Patents

Literature

41results about How to "Accelerated cooling and solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

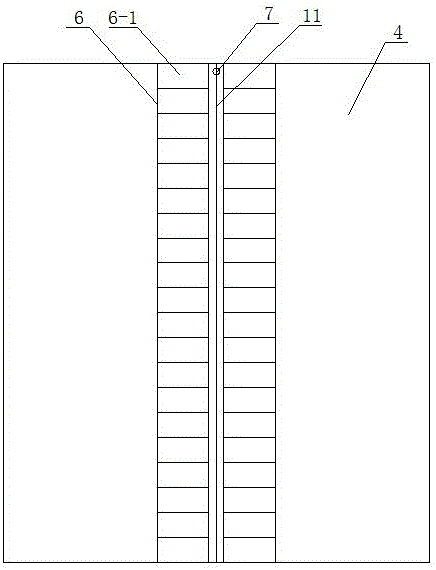

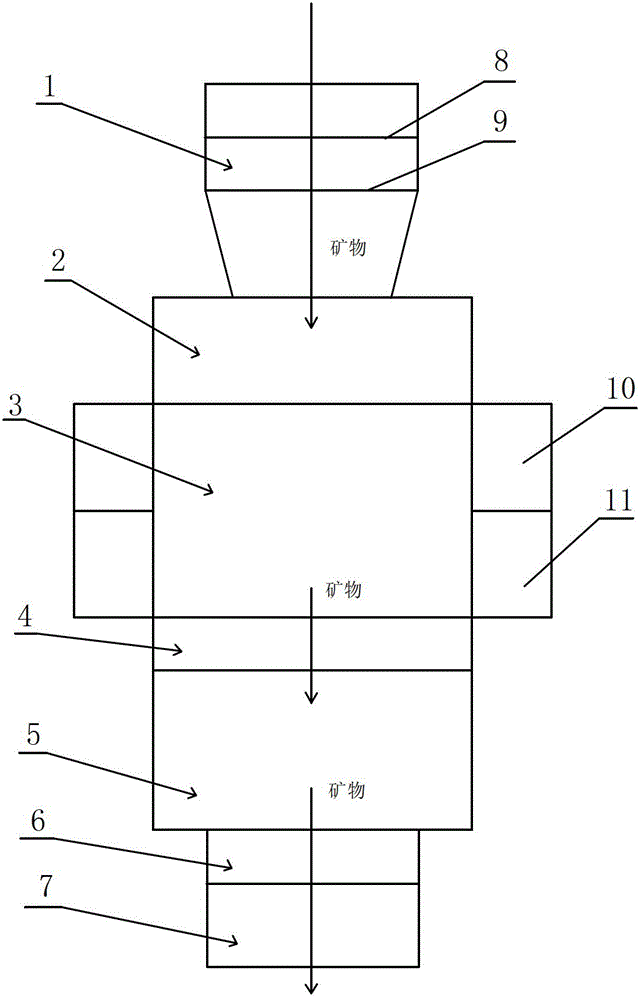

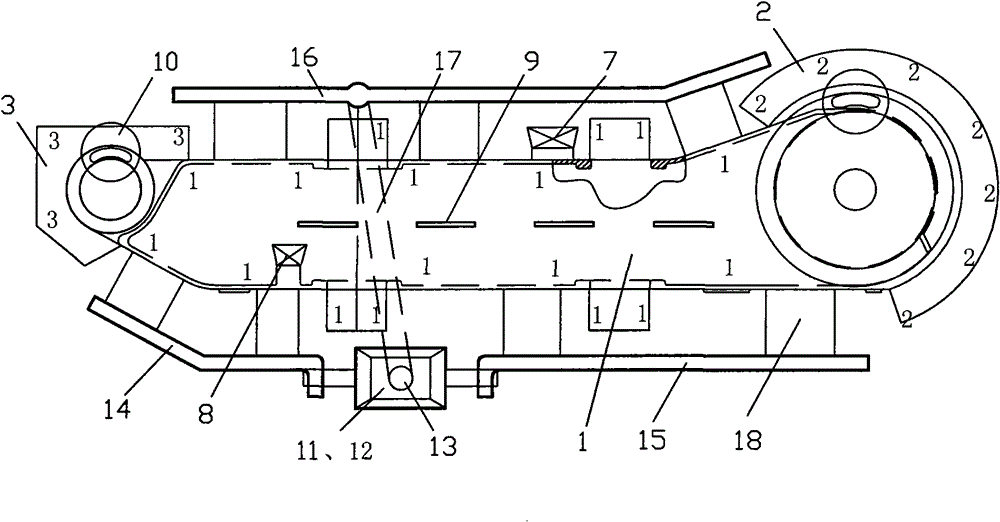

Mineral roasting reduction device and application method thereof

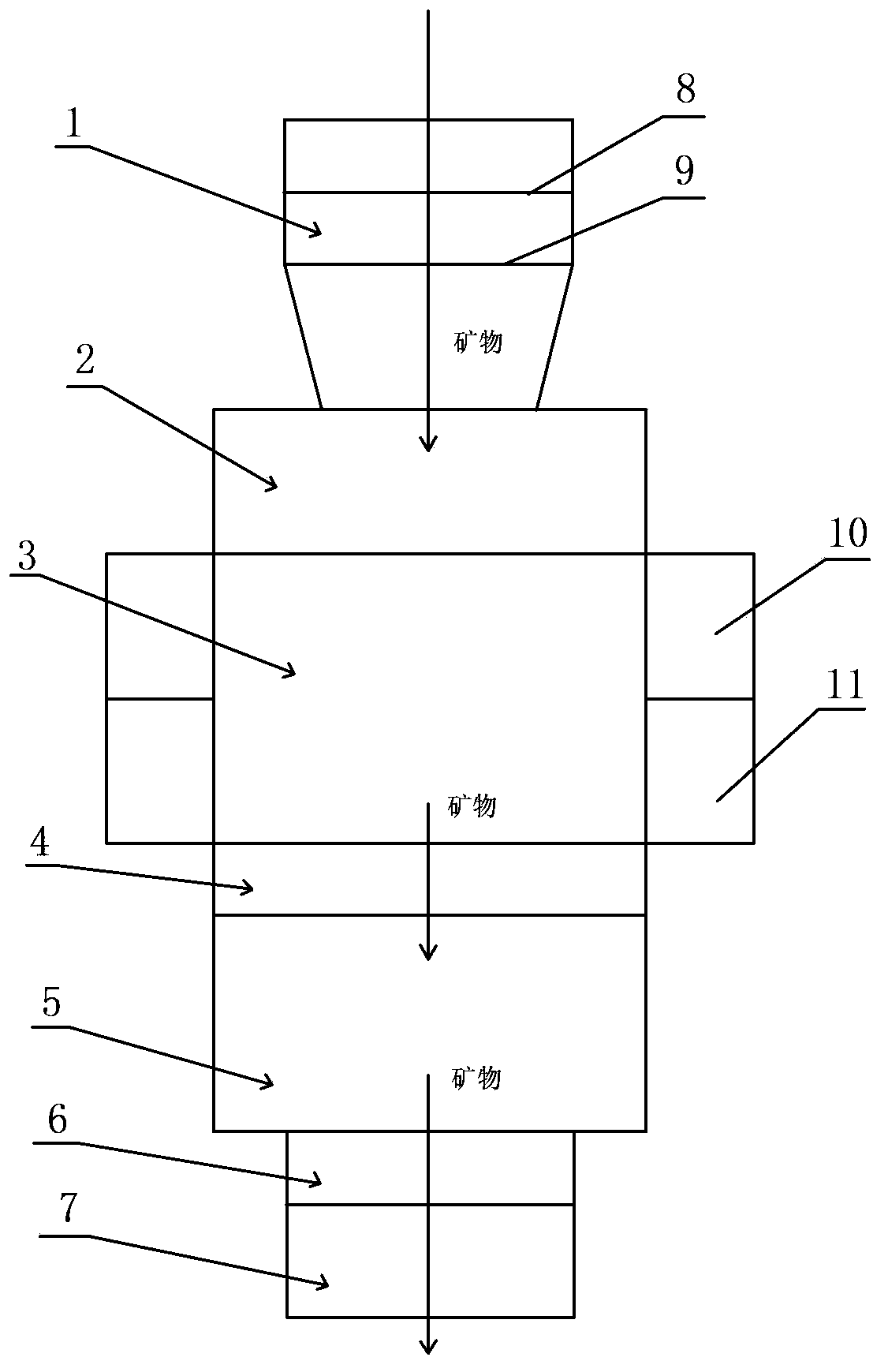

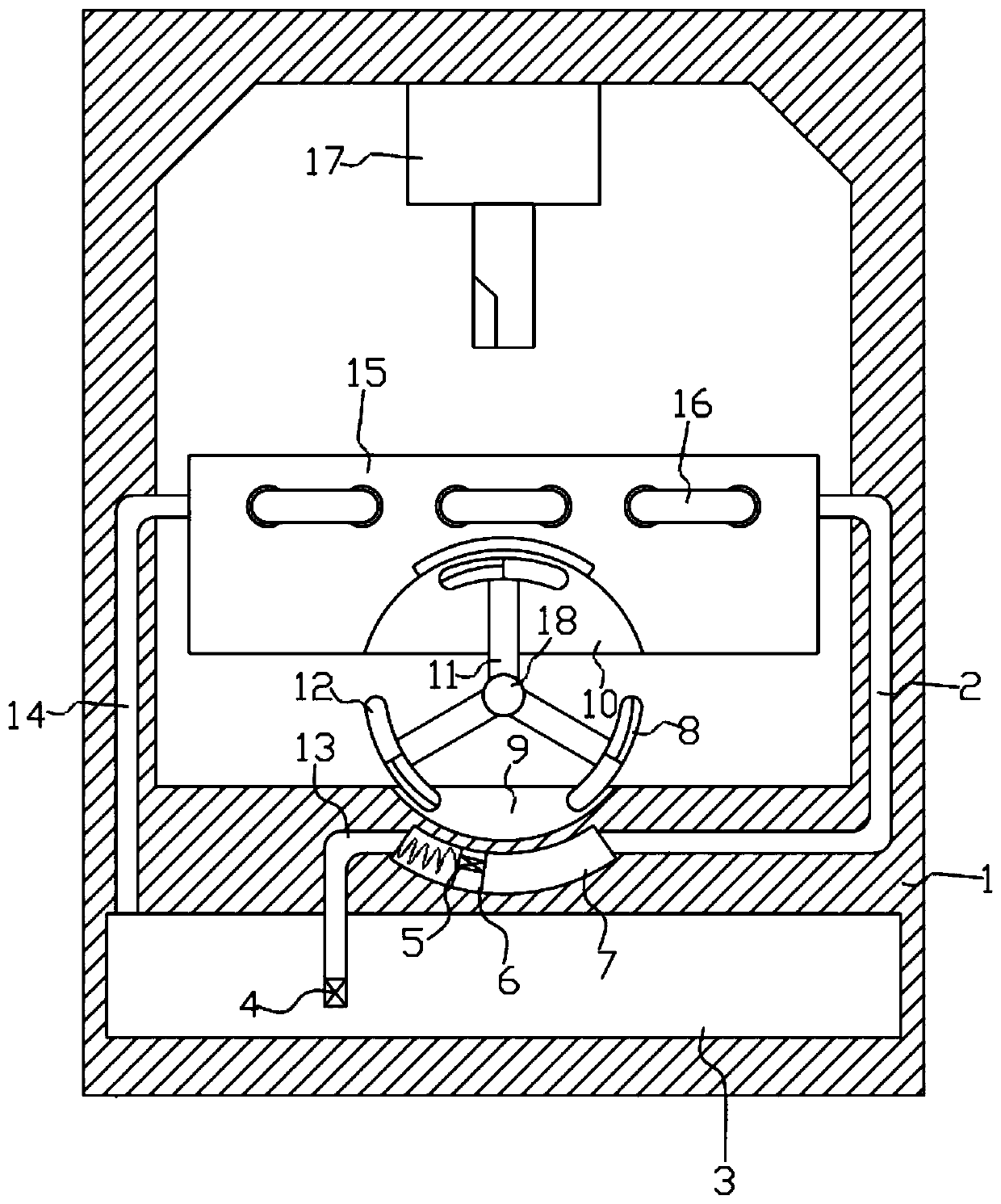

The invention discloses a mineral roasting reduction device. The device comprises a feeding zone, a drying preheating zone, a roasting oxidation reaction zone, a pressure-regulating zone, a reduction reaction zone, a discharging zone and a water-sealing cooling zone, which are arranged from the top down and communicated with one another, wherein the feeding zone is provided with an automatic sealing device; the drying preheating zone is provided with a directional pressurizing device for vacuum-pumping; the roasting oxidation reaction zone is provided with an incendiary agent adding device; the pressure-regulating zone is provided with a plurality of pressure-regulating air doors; the reduction reaction zone is provided with a reducing agent adding device. The mineral roasting reduction device is provided with the directional pressurizing device, so that negative pressure can be generated in the inner part of the device; molecular flows of both an incendiary agent and an reducing agent are in uplink, while mineral is in downlink, so that a convection current movement is formed to ensure conversion affinity of the solid phase and the gas phase; in the device, the mineral sequentially is subjected to drying, preheating, heating, resolving, reducing, water quenching, cooling and discharging from the top down, and all processes are performed in an air-free state thoroughly to complete roasting reaction.

Owner:QINGDAO ZHIBANG FURNACE DESIGN RES

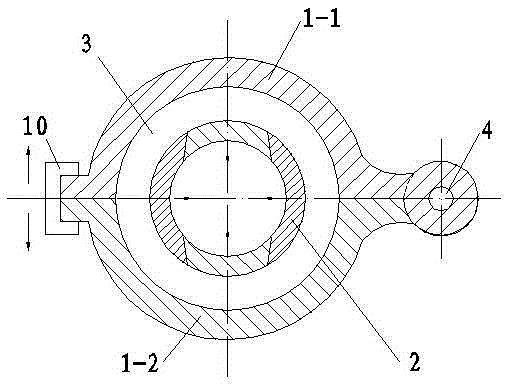

Casting method for copper bush with high lead bronze content

InactiveCN103742536AImprove quality requirementsImprove the authenticity rateFoundry mouldsBearing componentsCasting moldBronze

The invention relates to a casting method for a copper bush with high lead bronze content. The casting method is characterized in that a metal mould taking a parting surface of a casting and a pouring gate system as a half folding structure is used as an external casting mould; a metal mould core with a multi-piece parting structure is used as an internal casting mould; the copper bush with high lead bronze content comprises the following chemical components in percentage by weight: 18-23% of Pb, 4-6% of Sn and the balance of Cu; a water cooling device arranged at the periphery of the casting mould is used as a cooling means of the casting; and the casting method comprises the concrete casting steps: copper alloy smelting; deoxidation treatment; casting mould preheating; casting pouring; casting cooling; and casting head removal to obtain the copper bush with high lead bronze content. The casting method has the advantages of reasonable process, low production cost and the like and the quality of the produced copper bush is high.

Owner:JIANGSU RECODE RAIL TRANSIT TECH CO LTD

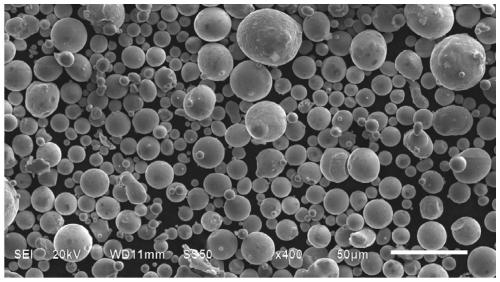

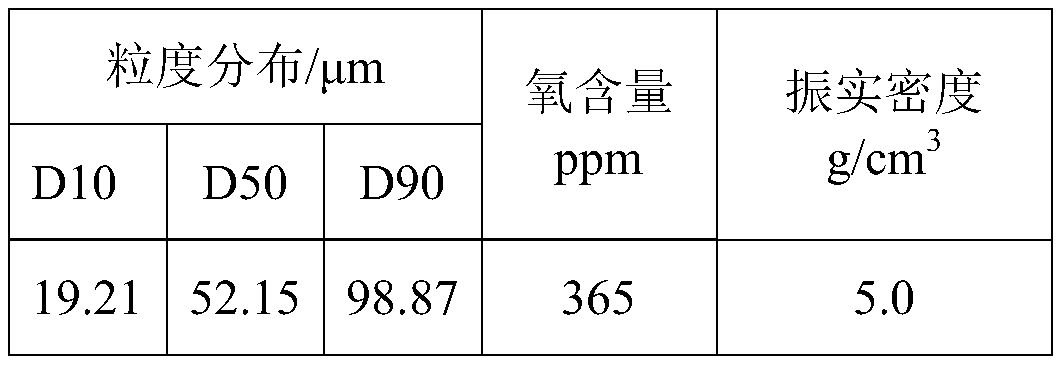

Preparation method of FeSi alloy powder with high direct current superposition characteristics

ActiveCN110039060AHigh tap densityImprove DC Superposition CharacteristicsTransportation and packagingMetal-working apparatusManganeseAlloy

The invention discloses a preparation method of FeSi alloy powder with high direct current superposition characteristics, and belongs to the technical field of alloy powder preparation. The FeSi alloypowder is mainly made of pure iron and metal silicon, and a small amount of manganese and chromium are added. The preparation method comprises the following steps of weighing the ingredients according to a specific proportion, carrying out non-vacuum melting to obtain the alloy melt of required components, and then atomizing to prepare alloy raw powder with an inert gas, obtaining fine powder after the raw powder is collected, screened and graded. According to the preparation method of FeSi alloy powder with high direct-current superposition characteristics, the alloy powder with uniform components and high purity can be obtained, and the powder spherical degree is high; the uniform and compact insulating layer can be easily formed after insulation coating, so that the contact of the alloy matrix is effectively blocked, and the pressed magnetic powder core has good direct-current superposition characteristics.

Owner:马鞍山新康达磁业股份有限公司

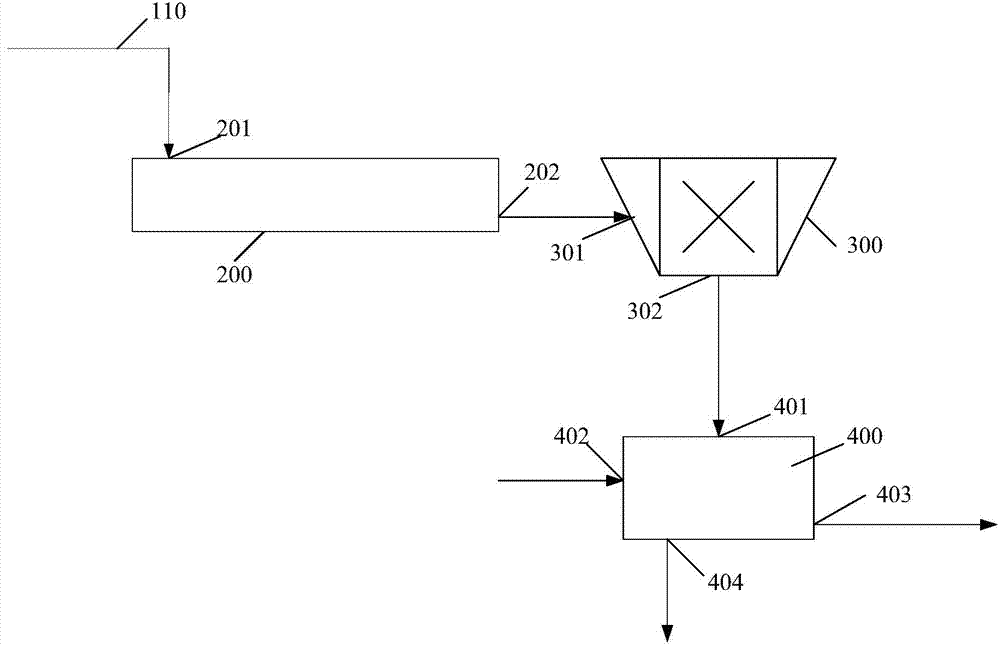

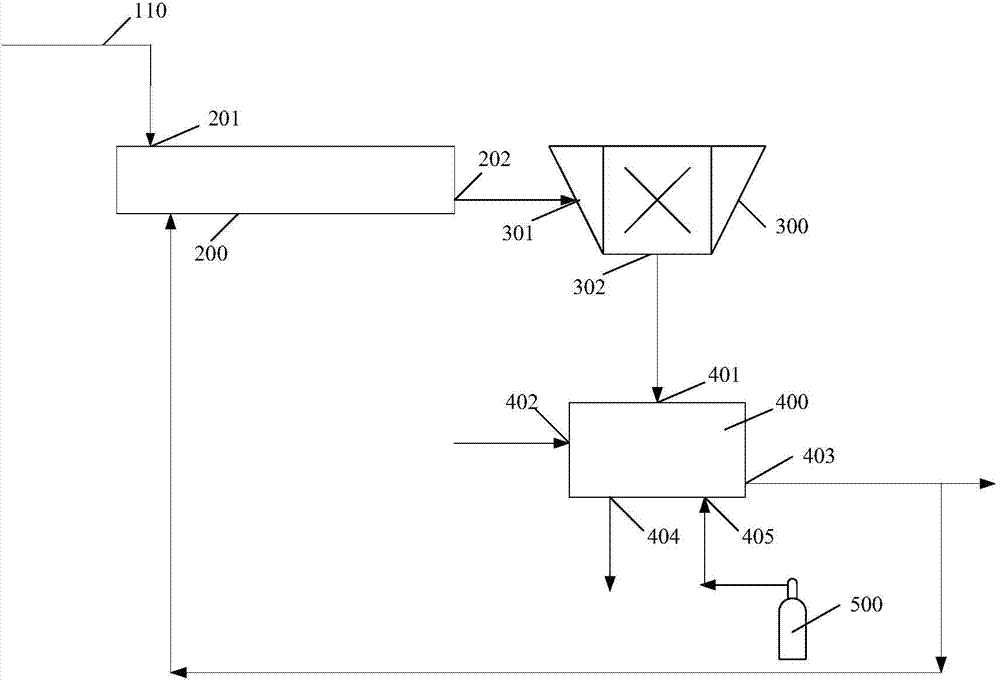

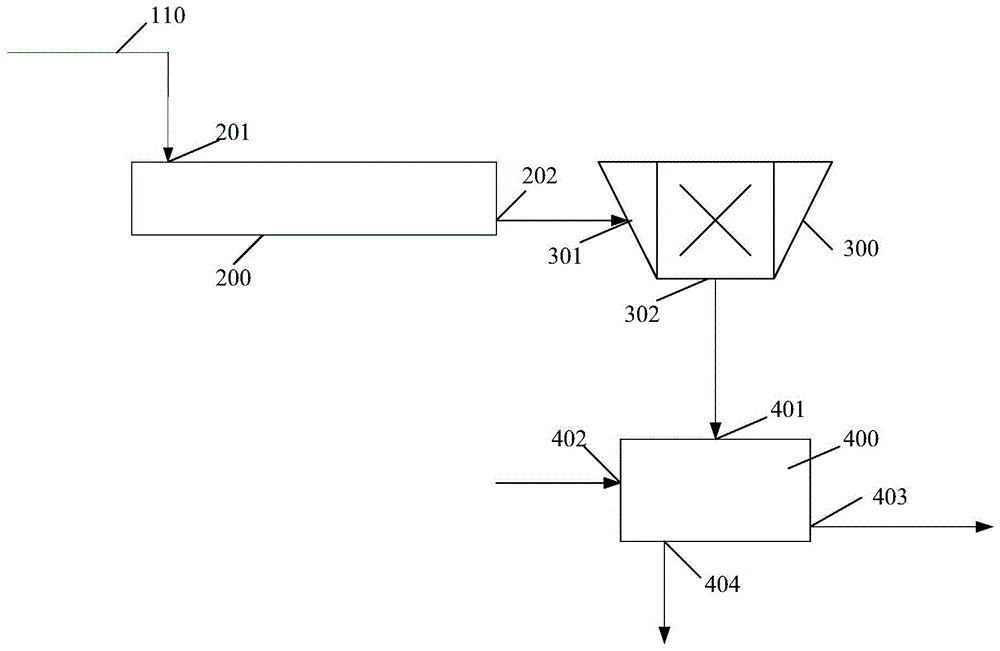

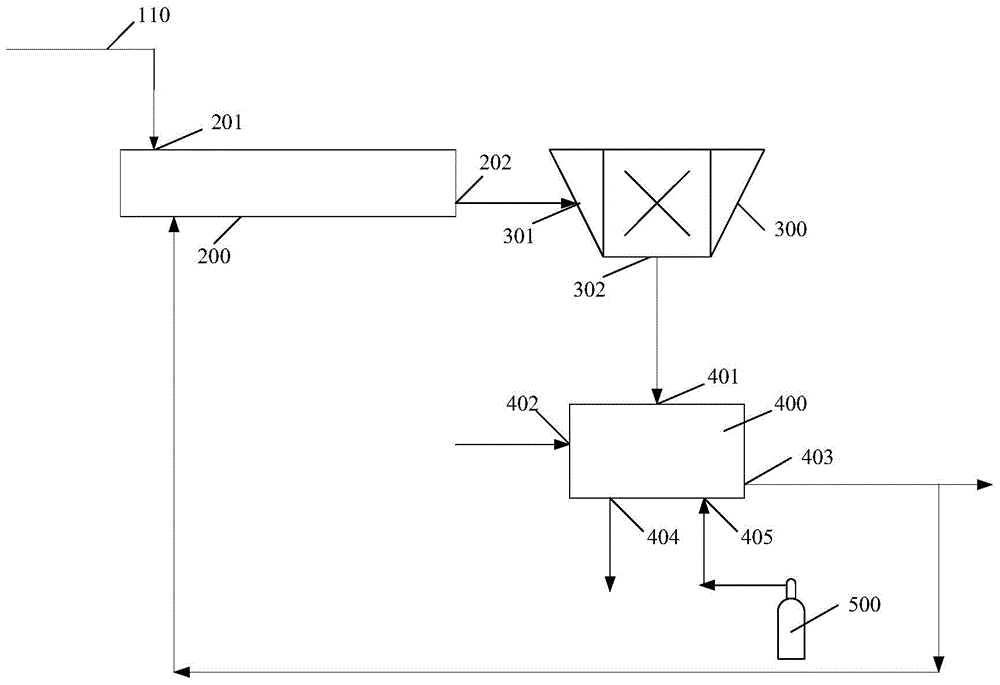

Lyocell fiber spinning solution waste recycling device and recycling method thereof

ActiveCN104711706ASmall sizeLarge specific surface areaArtificial filament recoveryTextile/flexible product manufactureManufacturing cost reductionSlag

The invention provides a lyocell fiber spinning solution waste recycling device and a recycling method thereof. The recycling device comprises a waste pipeline, a cooling device, a breaking device and a leaching device, wherein the waste pipeline is provided with a spinning solution waste inlet and a spinning solution waste outlet; the spinning solution waste inlet is connected to a spinning solution waste output device; the cooling device is provided with a cooling material inlet and a cooling material outlet; the cooling material inlet is communicated with the spinning solution waste outlet; the breaking device is provided with a breaking material inlet and a breaking material outlet; the breaking material inlet is communicated with the cooling material outlet; the leaching device is provided with a leaching material inlet, an NMMO leaching solvent inlet, a leaching liquid outlet and a leaching slag outlet; the leaching material inlet is communicated with the breaking material outlet; a plurality of extrusion holes are formed in the spinning solution waste outlet of the waste pipeline. By virtue of the application of the recycling device, the NMMO solvent in the lyocell fiber spinning solution waste is effectively recycled, so that the manufacturing cost is reduced.

