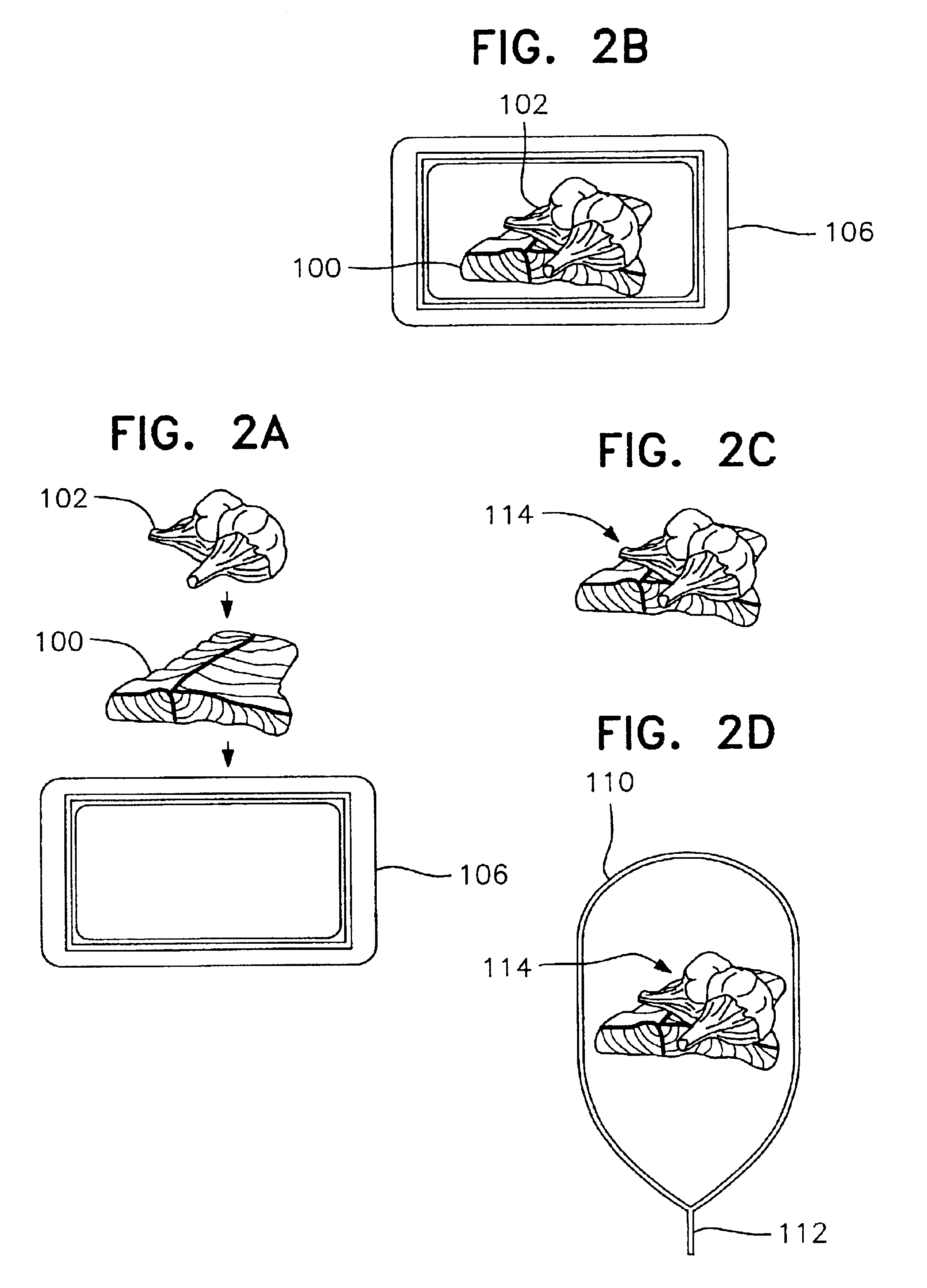

Cooking pouch containing a raw protein portion, a raw or blanched vegetable portion and a sauce and method of making

A frozen food product which includes a raw protein portion, a raw or an only partially cooked or blanched vegetable portion and a sauce, contained in a sealed cooking pouch made primarily of paper and a susceptor layer, preferably aluminum, which may be placed in an oven or microwave oven so as to cook the contents of the cooking pouch. The raw protein product is preferably one of fish, beef, poultry, pork or veal. The vegetables are raw or blanched vegetables such as julienne peppers, celery, carrots, onions, zucchini or broccoli. The blanched vegetables are only partially cooked so that the time remaining to complete cooking of the vegetables is approximately the same as the time required to cook the raw protein portion.

Owner:SMART POUCH

Superheated steam blanching method for improving quality of quick freezing edible fungi

InactiveCN101513209APromote passivationComplete passivationFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingQuick FreezeBiotechnology

The invention provides a superheated steam blanching method for improving the quality of quick freezing edible fungi which belongs to the edible fungi processing technical field and relates to the quick freezing processing of the edible fungi. The invention provides the application of superheated steam technology in the quick freezing processing of the edible fungi. The key technology is to utilize superheated steam for the blanching of the edible fungi. The process comprises edible fungi raw material selecting, cleaning, grading, blanching, quick freezing, packaging and frozen storing. The superheated steam has the characteristics of high temperature, oxygen-free property and low water content. Therefore, the superheated steam can passivate enzyme contained in the edible fungi raw material rapidly and thoroughly and achieve the effect of proper dehydration through the regulation of technological parameters. Thus, the proper water content of quick freezing edible fungi products is maintained. The superheated steam blanching method has the advantages of convenient operation, reliable operation and high production efficiency. The whole process has no escape of nutrients and lowers the quality deterioration of the processing process to the maximum extent, thereby obviously improving the quality of the quick freezing edible fungi products to reach to the longer high quality shelf-life.

