Ultra-low temperature freeze-thaw cycle test method of cement-based material

A cement-based material, freeze-thaw cycle technology, applied in the direction of analysis of materials, preparation of test samples, weighing by removing certain components, etc., can solve the problem of large volume of concrete specimens, increased workload, and power consumption of test equipment Large volume and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The purpose of the present invention is achieved through such technical solutions:

[0023] 1. Mix cement concrete or mortar according to the design mix ratio, and the shape is 70.7×70.7×70.7mm 3 For cube specimens, the concrete should pass through a 20mm sieve before molding, the formwork should be removed 24 hours after molding, and the standard curing room should be cured for 28 days;

[0024] 2. The freeze-thaw test starts when the specimen is 28 days old. The specimen is taken out from the curing place 72 hours before the freeze-thaw, and the appearance inspection is carried out, and then the freeze-thaw test is carried out after soaking in water at a temperature of 20±5°C for 72 hours. (The water surface should be at least 10mm above the top surface of the specimen).

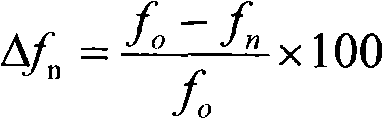

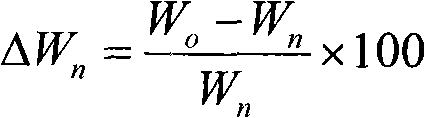

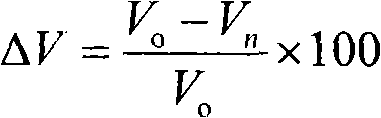

[0025] 3. After soaking, take out the test piece, wipe off the surface moisture with a damp cloth, weigh it, and measure the initial pulse velocity of the two pairs of sides of the test piece perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com