High-temperature melt unloading device for cooling crucible

A technology of unloading device and high-temperature melt, which is applied in crucible furnaces, furnaces, lighting and heating equipment, etc., to achieve the effects of simple operation, accelerated cooling and solidification, and conducive to melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

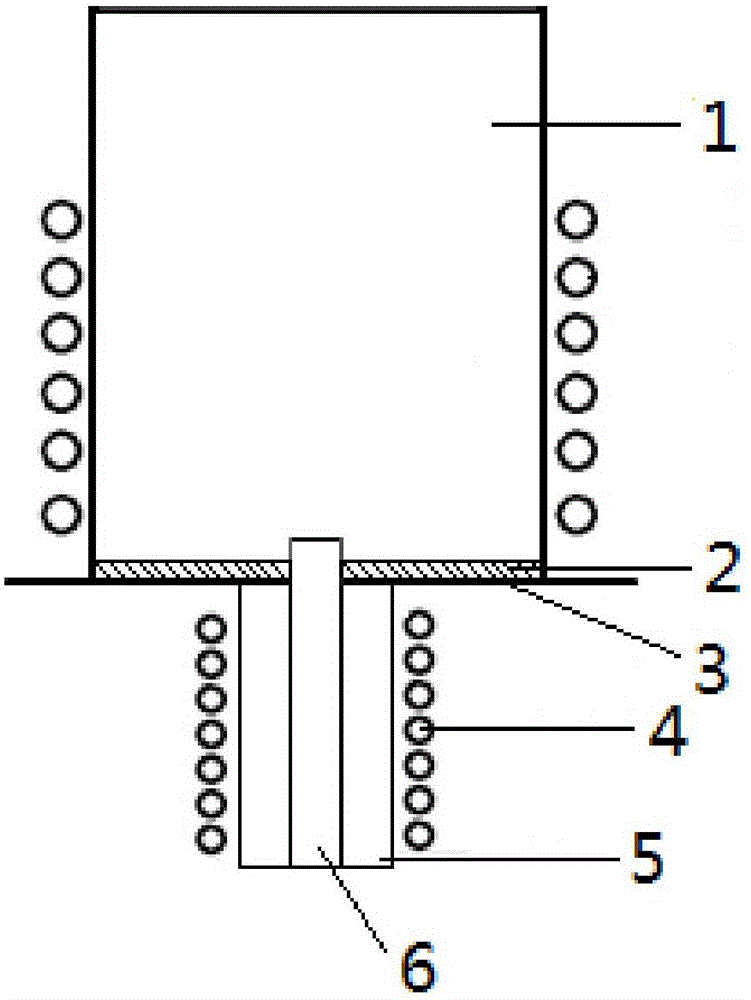

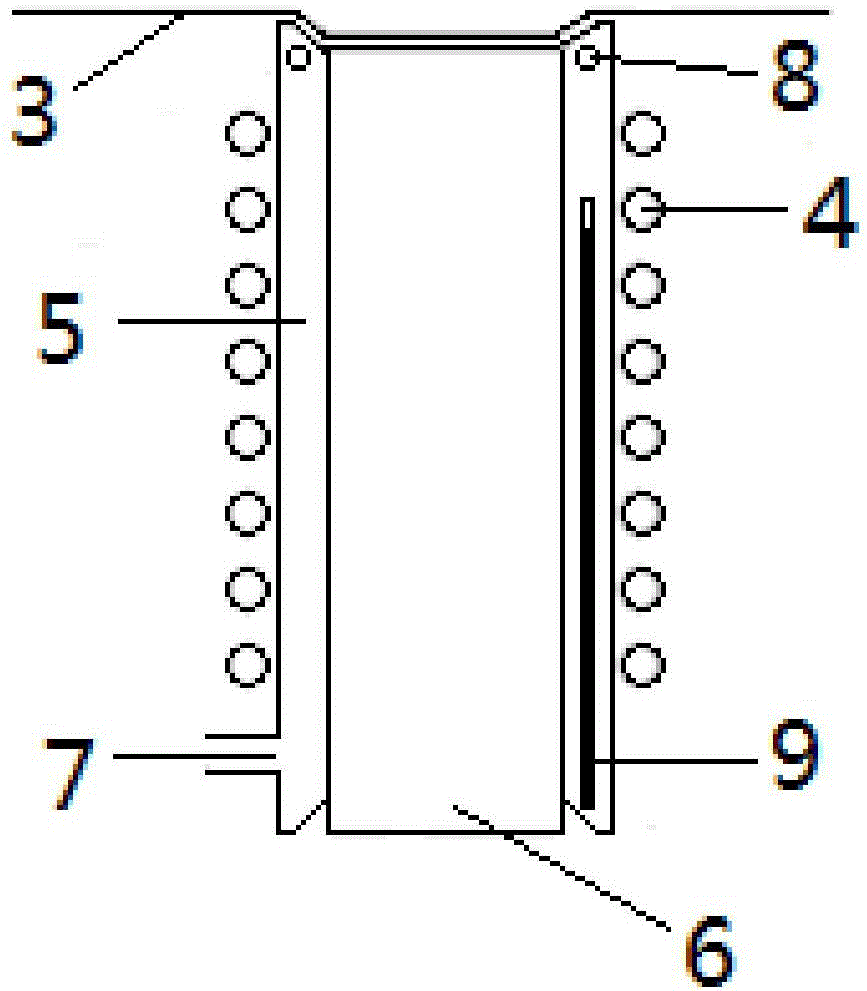

[0023] Such as figure 1 As shown, a high-temperature melt unloading device for a cold crucible is mainly composed of a crucible bottom 3 and a freeze-thaw valve unloading device. Freeze-thaw valve unloading device such as image 3 As shown, it mainly includes a discharge pipe 6 and an intermediate frequency induction coil 4; the discharge pipe 6 is made of stainless steel, the discharge pipe 6 penetrates into the crucible bottom 3, and the height inserted into the cold crucible 1 is slightly higher than the thickness of the cold shell 2 That is, adopting this structural design is mainly because the magnetic permeability effect of the cold crucible 1 and the bottom 3 of the crucible itself is not as good as that of the side wall, and the thickness of the cold shell 2 is thicker than that of the side wall. Flush, when the cold glass in the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com