Owner:JIANGNAN UNIV

Methods for preserving fresh produce

Methods of preserving fresh produce with a produce preservative which extends the shelf life of fresh produce, particularly cut fresh produce, and preserves the texture, flavor, appearance, crispness, and color of the fresh produce, particularly the exposed surface of the fresh produce, are provided. The method comprises: providing a solution of produce preservative comprising: water; a preservative cation which is selected from the group consisting of a strontium ion, lithium ion, barium ion, aluminum ion, copper ion, ammonium ion, iron ion, manganese ion, potassium ion, or mixtures thereof; and ascorbate ions, or erythorbate ions; wherein the ascorbate ions or erythorbate ions and the preservative cation are present in an ion ratio of preferably from 0.2:1 to 8:1, more preferably 0.75:1 to 8:1, even more preferably from 1:1 to 4:1, yet more preferably 1.5:1 to 3:1; most preferably 1.1:1 to 2.5:1; and, applying said produce preservative to the produce. The invention also relates to fresh produce preserved with the produce preservatives.

Owner:MANTROSE HAEUSER

Method for cultivating tricholoma lobayense by utilizing fungus dregs

InactiveCN101663960APrevent spoilageFruits/vegetable preservation by freezing/coolingHorticultureOysterTricholoma

The invention relates to a method for cultivating tricholoma lobayense by utilizing fungus dregs in the edible fungus production field, which is characterized by utilizing the leftovers, namely fungusdregs, of the edible fungi instead of cottonseed hulls to cultivate the tricholoma lobayense, utilizing the method of biological fermentation to treat the fungus dregs and adding bran and other nutrients to form culture media, and effectively realizing cultivation of the tricholoma lobayense through the process flows of bagging, sterilizing, inoculating, hypha fermenting, cultivating, bag removing, soil covering, fruiting and harvesting, etc., wherein, the leftovers of the edible fungi are used for cultivating oyster mushrooms and needle mushrooms, etc. The method not only realizes resource of the organic wastes and reduces pollution of the organic wastes on the environment by developing and utilizing the leftovers of the edible fungi and conforms to the requirement on striving to developcircular economy encouraged by the state, but also greatly reduces the usage amount of the cottonseed hulls and other substances for cultivation, effectively lowers the production cost of the tricholoma lobayense, increases the cultivation benefits and ensures the biological conversion ratio to be more than 80%. The method utilizes the wastes and attains two objectives, thus being suitable for popularization and application in the rural areas.

Owner:江苏江南生物科技有限公司

A refrigerated fresh keeping method for daylily

InactiveCN1875726AReduce browningSlow bud openingFruits/vegetable preservation by freezing/coolingChlorine dioxideDaylily

The invention discloses a kind of refrigeration and fresh-keeping method for yellow-flower-vegetable, comprise the procedure as follow: (1) poaching :make the yellow-flower-vegetable dip-bleach in chlorine dioxide water solution; (2) draining; preparation cold; the temperature is 2-4DEG C; (3)ozonation: the consistence of ozone is 3-6mg / m3, the treatment time is 3-6 hour; (4) put into fresh-keeping bag; (5) add antistaling agent; (6) put the antistaling agent that the weight is 0.2-0.3% yellow-flower-vegetable weight into the fresh-keeping bag; (7) store: the refrigetion temperature is 2-4DEG C. Adopt the method of the invention, the fresh yellow-flower-vegetable can store two monthes, still keeping the fresh characteristic.

Owner:ZHEJIANG UNIV

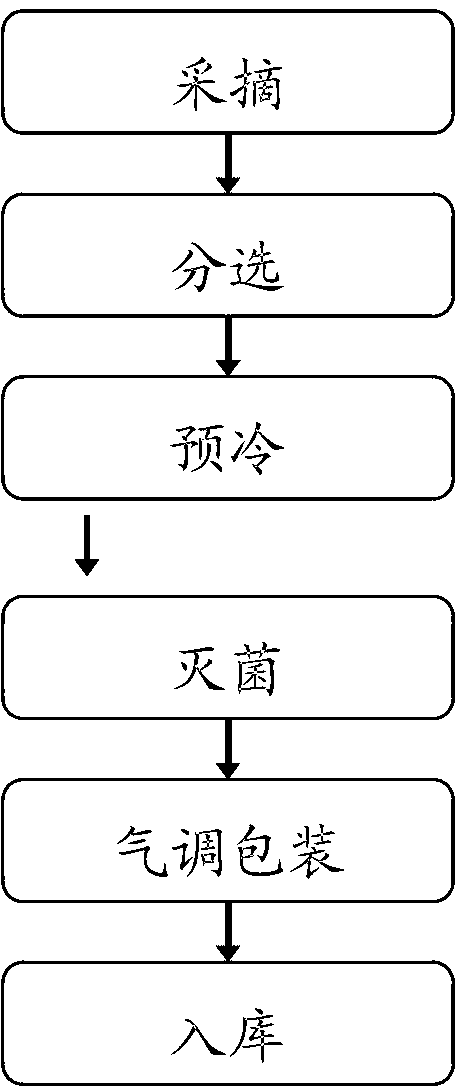

Modified atmosphere freshness-retaining method for vegetables

InactiveCN102793003ASlow breathingExtended shelf lifeFruits/vegetable preservation by freezing/coolingNitrogenModified atmosphere

The invention discloses a modified atmosphere freshness-retaining method for vegetables, comprising the following steps that: (1) the vegetables to be preserved are picked and selected; (2) the vegetables which are picked and selected are subjected to pre-cooling; (3) after pre-cooling, the vegetables are sterilized; (4) the vegetables which are sterilized are put in a packaging container and the mixed gas of oxygen, carbon dioxide and nitrogen is introduced into the packaging container to lead the nitrogen concentration to be 85-95%, the oxygen concentration to be 1-8% and the carbon dioxide concentration to be 1-6%; (5) after modified atmosphere packaging, the vegetables are put in a refrigerator for cold storage. The freshness-retaining method disclosed by the invention can prohibit in vivo respiration of the vegetables and preserve the water in the vegetables, thereby prolonging the freshness-retaining time thereof.

