Patents

Literature

148results about How to "Fast freezing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Probiotic ultralow temperature refrigeration technology and applications thereof in probiotic preparation

ActiveCN103333840AHigh activityLow freezing pointBacteriaFood preparationBacterial strainRefrigeration

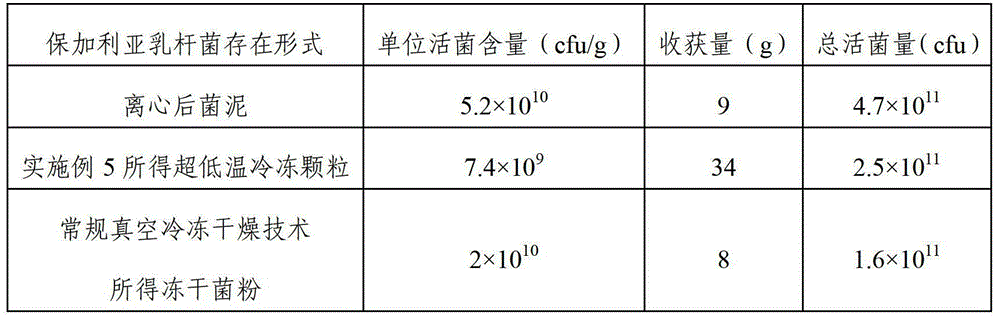

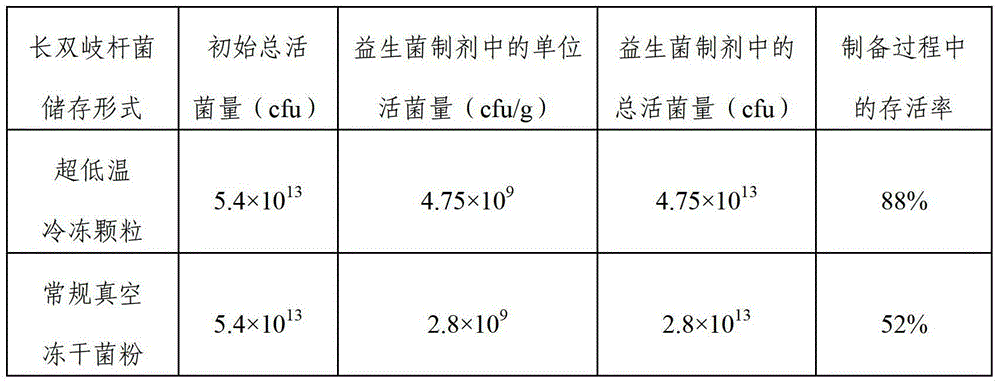

The invention discloses a probiotic ultralow temperature refrigeration technology, a formula of a total-salt cryoprotectant which is suitable for the probiotic ultralow temperature refrigeration technology, and probiotic ultralow temperature refrigeration particles prepared by using the probiotic ultralow temperature refrigeration technology. The probiotic ultralow temperature refrigeration technology comprises following steps: (1) preparing a fermentation medium; (2) culturing probiotics; (3) centrifuging; (4) preparing the cryoprotectant; (5) adding the cryoprotectant; and (6) quick-freezing and moulding. The invention also provides a probiotic preparation prepared by using the probiotic ultralow temperature refrigeration particles, and a preparation method of the probiotic preparation. The probiotic ultralow temperature refrigeration particles are probiotic refrigerated bacterial strains which do not need to be dried and possesses advantages of fast refrigeration speed, high living bacterial rate and excellent rehydration performance. The probiotic ultralow temperature refrigeration particles contain water, can be dissolved in solutions more quickly, and are capable of preventing probiotic cells from damage caused by rehydration of normal low temperature refrigeration dried probiotic powder, and increasing the living bacterial rate of the probiotic preparation greatly.

Owner:THANKCOME BIOLOGICAL SCI & TECH CO LTD

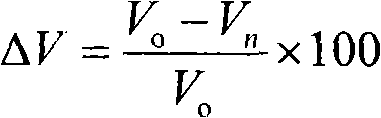

Ultra-low temperature freeze-thaw cycle test method of cement-based material

InactiveCN101788442ASpeed up the freeze-thaw damage processAccelerated freeze-thaw damageWeighing by removing componentAnalysing solids using sonic/ultrasonic/infrasonic wavesFreezing thawingLiquid state

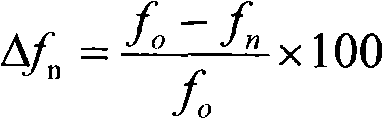

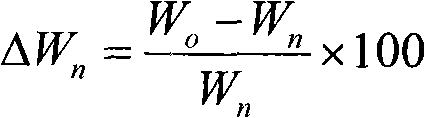

The invention relates to an ultra-low temperature freeze-thaw cycle test method of a cement-based material. In the method, liquid nitrogen is taken as a freezing raw material, and with utilization of the ultra-low temperature effect of the freezing raw material in gasification, the matrix of the cement-based material is damaged from the gel pore level so as to speed up freeze-thaw damage progress and quickly evaluate the freezing resistance and durability of the cement-based material. The invention achieves the convenience and quickness of the freeze-thaw cycle test of the cement-based material, and solves the problem of inconveniences of construction work and quality control due to slow process of the freeze-thaw cycle test. Moreover, the invention has the advantages of convenient, fast, good economic benefit and the like.

Owner:CHONGQING UNIV +1

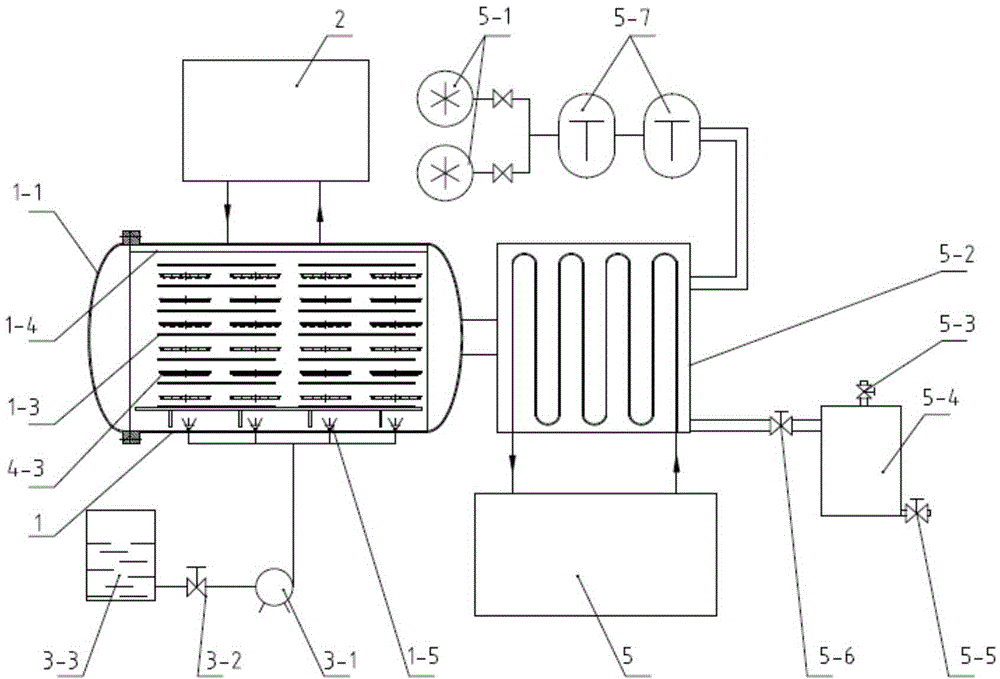

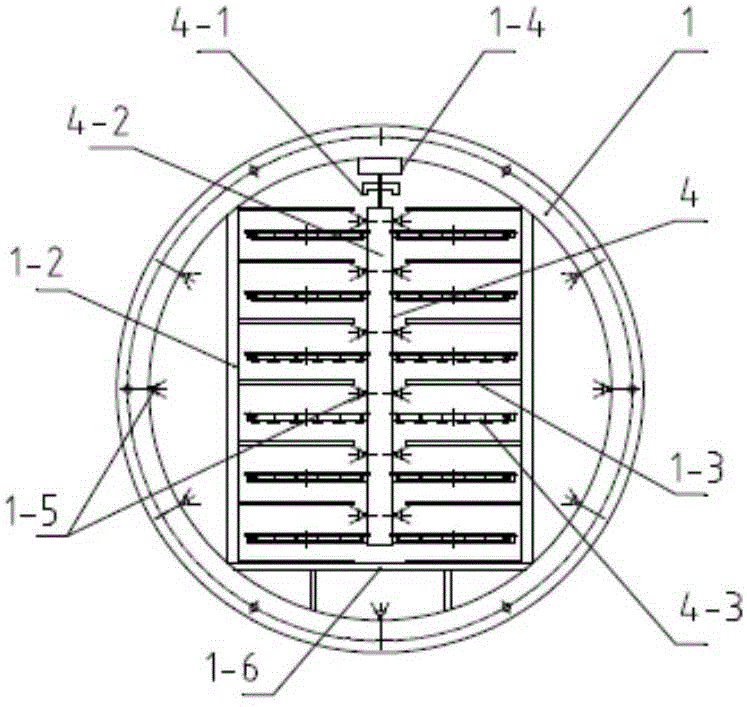

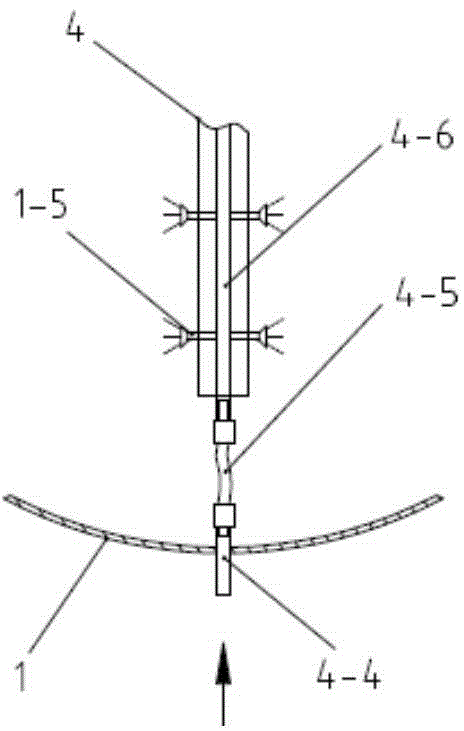

Integrated radiation vacuum freeze-dry device and method

ActiveCN104596206ALow costSimple processFruit and vegetables preservationDrying solid materials without heatWaxFreeze-drying

The invention relates to an integrated radiation vacuum freeze-dry device and method, further relates to a corresponding method, and belongs to the technical field of food devices. The freeze-dry device is characterized in that a vertical side bracket is fixed in a vacuum warehouse body, the side bracket extends out of heating shelves, and the heating shelves and a heat carrying agent heater form a heat exchange cycle system; an accommodating interval of a hanging material vehicle is formed between the two heating shelves on both sides, the hanging material vehicle comprises a vertical suspension which extends out of level trays which are positioned between the two adjacent level hollow heating shelves; spraying nozzles are distributed in the vacuum warehouse body, and are connected to a high pressure water conveying system through a pipeline. Through the adoption of the freeze-dry device disclosed by the invention, the low cost food freezing is realized, and all of the technological processes namely freezing and drying are completed once in the same device, so that the technological processes are simplified, the efficiency is obviously improved, and the freeze-dry device is suitable for various food materials, such as food materials which contain less water, are compact in texture or have wax coat surfaces.