Owner:CHINESE TEXTILE ACAD

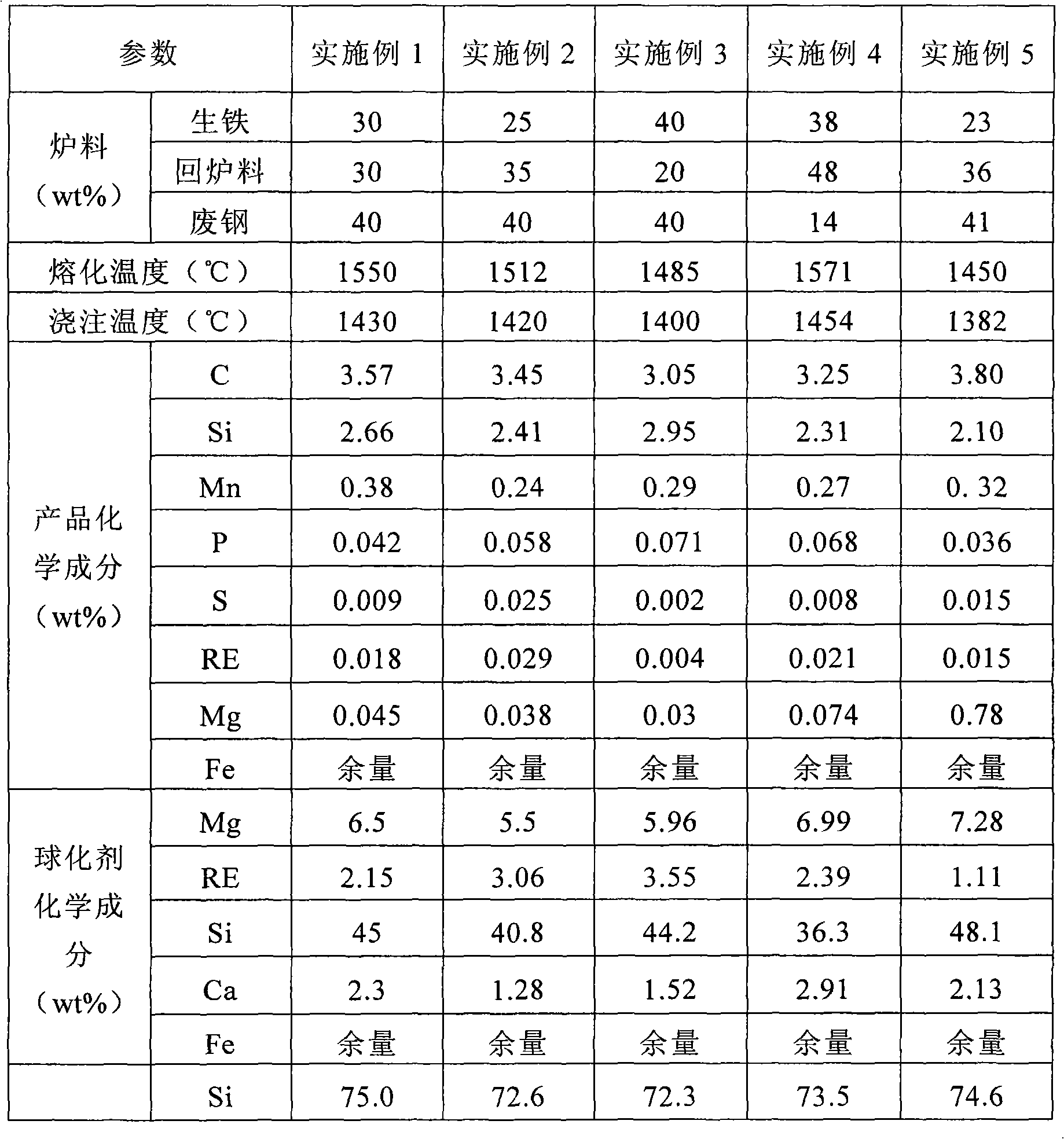

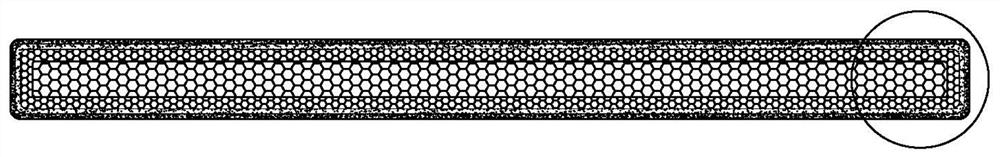

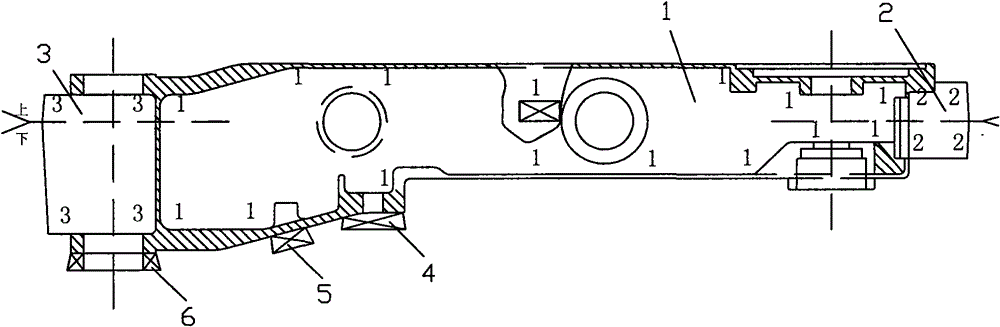

Method for casting mechanical arm casting of robot

ActiveCN102078956ANo shrinkage defectsAvoid slag inclusion defectsMolten metal pouring equipmentsMoulding toolsHardnessMechanical property

The invention discloses a method for casting a mechanical arm casting of a robot, which comprises the steps of: sand mulling, modeling, core molding, mold assembly, furnace charge smelting, tapping spheroidizing and inoculation treatment, casting, cooling, unpacking, casting cleaning and product quality inspection. In the method, a two-side distributed casting process is adopted in terms of process designing, and external chill is arranged on the thicker part of the casting. The casting has mechanical properties such as tensile strength of more than or equal to 450MPa, yield strength of more than or equal to 310MPa, elongation rate of more than or equal to 10 percent and body hardness of 160 to 210HBS, and does not have any casting shortcoming.

Owner:上海华新合金有限公司

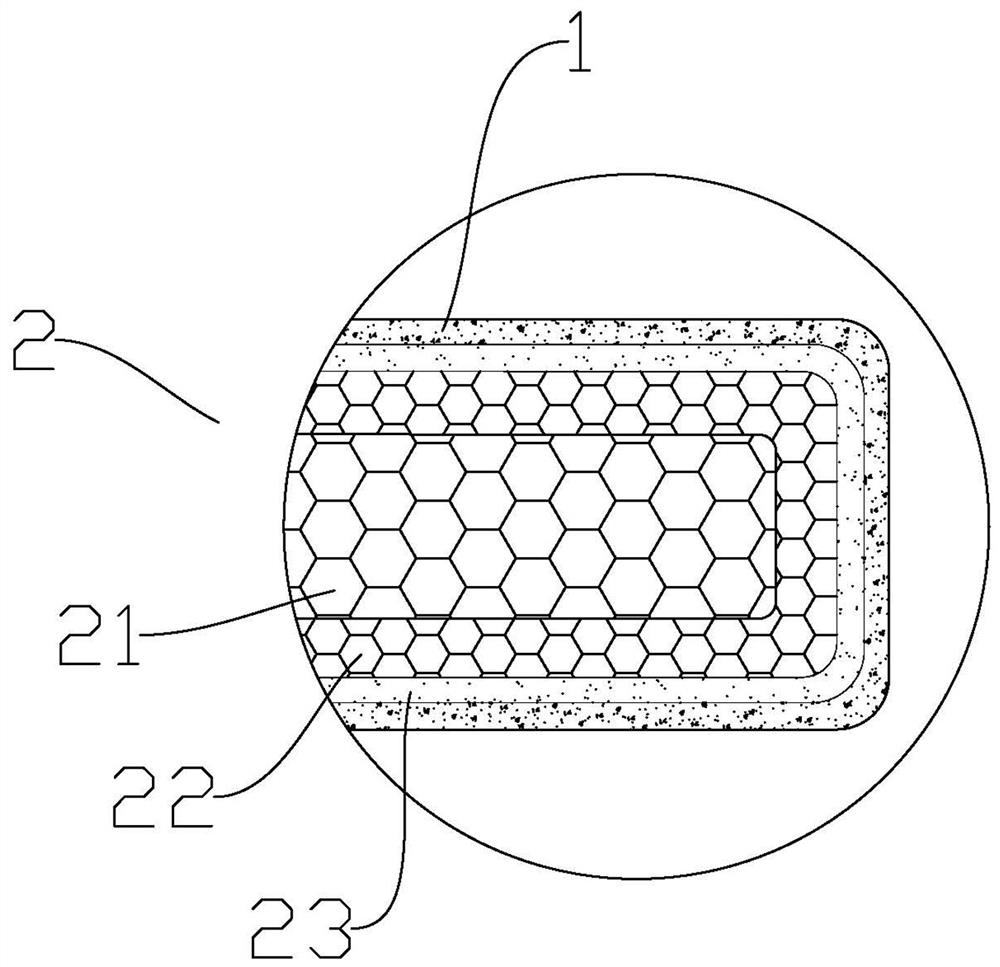

PVC co-extrusion foaming floor and preparation method thereof

ActiveCN112443120AAchieve light weightAchieving cohesionLamination ancillary operationsSynthetic resin layered productsPolymer scienceHigh density

The invention relates to a PVC co-extrusion foaming floor and a preparation method thereof, and belongs to the technical field of PVC foaming floors. The PVC co-extrusion foaming floor comprises a PVCfoaming core and a plastic surface layer, wherein the PVC foaming core comprises a first foaming layer, a second foaming layer and a skinning layer, the second foaming layer wraps the first foaming layer, the skinning layer wraps the second foaming layer, and all the layers of the PVC foaming core are integrally connected; the plastic surface layer wraps at least the upper surface of the skinninglayer; the first foaming layer is a low-density foaming layer, and the second foaming layer is a high-density foaming layer; and wood textures are formed in the plastic surface layer. According to the PVC co-extrusion foaming floor and the preparation method thereof, one-time forming is achieved through an improved foaming process, so that compared with a PVC foaming core in the prior art that the first foaming layer and the second foaming layer are not obviously distinguished and the skinning layer is thin, the PVC foaming core has the advantages of being clearer in structural hierarchy andhigher in overall strength; and the PVC foaming core is more suitable for wrapping the plastic surface layer.