Owner:SUZHOU YAHE PRESERVATION TECH

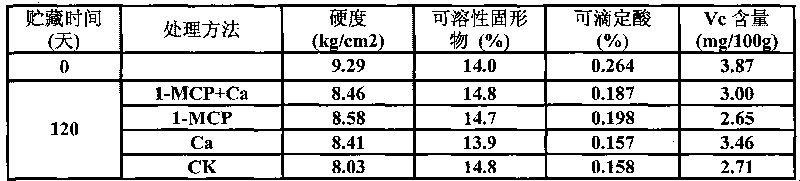

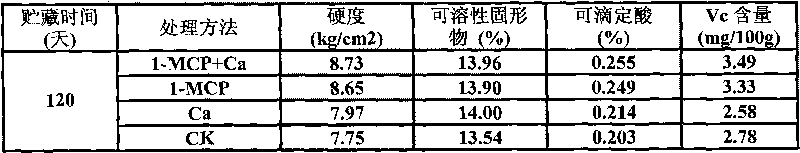

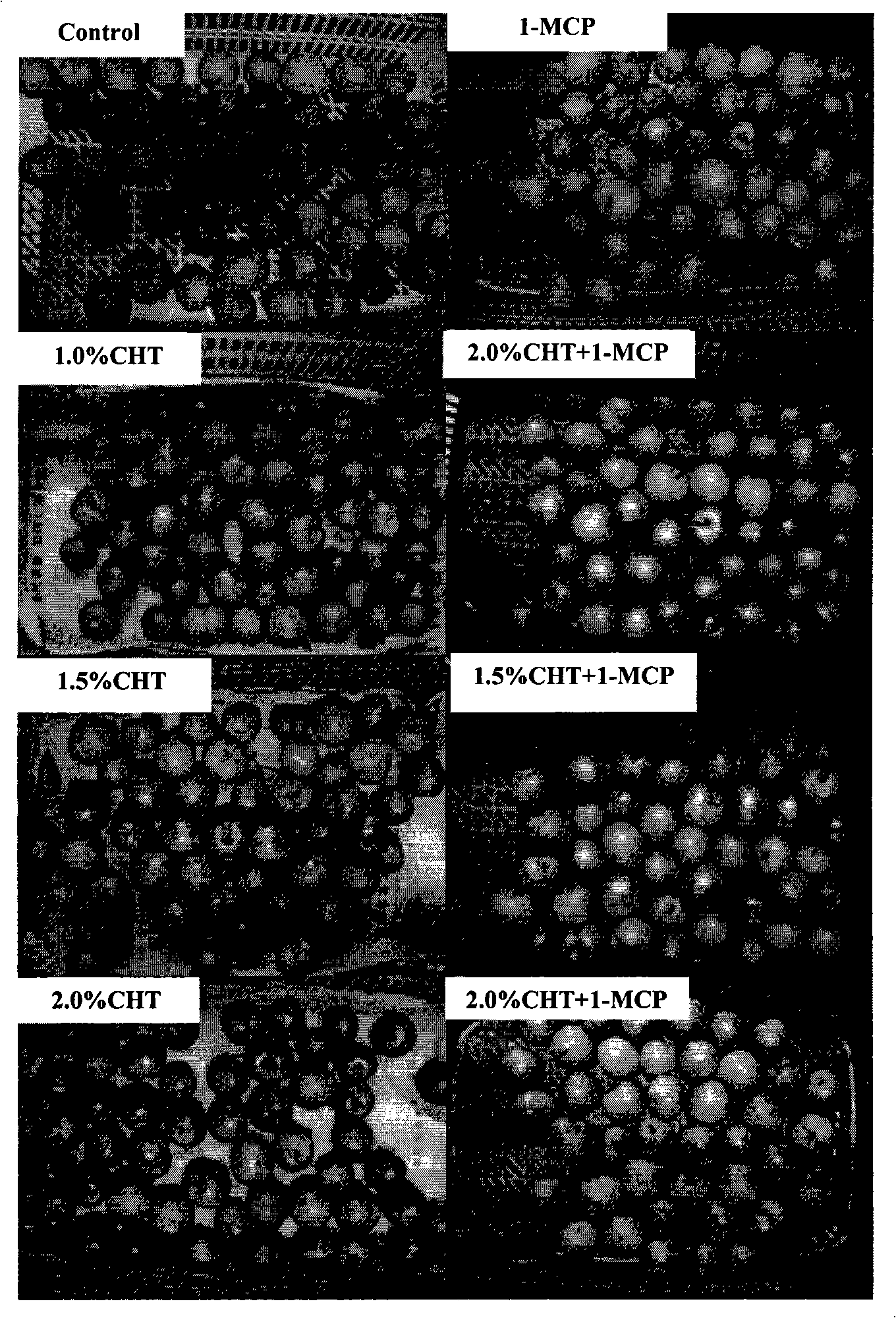

Storage and prevention two-stage compound pretreatment method for apples and pears

ActiveCN101708016AImprove qualityImprove anti-browning effectFruits/vegetable preservation by freezing/coolingPEARPretreatment method

The invention discloses a storage and prevention two-stage compound pretreatment method for apples and pears, which comprises the following steps: firstly, performing fumigation treatment on the picked apples and pears at normal temperature by using 1-methylcycloproene, wherein the content of 1-methylcycloproene is between 500 and 1,000nL L-1 and the fumigation time is between 18 and 24 hours; then, soaking the apples and the pears in 3 to 6 percent aqueous solution of CaCl2 for 3 to 5 minutes; and taking the apples and the pears out, drying the apples and the pears, and refrigerating the apples and the pears by the conventional method. The method can effectively prevent surfaces of the apples and the pears from browning, preserve the senescence of fruit, prevent the flesh of fruit from softening and preserve the nutritional quality, particularly can make contents of hardness, titratable acid, ascorbic acid and Vc of the fruit in a high level index in the later period of storing, is obviously superior to the effect of single treatment, and makes the surface brown index of bagged Huangguan pears declined by 71.6 percent.