Owner:JIANGSU BOLAIKE FROZEN TECH DEV CO LTD

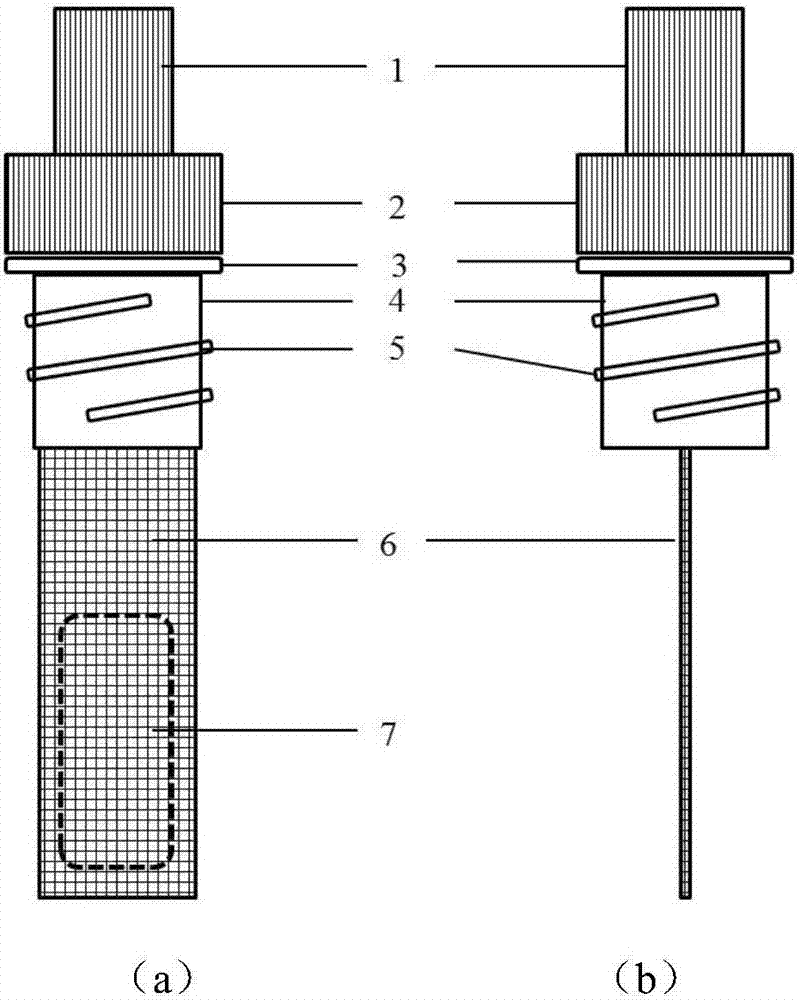

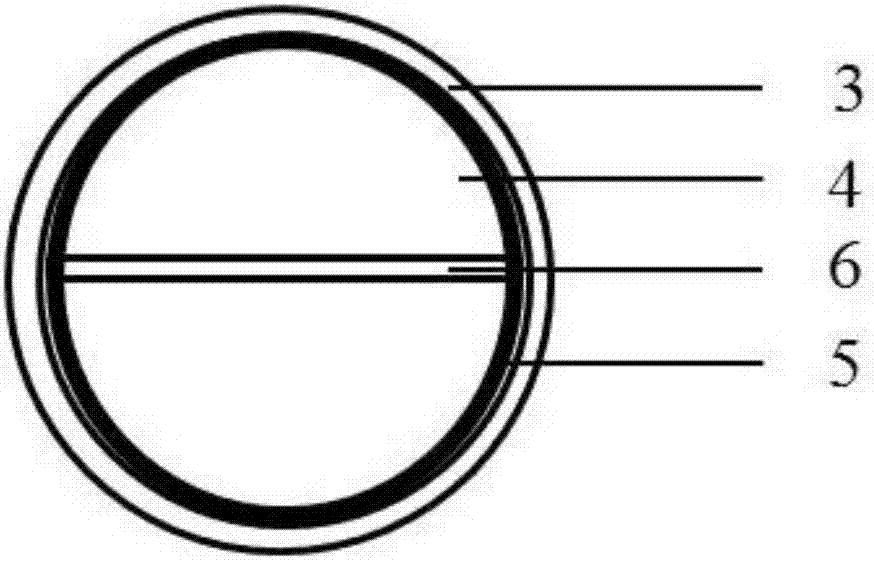

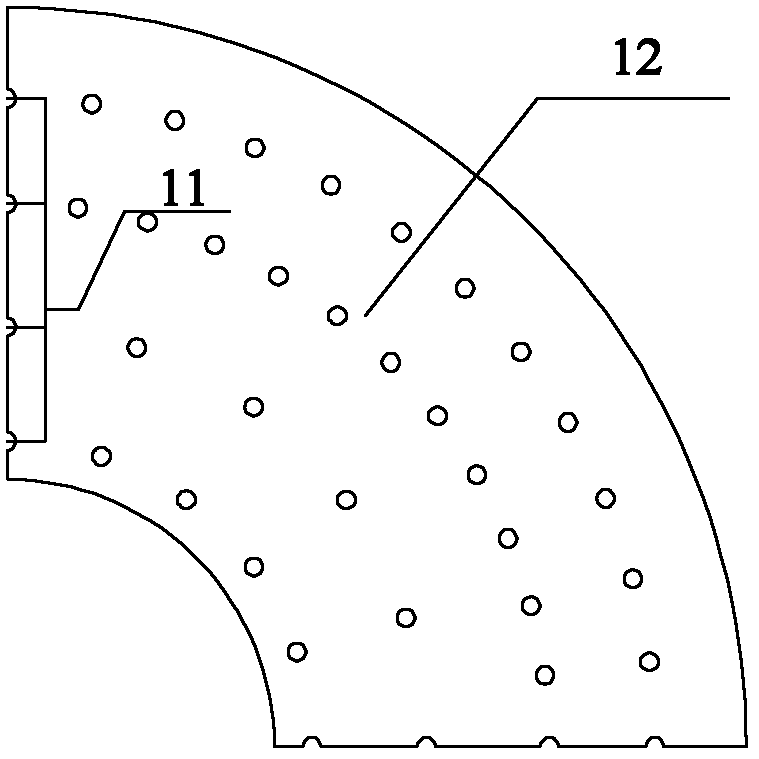

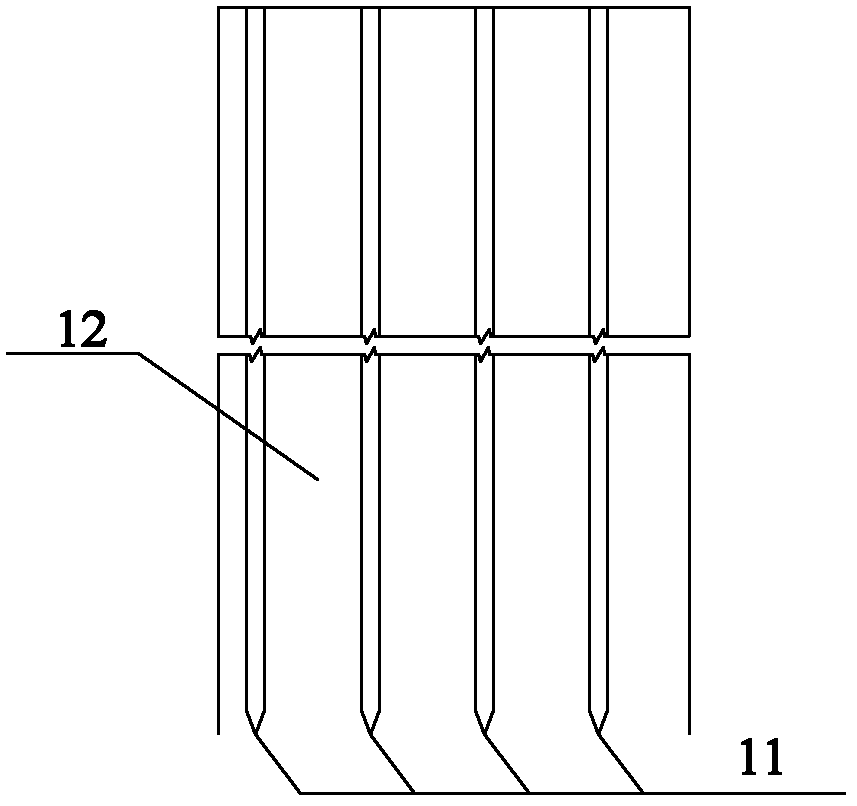

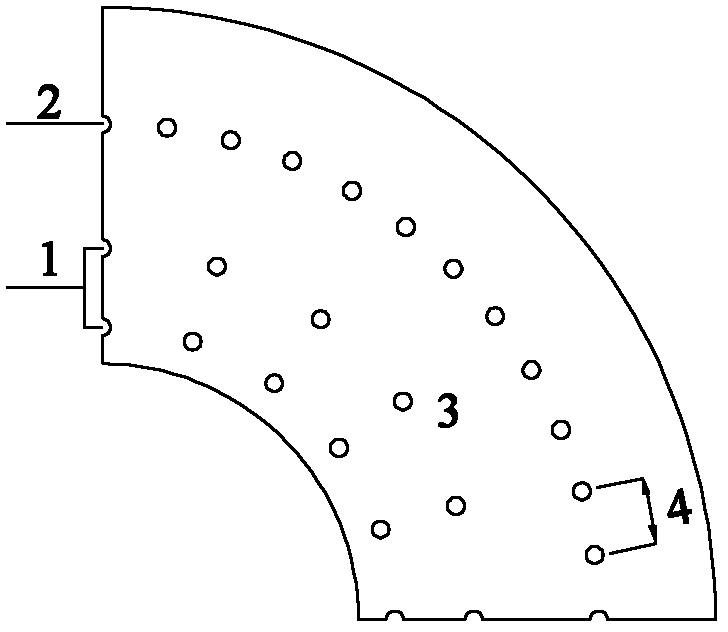

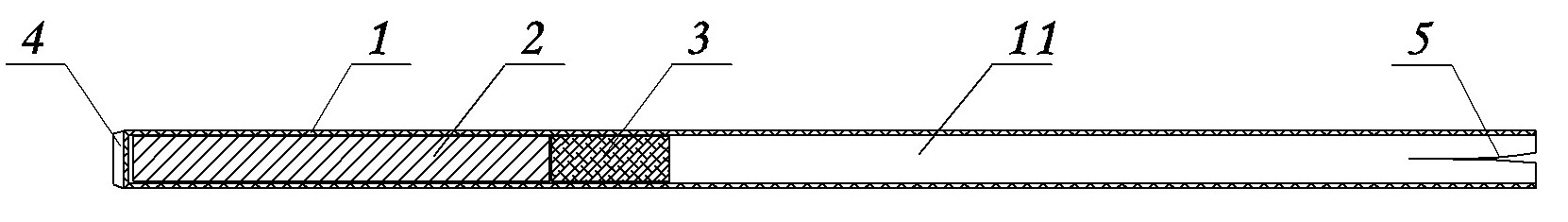

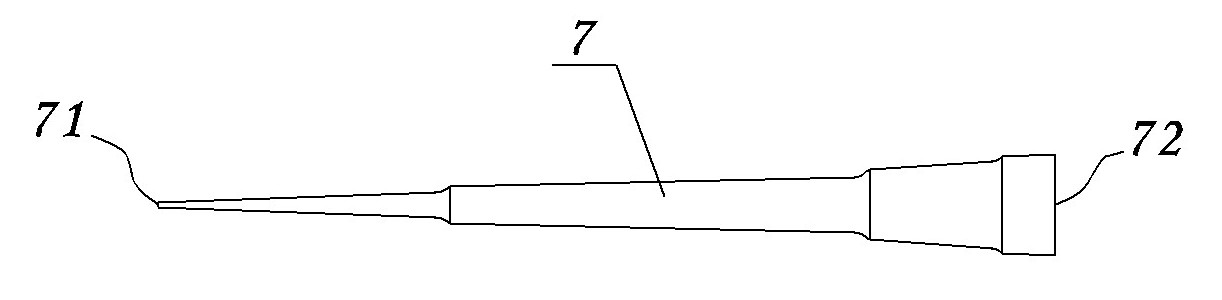

Cryopreservation method for oocyte / embryo and frozen carrier thereof

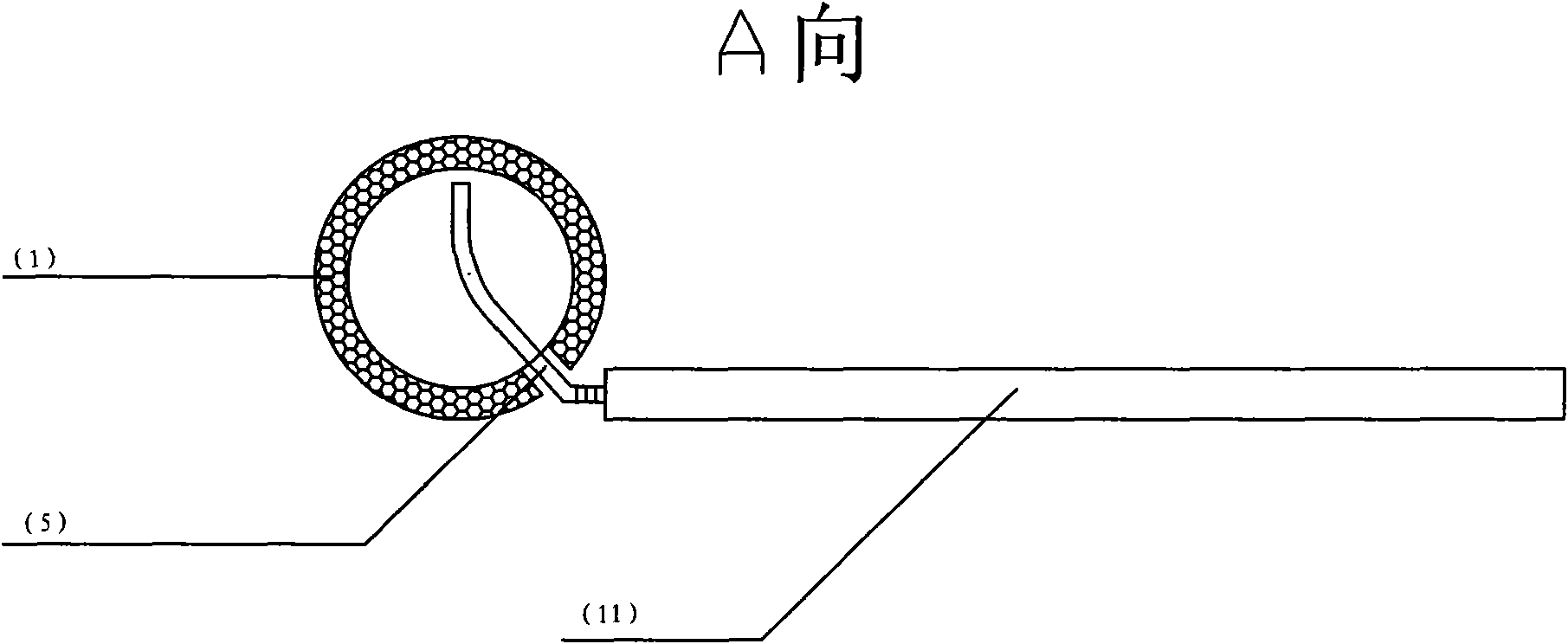

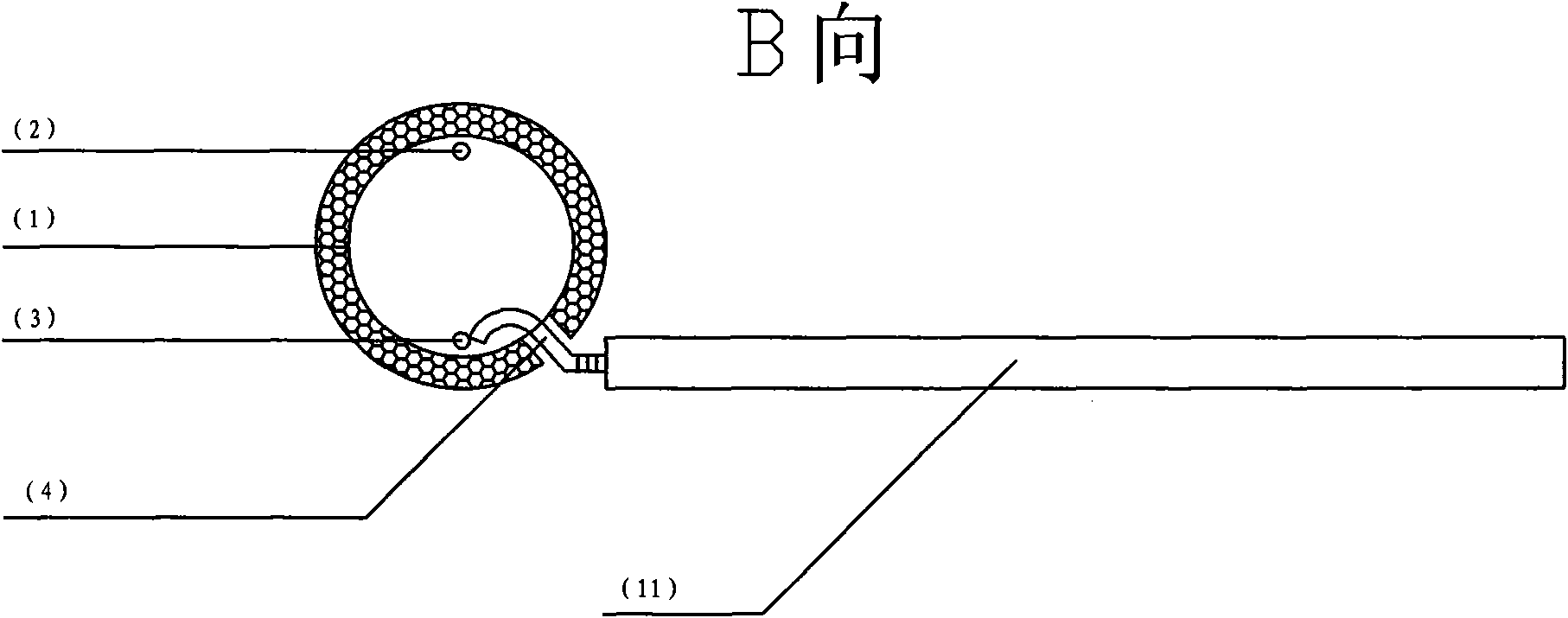

The invention relates to a method for conserving human bodies, animals or parts thereof and a frozen carrier thereof, in particular to a cryopreservation method for oocyte / embryo and a frozen carrier thereof. The method comprises the following steps: a step for preparing refrigerating fluid, a step for preparing thawing solution, a step for freezing and a step for thawing. The method is characterized in that the frozen carrier used in the step for freezing and the step for thawing is a frozen net. The frozen net includes a net body and a net handle. The invention provides the cryopreservation method for the oocyte or the embryo and the frozen carrier thereof. The method is characterized by simple operation, fast speed and high efficiency.

Owner:CHINA AGRI UNIV

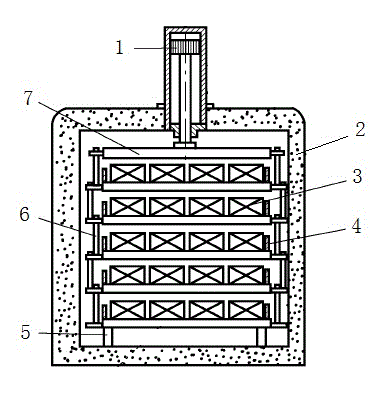

Contact type freezing device

InactiveCN104534777AFast freezingLighting and heating apparatusStationary refrigeration devicesHydraulic cylinderContact type

The invention discloses a contact type freezing device which comprises a freezing chamber. Operation doors are arranged on the two sides of the freezing chamber. Metal freezing plates, a hydraulic cylinder, connecting hinges and a cooling agent pipe are further arranged. The metal freezing plate is hollow. The hydraulic cylinder is arranged in the middle of the top of the freezing chamber. The vertically-arranged metal freezing plates are arranged in the freezing chamber. The adjacent metal freezing plates are connected through the connecting hinges. Compressed springs are arranged between the adjacent metal freezing plates. The metal freezing plate at the uppermost portion is connected with a piston rod of the hydraulic cylinder. One end of the cooling agent pipe is communicated with hollow parts of the metal freezing plates. The other end of the cooling agent pipe is communicated with an external cooling agent source. The contact type freezing device can improve freezing speed.