Owner:ANHUI SENTAI WPC TECH FLOOR CO LTD

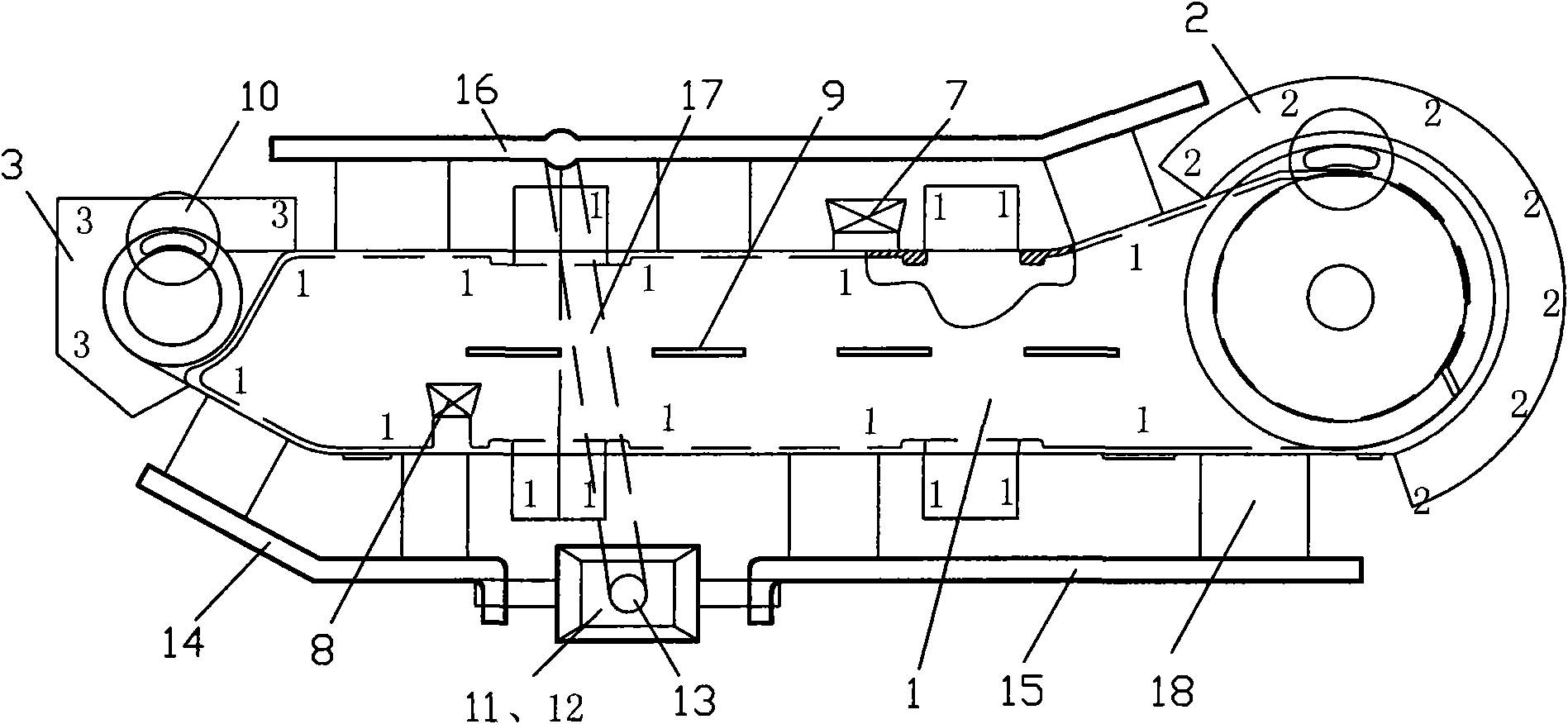

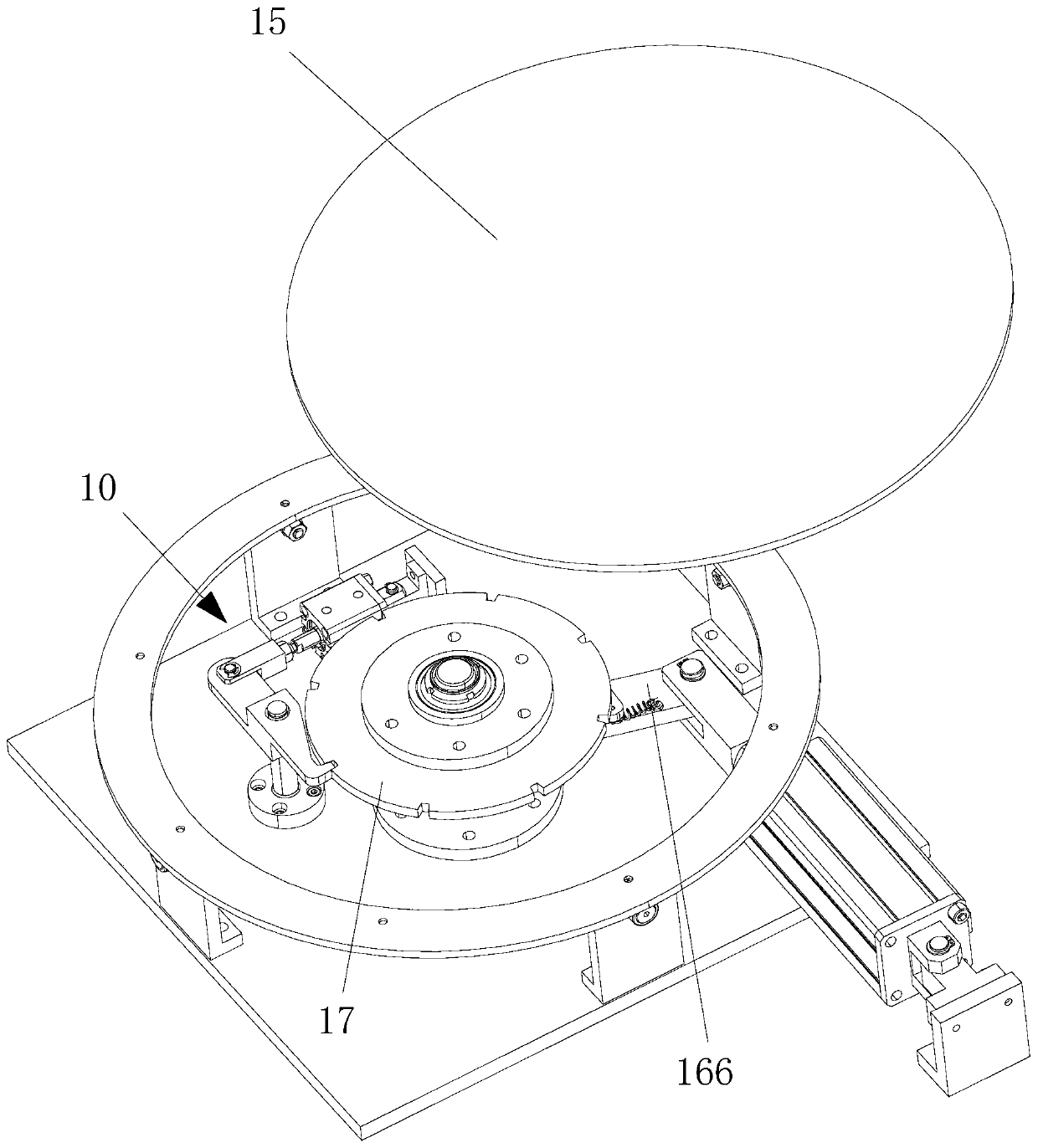

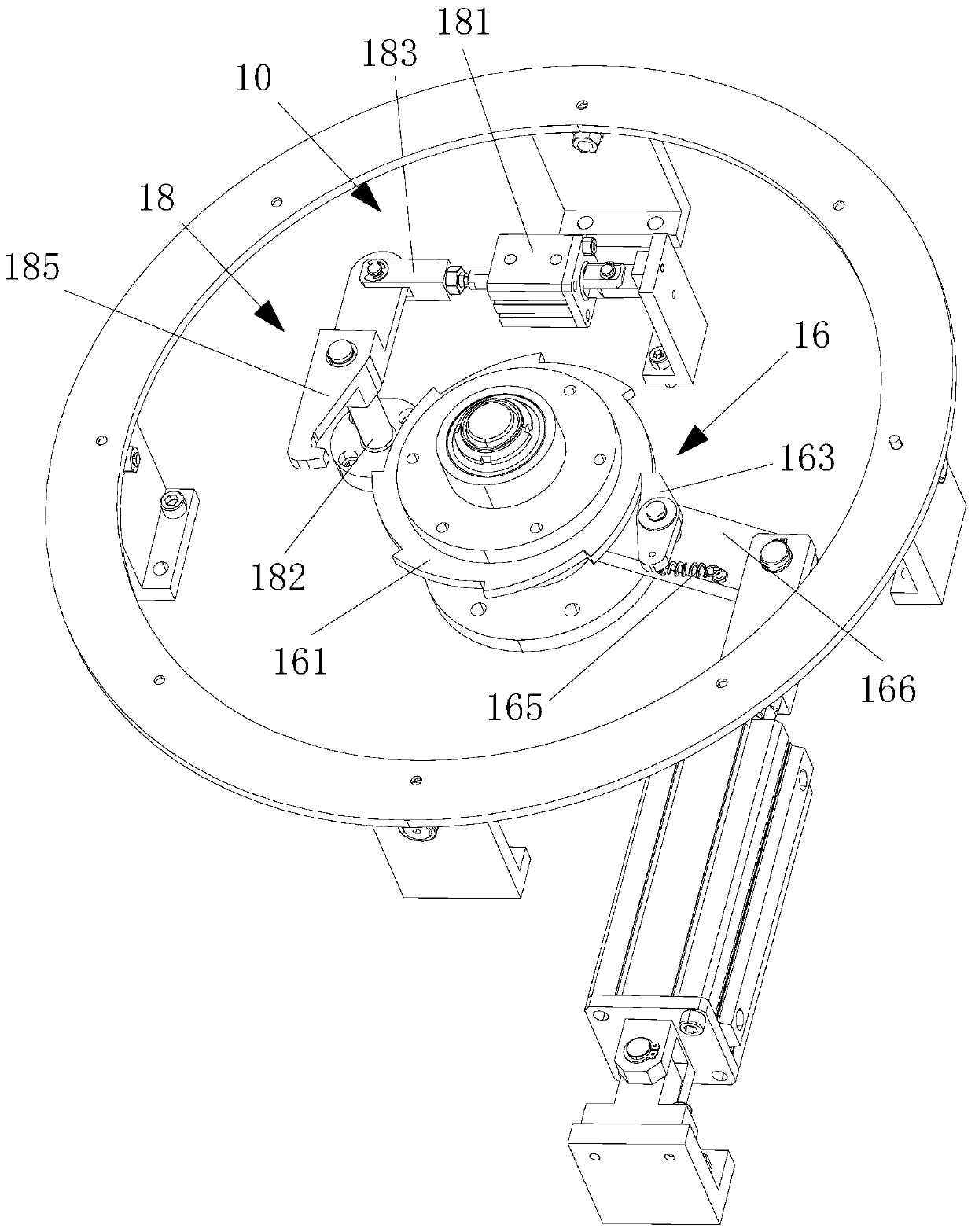

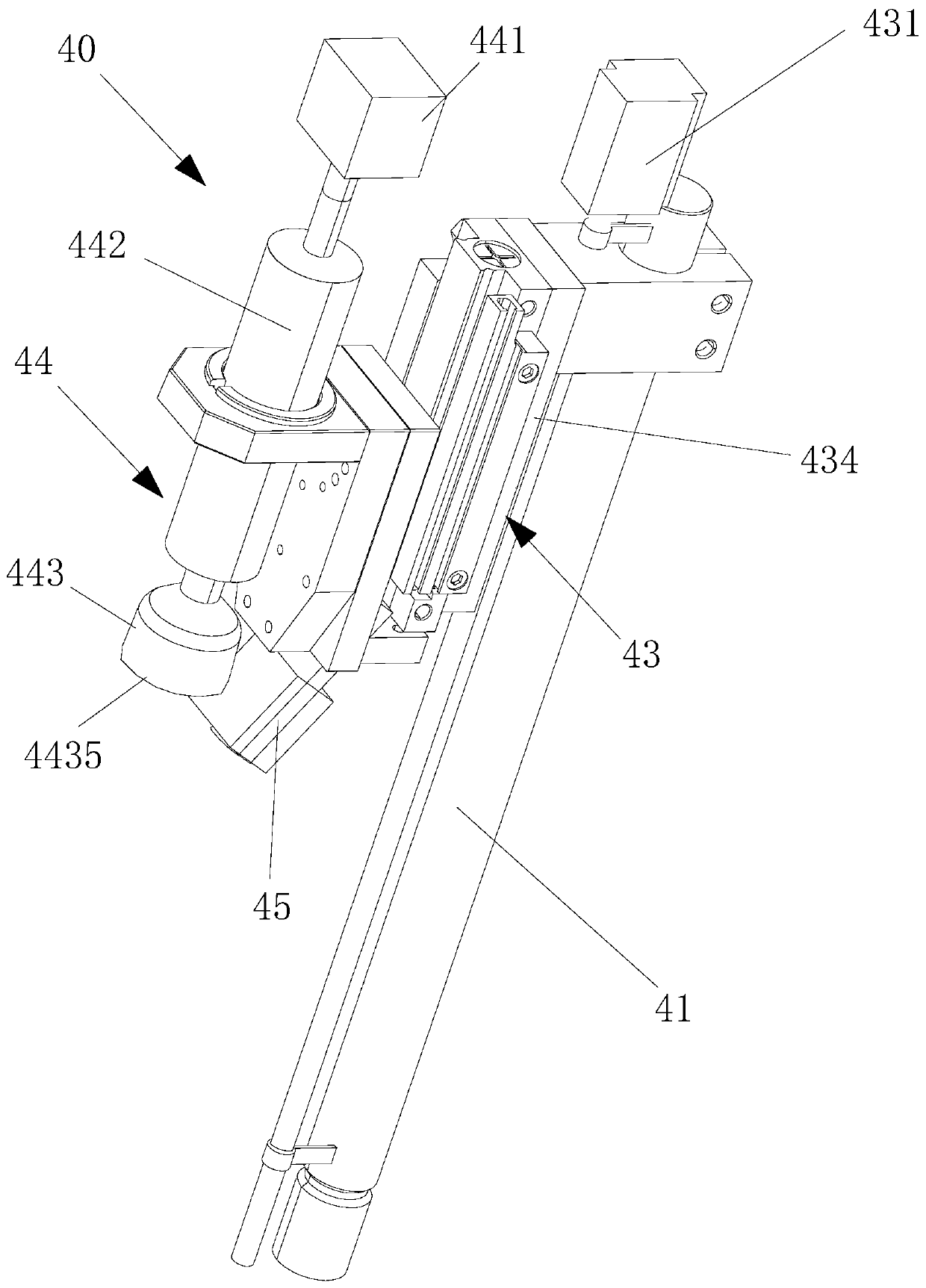

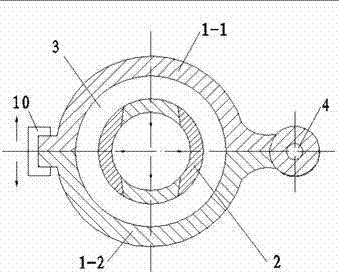

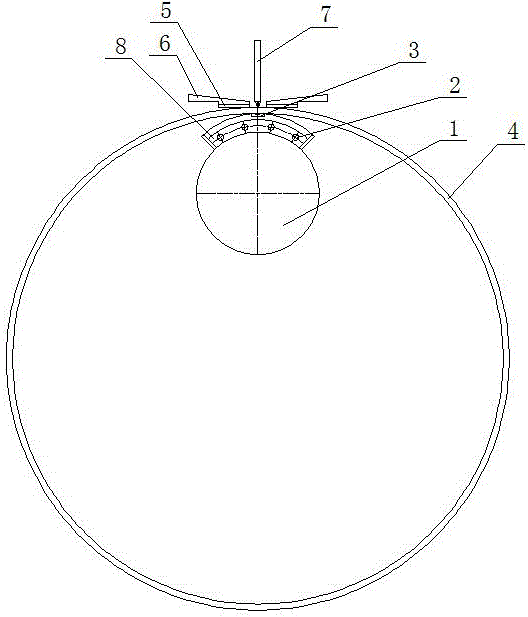

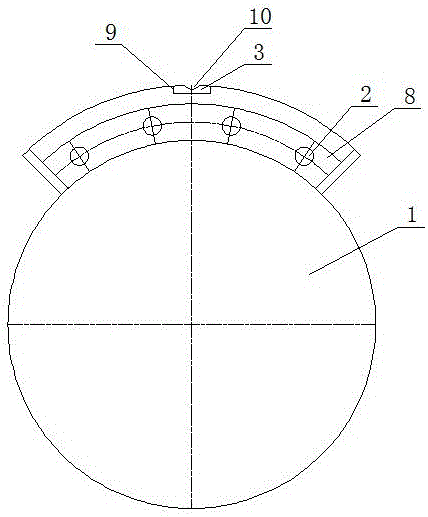

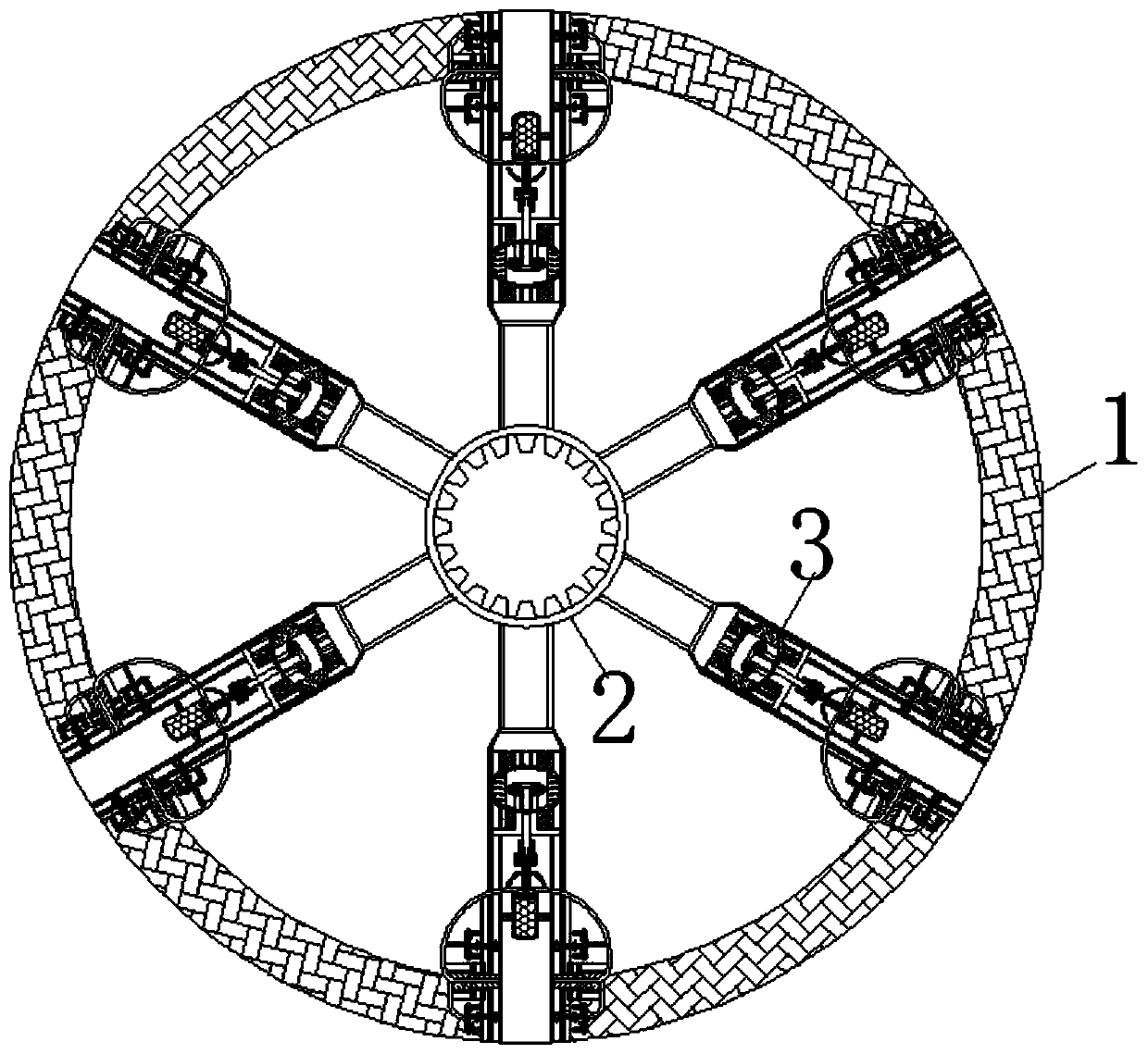

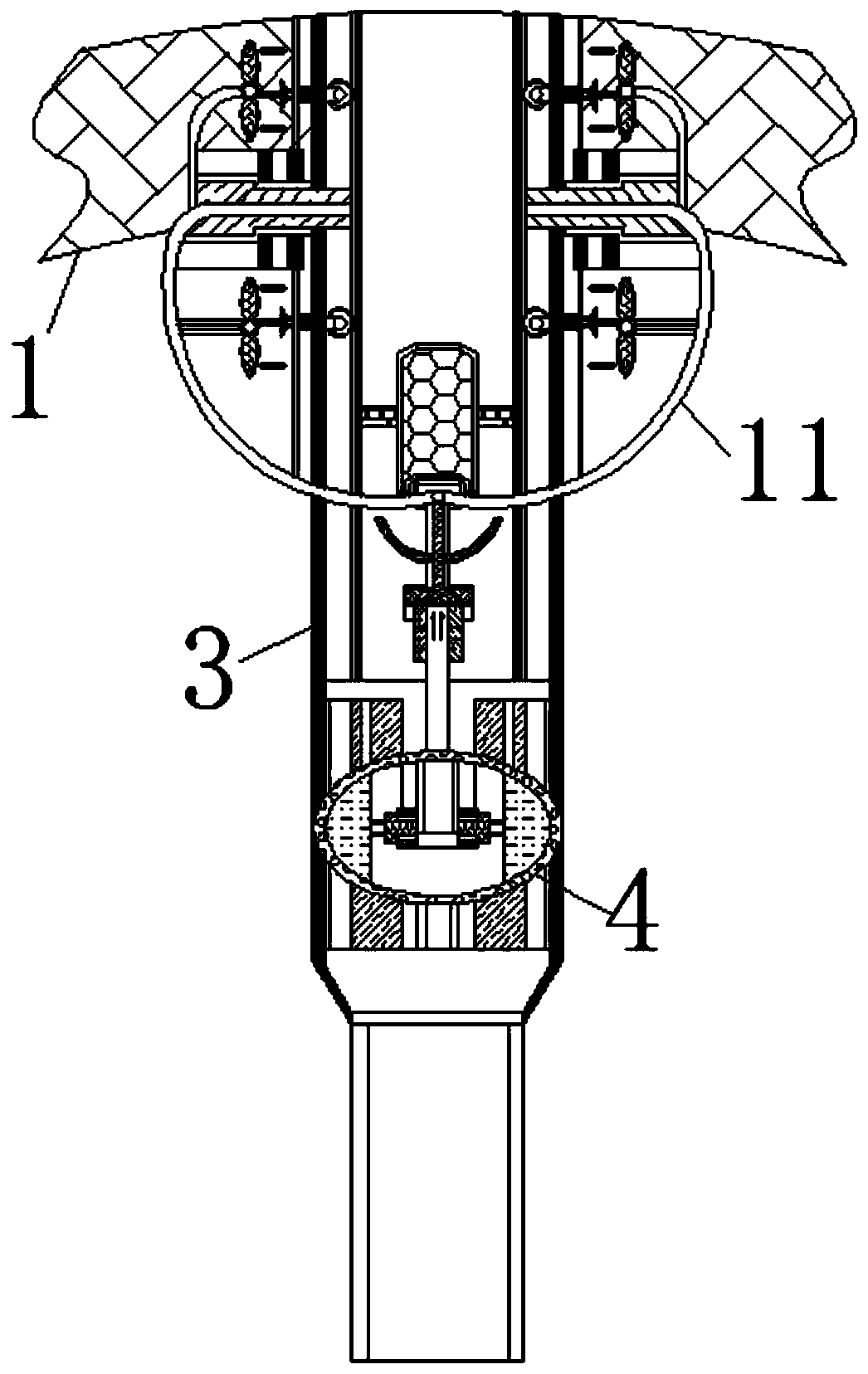

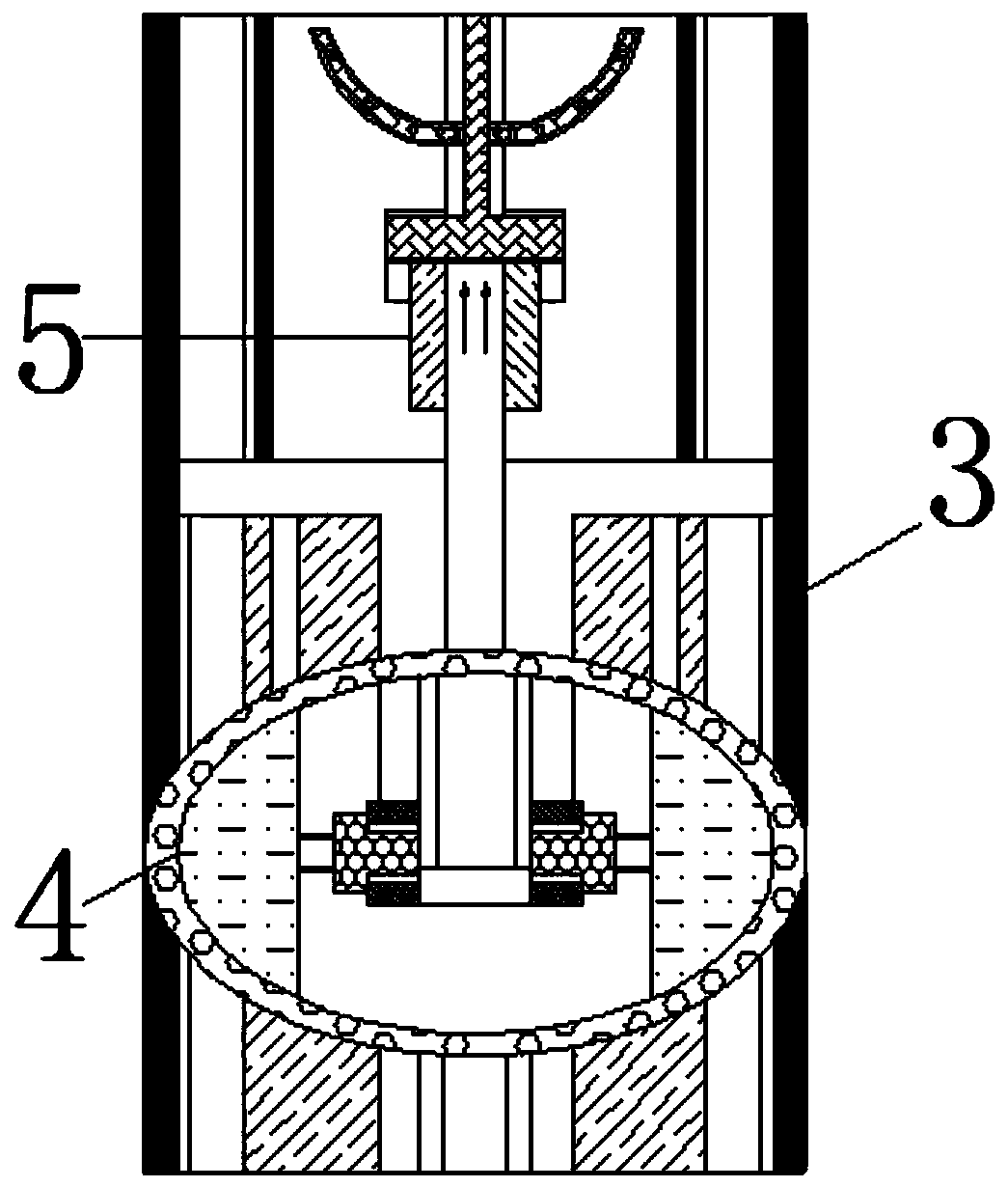

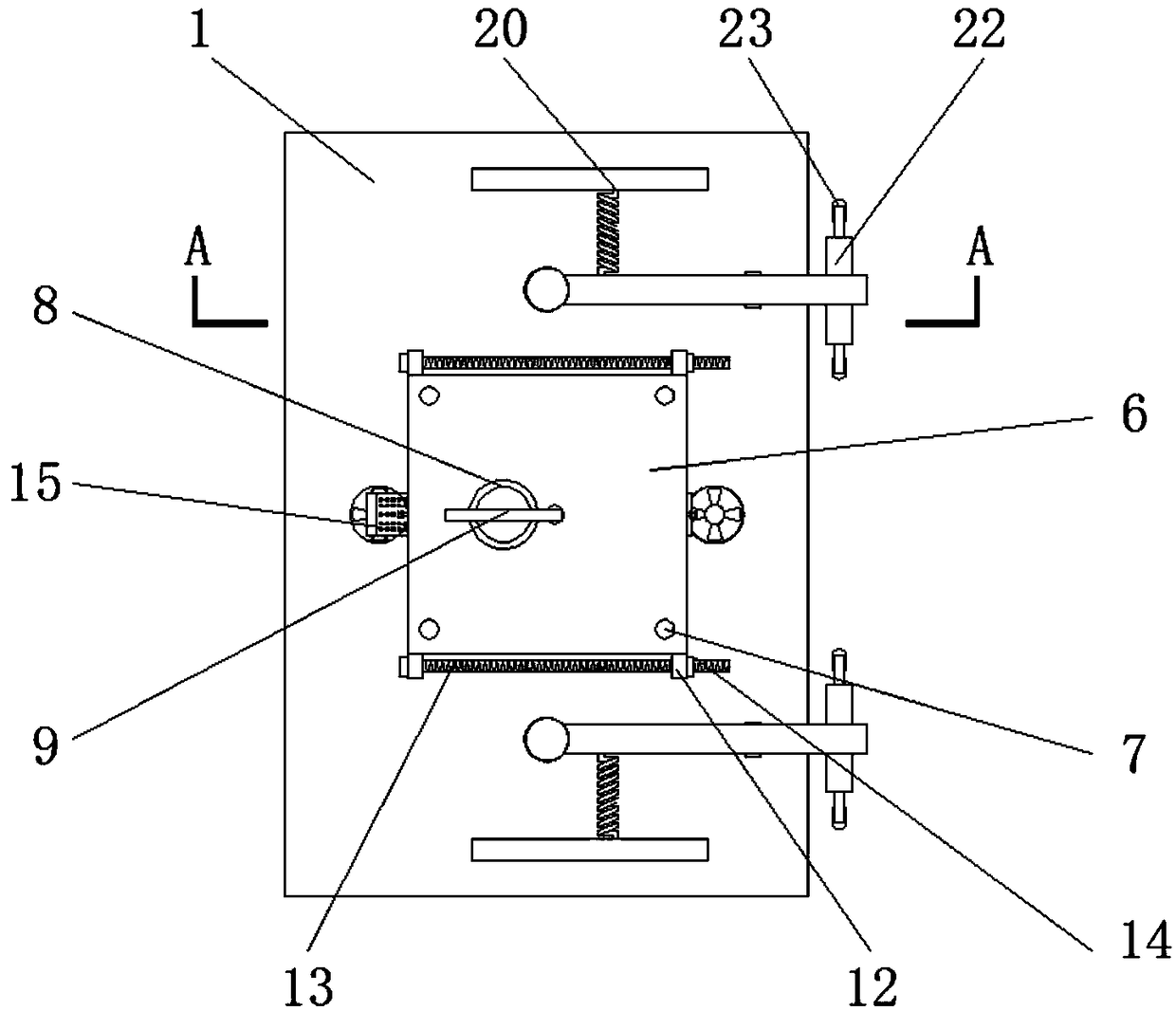

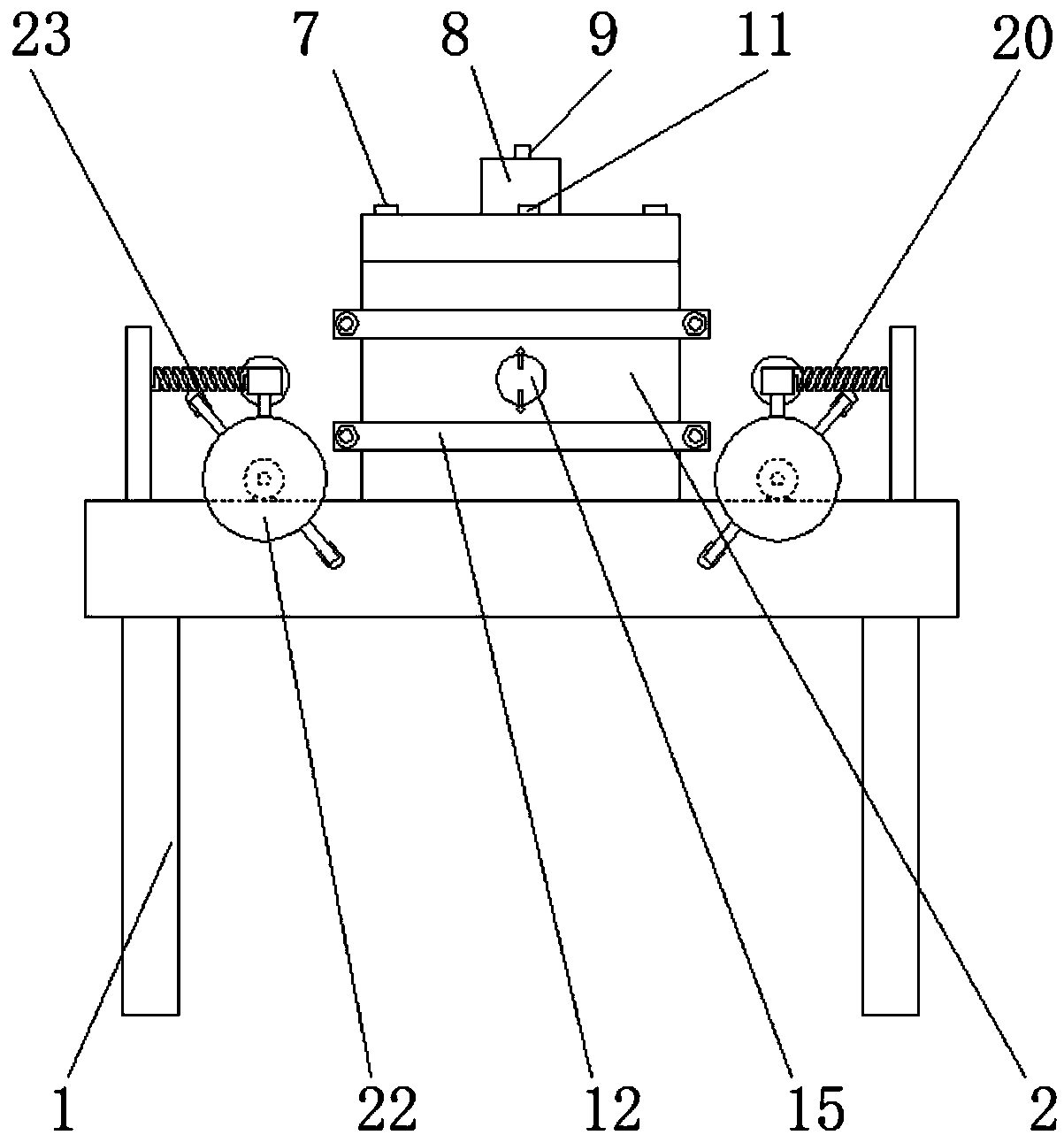

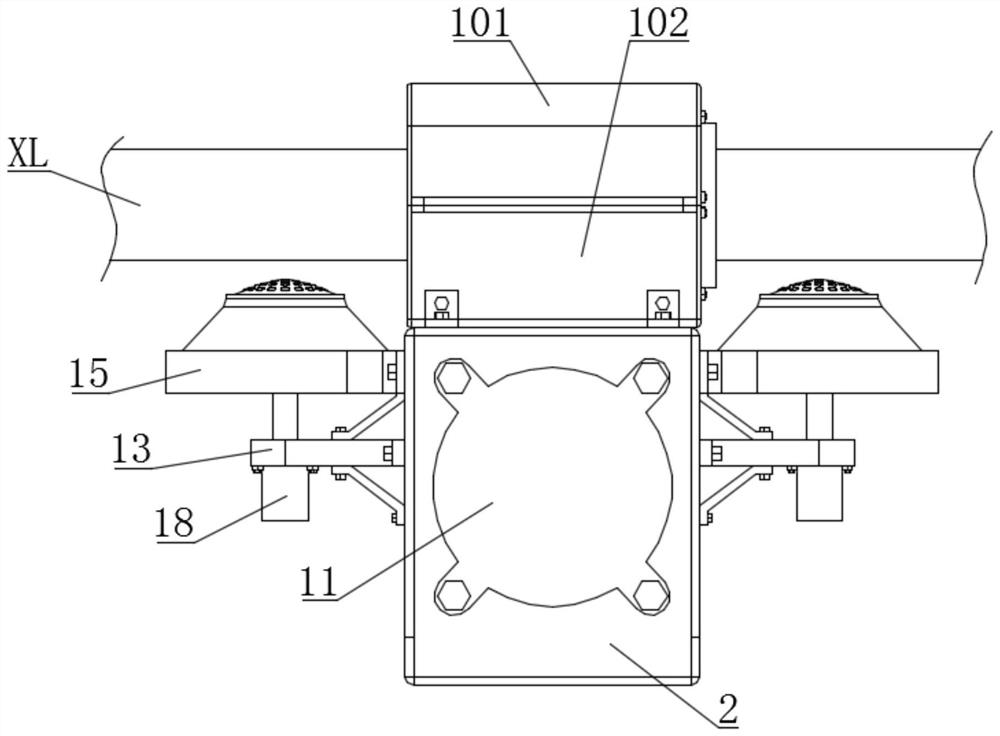

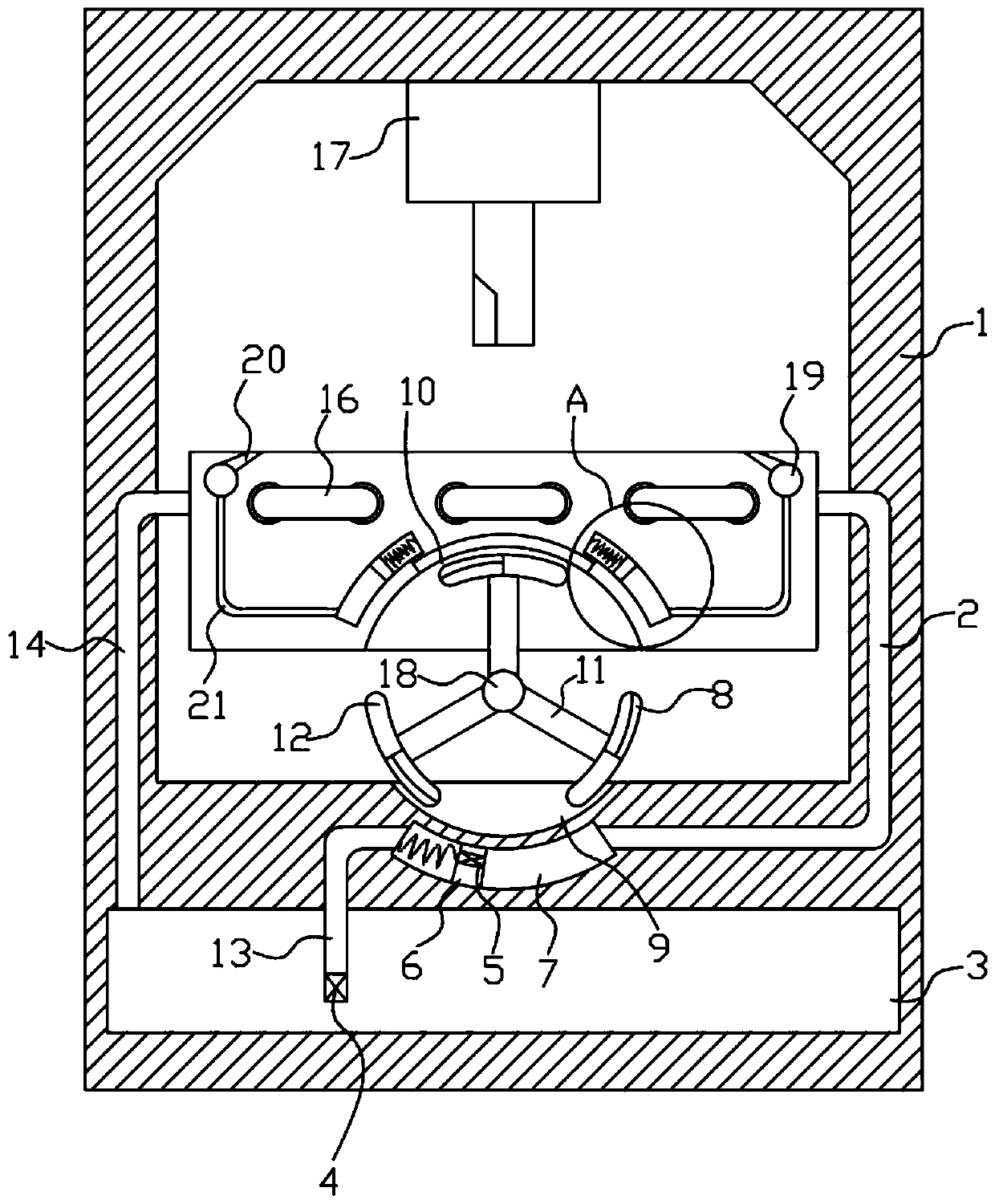

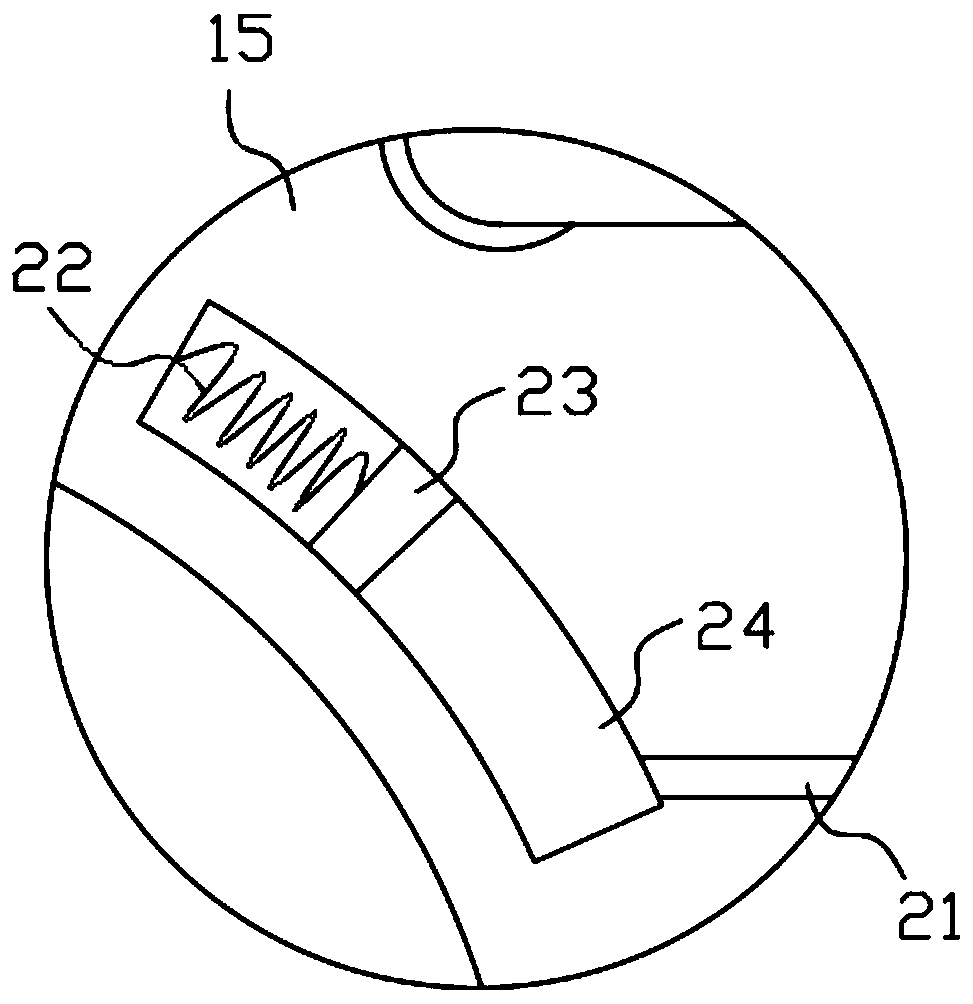

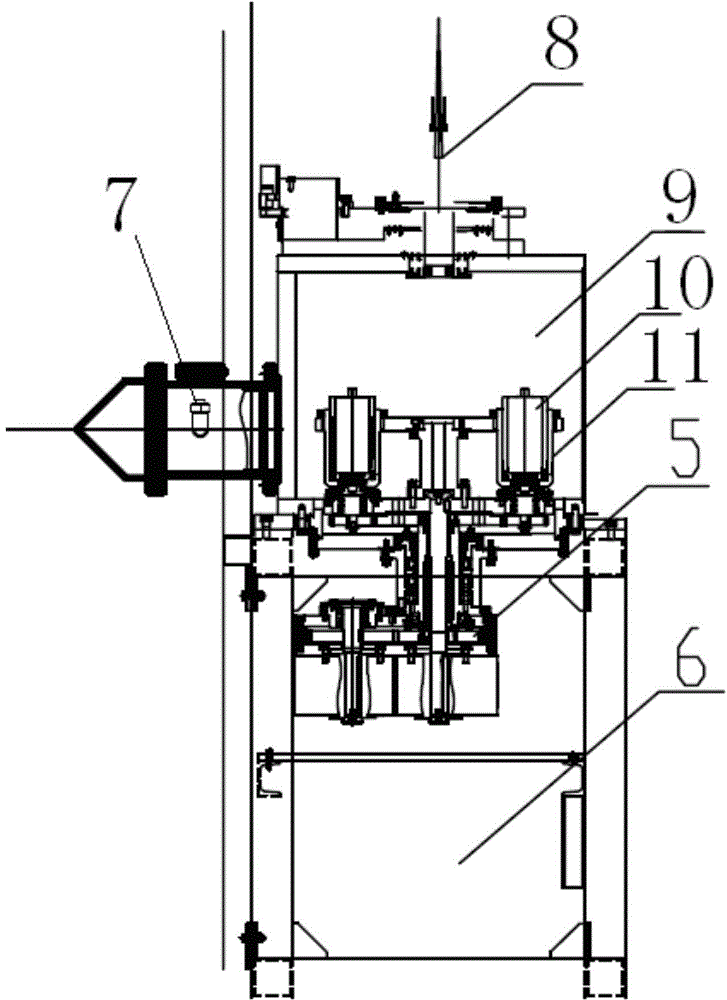

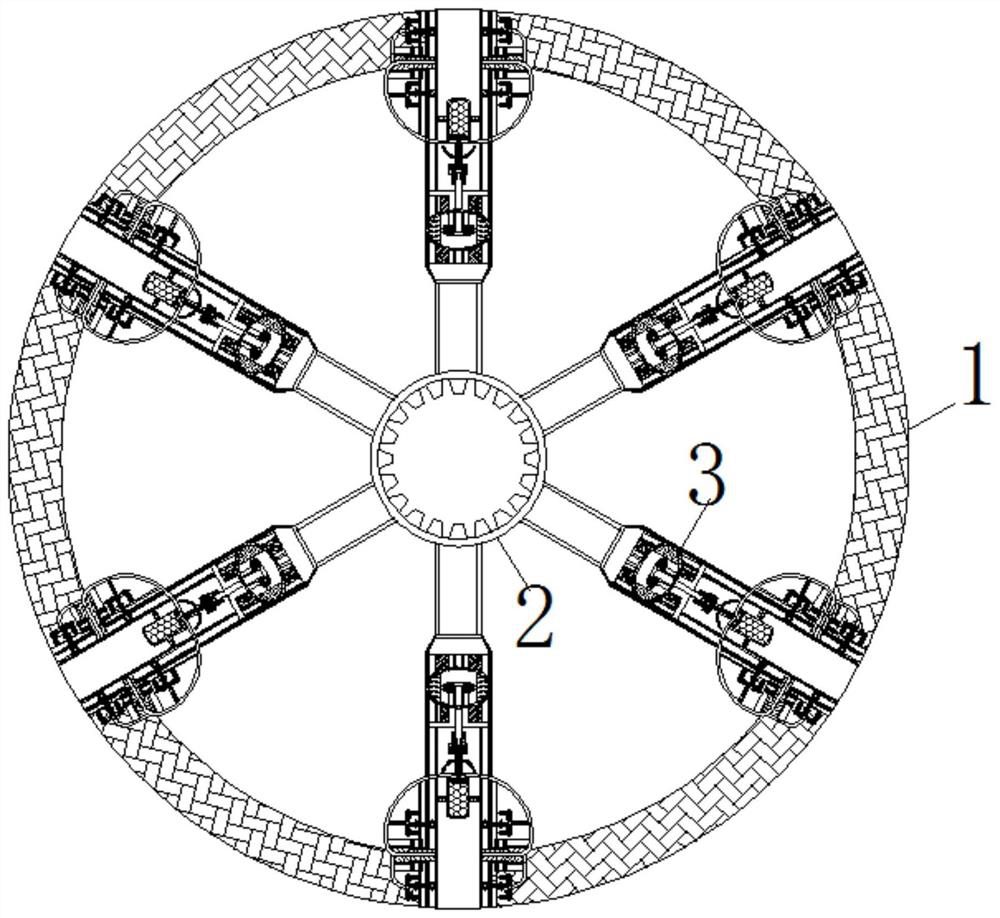

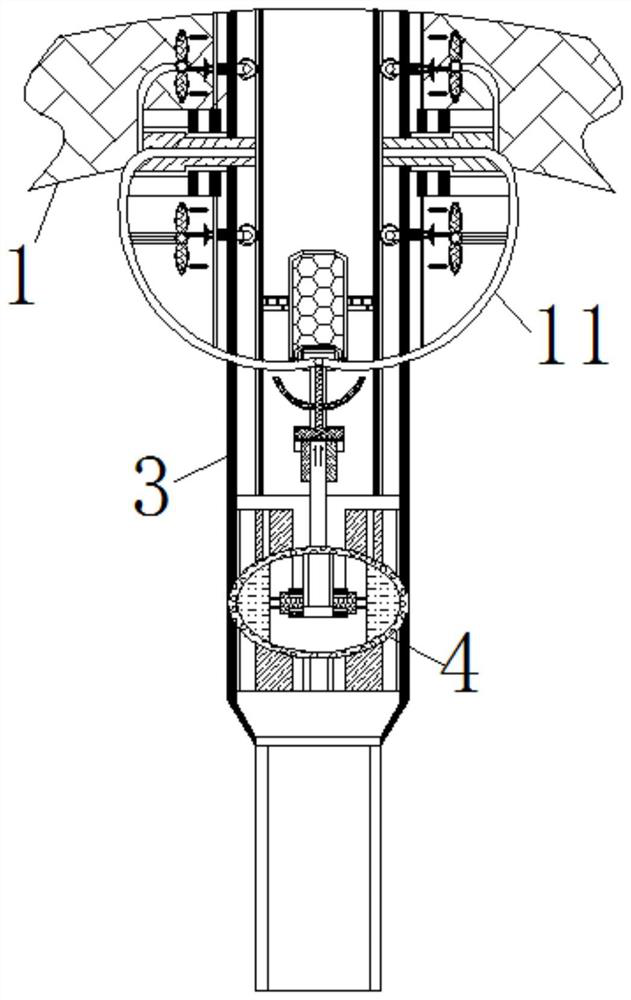

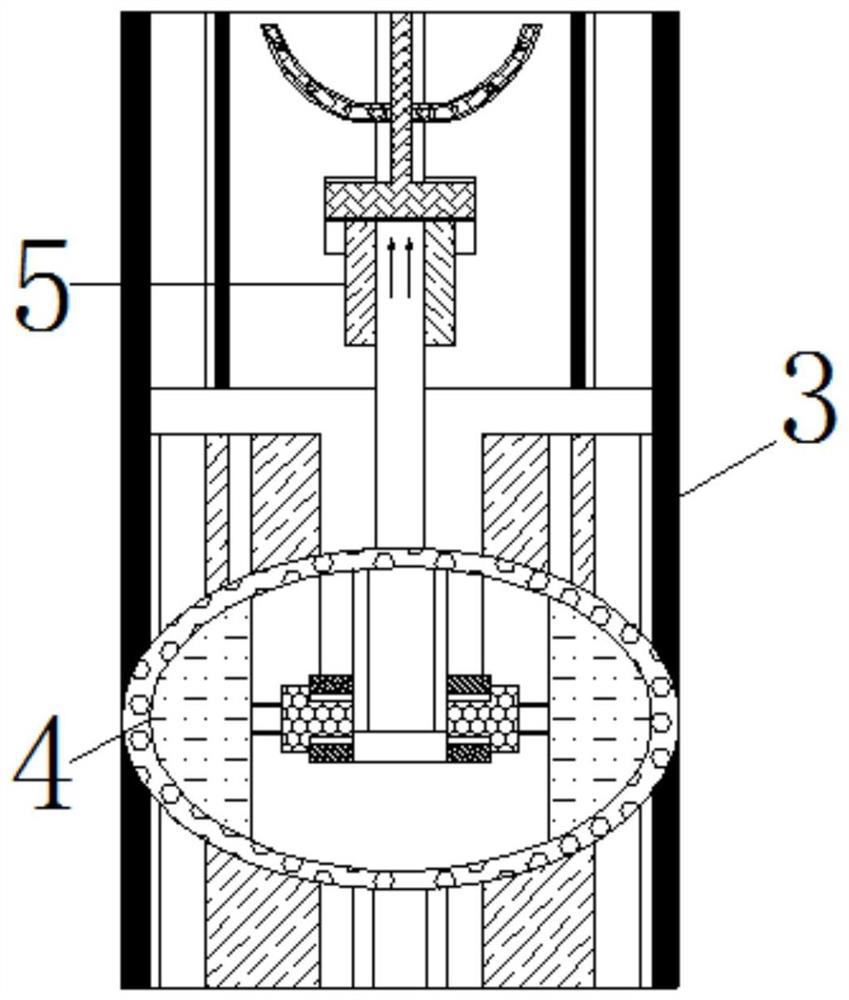

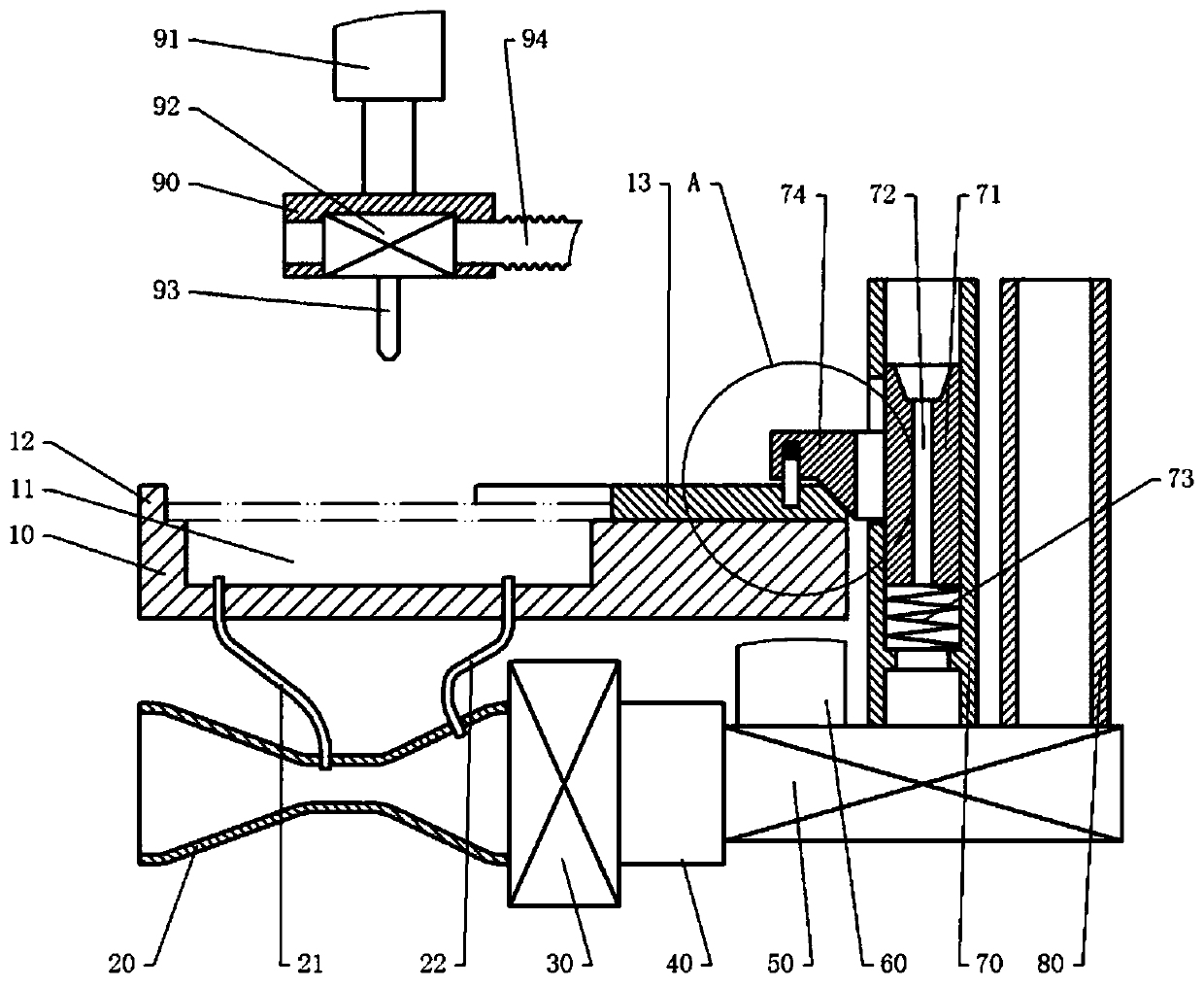

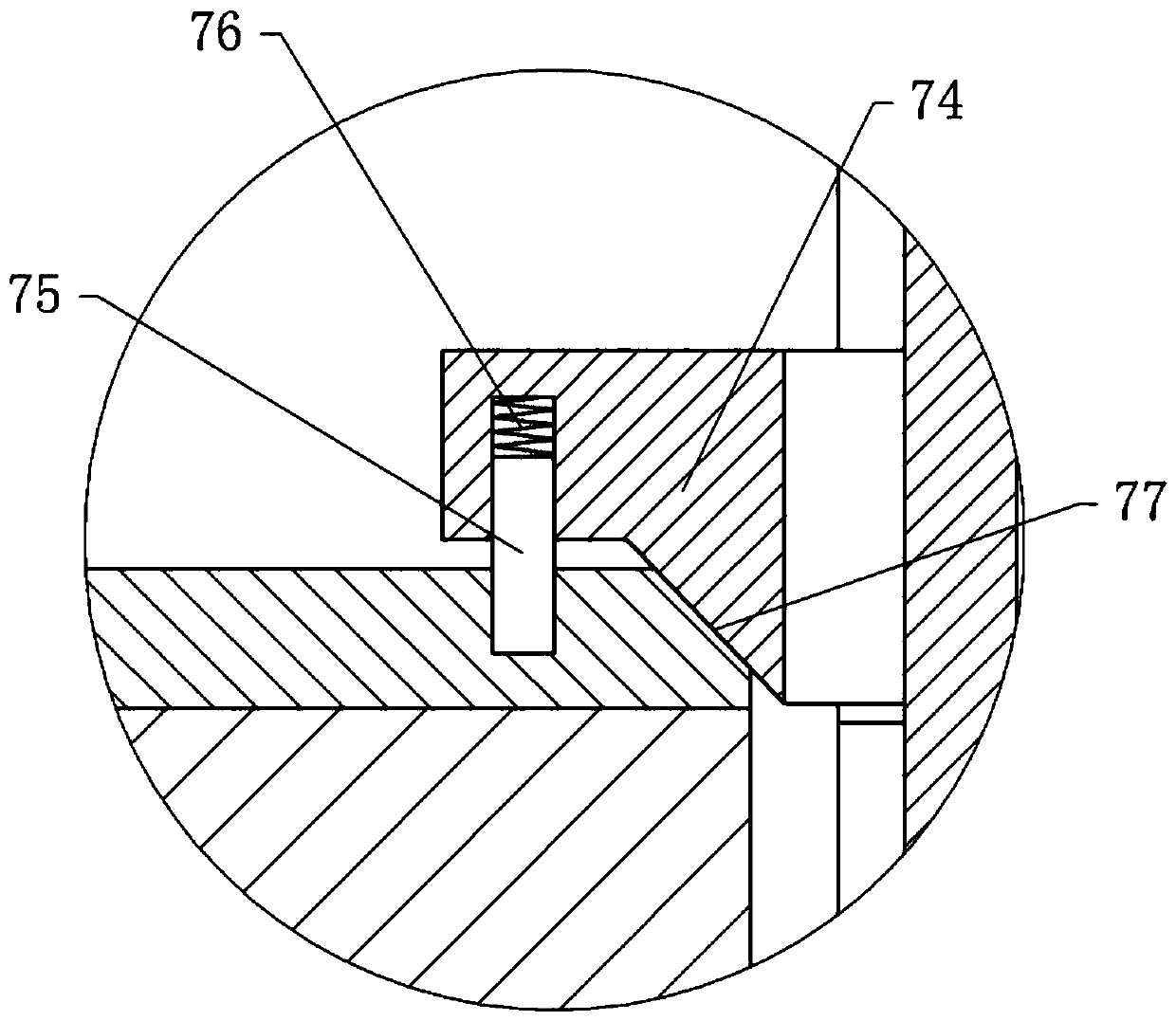

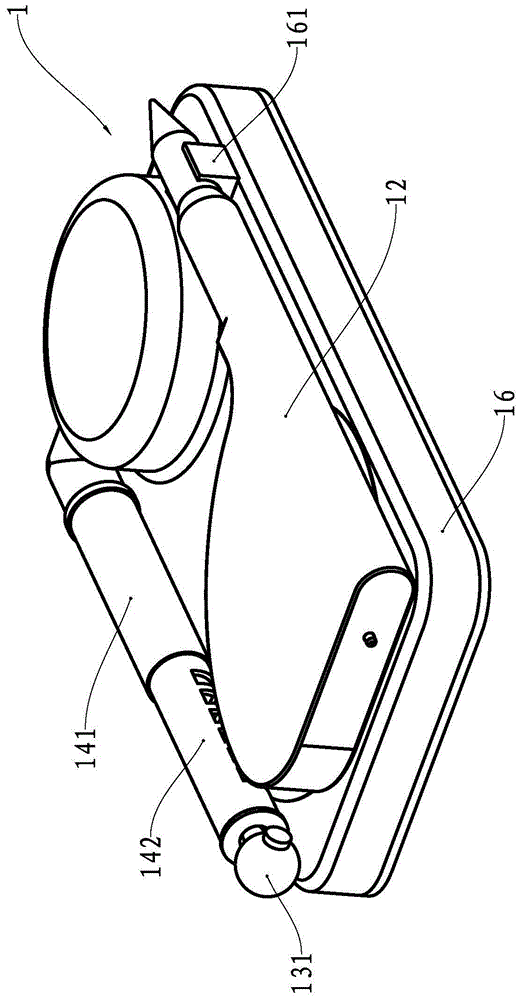

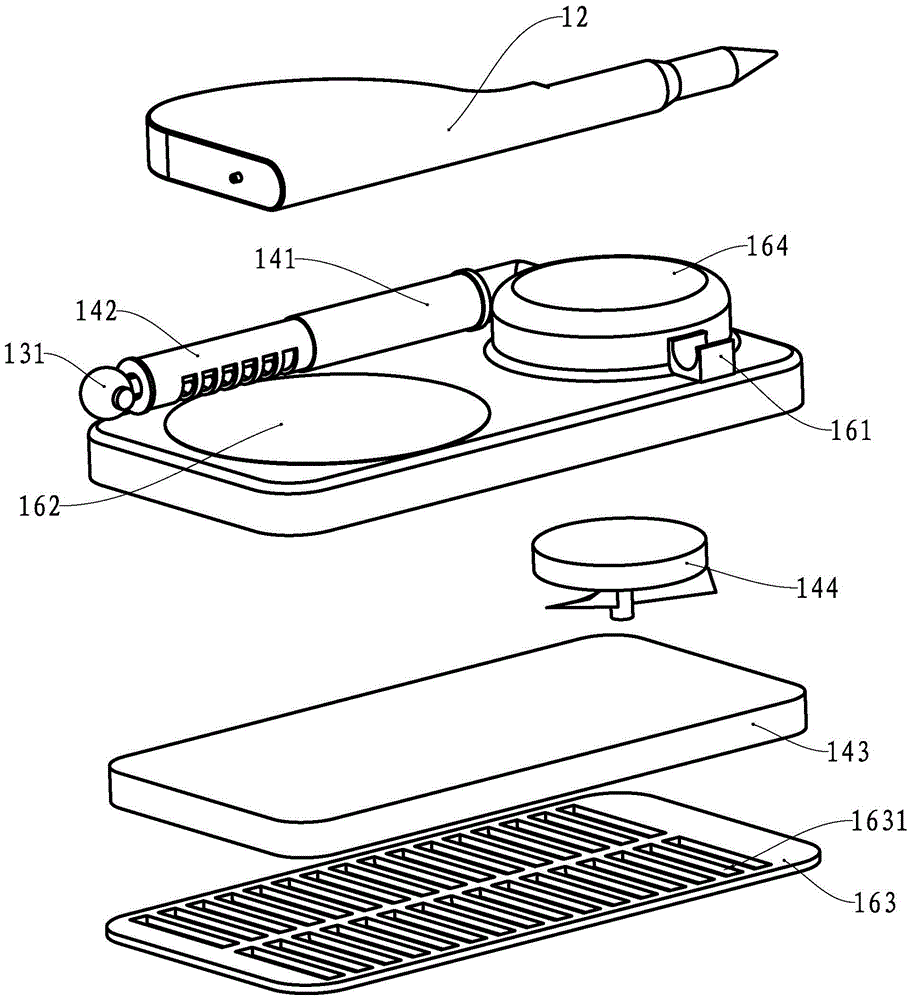

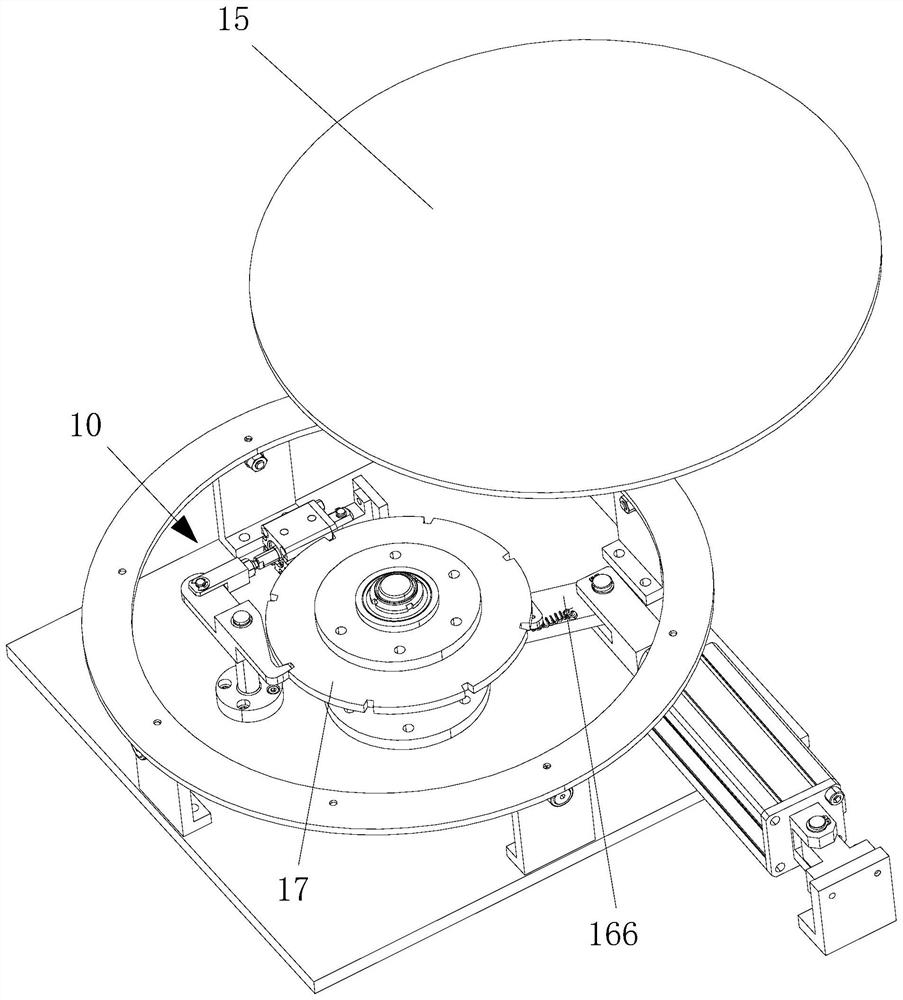

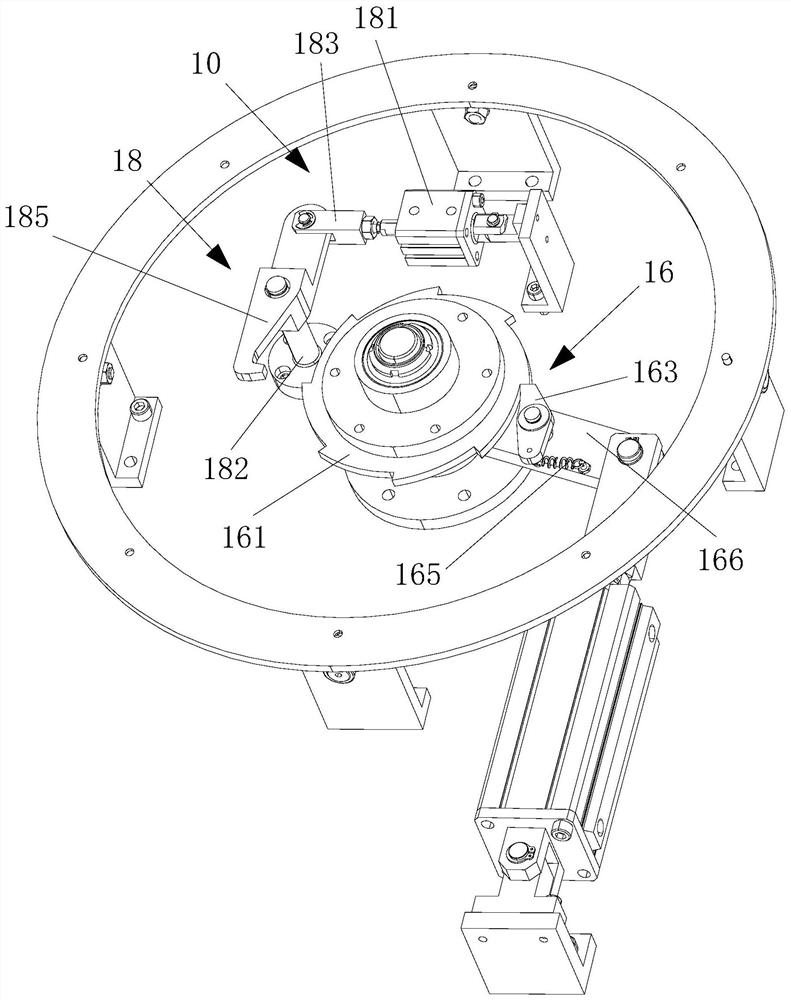

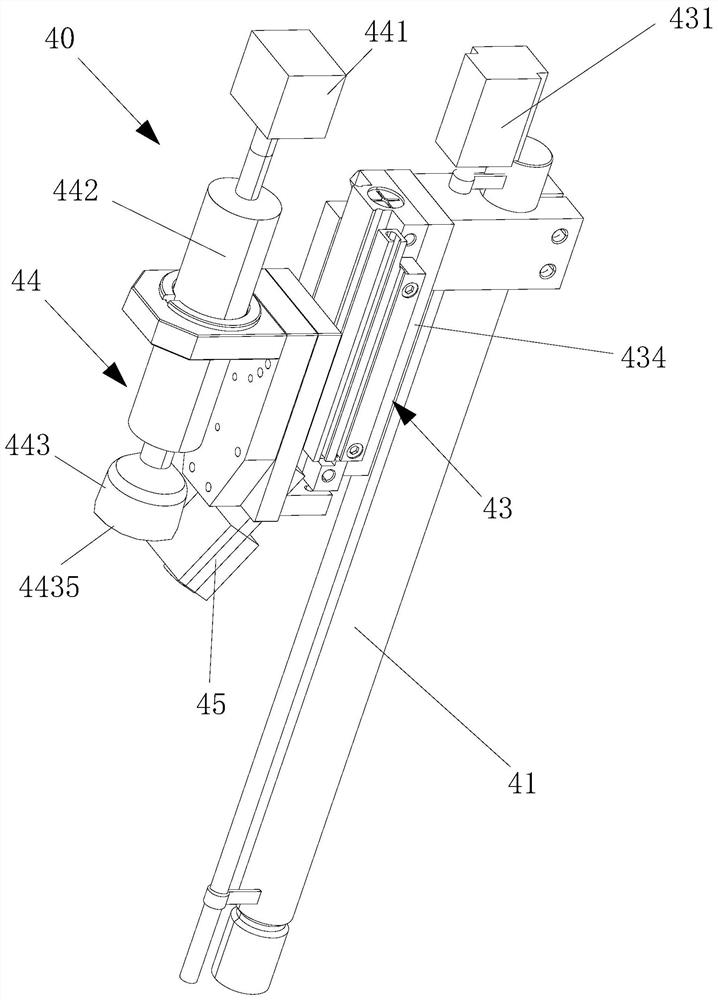

Ratchet wheel transmission type dispensing system for SMT mounting

ActiveCN111250359AAccelerated cooling and solidificationImprove adhesionPretreated surfacesCoatingsRatchetElectric machinery

The invention relates to a ratchet wheel transmission type dispensing system for SMT mounting. The ratchet wheel transmission type dispensing system for SMT mounting comprises a transmission mechanismand a plurality of dispensing mechanisms. The transmission mechanism comprises a driving motor and a circular workbench, and the circular workbench is mounted on the driving motor. The plurality of dispensing mechanisms are arranged around the periphery of the circular workbench. Each dispensing mechanism comprises a mounting beam, a lifting assembly, a dispensing assembly and a heating assembly,wherein the mounting beam is fixed on the ground and is provided with an accommodating groove, the accommodating groove is used for accommodating the periphery of the circular workbench, the liftingassembly is mounted on the mounting beam, and the dispensing assembly is mounted on the lifting assembly. The ratchet wheel transmission type dispensing system for SMT mounting can improve SMT mounting quality.

Owner:HEFEI LONGTUTEM INFORMATION TECH CO LTD

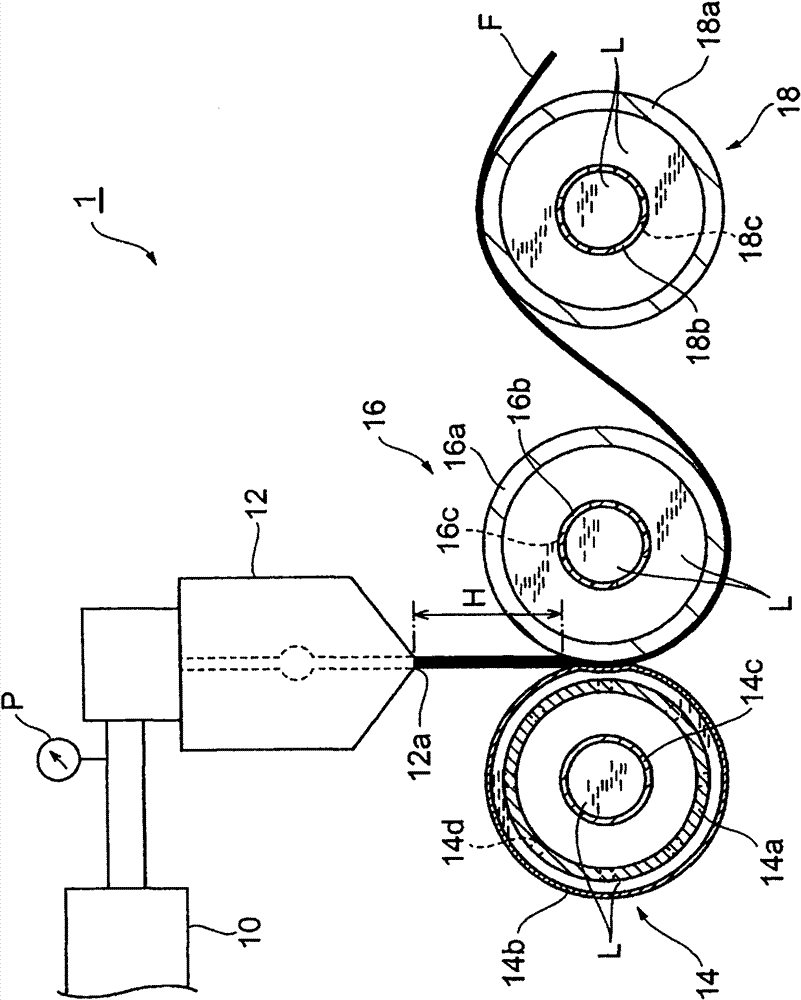

Casting method for high-lead bronze

InactiveCN107999705AQuality improvementImprove the authenticity rateFoundry mouldsBearing componentsCompound (substance)Casting mold

The invention relates to a casting method for a high-lead bronze copper bush. According to the casting method, a metal mold which takes the parting surface of a casting and a runner system of the casting as a half alignment structure serves as a casting outer mold body, a metal mold core of a multi-piece parting structure serves as a casting inner mold body, the high-lead bronze copper bush comprises the chemical components, by weight percentage, 18-23% of Pb, 4-6% of Sn and the balance Cu, and a water cooling device arranged on the periphery of a casting mold serves as a cooling means for thecasting. The casting method specifically comprises the steps of smelting a copper alloy, carrying out deoxidation treatment, preheating the casting mold, pouring the casting, cooling the casting andremoving a casting head so as to obtain the high-lead bronze copper bush. The casting method has the advantages of being reasonable in process and low in production cost, and the quality of the produced copper bush is good.

Owner:张玉英

Automatic welding device for aluminum alloy longitudinal joints

InactiveCN106425184AHeating evenlyAvoid lostWelding/cutting auxillary devicesAuxillary welding devicesKey pressingHeat losses

The invention provides an automatic welding device for aluminum alloy longitudinal joints and relates to a structure of a welding lathe. The automatic welding device comprises a welding gun, a mandrel and two rows of key pressing finger assemblies, wherein each row of key pressing finger assemblies comprises a plurality of pressing fingers; an arc-shaped steel pipe is arranged on the upper surface of the mandrel, an electric heating pipe penetrates through the arc-shaped steel pipe, the upper surface of the arc-shaped steel pipe is connected with a liner, and the liner is arranged below a workpiece longitudinal joint; the length direction of the arc-shaped steel pipe, the length direction of the electric heating pipe and the length direction of the liner are all consistent with the length direction of the workpiece longitudinal joint; and a heat insulating plate is connected below each pressing finger, and the heat insulating plates are arranged on the outer surface of a workpiece for insulating heat. By adopting the mandrel electric heating, key pressing finger and product surface heat insulating mode, heat losses caused by heat conduction in a welding process are minimized, heat is used for fully melting aluminum materials in a concentrated manner, the cooling and condensation of a welding pool are prolonged, and oxides and gas in the pool fully overflow, so that high-quality weld joints are obtained, and the welding efficiency is increased.