Owner:HEBEI ACADEMY OF AGRI & FORESTRY SCI INST OF GENETICS & PHYSIOLOGY

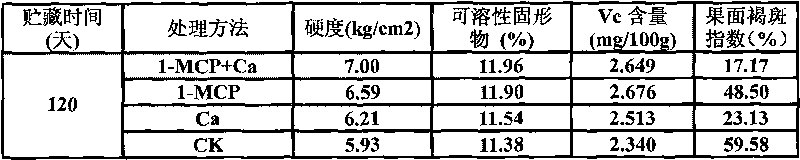

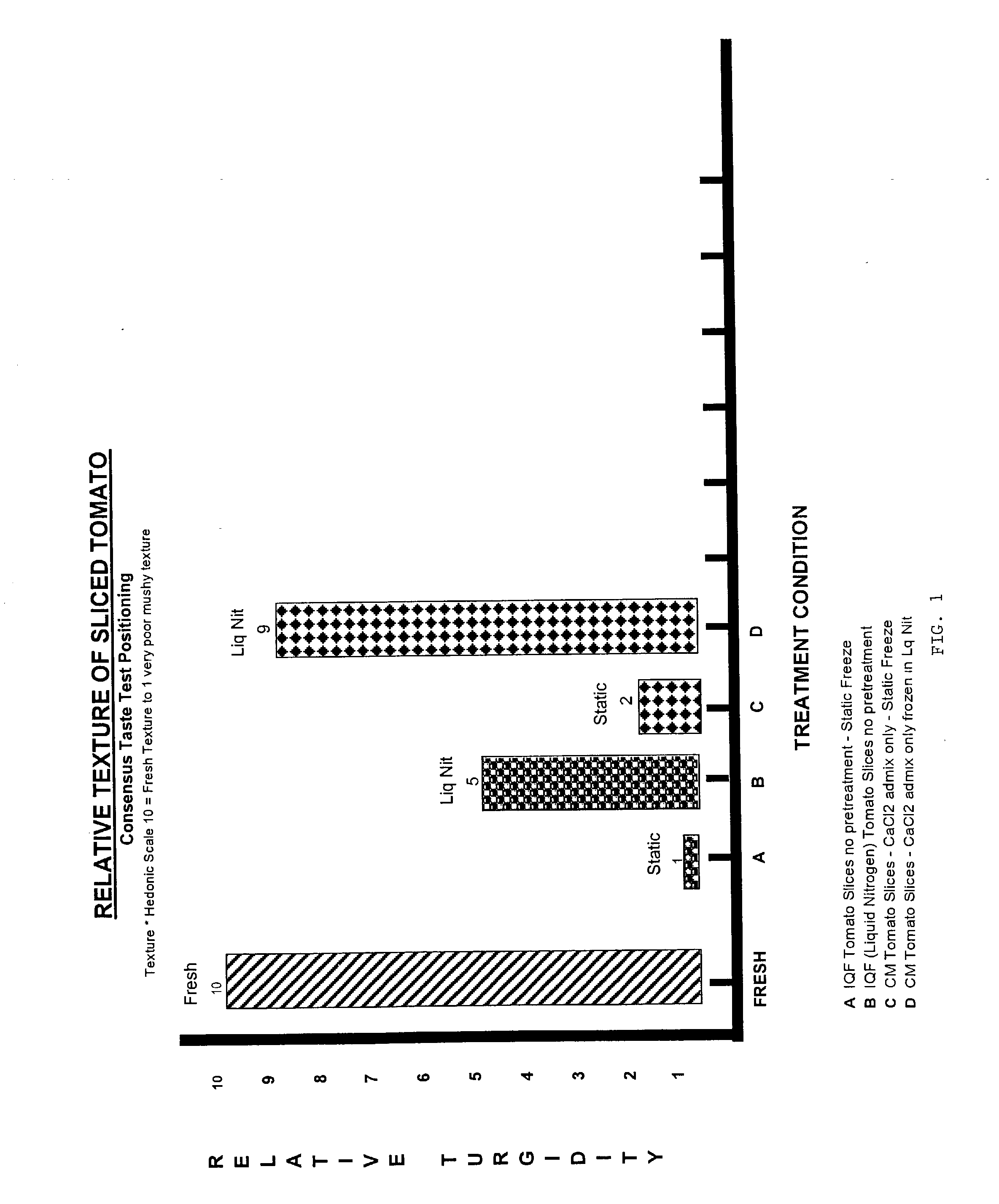

Method for production of frozen vegetables or fruits

InactiveUS20040096559A1Improve featuresLess leachingMilk preservationWort preparationFrozen vegetablesChemistry

The present invention relates to a method for producing frozen and dehydro-frozen vegetables and fruits, wherein the method includes the method of cryogenically freezing the fruits or vegetables.

Owner:CONAGRA FOODS +2

Fresh-keeping method for lichee

InactiveCN1965660AHas antibacterial propertiesImprove ventilation and water permeabilityFruits/vegetable preservation by heatingFruits/vegetable preservation by coatingSulfurEngineering

The invention relates to an antiseptic method of leechee, wherein the invention uses antiseptic polypropylene non-woven cloth, to prepare different fresh-keeping bags, and packs dibutyl fumarate into common non-woven cloth to prepare the non-woven package, while the mass ratio between leechee and fresh agent is 10000:0.1-2; then putts leechee into the fresh-keeping bags, uses lines to tie the bag or uses thermal method to seal the bag, putts into ventilate package box, or putts packed leechee into bamboo frame to be put into fresh-keeping bag. The invention can store leechee at 0-5Deg. C for 30-35days. When the leechee is treated with sulfur, the leechee can be stored at 0-5Deg. C for 90-100day.