Owner:CHONGQING XINTAIFA FOOD

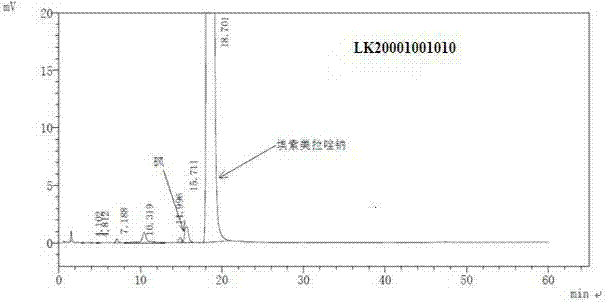

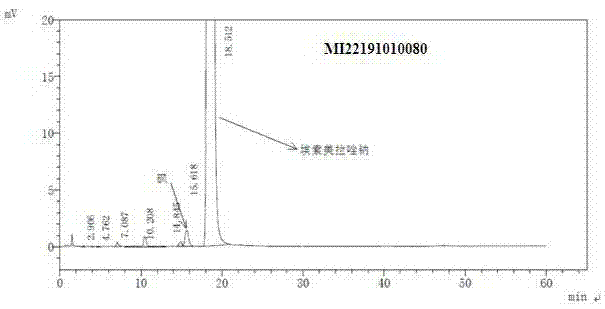

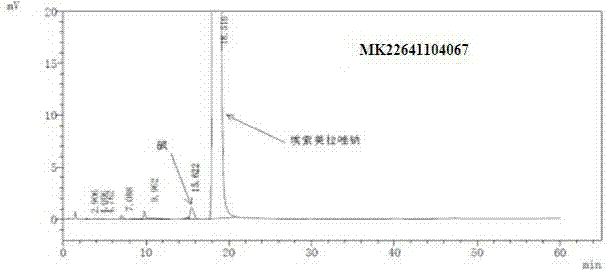

Pharmaceutical composition containing esomeprazole sodium, and preparation method thereof

ActiveCN102813651AEasy to shapeReduce contentOrganic active ingredientsPowder deliveryEsomeprazole SodiumPharmaceutical drug

Owner:CHENGDU GUOHONG PHARMA

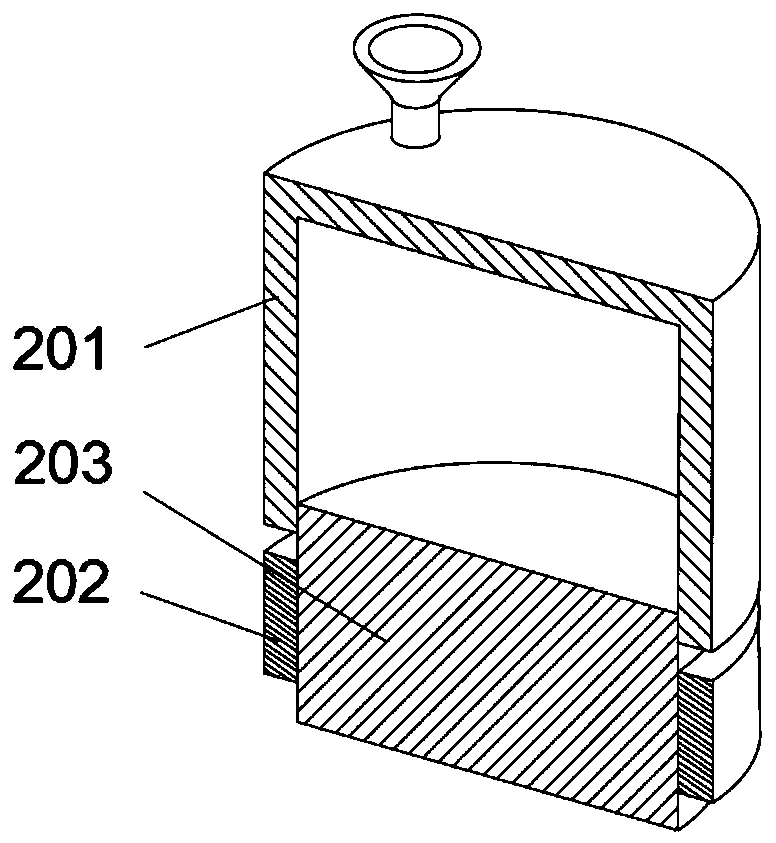

Large ovarian tissue vitrification freezing carrier and application thereof

PendingCN107535482ALow priceWide selection of materialsDead animal preservationGerm cellsVitrificationEngineering

The invention discloses a large ovarian tissue vitrification freezing carrier. The carrier consists of a carrier inner core and an outer sleeve, wherein the carrier inner core is in threaded connection with the outer sleeve, maintaining high airtightness and preventing cross infection of the ovarian tissue; meanwhile, the user operation is also facilitated; the carrier inner core consists of a handheld part, a cap part, a support part and a bearing part sequentially from top to bottom; the bearing part is clamped and fixed by the support part; when in use, a large ovarian tissue is put on an end part of the bearing part, away from the support part; the end part is a large ovarian tissue loading area; experiments prove that by using the carrier disclosed by the invention, the permeation efficiency of a refrigerant is improved; moreover, the operation is simple, the price is low, batch storage of large ovarian tissues is convenient, and the carrier is suitable for promotion and application.

Owner:SHANDONG UNIV QILU HOSPITAL

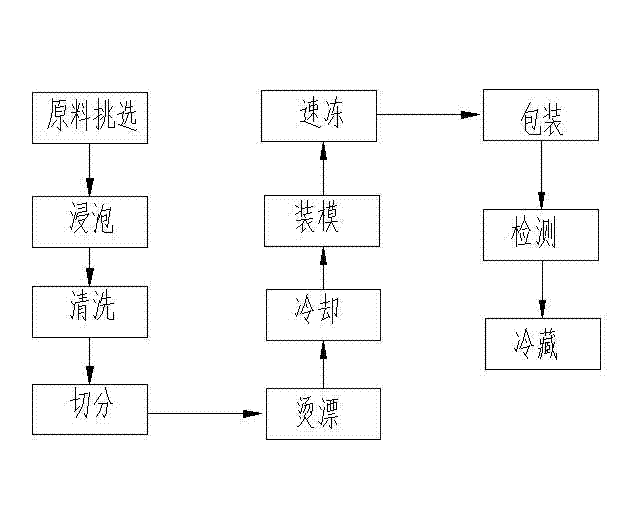

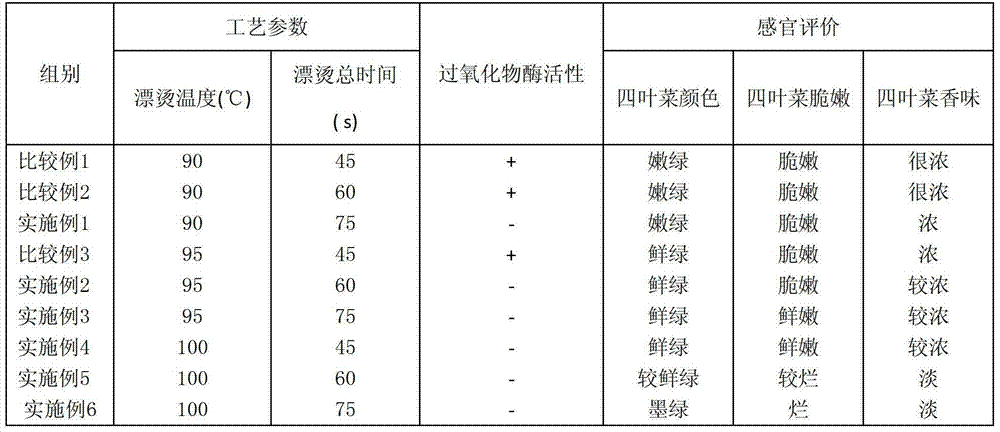

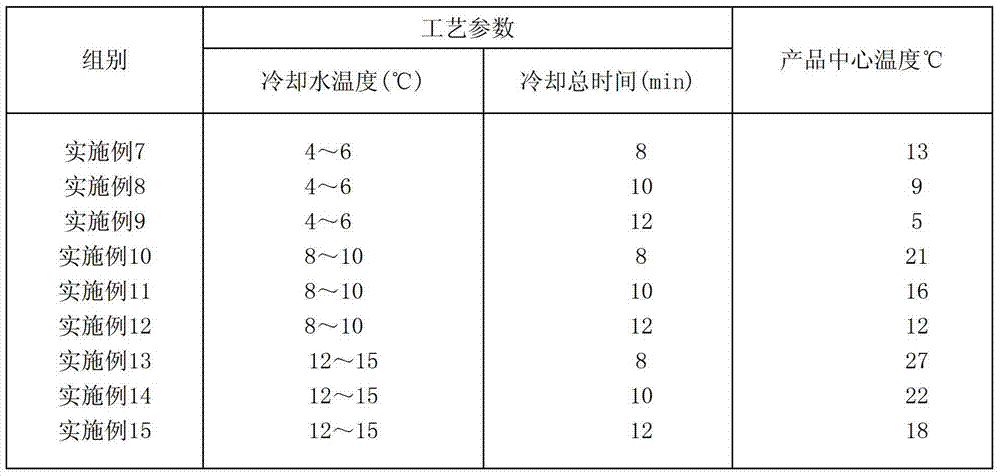

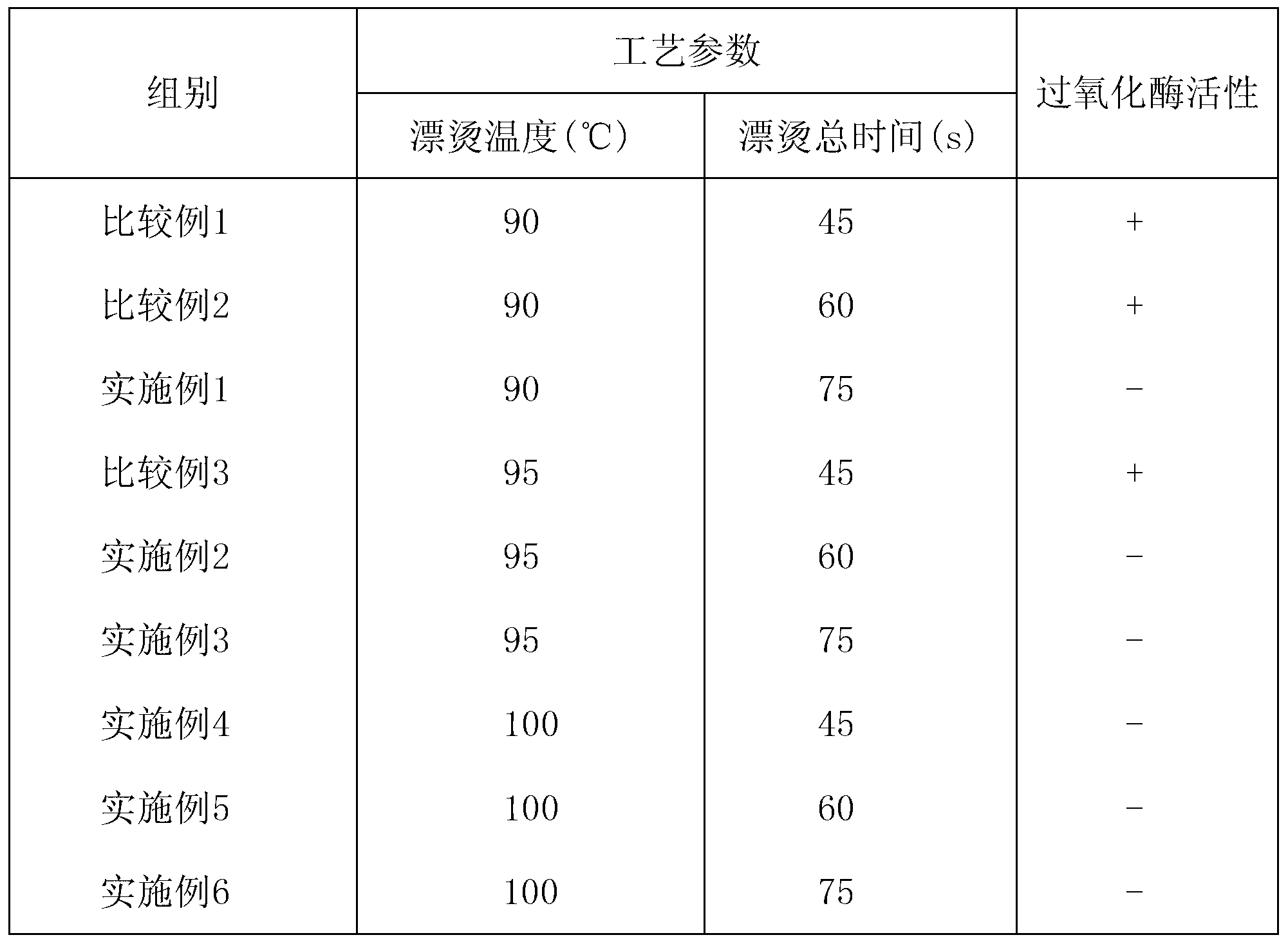

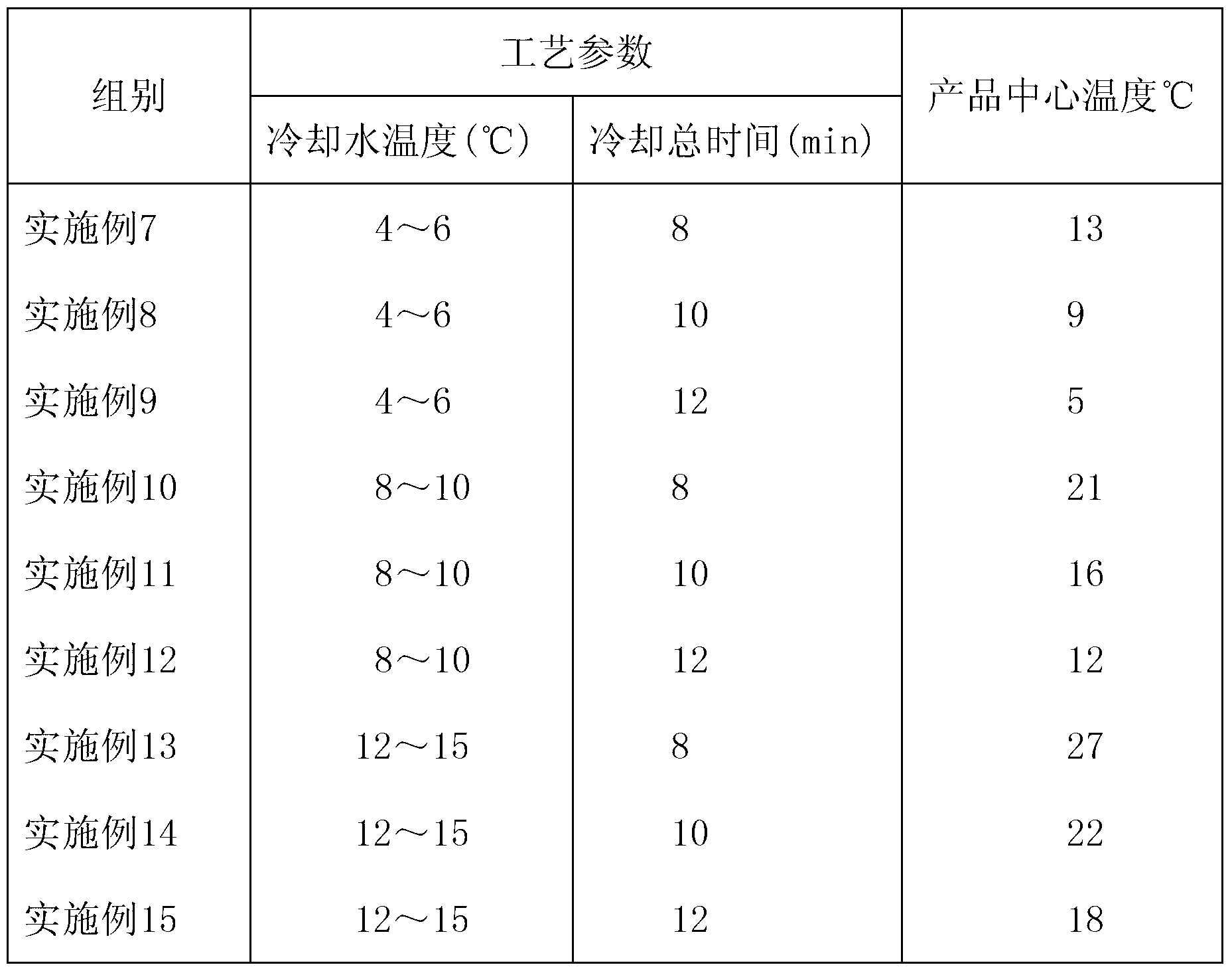

Quick freezing and preservation process for wild matsileaceae

InactiveCN103238663AGood fresh-keeping effectPreserve sensory qualitiesFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingSalt solutionCold storage

The invention relates to a quick freezing and preservation process for wild matsileaceae. The process comprises the following steps of: (1) soaking the matsileaceae in a soak solution consisting of materials, including 1% of a salt solution, and water in a volume ratio of 1:(9-11); (2) cleaning the matsileaceae to remove dust and silt; (3) blanching the matsileaceae in a blanching solution consisting of rinsing materials, including 0.1% of a L-cysteine solution, and hot water in a volume ratio of 1:(48-52); (4) cooling the matsileaceae by washing through cooling water until the matsileaceae is cooled from inside to outside, and draining excessive water after the matsileaceae is cooled to 4-5 DEG C; (5) performing quick freezing on the matsileaceae at -32 to -35 DEG C until the center temperature of the matsileaceae is below -18 DEG C; and (6) refrigerating the matsileaceae in a low-temperature cold storage at a constant temperature below -20 DEG C. According to the quick freezing and preservation process, the change of nutritional ingredients of the quick-frozen matsileaceae is alleviated, the original freshness, color and flavor of the matsileaceae are maintained to a certain degree, and the matsileaceae can be stored conveniently for a long time.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