Owner:JIANGSU JINXIN ELECTRIC CO LTD

Mineral roasting reduction device and application method thereof

ActiveCN103409615BGuaranteed Transformation AffinityAvoid secondary oxidationVacuum pumpingGas phase

The invention discloses a mineral roasting reduction device. The device comprises a feeding zone, a drying preheating zone, a roasting oxidation reaction zone, a pressure-regulating zone, a reduction reaction zone, a discharging zone and a water-sealing cooling zone, which are arranged from the top down and communicated with one another, wherein the feeding zone is provided with an automatic sealing device; the drying preheating zone is provided with a directional pressurizing device for vacuum-pumping; the roasting oxidation reaction zone is provided with an incendiary agent adding device; the pressure-regulating zone is provided with a plurality of pressure-regulating air doors; the reduction reaction zone is provided with a reducing agent adding device. The mineral roasting reduction device is provided with the directional pressurizing device, so that negative pressure can be generated in the inner part of the device; molecular flows of both an incendiary agent and an reducing agent are in uplink, while mineral is in downlink, so that a convection current movement is formed to ensure conversion affinity of the solid phase and the gas phase; in the device, the mineral sequentially is subjected to drying, preheating, heating, resolving, reducing, water quenching, cooling and discharging from the top down, and all processes are performed in an air-free state thoroughly to complete roasting reaction.

Owner:QINGDAO ZHIBANG FURNACE DESIGN RES

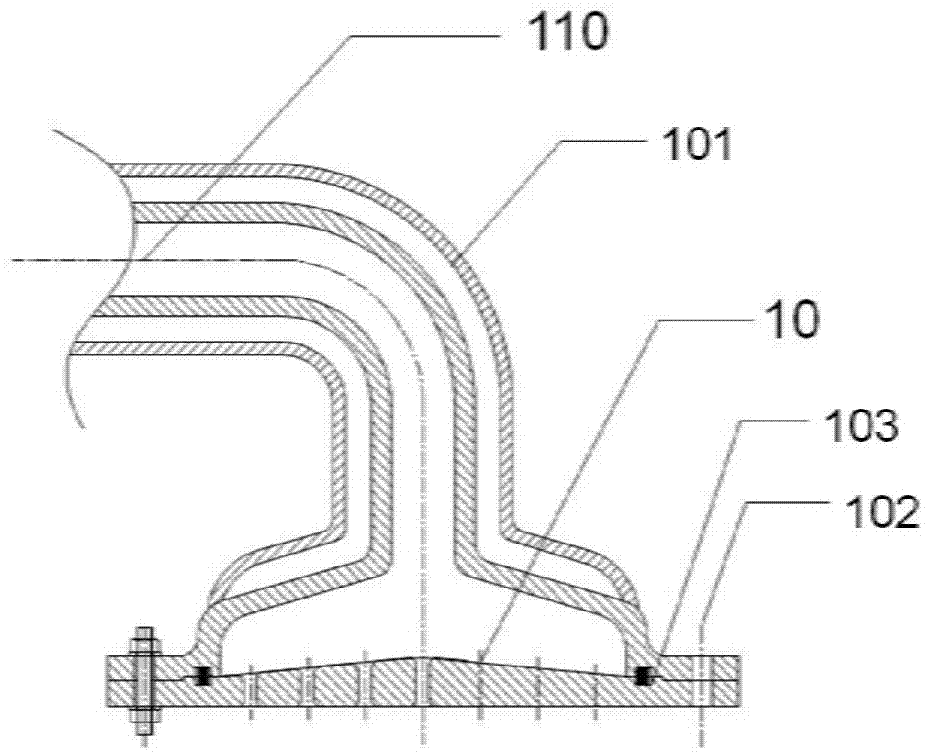

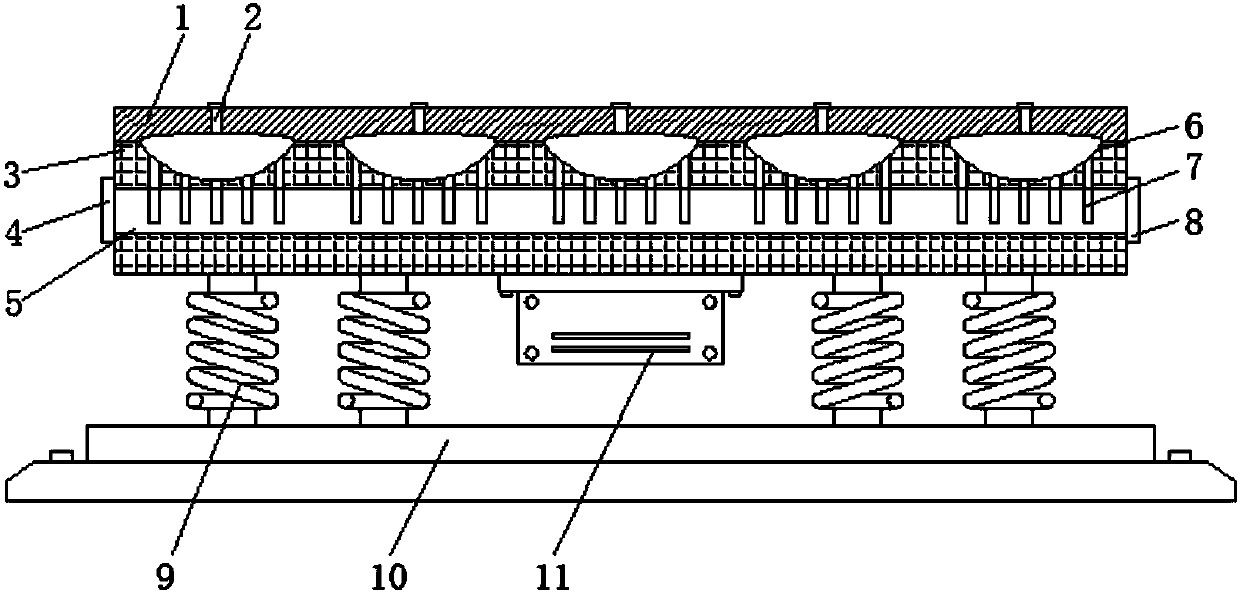

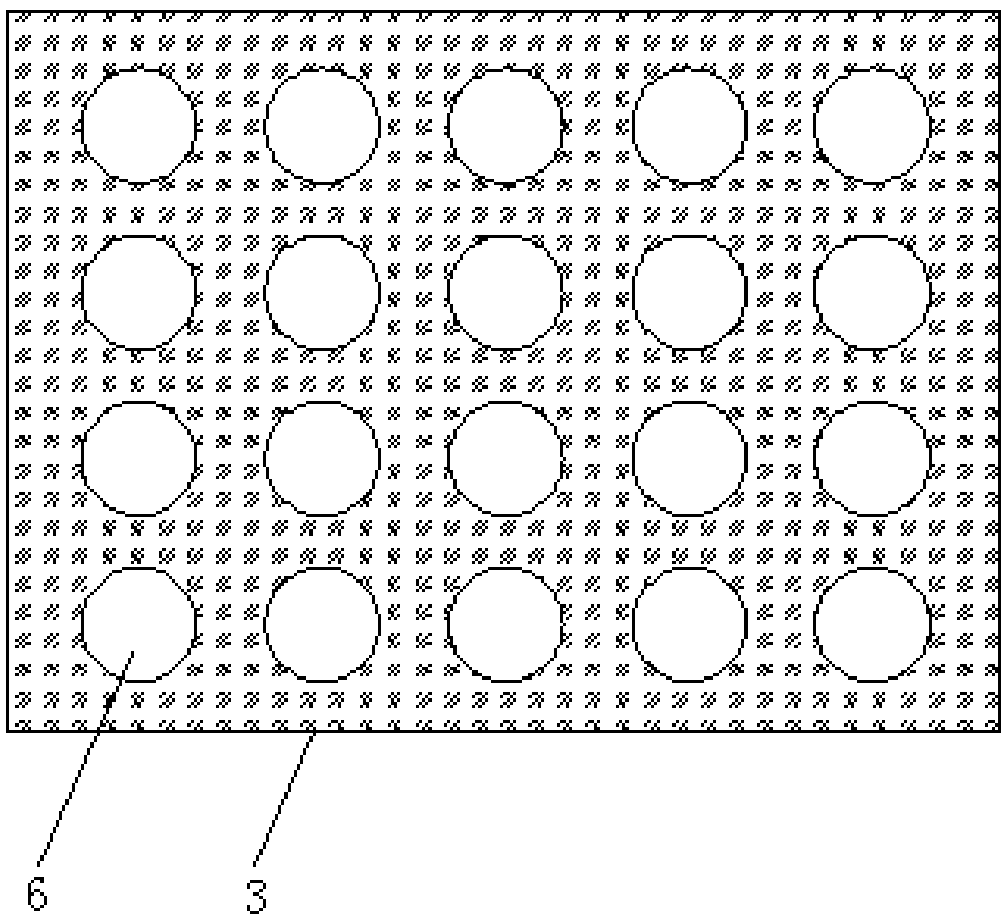

Breast implant silicone prosthesis production mold

InactiveCN110281441AEfficient exclusionEffectively brought outDomestic articlesMetallurgyHeat conducting

The invention discloses a breast implant silicone prosthesis production mold. The breast implant silicone prosthesis production mold comprises an upper mold and a lower mold. The lower mold is arranged at the bottom of the upper mold. The top of the lower mold is uniformly provided with a plurality of mold grooves. A cooling fluid flow channel is arranged in the position, located below the mold grooves, of the interior of the lower mold. The two sides of the bottom of the lower mold are elastically connected with a fixed base through vibration springs arranged symmetrically. Through arrangement of vibrators and the vibration springs, the mold can vibrate to effectively remove bubbles in molten silicone under the vibration effect so that silicone can be distributed uniformly in the mold grooves. Accordingly, the production quality of silicone prosthesis is effectively improved. The breast implant silicone prosthesis production mold is provided with heat conducting rods and the cooling fluid flow channel. The bottoms of the heat conducting rods can be immersed in cooling fluid. Under the flowing action of the cooling fluid, heat of the silicone is effectively taken out. Thus, cooling and solidifying of the silicone are accelerated, and the production efficiency of the silicone prosthesis is improved.

Owner:江苏威瑞医疗器械有限公司

Mobile disk connecting port manufacturing equipment for computer development

ActiveCN111601494AAccelerated cooling and solidificationReach adjustmentElectrical componentsAir springEngineering

The invention relates to the technical field of manufacturing of mobile disk connecting porters, and further discloses manufacturing equipment of a mobile disk connecting port for computer development. The manufacturing equipment comprises a shell, wherein a gear is movably connected to the interior of the shell, the surface of the gear is fixedly connected with a sliding groove, the surface of the sliding groove is slidably connected with a glue storage bag, a retaining plate is fixedly connected to the surface of the sliding groove and located above the glue storage bag, the surface of the retaining plate is movably connected with a scraping plate, a push rod is movably connected into the retaining plate, an air bag is fixedly connected to the surface of the sliding groove and located above a piston rod, a piston block is movably connected into the air bag, an air hole is formed in the surface of the piston block, an air supply pipe is movably connected to the surface of the air hole, and a correction plate is fixedly connected to the end, away from the air hole, of the air supply pipe. According to the invention, an air spring pushes a rolling wheel to make contact with the surface of the correction plate so as to push right an inclined chip, and cooling and solidification of a colloid can be accelerated through airflow, so that the effect of adjusting the position of the chip according to wind power balance is achieved.