Owner:SOUTH CHINA UNIV OF TECH

Method for quickly preparing non-puffing low sugar fruit freeze-dry crisp pieces

ActiveCN101433300AShorten freeze-drying timeLow costFruits/vegetable preservation by freezing/coolingFood preparationFreeze-dryingVacuum drying

The invention discloses a method for quickly preparing non-puffed low-sugar fruit jelly crispy chips and belongs to the technical field of fruit and vegetable food processing. Fruit chips are mainly prepared by the following steps: fruit washing, peeling, pit removal, slicing, pretreatment, freezing, freezing and drying, microwave vacuum drying, hot air drying and packaging. The method adopts freezing and drying in a sublimation drying stage of the fruit chips and controls the water content of products to be 37 percent. The method adopts microwave vacuum drying till the water content of the fruit chips is 10 percent in a resolving drying stage, and then adopts hot air dying to make the terminal water content of the fruit chips less than 5 percent. Low-sugar fruits are apples, pears or peaches which have a sugar degree of between 8 and 10. As post treatment of the freezing and drying, microwave vacuum drying and hot air drying greatly reduce energy consumption. Meanwhile, compared with lyophilized products, products dried by the method have no obvious change in quality and appearance.

Owner:SHANDONG LUHUA GROUP +1

Method for refrigerating and preserving juicy peach fruits

InactiveCN101978837AImprove cold resistanceImprove adaptabilityFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingCold injuryRefrigeration

The invention relates to the technical field of agricultural product preservation, and aims to provide a method for refrigerating and preserving juicy peach fruits. The method comprises the following steps of: precooling the juicy peach fruits; radiating the fruits by using ultraviolet rays; cooling gradually; refrigerating the fruits; heating gradually; and delivering the fruits from a warehouse. The cold injury of the juicy peach fruits in refrigeration can be remarkably prevented by treatment of the ultraviolet radiation and gradient temperature change, the rot is reduced, and the refrigeration preservation period of the juicy peach can reach 60 days. The method is convenient and effective to operate, is convenient to popularize and use, and is suitable for large-scale production.

Owner:ZHEJIANG UNIV

Processing method of flexible package fresh bamboo shoots

InactiveCN101731312APreserve the flavorRetain nutrientsFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by heatingVitamin CEngineering

The invention belongs to the technical field of agricultural and sideline product processing, in particular to a processing method of flexible package fresh bamboo shoots, comprising the specific technological processes: sorting, cleaning / tidying, blanching (killing out), cooling, screening, adding preservative, vacuum packaging, sterilizing, cooling and obtaining finished products. Compared with the current processing method in the market, the invention has unique technology and adopts a sulphur-free formula; the prepared flexible package fresh bamboo shoot has the advantages of high quality, high safety, convenient eating, small loss of vitamin C, convenient storage and transportation, long quality guarantee period (12 months for refrigeration, and 6 months for normal temperature) and the like. The flexible package fresh bamboo shoot prepared with the invention improves the economy of bamboo shoots and is suitable for diversifying consumer demand at present.

Owner:JIANGNAN UNIV

Method for processing dewatered fruits and vegetables

InactiveCN101129146AImprove hardness and brittlenessColor unchangedFruits/vegetable preservation by freezing/coolingFood preparationVacuum dryingFruits and vegetables

Owner:SOUTH CHINA AGRI UNIV

Combined refreshing method for prolonging shelf life of fresh vegetable lotus seed

InactiveCN102057981AReduce breathing intensityDelay agingFruits/vegetable preservation by freezing/coolingRoom temperatureModified atmosphere

The invention discloses a combined refreshing method for prolonging the shelf life of a fresh vegetable lotus seed, belonging to the technical field of fruit and vegetable refreshing and storing. The fresh lotus seed has the characteristics of difficulty in refreshing and storing and acceleration for the deterioration of quality and taste. The high-quality raw materials can be obtained by controlling the harvesting maturity and harvesting in due time according to the unified standard. By adopting vacuum pre-cooling, the field respiration heat of the fresh lotus seed can be quickly eliminated and the quality loss can be prevented. According to the invention, by using 1-methylcyclopropene (1-MCP) to fumigate on the fresh lotus see at lower temperature or room temperature, the ageing and the late maturity of the lotus seed can retarded; by pressurizing the mixed gas of argon gas and xenon gas or the mixed gas of argon gas and krypton gas at the pressure of 20MPa for one hour to carry out the water structured treatment for the fresh lotus seed, the activity of water molecules and the activities of various enzymes in the fresh lotus seed can be reduced and the metabolic activities of the lotus seed can be inhibited. Meanwhile, by combining with modified atmosphere packaging (MAP), the fresh lotus seed is cold stored at the temperature of 2-4DEG C so as to well maintain the quality and the taste of the lotus seed. The lotus seed can be refreshed for 15-16 days; and the shelf life of the lotus seed is 11-13 days longer than that of the untreated lotus seed stored at normal temperature and is 8-10 days longer than that of untreated lotus which is cold stored .