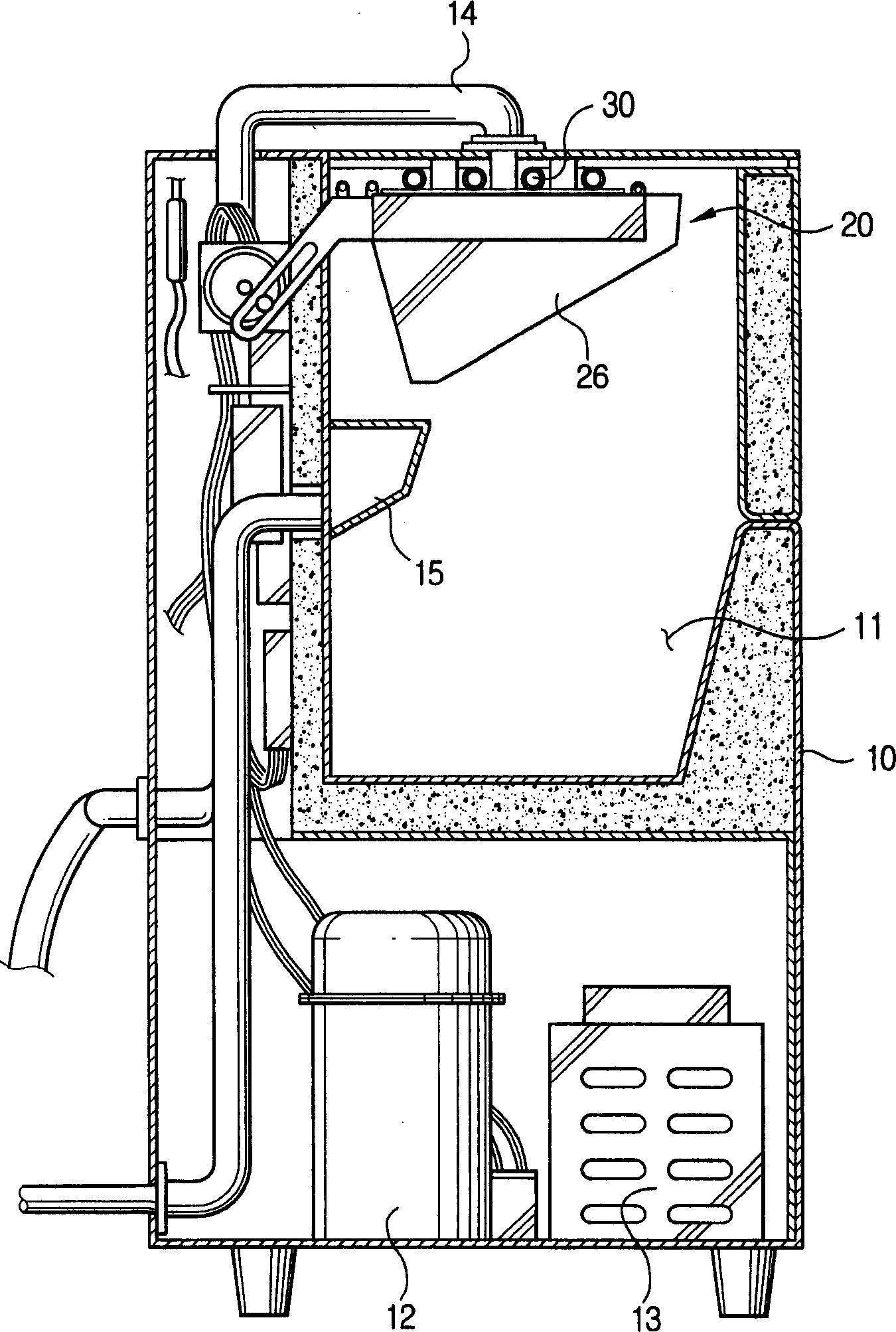

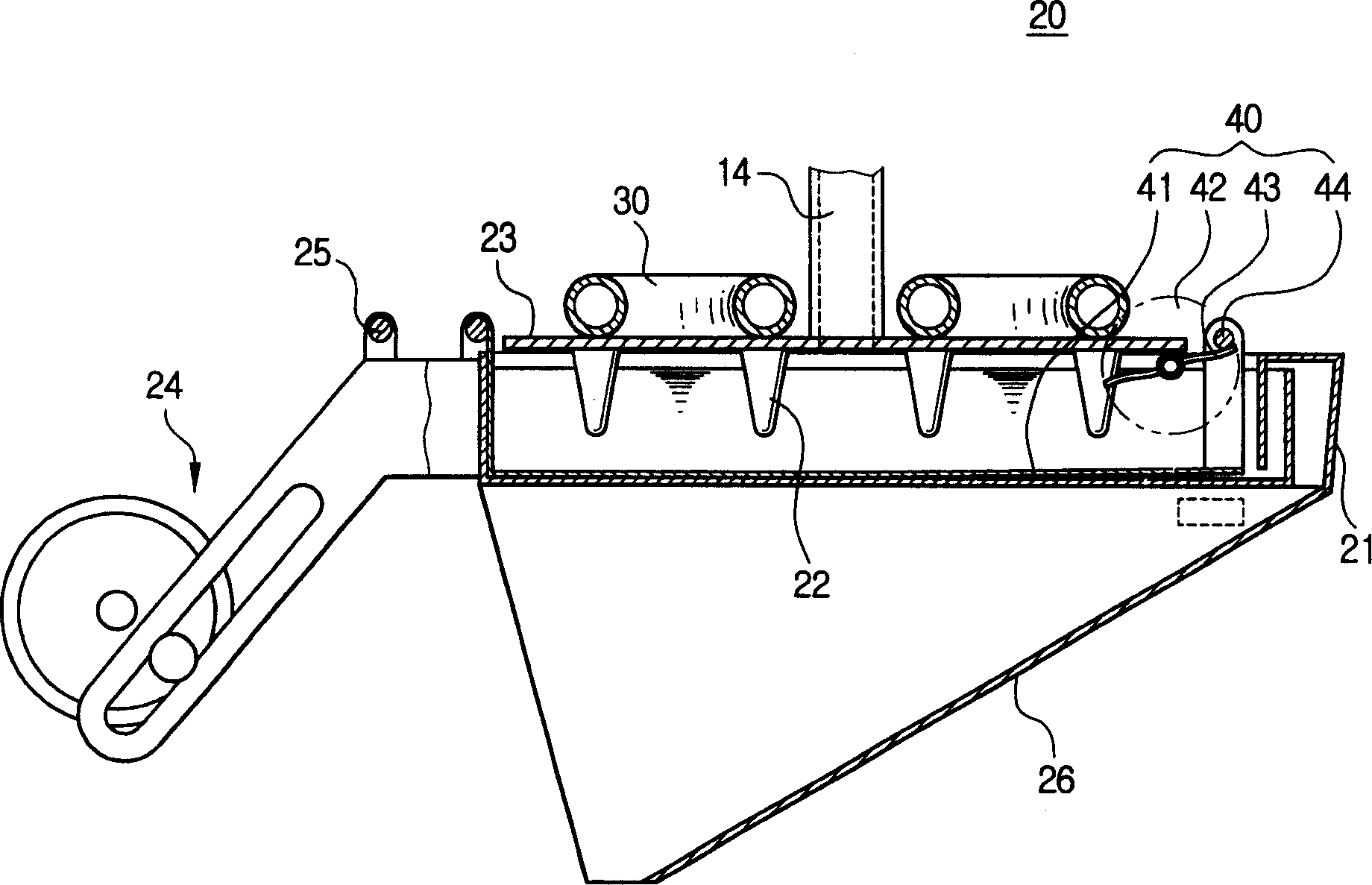

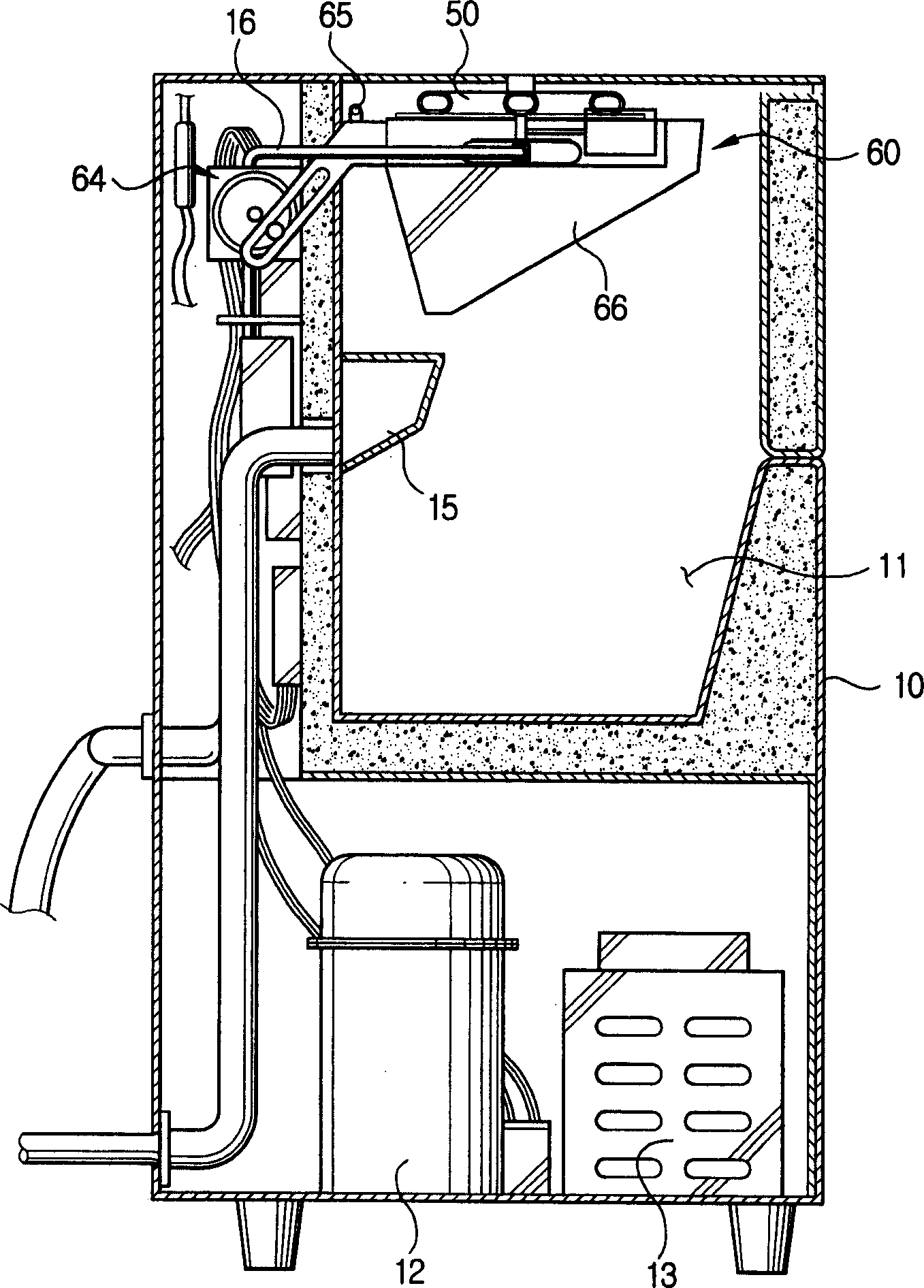

Ice machine

InactiveCN1493832AFast freezingShorten the timeLighting and heating apparatusIce productionEngineeringAir bubble

An ice making machine comprises a housing, an evaporator connected to a freezing system, a base frame having a plurality of freezing cells for being filled with water to be frozen, a freezing base plate provided with the evaporator and freezing fingers formed on the lower surface of the freezing base plate to be dipped into the water supplied to the freezing cells, and an air removing means for pumping the water into the freezing cells to remove air bubbles inside the water, thereby forming clear pieces of ice. The air removing means comprises a water path disposed at the base frame to be connected to the freezing cells, a water pocket connected to the water path and being replenished with water form an external water supply, and a pressing means for repeatedly pressing the water pocket to pump the water of the water pocket into each freezing cell.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Method for processing fresh solid pasteurized milk

The invention discloses a method for processing fresh solid pasteurized milk, which initially employs dipping ultrarapid freezing technology to preservation of dairy products. According to the technical scheme, the method includes inspection and acceptance of raw milk, pretreatment, pasteurization, cooling, filling, quick-freezing, cold storage and thawing. By means of cold chain, nutrients of the raw milk can be reserved to the maximum extent. The fresh solid pasteurized milk processed by the method is fast in freezing, ice crystal generated is small, macromolecular substances in the raw milk cannot be spoiled, the milk thawed is non-layering, has no settlement and completely retains nutrients of liquid pasteurized milk, the shelf life is prolonged greatly, the defects that the pasteurized milk is short in shelf life, unsuitable for long-range transport and only available for sales in certain areas are overcome, and batch production and large-range sale of the pasteurized milk are advantaged. The method is applicable to other dairy products of cow milk, goat milk, buffalo milk and the like, and can fully meet the technical requirement of dairy products in GB19645-2010.

Owner:杨公明

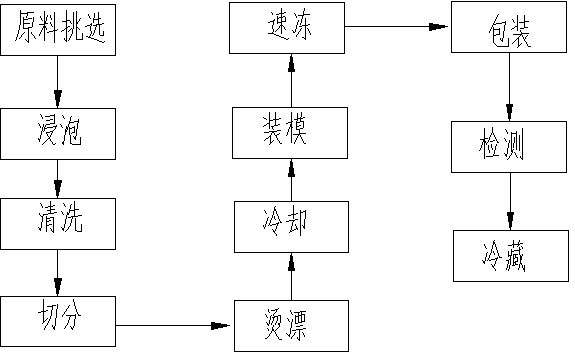

Preparation method of frozen spinach

InactiveCN107683895AEfficient removalImprove qualityFruits/vegetable preservation by heatingFruits/vegetable preservation by dehydrationLiquid nitrogenSalt solution

The invention relates to a preparation method of frozen spinach. The preparation method comprises the following steps: raw material pre-cleaning, raw material cleaning, cutting, blanching and cooling,draining and drying, moulding, freezing, and packaging and storing. According to the preparation method provided by the invention, through twice cleaning, pre-cleaning and ultrasonic cleaning, impurities that cannot be observed by naked eyes in frozen spinach can be effectively removed so as to improve the product quality; through soaking in a salt solution and blanching in a sodium bicarbonate solution, the color and mouthfeel of the unfrozen spinach segments can be remarkably improved; liquid nitrogen is adopted for spraying in a freezing area, and the liquid nitrogen has the advantages offast freezing, good product quality and little loss of moisture in the frozen product; the freezing temperature goes down sharply and then rises, and the crispness of the spinach segments after unfreezing can be remarkably improved.

Owner:江苏维乐益生食品科技有限公司

Method for utilizing overspeed freezing to manufacture banana pulp

The invention discloses a method for utilizing overspeed freezing to manufacture banana pulp. Ripe bananas serve as raw materials, the banana pulp is made by peel removal, line removal, color protection, pulping and homogenizing and the like, and overspeed-freezing banana pulp is obtained by vacuum packaging, precooling and overspeed freezing and is finally refrigerated at 20 DEG C below zero. The method is a quick-freezing low-temperature fresh-keeping method and is characterized that the freezing speed is quick, ice crystals are small, the preserving time of the quickly-frozen banana pulp is long, original flavor quality of the bananas can be preserved, heat in the bananas and energy for supporting various chemical activities are reduced, part of free water of cells is frozen simultaneously, water activity is lowered, nutrition of the bananas is preserved to the largest extent simultaneously without aids of any anticorrosive agent or addition agent, and the problem of browning in the banana processing process is solved thoroughly by optimizing a banana pulp preparation process. The method is efficient, advanced and simple and convenient to operate, and provides a novel effective way for processing of agricultural products.