Owner:熊君 +1

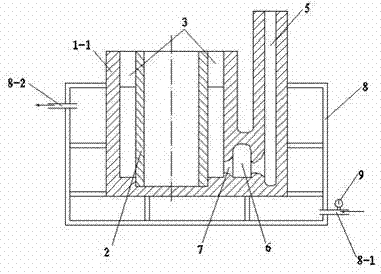

Production device for casting castings and avoiding generating cavities in castings

InactiveCN109158547AEasy to processThe position of the mold installation is accurateFoundry mouldsFoundry coresEngineeringWater tanks

The invention discloses a production device for casting castings and avoiding generating cavities in the castings. The production device comprises a table frame and a third mold, wherein a first moldis pasted onto a right side of the middle of an upper surface of the table frame; a first bump is fixedly connected to the right side of a second mold; a lower surface of the third mold is closely glued to the second mold and the first mold; a first bolt is connected to the third mold in a penetrating manner; a feed opening is formed in a left side above the third mold; a water tank is reserved ata center position below the third mold; a second heat dissipation device is arranged on the right side above a heating rod; and the second heat dissipation device comprises a second heat conducting pipe, a second heat conducting block and a rubber handle connecting block. The production device for casting castings and avoiding generating cavities in the castings can conveniently process tubular castings, has relatively accurate mold mounting positions, can conveniently take out finished products, can avoid generating bubbles and cavities in the finished products, and can be cooled rapidly.

Owner:陈李杰

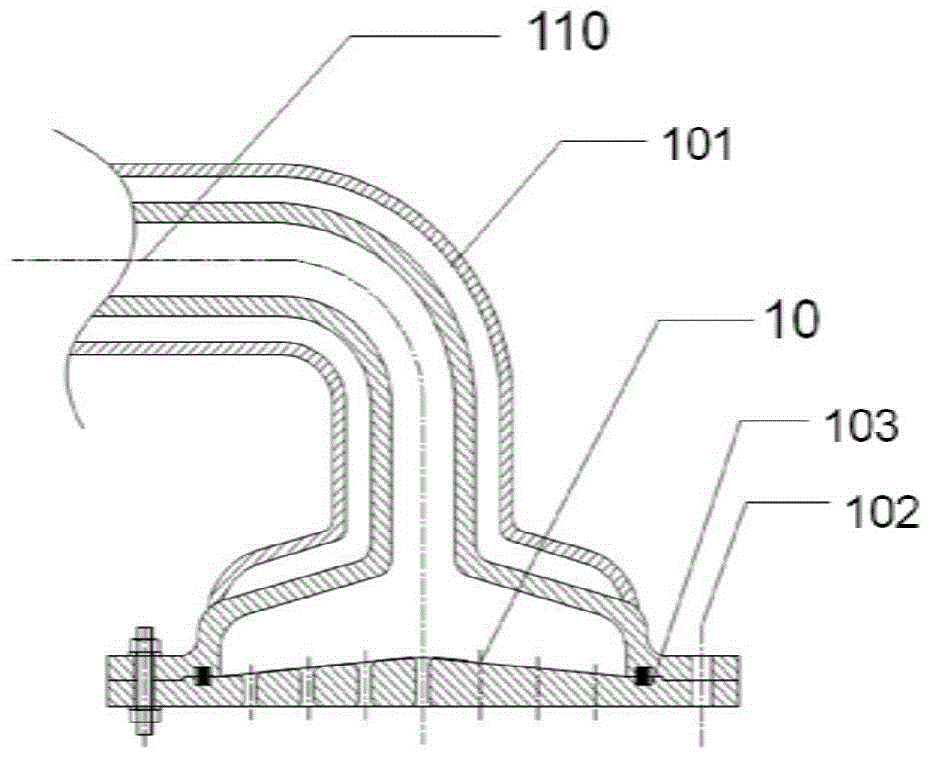

Insulating layer coating system for overhead cable transformation

PendingCN113192703AReduce oppressionNot a big burdenInsulating conductors/cablesCoating systemElectric cables

The invention discloses an insulating layer coating system for overhead cable transformation, and the system comprises a wrapping frame for clamping a cable and a discharging frame for discharging an insulating material; the wrapping frame comprises an upper frame and a lower frame; one side of the upper frame and one side of the lower frame are hinged with each other through a hinge, and the other side of the upper frame and the other side of the lower frame are connected with each other through a bolt; the upper frame and the lower frame are each provided with an empty groove used for wrapping a cable, one end of each empty groove is provided with a rolling wheel used for driving to move, the other end of each empty groove is provided with a spraying hole used for spraying an insulating material, the spraying holes are communicated with a discharging pipe through corresponding communicating grooves, and the discharging pipe is communicated with a discharging opening in the discharging frame through a communicating pipe. According to the system device, the pressure of gravity on the cable can be reduced, so that the damage to the cable is reduced, and the operation continuity is improved; meanwhile, the air flow speed at the two ends of the wrapping frame can be greatly increased, impurities on the cable can be cleaned, and cooling and solidification of an insulating coating can be accelerated.

Owner:国网福建省电力有限公司上杭县供电公司 +2

Recovery device and recovery method for lyocell fiber spinning dope waste

ActiveCN104711706BSmall sizeLarge specific surface areaArtificial filament recoveryTextile/flexible product manufactureManufacturing cost reductionLiquid waste

The invention provides a recycling device and a recycling method for Lyocell fiber spinning dope waste. The recovery unit includes waste pipeline, cooling unit, crushing unit and leaching unit. Wherein the waste pipeline has a spinning dope waste inlet and a spinning dope waste outlet, the spinning dope waste inlet is connected with the spinning dope waste output device; the cooling device has a cooling material inlet and a cooling material outlet, and the cooling material inlet is connected to the spinning dope waste output device. The waste material outlet is connected; the crushing device has a crushing material inlet and a crushing material outlet, and the crushing material inlet is connected to the cooling material outlet; the leaching device has a leaching material inlet, an NMMO leaching solvent inlet, a leaching liquid outlet and a leaching slag outlet, and the leaching material inlet and crushing and the waste material outlet of the waste material pipeline is provided with a plurality of extrusion holes. The recovery device can effectively recover the NMMO solvent in the waste material of the Lyocell fiber spinning stock solution, thereby reducing the manufacturing cost.