Owner:建德市山木食品有限公司 +1

Method for improving quick-freezing fruit vegetables thawing quality through low-frequency ultrasound wave

InactiveCN101138362AImprove defrosting qualityShorten freeze timeFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingOperational costsUltrasonic assisted

A method for improving the unfreezing quality of fast frozen fruit and vegetables with low-frequency ultrasonic belongs to the processing technical field of fruit and vegetable food. The present invention adopts ultrasonic for freezing in the process of fast freezing; the process is that the raw materials of fruit and vegetables are selected, cleaned and burnt to kill the enzyme; and then the materials are cooled, refrigerated and frozen with ultrasonic; at last the materials are packed up. The present invention adopts the process that the ultrasonic processing is combined in the process of dipping and freezing fruit and vegetable and improves the unfreezing quality of the fast frozen fruit and vegetables; the present invention is characterized by a short freezing time, excellent initial shape maintenance and low operational cost.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

Kiwi fresh fruit preservation technique

InactiveCN101223906ANo pollution in the processEasy to operateFruits/vegetable preservation by freezing/coolingVacuum pumpingActinidia

The invention relates to a preservative technique for fresh kiwifruit, which comprises technique processes of cold storage disinfection, precooling, bagging, air regulate case vacuum pumping, air distribution, preservation and unhouse packaging. The technique of the invention carries out laboratory study test on the storage of the fresh kiwifruit, the test shows that the kiwifruit can be preserved for more than 200 days with average fruit firmness more than or equal to 3.0kg / cm<2>, fruit firmness rate more than or equal to 90 percent, commercial fruits rate more than or equal to 95 percent, Vc keeping-rate more than or equal to 80 percent and freshness index more than or equal to 0.90. Pilot scale study was carried out in an air conditioned storehouse in Zhouzhi County Shanxi Province in 2006 by the technique of the invention to store 50 tons of Hayward kiwifruit for 215 days with commercial fruits rate of 96 percent. The invention has the advantages of simple operation, long preservation period, good preservation effect, no environmental pollution, obvious economic benefit, etc., which can be widely applied.

Owner:SHAANXI NORMAL UNIV

Processing and fresh-keeping method for fresh-eating walnut

InactiveCN101209067ACrunchy and sweetGood tasteFood preparationFruits/vegetable preservation by freezing/coolingFreeze thawingBiotechnology

The invention relates to a processing and preservation method for eating fresh walnut, which includes the fresh walnuts is selected after being picked firstly; attacked and rotten walnuts are picked out; a freeze thawing method is utilized to shuck off the green peels of the walnuts and then the freeze thawing method is utilized to shuck off the seed capsules of the walnuts; the walnut meat, the seed capsules of which are shucked off, is dipped in a VC solution with the chroma of 0.1 to 0.8 percent for 1 to 2 hours to carry through color protection; simultaneously, the water content is controlled and then vacuum or inert gas packing is carried through by classification; then the product is frozen to keep fresh until being sold and used. During the whole processing and preservation process, no antiseptic and antistaling agent are used, thus according with the requirement of nuisance-free products and belonging to green healthy food. The prepared walnut meet keeps the fragrance of the walnuts with the flavor of crisp and sweet; the nutrition matters are not washed away and the flavor as well as the quality of the walnut meet is better; and the walnut meet is convenient to eat. The invention has the advantages of keeping the nutrition component of the walnut meet to the utmost extent, improving the using value and eating quality, belonging to nuisance-free green food and being convenient to eat, etc.

Owner:SHANDONG INST OF POMOLOGY

Glass-state storage method for modifying quick-frozen conditioning fruit-vegetable quality

InactiveCN1676006AAvoid generatingOvercome the problem of low temperature fractureFruits/vegetable preservation by freezing/coolingLiquid stateEngineering

The present invention relates to a vetrification storage method for raising quality of fast-frozen fruit and vegetable. Said method mainly includes the following steps: (1) selecting vegetable and fruit raw material, washing, peeling (coring) and slicing / block cutting; (2) scalding (100 deg.C, 15 sec.) and cooling; (3) conditioning (vacuum osmosis treatment); (4) measuring glass-transition temperature of said raw material; (5) making the conditioned raw material undergo the processes of liquid nitrogen or liquid state CO2 quick dip freezing treatment so as to make the temperature of said raw material be quckly reduced to the required temperature, then packaging; and (6). cold-storing the frozen raw material in freezer chest (temperature can be regulated below the glass transition temperature of said raw material.

Owner:JIANGNAN UNIV

Fresh-keeping method for muskmelon

ActiveCN102823644AAdvantages of preservation methodLow process pollutionFruits/vegetable preservation by coatingFruits/vegetable preservation by freezing/coolingWaxSide effect

The invention discloses a fresh-keeping method for muskmelons; the method comprises the following specific steps: 1), selecting medium well-done muskmelons, picking, performing an overshadow treatment on the picked muskmelons by using a reflecting film; 2), performing 1-MCP (1-methylcyclopropene) fumigation on the muskmelons; 3), soaking the muskmelons in water; 4), blowing to dry the surfaces of the muskmelons; 5), spraying a fruit wax containing a fresh-keeping agent on the muskmelons; 6), drying the surfaces of the muskmelons; 7), putting the muskmelons in a refrigerator in which the temperature is 0 DEG C to 1 DEC C and the relative humidity is 75% to 85%, and pre-refrigerating for 1-2 days; 6), packaging each muskmelon by a micro-pore modified atmosphere fresh-keeping film; and 9), suspending the packaged muskmelons in the refrigerator in which the temperature is 0 DEG C to 1 DEC C and the relative humidity is 75% to 85%. The fresh-keeping method for the muskmelons is reliable and effective, and is low in pollution and side effect.

Owner:TIANJIN JIESHENG DONGHUI FRESH PRESERVATION TECH

Process for preparing reduced fat frozen potato strips

ActiveUS20060177544A1Beer brewingFruits/vegetable preservation by coatingAlternative methodsSuperheated steam

A method of preparing potato strips includes cutting potatoes into strips, blanching the strips, dipping the strips in an aqueous solution containing salt, color additives, SAPP or other additives, and drying the strips. The dry strips are parfried, partially deoiled, washed in water, cooled, exposed to superheated steam, dried in an impingement oven, cooled and frozen. The strips, before parfrying, may be coated with a batter. The frozen strips may be reconstituted by heating in an oven. In alternative methods, frozen strips are prepared with no or virtually no fat content.