Owner:杨公明

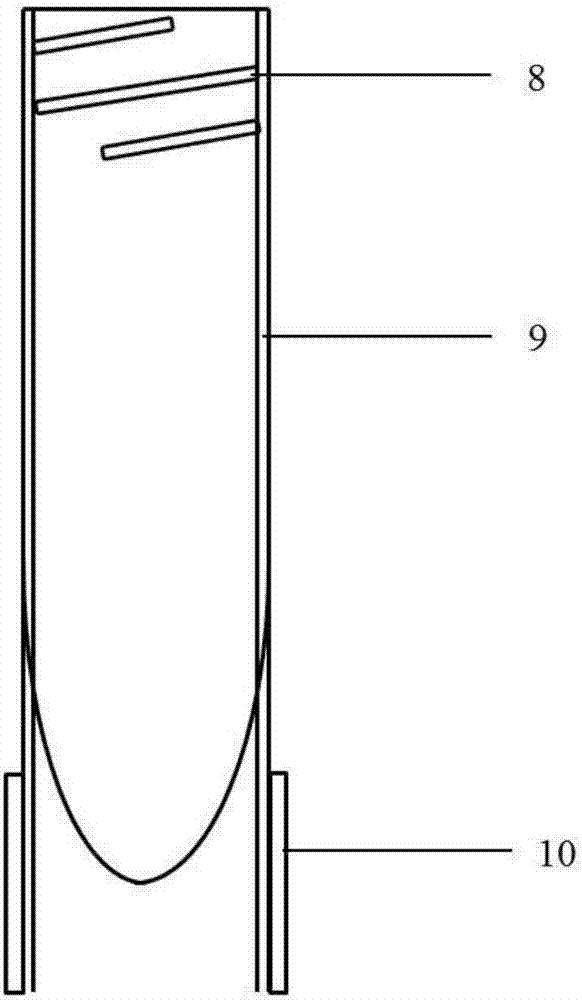

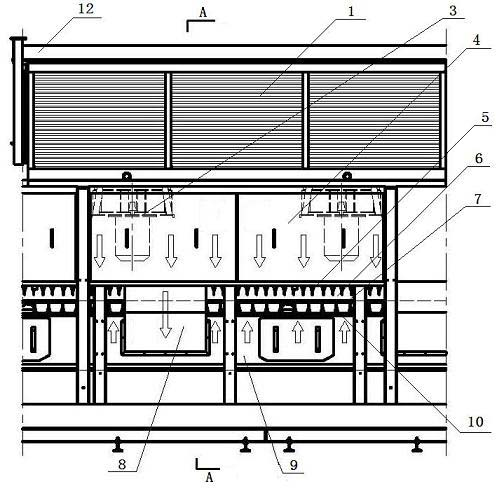

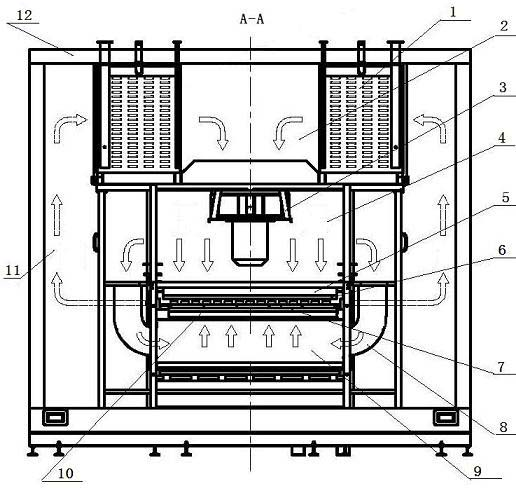

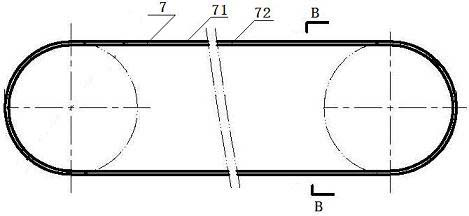

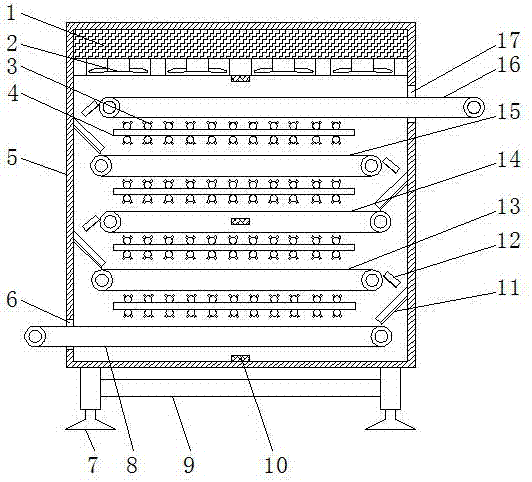

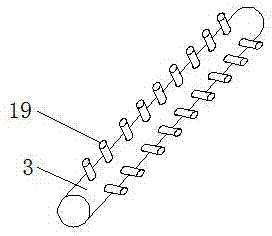

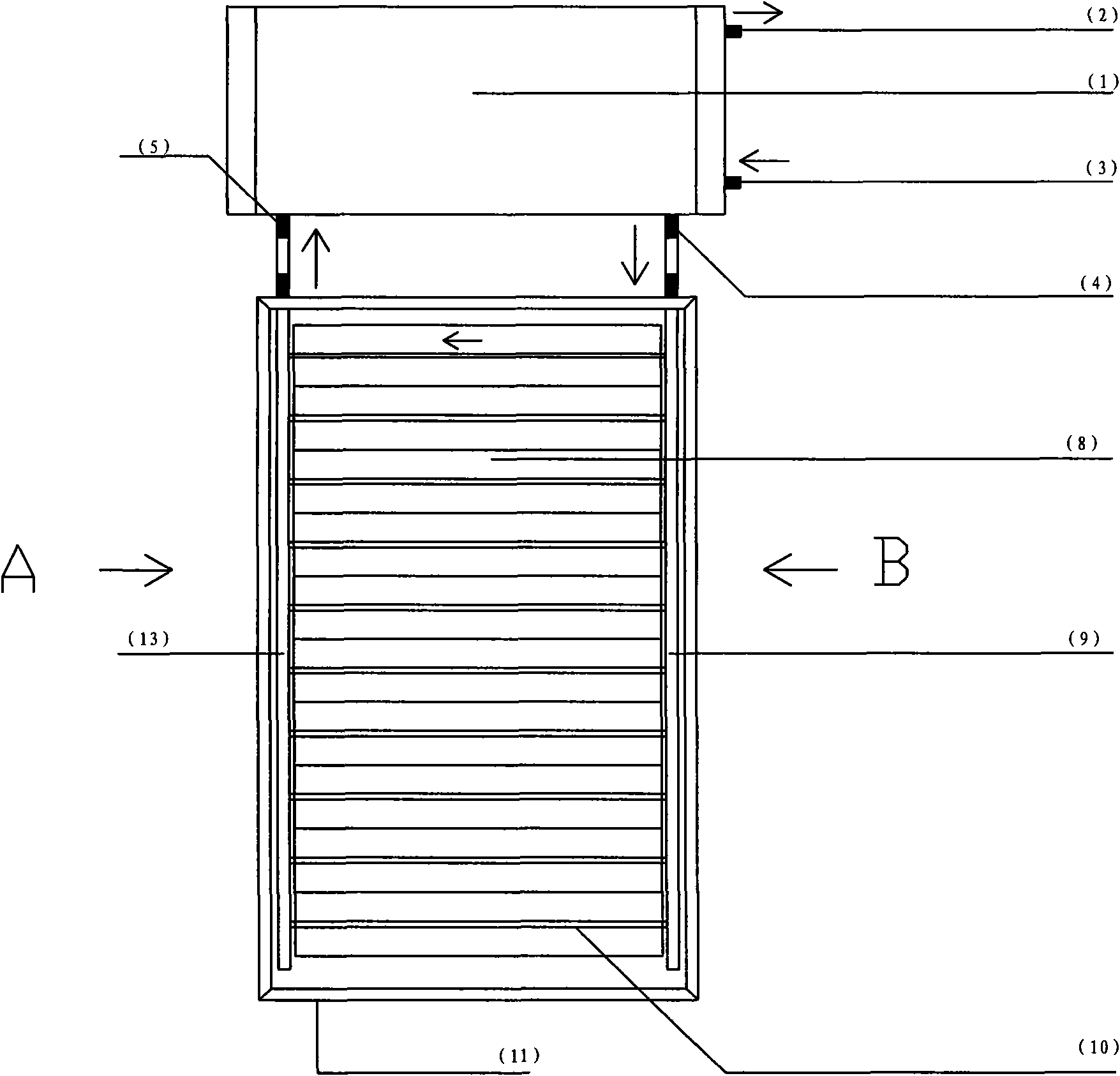

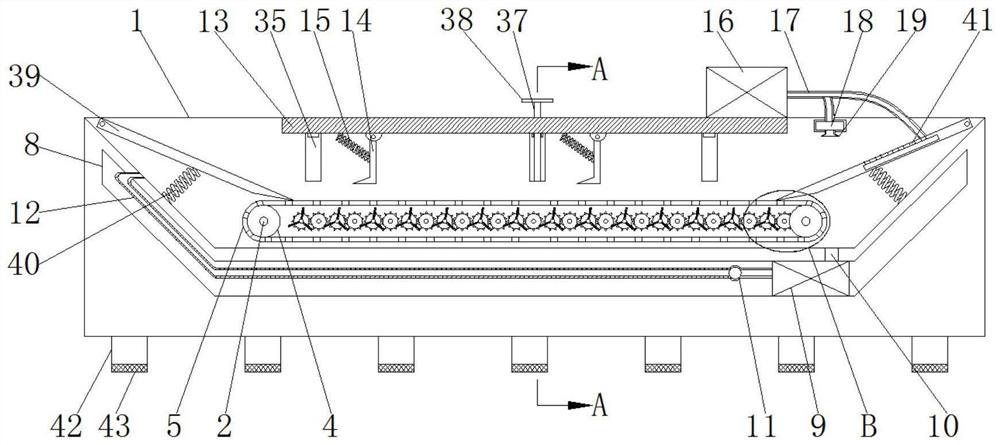

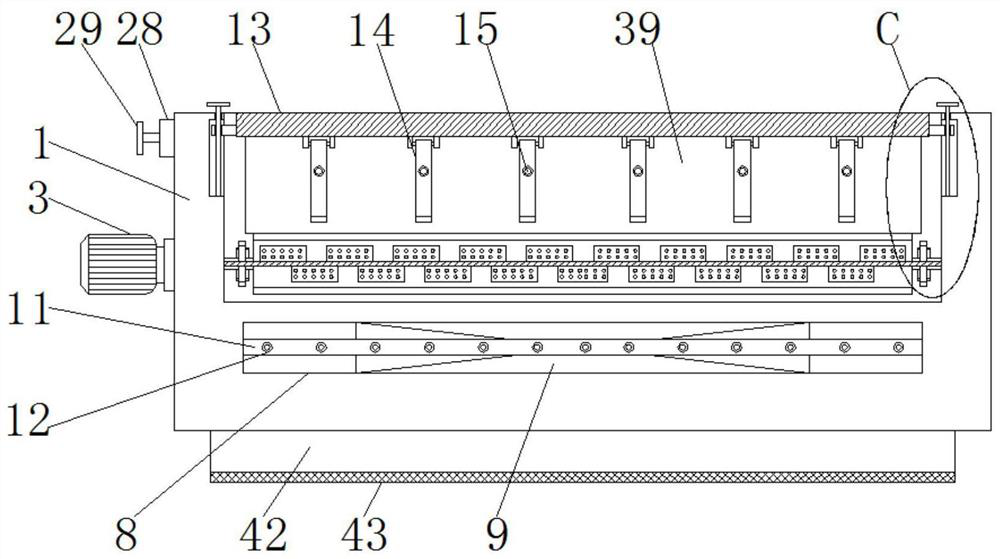

Flat-type efficient plate and strip instant freezer

InactiveCN102353209AImprove heat transfer coefficientGood frozen qualityLighting and heating apparatusStationary refrigeration devicesCold airEngineering

The invention relates to an F25D refrigerating machine, refrigeration equipment or system category in IPC (International Patent Classification) by searching, and in particular belongs to a flat-type efficient plate and strip instant freezer. The technical scheme is as follows: an evaporator (1) and a cold air room (2) are arranged in a library body (12); a centrifugal fan (3), an upper air blowing room (4), an upper nozzle (5) and a plate belt (7) are arranged below the evaporator (1) and the cold air room (2) in sequence; and the instant freezer is characterized in that the upper air blowing room (4) is connected with the evaporator (1) by an upper and lower air room ventilating duct (8), a lower air blowing room (9), a lower nozzle (10) and a return air room (11) in sequence. The instant freezer has the beneficial effect that the heat transfer area is increased manyfold because the upper and lower surfaces of a freezing object are jetted by cold airs at the same time, thus the freezing speed is quicker, the energy consumption is reduced, and the freezing quality of the freezing object is preferable.

Owner:FUJIAN SNOWMAN

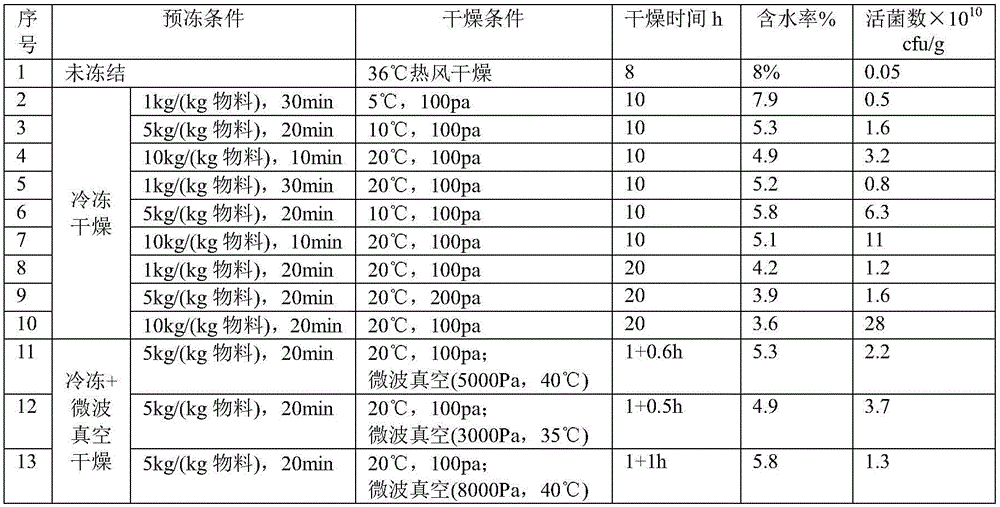

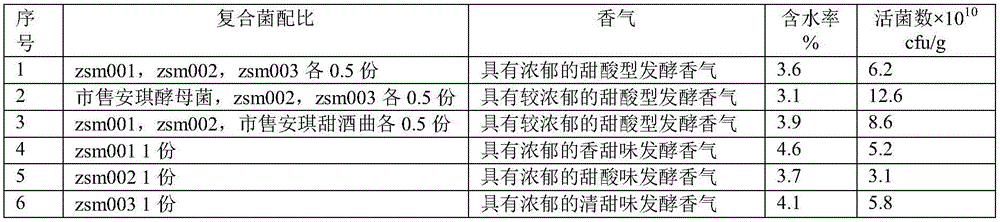

Probiotic grain powder and production method and application thereof

ActiveCN105685826APromote growthGood absorption and digestionAcidic food ingredientsFood ingredient functionsMonoglycerideGlycerol

The invention relates to the field of food processing, in particular to probiotic grain powder and a production method and application thereof. The probiotic grain powder comprises 105-1,012 cfu / g of probiotic, 10-300 mg / 100 g of GABA and 5-50 parts of peptide or free amino acid, and enzyme activity is larger than or equal to 500 u / g. The grain powder is prepared from 100 parts of grain, 0.5-2 parts of compound bacteria, 0.5-2 parts of compound enzyme, 1-20 parts of white granulated sugar, 0.1-0.5 part of amino acid, 1-10 parts of taurine, 1-10 parts of egg white protein powder, 50-200 parts of water, 0.1-5 parts of glycerinum, 1-6 parts of trehalose and 0.5-2 parts of monoglyceride, wherein compound bacteria, compound enzyme, white granulated sugar, amino acid, taurine and egg white protein powder serve as auxiliary materials, and water, glycerinum, trehalose and monoglyceride serve as protective agents. The method for preparing the probiotic grain powder comprises the steps of main material soaking and grinding into thick liquid, heating and curing are conducted, the auxiliary materials are added for fermentation, and finally drying is conducted. The technologies of sprouting, enzymolysis, nutrition compound and ultra-low-temperature freezing are adopted, and the nutrient contents and viable count are kept to the maximum extent.