Owner:CHINESE TEXTILE ACAD

Self-heat dissipation type material tray for 3D printing

InactiveCN111231318AElectric ScienceReduce energy consumptionManufacturing platforms/substratesManufacturing data aquisition/processingComputer printingElectric machinery

The invention discloses a self-heat dissipation type material tray for 3D printing. The material tray comprises a machine body, and a printing head arranged in the machine body. A supporting plate located below the printing head is arranged in the machine body, and a condensing pipe is embedded in the supporting plate; the part, located below the supporting plate, of the inner wall of the machinebody is rotatably connected with a rotating shaft, and the side wall of the rotating shaft is fixedly connected with a plurality of electromagnets in the circumferential direction of the rotating shaft equidistantly; and the magnetic line of force of each electromagnet is in the radial direction of the rotating shaft, and the outer end of each electromagnet is fixedly connected with cambered heat-conducting fins. According to the self-heat dissipation type material tray, the structure is arranged in a 3D printer, and no excessive space is occupied; in the using process, the rotating shaft is rotated intermittently, and does not make noise due to high-speed rotation; meanwhile, a motor is not required for driving the rotating shaft; in addition, the speed of the self-heat dissipation type material tray can be regulated according to the temperature of printed materials, so that the power utilization is more scientific, and the energy consumption is lower; and the self-heat dissipation type material tray meets the modern standards for environmental protection and energy saving more properly.

Owner:王浩怡

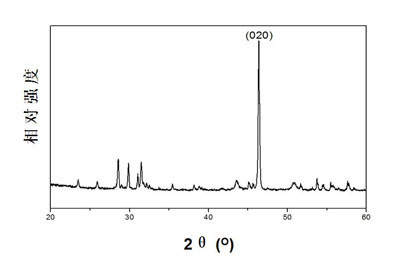

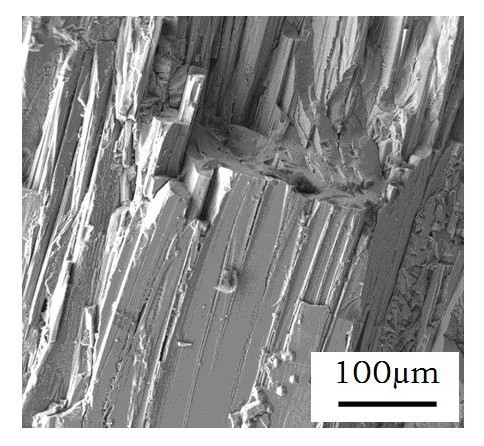

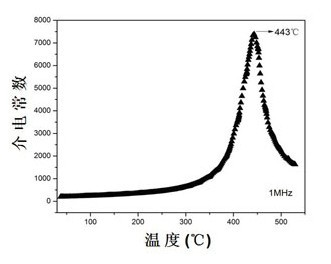

Laser synthesis method for barium dititanate ferroelectric ceramics

The invention belongs to the technical field of ferroelectric ceramic materials, and in particular relates to a laser synthesis method for barium dititanate ferroelectric ceramics. BaCO3 and TiO2 powder are taken as raw materials and fully mixed, ground and pressed into a blank; the materials are radiated by CO2 laser beams with 800-1,000W, fully reacted in short time and melted to form barium dititanate; and the molar ratio of the BaCO3 to the TiO2 is 1:2. The method has the advantages of simple process, low cost, short time and low energy consumption; and the obtained sample has a microstructure which has high degree of orientation and grows in preferred orientation along a b axis; the obtained sample has high purity, large size and compact structure; and the process has good repeatability.

Owner:ZHENGZHOU UNIV

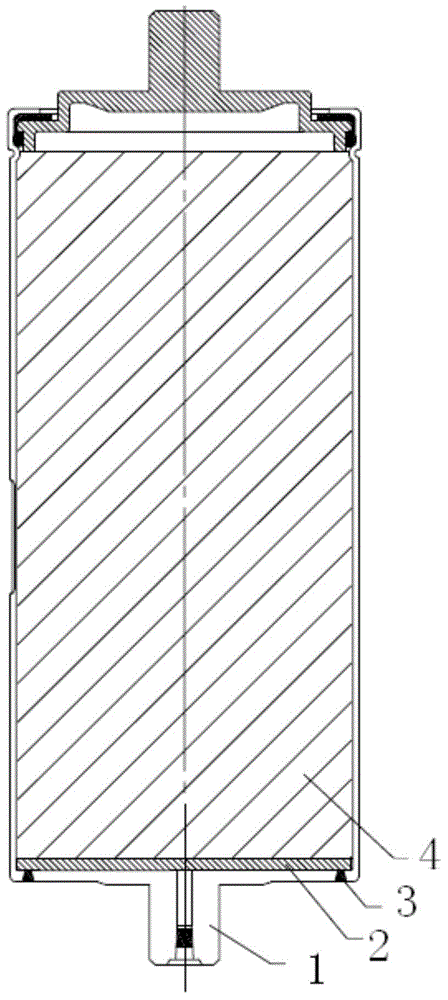

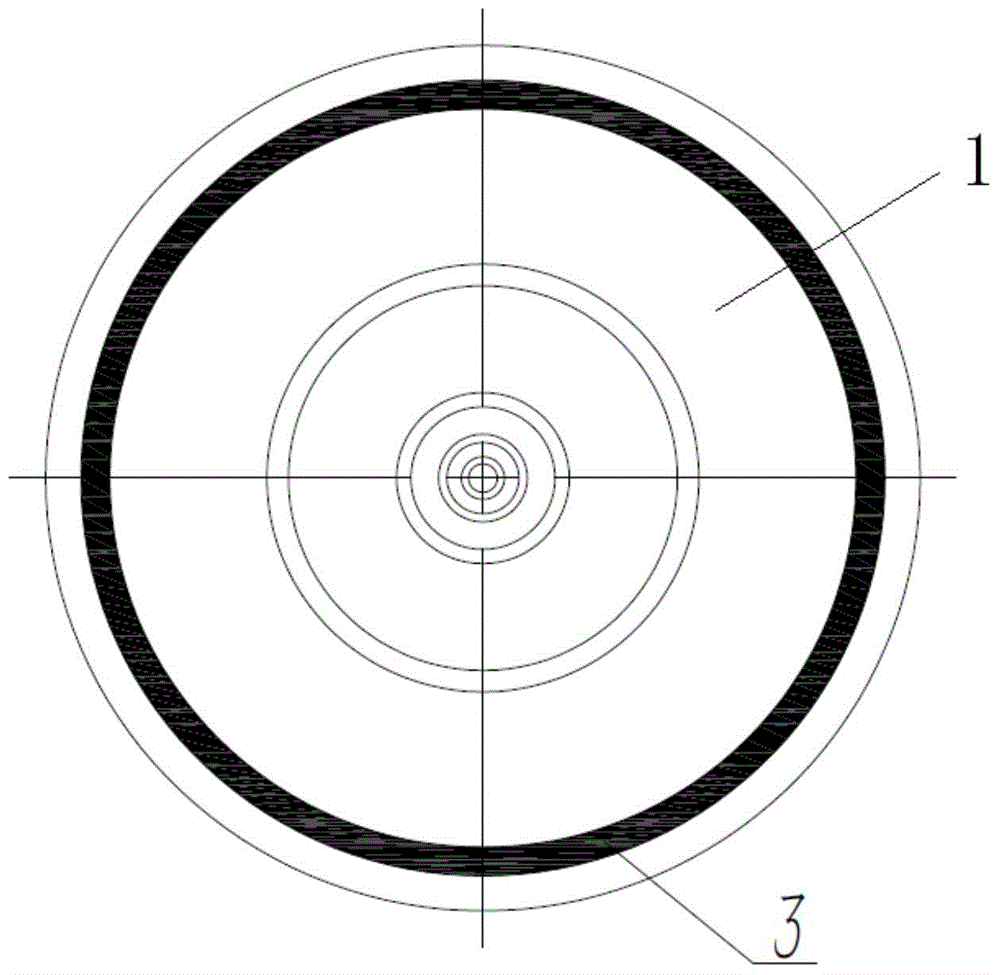

Connection method for super-capacitor current collector and metal housing, and device therefor

InactiveCN104966623AIncrease contact areaCircumferential continuous penetration fusion welds smoothlyHybrid cases/housings/encapsulationsHybrid/EDL manufactureInternal resistanceSupercapacitor

The invention discloses a connection method for a super-capacitor current collector and a metal housing, and a device therefor. The method is characterized in that 1), a current collector of the supercapacitor is welded with the metal housing through vacuum electron beam welding; 2) the current collector is provided with an arc-shaped outer edge, thereby guaranteeing the close fit of the metal housing with the current collector, and carrying out the circumferential continuous penetration melting welding in a vacuum environment through the vacuum electron beam welding technology. The method solves problems of liquid leakage, loosened welding, loosening easiness, big internal resistance, high self-discharge, and severe scraping because of a connection mode of a current collector and the metal housing in a current industry, and effectively reduces the production cost. The method and device are simple in technology, are reliable in connection, are easy to assemble, are good in sealing effect, and are novel.

Owner:HUNAN NEPUENERGY SCI & TECH

Device for making mobile disk connection port for computer development

ActiveCN111601494BAccelerated cooling and solidificationReach adjustmentElectrical componentsAir springEngineering