Owner:LAMB WESTON INC

Method for preparing fingered citron juice

InactiveCN101099588AIncrease the juice yieldIncrease profitFruits/vegetable preservation by freezing/coolingFruit juiceCITRUS MEDICA FRUIT

The present invention discloses a fruit juice extraction method, in the concrete, it relates to a freeze-juicing method of chayote, belonging to the field of food processing technology. Said method includes the following steps: firstly, freezing chayote fruit, after the chayote fruit is completely frozen, defreezing, crushing the defrozen chayote fruit and extracting its juice, adding the water into the fruit dregs to make secondary juice extraction, combining two juices so as to obtain the invented chayote fruit juice.

Owner:CHINA AGRI UNIV

Method for improving the freezing speed and quality of litchi chinensis through variable-frequency ultrasonic enhancement

ActiveCN103168828ASame sizeFast freezingFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingLoss ratePre treatment

The invention discloses a method of improving the freezing speed and quality of litchi chinensis through variable frequency ultrasonic enhancement. The method comprises the following steps: pretreating fresh litchi chinensis, precooling, adding refrigerating fluid for impregnating, and conducting variable-frequency ultrasonic treatment, namely treating for 20-60s under the frequency of 20-40kHz by adopting the ultrasonic wave with the power of 40-300W, and then increasing the frequency to 40-80kHz for treating for 20-60s under the equal power. With the method, the freezing speed of the litchi chinensis can be increased, the freezing time can be shortened, and unfrozen juice loss rate can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

Color protection fresh keeping method of fresh cut tuber

InactiveCN101518279AGood color protectionLow costFruits/vegetable preservation by heatingFood preparationSugarPlant Tubers

The invention discloses a color protection fresh keeping method of fresh cut tubers, which belongs to the technical field of fruit and vegetable fresh keeping. After being peeled, sliced, soaked by color protecting liquid, blanched, soaked by sugar, drained and packed, sampled fresh or stored tuber raw materials are refrigerated without suffering from browning reaction. The invention is easy to operate, has short period and can be widely used for keeping fresh cut vegetable fresh, such as potatoes, sweet potatoes, yams, and the like which are prone to browning reaction and provides a new thought for increasing the edible safety of clean tuber vegetables and extending the shelf life of products.