Owner:随州市金义米业有限公司

A Freezing Method of High Gradient Heterogeneous Freezing Wall

The invention discloses a method for freezing a high-gradient heterogeneous freezing wall. The mixed freezing mode of "salt water + liquid nitrogen" is adopted, and a freezing pipe is arranged at the place where the soil around the shaft needs to be frozen, and a brine freezing pipe is arranged inside the freezing wall. , and a liquid nitrogen freezing tube is arranged on the periphery. The liquid nitrogen freezing tubes are arranged in one row, and the brine freezing tubes are arranged in at least one row, and each row is arranged in a circular shape. When there are two or more rows of brine freezing pipes, the diameter of the ring in the innermost row should ensure that the temperature of the well side during excavation is not higher than the ideal value that is conducive to the stability of the well side; the brine temperature setting of the brine freezing pipes should ensure that It can form a temperature field that gradually decreases from the inside to the outside. The temperature field formed by the freezing tube layout method of the present invention has obvious high gradient non-uniformity. Compared with conventional brine freezing, under the same load conditions, the thickness of the frozen wall formed by this pipe layout is small but has a higher bearing capacity, which will reduce the amount of frost heaving and thawing, and reduce the amount of engineering work for freezing holes , The freezing period is shortened.

Owner:TONGJI UNIV

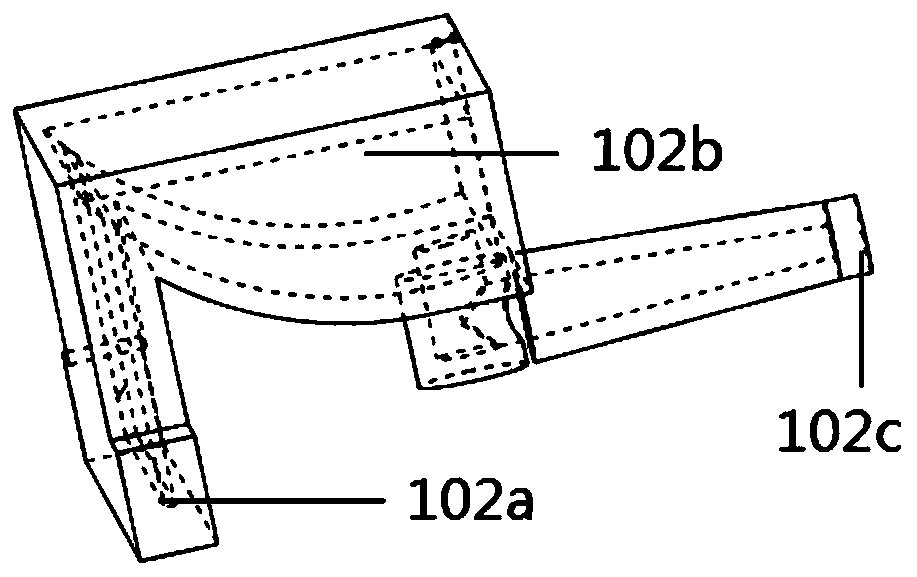

Mammal embryo and oocyte vitrification freezing carrier

InactiveCN102669088ANot lostReduces freeze damageDead animal preservationAnatomyBiomedical engineering

The invention discloses a mammal embryo and oocyte vitrification freezing carrier. The mammal embryo and oocyte vitrification freezing carrier comprises a freezing tubule and a tapered sucking head both of which are mounted in a matching and butting manner, wherein a metal weight body is arranged at the back end of the freezing tubule; and a sealing interlayer is arranged between the metal weightbody and an inner storage cavity of the freezing tubule. The mammal embryo and oocyte vitrification freezing carrier is low in cost as the manufacturing materials are the common materials, is easy tooperate and is capable of controlling amount of a freezing liquid precisely and freezing multiple oocytes and embryos for once. As the metal weight body is adopted, a sample cannot float on a liquid nitrogen surface and the sample cannot be lost; freezing damage of the sample is reduced due to the fast freezing speed and high freezing efficiency; and the carrier can be utilized repeatedly and cannot break to cause lost of the sample, so that cost is saved. Marks can be made on the tubule, so that convenience can be brought about for long-term preservation.

Owner:HENAN ACAD OF AGRI SCI

Copious cooling fast freezing infrared drying technology

InactiveCN109780821AImprove protectionNo pollution in the processDrying solid materials without heatLiquid waterFreeze-drying

The invention discloses a copious cooling fast freezing infrared drying technology and belongs to the technical field of chemical engineering and light industry machining. The copious cooling fast freezing infrared drying technology is characterized in that a gas turbine expanding refrigerating technology is adopted for performing copious cooling fast freezing on materials, compressed air at 0.5-0.9 Mpa is used, the initial air expanding pressure intensity ratio is 3-9, and fresh product vegetables and fruits and traditional Chinese medicinal materials except mineral drug are fast cooled to minus 20- minus 120 DEG C within 5-30 min, so that liquid water in a raw material organization structure fast solidifies, and becomes extremely micro ice crystal; and then, the materials are fed into aninfrared vacuum freezing drying bin to be heated, so that solid water in the materials sublimates into vaporous water, and the water content of the materials is lowered to 0-10%. The copious coolingfast freezing infrared drying technology has the characteristics of being high in freezing speed, low in cooling temperature, high in drying speed, uniform in material heating, uniform in material product quality and good in drying effect.

Owner:海尔生物医疗科技(成都)有限公司

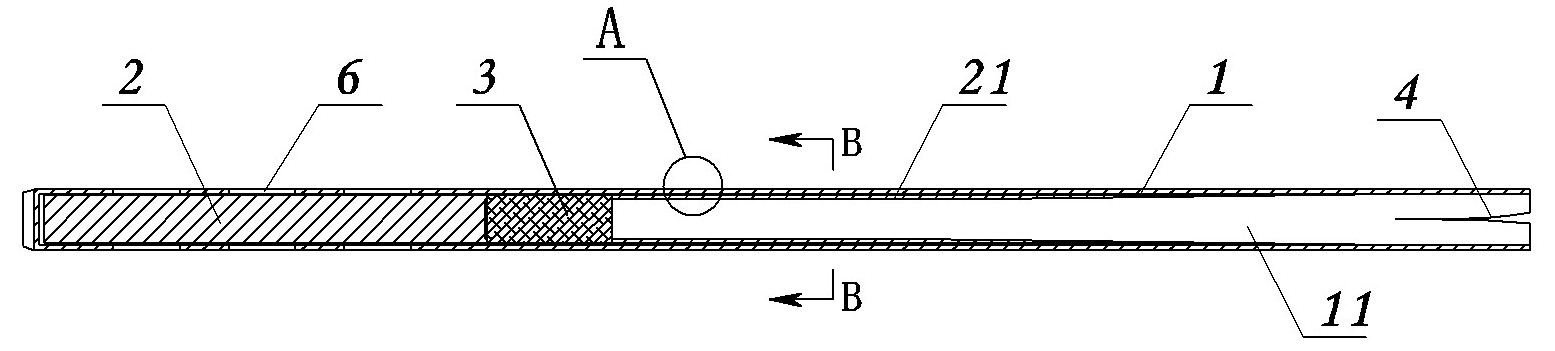

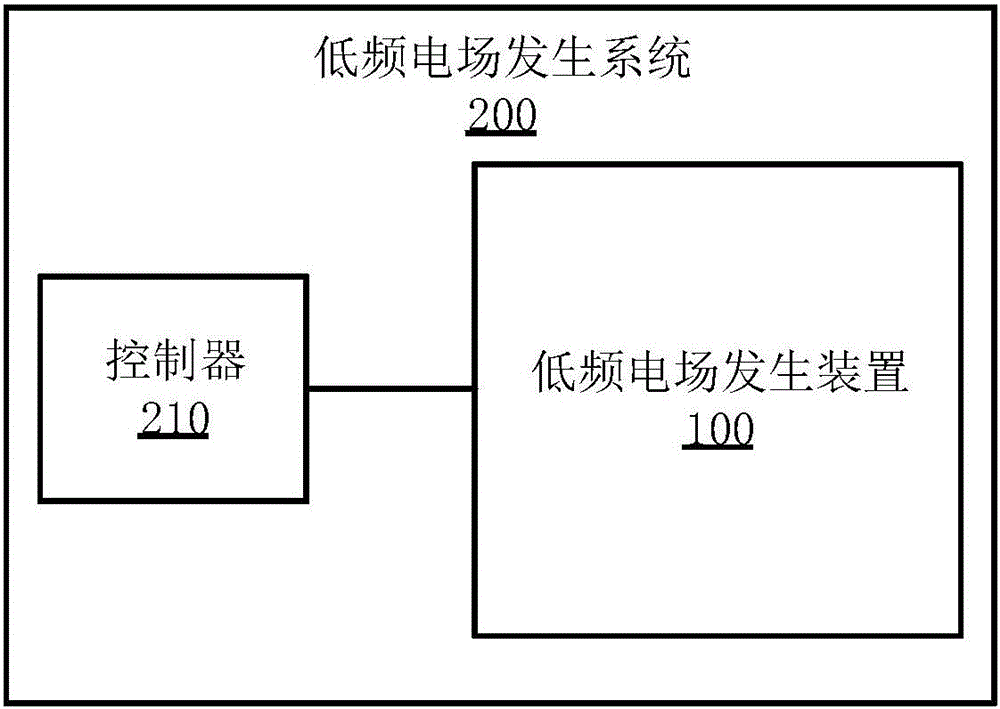

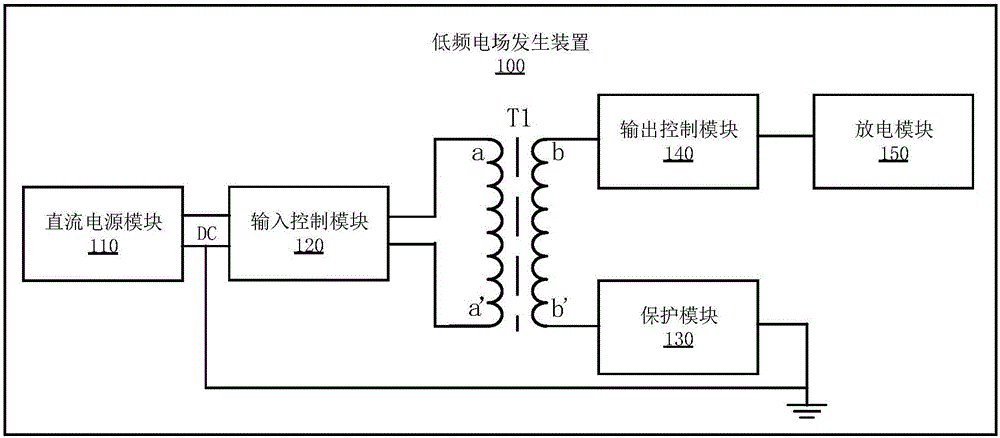

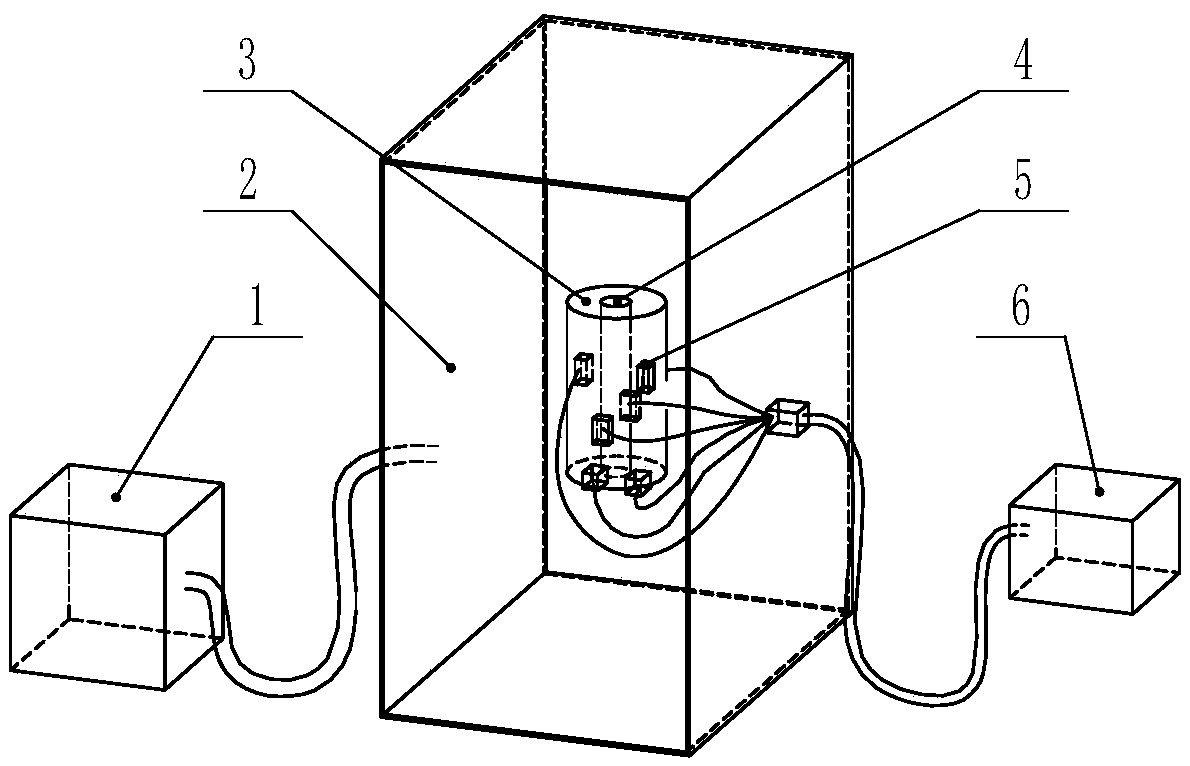

Low-frequency alternating electric field generating apparatus and system, and signal conditioning method

PendingCN106712532AImprove freshnessFast freezingFruits/vegetable preservation by irradiation/electric treatmentDielectric heating circuitsChemical reactionTransformer

The invention provides a low-frequency alternating electric field generating apparatus and system, and a signal conditioning method, which belong to the field of biomass fresh keeping devices. The low-frequency alternating electric field generating apparatus comprises a DC (direct current) power supply module, an input control module, a transformer, an output control module and a discharging module. An output end of the DC power supply module is coupled with an input end of the input control module, an output end of the input control module is coupled with a primary winding of the transformer, one end of a secondary winding of the transformer is coupled with an input end of the output control module, an output end of the output control module is coupled with the discharging module, and the other end of the secondary winding of the transformer is coupled with a ground-end equipotential point. A generated low-frequency alternating electric field can enables water molecules in fresh keeping biomass in the low-frequency alternating electric field to generate swinging of the same frequency, inhibits biochemical reaction and physiological metabolism, achieves a good fresh keeping effect, and also can accelerate the biomass freezing speed in a low-temperature environment.

Owner:余铭

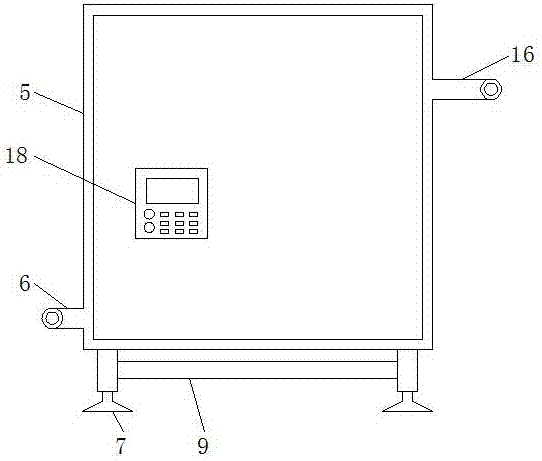

Quick freezer

ActiveCN107014139AImprove quick freezing effectNot a single structureLighting and heating apparatusStationary refrigeration devicesCold airEngineering

The invention discloses a quick freezer. The quick freezer comprises a quick freezer shell, an evaporator is installed at the top inside the quick freezer shell, a circulating draught fan is installed on the lower side of the evaporator, a discharging conveyer belt and a feeding conveyer belt are installed inside the quick freezer shell, the discharging conveyer belt is installed at the bottom inside the quick freezer shell and penetrates through a discharging outlet in the left side wall of the quick freezer shell, the feeding conveyer belt is installed below the circulating draught fan and penetrates through a feeding inlet in the right side wall of the quick freezer shell, and a first central conveyer belt, a second central conveyer belt and a third central conveyer belt are sequentially installed between the discharging conveyer belt and the feeding conveyer belt from bottom to top. A condenser installed externally and independently is adopted for heat exchange, the situation that integrated forming affects the refrigerating environment is avoided, a product can be sufficiently refrigerated by installing pressurized cold air delivery pipes and matched air jet heads between the conveyer belts, every two pressurized cold air delivery pipes are located on the two sides of a fixed plate, the quick freezing effect is further enhanced, and two refrigerating modes of the top evaporator and the pressurized cold air delivery pipes are adopted.