Owner:熊君 +1

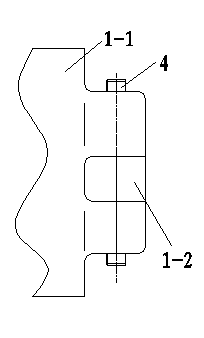

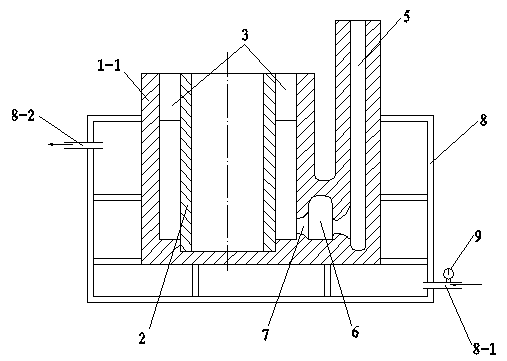

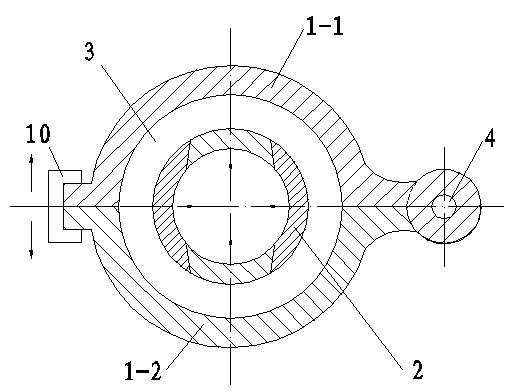

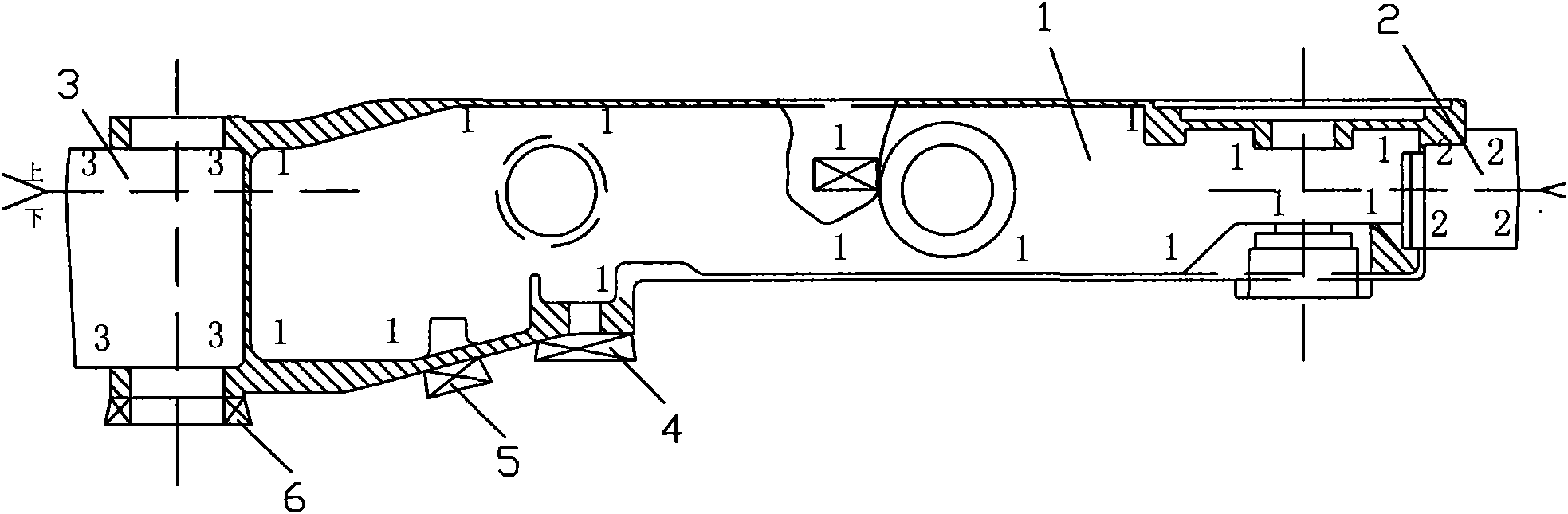

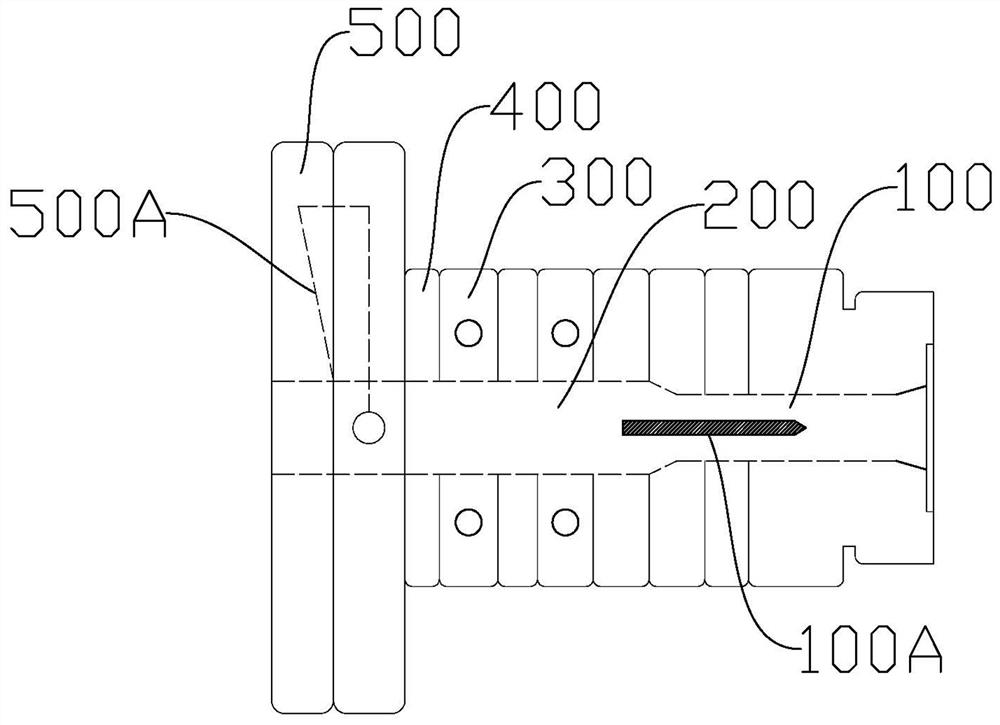

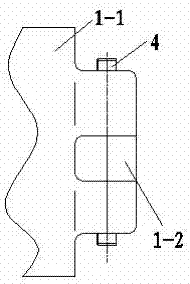

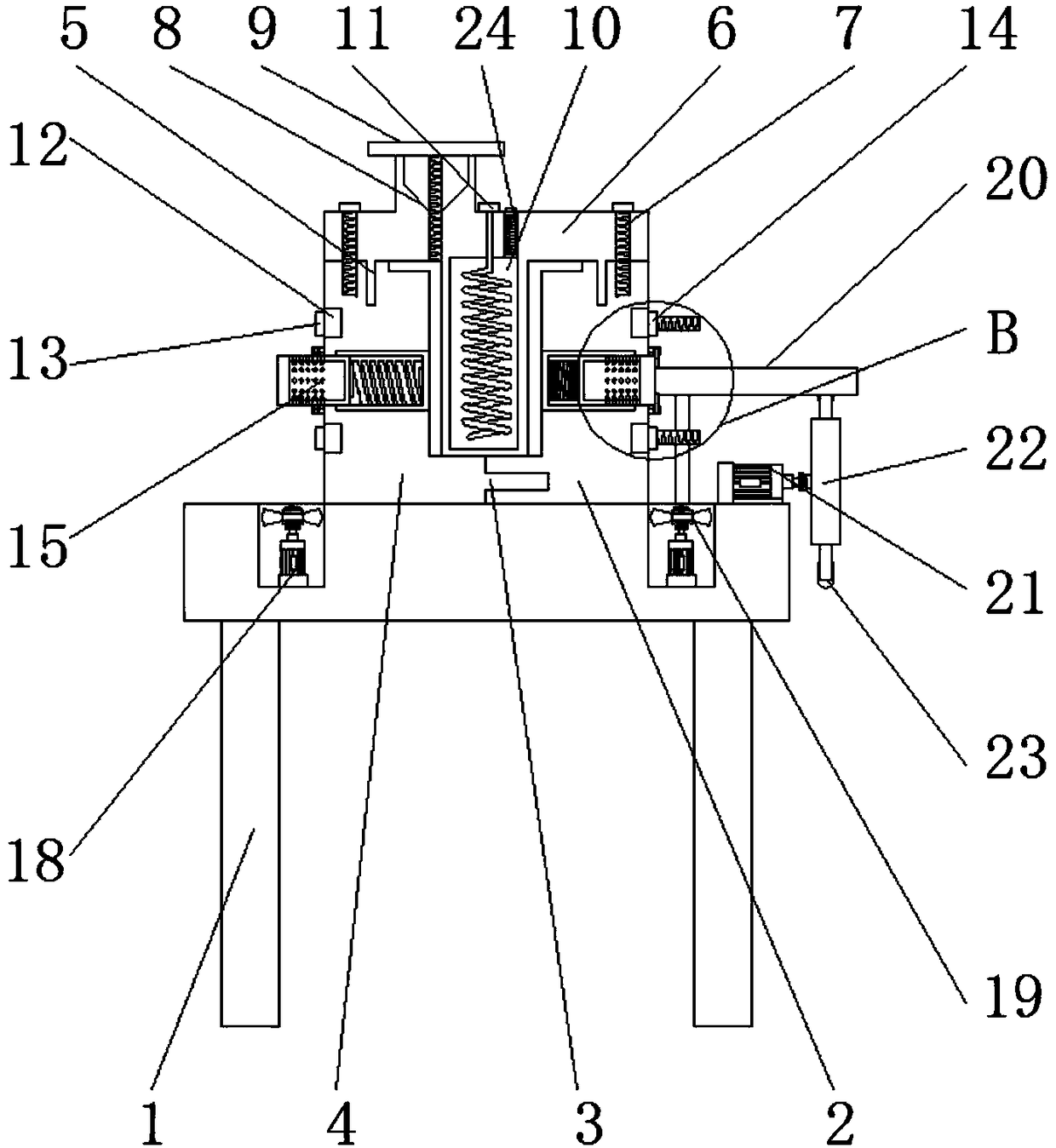

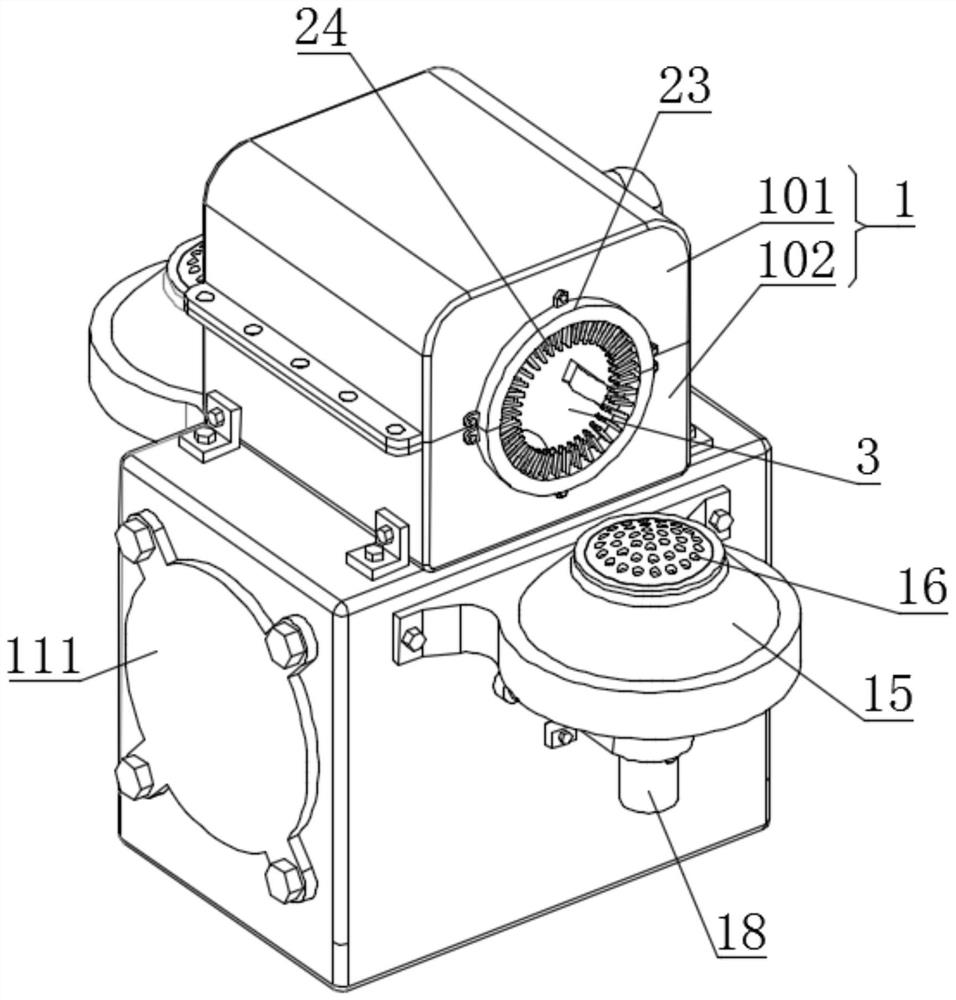

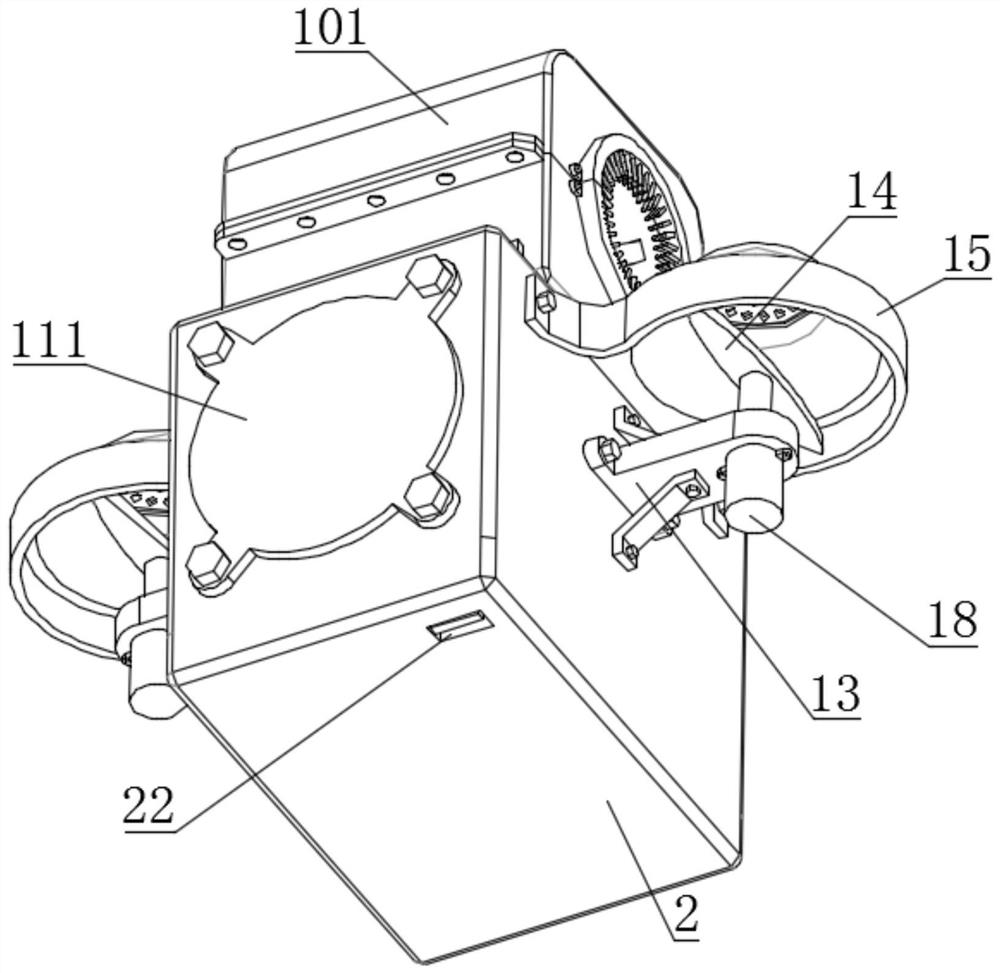

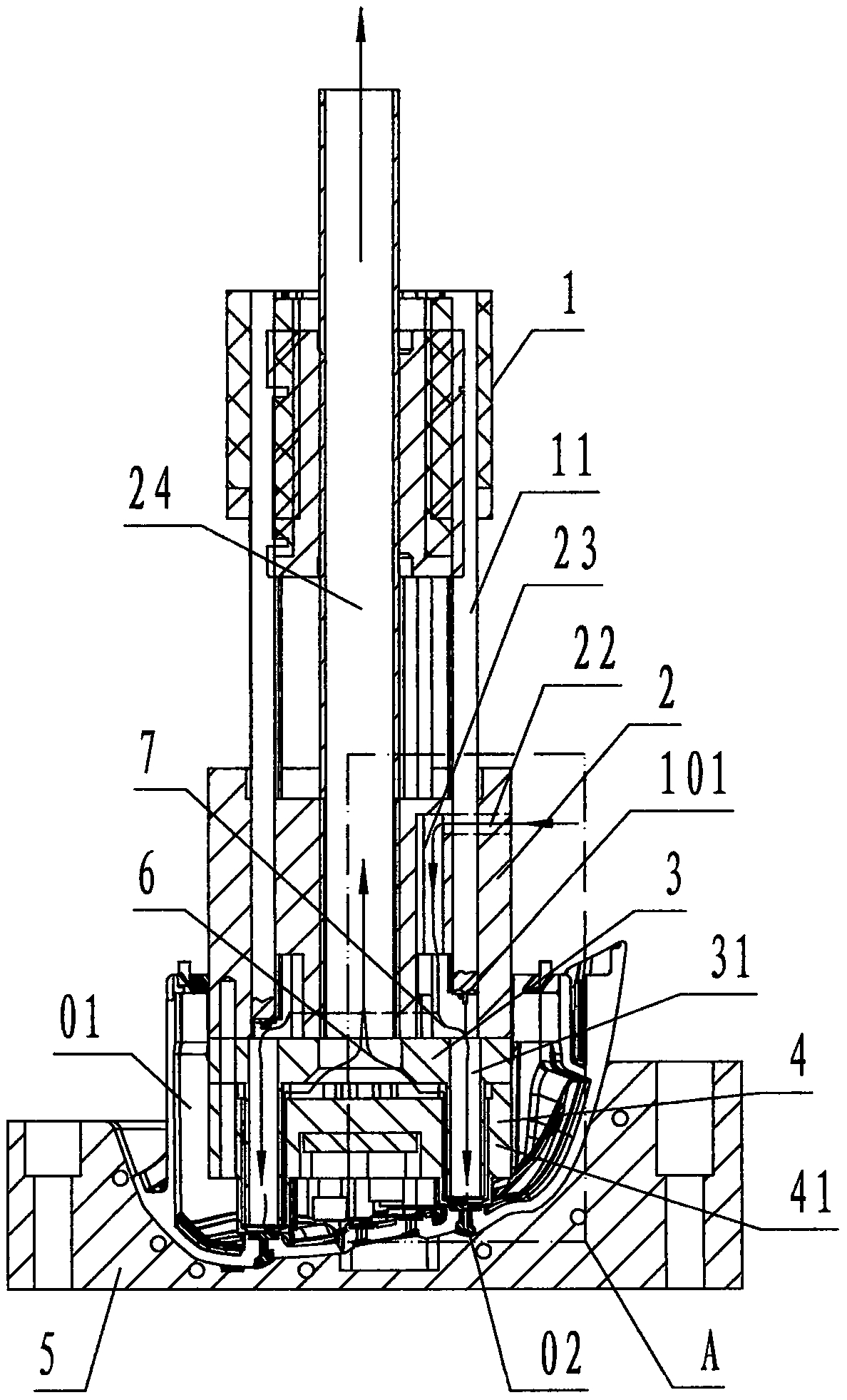

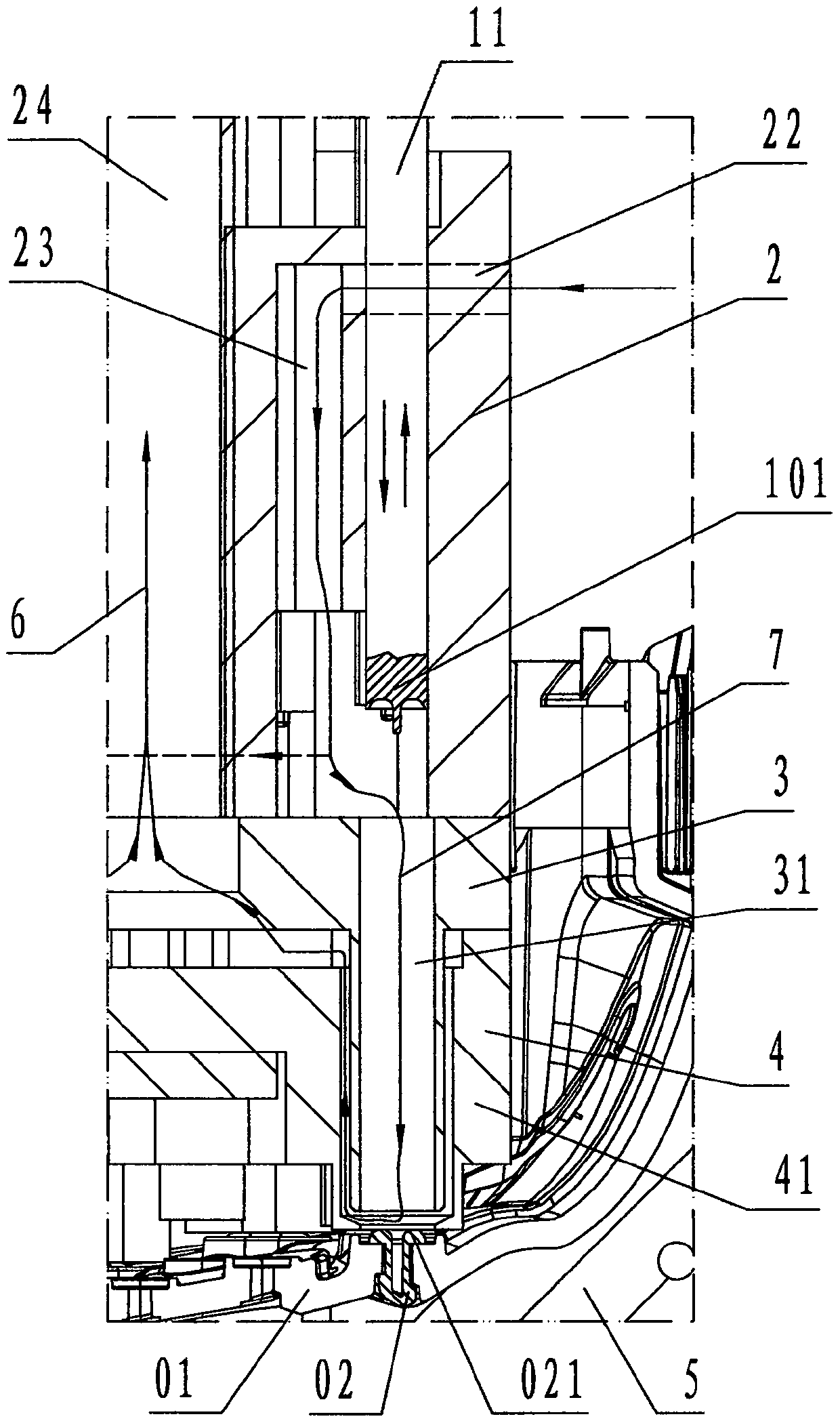

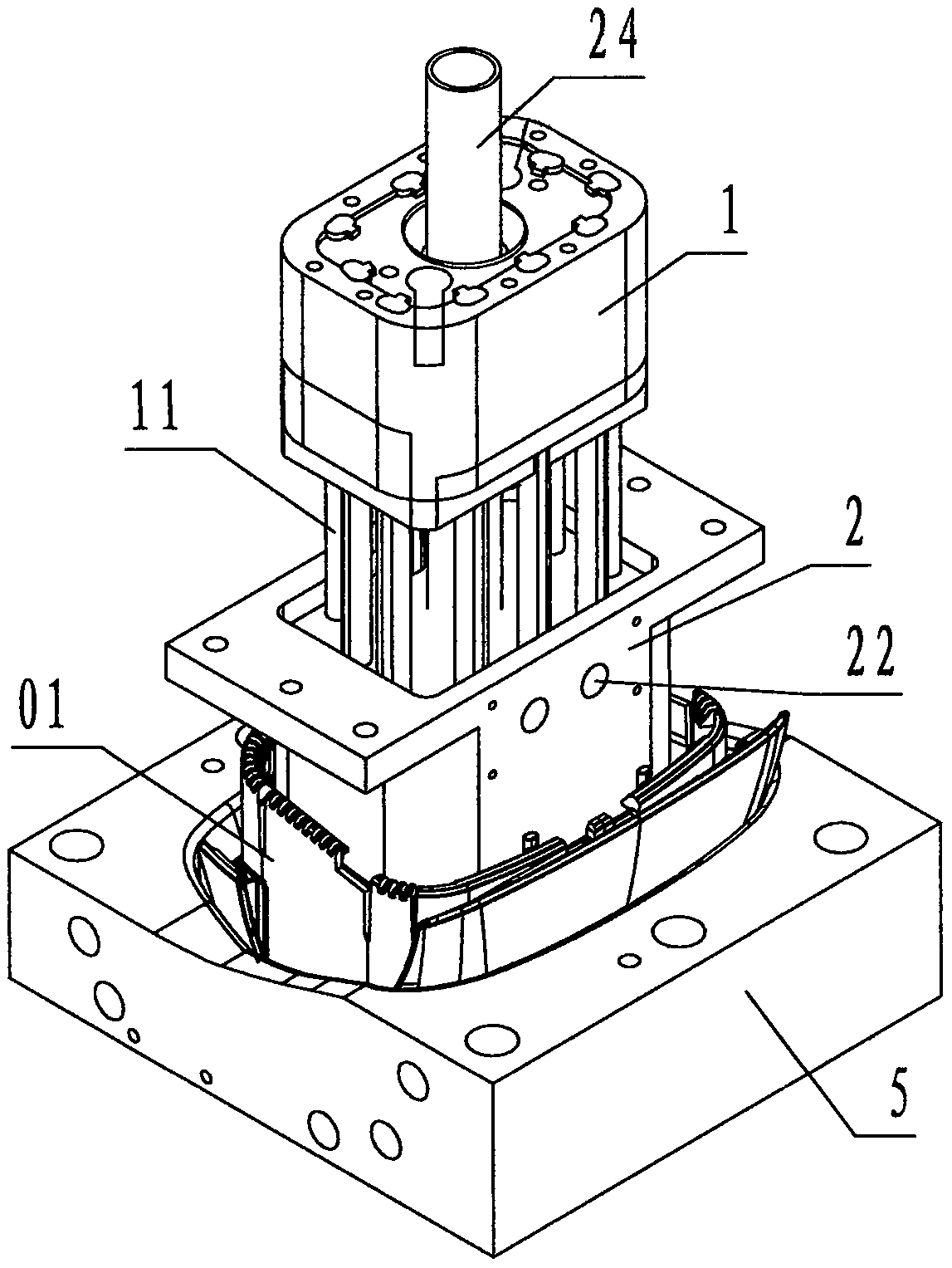

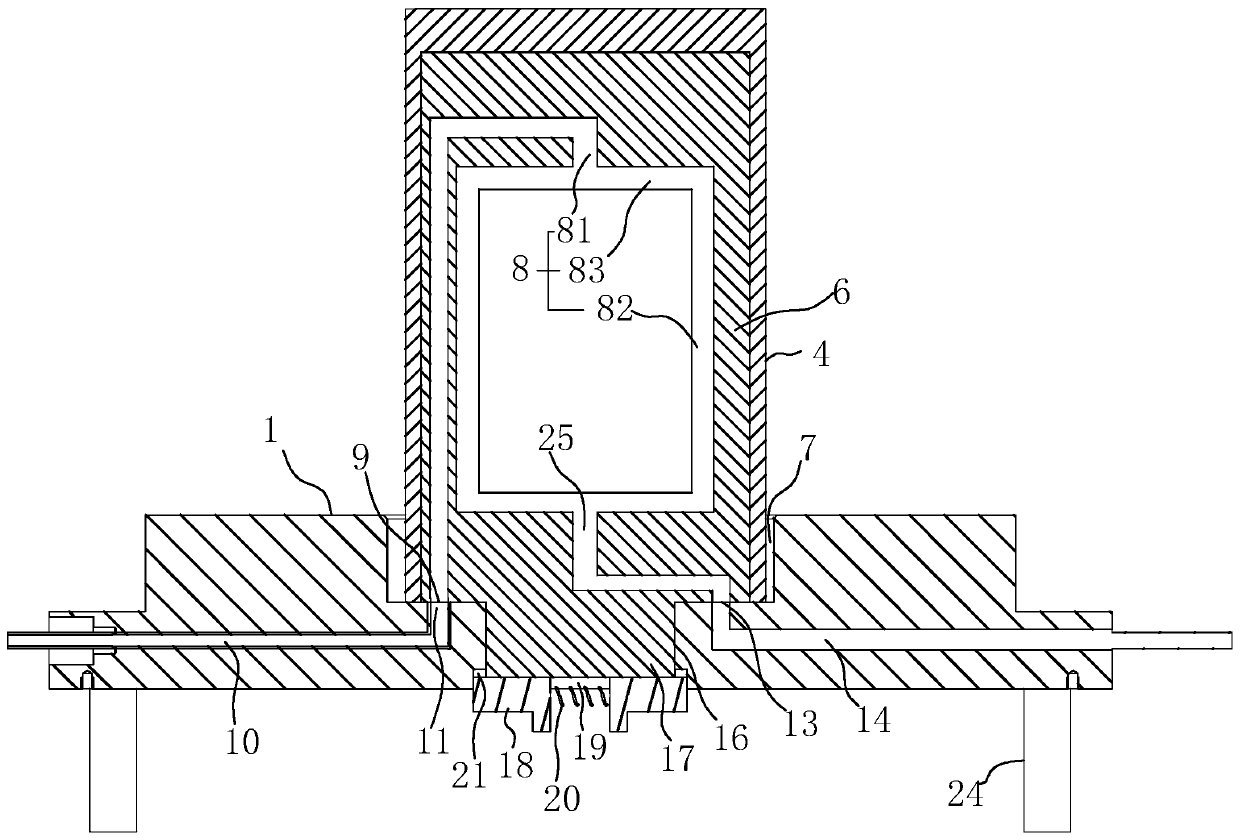

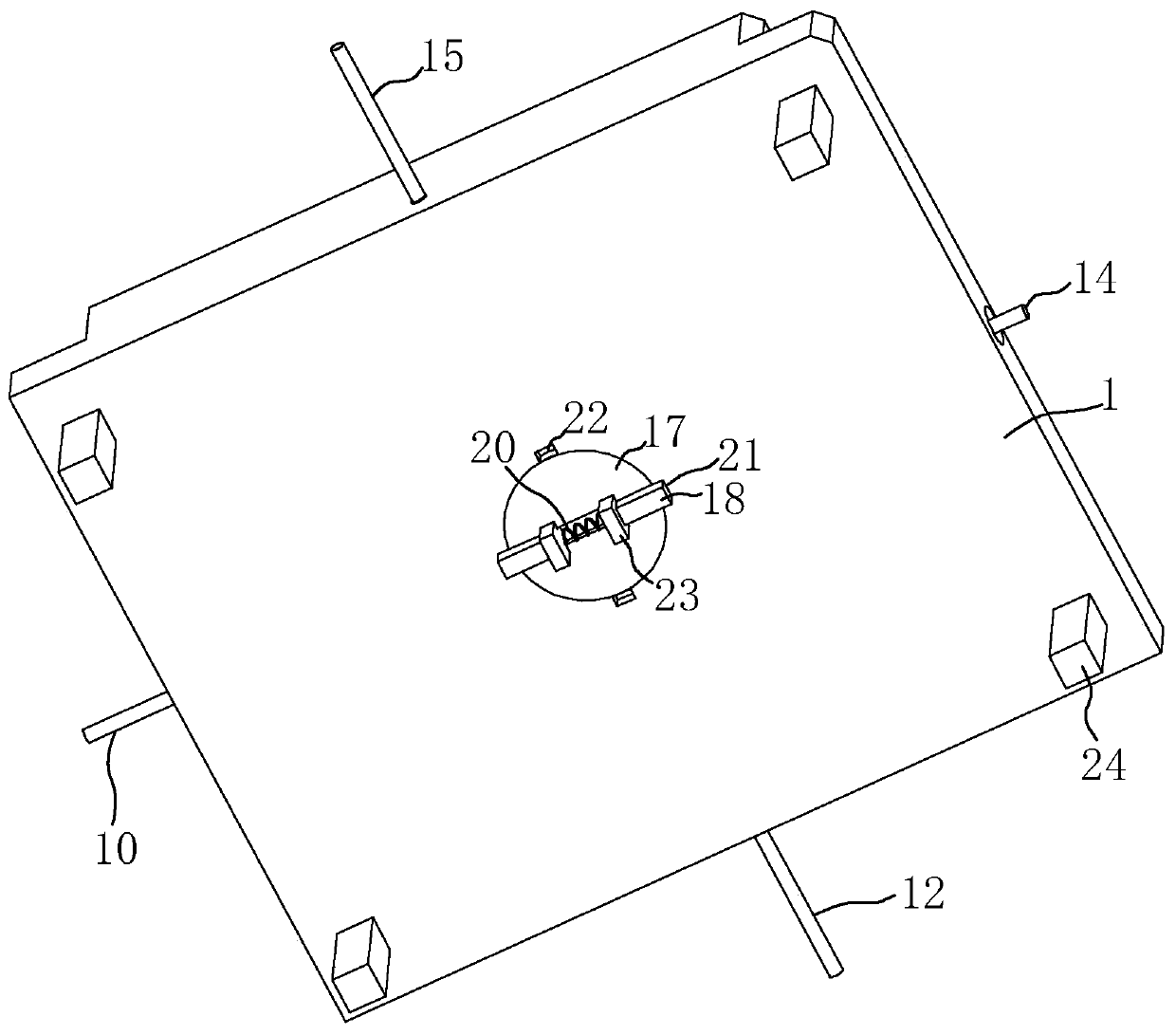

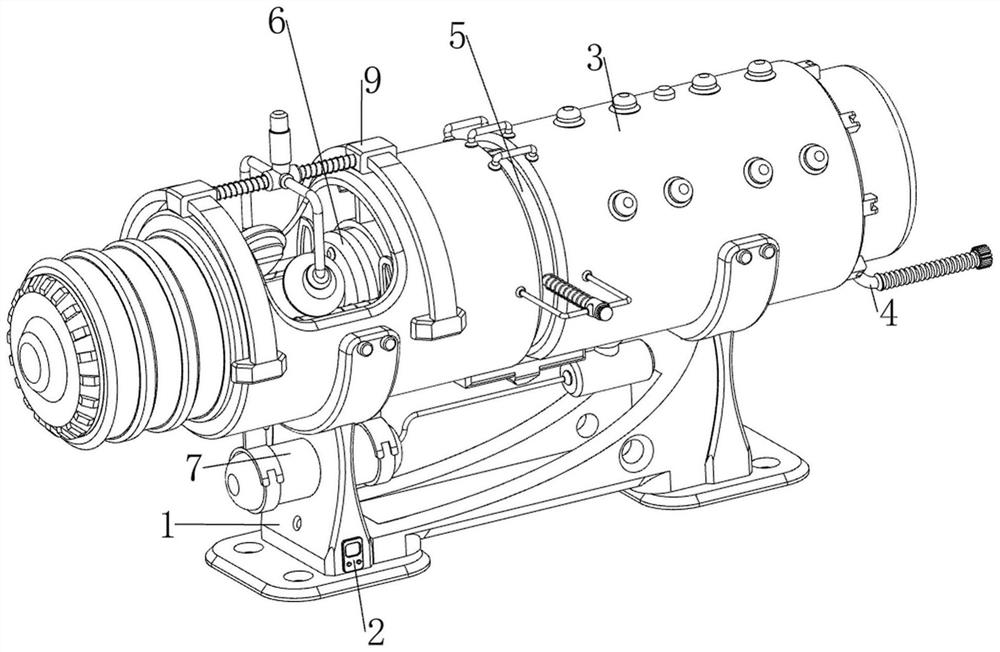

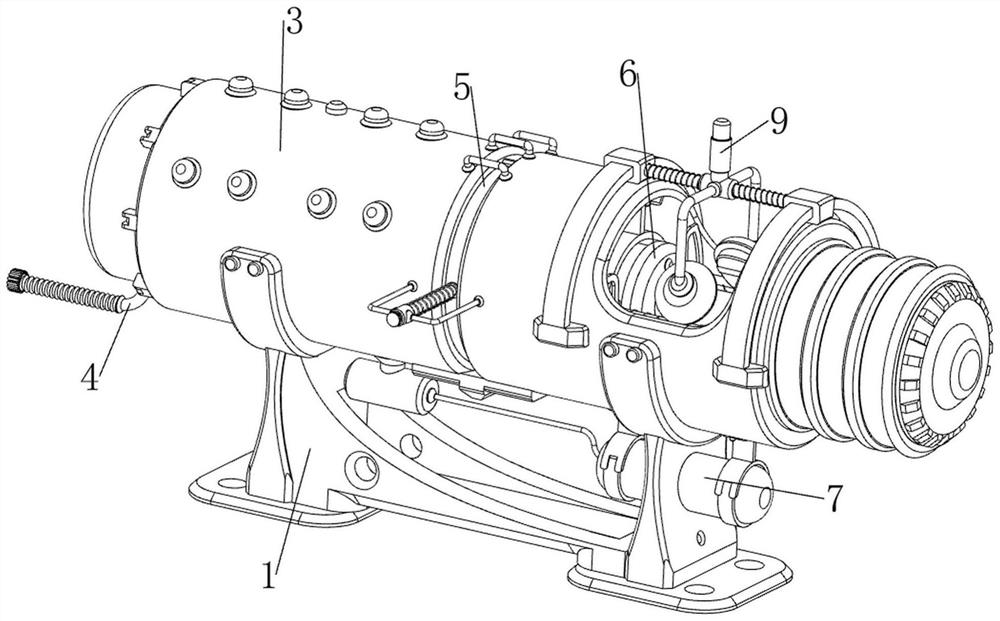

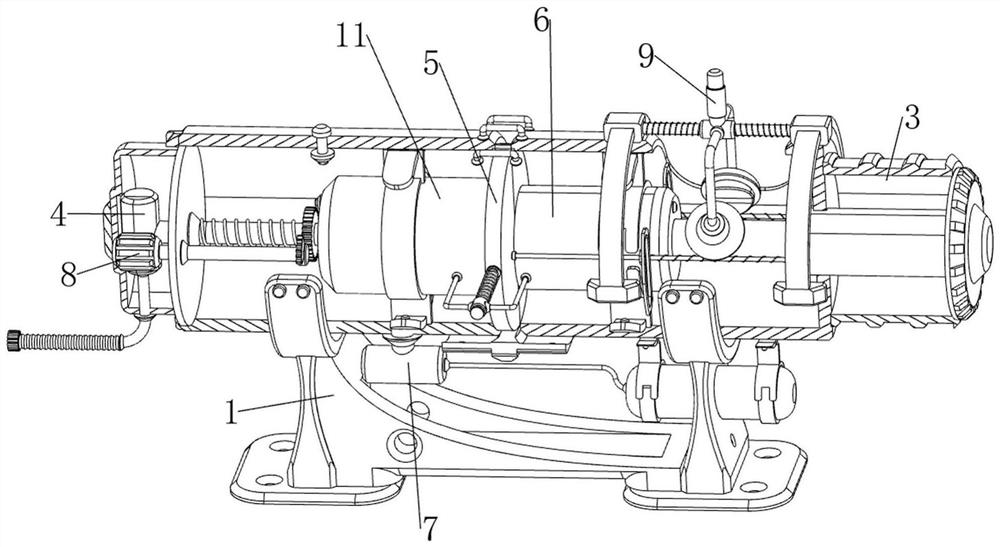

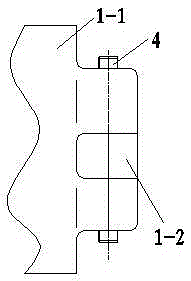

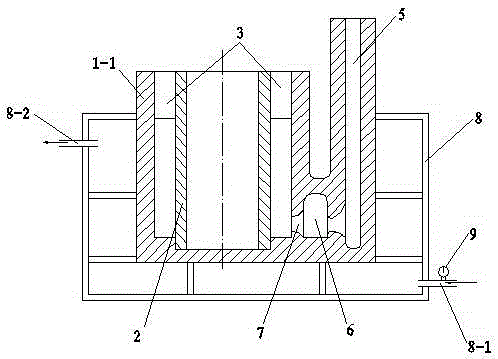

A hot air fusion welding riveting device provided with an air inlet channel and an air exhaust channel

ActiveCN106696285BAvoid the disadvantages of low efficiency caused by difficult cooling and solidificationAccelerated cooling and solidificationAtmospheric airFusion welding

The invention discloses a hot-air fusion welding and riveting device provided with an air inlet duct and an air outlet duct. The hot-air fusion welding and riveting device comprises a pressing rod seat (1), an air distributing seat (2), an air inlet seat (3), an exhaust seat (4) and a positioning template (5). The pressing rod seat is provided with pressing rods and an air pipe hole, wherein a pressing head is arranged at the lower end of each pressing rod. The air distributing seat is provided with pressing rod guiding holes, an air inlet, an air distributing duct and an air outlet pipe. The air inlet seat is provided with air inlet pipes. The exhaust seat is provided with exhaust pipes and exhaust grooves. The air inlet duct is a channel formed by connecting the air inlet, the air distributing duct and inner cavities of the air inlet pipes, and the air outlet duct is a channel formed by connecting the gaps between the outer walls of the air inlet pipes and the inner walls of the exhaust pipes, the exhaust grooves and an inner cavity of the air outlet pipe. Through the technical scheme that the air inlet duct and the air outlet duct are used for isolating hot air from other structures of an inner cavity of a cup-shaped injection-molded product and exhausting the hot air outwards into the atmosphere, the purposes that hot-air fusion welding and riveting can be conducted in the inner cavity of the cup-shaped injection-molded product, and the device adapts to automatic operation are achieved.