Owner:CHINA AGRI UNIV

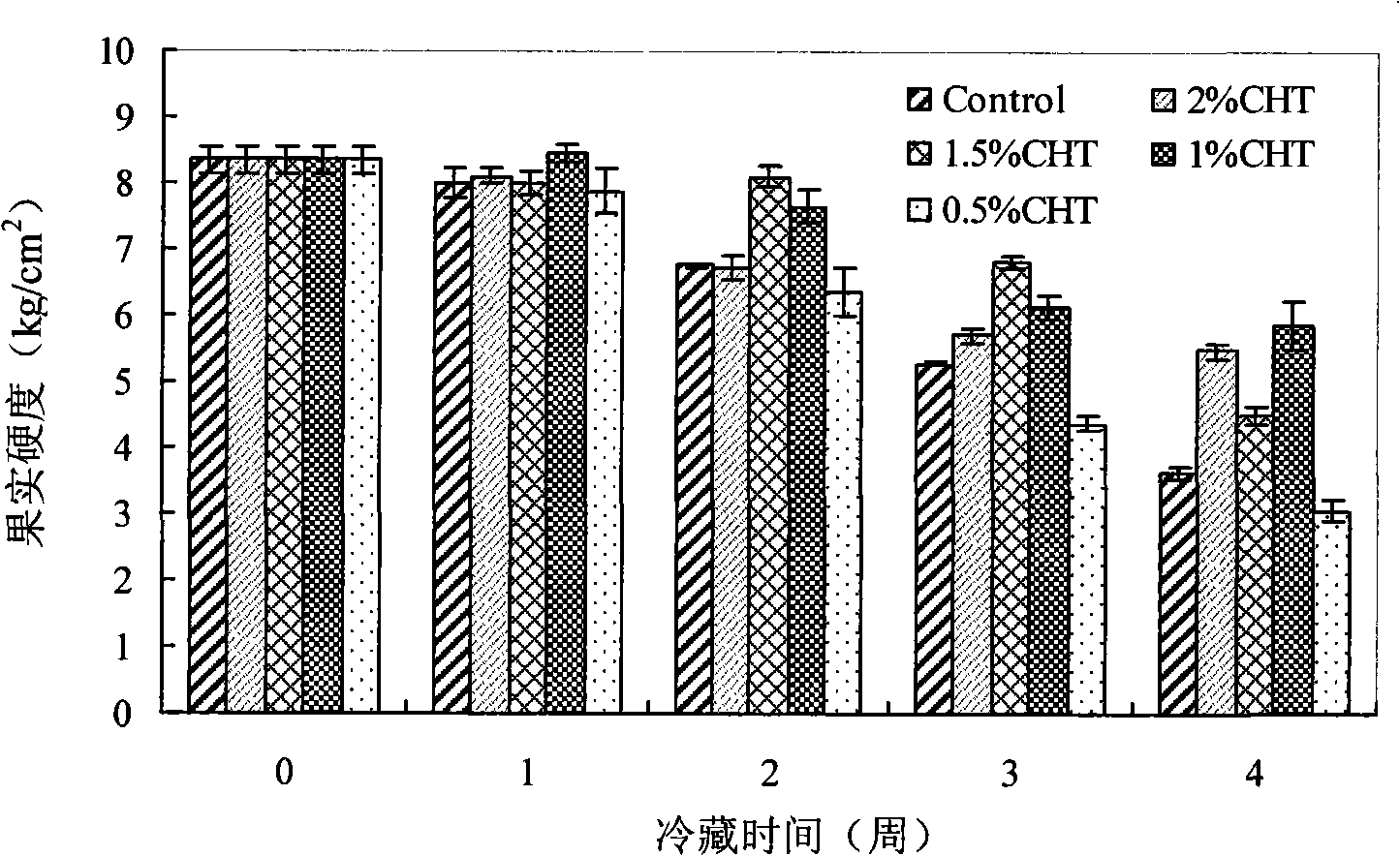

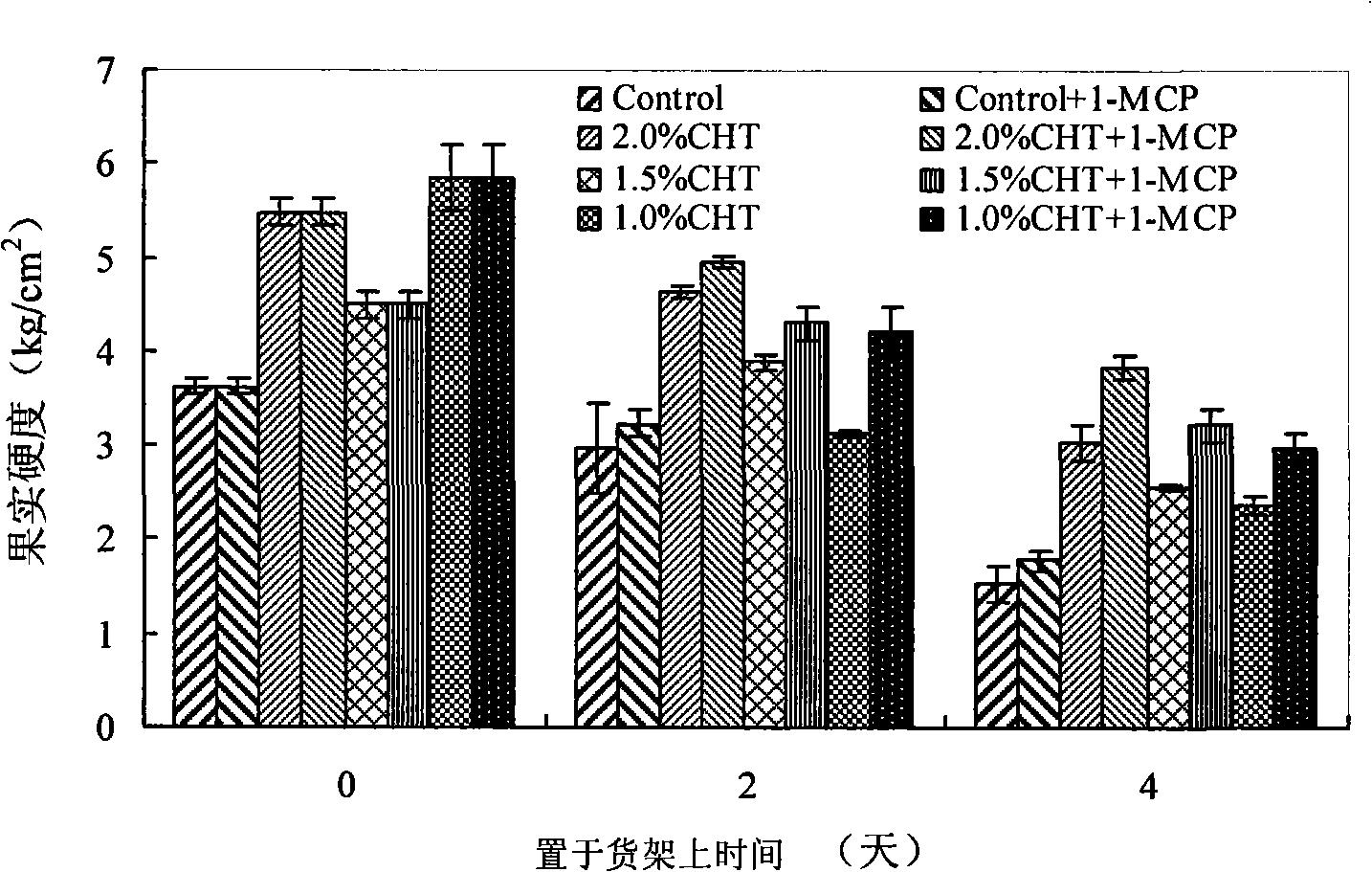

Fresh-keeping method of plum fruit

InactiveCN101301000AImprove qualityAvoid chillingFruits/vegetable preservation by freezing/coolingRoom temperatureHealth safety

The invention discloses a fresh keeping method for plum fruit, comprising the following steps: (1) immersing plum fruit in chitosan solution with a concentration ranging from 0.1g / 100ml to 3.0 g / 100ml at room temperature; (2) refrigerating the plum fruit immersed in step (1); (3) when entering into shelf life, keeping refrigerated plum fruit in an enclosed device, which contains 1-methyl cyclopropene gas with a concentration ranging from 0.5 mul / L to 5.0 mul / L, for 12-24 hours at room temperature; wherein, the concentration of 1-methyl cyclopropene gas is preferably in the range of from 1.0 mul / L to 2.0 mul / L. The fresh keeping method for plum fruit of the present invention has the advantages of high food health safety, simple application, easy spread, little investment but quick result, low price, broad market, notable economic and social profit etc, which is suitable for China and has great development and application value.

Owner:CHINA AGRI UNIV

Three-stage composite pretreating method for delaying fresh time of putresible fruit and vegetable

InactiveCN1709075AReduce weight lossExtend fresh storage periodFruits/vegetable preservation by freezing/coolingCellular respirationPretreatment method

The present invention relates to a three-stage combined pretreatment method for prolonging fresh-keeping period of putrefactive fruit and vegetable. Said method includes the following processes: according to conventional method selecting fruit and vegetable, washing and grading, controlling water content, quickly vacuum cooling so as to reduce respiration action of fruit and vegetable, utilizing high-pressure mixed gas to make water content be structured to deactivate enzyme activity of fruit and vegetable, finally applying nano silver antibacterial film to reduce putrefactive rate of fruit and vegetable so as to implement invented goal.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com