Owner:江苏神工智能科技有限公司

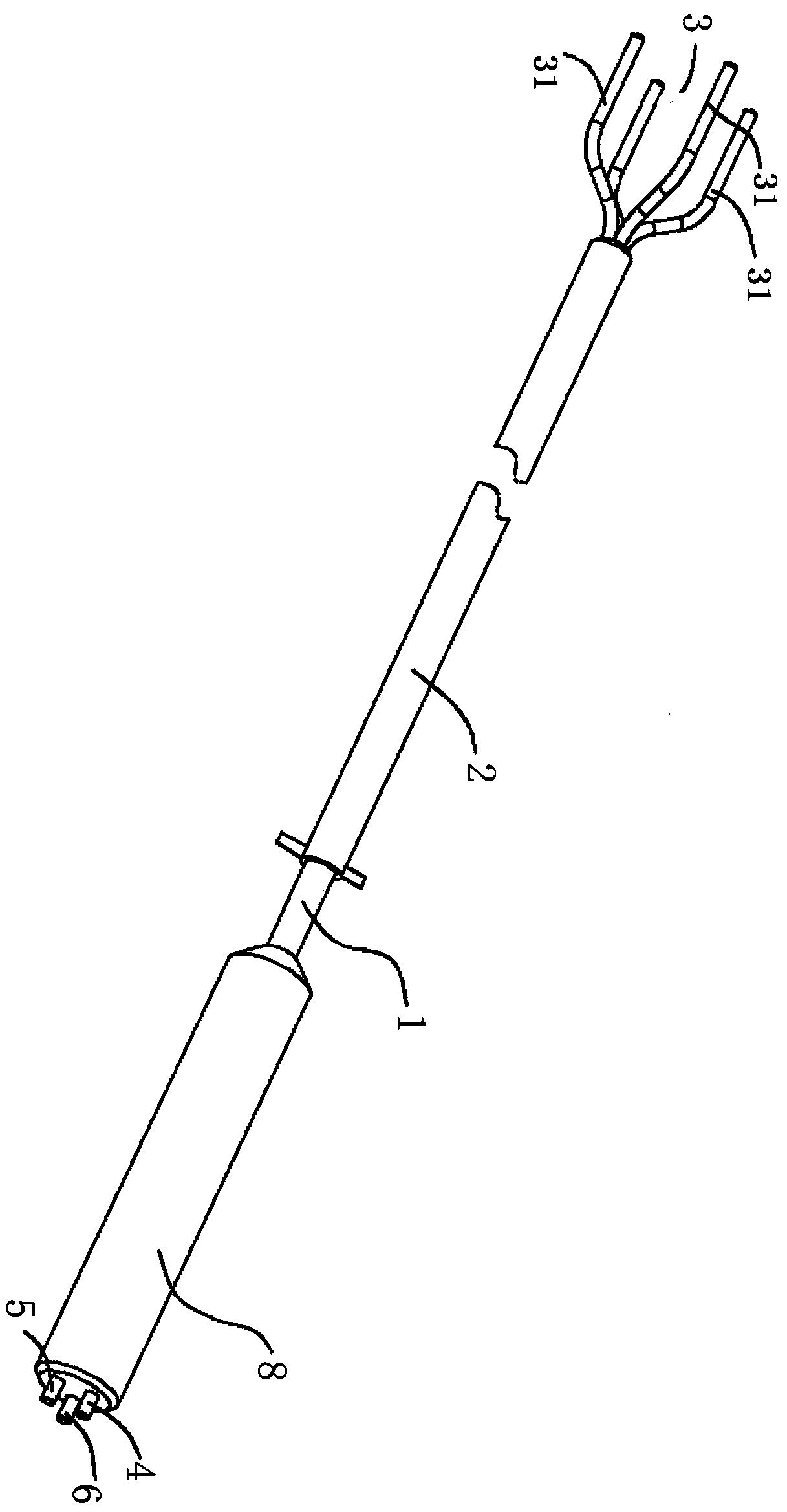

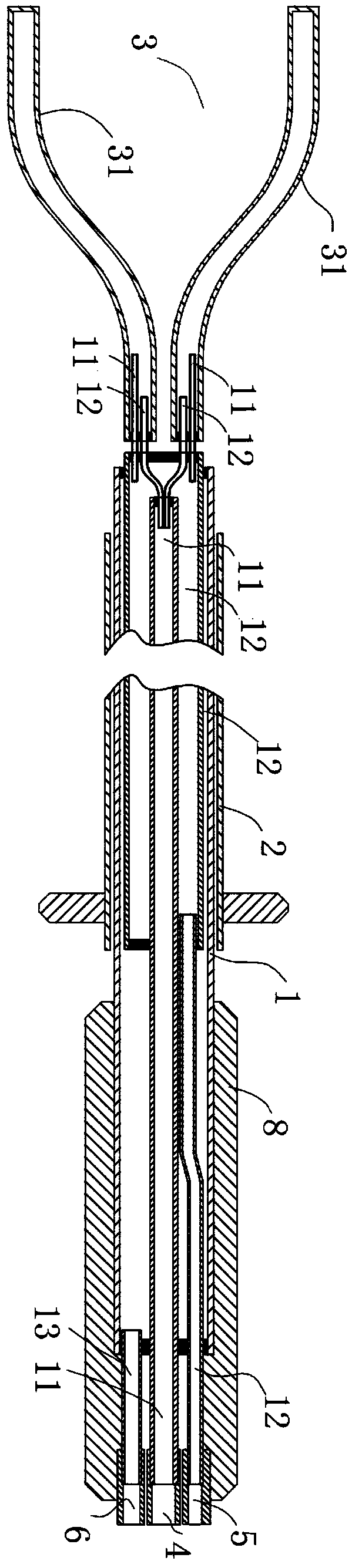

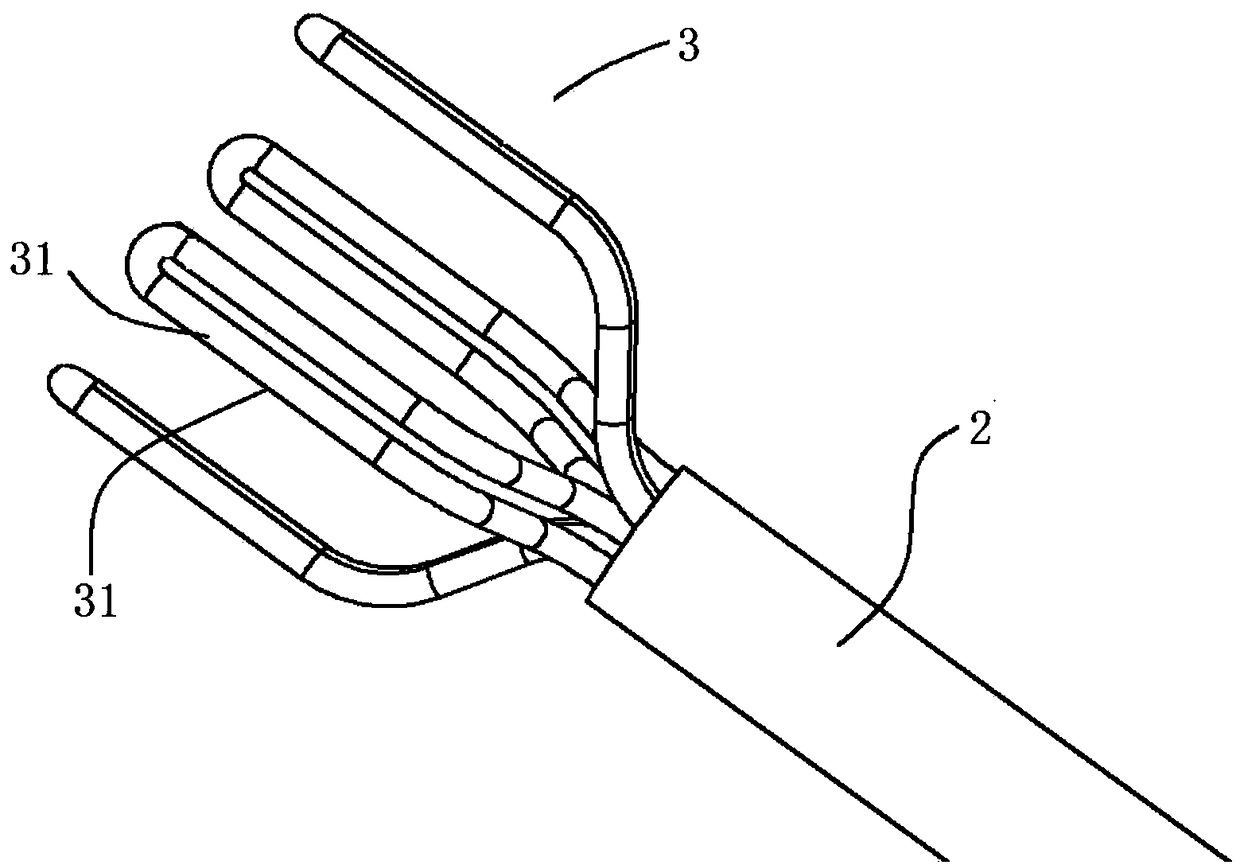

Expandable cryoablation catheter

PendingCN109480998APreserve physiological functionAchieve cryoablation areaCatheterSurgical instruments for coolingShape changeCatheter

The invention discloses an expandable cryoablation catheter. The catheter includes a catheter body, a sheath tube and a refrigerating device. The refrigerating device is arranged at and connected withthe distal end of the catheter body. The refrigerating device is composed of several refrigerating units. The distal ends of several refrigerating units are independent of each other, and the refrigerating unit can be restored to a set shape when released from the distal end of the sheath tube. The catheter body is movably arranged in a cavity of the sheath tube, the tail end of the catheter bodyis connected and communicated with the near ends of the refrigerating units, and when the catheter body and the sheath tube displace relatively, the distal ends of the refrigerating units displace synchronously relative to the distal end of the sheath tube to achieve expansion or contraction. The catheter can achieve full freezing in the circumferential direction of the natural cavity and also achieve uniform interval freezing in the circumferential direction of the natural cavity, in order to retain the important physiological function of the original cavity. Meanwhile the expansion and contraction stress of the refrigerating units can be reduced, and the influence of expansion and contraction on the shape change of the refrigerating units is reduced.

Owner:NINGBO SHENGJIEKANG BIOTECH

Antifreezing flat-plate solar heater

InactiveCN102338481AFast freezingAchieve antifreeze effectSolar heating energySolar heat devicesEngineeringSolar heater

The invention provides an antifreezing flat-plate solar heater, relating to the technical field of solar heaters. The antifreezing flat-plate solar heater comprises a heat insulation water tank and at least one group of flat-plate heat collectors, wherein the heat insulation water tank is provided with a heat insulation tank water inlet pipe, a heat insulation water tank water outlet pipe, a heat insulation water tank circulation water inlet pipe and a heat insulation water tank circulation water outlet pipe; and each flat-plate heat collector comprises heat absorption plates, heat absorption pipes, a first header and a second header, the water inlet end of each first header is connected with the water outlet end of the heat insulation water tank circulation water outlet pipe, the water outlet end of each second header is connected with the water inlet end of the heat insulation water tank circulation water inlet pipe, each heat absorption pipe is arranged horizontally, the first headers and the second headers are arranged vertically, the water inlet ends of the first headers and the water outlet ends of the second headers are respectively arranged at the upper part of the heat collector. The antifreezing flat-plate solar heater disclosed by the invention has a simple and reasonable structure and the cost can be reduced, therefore the flat-plate solar heater can be generalized easily.

Owner:徐泽山

Novel food quick-freezing device

PendingCN112683000AFast freezingFast frozen processingLighting and heating apparatusRefrigeration devicesThermodynamicsFood material

The invention discloses a novel food quick-freezing device. The novel food quick-freezing device comprises a tunnel type freezing processing tank, a stainless steel conveying belt and a rotating shaft. By arranging the tunnel type freezing processing tank, a non-volatile liquid secondary refrigerant can be injected into the tank to serve as a heat conduction medium to conduct quick freezing processing on food materials, and the freezing speed of food is greatly increased according to the fact that the heat conduction coefficient of liquid is far higher than that of the air; and a spraying and stirring mechanism is arranged in a freezing tank, stirring of the liquid secondary refrigerant is achieved, circulating flowing of the secondary refrigerant is promoted by means of movement of the conveying belt, the temperature difference of the secondary refrigerant at all positions in the freezing tank is smaller than or equal to 1 DEG C, and therefore the freezing uniformity of quick-frozen food raw materials is improved. Compared with a traditional air quick-freezing technology, the novel food quick-freezing device has the remarkable advantages of being efficient in heat conduction, uniform in freezing, efficient, capable of saving energy, improving the quality of quick-frozen food and reducing the quick-freezing processing cost and wide in application.

Owner:GUANGXI UNIV

Method for freezing prawns by adopting ultrasonic and high hydrostatic pressure

ActiveCN105494594AMaintain propertiesAvoid cooked denaturationMeat/fish preservation by freezing/coolingQuick FreezePrawn

The invention discloses a method for freezing prawns by adopting ultrasonic and high hydrostatic pressure. The method comprises the following steps: (1), preparing vacuum-packed prawn samples; (2), impregnating the prawn samples with a refrigerant medium of minus 18 to minus 20 DEG C, carrying out high hydrostatic pressure treatment by increasing the pressure to 100-600 MPa and maintaining the pressure for 25-35 min, and carrying out ultrasonic treatment in the high hydrostatic pressure treatment process; (3), carrying out compression release operation, continuously impregnating the prawn samples with a refrigerant medium of minus 18 to minus 20 DEG C for 3-5 min after compression release operation, and carrying out ultrasonic treatment in the impregnating process; (4), long-time storing the prawn samples in a refrigeration storage of minus 18 to minus 20 DEG C. According to the method for freezing prawns by adopting ultrasonic synergistic high hydrostatic pressure, heat treatment steps necessary for the conventional frozen prawn production process are not needed, protein denaturation due to heat treatment is avoided, an enzymatic inactivation sterilizing effect produced by heat treatment can be achieved, and the fresh quality of quick-freeze prawns is fundamentally ensured.

Owner:SOUTH CHINA UNIV OF TECH

Process for quick-freeze fresh keeping of wild chickweed tender tips

InactiveCN103300133AGood fresh-keeping effectPreserve sensory qualitiesFruits/vegetable preservation by freezing/coolingQuick FreezeStellaria media

The invention relates to a process for quick-freeze fresh keeping of wild chickweed tender tips. The process is characterized by comprising the following steps of: (1) soaking: soaking chickweed tender tips in a soaking solution, wherein the soaking solution consists of a material and water in a volume ratio of the material to the water of 1:(9-11), and the material comprises 1% of a common salt solution; (2) cleaning: removing dust and silt; (3) blanching: blanching in a blanching solution, wherein the blanching solution consists of a rinsing material and hot water in a volume ratio of the rinsing material to the hot water of 1:(48-52), and the rinsing material is a D-sodium isoascorbate aqueous solution of which the concentration is 0.4%; (4) cooling: flushing in cooling water until the inside and outside are completely cooled, and draining off excessive water; (5) quick-freezing: quick-freezing the chickweed tender tips at -32--35 DEG C by using an instant freezer until the central temperature of the product reaches lower than -18 DEG C; (6) storing: storing the chickweed tender tips at a constant temperature in a low-temperature cold store of which the temperature is lower than -20 DEG C. By adopting the process, the nutritional ingredient changes of the quick-frozen chickweed tender tips are reduced, so that the original freshness, color and flavor of the chickweed tender tips are kept to a certain extent, and the chickweed tender tips can be stored for a long time conveniently.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