Owner:NINGBO SHUANGLIN MOULD CO LTD

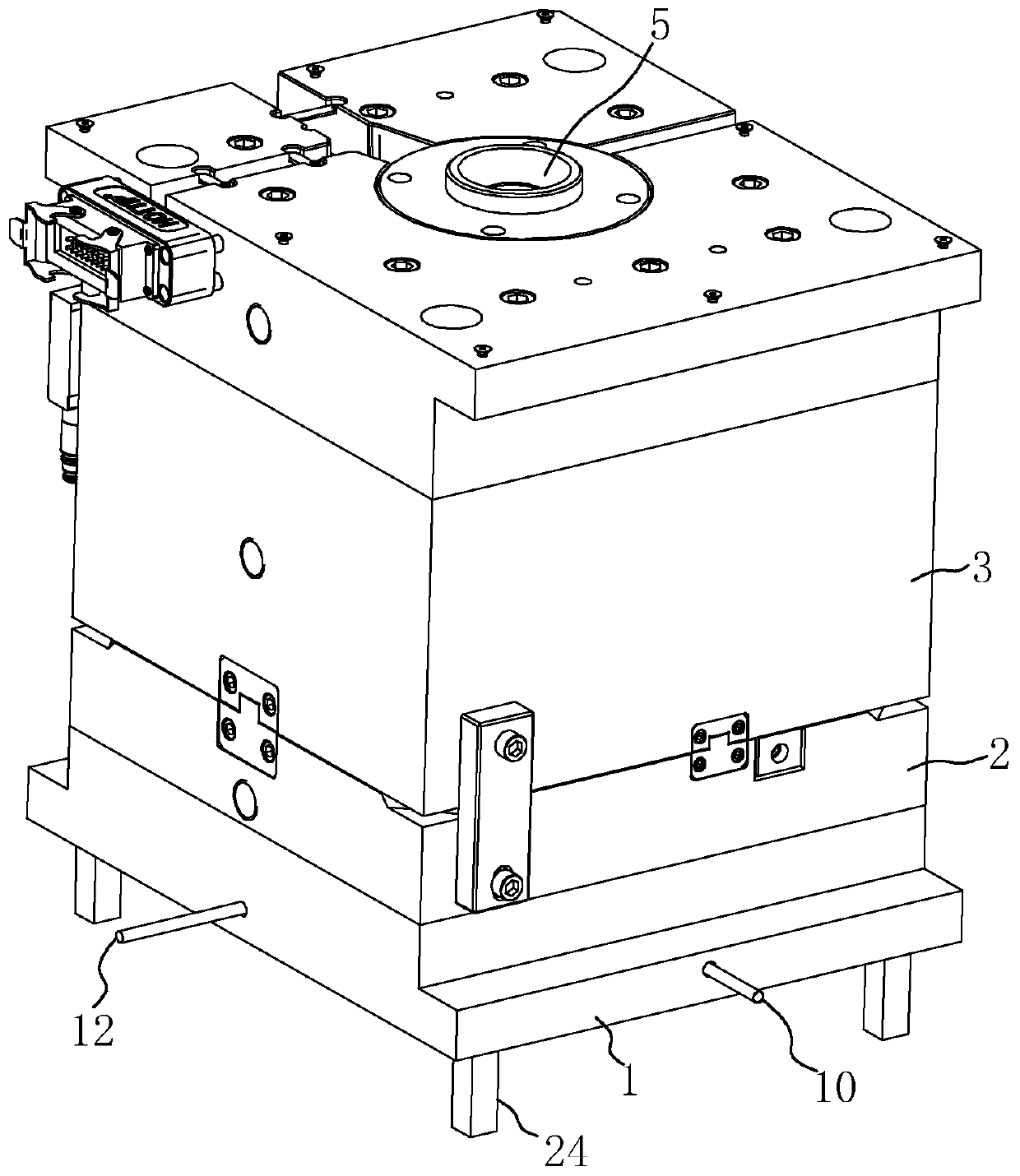

High-precision injection mold

The invention discloses a high-precision injection mold. The high-precision injection mold comprises a base, a male mold plate, a female mold plate and a top seat. A male mold is arranged in the malemold plate, a female mold is arranged in the female mold plate, and a cavity is formed between the male mold and the female mold. An injection port communicating with a cavity is formed in the top seat. An inner core rotationally connected with the male mold is arranged in the male mold, a channel and a liquid passing opening are formed in the inner core, and the inner core is rotationally connected to a groove base. The base is provided with a hot liquid channel used for conveying hot liquid. A first liquid inlet communicating with the liquid passing opening is formed in the bottom wall of agroove. A cooling liquid channel used for conveying cooling liquid is formed in the base. A second liquid inlet communicating with the liquid passing opening is formed in the bottom wall of the groove. During first-time use, the first liquid inlet is kept in communication with the liquid passing opening, hot liquid is introduced into a channel of the male mold to realize preheating, heat-melted plastic is not easy to solidify in the injection molding process, and better forming can be realized.

Owner:威鹏塑胶制品(深圳)有限公司

Drilling device for keyboard circuit board

InactiveCN108235577BRealize start and stopAccelerated cooling and solidificationInsulating layers/substrates workingEngineeringMechanical engineering

The invention relates to the field of processing of electronic circuits and particularly discloses a drilling device for a keyboard circuit board. The drilling device comprises a seat body, a first air pipe, a second air pipe and a drilling part, wherein the second air pipe is connected with a control part; a groove is formed in the seat body and is in sliding connection with a limiting part; thefirst air pipe adopts a Venturi tube, an inlet section of the first air pipe is communicated with a fan, and a throat and the inlet section are respectively communicated with the groove through a suction pipe; the control part comprises a first air inlet pipe and a second air inlet pipe; a pneumatic block is in sliding connection with the interior of the second air inlet pipe; an extrusion block is fixed on the pneumatic block, wedge surfaces which are mutually matched are formed on the extrusion block and the limiting part; the control part comprises a first station and a second station and is connected with the second air pipe through a reversing valve, the second air inlet pipe is communicated with the second air pipe when the reversing valve is positioned on the first station, and boththe second air inlet pipe and the first air inlet pipe are communicated with the second air pipe when the reversing valve is positioned on the second station. The drilling device disclosed by the invention can automatically cool the circuit board and remove chippings.

Owner:徐州致诚会计服务有限公司

Intelligent protection device for freeze-drying excipient containing binder

ActiveCN113819712AAccelerated cooling and solidificationPlay a cooling effectDrying solid materials without heatCooling fluid circulationEngineeringMechanical engineering

The invention relates to a protection device, in particular to an intelligent protection device for a freeze-drying excipient containing a binder. The intelligent protection device for the freeze-drying excipient containing the binder can be quickly cooled to be solidified, improve the yield and realize automatic production. According to the technical scheme, the intelligent protection device for the freeze-drying excipient containing the binder comprises a supporting frame, a first discharging barrel, an outer frame, a liquid pumping mechanism, a heat dissipation mechanism and a material taking mechanism, the outer frame is arranged on the upper part of the supporting frame, a material taking opening is formed in the left side of the upper part of the outer frame, the first discharging barrel is arranged on the right side in the outer frame, the liquid pumping mechanism is arranged on the right side in the outer frame, the heat dissipation mechanism is arranged in the middle of the outer frame, and the material taking mechanism is arranged on the left side in the outer frame. Water is pumped into the right side of the interior of the outer frame, so that cooling and solidification of the liquid freeze-dried excipient containing the binder can be accelerated.

Owner:深圳市广浦瑞科技有限公司

Hot melt type solid ink for gravure printing

The invention relates to a hot melt type solid ink for gravure printing, wherein the hot melt type solid ink comprises, by weight, 20-50 parts of a 138 resin or petroleum resin, 5-60 parts of wax, 10-30 parts of an EVA resin, 0.2-2 parts of a dispersant, and 10-20 parts of a pigment. According to the present invention, the hot melt type solid ink for gravure printing does not contain the organic solvent, and the organic solvent is not added during the printing process, such that no VOC is discharged during the use of the hot melt type solid ink for gravure printing, and the environment protection can be achieved; and the organic solvent is not added during the printing process so as to save the use cost.

Owner:荆门七色龙油墨有限公司

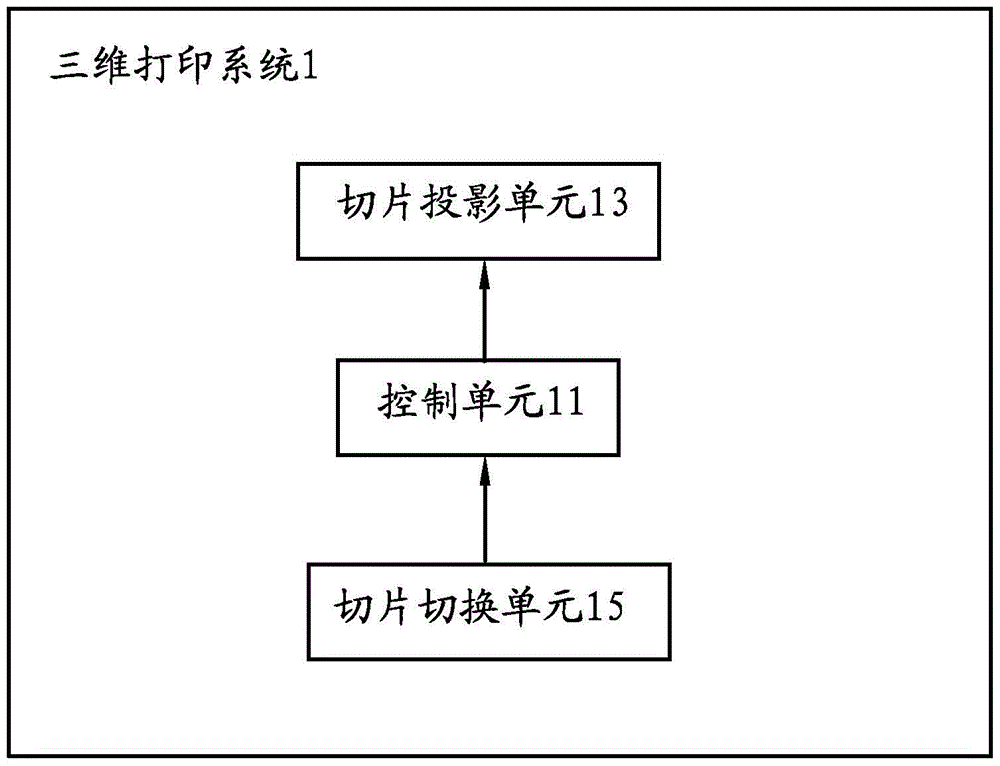

3D printing auxiliary device and 3D printing system

ActiveCN104336270BAccelerated cooling and solidificationGood print surfaceCocoaAdditive manufacturing with liquidsData interface3 dimensional printing

The invention relates to a three-dimensional printing system which comprises a three-dimensional printing pen. The system comprises a control unit as well as a slice projection unit and a slice switching unit in communication connection with the control unit, wherein the control unit comprises a data interface module for receiving a digital model of a three-dimensional object; the slice projection unit comprises a projector used for projecting a visible image of a slice layer of the digital model of the three-dimensional object to a printing face of the three-dimensional printing pen; the slice switching unit is used for controlling the projector to switch visible image projections of different slice layers of the digital model of the three-dimensional object. The three-dimensional printing system provided by the invention lowers the request on art essentials of basic training of a user when the three-dimensional printing pen is used and the non-professional user in art can also use the three-dimensional printing pen to print the three-dimensional object. In addition, the invention further provides a three-dimensional printing auxiliary device which is matched in use with the three-dimensional printing pen.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Casting Method of High-Lead Bronze Copper Set

InactiveCN103742536BImprove quality requirementsImprove the authenticity rateFoundry mouldsBearing componentsWater coolingBronze

The invention relates to a casting method for a copper bush with high lead bronze content. The casting method is characterized in that a metal mould taking a parting surface of a casting and a pouring gate system as a half folding structure is used as an external casting mould; a metal mould core with a multi-piece parting structure is used as an internal casting mould; the copper bush with high lead bronze content comprises the following chemical components in percentage by weight: 18-23% of Pb, 4-6% of Sn and the balance of Cu; a water cooling device arranged at the periphery of the casting mould is used as a cooling means of the casting; and the casting method comprises the concrete casting steps: copper alloy smelting; deoxidation treatment; casting mould preheating; casting pouring; casting cooling; and casting head removal to obtain the copper bush with high lead bronze content. The casting method has the advantages of reasonable process, low production cost and the like and the quality of the produced copper bush is high.

Owner:JIANGSU RECODE RAIL TRANSIT TECH CO LTD

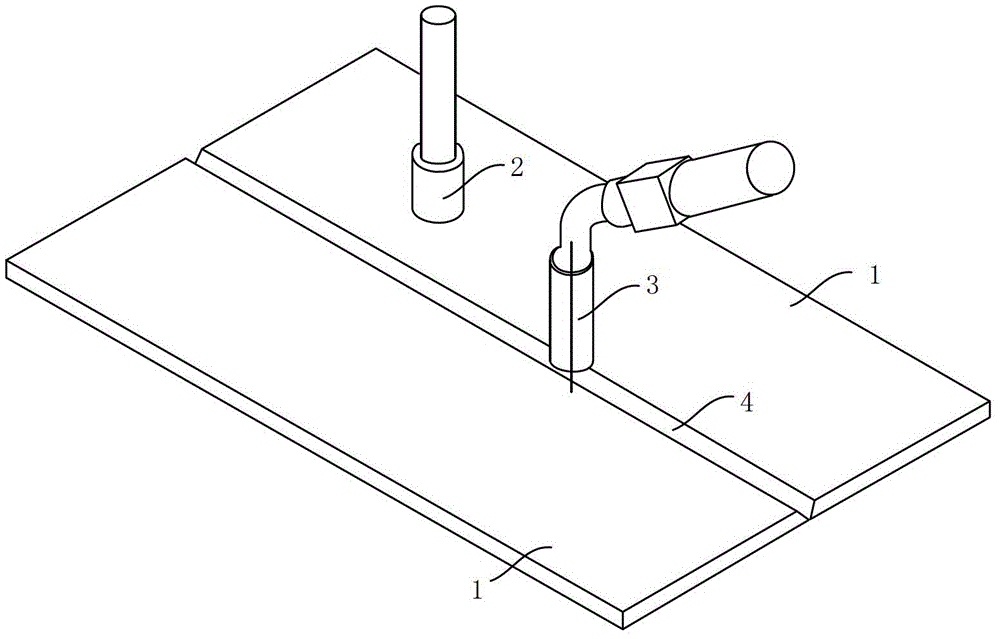

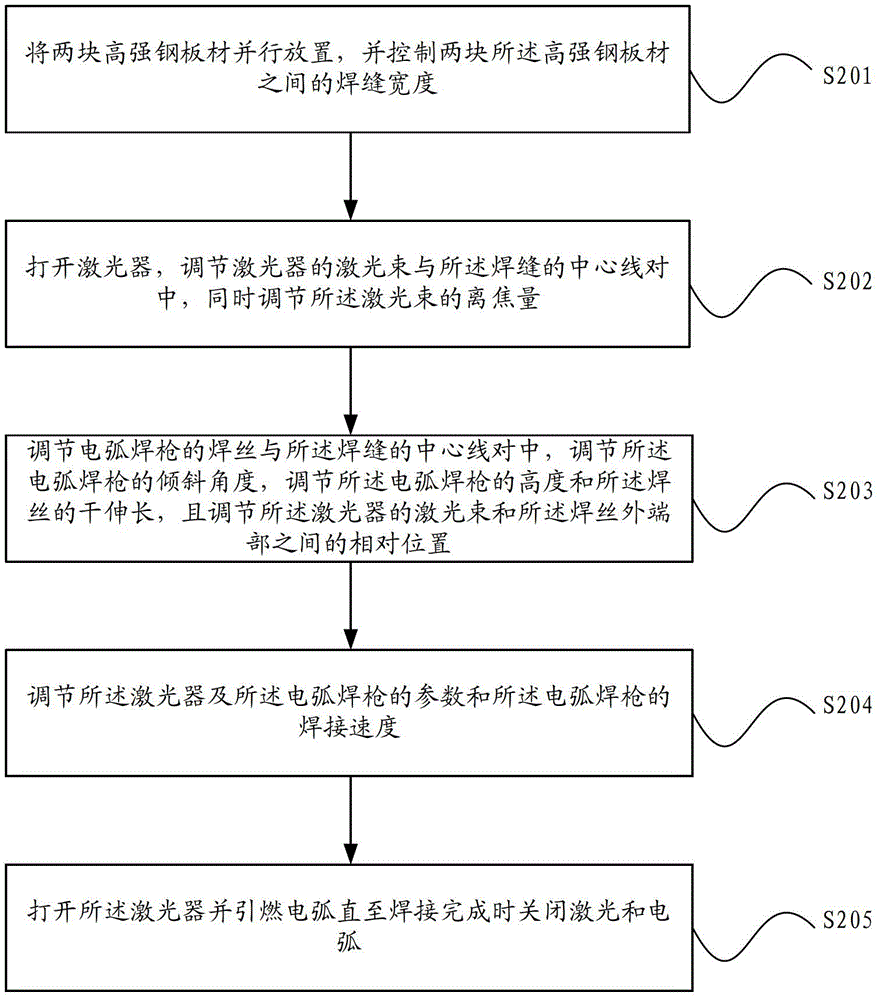

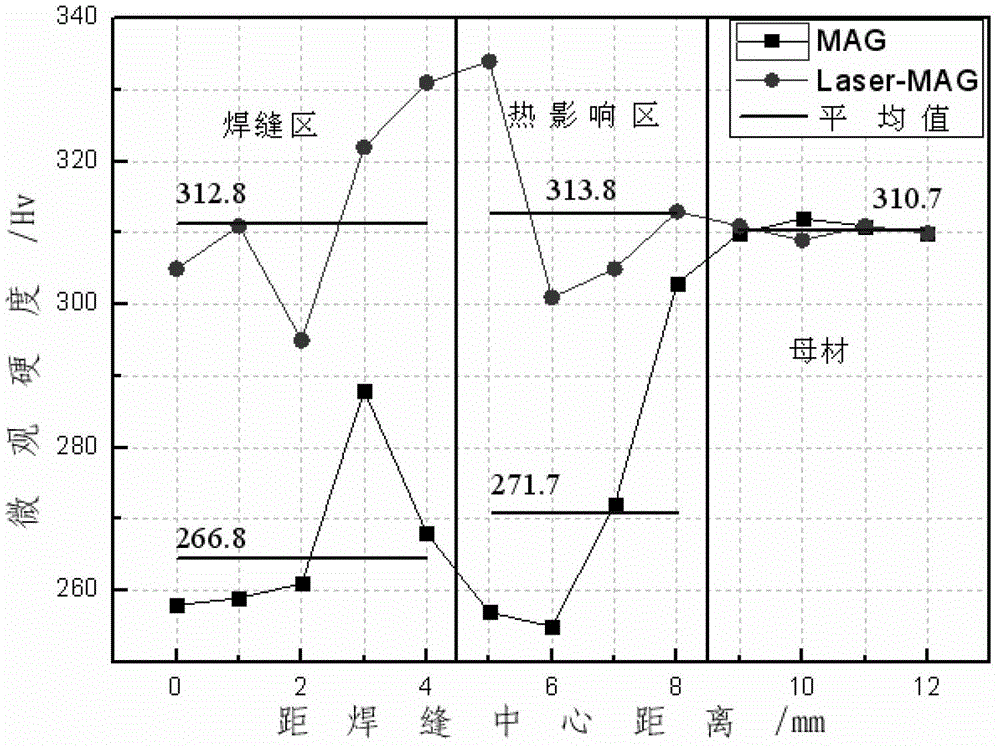

High-strength steel welding method

ActiveCN102962591BActive connectionMelting fastLaser beam welding apparatusHeat-affected zoneLaser beams

The invention discloses a welding method for high-strength steel, which comprises the steps of placing two high-strength steel plates in parallel, controlling the width of a welding gap between the two high-strength steel plates, switching on a laser, regulating a laser beam of the laser to be aligned with a center line of the welding gap, regulating defocusing amount of the laser beam, regulating a welding wire of an electrical arc welding torch to be aligned with the center line of the welding gap, regulating an inclination angle and height of the electrical arc welding torch and dry extension of the welding wire, regulating relative positions between the laser beam of the laser and the outer end part of the welding wire, regulating parameters of the laser and the electrical arc welding torch and welding speed of the electrical arc welding torch, switching on the laser and igniting an electric arc, and switching off the laser and extinguishing the electric arc after the welding is finished. The welding method for the high-strength steel adopts the laser and the electric arc as heat sources, the softening phenomenon of a heat affected zone of the welding gap in a high-strength steel welding structure is reduced, and the safety of the welding structure with a stronger bearing capacity is improved.

Owner:ZOOMLION HEAVY IND CO LTD

A ratchet drive dispensing system for smt placement

ActiveCN111250359BAccelerated cooling and solidificationImprove adhesionPretreated surfacesCoatingsRatchetElectric machine

Owner:HEFEI LONGTUTEM INFORMATION TECH CO LTD

Method for casting mechanical arm casting of robot

ActiveCN102078956BNo shrinkage defectsAvoid slag inclusion defectsMoulding toolsMolten metal pouring equipmentsHardnessMechanical property

Owner:上海华新合金有限公司

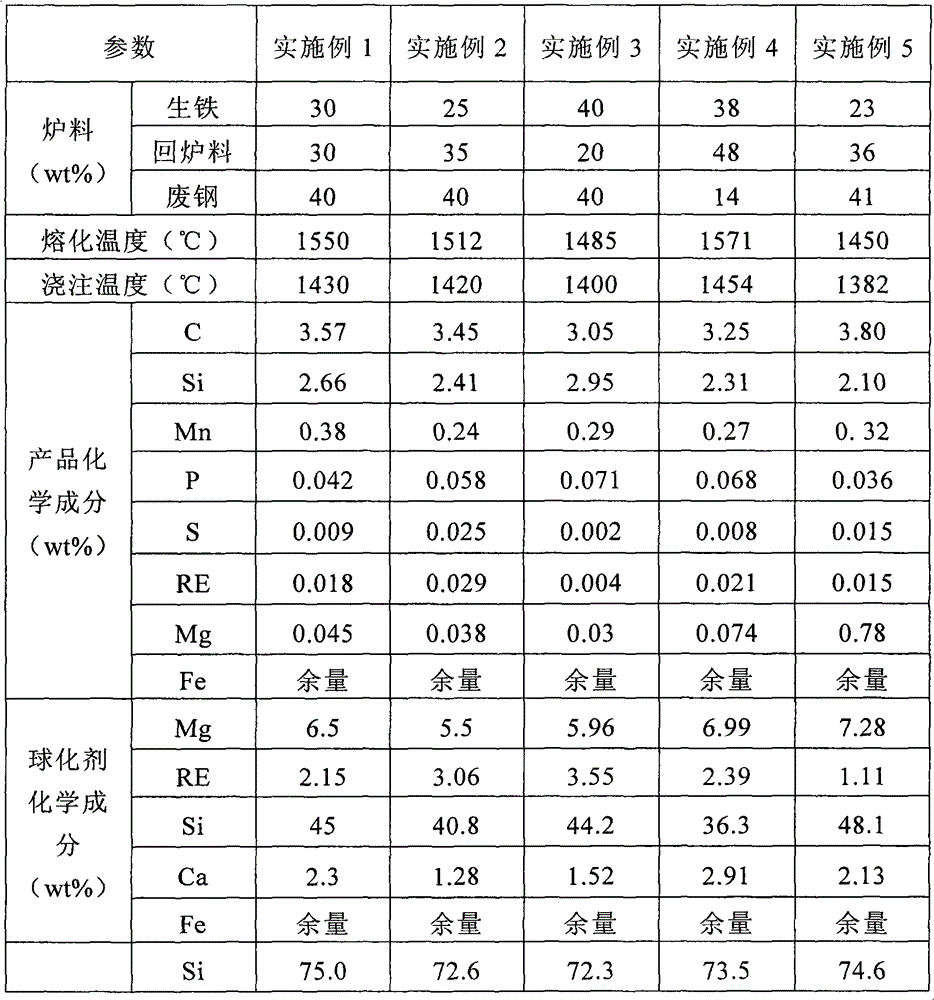

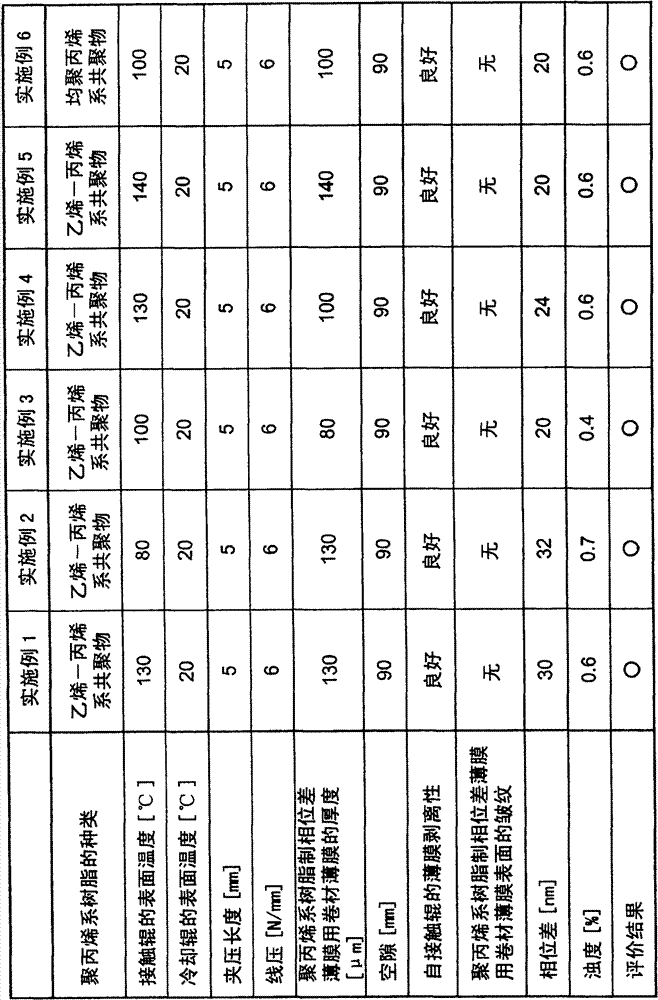

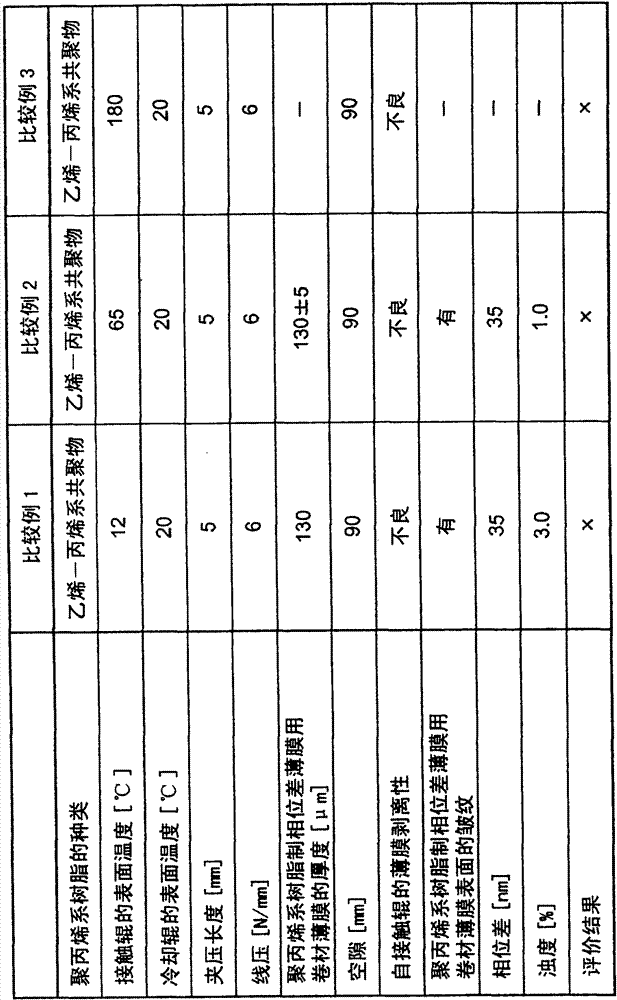

Process for producing raw film for retardation film made of polypropylene resin

InactiveCN101801639BAccelerated cooling and solidificationHigh transparencyOptical articlesPolarising elementsPhasonPolypropylene

There is provided a process for producing a precursor film for a polypropylene-based resin retardation film that can yield films with almost no orientation and with high transparency. The process for producing a precursor film for a polypropylene-based resin retardation film comprises a step of pressing a molten sheet formed by extruding a molten polypropylene-based resin from a T-shaped die 12 at 180° C. or higher and 300° C. or lower between a cooling roll 16 having a surface temperature regulated to −5° C. or higher and 30° C. or lower and a touch roll 14 having a surface temperature regulated to 80° C. or higher and 150° C. or lower, whereby the molten sheet is cooled and solidified.

Owner:SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com