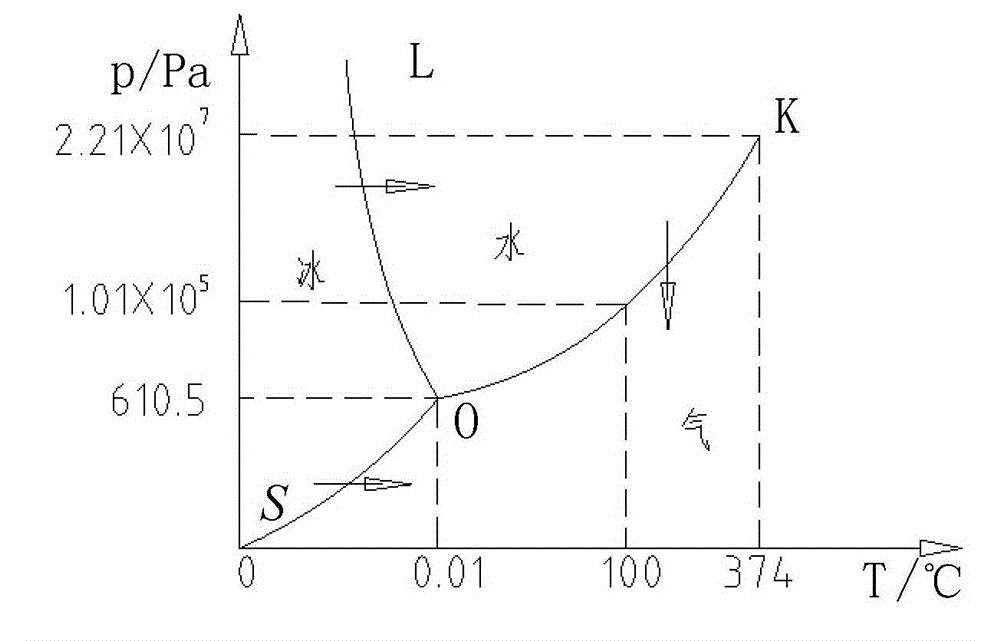

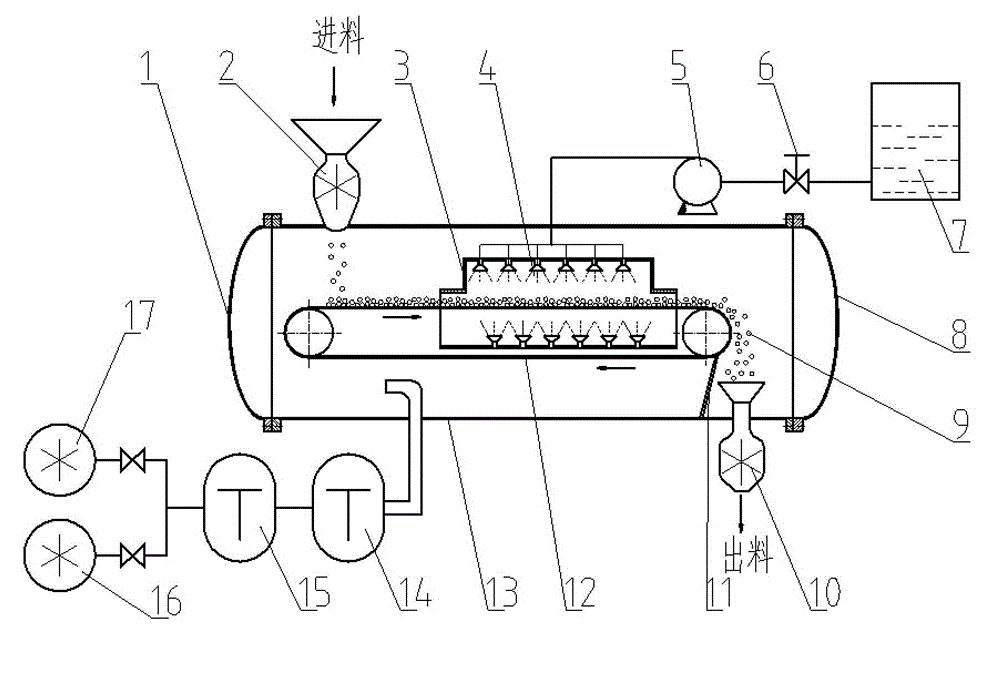

Continuous vacuum quick freezing device and continuous vacuum quick freezing method for foods

ActiveCN104585840AEfficient removalLow costFood freezingFood preservationQuick FreezePulp and paper industry

The invention relates to continuous vacuum quick freezing device for foods and synchronously relates to a corresponding method, belonging to the technical field of food equipment. The device comprises a vacuum chamber body; a discharging opening is formed in the top end of one end of the vacuum chamber body, and a discharging opening is formed in the bottom part of the other end of the vacuum chamber body; a loop conveying net belt is mounted in the vacuum chamber body; the receiving end of the conveying net belt is positioned below the feeding opening, and the discharging end of the conveying net belt is positioned above the discharging opening; the upper layer of the conveying net belt passes through an atomizing chamber body; at least one group of atomizing spray heads are mounted in the atomizing chamber body and spray towards the conveying net belt, wherein the atomizing spray heads are arranged in the conveying direction. According to the device, water has the natural physical property of being quickly evaporated and subjected to phase change to absorb lots of heat under a vacuum state, and accordingly, the foods can be quickly frozen with low cost, the adhering can be effectively inhibited, the temperature uniformity is easily ensured, a refrigerator set is omitted, the device cost and the working energy consumption are obviously reduced, and continuous production can be carried out.

Owner:JIANGSU BOLAIKE FROZEN TECH DEV CO LTD

Freezing construction method for tunnel contact channel

InactiveCN111173536AFulfil requirementsMeet the requirements of excavationMining devicesUnderground chambersSaline waterHydrology

The invention provides a freezing construction method for a tunnel contact channel. The freezing construction method comprises the steps that construction preparation is conducted; a freezing curtainis designed, and it is ensured that the frozen soil strength meets the requirements; freezing holes are designed; and temperature measuring holes and pressure relief holes are designed. Compared witha traditional freezing construction method for a tunnel contact channel, by setting the reasonable positive freezing time, the designed heat dissipation amount of each meter of freezing tube comprising a frozen rack tube is not less than 100 kcal / h, the low saline water temperature and the high saline water flow are adopted, thus the freezing speed is increased, the pressure relief holes are formed in the proper positions, and the influence of frost heaving on a tunnel is reduced; and by setting reasonable freezing hole number, distribution and mounting parameters on the contact channel, the requirements of the freezing holes in the contact channel are met, gush of a large amount of muddy water during drilling is prevented, construction is safe, and thus the excavation requirements of thecontact channel are met.

Owner:INSTALLATION ENG CO LTD OF CCCC FIRST HARBOR ENG +1

Quick-frozen Chinese cabbage making process

InactiveCN104585297AImprove qualityMeet mass productionFruits/vegetable preservation by freezing/coolingBiochemical engineeringImpurity

The invention relates to a quick-frozen Chinese cabbage making process which comprises the following steps: primarily processing; picking and cleaning; cleaning and re-checking; blanching; cooling with precooling water; draining by vibration; finally removing impurities; quickly freezing; cutting; clothing thin ice; and weighing and packaging. The quick-frozen Chinese cabbage making process provided by the invention can meet the requirement of batch production, and is high in freezing speed.

Owner:ANHUI DONGBAO FOOD

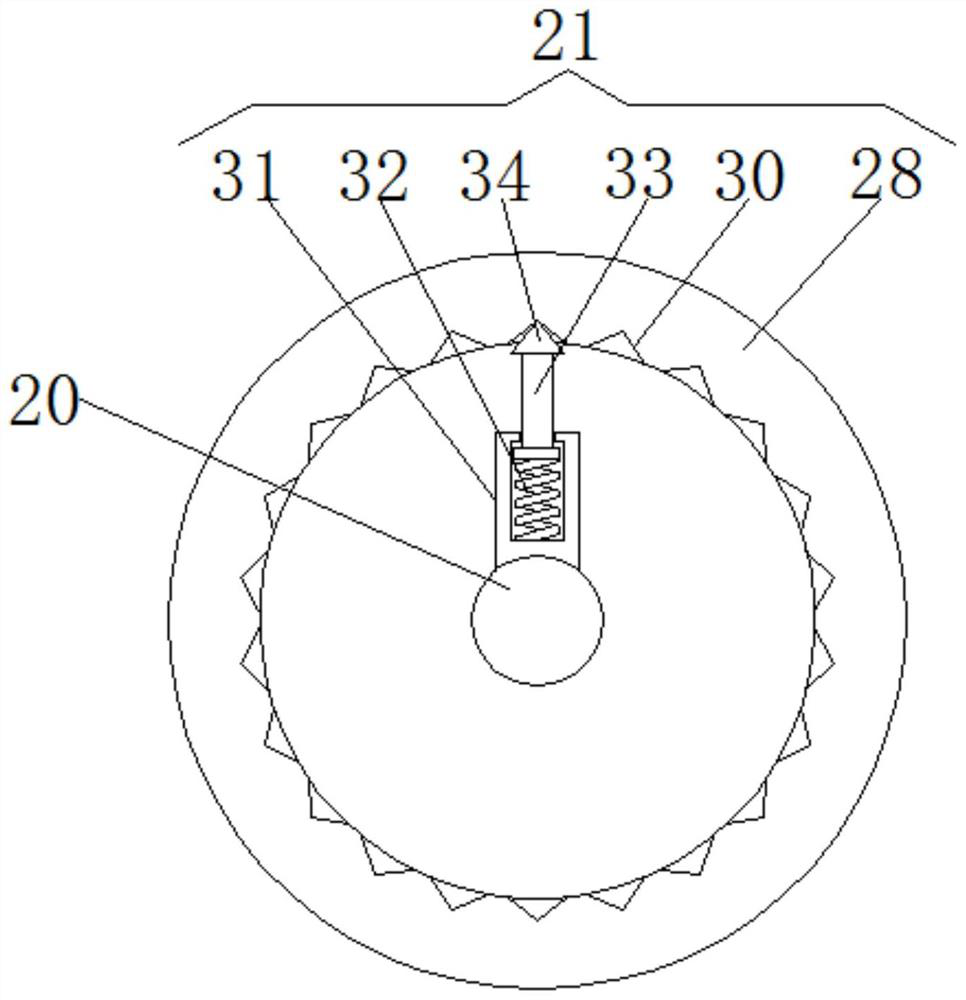

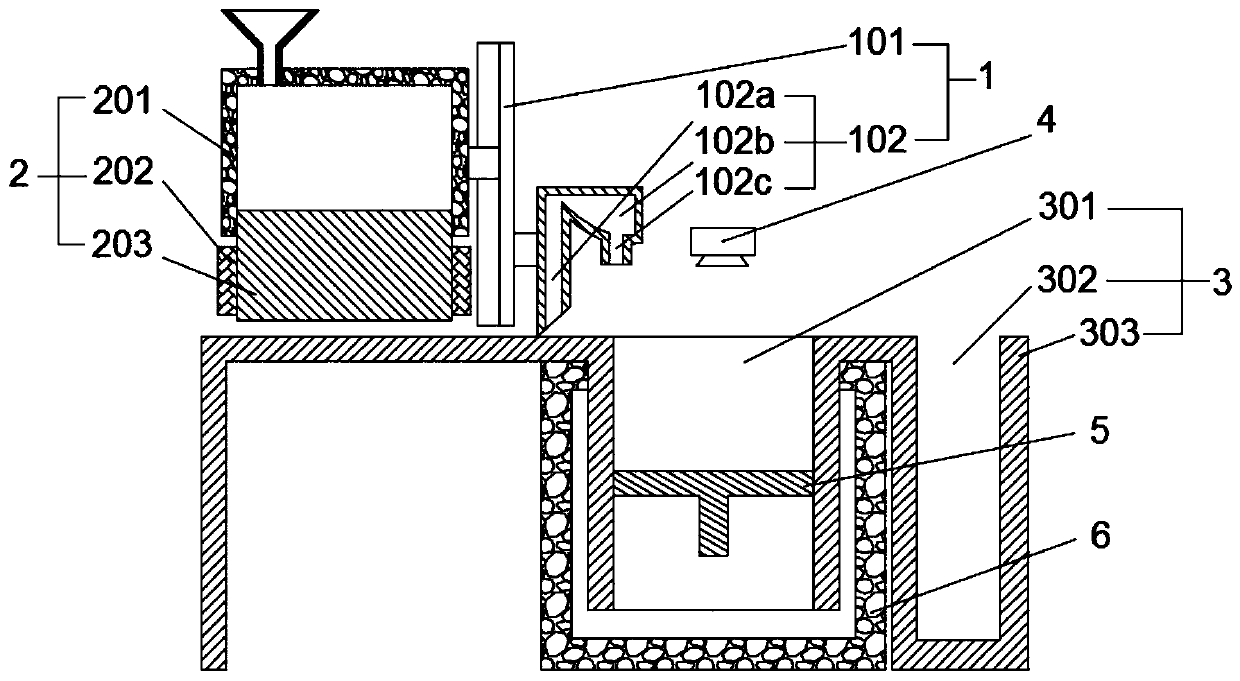

Frozen ceramic slurry 3D printing mechanism

ActiveCN111070375AHigh strengthGuarantee the stability of 3D printing processingAdditive manufacturing apparatusCeramic shaping apparatusComputer printingLaser scanning

The invention discloses a frozen ceramic slurry 3D printing mechanism. The frozen ceramic slurry 3D printing mechanism comprises a scraping device, a freezing device, a working table, a lifting platform, a laser scanning device and a cryogenic box. The scraping device is provided with a scraping knife capable of evenly discharging. The freezing device is provided with a controllable cryogenic freezing plate. The working table is provided with a processing chamber and a waste chamber. A driving device is used for driving the scraping device to lay a layer of slurry on the lifting platform. Unnecessary slurry is recovered by the waste chamber. The freezing device makes contact with a frozen material layer from top to bottom. The laser scanning device selectively irradiates the frozen material layer. The cryogenic box maintains the processing chamber in a cryogenic state to prevent the processed frozen material layer from being melted. Through the frozen ceramic slurry 3D printing mechanism, the material layer can be rapidly solidified to protect a blank against distortion in the layer-by-layer accumulation 3D printing process, and the 3D printing efficiency and processing stability are improved. Besides, a microstructure of a part can be improved by controlling the freezing crystallization process of a solvent in slurry.

Owner:XIAN TECHNOLOGICAL UNIV

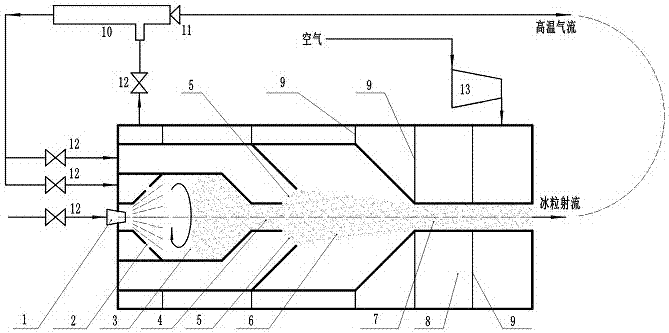

Continuous ice particle jet flow washing device based on vortex tube

InactiveCN107270767AGuaranteed generation speedGuaranteed setting strengthFood processingIce productionEngineeringCooling capacity

The invention provides a continuous ice particle jet flow washing device based on a vortex tube. The continuous ice particle jet flow washing device based on a vortex tube mainly comprises an atomizing nozzle, a swirl nozzle, an ice making chamber, a hollow tube, a hollow circulation nozzle, a mixing chamber, an ice particle jet flow nozzle, a pre-cooling cavity, the vortex tube and the like. The continuous ice particle jet flow washing device carries out refrigeration through the vortex tube and is simple in structure, small in volume, low in weight and convenient to use. Ice particle jet flow and high-temperature airflow alternately spray a heat dissipation surface, and online washing is completed. Water is atomized through the atomizing nozzle to form water drops, the swirl nozzle carries out swirl mixing in the ice making chamber to form ice particles in a freezing manner, through the jetting, entrainment and mixing effects of the hollow circulation nozzle, the ice particles are further frozen and shaped in the mixing chamber, the strength of the ice particles is high, and the ice particle jet flow is sprayed through the ice particle jet flow nozzle. The pre-cooling chamber carries out pre-cooling to reduce the temperature, recovers the cooling capacity and reduces and eliminates low-temperature air flow heat loss, and energy sources are saved. The system can be applied to various surface washing and treating occasions, especially to finned radiators.

Owner:QINGDAO UNIV

Processing method of potato sticks formed by vacuum low-temperature deep-frying

InactiveCN105011062AHigh substance contentModerate viscosityFood preparationDeep fryingJacket potato

The invention discloses a processing method of potato sticks formed by vacuum low-temperature deep-frying. The potato sticks are processed through the following steps: preparing raw materials of potatoes; cooking the potatoes; extruding the cooked potatoes into mashed potatoes; weighing whole potato flour, and mixing the whole potato flour and the mashed potatoes so as to obtain a mixture; forming the mixture into potato sticks; baking the formed potato sticks; freezing the baked potato sticks; deep-frying the frozen potato sticks; and performing oil removal. The potato sticks disclosed by the invention are processed by combining forming and baking with a vacuum low-temperature deep-frying technology, the original color, the original fragrance, the original taste and nutrient components of the potatoes are reserved, the mouth feel of the potato sticks is crisp, and other kinds of vegetables are added, so that the color of products is rich, and the potato sticks have the characteristics of being nutrient and delicious.

Owner:LAIYANG HENGRUN FOODSTUFF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com